Page 1

Relay

™

3000/4000

User Guide

International English Edition

SV63138 Rev. A

August 1, 2015

Document Inserting Systems with

Touch Screen and Barcode Scanning

Shipping & Mailing

Inserter

Page 2

Statement of FCC Compliance

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to part 15 of the FCC rules. These limits are designed to

provide reasonable protection against interference when the equipment is operated

in a commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction

manual, may cause interference to radio communications. Operation of this equipment

in a residential area is likely to cause interference, in which case the user will be

required to correct the interference at his own expense. Use only a shielded interface

cable to operate this equipment with a printer or other peripheral device.

CAUTION: Changes or modifications to this equipment not expressly approved by

the party responsible for compliance (Pitney Bowes) could void the user’s authority

to operate the equipment.

SV63138 Rev. A August 1, 2015

©2006, 2015 Pitney Bowes Inc. All rights reserved. This guide may not be

reproduced in whole or in part in any fashion or stored in a retrieval system of

any type or transmitted by any means, electronically or mechanically, without

the express, written permission of Pitney Bowes.

We have made every reasonable effort to ensure the accuracy and usefulness

of this manual; however, we cannot assume responsibility for errors or omissions

or liability for the misuse or misapplication of our products.

Due to our continuing program of product improvement, equipment and

material specications as well as performance features are subject to change

without notice. Your inserter system may not have some of the features

described in this book.

E-Z Seal is a registered trademark of Pitney Bowes Inc. ENERGY STAR is a

registered trademark of the United States Environmental Protection Agency.

It is certified that the equipment complies with all applicable Directives

of the European Union. The touch screen and main inserting system

contain a radio frequency transmitting device that is in compliance with

the European Union’s Directive 1999/5/EC on Radio Equipment and

Telecommunications Terminal Equipment and the mutual recognition of

their conformity.

LED SAFETY

LED emission according to EN 62471

Relay 3000/4000 is UL approved (US) and CUL approved (Canada).

Page 3

Table of Contents

iSV63138 Rev. A

Safety ................................................................................... v

Chapter 1 System Overview

Relay Inserter Introduction ................................................1-3

Inserter Component Identification ...................................... 1-4

Touch Screen Display Identification ...................................1-6

Control Panel Icons ...........................................................1-8

Turn the Touch Screen On/Off ......................................... 1-10

Use the Touch Screen Keyboard ..................................... 1-11

Change the Display Language ........................................ 1-11

Touch Screen Usernames and Passwords ......................1-12

Rename Default Usernames .................................... 1-12

Change an Existing Operator Password .................. 1-13

Recover an Existing Operator Password ................. 1-13

Rename an Existing Default Job .....................................1-14

Inserter Control Reports (on the Touch Screen) .............. 1-15

Report Data .............................................................. 1-15

Access Reports ........................................................ 1-16

Archive Reports ....................................................... 1-17

Print Reports ............................................................ 1-17

Chapter 2 Program a Job

Navigate Using the Touch Screen .....................................2-3

Scanning and Non-Scanning Jobs ............................. 2-4

Program a Job ...................................................................2-5

Log In ......................................................................... 2-5

Enter Supervisor Access Code .................................. 2-5

Select the Job Number (New or Existing Job) ........... 2-5

Program a Scanning Job ........................................... 2-6

Program a Non-Scanning Job .................................. 2-14

Modify an Existing Job ..................................................... 2-23

Delete a Job ....................................................................2-23

Page 4

Table of Contents

ii SV63138 Rev. A

Chapter 3 Run a Job

Run a Job ..........................................................................3-3

Verify the Inserter Has Power ............................................ 3-4

Turn On the Touch Screen .................................................3-4

Log In .................................................................................3-4

Select a Job ............................................................... 3-5

Manual Feed Jobs .............................................................3-6

Load Material .....................................................................3-7

Adjust and Load the Sheet Feeders .......................... 3-7

Adjust and Load the Envelope Feeder ....................... 3-8

Adjust and Load the Insert Feeder ........................... 3-10

Run a Trial Piece .............................................................3-12

Trial Pieces and Linked Feeding .............................. 3-12

Material Changes or Double Detect Issues

During Operation ................................................. 3-12

Start and Stop the Inserter ..............................................3-13

Fill the Sealer ...................................................................3-14

Adjust the Stacker ...........................................................3-14

Chapter 4 OMR Scanning

Optical Mark Recognition (OMR) ....................................... 4-3

Accuracy .................................................................... 4-3

OMR and Feeders on the Inserter ..................................... 4-3

OMR Scanning Types ........................................................4-4

Basic OMR ................................................................. 4-4

Enhanced OMR ......................................................... 4-4

OMR Mark Positions ..........................................................4-4

OMR Specifications ...........................................................4-5

Standard OMR Positions ........................................... 4-6

Offset OMR Positions ................................................. 4-7

Available OMR Marks .......................................................4-8

Benchmark ................................................................. 4-8

Safety ......................................................................... 4-8

End-of-Collation (EOC) .............................................. 4-8

Beginning-of-Collation (BOC) .................................... 4-8

Page 5

Table of Contents

iiiSV63138 Rev. A

Parity .......................................................................... 4-8

Re-timing Mark ........................................................... 4-8

Select Feed (SF1, SF2) ............................................. 4-9

Auto Batch ................................................................. 4-9

Wrap Around Sequence (WAS1, WAS2, WAS3) ....... 4-9

OMR Mark Grouping .......................................................4-10

C-Fold and Double-Fold Jobs .................................. 4-10

Z-Fold and Single-Fold Jobs .....................................4-11

Adjust the OMR Scanner ................................................. 4-12

OMR Troubleshooting ......................................................4-14

Error Recovery for OMR Jobs .................................. 4-14

Error Recovery for Accumulation Jobs ..................... 4-14

Error Recovery for Empty Feeders .......................... 4-14

OMR Error Messages ......................................................4-15

Chapter 5 Barcode Scanning

Barcode Scanning .............................................................5-3

How Barcode Scanning Works .................................. 5-3

1D and 2D Barcode Scanning ................................... 5-3

Jobs with Barcode Scanning ...................................... 5-4

Barcode Options ................................................................5-4

Basic Barcode Reading ............................................. 5-4

Enhanced Barcode Reading ...................................... 5-4

Barcode Placement Specifications ....................................5-5

Barcode Placement Areas ........................................ 5-5

Barcode Zones - Clear and Blank .............................. 5-7

2D Barcode Camera Setup ...............................................5-8

Turn On the 2D Barcode Camera .............................. 5-8

Adjust the Position of the 2D Barcode Camera ......... 5-9

2D Barcode Scanning Final Checklist .............................5-10

Barcode Error Messages ................................................. 5-11

2D Barcode Specifications ..............................................5-12

Paper Specifications ............................................... 5-12

2D Barcode Specifications ....................................... 5-12

Page 6

Table of Contents

iv SV63138 Rev. A

Chapter 6 Clear Material

Clear Material ....................................................................6-3

Access Areas of the Inserter for Jam Removal .................6-3

Sheet Feeders Trays - Remove and Replace ............ 6-3

Fold Plates - Remove and Replace ........................... 6-4

Insert Tray - Remove and Replace ............................ 6-4

Access the Carriage Assembly .................................. 6-4

Access to Envelope Feeder Area ............................... 6-5

Access the Envelope Exit Area .................................. 6-5

Access the Envelope Inserting/Sealing Area ............. 6-6

Access to the Sheet Feed Area ................................. 6-6

Chapter 7 Troubleshooting and Error Messages

General Troubleshooting ...................................................7-3

Changing the Sealer Unit Felts .................................. 7-7

Error Messages .................................................................7-9

Chapter 8 Material Specifications

Material Specifications .......................................................8-3

Inserter Specifications .......................................................8-7

Service ...............................................................................8-8

Page 7

Safety

v

SV63138 Rev. A

Safety Information

Follow these precautions whenever you use your inserting system:

• Read all instructions before you attempt to operate the system.

• Use this equipment only for its intended purpose.

• Place the system close to an easily accessible wall outlet.

• Place the system in an accessible location to allow for proper venting

of the equipment and to facilitate servicing.

• Use the AC power adapter included with this device. Third party

adapters may damage the device.

• Plug the AC adapter directly into a properly grounded wall outlet

located near the equipment and easily accessible. Failure to properly

ground the machine can result in severe personal injury and/or fire.

• The AC adapter/power cord is the primary means to disconnect this

device from the AC supply.

• DO NOT use a wall outlet controlled by a wall switch or one that is

shared with other equipment.

• DO NOT use an adapter plug on the line cord or wall outlet.

• DO NOT remove the ground pin from the line cord.

• DO NOT route the AC adapter power cord over sharp edges or trap it

between furniture. Make sure there is no strain on the power cord.

• If the unit becomes damaged, unplug it from the wall.

• Keep fingers, long hair, jewelry and loose clothing away from moving

parts at all times.

• Avoid touching moving parts or materials while the machine is in

use. Before clearing a jam, be sure machine mechanisms come to a

complete stop.

• Remove jammed material gently and carefully.

• DO NOT remove covers. Covers enclose hazardous parts that should

only be accessed by properly trained service personnel.

• DO NOT place lighted candles, cigarettes, cigars, etc., on the system.

• To prevent overheating, do not cover vent openings.

• Use only approved supplies.

• Improper storage and use of aerosol dusters or flammable aerosol

dusters can cause an explosive-like condition that could result in

personal injury and/or property damage.

• Never use aerosol dusters labeled flammable and always read

instructions and safety precautions on the duster container label.

Page 8

Safety

vi SV63138 Rev. A

• Operation of this equipment without periodic maintenance will inhibit

optimum operating performance and could cause the equipment to

malfunction.

• Always follow specific occupational safety and health standards for

your workplace.

• To reduce the risk of fire or electrical shock, DO NOT attempt to

remove covers or disassemble the control panel or its base. The

cabinet encloses hazardous parts.

• Before operating the main inserting machine with this device, make

sure the machine has been properly prepared and that any other

personnel in the area are standing clear of the inserter.

• Immediately report to service any damaged or non-functioning

components that renders the unit unsafe.

• Contact your system supplier for the following:

- Supplies

- Material Safety Data Sheets

- If you should damage the unit

- Required maintenance service schedule

If Your Stacker has an AC Adapter:

• Use the AC power adapter included with this device. Third party

adapters may damage the device

• To protect against electrical shock, plug the AC adapter power cord

into a properly grounded wall outlet.

• DO NOT route the power cord for the AC adapter over sharp edges or

trap it between it between pieces of furniture. Make sure there is no

strain on the power cord.

IMPORTANT: Some of the inserter features and options covered in this

content may not be available on your inserter.

Page 9

SV63138 Rev A

1 • System Overview

Contents

Relay Inserter Introduction .........................................1-3

Inserter Component Identification...............................1-4

Touch Screen Display Identification............................1-6

Control Panel Icons ....................................................1-8

Turn the Touch Screen On/Off .................................... 1-10

Use the Touch Screen Keyboard ................................ 1-11

Change the Display Language ...................................1-11

Touch Screen Usernames and Passwords.................1-12

Rename or Create an Operator Username ......... 1-12

Change or Create an Existing

Operator Password ........................................ 1-12

Recover an Existing Operator Password ............ 1-13

Change a Job Name...................................................1-13

Inserter Control Reports (on the Touch Screen) ......... 1-14

Report Data ......................................................... 1-14

Access Reports ................................................... 1-15

Archive Reports .................................................. 1-16

Print Reports ....................................................... 1-16

Page 10

This page is intentionally blank.

