Polaroid PDC2000, PDC-2000/40, PDC-2000/T, PDC3000, PDC-2000/60 Repair Manual

Repair Manual

Americas Business Center

Technical Services

201 Burlington Road

Bedford MA 01730

TEL: 1.781.386.5309

FAX: 1.781.386.5988

PDC2000/3000 Digital Cameras

January 1998

PDC 2000/300 Repair Manual Table of Contents

Table of Contents

Section Page

1. Description.......................................................................................................... 6

General Description .............................................................................................. 6

Models.................................................................................................................. 6

Features ............................................................................................................... 7

Specifications ....................................................................................................... 7

2. Theory of Operation........................................................................................... 10

Picture Data Flow ................................................................................................. 10

Median Filter Interpolator...................................................................................... 11

Standard Resolution Mode................................................................................. 11

High Resolution Mode ........................................................................................ 13

3. Testing and Adjustments................................................................................... 15

LabView................................................................................................................ 15

Overview............................................................................................................ 15

Front Panel ........................................................................................................ 16

Block Diagram.................................................................................................... 16

Icon/Connector................................................................................................... 16

Test Software....................................................................................................... 16

Tester Operation .................................................................................................. 17

Starting the Tester ............................................................................................. 17

Stopping the Tester ........................................................................................... 17

Quitting the Tester ............................................................................................. 17

Testing and Adjustment Guidelines ....................................................................... 18

Testing and Adjustments....................................................................................... 19

Current Profile Test............................................................................................ 19

Required Test Equipment and Tools................................................................ 19

Equipment Setup ............................................................................................. 19

Test Procedure ............................................................................................... 21

Calibration.......................................................................................................... 23

Required Test Equipment and Tools................................................................ 23

Equipment Setup ............................................................................................. 24

Test Procedure ............................................................................................... 28

Image performance............................................................................................ 34

Required Test Equipment and Tools................................................................ 34

Equipment Setup ............................................................................................. 34

Test Procedure ............................................................................................... 35

2

PDC 2000/3000 Repair Manual Table of Contents

Park Camera ..................................................................................................... 39

Required Test Equipment and Tools................................................................ 39

Equipment Setup ............................................................................................. 39

Test Procedure ............................................................................................... 40

Changing Camera Serial Number ....................................................................... 42

Required Test Equipment and Tools................................................................ 42

Equipment Setup ............................................................................................. 42

Test Procedure ............................................................................................... 43

Fast Flatness ..................................................................................................... 46

Required Test Equipment and Tools................................................................ 46

Equipment Setup ............................................................................................. 46

Test Procedure ............................................................................................... 47

Peak Tweak....................................................................................................... 49

Required Test Equipment and Tools................................................................ 49

Equipment Setup ............................................................................................. 49

Test Procedure ............................................................................................... 50

Dimestore .......................................................................................................... 52

Required Test Equipment and Tools................................................................ 52

Equipment Setup ............................................................................................. 52

Test Procedure ............................................................................................... 53

Big Hose ............................................................................................................ 57

Required Test Equipment and Tools................................................................ 57

Equipment Setup ............................................................................................. 57

Test Procedure ............................................................................................... 58

Clean Sweep ..................................................................................................... 60

Required Test Equipment and Tools................................................................ 60

Equipment Setup ............................................................................................. 60

Test Procedure ............................................................................................... 61

4. Diagnostics and Troubleshooting..................................................................... 63

Repair Check List ................................................................................................. 63

Troubleshooting Camera Malfunctions .................................................................. 64

Troubleshooting Guides ........................................................................................ 69

Physical Defects (Guide 1) ................................................................................ 69

Power (Batteries and External Power Adapter/Trickle Charger) (Guide 2)........ 72

Communication with Host Computer (Guide 3)................................................... 76

Image Quality (Guide 4)..................................................................................... 77

5. Parts Replacement .......................................................................................... 81

Disassembly Procedure Organization ................................................................ 82

3

PDC 2000/300 Repair Manual Table of Contents

Top Cover Removal ........................................................................................... 84

Top Cover Installation........................................................................................ 85

Transducer Removal.......................................................................................... 86

Transducer Installation....................................................................................... 86

Front End Removal ............................................................................................ 86

Front End Installation ......................................................................................... 88

Power Button Board Removal............................................................................ 88

Power Button Board Installation......................................................................... 89

Back End Board and Hard Drive/IDE Board Removal........................................ 89

Back End Board and Hard Drive/IDE Board Installation..................................... 90

Power Supply/Strobe Board Removal ............................................................... 91

Power Supply/Strobe Board Installation ............................................................ 92

Power and SCSI Overmold Removal................................................................. 93

Power and SCSI Overmold Installation.............................................................. 93

Strap Lug Removal/Installation .......................................................................... 94

Edit Board Removal........................................................................................... 95

Edit Board Installation........................................................................................ 96

Shutter Board Removal...................................................................................... 97

Shutter Board Installation................................................................................... 97

LCD Assembly Removal .................................................................................... 98

LCD Assembly Installation ................................................................................. 98

Autofocus Board Removal ................................................................................. 99

Autofocus Board Installation .............................................................................. 99

Input/Output Board Assembly Removal ............................................................. 100

Input/Output Board Assembly Installation .......................................................... 101

List of Illustrations

Figure Page

1-1 Polaroid digital camera, model PDC-2000 ......................................................... 5

2-1 Picture data flow through PDC-2000.................................................................. 9

2-2 Median filter interpolator function ....................................................................... 11

2-3 High resolution mode processing within host ...................................................... 13

