Page 1

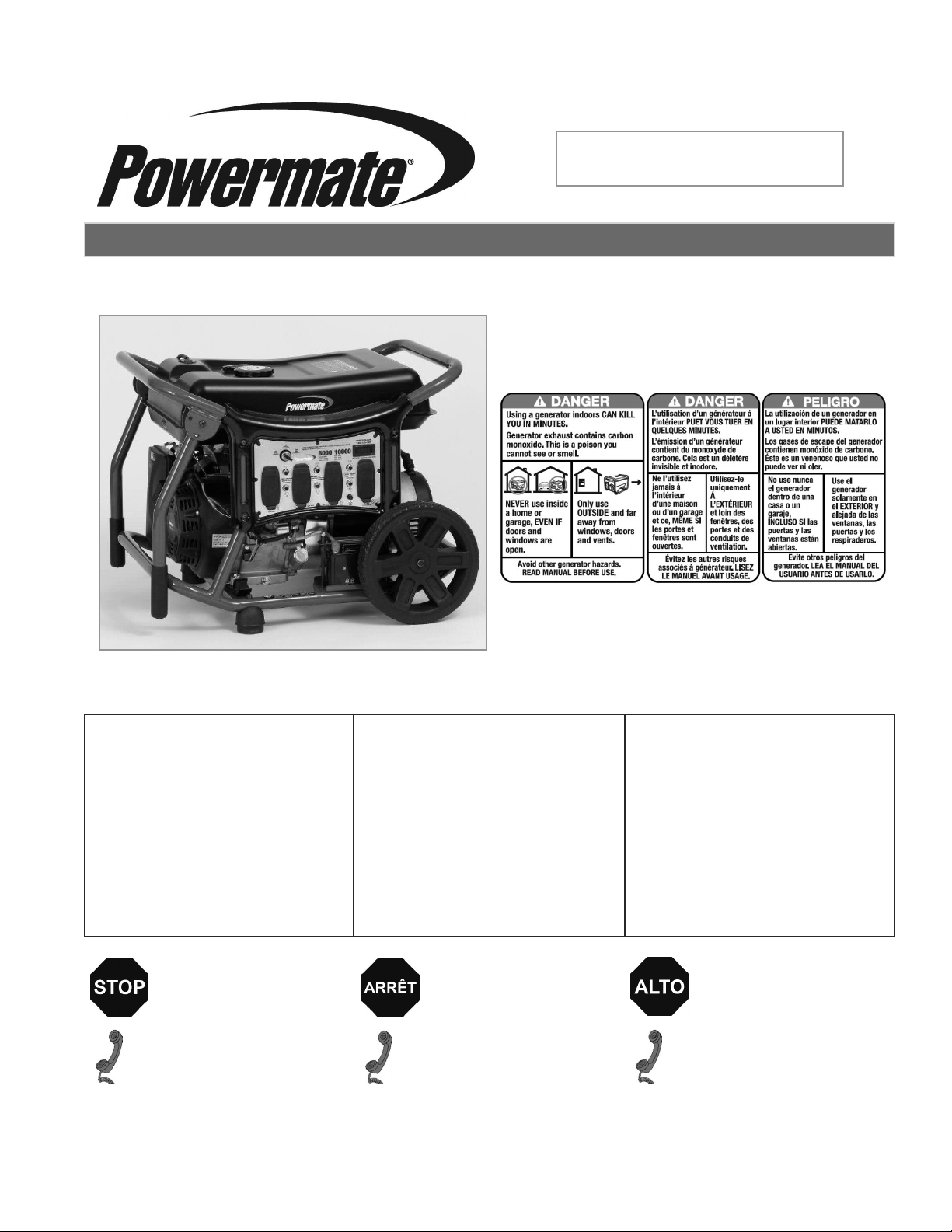

Operator Manual •

ELECTRIC GENERATOR • GROUPE ELECTROGENE • GENERADOR ELECTRICO

Manuel de l’opérateur • Manual del operador

PM0148000

IMPORTANT – Please make certain that

persons who are to use this equipment

thoroughly read and understand these

instructions and any additional

instructions provided prior to operation.

Record the serial number as indicated on

your Generator’s nameplate:

Serial No.______________________

DO NOT RETURN TO

STORE!

CALL US FIRST!

CUSTOMER HOTLINE

1-800-445-1805

FOR QUESTIONS OR SERVICE

INFORMATION

IMPORTANT - Prière de vous assurer que

les personnes destinées à utiliser cet

appareil ont pris soin d'en lire et d'en

comprendre le mode d'emploi ou les

directives avant de le mettre en marche.

Enregistrer le numéro de série figurant

sur la plaque signalétique du groupe

électrogène:

Nº de série ____________________

NE PAS RETOURNER

AU MAGASIN!

APPELEZ–NOUS D’ABORD!

ASSISTANCE TELEPHONIQUE

A LA CLIENTELE

1-800-445-1805

POUR L'INFORMATION DE

QUESTIONS OU SERVICE

IMPORTANTE - Asegúrese que las

personas que utilizarán este equipo lean

y entiendan completamente estas

instrucciones y cualquier instrucción

adicional proporcionada antes del

funcionamiento.

Registre de serie como se indica en la

placa del nombre de su generador:

No. de serie ___________________

NO LO DEVUELVA A

LA TIENDA!

¡PRIMERO LLÁMENOS!

LÍNEA DIRECTA DE ATENCIÓN

AL CLIENTE

1-800-445-1805

PARA la INFORMACION de

PREGUNTAS O SERVICIO

www.powermate.com 12/13 0070732

Page 2

TABLE OF CONTENTS

Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Spark arresting muffler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Determining total wattage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operating voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Unpacking the generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Generator features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Portability kit installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Before operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Ground fault circuit interrupter (GFCI) . . . . . . . . . . . . . . . . . . . . 9

Grounding the generator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Low oil sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Fuel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

High Altitude Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Electric Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Starting the unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Pre-start preparation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Starting the engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Applying load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Shutting the generator off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

TABLE DES MATIERES

Régles d’opération et de sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Silencieux pare-étincelles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Determination de la puissance totale nécessaire . . . . . . . . . . . . . . . 18

Vérifier la tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Unpacking the generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Caractéristiques du groupe electrogene. . . . . . . . . . . . . . . . . . . . . . 21

L’installation de kit de transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Avant de mettre en marche . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Protection avec disjoncteur différentiel (GFCI) . . . . . . . . . . . . . 23

Mise en place de l'appareil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Lubrification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Le détecteur de bas niveau d'huile . . . . . . . . . . . . . . . . . . . . . . 23

Carburant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Positionnement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Fonctionnement en altitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Démarrage électrique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Démarrage de l'appareil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Préparatifs au démarrage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Démarrage du moteur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Branchement des appareils . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Arrêt de l'appareil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Entretien périodique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

INDICE

Reglas de seguridad y de funcionamiento . . . . . . . . . . . . . . . . . . . . 31

Silenciador apagachispas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Como determinar el vataje total . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Requerimiento de voltaje . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Instalacion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Unpacking the generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Caracteristicas del generador . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Instalacion del juego de transport. . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Antes de la operacion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Protección de interruptor de circuito de falla de

conexión a tierra (GFCI, por sus siglas en inglés). . . . . . . . . . . 37

Puesta a tierra del generador. . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Lubricacion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

El sensor del nivel bajo de aceite . . . . . . . . . . . . . . . . . . . . . . . 38

Combustible . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Colocación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Funcionamiento a gran altitud . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Arranque eléctrico. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Arranque de la unidad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Preparacion antes de arrancar. . . . . . . . . . . . . . . . . . . . . . . . . . 40

Arranque del motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Como aplicar una carga . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Apagado del generador . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Spark plug. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Oil type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Oil replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Air filter cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Fuel shut off valve filter cleaning . . . . . . . . . . . . . . . . . . . . . . . 13

Fuel strainer cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Valve Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Spark arrester screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Brushes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Inspecting the brushes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Heat shield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Engine carburetor icing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Quick starting tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Service and storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Infrequent service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Long term storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Engine troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Engine specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Service information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Limited warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Parts drawings and parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46-49

Emission control warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Entretien . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

La bougie d’allumage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Le type d’huile. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Remplacement d’huile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Nettoyage du filtre à air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Nettoyage du filtre du robinet à essence . . . . . . . . . . . . . . . . . 27

Nettoyage de la crépine du réservoir à carburant . . . . . . . . . . 27

Jeu des soupapes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

L'écran pare-étincelles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Les balais . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Inspection des balais . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Écrans de chaleur. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Givrage du carburateur. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Trucs de démarrage rapide . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Usage et entreposage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Usage peu fréquent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Entreposage à long terme . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Depannage du moteur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Caracteristiques du moteur. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Service clientèle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Garantie limitée. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Schema des pièces et liste des pièces . . . . . . . . . . . . . . . . . . . . 46-49

Mantenimiento periódico. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Mantenimiento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Bujia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Tipo de aceite . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Cambio del aceite . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Cómo limpiar el filtro de aire. . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Cómo limpiar el filtro de la vàlvula de combustible . . . . . . . . . 41

Limpieza del filtro de combustible . . . . . . . . . . . . . . . . . . . . . . 41

Claridad de la valvula . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Protector del parachispas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Escobillas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Revisión de las escobillas . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Escudo contra el calor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Congelamiento del carburador del motor . . . . . . . . . . . . . . . . . 42

Instrucciones rápidas para el arranque . . . . . . . . . . . . . . . . . . 42

Servicio y almacenamiento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Servicio poco frecuente . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Almacenamiento a largo plazo . . . . . . . . . . . . . . . . . . . . . . . . . 42

Deteccion de fallos del motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Especificaciones del motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Informacion de servicio al cliente . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Garantia limitada. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Diagrama de piezas y lista de piezas . . . . . . . . . . . . . . . . . . . . . 46-49

2

Customer Hotline 1-800-445-1805

Page 3

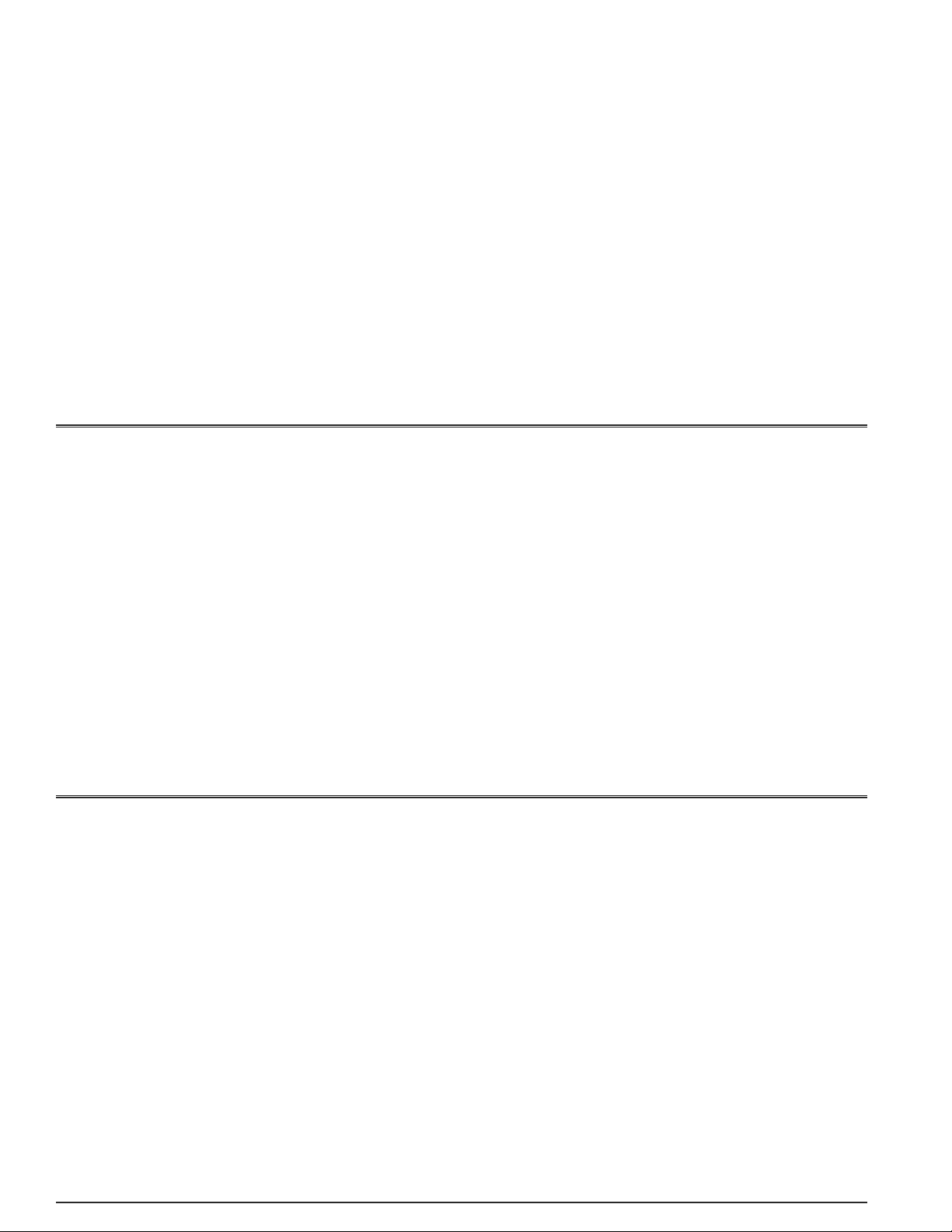

SAFETY INFORMATION

SAFETY INFORMATION

DANGER indicates a potentially

hazardous situation which, if not

avoided, WILL result in death or

serious injury.

