Pioneer PDR-555-RW Service manual

ORDER NO.

RRV1983

COMPACT DISC RECORDER

PDR-555RW

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Type

KU/CA AC120V

MY AC220-230V

Refer to the service guide RRV2055 for PDR-555RW.

•

Model

PDR-555RW

Power Requirement Remarks

FOR U.S. MODELS

NECESSARY INFORMATION FOR DHHS

RULES MARKED ON THE REAR BASE AND ON

THE TOP OF CD MECHANISM AS BELOW.

DANGER – LASER RADIA TION WHEN OPEN.

AVOID DIRECT EXPOSURE TO BEAM.

CONTENTS

1. SAFETY INFORMATION

2. EXPLODED VIEWS AND PARTS LIST

3. SCHEMATIC DIAGRAM

4. PCB CONNECTION DIAGRAM

5. PCB PARTS LIST

6. ADJUSTMENT

PIONEER ELECTRONIC CORPORATION 4-1, Meguro 1-Chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS SERVICE, INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER ELECTRONIC (EUROPE) N.V. Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 501 Orchard Road, #10-00 Wheelock Place, Singapore 238880

c

PIONEER ELECTRONIC CORPORATION 1998

...............................................

....................................................

......................................

................

.....................................

..........................

10

32

44

49

2

4

7. GENERAL INFORMATION

7.1 PARTS

7.1.1 IC

7.1.2 DISPLAY

8. PANEL FACILITIES AND SPECIFICATIONS...69

.........................................................

...........................................................

................................................

................................

T – IZK OCT. 1998 Printed in Japan

55

55

55

67

PDR-555RW

1. SAFETY INFORMATION

This service manual is intended for qualified service technicians ; it is not meant for the casual do-ityourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained

to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to cause

cancer, birth defects or other reproductive harm.

Health & Safety Code Section 25249.6 – Proposition 65

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement parts must

be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les pièces

de remplacement doivent avoir la même désignation.

(FOR USA MODEL ONLY)

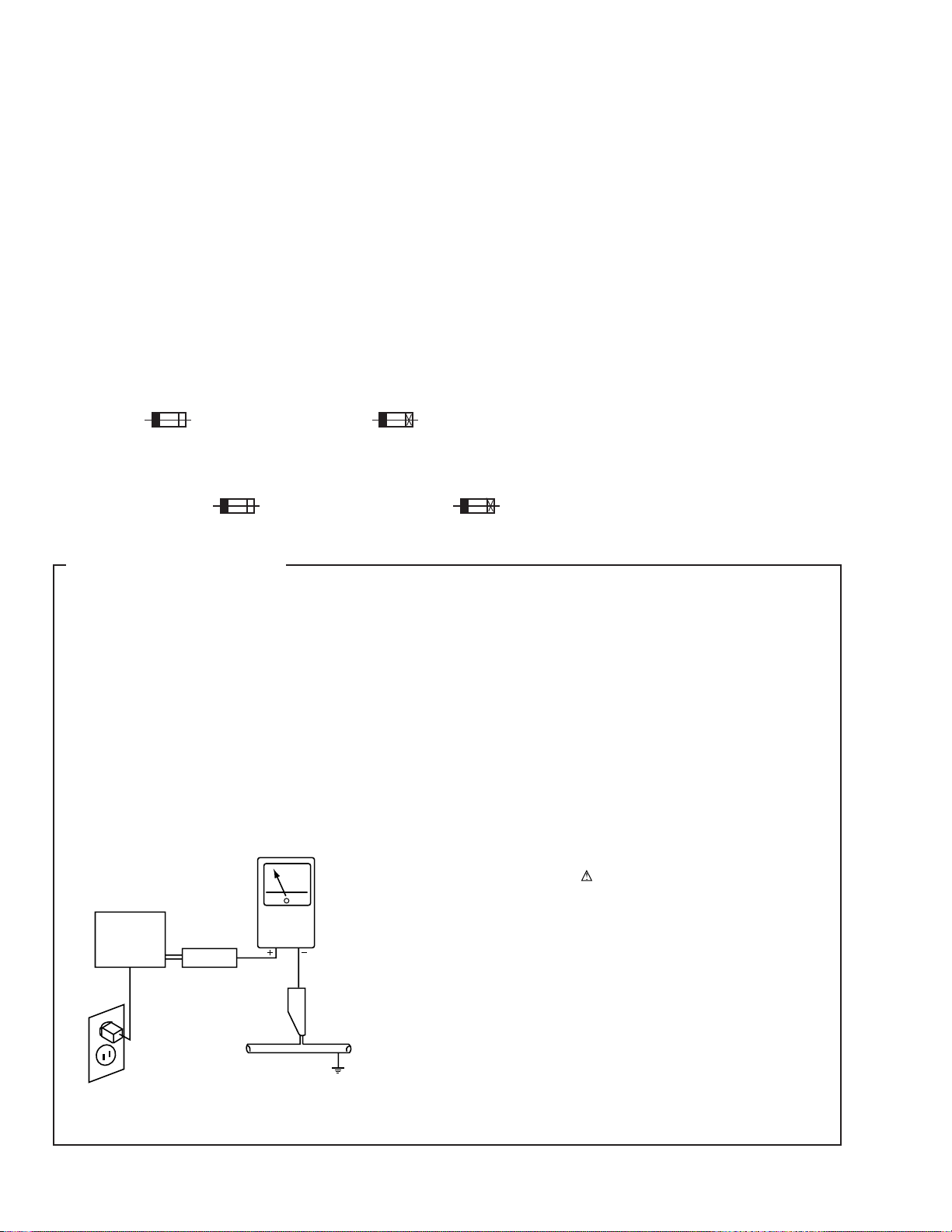

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and service

technician.

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground (water

pipe, conduit, etc.) by connecting a leakage current tester

such as Simpson Model 229-2 or equivalent between the

earth ground and all exposed metal parts of the appliance

(input/output terminals, screwheads, metal overlays, control

shaft, etc.). Plug the AC line cord of the appliance directly

into a 120V AC 60Hz outlet and turn the AC power switch

on. Any current measured must not exceed 0.5mA.

Reading should

not be above

0.5mA

Earth

ground

Device

under

test

Also test with

plug reversed

(Using AC adapter

plug as required)

Leakage

current

tester

Test all

exposed metal

surfaces

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE APPLIANCE TO THE CUSTOMER.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance

have special safety related characteristics. These are

often not evident from visual inspection nor the protection

afforded by them necessarily can be obtained by using

replacement components rated for voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this Service Manual.

Electrical components having such features are identified

by marking with a

in this Service Manual.

The use of a substitute replacement component which does

not have the same safety characteristics as the PIONEER

recommended replacement one, shown in the parts list in

this Service Manual, may create shock, fire, or other hazards.

Product Safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current PIONEER Service

Manual. A subscription to, or additional copies of, PIONEER

Service Manual may be obtained at a nominal charge from

PIONEER.

