Page 1

Relay™ 2000

Shipping & Mailing

Inserter

Document Inserting System

Operator Guide

International English Edition

SV63139 Rev A

August 1, 2015

Page 2

Statement of FCC Compliance

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to part 15 of the FCC rules. These limits are designed to

provide reasonable protection against interference when the equipment is operated

in a commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction

manual, may cause interference to radio communications. Operation of this equipment in a residential area is likely to cause interference, in which case the user will

be required to correct the interference at his own expense.

SV63139 Rev. A ©2006, 2015 Pitney Bowes Inc.

All rights reserved. This book may not be reproduced in whole or in part in any fashion

or stored in a retrieval system of any type or transmitted by any means, electronically or mechanically, without the express, written permission of Pitney Bowes. We

have made every reasonable effort to ensure the accuracy and usefulness of this

manual; however, we cannot assume responsibility for errors or omissions or liability

for the misuse or misapplication of our products.

Due to our continuing program of product improvement, equipment and material

specifications as well as performance features are subject to change without notice.

E-Z Seal is a registered trademark of Pitney Bowes.

Canada

This class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme á la norme NMB-003 du

Canada.

CAUTION: Changes or modifications to this equipment not expressly approved by

the party responsible for compliance (Pitney Bowes) could void the user’s authority

to operate the equipment.

It is certified that this system complies with all applicable Directives of

the European Union.

Page 3

Table of Contents

iiiSV63139 Rev. A

Safety ..................................................................................vii

Chapter 1 System Overview

Relay 2000 Inserter Introduction Overview .......................1-3

Product Features ...............................................................1-3

Relay 2000 Inserter (with Control Panel) -

Component Identification ................................................... 1-4

Control Panel Identification ................................................ 1-6

Control Panel Icons ...........................................................1-8

Change the Display Language ........................................1-10

Chapter 2 Program a Job

Navigate Using the Control Panel .....................................2-3

Scanning and Non-Scanning Jobs ............................. 2-4

Program a Job ...................................................................2-5

Setup Mode ................................................................ 2-5

Select the Job Number (New or Existing Job) ........... 2-5

Program a Scanning Job ........................................... 2-6

Program a Non-Scanning Job .................................. 2-14

Modify an Existing Job ..................................................... 2-22

Delete a Job ....................................................................2-22

Chapter 3 Run a Job

Run a Job ..........................................................................3-3

Verify the Inserter Has Power ............................................ 3-4

Select a Job ............................................................... 3-4

Manual Feed Jobs .............................................................3-5

Load Material .....................................................................3-6

Adjust and Load the Sheet Feeders .......................... 3-6

Adjust and Load the Envelope Feeder ....................... 3-7

Adjust and Load the Insert Feeder ............................. 3-8

Run a Trial Piece .............................................................3-10

Material Changes or Double Detect Issues

During Operation ................................................. 3-10

Start and Stop the Inserter .............................................. 3-11

Fill the Sealer ................................................................... 3-11

Page 4

Table of Contents

iv SV63139 Rev. A

Adjust the Stacker ...........................................................3-12

Chapter 4 OMR Scanning

Optical Mark Recognition (OMR) ....................................... 4-3

Accuracy .................................................................... 4-3

OMR and Feeders on the Inserter ..................................... 4-3

OMR Scanning Types ........................................................4-4

Basic OMR ................................................................. 4-4

Enhanced OMR ......................................................... 4-4

OMR Mark Positions ..........................................................4-4

OMR Specifications ...........................................................4-5

Standard OMR Positions ........................................... 4-6

Offset OMR Positions ................................................. 4-7

Available OMR Marks .......................................................4-8

Benchmark ................................................................. 4-8

Safety ......................................................................... 4-8

End-of-Collation (EOC) .............................................. 4-8

Beginning-of-Collation (BOC) .................................... 4-8

Parity .......................................................................... 4-8

Re-timing Mark ........................................................... 4-8

Select Feed (SF1, SF2) ............................................. 4-9

Auto Batch ................................................................. 4-9

Wrap Around Sequence (WAS1, WAS2, WAS3) ....... 4-9

OMR Mark Grouping .......................................................4-10

C-Fold and Double-Fold Jobs .................................. 4-10

Adjust the OMR Scanner ................................................. 4-11

OMR Troubleshooting ......................................................4-12

Error Recovery for OMR Jobs .................................. 4-12

Error Recovery for Accumulation Jobs ..................... 4-12

Error Recovery for Empty Feeders .......................... 4-12

OMR Error Messages ......................................................4-13

Chapter 5 Clear Material

Clear Material ....................................................................5-3

Page 5

Table of Contents

vSV63139 Rev. A

Access Areas of the Inserter for Jam Removal .................5-3

Sheet Feeders Tray - Remove and Replace .............. 5-3

Fold Plates - Remove and Replace ........................... 5-4

Insert Tray - Remove and Replace ............................ 5-4

Access the Carriage Assembly .................................. 5-4

Access to Envelope Feeder Area ............................... 5-5

Access the Envelope Exit Area .................................. 5-5

Access the Envelope Inserting/Sealing Area ............. 5-6

Access to the Sheet Feed Area ................................. 5-6

Chapter 6 Troubleshooting

General Troubleshooting ...................................................6-3

Error Messages .................................................................6-7

Chapter 7 Material Specifications

Material Specifications .......................................................7-3

Inserter Specifications .......................................................7-7

Service ...............................................................................7-8

Page 6

This page is intentionally blank.

Page 7

Safety

viiSV63139 Rev. A

Safety

Follow these precautions whenever you use your inserting system:

• Read all instructions before you attempt to operate the system.

• Use this equipment only for its intended purpose.

• Place the system close to an easily accessible wall outlet.

• Place the system in an accessible location to allow for proper venting

of the equipment and to facilitate servicing.

• Use the AC power adapter included with this device. Third party

adapters may damage the device.

• Plug the AC adapter directly into a properly grounded wall outlet

located near the equipment and easily accessible. Failure to properly

ground the machine can result in severe personal injury and/or fire.

• The AC adapter/power cord is the primary means to disconnect this

device from the AC supply.

• DO NOT use a wall outlet controlled by a wall switch or one that is

shared with other equipment.

• DO NOT use an adapter plug on the line cord or wall outlet.

• DO NOT remove the ground pin from the line cord.

• DO NOT route the AC adapter power cord over sharp edges or trap it

between furniture. Make sure there is no strain on the power cord.

• If the unit becomes damaged, unplug it from the wall.

• Keep fingers, long hair, jewelry and loose clothing away from moving

parts at all times.

• Avoid touching moving parts or materials while the machine is in

use. Before clearing a jam, be sure machine mechanisms come to a

complete stop.

• Remove jammed material gently and carefully.

• DO NOT remove covers. Covers enclose hazardous parts that should

only be accessed by properly trained service personnel.

• DO NOT place lighted candles, cigarettes, cigars, etc., on the system.

• To prevent overheating, do not cover vent openings.

• Use only approved supplies.

• Improper storage and use of aerosol dusters or flammable aerosol

dusters can cause an explosive-like condition that could result in

personal injury and/or property damage.

• Never use aerosol dusters labeled flammable and always read

instructions and safety precautions on the duster container label.

Page 8

Safety

viii SV63139 Rev. A

• Operation of this equipment without periodic maintenance will inhibit

optimum operating performance and could cause the equipment to

malfunction.

• Always follow specific occupational safety and health standards for

your workplace.

• To reduce the risk of fire or electrical shock, DO NOT attempt to

remove covers or disassemble the control panel or its base. The

cabinet encloses hazardous parts.

• Before operating the main inserting machine with this device, make

sure the machine has been properly prepared and that any other

personnel in the area are standing clear of the inserter.

• Immediately report to service any damaged or non-functioning

components that renders the unit unsafe.

• Contact your system supplier for the following:

- Supplies

- Material Safety Data Sheets

- If you should damage the unit

- Required maintenance service schedule

If your Stacker has an AC Adapter:

• Use the AC power adapter included with this device. Third party

adapters may damage the device

• To protect against electrical shock, plug the AC adapter power cord

into a properly grounded wall outlet.

• DO NOT route the power cord for the AC adapter over sharp edges or

trap it between it between pieces of furniture. Make sure there is no

strain on the power cord.

IMPORTANT: Some of the inserter features and options covered in

here may not be available on your inserter.

Page 9

SV63140 Rev A

1 • System Overview

Contents

Relay 2000 Inserter Introduction Overview .....................1-3

Product Features .............................................................1-3

Relay 2000 Inserter Component Identification ................1-4

Control Panel Identification..............................................1-6

Control Panel Icons .........................................................1-8

Change the Display Language ......................................1-10

Page 10

This page is intentionally blank.

Page 11

System Overview • 1

1-3

SV63139 Rev. A

Relay 2000 Inserter Introduction Overview

• The Relay 2000 is a two-station inserter with one sheet feeder and

one insert feeder.

• Jobs are programmed and run via the control screen built into the

system.

• Processing speed varies depending on machine configuration.

• Your system may be equipped with OMR (Optical Mark Recognition)

scanning, depending on the model you purchased.

Product Features

The Relay 2000 inserters with a control panel offer these features:

• Envelope seal/no seal option

• Fully automatic material separation on sheet feeders

• Fully automatic setting of fold plates

• Fully automatic envelope separation

• Fully automatic double document detection (when selected)

• Fold-only option (fold without insertion)

• Manually fed, semi-automatic insertion of single and multi-sheet

collations

• Option of single fold, letter (C) fold, accordion (Z) fold or double fold

• Job recall facility

• Optical Mark Recognition (OMR) scanning

Page 12

1 • System Overview

1-4 SV63139 Rev. A

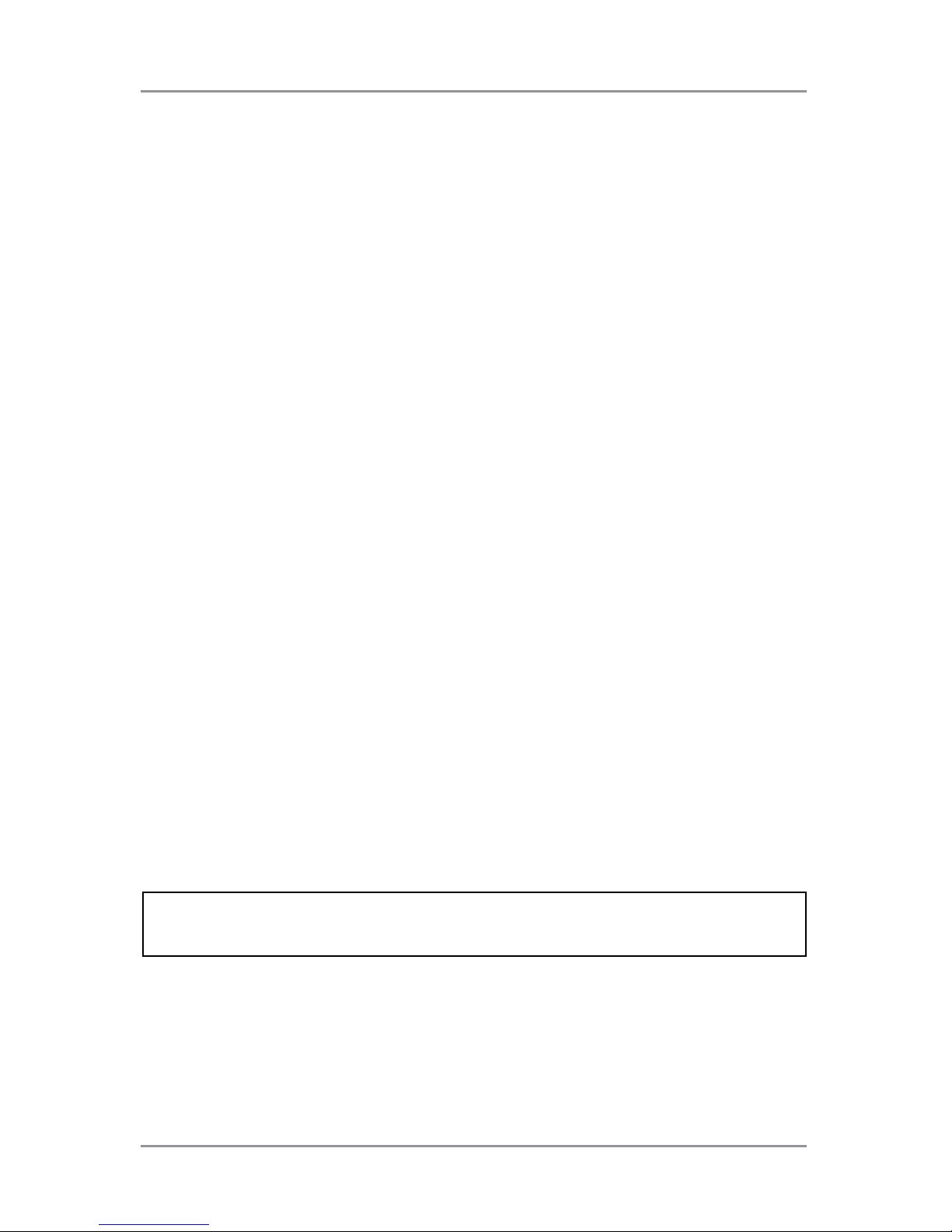

Relay 2000 Inserter (with Control Panel) -

Component Identification

1

Sheet Feeder 1 - This feeder is intended for feeding material

that requires folding.

