Page 1

Repair Manual

Americas Business Center

Technical Services

201 Burlington Road

Bedford MA 01730

TEL: 1.781.386.5309

FAX: 1.781.386.5988

Spectra/Image One Board

September 1996

Page 2

Table of Contents

Page

Section 1 - General Description........................................................................ 5

Scope of This Addendum ............................................................................... 5

Spectra Pro/Image Pro/Minolta Pro Operating Differences ............................. 5

Spectra Pro/Image Pro/Minolta Pro Performance Differences......................... 7

Spectra Pro/Image Pro/Minolta Pro External Physical Differences .................. 8

Section 2 - Disassembly and Reassembly ...................................................... 9

Special T ools.................................................................................................. 9

Cautions and Reminders ................................................................................ 10

Removing Mid-Cover...................................................................................... 11

Disassembling Mid-Cover .............................................................................. 12

Removing Ranging Board............................................................................... 14

Replacing Ranging Board............................................................................... 17

Removing LCD Board from Ranging Board ................................................... 18

Reconnecting LCD Board to Ranging Board................................................... 19

Removing One Board Strobe/Exposure Module Assembly.............................. 20

Section 3 - Testing and Adjustments ............................................................... 23

Functional T est................................................................................................ 23

Star Tester Model 12650-3 Description........................................................... 33

Star T ester Setup and Pre-Test Checks........................................................... 36

Order of Spectra Pro/Image Pro/Minolta Pro System T ests ............................. 39

Ambient Exposure T est................................................................................... 41

Strobe Exposure (Graywall) T est ..................................................................... 43

ZLS (Zonal Lumen Seconds) Graywall T est ..................................................... 45

Hybrid (ZLS/Blade Speed) T est ...................................................................... 47

Blade Speed Test........................................................................................... 49

Spectra Pro/Image Pro/Minolta Pro Star T ester Specifications........................ 50

Ambient Exposure Calibration Slide Adjustment ............................................. 51

IR Strobe Exposure Calibration Slide Adjustment............................................ 53

Hybrid Adjustment (Opening Blade Spring)..................................................... 55

Blade Speed Adjustment (Opening Blade Spring............................................ 56

Solenoid 1 Adjustment for Quintic Position...................................................... 57

2

Page 3

Section 4 Spectra Pro/Image Pro/Minolta Pro Troubleshooting.................... 59

Basic Requirements and Guidelines............................................................... 59

Abbreviations Used in This Section ................................................................ 62

Operating Problems and T ypical Causes ........................................................ 63

Wire Connections and T est Points .................................................................. 73

Schematic Diagrams...................................................................................... 74

List of Illustrations

Figure Page

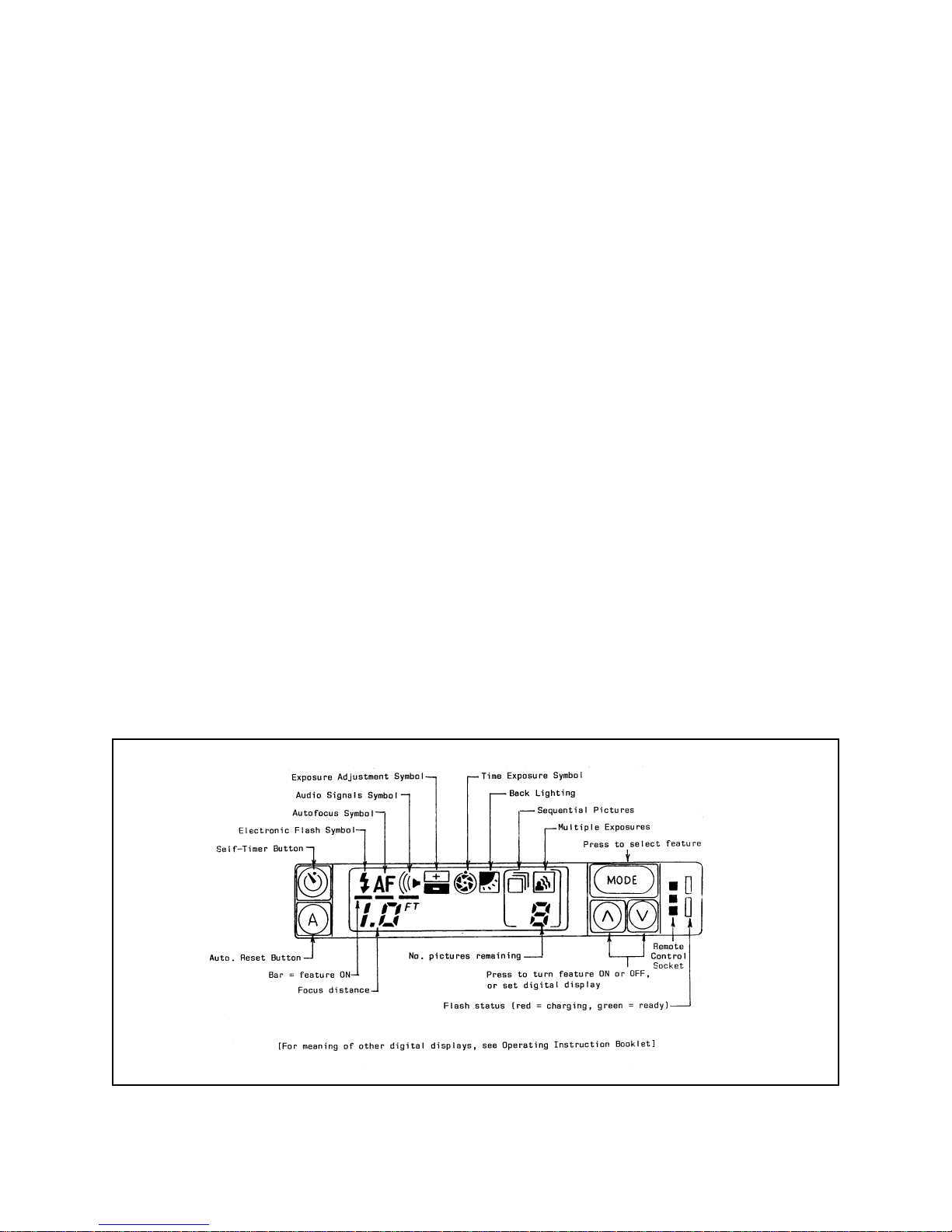

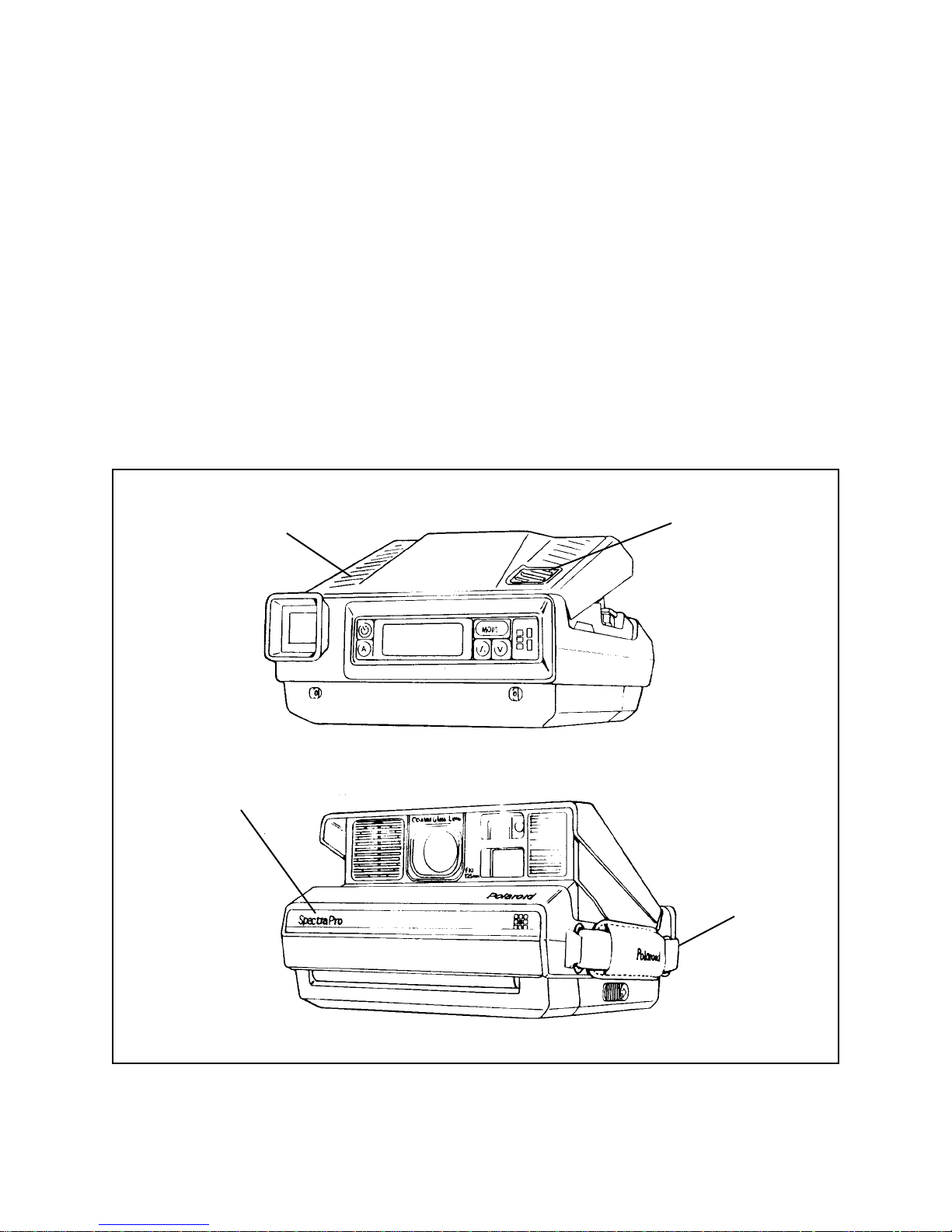

1-1 Spectra Pro/Image Pro/Minolta Pro Electronic Control Panel..................... 6

1-2 Spectra Pro/Image Pro/Minolta Pro External Physical Differences............. 8

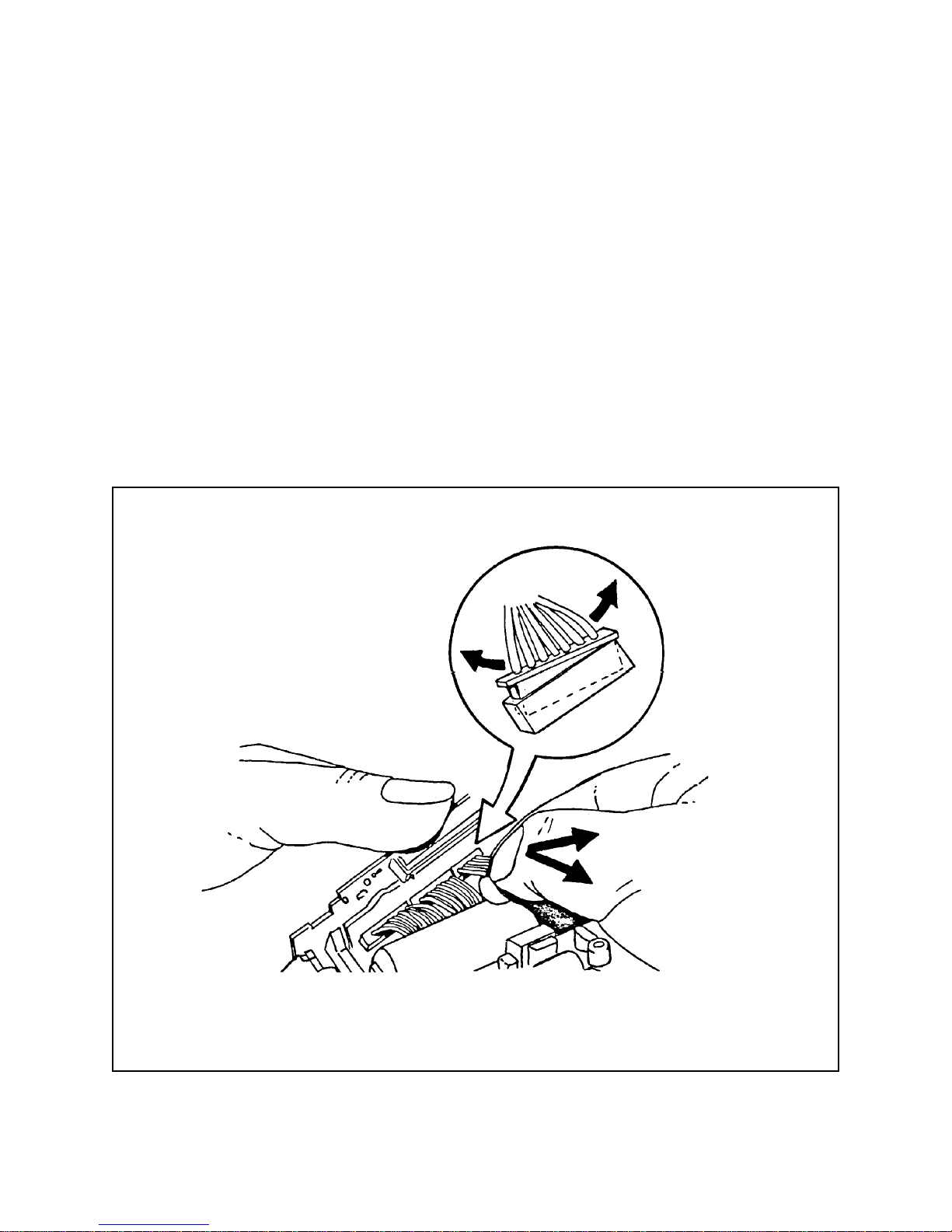

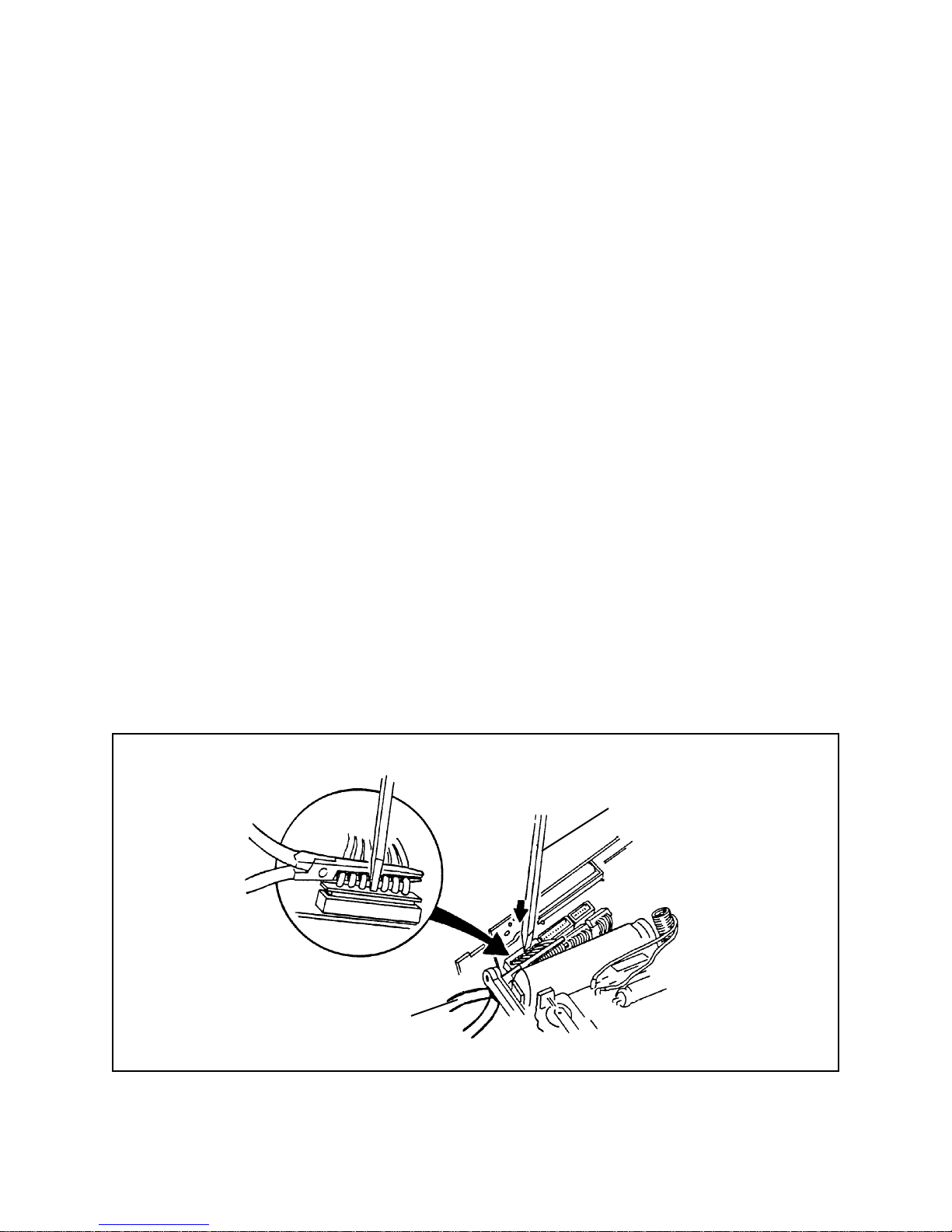

2-1 Proper Removal of a Typical Wire Connector ............................................ 10

