Page 1

Operating Instructions and Parts Manual

Accu-Fence®

for Models 66, 72A, PM2000, PM3000

Powermatic

427 New Sanford Rd.

LaVergne, TN 37086 Part No. M-2195079Z

Ph.: 800-274-6848 Revision C 01/2015

www.powermatic.com Copyright © 2015 Powerm atic

Page 2

Warranty and Service

Powermatic warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair,

please contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

Powermatic branded website.

• Powermatic products carry a limited warranty which varies in duration based upon the product. (See chart

below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Co vered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance. Powermatic woodworking machinery is designed to be used with

Wood. Use of these machines in the processing of metal, plastics, or other materials outside recommended

guidelines may void the warranty. The exceptions are acrylics and other natural items that are made specifically for

wood turning.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provide proof

of initia l p u rch a s e whe n calling. If a product requires further inspection, the Technical Service representative will

explain and assist with any additional action needed. Powermatic has Authorized Service Centers located throughout

the United States. For the name of an Authorized Service Center in your area call 1-800-274-6846 or use the Service

Center Locator on the Powermatic website.

More Informa tion

Powermatic is constantly adding new products. For complete, up-to-date product information, check with your local

distributor or visit the Powermatic website.

How State Law Appli es

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

POWERMATIC LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH

PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW

LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

POWERMATIC SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR

FOR INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF

OUR PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

Powermatic sells through distributors only. The specifications listed in Powermatic printed materials and on the official

Powermatic website are given as general information and are not binding. Powermatic reserves the right to effect at

any time, without prior notice, those alterations to parts, fittings, and accessory equipment which they may deem

necessary for any reason whatsoever.

Product Listing with Warranty Period

90 Days – Parts; Consumable items

1 Year – Motors, Machine Accessories

2 Year – Woodworking Machinery used for industrial or commercial purposes

5 Year – Woodworking Machinery

NOTE: Powermatic is a division of JPW Industries, Inc. References in this document to Powermatic also apply to

JPW Industries, Inc., or any of its successors in interest to the Powermatic brand.

2

Page 3

Table of Contents

Warranty and Servic e .............................................................................................................................. 2

Table of Contents .................................................................................................................................... 3

Specifica tions ................................................................................................................ .......................... 3

Unpac king ............................................................................................................................................... 4

Rail Installation on a Powermatic Table Saw ............................................................................................ 4

Installing the Front Rail......................................................................................................................... 5

Installing the Back Rail ......................................................................................................................... 5

Installing the Wood Extension Table ..................................................................................................... 6

Securing Wood Table to Front Rail ....................................................................................................... 7

Securing Wood Table to Back Rail ....................................................................................................... 8

Installing the Guide Tube ..................................................................................................................... 8

Mounting the Acc u-Fenc e .................................................................................................................... 9

Side Plate Replacement ..................................................................................................................... 11

Rail Install ation on a non-Powermatic Table Saw ................................................................................... 12

Installing the Front Rail....................................................................................................................... 12

Installing the Back Rail ....................................................................................................................... 13

Replacement Parts ................................................................................................................................ 14

Rail Assembly .................................................................................................................................... 14

Accu-Fence Parts .............................................................................................................................. 15

Accu-Fence Assembly........................................................................................................................ 16

Specifications

Fence side plate length:

For 10” cabinet saws ............................................................................................................. 37-3/8 ”

For 12” and 14” cabinet saws ................................................................................................ 45-5/8”

Fence width ...................................................................................................................................... 4-1/2”

Fence height:

For 10”, 12” and 14” cabinet saws ........................................................................................... 2-1/2”

Head length:

For 10”, 12” and 14” cabinet saws ............................................................................................... 16”

The above specifications were current at the time t his manual was published, but bec ause of our policy of

continuous im provement, Powerm atic reserves the right t o change specific ations at any time and without

prior notic e, wit hout incurring obligations.

3

Page 4

Unpacking

Open shipping cartons and check that all parts

are intact. Report any damage immediately to

your distributor. Read the instruction manual

thoroughly for assembly, alignment, and

maintenance instructions.