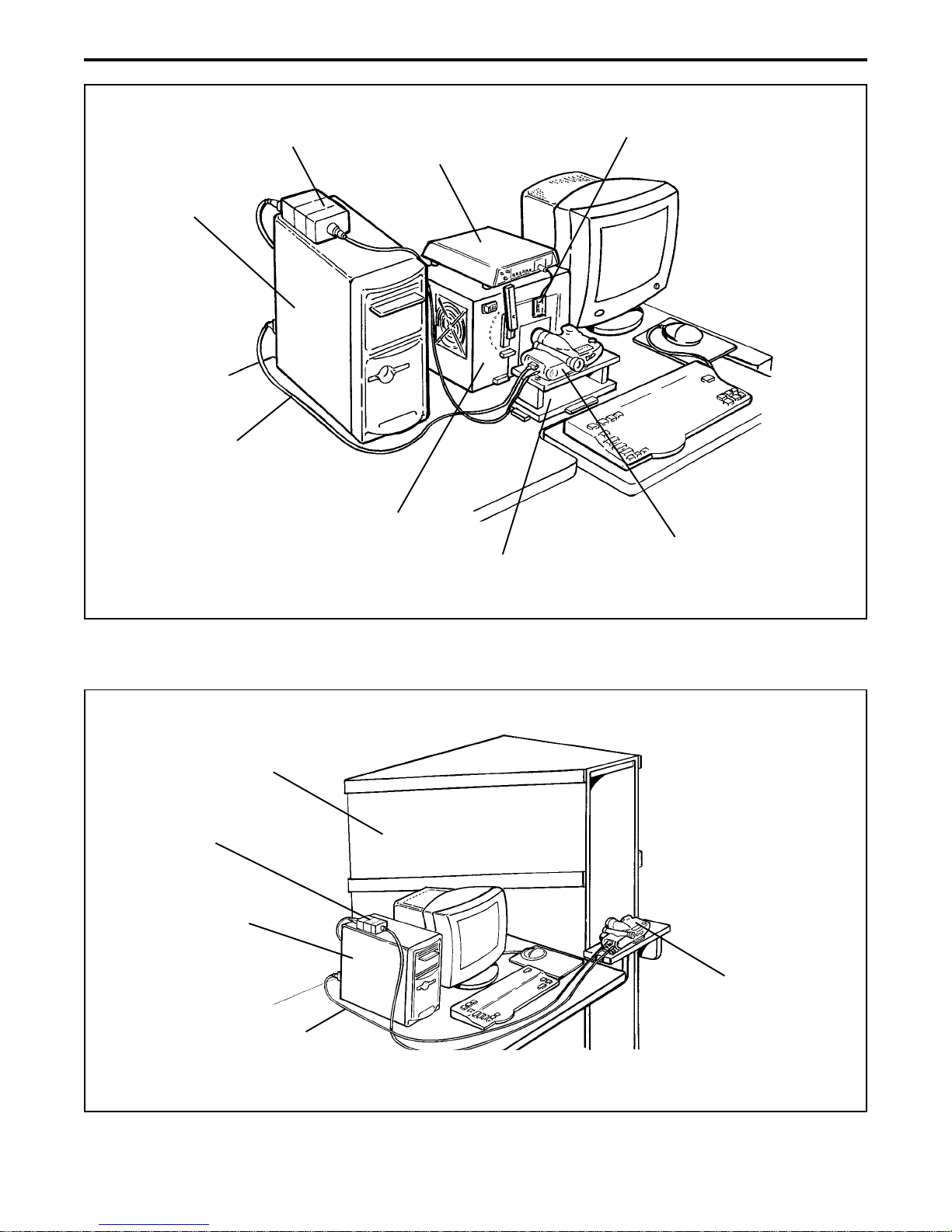

3-1 Current profile equipment setup ......................................................................... 20

3-2 Ambient setup .................................................................................................... 25

3-3 Strobe setup ...................................................................................................... 25

3-4 Color and focus test (Macbeth color checker chart) .......................................... 26

3-5 Color and focus test (checker/resolution target in front of target) ...................... 26

3-6 Color and focus test (vertical) ............................................................................ 27

3-7 Image performance test setup ........................................................................... 35

3-8 Parking camera setup ........................................................................................ 40

3-9 Changing camera serial number setup ............................................................... 43

3-10 Fast flatness setup............................................................................................. 47

3-11 Peak tweak setup .............................................................................................. 50

3-12 Dimestor setup................................................................................................... 53

3-13 Big hose setup ................................................................................................... 57

3-14 Clean sweep setup ............................................................................................ 61

4

PDC 2000/3000 Repair Manual Table of Contents

4-1 Camera top cover removed ............................................................................... 65

4-2 Camera opened for inspection ........................................................................... 67

4-3 Protective insulating material placed over opened camera................................. 68

5-1 Typical harness connection ................................................................................ 83

5-2 Removing screws securing top cover................................................................. 84

5-3 Pivoting top cover............................................................................................... 85

5-4 Removing transducer ......................................................................................... 86

5-5 Protective tape over transducer connection ....................................................... 87

5-6 Removing front end board.................................................................................. 87

5-7 Removing power button board ........................................................................... 89

5-8 Removing back end board and hard drive/IDE board......................................... 90

5-9 Removing power supply/strobe board................................................................ 91

5-10 Protective tape and foam block location ............................................................ 92

5-11 Installing power and SCSI overmold .................................................................. 93

5-12 Location of strap lugs......................................................................................... 94

5-13 Removing edit board.......................................................................................... 96

5-14 Removing shutter board..................................................................................... 97

5-15 Removing LCD board......................................................................................... 98

5-16 Removing autofocus board................................................................................. 99

5-17 Removing input/output board assembly.............................................................. 100

5-18 Protective tape over input/output board ............................................................. 101

List of Tables

Table Page

4-1 Physical Defects (Guide 1) ................................................................................ 69

4-2 Power (Batteries and External Power Adapter/Trickle Charger) (Guide 2)........ 72

4-3 Communication with Host Computer (Guide 3)................................................... 76

4-4 Image Quality (Guide 4)..................................................................................... 77

5-1 PDC-2000 Disassembly Requirements .............................................................. 83

5

PDC 2000/3000 Repair Manual Description

1. PDC-2000 Description

General Description

The Polaroid Digital Camera, Model PDC-2000 (Figure 1-1), captures high-quality color

pictures electronically. It has all the features of an automatic compact 35mm camera, including

automatic exposure, electronic flash and automatic focus. These features produce correct

exposure, accurate colors and sharp focus under a great variety of picture-taking conditions.

Manual overrides are also provided for unusual conditions.

With appropriate image-processing software (such as Polaroid PicturePro or Adobe

Photoshop) and the Polaroid PDC-2000 plug-in software on a Macintosh computer or PC,

users can view the pictures taken with the PDC-2000 camera and transfer them to their

computer via a standard SCSI-2 interface. They can then use image-processing software to

manipulate, enhance, save and print the pictures.

When the camera is connected to a computer, the camera can be controlled and operated via

the computer keyboard and mouse. This is useful when the camera is used in a stationary

setup.

Front

Rear

Figure 1-1. Polaroid digital camera, model PDC-2000

Models

The PDC-2000 is available in three different models:

Model Internal Storage Capacity (Megabytes)

PDC-2000/40 40 (40 images)

PDC-2000/60 60 (60 images)

PDC-2000/T None; tethered operation only

6

PDC 2000/3000 Repair Manual Description

Tethered operation refers to operation of the camera while it is connected to a computer. The

PDC-2000/T has no internal storage and must be connected to a computer to be operable.

Instead of storing images internally, it immediately transfers them to the computer as they are

captured.

Features

The PDC-2000 is designed for completely automatic, point-and-shoot operation. It

automatically sets exposure, focus and flash mode based on ambient light and distance to the

subject. Manual overrides are available for setting focus to infinity, setting flash mode to on or

off, and setting white balance to daylight, incandescent or fluorescent. A backlightcompensation setting is also available.

The camera is capable of transferring its images to the computer in either of two resolutions:

(1) standard (800x600 dpi) and high (1600x1200 dpi). Both resolution modes are 24-bit color.

Because the camera always stores enough raw image data to produce the high resolution

images, resolution is not selected until pictures are being transferred to the computer.

Power for the camera is provided by four AA rechargeable NiCad batteries. These batteries

can be charged in the camera, using the battery charger provided with the camera. The

camera is operable while the batteries are charging.

An LCD panel on the camera provides information about time and date, camera status,

remaining battery capacity and error conditions. Time and date are recorded in the header of

each picture file, and on-camera controls allow the user to attach an additional alphanumeric

label to each picture file header. Time, date, label, and camera status transfer with the image

to the computer to aid identification and troubleshooting.

