Page 1

DVD / CD RECEIVER

XV-S100DV

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Type

MYXJN AC220-230V 2

NVXJN AC230V 2

Model

XV-S100DV

Power Requirement Region No. Remarks

ORDER NO.

RRV2497

CONTENTS

1. SAFETY INFORMATION

2. EXPLODED VIEWS AND PARTS LIST

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

4. PCB CONNECTION DIAGRAM

5. PCB PARTS LIST

6. ADJUSTMENT

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS SERVICE, INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

c

PIONEER CORPORATION 2001

................................................

.....................................................

.......................................

.................

...

...........................

10

45

58

64

2

3

7. GENERAL INFORMATION

7.1 DIAGNOSIS

7.1.1 SELF-DIAGNOSTIC FUNCTION OF

PICKUP DEFECTIVE

7.1.2 TEST POINTS LOCATION

7.1.3 TEST MODE SCREEN DISPLAY

7.1.4 TROUBLE SHOOTING

7.1.5 ERROR CODE

7.1.6 DISASSEMBLY

7.2 PARTS

7.2.1 IC

7.2.2 DISPLAY

8. PANEL FACILITIES AND SPECIFICATIONS

..................................................

..........................................................

..........................................................

................................

...........................

...................

........

........................

.....................................

....................................

...............................................

....

T – IZK AUG. 2001 Printed in Japan

71

71

71

72

73

77

78

82

87

87

89

90

Page 2

XV-S100DV

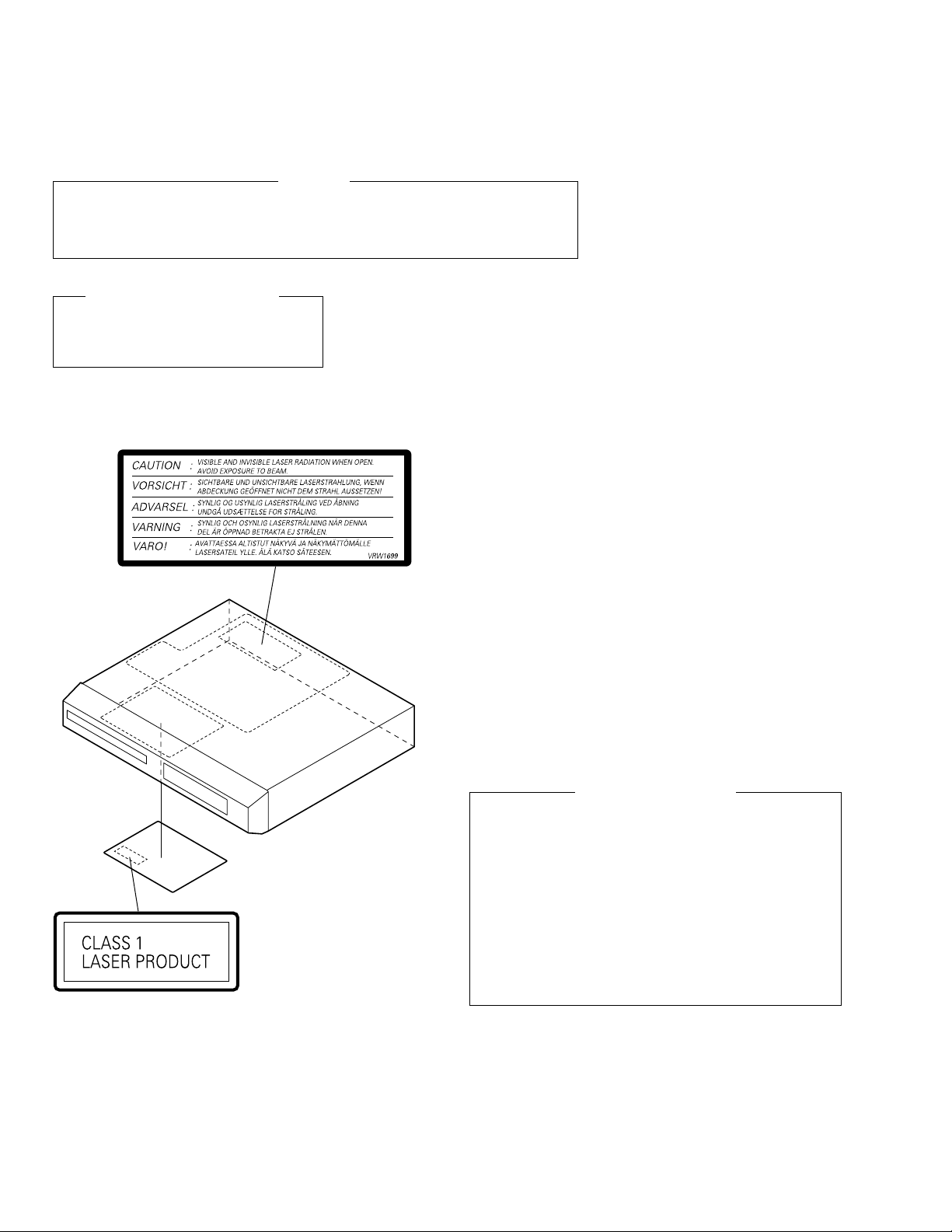

1. SAFETY INFORMATION

THE AEL (ACCESSIBLE EMISSION LEVEL) OF THE LASER POWER OUTPUT IS LESS THAN CLASS 1

BUT THE LASER COMPONENT IS CAPABLE OF EMITTING RADIATION EXCEEDING THE LIMIT FOR

CLASS 1.

A SPECIALLY INSTRUCTED PERSON SHOULD DO SERVICING OPERATION OF THE APPARATUS.

LASER DIODE CHARACTERISTICS

FOR DVD : MAXIMUM OUTPUT POWER : 5 mW

WAVELENGTH : 650 nm

FOR CD : MAXIMUM OUTPUT POWER : 5 mW

WAVELENGTH : 780 nm

WARNING !

LABEL CHECK

Additional Laser Caution

1. Loading-status detection switch (S101 on the LOAB assy) are detected

by the microprocessor (IC601 in the DVDM assy).

• To permit the laser diode to oscillate, it is required to set the loadingstatus detection switch for the clamp position (the center terminal of S101

is shorted to +3V). The 650 nm laser diode for DVD oscillation will continue

Name Sheet

if pin 19 of IC101 is shorted to +3V (fault condition) in the DVDM assy.

The 780 nm laser diode for CD oscillates if pin 20 of IC101 is shorted to

+3V in the DVDM assy.

In the test mode ∗ , the laser diode oscillates when microprocessor detects

a PLAY signal, or when the PLAY key is pressed (S5925 ON in the

DISPLAY assy), with the above requirements satisfied.

2. When the cover is open, close viewing through the objective lens with

the naked eye will cause exposure to the laser beam.

∗ : See page 66.

2

Page 3

XV-S100DV

(2) CONTRAST TABLE

XV-S100DV/MYXJN and NVXJN types are constructed the same except for the following :

Mark No. Symbol and Description

Part No.

Remarks

MYXJN Type NVXJN Type

1

15

16

17

18

19

20

Power Cord

Operating Instructions (German / Italian)

Operating Instructions (German / Italian)

Operating Instructions (Dutch / Spanish)

Operating Instructions (Dutch / Spanish)

Operating Instructions (Swedish / Portuguese)

Operating Instructions (Swedish / Portuguese)

ADG1154

ARC7366

ARC7367

ARC7368

ARC7369

ARC7370

ARC7371

ADG1156

Not used

Not used

Not used

Not used

Not used

Not used

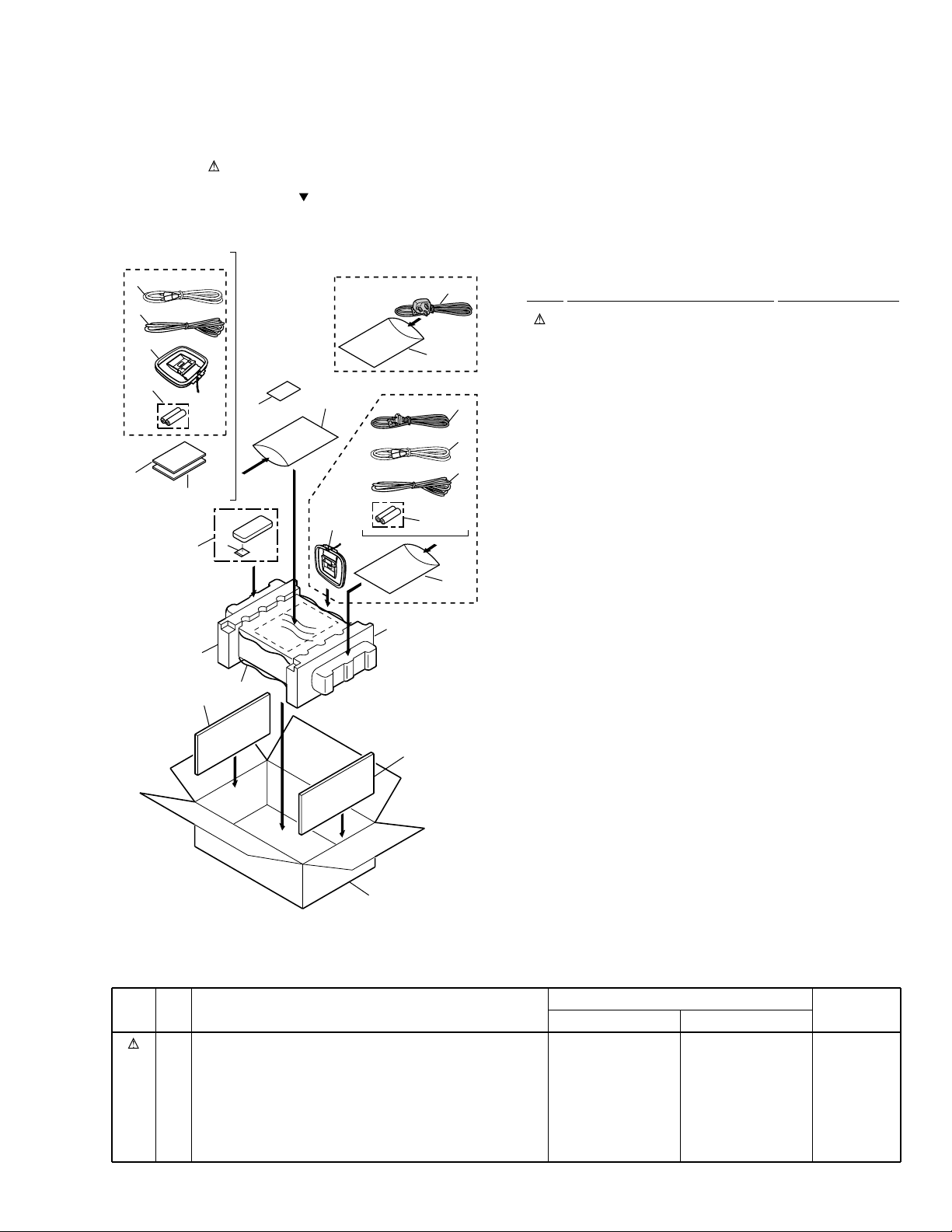

2. EXPLODED VIEWS AND PARTS LIST

NOTES:• Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

2.1 PACKING

For NVXJN Type

8

15 - 20

(MYXJN

Type

Only)

The mark found on some component parts indicates the importance of the safety factor of the part.

•

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on the product are used for disassembly.

•

For NVXJN Type

1

2

3

7

4

21, 22

6

5

9

13

11

14

3

For MYXJN Type

14

1

8

2

7

14

10

11

(1) PACKING PARTS LIST

Mark No. Description Part No.

1 Power Cord See Contrast table (2)

2 FM Antenna ADH7005

3 AM Loop Antenna ATB7009

NSP 4 Warranty Card ARY7022

5 Remote Control Unit AXD7315

6 Battery Cover XZN3117

NSP 7 Dry Cell Battery (R6P, AA) VEM-013

8 Video Cord (L = 1.5m) VDE1053

9 Pad L AHA7360

10 Pad R AHA7361

11 Spacer AHB7059

12 Packing Case AHD8038

13 Packing Sheet AHG7065

NSP 14 Polyethylene Bag Z21-038

(230 × 340 × 0.03)

15 Operating Instructions See Contrast table (2)

(German / Italian)

16 Operating Instructions See Contrast table (2)

(German / Italian)

17 Operating Instructions See Contrast table (2)

(Dutch / Spanish)

18 Operating Instructions See Contrast table (2)

(Dutch / Spanish)

19 Operating Instructions See Contrast table (2)

(Swedish / Portuguese)

20 Operating Instructions See Contrast table (2)

(Swedish / Portuguese)

21 Operating Instructions ARE7290

(English/French)

22 Operating Instructions ARE7291

(English/French)

12

3

Page 4

XV-S100DV

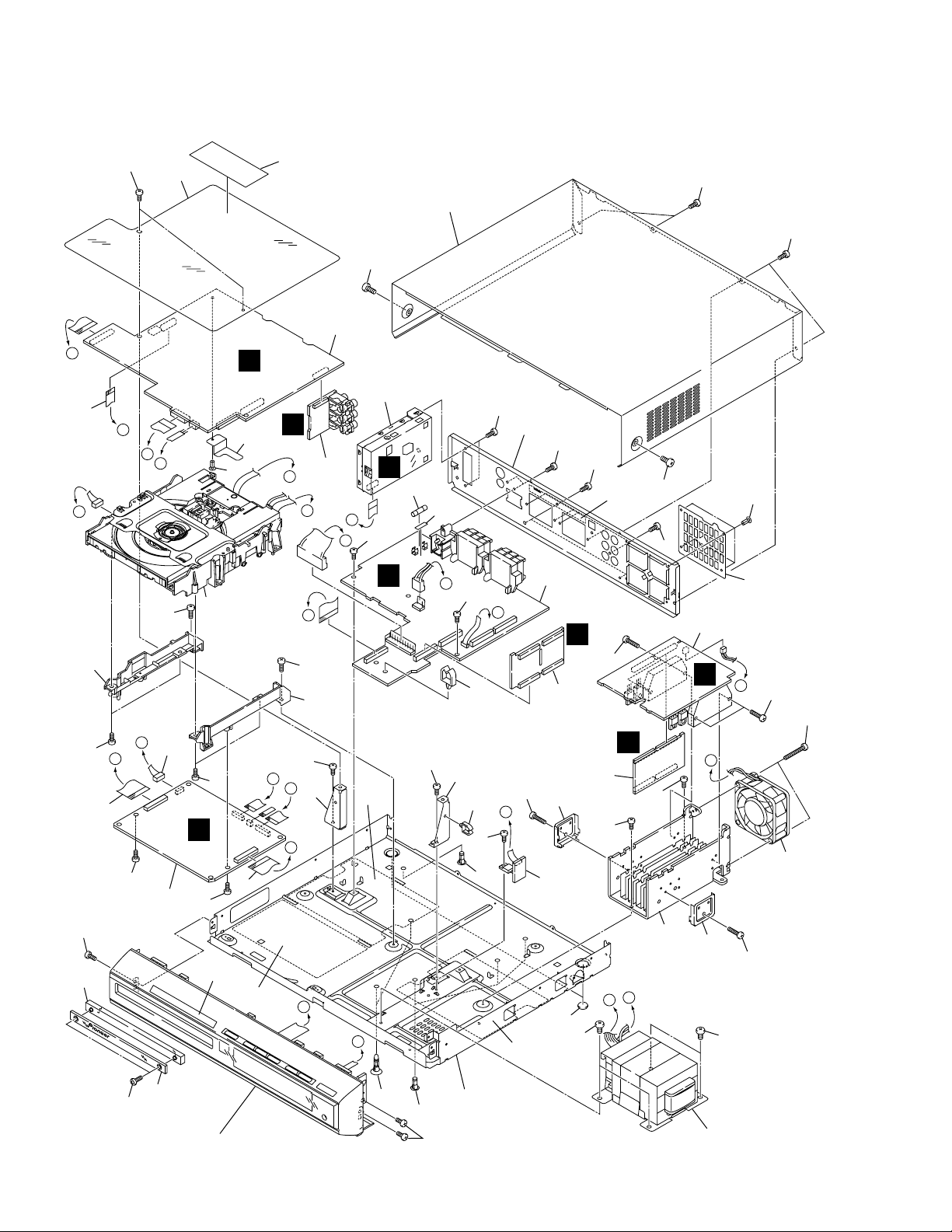

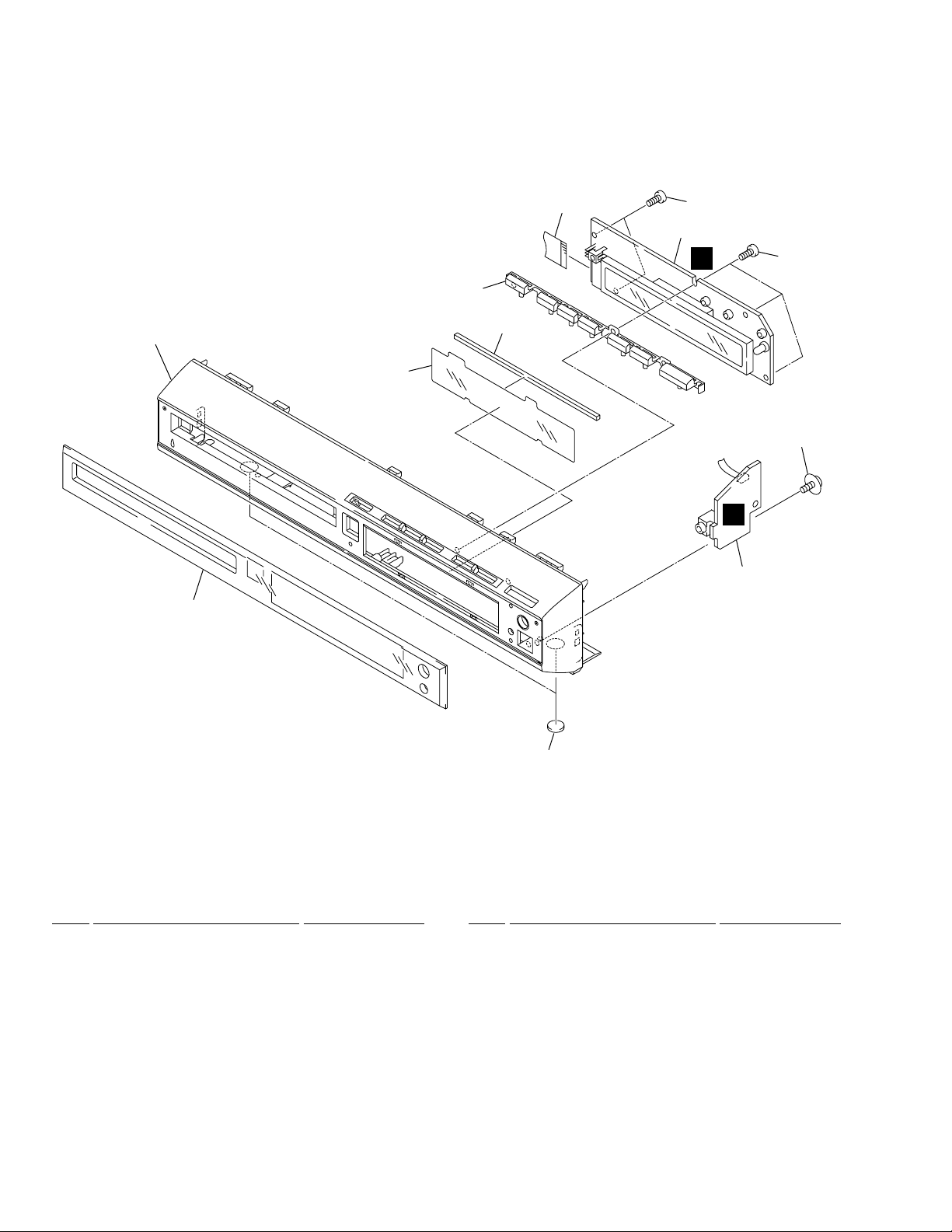

2.2 EXTERIOR SECTION

D

31

40

45

34

45

45

2

H

F

45

8

6

E

C

17

C

12

H

45

I

K

36

J

45

44

K

19

7

44

(1/2)

326

E

45

42

35

45

44

5

G

27

23

L

42

41

F

45

F

E

20

C

37

45

20

30

45

25

4

42

7

22

45

(2/2)

K

45

L

11

45

D

14

H

G

16

44

D

13

28

A

B

45

G

15

27

9

Refer to

"2.4 LOADING

MECHANISM ASSY".

44

B

44

1

13

44

45

32

43

39

38

33

Refer to

"2.3 FRONT PANEL SECTION".

A

B

29

25

18

45

24

37

I

46

21

22

42

J

46

10

4

Page 5

XV-S100DV

(2) CONTRAST TABLE

XV-S100DV/MYXJN and NVXJN types are constructed the same except for the following :

Mark No. Symbol and Description

Part No.

Remarks

MYXJN Type NVXJN Type

19 Rear Panel ANC8009 ANC8008

(1) EXTERIOR SECTION PARTS LIST

Mark No. Description Part No. Mark No. Description Part No.

1 DVDM Assy VWS1499

2 CONTROL Assy AWU7856

3 TRADE 1 Assy AWU7858

4 TRADE 2 Assy AWU7859

5 AMP Assy AWU7935

6 JACK Assy AWU7862

7 POWER Assy AWU7860

8 FM/AM TUNER Module AXQ7229

NSP 9 Loading Mechanism Assy VWT1188

10 Power Transformer (T1) ATS7311

11 DC FAN Motor AXM7014

12 Fuse (FU1 : 1.6A) REK1024

13 30P Flexible Cable / 60V ADD7325

14 13P Flexible Cable / 60V ADD7326

15 Connector Assy PG05KK-E10

16 Adapter 12 L ANW7231

17 Adapter 12 R ANW7232

NSP 18 Chassis ANA7130

19 Rear Panel See Contrast table (2)

20 Angle DCS ANG7361

NSP 21 Heat Sink ANH7141

22 FET Bracket XNG3016

23 Rear Plate AAK7911

24 Leg AEB7090

25 PCB Holder AEC7057

26 Wire Saddle AEC7297

27 Nyron Rivet AEC7318

28 PCB Cover AEC7348

29 Locking Card Spacer AEC7372

30 Mini Clamp AEC7373

31 Jack Barrier AEC7374

32 Tray Mold AAK7907

33 Tray Panel AAK7909

34 Bonnet AZN7884

35 Terminal Sheet AAK7912

NSP 36 Fuse Card AAX2377

37 Cover Sheet AAX7878

38 Name Sheet AAX7879

39 Getter Label DCS AAX7882

40 Label VRW1699

41 Screw BBZ30P300FZK

42 Screw BBZ30P140FMC

43 Screw ABA7060

44 Screw BPZ30P100FZK

45 Screw BBZ30P080FNI

46 Screw BBZ40P060FMC

5

Page 6

XV-S100DV

2.3 FRONT PANEL SECTION

3

9

4

7

8

10

1

J

10

11

I

2

6

5

FRONT PANEL SECTION PARTS LIST

•

Mark No. Description Part No. Mark No. Description Part No.

