Page 1

Offi ceRight™ Folding Machine

DF800/DF900

Operator Guide

English Version

Page 2

Page 3

Table of Contents

Chapter 1 Introduction

Safety ................................................................................1-1

To The Operator ................................................................1-3

About your System ............................................................1-3

Machine Configurations .....................................................1-4

Stacker ..............................................................................1-4

System Options .................................................................1-5

Machine Identification DF800/DF900 ................................1-6

Control Panel .....................................................................1-8

Fold Options ......................................................................1-9

Sheet Orientation Icons ...................................................1-10

Chapter 2 Operation

About this Chapter .............................................................2-1

Connecting Power .............................................................2-1

Language ...........................................................................2-1

Select a Job .......................................................................2-2

Feed Tray Setup for a Folding Job ....................................2-3

Setting up the Tray Stacker ...............................................2-5

Setting up the Conveyor Stacker .......................................2-6

Run a Trial Piece ...............................................................2-7

Running the Job

Manual Feed

Crossfold (optional extra for DF900 only) ........................2-10

................................................................2-7

......................................................................2-8

Chapter 3 Job Functions

Introduction ........................................................................3-1

Supervisor Access Code ...................................................3-1

Create a Job ......................................................................3-2

Create From ......................................................................3-7

Edit a Job ...........................................................................3-8

Delete Job .........................................................................3-8

iSDC820A

Page 4

Table of Contents

ii SDC820A

Chapter 4 Troubleshooting

Troubleshooting Tips .........................................................4-1

General Troubleshooting ...................................................4-2

Adjusting Double Detect Position ......................................4-5

Clearing Material Stalls ......................................................4-7

Removal and Replacement ..............................................4-8

Chapter 5 Reference

Machine Specifications ......................................................5-1

Material Specifications .......................................................5-2

Compliance ........................................................................5-4

Service ...............................................................................5-6

Operator/ Supervisor Training Check List ..........................5-7

Page 5

Table of Contents

Contacts Information List

USA Contacts

Product Name - DF800 / DF900

For frequently asked questions, go to: www.pb.com and click on

•

Customer Support.

To place requests for service or training, go to: www.pb.com and

•

click on My Account.

•

To order supplies and accessories, call the Supply Line™ at:

1.800.243.7824 or go to: www.pb.com and click on Online Store.

•

To view and pay invoices online, go to: www.pb.com and click on

My Account.

•

To view inventory, go to: www.pb.com and click on My Account.

To view material safety data sheets, call the Pitney Bowes

•

Supply Line™ at: 1.800.243.7824 or go to: www.pb.com and

click on Customer Support.

For direct questions, call: 1.800.522.0020. Customer Service

•

•

Representatives are available Monday through Friday, 8:00 AM

- 8:00 PM ET.

Canada Contacts

Product Name - DF800 / DF900

For frequently asked questions or to order supplies, go to: www.

•

pitneybowes.ca

For direct questions, call: 1.800.672.6937. Customer Service

•

Representatives are available Monday through Friday, 8:30 AM

- 4:00 PM ET.

Other Country Contacts

Contact information is given in a separate publication supplied

•

with the product.

iiiSDC820A

Page 6

Page 7

1 • Introduction

Safety

Follow the normal safety precautions for all office equipment:

• Use only Pitney Bowes approved supplies, in particular aerosol

dusters. Improper storage and use of aerosol dusters or

flammable aerosol dusters can cause an explosive-like condition

that could result in personal injury and/or property damage.

Never use aerosol dusters labeled flammable and always read

instructions and safety precautions on the duster label.

• To obtain supplies, please contact our Supply Line™ to place

orders. Material Safety Data Sheets can be obtained on the web

or from our Supply Line™. Refer to the Contact Information List

for more information.

• Use the power cord supplied with the machine and plug it into

a properly grounded wall outlet located near the machine and

easily accessible. Failure to properly ground the machine can

result in severe personal injury and/or fire.

• Avoid touching moving parts or materials while the machine is

in use. Keep hands, loose clothing, jewellery and long hair away

from all moving parts.

• Do not remove covers or defeat safety interlock switches. Covers

enclose hazardous parts that should only be accessed by

properly trained service personnel. Immediately report to service

any damaged or non-functioning components that renders the

unit unsafe.

• Place the unit in an accessible location to allow for proper

venting of the equipment and to facilitate servicing.

• The power cord wall plug is the primary means of disconnecting

the machine from the AC supply.

• Do not use an adapter plug on the line cord or wall outlet.

• Do not remove the ground pin from the line cord.

1-1SDC820A

Page 8

1 • Introduction

• Avoid using wall outlets that are controlled by wall switches, or

shared with other equipment.

• Do not route the power cord over sharp edges or trap between

furniture.

• Ensure there is no strain on the power cord and that it does not

become jammed between the equipment, walls or furniture.

• Be certain the area in front of the wall receptacle into which the

machine is plugged is free from obstruction.

• Before clearing a stoppage, be sure machine mechanisms come

to a stop.

• When removing stalled material, avoid using too much force to

protect against minor personal injury and damaging equipment.

• To prevent overheating, do not cover any vent openings.

• Operation of this equipment without periodic maintenance will

inhibit optimum operating performance and could cause the

equipment to malfunction. Contact your machine supplier for

required service schedule.

• Read all instructions before attempting to operate the equipment.

• Use this equipment only for its intended purpose.

• Always follow the specific occupational safety and health

standards for your workplace.

1-2 SDC820A

Page 9

Introduction • 1

To the Operator

These instructions explain how to setup and use your OfficeRight™

DF800/DF900 Folding Machine with your chosen Stacker. Please

spend a few moments reading through them; understanding what the

system does and how it does it will keep problems to a minimum and

help you get the best performance from it.

Before setting up and using the system, you should be thoroughly

familiar with its controls, programming options and setup procedure.

About your System

Your OfficeRight™ DF800/DF900 is a folding machine, equipped

with two fold plates which allow it to produce different types of folds

(see page 1-9 Fold Options for details). The DF900 also has an

optional kit available, enabling it to cross-fold sheets (see page 2-10

for more cross-fold information).

The folder has a pre-programmable feature allowing up to 20 job

definitions to be stored for automatic setting and running of the

machine.

Standard Features

The OfficeRight™ DF800/DF900 offers an impressive array of

standard features. Among them:

• Fully automatic material seperation on sheet feeder.

• Fold adjustment capabilities.

• Fully automatic double-detect, when selected.

• Choice of Single fold, C fold, Z fold, Double fold, Gate

fold, Offset C Fold or Offset Z fold.

• Total of 20 jobs, 19 of which can be edited and saved by

a supervisor.

• Multi-function operator controls.

