Page 1

User's Manual

ISW-504PS / ISW-514PS

ISW-514PS15 / ISW-514PSF

5-Port 10/100Mbps with

4-Port PoE Web Smart

Industrial Ethernet Switch

-1-

Page 2

Trademarks

Copyright © PLANET Technology Corp. 2010.

Contents subject to revise without prior notice.

PLANET is a registered trademark of PLANET Technology Corp. All other trademarks belong to their respective

owners.

Disclaimer

PLANET Technology does not warrant that the hardware will work properly in all environments and applications,

and makes no warranty and representation, either implied or expressed, with respect to the quality, performance,

merchantability, or fitness for a particular purpose.

PLANET has made every effort to ensure that this User’s Manual is accurate; PLANET disclaims liability for any

inaccuracies or omissions that may have occurred.

Information in this User’s Manual is subject to change without notice and does not represent a commitment on the

part of PLANET. PLANET assumes no responsibility for any inaccuracies that may be contained in this User’s

Manual. PLANET makes no commitment to update or keep current the information in this User’s Manual, and

reserves the right to make improvements to this User’s Manual and/or to the products described in this User’s

Manual, at any time without notice.

User’s Manual

If you find information in this manual that is incorrect, misleading, or incomplete, we would appreciate your

comments and suggestions.

FCC Warning

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15

of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the Instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

CE Mark Warning

This is a Class A product. In a domestic environment, this product may cause radio interference, in which case the

user may be required to take adequate measures.

Energy Saving Note of the Device

This power required device does not support Standby mode operation.

For energy saving, please remove the power cable to disconnect the device from the power circuit.

Without removing power cable, the device will still consuming power from the power source. In the view of Saving the

Energy and reduce the unnecessary power consuming, it is strongly suggested to remove the power connection for the

device if this device is not intended to be active.

-2 -

Page 3

WEEE Warning

To avoid the potential effects on the environment and human health as a result of the presence of

hazardous substances in electrical and electronic equipment, end users of electrical and electronic

equipment should understand the meaning of the crossed-out wheeled bin symbol. Do not dispose of

WEEE as unsorted municipal waste and have to collect such WEEE separately.

Revision

PLANET 5-Port 10/100Mbps with 4-Port PoE Web Smart Industrial Ethernet Switch User's Manual

FOR MODELS: ISW-504PS / ISW-514PS / ISW-514PS15 / ISW-514PSF

REVISION: 1.0 (JULY.2010)

Part No.: EM-ISW-5xxPS Series_v1.0 (2080-AH0240-000)

User’s Manual

-3 -

Page 4

User’s Manual

TABLE OF CONTENTS

1. INTRODUCTION ............................................................................................................7

1.1 PACKAGE CONTENTS................................................................................................................................. 7

1.2 PRODUCT DESCRIPTION .............................................................................................................................7

1.3 FEATURES.................................................................................................................................................8

1.4 SPECIFICATION ..........................................................................................................................................9

1.5 PRODUCT APPLICATION ........................................................................................................................... 11

2. INSTALLATION............................................................................................................12

2.1 HARDWARE DESCRIPTION ........................................................................................................................12

2.1.1 Physical Dimension......................................................................................................................... 12

2.1.2 Front Panel ..................................................................................................................................... 12

2.1.2 Front Panel ..................................................................................................................................... 13

2.1.3 LED Indicators ................................................................................................................................14

2.1.4 Switch Upper Panel ........................................................................................................................15

2.2 INSTALL THE SWITCH................................................................................................................................16

2.2.1 Installation Steps............................................................................................................................. 16

2.2.2 DIN-Rail Mounting........................................................................................................................... 16

2.2.3 Wall Mount Plate Mounting............................................................................................................. 19

2.3 WIRING THE POWER INPUTS .....................................................................................................................19

2.4 WIRING THE FAULT ALARM CONTACT....................................................................................................... 20

2.5 CABLING .................................................................................................................................................21

2.5.1 Installing the SFP transceiver (ISW-514PSF Only) ........................................................................ 21

2.5.2 Remove the module........................................................................................................................ 23

3 MANAGEMENT.............................................................................................................24

3.1 OVERVIEW............................................................................................................................................... 24

3.2 REQUIREMENTS .......................................................................................................................................24

3.3 MANAGEMENT METHOD ........................................................................................................................... 24

3.3.1 Web Management........................................................................................................................... 24

3.3.2 PLANET Smart Discovery Utility..................................................................................................... 27

4. WEB CONFIGURATION ..............................................................................................29

4.1 MAIN MENU ............................................................................................................................................. 29

4.2 WEB PANEL.............................................................................................................................................30

4.3 SYSTEM................................................................................................................................................... 31

-4 -

Page 5

User’s Manual

4.3.1 System Information ......................................................................................................................... 32

4.3.2 IP Configuration .............................................................................................................................. 33

4.3.3 Password Setting ............................................................................................................................ 34

4.3.4 Firmware Upgrade .......................................................................................................................... 34

4.3.5 Configuration Setting ...................................................................................................................... 38

4.3.6 Configuration Backup...................................................................................................................... 40

4.3.7 Managed IP..................................................................................................................................... 41

4.3.8 Fault Relay Alarm ........................................................................................................................... 41

4.3.9 Alert Trap Configuration.................................................................................................................. 42

4.3.10 System Reboot ............................................................................................................................. 43

4.4 PORT MANAGEMENT ................................................................................................................................44

4.4.1 Port Configuration ........................................................................................................................... 44

4.4.2 Port Status ...................................................................................................................................... 45

4.4.3 Port Security ................................................................................................................................... 46

4.5 VLAN .....................................................................................................................................................47

4.5.1 VLAN Group.................................................................................................................................... 50

4.5.2 VLAN Per Port Setting .................................................................................................................... 54

4.5.3 VLAN setting example: ...................................................................................................................56

4.6 QUALITY OF SERVICE...............................................................................................................................63

4.6.1 802.1p Tag Priority Mode................................................................................................................ 64

4.6.2 DSCP QoS Mode............................................................................................................................ 66

4.6.3 Port-Based Priority Mode................................................................................................................ 69

4.7 STORM CONTROL.....................................................................................................................................70

4.8 MISC CONFIGURATION ............................................................................................................................. 71

4.9 POE CONFIGURATION .............................................................................................................................. 73

4.9.1 Power over Ethernet Powered Device............................................................................................ 73

4.9.2 Power Management:....................................................................................................................... 73

4.10 LOGOUT ................................................................................................................................................76

5. SWITCH OPERATION..................................................................................................77

5.1 ADDRESS TABLE......................................................................................................................................77

5.2 LEARNING................................................................................................................................................77

5.3 FORWARDING & FILTERING ...................................................................................................................... 77

5.4 STORE-AND-FORWARD ............................................................................................................................ 77

5.5 AUTO-NEGOTIATION.................................................................................................................................78

-5 -

Page 6

User’s Manual

6. POWER OVER ETHERNET OVERVIEW.....................................................................79

7. THE POE PROVISION PROCESS...............................................................................82

7.1 LINE DETECTION......................................................................................................................................82

7.2 CLASSIFICATION ...................................................................................................................................... 82

7.3 START-UP................................................................................................................................................83

7.4 OPERATION .............................................................................................................................................83

7.5 POWER DISCONNECTION SCENARIOS........................................................................................................ 83

8. TROUBLESHOOTING..................................................................................................85

APPENDIX A NETWORKING CONNECTION .................................................................86

A.1 DATA OUT POE SWITCH RJ-45 PORT PIN ASSIGNMENTS (PORT 1 TO PORT-4)....................................... 86

A.2 10/100MBPS, 10/100BASE-TX ............................................................................................................... 86

APPENDIX B....................................................................................................................88

B.1 POWER OVER ETHERNET COMPATIBILITY TEST ......................................................................................... 88

B.2 COMPATIBLE 100BASE-FX SFP TRANSCEIVER LIST (ISW-514PSF)........................................................88

-6 -

Page 7

User’s Manual

1. INTRODUCTION

The PLANET Layer 2 Web Smart Industrial PoE Switch series – ISW-5xxPS is multiple 10/100Mbps ports Ethernet

Switched with 4-Port 802.3af PoE inject ability and robust layer 2 features; the description of these models as below:

ISW-504PS :

ISW-514PS :

ISW-514PS15 :

ISW-514PSF :

5-Port 10/100Mbps with 4-PoE Industrial Web Smart Switch (-10~60 Degree C)

4+1 100FX Port (SC) with 4-PoE Industrial Web Smart Switch - 2km (-10~60 Degree C)

4+1 100FX Port (SC) with 4-PoE Industrial Web Smart Switch - 15km (-10~60 Degree C)

4+1 100FX Port (LC) with 4-PoE Industrial Web Smart Switch (-10~60 Degree C)

1.1 Package Contents

Check the contents of your package for following parts:

Managed PoE Switch x1

User's Manual CD x1

Quick Installation Guide x1

DIN Rail Kit x 1

Wall Mount Kit x 1

If any of these pieces are missing or damaged, please contact your dealer immediately, if possible, retain the carton

including the original packing material, and use them against to repack the product in case there is a need to return it to us

for repair.

1.2 Product Description

The ISW-504PS / ISW-514PS series support MDI/ MDI-X convertible on 5 / 4-10/100Mbps ports, also provide PoE inject

function on port 1, 2, 3 and 4, which is able to drive 4 IEEE 802.3af compliant powered devices. The dual speed ports use

standard twisted-pair cabling and are ideal for SOHO or segmenting networks into small. Each 10/100Mbps port can

supports up to 200Mbps of throughput in full-duplex mode, ISW-504PS / ISW-514PS series also provides a simple,

cost-effective, and highly reliable network connection for data transmits. Furthermore, it is the ideal device for bridging

among Ethernet, Fast Ethernet workgroups and networks.

With 4 PoE interfaces, the ISW-504PS / ISW-514PS series is ideal for small business and workgroups requiring to deploy

the PoE for the wireless access points, IP-based surveillance camera or IP phones in any places easily, efficiently and cost

effective.

The front panel of ISW-504PS / ISW-514PS series provides LEDs for easy recognition of the switch operation status and

troubleshooting. These LED indicators display the power status for the system, LNK/ACT and speed for each10/100M

port. Also the PoE in use LED indicates for PoE ports (port 1 to port 4).

With data and power over Ethernet from one unit, the ISW-504PS / ISW-514PS series shall reduce cables and eliminates

the need for dedicated electrical outlets on the wall, ceiling or any unreachable place. A wire carries both data and power

lowering the installation costs, simplifying the installation effort and eliminating the need for electricians or extension cords.

-7 -

Page 8

User’s Manual

The smart functions make it easy to survey and control the PoE power provision to the devices by the Web interface. Basic

switching functions such as VLAN, bandwidth control and QoS are available for network management.

With Fast Ethernet SFP interface, the ISW-514PSF is with high reliability and flexibility to extend the distance from 2km to

20Km. It depends on the MFB family Fast Ethernet SFP modules.

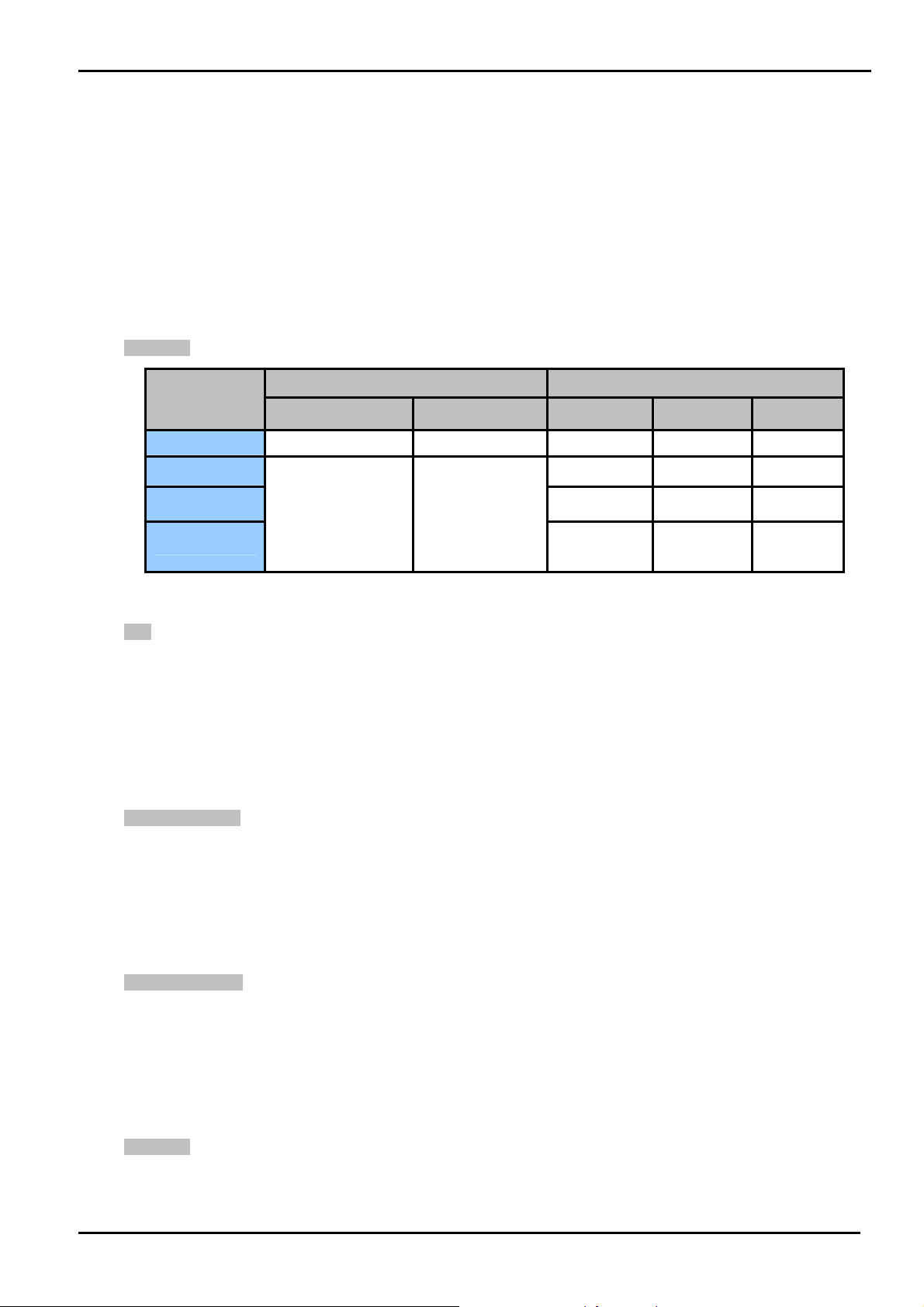

1.3 Features

¾ Interfaces

Model Name

Copper Optical Mode Connector Distance

ISW-504PS

ISW-514PS

ISW-514PS15

ISW-514PSF

4-Port support 48V DC power to PoE Powered Device

¾ PoE

Comply with IEEE 802.3af Power over Ethernet End-Span PSE

Up to 4 IEEE 802.3af devices powered

Support PoE Power up to 15.4 Watts for each PoE ports

Auto detect powered device (PD)