1 DISPLAY Assy AWU7861

2 HP Assy AWU7863

3 15P Flexible Cable / 60V ADD7327

4 Front Panel AMB7766

5 Leg AEB7090

6

6 Display Window AAK7941

7 FL Filter AAK7910

8 FL Spacer AEB7238

9 Button DCS AAD7648

10 Screw BPZ30P100FZK

11 Screw ABA1005

Page 7

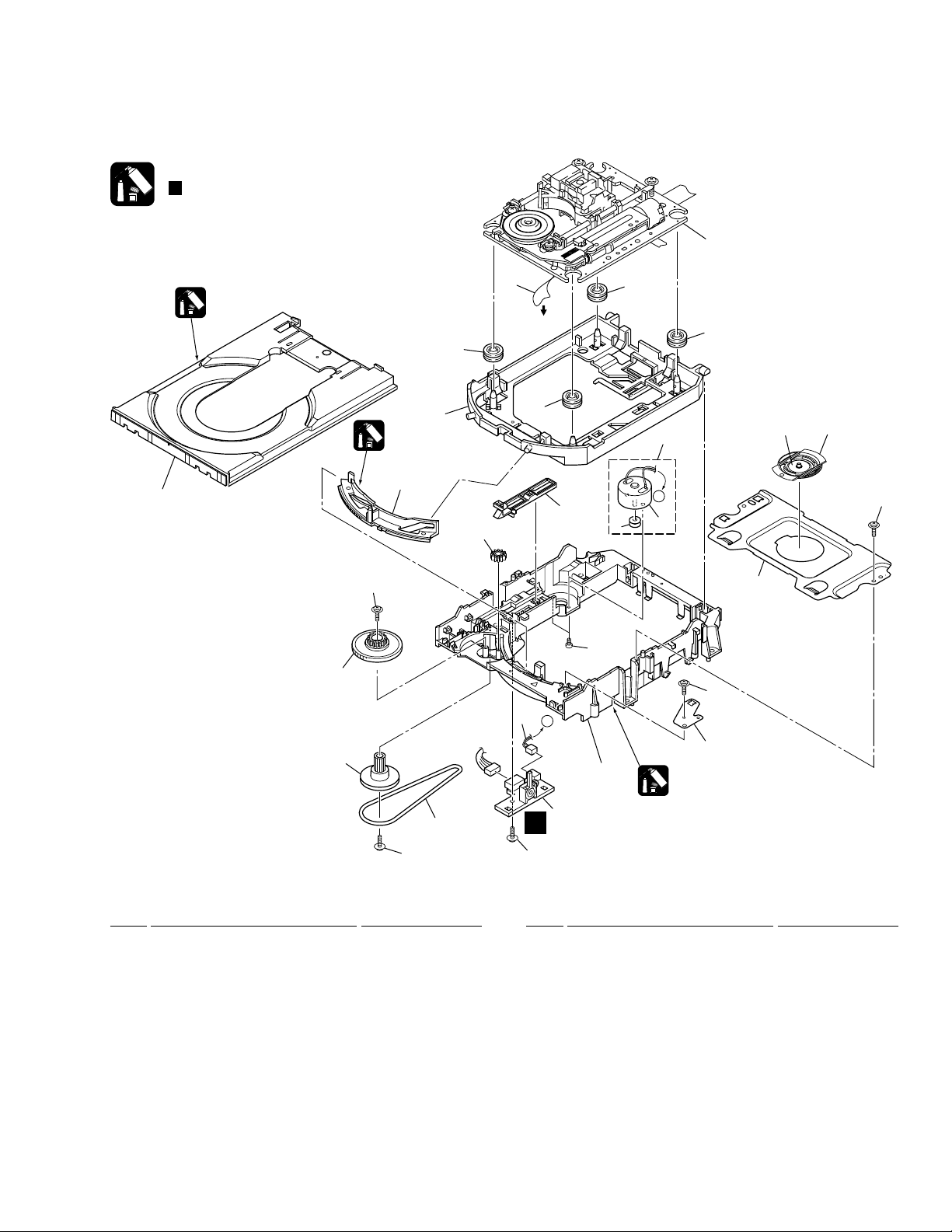

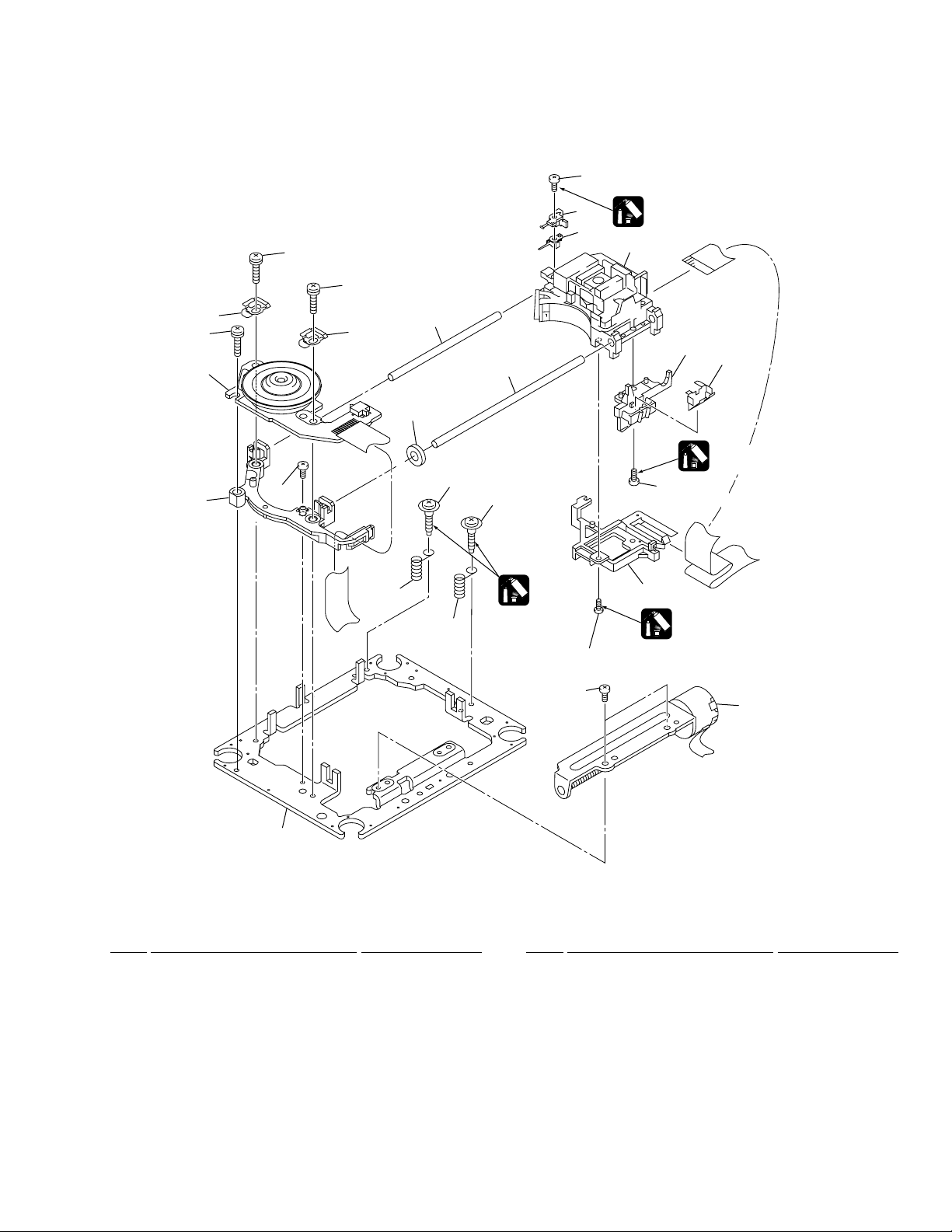

2.4 LOADING MECHANISM ASSY

Note :

Refer to

" Application of Lubricant".

Daifree

GEM1036

XV-S100DV

2

Refer to

"2.5 TRAVERSE MECHANISM

6

To DVDM

CN151

8

8

ASSY-S".

8

23

15

14

12

Lubricating Oil

GYA1001

13

22

9

22 22

16

8

20

3

17

21

7

A

11

1

A

A

4

5

22

10

Lubricating Oil

GYA1001

18

22

19

• LOADING MECHANISM ASSY PARTS LIST

Mark No. Description Part No.

NSP 1 LOAB Assy VWG2279

2 Traverse Mechanism Assy-S VXX2782

3 Loading Motor Assy VXX2505

4 Motor Pulley PNW1634

5 Carriage DC Motor / 0.3W PXM1027

6 Flexible Cable (26P) VDA1864

7 Connector Assy 2P VKP2253

8 Float Rubber VEB1327

9 Belt VEB1330

10 Stabilizer VNE2253

Mark No. Description Part No.

11 Loading Base VNL1917

12 Float Base DVD VNL1918

13 Drive Cam VNL1919

14 Gear Pulley VNL1921

15 Loading Gear VNL1922

16 Drive Gear VNL1923

17 SW Lever VNL1925

18 Clamper Plate VNE2251

19 Bridge VNE2252

20 Clamper VNL1924

21 Screw JGZ17P028FMC

22 Screw Z39-019

23 Tray VNL1920

7

Page 8

XV-S100DV

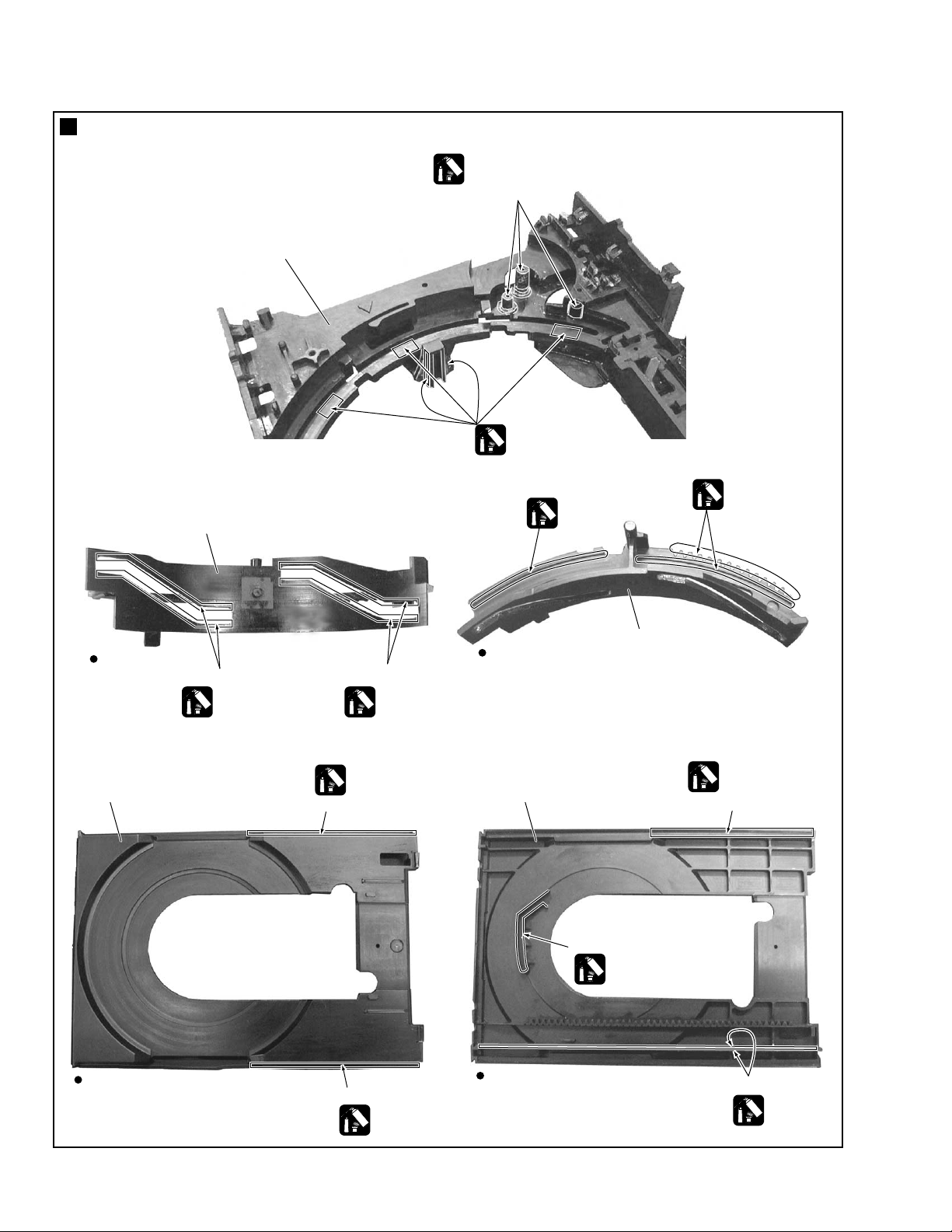

Application of Lubricant

Lubricating Oil

GYA1001

Around the shaft

No. 11

Loading Base

Lubricating Oil

GYA1001

Rear View

No. 23

Tray

No. 13

Drive Cam

Inner side of a ditch

Lubricating Oil

GYA1001

Inner side of a ditch

Lubricating Oil

GYA1001

Daifree

GEM1036

Concave of unevenness

Top View

No. 23

Tray

Lubricating Oil

GYA1001

Lubricating Oil

GYA1001

No. 13

Drive Cam

Daifree

GEM1036

Concave of unevenness

8

Top View

Concave of unevenness

Daifree

GEM1036

Bottom View

Inner side of a ditch

Dyfree

GEM1036

Side of the lib

Daifree

GEM1036

Page 9

2.5 TRAVERSE MECHANISM ASSY-S

XV-S100DV

17 (Torque : 0.12 ± 0.01 N•m)

13

18

10

1

16

18

18

10

12

8

7

6

19

4 (Adjustment Screw)

4 (Adjustment Screw)

5

5

Screw Tight

GYL1001

17 (Torque : 0.12 ± 0.01 N•m)

Silicone Adhesive

GEM1037

3

14

9

Silicone Adhesive

GEM1037

17

(Torque : 0.12 ± 0.01 N•m)

15

Silicone Adhesive

GEM1037

11

• TRAVERSE MECHANISM ASSY-S PARTS LIST

Mark No. Description Part No.

1 Spindle Motor VXM1088

(or VXM1089)

2 Stepping Motor VXM1090

(CARRIAGE) (or VXM1091)

3 Pickup Assy-S OXX8003

4 Skew Screw VBA1080

5 Skew Spring VBH1335

6 Guide Bar VLL1514

7 Sub Guide Bar VLL1515

8 Hold Spring VNC1017

16

2

Mark No. Description Part No.

9 Joint Spring VNC1019

10 Support Spring VNC1020

NSP 11 Mechanism Chassis VNE2248

12 Slider VNL1811

13 Spacer VNL1913

14 Joint VNL1914

15 FFC Holder VNL1915

16 Screw BBZ20P050FZK

17 Screw OBA8009

18 Screw PMA26P100FMC

19 Damper Sheet VEB1335

9

Page 10

1

23

XV-S100DV

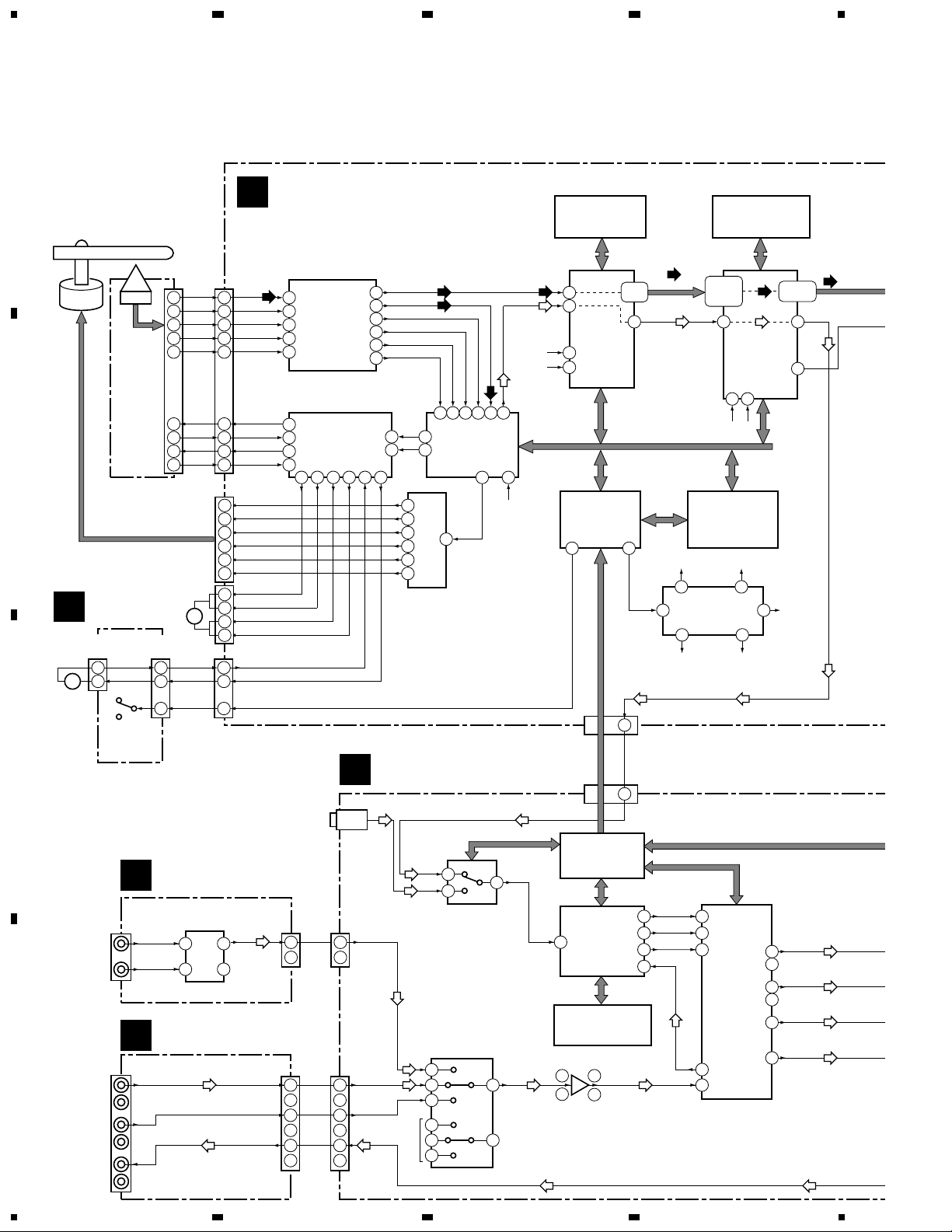

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

3.1 BLOCK DIAGRAM

A

DVDM ASSY

B

IC712

MNR4800DJ7

16M DRAM

4

IC805

MB81F161622C-80FN

16M SDRAM

CN120

(26P)

RF

B1

B2

B3

B4

(RF)

RF

11

20

21

15

16

3

B1

B2

B3

B4

6

LA9701M

7

8

9

IC101

RF IC

54

46

56

57

42

35

Spindle

Motor

PICKUP

(26P)

11

20

21

15

16

ASSY

25

24

23

26

CN251

9

8

7

6

5

4

2

1

3

4

CN52

2

1

4

(12P)

H1+

H1H2+

H2H3+

H3-

ST1+

ST1ST2+

ST2-

(5P)

LODPOS

T DRV

T RTN

F DRV

F RTN

12

IC351

13

M56788AFP

9

FTS Driver

10

35 34 31 32 15 14

JA8602

DIGITAL IN

(OPTICAL)

CONTROL ASSY (2/2)

D

(D)

T DRV

25

T RTN

24

F DRV

23

F RTN

B

LOAB

A

ASSY

CN602

(2P)

1

+-

2

M

Loading

Motor

Assy

S101

Loading

Position

Switch

26

CN3

(4P)

Stepping

Motor

(Carriage)

M

CN601

(5P)

LOD- LOD-

2

LOD+ LOD+

1

SW2

4

C

(RF) (RF)

RFO

DSP RF

(RF)

BH

PH

FE

TE

32 33 30 31 39 3

FDO

47

3

TDO

LC78652W

48

20

Servo DSP IC

9

10

11

12

13

14

21

IC251

BA6664FM

Spindle

Driver

IC201

46 14

SPDO

(RF)

ROMXA

(AD)

16M

(D)

(AD)

33M

16M

170

112

IC701

PE5108A

DVD

4

Decoder

107

BY Chip

IC601

PD6345A

System

Control

57

LODPOS

CONTROL

(VD)

SD0-SD7

57-60

63-66

CDDATA

111

105

DOUT

26

DOUT0

5

27M

(for IC801)

X48/44

X48/44

3

14 15

Clock Generator

10

22/24M

(for IC211)

(D)

CN21

(30P)

CN8001

(30P)

149,150,

(VD)

152-155,

158,159

48 74

IC801

M65774BFP

MPEG2

Decoder

5564

27M36/16M

IC603

VYW1857

8M

Flash Memory

16M

(for IC201, IC701)

13

IC481

BU2288FV

9

36/16M

(for IC801)

AV-1

(D)

95-98,

100-103

DOUT0

27M

93

33M

(for IC701)

(VD)

(D)

(D)

IC5501

(D)

(D)

(TX)

DIN0

3

DIN2

5

IC8101

LC89056W-E

DIR

16

DATAO

DIRDOUT

ANTENNA

FM

AM

FM/AM TUNER

C

MODULE

IC201

BN201

BA1451F

FM

AM

20110

CN201

(13P)

L

11

R

(TX)

7

9

Rch

Lch

CN5701

(13P)

7

9

IC3031

BU4052BCF

JACK ASSY

H

D

TV IN

VCR IN

VCR OUT

JA3001

L

R

L

R

L

R

(TV)

CN3001

(10P)

3

1

6

(FL) (FL)

4

10

8

TVL

TVR

VCRL

VCRR

RECL

RECR

CN3011

(10P)

3

1

6

4

10

8

AUDIO INPUT

(TX)

(TV)

Rch

SELECTOR

4

15 13

14

11

2

5

3

PDC086A

µ-COM

SDOB0

IC8701

85

YSS912C-F

DSP

47

46

45

CDCDOUT

84

IC8751

K6E0808CIE-JC15

SRAM

351

7

IC3041

NJM4558MD

Buffer

(FL) (FL)

CDCDOUT

SDOB1

SDOB2

LIN+

6

7

8

10

30

IC8301

AK4527BVQ

CODEC

(FL)

LOUT1

27

ROUT1

28

(SL)

LOUT2

25

ROUT2

26

(SW)

ROUT3

24

(C)

LOUT3

23

10

1234

Page 11

5

IC861

ADV7172KST

Video Encoder

(VD)

PD0-PD7

(RF)

(VD)

(V)

(Y)

(C)

35

33

2-9

29

48

27M

: RF SIGNAL ROUTE

: VIDEO DATA SIGNAL ROUTE

: VIDEO SIGNAL ROUTE

: V SIGNAL ROUTE

: Y SIGNAL ROUTE

: C SIGNAL ROUTE

DISPLAY ASSY

J

V

Y

C

Q901

Q902

Q903

22/24M

CN22

(30P)

(V)

V

5

1

3

29

V

(Y)

Y

Y

(C)

C

C

(AD)

: AUDIO DATA SIGNAL ROUTE

: AUDIO SIGNAL ROUTE

(D)

: AUDIO (DIGITAL) SIGNAL ROUTE

(TX)

: AUDIO SIGNAL ROUTE (TUNER)

(TV)

: TV IN AUDIO SIGNAL ROUTE

V5601 AAV7082

FL Tube

MSM9202-01

CN5601

(15P)

CN5611

(15P)

IC5601

FL Driver

KEY SW

X5951

Remote

Receiver

Unit

G

IC3212

NJM4558MD

Theater Bass

5

NJM4558MD

DSP Mute

1

6 7

IC3231

1

NJM4558MD

(SWB)

(SWB)

(FL)

IC3085

DSP Mute

(SW)

(FL)

IC3081

NJM4558MD

(FL) (FL) (FL) (FL)

LPF & Gain

IC3082

NJM4558MD

(SL) (SL) (SL)

LPF & Gain

IC3083

NJM4558MD

(SW)

LPF & Gain

IC3083

NJM4558MD

(C) (C) (C)

LPF & Gain

(FL)

6271627

627

2 1

6 7

3 1 5 7

678

K

POWER

ASSY (1/2)

CN5102

(30P)

(V)

26

(Y)

30

(C)

28

IC3302

(SW)

STK402-240

Power Amp.

