Polaroid SprintScan SS35, SprintScan SS35 ES, SprintScan SS35 PLUS Repair Manual

Repair Manual

Americas Business Center

Technical Services

201 Burlington Road

Bedford MA 01730

TEL: 1.781.386.5309

FAX: 1.781.386.5988

SprintScan Slide Scanner

SS35, SS35 ES, SS35 PLUS

October 1997

Slide Scanner Repair Manual Table of Contents

Table of Contents

Purpose of Manual .................................................................................................. 7

Manual Organization ............................................................................................... 7

Other Documents Required for Repair .................................................................. 7

Important Safety Instructions................................................................................. 8

1. Scanner Overview .............................................................................................. 9

Description ........................................................................................................... 11

Applications .......................................................................................................... 12

Features............................................................................................................... 1 4

Specifications ....................................................................................................... 19

Operation ............................................................................................................. 22

Setting up the Scanner ...................................................................................... 22

Installing the Software ....................................................................................... 23

Starting the Software......................................................................................... 24

Scanning the Slide/Film Strip ............................................................................. 25

Self-Check Routines............................................................................................. 26

Self-Test (Power-Up) ........................................................................................ 26

Calibration ......................................................................................................... 28

2. Functional Description....................................................................................... 31

Scanner Process Overview .................................................................................. 33

Scanner Transporter ............................................................................................ 34

Scanner Optics..................................................................................................... 37

Scanner Electronics.............................................................................................. 38

Power Supply PC Board.................................................................................... 38

Main Controller PC Board Power Distribution .................................................... 40

AC Inverter PC Board....................................................................................... 41

Image Sensor PC Board ...................................................................................... 42

CCD Image Sensor............................................................................................ 42

Associated Analog Signal Processing Support Circuitry..................................... 4 3

Main Controller PC Board..................................................................................... 4 3

Analog Signal Processing .................................................................................. 45

Digital Signal Processing ................................................................................... 45

Primary Correction ASIC................................................................................. 45

DRAM Controller (Buffer)................................................................................ 46

2

Slide Scanner Repair Manual Table of Contents

Secondary Color Correction ASIC .................................................................. 47

Color Modes ................................................................................................... 48

Scanner Control................................................................................................. 48

CCD Driver...................................................................................................... 48

Transporter Driver........................................................................................... 48

LED Indicator Driver........................................................................................ 4 8

Filter Wheel Driver .......................................................................................... 49

System Interface.................................................................................................. 49

3. Calibration and Adjustments ............................................................................. 50

Required Tools and Equipment............................................................................. 52

Warnings and Precautions.................................................................................... 53

Voltages ............................................................................................................ 53

Electrostatic Discharge Warning........................................................................ 53

Inspection and Cleaning........................................................................................ 54

Checking Scanner Self-Test (Power Up).............................................................. 56

Adjustments.......................................................................................................... 59

Power Supply .................................................................................................... 59

Focus/Magnification ........................................................................................... 60

Transporter Photo-Sensor Alignment................................................................. 69

Filter Wheel Set Photo-Sensor Tab Alignment ( Only for Slide Scanner

with Filter Wheel)............................................................................................... 70

4. Parts Replacement ............................................................................................. 72

Required Tools and Equipment............................................................................. 74

Electrostatic Discharge Warning .......................................................................... 74

Inspection and Cleaning........................................................................................ 74

Disassembly/Assembly of Electrical and Mechanical/Optical Assemblies............. 75

Top Housing....................................................................................................... 75

Removal.......................................................................................................... 75

Installation....................................................................................................... 77

Main Controller PC Board.................................................................................. 78

Removal.......................................................................................................... 78

Installation....................................................................................................... 79

3

Slide Scanner Repair Manual Table of Contents

Chassis Assembly ............................................................................................. 80

Removal.......................................................................................................... 80

Installation....................................................................................................... 81

Power Supply PC Board.................................................................................... 82

Removal.......................................................................................................... 82

Installation....................................................................................................... 83

AC Inverter PC Board........................................................................................ 84

Removal.......................................................................................................... 84

Installation....................................................................................................... 85

Replacement of Components ............................................................................... 86

Scanning Lamp .................................................................................................. 86

Scanner Fuses................................................................................................... 86

System (AC Power)........................................................................................ 86

Power Supply PC Board ................................................................................. 87

AC Inverter PC Board ..................................................................................... 88

SCSI Interface (Terminator Power) ................................................................ 89

Filter Wheel Stepper Motor (Only for Slide Scanner with Stepper Motor) ......... 90

Transporter Stepper Motor................................................................................ 91

CCD Board ........................................................................................................ 93

5. Diagnostics and Troubleshooting..................................................................... 96

Error Messages ................................................................................................... 99

Diagnostic (Digital Hardware) ............................................................................ 100

Operational........................................................................................................ 101

Calibration ......................................................................................................... 106

LabView Image Performance Test (IPT) Version 1.02-Mac................................. 113

Scanner Tester (w) Front Panel......................................................................... 113

Image Quality Test Outline ................................................................................ 118

