Page 1

PLASMA DISPLAY

PDP-501MX

PLASMA DISPLAY

PDP-V501X

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Type

KUC

PDP-501MX

Model

PDP-V501X

Power Requirement

AC120V

Remarks

ORDER NO.

ARP2997

• This manual does not contain the full schematic diagrams and the PCB connection diagrams.

CONTENTS

1. SAFETY INFORMATION

2. EXPLODED VIEWS AND PARTS LIST

3. SCHEMATIC DIAGRAM

4. PCB CONNECTION DIAGRAM

5. PCB PARTS LIST

6. ADJUSTMENT

PIONEER ELECTRONIC CORPORATION 4-1, Meguro 1-Chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS SERVICE, INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER ELECTRONIC (EUROPE) N.V. Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 501 Orchard Road, #10-00 Wheelock Place, Singapore 238880

PIONEER ELECTRONIC CORPORATION 1998

...............................................

....................................................

......................................

................

.....................................

..........................

12

20

20

38

2

5

7. GENERAL INFORMATION

7.1 IC

7.2 DIAGNOSIS

7.2.1 DISASSEMBLY

7.2.2 CIRCUIT BOARDS LOCATION

7.2.3 WIRING

7.2.4 TROUBLESHOOING

7.3 BLOCK DIAGRAM

8. PANEL FACILITIES AND SPECIFICATIONS

.................................................................

.................................................

.................................................

O – SZS AUG. 1998 Printed in Japan

................................

.....................................

.......................................

............

.............................

....

47

47

76

76

78

79

82

86

95

Page 2

PDP-501MX, PDP-V501X

1. SAFETY INFORMATION

This service manual is intended for qualified service technicians ; it is not meant for the casual do-ityourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained

to properly and safety repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may void

the warranty. If you are not qualified to perform the repair of this product properly and safety, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of

california to cause cancer,birth defects or other reproductive harm.

Health & safety code section 25249.6—Proposition 65

NOTICE

(FOR CANADIAN MODEL ONLY)

