Page 1

DI350 OfficeRight

Inserting System

Operator Guide

TM

SV40190-OG Rev. A

Page 2

Contents

NOTE: This equipment has been tested and found to

comply with the limits for a Class A device, pursuant to part

15 of the FCC rules. These limits are designed to provide

reasonable protection against interference when the

equipment is operated in a commercial environment. This

equipment generates, uses and can radiate radio frequency energy, and if not installed and used in accordance

with the instruction manual, may cause interference to

radio communications. Operation of this equipment in a

residential area is likely to cause interference, in which

case the user, at their own expense, will be required to

correct the interference.

Trademark Notice

OfficeRight™ and EZ Seal® are trademarks of Pitney Bowes Inc.

First Edition, September 2002

©2002 Pitney Bowes Inc.

All rights reserved. This book may not be reproduced in whole or in part

in any fashion or stored in a retrieval system of any type or transmitted

by any means, electronically or mechanically, without the express

written permission of Pitney Bowes.

We have made every reasonable effort to assure the accuracy and

usefulness of this manual, however we cannot assume responsibility

for errors or omissions or liability for the misuse or misapplication of our

products.

ii

Page 3

Contents

ABOUT THIS GUIDE

This guide explains how to setup and use the DI350

OfficeRight™ Inserting System . Please spend a few

moments reading through it. Understanding what the inserter

does, and how it does it, will keep problems to a minimum

and help you get the best performance possible.

This Guide is organized into seven sections:

1. INTRODUCTION

To the Operator 1-5

Three-Station Model .................................................... 1-5

Two-Station Model ...................................................... 1-6

One-Station Model ...................................................... 1-6

Safety ................................................................................ 1-7

Machine Identification ....................................................... 1-8

Control Panel .................................................................. 1-10

Control Panel Buttons ............................................... 1-10

Display Symbols ........................................................ 1-12

2. OPERATION

Connecting Power ............................................................. 2-1

Selecting and Running a Job ............................................ 2-1

Select the Job.............................................................. 2-1

Run a Trial Piece ......................................................... 2-2

Start Machine Operation ............................................. 2-3

Setting the Sheet Feeders ................................................ 2-3

Setting the Envelope Feeder............................................. 2-4

Setting the Insert Feeder................................................... 2-5

Filling the Sealer ............................................................... 2-6

Programming Options By Model ....................................... 2-7

iii

Page 4

Contents

3. CREATE A NEW NON-OMR JOB

Create New Non-OMR Job ............................................... 3-1

Entering the Setup Mode............................................. 3-1

Choosing the New Job Number .................................. 3-2

Selecting Non-OMR Option ......................................... 3-2

Flowchart for Non-OMR Job........................................ 3-3

Setting the Accumulation Function .............................. 3-5

Fold Type .................................................................... 3-6

Setting Sheet Feeder 1 ............................................... 3-7

Setting Sheet Feeder 2 ............................................... 3-8

Setting Insert Feeder ................................................... 3-9

Mode ........................................................................... 3-9

Sealer ........................................................................ 3-10

Paper Length ............................................................. 3-10

Fold A ........................................................................ 3-11

Fold B ........................................................................ 3-11

Envelope Depth ......................................................... 3-12

Envelope Stop ........................................................... 3-12

Batch Mode ............................................................... 3-13

Confirming the Job Setup .......................................... 3-13

Testing the Job .......................................................... 3-14

Changing an Existing Job ............................................... 3-15

Deleting a Job ................................................................. 3-15

iv

Page 5

Contents

4. WHAT IS OMR (OPTICAL MARK

RECOGNITION)?

What is OMR? ................................................................... 4-1

What Do OMR Marks Look Like on Paper? ...................... 4-2

How are OMR Marks Read on the DI350? ....................... 4-3

How are OMR Marks Generated?..................................... 4-4

What OMR Marks are Used on the DI350? ...................... 4-5

OMR Group Combinations ................................................ 4-9

Details of Basic Level OMR ............................................ 4-10

Group 1 Marks (“OMR”) ............................................. 4-10

Details of Enhanced Level OMR ..................................... 4-14

Group 2 Marks (“Select Feed”) ................................... 4-14

Group 3 Marks (“Sequence”) ...................................... 4-17

Considerations When Implementing OMR ...................... 4-20

v

Page 6

Contents

5. CREATE A NEW OMR JOB

Creating a New OMR job .................................................. 5-1

What Is OMR? ............................................................. 5-1

Entering the Setup Mode............................................. 5-1

Choosing the New Job Number .................................. 5-2

Selecting OMR Option................................................. 5-3

Flowchart for OMR Job ............................................... 5-4

Fold Type .................................................................... 5-6

Setting Main (Scanning) Sheet Feeder ....................... 5-7

Setting Other Sheet Feeder ........................................ 5-7

Setting Insert Feeder ................................................... 5-9

Sealer ........................................................................ 5-10

Paper Length ............................................................. 5-10

Fold A ........................................................................ 5-11

Fold B ........................................................................ 5-11

Envelope Depth ......................................................... 5-12

Envelope Stop ........................................................... 5-12

Batch Mode ............................................................... 5-13

Confirming the Job Setup .......................................... 5-13

Adjustment of OMR Scanner..................................... 5-14

Loading the Material .................................................. 5-17

Testing the Job .......................................................... 5-18

Changing an Existing Job ............................................... 5-19

Deleting a job .................................................................. 5-19

vi

Page 7

Contents

6. REFERENCE

Changing the Display Language ....................................... 6-1

Clearing Material ............................................................... 6-1

Hand Crank ................................................................. 6-1

Removal & Replacement of Sheet Feeder and

Envelope Trays ........................................................ 6-2

Removal & Replacement of the Fold Plates................ 6-2

Removal & Replacement of the Insert Tray ................ 6-3

Access to Carriage Assembly ..................................... 6-3

Access to Envelope Feeder Area ................................ 6-3

Access to the Envelope Exit Area ............................... 6-4

Access to the Envelope Inserting Area ....................... 6-4

Access to the Sheet Feed Area................................... 6-4

Troubleshooting ................................................................ 6-5

Error Messages ............................................................... 6-11

Paper Handling.......................................................... 6-11

OMR Errors ............................................................... 6-15

Material Specifications .................................................... 6-17

Sheet Feeders ........................................................... 6-17

Insert Feeder ............................................................. 6-17

Sealer ........................................................................ 6-18

Stacker ...................................................................... 6-18

Envelope Feeder ....................................................... 6-18

Material Requirements .............................................. 6-19

OMR Specifications (General) ........................................ 6-19

Machine Specifications ................................................... 6-20

Physical Dimensions: ................................................ 6-20

Noise Level................................................................ 6-20

Electrical/BTU Rating ................................................ 6-20

Speed ........................................................................ 6-20

Fold Modes................................................................ 6-20

Compliance ............................................................... 6-20

Usage ........................................................................ 6-21

Machine Life .............................................................. 6-21

Service ............................................................................ 6-21

vii

Page 8

Contents

APPENDIX A – TRAINING CHECKLIST

Operator Training Checklist .............................................. A-1

Introduction..................................................................A-1

Operation.....................................................................A-1

Create (Program) Non-OMR Job ................................ A-1

What Is OMR? .............................................................A-2

Create (Program) OMR Job ........................................A-2

Reference ....................................................................A-2

INDEX

viii

Page 9

Introduction

1. INTRODUCTION

To the Operator

Your Pitney Bowes DI350 Inserting System is a compact,

desk top unit, which is simple to set up and run while offering

the following features:

• Envelope seal/no seal option

• Semi-automatic single insert operation (not on single station model)

• Fully automatic material separation on sheet feeder(s)

• Fully automatic settings on fold plates

• Fully automatic envelope separation

• Fully automatic double document detection when selected

• Fold only option (fold without insertion)

• Semi-automatic insertion of single and multiple sheet Inserts

• Option of single fold, letter (C) fold, accordion (Z) fold or double fold

• Job recall, operator programmable (up to 20, depending on model)

• Switchable feeding

• Optical Mark Recognition (OMR) scanning for greater collation

integrity and additional feeding flexibility (3-station model only)

This guide covers all three models of the DI350 inserter system.

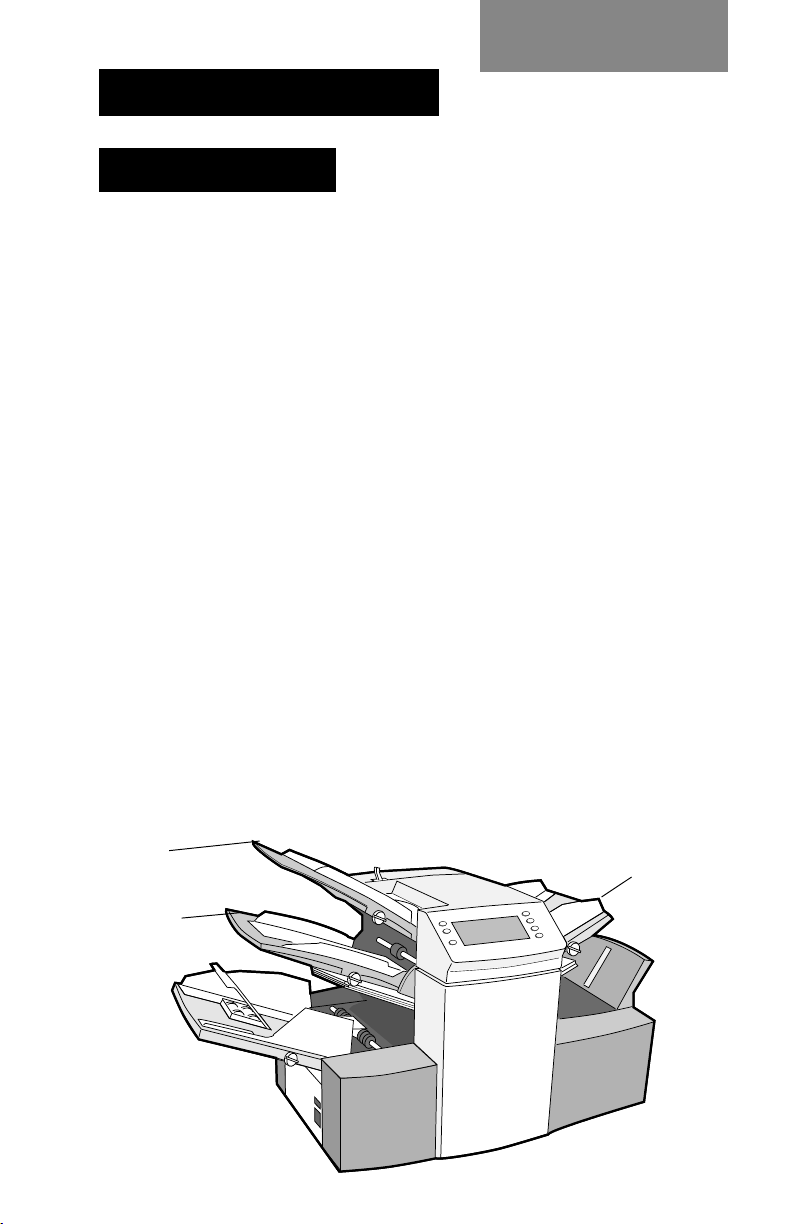

Three-Station Model

This model incorporates two sheet feeders and an insert feeder.

It is the only model that has OMR and has the most setup

options. For this reason, all illustrations in this guide show this

model.

Sheet

Feeder 1

Sheet

Feeder 2

1-1

Insert Feeder

Page 10

Introduction

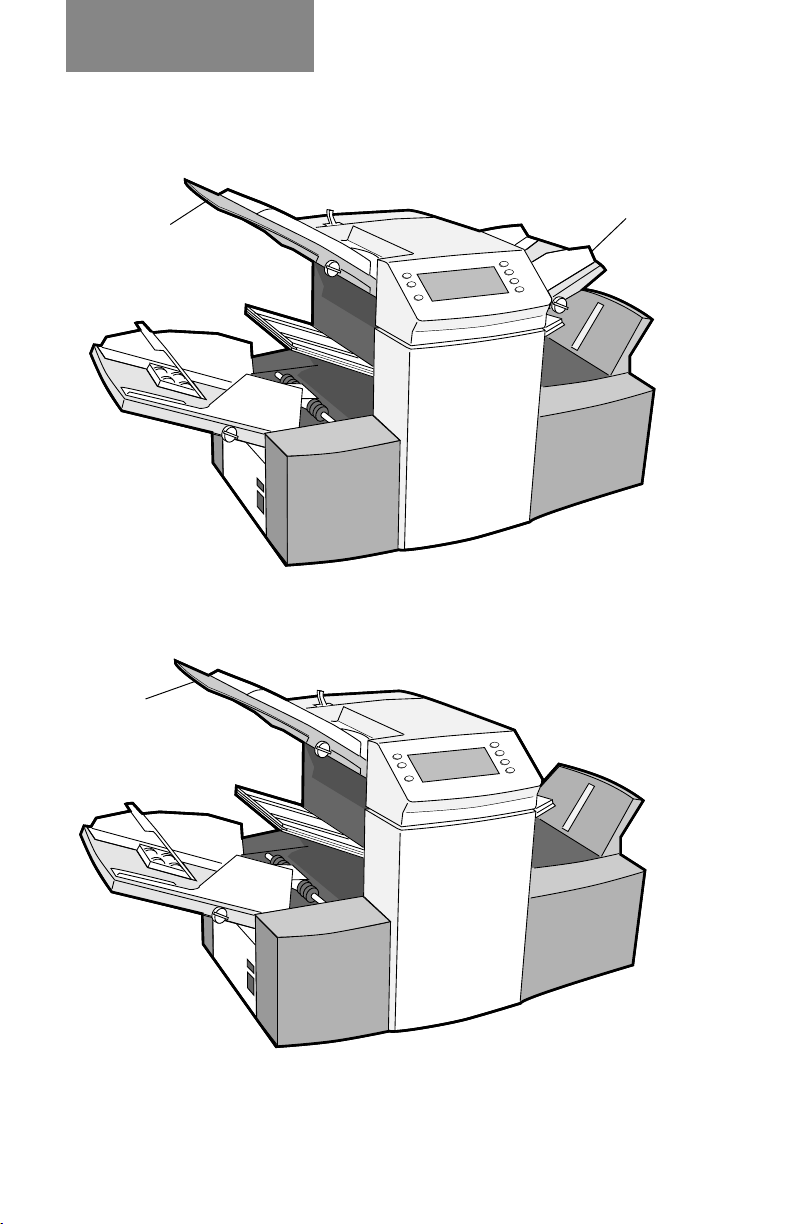

Two-Station Model

This model incorporates a single sheet feeder and an insert

feeder.

