Page 1

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2005

TIMER

MUSIC

STANDBY/ON

DVD/CD

MOVIE

TAPE

FRONT SURROUND

TUNER

SOUND MODE

LINE

KARAOKE

ENTER

VOLUME

REVERSE MODE

REC/STOP

ASES

PUSH OPEN

+-

TUNING

MS+/FF

MS-/REW

MIC VOL

PHONES SUB

MAIN

MIC

MIN MAX

XV-EV1000

ORDER NO.

RRV3189

STEREO DVD CASETTE DECK RECEIVER

XV-EV1000

XV-EV700

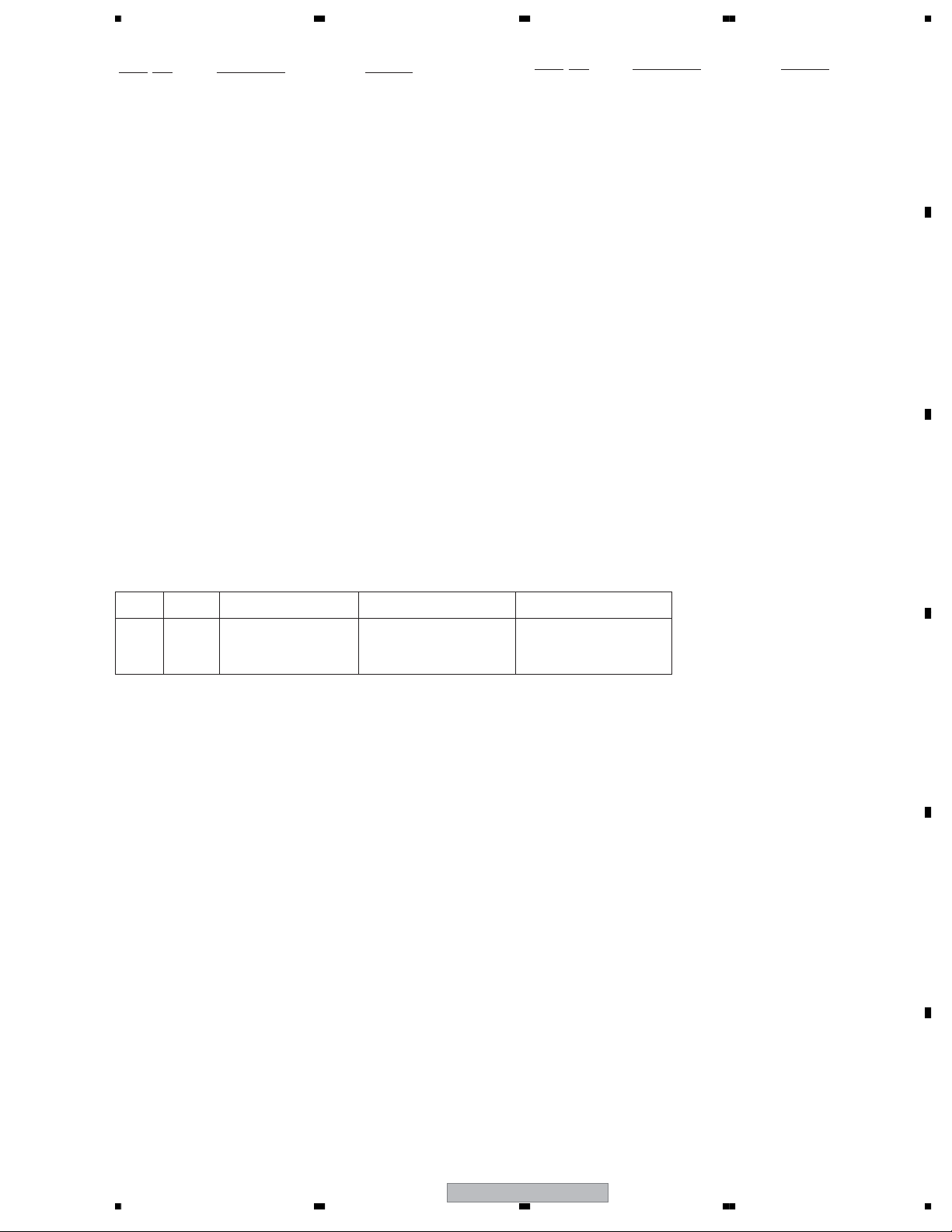

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Regional

Model Type Power Requirement

restriction codes

(Region No.)

XV-EV1000 DLXJ/NC AC110-127V/220-230V/240V 3 With the voltage selector

XV-EV700 DLXJ/NC AC110-127V/220-230V/240V 3 With the voltage selector

The voltage can be

converted by the

following method.

Remarks

For details, refer to "Important Check Points for good servicing".

T-ZZK AUG. 2005 printed in Japan

Page 2

1234

SAFETY INFORMATION

A

This service manual is intended for qualified service technicians ; it is not meant for the casual doit-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this

manual.Improperly performed repairs can adversely affect the safety and reliability of the product

and may void the warranty. If you are not qualified to perform the repair of this product properly and

safely, you should not risk trying to do so and refer the repair to a qualified service technician.

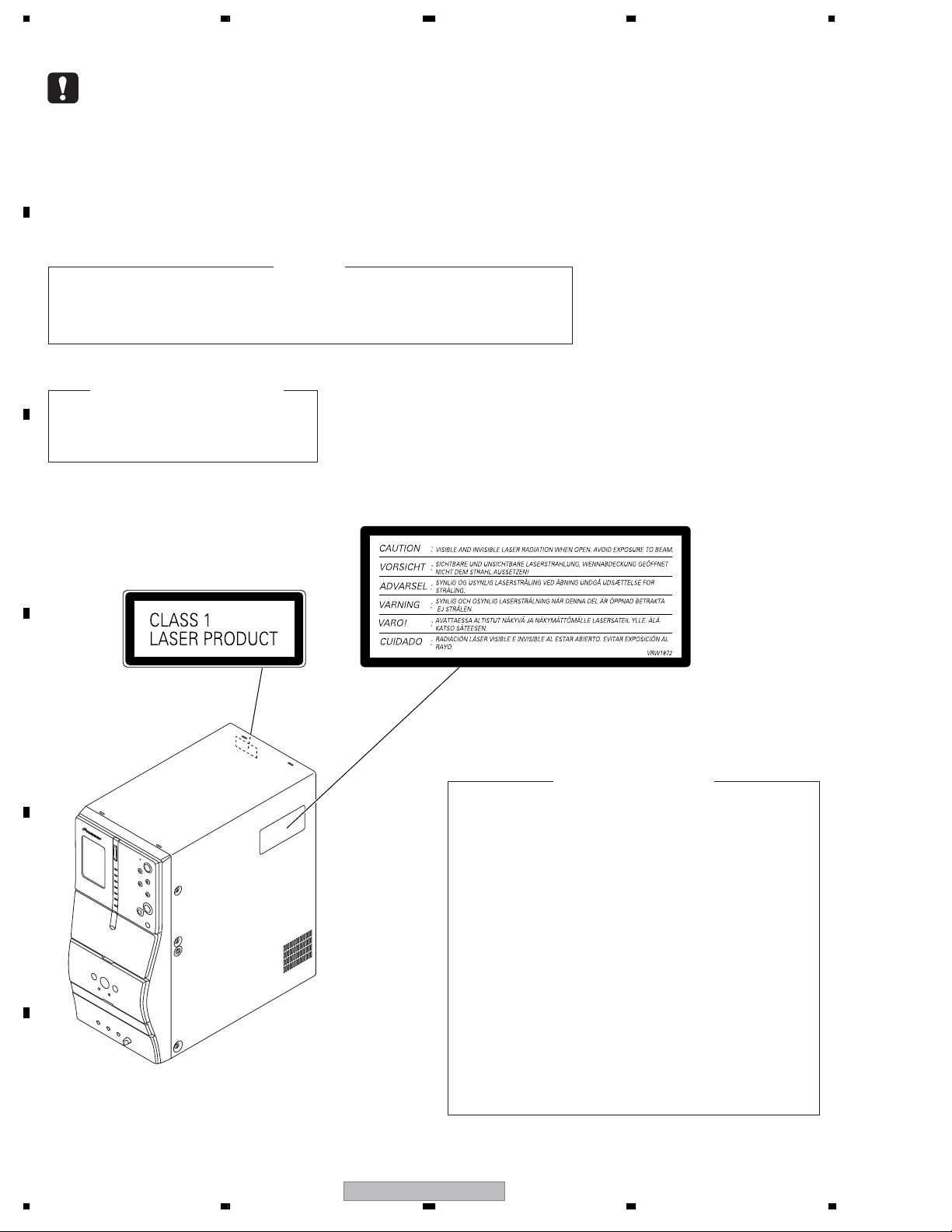

WARNING !

THE AEL (ACCESSIBLE EMISSION LEVEL) OF THE LASER POWER OUTPUT IS LESS THAN CLASS 1

BUT THE LASER COMPONENT IS CAPABLE OF EMITTING RADIATION EXCEEDING THE LIMIT FOR

B

CLASS 1.

A SPECIALLY INSTRUCTED PERSON SHOULD DO SERVICING OPERATION OF THE APPARATUS.

LASER DIODE CHARACTERISTICS

FOR DVD : MAXIMUM OUTPUT POWER : 5 mW

FOR CD : MAXIMUM OUTPUT POWER : 7 mW

WAVELENGTH : 650 nm

WAVELENGTH : 780 nm

LABEL CHECK

C

Printing on Rear Panel

D

E

VRW1872

Additional Laser Caution

1. Laser Interlock Mechanism

• Loading switch (S101 on the LOAB Assy) is used for interlock

mechanism of the laser.

When this switch turned ON in SW2 (CLOSE) side (OPEN signal is

0V and CLOSE signal is 3.5V), a laser becomes the status which can

completely oscillation.

Furthermore, the laser completely oscillates in the disc judgment and

disc playback.

When player is power ON state and laser diode is not completely

oscillating, 780nm laser diode is always oscillating by half power.

• Laser diode is driving with Q307 (650nm LD) and Q308 (780nm LD)

on the DVDM Assy.

Therefore, when short-circuit between the emitter and collector of these

transistors or the base voltage is supplied for transistors turn on, the

laser oscillates. (failure mode)

• In the test mode ∗ , there is the mode that the laser oscillates except

for the disc judgment and playback. LD ON mode in the test mode

oscillates with the laser forcibly.

The interlock mechanism mentioned above becomes invalid in this

mode.

2. When the cover is open, close viewing through the objective lens with

the naked eye will cause exposure to the laser beam.

F

2

1234

XV-EV1000

∗ : Refer to page 96.

Page 3

5678

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

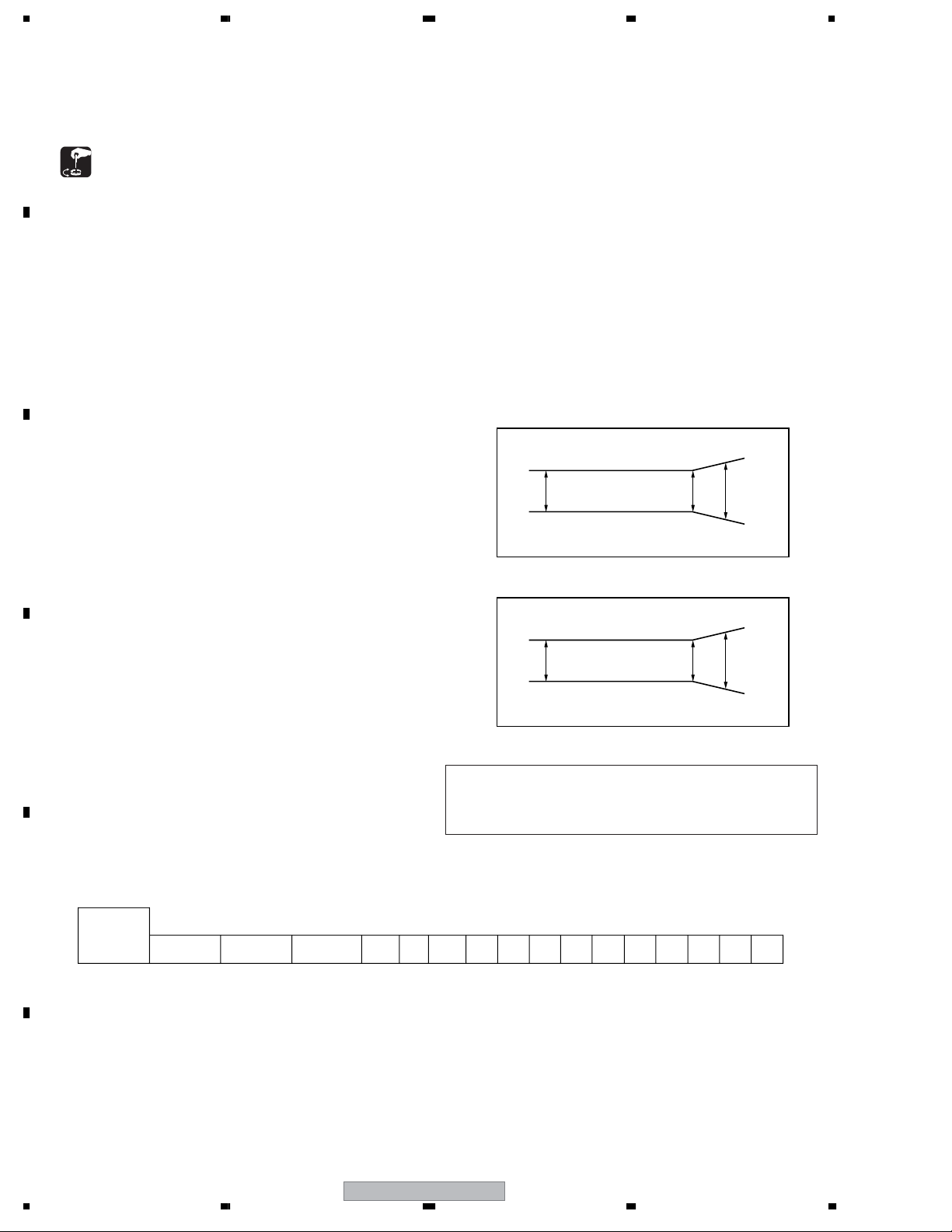

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

0 Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

A

B

C

D

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

Make sure the proper amount is applied.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

56

XV-EV1000

E

F

3

7

8

Page 4

1234

CONTENTS

SAFETY INFORMATION..................................................................................................................................... 2

1. SPECIFICATIONS ............................................................................................................................................ 5

2. EXPLODED VIEWS AND PARTS LIST ............................................................................................................ 7

A

B

C

D

E

F

2.1 PACKING ................................................................................................................................................... 7

2.2 EXTERIOR SECTION................................................................................................................................ 8

2.3 AMP SECTION ........................................................................................................................................ 10

2.4 FRONT PANEL SECTION ....................................................................................................................... 12

2.5 05 LOADER ASSY................................................................................................................................... 14

2.6 Traverse Mechanism Assy-S.................................................................................................................... 16

2.7 DECK MECHANISM ASSY ..................................................................................................................... 17

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM ..........................................................................................18

3.1 BLOCK DIAGRAM ................................................................................................................................... 18

3.2 OVERALL WIRING CONNECTION DIAGRAM and LOAB ASSY ........................................................... 20

3.3 DVDM ASSY (1/2).................................................................................................................................... 22

3.4 DVDM ASSY (2/2).................................................................................................................................... 24

3.5 IFAF ASSY (1/4)....................................................................................................................................... 26

3.6 IFAF ASSY (2/4)....................................................................................................................................... 28

3.7 IFAF ASSY (3/4)....................................................................................................................................... 30

3.8 IFAF ASSY (4/4)....................................................................................................................................... 32

3.9 DSP ASSY ............................................................................................................................................... 34

3.10 KEY, LED and DISPLAY ASSYS............................................................................................................ 36

3.11 HP/MIC ASSY........................................................................................................................................ 38

3.12 AMP ASSY............................................................................................................................................. 40

3.13 POWER ASSY (1/4)............................................................................................................................... 42

3.14 POWER (2/4) and TRADE ASSYS ........................................................................................................ 44

3.15 POWER ASSY (3/4)............................................................................................................................... 46

3.16 POWER ASSY (4/4)............................................................................................................................... 48

3.17 WAVEFORMS........................................................................................................................................ 50