Circuit protection prevent power interference between ports

Remote power feeding up to 100m

¾ PoE Management

5 x 10/100Base-TX NA NA NA NA

4 x 10/100Base-TX 1 x 100Base-FX

Ports Fiber Optical Interface

Multi-Mode SC 2km

Single-Mode SC 15km

Optional SFP

Module

LC

Depend on

SFP

Module

Total PoE power budget control

Enable / Disable PoE function on each port

PoE port Power feeding priority

Power limit on PoE port

PD classification detection

¾ Web Management

Web interface for remote management

Firmware upgrade through Web interface

SNMP Trap for alarm notification of events

VLAN and QoS configuration

PLANET Smart Discovery utility automatically finds PLANTE devices on the network

¾ Switching

Complies with IEEE 802.3 10Base-T, IEEE 802.3u 100Base-TX / 100Base-FX Ethernet standard

Supports Auto-Negotiation and 10/100Mbps Half / Full Duplex and Auto MDI / MDI-X

-8 -

Page 9

High performance Store and Forward architecture, Storm Control and runt/CRC filtering eliminates erroneous

packets to optimize the network bandwidth

Prevents packet loss with back pressure (Half-Duplex) and IEEE 802.3x PAUSE Frame flow control

(Full-Duplex)

Backplane (Switching Fabric): 1Gbps

Automatic address learning and address aging

Integrated address look-up engine, support 1K absolute MAC addresses

CSMA/CD Protocol

¾ Industrial Case / Installation

IP-30 Aluminum case / Protection

DIN Rail and Wall Mount Design

24 or 48V DC, redundant power with polarity reverse protect function

Supports EFT protection 6000V DC for power line

Supports 6000V DC Ethernet ESD protection

-10 to 60 Degree C operation temperature

User’s Manual

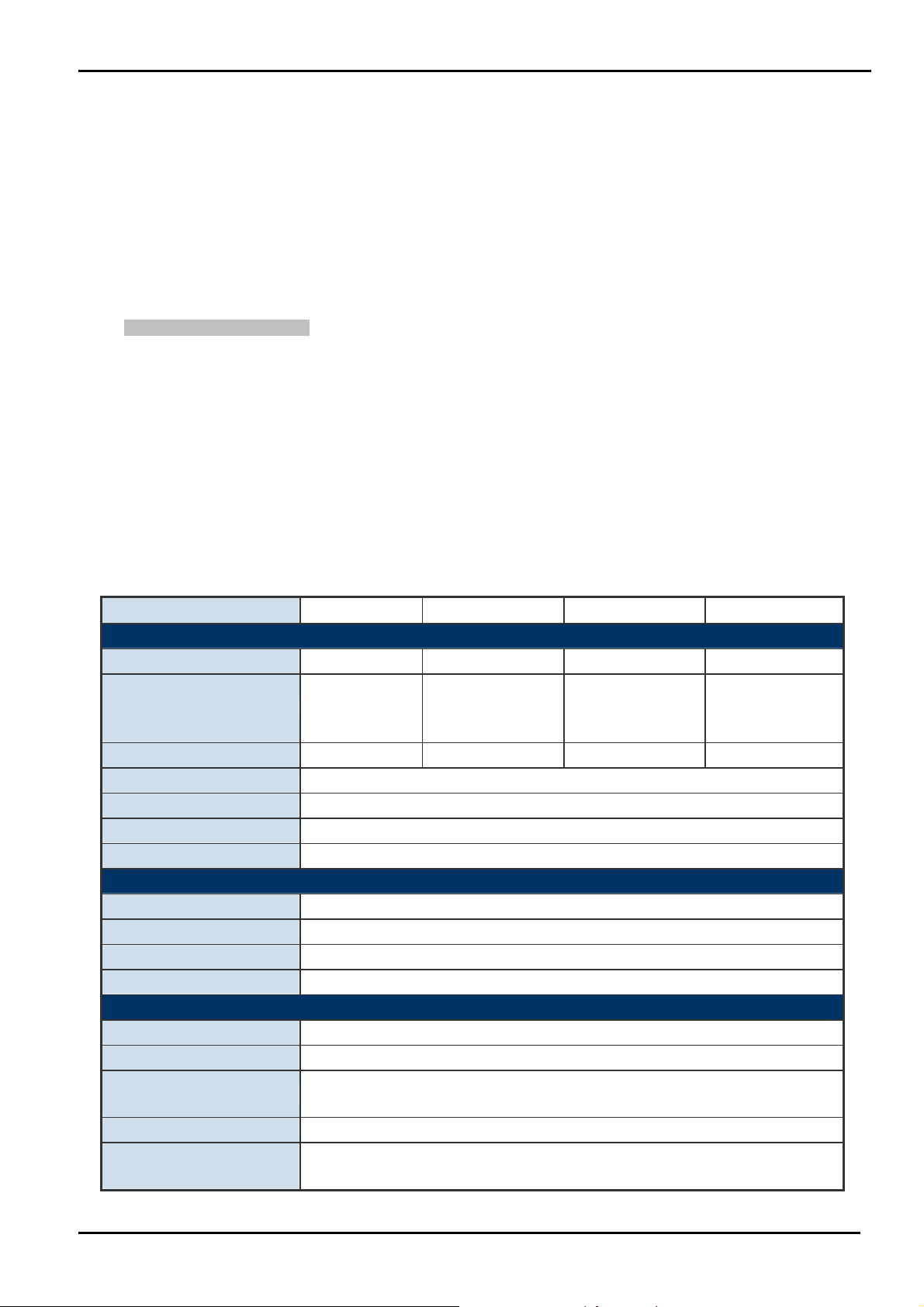

1.4 Specification

Model ISW-504PS ISW-514PS ISW-514PS15 ISW-514PSF

Hardware Specification

10/100Base-TX Ports 5 4 4 4

1

100Base-FX Interface N/A

IEEE 802.3af PoE Ports 4 4 4 4

Dimensions (D x W x H) 135mm x 87.8mm x 56mm

Weight 871g

Power Requirement 24 or 48V DC

Installation DIN Rail Kit and Wall Mount Ear

(SC-Multi Mode,

2km)

(SC-Single Mode,

Power Over Ethernet

PoE Standard IEEE 802.3af Power over Ethernet / PSE

PoE Power Supply Type End-Span

PoE Power Output 48V DC Per Port, 350mA . Max. 15.4 Watts

Power Pin Assignment 1/2(+), 3/6(-)

Switch Specification

Switch Processing Scheme Store-and-Forward

Address Table 1K entries

Flow Control

Switch Fabric 1Gbps

Throughput

(Packet Per Second)

Back Pressure for Half Duplex

IEEE 802.3x Pause Frame for Full Duplex

0.74Mpps

1

15km)

1

(LC-Opitional SFP

module )

-9 -

Page 10

10/100Base-TX:

Cat. 3, 4, 5, 5e, 6 UTP cable (100meters max.)

EIA/TIA-568 100-ohm STP (100meters max.)

Network Cables

Multi-mode optic fiber

NA

62.5/125μm,

50/125μm (2km max.).

Layer 2 Function

Management Web management, SNMP Trap

• Port-Based VLAN

VLAN

QoS

• IEEE 802.1Q Tag-Based VLAN

Up to 16 VLAN groups

2 priority queues for three type of Class of Service

• Port-Based

• IEEE 802.1p priority tag

• TCP/IP header’s DSCP classifier

Weighted Round Robin queue scheduling

Single-mode optic

fiber 9/125μm (15km

max.).

User’s Manual

Multi-mode optic

fiber 62.5/125μm,

50/125μm

Single-mode optic

fiber 9/125μm

(Vary on SFP

Module)

Bandwidth Control Inbound Rate Limit and Outbound Traffic shaping

Storm Control Disable, 12.5%, 25%, 50%, 62.5% 4 levels

Standards Conformance

IEEE 802.3 Ethernet

IEEE 802.3u Fast Ethernet

Standards Compliance

Temperature

Humidity Operating: 5~90%, Storage: 5~90% (Non-condensing)

Regulation Compliance FCC Part 15 Class A, CE

Stability Testing

IEEE 802.3x Full-Duplex Flow Control

IEEE 802.3af Power over Ethernet

IEEE 802.1Q VLAN

IEEE 802.1p Class of Service

Operating: -10 to 60℃

Storage: -40 to 70℃

IEC60068-2-32(Free Fall)

IEC60068-2-27(Shock)

IEC60068-2-6(Vibration)

-10 -

Page 11

User’s Manual

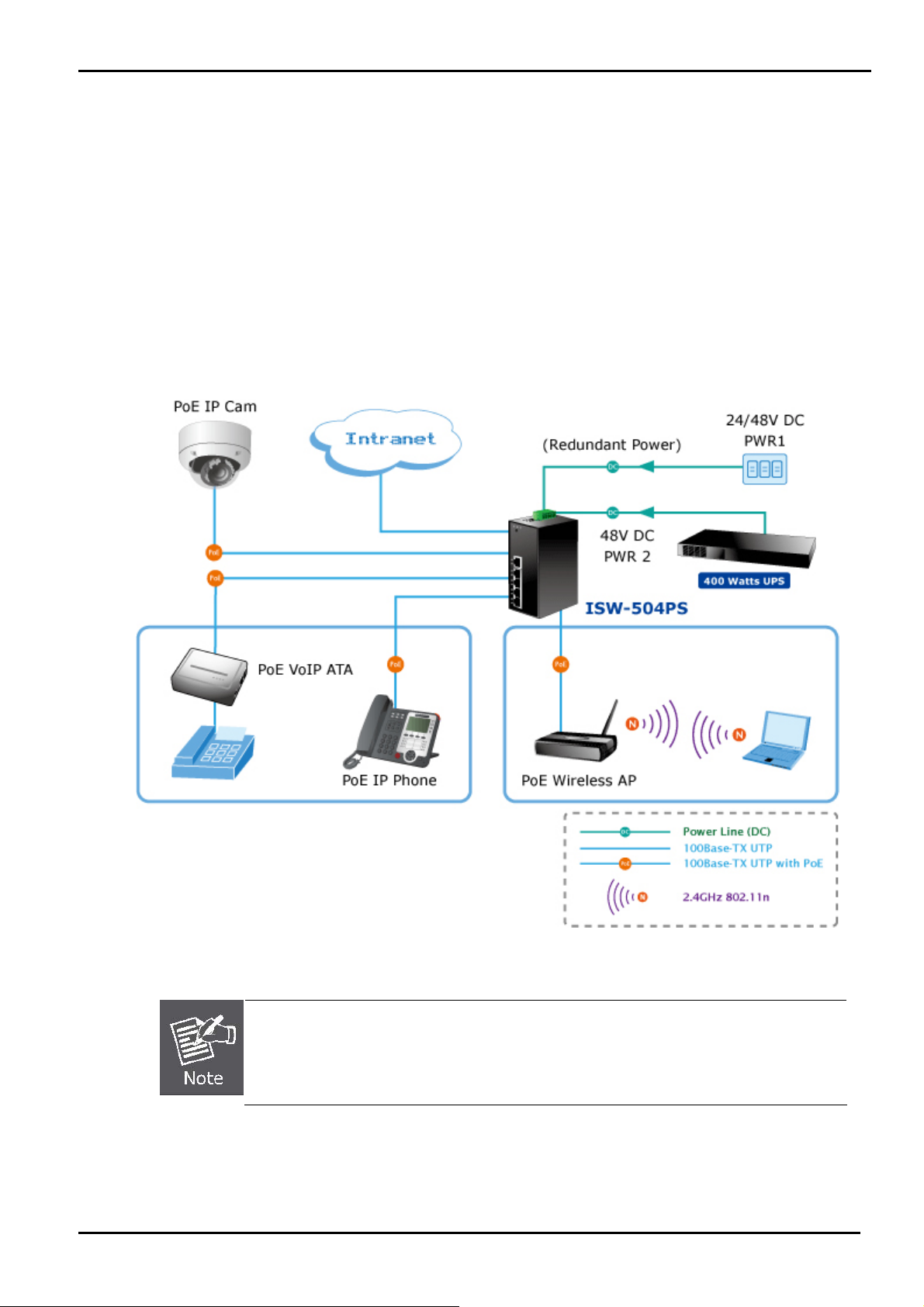

1.5 Product Application

As a department / workgroup PoE Switch

Providing up to 4 PoE, in-line power interface, the Industrial PoE Switch can easily build a power central-controlled IP

phone system, IP Camera system, AP group for the enterprise. For instance, 4 camera / AP can be easily installed around

the corner in the company for surveillance demands or build a wireless roaming environment in the office. Without the

power-socket limitation, the Industrial PoE Switch makes the installation of cameras or WLAN AP more easily and

efficiently.

Figure 1-1 PoE Switch connection

Cable distance for Switch

1. The UTP/STP cable distances between PCs should not exceed 100 meters.

2. The Fiber Optic cable distances between PCs should not exceed maximum distance support

by each model.

-11 -

Page 12

User’s Manual

2. INSTALLATION

2.1 Hardware Description

The ISW-504PS / ISW-514PS series provide two different running speeds – 10Mbps, 100Mbps in the same Switch and

automatically distinguish the speed of incoming connection.

This section describes the hardware features of ISW-504PS / ISW-514PS series. For easier management and control of

the Switch, familiarize yourself with its display indicators, and ports. Front panel illustrations in this chapter display the unit

LED indicators. Before connecting any network device to the ISW-504PS / ISW-514PS series, read this chapter carefully.

In the following section, the term “Industrial PoE Switch” means the ISW-504PS / ISW-514PS / ISW-514PS15 /

ISW-514PSF.

