Page 1

2013

XDJ-R1

DJ SYSTEM

XDJ-R1

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

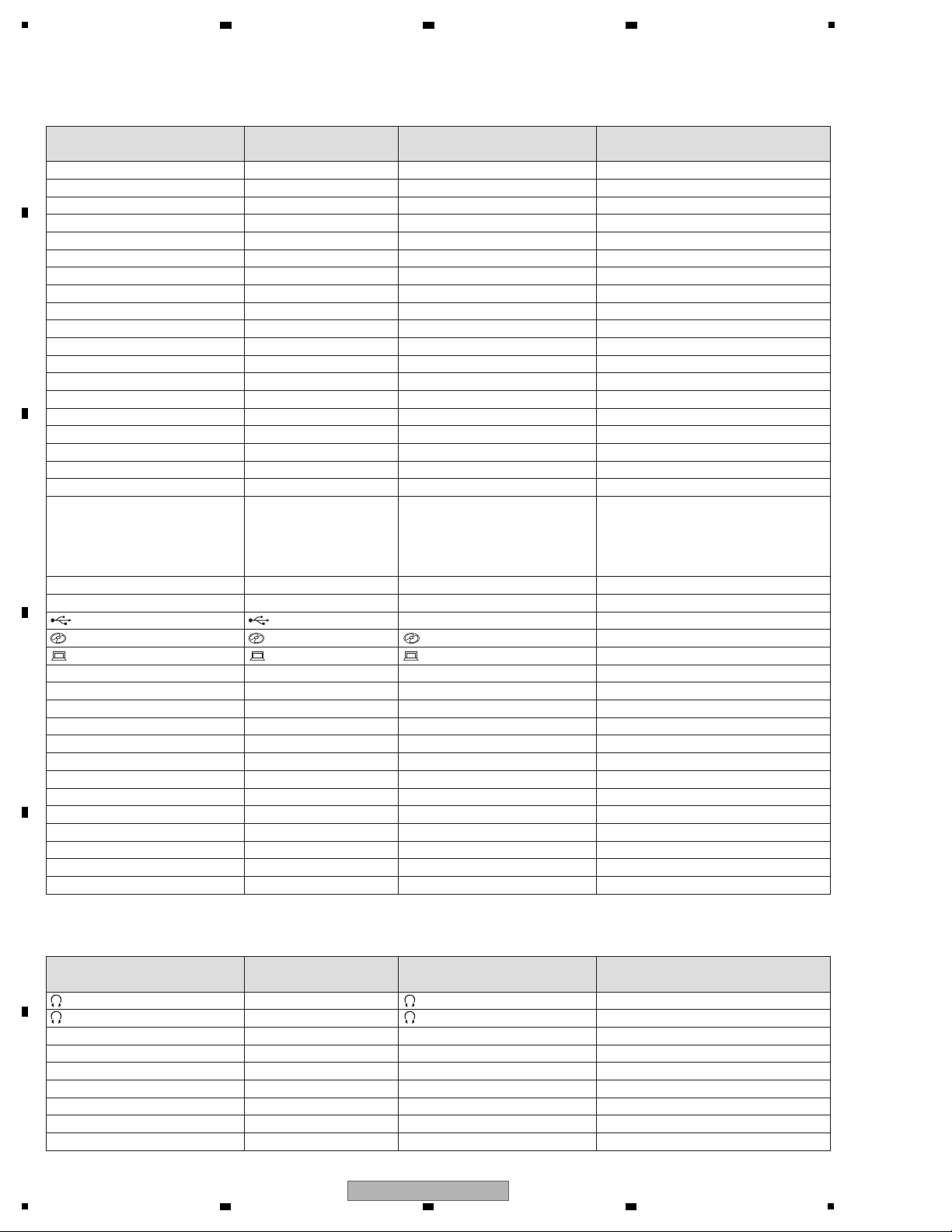

Model Type Power Requirement Remarks

XDJ-R1 SVWYXE8 AC 220 V to 240 V

XDJ-R1 CUXE AC 120 V

XDJ-R1 FLWPWXE AC 110 V to 120 V or 220 V to 240 V

XDJ-R1 KXE5 AC 220 V

XDJ-R1 AXE5 AC 220 V to 240 V

ORDER NO.

RRV4401

PIONEER CORPORATION 1-1, Shin-ogura, Saiwai-ku, Kawasaki-shi, Kanagawa 212-0031, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION

K-MZV JUNE

2013 Printed in Japan

Page 2

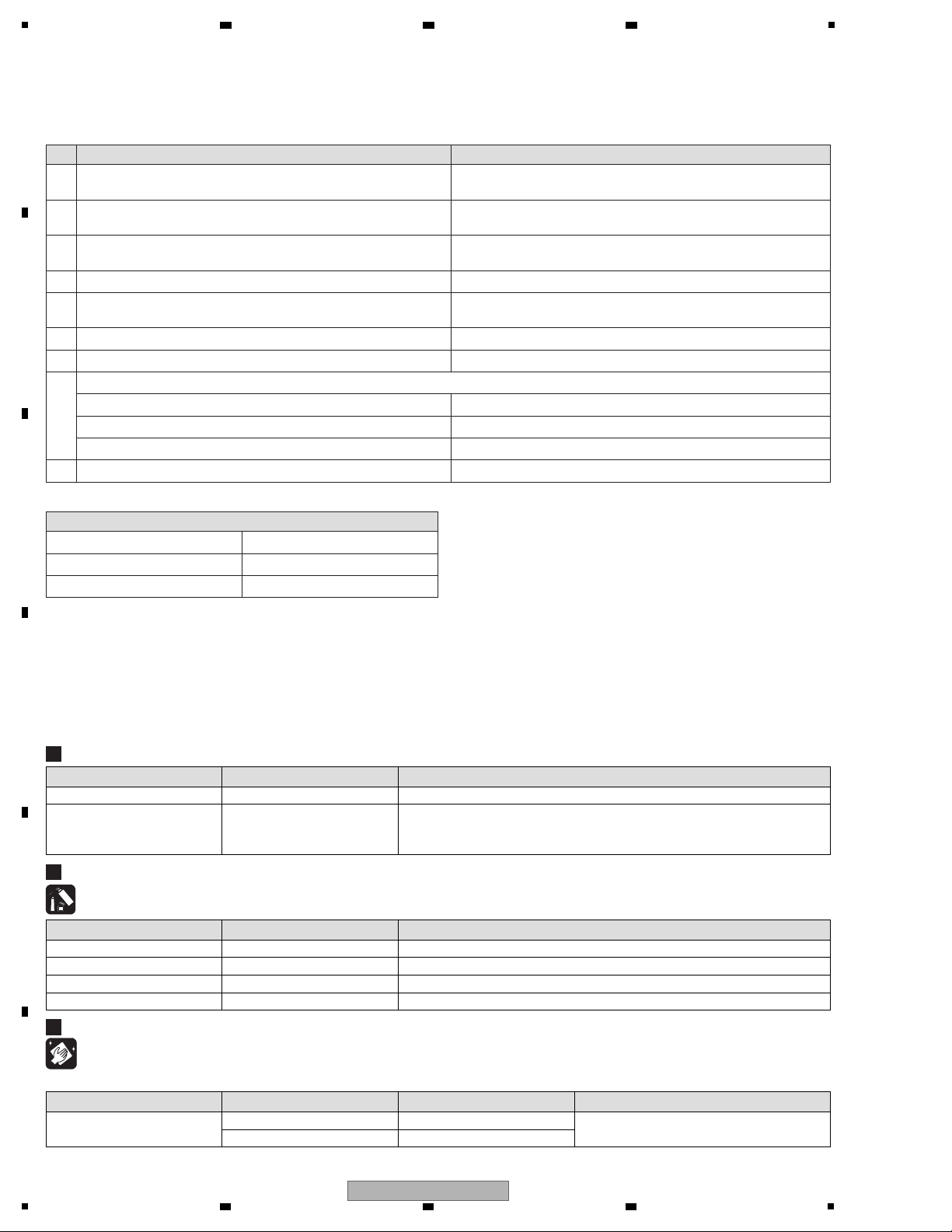

1

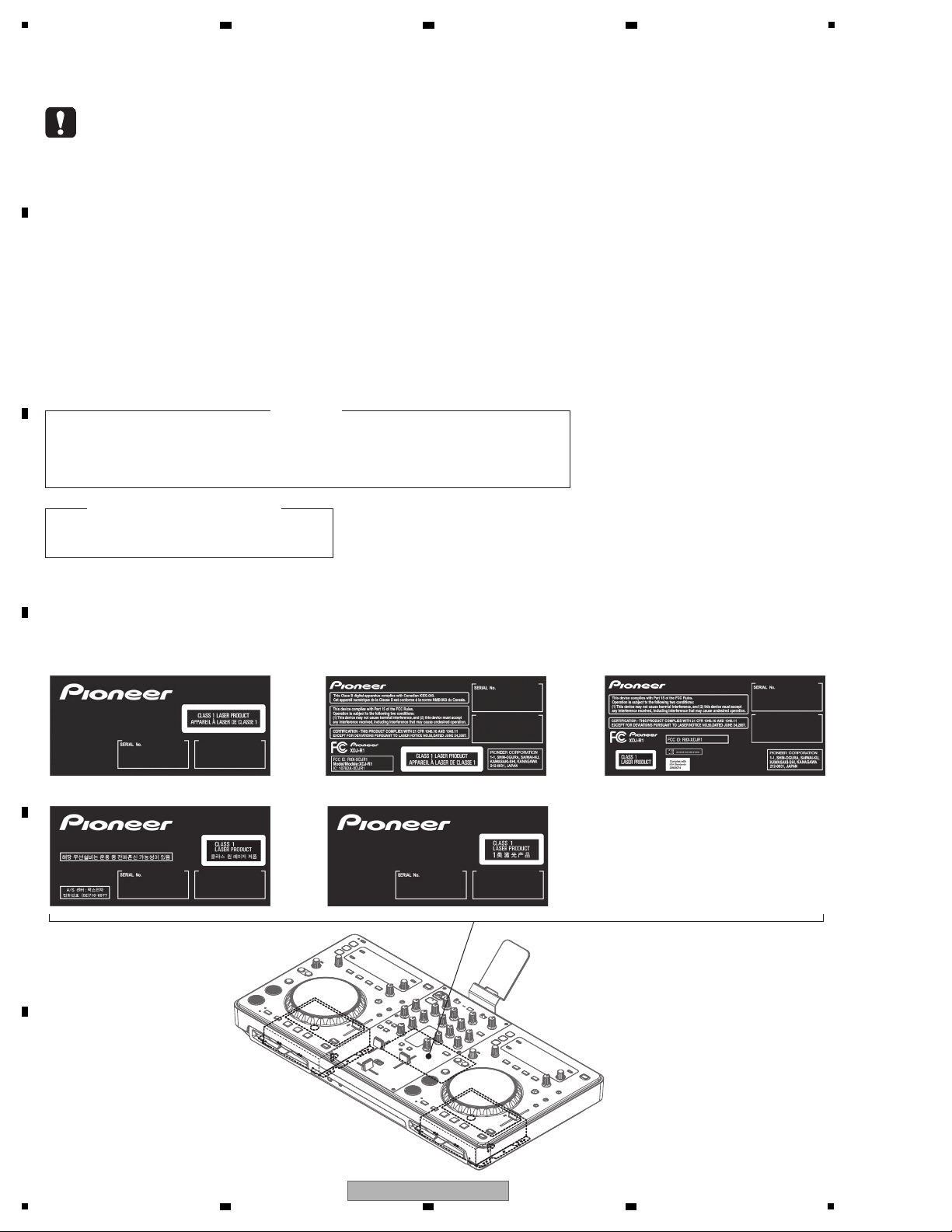

LABEL CHECK

WARNING

This product may contain a chemical known to the State of California to cause cancer, or birth defects or other reproductive

harm.

Health & Safety Code Section 25249.6 - Proposition 65

This service manual is intended for qualified service technicians; it is not meant for the casual do-it-

yourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained

to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING !

THE AEL (ACCESSIBLE EMISSION LEVEL) OF THE LASER POWER OUTPUT IS LESS THAN CLASS 1

BUT THE LASER COMPONENT IS CAPABLE OF EMITTING RADIATION EXCEEDING THE LIMIT FOR

CLASS 1.

A SPECIALLY INSTRUCTED PERSON SHOULD DO SERVICING OPERATION OF THE APPARATUS.

LASER DIODE CHARACTERISTICS

For CD Wave length : 775 - 800 nm

Output Power : Less than Class 1

for KXE5

for FLWPWXEfor SVWYXE8 for CUXE

for AXE5

2 3 4

SAFETY INFORMATION

A

B

C

D

E

F

2

1

2 3 4

XDJ-R1

Page 3

5

6 7 8

CONTENTS

SAFETY INFORMATION.......................................................................................................................................................... 2

1. SERVICE PRECAUTIONS ....................................................................................................................................................4

1.1 NOTES ON SOLDERING............................................................................................................................................... 4

2. SPECIFICATIONS .................................................................................................................................................................5

3. BASIC ITEMS FOR SERVICE ..............................................................................................................................................6

3.1 CHECK POINTS AFTER SERVICING ........................................................................................................................... 6

3.2 JIGS LIST .......................................................................................................................................................................6

3.3 PCB LOCATIONS ........................................................................................................................................................... 7

4. BLOCK DIAGRAM ................................................................................................................................................................8

4.1 OVERALL WIRING DIAGRAM .......................................................................................................................................8

4.2 OVERALL BLOCK DIAGRAM....................................................................................................................................... 10

4.3 SYSTEM BLOCK DIAGRAM ........................................................................................................................................12

4.4 LEVEL BLOCK DIAGRAM............................................................................................................................................ 14

5. DIAGNOSIS ........................................................................................................................................................................ 16

5.1 TROUBLESHOOTING.................................................................................................................................................. 16

5.2 CONFIMATION OF WIRELESS LAN COMMUNICATION ............................................................................................ 19

5.3 ERROR CODE LIST.....................................................................................................................................................20

6. SERVICE MODE................................................................................................................................................................. 21

6.1 SERVICE MODE .......................................................................................................................................................... 21

7. DISASSEMBLY ................................................................................................................................................................... 28

8. EACH SETTING AND ADJUSTMENT................................................................................................................................ 39

8.1 NECESSARY ITEMS TO BE NOTED........................................................................................................................... 39

8.2 UPDATING OF THE FIRMWARE ................................................................................................................................. 40

8.3 USER SETABLE ITEMS ............................................................................................................................................... 41

9. EXPLODED VIEWS AND PARTS LIST............................................................................................................................... 42

9.1 PACKING SECTION ..................................................................................................................................................... 42

9.2 EXTERIOR SECTION .................................................................................................................................................. 44

10. SCHEMATIC DIAGRAM .................................................................................................................................................... 48

10.1 I/O ASSY ....................................................................................................................................................................48

IXER, CH, CROSS FADER, USB and PHONES ASSEMBLIES .............................................................................50

10.2 M

10.3 DSP & POWER ASSY (1/2) and Wi-Fi PCB ASSY .................................................................................................... 52

10.4 DSP & POWER ASSY (2/2)........................................................................................................................................ 54

10.5 CD1 and CD2 ASSEMBLIES...................................................................................................................................... 56

10.6 SERVO ASSY............................................................................................................................................................. 58

10.7 SWITCHING POWER................................................................................................................................................. 60

10.8 WAVEFORMS............................................................................................................................................................. 62

11. PCB CONNECTION DIAGRAM........................................................................................................................................64

11.1 I/O ASSY ....................................................................................................................................................................64

11.2 MIXER ASSY..............................................................................................................................................................66

11.3 DSP & POWER ASSY................................................................................................................................................68

11.4 CH, CROSS FADER, USB and PHONES ASSEMBLIES...........................................................................................70

11.5 Wi-Fi PCB ASSY ........................................................................................................................................................ 71

11.6 CD1 and CD2 ASSEMBLIES...................................................................................................................................... 72

11.7 SERVO ASSY............................................................................................................................................................. 74

WITCHING POWER................................................................................................................................................. 75

11.8 S

12. PCB PARTS LIST .............................................................................................................................................................. 76

A

B

C

D

E

F

XDJ-R1

5

6 7 8

3

Page 4

1

• For environmental protection, lead-free solder is used on the printed circuit boards mounted in this unit.

Be sure to use lead-free solder and a soldering iron that can meet specifications for use with lead-free solders for repairs

accompanied by reworking of soldering.

• Compared with conventional eutectic solders, lead-free solders have higher melting points, by approximately 40 ºC.