Page 11

1 ● System Overview

1-3SV63138 Rev. A

Relay Inserter Introduction

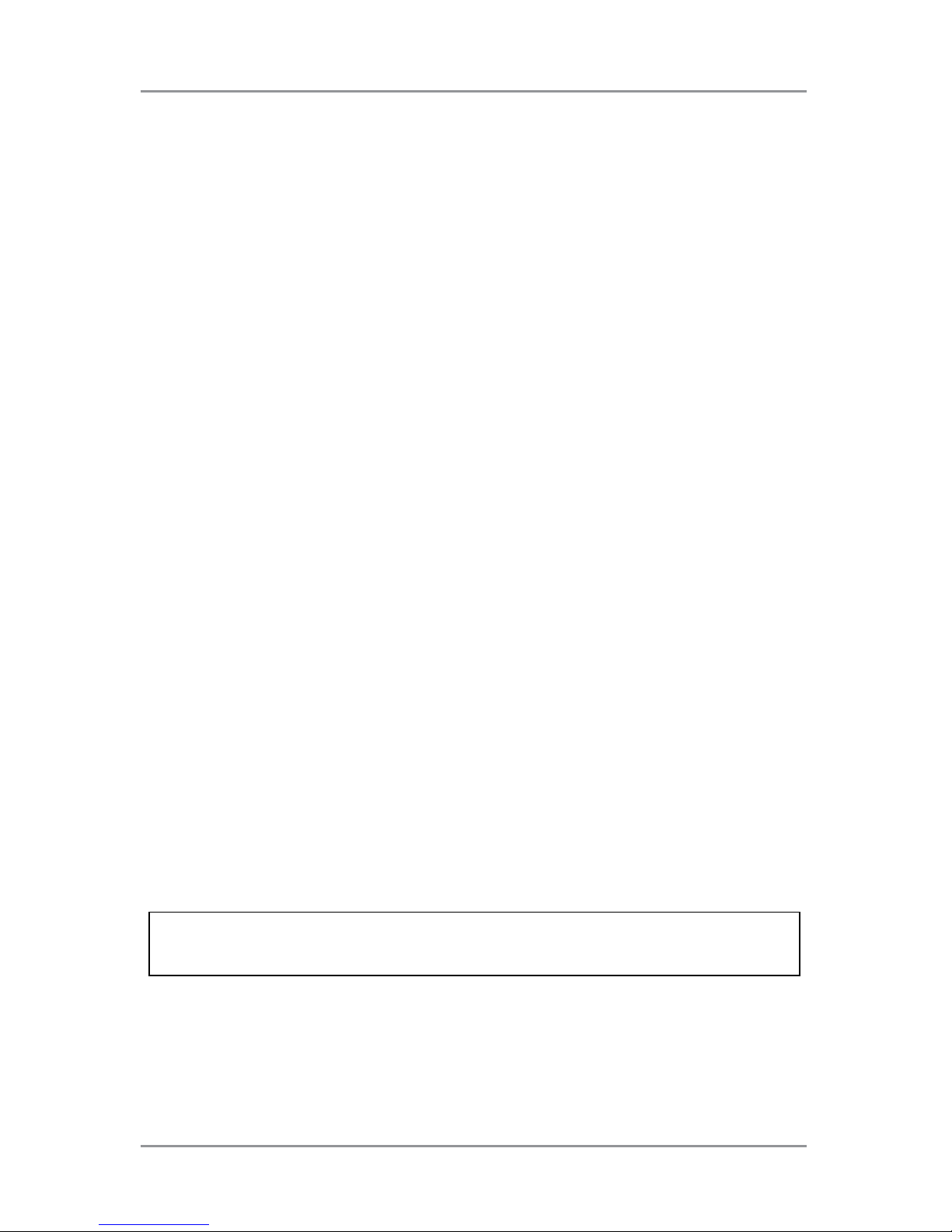

The Relay 3000 and 4000 Inserters offer touch screen functionality and

barcode scanning. The touch screen is standard on the Relay 4000 and

an option for the Relay 3000. The touch screen is necessary for barcode

scanning, which is an option for both systems.

Touch screen technology makes it easy to set up jobs and use the inserter.

Enhanced barcode scanning decodes barcode information and enables

the inserter to maintain the integrity of your mailpiece.

NOTE: The Relay Inserter touchscreen is a WiFi enabled device. If clients

choose to utilize this network connection it is the responsibility of the client

to ensure that the settings adhere to their IT department standards.

Touch Screen Control

Barcode Scanning

Page 12

1 ● System Overview

1-4 SV63138 Rev. A

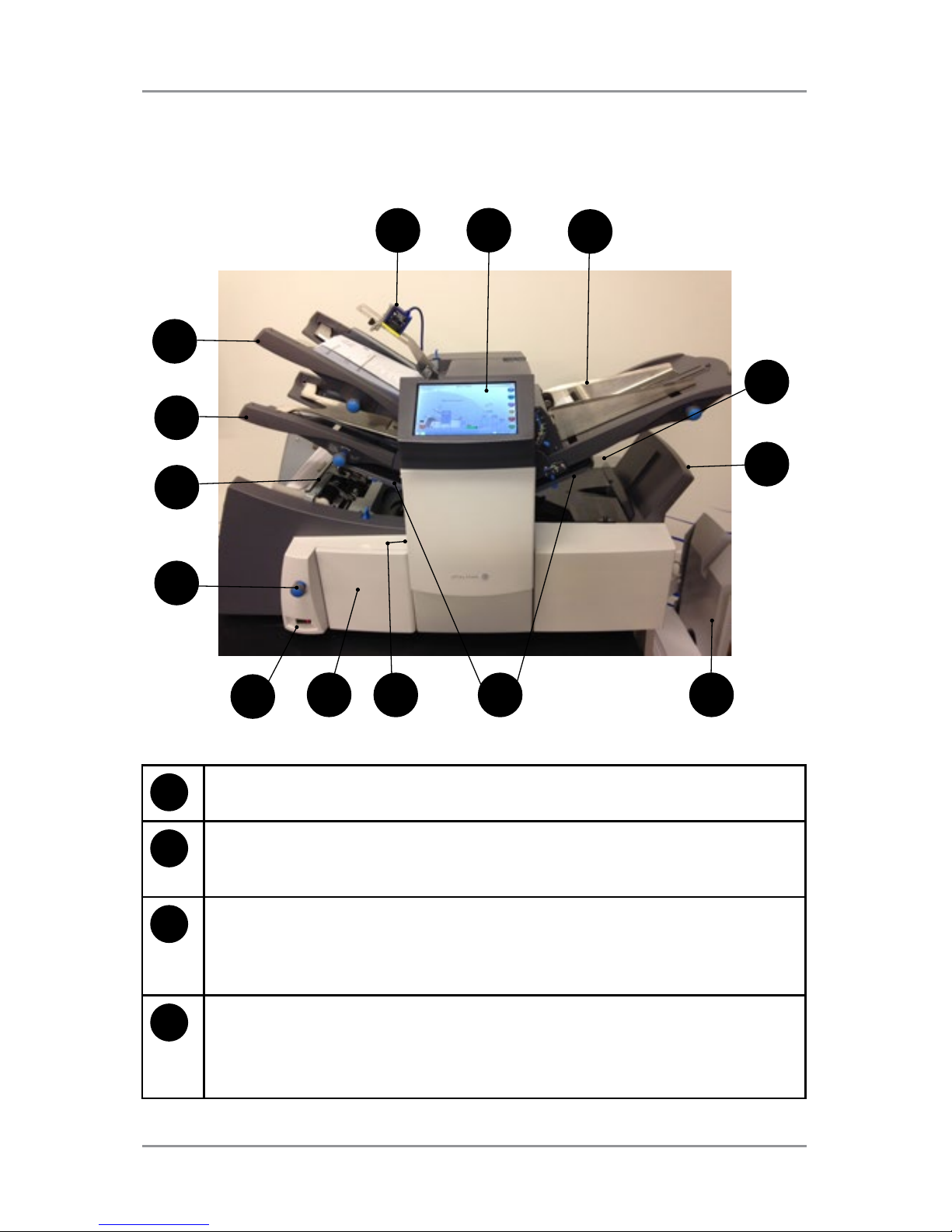

1

2D Camera — Converts barcode characters into mailpiece

processing information.

2

Touch Screen Display — Use this interface to enter commands,

setup jobs, and change settings. Symbols and icons on the display

show the system status.

3

Insert Feeder — Use this feeder to add additional inserts to your

envelope. Material fed from this feeder cannot be folded by the

inserter. However, this feeder is especially suited to feeding prefolded or thicker inserts.

4

Sealer Bottle — The sealer bottle is located on the rear of the

inserter on the right side. It is under a hinged cover, labeled with

the sealer icon. The sealer bottle provides sealing solution to the

envelope sealer.

Inserter Component Identification

1

2

3

4

5

6

78

12

13

14

11

9

10

Page 13

1 ● System Overview

1-5SV63138 Rev. A

5

Envelope Inverter - Transports the envelope into the stacker face up.

6

Drop Stacker or Output Device — located at the exit of the inserter,

this device collects finished mailpieces. This device can be latched

against the inserter when not in use. Alternatively, a range of power

stackers are available which offer greater capacity than the standard

drop stacker.

7

Fold Plate 1 and 2 — They create the desired fold in material

fed

from the sheet feeder(s). The fold plates are automatically set from

the control panel.

8

Measuring Scale — The scale is located on the left side of the

inserter near the sheet feeders; used as an aid in measuring material

and envelopes.

9

Manual Advance Knob — The knob is located under a cover on

the front, left, lower corner of the inserter. Use it to turn the inserter

mechanisms by hand to help clear a material.

10

Power Switch — This switch turns the inserter on and off.

11

Side Guide Adjustment Knob — Use this knob to adjust the side

guides on the envelope feeder.

12

Envelope Feeder — Feeds envelopes into the inserting area where

they are filled with material requested from the other feeder(s).

13

Sheet Feeder 2 — Feeds material that requires folding. Its functions

are similar to those of sheet feeder 1, but the manual feed option is

NOT available from this feeder.

14

Sheet Feeder 1 — this feeder is intended for feeding material that

requires folding.

In addition, you can set sheet feeder 1 to Manual Feed. In this mode,

you can run stapled sets of up to five sheets. The inserter waits for

you to feed each set by hand into sheet feeder 1 before folding and

inserting the set automatically.

