Page 1

Shipping & Mailing

Inserting

Relay™ 2500, 3500,

4500

Inserting System

User Guide

US English Edition

SV63298 RevB

December 3, 2018

Page 2

©2018 Pitney Bowes Inc.

All rights reserved. This book may not be reproduced in whole or in part in any fashion or

stored in a retrieval system of any type or transmitted by any means, electronically or

mechanically, without the express written permission of Pitney Bowes.

The use of this information by the recipient or others for purposes other than the training of

customers on Pitney Bowes equipment may constitute an infringement of intellectual

property rights of Pitney Bowes, and Pitney Bowes assumes no responsibility for any such

use of the information.

We have made every reasonable effort to ensure the accuracy and usefulness of this

manual. However, we cannot assume responsibility for errors or omissions or liability for the

misuse or misapplication of our products.

Except as provided in writing, duly signed by an officer of Pitney Bowes, no license either

express or implied, under any Pitney Bowes or third party’s patent, copyright or other

intellectual property rights is granted by providing this information.

Page 3

About this Book

This guide is designed to support proper setup, operation, troubleshooting, and basic maintenance

activities associated with the Relay™ 2500, 3500 and 4500 Inserting Systems.

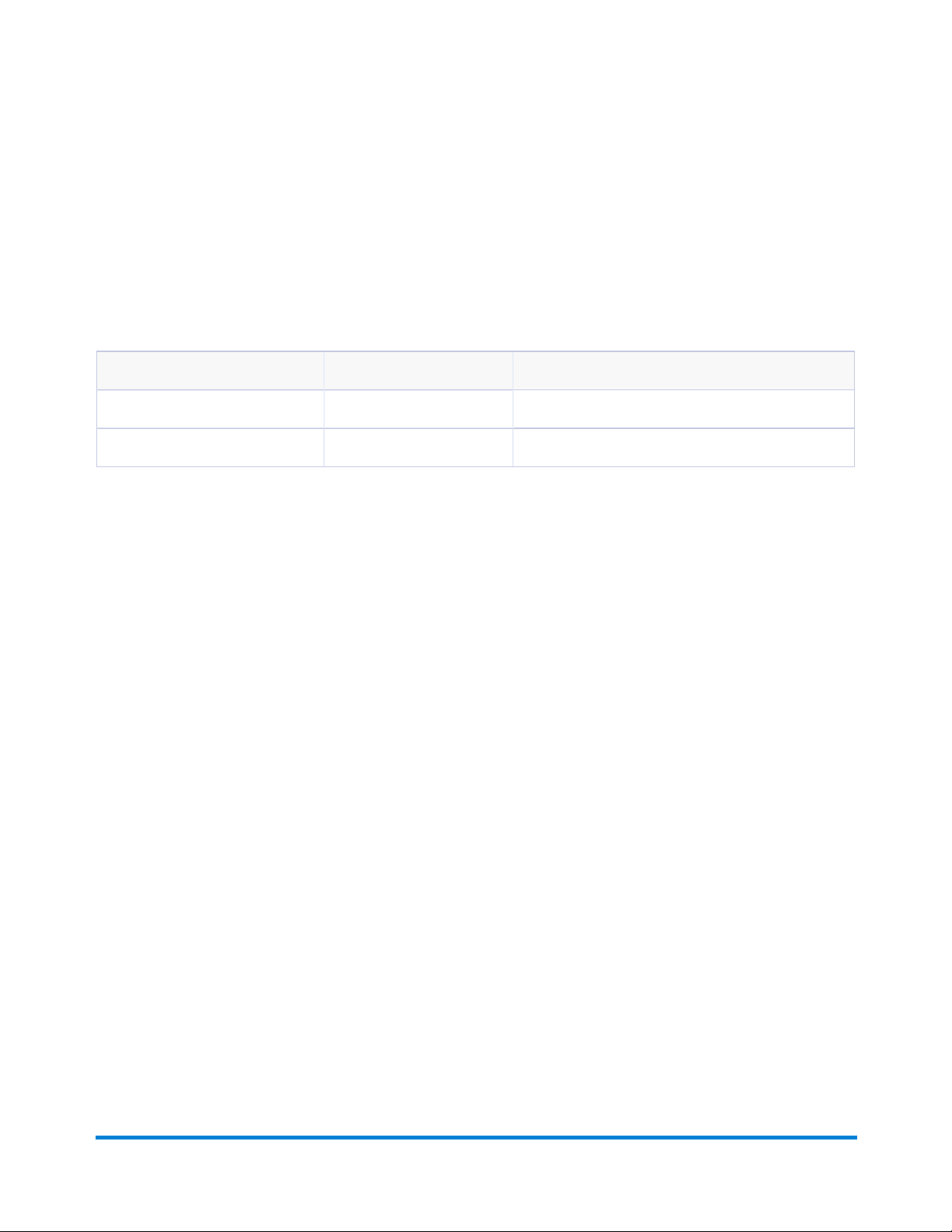

Version History

Document Part Number Release Date Comments

SV63298 Rev A October 1, 2018 Preliminary draft

SV63298 Rev B December 3, 2018 Initial release

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page iii of 7

Page 4

This page intentionally left blank.

Page 5

Setting the Sealer 33

Setting the Paper Length 34

1 - Safety

Safety Information 2

Warning Labels and Cautions 4

2 - Product Overview

Product Overview 6

Relay Inserter - Component Overview 8

3 - Using the Touchscreen

Turning on the Touchscreen 12

Navigating the Touchscreen 13

Using the Touchscreen Keyboard 17

Changing the Touchscreen Display Language 18

Logging In 19

Managing Operator Usernames and

Passwords 20

Changing an Existing Job Name 22

Setting Fold A 35

Setting Fold B 36

Setting the Envelope Depth 37

Setting the Envelope Stop 38

Setting the Batch Counter 39

Confirming Job Setup 40

Running a Trial Piece 41

Programming a non-Scanning Job 43

Initiating Job Setup 44

Selecting a Job 45

Disabling Scanning 46

Setting the Fold Type 47

Setting Accumulation Options 49

Setting the Main Sheet Feeder 50

Setting the Second (Supplementary) Sheet

Feeder 52

Setting the Insert Feeder 53

Setting the Mode Type - Insertion or Fold Only 54

Setting the Sealer 55

Setting the Paper Length 56

Setting Fold A 57

Setting Fold B 58

Setting the Envelope Depth 59

4 - Product Overview

Programming a Scanning Job 25

Initiating Job Setup 26

Selecting a Job 27

Enabling Scanning (OMR or Barcode) 28

Setting the Fold Type 29

Setting the Main Scanning Sheet Feeder 30

Setting the Second (Supplementary) Sheet

Feeder 31

Setting the Insert Feeder 32

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page vof 7

Setting the Envelope Stop 60

Setting the Batch Counter 61

Confirming Job Setup 62

Running a Trial Piece 63

Modifying an Existing Job 65

Deleting a Job 66

Page 6

5 - Running a Job

Running a Job 68

Turn on the Inserter 69

Turning on the Touchscreen 70

Logging In 71

Barcode Scanning Specifications 112

About Barcode Placement 114

Adjusting the Barcode Camera 117

Barcode Scanning Error Messages 118

Selecting a Job to Run 72

Loading the Sheet Feeder 73

Loading the Standard Envelope Feeder 77

Loading the High Capacity Envelope Feeder 79

Loading the Insert Feeder 83

Running a Trial Piece 87

Starting and Stopping the Inserter 89

Adding Sealer Solution 90

Adjusting the Drop Stacker 91

6 - OMR Scanning

About Optical Mark Recognition (OMR)

Scanning 94

About OMR Scanning and Feeders 95

About OMR Scanning Types 96

About OMR Scanning Marks 97

OMR Specifications 101

Standard OMR Position - Diagram 102

8 - Error Recovery and Clearing

Material Jams

Accumulation Jobs - Error Recovery 120

Empty Feeder - Error Recovery 121

OMR Message - Error Recovery 122

Clearing Material Jams 123

Clearing Material Jams in the Sheet Feeder 124

Clearing Material Jams in the Fold Plates 127

Clearing Material Jams in the Insert Trays 130

Clearing Material Jams in the Carriage

Assembly 133

Clearing Material Jams in the Envelope

Feeder Area 136

Clearing Material Jams in the Envelope Exit

Area 139

Clearing Material Jams in the Envelope

Inserting and Sealing Area 142

Clearing Material Jams in the Accumulation

Area 145

Adjusting the OMR Scanning Heads 103

OMR Scanning Error Messages 106

7 - Barcode Scanning

About Barcode Scanning 108

About 2D Barcode Data 109

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page vi of 7

9 - Reports

About Reports 150

Generating Reports for Scanning Jobs 151

Generating Productivity Reports for Jobs 153

Page 7

10 - Troubleshooting

Troubleshooting Touchscreen and Inserter

Issues 156

Troubleshooting Envelope Issues 157

Troubleshooting Sheet Issues 158

Troubleshooting Insert Issues 159

Troubleshooting Double Detect Issues 160

Error Messages 161

11 - Specifications

Material Specifications 166

Inserter Specifications 172

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page vii of 7

Page 8

1 - Safety

In this section

Safety Information 2

Warning Labels and Cautions 4

Page 9

Safety Information

Follow these precautions whenever you use your inserting system.

General Power Safety

l Place the system close to an easily accessible wall outlet

l Place the system in an accessible location to allow for proper venting of the equipment and to

facilitate servicing.

l Use the AC power adapter included with this device. Third party adapters may damage the device

l Plug the AC adapter directly into a properly grounded wall outlet located near the equipment and

easily accessible. Failure to properly ground the machine can result in severe personal injury

and/or fire.

Safety

l The AC adapter (power cord) is the primary means to disconnect this device from the AC supply.

l DO NOT use a wall outlet controlled by a wall switch or one that is shared with other equipment.

l DO NOT use an adapter plug on the line cord or wall outlet.

l DO NOT remove the ground pin from the line cord.

l DO NOT route the AC adapter power cord over sharp edges or trap it between furniture. Make

sure there is no strain on the power cord.

l If the unit becomes damaged, unplug it from the wall.

Operation

l Only trained personnel are permitted to operate this equipment. Training must include instruction

in operation under normal conditions and emergency situations.

l Read all instructions before attempting to operate the equipment.

l Use this equipment only for its intended purpose.

l Keep fingers, loose clothing, jewelry, long hair and neckties away from all moving parts.

l Avoid touching moving parts or materials while the machine is in use. Before clearing a jam, be

sure machine mechanisms come to a complete stop.

l Remove jammed material gently and carefully.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 2of 174

Page 10

Safety

l DO NOT remove covers. Covers enclose hazardous parts that should only be accessed by

properly trained service personnel.

l DO NOT place lighted candles, cigarettes, cigars, etc., on the system.

l To prevent overheating, do not cover vent openings.

l Always follow specific occupational safety and health standards for your workplace.

l Before operating the main inserting machine with this device, make sure the machine has been

properly prepared and that any other personnel in the area are standing clear of the inserter.

l Immediately report any damaged or non-functioning components that renders the unit unsafe to

Service.

