Page 1

PrintCart

User’s Manual

Page 2

Page 3

PrintCart

User’s Manual

251755-001F

Page 4

Trademarks

Printronix is a registered trademark of Printronix, Inc.

All other trademarks are the property of their respective owners.

Product Warranty

Printronix, Inc. makes no representations or warranties of any kind regarding

this material, including, but not limited to, implied warranties of

merchantability and fitness for a particular purpose. Printronix, Inc. shall not

be held responsible for errors contained herein or any omissions from this

material or for any damages, whether direct, indirect, incidental or

consequential, in connection with the furnishing, distribution, performance or

use of this material. The information in this manual is subject to change

without notice.

Communication Notices

This device complies with Part 15 of the FCC Rules. Operation is subject to

the following two conditions: (1) this device may not cause harmful

interference, and (2) This device must accept any interference received,

including interference that may cause undesired operation.

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la Class A est conform à la norme NMB-003 du

Canada.

Emergency Disconnect Procedure

In an electrical emergency disconnect the AC input line cord from any

external power source and disconnect the AC output line cords from any

equipment powered by the cart.

Unterbrechung der Stromversorgung im Notfall

Bei einem Notfall im Bereich der Elektro-Installation die

Spannungsversorgungskabel von allen externen Spannungsquellen sowie

die Spannungsversorgungskabel von allen über das Cart mit Spannung

versorgten Geräten abziehen.

Notice of Copyright

This document contains proprietary information protected by copyright. No

part of this document may be reproduced, copied, translated or incorporated

in any other material in any form or by any means, whether manual, graphic,

electronic, mechanical or otherwise, without the prior written consent of

Printronix, Inc.

Copyright © 2007, 2010 Printronix, Inc. All rights reserved.

Specifications subject to change without notice.

Page 5

Table of Contents

1 Quick Start And Setup .......................................... 7

Quick Start ............................................................................................. 7

Unpacking ....................................................................................... 7

Safety Inspection............................................................................. 9

Equipment Setup ................................................................................... 9

Mechanical Installation .................................................................... 9

Electrical Installation ..................................................................... 10

Startup ................................................................................................. 11

Operating Limitations ........................................................................... 12

2 PrintCart.............................................................. 15

Overview.............................................................................................. 15

PrintCart Layout................................................................................... 16

3 Operation ............................................................ 21

Line Power Operation .......................................................................... 21

Battery Power Operation ..................................................................... 23

PrintCart Operating Duration......................................................... 23

Indicator Panel..................................................................................... 24

Gaining Access To The Printer............................................................ 26

Slide The Tray To Service Position ............................................... 26

Load Media Or Ribbon .................................................................. 26

PrintCart Features ............................................................................... 27

PrintCart Accessories .......................................................................... 27

4 Troubleshooting .................................................. 31

Safety................................................................................................... 31

PrintCart Safety Features .................................................................... 32

Troubleshooting Guide ........................................................................ 33

Page 6

5 Maintenance........................................................ 37

Power Equipment Access .................................................................... 37

Serviceability Inspection ...................................................................... 40

Battery Replacement ........................................................................... 40

Inverter Replacement .......................................................................... 42

Fuse Replacement............................................................................... 43

Display Fuse ................................................................................. 43

Main Fuse ..................................................................................... 43

Power Cord Replacement.................................................................... 44

Wheel Replacement ............................................................................ 45

Caster Wheels............................................................................... 45

Fixed Wheels ................................................................................ 45

Hand Grip Replacement ...................................................................... 46

A Specifications ...................................................... 47

Physical Specifications ........................................................................ 47

Electrical Specifications ....................................................................... 48

B Wiring Schematics .............................................. 49

120V/60Hz ........................................................................................... 49

230V/50Hz ........................................................................................... 50

C Spare Parts ......................................................... 51

D Glossary .............................................................. 53

E Contact Information ............................................. 55

Printronix Customer Support Center.................................................... 55

Printronix Supplies Department ........................................................... 55

Corporate Offices................................................................................. 56

Page 7

1 Quick Start And Setup

Quick Start

Unpacking

WARNING

IMPORTANT

Dismounting the cart from the pallet requires strength. Two people is

recommended for the task.

1. Place the pallet on a flat, level surface, leaving enough room to roll the

PrintCart off the pallet.

2. Remove the two cardboard protective shipping sleeves and set them

aside.

3. Remove the plastic wrap and shipping bag from the PrintCart.

Make sure the caster brake is set.

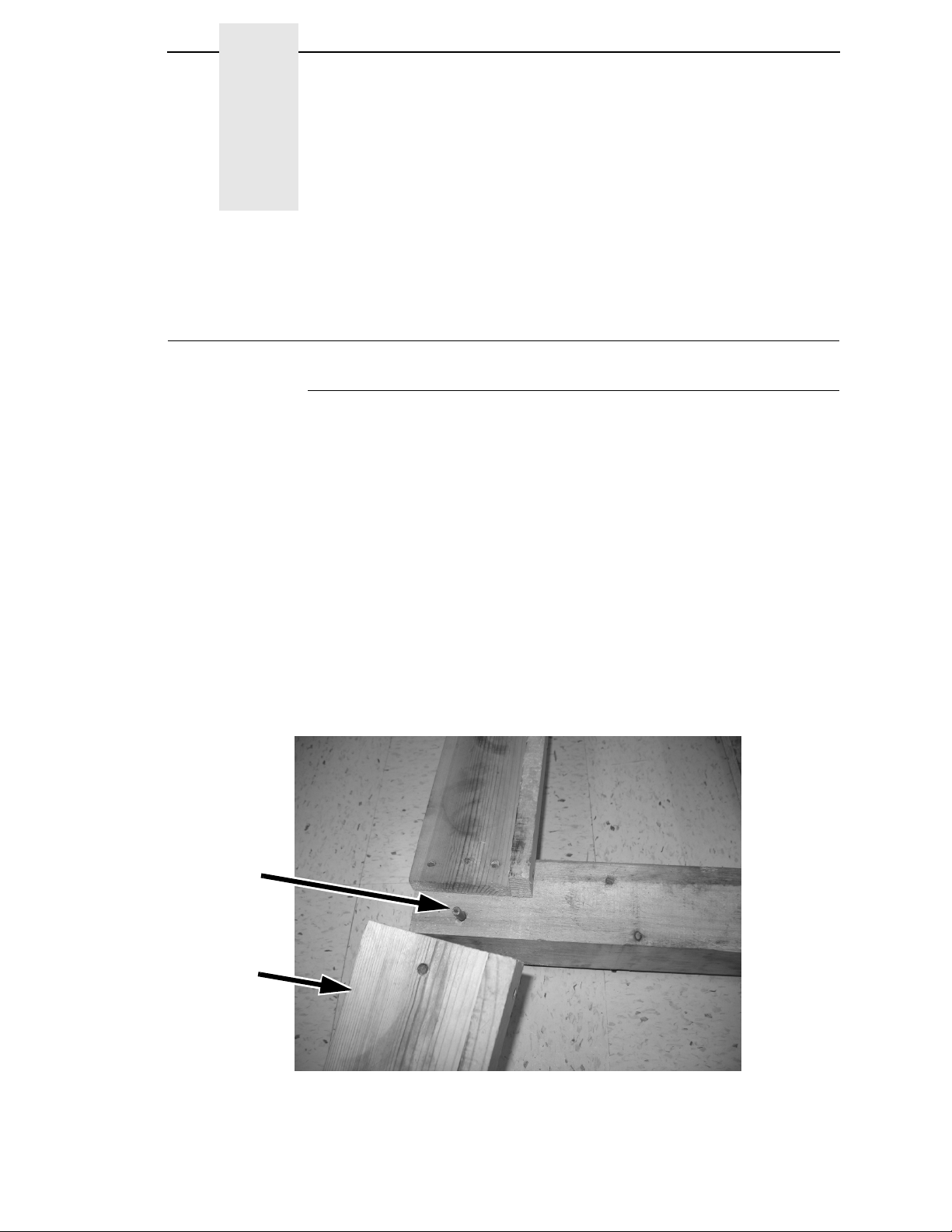

4. Cut the bands holding the unloading ramps.

5. Lift and remove the ramps off the locating pins.

6. Reverse the ramps and engage the locating pin in the angled blocks on

the end of the pallet. See

Figure 1.

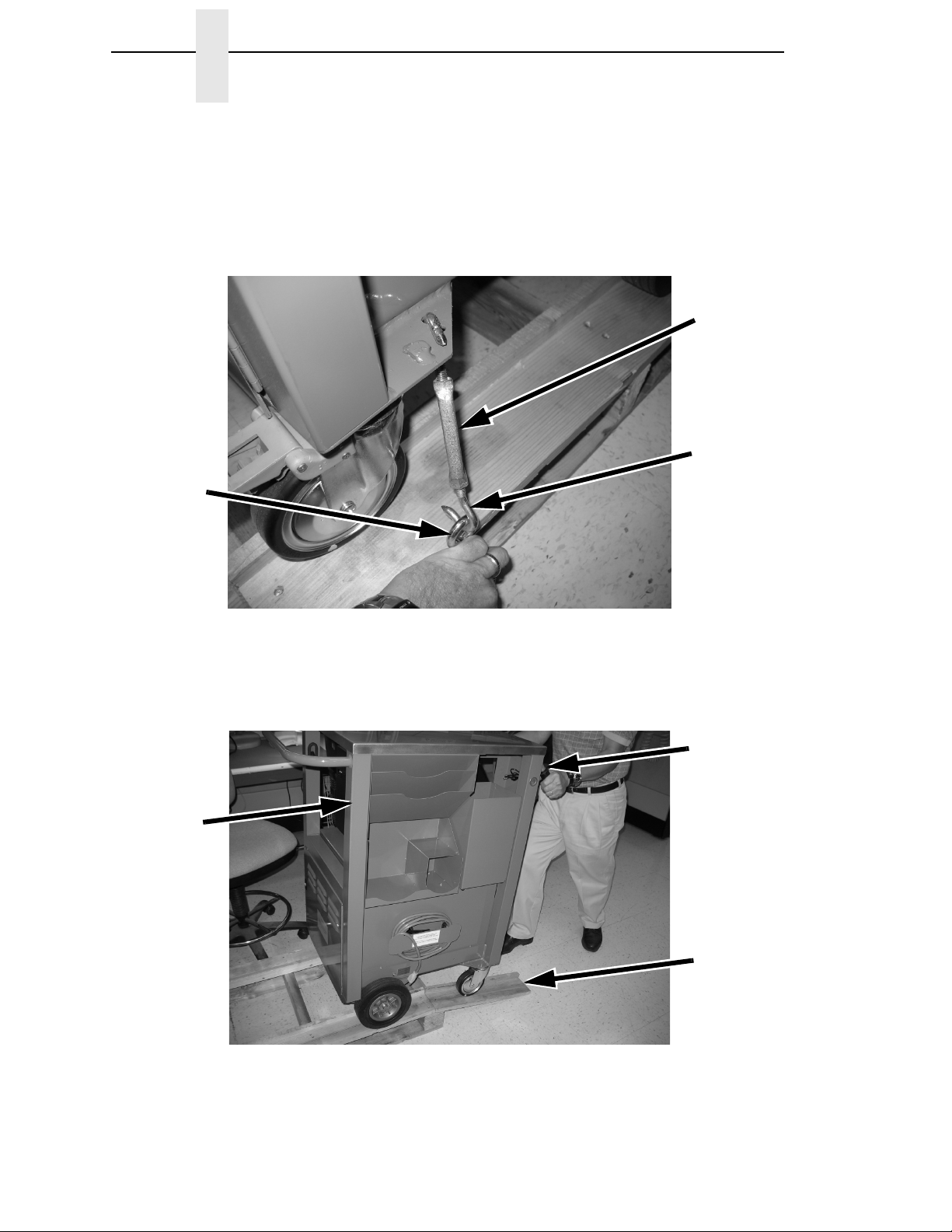

Locating Pin

Ramp

Figure 1. Reversing the Ramps and Engaging the Locating Pin

7

Page 8

Chapter 1 Quick Start

7. If necessary set the caster brake on the PrintCart.

8. Cut the shipping restraint tie wraps on all turnbuckles.

9. Insert a screwdriver through the center of each turnbuckle housing and

loosen the turnbuckle until you can remove the hook from the eyelet.