• Easy to use self prompting display.

• Out-of-material and stoppage detection.

• Batch count control.

• Manual feed facility.

Options

Optional Cross-Fold Kit on the DF900 which adds Cross-

•

fold capabilities. (see page 2-10 for more information).

Choice of Stackers to suit your level of use and

•

requirements.

1-3SDC820A

Page 10

1 • Introduction

Machine Configurations

The following machine configurations are available:

• DF800 (A4 Folding Machine) with Tray Stacker.

• DF900 (A3 Folding Machine) with Conveyor Stacker CS88.

Conveyor Stacker CS88 (Can be added as an additional

•

feature to the DF800)

• High Capacity Extension (Can be added as an additional

feature to either DF800 or DF900 with a Conveyor Stacker

CS88 already attached).

Cross-fold Kit (An optional extra feature on the DF900 Only).

•

IMPORTANT: Model and features availability varies by country.

Contact your machine supplier for more information.

Inclusion within this guide does not guarantee availability of a

particular model or feature within your country.

Stacker

Tray Stacker

Your OfficeRight™ Folder DF800 Machine comes equipped with

a Tray Stacker. This stacker sits on the table and collects exiting

material.

Conveyor Stacker CS88 - DF900 (optional extra for DF800)

Your OfficeRight™ Folder DF900 Machine comes equipped with

a Conveyor Stacker. A Conveyor Stacker can be added to your

DF800 as an optional extra. This stacker allows organised collation

of material on exit of your folding machine. It is able to hold larger

quantities of exiting material and is recommended for all frequently

used machines. Contact your sales representative for further

information.

High Capacity Extension (optional extra)

The High Capacity Stacker is an optional extra to your OfficeRight™

Folder DF800/DF900. The High Capacity Stacker is an extension to

the Conveyor Stacker and is able to hold larger quantities of material

which results in the stacker needing to be emptied less often. If you

run regular large quantity jobs, the High Capacity Extension may

be a beneficial addition to your OfficeRight™ Folder DF800/DF900

system. Contact your sales representative for further information.

1-4 SDC820A

Page 11

System Options

Introduction • 1

OfficeRight™ DF800

with Tray Stacker

OfficeRight™ DF900

or DF800 with

Conveyor Stacker

CS88

(Optional Extra on DF800)

OfficeRight™ DF800 or DF900

with High Capacity Extension

The High Capacity Extension can be added to both the OfficeRight™

Folder DF800 or DF900 if it is already equiped with a Conveyor

Stacker.

1-5SDC820A

Page 12

1 • Introduction

1-6 SDC820A

Machine Identification OfficeRight™ Folder

DF800/DF900

Top Access Cover (and Manual Advance Knob - A)

Lift the Top Access Cover to reveal the Manual Advance Knob

(see inset photo). The Manual Advance Knob can be used to

manually turn the machine mechanisms to assist in clearing a

material stoppage.

Sheet Feeder

The Sheet Feeder automatically feeds material that requires

folding. It can automatically detect if more than one sheet

feeds (Double Detect).

In addition, the sheet feeder can be set to ‘Manual Feed’ (see

item 6). This allows manual feed of stapled or unstapled sets

of up to 5 sheets of 80g/m2 (20lb) paper.

1

2

1

5

3

6

4

7

2

8

9

10

model shown DF900

12

11

A

Page 13

Introduction • 1

Fold Plate 1 (P1)

3

This Fold Plate is used to create the desired fold in material fed

from the Sheet Feeder. The Fold Plates are automatically set

from the Control Panel.

Information Label

4

This overlay offers quick reference information regarding the

fold options available when setting the machine.

Side Guides

5

The side guides are adjusted to control the alignment of sheets

being fed into the machine.

Manual Feed Lever

6

Position this lever to the right to set the machine to ‘Manual

Feed’ (see Page 2-11 for information on Manual Feed Jobs).

Position the lever to the left again for ‘Automatic Feed’.

Paper Adjust Lever (DF900 Only)

7

Position this lever to the left to adjust the tension of the Feed

Plate when using A3 sheets/larger sheets.

Fold Plate 2 (P2)

8

This Fold Plate is used to create the desired fold in material fed

from the Sheet Feeder. The Fold Plates are automatically set

from the Control Panel.

Control Panel

9

This is where you enter commands and where the machine

informs you of its status with the use of symbols and icons. Full

details of each key function are given on the following page.

Side Guide Adjuster

10

Use this knob to adjust the side guides (see item 5).

Skew Adjust

Use this knob to adjust the angle that material feeds into the

11

machine to correct slight alignment issues.

Stacker (not illustrated)

12

The Tray Stacker or Conveyor Stacker locates at the exit of the

machine to collect folded sheets. A High Capacity Extension is

also available.

1-7SDC820A

Page 14

1 • Introduction

Trial Piece Clear Deck

Start Stop

Back

Screen Keys

Control Panel

Control Panel Buttons

Trial Piece

Press to run a single test piece so you can check machine setup.

You must run a Trial Piece before you press Start to begin automatic

operation.

Clear Deck

Press this key to jog material clear of the machine following a

stoppage and make it ready for automatic operation.

Start

Starts automatic operation.

Stop

Stops automatic operation at the end of the next cycle. A double

press of the Stop key will stop the machine immediately.

Back

This key returns the machine to the previous screen, where

appropriate.

Screen Keys

These are the four oval keys located directly to the right of the

display. These keys correspond to the changeable options on the

display alongside them and therefore are not labelled.

1-8 SDC820A

Page 15

Introduction • 1

Fold Options

The OfficeRight™ DF800/DF900 Folding Machines are capable of

producing seven different fold types.

Fold Type Description Icon (as shown on

Single Fold Sheet folded once. The folds

can be adjusted to custom

lengths.

Z Fold Also known as Accordion fold.

Sheet folded twice in a zig-zag

of equal lengths.

C Fold Also known as Letter fold.

Sheet folded twice into the

centre, so that the sides overlap

and all sides are of almost

equal length.

Gate Fold Sheet folded twice into the

centre so that the edges join in

the centre without overlapping.

Control Panel)

Double Fold Sheet folded once and then the

folded sheet is folded a second

time creating a double fold.

Offset C Fold Sheet folded twice into the

centre with overlapping sides of

custom lengths.

Offset Z Fold Sheet folded twice in a zig-zag

with custom lengths.

1-9SDC820A

Page 16

1 • Introduction

Sheet Orientation Icons

The following icons indicate the required sheet orientation in the feed

tray and output stacker for each type of fold.

The ♦ symbol indicates the front panel/ address panel (depending

on your job) of the material being folded. This helps to detemine the

required orientation of material as it is fed into the machine.

Single-fold.

Gate-fold.