2-2 Removing Hinge Pins and Mid-Cover........................................................ 11

2-3 Removing Eye Cup and Buttons from Mid-Cover ....................................... 12

2-4 Removing LCD Window from Mid-Cover................................................... 13

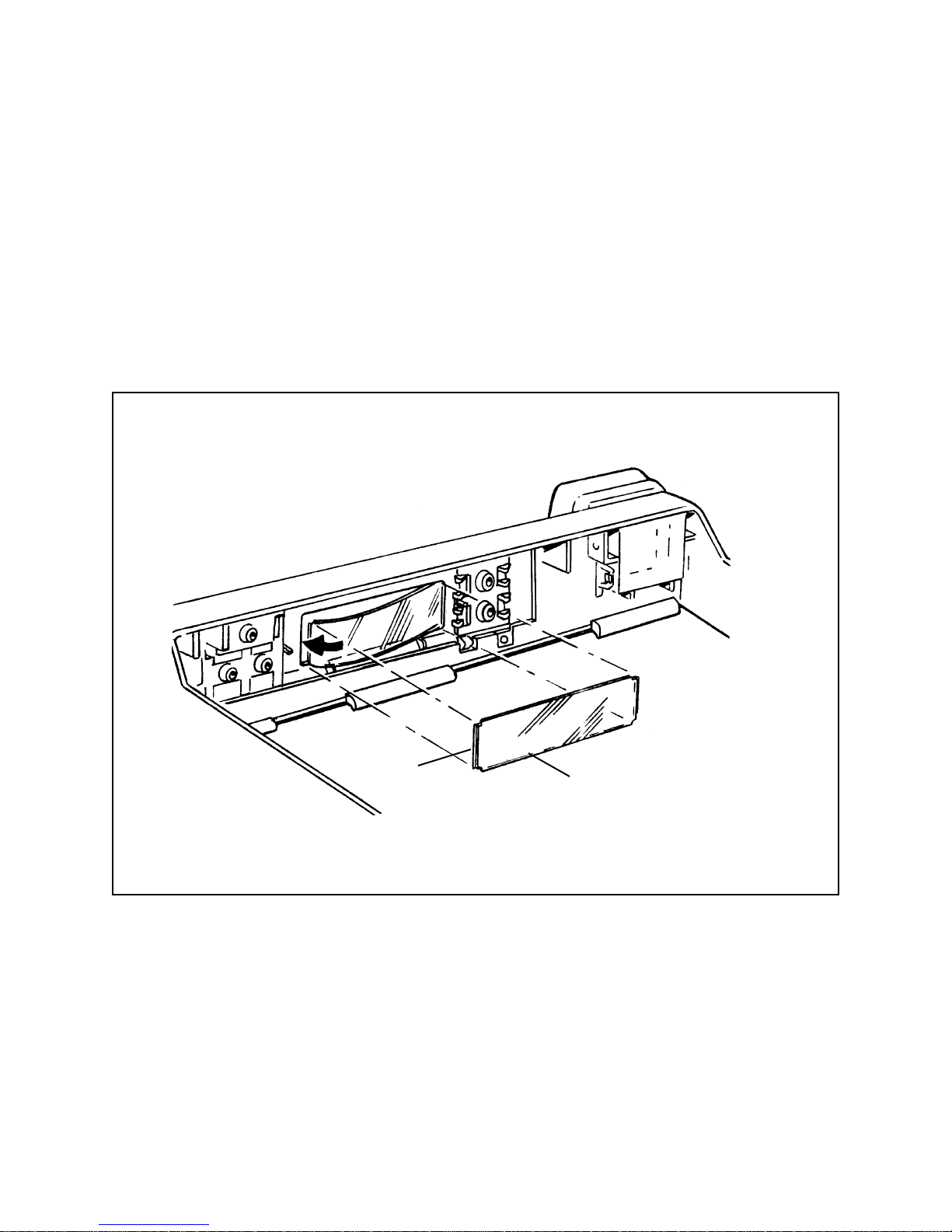

2-5 Ranging Board and Connectors for J1, J2 and J3...................................... 14

2-6 Releasing Connectors from Ranging Board............................................... 15

2-7 Releasing Ranging Board Wire Connections............................................. 16

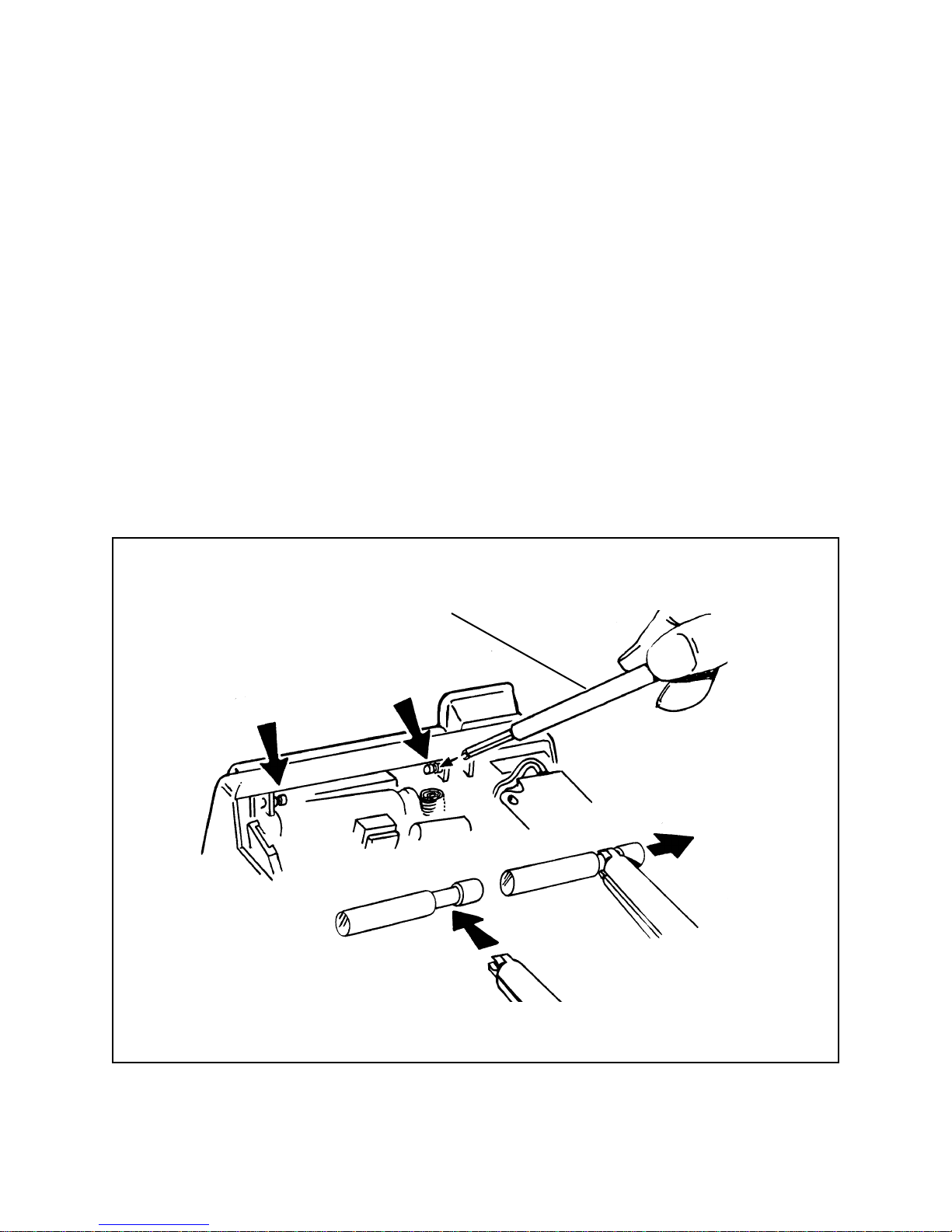

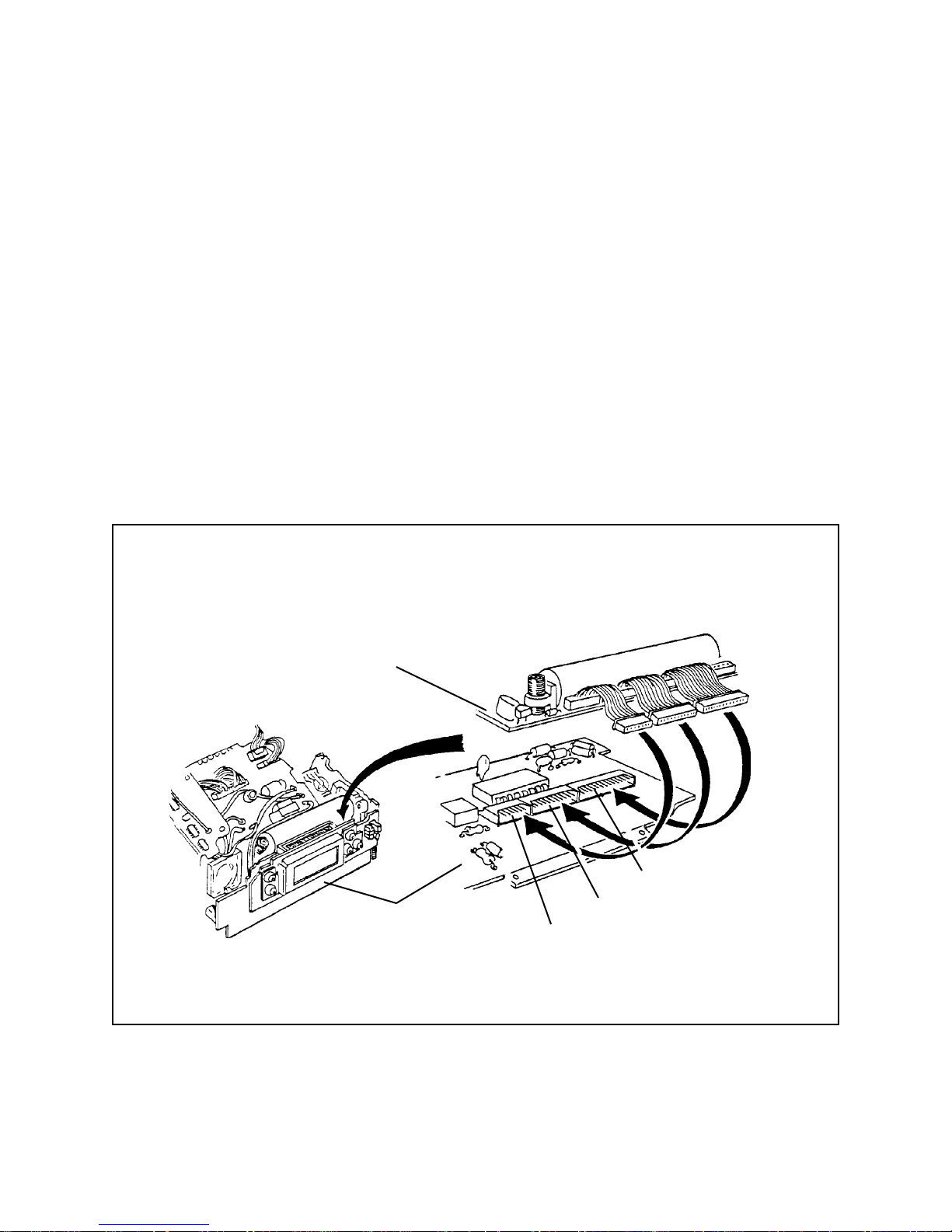

2-8 Reconnecting J1, J2 and J3 to Ranging Board .......................................... 17

