Page 1

Inserting System

Page 2

Statement of FCC Compliance

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to part 15 of the FCC rules. These limits are designed to

provide reasonable protection against interference when the equipment is operated

in a commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction

manual, may cause interference to radio communications. Operation of this equipment

in a residential area is likely to cause interference, in which case the user will be

required to correct the interference at his own expense.

Canada

This class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme á la norme NMB-003 du Canada.

CAUTION: Changes or modifications to this equipment not expressly approved by

the party responsible for compliance (Pitney Bowes) could void the user’s authority

to operate the equipment.

SV40189-OG Revision B June 2003 ©2003 Pitney Bowes Inc.

All rights reserved. This book may not be reproduced in whole or in part in any fashion

or stored in a retrieval system of any type or transmitted by any means, electronically

or mechanically, without the express, written permission of Pitney Bowes.

We have made every reasonable effort to ensure the accuracy and usefulness of this

manual; however, we cannot assume responsibility for errors or omissions or liability

for the misuse or misapplication of our products.

Due to our continuing program of product improvement, equipment and material

specifications as well as performance features are subject to change without notice.

OfficeRight is a trademark and E-Z Seal is a registered trademark of Pitney

Bowes.

Page 3

Contents

1. Introduction

Important Safety Information ...................................................... 2

About Your Machine .................................................................... 3

Machine Configurations .............................................................. 3

Machine Controls, Indicators and Features ................................ 4

The Controls ............................................................................... 6

2. Preparing and Loading

Connecting Power and Turning On ............................................. 8

Filling the Moistener ................................................................... 9

Loading the Sheet Feeders (Feeders A1 and A2) .................... 10

Loading the Envelope Feeder (Feeder B)................................. 11

Loading the Insert Feeder (Feeder C) ...................................... 12

3. Running Jobs

Job Listing ................................................................................ 13

Job 1: One Folded Sheet into an Envelope ............................ 15

Job 2: One Folded Sheet, No Envelope (Fold Only) .............. 16

Job 3: One Folded Sheet + One Insert into an Envelope ....... 17

Job 4: One Insert into an Envelope ........................................ 19

Job 5: Two Folded Sheets into an Envelope........................... 20

Job 6: Two Collated, Folded Sheets into an Envelope ........... 21

Job 7: Two Folded Sheets, No Envelope (Fold Only) ............. 22

Job 8: Two Collated, Folded Sheets, No Envelope

(Fold Only) ................................................................... 23

Job 9: Two Folded Sheets and an Insert into an Envelope .... 24

Job 10: Two Collated, Folded Sheets and an Insert into an

Envelope ...................................................................... 26

The Manual Feeder M .............................................................. 28

4. Advanced Menu Options

Reset Counter .......................................................................... 29

Change Paper Size................................................................... 30

Move the Address in the Window ............................................. 30

Sheet Double Detect On/Off ..................................................... 31

Insert Double Detect On/Off ..................................................... 32

Safe Seal On/Off....................................................................... 32

5. Reference

Error Messages ................................................................... 33-36

General Troubleshooting ........................................................... 37

Clearing Material Jams ............................................................. 38

Getting Help............................................................................. 39

Ordering Supplies ..................................................................... 40

Material Specifications.............................................................. 41

Machine Specifications ............................................................. 42

Index ....................................................................................... 43

Page

OfficeRight™ DI200

Operator’s Guide

1

Page 4

Safety

1. INTRODUCTION

Important Safety Information

• Please read all the instructions in this manual

operate your OfficeRight™ DI200. Save all instructions for future use.

WARNING! Always use the power cord supplied with

your machine and plug it into a

outlet that's located near the machine and easily

accessible. Failure to properly ground the machine can

result in severe personal injury and/or fire.

• DO NOT use a wall outlet controlled by a wall switch or one that is

shared with other equipment.

• Do not use an adapter plug on the line cord or wall outlet.

• Do not remove the ground pin from the line cord.

• Make sure the area in front of the wall outlet into which the machine is

plugged is free from obstruction.

• DO NOT route the power cord over sharp edges or trap it between

pieces of furniture. Make sure there is no strain on the power cord.

• To reduce the risk of fire or electrical shock, DO NOT attempt to

remove covers or disassemble the inserter. The cabinet encloses

hazardous parts. Refer servicing to qualified personnel.

• Keep fingers, long hair, jewelry and loose clothing away from moving

parts at all times.

• Never reach into the machine while it is running. Avoid touching

moving parts or materials while the machine is in use. Before clearing

a jam, be sure all machine mechanisms come to a complete stop.

• Know your equipment, especially

emergency.

• When removing jammed material, avoid using too much force to

protect against minor personal injury and damage to the equipment.

• Use the equipment only for its intended purpose.

• Always follow the specific occupational safety and health standards

prescribed for your workplace.

CAUTION! If you relocate an OfficeRight™ DI200 that

has the optional Second Sheet Feeder A2 installed,

remove it from the Second Sheet Feeder first—that is,

as you lift it clear, make sure it fully disengages from

the Second Sheet Feeder. Obtain help if necessary.

how to stop it in the event of an

before

you attempt to

properly grounded

wall

2

OfficeRight™ DI200

Operator’s Guide

Page 5

Introduction

About Your Machine

Your new OfficeRight™ DI200 is a compact folding and inserting machine

designed to speed the process of mail creation.

It has a minimal number of user adjustments and an intuitive, easy-to-use

control panel. This greatly simplifies machine operation and will enhance

the productivity of your mailing operation.

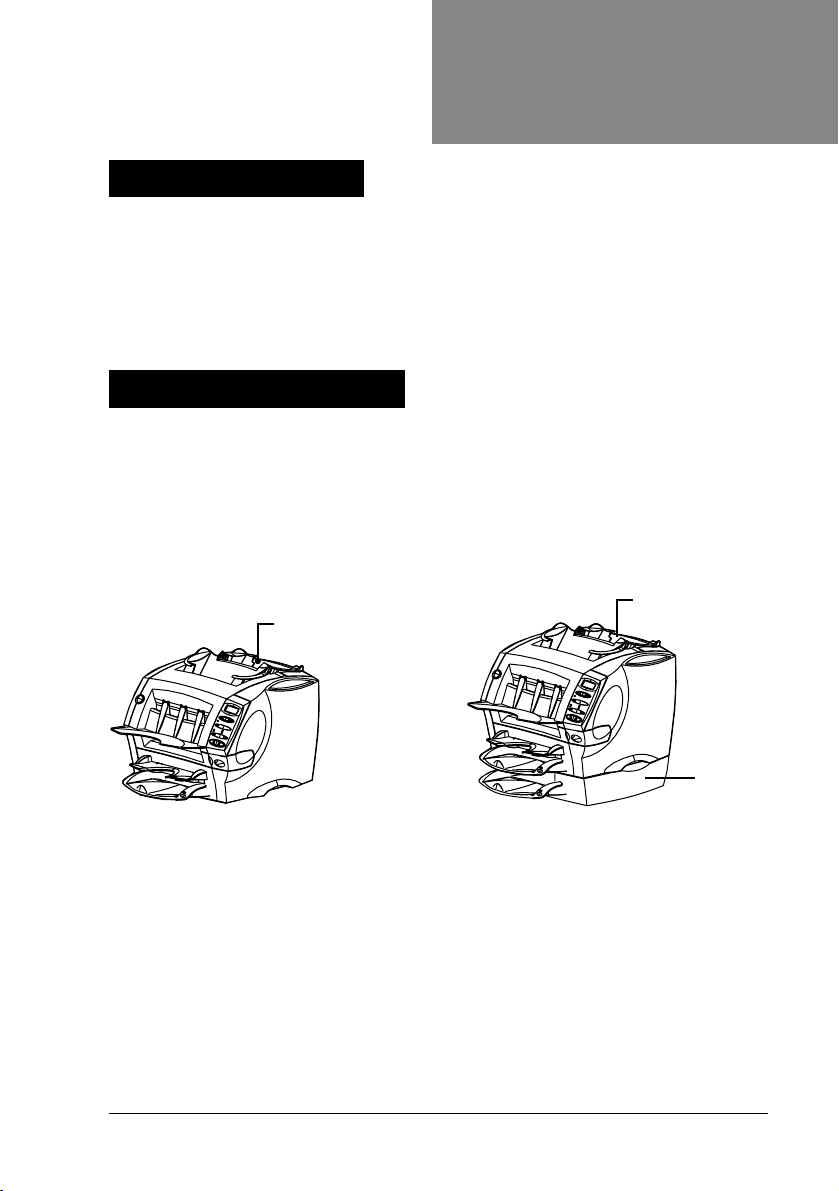

Machine Configurations

There are two configurations of the OfficeRight™ DI200 available. The

basic model is supplied with an insert feeder and one sheet feeder. The

second configuration is supplied with an insert feeder and two sheet

feeders.

insert feeder

insert feeder

Configuration 1

Basic machine with insert

feeder and one sheet feeder

OfficeRight™ DI200

Operator’s Guide

2nd sheet

feeder

Configuration 2

Machine with insert feeder

and a 2nd sheet feeder added

3

Page 6

Introduction

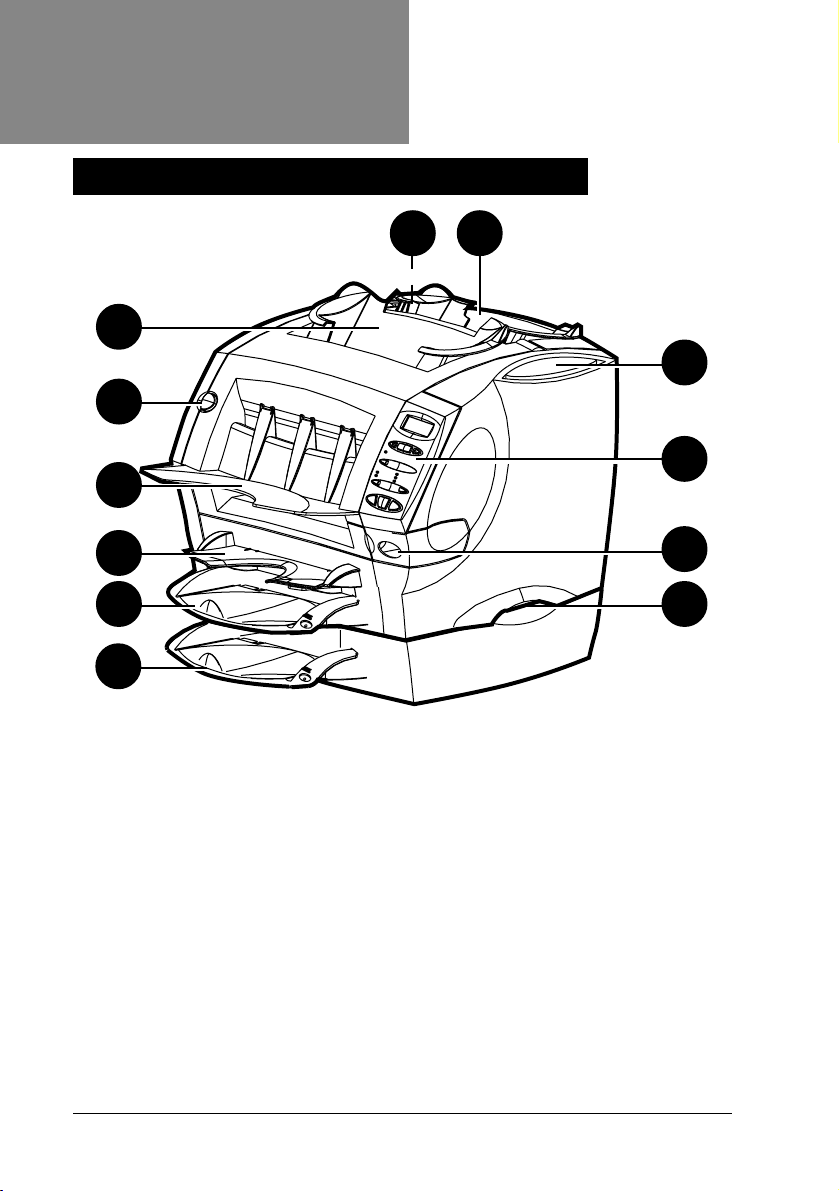

Machine Controls, Indicators and Features

1 2

12

11

10

3

4

9

8

7

1. Insert Cover E Release Button (Blue Button Marked E)

Press this button to release the insert cover if a jam occurs in this

area of the machine. The display prompts you if you need to open this

cover to remove jammed material.