Specifications

Description: Captures high-quality digital photographs, previously

available only from professional SLR digital cameras, with

point-and-shoot ease of use

PDC-2000 models: PDC-2000/40 - 40 megabytes of internal storage

PDC-2000/60 - 60 megabytes of internal storage

PDC-2000/T - No internal storage; tethered operation only

Automatic adjustments • Focus

in standard mode: • Exposure

• Flash on or off

7

PDC 2000/3000 Repair Manual Description

Manual controls User-selected manual controls for:

and overrides:

• Backlight conditions

• White balance options: daylight, incandescent or fluorescent

• Flash options: automatic, on or off

• Auto focus or fixed focus

• 10 character alpha-numeric image label

Sensor: Polaroid 1 million pixel CCD sensor

Resolution: Standard: 800 x 600 dpi, 24-bit color, 16.7 million colors,

1.4 MB file

High: 1600 x 1200 dpi, 24-bit color, 16.7 million colors, 5.6MB file

Image storage PDC-2000/40 - 40 images

capacity: PDC-2000/60 - 60 images

PDC-2000/T - No internal storage for images

Computer interface: SCSI-2

Standard lens: f/2.8, 11mm (38mm equivalent)

Focus range: 10 inches to infinity

Equivalent film speed: ISO 100

Shutter: Scanning aperture shutter (microprocessor controlled)

Shutter speed: 1/25 to 1/500 seconds

Aperture: f/2.8 - f/11

Flash: Internal, up 15 feet

Power supply: • 4 rechargeable AA NiCad batteries

• IEC Universal Power Adapter

Battery life: More than 150 pictures (at 50% flash use)

Dimensions: Length - 20.1cm (7.9 inches)

Width - 16.0 cm (6.3 inches)

Height - 5.6 cm (2.2 inches)

Weight (with batteries): 0.9 kg (2.0 lbs.)

8

PDC 2000/3000 Repair Manual Description

Standard accessories: • SCSI connector cable

• 25/50 SCSI adapter

• 4 rechargeable AA NiCad batteries

• IEC universal power adapter

• Country version power cord

• Neck strap

Software provided: • Plug-in for PhotoShop (Mac/Windows)

• Polaroid PicturePro (Mac/Windows)

• T WAIN driver for Windows

Optional accessories: • f/3.5, 17mm Lens (60mm equivalent); focus range: 24 inches

to infinity

• Slim SCSI card (PCMCIA-to-SCSI adapter for portable PCs

using the PCMCIA slot)

• 4-pack rechargeable AA NiCad batteries

• Eveready 5 hour charger

• 12 volt auto adapter

• Polaroid camera bag

Macintosh operating • Apple Macintosh or Powerbook computer with a 68030 or

requirements: later processor.

• Macintosh system software version 7.1 or later.

• 8 megabytes of available RAM (16 MB recommended).

• 10 megabytes of available hard disk space.

IBM/compatible • IBM PC or compatible computer with a 386 or later

operating processor (486 recommended)

requirements: • ASPI-compliant SCSI adapter card

• Microsoft Windows 3.1 or later

• 8 megabytes of available RAM (16 MB recommended)

• 10 megabytes of available hard disk space

9

PDC 2000/3000 Repair Manual Theory of Operation

2. Theory of Operation

Picture Data Flow

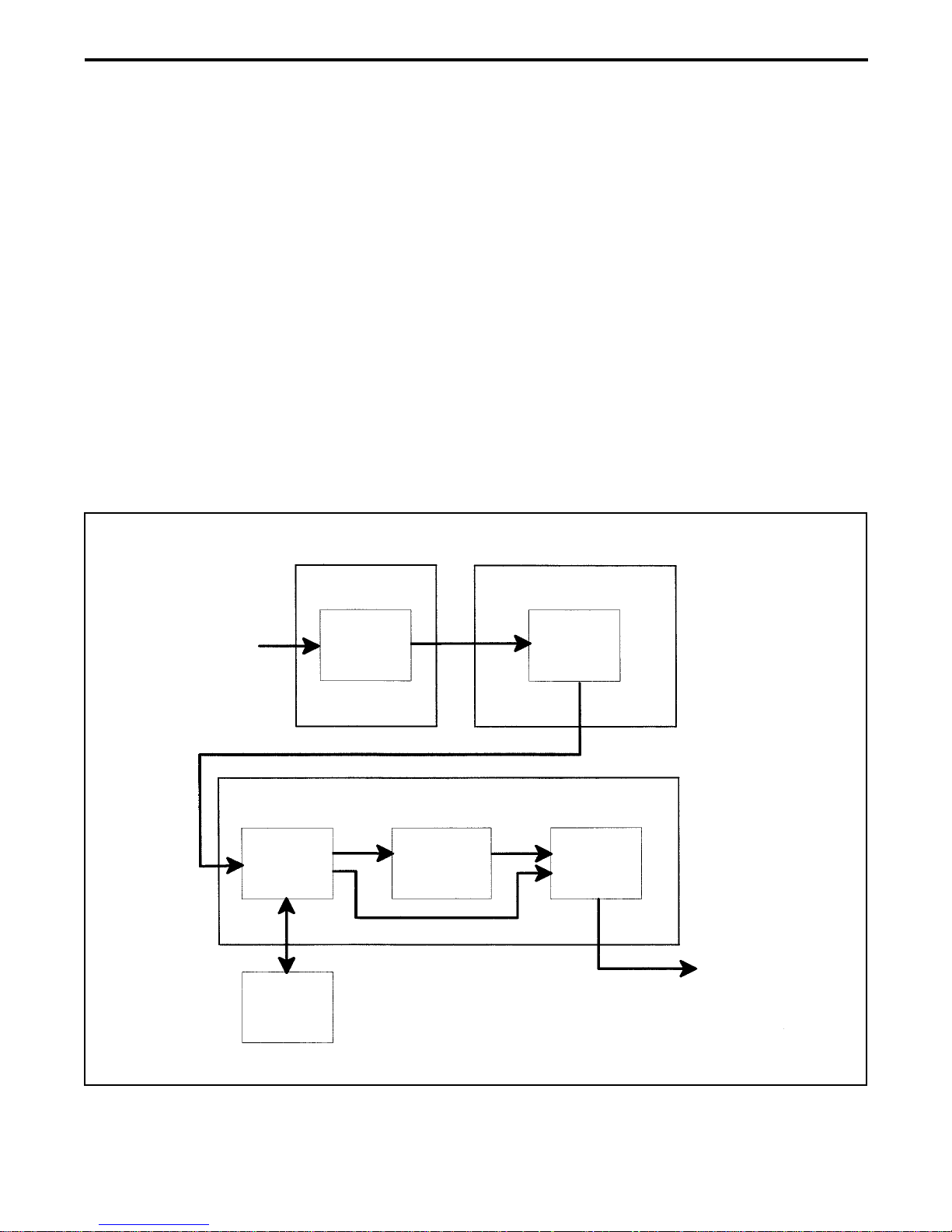

Picture data flows through the PDC-2000 camera from the CCD sensor to the SCSI interface is

shown in Figure 2-1. This analog and digital data is processed through the following modules:

• CCD sensor

• Video signal processor

• Frame buffer

• Internal storage

• Median filter interpolator

• SCSI interface

Light from Scene

Optics Module Front End (Analog) Board

CCD

Back End (Digital) Board

Frame

Buffer

Median

Filter

Interpolator

Video

Signal

Processor

SCSI

Interface

Internal

Storage

Figure 2-1. Picture data flow through PDC-2000

Picture Data

to Host via

SCSI Connector

10

PDC 2000/3000 Repair Manual Theory of Operation

Median Filter Interpolator

Standard Resolution Mode

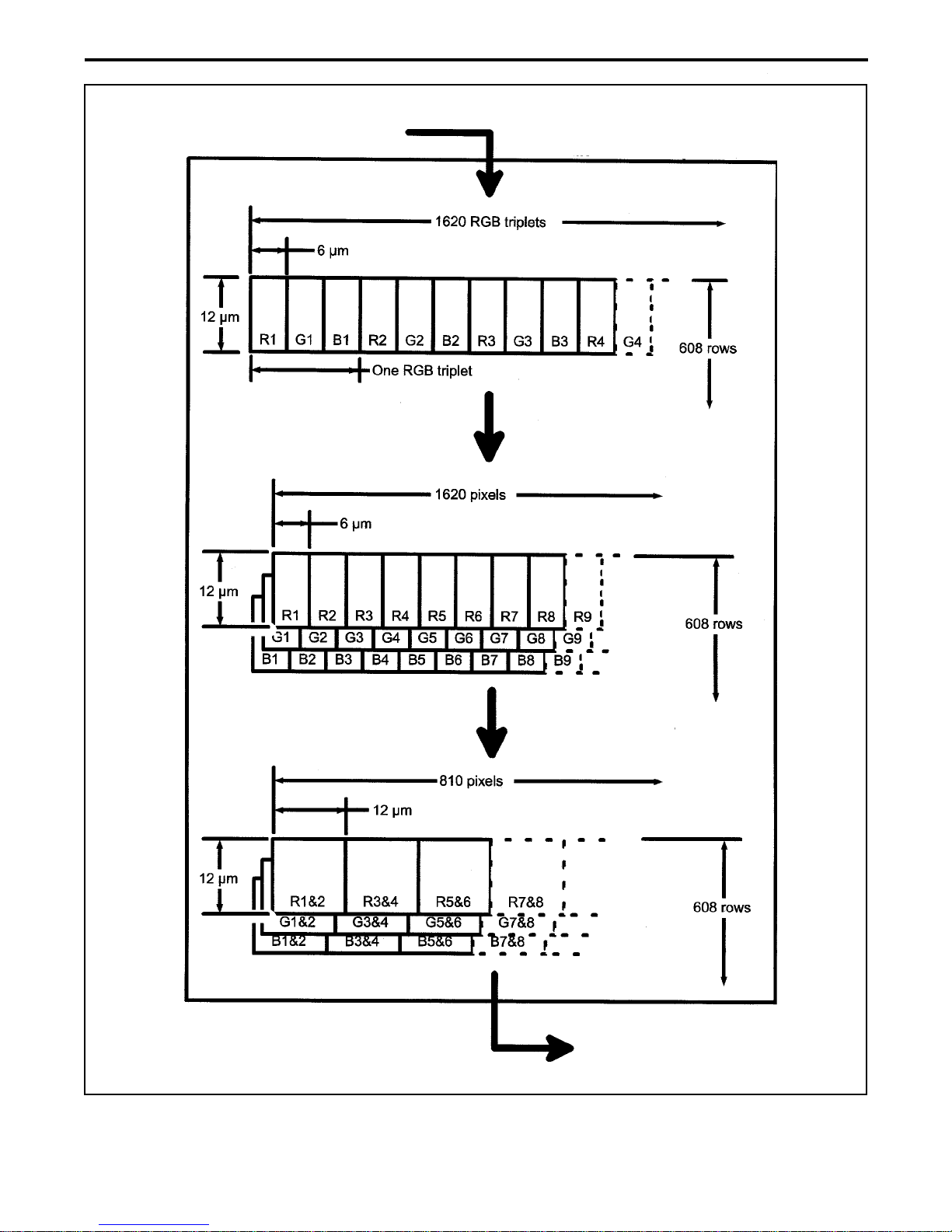

The median filter interpolator converts RGB triplets received from the frame buffer to an 800 x 600

(standard resolution for the PDC-2000) RGB image by arranging the pixels and averaging

adjacent horizontal pixels as shown in Figure 2-2. It sends the reconstructed pixel data to the

SCSI interface.

11

PDC 2000/3000 Repair Manual Theory of Operation

From Frame Buffer

Median Filter Interpolator

Figure 2-2. Median filter interpolator function

To SCSI Interface

and Host Computer

12

PDC 2000/3000 Repair Manual Theory of Operation

High Resolution Mode

When the operator through the host computer decides to transfer a picture in the high-resolution

mode (1600 x 1200) instead of standard resolution, data from the frame buffer passes directly to

the SCSI interface without passing through the camera’s median filter interpolator (Figure 2-1).

In this high resolution mode, the host computer processes the frame buffer data to produce a

1600 x 1200 pixel image as shown in Figure 2-3.

13

PDC 2000/3000 Repair Manual Theory of Operation

From Camera Frame Buffer

(Via SCSI Interface)

High-Resolution Proccessing

(Host Computer)

Figure 2-3. High resolution mode processing within host

T o Image-Processing

Application on Host Computer

14

PDC 2000/3000 Repair Manual Testing&Adjustment

3. PDC-2000 Testing and Adjustment

LabView

Overview

LabView is a graphical application program designed by National Instrument. It is used to

graphically program instrumentation systems for data acquisition and control, data analysis,

and data presentation. This application program offers an innovative method in which a

design engineer can graphically assemble software modules called virtual instruments (VI's)

instead of writing text-based programs. VI's can be used to acquire data from plug-in boards

and programmable instruments such as PDC 2000/3000 digital cameras. VI's can also be

assembled to analyze data and to present results through graphical user interfaces.

A LabView virtual instrument (VI) consists of:

• Front Panel

• Block Diagram

• Icon/Connector

The following paragraphs only gives an overview of the LabView components necessary to

design a test program. Refer to the LabView User's Guide for more detailed information

pertaining to the LabView components necessary to design a test program.

Front Panel

The front panel is the user interface. It serves as an interactive interface for supplying

inputs to and observing outputs from the instrumentation system. LabView makes

creating a front panel as simple as drawing a picture and gives the user a variety of

controls and indicators to use.

When the VI is completed, the user uses it to control his/her system - even while the VI is

running - by clicking a switch, moving a slide, tweaking a knob, or entering a value from

thekeyboard, the front panel responds immediately, providing real-time feedback from the

instrumentation system.

Once the necessary information is entered or selected from the applicable front panel, the

user then starts the VI by clicking on the Start button. It then performs the test and

displays its results in the Test Status window on the front panel. Refer to the applicable

Testing and Adjustment section for a detailed explanation of the PDC 2000/3000 front

panel.

15

PDC 2000/3000 Repair Manual Testing&Adjustment

Block Diagram

The block diagram is the source code of the VI. It is constructed, free from syntactical

details of conventional programming, by selecting functional blocks from LabView menus.

The selected functional blocks are then connected with lines called wires to pass data from

one block to the next. These blocks include arithmetic functions, advanced acquisition and

analysis VI's, Sub VI components which call other VI's, and network and file I/O functions

that store or retrieve data in ASCII, binary, or spreadsheet formats.

Icon/Connector

The icon/connector is the calling interface. The icon is the graphical ID of the VI, and the

connector assigns controls and indicators to VI input and output terminals.