Insert Feeder

Sheet Feeder 1

One-Station Model

This model incorporates a single sheet feeder.

Sheet Feeder 1

All models are set up and operated in a very similar way.

Procedures in this guide cover all models. If a function is

model dependent, the accompanying text will explain this.

1-2

Page 11

Introduction

Safety

Safety Precautions:

When using this machine, follow the normal safety precautions for all

office equipment:

Keep loose clothing, jewelry and long hair away from all moving parts.

Avoid touching moving parts or materials while the machine is in use.

Before clearing a jam, be sure machine mechanisms come to a stop.

When removing jammed material, avoid using too much force to

protect against minor personal injury and damaging equipment.

Use the power cord supplied with the machine and plug it into a

properly grounded wall outlet located near the machine and easily

accessible. Failure to properly ground the machine can result in severe

personal injury and/or fire.

The power cord wall plug is the primary means of disconnecting the

machine from AC supply.

DO NOT use an adapter plug on the line cord or wall outlet.

DO NOT remove the ground pin from the line cord.

Avoid using wall outlets that are controlled by wall switches, or shared

with other equipment.

DO NOT route the power cord over sharp edges or trapped between

furniture.

Insure there is no strain on the power cord where it becomes jammed

between the equipment, walls or furniture.

Be certain the area in front of the wall receptacle into which the

machine is plugged is free from obstruction.

Do not remove covers. Covers enclose hazardous parts that should

only be accessed by Pitney Bowes Customer Service. Report any

damage of covers to a Pitney Bowes Customer Service Representative.

To prevent overheating, do not cover the vent openings.

Read all instructions before attempting to operate the equipment.

Use this equipment only for its intended purpose.

In addition, follow any specific occupational safety and health

standards for your workplace or area.

1-3

Page 12

Introduction

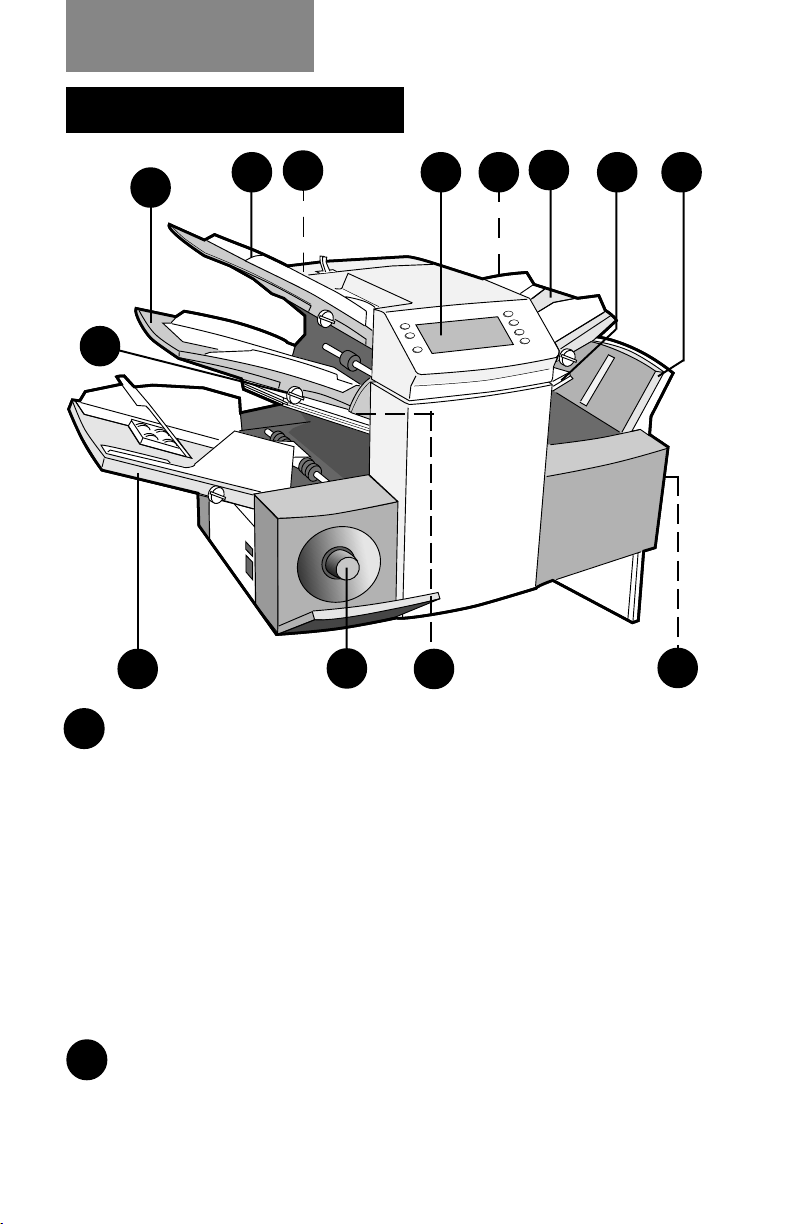

Machine Identification

12

2

1 6

11

3

5

9

1 Sheet Feeder 1

This feeder is intended for feeding material that requires

folding. If you are running addressed documents for

insertion into window envelopes, feed them from this

feeder.

8

13

4

10

7

In addition, sheet feeder 1 can be set to ‘manual feed’. In

this mode, stapled sets of up to 5 sheets may be run. The

machine waits for each set to be manually fed into sheet

feeder 1 before folding and inserting the set automatically. See the specifications section of Chapter 6

(Reference) for full details of the sets possible.

2 Sheet Feeder 2

For feeding material that requires folding. Its functions

are similar to sheet feeder 1 but ‘manual feed’ is NOT

available from this feeder.

(three-station machine only)

1-4

Page 13

Introduction

3 Insert Feeder

Use this feeder to add additional inserts to your

envelope. Material fed from this feeder cannot be folded

by the inserter. However, this feeder is especially suited

to feeding pre-folded or thicker inserts.

4 Fold Plate 2

5 Fold Plate 1

These units are used to create the desired fold in

material fed from the sheet feeder(s). The fold plates are

automatically set from the control panel.

6 Display/Control Panel

This is where you enter commands and where the

machine informs you of its status with the use of symbols

and icons. Full details of each button function are given

on the following page.

7 Stacker and Measuring Scale

Located at the right end, is the fold-down stacker. This

unit can be latched against the right side of the machine

when not in use to save space.

(two and three-station machines only)

A scale is located along the front edge of the stacker to

aid measurement of material and envelopes.

8 Hand Crank

The hand crank is located behind a drop down cover at

the left front. It can be used to manually turn the machine

mechanisms to free a material stoppage.

9 Envelope Feeder

This feeder feeds envelopes into the inserting area

where they are filled with the sheets requested from the

other feeders.

10 Envelope Inverter Unit

This unit exits the envelope into the stacker face up.11

1-5

Page 14

Introduction

11 Sealer Water Bottle

The sealer water bottle is located behind a drop down

cover at the right rear of the machine. It provides water or

EZ Seal® solution to the envelope sealer unit.

12 Upper OMR Scanner

Scanner used to read OMR marks on sheet feeder 1 from

above the sheet.

13 Lower OMR Scanner

Scanner used to read OMR marks on sheet feeder 2 from

under sheet.

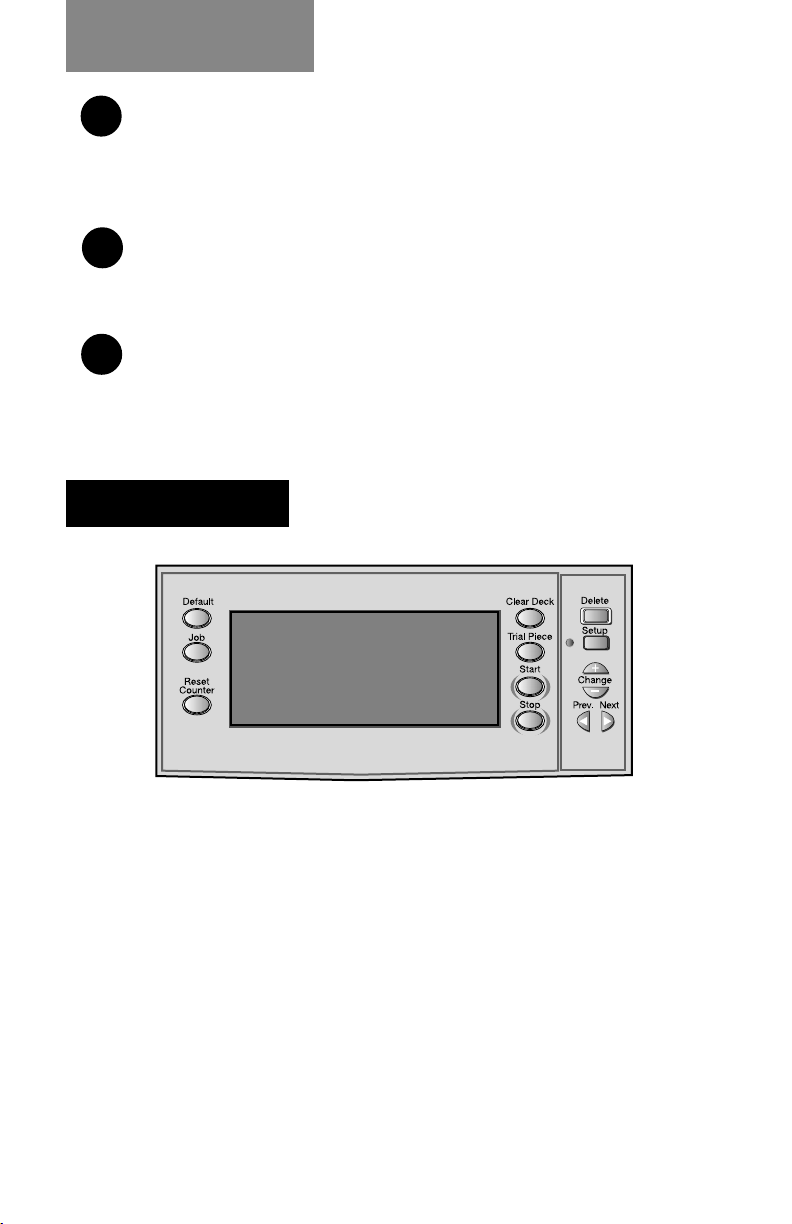

Control Panel

(three-station machine only)

(three-station machine only)

Control Panel Buttons

Default Press this button to return the system to its

‘standard’ settings. These settings come preconfigured from the factory but can be modified to

suit your needs by a Pitney Bowes Customer Service

Representative.

Job Press to step through the jobs you have programmed

into the machine’s memory. Up to twenty (20) jobs can

be held, depending on model (see page 2-9). See

Chapters 3 or 5 for details on programming jobs.

1-6

Page 15

Introduction

Reset Counter Press this button to reset the item counter.

Clear Deck Pressing this button will jog material through and out

of the machine. It can be used to clear the machine

ready for automatic operation after a stoppage has

occurred etc.

Trial Piece This button is used to run a single test piece so that

you can check machine setup. A trial piece must be

run before automatic operation can be commenced

using the Start button. If double detection is in use,

the machine sets itself automatically as it runs the

trial piece. This envelope will be unsealed and

counted as one item.

Start Starts automatic operation.

Stop Stops automatic operation at the end of the next

cycle.

Delete Used in setup mode to delete a programmed job

from memory.

Setup When pressed, the machine enters setup mode. This

mode allows you to program jobs into memory for

instant recall using the Job button.

Change + – In setup mode, used to select options or set values

of machine settings.

Prev. In setup mode, used to step backwards/forwards

Next

through the various machine settings.

1-7

Page 16

Introduction

Display Symbols

. . 3 . .

Used on sheet feeders to

signify that the feeder is

on without double

detection.

Used on sheet feeders to

signify that the feeder is

on with double detection.

Used on insert feeder to

signify that the feeder is on

without double detection.

Used on insert feeder to

signify that the feeder is

on with double detection.

Used on sheet feeder 1 to

signify that the feeder is

set for manual feed.

Used on envelope feeder

to signify that the feeder is

on.

Indicates the setting (from

1 to 5) of the envelope

stop.

Indicates that the sealer

water bottle needs refilling.

Indicates that the sealer

unit is on (automatic

envelope sealing).

Indicates a ‘C’ - Letter

fold is selected.

Indicates a ‘Z’ -

Accordion fold is

selected.

Indicates a double fold

is selected.

Indicates a single fold is

selected.

Indicates a no-fold insert

operation.