10. Unhook the opposite end from the PrintCart frame. See Figure 2.

Turnbuckle

Housing

Shipping

Restraint

Hook

PrintCart

Figure 2. Loosening the Turnbuckle from its Housing

11. On the opposite side of the PrintCart, repeat steps 9 and 10 to completely

disengage the shipping restraints.

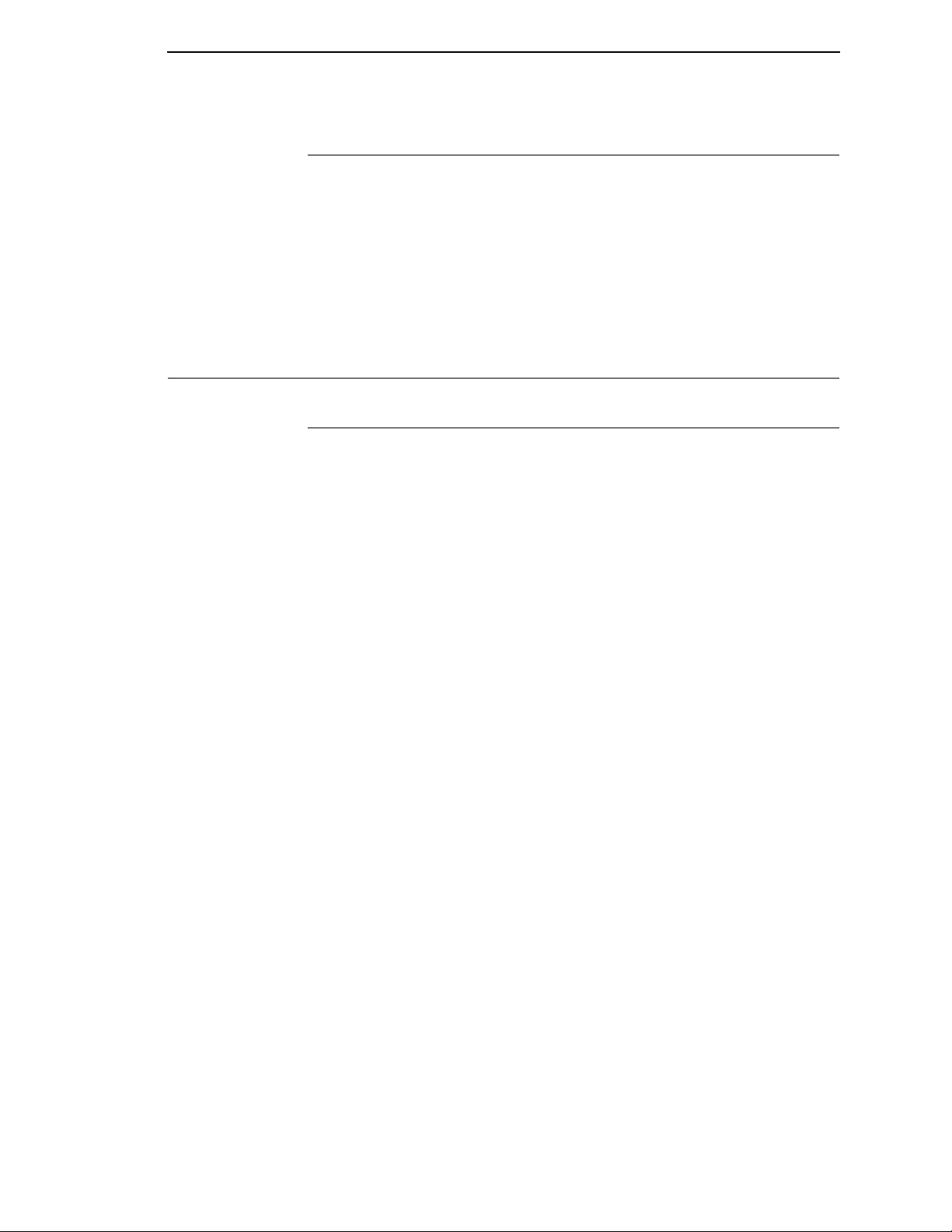

12. Release the caster brake. Grasp the hand grips and pull the PrintCart

down the unload ramps to the work surface.

Hand Grip

Ramp

Figure 3. Moving the PrintCart to the Work Surface

13. Replace the unloading ramps on the pallet and store the pallet and

turnbuckles for future re-use.

8

Page 9

Safety Inspection

1. Inspect the PrintCart for damage that may have occurred during

shipment.

2. Open the power compartment door and verify that the batteries are

securely restrained and the battery cable connections are tight.

3. Verify that the charger/inverter is held securely in place. If any

components have loosened during shipment, secure them before

applying power to the PrintCart.

Equipment Setup

Mechanical Installation

NOTE: If applicable, first install the terminal to the PrintCart. Access to the

Safety Inspection

underside of the work surface will be restricted after printer

installation.

Terminal Installation

1. Follow the manufacturer’s installation instructions to install the wireless

terminal.

The PrintCart is equipped with a central mounting rail under the stainless

steel work surface. This mount is predrilled with 2 rows of 5/16” holes on 1

inch centers. The size and spacing coincides with the hole pattern that

mates with the Symbol VRC 8900 series terminals bracket; it may fit

several others. The right-most row of holes is centered on the PrintCart

frame. The left-most row of holes is centered between the left edge and

the barcode scanner storage slot on the right rear of the PrintCart.

2. If the utility drawer is installed, remove the drawer by fully extending the

drawer and disconnecting the slide latch. This will provide access to the

mounting rail and provide additional overhead clearance.

3. Determine the appropriate mounting location and suitability of the desired

mounting bracket.

4. Find the holes (minimum of 2) that will properly position the terminal and

mark them on the underside.

5. Use the predrilled mounting rail as a template and drill up through the top

work surface using a power hand drill from below.

6. Secure the bracket to the PrintCart according to the manufacturer’s

instructions.

9

Page 10

Chapter 1 Equipment Setup

Printer Installation

1. Set the wheel lock on the caster wheel to prevent the PrintCart from

moving.

2. Lift the spring loaded handle located on the side of the slide out tray and

pull the tray out over the side of the PrintCart to the fully extended

position.

NOTE: The slide out tray clicks into place when the tray is fully extended.

IMPORTANT

WARNING

For Printronix thermal printers, the four rubber pads on the bottom of

the printer must be removed.

3. Tip the printer onto the left side (side with power compartment cover) and

unscrew the rubber pads. If necessary, use pliers to improve grip.

4. Install the four black rubber vibration mounts that are provided with the

PrintCart.

5. Tip the printer back upright.

The next step requires two people; one person to support the printer,

the other to align the mounts.

6. Carefully lift the printer and set it on the slide out tray, aligning the

threaded vibration mounts with the holes in the tray. The printer’s control

panel should face the end of the PrintCart with the hand grips.

7. Secure the printer to the tray using the four supplied lock nuts.

8. Lift the spring loaded handle and slide the tray back under the top work

surface of the PrintCart. It should click into a retracted and locked

position.

Electrical Installation

The electrical cable for the PrintCart equipment is routed through the right

rear leg into the power compartment.

10

Printer Hook-Up

The printer power cable is preinstalled in the PrintCart.

1. Connect the power cable to the printer. Make sure the cord is slightly

slack to provide a small service loop during movement of the slide out

tray.

2. Test the service loop length by extending the printer shelf and verify that

enough slack is available.

3. Bundle and secure any excess cord in the power compartment.

Page 11

Electrical Installation

Terminal Hook-Up

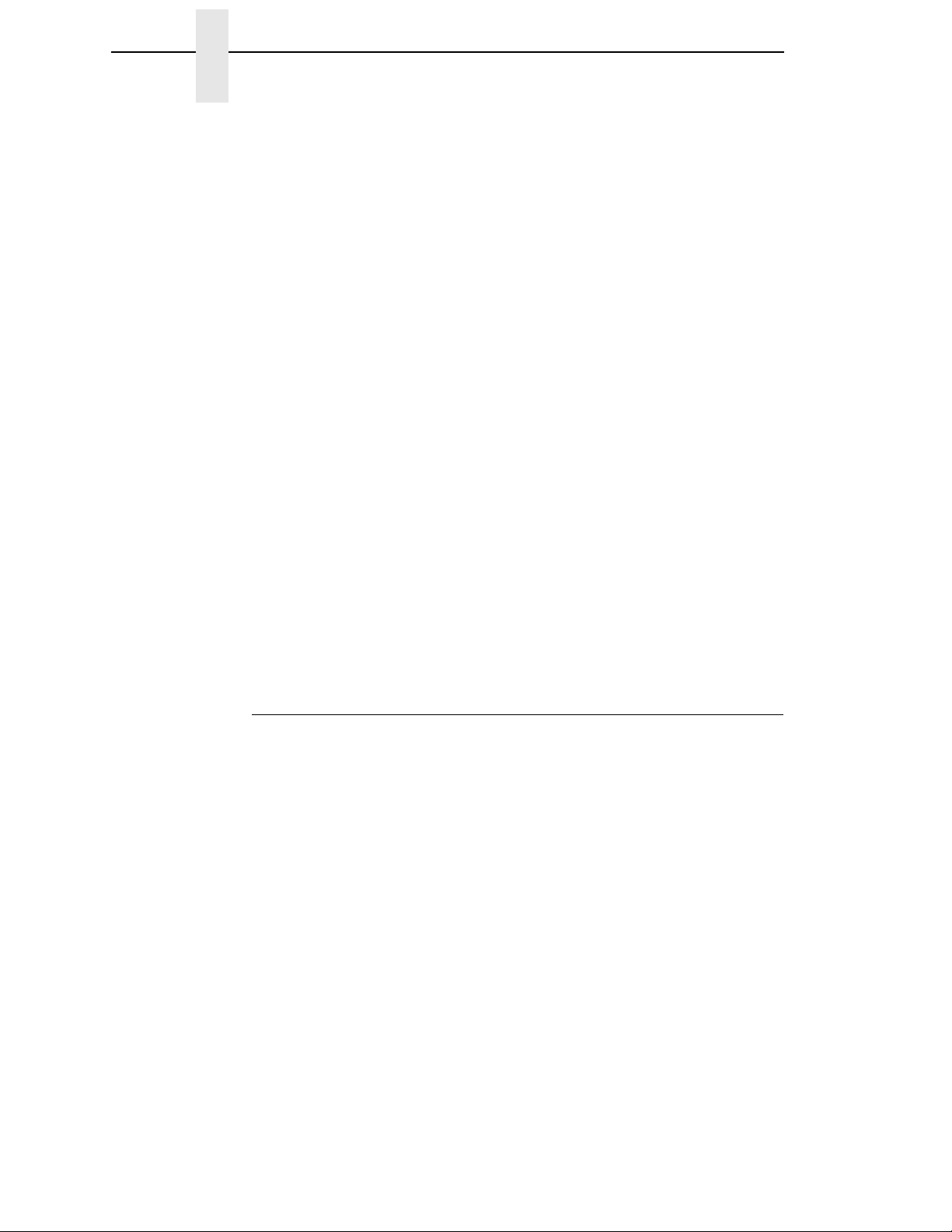

1. Install the power supply for the terminal in the pocket provided behind the

two slot notebook bin. See

Figure 4.