Safety alert symbol; To alert you to

potential personal injury hazards.

Risk of electrocution or shock.

Flammable materials.

Explosion hazard. Corrosive materials.

SAFETY AND OPERATION RULES

WARNING - Failure to follow these instructions

and warnings may result in death, personal

injury, or property damage.

WARNING indicates a

potentially hazardous situation

which, if not avoided, could

result in death or serious injury.

SAFETY SYMBOL GUIDE

Hazardous materials, toxic or very toxic

materials.

Rotating parts - entanglement hazard.

Hot surface, do not touch the surface.

8. Units should not be operated or stored in wet or

damp conditions or on highly conductive

locations such as metal decking and steel work.

CAUTION indicates a potentially

hazardous situation which, if not

avoided, may result in minor or

moderate personal injury, or

property damage.

1. Read carefully and understand operator manual

prior to operation of this product. Follow all

warnings and instructions.

2. Know your equipment. Consider the applications,

limitations, and the potential hazards specific to

your unit.

3. Equipment must be placed on a firm, supporting

surface.

4. Load must be kept within rating stated on

generator nameplate. Overloading will damage

the unit or shorten its life.

5. Engine must not be run at excessive speeds.

Operating an engine at excessive speeds increases

the hazard of personal injury.

Do not tamper with parts which may increase

or decrease the governed speed.

6. To prevent accidental starting, always remove the

spark plug or cable from the spark plug before

maintaining the generator or engine.

7. Units with broken or missing parts, or without

protective housing or covers, should never be

operated. Contact your service center for

replacement parts.

English Customer Hotline 1-800-445-1805

9. Keep the generator clean and free of oil, mud and

other foreign matter.

10.Extension cords, power cords, and all electrical

equipment must be in good condition. Never

operate electrical equipment with damaged or

defective cords.

11.Store the generator in a well ventilated area with

the fuel tank empty. Fuel should not be stored near

the generator.

12.Your generator should never be operated under

these conditions:

a. Uncontrolled change in engine speed.

b. Electrical output loss.

c. Overheating in connected equipment.

d. Sparking.

e. Damaged receptacles.

f. Engine misfire.

g. Excessive vibration.

h. Flame or smoke.

i. Enclosed compartment.

j. Rain, snow or inclement weather. Do not let

the unit get wet when operating.

3

Page 4

13.Check the fuel system periodically for leaks or

signs of deterioration such as chafed or spongy

hose, loose or missing clamps, or damaged tank or

cap. All defects should be corrected before

operation.

14.The generator should be operated, serviced, and

refueled only under the following conditions:

a. Start and run the generator outdoors. Do

not run the generator in an enclosed area,

even if doors or windows are open; avoid

areas where vapors may be trapped, such as

pits, garages, cellars, excavations and boat

bilges. DANGER - CARBON MONOXIDE

HAZARD: The engine exhaust contains

carbon monoxide, a poisonous, odorless,

invisible gas which, if breathed, may cause

death or serious personal injury. If you start

to feel sick, dizzy or weak while using the

generator, shut it off and get to fresh air

right away; you may have carbon monoxide

poisoning.

b.Good ventilation for cooling. Air flow and

temperatures are important for air cooled

units. Temperatures should not exceed 104º

F ambient (40º C).

c. Refuel the generator in a well lighted area.

Avoid fuel spills and never refuel while the

generator is running. Allow engine to cool for

two minutes prior to refueling.

d. Do not refuel near open flames, pilot lights, or

sparking electrical equipment such as power

tools, welders, and grinders.

e. The muffler and air cleaner must be installed

and in good condition at all times as they

function as flame arresters if backfiring occurs.

f. Do not smoke near the generator.

15.Ensure that generator is properly grounded. (See

“Grounding the generator” section in this

manual.)

damage the generator or cause personal injury.

21.Before transporting the generator in a vehicle,

drain all fuel to prevent leakage that may occur.

22.Use proper lifting techniques when transporting

the generator from site

to site. Improper lifting

techniques may result

in personal injury.

23.To avoid burns, do not touch engine muffler or

other engine or generator surfaces which became

hot during operation.

CALIFORNIA PROPOSITION 65 WARNING

The engine exhaust from this product contains chemicals

known to the State of California to cause cancer, birth defects,

or other reproductive harm.

SPARK ARRESTER

SPARK ARRESTER

YOUR PRODUCT MAY NOT BE EQUIPPED WITH A

SPARK ARRESTING MUFFLER. If the product will be

used around flammable materials, such as agricultural crops,

forests, brush, grass, or other similar items, then an approved

spark arrester should be installed and is legally required in the

State of California. The California statutes requiring a spark

arrester are Sections 13005(b), 4442 and 4443. Spark

Arresters are also required on some U.S. Forest Service land

and may also be legally required under other statutes and

ordinances. For more information, contact Pramac America,

LLC, P.O. Box 6001, Kearney, Nebraska 68847.

1-800-445-1805.

DETERMINING TOTAL WATTAGE

DETERMINING TOTAL WATTAGE

In order to prevent overloading and possible damage to

your generator it is necessary to know the total wattage of the

connected load. To determine which tools and/or appliances

your generator will run follow these steps:

16.Do not wear loose clothing, jewelry, or anything

that may be caught in the starter or other rotating

parts.

17.Unit must reach operating speed before electrical

loads are connected. Disconnect loads before

turning off engine.

18.To prevent surging that may possibly damage

equipment, do not allow engine to run out of fuel

when electrical loads are applied.

19.When powering solid state equipment, a Power

Line Conditioner should be used to avoid possible

damage to equipment.

20. Do not stick anything through ventilating slots,

even when the generator is not operating. This can

English Customer Hotline 1-800-445-1805

1. Determine if you want to run one item or multiple items

simultaneously.

2. Check wattage requirements for the items you will be

running by referring to the load’s nameplate or by

calculating it (multiply amps x volts = watts).

3. Total the watts for each item. If the nameplate only gives

volts and amps, multiply volts x amps = watts.

1 KW = 1,000 watts.

4. Motorized appliances or tools require more than their

rated wattage for start up.

NOTE: Allow 2 1/2 to 4 times the listed wattage for

starting equipment powered by electric motors.

5. The generator’s rated watts should match or exceed the

total number of watts required for the equipment you

want to run.

6. Always connect the heaviest load to the generator first,

then add other items one at a time.

4

Page 5

OPERATING VOLTAGE

OPERATING VOLTAGE

CAUTION: Operating voltage and frequency

requirement of all electronic equipment should be

checked prior to plugging them into this generator.

Damage may result if the equipment is not designed

to operate within a +/- 10% voltage variation, and +/3 hz frequency variation from the generator name

plate ratings. To avoid damage, always have an

additional load plugged into the generator if solid

state equipment (such as a television set) is used. A

power line conditioner is recommended for some solid

state applications.

A power line conditioner should be used when running

one or more of the following solid state items:

Garage door openers

Kitchen appliances with digital displays

Televisions

Stereos

Personal computers

Quartz clocks

Copy machines

Telephone equipment

Other solid state equipment may require a power line

conditioner. For more information, contact our Customer

Service Department at 1-800-445-1805.

INSTALLATION

INSTALLATION

To avoid backfeeding into utility systems, isolation of the

residence electrical system is required.

Before temporary connection of the generator to the

residence electrical system, turn off the main

service/disconnect.

If your generator is to be used as a stand-by power source

in case of utility power failure, it should be installed by a

registered electrician and in compliance with all applicable

local electrical codes.

Proper use requires that a double throw transfer switch be

installed by a licensed qualified electrician so that the

building's electrical circuits may be safely switched between

utility power and the generator's output, thereby preventing

backfeed into the power utility's electrical system.

To avoid backfeeding into utility systems, isolation of

the residence electrical system is required. Before

temporary connection of a generator to the residence

electrical system turn off the main switch. Before

making permanent connections a double throw

transfer switch must be installed. To avoid

electrocution or property damage, only a trained

electrician should connect generator to residence

electrical system. California law requires isolation of

the residence electrical system before connecting a

generator to residence electrical systems. Temporary

connection not recommended due to backfeeding.

Always follow local codes and regulations that apply to

the installation of any item that concerns this product.

1. NFPA 70 - National Electrical Code available from

www.nfpa.org.

To avoid possible personal injury or equipment

damage, a registered electrician or an authorized

service representative should perform installation

and all service. Under no circumstances should an

unqualified person attempt to wire into a utility

circuit.

English Customer Hotline 1-800-445-1805

2. NFPA 37 - Standard for Installation and Use of

Stationary Combustible Engines available from

www.nfpa.org.

3. NFPA 5000 - Building Construction and Safety Code

available from www.nfpa.org.

4. Agricultural Wiring Handbook available from

www.rerc.org.

5

Page 6

UNPACKING THE GENERATOR

w

ww.powermate.com 12/13 0070732

O

perator Manual •

M

anuel de l’opérateur • Manual del operador

E

LECTRIC GENERATOR • GROUPE ELECTROGENE • GENERADOR ELECTRICO

P

M0148000

I

MPORTANT - Prière de vous assurer que

l

es personnes destinées à utiliser cet

a

ppareil ont pris soin d'en lire et d'en

c

omprendre le mode d'emploi ou les

d

irectives avant de le mettre en marche.

Enregistrer le numéro de série figurant

s

ur la plaque signalétique du groupe

électrogène:

N

º de série ____________________

I

MPORTANT – Please make certain that

p

ersons who are to use this equipment

t

horoughly read and understand these

i

nstructions and any additional

i

nstructions provided prior to operation.

R

ecord the serial number as indicated on

y

our Generator’s nameplate:

Serial No.______________________

I

MPORTANTE - Asegúrese que las

p

ersonas que utilizarán este equipo lean

y

entiendan completamente estas

i

nstrucciones y cualquier instrucción

a

dicional proporcionada antes del

f

uncionamiento.

R

egistre de serie como se indica en la

placa del nombre de su generador:

N

o. de serie ___________________

D

O NOT RETURN TO

S

TORE!

C

ALL US FIRST!

C

USTOMER HOTLINE

1

-800-445-1805

F

OR QUESTIONS OR SERVICE

INFORMATION

NO LO DEVUELVA A

L

A TIENDA!

¡

PRIMERO LLÁMENOS!

L

ÍNEA DIRECTA DE ATENCIÓN

A

L CLIENTE

1

-800-445-1805

P

ARA la INFORMACION de

P

REGUNTAS O SERVICIO

NE PAS RETOURNER

A

U MAGASIN!

A

PPELEZ–NOUS D’ABORD!

