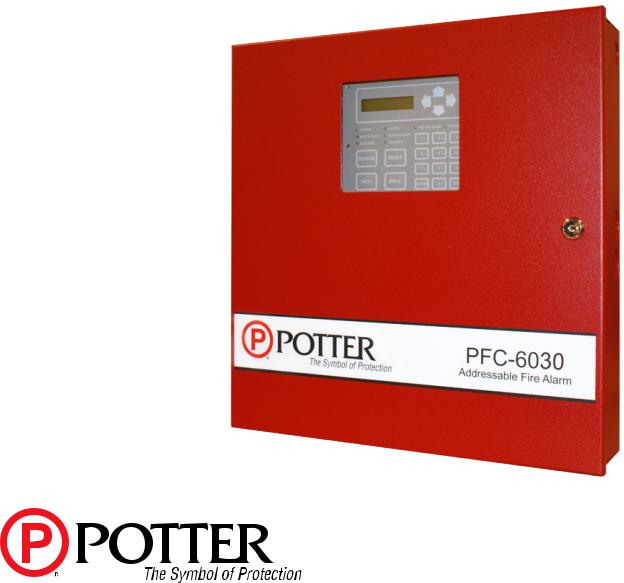

Potter PFC-6030 User Manual

PFC-6030 Fire Alarm

Control Panel

Installation, Operation & Programming Manual

Potter Electric Signal Company, LLC

St. Louis, MO

Customer Service: (866) 240-1870 • Technical Support: (866) 956-1211 • Fax: (314) 595-6999

www.pottersignal.com

Manual #5403595–Rev C 2/13

PFC-6030 • 5403595 • Rev C • 2/13

WARRANTY INFORMATION

The essential purpose of any sale or contract for sale of any of the products listed in the POTTER catalog or price list is the furnishing of that product. It is expressly understood that in furnishing said product, POTTER does not agree to insure the Purchaser against any losses the Purchaser may incur, even if resulting from the malfunction of said product.

POTTER warrants that the equipment herein shall conform to said descriptions as to all affirmation of fact and shall be free from defects of manufacture, labeling and packaging for a period of one (1) or five (5) year(s), depending on the product, from the invoice date to the original purchaser, provided that representative samples are returned to POTTER for inspection. The product warranty period is stated on

the exterior of the product package. Upon a determination by POTTER that a product is not as warranted, POTTER shall, at its exclusive option, replace or repair said defective product or parts thereof at its own expense except that Purchaser shall pay all shipping, insurance and similar charges incurred in connection with the replacement of the defective product or parts thereof. This Warranty is void in the case of abuse, misuse, abnormal usage, faulty installation or repair by unauthorized persons, or if for any other reason POTTER determines that said product is not operating properly as a result of causes other than defective manufacture, labeling or packaging.

The Aforesaid Warranty Is Expressly Made In Lieu Of Any Other Warranties, Expressed Or Implied, It Being Understood That All Such Other Warranties, Expressed Or Implied, Including The Warranties Of Merchantability And Fitness For Particular Purpose Are Hereby Expressly Excluded. In No Event Shall Potter Be Liable To Purchaser For Any Direct, Collateral, Incidental Or Consequential Damages In

Connection With Purchaser’s Use Of Any Of The Products Listed Herein, Or For Any Other Cause Whatsoever Relating To The Said Products. Neither Potter Nor Its Representatives Shall Be Liable To The Purchaser

Or Anyone Else For Any Liability, Claim, Loss, Damage Or Expense Of Any Kind, Or Direct Collateral, Incidental Or Consequential Damages Relative To Or Arising From Or Caused Directly Or Indirectly By Said

Products Or The Use Thereof Or Any Deficiency, Defect Or Inadequacy Of The Said Products. It Is Expressly

Agreed That Purchaser’s Exclusive Remedy For Any Cause Of Action Relating To The Purchase And/or Use Of Any Of The Products Listed Herein From Potter Shall Be For Damages, And Potter's Liability For Any And All Losses Or Damages Resulting From Any Cause Whatsoever, Including Negligence, Or Other Fault, Shall In No Event Exceed The Purchase Price Of The Product In Respect To Which The Claim Is Made, Or At The Election Of Potter, The Restoration Or Replacement Or Repair Of Such Product.

Potter Electric Signal Company, LLC

5757 Phantom Drive Ste 125 • St. Louis, MO 63042 • 314-595-6900 • 800-325-3936

2

PFC-6030 • 5403595 • Rev C • 2/13 |

|

Table of Contents |

|

Section 1: Introduction.............................................................................................................................. |

1-1 |

Purpose of This Manual........................................................................................................................... |

1-1 |

System Overview..................................................................................................................................... |

1-1 |

System Features....................................................................................................................................... |

1-1 |

P-Link Accessories............................................................................................................................ |

1-1 |

SLC Loop Accessories....................................................................................................................... |

1-2 |

Addressable Sensors.......................................................................................................................... |

1-2 |

Addressable Modules......................................................................................................................... |

1-2 |

How to Use this Manual.......................................................................................................................... |

1-2 |

Common Terminology............................................................................................................................. |

1-2 |

Section 2: Before You Start Installation.................................................................................................. |

2-3 |

System Specifications.............................................................................................................................. |

2-3 |

Environmental Specifications.................................................................................................................. |

2-3 |

System Configurations / Appliances........................................................................................................ |

2-3 |

Electrical Specifications.......................................................................................................................... |

2-4 |

System Size Specifications...................................................................................................................... |

2-4 |

Main Board Wiring Specifications.......................................................................................................... |

2-5 |

Circuit Separation............................................................................................................................. |

2-5 |

Wiring Types...................................................................................................................................... |

2-5 |

Cabinet Dimensions................................................................................................................................. |

2-6 |

Cabinet Wiring Connections.................................................................................................................... |

2-7 |

Battery Circuit Calculations.................................................................................................................... |

2-8 |

Battery Calculation Worksheets.............................................................................................................. |

2-8 |

SLC Current Draw Worksheet................................................................................................................. |

2-9 |

Isolator Device Load Calculation.......................................................................................................... |

2-10 |

Scenario 1: Class A Loop – Isolated Devices Configuration.......................................................... |

2-10 |

Scenario 2: Class B Loop – Isolated Branch Configuration........................................................... |

2-11 |

Battery Connections.............................................................................................................................. |

2-12 |

Main Supply Circuit.............................................................................................................................. |

2-12 |

Section 3: Installation.............................................................................................................................. |

3-13 |

Signaling Line Circuit (SLC) Installation............................................................................................. |

3-13 |

SLC Wiring Requirements................................................................................................................ |

3-13 |

Class B, Style 4 Wiring Configuration............................................................................................. |

3-13 |

Class A, Style 6 Wiring Configuration............................................................................................. |

3-14 |

Class A, Style 7 Wiring Configuration............................................................................................. |

3-14 |

Connecting Analog Detectors................................................................................................................ |

3-15 |

Connecting Addressable Modules......................................................................................................... |

3-15 |

Conventional Initiating Zones (CIZM-4) Class A........................................................................... |

3-15 |

Conventional Initiating Zones (CIZM-4) Class B........................................................................... |

3-16 |

Single Contact Module – 4 inch Mount (SCM-4)............................................................................ |

3-16 |

Dual Contact Module – 4 inch Mount (DCM-4)............................................................................. |

3-17 |

Twin Relay Module – 4 inch mount (TRM-4).................................................................................. |

3-17 |

Monitored Output Module – 4 inch mount (MOM-4)...................................................................... |

3-18 |

Analog Sounder Base (ASB)............................................................................................................ |

3-18 |

Analog Relay Base (ARB)................................................................................................................ |

3-18 |

Single Action / Dual Action Pull Station (APS-SA / APS-DA)........................................................ |

3-19 |

Addressing SLC Devices....................................................................................................................... |

3-20 |

3

PFC-6030 • 5403595 • Rev C • 2/13 |

|

Notification Appliance Circuits Installation.......................................................................................... |

3-22 |

NAC Wiring..................................................................................................................................... |

3-22 |

NAC Maximum Wiring Impedance Formula................................................................................... |