Maintenance

l Operation of this equipment without periodic maintenance will inhibit optimum operating

performance and could cause the equipment to malfunction.

l Use only approved supplies.

l To reduce the risk of fire or electrical shock, DO NOT attempt to remove covers or disassemble the

control panel or its base. The cabinet encloses hazardous parts.

l Improper storage and use of aerosol dusters or flammable aerosol dusters can cause an

explosive-like condition that could result in personal injury and / or property damage. Always read

instructions and safety precautions on the duster container label.

l Contact your system supplier for:

oSupplies

oMaterial Data Safety Sheets

oIf you damage the unit

If your stacker has an AC adapter

l Use the AC power adapter included with this device; third party adapters may damage the device

l To protect against electrical shock, plug the AC adapter power cord into a grounded wall outlet.

l DO NOT route the power cord for the AC adapter over sharp edges or trap it between it between

pieces of furniture. Make sure there is no strain on the power cord.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 3of 174

Page 11

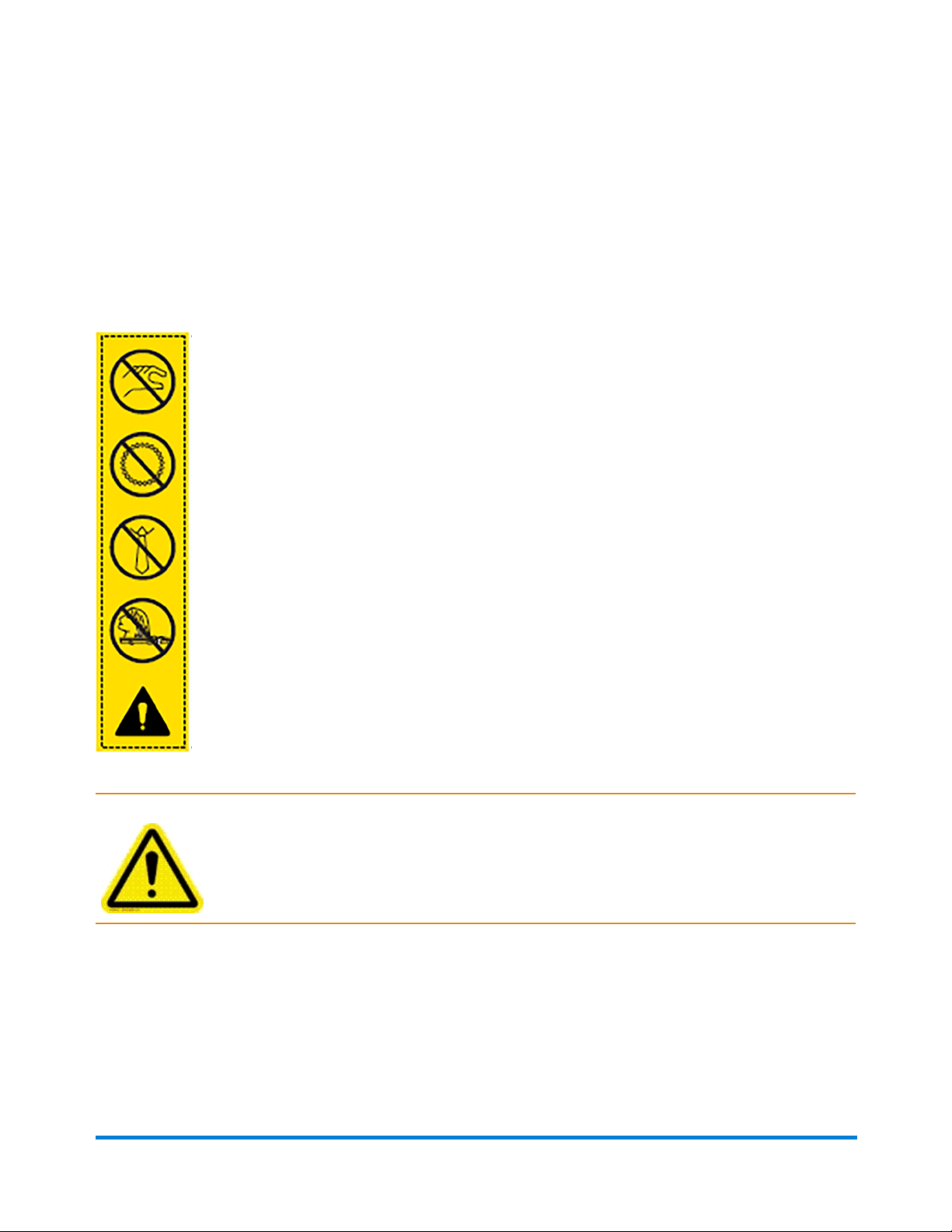

Safety

Warning Labels and Cautions

Pitney Bowes declines all liability in the event of material damage or bodily injury resulting from

negligence in the application of these precautions in respect to handling, operating, or servicing, even if

not expressly stated in these instructions.

Caution:

Moving mechanisms may result in personal injury. Keep hands, long hair, ties, jewelry

and loose clothing away from moving parts.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 4of 174

Page 12

2 - Product Overview

In this section

Product Overview 6

Relay Inserter - Component Overview 8

Page 13

Product Overview

Product Overview

This section provides an overview of the hardware components and features of the three Relay inserter

models - Relay 2500, Relay 3500 and Relay 4500.

All Relays are equipped with pre-fold accumulation. (This module is located under the top cover of the

machine). Pre-fold accumulation enables the collection of mailpieces before folding, all in one operation.

It works the same for all fold types.

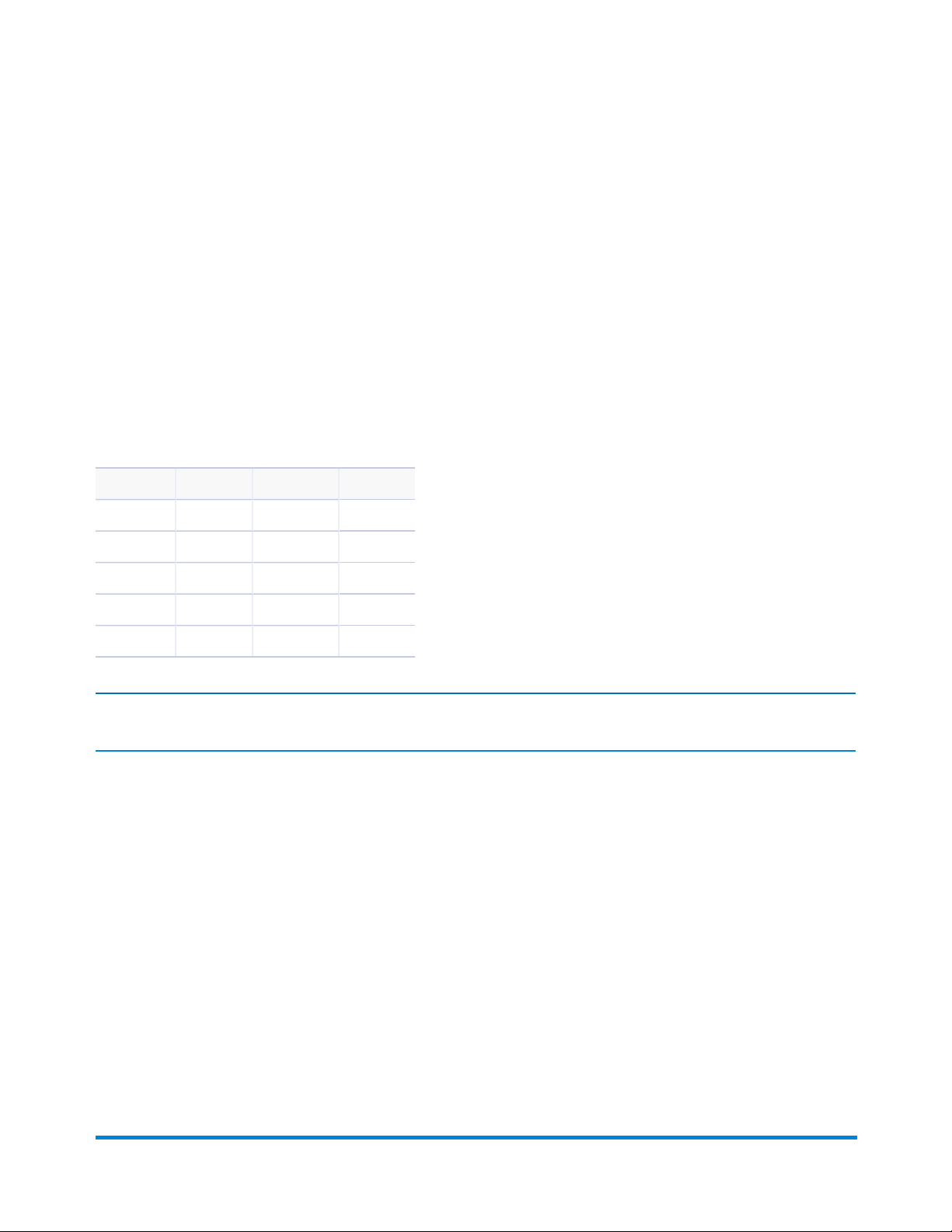

Relay Model Comparison - Hardware

Components Relay 2500 Relay 3500 Relay 4500

Sheet Feeder 1 2 2

Envelope Feeder shingle tray (1) shingle tray (1) elevator (1)

Insert Feeder 1 1 1

Integrated operator touchscreen* yes yes yes

* The touchscreen is a WiFi enabled device. If clients choose to utilize this network connection it is the

responsibility of the client to ensure the settings adhere to their IT department standards.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 6of 174

Page 14

Product Overview

Product features

Relay models 2500, 3500, 4500 all have these features and options.