Therefore, for lead-free soldering, the tip temperature of a soldering iron must be set to around 373 ºC in general, although

the temperature depends on the heat capacity of the PC board on which reworking is required and the weight of the tip of

the soldering iron.

Do NOT use a soldering iron whose tip temperature cannot be controlled.

Compared with eutectic solders, lead-free solders have higher bond strengths but slower wetting times and higher melting

temperatures (hard to melt/easy to harden).

The following lead-free solders are available as service parts:

• Parts numbers of lead-free solder:

GYP1006 1.0 in dia.

GYP1007 0.6 in dia.

GYP1008 0.3 in dia.

2 3 4

1. SERVICE PRECAUTIONS

1.1 NOTES ON SOLDERING

A

B

C

D

E

F

4

1

2 3 4

XDJ-R1

Page 5

5

Power requirements....AC 220 V to 240 V, 50 Hz/60 Hz (SVWYXE8)

AC 120 V, 60 Hz (CUXE)

AC 110 V to 120 V or 220 V to 240 V, 50 Hz/60 Hz (FLWPWXE)

AC 220 V, 60 Hz (KXE5)

AC 220 V to 240 V, 50/60 Hz (AXE5)

Power consumption................................................................... 30 W

Power consumption (standby) .................................................0.5 W

Main unit weight........................................................... 6.8 kg (15 lb)

Max. dimensions....... 623 mm (W) × 107.7 mm (H) × 308.4 mm (D)

(24.6 in. (W) × 4.3 in. (H) × 12.2 in. (D))

Tolerable operating temperature..... +5 °C to +35 °C (+41 °F to +95 °F)

Tolerable operating humidity............5 % to 85 % (no condensation)

Wireless LAN section

Supported standards ..................... IEEE 802.11b/g (2.4 GHz band)

Audio Section

Sampling rate .....................................................................44.1 kHz

A/D, D/A converter................................................................. 24 bits

Frequency characteristic

USB/LINE ............................................................ 20 Hz to 20 kHz

S/N ratio (MASTER OUT 1, rated output, A-WEIGHTED)

USB (when external input terminal not connected) ..............98 dB

LINE......................................................................................97 dB

CD ........................................................................................97 dB

PHONO ................................................................................86 dB

MIC.......................................................................................80 dB

Total harmonic distortion (MASTER OUT 1, 20 Hz — 20 kHzBW)

USB .................................................................................. 0.006 %

LINE..................................................................................0.007 %

Standard input level / Input impedance

LINE....................................................................... –12 dBu/47 kΩ

PHONO ................................................................. –48 dBu/47 kΩ

MIC........................................................................ –52 dBu/10 kΩ

AUX ....................................................................... –12 dBu/10 kΩ

Standard output level / Load impedance / Output impedance

MASTER OUT 1............................. +6 dBu/10 kΩ/330 Ω or lower

MASTER OUT 2............................................. +2 dBu/10 kΩ/1 kΩ

BOOTH........................................................... +2 dBu/10 kΩ/1 kΩ

PHONES ..........................................................+2 dBu/32 Ω/66 Ω

Rated output level / Load impedance

MASTER OUT 1.................................................... +22 dBu/10 kΩ

MASTER OUT 2.................................................... +18 dBu/10 kΩ

Crosstalk (20 Hz — 20 kHzBW)

LINE......................................................................................83 dB

Channel equalizer characteristic

HI................................................................ –∞ to + 9 dB (13 kHz)

MID............................................................... –∞ to + 9 dB (1 kHz)

LOW .............................................................. –∞ to +9 dB (70 Hz)

Microphone equalizer characteristic

LOW — CENTER — HI.... –12 dB (10 kHz) to 0 dB to –12 dB (100 Hz)

Input/output terminals

USB downstream port

Type A.................................................................................... 1 set

Power supply...................................................5 V/500 mA or less

USB upstream port

B type ....................................................................................1 set

MASTER OUT 1 output terminal

XLR connector....................................................................... 1 set

MASTER OUT 2 output terminal

RCA pin jacks........................................................................ 1 set

BOOTH output terminal

RCA pin jacks........................................................................ 1 set

PHONES output terminal

Stereo phone jack (Ø 6.3 mm) .............................................. 1 set

Stereo mini phone jack (Ø 3.5 mm)....................................... 1 set

PHONO/LINE input terminals

RCA pin jack........................................................................ 2 sets

MIC input terminal

Phone jack (Ø 6.3 mm).......................................................... 1 set

AUX input terminal

RCA pin jacks........................................................................ 1 set

• The specifications and design of this product are subject to

change without notice.

• Be sure to use the [MASTER OUT 1] terminals only for a

balanced output. Connection with an unbalanced input (such as

RCA) using an XLR to RCA converter cable (or converter

adapter), etc., may lower the sound quality and/or result in noise.

For connection with an unbalanced input (such as RCA), use the

[MASTER OUT 2] terminals.

• CD-ROM (The disc includes rekordbox, the driver software, the

XDJ-R1’s operating instructions and the operating instructions for

remotebox. The rekordbox license key is attached.)

(429-COMBO-144)

• VIRTUAL DJ LE license key (indicated on this unit’s bottom panel)

• Power cord

(SVWYXE8: 409-HDJ7100-055D)

(CUXE: 409-HDJ7100-054D)

(FLWPWXE: 409-HDJ7100-055D, 409-COMBO-226)

(KXE5: 409-COMBO-224)

(AXE5: 409-DMX101-218)

• Read Before Use (Important)/Quick Start Guide

(SVWYXE8: 502-XDR1B-3272)

(CUXE: 502-XDR1A-3271)

(FLWPWXE: 502-XDR1F-3276)

(KXE5: 502-XDR1E-3275)

(AXE5: 502-XDR1D-3274)

• About SSIDs and passwords

(501-XJR1-2506)

• Smartphone stand (703-COMBO-1395)

• Smartphone stand mount screws x 2 (200-BLACK-642)

• USB cable (408-100UG-087)

Accessories

2. SPECIFICATIONS

6 7 8

A

5

6 7 8

XDJ-R1

B

C

D

E

F

5

Page 6

1

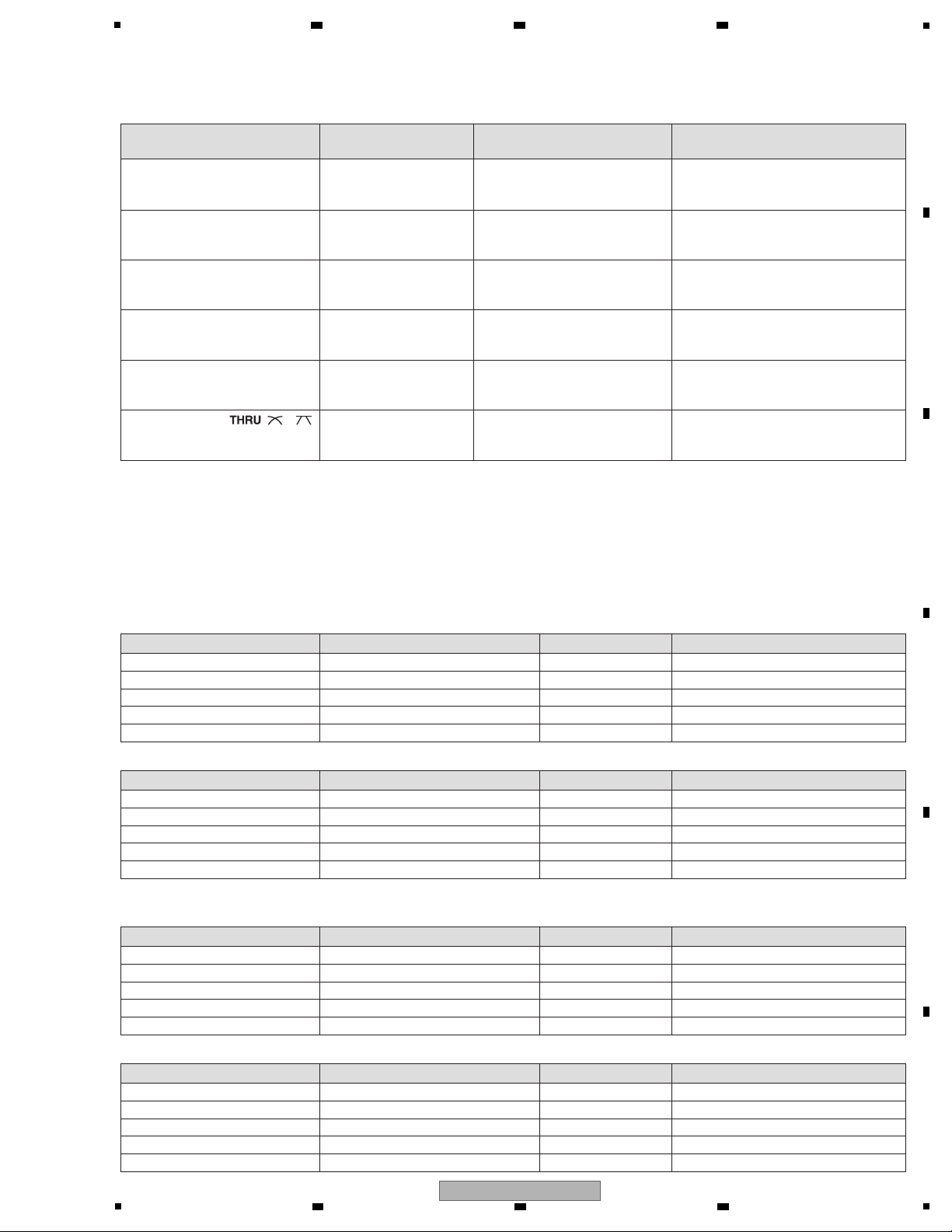

Items to be checked after servicing

1 Check the firmware version.

To keep the product quality after servicing, confirm recommended check points shown below.

The firmware version must be the latest one.

If it is not the latest one, be sure to update it.

2 Confirm whether the customer complain has been solved.

The customer complain must not be reappeared.

Audio and operations must be normal.

3

Check the analog audio output.

There must be no errors in audio output and operations of each

channel.

5

Check playback, using the fader function.

There must be no errors in audio output and operations of each

channel.

6 Check the MASTER output. Audio and operations must be normal.

7 Check the headphones output. There must be no errors, such as noise, in the audio output.

9 Check the appearance of the product.

Distortion

Noise

Volume too low

Volume too high

Volume fluctuating

Sound interrupted

No scratches or dirt on its appearance after receiving it for service.

Check playback, using the USB A. Audio and search etc. operations must be normal.

USB B The device must be properly recognized by the PC.

Wireless LAN The output signal can detect with a PC.

8

Check the connection of each interface.

4 Playback a CD disc. (track search) Audio, Search and operations must be normal.

See the table below for the items to be checked regarding audio.

No. Procedures

Item to be checked regarding audio

Check points

Lubricants and Glues List

Jigs List

Jig Name Part No. Purpose of use / Remarks

Position to be cleaned Name Part No.

Remarks

USB cable GGP1193 for PC connection

Name Part No. Remarks

Adhesive GYL1001

Pickup lens

Cleaning liquied

GEM1004

Cleaning paper GED-008

Refer to "7. DISASSEMBLY".

Refer to "7. DISASSEMBLY".

Adhesive GYL1005 Refer to "7. DISASSEMBLY".

Grease GEM1072 Refer to "7. DISASSEMBLY".

Silicon bond GYA1011 Refer to "7. DISASSEMBLY".

rekordbox

Supplied software

It must be confirmed that music files playbacked in the PC can be

transferred to the XDJ-R1 via wireless LAN, using rekordbox installed

on the PC. You can download rekordbox from the Pioneer Web site.

Cleaning

Before shipping out the product, be sure to clean the following positions by using the prescribed cleaning tools.