2. Insert Feeder (Not on All Models)

Use this feeder to add additional inserts to your envelope. Material

fed from this feeder

feeder is especially suited to feeding pre-folded or thicker inserts.

3. Operating Guide Slot

Store this Operating Guide in the slot provided so that it doesn’t get

lost and is readily available when you need it.

4. Control Panel

This is where you enter commands and where the machine informs

you of its status. See pages 6 and 7 for a full explanation of what

each button does.

4

cannot

be folded by the inserter. However, this

OfficeRight™ DI200

Operator’s Guide

5

6

Page 7

Introduction

5. Moistener Tank

This tank contains E-Z Seal® solution or water to moisten and seal

envelope flaps. It slides out to the right for refilling and has an oval

level indicator window at the front so you can easily check fluid level.

6. Lifting Handles (One Each Side)

Always lift the OfficeRight™ DI200 using the side handles. DO NOT

lift the machine by any of the feeders or the stacker.

7. Second Sheet Feeder A2 (Optional)

You can add this feeder to the machine to enable folding and

inserting of a second sheet into the envelope. It functions in exactly

the same way as the standard sheet feeder, A1.

IMPORTANT: When you use both sheet feeders A1

and A2 together, always load the address bearing

sheet into sheet feeder A2. If you fail to do this, the

address won’t show in the envelope window. Always

load sheets into feeder A2

first,

that is, with the bottom edge of the sheet furthest into the

machine.

8. Standard Sheet Feeder A1

This feeder enables folding and inserting of a sheet into the envelope.

Always load sheets into this feeder

face down

face down

and

bottom edge

and

bottom edge first.

9. Manual Feeder M

Use this feeder to manually feed stapled sets of

each.

The machine waits for you to feed each set by hand into this

feeder before it folds and inserts the set automatically. Always feed

sheets into this feeder

the bottom edge of the sheet furthest into the machine.

10. Stacker

The machine delivers finished pieces to this area.

11. Front Cover D Release Button (Blue Button Marked D)

Press this button to release the front cover if a jam occurs in this area

of the machine. The display prompts you if you need to open this

cover to remove jammed material.

12. Envelope Feeder B

This feeder feeds envelopes into the inserting area where they are

filled with sheets or inserts from other feeders.

OfficeRight™ DI200

Operator’s Guide

face down

and

bottom edge first,

up to three sheets

that is, with

5

Page 8

Introduction

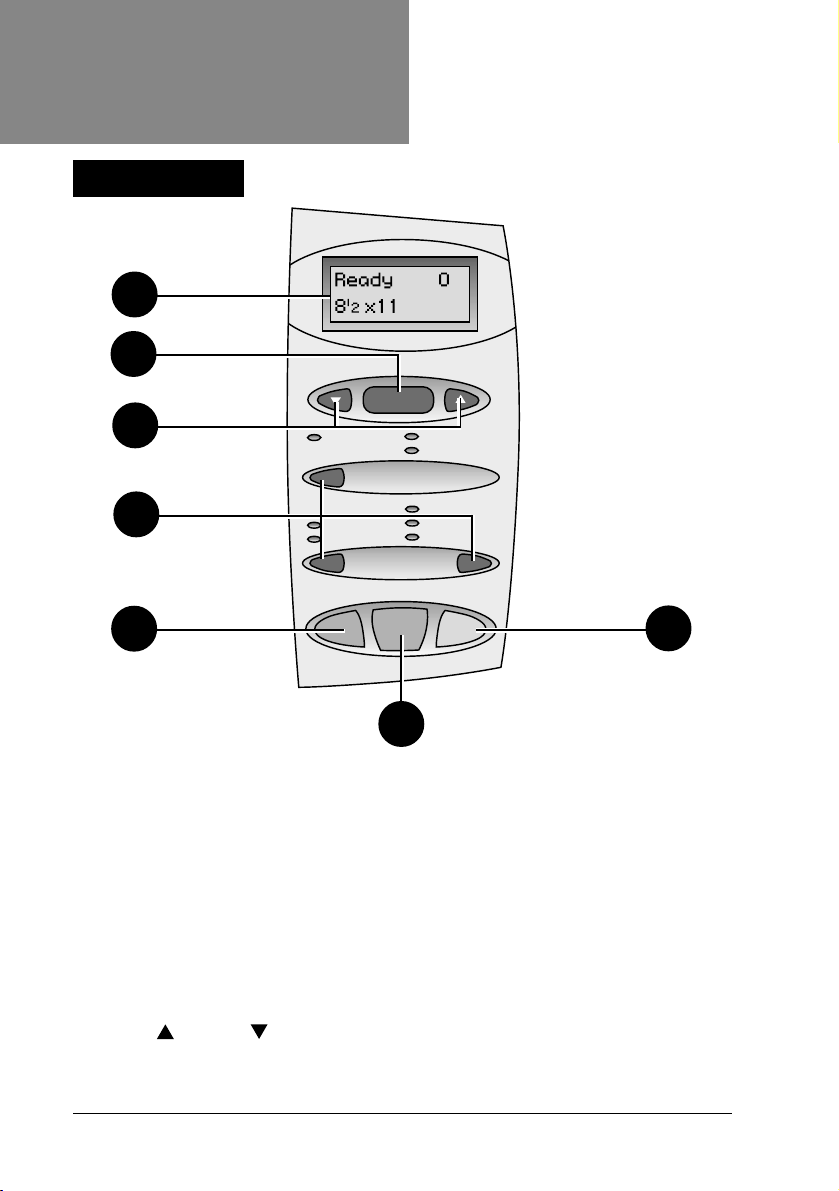

The Controls

1

2

3

4

Menu / Enter

no yes

Feeder A1

Seal

No Seal

Trial Piece Stop

Feeder A2

2nd Page

Envelope Fdr B

Insert Fdr C

Fold Only

Start

5

6

1. Display

Shows the current status of your OfficeRight™ DI200 and displays

prompts or error messages which help you in operating the machine.

2. Menu/Enter

Press this button to enter the menu options. Options available are:

• Reset Counter

• Change Paper Size. Choose 11” (letter size) or 14” (legal size)

• Move Address in Window

• Turn Sheet Double Detection On/Off

• Turn Insert Double Detection On/Off

• Turn Safe Seal On/Off

7

3. yes and no buttons

Once you’ve entered the menu using Menu/Enter, press these

buttons to answer yes or no to prompts. You also use them to change

(increase or decrease) settings offered by menu options.

6

OfficeRight™ DI200

Operator’s Guide

Page 9

Introduction

4. Selection Buttons and Indicator Lights

Press these buttons to step through the feeders and options that are

available on your machine.

Depending on your model configuration, some indicator lights and

associated feeders may be inoperable. If your model doesn’t have a

second sheet feeder, for example, the indicators associated with this

feeder will not light. This is normal.

A

green indicator

A

red indicator

combination of functions. Simply correct the error in selection and the

indicator(s) will change back to green.

An

unlit indicator

5. Trial Piece

After you’ve set up a job using the control panel, you

piece. If you press Start before running a trial piece, the machine

display will prompt you to run a trial piece first.

Press this button to run one fully collated piece as programmed via

the control panel. The envelope will not seal regardless of whether

the system has been told to seal or not. This allows you to inspect the

processed job to make sure that everything is inserted correctly and

that the address appears in the window.

The trial piece also allows the system to calibrate itself and set its

double detect feature, if selected.

6. Start

Press to begin automatic operation.

7. Stop

Press to stop automatic operation at the end of the next cycle.

shows that a feeder or function is selected for use.

shows that you selected an invalid (impossible)

means that the feeder or function is turned

must

IMPORTANT: Running the trial piece is an

function for the machine to perform. You

before a start every time you use a new batch of

material. This allows the system to re-calibrate in case

different batches of material vary slightly.

must

OFF.

run a trial

essential

do it

About the Sleep Mode

After 10 minutes of inactivity, the system enters a power-saving

“sleep mode” and displays Powersave On. Pressing any button will

wake the machine up. The machine remembers the last job setup.

OfficeRight™ DI200

Operator’s Guide

7

Page 10

Loading

2. PREPARING AND LOADING

This chapter explains how to connect and load the machine.

Once you understand the subjects covered in this chapter, you can quickly

set up and use the machine for a variety of jobs as explained later in

Chapter 3,

IMPORTANT: Before running a job, make sure your material meets our

published specifications (see

assure reliable operation and greatest productivity.

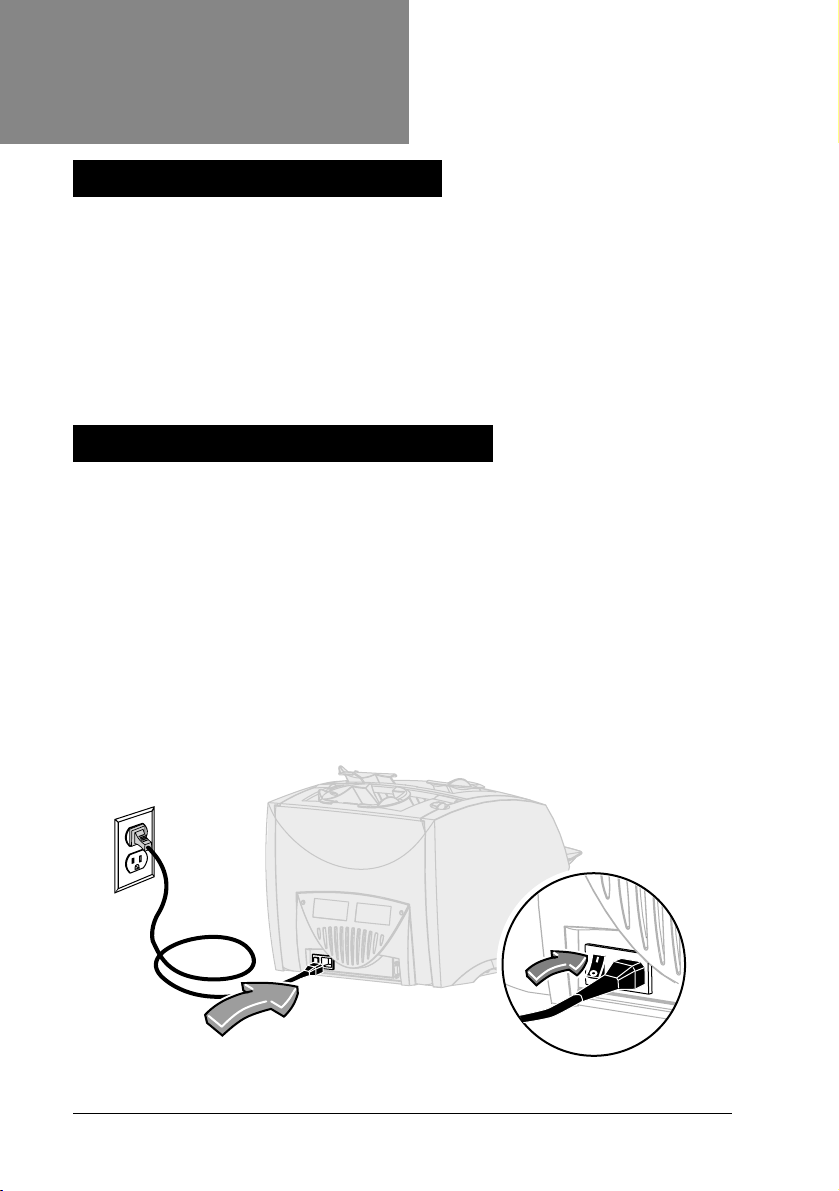

Connecting Power and Turning On

Running Jobs

.