Geometric Type Test Using GMT Target ....................................................... 118

Color Type Test Using CT Target................................................................... 118

Changing Type of Scanner Under Test ........................................................... 118

Changes to IPT Test Since LabView Version 3.1 (Summary) .............................. 119

Using Scanner Tester (W).................................................................................... 120

Required Tools and Equipment.......................................................................... 120

Initial Setup - Complete Image Performance for LabView Version 4 ................. 121

Entering Test Parameters.................................................................................. 123

Entering Optional Test Parameters.................................................................... 124

Starting Test...................................................................................................... 124

Auto Reference Finding Origin for GMT and CT Targets................................... 125

Error Reporting.................................................................................................. 126

4

Slide Scanner Repair Manual Table of Contents

Test Results ...................................................................................................... 126

Stored Test Results........................................................................................... 127

Pausing or Stopping Scanner Test..................................................................... 128

Pausing a Test in Progress............................................................................. 128

Stopping a Test in Progress ........................................................................... 128

IPT Scanner Tests - Understanding Test Results............................................... 129

Initialization Test ................................................................................................ 129

Distortion & Mag Test........................................................................................ 129

Left, Center, Right Resolution Test.................................................................... 130

Motion and Color Registration Test ................................................................... 131

Color Registration Test................................................................................... 131

Motion Test .................................................................................................... 132

Interpreting Measurements of the Color Registration & Motion Tests................ 133

Introduction ..................................................................................................... 133

Stand Alone Motion and Resolution Test Panel - Details ................................ 133

Test Panel Controls...................................................................................... 133

Test Report.................................................................................................. 134

Test Constraints ............................................................................................. 134

Analysis .......................................................................................................... 134

Left and Right Misalignment Windows ............................................................ 137

Mag and Tilt Adjustment Effects..................................................................... 137

Motion Problem Examples ................................................................................. 138

Uniformity II Test ............................................................................................... 140

Part 1 ............................................................................................................. 140

Part 2 ............................................................................................................. 140

Part 3 ............................................................................................................. 142

Part 4 ............................................................................................................. 142

Dark Noise II Test ............................................................................................. 144

Negative Calibration........................................................................................... 145

Error Reporting.................................................................................................. 145

Test Result Folder/Directory.............................................................................. 145

CCD Configuration............................................................................................. 146

Determining CCD Configuration Using Scanner Tester ................................... 146

IPT Scanner Test Descriptions............................................................................. 147

Motion and Color Registration Test ................................................................... 147

Static (Color Registration) ................................................................................. 147

Mean Vertical ................................................................................................. 147

Mean Horizontal.............................................................................................. 147

Dynamic (Motion Effects) .................................................................................. 148

Dark Noise II Test ............................................................................................. 149

Dark Uniformity Response (Streaks) .............................................................. 149

Dark Uniformity Response (Noise).................................................................. 150

Dark Uniformity Response (Fourier) ............................................................... 151

Control Panel.................................................................................................. 152

Uniformity II Test ............................................................................................... 152

5

Slide Scanner Repair Manual Table of Contents

Uncorrected Light Uniformity Test...................................................................... 153

Illumination ......................................................................................................... 155

Uncorrected Dark Uniformity Test...................................................................... 155

Bad Pixel Flag................................................................................................. 155

Uniformity II Stand - Alone Test Control Panel................................................... 156

6. System Diagrams ............................................................................................... 157

Power Supply Specification (Sheets 1 - 4) ........................................................... 159

AC Inverter PC Board .......................................................................................... 163

Image Sensor (CCD) PC Board Schematics (Sheets 1 - 3) ................................. 164

SS35/SS35 ES Main Controller PC Board Schematics (Sheets 1 - 8) ................. 167

SS35 PLUS Main Controller PC Board Schematics (Sheets 1 - 9)....................... 175

Appendix .................................................................................................................. 184

SS35 & 35 ES Firmware/Hardware Update History ............................................. 186

6

Slide Scanner Repair Manual Table of Contents

Purpose of this Manual

This Repair Manual is intended as a training and reference guide for the Polaroid and

Polaroid-authorized technical personnel servicing the SS35/SS35 ES/SS35 PLUS slide

scanner's.

Organization of this Repair Manual

Scanner Overview. General information about scanner capabilities and applications.

Functional Description. Detailed explanations of various slide scanner components and

systems for help in diagnosing problems and performing other service.

Calibration and Adjustments. Procedures for checking slide scanner self-test (calibration)

or for solving problems detected by the LabView Tester or setup after component

replacement.

Parts Replacement. Step-by-step procedures for assembly and component level

replacement.

Diagnostics and Troubleshooting. Internal diagnostic software for help in diagnosing

scanner malfunctions. It also gives a detailed explanation of the provided LabView Tester

for help in diagnosing poor image quality.

Schematic Diagrams. Electronic schematics for use as troubleshooting and reassembly

aids.

