Page 1

Read this

first…

Quick Install

Guide

Inserting System

Welcome

IMPORTANT - READ THIS FIRST

before plugging in your system

Follow the steps in

this booklet to install

your DI200

OfficeRight™.

IMPORTANT: If you

purchased the

optional second

sheet feeder, unpack

and position it on

the desktop

BEFORE you follow

these instructions.

Page 2

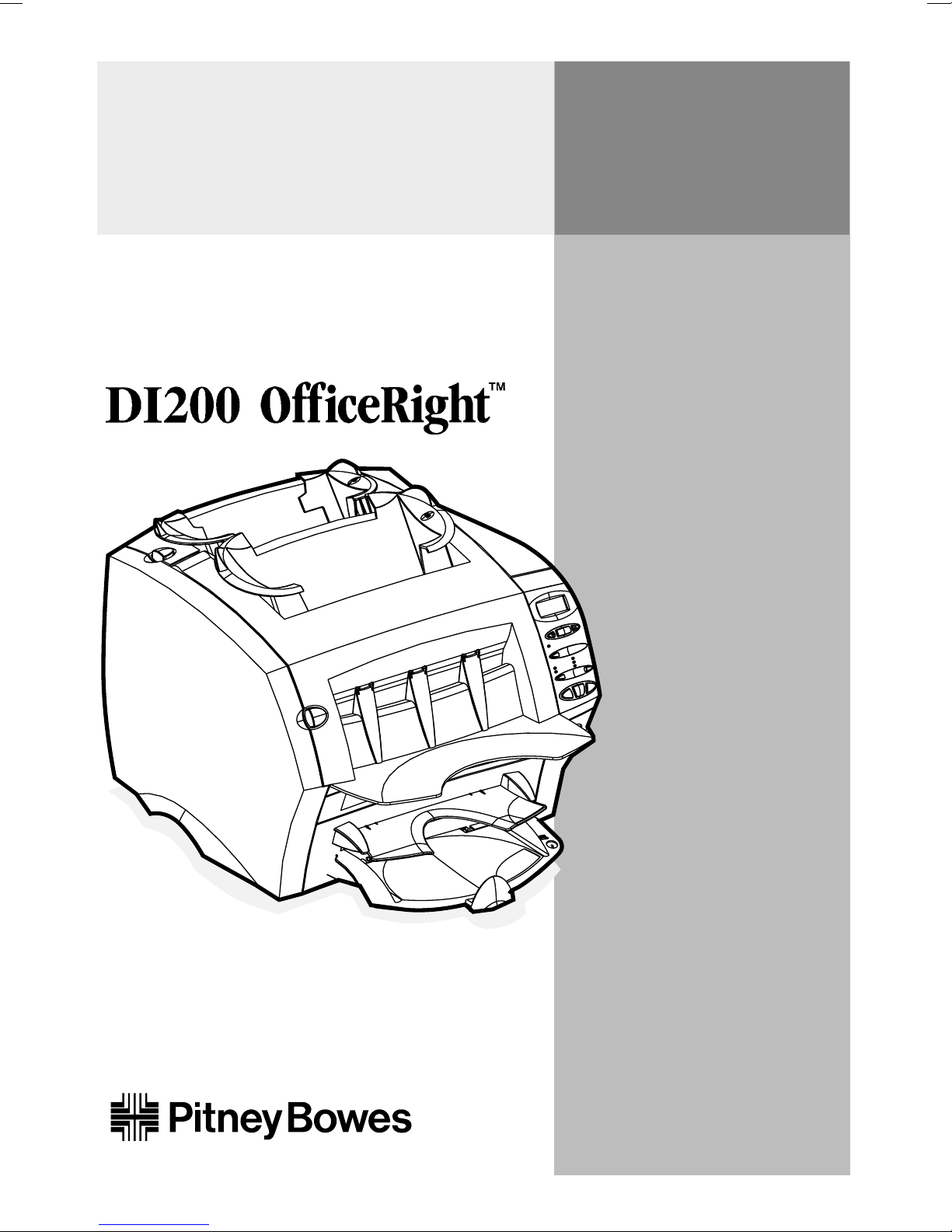

step

1. Unpack

a. Lift out the accessories

and put them

safely to one

side

b. Remove

cardboard

and foam

packing

Check that you have the following accessories:

Sample paper and envelopes (test material)