Specifications

on page 41). This helps

WARNING! Read all the safety information on page 2

the machine.

Connect the power cord to the socket on the back of the machine.

Plug the power cord into a suitable power outlet. Make sure the power

outlet is near the machine and is easily accessible.

Turn the power switch ON. After a few seconds, the display shows

When turned ON, the machine remembers the last job setup, but resets

the item counter back to zero automatically.

before

connecting

Ready.

8

OfficeRight™ DI200

Operator’s Guide

Page 11

Loading

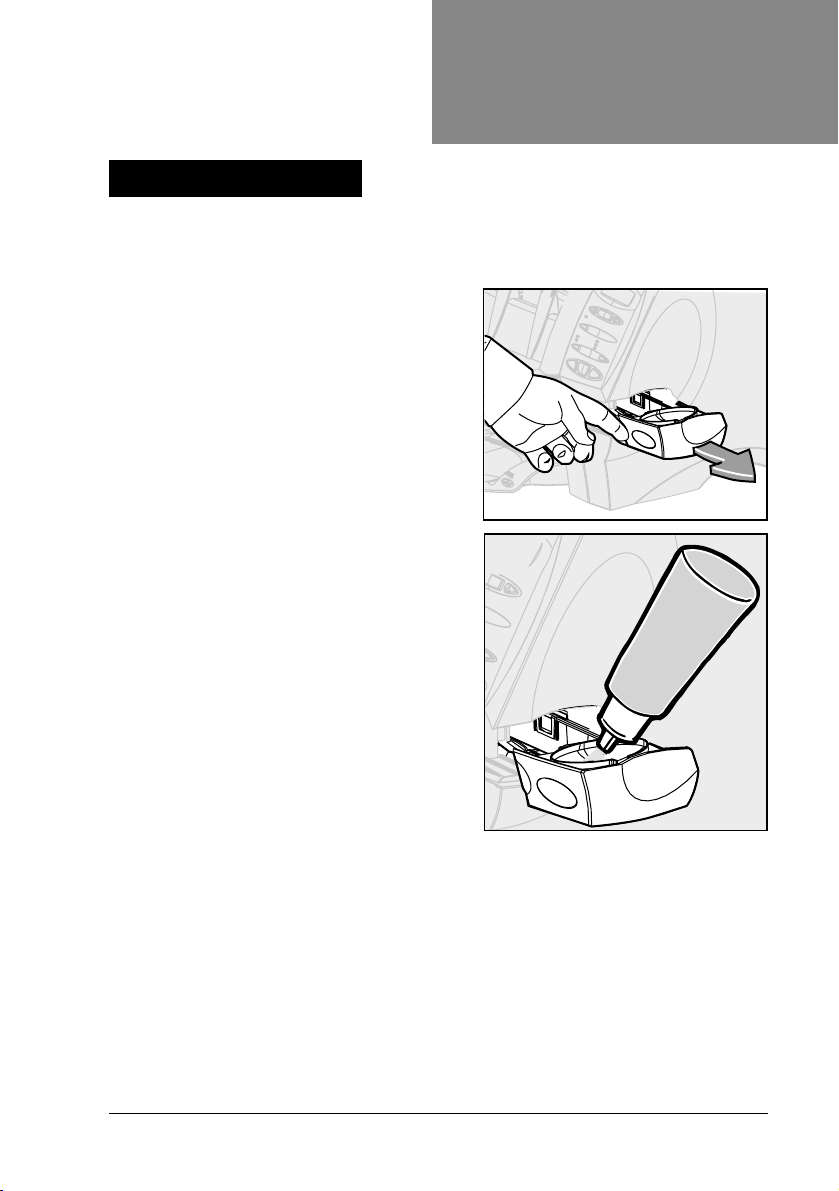

Filling the Moistener

Refill the moistener when the fluid gets low. Check fluid level through the

oval viewing window (figure, below right).

Slide the moistener out to the right.

IMPORTANT: Never open the

moistener while the machine is

processing material.

Carefully fill the moistener with E-Z

®

Seal

solution or water up to the “Max”

mark in the filler funnel.

We recommend E-Z Seal® to minimize

algae growth and scale buildup.

Slide the moistener back into the machine.

From the dry state, the moistener will take about five minutes to become

fully wet and ready for use.

OfficeRight™ DI200

Operator’s Guide

9

Page 12

Loading

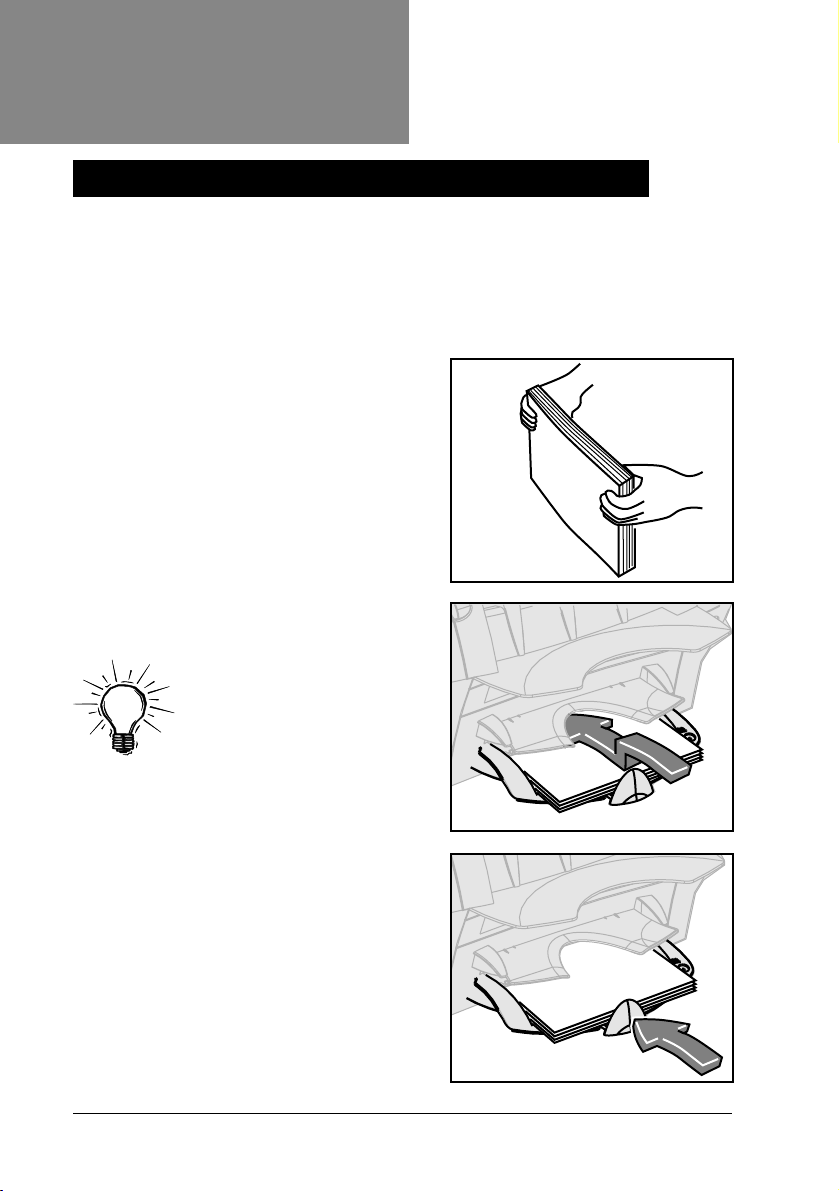

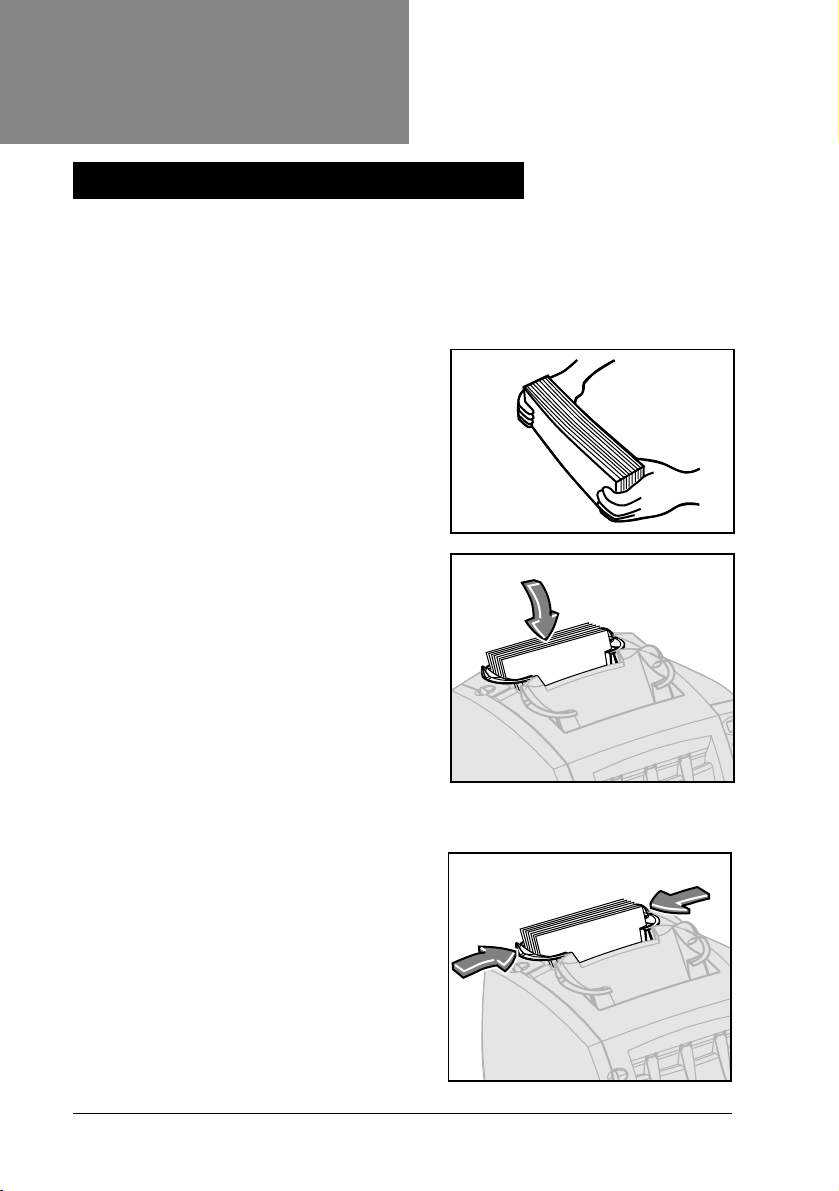

Loading the Sheet Feeders (Feeders A1 and A2)

Sheet Feeder A1 is common to all models and is located immediately

below the Manual Feeder M. Sheet Feeder A2 is an option on all models.

It allows the machine to insert a second folded sheet into an envelope.

Both feeders are used for sheets that require folding before inserting.

Load both feeders in exactly the same way.

Always fan (aerate) sheets before you

load them. This prevents them from

sticking together.

