Page 1

Page 2

PB Form SV40124 First Edition, July 2003 © 2003 Pitney Bowes

Inc. All rights reserved. This book may not be reproduced in

whole or in part in any fashion or stored in a retrieval system of

any type or transmitted by any means, electronically or mechanically, without the express written permission of Pitney Bowes Inc.

We have made every reasonable effort to assure the accuracy and

usefulness of this manual, however, we cannot assume responsibility for errors or omissions or liability for the misuse or misapplication of our products.

OfficeRight is a registered trademark and PB Supply Line is a

service mark of Pitney Bowes Inc.

FCC Compliance

This equipment had been tested and found to comply with the

limits for a Class A digital device, pursuant to Part 15 of the FCC

rules. These limits are designed to provide reasonable protection

against interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy, and if not installed and used in

accordance with the users manuals, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his

own expense.

Shielded cables must be used with this unit to insure compliance

with Class A limits.

Canadian DOC Compliance

This digital apparatus does not exceed in the Class A limits for

radio noise emissions from digital apparatus set out in the Interference-causing Equipment Regulations (Standard ICES-003) of

the Canadian Department of Communications.

NOTE: This equipment has been tested and found to comply

with the U.S. Standard for Safety UL60950, Third Edition, Safety

of Information Technology Equipment including Electrical Business Equipment and Canadian Standards C22.2 No 950-95,

Safety of Information Technology Equipment including Electrical Business Equipment.

Page 3

DF500 Folder Operator Guide

Table of Contents

Section Page

Safety.................................................................................................2

Description ..................................................................................... 2

Moving the DF500 .......................................................................8

Machine and Job Setup ..............................................................9

Automatic Fold Setup................................................................12

Operating The Folder................................................................ 13

Folder Mechanics For Understanding Fold Problems .... 15

Total and Batch Count ..............................................................20

Running a Job ..............................................................................23

Saving, Retrieving, or Deleting Jobs.....................................24

Manual Fold Setup......................................................................28

Manual Feed ................................................................................30

Operating Hints ..........................................................................32

Troubleshooting ..........................................................................36

Maintenance................................................................................ 40

Supplies......................................................................................... 40

Form Handling.............................................................................41

Equipment/Form Specifications............................................43

1SV40214 Rev. A

Page 4

DF500 Folder Operator Guide

SAFETY

A series of messages may be used throughout this manual to

alert you to potentially hazardous con di tions. These messages

are ex plained below:

WARNING - indicates the presence of a hazard that

can cause severe personal injury or loss of life,

or substantial property damage if the warning is

ignored.

CAUTION - indicates the presence of a hazard that

will or can cause minor personal injury or property

damage if the warning is ignored.

NOTE - calls attention to practices that could adversely affect equipment operation if instructions

are not followed exactly.

Always use safe operating procedures when running your folder.

Ob serve the following practices:

• Keep loose clothing, jewelry and long hair away from all moving parts.

• Avoid touching moving parts or materials while the machine

is in use. Before clearing a jam, unplug the machine. Be sure

machine mechanisms have come to a stop.

• To protect against electric shock, the machine should only

be plugged into a properly grounded wall outlet.

• The power cord wall plug is the primary means of disconnecting the folder from the AC supply.

• The wall outlet should be near the machine and easily accessible.

• DO NOT use an adapter plug on the line cord or wall outlet.

• DO NOT remove the ground pin from the line cord.

• Avoid using wall outlets that are controlled by wall switches.

• DO NOT route the power cord over sharp edges or trapped

be tween furniture.

2 SV40214 Rev. A

Page 5

DF500 Folder Operator Guide

• Ensure there is no strain on the power cord where it be-

comes jammed between the equipment, walls or furniture.

• Be certain the area in front of the wall receptacle into which

the machine is plugged is free from obstruction.

• DO NOT remove covers. This machine cabinet serves to en-

close hazardous parts. If the machine has been dropped or

has oth er wise been stressed in any way, report it to your Pitney Bowes Cus tom er Service Representative.

• To reduce the risk of fire and/or electrical shock, do not at-

tempt to disassemble this machine. If service is required,

contact your Pitney Bowes Customer Service Representative.

• To prevent overheating, do not cover the vent openings.

• All areas of the machine requiring disassembly or removal of

covers should be accessed only by your Pitney Bowes Customer Service Representative.

• Read all instructions before attempting to operate the equip-

ment.

• Use this equipment only for its intended purpose.

In addition, follow any specific occupational safety and health

stan dards for your workplace or area.

3SV40214 Rev. A

Page 6

DF500 Folder Operator Guide

DESCRIPTION

The Model DF500 Folder is a stand-alone tabletop folder capable of processing up to 40,000 doc u ments per month. The machine folds single and multi-part cut-sheet forms and then feeds

them folded onto the stacker. It is equipped with two fold plates

which allow it to produce single or double folds.

Two covers (one on top, one on the right side) can be opened to

allow access to the fold rollers and fold plates for maintenance

and clear ing of jams. When a cover is opened, the machine stops

automatically and cannot be started accidentally.

A control panel with an LCD display informs you of the status

of the machine and of the jobs your are running. Up to ten jobs

may be setup and saved for easy retrieval. In addition, system

di ag nos tics are available con ve nient ly from the control panel.

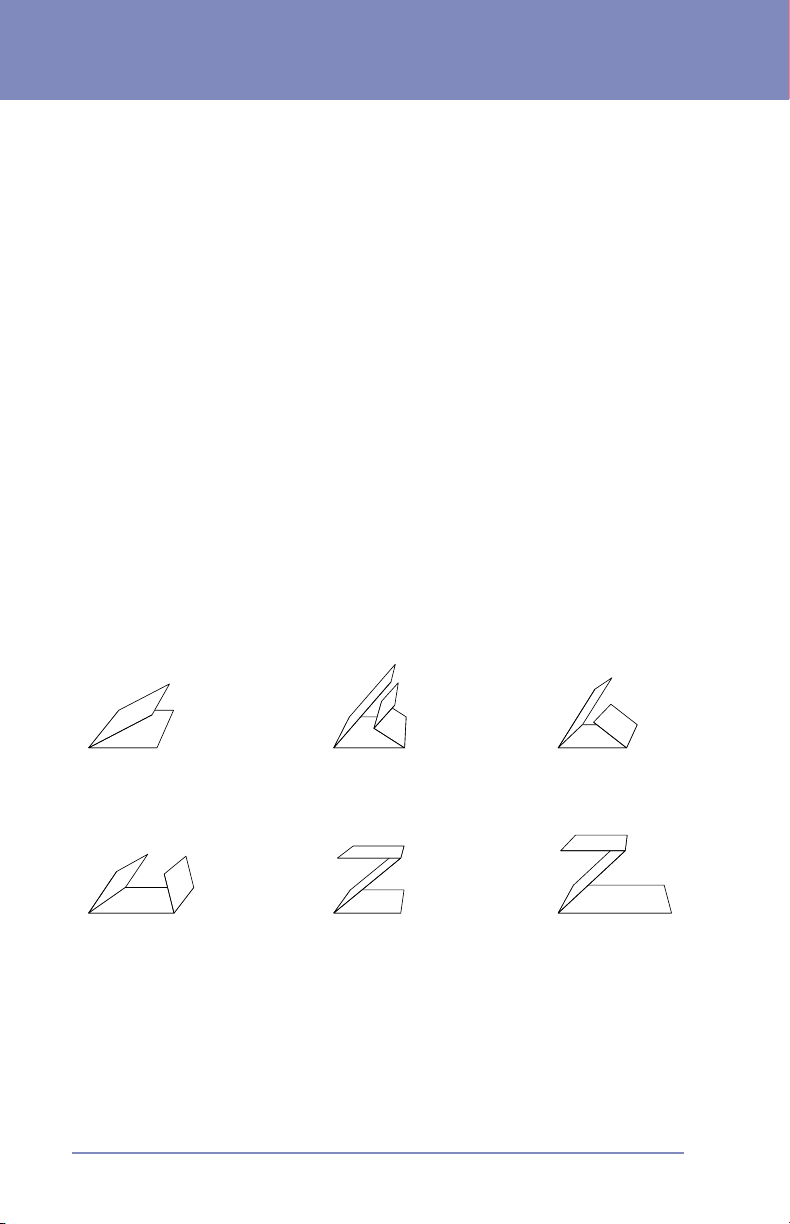

One feature of the DF500 is the Auto-Set mode for producing

com mon folds (see below). This mode allows the au to mat ic setting of dif fer ent pro grammed folds and the adjustment of the

paper thick ness. The following standard folds can be called up

via the Auto-Set mode:

Single Fold Double Parallel Fold Letter Fold

Gate Fold Z-Fold Z-Fold with Margin

In addition, other types of folds can be produced by entering the

mea sure ments manually as described later in this guide.

NOTE: The DF500 is built for folding paper and is unsuitable for

han dling other materials such as foils, plastics and textiles.

4 SV40214 Rev. A

Page 7

DF500 Folder Operator Guide

DF500 Controls and Features

2

1

3

4

5

6

7

1. Stacker Deck – holds the folded documents.

2. Top Cover – allows access inside of folder for removing

jams.

3. Material Feed Deck – where paper is fed into the folder.

4. Skew Adjustment Control – used to offset skewing when

feeding ma te ri al.

5. Fuses – disconnects power to the folder when there is an

over load of power con sumed by the machine.

6. AC Input for Power Cord – connects to AC line cord.

7. Power Switch – turns on and off machine.

8. Operator Side of Machine

9. Right Hand Cover (on side) – allows access to fold plate.

8

9

5SV40214 Rev. A

Page 8

DF500 Folder Operator Guide

More DF500 Controls and Features

3

2

8

1

4

5

7

6

1. Stacker Extension – allows more space for collected doc u ments after folding.

2. Stacker Rollers – helps guide material on to stacker belts.

3. Stacker Belts – moves folded documents away from exit

area.

4. Input Feed Deck Extension Guides – allows long sheets of

material to be supported. Flip up to activate.

5. Pre-feed Adjustment Knob – allows you to change the

amount of feed pressure for feeding various types of material.

6. Operating Guide Holder – holds this DF500 Operating

Guide.

7. Control Panel – allows user to setup and operate the folder.

8. Hand Wheel Knob (under cover) – allows for manual turning of fold rollers to aid in clearing jams.

6 SV40214 Rev. A

Page 9

DF500 Folder Operator Guide

DF500 Control Panel Features

1

2

3

5

1. Paper Size Indicators – shows the paper size in use.

2. Standard Fold Type Indicators – shows the type of fold

se lect ed.

3. LCD Display – displays machine and job status to operator.

4. Dual Function Buttons – used for setting paper thickness

or manual feeding. Also used for scroll ing in certain setup

menus.

5. Setup Buttons – sets up the folder functions.

6. Main Control Buttons – used to control main folder op er a tion.

4

6

7SV40214 Rev. A

Page 10

DF500 Folder Operator Guide

MOVING THE DF500

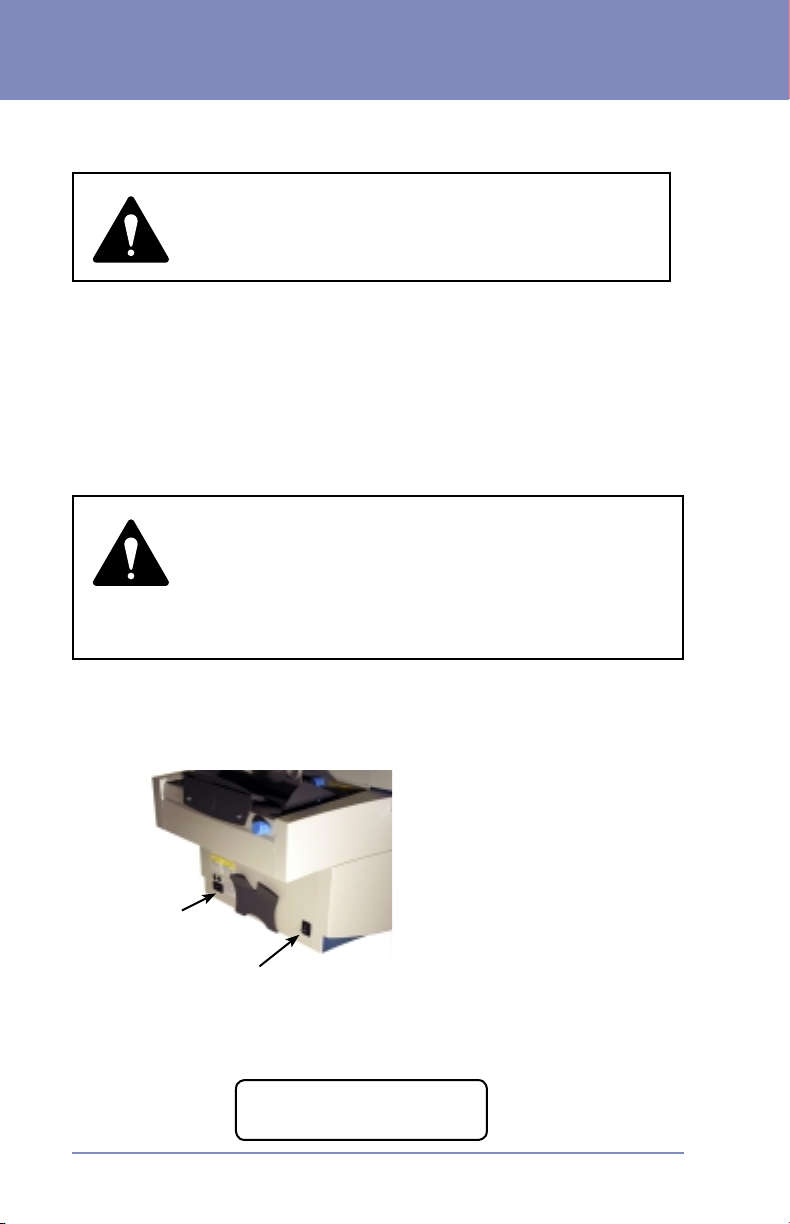

WARNING: To avoid personal injury or damage

to the machine, two people should be used to

lift the DF500.

1. If moving the DF500, make sure that it is unplugged and that

it is placed on an ap pro pri ate work surface. There has to be

a min i mum clear ance of 36" (914mm) on three sides of the

machine for op er a tor access. Rec om mend ed table height is

30" (762mm).

2. Lift the DF500 from under each end. Do not lift the unit using

the paper support guides, control panel, or fold plate door.

WARNING: To avoid personal injury or damage to

the machine, make sure you lift the folder by the

bottom of the chassis. Do not use the fold plate

compartment door on the side as a handle, as it

will open up and cause you to drop the machine.

3. Install the line cord into the AC input on the side of the

DF500 (see below) and then plug it in to a grounded 115

VAC outlet.

AC Input for

Power Cord

Power Switch

4. Turn the machine on and verify that the control panel displays the power-up screen (see below).

JOB: 1 READY

ШШШШШШ

8 SV40214 Rev. A

Page 11

DF500 Folder Operator Guide

MACHINE AND JOB SETUP

Feeder Setup

Setting the Paper Thickness

1. Turn the power switch to ON. The display will read:

JOB: 1 READY

ШШШШШШ

2. Press the Paper Thickness key on the control panel. The

display changes to:

SET THICKNESS?