2 3 4

3. BASIC ITEMS FOR SERVICE

3.1 CHECK POINTS AFTER SERVICING

A

B

C

D

3.2 JIGS LIST

E

F

6

1

XDJ-R1

2 3 4

Page 7

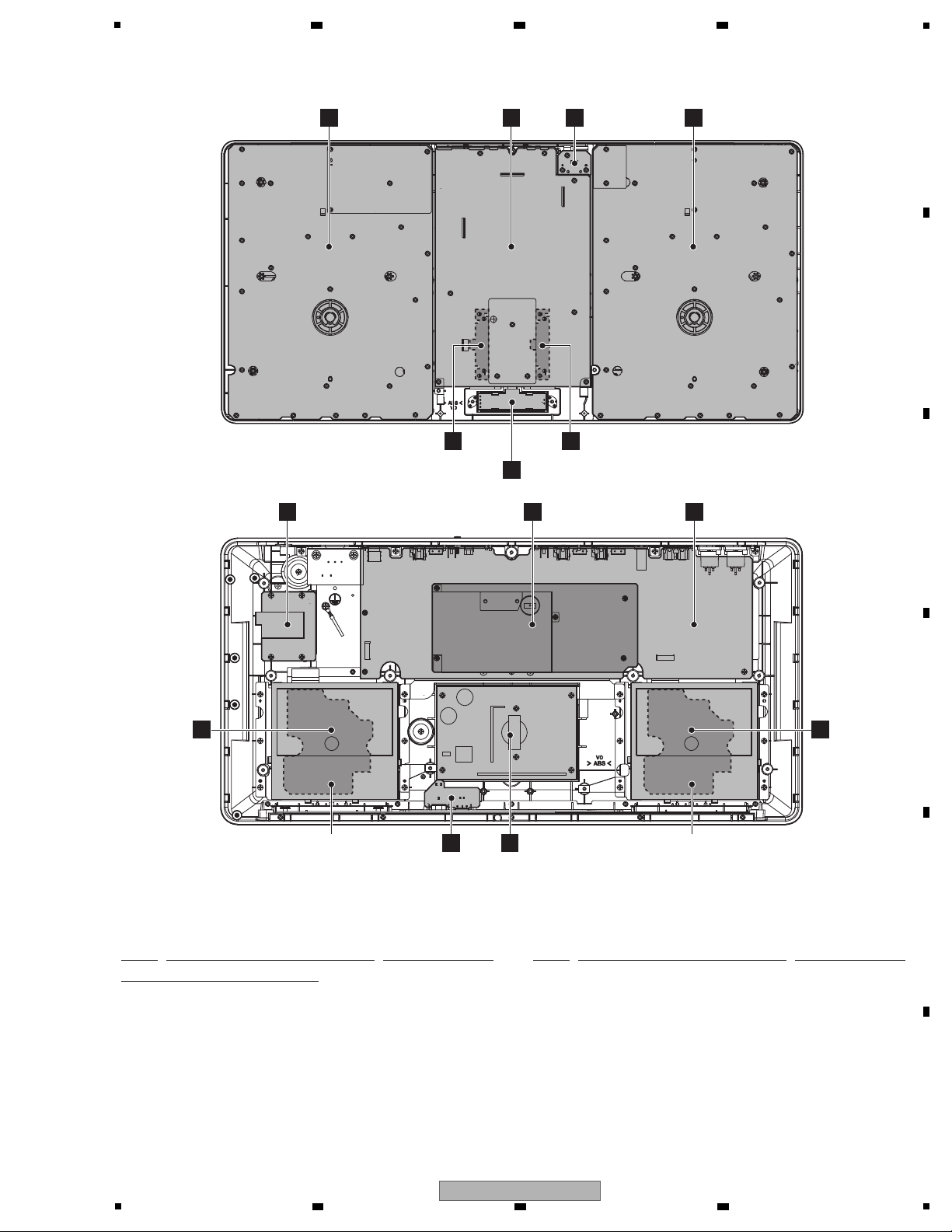

5

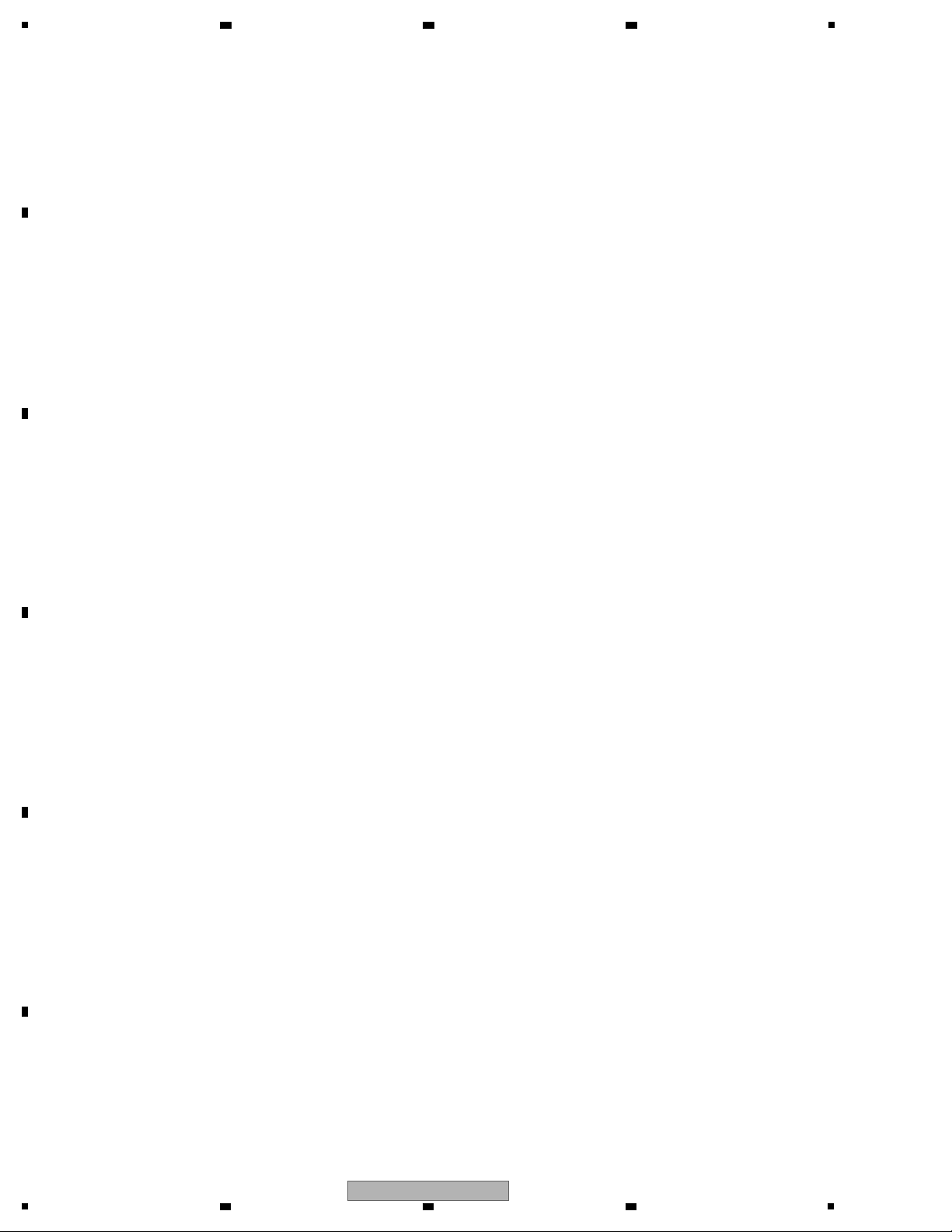

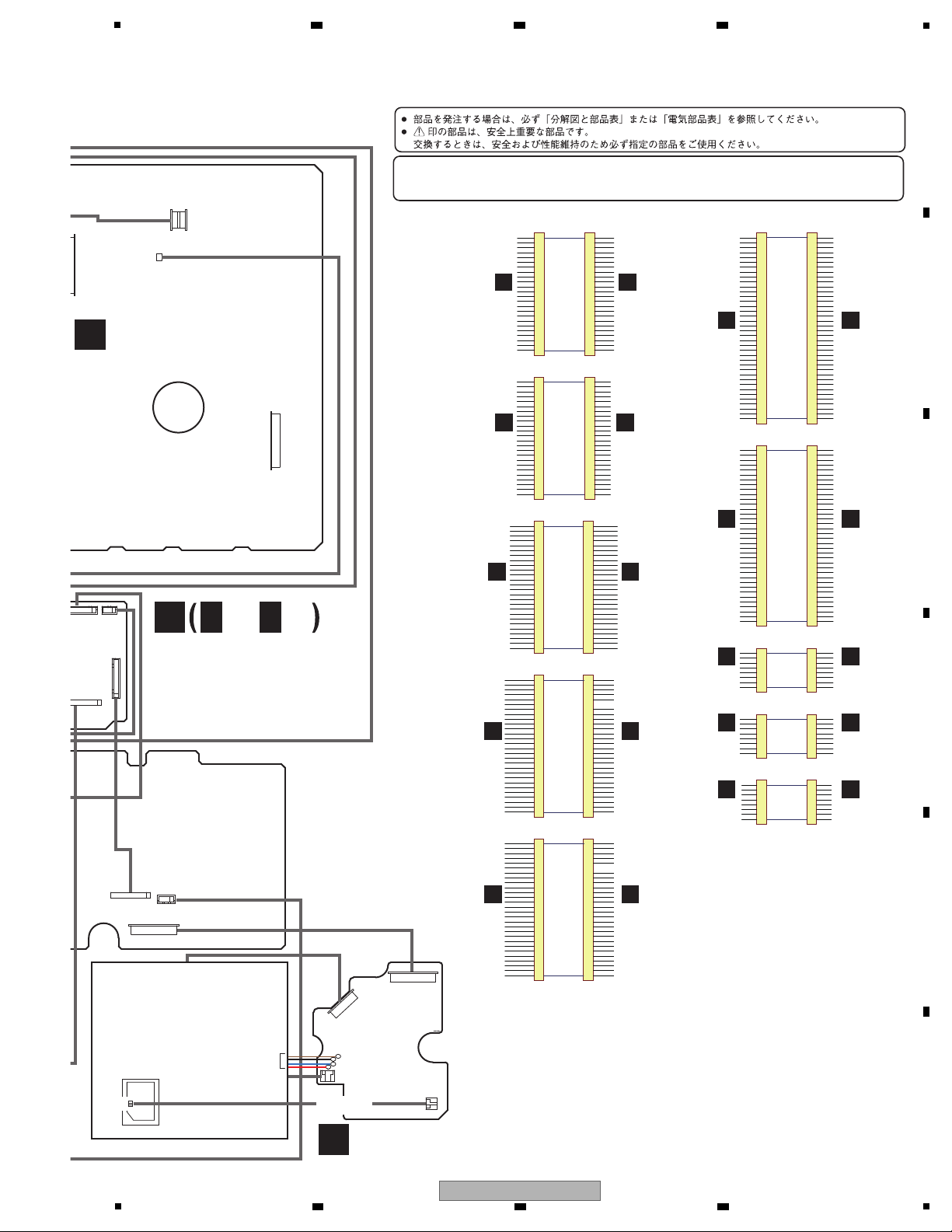

Mark No. Description Part No. Mark No. Description Part No.

LIST OF ASSEMBLIES

NOTES: - Parts marked by “NSP” are generally unavailable because they are not in our Master Spare Parts List.

-

The > mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

I/O ASSY 704-COMBO-A378

MIXER ASSY 704-COMBO-A376

CH ASSY 704-COMBO-A482

CROSS FADER ASSY 704-COMBO-A499

USB ASSY 704-COMBO-A381

PHONES ASSY 704-COMBO-A379

DSP & POWER ASSY 704-COMBO-A531

Wi-Fi PCB ASSY 704-COMBO-A380

CD1 ASSY 704-COMBO-A375

CD2 ASSY 704-COMBO-A476

SERVO ASSY 704-COMBO-A377

SWITCHING POWER 411-COMBO-887

SLOT-IN FEEDER MECHA ASSY

704-MCU300-9997-HA

D

CROSS FADER ASSY

F

PHONES

ASSY

K

SWITCHING

POWER

SLOT-IN FEEDER

MECHA ASSY

SLOT-IN FEEDER

MECHA ASSY

A

I/O ASSY

J

SERVO

ASSY

J

SERVO

ASSY

G

DSP & POWER

ASSY

H

Wi-Fi

PCB ASSY

C

CH ASSY (CH1)

C

CH ASSY (CH2)

E

USB ASSY

B

MIXER ASSY

I

CD2 ASSY

I

CD1 ASSY

3.3 PCB LOCATIONS

6 7 8

A

B

C

5

XDJ-R1

6 7 8

D

E

F

7

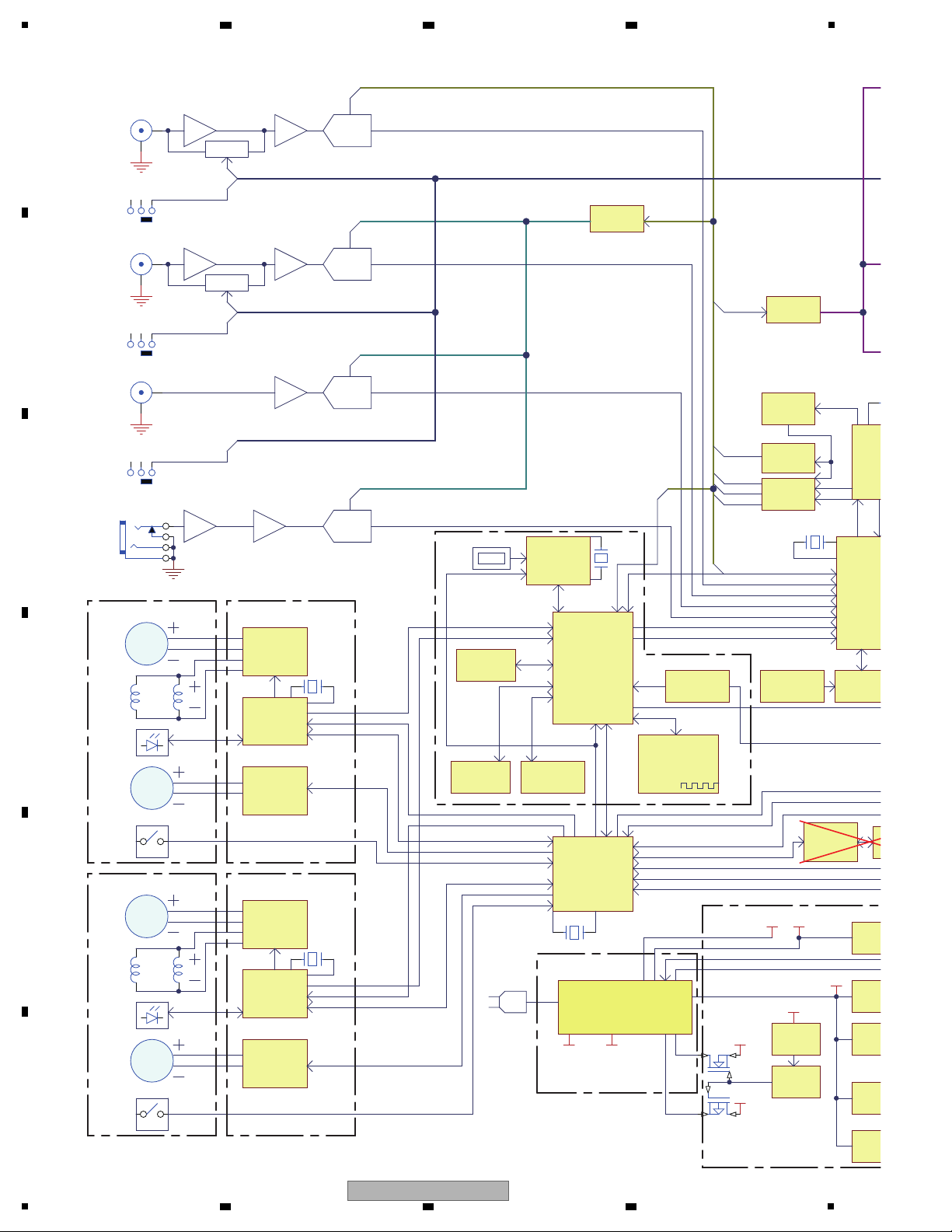

Page 8

1

A

I/O ASSY

(704-COMBO-A378)

B

MIXER ASSY

(704-COMBO-A376)

C

CH ASSY

(704-COMBO-A482)

(CH1)(CH2)

E

USB ASSY

(704-COMBO-A381)

F

PHONES ASSY

(704-COMBO-A379)

DS

(70

G

H

Wi-Fi PCB ASSY

(704-COMBO-A380)

I

CD1 ASSY

(704-COM

I

CD2 ASSY

(704-COMBO-A476)

J

SERVO ASSY

(704-COMBO-A377)

SLOT-IN FEEDER

MECHA ASSY

(DECK1)

SLOTMECH

(DECK

K

SWITCHING POWER

(411-COMBO-887)

CN2

W402B

CN102A

CN101

CN101

CN106

MOTOR

GND

S1

S0

PICKUP

CN105

W402A

W811

W806

CN808

CN810

CN806

CN809

W4

CN40

W5

W6

CN200CN210CN810

CN4

CN5

CN6

CN810

CN209

CN804

CN812A

CN812B

CN200 CN210

CN201

CN204

W203

W208B W208A

CN01

CN206B

CN201

CN204

W206

W812

CN201

W

W81

CN206A

CN209

CN1

W203

AC IN

CN2

W3

CN3

CN208 CN208

D

CROSS FADER ASSY

(704-COMBO-A499)

SP+ (RED)

SP- (BLUE)

LMB (BLACK)

LMA (BROWN)