Bottle of E-Z Seal

Power Cord

®

Page 3

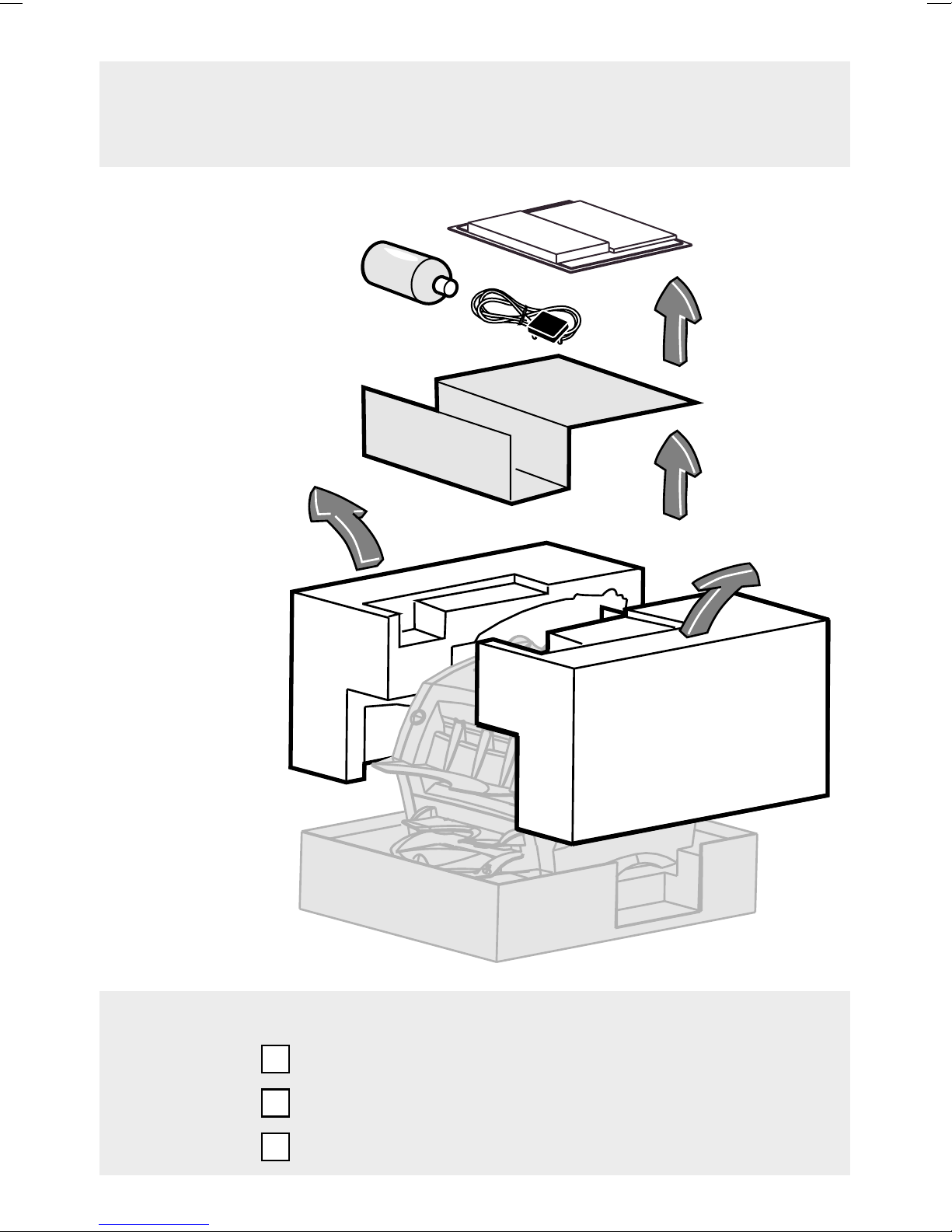

step

2. Locate

a. Lift the machine by

its handles and

place onto the

desk. See

“SAFETY

b. If you have the optional

2nd Sheet Feeder,

position the machine

onto the feeder now

SAFETY NOTICE!

NOTICE!” below

• Lift the machine only by its lifting handles.

• Lift correctly (bend knees and keep back straight).

• The machine weighs about 38 lb. (17.5kg)

We strongly recommend you get help to lift it.