l Pre-fold accumulation (located on top of machine under top cover)

l 2D barcode scanning (optional)

l OMR (Optical Mark Recognition) scanning (optional)

l Sealing - safe seal (supports a complete envelope seal) and no seal option

l Fold options - single-fold, C-fold, Z-fold, double-fold

l Fold-only option (fold without insertion)

l Fully automatic material separation on sheet feeders

l Fully automatic setting of fold plates

l Fully automatic envelope separation

l Fully automatic double document detection (when selected)

l Manually fed, semi-automatic insertion of single and multi-sheet collations

l Job recall functionality

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 7of 174

Page 15

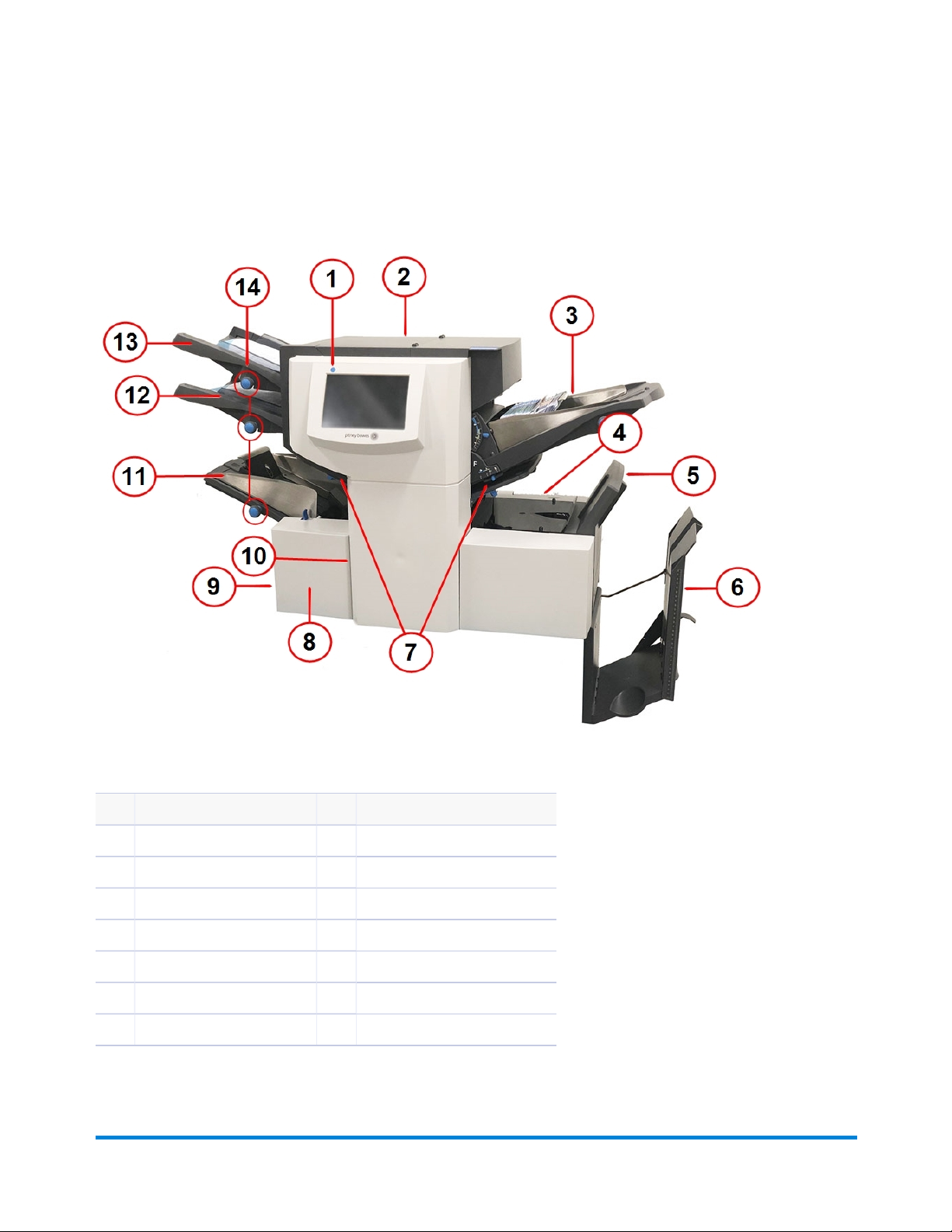

Relay Inserter - Component Overview

Product Overview

Relay 3500 Inserter (on the Relay 4500, the power switch and adjustment knobs are located on front panel)

Item Description Item Description

1 Touchscreen Power Button 8 Manual Advance Knob*

2 Accumulation Area* 9 Power Switch*

3 Insert Feeder 10 Measuring Scale*

4 Sealer Bottle** 11 Envelope Feeder

5 Envelope Inverter 12 Sheet Feeder 2

6 Drop Stacker*** 13 Sheet Feeder 1

7 Fold Plate 1 and 2 14 Side Guide Adjustment Knobs

* Not visible in this image

** Located in the back of the inserter

*** Document Inserter Vertical Stacker (DIVS) power stacker option available

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 8of 174

Page 16

Product Overview

Component Descriptions

l Touchscreen Power Button - turns on the touchscreen, an integrated interface to enter

commands, set up jobs, and change settings. Icons on the display show the system status.

l Accumulation area - accumulates the collation before folding.

l Insert Feeder - adds additional inserts to your envelope. Material fed from this feeder cannot be

folded by the inserter; especially suited to feeding pre-folded or thicker inserts.

l Sealer Bottle - provides sealing solution to the envelope sealer; located on the rear of the inserter

on the right side, under a hinged cover, labeled with the sealer icon.

l Envelope Inverter - transports envelope into the stacker face up.

l Drop Stacker - standard stacker, located at the exit of the inserter, it collects finished mailpieces.

This device can be latched against the inserter when not in use. An optional power stacker is

available, which offer greater capacity than the standard drop stacker.

l Fold Plate 1 and 2 - create the desired fold in material fed from the sheet feeder(s); the fold

plates are automatically set from the touchscreen.

l Manual Advance Knob - turns the inserter mechanisms manually to help clear material; located

under a cover on the front, left, lower corner of the inserter.

l Power Switch - turns the inserter on and off. (This is located on the front panel of the 4500.)

l Measuring Scale - used to help measure material and envelopes; located on the left side of the

inserter near the sheet feeders

l Envelope Feeder - feeds envelopes into the inserting area where they are filled with material

requested from the other feeder(s).

l Sheet Feeder 2 - feeds material that requires folding. Its functions are similar to those of sheet

feeder 1, but the manual feed option is NOT available from this feeder.

l Sheet Feeder 1 - this feeder is intended for feeding material that requires folding.

l Side Guide Adjustment Knobs - adjusts the side guides on the envelope feeder. (This is located

on the front panel of the 4500.)

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 9of 174

Page 17

Product Overview

Optional Document Inserter Vertical Stacker (DIVS) - Power Stacker

Some Relay Inserters may have an optional power vertical stacker that is attached at the exit of the

inserter. Envelopes are stacked on top of each other, with the newest envelope on the bottom. This

keeps completed mailpieces in the same order as they are processed.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 10 of 174

Page 18

3 - Using the Touchscreen

In this section

Turning on the Touchscreen 12

Navigating the Touchscreen 13

Using the Touchscreen Keyboard 17

Changing the Touchscreen Display Language 18

Logging In 19

Managing Operator Usernames and Passwords 20

Changing an Existing Job Name 22

Page 19

Using the Touchscreen

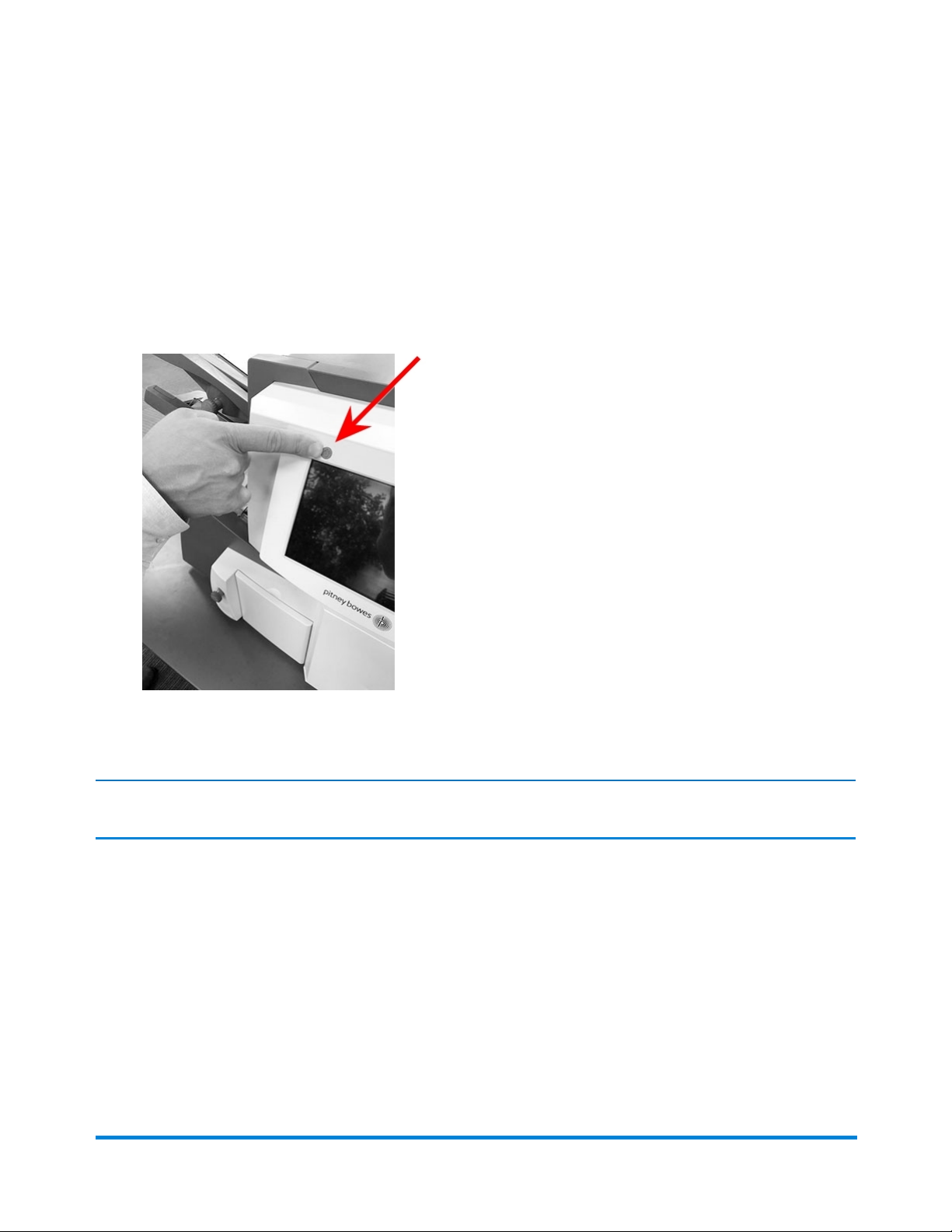

Turning on the Touchscreen

Be sure the inserter is powered up before turning on the touchscreen.

1. The ON/OFF power button is located on the top left of the touchscreen. Press and hold the power

button for a few seconds to turn the touchscreen on or off.