Then tap the stack of sheets onto a firm

surface to align the edges.

Place the sheets into Sheet Feeder A1

or A2 as required.

IMPORTANT: Always

load sheets into these

feeders

bottom edge first.

bottom edge of the

sheet is furthest into the machine.

face down

and

The

If you’re using both Sheet Feeders A1

and

A2 at the same time, you

the document printed with the address

into Sheet Feeder A2. If you load the

address-bearing document into Sheet

Feeder A1,

in the envelope window.

Slide the back stop in until it just

touches the paper stack.

10

the address won’t be visible

must

load

OfficeRight™ DI200

Operator’s Guide

Page 13

Loading

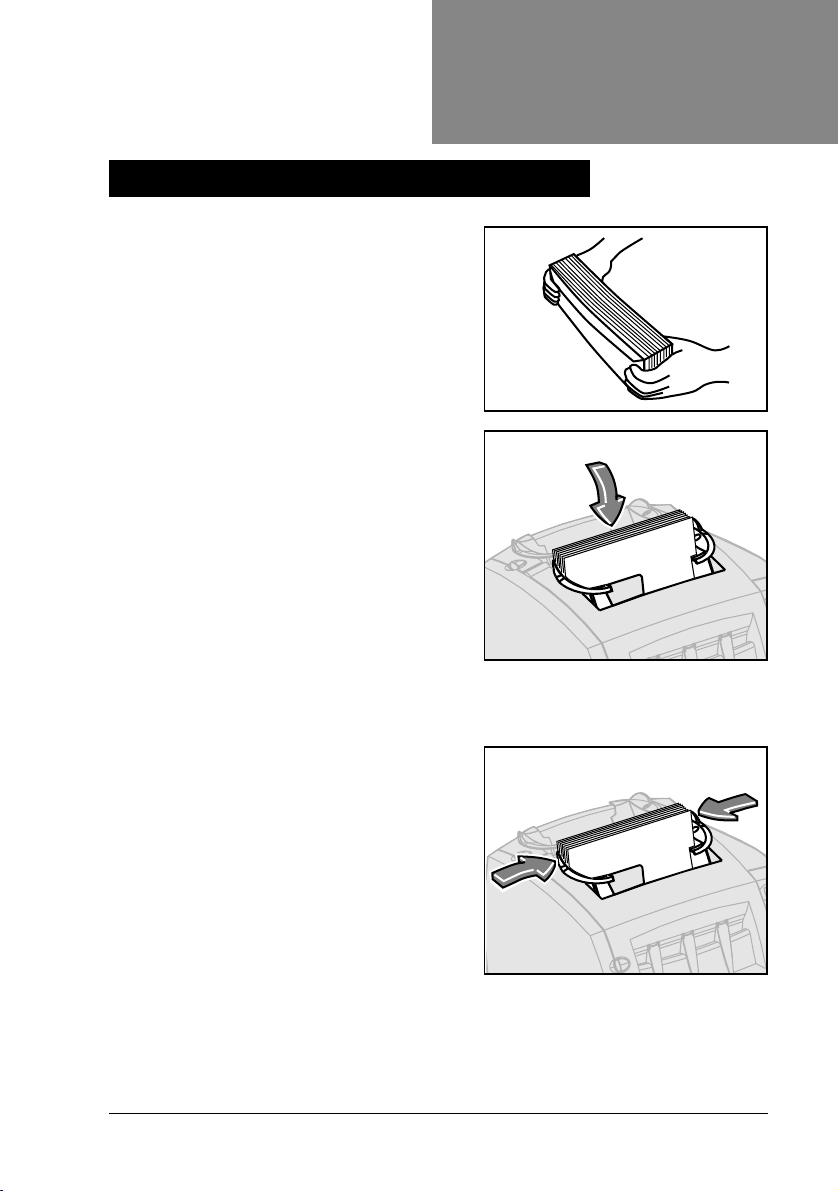

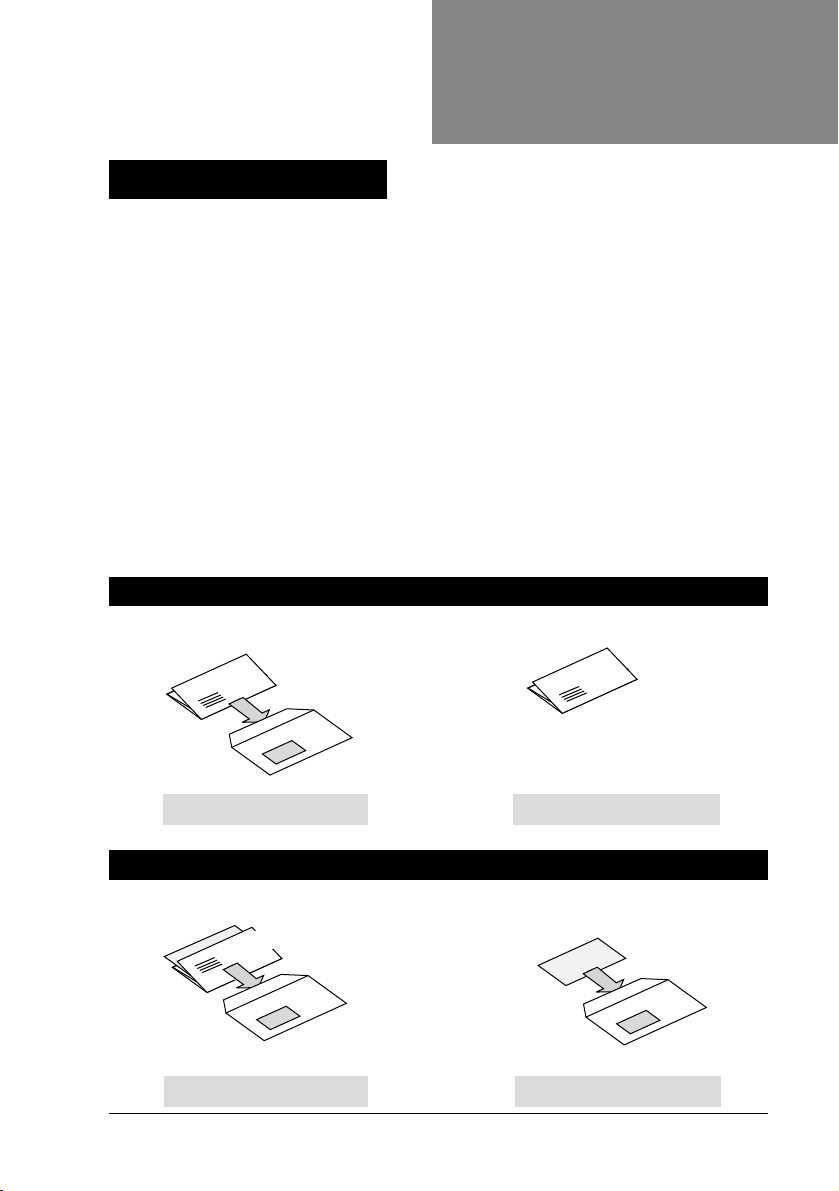

Loading the Envelope Feeder (Feeder B)

Always fan (aerate) envelopes before

you load them. This prevents them

from sticking together.

Then tap the stack of envelopes onto a

firm surface to align the edges.

IMPORTANT:

Load envelopes right way up and

facing you. This means that the

envelope flap is on the back of the

envelope and at the top. Any other

orientation will prevent the machine

from inserting properly.

Place the envelope stack into Feeder B

with the back envelope flat against the

feed belts. There’s no need to “shingle”

or stagger the envelope stack.

Slide the two side guides up to the

envelope stack then

off. Use the blue handles at the rear of

the guides when moving them.

The correct setting is achieved when

the guides control the envelopes but in

no way restrict their feed into the

machine or cause them to feed at an

angle (skew).

IMPORTANT: If the guides are too

tight, envelopes may not feed reliably; if the guides are too loose,

envelopes may skew as they feed into the machine.

OfficeRight™ DI200

slightly

Operator’s Guide

back them

11

Page 14

Loading

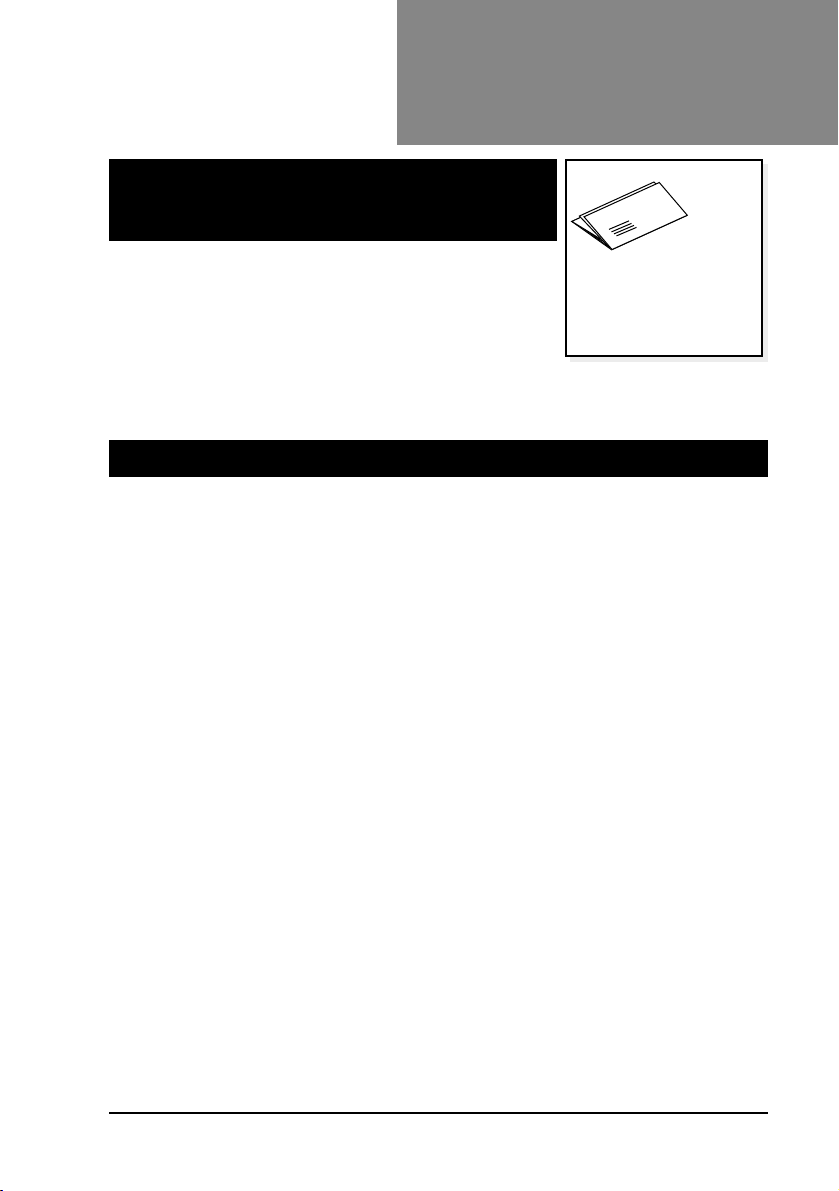

Loading the Insert Feeder (Feeder C)

Insert Feeder C is only available on certain machine configurations. Use

do not

this feeder to add additional inserts to your envelope that

folding by the machine. Feeder C is especially suited to feeding pre-folded

or thicker inserts such as business reply envelopes (BREs), response

cards and similar materials.

Always fan (aerate) inserts before you

load them. This prevents them from

sticking together.

Then tap the stack of inserts onto a firm

surface to align the edges.

Place the insert stack into Feeder C.