C Fold / Offset C Fold.

Z-fold / Offset Z Fold.

Double-fold.

1-10 SDC820A

Page 17

2-1SDC820A

2 • Operation

About this Chapter

This chapter explains functions on the machine required to run a job.

These include:

• Selecting and running a pre-programmed Job Definition

• Loading the feeder

• Using the Manual Feeder

Crossfolding (DF900 with Crossfold Kit only)

Functions related to creating, editing and deleting Job Definitions are

covered in Chapter 3 ‘Job Functions’.

Connecting Power

Read the safety information on page 1-1 before

connecting the machine.

Connect the power cord to the socket on the left side of the machine.

Plug the power cord into a suitable power outlet. Make sure the

power outlet is near the machine and is easily accessible.

Turn the power switch ON.

•

Image of power switch

Image of power switch

Language

Your machine will start set to the the default language. The default

language is set by the engineer at the time of installation.

To choose a different language for this use select Menu and then

Display Preferences soft keys before selecting the Language option.

you can then scroll through to choose any another language that is

set up on your machine.

Page 18

2 • Operation

2-2 SDC820A

Select a job

This section assumes the job to be run has already been created. If

the job has not been created, refer to Chapter 3 Job Functions.

A few seconds after the machine is switched on, the Home Screen

will appear. The last Job Definition selected will be loaded, with

the message ‘Ready to Run Trial Piece’ displayed at the top of the

screen.

If the job loaded is not the one required, press the Select Job

Screen Key. A list of Job Definitions that have been created and

stored appears on the screen. Then...

• If you are certain which job you want, press the

Screen Keys to select the job that you require and then

press the OK Screen Key to confirm.

• If you need confirmation of the job details, press the

Screen Keys to select a job and then press the

Summary Screen Key to view the job details.

You may access loading details from either the Home Screen or the

Job Summary screen by pressing the

Loading Details Screen Key.

Job

To exit the Load Tray, Loading Details or Job Summary screens

select OK or Done until you return to the Trial Piece screen.

Page 19

Operation • 2

Feed Tray setup for a Folding Job

This section describes setting up and loading the Feed Tray for

automatic feed of sheets.

If you select a Manual Feed job (where the Feed Tray is set for

manual feed of sheets), the Feed Tray should not be loaded with

material. This is because the sheets are manually fed one set at a

time. See Manual Feed on page 2-8 for more information.

To process a Crossfold job (available as an option on the DF900

only), refer to the Crossfold Setup procedure on page 2-10.

You can view information about the feed requirements for your job.

1. Press the Loading Details and then Load Tray Screen Keys.

2. Adjust the Side Guides to

the width of the sheets being

fed, using the Side Guide

Adjustment Knob, then backoff a 1/4 of a turn. This will

set the correct clearance

between the guides and the

material.

3. Take the stack of sheets

and aerate it to ensure the

individual sheets are not

stuck together.

4. Jog the stack back into

alignment.

2-3SDC820A

Page 20

2 • Operation

2-4 SDC820A

5. The display will indicate with a ♦ symbol the correct orientation

of the paper needed to achieve the chosen fold type (see page

1-9 for more fold type information).

6. The Feed Tray takes the

sheet stack aligned in a

similar way to many printers

and photocopiers.

Place the stack onto the Feed

Tray Deck.

Depress the Feed Tray Deck

and slide the stack fully under

the feed roller.

7. The DF900 is capable of

feeding large sheets. The

marker on the Side Guide will

indicate the correct position

for the Paper Adjustment

Lever.

Match the position of the

Paper Adjustment Lever to

the setting shown on the

Feed Tray.

Position 1 is the normal

position for standard sized

sheets.

Position 2 increases the

tension on the lift plate for

larger sheets (e.g. A3).

Remember to reset the lever

after completion of the job.

Now go to Setting up the Conveyor Stacker on Page 2-6.

Position 1

Position 2

Page 21

Setting up the Tray Stacker

The Tray Stacker is provided as standard

with your OfficeRight™ Folder DF800

Machine.

Folded material will exit the machine and

will be neatly stacked in the Tray Stacker.

The stacker tray can be extended by pulling

the tray outwards to match the size of the

material being processed.

Before attaching or removing the

stacker pull the collection tray to

its full extension, so that the tray

does not catch under the machine

when unhooking.

Operation • 2

The stacker is fitted to the

machine with two hooks which

slide into the apertures at the

base of the machine.

Note: Opening the Exit Path Cover before proceeding can assist

in attaching or removing the stacker. This is because it allows

ease of access to the apertures.

2-5SDC820A

Page 22

2 • Operation

2-6 SDC820A

Setting up the Conveyor Stacker CS88

The Conveyor Stacker is the

standard stacker unit provided

with your OfficeRight™

Folder DF900 Machine and is

available as an option on your

OfficeRight™ Folder DF800.

It is fitted to the machine with

two hooks which slide into the

apertures at the exit of the

machine.

If you are using the Conveyor

Stacker, it will need to be set up

before commencing a job.

During job setup the screen will

show a stacker setup number.

Lift the Stacker Roller and place

both ends in the corresponding

number slot.

Note: Ensure that both ends are

in the correct number slot or this

could result in material skew on

exit of the machine.

When stacker setup is complete, continue with running a Trial Piece

as described on the next page.

High Capacity Extension

The High Capacity Extension is an optional extension to the

Conveyor Stacker. The High Capacity Extension will allow you to run

a large volume of material before needing to empty the stacker.

Connect the High Capacity Extension to the end of the Conveyor

Stacker with the hooks through the key holes. You can then secure

the Extension to the Stacker with the Thumb Screw.

Page 23

Operation • 2

Run a Trial Piece

A Trial Piece is required to enable you to check the processed

material and to allow the machine to calibrate itself for the material

being run.

Press the Trial Piece key. The machine runs a single sheet or

manually fed set which exits the machine for you to check. The

machine then asks if the Trial Piece is OK.

If the Trial Piece is OK you can begin running the job (see below).

If the Trial Piece is not OK minor changes to the job settings can

be made at this stage. Select Adjust Job to access further screens

which allow you to make changes to your job and then Re-Run Trial

to confirm changes.

The machine will now ask you whether you wish to save the

changes. Select Yes or No screen keys as required. All jobs except

the Operator Job require Supervisor access to save changes.

Running the Job

After confirming the Trial Piece is OK...

You are taken back to the Home screen which indicates ‘Ready to

Run’.

Press the Start key to commence automatic operation.

The machine operates until:

● materialrunsout

● theStop key is pressed

● thebatchcountisreached(ifbatchcountisbeingused)

Batch Count

If the Batch Count function was set when the job was created, the

machine stops automatically after processing the required number of

items. The End of Batch Count screen displays to inform you that the

batch is complete. Select the OK Screen Key. Remove the batch and

press Start to commence processing of a new batch, if needed.