on the schematics and on the parts list

AC Leakage Test

2

PDR-555RW

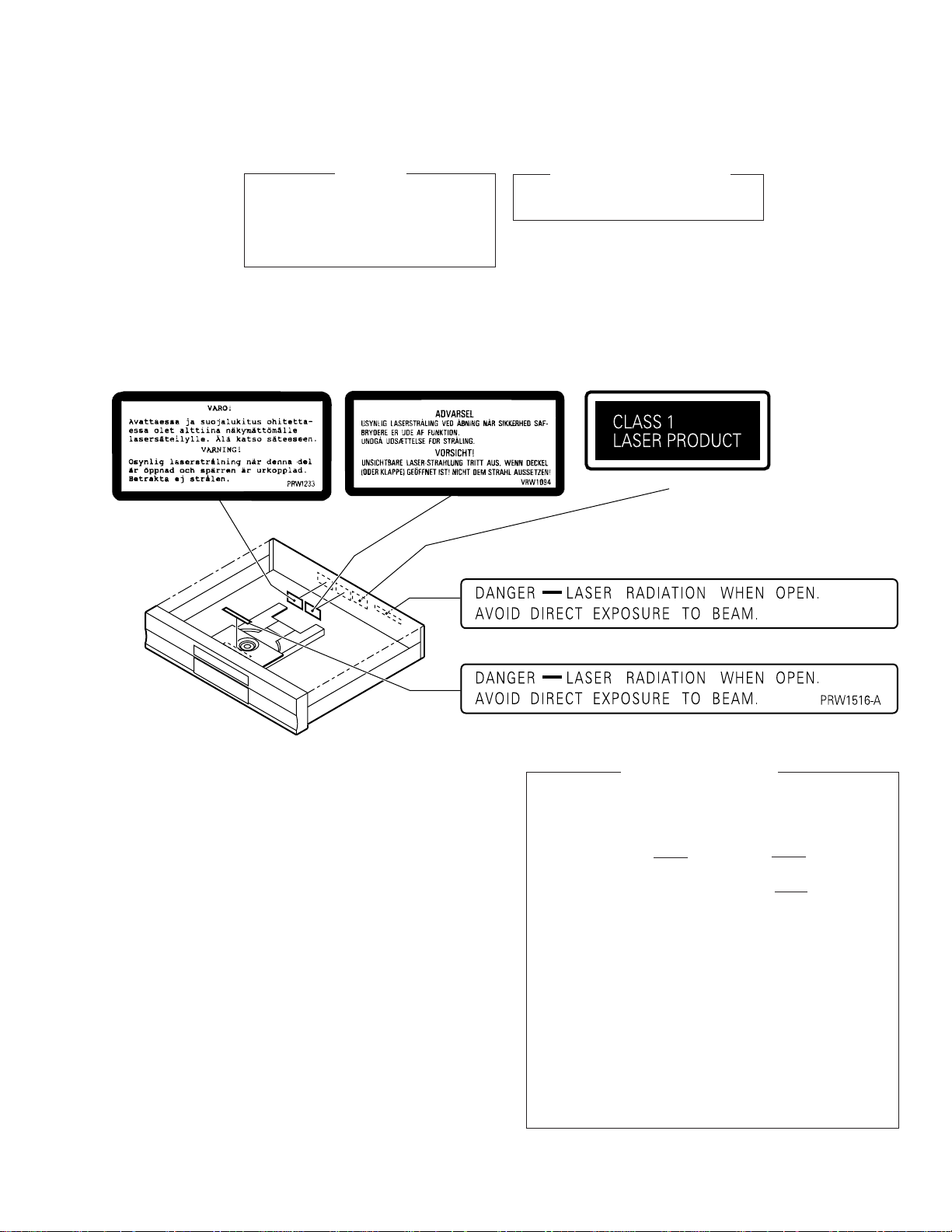

KU/CA type

Printed on Rear Panel

Printed on Rear Panel

MY Type

MY Type MY Type

LABEL CHECK

IMPORTANT

THIS PIONEER APPARATUS CONTAINS

LASER OF CLASS ΙΙΙ b.

SERVICING OPERATION OF THE APPARATUS

SHOULD BE DONE BY A SPECIALLY

INSTRUTED PERSON.

LASER DIODE CHARACTERISTICS

MAXIMUM OUTPUT POWER: 23 mW

WAVELENGTH: 778 – 787 nm

Additional Laser Caution

1. Laser Interlock Mechanism

The position of the switch (S601) for detecting loading

state is detected by the system microprocessor, and the

design prevents laser diode oscillation when the switch

(S601) is not on CLMP terminal side (CLMP signal is OFF

or high level.). Thus, the interlock will no longer function if

the switch (S601) is deliberately set to CLMP terminal side

(low level).

The interlock also does not function in the test mode ∗.

Laser diode oscillation will continue, if pin 1 of M51593FP

(IC101) on the PRE-AMP BOARD ASSY mounted on the

pickup assembly is connected to GND, or pin 19 is

connected to low level (ON), or else the terminals of Q101

are shorted to each other (fault condition).

2. When the cover is opened with the servo mechanism

block removed and turned over, close viewing of the

objective lens with the naked eye will cause exposure to a

Class 1 laser beam.

∗ Refer to page 49 .

3

PDR-555RW

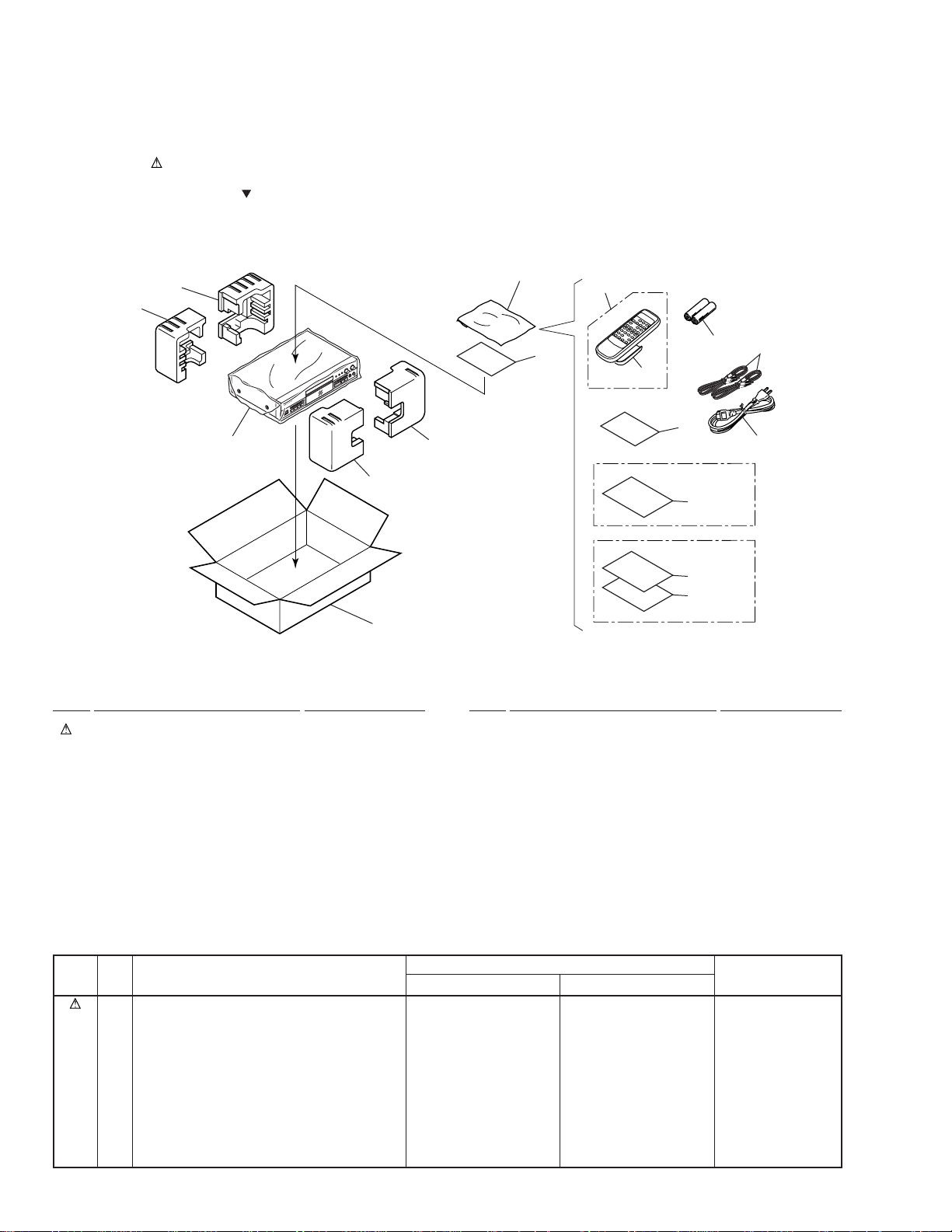

2. EXPLODED VIEWS AND PARTS LIST

NOTES:• Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

2.1 PACKING

The mark found on some component parts indicates the importance of the safety factor of the part.

•

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on the product are used for disassembly.

•

12 (2/2)

12 (1/2)

13

(1) PACKING PARTS LIST

Mark No. Description Part No.

11 (1/2)

10

11 (2/2)

9

2

6

8

3

7

5

KU/CA Type only

4

MY Type only

14

15

1

Mark No. Description Part No.

1 AC Power Cord See Contrast table (2)

NSP 2 Warranty Card See Contrast table (2)

3 Audio Cable PDE1248

4 Operating Instructions See Contrast table (2)

5 Caution See Contrast table (2)

6 Remote Control Unit PWW1144

(CU-PD099)

7 Battery Cover AZA7123

NSP 8 Dry Cell Battery (R6P,AA) VEM-013

9 Polyethylene Bag Z21-038

10 Packing Case See Contrast table (2)

11 Protector (F) RHA1238

12 Protector (R) RHA1239

13 Seat Z23-007

14 Operating Instructions See Contrast table (2)

15 Operating Instructions See Contrast table (2)

(2) CONTRAST TABLE

PDR-555RW/KU/CA and MY are constructed the same except for the following :

Mark No. Symbol and Description

1 AC Power Cord ADG7021 ADG1127

NSP 2 Warranty Card ARY7023 ARY7022

4 Operating Instructions (English) PRB1270 Not used

5 Caution PRM1046 PRM1045

10 Packing Case PHG2317 PHG2318

14 Operating Instructions Not used PRD1031

(Dutch/Swedish/Spanish/Danish)

15 Operating Instructions Not used PRE1269

(English/French/German/Italian)

PDR-555RW/KU/CA PDR-555RW/MY

Part No.

Remarks

4

12

29

20

11

21

16

17

13

35

13

15

Refer to "2.4 LOADING

MECHANISM ASSY".

Refer to "2.3 FRONT

PANEL SECTION".

33

C

I

F

A

B

33

28

18

12

39

2

11

11

34

14

34

31

40

12

14

27

30

5

6

8

3

1

4

12

7

11

14

24

9

11

11

11

30

30

24

24

23

10

12

34

34

22

IC308

24

37

36

38

MY

Type only

G

A

H

I

B

C

D

D

J

J

E

G

H

E

F

KU/CA

Type only

KU/CA Type only

2.2 EXTERIOR SECTION

PDR-555RW

5

PDR-555RW

(1) EXTERIOR SECTION PARTS LIST

Mark No. Description Part No. Mark No. Description Part No.