In addition, you can set sheet feeder 1 to Manual Feed. In this

mode, you can run stapled sets of up to five sheets. The inserter

waits for you to feed each set by hand into sheet feeder 1 before

folding and inserting the set automatically.

2

Display/Control Panel - This is where you enter commands

and where the inserter status is displayed through symbols

and icons.

10

2

1

3

5

6

4

9

8

7

Page 13

System Overview • 1

1-5

SV63139 Rev. A

3

Insert Feeder - Use this feeder to add additional inserts to

your envelope. Material fed from this feeder cannot be folded

by the inserter. However, this feeder is especially suited to

feeding pre-folded or thicker inserts.

4

Sealer Bottle - The sealer bottle is located on the rear of the

inserter on the right side. It is under a hinged cover, labeled

with the sealer icon. The sealer bottle provides sealing

solution to the envelope sealer.

5

Envelope Inverter - Transports the envelope into the stacker

face up.

6

Drop Stacker or Output Device (not shown in image) -

Located at the exit of the inserter, this device collects finished

mailpieces. This device can be latched against the inserter when

not in use. Alternatively, a range of power stackers are available

which offer greater capacity than the standard drop stacker.

7

Fold Plate - This creates the desired fold in material

fed from

the sheet feeder. The fold plate is automatically set from the

control panel.

8

Measuring Scale — The scale is located on the left side of the

inserter near the sheet feeders; used as an aid in measuring

material and envelopes.

9

Manual Advance Knob - The knob is located inside a cover

at the lower center of the inserter. Use it to turn the inserter

mechanisms by hand to help clear a material.

10

Envelope Feeder - Feeds envelopes into the inserting area

where they are filled with material requested from the other

feeder(s).

Page 14

1 • System Overview

1-6 SV63139 Rev. A

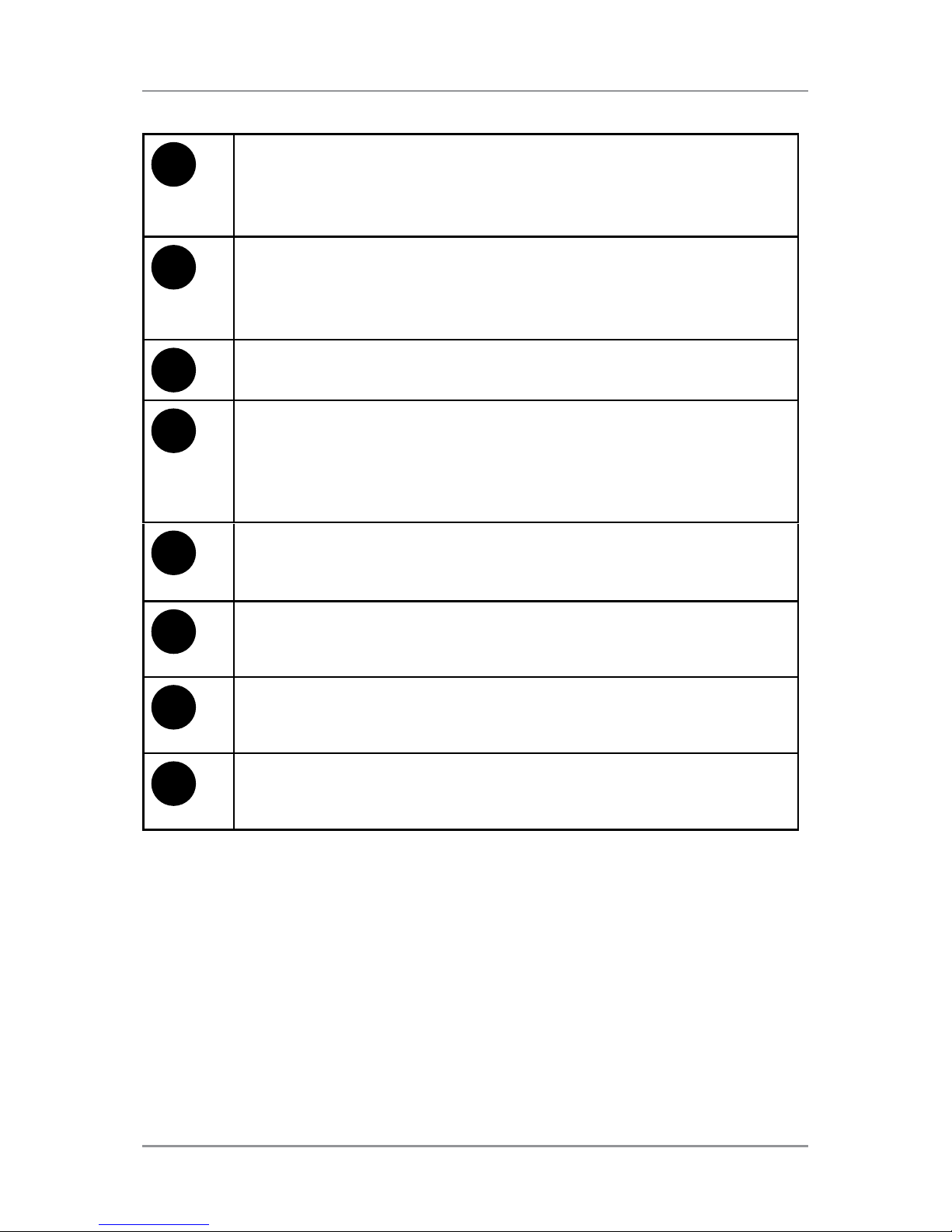

Control Panel Identification

Use the buttons on the system control panel to set up and run jobs. The

display screen shows the system status.

9

10

11

8

1

7

4

3

5

6

2

1

Clear Deck - Press to jog material through and out of the

inserter. Also use it to clear the inserter and make it ready for

automatic operation after a stoppage has occurred.

2

Trial Piece - Press to run a single test piece to check inserter

setup. You must run a trial piece before you begin automatic

operation using the Start button. If double detection is

enabled, the inserter sets itself automatically to run the trial

piece. The trial piece envelope will be unsealed and counted

as one item.

3

Delete - Press while in setup mode to delete a programmed

job from memory.

4

Setup - Press to enter the setup mode. This mode allows you

to program jobs into memory for instant recall using the Job

button.

5

Change + – - In setup mode, press to select options or set

values of inserter settings.

6

Prev ◄ ► Next - In setup mode, press to step backward or

forward through the various job settings.

Page 15

System Overview • 1

1-7

SV63139 Rev. A

7

Start - Press to start automatic operation.

8

Stop - Press to stop automatic operation at the end of the

next cycle.

9

Reset Counter - Press to reset the item or batch counter.

10

Job - Press to scroll through the jobs programmed in the

inserter’s memory. You can program up to 20 jobs in the

inserter.

11

Default - Press to return the inserter to its default or standard

settings. These settings come pre-configured from the factory,

but a Pitney Bowes Service Representative can modify for

your specific application.

Page 16

1 • System Overview

1-8 SV63139 Rev. A

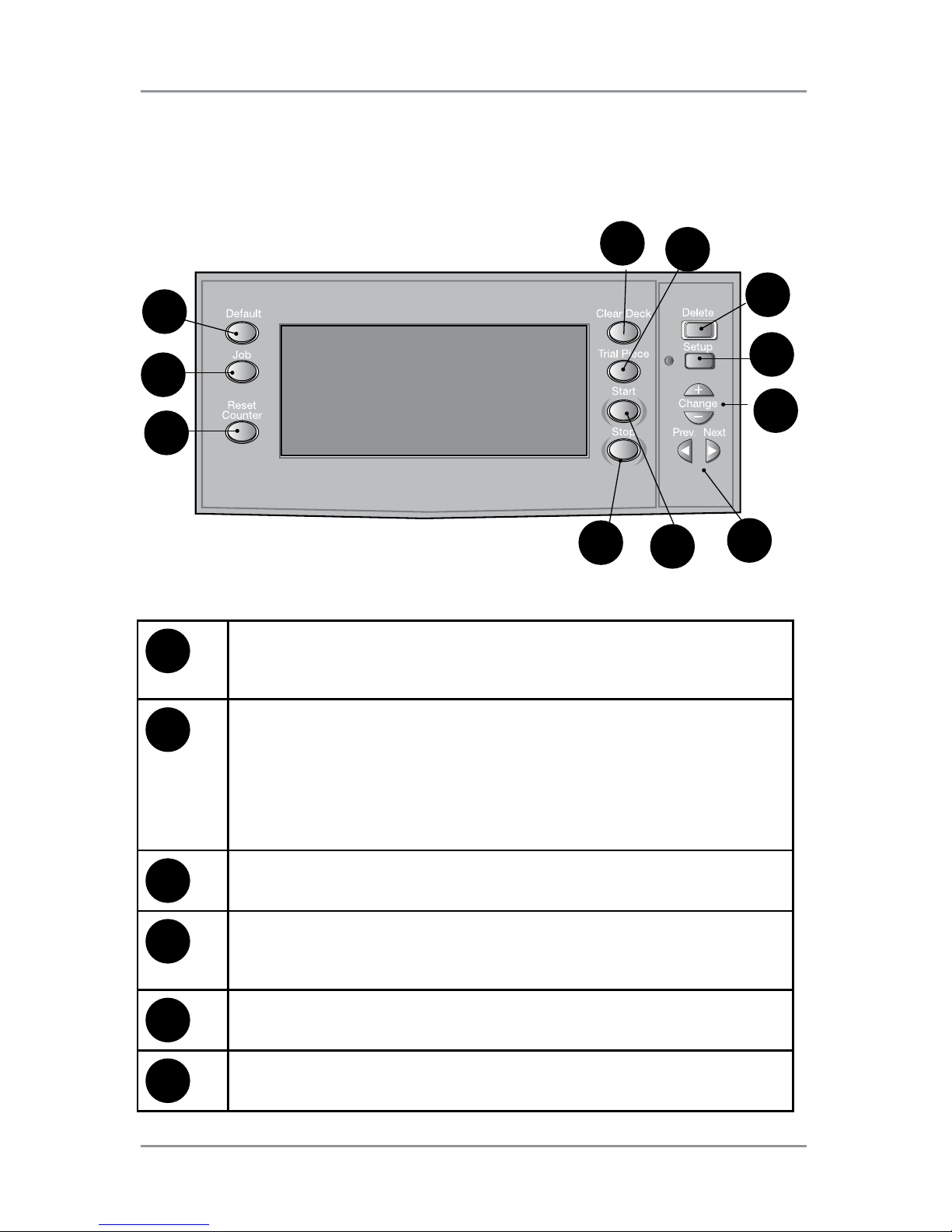

Used on sheet feeders to signify that the feeder is on

without double detection.

Used on sheet feeders to signify that the feeder is on

with double detection.

Used on insert feeder to signify that the feeder is on

without double detection.

Used on insert feeder to signify that the feeder is on

with double detection.

Used on sheet feeder 1 to signify that the feeder is set

for manual feed.

Used on envelope feeder to signify that the feeder is on.