Page 14

1 ● System Overview

1-6 SV63138 Rev. A

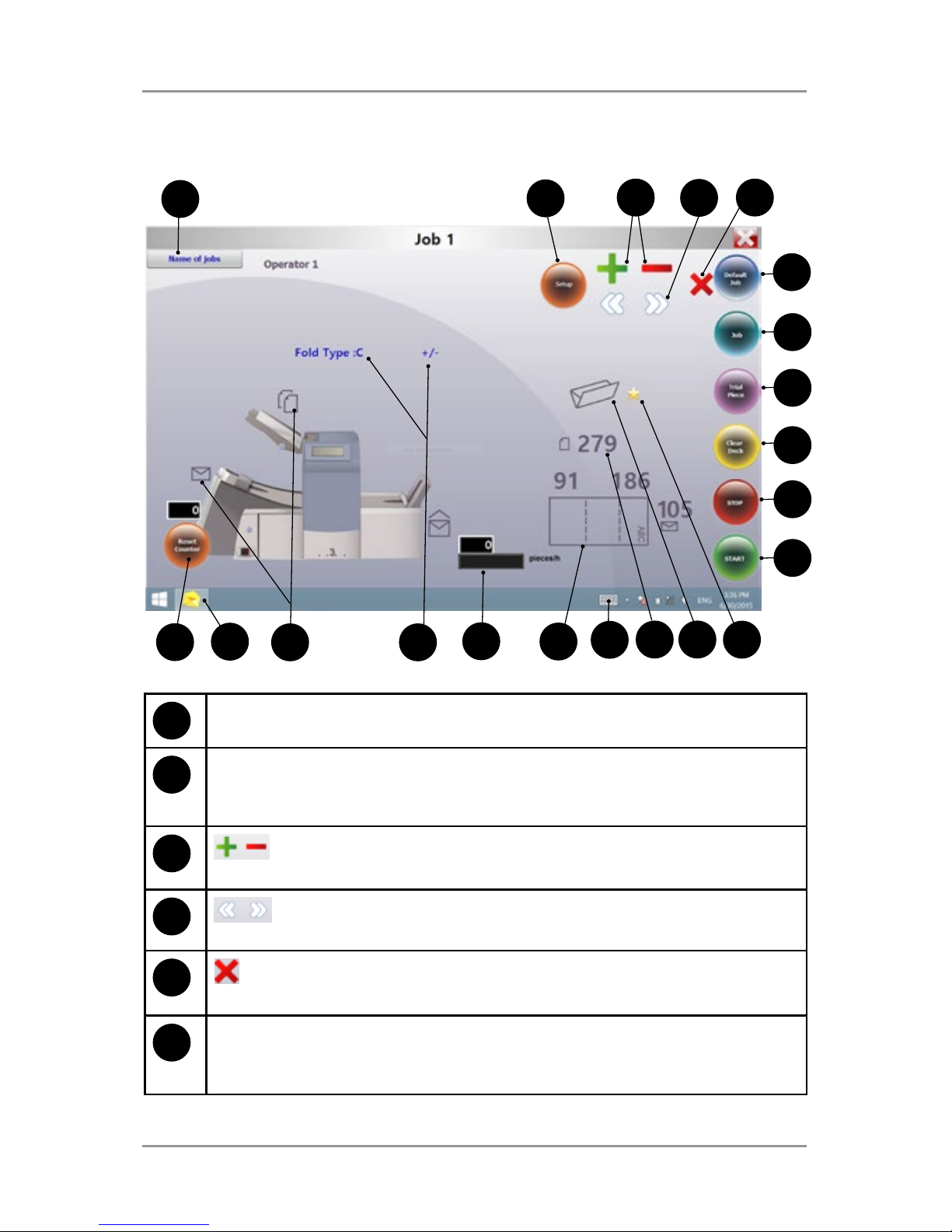

Touch Screen Display Identification

6

2

7

8

9

10

11

20

3

4

5

15

1

14 13

12

16

1

Name of Jobs - Accesses the change job name screen.

2

Setup - Tap to access setup mode to program jobs into system

memory and change options in existing jobs. (Supervisor function;

setup mode only)

3

- Tap these icons to scroll through available options for job

settings. (Supervisor function; setup mode only)

4

- Tap these icons to scroll through available job settings.

(Supervisor function; setup mode only)

5

- Tap to delete a programmed job from the inserter memory.

(Supervisor function; setup mode only)

6

Default Job - Tap to return inserter to its default or standard

settings, which are pre-configured from the factory. A Pitney

Bowes Service Representative can change these settings.

1819

17

21

Page 15

1 ● System Overview

1-7SV63138 Rev. A

7

Job - Tap repeatedly to scroll through programmed jobs that

are stored in the inserter and select a job you want to run. The

inserter can store up to 21 jobs (including one default job).

8

Trial Piece - Tap to run a single test piece to check inserter setup.

You must run a trial piece before you begin automatic operation

using the Start button. If you use double detection, the inserter

sets itself automatically as it runs the trial piece. The trial piece

envelope will be unsealed and counted as one item.

9

Clear Deck - Tap to jog material through and out of the inserter.

Also use it to clear the inserter and make it ready for automatic

operation after a stoppage has occurred.

10

Stop - Tap to stop automatic operation at the end of the next

cycle

11

Start - Tap to start automatic operation.

12

Gold Star - Helps guide you through the job settings by

displaying next to the icon of the setting you are programming /

changing.

13

Fold Type Icon - Represents the selected fold option.

14

Sheet Length Icon - Indicates in millimeters the length of the

unfolded sheet.

15

Keyboard Icon - Tap to display a full keyboard displays on the

lower half of the touch screen.

16

Letter Fold Icon - Indicates in millimeters the fold areas for the

selected fold type.

17

Counter - Shows the number of mailpieces produced per hour.

18

Option Icons - Indicate there are available options within the

selected setting.

19

Symbol Icons - Example of an icon that represents the contents

of the feeder (double detect and envelope feed in this example).

20

Insert Control Icon - Tap to return display to opening screen.

21

Reset Counter - tap to reset the item or batch counter.

Page 16

1 ● System Overview

1-8 SV63138 Rev. A

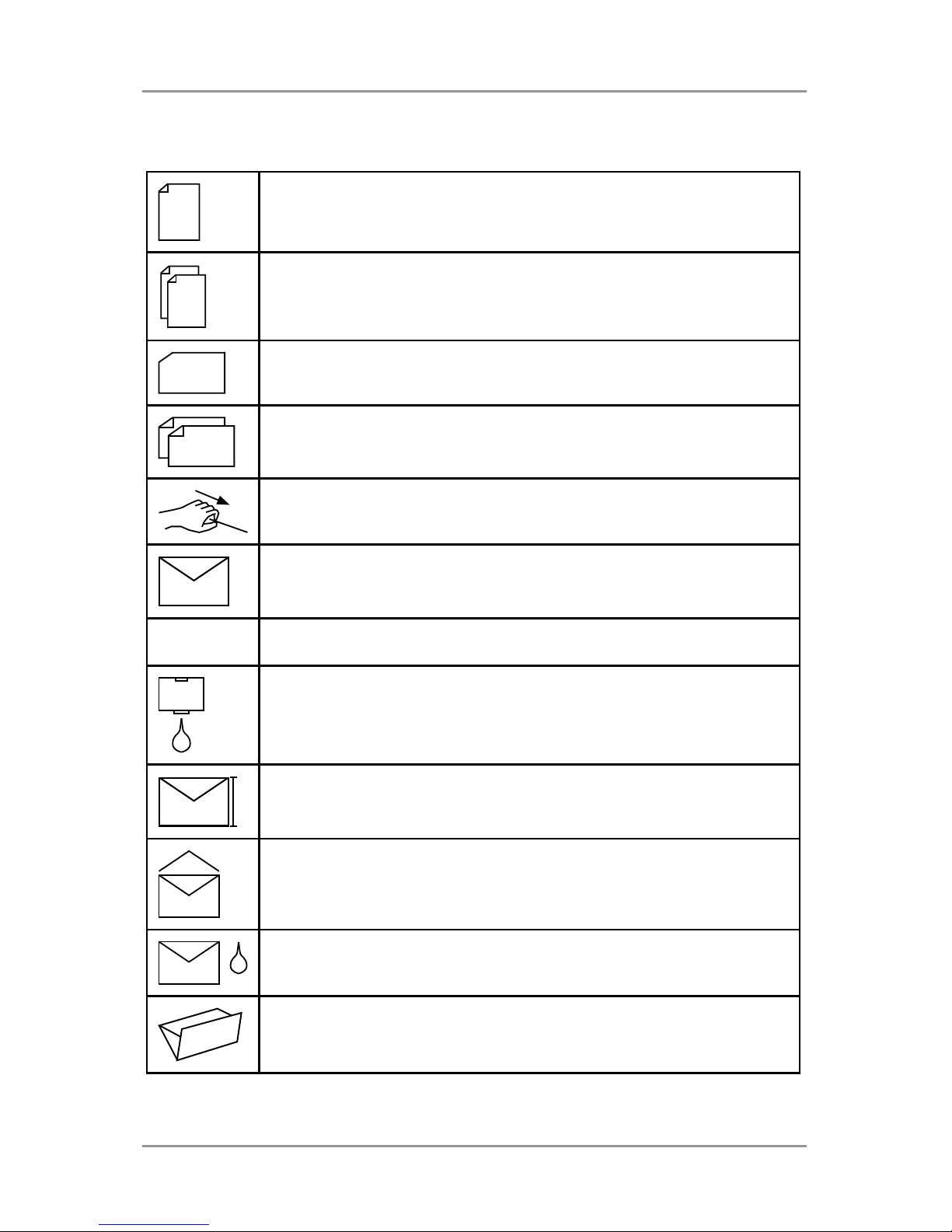

Control Panel Icons

Used on sheet feeders to signify that the feeder is on

without double detection.

Used on sheet feeders to signify that the feeder is on with

double detection.

Used on insert feeder to signify that the feeder is on

without double detection.

Used on insert feeder to signify that the feeder is on with

double detection.

Used on sheet feeder 1 to signify that the feeder is set for

manual feed.

Indicates the setting (from 1 to 5) of the envelope stop.

. . 3 . .

Indicates that the sealer bottle needs refilling.

Indicates the envelope depth.

Indicates the sealer unit is off (envelopes not sealed).

Indicates the sealer unit is off (envelopes not sealed).

Indicates the sealer unit is on (automatic envelope sealing)

Indicates a C (letter) fold is selected

Page 17

1 ● System Overview

1-9SV63138 Rev. A

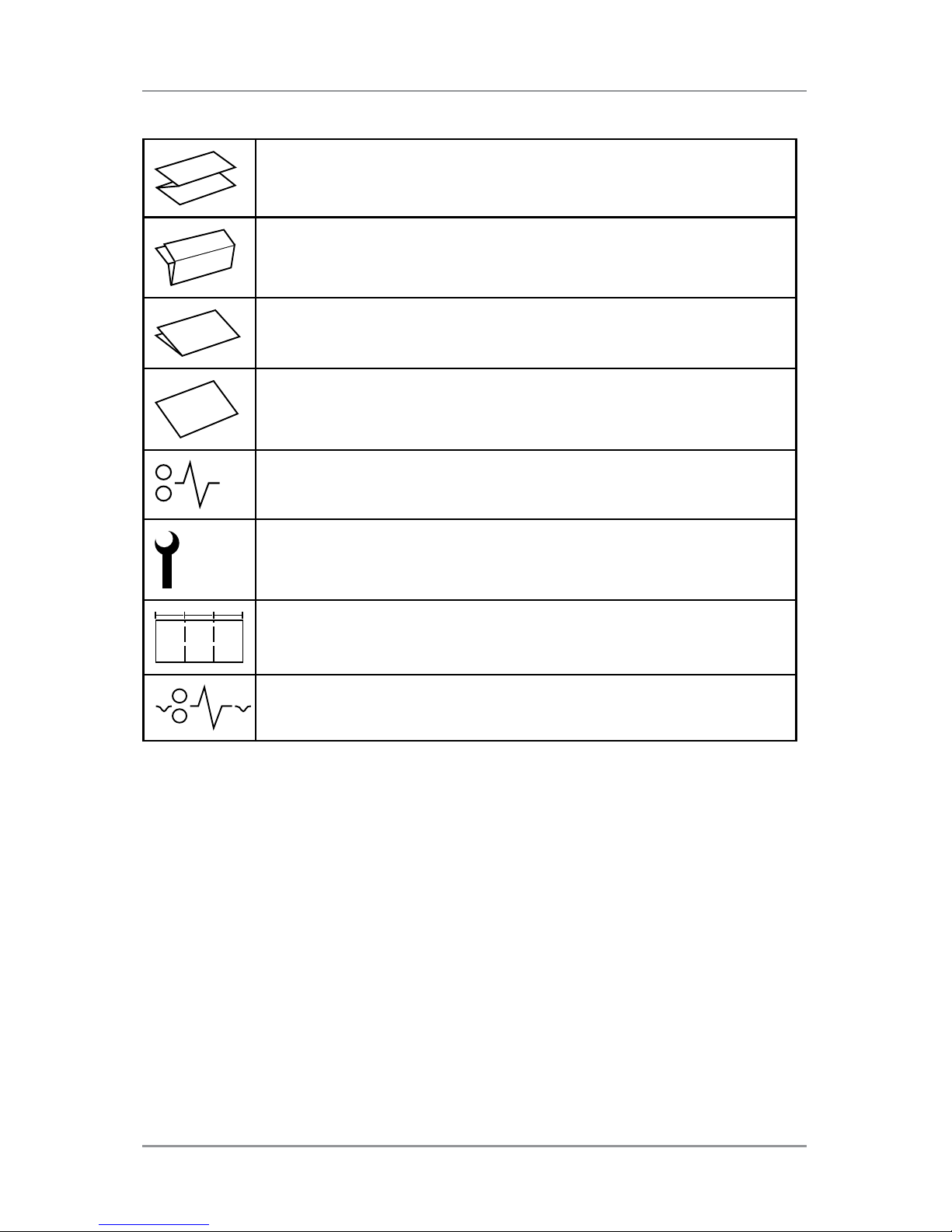

Indicates a Z (accordion fold) is selected

Indicates a double fold is selected

Indicates a single fold is selected

Indicates a no-fold insert operation

Indicates a material stoppage. The position of this symbol

in the display indicates where the stoppage has occurred.