1 SERVO DIGITAL Assy See Contrast table (2)

2 AUDIO Assy See Contrast table (2)

3 POWER Assy See Contrast table (2)

4 TRANS Assy See Contrast table (2)

5 Jumper Wire (J) D20PYY0335E

6 Connector Assy (8P) PDE1300

7 Connector Assy PG05KK-E10

8 Connector Assy PG09KK-E35

9 Power Transformer See Contrast table (2)

10 Fuse (FU1) See Contrast table (2)

11 Screw (Steel) ABA1011

12 Screw (Steel) ABA1207

NSP 13 PCB Mould AMR1525

NSP 14 Cord Stopper DNF1128

15 Bonnet PYY1254

NSP 16 Under Base PNA2427

17 Rear Base See Contrast table (2)

NSP 18 Mecha Base PNB1591

19 • • • • •

NSP 20 Binder Holder PNW1021

NSP 22 Cap VEC1810

NSP 40 Laser Caution Label See Contrast table (2)

21 Insulator PNW2766

23 Cord Clamper RNH-184

24 Screw RBA1132

25 • • • • • •

26 • • • • • •

27 Power Button PAC1877

28 Tray Panel PNW2798

29 Screw BBZ30P080FCC

30 Screw IBZ30P060FCC

31 Screw BBZ30P100FCC

32 • • • • • •

33 Screw FBT40P080FZK

34 Screw IBZ30P180FCC

35 Binder ZCA-SKB90BK

36 Black Label PRW1470

37 Caution Label HE See Contrast table (2)

38 Caution Label See Contrast table (2)

39 65 Label See Contrast table (2)

(2) CONTRAST TABLE

PDR-555RW/KU/CA and MY are constructed the same except for the following :

Mark No. Symbol and Description

1 SERVO DIGITAL Assy PWM2217 PWM2216

2 AUDIO Assy PWZ3723 PWZ3729

3 POWER Assy PWZ3724 PWZ3741

4 TRANS Assy PWZ3750 PWZ3725

9 Power Transformer PTT1345 PTT1346

PDR-555RW/KU/CA PDR-555RW/MY

Part No.

Remarks

10 Fuse (FU1 : 1A) REK1075 Not used

10 Fuse (FU1 : T500mA) Not used AEK1051

17 Rear Base PNA2428 PNA2429

37 Caution Label HE Not used PRW1233

38 Caution Label Not used VRW1094

39 65 Label ORW1069 Not used

NSP 40 Laser Caution Label PRW1516 Not used

6

23

23

23

8

7

17

19

26

3

9

18

22

5

2

6

21

Accessories for the

VR ASSY.

13

14

20

23

4

A

A

11

15

16

25

12

24

1

2.3 FRONT PANEL SECTION

PDR-555RW

(1) FRONT PANEL SECTION PARTS LIST

Mark No. Description Part No. Mark No. Description Part No.

1 FUNCTION Assy See Contrast table (2)

2 HEADPHONE Assy See Contrast table (2)

3 VR Assy PWZ3689

4 22P F•F•C/60V PDD1190

5 Screw With Washer ABA1005

6 Knob PAC1707

7 Mode Button PAC1873

8 Manual Button L PAC1874

9 REC Button PAC1876

10 • • • • • •

11 Manual Button R PAC1878

12 VOL Knob Assy PXA1616

13 VOL Knob L PAC1902

14 VOL Knob R PAC1903

15 FL Sheet See Contrast table (2)

(2) CONTRAST TABLE

PDR-555RW/KU/CA and MY are constructed the same except for the following :

Mark No. Symbol and Description

1 FUNCTION ASSY PYY1258 PYY1259

2 HEADPHONE Assy PWZ3713 PWZ3688

15 FL Sheet PAM1756 PAM1762

21 Front Panel 555 PNW2799 PNW2817

25 Getter Label 555 PRW1488 PRW1504

16 Display Window PAM1757

17 LED Lens PNW2745

18 REC Ring PNW2795

19 Lens PNW2796

20 Sub Panel PNW2797

21 Front Panel 555 See Contrast table (2)

22 Play Button B RAC2204

23 Screw PPZ30P100FMC

24 Name Plate PAN1376

25 Getter Label 555 See Contrast table (2)

26 IC (EEPROM) PYY1196

Part No.

PDR-555RW/KU/CA PDR-555RW/MY

Remarks

7

PDR-555RW

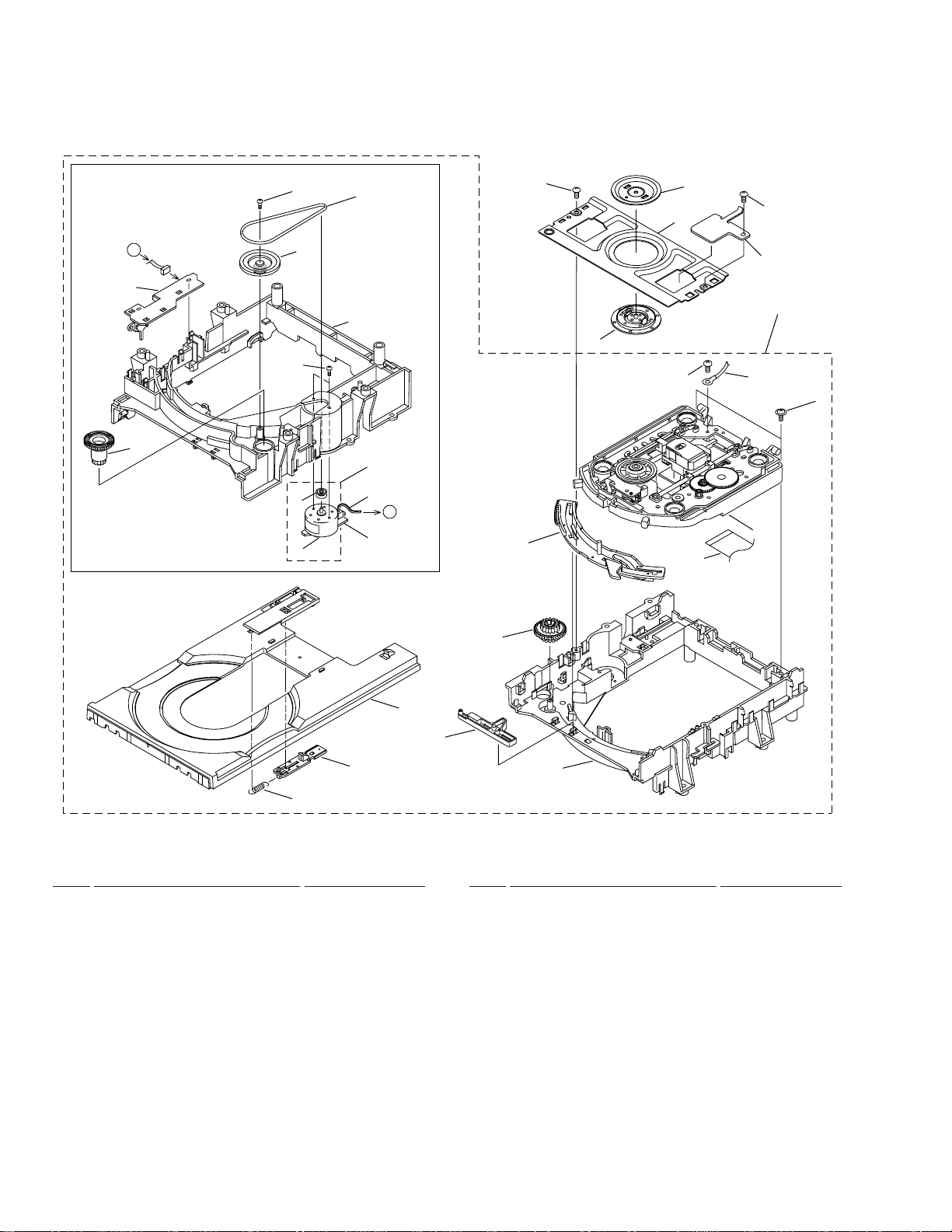

2.4 LOADING MECHANISM ASSY

• Bottom View

A

27

13

20

12

7

6

4

9

Loading Base

21

3

A

28

26

25

15

19

24

23

26

29

22

2

5

18

1

14

11

16

17

8

LOADING MECHANISM ASSY PARTS LIST

•

10

Mark No. Description Part No. Mark No. Description Part No.