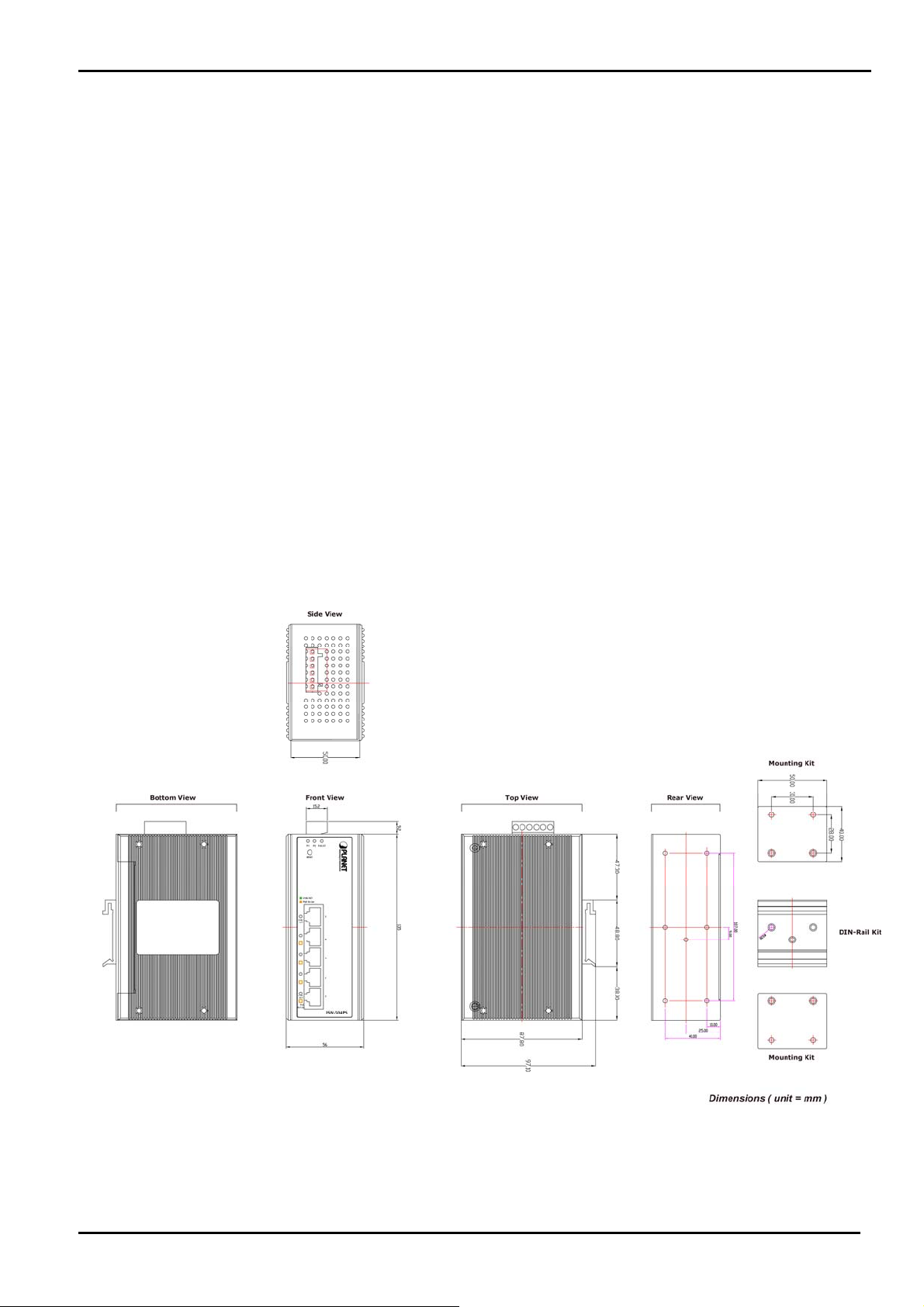

2.1.1 Physical Dimension

ISW-5xxPS series Web Smart Industrial Switch dimension (D x W x H) : 135mm x 87.8mm x 56mm

-12 -

Page 13

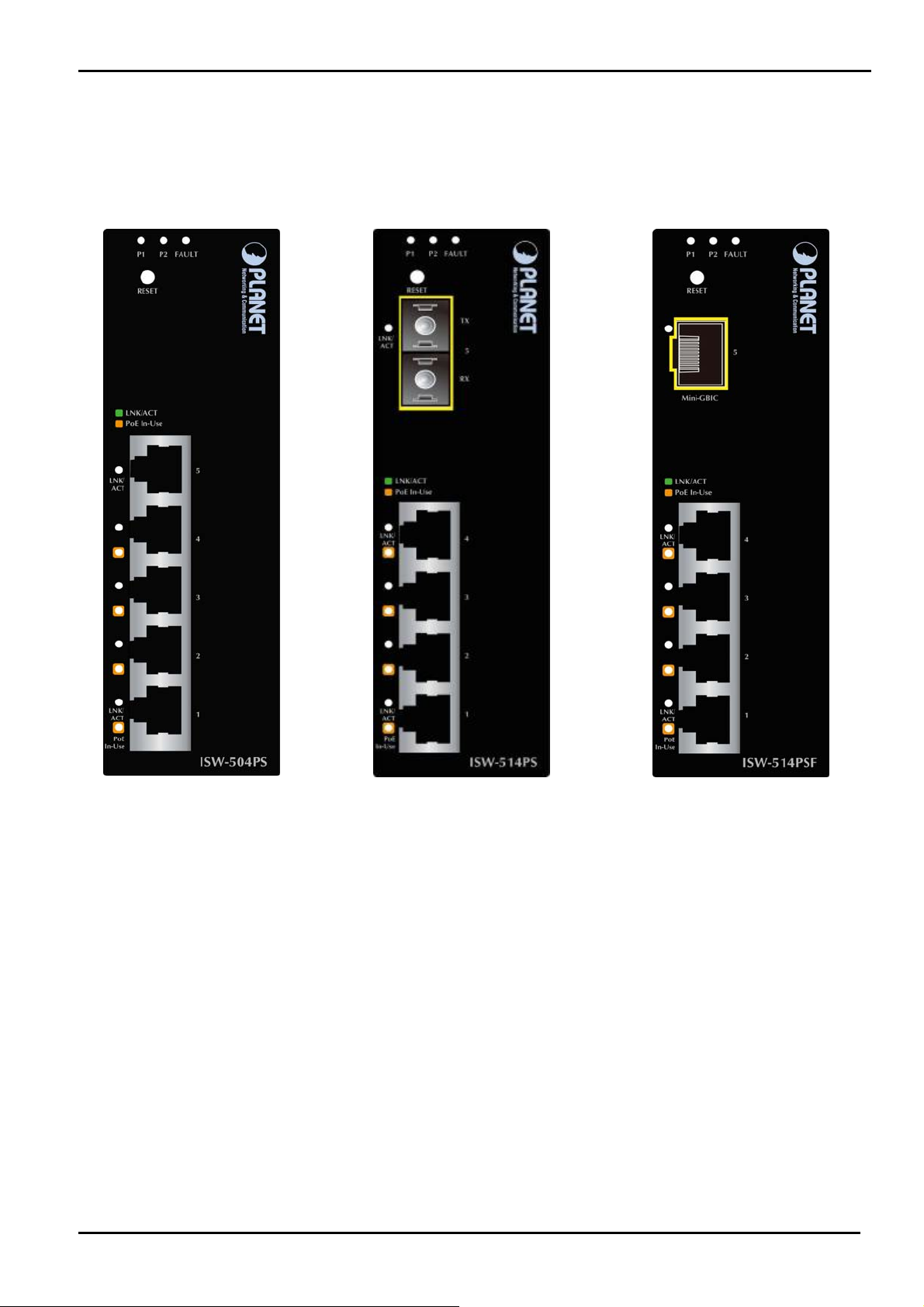

2.1.2 Front Panel

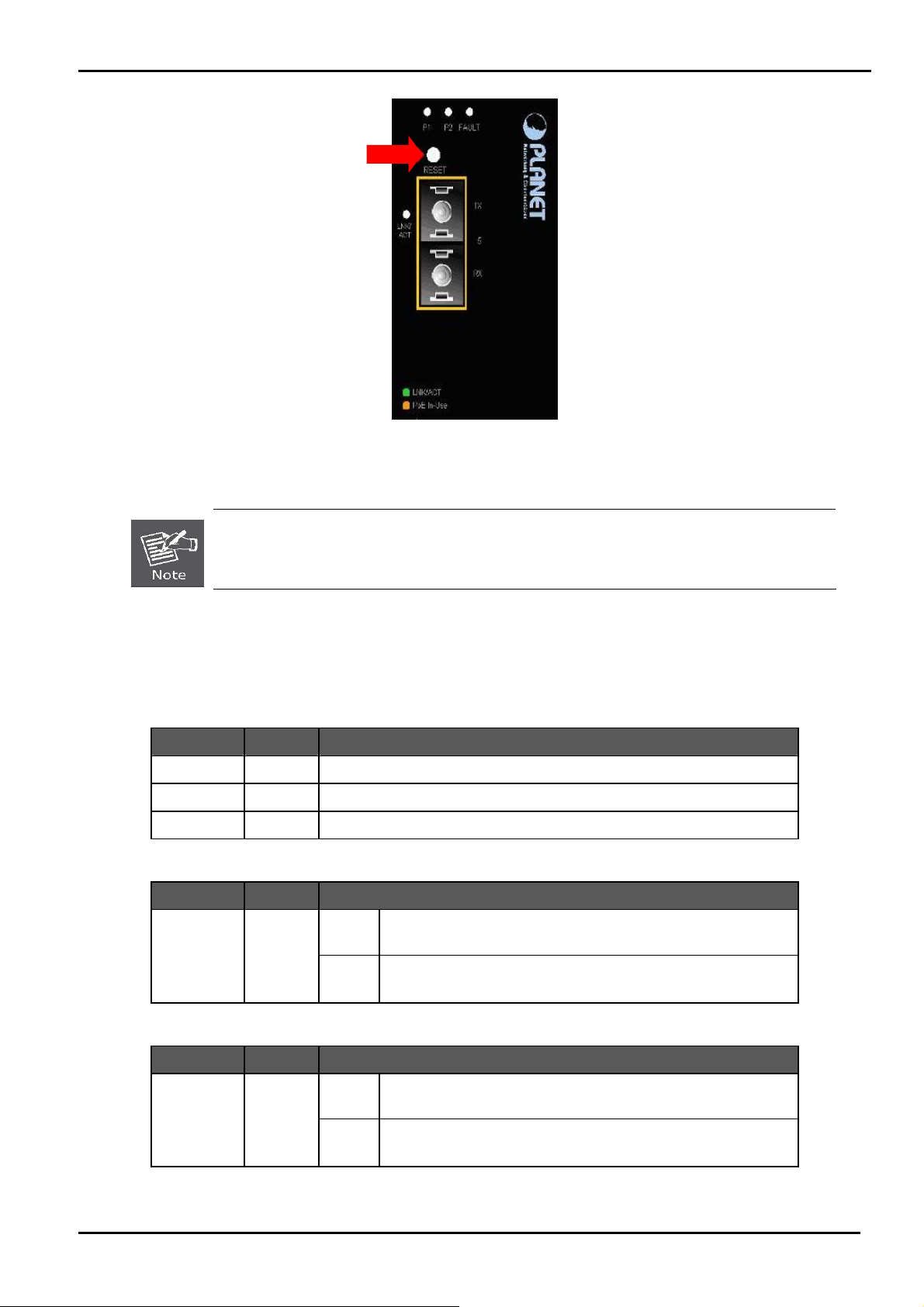

Figure 2-1 shows a front panel of Industrial PoE Switch.

User’s Manual

Figure 2-1 ISW-504PS and ISW-514PS / ISW-514PS15 and ISW-514PF Switch front panel

■ Reset Button

At the left of front panel, the reset button is designed for reboot the Industrial PoE Switch without turn off and on the

power, also can reset the Industrial PoE Switch to factory default mode.

-13 -

Page 14

User’s Manual

Figure 2-2 Reset button of Industrial PoE Switch

1. Press the RESET button once. The Industrial PoE Switch will reboot automatically.

2. Press the RESET button for 5 seconds. The Industrial PoE Switch will back to the factory

default mode; the entire configuration will be erased.

2.1.3 LED Indicators

System

LED Color Function

P1 Green Indicate the power 1 has power.

P2 Green Indicate the power 2 has power.

Fault Green Indicate the either power 1 or power 2 has no power.

Per 10/100Base-TX Port

LED Color Function

LNK / ACT Green

Light

Blink

Indicate the link through that port is successfully

established at 10 or 100Mbps.

Indicate that the Switch is actively sending or receiving

data over that port.

Per 100Base-FX Port

LED Color Function

LNK/ ACT Green

Light

Blink

Indicate the link through that port is successfully established

at 10 or 100Mbps.

Indicate that the Switch is actively sending or receiving data

over that port.

-14 -

Page 15

User’s Manual

PoE Port

LED Color Function

PoE In Use Orange Indicate the port is providing 48V DC in-line power. (1-4 ports)

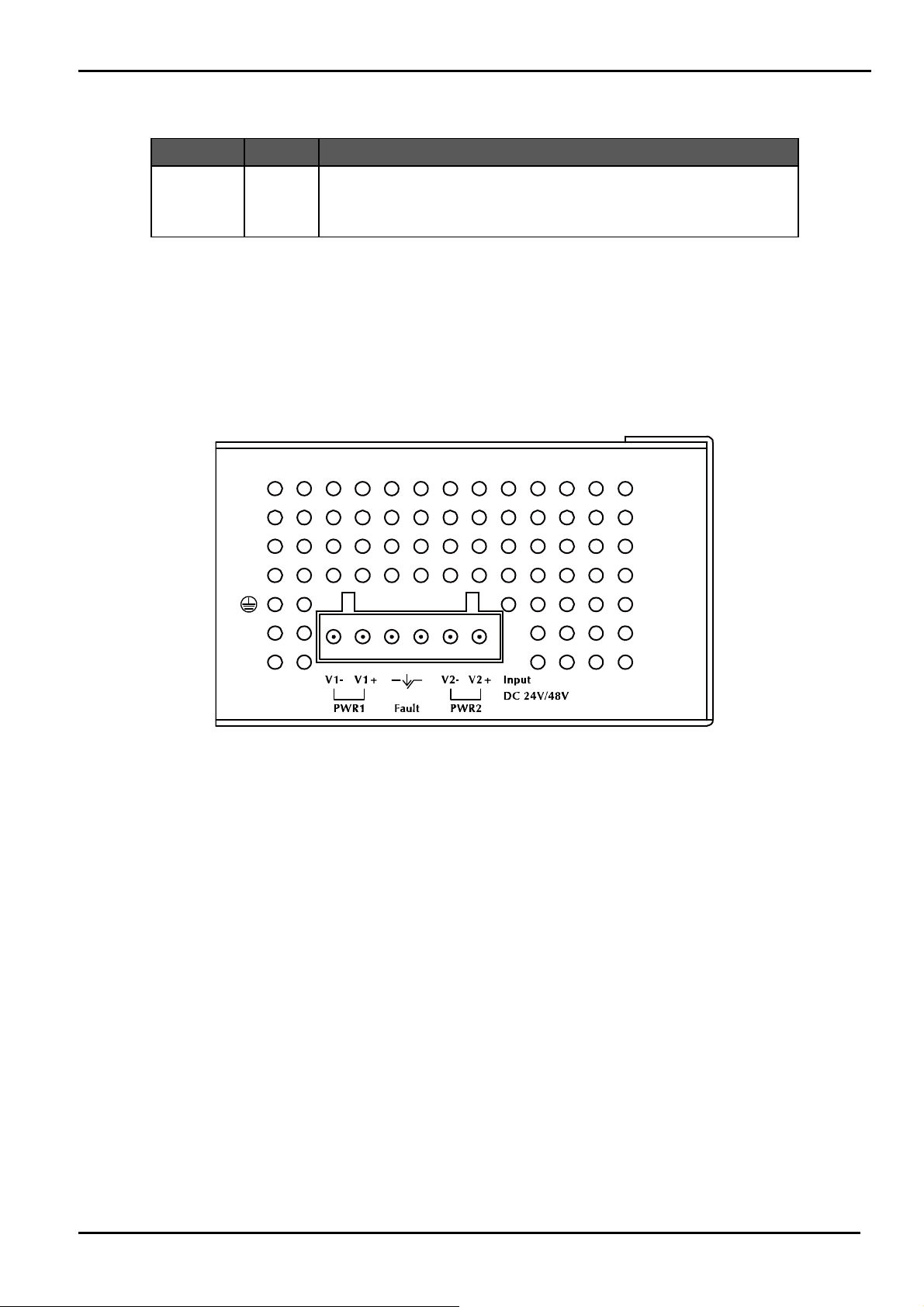

2.1.4 Switch Upper Panel

The Upper Panel of the Industrial PoE Switch indicates a DC inlet power socket and consist one terminal block connector

within 6-contacts. It accepts input power from 24 or 48V DC.