ON/OFF Power Button

NOTE: If the touchscreen is in sleep mode, lightly press the ON/OFF power button.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 12 of 174

Page 20

Using the Touchscreen

Navigating the Touchscreen

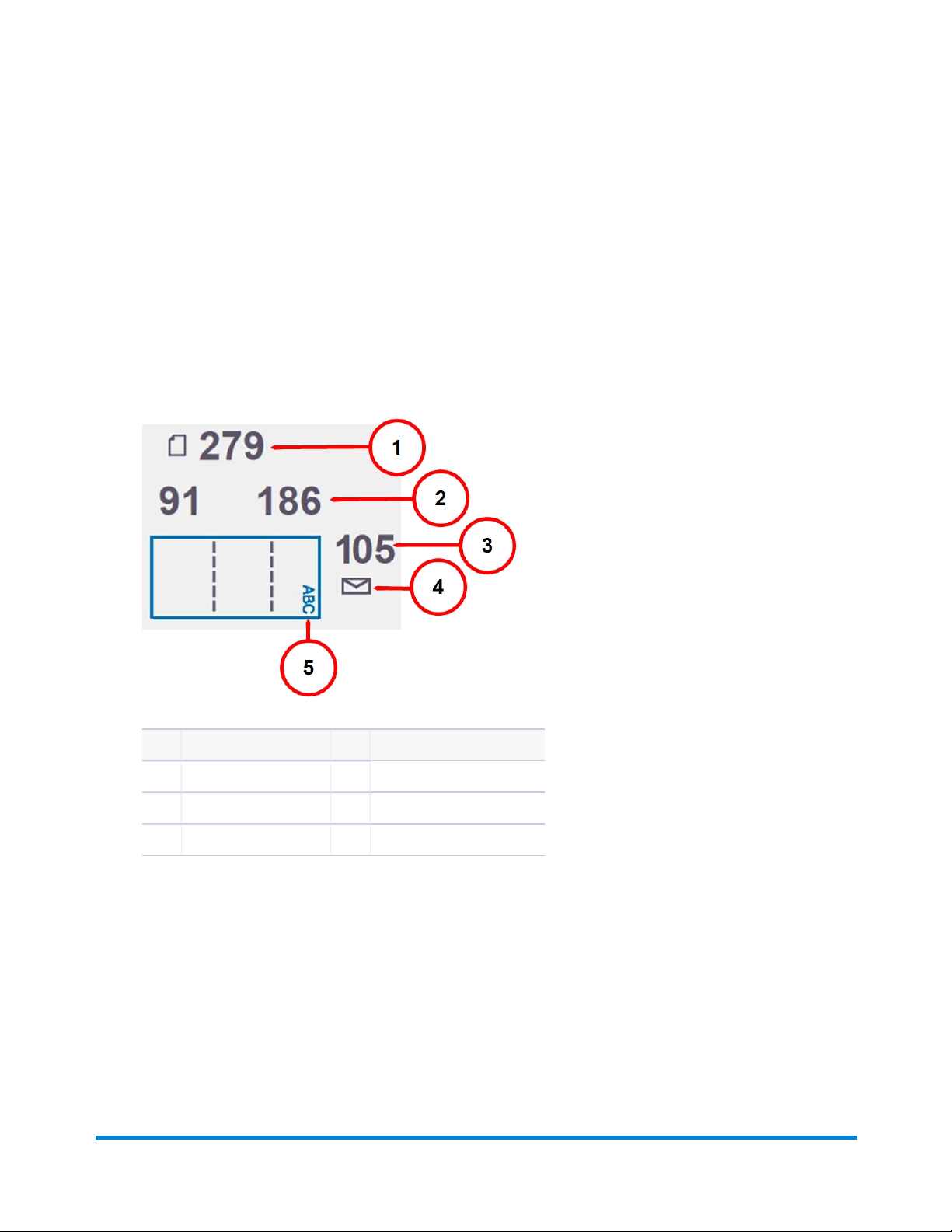

You can set up and run jobs using the integrated touchscreen. This section provides a basic overview of

the main touchscreen elements.

Integrated Touchscreen

Item Description Item Description

1 Operator Name 6 Speed Indicator

2 Job Name 7 Reset Counter

3 Setup Button 8 Inserter Model

4 Menu 9 Job Options and System Messages

5 Paper Area 10 Name of jobs Button

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 13 of 174

Page 21

Using the Touchscreen

Touchscreen Descriptions

l Operator name - logged in operator

l Job Name - job name appears here

l Setup - tap to access setup mode to program jobs and change options in existing jobs

l Menu - set of buttons to select jobs, run a trial piece, start and stop the inserter, clear the deck

l Material Setup Area - uses icons and numbers to display material details - paper size, fold(s) set

for sheet feeder, envelope depth and address orientation

Item Description Item Description

1 Paper Length (mm) 4 Closed or Open Envelope

2 Fold Lines (mm) 5 Address Orientation

3 Envelope Depth (mm)

l Speed Indicator - number of mailpieces produced per hour

l Reset Counter - tap to reset the item counter; it ascends for each completed mailpiece that exits

the machine

l Inserter Model - visual representation of the inserter

l Job Options and System Messages - displays job options and system errors or messages

l Name of jobs - tap to access the change job name screen

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 14 of 174

Page 22

Using the Touchscreen

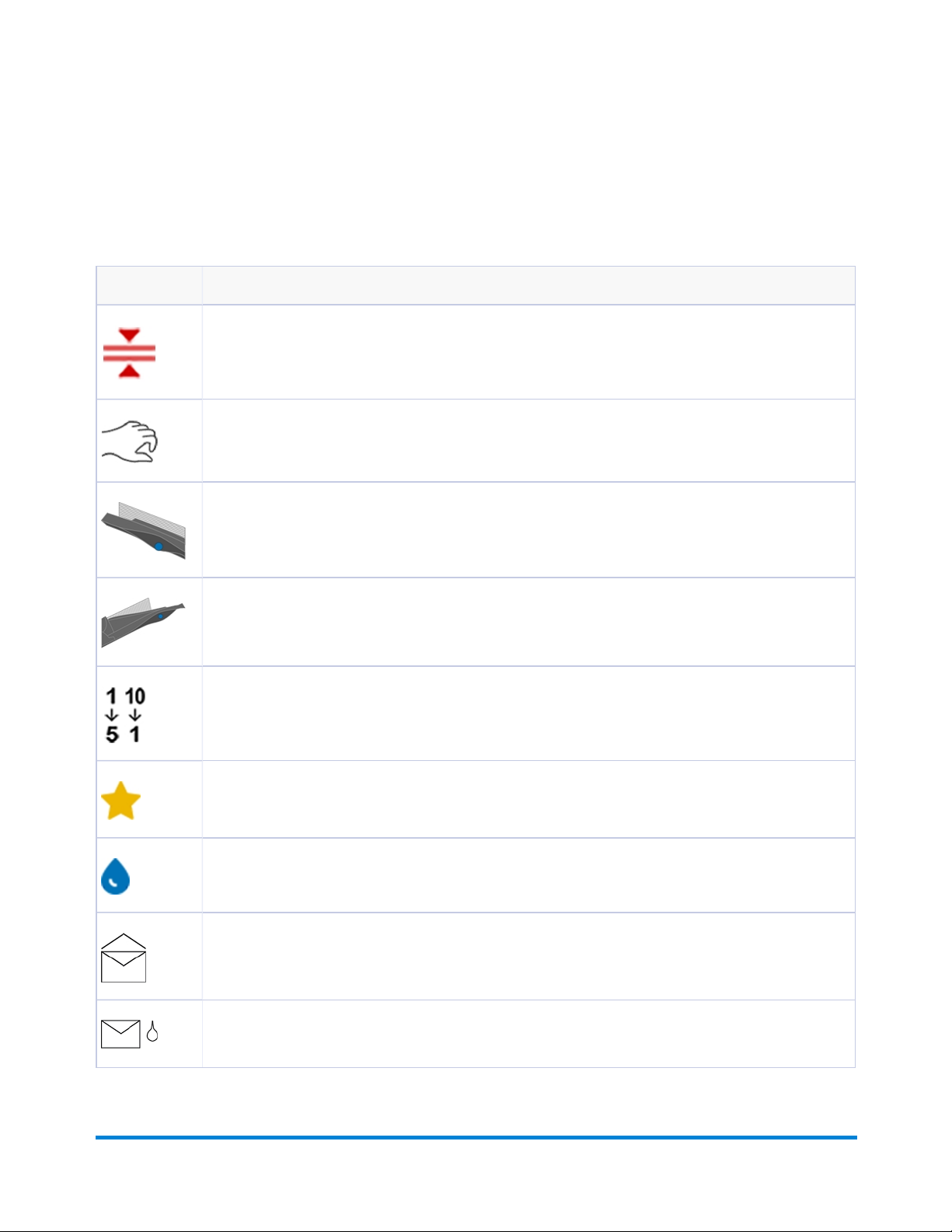

Touchscreen Icons

These icons display to help guide you through setting up and running a job. They indicate envelope

specifications, fold types, system status and messages, material jams and other job settings.