Test Software

The Test Software is an application program that was developed using LabView software

(National Instrument) and Concept VI Image Processing Library (Graftek). It is intended to

help the repair person diagnose PDC 2000/3000 digital camera malfunctions. Programs

developed using LabView are called virtual instruments (VI's).

The developed software consists of a Tester which invokes the necessary sub-VI's routines

that allow the repair person to check the PDC 2000/3000 digital camera.

When the Tester is invoked, it performs and verifies specified camera tests.

At the completion of the specified test, a report file is generated by the Tester indicating

whether or not the tested functions passed ( Pass ) or failed ( Fail ). It also list the current

parameters for the test functions so that repair person can verify the tested functions with the

PDC 2000/3000 digital camera specifications.

If the report file indicates that all or a particular function failed ( Fail ), the repair person can

compare the current parameters with the PDC 2000/3000 digital camera specifications to

determine how to bring the failed function/functions back into specification.

16

PDC 2000/3000 Repair Manual Testing&Adjustment

Tester Operation

Starting the Tester

1. If applicable, click the mouse on the front panel white arrow to start the tester.

2. Click the mouse on the Start button to start the test sequence.

3. Tester prompts the user to perform specified function when testing the PDC 2000/3000

digital camera.

4. Once all user prompts are completed, the test sequence for the PDC 2000/3000 digital

camera begins.

5. Upon completion of all or partial tests, a test completed message appears in the Status box

of the test panel.

Also, a test report and the Pass / Fail indicators displayed on the test panel are updated.

Stopping the Tester

Note: The Tester should not be stopped in the middle of a test sequence. However, if an

emergency situation occurs, use the following steps to stop and restart the Tester.

1. Click the mouse on the stop box to completely stop the camera's test sequence.

The black arrow changes to a white arrow indicating that the run-time version of LabView

stopped running.

2. To restart the Tester, just click the mouse on the white arrow; the arrow becomes black

again and the tester resumes.

Quitting the Tester

To quit the Tester due to a malfunction or before the selected tests are completed, just

click the mouse on the Closing box.

17

PDC 2000/3000Repair Manual Testing&Adjustment

Testing and Adjustment Guidelines

As the selected LabView test program runs, many windows and dialog boxes appear and

disappear throughout the test process. Use the following test guidelines to perform the

requested user tasks.

• Yes/No - Click on appropriate response (Yes or No).

Dialog Boxes

• Message Windows - Perform requested task and then click on Start button.

w/Start Button

• Auto Sequence - No user input.

Windows

18

PDC 2000/3000 Repair Manual Testing&Adjustment

Testing and Adjustments

Current Profile Test

Required Test Equipment and Tools

• Macintosh Centris 650 Computer or Equivalent

• 1-ohm resistor box

• 0 - 10 Vdc Power Supply

• Camera Test Fixture (Nest)

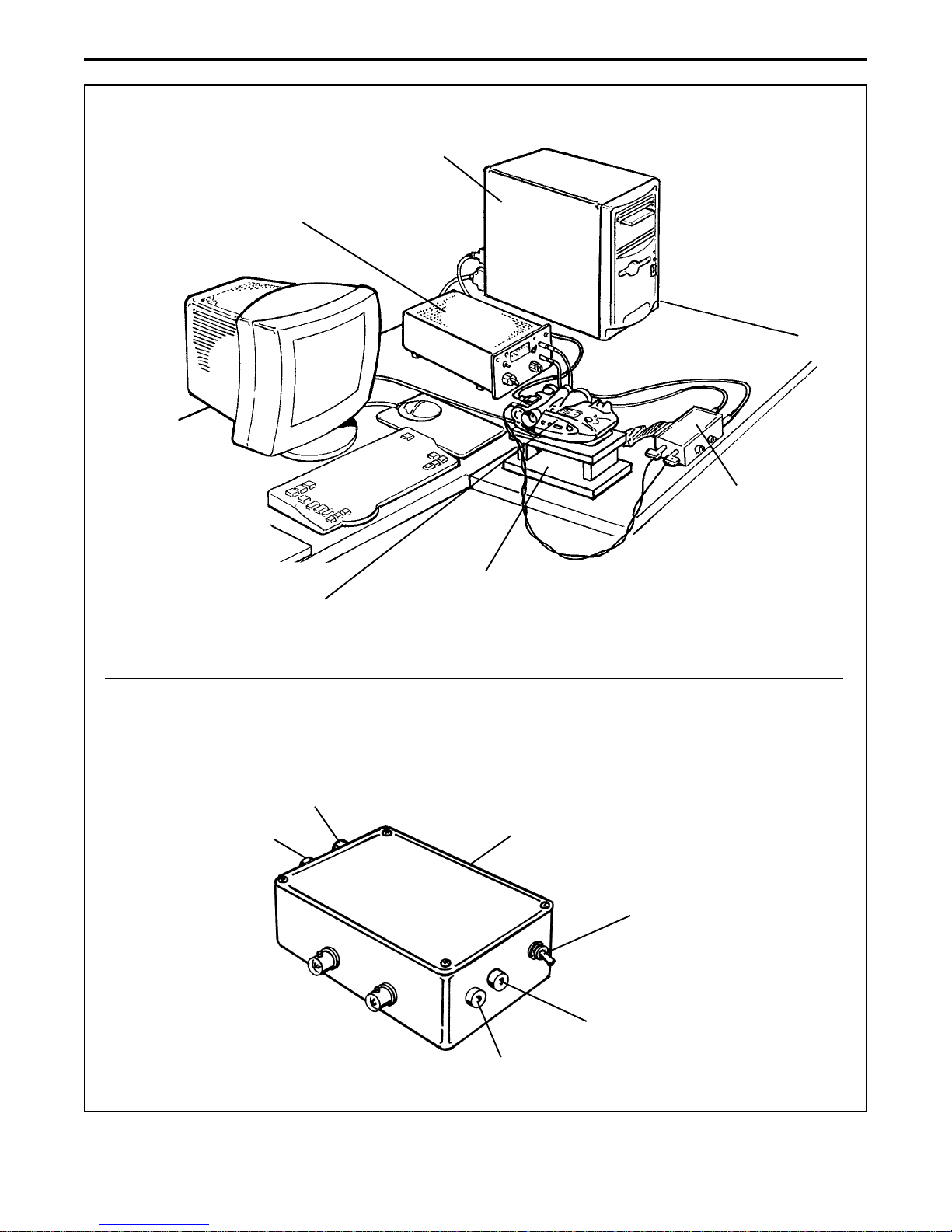

Equipment Setup (Figure 3-1)

1. Place the camera onto a workbench.

2. Connect the external power supply output cable to the 6 Vdc input on the 1-ohm resistor

box.

3. Connect the 1-ohm resistor box 6 Vdc output cable to the camera power jack.

4. Connect the computer ribbon cable to the 1-ohm resistor box.

5. Turn on the test equipment as follows:

• Macintosh Centris 650 computer On/Off (0/1) switch to On (1).