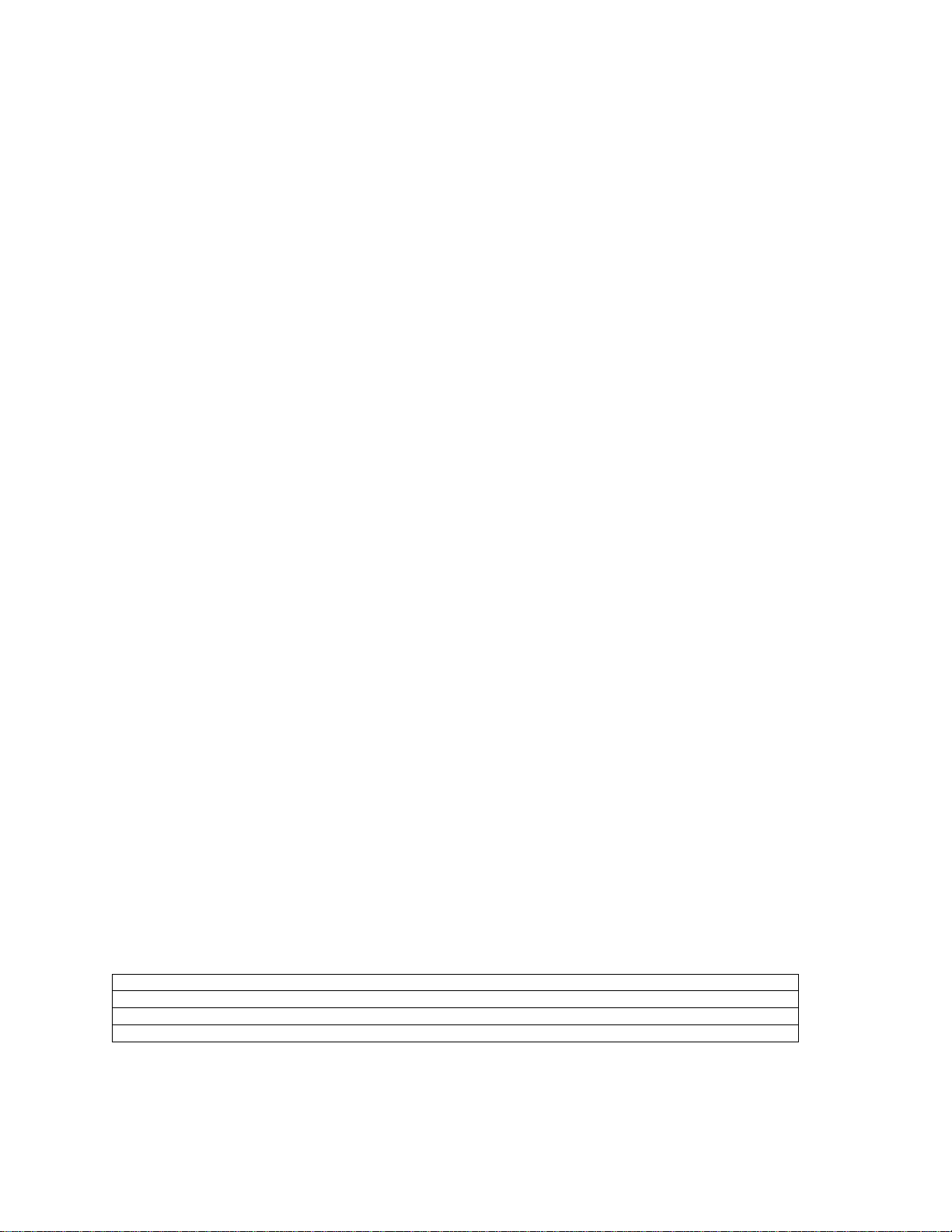

Box contents

Box One

1 Accu-Fence (A)

1 Lock Lever Knob (B)

2 Plastic Shims (not shown)

1 Owner’s Manual (not shown)

Box Two

1 Front Rail (C)

1 Back Rail (D)

1 Guide Tube (E)

2 End Caps (not shown)

1 Hardware Bag (see contents below)

Contents of Hardw ar e B ag (shown at right)*

02 5/16-18 x 7/8" Hex Cap Screw

06 5/16-18 x 1-1/2" Hex Cap Screw

14 5/16" Flat Washer

08 5/16" Lock Washer

06 5/16" Hex Nut

10 1/4-20 x 1-1/2" Flat Head Screw

08 1/4-20 x 3/4" Hex Cap Screw

10 1/4" Flat Washer

18 1/4" Lock Washer

10 1/4" Hex Nut

* NOTE: Hardware bag is shipped inside the

guide tube.

Contents of Box 1

Contents of Box 2

Rail Installation on a

Powermatic Table Saw

Tools required

10mm and 12mm wrenches

Cross-Point (“Philips”) screwdriver

5mm hex wrench

Adjustable square

Rubber mall et (or hammer and wood bloc k )

Straight edge

The following instructions are for installing the

Accu-Fence and Rail System on a Powermatic

Model 66, 72A, PM2000 or PM3000 table saw.

The rail s should bolt up to the Powermatic saw

without any drilling.