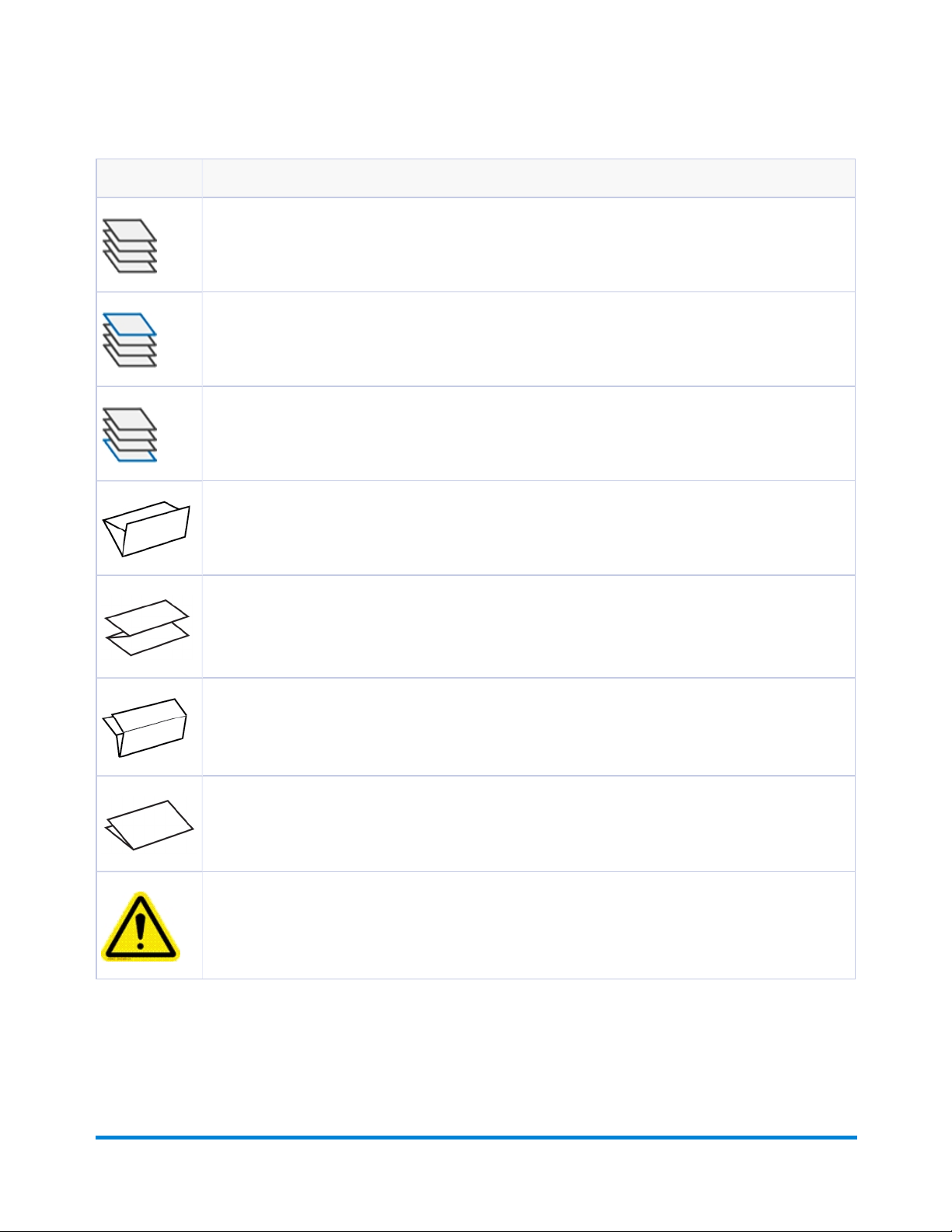

Icon Description

Indicates Double detect is on (Double detect stops the inserter if two or more sheets are fed

simultaneously.)

Indicates manual feed (icon displays next to feeder set for manual feed)

Indicates when a sheet feeder is being used (if the feeder is not being used the icon does not display)

Indicates when an insert feeder is being used (if the feeder is not being used the icon does not

display)

Indicates sheet order and quantity - order of sheets in the feeder and number of sheets accumulated

from that feeder

This icon displays next to the setting you are programming or changing to help guide you through the

setup process

Flashes when the sealer bottle needs refilling

Indicates the sealer unit is off (envelopes not sealed)

Indicates the sealer unit is on (automatic envelope sealing)

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 15 of 174

Page 23

Icon Description

Indicates there is no prime address sheet

Indicates prime address sheet is on the top, face up

Indicates prime address sheet is on the bottom, face down

Indicates a C-fold is selected

Using the Touchscreen

Indicates a Z-fold is selected

Indicates a double-fold is selected

Indicates a single-fold is selected

A warning symbol displays on the insert model, indicating a material stoppage; the position of the

symbol indicates where the stoppage has occurred.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 16 of 174

Page 24

Using the Touchscreen

Using the Touchscreen Keyboard

Launching the keyboard

l The keyboard automatically launches when you tap in a text field to enter text.

Closing the keyboard

l The keyboard closes when you tap the Enter arrow key on the keyboard.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 17 of 174

Page 25

Using the Touchscreen

Changing the Touchscreen Display Language

You can change the display language on the touchscreen to a non-English language.

1. Double-tap the inserter icon on the touchscreen desktop.

2. When the Operator List displays, tap the checkmark.

3. Select Language > Program from the main menu bar. A screen opens displaying country flags

associated with available languages.

4. Tap the flag that represents the language you want to display on the touchscreen. The flag screen

closes automatically and the new language displays.

5. Tap the checkmark.

6. Log in with your password or tap X to exit.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 18 of 174

Page 26

Using the Touchscreen

Logging In

1. Double-tap the inserter icon on the touchscreen desktop.

2. When the List of operators dialog opens, highlight an Operator and tap the checkmark.

3. Tap in the Password field. When the keyboard launches, type the password in the field.

4. Tap the checkmark to log in.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 19 of 174

Page 27

Using the Touchscreen

Managing Operator Usernames and Passwords

The Relay system comes with a set of default operator usernames and passwords. You can change

these default usernames and passwords to something unique to each operator. A maximum of 10

operators can be programmed into the touchscreen.

Default Operator Usernames and Passwords

Refer to these default usernames and passwords if you want to change them in your system.

Default Operator Usernames

Username Password Username Password

Operator 1 MDP1 Operator 6 MDP6

Operator 2 MDP2 Operator 7 MDP7

Operator 3 MDP3 Operator 8 MDP8

Operator 4 MDP4 Operator 9 MDP9

Operator 5 MDP5 Operator 10 MDP10

NOTE: The Supervisor password is 71.

Creating operator usernames (renaming default usernames)

You can rename a default Operator username to customize for your users.

1. Double-tap the inserter icon on the touchscreen desktop.

2. When the List of operators dialog displays, highlight a default Operator to rename (Operator 1 –

Operator 10).

3. Tap the checkmark.

4. Tap in the Password field. When the keyboard launches, type either the Supervisor (71) or the

default Operator password in the field.

5. Select File > Operators > Change from the main menu bar.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 20 of 174

Page 28

Using the Touchscreen

6. Tap in the New Name field and type a new operator name using the touchscreen keyboard.

7. Tap the checkmark to log in or X to exit.

Changing operator passwords

1. Double-tap the inserter icon on the touchscreen desktop.

2. When the List of operators dialog opens, highlight an Operator and tap the checkmark.

3. Tap in the Password field. When the keyboard launches, type the current Operator password in

the field. (DO NOT tap the checkmark.)

4. Select File > Password > Change from the menu bar.

5. Tap in the New Password field and type the new password.

6. Tap in the Confirm field and type the new password again.

7. Tap the checkmark to accept the password.

8. Tap the checkmark to log in or X to exit.

Recovering lost operator passwords

This is a supervisor activity.

1. Double-tap the inserter icon on the touchscreen desktop.

2. When the List of operators dialog opens, select the Operator associated with the lost password

and tap the checkmark.

3. Tap in the Password field. When the keyboard launches, type the Supervisor password (71) in

the field. (DO NOT tap the checkmark.)

4. Select File > Password > Recover from the main menu bar. The recovered password displays in

the dialog box. (Record the password for future reference.)

5. Tap OK to close the dialog box.

6. Type the recovered password into the Password field.

7. Tap the checkmark to log in or X to exit.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 21 of 174

Page 29

Using the Touchscreen

Changing an Existing Job Name

You can assign a new name to an existing job.

1. Double-tap the inserter icon on the touchscreen desktop.

2. When the List of operators dialog displays, highlight a default Operator to rename (Operator 1 –

Operator 10).

3. Tap the checkmark

4. Tap in the Password field. When the keyboard launches, type either the Supervisor (71) or the

Operator password in the field.

5. Tap the checkmark.

6. Tap the Name of jobs button.

7. When the Name of jobs list opens, highlight a job and tap Change.

8. Tap in the New Job Name field and type the new job name.

9. Tap the checkmark to accept the new job name.

10. Tap the checkmark to log in or X to close the Name of jobs window.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 22 of 174

Page 30

4 - Product Overview

In this section

Programming a Scanning Job 25

Initiating Job Setup 26

Selecting a Job 27

Enabling Scanning (OMR or Barcode) 28

Setting the Fold Type 29

Setting the Main Scanning Sheet Feeder 30

Setting the Second (Supplementary) Sheet Feeder 31

Setting the Insert Feeder 32

Setting the Sealer 33

Setting the Paper Length 34

Setting Fold A 35

Setting Fold B 36

Setting the Envelope Depth 37

Setting the Envelope Stop 38

Setting the Batch Counter 39

Confirming Job Setup 40

Running a Trial Piece 41

Programming a non-Scanning Job 43

Initiating Job Setup 44

Selecting a Job 45

Disabling Scanning 46

Setting the Fold Type 47

Setting Accumulation Options 49

Setting the Main Sheet Feeder 50

Setting the Second (Supplementary) Sheet Feeder 52

Setting the Insert Feeder 53

Setting the Mode Type - Insertion or Fold Only 54

Setting the Sealer 55

Page 31

Product Overview

Setting the Paper Length 56

Setting Fold A 57

Setting Fold B 58

Setting the Envelope Depth 59

Setting the Envelope Stop 60

Setting the Batch Counter 61

Confirming Job Setup 62

Running a Trial Piece 63

Modifying an Existing Job 65

Deleting a Job 66

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 24 of 174

Page 32

Product Overview

Programming a Scanning Job

Follow these steps to program a scanning job. As you move through the various job settings, a star icon

displays next to the area you are programming, to help guide you through the process.

l Log in

l Initiate job setup

l Select a job

l Enable scanning (OMR On or Off)

l Set fold type

l Set the main scanning sheet feeder

l Set the second sheet feeder

l Set the insert feeder

l Set the sealer

l Set paper length

l Set fold A

l Set fold B

l Set envelope depth

l Set envelope stop

l Set batch counter

l Confirm job setup

l Run a trial piece

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 25 of 174

Page 33

Product Overview

Initiating JobSetup

1. Log in.

2. From the main screen, tap the Setup button. The Enter Access Code: field displays over the

inserter model and the keypad appears on the touchscreen display.

3. Using the keypad, type the Supervisor code (71) and tap the Enter key. The Enter Access

Code: field counts up or down to display the password code entered.

Item Description Item Description

1 Setup Button 4 Keypad

2 Job Options and Settings 5 Enter Key

3 Fast Scroll Buttons* 6 Enter Access Code Field

* These keys are used as a fast forward to move through large changes in job setup settings

4. Tap >> to accept the access code and advance to the job settings.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 26 of 174

Page 34

Product Overview

Selecting a Job

You can select an existing job and modify the settings to fit a new job.

1. Tap the + and – buttons to scroll through the jobs; highlight the desired job. (The job name in the

screen banner changes to display the current jobs.)

2. Tap the >> to accept the job and advance to the first setting option.

NOTE: If you use an existing job, the old settings will be overwritten with the new settings selected.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 27 of 174

Page 35

Product Overview

Enabling Scanning (OMR or Barcode)

1. To set the scanning options, tap the + and – buttons and select the option you want for the job.

OMR and Barcode Settings

Setting Scanning Description

OMR off - OMR scanning off

OMR on - OMR scanning

- Standard OMR mark positioning

OMR + Sequence - OMR scanning

- Wrap Around Sequence

- Standard OMR mark positioning

OMR + Select feed - OMR scanning + Select feed / Autobatch

- Standard OMR mark positioning

OMR + Select feed + Sequence - OMR scanning + Select feed / Autobatch

- Wrap Around Sequence OR barcode

- Standard OMR mark positioning

2D BCR On - 2D barcode scanning on

2. Tap the >> button to accept the selection and advance to the next setting.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 28 of 174

Page 36

Product Overview

Setting the Fold Type

1. Tap the + and – buttons to scroll through the fold types.

Fold Types

Fold Description

C-fold

Z-fold

Double-fold

Single-fold

2. Tap the >> button to accept the fold type and advance to the next setting.

Paper Orientation

Depending on the fold type selected, the display shows the paper orientation for loading into the feeders.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 29 of 174

Page 37

Setting the Main Scanning Sheet Feeder

The main sheet feeder is automatically set for you based on the fold type you selected.

l C- fold and double-fold - Sheet Feeder 1 is set as the main sheet feeder

l Z-fold and single fold - Sheet Feeder 2 is set as the main sheet feeder

1. Tap the + and – buttons to scroll through the job options.

Icon Option Description

Feeder On Feeder on

Product Overview

Double Detect Feeder running double detect. (Double detect stops the inserter if two

or more sheets are fed simultaneously.)