3-22 |

NAC Wiring Configurations ........................................................................................................... |

3-22 |

Relay Output Wiring.............................................................................................................................. |

3-24 |

CA-6075 Class A Expander Installation................................................................................................ |

3-24 |

P-Link Devices...................................................................................................................................... |

3-25 |

Configuration Characteristics......................................................................................................... |

3-25 |

Maximum Wire Resistance Formula................................................................................................ |

3-25 |

P-Link Addresses............................................................................................................................. |

3-26 |

Remote Annunciators Installation (RA-6500 and RA-6075)................................................................ |

3-27 |

Setting Addresses............................................................................................................................. |

3-27 |

LED Annunciators Installation (LED-16)............................................................................................. |

3-27 |

LED Drivers Installation (DRV-50)....................................................................................................... |

3-28 |

Relay Board Installation (RLY-5).......................................................................................................... |

3-30 |

Fire Communications Bridge Installation (FCB-1000)......................................................................... |

3-31 |

Fiber Interface Bridge Installation (FIB-1000)..................................................................................... |

3-32 |

FIB-1000 Wiring.............................................................................................................................. |

3-33 |

Serial Parallel Gateway Installation (SPG-1000).................................................................................. |

3-34 |

DACT Installation................................................................................................................................. |

3-35 |

P-Link & Dip Switch Locations....................................................................................................... |

3-36 |

Section 4: Operation................................................................................................................................ |

4-37 |

Control Panel Basic Operation.............................................................................................................. |

4-37 |

LCD Display.................................................................................................................................... |

4-37 |

Menu Navigation Keys..................................................................................................................... |

4-38 |

Numeric Keypad.............................................................................................................................. |

4-38 |

Function Pushbuttons...................................................................................................................... |

4-38 |

Status LEDs..................................................................................................................................... |

4-39 |

Control Panel Menu Tree....................................................................................................................... |

4-40 |

Section 5: Programming......................................................................................................................... |

5-41 |

Programming Options........................................................................................................................... |

5-41 |

Programming Overview........................................................................................................................ |

5-44 |

The Programming Cycle........................................................................................................................ |

5-44 |

Software Installation.............................................................................................................................. |

5-44 |

LEARN Programming........................................................................................................................... |

5-45 |

Connecting the Computer and Panel..................................................................................................... |

5-45 |

Transferring Data................................................................................................................................... |

5-47 |

Uploading from Panel to Computer................................................................................................ |

5-48 |

Downloading Configuration File to Panel............................................................................................. |

5-49 |

Enable Remote Access..................................................................................................................... |

5-49 |

File New........................................................................................................................................... |

5-50 |

File Save / Save As........................................................................................................................... |

5-50 |

Audit Errors..................................................................................................................................... |

5-50 |

Uploading History Events & Detector (Sensitivity) Status Reports...................................................... |

5-52 |

History Reports................................................................................................................................ |

5-52 |

Detector Sensitivity Status Reports.................................................................................................. |

5-53 |

Printing Reports.............................................................................................................................. |

5-54 |

4

PFC-6030 • 5403595 • Rev C • 2/13 |

|

Panel Software Overview...................................................................................................................... |

5-55 |

Window Regions / Areas.................................................................................................................. |

5-55 |

Program Icons................................................................................................................................. |

5-56 |

Programming Functions Overview........................................................................................................ |

5-57 |

Remote Access Code............................................................................................................................. |

5-58 |

User Name / Password.................................................................................................................... |

5-58 |

General System Functions..................................................................................................................... |

5-59 |

Job Details....................................................................................................................................... |

5-59 |

General Options.............................................................................................................................. |

5-59 |

Day/Night Sensitivity Mode and Holiday Scheduling..................................................................... |

5-60 |

User Codes...................................................................................................................................... |

5-61 |

System E-mail Functions....................................................................................................................... |

5-62 |

P-Link E-mail Notification Requirements........................................................................................ |

5-63 |

Connecting the Panel to a Network................................................................................................. |

5-63 |

E-mail Sent from Panel.................................................................................................................... |

5-64 |

E-mail Report Requested from PC.................................................................................................. |

5-65 |

Receiving E-mail Status Reports..................................................................................................... |

5-67 |

Creating E-mail Reminders............................................................................................................. |

5-69 |

System Programming............................................................................................................................ |

5-70 |

Mapping Zones Overview................................................................................................................ |

5-70 |

Single Zones..................................................................................................................................... |

5-70 |

Multiple Zones................................................................................................................................. |

5-70 |

Mapping Terminology...................................................................................................................... |

5-71 |

Zone Types / Styles........................................................................................................................... |

5-71 |

Zone Attributes................................................................................................................................ |

5-72 |

Creating Zones................................................................................................................................. |

5-74 |

Configuring Zones........................................................................................................................... |

5-75 |

Configuring Points........................................................................................................................... |

5-75 |

NAC Functions................................................................................................................................ |

5-76 |

SLC Functions................................................................................................................................. |

5-77 |

Adding Points to Zones.................................................................................................................... |

5-80 |

Group by Area.................................................................................................................................. |

5-82 |

Cross Zone Configurations.................................................................................................................... |

5-83 |

Programming Modules.......................................................................................................................... |

5-84 |

CA-6075 Class A Converter Module............................................................................................... |

5-84 |

Remote Annunciators (RA-6500 and RA-6075)............................................................................... |

5-84 |

LED Annunciators (LED-16)........................................................................................................... |

5-85 |

LED Driver (DRV-50)..................................................................................................................... |

5-85 |

Relay Board (RLY-5)........................................................................................................................ |

5-86 |

Fiber Interface Bridge (FIB-1000).................................................................................................. |

5-86 |

Fire Communications Bridge (FCB-1000)...................................................................................... |

5-87 |

Serial Parallel Printer (SPG-1000)................................................................................................. |

5-88 |

DACT (UD-1000)............................................................................................................................ |

5-89 |

Section 6: PSN-1000 / PSN-1000(E) – Installing, Operating & Programming.................................. |

6-91 |

Board Specifications.............................................................................................................................. |

6-91 |

Cabinet Descriptions.............................................................................................................................. |

6-91 |

Environmental Specifications................................................................................................................ |

6-91 |

5

PFC-6030 • 5403595 • Rev C • 2/13 |

|

Electrical Specifications........................................................................................................................ |

6-91 |

Wiring Specifications............................................................................................................................. |

6-91 |

Circuit Separation........................................................................................................................... |

6-91 |

Wiring Types.................................................................................................................................... |

6-92 |

Cabinet Dimensions............................................................................................................................... |

6-92 |

Cabinet Installation................................................................................................................................ |

6-93 |

Cabinet Wiring Connections.................................................................................................................. |

6-94 |

Rechargeable Battery Circuit................................................................................................................. |

6-95 |

Battery Circuit Calculation.................................................................................................................... |

6-95 |

PSN-1000/PSN-1000(E) Battery Calculation Worksheet..................................................................... |

6-96 |

Notification Appliance Circuits (NACs)................................................................................................ |

6-97 |

NAC Wiring..................................................................................................................................... |

6-97 |

NAC Wiring Configurations............................................................................................................ |

6-97 |

Input Circuits......................................................................................................................................... |

6-99 |

Configuration Characteristics......................................................................................................... |

6-99 |

Wiring to Control Panel.......................................................................................................................... |

6-99 |

Repeater Output................................................................................................................................... |

6-100 |

Configuration Characteristics....................................................................................................... |

6-100 |

Maximum Wire Resistance Formula.............................................................................................. |

6-100 |

Municipal Box Connection.................................................................................................................. |

6-101 |

Configuration Characteristics....................................................................................................... |

6-101 |

Relay Outputs...................................................................................................................................... |

6-101 |

PSN-1000/PSN-1000(E) Operations................................................................................................... |

6-102 |

Status LEDs................................................................................................................................... |

6-102 |

PSN-1000/PSN-1000(E) Programming............................................................................................... |

6-103 |

Adding a Power Supply................................................................................................................. |

6-103 |

Deleting a Power Supply............................................................................................................... |

6-104 |

Section 7: IP Communication............................................................................................................... |

7-105 |

Programming the IP Communicator.................................................................................................... |

7-106 |

IP Reporting Accounts................................................................................................................... |

7-106 |

Appendix A: Basic Operating Instructions............................................................................................ |

A-1 |

Appendix B: Modem Connectivity Setup................................................................................................ |

B-1 |

Appendix C: System Maintenance and Testing..................................................................................... |

C-1 |

Appendix D: PSN-1000/PSN-1000(E) Maintenance and Testing......................................................... |

D-1 |

Appendix E: Compatible Devices Table.................................................................................................. |

E-1 |

Appendix F: Troubleshooting Tips........................................................................................................... |

F-1 |

Appendix G: Control Panel Menu.......................................................................................................... |

G-1 |

6

PFC-6030 • 5403595 • Rev C • 2/13

Section 1: Introduction

The Model PFC-6030 is a listed and approved, microprocessor based addressable fire control panel and complies with UL-864, NFPA-13, NFPA-70, and NFPA-72.