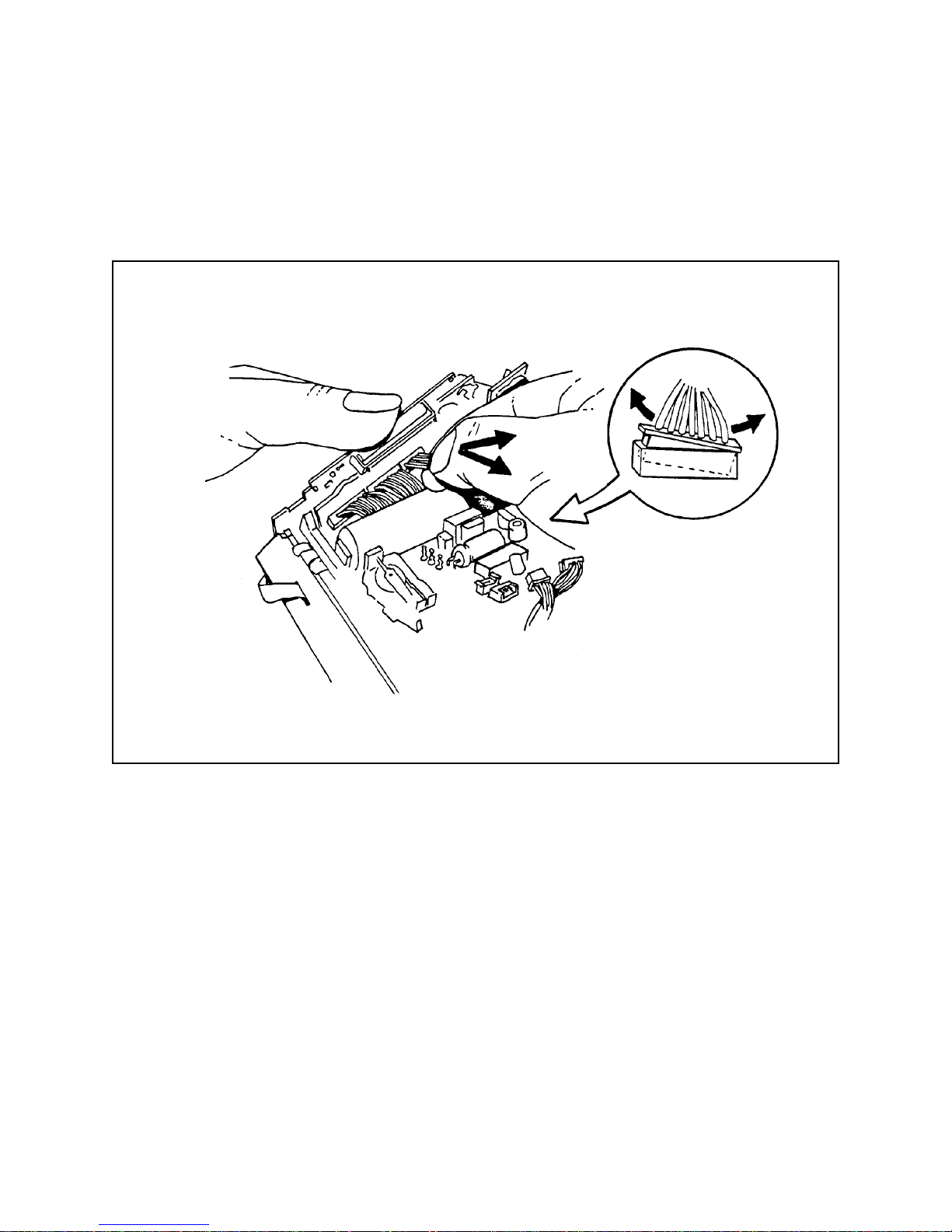

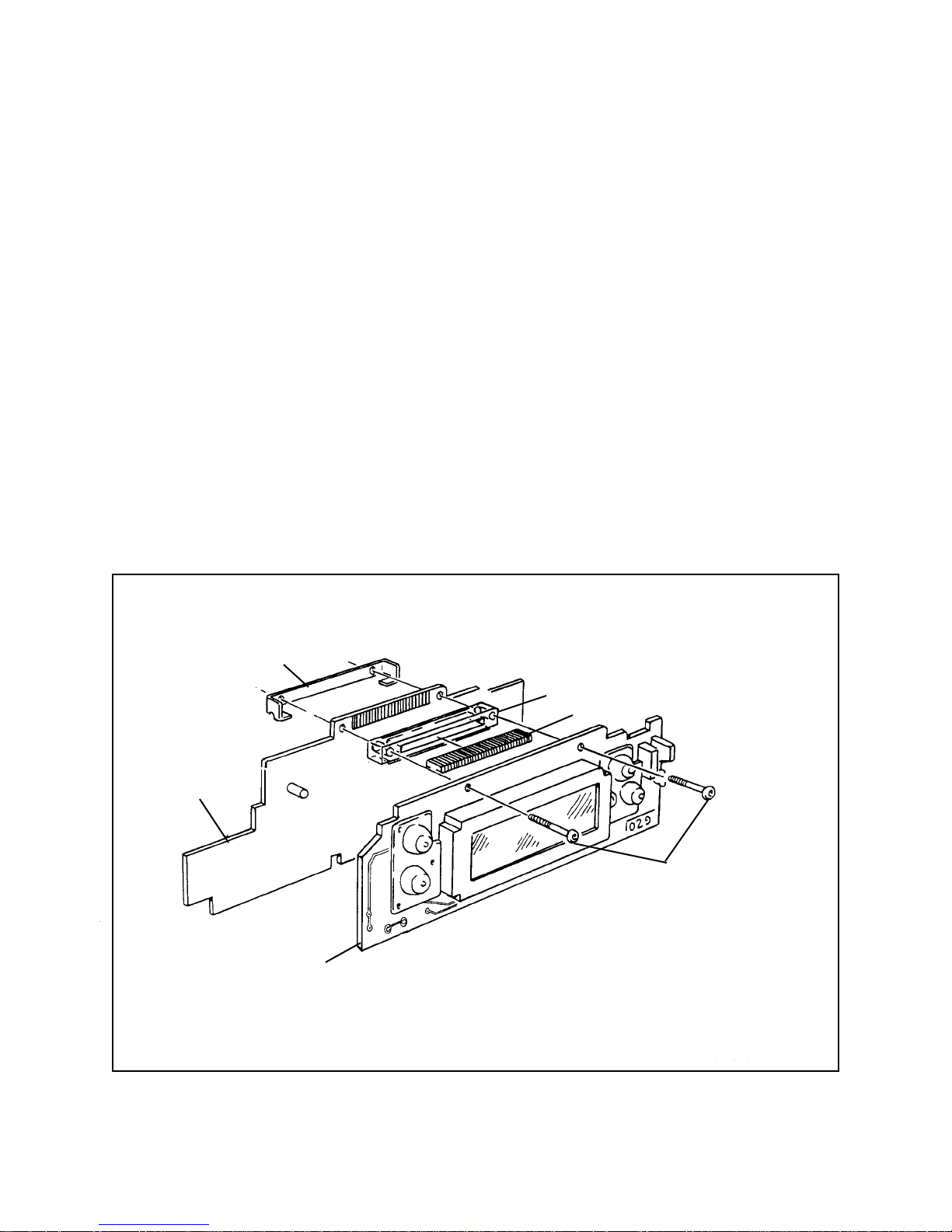

2-9 Removing LCD Board............................................................................... 18

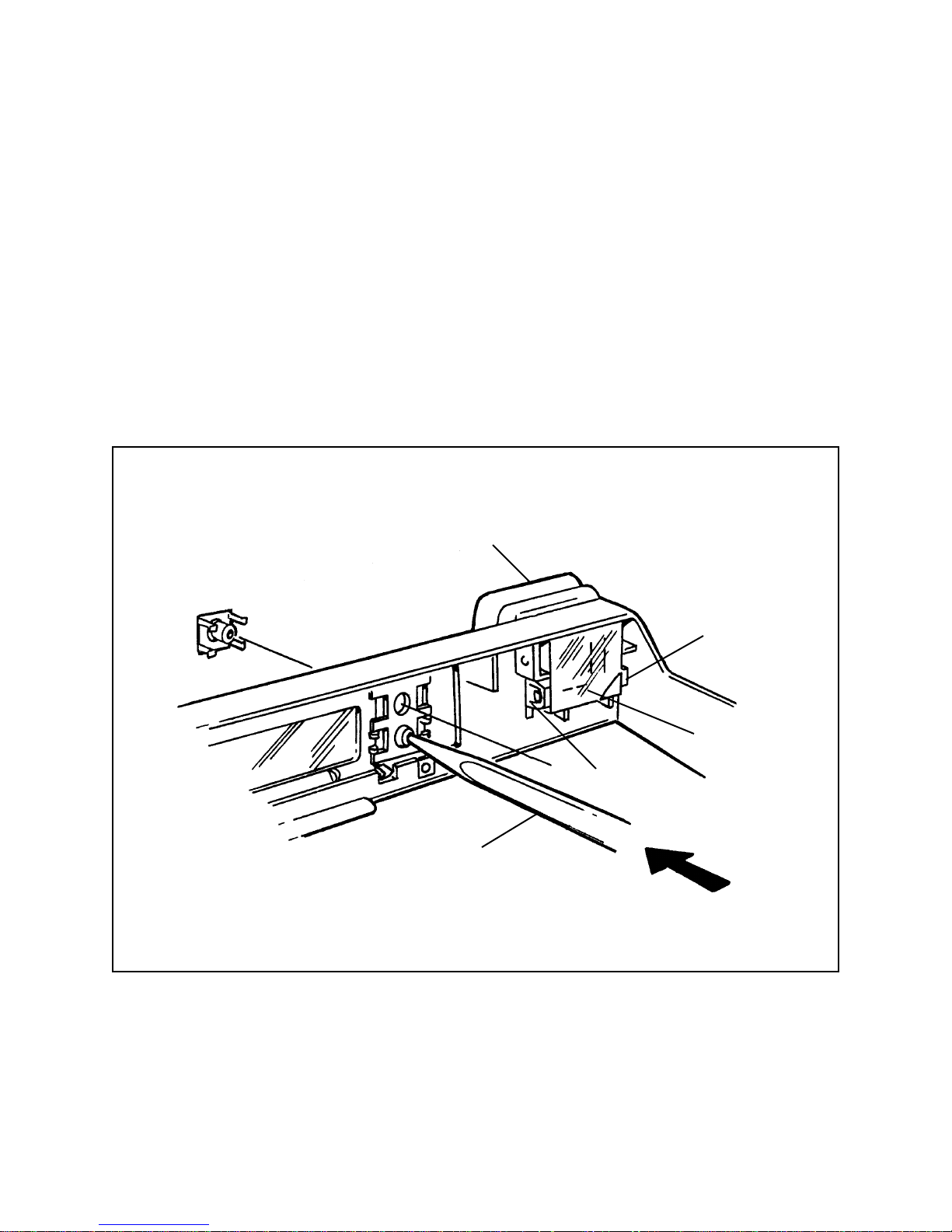

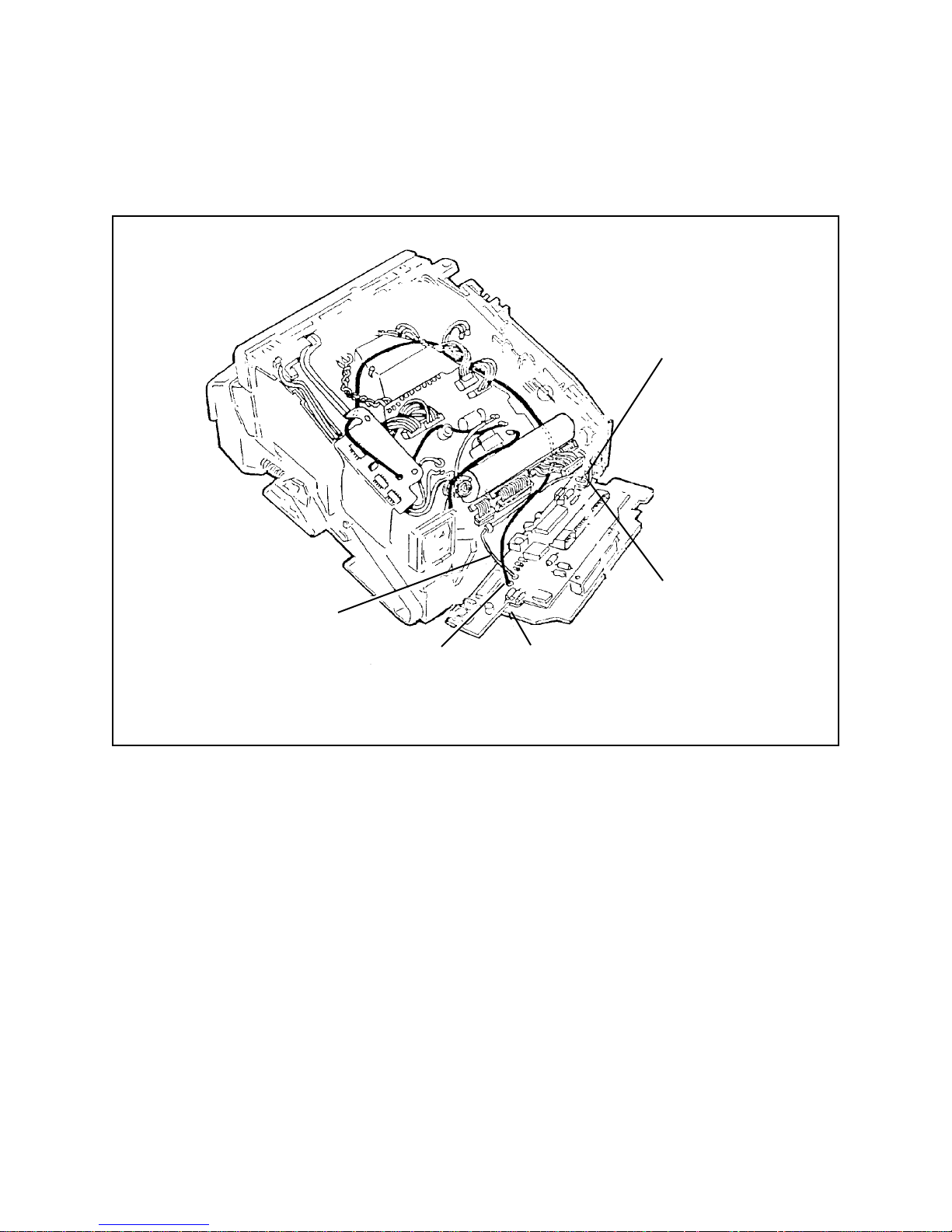

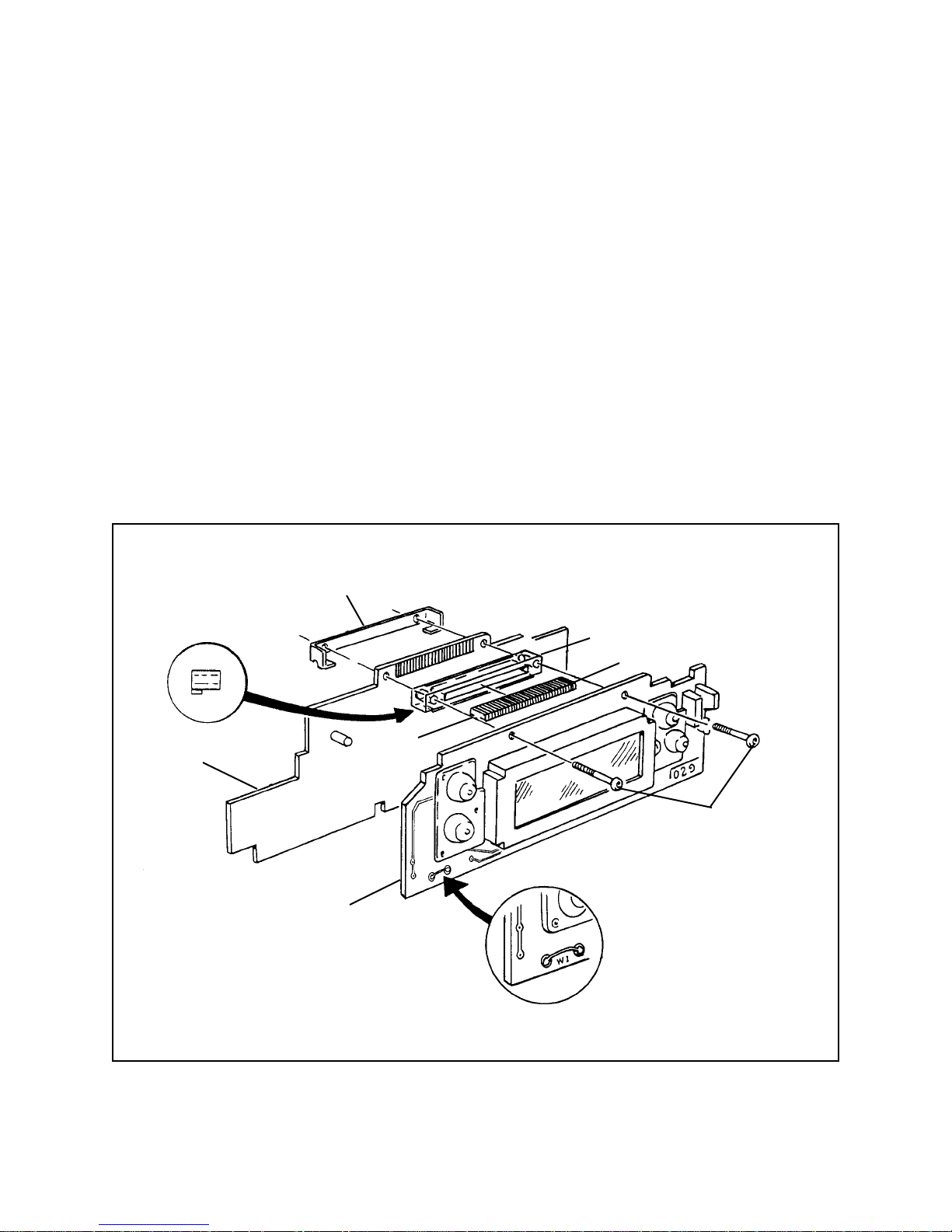

2-10 Replacing LCD Board............................................................................... 19