Contents of Hardw ar e B ag

4

Page 5

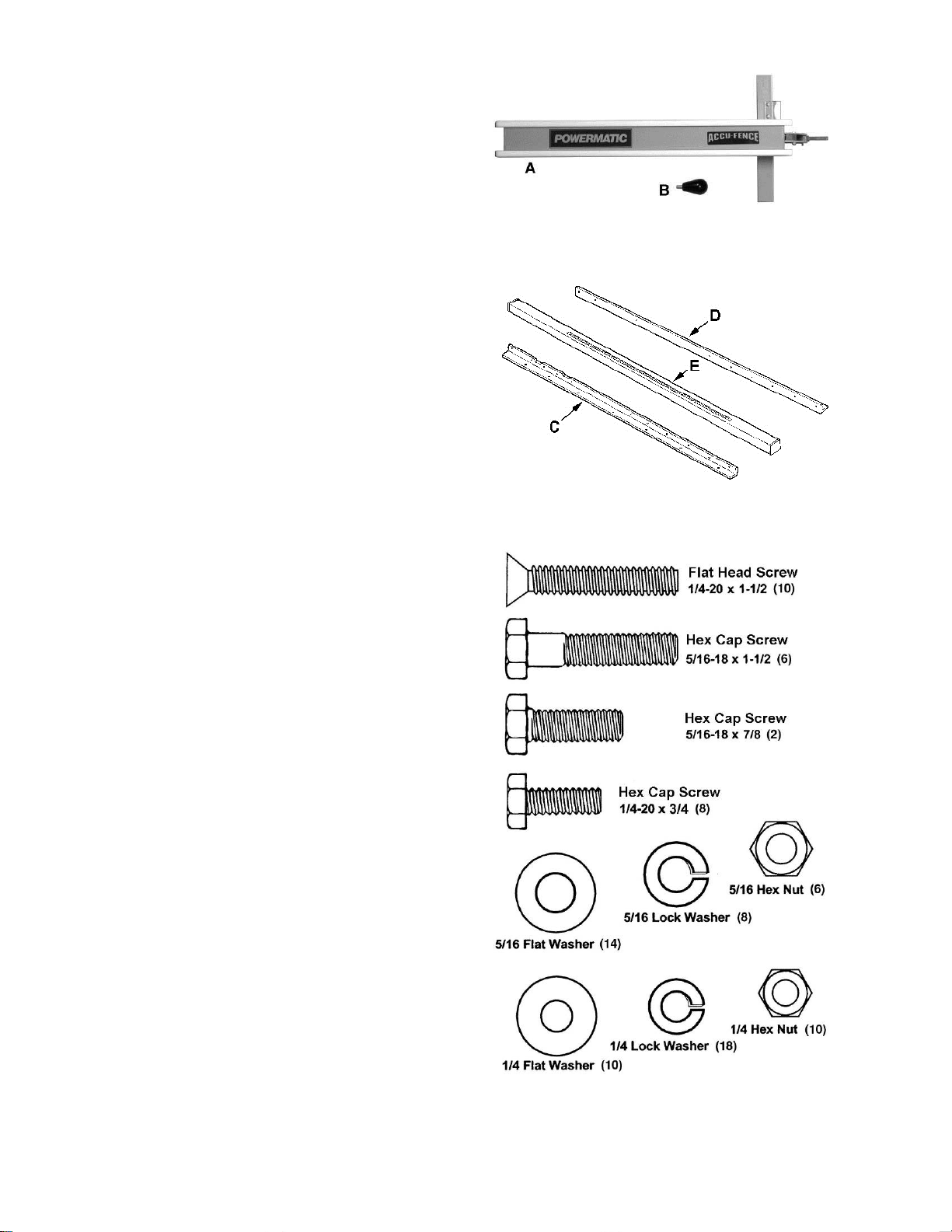

Installing the Front Rail

1. Identify the front rail, which is 3" x 3" with

notches on one side.

2. Align the holes on the notched side of the

front rail t o the hol es i n the f r ont edge of t he

table saw top, as shown in Figure 1. The

notches should fall below the miter slots in

the table.

Note: The rail's second hole from the left

should line up wit h the first hole in the tabl e

top as shown. The saw's extension wings

are not pre-drilled at the factory, so use of

the first hol e on the rail is optional.

3. Lightly secure the fr ont rail to the saw table

with four 1/4-20 x 1-1/2 flat head screws,

four 1/4 flat w ashers, f our 1/ 4 lock washers,

and four 1/4 hex nuts (Figure 2). Fingertighten only .

The front rail m ust be paral lel to the t able top i n

order for the Accu-Fence system to function

properly.

Figure 1

1. Pl ace an adjustable square on the table as

shown in Figure 3.

2. Check t he height of the front rail at several

locations along t he surface of the saw table.

The measurements should be the same

along the length of the rail. (Generally, this

dimension will be about 2-27/32”.)

3. When the front rail has been correctly

positioned, tighten all mounting screws

securely with a screwdriver and 10mm

wrench.