(SL)

18 16

IC3301

STK402-240

(C)

(FL)

Power Amp.

18 16

CN5532

(23P)

(FL)

(SL)

(SW)

(C)

17

17

E

TRADE 1

ASSY (1/2)

CN5522

(30P)

16

16

20

20

18

18

CN3301

(23P)

8

5

22

19

12

16

18

16

14

12

22

20

CN3302

(23P)

(V)

(Y)

(C)

FLOUT FLOUT

SLOUT SLOUT

SWOUT SWOUT

COUT COUT

CIN

SWIN

SLIN

FLIN

AMP ASSY

IC3131

M62446FP

(SWB)

E-VOL

LIN

15

RIN

13

SLIN

9

SRIN

(SW)

8

SWIN SWOUT

6

CIN COUT

11

RBASS1

22

RBASS2

23

RBASS3

24

6

31

32

34

35

36

33

LOUT

ROUT

SLOUT

SROUT

(FL)

D

CONTROL

ASSY (1/2)

CN5512

(23P)

(FL)

(SL)

(SW)

(C)

CN5502

(30P)

12

14

13

2

12

6

14

4

13

IC8801

MM1540BF

Video Amp.

(9dB Amp. + LPF)

: FL ch AUDIO SIGNAL ROUTE

: SL ch AUDIO SIGNAL ROUTE

: SW ch AUDIO SIGNAL ROUTE

: C ch AUDIO SIGNAL ROUTE

TRADE 2

F

ASSY

CN3311

(23P)

8

5

22

19

12

16

CN3312

(23P)

18

16

14

12

22

20

(FL)

(SL)

(SW)

(C)

CN3321

(23P)

(C)

(SW)

(SL)

(FL)

CN3322

(23P)

8

5

22

19

12

16

CIN

18

SWIN

16

SLIN

14

12

FLIN

22

20

E

TRADE 1

ASSY (2/2)

CN5501

(23P)

1

CN3902

(5P)

4

10

12

8

6

1

3

(SL)

(SW)

(C)

(FL) (FL)

FLIN

SLIN

SWIN

HP L

HP R

CIN

CN5511

(23P)

23

20

14

12

16

18

1

3

J3901

(5P)

(SW)

I

7

(V)

27

(Y)

23

(C)

25

POWER

K

ASSY (2/2)

RY3641

15

18

RY3643

1

4

11

7

RY3642

CN3331

(23P)

CN3332

(23P)

CN5531

(23P)

CN5521

(23P)

(C)

(SL)

(FL)

6

8

10

12

2

4

(FL)

(SL)

(C)

HP ASSY

XV-S100DV

JA8803

V

Y

C

(FL)

(SW)

(SL)

(SW)

20 14 12 16

23

FLIN

SLIN

(FL)

(SL)

23

20

14

12

16

18

JA3901

PHONES

COMPOSITE

VIDEO OUT

S VIDEO

(C)

18

CIN

SWIN

(SW)

8

A

B

CN3301

FL

FR

SW

CN3301

C

SL

SR

C

(C)

D

11

Page 12

1

23

4

XV-S100DV

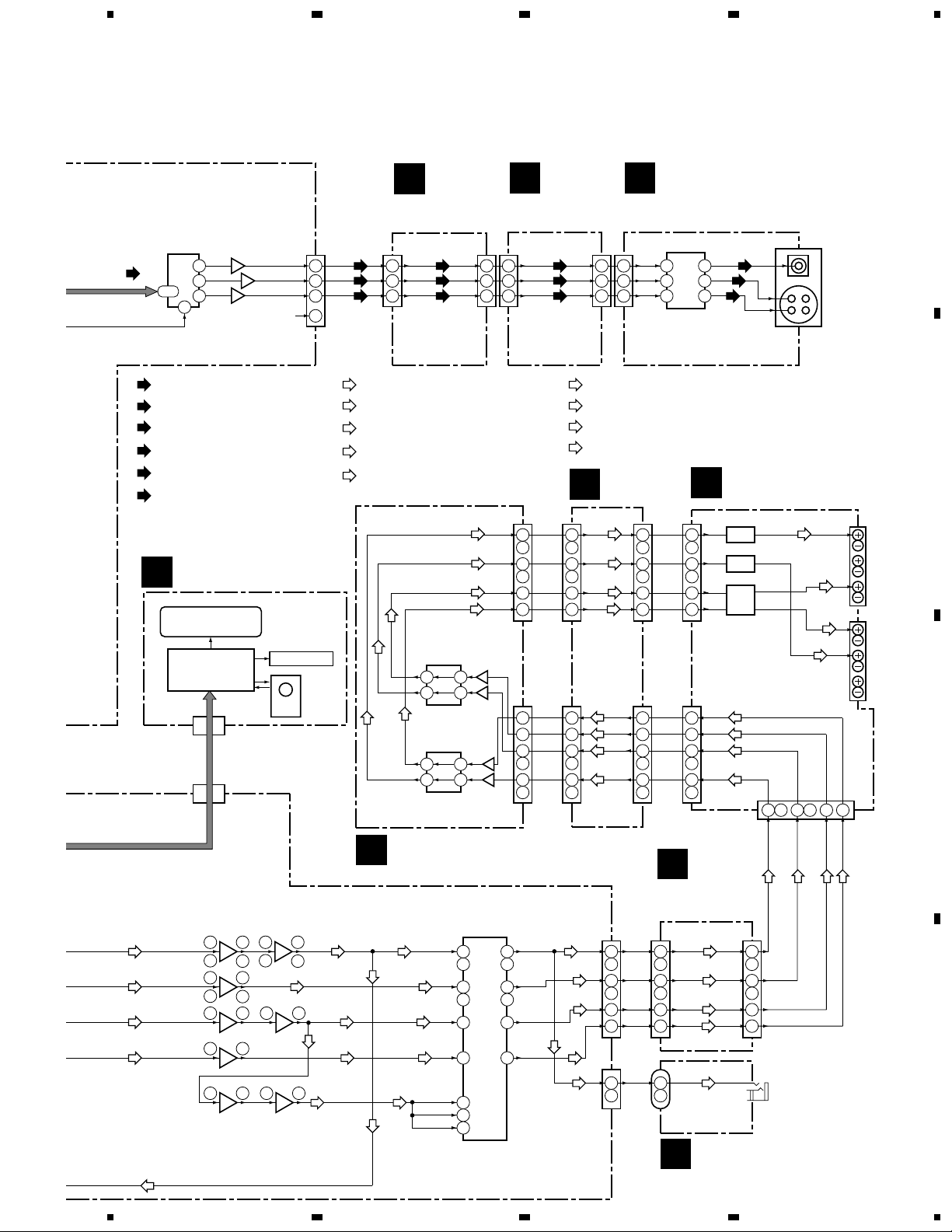

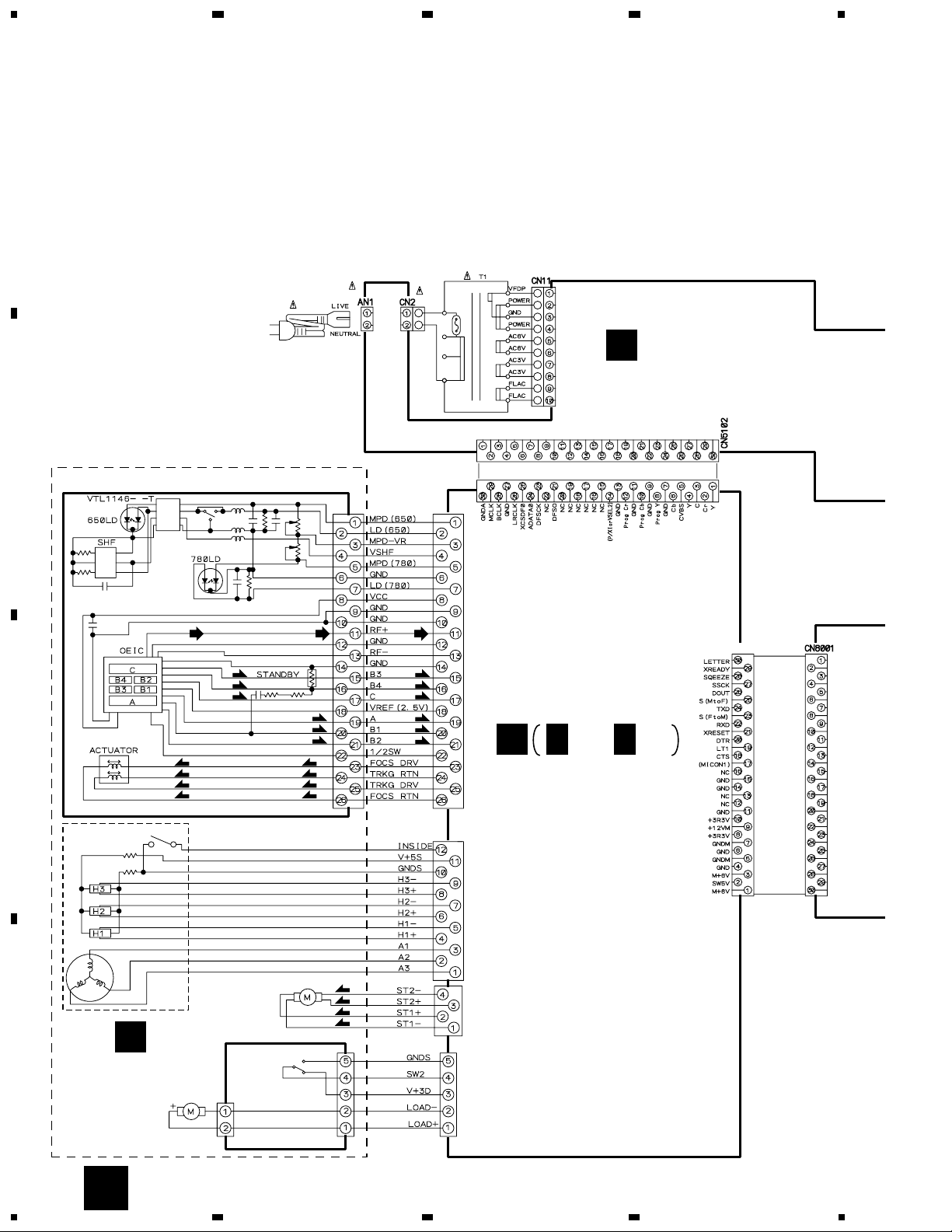

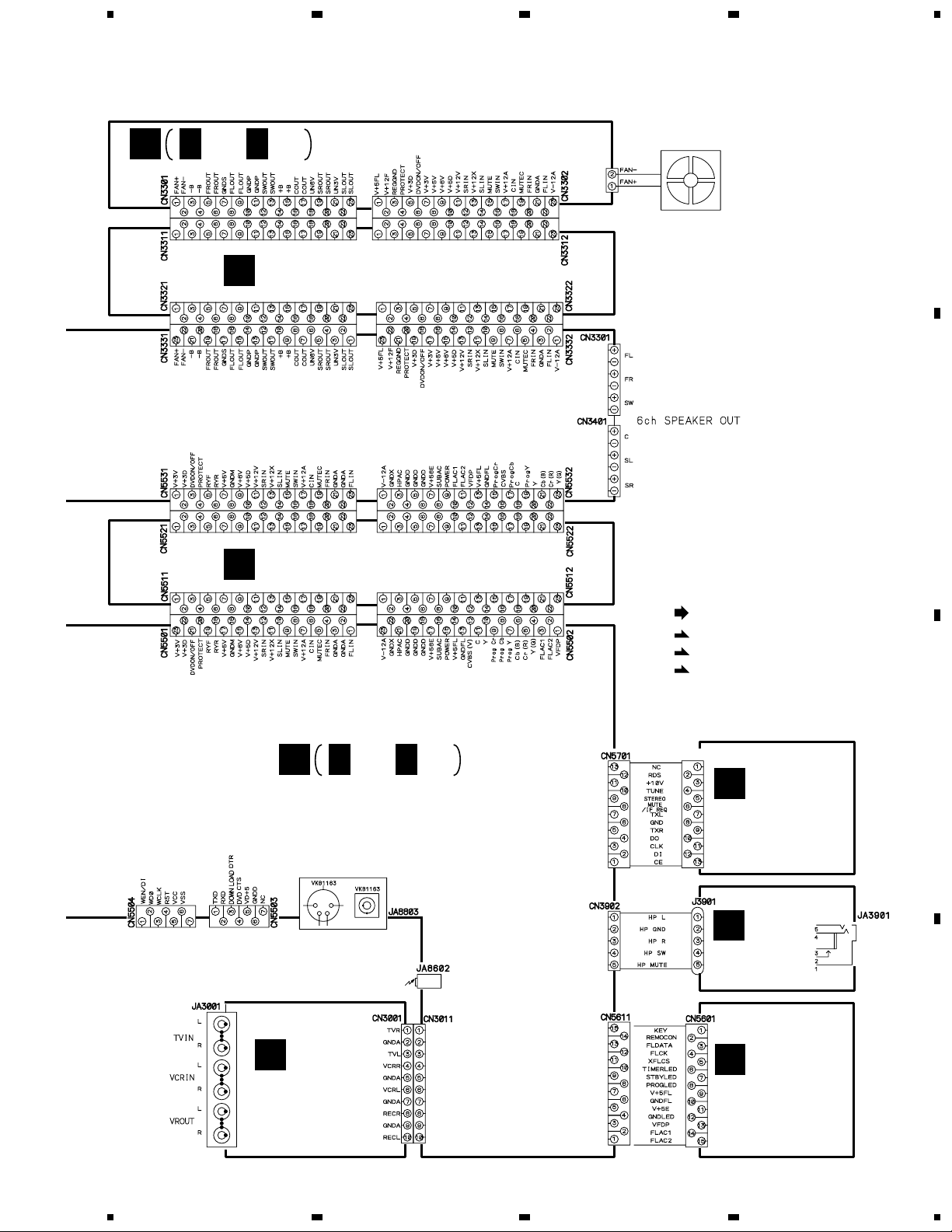

3.2 LOAB ASSY and OVERALL WIRING DIAGRAM

Note : When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS LIST" or "PCB PARTS LIST".

A

POWER

TRANSFORMER

(ATS7311)

LOADING MECHANISM ASSY (VWT1188)

B

PICKUP ASSY-S (OXX8003)

(F)

(F)

(T)

C

SPINDLE MOTOR

: VXM1088

(F)

(T)

(T)

(F)

POWER CORD

MYXJN : ADG1154

NVXJN : ADG1156

(T)

(F)

(F)

(F)

(T)

(T)

(F)

POWER ASSY

K

(AWU7860)

CN22

(RF)(RF)(RF)

CN21

(F)

(F)

(T)

(T)

(F)

(F)

B

B 1/4- B 4/4

DVDM ASSY

(VWS1499)

CN120

CN251

STEPPING

MOTOR

(CARRIAGE)

: VXM1090

A

D

12

LOAB ASSY

(VWG2279)

LOADING

MOTOR

ASSY

: VXX2505

A

1234

S101

: VSK1011

CN602

S2B-PH-K

CN601

S5B-PH-K

(S)

(S)

(S)

(S)

CN3

CN52

Page 13

5

678

XV-S100DV

G

G 1/2, G 2/2

TRADE 2 ASSY (AWU7859)

F

TRADE 1 ASSY (AWU7858)

E

AMP ASSY (AWU7935)

CN3651

DC FAN MOTOR

: AXM7014

A

B

SYSTEM

DOWNLOAD

DVD

DOWNLOAD

D

D 1/5- D 5/5

CONTROL ASSY

(AWU7856)

OUT

DIGITAL INPUT

COMPOSITE

VIDEO OUT

OPTICAL

S VIDEO

(RF)

: RF SIGNAL ROUTE

(F)

: FOCUS SERVO LOOP LINE

(T)

: TRACKING SERVO LOOP LINE

(S)

: SLIDER SERVO LOOP LINE

CN201

C

FM/AM TUNER

MODULE

(AXQ7229)

I

HP ASSY

(AWU7863)

C

PHONES

JACK ASSY

(AWU7862)

5

H

J

D

DISPLAY ASSY

(AWU7861)

13

6

7

8

Page 14

1

XV-S100DV

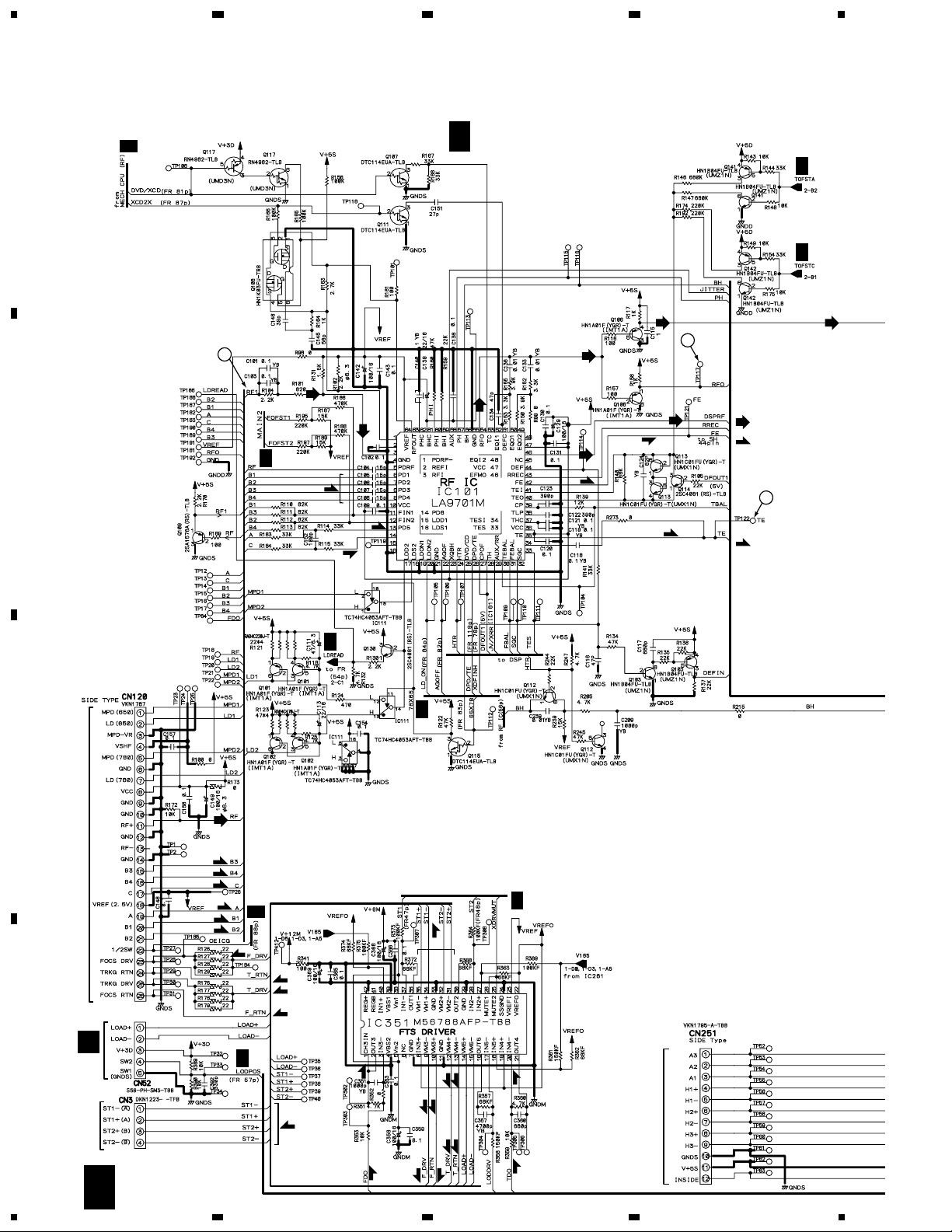

3.3 DVDM ASSY (1/4)

23

4

2/4

B

A

1

(RF)

(RF)

B

B

2/4

(F)

(T)

(T)

B 1/4

DVDM ASSY (VWS1499)

(V) (V)

(V)

(V)

(F)

(A)

(F)

(T)

B

2/4

B

2/4

2

(A)

(A)

(F)

4

(T)

B

2/4

B

2/4

C

(RF)

(F)

(F)

PICKUP ASSY

(T)

(T)

(F)

(F)

2/4

B

(S)

(F)

(T)

(T)

(F)

B

2/4

A

B

CN601

D

MOTOR

STEPPING

(CARRIAGE)

14

1/4

B

1234

2/4

(F)

(T)(T)

(F)

(S)

(F)

(F)

(T)(T)

(F)

(F)

(T)

SPINDLE

MOTOR

(T)

Page 15

5

678

XV-S100DV

B

3/4

IC304

TC7SHU04F

B

3/4

(V)

(V) (V)

(RF)

: RF SIGNAL ROUTE

(V)

: RF (VIDEO) SIGNAL ROUTE

(A)

: RF (AUDIO) SIGNAL ROUTE

(AD)

: AUDIO DATA SIGNAL ROUTE

(F)

: FOCUS SERVO LOOP LINE

(T)

: TRACKING SERVO LOOP LINE

(S)

: SLIDER SERVO LOOP LINE

A

2/4

B

B

6

(AD)

B

2/4

3/4

B

(T)

(F)

(A)

(F)

(T)

B

2/4

(T)

(F)

(A)

(F)

(T)

B

3/4

5

C

B

2/4,3/4

8 9

7

B

2/4

B

3/4

5

6

7

1110

D

B

3/4

B

1/4

8

15

Page 16

1

XV-S100DV

3.4 DVDM ASSY (2/4)

23

4

A

B 2/4

IC603 VYW1857

1/4

B

DVDM ASSY (VWS1499)

1/4

3/4

B

1/4

B

3/4

B

B

1/4,3/4

B

1/4

B

3/4

B

B

B

1/4

C

B

1/4

D

B

1/4

B

4/4

SH5

4/4

B

4/4

B

B

1/4

4/4

B

SH5

16

2/4

B

1234

Page 17

5

678

XV-S100DV

B

3/4

B

3/4

B

3/4

B

1/4

B

B

3/4

1/4

A

B

1/4

B

3/4

B

(D)

: AUDIO (DIGITAL) SIGNAL ROUTE

C

CN21

RKN1039

D 1/5

CN8001

(D)

(D)

B

B

3/4

3/4

(D)

D

: The power supply is shown with the marked box.