Figure 2-3 Industrial PoE Switch Upper Panel

-15 -

Page 16

User’s Manual

2.2 Install the switch

This section describes how to install your Managed Industrial Switch and make connections to the Managed Industrial

Switch. Please read the following topics and perform the procedures in the order being presented. To install your switch on

a desktop or shelf, simply complete the following steps.

In this paragraph, we will describe how to install the Industrial Switch and the installation points attended to it.

2.2.1 Installation Steps

1. Unpack the Indu strial switch

2. Check if the DIN-Rail is screwed on the Industrial switch or not. If the DIN-Rail is not screwed on the Industrial

switch, please refer to DIN-Rail Mounting section for DIN-Rail installation. If users want to wall mount the Industrial

switch, please refer to Wall Mount Plate Mounting section for wall mount plate installation.

3. To hang the Industrial switch on the DIN-Rail track or wall.

4. Power on the Industrial switch. Please refer to the Wiring the Power Inputs section for knowing the information

about how to wire the power. The power LED on the Industrial switch will light up. Please refer to the LED Indicators

section for indication of LED lights.

5. Prepare the twisted-pair, straight through Category 5 cable for Ethernet connection.

6. Insert one side of RJ-45 cable (category 5) into the Industrial s witch Ethernet port (RJ-45 port) and another side

of RJ-45 cable (category 5) to the network device’s Ethernet port (RJ-45 port), ex: Switch PC or Server. The UTP

port (RJ-45) LED on the Industrial switch will light up when the cable is connected with the network device. Please

refer to the LED Indicators section for LED light indication.

Make sure that the connected network devices support MDI/MDI-X. If it does not support, use

the crossover category-5 cable.

7. When all con nections are set and LED lights all show in normal, the installation is complete.

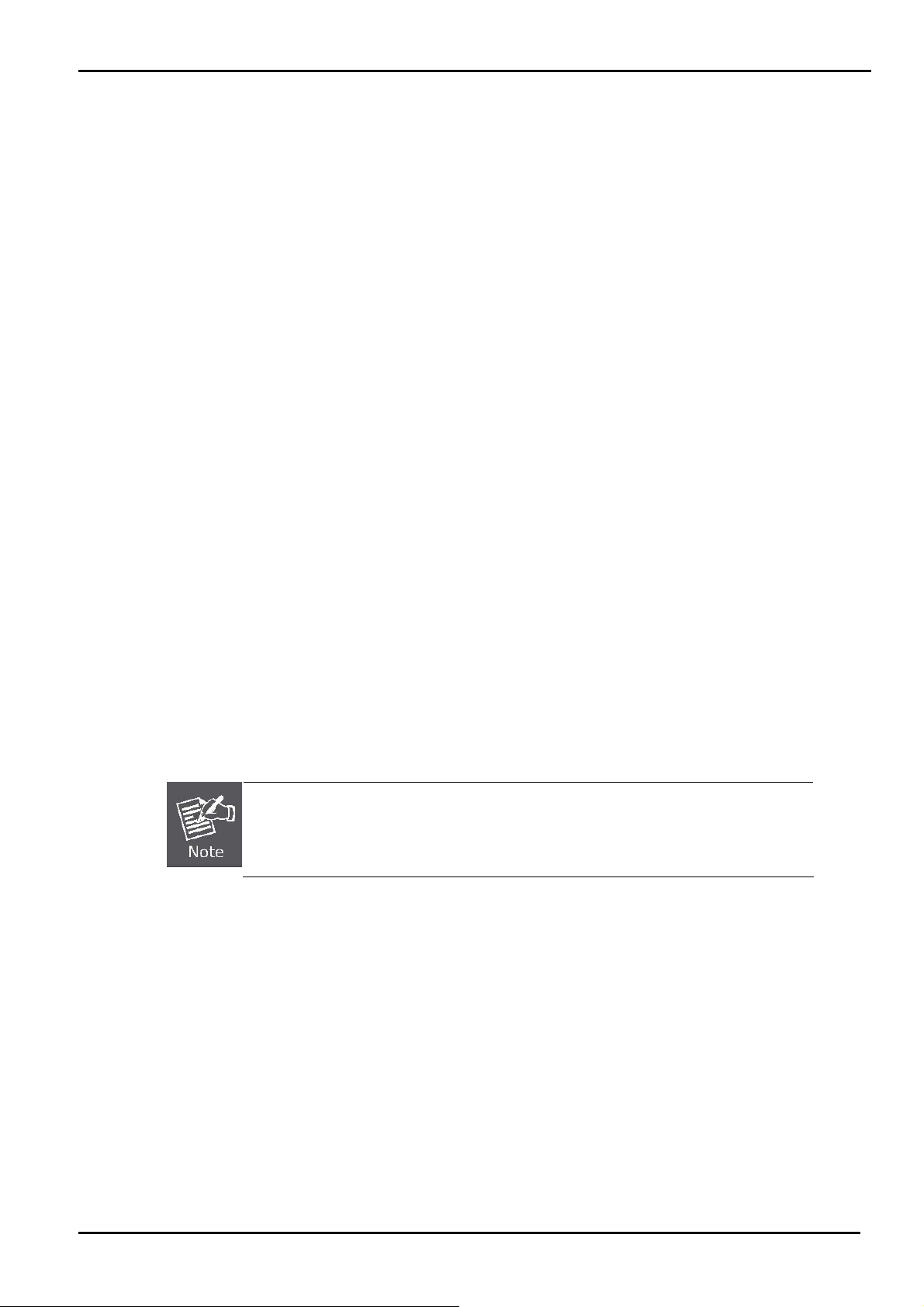

2.2.2 DIN-Rail Mounting

This section describes how to install the Industrial PoE Switch.

There have two methods to install the Industrial PoE Switch. DIN-Rail Mounting and Wall Mount Plate Mounting. Please

read the following topics and perform the procedures in the order being presented.

-16 -

Page 17

Step 1: Screw the DIN-Rail on the Industrial PoE Switch.

User’s Manual

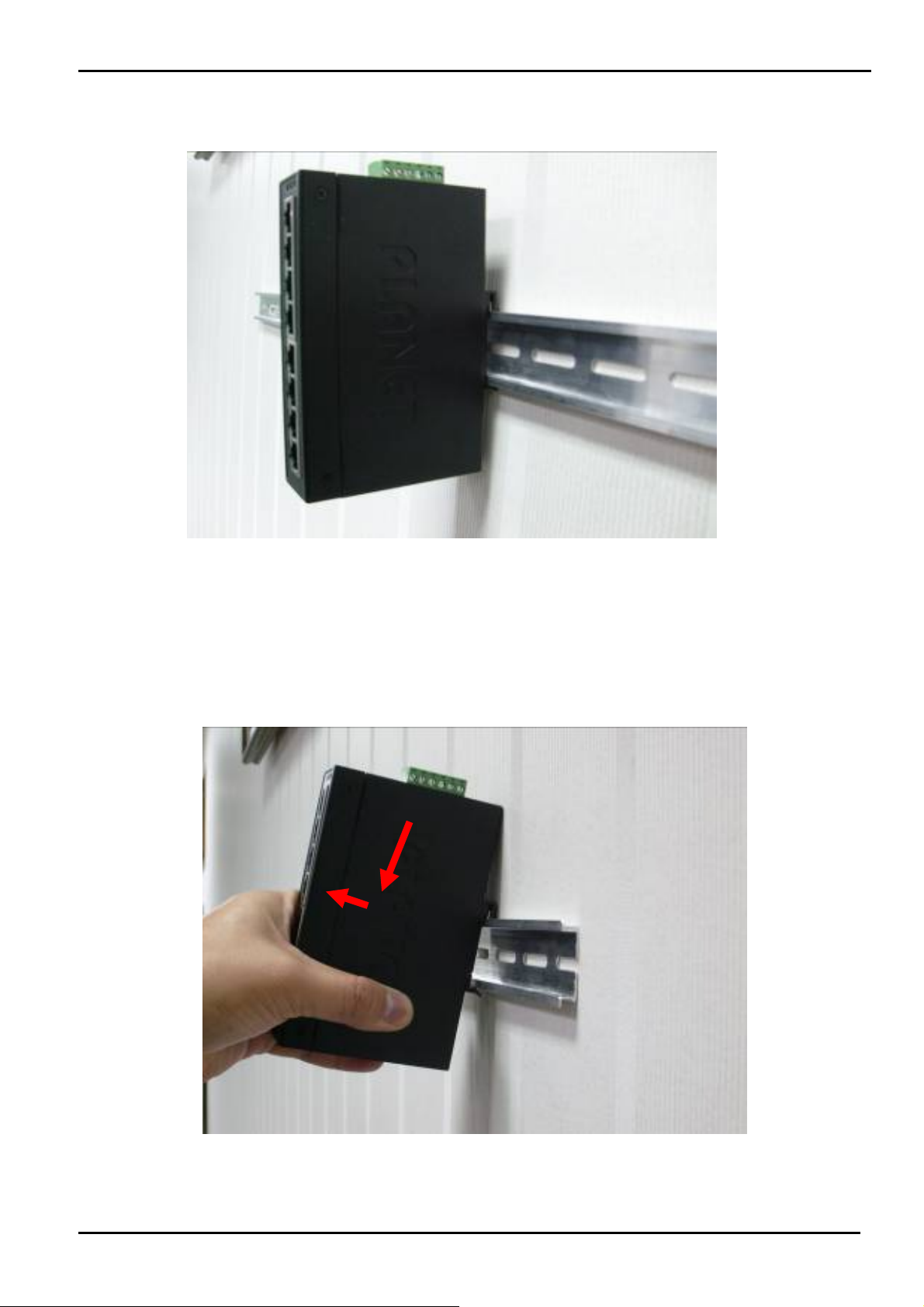

Step 2: Lightly press the button of DIN-Rail into the track.

-17 -

Page 18

Step 3: Check the DIN-Rail is tightly on the track.

User’s Manual

Please refer to following procedures to remove the Industrial PoE Switch from the track.

Step 5: Lightly press the button of DIN-Rail for remove it from the track.

-18 -

Page 19

User’s Manual

2.2.3 Wall Mount Plate Mounting

To install the Industrial PoE Switch on the wall. Please follow the instructions below.

Step 1: Remove the DIN-Rail from the Industrial PoE Switch. Use the screwdriver to loose the screws and remove the

DIN-Rail.

Step 2: Place the wall mount plate on the rear panel of the Industrial PoE Switch.

Step 3: Use the screwdriver to screw the wall mount plate on the Industrial PoE Switch.

Step 4: Use the hook holes at the corners of the wall mount plate to hang the Industrial PoE Switch on the wall.

Step 5: To remove the wall mount plate, reverse steps above.

2.3 Wiring the Power Inputs

The 6-contacts terminal block connector on the top panel of Industrial PoE Switch is used for two DC redundant power

inputs. Please follow the steps to insert the power wire. The PWR1 is 1(-) & 2(+) and PWR2 is 5(-) & 6(+) contact.

Remember: Tighten the wire-clamp screws for preventing the wires from loosing.

-19 -

Page 20

Power Notice:

User’s Manual

1 2 3 4 5 6

Power 1 Fault Power 2

- + - +

Figure 2-4: 6-Contacts of Terminal Block Connector

1. The wire gauge for the terminal block should be in the range between 12 ~ 24 AWG.

2. Performing any of the procedures like inserting the wires or tighten the wire-clamp screws. Ensure

the power is OFF to prevent to get an electric shock.

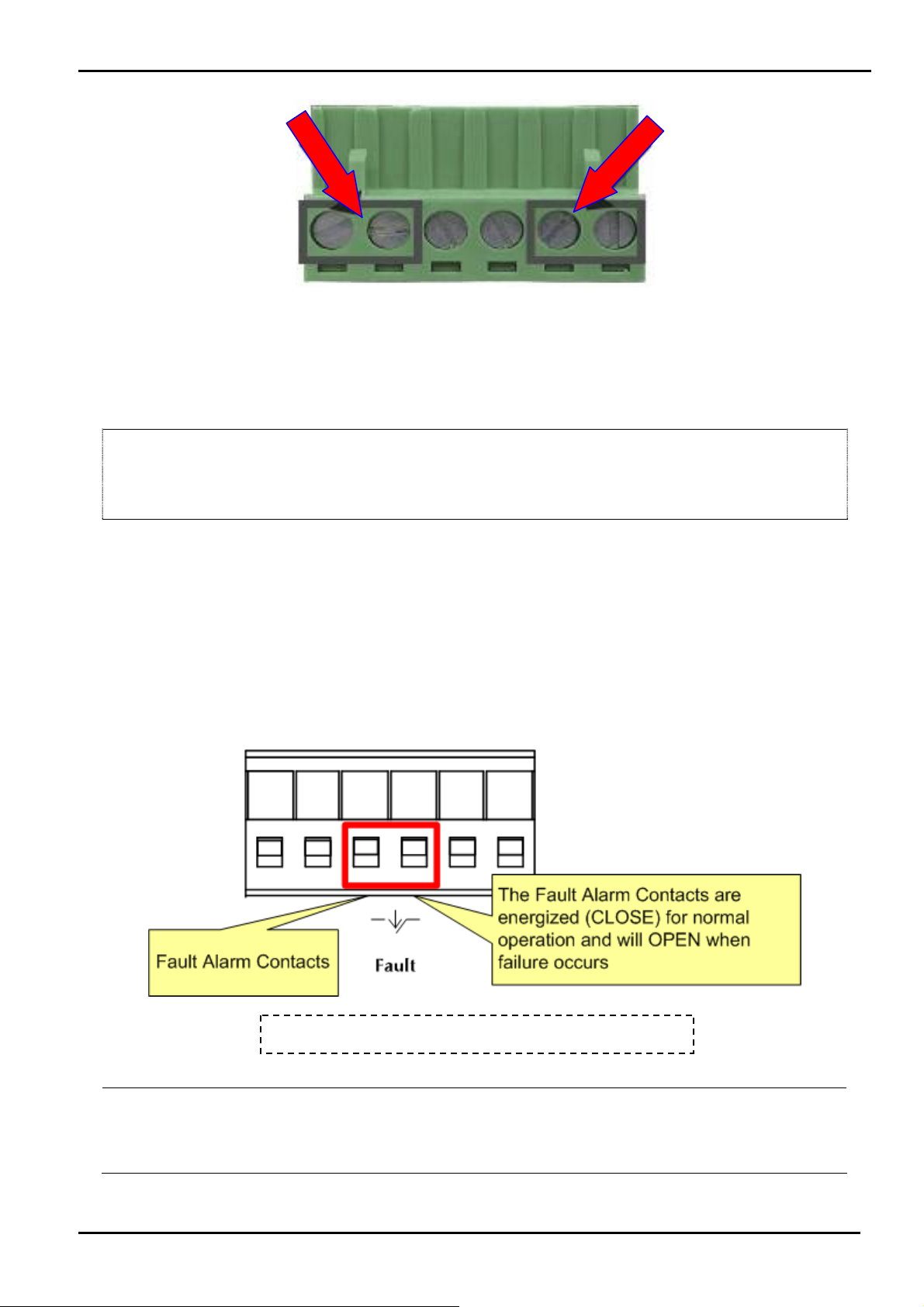

2.4 Wiring the Fault Alarm Contact

The fault alarm contacts are in the middle (3 & 4) of the terminal block connector as the picture shows below. Inserting the

wires, the Industrial PoE Switch will detect the fault status of the power failure, or port link failure (available for managed

model).