IMPORTANT: The orientation of the

insert stack depends on the nature of

the material being run. For pre-folded

inserts, it’s normally best to load with

the “closed” edge feeding first. You can

usually load business reply envelopes

right way up and facing you. However, if

the flaps are pulled open when feeding,

try loading the envelopes with the flaps

down and facing you.

require

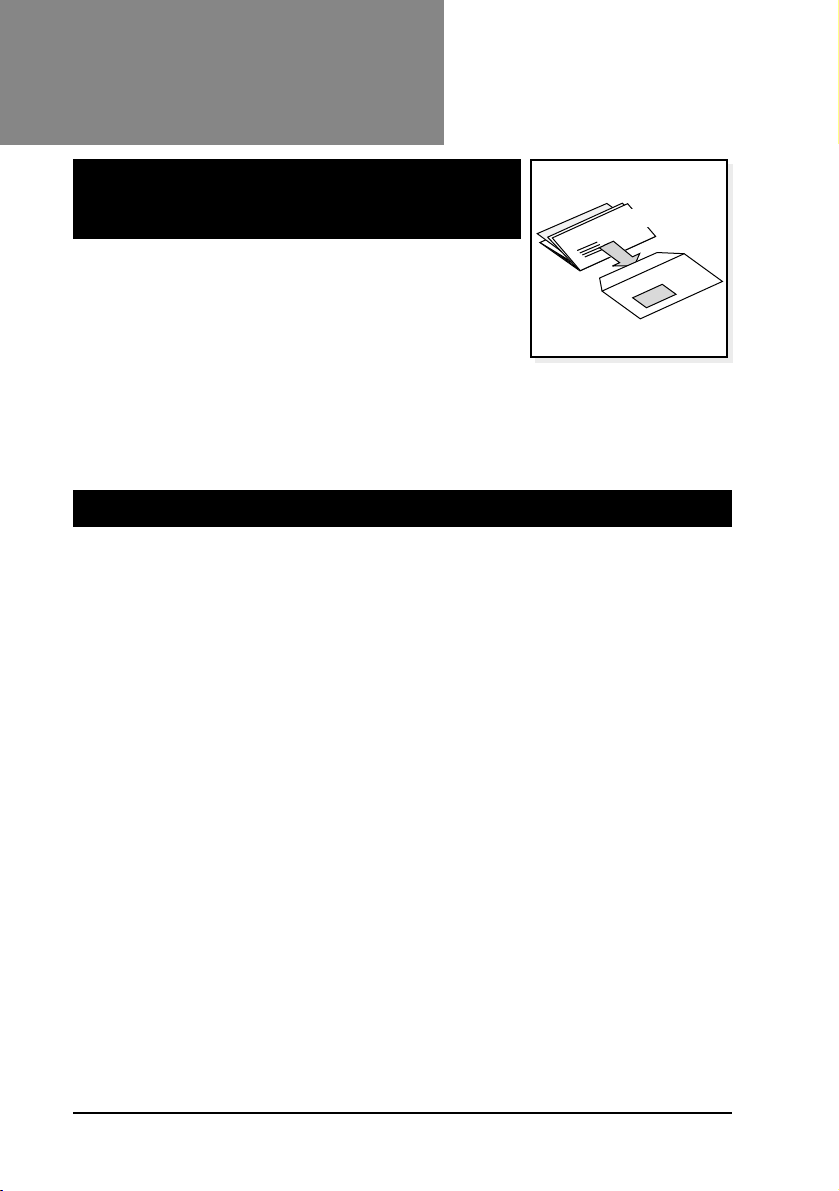

Slide the two side guides up to the

insert stack then

Use the blue handles at the rear of the

guides when moving them.

IMPORTANT: The setting is correct

when the guides control the inserts but

in no way restrict their feed into the

machine or cause them to feed at an

angle (skew). If the guides are too tight,

inserts may not feed reliably; if they are

too loose, inserts may skew as they

feed into the machine.

12

slightly

back them off.

OfficeRight™ DI200

Operator’s Guide

Page 15

1 folded sheet

no envelope (fold only)

envelope

1 insert

Running

3. RUNNING JOBS

Chapter 1 explained the main features of the machine and how to use the

control panel. Chapter 2 described how to turn the machine ON and load the

feeders and moistener unit.

This chapter assumes you understand the content of the previous chapters.

It includes illustrations that identify the various jobs you can run on your

OfficeRight™ DI200, and then gives a table of quick steps to set up and run

each job.

Once you’re familiar with the machine, use this chapter as a quick reference

when you have to change a job setup.

The Manual Feeder M is used to feed stapled sets of up to three sheets by

hand. See page 28 for an explanation of how to set up and use this feeder.

Job Listing

ALL MODELS

1 folded sheet

MODELS with an INSERT FEEDER C

OfficeRight™ DI200

envelope

JOB 1 Page 15

1 insert

1 folded sheet

envelope

JOB 3 Page 17 JOB 4 Page 19

Operator’s Guide

JOB 2 Page 16

13

Page 16

Running

MODELS with an OPTIONAL SECOND SHEET FEEDER A2

2 folded sheets

envelope

JOB 5 Page 20 JOB 6 Page 21

2 folded sheets

no envelope (fold only)

JOB 7 Page 22 JOB 8 Page 23

MODELS with an INSERT FEEDER C and SECOND SHEET

FEEDER A2

1 insert

2 folded sheets

1 insert

2 folded sheets

(collated)

envelope

2 folded sheets

(collated)

no envelope (fold only)

2 folded sheets

(collated)

see note below

*

see note below

*

envelope

JOB 9 Page 24 JOB 10 Page 26

envelope

see note below

*

NOTE: Jobs marked with an asterisk (*) use the second sheet feeder, A2,

in “2nd Page” mode to feed 2-sheet collated sets. You must load sheets

into the feeder in their collated sequence: first page, second page, first

page, second page, etc., just as they are printed by a typical office laser

printer.

14

OfficeRight™ DI200

Operator’s Guide

Page 17

Job 1

One Folded Sheet into an Envelope

Model Required: Any OfficeRight™DI200

Notes: If your machine has the optional 2nd sheet

feeder A2, you can use it instead of A1, as long as

you load and select it as described in steps 1 and 3

below.

Step Action Tips More Details…

1 Make sure paper size Choose 11” or 14” Page 30

setting is correct

2 Load sheets Load face down Page 10

into Sheet Feeder and bottom edge first

A1

3 Load envelopes Load right way up Page 11

into Feeder B and facing you

4 Press button Make sure green Page 6, 7

to select Feeder A1 indicator lights

1 folded sheet

envelope

5 Press button to Make sure green Page 6, 7

select Envelope indicator lights

Fdr B

6 Press button to Make sure moistener has Page 6, 7

choose Seal or E-Z Seal

No Seal

7 Press Trial Piece Trial piece will not Page 6, 7

button and check seal—this is normal

trial piece

8 Press Start button Stop button will stop Page 6, 7

to run job machine at end of cycle

Problems? See

OfficeRight™ DI200

Error Messages,

Operator’s Guide

page 33, and

®

or water

Troubleshooting

, page 37

15

Page 18

Job 2

1 folded sheet

no envelope (fold only)

One Folded Sheet, No Envelope

(Fold Only)

Model Required: Any OfficeRight™DI200

Notes: If your machine has the optional 2nd sheet

feeder A2, you can use it instead of Feeder A1, as

long as you load and select it as described in steps 1

and 3 below.

Step Action Tips More Details…

1 Make sure paper size Choose 11” or 14” Page 30

setting is correct

2 Load sheets Load face down and Page 10

into Sheet Feeder bottom edge first

A1

3 Press button Make sure green Page 6, 7

to select Feeder A1 indicator lights

4 Press button to Make sure green Page 6, 7

select Fold Only indicator lights

5 Press Trial Piece Check trial piece Page 6, 7

button and look for a

6 Press

to run job machine at end of cycle

Problems? See

16

a good fold

Start button Stop button will stop Page 6, 7

Error Messages,

page 33, and

Troubleshooting

OfficeRight™ DI200

, page 37

Operator’s Guide

Page 19

Job 3

One Folded Sheet + One Insert

into an Envelope

Model Required: OfficeRight™DI200

Insert Feeder C

Notes: Inserts are pre-folded sheets or unfolded

items such as business reply envelopes, response

cards and similar items. If your machine has the

optional 2nd sheet feeder A2, you can use it instead

of Feeder A1, as long as you load and select it as described in steps 1 and 4

below.

Step Action Tips More Details…

1 Make sure paper size Choose 11” or 14” Page 30

setting is correct

2 Load sheets Load face down Page 10

into Sheet Feeder and bottom edge first

A1

3 Load envelopes Load right way up Page 11

into Feeder B and facing you

4 Load inserts Loading orientation Page 12

into Insert Feeder C depends on item

must

have an

1 insert

1 folded sheet

envelope

5 Press button Make sure green Page 6, 7

to select Feeder A1 indicator lights

6 Press button Make sure BOTH Page 6, 7

to select Envelope green indicators

Fdr B and Insert are lit

Fdr C

7 Press button to Make sure moistener Page 6, 7

choose Seal or has E-Z Seal

No Seal

OfficeRight™ DI200

Operator’s Guide

®

or water

Continues on next page...

17

Page 20

Job 3

One Folded Sheet + One Insert

into an Envelope (continued)

Step Action Tips More Details…

8 Press Trial Piece Trial piece will not Page 6, 7

button and check seal—this is normal

trial piece

9 Press Start button Stop button will stop Page 6, 7

to run job machine at end of cycle

Problems? See

Error Messages,

page 33, and

Troubleshooting

, page 37

18

OfficeRight™ DI200

Operator’s Guide

Page 21

Job 4

One Insert into an Envelope

Model Required: Your OfficeRight™ DI200

must

1 insert

have an Insert Feeder C.

Notes: Inserts are pre-folded sheets or unfolded

items such as business reply envelopes,

envelope

response cards and similar materials.

Step Action Tips For More Details…

1 Load envelopes Load right way up Page 11

into Feeder B and facing you

2 Load inserts Loading orientation Page 12

into Insert depends on item

Feeder C

3 Press button Make sure BOTH Page 6, 7

to select Envelope green indicators

Fdr B and Insert are lit

Fdr C

4 Press A1/A2 select Make sure NO Page 6, 7

button until both indicators are lit for

feeders and 2nd A1 or A2 or 2nd Page

Page are turned

OFF

5 Press button to choose Make sure moistener Page 6, 7

Seal or No Seal has E-Z Seal

6 Press Trial Piece button Trial piece will not Page 6, 7

and inspect trial piece seal—this is normal

7 Press Start button Stop button will stop Page 6, 7

to run job machine at end of cycle

Problems? See

OfficeRight™ DI200

Error Messages,

Operator’s Guide

page 33, and

®

or water

Troubleshooting

, page 37

19

Page 22

Job 5

Two Folded Sheets into an Envelope

Model Required: Your OfficeRight™ DI200

must

2 folded sheets

have the optional Sheet Feeder A2.

Notes: Run the address-bearing document from

envelope

Sheet Feeder A2 and a second sheet that needs

folding from Sheet Feeder A1.

Step Action Tips For More Details…

1 Make sure paper size Choose 11” or 14” Page 30

setting is correct

2 Load addressed sheets Load face down Page 10

into Sheet Feeder A2 and bottom edge first

3 Load second sheets Load face down Page 10

into Sheet Feeder A1 and bottom edge first

4 Load envelopes Load right way up Page 11

into Feeder B and facing you

5 Press button to select Make sure BOTH Page 6, 7

Feeders A1 and A2. green indicators are lit

6 Press button to select Make sure green Page 6, 7

Envelope Fdr B indicator lights

7 Press button to choose Make sure moistener Page 6, 7

Seal or No Seal has E-Z Seal

8 Press Trial Piece button Trial piece will not Page 6, 7

and check trial piece seal—this is normal

9 Press Start button Stop button will stop Page 6, 7

to run job machine at end of cycle

Problems? See

20

Error Messages,

page 33, and

®

or water

Troubleshooting

OfficeRight™ DI200

, page 37

Operator’s Guide

Page 23

Job 6

Two Collated, Folded Sheets into an

Envelope

Model Required: Your OfficeRight™ DI200

must

2 folded sheets

(collated)

have the optional Sheet Feeder A2.