YES: Enter NO:

3. Press Enter. The sheet separator in the feeder will open and

the display will prompt:

!

INSERT ONE SHEET

DONE - Enter

4. Insert a sample sheet of the paper

you want to fold into the feeder.

Push in the pressure roll er and

insert the pa per into the feeder

(see be low) about 2" (50mm).

5. Press the Enter key. The DF500 will now automatically adjust

itself to the thickness of the paper.

6. If your fold is already setup, you may now press the Trial

Piece key to fold this sample sheet. If you have not yet setup

your fold, withdraw the sheet. You will feel a slight resistance.

7. The display will again show:

JOB: 1 READY

ШШШШШ1

9SV40214 Rev. A

Page 12

DF500 Folder Operator Guide

Setting the Paper Guides

1. Squeeze the blue lever against the right hand paper guide,

and, using two hands,

move the guides to the

width of the paper.

2. Allow about 1/32"

(1mm) clear ance so that

the paper is not held

too tightly (see below).

Do not allow too much

clear ance as this will affect fold accuracy.

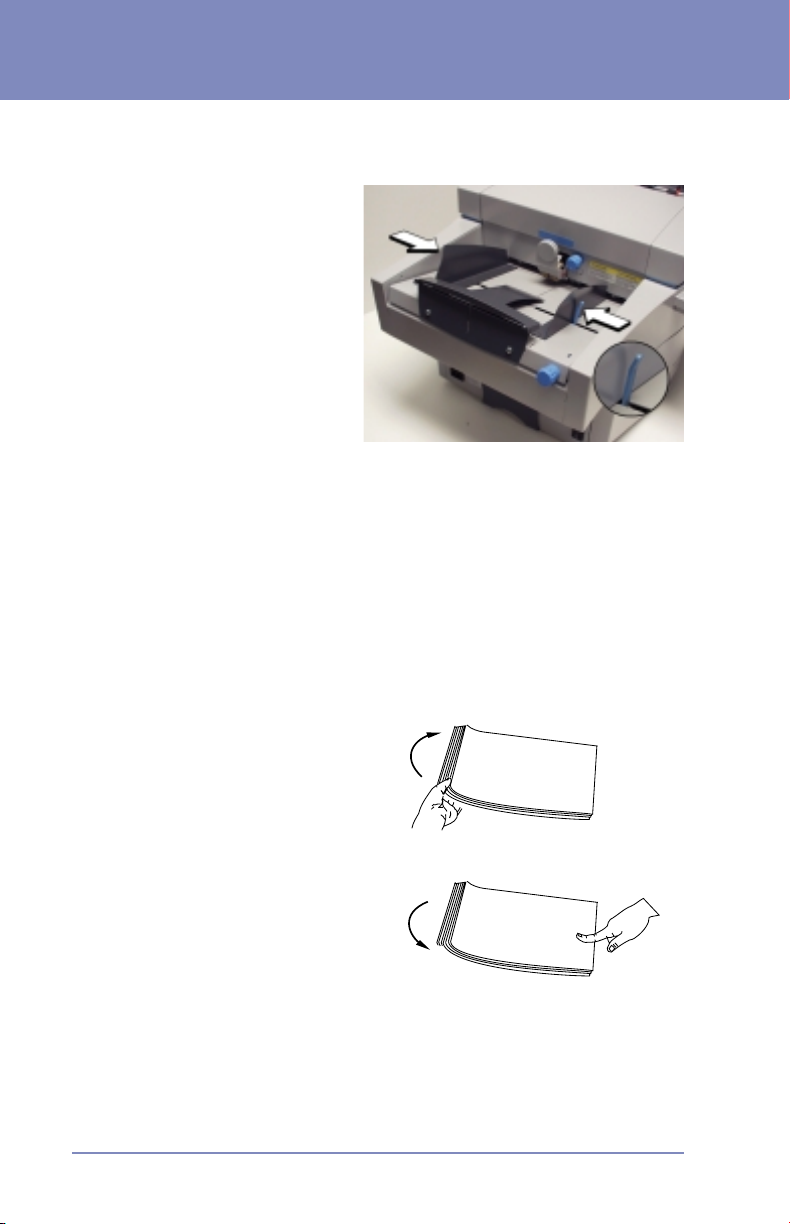

Loading Paper

When paper is loaded into the DF500, the top sheet of the paper stack is fed first. This means that the paper stack must be

“fanned out” so that the top sheet is closest to the feed roller.

1. Place a stack of paper onto the feed table. Firmly grasp the

upper end of the stack with your left hand and bend the entire stack up and forward as shown.

2. While still holding the stack with your left hand, press down

on the lower end of the stack

with your right hand. Now

release the upper end of the

stack and let it fall onto the

feed table. The stack should

appear slightly fanned out.

3. Repeat this process several

times and the stack will be

fanned out properly. Allow

the fanned stack to slide

down into the mouth of the

feeder as far as it will go

without forcing it.

10 SV40214 Rev. A

Page 13

DF500 Folder Operator Guide

Using the Table Extension

1. Lift the table extension up to sup port longer paper like legal

size.

Setting the Pressure Roller

The pressure roller knob allows you to set the pressure applied to

the first set of feed rollers.

• For 20 lb. bond paper,

set the knob halfway

between "+" and "–".

• For heavier paper, or if

you see the feed rollers

slipping, move the knob

towards "+".

• For lighter paper, or

if the paper tends to

bunch up under the

feed rollers, set the knob

towards "–".

11SV40214 Rev. A

Page 14

DF500 Folder Operator Guide

AUTOMATIC FOLD SETUP

Selecting Paper Size

1. Press the Paper key to select the desired paper size length.

Each press of the key will step through the three standard

paper sizes and “other” and will light the appropriate paper

size indicator on the control panel.

2. At the same time, the display will show the selected paper

length in millimeters. For example:

T1 PAPER = 297.Ø

CHG: DONE: Enter

3. If your paper isn’t a standard size, press the " or ! key, to

change the size. Each key press will change the paper size by

about 1/64" (0.5mm). Holding the key down for more than

one second will increase the step size, allowing large changes

to be made rapidly.

4. When the correct paper size is shown, proceed with “Selecting Fold Type” below. NOTE: The DF500’s electronic control

system will not allow you to deviate too far from the standard

settings. This will prevent jams caused by “impossible” folds.

Selecting Fold Type

Before selecting a fold, make sure you have already set the

DF500 to the correct paper size length. This will prevent the machine from setting up a fold for the wrong paper length, which

could result in a paper jam.

1. Press the Fold Type key to select one of the six pre-pro-

grammed fold types. Each key press will turn on the indicator

associated with each fold type.

2. When you have made your selection, press the Enter key. The

display will show:

TEMP JOB: 1 READY

ШШШШШШ

3. While the machine is setting up the fold, all keys on the control panel are disabled and will not respond if pressed.

(continued on next page)

12 SV40214 Rev. A

Page 15

DF500 Folder Operator Guide

Selecting Fold Type (continued)

4. When the setup is complete, the display will change back to

the “Ready” state.

TEMP JOB: 1 READY

ШШШШШШ

NOTE: “TEMP JOB” or “T” in the display means that the job

just setup is considered a temporary job because it has not

yet been saved in memory.

OPERATING THE FOLDER

Setting the Speed

Set the proper speed before attempting to run the folder. The

speed setting depends on the weight and size of the paper used.