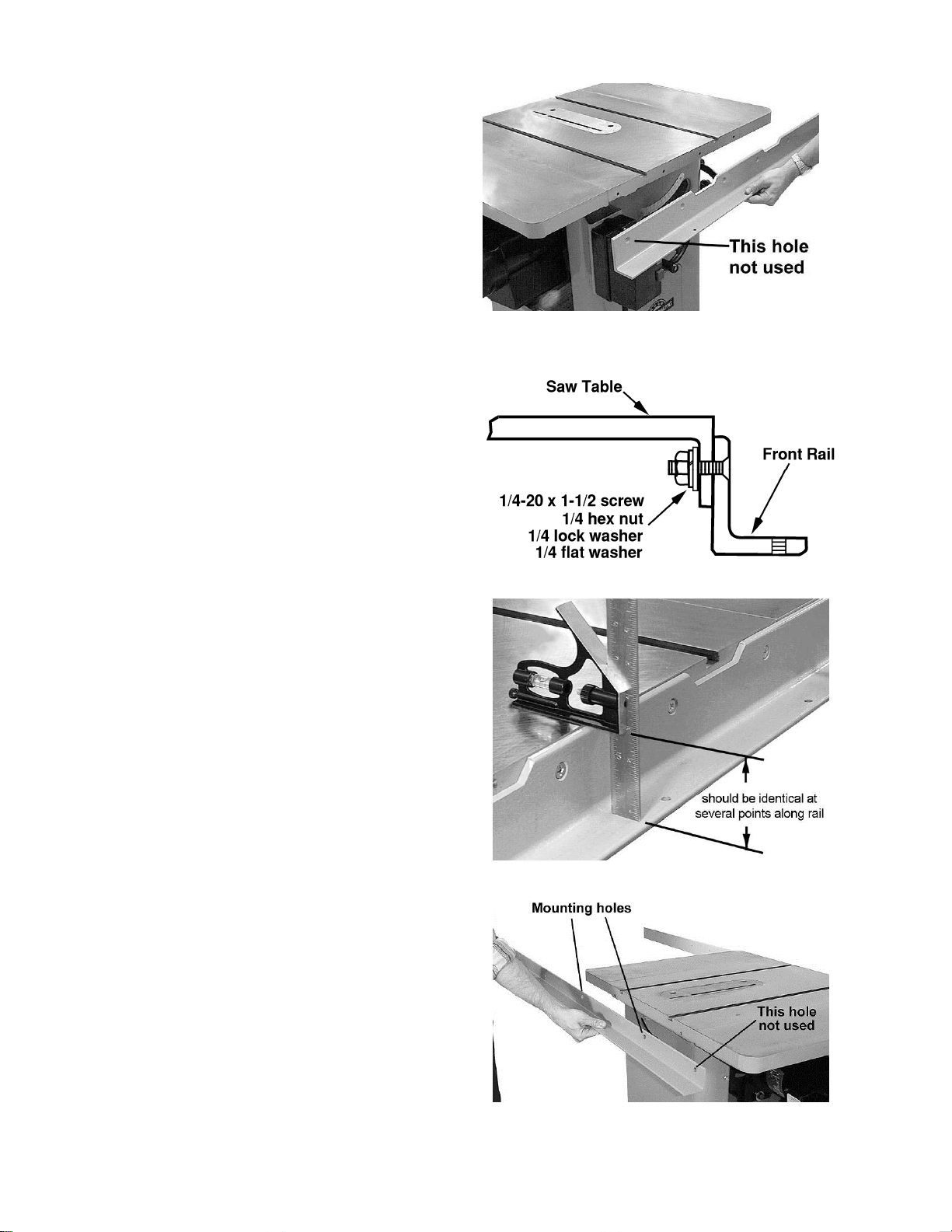

Installing the Back Rail

1. Locate the back rail which is 2" x 2" with

holes running al ong one si de only . T he back

rail should be installed parallel to the table

top.

Figure 2

Figure 3

2. Align the holes in the back rail to the holes in

the table top, as shown in Figure 4.

Note: The rail's second hole from the right

should line up wit h the first hole in the tabl e

top as shown. The saw's extension wings

are not pre-drilled at the factory, so use of

the first hol e on the rail is optional.

Figure 4

5

Page 6

Referring to Fi gur e 5:

3. Secure the back rail (A) to the pre-tapped

holes in the saw table (B) i n two places with

5/16-18 x 7/8 hex cap scr ews (C), 5/16 lock

washers (D), and 5/16 flat washers (E).

Finger tighten only.

4. Use the adjustable square to measure at

several points along the rail to achieve

parallel with table. Tighten screws securely

with a 12mm wrench.

Important: If you are installing an optional wood

extension table on your saw, it should be

installed first before mounting the guide tube.

This will prev ent having to mount and align t he

guide tube twic e.