1. -Ef

2. +Ef

1. VB

2. D-

3. D+

4. DGND

5. DGND

1. SAD3.3V

2. CR0F

3. SADGND

1. +Ef 3.4V /V7

2. -EF

3. GND

4. +32V/V6

1. L

2. G

3. G

4. R

1. CLKIN

2. GND

1. 7V

2. M

3. M

4. P

5. ST5V

6. A-15V

7. A+15V

8. A

9. STBY

10. MUTE

11. /MST

1. A5V

2. A3.3V

3. ADDA

4. ADDA

5. D

6. D

7. V-CHK

8. D5V

9. PD

10. 5V

11. 32V

12. D3.3V

1. Vcc

2. VC

3. VEE

4. E

5. B

6. C

7. D

8. A

9. F

10. PD

11. AGND

12. LD

13. VR

14. FC-

15. TC-

16. TC+

17. FC+

1. D3.3V

2. D3.3V

3. GND

4. GND

1. D_MOSI

2. D_MI

3. WSCK

4. GND

5. PF0

6. PF1

7. /WRST

8. GND

1. + 7V/V1

2. + 7V/V1

3. GND

4. GND

5. ST5V/V2

6. GND

7. +15V/V3

8. GND

9. -15V/V4

10. GND

11. GND

12. +6V/V5

13. +6V/V5

14. STBY:5V->Power ON

LN

1. SAD3.3V

2. CR0F

3. SADGND

1. SAD3.3V

2. AD16

3. SADGND

1. SAD3.3V

2. AD15

3. SADGND

1. -Ef

2. +Ef

1. -Ef

2. +Ef

1. -Ef

2. +Ef

GND

S1

S0

89

7

6

4

3

1

a

W205

1. SL-

2. SL+

3. Disc Detecting Switch

4. S3.3V

1. Q1

2. Q2

3. DGND

2 3 4

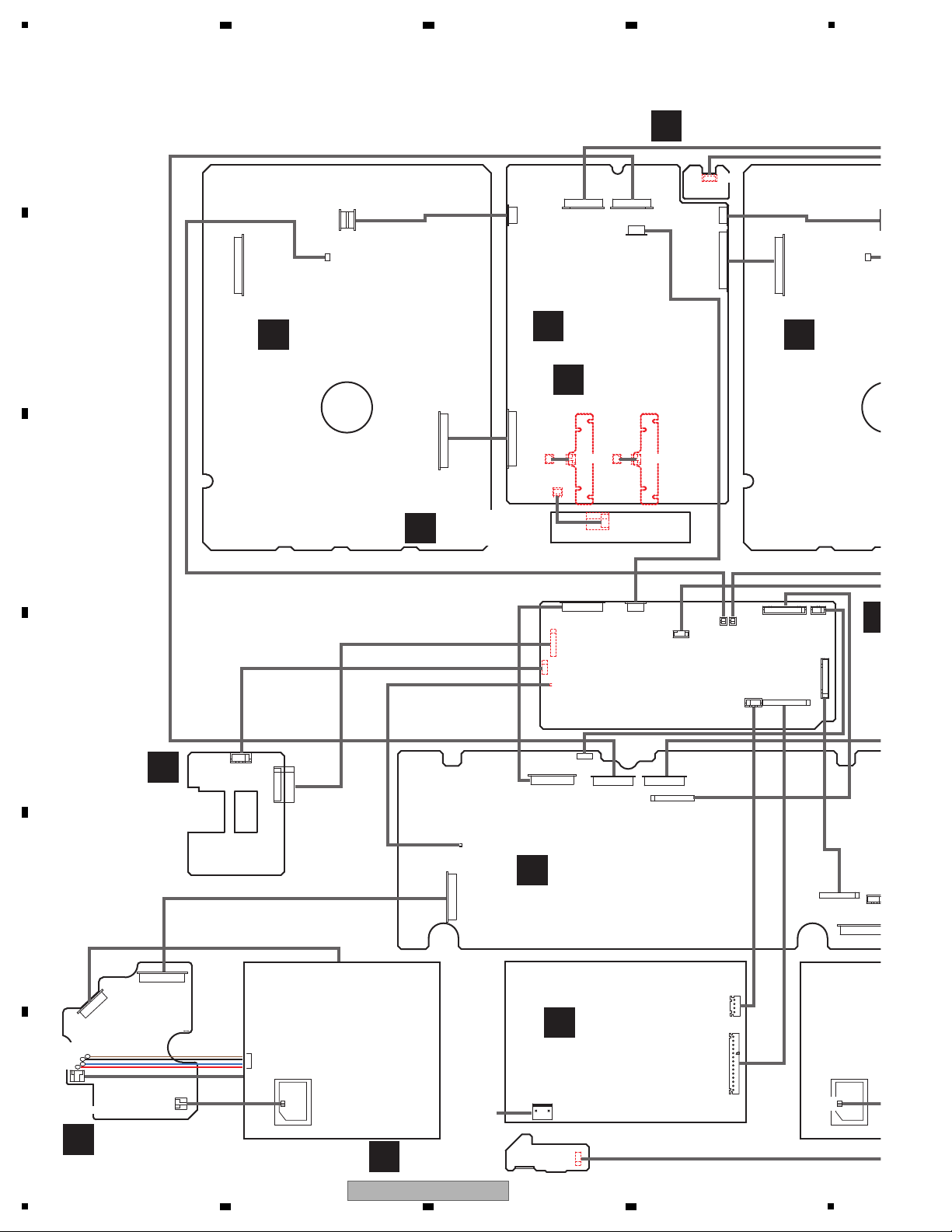

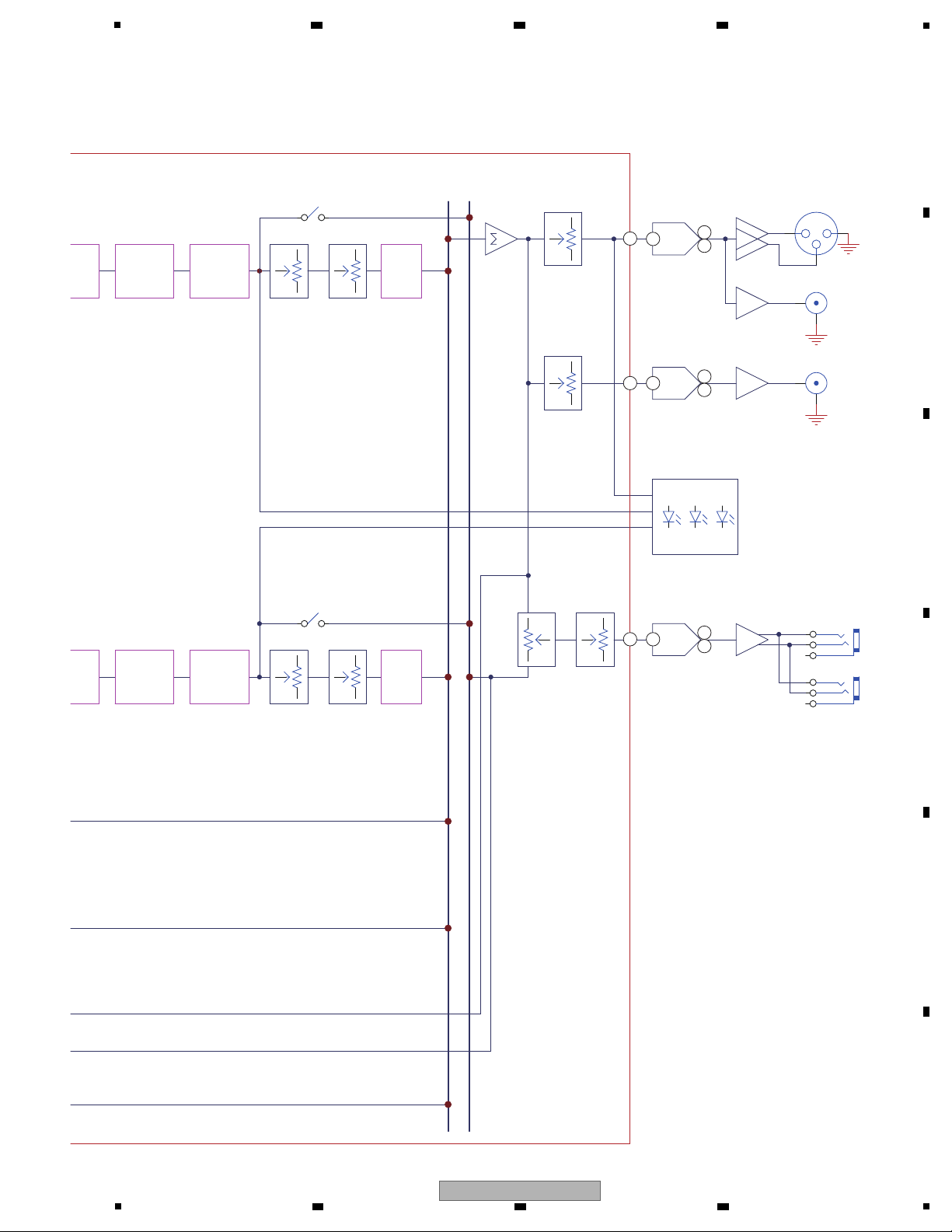

4. BLOCK DIAGRAM

4.1 OVERALL WIRING DIAGRAM

A

B

C

D

E

F

8

1

XDJ-R1

2 3 4

Page 9

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

CN810

D

D

D

D

D

D

D

UTX"

DO1

DO2

CD2 SCOR2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

CN810

CN808

DGND

DGND

CDRST

MCK

R/W

BUSY

SUBDA

SUBCK

SCOR1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

CN102A

DD1

3.3V

3.3V

S3.3V

S3.3V

AGND

7V

7V

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

CN210

406-COMBO-1255

SAD3.3V

SADGND

SADGND

SADGND

SADGND

SADGND

SADGND

SADGND

SADGND

SADGND

SADGND

SADGND

SADGND

AD3

AD7

AD9

AD10

AD11

AD12

AD15

AD16

AD17

AD18

CROF

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

CN210

SAD3.3V

SADGND

SADGND

SADGND

SADGND

SADGND

SADGND

SADGND

SADGND

SADGND

SADGND

SADGND

SADGND

AD3

AD7

AD9

AD10

AD11

AD12

AD15

AD16

AD17

AD18

CROF

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

CN200

SCL

SDA

/URST

D5V

5V

5V

32V

ST5V

STBY

SWB

SWA

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

CN200

D

D

D

D

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

CN201

DSO1/2

DSO2/8

DSO5/6

AD3/7

AD1/5

AD2/6

AD4/8

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

CN201

STCP

AGND

AGND

D5V

AD5V

VH

SCK

5V

D

D

D

/OE1

SADGND

SADGND

SAD3.3V

STCP

DSO2

DSO6

5V

SCK

D

D

D

D

D5V

VH

AD

AD

AD5V

/OE1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

CN204

SADGND

SAD3.3V

AD3/7

AD1/5

AD2/6

AD4/8

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

CN204

1

2

3

4

5

6

7

8

CN206A

DATA1

1

2

3

4

5

6

7

8

W206

GND

GND

URX

UTX

1

2

3

4

5

6

7

8

CN209

GND

GND

1

2

3

4

5

6

7

8

CN209

DSP & POWER ASSY

(704-COMBO-A531)

G

G G

1/2,

2/2

I

CD1 ASSY

(704-COMBO-A375)

SLOT-IN FEEDER

MECHA ASSY

(DECK2)

J

SERVO ASSY

(704-COMBO-A377)

PICKUP

CN101

CN101

CN106

CN105

CN102A

CN809

W4

CN401

CN4

CN6

CN201

CN204

W206

W812

W3

1. L

2. GND

3. GND

4. R

1. 7V

2. M

3. M

4. P

5. ST5V

6. A-15V

7. A+15V

8. A

9. STBY

10. MUTE

11. /MST

1. Vcc

2. VC

3. VEE

4. E

5. B

6. C

7. D

8. A

9. F

10. PD

11. AGND

12. LD

13. VR

14. FC-

15. TC-

16. TC+

17. FC+

1. -Ef

2. +Ef

SP+ (RED)

SP- (BLUE)

LMB (BLACK)

LMA (BROWN)

MOTOR

GND

S1

S0

-

When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS LIST" or "PCB PARTS LIST".

-

The > mark found on some component parts indicates the impor tance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

B

MIXER ASSY

B

MIXER ASSY

A

I/O ASSY

B

MIXER ASSY

I

CD1 ASSY

A

I/O ASSY

G

DSP & POWER

ASSY

A

I/O ASSY

1

406-COMBO-1249

6

B

MIXER ASSY

I

CD2 ASSY

I

CD1 ASSY

B

MIXER ASSY

406-COMBO-1250

7

406-COMBO-1251

8

8

406-COMBO-1247

2

404-COMBO-1244

3

J

SERVO

ASSY

A

I/O ASSY

406-COMBO-1245

406-MEP4-1201

4

5

2

/INT1

LN1-SW

LN2-SW

AUX-SW

V-CHK

LN1-G

LN2-G

PD

PD

SCL

SDA

/URST

D5V

5V

5V

32V

ST5V

STBY

SWB

SWA

D

D

D

D

/INT1

LN1-SW

LN2-SW

AUX-SW

V-CHK

LN1-G

LN2-G

PD

PD

LRCK1

LRCK2

BCK1

BCK2

BCK3

LRCK3

D09

D010

SPI SCK"

SPI MOSI/MI

SPI CS"

CD1 SCOR1

/RST-532

SPI HREQ

SPI RTS

D

D

D

D

D

D

D

UTX"

DO1

DO2

CD2 SCOR2

LRCK1

LRCK2

BCK1

BCK2

BCK3

LRCK3

D09

D010

SPI SCK"

SPI MOSI/MI

SPI CS"

CD1 SCOR1

/RST-532

SPI HREQ

SPI RTS

DISC SW1

DISC SW2

OPSW

CLSW

LMDLMD+

DIO

WFCK

BCK1

LRCK1

PGND

DGND

DGND

CD1 CDRST

CD1 MCK

CD1 R/W

CD1 BUSY

CD1 SUBDA

CD1 SUBCK

CD1 SCOR1

DO1

3.3V

3.3V

A3.3V

A3.3V

AGND

7V

7V

CD1 DISC SW1

CD1 DISC SW2

CD1 OPSW

CD1 CLSW

CD1 LMDCD1 LMD+

CD1 DIO

CD1 WFCK

BCK1

LRCK1

PGND

CN809

DGND

DGND

CDRST

MCK

R/W

BUSY

SUBDA

SUBCK

SCOR1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

CN102A

DD1

3.3V

3.3V

S3.3V

S3.3V

AGND

7V

7V

J

SERVO

ASSY

A

I/O ASSY

406-COMBO-1245

406-MEP4-1201

5

DISC SW1

DISC SW2

OPSW

CLSW

LMDLMD+

DIO

WFCK

BCK1

LRCK1

PGND

DGND

DGND

CD2 CDRST

CD2 MCK

CD2 R/W

CD2 BUSY

CD2 SUBDA

CD2 SUBCK

CD2 SCOR1

DO2

3.3V

3.3V

A3.3V

A3.3V

AGND

7V

7V

CD2 DISC SW1

CD2 DISC SW2

CD2 OPSW

CD2 CLSW

CD2 LMDCD2 LMD+

CD2 DIO

CD2 WFCK

BCK2

LRCK2

PGND

PGND

PGND

PGND

LAT1

BK1

PA1

PB1

KR1

/PL

STB-LED

STB-SW

KS1

KS2

KS3

KS4

KS5

KS1

KS2

KS3

KS4

KS5

DSO1/2

DSO2/8

DSO5/6

AD3/7

AD1/5

AD2/6

AD4/8

STCP

AGND

AGND

D5V

AD5V

VH

SCK

5V

GND

GND

GND

/OE1

SADGND

SADGND

SAD3.3V

PGND

PGND

PGND

LAT1/2

BK1/2

PA1/2

PB1/2

KR1/2

/PL

STB-LED

STB-SW

KS1

KS2

KS3

KS4

KS5

PD

PD

PD

LAT2

BK2

PA2

PB2

KR2

/PL

MISO

STCP

DSO1/2

DSO6/3

5V

SCK

D

D

D

D

D5V

VH

AD

AD

AD5V

/OE1

SADGND

SAD3.3V

AD3/7

AD1/5

AD2/6

AD4/8

KS1

KS2

KS3

KS4

KS5

PD

PD

PD

LAT1/2

BK1/2

PA1/2

PB1/2

KR1/2

/PL

DSO5/6

CLK1

LS1

LS2

LS3

LS4

DATA

GND

GND

CLK

LS1

LS2

LS3

LS4

1

2

3

4

5

6

7

8

CN206B

DATA2

1

2

3

4

5

6

7

8

W206

GND

GND

I

CD2 ASSY

B

MIXER ASSY

B

MIXER ASSY

G

DSP & POWER

ASSY

406-COMBO-1251

9

406-COMBO-1248

a

CLK2

LS1

LS2

LS3

LS4

DATA

GND

GND

CLK

LS1

LS2

LS3

LS4

PA1

PB1

PA2

PB2

URX

UTX

GND

GND

PA1

PB1

PA2

PB2

1. SL-

2. SL+

3. Disc Detecting Switch

4. S3.3V

1. Q1

2. Q2

3. DGND

5

5

6 7 8

XDJ-R1

6 7 8

A

B

C

D

E

F

9

Page 10

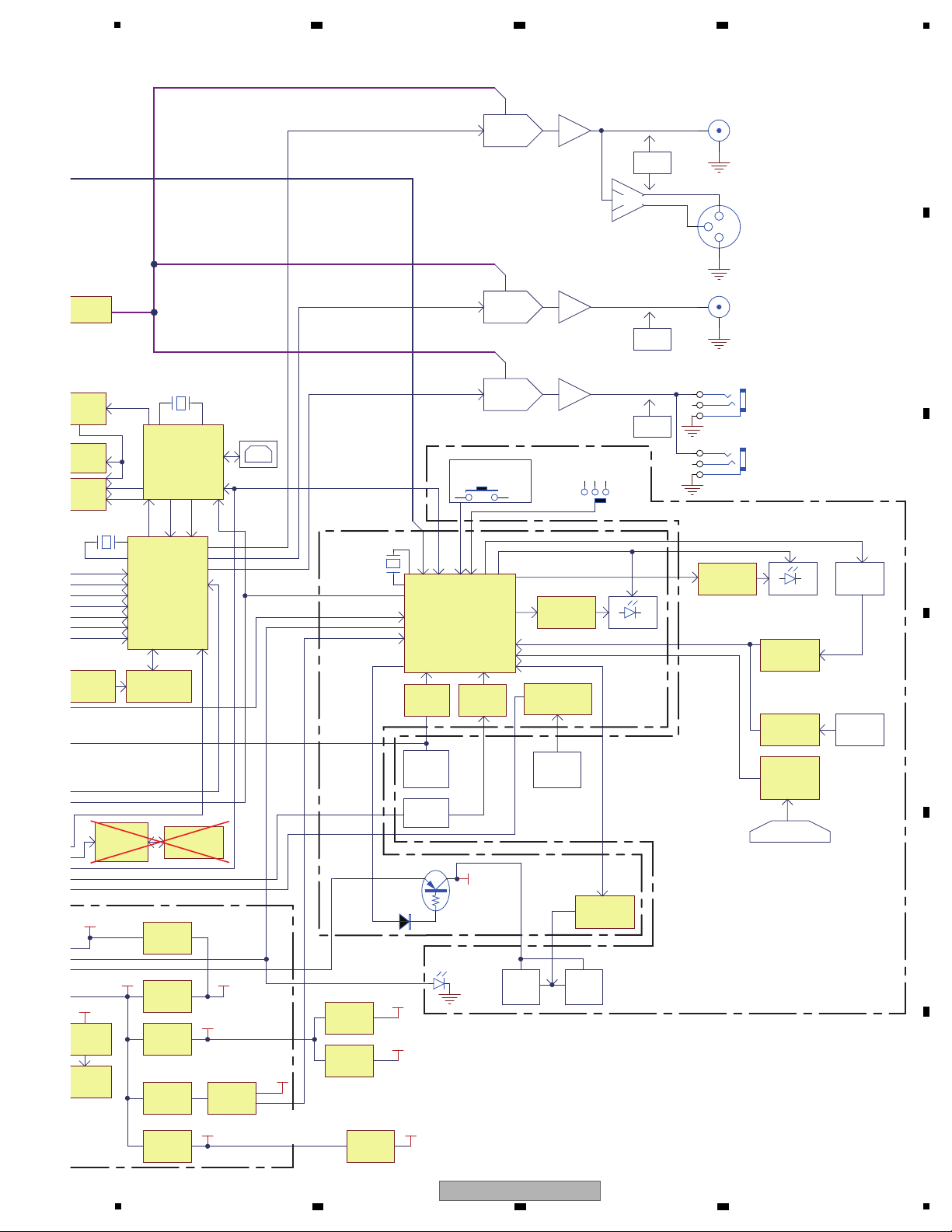

1

MCL K

TP S54

BD4745

6V

+15V

-15V

BUC

Compare

LI NE1/P H1

-9.05dB

-9.05dB

-9.05dB

ADC

PCM1803

NJM4580

0dB

RIAA

+36dBPH

NJM4580

2

C 1

1

LN/PH

+20dB

ADC

LN

LI NE2/P H2

ADC

NJM4580

0dB

RIAA

+36dBPH

NJM4580

2

C 1

1

LN/PH

LN

AUX

ADC

NJM4580

2C11

Boost

L

3

R

2

G

1

S

4

MI C.