Pocket

Two Slot

Notebook Bin

Startup

Figure 4. Installing Power to the Terminal

If this accessory is not included with the PrintCart:

2. Locate power supply in the power compartment to the left of the inverter.

3. Connect an AC power cord to the power supply and connect it to the

remaining receptacle by routing it down through the right rear leg into the

inverter compartment.

4. Bundle and secure any excess cord.

5. Route the DC power cable from the terminal to the power supply and

secure all excess cable length (terminal P/S pocket behind the letter bin).

Make sure all PrintCart equipment has been installed and power cords have

been routed and connected to the inverter.

1. Check that the equipment power switches are in the OFF (0) position.

The PrintCart is now prepared for start-up.

2. Open the power compartment front door (hand grip end) and connect the

main inverter power/battery cable to the connector on the battery

subpallet.

3. Open the power compartment rear door and locate the inverter operating

switch on the upper-right of the inverter.

4. Slide the switch left to the “AUTO/INVERT” position. The inverter will

begin producing power as indicated by the yellow mode indicator on the

inverter.

11

Page 12

Chapter 1 Operating Limitations

5. Close and latch the rear door.

Inverter and battery status are indicated on the LED display panel located on

the front of the PrintCart adjacent to the hand grips. The batteries in a new

PrintCart arrives nearly fully charged. Battery state of charge “gas gauge”

shows all LED’s lit, (2 red, 2 yellow, and 2 green). If all of the battery status

LED’s are not lilt, charge the PrintCart prior to use.

Power is available when the inverter is in the auto position; the equipment

may now be switched on. If the connected equipment does not receive power,

perform the following:

• 120V units

Examine the GFCI duplex outlet to the left of the inverter. If the trip

indicator lamp located on the right side of the GFCI is illuminated, the

GFCI has faulted. Reset the GFCI by depressing the RESET button

between the two plugs.

• 230V units

Examine the “Load C/B” (load circuit breaker) located above the inverter

output receptacles. If it extends beyond the mounting more that a couple

of millimeters, it has faulted. Reset the load circuit breaker by pressing it

in.

Close and latch the power compartment door.

Operating Limitations

When the cart is not in service, leave it plugged in to maintain battery charge.

Otherwise, charge the cart battery every 90 days.

CAUTION

Recharge the batteries as soon as possible after use. Failure to quickly

recharge batteries can result in permanent battery damage. Batteries

left in a discharged state for extended periods may be so damaged that

they will not accept a charge and recharging them could be dangerous.

Any attempt to recharge partially discharged batteries left for an

extended time requires frequent supervision to ensure that venting or

excessive heating does not occur.

Do not charge a fully discharged battery at a rate greater than 1/10 of the

amp-hour capacity. This cart is equipped with fail safe controls to

prevent full discharge. If the batteries become fully discharged, possibly

due to long term inactivity, switch the inverter/charger to slow charging

mode to revive them. Slow charging prevents further damage to the

battery and reduces the risk of battery out-gassing or destructive

heating if the battery is damaged beyond recovery.

12

Page 13

Electrical Installation

120V/60Hz Models

Eight switches are located on the top center of the RV750ULHW inverter/

charger front panel. The far left switch is for charge rate. The down (normal)

position is fast (45A) charge; the up position is slow (11A) charge. Use the UP

position to recharge fully discharged batteries. If the batteries accept a full

charge without excessive heating or out-gassing, the capacity selector can be

retuned to the full (down) setting.

230V/50Hz Models

A red button labeled “Sleeping Mode” is located on the right side of the

charger (blue device at the bottom of the power module). Depressing this

button reduces the charge rate to approximately 1/3 the normal rate. If the

batteries accept a full charge without excessive heating or out-gassing, the

sleep mode button can be retuned to the full or out position.

WARNING

CAUTION

If the batteries become excessively hot or emit a detectable odor, the

batteries are damaged beyond repair and are dangerous to use. Stop

charging immediately. Remove the batteries from service and dispose

of them according to local regulations.

Do not charge the batteries at a rate greater than 1/4 of the amp-hour

capacity. For example, a 100 amp-hour battery should be charged no faster

than 25 amps (or a pair of 100 amp-hour batteries no faster than 50A).

The charger on this cart provides the maximum recommended charge rate for

the batteries with which it is equipped.

Do not use additional or larger chargers to speed recharging.

Permanent battery damage will occur and the potential for catastrophic

failure is high.

Before connecting or disconnecting the batteries, turn off battery powered

electrical equipment and disconnect both the main DC disconnect and display

power cable.

Make sure that battery terminal covers are in place to prevent accidental

shorts between the battery and surrounding frame or equipment.

Use insulated tools to service any power connections that cannot be

disconnected from battery power.

13

Page 14

Chapter 1 Operating Limitations

14

Page 15

2 PrintCart

Overview

The PrintCart is a wireless, cordless work platform capable of transporting

several pieces of electrically powered equipment to a work site. On site, the

PrintCart can operate indefinitely on line power or for an extended period of

time (depending on equipment) on battery power. The PrintCart is designed to

support continuous operation of all connected equipment without shutting

down.

The PrintCart contains three separate levels:

Bottom Level

The bottom level is the power compartment, which houses the power storage,

power conversion equipment, and the electrical safety devices that ensure

safe PrintCart operation.

Middle Level

The middle level contains the printer and storage of materials and waste. The

printer shelf is mounted on slides that permit a thermal printer to extend out

the right side of the PrintCart for service. To the left of the printer shelf is a

refuse bin, document holders, and a media storage bin. Above the printer is a

utility drawer.

Top Level

The top level has a stainless steel work area which supports electronic

wireless terminal mounting and installation of a barcode scanner storage slot.

The power compartment is enclosed and latched with a mechanism that

requires a tool to open to prevent incidental access. It contains two sealed

lead acid batteries for electricity storage. Power is provided by a combination

device called an inverter/charger. Inversion is the process of using the 12 volt

direct current stored in the batteries and converting it to a suitable alternating

current at a voltage and frequency for operating equipment mounted on the

PrintCart. The PrintCart operating voltage can be 120 volts AC @ 60 Hertz

(North American standard) or 230 volts AC at 50 Hertz (European standard).

Operating voltage is specified at the time of order and can be changed by

swapping out the Power Equipment Subpallet (PESP).

15

Page 16

Chapter 2 PrintCart Layout

The battery charge function is performed in the inverter/charger. When AC

line power is applied, the inverter charger automatically transfers (switches)

power directly to the PrintCart equipment and begins charging the batteries.

The charger provides power to the batteries in three separate stages to

optimize the storage capacity and battery life.

The PrintCart can support multiple pieces of electrical equipment. The

primary intent is to support one Printronix four inch or six inch thermal printer

on the printer shelf. The PrintCart includes an installation kit consisting of four

bolt-on shock mount isolators for securing the printer to the shelf.

The top work area can be used for any application but is intended for use with

a wireless terminal and barcode scanner. The barcode scanner storage bin

can be mounted on the right rear of the work surface. On the front left is a

display panel with integral controller. The display panel has a set of battery

charge status LEDs that report the battery state of charge. It also has a set of

stop light LEDs that display the inverter/charger mode status.

Additionally, there is an alarm to alert the user to recharge the batteries. The

built-in controller monitors power consumption and signals the user when the

batteries need recharging. The controller provides progressive alarms to the

user, indicating that there is a warning period to permit completion of the

current task, progressing to a shorter shutdown period. This indicates that the

PrintCart will soon enter automatic shutdown if not connected to line power for

recharging.

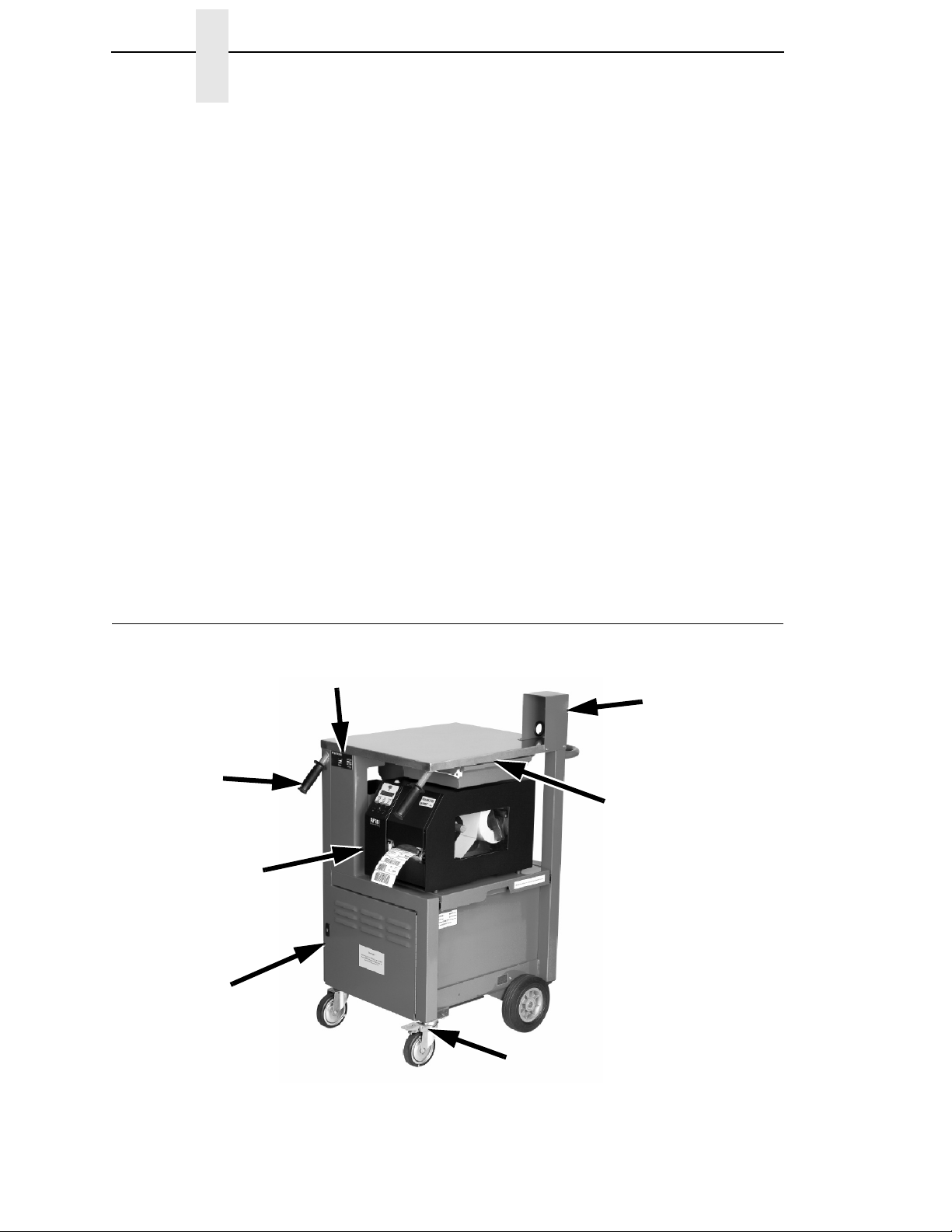

PrintCart Layout

Hand Grip (2)