The PFC-6030 system software is compatible with Windows XP, Windows Vista and Windows 7 Operating Systems; additionally, the latest version of Microsoft .NET Framework is required. The system software incorporates conventional shortcuts, and provides great flexibility in effectively programming individual or groups of devices. The operational mode behavior of the

two (2) on-board NAC 1 and 2 circuits can be customized. This flexibility enables configuration of system points to maximize protection throughout controlled site(s).

Purpose of This Manual

This manual is intended to assist in the installation and programming the PFC-6030 Fire Alarm Control Panel. Refer to this manual to properly install and program the PFC-6030. It is recommended that the user follows the procedures as outlined in this manual to assist in proper installation and prevent damage to the control panel and associated equipment.

System Overview

The PFC-6030 system is designed for use as a fire control panel for life safety applications.

System Features

yy The PFC-6030 features a built in signaling line circuit (SLC), and is capable of supporting 30 Potter/Nohmi protocol devices. yy 3.5 Amp 24vdc Power Supply

yyTwo (2) Notification Appliance Circuits (NACs) each rated at 3.0 Amps maximum. yy Power Limited

yy Built in Sync

yy Cadence Patterns yy Auxiliary Power

yySupport for all major synchronization patterns. yy Potter

yy Gentex®

yy CooperWheelock® yy System Sensor®

yy Built-in Ethernet port for programming and network connectivity.

yy Built-in e-mail support to communicate system status and event information. yy Customizable Reminder E-mails.

yy P-Link RS-485 bus supports system accessories. yy 1,000 event non-volatile history buffer.

yy Learn mode enrolls connected sensors and modules for efficient system programming. yy 99 Software Zones

yy Dead-front Cabinet Design yy 2 X 16 character LCD display

yy Dedicated Alarm, Supervisory and Trouble Form C Relays

yyAnalog / Addressable Sensing Technology yy Drift Compensation

yy Drift Alert

yy NFPA 72 compliant calibrated smoke test built-in

P-Link Accessories

yy RA-6500 or RA-6075 Remote Annunciator – Maximum of 31 per system in any combination yy UD-1000 Dual Line Fire Communicator – Maximum of 1 per system

yyCA-6075 Class A converter module – Maximum of 1 per system allows for Class A wiring of the SLC circuit, P-Link communication bus and the two (2) built-in NAC circuits

1-1

PFC-6030 • 5403595 • Rev C • 2/13

yyPSN-1000 / PSN-1000(E) Intelligent Power Supply Expander – An accessory to the panel providing ten (10) amps of additional power, with four (4) input points, six (6) notification circuits and a P-Link interface

yyLED-16 Annunciator module - Maximum of 10 total per system (the total may be any combination of LED-16 and DRV-50 LED modules) allows for up to 16 zones alarm, supervisory and trouble conditions to display, and 5 nonprogrammable system LEDs that display system's overall condition

yyDRV-50 LED Driver module - Maximum of 10 total per system (the total may be any combination of LED-16 and DRV-50 LED modules) allows output to up to 50 LEDs, 4 dry contact inputs, and 5 non-programmable system LEDs that display system's overall condition

yy RLY-5 Relay Board module - Maximum of 31 per system provides five (5) Form-C relay outputs

yy FCB-1000 Fire Communications Bridge - An accessory that provides a remotely-located IP connection to the panel

yyFIB-1000 Fiber Interface Bridge - An accessory to the panel that converts the standard 4-wire P-Link bus to and from optic cable capable of Class A operation; maximum of 31 per system

yySPG-1000 Serial Parallel Gateway - An accessory to the panel that allows a serial or parallel printer connection; up to 31 maximum per system

SLC Loop Accessories

•Addressable Sensors

yy Photoelectric Smoke Detector (PSA)

yy Photoelectric/Heat Smoke Detector (PSHA) yy Fixed Temperature Heat Detector (FHA)

yy Rate of Rise/Fixed Temperature Heat Detector (RHA) yy Addressable Isolator Base (AIB)

yy Addressable Relay Base (ARB) yy Addressable Sounder Base (ASB) yy Addressable Pull Station (APS)

•Addressable Modules

yy Miniature Contact Module (MCM) yy Single Contact Module (SCM-4) yy Dual Contact Module (DCM-4) yy Twin Relay Module (TRM-4)

yy Monitored Output Module (MOM-4)

yy Conventional Input Zone Module (CIZM-4) yy Short Circuit Isolator (SCI)

How to Use this Manual

Refer to this manual before contacting Technical Support. The information in this manual is the key to a successful installation and will assist you in understanding proper wire routing, system requirements, and other guidelines specific to the PFC-6030 system.

Common Terminology

The following table provides you with a list of terms and definitions used with the PFC-6030 system:

|

Table 1: Terminology |

Term |

Definition |

PFC-6030 Cabinet |

Enclosure |

EOLD or Diode Assembly |

End of Line Diode Assembly |

EOLR |

End of Line Resistor Assembly |

Remote Annunicator |

LCD type Remote Annunicator |

NAC |

Notification Appliance Circuit |

SLC |

Signaling Line Circuit |

DACT |

Digital Alarm Communicator Transmitter (UD-1000) |

|

1-2 |

PFC-6030 • 5403595 • Rev C • 2/13

Section 2: Before You Start Installation

This section addresses information that will help you in completing a successful installation, such as the PFC-6030 cabinet layout, specifications, environmental considerations, and calculating the battery circuit and SLC current draw requirements.

System Specifications

Cabinet Description

yy Sixteen (16) gauge sheet steel with hinged, removable locked door yy Enclosure dimensions – 16" x 17" x 3-7/8"

Visual Indicators

yy LCD (2 x 16 alphanumeric character display) yy LED indicators (Red, Green, Amber)

LCD Description

yy Alarm, Supervisory and Trouble conditions display applicable condition, status and circuit for each correlating condition

Environmental Specifications

yy Mount indoors only.

yy Temperature 32° to 120°F, humidity 93% non-condensing. yy Verify panel is properly grounded.

yy Remove all electronic assemblies prior to any drilling, filing, reaming, or punching of the enclosure. When possible, make all cable entries from the sides, bottom, or rear of the cabinet. Verify that they will not interfere with the batteries or other components.

yy The panel and system must be tested and maintained in accordance with all local and national codes and ordinances.