The following illustration shows an application example for wiring the fault alarm contacts

Power Notice:

Insert the wires into the fault alarm contacts

1. The wire gauge for the terminal block should be in the range between 12 ~ 24 AWG.

2. Performing any of the procedures like inserting the wires or tighten the wire-clamp screws. Ensure

the power is OFF to prevent to get an electric shock.

-20 -

Page 21

User’s Manual

2.5 Cabling

100Base-TX and 100Base-FX

The 10/100Mbps RJ-45 ports come with Auto-Negotiation capability. Users only need to plug in working network

device into one of the 10/100Mbps RJ-45 ports. The ISW-504PS / ISW-514PS series will automatically run in 10Mbps

or 100Mbps after the negotiation with the connected device. The ISW-514PS has one 100Base-FX SC Interface

(Multi-mode, 50/125μm or 62.5/125μm fiber cable and the available distance is 2km). The ISW-514PS15 has one

100Base-FX SC Interface (Single-mode, 9 / 125μm fiber cable and the available distance is 15km). The ISW-514PSF

has one 100Base-FX SFP interface (Optional Multi-mode / Single-mode 100Base-FX SFP module)

Cabling

Each 10/100Base-TX ports use RJ-45 sockets -- for connection of unshielded twisted-pair cable (UTP).

The 100Base-FX port is uses as SC / LC connector. Please see table below and know more about the cable’s

specification.

Port Type Cable Type Connector

10Base-T Cat 3, 4, 5, 2-pair RJ-45

100Base-TX Cat.5, 5e, 6 UTP, 2-pair RJ-45

100Base-FX 50 / 125μm or 62.5/125μm SC (Multi-mode)

100Base-FX 9 / 125μm SC (Single-mode)

100Base-FX

Any Ethernet devices like Hubs / PCs can connect to the Industrial PoE Switch by using straight-through wires. The

10/100Mbps RJ-45 ports are auto-MDI / MDI-X can be used on straight-through or crossover cable.

50 / 125µm or 62.5 / 125µm multi-mode

LC (Multi / Single mode)

9 / 125µm single-mode

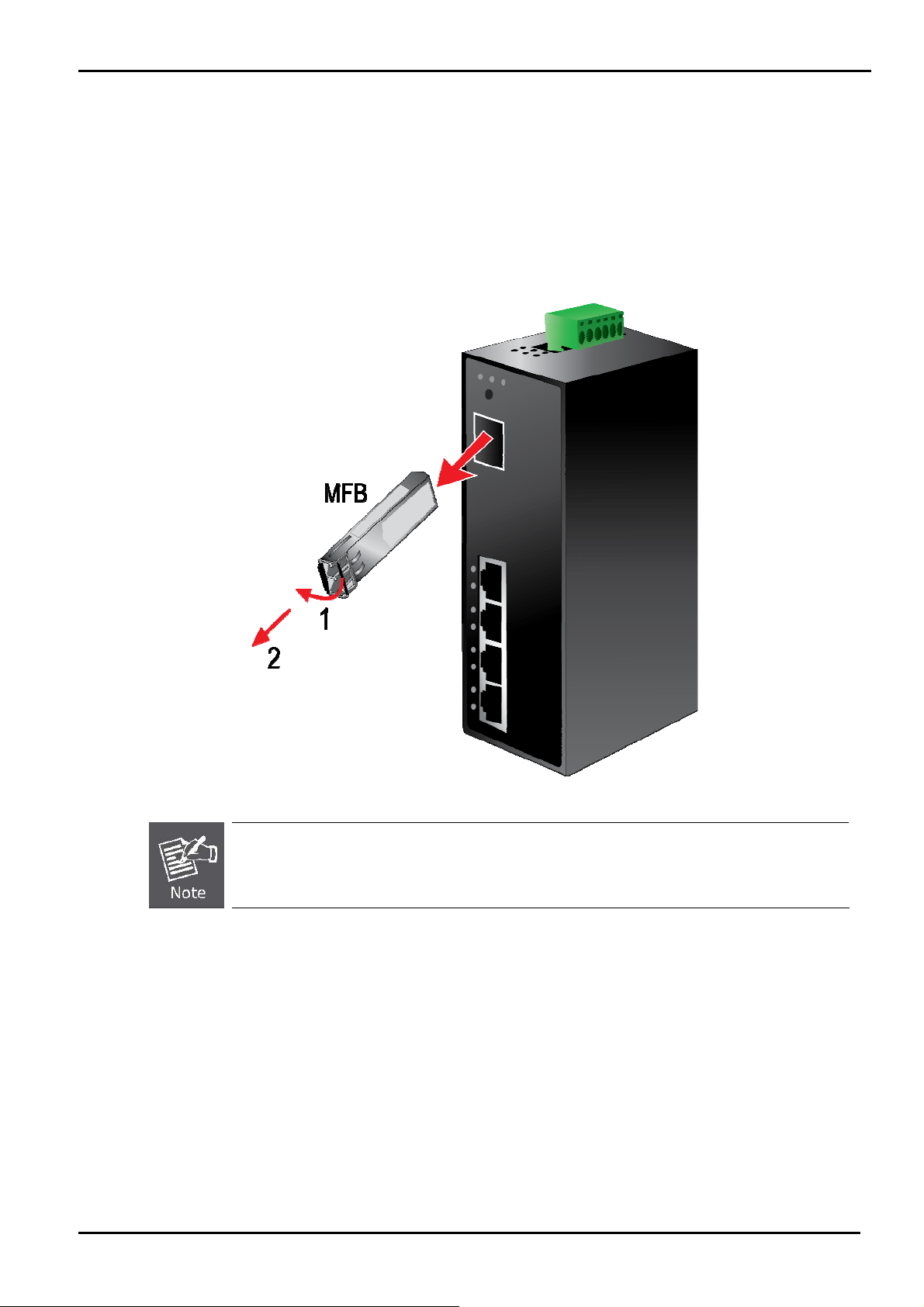

2.5.1 Installing the SFP transceiver (ISW-514PSF Only)

The sections describe how to insert an SFP transceiver into an SFP slot.

The SFP transceivers are hot-pluggable and hot-swappable. You can plug-in and out the transceiver to/from any SFP port

without having to power down the Switch/Media Converter. As the Figure 2-6 appears.

-21 -

Page 22

User’s Manual

Figure 2-6 Plug-in the SFP transceiver

Before connect the other switches, workstation or Media Converter.

1. Make sure both side of the SFP transceiver are with the same media type or WDM pair, for example: 100Base-FX to

100Base-FX, 100Base-BX20-U to 100Base-BX20-D.

2. Check the fiber-optic cable type match the SFP transceiver model.

¾ To connect to MFB-FX SFP transceiver, use the multi-mode fiber cable- with one side must be male duplex LC

connector type.

¾ To connect to MFB-F20/F40/F60/FA20/FB20 SFP transceiver, use the single-mode fiber cable-with one side

must be male duplex LC connector type.

Connect the fiber cable

1. Attach the duplex LC connector on the network cable into the SFP transceiver.

2. Connect the other end of the cable to a device – switches with SFP installed, fiber NIC on a workstation or a Media

Converter.

3. Check the LNK/ACT LED of the SFP slot of the switch / converter. Ensure that the SFP transceiver is operating

correctly.

4. Check the Link mode of the SFP port if the link failed. Co works with some fiber-NICs or Media Converters, set the Link

mode to “100 Force” is needed.

-22 -

Page 23

User’s Manual

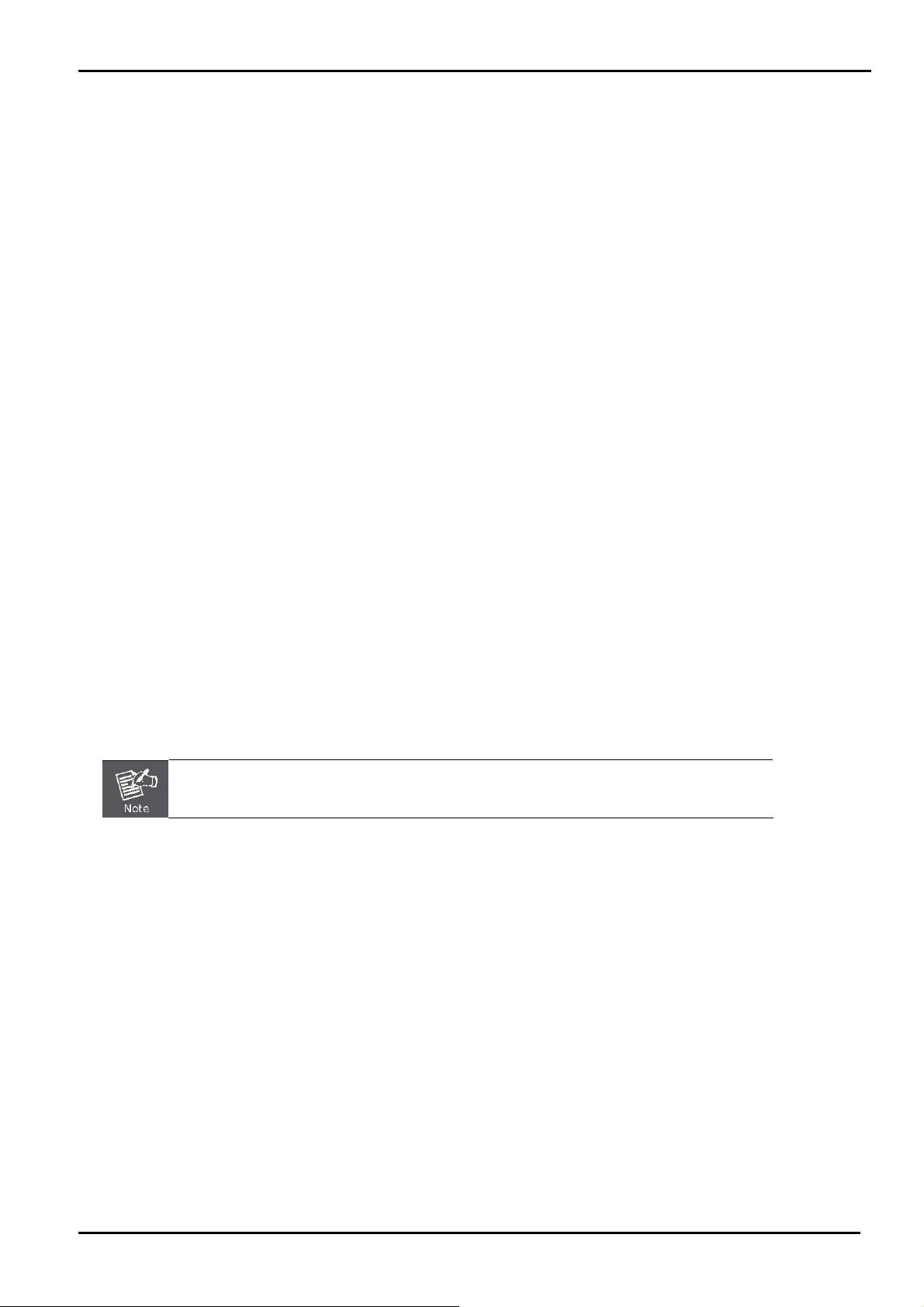

2.5.2 Remove the module

1. Make sure there is no network activity by consult or check with the network administrator. Or through the management

interface of the switch/converter (if available) to disable the port in advance.

2. Remove the Fiber Optic Cable gently.

3. Turn the handle of the MFB module to horizontal.

4. Pull out the module gently through the handle.

Figure 2-7 Pull Out the SFP transceiver

Never pull out the module without pull the handle or the push bolts on the module. Direct pull out the

module with violent could damage the module and SFP module slot of the device.

-23 -

Page 24

User’s Manual

3 MANAGEMENT

This chapter describes how to manage the Industrial PoE Switch Topics include:

- Overview

- Management method

- Logging on to the Industrial PoE Switch

3.1 Overview

The Industrial PoE Switch provides a user-friendly, Web interface. Using this interface, you can perform various device

configuration and management activities, including:

System

Power over Ethernet

Tools

3.2 Requirements

Network cables. Use standard network (UTP) cables with RJ-45 connectors.

Subscriber PC installed with Ethernet NIC (Network Card)

The operate system of subscriber PC that running Windows XP/2003, Vista, Windows 7, MAC OS X , Linux,

Fedora, Ubuntu or other platform compatible with TCP/IP protocols.

It is recommended to use Internet Explore 7.0 or above to access Industrial PoE Switch.

3.3 Management Method

User can manage the Industrial PoE Switch by Web Management via a network connection.