Other Documents Required for Repair

Effective repair for the slide scanner's also requires familiarity with the following documents in

addition to this Repair Manual:

• SS35/SS35 ES/SS35 PLUS User Guides

• SS35/SS35 ES/SS35 PLUS Slide Scanner Repair Manual

• SS35/SS35 ES/SS35 PLUS Slide Scanner Parts Catalog

• EZ - SCSI Lite Software Manual (IBM and Mac versions)

• SS35/SS35 ES/SS35 PLUS Software Manual (IBM and Mac versions)

• LabView User's Guide

7

Slide Scanner Repair Manual Table of Contents

IMPORTANT SAFETY INSTRUCTIONS

When using the Slide Scanner, basic safety precautions should always be followed including the

following:

• Read and understand all instructions before using.

• Position the cord so that it will not be tripped over, pulled, or contact hot or sharp surfaces.

• If an extension cord is necessary, a UL recognized grounded cord with a rating at least

equal to that of the slide scanner should be used. Extension cords rated for less amperage

may overheat. Connect the slide scanner to a grounded outlet.

• Always turn the host computer OFF and then the slide scanner OFF before unplugging.

• Always unplug the slide scanner from the electrical outlet before cleaning and servicing and

when not in use. Never pull the cord from the outlet. Grasp and pull the plug from the outlet

to disconnect.

• Do not disassemble the slide scanner, but take it to a qualified service person when service

or repair work is required. Incorrect assembly can cause electrical shock when the slide

scanner is used subsequently.

8

Slide Scanner Repair Manual Scanner Overview

1. Scanner Overview

9

Slide Scanner Repair Manual Scanner Overview

1. Scanner Overview

Contents

Description ......................................................................................................... 11

Applications ........................................................................................................ 12

Features .............................................................................................................. 14

Specifications ..................................................................................................... 19

Operation ............................................................................................................ 22

Setting up the Slide Scanner.............................................................................. 22

Installing the Software ....................................................................................... 23

Starting the Software......................................................................................... 24

Scanning the Slide/Film Strip ............................................................................. 25

Self-Check Routines .......................................................................................... 26

Self-Test (Power-Up) ........................................................................................ 26

Calibration ......................................................................................................... 28

10

Slide Scanner Repair Manual Scanner Overview

Description

This section of the Repair Manual gives an overview of the SprintScan 35, the SprintScan 35

ES, and the SprintScan 35 PLUS slide scanner. It only provides the necessary information

pertaining to features and specifications for each slide scanner.

For detailed information pertaining to setting up the slide scanner, installing and starting their

software, assigning SCSI ID's and checking SCSI connections, scanning transparencies, and

using application software, refer to the applicable slide scanner User Guide.

The slide scanners are desktop, fixed-format, high-speed 35 mm transparency film scanners,

capable of scanning positive and negative media, mounted and unmounted transparencies and

unmounted transparency filmstrips.

Each system (Figure 1-1) consists of a:

• Slide Scanner

• Power Cord

• SCSI cable with 25-pin and 50-pin connector ends

• SCSI terminator (Supplied only with SprintScan 35 ES)

• SprintScan software diskette

• Adaptec AT-to-SCSI Host Adapter with EZ-SCSI Lite application diskette and

documentation (Windows version only)

• Adobe PhotoDeluxe CD (Mac/Windows)

• Filmstrip carrier for negative strip or unmounted slide film

11

Slide Scanner Repair Manual Scanner Overview

Applications

Table 1-1 indicates a partial list of applications for each slide scanner. For a more detailed list

of applications for each slide scanner, refer to the applicable slide scanner User Guide.

Table 1-1. Slide Scanner Applications

Applications\User Groups SS 35/SS 35 ES SS 35 PLUS

Digital Design:

Graphic Designs •• •

Corporate Design Departments •• •

Advertising Agencies •• •

Web-Page Design ••

Multimedia Design ••

Publishing:

Catalog Publishers •• •

Magazine Publishers •• •

Newspapers •• •

Printing:

Prepress Houses •

Printers •

Photo Retouching:

Studio Photography •• •

ProPhoto Labs •• •

• • - Ideally suited.

12

Slide Scanner Repair Manual Scanner Overview

SprintScan 35/35ES

Polaroid SprintScan 35

SprintScan 35 PLUS

Polaroid SprintScan 35 PLUS

Figure 1-1. Slide scanners

13

Slide Scanner Repair Manual Scanner Overview

Features

Table 1-2 list and describes the features of the slide scanners (Figure 1-2).

Table 1-2. Slide Scanner Features

Feature Description

Power LED Indicator This green LED indicator lights to indicate when the

slide scanner power is turned on.

Note: During power-up the slide scanner initiates its

self-test mode.

Ready LED Indicator This yellow LED indicator lights to indicate when the

slide scanner is ready to operate (passed power up

self-test).

Notes: • This indicator continually blinks while the

slide scanner cycles through its self-test.

• Upon completion, this indicator lights steady

to indicate that the slide scanner is ready to

operate.

Top Access Slot The top access slot is used when scanning 35 mm slide

transparencies.

Side Access Slot The side access slot is used when scanning unmounted

slides and 35 mm filmstrips using the filmstrip carrier

included in the accessory kit.