Indicates the setting (from 1 to 5) of the envelope stop.

Indicates that the sealer bottle needs refilling.

Indicates the envelope depth.

Indicates the sealer unit is off (envelopes not sealed).

Control Panel Icons

. . 3 . .

Page 17

System Overview • 1

1-9

SV63139 Rev. A

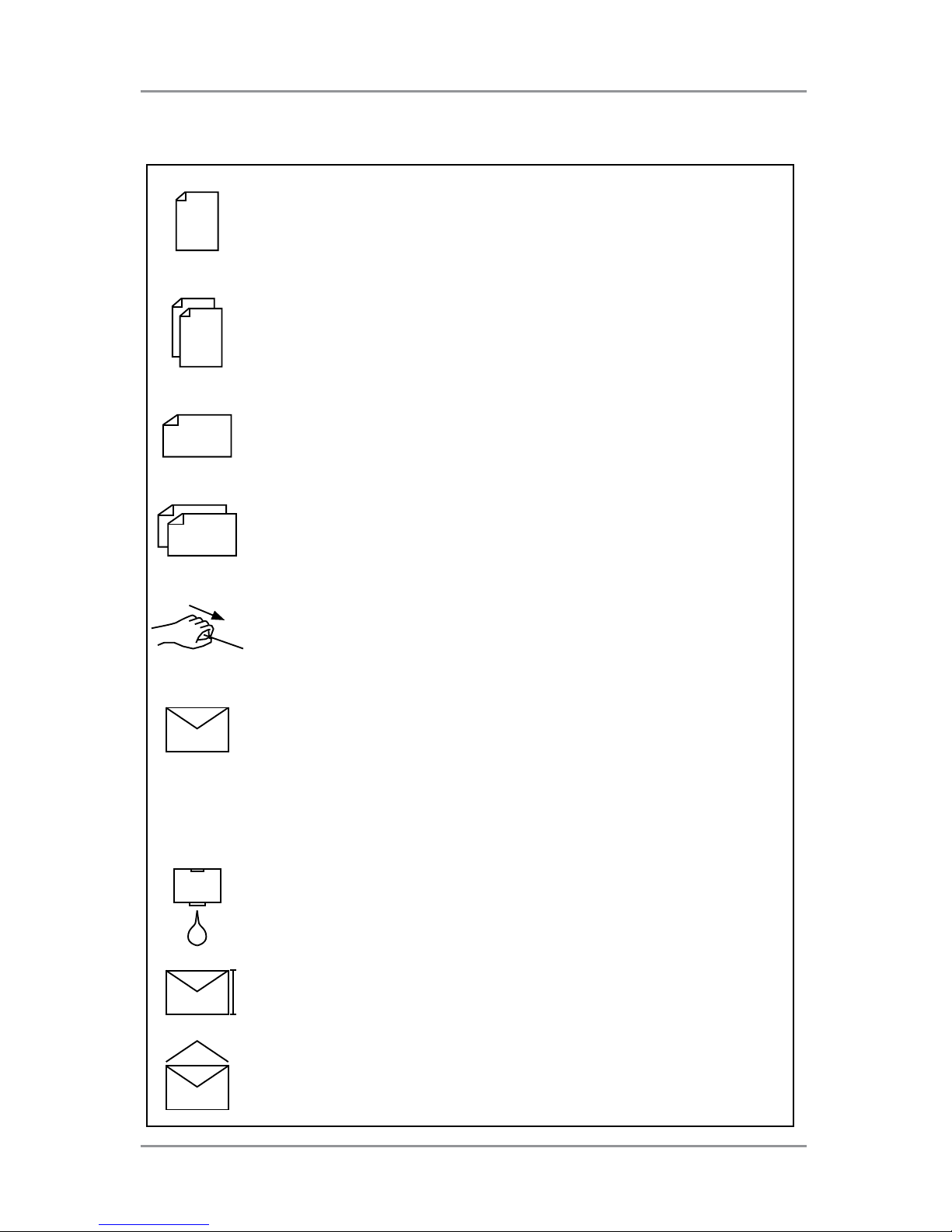

Control Panel Icons (continued)

ABC

Indicates the sealer unit is on (automatic envelope

sealing)

Indicates a C (letter) fold is selected

Indicates a Z (accordion fold) is selected

Indicates a double fold is selected

Indicates a single fold is selected

Indicates a no-fold insert operation

Indicates a material stoppage. The position of this symbol

in the display indicates where the stoppage has occurred.

Call Pitney Bowes for service

Indicates the paper size, address orientation and fold(s)

set for sheet feeder

Indicates a material stoppage in a downstream device,

such as a power stacker.

Page 18

1 • System Overview

1-10 SV63139 Rev. A

Change the Display Language

To change the language on the control panel display:

1. Open the cover to the right of the control panel display to access the

setup buttons.

2. Press Setup. The inserter prompts for an access code.

3. Press Change (+/-) to increase or decrease to access code 99.

4. Press Next (►) to select the languages option.

5. Press Change (+/-) to scroll through the available languages.

6. When the desired language displays, press Setup to select the

language and exit setup mode.

Page 19

SV63139 Rev A

2 • Program a Job

Contents

Navigate Using the Control Panel ..................... 2-3

Scanning and Non-Scanning Jobs .............. 2-4

Program a Job ................................................... 2-5

Setup Mode .................................................2-5

Select the Job Number

(New or Existing Job) .............................. 2-5

Program a Scanning Job ............................2-6

Program a Non-Scanning Job ...................2-14

Modify an Existing Job..................................... 2-22

Delete a Job .................................................... 2-22

Page 20

This page is intentionally blank.

Page 21

Program a Job • 2

2-3SV63139 Rev. A

This section provides step-by-step instructions for setting up and saving a

new scanning or non-scanning job using the control panel. Programming a

job is typically a Supervisor activity.

Navigate Using the Control Panel

Open the hinged cover to the right of the control panel display to access

the setup buttons. Use the setup buttons to navigate the job programing

options. To help visually guide you through the programming sequence, an

asterisk (*) flashes on the control panel display next to the area being set.

• To access the setup buttons, open the hinged cover to the right of the

display screen.

• Use the Prev (◄) and Next (►) buttons to scroll through the available

settings.

• Once the desired setting displays, use the Change (+/-) buttons to

select options or set values within the settings.

Page 22

2 • Program a Job

2-4 SV63139 Rev. A

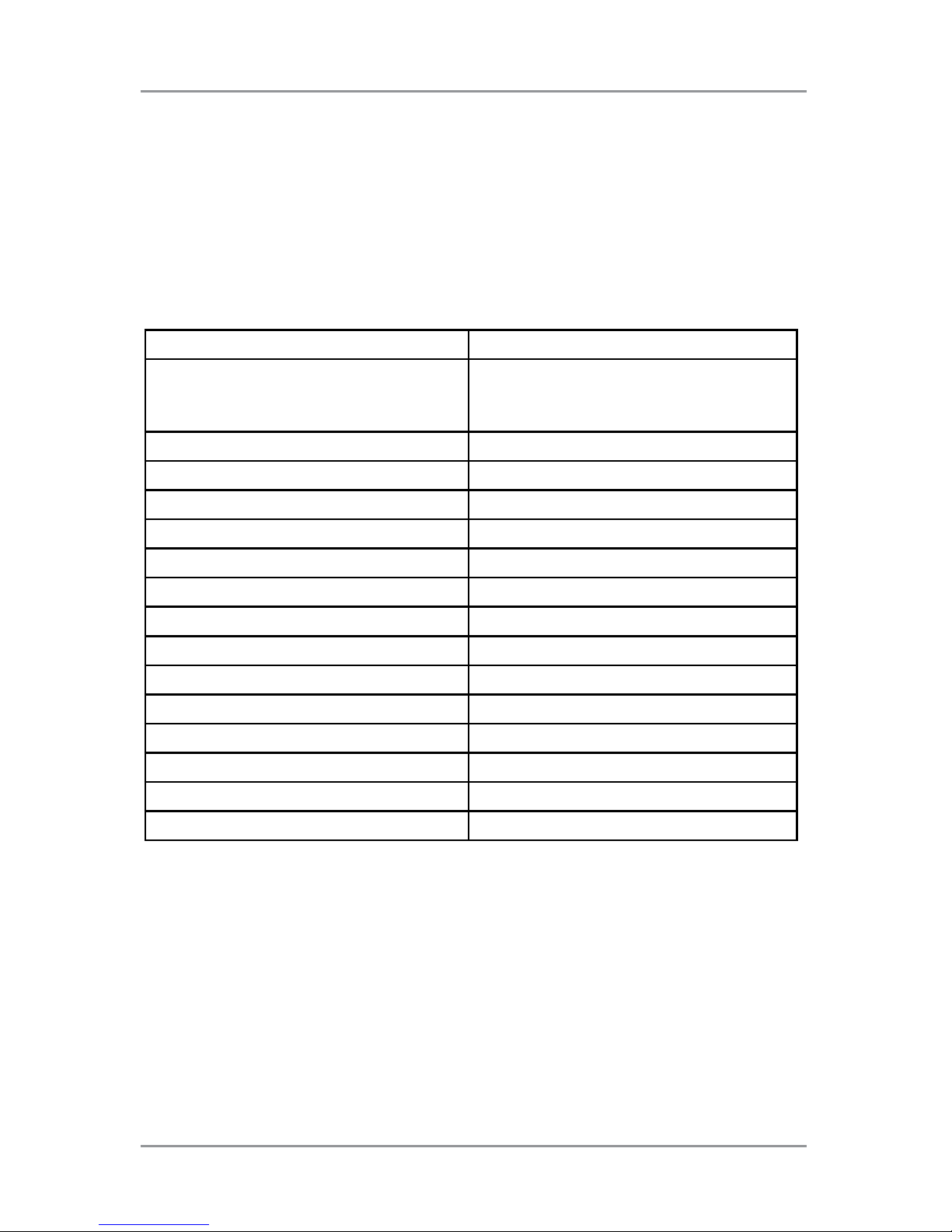

Scanning and Non-Scanning Jobs

If OMR scanning functionality is enabled on your system, operators can

turn scanning on and off depending on the job. If scanning functionality is

not available on your inserter, your job setup will differ slightly.

Refer to the table below to review the steps that apply to your job type and

follow the step-by-step instructions provide in this section.

Scanning and Non-Scanning Job Sequence

Scanning Jobs Non-Scanning Jobs

Enable scanning (OMR On or Off) Disable scanning (OMR Off) if

available on your inserter. (Skip if you

inserter does not have scanning)

Set fold type Set fold type

Set main (scanning) sheet feeder Set accumulation

Set second/supplementary feeder Set sheet feeder 1

Set the sealer Set sheet feeder 2

Set paper length Set insert feeder

Set fold A /fold B Set mode type (insertion or fold)