SF (Select Feed) Select feed on. (Select feed tells a feeder to feed one extra sheet per

envelope).

NOTE: If there is no feeder icon displayed, the feeder is not active for this job

2. Tap the >> button to accept the option and advance to the next setting.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 30 of 174

Page 38

Product Overview

Setting the Second (Supplementary) Sheet Feeder

Set the options for the second scanning sheet feeder.

1. Tap the + and – buttons to scroll through the options.

Icon Option Description

Feeder On Feeder on

Double Detect Feeder running double detect. (Double detect stops the inserter if two

or more sheets are fed simultaneously.)

Select Feed Select feed on. (Select feed tells a feeder to feed one extra sheet per

envelope).

NOTE: If there is no feeder icon displayed, the feeder is not active for this job

2. Tap the >> button to accept the options and advance to the next setting.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 31 of 174

Page 39

Product Overview

Setting the Insert Feeder

Determine if you want to use the insert feeder and how it will be used. Set the options accordingly.

1. Tap the + and - buttons to scroll through the options.

Icon Option Description

Feeder On Feeder on.

Double Detect On Feeder running double detect. (Double detect stops the inserter if two

or more sheets are fed simultaneously.)

Select Feed On .Select Feed on. (Select feed tells a feeder to feed one extra sheet per

envelope.)

NOTE: If there is no feeder icon displayed, the feeder is not active for this job

2. Tap the >> button to accept the option and advance to the next setting.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 32 of 174

Page 40

Product Overview

Setting the Sealer

Decide whether you want to seal envelopes and then set the sealer.

1. Tap the + and – buttons to toggle the seal option to On or Off.

Icon Option Description

On Turns the sealer unit on for automatic sealing of envelopes. Make sure the sealer bottle is

full of E-Z Seal®.

Off Turns the sealer unit off. Envelopes will be processed unsealed.

2. Tap the >> button to accept the option and advance to the next setting.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 33 of 174

Page 41

Setting the Paper Length

1. Use the scale on the side of the inserter cover to measure the paper.

Product Overview

l US letter - 279 mm (11 inches)

l A4 paper - 297 mm

2. Tap the + and – buttons to scroll through paper lengths (displayed in mm).

3. Tap the >> button to accept the paper length value and advance to the next setting.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 34 of 174

Page 42

Product Overview

Setting Fold A

Depending on the fold type and paper length settings you selected earlier, the inserter suggests the

correct dimension for the first fold. Usually this setting will be fine.

If you want to keep the setting:

1. Tap the >> button to accept the option and advance to the next setting.

If you want to change the setting:

1. To change the standard fold setting, tap the + and – buttons until the length of required fold

displays.

NOTE: The inserter automatically limits your options to available specifications on your inserter.

As the length of fold A is changed, the dimensions of fold B change automatically to keep within

the correct paper length and inserter specifications.

2. Tap the >> button to accept the fold value and advance to the next setting.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 35 of 174

Page 43

Product Overview

Setting Fold B

Similar to setting fold A, the inserter suggests the correct dimension for fold B.

If you want to keep the setting:

1. Tap the >> button to accept the option and advance to the next setting.

If you want to change the setting:

1. Tap the + and – buttons until the length of fold required displays. A star icon displays next to the

fold panel you are setting.

2. Tap the >> button to accept the fold value and advance to the next setting.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 36 of 174

Page 44

Product Overview

Setting the Envelope Depth

1. Use the measuring scale on the front cover to measure the envelope depth.

2. Tap the + and – buttons to scroll through the measurements (displayed in mm).

3. Tap the >> button to accept the value and advance to the next setting.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 37 of 174

Page 45

Product Overview

Setting the Envelope Stop

The stop has five positions numbered 1 to 5. Setting 3 is the standard setting for normal weight paper

with standard folds. A thinner, lighter insert requires a lower setting and a thicker, heavier insert requires

a higher setting.

1. Tap the + and – buttons to scroll through the envelope stop positions.

2. Tap the >> button to accept the position and advance to the next setting.

NOTE: After the envelope stop is set, the setting displays on the bottom of the inserter model on the

touchscreen. (For example, ..3.., for position 3.)

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 38 of 174

Page 46

Product Overview

Setting the Batch Counter

l Batch Counter On - If the batch counter is turned on, it allows pre-defined batches of finished

mailpieces to be automatically processed. When the batch is complete, the inserter automatically

stops.

l Batch Counter Off - If the batch counter is not turned on, the display counter counts the number

of items processed until you tap Reset Counter. Tap the Start button to begin processing the

next batch of mailpieces.

To set the batch counter:

1. Tap the + and – buttons to toggle the batch mode to On or Off.

NOTE: If the batch counter is set to on, the inserter prompts for batch quantity. The default

quantity is 50, but any value can be selected up to 999 by tapping the + and – buttons.

2. Tap the >> button to accept the setting.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 39 of 174

Page 47

Product Overview

Confirming Job Setup

Job setup is now complete. Using the inserter model and icons, the touchscreen display shows all of the

selected job settings.

1. Review the job settings.

2. Tap the << and >> buttons to scroll back and change a setting.

3. When the setup changes are complete, tap the Setup button to accept the new settings and exit

setup mode.

The touchscreen displays the new job settings with the message Trial Piece Required.

4. Test the setup by running a trial piece.

NOTE: The inserter retains job settings until they are changed or deleted, even when the power is

disconnected.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 40 of 174

Page 48

Product Overview

Running a Trial Piece

Run a trial piece to test the job settings.

1. Load material and tap the Trial Piece button on the menu.

NOTE: When the first job is run after powering up the system, the touchscreen displays the

message "Check / Clear Accumulator." This is to verify there are no pages staged in the

accumulator area. If this message is displayed:

a. Open the accumulator cover to check for pieces.

b. Remove any material.

c. Close the cover and tap Trial Piece.

2. Assess the unsealed trial piece to make sure everything inside the envelope is correct. If you need

to make changes to the settings:

a. Tap the Setup button on the main screen.

b. Log in with Supervisor password (71).

c. Tap the << >> buttons to scroll to the setting you wish to modify.

d. Tap the + and – buttons to scroll to the desired option.

3. When the setup changes are complete, tap the Setup button to accept the new settings and return

to run mode. The inserter saves the job with the new settings.

4. Run another trial piece to test the modified settings.

NOTE: Any time you modify settings you must run a trial piece.

Running trial pieces with linked feeding

When a trial piece is requested for a job where linked feeding is enabled, both feeders must be loaded, as

a trial piece will feed from each feeder. Two trial pieces are produced.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 41 of 174

Page 49

Product Overview

Incorrect Address Position - Adjust Fold Setting

If the address is in the incorrect position when you run a trial piece, refer to these fold settings to help fine

tune the fold setting.

Fold Type Address too High Address too Low

C-fold Decrease Fold A Increase Fold A and increase Fold B by the same amount

Z- fold Increase Fold A Decrease Fold A and increase Fold B by the same amount

Single-fold Increase Fold A Decrease Fold A

Double-fold Decrease Fold A Increase Fold A

It is recommended that the fold is only adjusted by 0.20 inches (5 mm) each time.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 42 of 174

Page 50

Product Overview

Programming a non-Scanning Job

Follow these steps to program a non-scanning job. As you move through the various job settings, a star

icon displays next to the area being programmed, to help guide you through the process.

l Log in

l Initiating job setup

l Select a job

l Disable scanning (OMR Off) (Skip this step if your inserter does not have scanning)

l Set fold type

l Set accumulation

l Set main sheet feeder

l Set second sheet feeder

l Set insert feeder

l Set mode type (insertion or fold)

l Set the sealer

l Set paper length

l Set fold A

l Set fold B

l Set envelope depth

l Set envelope stop

l Set batch counter

l Confirm job setup

l Run a trial piece

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 43 of 174

Page 51

Product Overview

Initiating JobSetup

1. Log in.

2. From the main screen, tap the Setup button. The Enter Access Code: field displays over the

inserter model and the keypad appears on the touchscreen display.

3. Using the keypad, type the Supervisor code (71) and tap the Enter key. The Enter Access

Code: field counts up or down to display the password code entered.

Item Description Item Description

1 Setup Button 4 Keypad

2 Job Options and Settings 5 Enter Key

3 Fast Scroll Buttons* 6 Enter Access Code Field

* These keys are used as a fast forward to move through large changes in job setup settings

4. Tap >> to accept the access code and advance to the job settings.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 44 of 174

Page 52

Product Overview

Selecting a Job

You can select an existing job and modify the settings to fit a new job.

1. Tap the + and – buttons to scroll through the jobs; highlight the desired job. (The job name in the

screen banner changes to display the current jobs.)

2. Tap the >> to accept the job and advance to the first setting option.

NOTE: If you use an existing job, the old settings will be overwritten with the new settings selected.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 45 of 174

Page 53

Disabling Scanning

If scanning (OMR or barcode) is enabled on your system, set it to OMR off.

1. When prompted, tap the + and – buttons to select OMR off.

2. Tap the >> button to accept the selection and advance to the next setting.

Product Overview

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 46 of 174

Page 54

Product Overview

Setting the Fold Type

1. Tap the + and – buttons to scroll through the fold types.

Fold Types

Icon Fold

C-fold

Z-fold

Double-fold

Single-fold

2. Tap the >> button to accept the fold type and advance to the next setting.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 47 of 174

Page 55

Product Overview

Paper Orientation

Depending on the fold type selected, the display shows the paper orientation for loading into the feeders.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 48 of 174

Page 56

Product Overview

Setting Accumulation Options

Accumulation allows multiple sheets to be fed from the sheet feeder into the envelope.

1. Tap the + and – buttons to scroll through the accumulation options.

2. If you set accumulation to ON:

a. Tap the >> button to set number of pages to feed in each envelope. (Accumulation = 2 to 10)

b. Tap the + and – buttons to enter the number of pages.

3. Tap the >> button to accept the option and advance to the next setting.

Inserter Accumulation Settings

Setting Description

Accumulation: OFF Only one page can be fed from each feeder

Accumulation from Main Multiple sheets will be folded together and inserted into the envelope. (Up to 5 sheets for

C-folds, Z-folds, up to 10 sheets for single-folds - a service adjustment may be required to

run more than 8 sheets - and up to 3 sheets for double-folds.)