Printer (not included)

Battery Access Door

Status Display

Barcode Scanner

Storage Slot

Stainless Steel

Work Surface

Brake/Locking

Caster

16

Figure 5. Front Right View of the PrintCart

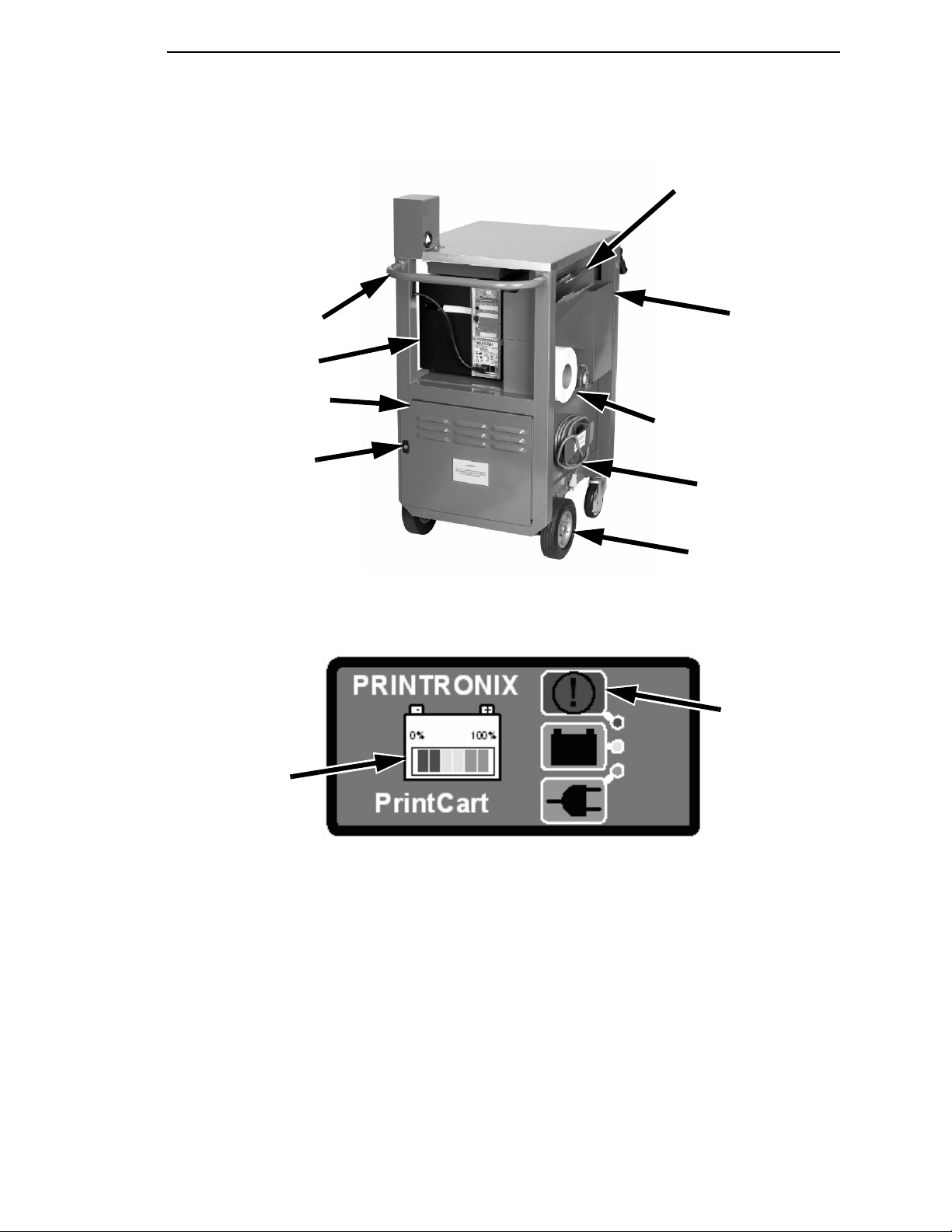

Page 17

Document Holder (2)

Rear Loop-Handle and

Terminal Protector

Printer (not included)

Power Equipment

Compartment

Power Compartment

Latch

Refuse Bin

Media/Ribbon

Storage

Power Cord

8” Fixed Wheel (2)

Figure 6. Rear Left View of the PrintCart

Power Status

Indicator

Battery Status

Indicator

Figure 7. Display Panel

17

Page 18

Chapter 2 PrintCart Layout

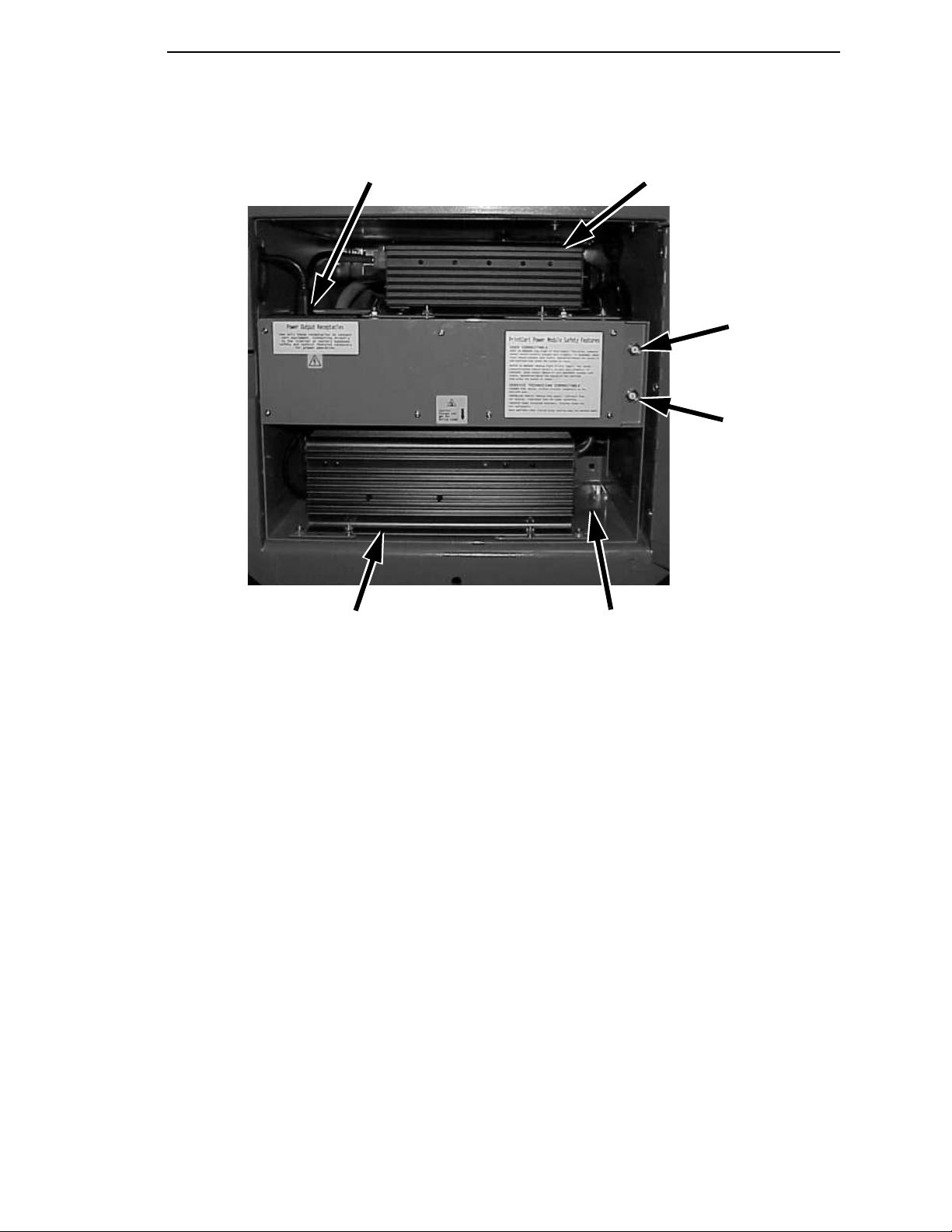

AC Output GFCI

Inverter Setup

Switches

Inverter Display

Indicator

External Display

Panel Connector

Main Inverter

Power/Mode Switch

Grounding Lug

(AC)

Negative Battery

Cable Input

Positive Battery

Cable Input

Battery Charger

Circuit Breaker (8A)

Main AC Input Power

Circuit Breaker (15A)

Figure 8. Power Pallet Features and Safety Devices (120V)

18

Page 19

Cart Equipment Outlet

AC Power Inverter

AC Input Circuit

Breaker (8A)

AC Output Circuit

Breaker (5A)

Battery Charger Module

Battery Charger Sleep

Mode Button Location

Figure 9. Power Module Features and Safety Devices (230V)

19

Page 20

Chapter 2 PrintCart Layout

20

Page 21

3 Operation

Line Power Operation

When the line cord is connected to a wall receptacle, AC line power is

transferred by an Automatic Transfer Switch (ATS) directly to the cart

equipment. There is a short delay in applying line power (approximately 20

seconds for the 120V and 8 seconds for the 230V) to permit the plug to be

secured in the receptacle. The transfer happens quickly so operation of the

connected equipment is not interrupted.

NOTE: There is no need to power the PrintCart equipment off when either

connecting or disconnecting from line power.

When operating on AC line power, the green mode indicator (line power) on

the display illuminates.

The charger begins to charge the batteries after the ATS transfers line power

to the PrintCart. The charger is a three stage device designed for optimal

battery charging.

• Stage 1 – when the charging cycle starts, the charger provides maximum

rated charge until the battery reaches approximately 75% capacity.

Completely charging the battery before reusing the PrintCart provides

good PrintCart longevity.

• Stage 2 – the charge rate is reduced from full capacity to 10% capacity to

charge the last 25% of the battery. Completion of second stage charging

only slightly improves short term operating longevity but greatly improves

long term battery life.

• Stage 3 – when the battery is fully charged, a trickle charge is applied to

keep the battery at full capacity.

The time required for a recharge depends on the state of discharge, the size

of the battery bank, and the charger’s capacity. The PrintCart controller

prevents the batteries from discharging more than 70% of their energy (Depth

of Discharge or DoD); this reduces the rate of permanent battery damage.

Maximum recharge times for the PrintCart are listed in

When the charging begins, the charger will indicate battery state improvement

through the State of Charge (SoC) LEDs, but displays differently between the

120V and 230V carts.

Table 1 on page 22.

21

Page 22

Chapter 3 Line Power Operation

• 120V – as charging progresses, yelow and green bars illuminate

individually with each 10-15% increase in charge state.

• 230V – the two red bars light when the charger is in Stage 1 (30-75%

charge). When the charger enters Stage 2 (76-98% charge), the two

yellow lights also illuminate. The two green lights illuminate together when

the charger enters Stage 3 (greater than 98% charge). When all SoC

lamps are illuminated, the PrintCart is fully charged.