Call Pitney Bowes for service

ABC

Indicates the paper size, address orientation and fold(s)

set for sheet feeder

Indicates a material stoppage in a downstream device,

such as a power stacker.

Page 18

1 ● System Overview

1-10 SV63138 Rev. A

Turn the Touch Screen On/Off

1. Verify the inserter is powered up before you turn on the touch screen.

2. Press and hold the ON/OFF power button for a few seconds. The

power button is located on the top eft frame of the touch screen.

NOTE: If the touch screen is in sleep mode, press the ON/OFF button.

Touch Screen ON/OFF Power Button

Page 19

1 ● System Overview

1-11SV63138 Rev. A

Use the Touch Screen Keyboard

NOTE: If the Windows task bar does not show along the bottom of the display,

swipe your finger down toward the bottom of the screen.

1. To launch the keyboard, tap the icon on the task bar in the lower

right corner of the display.

2. Tap the desired characters to enter information.

3. To close the keyboard tap the

in the upper right corner.

Capital Letters

• For single caps tap the

key once.

• To turn Caps Lock on tap the

key twice.

Change the Display Language

To change the language on the touch screen display:

1. Tap the icon on the opening screen.

2. When the Operator List displays, tap .

3. Select Language>Program from the menu bar. A screen opens

displaying country flags associated with available languages.

4. Tap the flag that represents the language you want to display on the

touch screen. (This screen automatically closes and the display is now

in the newly selected language.)

Page 20

1 ● System Overview

1-12 SV63138 Rev. A

Touch Screen Usernames and Passwords

Operators and Supervisors can rename operator usernames and change

operator passwords.

NOTE: The customer service representative who installs your system

provides the Supervisor password. Supervisor passwords cannot be

changed.

Rename Default Operator Usernames

Each operator requires a unique username. This procedure can be used

to rename an existing default operator username to a specific operator

username. A maximum of 10 operators can be programmed into the touch

screen.

1. Tap the icon twice.

2. When the Operator List displays select a default Operator to rename

(typically indicated as Operator 1 – Operator 10).

3. To launch the keyboard, tap the icon (bottom right corner of the

screen) and enter either the Supervisor or Operator password in the

field. (DO NOT tap .)

4. Select File>Operators>Change from the menu bar.

5. Use the touch screen keyboard to enter the new operator name.

6. Tap .

Page 21

1 ● System Overview

1-13SV63138 Rev. A

Change an Existing Operator Password

This procedure can be used to change an existing operator password.

1. Tap the icon twice.

2. When the Operator List displays select an Operator username and

tap

.

3. To launch the keyboard, tap the icon on the bottom right corner of

the screen and enter the Operator password in the field. (DO NOT tap

.)

4. Select File>Password>Change from the menu bar.

5. Use the touch screen keyboard to enter the new password; re-enter

the password to confirm.

6. Tap .

7. Tap .

Recover an Existing Operator Password

This activity requires Supervisor level access.

1. Tap the icon twice.

2. When the Operator List displays, select the Operator name

associated with the lost password and tap .

3. Tap the touch screen keyboard and enter the Supervisor password

(71) in the field. (DO NOT tap .)

4. Select File>Password>Recover from the menu bar. The recovered

password displays in the dialog box. (Be sure to record the password

for future reference.)

5. Tap OK to close the dialog box.

6. Type the recovered password into the password field and tap .

Page 22

1 ● System Overview

1-14 SV63138 Rev. A

Rename an Existing or Default Job

When a new job is created, a new name can be assigned to a default job.

Operators and Supervisors can rename a job.

1. Tap the icon twice.

2. When the Operator List displays select an Operator and tap .

3. To launch the keyboard, tap the icon on the bottom right corner of

the screen and enter the Operator password in the field.

4. Tap .

5. At the main control screen, tap the Name of jobs button in the upper

left corner of the display.

6. Highlight a job in the Name of jobs list and tap Change.

7. Using the touch screen keyboard enter the new job name in the field.

8. Tap to accept the new job name and tap again to exit.

Page 23

1 ● System Overview

1-15SV63138 Rev. A

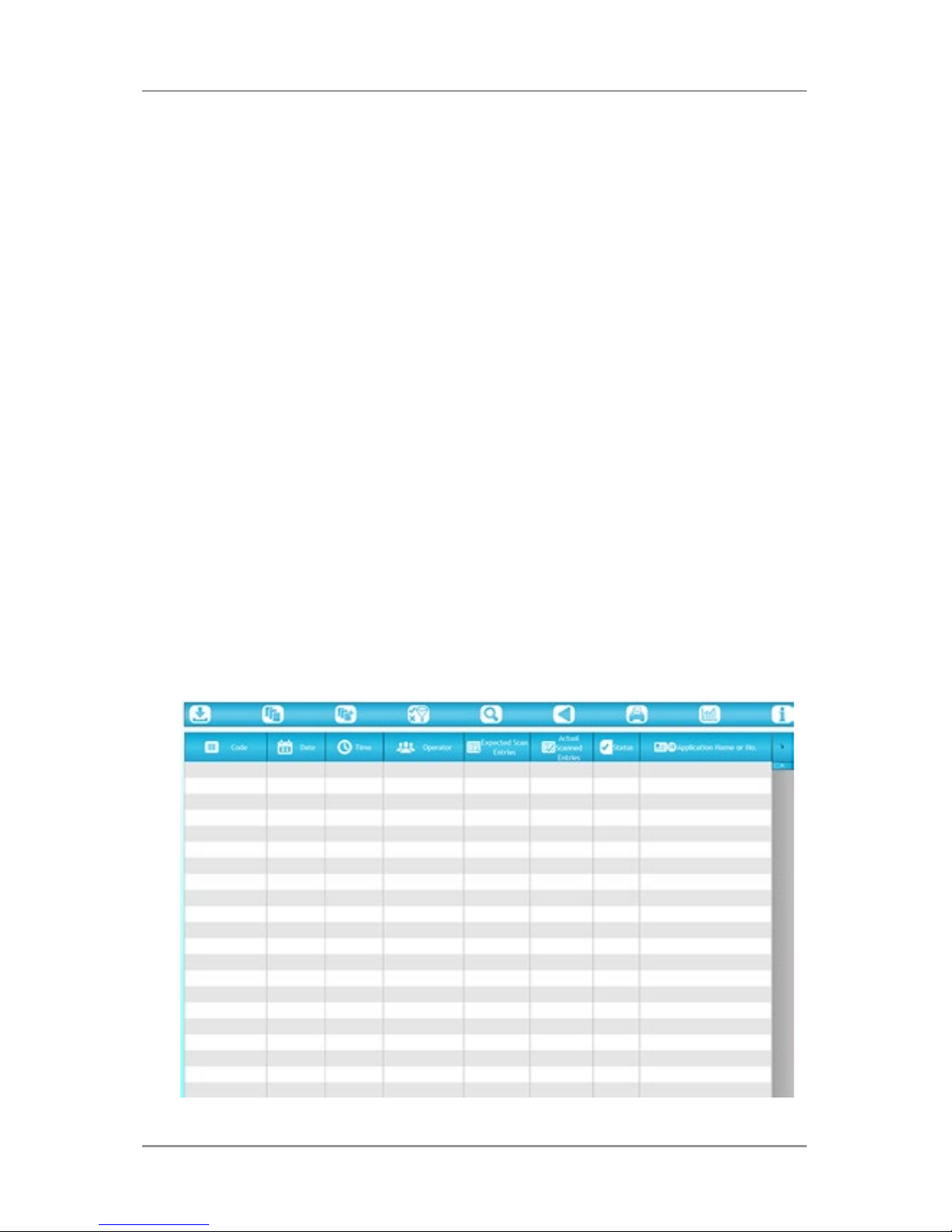

Inserter Control Reports (on the Touch Screen)

The touch screen offers mailpiece reporting features on inserters running

enhanced barcode scanning applications.

The reports capture mailpiece data for a specified period of time or for

specific jobs.

Report Data

When running an enhanced barcode scanning application, the reports

contain unique information found within the barcode.

• Date mailpiece was processed

• Time mailpiece was processed

• Operator name

• Job name

• Expected number of sheets

• Actual number of sheets (processed from feeder with barcode reader)

• Missing sheets

• Total number of envelopes

• Mailpiece status (correctly processed indicated by OK or NOK)

• Job start and end time

Page 24

1 ● System Overview

1-16 SV63138 Rev. A

Access Reports

Users are not required to log in to the touch screen to access inserter

reports. There are two ways to access report data - you can select a

specific date or set of dates or you can select a specific job or set of jobs.

Select by Date

To view inserter reports by a date or set of dates, follow these steps.

1. Tap the reports icon at the bottom of the

touch screen desktop.

2. To select a report from a specific date,

tap the Open by date icon at the top of

the screen.

3. Select the date on the calendar and the

report data populates the screen.

4. You can include information from

additional dates in the report by

repeating the date selection process.

Select by Job File

To view and/or print inserter reports by specific job(s) follow these steps.

1. Tap the reports icon at the bottom of the

touch screen desktop.

2. To select a report by job, tap the Open

by file icon at the top of the screen.

3. Browse for and select the desired the

.CRV file. The report data populates the

screen.