A

SSISTANCE TELEPHONIQUE

A LA CLIENTELE

1

-800-445-1805

P

OUR L'INFORMATION DE

Q

UESTIONS OU SERVICE

UNPACKING THE GENERATOR

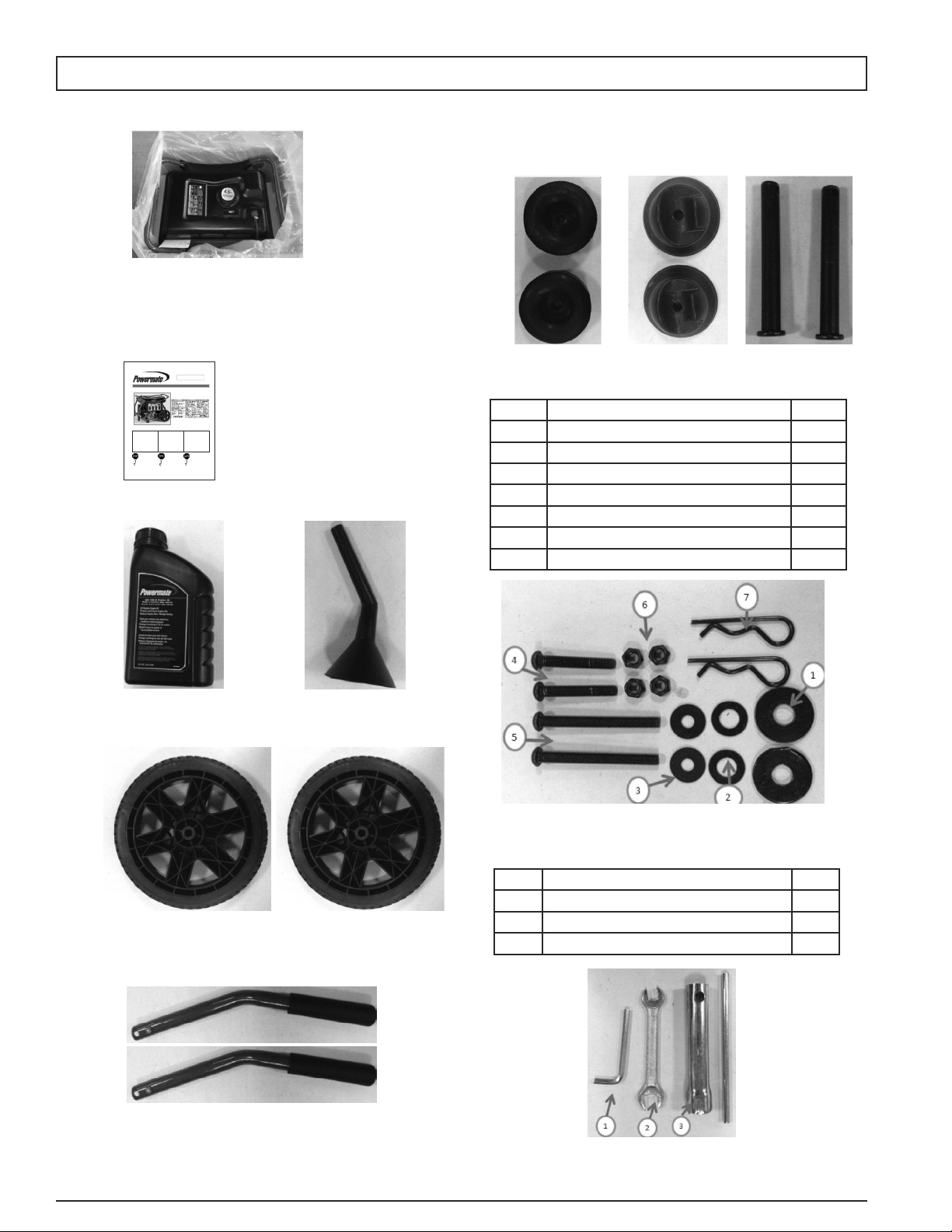

1. Open carton and remove packaging materials.

2. Remove generator, accessory boxes, and literature

from carton. If any items are missing or damaged,

contact our Product Service Department at

1-800-445-1805.

• 1 - Operator Manual

• 1 - Hardware Bag containing:

• 2 - Rubber Feet • 2 - Foot Spacers

• 2 - Axle Pins

• 1 - Fastener Bag containing:

ITEM DESCRIPTION QTY

1 M12 X 4MM FLAT WASHER 2

2 M12 X 1.5MM FLAT WASHER 2

3 M8 FLAT WASHER 2

4 M8 X 50 BOLT 2

5 M8 X 80 BOLT 2

6 M8 NYLOC NUT 4

7 LOCK PIN 2

• 1 - 1.0L Oil SAE 10-W30 • 1 - Oil Funnel

• 2 - 12” Flat Free Wheels

• 2 - Handles

• 1 - Tool Kit containing:

ITEM

DESCRIPTION

5 MM HEX KEY

1

DOUBLE OPEN WRENCH 10X13 MM

2

SPARK PLUG WRENCH W/ROD

3

QTY

1

1

1

6

Customer Hotline 1-800-445-1805English

Page 7

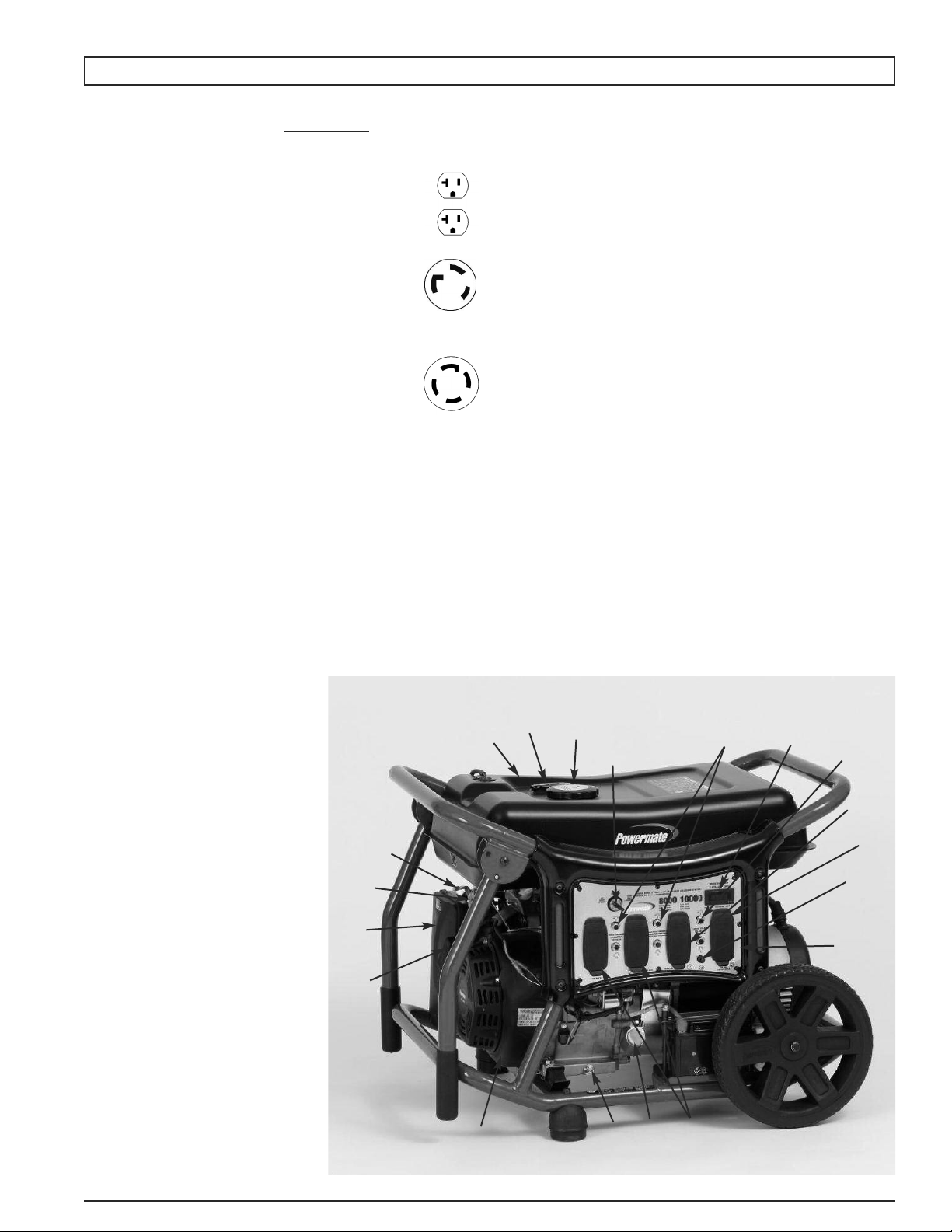

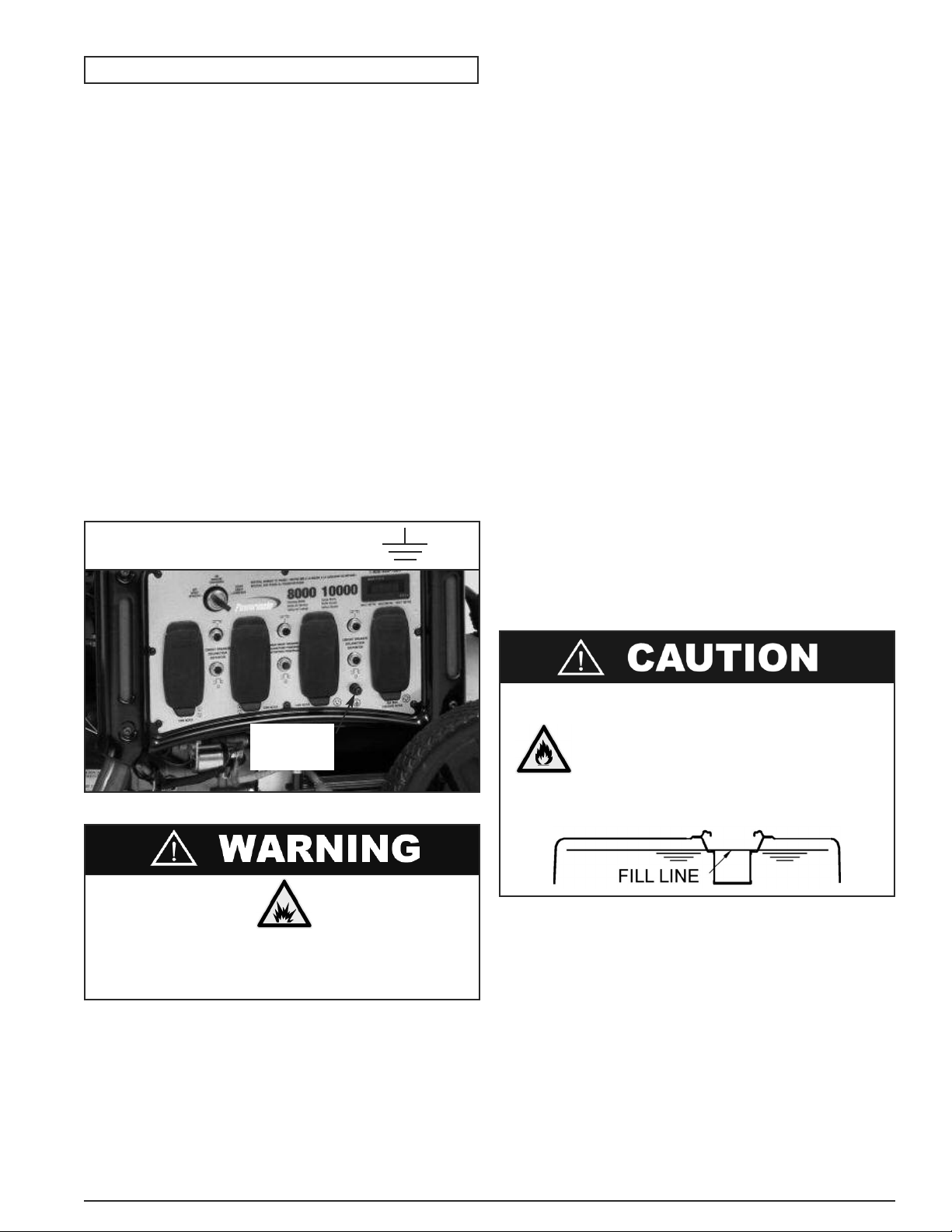

GENERATOR FEATURES

GENERATOR FEATURES

A. Control Panel

NOTE: Total power drawn from all receptacles must not exceed

the nameplate ratings.