When battery power is available to the PrintCart, the Battery Powered

mode indicator (yellow) illuminates. When the PrintCart is connected via

line power, the Line Powered mode indicator (green) illuminates.

Make sure the source of AC power is through a modern 3-prong grounded

outlet and is a reliable service capable of delivering the required current.

Normal and maximum current specifications are listed in Appendix A on

page 47. Table 1 on page 22 shows the maximum recharge time.

Table 1. PrintCart Charge Time

IMPORTANT

Battery Type Maximum (hrs) Typical (hrs )

2x100 Ah 4.7 3.7

The line cord design uses a short PrintCart cord connected to an extension

cord. The two are connected together inside a cord wrapping device. This

method provides an easy, user level repair to encourage maintenance. The

cord can be replaced with a variety of cords as long as they meet the original

specification and are not longer than 25 feet.

for cord requirements.

Using a cord or series of cords longer than 25 feet may result in power

loss. This could affect operation of either the PrintCart equipment or

power system.

See “Spare Parts” on page 51

22

Page 23

Battery Power Operation

When the PrintCart is unplugged from the AC outlet, the power system

automatically switches equipment to inverter power via the automatic transfer

switch.

NOTE: The PrintCart equipment does not have to be turned off and there will

be no significant power interruption to the equipment.

The Battery Powered mode indicator (yellow) on the display indicates that the

battery is now providing power. When running in Battery Powered mode, the

battery system is no longer being charged.

PrintCart Operating Duration

1. Select a printer family (SL4M/T4M or SL5000r/T5000r). Other printer

models are categorized between the two printer families.

2. Within the printer family, select whether a notebook or wireless terminal

will be used.

NOTE: A desktop or compact PC is not the same as a notebook or terminal

due to higher power consumption.

PrintCart Operating Duration

3. Determine the minimum operating time (in hours) at the intersection of the

battery bank row and the equipment column.

Tabl e 2. Minimum Hours of System Operation Before Automatic Shutdown

SL4M/T4M with

Battery Bank

Capacity

(Ah)

2x100 35.4 18.6 19.9 13.2

Printer Weight

NOTE: The operating time span specified is the minimum available at the

NOTE: Frequently charging the PrintCart prior to reaching maximum

Wireless Terminal

Printer with

Average

end of battery life. This ensures that operational requirements will be

met as the battery capacity declines by approximately 30% as the

battery ages.

allowable discharge will maintain battery life and delay declining

capacity.

Notebook

Weight Avearge

Printer Weight

SL5000r/T5000r with

Wireless Terminal

Average

Weight Average

Printer with

Notebook

23

Page 24

Chapter 3 Indicator Panel

Indicator Panel

Colored LEDs on the indicator panel displays operational status. The display

is arranged in two sections: battery indicator (state of charge) on the left and

power status (operating mode) on the right.

Battery Indicator

(gas gauge)

Figure 10. Display Panel Layout Indicator Colors

Power Status

Mode Indicators

Battery Indicator

(at full battery charge)

Figure 11. Operating in Battery Powered Mode with a Full Battery Charge

Battery Indicator

(charging at stage 1,

gas gauge red)

NOTE: All power status mode indicators will not display simultaneously.

Battery Powered

Mode

NOTE: The yellow LED illuminates in Battery Powered mode with a full

battery charge.

Line Powered

Mode

24

Figure 12. Operating in Unrestricted, Line Powered Mode

NOTE: In unrestricted, Line Power mode, the green LED is illuminated.

Battery power is available if line power is disconnected.

Page 25

PrintCart Operating Duration

Battery Indicator

(discharged battery,

flashing red gas gauge)

Fault Mode

Line Powered

Mode

Figure 13. Discharged Battery, Operating on Inverter

NOTE: When the battery is discharged, the alarm timer activates (flashing

red gas gauge) and the battery operates on inverter.

An illuminated Fault mode LED indicates that either the charger or the inverter

are not operating correctly. A fault will not prevent the cart from operating in

Line Power mode but the cart will not operate correctly on battery power. Stop

operation and report the problem to supervisors and maintenance personnel

for corrective action.

Implement the following restrictions to protect the batteries:

• Battery discharge is limited to 70% (as low as 30% state of charge).

When the SoC reaches the discharge trigger at 40% (2 red) a

warning timer starts and the state of charge indicator flashes slowly.

The warning timer default is 60 minutes during which the cart will

operate.

When the warning timer expires, the shutdown timer starts. The state

of charge indicator begins flashing more rapidly and an audible beep

sounds. The shutdown timer default is 10 minutes during which the

cart should no longer be used and should be plugged in as soon as

possible. Failure to begin charging prior to expiration of the shutdown

timer will result in a cutoff of all power to the cart equipment.

• A minimum amount of battery recharge must occur prior to permitting the

cart to return to cordless operation.

If the battery discharge trigger is activated, that is an indicator that the

discharge was significant. The recharge that follows must restore

approximately half the charge before the cart can be used in cordless

mode again.

Power shutdown control is achieved through the warning and

shutdown timers. Once activated, the timers can only be stopped by

plugging in the cart. A stopped timer will restart any time the cart is

unplugged provided that the charge level has not been raised enough

to be reset. The reset level for the 120V cart is 60% (2 red and 1

yellow). The reset level for the 230V cart is 75% (2 red and 2 yellow).

The SoC indicator continues to flash during charging to indicate that

the discharge floor was reached and the timers have yet to be reset.

25

Page 26

Chapter 3 Gaining Access To The Printer

If the cart is unplugged prior to the reset, the timer controlled

shutdown will resume from its previous activation and shut down the

cart when the remaining time expires. If both timers have previously

expired, the cart will shut down immediately.

• If the FAULT (red) mode LED illuminates, that indicates there is apower

irregularity.

120V: if lit, the inverter is providing power in excess of its continuous duty

rating and will overheat if maintained long enough (a safe operating

condition). If flashing, the inverter has shut down due to overheating.

230V: if lit, either the charger or the inverter is not outputting power when

it should. It is also possible for the fault light to illuminate for a sort time if

the charger is working but the batteries are very significantly discharged.

• A fault does not prevent the cart equipment from operating in Line Power

Mode. However, the cart will not operate on battery power and should be

removed from operation and reported to supervisors and maintenance

personnel for corrective action.

Gaining Access To The Printer

The printer is mounted on a slide out shelf to provide quick access for

servicing or media and ribbon replacement.

Slide The Tray To Service Position

1. Locate the shelf lock handle located under the tray on the side of the

PrintCart.

2. Make sure there is enough slack in the printer power cord to permit 10

inches of sideways movement.

3. Pull up on the spring-loaded lock handle and slide the tray with the printer

out of the right side of the PrintCart until the tray locks in the full outboard

position.

You will hear a click when the tray reaches the full outboard position and

the printer will not be able to slide back in.

Load Media Or Ribbon

1. Open the printer side media cover and follow the loading instructions in

the printer’s user’s manual.

WARNING

The media cover will only open to approximately 90 degrees. Be careful

not to hit your head on it while working.

26

2. When printer servicing is completed, close the media cover, depress and

hold the lock handle and slide the printer back to its retracted position.

3. Make sure the power cord does not become tangled.

4. Place the printer back online.

Page 27

PrintCart Features

Wheel Brake/Lock

The PrintCart is equipped with a wheel brake/lock on one of the front casters.

When applied, the brake prevents the wheel from rotating and the lock

prevents the caster from pivoting. Set this brake when using the PrintCart on

a non-level surface or loading ramp. This feature is standard on all PrintCarts.

Figure 14. PrintCart Wheel Break/Lock

Load Media Or Ribbon

Wheel Brake/Lock

PrintCart Accessories

Refuse Bin

A waste container is provided on the left side of the PrintCart near the front.

To dump the container, tilt it out and down far enough to permit dumping of

contents.

CAUTION

Do not pour liquid into this container as it is not liquid tight. The liquid

could enter the power compartment and cause damage.

Refuse Bin

Figure 15. Dumping the Refuse Bin

27

Page 28

Chapter 3 PrintCart Accessories

Document Holders

A factory or field installable dual document/notebook holder allows local

storage of documents. The holders are recessed to prevent damage when the

PrintCart is moved close to other objects.

Document

Holders

Media Storage

Compartment

Figure 16. Dual Document Holders and Media Storage Compartment

Media Storage Compartment

A media storage compartment is either factory or field installable. It allows the

storage of one printer ribbon up to 6 3/4” wide and 4” in diameter, and one roll

of media up to 6 3/4” wide and 8” in diameter. See

Figure 16 on page 28.

Barcode Scanner Storage Slot

A barcode scanner storage slot is either factory or field installable.

It prevents the scanner from accidentally falling off the PrintCart.

Barcode Scanner

Storage Slot

Utility

Drawer

28

Figure 17. Barcode Scanner Storage Slot and Utility Drawer

Page 29

Load Media Or Ribbon

Utility Drawer

A utility drawer is available to store up to 8 1/2 x 11” size paper as well as

other small items. This allows the top work surface to be kept clutter free.

Power Cord

The power cord is wrapped on a hanger on the left side of the power

compartment (see

compartment through a hole with a grommet around it, in the center of the

cord hanger. It is intentionally not long enough to reach either a wall

receptacle or the floor. PrintCarts can be rendered inoperative due to power

cord damage resulting from driving over the plug or pulling the cord to

disconnect it from a wall receptacle.

To operate the PrintCart, an external cord must be attached (one is supplied

and installed). The 120V PrintCart is supplied with a heavy gauge (14 awg)

cord approximately 10 feet long. The 230V PrintCart is supplied with a 4.3 m

(3 wire, 2mm) standard business machine power cable. An extension from the

inverter input provides an IEC 320 receptacle for connection of the business

machine cable. Choosing the appropriate business machine plug type at time

of order accommodates differing plug types.

Figure 18 on page 29). The line cord exits the power

The appropriate cord is attached to the PrintCart and secured with a

connector lock. The locked connectors are stored inside the cord hanger and

the extension cord exits the front of the hanger through a hole with a grommet

around it. When the AC extension cord is not being used, wind it around the

hanger. This prevents the cord from becoming a trip hazard or damaged by

getting stepped on or driven over. The cord hanger has extended flanges to

ensure the cord will not unwind during transport. The cord hanger is not

intended to carry more than 25 feet of cable.

Hanger

Hanger

120V NEMA 5-15 Plug and 10 ft.

Extension Cable

Figure 18. Power Cords

230V - 4.2M UK Business

Machine Cable

29

Page 30

Chapter 3 PrintCart Accessories

30

Page 31

Safety

4 Troubleshooting

During any troubleshooting activities that require access to the power

compartment, you must disconnect the input AC power cord from any external

AC outlet and set the inverter main switch to the OFF (center) position. This

removes the presence of any high voltage AC power. Always work on a level,

dry area with the caster brake set to prevent accidental PrintCart movement.

IMPORTANT

WARNING

WARNUNG

Allow only trained personnel access to the power compartment.

Gestatten Sie nur geschulten und befugten Mitarbeitern den Zugang

zum Stromversorgungsfach.

This product contains lead-acid batteries. Special care must be taken

when handling batteries.

• Batteries contain toxic materials; handle batteries with care.

• Do not puncture, disassemble or incinerate batteries.

• Charge batteries in a well ventilated area away from ignition

sources.