Set envelope depth Set the sealer

Set envelope stop Set paper length

Set batch counter Set fold A /fold B

Confirm job setup Set envelope depth

Run a trial piece Set envelope stop

Set batch counter

Confirm job setup

Run a trial piece

Page 23

Program a Job • 2

2-5SV63139 Rev. A

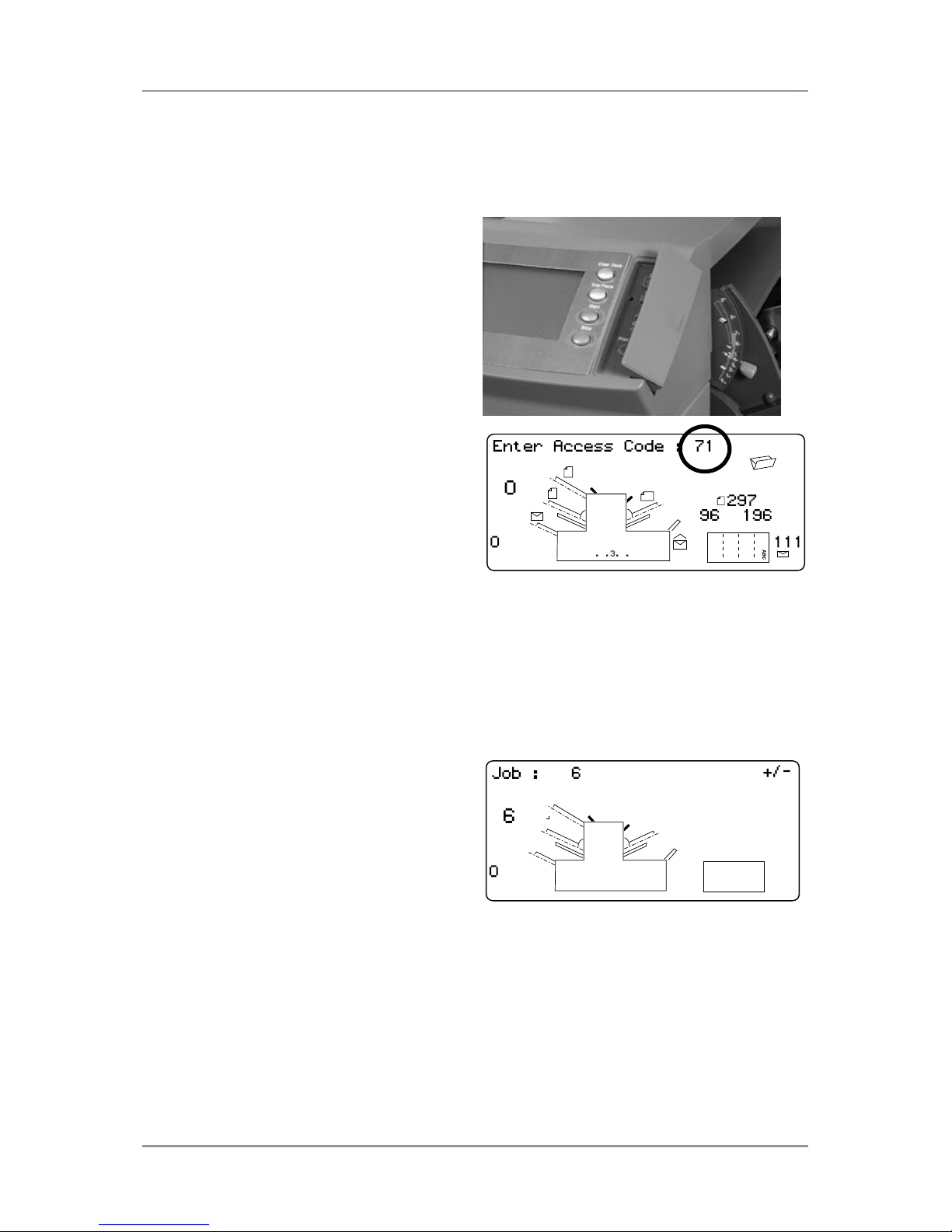

Program a Job

Setup Mode

1. Open the hinged cover to the

right of the display to access

the setup buttons.

2. Press Setup. The inserter

prompts for an access

code. (This code prevents

unauthorized personnel from

changing inserter settings).

3. Press Change (+/-) to increase

or decrease to access code 71.

4. Press Next (►) to accept the

code and advance to the next

job setting.

Select the Job Number (New or Existing Job)

When prompted for the job number, follow these steps to select or create

the job. You can select an existing job and overwrite its current settings or

you can select an unused job and program new settings.

1. Press Change (+/-) to scroll

through the job numbers

until you find the desired job

number. (To identify an unused

job, scroll through the jobs until

there are no setup symbols

displayed on the screen.)

2. Press Next (►) to accept the

job number and advance to the

first setting.

NOTE: If you use an existing job number, the old settings will be overwritten by

the new settings you are adding.

Page 24

2 • Program a Job

2-6 SV63139 Rev. A

Program a Scanning Job

Enable OMR Scanning

1. When prompted, press Change (+/-) to select an OMR on settings.

(Refer to the OMR Settings table included here.)

2. Press Next (►) to accept the selection and advance to the next

setting.

OMR Scanning Settings Table

Use the OMR functions that apply to your scanning job.

OMR Settings Table

OMR Settings Description

OMR off OMR scanning is turned off for this job

OMR on OMR scanning is enabled for this job with

standard OMR mark positioning.

OMR + Sequence OMR scanning + Wrap Around Sequence

scanning is enabled for this job, with standard

OMR mark positioning.

OMR + Select feed OMR scanning + Select Feed/Autobatch

scanning for this job, with standard OMR mark

positioning.

OMR + Select feed +

Sequence

OMR scanning + Select Feed/Autobatch

+ Wrap Around Sequence scanning is

enabled for this job, with standard OMR mark

positioning.

OMR Offset on OMR scanning is turned on for this job, with

offset OMR mark positioning.

OMR Offset + Sequence OMR scanning + Wrap Around Sequence

scanning is enabled for this job, with offset

OMR mark positioning.

OMR Offset + Select feed OMR scanning + Select Feed/Autobatch

scanning is enabled for this job, with offset

OMR mark positioning.

OMR Offset + SF +

Sequence

OMR scanning + Select Feed/Autobatch +

Wrap Around Sequence scanning for this job,

with offset OMR mark positioning.

NOTE: Available options depend on the scanning functionality of your inserter.

Page 25

Program a Job • 2

2-7SV63139 Rev. A

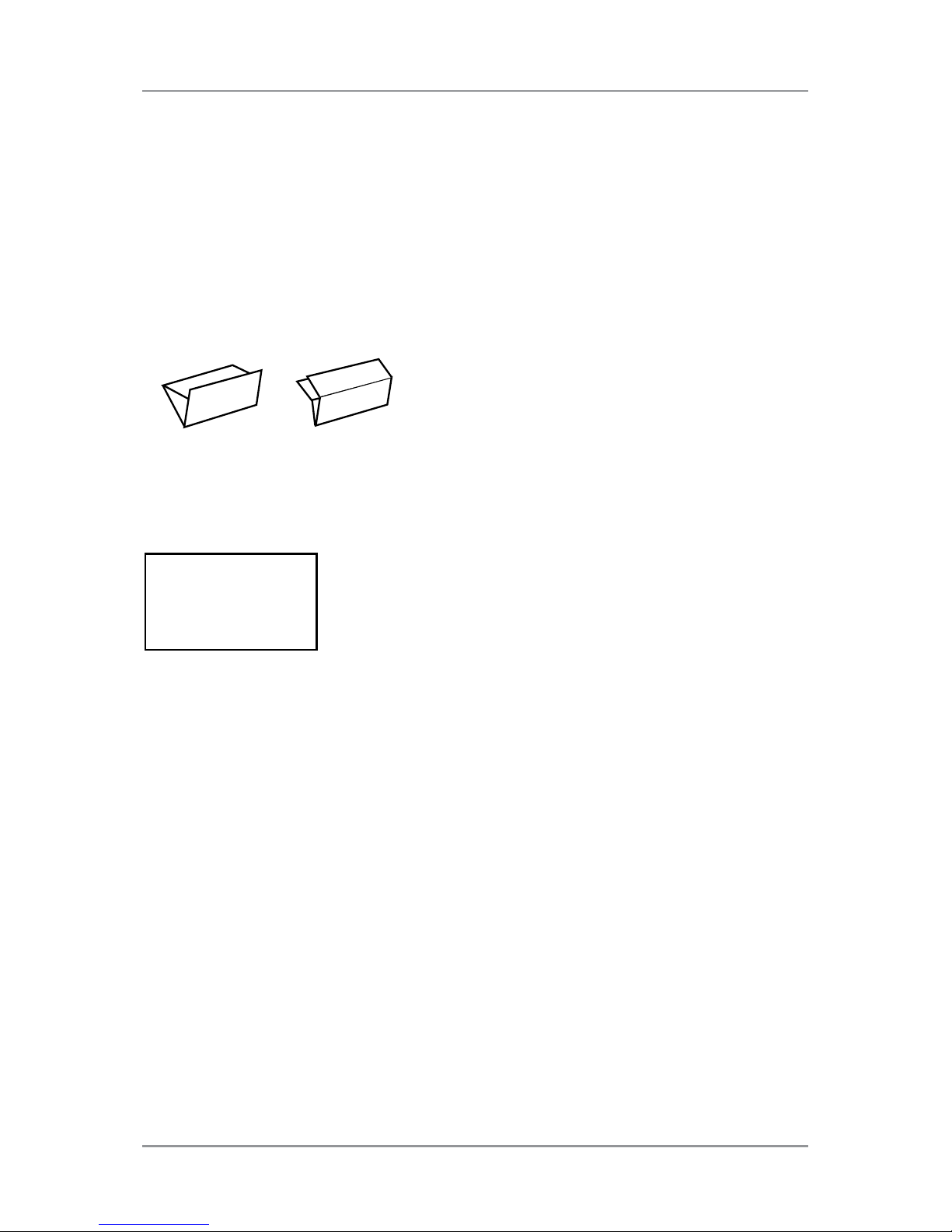

Set the Fold Type

1. Press Change (+/-) to scroll through the fold types.

2. Press Next (►) to accept the fold type selection and advance to the

next setting.

Fold Types

C - Letter Double

Only fold types C and double are available when using OMR scanning.

When the fold type is selected, the display indicates the correct orientation

of the paper for loading into the feeders:

FACE UP

HEAD FIRST

ABC

Page 26

2 • Program a Job

2-8 SV63139 Rev. A

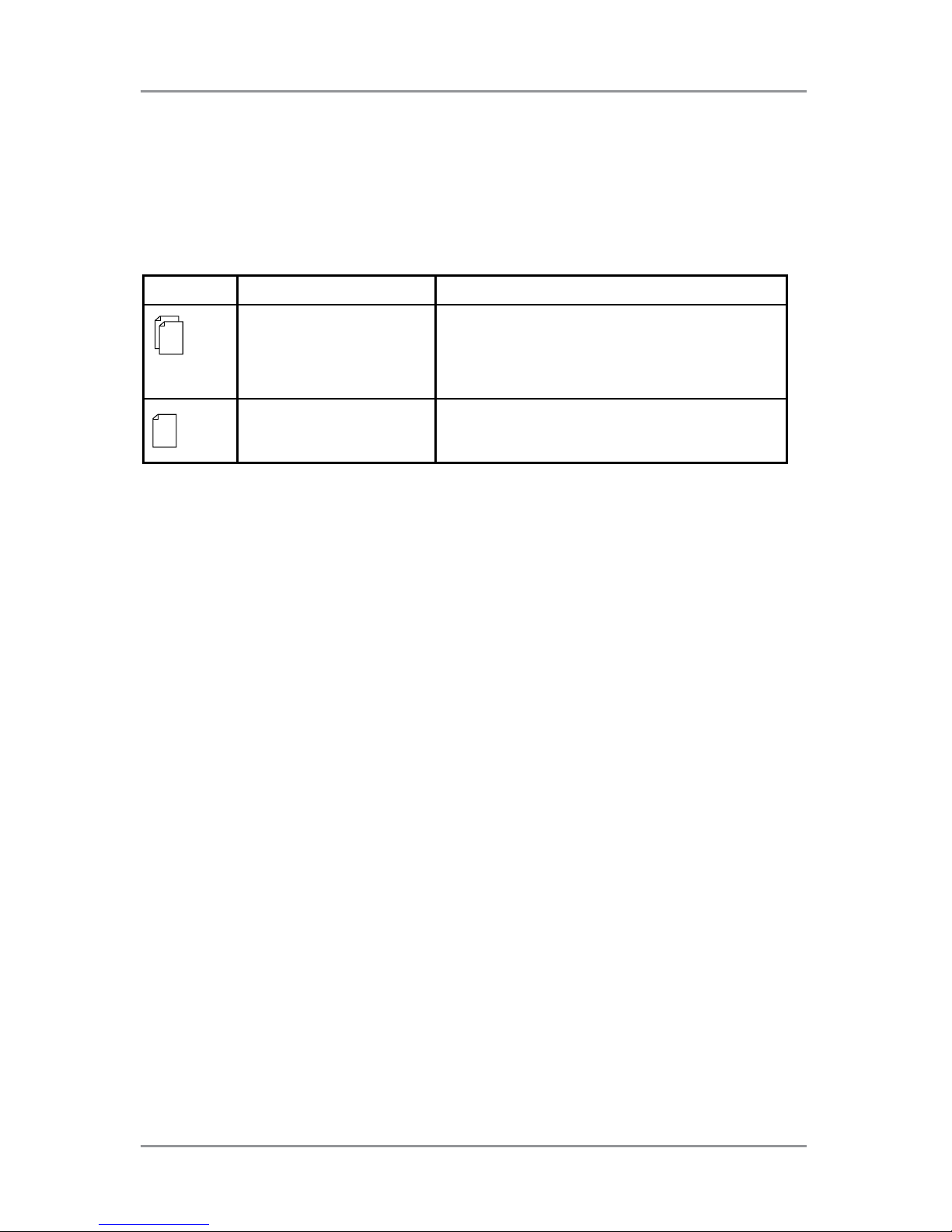

Set the Main (Scanning) Sheet Feeder

1. Press Change (+/-) to scroll through the options.

2. Press Next (►) to accept the option and advance to the next setting.

Main (Scanning) Sheet Feeder Options (Scanning Jobs)

Icon Option Description

On Double Detect Feeder on with the double detector

operating. (The double detector stops

the inserter if two or more sheets feed

simultaneously.)