NSP 2 Earth Lead Unit PDF1088

1 32P F•F•C/30V PDD1187

3 Connector Assy PG02KK-E35

4 DC Motor PXM1027

5 Screw DBA1006

6 Motor Pulley PNW1634

7 Screw VBA1055

8 Tray Stopper Spring VBH1277

9 Rubber Belt VEB1260

10 Loading Base VNL1730

11 Tray VNL1731

12 Gear Pulley VNL1733

13 Loading Gear VNL1734

14 Drive Gear VNL1735

15 Drive Cam VNL1736

NSP 18 CD-RW SERVO MECH Assy PXA1609

NSP 22 Loading Mechanism Assy PXA1608

NSP 27 LOADING A Assy PWZ3727

NSP 28 LOADING B Assy PWZ3728

16 Lock Plate VNL1820

17 Tray Stopper VNL1739

19 Screw BBZ26P040FMC

20 Screw IPZ20P080FMC

21 Loading Motor Assy VXX2505

23 Clamper Plate VNE2068

24 Bridge VNE2069

25 Clamper VNL1738

26 Screw IPZ26P060FCU

29 Tray Holder PNM1326

8

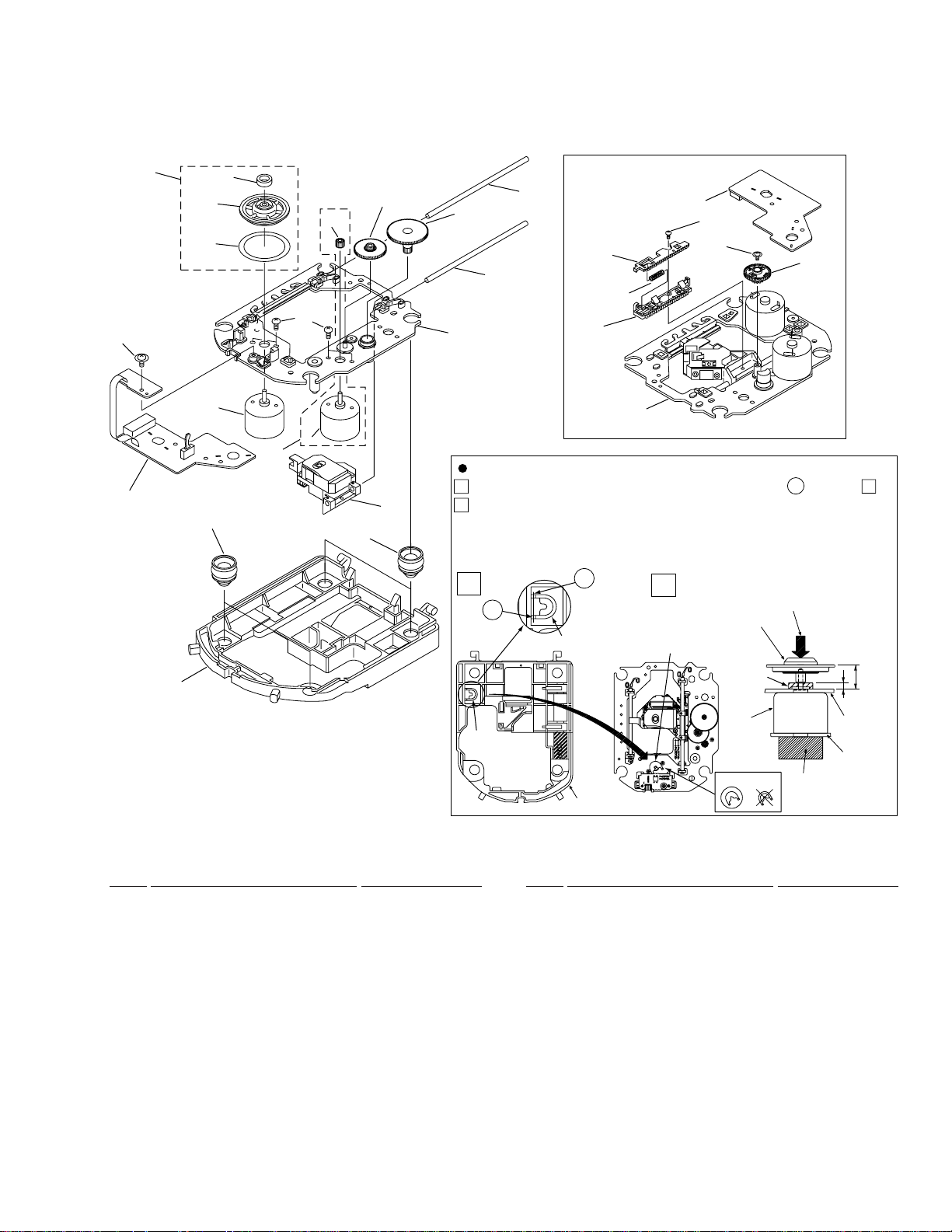

2.5 SERVO MECHANISM ASSY

PDR-555RW

22

25

15

20

10

9

7

23

2

3

26

11

16

19

18

• Bottom View

SERVO MECH ASSY

14

6

13

Carriage Base S

24

22

12

How to Install the Disc Table

1

1

4

21

5

Use nippers or other tool to cut the two sections marked A in figure

2

While supporting the spindle motor shaft with the stopper, put spacer on

top of the carriage base, and stick the disc table on top (takes about 9kg

pressure). Take off the spacer.

1

A

A

Spacer

2

Spacer setting

Position

(Pressure of about 9kg)

Disc table Assy

1

.

8

SERVO MECHANISM ASSY PARTS LIST

•

Spacer

Servo Base

Spacer

Spindle

motor

OK NG

Stopper

Mark No. Description Part No. Mark No. Description Part No.

NSP 1 SERVO MECH Assy PWZ3758

2 D.C.mortor Assy PEA1235

NSP 3 DC Motor PXM1042

4 Float Rubber A AEB7063

5 Float Rubber B AEB7066

NSP 6 Rack Spring DBH1285

NSP 7 Mirror Sheet PNM1325

8 Servo Base PNW2853

9 Pinion Gear PNW2854

10 Gear A PNW2855

11 Gear B PNW2856

12 Gear C PNW2857

13 Rack PNW2858

14 Rack Stopper PNW2859

NSP 15 Disc Table PNW2860

NSP 20 Magnet VYM1024

16 Carriage Base S PNW2874

17 • • • • •

18 Guide Bar VLL1488

19 Sub Guide Bar VLL1489

21 CD-R Pickup PEA1351

22 Screw IPZ20P060FMC

23 Screw PMZ20P030FMC

24 Screw JGZ17P030FMC

25 Disc Table Assy PEA1349

26 Carriage Motor Assy PEA1350

11mm

2.8mm

Carriage

Base

PCB

9

1

23

4

PDR-555RW

3. SCHEMATIC DIAGRAM

3.1 OVERALL CONNECTIONS, LOADING A, B, and SERVO MECH ASSEMBLIES

A

PICKUP ASSY

D

SERVO DIGITAL ASSY

B

C

SERVO

MECH ASSY

(PWZ3758)

PEA1350

PEA1235

(PWM2217 : KU/CA)

(PWM2216 : MY)

D

1/6

D

6/6

B

C

LOADING B

ASSY

(PWZ3728)

VXX2505

PC651

NJL5803K–F1

LOADING A ASSY

A

D

10

A

(PWZ3727)

B C

1234

5

678

PDR-555RW

Note : When ordering service parts, be sure to refer to "EXPLODED VIEWS and P AR TS LIST" or "PCB PARTS LIST".

E

E

1/2,

E

2/2

AUDIO ASSY

(PWZ3723: KU/CA)

(PWZ3729: MY)

HEADPHONE

F

ASSY

(PWZ3713:KU/CA)

(PWZ3688:MY)

VR ASSY

G

(PWZ3689)

J851

A

B

POWER ASSY

H

(PWZ3724: KU/CA)

(PWZ3741: MY)

TRANS ASSY

I

(PWZ3750 : KU/CA)

LIVE

NEUTRAL

KU/CA : ADG7021

MY : ADG1127

J3

C

(PWZ3725 : MY)

D

J

FUNCTION ASSY

(PWZ3687: KU/CA)

(PWZ3697: MY)