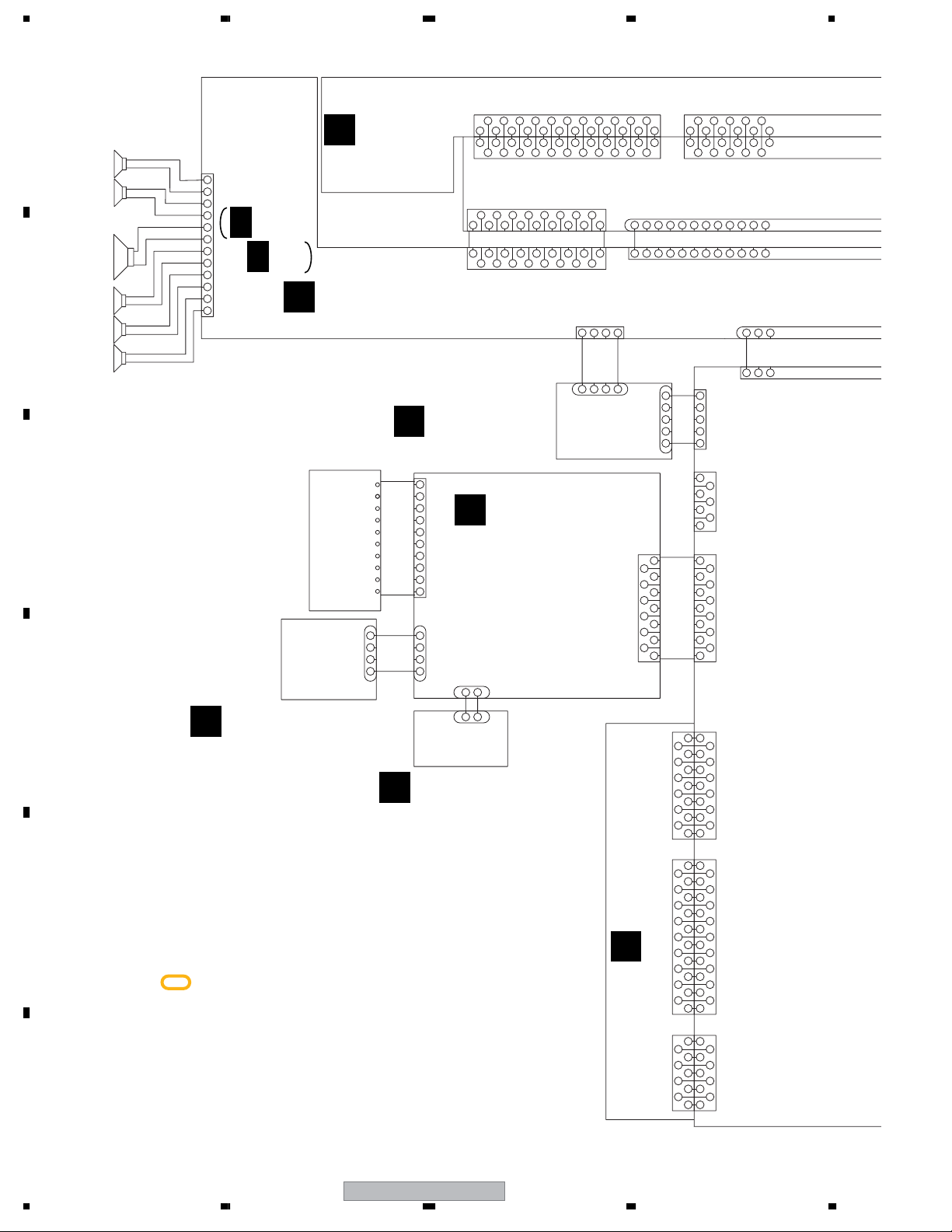

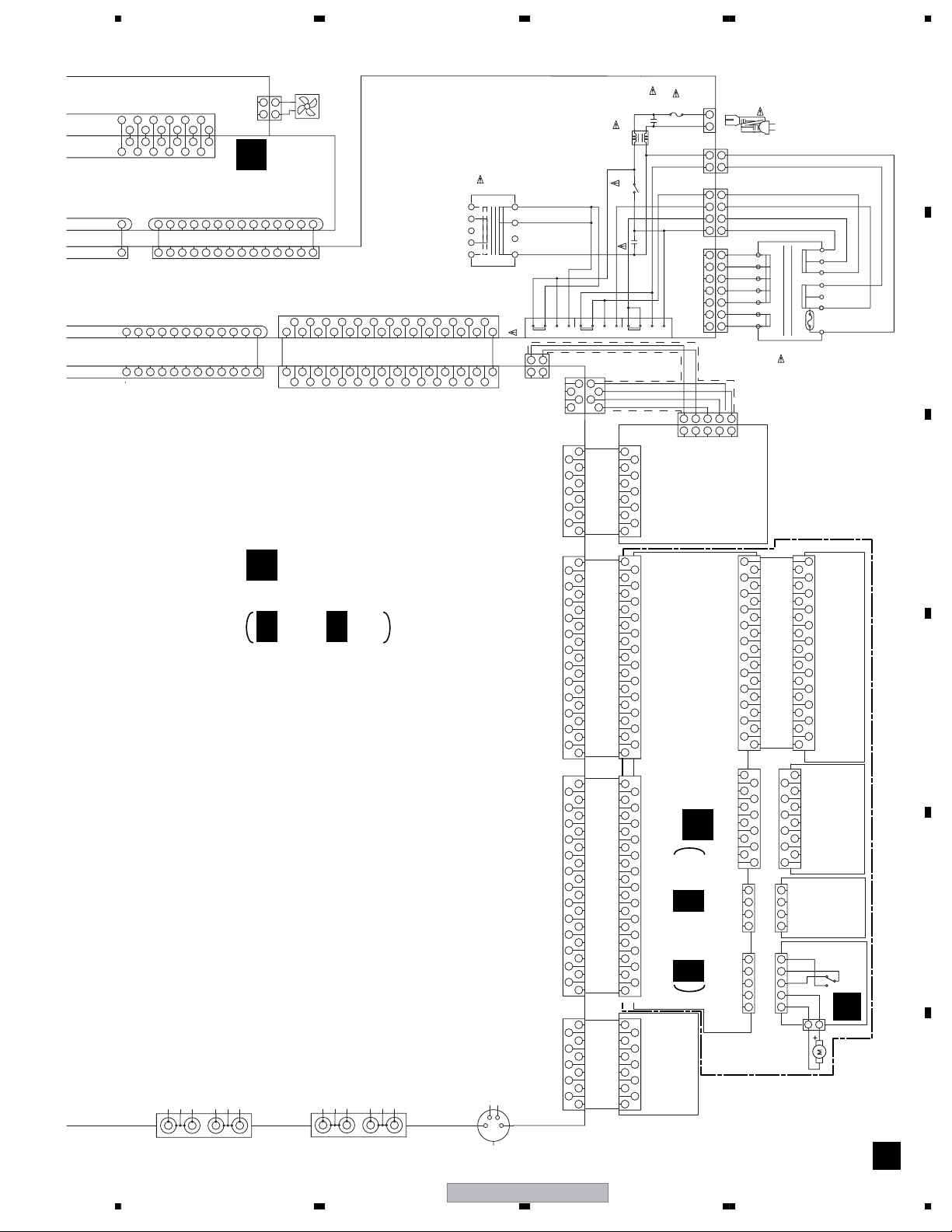

4. PCB CONNECTION DIAGRAM ..................................................................................................................... 51

4.1 LOAB ASSY............................................................................................................................................. 51

4.2 DVDM ASSY............................................................................................................................................ 52

4.3 IFAF ASSY ............................................................................................................................................... 54

4.4 KEY, LED and DISPLAY ASSYS.............................................................................................................. 58

4.5 AMP ASSY............................................................................................................................................... 60

4.6 POWER ASSY......................................................................................................................................... 62

4.7 HP/MIC and TRADE ASSYS ................................................................................................................... 66

4.8 DSP ASSY ............................................................................................................................................... 68

5. PCB PARTS LIST ........................................................................................................................................... 69

6. ADJUSTMENT ............................................................................................................................................... 88

6.1 DECK SECTION ...................................................................................................................................... 88

6.1.1 ADJUSTMENT CONDITION ............................................................................................................. 88

6.1.2 PLAYBACK and RECORDING SECTION ......................................................................................... 89

6.2 DVD SECTION......................................................................................................................................... 91

6.2.1 ADJUSTMENT ITEMS AND LOCATION........................................................................................... 91

6.2.2 JIGS AND MEASURING INSTRUMENTS ........................................................................................ 91

6.2.3 NECESSARY ADJUSTMENT POINTS............................................................................................. 92

6.2.4 TEST MODE ...................................................................................................................................... 93

6.2.5 MECHANISM ADJUSTMENT............................................................................................................ 94

7. GENERAL INFORMATION ............................................................................................................................. 96

7.1 DIAGNOSIS ............................................................................................................................................. 96

7.1.1 TEST MODE ...................................................................................................................................... 96

7.1.2 DISPLAY SPECIFICATION OF THE TEST MODE............................................................................ 97

7.1.3 FUNCTIONAL SPECIFICATION OF THE SHORTCUT KEY ............................................................ 98

7.1.4 SPECIFICATION OF MODEL INFORMATION DISPLAY.................................................................. 99

7.1.5 FUNCTIONAL SPECIFICATION OF THE SERVICE MODE........................................................... 100

7.1.6 SERVICE TEST MODE ................................................................................................................... 101

7.1.7 METHOD FOR DIAGNOSING DEGRADATION OF THE LDs ON THE PICKUP ASSY................. 103

7.1.8 DVD TROUBLE SHOOTING............................................................................................................ 104

7.1.9 ID NUMBER AND ID DATA SETTING ............................................................................................. 107

7.1.10 DSP TROUBLE SHOOTING ......................................................................................................... 110

7.1.11 DISASSEMBLY .............................................................................................................................. 112

7.2 PARTS.................................................................................................................................................... 122

7.2.1 IC ..................................................................................................................................................... 122

7.3 EXPLANATION ...................................................................................................................................... 125

7.3.1 SEQUENCE AFTER POWER ON................................................................................................... 125

7.3.2 PROTECTION CIRCUIT.................................................................................................................. 126

8. PANEL FACILITIES ...................................................................................................................................... 131

4

1234

XV-EV1000

Page 5

5678

1. SPECIFICATIONS

• Amplifier section

Continuous power output:

Front . . . . . . . . . . . . . . . . . . . . 100 W per channel

(1kHz, 10 % T.H.D., 6

Center . . . . . . . . . 100 W (1kHz, 10 % T.H.D., 6

Ω)

Ω)

Surround . . . . . . . . . . . . . . . . .100 W per channel

(1kHz, 10 % T.H.D., 6

Ω)

Subwoofer . . . . . 100 W (100Hz, 10 % T.H.D., 6Ω)

• Disc section

Digital audio

characteristics . . . . . . . . . DVD fs: 96 kHz, 24-bit

Type. DVD system, Video CD/Super VCD system

and Compact Disc digital audio system

Frequency response . . . . . . . . . . .4 Hz to 44 kHz

S/N ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . 95 dB

Dynamic range . . . . . . . . . . . . . . . . . . . . . . 95 dB

Total harmonic distortion . . . . . . . . . . . . 0.005 %

Wow and Flutter . . . . . . . . .Limit of measurement

(±0.001 % W.PEAK) or less (JEITA)

• Cassette deck section

Systems . . . . . . . . . . . . 4 track, 2-channel stereo

Heads . . . . . . . . . . . Recording/playback head x 1

Erasing head x 1

Motor . . . . . . . . . . . . . . . . . . . DC servo motor x 1

Tape types . . . . . . . . . . . . . . . . . Type I (Normal)

• FM tuner section

Frequency range . . . . . . . . 87.5 MHz to 108 MHz

Antenna . . . . . . . . . . . . . . . . . . . 75

Ω, unbalanced

Power consumption

. . . . . . . . . . . . . . . . . 179 W

Power consumption in standby mode . . . . . 0.5 W

Dimensions:

DVD Tuner Deck Receiver . . . . 170(W) 352.5 (H)

340.1 (D) mm

Weight:

DVD Tuner Deck Receiver . . . . . . . . . . . . . 7.2 kg

• Accessories (Stereo DVD Tuner Deck)

Remote control . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Power cord

Central and South American, Taiwan,

Philippines, Argentina, Mexico models . . . . . . 2

All other models . . . . . . . . . . . . . . . . . . . . . . . .1

Power plug adapter (Central and South American,

US Military and Duty Free models only) . . . . . . . 1

Video cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

AM loop antenna . . . . . . . . . . . . . . . . . . . . . . . . . 1

FM antenna . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Dry cell batteries (AA/R6) . . . . . . . . . . . . . . . . . . 2

Warranty Card (US Military and Duty

Free models only) . . . . . . . . . . . . . . . . . . . . . . . . 1

Operating instructions

Manufactured under license from Dolby

Laboratories.“Dolby”, “Pro Logic” and the double-D

symbol are trademarks of Dolby Laboratories.

“DTS” and “DTS Digital Surround” are registered

trademarks of Digital Theater Systems, Inc.

A

B

C

• AM tuner section

Frequency range

With 9kHz step . . . . . . . . 531 kHz to 1,602 kHz

With 10kHz step. . . . . . . 530 kHz to 1,700 kHz

Antenna . . . . . . . . . . . . . . . . . . . . . Loop antenna

• Miscellaneous

Power requirements

Multi voltage model . . . . AC 110-127/220-230/

240 V (switchable), 50/60 Hz

Accessories

• Power cord

(ADG1154)

• AM Loop Antenna

(ATB7013)

• Dry Cell Batteries

• FM Antenna (ADH7030)

• Remote Control

(XXD3098)

• Video Cord

(L = 1.5m) (XDE3046)

Yellow

ANGLE ZOOM

DVD

SUBTITLE

AUDIO

DVD/CD TAPE FM/AM LINE

STANDBY/ON

FRONT

SURROUND

ADVANCED

DSP

SURROUND

X.BOOM

i

–

KEYCON

–

I

DISPLAY MUTE

ECHO

KARAOKE

TOP MENU

VOLUME

SYSTEM SETUP

TUNE +

DVD MENU

HOME

MENU

D

E

¡

¢

RETURN

E/

CLEAR

ST +ST

–

TUNE

ENTER

–

SOUND

MODE

ENTER

7

TIMER

CHANNEL VOLUME

RANDOM

3

3

3

/e

1

TV CONTROL

8

4

REPEAT

PROGRAM

123

MONO

ST.MEMORY

456

CH LEVEL

TEST TONE

7890

INPUT

SHIFT

F

56

XV-EV1000

5

7

8

Page 6

1234

Disc / content format playback

A

B

compatibility

This player is compatible with a wide range of

disc types (media) and formats. Playable discs

will generally feature one of the following logos

on the disc and/or disc packaging. Note

however that some disc types, such as

recordable CD and DVD, may be in an

unplayable format.

See the Disc compatibility table below for more

information.

DVD-Video DVD-R DVD-RW

Audio CD CD-R

C

• is a trademark of Fuji Photo Film Co. Ltd.

Video CD

Fujicolor CD

CD-RW

• is a trademark of DVD Format/Logo

Licensing Corporation

• Also compatible with KODAK Picture CD

This player supports the IECís Super VCD standard for superior picture quality, dual

soundtracks, and widescreen support.

VIDEO

CD

D

Super Video CD (Super VCD)

E

F

6

1234

XV-EV1000

Page 7

>

5678

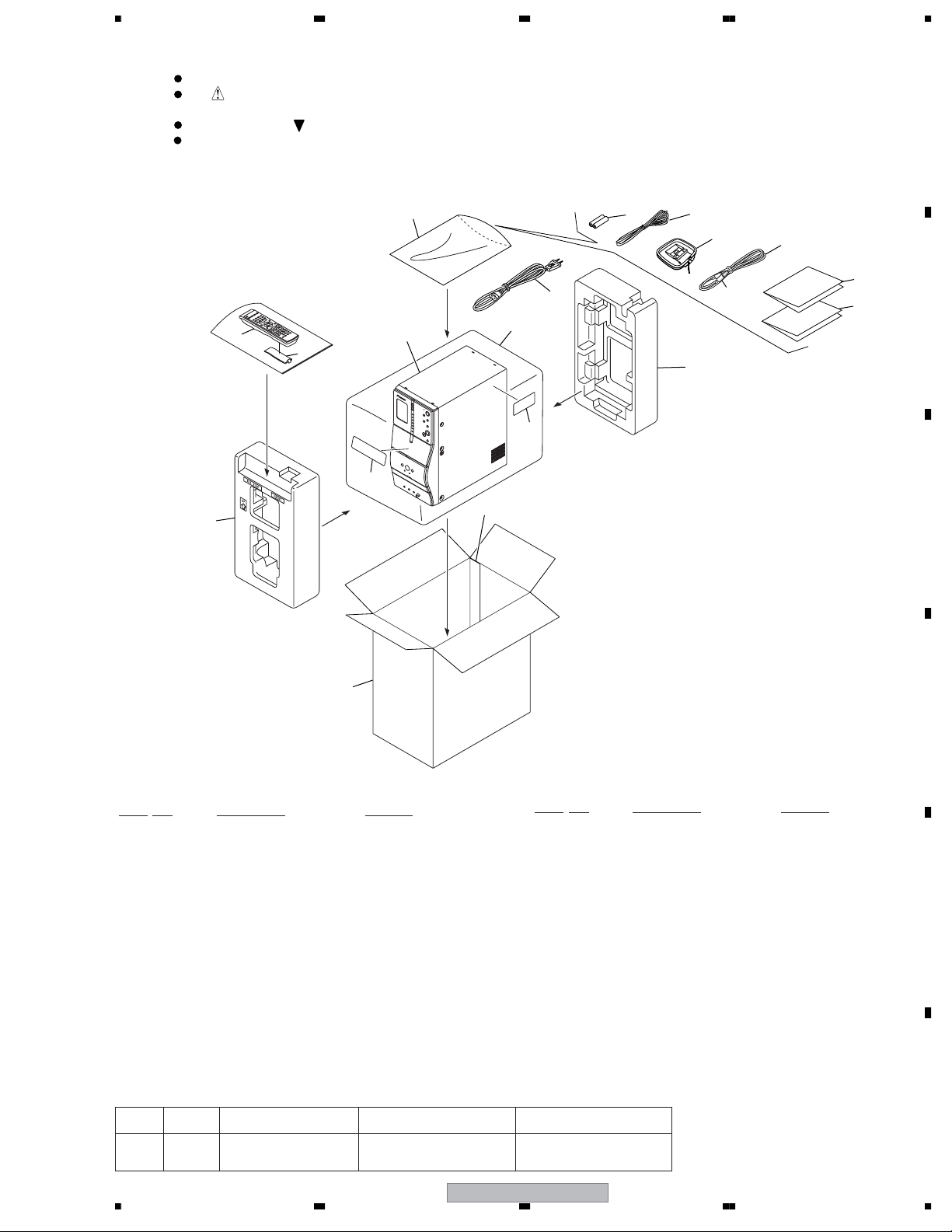

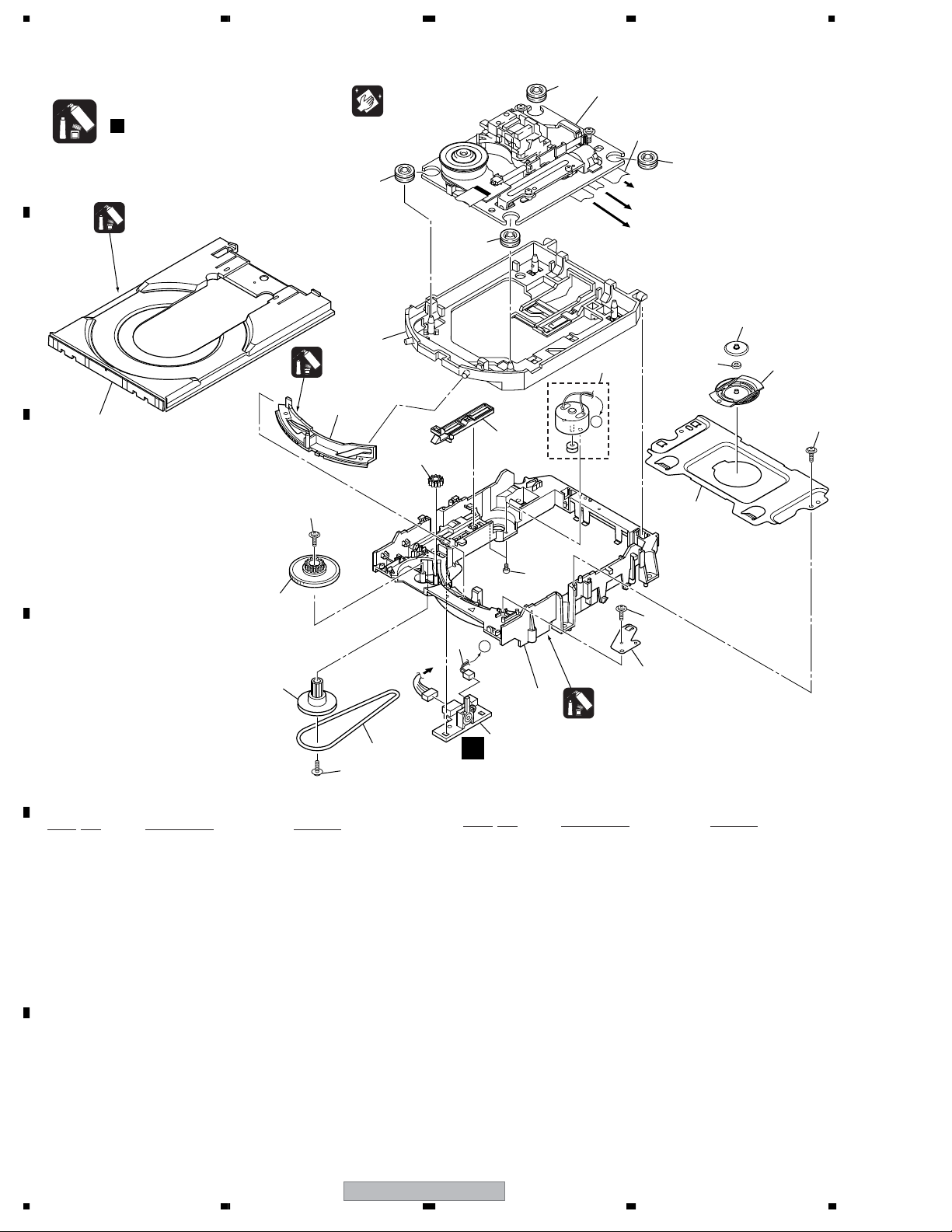

2. EXPLODED VIEWS AND PARTS LIST

NOTES:

Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on product are used for disassembly.

For the applying amount of lubricants or glue, follow the instructions in this manual.

(In the case of no amount instructions, apply as you think it appropriate.)