Page 25

1 ● System Overview

1-17SV63138 Rev. A

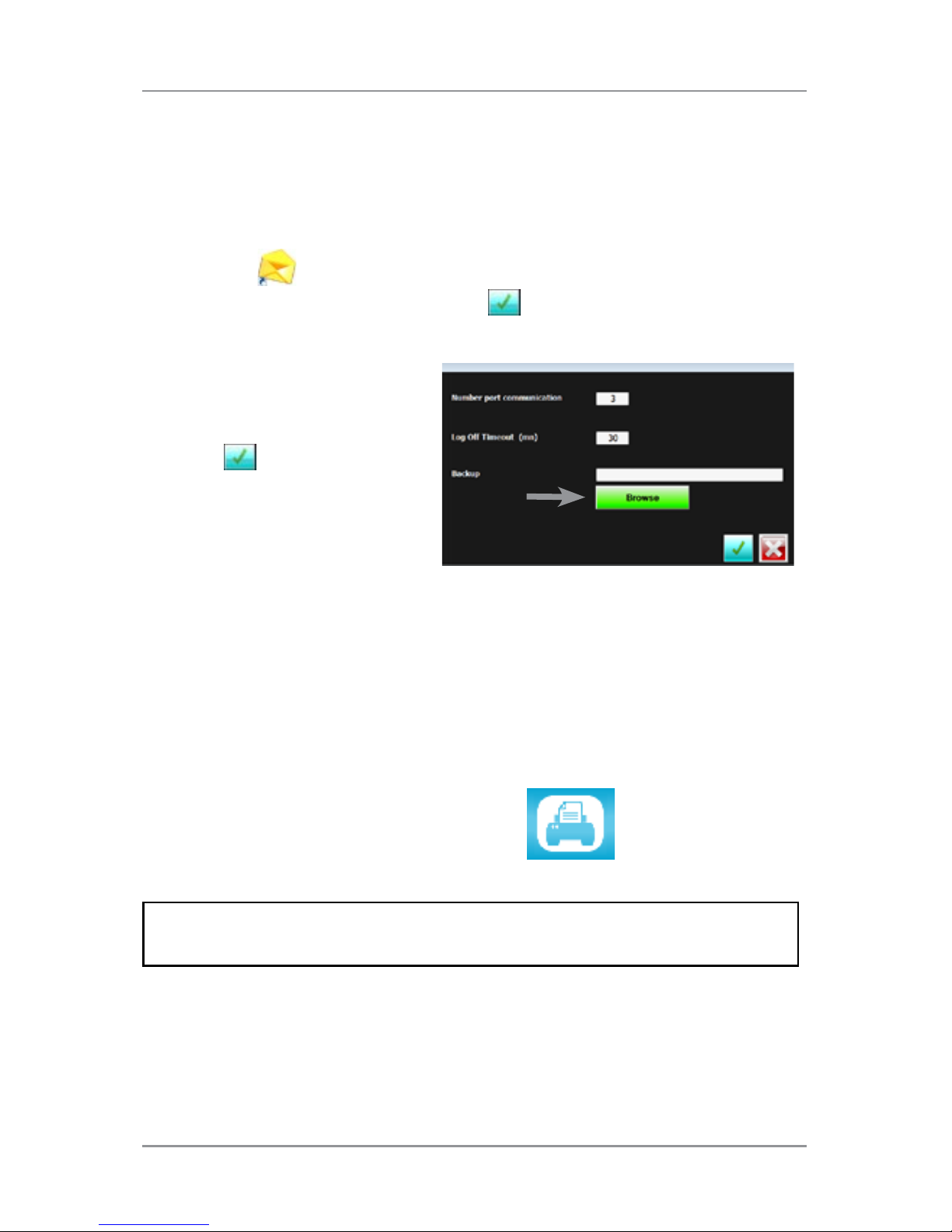

Archive Reports

You can archive reports by setting up the system to automatically save

them to the pre-installed SD card in the touch screen. This is typically a

Supervisor activity.

1. Tap the

icon twice.

2. Select an Operator name and tap .

3. Tap Settings from the menu bar.

4. Tap Browse and set the

Backup field to the SD

drive (usually D:\).

5. Tap

.

All reports are automatically

archived by date on the SD drive.

Print Reports

You can print reports directly through the touch screen if it is connected to

an external printer on your wireless network.

1. Populate the screen with report data

(either by date or job).

2. Tap the print icon to print the report.

NOTE: If clients choose to print reports, it will be the responsibility of the

client to connect the touch screen to their wireless network.

Page 26

This page is intentionally blank.

Page 27

SV63138 Rev A

2 • Program a Job

Contents

Navigate Using the Touch Screen ..........................2-3

Scanning and Non-Scanning Jobs .........................2-4

Program a Job ........................................................2-5

Log In ...............................................................2-5

Enter Supervisor Access Code ........................2-5

Select the Job Number

(New or Existing Job) ..................................2-5

Program a Scanning Job .................................2-6

Program a Non-Scanning Job ........................2-14

Modify an Existing Job..........................................2-23

Delete a Job .........................................................2-23

Page 28

This page is intentionally blank.

Page 29

Program a Job ● 2

2-3SV63138 Rev. A

This section provides step-by-step instructions for setting up and saving

a new scanning or non-scanning job and saving it using the touch screen

display. Programming a job is typically a Supervisor activity.

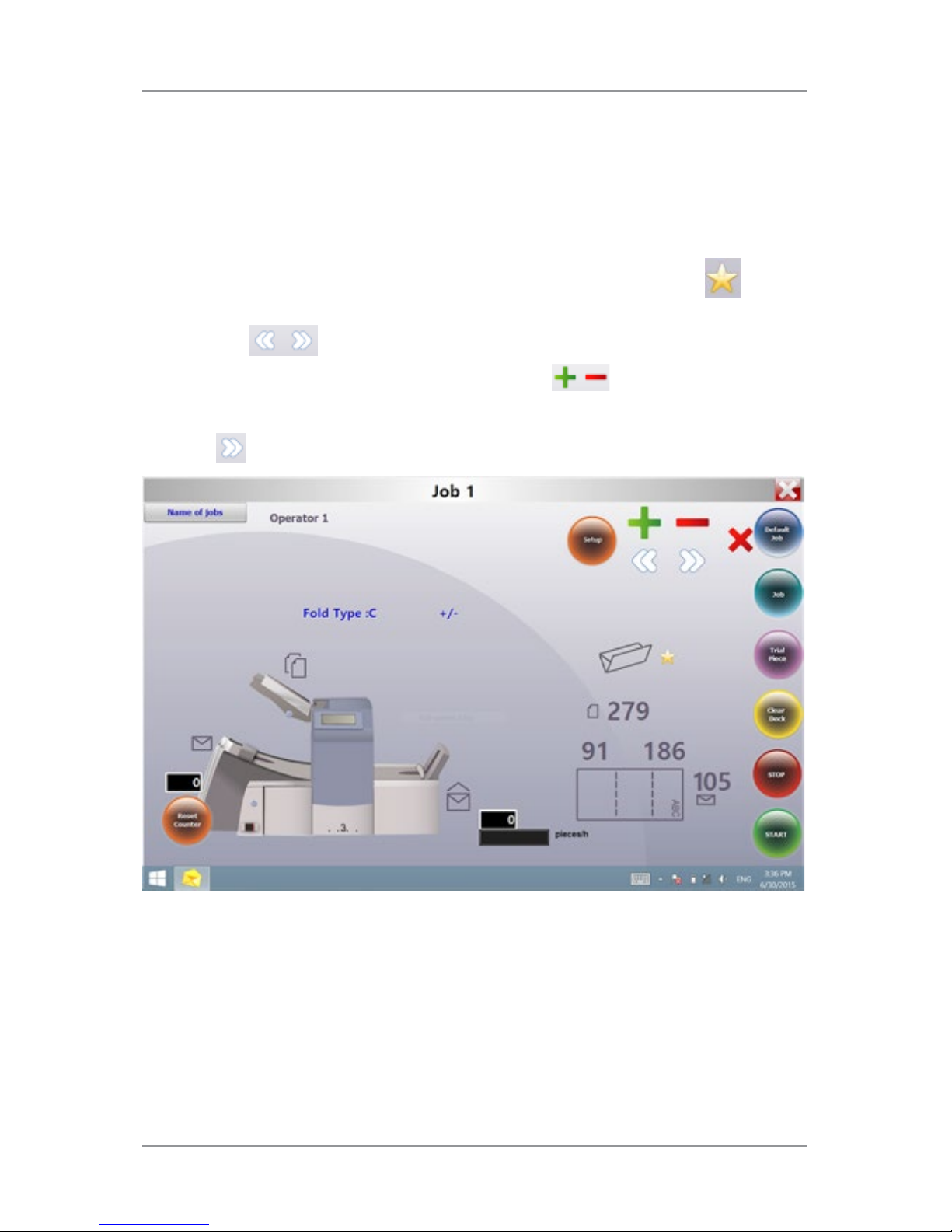

Navigate Using the Touch Screen

To help visually guide you through the programing sequence, a icon

appears on the display next to the area being set.

• Tap the icons to scroll through and select available settings.

• Once the desired setting displays, tap the icons to scroll

through available options or values for the selected setting.

• Tap to accept the selection and advance to the next setting.

NOTE: For icon locations and descriptions, refer to the "System Overview" section

of this guide.

Page 30

2 ● Program a Job

2-4 SV63138 Rev. A

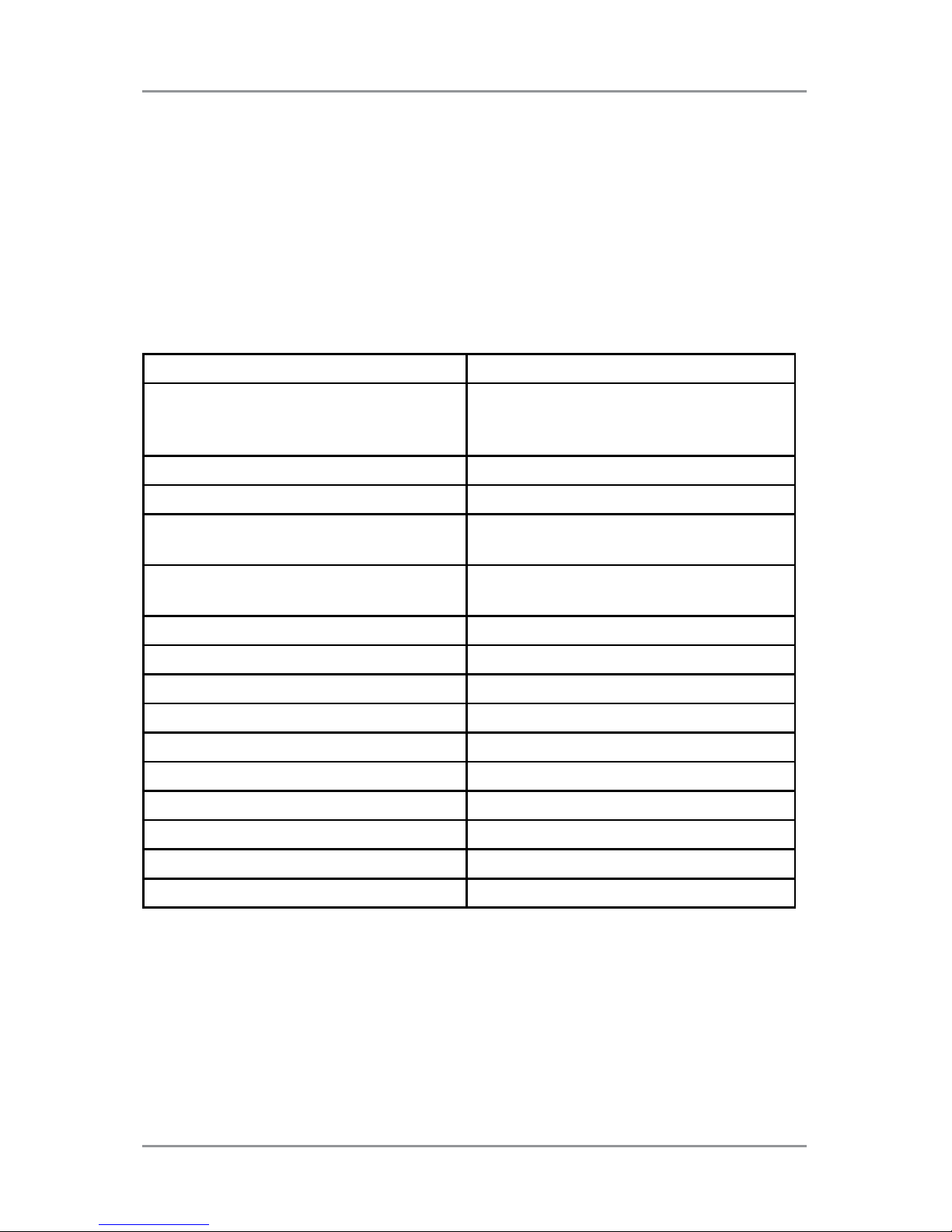

Scanning and Non-Scanning Jobs

If scanning functionality (OMR or barcode) is enabled on your system,

operators can toggle scanning on and off depending on the job. If scanning

functionality is not available on your inserter, your job setup will differ

slightly.