Page 4

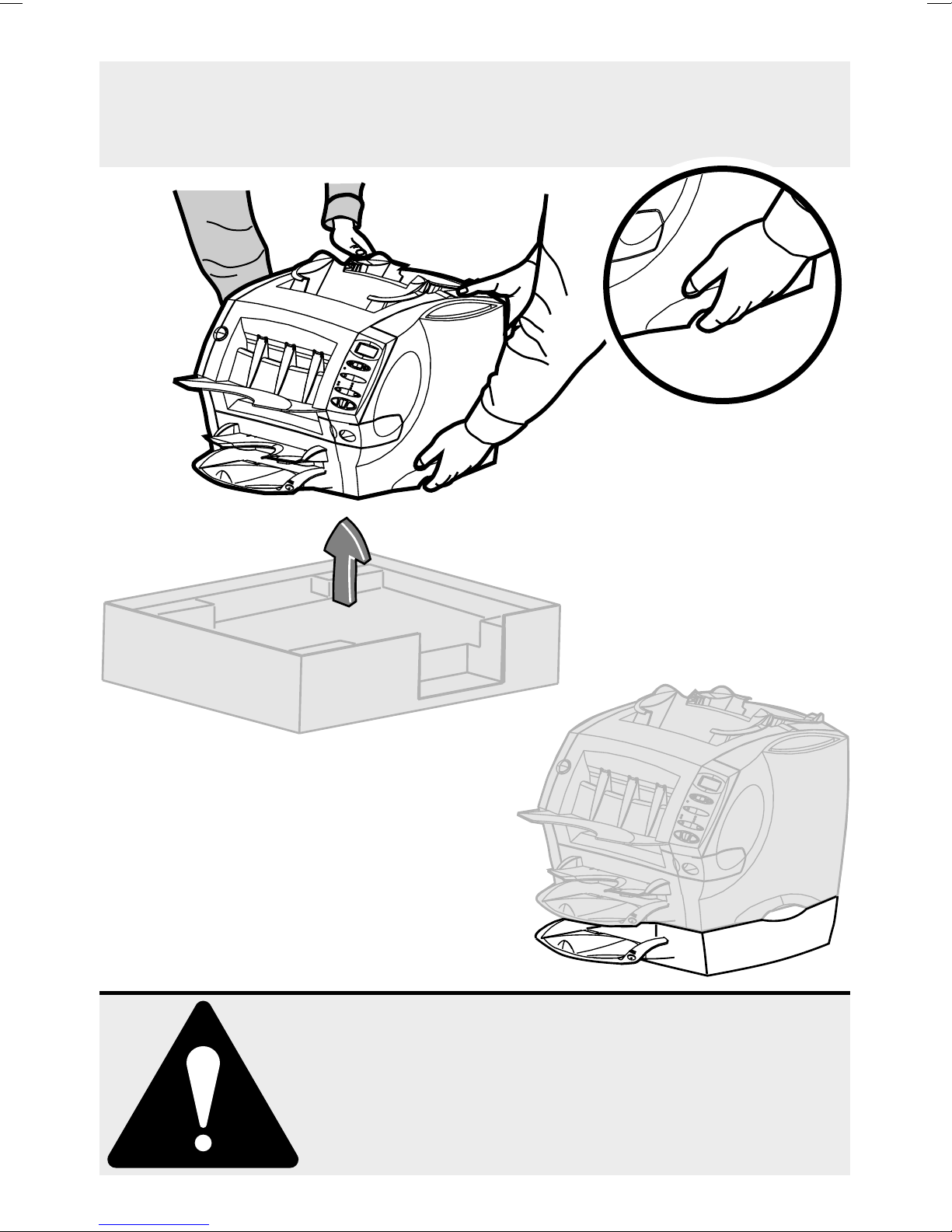

step

a. Connect

3. Connect and turn on

power cord

b. Turn machine ON.

The power switch

is on the back panel

next to the power

cord as shown here

c. Display will show “READY” in a few

seconds

SAFETY NOTICE!

• Locate the machine close to a power socket.

• Use the power cord supplied.

• See the

DI200 OfficeRight™ Operating Guide

complete safety and connection information.

for

Page 5

step

4. Fill moistener

a. Slide moistener open

b. Fill with E-Z Seal®.

Use the entire

bottle supplied

c. Slide moistener closed

The moistener takes about five minutes to become fully wet and

ready for use.

Continue with the steps in this booklet in the meantime.

Page 6

step

5. Load envelopes

We’ve included test paper and envelopes so you can practice using

the machine and check that it’s working OK…

a. Fan envelopes and tap stack to align edges

b. Place envelopes in feeder B

1

2

2

c. Slide side guides

until they just

touch envelopes.