On Feeder on without the double detector.

Page 27

Program a Job • 2

2-9SV63139 Rev. A

Set the Insert Feeder

Select feed allows for one piece to be selectively fed from the insert feeder

(this is controlled by the OMR marks) and inserted into the envelope.

1. Press Change (+/-) to scroll through the options. (Refer to the

Additional Feeder Options, Scanning Jobs table for details.)

2. Press Next (►) to accept the selection and advance to the next

setting.

Additional Feeder Options (Scanning Jobs)

Icon Option Description

On Double Detect -

can be selected with or

without SF (Selective

Feed)

Feeder on with the double detect

operating. (Double detect stops the

inserter if two or more sheets feed

simultaneously.)

On without Double

Detect - can be selected

with or without SF

(Selective Feed)

Select feeder on without the double

detector.

Off Feeder turned off for this job.

Page 28

2 • Program a Job

2-10 SV63139 Rev. A

Set the Sealer

This setting appears only if insertion mode is selected. To select whether

or not you want to seal envelopes.

1. Press Change (+/-) to toggle the option to On or Off.

2. Press Next (►) to accept the option and advance to the next setting.

Sealer Options

Icon Option Description

On Turns the sealer unit on for automatic sealing of

envelopes. Make sure the sealer water bottle is full of E-Z

Seal® or water.

Off Turns the sealer unit off. Envelopes will be ejected

unsealed.

Set Paper Length

1. Use the scale on the side of

the inserter cover to measure

the paper.

- US letter - 279mm (11 inches)

- A4 paper - 297mm

2. Press Change (+/-) to

scroll through paper lengths

(displayed in mm).

3. Press Next (►) to accept

the paper length value and

advance to the next setting.

Page 29

Program a Job • 2

2-11SV63139 Rev. A

Set Fold A

1. Select the size of the first fold required.

NOTE: Depending on the settings you made earlier for fold type and paper

length, the inserter suggests the correct dimension for the first fold. Most of the

time this setting will prove satisfactory.

2. To change the standard fold setting, press Change (+/-) until the

length of required fold displays. The symbol | –––– | displays next to

the fold panel you are setting.

NOTE: The inserter automatically limits your options to available specifications

on your inserter. (As you change the length of fold A, the dimension of fold

B changes automatically to keep within the correct paper length and inserter

specifications.)

3. Press Next (►) to accept the fold value and advance to the next

setting.

Set Fold B

1. Select the size of the second fold required.

NOTE: Like fold A, the inserter suggests the correct dimension for fold B.

2. To change the standard setting, press Change (+/-) until the length of

fold required displays. The symbol | –––– | displays next to the fold

panel you are setting.

3. Press Next (►) to accept the fold value and advance to the next

setting.

Set Envelope Depth

1. Use the scale on the front cover to measure the envelope depth.

2. Press Change (+/-) to scroll through the measurements (displayed

in mm).

3. Press Next (►) to accept the value and advance to the next setting.

Page 30

2 • Program a Job

2-12 SV63139 Rev. A

Set the Envelope Stop

NOTE: The stop has five positions numbered 1 to 5. Setting 3 is the standard

setting for normal weight paper with standard folds. A thinner/lighter insert requires

a lower setting and a thicker/heavier insert requires a higher setting.

1. Press Change (+/-) to scroll through the envelope stop positions.

2. Press Next (►) to accept the position and advance to the next setting.

Set the Batch Counter

The batch counter allows you to automatically process pre-defined

batches of finished mailpieces. When the batch is complete, the inserter

automatically stops.

NOTE: If the batch counter is not turned on, the display counter simply counts the

number of items processed until you press Reset Counter.

1. Press Start to begin processing the next batch.

2. Press Change (+/-) to toggle the batch mode to On or Off.

NOTE: If the batch counter is turned on, the inserter prompts for the batch

quantity. The default quantity is 50, but you may select any value up to 999 by

tapping the Change (+/-) icons.

3. Press Next (►) to accept the setting.

Confirm Job Setup

Job setup is now complete. Using the inserter model and icons, the touch

screen display shows all the selected job settings.

1. Review the job settings.

2. Press Prev (◄) to scroll back and change a setting.

3. Press Setup to accept the new settings and exit setup mode.

4. When setup changes are complete, the touch screen displays the new

job settings with the message Trial Piece Required.

5. Test the setup by running a trial piece.

NOTE: The inserter retains job settings until you change or delete them, even

when the power is disconnected. If you need to change the name of the job, refer

to “Change a Job Name” in the System Overview chapter of this guide.

Page 31

Program a Job • 2

2-13SV63139 Rev. A

Run a Trial Piece

Run a trial piece to test the job settings.

1. Load material and press Trial Piece.

2. If you need to make changes to the settings based on the trial piece:

a. Press Setup.

b. Log in with Supervisor access level.

c. Press Prev (◄), Next (►) to scroll to the setting you wish to

modify.

d. Press Change (+/-) to scroll to the desired option.

3. Press Setup to accept the setting modification and return to run mode.

The inserter saves the job with the new settings.

4. Run another trial piece to test the modified settings.

NOTE: Any time you modify settings you must run a trial piece.

Incorrect Address Position - Adjust Fold Settings

When you run a trial piece, if the address is not in the correct position refer

to the Adjust Fold Settings table to help you fine tune your folds settings.

Adjust Fold Settings Table

Fold Type Address Too Low Address Too High

C - Letter Fold Decrease Fold A Increase Fold A and

increase Fold B by the

same amount.

Double Fold Decrease Fold A Increase Fold A

It is recommended the fold is only adjusted by 0.20 inches (5mm) each time.

Page 32

2 • Program a Job

2-14 SV63139 Rev. A

Program a Non-Scanning Job

Follow this sequence of steps to program a non-scanning job.

NOTE: If scanning is not available on your system, begin with “Set Accumulation.”

Disable OMR Scanning if Functionality Exists

If scanning is enabled on your system, set it to OMR off.

1. When prompted, press Change (+/-) to select OMR off.

2. Press Next (►) to accept the selection and advance to the next

setting.

Set the Fold Type

1. Press Change (+/-) to scroll through the fold types.

2. Press Next (►) to accept the fold type and advance to the next

setting.

Fold Types

C - Letter Z - Accordion Double Single

When the fold type is selected, the display indicates the correct orientation

of the paper for loading into the feeders:

FACE UP

HEAD FIRST

ABC

FACE DOWN

FEET FIRST

ABC

NOTE: For accumulation jobs, DO NOT manually change the automatic fold length

dimensions at the Fold A and Fold B settings.

Page 33

Program a Job • 2

2-15SV63139 Rev. A

Set Accumulation

If accumulation is enabled, it allows multiple sheets to be fed from the

sheet feeder into the envelope. This setting is only available for non-

scanning jobs.

1. Press Change (+/-) to scroll through the accumulation options.

2. If you set accumulation to ON:

a. Press Next (►) to set the number of pages to feed into each

envelope. (Accumulation = 2 to 10)

b. Press Change (+/-) the to enter the number of pages.

3. Press Next (►) to accept the option and advance to the next setting.

Inserter Accumulation Settings

Setting Description

Accumulation: OFF

Accumulation is turned off for this job.

Accumulation: ON Accumulation is turned on for this job.

Accumulation = (2 to 10) If Accumulation is ON, select how many pages

you want to feed into each envelope

IMPORTANT! The number of sheets that can be accumulated is limited by

inserter specications. Exceeding this limit can cause a malfunction.

Page 34

2 • Program a Job

2-16 SV63139 Rev. A

Set Sheet Feeder

1. Press Change (+/-) to scroll through the options.

2. Press Next (►) to accept the selection and advance to the next

setting.

First/Main Sheet Feeder Options (Non-Scanning Jobs)

Icon Option Description

On Double Detect Feeder on with the double detector

operating. (The double detector stops

the inserter if two or more sheets feed

simultaneously.)

Off Feeder turned off for this job.

On Feeder on without the double detector.

Manual Feed (see the

description following

this table)

Able to manually feed collated sets. Only

available on sheet feeder 1.

Manual Feed Option

• The manual feed setting allows you to run stapled sets of up to five

sheets - a maximum of 100 lbs.(400 gsm) per set. The maximum

compressed thickness of the set after folding must not exceed 0.08

inches (2mm).

• The inserter waits for manual insertion of each set into sheet feeder 1

after which it will fold and insert the set automatically.

• The manual feed option is only available when Accumulation is set to

OFF.

Page 35

Program a Job • 2

2-17SV63139 Rev. A

Set the Insert Feeder

Select whether you want to use the insert feeder and how it will be used.

1. Press Change (+/-) to scroll through the options. (Refer to the Insert

Feeder Options table for descriptions.)

2. Press Next (►) to accept the option and advance to the next setting.

Insert Feeder Options

Icon Option Description

On Double Detect Feeder on with the double detector

operating. (The double detector stops

the inserter if two or more sheets feed

simultaneously.)

On Feeder on without the double detector.

Off Feeder turned off for this job.

Set the Mode Type - Insertion or Fold-Only

This setting only appears if Accumulation is not turned on.

The inserter needs to know if the job requires inserting material into an

envelope or if it is a fold-only job.

To set the mode type:

1. Press Change (+/-) to toggle between the options.

• Insertion Mode

Activates the envelope feeder for a normal inserting job.

• Fold-Only Mode

Turns the envelope feeder off and sets the inserter to act as a folding

module.

2. Press Next (►) to accept the mode type and advance to the next

setting.

Page 36

2 • Program a Job

2-18 SV63139 Rev. A

Set the Sealer

This setting appears only if insertion mode is selected. To select whether

or not you want to seal envelopes:

1. Press Change (+/-) to toggle the option to On or Off.

2. Press Next (►) to accept the option and advance to the next setting.

Sealer Options

Icon Option Description

On Turns the sealer unit on for automatic sealing of

envelopes. Make sure the sealer water bottle is full of E-Z

Seal® or water.

Off Turns the sealer unit off. Envelopes will be ejected

unsealed.

Set Paper Length

1. Use the scale on the side of

the inserter cover to measure

the paper.

- US letter - 279mm (11 inches)

- A4 paper - 297mm

2. Press Change (+/-) to

scroll through paper lengths

(displayed in mm).

3. Press Next (►) to accept

the paper length value and

advance to the next setting.

Page 37

Program a Job • 2

2-19SV63139 Rev. A

Set Fold A

1. Select the size of the first fold required.

NOTE: Depending on the settings you made earlier for fold type and paper

length, the inserter suggests the correct dimension for the first fold. Most of the

time this setting will prove satisfactory.

2. To change the standard fold setting, press Change (+/-) until the

length of required fold displays. The symbol | –––– | displays next to

the fold panel you are setting.

NOTE: The inserter automatically limits your options to available specifications

on your inserter. (As you change the length of fold A, the dimension of fold

B changes automatically to keep within the correct paper length and inserter

specifications.)

3. Press Next (►) to accept the fold value and advance to the next

setting.

Set Fold B

1. Select the size of the second fold required.

NOTE: Like fold A, the inserter suggests the correct dimension for fold B.

2. To change the standard setting, press Change (+/-) until the length of

fold required displays. The symbol | –––– | displays next to the fold

panel you are setting.