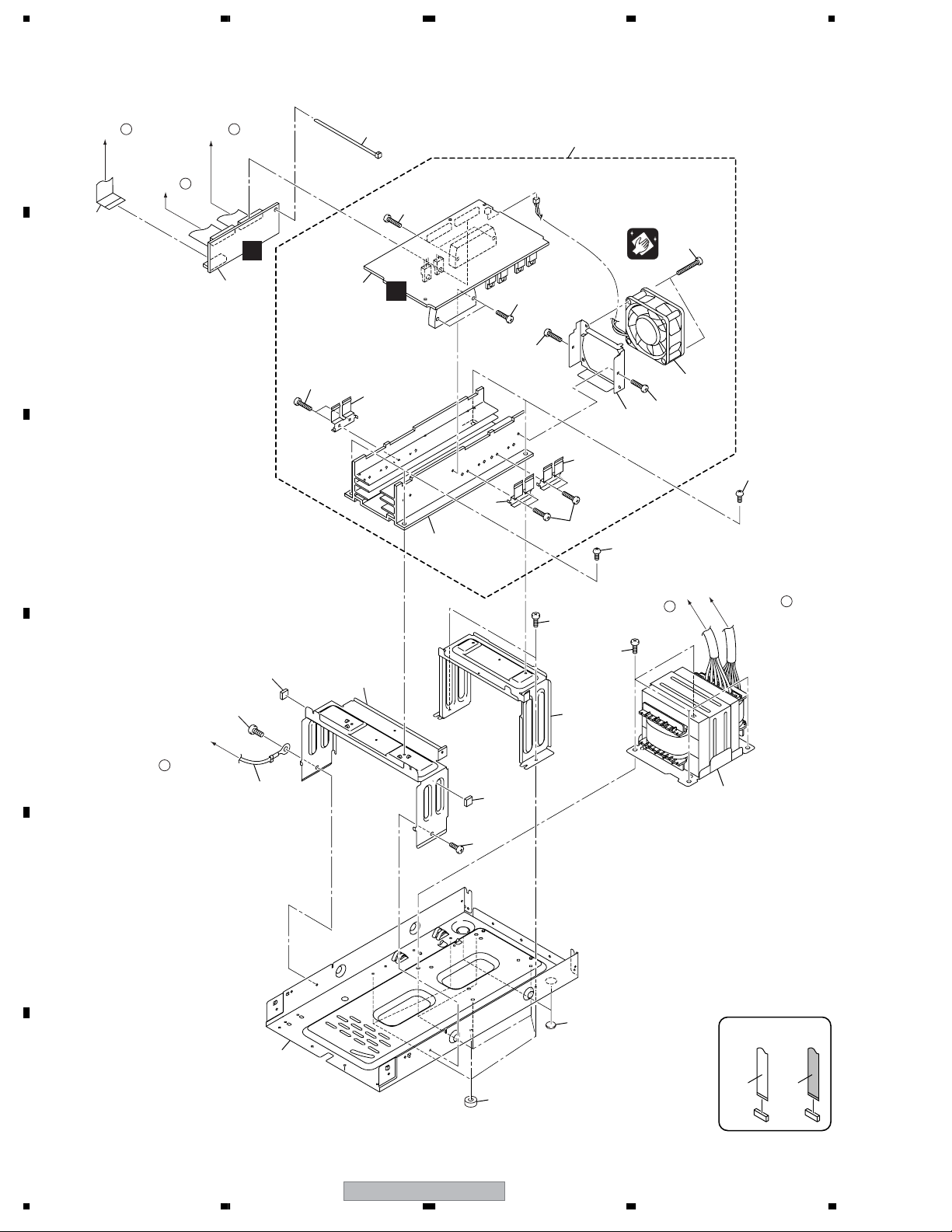

2.1 PACKING

10

12

16

11

XV-EV1000 or

XV-EV700

2

Junction

15

A

6 4

5

3

1

Yellow

13

7

8

9

B

C

14

(1) PACKING SECTION PARTS LIST

Mark No. Description Part No.

1 Label VRW1872

NSP 2 Getter Label See Contrast table (2)

3AC Power Cord ADG1154

4 FM Antenna ADH7030

5 AM Loop Antenna ATB7013

NSP 6 Dry Cell Batteries (AA/R6) VEM1031

7 Video Cord XDE3046

8 Operating Instructions (English) XRB3053

9 Operating Instructions (Chinese)XRC3209

10 Remote Control XXD3098

Mark No. Description Part No.

NSP 11 Polyethylene Bag Z21-038

12 Front Pad XHA3156

13 Rear Pad XHA3157

14 Packing Case See Contrast table (2)

15 Packing Sheet XHG3010

16 Battery Cover AZN7933

(2) CONTRAST TABLE

XV-EV700/DLXJ/NC and XV-EV1000/DLXJ/NC are constracted the same except for the following :

Mark No. Description XV-EV1000/DLXJ/NC XV-EV700/DLXJ/NC

NSP 2 Getter Label XAX3539 XAX3526

14 Packing Case XHD3565 XHD3555

56

XV-EV1000

7

D

E

F

7

8

Page 8

1234

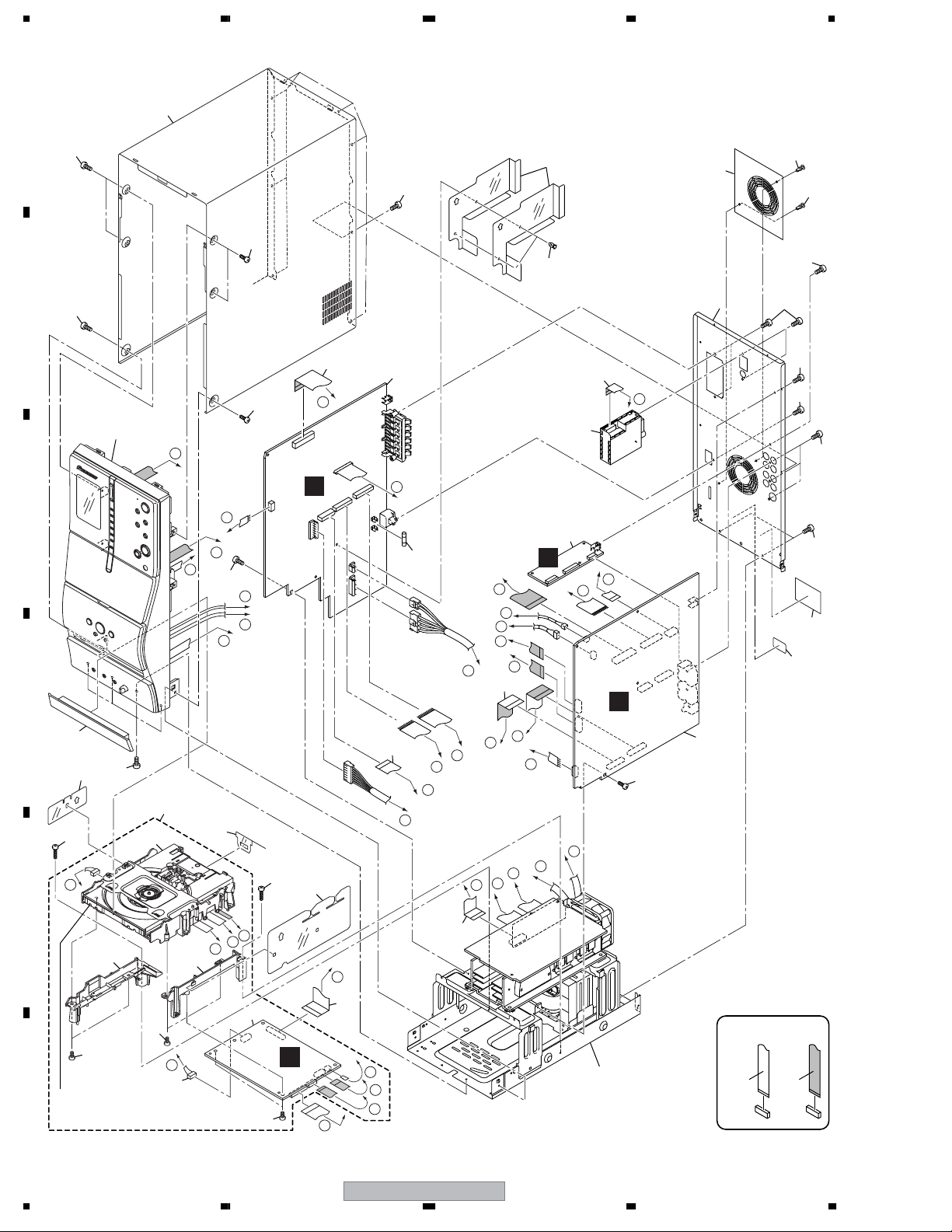

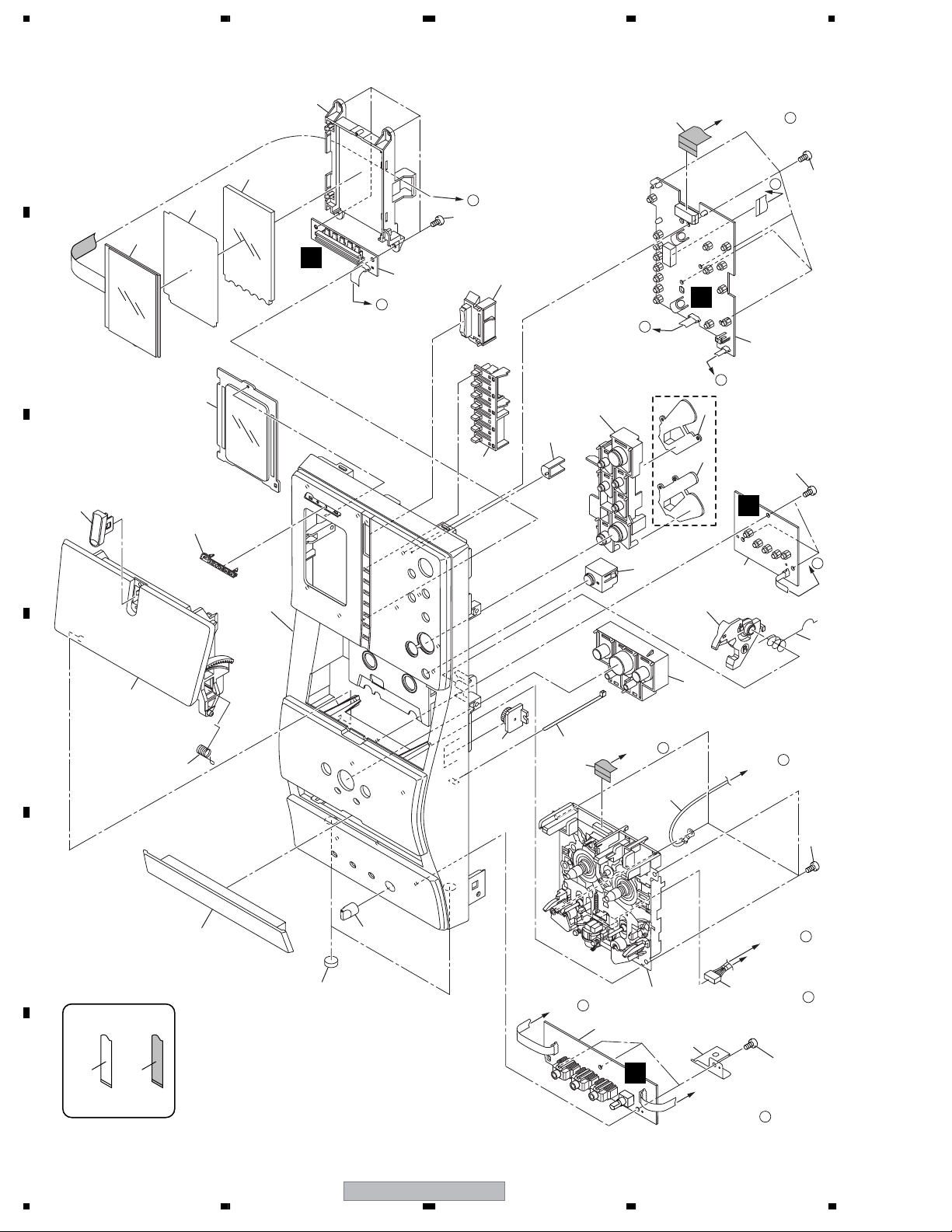

2.2 EXTERIOR SECTION

A

29

28

B

Refer to

"2.4 FRONT PANEL

SECTION".

C

D

24

28

22

31

N

E

14

29

Refer to

"2.5 05 LOADER ASSY".

F

12

29

25

11

16

18

18

28

20

23

29

28

28

28

30

28

18

17

10

A

3

6

C

2

O

J

Q

B

1

P

Q

32

S

R

T

5

H

D

A

S

R

P

O

C

B

28

28

27

26

8

C

J

I

F

T

28

H

G

F

E

D

7

21

K

7

E

D

G

31

19

M

L

15

J

13

N

B

29

9

M

L

K

I

Refer to

"2.3 AMP SECTION".

4

NON-CONTACT

SIDE

CONTACT SIDE

8

1234

XV-EV1000

Page 9

>

5678

(1) EXTERIOR SECTION PARTS LIST

No. Description Part No.

Mark

1 DSP Assy AWX8588

2 FM/AM TUNER Unit AXX7173

3POWER Assy See Contrast table (2)

4IFAF Assy See Contrast table (2)

5 Fuse (FU1) (5.0A/250V) REK1029

No. Description Part No.

Mark

21 FFC Barrier XEC3064

22 Cable Barrier XEC3065

23 Fan Barrier XEC3066

24 Tray Cap XAK3504

25 Bonnet Case XZN3179

A

6 11P F.F.C/60V XDD3179

7 17P F.F.C/60V XDD3180

8 25P F.F.C/60V XDD3182

9 27P F.F.C/60V XDD3183

10 27P F.F.C/60V XDD3186

NSP 11 DVD Assy XXA3037

NSP 12 05 LOADER Assy VWT1219

13 DVDM Assy AWM7964

14 Adaptor 05 L XNW3014

15 Adaptor 05 R XNW3015

16 Connector Assy PG05KK-E07

17 Rear Panel See Contrast table (2)

18 Push Rivet XEC3034

19 Mecha Barrier XEC3062

20 Primary Barrier XEC3063

NSP 26 Label VRW1629

NSP 27 ID Label Assy VXW1002

28 Screw BBZ30P080FNI

29 Screw BPZ30P080FNI

30 Screw PPZ30P080FNI

31 Screw XBA3015

32 Screw ABA7112

(2) CONTRAST TABLE

XV-EV700/DLXJ/NC and XV-EV1000/DLXJ/NC are constracted the same except for the following :

Mark No. Description XV-EV1000/DLXJ/NC XV-EV700/DLXJ/NC

3POWER Assy XWZ4016 XWZ4018

4IFAF Assy XWZ4003 XWZ4006

17 Rear Panel XNC3399 XNC3381

B

C

D

E

F

56

XV-EV1000

9

7

8

Page 10

1234

2.3 AMP SECTION

Refer to

A

"2.2 EXTERIOR

SECTION. "

B

C

D

Refer to

"2.2 EXTERIOR

SECTION. "

4

Refer to

"2.2EXTERIOR

SECTION. "

E

F

1

K

21

17

21

6

I

8

10

21

21

8

21

5

22

Cleaning paper

GED-008

7

21

9

8

19

19

Refer to

"2.2 EXTERIOR

18

15

D

Refer to

"2.4 FRONT PANEL

SECTION. "

E

U

19

3

12

15

19

SECTION. "

20

13

16

H

Refer to

"2.2 EXTERIOR

SECTION. "

2

G

11

F

10

1234

XV-EV1000

14

NON-CONTACT

SIDE

CONTACT SIDE

Page 11

>

5678

AMP SECTION PARTS LIST

No. Description Part No.

Mark

1 TRADE Assy XWZ4022

2Power Transformer (T1) XTS3099

NSP 3 Cord With Plug DE015VE0

4 17P F.F.C/60V XDD3180

NSP 5 AMP Unit XXQ3005

6 AMP Assy XWK3202

7 DC Fan Motor XXM3009

8 FET Bracket A ANG7418

9Fan Plate ANG7462

NSP 10 Heat Sink XNH3038

A

NSP 11 Chassis Hal XNA3025

12 AMP Support F XNG3141

13 AMP Support R XNG3142

NSP 14 Spacer AEB7092

15 Rubber Cushion XEB3047

16 LEG Cushion R XEB3050

17 Binder ZCA-SKB90BK

18 Screw BBZ30P060FTC

19 Screw BBZ30P080FNI

20 Screw BBZ40P060FTC

21 Screw BBZ30P140FTC

22 Screw BBZ30P300FTC

B

C

D

56

XV-EV1000

E

F

11

7

8

Page 12

1234

2.4 FRONT PANEL SECTION

A

20

24

5

17

8

V

36

Refer to

"2.2 EXTERIOR

SECTION. "

O

V

36

F

4

B

21

32

C

28

W

30

35

23

34

W

XV-EV1000

Only

G

2

X

25

26

36

E

31

27

33

D

13

14

E

22

15

19

Refer to

"2.2 EXTERIOR

SECTION. "

18

7

Q

1

Refer to

"2.2 EXTERIOR

SECTION. "

16

29

P

6

10

11

3

Refer to

"2.3 AMP

SECTION. "

Refer to

"2.2 EXTERIOR

SECTION. "

Refer to

"2.2 EXTERIOR

9

SECTION. "

X

12

U

36

S

R

36

H

F

NON-CONTACT

SIDE

CONTACT SIDE

Refer to

"2.2 EXTERIOR

SECTION. "

T

12

XV-EV1000

1234

Page 13

5678

(1) FRONT PANEL SECTION PARTS LIST

No. Description Part No.

Mark

1 HP/MIC Assy XWZ4014

2 DISPLAY Assy See Contrast table (2)

3 KEY Assy XWZ4013

4 LED Assy XWZ4023

5Vertical LCD XAV3028

No. Description Part No.

Mark

21 LCD Window XAK3503

22 Tray Cap XAK3504

23 Timer Lens XAK3506

24 Diffusion Sheet XAK3510

25 FUNC. LT. Cond. See Contrast table (2)

A

NSP 6 Cord With Plug DE015VE0

7 11P F.F.C/60V XDD3184

8 13P F.F.C/60V XDD3185

9 Cable Assy XDE3066

10 DECK Mechanism Unit XYM3019

11 GND Plate XNG3143

12 Ratch Spring R ABH7131

13 Damper Assy AXA7052

14 Door Spring R XBH3002

15 Leg Cushion F XEB3051

16 Ratch Mold R XMR3002

17 LCD Holder XMR3095

18 Binder ZCA-SKB90BK

19 MIC Knob XAA3029

20 LCD LT Cond XAK3502

26 VOL. LT. Cond. See Contrast table (2)

27 Front Panel Assy See Contrast table (2)

28 Pioneer Name Plate VAM1129

29 Operation Button XAD3225

30 Sub Button See Contrast table (2)

31 Sensor Cover XAK3505

32 DECK Panel See Contrast table (2)

33 DECK Door XAN3056

34 Main Button Assy See Contrast table (2)

35 X.Boon Button Assy XXG3230

36 Screw BPZ30P080FNI

(2) CONTRAST TABLE

XV-EV700/DLXJ/NC and XV-EV1000/DLXJ/NC are constracted the same except for the following :

Mark No. Description XV-EV1000/DLXJ/NC XV-EV700/DLXJ/NC

2 DISPLAY Assy XWZ4012 XWZ4010

25 FUNC. LT. Cond. XAK3514 Not used

26 VOL. LT. Cond. XAK3515 Not used

27 Front Panel Assy XZN3182 XZN3180

30 Sub Button XAD3227 XAD3224

32 DECK Panel XAK3512 XAK3508

34 Main Button Assy XXG3218 XXG3217

B

C

D

56

XV-EV1000

E

F

13

7

8

Page 14

1234

2.5 05 LOADER ASSY

A

B

C

Note :

Refer to

" Application of Lubricant".

Daifree

GEM1036

23

Lubricating Oil

GYA1001

13

22

Pickup leneses

Cleaning liquid

GEM1004

Cleaning paper

GED-008

8

12

16

8

8

17

Refer to

2

"2.4 Traverse Mechanism Assy-S".

6

8

To DVDM CN101 (Pickup)

To DVDM CN104 (Stepping Motor)

To DVDM CN102 (Spindle Motor)

18

3

A

24

19

20

22

15

14

D

05 LOADER ASSY PARTS LIST

No. Description Part No.