Notes: This job uses the second sheet feeder

envelope

A2 in 2nd Page mode to feed two-sheet, collated

sets. Load sheets into the feeder in their collated

sequence: page one, page two, page one, page two and so on.

Step Action Tips For More Details…

1 Make sure paper size Choose 11” or 14” Page 30

setting is correct

2 Load sheets into Load face down Page 10

Sheet Feeder A2. and bottom edge first

See note above for

loading sequence

3 Load envelopes Load right way up Page 11

into Feeder B and facing you

4 Press button to select Make sure BOTH Page 6, 7

Feeder A2 and 2nd green indicators are lit

Page

5 Press button to select Make sure green Page 6, 7

Envelope Fdr B indicator lights

6 Press button to choose Make sure moistener Page 6, 7

Seal or No Seal has E-Z Seal

7 Press Trial Piece button Trial piece will not Page 6, 7

and check trial piece seal—this is normal

8 Press Start button Stop button will stop Page 6, 7

to run job machine at end of cycle

Problems? See

OfficeRight™ DI200

Error Messages,

Operator’s Guide

page 33, and

®

or water

Troubleshooting

, page 37

21

Page 24

Job 7

Two Folded Sheets, No Envelope

(Fold Only)

Model Required: Your OfficeRight™ DI200

have an optional Sheet Feeder A2.

must

2 folded sheets

no envelope (fold only)

Notes: Run the address-bearing document from

Sheet Feeder A2 and a second sheet that needs

folding from Sheet Feeder A1.

Step Action Tips For More Details…

1 Make sure paper size Choose 11” or 14” Page 30

setting is correct

2 Load addressed sheets Load face down Page 10

into Sheet Feeder A2 and bottom edge first

3 Load second sheets Load face down Page 10

into Sheet Feeder A1 and bottom edge first

4 Press button to select Make sure BOTH Page 6, 7

Feeder A1 and green indicators

Feeder A2 are lit

5 Press button to Make sure green Page 6, 7

select Fold Only indicator lights

6 Press Trial Piece button Check trial piece Page 6, 7

and check trial piece for a good fold

7 Press Start button Stop button will stop Page 6, 7

to run job machine at end of cycle

Problems? See

22

Error Messages,

page 33, and

Troubleshooting

OfficeRight™ DI200

, page 37

Operator’s Guide

Page 25

Two Collated, Folded Sheets,

No Envelope (Fold Only)

Job 8

Model Required: Your OfficeRight™ DI200

have an optional Sheet Feeder A2.

must

2 folded sheets

(collated)

no envelope (fold only)

Notes: This job uses the second sheet feeder

A2 in 2nd Page mode to feed two-sheet collated

sets. Load sheets into the feeder in collated sequence: first page, second

page, first page, second page and so on.

Step Action Tips For More Details…

1 Make sure that paper Choose 11” or 14” Page 30

size setting is correct

2 Load sheets into Load face down Page 10

Sheet Feeder A2. and bottom edge

See note above for first

loading sequence

3 Press button to select Make sure BOTH Page 6, 7

Feeder A2 and green indicators

2nd Page are lit

4 Press button to Make sure green Page 6, 7

select Fold Only indicator lights

5 Press Trial Piece button Check trial piece Page 6, 7

and check trial piece for a good fold

6 Press Start button Stop button will stop Page 6, 7

to run job machine at end of

cycle

Problems? See

OfficeRight™ DI200

Error Messages,

Operator’s Guide

page 33, and

Troubleshooting

, page 37

23

Page 26

Job 9

envelope

1 insert

2 folded sheets

Two Folded Sheets and an Insert

into an Envelope

Model Required: Your OfficeRight™ DI200

must

have the optional Sheet Feeder A2 and an Insert

Feeder C

Notes: Run the address-bearing document from

Sheet Feeder A2 and a second sheet that needs

folding from Sheet Feeder A1. Inserts are pre-folded sheets or unfolded

items such as business reply envelopes, response cards and similar

materials.

Step Action Tips For More Details…

1 Make sure that paper Choose 11” or 14” Page 30

size setting is correct

2 Load addressed sheets Load face down Page 10

into Sheet Feeder A2 and bottom edge first

3 Load second sheets Load face down Page 10

into Sheet Feeder A1 and bottom edge first

4 Load envelopes Load right way up Page 11

into Feeder B and facing you

5 Load inserts Loading orientation Page 12

into Insert Feeder C depends on item

6 Press button to select Make sure BOTH Page 6, 7

Feeder A1 and green indicators

Feeder A2 are lit

7 Press button to Make sure BOTH Page 6, 7

select Envelope Fdr green indicators

B and Insert Fdr C are lit

8 Press button to choose Make sure moistener Page 6, 7

24

Seal or No Seal has E-Z Seal

®

or water

OfficeRight™ DI200

Operator’s Guide

Page 27

Job 9

Two Folded Sheets and an Insert

into an Envelope (continued)

Step Action Tips For More Details…

9 Press Trial Piece button Trial piece will not Page 6, 7

and check trial piece seal—this is normal

10 Press Start button Stop button will stop Page 6, 7

to run job machine at end of

cycle

Problems? See

Error Messages,

page 33, and

Troubleshooting

, page 37

OfficeRight™ DI200

Operator’s Guide

25

Page 28

Job 10

Two Collated, Folded Sheets and an

Insert into an Envelope

Model Required: Your OfficeRight™ DI200

must

1 insert

2 folded sheets

(collated)

have the optional Sheet Feeder A2 and an Insert

Feeder C.

envelope

Notes: This job uses the second sheet feeder

A2 in 2nd Page mode to feed two-sheet, collated sets. Load sheets into

the feeder in collated sequence: first page, second page, first page,

second page and so on. Inserts are pre-folded sheets or unfolded items

such as business reply envelopes, response cards and so on.

Step Action Tips For More Details…

1 Make sure that paper Choose 11” or 14” Page 30

size setting is correct

2 Load sheets into Load face down Page 10

Sheet Feeder A2. and bottom edge first

See note above for

loading sequence

3 Load envelopes Load right way up Page 11

into Feeder B and facing you

4 Load inserts Loading orientation Page 12

into Insert Feeder C depends on item

5 Press button to select Make sure BOTH Page 6, 7

Feeder A2 and green indicators

2nd Page are lit

6 Press button to Make sure BOTH Page 6, 7

select Envelope green indicators

Fdr B and are lit

Insert Fdr C

7 Press button to choose Make sure moistener Page 6,7

Seal or No Seal has E-Z Seal

26

®

or water

OfficeRight™ DI200

Operator’s Guide

Page 29

Job 10

Two Collated, Folded Sheets and an

Insert into an Envelope (continued)

Step Action Tips For More Details…

8 Press Trial Piece button Trial piece will not Page 6, 7

and check trial piece seal—this is normal

9 Press Start button Stop button will stop Page 6, 7

to run job machine at end of

cycle

Problems? See

Error Messages,

page 33, and

Troubleshooting

, page 37

OfficeRight™ DI200

Operator’s Guide

27

Page 30

Manual Feed

The Manual Feeder M

All OfficeRight™ DI200 models have a Manual Feeder M that allows you

to feed stapled sets of

by the machine.

up to three sheets,

one set at a time, for processing

Using the manual feeder

can, however, use the manual feeder along with the envelope, insert, foldonly and sealer selections to run a variety of jobs manually.

To use the manual feeder, set up the machine as you normally would for

the job you’re running. The selections shown by the indicators for Sheet

Feeders A1 and/or A2 will be

apply to the manual job.

Feed stapled sets into the manual

feeder in the normal orientation for

sheets fed into the OfficeRight™

DI200; that is,

edge

first.

Take one stapled set and feed it gently

into the manual feed slot until the

machine automatically starts and draws

the set from you. The machine

processes the set and ejects it into the

stacker in the usual manner.

NOTES:

• Be sure to feed the set in squarely. If you feed it in at an angle, a poor

fold or jam could result.

• Feed the set into the machine gently. Very little force is needed.

• The first set will

“trial” feature allows you to inspect the processed job to make sure

that all pieces were inserted correctly and that the address appears in

the envelope window.

face down

automatically turns off both sheet feeders

ignored

and

bottom

not

seal even if you set up the system to do so. This

by the machine. All other selections

Feed sets

face down,

bottom edge

first

. You

28

CAUTION! Feeding more than three sheets in a set may

damage your machine.

OfficeRight™ DI200

Operator’s Guide

Page 31

4. ADVANCED MENU OPTIONS

The Menu

Press the

Menu/Enter

Button to get to the advanced menu options. These

allow you to:

• Reset the counter

Choose this option if you want to set the piece

counter back to zero.

• Change paper size

Menu / Enter

Choose this option to select letter-size

no yes

sheets (8-1/2 x 11 inches) or legal-size

sheets (8-1/2 x 14 inches).

Feeder A1

Feeder A2

2nd Page

• Move the address in the window

Select this menu option to center the

address vertically in the envelope window

• Turn sheet double detection on or off

Seal

No Seal

Trial Piece Stop

Envelope Fdr B

Insert Fdr C

Fold Only

Start

Turn this option on if you want the machine to

stop automatically when it senses a double feed.

• Turn insert double detection on or off

Turn this option on if you want the machine to stop automatically when

it detects a double insert feed.

• Turn safe seal on or off

Turn this option on if you need to improve envelope sealing quality.

The above options appear in the order listed. To scroll through them, press

the

Menu/Enter

press the

as they appear. To return to the

Menu/Enter

button repeatedly until you see the option you want. Or

Menu/Enter

button once and answer

Ready

screen at any time, press the

no

to each of the options

button repeatedly.

Reset Counter

This option allows you to reset the

counter to zero. To access it, press the

Menu/Enter

Prompts:

Press

no

( ) to go to the next menu option.

OfficeRight™ DI200

button once. The screen

Reset Counter?

yes

( ) to reset the counter and return to the ready screen. Press

Operator’s Guide

ResetReset

Reset

ResetReset

Counter?Counter?

Counter?

Counter?Counter?

29

Page 32

The Menu

Change Paper Size

Choose this menu option to select the

paper (sheet) size you want to run. You

can set your OfficeRight™ DI200 to

process letter-size sheets (8-1/2 x 11

inches) or legal-size sheets (8-1/2 x 14

inches).

Press the

current paper size selection:

1/2 x 14 Change Size?

Press

Press

size setting. Press the

Ready

Please note that the paper size setting applies to

feeders: that is, Sheet Feeder A1; the optional Sheet Feeder A2 (if your

machine is so equipped); and Manual Feeder M.

Menu/Enter

yes

( ) to change paper size. The display confirms the change.

no

( ) to go to the next menu option without changing the paper

screen.

IMPORTANT: Always make sure the sheets you load are

the same size you’ve set the machine to run. If you load the

wrong size sheets, the machine will jam.

button repeatedly until the display shows the

Paper: 8-1/2 x 11 Change Size?

Menu/Enter

button repeatedly to go back to the

Paper: 8-1/2 x 11Paper: 8-1/2 x 11

Paper: 8-1/2 x 11

Paper: 8-1/2 x 11Paper: 8-1/2 x 11

Change Size?Change Size?

Change Size?

Change Size?Change Size?