+11dB

NJM2068

BU9543K V

CD DSP

BA5826FP

4CH Driver

BA6218

Motor Driver

STM8S207MBT3

CD MCU

SP/SL

Motor

Motor

Load

Spindle

Slide

Focus Track

16.9344M

Opitical

12

Disc

Sensor

SP/SL

Motor

Motor

Load

Spindle

Slide

Focus Track

16.9344M

Opitical

12

Disc

Sensor

DECK DSP

parallel

parallel

BCK 1

LRCK 1

BCK 2

LRCK 2

DO1

DO2

DO3

DO4

RX0 I2S

RX1 I2S

Flash ROM

29W800D

SDRAM* 2

IS42S83200G

ISP1761

USB IF

CD1 /RST

SPI

SPI

AXM22001

WiF i Module

ANT

USB Host

DSP567

TX0 I2S

TX1 I2S

DO5

DO6

TU

ICS501

2*PL L

74HC4050

Buffer

SCK 3

BCK

LRCK

BCK 3

LRCK 3

BCK 3

LRCK 3

BCK 3

LRCK 3

BCK 3

LRCK 3

TX used BCK3&L RCK 3

DI 1DO7 D

SDRAM*

EM638165T

LATCH* 2

74LV573

6V/4A,+15V&- 15V/0.4A,7V/2A

STB5V/0.2A,32V/0.35A

+Ef&- Ef(3.4V/0.8A)

+Ef -Ef

VF D Filament

7V

CD Driv

er

STB5V

UI MCU

OPA

BA0

LDO

TP S54

BUCK

BA0

LDO

A5V

AC Plug

STBY

LD11

2.5V(Ek)

74HC14

(HW)

18.432M

/RST -532

/RST- 724

SPI(SW)

CD2 /RST

EN25Q64

Flash MEMO.

SCK 3

BCK 3

LRCK 3

BCK 3

LRCK 3

Buffer

SCK 4

SCK 4

Buffer

SCK 4 SCK 4A

Buffer

SCK 3A SCK 3

24.576M

12M

SLOT-IN FEEDER

MECHA ASSY

(DECK1)

SLOT-IN FEEDER

MECHA ASSY

(DECK2)

SERVO ASSY

SERVO ASSY

SWITCHING POWER

DSP & POWER

ASSY

DSP & POWER

ASSY

I/O ASSY

SWITCHING POWER

Power

Delay

ADSP-BF532

Hysteresis

MIXER

SN74LVC1G17

USB

SN74LVC1G17

SN74LVC1G17

IC416

IC418

IC419

IC420

IC421

IC814

IC815

IC401

IC

IC40

IC402

IC813

IC802

IC805

IC815

IC414,IC415 IC412,IC4

IC811

IC812

IC7

IC4

IC1

IC2

IC3

IC5

IC803

IC813,IC814

IC816

X801

X401

X402

X

IC417

IC403

PCM1803

IC405

PCM1803

IC404

PCM1803

IC406

IC102

BA5826FP

4CH Driver

IC102

IC101

BU9543K V

CD DSP

IC101

IC103

BA6218

Motor Driver

IC103

X102

X102

SI,SO,/CS,SCK

F

QS3245

Buffer

74HCT08

2 3 4

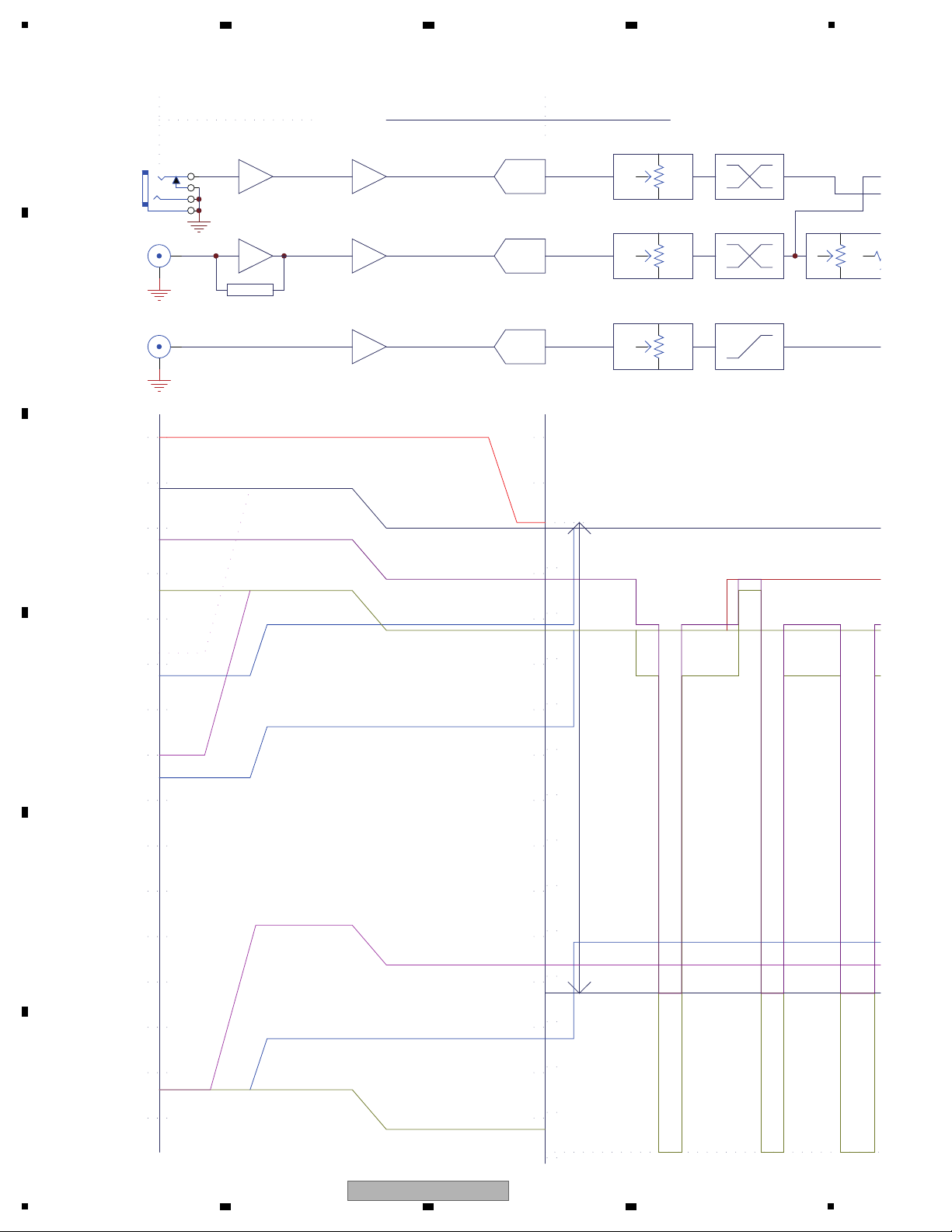

4.2 OVERALL BLOCK DIAGRAM

A

B

C

D

E

F

10

1

XDJ-R1

2 3 4

Page 11

5

USB PortB

Tact SW

EXT. AD

HC4052* 2

X.Curve

PIC16F 16*2

PWM

TOUCH P L AT* 2

Wheel

Encoder

SER.- ->PAL .

74595

MCL K

6M

U5V

MASTER OUT(RCA)

Rotary*7

Fast

TP S54232

BD4745

D3.3V

6V

BUCK

A5V

Rotary*15

send

return

NJM4580

D5V

DSP56724

TUSB3200

CS501

BCK

LRCK

DI 1DO7 DO8

MUTE

2

3

1

BOOTH OUT(RCA)

NJM4580

MUTE

DAC

NJM4556

MUTE

L

3

R

2

G

1

JK9

L

3

R

2

G

1

JK9

DI 2

DI 3

DI

4

SDRAM* 2

EM638165TS

STM8S207MBT3

UI MCU

I2C,I NT

TX,RX

74HC165

74HC165

PAL .-->SER.

PAL .-->SER.

CP ,/PL,D1,D2

Encoder

*6

Rotary

*64

*31

*54

*2

Normal

DECK 1

VFD

DECK 2

VFD

Serial

-Ef

Filament

32V

VFD Driv er

BA05

LDO

TP S54232

BUCK

BA05

LDO

A5V

DAC

USB Host

Current CHK

LD1117

2.5V(Ek)

+16.8dB

+16.8dB

+4dB

+10.95dB

BD12K A

LDO

D1.2V

DSP Core

Stand By

TP S2553

Curr.L TD

min.1100mA

STM8S003F3

VFD MCU

TX1/RX1

18.432M

/URST

Comparator

LM339

X.F ader

2

C 1

1

FUCN. SW.* 2

Hy steresis

74HC14

Buffer

SCK 4A

ADC

AD3.3V_1

BU33TD3

ADC

AD3.3V_2

BU33TD3

24.576M

ER

CD ASSY

MIXER ASSY

I/O ASSY

Power

Delay

MCU,PLL,Logic,VFD

DSP,SDRAM,Wi-Fi,

USB IF,Servo Driver,

FlashRom

MIXER DSP

4LVC1G17

USB Controllor

MASTER OUT(XLR)

1/4" PHONES OUT

3.5mm PHONES OUT

HP Cue1/Cue2

Comment: STBY SW

2nd order LPF

2nd order LPF

2nd order LPF

LEDs

LEDs

IC400

IC408

IC7

IC4

IC1

IC2

IC3

IC5

IC407

IC817

IC816

IC100

IC207

IC101

IC104

IC103

IC209 IC208

IC200

IC202

SER.- ->PAL .

74595

IC102

IC425

IC424

IC423

IC422

PCM1754

IC411

DAC

PCM1754

IC410

DAC

PCM1754

IC409

X200

IC203,IC205

IC100

IC6

X400

EN25F 10

Flash MEMO.

QS3245

Buffer

74HCT08

6 7 8

A

B

C

D

E

5

XDJ-R1

6 7 8

F

11

Page 12

1

12

LN/P H SW

ADC

31

2

31

2

31231

2

12

LN/P H SW

ADC

31

2

31

2

31231

2

AUX

12

LI NE BOOST

L/R

ADC

L

3

R

2

G

1

ADC

12

12

31

2

31

2

31

2

USB PortB

1

2

C1

1

2

C1

USB Audio IN

USB Audio OUT

CH1 CD Deck

CH2 CD Deck

1

2

C1

1

2

C1

1

2

C1

1

2

C1

USB IN1

USB IN2

DECK DSP

MIXER DSP

SOURCE Select

SOURCE Select

CH1

CH2

USB Audio Mix

USB Audio HP

USB MASTER OUT

USB Audio IN1

USB Audio IN2

EQ

1

2

C1

1

2

C1

PC,USB,CD Select

PC,USB,CD Select

CH-1

LINE/PHONO

L/R

CH-2

LINE/PHONO

L/R

USB PortA

MIC mono

6.4mm

AUX Input level

AUX ON/OFF

MIC ON/OFF

MIC Input level

3 Band Isolator

3 Band Isolator

ROLL

EFFECT

COLOR

EFFECT

ROLL

EFFECT

COLOR

EFFECT

IC403

IC805

IC405

IC404

IC406

IC408

12

12

12

12 98

86

87

88

4.3 SYSTEM BLOCK DIAGRAM

A

B

2 3 4

C

D

E

F

12

1

XDJ-R1

2 3 4

Page 13

31

2

31

2

31

2

DAC

MASTER2(RCA)

DAC

31

2

BOOTH(RCA)

2

3

1

31

2

DAC

31

2L

3

R

2

G

1

L

3

R

2

G

1

Phones JACK

6.4mm

3.5mm

M ASTER

C UE

12

CH1 CUE

31

2

31

2

12

CH2 CUE

MAS CH2CH1

LEVEL Meter

ECT

COLOR

EFFECT

TRANS

FLANGER

EFFECT

ECT

COLOR

EFFECT

TRANS

FLANGER

EFFECT

ECHO

EFFECT

ECHO

EFFECT

MASTER TRIM

BOOTH TRIM

MASTER/CUE

MIX

HP LEVEL

MASTER(XLR)

BALANCE

IC408

IC409

IC410

2

7

8

2

7

8

125

124

IC411

2

7

8

122

5

6 7 8

A

B

C

D

E

F

XDJ-R1

5

6 7 8

13

Page 14

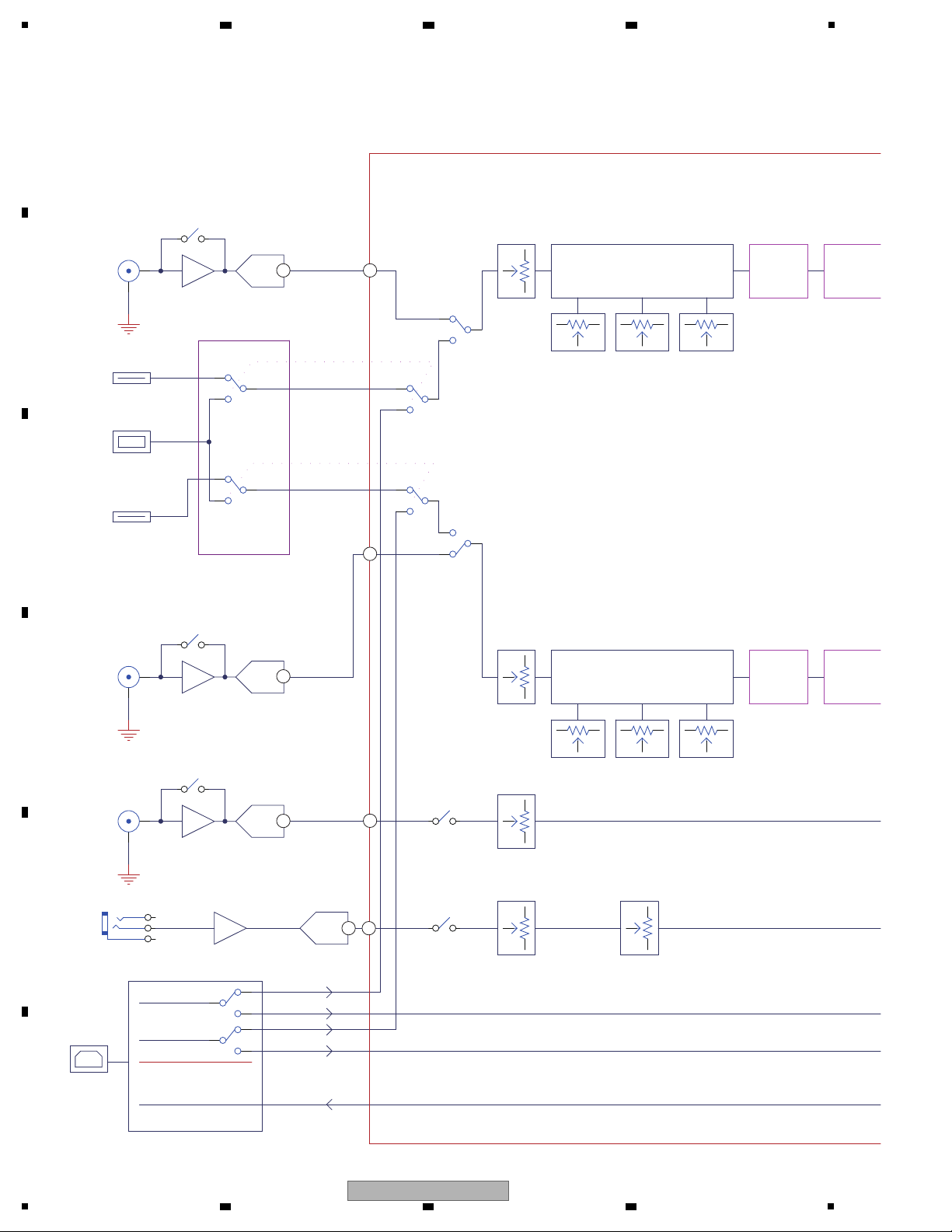

1

Line/P hono

-9.05

A/D

dBV

Max Input Lev el

0

10

20

-10

-20

-30

-40

-50

-60

-70

-80

-90

-100

-110

-120

-130

PCM1803

dBV

0

10

20

-10

-20

-30

-40

-50

-60

-70

-80

-90

-100

-110

-120

-130

dBF S

31

2

EQ

31

23

2

CH.F ader * C

0(+0.5dBV)

-10

-20

-30

-40

-50

-60

-70

-80

-90

-100

-110

-120

-130

DR:103dB

-140

-9.05

NJM4580

11dBu(8.79dBV)

-0.26dBV

200mVrm s

-14dBV

AUX Boost

+9~ -∞ dB

-9.05

-144dBF S@24bit

Noise Level

@-123dBV

Clip=19.59dBV

MI C Level

-54dBV

+9.9

Phono Level

-50dBV

+36

RIAA

LN:0

PH:+36

0~-9~ -∞ dB 0~ -∞ dB

AUX

A/D

PCM1803-9.28

NJM4580

31

2

0~-9~ -∞ dB

NJM4580

+9.9

ADC

PCM1803

L

3

R

2

G

1

S

4

NJM2068

+0

NJM2068

TONE

0~ -12 dB

31

2

0~-9~ - ∞ dB

Boost

0~+12dB

-23.05dBV

Center

Max.