B. 120 V, 20 Ampere Receptacle

20 amps of current may be drawn from the receptacle.

However, total power drawn must be kept within nameplate

ratings.

C. 120 Volt, 30 Ampere Twistlock Receptacle

You may draw a maximum of 30 amps from this

receptacle. If other receptacles are used at the same time,

total power used must be kept within nameplate ratings.

D. 120/240 V, 30 Ampere Twistlock Receptacle

Maximum full load current may be drawn from the

120/240 volt receptacle. Total current must be limited to

the nameplate rating. If the 120/240 volt receptacle is used

along with the 120 volt receptacle, the total load drawn

must not exceed the nameplate ratings.

E. Circuit Protectors

The receptacles are protected by an AC circuit protector. If the

generator is overloaded or an external short circuit occurs, the circuit

protector will trip. If this occurs,

disconnect all electrical loads and try to determine the cause

of the problem before attempting to use the generator again. If

overloading causes the circuit protector to trip, reduce the

load. NOTE: Continuous tripping of the circuit protector may

cause damage to generator or equipment. The circuit protector

may be reset by pushing the button of the protector.

R. Multimeter

• When the generator is started, the voltage value is shown first.

• Press and release the mode button to toggle between Voltage,

Frequency, Total Hour Meter and Run/Maintenance

Timer.

• Voltage (V) displays the operating voltage of the generator.

• Frequency (F) displays the frequency in hertz at which the

generator is running.

• The Run/Maintenance Timer displays the time in hours and

minutes each time the generator is ran. The run timer resets

to 00:00 when the generator is shut off. Built into this run

timer is a maintenance reminder. When the new generator is

ran for 25 hours, the meter will display P25. This is to

remind you to change the oil after the initial 25 hours of run

time.

• When the Run/Maintenance Timer displays P50, it is

reminding you to clean the air filter.

• When the Run/Maintenance Timer displays P100, it is

reminding you to change/clean the fuel filter, clean the air

filter, and change the oil.

F. Ground Terminal

G. Air Filter

H. Engine On/Off/Start Switch

I. 445 CC OHV Engine

J. Recoil Starter

K. Engine Choke Lever

L. Oil Filler Cap

M. Oil Drain Plug

N. 7 Gallon Metal Fuel Tank

O. Fuel Tank Cap

P. Fuel Gauge

Q. Fuel Shut-Off Valve

Q

G

J

K

N

P

O

H

E

R

E

C

D

F

A

English

I

7

M

Customer Hotline 1-800-445-1805

B

L

Page 8

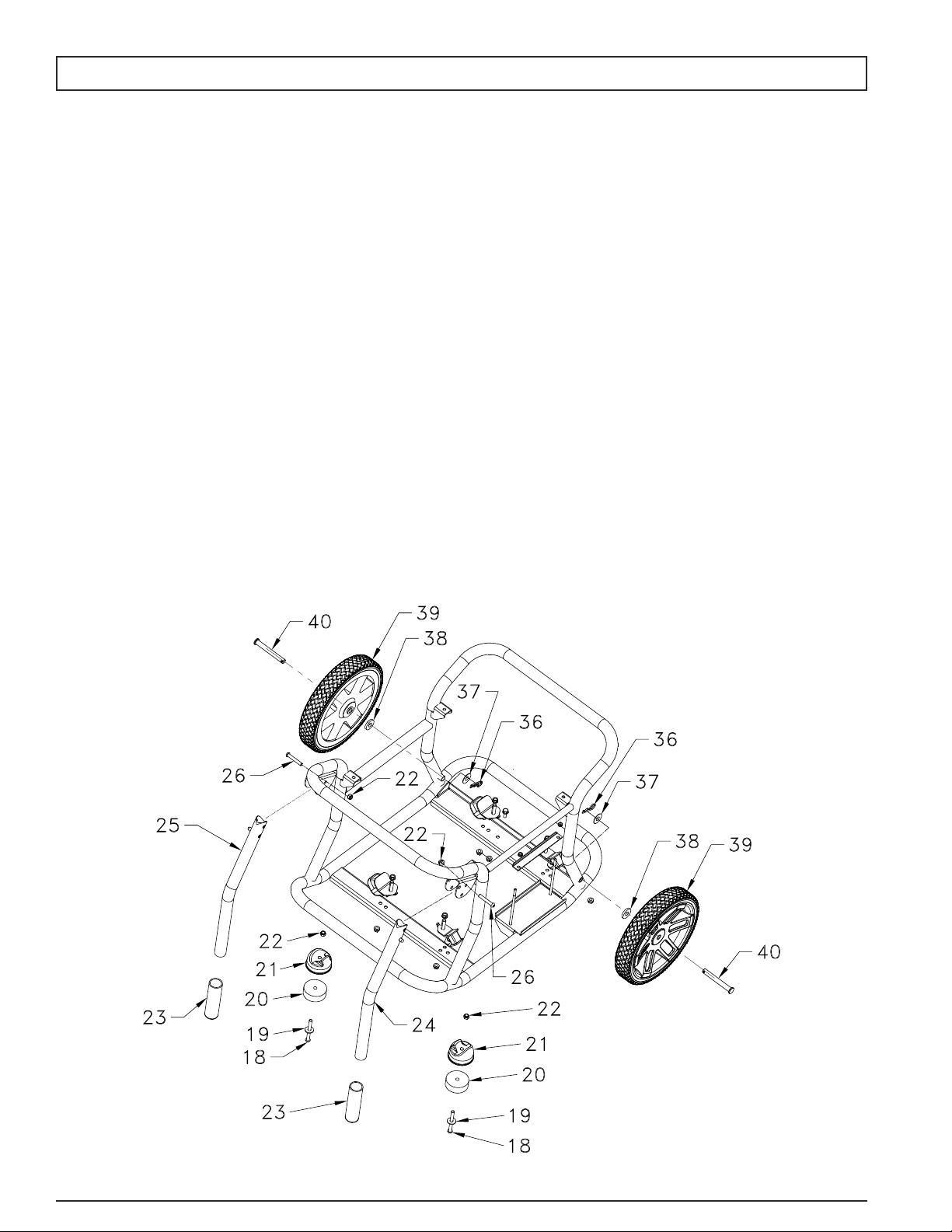

PORTABILITY KIT INSTALLATION

PORTABILITY KIT INSTALLATION

PORTABILITY KIT PART NUMBER: 0070922

TOOLS REQUIRED: 10x13 mm wrench and 5 mm hex key (provided in tool kit), block(s) of wood (minimum of 6” tall).

Refer to the parts list on page 47.

WHEEL INSTALLATION

1. Block up the alternator end of generator to install wheel kit.

2. Slide the wheel (item 39) and spacer (item 38) onto the axle (item 40).

3. Slide axle through the axle tube on the carrier, with the offset side of the wheel hub against the axle tube.

4. Secure the wheel to the axle with the M12 washer (item 37) and pin (item 36).

5. Repeat above instructions for the remaining wheel.

FOOT INSTALLATION

1. Blocking up the engine side of the generator, assemble the foot spacer (item 21) and foot (item 20) to the carrier (align

with holes in tubing) with an M8 washer (item 19) and M8 x 80 bolt (item 18). Thread an M8 nyloc nut (item 22) to the

bolt to secure the assembly.

2. Repeat above instructions for the remaining foot.

HANDLE INSTALLATION

1. Slide M8 x 50 bolt (item 26) through handle bracket and handle (item 23 and 24 or 25) as shown in diagram and

secure with M8 nut (item 22). Tighten until handle is securely clamped to the carrier.

2. To extend the handle, press the handle release button. Pull the handle up until the handle release button locks in place.

3. Repeat above instructions for the remaining handle.

English

8

Customer Hotline 1-800-445-1805

Page 9

BEFORE OPERATION

BEFORE OPERATION

GROUND FAULT CIRCUIT INTERRUPTER (GFCI)

PROTECTION

Some jobsites and local codes may require GFCI

protection for personnel before operation of your generator. If

your generator is not already equipped with a GFCI

receptacle, GFCI In-line cord sets may be purchased from

your local electrical supply store or home builder appliance

store.

These cord sets are available in various plug and

amperage configurations. (Make sure your generator is

properly Grounded.)

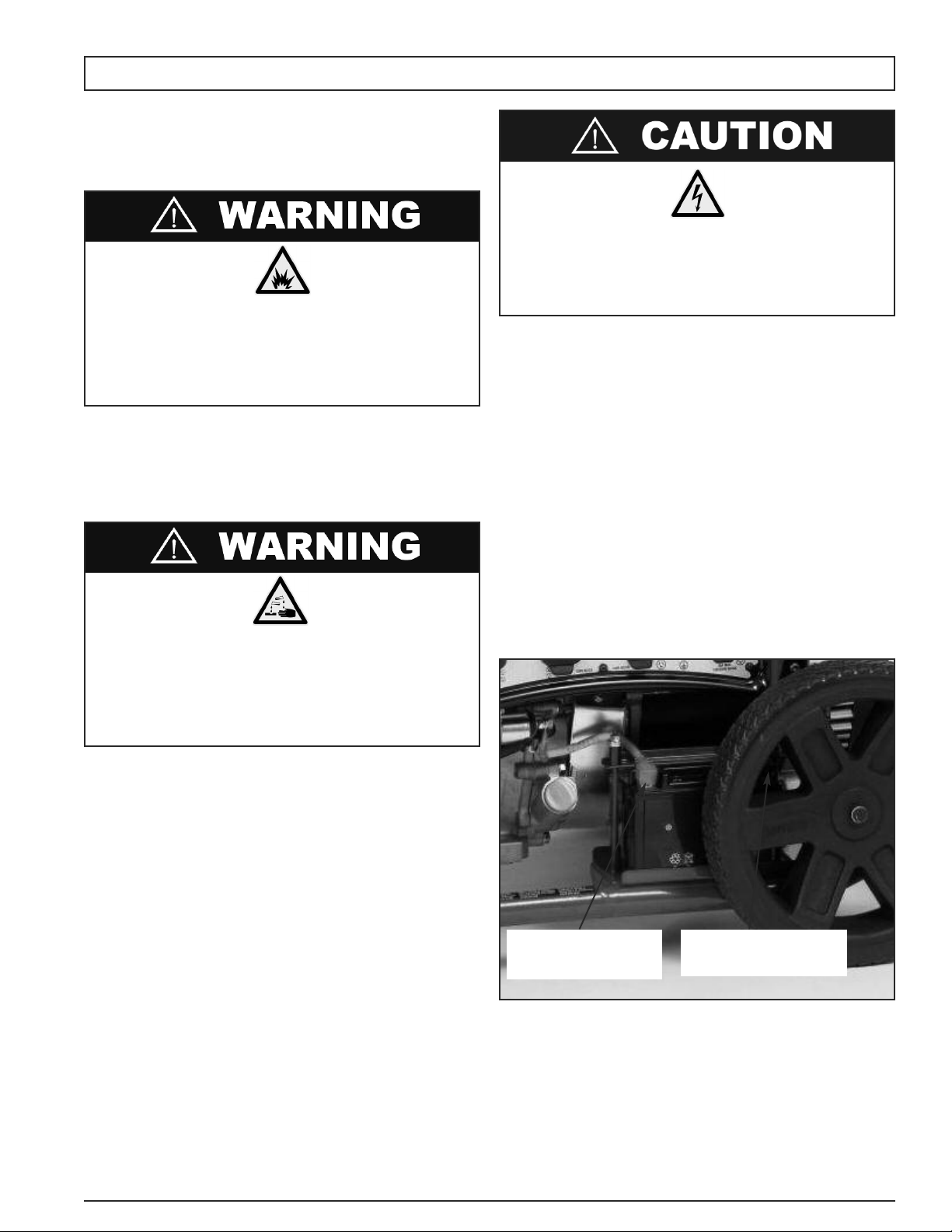

GROUNDING THE GENERATOR

The National Electric Code requires that this product be

properly connected to an appropriate earth ground to help

prevent electric shock. A ground terminal connected to the

frame of the generator has been provided for this purpose.