To Reset the Counters, at the Home Screen, select the Reset

Counters Soft Key. You can then reset the batch count, piece count

or both.

2-7SDC820A

Page 24

2 • Operation

2-8 SDC820A

Manual Feed

This section describes the setup for manual feed of sheets or sets.

For sets on manual feed you must specifically ensure that the

material complies with Material Specifications (See Material

Specifications on Page 5-2).

If you are selecting a job that has already been saved, you can

check to see whether the job definition is set to Manual Feed in the

Job Summary screen.

Adjustments for Manual Feed Jobs

Move the Manual Feed Lever

to the right, which opens the

Separator Assembly for Manual

Feed operation.

Adjust the Side Guide to the width

of the sheets being fed, using

the Side Guide Adjustment Knob,

then back-off a 1/4 of a turn. This

will set the correct clearance

between the guides and the

material.

Note: When using manual feed the material weight should not

exceed 5 sheets of 80gsm or a total weight of 400gsm. The machine

speed is automatically limited to Level 1 for ease of use when

running a manual feed job.

Set up the Stacker as described on Page 2-5/2-6.

Page 25

Operation • 2

Feeding a Manual Feed Job

A Manual Feed job requires that sheets or sets are individually

inserted by hand into the feed rollers.

Press the

wait for the motor to start, then

carefully feed material under the

feed roller by hand. The machine

will take the sheet or set and

process it.

You can accept the Trial Piece or adjust the job and re-run the job as

described on page 2-7.

Trial Piece key and

WARNING: Hold the material loosely and keep your

fingers away from the Feed Roller at all times when

processing Manual Feed jobs. See image above.

When ready, press the Start key and feed material one set at a time.

If the machine times out or is stopped by pressing the Stop key, it

may be restarted by pressing the Start key again. When you have

completed feeding the sets you require, the machine can be left to

time out (stop running) or the Stop key can be pressed to confirm

that the job is complete.

Note: On completion of your Manual Feed job, remember to reset

the Manual Feed Lever to its standard setting (Automatic Feed)

before leaving the machine.

2-9SDC820A

Page 26

2 • Operation

2-10 SDC820A

Crossfold (optional extra on OfficeRight™ DF900)

The crossfold kit is sold as an optional extra on the A3 folder (DF900)

only. This kit allows you to fold material that has already been folded

by the machine a second time perpendicular to the first fold. This kit

is engineer installed.

Setting up a Crossfold Job

Initially run a Single Fold folding job with equal length panels to

provide the first fold, by following the instructions in Create a Job on

page 3-2 of this guide or by selecting an exisiting single fold job as

described in Select a Job on page 2-2.

You are now working with folded material and need to setup a

crossfold job for your second fold. Prior to this, follow the instructions

below to physically set the folder to process the pre-folded material.

Setting Machine for Crossfold Job

1. Adjust the Side Guides to

the width of the sheets being

fed, using the Side Guide

Adjustment Knob, then backoff a 1/4 of a turn. This will

set the correct clearance

between the guides and the

material.

2. Set the Manual/ Auto feed

lever to Manual (to the right).

Page 27

3. Open the top cover.

4. Lift the Crossfold paper path.

Crossfold Paper Path

Caution: When the crossfold kit is fitted and you need

to move the roller, you must first set the machine

to ‘Manual Feed’ using the Manual Feed Lever to

prevent damage to the separator roller and separator

pad.

5. Unlock the Upper Blue Lever

and slide the Feed Roller

Housing to the Front Side

Guide aligning the marker on

the housing to the marking on

the Side Guide.

Operation • 2

6. Lock the blue lever.

7. Remove the Feed Tray.

2-11SDC820A

Page 28

2 • Operation

8. Unlock the separator pad

(lower blue lever), and align

with the separator roller and

relock in position.

Note: When using Manual Feed

on a Crossfold job, the Separator

Roller and Pad must be in the

central position and the Manual

Feed Lever must be set to

Manual.

9. Refit the Feed Tray.

10. Close the top cover

11. Set the Manual Feed Lever back to Auto.

12. Lift the weighted roller.

13. Load material with the

crease/ folded edge under the

weighted roller.

NOTE:

number of sheets in the tray

in Auto mode is 20.

14. Lower the weighted roller

back into position, over the

creased/ folded edge of the

material.

After setting up the machine and setting the stacker follow the

Create a Job setup on page 3-2 of this guide and select the crossfold

option when asked before proceeding with your crossfold job. If

your crossfold job is already saved as a job continue as described in

Select a Job on page 2-2.

The Maximum

Weighted Roller

2-12 SDC820A

Page 29

3-1SDC820A

3 • Job functions

Introduction

This chapter describes the job administration functions.

All of the functions are set by following a sequence of screens and

answering simple questions presented on the display. Therefore,

this chapter does not take you through every function step by step. It

gives you background information on the function and offers helpful

tips to get the best out of your machine.

To administer most jobs on the system you will require Supervisor

Access as explained below. This is to protect these jobs from

unauthorised changes.

An operator without Supervisor Access can select a job to use from

the saved job library. However, if the required job is not available, or

if a one off job is required, an operator can create a special job called

‘-operator job-’. Only one operator job is stored in the machine. It is

the same as any other job except that it cannot be renamed and will

therefore be overwritten when a new operator job is created.

Supervisor Access Code

Many of the following functions will require you to enter a Supervisor

Access Code during the process. This prevents unauthorised access

to functions mainly relating to administration of jobs.

Your installing engineer will tell you the Supervisor Access Code. If

you wish, you can write it in the box on this page as a reminder.

However, please be aware that this is then available to anyone

using this Operator Guide and so you may wish to make a note

of it and keep it in a more secure location.

The Supervisor Access Code cannot be changed from the one given

to you by the installing engineer. You will remain logged on, and

therefore supervisor functions remain available to all users until such

time as you log out of supervisor mode (see page 3-7 for how to log

off).

Supervisor Access Code:

Entering the Code

When asked to enter the Supervisor Access Code, use the

screen keys to highlight the first digit of the code on the Numeric

Matrix displayed, and confirm this digit by pressing Select. Repeat

for the each digit. When complete, select Done.

Page 30

3 • Job Functions

Create a Job

This section describes how to create and save a new job. The

machine can store a maximum of 19 configurable job definitions,

plus the ‘-operator job-’.

The machine asks you a number of specific, easy-to-answer

questions about the make up of the finished piece in order to create

the Job Definition.

Some of the questions asked will be based on the answers

previously given and so the sequence will vary from job to job.