Filmstrip Carrier Included with the accessory kit.

Used to scan a 35 mm negative strip or an unmounted

slide. Supports 35 mm filmstrips from 1 - 6 frames.

Release Button This button is used to release the front cover when

replacing the lamp. (Spare lamp located inside front

cover.)

Power On/Off (1/0) Switch This switch turns the slide scanner power on or off. The

green Power LED lights to indicate that the slide scanner

is turned on.

14

Slide Scanner Repair Manual Scanner Overview

Table 1-2. Slide Scanner Features (Cont'd)

Feature Description

Power Receptacle Standard receptacle with ground.

Power Cord Standard cord with ground.

Power Fuse Receptacle The fuse receptacle contains two fuses: active and

(SS35 Only) spare.

The active fuse protects the slide scanner's electronics

from any sudden surges or overloads.

Note: If the active fuse fails (blows), always attempt to

find out the cause of the malfunction before

replacing the blown fuse with the provided spare.

Replace the spare fuse with a new one as

soon as possible.

Power Fuse Not user accessible. Located on power supply PC

(SS35 PLUS) board.

SCSI ID Selector/Indicator The slide scanner's SCSI ID is preset at the factory

to 6.

SCSI ID position 7 is reserved for the SCSI adapter to

which the SCSI device(s) are connected.

Note: DO NOT change this value unless other SCSI

devices are attached to the slide scanner and

one of them is assigned to SCSI value 6.

If the preset SCSI value must be changed, refer

to the applicable slide scanner User's Guide for

detailed instructions on how to change the slide

scanner's SCSI value.

15

Slide Scanner Repair Manual Scanner Overview

Table 1-2. Slide Scanner Features (Cont'd)

Feature Description

SCSI Receptacles SS35/SS35 ES: (Top and Bottom)

Two (2) 50-pin standard SCSI receptacles.

SS35 PLUS:

One (1) 50-pin standard SCSI receptacle.

One (1) 25-pin standard SCSI receptacle.

SCSI Cable This cable (25-pin and 50-pin connector ends) connects

th eslide scanner to the host computer.

Note: The 50-pin end of the SCSI cable connects to the

top SCSI receptacle. The 25-pin end of the SCSI

cable connects to the 25-pin SCSI port at the

rear of the host computer (Adaptec AT-to-SCSI

Host Adapter port for Windows version).

SCSI Terminator SS35/SS35 ES:

SCSI terminator connects to the bottom receptacle.

SS35 PLUS:

SCSI terminator built in. To activate SCSI terminator,

set SCSI terminator switch to its ON position.

Notes: • To function properly, a SCSI chain must be

terminated at each end.

• The Adaptec AT-to-SCSI Host Adapter for

Windows version is internally terminated, which

means that it is the first one of the required

terminators.

• If the slide scanner is the only SCSI device to

be connected to the host computer, connect the

SCSI terminator to the bottom SCSI receptacle.

For SS35 PLUS turn on the terminator switch.

16

Slide Scanner Repair Manual Scanner Overview

Table 1-1. Scanner Features (Cont'd)

Feature Description

SCSI Terminator

(Cont'd) Warning: If the slide scanner is being added to an

existing SCSI device chain, make sure that

only two SCSI terminators (internal or

external) exist in the SCSI device chain.

More than two SCSI terminators in the SCSI

device chain can damage the host computer

or the devices.

Adaptec AT-to-SCSI This adapter provides the interface through which the

Host Adapter slide scanner and host computer communicate.

(Windows Version ONLY)

Notes: • The adapter is preset at the factory for default

interrupts and port address values.

• Host adapter not included with all models

EZ-SCSI Lite Software Included with the Adaptec AT-to-SCSI Host Adapter.

(Windows Version ONLY)

This software application is used to configure the host

computer for the SCSI adapter. It also provides

additional driver files for the SCSI interface.

Notes: • The host computer must always be restarted

after the EZ-SCSI Lite software is installed.

• If necessary, contact Adaptec for latest version

drivers. Drivers can be downloaded from

Adaptec's website at:

http://www.adaptec.com

17

Slide Scanner Repair Manual Scanner Overview

Table 1-1. Scanner Features (Cont'd)

Feature Description

SprintScan 35 Software Included with the slide scanner.

This software includes the SprintScan application and the

Scanner Control Panel which is a TWAIN source driver.

Note: TWAIN is a software protocol that allows

applications to use image-acquisition devices,

such as the SprintScan 35 Slide Scanner and

other image digitizers.

The software allows the scanned image to be

manipulated. Manipulation includes rotating,

cropping, zooming, re-sizing, and changing the

output image. For more detailed information

pertaining to image manipulation refer to the

applicable slide scanner User's Guide.

Adobe PhotoDeluxe This software application allows the scanned image to

be manipulated. Manipulation includes rotating, cropping,

zooming, re-sizing, and changing the output image. For

more detailed information pertaining to image manipulation

refer to the applicable slide scanner User's Guide.