• Prevent positive and negative terminals from contacting each other

(short circuit). Shorting terminals causes permanent battery damage

and can result in a fire or serious personal injury.

• Do not remove or lift the battery by its output leads. Move or lift the

battery by picking up its case or by using the integrated handles.

• Dispose of batteries in according to local regulations. Lead acid

batteries may not be disposed of in household or industrial waste

containers. Disposal through hazardous waste facilities/services is

required to avoid ecological harm from battery materials. Severe

penalties may result from improper or illegal disposal.

Dieses Produkt enthält Bleiakkus. Beim Umgang mit Batterien ist

besondere Sorgfalt geboten.

• Akkus enthalten Giftstoffe und sind daher besonders sorgfältig zu

handhaben.

• Akkus keinesfalls zerstören, zerlegen oder verbrennen.

• Akkus in einem gut belüfteten Raum und nicht in der Nähe von

Zündquellen laden.

31

Page 32

Chapter 4 PrintCart Safety Features

• Der Kontakt zwischen positiven und negativen Anschlüsse ist

unbedingt zu vermeiden (Kurzschluss). Kurzschlüsse können Akkus

dauerhaft schädigen und einen Brand oder Verletzungen

verursachen.

• Den Akku keinesfalls an den Ausgangsleitungen fassen, um ihn zu

entfernen oder anzuheben. Fassen Sie den Akku stets am Gehäuse

oder an den integrierten Griffen.

• Akkus den lokalen Vorschriften entsprechend entsorgen. Bleiakkus

keinesfalls im Hausmüll oder in Behältern für Industrieabfälle,

sondern zur Vermeidung von Umweltbelastungen als Sondermüll

entsorgen. Für unsachgemäße und illegale Entsorgung können

empfindliche Strafen verhängt werden.

California Proposition 65

WARNING

Battery posts, terminals, and related accessories contain lead and lead

compounds, chemicals known to the State of California to cause cancer

and reproductive harm. Wash your hands after handling batteries.

PrintCart Safety Features

The PrintCart is equipped with numerous electrical safety devices to interrupt

electrical power should electrical malfunctions or overloads occur. These

devices are designed to protect both the power equipment and the operator.

They are located in the power compartment and can be accessed through the

front and rear access doors using a screw driver or coin.

NOTE: Access to the power compartment should be limited to specifically

trained and authorized personnel.

The 12VDC battery input to the inverter is protected with a 100-amp flat lug

type input fuse. It is bolted to the battery subpallet on top of the batteries and

is covered by a snap-on plastic cover which must remain in place when the

service disconnect is connected. The fuse has no visible indicator of its

condition, and operability must be confirmed with an electronic meter.

The 12VDC power to the upper display/control is provided through a two wire,

16 gauge cable bolted directly to the front battery. This cable includes an

automotive type ATC blade fuse adjacent to the positive battery terminal to

protect the circuit.

CAUTION

32

Prior to accessing the display panel, unplug the quick disconnect to

prevent any electrical shorts during access.

The AC input is protected by two circuit breakers, both mounted on the

inverter. There is a breaker for the charger portion of the inverter/charger

subsystem located immediately to the right of the inverter fan shroud (same

for 120V and 230V models). It is 8 Amperes for 120V charger and 3/5

Amperes for the 230V charger. The second breaker differs in capacity,

location, and purpose between the 120V and 230V units, as follows:

Page 33

• For the 120V PrintCart input, there is a 15 ampere main circuit breaker

mounted on the inverter connector panel. It controls all input power to the

PrintCart and when tripped, interrupts both charger power and passthrough (ATS) power.

• For the 230V PrintCart input, there is no main breaker. There are

separate breakers for the charger and transfer power. The transfer

breaker is 4/6 Amperes and is located to the right of the charger breaker.

In this case, if either breaker trips, the other branch remains powered.

Troubleshooting Guide

Tabl e 3. Troubleshooting Problems

Symptom Possible Cause Corrective Action

Primary Secondary

No AC ouput

regardless of

presence or

absence of AC

input.

All indicator lights

are off.

Main DC cable is

disconnected from

battery.

DC power cable is

unpluged from relay

PCBA.

Relay PCBA blad fuses

open.

Batteries are completely

discharged or

unserviceable.

Connect main DC cable

to battery.

Connect DC input to relay

PCBA.

Check and replace the

right most 1A blade fuses

on relay PCBA.

Charge batteries with an

external battery charger

for 20 minutes. Switch

onboard charger to sleep

mode by depressing the

red square button on the

right side of the charger

This lowers charging rate

to reduce the hazard of

charging unserviceable

batteries.

Reconnect to AC line

power. If a full recharge

solves the problem,

deactivate sleep mode.

Defective relay or display

PCBA.

Replace PCBA.

33

Page 34

Chapter 4 Troubleshooting Guide

Table 3. Troubleshooting Problems

Symptom Possible Cause Corrective Action

No AC output in

battery mode.

AC input is not

present.

No AC output in

battery mode.

AC input is not

present.

(continued)

1. Battery mode

LED (yellow)

is off.

2. Battery

charge is red

and flashing.

1. Battery mode

LED (yellow)

is off.

2. Battery

charge is

greater than

2 red.

3. Fault mode

LED (red) is

flashing.

1. Battery mode

LED (yellow)

is on.

2. Battery

charge is ok.

Battery is below

shutdown threshold and

has shut off inverter

power to prevent battery

damage.

Inverter output is

unplugged.

Inverter is switched off. Switch inverter on (right

Inverter fuse is open or

inverter has failed.

Equipment power cords

are not connected to

power module outlet.

Output circuit breaker is

tripped (bottom push

button breaker).

Plug in and recharge until

battery meter no longer

flashes or until a full

charge is achieved

(preferred).

Plug output cord into

inverter (right side of top

equipment on power

module).

side of top equipment on

power module).

Evaluate potential cause

of overload and remove.

Replace inverter (fuse not

replaceable).

Connect power cords to

the power module outlets.

Disconnect load and

reset output circuit

breaker by pressing it

back in. Reconnect and

switch loads on one at a

time.

34

Page 35

Table 3. Troubleshooting Problems

Symptom Possible Cause Corrective Action

AC input is

connected but

not shown as

available.

AC input is

connected and

available but the

charger is not

charging.

1. Line mode

LED (green)

is off.

2. Charger is

not

operating.

1. Line mode

LED (green)

is on.

2. Fault mode

LED (red) is

flashing.

3. Charger fan

is not

operating.

Input circuit breaker is

tripped (top push button

breaker).

Power is not present in

wall socket.

Input extension cord has

broken internally.

Input extension has

separated from cart input

cord inside the cord wrap.

Relay or display PCBA is

defective.

Charger is switched off. Turn on the charger

Charger fuse is open. Replace charger fuse on

Charger is inoperative. Replace charger.

Disconnect load and

reset input circuit breaker

by pressing it back in.

If charger operates,

reconnect and switch

loads on one at a time.

Test presence of power in

wall socket with another

piece of equipment or

meter.

Replace input extension

cord.

Inspect cord coupling and

ensure securing clip is in

place and functional.

Replace PCBA.

switch on the left side of

the charger (lower piece

of equipment).

left of charger (round

black projection).

35

Page 36

Chapter 4 Troubleshooting Guide

36

Page 37

5 Maintenance

Power Equipment Access

Gain access to the power equipment through tool latchable doors on the front

and rear of the PrintCart. Inside the power compartment, the power system is

divided into two separate replaceable subpallets. The battery subpallet (BSP)

contains the two batteries, the main fuse battery and the quick disconnect

battery. The power equipment subpallet (PESP) contains the inverter/charger,

a GFCI duplex outlet (120V version), and a power quick disconnect cable to

the BSP. These subpallets can be removed independently and are held in

place by a set of restraining bolts located on the outside of the PrintCart near

the bottom edge.

NOTE: It is not necessary to move the equipment subpallet inside the frame

to access the power equipment for inspecting or resetting safety

devices (breakers or GFCI). Simply open the door and all devices are

visible and readily accessible.

If greater access is required, such as for servicing equipment or replacing

batteries, the subpallets can be completely removed (see

Subpallet (PESP) Removal” below).

Make sure that the screws joining the two subpallets are removed. Some

factory configurations are shipped with the PESP bolted to the BSP; they

must be removed as a single unit and the mating bolts removed before the

subpallets can be handled separately. To remove the pallet as a single unit,

disconnect the PESP side as indicated below but do not remove it. Prepare

the BSP and remove the entire unit as indicated in the BSP removal process

(see

“Battery Subpallet (BSP) Removal” on page 39).

“Power Equipment

NOTE: It is not necessary for the subpallets to be joined for proper operation

and they may be replaced in the PrintCart as separate units.

Power Equipment Subpallet (PESP) Removal

1. Make sure the mating screws joining the two subpallets are removed.

2. If PrintCart is plugged into an AC outlet, disconnect the plug from the

outlet.

3. Open the rear access door on the inverter side.

4. Shut off the inverter/charger main switch located on the front of the

inverter.

5. Disconnect the PrintCart equipment power cords either in the

CFCI (120V) or in the face of the inverter (230V).

6. Disconnect the blue inverter display data cable from the inverter.

37

Page 38

Chapter 5 Power Equipment Access

7. Loosen the AC grounding lug and remove the green grounding wire that

runs to the PrintCart frame.

8. Open the front door of the PrintCart and unplug the battery main quick

disconnect.

9. Disconnect the AC input cord according to the model you have.

120V PrintCart

a. Unwind the extension cord and expose the plug connector stored

inside the cord wrap.

b. Raise and disconnect the coupled plugs.

c. Push the plug through the grommet hole, back into the power

compartment.

d. Pull the short input cord and wrap it over the inverter to make sure it

does not catch.

230V PrintCart

a. Unplug the IEC 320 input plug from the front of the inverter and hang

the cable out of the way over the door.

10. Remove the two restraining bolts located on each side of the PrintCart

that hold the equipment subpallet.

11. Slide the equipment pallet out the rear door far enough to get a good grip

on it. Be prepared to support 25 lbs of the subpallet.

12. Pull the subpallet out the remaining distance and lift the unit from the

PrintCart.