If guides are too

tight, envelopes

may stall; if they

are too loose,

envelopes may

skew

Use test envelopes marked with the letter B.

IMPORTANT: Always fan (aerate) envelopes before loading. Load

envelopes RIGHT WAY UP and FACING YOU.

Slide guides until they just touch envelopes, but do not restrict enve-

lope feed. Use blue handles at rear of guides when moving them.

Page 7

step

6. Load sheets

a. Fan sheets and tap stack to align edges

b. Place sheets in feeder A1,

FACE DOWN and

BOTTOM EDGE FIRST

c. Push backstop in until it

just touches the stack

of sheets

Use test sheets marked with A1. Use Sheet Feeder A1 for sheets

that need folding.

IMPORTANT: Always fan (aerate) sheets before loading. Always

load sheets FACE DOWN and BOTTOM EDGE FIRST.

Page 8

step

7. Setup

a. Repeatedly

press button

until

Feeder A1

lights green

only

no yes

Menu / Enter

c. Repeatedly

press button

until Seal

lights green

Feeder A1

Seal

No Seal

Trial Piece Stop

Start

Feeder A2

2nd Page

Envelope Fdr B

Insert Fdr C

Fold Only

b. Repeatedly

press button

until

only

Envelope

Fdr B lights

green

A green indicator shows that a feeder or function is selected.

Repeatedly pressing the selection buttons (a, b and c above)

steps through the feeders and options available on your particular

machine.

Page 9

step

8. Run test job

a. Press

Trial Piece

button

no yes

Feeder A1

Seal

No Seal

Trial Piece Stop

Menu / Enter

Feeder A2

2nd Page

Envelope Fdr B

Insert Fdr C

Fold Only

Start

c. Press Stop

to stop

processing

The trial piece will not be sealed so you can check the contents of

the envelope. This is normal.

The counter will show the number of items processed.

b. If Trial Piece is

OK, press Start

Page 10

step

9. Congratulations!

Your DI200 OfficeRight™ is now ready to use

Yo u ’ll find your

ating Guide

sure to read it to get

the most out of your

DI200 OfficeRight™.

Oper-

here. Be

This Quick Install Guide allows you to unpack and test the

machine in the shortest possible time.

The

Operating Guide

It’s located in a slot in the top right hand cover of the machine as

shown above.

fully explains how to use your new system.

Page 11

Problems?

Always Check Your

If you experience any problems installing your equipment, please refer to the

Troubleshooting section in the

Web Support

Yo u ’ll find helpful answers to frequently asked questions at our web site.

Please go to

Phone Support ☎

If problems continue, technical assistance is readily available from the Pitney

Bowes Customer Support Center. Before you call, please have the following

information at hand:

❒ Product name: DI200 OfficeRight™

❒ Serial number: #__________________________. This is located on the

back cover of the machine.

❒ Nature of the problem: What happens and when does it happen?

Did the machine display an error message? What was it?

❒ The steps you've already taken to solve the problem and the results.

Then call:

www.pitneybowes.com/support

Operating Guide

Operating Guide

First

furnished with your machine.

In the USA 1.800.253.6565

In Canada 1.800.672.6937

Supplies

Pitney Bowes has made it easier than ever to order supplies—such as

E-Z Seal® (Item Code 601-0, USA only) and H200/H201 Moistener Wick

Replacement (Item Code 639-0)—that are designed specifically for your

DI200 OfficeRight™.

Order Online (USA Only)

Just point your browser to www.pitneybowes.com/supplies. You'll find a

complete, easy-to-navigate online store that offers a wide assortment of

genuine Pitney Bowes supplies at attractive prices.

Order by Phone

Our representatives will be happy to answer your questions and take your

order.

☎ In the USA, call 1.800.243.7824

☎ In Canada, call 1.800.672.6937

Ask for a PB Supply Catalog (USA Only)

Call the number above or e-mail us at supplies@pb.com.

Page 12

One Elmcroft Road

Stamford, Connecticut 06926-0700

www.pitneybowes.com

Pitney Bowes Canada

2200 Yonge Street Suite 100

Toronto, Ontario M4S 3E1

1.800.672.6937

IMPORTANT - READ THIS FIRST

before plugging in your system

*SV40189-QSREVA*

SV40189-QS Rev. A 9/02

© 2002 Pitney Bowes Inc.

Printed in England

Loading...

Loading...