Indicates a material

stoppage. The position of

this symbol in the display

indicates where the

stoppage has occurred.

Indicates the envelope

depth.

Indicates that the sealer

unit is off (envelopes not

sealed).

Used on any feeder to

indicate feeder is not in use.

Call Pitney Bowes

Service.

Indicates the paper size,

address orientation and

fold(s) set for sheet

feeder.

1-8

Page 17

Operation

2. OPERATION

This section explains operation of the DI350 inserter, assuming the job to be run is already programmed into the machine.

If the job has not been programmed, refer to “Create Non-

OMR Job” on page 3-1 or “Create OMR Job” on page 5-1.

Connecting Power

Read the safety

information on

!

Connect the power cord to

the socket on the left side of

the machine. Plug the power

cord into a suitable power

outlet. Make sure the power outlet is near the machine and is

easily accessible. Turn the machine power switch ON.

page 1-3 before

connecting the

machine.

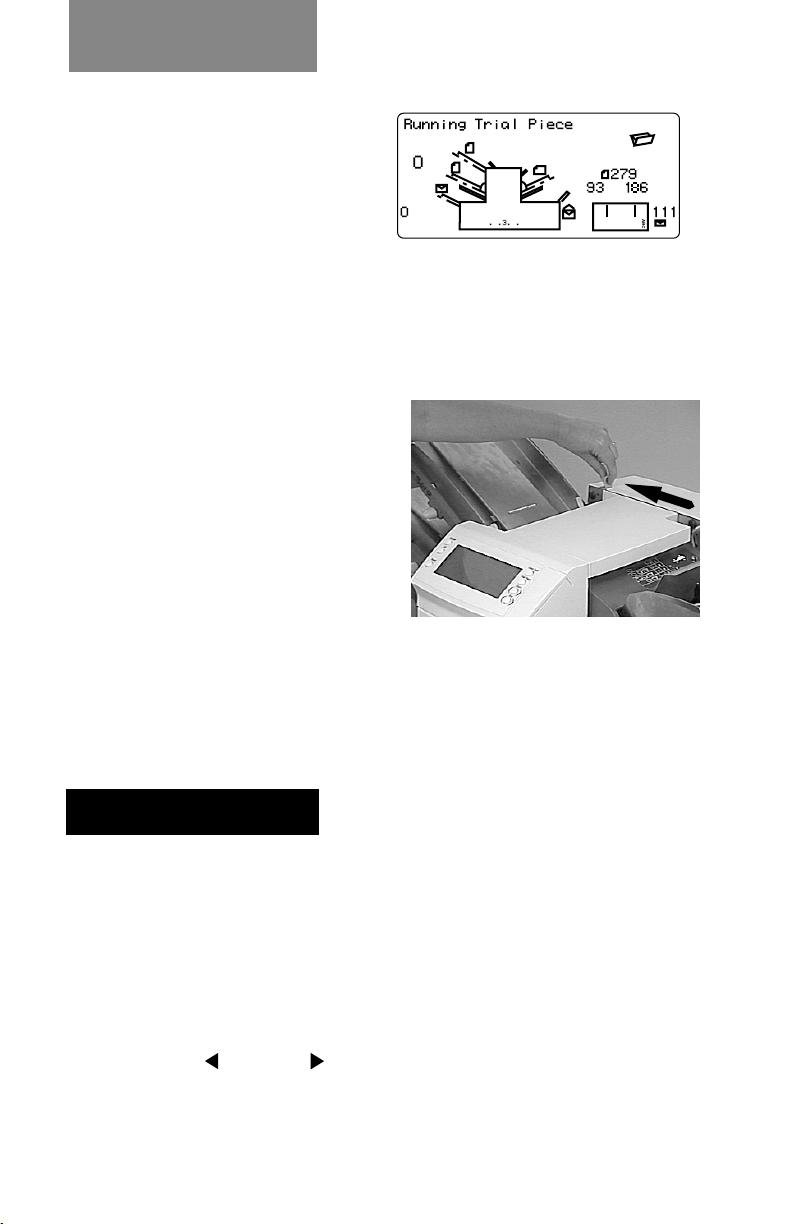

Selecting and Running a Job

Select the Job

When the machine is turned

ON, the display will show the

last job run and ‘Trial Piece

Required’.

Press the Job button until the

job you require is displayed,

or press Default if you want to run the machine with your

‘standard’ settings.

Note: The default job can be altered only by a Pitney Bowes

Customer Service Representative.

2-1

Page 18

Operation

If you have material loaded,

press Trial Piece. The

machine will set itself and

run a test piece for you to

check.

If you don’t have material loaded, do this now, then return to

this section. Loading feeders etc. is covered on the following

pages.

Note:

You may have selected a

‘manual feed’ job where

sheet feeder 1 is set for

manual feed of collated sets.

If this is the case, the sheet

feeder should not be loaded,

as the collated sets are fed

one at a time as required by

the machine. However, the

lever shown in the illustration should be pulled back to open

the feed mechanism to ready the manual feed operation.

Remember to return this lever to its normal position when

you use the feeder for automatic operation.

Run a Trial Piece

Once material is in place, press Trial Piece so you can

check that the setup is correct.

Note: In switchable mode both sheet feeders must be loaded. A

trial piece will be run for both feeders.

Minor changes to the job settings can be made at this stage

if the trial piece needs ‘fine tuning’. Press Setup, then use

the Prev ( ), Next ( ) and Change (+/-) buttons as

required to modify job settings. When you have made the

necessary changes, press Setup again to return to run

mode. The job will be saved with the new settings.

2-2

Page 19

Operation

Start Machine Operation

Press Start to begin automatic operation. The machine will

operate until either material runs out or the Stop button is

pressed.

Note: If the three station machine is set for switchable

feeding, the display will show:

Ready: 1 > 2 > 1

This confirms that feeding will automatically switch between

sheet feeders. See page 3-8 or 5-7 for more details.

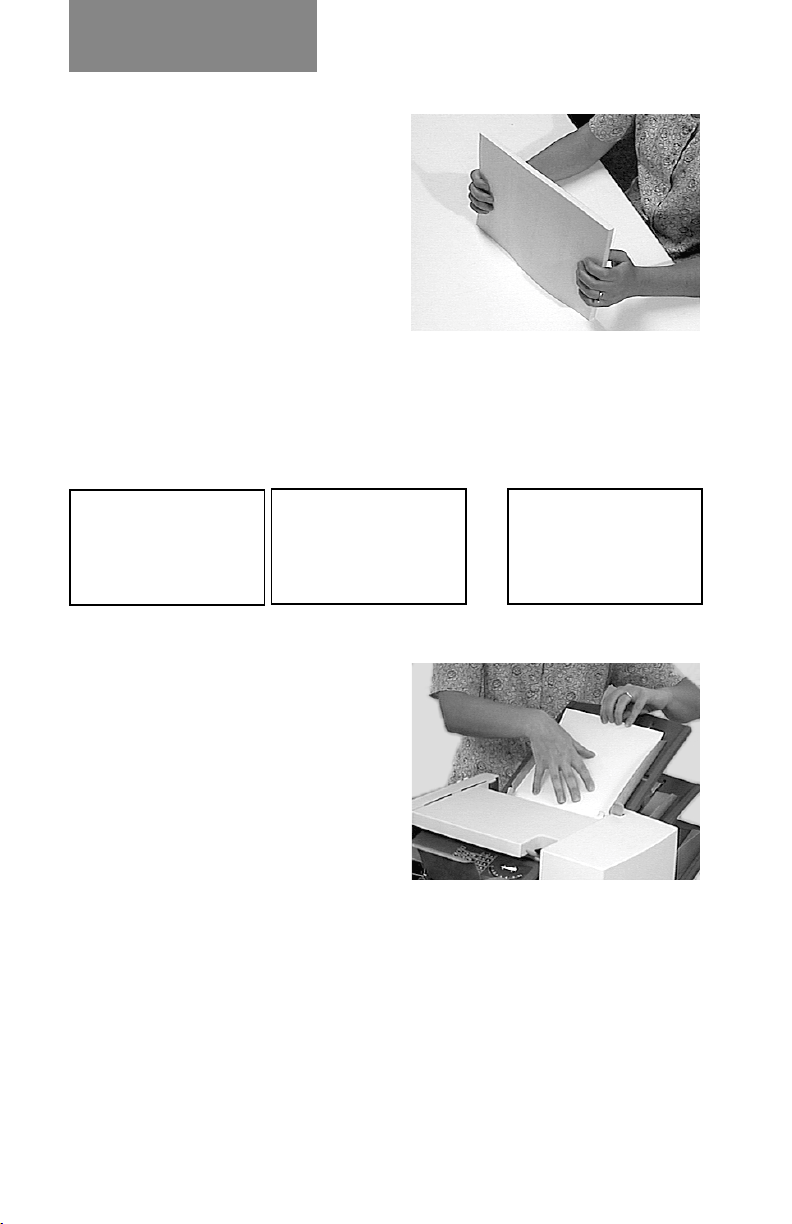

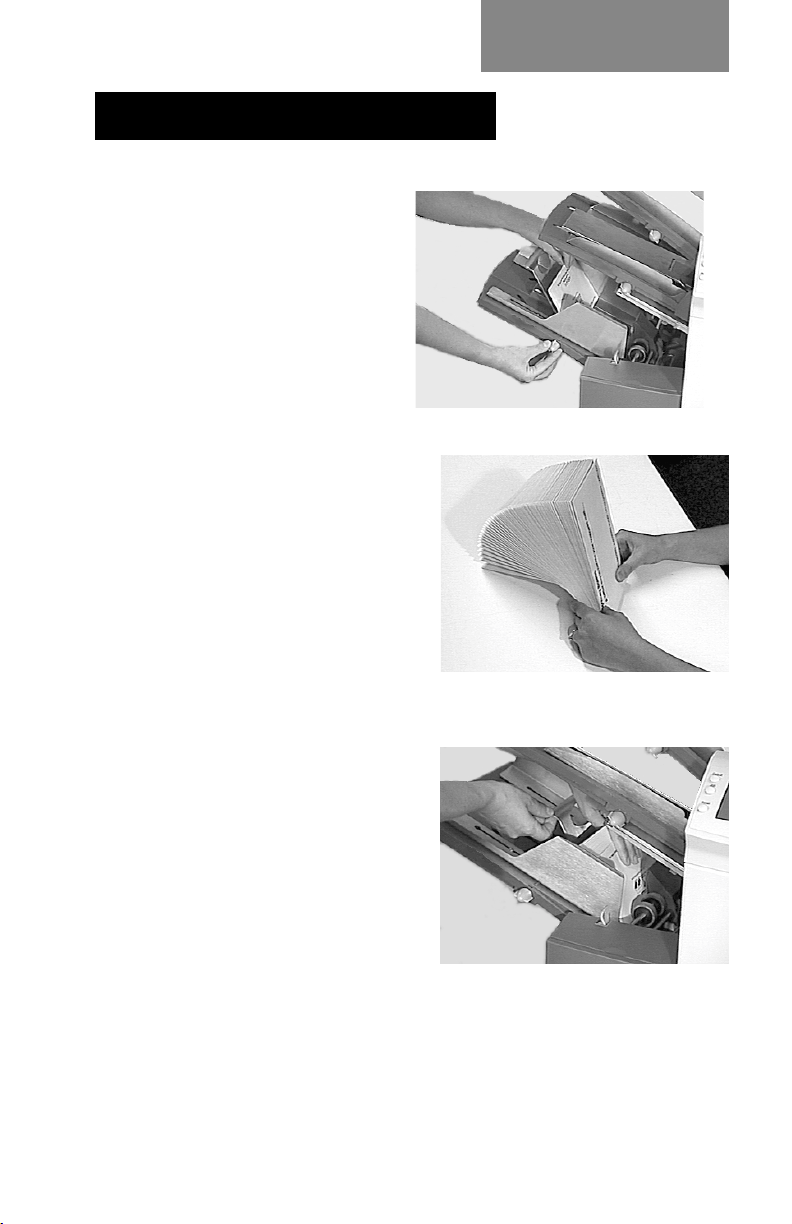

Setting the Sheet Feeders

1. Adjust the side guides to

the width of the material

being fed, then back-off a

quarter turn on the side

guide control. This will

set the correct clearance

between the guides and

the material.

2. Take the stack of paper

and aerate it to ensure

the individual sheets are

not stuck together.

2-3

Page 20

Operation

3. Jog the stack back into

alignment. The sheet

feeders take the paper

stack aligned in a similar

way to a photocopier

paper cassette.

4. The three possible

choices for loading you documents with addresses are

listed below. NOTE: The display will indicate the correct

orientation of the paper in the first two cases only.

FACE UP

HEAD FIRST

ABC

FACE DOWN

FEET FIRST

ABC

ABC

FACE UP

FEET FIRST

5. Place the paper stack onto

the feed deck. Allow the

deck to move down and

the top of the paper stack

to slide under the feed

roller.

Note: When using both

sheet feeders with

accordion

fold, sheet

feeder 2 must be used for

the prime (address bearing)

document.

6. You can pull out the sliding supports from the end of the

deck to help support long material.

2-4

Page 21

Setting the Envelope Feeder

1. Adjust the side guides

to the width of the

envelopes being fed,

then back-off half a

turn on the side guide

control. This will set

the correct clearance

between the guides

and the envelopes.

2. Aerate the stack of

envelopes to be run.

Operation

3. Place them on the feed

deck with the flaps up

and trailing. The lead

edge of the first

envelope should be

under the front feed

roller.

Let the ‘wedge’ slide

down behind the stack so

that the envelopes are

supported.