To Create a Job press the Menu screen key and then Manage Jobs.

Then select the option to Create Job. The set up process takes you

through several easy steps to set up your job.

Note:

If you select Create Job and the maximum number of saved jobs

has been reached, the machine informs you. If you wish to save

the new job into the job library, you must cancel and proceed with

deleting another job before creating a new one. Alternatively you can

proceed by overwriting the ‘-operator job-’.

The following sections give background information on each function

that needs to be defined when creating a job.

Select type of job

You may be asked whether you want to save your job as an Operator

job or a Supervisor job.

An Operator Job, as previously described, can be created without

supervisor access and overwrites any existing Operator Job.

A Supervisor Job requires Supervisor Access to save it to the job

library.

3-2 SDC820A

Page 31

Job Functions • 3

Fold Types

Seven fold types are available. See Fold Options on Page 1-9 of this

guide. The fold type dictates how the sheet will be folded before it

exits the machine.

Once a fold type is selected and the new job is created, the display

indicates the correct orientation of the paper for loading into the Feed

Tray.

Note:

Later in the Create Job sequence you are able to specify custom fold

lengths to modify your basic fold. See Fold Panel Lengths on Page

3-4.

Paper Length

Select the paper length.

Use the scale on the machine

to measure the sheet length, if

necessary.

Quick reference:

A4 Paper length – 297mm

A3 Paper length – 420mm

US Letter length – 11" (279mm)

US 11x17 sheet length – 17" (430mm)

Select a relevant preset length (i.e. US Letter/ A4) by screen key or

select Custom and then press the +/- keys until the length of your

paper (in millimetres) is displayed. When the paper length is correct,

press OK…

3-3SDC820A

Page 32

3 • Job Functions

Fold Panel Lengths

It is possible to dictate the fold panel lengths/fold positions on your

job within the boundaries of the sheet length and the machine

capabilities.

Depending on the settings previously made for fold type and paper

length, the machine suggests the correct fold dimensions. Therefore,

most times, this setting will not require alteration.

If you want to change the ‘standard’ setting, press the

the length of the fold required (in millimetres) is displayed.

The highlighted, flashing icon on the screen shows the fold panel you

are adjusting.

Note: The fold panel marked with a diamond (♦) should be adjusted

first as this will minimise interaction on adjustment of the other

panels.

The machine will automatically limit your choices to what is

physically possible within the machine specifications. For example,

as you change the length of a fold panel, you will see the dimension

of the other fold panel(s) automatically changing to keep within paper

length and machine specifications.

When the setting is correct, select

fold panel length setting, if required.

Once all fold panel lengths are correct, select the

Next Panel to advance to the next

+/- keys until

Done Screen Key.

3-4 SDC820A

Page 33

Job Functions • 3

Feed Options

If your job is running sheets automatically from the Feed Tray, select

Automatic Feed.

If you are feeding sheets or sets individually, select Manual Feed.

The Manual Feed setting allows stapled or unstapled sets of up to 5

sheets (to a maximum of 400g/m2 (105lb) per set) to be run. Manual

Feed may also be used to feed single sheets of special material (see

Page 3-6).

For more details on Manual Feed, see page 2-8 of this guide.

Crossfold Options (Additional Kit Required, DF900 Only)

This function allows a single-fold job to be run through the machine

again so that a further fold can be made at right-angles to the first

fold (a cross fold).

See Crossfold Setup on page 2-10 of this guide.

If your system does not have a crossfold option, this screen will not

display during your create job procedure.

Double Detect

The double detector stops the machine if more than one sheet

simultaneously feeds from the feeder. The Double Detect function

can be run on single sheet jobs only and will stop the machine when

a double feed occurs. This allows the operator to identify the double

feed and to remove the sheets before proceeding with the job.

Double detect can be used on material up to 120gsm.

If you have selected manual feed or crossfold options, this screen

will not display during your create job procedure as Double Detect is

not available in these modes.

3-5SDC820A

Page 34

3 • Job Functions

Special Material

Some thicker or densely printed material may not process efficiently

with the standard machine settings. If you plan to use such material

the machine must be programmed for ‘Special Material’ during Job

Setup to avoid mis-operation. This option should only be taken if

found to be necessary. Run a Trial Piece or trial batch to test.

Set Speed

The speed that the folder can run with it’s maximum throughput is

dependant on the job type and material being fed. This is not always

the maximum speed that the machine can operate at.

The Set Speed screen allows you to increase or decrease the

machine’s running speed when you press the Start key.

The speed can also be adjusted as required once the machine is

running.

Press the Set Speed soft key and then use the Faster or Slower

Screen Keys to set the speed. Then select OK to confirm.

This mode is not available when running a manual feed job as the

speed is automatically set to Level 1.

Batch Counter

The Batch Counter allows you to automatically process pre-defined

batches (number/quantities of pieces) of finished material. When

the batch is complete, the machine stops automatically. Remove the

batch and press Start to begin a new batch, if required.

If Batch Counter is not selected, the display counter will simply

count the number of items processed until reset by pressing Reset

Counter.

When asked to enter the Batch Count, use the screen keys

to highlight the first digit of the count you require on the Numeric

Matrix displayed, and confirm this digit by pressing Select. Repeat

for subsequent digits. When complete, select Done. Leaving the

batch count field blank turns the batch counter off for the job and the

job will run until the material runs out, the machine times out or you

press the Stop key.

3-6 SDC820A

Page 35

Job Functions • 3

Enter Job Name

When job setup is now complete, the Enter Job Name screen

prompts you to name and save the job. If you are saving an operator

job, this screen will not appear as the job will always have the

‘-operator job-’ name.

When asked to enter the Job name, use the screen keys to

highlight the first digit of the name on the Alpha/Numeric Matrix

displayed, and confirm this digit by pressing Select. Repeat for the

subsequent digits. When complete, select Done.

Note: Further characters can be displayed for selection at any time

by selecting ‘abc’ or ‘ABC’ (some countries will have a Next option

for more characters).

The display shows the new job with the message ‘Ready for Trial

Piece’. Run a Trial Piece to confirm settings. See Page 2-7 of this

guide for how to run a Trial Piece.

Job settings are retained by the machine even with power

disconnected and may be recalled as required.

Logging Out of Supervisor Mode

If you are logged in as a Supervisor you must log out by pressing

the Stop key whilst the Menu screen is displayed. If you do not,

the machine will remain logged on and all supervisor functions will

remain accessible to any user.

Create From

If you wish to create a NEW Job Definition which is SIMILAR to an

existing job and leave the existing Job Definition untouched, use the

Create From function.

Press the Menu screen key and then Manage Jobs. Then select

Create From.