Mark

NSP 1 LOAB Assy VWG2346

2Traverse Mechanism Assy-S DXX2568

3 Loading Motor Assy VXX2912

E

4• • • • •

5• • • • •

6 Flexible Cable (24P) VDA2008

7 Connector Assy 2P VKP2253

8 Floating Rubber VEB1351

9 Belt VEB1358

10 Stabilizer VNE2253

22

To

DVDM CN103

9

21

22

7

A

10

11

1

A

No. Description Part No.

Mark

16 Drive Gear VNL1923

17 SW Lever VNL1925

18 Clamper Plate 04 VNE2342

19 Bridge 04 VNE2343

20 Clamper 04 VNL1969

21 Screw JGZ17P028FTC

22 Screw VBA1094

23 Tray VNL1920

24 Clamp Magnet VMG1029

Lubricating Oil

GYA1001

11 Loading Base VNL1917

12 Float Base 04 VNL1968

F

13 Drive Cam VNL1919

14 Gear Pulley VNL1921

15 Loading Gear VNL1922

14

1234

XV-EV1000

Page 15

5678

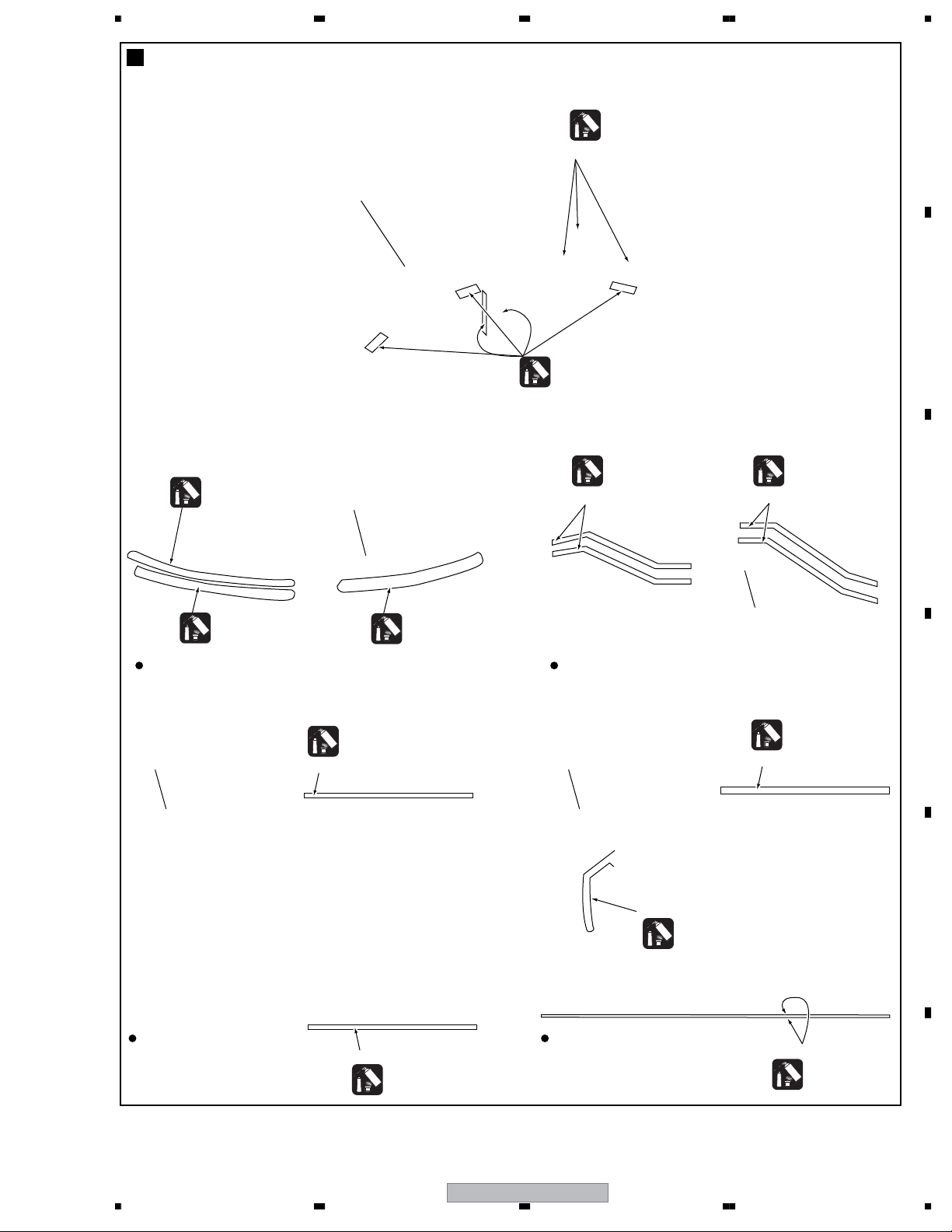

Application of Lubricant

Lubricating Oil

GYA1001

No. 11

Loading Base

No. 13

Drive Cam

Lubricating Oil

GYA1001

Around the shaft

Lubricating Oil

GYA1001

Lubricating Oil

GYA1001

Inner side of a ditch

A

B

Lubricating Oil

GYA1001

Inner side of a ditch

C

Lubricating Oil

GYA1001

Lubricating Oil

GYA1001

Front View Rear View

No. 23

Tray

Daifree

GEM1036

Concave of unevenness

No. 23

Tray

Top View Bottom View

Concave of unevenness

Daifree

GEM1036

Inner side of a ditch

Daifree

GEM1036

No. 13

Drive Cam

D

Daifree

GEM1036

Concave of unevenness

E

Side of the rib

Daifree

GEM1036

F

56

XV-EV1000

15

7

8

Page 16

1234

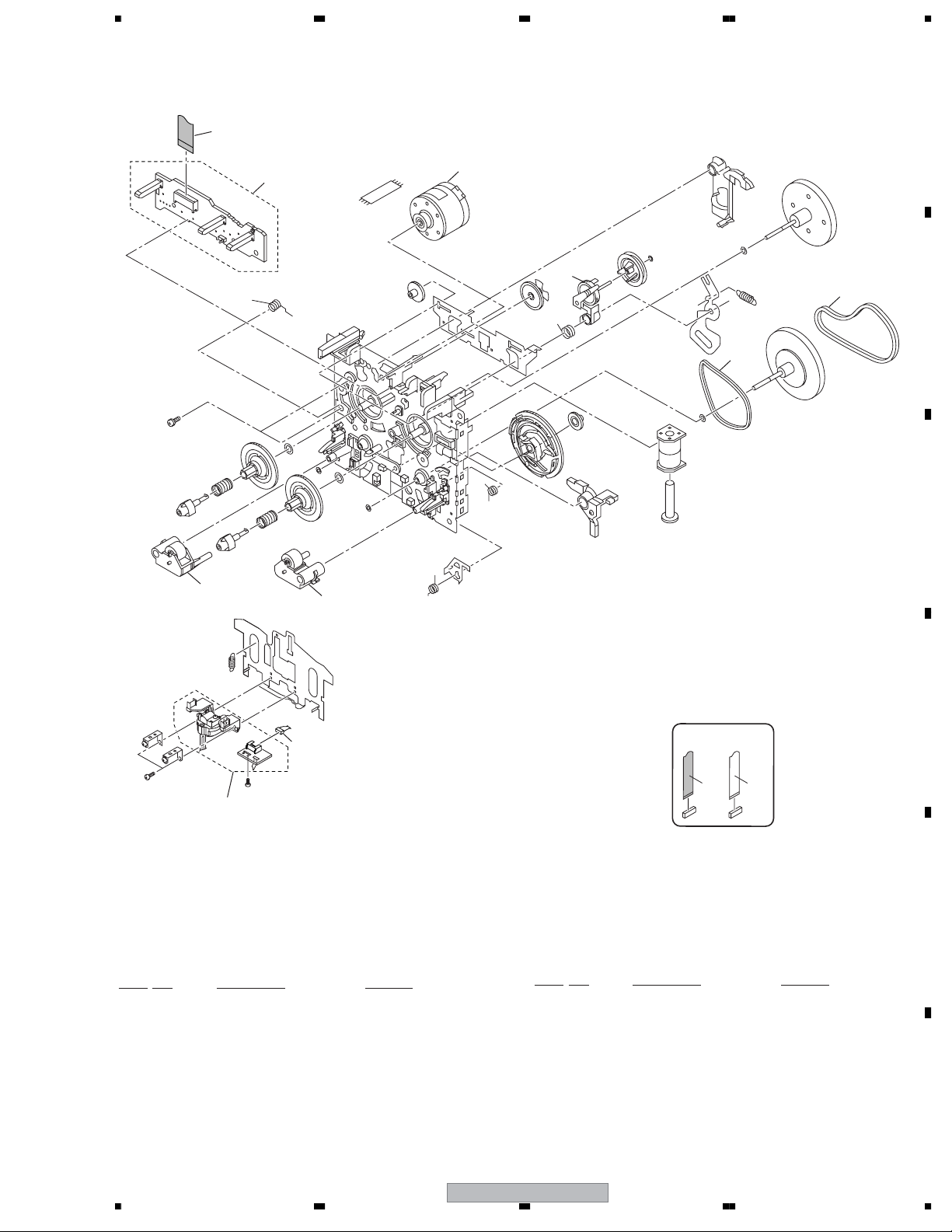

2.6 Traverse Mechanism Assy-S

>

Note :

A

B

C

Refer to

" Application of Lubricant".

Note : When part #2 is replaced,

2

11

To DVDM CN102

(Spindle Motor)

part #13 also need to be

replaced at the same time.

4

10

11

Pickup leneses

Cleaning liquid

GEM1004

Cleaning paper

GED-008

3

10

1

5

6

9

Silicone Adhesive

GEM1037

To

DVDM CN101

(Pickup Assy)

D

8

Note : Spindle screw (DBA1252) of No.13 is the screw which applied special bond.

E

13

Therefore the adhesion becomes ineffective when takes it off once. Spindle screw is the part which cannot recycle.

When part #2 is replaced, part #13 also need to be replaced at the same time.

Traverse Mechanism Assy-S PARTS LIST

Mark

No. Description Part No.

1 05SD Pickup Assy-S OXX8014

2 Spindle Motor N200 DXM1197

3 Guide Shaft VK1 DLA1940

4 Sub Guide Shaft VK1 DLA1941

NSP 5 Joint VK1B DNK4272

12

NON-CONTACT

SIDE

Mark

No. Description Part No.

10 Skew Screw VK1 DBA1211

11 Skew Spring VK1 DBH1516

NSP 12 Stepping Screw DBA1205

13 Spindle Screw VK1(for Service) DBA1252

7

To

DVDM CN104

(Stepping Motor)

CONTACT SIDE

F

6 Joint Spring VK1 DBK1235

7 Stepping Motor VK1 DXM1201

NSP 8 Mechanism Frame VK1 DNK4160

9 Precision Screw VK1 DBA1209

16

1234

XV-EV1000

Page 17

5678

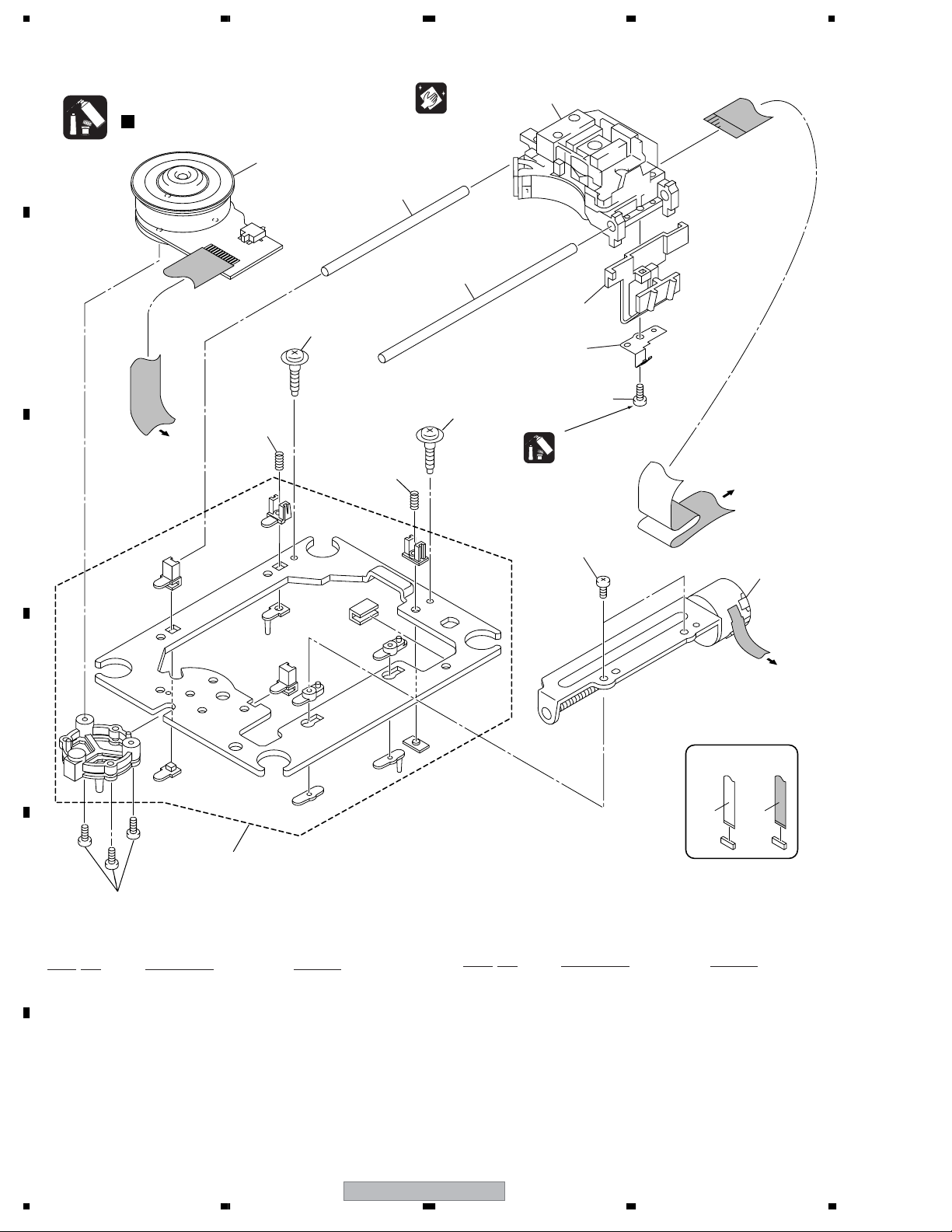

2.7 DECK MECHANISM ASSY

10

A

8

5

4

7

6

1

B

2

C

9

3

DECK MECHANISM ASSY PARTS LIST

No. Description Part No.

Mark

1 Main Belt FF20B-13A

2 F/R Belt FF19S-31

3 Plate HD Blk F513-926

4 Roller Pinch Blk R F514-133

5 Roller Pinch Blk L F514-134

6 Clutch Assy Blk F522-063

7 Motor Main Blk F525-394

8 PCB Control Blk F567-747

CONTACT SIDE

No. Description Part No.

Mark

9 Cable Assy XDE3066

10 11P F.F.C/60V XDD3184

NON-CONTACT

SIDE

D

E

F

56

XV-EV1000

17

7

8

Page 18

MPEG Video Decoder

Video

Encoder

Video

DAC

(withPictureContorol)

rogressive: 54MHz

(VRmode with CPRM)

Audio Decoder

-DD MPEG

JPEG Viewer

WMA Playback

RW Playback

64M SDRAM

16M

FLASH ROM

+ -

6IN-6OUT

VIDEO DRIVER

system control

+ -

DOUT

Cb

Cr

DolbyDigital Decoder

DTS Decoder

DolbyPrologicII

FLO/FRO

SWO

CO

SLO/SRO

PBL/

Lch

Rch

PBR

SBLO/

SBRO

TUNER MODULE

MECHA

AUXL/

AUXR

TXL/

TXR

YO

Y1

X1

XO

DSPINL/

DSPINR

DOWNMIX

SBLO/SBRO

DECKL/

DECKR

SPINDLE

03SD PU

*SINGLE DISC MECHA

Stepping

Motor

Load

Motor

Motor

27MHz

SC

SY

COMPONENT&

COMPOSITE

Y2

X2

X3

Y(Lch)

X(Rch)