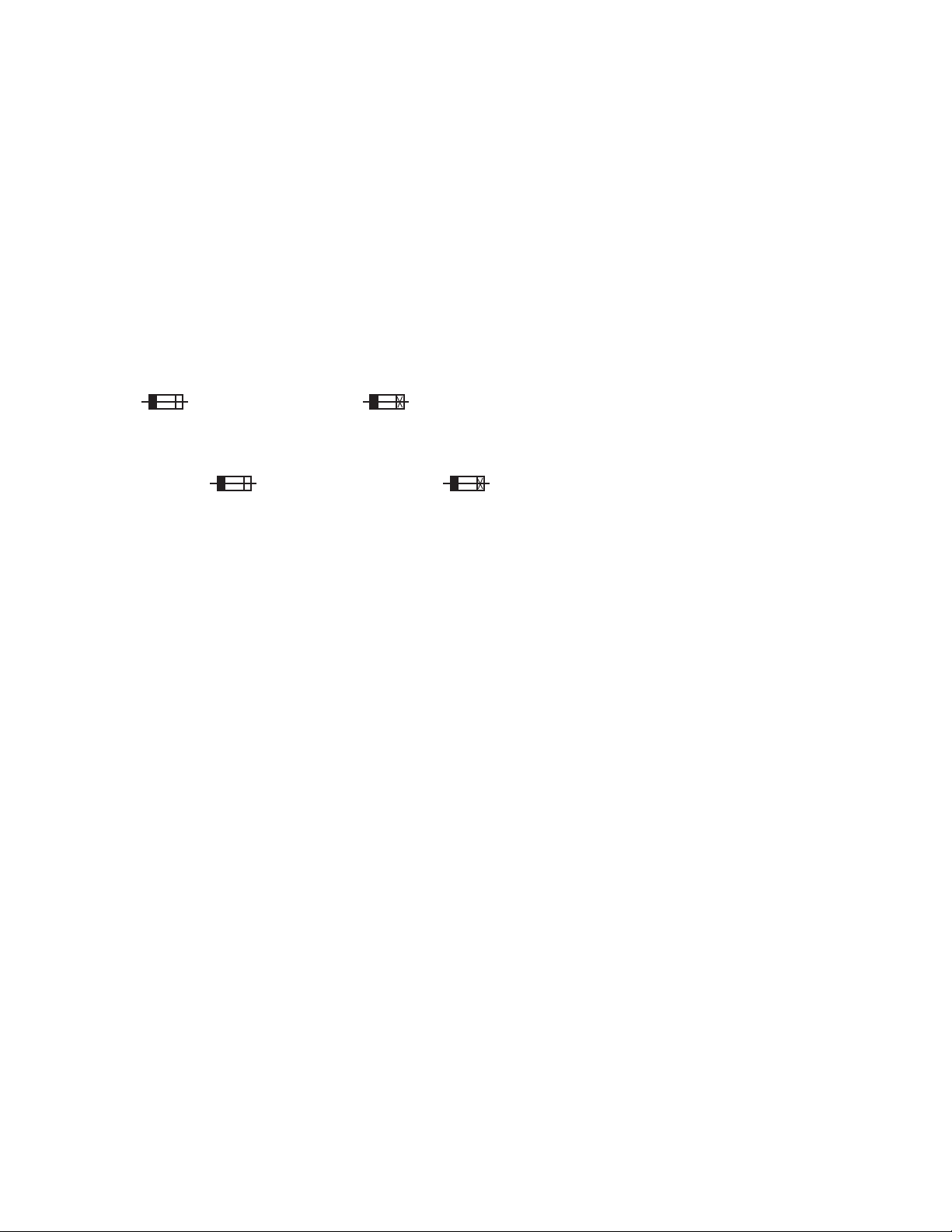

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement parts must be

of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les pièces de

remplacement doivent avoir la même désignation.

1.1 SAFETY PRECAUTIONS

NOTICE : Comply with all cautions and safety related

notes located on or inside the cabinet and on the chassis.

The following precautions should be observed :

1. When service is required, even though the PDP UNIT

an isolation transformer should be inserted between the

power line and the set in safety before any service is

performed.

2. When replacing a chassis in the set, all the protective

devices must be put back in place, such as barriers,

nonmetallic knobs, adjustment and compartment

covershields, isolation resistor-capacitor, etc.

3. When service is required, observe the original lead

dress. Extra precaution should be taken to assure correct

lead dress in the high voltage circuitry area.

4. Always use the manufacture's replacement components.

Especially critical components as indicated on the

circuit diagram should not be replaced by other

manufacture's.

Furthermore where a short circuit has occurred, replace

those components that indicate evidence of overheating.

5. Before returning a serviced set to the customer, the

service technician must thoroughly test the unit to be

certain that it is completely safe to operate without

danger of electrical shock, and be sure that no protective

device built into the set by the manufacture has become

defective, or inadvertently defeated during servicing.

Therefore, the following checks should be performed

for the continued protection of the customer and service

technician.

6. Perform the following precautions against unwanted

radiation and rise in internal temperature.

• Always return the internal wiring to the original styling.

• Attach parts (Ground, Rear Cover, Shield Case) surely

after disassembly.

7. Perform the following precautions for the PDP panel.

• When the front case is removed, make sure nothing hits

the panel face, panel corner, and panel edge (so that

the glass does not break).

• Make sure that the panel vent does not break. (Check

that the cover is attached.)

• Handle the FPC connected to the panel carefully.

Twisting or pulling the FPC when connecting it to the

connector will cause it to peel off from the panel.

8. Pay attention to the following.

• Be sure to wire the fan. If the fan does not work, the

temperature will rise and cause the protection circuit

to operate.

• When the front case is removed, infrared ray is radiated

and may disturb reception of the remote control unit.