3. Press Next (►) to accept the fold value and advance to the next

setting.

• Inserting jobs - continue to the Set the Envelope Depth setting.

• Fold-only job - there are no more job settings, skip to Confirming

the Job Setup.

Set Envelope Depth

1. Use the scale on the front cover to measure the envelope depth.

2. Press Change (+/-) to scroll through the measurements (displayed

in mm).

3. Press Next (►) to accept the value and advance to the next setting.

Page 38

2 • Program a Job

2-20 SV63139 Rev. A

Set the Envelope Stop

NOTE: The stop has five positions numbered 1 to 5. Setting 3 is the standard

setting for normal weight paper with standard folds. A thinner/lighter insert requires

a lower setting and a thicker/heavier insert requires a higher setting.

1. Press Change (+/-) to scroll through the envelope stop positions.

2. Press Next (►) to accept the position and advance to the next setting.

Set the Batch Counter

The batch counter allows you to automatically process pre-defined

batches of finished mailpieces. When the batch is complete, the inserter

automatically stops.

NOTE: If the batch counter is not turned on, the display counter simply counts the

number of items processed until you press Reset Counter.

1. Press Start to begin processing the next batch.

2. Press Change (+/-) to toggle the batch mode to On or Off.

NOTE: If the batch counter is turned on, the inserter prompts for the batch

quantity. The default quantity is 50, but you may select any value up to 999 by

pressing Change (+/-).

3. Press Next (►) to accept the setting.

Confirm Job Setup

Job setup is now complete. Using the inserter model and icons, the touch

screen display shows all the selected job settings.

1. Review the job settings.

2. Press Prev (◄) to scroll back and change a setting.

3. Press Setup to accept the new settings and exit setup mode.

4. When setup changes are complete, the touch screen displays the new

job settings with the message Trial Piece Required.

5. Test the setup by running a trial piece.

NOTE: The inserter retains job settings until you change or delete them, even

when the power is disconnected. If you need to change the name of the job, refer

to “Change a Job Name” in the System Overview chapter of this guide.

Page 39

Program a Job • 2

2-21SV63139 Rev. A

Run a Trial Piece

Run a trial piece to test the job settings.

1. Load material and press Trial Piece.

2. If you need to make changes to the settings based on the trial piece:

a. Press Setup.

b. Log in with Supervisor access level.

c. Press Prev (◄), Next (►) to scroll to the setting you wish to

modify.

d. Press Change (+/-) to scroll to the desired option.

3. Press Setup to accept the setting modification and return to run mode.

The inserter saves the job with the new settings.

4. Run another trial piece to test the modified settings.

NOTE: Any time you modify settings you must run a trial piece.

Incorrect Address Position - Adjust Fold Settings

When you run a trial piece, if the address is not in the correct position refer

to the Adjust Fold Settings table to help you fine tune your folds settings.

Adjust Fold Settings Table

Fold Type Address Too Low Address Too High

C - Letter Fold Decrease Fold A Increase Fold A and

increase Fold B by the

same amount.

Single Fold Increase Fold A Decrease Fold A

It is recommended the fold is only adjusted by 0.20 inches (5mm) each time.

Page 40

2 • Program a Job

2-22 SV63139 Rev. A

Modify an Existing Job

To modify an existing job follow these steps. (This requires Supervisor

level access.)

1. Press Setup to enter setup mode.

2. Press Change (+/-) to increase or decrease to access code 71.

3. Press Next (►) to accept the code and advance to the job selection.

4. Use Change (+/-) to display the job you wish to modify.

5. Press Next (►) to accept the job selection and advance to the job

programming settings.

6. Use Prev (◄) and Next (►) to scroll through the settings.

7. When you find the desired setting, use Change (+/-) to scroll through

the options and/or values you want.

8. Press Next (►) to accept the job setting.

9. Press Setup to exit the setup mode and save the changes.

Delete a Job

To delete an existing job from the inserter system follow these steps. (This

requires Supervisor level access.)

1. Press Setup to enter setup mode.

2. Press Change (+/-) to increase or decrease to access code 71.

3. Press Next (►) to accept the code and advance to the job selection.

4. Press Change (+/-) to display the job you wish to delete.

5. Press Delete. The display reads “Press again to confirm.”

6. Press Delete again. The display briefly reads “Deleting Job” as the job

is erased.

7. Press Setup to exit the setup mode.

Page 41

SV63139 Rev. A

3 • Run a Job

Contents

Run a Job ............................................................3-3

Verify the Inserter Has Power .............................. 3-4

Select a Job .................................................. 3-4

Manual Feed Jobs ...............................................3-5

Load Material ....................................................... 3-6

Adjust and Load the Sheet Feeders ............. 3-6

Adjust and Load the Envelope Feeder .......... 3-7

Adjust and Load the Insert Feeder ................ 3-8

Run a Trial Piece ...............................................3-10

Issues During Operation ............................. 3-10

Start and Stop the Inserter ................................ 3-11

Fill the Sealer..................................................... 3-11

Adjust the Stacker .............................................3-12

Page 42

This page is intentionally blank.

Page 43

3 ● Run a Job

3-3SV63139 Rev. A

Run a Job

The operating activities outlined here assume that a job has already been

programmed into the Relay 2000 inserter. (Programming a job is typically

a Supervisor function.)

Activities Operators perform with the touch screen to run a previously

programmed job:

• Verify the inserter has power

• Select a job

• Load material

• Adjust and load the sheet feeder

• Adjust and load the envelope feeder

• Adjust and load the insert feeder

• Run a trial piece

• Run the job

• Fill the sealer (if needed)

• Adjust the stacker (if needed)

Read the safety information in this guide before

connecting the inserter.

Page 44

3 ● Run a Job

3-4 SV63139 Rev. A

Verify the Inserter Has Power

1. Verify the power cord is

connected to the socket on the

back of the inserter.

2. Verify the power cord is

plugged into a power outlet

near the machine and is easily

accessible.

3. Turn the power switch ON.

Select a Job

When the machine is turned ON,

the control panel display shows the

last job run and the message Trial

Piece Required.

To select the job you wish to run:

1. Press the Job button until the

job you want displays, OR

press Default if you want to run

the inserter with your standard,

default job settings

NOTE: Only a PB Service

Representative can modify default

job settings.

2. Load material - refer to the

Loading Material section.

3. If material is already loaded,

press Trial Piece. The inserter

sets itself and runs a test piece

to check.

Page 45

3 ● Run a Job

3-5SV63139 Rev. A

Manual Feed Jobs

If you select a manual feed job

where sheet feeder 1 is set for

manual feed of collated sets,

DO NOT load the sheet feeder.

Instead, you will feed collated sets

one at a time, by hand, as required.

Before you run a manual feed job,

pull back the lever (shown here).

This opens the feed mechanism for

manual feed operation.

NOTE: Return this lever to its normal

position when you use the feeder for

automatic operation.

Page 46

3 ● Run a Job

3-6 SV63139 Rev. A

Load Material

Adjust and Load the Sheet Feeders

1. Adjust the side guides to the

width of the material, then

back-off a quarter turn on the

side guide control. This sets

the correct clearance between

the guides and the material.

2. Aerate (fan) the stack of paper

to ensure that individual sheets

are not stuck together.

3. Jog stack back into alignment.

The display indicates the correct

orientation of the paper.

FACE UP

HEAD FIRST

ABC

FACE DOWN

FEET FIRST

ABC

4. Place the paper stack onto the

feed deck. Allow the deck to

move down and the top of the

paper stack to slide under the

feed roller.

Page 47

3 ● Run a Job

3-7SV63139 Rev. A

Adjust and Load the Envelope Feeder

The envelope feeder feeds the outer envelope for the inserting job.

1. Use the side guide adjustment

knob to adjust the side guides

to the width of the envelopes.

Once adjusted, back-off the

adjustment knob 1/4 turn.

This sets the correct clearance

between the guides and envelopes.

2. Take the stack of envelopes;

aerate and fan it to ensure that

individual envelopes are not

stuck together.

3. Place the envelopes on the

feed deck with the flaps up and

trailing.

IMPORTANT! Check that lead

edge of the first envelope is under

the front feed roller and that the

stack of envelopes is shingled on

the deck as shown.

4. Let the wedge slide down

behind the stack so that the

envelopes are supported.

Page 48

3 ● Run a Job

3-8 SV63139 Rev. A

Adjust and Load the Insert Feeder

The insert feeder feeds items that do not require folding. Depending on

configuration of your inserter, you may not have an insert feeder.

1. Use the side guide adjustment

knob to adjust the side guides

to the width of the inserts you

are running. Once adjusted,

back-off the adjustment knob

1/4 turn.

This sets the correct clearance

between the guides and inserts

.

2. Refer to the label located on

the insert feeder and match

your insert type with the icon

(letters A to D).

Identifying Your Insert

If the label indicates a range of

settings, we recommend you

select a higher number or letter for

a thicker the insert

.

3. Set the blue lever to the

number required.

4. Set the separator shield to the

letter required.

Page 49

3 ● Run a Job

3-9SV63139 Rev. A

5. Aerate and fan the stack of

inserts to ensure the individual

pieces are not stuck together.

Loading orientation can vary

depending on the inserts being

run. As a general rule, load inserts

using the orientation guidelines in

the table below.

6. Let the wedge (material prop)

slide down behind the stack to

support the inserts.

Orientation Table for Loading Inserts

Insert Type Orientation

Slip Face up, bottom edge first

Reply Envelope Face up, top edge first

Pre-Folded Face up, closed edge first

Booklet Face up, bound edge first

Page 50

3 ● Run a Job

3-10 SV63139 Rev. A

Run a Trial Piece

Run a trial piece to test the job settings.

1. Load material and press the Trial Piece button on the control panel to

run a trial piece and verify the job setup is correct.

2. You can still make changes to the job settings at this point if the trial

piece needs fine tuning. (This requires Supervisor level access.)

a. Press the Setup button.

b. Log in at a Supervisor access level.

c. Use the Prev (◄), Next (►) and Change (+/-) buttons to scroll

through the settings and modify the one(s) you wish to change.

3. When you have made the necessary changes, press Setup again to

return to run mode.

4. Run another trial piece to test the modified settings.

Material Changes or Double Detect Issues During Operation

If you load material during a job run with different characteristics (weight,

color shade, etc.), OR if you have problems with the double detect, run

another trial piece.

This causes the inserter to recalibrate the double detect function for the

new material.