2-5

Page 22

Operation

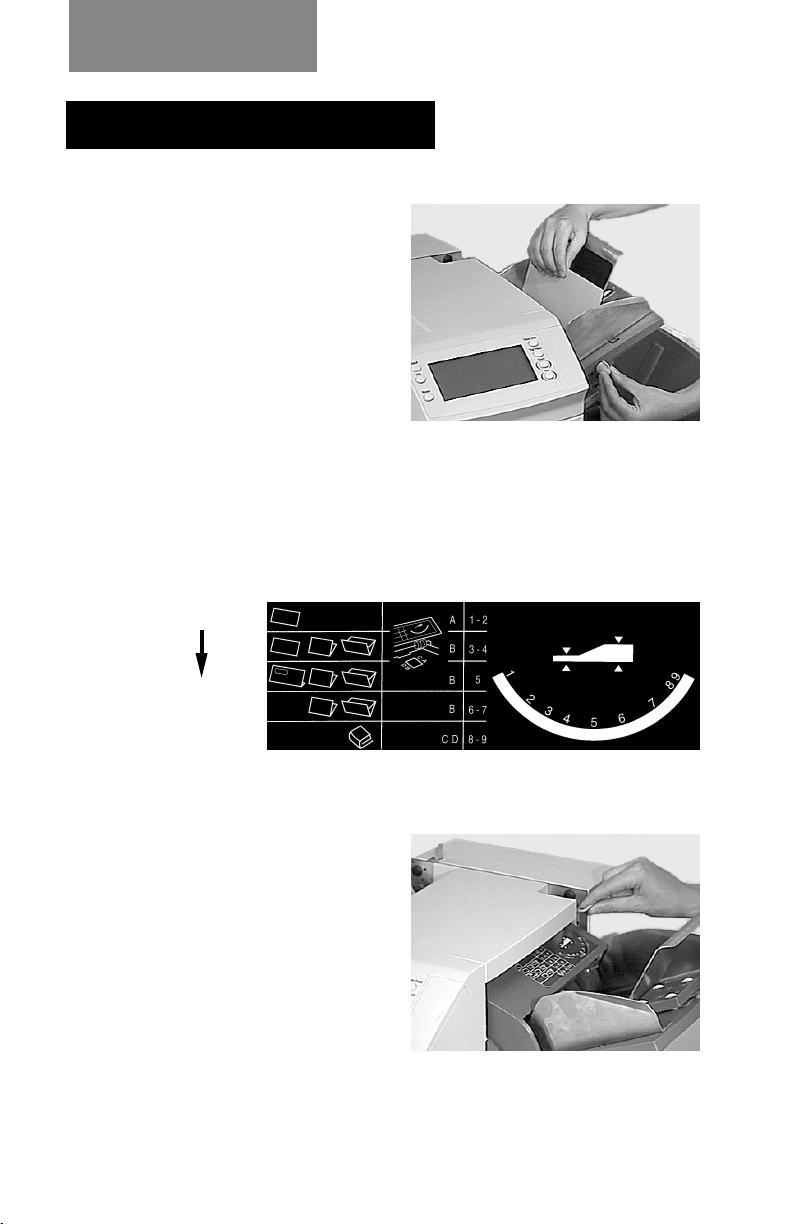

Setting the Insert Feeder

1. Adjust the side guides to

the width of the material

being fed, then back-off a

quarter turn on the side

guide control. This will

set the correct clearance

between the guides and

the material.

2. Refer to the ‘label’

located on the insert

feeder. Compare your insert with the diagram. Read off

the settings for the insert feeder blue lever (numbers 1 to

9) and the separator shield (letters A to D).

Thin Material

Thicker Material

Thick Inserts/

Booklets etc.

3. Set the blue lever to the

number required.

2-6

Page 23

4. Set the separator shield

to the letter required.

5. Fan the inserts to be run

and place them onto the

feed deck face up with

their bottom edge feeding

first.

Operation

Let the ‘wedge’ slide

down behind the stack so

that the inserts are

supported.

2-7

Page 24

Operation

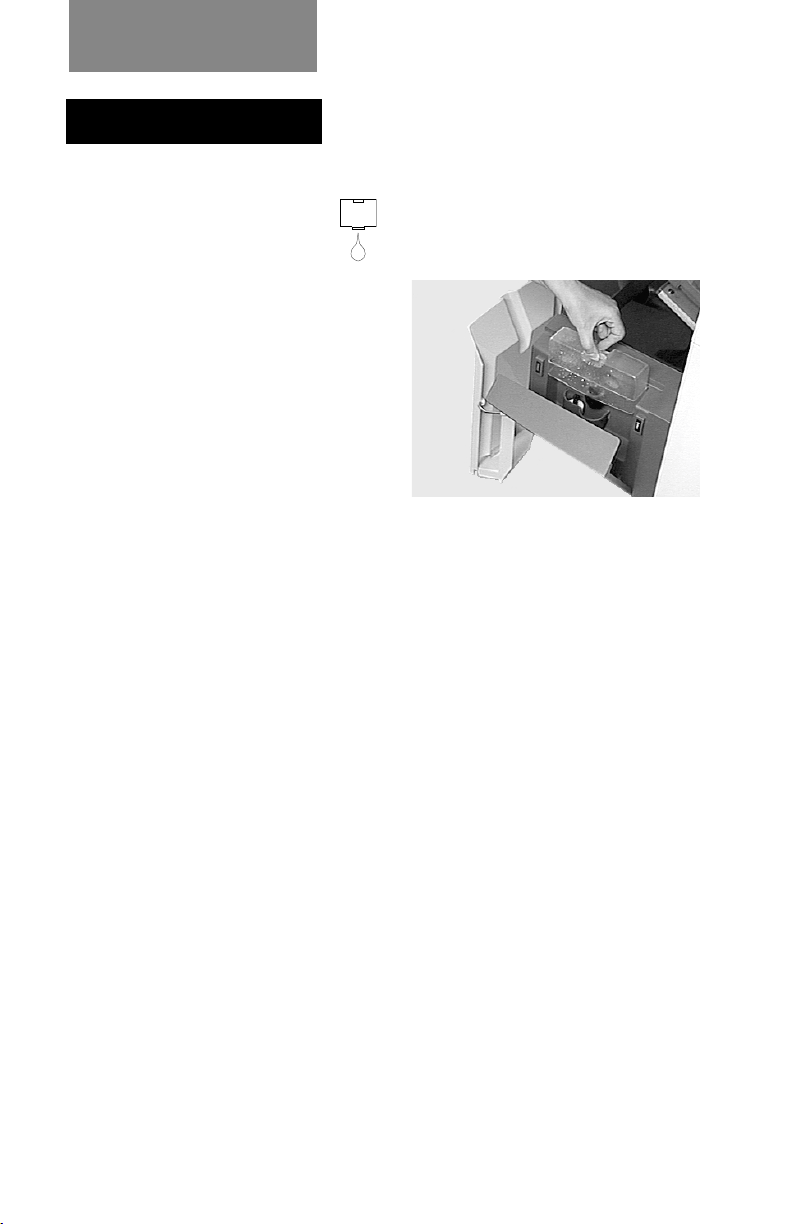

Filling the Sealer

When the sealer unit needs refilling, the Add Fluid symbol

will flash in the display.

Add Pitney Bowes EZ Seal®

solution or water in the

following way:

Note: EZ Seal® solution is

recommended to minimize

growth of algae and scale

build-up.

Hinge open the Water Bottle

Cover located at the rear right hand side of the machine.

Remove the bottle

Fill the bottle up to the level indicated.

Replace the water bottle and close the cover.

If the sealer unit has been allowed to completely empty, you

should allow time for water to soak through the sealer

mechanism.

2-8

Page 25

Operation

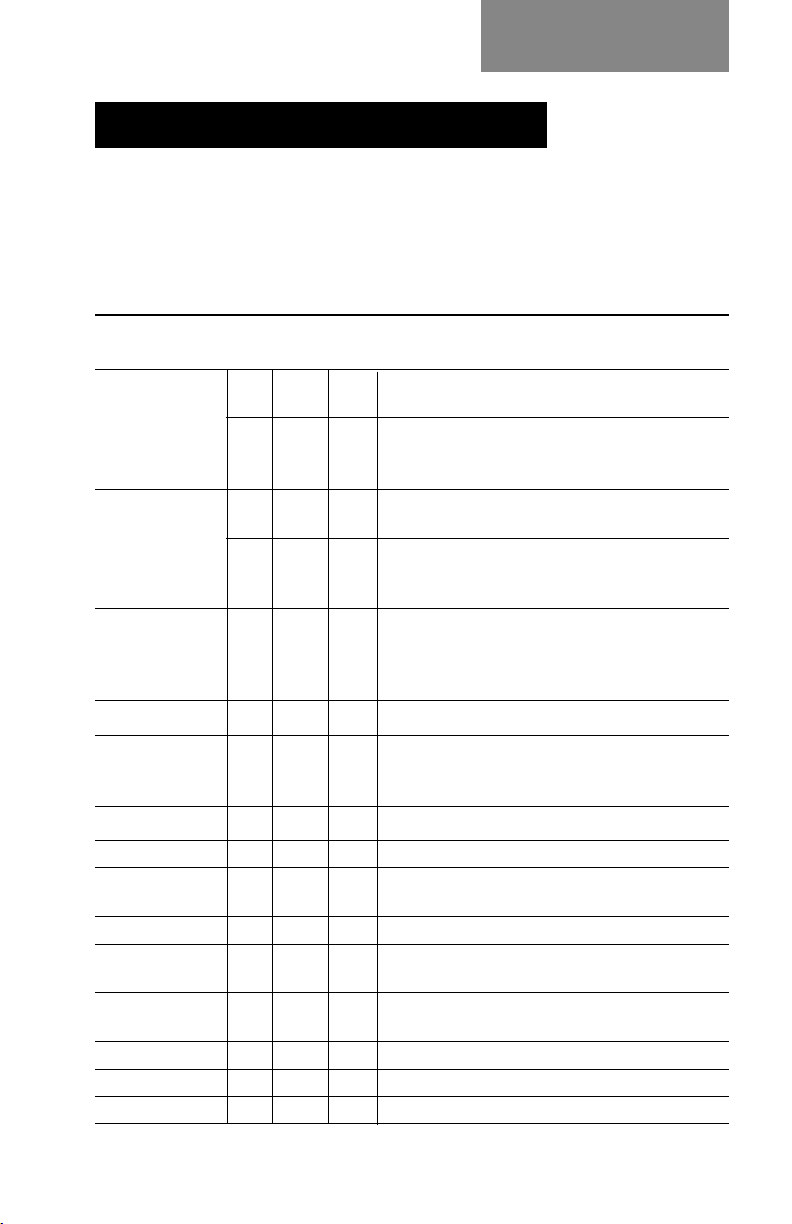

Programming Options By Model

The DI350 has the ability to be programmed by the operator

with up to 20 jobs (depending on model) which can be recalled

at the touch of a button. The following table shows which

functions are available on a machine by the number of stations

it has (

✓ = present on machine):

Function

Sheet Feeder 1 ✓✓✓On (with double detect), On (without

Insert Feeder ✓✓On (with double detect), On (without

Sheet Feeder 2 ✓ On (with double detect), On (without

Accumul Mode ✓✓✓Off or On (with 2, 3,4, or 5 pages)

OMR Mode ✓ Off, On, OMR + Sequence, OMR +

Mode ✓✓✓Insertion Mode, Fold Only Mode

Number of Jobs 10 10 20 Each job can be programmed by operator

Fold Type ✓✓✓C - Letter, Z - Accordion, Double or

Paper Length ✓✓✓any within machine specification limits

Fold A ✓✓✓any within machine/fold specification

Fold B ✓✓✓any within machine/fold specification

Envelope Depth ✓✓✓any within machine specification limits

Envelope Stop ✓✓✓1 to 5

Batch Mode ✓✓✓Off or On (from 50 to 99)

# of Stations

1 2 3

Possible Settings

double detect), Off, or Manual Feed

✓ In addition to above: Select Feed (with

double detect), or Select Feed (without

double detect)

double detect), Off

✓ In addition to above: Select Feed (with

double detect), or Select Feed (without

double detect)

double detect), Off, Select Feed (with

double detect), or Select Feed (without

double detect)

Select Feed and Sequence, OMR +

Select Feed

Single

limits

limits

2-9

Page 26

Operation

2-10

Page 27

Create Non-OMR Job

3. CREATE NON-OMR JOB

This section takes you step-by-step through the process of

setting up a new (non-OMR) job and saving it in the memory.