18

Slide Scanner Repair Manual Scanner Overview

Front

Rear

Ready

LED Indicator

Power

LED Indicator

Polaroid SprintScan 35

Release

Button

Top

Access Slot

SCSI

ID Selector

Side

Access Slot

Power

Receptacle

SCSI Receptacles

SS35/SS35 ES

SS35 PLUS

(Top and Bottom)

Terminator Switch

Power On/Off

(1/0) Switch

SCSI

Power On/Off

(1/0) Switch

Fuse

Receptacle

Fan

SCSI Receptacles

(Top and Bottom)

SCSI

ID Selector

Power

Receptacle

Fan

Figure 1-2. Slide scanner features

19

Slide Scanner Repair Manual Scanner Overview

Specifications

Physical:

Dimensions - 5 x 7 x 10 inches (13 x 18 x 26 cm)

Weight - approximately 5.5 pounds (2.5Kg)

Power:

Operating Voltage - 105 - 130 VAC @ 48 - 62 Hz (USA)

- 90 - 110 VAC @ 48 - 62 Hz (Japan)

- 190 - 210 VAC @ 48 - 62 Hz

- 210 - 260 VAC @ 48 - 62 Hz (Europe)

Idle Power - 30 Watts @ 115 VAC, 60 Hz (lamp off)

Operating Power - 35 Watts @ 115 VAC, 60 Hz (lamp on)

Light Source:

Lamp - Phillips Coolwhite (US - Type TL4W/33)

(European Equivalent - Type F4T5)

Environmental Conditions:

Operating Temperature - 50°F (10°C) to 104°F (40°C)

Optimum @ 60°F (16°C) to 80°F (27°C)

Storage Temperature - 20°F (-30°C) to 160°F (70°C)

Operating Relative Humidity - 20% to 80%

Optimum @ 30% to 60%

Media Type/Orientation

35 mm Slide Size - 1.4" x 1.4" (36 mm x 36 mm) mounted, including

ANSI-standard plastic mounts

35mm Slides, Mounted - Landscape/portrait orientation, superslide (36mm x 36mm)

35mm Slides, Unmounted - Landscape orientation only (Used with filmstrip carrier)

Filmstrips - 35 mm filmstrips, unmounted, in lengths of

Scanning:

Time - Under 30 seconds

Resolution - 127 dpi - 2700 dpi

Maximum Scan Area - 36 mm x 24 mm or 24 mm x 36 mm

1- to - 6 frames (Used with filmstrip carrier)

20

Slide Scanner Repair Manual Scanner Overview

Host Computer Platforms: Macintosh IBM PC or Equivalent

Operating Systems

Hardware Requirements

RAM

Monitor

Digitized Image

Formats

- System 7.1 or higher MS Windows 3.1 or higher,

Windows 95, Windows NT 4.0

- Power PC Mac, Mac II, Minimum 386SX @16Mhz

Quadra or Centris with Recommended 486 @ 33Mhz

floating point with floating point

co-processor co-processor

- Recommended: 24 MB Recommended: 24 MB

- VGA Color Monitor and VGA Color Monitor and

Video Card Video Card

Recommended: True Color Recommended: True Color

Video Card (24-bit color) Video Card (24-bit color)

with at least 800 x 600 with at least 800 x 600

resolution resolution

- TIFF, PICT, RAW TIFF, PCX, GIF, BMP,

TGA, JPG

Software: (Included with Slide Scanner)

Diskettes/CD - Adobe PhotoDeluxe SprintScan 35 for Windows 3..x

Version 2.5.1 or Later SprintScan 35 for windows 95

- SprintScan 35 ES/PLUS Adaptec AT-to-SCSI Host

Adapter with EZ-SCSI Lite

- Apple Shared Library (Not included with all Models.)

(Required for Non-Power PC's.)