2/4

B

5

6

7

8

17

Page 18

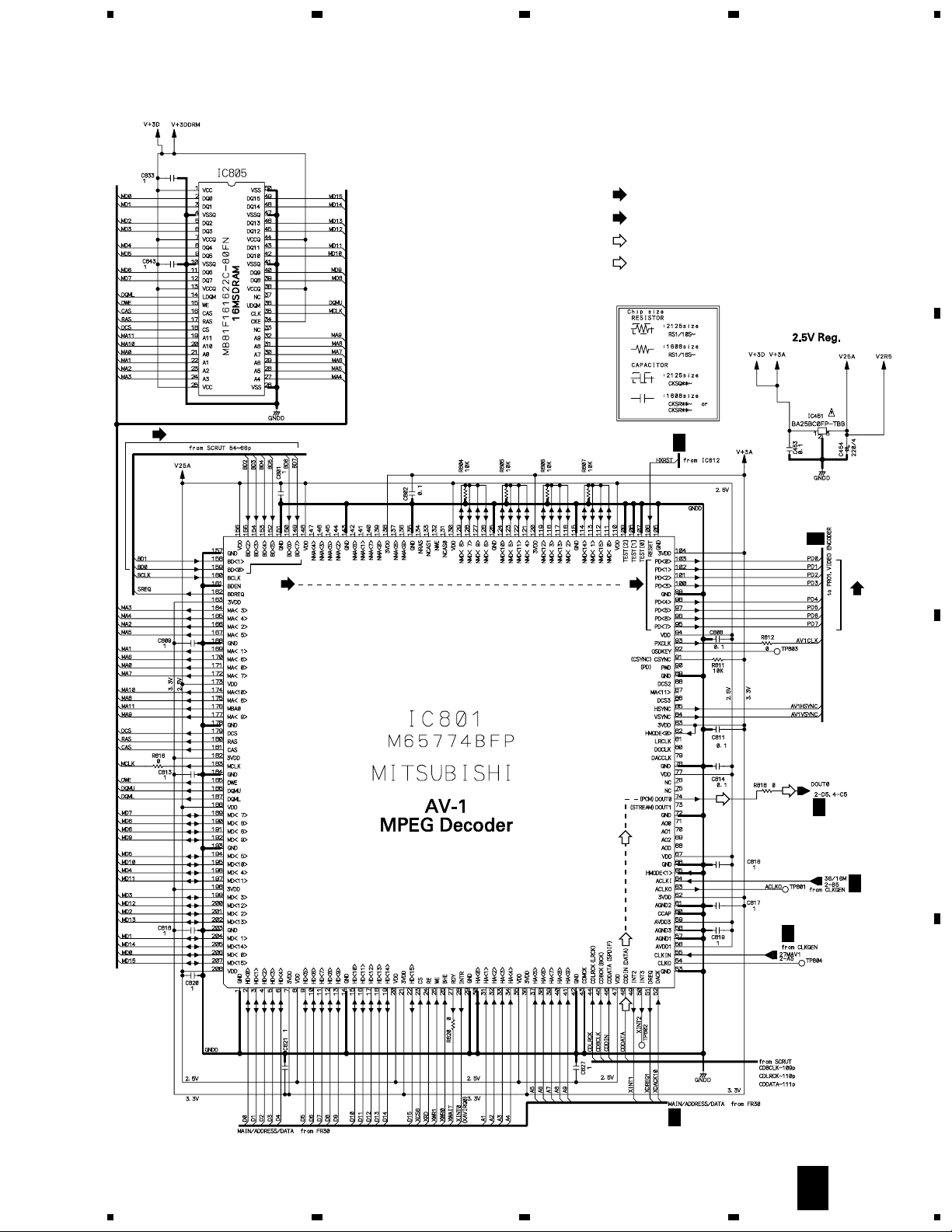

1

XV-S100DV

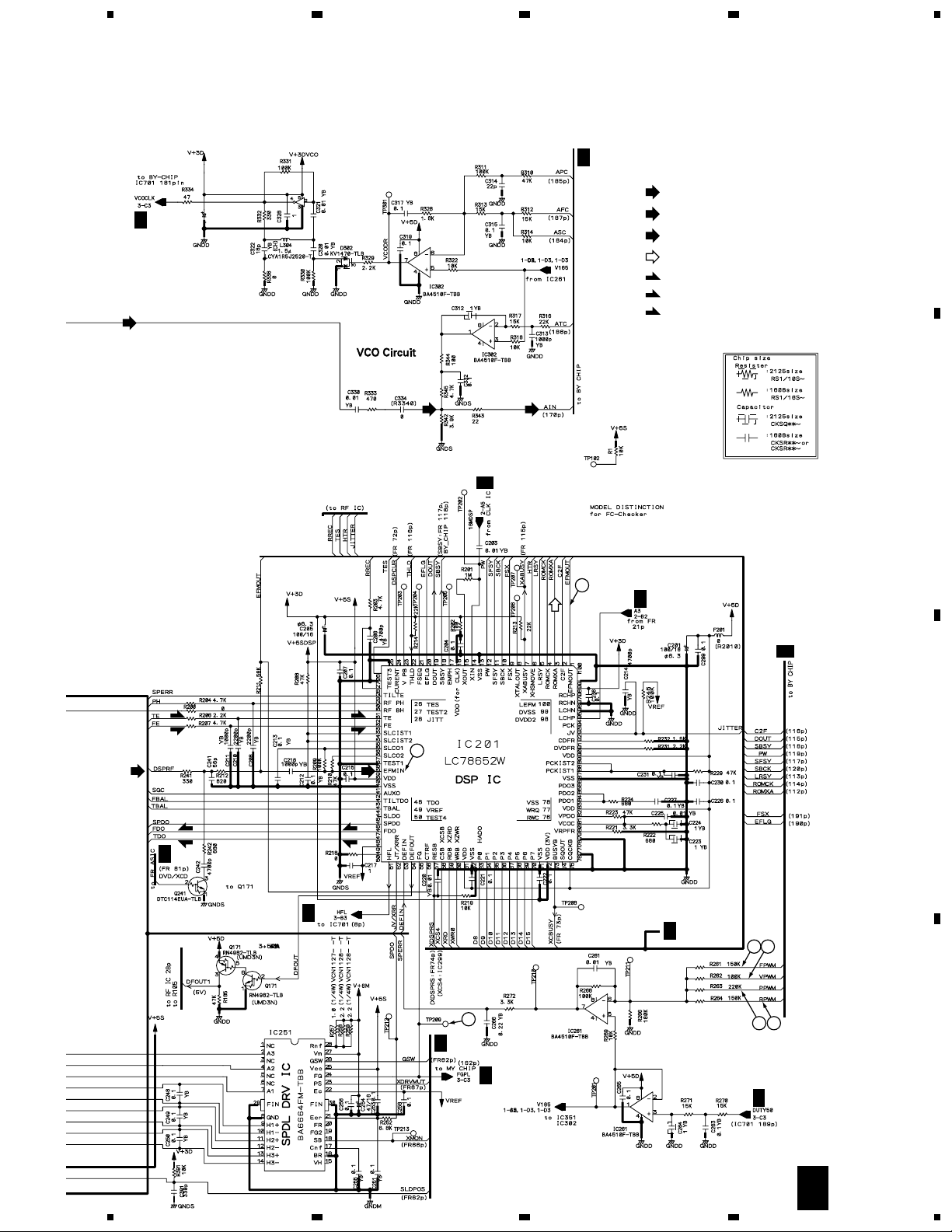

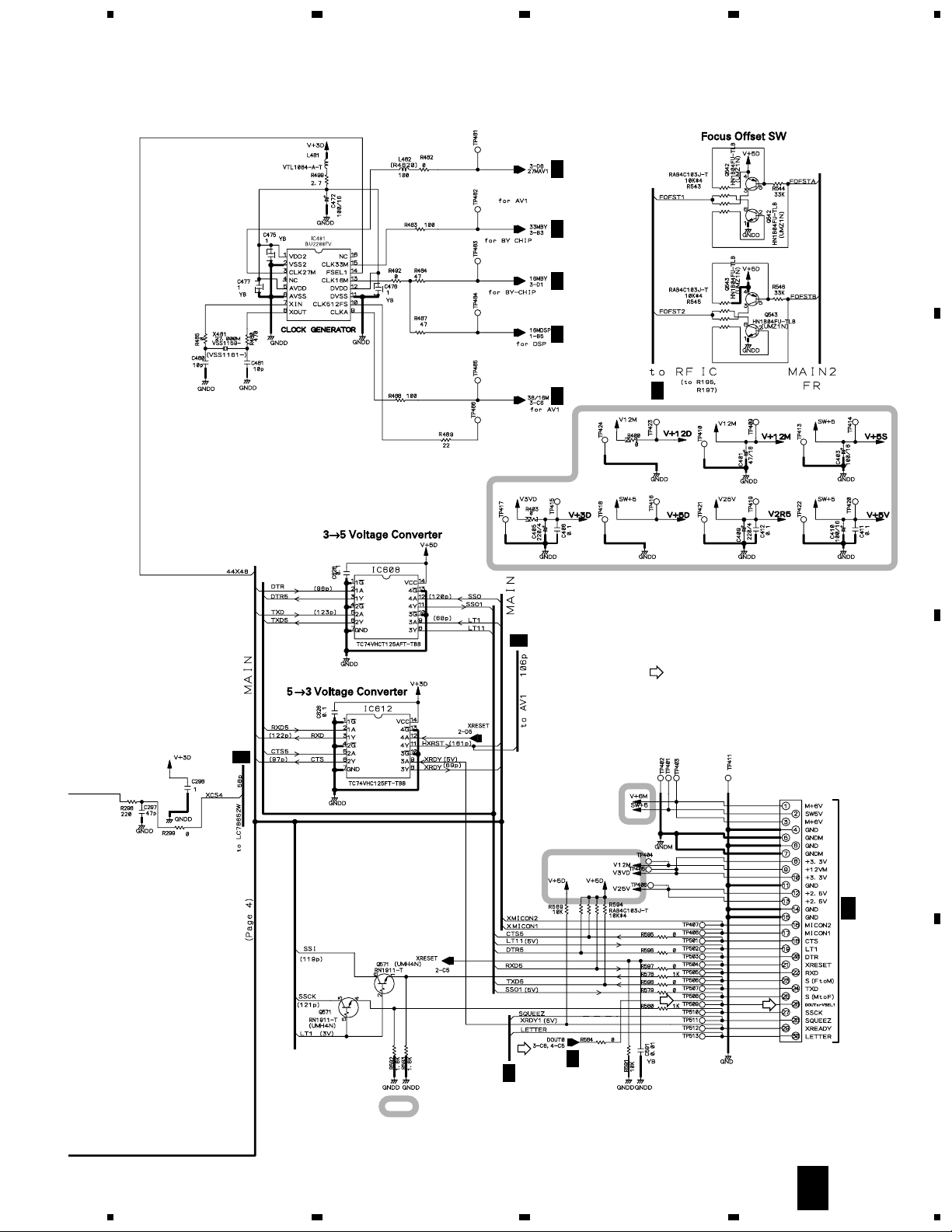

3.5 DVDM ASSY (3/4)

A

23

B 3/4

DVDM ASSY

(VWS1499)

B

1/4

B

2/4

IC712

MNR4800DJ7

B

1/4

B

4

4/4

B

BY-5

2/4

B

(VD)

(VD)

B

2/4

C

B

2/4

B

2/4

B

2/4

(AD)

(AD)

(AD)

(AD)

(V)

B

1/4

(V)(V)

B

2/4

B

B

1/4

B

1/4

B

1/4

B

2/4

B

1/4

1/4

B

2/4

D

18

3/4

B

1234

B

1/4

Page 19

5

678

XV-S100DV

A

(V)

: RF (VIDEO) SIGNAL ROUTE

(VD)

: VIDEO DATA SIGNAL ROUTE

(AD)

: AUDIO DATASIGNAL ROUTE

(D)

: AUDIO (DIGITAL) SIGNAL ROUTE

(VD)

(VD) (VD)

(D)

B

2/4

B

4/4

B

(VD)

C

(D)

(D)

B

2/4

B

2/4

B

2/4

(AD)

(AD)

D

B

2/4

3/4

B

5

6

7

8

19

Page 20

1

XV-S100DV

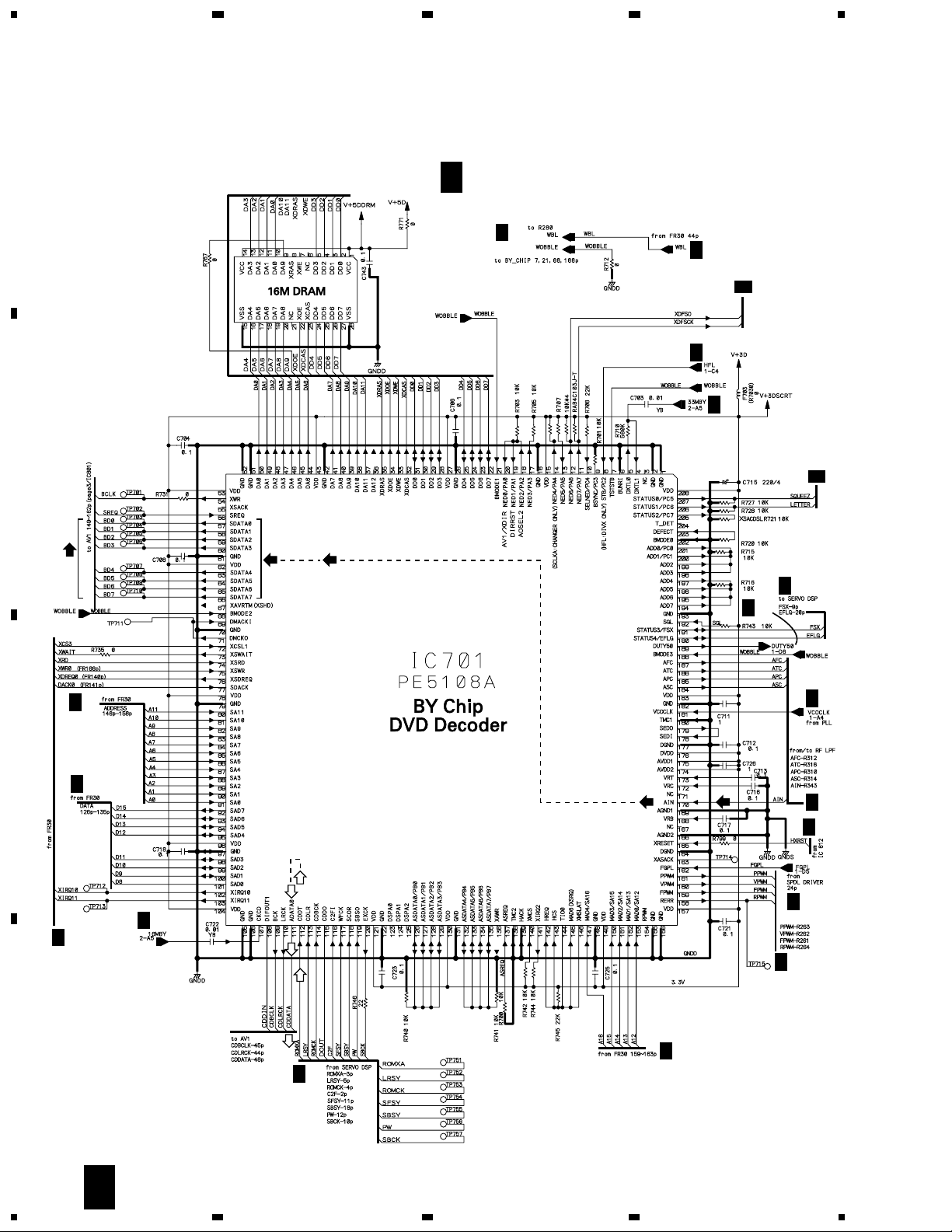

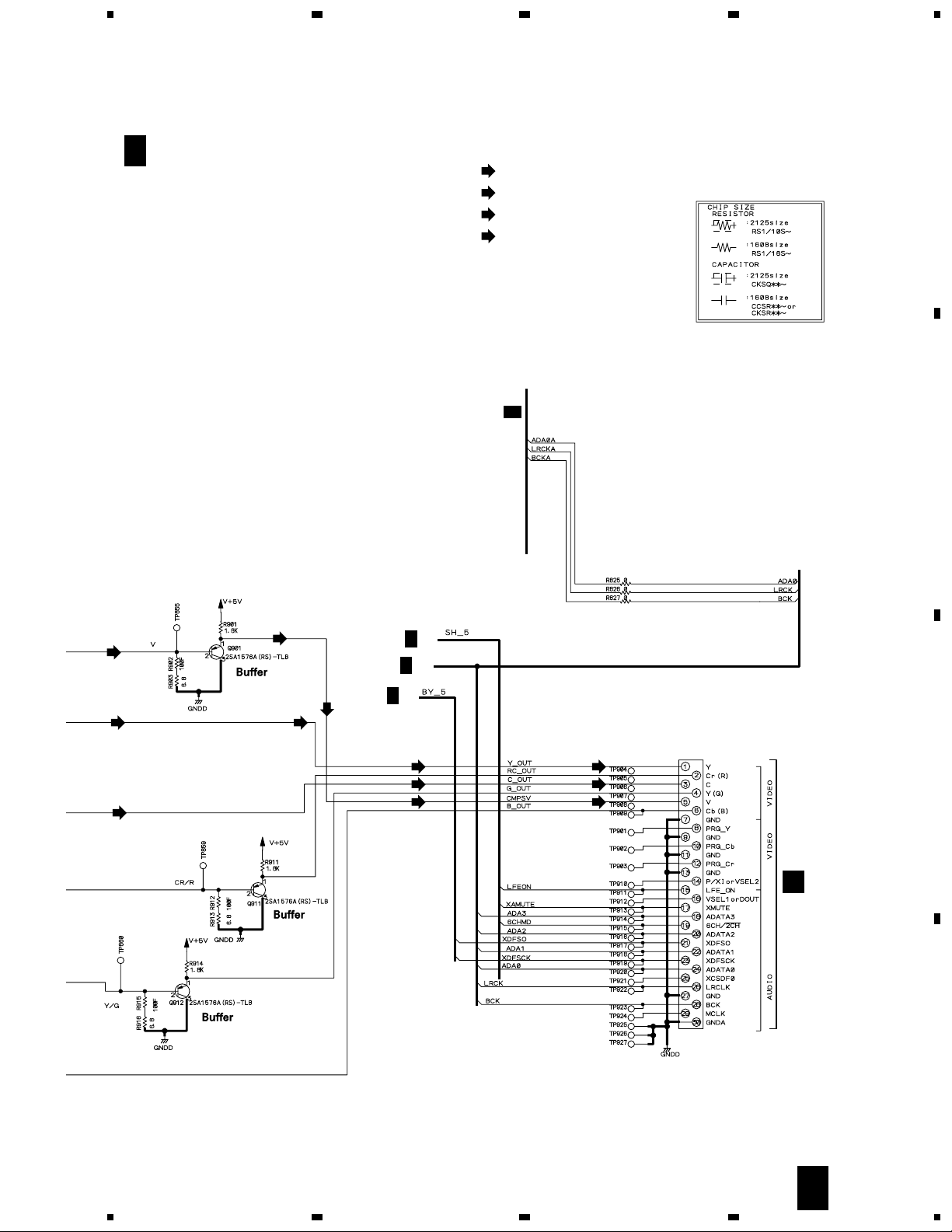

3.6 DVDM ASSY (4/4)

A

B

23

4

(V) (V)

B

3/4

2/4

B

C

(V)

(Y)

(C)

(V)

(VD) (VD)

D

(Y)

(C)

(Y)

(C) (C)

(Y)

20

B

2/4

4/4

B

1234

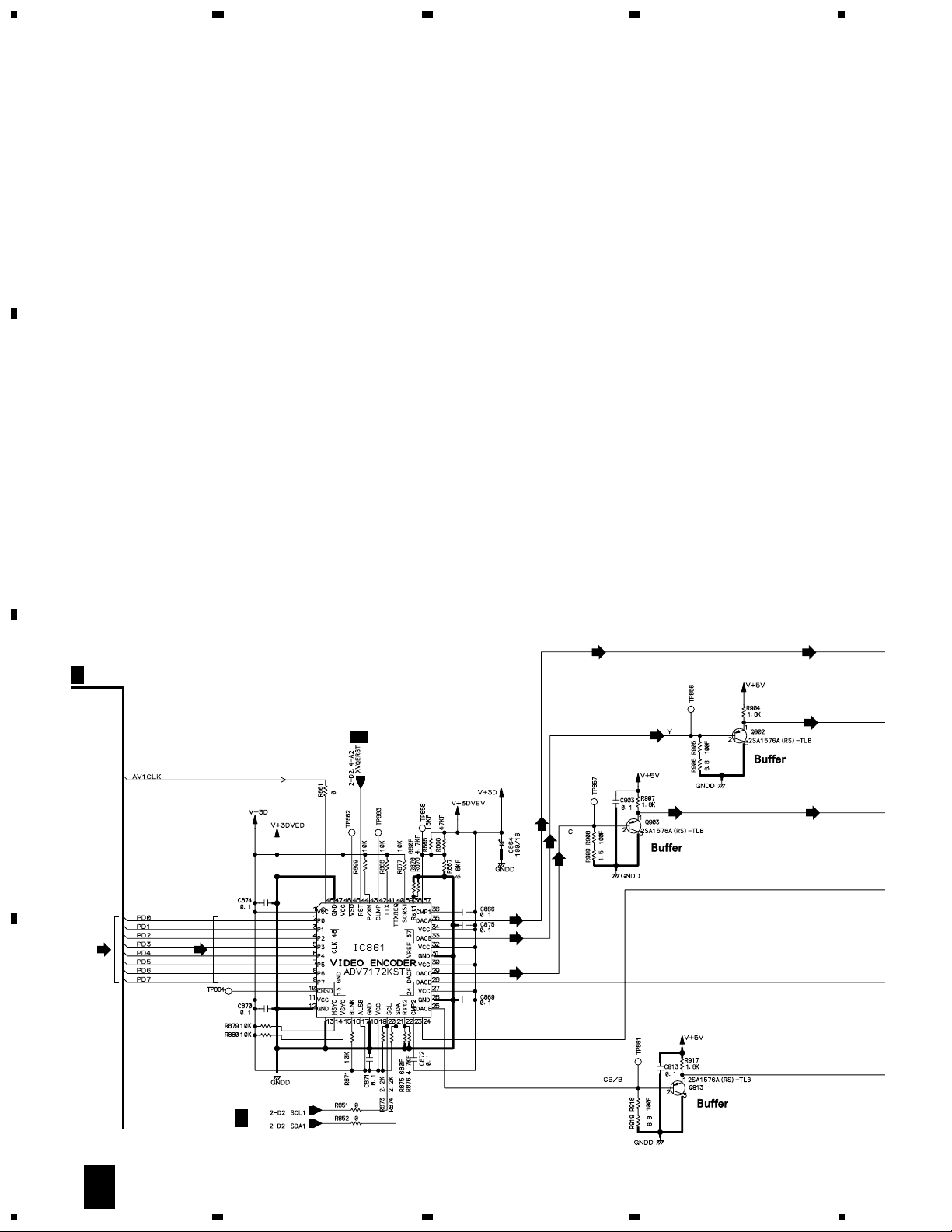

Page 21

5

678

XV-S100DV

B 4/4

DVDM ASSY

(VWS1499)