Paper: 8-1/2 x 14Paper: 8-1/2 x 14

Paper: 8-1/2 x 14

Paper: 8-1/2 x 14Paper: 8-1/2 x 14

Change Size?Change Size?

Change Size?

Change Size?Change Size?

or

Paper: 8-

all

your machine’s sheet

CAUTION: DO NOT intermix sheet sizes in the same job.

The machine will jam if you attempt to do so.

Move the Address in the Window

This menu option allows you to change the length of the fold panel so that

the address is centered in the envelope window. Make this adjustment if

the address in your trial piece appears to be too high or too low in the

window.

Make the adjustment by entering a number from 1 to 9. The

number, the

30

lower

the address will appear in the window.

OfficeRight™ DI200

higher

the

Operator’s Guide

Page 33

The Menu

Press the

until the screen displays:

in window?

Press

The screen displays:

(where X is the current setting)

Set the desired number using the

reach the setting you want, press the

takes you to the next menu option.

Run another trial piece and check it. If the address is centered in the

window, press

the procedure until you get the result you want.

Pressing

window takes you to the next menu option.

Menu/Enter

yes

( ) to enter the function.

Start

no

( ) when you have the option to move the address in the

button repeatedly

Move address

Shift...X

yes

to run your job. If the address is not centered, repeat

Move addressMove address

Move address

Move addressMove address

In window?In window?

In window?

In window?In window?

Shift.. XShift.. X

Shift.. X

Shift.. XShift.. X

Down Down

Down

Down Down

( ) and

Menu/Enter

no

( ) buttons. When you

button to confirm it. This

Up Up

Up

Up Up

Sheet Double Detect On/Off

This option lets you turn the sheet feeder(s) double document detection on

or off.

When turned on…

The machine stops automatically when it senses a double feed (two

sheets feed when only one should). If you’re running a job with individually

addressed inserts, it’s best to turn double detection on.

When turned off…

The machine ignores any double feeds that may occur. You may want to

turn double detection off if you’re running a mail job and it is of little

concern if a mail recipient receives duplicate sheets.

Press the

until the display shows the sheet DD

status:

Press

double detect status. The display will confirm the change. Press

go to the next menu option without changing this setting.

Turn safe seal on/off

OfficeRight™ DI200

Menu/Enter

Sheet DD is On (Off). Change?

yes

( ) to change the sheet

button repeatedly

Operator’s Guide

Sheet DD isSheet DD is

Sheet DD is

Sheet DD isSheet DD is

On. Change?On. Change?

On. Change?

On. Change?On. Change?

no

( ) to

31

Page 34

The Menu

Insert Double Detect On/Off

This option lets you turn the insert feeder’s double document detection on

or off.

When turned on…

The machine records the thickness of the piece. When you start the run,

the machine automatically stops when it senses a double feed.

When turned off…

The machine ignores any double feeds that may occur. You may want to

leave double detection off if you are running a mail job and occasional

duplicate inserts are not a concern.

Press the

until the display shows the insert DD

status:

Press

firms the change. Press

detection setting remains unchanged.

Menu/Enter

Insert DD is On (Off). Change?

yes

( ) to change the insert double detect setting. The display con-

button repeatedly

no

( ) to go to the next option. The double

Insert DD isInsert DD is

Insert DD is

Insert DD isInsert DD is

On. Change?On. Change?

On. Change?

On. Change?On. Change?

Safe Seal On/Off

This option allows you to turn safe seal on or off. If you’re having problems

with envelope flaps not sticking, try turning this option on.

Safe seal slows the machine slightly, allowing more time for moisture to

transfer onto the envelope flap during the seal cycle. Some gums require

this added time to break down properly and become sticky. This function

therefore produces a better seal on many types of envelopes.

Press the

peatedly until the display shows the

safe seal status:

Change?

Press

change. Press

safe seal setting.

Menu/Enter

yes

( ) to change the safe seal status. The display confirms the

button re-

Safe Seal is On (Off).

no

( ) to exit from the menu options without changing the

Safe Seal isSafe Seal is

Safe Seal is

Safe Seal isSafe Seal is

On. Change?On. Change?

On. Change?

On. Change?On. Change?

32

OfficeRight™ DI200

Operator’s Guide

Page 35

Reference

5. REFERENCE

Error Messages

Message Meaning and Action

CANNOT No sheet feeder has been selected in the job setup. The

SHIFT display automatically times out from this message after

ADDRESS two seconds and moves on to the turn double detect

ON INSERTS On/Off menu function.

CLOSE The machine has detected that the front cover D is open.

COVER D Check that cover D is closed properly.

CLOSE The machine detected that the rear cover E is open.

COVER E Check that cover E is closed properly.

CHECK AREAS Check for an unsuccessful clearance of a jam between

A1 & D the sheet feeder A1 and the collation area. Remove the

paper in sheet feeder A1, open front cover D and check

that the machine is clear of material. Close front cover

D, reload and start run.

CHECK AREAS This could be due to an unsuccessful clearance of a jam

A1, A2 & D between the sheet feeders A1, A2 and the collation area.

Remove the paper in sheet feeders A1, A2, open front

cover D and check that the machine is clear of material.

Close front cover D, reload and start run.

CHECK / CLEAR Inserts failed to feed. Check that the side guides in feeder

INSERT FDR C C are not too tight. Reload feeder C and start run.

CHECK SHEET Sheet feeder A1 out of paper, failed to feed or a jam was not

FEEDER A1 cleared successfully from this area. Remove the paper in

sheet feeder A1, reload and start run.

OfficeRight™ DI200

Operator’s Guide

33

Page 36

Reference

Message Meaning and Action

CHECK SHEET Sheet feeder A2 out of paper, failed to feed or a jam was not

FEEDER A2 cleared successfully from this area. Remove the paper in

sheet feeder A2, reload and start run.

CHECK SHEET The machine has detected a material jam between sheet

FEEDER A2 feeder A2 and the collation area. Open the front cover

LIFT COVER D cover D and remove all material inside. Close frontcover

REMOVE ALL D. Remove material from sheet feeder A2. Reload and

start run.

CLEAR FEEDER This is due to the Manual Feeder M being blocked prior to

M powering the machine up or starting it up. Check that there’s

no material in the feeder. If there is, remove it and restart.

CLEAR This could be due either to a previous jam not being

STACKER AREA cleared correctly in the stacker area or there is a jam

in the stacker area. Check that stacker area is clear.

Remove any material and resume run.

DOUBLE FEED The machine has detected a double feed from sheet feeder

CHECK FDR A1 A1. Remove the paper in sheet feeder A1, reload and start

run.

DOUBLE FEED The machine has detected a double feed from sheet feeder

CHECK FDR A2 A2. Remove the paper in sheet feeder A2, reload and start

run.

FOLD ONLY Fold only has been selected but no sheets, either

REQUIRES from feeder A1 or A2 (if applicable), have been selected.

SHEETS In this state the indicators for sheet feeder A1 will be red,

not green. Press the sheet feeder selection button until the

required feeder is selected.

34

OfficeRight™ DI200

Operator’s Guide

Page 37

Reference

Message Meaning and Action

INSERT The machine has detected a double feed from the

DOUBLE FEED insert feeder. Lift cover D and remove material. Reload

inserts and start run.

LIFT COVER D This state could be produced by any kind of material

REMOVE ALL crash in or near the insertion area, or a previous jam

not being cleared correctly. It can also be caused by

dust covering a sensor. Open front cover D and remove any material in the machine. Also blow out any

dust that may have accumulated in the area. Close

cover D and start run.

LIFT COVER D This could be due to a previous envelope jam not being

REMOVE ENV cleared correctly in the insertion area. Open front

D, remove envelope and start run. If no envelope

is visible in the machine, remove all material visible in

the feeder then reload and start run.

OPEN COVER E This could be due to a previous jam not being cleared

REMOVE ALL correctly. Open rear cover E and remove any material

in the machine. Close rear cover E and start run.

POWER ON/OFF Turn off power to the machine, wait for a minute and

then turn the power back on.

RELOAD Feeder B may be out of envelopes, or an envelope

ENVELOPES feed failed or was slow. Check that there are envelopes

loaded. If not, reload and start run. If there are

envelopes, check that the side guides on feeder B are

not too tight and that you have not overloaded the

envelopes. Reload feeder B and start run.

RELOAD Insert feeder C is empty. Reload inserts and start

INSERTS run.

OfficeRight™ DI200

Operator’s Guide

35

Page 38

Reference

Message Meaning and Action

REMOVE ALL This could be due to a material jam in fold plate 1 or near

FROM D & E the insertion area. Open front cover D and remove any

material that’s there. Close cover D. Open rear cover E and

remove any material in the area. Close rear cover E and start

run.

REMOVE ALL This is due to a poor feed from manual feeder M. Check

FROM M & D that there’s no material in manual feeder M. If there is,

remove it. Also open front cover D and remove any material

inside. Close front cover D, reload and start run.

REMOVE SHEET A sheet has failed to feed from sheet feeder A1. Remove

FROM A1 paper from A1, then reload and start run.

REPLACE Check that sheet feeder A1 is pushed fully into position.

FDR A1 TRAY

SHEETS Envelopes have been selected but no sheet feeder was

REQUIRED selected. The indicators for sheet feeder A1 and envelopes

will be red. Press the sheet feeder selection button until the

required feeder is selected.

SYSTEM ERROR This is an unrecoverable system error. Please call

CALL SERVICE Pitney Bowes for assistance at 1.800.253.6565 (USA) or

1.800.672.6937 (Canada).

36

OfficeRight™ DI200

Operator’s Guide

Page 39

Reference

General Troubleshooting

Poor folding

If you’re running perforated material, the machine may have problems

folding. If a machine fold almost corresponds with the perforation, a “box

fold” may occur. This happens when another fold is created just off of the

perforation and buckles slightly, creating, in effect, a third fold.

If this happens, adjust the machine fold slightly. Run a trial piece and

inspect the fold. If there is a box fold, access the advanced menu options

and select

and re-run a trial piece. Inspect the fold again and, if required, change the

move address in window

Machine stops for doubles that aren’t there

If you have a problem with incorrect double detection, it may be due to the

fact that you are using a new batch of material that is slightly thicker. Try

running a new trial piece.

When you ran the original trial piece, the machine calibrated itself to the

original material thickness. When it senses the new, thicker material, the

system thinks that a double was fed. You can turn double detection off if

an occasional duplicate insert is not important (see pages 31 and 32).

move address in window

function until the box fold is eliminated.

. Change the setting higher or lower

Machine feeds doubles without stopping

Check that double detection is turned on. See page 31. Make sure you’ve

run a trial piece. This automatically sets the double detector. See page 7.

Envelope flaps won’t seal

• Check that Seal is selected (green indicator lit). See page 7.

• Check that the moistener isn’t empty. See page 9.

• Try selecting safe seal mode. See page 32.

Address position wrong or address doesn’t appear in envelope

window

• Is the addressed sheet loaded properly? See page 10.

• Is the addressed sheet in Sheet feeder A2 (if installed)?

• Try adjusting the address position. See page 30.

OfficeRight™ DI200

Operator’s Guide

37

Page 40

Reference

Inserts or business reply envelopes feed poorly from Insert Feeder

Changing the orientation of the insert stack may help. For pre-folded

inserts it’s normally best to load with the closed edge feeding first.

Business reply envelopes can normally be loaded right way up and facing

you. However, if the flaps are pulled open when feeding, try loading with

the flaps down and facing you.

Following installation of Sheet Feeder 2, the system doesn’t work

• Check that the OfficeRight™ DI200 is correctly located onto Sheet

Feeder 2.

• Turn the machine off, wait a few seconds and then turn it back on.

• Check that no debris (dust, paper, etc.) has fallen into the Sheet

Feeder 2 electrical connector.