Refer to the table below to review the steps that apply to your job type and

follow the step-by-step instructions provide in this section.

Scanning and Non-Scanning Job Sequence

Scanning Job Non-Scanning Jobs

Enable scanning (OMR On or Off) Disable scanning (OMR Off) if

available on your inserter. (Skip if you

inserter does not have scanning)

Set fold type Set fold type

Set main (scanning) sheet feeder Set accumulation

Set select/supplementary sheet or

insert feeder

Set first/main sheet feeder

Set the sealer Set second/supplementary sheet

feeder

Set paper length Set insert feeder

Set fold A /fold B Set mode type (insertion or fold)

Set envelope depth Set the sealer

Set envelope stop Set paper length

Set batch counter Set fold A /fold B

Confirm job setup Set envelope depth

Run a trial piece Set envelope stop

Set batch counter

Confirm job setup

Run a trial piece

Page 31

Program a Job ● 2

2-5SV63138 Rev. A

Program a Job

Log In

Log in with Supervisor level access.

1. Tap the

icon twice at the bottom of the touch screen desktop.

2. When the Operator List displays select Supervisor username or an

Operator not in use (typically indicated as Operator 1 - Operator 10).

3. Tap .

4. To launch the keyboard, tap the icon in the bottom right corner of

the screen and type the Supervisor password (71) in the field.

5. Tap . The main control screen opens.

6. Tap in the upper right corner to close the keyboard.

Enter Supervisor Access Code

1. Tap the Setup button. The Enter Access Code field displays over the

inserter model on the touch screen display.

2. Tap the icons to increase or decrease to 71.

3. Tap to accept the access code and advance to the job settings.

Select the Job Number (New or Existing Job)

When prompted for the job number, follow these steps to select or create

the job. You can select an existing job and overwrite its current settings or

you can select an unused job and program new settings.

1. Use the icons to scroll through the job numbers until you find

the desired job number. (To identify an unused job, scroll through the

jobs until there are no setup symbols displayed on the screen.)

2. Tap to accept the job number and advance to the first setting.

NOTE: If you use an existing job number, the old settings will be overwritten by the

new settings you are adding.

Page 32

2 ● Program a Job

2-6 SV63138 Rev. A

Program a Scanning Job

Enable Scanning (OMR or Barcode)

1. When prompted, tap the icons to select one of the OMR on

settings. (Refer to the OMR Settings table included here.)

2. Tap to accept the selection and advance to the next setting.

Page 33

Program a Job ● 2

2-7SV63138 Rev. A

Scanning Settings Table (OMR and Barcode)

Some of the OMR settings have been configured to apply to both OMR

and barcode scanning jobs. When you are running barcode scanning

applications, use the OMR functions that apply to barcode scanning.

OMR and Barcode Settings Table

OMR Settings Description

OMR off OMR or barcode scanning is turned off for this

job.

OMR on OMR or Basic barcode scanning is enabled for

this job with standard OMR mark positioning.

OMR + Sequence OMR scanning + Wrap Around Sequence

scanning is enabled for this job, with standard

OMR mark positioning.

OMR + Select feed OMR scanning + Select Feed/Autobatch

scanning for this job, with standard OMR mark

positioning.

OMR + Select feed +

Sequence

OMR scanning + Select Feed/Autobatch

+ Wrap Around Sequence OR Enhanced

barcode scanning is enabled for this job, with

standard OMR mark positioning.

OMR Offset on OMR scanning is turned on for this job, with

offset OMR mark positioning.

OMR Offset + Sequence OMR scanning + Wrap Around Sequence

scanning is enabled for this job, with offset

OMR mark positioning.

OMR Offset + Select feed OMR scanning + Select Feed/Autobatch

scanning is enabled for this job, with offset

OMR mark positioning.

OMR Offset + SF +

Sequence

OMR scanning + Select Feed/Autobatch +

Wrap Around Sequence scanning for this job,

with offset OMR mark positioning.

NOTE: Available options depend on the scanning functionality of your inserter.

NOTE: The maximum number of pages per envelope that can be fed from this

feeder when using barcode scanning must fall within the limits of the inserter.

NOTE: Sheet feeder options SF Double Detect and On SF are not supported

when using barcode scanning.

Page 34

2 ● Program a Job

2-8 SV63138 Rev. A

Set the Fold Type

1. Tap the icons to scroll through the fold types.

2. Tap to accept the fold type and advance to the next setting.

Fold Types

C - Letter Z - Accordion Double Single

When the fold type is selected, the display indicates the correct orientation

of the paper for loading into the feeders:

FACE UP

HEAD FIRST

ABC

FACE DOWN

FEET FIRST

ABC

Set the Main (Scanning) Sheet Feeder

1. Tap the icons to scroll through the options.

2. Tap to accept the option and advance to the next setting.

Main Sheet Feeder 1 Options (Scanning Jobs)

Icon Option Description

On Double Detect Feeder on with the double detector

operating. (The double detector stops

the inserter if two or more sheets feed

simultaneously.)

On Feeder on without the double detector.

Page 35

Program a Job ● 2

2-9SV63138 Rev. A

Set Select/Supplementary Sheet or Insert Feeder

Select feed allows for one piece to be selectively fed from either feeder per

envelope.

1. Tap the icons to scroll through the options. (Refer to the

Additional Feeder Options, Scanning Jobs table for details.)

2. Tap to accept the option and advance to the sealer setting.

Additional Feeder Options (Scanning Jobs)

Icon Option Description

On Double Detect Feeder on with the double detector

operating. (The double detector stops

the inserter if two or more sheets feed

simultaneously.)

On SF Double Detect

(not shown on single or

Z folds)

Select feeder on with the double detector

operating. (The double detector stops

the inserter if more than one sheet

simultaneously feeds from the feeder.)

On SF (not shown on

single or Z folds)

Select feeder on without the double

detector.

Off Feeder turned off for this job.

On (not shown on single

or Z folds)

Feeder on without the double detector or

select feed.

Setting the Scanning Feeder:

• If sheet feeder 1 is set for the main/scanning feeder - you can

program sheet feeder 2 and/or the insert feeder for normal (one per

envelope) feeding or select feeding.

• If sheet feeder 2 is set for the main/scanning feeder - you can

program sheet feeder 1 and/or the insert feeder for normal (one per

envelope) feeding or select feeding.

Page 36

2 ● Program a Job

2-10 SV63138 Rev. A

Set the Sealer

This setting appears only if insertion mode is selected. To select whether

or not you want to seal envelopes.

1. Tap the icons to toggle the option to On or Off.

2. Tap to accept the option and advance to the next setting.

Sealer Options

Icon Option Description

On Turns the sealer unit on for automatic sealing of

envelopes. Make sure the sealer water bottle is full of

E-Z Seal® or water.

Off Turns the sealer unit off. Envelopes will be ejected

unsealed.

Set Paper Length

1. Use the scale on the side of

the inserter cover to measure

the paper.

- US letter - 279mm (11 inches)

- A4 paper - 297mm

2. Tap the icons to

scroll through paper lengths

(displayed in mm).

3. Tap to accept the paper

length value and advance to

the next setting.

Page 37

Program a Job ● 2

2-11SV63138 Rev. A

Set Fold A

1. Select the size of the first fold required.

NOTE: Depending on the settings you made earlier for fold type and paper

length, the inserter suggests the correct dimension for the first fold. Most of the

time this setting will prove satisfactory.

2. To change the standard fold setting, tap the icons until the

length of required fold displays. A icon displays next to the fold

panel you are setting.

NOTE: The inserter automatically limits your options to available specifications

on your inserter. (As you change the length of fold A, the dimension of fold

B changes automatically to keep within the correct paper length and inserter

specifications.)

3. Tap to accept the fold value and advance to the next setting.

Set Fold B

1. Select the size of the second fold required.

NOTE: Similar to setting fold, the inserter suggests the correct dimension for

fold B.

2. To change the standard setting, tap the icons until the length of

fold required displays. A icon displays next to the fold panel you

are setting.

3. Tap to accept the fold value and advance to the next setting.

• Inserting jobs - continue to the Set the Envelope Depth setting.

• Fold-only job - there are no more job settings, skip to Confirming

the Job Setup.

Set Envelope Depth

1. Use the scale on the front cover to measure the envelope depth.

2. Tap to scroll through the measurements (displayed in mm).

3. Tap to accept the value and advance to the next setting.

Page 38

2 ● Program a Job

2-12 SV63138 Rev. A

Set the Envelope Stop

NOTE: The stop has five positions numbered 1 to 5. Setting 3 is the standard

setting for normal weight paper with standard folds. A thinner/lighter insert requires

a lower setting and a thicker/heavier insert requires a higher setting.

1. Tap the icons to scroll through the envelope stop positions.

2. Tap to accept the position and advance to the next setting.

Set the Batch Counter

The batch counter allows you to automatically process pre-defined

batches of finished mailpieces. When the batch is complete, the inserter

automatically stops.

NOTE: If the batch counter is not turned on, the display counter simply counts the

number of items processed until you press Reset Counter.

1. Tap the Start button to begin processing the next batch.

2. Tap the icons to toggle the batch mode to On or Off.

NOTE: If the batch counter is turned on, the inserter prompts for the batch

quantity. The default quantity is 50, but you may select any value up to 999 by

tapping the icons.

3. Tap to accept the setting.

Confirm Job Setup

Job setup is now complete. Using the inserter model and icons, the touch

screen display shows all the selected job settings.

1. Review the job settings.

2. Tap the icons to scroll back and change a setting.

3. Tap the Setup button to accept the new settings and exit setup mode.

4. When setup changes are complete, the touch screen displays the new

job settings with the message Trial Piece Required.

5. Test the setup by running a trial piece.

NOTE: The inserter retains job settings until you change or delete them, even

when the power is disconnected. If you need to change the name of the job, refer

to "Change a Job Name" in the System Overview chapter of this guide.

Page 39

Program a Job ● 2

2-13SV63138 Rev. A

Run a Trial Piece

Run a trial piece to test the job settings.

1. Load material and tap the Trial Piece button.

2. If you need to make changes to the settings based on the trial piece:

a. Tap the Setup button.

b. Log in with Supervisor access level

c. Tap the icons to scroll to the setting you wish to modify.

d. Tap the icons to scroll to the desired option.

3. Tap the Setup button to accept the setting modification and return to

run mode. The inserter saves the job with the new settings.

4. Run another trial piece to test the modified settings.

NOTE: Any time you modify settings you must run a trial piece.

Incorrect Address Position - Adjust Fold Settings

When you run a trial piece, if the address is not in the correct position refer

to the Adjust Fold Settings table to help you fine tune your folds settings.

Adjust Fold Settings Table

Fold Type Address Too Low Address Too High

C - Letter Fold Decrease Fold A Increase Fold A and

increase Fold B by the

same amount.

Z - Accordion Fold Increase Fold A Decrease Fold A and

increase Fold B by the

same amount

Single Fold Increase Fold A Decrease Fold A

Double Fold Decrease Fold A Increase Fold A

It is recommended the fold is only adjusted by 0.20 inches (5mm) each time.

Page 40

2 ● Program a Job

2-14 SV63138 Rev. A

Program a Non-Scanning Job

Follow this sequence of steps to program a non-scanning job.