5

6

7

8

11

1

PDR-555RW

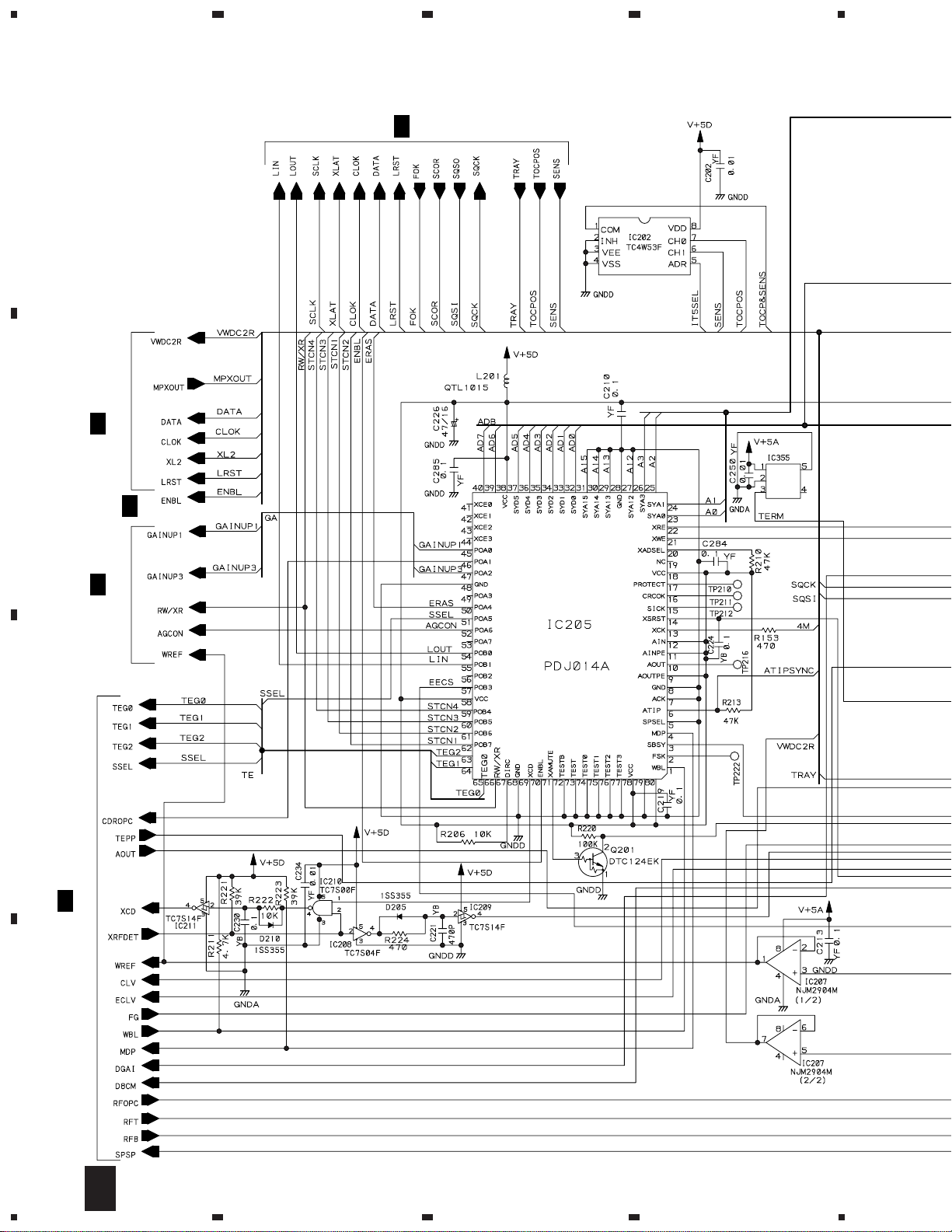

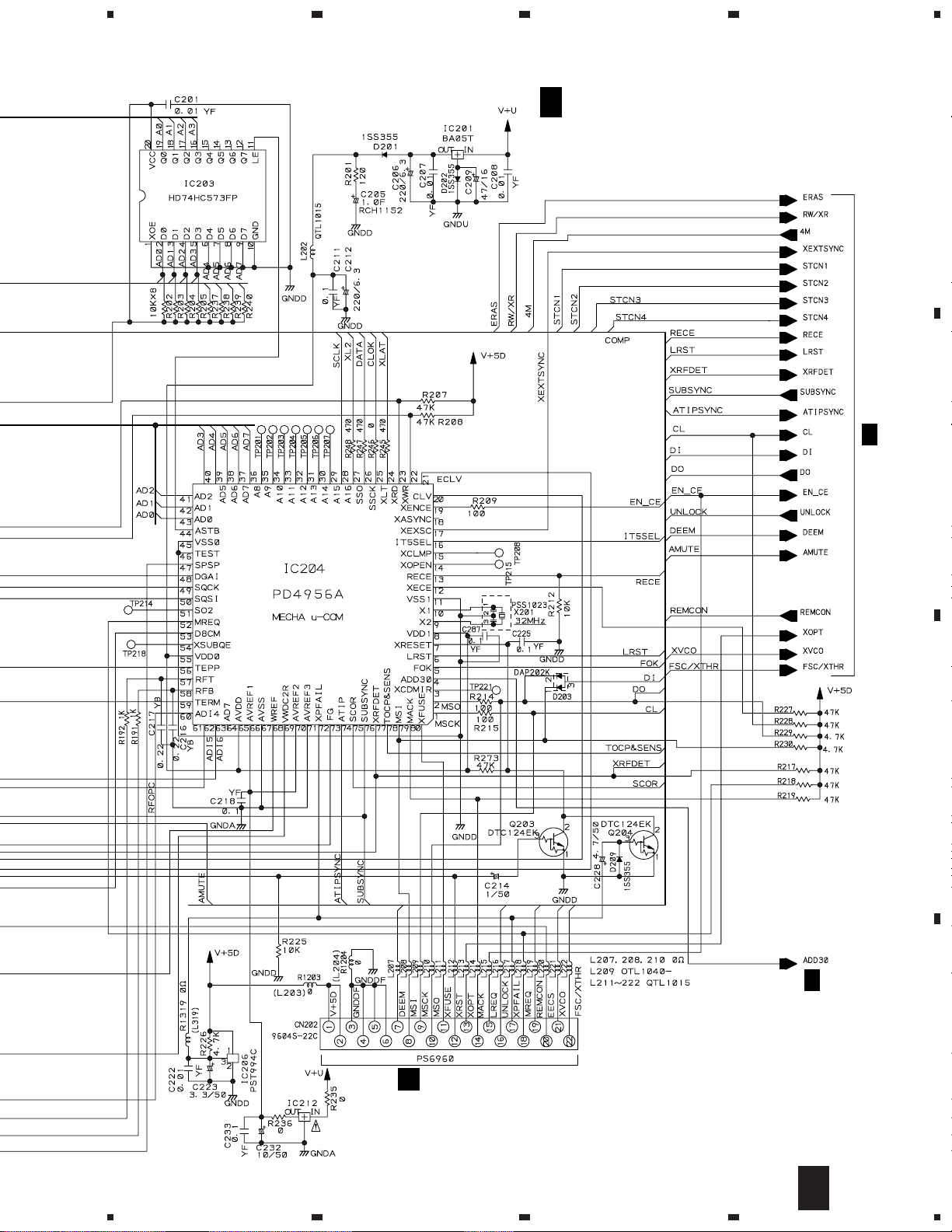

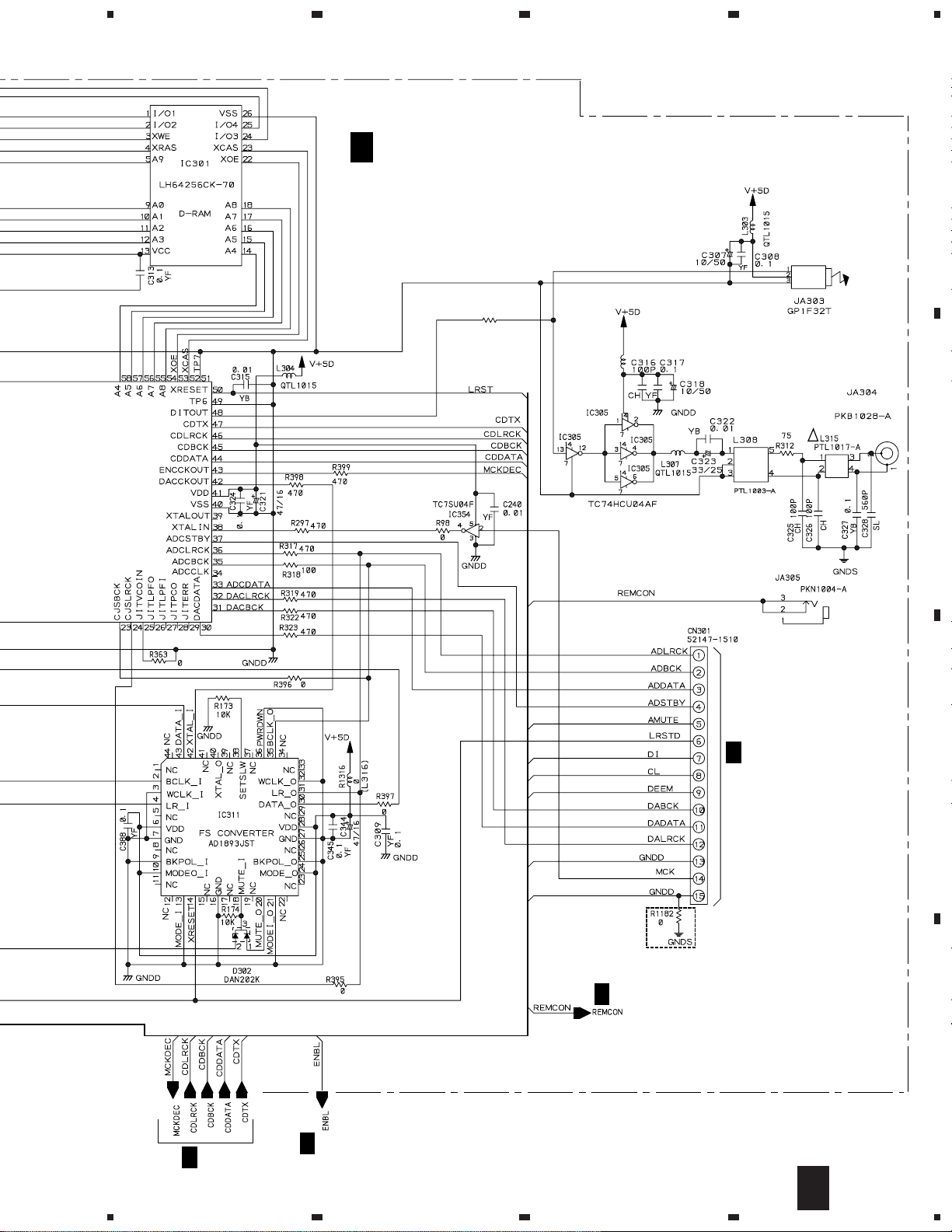

3.2 SERVO DIGITAL ASSY(1/6)

A

2/6

D

B

23

5/6

D

4

4/6

D

2/6

D

ATIP DECODER

C

3/6

D

TK11041M-1

D

12

1/6

D

1234

5

678

PDR-555RW

8BIT LATCH

D

SERVO DIGITAL ASSY(1/6)