Light weight and large size papers (lighter than 20 lb. bond and

larger than 8-1/2" by 11") must be run slower than heavy paper

and smaller sheets. A good value to start with is 35.

1. Press the Speed key. The display will typically show:

T1 SPEED = 40

CHG: DONE: Enter

2. To change the speed, press the " or ! key, then press Enter.

3. If you forgot to press Enter and try to start the folder, the

display will show:

USE NEW SETTING?

YES: Enter No:

!

This message will also appear if you have entered any other

new parameter such as paper size, fold type, batch or fold

plate setting.

4. Press Enter now to activate your setting or the ! key to stay

with your previous setting.

(continued on next page)

13SV40214 Rev. A

Page 16

DF500 Folder Operator Guide

Setting the Speed (continued)

The speed can also be changed while the machine is running.

1. Press the Speed key. The display will change to:

SPEED 35

ШШШШШШ

2. Use the " or ! keys to run slower or faster.

3. The speed will change instantly. You need not press the Enter

key to activate the new setting.

Running a Trial Piece

Always run a trial piece before starting a run. It is also a good

idea to run a trial piece each time a new stack of paper has been

loaded onto the feed table. This will prevent a jam if the stack

has been loaded incorrectly.

1. Press the Trial Piece key. A single sheet will be folded and

de liv ered to the stacker for you to check.

Startup

1. If you are happy with the trial piece, press the Start key to

begin the au to mat ic feeding and folding. The folded sheets

will be delivered neatly shingled on the stacker table.

2. Remove the folded sheets as soon as they start piling up in

front of the stacker extension.

3. When the entire paper stack has been fed the machine will

stop and the display will show:

– FAIL TO FEED –

DONE - Enter

4. Reload the feed table with a new stack of paper and press the

Enter key to clear the message on the display.

TEMP JOB: 1 READY

ШШШШШШ

5. When the display shows ‘Ready’, press the Start key to resume folding.

14 SV40214 Rev. A

Page 17

DF500 Folder Operator Guide

Stop ping the DF500

1. To in ter rupt the folding process at any time, press the Stop

key. This will stop the machine in a controlled manner.

2. The sheets already in process will be folded and delivered be-

fore the machine stops. The stacker belts will move all folded

sheets to the end of the stacker table for easy removal.

CAUTION: Unless there is an emergency

situation, do not stop the ma chine by turning

power off by the main switch or wall socket.

Doing this while the DF500 is folding will

result in a paper jam inside the machine.

FOLDER MECHANICS FOR UNDERSTANDING FOLD

PROBLEMS

There can be many reasons for a fold to be slightly off–the paper

composition, paper weight, size and direction of grain. Also, folding speed and ambient conditions like temperature and humidity

can have an effect. Consequently, an understanding of what is

hap pen ing in the folder can be helpful when correcting a fold

problem.

A. The top sheet of paper is fed into the folder and is driven by

rollers (1) and (2) into fold plate 1.

6

4

5

2

3

1

Stop

Fold plate 1

(continued on next page)

Stop

Fold plate 2

15SV40214 Rev. A

Page 18

DF500 Folder Operator Guide

Folder Mechanics (continued)

B. The paper con tin ues into the fold plate until it hits the stop.

Since the two rollers are still driving the paper, a buckle will

form at the en trance to the fold plate and will, eventually, be

caught be tween fold rollers (2) and (3). This is how the first

fold is made.

C. The folded edge will be guided by the deflector into the grip

of rollers (3) and (4). Here the same thing happens as in the

first fold plate and a second fold is made.

NOTE: If a single fold is selected, the second fold plate is au-

to mat i cal ly closed off and the folded sheet is routed past it.

4

2

3

1

6

4

5

3

2

1

D. The folded sheet is now guided by the second deflector into the

grip of rollers (5) and (6) where it is fed out onto the stacker.

It is obvious that the position of each fold plate stop determines

the length of the fold resulting from it. Keeping this in mind, it

is easy to make corrections to each fold by simply moving the

relevant stop in or out. You only need to know which end of the

sheet entered the machine first to recognize which was the first

fold and which was the second.

16 SV40214 Rev. A

Page 19

DF500 Folder Operator Guide

Fine Tuning the Folder

Fold corrections can be made with the machine stopped or running.

Correcting a fold with the machine stopped…

1. Select which fold you want to correct by pressing the Fold 1

or Fold 2 key. (If a single fold is set, the Fold 2 key will not

respond). The display shows, for example:

T1 FOLD1 = 148.Ø

CHG:

DONE: Enter

2. Change the value by pressing the " or ! key, then press

Enter to confirm the new setting. The fold is now set and the

display shows:

TEMP JOB: 1 READY

ШШШШШШ

3. If you try to start the machine without pressing Enter, the

display will prompt:

USE NEW SETTING?

YES: Enter No:

The machine will not start until you press either Enter or ! key.

!

Correcting a fold with the machine running…

1. Select which fold you want to correct by pressing the Fold 1

or Fold 2 key. (If a single fold is set, the Fold 2 key will not

respond). The display shows, for example:

or

FOLD 1 = 148.Ø

ШШШШШ1

FOLD 2 = 74.Ø

ШШШШШ1

2. Change the value by pressing the " or ! key. You can judge

the result instantly by taking a folded sample from the stacker.

NOTE: This procedure should only be used to correct small

errors; oth er wise you will produce many reject sheets before you get the fold right.

3. The correction display will remain until you either press

Enter, Speed, or you stop the machine.

17SV40214 Rev. A

Page 20

DF500 Folder Operator Guide

Correcting a Skewed Fold

A skewed fold will result if the paper has not been fed exactly at

right angles with respect to the fold rollers. To correct a skew, the

entire feed table can be moved left or right by turning the skew

ad just ment knob. A pointer in the slot above the knob will show

which way the deck is moving

when turn ing the knob. As a general rule, the pointer should be

in the center of the slot.

NOTE: Before attempting to

correct the skew, make sure the

feeder side guides are adjusted

as close to the paper as possible without binding.

The steps below de scribe in detail how to correct a skewed fold.

1. Remove the paper from the feed table.

2. Turn the skew adjustment knob to center the pointer in its

slot.

3. Reload the paper making sure there isn’t too much clear ance

between the stack and the side guides.

4. Set the machine for a half (single) fold. This makes it easier

to determine which way to turn the skew ad just ing knob.

5. Run a trial piece.

6. If the fold is skewed, compare your sample with the drawings

below.

If the sample looks like "A", turn the skew

ad just ment knob counter-clockwise slightly.

If the sample looks like "B", turn the skew

ad just ment knob clock wise slightly.

7. Remove and reload the paper stack. This is

im por tant – if you do not reload the stack

the adjustment you just made may not take ef fect immediately.

8. Run another trial piece and readjust if necessary.

18 SV40214 Rev. A

Page 21

DF500 Folder Operator Guide

Fine Tuning the Feeder for "Problem" Paper

The fine tuning feature allows you to adjust the feeder gap (the

opening through which the paper must pass) in small steps while

the machine is running. This is helpful with some “problem”

papers, such as lightweight recycling papers and heavy stock because the stan dard feeder settings tend to mark the coated surface of the paper.

Observe the paper feed while folding. If the feeding is erratic

(paper seems to hesitate before entering the folder) or if you get

“FAIL TO FEED” messages, check first whether the pressure roller

is exerting enough pressure on the paper (see page 11 for details). If more pressure does not help, you must open the feeder

gap a little. If you tend to get double sheets being fed, you must

close the gap slightly.

The steps below de scribe in detail how to fine tune paper feeding.