Programming is carried out in the ‘Setup Mode’…

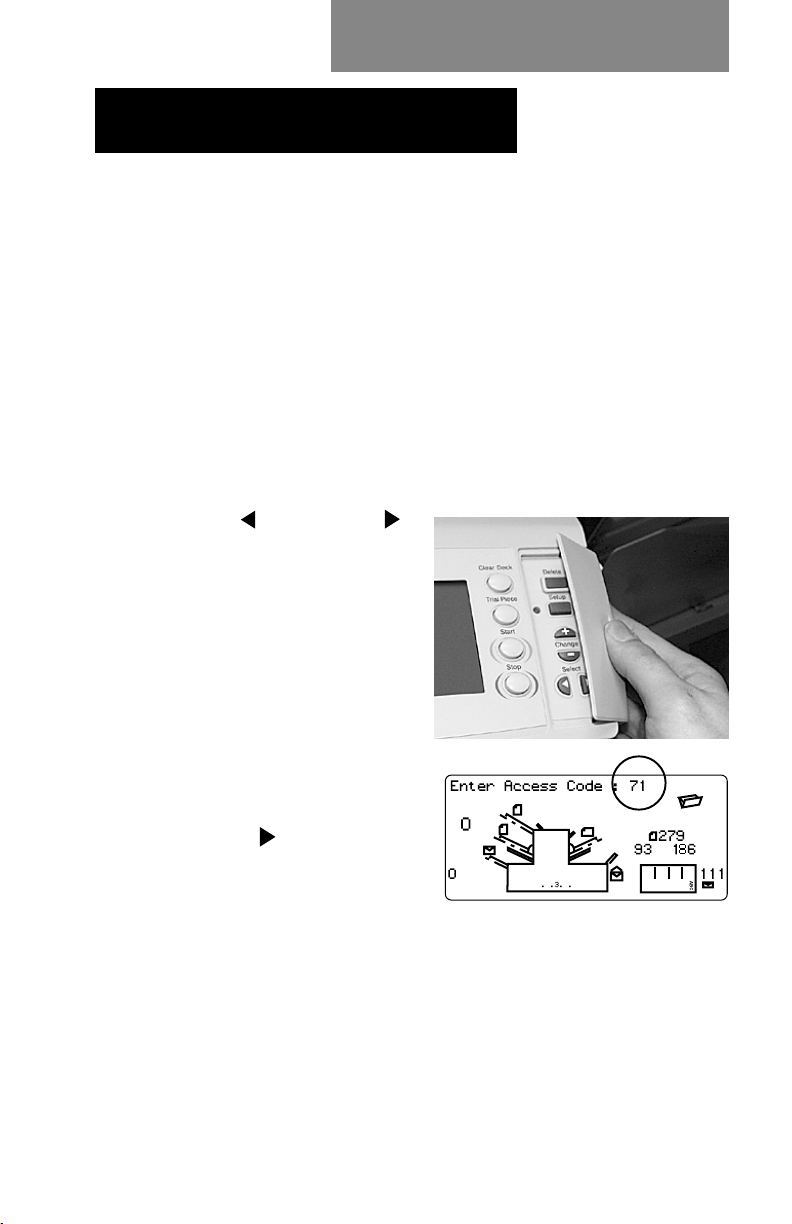

Entering the Setup Mode

Open the hinged cover to the right of the display. This will

expose the setup buttons.

Press Setup. The indicator will light and the machine will ask

for an access code. This code prevents the machine’s

settings being changed by unauthorized personnel.

The Prev (

buttons are used to step

forward or backwards through

the settings available. Once

the item is displayed, the

Change (+/-) buttons are

used to select the option or

value you want.

Use the Change (+/-) buttons

to select the access code 71.

Press Next (

to the next setting….

) and Next ( )

) to advance

3-1

Page 28

Create Non-OMR Job

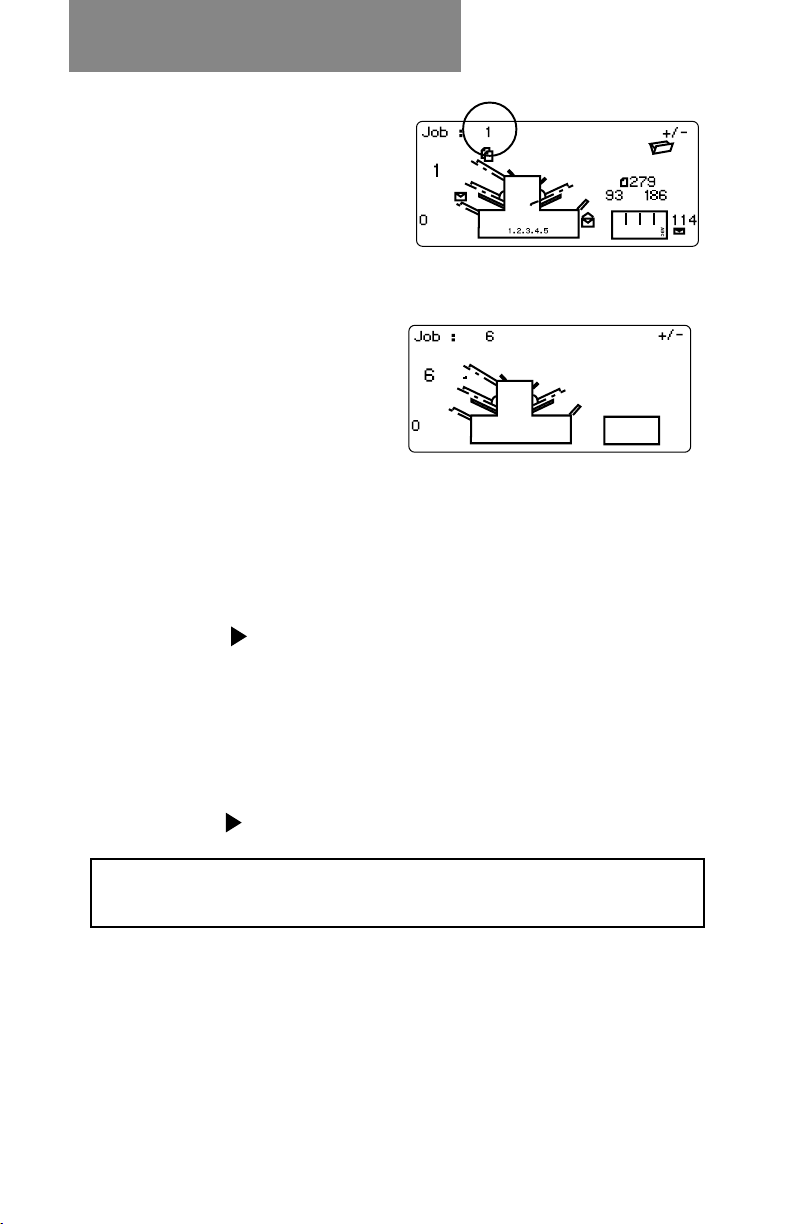

Choosing the new job number

The machine will ask for the

job number you wish the new

settings to be stored under

(the default job number is 1).

Use the Change (+/-) buttons

to display the job number you want.

Notes:

• If you use an existing job

number, the old settings

will be overwritten by the

new settings you are

about to make.

• If you want to find a

currently unused job number, press Change (+/-)until you

see a job where the display shows no symbols alongside

the feeders or in the fold setup area. This means the job

is currently empty.

Press Next (

) to advance to the next setting…

Selecting Non-OMR Option

Press Change (+/-) until you see this option:

OMR off

Press Next (

The flowchart on the following pages describe the setup for a

non-OMR job.

OMR is turned off for this job.

) to advance to the next setting... (see page 3-5)

3-2

Page 29

Create Non-OMR Job

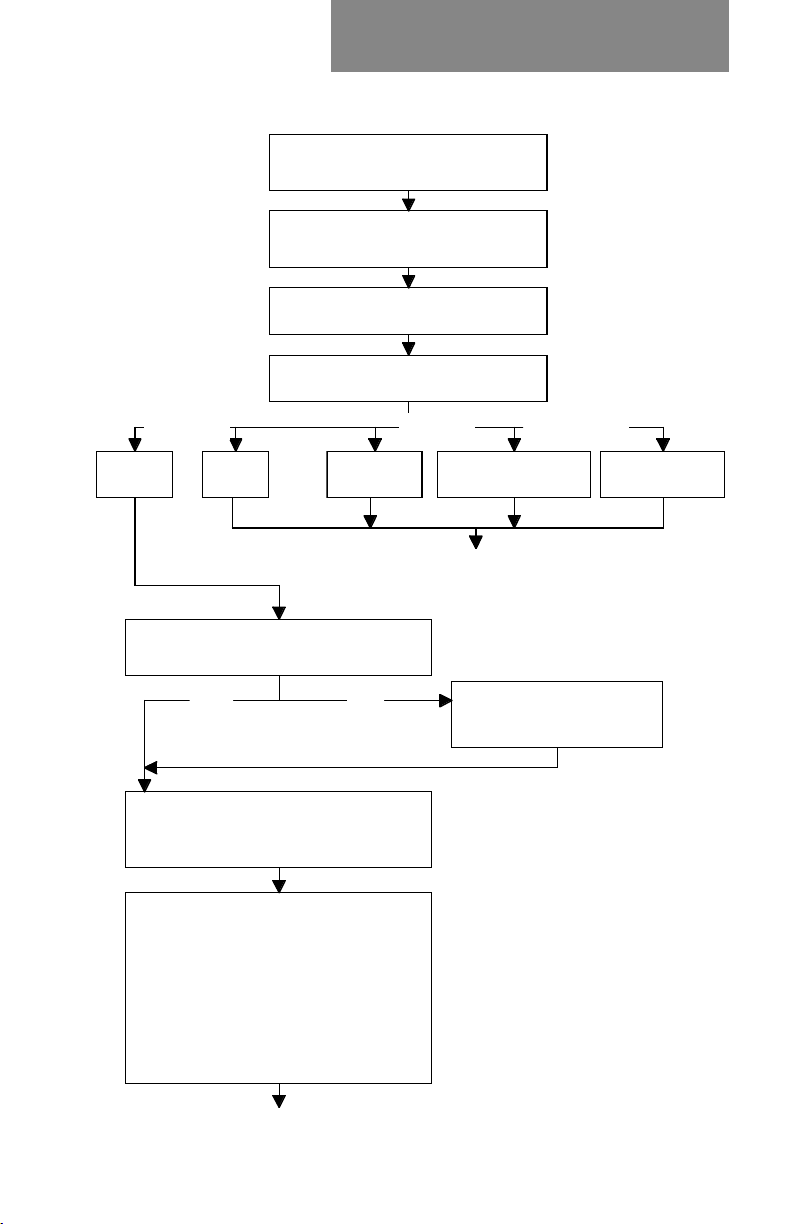

Flowchart for Non-OMR Job Setup

Open hinged cover on right side of

control panel and press Setup key

Use + / - keys to enter 71 for

access code, then press > key

Use + / - keys to enter job number,

Base Level Enhanced

OMR off OMR on

Use + / - keys to select accumulation

Off or On, then press > key

Use + / - keys to select fold type

(c-letter, z-accordion, double, single),

then press > key

then press > key

Use + / - keys to select OMR

function, then press > key

OMR +

Sequence

OnOff

Level Only

OMR + Select

Feed + Sequence

See Separate

Flowchart for

OMR Job

Use + / - enter keys to

select 2, 3, 4 or 5 pages,

then press > key

OMR + Select

Feed

Use + / - keys to select whether the

main sheet feeder is:

• On Double Detect

• Manual Feed

• On

• Off

• Switchable - On Double Detect

• Switchable - On

then press > key

continued on next page

3-3

Page 30

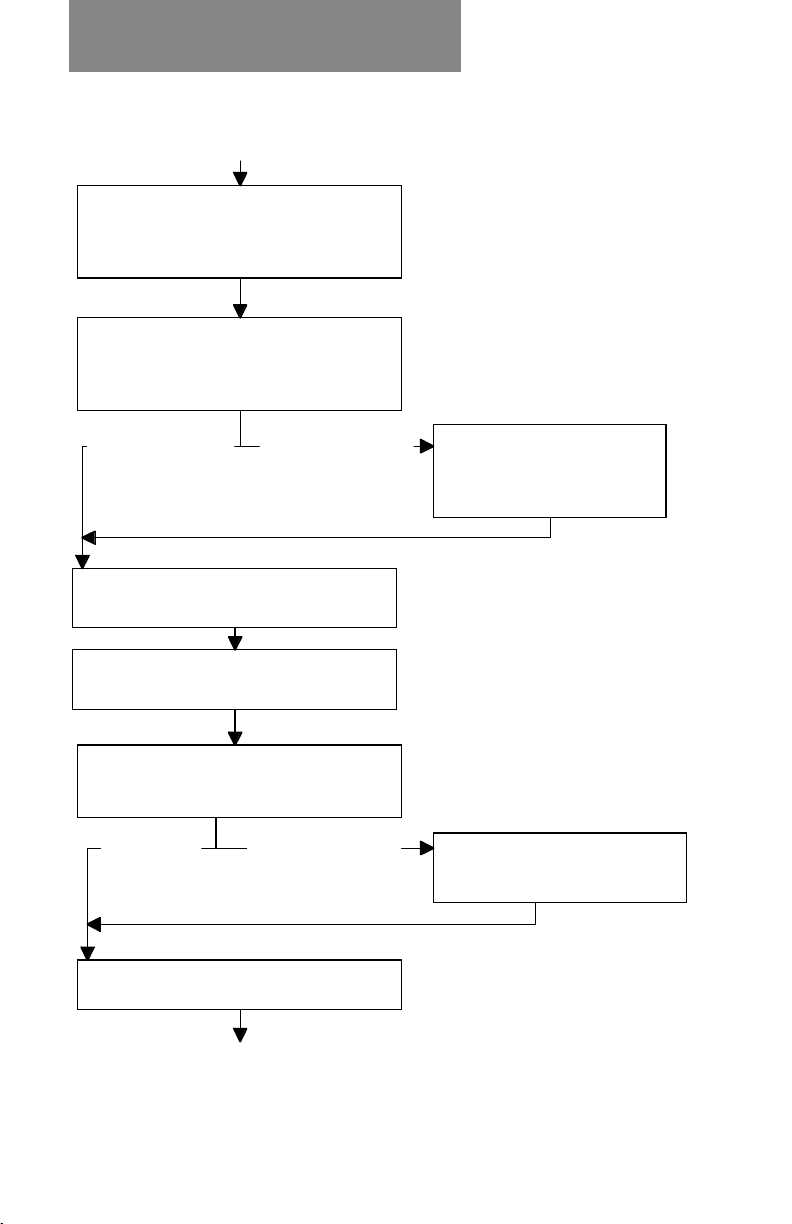

Create Non-OMR Job

Flowchart for Non-OMR Job Setup

continued from previous page

Use +/ - keys to select whether other

sheet feeder is Off, On with

double detect or On with no double

detect, then press > key

Use + /- keys to select whether insert

feeder is Off, On with

double detect or On with no double

detect, then press > key

Insert Feeder On

Use +/ - keys to select whether sealer

is Off or On, then press > key

Use +/ - keys to change paper length of

your sheets, then press > key

Use + /- keys to change Fold A setting

(if neccesary), then press > key to

continue

Single Fold

Use +/ - keys to change envelope depth,

then press > key

Insert Feeder Off

C, Z, Double Folds

Use +/ - keys to select

whether insert feeder is in

insertion mode or fold only

mode, then press > key

Use +/- keys to change Fold B

setting (if neccesary), then

press > key to continue

continued on next page

3-4

Page 31

Create Non-OMR Job

Flowchart for Non-OMR Job Setup

continued from previous page

Use +/ - keys to change envelope stop

setting, then press > key

Use +/ - keys to select whether batch

mode is Off or On, then press > key

Use +/ - keys to enter batch

Batch OnBatch Off

Job number displays (back at beginining)

Setting the Accumulation Function

Press Change (+/-) until you see the option you want:

counter (from 50 to 999),

then press > key

Accumulation: OFF

Accumulation is turned off for

this job.