Page 51

3 ● Run a Job

3-11SV63139 Rev. A

Start and Stop the Inserter

1. Press Start on the control to begin automatic operation.

2. The inserter runs until it runs out of material or you press the Stop.

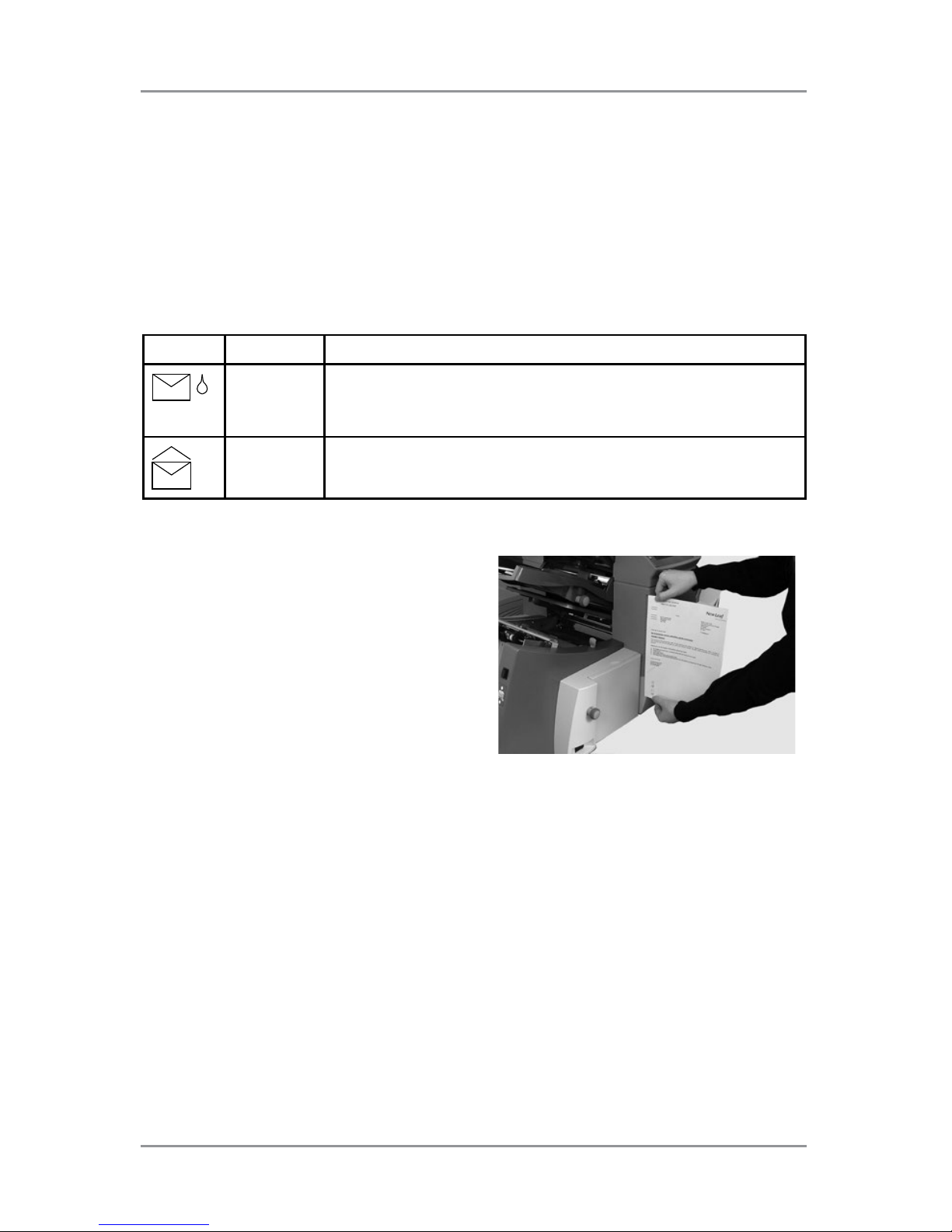

Fill the Sealer

When the sealer unit needs

refilling, the Add Sealing Solution

icon flashes in the display.

When this happens, add E-Z Seal®

Sealing Solution or water:

1. Open the sealer bottle cover

hinge located at the rear, right

side of the inserter and remove

the bottle.

2. Fill the bottle with solution or

water to the level indicated.

3. Place the sealer bottle in

position in the inserter and

close the cover.

NOTE: If the sealer unit was

completely empty, allow time

for the fresh solution or water to

soak through the sealer before

you resume operation. This helps

assure a good seal.

NOTE: We recommend Pitney

Bowes E-Z Seal to minimize algae

growth and scale build-up.

Page 52

3 ● Run a Job

3-12 SV63139 Rev. A

Adjust the Stacker

If necessary, adjust the drop stacker to accommodate the job material.

1. Lift the lever at the rear of the

stacker and adjust the stacker

to one of the preset positions.

2. Lower the lever to lock the

stacker into position.

NOTE: When not in use, you

can raise the stacker and latch it

vertically against the exit area of

the inserter.

Page 53

SV63139 Rev A

4 • OMR Scanning

Contents

Optical Mark Recognition (OMR)...........................4-3

Accuracy .........................................................4-3

OMR and Feeders on the Inserter .........................4-3

OMR Scanning Types ............................................4-4

Basic OMR ......................................................4-4

Enhanced OMR ..............................................4-4

OMR Mark Positions..............................................4-4

OMR Specifications ...............................................4-5

Standard OMR Positions ................................4-6

Offset OMR Positions......................................4-7

Available OMR Marks ...........................................4-8

Benchmark ......................................................4-8

Safety ..............................................................4-8

End-of-Collation (EOC) ...................................4-8

Beginning-of-Collation (BOC) .........................4-8

Parity ...............................................................4-8

Re-timing Mark ................................................4-8

Select Feed (SF1, SF2) ..................................4-9

Auto Batch ......................................................4-9

Wrap Around Sequence ..................................4-9

OMR Mark Grouping ...........................................4-10

C-Fold and Double-Fold Jobs .......................4-10

Adjust the OMR Scanner ..................................... 4-11

OMR Troubleshooting..........................................4-12

Error Recovery for OMR Jobs .......................4-12

Error Recovery for Accumulation Jobs ..........4-12

Error Recovery for Empty Feeders ...............4-12

OMR Error Messages ..........................................4-13

Page 54

This page is intentionally blank.

Page 55

OMR Scanning • 4

4-3SV63139 Rev.A

Optical Mark Recognition (OMR)

An OMR mark is normally a dark solid line on a

sheet of light colored paper that is perpendicular

to the direction of paper travel. This line must be

thick and dense to trigger the OMR scanner.

The OMR scanner works with the OMR system

software to check for one or more different OMR

marks on a document as it is fed through the

system. Tracking of these marks enhances mail

piece integrity by assuring the documents that

belong together (a set) stay together throughout

the inserting process.

NOTE: Depending on the model, your inserter

may be equipped with OMR scanning.

NOTE: For instructions on programing an OMR job, refer to the

Programing a Job section of this manual.

Accuracy

OMR on this system uses extensive error checking. This means insertion

accuracy is very high: the probability of the wrong set of sheets being

inserted into an envelope is low.

OMR and Feeders on the Inserter

OMR-equipped models have scanning heads on each sheet feeder.

The sheet feeder holds sheets with OMR marks and they feed multiple

sheets per envelope and can handle C-folds and double folds.

You can set up only the insert feeder to be under the selective control

of the OMR sheets. As a result, you can use OMR to fill an envelope

with a variable number of sheets from one feeder, with or without a

supplementary sheet and an insert.

A folded insert is nested with the first sheet in the envelope. Because OMR

applications allows each envelope to contain tailored contents, the last

sheet in the envelope includes address information for use with windowed

envelopes. This ensures that each set of sheets is addressed to the

correct recipient.

Typical

OMR marks

Page 56

4 • OMR Scanning

4-4 SV63139 Rev. A

OMR Scanning Types

Basic OMR

• Enables the collation of multi-page documents.

• Enables you to vary the number of pages per envelope.

• The inserter folds each OMR sheet separately and inserts it into an

envelope, starting with the last sheet of the set and adding each folded

sheet in turn until the address sheet has been inserted.

Enhanced OMR

• Allows you to stop feeding sheets at selected points in a run and/or

select whether the other feeders are used.

• It provides a higher level of mailpiece integrity so that sensitive

documents are not sent to the wrong customer.

OMR Mark Positions

For the inserter scanners to read the printed OMR marks correctly, they

must be located within a defined range of positions on the page.

• Standard OMR positions OR

• Offset OMR positions allow the marks to be positioned further down

the page.

Page 57

OMR Scanning • 4

4-5SV63139 Rev.A

OMR Specifications

The OMR mark must be a solid black line between 1pt and 2pts thick

(0.014 inch (0.35mm) to 0.027 inch (0.7mm]) and at least 0.393 inch

(10mm) wide.

Each mark position must be evenly spaced, at least 0.118 inch (3mm)

apart.

The area around the marks (the clear zone) should be kept clear from print

and any other marks that the scanner might read in error.

There should be no print on the opposing face of the sheet immediately

behind the clear zone.

(Note: diagram is not to scale)

42mm maximum

3mm minimum pitch

10mm

minimum

1pt to 2pt

0.35mm to

0.7mm thick

2mm

minimum

2mm minimum

(see following diagrams for

more detail of this area)

Clear Zone

(see following diagrams for

more detail of this area)

Page 58

4 • OMR Scanning

4-6 SV63139 Rev. A

(diagram is not to scale)

Position OMR marks as follows:

• C-Fold and Double Fold: top scanning, top left corner.

Standard OMR Positions

54mm

min

96mm

max

20mm

min

Clear Zone

20mm x 115mm min

*

Feed

Direction

for Top

Scanning

(C- and

Double Fold)

115mm

min

Vertically center group

within area indicated

*

Page 59

OMR Scanning • 4

4-7SV63139 Rev.A

Position OMR marks as follows:

• C-Fold and Double Fold: top scanning, left margin.

Offset OMR Positions

125mm

min

20mm

min

Feed

Direction for

Top Scanning

(C- and

Double Fold)

95mm

max

Bench Mark

65mm

min

(diagram is not to scale)

Page 60

4 • OMR Scanning

4-8 SV63139 Rev. A

Available OMR Marks

This section gives brief descriptions of the OMR marks that can or must

be allocated to an OMR Code.

NOTE: Some marks within this section are available as added features

that expand OMR capability. OMR features will vary depending on the

options you purchased.

Benchmark

This is a mandatory mark. It must be the first mark of the code and will

appear on every page within the set.

Safety

This is a mandatory mark that improves the integrity of your mail piece. It

is automatically placed immediately after the benchmark.

End-of-Collation (EOC)

This mark indicates that this sheet is the last sheet fed within the collation/

set (the address sheet).

Your system operates on the absence of this mark, that is, the action will

take place if the mark is not read by the scanner. It is therefore indicated

on the OMR code as Not EOC.

Beginning-of-Collation (BOC)

This mark indicates this sheet is the first sheet fed within the collation/set.

Your system operates on the absence of this mark, that is, the action will

take place if the mark is not read by the scanner. It is therefore indicated

on the OMR code as Not BOC.

Parity

This mark is a security feature that makes the number of marks total an

even number when printed. If any one of the marks in the code is missed

during scanning, the inserter stops so the operator can correct the error.

Re-timing Mark

This mark is mandatory in each group of OMR marks making up the code

(see later in this section for an explanation of OMR mark grouping).

It allows the inserter to recalibrate for accurate scanning. Re-timing marks

count in the parity calculation.

Page 61

OMR Scanning • 4

4-9SV63139 Rev.A

Select Feed (SF1, SF2)

These marks are used to control the feed of material from the feeder

holding the supplementary inserts on a set-by-set basis.

Use Select Feed 2 marks in the primary sheet feeder to select material

from the insert feeder. For C- and double fold, the primary feeder is sheet

feeder 1.

Auto Batch

This mark identifies the last set of a batch, when the batch function is

in use. It must appear on all sheets of the OMR set that requests this

function.

Wrap Around Sequence (WAS1, WAS2, WAS3)

This is a numbering system which uses a sequential binary coding. If a

page is missing or the set goes out of sequential order, the system stops

processing and declares an error.

Three wrap around sequence marks are used within the code. The use of

three binary digits allows a decimal count of 0 to 7. Pages are numbered

from 0 up to 7, and then back to 0 on a continuous cycle throughout the

print run.

Page 62

4 • OMR Scanning

4-10 SV63139 Rev. A

OMR Mark Grouping

Each OMR code begins with two fixed marks: benchmark and safety

mark. These marks are located at the end nearest to the sensor. These

are followed by one, two, or three groups of marks where each group

comprises three data marks followed by a fixed mark. Each data mark is

present or absent as required to reflect the desired function. Each code

must end with a re-timing mark.

The Basic OMR mode uses only Group 1. The Enhanced OMR mode

uses Group 1 plus Group 2 and/or Group 3, as needed for a particular job.

C-Fold and Double-Fold Jobs

Place marks in the upper left corner of the sheet. Print marks in top-tobottom order.

Printing

Print sheets in reverse collation order. When you do this, the last sheet

processed in each set is the address sheet and the first sheet processed

is the last of each set.

Benchmark (fixed)

Safety (fixed)

Not EOC

Not BOC

Parity

Re-timing (fixed)

Select Feed 1

Select Feed 2

Auto Batch

Re-timing (fixed if this group is in use)

Wrap Around Sequence 3 (WAS3)

Wrap Around Sequence 2 (WAS2)

Wrap Around Sequence 1 (WAS1)

Re-timing (fixed if this group is in use)

Group 1

(Mandatory)

Group 2

Group 3

Feed Direction

Page 63

OMR Scanning • 4

4-11SV63139 Rev.A

Adjust the OMR Scanner

In order for OMR scanning to work correctly, it is important to ensure that

the scanning heads are positioned in line with the Scan Dash (OMR)

marks printed on the material.

1. To locate the scanning head for sheet feeder 1, open the top cover.

The scanning head is at the rear of the inserter.