1. With the machine running, press the " or ! key. The display

will change to:

TUNE THICKNESS

ШШШШШ1

2. Press the " key to open the gap, or the ! key to close the

gap. Typically, the display will show:

:+ ENTER

ШШШШШ1

NOTE: A "+" symbol on the display shows you are opening

the gap a little. A "–" symbol on the display shows you are

closing the gap a little.

3. By using the " or ! keys, you can open or close the gap in

steps shown on the display by up to five "+" or five "–" sym bols. Consequently, a typical display might be something like:

or

:+++++ ENTER

ШШШШШ1

:----- ENTER

ШШШШШ1

If no symbols show on the display, you are back to the stan-

dard feeder setting.

(continued on next page)

19SV40214 Rev. A

Page 22

DF500 Folder Operator Guide

Fine Tuning the Feeder (continued)

4. To leave the fine tuning mode, press Enter. The display will

switch back to normal running mode.

If you don’t press Enter, the machine will stay in fine tuning

mode until power is turned off. When the machine is turned

back on again, the display will be back in normal running mode.

NOTE: The paper thickness setting will not automatically

change when switching jobs. You must set paper thickness

first when starting a new job (see page 9). It is good practice

to set paper thickness even when the same weight of paper is

used with the new job.

TOTAL AND BATCH COUNT

Clearing Total Count

The total count feature is always active and cannot be turned off.

The counter must therefore be reset for each individual job that

requires counting.

1. To reset the count, press the Reset Counter key. The display

shows:

RESET ØØØØ29

YES: Enter No:

!

2. Press the Enter key to reset the counter, or the ! key, if you

have changed your mind. The counter digits at the bottom

right of the display will revert to zero:

TEMP JOB: 1 READY

ШШШШШШ

20 SV40214 Rev. A

Page 23

DF500 Folder Operator Guide

Setting a Batch Count

The batch count feature will make the machine fold a pre-selected number of sheets (a batch) and then stop. The remaining

folded sheets on the stacker will be carried to the end of the

stacker table to aid removal. Follow the steps below to set a batch

count function.

1. Press the Batch key. The indicator next to the key will light

and the display will show:

T1 BATCH = ØØ5

CHG:

DONE: Enter

2. Change the batch count number (which must be from 5 to

999) by using the " or ! keys, then press Enter to confirm.

3. The indicator will remain lit and the display will change to:

TEMP JOB: 1 READY

BATCH: Ш5Ш ШШШШШШ

4. Folding of the next batch is resumed by pressing the Start key.

Turning off the batch count

The batch count function will operate as long as the batch indicator is on, even if the paper size and/or fold type is changed.

1. Press the Batch key.

2. The indicator will go off and the display will briefly show:

BATCH MODE OFF

then go back to the normal running mode display:

TEMP JOB: 1 READY

ШШШШШШ

21SV40214 Rev. A

Page 24

DF500 Folder Operator Guide

Restoring a Batch Count

If you have set a batch of 50, for instance, and have taken a trial

piece or have run several pieces you cannot use, you may want to

restore the batch count to 50 before starting a folding run. Follow the steps below to restore a batch count.

1. Press the Batch key (to turn batch off).

2. Press the Batch key a second time (batch setting mode on).

3. Press Enter. The batch count will be restored and the machine is ready to run a full batch.

22 SV40214 Rev. A

Page 25

DF500 Folder Operator Guide

RUNNING A JOB

Normal Job

The Normal Job is a commonly used setup which can be recalled

very quickly when required. From the factory, this job is set to

give a letter (C) fold on 8-1/2" by 11" paper. However, it can be

set to a dif fer ent fold and paper com bi na tion, if required, by a

Pitney Bowes service engineer. Follow the steps below to select a

normal job.

1. Simply press the Normal Job key. The display will prompt:

SET NORMAL JOB?

YES: Enter No:

2. Press Enter to activate the Normal Job settings or press ! if

you have changed your mind.

3. During activation of the Normal Job, the display will show:

SETTING

4. When the Normal Job is set, the display will only show:

!

READY

ШШШШШШ

Temporary Job

A Temporary Job is any folding job setup without it having been

stored in the machine’s memory. The settings are not retained by

the machine and cannot be recalled at a future date. A Temporary Job will be shown in the display by the word “TEMP” or the

letter “T”:

TEMP JOB: 1 READY

ШШШШШШ

T1 PAPER = 297.Ø

CHG:

DONE: Enter

If you recall a programmed job and change any of its settings,

it will be regarded as a Temporary Job by the DF500 until it is

saved again to memory. See page 24 for details of saving a job in

memory or updating a job already in memory.

23SV40214 Rev. A

Page 26

DF500 Folder Operator Guide

SAVING, RETRIEVING, OR DELETING JOBS

After setting up and running a job, you might want to save it for

later use. This is especially useful for jobs which occur frequently

or for difficult jobs that run well only at a certain speed and fold

plate setting. The following parameters are saved with a job:

• The paper size (standard or not)

• The type of fold (including any manual fold plate corrections)

• The speed

• The batch count (if any)

You can save up to nine different jobs on the DF500.

Saving A New Or Replacement Job

1. Press the Store Job key. The display will prompt:

MAKE NEW JOB: 2?

YES: Enter No:

!

2. If you don’t want to save the job, press the ! key. The display

will go back to running mode and the job will not be saved.

3. To save the job, press the Enter key. If the memory space is

available, the display will show for a few seconds…

STORED AS: JOB2

… then return to running mode with the job saved.

JOB: 2 READY

ШШШШШШ

If the memory space is already occupied by another job, the

display will show:

REPLACE JOB2?

YES: Enter No:

(continued on next page)

24 SV40214 Rev. A

!

Page 27

DF500 Folder Operator Guide

Saving a New or Replacement Job (continued)

4. If you press Enter, the job previously saved under “JOB 2”

(for this example) will be replaced by the new job under the

same job number:

STORED AS: JOB2

5. If you don’t want to erase the job already in memory, press

the ! key. The display will increment the job number up by

one and will prompt:

MAKE NEW JOB3?

YES: Enter No:

6. The new job number offered (in this example 3), is always

the lowest available job number. In this case jobs 1 and 2

are already occupied, while job numbers 3 to 9 are available.

Available job numbers are always offered in ascending order.

It is not pos si ble to “jump” one number.

!

7. Press Enter to save your new job under the new job number.

STORED AS: JOB3

8. If all 9 memory spaces are full and you choose not to replace

an existing job, the display will show:

–PROGRAMS FULL–

CLEAR JOB FIRST

9. To store any more jobs you must first delete existing job(s) as

described in "Deleting a Job from Memory" on page 27.

25SV40214 Rev. A

Page 28

DF500 Folder Operator Guide

Retrieving A Job From Memory

1. To retrieve a job from memory and set it up, press the Select

Job key repeatedly until the job you want is displayed:

SELECT JOB: 2?

YES: Enter No:

2. If you press Enter, the job shown will be set up and the dis-

play will show in succession:

!

JOB: 2

SETTING

JOB: 2 READY

ШШШШШШ

3. If you press ! key, the display will return to the normal running mode without a job being selected.

Identifying A Job In Memory

1. Use the Select Job key to step through the available jobs

stored in memory. The appropriate indicators for paper size

and fold type will light up for each job. This way you can tell

what kind of job is stored under each job number.

SELECT JOB: 2?

YES: Enter No:

!

2. If you want to know exactly what dimensions are stored for

each fold plate, press the Fold 1 or Fold 2 keys. The display

will briefly show the fold plate dimension set for the job:

SELECT JOB: 2?

FOLD 1 = Ø9Ø.Ø

3. If the job has a single fold, pressing Fold 2 will not display

a di men sion as fold plate 2 is closed for single fold applications.