If you are not mounting an optional wood table,

proceed to Installing t he Guide Tube on page 8.

Installing the Wood Extension Table

The wood extension table is an optional

accessory.

Tools required:

Electric drill

Philips screwdriver

10mm and 12mm wrenches

Four clamps

Straight edge

Hammer (or rubber m allet)

Installing the Legs

Legs are optional accessories. If your wood

table does not require legs, proceed to

“Installing the Table.”

Figure 5

1. Place the optional wood extension table

upside down. (U se a mat or cloth to prot ect

the surface) . Position the legs at the i nside

corners of t he wood table at the end where

the Powermatic logo is placed. See Figure

6.

Note: If you are usi ng a mobile base under

your saw, you may need to shift the

placement of the legs so that they rest

properly upon t he shelves of the base.

2. Drill pilot holes, making sure not to drill

completely through the table and sides.

3. Secure with the eight screws provided.

4. Turn the wood table ri ght-side up.

5. The f ootpads on the legs can be rotated to

help level the wood table with the saw

during the following procedure. Tighten the

nut against the end of the leg to secure a

footpad’s position.

Figure 6

6

Page 7

Installing the Table

The optional wood ext ension t able (i ncludi ng the

optional router table) sits flush against the saw

table and along the inside of the rails. The

Powermatic logo (or warning label on the router

table) should face outward. T he ex t ension tabl e

is not bolt ed to the saw table. It is bolted only t o

the rails.

The extension table and saw table must be

aligned properly so the Accu-Fence will slide

smoothly fr om one to the ot her .

1. Pl ace the extension table bet ween the rails

and up against the saw table, leaving the

extension t abl e raised just sli ghtly abov e the

saw table. Cl amp the extension table to the

front and back rails as shown in Figure 7.

Clamping pressure should be enough to

secure the table yet allow minor

adjustments.

2. Use a rubber m all et ( or a hammer and bl ock

of wood) to tap t he ext ension table up f lush

against the cast iron saw table (Figure 6).

Then tap down the extension table at

various point s along its edge where it meet s

the saw table, until it is level with the saw

table (Figure 8).

3. As one part of the edge becomes l evel with

the table, tighten the clamp on that side.

Then move to the other side and repeat,

until the full lengt h of the edge is level with

the saw table.

Figure 7

Figure 8

4. Lay a straight edge across both extension

table and saw table to ensure proper

leveling.

5. When extension table is properly aligned,

drill holes into the wood table using the

holes in the rai ls as your gui de. See F igure

9. (You may wish to drill 3/32" pilot holes

first. ) Drill 1/4" holes int o the front edge of

the table usi ng the holes in the front rail as a

guide. Dri ll 5/16" holes into the bac k edge

of the table using t he holes in the back rail

as a guide.

Securing Wood Table to Front Rail

Referring to Fi gur e 10:

Inser t six flat head screws (A) through the front

rail and wood extension table and secure with

six each flat was hers (B), lock washers (C) and

hex nuts (D). Finger - tighten only.

Figure 9

Figure 10

7

Page 8

Securing Wood Table to Back Rail

Referring to Fi gur e 11:

1. Insert six hex head screws (E) and flat

washers (F) through the back rail and

wooden extension t able and secure with six

flat was hers (F), lock washers (G) and hex

nuts (H). Finger- tighten only at this time.

2. Re-check the table for alignment along the

front and back rails. Make further

adjustments if necessary, then tighten all

screws and nuts.

Installing the Guide Tube

1. The guide tube m ounts to the front rail wi th

the scale facing t oward the operator (Figur e

12). Align the holes in the bottom of the

guide tube with the holes in the front rail.

When properly positioned the guide tube

should extend bey ond the f ront rai l about 6"

in both directions.

2. Fasten the guide tube to the rail from

beneath, with eight 1/4-20 x 3/4 hex cap

screws and eight 1/4 lock washers (Figure

13). Finger-tighten only.

3. The hol es in the front rail ar e over-si zed to

allow slight adjustment of the guide tube.

Pull the guide tube a way f rom the r ail as far

as it will go.

4. Measure the distance from edge of guide

tube to front rail; do this at both ends of the

guide tube to ensure that guide tube is

parallel to front rail. (The distance itself is

not important, but it should be the same

along the length of t he guide tube.)

Figure 11

Figure 12

5. Tighten all screws with a 10mm wrench.

6. Insert a plasti c end cap into t he ends of the

guide tube. Use a r ubber m all et if needed t o

gently push in the caps.

Figure 13

8

Page 9

Mounting the Accu-Fence

1. Screw the lock l ever knob i nto the threaded

handle on the Accu-F enc e ( see Figur e 14) .

The lock lever has three functional positions.