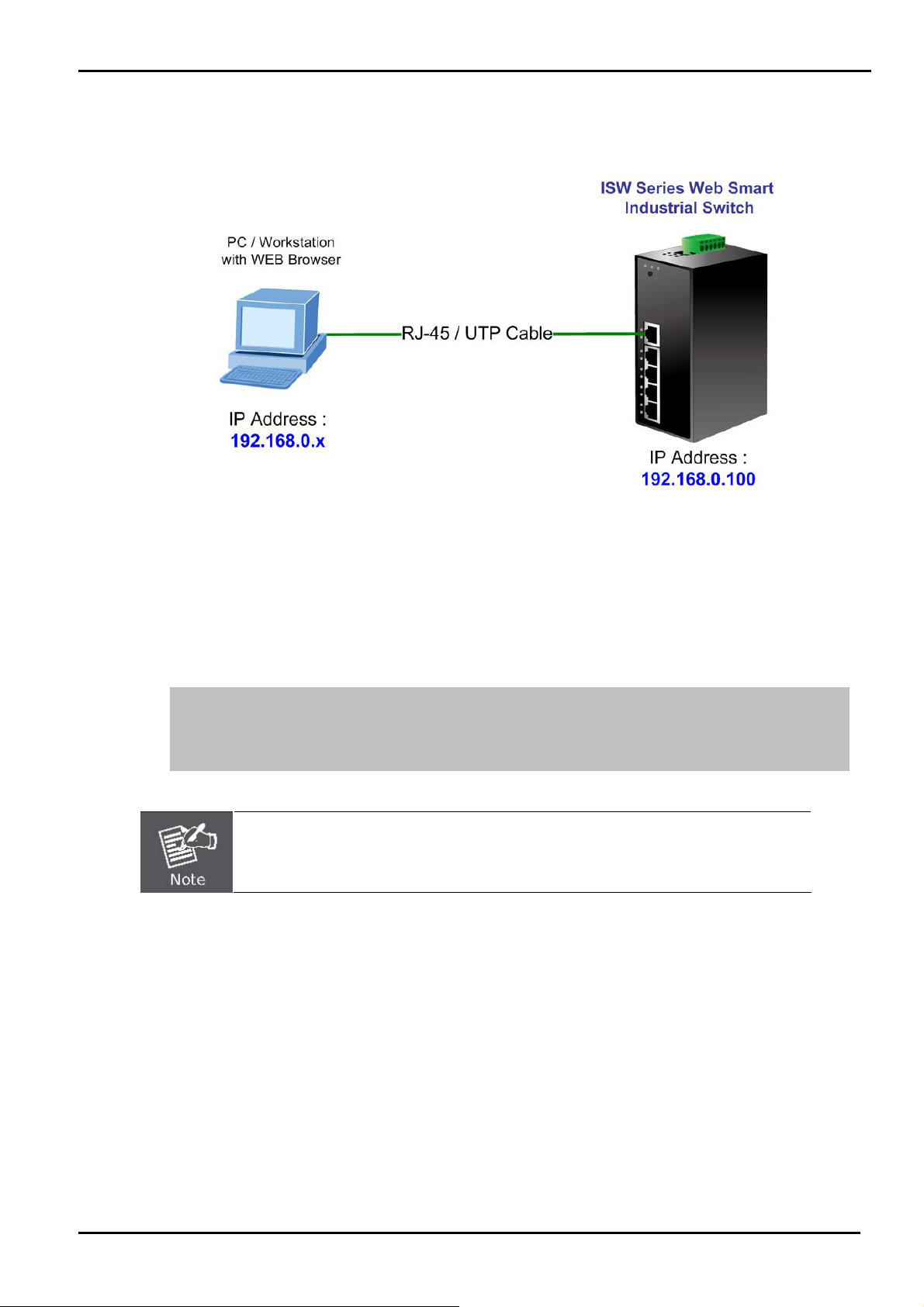

3.3.1 Web Management

The Industrial PoE Switch can be configured through an Ethernet connection, make sure the manager PC must be set on

same the IP subnet address with the Industrial PoE Switch.

For example, if you have changed the default IP address of the Device to 192.168.99.123 with subnet mask 255.255.255.0

via console, then the manager PC should be set at 192.168.99.x (where x is a number between 2 and 254) with subnet

mask 255.255.255.0. Or you can use the factory default IP address 192.168.0.100 to do the relative configuration on

manager PC.

-24 -

Page 25

User’s Manual

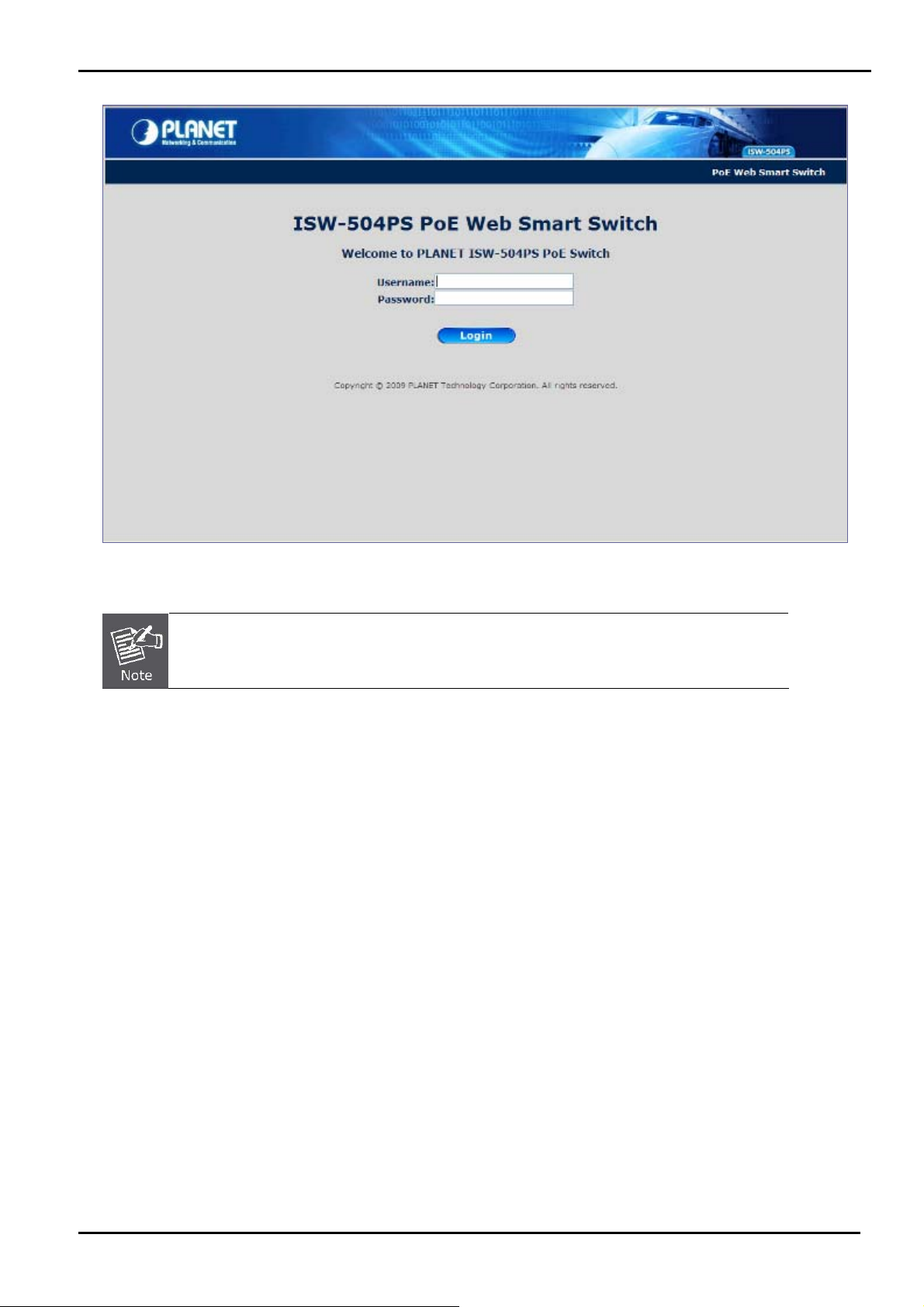

1. Use Internet Explorer 7.0 or above Web browser. Enter IP address http://192.168.0.100 (the factory-default IP

address) to access the Web interface.

Figure 3-1 Web Management over Ethernet

2. When the following login screen appears, please enter Planet’s default Username "admin" and Password “admin”

to login the main screen of Industrial PoE Switch. The login screen in Figure 3-2 appears.

3.

Default IP Address: 192.168.0.100

Default Account: admin

Default Password: admin

The following screen based on ISW-504PS, for ISW-514PS / ISW-514PS15 / ISW-514PSF.

-25 -

Page 26

User’s Manual

Figure 3-2 Web Login screen

1. For security reason, please changes and remembers the new password after this first setup.

2. Only accept command in lowercase letter under WEB interface.

-26 -

Page 27

User’s Manual

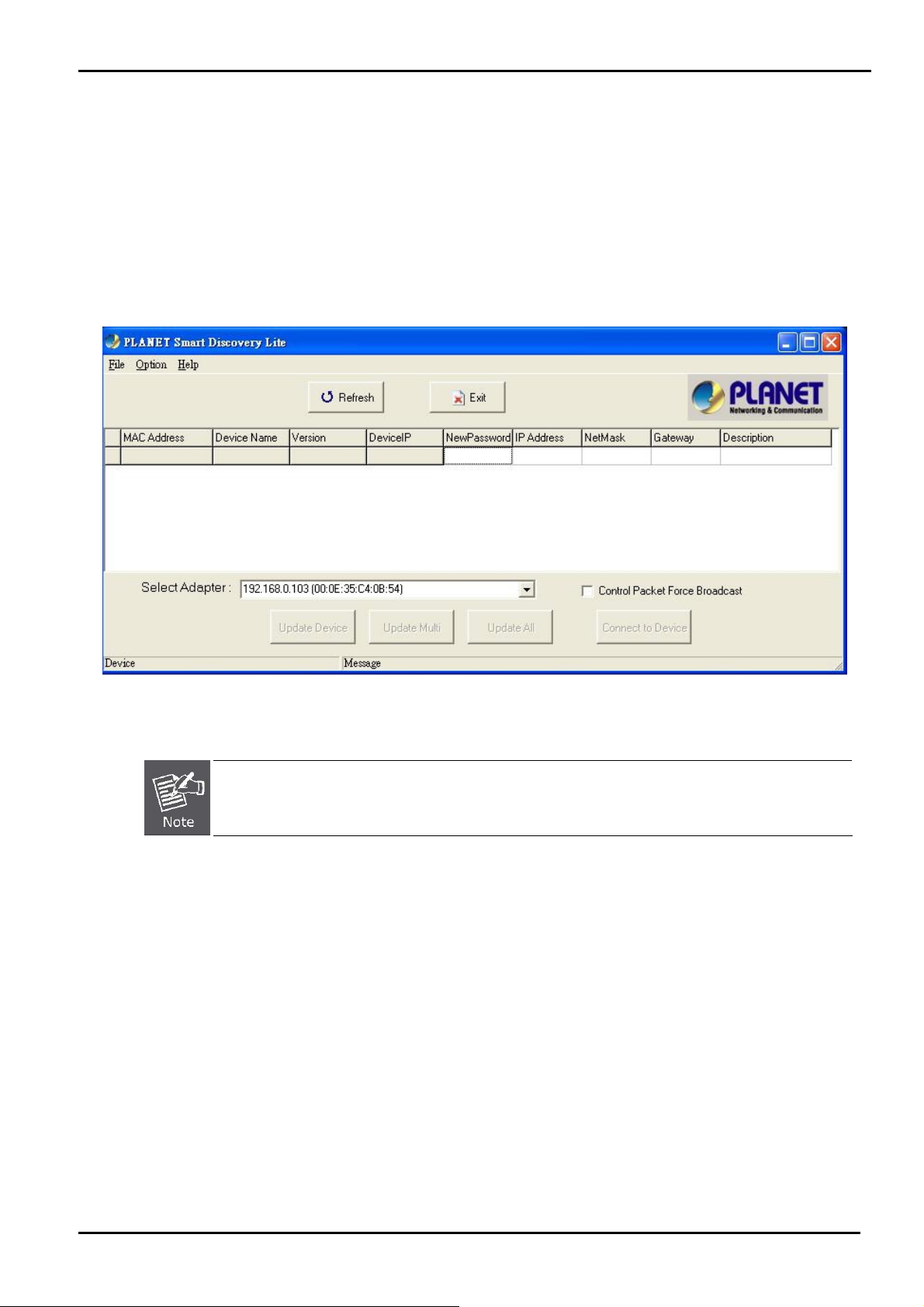

3.3.2 PLANET Smart Discovery Utility

For easily list the Industrial PoE Switch in your Ethernet environment, the Planet Smart Discovery Utility from user’s

manual CD-ROM is an ideal solution.

The following install instructions guiding you for run the Planet Smart Discovery Utility.

1. Deposit the Planet Smart Discovery Utility in administrator PC.

2. Run this utility and the following screen appears.

Figure 3-3 PLANET Smart Discovery Utility Screen

If there are two LAN cards or above in the same administrator PC, choose different LAN card by use the

“Select Adapter” tool.

3. Press “Refresh” button for list current connected devices in the discovery list, the screen is shown as follow.

-27 -

Page 28

Figure 3-4 PLANET Smart Discovery Utility Screen

User’s Manual

4. This utility shows all necessary information from the devices, such as MAC Address, Device Name, firmware version,

Device IP Subnet address, also can assign new password, IP Subnet address and description for the devices.

5. After setup completed, press “Update Device”, “Update Multi” or “Update All” button to take effect. The meaning

of the 3 buttons above are shown as below:

Update Device: update the current setting on one single device.

Update Multi: choose the multi-devices for updating the current setting.

Update All: use current setting on whole devices in the list.

The same functions mentioned above also can be finding in “Option” tools bar.

6. To click the “Control Packet Force Broadcast” function, it can allow assign new setting value to the Switch under

different IP subnet address.

7. “Connect to Device” button, the Web login window screen will appear, just like Figure 3-2.

8. Press “Exit” button to shutdown the Planet Smart Discovery Utility.

-28 -

Page 29

User’s Manual

4. WEB CONFIGURATION

The Industrial PoE Switch provides Web interface for PoE smart function configuration and make the Industrial PoE Switch

operate more effectively - They can configure through the Web Browser and the network administrator can manage and

monitor the Industrial PoE Switch from the local LAN. This section indicates how to configure the Industrial PoE Switch to

enable its smart function.

4.1 Main Menu

After a successful login, the main screen appears. The main screen displays the product name, the function menu, and the

main information in the center. As shown in Figure 4-1 and description on Table 4-1.

Figure 4-1 Main Menu Screen

System:

Port Management

VLAN

Quality of Service

Storm Control

Misc Configuration

Provide System information and configuration of Switch. Explained in section 4.3.

Setup Per Port mode, Rate Limit, Port description. Explained in section 4.4.

Configure VLAN Member / Port Configuration. Explained in section 4.5.

Mapping the packet level to classify the packets priority. Explained in section 4.6.

Enable Storm Control function to reduce broadcast packets on the Switch.

Explained in section 4.7.

Configure MAC address table aging, aging time mode and port flow control. Explained

-29 -

Page 30

in section 4.8.

User’s Manual

PoE Configuration

Logout:

Provide PoE Management configuration of Switch. Explained in section 4.9.

Provide Logout function of Switch.

Table 4-1 Descriptions of the Function items

4.2 Web Panel

On the left of the Web management page, the active panel displays the link status of management port and PoE ports.

LED Color Function

P1 Green

P2

Green

Indicate the power 1 has

power.

Indicate the power 2 has

power.

Indicate the either power

Green

Orange

1 or power 2 has no

power.

Indicate the link through

that port is successfully

established

Indicate the port is

providing 48V DC in-line

power. (1-4 ports)

FAULT

LNK/ACT Green

PoE In

Use

Table 4-2 Descriptions of the LED Objects

Figure 4-2 Left Side of Main Menu Screen(Light Indication)

-30 -

Page 31

4.3 System

The System function allows viewing System information, IP Configuration, Password Setting and etc.

As shown in Figure 4-3 and description on Table 4-3

User’s Manual

Figure 4-3 System Screen

The page includes the following information:

Object Description

System Information Display the MAC address, Software Version, Hardware Version, IP address, Subnet

Mask and Gateway. Explained in section 4.3.1

IP Configuration Allow to change the IP subnet address of Switch. Explained in section 4.3.2

Password Setting Allow to change the username and password of Switch. Explained in section 4.3.3

Firmware Upgrade Allow proceed firmware upgrade process of Switch. Explained in section 4.3.4

Configuration Setting Allow to restore / backup configuration of Switch and reset Switch to factory default.