• 0 - 10 Vdc external power supply On/Off switch to On. Adjust power supply output to

6 Vdc.

19

PDC 2000/3000 Repair Manual Testing&Adjustment

Equipment

Setup

Macintosh Centris 650

Power PC

External Power

Supply (6 Vdc)

1-Ohm

Resistor Box

1-Ohm

Resistor Box

PDC2000/3000

Camera

6 Vdc - Out to PC

Grn

T est Fixture

(Nest)

Ribbon Cable - not shown

(Out to computer)

Manual/L V

(LabView)

Switch

6Vdc - In

(From external power supply)

Grn

Figure 3-1. Current profile equipment setup

20

PDC 2000/3000 Repair Manual Testing&Adjustment

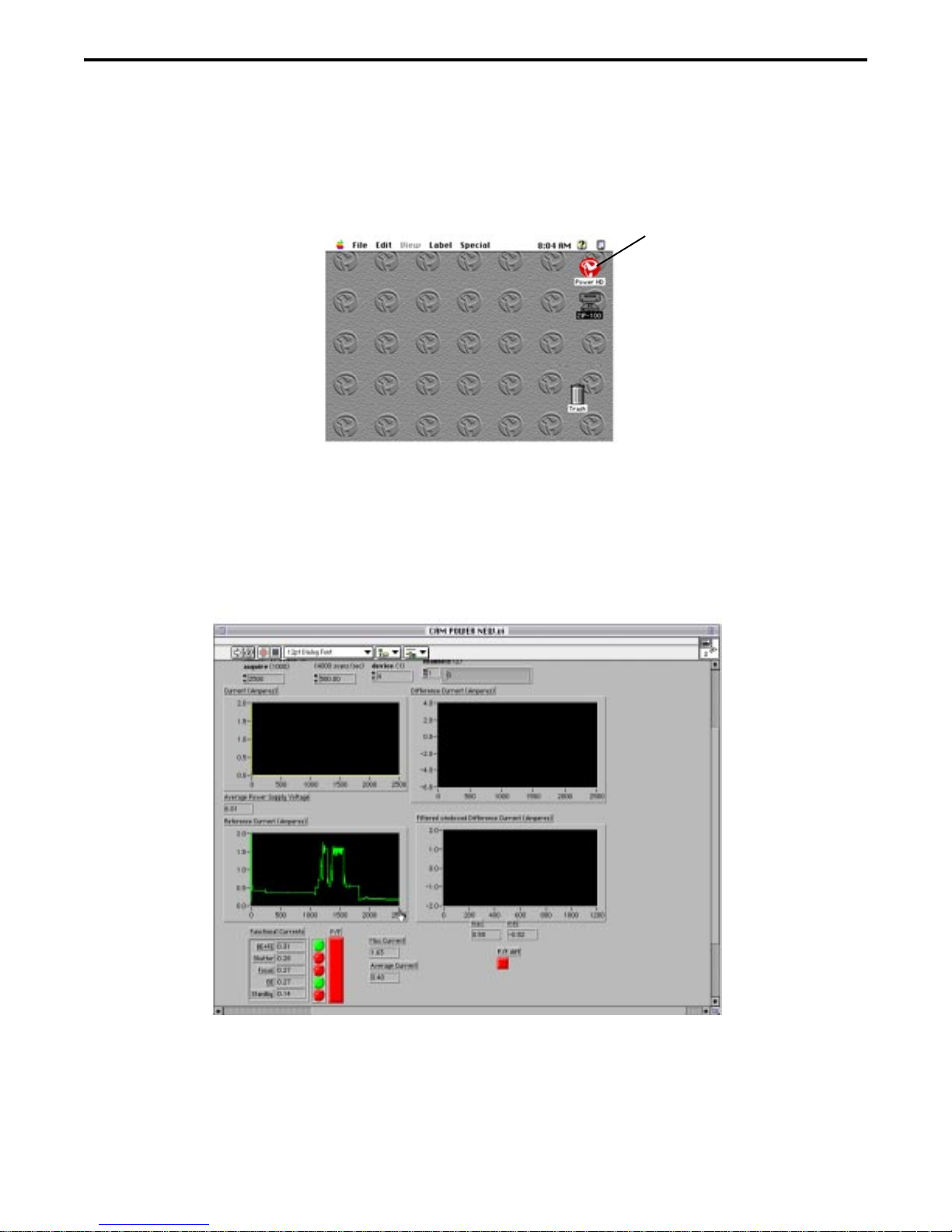

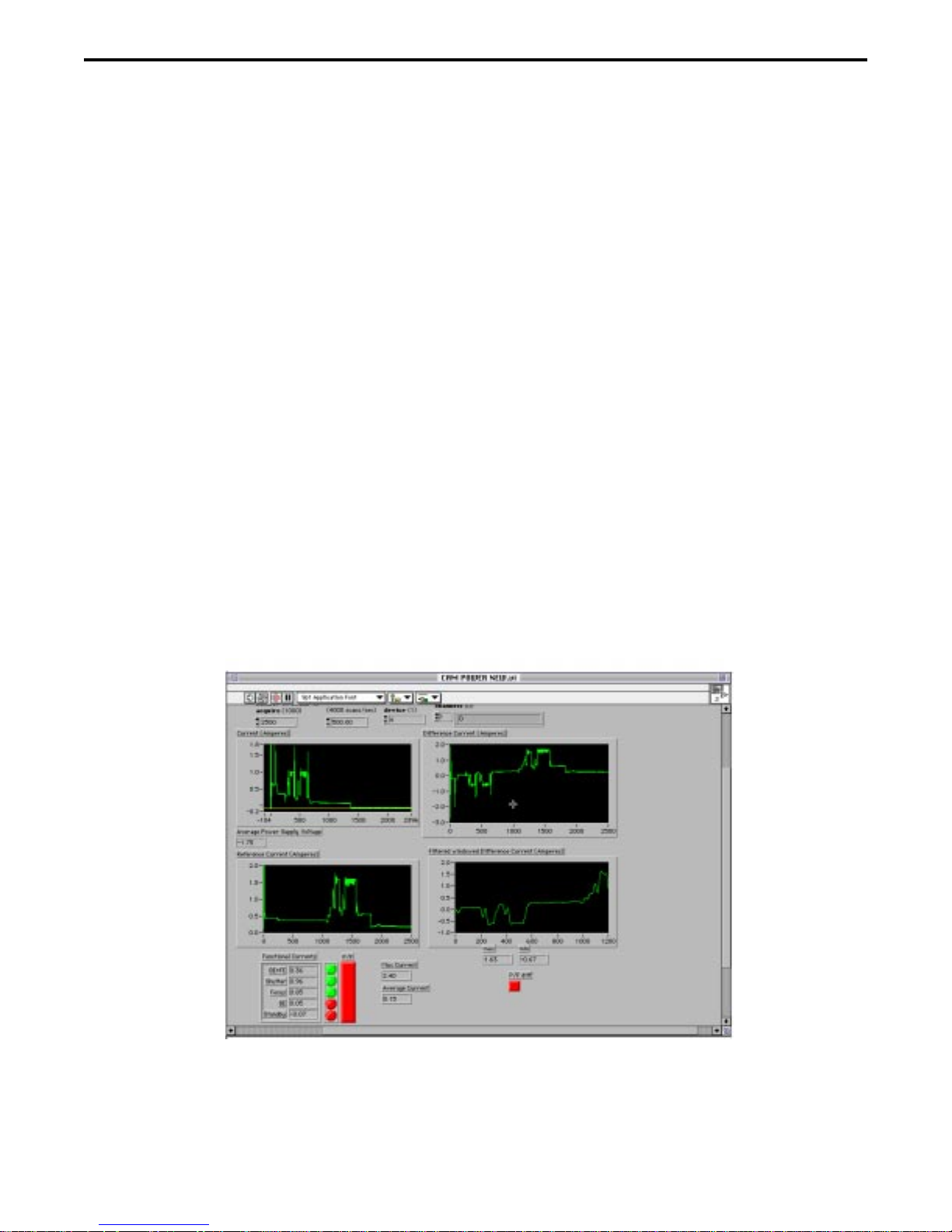

Test Procedure

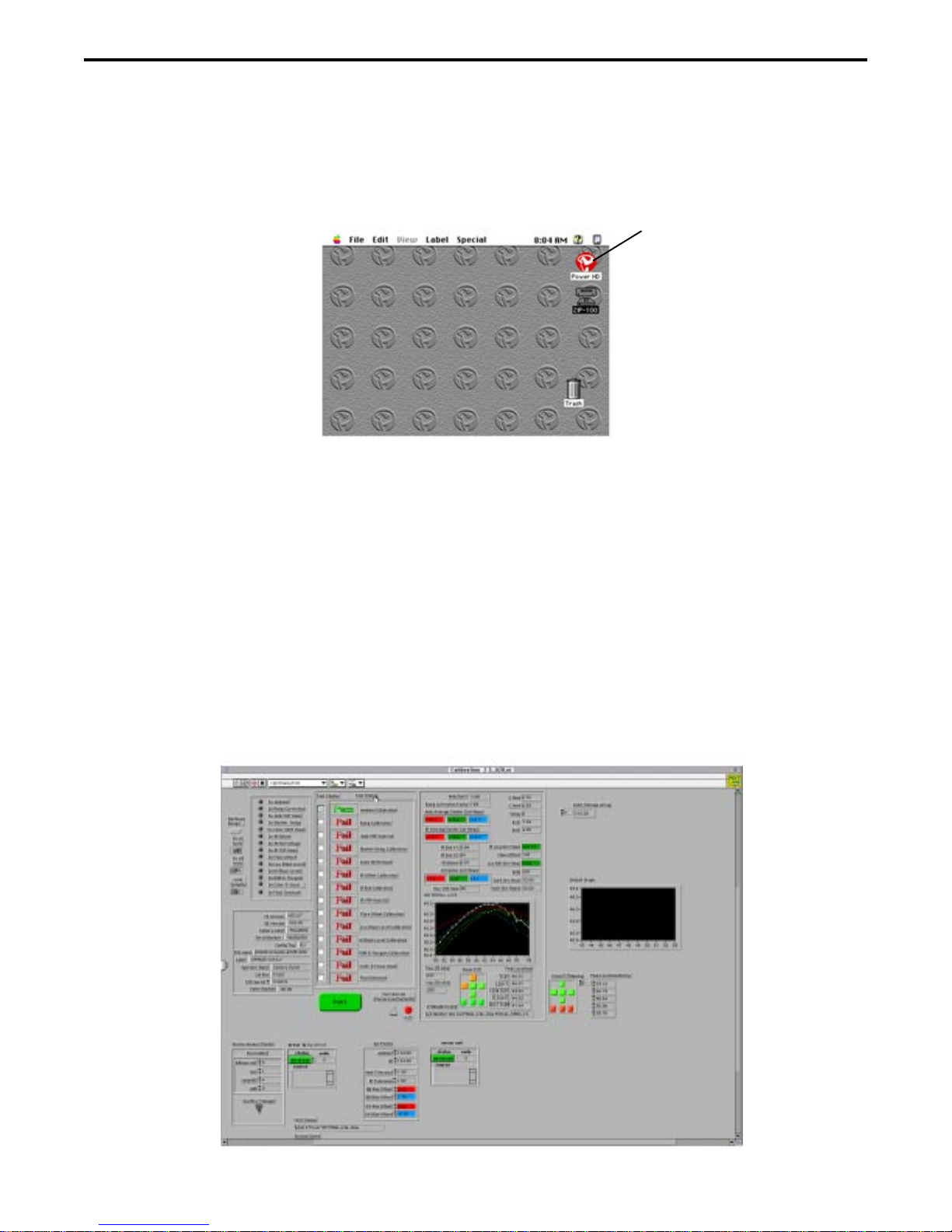

1. If applicable, enter user password.

2. Double click on the hard drive (HD) icon. The HD windows appears.

HD Icon

3. Double click on the Current Profile VI icon.

This action loads the specified LabView VI test program.

4. Once the LabView VI test program is loaded, the Cam Power New.VI panel appears.

5. Set the 1-ohm resistor box Manual/LV switch to Manual.

6. Turn on the digital camera under test.

Note: Make sure camera strobe is turned off.

21

PDC 2000/3000 Repair Manual Testing&Adjustment

7. Set the 1-ohm resistor box Manual/LV switch to LV (LabView).

8. Click on the white arrow. Arrow should change to black.

9. Click on the black arrow to start the selected LabView VI test program.

The test program starts as indicated by the yellow Running box directly under the black

start arrow.

Note: Follow all instructions that appear on the screen while the test program runs.

Click on the appropriate responses that appear in the dialog boxes.

10.Upon completion of the current profile test program, current waveforms for the following

appear:

• Current (Amperes) - Waveform should be smooth.

• Reference Current (Amperes) - Waveform should be smooth.

• Difference Current (Amperes) - Not used.