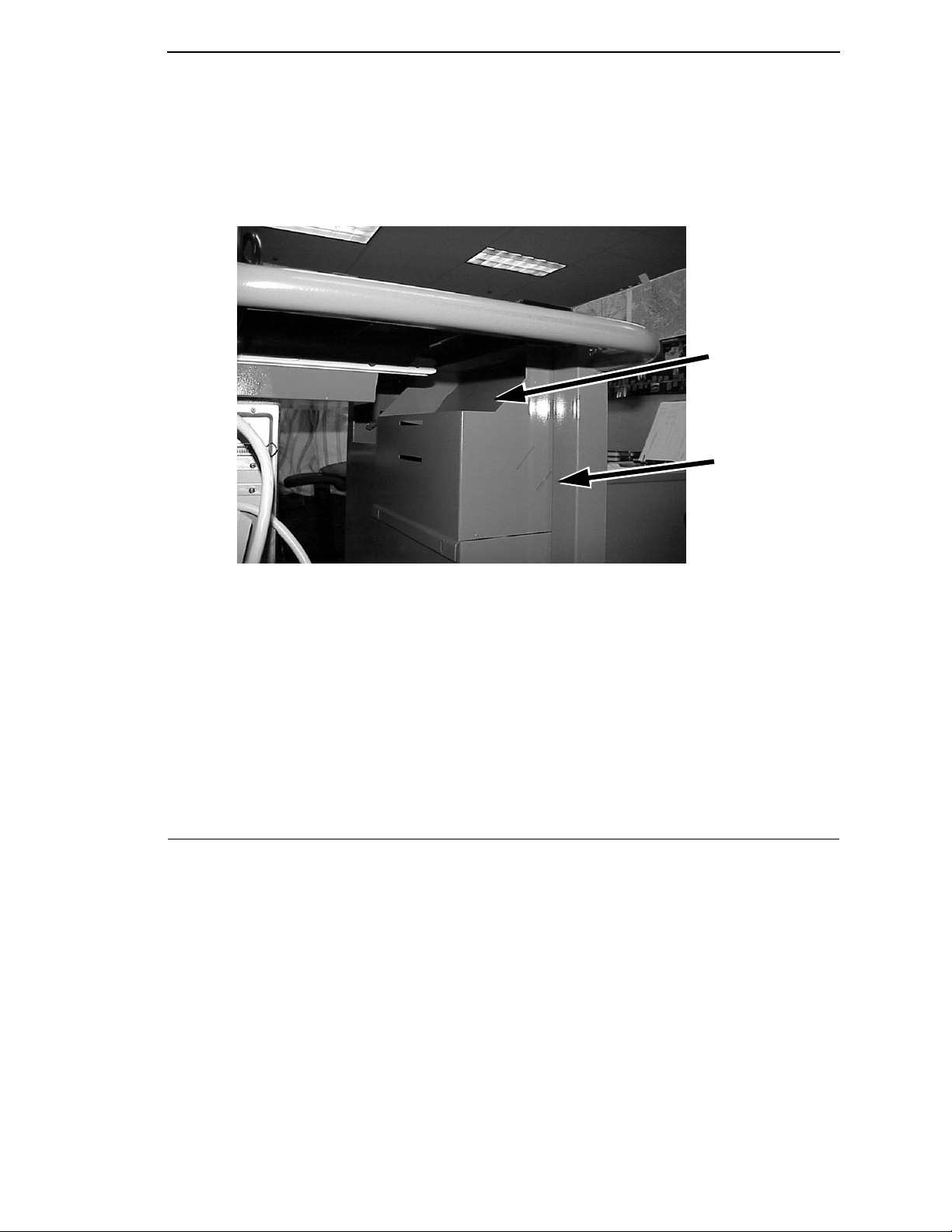

Power Equipment

Subpallet

Figure 19. Power Equipment Subpallet

38

Page 39

Battery Subpallet (BSP) Removal

1. If the PrintCart is plugged into an AC outlet, disconnect the plug from the

outlet.

2. Open the rear access door.

3. Shut off the inverter/charger main switch located on the front of the

inverter.

4. Open the front door and disconnect the main battery quick disconnect

and hang it so it is out of the way.

5. Disconnect the display power cord quick disconnect and move it to the

side.

6. Remove the two side restraining bolts that hold the BSP in place. These

are located on the side of the PrintCart frame.

7. Obtain a pallet jack and center one leg of the jack approximately

18 inches under the BSP.

8. If using a pallet jack, lift the BSP about 1/4 inch and slowly pull back on

the jack to remove the pallet from the PrintCart frame. If the BSP gets

caught with the PrintCart, the lift may be either too little or too much.

WARNING

The BSP weighs between 150 and 230 lbs (depending on batteries

used). Be careful when removing the battery subpallet.

Battery Subpallet

Pallet Jack

Figure 20. Battery Subpallet

39

Page 40

Chapter 5 Serviceability Inspection

Serviceability Inspection

NOTE: Only trained personnel should perform this inspection/maintenance.

Periodically open the power compartment and inspect the internal

components for signs of loose connections, excessive dirt and dust buildup,

or any other condition that is out of the ordinary. Clean the cooling fan intake

and exhaust ports on the inverter every six months. Other ventilation features

should also be serviced at that time.

Any time the power compartment is accessed, disconnect the AC line power

cord from AC power and set the inverter to the OFF position.

Battery Replacement

Battery replacement is only required when batteries fail to hold sufficient

charge to support PrintCart operational requirements. If operated in

accordance with these instructions, the batteries should perform well for a

minimum of 3 years (600 charge/discharge cycles of 70%). Batteries will

slowly lose some of their charging capacity over time. This should be

noticeable but will not affect operational requirements.

WARNING

WARNING

When the batteries begin to fail, both batteries will not necessarily fail together

but the failure of one battery will cause the failure of the other. By the time you

notice a significant degradation in performance, one battery has already failed

and has probably damaged the remaining battery enough that it cannot

recover. For this reason, both batteries must be replaced at the same time.

Both replacement batteries must also be identical in capacity, and preferably

be made by the same supplier. Replacement batteries must conform to the

standards established in the repair parts section for dimensions, battery type,

and terminal type (see

these requirements will ensure that you do not compromise safety and

performance standards.

Because of the high electrical energy and potential for flammable gases

associated with lead acid batteries, use extreme care when servicing the

batteries. Maintenance must be done in a well-ventilated area by a

trained service technician. The service technician must wear safety

glasses, leather gloves, and steel-toed boots or shoes.

To easily and safely replace the battery, remove the BSP first (see page 39)

and place it on a suitable work surface.

Do not work on the BSP while it is resting on the pallet jack fork.

“Electrical Specifications” on page 48). Adherence to

40

Page 41

To Replace Batteries

1. Lift the protective covers on the battery (-) terminals and remove the bolts

and washers holding the cables in place. See

2. Perform the same operation on the battery (+) terminals. Be sure to save

all nuts, bolts and washers removed.

3. Loosen and remove the battery clamp knob.

4. Lift the clamp plate, cables, fuse and disconnects from the battery pallet

as a single unit.

5. Ensure the pallet is fully supported all around, then remove both batteries

from the subpallet one at a time and set them aside for disposal.

6. Obtain a new set of batteries to be installed and place them into the same

position on the subpallet as the old batteries. Be sure and observe that

the polarity of the battery terminals is correct.

Figure 21 on page 42.

WARNING

WARNING

Exercise care in lifting. Use a second person if necessary to avoid back

strain.

If the batteries are a different length, adjust the bottom brackets to the

appropriate width to keep both batteries centered. If the batteries are a

different height, loosen the lock nut at the base of the thread rod and raise

or lower the thread rod to make the top approximately 1/2” to 3/4” higher

than the top of the battery.

7. Replace the clamp plate and secure the center knob so it is tightly snug.

8. Re-install the battery terminal wiring (red to (+) positive terminal and black

to (–) negative terminal) and secure the terminal hardware.

Reversing battery polarity on the interconnect cables could result in

damage to the cables and batteries and can also cause an explosion.

Make sure that the terminal covers are also in place and adequately

cover the terminal hardware.

9. Re-install the BSP into the PrintCart frame.

10. Install the restraining bolts on both sides of the PrintCart to secure the

pallet in place if daily battery exchange is not practiced for PrintCart

operation. Before installing the screws, use the tip of the screwdriver to

insure the hole in the BSP is aligned with the hole.

11. Re-connect the LED display power cord and the main battery disconnect.

12. Close and latch the front door.

This completes the battery replacement procedure. Be sure to fully charge the

new batteries before using them.

41

Page 42

Chapter 5 Inverter Replacement

Battery (+)

Protective Covers

Clamp Plate, Cables,

Fuse, and Disconnects

Battery

Clamp Knob

Battery (-)

Protective

Covers

Figure 21. Replacing the Battery

Inverter Replacement

Make sure other causes for power failure are eliminated before replacing the

inverter, (see

inspection may prevent unnecessary replacements. The inverter is an integral

part of the power equipment subpallet (PESP) and is not available as a stand

alone unit. The PESP must be replaced as a single unit. The removal process

is described in

Table 3, Troubleshooting Problems on page 33). Simple

“Power Equipment Subpallet (PESP) Removal” on page 37.

42

Figure 22. Inverter Replacement

Page 43

Fuse Replacement

There are two fuses on the PrintCart:

• Display Panel Fuse – located between the front most battery terminals in

an in-line holder.

• Main Fuse – located on top of the battery clamp plate inside a black

plastic housing.

An open fuse means an abnormal situation exists in the power system.

Excessive equipment loading or possible short circuits may exist. Carefully

examine all components and wiring in the system for damage before

replacing a fuse to prevent a re-occurrence of the failure.

Display Fuse

1. Open the rubber fuse holder and pull the blown fuse out.

2. Replace only with an identical 1 Amp blade fuse (ATO 1).

3. Close the rubber fuse holder after replacement.

Display Fuse

Main Fuse

1. Switch the inverter OFF.

2. Unplug the DC power service disconnect on top of the battery clamp

plate.

3. Unplug the LED display power cord disconnect.

4. Using a pallet jack or subpallet carrier, remove the battery pack.

5. Lift the snap-on cover on the front until it opens.

6. Loosen and remove both M8 nuts (13 mm or 1/2 inch open end wrench)

and carefully lift the fuse from the threaded terminal posts.

7. Install the new fuse onto the studs.

8. Reverse the above procedure to reinstall connections.

M8 Nuts

Figure 23. Replacing the Main DC Power Fuse

43

Page 44

Chapter 5 Power Cord Replacement

Power Cord Replacement

The AC line cord (power cord) is designed to be user replaceable. The

connection between the external cord and the inverter input cord is located in

the cord hanger on the side of the PrintCart.

1. Completely unwrap the cord from the storage hanger.

2. Lift the plug connector out of the hanger recess.

3. Remove the cord coupling and disconnect the two cords.

4. Obtain a proper replacement extension cord and reverse this procedure

to reinstall.

The 120VAC and 230VAC PrintCarts have different connector styles.

The 120VAC PrintCart uses a NEMA 5-15 connector (see Figure 24).

The 230VAC PrintCart uses an IEC-320 connector (see Figure 25).

The IEC 320 connector allows a variety of business machine power cables to

be used depending on the connector the user requires.

Figure 24. NEMA 5-15 Connector

Figure 25. IEC-320 Connector

NEMA 5-15

Connector

IEC-320

Connector

44

Page 45

Wheel Replacement

Caster Wheels

Removal

Recommended replacement caster wheels are specified in the repair parts

section (see

1. Prevent the PrintCart from rolling by placing a 3/4 inch (approximately

19 mm) thick board behind the fixed wheel.

2. Elevate and support the entire end of the PrintCart, lifting the caster end

approximately 1 inch off the ground.

3. Remove the three 5/16 Nylock retaining nuts (1/2 inch open end wrench).

4. Remove the caster wheel.

Installation

Caster Wheels

“Spare Parts” on page 51).

1. Install the new caster by reversing the above process.

2. Make sure the nuts are tight.

3. Replace any nylock nuts if the nylon locking element is too worn to

provide retention.

Casters are available in various brands and styles. If the replacement is a

different brand than the original, it may be necessary to replace both since

caster mount heights vary enough to cause the PrintCart to rock.

Fixed Wheels

Removal

Recommended replacement wheels are specified in the repair parts section

(see

“Spare Parts” on page 51).

1. Engage the caster wheel lock.

2. Lift and support the entire end of the PrintCart so the wheel is raised

approximately 1 inch off the ground.

3. Remove the external snap ring and thrust washer from the end of the

axle.

4. Remove the wheel.

Installation

Install the new wheel by reversing the above process.