Explained in section 4.3.

Configuration Backup Allow to download / upload the configuration file of Switch. Explained in section 4.3.6

Managed IP Allow to set the specific IP address to access the Web Smart Page. Explained in

section 4.3.7

Fault Relay Alarm Monitor the Power 1 and 2. Explained in section 4.3.8

Alert Trap Configuration Set up SNMP trap receiver’s IP address and trap event. Explained in section 4.3.9

System Reboot Allow reboot the Switch. Explained in section 4.3.10

Table 4-3 Descriptions of the System Column

-31 -

Page 32

User’s Manual

4.3.1 System Information

The System information will show the system MAC Address, Software Version, Hardware Version, IP Address, Subnet

Mask and Gateway. As shown in Figure 4-4 and description on Table 4-4

Figure 4-4 System Information screen

The page includes the following fields:

Object Description

MAC Address

Software Version

Hardware Version

IP Address

Subnet Mask

Gateway

Description

Temperature

Power Status

Specifies the Switch MAC address.

The current software version running on the Switch.

The current hardware version of the Switch.

The current IP Address of the Switch.

The current IP Subnet Mask value of the Switch.

The current Gateway value of the Switch.

The current description of the Switch.

The current Temperature of the Switch

The current Power units are Connect / Disconnect. Green: Connect Grey: Disconnect

Table 4-4 Descriptions of the System Information

-32 -

Page 33

User’s Manual

4.3.2 IP Configuration

This section provides DHCP Client, change the IP Address, Subnet Mask, Gateway and Description. As shown in Figure

4-5 and description on Table 4-5

Figure 4-5 IP Configuration Screen

The page includes the following configurable data:

Object Description

DHCP Client

IP Address The IP address of the Switch. The factory default value is 192.168.0.100.

Subnet Mask The IP subnet mask of the Switch. The factory default value is 255.255.255.0.

Gateway The default gateway of the Switch. The factory default value is 192.168.0.254.

Choose what the Switch should do following power-up: transmit a DHCP request, or manual

setting (Disable).

The DHCP client function only works if you haven't assigned a static IP address that different

than the Switch default IP. Once the default IP has been changed the DHCP will not effective

and the Switch will continue using the manually entered static IP. If you have changed the

Switch to a static IP address, you can set the IP address back to its default IP address or you

can reset the Switch back to factory default. And then you can enable the DHCP client function

to work.

The factory default is Disable.

Description

This field helps to identify the description of Switch.

Table 4-5 Descriptions of the IP Configuration

-33 -

Page 34

User’s Manual

4.3.3 Password Setting

This section provides password change Configuration of Industrial PoE Switch, please input the old password in “Old

Password” space and input the new password in “New Password” space then input the new password again in

“Confirm” space. After fill-in completed, please press “Apply” button to take effect and the Switch will logout

automatically. Please login web interface with new password. As shown in Figure 4-6 and description on Table 4-6

Figure 4-6 Password Setting Screen

The page includes the following configurable data:

Object Description

Login Name

Old Password

New Password Specifies the new password. The password will not display. As it entered “y” corresponding to

Confirm This confirms the new password. The password entered into this field must be exactly the same

Displays the login user name.

Enter the old password is required before entering the new password.

each character is displayed in the field.

(The maximum length is 16 characters)

as the password entered in the Password field.

Table 4-6 Descriptions of the Password Setting

4.3.4 Firmware Upgrade

This section provides firmware upgrade of Industrial PoE Switch. As shown in Figure 4-7. Please press “Update” button

to continue following firmware upgrade process.

-34 -

Page 35

User’s Manual

Figure 4-7 Firmware Upgrade screen

Please wait for two seconds and the page will turn to next firmware upgrade web page. As shown in Figure 4-8.

Figure 4-8 Firmware Upgrade screen

Please press “Browser” to locate the latest firmware of Switch that deposit in your PC and press “Upgrade” to start the

firmware upgrade process. As shown in Figure 4-9 and Figure 4-10.

-35 -

Page 36

User’s Manual

Figure 4-9 Firmware Upgrade screen(1)

Figure 4-10 Firmware Upgrade screen (2)

-36 -

Page 37

User’s Manual

1. Do not Power Off the Industrial PoE Switch during the firmware upgrade installation.

2. Do not Quit / Close the Firmware Upgrade page without press the “Upgrade” button - after the

image is loaded. Or the system won’t apply the new firmware. Users have to repeat the firmware

upgrade processes again.

Do not use Firefox or Windows Vista platform for ISW-504PS / ISW-514PS series firmware

upgrade or it might cause the firmware upgrade fail. Because of the short “HTTP respond time” for

Firefox and Windows Vista. While firmware upgrade, there is no immediately respond each to the

Firefox and Windows Vista, they will break the connection as http time out. It suggested to use the

Microsoft IE 7.0 at Windows XP platform for firmware upgrade.

-37 -

Page 38

User’s Manual

4.3.5 Configuration Setting

This function allows backup and restore the current configuration of Industrial PoE Switch, or reset the Industrial PoE

Switch to factory default. The description of the three items as follow and as shown in Figure 4-11.

■ Backup - To backup / save the current configuration to the storage block on this Switch.

■ Restore – To restore the previous backup configuration from the storage block.

■ Factory – To reset the Industrial PoE Switch back to the factory default mode.

Figure 4-11 Configuration Setting screen

■ Backup

All current configurations (except IP Configuration) will save to Industrial PoE Switch when press the “Backup” button. As

shown in Figure 4-12.

Figure 4-12 Configuration Setting\Backup screen

-38 -

Page 39

If finish the Backup and work successfully, it will show a message that tells you it done. As shown in Figure 4-13.

Figure 4-13 Configuration backup successes screen

Restore

User’s Manual

The Industrial PoE Switch will restore to previous backup/saved configuration while the “Restore” button be pressed. And

please note that once the Restore button be pressed, Web interface will disconnected for a while. Reload the Web browser

to re-login the system.

Figure 4-14 Configuration restore screen

Factory Reset

The Factory Reset button can reset the Industrial PoE Switch back to the factory default mode. Be aware that the entire

configuration will be reset, and the IP address of the Industrial PoE Switch will be set to “192.168.0.100”.

Figure 4-15 Factory Reset screen

Once the Factory Reset item is pressed, the screen in Figure 4-16 appears.

-39 -

Page 40

Figure 4-16 Factory Reset screen

4.3.6 Configuration Backup

This function allows downloading the current configuration as a file. The filename extension will be “cfg” file.

If already downloads 3 different setting of files as file 1, file 2 and file 3. As showed in Figure 4-17.

The Upload function allows selecting any one of them to restore back the setting.

■ Upload - To select the file and restore back the configuration

■ Download – To download the current configuration as a file and save on your PC

User’s Manual

Figure 4-17 Configuration Backup Screen

-40 -

Page 41

4.3.7 Managed IP

The function allows setting 5 specific IP address to access the Industrial PoE Switch. As shown in Figure 4-18.

User’s Manual

Figure 4-18 Managed IP Screen

4.3.8 Fault Relay Alarm

This Function allows controlling the Power Failure. If the terminal block connector has connected the fault alarm contacts

(3 & 4). The setting just like below picture. For example: when one of the power failure then it will trigger the warning device

and sound the alarm. As shown in Figure 4-19.

Figure 4-19 Fault Relay Alarm Screen

-41 -

Page 42

User’s Manual

4.3.9 Alert Trap Configuration

This function displays the Industrial PoE Switch alert trap configuration; include “Enable” or “Disable” the trap mode and

set the alert IP address. As shown in Figure 4-20 and description on Table 4-7.

Trap mode

Alert IP address

Trap event

Figure 4-20 Alert Trap Configuration screen

Object Description

Can choose enable/disable to get the trap

Assign one IP address of host to receive SNMP trap from the device.

Choose the events to send the SNMP trap. The trap events include:

Cold Start

Login Fail

Password changed

IP Changed

Link up

Link down

PoE Alert

Table 4-7 Descriptions of the Alert Trap Configuration

-42 -

Page 43

User’s Manual

4.3.10 System Reboot

This section provides reboot the Industrial PoE Switch, after choose this function and the following screen appears in

Figure 4-21. Please press “OK” button to take effect and the Industrial PoE Switch will reboot and ask you to re-login web

interface with correct user name “admin” and password, as shown in Figure 4-22 and Figure 4-23.

Figure 4-21 reboot system Web Page screen

Figure 4-22 System Rebooting Web Page screen

Figure 4-23 Login Web Page screen

-43 -

Page 44

User’s Manual

4.4 Port Management

In this chapter, there are three sub-functions can be configure and monitor about network interfaces:

Port Configuration

Port Status

Port Security

4.4.1 Port Configuration

This section introduces detail settings of per port of Industrial PoE Switch as shown in Figure 4-24 and Table 4-8 describes

the Port Setup objects of Industrial PoE Switch.

Figure 4-24 Port Setup Web Page screen

The page includes the following configurable data:

Object Description

Port Indicate port 1 to port 5.

Link Display the current Port link status.

Mode Allow configuration the port speed and operation mode. Draw the menu bar to

select the mode

• Auto Speed - Setup Auto negotiation

• 10 Half - Force sets 10Mbps/Half-Duplex mode

• 10 Full - Force sets 10Mbps/Full-Duplex mode

• 100 Half - Force sets 100Mbps/Half-Duplex mode

• 100 Full - Force sets 100Mbps/Full-Duplex mode

• Disable - Shutdown the port manually

Default: Auto Speed

Ingress Rate Limit

The value of inbound traffic limitation in kilobit-per-second (kbps).

Default : No Limit

-44 -

Page 45

User’s Manual

• No Limit

• 128K

• 256K

• 512K

Egress Shaping

Description Allow to set value for port Description, This column accepts characters —“0-9,

Table 4-8 Descriptions of the Port Setup screen Objects

When the ports are being set as fixed 100M Full, 100M Half, 10M Full, and 10M Half-speed

modes, the Auto-MDIX function will disable.

The value of outbound traffic limitation in kilobit-per-second (kbps).

Default : No Limit

• No Limit

• 128K

• 256K

• 512K

A-Z, a-z, @, - _ and * “

Maximum: 8 characters

• 1M

• 2M

• 4M

• 8M

• 1M

• 2M

• 4M

• 8M

4.4.2 Port Status

This section provides current status of each port from Industrial PoE Switch, as shown in Figure 4-25.

Figure 4-25 Port Status Web Page screen

-45 -

Page 46

User’s Manual

4.4.3 Port Security

The Layer 2 MAC address learning function can be per-port disable for security management purposes. When the port is in

security mode, the port will be "locked" without permission of address learning.

For Example:

1. Enable the Port 1 Security and the port will record the first receiving packet's source MAC

address as a "Security MAC address ".

2. A security port only allows that packet which has the "Security MAC address" to active on.

Object Description

Port

Port Security Enable

Check Box

Figure 4-26 Port Security screen

Which selecting this option locks the specified interface.

Enable Source MAC address lock function on specified port. By which locks the

port using the classic lock mechanism. The port is immediately locked without

permission of address learning.

Table 4-9 Descriptions of the Port Security screen Objects

1. The Device will reboot after enable Port Security.

2. After reboot, each port will record the first receiving packet's source MAC address as a "Security

MAC address ".

3. A security port only allows that packet which has the "Security MAC address" to active on.

-46 -

Page 47

User’s Manual

4.5 VLAN

A Virtual LAN (VLAN) is a logical network grouping that limits the broadcast domain. It allows you to isolate network traffic

so only members of the VLAN receive traffic from the same VLAN members. Basically, creating a VLAN from a switch is

logically equivalent of reconnecting a group of network devices to another Layer 2 switch. However, all the network

devices are still plug into the same switch physically.

The ISW-504PS / ISW-514PS series Ethernet Switch supports 802.1Q (tagged-based) and Port-Base VLAN setting in

web management page. The default configuration of VLAN setting is “Disable”.

Port-based VLAN

Port-based VLAN limit traffic that flows into and out of switch ports. Thus, all devices connected to a port are members of

the VLAN(s) the port belongs to, whether there is a single computer directly connected to a switch, or an entire

department.

On Port-based VLAN, NIC do not need to be able to identify 802.1Q tags in packet headers. NIC send and receive normal

Ethernet packets. If the packet's destination lies on the same segment, communications take place using normal Ethernet

protocols. Even though this is always the case, when the destination for a packet lies on another switch port, VLAN

considerations come into play to decide if the packet is dropped by the Switch or delivered.

IEEE 802.1Q VLAN

IEEE 802.1Q (tagged) VLAN are implemented on the Switch. 802.1Q VLAN require tagging, which enables them to span

the entire network (assuming all switches on the network are IEEE 802.1Q-compliant).

VLAN allow a network to be segmented in order to reduce the size of broadcast domains. All packets entering a VLAN will

only be forwarded to the stations (over IEEE 802.1Q enabled switches) that are members of that VLAN, and this includes

broadcast, multicast and unicast packets from unknown sources.

VLAN can also provide a level of security to your network. IEEE 802.1Q VLAN will only deliver packets between stations

that are members of the VLAN. Any port can be configured as either tagging or untagging. The untagging feature of IEEE

802.1Q VLAN allows VLAN to work with legacy switches that don't recognize VLAN tags in packet headers. The tagging

feature allows VLAN to span multiple 802.1Q-compliant switches through a single physical connection and allows

Spanning Tree to be enabled on all ports and work normally.

Some relevant terms:

Tagging - The act of putting 802.1Q VLAN information into the header of a packet.

Untagging - The act of stripping 802.1Q VLAN information out of the packet header.

802.1Q VLAN Tags

The figure below shows the 802.1Q VLAN tag. There are four additional octets inserted after the source MAC address.

Their presence is indicated by a value of 0x8100 in the Ether Type field. When a packet's Ether Type field is equal to

0x8100, the packet carries the IEEE 802.1Q/802.1p tag. The tag is contained in the following two octets and consists of 3

bits of user priority, 1 bit of Canonical Format Identifier (CFI - used for encapsulating Token Ring packets so they can be

-47 -

Page 48

User’s Manual

carried across Ethernet backbones), and 12 bits of VLAN ID (VID). The 3 bits of user priority are used by 802.1p. The VID

is the VLAN identifier and is used by the 802.1Q standard. Because the VID is 12 bits long, 4094 unique VLAN can be

identified.

The tag is inserted into the packet header making the entire packet longer by 4 octets. All of the information originally

contained in the packet is retained.

IEEE 802.1Q Tag

User Priority CFI VLAN ID (VID)

3 bits 1 bits 12 bits

TPID (Tag Protocol Identifier) TCI (Tag Control Information)

2 bytes 2 bytes

Preamble

Destination

Address

6 bytes 6 bytes 4 bytes 2 bytes 46-1517 bytes 4 bytes

Source

Address

VLAN TAG

Ethernet

Type

Data FCS

The Ether Type and VLAN ID are inserted after the MAC source address, but before the original Ether Type/Length or

Logical Link Control. Because the packet is now a bit longer than it was originally, the Cyclic Redundancy Check (CRC)

must be recalculated.