1/6

(PWM2217 : KU/CA)

(PWM2216 : MY)

•

MECHA.CONTROL MICOM BLOCK

D

A

4/6

B

C

6/6

D

CN701

LP2950CZ–5.0

(NS)

5

J

1/6

D

6

7

8

13

D

1

23

PDR-555RW

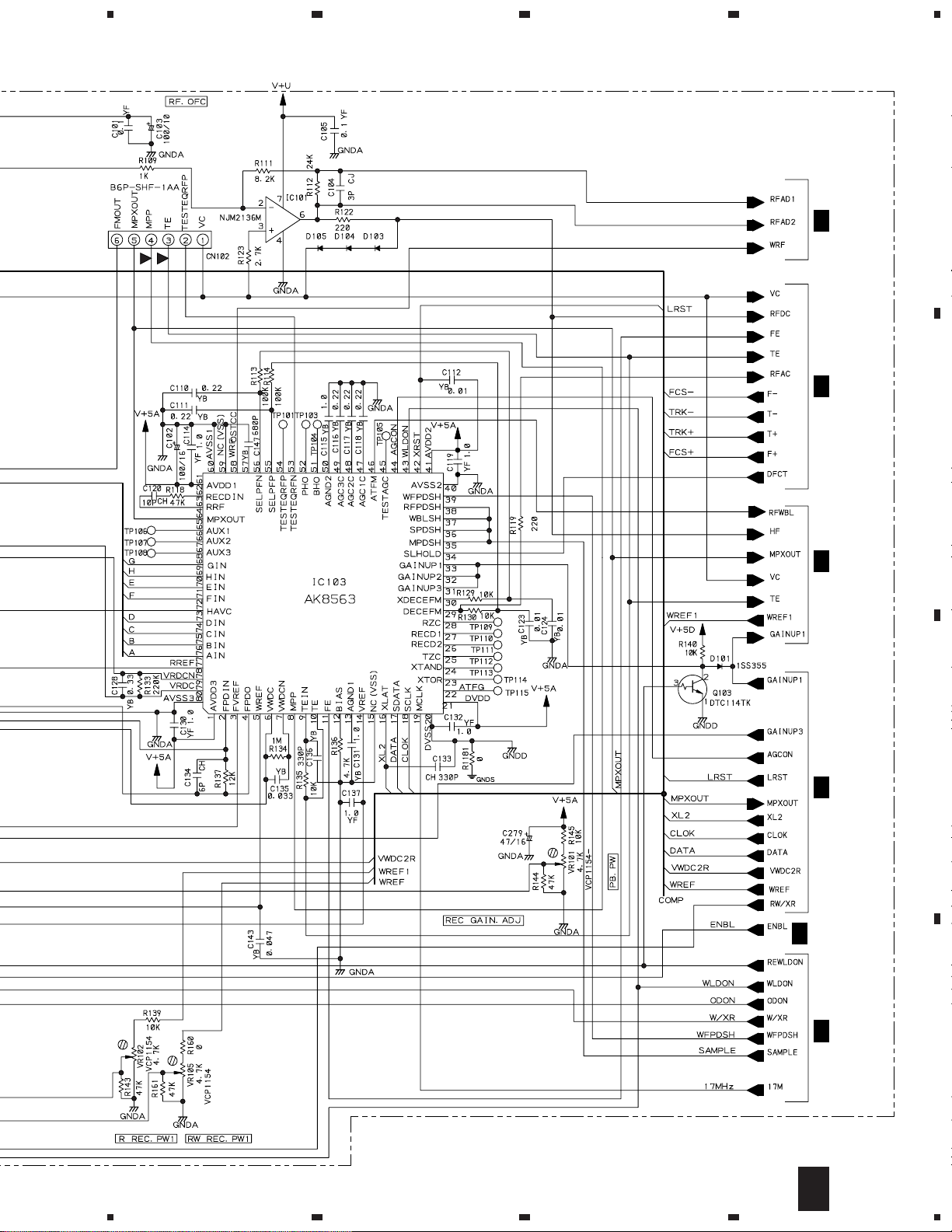

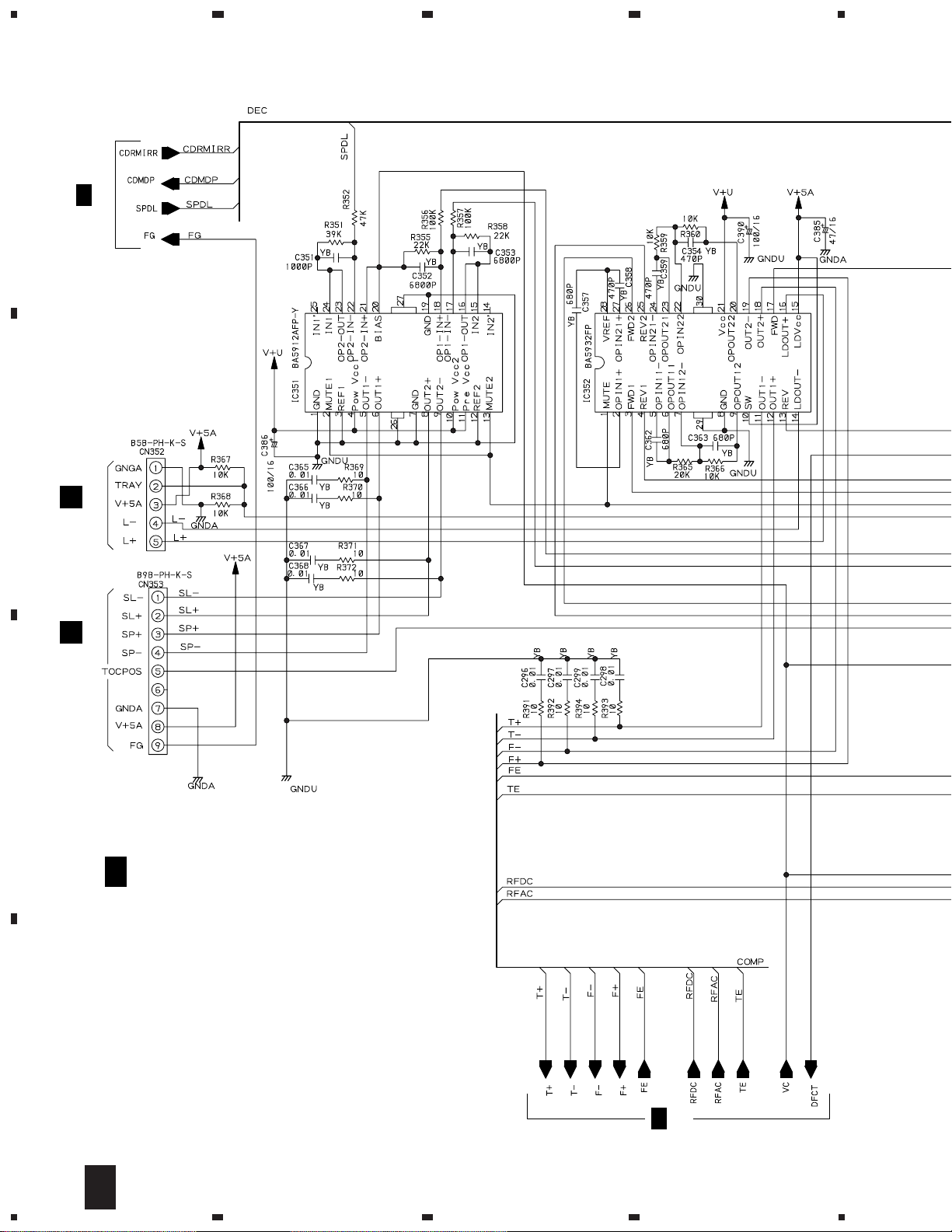

3.3 SERVO DIGITAL(2/6) and PICKUP ASSEMBLIES

4

D

A

B

SERVO DIGITAL ASSY(2/6)