System Configurations / Appliances

Table 2: System Configurations / Appliances

Model |

Description |

Local |

Auxiliary |

Remote |

Central |

Proprietary |

|

Station |

Station |

||||||

|

|

|

|

|

|||

PFC-6030 |

Main Board/Panel Assembly |

Y |

Y |

Y |

Y |

Y |

|

|

|

|

|

|

|

|

|

CA-6075 |

Class A Expander |

O |

O |

O |

O |

O |

|

|

|

|

|

|

|

|

|

UD-1000 |

DACT |

N |

N |

Y |

Y |

Y |

|

|

|

|

|

|

|

|

|

RA-6500 |

LCD type remote Annunciator |

O |

O |

O |

O |

O |

|

or RA-6075 |

|||||||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

PSN-1000 or |

Intelligent Power Supply Expander |

O |

O |

O |

O |

O |

|

PSN-1000(E) |

|||||||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

LED-16 |

LED Annunciator |

O |

O |

O |

O |

O |

|

|

|

|

|

|

|

|

|

DRV-50 |

LED Driver |

O |

O |

O |

O |

O |

|

|

|

|

|

|

|

|

|

RLY-5 |

Relay Expander |

O |

O |

O |

O |

O |

|

|

|

|

|

|

|

|

|

FCB-1000 |

Fire Communications Bridge |

O |

O |

O |

O |

O |

|

|

|

|

|

|

|

|

|

FIB-1000 |

Fiber Interface Bridge |

O |

O |

O |

O |

O |

|

|

|

|

|

|

|

|

|

SPG-1000 |

Serial/Parallel Gateway |

O |

O |

O |

O |

O |

|

|

|

|

|

|

|

|

|

3005013 |

End of line resistor assembly |

Y |

Y |

Y |

Y |

Y |

|

|

|

|

|

|

|

|

|

3005012 |

End of line resistor and diode |

N |

Y |

N |

N |

N |

|

|

|

|

|

|

|

|

Y = Yes, required for applicable section

N = No, not required for applicable section

O = Optional, may or may not be used, has no affect on the applicable section.

2-3

PFC-6030 • 5403595 • Rev C • 2/13

Electrical Specifications

Please refer to the table below for electrical specifications:

Table 3: System Panel Electrical Specifications

Panel |

# NACs |

Rating |

I/O Circuits |

SLC Power |

Notes |

Style and Class |

|

per NAC |

(As Outputs) |

||||||

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SLC – Class A or B |

|

|

|

|

|

|

|

NAC – Class A or B |

|

PFC-6030 |

2 NACs |

3 Amp |

1 Amp |

Maximum Load |

Maximum of 30 |

P-Link – Class A or B |

|

of 56.055 mA |

addressable points |

|

|||||

|

|

|

|

All are Low Voltage |

|||

|

|

|

|

|

|

||

|

|

|

|

|

|

and Power Limited |

|

|

|

|

|

|

|

|

System Size Specifications

Please refer to the table below for system size specifications:

Table 4: System Size Specifications

Accessories/Subassemblies |

|

Maximum System Size |

|

|

|

|

|

PFC-6030 |

• |

One (1) built-in SLC Loop with 30 addressable points |

|

• |

Two (2) notification circuits on the main board |

||

|

|||

|

|

||

UD-1000 |

One (1) DACT |

||

|

|

|

|

2-4

PFC-6030 • 5403595 • Rev C • 2/13

Main Board Wiring Specifications

There are several wiring requirements to consider before connecting circuits to the main board: (1) the circuit separation, and (2) wiring types.

Circuit Separation

Proper separation between the different types of circuits must be maintained between Power Limited, Non-Power Limited, and High Voltage wiring to reduce electrical interferences, transient voltage or voltage ratings.

yy Separations between the different wiring types must be maintained by at least ¼ inch and the wire insulation must be for the higher voltage.

yy The control panel cabinet has sufficient knockouts located around the periphery allowing the installer to maintain separation between power limited and non-power limited connections.

Wiring Types

Wiring specifications must be followed to prevent damage or other consequences.

Refer to table below for a breakout of the different wiring requirements shown by circuit type:

Table 5: Main Board Circuit Wiring Types

|

|

Wiring Type |

|

Type of Circuit |

Voltage |

|

Power |

|

|

|

|

AC Connection |

High Voltage |

|

Non-Power Limited |

|

|

|

|

Battery Connection |

Low Voltage |

|

Non-Power Limited |

|

|

|

|

Trouble Relay |

Low Voltage |

|

Non-Power Limited |

|

|

|

|

Supervisory Relay |

Low Voltage |

|

Non-Power Limited |

|

|

|

|

Alarm Relay |

Low Voltage |

|

Non-Power Limited |

|

|

|

|

I/O Circuits |

Low Voltage |

|

Power Limited |

|

|

|

|

Notification Device Circuits (NACs) |

Low Voltage |

|

Power Limited |

|

|

|

|

P-Link RS-485 Connections |

Low Voltage |

|

Power Limited |

|

|

|

|

Signaling Line Circuit |

Low Voltage |

|

Power Limited |

|

|

|

|

Phone Line – DACT |

High Voltage |

|

Non-Power Limited |

|

|

|

|

2-5

PFC-6030 • 5403595 • Rev C • 2/13

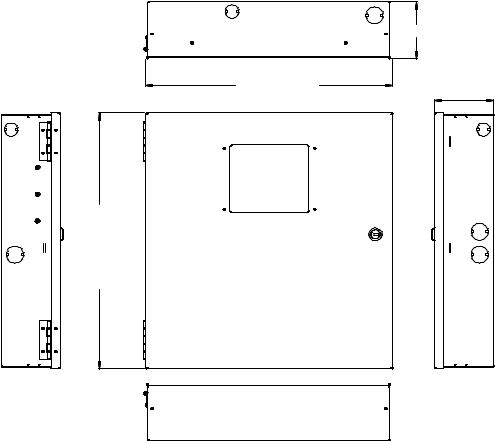

Cabinet Dimensions

Figure 1. PFC-6030 Cabinet Dimensions

TOP |

DEPTH = 3.75 " |

DOOR = 16.07" |

DEPTH = 3.84" |

BACKBOX = 15.77" |

BACKBOX = 16.56"

DOOR = 16.78 "

LEFT SIDE |

RIGHT SIDE |

BOTTOM

DWG #593-1

2-6

PFC-6030 • 5403595 • Rev C • 2/13

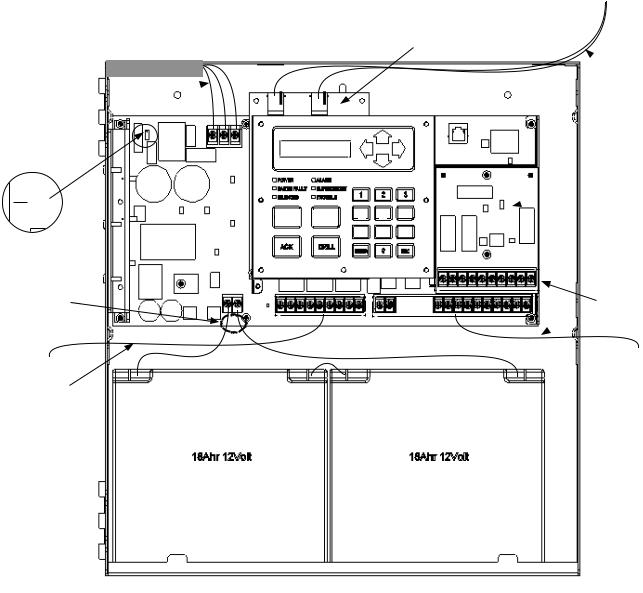

Cabinet Wiring Connections

Figure 2. PFC-6030 Cabinet Wiring

120VAC 50Hz-60Hz  240VAC 50Hz-60Hz

240VAC 50Hz-60Hz

Connect to separate unswitched AC circuits

120 240

120/240 VAC

Jumper Position

Non-power limited battery connection

Non-power limited relay connection

POWER |

|

ALARM |

|

|

|

|

|

|

EARTH FAULT |

|

SUPERVISORY |

|

|

|

|

|

|

SILENCED |

|

TROUBLE |

|

1 |

|

2 |

|

3 |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

SILENCE |

RESET |

4 |

5 |

6 |

|

|

|

||

|

|

7 |

8 |

9 |

Optional

UD-1000 DACT

High voltage phone connections

High voltage phone connections

Optional CA-6075

Class A Expander

Class A Expander

ACK |

|

DRILL |

|

|

|

|

|

|

|

|

ENTER |

|

0 |

|

ESC |

||

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Power limited

wiring

wiring

18Ahr 12Volt |

|

18Ahr 12Volt |

DWG #593-2

2-7

PFC-6030 • 5403595 • Rev C • 2/13

Battery Circuit Calculations

Before selecting the battery, it is important to determine the minimum size batteries for standby and alarm times desired for each application and SLC current draw. If the wrong batteries are installed in a specific application or incorrect current draw used, the proper standby and minimum alarm time will not be present.