1234

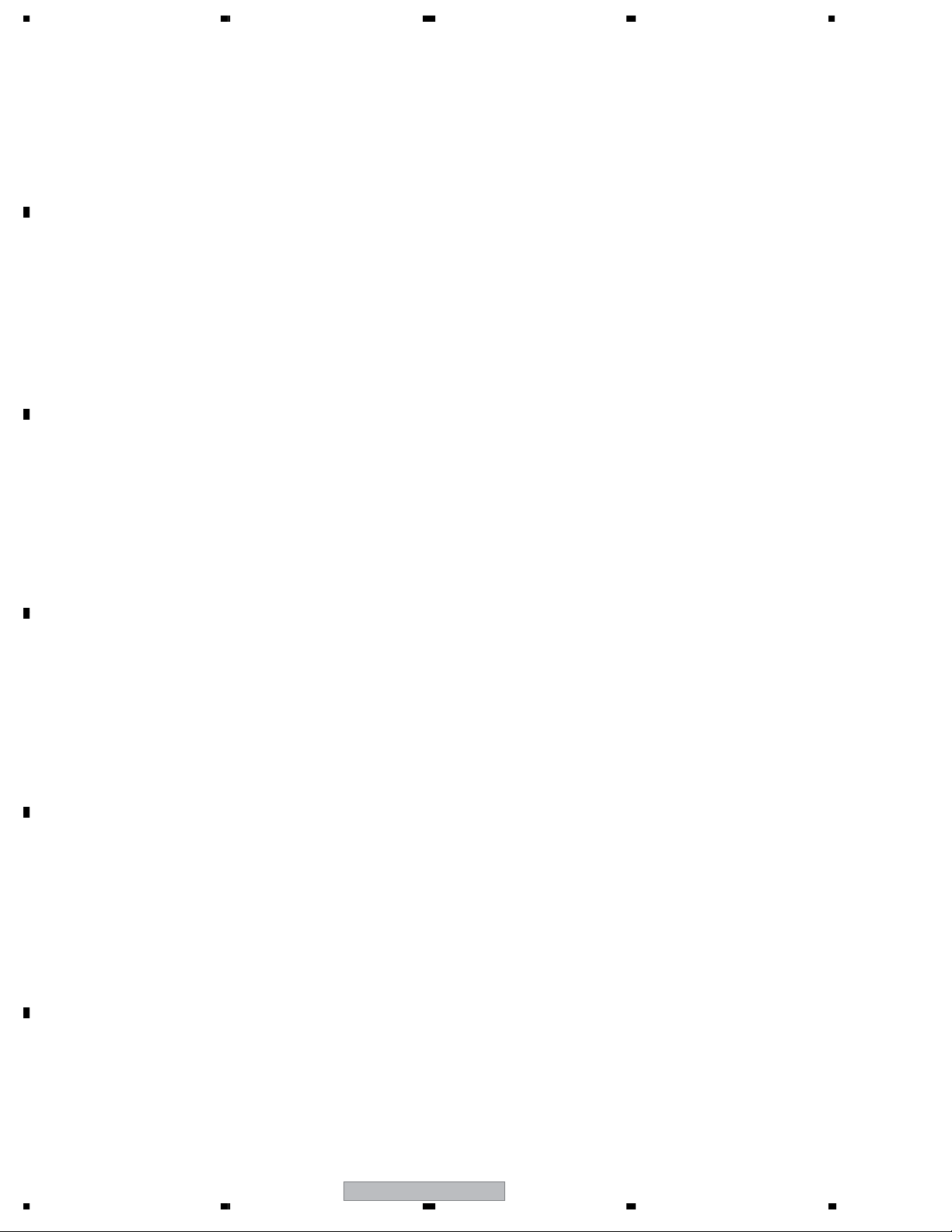

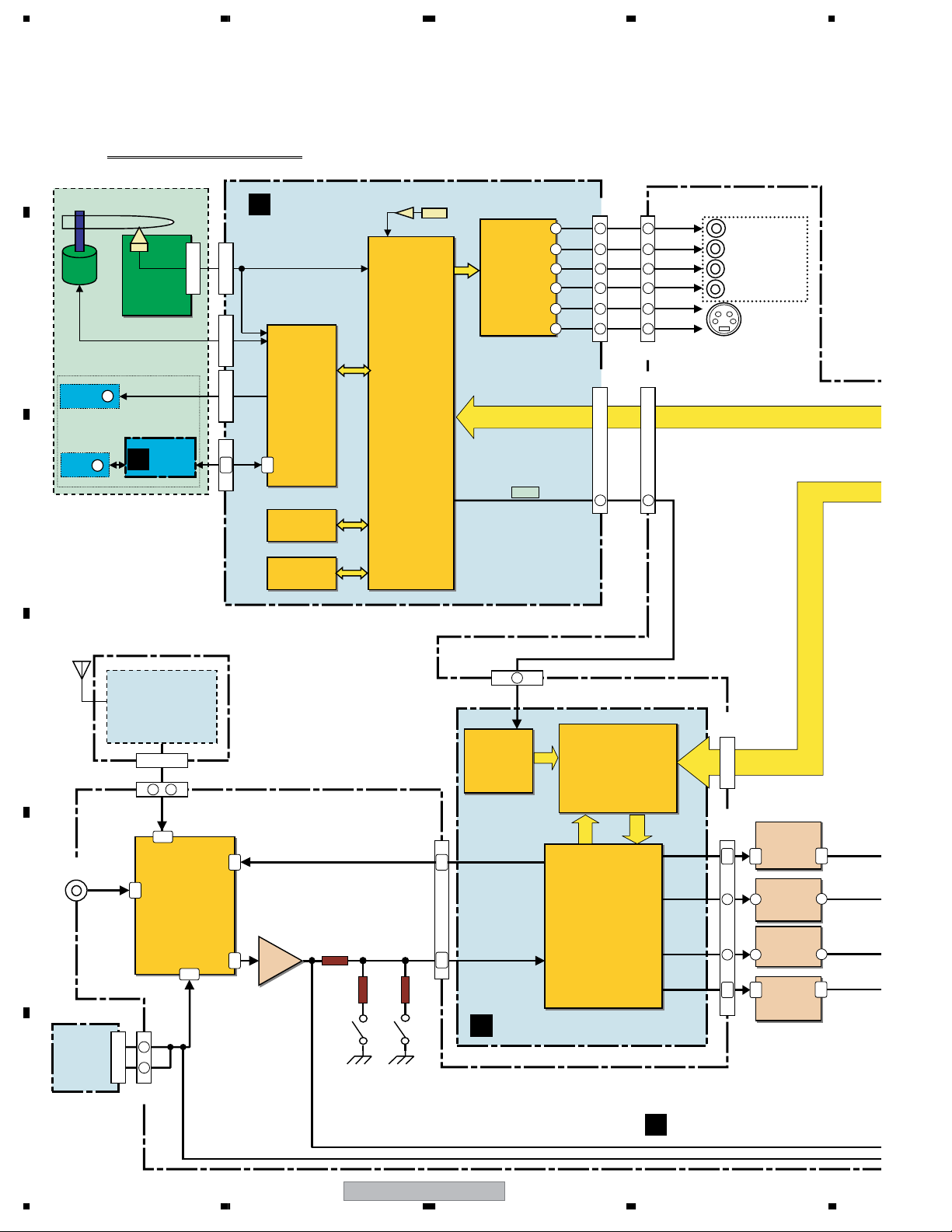

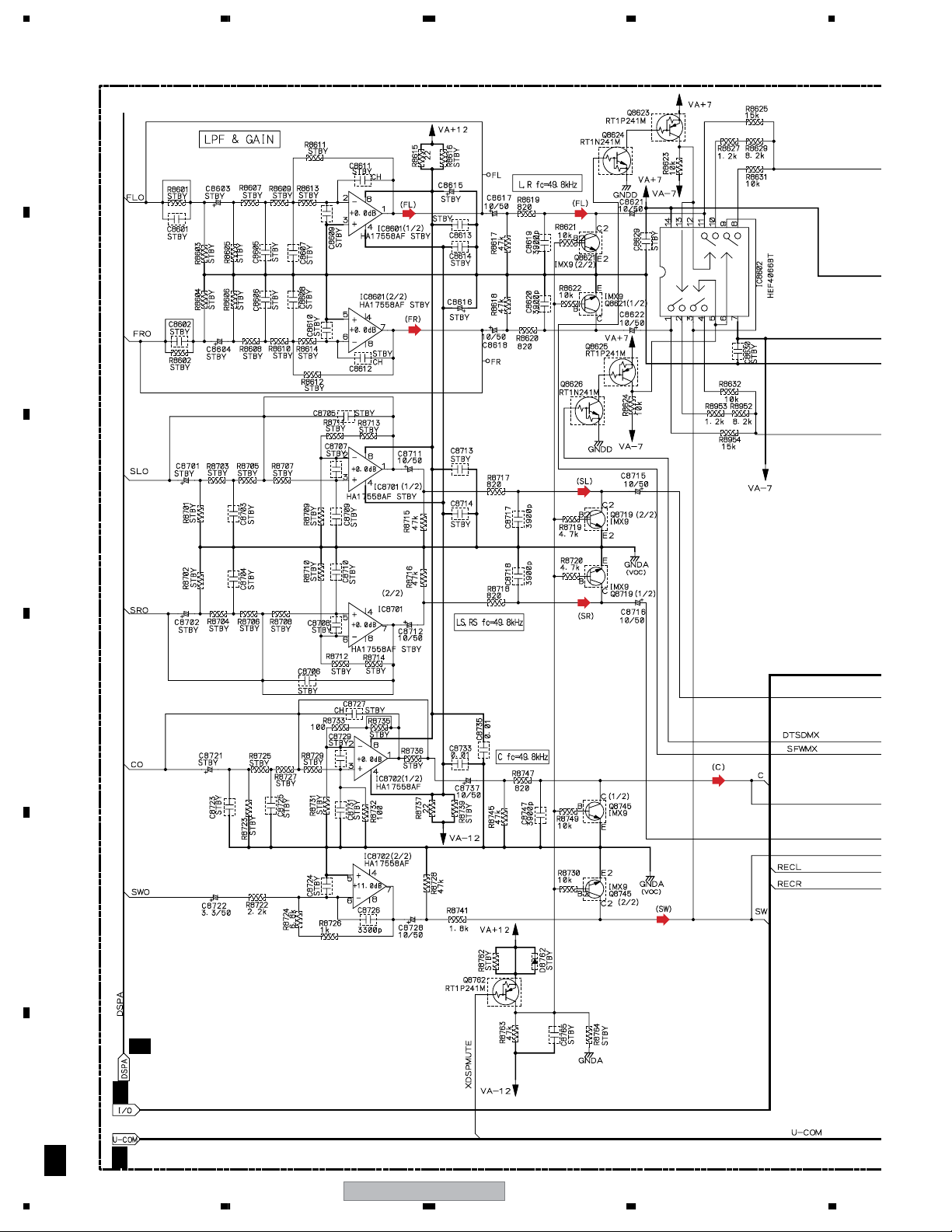

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

3.1 BLOCK DIAGRAM

A

VERTICAL Block Diagram

B

C

SPINDLE

Motor

*SINGLE DISC MECHA

Stepping

M

Motor

+ -

Load

M

+ -

Motor

03SD PU

PlCK UP

ASSY

LOAB

A

ASSY

CN1013

(24P)

CN101

(24P)

CN102

(12P)

CN103

(4P)

1

2

CN104

(5P)

DVDM ASSY

B

FTS DRlVER

IC101

BD7995EFS

1

2

IC202

64M SDRAM

IC203

16M

FLASH ROM

BACK END IC

IC201

MT1389FE/C2-L

system control

·MPEG Video Decoder

·Video

(withPictureContorol)

·Video

(Progressive: 54MHz

·Audio Decoder

-DD MPEG

·JPEG Viewer

·WMA Playback

·RW Playback

(VRmode with CPRM)

Encoder

DAC

27MHz

)

VIDEO DRIVER

AMP

IC401

MN1623BF

6IN-6OUT

DOUT

CN902

(27P)

R

16

16

G

20

12

B

18

14

V

23

26

21

SC

SY

CN901

(25P)

8

6

10

16

CN8301

CN5102

16

12

14

10

(27P)

(25P)

16

8

6

Cr

Y

Cb

V

C

4

Y

3

COMPONENT&

COMPOSITE

VIDEO OUT

JA8850

S-VIDEO

OUT

CN8830

D

E

F

LINE IN

CN8401

TAPE DECK

MECHA

XYM3019

TUNER MODULE

AUXL/

AUXR

6 8

TXL/

TXR

1 12

2

Y2

15

X2

(BUH4052BCF)

Lch

3

Rch

1

CN2301

(4P)

DECKL/

DECKR

CN5701

(11P)

YO

XO

FUNCTION

SELECTOR

IC8101

HEF4052BT

Y3Y3X3

4 11

PBL/

PBR

Y(Lch)

X(Rch)

X1

Y1

14

5

3

13

SBLO/

SBRO

3

BUFFER

5

IC8111

HA17558AF

1

7

ATTENUATOR

- 6dB

DSPINL/

DSPINR

- 10dB

CN5506

(1/2)

(19P)

CN5505

17

19

1

3

(9P)

DIR

IC8201

AK4114

DOWNMIX

SBLO/SBRO

DSP ASSY

D

2

IC8501

DSPD56367PV150

·DolbyDigital Decoder

·DolbyPrologicII

·DTS Decoder

IC8401

AK4529

8ch

CODEC

FLO/FRO

SWO

CO

SLO/SRO

IFAF ASSY

C

CN5507

(13P)

CN5506

(2/2)

(19P)

5

7

13

15

9

11

PASSIVE

LPF

IC8601

2

HA17558AF

6

LPF

6

IC8702(1/2)

HA17558AF

LPF

IC8702(2/2)

3

HA17558AF

PASSIVE

3

5

LPF

IC8701

HA17558AF

1

7

7

1

1

7

18

XV-EV1000

1234

Page 19

Power Amp

HFE4066BT

AMP

ECHO

RECL/

RECR

DECKL/

DECKR

MICDET

MIC DET

FL/FR

SW

SL/SR

FL/FR

SW

SL/SR

MIC

ANDREW CIRCUIT

POWER AMP

MODULE

M65847AFP

NJM4565M

SL

SR

S5101-S5108

D5207,5209

D5211-5213

S5201-S5207

GP1UM28XK0VF

Power Amp

5678

LED ASSY

F

D5207,5209

D5211-5213

J1

(4P)

J1

(4P)

IR

SENSOR

IC5201

GP1UM28XK0VF

MICROPROCESSOR

IC5501

PDC127

KEY

CONTROL

IC8201

M65847AFP

VOCAL

FADER

IC8301

BA3838F

2

3

13

6

9

S5101-S5108

S5201-S5207

3

E

S5301

OPEN/CLOSE

S5304

MS-/REW

MICDET

RECL/

RECR

KEY ASSY

1

J2

(2P)

1

J2

(2P)

G

CN5105

(5P)

5 5

3 3

S5302

PLAY

S5305

MS+/FF

S5303

STOP

DISPLAY ASSY

MIC DET

J5401

(5P)

H

MIC ECHO

8

IC5401

BU9255FS

LCD ASSY

LCD DISPLAY

LCD DRIVER

CN5104

(10P)

CN5101

(13P)

HP/MIC ASSY

9

IC5402

HA17558AF

MIC

7

AMP

CN5501

(13P)

2

MIC 2

JA5401

MIC 1

JA5402

A

B

C

DECKL/

DECKR

IC 8602

HFE4066BT

1

11

CN8303

11

(27P)

9

7

1

3

5

10

9

3

9

11

7

1

3

5

CN3051

(27P)

4

8

19

FL/FR

17

SW

9

15

C

13

SL/SR

11

BD3814FV

27

28

32

E-VOL

IC3062

29

30

31

FL/FR

SW

C

SL/SR

POWER ASSY

J

3

IC3056

5

HA17558AF

IC3058(1/2)

5

HA17558AF

ANDREW CIRCUIT

IC3058(2/2)

3

HA17558AF

IC3057

3

5

HA17558AF

1

7

7

1

1

7

3

5

CN3011

HEADPHONE

AMP

IC3901

NJM4565M

CN3031

(17P)

6

6

8

8

12

12

10

10

14

14

16

16

(17P)

7

17

19

20

21

22

23

CN3021

(23P)

XV-EV1000

56

241

CN3008

(4P)

CN3002

(23P)

17

19

20

21

22

23

TRADE ASSY

K

2

4

J3902

(4P)

AMP ASSY

I

11

15

STK433-270

16

Power Amp

16

STK433-270

Power Amp

11

15

POWER AMP

MODULE

IC3401

3ch

IC3301

3ch

7

4-7

181914

18

19

4-7

CN3001

18

19

22

23

15

10

11

3

4

7

8

(23P)

CN3022

(23P)

18

19

22

23

14

15

10

11

3

4

7

8

J3033

(14P)

SR

SL

J3032

(13P)

HEADPHONE

JACK

JA5403

CN3013

(14P)

3

3

6

6

8

8

11

11

14

14

3

3

CN3012

(13P)

LINE

OUT

CN8401

JA3301

(12P)