(VD)

: VIDEO DATA SIGNAL ROUTE

(V)

: V SIGNAL ROUTE

(Y)

: Y SIGNAL ROUTE

(C)

: C SIGNAL ROUTE

3/4

B

A

B

(V)

(V)

(Y) (Y)

(C)

B

2/4

B

3/4

B

(V)

3/4

(C)

(V)

CN22

(Y)

(Y)

(C)

(V)

RKN1039

K

C

CN5102

D

4/4

B

5

6

7

8

21

Page 22

1

XV-S100DV

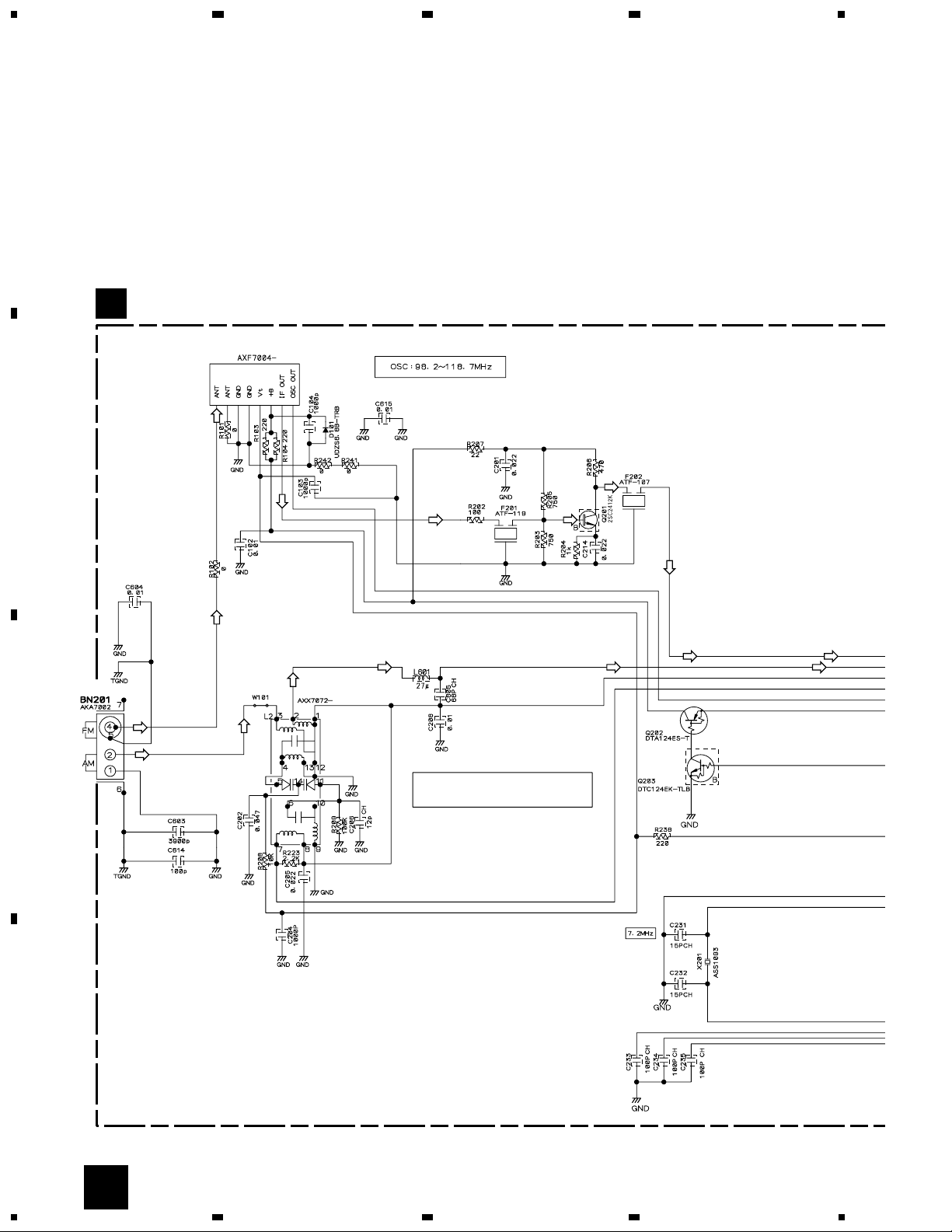

3.7 FM/AM TUNER MODULE

A

FM/AM TUNER MODULE (AXQ7229)

C

FM FRONT END

23

4

B

(FM)

(FM)

(FM) (FM)

(AM) (AM)

MW RF TUNING BLOCK

(AM)

(FM)

(AM)

C

(AM)

OSC : 981 - 2052kHz 9k step

(FM)

(FM)

(FM)

(FM) (FM)

(AM)

D

22

C

1234

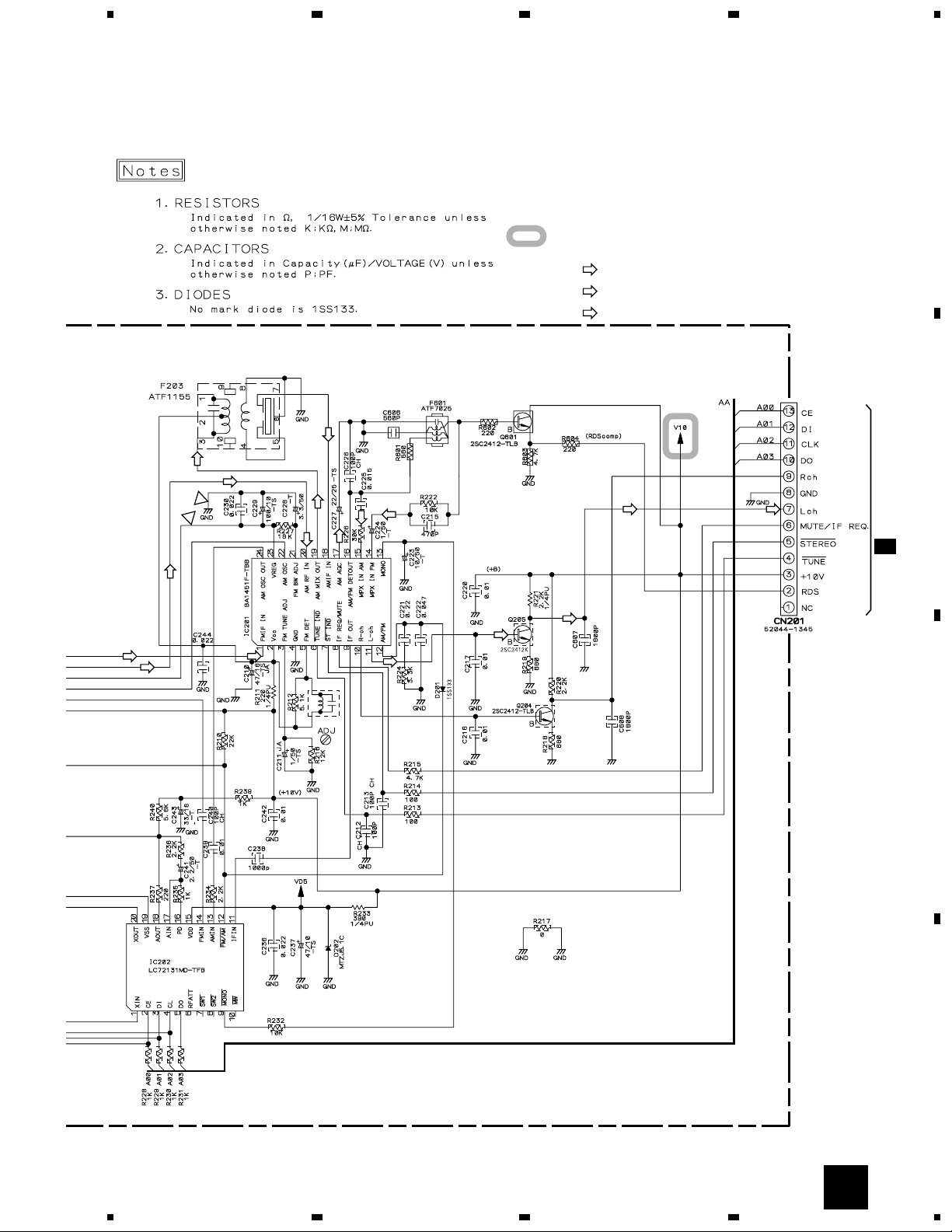

Page 23

5

678

XV-S100DV

A

: The power supply is shown with the marked box.

(TX)

: AUDIO SIGNAL ROUTE (TUNER)

(AM)

: AM SIGNAL ROUTE

(FM)

: FM SIGNAL ROUTE

(AM)

(FM)

(AM)

(AM)

(AM)

(AM)

(FM)

(AM)

(AM)

(FM)

(AM)

L201

ATE7003

(TX)

(AM)

(FM)

(TX)

(TX)

(TX)

(TX)

B

CN5701

D 4/5

C

D

C

5

6

7

8

23

Page 24

1

23

XV-S100DV

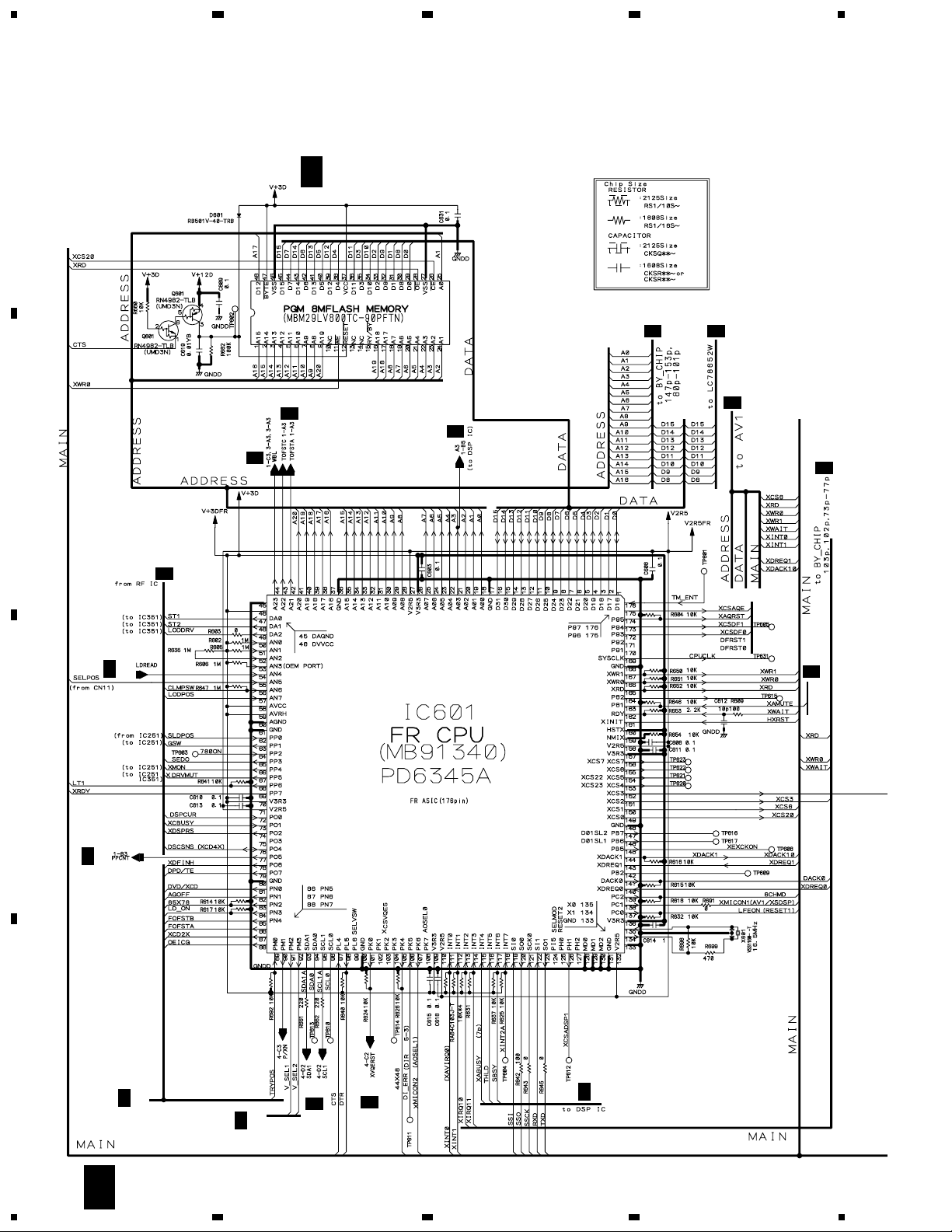

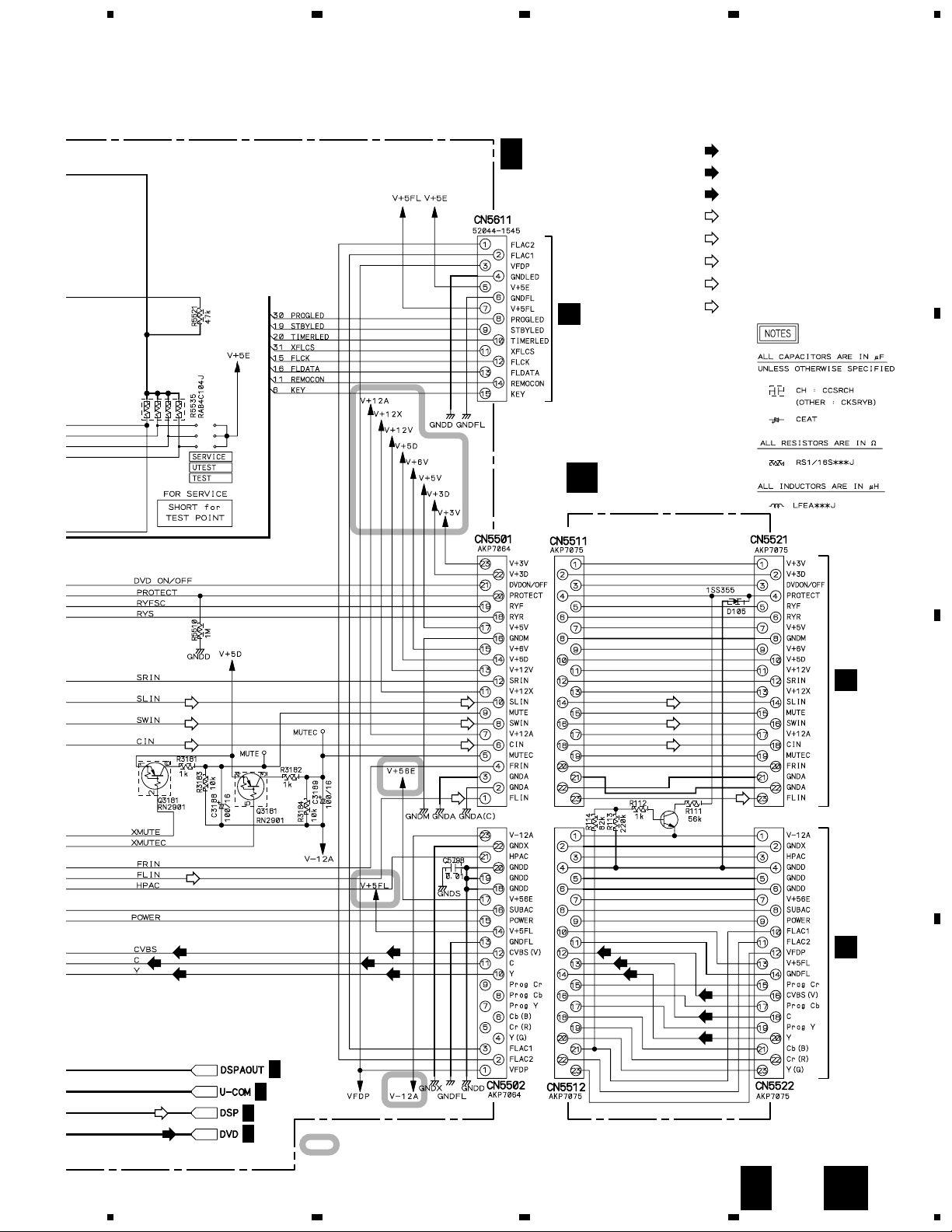

3.8 CONTROL (1/5) and TRADE 1 ASSYS

A

D

4/5,5/5

D

4/5

D

3/5,5/5

D

3/5

D

B

4/5

4

D

2/5

D

2/5

D

3/5-5/5

D

4/5

D

2/5-5/5

D

4/5,5/5

(SL)

Q5501

2SC4081(QR)

C

Q5572

2SC4081(QR)

Q5571

B 2/4

UN521L

(SW)

(C)

(FL)

CN21

(V)

(C)

(D) (D)

D

24

1/5

D

1234

(D)

(Y)

(D)

(C)(Y)(V)

Page 25

5

678

XV-S100DV

(V)

D 1/5

CONTROL

ASSY

(AWU7856)

: V SIGNAL ROUTE

(Y)

: Y SIGNAL ROUTE

(C)

: C SIGNAL ROUTE

(D)

: AUDIO (DIGITAL) SIGNAL ROUTE

(FL)

: FL ch AUDIO SIGNAL ROUTE

(SL)

: SL ch AUDIO SIGNAL ROUTE

(SW)

: SW ch AUDIO SIGNAL ROUTE

(C)

: C ch AUDIO SIGNAL ROUTE

A

J

CN5601

B

TRADE 1 ASSY

E

(AWU7858)

(D)

(C)(Y)(V)

(SL)

(SW)

(FL)

(C)

(C)

(SL)

(SW)

(C)

(FL)

(V)

(Y)

D

3/5,5/5

D

4/5,5/5

D

3/5,5/5

D

2/5

: The power supply is shown with the marked box.

(SW)

2SD2114K(VW)

(V)(V)

(C)(C)

(Y)(Y)

(SL)

(C)

(FL)

Q107

(V)

(C)

(Y)

K

CN5531

C

K

CN5532

D

1/5

D

5

6

7

E

8

25

Page 26

1

XV-S100DV

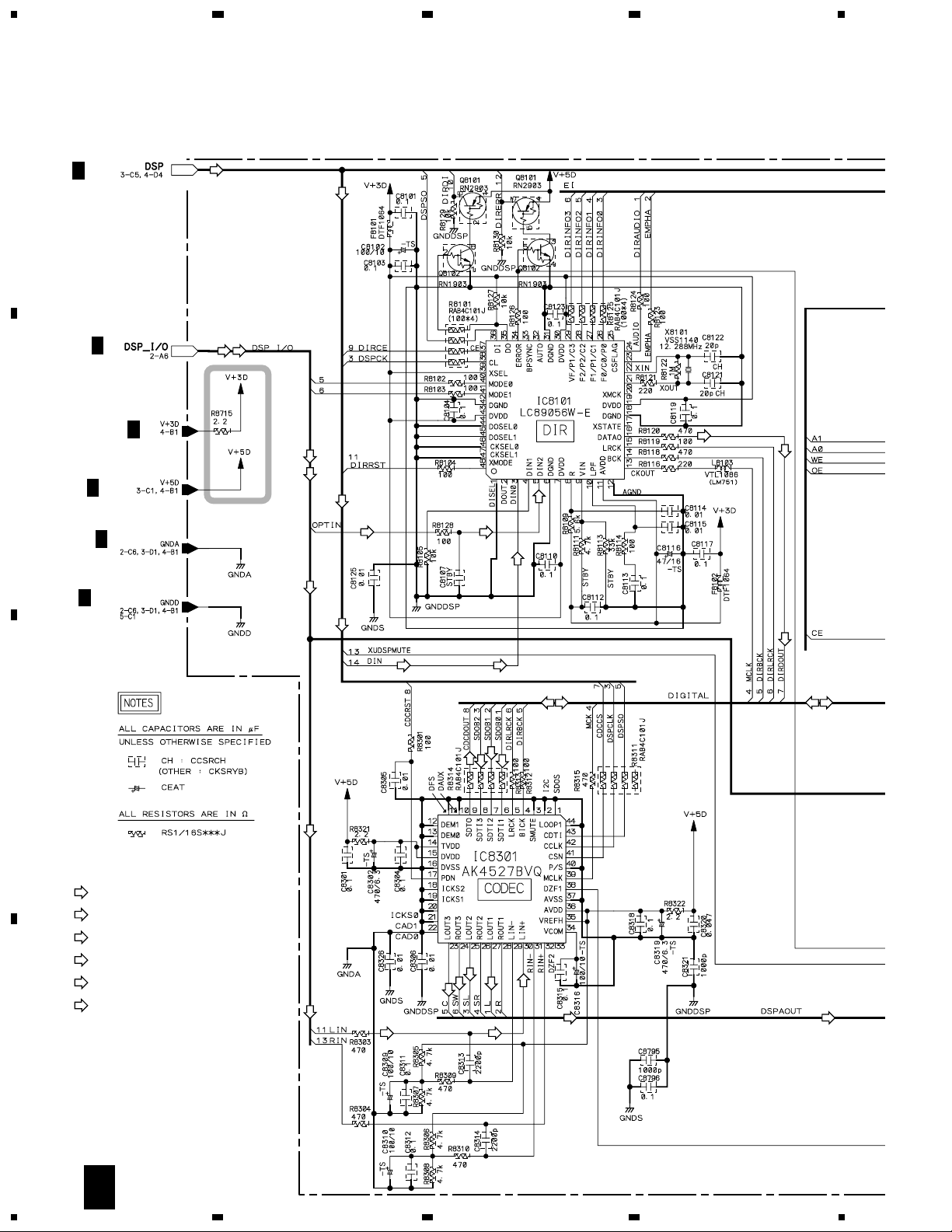

3.9 CONTROL ASSY (2/5)

A

23

4

D 2/5

CONTROL ASSY

(AWU7856)