21

Slide Scanner Repair Manual Scanner Overview

Operation

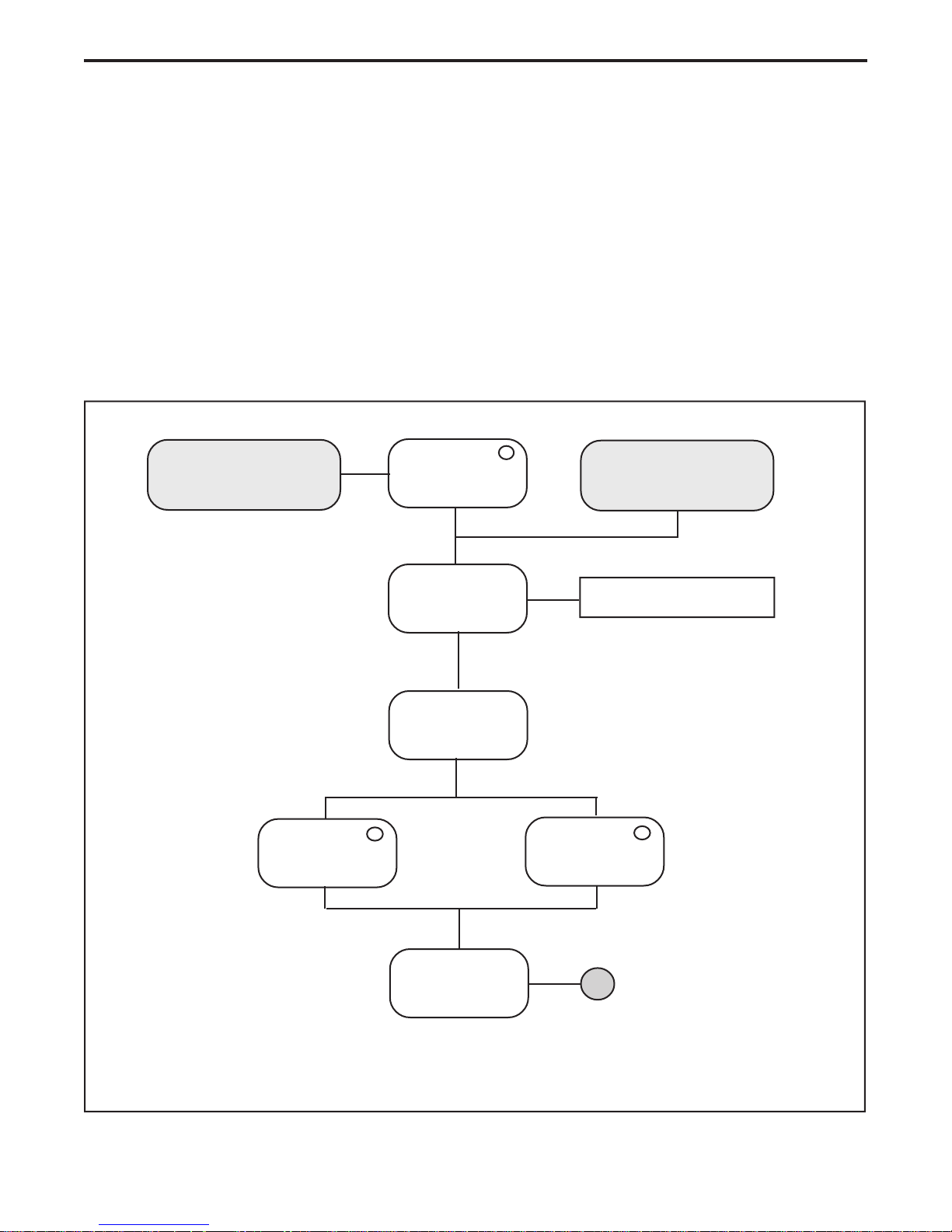

The following operational flow diagrams (Figures 1-3 through 1-6) briefly describe how to setup

the slide scanners, install and start their software, assign their SCSI ID value, and scan a

mounted or unmounted 35 mm transparency using the SprintScan 35 application software.

Each operational flow diagram is intended to be used only as a Quick reference for the repair

person. For detailed information pertaining to the information in each operational flow diagram

(setting up the slide scanner, installing and starting its software, assigning its SCSI ID and

checking the SCSI connection, and scanning a 35 mm transparency using SprintScan, refer to the

applicable slide scanner User's Guide.

Setting Up the Slide Scanner

Windows Version

SS35/SS35 ES

Connect

SCSI Terminator

to Scanner

Install

Adaptec SCSI

Adapter to Host

Assign /Select

SCSI ID

Connect

Scanner to Host

2

1

SS35 PLUS

Turn On

SCSI Terminator

Switch

Mac Version

Set to 6

2

Notes: 1 - If host already has a SCSI adapter, add slide scanner to SCSI chain.

2 - If slide scanner is only, or last device, in SCSI chain.

DO NOT CONNECT SS35 ES SLIDE SCANNER TO SCSI CHAINS

WITH HARD DRIVES (Applies to PC, only and slide scanners with

firmware version 1.02 or lower).

Figure 1-3. Setting up slide scanner

Turn On Scanner,

then Host

22

A

Slide Scanner Repair Manual Scanner Overview

Installing the Software

Windows Version

Install Adaptec

EZ-SCSI Lite/EZ-SCSI

Software

EZ-SCSI Lite/EZ-SCSI:

• Configures host computer

for SCSI adapter

• Provides additional driver

files for SCSI interface

SprintScan:

• Provides Scanner Control

Panel

• Provides additional driver

files for SCSI interface

A

Reboot

Host

Install

Applicable

SprintScan 35

Software

Mac Version

Install

Adobe PhotoShop

Software

Adobe Photoshop:

• Automatically transfers

final scans into Adobe

PhotoShop

• Provides digitized image

manipulation

Figure 1-4. Installing sprintscan 35 software

Reboot

Host

Check

SCSI

Connection

Turn Off Host,

then Scanner

23

B

Slide Scanner Repair Manual Scanner Overview

Starting the Software

Windows Version

Click on

Adobe PhotoShop

Click on

File Menu

Click on

Import

Select

Twain_32 Source,

then SprintScan 32-Bit

1

B

Turn On Scanner,

then Host

Mac Version

Click on

Adobe PhotoShop

Click on

File Menu

Click on

Import/Acquire

Select

SprintScan 35...