• Pay extreme caution when the front case and rear panel

are removed because this may cause a high risk of

disturbance to TVs and radios in the surrounding.

2

Page 3

PDP-501MX, PDP-V501X

Leakage Current Cold Check

With the AC plug removed from an AC power source, place

a jumper across the two plug prongs. Turn the AC power

switch on. Using an insulation tester (DC 500V), connect

one lead to the jumpered AC plug and touch the other lead

to each exposed metal part (input/output terminals,

screwheads, metal overlays, control shafts, etc.),

particularly any exposed metal part having a return path

to the chassis. Exposed metal parts having a return path to

the chassis should have a minimum resistor reading of

0.3MΩ and a maximum resistor reading of 5MΩ. Any

resistor value below or above this range indicates an

abnormality which requires corrective action. Exposed

metal parts not having a return path to the chassis will

indicate an open circuit.

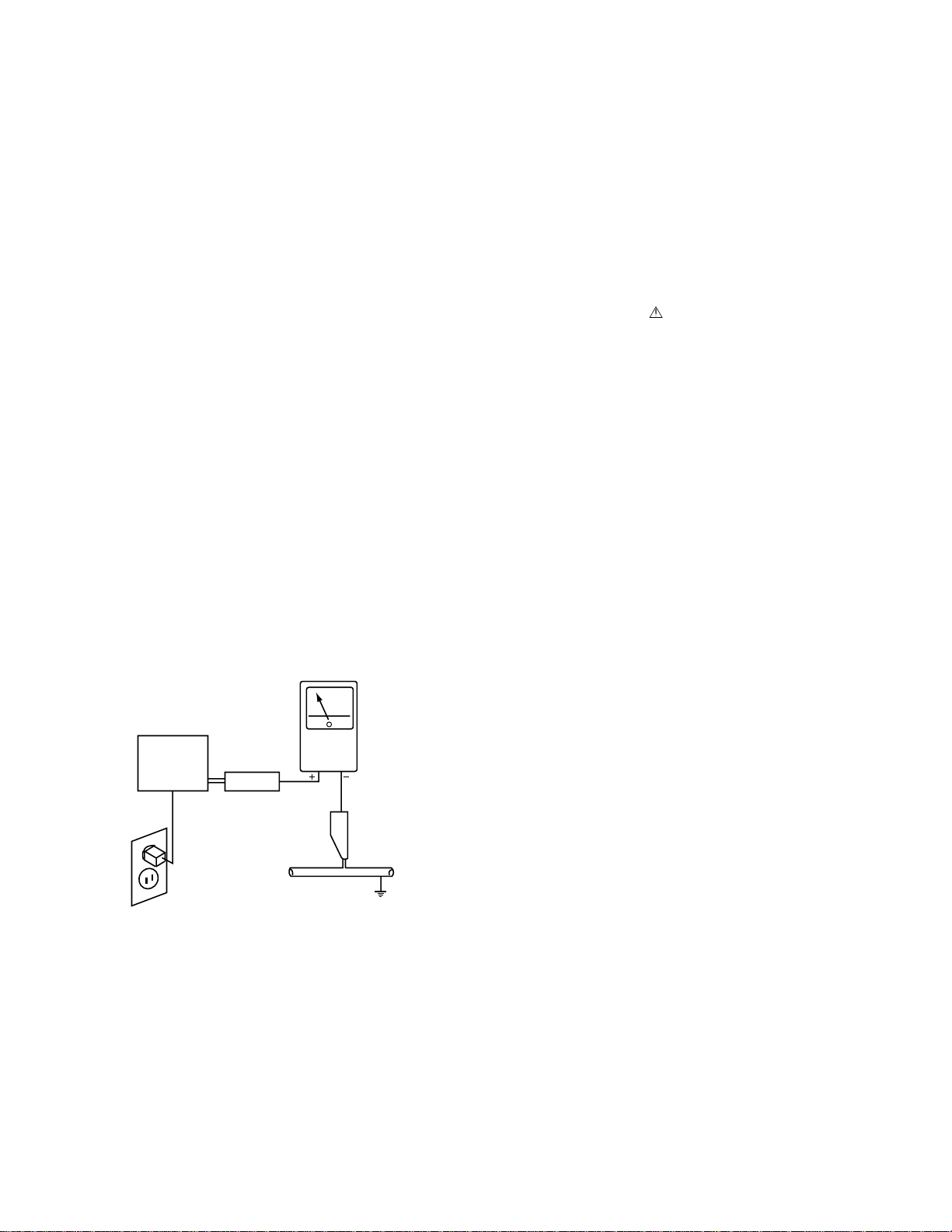

Leakage Current Hot Check

Plug the AC line cord directly into an AC power source

(do not use an isolation transformer for this check).

Turn the AC power switch on.

Using a "Leakage Current Tester (Simpson Model 229

equivalent)", measure for current from all exposed metal

parts of the cabinet (input/output terminals, screwheads,

metal overlays, control shaft, etc.), particularly any

exposed metal part having a return path to the chassis, to a

known earth ground (water pipe, conduit, etc.). Any

current measured must not exceed 0.5mA.

1.2 PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in PIONEER set have

special safety related characteristics. These are often not

evident from visual inspection nor the protection afforded

by them necessarily can be obtained by using replacement

components rated for higher voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this Service Manual.

Electrical components having such features are identified

by marking with a on the schematics and on the parts

list in this Service Manual.

The use of a substitute replacement component which dose

not have the same safety characteristics as the PIONEER

recommended replacement one, shown in the parts list in

this Service Manual, may create shock, fire or other

hazards.

Product Safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current PIONEER Service

Manual. A subscription to, or additional copies of,

PIONEER Service Manual may be obtained at a nominal

charge from PIONEER.

Reading should

not be above

0.5mA

Earth

ground

Device

under

test

Also test with

plug reversed

(Using AC adapter

plug as required)

Test all

exposed metal

surfaces

Leakage

current

tester

AC Leakage Test

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE SET TO THE CUSTOMER.