Referring to Fi gur e 15:

• The upright posit ion permits mounting

and removal of fence from the saw.

• The unlock position permits easy fence

positioning.

• The lower position locks the fence to the

front rail. The cam handl e shoul d be

pushed down firml y agai nst the pin.

2. Place the Accu-Fence on the table t op and

check the hei ght of the si de plates from the

table top. The Accu-Fence has been pre-set

at the factory for a side plate hei ght of 1/32"

from the t able top of your saw. If , however,

some misalignment has occurred during

shipment, you can easily reset your side

plates to the correct height as described in

the following section.

Setting the Side Plate Height

1. Figure 16 shows a fence where

misalignment of the side plates has

occurred; t he side plates are in cont act with

the front edge of t he table saw top.

2. Turn the Accu-Fence upside down and with

a rubber mallet (or a hammer and block of

wood), gentl y tap the side pl ates to create a

height greater than 1/32" from the table top.

Note: Do not use a steel faced hammer

directly on the side plates as this will

damage them.

Back Rail

Space should be 1/32"

along entire length of fence

Figure 14

Figure 15

Fence Side Plate

Table Top

Incorrect contact

Figure 16

Front Rail

Guide Tube

3. Reposition the Accu-Fence on the table and

place the plastic shims (included with the

shipping contents) beneath the side plates.

With the hammer and wood block, tap the

sides down until they contact the shims as

shown in Figure 17.

4. Remove the shim s. The Accu-Fence should

now have correctly posi tioned side plates.

Figure 17

9

Page 10

Adjusting Fence Parallel to the Miter Slot

Referring to Fi gur e 18:

1. Place the f ence (A) on the table (B). Adjust it

so the edge (C) l ines up with the right miter

slot (D) and lock it.

2. The locked fence must be even (parallel)

with the mite r slot from front to bac k.

3. If the fence is not even al ong the length of

the miter slot , unl ock and rem ov e it from the

guide rail (Figur e 19) .

4. Adjust one of the two setscrews (H, Figure

19) with a 5mm hex wrench unt il the fence is

even with t he miter slot edge al ong i ts enti r e

length when locked.

Note: You may need to re-adjust the clamping

pressure (described below) after aligning the

fence.

Clamping Pressure Adjustment

The Accu-Fence has been adjusted at the

factory to lock securel y when the lock handle is

pushed down. If adjustm ent is needed:

1. Unlock the fence.

Figure 18

2. Remove the fence from the guide rail

(Figure 19).

3. Adjust each of the t wo setscrews (H, Figure

19) exactly the same number of rotations

until the fence is hel d securely when the lock

handle is pushed down.

A clockwise rotation of the setscrews will

increase the cam pressure. Counterclockwise

rotation will dec r ease cam pr essure.

90° to the Table Adjustment

1. Place the fence on the saw table and lock it.

2. Place a square (E, Figure 18) on the table

next to the fence. The f ence should be 90°

to the table.

3. If adjustm ent is necessary, unlock the f enc e,

and turn one of the two nylon adjustment

screws (F, Fi gure 18) until the fence is 90°

to the table.

4. Lock the fence and check the adjustment

again.

Cursor Adjustment

1. Disconnect the table saw from the power

source.

Figure 19

2. Raise the saw blade abov e the t abletop.

3. Unlock the fence and slide it to

approximately four inches from the saw

blade.

4. Lock the fence.

10

Page 11

5. Measure the distance between the saw

blade and the inside of the f enc e.

6. Adjust the cur sor (G, F igure 18) to read t he

distance just measured and tighten the

cursor assembly to t he fence.

7. Take a test cut and confirm that the

adjustment is correct.

Note: If t he cursor does n ot have enough t ravel

to give the correct measurement, loosen the

guide rail and adjust as needed. If you still do

not get the correct measurement, loosen the

front rail and adjust as needed. If you have to

adjust the fr ont rail you will need to go through

the front rail assembly instructions again.

This adjustment must be checked whenever a

different blade is installed.

Side Plate Replacement

The Accu-Fence is specially designed to save

you many hours of down-time when side plates

need to be replaced. In an operation that can

last an entire day with other fences, the Accu-

Fence side replacement takes only a few

minutes.

Figure 20

Here's how it's done:

1. Turn the fence upside d own and loosen the

five 1/4 l oc k nuts with a 7/16 wrench through

the slots.

Note: A socket wrench can f it into the slot,

and will speed the process (Figure 20).

2. Remove the lock nuts.

3. Turn the fenc e on its side and pull the side

plate from the main frame (Figure 21).

4. Replacement side plates come with

fasteners already attached. With the fence

still on i ts side, al ign the new side plate so

that the att ached bol t s li ne up wit h the hol es

on the mai n frame. See Figure 21. Mount

the new side plate to the main frame.