(V)

(C)

(Y)

B

C

D

1/5

D

1/5

D

1/5,3/5

D

26

2/5

D

1234

(V)

(V)

(C)

(C)

(Y)

(Y)

Page 27

5

678

XV-S100DV

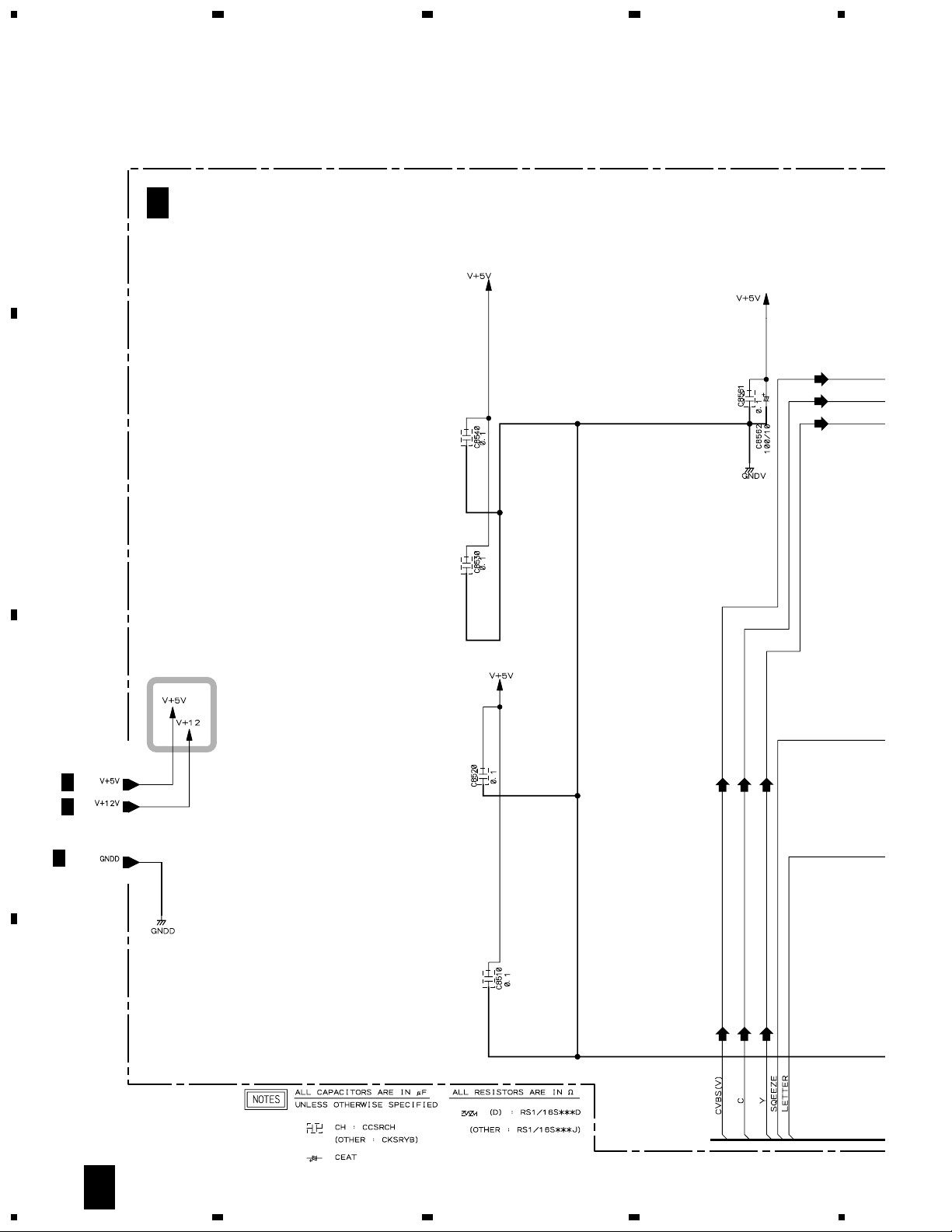

(V)

(C)

(Y)

: The power supply is shown with the marked box.

Q8801

2SD1858X(QR)

(V)

(C)

(Y)

(V)

1

(C)

(Y)

4

5

2

3

(V)

: V SIGNAL ROUTE

(Y)

: Y SIGNAL ROUTE

(C)

: C SIGNAL ROUTE

(V)(V)

COMPOSITE

VIDEO

A

B

(Y)

(C)

(C)

(Y)

S VIDEO

C

D

(V)(Y)(C)(V)(Y)(C)

5

6

7

D

1/5

D

2/5

27

8

Page 28

1

XV-S100DV

3.10 CONTROL ASSY (3/5)

23

4

A

B

D

1/5,5/5

D

4/5

D

D

1/5,5/5

D

1/5,4/5,5/5

D

1/5,2/5,4/5,5/5

1/5

(D)

(D)

(D)(D)(D)

(D)

(D)

(D) (D)

(D)

(D) (D)

C

: AUDIO SIGNAL ROUTE

(D)

: AUDIO (DIGITAL) SIGNAL ROUTE

(FL)

: FL ch AUDIO SIGNAL ROUTE

(SL)

: SL ch AUDIO SIGNAL ROUTE

(SW)

: SW ch AUDIO SIGNAL ROUTE

(C)

: C ch AUDIO SIGNAL ROUTE

D

(C)

(SW)

(SL)

(FL)

(FL)

(SL)

(SW)

(C)

(C)

(FL)

(SL)(SW)

28

3/5

D

1234

Page 29

5

678

XV-S100DV

A

D 3/5

CONTROL ASSY

(AWU7856)

B

(C) (C)

(FL)(SL)(SW) (FL)(SL)(SW)

5

(C)

: The power supply is shown with the marked box.

6

(FL)(SL)(SW) (FL)(SL)(SW)

7

(C)

D

D

1/5,5/5

3/5

8

C

D

29

Page 30

1

XV-S100DV

3.11 CONTROL ASSY (4/5)

A

23

4

B

H

CN3001

D 4/5

(TV)

(FL)

(D)

CONTROL ASSY (AWU7856)

(TV) (TV)

(D)

(FL)

Q3051

2SD2114K(VW)

Q3052

2SD2114K(VW)

Q3601

UN5112

(TX)

(FL)(FL)

(D)

(FL)

(TX) (TX)

2/2

(D)

Q3906

2SA1576A(QR)

(FL)

C

(FL)

(FL)

I

J3901

1/2

D

(TX)

30

4/5

D

1234

Page 31

5

678

XV-S100DV

(TX)

(TV)

(TV)

(TX)

: The power supply is shown with the marked box.

Q3031

2SC4081(QR)

Q3032

2SC4081(QR)

: AUDIO SIGNAL ROUTE

: TV IN SIGNAL ROUTE (L ch)

: TX SIGNAL ROUTE (L ch)

(D)

: AUDIO (DIGITAL) SIGNAL ROUTE

(FL)

: FL ch AUDIO SIGNAL ROUTE

D

(D)

(FL)(FL)(FL)

3/5

D

1/5,5/5

D

1/5

D

1/5

D

1/5,5/5

D

5/5

A

B

(D)

(FL)

Q3033

UN5112

Q5711

2SC4081(QR)

(TX)

(TX)

(D) (D)

D

5/5

D

1/5,3/5

D

1/5

D

1/5-3/5,5/5

(FL)(FL)

D

1/5,5/5

C

CN201

C

D

(TX)(TX)

4/5

D

5

6

7

8

31

Page 32

1

XV-S100DV

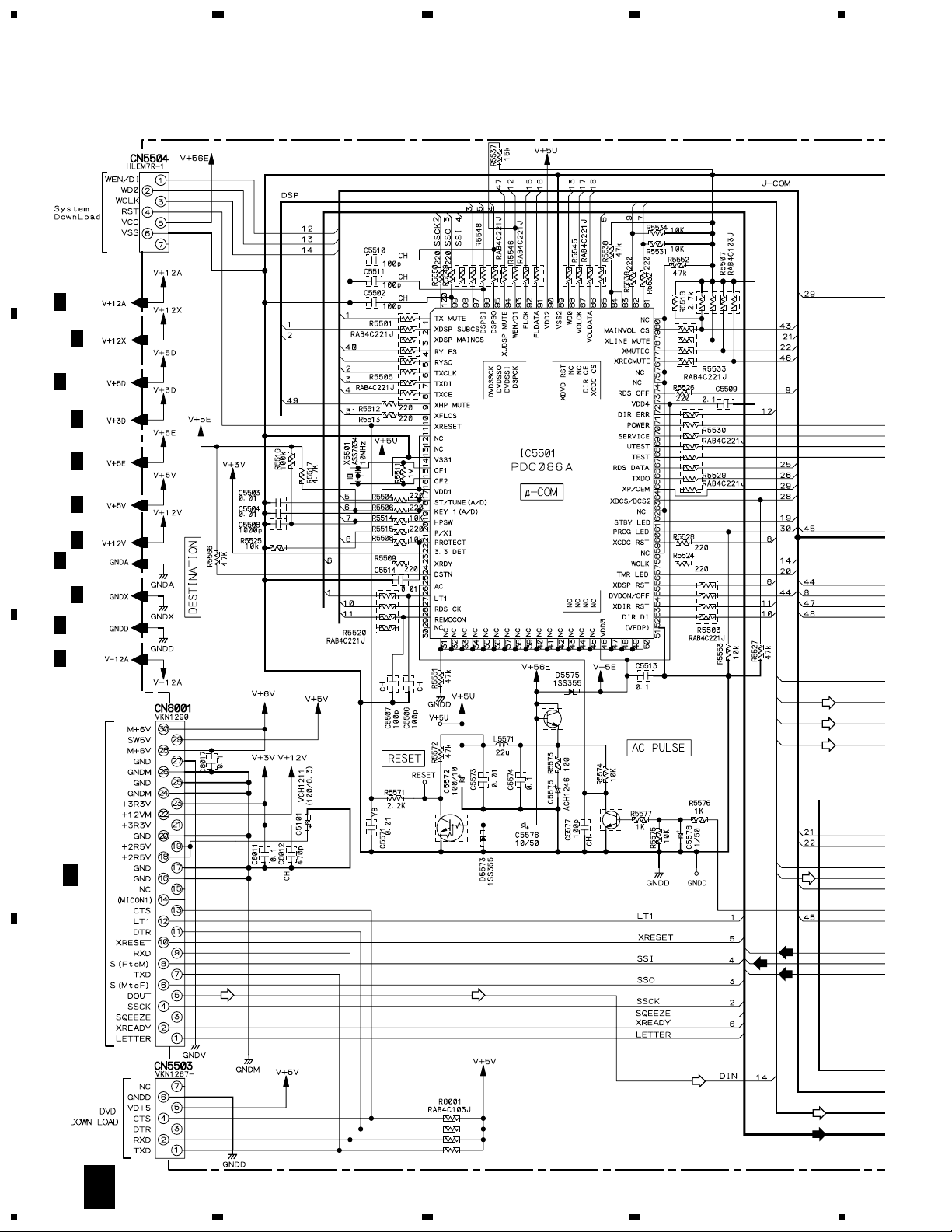

3.12 CONTROL ASSY (5/5)

D

4/5

D

A

4/5

(FL)

23

(FL)

4

(FL)

(FL)

(FL)

(FL)

(FL)

Q3121

2SD2114K(VW)

Q3122

2SD2114K(VW)

(FL)

2/2

1/2

(FL)(FL)(FL)

B

D

1/5,3/5

(FL)

(SL)

(C)

(SW)

(SL)

(SL)

Q3123

2SD2114K(VW)

Q3124

2SD2114K(VW)

(SL)

(FL)

(C)

(SL)

(SW)

(C)

2/2

(SW)

(SW)

(SWB)

(SWB)

(SWB)

1/2

(C)

C

(SWB)

(SWB)

(C)

1/2

(SW)

(SWB)

Q3126

2SD2114K(VW)

2/2

(SW)

D

1/5,4/5

D

1/5,3/5

(SW)

D

1/5,3/5,4/5

D

1/5,4/5

D

1/5,4/5

Q3127

UN5112

D

Q3125

2SD2114K(VW)

(C)

(SW)

(SWB)

(SWB)

(SWB)

32

5/5

D

1234

Page 33

5

678

XV-S100DV

(FL)

: FL ch AUDIO SIGNAL ROUTE

D 5/5

CONTROL ASSY

(AWU7856)

(SL)

: SL ch AUDIO SIGNAL ROUTE

(SW)

: SW ch AUDIO SIGNAL ROUTE

(C)

: SW ch AUDIO SIGNAL ROUTE

(SWB)

: SW ch AUDIO SIGNAL ROUTE

(THEATER BASS)

A

B

(FL)

(C)

(SL) (SL)

(SW)

(SWB)

(FL) (FL)

(C)

(SW)

(SWB)

(SW)

(SWB)

(SL)

(C)

(FL)

(FL)

(FL)

(SL)

(SW)

(FL)

(SL)

(SW)

(C)

(FL)

(SL)

(SW)

(C)

D

1/5,3/5

D

C

1/5,4/5

: The power supply is shown with the marked box.

5/5

D

5

6

7

8

33

D

Page 34

1

23

XV-S100DV

3.13 TRADE 2 and AMP (1/2) ASSYS

A

4

B

K

CN3331

(FL)

(SW)

(C)

(SL)

(FL)

(SW)

(C)

(SL)

G 1/2

AMP ASSY (AWU7935)

(FL)

(SW)

(SL)

(FL)

(SW)

(C)(C)

(SL)

(FL)

C

D

K

CN3332

34

F

(C)

(SL)

(SW)

(C) (C)

(FL)

TRADE 2 ASSY

F

(AWU7859)

G

2/2

1/2

G

1234

(SL)

(SW)

(FL)

(FL) (C)(SL)(SW)

Q106

(C)

(SW)

(SL)

(FL)

(FL)(SL)

(SW)(C) (C)

UN5212

(SW)

(FL)

(C)

(SL)

(SW)

(FL)(SL)

(SW)(C)

(FL)(SL)

Page 35

5

678

XV-S100DV

(SW)

(SL)(FL)

(FL)

(SW)

(C)

(SL)

Q72

2SD2114K(VW)

(FL) (FL)

Q3301

2SD2114K(VW)

Q3302

2SD2114K(VW)

Q71

2SB1237X(QR)

Q83

2SB1237X(QR)

: The power supply is shown with the marked box.

Q94

(SW)(C)(C)(C)

(SL)(FL)

(FL)

(FL)

(SL)(FL)

Q81

2SB1375

Q91

2SB1375

(SW)

2SC4081(QR)

(FL)

Q82

Q92

2SC1740S(QR)

Q93

2SC4081(QR)

2SB1237X(QR)

(C)

(C)

(FL)

A

B

(SL)(FL)(C) (C)(SW) (SL)(FL)(SW)

(C) (C)

Q3501

2SD2114K(VW)

Q3502

2SD2114K(VW)

(SL)

(SW)

(FL)

: FL ch AUDIO SIGNAL ROUTE

(SL)

: SL ch AUDIO SIGNAL ROUTE

(SW)

: SW ch AUDIO SIGNAL ROUTE

(C)

: C ch AUDIO SIGNAL ROUTE

5

(SL)

Q3401

2SD2114K(VW)

Q3402

2SD2114K(VW)

(SW)

6

Q3551

2SD2114K(VW)

(SL)

(SW)

(C)

7

(SL)

(SW)

(SW)

(SW)

(SL)

(SW)

(SL)

G

(SL)(SW)

1/2

8

C

D

35

Page 36

1

XV-S100DV

3.14 AMP ASSY (2/2)

A

23

4

(FL)

(FL)

(SL)

(FL)

(FL)

(FL) (FL)

(SL)

(SL)

B

(SL) (SL)

(FL)

(SL)

(C)

(C)

C

(C) (C)

(SW) (SW)

(SW)

(SW)

(C)

(FL)

(SL)

(SW)

(C)

D

G

1/2

(SW)

(SL)

(FL)

(FL)

(SL) (C)

(SW)

(SW)

(SL)

(FL)

(C)(C)

(SW)

(SL)

(FL)

36

2/2

G

1234

Page 37

5

G 2/2

678

AMP ASSY (AWU7935)

XV-S100DV

(FL)

: FL ch AUDIO SIGNAL ROUTE

(SL)

: SL ch AUDIO SIGNAL ROUTE

(SW)

: SW ch AUDIO SIGNAL ROUTE

(C)

: C ch AUDIO SIGNAL ROUTE

A

(FL)

(SL)

(C)

(SW) (SW)

(FL)

(SW)

(SL)

(C) (C)

(SW)

(SW)

(SL)

(FL)

B

(FL)

(C)

(SW)

(C)

(SW)

(SL)

(FL)

C

(C)

(FL)

(SL)

(SW)

D

(C)

(SW)

(SL)

(FL)

2/2

G

5

6

7

8

37

Page 38

1

XV-S100DV

3.15 JACK ASSY

A

B

23

JACK ASSY (AWU7862)

H

(TV)

(TV)

: TV IN SIGNAL ROUTE (L ch)

(FL)

: FL ch AUDIO SIGNAL ROUTE

(TV) (TV)

4

(TV)

(TV)

(TV)

D 4/5

CN3011

(FL)

C

(FL)

(FL)

(FL)

D

38

H

1234

Page 39

1

3.16 HP ASSY

I

234

HP ASSY (AWU7863)

(FL) (FL) (FL)

Q3901

2SD2114K(VW)

Q3905

2SD2114K(VW)

(FL)

Q3906

2SD2114K(VW)

(FL)

: FL ch AUDIO SIGNAL ROUTE

(FL)

XV-S100DV

A

PHONES

B

CN3902

D 4/5

Q3902

2SD2114K(VW)

C

D

39

I

1

2

3

4

Page 40

1

XV-S100DV

3.17 DISPLAY ASSY

A

B

23

DISPLAY ASSY (AWU7861)

J

Q5691

2SC4081(QR)

4

Q5692

2SC4081(QR)

C

D

D 1/5

CN5611

40

J

Q5681

UN5212

X5951

1SS133

1234

Page 41

5

678

XV-S100DV

A

: The power supply is shown with the marked box.

B

Q5934

UN5212

Q5933

UN5212

5

C

SWITCHES

S5921 : STANDBY / ON

S5922 : + (UP)

S5923 : – (DOWN)

S5924 : TUNER (AM/FM)

S5925 : 6 (PLAY/PAUSE)

S5926 : 7 (STOP)

S5927 : 0 (OPEN/CLOSE)

6

7

VOLUME

J

8

D

41

Page 42

1

XV-S100DV

3.18 POWER ASSY

23

4

A

B

F

CN3321

(1.6A)

• NOTE FOR FUSE REPLACEMENT

CAUTION -

FOR CONTINUED PROTECTION AGAINST RISK OF FIRE.

REPLACE WITH SAME TYPE AND RATINGS ONLY.

(FL)

(SW)

(C)

POWER TRANSFORMER

T1

ATS7311

Q51

2SD1858X(QR)

C

D

F

CN3322

(SL)

(SL)

(SW)

(C)

(FL)

(SL)

(FL)

(SL)

(SW)

(C)

(SW)

(C)

(FL)(SL)(SW)(C)

(SL)

(SW)(C) (C)

(FL)

(FL)

VFDP

BLOCK

(SW)

(SL)

(FL)

(Y)

(C)

(V)

(C)

(Y)

(V)

42

CN5521

E

E

CN5522

K

1234

Page 43

5

678

XV-S100DV

POWER ASSY

Q3635

UN5112

K

(AWU7860)

CAUTION : FOR CONTINUED PROTECTION AGAINST RISK OF FIRE.

REPLACE ONLY WITH SAME TYPE NO. 491007 MFD, BY

LITTELFUSE INK. FOR IC11 and IC12 (AEK7047).

A

(FL)

Q3601

2SC4081(QR)

(FL)(FL)(SL)(C)

(SW)

Q3621

(C)

(SL) (SL)

2SC4081(QR)

Q3644

2SC4081(QR)

Q3602

2SC4081(QR)

(SW)

(C)

Q3622

2SC4081(QR)

Q3645

UN5112

(FL)

(FL) (FL)

(SW)

(C)

Q3643

UN5212

(C)

Q3641

2SD1858X(QR)

(SL)

(SL)

(FL)

(SW)

B

(C)

(SL)

Q3611

2SC4081

(QR)

Q3612

2SC4081(QR)

Q3631

2SC4081(QR)

(SW)

(FL)

(SL)

(C)

(Y)

(C)

(V)

(Y)

(C)

(V)

B 4/4

CN22

(V)

(Y)

(C)

: The power supply is shown with the marked box.

(V)

: V SIGNAL ROUTE

(Y)

: Y SIGNAL ROUTE

(C)

: C SIGNAL ROUTE

Q3642

2SC4081(QR)

(FL)

(SL)

(SW)

(C)

Q3652

DTA124TK

Q3653

UN5112

Q3654

2SD2144S(VW)

: FL ch AUDIO SIGNAL ROUTE

: SL ch AUDIO SIGNAL ROUTE

: SW ch AUDIO SIGNAL ROUTE

: C ch AUDIO SIGNAL ROUTE

C

D

K

5

6

7

8

43

Page 44

XV-S100DV

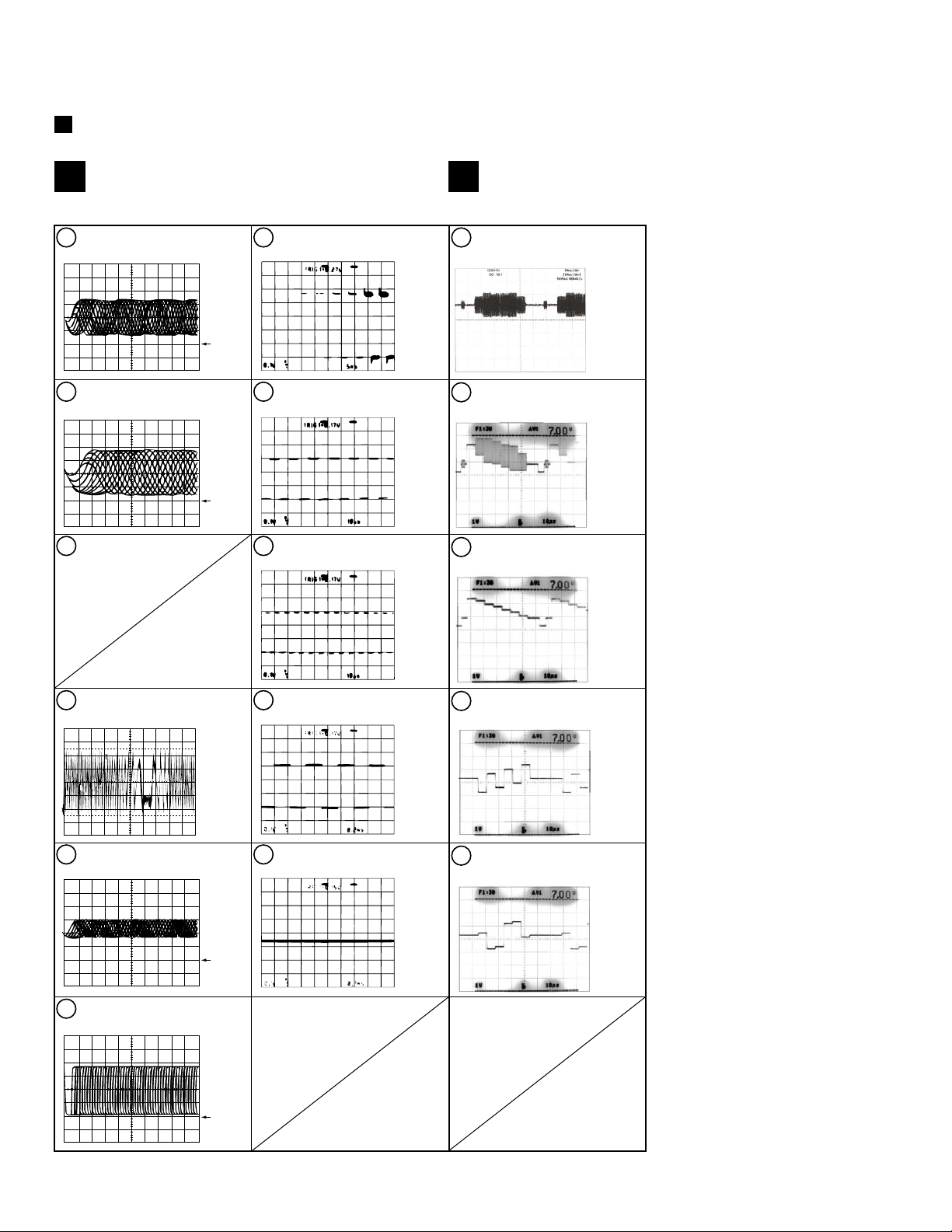

WAVEFORMS

Note : The encircled numbers denote measuring point in the schematic diagram.