• Filtered Windowed Difference current (Amperes) - Not used.

Note: Spikes displayed in the current profile waveforms indicate that the camera is

defective. Refer to the camera troubleshooting section in the repair manual to

determine the cause of the camera malfunction and how to correct it.

22

PDC 2000/3000 Repair Manual Testing&Adjustment

Calibration

Required Test Equipment and Tools

• Power Computing Power PC or equivalent

• PDC2000 Switching Power Supply

• Camera SCSI Cable

• Camera Test Fixture (Nest)

• Keithly 485 AutoRanging Picoammeter or Equivalent

• Polaroid Model B Light Source (PDC Blue Box) with Photodiode

attached to glass

• Graywall Booth

• Diorama Test Bench

• PDC Diorama Camera Test Fixture (Nest)

• MacBeth Color Chart

• Neutral Density Filter

• Auxiliary Strobe

23

PDC 2000/3000 Repair Manual Testing&Adjustment

Equipment Setup (Figures 3-2 through 3-6)

Note: Figures 3-2 through 3-6 shows the equipment setup for the ambient, strobe and

color/focus parts of the calibration procedure.

1. Place the camera onto the test fixture (camera nest).

2. Connect the camera SCSI cable from the host computer SCSI connector to the camera

SCSI connector.

3. Connect the switching power supply cable to the camera’s external power connector.

4. If applicable, set the camera’s SCSI ID to 4.

5. If applicable, replace camera lens with an 11mm lens.

Note: 11mm lens is standard. Some camera’s come in for repair with the

optional 17mm lens attached.

For testing purposes the standard 11mm lens must be used.

6. Turn on the test equipment as follows:

• Power Computing PC On/Off (0/1) switch to On (1).

• Keithly 485 AutoRanging Picoammeter On/Off pushbutton to On. Adjust to ????.

• Model B Light Source Power On/Off rocker switch to On.

Note: Allow the Model B Light Source to warm up for approximately

five (5) minutes before use.

• Turn on the camera.