Connecting a length of heavy gauge (12 AWG min.) copper

wire between the generator Ground Terminal and a copper rod

driven into the ground should provide a suitable ground

connection. However, consult with a local electrician to insure

that local codes are being adhered to.

GROUND TERMINAL LOCATION:

LUBRICATION

DONOT attempt to start this engine without filling the

crank case with the proper amount and type of oil. Your

generator has been shipped from the factory without oil in the

crankcase. Operating the unit without oil can damage the

engine.

Fill the engine with oil according to the operator manual.

For units with a dipstick, fill oil to the proper level. Units

without a dipstick should be filled to the top of the opening of

the oil fill.

LOW OIL SENSOR

The unit is equipped with a low oil sensor. If the oil level

becomes lower than required, the sensor will activate a

warning device or stop the engine.

If generator shuts off and the oil level is within

specifications, check to see if generator is sitting at an angle

that forces oil to shift. Place on an even surface to correct this.

If engine fails to start, the oil level may not be sufficient to

deactivate low oil level switch. Make sure the sump is

completely full of oil.

FUEL

Fill the tank with clean, fresh unleaded automotive

gasoline. Regular grade gasoline may be used provided a high

octane rating is obtained (at least 85 pump octane). We

recommend always using a fuel stabilizer. A fuel stabilizer

will minimize the formulation of fuel gum deposits during

storage. The fuel stabilizer can be added to the gasoline in the

fuel tank, or into the gasoline in a storage container.

Ground

Terminal

Do not use a pipe carrying combustible material as

the ground source.

• SLOWLY ADD UNLEADED GASOLINE

TO FUEL TANK

• DO NOT OVERFILL TANK

• DO NOT FILL ABOVE TOP OF FUEL

SCREEN. THIS WILL ALLOW

EXPANSION IN HOT WEATHER AND

PREVENT OVERFLOW.

English

9

Customer Hotline 1-800-445-1805

Page 10

POSITIONING

HIGH ALTITUDE OPERATION

HIGH ALTITUDE OPERATION

• Place the generator set on a flat and solid surface to

prevent it from sinking.

• Keep fuel, oil or other explosives at a safe distance from

the generator set.

• Select a site that is well ventilated and protected from the

weather.

• Place the generator set safely away from people and

animals.

CAUTION: TILTING CAN CAUSE FUEL

SPILLAGE

At high altitude, the standard carburetor air-fuel mixture

will be too rich. Performance will decrease and fuel

consumption will increase. A very rich mixture will also foul

the spark plug and cause hard starting. Operation at an

altitude that differs from that at which this engine was

certified, for extended periods of time, may increase emissions.

High altitude performance can be improved by specific

modifications to the carburetor. If you always operate your

engine at altitudes above 914 meters (3,000 feet), have your

authorized service center perform a carburetor modification.

HIGH ALTITUDE KIT PART NUMBER: 0071089

Even with a carburetor modification, engine horsepower

will decrease about 3.5% for each 300 meter (1,000 foot)

increase in altitude. The effect of altitude on horsepower will

be greater if no carburetor modification is made. A decrease

in engine horsepower will decrease the power output of the

generator.

When the carburetor has been modified for high

altitude operation, the air-fuel mixture will be too lean

for low altitude use. If the generator is used at low

altitudes after a carburetor modification, the

carburetor may cause the engine to overheat and result

in serious engine damage. For use at low altitudes,

have your authorized service center return the

carburetor to original factory specifications.

NOTICE: Warranty is Void if the necessary adjustments for

high altitude use are not made.

English

10

Customer Hotline 1-800-445-1805

Page 11

ELECTRIC START

ELECTRIC START

This generator model is provided with both electric start and recoil

start capabilities. The charger is a low amperage maintenance type

charger. It will charge your battery as your generator runs. Avoid

prolonged cranking, as it can damage the engine.

• Do not short-circuit the battery terminals.

• Do not charge in a sealed container.

• Keep sparks, flame away.

Storage batteries give off EXPLOSIVE hydrogen gas

while charging. Do not allow smoking, open flames,

sparks, or spark producing equipment in the area

while charging.

The battery provided is a nominal 12 volt sealed rechargeable

lead-acid battery and can be operated in any position without leakage.

It’s convenient size offers a reduction over conventional batteries.

Length = 5.91 inches, Width = 3.35 inches, Height = 5.12 inches

14AH Rating

Battery electrolyte fluid is comprised of sulfuric acid

that can be very dangerous and cause severe burns.

Do not allow this fluid to contact eyes, skin, clothing,

etc. If contact or spillage does occur, flush the area

with water immediately.

Battery Kit Parts List:

Installation:

1. Place the battery in the position provided.

2. Place the Hold-Down bracket on the battery pan bolts.

3. Tighten down the Hold-Down assembly with the M6 nuts

provided.

Hook up the new battery, or re-install the new battery, as follows:

Remove vinyl caps from red and black wire terminals. Connect the

Red wire to the positive (+) terminal and the Black wire to the

negative (-) terminal with the bolt, nut, and washer provided. Make

sure all connections are tight. Your battery is now connected and

ready for use. Turn the key switch to crank the engine.

Note: Be sure Oil has been added to the engine as specified in the

Owner's Manual.

Refer to the parts list on pages 46 and 47.

Note: Brand New Generators are shipped with the Battery

Connections disconnected. The Positive and Negative Terminals

must be connected to the Battery before the Electric Start

Feature will work.

Initial Battery Connection - Refer to the Installation Instructions

Below.

Battery Removal & Installation:

Removal: Remove the nut and bolt from the negative and positive

post, being careful not to short across the terminals. (Shorting the

terminals together can cause sparks, damage to the battery or

generator or even burns or explosions.) Always abide by the safety

warnings provided with the battery. Remove the battery and re-cycle

and dispose of properly.

POSITIVE (+)

TERMINAL (RED)

11

NEGATIVE (-)

TERMINAL (BLACK)

Customer Hotline 1-800-445-1805English

Page 12

STARTING THE UNIT

STARTING THE UNIT

Gasoline is very dangerous.

Serious injury or death may result from fire caused

by gasoline contacting hot surfaces.

1. Do not fill fuel tank with engine running.

2. Do not spill fuel while refilling tank.

3. Do not mix oil with gasoline.

4. Follow all instructions and warnings in the

operator manual.

PRE-START PREPARATION

Before starting the generator, check for loose or missing

parts and for any damage which may have occurred during

shipment.

This generator must not be operated without all

factory installed heat shields in place. Failure to

comply may cause the fuel tank to overheat and result

in personal injury from fire.

STARTING THE ENGINE

1. Check oil level and fuel.

2. Disconnect all electrical loads from the unit.

3. Open fuel shut off valve (A).

4. Adjust choke (B) as necessary.

5. Set the key switch (C) to the “ON" position.

6. MANUAL START: Pull on the starter rope (D) with fast

steady pull. As the engine warms up, readjust the choke.

7. ELECTRIC START: Turn the key switch to “START”.

Release key switch after the engine starts. As the engine

warms up, readjust the choke.

B

D

ST

A

RT RUN

Allow generator to run at no load for five minutes upon

each initial start-up to permit engine and generator to

stabilize.

A

C

• Provide adequate ventilation for toxic exhaust

gases and cooling air flow.

• Do not start or run the generator in an enclosed

area, even if door or windows are open.

• Engines give off carbon monoxide, an odorless,

colorless, poison gas.

• Breathing carbon monoxide can cause nausea,

fainting or death.

APPLYING LOAD

This unit has been pretested and adjusted to handle its full

capacity. When starting the generator, disconnect all load.

Apply load only after generator is running. Voltage is

regulated via the engine speed adjusted at the factory for correct

output. Readjusting will void warranty.

When applying a load, do not exceed the maximum

wattage rating of the generator when using one or

more receptacles. Also, do not exceed the amperage

rating of any one receptacle.

Do not apply heavy electrical load during break-in

period (the first two to three hours of operations).

SHUTTING THE GENERATOR OFF

1. Remove entire electrical load.

2. Let the engine run for two minutes without load.

3. Move the key switch to the “OFF” position.

4. Do not leave the generator until it has completely

stopped.

5. Close the fuel shut off valve if the engine is to be put in

storage or transported.

6. If a cover is used, do not install until unit has cooled.

7. If the generator will not be used again for an extended

time period, refer to the SERVICE AND STORAGE

section of this manual.

English

12

Customer Hotline 1-800-445-1805

Page 13

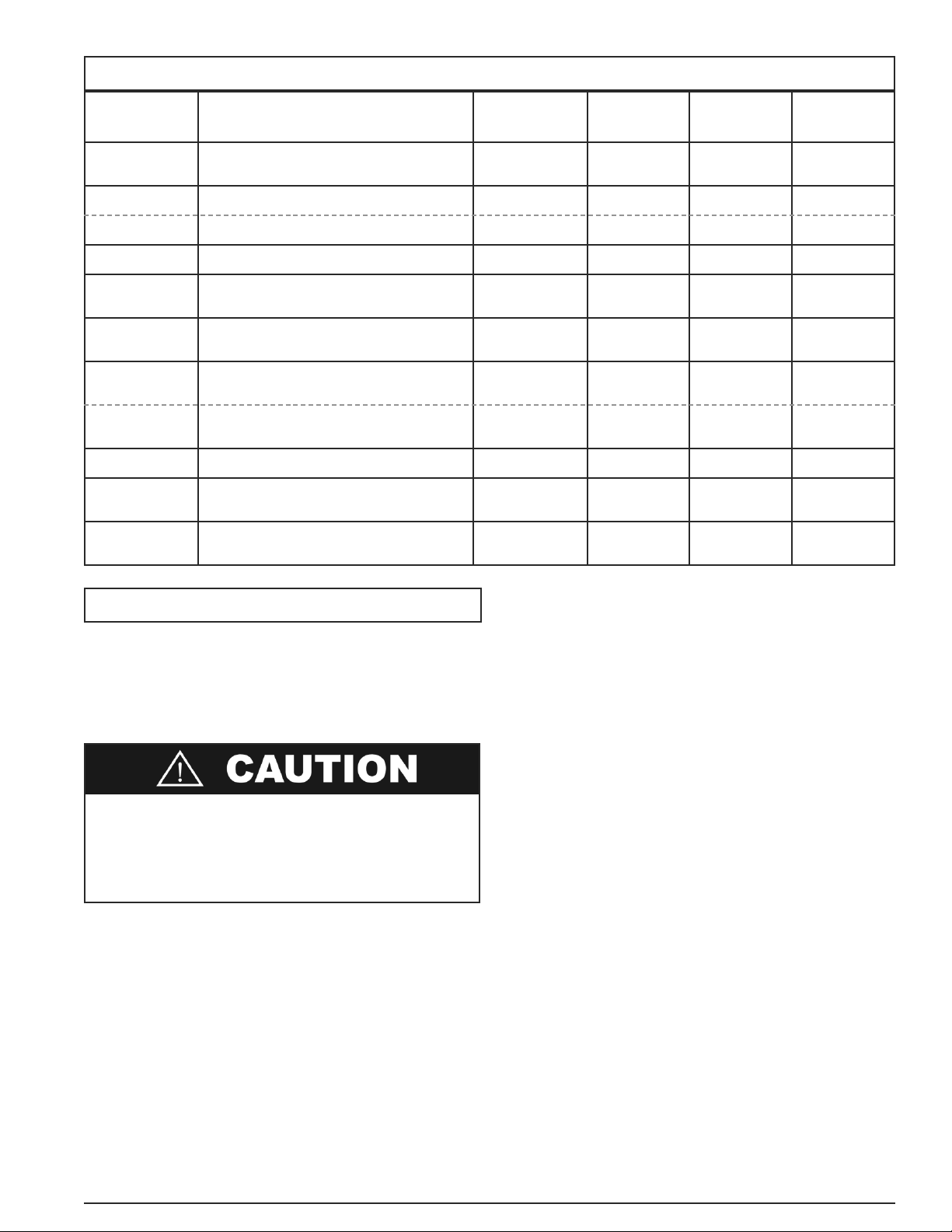

PERIODIC MAINTENANCE

PERIODIC MAINTENANCE

ITEM NOTES

Spark Plug

Engine Oil Check oil level.