Adding an IEEE 802.1Q Tag

Dest. Addr. Src. Addr. Length/E. type Data Old CRC

Original Ethernet

Dest. Addr. Src. Addr. E. type Tag Length/E. type Data New CRC

Priority CFI VLAN ID

New Tagged Packet

Port VLAN ID

Packets that are tagged (are carrying the 802.1Q VID information) can be transmitted from one 802.1Q compliant network

device to another with the VLAN information intact. This allows 802.1Q VLAN to span network devices (and indeed, the

entire network – if all network devices are 802.1Q compliant).

Every physical port on a switch has a PVID. 802.1Q ports are also assigned a PVID, for use within the switch. If no VLAN

are defined on the switch, all ports are then assigned to a default VLAN with a PVID equal to 1. Untagged packets are

assigned the PVID of the port on which they were received. Forwarding decisions are based upon this PVID, in so far as

VLAN are concerned. Tagged packets are forwarded according to the VID contained within the tag. Tagged packets are

also assigned a PVID, but the PVID is not used to make packet forwarding decisions, the VID is.

Tag-aware switches must keep a table to relate PVID within the switch to VID on the network. The switch will compare the

VID of a packet to be transmitted to the VID of the port that is to transmit the packet. If the two VID are different the switch

will drop the packet. Because of the existence of the PVID for untagged packets and the VID for tagged packets, tag-aware

and tag-unaware network devices can coexist on the same network.

-48 -

Page 49

User’s Manual

A switch port can have only one PVID, but can have as many VID as the switch has memory in its VLAN table to store

them.

Because some devices on a network may be tag-unaware, a decision must be made at each port on a tag-aware device

before packets are transmitted – should the packet to be transmitted have a tag or not? If the transmitting port is connected

to a tag-unaware device, the packet should be untagged. If the transmitting port is connected to a tag-aware device, the

packet should be tagged.

Default VLAN

The Switch initially configures one VLAN, VID = 1, called "default." The factory default setting assigns all ports on the

Switch to the "default". As new VLAN are configured in Port-based mode, their respective member ports are removed

from the "default."

The Switch supports SVL (Shared VLAN Learning), all VLAN groups share the same Layer

2 learned MAC address table.

1 No matter what basis is used to uniquely identify end nodes and assign these nodes

VLAN membership, packets cannot cross VLAN without a network device performing a

routing function between the VLAN.

2 The Switch supports Port-based VLAN and IEEE 802.1Q VLAN. The port untagging

function can be used to remove the 802.1 tag from packet headers to maintain

compatibility with devices that are tag-unaware.

-49 -

Page 50

User’s Manual

4.5.1 VLAN Group

The VLAN Group page contains fields for managing VLAN mode of the Industrial PoE Switch and setting ports that are part

of a VLAN. The port default VLAN ID (PVID) is configured on the VLAN Port Configuration page. All untagged packets

arriving to the device are tagged by the ports PVID. As shown in Figure 4-27 & 4-28.

The VLAN mode had three modes:

■ Disable (No VLAN)

■ Port-Based VL AN

■ 802.1Q VLAN

The Industrial PoE Switch supports Port-based VLAN and 802.1Q VLAN (Tagged-based) in Web management page. In

the default configuration, VLAN support is “Disable”.

Figure 4-27 VLAN Group screenshot

4.5.1.1 Port-Based VLAN

By setting the VLAN Type with Port-Based, Port-Based VLAN is enabled and 802.1Q VLAN tagging is ignored. The VLAN

group classification of an incoming packet on a Port-Based VLAN is defined by the VLAN group table.

A port is limited to communicate with other ports within the same group when the function is enabled and configured.

Frame will be limited in a VLAN group and will not be forwarded out this VLAN group. A port can be assigned to one or

more VLAN groups.

-50 -

Page 51

User’s Manual

Figure 4-28 VLAN Group – Port-Based VLAN screen

When Port-Based VLAN mode is selected, the displayed page includes the following configurable data. Description on

Table 4-10

Object Description

VLAN Type

Management VLAN

Group

There’re three VLAN mode support – 802.1Q VLAN, Port-Bas VLAN and No

VLAN.

• 802.1Q – Packets income will be tagged with VID as the PVID setting. All ports

on the switch belong to default VLAN (VID 1).

• Port-Base - Packets can only be broadcast among other members of the same

VLAN group. Note all unselected ports are treated as belonging to the default

system VLAN.

• Disable - Forbidden ports are not included in the VLAN

If Port-based VLAN are enabled, then VLAN-tagging feature is ignored.

At Port-Based VLAN mode, up to 5 VLAN groups can be configured.

Member Port

Select the physical interface for which you want to display or configure data.

Table 4-10 Descriptions of the Port-Based VLAN item

-51 -

Page 52

User’s Manual

4.5.1.2 IEEE 802.1Q VLAN

This function group individual ports into a small “Virtual” network of their own to be independent of the other ports. By

setting the VLAN Type with 802.1Q, IEEE 802.1Q tag-based VLAN is enabled. VLAN classification is the first step before

VLAN table lookup. The PoE Switch will check the VID value of the received packets and the VLAN table ingress / egress

rule, then forwards the packets to valid destination ports.

Select “802.1Q VLAN” and press “Apply” button, to enable the IEEE 802.1Q VLAN function then continue configure 16

802.1Q VLAN groups as your request. After setup completed, please press “Apply” to take effect. As shown in Figure

4-29 and description on Table 4-11

Figure 4-29 VLAN Group – 802.1Q VLAN screen

The page includes the following fields:

Object Description

VLAN Type

There’re two VLAN mode support – 802.1Q VLAN and Port-Based VLAN

• 802.1Q – Packets income will be tagged with VID as the PVID setting. All ports

• Port-Based - Packets can only be broadcast among other members of the

on the switch belong to default VLAN (VID 1).

same VLAN group. Note all unselected ports are treated as belonging to the

default system VLAN.

-52 -

Page 53

• Disable - Forbidden ports are not included in the VLAN

User’s Manual

• VL AN Group

• VID

• Member Port

1. The VID value of each VLAN group must follow the rule -> there is an interval value 16 of

available VID value. For example, VLAN 2 VID must be 2, 18, 34, ….; VLAN 3 VID must be 3,

19, 35…

The VLAN entry index. Select the column to specify the VLAN group for VLAN

member ports configure.

The Switch supports up to 16 active VLAN groups.

Specify the VLAN Identifier for the 802.1Q VLAN.

The available range of the VID is (1 to 4094).

( 802.1Q mode only)

Select the physical interface for which you want to add or remove from the specify

VLAN group. Checked the Member box to select the members for the VLAN

group. Number 1-5 is the Physical interface ID of the PoE Switch.

After setup completed, please press “Apply” to take affect.

Table 4-11 Descriptions of the 802.1Q VLAN item

2. There is no way to delete a VLAN group on the PoE Switch. Just cancel all the check box from

Port-1 to Port-5 to make the VLAN group be not active.

-53 -

Page 54

User’s Manual

4.5.2 VLAN Per Port Setting

The Industrial PoE Switch inserts or removes a tag of frame if Tag / UnTag function is enabled. The operation is illustrated

as follows. As shown in Figure 4-30 and description on Table 4-12.

Understand nomenclature of the 802.1Q VLAN aware Switch

Tagging and Untagging

Every port on an 802.1Q compliant switch can be configured as tagging or untagging.

。 Tagging: Ports with tagging enabled will put the VID number, priority and other VLAN information into the header of

all packets that flow into those ports. If a packet has previously been tagged, the port will not alter the packet, thus

keeping the VLAN information intact. The VLAN information in the tag can then be used by other 802.1Q compliant

devices on the network to make packet-forwarding decisions.

。 Untagging: Ports with untagging enabled will strip the 802.1Q tag from all packets that flow into those ports. If the

packet doesn't have an 802.1Q VLAN tag, the port will not alter the packet. Thus, all packets received by and

forwarded by an untagging port will have no 802.1Q VLAN information. (Remember that the PVID is only used

internally within the Switch). Untagging is used to send packets from an 802.1Q-compliant network device to a

non-compliant network device.

Frame Income

Frame Leave

Leave port is tagged Frame remains tagged

Leave port is untagged Tag is removed

Income Frame is tagged Income Frame is untagged

Tag is inserted

(Tag=PVID or Original VID be remained)

Frame remain untagged

(Tag=PVID be removed)

Figure 4-30 VLAN Per port setting screen

-54 -

Page 55

The page includes the following fields:

Object Description

User’s Manual

Port

Link Type

PVID

Indicate the physical interface for which you want to display or configure data.

Allow 802.1Q Untagged or Tagged VLAN for selected port.

When adding a VLAN to selected port, it tells the switch whether to keep or

remove the tag from a frame on egress.

• Untag: outgoing frames without VLAN-Tagged.

• Tagged: outgoing frames with VLAN-Tagged.

( 802.1Q mod only)

Allow assign PVID for selected port. The range for the PVID is 1-4094

The PVID will be inserted into all untagged frames entering the ingress port. The

PVID must as same as the VLAN ID that the port belong to VLAN group, or the

untagged traffic will be dropped.

Table 4-12 Descriptions of the 802.1Q VLAN Per Port item

-55 -

Page 56

User’s Manual

4.5.3 VLAN setting example:

4.5.3.1 Two separate 802.1Q VLAN

The diagram shows how the Industrial PoE Switch handle Tagged and Untagged traffic flow for two VLANs. VLAN Group

2 and VLAN Group 3 are separated VLAN. Each VLAN isolate network traffic so only members of the VLAN receive traffic

from the same VLAN members. As shown in Figure 4-31 and Table 4-13 describes the port configuration of Industrial PoE

Switch.

Figure 4-31 two separate VLAN diagram

VLAN Group VID Untagged Members Tagged Members

VLAN Group 1 1 Port-5 N/A

VLAN Group 2 2 Port-1,Port-2 Port-2

VLAN Group 3 3 Port-3,Port-4 Port-4

Table 4-13 VLAN and Port Configuration

The scenario described as follow:

Untagged packet entering VLAN 2

1. While [PC-1] transmit an untagged packet enters Port-1, the switch will tag it with a VLAN Tag=2. [PC-2] will

received the packet through Port-2.

2. [PC-3] and [PC-4] received no packet.

3. While the packet leaves Port-2, it will keep as a tagged packet with VLAN Tag=2.

-56 -

Page 57

Tagged packet entering VLAN 2

4. While [PC-2] transmit a tagged packet with VLAN Tag=2 enters Port-2, [PC-1] will received the packet

through Port-1.

5. While the packet leaves Port-1, it will be stripped away it tag becoming an untagged packet.

Untagged packet entering VLAN 3

1. While [PC-3] transmit an untagged packet enters Port-3, the switch will tag it with a VLAN Tag=3. [PC-4] will

received the packet through Port-4.

2. While the packet leaves Port-4, it will keep as a tagged packet with VLAN Tag=3.

At this example, VLAN Group 1 just set as default VLAN, but only focus on VLAN 2 and VLAN 3

traffic flow

User’s Manual

Setup steps

1. Create VLAN Group

Set VLAN Group 1 = default-VLAN with VID (VLAN ID)=1

Add two VLANs – VLAN 2 and VLAN 3

VLAN Group 2 with VID=2

VLAN Group 3 with VID=3

2. Assign VLAN Member :

VLAN 2 : Port-1and Port-2

VLAN 3 : Port-3 and Port-4

VLAN 1 : Port 5

-57 -

Page 58

User’s Manual

Figure 4-32 Assign VLAN 2 Group members screen

Remember to remove the Port 1 – Port 4 from VLAN 1 membership, since the Port 1 – Port 4 had been assigned to

VLAN 2 and VLAN 3.

It’s import to remove the VLAN members from VLAN 1 configuration. Or the ports would become

overlap setting. ( About the overlapped VLAN configuration, see next VLAN configure sample)

3. Assign PVID for each port:

Port-1 and Port-2: PVID=2

Port-3 and Port-4 : PVID=3

Port-5: PVID=1

4. Enable VLAN Tag for specific ports

Link Type: Port-2 (VLAN-2) and Port-4 (VLAN-3) be set to “Tagged”.

The Per Port VLAN configuration in Figure 4-33 appears.

-58 -

Page 59

User’s Manual

Figure 4-33 Port 1-Port 5 VLAN Configuration

4.5.3.2 Two VLANs with overlap area

Follow the example of 4.5.3.1. There’re two exist separate VLANs – VLAN 2 and VLAN 3, and the PCs of each VLANs are

not able to access each other of different VLANs. But they all need to access with the same server. The screen in Figure

4-34 appear. This section will show you how to configure the port for the server – that could be accessed by both VLAN 2

and VLAN 3.

Figure 4-34 A Server connect to the VLAN overlap area

-59 -

Page 60

User’s Manual

1. Specify Port-5 on the device to connect to the server.

2. Assign Port-5 to both VLAN 2 and VLAN 3 at the VLAN Member configuration page. The screen in Figure 4-35

appears.

Figure 4-35 VLAN overlap port setting

3. Define a VLAN 1 as a “Public Area” that overlapping with both VLAN 2 members and VLAN 3 members.

-60 -

Page 61

User’s Manual

Figure 4-36 VLAN 1 – The public area member assigning

4. Setup Port-5 with “PVID=1” at VLAN per Port Configuration page. The screen in Figure 4-37 appears.

Figure 4-37 Setup Port-5 with PVID-1

That is, although the VLAN 2 members: Port-1 to Port-2 and VLAN 3 members: Port-3 to Port-4, are also belonging to

VLAN 1. But with different PVID settings, packets form VLAN 2 or VLAN 3 is not able to access to the other VLAN.

-61 -

Page 62

User’s Manual

4.5.3.3 Port-based VLAN setting example:

VLAN scenario

1. Port-5 is the file server port for all the workstations

2. Port-1 to Port-4 is different devices that do not need to see each other

Setup steps

1. Port Setting

1.1 Assign VLAN 2 for the second VLAN group with Port-1 and Port-5

1.2 Repeat the same steps for Port-2 to Port-7. i.e. 2 & 5, 3 & 5 … 4 & 5

After the above steps Port-1 to Port-4 is being separated physically due to it belongs to different VLAN groups

(different VLAN). However, they all can access Port-5 because of Port-5 is using PVID 1 to communicate with

Port-1 to Port-4.

Figure 4-38 Port-Based VLAN setting example

-62 -

Page 63

User’s Manual

4.6 Quality of Service

Quality of Service (QoS) is an advanced traffic prioritization feature that allows you to establish control over network

traffic. QoS enables you to assign various grades of network service to different types of traffic, such as multi-media, video,

protocol-specific, time critical, and file-backup traffic.

QoS reduces bandwidth limitations, delay, loss, and jitter. It also provides increased reliability for delivery of your data and

allows you to prioritize certain applications across your network. You can define exactly how you want the switch to treat

selected applications and types of traffic.