D

FL/FR

OUT

SW

OUT

CENTRE

OUT

SL/SR

OUT

E

F

19

8

Page 20

1234

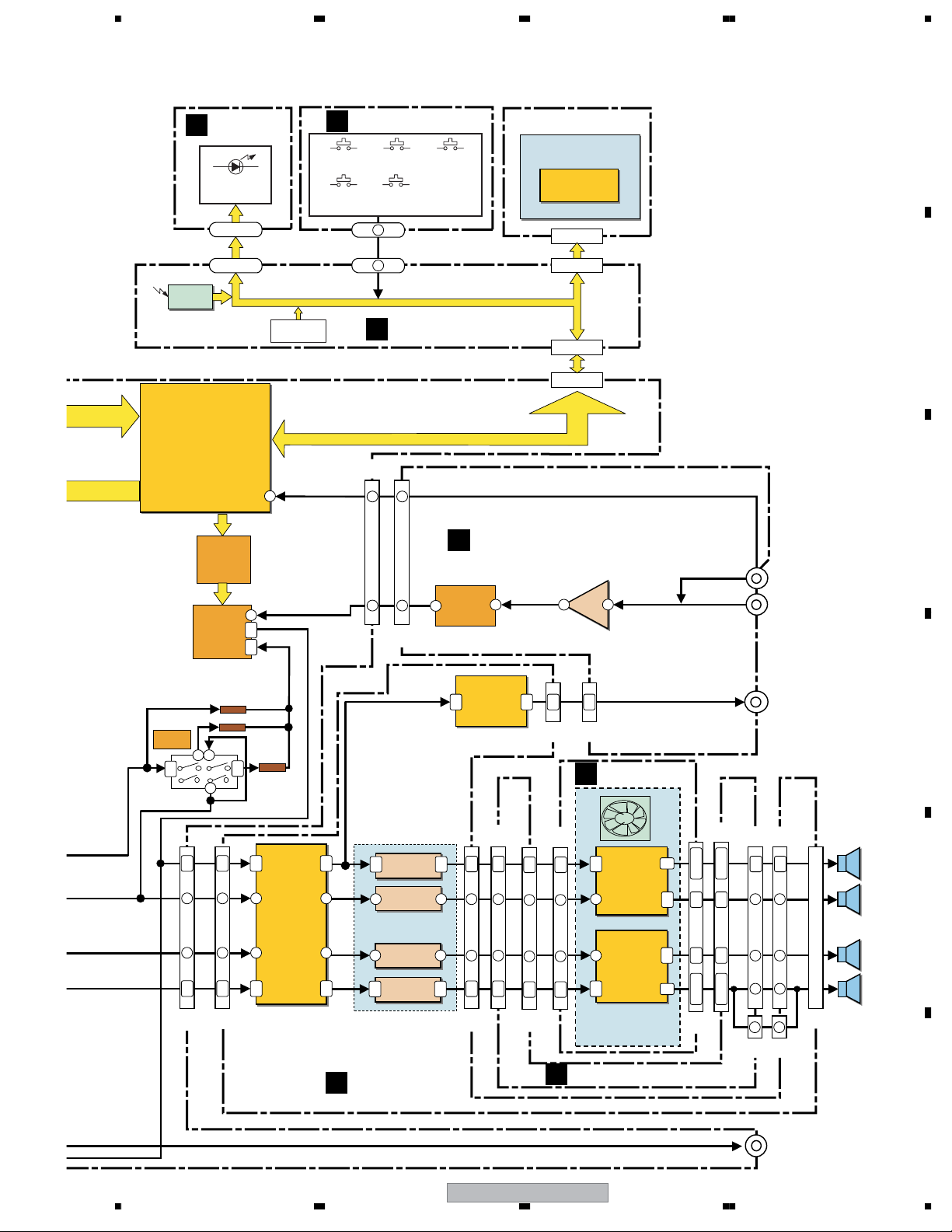

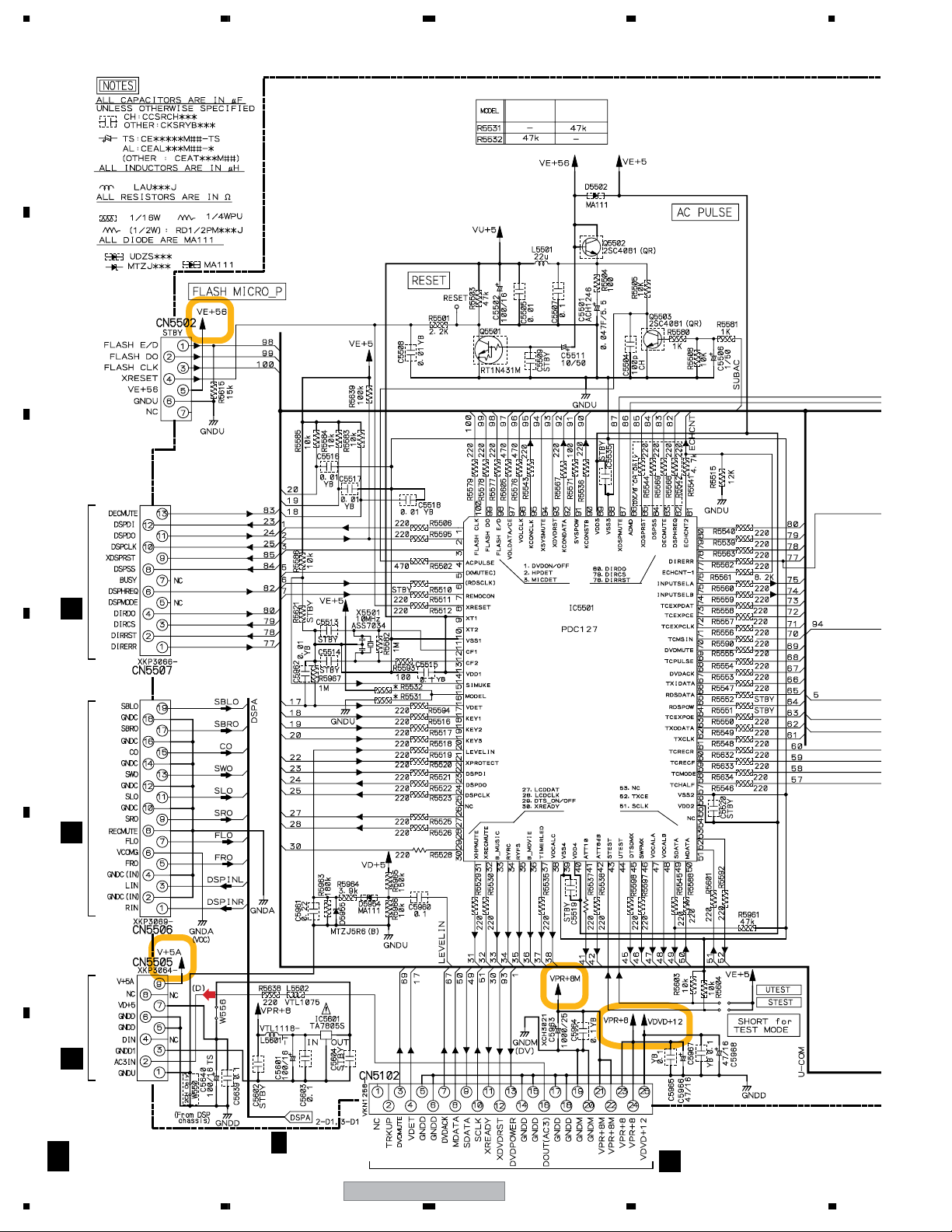

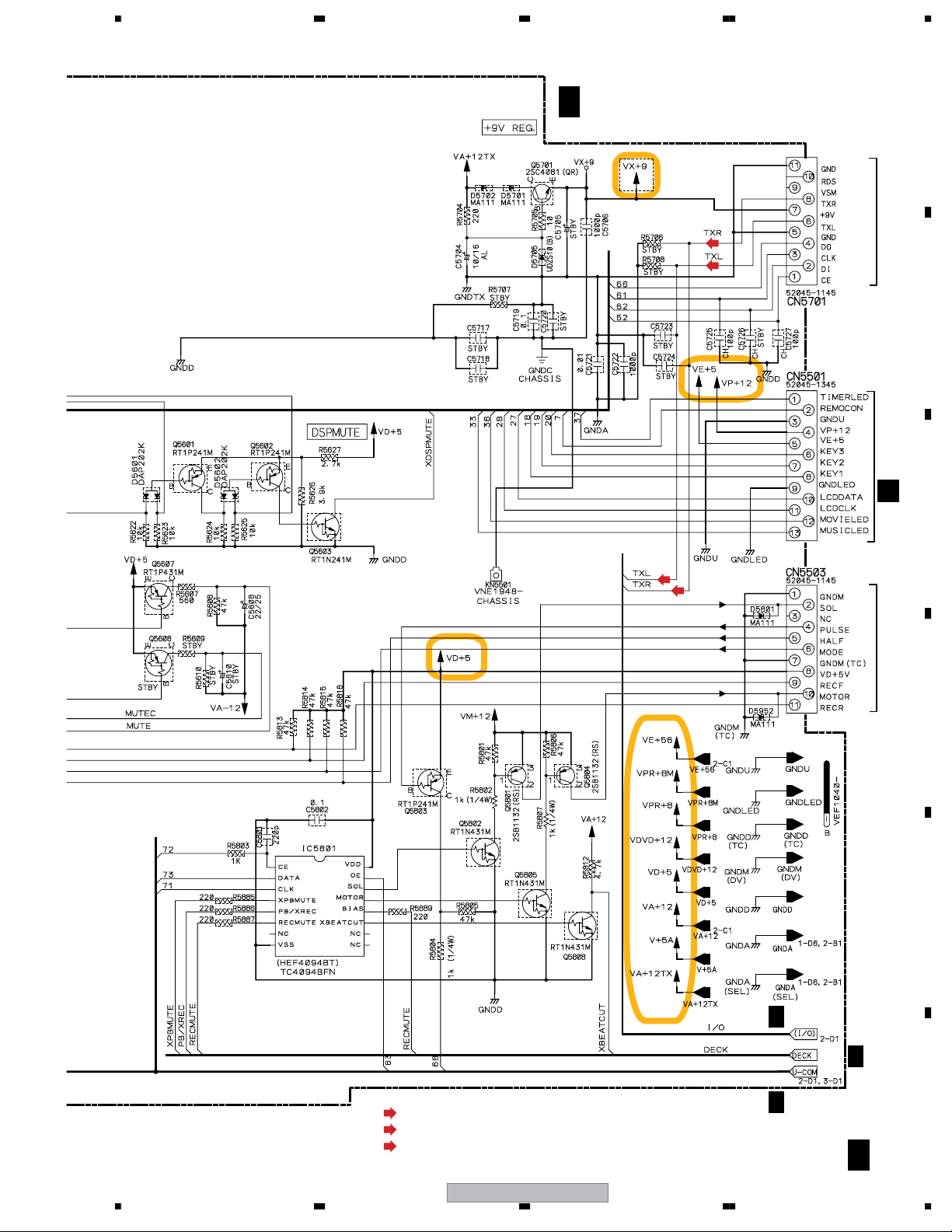

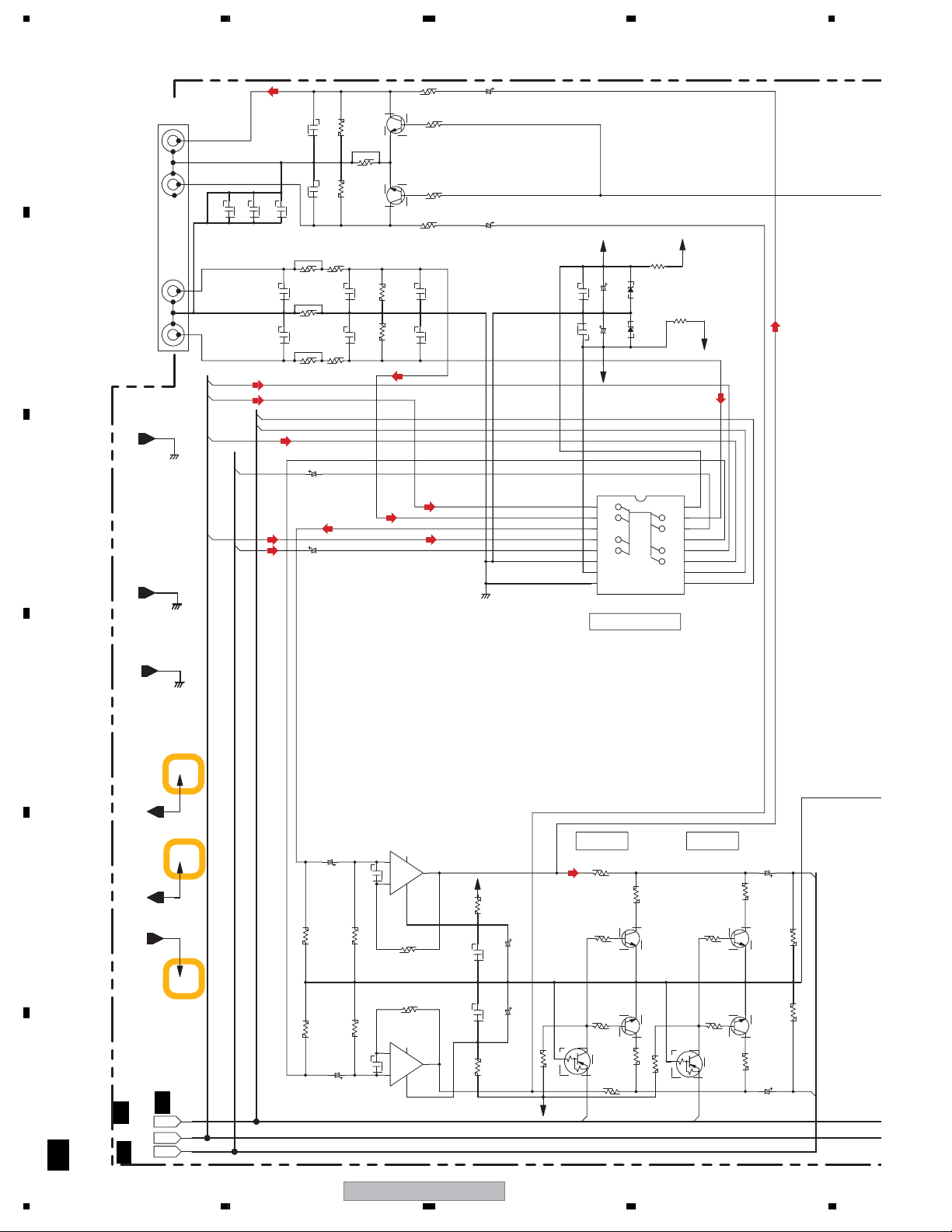

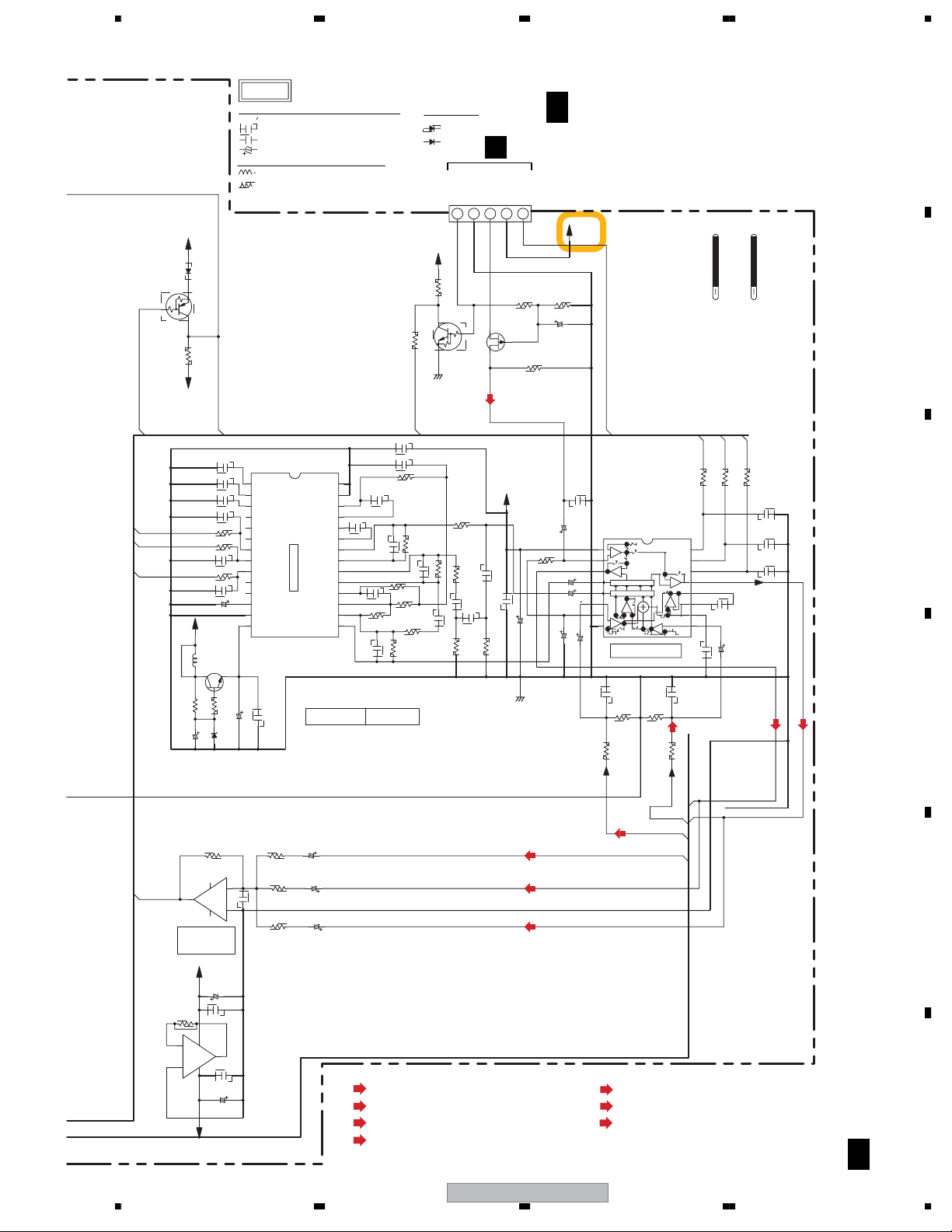

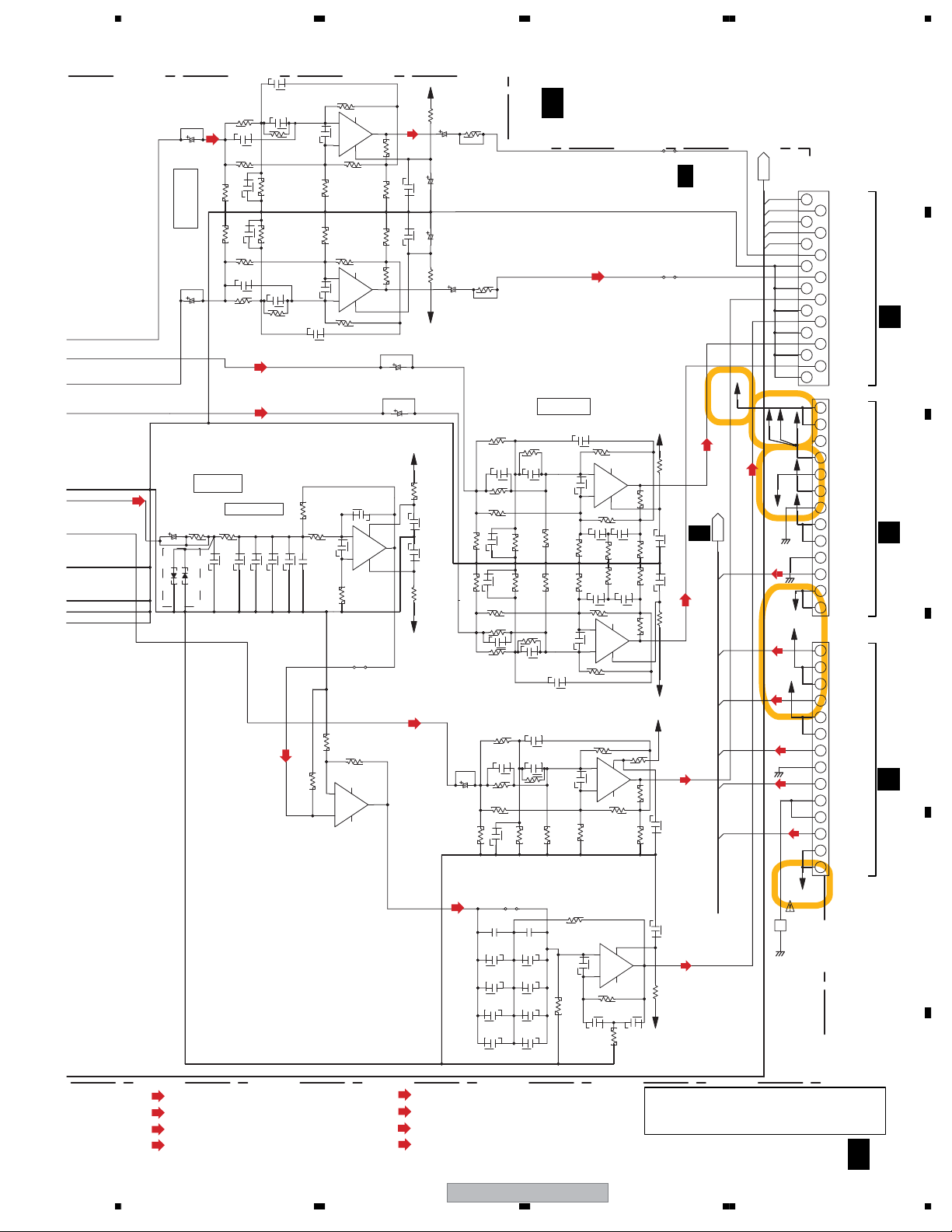

3.2 OVERALL WIRING CONNECTION DIAGRAM and LOAB ASSY

FLOUT

FLOUT

VL-

VL-

FROUT

FROUT

VL+

VL+

SWOUT

VH+

COUT

VH+

A

1

Speaker for FL/FR

B

Speaker for SL/SR/C/SW

2

3

4

5

6

7

8

9

10

11

12

JA3301

XKE3037

J 1/4-

J 4/4

J

AMP ASSY

I

(XWK3202)

POWER ASSY

(XV-EV1000:XWZ4016)

(XV-EV700:XWZ4018)

23

23

GNDA

16

17 131415

17 15

16

GNDA

22

22

FLOUT

SRIN

SRIN

21

FLOUT

GNDA

14

GNDA

20

21

20

VL-

VL-

SLIN

13

SLIN

SWOUT

181516

14

19

GNDA

12

GNDA

19

13

17

151617

131211

18

14

VL+

VL+

FROUT

FROUT

SWOUT

SWOUT

GNDA

SWIN

GNDA

CIN

GNDA

FRIN

10

8

11129

7653211213

XDD318017P FFC

11

9

7653211312

8

10

CIN

FRIN

SWIN

GNDA

GNDA

GNDA

HP/MIC ASSY

H

(XWZ4014)

NC

10P FPC

D20PYY0410

1

VLCD

2

VSS

3

NC

4

VDD

5

NC

6

LCDCLK

7

LCDDAT

8

NC

9

NC

10

52492-1020

CN5104

VP+12

4

LEDCN2

3

LEDCN1

2

GNDLED

1

D20PYY0225

DISPLAY ASSY

G

(XV-EV1000:XWZ4012)

(XV-EV700:XWZ4010)

KEY3

GNDU

21

J2

51048-0200

21

J2_

GNDU

KEY3

51048-0200

LCD ASSY

(XAV3028)

C

D

LED ASSY

F

(XWZ4023)

NC

NC

LCDDAT

LCDCLK

NC

VDD

NC

VSS

VLCD

NC

VP+12

4

LEDCN2

3

LEDCN1

2

GNDLED

1

51048-0400 51048-0400

J1_ J1

KEY ASSY

E

(XWZ4013)

NOTES: • When ordering service parts, be sure to refer to “EXPLODED

VIEWS and PARTS LIST” or “PCB PARTS LIST”.

E

F

• The > mark found on some component parts indicates the

importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical

designation.

• : The power supply is shown with the marked box.