26 SV40214 Rev. A

Page 29

DF500 Folder Operator Guide

Deleting A Job From Memory

1. Select the job number you want to delete by pressing Select

Job until the correct job number is displayed.

2. Press the Reset Counter key. The display will prompt:

DELETE JOB: 3?

YES: Enter No:

3. Press Enter to delete the job:

JOB DELETED

4. The memory location is now clear and another job may be

stored under that number. This job number will be automatically offered when you want to store a new job without erasing any others.

!

27SV40214 Rev. A

Page 30

DF500 Folder Operator Guide

MANUAL FOLD SETUP

Setting A Standard Fold With Non-standard Size Paper

1. Press the Fold Type key to select the desired type of standard

fold.

2. Press the Paper key until the “Other” indicator lights. The

display will show:

TØ PAPER = 297.Ø

CHG: DONE: Enter

3. Use the " or ! keys to change the dimension shown to the

length of your paper in millimeters.

4. Press Enter and the fold will be setup automatically. The display will first show…

TEMP JOB: Ø

SETTING

… then return to the normal running mode display.

TEMP JOB: Ш READY

ШШШШШШ

5. Run a trial piece to check the fold. If necessary, make cor rec tions as described on page 14.

NOTE: The DF500’s electronic control system will not allow

you to deviate too far from the standard settings. This will

prevent jams caused by “impossible” folds.

28 SV40214 Rev. A

Page 31

DF500 Folder Operator Guide

Setting A Non-standard Fold With Any Size Paper

1. Press the Paper key to select any of the 3 standard paper

sizes, or select “Other” and set the paper size as described

above.

2. Press the Fold Type key to select a fold which comes closest

to the type of fold you want.

3. Press the Fold 1 key to set fold plate 1. Measure the length of

the first fold on your sample and transfer the measurement

using the " or ! keys.

4. Press Fold 2 and transfer the measurement of the second

fold. If your special fold is a single fold, you do not need to

set fold plate 2.

5. Press Enter, the machine will set itself automatically.

TEMP JOB: Ø

SETTING

TEMP JOB: Ш READY

ШШШШШШ

6. Run a trial piece to check the fold. If necessary make correc-

tions as described on page 14.

29SV40214 Rev. A

Page 32

DF500 Folder Operator Guide

MANUAL FEED

The manual feed mode allows you to hand-feed sets of two or

more sheets, loose, glued or stapled. The limit is five sheets of 20

lb. (80g/m

In manual feed mode the fold rollers will be turning, but the

feeder is disabled. Automatic feeding is not possible because the

paper is fed by hand, one set at a time.

Setting The Feeder For Manual Feed

1. Press the Manual Feed key. The display will show:

2)

bond, folded into a single, letter (C) or Z fold.

CAUTION: Do not attempt to fold sets into

any other type of fold. This could result in

serious damage to the machine.

MANUAL FEED MODE

YES: Enter No:

!

2. Press Enter. You will hear a small motor opening the feeder

gap, which will enable you to feed more than one sheet at a

time. After the motor stops, the display will show:

MAN. FEED READY

ШШШШШШ

3. Press Start and start feeding your collated sets one by one.

In order to get cleanly folded sets, make sure to insert the

sets straight down the paper guides on the feed table.

MAN. FEED RUN

ШШШШШ1

NOTE: If the pressure rollers interfere with hand feeding,

turn the pressure roller setting knob fully to "-".

4. Press Stop to halt feed motors when finished.

30 SV40214 Rev. A

Page 33

DF500 Folder Operator Guide

Returning To Automatic Feed

1. To get out of the manual feed mode, press the Manual Feed

key again. The display will prompt:

MANUAL FEED EXIT?

YES: Enter No:

2. Press the Enter key. The display will show:

INSERT ONE SHEET

DONE - Enter

3. Insert a sheet of paper to be fed automatically and press Enter.

The machine will set the feed gap to the thickness of the

sample sheet and the display will return to normal running

mode.

4. Remove the sample sheet or press Trial Piece to feed the

sheet through the machine.

!

31SV40214 Rev. A

Page 34

DF500 Folder Operator Guide

OPERATING HINTS

Clearing A Jam

Jams can occur for a number of reasons, including:

• Double sheets being fed

• Running a certain type of fold with the wrong size paper

• Running very light paper too fast

• Running heavy stock too slow

Whenever there is a jam in the machine, errors such as these may

display:

–JAM IN FOLDER–

OPEN TOP COVER

–JAM IN STACKER–

DONE - Enter

Follow the steps below to clear a jam.

1. Open the top cover and look for any paper stuck inside. With

the cover open, either turn the fold rollers by hand or use

the handwheel knob to remove any stalled paper.

2. To use the handwheel

knob (see figure on

right), press in on the

end of the knob and

then release. This will

cause it to pop out to its

operating position. For

safety rea sons, the knob

is still disengaged in

this po si tion.

3. Pull the knob out as far as it will go to engage the gears inside. Turn the knob while keeping it pulled out. Turning it

clockwise will feed the paper towards the stacker.

(continued on next page)

32 SV40214 Rev. A

Page 35

DF500 Folder Operator Guide

Clearing a Jam (continued)

4. If the paper is bunched up inside, making it hard to turn the

knob or the fold roller directly,

remove the two de flec tor bars.

Using the screw as a handle,

push the bar towards the control panel, then lift it out. Any

paper inside should now be visible and is easily removed.

5. Refit the deflector bars by inserting the round end with the

spring into its hole in the operator side frame. Guide the

other end of the bar into the square hole on the opposite

side frame.

6. When you have finished using the manual turnover knob,

press it back in so that it latches into position.

7. While the top cover is open, the display will show:

TOP–COVER OPEN

Close the cover and the display will return to normal running

mode, showing whatever fold job, etc.. had been there before

the jam.

8. If the display still shows “JAM IN FOLDER”, press Enter and

the display should return to running mode.

9. If the error message does not go away, this means that there

is paper stuck in the fold plate. Turn off the main power

switch and refer to the following section “Removing the fold

plates”.

33SV40214 Rev. A

Page 36

DF500 Folder Operator Guide

Removing The Fold Plates

You will need to remove the fold plate assembly if paper is stalled

in this area and you have been unable to clear a jam as described

in the previous “Clearing a Jam” section.

CAUTION: Before opening the fold plate

door, always turn off the power first. This

will prevent any possibility of dam age to

the machine’s electronic control system.

Follow the steps below to remove the fold plates.

1. Turn power OFF.

Fold Plate Door

2. Open the fold

plate door by

pulling it away

from the ma chine. NOTE:

Some force may

be needed to

open the door.

The door will

stay in its up per most po si tion.

Silver Handle

Fold Plate Assembly

Blue Lock Levers

3. Press and release the two blue lock levers on either side of

fold plate assembly. This will cause the fold plate assembly to

drop slightly.

4. Grab the silver handle and lift the fold plate assembly up and

out.

(continued on next page)

34 SV40214 Rev. A

Page 37

DF500 Folder Operator Guide

Removing Fold Plates (continued)

5. Check for any paper in the fold plates or between the fold

rollers in the machine. Turn the rollers by hand or use the

hand wheel knob to make sure that all paper has been removed.

6. Reinstall fold plates by sliding fold plate assembly back into

folder until it is supported by the latch mechanism.

7. Push up from bottom of fold plate assembly until you feel

and hear the latches fully engage.

8. Close fold plate compartment door.

CAUTION: If door does not close, the fold plate

assembly has not been installed correctly.

Redo Steps 6 and 7 above until you can close

the door properly.

9. Turn power on. The display will return to running mode and

folding may be resumed.