NOTE: If scanning is not available on your system, begin with "Set Accumulation."

Disable Scanning (OMR or Barcode) if Functionality Exists

If scanning is enabled on your system, set it to OMR off.

1. When prompted, tap the icons to select OMR off.

2. Tap to accept the selection and advance to the next setting.

Set the Fold Type

1. Tap the icons to scroll through the fold types.

2. Tap to accept the fold type and advance to the next setting.

Fold Types

C - Letter Z - Accordion Double Single

When the fold type is selected, the display indicates the correct orientation

of the paper for loading into the feeders:

FACE UP

HEAD FIRST

ABC

FACE DOWN

FEET FIRST

ABC

NOTE: For accumulation jobs, DO NOT manually change the automatic fold length

dimensions at the Fold A and Fold B settings.

Page 41

Program a Job ● 2

2-15SV63138 Rev. A

Set Accumulation

If accumulation is enabled, it allows multiple sheets to be fed from the

sheet feeder into the envelope. This setting is only available for non-

scanning jobs.

1. Tap the icons to scroll through the accumulation options.

2. If you set accumulation to ON:

a. Tap to set the number of pages to feed into each

envelope. (Accumulation = 2 to 10)

b. Tap the icons to enter the number of pages.

3. Tap to accept the option and advance to the next setting.

Inserter Accumulation Settings

Setting Description

Accumulation: OFF

Accumulation is turned off for this job.

Accumulation From Main Accumulation is turned on with sheets feeding

from the main feeder. This feeder normally

contains the address sheet.

Accumulation From Suppl Accumulation is turned on with sheets feeding

from the supplementary feeder - one address

sheet from the main feeder followed by multiple

sheets from the supplementary feeder.

Accumulation = (2 to 10) If Accumulation is ON, select how many pages

you want to feed into each envelope.

IMPORTANT! The number of sheets that can be accumulated is limited by inserter

specications. Exceeding this limit can cause a malfunction.

Page 42

2 ● Program a Job

2-16 SV63138 Rev. A

Set First/Main Sheet Feeder

The first feeder is automatically selected depending on the fold type.

• Collating different sheets using both sheet feeders - load the prime

(address-bearing) document into sheet feeder 1 for C and double

folds. Load it into sheet feeder 2 for Z or single folds.

• Running a single sheet - use either sheet feeder or use both with

the linked feeder feature described in the following Sheet Feeder 1

Options table.

1. Tap the icons to scroll through the options.

2. Tap to accept the selection and advance to the next setting.

First/Main Sheet Feeder Options (Non-Scanning Jobs)

Icon Option Description

On Double Detect Feeder on with the double detector

operating. (The double detector stops

the inserter if two or more sheets feed

simultaneously.)

Off Feeder turned off for this job.

On Feeder on without the double detector.

Manual Feed (see the

description following

this table)

Able to manually feed collated sets. Only

available on sheet feeder 1.

Linked: On

(only available on

3-station inserters)

Feed will initially come from the first

sheet feeder. When that feeder is empty,

the inserter automatically switches

feeding from the second sheet feeder.

When a trial piece is requested, both

feeders must be loaded, as a trial piece

will feed from each feeder.

Linked: On Double

Detect

(only available on

3-station inserters)

Page 43

Program a Job ● 2

2-17SV63138 Rev. A

Manual Feed Option

• The manual feed setting allows you to run stapled sets of up to five

sheets - a maximum of 100 lbs.(400gsm) per set. The maximum

compressed thickness of the set after folding must not exceed 0.08

inches (2mm).

• The inserter waits for manual insertion of each set into sheet feeder 1

after which it will fold and insert the set automatically.

• When running manual feed mode, sheet feeder 2 becomes inoperable.

• The manual feed option is only available when Accumulation is set to

OFF.

Set Second/Supplementary Sheet Feeder

If you want to use the second sheet feeder use these settings.

1. Tap the icons to scroll through the options. (Refer to the

Second/Supplementary Sheet Feeder Options, Non-Scanning Jobs

table for descriptions)

2. Tap to accept the option and advance to the next setting.

Second/Supplementary Sheet Feeder Options (Non-Scanning Jobs)

Icon Option Description

On Double Detect Feeder on with the double detector

operating. (The double detector stops

the inserter if two or more sheets feed

simultaneously.)

On Feeder on without the double detector.

Off Feeder turned off for this job.

Page 44

2 ● Program a Job

2-18 SV63138 Rev. A

Set the Insert Feeder

Select whether you want to use the insert feeder and how it will be used.

1. Tap the icons to scroll through the options. (Refer to the Insert

Feeder Options table for descriptions.)

2. Tap to accept the option and advance to the next setting.

Insert Feeder Options

Icon Option Description

On Double Detect Feeder on with the double detector

operating. (The double detector stops

the inserter if two or more sheets feed

simultaneously.)

On Feeder on without the double detector.

Off Feeder turned off for this job.

Set the Mode Type - Insertion or Fold-Only

This setting only appears if Accumulation is not turned on.

The inserter needs to know if the job requires inserting material into an

envelope or if it is a fold-only job.

To set the mode type:

1. Tap the icons to toggle between the options.

• Insertion Mode

Activates the envelope feeder for a normal inserting job.

• Fold-Only Mode

Turns the envelope feeder off and sets the inserter to act as a folding

module.

2. Tap to accept the mode type and advance to the next setting.

Page 45

Program a Job ● 2

2-19SV63138 Rev. A

Set the Sealer

This setting appears only if insertion mode is selected.

1. Select whether or not you want to seal envelopes.

2. Tap the icons to toggle the option to On or Off.

3. Tap to accept the option and advance to the next setting.

• If you selected either of the sheet feeders, continue to the Set

Paper Length setting.

• If you are using the insert feeder only, folding is not possible; skip

to the Set Envelope Depth setting.

Sealer Options

Icon Option Description

On Turns the sealer unit on for automatic sealing of

envelopes. Make sure the sealer water bottle is full of

E-Z Seal® or water.

Off Turns the sealer unit off. Envelopes will be ejected

unsealed.

Set Paper Length

1. Use the scale on the side of

the inserter cover to measure

the paper.

- US letter - 279mm (11 inches)

- A4 paper - 297mm

2. Tap the icons to

scroll through paper lengths

(displayed in mm).

3. Tap to accept the paper

length value and advance to

the next setting.

Page 46

2 ● Program a Job

2-20 SV63138 Rev. A

Set Fold A

1. Select the size of the first fold required.

NOTE: Depending on the settings you made earlier for fold type and paper

length, the inserter suggests the correct dimension for the first fold. Most of

the time this setting will prove satisfactory.

2. To change the standard fold setting, tap the icons until the

length of required fold displays. A icon displays next to the fold

panel you are setting.

NOTE: The inserter automatically limits your options to available specifications

on your inserter. (As you change the length of fold A, the dimension of fold

B changes automatically to keep within the correct paper length and inserter

specifications.)

3. Tap to accept the fold value and advance to the next setting.

Set Fold B

1. Select the size of the second fold required.

NOTE: Similar to setting fold A, the inserter suggests the correct dimension

for fold B.

2. To change the standard setting, tap the icons until the length of

fold required displays. A icon displays next to the fold panel you

are setting.

3. Tap to accept the fold value and advance to the next setting.

• Inserting jobs - continue to the Set the Envelope Depth setting.

• Fold-only job - there are no more job settings, skip to Confirming

the Job Setup.

Set Envelope Depth

1. Use the scale on the front cover to measure the depth of your

envelope.

2. Tap to scroll through the measurements (displayed in mm).

3. Tap to accept the value and advance to the next setting.

Page 47

Program a Job ● 2

2-21SV63138 Rev. A

Set the Envelope Stop

NOTE: The stop has five positions numbered 1 to 5. Setting 3 is the standard

setting for normal weight paper with standard folds. A thinner/lighter insert requires

a lower setting and a thicker/heavier insert requires a higher setting.

1. Tap the icons to scroll through the envelope stop positions.

2. Tap to accept the position and advance to the next setting.

Set the Batch Counter

The batch counter allows you to automatically process pre-defined

batches of finished mailpieces. When the batch is complete, the inserter

automatically stops.

NOTE: If the batch counter is not turned on, the display counter simply counts the

number of items processed until you press Reset Counter.

1. Tap the Start button to begin processing the next batch.

2. Tap the icons to toggle the batch mode to On or Off.

NOTE: If the batch counter is turned on, the inserter prompts for the batch

quantity. The default quantity is 50, but you may select any value up to 999 by

tapping the icons.

3. Tap to accept the setting.

Confirm Job Setup

Job setup is now complete. Using the inserter model and icons, the touch

screen display shows all the selected job settings.

1. Review the job settings.

2. Tap the icons to scroll back and change a setting.

3. Tap the Setup button to accept the new settings and exit setup mode.

4. When setup changes are complete, the touch screen displays the new

job settings with the message Trial Piece Required.

5. Test the setup by running a trial piece.

NOTE: The inserter retains job settings until you change or delete them, even

when the power is disconnected. If you need to change the name of the job, refer

to "Change a Job Name" in the System Overview chapter of this guide.

Page 48

2 ● Program a Job

2-22 SV63138 Rev. A

Run a Trial Piece

Run a trial piece to test the job settings.

1. Load material and tap the Trial Piece button.

2. If you need to make changes to the settings based on the trial piece:

a. Tap the Setup button.

b. Log in with Supervisor access level.

c. Tap the icons to scroll to the setting you wish to modify.

d. Tap the icons to scroll to the desired option.

3. Tap the Setup button to accept the setting modification and return to

run mode. The inserter saves the job with the new settings.

4. Run another trial piece to test the modified settings.

NOTE: Any time you modify settings you must run a trial piece.

Incorrect Address Position - Adjust Fold Settings

When you run a trial piece, if the address is not in the correct position refer

to the Adjust Fold Settings table to help you fine tune your folds settings.

Adjust Fold Settings Table

Fold Type Address Too Low Address Too High

C - Letter Fold Decrease Fold A Increase Fold A and

increase Fold B by the

same amount.

Z - Accordion Fold Increase Fold A Decrease Fold A and

increase Fold B by the

same amount

Single Fold Increase Fold A Decrease Fold A

Double Fold Decrease Fold A Increase Fold A

It is recommended the fold is only adjusted by 0.20 inches (5mm) each time.

Page 49

Program a Job ● 2

2-23SV63138 Rev. A

Modify an Existing Job

To modify an existing job follow these steps. (This requires Supervisor

level access.)

1. Tap the Setup button to enter setup mode.

2. The Enter Access Code field displays over the inserter model on the

touch screen display. Tap to increase or decrease to 71.

3. Tap to accept the code and advance to the job selection.

4. Tap the icons to display the job you wish to modify.

5. Tap to accept the job selection and advance to the job

programming settings.

6. Tap the icons to scroll through the setting(s).

7. Tap the icons to scroll through the options or desired values.

8. Tap to accept the job setting.

9. Tap the Setup button to save the changes and exit setup mode.

Delete a Job

To delete an existing job from the inserter system follow these steps. (This

requires Supervisor level access.)

1. Tap the Setup button to enter setup mode.

2. The Enter Access Code field displays over the inserter model on the

touch screen display. Tap to increase or decrease to 71.

3. Tap to accept the code and advance to the job selection.

4. Tap the icons to display the job you wish to delete.

5. Tap the to delete the job. The display shows “Press again to

confirm.”

6. Tap the again. The display briefly shows “Deleting Job” as the job

is erased.

7. Tap the Setup button to exit setup mode.

Page 50

This page is intentionally blank.