The battery circuit is rated for 8 to 55 AH batteries and will operate the panel alarm for at least 24 hours and 5 minutes. The cabinet will house up to two (2) 8 AH or two (2) 18 AH batteries.

Please use the worksheets listed below to calculate the battery size and current draw required for each application and the SLC:

(1) Battery Calculation Worksheet; and (2) SLC Current Draw Worksheet

Battery Calculation Worksheets

|

|

|

|

|

|

|

|

|

|

|

|

|

Standby |

Total |

Alarm |

Total |

|

Description |

|

Quantity |

Alarm |

|||||

|

|

|

|

(mA) |

Standby (mA) |

(mA) |

(mA) |

|

Main board (PFC-6030) |

|

|

1 |

130 |

|

220 |

|

|

|

|

|

|

|

|

|

|

|

LCD Remote RA-6075 |

|

|

|

20 |

|

25 |

|

|

|

|

|

|

|

|

|

|

|

LCD Remote RA-6500 |

|

|

|

20 |

|

50 |

|

|

|

|

|

|

|

|

|

|

|

CA-6075 Class A Expander |

|

|

12 |

|

44 |

|

|

|

UD-1000 DACT |

|

|

|

16 |

|

23 |

|

|

PSN-1000/E Power Expander |

|

|

15 |

|

15 |

|

|

|

|

|

|

|

|

|

|

|

|

LED-16 P-Link |

|

|

|

25 |

|

25 |

|

|

LED-Current (if applicable, see Note 6) |

|

|

15 |

|

100 |

|

|

|

DRV-50 |

|

|

|

25 |

|

25 |

|

|

LED-Current (if applicable, see Note 6) |

|

|

10 |

|

215 |

|

|

|

RLY-5 |

|

|

|

25 |

|

35 |

|

|

Relay Current (if applicable, see Note 6) |

|

|

10 |

|

135 |

|

|

|

FCB-1000 |

|

|

|

25 |

|

25 |

|

|

FIB-1000 |

|

|

|

30 |

|

30 |

|

|

SPG-1000 |

|

|

|

40 |

|

40 |

|

|

NAC 1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NAC 2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SLC Current Draw - (refer to "SLC Current Draw |

|

|

|

|

|

|

||

Worksheet" for calculation) |

|

|

|

|

|

|

|

|

|

|

|

|

Total (ma) |

|

Total (ma) |

|

|

|

|

|

Convert to Amps |

x 0.001 |

Convert to Amps |

x 0.001 |

||

|

(*Refer to maximum allowable standby current) Total A: |

|

Total A: |

|

|

|||

|

|

|

|

|

|

60 minutes per hour |

|

|

|

|

|

|

|

|

Alarm time (minutes) |

|

|

|

|

Multiply by standby hours |

x____ |

Example: |

÷ ____ |

|

||

|

|

|

|

|

|

5 minute alarm: enter 12 |

|

|

|

|

|

|

|

|

10 minute alarm: enter 6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Total Standby AH |

|

Total Alarm AH |

|

|

|

|

|

|

|

|

|

+Total Standby AH |

|

|

|

|

|

|

|

|

Total AH |

|

|

|

|

|

|

|

|

Efficiency Factor |

÷ 0.85 |

|

|

|

|

|

|

|

Required AH |

|

|

|

|

|

|

|

|

|

|

|

*Maximum Allowable Standby Current |

Important Notes: |

|

|

|

|

|

||

1) FACP enclosure can house up to two (2) 18 AH batteries. Larger batteries require accessory |

|

|||||||

(UL 24-Hour standby time) |

|

|||||||

enclosure, part #SSU00500. |

|

|

|

|

||||

7 AH |

.230 A |

|

|

|

|

|||

2) NFPA 72 requires 24 hours of standby power followed by 5 minutes alarm activation. |

|

|||||||

18 AH |

.619 A |

|

||||||

3) NFPA 12, 12A requires 24 hours and five minutes of alarm activation. |

|

|

||||||

33 AH |

1.151 A |

|

|

|||||

4) Door holder circuits configured to disconnect upon AC loss need not be included in the |

|

|||||||

55 AH |

1.930 A |

|

||||||

battery standby calculation since they will not draw power during that time. Door holders |

|

|||||||

|

|

|

||||||

|

|

will contribute to standby current draw when AC is present. |

|

|

||||

|

|

5) Total current must not exceed power supply rating (3.5A). |

|

|

||||

|

|

6) LED/Relay current must be accounted for in the battery calculation for the supplying source. |

|

|||||

|

|

|

|

|

|

|

|

|

2-8

PFC-6030 • 5403595 • Rev C • 2/13

SLC Current Draw Worksheet

|

|

Standby |

Total |

Alarm |

Total |

|

Device Type |

Qty |

Standby |

Alarm |

|||

(mA) |

(mA) |

|||||

|

|

(mA) |

(mA) |

|||

|

|

|

|

|||

Analog photo smoke detector (PSA) |

|

0.325 |

|

0.325 |

|

|

|

|

|

|

|

|

|

Analog photo DUCT smoke detector (DSA) |

|

0.325 |

|

0.325 |

|

|

|

|

|

|

|

|

|

Analog photo smoke / fixed heat detector (PSHA) |

|

0.325 |

|

0.325 |

|

|

|

|

|

|

|

|

|

Analog fixed heat detector (FHA) |

|

0.325 |

|

0.325 |

|

|

|

|

|

|

|

|

|

Analog combo heat detector (RHA) |

|

0.325 |

|

0.325 |

|

|

|

|

|

|

|

|

|

Conventional initiating zone module - 4 inch mount (CIZM-4) *Note 1 |

|

0.325 |

|

1.000 |

|

|

|

|

|

|

|

|

|

Miniature contact module (MCM) |

|

0.325 |

|

0.325 |

|

|

|

|

|

|

|

|

|

Single contact module - 4 inch mount (SCM-4) |

|

0.325 |

|

1.000 |

|

|

|

|

|

|

|

|

|

Dual contact module - 4 inch mount (DCM-4) |

|

0.325 |

|

1.000 |

|

|

|

|

|

|

|

|

|

Monitored output module - 4 inch mount (MOM-4) *Note 2 |

|

0.325 |

|

1.000 |

|

|

|

|

|

|

|

|

|

Twin relay module - 4 inch mount (TRM-4) |

|

0.325 |

|

1.000 |

|

|

|

|

|

|

|

|

|

Short circuit isolator (SCI) |

|

0.325 |

|

2.34 |

|

|

|

|

|

|

|

|

|

Analog sounder base (ASB) *Note 3 |

|

0.325 |

|

0.325 |

|

|

|

|

|

|

|

|

|

Analog relay base (ARB) *Note 4 |

|

0.325 |

|

0.325 |

|

|

|

|

|

|

|

|

|

Isolator base (AIB) |

|

0.325 |

|

2.34 |

|

|

|

|

|

|

|

|

|

SLC alarm LED Current |

n/a |

n/a |

|

n/a |

27.0 |

|

|

|

|

|

|

|

|

|

|

SLC Standby |

|

SLC Alarm |

|

|

|

|

Current |

|

Current |

|

*Note 1: CIZM requires 24VDC power source. Standby current Style D = 4.90 mA, Style B (8.5 mA). Alarm Current = 50.0 mA

*Note 2: MOM requires 24VDC power source. Standby current = 1.60 mA. Alarm Current = 1.60 mA

*Note 3: ASB requires 24VDC power source. Standby current = 5 mA. Alarm Current = 100 mA

*Note 4: ARB requires 24VDC power source. Standby current = 5 mA. Alarm Current = 50 mA

2-9

PFC-6030 • 5403595 • Rev C • 2/13

Isolator Device Load Calculation

This section covers the distinction between an addressable sensor and an isolator to correctly calculate the total SLC device load. A device uses an address and consumes power. Whereas, an isolator does not use an address, but does consume power.

The following scenarios explain how to calculate the current device load based on the SLC configuration.