Accumulation: ON

Accumulation is turned on for

this job.

Accumulation = 2/3/4/5

Select how many pages you want to

feed into each envelope. Either 2, 3, 4 or 5 pages can be

selected.

Press Next (

) to advance to the next setting…

3-5

Page 32

Create Non-OMR Job

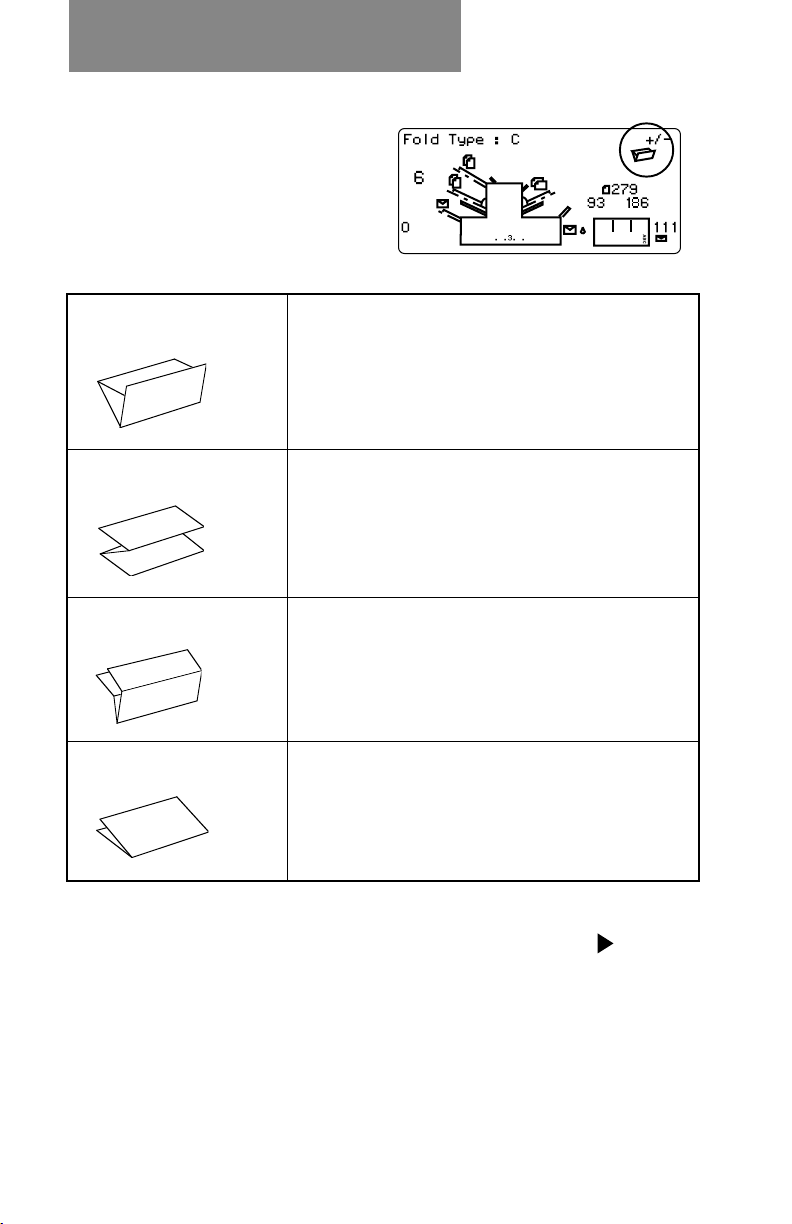

Fold Type

Select the type of fold.

Press Change (+/-)

until you see the option

you want:

C - Letter

Z - Accordion

Double

Single

Folds your sheet into a standard ‘C’

or letter fold.

Folds your sheet into a ‘Z’ or

accordion fold.

Folds your sheet in half and then in

half again.

Folds your sheet once.

When the fold type is set as required, press Next ( ) to

advance to the next setting…

3-6

Page 33

Create Non-OMR Job

Setting Sheet Feeder 1 (Upper Feeder)

Select whether you want to use sheet feeder 1 and, if so,

how it will be used.

Press Change (+/-) until you see the option you want:

On Double Detect

On

Manual Feed

Off

Switchable: On

Switchable: On Dble Detect

Feeder on with the double

detector operating. (The double

detector stops the machine if

more than one sheet

simultaneously feeds from the

feeder).

Feeder on without the double

detector.

Allows you to manually feed

collated sets (see notes below).

Feeder turned off for this job.

These functions are available only

on the three-station machine.

Feed will initially be from Sheet

Feeder 1. When the feeder is

empty, the machine will

automatically switch to feeding

from sheet feeder 2.

When a trial piece is requested,

both feeders must be loaded as a

trial piece will be fed from each

feeder

Notes About Manual Feed:

1. The manual feed setting allows stapled sets of up to 5 sheets

of 20/24 lb (to a maximum of 120 lbs per set) to be run. The

maximum compressed thickness of the set

not exceed 2mm. The machine will wait for manual insertion of

each set into sheet feeder 1 after which it will fold and insert

the set automatically.

2. When running manual feed mode, sheet feeder 2 becomes

inoperable

3-7

after folding

must

Page 34

Create Non-OMR Job

When sheet feeder 1 is set as required, press Next ( ) to

advance to the next setting…

Setting Sheet Feeder 2 (Lower Feeder)

Select whether you want to

use the sheet feeder 2. This

function is available only on

the three-station model.

Press Change (+/-) until you

see the option you want:

On Double Detect

On

Off

Feeder on with the double detector

operating. (The double detector

stops the machine if more than

one sheet simultaneously feeds

from the feeder).

Feeder on without the double

detector.

Feeder turned off for this job.

When sheet feeder 2 is set as required, press Next ( ) to

advance to the next setting…

3-8

Page 35

Create Non-OMR Job

Setting Insert Feeder

Select whether you want to use the insert feeder and, if so,

how it will be used. This function is available only on the two

and three-station models.

Press Change (+/-) until you see the option you want:

On Double Detect

On

Off

Feeder on with the double detector

operating. (The double detector

stops the machine if more than

one insert simultaneously feeds

from the feeder).

Feeder on without the double

detector.

Feeder turned off for this job.

When the insert feeder is set as required, press Next ( ) to

advance to the next setting…

Mode

This option only appears if you have the insert feeder turned

off. In this case, the machine needs to know if the job

requires inserting into an envelope or if it is a fold only job.

If the insert feeder has been set to ‘on’, the machine

automatically sets itself to Insertion Mode and advances to

the Sealer option on the next page.

If ‘Insertion Mode’ appears on the display, you must choose

the machine’s mode of operation. Press Change (+/-) to

switch between the options:

Insertion Mode

Fold Only Mode

Activates the Envelope Feeder for a normal

inserting job.

Turns the Envelope Feeder off and makes the

machine act as a folding machine.

When the mode is set as required, press Next ( ) to advance

to the next setting…

3-9

Page 36

Create Non-OMR Job

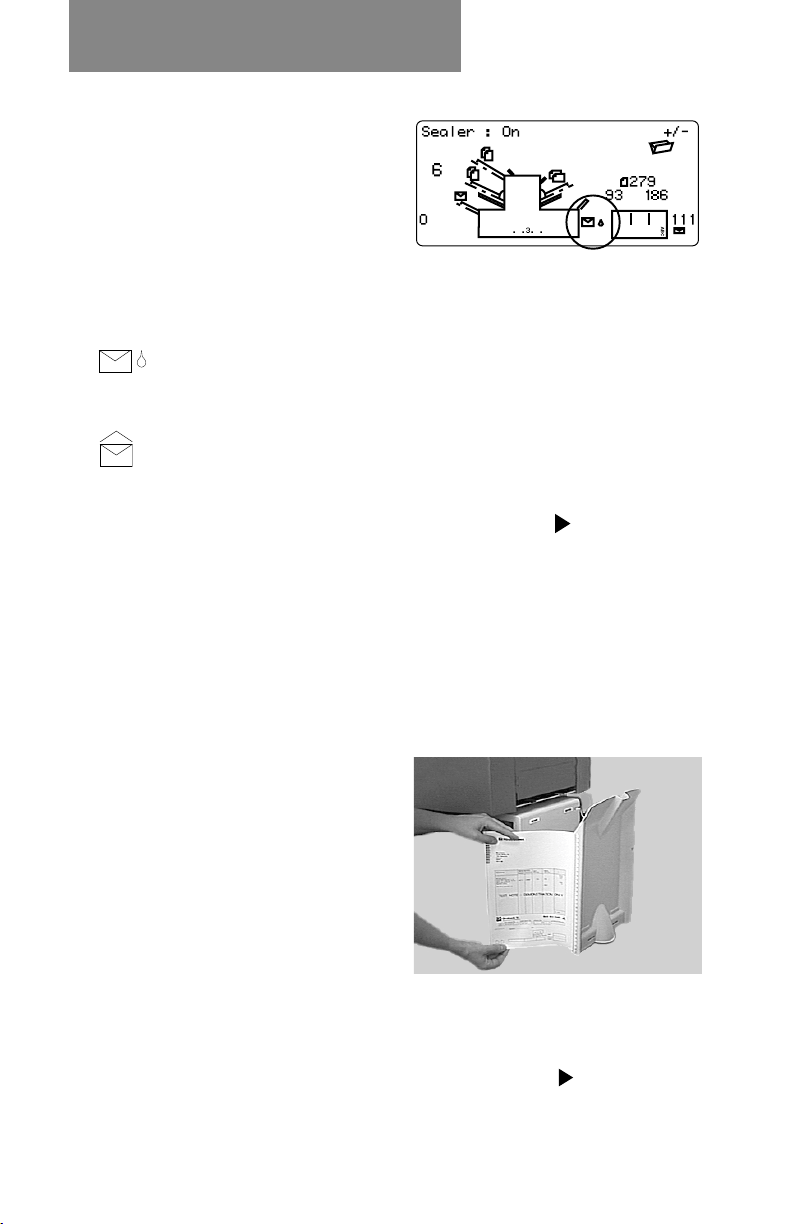

Sealer

This setting only appears if an

insertion mode has been

selected.

Select whether you want to seal

envelopes or not.

Press Change (+/-) to switch the option on or off:

On

Off

Turns the sealer unit on for automatic sealing of

envelopes. Make sure the sealer water bottle is full

of EZ Seal® or water (see page 2-8).

Turns the sealer unit off. Envelopes will be ejected

unsealed.

When the sealer is set as required, press Next ( ) to advance

to the next setting…

If you have selected either of the sheet feeders, the next

setting offered will be fold type. However, if you are using the

insert feeder only, folding is not possible and the machine will

advance directly to the envelope depth setting (page 3-12).

Paper Length

Select the paper length.

Use the scale on the edge of

the stacker.

Quick reference:

US Letter length 11" (279mm)

A4 paper length 297mm

Press Change (+/-) until the length of your paper (in

millimeters) is displayed.

When the paper length is correct, press Next (

) to advance

to the next setting…

3-10

Page 37

Create Non-OMR Job

Fold A

Select the size of the first

fold required.

Depending on the settings

previously made for fold type

and paper length, the machine will be suggesting the correct

dimension for the first fold. Most times, therefore, this setting

will not require alteration.

If you want to change the ‘standard’ setting, press Change

(+/-) until the length of fold required is displayed. The symbol

| –––– | shows the fold panel

you are adjusting.

The machine will

automatically limit your

choices to what is physically

possible within the machine

specifications. (As you change the length of fold A, you will

see the dimension of fold B automatically changing to keep

within paper length and machine specifications.)

When the setting is correct, press Next (

the next setting…

) to advance to

Fold B

Select the size of the second

fold required.

In a similar way to fold A, the

machine will be suggesting

the correct dimension for the

fold.

If you want to change the ‘standard’ setting, press Change

(+/-) until the length of fold required is displayed. The symbol

| –––– | shows the fold panel you are adjusting.

When the setting is correct, press Next (

next setting…

3-11

) to advance to the

Page 38

Create Non-OMR Job

If you are programming an inserting job the setting Envelope

Depth will now appear. If you are programming a fold only

job, the display will jump straight to the ‘Confirming the Job

Setup’ section on the next page.

Envelope Depth

Select the depth of your envelopes (in millimeters).