Clearing Material Jams

First, remove all paper from the affected

feeders as indicated on the display.

Then, if neccessary, clear sheets

…from sheet feeders/manual feeder

If the display indicates a jam in the sheet

feeder(s) or manual feeder areas, pull

the feeder assembly from the machine

as shown. Then carefully remove any

stalled material from the machine.

…from area beneath cover D

If the display indicates a jam beneath

cover D, press the blue button marked D

to release the cover. Lift the cover using

the finger grips on each side of the

stacker. Then carefully remove any

stalled material from the machine.

When closing the cover, latch it closed

by pressing down on the finger grips or

the central part of the cover in front of

the envelope feeder. DO NOT press

down on the stacker.

38

Button D

Continues on next page...

OfficeRight™ DI200

Operator’s Guide

Page 41

Reference

…from area beneath cover E

If the display indicates a jam beneath

cover E, press the blue button marked

E to release the cover. Push the cover

backwards to gain full access.

Then carefully remove any stalled

material from the machine.

Button E

Getting Help

Should you experience a problem with your OfficeRight™DI200, please

refer to the troubleshooting information starting on page 37. In many

cases, it should help you resolve the problem.

There may be times when you need additional help to solve a problem, or

you may want more information about how to handle a particular OfficeRight Mailer™ application.

Online Support

We encourage you to visit

The site offers helpful answers to frequently asked questions.

Phone Support

Technical help is readily available from our customer support line.

Before You Call...

Please have the following information at hand—

❒ Product name: OfficeRight™ DI200

❒ Serial number: This is located on the machine’s back cover.

❒ Nature of the problem: What happens and when does it happen? Did

the machine display an error message? What was it?

❒ The steps you've already taken to solve the problem and the results.

Then call:

http://www.pitneybowes.com/support

☎

In the USA 1.800.522.0020

In Canada 1.800.672.6937

OfficeRight™ DI200

Operator’s Guide

39

Page 42

Reference

Ordering Supplies

Pitney Bowes has made it easier than ever to order supplies—such as E-Z

®

Seal

(Item Code 601-0, USA only) and Moistener Wick Replacement

(Item Code 639-0)—that are designed specifically for your OfficeRight™

DI200.

Ordering Online (USA Only)

Just point your browser to http://www.pitneybowes.com/supplies

You'll find a complete, easy-to-navigate online store that offers a wide

assortment of genuine Pitney Bowes supplies at attractive prices. Be sure

to take advantage of special quantity pricing and online discounts.

Ordering by Phone

Our representatives will be happy to answer your questions and take your

order.

☎ In the USA, call 1.800.243.7824

☎ In Canada, call 1.800.672.6937

Requesting a PB Supply Catalog (USA Only)

Call the number above or e-mail us at supplies@pb.com.

40

OfficeRight™ DI200

Operator’s Guide

Page 43

Reference“

Reference

Material Specifications

Sheet Feeders A1 and/or A2:

Sheet Size Letter (8-1/2 x 11”) or Legal (8-1/2 x 14”)

Paper Weight 20 to 24 lb. bond

Capacity 80 sheets of 20 lb. bond maximum

Limitations DO NOT run NCR or litho/inkjet coated papers

Insert Feeder C (Optional):

Sheet Size Width: 5 to 8-3/4”

Depth: 3-3/8 to 3-7/8”

Material Weight Unfolded document: 18 lb. bond to 80 lb. card

stock

Trifolded document: 18 to 24 lb. bond

Capacity 60 Business Reply Envelopes, 24 lb. bond,

maximum

Type Suitable for pre-folded, single panel inserts,

business reply envelopes, etc.

Envelope Feeder B:

Envelope Size Number 10 only

Width: 9-1/2”

Depth: 4-1/8”

Envelope Weight 18 to 24 lb. bond

Capacity 60 envelopes, 24 lb. bond, maximum

Envelope Flap Type Executive (triangular) flap

Envelope Flap Length 1-1/4” to 2-1/4”

End Clearance End clearance between the contents (inserts)

and envelope must be a minimum of 1/4” on

each side (1/2” overall). Take this

measurement with

envelope.

Depth Clearance The contents must allow a minimum clearance

of 1/4” below the flap crease after insertion

into the envelope.

OfficeRight™ DI200

Operator’s Guide

all

contents placed into the

41

Page 44

Reference

Manual Feeder M

You can process stapled sets of up to three sheets of 20 lb. bond

paper. Sheet Feeders A1 and A2 are not designed to work in

conjunction with the Manual Feeder. We DO NOT recommend using

glossy/coated sheets.

Sealer Capacity

The machine can seal up to a maximum of 1,000 envelopes

between refills.

Stacker

Stacker capacity is up to 60 filled envelopes, depending on the

contents of envelope.

Material Requirements

Materials should be of good quality and properly stored.

Recommended storage conditions: 18 to 25°C; 40 to 60% relative

humidity.

Reference

Machine Specifications

Physical Dimensions

Width 17-3/8”

Depth 20-3/4”

Height 14-3/8” (without optional sheet feeder 2)

17-3/8” (with optional sheet feeder 2)

Weight 38 lb. (17.5kg)

Electrical

115V, 60Hz, 1A

Speed

Up to a maximum of 900 cycles per hour

Due to our continuing program of product improvement, equipment and material specifications are subject to change without notice. Physical dimensions are approximate.

42

OfficeRight™ DI200

Operator’s Guide

Page 45

Index

A

Address

Not Centered in Window 37

Position Wrong 37

Address-Bearing Sheet

Considerations when Using Sheet

Feeder A2 5

C

Cannot shift address on Inserts

Error Message 33

Check Areas A1 & D

Error Message 33

Check Areas A1, A2 & D

Error Message 33

Check Sheet Feeder A1

Error Message 33

Check Sheet Feeder A2

Error Message 34

Check/Clear Insert Fdr C

Error Message 33

Clear Feeder M

Error Message 34

Clear Stacker Area

Error Message 34

Close Cover D

Error Message 33

Close Cover E

Error Message 33

Configurations, Machine 3

Control Panel

Location and Function of 4

Controls, Front Panel

Illustration and explanation of 6

Controls, Machine 4

Counter

Resetting the Piece 29

D

Display, Front Panel 6

Double Detection

Insert

Turning On and Off 32

Sheet

Turning On and Off 31

Double Feed Check Fdr A2

Error Message 34

Doubles (Double Feed)

False Detection of 37

Machine Fails to Stop for 37

E

E-Z Seal®

Importance of 9

Envelope Feeder

Loading 11

Envelope Feeder B

Location and Function of 5

Equipment Specifications 41

Error Message

Check Areas A1 & D 33

Close Cover D 33

Replace Fdr A1 Tray 36

Error Messages

Cannot Shift Address on Inserts 33

Check Areas A1, A2 & D 33

Check Sheet Feeder A1 33

Check Sheet Feeder A2 34

Check/Clear Insert Fdr C 33

Clear Feeder M 34

Clear Stacker Area 34

Double Feed Check Fdr A2 34

Fold Only Requires Sheets 34

Insert Double Feed 35

Lift Cover D Remove All 35

Lift Cover D Remove Env 35

Open Cover E Remove All 35

Power On/Off 35

Reload Envelopes 35

Reload Inserts 35

OfficeRight™ DI200

Operator’s Guide

43

Page 46

Index

Remove All from D & E 36

Remove All from M & D 36

Remove Sheet from A1 36

Sheets Required 36

System Error 36

F

Feed, Manual 28

Fold Only Requires Sheets

Error Message 34

Folds Poor 37

Front Cover D Release Button

Location and Function of 5

H

Help, Getting 39

I

Indicator Lights, Control Panel 7

Insert Cover E Release Button

Location and Function of 4

Insert Double Feed

Error Message 35

Insert Feeder

Loading the 12

Insert Feeder (Optional)

Location and Function of 4

Inserts Feed Poorly 38

J

Jam Clearance 38

Jams

Clearing from Area Beneath Cover D

38

Clearing from Sheet Feeders 38

Job Setup

One Folded Sheet + One Insert into

an Envelope 17, 18

One Folded Sheet into an Envelope

15

One Folded Sheet, no Envelope

(Fold Only) 16

One Insert into an Envelope 19

Two Collated, Folded Sheets and an

Insert into an 26, 27

Two Collated, Folded Sheets into an

Envelope 21

Two Collated, Folded Sheets, No

Envelope (Fold Only) 23

Two Folded Sheets and an Insert

into an Envelope 24

Two Folded Sheets and an Insert

into an Envelope (c 25

Two Folded Sheets into an Envelope

20

Two Folded Sheets, No Envelope

(Fold Only) 22

Job Setups

Illustrated Guide to 13, 14

Jobs, Running 13

L

Lift Cover D Remove All

Error Message 35

Lift Cover D Remove Env

Error Message 35

Lifting Handles

Location and Function of 5

Loading

Envelope Feeder 11

Insert Feeder 12

Sheet Feeders 10

M

Machine Configurations 3

Machine Controls, Indicators and

Features 4

Machine Specifications 42

Manual Feed 28

Manual Feeder M

Location and Function of 5

Material Specifications 41

Menu Options

Address, Centering in Window 30

44

OfficeRight™ DI200

Operator’s Guide

Page 47

Index

Advanced 29

Double Detection

Turning On and Off 32

Double Detection , Sheet

Turning On and Off 31

Paper Size, Changing 30

Reset Counter 29

Safe Seal Feature

Turning On and Off 32

Menu/Enter Button 6

Moistener

Filling the 9

Moistener Tank

Location and Function of 5

N

No Button, Function of 6

O

Open Cover E Remove All

Error Message 35

Operating Guide Slot

Location of 4

Ordering Supplies 40

P

Paper Size, Changing 30

Perforations

Problems Cause By 37

Phone Support 39

Power Connection 8

Power On/Off

Error Message 35

Problems.

R

Reload Envelopes

Error Message 35

Reload Inserts

Error Message 35

Remove All from D & E

Error Message 36

See

Troubleshooting

Remove All from M & D

Error Messages 36

Remove Sheet from A1

Error Message 36

Replace Fdr A1 Tray

Error Message 36

Running Jobs 13

S

Safe Seal Feature

Turning On and Off 32

Safety Information 2

Sealing

Poor

How to correct 32

Sealing, Envelope

Poor 37

Second Sheet Feeder A2

Location and Function of 5

Selection Buttons, Control Panel 7

See

Setting Up a Job.

Illustrated Guide to

Sheet Feeders A1 and A2

Loading 10

Sheets Required

Error Message 36

Sleep Mode, Explained 7

Specifications

Machine 42

Material 41

Standard Sheet Feeder A1

Location and Function of 5

Start Button, Control Panel 7

Stop Button, Control Panel 7

Supplies, Ordering 40

System Error

Error Message 36

System Won't Work with Sheet Feeder

2 38

Job Setups:

OfficeRight™ DI200

Operator’s Guide

45

Page 48

Index

T

Technical Support 39

Trial Piece, Purpose of 7

Troubleshooting 37

Address Position Wrong 37

Double Feeds Don't Stop Machine

37

Envelope Seals Bad 37

False Doubles 37

Folds Bad 37

Inserts Feed Poorly 38

System Won't Work 38

Turning Machine On 8

W

Web Address, Pitney Bowes 39

Y

Yes Button, Function of 6

46

OfficeRight™ DI200

Operator’s Guide

Page 49

Operating Guide

One Elmcroft Road

Stamford, Connecticut 06926-0700

www.pitneybowes.com

Pitney Bowes Canada

2200 Yonge Street Suit 100

Toronto, Ontario M4S 3E1

1.800.672.6937

SV40189-OG Rev. B 6/03

*SV40189-OGREVB*

© 2003 Pitney Bowes Inc.

Printed in England

Loading...

Loading...