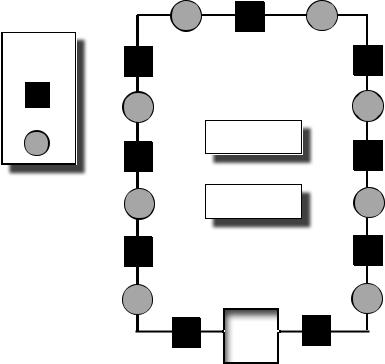

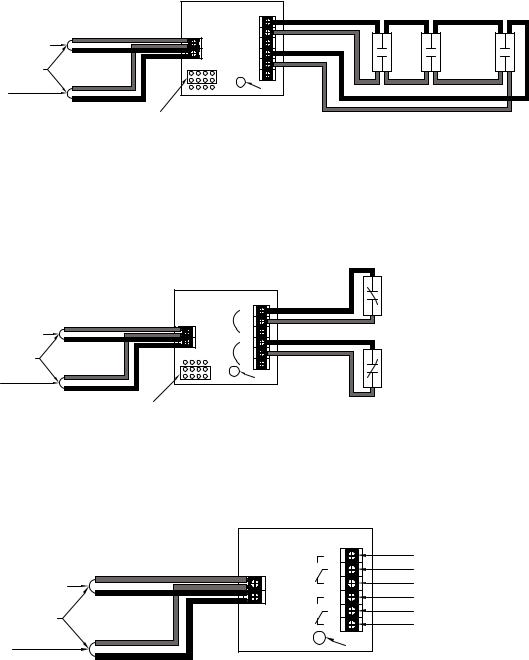

Scenario 1: Class A Loop – Isolated Devices Configuration

In this configuration, each sensor and isolator device / module counts as one (1) when calculating the total device load.

Formula: Total # addressable devices + Total # isolators = Total power unit allocations (or device load)

Figure 3. Example of a Class A Loop – Isolated Branches

LEGEND:

ISO Module/

Device

Sensor

PANEL

DWG # 593-4

Configuration Summary:

Total addressable devices = 8 (sensors only) out of 30 possible addressable points.

Total device load = 17 (calculated as follows: 8 sensors + 9 isolators) out of 127 power unit allocations.

Example: If a configuration uses 30 sensors, up to 97 isolators may be supported.

Solution: 127 - 30 = 97

2-10

PFC-6030 • 5403595 • Rev C • 2/13

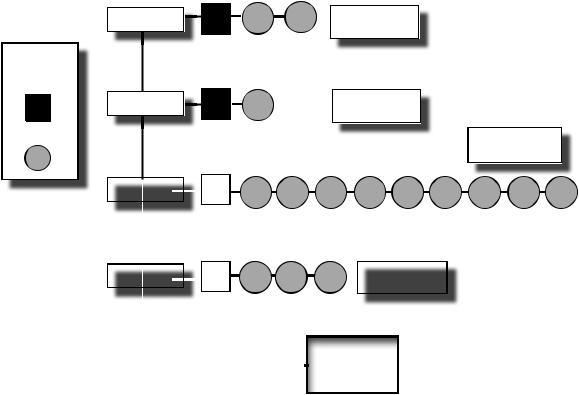

Scenario 2: Class B Loop – Isolated Branch Configuration

In this configuration, there are 4 separate branches each with an isolation device / module and 1 or more sensors. Each sensor requires an address, as shown in Scenario #1 (isolators do not require an address). However, in this scenario, each isolator consumes power equal to 8 devices. To calculate the total device load, refer to the following rule:

Device Load Rule for Branch Configurations

Count all devices, including isolators, on the branch.

•If the count is <=8, allocate 8 as the device load.

•If the count is >8, allocate the actual device count number.

Figure 4. Example of a Class B Loop – Isolated Branches

LEGEND:

ISO Module/

Device

Sensor

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PANEL |

DWG #593-3 |

|

|

|

|

|

|

|||

|

|

|

|

|

|||

Configuration Summary:

Branch #1 has 3 devices = 8 power allocations

Branch #2 has 2 devices = 8 power allocations

Branch #3 has 10 devices = 10 power allocations

Branch #4 has 4 devices = 8 power allocations

Total addressable devices = 15 (sensors only) out of 30 addressable points.

Total device load = 34 out of a possible 127 power unit allocations.

2-11

PFC-6030 • 5403595 • Rev C • 2/13

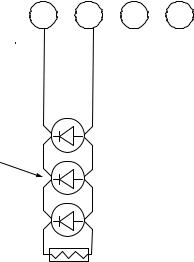

Battery Connections

The battery charging circuit is located on the main panel in the lower left portion of the board. The maximum battery charging circuit is 1.0 amp DC; the charging voltage is approximately 27.3 VDC and is supervised.

Note: The battery should be clearly labeled as “Sealed Lead Acid Battery” or equivalent UL listed or UL Recognized.

Connect the battery wire leads to the terminal connections, as shown. Batteries should be replaced every five (5) years or sooner depending on annual testing.

Figure 5. PFC-6030 Battery Connections

|

|

Panel |

- |

+ |

Connections |

BATTERY |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

- |

|

+ |

|

- |

+ |

||||||||||

|

|

|

12 V |

|

|

|

|

|

|

|

|

12 V |

|||

|

|

|

Battery |

|

|

|

|

|

|

|

Battery |

||||

DWG # 593-5

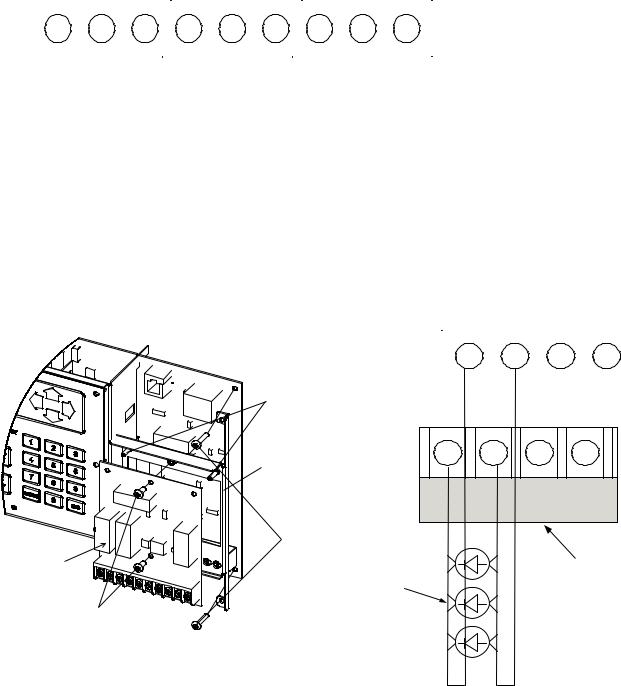

Main Supply Circuit

The AC terminals are located in the upper left hand portion of the main board. The main board supervises the main AC power and provides indication that the AC power is absent.

Figure 6. PFC-6030 AC Terminals

120VAC 50/60 Hz

240VAC 50/60 Hz Connect to separate Unswitched AC circuit

Black

White

Ground

B W G

AC POWER

AC120V/AC230V,50/60Hz

DWG #593-6

The terminals are rated at 120 VAC/240 VAC 50/60 Hertz and are marked accordingly on the board. The earth ground connection is marked as “G” and is the furthest connection from the line voltage connection.

The AC input power ratings are as follows:

•Maximum of 3A at the nominal 120 VAC rating.

•Maximum of 2A at the nominal 240 VAC rating.

2-12

PFC-6030 • 5403595 • Rev C • 2/13

Section 3: Installation

This section addresses installation procedures for SLCs, NACs and optional modules, including the DACT (UD-1000),

Class A Card, and Remote Annunciators. Wiring requirements and configuration examples are included throughout this section. Instructions for addressing SLC devices which must be completed before programming your system are also included. Please read this section carefully before installing devices and/or modules to insure proper installation.

Note: Instructions for installing the PSN-1000/PSN-1000(E) and/or the IP Dialer accessories are located in Sections 6 and 7, respectively.

Signaling Line Circuit (SLC) Installation

The SLC panel provides power and communication to each of the sensors and modules connected. The SLC is polled by the system every 4–5 seconds. This panel has a loop capacity of 30 addressable points, which may be configured in any combination of smoke sensors, heat detectors, and input or output modules.