2-1 1 Disconnecting One Board Strobe/Exposure Module.................................. 20

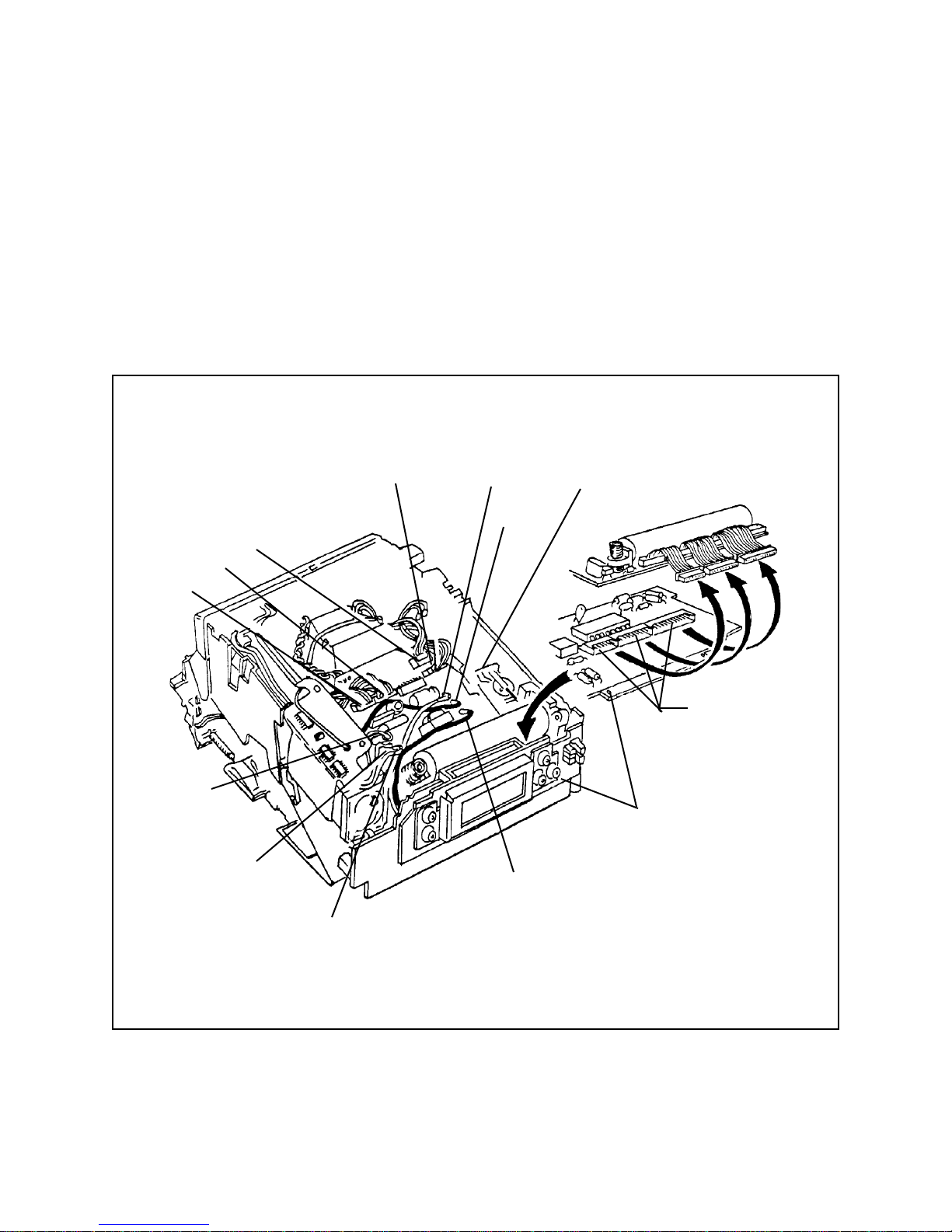

2-12 Removing J8 from One Board Strobe/Exposure Module ............................ 21

2-13 Removing Photodiode Retainer................................................................. 22

3-1 Setup for Spectra Pro/Image Pro/Minolta Pro Functional T est.................... 24

3-2 Closing Door Latch ................................................................................... 25

3-3 LCD Control Panel at Completion of Dark Slide ........................................ 26

3-4 Covering Transducer to Stimulate Infinity Exposure.................................... 28

3-5 Quintic Lens Moves to Short-Distance Setting ........................................... 29

3-6 Quintic Lens Moves to Infinity Setting ......................................................... 31

3-7 Star T ester 12650-3 Controls and Indicators (See text for description) ....... 35

3-8 Locating Star T ester in Relation to Graywall Target..................................... 36

3-9 Tripping Spectra System Door Switch to DOWN Position.......................... 37

3-10 Positioning Camera on Horn against Star T ester ....................................... 38

3-1 1 Display for Flash, Autofocus, Audio and Exposure Adjust OFF .................. 42

3

Page 4

3-12 Display for Flash, Autofocus ON , Audio and Exposure Adjust OFF ........... 43

3-13 Display for Flash ON , All Other Functions OFF.......................................... 45

3-14 Display for Flash and Autofocus ON, All Other Functions OFF ................... 47

3-15 Display for Flash and Autofocus and Audio OFF........................................ 49

3-16 Removing Top Cover from Camera (See Section 2 for Details) ................. 51

3-17 Adjusting Ambient (Visible Light) Calibration Slide.................................... 52

3-18 Adjusting IR Strobe Exposure Calibration Slide ......................................... 53

3-19 Hybrid Adjustment (Opening Blade Spring T ension Adjustment)................. 55

3-20 Adjusting Solenoid 1 to Change Quintic Speed ......................................... 58

4-1 One Board Strobe/Exposure Module Connections on Ranging Board........ 60

4-2 Elastomeric “Zebra” Connector.................................................................. 60

4-3 Initial Test Procedure for Ranging Board and LCD Board .......................... 61

4-4 Wire Connections, T est Points: Strobe/Exposure Module

and Ranging Board ................................................................................... 73

4-5 One Board Spectra Pro/Image Pro/Minolta Pro System Schematic ........... 75

4-6 One Board Strobe/Exposure Module Schematic........................................ 76

4-7 Ranging Board Schematic ........................................................................ 77

4-8 Features Module and Display Module Schematic ...................................... 78

4

Page 5

Section 1 - General Description

Scope of This Addendum

This Service Manual addendum describes only those One Board Spectra Pro/Image

Pro/Minolta Pro mechanical parts, electronic circuits, operating modes and service

procedures that are different from those of the Spectra camera. Information common to

One Board Spectra Pro/Image Pro/Minolta Pro cameras and Spectra cameras is not

included in this addendum. Refer to Spectra Service Manual for this common

information.

To use this addendum effectively , you should also be familiar with the design, operation,

disassembly and calibration information presented in the Spectra Manual.

This addendum applies only to Spectra Pro/Image Pro/Minolta Pro cameras with the One

Board Strobe/Exposure Module Assembly (Part No. 1B0632A) installed. (These cameras

can be identified by the letter G as the tenth character in their serial numbers.) For

servicing Spectra Pro/Image Pro/Minolta Pro cameras without the One Board assembly ,

see Spectra Pro/Image Pro Camera Service Manual Addendum of January , 1990.

The name Spectra Pro as used in this addendum refers to the Spectra Pro, Image Pro

and Minolta Pro cameras unless otherwise noted.

Spectra Pro/Image Pro/Minolta Pro Operating Differences

The major differences between Spectra Pro/Image Pro/Minolta Pro cameras and

Spectra cameras relate to the operating modes available to the user, how they are

selected and how their status is displayed.

5

Page 6

The Spectra Pro/Image Pro/Minolta Pro has the following operating features:

• Automatic (sonar) focusing or manual focus distance setting

• Manual shutter opening and closing (bulb mode)

• Programmable time exposures (1-12- seconds)

• Automatic sequential exposures at programmable intervals

• Up to five exposures on a single frame

• Exposure compensation for severely backlit subjects

• Exposure lighten/darken adjustment

• Tilting accessory strobe

• Sound on or off (tone, chime and beep signals)

• Digital (LCD) display of exposures remaining, subject distance, time exposure

duration, interval between multiple time exposures and elapsed time in “bulb” mode

These operating modes are selected, programmed and displayed by the buttons and LCD

displays on the control panel (Figure 1-1).

Figure 1-1. Spectra Pro/Image Pro/Minolta Pro electronic control panel

6

Page 7

Pressing MODE repeatedly displays one feature symbol after another; up and down

arrows (_and_) turn the feature on or off and set digital displays; A resets the camera to

fully automatic operation. When a feature is ON (active), a horizontal bar appears below

the corresponding symbol on the LCD panel.

Note: For more information on these features, see Spectra Pro/Image Pro/Minolta Pro

Operating Instructions.

Spectra Pro/Image Pro/Minolta Pro Performance Differences

Several features to improve exposure accuracy and picture sharpness have been incorporated in the Spectra Pro/Image Pro/Minolta Pro design. These include the following:

• Improved lens

Spectra Pro/Image Pro/Minolta Pro cameras have color corrected, coated, f/10,

125mm triplet glass lenses.

• Intentional ambient overexposure to brighten scene

For light levels greater than 624 cd/ft2, a limited exposure kickup occurs to produce

a bright picture (truer whites, better facial exposure) without sacrificing detail.

• Double measurement of ambient brightness

Camera electronics remeasure the scene brightness when the second stage of the

shutter button is closed. This ensures that the latest data is used in the exposure

calculation, preventing errors caused by previewing one scene then shooting another

without releasing the S1 button.

• Intermediate fill flash mode

This additional strobe exposure program mode allows mixing a 50% flash contribution

with a 50% ambient contribution for light levels between 8 and 24 cd/ft2. This

brightens the backgrounds of low-light pictures and increases the shadow fill at

higher levels.

• Bias focus

When available depth of field permits, the Spectra Pro intentionally focuses one or

two zones behind the subject, improving overall scene sharpness.

7

Page 8

Spectra Pro/Image Pro/Minolta Pro External Physical Differences

Figure 1-2 illustrates the physical external differences between Spectra Pro/Image

Pro/Minolta Pro cameras and Spectra cameras:

• New top cover insert

• New S1/S10 button inlay

• New front decorative plate (with Spectra Pro/Image Pro/Minolta Pro name)

• New hand strap

T op Cover Insert

Front Decorative Plate

S1/S10

Button

Hand Strap

Figure 1-2. Spectra Pro/Image Pro/Minolta Pro external physical differences

8

Page 9

Sectiion 2 - Disassembly and Reassembly

Note: This section presents only the One Board Spectra Pro/Image Pro/Minolta Pro

camera disassembly and reassembly procedures that are different from those of

the Spectra camera. See Spectra Service Manual for all disassembly and

reassembly procedures not covered here.

Special Tools

Special T ools for Disassembly

• Hinge Pin Removal/Insertion Tool

P/N 13384 (for grasping Mid-Cover Hings Pins; See Figure 2-1)

• Square Socket T ool Bit with Handle

P/N 1 1913 (for removing screws holding LCD Board to Ranging Board;

see Figure 209)

Warning: Do not use the torque-limiting screwdriver to remove these screws.

Special T ools for Reassembly

• Torque-Limiting Screwdriver

P/N CR13397, with special Square Bit, P/N CR 13398 (for installing screws holding

LCD Board to Ranging Board; See Figure 2-9)

• Solder AideTool (green/black stick) P/N 942268

• Long needle-nose pliers with coated jaws

P/N 13186 (for reassembly of wire connectors use them to position the wire

connector with the pin connector, then use the Solder Aide Tool to press into position)

Warning: Do not use these pliers for disassembly.

9

Page 10

Cautions and Reminders

Use proper grounding to protect delicate CMOS circuitry from static discharge damage.

Avoid shock from the photoflash capacitor by discharging it with Dump Probe P/N

131 19 immediately after removing the Top Cover.

Handle flexes (Features Flex, Motor Gear Drive Flex) carefully to avoid crimping or

crarcking from sharp bends.

Remove wire connectors with fingers only . Do not use pliers or other tools. Carefully

grasp the wires near the connector betwen thumb and index finger and pull gently while

rocking the connector from side to side (Figure 2-1).

Figure 2-1. Proper removal of a typical wire connector

10

Page 11

Removing Mid-Cover

1. Remove the top cover as directed in Spectra Service Manual

2. With the special Hinge Pin Insertion/Removal Tool P/N 13384 (Figure 2-2), grasp the

hinge pins at the reduced diameter section and pull them toward the center line of the

camera to remove them.

3. Close the camera (if erected) and open the front door. Insert a soldering aide (green

stick) betwen the mid-cover and the side of the main frame, twisiting the greenstick

while holding the side of the mod-cover out. Then insert the greenstick on the

opposite side and pry outward.

4. Close the font door and lay the camera flat. Bend the sides out slightly, pivoting the

locating cutouts on the bottom cover. Then lift off the mod-cover.

Hinge Pin Removal/Insertion Tool (P/N 13384

Figure 2-2. Removing hinge pins and mid cover

Pull

Grasp

11

Page 12

Disassembling Mid-Cover

1. To remove the eye cup, use a greenstick to spring out the tabs on the eye wedge

retainer (Figure 2-3). Remove the clear plastic eye wedge. The eye cup can now be

removed from the eye wedge retainer.

2. To remove the five control panel buttons, insert the point of a greenstick in the center

of the button, and push the button out.

Note: When replacing buttons, be sure the markings are oriented correctly .

If they are not, the button cannot be inserted in the panel.

Eyecup

Control Panel Button

Tab

Eye Wedge

Tab

Greenstick

Figure 2-3. Removing eye cup and buttons from mid-cover

12

Page 13

3. T o remove the LCD window (Figure 2-4), press it carefully from the outside, bowing

the window slightly to free the tab at the end. Lift it out of the mod-cover.

Note: When replacing the LCD window, insert the end nearest the viewfinder first.

Then bow the window slightly as shown and snap the other end into place.

4. To replace the font decorative plate, pry up the end with an Exacto knife and peel it

off. Make sure the knife does not slip and scratch the cover.

Figure 2-4. Removing LCD window from mid-cover

Tab

LCD Window

13

Page 14

Removing Ranging Board

Note: Be sure to note the position of all wires and wire connectors before you remove

any parts, then return them to their original positions upon reassembly .

1. Remove the top, mid and bottom covers.

2. Disengage the S10/S1 assembly from the spring tab.

3. Disconnect the follwing wire connectors from the One Board Strobe/Exposure

Module Assembly; J7, J6, J4, J5. (See page 4-15 for locations.)