Accumulation From Suppl A single address main is fed from the main feeder, and up to 4 additional sheets can be

collated from the second feeder

Accumulation = (2 to 10) If Accumulation is ON, select how many pages you want to feed into each envelope.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 49 of 174

Page 57

Setting the Main Sheet Feeder

The main sheet feeder is automatically selected depending on the fold type you selected.

l C- fold and double-fold - Sheet Feeder 1 is set as the main sheet feeder

l Z-fold and single fold -Sheet Feeder 2 is set as the main sheet feeder

1. Tap the + and – buttons to scroll through the job options.

Icon Option Description

Feeder On Feeder on

Product Overview

Double Detect Feeder running double detect. (Double detect stops the inserter

if two or more sheets are fed simultaneously.)

Manual Feed Manually feeds collated sets; only available on sheet feeder 1.

The inserter waits for manual insertion of each set into sheet

feeder 1, after which it will fold and insert the set automatically.

Linked Feeding: On (only

available on Relay 3500 and

4500 models)

NOTE: If there is no feeder icon displayed, the feeder is not active for this job

Linked feeding on. (Feed comes from the first sheet feeder and

when empty, automatically switches feeding from the second

sheet feeder.)

2. Tap the >> button to accept the option and advance to the next setting.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 50 of 174

Page 58

Product Overview

About Linked Feeding

Linked feeding can only be set on the main sheet feeder on non-scanning jobs. With linked feeding,

sheets are initially fed from the main sheet feeder. When that feeder is empty, the inserter automatically

switches feeding from the second sheet feeder.

While the job is running with linked feeding enabled, above the inserter model on the touchscreen the

display shows: 1 > 2 > 1. This confirms feeding automatically switches between feeders.

About the Manual Feed Option

l The manual feed setting allows you to run stapled sets of up to five sheets - a maximum of 100 lbs.

(400 gsm) per set. The maximum compressed thickness of the set after folding must not exceed

0.08 inches (2 mm).

l The inserter waits for manual insertion of each set into sheet feeder 1, after which it will fold and

insert the set automatically.

l When running manual feed mode, sheet feeder 2 becomes inoperable.

l The manual feed option is only available when Accumulation is set to OFF.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 51 of 174

Page 59

Product Overview

Setting the Second (Supplementary) Sheet Feeder

Set the options for the second sheet feeder.

1. Tap the + and – buttons to scroll through the options.

Icon Option Description

Feeder On Feeder on.

Double Detect Feeder running double detect. (Double detect stops the inserter if two

or more sheets are fed simultaneously.)

NOTE: If there is no feeder icon displayed, the feeder is not active for this job

2. Tap the >> button to accept the option and advance to the next setting.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 52 of 174

Page 60

Product Overview

Setting the Insert Feeder

Determine if you want to use the insert feeder and how it will be used. Set the options accordingly.

1. Tap the + and - buttons to scroll through the options.

Icon Option Description

Feeder On Feeder on.

Double Detect On Feeder running double detect. (Double detect stops the inserter if two

or more sheets are fed simultaneously.)

Select Feed On .Select Feed on. (Select feed tells a feeder to feed one extra sheet per

envelope.)

NOTE: If there is no feeder icon displayed, the feeder is not active for this job

2. Tap the >> button to accept the option and advance to the next setting.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 53 of 174

Page 61

Product Overview

Setting the Mode Type - Insertion or Fold Only

This setting only appears if accumulation is not turned on. The inserter needs to know if the job requires

inserting material into an envelope or if it is a fold-only job.

l Insertion mode - activates the envelope feeder for a normal inserting job.

l Fold-Only mode - turns the envelope feeder off and sets the inserter to act as a folding module.

To set the mode type:

1. Tap the + and – buttons to toggle between the options.

2. Tap the >> button to accept the mode type and advance to the next setting.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 54 of 174

Page 62

Product Overview

Setting the Sealer

This setting appears on non-scanning jobs only if insertion mode is turned on. Decide if you want to seal

envelopes and set the sealer.

1. Tap the + and – buttons to toggle the option to On or Off.

Icon Option Description

On Turns the sealer unit on for automatic sealing of envelopes. Make sure the sealer bottle is

full of E-Z Seal®.

Off Turns the sealer unit off. Envelopes will be ejected unsealed.

2. Tap the >> button to accept the option and advance to the next setting.

l If you selected either of the sheet feeders, continue to the Setting the Paper Length.

l If you are using the insert feeder only, folding is not possible; skip to Setting Envelope Depth.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 55 of 174

Page 63

Setting the Paper Length

1. Use the scale on the side of the inserter cover to measure the paper.

Product Overview

l US letter - 279 mm (11 inches)

l A4 paper - 297 mm

2. Tap the + and – buttons to scroll through paper lengths (displayed in mm).

3. Tap the >> button to accept the paper length value and advance to the next setting.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 56 of 174

Page 64

Product Overview

Setting Fold A

Depending on the fold type and paper length settings you selected earlier, the inserter suggests the

correct dimension for the first fold. Usually this setting will be fine.

If you want to keep the setting:

1. Tap the >> button to accept the option and advance to the next setting.

If you want to change the setting:

1. To change the standard fold setting, tap the + and – buttons until the length of required fold

displays.

NOTE: The inserter automatically limits your options to available specifications on your inserter.

As the length of fold A is changed, the dimensions of fold B change automatically to keep within

the correct paper length and inserter specifications.

2. Tap the >> button to accept the fold value and advance to the next setting.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 57 of 174

Page 65

Product Overview

Setting Fold B

Similar to setting fold A, the inserter suggests the correct dimension for fold B.

If you want to keep the setting:

1. Tap the >> button to accept the option and advance to the next setting.

If you want to change the setting:

1. Tap the + and – buttons until the length of fold required displays. A star icon displays next to the

fold panel you are setting.

2. Tap the >> button to accept the fold value and advance to the next setting.

l Inserting jobs - continue to the Setting the Envelope Depth.

l Fold-only job - there are no more job settings, skip to Confirming the Job Setup.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 58 of 174

Page 66

Product Overview

Setting the Envelope Depth

1. Use the measuring scale on the front cover to measure the envelope depth.

2. Tap the + and – buttons to scroll through the measurements (displayed in mm).

3. Tap the >> button to accept the value and advance to the next setting.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 59 of 174

Page 67

Product Overview

Setting the Envelope Stop

The stop has five positions numbered 1 to 5. Setting 3 is the standard setting for normal weight paper

with standard folds. A thinner, lighter insert requires a lower setting and a thicker, heavier insert requires

a higher setting.

1. Tap the + and – buttons to scroll through the envelope stop positions.

2. Tap the >> button to accept the position and advance to the next setting.

NOTE: After the envelope stop is set, the setting displays on the bottom of the inserter model on the

touchscreen. (For example, ..3.., for position 3.)

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 60 of 174

Page 68

Product Overview

Setting the Batch Counter

l Batch Counter On - If the batch counter is turned on, it allows pre-defined batches of finished

mailpieces to be automatically processed. When the batch is complete, the inserter automatically

stops.

l Batch Counter Off - If the batch counter is not turned on, the display counter counts the number

of items processed until you tap Reset Counter. Tap the Start button to begin processing the

next batch of mailpieces.

To set the batch counter:

1. Tap the + and – buttons to toggle the batch mode to On or Off.

NOTE: If the batch counter is set to on, the inserter prompts for batch quantity. The default

quantity is 50, but any value can be selected up to 999 by tapping the + and – buttons.

2. Tap the >> button to accept the setting.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 61 of 174

Page 69

Product Overview

Confirming Job Setup

Job setup is now complete. Using the inserter model and icons, the touchscreen display shows all of the

selected job settings.

1. Review the job settings.

2. Tap the << and >> buttons to scroll back and change a setting.

3. When the setup changes are complete, tap the Setup button to accept the new settings and exit

setup mode.

The touchscreen displays the new job settings with the message Trial Piece Required.

4. Test the setup by running a trial piece.

NOTE: The inserter retains job settings until they are changed or deleted, even when the power is

disconnected.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 62 of 174

Page 70

Product Overview

Running a Trial Piece

Run a trial piece to test the job settings.

1. Load material and tap the Trial Piece button on the menu.

NOTE: When the first job is run after powering up the system, the touchscreen displays the

message "Check / Clear Accumulator." This is to verify there are no pages staged in the

accumulator area. If this message is displayed:

a. Open the accumulator cover to check for pieces.

b. Remove any material.

c. Close the cover and tap Trial Piece.

2. Assess the unsealed trial piece to make sure everything inside the envelope is correct. If you need

to make changes to the settings:

a. Tap the Setup button on the main screen.

b. Log in with Supervisor password (71).

c. Tap the << >> buttons to scroll to the setting you wish to modify.

d. Tap the + and – buttons to scroll to the desired option.

3. When the setup changes are complete, tap the Setup button to accept the new settings and return

to run mode. The inserter saves the job with the new settings.

4. Run another trial piece to test the modified settings.

NOTE: Any time you modify settings you must run a trial piece.

Running trial pieces with linked feeding

When a trial piece is requested for a job where linked feeding is enabled, both feeders must be loaded, as

a trial piece will feed from each feeder. Two trial pieces are produced.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 63 of 174

Page 71

Product Overview

Incorrect Address Position - Adjust Fold Setting

If the address is in the incorrect position when you run a trial piece, refer to these fold settings to help fine

tune the fold setting.

Fold Type Address too High Address too Low

C-fold Decrease Fold A Increase Fold A and increase Fold B by the same amount

Z- fold Increase Fold A Decrease Fold A and increase Fold B by the same amount

Single-fold Increase Fold A Decrease Fold A

Double-fold Decrease Fold A Increase Fold A

It is recommended that the fold is only adjusted by 0.20 inches (5 mm) each time.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 64 of 174

Page 72

Product Overview

Modifying an Existing Job

Modifying an existing job requires Supervisor level access.

1. Tap the Setup button on the main screen. The Enter Access Code: field displays over the

inserter model and the keypad appears on the touchscreen display.

2. Using the keypad, type the Supervisor code (71) and tap the Enter key. The Enter Access

Code: field counts up or down to display the password code entered.

3. Tap the >> button to accept the code and advance to the job selection.

4. Tap the + and – buttons to display the job you wish to modify.

5. Tap the >> button to accept the job selection and advance to the job programming settings.

6. Tap the << and >> button to scroll through the setting(s).

7. Tap the + and – buttons to scroll through the options or desired values.

8. Tap the >> button to accept the job setting.

9. Tap the Setup button to save the changes and exit setup mode.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 65 of 174

Page 73

Product Overview

Deleting a Job

Deleting an existing job requires Supervisor level access.

1. Tap the Setup button on the main screen. The Enter Access Code: field displays over the

inserter model and the keypad appears on the touchscreen display.