All devices require an address prior to connecting to the control panel. Refer to “Addressing SLC Devices” located later in this section for details.

SLC Wiring Requirements

The wiring parameters listed below MUST be followed to ensure proper installation:

•Maximum wiring resistance between two (2) Short Circuit Isolators (SCIs) must be less than 10 ohms.

•Total resistance must be below 50 ohms.

•Maximum wire resistance must be calculated based on 0.1 ohm per SCI.

•Maximum loop capacitance must be 0.5 micro farads.

•All SLC wiring is low voltage and power limited.

Class B, Style 4 Wiring Configuration

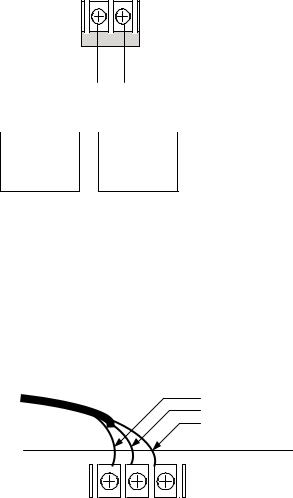

Figure 7. Example of SLC Wiring - Class B, Style 4

PFC-6000

Series

SLC Loop (Class B)

Terminal Connections

7 6

7 6

8

8

3

Address No. |

|

24- |

|

24+ |

S- |

S+ |

|

|

||||||||||||

|

|

|

|

|

|

Potter Electric Signal Company |

||||||||||||||

|

U |

|

|

|

Conventional Initiating Zone Module |

|||||||||||||||

L |

|

|

|

|||||||||||||||||

|

|

|

|

|

|

Model No. CIZM-4 |

|

|

|

|

|

|||||||||

ALARMFIRE XXXX |

|

|

|

|

|

|

|

Ser. No. xxxxxx |

|

|

|

|

|

|||||||

|

|

|

Document: TN51313e date:XX.XX.2009 |

|||||||||||||||||

|

|

|

|

|

|

Compatibility Identi er: INTE01 |

||||||||||||||

EQUIPMENT |

|

|

|

WARNING |

|

|

|

|

|

|

|

|

||||||||

|

|

|

All Terminals are power limited. |

|||||||||||||||||

|

|

|

|

|

|

Power supply for terminals 24+ and 24must |

||||||||||||||

|

|

|

|

|

|

be power limited |

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B- |

|

B+ |

A- |

A+ |

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5.1kΩ

5.1kΩ

S- |

S+ |

C |

NO |

(NC) |

Potter Electric Signal Company

Miniature Contact Module

Model No. MCM

Ser. No. xxxxxx

Document:

TN51314e date: XX.XX.2009

WARNING:

All Terminals are power limited

SIGNALING FIRE ALARM EQUIPMENT

XXXX

UL

LISTED |

Address No. |

DWG # 593-7A

3-13

PFC-6030 • 5403595 • Rev C • 2/13

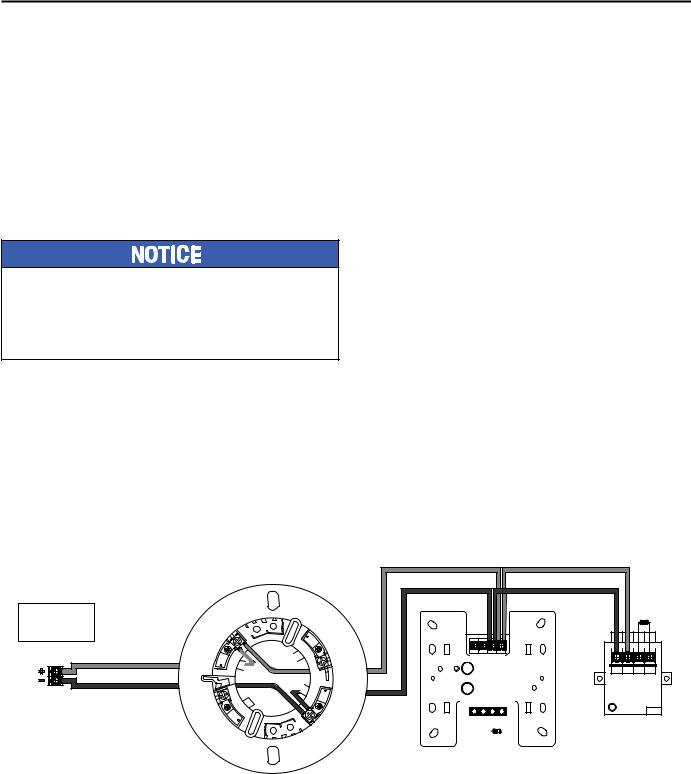

Class A, Style 6 Wiring Configuration

Figure 8. Example of Class A, Style 6 Requiring CA-6075

S- |

S+ |

S- |

S+ |

S- |

S+ |

24- |

24+ |

S- |

S+ |

Potter Electric Signal Company |

|

Potter Electric Signal Company |

Potter Electric Signal Company |

Potter Electric Signal Company |

|||||

Single Contact Module |

|

Dual Contact Module |

|

|

Twin Relay Module |

Monitored Output Module |

|||

Model No. SCM-4 |

|

Model No. DCM-4 |

|

|

Model No. TRM-4 |

Model No. MOM-4 |

|||

Ser. No. xxxxxx |

|

|

Ser. No. xxxxxx |

|

|

Ser. No. xxxxxx |

Ser. No. xxxxxx |

||

Document: TN51315e date:XX.XX.2009 |

|

Document: TN51316e date:XX.XX.2009 |

Document: TN51317e date:XX.XX.2009 |

Document: TN51318e date:XX.XX.2009 |

|||||

|

|

|

|

|

|

|

WARNING : |

WARNING |

: |

WARNING : |

|

WARNING |

: |

|

|

Terminals S+, S- are power limited. |

Power supply for terminals 24+ and 24must |

||

|

|

|

Terminals NO1, C1, NC1, NO2, C2, NC2 are |

be power limited. |

|||||

All Terminals are power limited. |

|

All Terminals are power limited. |

|

non power limited |

All Terminals are power limited. |

||||

Z NO C |

Z2 |

NO2 |

C2 |

Z1 |

NO1 |

C1 |

NC2 C2 NO2 NC1 C1 NO1 |

A- |

A+ |

(NC2) |

(NC1) |

||||||||

5.1kΩ |

5.1kΩ |

5.1kΩ |

5.1kΩ |

5.1kΩ |

5.1kΩ |

PFC-6000

Series

SLC Loop (Class A)

Terminal Connections

5.1kΩ

6

3

7

7

8

8

2424+ |

S- |

S+ |

|

|

|

|

|

|

Potter Electric Signal Company |

S- |

S+ |

C |

NO |

||

|

Conventional Initiating Zone Module |

||||||

|

No. CIZM-4 |

|

(NC) |

||||

|

Model Ser. No. xxxxxx |

|

|

||||

|

Document: TN51313e date:XX.XX.2009 |

Potter Electric Signal Company |

|||||

|

Compatibility Identi er: INTE01 |

Miniature Contact Module |

|

||||

|

WARNING |

: |

|

Model No. MCM |

|

|

|

|

Power supply for terminals 24+ and 24must |

|

Ser. No. xxxxxx |

|

|||

|

be power limited |

|

Document: |

|

|

||

|

All Terminals are power limited. |

|

TN51314e date: XX.XX.2009 |

||||

B- |

B+ |

A- |

A+ |

WARNING: |

|

|

|

All Terminals are power limited |

|||||||

|

|

|

|

UL |

|

|

|

|

|

5.1kΩ |

DWG #593-8 |

||||

Notes:

1.The Class A, Style 6 configuration does not provide the level of protection as Class A, Style 7.

2.Class A, Style 7 requires installation of a CA-6075.

3.The use of a SCI or AIB is not required.

4.The SLC connection requires that the wires are separated 10’, installed in conduit or other mechanical protection.

5.Maximum wiring resistance must not exceed 50 ohms.