Again, you can use the

scale on the stacker to

measure the depth of your

envelopes. Press Change

(+/-) until the correct

dimension is displayed.

When the envelope depth is

set as required, press Next (

setting…

Envelope Stop

Select the position of the machine’s envelope stop.

) to advance to the next

The stop has five positions

numbered 1 to 5. Setting 3 is

the ‘standard’ setting for

normal weight paper with

standard folds. A thinner/

lighter envelope will require a

lower setting and thicker/heavier envelope a higher setting.

Press Change (+/-) until the setting you want is displayed.

When the envelope stop is set as required, press Next (

advance to the next setting…

3-12

) to

Page 39

Create Non-OMR Job

Batch Mode

The batch mode allows you to automatically process predefined batches of finished mailpieces. The system “counts

down” from the number programmed for that job. When the

batch is complete (has reached “0”), the machine will stop,

allowing you to empty the stacker. Pressing Start will

commence processing of the next batch.

If batch mode is not selected, the display counter will simply

count the number of items processed until reset by pressing

Reset Counter.

Press Change (+/-) to switch

batch mode On or Off.

When the setting is correct,

press Next ( ).

If batch mode is turned On,

the machine will now request

the batch quantity. The

default quantity is 50, but you

may select any value up to

999 using the Change (+/-) buttons.

When the setting is correct, press Next (

).

Confirming the Job Setup

Job setup is now complete.

The display will show the

complete job setup for you to

confirm. If you see a setting

that is incorrect, use the Prev

( ) button to backtrack to

the setting and correct it.

When you are satisfied with the program, press the Setup

button. The machine will save the job into its memory and

reset to the new job.

3-13

Page 40

Create Non-OMR Job

When this is complete, the

display will show the new job

with the message ‘Trial Piece

Required’.

Job settings will be retained by the machine

disconnected

until they are changed or deleted as described

even with power

on the following page.

Testing the Job

Load material and press Trial Piece so that you can check

that the setup is correct.

Minor changes to the job settings can be made at this stage

if the trial piece needs ‘fine tuning’. Press Setup, then use

the Prev (

), Next ( ) and Change (+/-) buttons as

required to modify job settings. A chart is provided below to

help ‘fine tune’ your fold settings.

FOLD TYPE ADDRESS TOO LOW ADDRESS TOO HIGH

“C” - Letter Fold Decrease Fold A Increase Fold A and

increase Fold B by the

same amount

“Z” - Accordion Increase Fold A Decrease Fold A and

Fold increase Fold B

by the same amount

Single Fold Increase Fold A Decrease Fold A

Double Fold Decrease Fold A Increase Fold A

It is recommended that the folds are changed by 5mm each

time and a new trial piece run to test the settings. When you

have made the necessary changes, press Setup again to

return to run mode. The job will be saved with the new

settings.

3-14

Page 41

Create Non-OMR Job

Changing an existing job

To change an existing job…

1. Enter the setup mode as described on page 3-1.

2. Use the Change (+/-) buttons to display the job you wish

to edit.

3. Use the Prev (

setting(s) you wish to change.

4. Use the Change (+/-) buttons to change the options/

dimensions you wish to amend.

5. Press the Setup button to leave setup mode and save

the changes.

) and Next ( ) buttons to display the

Deleting a job

To erase an existing job from memory, follow the steps

below:

1. Enter the setup mode as described on page 3-1.

2. Use the Change (+/-) buttons to display the job you wish

to delete.

3. Press the Delete button. The display reads “Press again

to confirm”. Press Delete again. The display will briefly

read ‘Deleting Job’ as the job is erased.

4. Press the Setup button to leave setup mode.

3-15

Page 42

Create Non-OMR Job

3-16

Page 43

What is OMR?

4. WHAT IS OMR?

DI350 inserters that are 3-station models have an Optical

Mark Recognition (OMR) scanner installed on the upper and

lower sheet feeders. This section describes what OMR is and

how it can be used to enhance your use of the machine for

your inserting needs. Once you understand the OMR concepts (and you have printed your documents with the proper

OMR marks), go to Chapter 5 for instructions on setting up

an OMR job and adjusting the OMR scanners.

What is OMR (Optical Mark Recognition)?

OMR (Optical Mark Recognition) is a system whereby marks

are pre-printed on all pages that make up a document,

statement, advertisement, etc. These pages are fed into the

machine and their OMR marks “read” by the system, whose

job is to interpret the marks and do the prescribed tasks

associated with those marks (such as feeding sheets or

verifying the end of a document).

The tracking of these OMR marks by the system assures that

sheets of a document which belong together (a collated set)

actually stays together throughout the inserting process. This

is known as

are printed and read, the better the collated set integrity.

However, more space and programming is required to print

additional marks on a document, so you will need to weigh

the trade-off between more integrity and the space you have

available on your document.

The OMR mark itself is normally a dark solid line on a sheet

of light-colored paper (usually white) that is horizontally

positioned so it matches the direction of travel of the paper.

This line must be printed to certain specifications in width,

length, and separation to be read by the OMR scanner on the

system. Normally, there are several of these OMR marks

printed in a group in one area on the paper (away from any

text, pictures, or other lines) where the OMR scanner “reads”

or scans them.

collation set integrity

4-1

. The more OMR marks that

Page 44

What is OMR?

What Do OMR Marks Look Like on Paper?

The example below shows OMR marks that may be typically

used on a document for the DI350:

Example of OMR Marks on a Document (not drawn to scale)

Feed Direction

(for this example)

OMR Marks

This is a test last page for a collation. This is a test page for a

{

collation. This is a test page for a collation.

This is a test page for a collation. This is a test page for a

collation. This is a test page for a collation.

This is a test page for a collation. This is a test page for a

collation. This is a test page for a collation. This is a test page

for a collation. This is a test page for a collation. This is a test

page for a collation.

This is a test page for a collation. This is a test page for a

collation. This is a test page for a collation.

This is a test page for a collation. This is a test page for a

collation. This is a test page for a collation.

This is a test page for a collation. This is a test page for a

collation. This is a test page for a collation. This is a test page

for a collation. This is a test page for a collation. This is a test

page for a collation.

Sincerely,

John Smith,

Solicitor General

OMR Marks Being Read by a DI350 Scanner

4-2

Page 45

What is OMR?

How are OMR Marks Read on the DI350?

There are two OMR scanners (the devices that “read” the

OMR marks) on the DI350 inserter. One is top-mounted on

sheet feeder 1 and the other is bottom-mounted on the sheet

feeder 2 (see figures below).

Top-Mounted

OMR Scanner on

Sheet Feeder 1

(upper)

BottomMounted OMR

Scanner on

Sheet Feeder 2

(lower )

4-3

Page 46

What is OMR?

The top-mounted scanner reads the marks from on top of the

sheet, while the bottom-mounted scanner reads the marks

from underneath the sheet of paper. This configuration allows

you the maximum flexibility for your document folding needs

when processed through the system. Specifically:

• the top-mounted scanner supports C-fold and double fold

documents so the address can be visible in window envelopes

• that bottom-mounted scanner supports Z and half-fold

documents so the address can be visible in window envelopes

How are OMR Marks Generated?

There are several ways to print the special OMR marks on a

document. Pitney Bowes offers a PC-based product called PB

FIRST™ that enables you to add the OMR marks to your

documents so they can be read by the DI350 inserter (it also

allows you to setup OMR marks for the DI400 and DI800

inserters). What’s nice is that once you’ve setup PB FIRST™

correctly to generate the marks, the marks are printed to the

proper specifications – no “experimentation” is necessary.

If you have a computer/IT department in your organization, you

may be able to use them also as a resource to create and print

the OMR marks for you, based on the DI350 OMR specifications given in this chapter (see pages 4-25 and 4-26).

Additional information on implementing OMR marks can be

found in Pitney Bowes publication SV40193 and the OMR

template that are included with your DI350 inserter.

IMPORTANT: Unless you (or your organization) has had

previous experience working with OMR marks or PB FIRST™,

we recommend that you have a Pitney Bowes Consultant

setup your OMR marks for you (at a cost to be estimated).

Pitney Bowes does not cover the implementation of OMR

marks on your documents under the standard support

agreements for the DI350 inserter.

4-4

Page 47

What is OMR?

What OMR Marks are Used on the DI350?

The DI350 has two feature levels of OMR – the feature level

you have depends on the level installed on your machine.

Basic Level OMR

the ability to have variable-sized collation sets (a different

number sheets may be fed for each document based on

what the marks on those sheets indicate to the system). It

consists of these marks, known as Group 1:

Group 1 (“OMR”)

• Benchmark

• Safety

• Not EOC (end-of-collation)

• Not BOC (beginning-of-collation)

• Parity [even]

• Retime Mark

Enhanced Level OMR

size collation sets as well as greater collation set integrity.

The Enhanced OMR Level allows for two additional groups of

marks, which consist of:

Group 2 (“Select Feed”)

• SF1 (feed from the other sheet feeder)

• SF2 (feed from the insert feeder)

• Auto-Batch

• Retime Mark

– provides basic collation set integrity and

– allows more flexibility in variable-

Group 3 (“Sequence”)

• WAS3 (wrap-around sequence)

• WAS2 (wrap-around sequence)

• WAS1 (wrap-around sequence)

• Retime Mark

NOTE: Each group of OMR marks must be treated as one unit

when programing and printing the marks for your documents

(that is, space must be allocated for every mark within each

group, whether the mark is used or not). Also, Basic OMR

(Group 1) is always used; Group 2 and 3 marks are optional.

4-5

Page 48

What is OMR?

Overview of Group 1 OMR Marks

Group 1

(Mandatory)

Benchmark (BM) Identifies the start of the

Safety Determines the line

Not EOC

(End-of-Collation)

Not BOC

(Beginning-ofCollation)

Parity Helps in the detection of

Retime Indicates the end of

Description How it Works When You Would

OMR marks on a sheet

spacing of the OMR

marks.

Identifies the last sheet

(as fed into the system)

of a collated set

Identifies the first sheet

(as fed into the system)

of a collated set

misread OMR marks on

a sheet

OMR marks for Group 1

Mark always appears

at beginning of OMR

marks

The measurement of

the space between the

BM and the Safety

marks becomes the

standard of what the

system should expect

in the space between

all the subsequent

OMR marks on that

document. Mark

always appears.

When mark appears

on a sheet, indicates to

system the end of a

collated set

When mark appears

on a sheet, indicates to

system the start of a

new collated set

Verifies that the

number of OMR marks

is even.

Mark always appears.

Helps the systems

avoid “losing its place”

when tracking the

marks

Use Mark

Mandatory for

OMR on DI350

Mandatory for

OMR on DI350

Mandatory for

OMR on DI350

Mandatory for

OMR on DI350

Mandatory for

OMR on DI350

Mandatory for

OMR on DI350

OMR Group 1 Marks (Basic)

Feed Direction

(for this example)

BM

Safety

Not EOC

Not BOC

Parity

Retime

Group 1 Marks - Mandatory

}

4-6

Page 49

Overview of Group 2 OMR Marks

What is OMR?

Group 2

(Optional)

Select Feed 1

(SF1)

Select Feed 2

(SF2)

Auto-Batch Instructs the system to

Retime Indicates the end of

Description How it Works When You Would

Dynamically turns on

and off the other sheet

feeder as necessary for

each collated set.

Dynamically turns on

and off the insert feeder

as necessary for each

collated set.

stop (but not end) the

job when it encounters

a collated set which

contains this mark

OMR marks for Group 2

Presence of a mark

indicates that the other

sheet feeder feeds one

sheet. The absence of

the mark indicates that

other feeder will

operate in passthrough mode for the

indicated collated set.

Presence of a mark

indicates that the insert

feeder feeds one

sheet. The absence of

the mark indicates that

the insert feeder will

operate in passthrough mode for the

indicated collated set.

Presence of a mark

indicates that system

should stop after this

collated set. This mark

must be on all pages

within the collated set.

Mark always appears.

Helps the systems

avoid “losing its place”

when tracking the

marks

Use Mark

For feeding

additional fullpage sheets from

the other sheet

feeder as

necessary to add

to collated sets

For feeding

inserts from the

insert feeder as

necessary to add

to collated sets

For separating

collated sets that

may need special

handling (like a

mail tray) within

the same job run

Mandatory when

using this OMR

Group on DI350

OMR Group 1 and 2 Marks (Enhanced Level)

Feed Direction

(for this example)

BM

Safety

Not EOC

Not BOC

Parity

Retime

SF1

SF2

Auto-Batch

Retime

Group 1 Marks - Mandatory

}

Group 2 Marks (“Select Feed” ) - Optional

}

4-7

Page 50

What is OMR?

Overview of Group 3 OMR Marks

Group 3

(Optional)

Wrap-Around

Sequence

(WAS3)

Wrap-Around

Sequence

(WAS2)

Wrap-Around

Sequence

(WAS1)

Retime Indicates the end of

Description How it Works When You Would

Allows the system to

track each sheet from

the feeder by a number

sequence. The

numbers repeat, or

"wrap-around", when

they come to the end of

the sequence, with the

sequence repeating as

more sheets are fed.

The system reads the

marks in ascending

order (as in 0, 1, 2, 3, 4,

5, 6, 7, 0, 1, 2, 3, 4...).

Part of above Mark appears as

Part of above Mark appears as

OMR marks for Group 3

The sequence of

numbers (from 0-7) is

based on the

combinations that can

be created in binary

format from three OMR

marks (see chart).With

the proper sequence

printed on all

mailpieces, the system

easily detects when a

sheet is not fed in the

proper order. Mark

appears as necessary

to create binary

number sequence.

necessary to create

binary number

sequence

necessary to create

binary number

sequence

Mark always appears.