COUT

12

10

11

9

987

10

VH+

VH+

COUT

COUT

FLIN

MUTE

MUTEC

RYFS

4

4

FLIN

RYFS

MUTE

MUTEC

HP DET

CN3008

52151-0410

HP DET

51048-0400

J3902

SLOUT

SLOUT

GNDS

GNDP

GNDP

SROUT

SROUT

8

4

7

365

3

4

652

GNDS

GNDP

GNDP

SLOUT

SLOUT

SROUT

SROUT

RYRC

XPROT

VPR+8

52044-1745

52044-1745

VPR+8

RYRC

XPROT

CN3011 CN3031

HP L

HP R

GNDHP

4132

D20PYY0430E

2143

HP R

GNDHP

51048-0500

MUSICLED

MOVIELED

LCDCLK

LCDDAT

GNDLED

REMOCON

TIMERLED

CN5101

HP L

ECHOVOL

J5401

KEY1

KEY2

KEY3

VE+5

VP+12

GNDU

52044-1345

MICSW

VA+12V

12

10

DSP ASSY

D

VH-

2

1

1

VH-

VPR+8

VPR+8

GNDA

MIC

11

9

8

77

6

5

4

3

2

1

DECMUTE

DSPDI

DSPDO

DSPCLK

XDSPRST

DSPSS

DSPHREQ

DSPMODE

DIRDO

DIRCS

DIRRST

DIRERR

GNDC

SBRO

GNDC

GNDC

GNDC

(AWX8588)

GNDC

RECMUTE

VCOMG

GNDC(IN)

GNDC(IN)

GNDD

GNDD

GNDD1

AC3IN

GNDU

VH-

VH-

VFL+5

10 7811 456932

VFL+5

5

44

33

2

1

XDD3185

13P FFC

BUSY

XKP3078-

SBLO

CO

SWO

SLO

SRO

FLO

FRO

LIN

RIN RIN

XKP3080-

V+5A

NC

VD+5

DIN

XKP3076-

SLIN

SRIN

22

23

21

XKP3071

CN3001

23

21

22

XKP3082-

SLIN

SRIN

CN3022

VP+12

VD+5

VA-12

D20PYY1315E

VD+5

VA-12

VP+12

5

2

D20PYY0520E

1

CN5105

52147-0510

1

3

5

7

HLEM7S

CN5502

1313

11

9

5

3

1

52044-1345

CN5501

13

11

9

7

5

3

1

CN5507

XKP3066-

19

17

15

13

11

9

7

5

3

1

XKP3069-

CN5506

9

7

5

3

1

CN5505

XKP3064-

SWIN

CIN

FLIN

GNDA

FRIN

20

18

16

17

19

19

17

20

18

16

CIN

FLIN

FRIN

SWIN

GNDA

UN+8V

UN+8V

GNDF

GNDREG

610 5 479811 3 2

GNDF

UN+8V

UN+8V

GNDREG

15 1314

51048-1500

J3002

15 1314

CN8302

52147-1510

MICSW

GNDA

MIC

VA+12V

ECHOVOL

FLASH E/D

FLASH DO

2

FLASH CLK

XRESET

4

VE+56

GNDU

6

NC

FLASH MICRO_P

MUSICLED

12

MOVIELED

LCDCLK

10

LCDDAT

GNDLED

8

KEY1

KEY2

6

KEY3

VE+5

4

VP+12

GNDU

2

REMOCON

TIMERLED

DECMUTE

12

DSPDI

DSPDO

10

DSPCLK

XDSPRST

8

DSPSS

BUSY

6

DSPHREQ

DSPMODE

4

DIRDO

DIRCS

2

DIRRST

DIRERR

SBLO

18

GNDC

SBRO

16

GNDC

CO

GNDC

14

SWO

GNDC

12

SLO

GNDC

10

SRO

8

RECMUTE

FLO

6

VCOMG

FRO

GNDC(IN)

4

LIN

GNDC(IN)

2

V+5A

8

NC

VD+5

6

GNDD

GNDD

4

DIN

GNDD1

2

AC3IN

GNDU

VPR+8

15

15

VPR+8

VD+5

VD+5

VPR+8

14

14

VPR+8

SLOUT

SLOUT

VA+5

VA+5

MUTE

13

MUTE

MUTEC

13

MUTEC

VL-

VL-

VP+12

VP+12

20

XV-EV1000

1234

Page 21

5678

RYRC

VFL+5

RYFS

VA-12

VP+12

8

121110

11

987

12

10

RYFS

VA-12

VFL+5

VP+12

VL-

14

51048-1300

J3032

114113 12

VL-

52147-1310

GNDF

XPROT

VD+5

GNDREG

GNDREG

UN+8V

UN+8V

6

2

4

793

5

5

3

4

6

2

VD+5

GNDF

UN+8V

UN+8V

XPROT

GNDREG

GNDREG

SROUT

COUT

VL+

VL+

11

1213

D20PYY1415E

10 7811 4569132

VL+

VL+

COUT

SROUT

1

1

RYRC

VH+

VH+

CN3012

GNDM(DV)

GNDM(TC)

VPR+8M

VPR+8M

12 911 10 67854213

D20PYY1515E

12 911 10 67854213

VPR+8M

GNDM(TC)

GNDM(DV)

VPR+8M

L

GNDD

GNDD

GNDD

GNDD

LINE IN

R

VPR+8

VPR+8

VPR+8

VPR+8

CN3651

KM200SA2

CN3002

XKP3082- XKP3071

K

CN3021

SWOUT

VH+

GNDS

VH+

SWOUT

VA-12

GNDTX

VA-12

GNDTX

L

LINE OUT

GNDS

VA+12TX

VA+12TX

R

FAN

XXM3009

1

2

TRADE ASSY

(

XWZ4022

GNDP

FLOUT

61054798

GNDP

FLOUT

FROUT

GNDP

321

GNDP

FROUT

)

51048-1400

VH-

VH-

J3033

VH-

VH-

52147-1410

CN3013

GNDU

VE+56

RYFS

RYRC

VA+12

CN3051

VA+12

CN8303

27

52044-2745

27

52044-2745

GNDU

26

26

VE+56

252223

25

NC

MUTECNCMUTE

24

23

24

MUTEC

RYRC

22

RYFS

21

21

MUTE

EVOLDATA

EVOLCLK

SYSPOW

HPAC1

2013161514

171819

171615

19

20

18

HPAC1

SYSPOW

EVOLCLK

EVOLDATA

IFAF ASSY

C

(XV-EV1000:XWZ4003)

(XV-EV700:XWZ4006)

C 1/4- C 4/4

AKB7015

CN8401

Y

Cb

VIDEO/COMPONENT OUT

XPROTECT

HPDET

SUBAC

XHPMUTEFRGNDAFLGNDA

GNDA

10

12

987456123

11

27P FFC

XDD3186

9

13

8

121110

GNDAFRGNDAFLGNDASWGNDASRGNDASLGNDA

XPROTECT

VKB1168-

JA8850

Video

HPDET

XHPMUTE

Cr

14

SUBAC

9

8

7

6

5

SW

GNDASRGNDASLGNDA

567

4

S-VIDEO OUT

T2

ATT7080

230V1230VNC100VNC120V

115V

2

C

S1

123

C

CN2302

CN2301

AKP7179-

NC3NC NC

0V40V 0V0V

lkji

XKX3001

2

1

2

1

GNDA

L CH

BIAS

VREF

VREF

R CH

B2B-PH-K-S

B4B-PH-K-S

GNDM

SOL

NC

PULSE

HALF

MODE

GNDM(TC)

VD+5V

RECF

MOTOR

RECR

52045-1145

CN5503

NC

TRKUP

DVDMUTE

VDET

GNDD

GNDD

DVDACK

MDATA

SDATA

SCLK

XREADY

XDVDRST

DVDPOWER

GNDD

GNDD

DOUT(AC3)

GNDD

GNDD

GNDM

GNDM

VPR+8M

VPR+8M

VPR+8

VPR+8

VDVD+12

VKN1256

CN5102

NC

GNDA

NC

GNDA

GNDD

NC

GNDD

NC

GNDD

NC

GNDD

R

GNDD

B

GNDD

G

GNDD

SY

GNDD

V

GNDD

SC

ASPECT

VSEL1

VSEL2

SQUEEZE

NC

VKN1258-

CN8301

CE

DI

CLK

DO

GND

TXL

+9V

TXR

VSM

RDS

GND

52045-1145

CN8830

CN5701

NC

NC

hgf

44

232

1

1

2

3

4

5

6

7

8

9

10

11

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

1

2

3

4

5

6

7

8

9

10

11

3

1

XDD3184

11P FFC

XDD3175

25P FFC

XDD3176

27P FFC

XDD3179

11P FFC

L1

XTF3004

Deck Shield Wire 5P

XV-EV1000

56

ACE7013

RY81

XSR3008

C3

edc ab

1

2

3

4

5

6

7

8

9

10

11

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

VKN1256-

CN901

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

VKN1258-

1

2

3

4

5

6

7

8

9

10

11

7

C1

FU1

H2

0.01

AEK1061

0.01

ACE7013

XDE5066

GNDM

SOL

NC

PULSE

HALF

MODE

GNDM(TC)

VD+5V

RECF

MOTOR

RECR

NC

TRKUP

DVDMUTE

VDET

GNDD

GNDD

ACK

MDATA

SDATA

SCLK

XREADY

XDVDRST

DVDPOWER

GNDD

GNDD

DOUT

GNDD

GNDD

GNDM

GNDM

VPR+8M

VPR+8M

VPR+8

VPR+8

VDVD+12

NC

GNDA

NC

GNDA

GNDD

NC

GNDD

NC

GNDD

NC

GNDD

R

GNDD

B

GNDD

G

GNDD

SY

GNDD

V

GNDD

SC

ASPECT

VSEL1

VSEL2

SQUEEZE

NC

CN902

CE

DI

CLK

DO

TXL

+9V

TXR

VSM

RDS

GND

AN1

XKP3084

H1

LIVE

2

1

NEUTRAL

CN1

B2P3-VH

2

2

0v

1

1

120v

CN2

B4P7-VH

0v

4

4

0v

3

3

10v

2

2

120v

1

1

CN4

B7P-VH

BHAC1

1

BHAC1

BLAC1

2

BLAC1

BLAC2

BHAC2

SUBAC1

SUBAC1

BIAS

GND

3

GND

BLAC2

4

BHAC2

5

SUBAC1

6

SUBAC1

7

R CH

VREF

VREF

TAPE DECK

MECHA

XYM3019

FOCS RTN

FOCS DRV

TRKG RTN

TRKG DRV

VSHF

GND

LD(650)

PD

LD(780)

GND

MPD(780)

MD

MPD(650)

VREF(2.1V)

B2

B1

A

OEICG

C

780/650

B4

B3

VCC

GND

INSIDE

V+5S

GNDS

H3-

DVDM ASSY

(AWM7964)

H3+

H2-

H2+

H1-

B

H1+

A1

A2

A3

ST2-

ST2+

ST1+

ST1-

AKN7035

CN103

SW1

V+3D

B 1/2- B 2/2

SW2

LOAD+

LOAD-

S5B-PH-SM3

CN104

TUNER MODULE

L CH

24

22

20

18

16

14

12

10

8

6

4

2

1

3

5

7

9

11

4

3

2

1

5

4

3

2

1

XTS3099-A

DVD MODULE

23

21

19

17

VKN1482

15

13

11

ADD7418

9

7

5

3

CN101

1

2

4

AKN7301

6

8

10

10

12

12

CN102

4

3

2

1

5

4

3

2

1

CN602

T1 *

23

21

19

17

15

13

11

24P FFC

9

7

5

3

1

INSIDE

1

2

V+5S

GNDS

3

H3-

4

H3+

5

6

H2H2+

7

8

H1H1+

9

A1

A2

11

A3

S5B-PH-K-S

CN601

SW1

V+3D

SW2

LOAD+

LOAD-

LOADING

MOTOR

ASSY

120

10

0

0 0

XXA3037

FOCS RTN

24

FOCS DRV

TRKG RTN

22

TRKG DRV

VSHF

20

GND

18

LD(650)

PD

LD(780)

16

GND

14

MPD(780)

MD

MPD(650)

12

VREF(2.1V)

10

B2

B1

A

8

OEICG

C

6

780/650

B4

4

B3

VCC

2

GND

CN1013

SPINDLE

MOTOR

STEPPING

MOTOR

2

1

: VXX2912

8

120120

0 0

PICKUP ASSY

LOAB ASSY

(VWG2346)

A

A

A

B

C

D

E

F

21

Page 22

1234

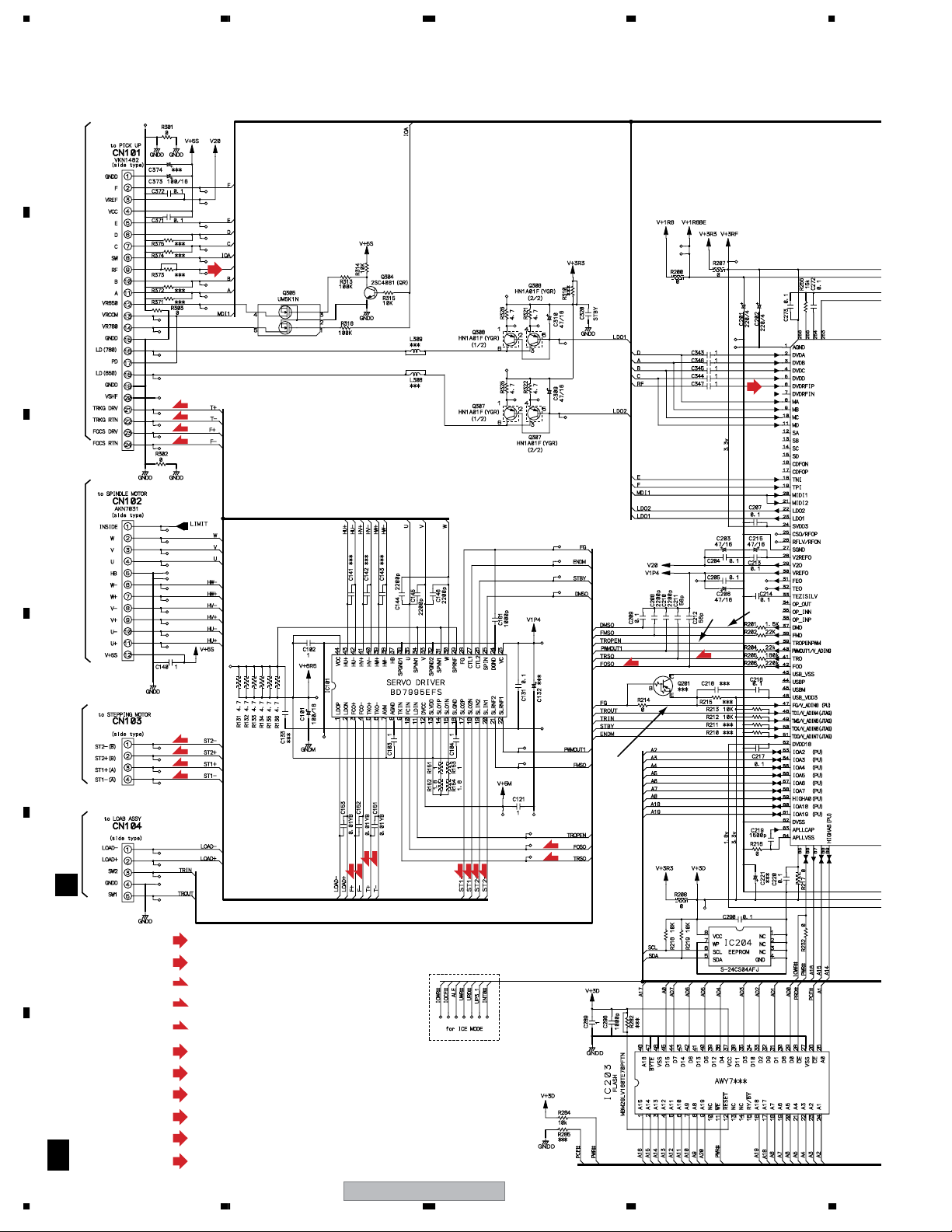

3.3 DVDM ASSY (1/2)

A

(RF)

B

LD Driver for CD

(RF)

(T)

(T)

(F)

(F)

LD Driver for DVD

C

FTS DRIVER

3

2

(F)

(T)

D

E

F

B

A

22

AKN7035

MOTOR

STEPPING

S5B-PH-SM3

CN601 PICKUP ASSY CN1013SPINDLE MOTOR

A

(RF)

(D)

(F)

(T)

(S)

(C/V)

(R/Cr)

(G/Y)

(B/Cb)

(S_Y)

1/2

(S_C)

1234

(S)

(S)

(S)

(S)

: RF SIGNAL ROUTE

: AUDIO SIGNAL ROUTE(DIGITAL)

: FOCUS SERVO LOOP LINE

: TRACKING SERVO LOOP LINE

: STEPPING SERVO LOOP LINE

: VIDEO SIGNAL ROUTE

: VIDEO SIGNAL ROUTE(R/Cr)

: VIDEO SIGNAL ROUTE(G/Y)

: VIDEO SIGNAL ROUTE(B/Cb)

: S VIDEO SIGNAL ROUTE

: S VIDEO SIGNAL ROUTE

(F)

(F)

(T)

(T)

XV-EV1000

1

(F)

(S)

(S)

(S)

(S)

(T)

Page 23

5678

(D)

!

(R/Cr)

(B/Cb)

B

DVDM ASSY

1/2

A

(AWM7964)

2/2B

2/2

B

(S_Y)

(S_C)

(G/Y)

(C/V)

B

C

56

XV-EV1000

D

E

2/2

B

F

B

1/2

23

7

8

Page 24

1234

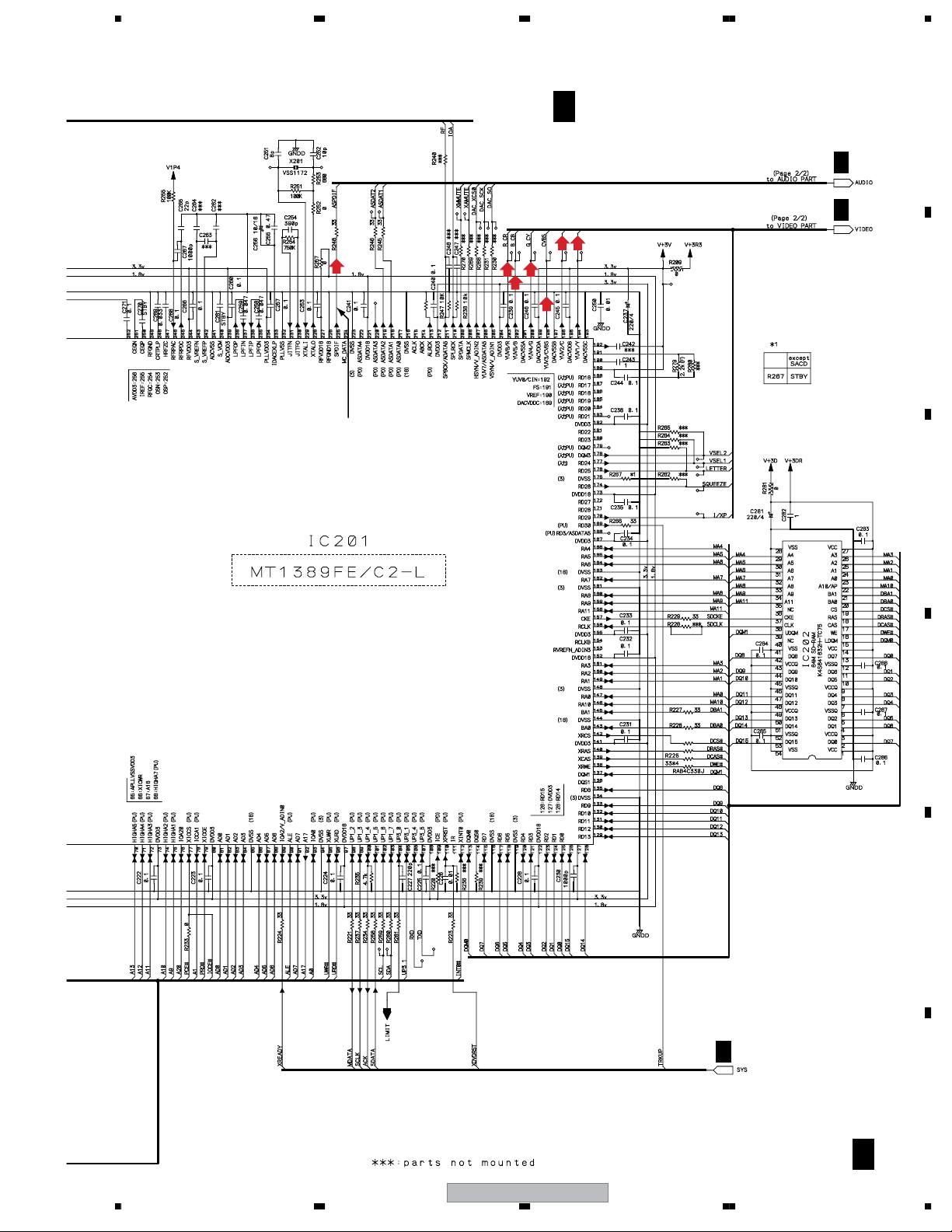

3.4 DVDM ASSY (2/2)

B

A

DVDM ASSY

2/2

(AWM7964)

(D)

1/2B

B

B

1/2

C

D

E

1/2

B

F

B

2/2

A

24

1234

XV-EV1000

Page 25

5678

A

1.8V Regulator

5.0V

3V Regulator

5V Regulator

7.8V

6.4V

Video Driver Amp

6.5V Regulator

7.8V

(D)