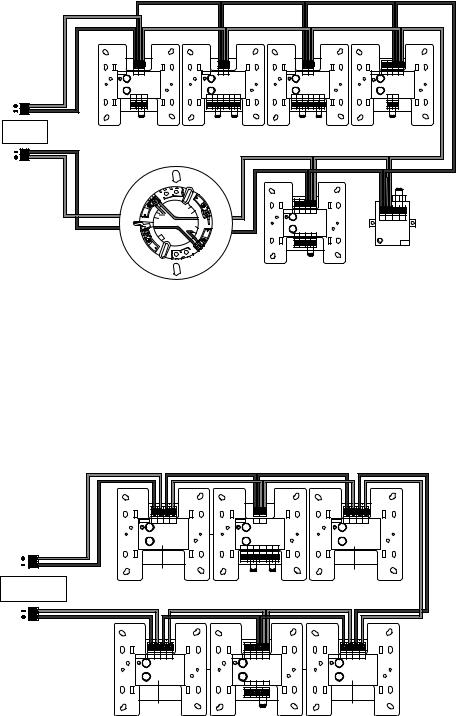

Class A, Style 7 Wiring Configuration

Figure 9. Example of SLC Wiring - Class A, Style 7 Requiring CA-6075

S-2 S+2 |

S-1 S+1 |

S- |

S+ |

S-2 S+2 |

S-1 S+1 |

Potter Electric Signal Company |

Potter Electric Signal Company |

Potter Electric Signal Company |

||||

Short Circuit Isolater |

Dual Contact Module |

|

|

Short Circuit Isolater |

||

Model No. SCI |

Model No. DCM-4 |

|

|

Model No. SCI |

||

Ser. No. xxxxxx |

|

Ser. No. xxxxxx |

|

|

Ser. No. xxxxxx |

|

Document: TN51313e date:XX.XX.2009 |

Document: TN51316e date:XX.XX.2009 |

Document: TN51313e date:XX.XX.2009 |

||||

WARNING : |

WARNING |

: |

|

|

WARNING : |

|

All Terminals are power limited. |

All Terminals are power limited. |

|

All Terminals are power limited. |

|||

Z2 |

NO2 |

C2 |

Z1 |

NO1 |

C1 |

|

(NC2) |

(NC1) |

|

||||

|

SCI |

5.1kΩ |

5.1kΩ |

SCI |

PFC-6000 |

|

|

|

|

Series |

|

|

|

|

SLC Loop (Class A Style 7) |

|

|

|

|

Terminal Connections |

|

|

|

|

S-2 S+2 S-1 S+1 |

2424+ |

S- |

S+ |

S-2 S+2 S-1 S+1 |

Potter Electric Signal Company |

Potter Electric Signal Company |

Potter Electric Signal Company |

||

Short Circuit Isolater |

Conventional Initiating Zone Module |

Short Circuit Isolater |

||

Model No. SCI |

Model No. CIZM-4 |

|

Model No. SCI |

|

Ser. No. xxxxxx |

Ser. No. xxxxxx |

|

Ser. No. xxxxxx |

|

Document: TN51313e date:XX.XX.2009 |

Document: TN51313e date:XX.XX.2009 |

Document: TN51313e date:XX.XX.2009 |

||

Compatibility Identi er: INTE01 |

||||

|

WARNING |

: |

|

|

WARNING : |

Power supply for terminals 24+ and 24must |

WARNING : |

||

be power limited |

|

|||

All Terminals are power limited. |

All Terminals are power limited. |

All Terminals are power limited. |

||

|

B- B+ |

A- |

A+ |

|

SCI |

5.1kΩ |

SCI |

DWG #593-9

Notes:

1.The Class A, Style 7 requires installation of an isolator close nipple connected to every module or sensor. Isolators may be either a SCI or an AIB addressable base.

2.Class A, Style 7 requires installation of a CA-6075.

3.The SLC connection requires that the wires are separated by a minimum of 10’and installed in conduit or other mechanical protection.

4.Maximum wiring resistance must not exceed 50 ohms.

3-14

PFC-6030 • 5403595 • Rev C • 2/13

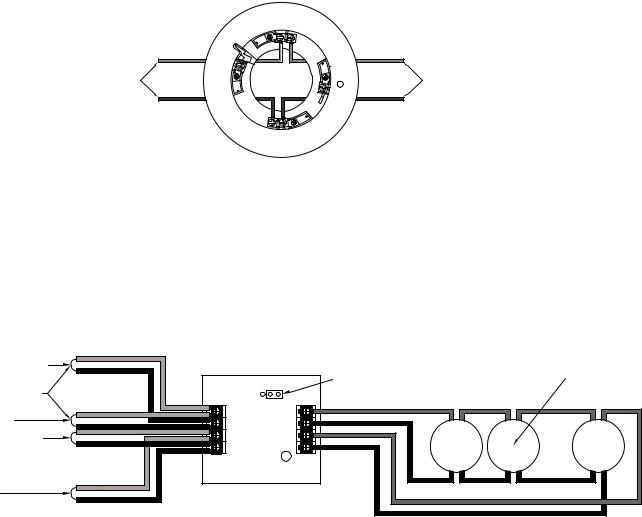

Connecting Analog Detectors

When installing analog detectors, such as a photoelectric smoke sensor (PSA), photo smoke/fixed heat detector (PSHA), heat detector (FHA), or an analog combination type heat detector (RHA), use detector bases (i.e. AB-6). An analog detector activates its response LED when activated. An example of wiring an analog detector is shown below.

Figure 10. Analog Detector Wiring Example

S+ |

S+ |

From FACP or the previous |

|

To the next addressable device |

|

addressable device on the SLC loop |

|

||

S- |

S- |

||

|

DWG #593-10

Connecting Addressable Modules

This section provides examples of wiring addressable modules, including Conventional Initiating Zones (CIZM-4), Miniature Contact (MCM), Single Contact (SCM-4), Dual Contact Module (DCM-4), Twin Relay (TRM-4), Monitored Output (MOM-4), Analog Relay (ARB), Analog Sounder Base (ASB), and Addressable Pull Station (APS) modules.

Conventional Initiating Zones (CIZM-4) Class A |

|

|

|

|

||

Figure 11. CIZM-4, Class A |

Note: The resistance of external wiring shall be less that 100Ω. |

|

|

|

||

From FACP or |

|

|

|

|||

capacitance of external wiring shall be less than 1 micro farads. |

|

|

||||

Previous Module |

|

Select Style D |

|

|

Conventional |

|

|

|

|

|

|||

|

JP1 |

|

|

Detector |

||

SLC Loop |

|

|

|

|||

|

|

|

|

|

||

To Next Module |

S+ |

B+ |

|

|

|

|

S- |

B- |

+ |

+ |

+ |

||

|

||||||

From FACP |

24+ |

A+ |

||||

24- |

A- |

|

|

|

||

or Previous Module |

_ |

_ |

_ |

|||

|

|

|||||

|

|

LED |

||||

|

|

|

|

|

||

|

Conventional Initiating Zone Module |

|

|

|

||

|

Model No. CIZM-4 |

|

|

|

|

|

To Next |

|

|

|

|

|

|

Module |

|

|

|

|

|

|

|

|

|

|

|

DWG #593-11 |

|

Notes:

1.The resistance of external wiring shall be less than 100 ohms.

2.The capacitance of external wiring shall be less than 1 micro F.

3.In this style, the open circuit “trouble condition” of IDC is latched at the control panel until system is reset. Therefore, the system MUST be reset at the control panel after clearing the open circuit condition at the site.

4.Refer to the CIZM data sheet for information on compatible devices.

3-15

PFC-6030 • 5403595 • Rev C • 2/13

Conventional Initiating Zones (CIZM-4) Class B

Figure 12. CIZM-4, Class B

From FACP or |

|

|

Select Style B |

|

|

|

Previous Module |

|

|

|

Conventional |

||

|

|

JP1 |

|

|

||

SLC Loop |

|

|

|

Detector |

||

|

|

|

|

|||

|

S+ |

B+ |

|

|

|

|

To Next Module |

S- |

B- |

+ |

+ |

+ |

|

From FACP or |

24+ |

A+ |

||||

|

|

|

||||

Previous Module |

24- |

A- |

_ |

_ |

_ |

|

|

|

|||||

|

|

LED |

||||

|