This function allows you to select the similar existing job and edit it

as in Edit Jobs (See page 3-8 of this guide). You are prompted to

save it with a new job name before you make any changes.

3-7SDC820A

Page 36

3 • Job Functions

Edit Job

The Edit Job function is used to change a Job Definition, and

so always overwrites the original Job Definition in the machine’s

memory (even if the Job Name has been edited).

If you wish to create a NEW Job Definition which is similar to an

existing job and leave the existing Job Definition untouched, use the

Create From function described on page 3-7.

Press the Menu Screen Key and then Manage Jobs. Then select

Edit Job. Select the job you wish to edit and then follow the easy

steps to complete the editing process. Press Save and Exit when

complete.

Delete Job

To erase an existing job from memory:

Press the

Delete Job.

Use the Screen Keys to select the job you wish to delete. Then

select Delete Job.

You may review the definitions of the job you are about to delete by

selecting the Job Summary Screen Key prior to deletion.

Select

delete the job.

Menu screen key and then Manage Jobs. Then select

Confirm Delete to confirm that you wish to permanently

3-8 SDC820A

Page 37

4 • Troubleshooting

Troubleshooting Tips

In most cases, the machine will generate a message when a

problem occurs, and the display will offer advice on how to rectify the

problem immediately.

This Operating Guide contains additional troubleshooting information

which, with the troubleshooting sources above, should resolve most

problems.

If problems related to material handling persist, make sure your

material conforms to the material specifications given in Chapter 5

- Reference, of this guide.

If you still cannot resolve the problem, call your machine supplier for

help. Contact details can be found:

• On the back cover of this guide

• In the System Information option in the menus:

At the Home Screen, select Menu.

Then select System Information.

4-1SDC820A

Page 38

4 • Troubleshooting

General Troubleshooting

Problem Remedy Page

MACHINE

Blank Screen

No power. Check power cord is firmly

connected and wall socket is

switched ON.

Machine not

switched ON.

Display adjustment

set incorrectly.

Turn power switch (located on the

left side of machine) ON.

Change the display contrast and

brightness to an acceptable setting.

At the Home Screen, select Menu.

Then select Display Preferences.

2-1 (see

also 1-1

safety)

2-1 (see

also 1-1

safety)

Performance

Machine runs

slowly.

Language

The wrong

language is

displayed on the

screen.

The machine speed can be

dependant on the job being run.

Check the machine’s speed setting

using the Edit function, or whilst the

job is running to ensure it is set to a

suitable level.

Turn the machine off and then after

a few seconds on again. This will

revert the language to default.

To change the language, at the

Home Screen, select Menu, then

Display Preferences, and then

Language Soft Keys.

3-6

4-2 SDC820A

Page 39

Troubleshooting • 4

Problem Remedy Page

SHEETS

Poor Sheet Feed

Feed Tray side

guides set

incorrectly.

Sheets loaded

incorrectly.

Paper Adjustment

Lever setting

incorrect (DF900

only).

Sheets skewing as

they feed through

the machine.

DF900 Fail to Feed

with photocopied

sheets

Set guides to sheet width and back

off 1/4 turn.

Make sure stack has been fanned

before loading.

Ensure the Paper Adjustment

Lever is set to the correct paper

size (especially if feeding larger

material) DF900 only.

Use the Skew Adjustment Knob to

correct. See Skew Adjust in Poor

Folding and check side guides

adjustment.

Remove some of the material stack

from the feeder. Large quantities of

photocopied sheets which can be

wavy can sometimes cause feed

problems when stacked in large

quantities.

2-3

2-3

2-4

4-3SDC820A

Page 40

4 • Troubleshooting

Problem Remedy Page

SHEETS

Poor Folding

A fold length is

incorrect, causing

a ‘box fold’ or third

fold.

Sheets skewing as

they feed through

the machine.

Run a Trial Piece. Say No to Trial

Piece OK? and adjust the fold

positions.

Check the Side Guides are

adjusted correctly. If this does not

correct the problem-

Use the Skew Adjustment Knob to

correct the paper skew.

2-7 &

3-4

2-3

Tip: It may be beneficial to set up a

single fold job to run when adjusting

skew to make the adjustment

results more apparent.

Sheets creasing

as they exit the

machine. (DF900

Only).

Conveyor Stacker CS88

The material

entering the

Conveyor Stacker

does not stack

correctly.

4-4 SDC820A

Reduce the running speed. Lighter

material and larger sheets can

sometimes crease when folding.

Slowing the machine down will

allow the material to be folded

crease free.

The Conveyor Stacker may not

be set up correctly. Adjust the

Conveyor Stacker wheels by

moving them closer or further away

to maximise their effectiveness.

3-6

Page 41

Troubleshooting • 4

Problem Remedy Page

DOUBLE DETECT

Machine stops for ‘doubles’ that aren’t there or feeds ‘doubles’

without stopping

Double Detect is

not turned ON.

Material does not

meet specifications

for Double Detect.

Double Detect

is not correctly

calibrated.

Material is too

densely printed on

the leading edge of

the material.

Check Double Detect status.

Press the Select Job Screen Key

and then press the Job Summary

Screen Key to view the job details.

Correct loading or have Supervisor

correct Job Definition as necessary.

Material weight must be between

60 g/m2 and 120 g/m2 (16lb and

32lb). For material outside these

limits, turn Double Detect off.

Run a Trial Piece whenever a

new batch of material is loaded to

recalibrate Double Detect. The new

batch might be of slightly different

thickness.

Change the double-detect position

to read material in a less densely

printed position. See Adjusting

Double Detect Position below.

3-5

5-2

2-7

Adjusting Double Detect Position

If you continually get doubles detected when no doubles exist, it may

be that the machine’s Double Detect sensors are being confused by

densely printed areas on the sheets.

The sensors detect along the centre line of the sheets in a

predefined window of approximately 27mm (1”) length, the default

starting position of this window is approximately 5mm (0.2”) from the

lead edge.

When Double Detect errors are sensed, the dialogue displayed will

give the option to change the Double Detect position.

4-5SDC820A

Page 42

4 • Troubleshooting

Initially, re-run a Trial Piece and select the OK Screen Key without

making any adjustments. This will re-calibrate the Double Detect

function.

If there are still Double Detect problems, select the Change Position

Screen Key and change the distance (shown as X on the diagram

below) from the lead edge to the start of the Double Detect window.

This allows you to move the window down the sheet to a less

densely printed area.

The machine will limit this adjustment relative to the size of the

material.

If the print density on your material does not allow you to allocate a

27mm (1”) Double Detect window which can sense accurately, you

will be required to turn Double Detect off for this job.