NC

CN5102

B

1/4C

C

(D)

: AUDIO SIGNAL ROUTE

(C/V)

: VIDEO SIGNAL ROUTE

(R/Cr)

: VIDEO SIGNAL ROUTE(R/Cr)

(G/Y)

: VIDEO SIGNAL ROUTE(G/Y)

(B/Cb)

: VIDEO SIGNAL ROUTE(B/Cb)

(S_Y)

: S VIDEO SIGNAL ROUTE

(S_C)

: S VIDEO SIGNAL ROUTE

56

(S_C)

(C/V)

(S_Y)

(G/Y)

(B/Cb)

(R/Cr)

XV-EV1000

(S_C)

(C/V)

(S_Y)

(G/Y)

(B/Cb)

(R/Cr)

G

B

R

NC

NC

NC

NC

NC

D

CN8301

3/4

C

E

F

B

2/2

A

25

7

8

Page 26

1234

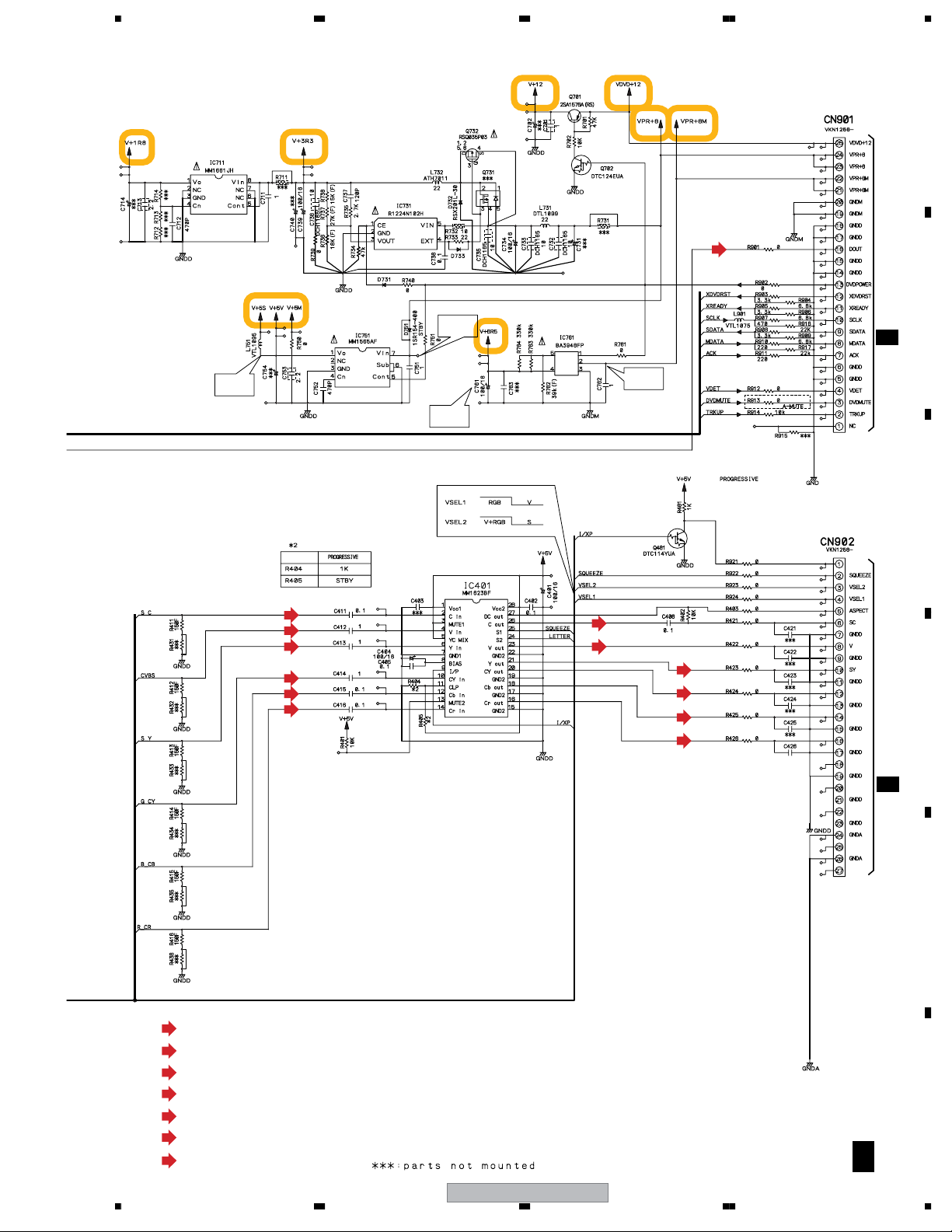

3.5 IFAF ASSY (1/4)

A

B

C

XV-EV1000 XV-EV700

CN951CN701CN901

D

D D

E

D

F

2/4, 3/4C

C

26

1/4

XV-EV1000

1234

B

CN901

Page 27

5678

C

IFAF ASSY

1/4

(XV-EV1000:XWZ4003)

(XV-EV700:XWZ4006)

A

TUNER MODULEDECK MECH

B

CN5101

G

C

: AUDIO SIGNAL ROUTE

(D)

: AUDIO SIGNAL ROUTE

(TXL)

: AUDIO SIGNAL ROUTE

(TXR)

56

XV-EV1000

D

E

2/4C

C

4/4

2/4, 3/4

C

C

1/4

7

8

F

27

Page 28

1234

3.6 IFAF ASSY (2/4)

STBY

C8405

STBY

C8406

GNDA

(SEL)

C8509

10/50

C8510

10/50

VA+5

TS

C8103

0.01

C8907

47/16

TS

0.01

C8101

47/16

C8908

VA-5

Y0

116

2

Y(Lch)

314

Y3

4

Y1 X0

5

INH

6

VEE

7

VSS

8

HEF4052BT

(BUH4052BCF)

FUNCTION SELECTOR

R8901

1/4W

1k

D8901

MTZJ5R6(B)

D8902

MTZJ5R6(B)

IC8101

X(Rch)

1k

VDD

VA+12

R8904

VA-12

X2Y2

X1

X3

A

B

1/4W

(AUX)

15

13

12

11

10

9

AUXR

E2

C2

(AUX)

C

E

(AUX)

STBY

R8405

STBY

R8406

B

B2

(TC)

R8511

1.8k

R8513

4.7k

R8514

R8512

1.8k

(TX)

4.7k

A

LINE OUT

B

LINE IN

AKB7015-

CN8401

L

R

L

R

GNDA

GNDA

PBR

TXR

TXL

STBY

C8518

(TX)

(TX)

STBY

C8513

SBRO

74

75

(TC)

C8514

220p

C8401

220p

C8402

STBY

R8401

STBY

R8411

STBY

R8402 R8404

STBY

C8752

10/50

470p

C8517

470p

C8516

R8403

330

C8404

330

R8515

R8516

STBY

C8403

STBY

220k

220k

R8517

STBY

Q8501

IMX9

(1/2)

AUXL

Q8501

IMX9

(1/2)

C

(TC)

SBLO

C8751

10/50

GNDA

(SEL)

GNDA

(SEL)

PBL

GNDA

(VOC)

GNDA

(VOC)

D

VA+12

VA+12

R8103

R8104

C8115

10/50

47k

47k

C8116

10/50

-TS

4

R8124

100

R8125

100

IC8111

HA17558AF

1

8

8

7

4

IC8111

R8107

0.01

C8107

0.01

C8108

R8108

VA+12

22

STBY

C8119

STBY

C8120

22

VA-5

+

R8105

R8106

STBY

C8117

47k

47k

STBY

C8118

3

(1/2)

-

2

HA17558AF

6

-

(2/2)

5

+

-TS

XV-EV1000

VE+56

C

C

VE+56

VA-12

1/4,

3/4

1/4

VA-12

1/4C

U-COM

(I/O)

DSPA

E

F

C

2/4

28

ATT 6dB ATT 10dB

R8111

1.5k

R8113

Q8111

2SC4081(QR)

R8115

10k

2SC4081(QR)

Q8112

R8116

10k

Q8115

RT1P241M

C

100k

R8117

B

R8114

E

R8112

1.5k

42

1.5k

1.5k

B

100k

R8118

Q8116

2SC4081(QR)

R8119

2SC4081(QR)

R8120

C

E

RT1P241M

41

Q8113

10k

Q8114

10k

680

R8121

680

R8122

C8121

10/50

DSPINL

C8122

10/50

R8127

STBY STBY

R8126

DSPINR

DSPA

1234

Page 29

5678

NOTES

CN5105

R5404

R8217

15k

R8206

4700p

C8216

R8207

6.8k

R8208

15k

R8209

6.8k

R8211

52147-0510

VD+5

220

C8224

STBY

C8206

8200p

4.7k

ALL DIODE

:MA111

:1SS133

R5403

C

E

Q5403

RT1N431M

GNDD

(MICDET)

3

R8205

C8217

470p

C8218

10k

10k

MIC SW

R8201

10k

0.01

C8204

B

R8204

C8205

0.01

R8203

GNDA

C8203

5.6k

0.01

10k

H

S

D

VA+12

0.01

MIC

Q5402

2SJ103

(MIC)

C8202

0.047

R8202

10k

J5401

ECHOVOL

VA+12

12534

R5431

1M

(GR)

G

R5434

22K

R8308

10k

C8310

C8201

47/16

C

R5432

C5433

0.22/50

2.2/50

IFAF ASSY(XV-EV1000:XWZ4003)

2/4

(XV-EV700:XWZ4006)

BA3838F

RIN

VEF1040-

16

15

14

13

12

11

10

9

C8306

A

STBY STBY

U-COM

483847

1k

1k

R8301

R8302

ROUT

C8304

0.22

C8305

2.2/50

0.047

D

1k

R8303

C8301

0.1

C8302

0.1

C8303

0.1

1M

2.2/50

C8309

C8307

C8313

0.01

C8312

MIC IN

REF

47/16

VA+12

4.7/50

LOUT

C8308

2.2/50

1

2

3

4

5

LIN

6

7

8

ECHCNT

IC8301

SW2

SW1

VOCAL FADER

A

B

C

ALL CAPACITORS ARE IN µF

UNLESS OTHERWISE SPECIFIED

CH : CCSRCH

TY : CFTYA

AL : CEAL

ALL RESISTORS ARE IN

RD1/4PU***J

RS1/16S***J

VE+56

D8501

MA111

E

RT1P241M

Q8503

B

C

47k

R8518

VA-12

32

92

95

90

CH

C8207

0.068

C8208

0.068

C8209

0.068

C8210

STBY

R8212

R8213

C8211

STBY

R8214

C8212

100p

C8213

47/16

VA+12

L8201

STBY

1k

1k

1k

Q8201

HPAC1

10

11

12

13

14

2SD1858X(QR)

IC8201

M65847AFP

ADCONT

1

DACCONT1

2

DACCONT2

3

KEYDOWN

4

KEYUP ADINT OUT

5

CLKO

6

SDATA

7

SCK

8

STROBE

9

KEY4

KEY CON

KEY5

REF

GND

Vcc

MODE2

MODE1

DAINT OUT

DAINT IN

ADINT IN

LPF1IN

LPF1OUT

HPFIN

HPFOUT

LPF2IN

LPF2OUT

MIX IN

MIX OUT

(OTHER : CKSR

(OTHER : CEAT)

28

C8214

0.22

27

26

C8215

25

0.22CH10k

24

23

22

21

C8219

20

1200p

19

18

17

R8210

16

15

4.7k

C8220

1000p

LEVELIN

HA17558AF

IC8801

HA17558AF

IC8801

R8816

STBY

6

5

VA-12

1/4W

1k

R8216

C8221

10/50

1

LCD

SPECTRUM

INDICATOR

VA+12

8

(2/2)

+

4

68

R8215

D8201

MTZJ5R6(B)

R8805

56k

2

8

-

(1/2)

3

+

4

C8831

STBY

C8830

0.01

7

C8828

0.01

C8829

STBY

C8222

C8803

47/16

STBY

C8223

R8803

10K

R8801

10k

R8802

10k

0.047

C8835

10/50

C8833

10/50

C8834

10/50

Gain for

IC8301 input

-12.7dB

: AUDIO SIGNAL ROUTE (L ch)

: AUDIO SIGNAL ROUTE (Front L ch)

(FL)

: AUDIO SIGNAL ROUTE (Front R ch)

(FR)

: AUDIO SIGNAL ROUTE (Center ch)

(C)

GNDA

(VOC)

(C)

(FL)

(FR)

XV-EV1000

56

STBY

C8316

R8306

820

2.7k

R8307

(FL)

: AUDIO SIGNAL ROUTE

(AUX)

: AUDIO SIGNAL ROUTE

(TX)

: AUDIO SIGNAL ROUTE

(TC)

7

R8305

820

R8304

2.7k

FR

FL

STBY

C8315

(FR)

DECKL

RECL

RECR

DECKR

C

(FL)

(FR)

D

E

F

C

2/4

29

8

Page 30

1234

3.7 IFAF ASSY (3/4)

A

B

C

D

E

1/4C

2/4C

F

1/4C

XV-EV1000

1234

30

C

3/4

Page 31

5678

2/2B

CN902

C

3/4

IFAF ASSY

(XV-EV1000:XWZ4003)

(XV-EV700:XWZ4006)

A

B

VIDEO/COMPONETS-VIDEO

C

(FR)

: AUDIO SIGNAL ROUTE (Front R ch)

(FL)

: AUDIO SIGNAL ROUTE (Front L ch)

(C)

: AUDIO SIGNAL ROUTE (Center ch)

(SR)

: AUDIO SIGNAL ROUTE (Surround Rch)

(SL)

1/4

J

56

CN3051

XV-EV1000

: AUDIO SIGNAL ROUTE(Surround Lch)

(SW)

: AUDIO SIGNAL ROUTE(Sub Woofer ch)

D

CN3002

1/4J

E

F

C

3/4

31

7

8

Page 32

1234

3.8 IFAF ASSY (4/4)

A

(TC)

2SK373(YGR)

Q2301

S

D

CN2301

B4B-PH-K-S

4

Lch

3

D2301

2

Rch

YK56R-AA4N3

B

1

CN2302

B2B-PH-K-S

1

GNDA

2

D2304

D2302

CH

D2303

R2399

0

CH

10P

C2302

Q2302

2SK373(YGR)

C2301

D2305

R2302

D

10P

D2306

1M

G

G

R2301

S

1M

VA+12V

Q2303

DTC114TK

Q2304

DTC114TK

C2303

680p

B

330K

R2303

C2304

680p

B

C2315

330K

R2304

(TC)

D2307

VEF1040-

Q2352

M

R2426

1k

0.012

1k

R2425

STBY

47K

R2351

C2419

1/50

B

Q2455

2SD2114K

2SD2114K

Q2456

B

VA+12V

C2420

1/50

105KHz

10K

R2802

C2802

6800P

M

10K

R2801

L2802

0.12mH

LFA121J

Q2351

RT1P241M

6.8k

R2455

6.8k

R2456

C2425

47/16

M

C2804

M

C2803

GNDA

7

R2431

33k

C2405

MB

0.068

C2406

MB

0.068

R2432

33K

8

1

43

GNDA

4700P

4700P

2SC1815(YGR)

RT1N241M

IC2401(1/2)

5

+

6

-

C2431

1200P

R2413

47k

R2411

82k

R2412

82k

R2414

47k

C2432

1200P

-

2

+

IC2401(2/2)

Q2802

2SC1815(YGR)

R2803

(1/2W)VM

Q2801

2SC1815(YGR)

Q2805

HA17558AF

47p

C2402

C2407

33/50

L2403

4.7mH

C2409

C2410

R2416 R2415

L2404

4.7mH

C2408

33/50

47p

C2401

HA17558AF

4.7

XV-EV1000

C

C

R2899

220P

0

RTF1004

10mH

L2401

C2423

(FL)

R2423

11k

C2421

1500P

CH

D

REC EQ AMP

(FR)

220P

1500P

C2424

C2422

CH

M

L2402

R2424

10mH

11k

RTF1004

R2813

6.2K

R2814

6.2K

E

100K-B

0

1

3

R2898

0

C2805

33/10

C2806

33/10

GNDM(TC)

JQ

JQ

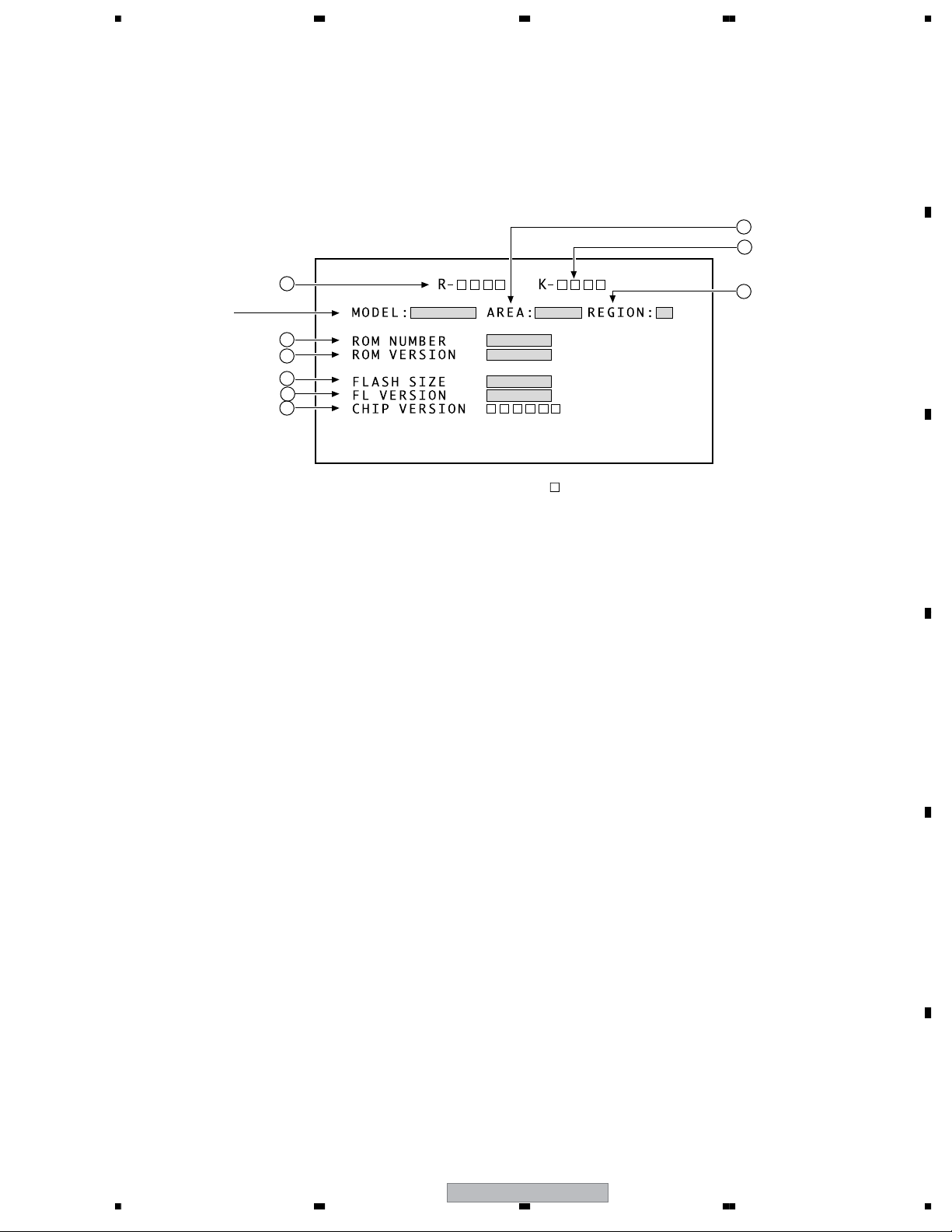

BIAS OSC.