DVDM ASSY

B

Measurement condition : No. 1 to 4 and 6 to 11 : MJK1, Title 1-chp 1

No. 5 : CD, ABEX-784 Track 1

Foot of R104 (RF)

1

V: 100mV/div. H: 0.2µsec/div.

TP117 (RFO)

2

V: 500mV/div. H: 0.1µsec/div.

3

GND

GND

TP209 (FG)

7

V: 1V/div. H: 5msec/div.

Foot of R261 (FPWM)

8

V: 1V/div. H: 5msec/div.

Foot of R262 (VPWM)

9

V: 1V/div. H: 5msec/div.

CONTROL ASSY

D

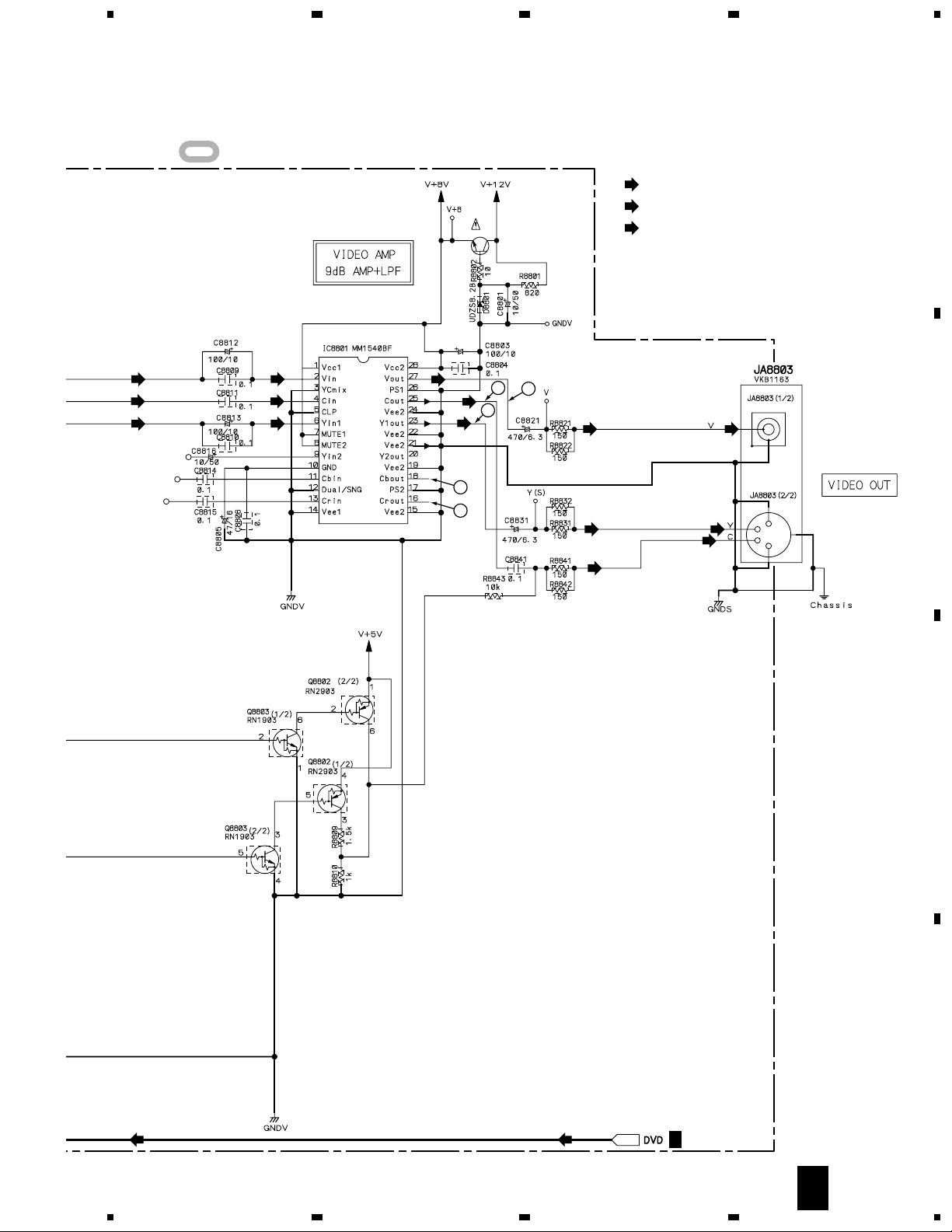

Measurement condition : DVD-REF-A1, T2-Chap.19

IC8801 - pin 25 (C)

1

V: 1V/div. H: 10µsec/div.

IC8801 - pin 27 (V)

2

V: 1V/div. H: 10µsec/div.

IC8801 - pin 23 (Y)

3

V: 1V/div. H: 10µsec/div.

TP122 (Tracking Error)

4

(AI-Inner Tracking Off)

V: 500mV/div. H: 2msec/div.

IC201 - pin 39 (EFM before slice)

5

V: 1V/div. H: 1µsec/div.

IC201 - pin 1 (EFM)

6

V: 1V/div. H: 0.2µsec/div.

GND

GND

Foot of R263 (PPWM)

10

V: 1V/div. H: 5msec/div.

Foot of R264 (RPWM)

11

V: 1V/div. H: 5msec/div.

IC8801 - pin 18 (Cb)

4

V: 1V/div. H: 10µsec/div.

IC8801 - pin 16 (Cr)

5

V: 1V/div. H: 10µsec/div.

44

Page 45

1

SIDE A SIDE B

(VNP1836-B)

(VNP1836-B)

CN52

B

LOAB ASSY

A

LOAB ASSY

A

LOADING

MOTOR

ASSY

M

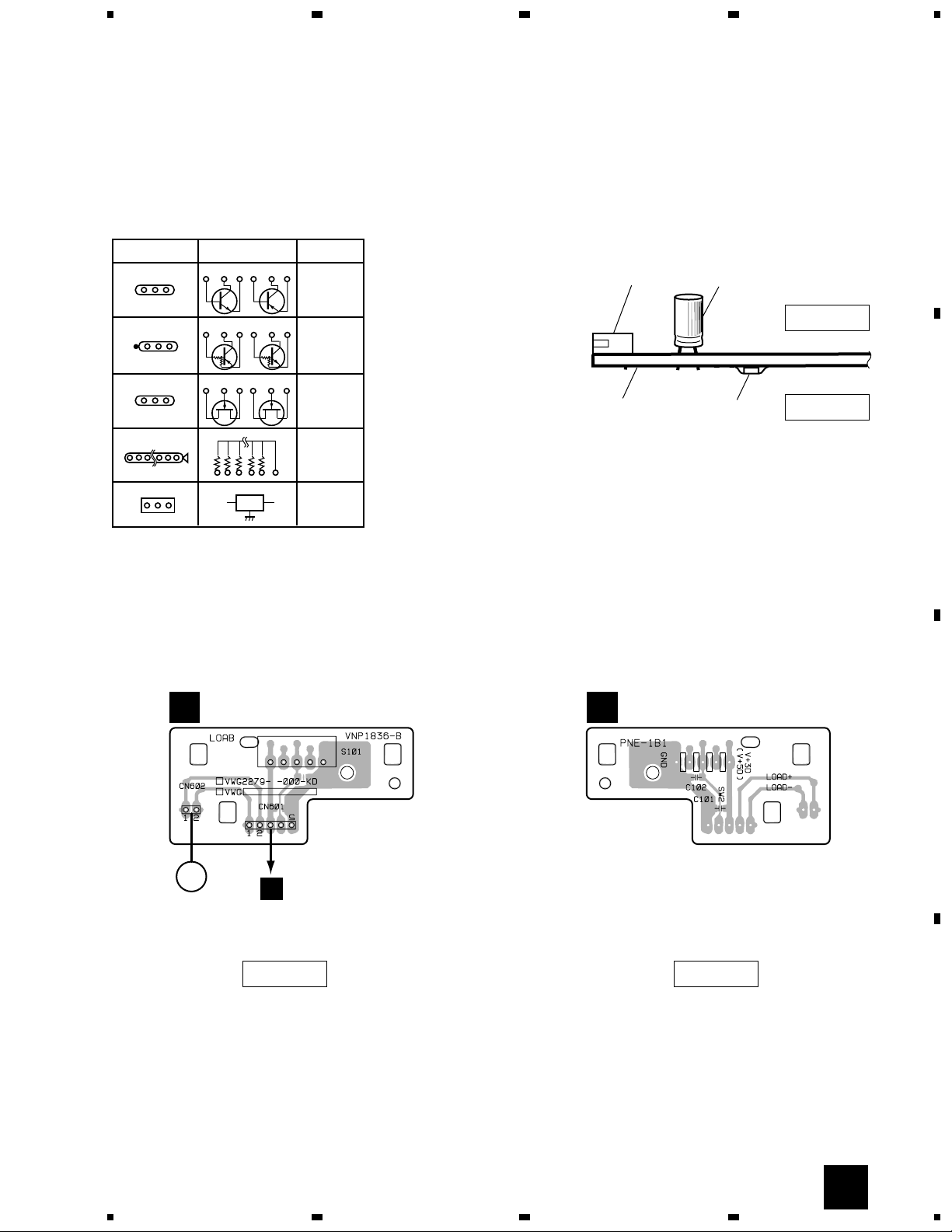

NOTE FOR PCB DIAGRAMS :

4. PCB CONNECTION DIAGRAM

4.1 LOAB ASSY

1. Part numbers in PCB diagrams match those in the schematic

diagrams.

2. A comparison between the main parts of PCB and schematic

diagrams is shown below.

3. The parts mounted on this PCB include all necessary parts for

several destinations.

For further information for respective destinations, be sure to

check with the schematic diagram.

4. View point of PCB diagrams.

Symbol In PCB

Diagrams

Symbol In Schematic

Diagrams

Part Name

BCE

D

DGGSS

BCE

BCE

DGS

BCEBCE

BCE

Transistor

Transistor

with resistor

Field effect

transistor

Resistor array

3-terminal

regulator

Capacitor

Connector

P.C.Board

Chip Part

SIDE A

SIDE B

234

XV-S100DV

A

B

1

C

D

A

2

3

4

45

Page 46

1

XV-S100DV

4.2 DVDM ASSY

A

B

DVDM ASSY

B

23

CN8001

D

4

Q601

IC601

Q571

IC608

IC612

IC302

IC304

IC261

IC303

IC712

Q141

IC481

IC451

IC805 IC806

C

IC861

IC881

Q911 Q913 Q902

Q111

Q107

Q118

Q116

Q115

Q114

IC281

IC201

IC351

Q117

Q108

Q109

Q102

Q922

Q923

(VNP1850-A)

CN5102

D

K

SIDE A

46

B

1234

Page 47

CN601

A

1

DVDM ASSY

B

234

XV-S100DV

A

IC603

IC701

IC299

ASSY

PICKUP

(CARRIAGE)

STEPPING MOTOR

MOTOR

SPINDLE

Q542

Q543

Q106

Q142

Q103

IC101

Q171

IC271

Q241

IC807

Q271

Q281

IC801

IC291

Q292

Q112

IC111

Q130

IC251

Q901 Q903 Q912

B

C

Q921

(VNP1850-A)

D

SIDE B

B

1

2

3

4

47

Page 48

1

23

XV-S100DV

4.3 CONTROL and TRADE 1 ASSYS

A

H

CN3001

SIDE A

B

CONTROL ASSY

D

4

TRADE 1 ASSY

E

C

CN5532

K

CN5531

K

(ANP7414-B)

D

Q107

48

D E

I

J3901

1234

J

CN5601

Page 49

5

678

XV-S100DV

A

Q8802

Q8803

Q8102

Q8101

IC8101

Q8801

IC3031

IC8301

Q3031

Q3032

Q8551

IC8801

Q3052

Q3051

Q8353

Q3601

Q3127

IC8701

Q8501

Q8541

IC3041

Q8351

IC8751

IC8501

Q8521

Q8531

B

Q8511

C

CN201

B

CN21

IC3083 IC3082

IC3085

IC3212

Q5572

IC3251

IC5501

Q5501

Q3231

IC3131

IC5701

IC8581

Q3181

IC3091

Q3906

IC3081

C

(ANP7414-B)

D

D

5

6

7

8

49

Page 50

XV-S100DV

A

1

Q3033

23

CONTROL ASSY

D

4

B

Q3124 Q3123

C

Q5711

Q3126

Q3122 Q3121

Q5571

Q3125

D

50

D

1234

Page 51

5

678

XV-S100DV

A

SIDE B

B

TRADE 1 ASSY

E

C

(ANP7414-B)

D

(ANP7414-B)

D E

5

6

7

8

51

Page 52

1

23

XV-S100DV

4.4 FM/AM TUNER MODULE

4

A

B

C

FM/AM TUNER MODULE

SIDE A

D

CN5701

Q202

C

FM/AM TUNER MODULE

C

D

(ANP7338-B)

SIDE B

52

Q201

IC201 Q205

Q203

IC202

(ANP7338-B)

Q204

C

1234

Page 53

1

4.5 TRADE 2 and AMP ASSYS

234

XV-S100DV

TRADE 2 ASSY

F

CN3331

K

CN3332

K

(ANP7414-B)

AMP ASSY

G

(ANP7414-B)

A

B

SIDE A

SIDE B

TRADE 2 ASSY

F

Q103

Q104

Q106

AMP ASSY

G

Q83Q94 Q91

Q92

Q71

DC FAN

MOTOR

IC72Q81

IC3151

IC3302

IC3303IC3301IC3161IC3171IC82

(ANP7414-B)

C

D

Q82 Q101

(ANP7414-B)

1

Q72

Q102Q93 Q3502 Q3501 Q3302 Q3301Q3552

2

IC3002

Q3144

IC3003Q3143

3

Q3402 Q3551Q3401 IC3551

GF

4

53

Page 54

1

XV-S100DV

23

4

4.6 JACK, HP, DISPLAY and POWER ASSYS

A

JACK ASSY

H

D

CN3011

B

I

(ANP7415-B)

HP ASSY

POWER

K

ASSY

AC IN

LIVE

NEUTRAL

D

CN3902

(ANP7415-B)

C

DISPLAY ASSY

J

D

CN5611

D

(ANP7415-B)

(ANP7415-B)

54

H I J K

1234

Page 55

5

678

XV-S100DV

A

Q3641

Q3654

T1

POWER

TRANSFORMER

E

CN5521

E

CN5522

CN3321

F

Q51

CN3322

F

IC51

IC21

IC11 IC12

B

C

IC22

-B)

IC61

IC32

B

CN22

Q32

D

SIDE A

K

5

6

7

8

55

Page 56

1

XV-S100DV

23

4

A

Q3635

Q3652

Q3601

Q3602

B

Q3653

Q3651

Q3633

Q3632

Q3642

Q3643 Q3644

Q3645

Q3631

Q3634

Q3622

Q3611

Q3612

Q3621

C

D

SIDE B

56

K

1234

Page 57

5

678

XV-S100DV

POWER

K

A

ASSY

JACK ASSY

H

DISPLAY ASSY

J

(ANP7415-B)

HP ASSY

I

(ANP7415-B)

(ANP7415-B)

Q3901

Q3902

B

Q3905

Q3906

Q3903

C

Q5933

Q5941

5

(ANP7415-B)

Q5934Q5932

Q5681 IC5601 Q5602

6

7

Q5691

H I J K

8

57

D

Page 58

XV-S100DV

Mark No. Description Part No. Mark No. Description Part No.

5. PCB PARTS LIST

NOTES:•Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

•

Therefore, when replacing, be sure to use parts of identical designation.

When ordering resistors, first convert resistance values into code form as shown in the following examples.

•

Ex.1 When there are 2 effective digits (any digit apart from 0), such as 560 ohm and 47k ohm (tolerance is shown by J=5%,

and K=10%).

560 Ω→56 × 10

47k Ω→47 × 10

0.5 Ω→R50 .....................................................................................RN2H

1 Ω→1R0 ..................................................................................... RS1P

Ex.2 When there are 3 effective digits (such as in high precision metal film resistors).

5.62k Ω→ 562 × 10

1

→ 561 ........................................................ RD1/4PU 5 6 1 J

3

→ 473 ........................................................ RD1/4PU 4 7 3 J

R 5 0

1 R 0

1

→ 5621 ...................................................... RN1/4PC 5 6 2 1 F

K

K

Mark No. Description Part No.

LIST OF ASSEMBLIES

NSP LOADING MECHANISM ASSY VWT1188

NSP LOAB ASSY VWG2279

DVDM ASSY VWS1499

FM/AM TUNER MODULE AXQ7229

NSP DCS MAIN ASSY AWM7634

NSP DCS COMPLEX ASSY AWM7635

LOAB ASSY

SWITCH

OTHERS

CONTROL ASSY AWU7856

TRADE 1 ASSY AWU7858

TRADE 2 ASSY AWU7859

AMP ASSY AWU7935

JACK ASSY AWU7862

HP ASSY AWU7863

DISPLAY ASSY AWU7861

POWER ASSY AWU7860

A

S101 VSK1011

CN602 KR CONNECTOR S2B-PH-K

CN601 KR CONNECTOR S5B-PH-K

PC BOARD LOAB VNP1836

Mark No. Description Part No.

IC712 MNR4800DJ7

IC601 PD6345A

IC701 PE5108A

IC111 TC74HC4053AFT

IC612 TC74VHC125FT

IC608 TC74VHCT125AFT

IC304 TC7SHU04F

IC603 VYW1857

Q109,Q901-Q903,Q911-Q913 2SA1576A

Q114,Q130 2SC4081

Q107,Q111,Q115,Q241 DTC114EUA

Q101,Q102,Q106 HN1A01F

Q103,Q141,Q142,Q542,Q543 HN1B04FU

Q112,Q113 HN1C01FU

Q108 HN1K03FU

Q571 RN1911

Q117,Q171,Q601 RN4982

D302 KV1470

D601 RB501V-40

COILS

L304 LCYA1R5J2520

L481 CHIP BEAD VTL1084

CAPACITORS

C480,C481,C612 CCSRCH100D50

C152 CCSRCH101J50

C104-C108 CCSRCH150J50

C322 CCSRCH180J50

C314 CCSRCH220J50

DVDM ASSY

B

SEMICONDUCTORS

IC861 ADV7172KST

IC451 BA25BC0FP

IC261,IC302 BA4510F

IC251 BA6664FM

IC481 BU2288FV

IC101 LA9701M

IC201 LC78652W

IC351 M56788AFP

IC801 M65774BFP

IC805 MB81F161622C-80FN

58

C151 CCSRCH270J50

C391,C392 CCSRCH331J50

C146 CCSRCH390J50

C122,C123 CCSRCH391J50

C116,C134,C297 CCSRCH470J50

C145,C241 CCSRCH560J50

C117,C360 CCSRCH681J50

C124 CCSRCH820J50

C129,C142,C149,C201,C205 CEV101M16

C358,C368,C369,C403,C410 CEV101M16

C472,C864 CEV101M16

C113,C139 CEV220M16

C405,C409,C454,C715 CEV221M4

C254,C401 CEV470M16

C111 CEV470M6R3

Page 59

XV-S100DV

Mark No. Description Part No. Mark No. Description Part No.