Air Filter Clean, replace if necessary.

Fuel Filter

Fuel Line

Exhaust

System

Carburetor Check choke operation.

Starting

System

Fittings/

Fasteners

Check condition. Adjust gap and

clean. Replace if necessary.

Replace.

Clean fuel filter and fuel tank strainer.

Replace if necessary.

Check fuel hose for cracks or other

damage. Replace if necessary.

Check for leakage. Retighten or

replace gasket if necessary.

Check spart arrester screen.

Clean/replace if necessary.

Check recoil starter operation.

Check. Replace if necessary.

Daily (Before

operation)

ü

ü

ü

ü

ü

Initial

25 hours

Every

50 hours

ü

ü ü

ü

Every

100 hours

ü

ü

ü

MAINTENANCE

MAINTENANCE

SPARK PLUG

Remove the spark plug and clean the electrodes section

with a wire brush or sandpaper. Next, set the gap at .028/.031

inches (0.7-0.8 mm) by adjusting the negative electrode.

Replace the spark plug with correct torque: 14 ft-lb (20 N.m)

Replace with only the same type of spark plug which

was removed. An improper spark plug can cause the

engine to overheat, emit smoke, or otherwise perform

poorly.

OIL TYPE

Use new good quality oil, SJ or later service category.

The oil to be used depends upon the temperature at which the

engine is operated:

Below 32° F (0° C) . . . . . . . . .SAE 10W, 10W-30, or 10W-40

32 to 80° F (0 to 25° C) . . . . . .SAE 20W, 10W-30, or 10W-40

80 to 95° F (25 to 35° C) . . . . .SAE 30W, 10W-30, or 10W-40

Above 95° F (35° C) . . . . . . . . . . . . . . . . . . . . . . . . .SAE 40W

OIL REPLACEMENT

1. Change oil while engine is warm.

2. Place the generator unit on a level surface.

3. Remove the oil filler cap.

4. Open the oil drain plug and let oil drain completely into a

pan placed under the engine.

5. Check gaskets. Replace if required.

6. Reinstall the oil drain plug and refill engine with clean

oil.

7. Replace the oil filler cap.

AIR FILTER CLEANING

1. Unscrew the air filter cover.

2. Remove filter element and wash well in solvent.

3. Pour a small amount of oil onto the filter element and

gently squeeze out any excess oil.

4. Replace the filter element and air filter cover.

5. Be sure the filter cover seals properly all around.

FUEL SHUT OFF VALVE FILTER CLEANING

1. Remove the cup at the bottom of the fuel shut off valve

with a small wrench.

2. Remove the fuel shut off valve filter.

3. Clean and wash out the filter and cup and replace.

FUEL STRAINER CLEANING

1. Remove the plastic fuel strainer, located below the fuel

tank cap.

2. Wash the strainer in solvent and replace.

13

Customer Hotline 1-800-445-1805English

Page 14

VALVE CLEARANCE

Intake — 0.1 mm - 0.15 mm (.004 inch - .006 inch)

Exhaust — 0.15 mm - 0.2 mm (.006 inch - .008 inch)

After the first 50 hours of operation, check the valve clearance in

the engine and adjust if necessary.

NOTICE: If unsure about doing this procedure or the proper tools are

not available, take the generator to the nearest service center to have

the valve clearance adjusted. This is a very important procedure to

ensure longest life for the engine.

HEATSHIELD:

Inspect to ensure that all heat shields and heat deflectors are intact

and in place. Do not remove any parts or modify parts. Removing or

modifying parts could cause serious damage to the unit.

ENGINE: Carburetor Icing

During the winter months, rare atmospheric conditions may

develop which will cause an icing condition in the carburetor. If this

develops, the engine may run rough, loose power, and may stall. Call

Product Service for more information.

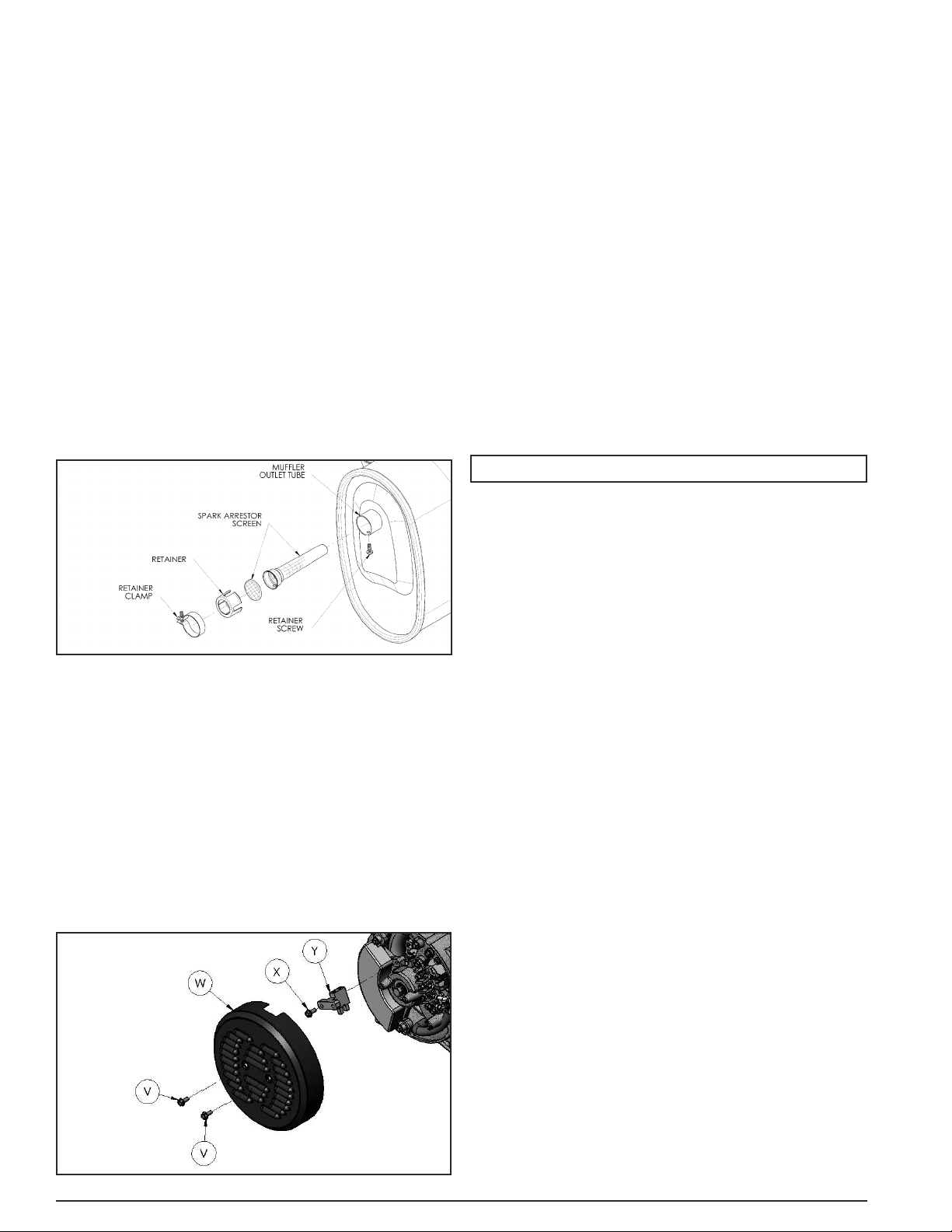

SPARK ARRESTER SCREEN

Remove screen every 50 hours for cleaning and inspection.

Replace if damaged.

Clean and inspect the spark arrester as follows:

1. Remove the screen retainer by removing the retainer clamp.

2. Remove the retainer screw from the muffler outlet tube.

3. Slide the spark arrester screen out from the muffler outlet tube.

4. Be careful not to damage the spark arresting screen. The spark

arrester must be free of breaks and holes. If screen is not

damaged, clean it with a commerical solvent.

5. Replace the screen and retainer and secure with retainer screw

and clamp.

GENERATOR: Brushes

The brushes in the generator should be inspected once every year

for chips and cracks. Brushes should be replaced when they are worn

to 1/4 inch (7mm).

NOTE: Replace brushes in sets only, never separately.

Replace only with brushes specified in parts list. Other brushes

may appear to be identical but may have completely different

mechanical and electrical characteristics.

INSPECTING THE BRUSHES:

1. Remove 2 screws (V) and end cover (W).

2. Remove screw (X) holding the brush module (Y).

3. Disconnect the blue (+) and yellow (-) brush wires from the

tabs.

4. Replace if worn to 1/4 inch (7mm).

5. Do not over tighten screw.

QUICK STARTING TIPS FOR UNITS THAT HAVE BEEN

SITTING FOR AWHILE:

If your unit has been sitting around for a long time period and is

hard to start, try doing some of these easy steps before calling the

Customer Hotline.

1. Check the oil level.

2. Replace the old fuel.

3. Change the spark plug.

4. Check the fuel lines. Make sure the fuel shut off valve is open.

5. Check all generator parts for integrity.

6. Clean the Carburetor.

SERVICE AND STORAGE

SERVICE AND STORAGE

INFREQUENT SERVICE

If the unit is used infrequently, difficult starting may result. To

eliminate hard starting, follow these instructions:

1. Run the generator at least 30 minutes every month.

2. Run the generator, then close the fuel shut-off valve and allow

the unit to run until the engine stops.

3. Move the engine switch to the “OFF” position.

LONG TERM STORAGE

When the generator set is not being operated or is being stored

more than one month, follow these instructions:

1. Replenish engine oil to upper level.

2. Run the generator, then close the fuel shut-off valve and allow

the unit to run until the engine stops.

3. Move the engine switch to the “OFF” position.

4. After the unit has cooled, drain gasoline from fuel tank, fuel line

and carburetor.

5. Pour about one teaspoon of engine oil through the spark plug

hole, pull the recoil starter several times and replace the plug.

Then pull the starter until you feel the piston is on its

compression stroke and leave it in that position. This closes

both the intake and exhaust valves to prevent the inside of the

cylinder from rusting.

6. Cover the unit and store in a clean, dry place that is well

ventilated away from open flame or sparks.

NOTE: We recommend always using a fuel stabilizer. A fuel

stabilizer will minimize the formulation of fuel gum deposits

during storage. The fuel stabilizer can be added to the gasoline

in the fuel tank, or into the gasoline in a storage container.