The wheel is a commonly available style using an 8 inch outer diameter and a

5/8 inch bore. The hub is offset. Local replacements may be available that fit

this requirement. If the replacement is not identical to the original, it may be

necessary to replace both to ensure that the PrintCart does not rock.

45

Page 46

Chapter 5 Hand Grip Replacement

Hand Grip Replacement

1. Remove the hand grips by placing your fingertips on the innermost

shoulder of the grip and pulling it straight off the steel handle.

If that is too difficult, insert a small flat screwdriver blade under the grip to

loosen it and stretch the grip away from the steel handle.

2. Twist the grip while pulling it off.

3. Install the new grip onto the handle by pushing only on the end of the grip.

If it is too tight, apply a small amount of a mild solution of soap and water.

Replacement grips can be found from local sources and need to fit a 1 inch

outer diameter tube. Some are specified in the spare parts section

(see “Spare Parts” on page 51).

46

Page 47

A Specifications

Physical Specifications

Characteristic

Operating

Height (SS top/barcode storage) 40 in./47 in. (101.6 cm/119.4 cm)

Width (frame/wheels) 21 in./22 in. (53.3 cm/55.9 cm)

Length (SS top/handles) 25 in./36 in. (63.5 cm/91.5 cm)

Weight (without printer or terminal) 280 lbs (127 kg)

Printer Shelf Load Capacity 70 lbs (32 kg)

Work Surface Stainless Steel

Printer Slide-Out Shelf Painted Steel

Printer Shelf Extension 11 in. (27.9 cm)

Wheels 2 - 5 in. (12.7 cm) caster, one locking (front)

North American

(120V/60 Hz)

21 in. (53.3 cm) wide x 25 in. (63.5 cm) long

14 in. (35.6 cm) wide x 20.25 in. (51.4 cm)

length with predrilled mounting for SL5000r/

T5000r printers. Includes shock mounts.

2 - 8 in. (20.3 cm) fixed wheel (rear)

European

(230V/50Hz)

47

Page 48

Appendix A Electrical Specifications

Electrical Specifications

Characteristic

Battery Capacity

2 x 100 Amp-hour

Battery Type Sealed Lead Acid, Absorbed Glass Mat (AGM)

Charger/Inverter Type RV750ULHW APSX600

AC Inverter Output 120V/60 Hz/750 w 230V/50 Hz/600 w

12VDC Charger Capacity 45A 45A

Input Current (Maximum) 15A (@ 120VAC) 8A (@ 230VAC)

Input Plug NEMA 5-15 male

Output Receptacle 2 - NEMA 5-15 on

Warning Alarm - working time prior to

shutdown alarm

Shutdown Alarm - delay prior to shutdown 10 minutes

North American

(120V/60 Hz)

Recharge time to recover 60+% charge

3.2 hr 4.0 hr

3-prong plug (fixed)

GFCI

60 minutes

European

(230V/50Hz)

User selectable

(IEC 320 male socket

connector)

2 - IEC 320 female

48

Page 49

B Wiring Schematics

120V/60Hz

Figure 26. Wiring Schematic for North American Models (120V/60Hz)

49

Page 50

Appendix B 230V/50Hz

230V/50Hz

This design concept consists of a 2 part

control system. A "relay" PCBA

manages AC power switching and a

display/control PCBA for control logic

and display functions. The relay PCBA

is located in the cart power module

interconnected compartment where

equipment and cabling can connect

directly. The display/control PCBA is

located in the top front left corner of the

cart where it is visible to the user. It is

linked to the relay PCBA with a 7 ft. Cat

5 network cable. The micro-controller

senses DC voltage separately for

charge and discharge cycles and

displays a relative battery state of

charge on the 6 segment LED bar

display.

50

Figure 27. Wiring Schematic for European Models (230V/50Hz)

Page 51

C Spare Parts

Description Capacity Style Printronix PN

Battery, AGM 100 Amp Hr NB Terminal 205235-001

Battery Charger (230VAC) 12v @ 45A 230V 50 Hz 205327-001

Inverter (120VAC) 750 Watt-120V 120V 60 Hz 205394-001

Mod. Sine Inverter (230VAC) 600 Watt 12VDC Input 205334-001

Main DC Fuse 100 A Bolt through tab 205296-001

Display Fuse 2 A Std Blade 205297-001

Display Fuse 1 A ATC Blade 211014-001

Output Breaker 5A - 230V Push to Reset 211040-001

Input Breaker 8A - 230V Push to Reset 211041-001

5 inch Caster 300 lbs Bolt on Plate 205300-001

5 inch Caster with Lock 300 lbs Bolt on Plate 205299-001

8 inch Offset Wheel 400 lbs 5/8 inch ID with

Bearing

Power Cord 14 ga./3 wire NEMA 5-15 plug 205426-001

240V, 6A, UK, Detachable 6A UK 3 Prong 102512-007

250V, 6A, Shuko Detachable 6A UK 3 Prong 102512-004

Relay & Display PCBA Separable PCBAs Version 3 only 253090-001

Rubber Hand Grip Fit 1 inch OD Cushioned, Smooth 205339-001

205301-001

51

Page 52

Appendix C

52

Page 53

D Glossary

AC Alternating Current, current that reverses direction

periodically. The output of the inverter system or a

wall receptacle is AC power.

AGM Absorbed Glass Mat, the type of lead acid battery

used in the PrintCart. The electrolyte in the battery is

absorbed into a fiberglass sheet in proximity to the

lead plates.

Amp Ampere, a measure of electrical current. One

coulomb of charge per second equals 1 Amp.

Amp-Hour A term used to describe the charge storage capacity

of a battery. For example, a 100 amp-hour battery

should be able to deliver a current of 10 amps for 10

hours or 5 amps for 20 hours, etc.

Battery An electro-chemical storage device that stores

electrical charge.

Charger An electrical device that supplies electrical current,

used to replace the charge in batteries.

Circuit Breaker An electronic device designed to open or break a

circuit when the current flowing through the device

exceeds a specified amount, and which can be reset

to allow current to flow.

Coulomb A unit of electrical charge equal to the quantity of

electricity transferred by a current of 1 Amp in

1 second.

Current The amount of electrical charge flowing through a

wire or circuit per unit time. It is measured in

Amperes.

DC Direct Current, current that flows in a single direction.

Depth of Discharge A term used to describe the percentage amount of

the total charge that has been drained from a battery.

For example, if the depth of discharge of a battery is

70%, that means that 70% of the total charge has

been drained leaving approx. 30% remaining in the

battery.

53

Page 54

Appendix D

Electrolyte An ionic solution, usually distilled water and sulphuric

acid, that enables the flow of electrons in a battery

from the negative plate to the positive plate.

Fuse An electrical device designed to melt, break, or open

when electrical current flowing through it exceeds the

specified amount. Its purpose is to protect electrical

circuitry from damage caused by excessive current

flow.

Inverter An electrical device that converts direct current (DC)

into alternating current (AC).

LED Light Emitting Diode. Used in the PrintCart display.

Load A descriptive term used to represent a piece of

equipment or anything that requires or draws

electrical power to operate.

OEM Original Equipment Manufacturer.

Power The mathematical product of Voltage x Current.

Expressed in the units of Watts.

State of Charge A term used to describe the percentage of total

charge that remains in a battery. For example, if the

state of charge in a battery is 70%, it means that 70%

of the total charge capacity is still present in the

battery and roughly 30% has been drained.

Volt A unit of electrical potential or electromotive force.

The PrintCart electrical system is based on 12-volt

batteries.

54

Page 55

E Contact Information

Printronix Customer Support Center

IMPORTANT

Please have the following information available prior to calling the

Printronix Customer Support Center:

• Model number

• Serial number (located on the back of the printer)

• Installed options (i.e., interface and host type if applicable to the problem)

• Configuration printout:

Thermal Printer

See “Printing A Configuration” in the

Line Matrix Printer

Press PRT CONFIG on the control panel, then press Enter

• Is the problem with a new install or an existing printer?

• Description of the problem (be specific)

• Good and bad samples that clearly show the problem (faxing of these

samples may be required)

Americas (714) 368-2686

Europe, Middle East, and Africa (31) 24 6489 311

Asia Pacific (65) 6548 4114

China (86) 800-999-6836

Quick Setup Guide

http://www.printronix.com/support.aspx

Printronix Supplies Department

Contact the Printronix Supplies Department for genuine Printronix supplies.

Americas (800) 733-1900

Europe, Middle East, and Africa 33 (0) 1 46 25 19 07

Asia Pacific (65) 6548 4116

China (86) 400-886-5598

http://www.printronix.com/supplies-parts.aspx

or (65) 6548 4182

55

Page 56

Appendix E Corporate Offices

Corporate Offices

Printronix, Inc.

14600 Myford Road

P.O. Box 19559

Irvine, CA 92623-9559

Phone: (714) 368-2300

Fax: (714) 368-2600

Printronix, Inc.

Nederland BV

P.O. Box 163, Nieuweweg 283

NL-6600 Ad Wijchen

The Netherlands

Phone: (31) 24 6489489

Fax: (31) 24 6489499

Printronix Schweiz GmbH

42 Changi South Street 1

Changi South Industrial Estate

Singapore 486763

Phone: (65) 6542 0110

Fax: (65) 6546 1588

Printronix Commercial (Shanghai) Co. Ltd

22F, Eton Building East

No.555, Pudong Av.

Shanghai City, 200120, P R China

Phone: (86) 400 886 5598

Fax: (86-21) 5138 0564

Visit the Printronix web site at www.printronix.com

56

Page 57

Index

Numerics

120V/60Hz Wiring Schematics, 49

230V/50Hz Wiring Schematics, 50

A

Accessories, 27

refuse bin, 27

B

Barcode Scanner Storage Slot, 28

Battery Power Operation, 23

PrintCart operating duration, 23

Battery Replacement, 40

Battery Subpallet Removal, power equipment, 39

C

Caster Wheels, replacement, 45

Contact information, 55

Customer Support Center, 55

D

F

Fixed Wheels, replacement, 45

Fuse Replacement, 43

display fuse, 43

main fuse, 43

H

Hand Grip, replacement, 46

I

Indicator Panel, 24

Inverter Replacement, 42

L

Layout, PrintCart, 16

Limitations, operating, 12

Line Power Operation, 21

Load Media, 26

Load Ribbon, 26

M

Display Fuse Replacement, 43

Document Holders, 28

E

Electrical Installation, 10

printer hook-up, 10

terminal hook-up, 11

Electrical Specifications, 48

Equipment Setup, 9

electrical, 10

mechanical, 9

Main Fuse Replacement, 43

Maintenance, 37

battery, 40

caster wheels, 45

display fuse, 43

fixed wheels, 45

fuse, 43

hand grip, 46

inverter, 42

main fuse, 43

power cord, 44

serviceability inspection, 40

57

Page 58

Mechanical Installation, 9

printer, 10

terminal, 9

Media Storage Compartment, 28

O

Operating Limitations, 12

Operation

battery power, 23

line power, 21

PrintCart, 23

Overview, PrintCart, 15

P

Physical Specifications, 47

Power Cord, 29

replacement, 44

Power Equipment

access, 37

battery subpallet removal, 39

subpallet removal, 37

PrintCart

accessories, 27

barcode scanner storage slot, 28

battery power operation, 23

battery replacement, 40

bottom level, 15

caster wheels, 45

document holders, 28