Leading Edge

5mm

Adjustable

Dimension

X

DENSE PRINTING

(0.2”)

(1”)

27mm

Double

Detect

Window

DENSE PRINTING

5mm

Trailing Edge

4-6 SDC820A

(0.2”)

Page 43

Troubleshooting • 4

Clearing Material Stalls

Your machine has been designed to assure maximum performance.

In the event of a material stall, the display indicates where the stall

has occurred and suggests remedial action.

First press

the machine. The sections below tell you how to gain access to the

material if necessary.

Top Cover

Lift Top Cover to access

Manual Advance Knob and

stalled material. (See page

1-6/1-7).

Manual Feed Lever before

attempting to remove any

stalled material to prevent

damage to the machine.

Clear Deck in an attempt to feed the material through

CAUTION: It is

recommended

that you lower the

The Manual Advance Knob (A)

Having located the material,

you may need to use the

Manual Advance Knob to

manually feed material out of

the rollers, etc.

Folder Access Cover (B)

Lift the blue lever to raise the

Rear Access Cover. This will

allow access to any stalled

material and rollers at the

exit (right hand side) of the

machine.

4-7SDC820A

Page 44

4 • Troubleshooting

Removal and Replacement

Removal & Replacement of Fold Plates

To remove....

Pull the two blue levers gently

outwards on either side of the

Fold Plate simultaneously. Pull

the plate straight outwards

from the machine.

If removing Fold Plate 2, lift the

plate slightly before pulling out

from the machine.

To replace…

Place the Fold Plate into its location guides in the frame. Pull the two

blue levers gently outwards on either side of the Fold Plate. Push the

Fold Plate gently into the machine. The plate will automatically drop

into its correct location and the levers can be released.

4-8 SDC820A

Page 45

Troubleshooting • 4

Removal & Replacement of the Feed Tray

To remove…

Lift the rear of the tray slightly

and pull it straight outwards

from the machine (to the left).

Note:

If the tray is loaded, gently

press the material down

against the spring to prevent

it sliding forward as the tray is

removed.

CAUTION: Ensure that the Manual Feed Lever is set to

Automatic Feed before removing or replacing the Feed

Tray. This is because if the Manual Feed mechanism is

lowered when the Feed Tray is removed or replaced it

could cause damage to your machine.

To replace…

Remove all material from the tray. Place the tray into its location

guides in the side frame. Lift the rear of the tray slightly and push

it into the machine. The tray will automatically drop into its correct

location. Reload the tray as described on page 2-3 of this guide.

4-9SDC820A

Page 46

4 • Troubleshooting

4-10 SDC820A

Page 47

5 • Reference

Machine Specifications

Physical Dimensions

Length (without stacker) DF800 645mm (25.4”)

(without stacker) DF900 660mm (26”)

Depth DF800 515mm (20.3”)

DF900 585mm (23”)

Height DF800 460mm (18”)

DF900 545mm (24.5”)

Folder Weight DF800 22kg

DF900 29kg

Tray Stacker Weight 1kg

Conveyor Stacker CS88 Weight 6kg

High Capacity Extension Weight 5kg

Weights stated do not include material.

Noise Level

Running DF800 Approx 74dBA (80gsm,C Fold,Speed 3)

71dBA <81dBA dependant on material and

running speed.

DF900 Approx 74dBA (80gsm,C Fold,Speed 4)

65dBA <88dBA dependant on material and

running speed.

Please note that when running at sound levels over 80dBA (First

Action Level), operator hearing protection must be provided. For

sound levels over 85dBA (Second Action Level), the use of hearing

protection is mandatory.

Electrical 100-240VAC, 50/60Hz, 5A

Maximum Speed:

Actual folder throughput may vary, depending on the material used,

machine condition and operator skill.

DF800: Up to a maximum speed of 13,000 cycles per hour.

DF900: Up to a maximum speed of 20,000 cycles per hour.

ALL SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT

NOTIFICATION AND ARE SUBJECT TO TEST

5-1SDC820A

Page 48

5 • Reference

Material Specifications

Minimum Material size: DF800 127mm (5”) Length

127mm (5”) Width

DF900 127mm (5”) Length

127mm (5”) Width

Maximum Material size: DF800 406 mm (16”) Length

229 mm (9”) Width

DF900 432mm (17”) Length

305mm (12”) Width

Paper weights: DF800 Minimum

Maximum 120

55g/m2 (15 lbs)

g/m2 (32 lbs)

DF900 Minimum 55g/m2 (15 lbs)

Maximum 200g/m2 (53 lbs)

Double-detect Minimum 55g/m

2

(16 lbs)

Maximum 120g/m2 (32 lbs)

Cross-fold Pre-folded material

2

Minimum 55g/m

(15 lbs)

Maximum 100g/m2 (27 lbs)

Fold configurations: Fold Panel Min/ Max Dimensions

Fold Panel 1

Minimum DF800/DF900 80mm (3.15”)

Maximum DF800 235mm (9.25”)

Maximum DF900 320 mm (12.6”)

Fold Panel 2

Minimum DF800/DF900 75 mm (3”)

Maximum DF800 235mm (9.25”)

Maximum DF900 325mm (12.8”)

ALL SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT

NOTIFICATION AND ARE SUBJECT TO TEST

5-2 SDC820A

Page 49

Reference • 5

Stacker capacity: Tray Stacker

Maximum 135 finished pieces of C-Folded

A4 (Letter) Sheets of 80g/m2 (20lb).

Conveyor Stacker

Maximum 500 finished pieces of C-Folded

A4 (Letter) Sheets of 80g/m2 (20lb).

High Capacity Extension (attached to

Standard Stacker)

Maximum 1000 finished pieces of C-Folded

A4 (Letter) Sheets of 80g/m2 (20lb).

Manual Feed Mode

DF800/DF900: Stapled or unstapled sets up to five sheets of

80g/m2 (20lb) to a maximum total weight of 400g/m2 (105lb) per set

can be processed through the Manual Feed Mode.

Manual Feed Requirements

Glossy/Coated ‘Special’ material is not recommended.

•

If stapled sets are used, no staples can be in an area of 35mm

•

(1.4”) both sides of the centre line of the material being fed.

Staples must be horizontal to lead edge to prevent

•

catching/damage to the machine.

NOTE: The machine speed when running a Manual Feed or

Crossfold job is limited to Setting 1 (4,100 per hour).

Material Requirements

For best performance, use only materials approved by your machine

supplier.

Materials should be good quality and properly stored. Rotate your

material stock so that older material is used first.

Recommended Storage conditions: 18

Relative humidity: 40% to 60%

Low humidity could cause sheets to stick together because of static

charge; high humidity can cause paper to become limp and curled.