Click on File Menu

Select

Twain_32

Note: 1 - Required for first scan only.

Figure 1-5. Starting sprintscan 35 software

Scanner Control Panel

Displays

Scan

Slide/Film Strip

C

24

Slide Scanner Repair Manual Scanner Overview

Scanning the Slide/Film Strip

C

Scan

Scan

Mounted Slide

Insert

Mounted Slide

into Scanner

Top Slot

Unmounted

or

Film Strip

Open Carrier

Scan

Slide/Film Strip

Place

Unmounted Slide

or

Film Strip

into Carrier

Insert

Carrier into

Scanner

Right-Side Slot

Note: Refer to the applicable slide scanner User's Guide for information pertaining to

scanning a mounted slide, unmounted slide or film strip.

Figure 1-6. Scanning a slide/film strip

25

Slide Scanner Repair Manual Scanner Overview

Self-Check Routines

The slide scanner provides two internal self-check software routines that are used to

automatically check (verify) its operation. The two internal self-check software routines are:

• Self-Test (Power-Up)

• Calibration

Self-Test (Power-Up) Routine

When the slide scanner is turned on, the self-test (power-up) routine is automatically invoked.

This routine checks and verifies the following operations:

• Initializes all system electronics (image sensor and main controller PC boards).

• Finds calibration window (Transporter moves shutter to its calibration window

position and stops.)

Note: If the calibration window position can not be found, the transporter moves

to its top position and then returns the shutter to what it thinks is the correct

position.

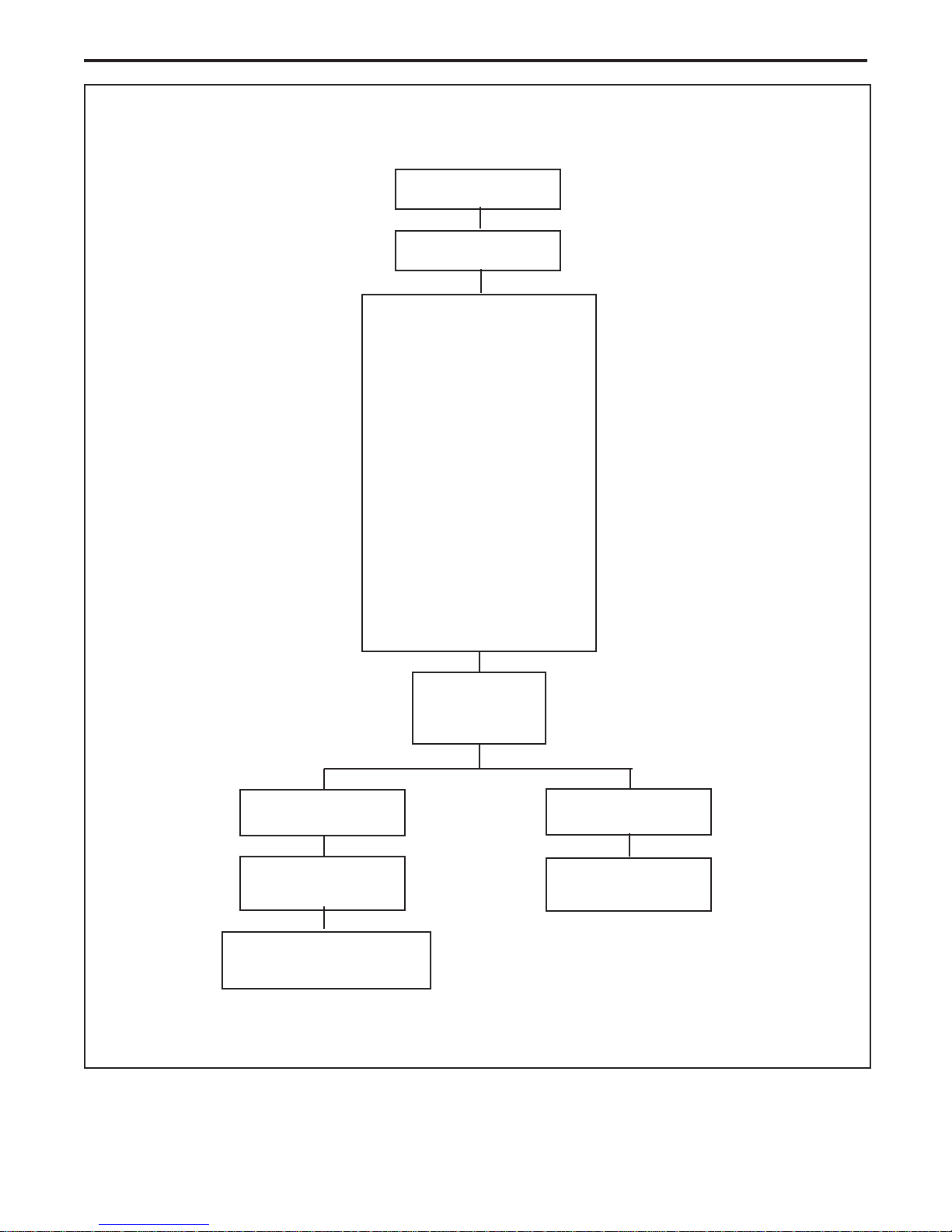

Refer to the simplified flow diagram shown in Figure 1-7 for the necessary steps to self-test the

slide scanner during power-up.