4. Lift the ranging board slightly to free it from the tabs at the bottom-rear of the main

frame and to gain access to connectors J9, J10 and J11 on the ranging board

(Figure 2-5).

J1

J2

One Board

Strobe/Exposure

Module

J3

Figure 2-5. Ranging board and connectors for J1, J2 and J3

Ranging

Board

J9

J10

J11

14

Page 15

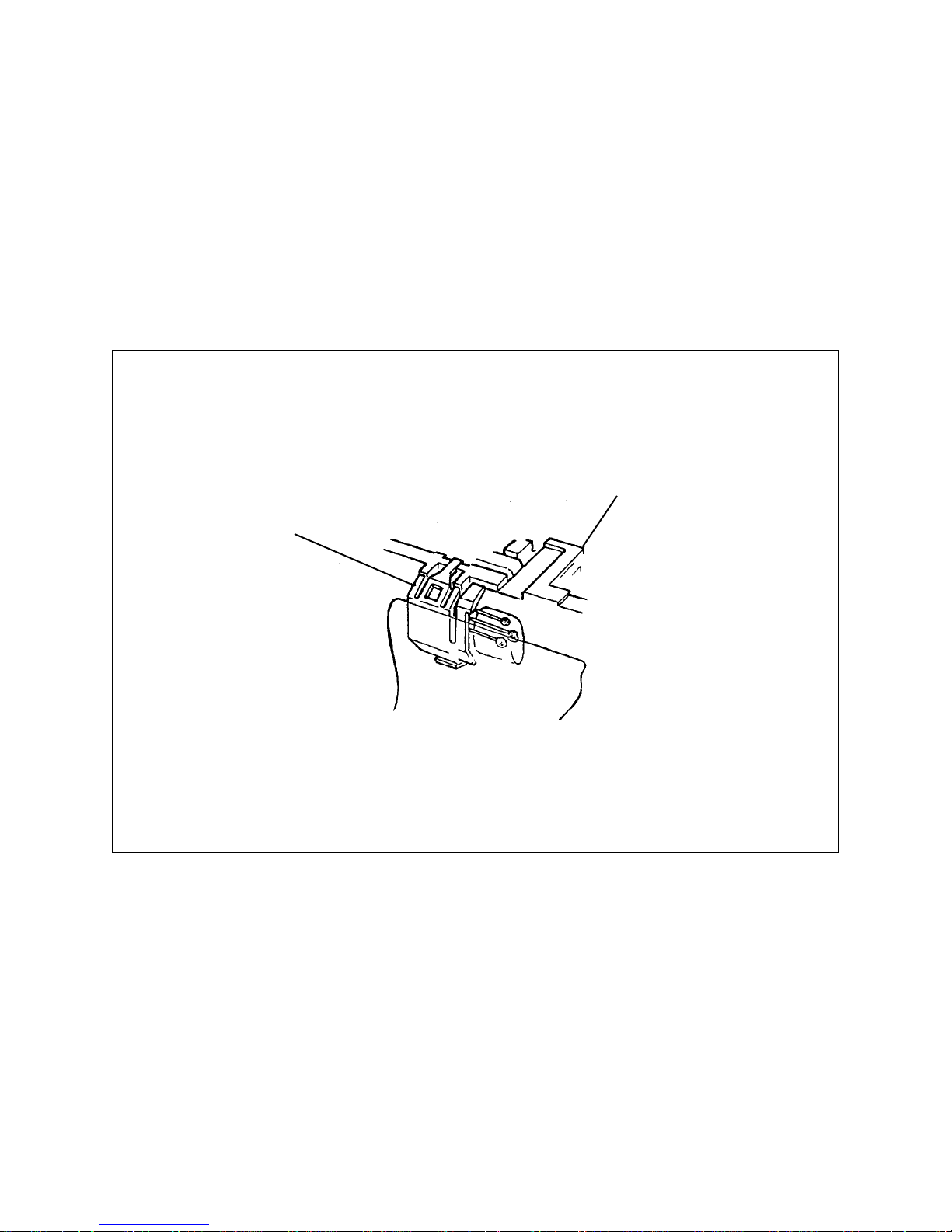

5. Release connectors J1, J2 and J3 from the ranging board by grasping the wires

between your thumb and index finger and rocking the connector from side to side

(Figure 2-6).

Figure 2-6. Releasing connectors from ranging board

6. Release the white wire (J5) and the brown wire (J4) from the MiniSert self-locking

terminals on the ranging board (Figure 2-7).

7. Release the paired black/red transducer wires from connectors J1 and J20 on the

ranging board (Figure 2-7). Straighten out the bare ends of the wires bent back over

terminals J19 and J20. Then either: (a) pull the wires out of the terminals, or (b)

unsolder them and pull them out.

15

Page 16

8. Remove the ranging board (with the LCD board attached).

White Wire

to J5

Brown Wire

to J4

Ranging

Board

Black/Red Wire

to J20

Black Wire

to J19

Figure 2-7. Releasing ranging board wire connections

16

Page 17

Replacing Ranging Board

1. Reconnect the following wires to the ranging board (Figure 2-7) on previous page):

• White wire to self-locking terminal J5

• Brown wire to self-locking terminal J4

• Black trnsducer lead to terminal J19 (GND)

• Black/red lead to terminal J20

2. With needle-nose pliers, alighn the wire connector J1 (from the One Board

Strobe/Exposure Module Assembly) with the mating pin connector on the ranging

board (Figure 2-8), then press the wire connector into position with solder aide

tool 941168.

3. Using the same technique described in step 2, reconnect wire connectors J2 and J3

(from the One Board Strobe/Exposure Module Assembly) with their mating pin

connectors on the ranging board.

4. Place the ranging board in its normal position, with the projecting tabs on the main

frame in the notches at the bottom of the ranging board.

Solder Aide

Tool

Needle-Nose

Pliers

Figure 2-8. Reconnecting J1, J2 and J3 to ranging board

17

Page 18

Removing LCD Board from Ranging Board

1. Hold the camera vertically, with the front down.

2. Using Square Socket T ool Bit with Handle, P/N 11913, carefully remove the two

machine screws (A in Figure 2-9) securing the LCD board to the ranging board.

Hold the bracket (D in Figure 2-9) temporarily in place with your finger .

Warning: Do not use Torque Limiting Screwdriver, P/N CR 13397, to

remove the screws.

3. Carefully lift off the LCD board. Be careful not to lose the following parts, which are

released when the LCD board is removed:

• Clear plastic spacer block (C in Figure 2-9)

• Gold-colored elastomeric zebra connector (B in Figure 2-9)

• Metal retainer (D in Figure 2-9)

Ranging Board

D

C

B

A

Warning: Remove only with Square

Socket Toll Bitwith Handle (P/N 11913).

Do not use Torque Limiting Screwdriver.

LCD Board

Figure 2-9. Removing LCD board

18

Page 19

Reconnecting LCD Board to Ranging Board

1. Using your finger, hold the metal retainer ( D in Figure 2-10) in place behind the

ranging board.

2. Place the zebra connector (B in Figure 2-10) in the slot in the plastic spacer block

(C), concave side down.

3. Align the holes in spacer block (C) with the holes in the ranging board. Orient the

block as show, with the end notches facing down and the projecting shoulder in the

position shown.

4. Using Torque Limiting Screwdriver, P/N CR 13397, (factory-set for 8 oz-in.) with

Square Bit, P/N CR 13398, install the two mounting screws. Alternatively tighten

each one a small amount until you reach the se torque (screwdriver clutch slips).

D

Ranging Board

To display distance in metric units,

cut jumper w1.

C

B

Concave

Side

A

Warning: Install only with

Torque Limiting screwdriver

(P/N CR 13397) and Square Bit

(P/N CR 13398.

LCD Board

Figure 2-10. Replacing LCD board

19

Page 20

Removing One Board Strobe/Exposure Module Assembly

1. Remove the top cover, mid cover and bottom covers.

2. Disengage the S10/S1 assembly from the spring tab.

3. Push the S10/S1 assembly tab (Figure 2-11) to free it from the One Board

Strobe/ExposureModule Assembly .

Push Tab

to Free

S1/S10

Assembly

J4

J5

J6

J7

Red Wire

t0 J14

J26

Green Wire

to J17

White Wire

to Trigger

Coil (soldered)

Figure 2-11. Disconnecting one board strobe exposure module

J9, J10, J11

(Lift One

Board/Strobe

Exposure

Module

to access)

Ranging

Board

Black Wire

to J15

Orange Wiew

to J16

20

Page 21

4. Disconnect the following wires from the One Board Strobe/Exposure Module

Assembly (Figure 2-11):

• Black wire from J26

• Red wire from J14

• Black wire from J15

• Orange wire from J16

• Green wire from J17

5. Unsolder the white wire from the trigger coil (Figure 2-11)

6. Disconnect wire connectors J7, J6, J4, and J5 from the One Board Strobe/Exposure

Module Assembly .

7. Lift the One Board Strobe/Exposure Module Assembly to access wiring connectors

J9, J10, and J11 on the ranging board.

8. Release each of the three connectors (J1, J2, J3) from the ranging board

(Figure 2-11) by grasping each connector between your thumb and index finger

and lifting one side of the connector at a time.

9. Release wire connector J8 (from the Wire/Motor Gear Drive Flex Assembly) from the

One Board Strobe/Exposure Module Assembly (Figure 2-12).

J8

Motor/Gear Drive

Flex assembly

Figure 2-12. Removing J8 from one board strobe/exposure module

21

Page 22

10.Use tweezes to remove the photodiode ratainer from the shutter base block

(Figure 2-13).

1 1.Lift out the One Board Strobe/Exposure Module Assembly.

Note: To install a One Board Strobe/Exposure Module Assembly, reverse this

procedure.

Shutter Baseblock

Photodiode Retainer

Figure 2-13. Removing photodiode retainer

22

Page 23

Section 3 - Testing and Adjustments

Spectra Pro/Image Pro/Minolta Pro System Functional T est

Purpose

The purpose of the functional test is to determine if the camera is operating properly

during various phases of simulated operation. In this test the camera is cycled through

dark slide, strobe exposures, non-strobe exposures, and end-of-pack. The intent is to

isolate problems for troubleshooting. If the camera does not operate as described

below , consult the troubleshooting chart most closely allied with the problem.

Equipment Required

• Film Pack Simulator #12467

• Film Pack Simulator Adapter #13130

• Power Supply - Power Mate #12531 or Lambda #12429

23

Page 24

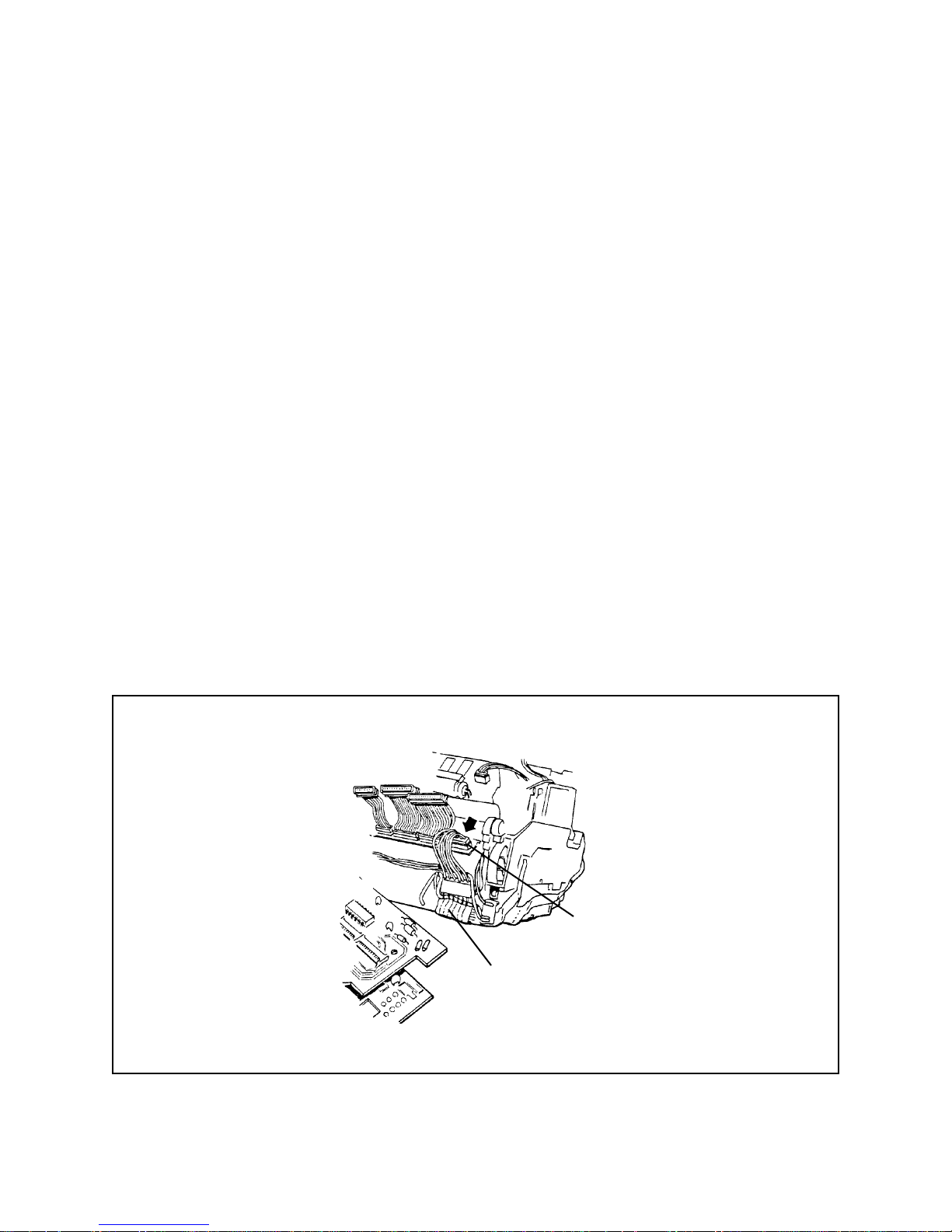

Test Setup

1. Insert the Film Pack Simulator Adapter #13130 onto the Film Pack Simulator #12467

(Figure 3-1).

2. Plug the Film Pack Simulator with adapter into the power supply (either Power Mate

#12531 or Lambda #12429).

3. Plug the power supply into a 110 VAC power source.

4. Turn the power supply ON.

5. Adjust the power supply output voltage to 6 VDC.

Figure 3-1. Setup for spectra pro/image pro/minolta pro functional test

Film Pack Simulator

#12467

Film Pack Simulator

Adapter #13130

24

Page 25

Test Procedure

1. Erect the camera and open the film door.

2. Install the film pack simulator with the adapter into the camera. The camera should

not cycle.

3. Remove the film pack simulator from the camera.

4. Using the tip of a solder aide, close the camera door latch (Figure 3-2).

Push in with soldering

aide (greenstick) to

close door latch.

Figure 3-2. Closing door latch

25

Page 26

5. Install the film pack simulator into the camera again. The camera should go through a

dark slide cycle with the following events happening:

• The strobe should not fire.

• The camera shutter blades should remain closed.

• The strobe charging light (red) should come on and then go off.

• The strobe ready light (green) should come on. (The green ready light will stay on

for approximately 30 seconds and will then extinguish if the camera is not used.)

• The LCD control panel should appear as shown in Figure 3-3.