C140,C223,C224,C264,C312 CKSQYB105K10

C475-C477 CKSQYB105K10

C209,C211,C216,C313,C351 CKSRYB102K50

C133,C136,C203,C220,C225 CKSRYB103K50

C239,C261,C320,C321,C330 CKSRYB103K50

C591,C619,C703,C722 CKSRYB103K50

C101,C103,C118,C119,C121 CKSRYB104K16

C212,C213,C227,C231 CKSRYB104K16

C248-C251,C255,C263,C315 CKSRYB104K16

C317,C406,C411,C412,C453 CKSRYB104K16

C208,C210 CKSRYB222K50

C266 CKSRYB224K10

C206,C214,C242,C357 CKSRYB472K50

C102,C109,C120,C130,C131 CKSRYF104Z25

C138,C143,C148,C154 CKSRYF104Z25

C157,C158,C204,C207,C215 CKSRYF104Z25

C221,C222,C226,C230,C236 CKSRYF104Z25

C253,C256,C258,C265,C299 CKSRYF104Z25

C319,C332,C353,C359 CKSRYF104Z25

C365,C366,C603,C606 CKSRYF104Z25

FM/AM TUNER MODULE

C

SEMICONDUCTORS

IC201 BA1451F

IC202 LC72131MD-TFB

Q201,Q204,Q205,Q601 2SC2412K

Q202 DTA124ES

Q203 DTC124EK

D201 1SS133

D202 MTZJ5.1C

D101 UDZS6.8B

COILS AND FILTERS

L201 FM DET. COIL ATE7003

F202 FL CERAMIC FILTER ATF-107

F201 FM CERAMIC FILTER ATF-119

F203 AM CERAMIC FILTER ATF1155

F601 ANTIBIRDY FILTER ATF7025

L601 LCTA270J2520

C608-C611,C613,C615,C618 CKSRYF104Z25

C626,C628,C631,C704,C706 CKSRYF104Z25

C708,C712,C713,C716-C718 CKSRYF104Z25

C721,C723,C725,C743,C802 CKSRYF104Z25

C808,C811,C814,C866 CKSRYF104Z25

C869-C872,C874,C875,C903 CKSRYF104Z25

C913 CKSRYF104Z25

C115,C217,C328,C614,C711 CKSRYF105Z10

C726,C801,C809,C813 CKSRYF105Z10

C816-C821,C827,C833,C843 CKSRYF105Z10

RESISTORS

R543,R545,R594,R631,R707 RAB4C103J

R121 RAB4C220J

R123 RAB4C470J

R400,R403 RS1/10S0R0J

R341 RS1/10S101J

R126-R129,R176-R179 RS1/10S220J

R902,R905,R908,R912,R915 RS1/16S1000F

R918 RS1/16S1000F

R364,R369,R373,R375 RS1/16S1003F

R865 RS1/16S1502F

R358,R361 RS1/16S1503F

R876,R878 RS1/16S4701F

R866 RS1/16S4702F

R870,R875 RS1/16S6800F

R867 RS1/16S6801F

R357,R362,R363,R368,R372 RS1/16S6802F

R374 RS1/16S6802F

R257 (1Ω) VCN1127

R258,R259 (2.2Ω) VCN1128

Other Resistors RS1/16S J

OTHERS

CN3 4P FFC CONNECTOR DKN1223

CN21,CN22 30P CONNECTOR RKN1039

CN52 PH CONNECTOR S5B-PH-SM3

9007 FLEXIBLE CABLE (07P) VDA1681

CN120 FLEXIBLE CONNECTOR VKN1787

CN251 12P FFC CONNECTOR VKN1795

X481 CRYSTAL RESONATOR VSS1159

X601 CERAMIC RESONATOR VSS1160

(27.000MHz)

(16.5MHz)

CAPACITORS

C605 CCSQCH680J50

C212,C213,C226,C233-C235 CCSRCH101J50

C240,C614 CCSRCH101J50

C206 CCSRCH120J50

C231,C232 CCSRCH150J50

C223 CEAT100M50

C229 CEAT101M10

C224 CEAT1R0M50

C227 CEAT220M25

C241 CEAT2R2M50

C243 CEAT330M16

C228 CEAT3R3M50

C237 CEAT470M10

C211 CEJA1R0M50

C210 CEJA470M16

C103,C104,C204,C238 CKSRYB102K50

C102,C208,C216,C217,C220 CKSRYB103K50

C239,C242,C604,C615 CKSRYB103K50

C225 CKSRYB153K50

C607,C608 CKSRYB182K50

C201,C205,C214,C230,C236 CKSRYB223K50

C244 CKSRYB223K50

C221 CKSRYB224K10

C603 CKSRYB392K50

C215 CKSRYB471K50

C202,C222 CKSRYB473K16

C606 CKSRYB561K50

RESISTORS

R211 RD1/4PU221J

R221 RD1/4PU222J

R233 RD1/4PU391J

R103,R104 RS1/10S221J

Other Resistors RS1/16S J

OTHERS

CN201 13P FFC CONNECTOR 52044-1345

BN201 2P TERMINAL with PAL AKA7002

SHIELD CASE T ANK7072

SHIELD CASE B ANK7073

X201 CRYSTAL RESONATOR ASS1093

(7.2MHz)

59

Page 60

XV-S100DV

Mark No. Description Part No. Mark No. Description Part No.

C3051,C3052,C3081,C3082 CEAT100M50

CONTROL ASSY

D

SEMICONDUCTORS

IC8301 AK4527BVQ

IC5701 BU1923F

IC3031 BU4052BCF

IC8751 K6E0808C1E-JC15

IC8101 LC89056W-E

IC3131 M62446FP

IC8801 MM1540BF

IC3041,IC3081-IC3083,IC3085 NJM4558MD

IC3212,IC3231 NJM4558MD

IC3901 NJM4560M

IC5501 PDC086A

IC8701 YSS912C

Q3906 2SA1576A

Q8801 2SD1858X

Q3031,Q3032,Q5501,Q5572,Q5711 2SC4081

Q3051,Q3052,Q3121-Q3126 2SD2114K

Q3231 HN1C01FU

Q8102,Q8803 RN1903

Q3181 RN2901

Q8101,Q8351,Q8802 RN2903

Q3033,Q3127,Q3601 UN5112

Q8353 UN5212

Q5571 UN521L

D3033,D3602,D5573,D5575,D5712 1SS355

D5721 1SS355

D8353 DAN202K

D3231 DAN217

D8351,D8352 DAP202K

D5711 UDZ11B

D3031,D3032 UDZS5.1B

D3131,D3132 UDZS6.8B

D8801 UDZS8.2B

COILS AND FILTERS

F8101,F8102,F8701,F8702,F8751 DTF1064

L5571 LFEA220J

F8604 CHIP SOLID INDUCTOR VTF1096

L8103 CHIP BEAD VTL1086

CHIP BEAD

CAPACITORS

C5575 ACH1246

C3144-C3146,C5502,C5506,C5507 CCSRCH101J50

C5510,C5511,C5577,C5721-C5723 CCSRCH101J50

C8705,C8708,C8715,C8718,C8724 CCSRCH101J50

C8727,C8733,C8734,C8756 CCSRCH101J50

C8121,C8122,C8713,C8714 CCSRCH200J50

C3913,C3914 CCSRCH221J50

C5706,C5707 CCSRCH270J50

C5702 CCSRCH271J50

C3909,C3910 CCSRCH470J50

C8012,C8721 CCSRCH471J50

C5703 CCSRCH561J50

C3089,C3090 CCSRCH680J50

C3099,C3100,C3109 CCSRCH820J50

C3126,C3136,C3213,C3214 CEAL100M16

C3241 CEAL1R0M50

C3113,C3114 CEAL220M16

C3240,C3242 CEAL4R7M16

C3234 CEALR47M50

C3033,C3034,C3041,C3042 CEAT100M50

RESISTORS

C3091,C3092,C3101,C3102 CEAT100M50

C3123-C3125,C3133-C3135,C3142 CEAT100M50

C3217,C3218,C3243,C3249,C3250 CEAT100M50

C3906-C3908,C3911,C3912 CEAT100M50

C3917,C3918,C5576,C5701,C5711 CEAT100M50

C8801,C8816 CEAT100M50

C5572,C8102,C8309,C8310,C8316 CEAT101M10

C8562,C8704,C8753,C8803 CEAT101M10

C8812,C8813 CEAT101M10

C3188,C3189 CEAT101M16

C5578 CEAT1R0M50

C8702 CEAT220M50

C3137,C3138 CEAT221M10

C8751 CEAT221M6R3

C3043,C3044,C5705,C8116,C8805 CEAT470M16

C8302,C8319,C8821,C8831 CEAT471M6R3

C3244 CEATR10M50

C3247,C3248,C8610 CEJQ470M10

C3131,C3132 CEV100M16

C5731,C5732 CEV2R2M50

C3106 CFTYA224J50

C5508,C8321,C8794,C8795 CKSRYB102K50

C3031,C3032,C3111,C3112 CKSRYB103K50

C3115-C3118,C3139-C3141 CKSRYB103K50

C3149,C3150,C3215,C3216,C3235 CKSRYB103K50

C5503,C5504,C5514,C5571,C5573 CKSRYB103K50

C5704,C5792,C5794-C5796,C5798 CKSRYB103K50

C8114,C8115,C8125,C8305,C8306 CKSRYB103K50

C8326 CKSRYB103K50

C5509,C5513,C5574,C5791,C5793 CKSRYB104K16

C8011,C8017,C8101,C8103,C8104 CKSRYB104K16

C8110,C8112,C8113,C8117,C8119 CKSRYB104K16

C8123,C8301,C8304,C8311,C8312 CKSRYB104K16

C8315,C8318,C8510,C8520,C8530 CKSRYB104K16

C8540,C8561,C8609,C8611,C8701 CKSRYB104K16

C8703,C8707,C8710,C8712,C8717 CKSRYB104K16

C8720,C8723,C8726,C8729,C8731 CKSRYB104K16

C8752,C8754,C8796,C8804,C8806 CKSRYB104K16

C8809-C8811,C8814,C8815,C8841 CKSRYB104K16

C3085,C3086,C3095,C3096,C3105 CKSRYB122K50

C3083,C3084,C3093,C3094,C3103 CKSRYB152K50

C3110,C8313,C8314 CKSRYB222K50

C3037,C3038 CKSRYB223K50

C3231,C3237,C3238,C3245,C8320 CKSRYB473K25

C8732 CKSRYB473K25

C5101 (100µF/6.3V) VCH1211

R8101,R8125,R8311,R8314 RAB4C101J

R8703-R8705,R8709-R8711 RAB4C101J

R8713 RAB4C102J

R5507,R8001 RAB4C103J

R5535 RAB4C104J

R5501,R5503,R5505,R5520 RAB4C221J

R5529,R5530,R5533,R5545,R5546 RAB4C221J

R5548 RAB4C221J

R3139,R3140 RAB4C681J

Other Resistors RS1/16S J

60

Page 61

XV-S100DV

Mark No. Description Part No. Mark No. Description Part No.

OTHERS

CN5611 15P FFC CONNECTOR 52044-1545

CN5701 13P FFC CONNECTOR 9604S-13C

CN5501,CN5502 23P PLUG AKP7064

X5701 CRYSTAL RESONATOR ASS7004

X5501 CERAMIC RESONATOR ASS7034

JA8602 GP1FA501RZ

CN5504 FFC CONNECTOR 07P HLEM7R-1

CN3011 10P PLUG KM200TA10

JA8803 VKB1163

CN5503 7P FFC CONNECTOR VKN1267

CN8001 30P FFC CONNECTOR VKN1290

KN5791 EARTH METAL FITTING VNF1084

X8101,X8701

TRADE 1 ASSY

E

(10MHz)

CRYSTAL RESONATOR VSS1140

(12.288MHz)

SEMICONDUCTORS

Q107 2SD2114K

D105 1SS355

RESISTORS

All Resistors RS1/16S J

OTHERS

CN5511,CN5512,CN5521,CN5522 AKP7075

TRADE 2 ASSY

F

23P SOCKET

OTHERS

CN3311,CN3312,CN3321,CN3322 AKP7075

23P SOCKET

CAPACITORS

C3159,C3160,C3169,C3170,C3180 CCSRCH100D50

C3305,C3306,C3405,C3406,C3455 CCSRCH221J50

C3505 CCSRCH221J50

C3190 CCSRCH470J50

C3309,C3310,C3409,C3410,C3509 CCSRCJ3R0C50

C3559 CCSRCJ3R0C50

C3307,C3308,C3407,C3408,C3507 CEAT100M50

C3551,C3561 CEAT100M50

C83,C86,C92,C93 CEAT101M10

C101,C102 CEAT1R0M50

C3321,C3322,C3421,C3422,C74 CEAT220M50

C3323,C3324,C3423,C3424 CEAT221M25

C3167,C3168,C3179,C3401,C3402 CEAT2R2M50

C3501 CEAT2R2M50

C3211,C3212,C3557,C72,C73 CEAT470M16

C82,C85,C95 CEAT470M16

C3653 CEAT470M25

C3181,C3183 CFTYA154J50

C3303,C3304,C3403,C3404,C3503 CKSRYB102K50

C3553 CKSRYB102K50

C3153,C3154,C3163,C3164,C3172 CKSRYB103K50

C3191-C3198 CKSRYB103K50

C3317,C3318 CKSRYB104K16

C3155,C3156,C3165,C3166,C3175 CKSRYB223K50

C3311,C3312,C71,C75 CKSRYB223K50

C81,C84,C91 CKSRYB473K25

C3319,C3320 CKSRYB683K16

RESISTORS

R3211,R3212 RAB4C681J

R3321,R3322,R3421,R3422 RD1/4MUF101J

Other Resistors RS1/16S J

OTHERS

CN3301,CN3302 23P PLUG AKP7064

CN3651 2P PLUG KM200SA2

AMP ASSY

G

SEMICONDUCTORS

IC82 BA05T

IC72 NJM7812FA

IC3301,IC3302 STK402-240

Q81,Q91 2SB1375

IC3151,IC3161,IC3171 NJM4558MD

Q71,Q83,Q94 2SB1237X

Q92 2SC1740S

Q82,Q93 2SC4081

Q3301,Q3302,Q3401,Q3402 2SD2114K

Q3501,Q3502,Q3551,Q72 2SD2114K

Q104 RN1901

Q102 RN1903

Q103 RN2901

Q101 RN2903

Q106 UN5212

D101-D103,D94 1SS355

D74 DAN202K

D104 DAP202K

D3211,D3212 UDZS8.2B

JACK ASSY

H

CAPACITORS

C3001,C3002,C3005,C3006 CCSRCH101J50

C3011,C3012,C3015,C3016 CCSRCH101J50

C3051,C3052 CCSRCH101J50

C3004,C3014,C3054 CKSRYB103K50

RESISTORS

R3015 RD1/4PU331J

Other Resistors RS1/16S J

OTHERS

JA3001 6P PIN JACK AKB7050

CN3001 10P SOCKET KP200TA10L

61

Page 62

XV-S100DV

Mark No. Description Part No. Mark No. Description Part No.

HP ASSY

I

SEMICONDUCTORS

Q3901,Q3902,Q3905,Q3906 2SD2114K

Q3903 UN5112

COILS

L3901,L3902 CHIP BEAD VTL1096

CAPACITORS

C3901,C3902 CKSRYB102K50

C3905 CKSRYB103K50

C3907 CKSRYB104K16

C3903,C3904 CKSRYB333K25

RESISTORS

R3901,R3902,R3911,R3912 RD1/4PU330J

Other Resistors RS1/16S J

OTHERS

3902 5P CABLE HOLDER 51048-0500

JA3901 MINI JACK AKN7003

J3901 5P JUMPER WIRE D20PYY0525E

KN3901 EARTH METAL FITTING VNF1084

DISPLAY ASSY

J

SEMICONDUCTORS

IC5601 MSM9202-01

Q5691,Q5692 2SC4081

Q5932 HN1A01FU

Q5681,Q5933,Q5934 UN5212

D5681 1SS133

D5931 VRPG5615S

COILS

L5563 LAU100J

L5562 LAU220J

SWITCHES

S5921-S5927 ASG7013

CAPACITORS

C5674 CCSRCH470J50

C5681 CEJQ2R2M50

C5564 CEJQ101M10

C5678 CEJQ220M35

C5953 CEJQ470M16

C5671-C5673 CKSRYB102K50

C5677,C5682 CKSRYB103K50

C5562,C5563,C5661-C5666,C5675 CKSRYB223K50

C5952 CKSRYB223K50

RESISTORS

All Resistors RS1/16S J

OTHERS

CN5601 15P FFC CONNECTOR 52044-1545

V5601 FL TUBE AAV7082

5671 FL SPACER AEB7242

X5951 REMOTE RECEIVER UNIT GP1UM27XK

POWER ASSY

K

SEMICONDUCTORS

IC11,IC12 PROTECTOR(7A) AEK7047

IC51 NJM78M56FA

IC61 NJM7912FA

Q32 2SB1375

Q51 2SD1858X

D22 D3SBA20(B)

D11 D5SBA20(B)

D51 S1WB(A)60SD

Q3601,Q3602,Q3611,Q3612 2SC4081

Q3621,Q3622,Q3631,Q3642,Q3644 2SC4081

Q3641 2SD1858X

Q3654 2SD2144S

Q3652 DTA124TK

Q3634 HN1C01FU

Q3633 RN1901

Q3651 RN1903

Q3632 RN2903

Q3635,Q3645,Q3653 UN5112

Q3643 UN5212

D35,D3632-D3634,D3655 1SS133

D52-D54 1SS133

D3601,D3602,D3611,D3612 1SS355

D3621,D3622,D3636,D3637 1SS355

D3641-D3643,D3651-D3653 1SS355

D21 D2SBA20(B)

D3635 DAN202K

D3644 DAN217

D3603,D3613,D3623 DAP202K

D61,D72 MTZJ15C

D33,D34 MTZJ18A

D93 MTZJ4.7A

D3631 MTZJ5.1A

D36 MTZJ6.8B

D82,D84 MTZJ7.5C

D31,D32,D3656 S5688G

COILS

L1 LINE FILTER ATF7019

L3361,L3362,L3461,L3462,L3561 ATH-059

AF CHOKE COIL

L3661 AF CHOKE COIL ATH-059

TRANSFORMERS

T2 ATT7050

RELAYS

RY1 ASR7018

RY3641-RY3643 ASR7008

CAPACITORS

C1,C2 (0.022µF) ACE7029

C3 ACG7033

C35,C62 CEAT100M50

C3632 CEAT101M10

C3651 CEAT101M25

C52 CEAT102M25

C36,C37 CEAT1R0M50

C34 CEAT220M50

C32 CEAT221M63

C3631,C3652 CEAT2R2M50

62

Page 63

XV-S100DV

Mark No. Description Part No. Mark No. Description Part No.

C33 CEAT330M50

C54 CEAT470M16

C15,C16 CEAT472M35

C24 CEAT682M16

C23 CEAT682M25

C3369,C3370,C3469,C3470,C3569 CKSRYB103K50

C3669,C53 CKSRYB103K50

C3361-C3364,C3461-C3464,C3561 CKSRYB223K50

C3563,C3661,C3663,C61 CKSRYB223K50

C3365-C3368,C3465-C3468,C3565 CKSRYB473K25

C3567,C3665,C3667 CKSRYB473K25

C12,C13 CQMA103J50

RESISTORS

R11 RD1/2PMF100J

R3361,R3362,R3461,R3462,R3561 RD1/2PMF101J

R3661 RD1/2PMF101J

R31 RD1/2PMF332J

R36,R37 RD1/4PU101J

R3635 RD1/4PU332J

R3657 RF1/4PS330J

R35,R3631,R3632 RD1/4PU472J

R3646 RS1/10S472J

R3607,R3608,R3617,R3618 RS1LMFR22J

R3627,R3628 RS1LMFR22J

Other Resistors RS1/16S J

OTHERS

61 4P CABLE HOLDER 51048-0400

CN3301,CN3401 AKE7066

CN3331,CN3332,CN5531,CN5532 AKP7064

H1,H2 FUSE CLIP AKR7001

CN11 10P VH CONNECTOR B10P-VH

CN2 2P VH CONNECTOR B2P3-VH

J61 4P JUMPER WIRE D20PDD0410E

11 PCB BINDER VEF1040

CN5102 30P FFC CONNECTOR VKN1261

KN11 EARTH METAL FITTING VNF1084

AN1 1P AC INLET XKP3041

6P APEAKER TERMINAL

23P PLUG

63

Page 64

XV-S100DV

6. ADJUSTMENT

6.1 DVD SECTION

6.1.1 ADJUSTMENT ITEMS AND

LOCATION

Adjustment Items

[Mechanism Part]

1

Tangential and Radial Height Coarse Adjustment

2

DVD Jitter Adjustment

3

Initialize the Focus Sweep Setting

[Electrical Part]

Electrical adjustments are not required.

Adjustment Points (Mechanism Part)

Cautions: After adjustment, adjustment screw locks with the

Screw tight.

1 2

Tangential

adjustment

screw

1 2

Radial

adjustment

screw

6.1.2 JIGS AND MEASURING

INSTRUMENTS

Screwdriver (large)

TV monitor

Screwdriver (medium)

Test mode remote control

unit (GGF1067)

64

Precise screwdriver

Screw tight

(GYL1001)

DVD test disc

(GGV1025)

Page 65

6.1.3 NECESSARY ADJUSTMENT POINTS

When Adjustment Points

Exchange Parts of Mechanism Assy

XV-S100DV

Exchange the Pickup

Exchange the Traverse Mechanism

Exchange the Spindle Motor

Exchange PCB Assy

Exchange PC Board

Mechanical

point

Electric

point

Mechanical

point

Electric

point

Mechanical

point

Electric

point

Mechanical

point

~, Ÿ, !

!

Ÿ, !

∗ After adjustment, screw locks

with the Screw tight.

∗ After adjustment, screw locks

with the Screw tight.

LOAB, DVDM ASSY

∗

Purpose: To set the sweep which was correct with the

individual Traverse mechanism.

Be sure to perform the following step finally when replaced

Pickup, Traverse Mechanism and Spindle Motor.

ESC CLEAR

GGF1067

Test mode

remote control

unit

(It is necessary when performed adjustment procedure Ÿ.)

Electric

point

65

Page 66

XV-S100DV

6.1.4 TEST MODE

TEST MODE: ON

POWER

ON

ESC TEST

GGF1067

Test mode

remote control

unit

TEST MODE: DISC SET

<TRAY OPEN>

OPEN/CLOSE

(Player or Remote

Control Unit)

DVD disc

TEST MODE: PLAY

<PLAY>

TV/LDP

An address is displayed

< When playback with the target address of disc (DVD)>

For example, when playback with # 30000

OPEN/CLOSE

(Player or Remote

Control Unit)

DSC -

CHECK

DVD, CD

&&&

During PLAY

+10 3 0 0 0 0 CHP/TIM

TEST MODE: OFF

POWER

OFF

66

Press keys in order

030000

ESC

OR

GGF1067

Test mode

remote control

unit

Page 67

6.1.5 MECHANISM ADJUSTMENT

Tangential and Radial Height Coarse Adjustment

1

XV-S100DV

START

• Remove the servo mechanism.

• Remove a Spacer for height adjustment

attached to the back side (shaded area)

of the Servo Mechanism (Float Base) with

nippers.

Servo Mechanism

Float Base

Spacer for Height adjustment

Note:

Turn the Short switch to Short side when

removing the Pickup Flexible Cable.

(Refer to "7.1.6 DISASSEMBLY".)

Cautions:

Because there is not a Spacer for height adjustment in

adjustment after the second time, will keep it at need.

(This parts is Traverse mechanism exclusive use of a model

for 2001 years)

7.3mm

Put a spacer between a Tangential (or Radial) adjustment

screw and Mechanism Base and turn each screw to adjust

the height. (Refer to "6.1.1 ADJUSTMENT ITEMS AND

LOCATION".)

Turn a flat side

into bottom

67

Page 68

XV-S100DV

DVD Jitter Adjustment

2

• Playback method of inner and outer address for the purpose is refererd to "6.1.4 TEST MODE".

• Jitter indication of the monitor is refererd to "7.1.3 TEST MODE SCREEN DISPLAY".

START

• Test mode

• Play the DVD test disc

at outer track

(around #200000)

Mechanism Assy

Adjust the Tangential

Adjustment Screw so that

jitter becomes minimum.

J4 : Min

Use disc: GGV1025

• Play the DVD test disc

at inner track

(around #30000)

Mechanism Assy

Adjust the Radial

Adjustment Screw so that

jitter becomes minimum.

J4 : Min

Turn the POWER OFF in

case of NG once, and

perform the adjustment

once again.

If error rate is OK,

locks a root of

tangential and radial

adjustment screws with

the Screw tight, and

go to step

!

.

CHECK

NG

OK

J4 : - - - -

Player

Monitor

Confirm the error rate that is

displayed "OK"

(Example ER (av): 2.5e - 5-*OK )

Disc playback normally.

• The measurement of block error rate

5ESC

• Play the DVD test disc

at outer track

(around #200000)

Mechanism Assy

Readjust the Tangential