2/6

(PWM2217 : KU/CA)

(PWM2216 : MY)

•

RF PROCESSOR BLOCK

MA700

C

D

14

2/6

D

1234

5

678

PDR-555RW

A

3/6

D

D103–D105 : 1SS355

5/6

D

B

D

D

D

4/6

3/6

C

1/6

6/6

D

D

2/6

D

5

6

7

8

15

1

PDR-555RW

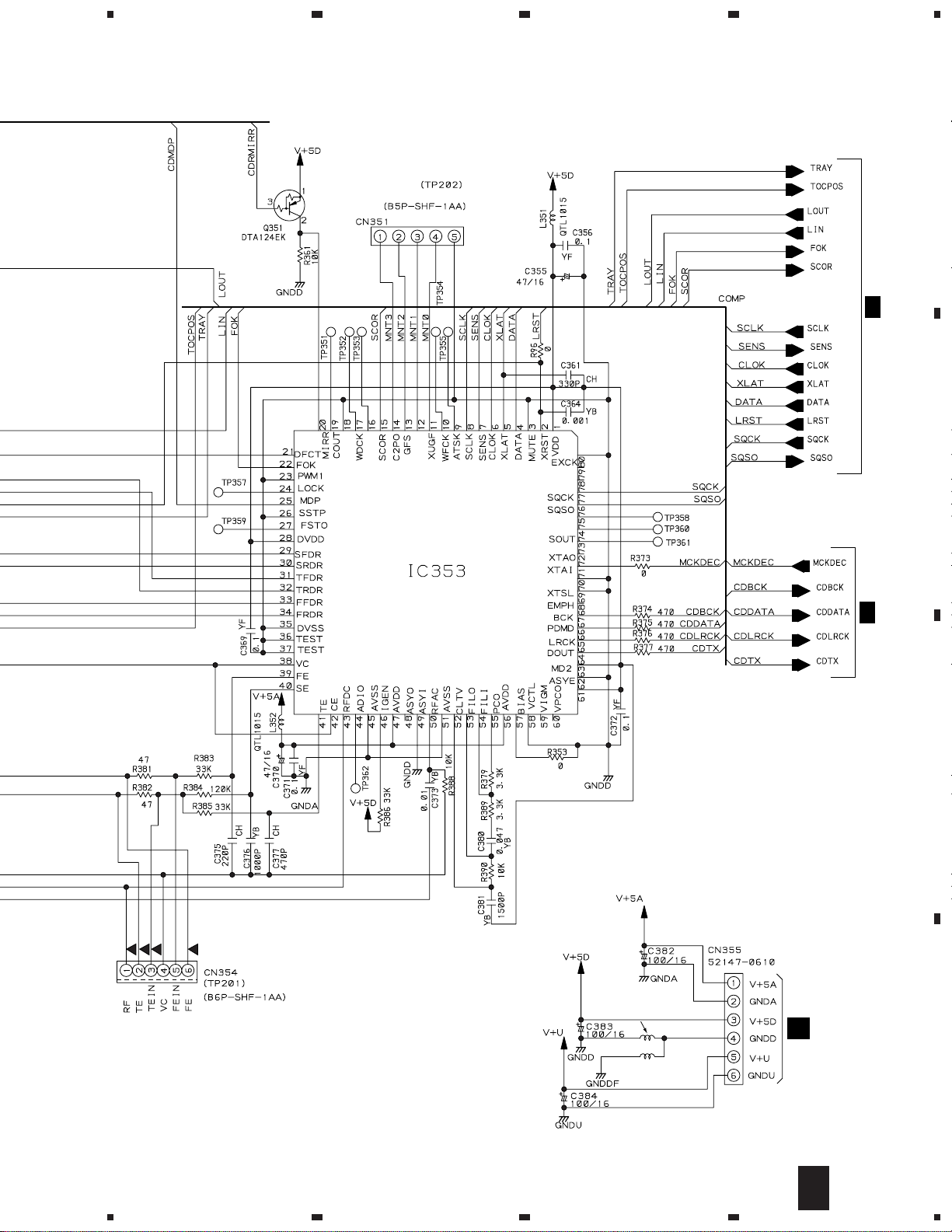

3.4 SERVO DIGITAL ASSY(3/6)

A

2/6

D

1/6

D

B

23

NJM2107F

4

5/6

D

C

2/6

D

D

16

3/6

D

1234

5

678

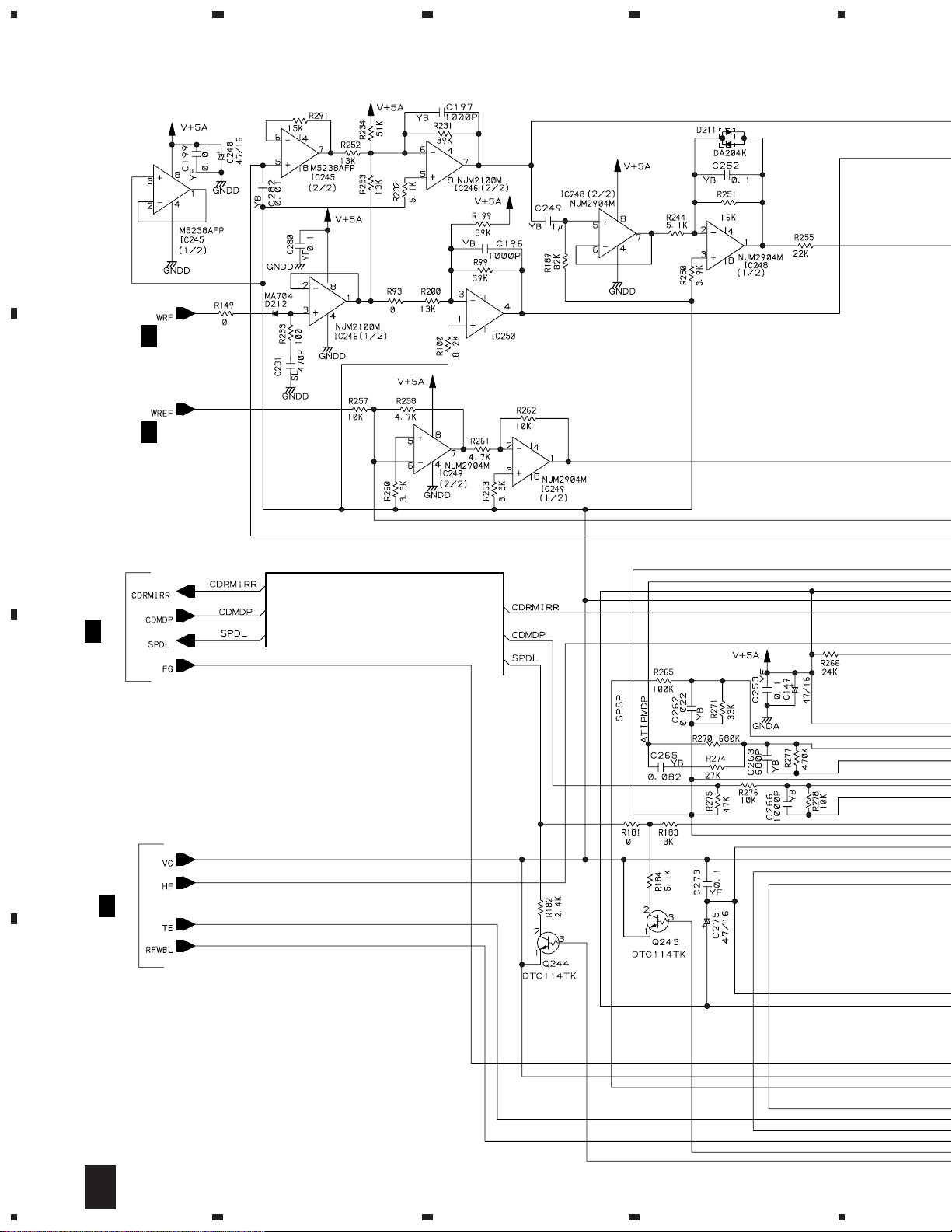

PDR-555RW

D

1/6

D

SERVO DIGITAL ASSY(3/6)

3/6

(PWM2217 : KU/CA)

(PWM2216 : MY)