35SV40214 Rev. A

Page 38

DF500 Folder Operator Guide

TROUBLESHOOTING

Feeding and folding problems are usually due to im prop er ad just ment of the machine or to improperly setting up a job. Refer

to the Symptom/Probable Cause section below and the Error

Mes sag es Dis played on the Control Panel table (starting on the

next page) to help you resolve prob lems when operating the

DF500.

Symptom Probable Cause–Solution

Folder will not run

Forms folded improperly

Forms skew to one side

Improper stacking

Rollers do not rotate while

motor is running

No display

Line plug loose or pulled

out–attach.

Power switch is off–Turn ON.

Safety cover not completely

closed–close.

Circuit breaker needs to be

reset–reset.

Need to redo setup proce-

dures–page 17.

Infeed guides not set prop-

erly–adjust.

Form stop bracket not po-

sitioned properly–check job

setup.

Form guides not positioned

properly –adjust.

Internal problems –contact

Service personnel.

Internal problems–contact

Service personnel.

36 SV40214 Rev. A

Page 39

DF500 Folder Operator Guide

Error Messages Displayed on the Control Panel

Error Message What It Means Operator Action

Fail To Feed

Done Enter

Fold Is

Not Available

Fold Plate Error

The paper was fed

either too late or

not at all.

You have tried to set

up an “impossible”

fold.

The fold plate stop

is prevented from

travelling along its

guide screw by an

obstruction like an

accumulation of

dirt and paper dust.

• Remove the paper stack from the feed

table, fan it out and place it back on

the feeder. Slide the stack down into

the grip of the pressure roller.

• Adjust side guides (see page 10) to

loosen the side guides.

• Adjust the roller pressure setting (see

page 11).

• Adjust the feeder gap (see page 19).

Although this is set automatically

using the Paper Thickness control,

certain papers may need manual

adjustment.

Do not go beyond the setup parameters

of the machine. For example, you may

have tried to set a “Z” fold for a paper

length of 4” (100mm). Such a folded

piece would become too small to

transport through the machine and so

the internal electronic control system

rejects the request.

• Press Enter. The fault may be cleared

automatically and the display will

revert to the normal running mode.

• If this does not help, turn power off

and remove the fold plate assembly as

described on page 33. Place the fold

plate assembly on its side. Working

through the openings in each fold

plate, try to turn the long guide screw

on which the fold plate stop travels.

Turn the screw several turns each way

to clean out any paper dust which may

have accumulated in the brass nut

of the paper stop. If you fi nd that the

paper stop has travelled to the very

end of its travel at either end, turn

the screw so that the stop is at least

3/4” (20mm) away from the extreme

position. Refi t the fold plate assembly

as described on page 33 and turn

power back on. The fold plate stops

will move to their proper positions and

the display will return to the running

mode. If the “FOLD PLATE ERROR”

message appears again, try the above

procedure once or twice more. If the

fault persists, call Pitney Bowes for

assistance.

37SV40214 Rev. A

Page 40

DF500 Folder Operator Guide

Error Messages Displayed on the Control Panel (continued)

Error Message What It Means Operator Action

Jam In Folder

Open Top Cover

Jam In Stacker

Done Enter

Limit Switch F.P.1

Or

Limit Switch F.P.2

Motor Stopped

Open Top Cover

Programs Full

Clear Job First

A paper jam has occurred

within the machine.

A folded sheet has not

been ejected properly

onto the stacker table. It

is usually caused by paper

piling up when the stacker

table is full or by a double

sheet. In rare cases, with

certain types of paper,

it can also happen when

a folded sheet catches

the topmost panel of the

preceding sheet. The

sheet causing the jam will

probably look like this: Z

or like this: Z

The stop in either fold

plate 1 (F.P.1) or fold plate

2 (F.P.2) has moved to

the very end of its travel

and has operated the

emergency limit switches

at those positions.

A large paper jam caused

the motor to stall. The

internal electronic control

in the DF500 will shut

down the motor and

display this message.

You have attempted to

save a new job but all nine

memory locations are

already full.

Refer to “Clearing a jam”

on page 32 and “Removing

the fold plates” on page

33.

• Remove all paper from

the stacker table,

then press Enter. The

stacker wheels will

return to their operating

position and the display

will show operating

mode again.

• Open the top cover

and remove any paper

inside. Close the top

cover and press Enter

to clear the display

message.

• If possible, adjust the

fold to look more even

like this: Z

Follow the procedure for

“FOLD PLATE ERROR”

above to clear this

condition.

Refer to “Clearing a jam”

on page 32 and “Removing

the fold plates” on page

33.

Delete some jobs to make

room (see page 27).

38 SV40214 Rev. A

Page 41

DF500 Folder Operator Guide

Error Messages Displayed on the Control Panel (continued)

Error Message What It Means Operator Action

Stacker Error

Use New Setting ?

Yes: Enter No:!

There is a problem

with the stacker

rollers.

This message

appears when you

have changed a

setting but have

not confi rmed it by

pressing Enter.

• Press Enter and the problem may

clear itself automatically.

• If this does not help, turn power off

and remove the fold plate assembly

as described on page 33. This

gives access to the stacker drive

mechanisms on the underside of

the stacker table. Locate the stacker

motor and turn the small drive gear

on the motor shaft. This will move the

stacker rollers. Turn the gear in the

direction that will move the stacker

rollers away from the extreme end

of their travel. Keep turning until the

stacker rollers have moved about 3/4”

(20mm) away from the end of their

guide slots in the stacker table. Refi t

the fold plate assembly as described

on page 33 and turn power back

on. The stacker rollers will move to

their proper position and the display

will return to the running mode. If

the rollers return to their extreme

position and the “STACKER ERROR”

message appears again, try the above

procedure once or twice more. If the

fault persists, call Pitney Bowes for

assistance.

Press Enter to activate your setting or

! to stay with your previous setting.

39SV40214 Rev. A

Page 42

DF500 Folder Operator Guide

MAINTENANCE

Regular and proper cleaning contributes to a long life of the ma chine and a consistent quality. It is important, therefore, to clean

the machine at regular intervals. The interval between machine

main te nance depends on the workload, but once a week is a

good starting point. Maintenance of the DF500 includes:

• Removing accumulated paper dust

• Removing any built-up debris on the fold rollers. This should

be done with a stiff brush only-not with liquids

as soap and water, alcohol, roller cleaner, ink re mov er, etc.

would dam age the rollers' anti-static surface and cause folding prob lems.

• Cleaning the outside

a damp ened cloth and a water-based mild liquid or spray

clean er.

WARNING: Before cleaning or doing any

maintenance on the ma chine, always

unplug the AC cord from the wall.

surface of the DF500 as needed with

. Liquids such

Do not attempt to service the Model DF500 your self, as re mov ing

covers may expose you to dangerous voltage and moving parts.

Refer all servicing to a trained Pitney Bowes Cus tom er Service

Rep re sen ta tive.

SUPPLIES

To order the following item, just call the PB Supply Line at 1-800-243782 4 .

Multipurpose Cleaning Kit, Item code F902-0

40 SV40214 Rev. A

Page 43

DF500 Folder Operator Guide

FORM HANDLING

Material Handling Notes

Material handling problems with paper handling equipment are

often due to distortion (warping, curl, sticking, etc.). This can be

a result of poor packaging, improper handling or environmental

ex tremes during manufacture, transit, or storage. This is particularly true of material which contains glue that is extremely sensitive to tem per a ture and humidity.

Fortunately, there are a number of easy and effective measures

you can take to minimize problems, improve production and get

the most out of your Pitney Bowes equipment.

Be Sure Material Meets Our Forms Specifications

The DF500 is designed to handle a certain range of material.