Helps the systems

avoid “losing its place”

when tracking the

marks.

Use Mark

For greater

collated set

integrity, such as

in high-sensitivity

jobs.

Part of above

Part of above

Mandatory when

using this OMR

Group on DI350

OMR Group 1, 2, and 3 Marks (Enhanced Level)

Feed Direction

(for this example)

BM

Safety

Not EOC

Not BOC

Parity

Retime

SF1

SF2

Auto-Batch

Retime

WAS3

WAS2

WAS1

Retime

Group 1 Marks - Mandatory

}

Group 2 Marks (“Select Feed” ) - Optional

}

Group 3 Marks (“Sequence”) - Optional

}

4-8

Page 51

What is OMR?

OMR Group Combinations

Under Enhanced Level OMR, you have the option of adding

Group 2 marks, Group 3 marks, both groups, or no groups to

Basic OMR (Group 1). Groups must be contiguous, that is, if

you are not using Group 2, Group 3 marks must immediately

follow Group 1 (see figure below). In every case, you must

always select Basic Level OMR before choosing the optional

Group 2 and/or Group 3 marks.

OMR Group 1 and 3 Marks (Enhanced Level)

Feed Direction

(for this example)

BM

Safety

Not EOC

Not BOC

Parity

Retime

WAS3

WAS2

WAS1

Retime

Group 1 Marks - Mandatory

}

Group 3 Marks (“Sequence”) - Optional

}

The table below lists the combination of OMR groups that

may be used together.

OMR Group Combinations Table

Basic OMR Enhanced OMR

Group 1

Marks

✔

✔✔

✔✔ ✔

✔✔

Group 2

Marks

Group 3

Marks

4-9

Page 52

What is OMR?

Details of Basic Level OMR

Basic Level OMR consists of six OMR marks, which make up

Group 1. Space must be allocated for every mark in the group,

whether the mark is used or not. In the OMR job setup on the

system control panel, Group 1 is referred as simply “OMR”.

OMR Group 1 Marks (Basic)

Feed Direction

(for this example)

BM

Safety

Not EOC

Not BOC

Parity

Retime

Group 1 Marks (“OMR”)

• Benchmark (BM)

The Benchmark (BM) is the first OMR mark scanned and

must be on every page in a collated set. This mark indicates

to the system the start of the OMR marks on a page.

Group 1 Marks - Mandatory

}

• Safety

The Safety mark is the second OMR mark scanned and must

be on

line spacing of the OMR marks. Specifically, the measurement of the space between the BM and the Safety marks

becomes the standard of what the system should expect in

the space between all the subsequent OMR marks on that

document.

• Not End-Of-Collation (EOC)

The Not End-Of-Collation (EOC) mark is the third OMR mark

scanned and must be on every page in a collated set, except

the last page fed into the system (which is the first printed

page of a document). When the system reads a Not EOC

mark on a sheet, it knows that this is the not the last page of

a collated set. However, when it doesn’t see a Not EOC

mark, it knows this is the last page of a collated set. This

feature allows different size collated sets to be processed on

the DI350 inserter.

every page in a collated set. It used to determine the

4-10

Page 53

What is OMR?

While the feeders within the system have double detection

sensors, a combination of paper slippage and other variables

could result in two full collated sets being mailed as one. The

Not EOC configuration adds the benefit in that it avoids

putting two documents into a single envelope if the Not EOC

mark is ever missed by the scanner.

• Not Beginning-Of-Collation (BOC)

The Not Beginning-Of-Collation (BOC) mark is the fourth

OMR mark scanned and must be on

set, except the first page fed into the system (which is the

last printed page of a document). When the system reads a

Not BOC mark on a sheet, it knows that this is the not the

first page of a collated set. However, when it doesn’t see a

Not BOC mark, it knows this is the first page of a collated set.

This provides additional verification that a collated set is not

being split or combined with another collated set into one

package.

• Parity (even)

The Parity mark is the fifth OMR mark scanned, but because

of how it is used, it may or may not be printed on every page

in a collated set. The Parity mark is used to ensure that the

total number of OMR marks read by the scanner on one

piece of paper is always an even number. This provides an

internal check on the scan set of marks on a single sheet and

helps detect sensitivity problems associated with the scanner

or excessive paper skew. Because the system checks for an

even number of marks, it is known as “even” parity (if the

system checked for an odd number, it would be called “odd”

parity).

every page in a collated

4-11

Page 54

What is OMR?

For example, for a one-page document, the marks printed on

the page are:

BM 1 mark

Safety 1 mark

Not EOC 0 mark (not printed, as it is the end of document)

Not BOC 0 mark (not printed, as it is the start of document)

Retime 1 mark (see description below)

-----------------------Total = 3 marks (odd number; needs Parity mark)

Parity + 1 mark

-------------------------New total= 4 marks (even number; all OK)

In this example, the Parity mark is printed on this page to

make the number of marks go from odd (3) to even (4).

As another example, for the last page fed of a two-page

collated set, the marks printed on the page are:

BM 1 mark

Safety 1 mark

Not EOC 0 mark (not printed, as it is the end of collated set)

Not BOC 1 mark

Retime 1 mark

-----------------------Total = 4 marks (even number; all OK, no Parity mark)

Parity + 0 mark (not printed, as it is not needed)

-------------------------New total= 4 marks (even number; all OK)

In this example, the Parity mark is not printed on this page

because the total number of marks is even (4) to begin with.

• Retime

The Retime mark is the last OMR mark scanned and must be

on

every page in a collated set. This mark indicates to the

system the end of OMR marks for Group 1 and helps the

systems avoid “losing its place” when tracking the marks.

4-12

Page 55

Example of Group 1 Marks Printed on Several

Documents for Feeding from Sheet Feeder 1

Retime

Parity

Not BOC

Not EOC

Safety

BM

Feed Direction

(for this example)

Page 1 of Document 1

Page 2 of Document 1

(fed first from feeder)

Page 2 of Document 3

Page 3 of Document 3

Document 2 (one page)

page for a collation.

test last page for a collation. This is a test last

This is a test last page for a collation. This is a

page for a collation.

test last page for a collation. This is a test last

ABC Company

This is a test last page for a collation. This is a

page for a collation.

Respectfully Yours,

test last page for a collation. This is a test last

This is a test last page for a collation. This is a

page for a collation.

Dear Mr. Customer:

test last page for a collation. This is a test last

This is a test last page for a collation. This is a

Anytown, USA 11111

111 Maple St.

page for a collation.

Mrs. Jane Hancock

test last page for a collation. This is a test last

This is a test last page for a collation. This is a

page for a collation.

test last page for a collation. This is a test last

This is a test last page for a collation. This is a

What is OMR?

Page 1 of Document 3

(fed last from feeder)

page for a collation.

test last page for a collation. This is a test last

This is a test last page for a collation. This is a

page for a collation.

test last page for a collation. This is a test last

This is a test last page for a collation. This is a

page for a collation.

ABC Company

Respectfully Yours,

page for a collation.

test last page for a collation. This is a test last

ABC Company

Respectfully Yours,

llation. This is a test last page for a collation.

page for a collation.

test last page for a collation. This is a test last

This is a test last page for a collation. This is a

page for a collation.

test last page for a collation. This is a test last

This is a test last page for a collation. This is a

Dear Mr. Customer:

Anytown, USA 11111

111 Maple St.

Mrs. Jane Hancock

Retime

Parity

Not EOC

Not BOC

Safety

BM

This is a test last page for a collation. This is a

page for a collation.

test last page for a collation. This is a test last

This is a test last page for a collation. This is a

page for a collation.

test last page for a collation. This is a test last

This is a test last page for a collation. This is a

Retime

Parity

Not EOC

Not BOC

Safety

BM

test last page for a collation. This is a test last

This is a test last page for a collation. This is a

page for a collation.

test last page for a collation. This is a test last

This is a test last page for a collation. This is a

page for a collation.

test last page for a collation. This is a test last

This is a test last page for a collation. This is a

page for a collation.

a test last page for a collation. This is a test last

This is a test second page for a collation. This is

Retime

Parity

Not EOC

Not BOC

Safety

BM

page for a collation.

test last page for a collation. This is a test last

This is a test last page for a collation. This is a

page for a collation.

test last page for a collation. This is a test last

This is a test last page for a collation. This is a

page for a collation.

test last page for a collation. This is a test last

This is a test last page for a collation. This is a

page for a collation.

test last page for a collation. This is a test last

This is a test last page for a collation. This is a

Dear Mr. Customer:

Anytown, USA 33333

333 Marble Dr.

Mr. John Doe

Retime

Parity

Not EOC

Not BOC

Safety

BM

Retime

Parity

Not EOC

Not BOC

Safety

BM

Feed Direction

Retime

Parity

Not EOC

Not BOC

Safety

BM

4-13

Page 56

What is OMR?

Details of Enhanced Level OMR

Enhanced Level OMR adds the availability of two additional

groups of marks, Groups 2 and 3. Like Group 1 marks, space

must be allocated for every mark within each group, whether

the mark is used or not.

Under Enhanced Level OMR, you have the option of adding

Group 2 marks, Group 3 marks, both groups, or no groups to

Basic OMR (Group 1). Groups must be contiguous, that is, if

you are not using Group 2, Group 3 marks must immediately

follow Group 1. In every case, you must always select Basic

Level OMR before choosing the optional Group 2 and/or

Group 3 marks. The table below lists the combination of OMR

groups that may be used together.

OMR Group Combinations

Basic OMR Enhanced OMR

Group 1

Marks

✔

✔✔

✔✔ ✔

✔✔

Group 2

Marks

Group 3

Marks

Group 2 Marks (“Select Feed”)

In the OMR job setup on the system control panel, Group 2

marks are referred to as “Select Feed”.

OMR Group 2 Marks (“Select Feed” ) - Optional

Feed Direction

(for this example)

SF1

SF2

Auto-Batch

Retime

4-14

Page 57

What is OMR?

• Selective Feed 1 (SF1)

Selective Feed marks in general are used in applications

where some pages are not fed as part of the initial collated

set for certain mailpieces (e.g., perhaps confidential or

restricted information should not be sent to each individual in

a mailing). The Select Feed 1 mark specifically allows you to

dynamically turn on and off the other sheet feeder for each

collated set. For example, if you are feeding your control

(also known as the main or prime) document from the upper

sheet feeder, SF1 would allow you to feed from the lower

sheet feeder as necessary.

Presence of a mark indicates that the other sheet feeder

feeds one sheet. The absence of the mark indicates that

other feeder will operate in pass-through mode for the indicated collated set. NOTE: The

pattern must be on all sheets within a collated set.

• Selective Feed 2 (SF2)

You can use also dynamically turn on and off the insert

feeder as necessary for each collated set using the Selective

Feed 2 mark on the control document. Presence of a mark

indicates that the insert feeder feeds one sheet. The absence

of the mark indicates that the insert feeder will operate in

pass-through mode for the indicated collated set. NOTE: The

same selective feed mark pattern must be on all sheets

within a collated set.

same selective feed mark

• Auto-Batch

An Auto-batch mark instructs the system to stop (but not

end) the job after it processes a collated set which contains the

Auto-batch mark. This allows you to separate collated sets

that may need special handling (like a mail tray) within the

same job run. NOTE: The

on all sheets within a collated set.

• Retime

This Retime mark must be on

It indicates to the system the end of this group of OMR marks

on a page and helps the systems avoid “losing its place”

when tracking the marks.

same Auto-batch marks must be

every page within a collated set.

4-15

Page 58

What is OMR?

Example of Group 1 and 2 Marks Printed on Several

Documents for Feeding from Sheet Feeder 1

Retime

Auto-batch

SF2

SF1

Retime

Parity

Not BOC

Not EOC

Safety

BM

Feed Direction

(for this example)

Document 2 (one page)

Page 1 of Document 1

Page 2 of Document 1

(fed first from feeder)

Feed Direction

Page 2 of Document 3

Page 3 of Document 3

ABC Company

Respectfully Yours,

llation. This is a test last page for a collation.

page for a collation.

test last page for a collation. This is a test last

This is a test last page for a collation. This is a

page for a collation.

test last page for a collation. This is a test last

page for a collation.

test last page for a collation. This is a test last

This is a test last page for a collation. This is a

page for a collation.

test last page for a collation. This is a test last

ABC Company

Respectfully Yours,

page for a collation.

test last page for a collation. This is a test last

This is a test last page for a collation. This is a

page for a collation.

test last page for a collation. This is a test last

This is a test last page for a collation. This is a

page for a collation.

test last page for a collation. This is a test last

This is a test last page for a collation. This is a

This is a test last page for a collation. This is a

page for a collation.

test last page for a collation. This is a test last

This is a test last page for a collation. This is a

Dear Mr. Customer:

Anytown, USA 11111

111 Maple St.

Mrs. Jane Hancock

Retime

Auto-Batch

SF2

SF1

Retime

Parity

Not EOC

Not BOC

Safety

BM

This is a test last page for a collation. This is a

Dear Mr. Customer:

Anytown, USA 11111

111 Maple St.

Mrs. Jane Hancock

Retime

Auto-Batch

SF2

SF1

Retime

Parity

Not EOC

Not BOC

Safety

BM

Legend of OMR Features on Documents

Feature Document 1 Document 2 Document 3

Select Feed 1-SF1

(feed page from

supplementary

feeder)

Select Feed 2-SF2

(feed page from insert

feeder)

Auto-Batch (stop job

after processing this

document)

Page 1 of Document 3

(fed last from feeder)

page for a collation.

test last page for a collation. This is a test last

This is a test last page for a collation. This is a

page for a collation.