Upon completion (passed self-test), the transporter returns to its home position and the Ready

LED lights steady to indicate that the slide scanner is ready to operate.

Notes: • If the yellow Ready LED continually blinks, the slide scanner failed its self-test.

Run the LabVIEW IPT test to determine why the slide scanner failed its

self-test . (Refer to the applicable LabVIEW test in Section 5 of this Repair

Manual for detailed instructions on how to run the LabVIEW test procedure.)

• If the yellow Ready LED does not light after the self-test is performed, turn off

the slide scanner (power-down), wait approximately 10 seconds and then

power-up again.

Causes of self-test (power-up) failure are usually due to a defective EEPROM, incorrect

EEPROM data, the inability to find the calibration window, or a blown SCSI terminator fuse.

Refer to Section 5 in this Repair Manual for self-test errors.

26

Slide Scanner Repair Manual Scanner Overview

Self-Test

Initializes (Resets)

System

Electronics

Filter

Wheel

**

Transporter SCSI

A/D

Converters

*

ASIC's

*

*

Ready LED

Continually Blinks

Self-Test

Failed

Run LabVIEW Test

(See Section 5 for Details)

Transporter

Seeks Calibration

Window

Self-Test

Completed

*

*

Ready LED

Lights Steady

Self-Test

Passed

* For SS35 PLUS, self-test of these components only occurs after the host software downloads (initializes) programmable code.

** Filter Wheel used only on early SprintScan Models.

Figure 1-7. Self-Test simplified flow diagram

27

Slide Scanner Repair Manual Scanner Overview

Calibration

For SS35/SS35 ES slide scanners, the first calibration is performed at the first requested scan.

It is also performed when the slide scanner detects a specified amount of drift in the lamp or

front end during subsequent scans. The SS35 PLUS performs a full calibration before each

scan.

Refer to Figure 1-8 for a simplified flow diagram of the SS35/SS35 ES slide scanner calibration

routine and to Figure 1-9 for a simplified flow diagram of the SS35 PLUS slide scanner

calibration routine.

Upon completion (passed calibration), the Ready LED indicator lights steady to indicate that the

slide scanner is ready to operate.

Note: The Ready LED indicator continually blinks while the slide scanner cycles through its

calibration.

The following types of adjustments occur during the first calibration:

• Base line integration time to ensure a minimum signal and mitigation of saturation

• Analog gain and offset for base line neutral settings

• Digital uniformity offset calibration

• Digital uniformity gain calibration

• Bad pixel identification

Subsequent scans may require additional analog gain and offset and/or integration time

adjustments to accommodate white points requested by the host or film tables, as a function of

the specific calibration algorithms.

A drift check is also performed with each scan to verify the stability of the front end. Each

calibration that requires a significant change in the front end settings necessitates a

recalculation of the digital uniformity offset correction during the actual scan.

Causes of calibration failure are usually due to a defective lamp, obstructions in the optical path,

a defective sensor (CCD) PC board, a defective main controller PC board, a defective filter, or

a misaligned filter wheel (Original SS35 only).

Refer to Section 5 in this Repair Manual for a detailed list and definition of all calibration type

errors.

28

Slide Scanner Repair Manual Scanner Overview

SS35/SS35 ES

Calibration Routine

Start

First Scan

Calibrate

Check and adjust, if

necessary:

• Base line integration time

to ensure a minimum signal

and mitigation of saturation

• Analog gain and offset for

base line neutral settings

• Digital uniformity

offset calibration

• Digital uniformity

gain calibration

Start

Subsequent Scans

Check

Drift in Lamp

or

Front End

Fail

Pass

• Bad pixel identification

• Drift test

Calibration

Completed

Fail

Ready LED

Continually Blinks

No Scan

Run LabVIEW Test

(See Section 5 for Details)

Pass

Ready LED

Lights Steady

Figure 1-8. Calibration simplified flow diagram

Scan

29

Slide Scanner Repair Manual Scanner Overview

SS35 PLUS Calibration

Routine

Start Scan

Calibrate

Check and adjust, if

necessary:

• Base line integration time

to ensure a minimum signal

and mitigation of saturation

• Analog gain and offset for

base line neutral settings

• Digital uniformity

offset calibration

• Digital uniformity

gain calibration

• Bad pixel identification

• Drift test (lamp/front end)

Fail

Ready LED

Continually Blinks

No Scan

Run LabVIEW Test

(See Section 5 for Details)

Calibration

Completed

Pass

Ready LED

Lights Steady

Scan

Figure 1-9. Calibration simplified flow diagram

30

Loading...

Loading...