•

SERVO BLOCK

D

6/6

D

1/6

D

A

2/6

B

CDR SERVO AMP

D206–D208 : 1SS355

D

1/6

C

D

3/6

D

5

6

7

8

17

1

PDR-555RW

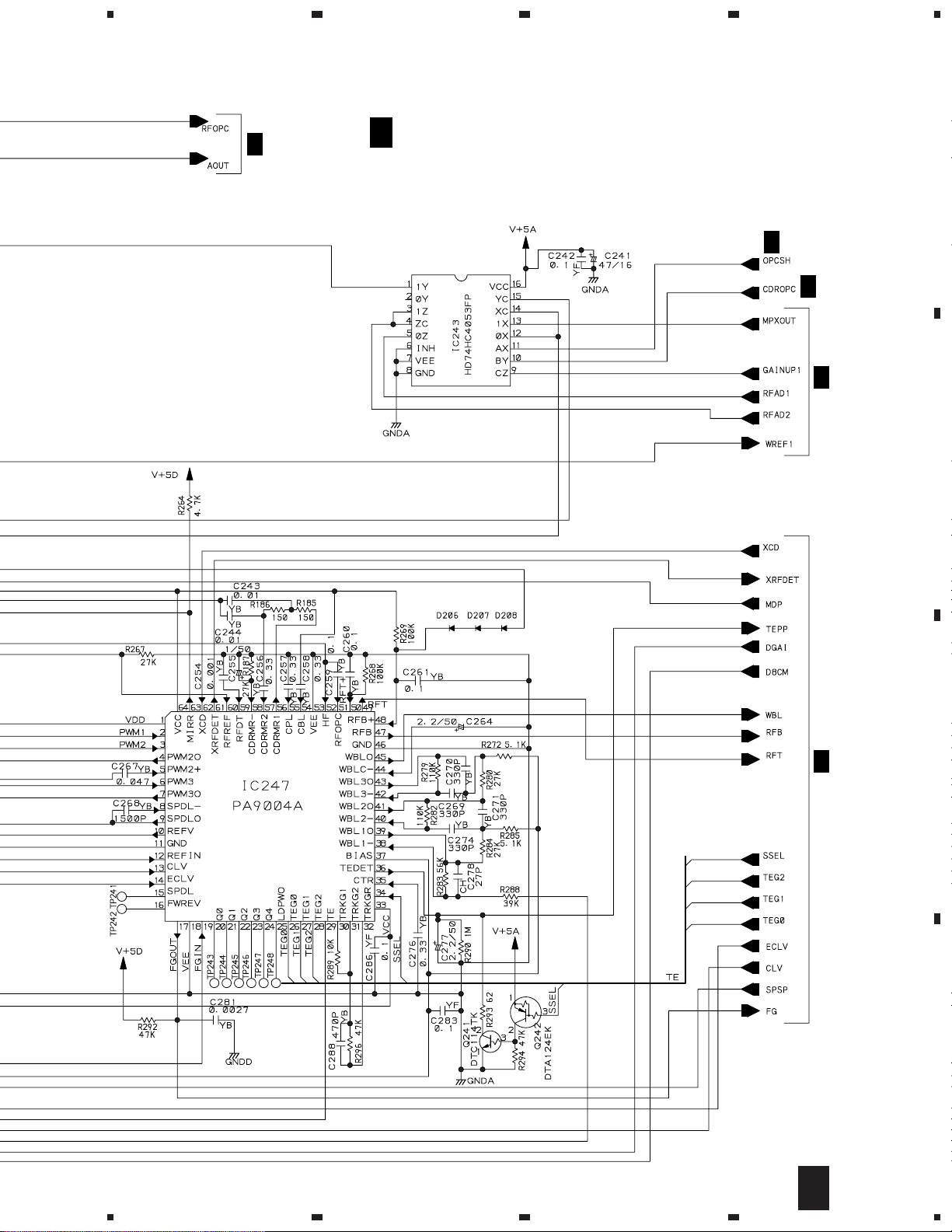

3.5 SERVO DIGITAL ASSY(4/6)

A

6/6

D

B

23

4

OPTICAL

INPUT

COAXIAL INPUT

!

(5/6)

C

(3/4)

(3/4)

(2/4)

(1/4)

(2/4)

(4/4)

(4/4)

(4/6)

NJM2904M

R1310 0 : KU/CA

L310 QTL1015 : MY

!

2/2

1/2

L1097 QTL1015

: KU/CA

R97 0 : MY

(1/4)

D

1/6

D

18

4/6

D

1234

5

678

PDR-555RW

D

SERVO DIGITAL ASSY(4/6)

4/6

(PWM2217 : KU/CA)

(PWM2216 : MY)

•

DIGITAL BLOCK

L1171 QTL1015 :

KU/CA

R171 0 : MY

R1305 0 : KU/CA

L305 QTL1015 : MY

(1/6)

(6/6)

(3/6)

(2/6)

A

OPTICAL OUTPUT

COAXIAL OUTPUT

!

B

D

5/6

5

D

2/6

1/2

E

J801

MY TYPE

ONLY

1/6

D

4/6

D

6

7

8

19

C

D

1

PDR-555RW

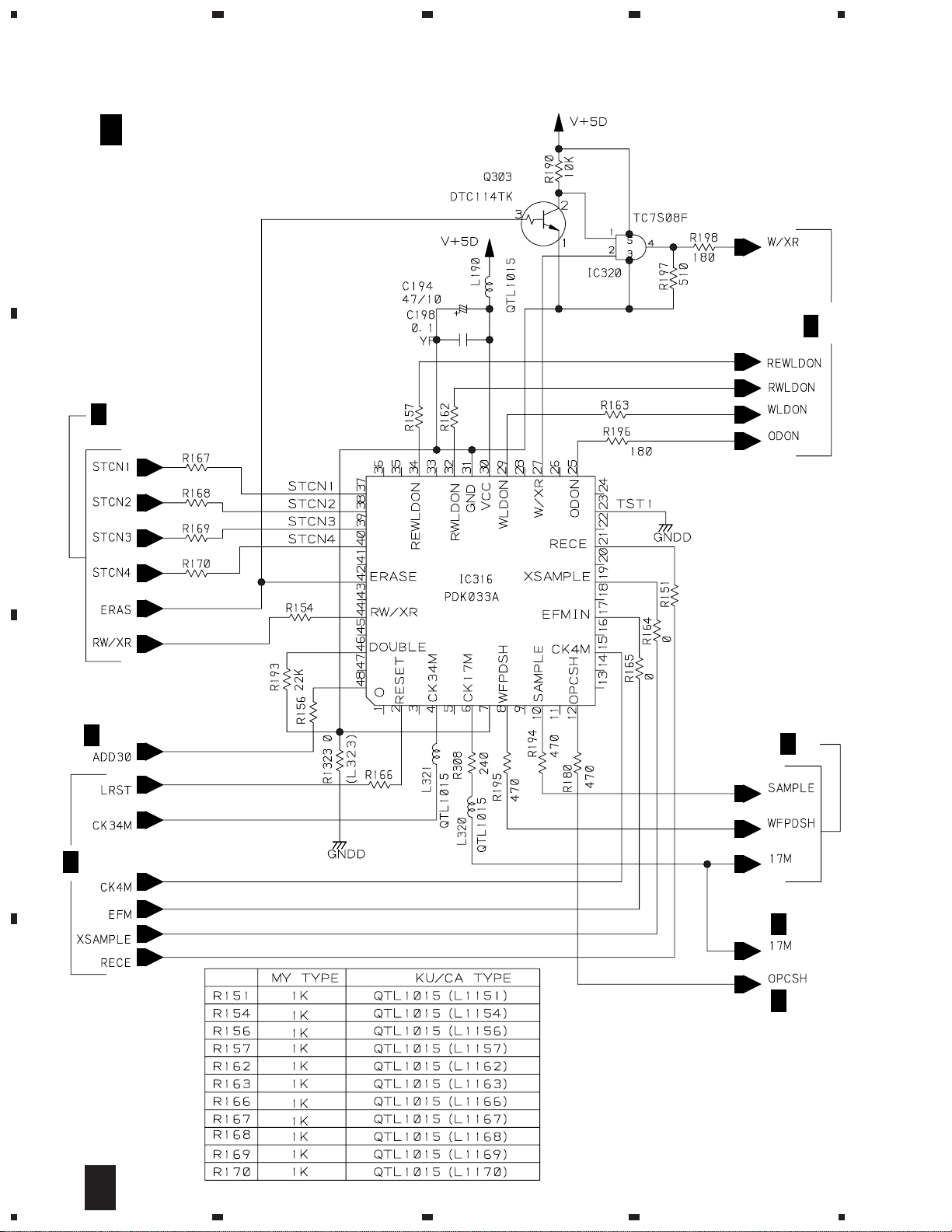

3.6 SERVO DIGITAL ASSY(5/6)

A

3/6

D

B

23

4

A

CN501

C

CN601

C

D

SERVO DIGITAL ASSY(5/6)

5/6

(PWM2217 : KU/CA)

(PWM2216 : MY)

•

DECODER BLOCK

D

2/6

D

20

5/6

D

1234

5

678

PDR-555RW

A

1/6

D

B

CXD2585Q

R1354 0 : KU/CA

L354 QTL1015 : MY

H

J21

D

4/6

C

R1353 0 : KU/CA

L353 QTL1015 : MY

5/6

D

5

6

7

8

21

D

1

23

PDR-555RW

3.7 SERVO DIGITAL ASSY(6/6)

4

D

A

4/6

D

B

SERVO DIGITAL ASSY(6/6)

6/6

(PWM2217 : KU/CA)

(PWM2216 : MY)

•

STRATEGY BLOCK

D

2/6

1/6

D

C

4/6

D

D

D

D

D

4/6

3/6

2/6

22

6/6

D

1234

Loading...

Loading...