24

PDC 2000/3000 Repair Manual Testing&Adjustment

Camera Power

Power Computing

Power PC

Camera

SCSI Cable

Supply

Picoammeter

Model B

Light Box

Camera Nest

Photodiode

PDC 2000/3000

Camera

Graywall

Booth

Camera Power

Supply

Power Computing

Power PC

SCSI Cable

Figure 3-2. Ambient setup

PDC 2000/3000

Camera

Camera

Figure 3-3. Strobe setup

25

PDC 2000/3000 Repair Manual Testing&Adjustment

Diorama

Bench

Camera Power

Supply

Power Computing

Power PC

Camera

SCSI Cable

Macbeth Color

Checker Chart

Resolution

Neutral Density

Filter

Auxiliary

Strobe

Chart

PDC 2000/3000

Camera

Diorama

Camera Nest

Figure 3-4. Color and focus test (macbeth color checker chart)

Camera Power

Supply

Power Computing

Power PC

Camera

SCSI Cable

Diorama

Bench

Neutral Density

Checker/Resolution

T arget

Filter

Auxiliary

Strobe

PDC 2000/3000

Camera

Diorama

Camera Nest

Figure 3-5. Color and focus test (checker/resolution target in front of camera)

26

PDC 2000/3000 Repair Manual Testing&Adjustment

Camera Power

Supply

Power Computing

Power PC

Camera

SCSI Cable

Diorama

Bench

PDC 2000/3000

Camera

Neutral Density

Filter

Camera Nest

Auxiliary

Strobe

Diorama

Figure 3-6. Color and focus test (vertical)

27

PDC 2000/3000 Repair Manual Testing&Adjustment

Test Procedure

1. If applicable, enter user password.

2. Double click on the hard drive (HD) icon. The HD windows appears.

HD Icon

3. Double click on the PDC Calibration folder. The PDC Calibration window appears.

4. Double click on the applicable Calibration icon. The Calibration window appears.

Notes: • 40/60 hard drive camera type - click on V3.020 icon

• Tither camera type - click on V3.021 icon

5. Double click on the Calibration .iib icon. This action loads the specified LabView VI test

program.

6. Once the LabView VI test program is loaded, the Calibration front panel appears.

28

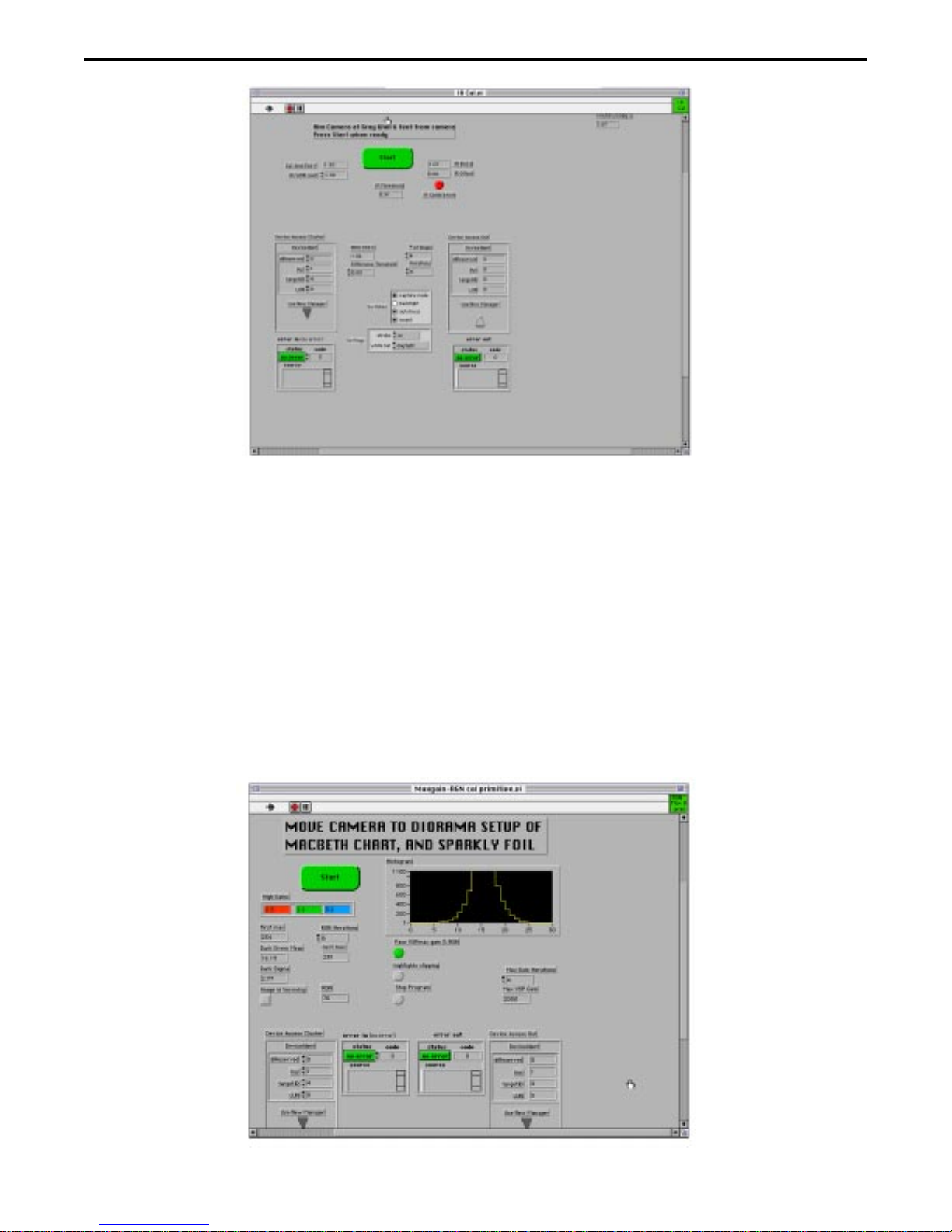

PDC 2000/3000 Repair Manual Testing&Adjustment

7. Set test parameters as follows: (Left side of VI front panel)

• Do no tests to OFF

• Do all tests to ON

• Load defaults to ON

8. Click on the white arrow. Arrow should change to black.

9. Click on the green Start button to automatically start the selected LabView VI test

program. The EEPROM calibration data panel appears.

Note: If the camera is not turned on, turn on the camera under test and then

repeat step 7 through 9.

10. Click on the Start button to automatically start the ambient part of this calibration

procedure.

Note: Follow all instructions that appear on the screen while the ambient part of this

calibration procedure runs. Click on the appropriate responses that appear in

the dialog boxes.

11. Upon completion of the ambient part of the calibration procedure, the IR CAL.VI panel

appears. This panel prompts you to move the camera under test to the Graywall Booth

(Figure 3-3).

29

PDC 2000/3000 Repair Manual Testing&Adjustment

12. Place the camera and nest onto the shelf in front of the Greywall Booth (Figure 3-3).

13. Click on the Start button to automatically start the strobe part of this calibration

procedure.

Note: Follow all instructions that appear on the screen while the strobe part of this

calibration procedure runs. Click on the appropriate responses that appear in

the dialog boxes.

14. Upon completion of the strobe part of the calibration procedure, a prompt appears

indicating that the camera be moved to the Diorama bench (Figure 3-4).

30

Loading...

Loading...