ALL SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT

NOTIFICATION AND ARE SUBJECT TO TEST

˚C to 25˚C

5-3SDC820A

Page 50

5 • Reference

Compliance

Conforms to the Following:

FCC Rules

This equipment has been tested and found to comply with the limits

for a Class A digital device, pursuant to part 15 of the FCC rules.

These limits are designed to provide reasonable protection against

interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in accordance

with the instruction manual, may cause interference to radio

communications. Operation of this equipment in a residential area is

likely to cause interference, in which case the user will be required to

correct the interference at his own expense.

CAUTION: Changes or modifications to this equipment not expressly

approved by the party responsible for compliance could void the

user’s authority to operate the equipment.

It is certified that the system complies with all applicable

Directives of the European Union.

For a formal Declaration of Conformity please contact Compliance

Engineering. Contact information is given in the front of this guide or

on a separate document supplied with your system.

WARNING: This is a Class A product. In a domestic environment this

product may cause radio interference in which case the user may be

required to take adequate measures.

5-4 SDC820A

Page 51

Reference • 5

Electromagnetic

Electromagnetic

US: FCC Part 15 Class A, subparts as applicable

Canada: ICES-003

EU: EMC Directive 2004/108/EEC, referencing EN55022 and

EN61000-3

Australia and New Zealand: AS/NZS 3548 (Equivalent to EN55022)

Safety

US: CTUVUS

Canada: CSA Approval, Standard C22.2 as applicable

EU: EN60950 & TUVGS. x CB CERTIFIED

5-5SDC820A

Page 52

5 • Reference

Service

Service for your new OfficeRight™ Folder DF800 or DF900 Machine

is available throughout the world.

Should you have questions about your machine, or require service or

assistance with your particular application, please call your machine

supplier.

Your machine supplier will also offer a service maintenance contract

to keep your machine in top condition at nominal cost.

Contact details can be found:

• On the separate leaflet supplied with your system.

• In the System Information option in the menus:

At the Home Screen, select Menu.

Then select System Information.

5-6 SDC820A

Page 53

Reference • 5

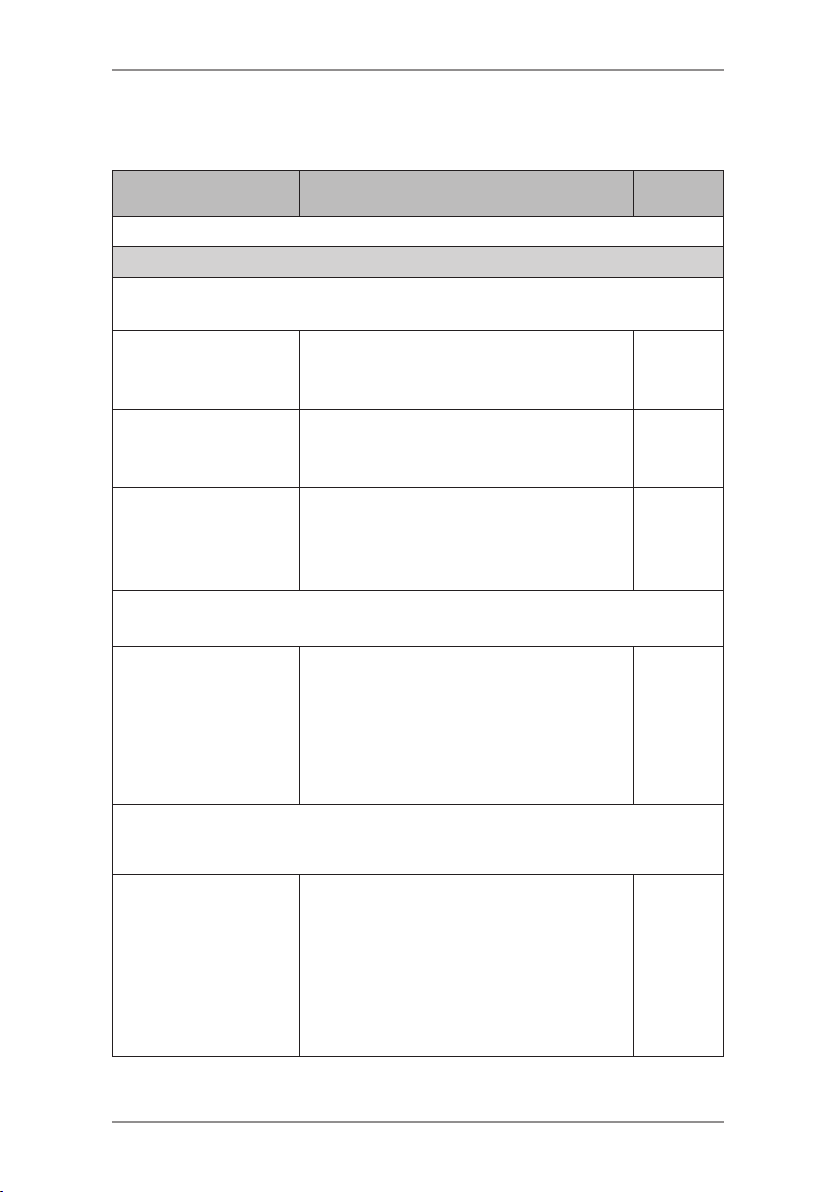

Operator/Supervisor Training Check list

During initial Operator Training, the following aspects of the machine

should be described:

Sheet Feeder

Manual Feeding

Access Areas and Fold Plates

Manual Advance Knob

Measuring Scale

Crossfold Options (if applicable DF900 only)

Control Panel

Screen Keys, Hard Keys

Relevant Stacker

High Capacity Extension (if applicable)

Power Switch

Screens for operator(s):

• Select Job – select and run a sample job

• Trial Piece

• Running a Job

• Manual Feed

• Menu: Language

Display adjustments

System Information

5-7SDC820A

Page 54

5 • Reference

Job Functions

• Supervisor Access/ Operator Access

• Create Job

• Edit Job

• Create From

• Delete Job

Stoppage Recovery

Maintenance/ Cleaning

The following operators have been trained on this equipment:

Name Level Date

Operator

Supervisor

Operator

Supervisor

Operator

Supervisor

Operator

Supervisor

Operator

Supervisor

Operator

Supervisor

5-8 SDC820A

Page 55

Page 56

Elizabeth Way,

Harlow, Essex, CM19 5BD, UK

www.pitneybowes.co.uk

For Service and Supplies

PB Form SDC820A (11-08)

© Pitney Bowes Limited, 2008

We have made every reasonable effort to assure the accuracy and usefulness of this

guide, however we cannot assume responsibility for errors or omissions or liability for

the misuse or misapplication of our products.

Printed in the UK

Printed on recyclable paper

*SDC820A*

Loading...

Loading...