English

14

Customer Hotline 1-800-445-1805

Page 15

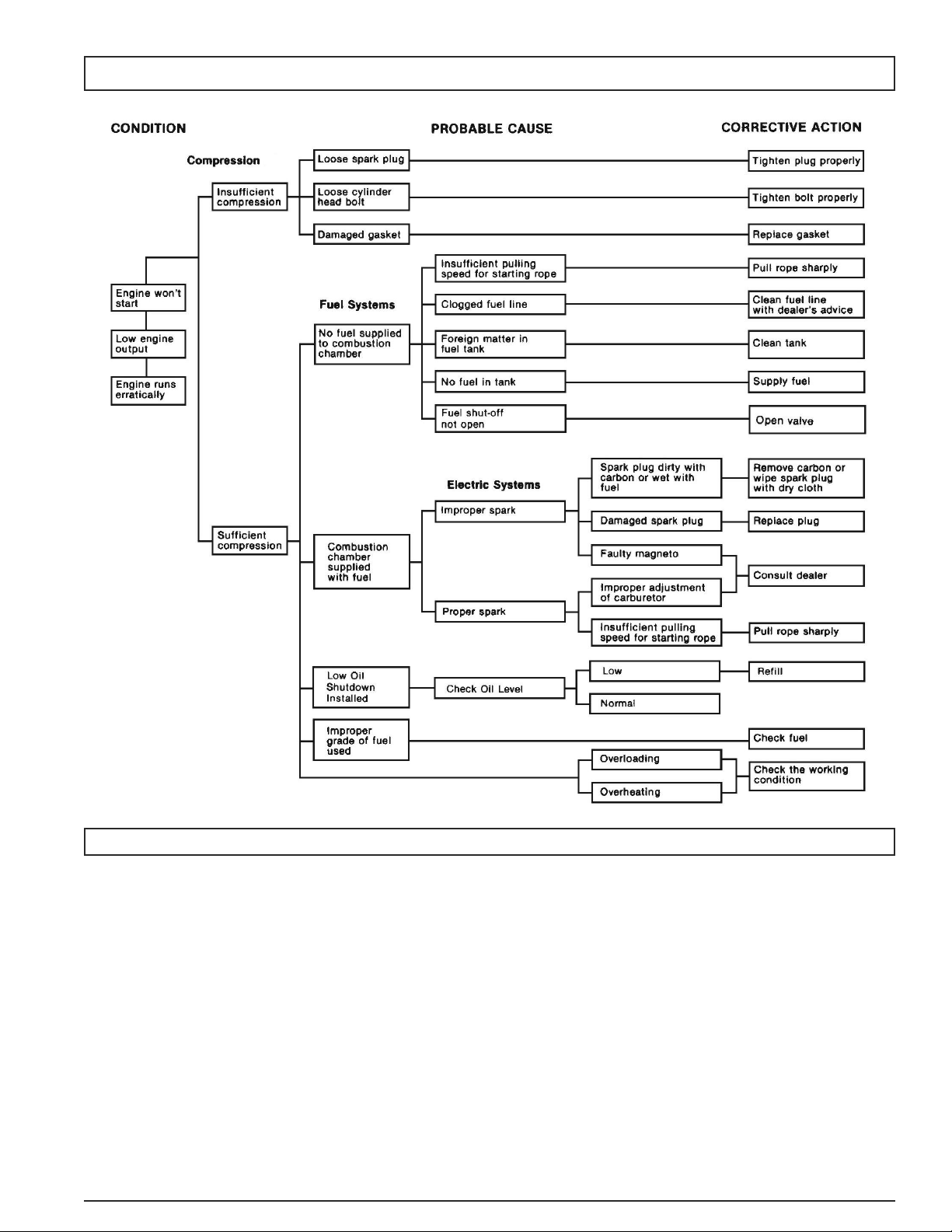

ENGINE TROUBLESHOOTING

ENGINE TROUBLESHOOTING

English

ENGINE SPECIFICATIONS

ENGINE SPECIFICATIONS

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-stroke, single cylinder, gasoline, OHV

Displacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .445 cc, 27.16 cubic inches

Maximum HP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14 HP @ 3600 rpm

Starting System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Recoil (electronic ignition)

Driving System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Direct coupling, tapered crank

Oil Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37 oz.

Spark Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .NGK BPR7ES or equivalent

Governor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Mechanical (adjustable)

Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Forced air cooling

Carburetor Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Float

Air Cleaner Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Foam element

15

Customer Hotline 1-800-445-1805

Page 16

SERVICE INFORMATION

SERVICE INFORMATION

CONTACT THE

PRAMAC AMERICA

LIMITED WARRANTY

LIMITED WARRANTY

Warranty Coverage: Pramac America, LLC (the Company)

warrants to the original retail customer in North America that

it will repair or replace, free of charge, any parts found by

the Company or its authorized service

representative to be defective in material or workmanship.

This warranty covers the cost of replacement parts and labor

for defects in material or workmanship.

PRODUCT SERVICE

DEPARTMENT AT

1-800-445-1805

or at www.powermate.com

to obtain warranty service

information or to order

replacement parts or

accessories.

HOW TO ORDER REPLACEMENT PARTS

Even quality built equipment such as the electric

generator you have purchased, might need occasional

replacement parts to maintain it in good condition over the

years. To order replacement parts, please give the following

information:

1. Model No. and Serial No. and all specifications shown

on the Model No./Serial No. plate.

2. Part number or numbers as shown in the Parts List

section.

3. A brief description of the trouble with the generator.

Pramac America, LLC

4970 Airport Road

P. O. Box 6001

Kearney, NE 68847

1-800-445-1805

www.powermate.com

Not Covered:

· Transportation charges for sending the product to the

Company or its authorized service representative for

warranty service, or for shipping repaired or replacement

products back to the customer; these charges must be borne

by the customer.

· If a separate operator's manual and engine warranty

from the engine manufacturer is included with this product,

only that warranty will apply to the engine.

· Damages caused by abuse or accident, and the effects

of corrosion, erosion and normal wear and tear.

· Warranty is voided if the customer fails to install,

maintain and operate the product in accordance with the

instructions and recommendations of the Company set forth

in the owner's manual, or if the product is used as rental

equipment.

· The Company will not pay for repairs or adjustments to

the product, or for any costs or labor, performed without the

Company's prior authorization.

Warranty Period: Two (2) years from the date of purchase

on products used solely for consumer applications; if a

product is used for business or commercial applications, the

warranty period will be limited to one (1) year from the date

of purchase. For warranty service, the customer must

provide dated proof of purchase and must notify the

Company within the warranty period.

For warranty service: Call toll free 800-445-1805, or

write to Pramac America, LLC, Product Services, 4970

Airport Road, P. O. Box 6001, Kearney, NE 68847.

EXCLUSIONS AND LIMITATIONS: THE COMPANY MAKES

NO OTHER WARRANTY OF ANY KIND, EXPRESS OR

IMPLIED. IMPLIED WARRANTIES, INCLUDING

WARRANTIES OF MERCHANTABILITY AND OF FITNESS

FOR A PARTICULAR PURPOSE, ARE HEREBY

DISCLAIMED. THE WARRANTY SERVICE DESCRIBED

ABOVE IS THE EXCLUSIVE REMEDY UNDER THIS

WARRANTY; LIABILITY FOR INCIDENTAL AND

CONSEQUENTIAL DAMAGES IS EXCLUDED TO THE

EXTENT PERMITTED BY LAW.

REGISTER YOUR PRODUCT

Register your Powermate® generator

online at www.powermate.com.

English

This warranty gives you specific legal rights, and you may

also have other rights which vary from state to state. Some

states do not allow a disclaimer of implied warranties, or the

exclusion or limitation of incidental and consequential

damages, so the above disclaimers and exclusions may not

apply to you.

16

Customer Hotline 1-800-445-1805

Page 17

SÉCURITÉ

SÉCURITÉ

DANGER signifie une situation

susceptible de présenter un danger

qui, s'il n'est pas évité,

CAUSERA de sérieuses

blessures, voire la mort.

GUIDE DES SYMBOLES DE SÉCURITÉ

Symbole d'alerte de sécurité; pour vous

avertir des éventuels risques de

blessures.

Risque d'électrocution ou de décharge.

Matières inflammables.

Risque d’explosion. Matières corrosives.

RÈGLES D’OPÉRATION ET DE SÉCURITÉ

L'AVERTISSEMENT Indique une

situation présentant un danger

potentiel et qui, en l'absence

d'intervention, pourrait conduire à la

mort ou entraîner de graves

blessures.

Matières dangereuses, toxiques ou très

toxiques.

Pièces rotatives - risque d’emmêlement.

Surface chaude - ne touchez pas la

surface.

La mention ATTENTION sert à

prévenir l'utilisateur d'un danger

potentiel qui risque d'occasionner

des dommages ou des blessures

légères ou modérées.

AVERTISSEMENT - L'inobservation des présentes

consignes et l'ignorance des avertisse ments qui en

découlent risquent de causer des blessures et des

dommages ou d'entraîner la mort.

métalliques.

1. Lire attentivement le guide d'utilisation, puis s'assurer de

les comprendre avant de mettre l'appareil en marche.

Observer l'ensemble des avertissements et des directives

s'y rapportant.

2. Se familiariser avec l'appareil et tenir compte des

domaines d'usage, des restrictions et des risques

potentiels qui découlent de son utilisation.

3. On doit placer l’équipement sur un support plat et solide

4. La charge doit être dans les normes spécifiées sur la

plaque signalétique de l'appareil. Toute surcharge abîme

l'appareil et en raccourcit la durée de vie utile.

5. Le moteur ne doit pas tourner à des vitesses excessives

car ceci augmente les risques de blessures personnelles.

Ne touchez pas aux pièces ce qui pourrait augmenter

ou réduire la vitesse régulée.

6. Afin d’empêcher les démarrages imprévus, toujours

enlever la bougie ou le câble de la bougie avant d’ajuster

le groupe électrogène ou le moteur.

7. Un appareil dont les pièces sont cassées, auquel il

manque des pièces ou qui n’a pas de carter ou de

coquille protectrice ne doit en aucun cas être

utilisé. Contacter notre service après-vente pour

des pièces de rechange.

Français Assistance Téléphonique 1-800-445-1805

9. Garder l'appareil propre et libre de toute huile, boue ou

autre matière étrangère.

10. Les rallonges, les cordons d’alimentation et tout appareil

électrique doivent être en bon état. Ne jamais faire

fonctionner un appareil électrique dont le cordon

d’alimentation est abîmé ou défectueux.

12. Vous ne devez jamais utiliser votre appareil sous ces

conditions:

a. Modification irrépressible du régime moteur.

b. Perte de puissance électrique.

c. Surchauffe d’appareils connectés.

d. Jaillissement d’étincelles.

e. Prises endommagées.

f. Le moteur a des ratés.

g. Vibrations excessives.

h. Flammes ou fumée.

i. Compartiment fermé.

j. Temps mauvais ou pluvieux ou neige. Éviter

d'exposer l'ap pareil à l'humidité en cours de

fonctionnement.

17

8. Ne pas faire fonctionner ou entreposer l’appareil dans un

endroit humide ni sur une surface mouillée, ni dans un

endroit où il sera en contact avec des surfaces

conductrices telles que des planchers ou armatures

11. Rangez le nettoyeur haute pression dans un endroit bien

ventilé, réservoir d’essence vide. On ne doit pas ranger

l’essence près du groupe électrogène.

Page 18

13. Vérifiez le système de carburant régulièrement pour

toute fuite ou signes de détérioration tels un tuyau

spongieux ou usé, une bride qui manque ou desserrée

ou un réservoir ou couvercle endommagé. On doit

corriger ces problèmes avant de faire fonctionner

l’appareil.

20. Ne rien mettre dans les fentes d’aération, même quand

l'appareil n’est pas en marche. Ceci pourrait l’abîmer ou

provoquer des blessures.

21. Avant de transporter la génératrice dans un véhicule, le

vider de tout carburant afin d’empêcher les fuites.

14. Le fonctionnement, l'entretien et le ravitaillement en

carburant de l'appareil ne doivent se faire que dans

les conditions suivantes :

a. Faites démarrer et fonctionner la génératrice

à l'extérieur. Ne faites jamais fonctionner la

génératrice dans un endroit clos, même si les

portes et les fenêtres sont ouvertes. Évitez les

endroits où les vapeurs peuvent être enfermées,

comme des fosses, des garages, des caves, des

excavations et des fonds de cale de bateau.

DANGER - RISQUE D'ÉMISSION DE

MONOXYDE DE CARBONE :

L'échappement des moteurs contient du

monoxyde de carbone, un gaz toxique, inodore et

invisible qui, s'il est respiré, peut causer de

sérieuses blessures, voire la mort. Si vous ne vous

sentez pas bien, êtes pris d'étourdissement ou vous

sentez faible en utilisant la génératrice, mettez-la

hors tension et respirez de l'air frais

immédiatement car vous souffrez peut-être

d'un empoisonnement au monoxyde de carbone.

b. Bonne aération pour le refroidissement. Le débit

d'air et la température sont importants pour les

systèmes à refroidissement à air. La température

ne devrait pas dépasser 104º F (40º C).

c. Refaites le plein du groupe électrogène dans un

endroit bien éclairé. Évitez les débordements de

carburant et ne refaites jamais le plein lorsque

l'appareil est en marche.

d. Ne faites pas le plein près de flammes nues, de

veilleuses ou d’équipement électrique projetant des

étincelles comme les outils électriques, les soudeuses

et les meuleuses.

e. Le silencieux et le filtre à air doivent toujours être en

place et en bon état puisqu’ils jouent le rôle de

coupe-flammes s’il y a des ratés.

f. Ne pas fumer près du générateur.

15. S’assurer que l'appareil est correctement posé sur le sol.

(Voir la section «Mise en place de l'appareil» dans le

présent manuel.)

16. Ne portez pas de vêtements amples, de bijoux ou toute

autre chose qui pourrait se prendre dans le démarreur

ou autres pièces rotatives.