-23.55dBF S

Phono Noise

-96.05dBV

-32.55dBF S

MI C Noise -113.1dBV

Max.P hono Level -25dBu

Max. MIC Level

-29dBu

DR:103dB

DR:103dB

DR:103dB

-20.76dBF S

Reference level 0dBu

+12

+21

DSP Gain

ANALOG

limit +0.5dBV

limit +0.5dBV

MIC.

GAIN

GAIN

TRIM

DIGITAL

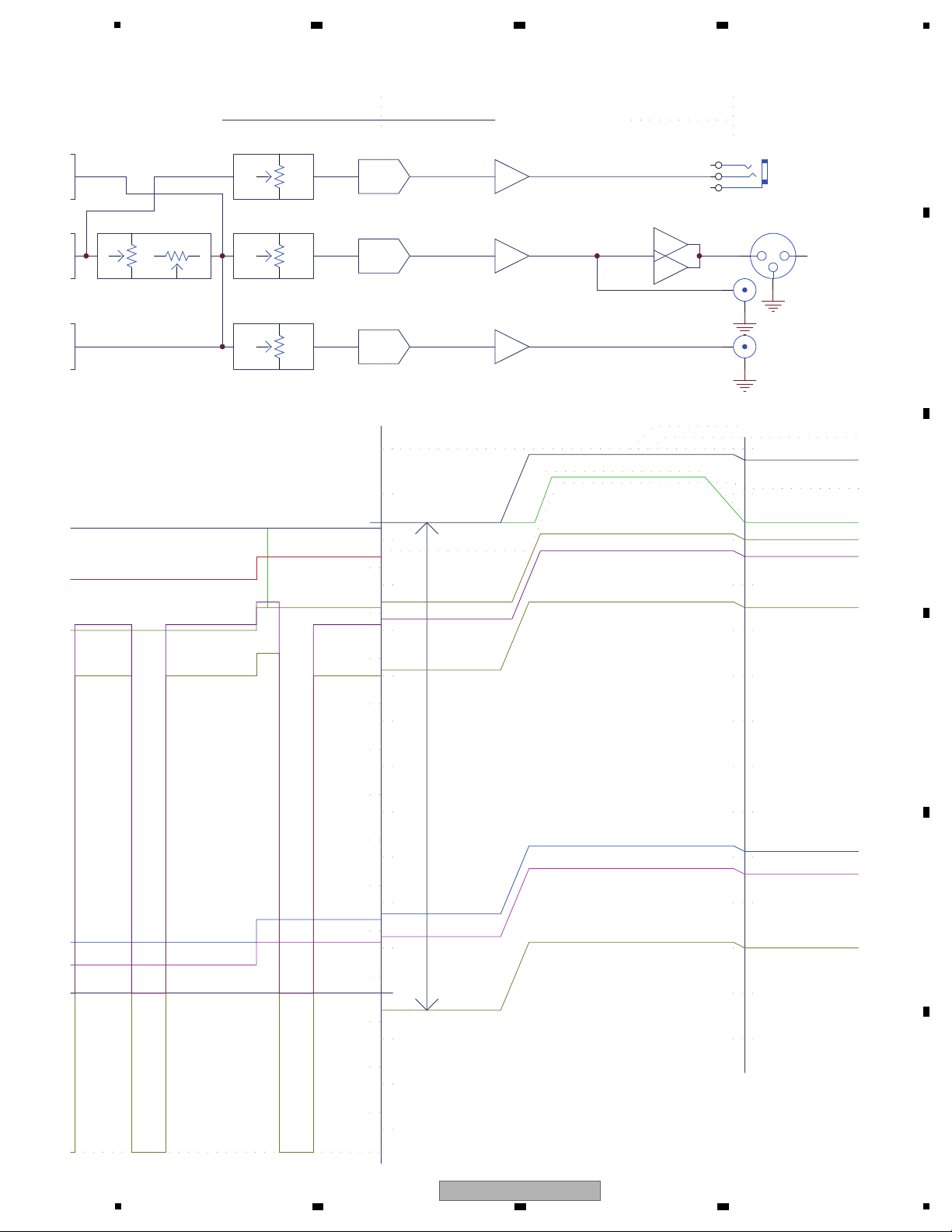

4.4 LEVEL BLOCK DIAGRAM

A

2 3 4

B

C

D

E

F

14

1

XDJ-R1

2 3 4

Page 15

5

31

231

2

CH.F ader * CR.Fader

dBV

0

10

20

-10

-20

-30

-40

-50

-60

-70

-80

-90

-100

-110

-120

-130

D/A

DR:106dB

PCM1754

0dBF S=3dBV

31

2

Master Level NJM4580

Master Out

DR:105.24dB

Max.

+4

2

3

1

NJM4556

12.55dBV

+17.79

25dBu

dBV

0

10

20

-10

-20

-30

-40

-50

-60

-70

-80

-90

-100

-110

AUX Boost

-29.55dBV

+16.8

+10.95

11.07dBV

3dBV

BAL ANCE

AUX L ev el 12dBV

Unbalance Out 0dBV

dBF S@24bit

DSP-->DA@- 87.41dBV

Clip=19.59dBV Unbalance Clip

Balance Clip=25.59dBV

D/A

DR:123dB

PCM1754

0dBF S=3dBV

31

2

+10.95

Phones Max. 70mW

Unbalance Max. 20dBu

Phones Clip +14dBV

L

3

R

2

G

1

PHONES

+20~ -∞ dB

0~ -∞ dB +5~ -∞ dB

D/A

DR:106dB

PCM1754

0dBF S=3dBV

31

2

Booth Level NJM4580

+5~ -∞ dB

RCA

Booth Out

RCA

80%position

100%position

-15.55dBV

+16.8

Unbalance Out -14dBV

2.24dBV(Max.)

+5

Phono@- 72.77dBV

0

-10

-20

-30

-40

-50

-60

-70

-80

-90

-100

-110

-120

-130

dBF S

+16.8

-32.55dBF S

CUE

90%position

MIC@- 68.78dBV

80%position-20.76dBF S

Unbalance Out 0dBu(Ref.)

CUE Level

DIGITAL

ANALOG

XLR

6 7 8

A

B

C

D

E

F

5

6 7 8

XDJ-R1

15

Page 16

1

[1] Power failure

Symptom: SWITCHING POWER is fault.

Diagnostic procedure:

1. Check if SWITCHING POWER CN1: AC 100 V to AC 240 V is normal.

2. Check SWITCHING POWER CN3:

V1 → +7V, V2 → ST5V, V3 → +15V, V4 → -15V, V5 → 6V.

3. Check waveform for SWITCHING POWER, confirm it is correct.

SWITCHING POWER C28 positive to ground is +7V figure

(Waveform ).

SWITCHING POWER C47 positive to ground is ST5V figure

(Waveform ).

SWITCHING POWER C31 positive to ground is +15V figure

(Waveform ).

SWITCHING POWER C24 negative to ground is -15V figure

(Waveform ).

SWITCHING POWER C21 positive to ground is +6V figure

(Waveform ).

4. If Waveform is abnormal, you could change it.

[2] VFD dose not light

Symptom:

VFD module is fault, it is no light-emitting.

Diagnostic procedure:

1. Check waveform for VFD module, you confirm it is correct.

Check CD Assy C112 positive to ground is +Ef figure

(Waveform ).

Check CD Assy C112 negative to ground is -Ef figure

(Waveform ).

Check CD Assy C103 positive to ground is VH figure

(Waveform ).

2. If Waveform is abnormal, you could change it.

[3] LED dose not light

Symptom: LED part is fault, it is no light-emitting.

Diagnostic procedure:

1. Check waveform for LED, you confirm it is correct.

2. It is tested at CD Assy Q102 to Q105 pin C (CH1).

It is tested at CD Assy Q106 to Q112 pin C (CH2).

Waveform for LED ON is figure

(Waveform ).

Waveform for LED OFF is figure

(Waveform ).

3. If Waveform is abnormal, you could change it.

[4-1] No key functions

Symptom:

No key function.

Diagnostic procedure:

1. Check waveform for KEY, you confirm it is correct.

Waveform for KEY OFF is figure

(Waveform )

(CH1 → KEY pin 1/CH2 → KEY pin 2).

Waveform for KEY ON is figure

(Waveform )

(CH1 → KEY pin 1/CH2 → KEY pin 2).

2. If Waveform is abnormal, you could change it.

[4-2] Rotary selector not controllable

Symptom: Rotary selector of encoder switch is fault.

Diagnostic procedure:

1. Check waveform for rotary encoder, you confirm it is correct.

Waveform for rotary encoder is figure

(Waveform )

(CH1 → encoder pin 1/CH2 → encoder pin 3).

2. If Waveform is abnormal, you could change it.

[4-3] Slider volume not controllable

Symptom:

Crossfader and channel-fader VR is fault.

Diagnostic procedure:

1. Check waveform for VR, you confirm it is correct.

C802 (CROSSFADER), C807 (CH1 FADER), C806 (CH2 FADER) that positive to ground is VR out.

Waveform for min VR out is figure

(Waveform ).

Waveform for max VR out is figure

(Waveform ).

2. If Waveform is abnormal, you could change it.

1-1

1-2

1-3

1-4

1-5

2-1

2-2

2-3

3-1

4-1

4-2

4-3

4-4

4-5

3-2

2 3 4

5. DIAGNOSIS

5.1 TROUBLESHOOTING

A

B

C

D

E

F

16

1

XDJ-R1

2 3 4

Page 17

5

[6] Jog rotation can not be detected

Symptom: Jog rotation is fault.

Diagnostic procedure:

1. Check waveform for jog rotation circuit, you confirm CD Assy is correct.

2. CD Assy Q100 C pin (CH1) and Q101 C pin (CH2) is figure

(Waveform ).

3. If Waveform is abnormal, you could change it.

[7] Jog touch can not be detected

Symptom: Jog touch is fault.

Diagnostic procedure:

1. Check waveform for jog touch circuit, you confirm it is correct.

2. Check Waveform that CD Assy C113 positive to ground, if Waveform is abnormal.

3. Waveform without touch condition is figure

(Waveform ).

4. Waveform for touch is figure

(Waveform ).

[8] Disc can not be inserted or Ejected

Symptom: CD DECK is fault.

Diagnostic procedure:

1. Check waveform for SERVO Assy IC103 pin 7 LMA (CH1), pin 9 LMB (CH2), you confirm SERVO Assy is correct.

IC103 pin 7LMA (CH1) and pin 9 LMB (CH2) Waveform for insert disc is figure

(Waveform ).

IC103 pin 7LMA (CH1) and pin 9 LMB (CH2) Waveform for eject disc is figure

(Waveform ).

2. Check SERVO Assy CN102A pins 9 to 12 for CLSW (CH2)/OPSW (CH3)/DISC SW1 (CH1)/DISC SW2 (CH4).

CN102A pin 12 CLSW (CH2), pin 11 PSW (CH3), pin 9 DISC SW1 (CH1), pin 10 DISC SW2 (CH4) waveform

for no disc is figure

(Waveform ).

CN102A pin 12 CLSW (CH2), pin 11 PSW (CH3), pin 9 DISC SW1 (CH1), pin 10 DISC SW2 (CH4) waveform

for eject disc is figure

(Waveform ).

CN102A pin 12 CLSW (CH2), pin 11 PSW (CH3), pin 9 DISC SW1 (CH1), pin 10 DISC SW2 (CH4) waveform

for insert disc is figure

(Waveform ).

3. If Waveform is abnormal, you could change it.

6-1

[5] DECK, PHONO/LINE selector switch can not work

Symptom: DECK, PHONO/LINE selector switch is fault.

Diagnostic procedure:

1. Check waveform for DECK, PHONO/LINE selector switch, you confirm switch out is correct.

MIXER Assy C207 (CH1 SW) and C220 (CH2 SW) that positive to ground is switch out.

Waveform for switch on is figure

(Waveform ).

Waveform for switch off is figure

(Waveform ).

2. If Waveform is abnormal, you could change it.

5-2

5-1

7-1

8-1

8-2

8-3

8-4

8-5

7-2

[9] Spindle motor does not rotate

Symptom: CD DECK is fault.

Diagnostic procedure:

1. Check waveform for SERVO Assy IC102 pin 1 (SP-), 2 (SP+), you confirm it is correct.

Waveform for spindle motor is figure

(Waveform ).

2. If Waveform is abnormal, you could change it.

[10] No sound input/output from USB

Symptom: The USB audio not activated.

Diagnostic procedure:

1. Check Waveform for I/O Assy IC400 pin 35 (LRCK)

(Waveform )

, pin 34 (BCK)

(Waveform )

,

pin 44 (MCLKO)

(Waveform )

, you confirm it is correct.

2. If Waveform is abnormal, you could change it.

9-1

10-1

10-2

10-3

6 7 8

A

B

C

D

E

5

6 7 8

XDJ-R1

F

17

Page 18

1

[11] No sound output from MASTER1/MASTER2 (UNBALANCE)

Symptom: The audio output is not activated.

Diagnostic procedure:

1. Check Waveform for I/O Assy IC409 pin 16 (SCK)

(Waveform )

, pin 1 (BCK)

(Waveform )

,

pin 3 (LRCK)

(Waveform )

, pin 2 (DATA)

(Waveform )

, you confirm it is correct.

2. If Waveform is abnormal, you could change it.

11-1

11-2

11-3

11-4

[12] No sound output from BOOTH

Symptom: The audio output is not activated.

Diagnostic procedure:

1. Check Waveform for I/O Assy IC410 pin 16 (SCK)

(Waveform )

, pin 1 (BCK)

(Waveform )

,

pin 3 (LRCK)

(Waveform )

, pin 2 (DATA)

(Waveform )

, you confirm it is correct.

2. If Waveform is abnormal, you could change it.

12-1

12-2

12-3

12-4

[13] No sound output from PHONES

Symptom: The audio output is not activated.

Diagnostic procedure:

1. Check Waveform for I/O Assy IC411 pin 16 (SCK)

(Waveform )

, pin 1 (BCK)

(Waveform )

,

pin 3 (LRCK)

(Waveform )

, pin 2 (DATA)

(Waveform )

, you confirm it is correct.

2. If Waveform is abnormal, you could change it.

13-1 13-2

13-3 13-4

[14] No sound input from MIC1/MIC2

Symptom: The audio input is not activated.