2. Fold a sheet of material in half and measure the distance from the side

of the sheet to the middle.

• A4 size sheet = this measurement is 105mm

• Letter size sheet = 8.5 x 11 inches (108mm)

3. Next, measure the distance from the edge of the sheet to the middle of

the scan dash marks (as shown in the following example), and subtract

this measurement from the half-fold measurement.

Folding Example:

105mm

10mm

10mm

For an A4 size sheet, the half

fold measurement is 105mm.

If the distance from the edge

of the form to the middle of the

scan dash marks is 10mm, the

scanning head setting will be

95mm (105mm – 10mm).

4 Loosen the locking knob and

set the relevant scanning

head to the correct setting.

5. Retighten the locking knob.

Locking Knob

Page 64

4 • OMR Scanning

4-12 SV63139 Rev. A

OMR Troubleshooting

Error Recovery for OMR Jobs

If the inserter stops during an OMR job, and indicates one of the error

messages listed below, follow these steps.

1. Press the Clear Deck key on the control panel. Any envelope at the

insertion area will eject into the stacker.

2. The remaining pages of the current set will feed/fold and eject into

the stacker. Manually insert into the envelope if necessary.

3. The FIRST page of the NEXT set will pre-feed into the feed rollers

and stop. Pull the sheet back to the normal feed position .

4. Resume operation.

Error Recovery for Accumulation Jobs

If the inserter stops during an accumulation job, follow these steps.

1. Press the Clear Deck key on the control panel

2. The envelope at the insertion area ejects into the stacker. You must

manually remove the remaining pages of the set from the feeder.

3. Fold/insert the remaining pages into the envelope.

4. Resume operation once you’ve determined the cause of the

stoppage.

Error Recovery for Empty Feeders

If any feeder runs out of material the inserter will stop, and the following

instructions scroll across the display.

1. Re-fill the empty tray.

2. Press START to continue OR press STOP and Clear Deck.

3. Reload the feeders and proceed as required.

Page 65

OMR Scanning • 4

4-13SV63139 Rev.A

Message Action

Bad OMR marks

Spacing

Two marks that are closer together than half the

expected distance are read. Check scan marks on

material.

No OMR marks • No marks on paper.

• Scan sensor is not centered over scan marks.

• Paper not loaded correctly.

Bad OMR Code

length

Code type on paper does not match the setup.

(Example: setup has OMR+ Sequence but paper

has OMR + Select Feed + Sequence.)

Bad OMR Code

format

A re-timing scan mark is missing. Check material.

(Example: mark 6 missing from a 10 mark code.)

Expected 1st

Sheet of set

The BOC mark (position 4) was present when it was

not expected. First page of the set was expected.

Not a new

Envelope

The BOC mark (position 4) was absent when it was

expected. Pages other than the first page of the set

were expected.

OMR: Parity Error The code doesn't have an even number of marks.

OMR: Sequence

Error

The sequence number is not sequential with the

previous page fed. Therefore, sheets are in the

wrong order or missing.

OMR: SF marks

Inconsistent

The Selective feed and Autobatch marks at

positions 7 to 9 are different from those on the

previous sheet of this set.

OMR: SF not in

Use

A selective feed mark is present at positions 7 to 8,

but the job setup does not include select feed.

OMR: Set too

Large

The set contains too many sheets from the main

feeder.

OMR: End of

Batch

Ready to Run

• Inserter has stopped for “End of Batch."

• Allows the operator to manually sort envelopes.

Mode Change

Recheck Feeders

Check sheet and insert feeder settings against the

job you are loading before exiting the setup mode.

OMR Error Messages

Page 66

This page is intentionally blank.

Page 67

SV63139 Rev. A

5 • Clear Material

Contents

Clear Material ........................................................5-3

Access Areas of the Inserter

for Jam Removal ..............................................5-3

Sheet Feeders Trays -

Remove and Replace ................................5-3

Fold Plates - Remove and Replace ................5-4

Insert Tray - Remove and Replace .................5-4

Access the Carriage Assembly .......................5-4

Access to Envelope Feeder Area ....................5-5

Access the Envelope Exit Area .......................5-5

Access the Envelope Inserting/Sealing Area ..5-6

Access to the Sheet Feed Area ......................5-6

Page 68

This page is intentionally blank.

Page 69

Clear Material • 5

5-3SV63139 Rev. A

Clear Material

The inserter is designed to assure maximum performance. In the event

of a material stoppage, the display flashes a symbol indicating where the

stoppage has occurred.

To clear a jam follow these steps.

1. Press Clear Deck to attempt to feed the material through the inserter.

2. If this doesn’t work, manually remove the remove the trays and fold

plates related to the jam to gain access to the jammed material.

Manual Advance Knob

Once you locate the jammed

material, you may need to use

the manual advance knob to

manually feed paper out of the

grip of feed rollers.

The manual advance knob is

located behind the drop-down

cover at the left front of the

inserter.

Access Areas of the Inserter for Jam Removal

Sheet Feeders Tray - Remove and Replace

To remove the sheet feeder tray:

1. Lift the rear of the tray slightly

and pull it straight out from

the inserter.

NOTE: If the tray is loaded,

gently hold the material in place

to prevent it sliding forward as

the tray is removed.

To replace the sheet feeder tray:

1. Place the tray into its location guides in the side frames.

2. Lift the rear of the tray slightly and push it into the inserter. The tray

automatically drops into its correct position.

Page 70

5 • Clear Material

5-4 SV63139 Rev. A

Fold Plates - Remove and Replace

To remove the fold plates:

1. Pull the two catches on

the underside of the plate

outward to release them.

2. Pull the plate straight out of

the inserter.

To replace the fold plates:

1. Pull the two catches (on the underside of the plate) outward to

release.

2. Slide the plate into its location guides and release the catches to

lock the plate in position.

Insert Tray - Remove and Replace

To remove the insert tray, pull the

insert tray straight out from the

inserter.

To replace the insert tray, slide

the tray into the location guides;

push until it clicks into place.

Access the Carriage Assembly

Pull out the carriage assembly to

access the jam.

1. Remove the insert feeder.

2. Remove fold plate 2.

3. Pull out the carriage

assembly.

Page 71

Clear Material • 5

5-5SV63139 Rev. A

Access to Envelope Feeder Area

Unlatch the envelope area feed

rollers to access a jam in the

envelope feeder area.

1. Pull the release lever in the

direction of the arrow.

2. Lift the envelope area feed

rollers for access to the jam.

To relatch the feed rollers:

1. Release the envelope area feed rollers and let them rest in position

2. Push the rollers firmly down until they latch into position.

Access the Envelope Exit Area

1. Pull down the access door

(shown here) to gain access

to the jammed material.

2. When you close the access

door, make sure to latch it

firmly in position.

Page 72

5 • Clear Material

5-6 SV63139 Rev. A

Access the Envelope Inserting/Sealing Area

You can access the insertion and sealing area by lifting the tinted

plastic cover and lowering the envelope inverter access door.

Access to the Sheet Feed Area

Unlatch the blue handles to

access a jam in the sheet feeder

area.

1. Open the top cover.

2. Squeeze the two blue

handles together and pivot

the guide assembly to the

right to gain access to the

jammed material.

To relatch the blue handles:

1. Squeeze the two blue handles together and pivot the guide

assembly back to its closed position.

2. Release the two blue handles, making sure the assembly is

securely latched into position.

3. Close the top cover.

Page 73

SV63139 Rev. A

6-1

6-1

6 • Troubleshooting

and Error Messages

Contents

General Troubleshooting .......................................6-3

Error Messages .....................................................6-7

Page 74

This page is intentionally blank.

Page 75

Troubleshooting and Error Messages • 6

6-3SV63139 Rev. A

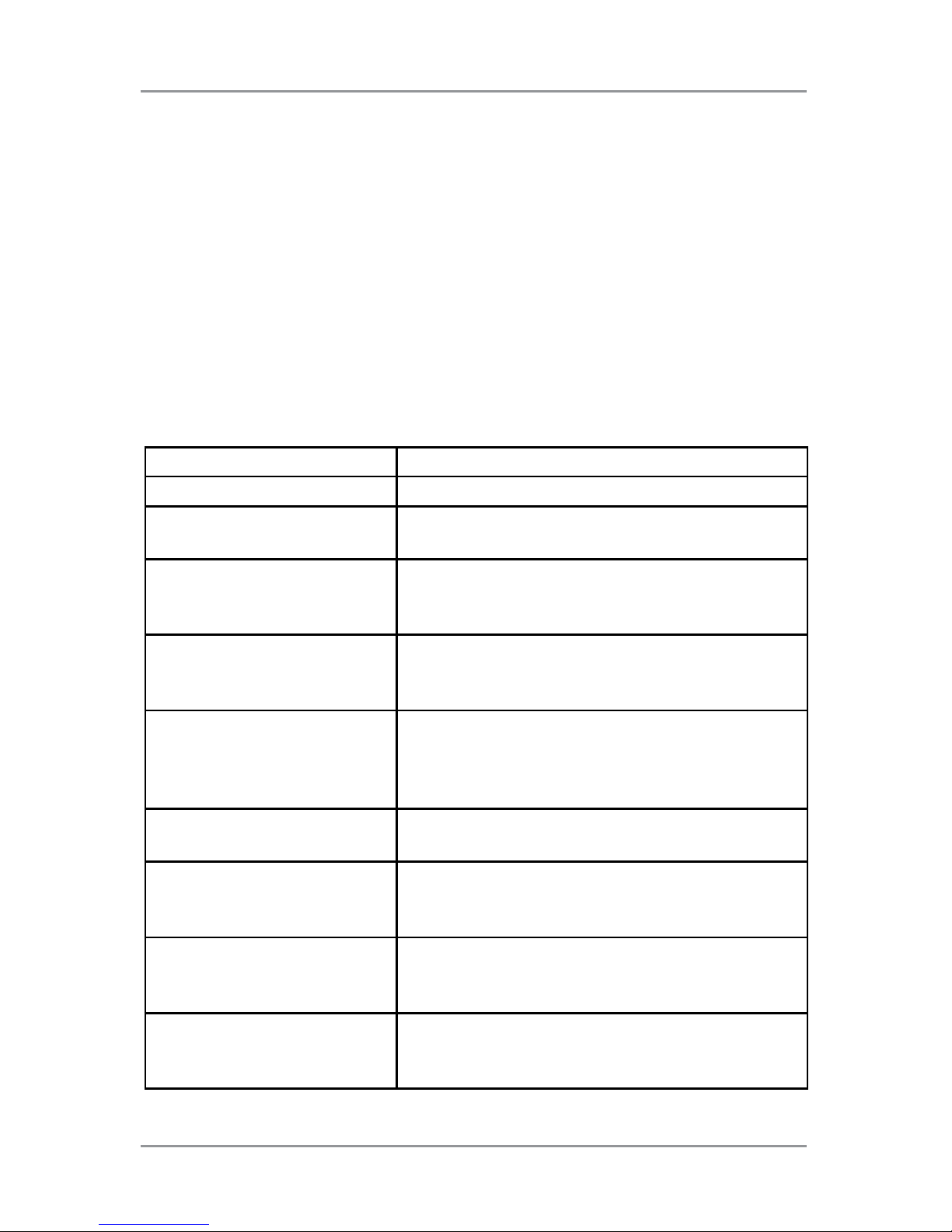

Issue Possible Solutions

INSERTER

Blank Screen

No power. Check that the power cord is firmly connected and

the wall socket is switched ON.

Inserter not

switched ON.

Turn the power switch (located on left side) ON.

Inserter will not Operate

Cover open. Check that all covers are closed - check display for

cover information.

Feed trays/fold

plates not located

correctly.

Remove and relocate all feeders and fold plates.

Verify they are in the correct positions and fully

seated.

Insertion Problems

Outer envelope

contents do not

enter the envelope

correctly.

Check the envelope troubleshooting information.

Check that the fold selected is correct for the

material size.

If running heavy or light material, the envelope stop

adjustment might need changing.

General Troubleshooting

Page 76

6 • Troubleshooting and Error Messages

6-4 SV63139 Rev. A

Issue Possible Solutions

ENVELOPES

Poor Envelope Feed