17. L'appareil doit atteindre son régime de fonctionnement

avant que toute charge y soit connectée. Débrancher

toute charge avant d’arrêter le moteur.

18. Afin d’empêcher les pointes de tension qui pourraient

endommager les appareils branchés sur la génératrice,

ne pas laisser le moteur tomber en panne de carburant

pendant que des appareils sont branchés dessus.

19. Lorsque vous utilisez de l’équipement en solide, vous

devriez utiliser un protecteur de surtension pour éviter

d’endommager l’équipement.

22. Pour transporter l'appareil d’un site à l’autre, utilisez les

bonnes techniques de

levage sinon vous

pourriez vous blesser.

23. Pour éviter les brûlures, ne touchez pas au silencieux du

moteur ou à toute autre surface du moteur ou du

générateur qui se réchauffe durant le fonctionnement.

PROPOSITION 65 DE LA CALIFORNIE – AVERTISSEMENT

Le tuyau d'échappement de ce produit contient des produits

chimiques qui sont reconnus par l'État de Californie comme

pouvant causer le cancer, des anomalies congénitales ou

d'autres problèmes reproductifs.

PARE-ÉTINCELLES

PARE-ÉTINCELLES

VOTRE PRODUIT PEUT NE PAS ÊTRE MUNI D'UN

SILENCIEUX PARE-ÉTINCELLES. S’il doit être utilisé à

proximité de matériaux inflammables tels que récoltes, forêts,

broussailles, herbes ou autres, il est fortement recommandé d’installer

un pare-étincelles, par ailleurs obligatoire en Californie. Les articles

de la loi californienne relatifs à l’usage de pare-étincelles sont les

suivants : 13005(b), 4442 et 4443. L’usage d’un pare-étincelles est

également exigé sur certains des territoires du service des Forêts

américain et peut également l’être par d’autres lois et règlements.

Pour de plus amples renseignements à cet égard, prière de contacter

Pramac America, LLC, P. O. Box 6001, Kearney, Nebraska 68847.

Téléphone : 1-800-445-1805.

DÉTERMINATION DE LA PUISSANCE

DÉTERMINATION DE LA PUISSANCE

TOTALE NÉCESSAIRE

TOTALE NÉCESSAIRE

Afin d’éviter à la génératrice la surcharge et les dommages

possibles, il faut connaître la puissance totale de la charge branchée.

Pour déterminer quels outils et/ou quels appareils peuvent fonctionner avec votre générateur, suivez ces étapes :

1. Déterminez si vous désirez faire fonctionner un ou plusieurs

appareils simultanément.

2. Vérifiez les exigences normales pour démarrer et faire

fonctionner les appareils voulus en vous reportant à la plaque

signalétique de charge ou en effectuant ce calcul

(multipliez les ampères x volts = watts).

3. Additionnez le nombre de watts de démarrage et de

fonctionnement de chaque appareil. Toutefois, la plaque

signalétique de l’équipement vous donnera des chiffres de

consommation d’électricité plus exacts. Si la plaque ne vous

donne que des volts et des ampères, multipliez les volts par les

ampères = watts. 1KW = 1 000 watts.

4. Les appareils ou les outils à moteur exigent plus que leur

puissance indiquée pour le démarrage.

REMARQUE : Prévoir 2 1/2 - 4 fois la puissance indiquée

pour la mise en marche de l’appareil.

Français

18

Assistance Téléphonique 1-800-445-1805

Page 19

5. La puissance nominale du générateur devrait être égale ou

supérieure au nombre total de watts nécessaires au

fonctionnement de l'équipement à alimenter.

6. Branchez toujours d’abord la charge la plus lourde au

générateur, puis ajoutez les les autres une à une.

VÉRIFIER LA TENSION

VÉRIFIER LA TENSION

ATTENTION : Vérifier la tension et la fréquence

requises avant de brancher tout équipement

électronique sur le générateur. Le générateur peut se

trouver endommagé si les appareils branchés ne sont

pas prévus pour fonctionner à une tension égale à ±

10% et une fréquence égale à ± 3 hz de celles

indiquées sur la plaque signalétique du générateur.

Pour éviter tout dommage, toujours brancher une

charge additionnelle sur le générateur lorsqu’un

appareil à circuits intégrés (tel qu’un téléviseur) est

utilisé. Une varistance peut être aussi nécessaire pour

certaines applications, dans le cas d’un ordinateur,

par exemple. Une varistance peut être aussi

nécessaire pour certaines applications de

l’équipement en solide.

Pour éviter les retours de courant dans l’installation

électrique de la maison, il est nécessaire d’assurer son

isolation.

Avant de procéder au raccordement temporaire du

générateur au système électrique de la résidence, débrancher le

sectionneur du réseau d'alimentation principal.

Si du générateur est utilisée comme source auxiliaire en

cas de panne de courant, il doit être installé par un électricien

qualifié et en conformité avec tous les codes locaux

applicables.

Pour que l’installation soit correcte, un commutateur de

transfert à deux directions doit être installé par un électricien

qualifié et licencié de façon à ce que les circuits électriques du

bâtiment puissent être commutés du secteur au générateur sans

danger, empêchant ainsi les retours de courant dans le secteur.

Il est préférable d'utiliser un filtre de secteur lors de la

mise en fonction d'un ou de plusieurs des composants à

semiconducteurs suivants:

Ouvres-portes de garage

Appareils de cuisine à affichage digital

Téléviseurs

Stéréos

Ordinateurs personnel

Pendules à quartz

Machines à photocopier

Équipement téléphonique

D'autres composants à semiconducteurs peuvent

nécessiter l'usage d'un filtre de secteur. Pour de plus amples

renseignements à cet égard, prière de contacter le service à la

clientèle en composant le numéro de téléphone

1 800 445 1805.

INSTALLATION

INSTALLATION

Pour éviter les retours de courant dans le secteur, il est

nécessaire d’assurer l’isolation électrique de la maison.

Avant d’effectuer la connexion temporaire du générateur

sur l’installation électrique de la maison, couper le courant

à l’interrupteur principal. Avant de réaliser des connexions

permanentes, installer un commutateur de transfert à deux

directions. Pour éviter toute électrocution ou des dommages

matériels, faire connecter le générateur à l’installation

électrique de la maison par un électricien qualifié. Les lois

californiennes exigent l’isolation de l’installation électrique

de la maison avant d’y connecter un groupe électrogène. Il

n'est pas recommandé de procéder au raccordement

temporaire de l'appareil en raison de la réalimentation.

Toujours observer les codes et règlements locaux qui

s'appliquent à l'installation de tout appareil compatible

avec ce produit.

1. NFPA 70 - Code national de l'électricité disponible sur

le site www.nfpa.org

2. NFPA 37 - Norme d'installation et d'utilisation des

moteurs fixes à combustible disponible sur le site

www.nfpa.org

Pour éviter toute blessure et tout dommage aux appareils,

faire effectuer l’installation électrique et toutes réparations

par un électricien licencié ou un specialiste du service

après-vente agréé. En aucune circonstance, une personne

non qualifiée ne doit-elle essayer de réaliser le câblage sur

l’installation électrique existante.

Français

3. NFPA 5000 - Construction de bâtiment et code de

sécurité, disponible sur le site www.nfpa.org

4. Manuel de câblage du réseau d'alimentation de

secours des appareils agricoles disponible sur le site

www.rerc.org

19

Assistance Téléphonique 1-800-445-1805

Page 20

DÉBALLAGE DE VOTRE GÉNÉRATRICE

www.powermate.com 12/13 0070732

O

perator Manual •

M

anuel de l’opérateur • Manual del operador

E

LECTRIC GENERATOR • GROUPE ELECTROGENE • GENERADOR ELECTRICO

PM0148000

I

MPORTANT - Prière de vous assurer que

l

es personnes destinées à utiliser cet

a

ppareil ont pris soin d'en lire et d'en

c

omprendre le mode d'emploi ou les

d

irectives avant de le mettre en marche.

E

nregistrer le numéro de série figurant

sur la plaque signalétique du groupe

é

lectrogène:

N

º de série ____________________

I

MPORTANT – Please make certain that

p

ersons who are to use this equipment

t

horoughly read and understand these

i

nstructions and any additional

i

nstructions provided prior to operation.

Record the serial number as indicated on

y

our Generator’s nameplate:

S

erial No.______________________

I

MPORTANTE - Asegúrese que las

p

ersonas que utilizarán este equipo lean

y

entiendan completamente estas

i

nstrucciones y cualquier instrucción

a

dicional proporcionada antes del

funcionamiento.

Registre de serie como se indica en la

p

laca del nombre de su generador:

N

o. de serie ___________________

D

O NOT RETURN TO

STORE!

CALL US FIRST!

CUSTOMER HOTLINE

1-800-445-1805

F

OR QUESTIONS OR SERVICE

I

NFORMATION

N

O LO DEVUELVA A

LA TIENDA!

¡

PRIMERO LLÁMENOS!

L

ÍNEA DIRECTA DE ATENCIÓN

A

L CLIENTE

1

-800-445-1805

P

ARA la INFORMACION de

P

REGUNTAS O SERVICIO

N

E PAS RETOURNER

AU MAGASIN!

A

PPELEZ–NOUS D’ABORD!

A

SSISTANCE TELEPHONIQUE

A

LA CLIENTELE

1

-800-445-1805

P

OUR L'INFORMATION DE

Q

UESTIONS OU SERVICE

DÉBALLAGE DE VOTRE GÉNÉRATRICE

1. Ouvrez la boîte et retirez les matériaux d’emballage.

2. Retirez tous les accessoires, les sacs de pièces de

quincaillerie et la documentation de la boîte. Si un

article est manquant ou endommagé, contactez notre

département de service pour les produits au

1-800-445-1805.

• 1 - Sac de pièces de quincaillerie comprenant :

• 2 - Pieds en caoutchouc

• 2 - Pièces d’espacement de pied

• 2 - Clavettes d’essieu

• 1 - Sac d’éléments de fixation comprenant :

• 1 - Manuel de l’opérateur

• 1 - 1,0 L d’huile SAE 10-W30

• 1 -Entonnoir à huile

ARTICLE

DESCRIPTION

1

M12 X 4MM RONDELLE PLATE

2

M12 X 1.5MM RONDELLE PLATE

3

M8 RONDELLE PLATE

4

M8 X 50 BOULON

5

M8 X 80 BOULON

6

M8 ÉCROUS NYLOC

7

GOUPILLE

• 1 - Ensemble d’outils comprenant :

QUANTITÉ

2

2

2

2

2

2

2

• 2 - Roues de 12 po à l’épreuve des crevaisons

• 2 - Poignées

20

ARTICLE

1

2

3

DESCRIPTION

CLÉ HEXAGONALE DE 5 MM

CLÉ À FOURCHE DOUBLE 10X13 MM

CLÉ À BOUGIE AVEC TIGE

Assistance Téléphonique 1-800-445-1805Français

QUANTITÉ

1

1

1

Page 21

CARACTÉRISTIQUES DU GROUPE ELECTROGENE

CARACTÉRISTIQUES DU GROUPE ELECTROGENE

A. Tableau de commande

NOTE : Le total charge dessiné de toutes prises

dépasser les limites indiquées de plaque.

B. Prise de 120 V, 20 A

20 ampères de courant peuvent être dessinés de la

prise. La charge totale doit cependant rester dans les limites

indiquées sur la plaque signalétique.

C. Prise à verrouillage de 120 V, 30 A

Cette prise fournit un maximum de 30 A. Si d’autres

prises sont utilisées en même temps que celle-ci, la charge

totale doit rester dans les limites indiquées sur la plaque

signalétique.

D. Prise à verrouillage de 120/240 V, 30 A

Le courant de chargement plein maximum pourrait

être dessiné de la 120/240 prise de volt. La charge totale

doit rester dans les limites indiquées sur la plaque

signalétique. Si la prise de 120/240 V est utilisée en

conjonction avec les prises de 120 V, la charge totale ne

doit pas dépasser les limites indiquées sur la plaque.

E. Protecteurs de circuit

Les prises sont protégées par un protecteur de circuit alternatif.

En cas de surcharge ou de court-circuit extérieur, le protecteur de

circuit saute. Si cela se produit, débrancher tout appareil relié au

groupe électrogène et essayer de déterminer la cause du problème