Diagnostic procedure:

1. Check Waveform for I/O Assy IC406 pin 15 (SCK)

(Waveform )

, pin 11 (BCK)

(Waveform )

,

pin 10 (LRCK)

(Waveform )

, pin 12 (DOUT)

(Waveform )

, you confirm it is correct.

2. If Waveform is abnormal, you could change it.

14-1 14-2

14-3 14-4

A

2 3 4

B

C

D

E

F

18

1

2 3 4

XDJ-R1

Page 19

5

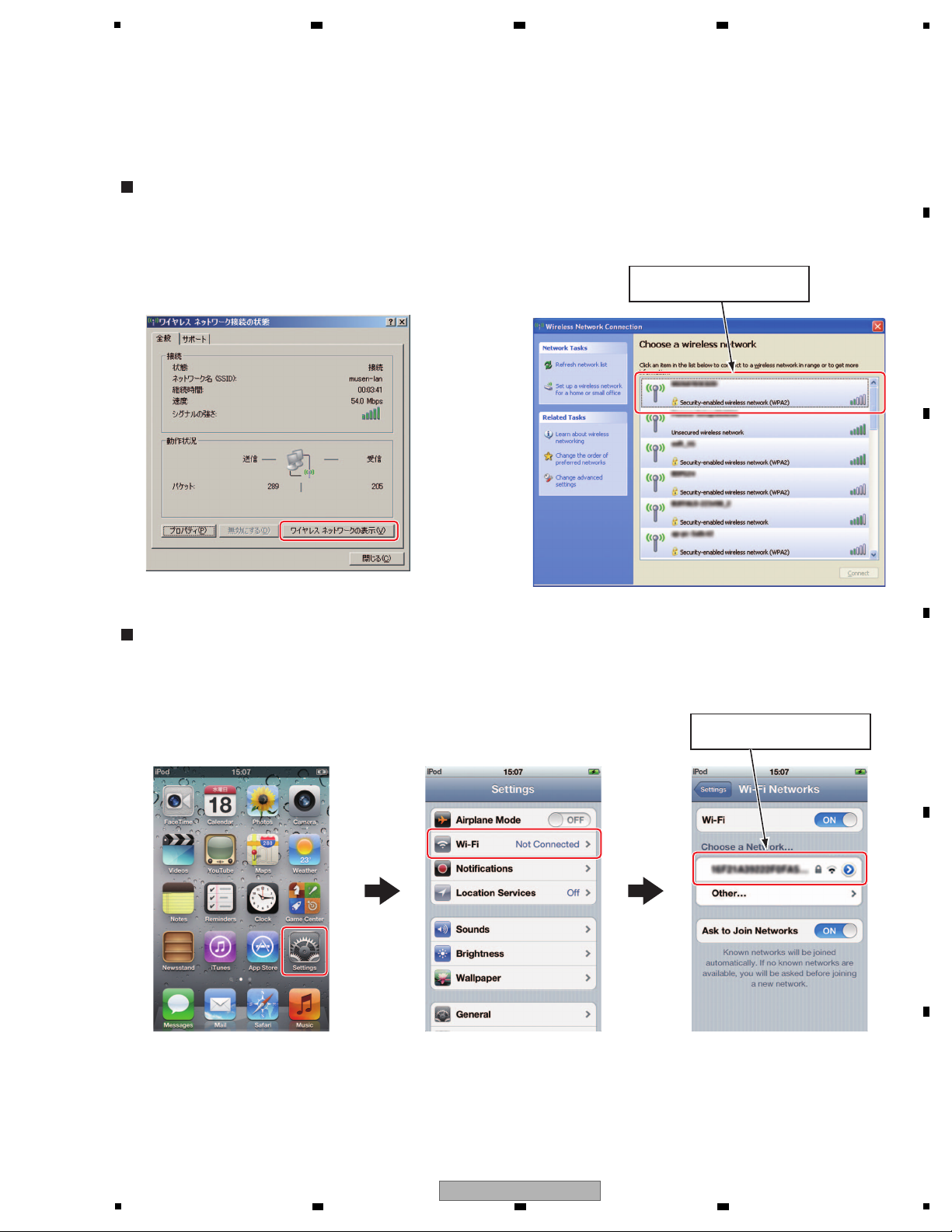

To confirm wireless LAN communication, confirm the SSID with this unit then confirm the signal with a PC equipped with

a wireless LAN device or with a smartphone/tablet PC.

1 Click on the wireless network icon on the system tray.

2 After the Wireless Network Connection Status dialog box is displayed, select the View Wireless Networks button.

3 When the "Choose a wireless network" dialog box is displayed, check that the SSID selected of this unit is displayed.

How to Confirm with a PC (Example: Windows XP)

1 On the top screen of an iPod touch, select Settings.

2 Select Wi-Fi (Not Connected)

3 Check that the SSID selected of this unit is displayed in the "Choose a Network" box.

How to Confirm with a Smartphone/Tablet PC (Example: iPod touch)

Check that the SSID selected

of this unit is displayed.

Check that the SSID selected

of this unit is displayed.

6 7 8

5.2 CONFIMATION OF WIRELESS LAN COMMUNICATION

A

B

C

D

E

F

XDJ-R1

5

6 7 8

19

Page 20

1

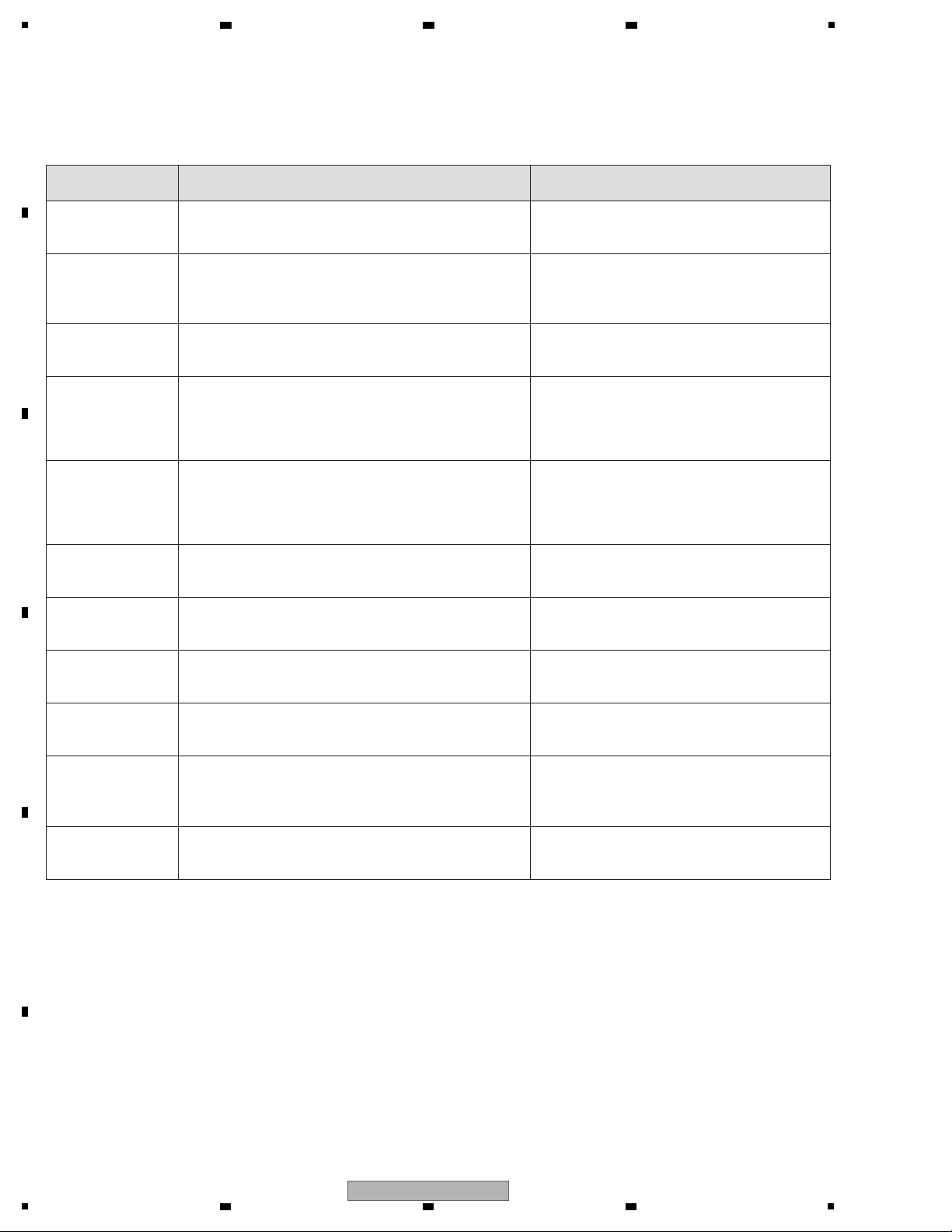

Error indication

Error contents

E-6002 DSP DEVICE ERROR

• The DSP does not operate normally.

• A program is not downloadable.

Remarks

ERROR at the time of POWER ON.

E-7024 MAIN CPU ERROR

• The main Ucom does not operate normally.

It becomes this error, when update of a Ucom goes

wrong and the MAIN Ucom operates by an

emergency function.

ERROR at the time of POWER ON.

E-7201 CANNOT READ DISC

• TOC data cannot be read.

It does not display, when music is LOAD (ed) from

USB.

E-8307 USB ACCESS ERROR

• Not corresponding USB apparatus was connected.

An unsupported USB device is connected.

E-8709 COMMUNICATION ERROR

• Communication of "UI Ucom" and "DSP" cannot be

performed.

This error code is displayed when no communication

is established between the UI Ucom and DPS,

because of inappropriate connection, etc.

ERROR at the time of POWER ON.

E-9101 MECHANICAL TIMEOUT

• A mechanical operation could not be completed within the

specified time.

E-8303 CANNOT PLAY TRACK

• A buffer write-in error.

E-8304 UNSUPPORTED FILE FORMAT

• Decoding error.

E-8305 UNSUPPORTED FILE FORMAT

• A not corresponding format.

E-8301 CANNOT READ DISC

• A desired address was not able to be searched.

• An address cannot be read.

• A focal servo cannot be closed.

• A pickup does not return to inner circumference.

It does not display, when music is LOAD(ed) from

USB.

Abnormalities occurred during starting.

E-8302 CANNOT PLAY TRACK

• A desired address was not able to be searched.

• An address cannot be read.

• A focal servo cannot be closed.

• FILE OPEN ERR

Abnormalities occurred during playback.

If an error is generated, the error code may be shown on the display, depending on the type of error.

The error codes and descriptions of errors are listed below. The track No. at which an error was generated will be also shown

on the display.

2 3 4

5.3 ERROR CODE LIST

A

B

C

D

E

F

20

XDJ-R1

1

2 3 4

Page 21

5

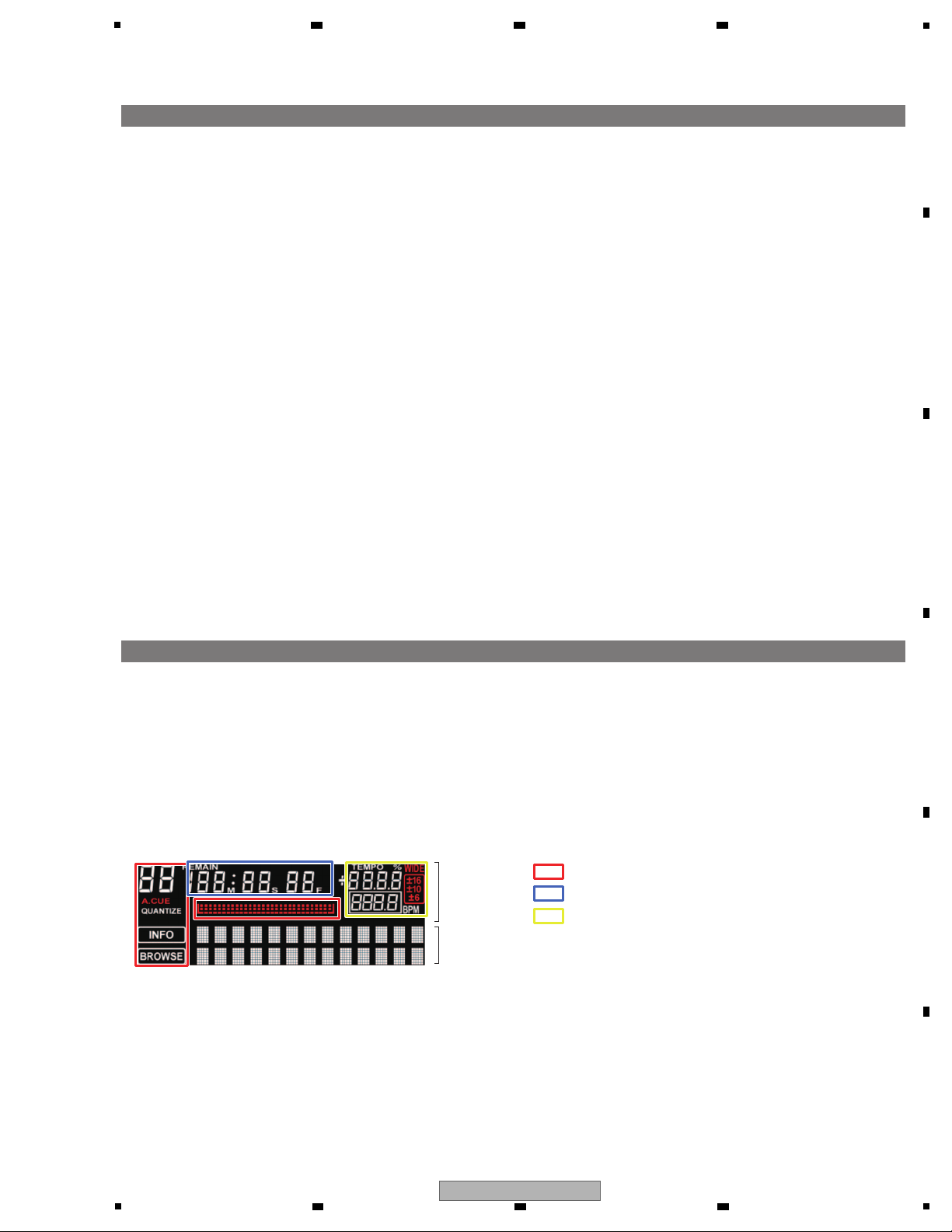

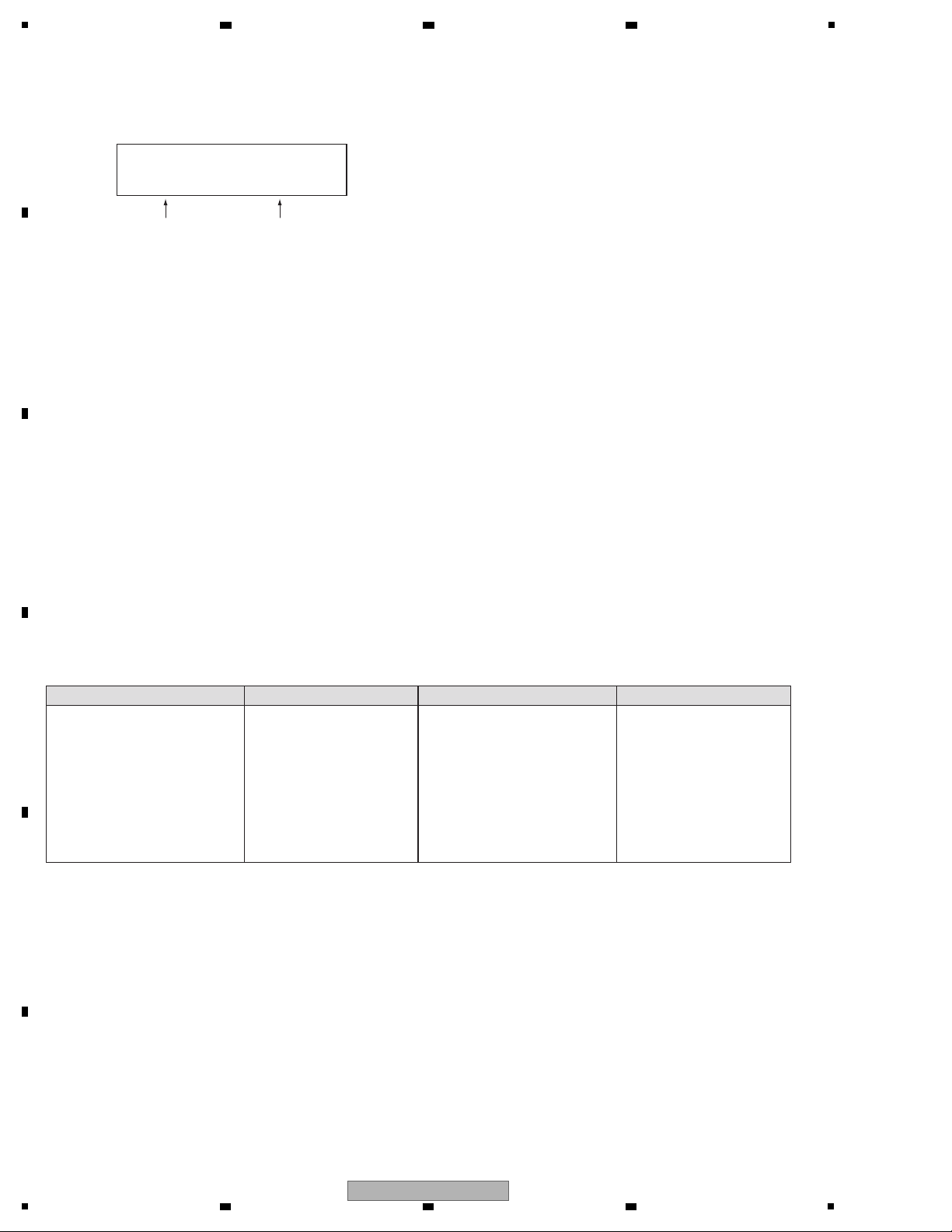

[1] Service mode

This unit supports the Service mode as follows:

1. Mode to check buttons and displays

• This is a mode which can check if buttons and displays are properly performed.