Ma te ri al which falls outside this range may run poorly or not at

all. Many operating problems are actually due to out-of-spec i fi ca tion material.

Store and Handle Material with Care

• Do not "crash" skids, loaded with the material, onto loading

docks, in trans port vans, or in the final storage area.

• Block loaded skids in transport vans.

• Do not expose cartons to the elements; prolonged exposure to

intense sunlight, high humidity and so on can damage material.

• Store materials in a controlled environment. We recommend

a nominal temperature of 75°F at 50% relative humidity. Glue

formulas do vary, however, so temperature and humidity limits

above and below these may be better for certain materials.

• Store cartons on skids or shelves to prevent absorption of

moisture, never directly on floors or against cement walls.

Very dry material may accumulate static and be difficult to handle, whereas damp material will almost certainly stick together.

• Do not stack cartons too high; this can deform the cartons

on the bottom and damage the material. Try to stack cartons

so that material lies flat.

41SV40214 Rev. A

Page 44

DF500 Folder Operator Guide

FORM HANDLING (continued)

Rotate Stock; Give Material Time to Stabilize

• Rotate stock; use oldest stock first (first in, first out).

• Transfer cartons from the storage area to the work area no

more than several hours before use.

• Do not remove boxes from their cartons until they are needed.

• Allow about one hour of stabilization time for each degree of

temperature change from the storage to the processing area.

42 SV40214 Rev. A

Page 45

DF500 Folder Operator Guide

EQUIPMENT/FORM SPECIFICATIONS

Equipment

Dimensions

Weight

Electrical

Operating Speed

Nominal Usage

Sound Level:

Environment Amb.

Temperature

Operation

Fold Types

Fold Plate Range

Width: 25" (640mm)

Length: 34" (860mm)

Height: 17" (430mm)

95 lbs. (43 kg) shipping weight

120 VAC, 60 Hz, 3A (also 230 VAC, 50 Hz, 2A)

Up to 20,000 sheets per hour, depending

on fold (actual speed will depend on the

paper size, paper quality, system setup,

operator experience, and environmental

conditions)

2,000 pieces/day; 40,000 pieces/month

Maximum peak operation is 40,000 piec-

es per day, no more than once a month.

75 dBA, based on folding 20 lb. bond

2

(80 g/m

) paper into a letter (C) fold at

a speed of 10,000 sheets per hour (Aweighted sound level at op er a tor position).

55 - 95°F (13 - 35 °C)

Max. Wet Bulb: 80 °F (27 °C)

Relative humidity: 20 - 80% (noncondense)

• Single (half fold)

• Z-fold (accordion)

• Letter (C) fold

• Double Parallel fold

• Z+ fold with margin

Fold plate 1: min. 1-9/16" (40 mm),

max. 12-3/4" (324 mm)

Fold plate 2: min. 1-9/16" (40 mm),

max. 8-1/2" (216 mm)

43SV40214 Rev. A

Page 46

DF500 Folder Operator Guide

Skew Allowance -based on 20 lb. 8.5" x 11" (80 g/m2 A4 bond paper)

• 68% of samples will deviate from the ideal fold center line

within ±.02" (±0.5mm)

• 28% of samples will deviate from the ideal fold center line

within ±.02-.04" (±0.5-1.0mm)

• 4% of samples will deviate from the ideal fold center line

within ±.04-.06" (±1.0-1.5mm)

Multi-Skew Allowance:

Collated sets of up to five sheets may deviate from the ideal fold

life by a maximum of ±1/12" (±2mm) either side.

Ideal Fold Line

+.02"

-.02"

Ideal Fold Line

Fold Deviation: Based on 20 lb. 8.5" x 11" (80 g/m2 A4 bond paper)

• 68% of samples will deviate from the ideal fold center line

within ±.02" (±0.5mm)

• 28% of samples will deviate from the ideal fold center line

within ±.02-.04" (±0.5-1.0mm)

• 4% of samples will deviate from the ideal fold center line

within ±.04-.06" (±1.0-1.5mm)

44 SV40214 Rev. A

Page 47

DF500 Folder Operator Guide

Multi-Sheet Fold Allowance: Collated sets of up to five sheets

may deviate from the ideal fold life by a max. of ±1/12" (±2mm)

either side.

+.02"

Ideal Fold Line

-.02"

Forms

Size

Form Weight

Thickness

Feeding

Capacity

Paper Ratio

Width: min. 3-1/2" (90 mm), max. 12" (305 mm)

Length: min. 4" (100 mm), max. 17" (432 mm)

2

Minimum: 14 lb. bond (53 g/m

Maximum: 65 lb. bond (180 g/m

)

2

)

The DF500 can process, hand fed, stapled, or

non-stapled collations of up to five sheets of

2

8-1/2" by 11" 20 lb. (80 g/m

) material. Maxi-

mum thickness is 0.020"(0.5mm).

The feed and stacking areas will ac com -

2

mo date 250 sheets of 20 lb. (80 g/m

) material

The length of the paper must be at least two

times the width of the paper.

Length

Width

45SV40214 Rev. A

Page 48

DF500 Folder Operator Guide

Index

A

Adjustments

Feeder Gap 19

Fold Type 17

Paper Guides 10

Pressure Roller 11

Skewed Fold 18

Automatic Fold Setup 12

Automatic Feed 31

B

Batch Count, Setting 21, 22

C

Clearing a Jam 32

Controls/Features 5, 6, 7

Control Panel, Description 7

D

Deleting a Job 27

Description, Machine 4

Double Parallel Fold

Description 4

Setup 12

E

Equipment Specifications 43

Error Messages 37, 38, 39

F

Feed, Manual 30

Feed, Automatic 31

Feeder Gap, Adjusting 19

Feeder, Setup 9, 10, 11

Folder Mechanics 15

Fold Plates, Removing 34

Fold Types

Description 4, 43

Fine Tuning 17

Setup, Automatic 12

Setup, Manual 28, 29

Form Handling 41

Forms Specifications 45

G

Gap, Feeder, Adjusting 19

Gate Fold

Description 4

Setup 12

I

Identifying a Job 26

J

Jam, Clearing 32

Jobs

Deleting Job 27

Identifying Job 26

Normal Job, Setup 23

Retrieving Job 26

Running Job 23

Saving Job 24

Temporary Job, Setup 23

L

Letter Fold

Description 4

Setup 12

M

Machine Setup 9

Maintenance 40

Manual Feed 30

Manual Fold Setup 28, 29

Moving the DF500 8

46 SV40214 Rev. A

Page 49

DF500 Folder Operator Guide

N

Non-Standard Fold, Man.Setup 28

Normal Job, Setup 23

O

Operating, Folder 13

Operating Hints 32

P

Paper Guides, Adjusting 10

Paper, Loading 10

Paper Size

Setup for Automatic Fold 12

Setup for Manual Fold 28

Pressure Roller, Adjusting 11

R

Retrieving Job 26

Running Job 23

S

Safety 2

Saving Job 24

Single Fold

Description 4

Setup 12

Skewed Fold, Adjusting 18

Specifications,

Equipment 43, 44

Forms 45

Speed, Setting 13

Standard Fold, Manual Setup 28

Start/Stopping Machine 14, 15

Supplies 40

Symptoms , Troubleshooting 36

T

Table Extension 11

Temporary Job, Setup 23

Theory, Folder Mechanics 15

Total Count, Clearing 20

Trial Piece, Running 14

Troubleshooting 36, 37, 38, 39

Z

Z-Fold

Description 4

Setup 12

Z-Fold with Margin

Description 4

Setup 12

47SV40214 Rev. A

Page 50

DF500 Folder Operator Guide

48 SV40214 Rev. A

Page 51

Loading...

Loading...