Figure 3-3. LCD control panel at completion of dark slide

6. Aim the camera at an object less than one foot (.1 meter) away and press the

S1/S10 button halfway down (preview mode). The following should happen:

• A warning tone (beep! beep!) will sound.

• A flashing yellow triangle within a yellow square will be visible in the viewfinder.

• A red figure “1” will be visible in the viewfinder (USA cameras)

-OR- a red ”.1” will be visible in the viewfinder (non-USA cameras).

• The LCD panel will display “1.0 FT (USA cameras) -OR- will display “.1M”

(non-USA cameras).

26

Page 27

7. Aim the camera at an object exactly four feet (1.2 meters) away and press the

S1/S10 button down half way . The following should happen:

• A green circle within a green square will be visible in the viewfinder.

• A red figure “4” will be visible in the viewfinder (USA cameras) -OR-

a red figure “1.2” will be visible in the viewfinder (non-USA cameras).

• The LCD panel will display “4.0 FT” (USA cameras) -OR- the LCD panel will

display “1.2M” (non USA cameras).

8. Cover the transducer using the fingers or palm of your left hand (Figure 3-4) or you

can cover the transducer with photographic tape. Use care to prevent covering the

photocell. Press the S1/S1 button half way down. (This simulates an infinity

exposure.) The following should happen:

• No red figure should be visible in the viewfinder .

• The LCD panel will display “0 0 FT” (USA cameras) - OR- the LCD panel will

display ”0 0 M” (non USA cameras).

• Depending on the ambient light available, a flashing yellow triangle within a yellow

square (with warning beeps) or a green circle within a green square will be visible

in the viewfinder. The warning yellow triangle will appear in low light level

situations, while the green circle will appear if there is adequate light for a good

exposure.

27

Page 28

Cover transducer

with

hand or tape.

Do not

cover photocell

Figure 3-4. Covering transducer to simulate infinity exposure

9. Now, aim the camera at an object within the range of 2 feet (.6 meter) to 15 feet (4.5

meters) and press the S1/S10 button all the way. The following should happen:

• The strobe should fire.

• Y ou should hear the camera go through an exposure cycle. (The blades should

open and close, the Quintic lens should move, and the motor should run.)

• The LCD panel should change from 10 to 9 in the Frames Remaining area.

• The red strobe charging light should come on and then go off.

• The green strobe ready light should come on.

10.Repeat the previous step six more times and observe that the camera operates as

indicated above.

28

Page 29

11. Use the Mode button and either of the UP/DOWN buttons on the control panel to turn

the strobe switch off. (The bar under the strobe symbol disappears.) Turn the front

of the camera toward you. Cover the photocell with black photographic tape. Insert

a soldering aide between the flapper door and the bottom of the shutter (Figure 3-5).

12.With the camera aimed toward you, press the S1/S10 button all the way.

The following should happen:

• The warning beeps should sound.

• There should be no strobe fire.

• The moving Quintic frame should swing down below the level of the shutter during

the exposure and should be visible through the open flapper door as seen in

Figure 3-5. (This is the short distance Quintic position.)

• The shutter blades should open and stay open for the maximum time-out period

of 2.8 seconds.

• The camera motor should run.

• The Frames Remaining number on the LCD control panel should change from “3”

to “2”.

Strobe switch

in OFF position

Quintic lens moves

all the way down

Insert soldering aide in

far left side to hold

flapper door open

Figure 3-5. Quintic lens moves to short-distance setting

29

Page 30

13.Turn the autofocus feature off and set the distance to infinity as follows:

• Press the MODE button until only the autofocus symbol (AF) is visible in the LCD

display .

• Press the up or down arrow button to remove the bar from beneath the autofocus

symbol. The display will show either “5.0FT” or “1.6M”.

• Press the MODE button. The “5.0FT” or “1.6M” will begin to flash.

• Repeatedly press the down arrow button until the infinity symbol replaces either

“5.0FT” or “1.6M”.

• Press the MODE button to return to a full display .

If the flash or audio features need to be turned off, press the MODE button until

the symbol for the desired feature is displayed. Then press the up or down arrow

button to remove the bar from beneath the symbol. (No bar beneath the symbol

indicates thatthe feature is off.)

Note: The display automatically turns off after 30 seconds to conserve power.

To turn it on again, press the MODE button or the shutter button.

14.With the camera aimed toward you, press the S1/S10 button all the way. (The

photocell should remain covered with the black photographic tape and the soldering

aide should still be inserted into the flapper door area.) The following should happen:

• The warning beeps should sound.

• There should be no strobe fire.

• The moving Quintic lens frame should swing down below the level of the shutter

and should be visible through the open flapper door (Figure 3-6). This is the

infinity Quintic position.

• The shutter blades should open and stay open for the maximum time-out of 2.8

seconds.

• The camera motor should run.

• The Frames Remaining number should change from “2” to “1” on the LCD control

panel.

30

Page 31

15.Remove the soldering aide from the flapper door and remove the black photographic

tape from the photocell. Press the green A button on the control panel to return the

camera to its original settings.

AF switch in OFF setting

Quintic lens moves

down part way

Figure 3-6. Quintic lens moves to infinity setting

16.Press the self-timer button. The following should happen:

• The warning tones (beep! beep! should sound. The tones should get

progressively faster until two seconds before the exposure when the tone

becomes steady.

• At the front of the shutter, the red led next to the photocells should flash. The

flashing will get progressively faster until two seconds before the exposure when

the led stays on.

• At the end of 12 seconds, the strobe will fire and the camera will cycle.

• The Frames Remaining number on the LCD control panel will change from “1”

to “0”.

• The end of pack chimes will ring three time.

31

Page 32

17.Press the S1/S10 button all the way down. The following should happen:

• The end of pack chimes will sound three times.

• The strobe will fire.

• Release the S1/S10 button.

• The camera will cycle.

• The end of pack chimes will sound three times.

18.Look into the viewfinder and press the S1/S10 button half way down. The following

should happen:

• A flashing “0” will be visible in the viewfinder.

• The end of pack chimes will ring three times.

Note: If the S1/S10 switch is pressed all the way down with an empty film pack, the

strobe will fire. After the switch is released the camera will cycle. This is

normal.

This completes the functional test of the Spectra pro/Image Pro/Minolta Pro

camera. If the camera does not function as described, go the failure mode

section and refer to the chart which most closely corresponds to the malfunction.

32

Page 33

Star Tester Model 12650-3 Description

This Star Tester is an upgrade of the Model 12650-2 (for 600 Series and other

cameras). The 12650-3 permits testing Spectra System Cameras for seven different

exposure-and timing-related operating characteristics, as well as 600-Series and other

cameras.

Except for a new Horn (P/N 13146) for holding Spectra System Cameras and a few

name changes of Selector Switch positions, the 12650-3 Tester is outwardly identical to

the earlier Model 12650-2 Star Tester.

Model 12650-3 Controls and Indicators

Listed below are the Star Tester 12650 - 3 controls and indicators shown in Figure 3-7.

The integrating light sphere and electronics required to compute and display exposure,

timing and functional characteristics of the camera under test are all housed within the

Tester cabinet.

Figure 3-7

KEY CONTROL/INDICA T OR FUNCTION

1 Disc Position Lamps* Not used

2 Reset Button Clears electronics between tests

3 Disc/Ride Time Switch* Selects T est mode (7000 ZLS,

Flash Exposure, Ambient & Blade

Speed for Spectra camera.)

5 Horn Volts Selector Switch Selects 5V (low), 6V (nom) or

6.8V (high). Simulates film pack

battery voltage.

6 20V/2000V Selector With Volt Probe Jack and DC

Voltmeter , allows use of T ester as

voltmeter .

7 V olt Probe Jack For checking DC voltages in

camera under test, with standard

probe.

8 Timing Meter Digital readout of strobe recycle

time or blade speed.

9 DC V oltmeter Digital readout of circuit voltages;

also use with probe in Volt ProbeJack.

* Not used for testing Spectra cameras

33

Page 34

Figure 3-7

KEY CONTROL/INDICAT OR FUNCTION

10 Stops Error Meter Digital readout for Ambient,

Hybrid, Strobe Expos. T ests.

11 DC Current Meter Digital readout of energy req’d

to charge Strobe capacitor.

12 ZLS Meter Digital readout of strobe light

output in Zonal Lumen seconds.

13 Power Switch AC line voltage On/Off to T ester,

Lights when T ester is powered.

14 Pack Simulator Jack Connection for film pack

simulation voltage. Lets tester

function as a power supply.

15 Strobe Adaptors (two)* Aligns electronic flash of 600/680

camera under test to Star

T ester .

16 Horn Cable Connector Accepts plug on Horn cable.

17 Disc Detector Connector* Accepts cable from 600 Disc

Detect/Ride Time Fixture.

18 J4 Connector* For future applications.

19 T est Point Connectors For connections to oscilloscope.

Also used for calibrating T ester.

* Not used for testing Spectra cameras

Caution: When the tester is not in constant use, turn the

selector switch to 7000 ZLS. This reduces light

source wear and keeps the tester in a neutral state,

ready for immediate resumption of testing.

34

Page 35

Figure 3-7. Star tester 12650-3 controls and indicators (see text for descriptions)

35

Page 36

Star Tester Setup and Pre-Test Checks

Star Tester Setup

1. Install Tester on level surface with clear area around Tester to allow sufficient air flow

for cooling.

2. Locate the Tester on a bench or table so that when the Spectra on its Horn is placed

on the top of the Tester, the Spectra lens will be exactly 4.5 feet (135 cm) from a

graywall target. Also, be sure that the front of the camera is parallel to the graywall

(or the long axis of the camera, front to back, is at right angles to the graywall

Figure 3-8).

3. Be sure that the area between camera and graywall, for a width of approximately 4

feet (or what can be seen in the Spectra viewfinder), is clear of any objects. This will

prevent erroneous readings caused by reflections from the sonar side lobes of the

Spectra camera.

Figure 3-8. Locating star tester in relation to graywall target

36

Page 37

Pre-Test Checks

1. Connect the Tester to 115 VAC, 50/60 Hz line.

2. Mount the camera on the Spectra Horn (P/N 13146) and connect the cable from Horn

to the receptacle marked “Horn” (key #16 in Figure 3-7) on the right side of theTester.

3. Turn the Tester Power Switch ON (switch will illuminate if the Tester is receiving

power). Let the Tester warm up a minimum of 10 minutes before performing tests.

4. Open the Front Door of the Spectra camera and with a greenstick (solder aid tool),

trip the Door Switch into DOWN position (Figure 3-9).

5. Position the Horn with the camera mounted on it against the front of the Tester, with

the guide tab on the right side of the Horn against right edge of window mounting

plate (Figure 3-10).

6. Fully depress the camera Shutter Button five times. Read the Stops Error Meter and

check the Spectra Specification for agreement.

7. AT LEAST WEEKLY: Using a Standard Spectra camera as a reference, perform the

Ambient Exposure Test to check that the Star Tester is operating properly.

Figure 3-9. Tripping spectra system door switch to DOWN position

37

Page 38

Guide T ab

Figure 3-10. Positioning camera on horn against star tester

38

Page 39

Order of Spectra Pro/Image Pro/Minolta Pro System T ests

Tests on Spectra Pro/Image Pro cameras should be performed as described below.

Mandatory Tests

Perform the following tests in the order shown on all cameras:

1. Ambient Exposure at 100 C/FS.

2. Strobe Exposure (Graywall).

Strobe Exposure Test Reading Cannot be Corrected

via IR Exposure Calibration Slide

If the Strobe Exposure (Graywall) test reading is out of specification and cannot be

corrected by adjusting the IR Exposure Calibration Slide, follow the steps below:

1. Perform the ZLS Graywall Test.

• If the ZLS Graywall Test result is not within spec, replace the Strobe Board or the

Flashtube Assembly as required.

• If the ZLS Graywall Test is now within spec but the Strobe Exposure (Graywall)

reading remains out-of-spec, go to step 2.

2. Perform the Hybrid (ZLS/Blade Speed) Test.

• If the Hybrid Test reading is within spec but the Strobe Exposure test reading

remains out of spec, replace the exposure flex and retest.

• If the Hybrid Test reading is out-of-spec, perform the Hybrid Adjustment

(Opening Blade Spring). If this adjustment brings the reading within

specification, discontinue testing. If the adjustment fails to bring the reading

within specification, go to step 3.

39

Page 40

3. Perform the Blade Speed Test.

• If the Blade Speed is within spec but the Strobe Exposure Test reading remains

out of spec, replace the exposure flex and retest.

• If the Blade Speed Test reading is not within spec, perform the Blade Speed

Adjustment. If the Blade Speed Adjustment does not correct Blade Speed,

repair the Shutter Assembly and retest.

Excessive Battery Drain

If battery drain is excessive, perform the Strobe Integrated Current Test. If this reading

is out of spec, replace the strobe board.

Long Strobe Recharge Time

If the Strobe takes too long to recharge, perform the Strobe Charge Time Test. If the

reading is out of spec, replace the strobe board.

40

Page 41

Ambient Exposure T est

Purpose

This Test measures the energy on the film plane during an ambient (visible) light

exposure. The Star Tester light integrating sphere provides a constant scene

brightness level of 100 candles/ft2.

Test Setup

1. Trip the Door Switch on the camera into the down position.

2. Place the camera on the Horn against the Tester window.

3. Use the following steps to turn OFF the Autofocus, Flash, Audio and Exposure

Adjustment functions:

• Press the MODE button until only the auto focus symbol (AF) is visible in the LCD

display. Then press the up or down arrow button to remove the bar from beneath

theautofocus symbol. (no bar indicates that the feature is off.) Press the MODE

button twice to return to a full display.

• Press the MODE button until the symbol for flash is displayed. Then press the up

or down arrow button to remove the bar from beneath the symbol. Press the

MODE button once to return to a full display.

• Press the MODE button until the symbol for audio is displayed. Then press the up

or down arrow button to remove the bar from beneath the symbol. Press the

MODE button once to return to a full display.

• Press the MODE button until the symbol for the Exposure Adjustment function is

displayed. Then press the up or down arrow button to remove the bar from

beneath the symbol. Press the MODE button once to return to a full display

(Figure 3-11).

41

Page 42

Figure 3-11. Display for flash, autofocus, audio and exposure adjust OFF

Note: The display automatically turns off after 30 seconds to conserve power.

To turn it on again, press the MODE button or the shutter button.

4. Leave the Photocell on the camera uncovered.

5. Set the Test Selector Switch to AMBIENT.

Test Procedure

1. Press the Shutter Button fully and record the Stops Error Meter reading. Compare

the reading to the Specification.

2. Repeat the process two more times, recording all readings.

3. If the readings are within spec, proceed to the Strobe Exposure (Graywall) Test.

4. If the test readings are not within Spec, adjust the Ambient Exposure Calibration Slide

and retest. If reading is now within spec, proceed to Strobe Exposure (Graywall)

Test below.

5. If adjustment fails to bring the reading within spec, verify the following:

• The green ambient filter is in the proper position.

• The photocell cap is in position.

• The photocell is seated in the base block.

6. If the above steps do not bring the Ambient Exposure reading within spec, replace the

Exposure Flex and/or the Shutter Assembly and retest.

42

Page 43

Strobe Exposure (Graywall) T est

Purpose

This Test measures the resultant energy on the film plane during a 4.5 - foot (135 cm)

graywall exposure.