2. Using the keypad, type the Supervisor code (71) and tap the Enter key. The Enter Access

Code: field counts up or down to display the password code entered.

3. Tap the >> button to accept the code and advance to the job selection.

4. Tap the + and – buttons to display the job you wish to delete.

5. Tap the X button to delete the job. The display shows “Do you want to delete this application?”

6. Tap the checkmark.

7. Tap the X button to delete the job. The display briefly shows “Deleting Job” as the job is erased.

8. Tap the Setup button to exit job setup mode.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 66 of 174

Page 74

5 - Running a Job

In this section

Running a Job 68

Turn on the Inserter 69

Turning on the Touchscreen 70

Logging In 71

Selecting a Job to Run 72

Loading the Sheet Feeder 73

Loading the Standard Envelope Feeder 77

Loading the High Capacity Envelope Feeder 79

Loading the Insert Feeder 83

Running a Trial Piece 87

Starting and Stopping the Inserter 89

Adding Sealer Solution 90

Adjusting the Drop Stacker 91

Page 75

Running a Job

These activities assume the job has already been programmed.

l Turn on the inserter

l Turn on the touchscreen

l Log into the system

l Select a job

l Load the sheet feeders

l Load the envelope feeders

l Load the insert feeders

l Run a trial piece

Running a Job

l Start the inserter

l Fill the sealer (if needed)

l Adjust the stacker (if needed)

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 68 of 174

Page 76

Running a Job

Turn on the Inserter

1. Verify the power cord is connected to the socket on the back of the inserter.

2. Verify the power cord is plugged into a power outlet near the machine and is easily accessible.

3. Turn the power switch to the ON position.

Relay 4500 Model shown here

NOTE: On Relay Inserter 2500 and 3500 models, the power switch is located on the front, left side of

the inserter, under the envelope feeder.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 69 of 174

Page 77

Running a Job

Turning on the Touchscreen

Be sure the inserter is powered up before turning on the touchscreen.

1. The ON/OFF power button is located on the top left of the touchscreen. Press and hold the power

button for a few seconds to turn the touchscreen on or off.

ON/OFF Power Button

NOTE: If the touchscreen is in sleep mode, lightly press the ON/OFF power button.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 70 of 174

Page 78

Running a Job

Logging In

1. Double-tap the inserter icon on the touchscreen desktop.

2. When the List of operators dialog opens, highlight an Operator and tap the checkmark.

3. Tap in the Password field. When the keyboard launches, type the password in the field.

4. Tap the checkmark to log in.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 71 of 174

Page 79

Running a Job

Selecting a Job to Run

When you log in, the touchscreen displays the last job run with the message "Trial Piece Required." This

is when you select the job you wish to run.

1. Tap the Job menu button to scroll through the jobs; keep tapping until the job you want displays.

You can also tap the Default Job button (most used job) if you want to run the inserter with the

default job settings.

2. Begin loading material; follow the steps in the next section.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 72 of 174

Page 80

Running a Job

Loading the Sheet Feeder

Automatic Feed Jobs

1. Adjust the side guides to the width of the material. Once the guides are touching both sides of the

material, turn the side guide control 1/4-turn in the opposite direction. This sets the correct

clearance between the guides and the material.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 73 of 174

Page 81

2. Aerate (fan) the stack of paper to ensure that individual sheets are not stuck together.

Running a Job

3. Jog the stack of paper back into alignment. The display indicates the correct orientation of the

paper.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 74 of 174

Page 82

Running a Job

4. Place the stack of paper onto the feed deck. Allow the deck to move down and the top of the stack

of paper to slide under the feed roller.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 75 of 174

Page 83

Running a Job

Manual Feed Jobs

If you select a manual feed job where sheet feeder 1 is set for manual feed of collated sets, DO NOT load

the sheet feeder. Instead, you will feed collated sets one at a time, by hand, as required.

1. Before running a manual feed job, pull back the lever. This opens the feed mechanism for manual

feed operation.

NOTE: Return this lever to its normal position when the feeder is used for automatic operation.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 76 of 174

Page 84

Running a Job

Loading the Standard Envelope Feeder

The Relay 2500 and 3500 use a standard (tray style) sheet feeder to feed the outer envelope for the job.

1. Use the side guide adjustment knob to adjust the side guides to the width of the envelopes.

2. Once the guides are touching both sides of the envelope, turn the adjustment knob 1/4-turn in the

opposite direction. This sets the correct clearance between the guides and the envelope.

3. Aerate and fan the stack of envelopes so the individual envelopes are not stuck together.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 77 of 174

Page 85

Running a Job

4. Place the envelopes on the feed deck with the flaps up and trailing. IMPORTANT! Check that the

lead edge of the first envelope is under the front feed roller and the stack of envelopes is shingled

on the deck.

5. Let the wedge slide down behind the stack so the envelops are supported.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 78 of 174

Page 86

Running a Job

Loading the High Capacity Envelope Feeder

The Relay 4500 uses a high capacity (elevator style) envelope feeder to feed the outer envelopes.

1. Press the envelope feeder loading switch to lower the envelope feeder platform.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 79 of 174

Page 87

Running a Job

2. Use the side guide adjustment knob to adjust the side guides to the width of the envelopes. Once

the guides are touching both sides of the envelope, turn the adjustment knob 1/4-turn in the

opposite direction. This sets the correct clearance between the guides and the envelope.

3. Aerate the stack of envelopes and fan it so the individual envelopes are not stuck together.

4. Place the stack of envelopes into the feeder with the flap side UP and flap LAST.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 80 of 174

Page 88

Running a Job

5. Press the envelope feeder loading switch again to raise the envelope stack to the normal feeding

position.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 81 of 174

Page 89

Loading envelopes without stopping the inserter

Shown here on the Relay 4500 with a high capacity (elevator style) envelope feeder.

1. Press the envelope feeder loading switch to lower the feeder platform.

Running a Job

2. Load envelopes as described earlier in this section.

3. Press the envelope feeder loading switch again. The envelope stack rises to the normal feeding

position and continues to process automatically.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 82 of 174

Page 90

Running a Job

Loading the Insert Feeder

The insert feeder feeds items that do not require folding. The insert feeder may be removed if it is not

required fora job.

1. Use the side guide adjustment knob to adjust the side guides to the width of the inserts you are

running.

2. Once the guides are touching both sides of the insert, turn the adjustment knob 1/4-turn in the

opposite direction. This sets the correct clearance between the guides and the insert.

3. Refer to the labels located on the insert feeder and match the insert type (slip, reply envelope, prefolded, booklet) with the icon and color.

Identifying the Insert - If the label indicates a range of settings, we recommend you select a

higher number or letter for a thicker the insert.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 83 of 174

Page 91

4. Set the blue separator gap lever to the number required.

Running a Job

5. Set the blue separator shield lever to the letter required.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 84 of 174

Page 92

Running a Job

6. Aerate and fan the stack of inserts so the individual pieces are not stuck together.

7. Shingle the inserts and place them on the feed deck. Loading orientation can vary depending on

the inserts. Load inserts using these orientation guidelines.

Insert Type Orientation

Slip Face up, bottom edge first

Reply Envelope Face up, top edge first

Pre-folded Face up, closed edge first

Booklet Face up, bound edge first

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 85 of 174

Page 93

8. Let the wedge (material prop) slide down the stack to support the envelopes.

Running a Job

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 86 of 174

Page 94

Running a Job

Running a Trial Piece

Run a trial piece to test the job settings.

1. Load material and tap the Trial Piece button on the menu.

NOTE: When the first job is run after powering up the system, the touchscreen displays the

message "Check / Clear Accumulator." This is to verify there are no pages staged in the

accumulator area. If this message is displayed:

a. Open the accumulator cover to check for pieces.

b. Remove any material.

c. Close the cover and tap Trial Piece.

2. Assess the unsealed trial piece to make sure everything inside the envelope is correct. If you need

to make changes to the settings:

a. Tap the Setup button on the main screen.

b. Log in with Supervisor password (71).

c. Tap the << >> buttons to scroll to the setting you wish to modify.

d. Tap the + and – buttons to scroll to the desired option.

3. When the setup changes are complete, tap the Setup button to accept the new settings and return

to run mode. The inserter saves the job with the new settings.

4. Run another trial piece to test the modified settings.

NOTE: Any time you modify settings you must run a trial piece.

Running trial pieces with linked feeding

When a trial piece is requested for a job where linked feeding is enabled, both feeders must be loaded, as

a trial piece will feed from each feeder. Two trial pieces are produced.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 87 of 174

Page 95

Running a Job

Incorrect Address Position - Adjust Fold Setting

If the address is in the incorrect position when you run a trial piece, refer to these fold settings to help fine

tune the fold setting.

Fold Type Address too High Address too Low

C-fold Decrease Fold A Increase Fold A and increase Fold B by the same amount

Z- fold Increase Fold A Decrease Fold A and increase Fold B by the same amount

Single-fold Increase Fold A Decrease Fold A

Double-fold Decrease Fold A Increase Fold A

It is recommended that the fold is only adjusted by 0.20 inches (5 mm) each time.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 88 of 174

Page 96

Running a Job

Starting and Stopping the Inserter

l Tap the Start button on the touchscreen to begin automatic operation. The inserter runs until it

runs out of paper or you stop it.

l Tap the Stop button on the touchscreen to stop the inserter.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 89 of 174

Page 97

Running a Job

Adding Sealer Solution

1. When the Add sealing solution icon flashes, add E-Z Seal® Solution.

Icon Description

Add sealing solution

2. Open the sealer bottle cover hinge located at the rear, right side of the inserter and remove the

bottle.

3. Fill the bottle with the solution to the level indicated.

4. Place the sealer bottle in position in the inserter and close the cover.

NOTE: If the sealer unit was completely empty, allow time for the fresh solution to soak through the

sealer before resuming operation. This helps ensure a good seal.

NOTE: We recommend Pitney Bowes E-Z Seal to minimize algae growth and scale build-up.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 90 of 174

Page 98

Running a Job

Adjusting the Drop Stacker

If necessary, adjust the drop stacker to accommodate the job material.

1. Lift the lever at the rear of the stacker and adjust the stacker to one of the preset positions.

2. Lower the lever to lock the stacker into position.

NOTE: When not in use, the stacker can be raised and latched vertically against the exit area of the

inserter.

Pitney Bowes Relay™ 2500, 3500, 4500 User Guide December, 2018 Page 91 of 174

Page 99

This page intentionally left blank.

Page 100

6 - OMR Scanning

In this section

About Optical Mark Recognition (OMR) Scanning 94

About OMR Scanning and Feeders 95

About OMR Scanning Types 96

About OMR Scanning Marks 97

OMR Specifications 101

Standard OMR Position - Diagram 102

Adjusting the OMR Scanning Heads 103

OMR Scanning Error Messages 106

Loading...

Loading...