2. Mode to check LED

• This is the mode which can examine whether LED turns on.

• All LED turns on with this mode.

3. JOG dial load measurement mode

• Mode to measure the load when the JOG dial is rotated.

4. CD drive diagnostic mode

• Mode to check if the CD drive is properly performed.

5. Version checking mode (when multiple micro processors are used, this mode is supported.)

• Mode to check each micro processor's software version.

6. Error history display mode

• Mode to check error history (saved up to 16)

7. Displaying A/D values mode

• Mode to check A/D values, such as volume.

8. Center settingfor the controls

• Mode to set the center value for the controls.

9. Factory reset

• Mode to reset the PLAYER's settings to factory default.

10. Firmware update

The above modes are applicable to both DECK 1 and 2 with a few exceptions.

[2] Detailed specifications of each mode

• When the unit is powered on while pressing both the TIME and TEMPO RANGE button on DECK1 simultaneously,

this mode starts after [SERVICE MODE] is displayed for 2 seconds on the dot display.

• You can check whether buttons, knobs and displays are performed properly in this mode.

• In the dot display, TIME display mode is always shown in the upper row and the button names excluding the INFO/UTILITY

button light up in the lower row while they are pressed.

• TIME display mode starts from the DECK VOL display mode.

• When the TEMPO slider is moved far down to the [+] side during this mode, the mode is switched to JOG dial load

measurement mode.

Dot display

Time display

: (1)

: (2)

: (3)

1. MODE to check buttons and displays

6 7 8

6. SERVICE MODE

6.1 SERVICE MODE

A

B

C

D

E

F

XDJ-R1

5

6 7 8

21

Page 22

1

TEMPO RANGE

TEMPO indicator

—————TEMPO RANGE button

MASTER TEMPO MASTER TEMPO indicator —————MASTER TEMPO button

MASTER MASTER indicator —————MASTER button

SYNC SYNC indicator —————SYNC button

TIME/ACUE ————— —————

TIME (AUTO CUE, QUANTIZE) button

DECK, MIXER1, MIXER2

(Toggle DECK, MIXER1 or MIXER2)

————— Switch to TIME display mode.

DECK: DECK VOL mode

MIXER1 & MIXER2: Mixer VOL mode

These are always displayed in the upper

row of the dot display.

INFO (UTILITY) button

————— AllLED light up. All VFD light up.BACK (TOP) button

DISC h DISC h indicator —————DISC h button

USB WLAN indicator (1) are all light up. USB button

CD CD indicator (2) are all light up. CD button

MIDI MIDI indicator (3) are all light up. MIDI button

USB STOP USB STOP indicator —————USB STOP button

0 to FF (in TRACK of TIME display)

—————

Always displayed on the TIME display VFD.

AUTO BEAT LOOP control (Turn)

AUTO BEAT AUTO BEAT LOOP indicator —————AUTO BEAT LOOP control (Press)

0 to FF (in MIN of TIME display)

—————

Always displayed on the TIME display VFD.

BEAT control (Turn)

BEAT BEAT indicator —————BEAT control (Press)

0 to FF (in SEC of TIME display)

—————

Always displayed on the TIME display VFD.

LEVEL/DEPTH control (Turn)

TA P

TAP indicator —————TAP button

0 to FF (in FRAME of TIME display)

—————

Always displayed on the TIME display VFD.

Rotary selector (SELECT PUSH) (Turn)

PUSH

————— —————

Rotary selector (SELECT PUSH) (Press)

TOUCH

JOG illumination —————JOG dial TOUCH SENSOR

JOG d

————— —————JOG dial turn (clockwise)

c JOG

————— —————JOG dial turn (counterclockwise)

VINYL VINYL MODE indicator —————VINYL MODE button

* Check the operation of TEMPO SLIDER by normal startup.

DECK area

Characters shown

on the display

Lit-up LED Note/RemarksButtons and volume knobs

PLAY d d/e (PLAY/PAUSE) indicator —————d/e (PLAY/PAUSE) button

CUE

CUE indicator —————CUE button

SHIFT SHIFT indicator —————SHIFT button

TRACK o

TRACK SEARCH (o) indicator

—————TRACK SEARCH (o) button

TRACK SEARCH p

TRACK SEARCH (p) indicator

—————TRACK SEARCH (p) button

MODE MODE indicator —————MODE button

CALL

CALL indicator —————CALL button

HOT CUE A

HOT CUE/4-BEAT SAMPLER (A) indicator

—————

HOT CUE/4-BEAT SAMPLER (A) button

HOT CUE B

HOT CUE/4-BEAT SAMPLER (B) indicator

—————

HOT CUE/4-BEAT SAMPLER (B) button

HOT CUE C

HOT CUE/4-BEAT SAMPLER (C) indicator

—————

HOT CUE/4-BEAT SAMPLER (C) button

TRANS

BEAT FX (TRANS) indicator —————BEAT FX (TRANS) button

FLANGER

BEAT FX (FLANGER) indicator

—————BEAT FX (FLANGER) button

ECHO

BEAT FX (ECHO) indicator —————BEAT FX (ECHO) button

ROLL

BEAT FX (ROLL) indicator —————BEAT FX (ROLL) button

MIXER area

Characters shown

on the display

Lit-up LED Note/RemarksButtons and volume knobs

HP CUE CH1 (CH1) indicator ————— (CH1) button

HP CUE CH2 (CH2) indicator ————— (CH2) button

AUX AUX (ON/OFF) indicator —————AUX (ON/OFF) button

MIC MIC (ON/OFF) indicator —————MIC (ON/OFF) button

USB STOP USB STOP indicator —————USB STOP button

PITCH

SOUND COLOR FX (PITCH) indicator

—————

SOUND COLOR FX (PITCH) button

FILTER

SOUND COLOR FX (FILTER) indicator

—————

SOUND COLOR FX (FILTER) button

NOISE

SOUND COLOR FX (NOISE) indicator

—————

SOUND COLOR FX (NOISE) button

CRUSH

SOUND COLOR FX (CRUSH) indicator

—————

SOUND COLOR FX (CRUSH) button

A

B

C

D

E

2 3 4

F

22

1

XDJ-R1

2 3 4

Page 23

MIXER area

Switching to the TIME display mode

Each time INFO (UTILITY) button is pressed, the TIME display mode is switched to show the values of VOL, Fader, etc.

of the MIXER area.

The display modes to be shown when INFO (UTILITY) button is pressed are listed below.

DECK VOL display mode → MIXER VOL display mode 1 → MIXER VOL display mode 2 → DECK VOL display mode → • • •

Characters shown

on the display

Lit-up LED Note/RemarksButtons and volume knobs

————— LEVEL indicator (CH1)

(+9 dB, +4 dB)

Relationship between select position

and LED is as follows:

Left: +9 dB, Right: +4 dB

DECK1, PHONO1, LINE1

selector switch

————— LEVEL indicator (CH2)

(+9 dB, +4 dB)

Relationship between select position

and LED is as follows:

Left: +9 dB, Right: +4 dB

DECK2, PHONO2, LINE2

selector switch

————— LEVEL indicator (CH1)(-12 dB) Relationship between select position

and LED is as follows:

0 dB: -6 dB, 12 dB: -12 dB

LINE, POTABLE PLAYER

selector switch

————— LEVEL indicator (CH1)

(+2 dB, 0 dB)

Relationship between select position

and LED is as follows:

PHONO: +2 dB, LINE: 0 dB

LINE, PHONO selector switch

(CH1)

————— LEVEL indicator (CH2)

(+2 dB, 0 dB)

Relationship between select position

and LED is as follows:

PHONO: +2 dB, LINE: 0 dB

LINE, PHONO selector switch

(CH2)

————— LEVEL indicator (CH2)

(-6 dB, -12 dB, -18 dB)

Relationship between select position

and LED is as follows:

Left: -6 dB, Middle: -12 dB, Right: -18 dB

CROSS F. CURVE ( , , )

(crossfader curve selector switch)

MIXER VOL display mode 1

[CH1]

Characters shown on the display Lit-up LED Note/RemarksButtons and volume knobs

0 to FF (in TRACK of TIME display) ————— Always on TIME display VFD.TRIM control

0 to FF (in MIN of TIME display) ————— Always on TIME display VFD.EQ (HI) control

0 to FF (in SEC of TIME display) ————— Always on TIME display VFD.EQ (MID) control

0 to FF (in FRAME of TIME display) ————— Always on TIME display VFD.EQ (LOW) control

0 to FF (in TEMPO number display) ————— Always on TIME display VFD.COLOR control

MIXER VOL display mode 2

Characters shown on the display

Lit-up LED Note/RemarksButtons and volume knobs

0 to FF (in TRACK of TIME display) ————— Always on TIME display VFD.HEADPHONE MIXING control

0 to FF (in MIN of TIME display) ————— Always on TIME display VFD.HEADPHONE LEVEL control

0 to FF (in SEC of TIME display) ————— Always on TIME display VFD.MASTER LEVEL control

0 to FF (in FRAME of TIME display) ————— Always on TIME display VFD.BOOTH MONITOR control

0 to FF (in TEMPO number display) ————— Always on TIME display VFD.Channel fader (CH1)

MIXER VOL display mode 1

[CH2]

Characters shown on the display Lit-up LED Note/RemarksButtons and volume knobs

0 to FF (in TRACK of TIME display) ————— Always on TIME display VFD.TRIM control

0 to FF (in MIN of TIME display) ————— Always on TIME display VFD.EQ (HI) control

0 to FF (in SEC of TIME display) ————— Always on TIME display VFD.EQ (MID) control

0 to FF (in FRAME of TIME display) ————— Always on TIME display VFD.EQ (LOW) control

0 to FF (in TEMPO number display) ————— Always on TIME display VFD.COLOR control

MIXER VOL display mode 2

Characters shown on the display Lit-up LED Note/RemarksButtons and volume knobs

0 to FF (in TRACK of TIME display) ————— Always on TIME display VFD.AUX LEVEL control

0 to FF (in MIN of TIME display) ————— Always on TIME display VFD.MIC LEVEL control

0 to FF (in SEC of TIME display) ————— Always on TIME display VFD.MIC EQ control

0 to FF (in FRAME of TIME display) ————— Always on TIME display VFD.Crossfader

0 to FF (in TEMPO number display) ————— Always on TIME display VFD.Channel fader (CH2)

5

6 7 8

A

B

C

D

E

F

5

6 7 8

XDJ-R1

23

Page 24

1

• When the TEMPO slider is moved far down to the [+] side during the button and function checking mode, the mode is

switched to the JOG dial load measurement mode to show the Max speed and time in the dot matrix.

•

When the JOG dial is swiftly rotated, the figures are displayed. The jog dial can be rotated either clockwise or counterclockwise.

• For example, when "8.6: 115" is shown on the display, which indicates as follows:

X 8.6: Maximum speed (X1 is defined as 1.8 second required for one revolution.)

115: Time (msec) required to lower the revolution speed from X3 to X1.5

• In order to measure the time to lower the rotation speed, the maximum speed of the jog wheel should be X7.0 or more.

• When time is measured several times in a row, up to the fourth largest msec among the several times of measurement other

than the first one is averaged.

• When the unit is powered on while the TIME and HOT CUE A buttons of DECK 1 are pressed simultaneously, this mode

starts after the "TEST MODE" is displayed in the dot display area.

• This mode is comprised of the following 2 modes:

CD drive performance mode

• Mode to measure servo's basic actions such as set up, play, pause and track search and error rate.

• Before the CD drive diagnostic mode starts, this mode is first displayed.

Test performance mode

• This mode can precisely control servo's actions step by step.

* Commands in this diagnostic mode are for testing mainly the mechanism and servo systems but not for testing

the DJ functions, such as SCAN and TEMPO.

Commands of the CD drive performance mode

Play (trace) / Pause (d/e (PLAY/PAUSE))

• If the CD drive is in stopped state, it is set up to start playback.

• When a track is playing, each time the button is pressed, the track is alternately paused and played.

• The current playing address is displayed in the time display.

Track Search F/R (TRACK SEARCH o, p)

• A track displayed is searched clockwise or counterclockwise and paused.

Eject (DISC h)

• A Disc is ejected.

Mode Change (MASTER TEMPO)

• When the MASTER TEMPO button is pressed in the CD drive performance mode, the MASTER TEMPO's LED lights up

and shifted to Test performance mode.

3. JOG dial load measurement mode

4. CD drive diagnostic mode

Max speed

0. 0 :

0ms

Time (msec)

Buttons on the unitFunction

d/e (PLAY/PAUSE)

TRACK SEARCH o, p

DISC h

MASTER TEMP

<CD drive performance mode>

Play (trace) / Pause

Track Search F/R

Eject

Mode Change

Buttons on the unitFunction

INFO (UTILITY)

TEMPO

BEAT FX (TRANS)

BEAT FX (FLANGER)

BEAT FX (ECHO)

TRACK SEARCH p

TRACK SEARCH o

BEAT FX (ROLL)

MASTER TEMPO

<Test performance mode>

Servo All Off (Stop)

LD On/Off

Focus On

Spindle Kick, Tracking On/Off

Tracking Off

Slide FWD (2 mm)

Slide REV (2 mm)

Pickup Up/Down

Mode Change

A

2 3 4

B

C

D

E

F

24

XDJ-R1

1

2 3 4

Page 25

5

Commands of Test performance mode

This mode can precisely control servo's actions step by step.

Cautions for the usage of the Test performance mode because it could damage the CD drive if it is not used properly.

Servo All Off (INFO (UTILITY))

• When the INFO (UTILITY) button is pressed while servo is on, all the servo is off and [ALL OFF] is displayed

on the dot display area.

LD On/Off (TEMPO)

• When the TEMPO button is pressed, LD (Laser diode) is alternately turned on and off and [LD ON] or [LD OFF]

is displayed in the dot display area.

Focus On (BEAT FX (TRANS))

• When the BEAT FX (TRANS) button is pressed during PAUSE, LD is turned on and automatically focused and [FCS ON]

is displayed in the dot display area.

Spindle Kick, Tracking On/Off (BEAT FX (FLANGER))

• When the BEAT FX (FLANGER) button is pressed while tracking servo is off, spindle kick is performed, auto adjustment

and tracking servo are turned on and [TRK ON] is displayed in the dot display area.

• When the BEAT FX (FLANGER) button is pressed while tracking servo is on, tracking servo is turned off and [TRK OFF]

is displayed in the dot display area.

Tracking Off (BEAT FX (ECHO))

• When the BEAT FX (ECHO) button is pressed while tracking servo is on, tracking servo is turned off and [TRK OFF] is

displayed in the displayed in the dot display area.

Slide FWD (TRACK SEARCH p)

• When the TTRACK SEARCH p button is pressed while tracking servo is on, tracking servo is turned off and the slider is

moved approximately 2 mm in FWD direction and [SLD FWD] is displayed in the dot display area.