Test Setup

1. Trip the Door Switch on the camera into the down position.

2. Place the camera on the Horn on top of the Tester, with the lens 4.5” from the

graywall. The front of the camera must be parallel to the graywall, and the area

visible in the viewfinder must be clear of objects.

3. Make sure the Flash and Autofocus features are ON (bar displayed below each

symbol), and Audio and Exposure Adjustment are OFF (no bar). The display should

be as shown in Figure 3-12.

To turn a function ON or OFF, press MODE button until only the desired symbol is

displayed. Then press up or down arrow buttons to insert bar (turn ON) or delete bar

(turn OFF the function). To return to the full display, press MODE.

Note: The display automatically turns off after 30 seconds. To bring it back, press

either the MODE or Shutter button.

Figure 3-12. Display for flash and autofocus ON, audio and exposure adjust OFF

4. Leave the Photocell on the camera uncovered.

5. Set the Test Selector Switch to FLASH EXPOSURE.

43

Page 44

T

est Procedure

1. Press Shutter Button fully and note reading on the Stops Error Meter.

2. Repeat the procedure two more times, noting the Stops Error Meter readings.

Compare the readings to the Specification

3. If the test readings are not within Spec, adjust IR Strobe Exposure Calibration Slide

and retest.

4. If adjusting the IR Calibration Slide fails to bring the Strobe Exposure Test reading

within spec verify the following:

• The IR black filter is seated

• The photocell is seated in the base block

• The photocell cap is seated properly.

• If the above steps do not bring the Strobe Exposure (Graywall) reading within

spec, proceed to the LS Graywall Test.

44

Page 45

ZLS (Zonal Lumen Seconds) Graywall T est

Purpose

This Test measures the maximum strobe output. This is done by measuring the energy

on the film plane during a 4.5 foot (135 cm) graywall exposure with the shutter blades

fully open.

Test Setup

1. Trip the Door Switch on the camera into the down position.

2. Place the camera on the Horn on top of the Tester, with the lens 4.5” from the

graywall. The front of the camera must be parallel to the graywall, and the area

visible in the viewfinder must be clear of objects.

3. Flash should be ON (bar below symbol), and all other functions should be OFF (no

bar) as shown in Figure 3-13.

Figure 3-13. Display for flash ON, all other functions OFF

If necessary, turn the appropriate features on or off as follows:

• To turn flash ON: Press the MODE button until the symbol for flash is displayed.

Then press the up or down arrow button to display a bar under the symbol.

Press MODE once to return to full display.

• T o turn autofocus OFF: Press MODE until only the autofocus symbol is visible in

theLCD display. Then press the up or down arrow to remove the bar from

beneath the autofocus symbol. (No bar indicates that the feature is off.)

Press MODE twice to return to a full display.

• To turn audio OFF: Press the MODE button until the symbol for audio is

displayed. Then press the up or down arrow button to remove the bar from

beneath the symbol. Press the MODE button once to return to a full display.

45

Page 46

• To turn exposure adjustment OFF: Press the MODE button until the symbol for

theExposure Adjustment function is displayed. Then press the up or down arrow

button to remove the bar from beneath the symbol. Press the MODE button once

to return to a full display.

4. Cover the Photocell.

5. Set the Test Selector Switch to 7000 ZLS.

Test Procedure

1. Press the Shutter Button fully and note the reading on the ZLS Meter. Compare the

reading to the Specification.

2. If the ZLS Test reading is out of Specification, replace either the Flashtube Assembly

or the Strobe Board and retest.

3. If the ZLS Test reading is within specification but the Strobe Exposure (Graywall)

reading is still out of spec, perform the hybrid Test below.

46

Page 47

Hybrid (ZLS/Blade Speed) T est

Purpose

This Test measures the resultant energy on the film plane from full strobe output through

partially open blades, to determine whether the blades open at the proper speed and the

strobe fires at the proper time. If the results of this test are satisfactory, it means that

maximum strobe output, blade speed and ranging are all functioning properly .

Test Setup

1. Trip the Door Switch on the camera into the down position.

2. Place the camera on the Horn on top of the Tester, with the lens 4.5 ft. from the

graywall. The front of the camera must be parallel to the graywall and the area

visible in the viewfinder must be clear of objects.

3. Turn ON the Flash and Autofocus (bar under each symbol), and turn OFF the Audio

(no bar) so the display is as shown in Figure 3-14.

If necessary, turn the features on or off as follows:

• Press MODE until only the desired symbol is visible in the display . Then press

the up or down arrow to turn the feature on or off. (A bar under the symbol

indicates ON.)

• Press MODE to return to a full display.

4. Cover the Photocell.

5. Set the Test Selector Switch to 7000 ZLS.

Figure 3-14. Display for flash and autofocus ON, all other features OFF

47

Page 48

Test Procedure

1. Press the Shutter Button fully and note the reading on the ZLS Meter.

2. Repeat the procedure two more times, noting each Meter reading. Compare the

readings to the Specification.

3. If the test readings are not within Spec, perform the Hybrid Adjustment procedure

and retest.

4. If this adjustment does not bring the Hybrid T est reading within specification, proceed

to the Blade Speed Test below.

5. If the Hybrid Test reading is within spec but the Strobe Exposure Test reading is still

out of spec, replace the Exposure Flex and retest.

48

Page 49

Blade Speed Test

Purpose

This Test measures the time between first light detection and 95% blade opening.

Test Setup

1. Trip the Door Switch on the camera into the down position

2. Place the camera on the Horn against the Tester window.

3. Turn OFF the Flash, Autofocus and Audio functions. The display should be as shown

in Figure 3-15.

If necessary, turn the features on or off as follows:

• Press MODE until only the desired symbol is visible in the display . Then press

the up or down arrow to turn the feature on or off. (A bar under the symbol

indicates ON.)

• Press MODE to return to a full display . (If you are turning Autofocus OFF, you

must press the MODE button twice to return to a full display.)

4. Cover the Photocell.

5. Set the Test Selector Switch to BLADE SPEED.

Figure 3-15. Display for flash, autofocus and audio OFF

49

Page 50

Test Procedure

1. Push the Reset button on the Tester, then depress the Shutter Button. Disregard the

meter reading (this sets up Tester circuitry).

2. Press the Shutter Button again and watch the Timing Meter carefully. Note the

reading that remains constant for two seconds. Compare this reading to the

Specification.

3. If the reading is not within spec, adjust the blade speed (page 3-30) and retest the

camera.

4. If the adjustment did not bring the Blade Speed within specification, repair or replace

the Shutter Assembly and retest.

5. If Blade Speed is now within specification but Strobe Exposure is still out of spec,

replace the Exposure Flex and retest.

Spectra Pro/Image Pro/Minolta Pro Star Tester Specifications

Covered Ambient: -.1- to +.30 stops

(Install T est Cover on

camera for test purposes)

Covered Strobe Exposure -.30 to +.2- stops

(Graywall):

The following additional tests are required only if the Strobe Exposure (Graywall) cannot

be corrected by adjusting the IR exposure calibration slide. See page 3-14 of the

Spectra Camera Service Manual.

ZLS Graywall: 230 ZLS to 350 ZLS

Hybrid: (60 ZLS to 110 ZLS)

Blade Speed: 20 to 24 ms

50

Page 51

Ambient Exposure Calibration Slide Adjustment

1. Remove the Top Cover from the camera (Figure 3-16).

Warning: HIGH VOLTAGE EXPOSURE! Up to 320V is

present on top flash tube terminal (green wire)

and at various other locations on the strobe board.

Figure 3-16. Removing top cover from camera (see Section 2 for details)

2. If the Ambient Exposure Test readings are too low, use a dental pick and slide the

Ambient Calibration Slide (Figure 3-17) to the right in proportion to the amount the

reading is too low. The Ambient Calibration Slide is the one next to the Shutter Base

Block (rear most Slide, when Base Block is viewed from the rear of the camera).

3. If the Ambient Exposure Test readings are too high, slide the Ambient Calibration

slide to the left, in proportion of the amount the reading is too high.

4. Put the Test Top Cover in place and retest the camera. Readjust the Ambient

Calibration Slide if necessary .

51

Page 52

5. When the Ambient Exposure Test reading is within specification, replace the Test Top

Cover with the camera’s own Top Cover.

Note: If adjusting the Ambient Calibration Slide fails to bring the readings within

specification, refer to Steps 4, 5 and 6 of the Ambient Exposure Test

procedure.

Ambient

Calibration Slide

Figure 3-17. Adjusting ambient (visible light) calibration slide

52

Page 53

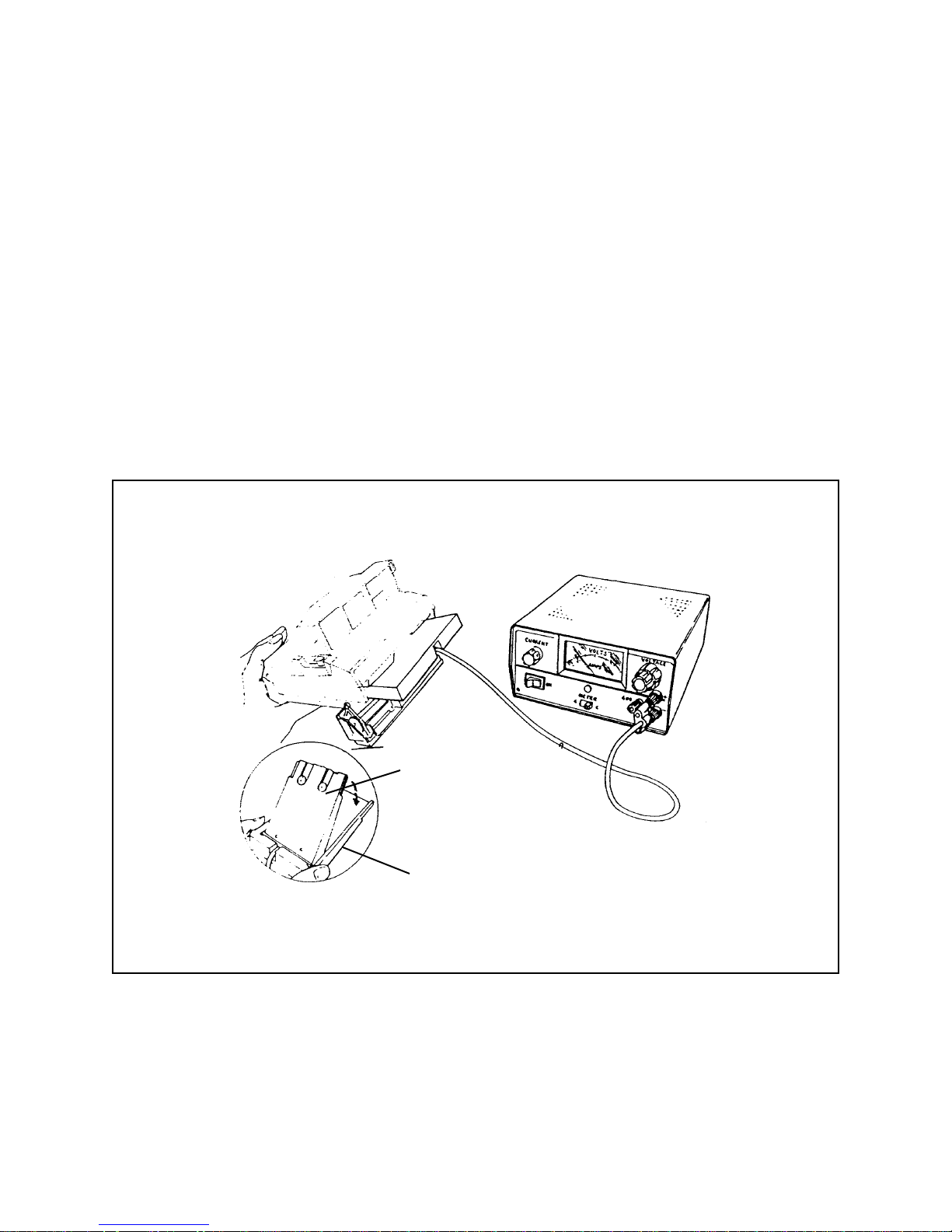

IR Strobe Exposure Calibration Slide Adjustment

1. Remove the Top Cover from the camera (Figure 3-16).

Warning: HIGH VOLT AGE EXPOSURE! Up to 320V

is present on top flash tube terminal (green

wire) and at various other locations on the

strobe board.

2. If the Strobe Exposure Test readings are too low, use a dental pick and slide the IR

strobe Exposure Calibration Slide (Figure 3-18) to the right, in proportion to the

amount the reading is too low. The IR Strobe Exposure Calibration Slide is the

nearer or front-most Slide, when the Base Block is viewed from the rear of the

camera).

3. If the Strobe Exposure Test readings are too high, slide the IR Calibration Slide to the

left, in proportion to the amount the reading is too high.

IR Strobe

Calibration Slide

Figure 3-18. Adjusting the IR strobe exposure calibration slide

53

Page 54

4. Put the Test Top Cover in place and retest the camera. Readjust the IR Strobe

Exposure Calibration Slide if necessary, using the Test Top Cover.

5. When the Strobe Exposure Test reading is within specification, replace the Test Top

Cover with the camera’s own Top Cover.

Note: If adjusting the IR Calibration Slide fails to bring the Strobe Exposure Test

reading within specification, refer to steps 4 and 5 of the Strobe Exposure

(Graywall) Test.

54

Page 55

Hybrid Adjustment (Opening Blade Spring)

1. Remove the Top Cover from the camera (Figure 3-16).

Warning: HIGH VOLT AGE EXPOSURE! Up to 320V

is present on top flash tube terminal (green wire)

and at various other locations on the strobe board.

2. If the Hybrid (ZLS/Blade Speed) Test readings are too low , increase the tension on

the Opening Blade Spring (Figure 3-19) by moving it one notch to the right (when

facing the back of the camera).

3. If the Hybrid T est readings are too high, decrease the tension on the Opening Blade

Spring by moving it one notch to the left (when facing the back of the camera).

4. Put the Test Top Cover on the camera and retest. Repeat the procedure, if

necessary, moving the Opening Blade Spring one notch at a time and replacing the

Test Top Cover each time before retesting.

5. When the Hybrid T est Reading is within specification, replace the Test Top Cover with

the camera’s own Top Cover.

Note: If changing the tension of the Opening Blade Spring fails to bring the

readings into the specification, refer to steps 4 and 5 of the

Hybrid (ZLS/Blade Speed) Test.

Change position of spring

in rack to change blade speed

Decrease Speeds

Increase Speeds

Figure 3-19. Hybrid adjustment (opening blade spring tension adjustment)

55

Page 56

Blade Speed Adjustment (Opening Blade Spring)

1. Remove the Top Cover from the camera (Figure 3-16).

Warning: HIGH VOLT AGE EXPOSURE! Up to 320V

is present on top flash tube terminal (green wire)

and at various other locations on the strobe board.

2. Using tweezers, carefully lift the upper end of the Opening Blade

Spring out of its

notch in the Shutter Base Block (Figure 3-19).

Caution: Do not overstretch spring!

3. If the Blade Speed is too slow, reposition the Opening Blade Spring one notch to the

right (when camera is viewed from the rear). If the speed is too fast, reposition the

Spring one notch to the left.

4. Put the T est Top Cover on the camera and retest Blade Speed. Readjust the

Spring position of necessary .

5. When the Blade Speed is within specification, replace the Test Top Cover with

camera’s own Top Cover.

6. If adjusting the Spring position will not bring the Blade Speed within specification,

replace the Spring and retest.