5. Turn the fence on its back and secure the

side plate by lightly tightening all nuts.

6. Make any necessary adj ustments to t he si de

plate height (see Setting the Side Plate

Height on page 9).

Figure 21

11

Page 12

Rail Installation on a

non-Powermatic Table Saw

The following instructions are for installing the

Accu-Fence and Rail System on a table saw

other than a Powermatic model. Som e drilling i s

required.

Tools required

10mm and 12mm wrenches

Philips screwdriver

Adjustable square

Rubber mallet (or hammer and block of

wood)

Straight edge

Electri c drill with 1/4" and 5/16" bits

Installing the Front Rail

1. Identify the front rail, which is 3" x 3" with

notches on one side.

2. Place a mark 18" from the left end of the

front rail (Fi gure 22). This mark will be lined

up with the saw blade.

3. Lay a straight edge flush against the right

side of the saw blade, as shown in Figure

23, and place the notched side of t he front

rail against the saw table as shown. Hold

front rail to the saw table with clamps. Make

sure the mark on t he front rail lines up wit h

the left edge of the straight edge (and thus

in line with the blade) .

Figure 22

Figure 23

4. The front rail must be parallel to the table

top in order for the Accu-Fence system to

function properly. Place an adjustable

square on the table as shown in Figure 24.

5. Check t he height of the front rail at several

locations along t he surface of the saw table.

The measurements should be the same

along the length of the rail. Adjust as

needed.

6. When the front rail has been correctly

positioned, and y our mark still lined up wit h

the straight edge, drill 1/ 4" holes into t he lip

of the table saw top, using t he holes in the

front rail as a guide (Figur e 25) .

7. Lightly secure the fr ont rail to the saw table

with four 1/4-20 x 1-1/2 flat head screws,

four 1/4 flat w ashers, f our 1/ 4 lock washers,

and four 1/4 hex nuts (Figure 26). Fingertighten only .

Figure 24

12

Page 13

Installing the Back Rail

1. Locate the back rail which is 2" x 2" with

holes running along one side only. The

height of the back rail when attached to t he

saw is not crit ical, but it shoul d be paral lel t o

the table top.

2. Position the back rail approximately 9/16"

below the surf ace of the table top, wit h the

ends even with those of the front rail

(Figure 27). Hold the back rail to the saw

with clamps.

3. Drill 5/16" hol es into the lip of the sa w table

using the holes in the back rail as a guide

(see Figure 28).

Referring to Fi gur e 29 :

4. Insert hex cap screws (A) and flat washers

(B) through t he back rail and saw table and

secure with flat washers (B), lock washers

(C) and hex nuts (D). Finger- tighten only at

this time.

The rest of the installation is the same as with a

Powermatic table saw. Refer back to page 6 to

mount the optional wood ex tension table (if

applicable) and the guide tube on page 8, and

proceed fr om ther e.

Figure 25

Figure 26

Figure 27

Figure 28

Figure 29

13

Page 14

Replacement Parts

To order parts or reach our service department, call 1-800-274-6848, Monday through Friday (see our website

for business hours, www.powermatic.com). Having the Model Number and Serial Number of your machine

available when you ca ll will allow us to serve y ou quickly and accurately.

Rail Assembly

Index No. Part No. Description Size Qty

.................. 2653031Z ............PM2000//PM3000/66/72A Rail Ass embly - Standard ..... 50” rip ............................ 1

.................. 2653039Z ............PM2000/66 Rail Assembly – Short ................................. 30” rip ............................ 1

1 ................ 3653217 ..............Front Fence Rail – Standard (50” rip) ............................. 72” L .............................. 1

.................. 3653237 ..............Front Fence Rail – Short (30” rip) ................................... 52-1/2” L........................ 1

2 ................ TS-081F081 ........Fl at Head Screw ............................................................ 1/4-20 x 1-1/2 .............. 10

3 ................ TS-0720071 ........Lock Washer................................................................... 1/4 ............................... 18

4 ................ TS-0561011 ........Hex Nut........................................................................... 1/4-20 .......................... 10

5 ................ TS-0050031 ........Hex Cap Screw............................................................... 1/4-20 x 3/4 ................... 8

6 ................ 3254010 ..............Fron t Fence Guide – Standard (50” rip) ......................... 84” L .............................. 1

.................. 3254022 ..............Fron t Fence Guide – Short (30” rip) ............................... 64” L .............................. 1

7 ................ 3653218 ..............Back Fence Rail – Standard (50” rip) ............................. 72” L .............................. 1

.................. 3653238 ..............Back Fence Rail – Short (30” rip) ................................... 52-1/2” L........................ 1

8 ................ TS-0051071 ........Hex Cap Screw............................................................... 5/16-18 x 1-1/2 .............. 6