Page 51

3-1

SV63138 Rev. A

3 • Run a Job

Contents

Run a Job ............................................................3-3

Verify the Inserter Has Power .............................. 3-4

Turn On the Touch Screen...................................3-4

Log In...................................................................3-4

Select a Job .................................................. 3-5

Manual Feed Jobs ...............................................3-6

Load Material ....................................................... 3-7

Adjust and Load the Sheet Feeders ............. 3-7

Adjust and Load the Envelope Feeder .......... 3-8

Adjust and Load the Insert Feeder .............. 3-10

Run a Trial Piece ...............................................3-12

Trial Pieces and Linked Feeding ................. 3-12

Material Changes or Double Detect

Issues During Operation ........................ 3-12

Start and Stop the Inserter ................................3-13

Fill the Sealer.....................................................3-14

Adjust the Stacker .............................................3-14

Page 52

This page is intentionally blank.

Page 53

3 ● Run a Job

3-3SV63138 Rev. A

Run a Job

The operating activities outlined here assume that a job has already been

programmed into the Relay 3000 or 4000 inserter. (Programming a job is

typically a Supervisor function.)

Activities Operators perform with the touch screen to run a previously

programmed job:

• Verify the inserter has power

• Turn on the touch screen

• Log into the system

• Select a job

• Load material

• Adjust and load the sheet feeders

• Adjust and load the envelope feeders

• Adjust and load the insert feeders

• Run a trial piece

• Run the job

• Fill the sealer (if needed)

• Adjust the stacker (if needed)

Read the safety information in this guide before

connecting the inserter.

Page 54

3 ● Run a Job

3-4 SV63138 Rev. A

Verify the Inserter Has Power

1. Verify the power cord is

connected to the socket on the

back of the inserter.

2. Verify the power cord is

plugged into a power outlet

near the machine and is easily

accessible.

3. Turn the power switch ON.

Turn On the Touch Screen

1. Make sure the inserter is

powered up before you power

up the touch screen.

2. Press and hold the ON/

OFF power button for a few

seconds. The power button is

located on the top left rim of

the touch screen.

NOTE: If the touch screen is in

sleep mode, press the ON/OFF

button.

Touch Screen ON/OFF power button

Log In

1. Tap the icon twice.

2. Highlight the operator name from the list and tap .

3. To launch the keyboard, tap the

icon in the bottom right corner of

the screen and type the password in the field..

4. Tap

. The main control screen opens.

Operators can run all pre-programmed jobs using the touch screen main

control screen.

Page 55

3 ● Run a Job

3-5SV63138 Rev. A

Select a Job

When the inserter is turned ON and you are logged in, the touch screen

displays the last job run with the message Trial Piece Required.

Select the job you wish to run.

1. Tap the Job button to scroll through the jobs,

until the job you want displays, OR tap the

Default button if you want to run the inserter

with your default job settings.

NOTE: Only a PB Service Representative can

modify default job settings.

2. Load material - refer to the Loading Material

section in this guide.

3. If material is already loaded, tap the Trial

Piece button. The inserter sets itself and runs

a test piece for you to check.

Page 56

3 ● Run a Job

3-6 SV63138 Rev. A

Manual Feed Jobs

If you select a manual feed job

where sheet feeder 1 is set for

manual feed of collated sets,

DO NOT load the sheet feeder.

Instead, you will feed collated sets

one at a time, by hand, as required.

Before you run a manual feed job,

pull back the lever (shown here).

This opens the feed mechanism for

manual feed operation.

NOTE: Return this lever to its normal

position when you use the feeder for

automatic operation.

Page 57

3 ● Run a Job

3-7SV63138 Rev. A

Load Material

Adjust and Load the Sheet Feeders

1. Adjust the side guides to the

width of the material, then

back-off a quarter turn on the

side guide control. This sets

the correct clearance between

the guides and the material.

2. Aerate (fan) the stack of paper

to ensure that individual sheets

are not stuck together.

3. Jog stack back into alignment.

The display indicates the correct

orientation of the paper.

FACE UP

HEAD FIRST

ABC

FACE DOWN

FEET FIRST

ABC

4. Place the paper stack onto the

feed deck. Allow the deck to

move down and the top of the

paper stack to slide under the

feed roller.

Page 58

3 ● Run a Job

3-8 SV63138 Rev. A

Adjust and Load the Envelope Feeder

The envelope feeder feeds the outer envelope for the inserting job.

1. Press the envelope feeder

loading switch to lower the

feeder tray.

2. Use the side guide adjustment

knob to adjust the side guides

to the width of the envelopes.

Once adjusted, back-off the

adjustment knob 1/4 turn.

This sets the correct clearance

between the guides and envelopes.

3. Take the stack of envelopes;

aerate and fan it to ensure that

individual envelopes are not

stuck together.

4. Place the stack of envelopes

into the feeder with the flap

side UP and flap LAST.

5. Press the envelope feeder

loading switch again to raise

the envelope stack to the

normal feeding position.

Page 59

3 ● Run a Job

3-9SV63138 Rev. A

Load Envelopes without Stopping the Inserter

1. Press the envelope feeder

loading switch to lower the

feeder tray.

2. Load envelopes as described

earlier in this section.

3. Press the envelope feeder

loading switch again.

The envelope stack rises to

the normal feeding position

and processing continues

automatically.

Page 60

3 ● Run a Job

3-10 SV63138 Rev. A

Adjust and Load the Insert Feeder

The insert feeder feeds items that do not require folding. Depending on

configuration of your inserter, you may not have an insert feeder.

1. Use the side guide adjustment

knob to adjust the side guides

to the width of the inserts you

are running. Once adjusted,

back-off the adjustment knob

1/4 turn.

This sets the correct clearance

between the guides and inserts

.

2. Refer to the labels located on

the insert feeder and match

your insert type (slip, reply

envelope, pre-folded, booklet)

with the icon and color.

Identifying Your Insert

If the label indicates a range of

settings, we recommend you

select a higher number or letter for

a thicker the insert

.

3. Set the blue separator gap

lever to the number required.

4. Set the blue separator shield

lever to the letter required.

Page 61

3 ● Run a Job

3-11SV63138 Rev. A

5. Take the stack of inserts and

aerate and fan it to ensure that

individual pieces are not stuck

together.

6. Shingle the inserts (as shown

here) and place them on the

feed deck.

Loading orientation can vary

depending on the inserts. As a

general rule, load inserts using the

orientation guidelines in the table

below.

7. Let the wedge (material prop)

slide down behind the stack to

support the inserts.

Orientation Table for Loading Inserts

Insert Type Orientation

Slip Face up, bottom edge first

Reply Envelope Face up, top edge first

Pre-Folded Face up, closed edge first

Booklet Face up, bound edge first

Page 62

3 ● Run a Job

3-12 SV63138 Rev. A

Run a Trial Piece

Run a trial piece to test the job settings.

1. Load material and tap the Trial Piece button to verify setup is correct.

2. You can still make changes to the job settings at this point if the trial

piece needs fine tuning. (This requires Supervisor level access.)

a. Tap the Setup button.

b. Log in with Supervisor access level.

c. Tap the icons to scroll to the setting you wish to modify.

d. Tap the icons to scroll to the desired option.

3. Tap the Setup button to accept the change to the setting and return to

run mode. The inserter saves the job with the new settings.

4. Run another trial piece to test the modified settings.

Trial Pieces and Linked Feeding

• If you are using linked feeding, load both sheet feeders before running

a trial piece.

• Two trial pieces are produced when linked feeding is enabled.

• When running the inserter the display shows: 1 > 2 > 1. This confirms

feeding automatically switches between feeders.

Material Changes or Double Detect Issues During Operation

If you load material during a job run with different characteristics (weight,

color shade, etc.), OR if you have problems with the double detect, run

another trial piece.

This causes the inserter to recalibrate the double detect function for the

new material.

Page 63

3 ● Run a Job

3-13SV63138 Rev. A

Start and Stop the Inserter

1. Tap the Start button on the touch screen

to begin automatic operation.

2. The inserter runs until it runs out of

material or you tap the Stop button on

the touch screen.

Stop

Start

Page 64

3 ● Run a Job

3-14 SV63138 Rev. A

Fill the Sealer

When the sealer unit needs

refilling, the Add Sealing Solution

icon flashes in the display.

When this happens, add E-Z Seal®

Sealing Solution or water:

1. Open the sealer bottle cover

hinge located at the rear, right

side of the inserter and remove

the bottle.

2. Fill the bottle with solution or

water to the level indicated.

3. Place the sealer bottle in

position in the inserter and

close the cover.

NOTE: If the sealer unit was

completely empty, allow time

for the fresh solution or water to

soak through the sealer before

you resume operation. This helps

assure a good seal.

NOTE: We recommend Pitney

Bowes E-Z Seal to minimize algae

growth and scale build-up.

Adjust the Stacker

If necessary, adjust the drop stacker to accommodate the job material.

1. Lift the lever at the rear of the

stacker and adjust the stacker

to one of the preset positions.

2. Lower the lever to lock the

stacker into position.

NOTE: When not in use, you

can raise the stacker and latch it

vertically against the exit area of

the inserter.

Page 65

SV63138 Rev A

4 • OMR Scanning

Contents

Optical Mark Recognition (OMR)...........................4-3

Accuracy .........................................................4-3

OMR and Feeders on the Inserter .........................4-3

OMR Scanning Types ............................................4-4

Basic OMR ......................................................4-4

Enhanced OMR ..............................................4-4

OMR Mark Positions..............................................4-4

OMR Specifications ...............................................4-5

Standard OMR Positions ................................4-6

Offset OMR Positions......................................4-7

Available OMR Marks ...........................................4-8

Benchmark ......................................................4-8

Safety ..............................................................4-8

End-of-Collation (EOC) ...................................4-8

Beginning-of-Collation (BOC) .........................4-8

Parity ...............................................................4-8

Re-timing Mark ................................................4-8

Select Feed (SF1, SF2) ..................................4-9

Auto Batch ......................................................4-9

Wrap Around Sequence

(WAS1, WAS2, WAS3) ..............................4-9

OMR Mark Grouping ...........................................4-10

C-Fold and Double-Fold Jobs..............................4-10

Z-Fold and Single-Fold Jobs ...............................4-11

Adjust the OMR Scanner .....................................4-12

OMR Troubleshooting..........................................4-14

Error Recovery for OMR Jobs .......................4-14

Error Recovery for Accumulation Jobs ..........4-14

Error Recovery for Empty Feeders ...............4-14

OMR Error Messages ..........................................4-15

Page 66

This page is intentionally blank.

Page 67

OMR Scanning • 4

4-3SV63138 Rev.A

Optical Mark Recognition (OMR)

An OMR mark is normally a dark solid line on a

sheet of light colored paper that is perpendicular

to the direction of paper travel. This line must be

thick and dense to trigger the OMR scanner.

The OMR scanner works with the OMR system

software to check for one or more different OMR

marks on a document as it is fed through the

system. Tracking of these marks enhances mail

piece integrity by assuring the documents that

belong together (a set) stay together throughout

the inserting process.

NOTE: Depending on the model, your inserter

may be equipped with OMR scanning.

NOTE: For instructions on programing an OMR job, refer to the

Programing a Job section of this manual.

Accuracy

OMR on this system uses extensive error checking. This means insertion

accuracy is very high: the probability of the wrong set of sheets being

inserted into an envelope is low.

OMR and Feeders on the Inserter

OMR-equipped models have scanning heads on each sheet feeder.

One of the sheet feeders holds sheets with OMR marks and they feed

multiple sheets per envelope.

• Sheet feeder 1 for C-fold and double fold

• Sheet feeder 2 for Z-fold and single fold

You can set up the sheet and insert feeders to be under the selective