7. If the Blade Speed is still out of specification, disassemble the camera to the shutter

level (See the Disassembly/Reassembly Section of the Manual). Examine the

blade-opening parts. (Walking Beam/Inertia Assembly , Drive Link, etc.) and the

Shutter Blades for dirt, binding parts and damage. Correct any problems found,

reassemble the camera and retest the Blade Speed. Readjust the Opening Blade

Spring if necessary.

56

Page 57

Solenoid 1 Adjustment for Quintic Position

If the movable Quintic lens element travels at too high or too low a speed, its final

(focused) position may not be correct for the distance measured by the camera’s

sonar system. (If the Quintic moves too fast, for example, the Catch Pawl may not

be able to stop it at the correct position.)

Quintic speed can be adjusted as follows:

1. Remove the Top Cover from the camera (Figure 3-15).

Warning: HIGH VOLT AGE EXPOSURE! Up to 320V

is present on top flash tube terminal (green wire)

and at various other locations on the strobe board.

2. Using a small screwdriver , carefully turn the adjusting screw of Solenoid 1

(Figure 3-20) one-half turn at a time. Turn the screw counter-clockwise to increase

Quintic speed, clockwise to decrease Quintic speed.

3. Put the Test Top Cover in place on the camera.

4. Retest the camera to verify that the Catch Pawl catches (stops) the Quintic at the

correct position. If it does not, readjust the Solenoid 1 adjusting screw, one-half turn

at a time, until the Quintic is caught by the Catch Pawl.

5. When the proper Quintic catch is achieved, replace the Test Top Cover with the

camera’s own Top Cover.

6. If steps 1-3 fail to produce correct Quintic catch, disassemble the camera to the

shutter level and inspect the plunger of Solenoid 1, the Catch Pawl and the Quintic

element for dirt, damage, binding, etc. Correct any problems that are found,

reassemble the shutter and retest the camera.

57

Page 58

To increase Quintic speed,

turn screw CCW

T o decrease Quintic speed,

turn screw CW

Solenoid 1

Adjusting Screw

Figure 3-20. Adjusting solenoid 1 to change quintic speed

58

Page 59

Section 4 - Troubleshooting

Basic Requirements and Guidelines

Spectra Camera Familiarity

Before troubleshooting Spectra Pro/Image Pro Cameras, you should have received

training in Spectra servicing methods, have read the Spectra Service Manual, and know

how to use the Spectra Troubleshooting Charts.

Use of Logic Probe Model PRB-50

Follow all safety precautions and know the correct procedure and switch settings for

using this Probe, as described on the first page of the Spectra Troubleshooting Charts.

Pictorial and Schematic Diagrams

For convenient reference during troubleshooting, a pictorial and schematic diagrams of

the camera are included in this section. The pictorial identifies all test points and signal

paths.

Glossary of Abbreviations and Numbered Index

Abbreviations such as “RM “ (Ranging Module), “EM” (Exposure Module), etc., used in the

operating problem descriptions, are defined at the beginning of this section. Also, the

Operating Problems are listed in the approximate order of camera operation, and for

convenient reference, are numbered and indexed at the beginning of the section.

Basic Troubleshooting Approach

At the start, look for the obvious causes of a problem first: most occur at connections

points between the Exposure Flex and the Burndy connectors on the Ranging Board (Figure 4-1). Common causes of problems include:

• Wire connectors not completely pressed into pin connectors

• Contamination on the elastomeric (“zebra”) connector fingers

• Damaged elastomer in the “zebra” connector (Figure 4-2)

• Solenoids are not connected

• Encoder wires are not connected

• FEAT-TP (brown) wire is not connected, or is crossed with VBATT

(white) wire (see schematics)

59

Page 60

J1

J2

One Board

J3

Strobe/Exposure

Module

Ranging

Board

Figure 4-1. One board strobe/exposure module connections on ranging board

Elastomer

Figure 4-2. Elastomeric “Zebra” connector

Gold Contact

Fingers

60

Page 61

Intermittent Problems

Intermittent problems are typically caused by open circuits, resulting from a cold solder

joint, contamination (dirt, oil, oxide, etc.) on a connector pad, a loose connection, broken

street from a sharp fold in a flex, or a partially seated connector .

For intermittent failures involving the Ranging and LCD Boards, Figure 4-3 shows initial

“quick check” tests.

LCD to Ranging Module

Continuity Check

Good

Check Continuity:

Ranging Module to Rest of Camera

Good

Remove LCD Board and Elastomer

• Inspect Gold Fingers & Elastomer

• Check Finger Alignment: LCD to

Ranging Module

• Attach Known Good LCD and

Connector. Retest Camera.

Bad

• Lift Ranging Module: Check

Continuity

• Examine Burndy Connectors for

Cold Solder Joints & Shorts.

• Analyze Rest of Camera.

Bad

Bad

Loosen & Retighten Screws

Retest

Bad

Good

Original LCD or Connector

failure:

• Change LCD Board & retest

• Change elastomer & retest.

Figure 4-3. Initial test procedure for ranging board and LCD board

61

Page 62

Abbreviations Used in This Section

ONEBD One Board Strobe/Exposure Module

FM Features Module

RM Ranging Module

B+ Battery

EOP End of Pack

EOC End of Cycle

SPD Film Speed

VER Erect Voltage

SOL 1 Solenoid #1

SOL 2 Solenoid #2

STROBE Strobe Board

LCD Liquid Crystal Display Module

BB Camera Base Block

62

Page 63

Operating Problems and Typical Causes

T ypical causes of these operating problems are listed on the following pages:

Problem Page

No Dark Slide 4 - 6

Incomplete Dark Slide 4 - 6

Blades don’t Open 4 - 7

No S1 Cycle 4 - 7

Sticky S1/S10 4 - 7

Sensitive S1 4 - 8

No Motor Drive 4 - 8

Counter Wheel Hangs Up 4 - 8

Poor LCD Module Connection 4 - 9

LCD Display Problems (Missing/Extra Segments, Shadows) 4 - 9

Buttons don’t Work or Hard to Press 4 - 9

Erratic Camera behavior 4 - 9

No Self-Timer or Incorrect Self-Timer Cycle 4 - 10

No Piezo 4 - 10

Incorrect Piezo Speed 4 - 10

No End-of Pack Chime 4 - 11

Incorrect Blade Speed 4 - 11

Motor doesn’t Run 4 - 11

Film Speed Switch Failure 4 - 11

Quintic Hangs Up 4 - 12

Strobe Exposure Adjustment Failure 4 - 12

Ambient Exposure Adjustment Failure 4 - 12

Strobe Doesn’t Fire 4 - 13

Strobe Fires at Wrong Time 4 - 13

LED’s Don’t Light or Light at Wrong Time 4 - 13

Ranging Incorrect 4 - 13

Ranging to 8 FT/M Only 4 -14

IC Timeout Error 4 -14

Exposure: Long Timeout 4 -14

63

Page 64

No Dark Slide

T ypical causes:

• Motor flex not seated to wireform switch

• Poor connection to LCD module

• Red or black wire not seated to strobe (J14-J15)

• Erect pin missing

• Wireform switch block distorted

• Flex not seated to motor

• Wire broken on wireform switch block

• Wireform switch block melted

• S-9 switch distorted at wireform switch block

• Wire connector from motor flex not connected to One Board

• Pick spring not seated

• Door link not making VER switch to battery switch (at wireform switch block)

• Counter wheel hang up

• Battery contacts not seated or missing

• Door latch distorted

• Shutter not seated

• No S1 cycle (See No S1 Cycle, Page 4-7)

Incomplete Dark Slide

T ypical causes:

• Locking cap on Ranging Board Burndy connector not closed

• Poor LCD Module connection at Ranging Board

• Defective RM

64

Page 65

Blades don’t Open

T ypical causes:

• Shutter not seated

• SOL 1 not adjusted properly

• Wire connectors not connected to SOL 1 or SOL 2

• Kicker spring not seated

• Solenoid not seated straight

• Sticky blades

• No SOL 1 drive

• Drive link not seated to walking beam

• Encoder wire hitting SOL 2 plunger

• Base block Quintic post distorted

• SOL 2 plunger sticky

• Wireform switch not in correct position

• Broken drive link

• Catch pawl hang-up

• Photodiode not glued properly

• SOL 2 moves in frame

• Encoder lead broken

• Counter wheel hang up

• Door latch distorted

• Black and red wires not seated to Strobe Board (J14-J15)

• Poor LCD module connection (See Poor LCD Module Connection, Page 4-9)

No S1 Cycle

T ypical causes:

• S1/S10 switch distorted

• Wire connectors not seated to RM, FM, Strobe or motor flex

• Defective Strobe

• Poor LCD Module connection (See Poor LCD Module Connection, Page 4-9)

• LCD module defective

Sticky S1/S10

T ypical causes:

• Button hung up on top cover insert

• S1/S10 button bezel not seated

65

Page 66

Sensitive S1

T ypical causes:

• S1/S10 switch distorted

No Motor Drive

T ypical causes:

• Motor connector not plugged into One Board

• VBATT wire (white) not connected to RM

• No contact from VER to battery (red wire) on strobe board

• Broken red wire

• Door switch not in correct position

• Motor pinion gear binding

• Motor not seated

• Motor flex folded over

• One Board not connected to SOL1 or SOL2

• Strobe board and S1/S10 not seated

• RM damaged

• Encoder wire not seated

Counter Wheel Hangs Up

Note: Counter wheel and mechanism are present, even though exposure

counter display is electronic.

T ypical causes:

• Trim off plastic flash from main frame

• Bad pack pawl

• S9, S10 always making

• Motor flex retainer not seated

• LED leads too long

• Remote socket too high

• Counter spring not seated, or defective

• Pick damaged

• Defective timing gear

• Gear drive cover not seated

• Brown wire caught in counter wheel

66

Page 67

Poor LCD Module Connection

T ypical causes:

• Elastomeric connector contaminated

• Elastomeric connector damaged

• Elastomeric connector size out of spec

• Contamination on gold fingers (LCD or RM)

• Elastomeric connector screws not tightened

• LCD and/or RM excessively warped

LCD Display Problems (Missing or Extra Segments, Shadows in Display)

T ypical causes:

• Bezel not tight

• Glass improperly seated

• Defective glass

• Defective LCD module

• Gold pads under LCD glass contaminated

Buttons don’t Work or are Hard to Press

T ypical causes:

• Rubber switches loose or missing

• Plastic buttons hung up on flash

• Features cap not seated

• Mid Cover not seated

• RM not seated

• RTV on RM incorrectly applied (prevents RM from seating)

• LCD module excessively warped

Erratic Camera Behavior

T ypical causes:

• Poor LCD module connection

• LCD module defective

• RM defective

• ONEBD not seated to RM

• Dirty solenoid

67

Page 68

No Self-Timer or Incorrect Self-Timer Cycle

T ypical causes:

• Defective LCD module

• Defective FM

• Self-Timer LED improperly installed

• Defective piezo

• Piezo cover missing

• Piezo not plugged into FM

• Defective RM

• Brown and white wires on RM revered or unplugged

• Self-timer switch loose or missing

• Poor LCD module connection

No Piezo

T ypical causes:

• Piezo wire ends shorted

• Defective FM

• Piezo connectors on FM shorted

• FM cracked at J25

• Defective piezo

• Piezo cover missing

• Piezo wires not seated

• Poor LCD module connection (see Poor LCD Module connection, page 4-9)

• FEAT-TP wire (brown) not connected to RM or FM

Incorrect Piezo Speed

T ypical causes:

• FEAT-TP and VBATT wires (brown and white) reversed

• FEAT-TP wire (brown) not plugged in

68

Page 69

No End of Pack (EOP) Chime

T ypical causes:

• See No Piezo, Page 4-1 1

• Deformed wireform switch (EOP not making)

• Defective FM

• Counter wheel hang up (See Counter Wheel Hangs Up, Page 4-8)

Incorrect Blade Speed

T ypical causes:

• Flex at SOL 1 folded over shorting itself

• Opening blade spring not in correct position

• Shutter blades not free, walking beam inertia, distorted base block

• T oo many blades

• Dirty blades

Motor doesn’t Run

T ypical causes:

• Wireform switch not making S9 to VER

• Quintic hung up

• RM not seated

• Poor LCD module connection (See Poor LCD Module Connection, Page 4-9)

Film Speed Switch Failure

T ypical causes:

• Distorted wireform switch block

• Gear drive flex distorted, torn, folded (causing short)

• Gear drive flex not making with speed switch

69

Page 70

Quintic Hangs Up

T ypical causes:

• Quintic post distorted

• Quintic frame damaged

• Counterweight

• Quintic return spring

• Encoder wire not seated

• Flash on baseblock

Strobe Exposure Adjustment Failure

T ypical causes:

• Photodiode cap not seated

• Cal wedges not seated, missing or distorted (check IC, pin 7)

• Transducer clip broken

• Defective flashtube

• Defective strobe

Ambient Exposure Adjustment Failure

T ypical causes:

• Cal wedges not seated, missing or distorted

• Photodiode cap not seated

• Yellow dot in wrong position (do not remove any yellow dots)

• Adjusting gear wheel not catching wedge

70

Page 71

Strobe doesn’t Fire

T ypical causes:

• S9 contact bent

• Defective strobe

• Green and orange wires reversed

• Flashtube assembly defective

• Orange wire not connected to strobe

• White trigger wire not soldered or cold soldered

• Flashtube not seated

• Flashtube assembly incorrectly assembled

• S1/S10 not held down in snap

Strobe Fires at Wrong Time

T ypical causes:

• Poor LCD module connection (See Poor LCD Module Connection, Page 4-9)

LEDs don’t Light or Light at Wrong Time

T ypical causes:

• Poor LCD module connection (See Poor LCD Module Connection, Page 4-9)

• Defective LED - replace LCD module

Ranging Incorrect

T ypical causes:

• S9 never open

• S9, S10 short on wireform switch block

• Defective RM

• Defective transducer

• Quintic not free

• Ranging in wrong units (feet/meters): check jumper W1, LCD module

• Defective encoder

• Poor LCD module connection (See Poor LCD Module Connection, Page 4-9)

• Defective LCD module

71

Page 72

Ranging to 8 FT/M Only

T ypical causes:

• Transducer wires not connected to RM

• Defective transducer

• Defective prism display board

• Defective FM

• Incorrect shutter assembly

IC Timeout Error

T ypical causes:

• White trigger wire caught under features shield

• Burndy connector locking cap not closed

• Brown wire routed too close to features IC’s

Exposure: Long Timeout

T ypical causes:

• Poor LCD module connection (See Poor LCD Module Connection, Page 4-9)

• Defective LCD module

72

Page 73

Wire Connections and Test Points

Figure 4-4 shows the wire connections and test points required for most troubleshooting.

Figure 4-4. Wire connections, test points: strobe/exposure module

and ranging board

73

Page 74

Schematic Diagrams

One Board schematic diagrams are provided on the following pages:

Description Figure Page

Spectra Pro/Image Pro/Minolta Pro Schematic 4-5 75

One Board Strobe/Exposure Module Schematic 4-6 76

Ranging Board Schematic 4-7 77

Features Module and Display Module Schematic 4-8 78

74

Page 75

Figure 4-5. Spectra pro/image pro/minolta pro system schematic

75

Page 76

Figure 4-6. One board strobe/exposure module schematic

76

Page 77

Figure 4-7. Ranging board schematic

77

Page 78

Figure 4-8. Features module and display module schematic

78

Loading...

Loading...