9 ................ TS-0680031 ........Flat Washer .................................................................... 5/16 ............................. 14

10 .............. TS-0561021 ........Hex Nut........................................................................... 5/16-18 .......................... 6

11 .............. TS-0720081 ........Lock Washer................................................................... 5/16 ............................... 8

12 .............. 6687008 ..............Scale............................................................................... 53 " L x 3/4" W ............... 1

.................. 6687013 ..............Scale............................................................................... 32" L x 3/4" W ............... 1

13 .............. 6166069 ..............Cap Plug ......................................................................... ...................................... 2

14 .............. TS-0051041 ........Hex Cap Screw............................................................... 5/16-18 x 7/8 ................. 2

.................. 2405120 ..............Hardware Kit (not shown) ............................................... ...................................... 1

15 .............. TS-0680021 ........Flat Washer .................................................................... 1/4 ............................... 10

14

Page 15

Accu-Fence Parts

Index No. Part No. Description Size Qty

.................. 2195079Z ............. 66 & PM2000 Accu-Fence Assembly .................... ............................................. 1

.................. 2195080 ............... 72A & PM3000 Accu-Fence Assembly .................. ............................................. 1

.................. 2726008 ............... Fen ce Side Plate (Models 66, PM2000) ................ ...................................... 1(set)

(includes one side plate (item 1) and items 15, 22)

.................. 2726009 ............... Fence Side Plate Kit (Models 72A, PM3000) ........ ............................................. 1

(includes two side plates (item 1) and items 15, 22)

1 ................ 2726009FSP ........ Fen ce Side Plate (Models 72A, PM3000) .............. ............................................. 2

(includes one side plate only, no fasteners)

2 ................ 2056033 ............... Fen ce Body (Weld Models 66, PM2000) ............... ............................................. 1

.................. 2056034 ............... Fen ce Body (Weld Models 72A, PM3000) ............. ............................................. 1

4 ................ 800708950D......... Cursor .................................................................... ............................................. 1

5 ................ 800708950C......... Cursor Bracket ....................................................... ............................................. 1

6 ................ 3575080 ............... Flu oroway Pad ....................................................... ............................................. 2

7 ................ 6813042 ............... Compressi on Spring .............................................. ............................................. 1

8 ................ 3215301 ............... Foot Cam ............................................................... ............................................. 1

9 ................ TS-0152031 ......... Carriage Bolt .......................................................... 5/16-18 x 1-1/2..................... 1

10 .............. TS-0151041 ......... Carriage Bolt .......................................................... 1/4-20 x 1-1/2....................... 1

11 .............. 6626031 ............... Sprin g Pin .............................................................. ............................................. 1

12 .............. TS-0640071 ......... Lock Nut ................................................................. 1/4-20................................... 1

14 .............. TS-0640081 ......... Lock Nut ................................................................. 5/16-18................................. 1

15 .............. XF2-9 ................... T-Square Bolt (66, PM2000) .................................. 1/4-20 x 3/4 ........................ 10

.................. XF2-9 ................... T-Square Bolt (72A, PM3000) ............................... 1/4-20 x 3/4 ........................ 12

17 .............. 3076232 ............... Locking Cam .......................................................... ............................................. 1

19 .............. 6430055 ............... Knob w/ Stud ......................................................... ............................................. 1

21 .............. XF-5 ..................... Nylon Adjustmen t Screw ........................................ ............................................. 2

22 .............. TS-0640071 ......... Lock Nut (66, PM2000) .......................................... 1/4-20................................. 10

.................. TS-0640071 ......... Lock Nut (72A, PM3000) ....................................... 1/4-20................................. 12

23 .............. TS-0271031 ......... Set Screw .............................................................. 3/8-16 x 3/8 .......................... 2

24 .............. 6166069 ............... Cap Plug ................................................................ ............................................. 1

25 .............. 3312341 ............... Powermatic Logo ................................................... ............................................. 1

26 .............. 3408241 ............... Accu-F ence Label .................................................. ............................................. 1

27 .............. XF2-108 ............... Pad ........................................................................ ............................................. 1

28 .............. TS-081D021 ......... Flat Head Machine Screw ...................................... 10-32 x 3/8 ........................... 2

29 .............. TS-0733031 ......... Ext. Tooth Lock Washer ........................................ #10 ....................................... 2

30 .............. TS-0560081 ......... Hex Nut .................................................................. 10-32.................................... 2

31 .............. TS-081D022 ......... Pan Head Machine Screw ..................................... 10-32 x 3/8 ........................... 2

32 .............. TS-0680021 ......... Flat Washer ........................................................... 1/4 ........................................ 2

15

Page 16

Accu-Fence Assembly

427 New Sanford Rd.

LaVergne, TN 37086

Phone: 800-274-6848

www.powermatic.com

16

Loading...

Loading...