3

Page 4

PDP-501MX, PDP-V501X

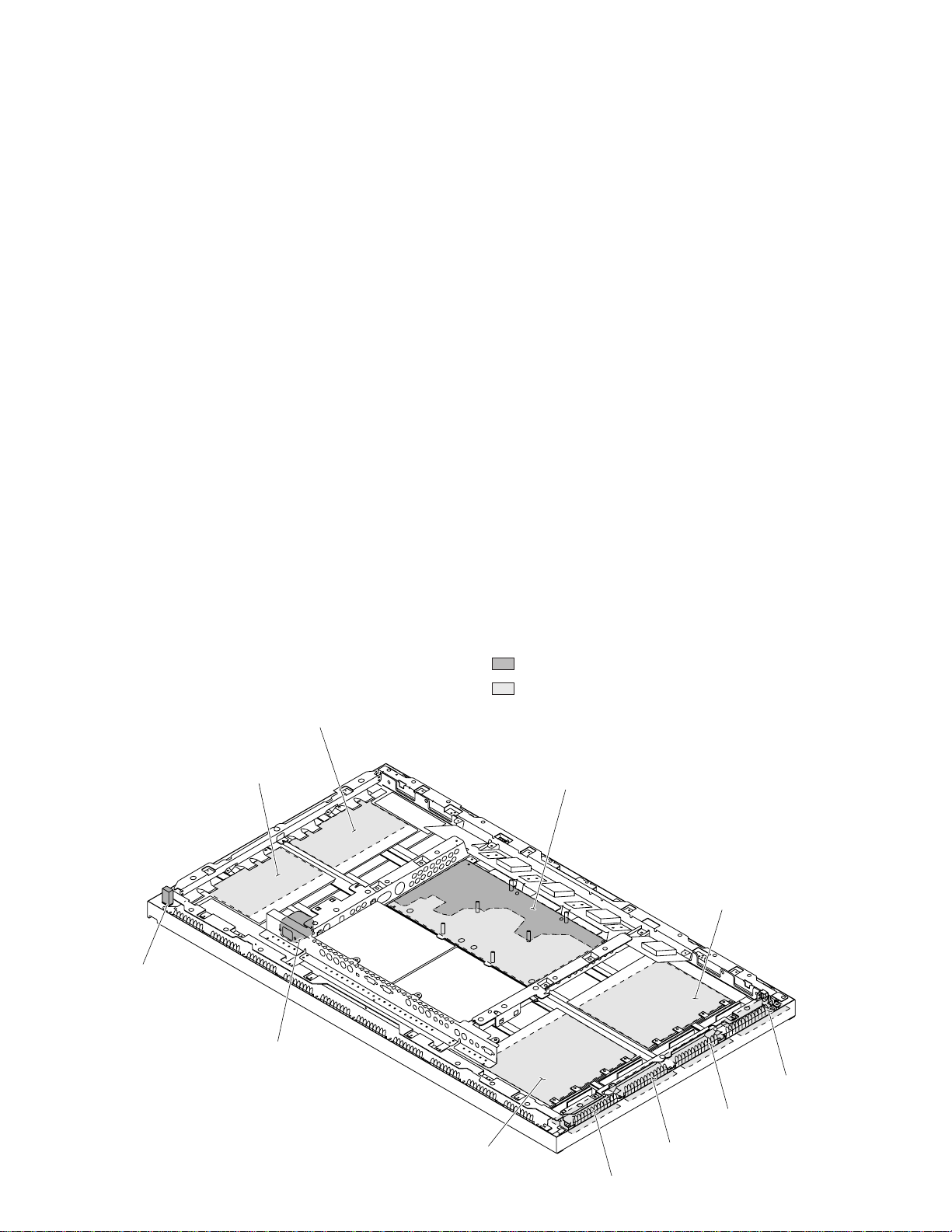

1.3 CHARGED SECTION AND HIGH VOLTAGE GENERATING POINT

7 Charged Section

The places where the commercial AC power is used

without passing through the power supply transformer.

If the places are touched, there is a risk of electric shock.

In addition, the measuring equipment can be damaged if it

is connected to the GND of the charged section and the

GND of the non-charged section while connecting the set

directly to the commercial AC power supply. Therefore,

be sure to connect the set via an insulated transformer and

supply the current.

7 Charged Section

(Power supply primary side)

1. AC Power Cord

2. AC Inlet with Filter

3. Power Switch (S1)

4. Fuse (In the MAIN POWER ASSY)

5. STB Transformer and Converter Transformer

(In the MAIN POWER ASSY)

6. Other primary side of the MAIN POWER ASSY

For the places, refer to the EXPLODED VIEWS, the

SCHEMATIC DIAGRAM and the PCB CONNECTION

DIAGRAM sections.

X DRIVE (A) ASSY

7 High Voltage Generating Point

The places where voltage is 100V or more except for the

charged places described above. If the places are touched,

there is a risk of electric shock.

1. POWER SUPPLY MODULE (170V)

2. X DRIVE (A) ASSY (170V)

3. X DRIVE (B) ASSY (170V)

4. Y DRIVE (A) ASSY (170V)

5. Y DRIVE (B) ASSY (170V)

6. SCAN ASSY (A),(B),(C),(D) (150V)

For the places, refer to the EXPLODED VIEWS, the

SCHEMATIC DIAGRAM and the PCB CONNECTION

DIAGRAM sections.

Part is charged section.

Part is the high voltage generating points other than

the charged section.

POWER SWITCH (S1)

4

X DRIVE (B) ASSY

AC INLET

POWER SUPPLY MODULE

Y DRIVE (B) ASSY

Y DRIVE (A) ASSY

SCAN A ASSY

SCAN B ASSY

SCAN C ASSY

SCAN D ASSY

Page 5

PDP-501MX, PDP-V501X

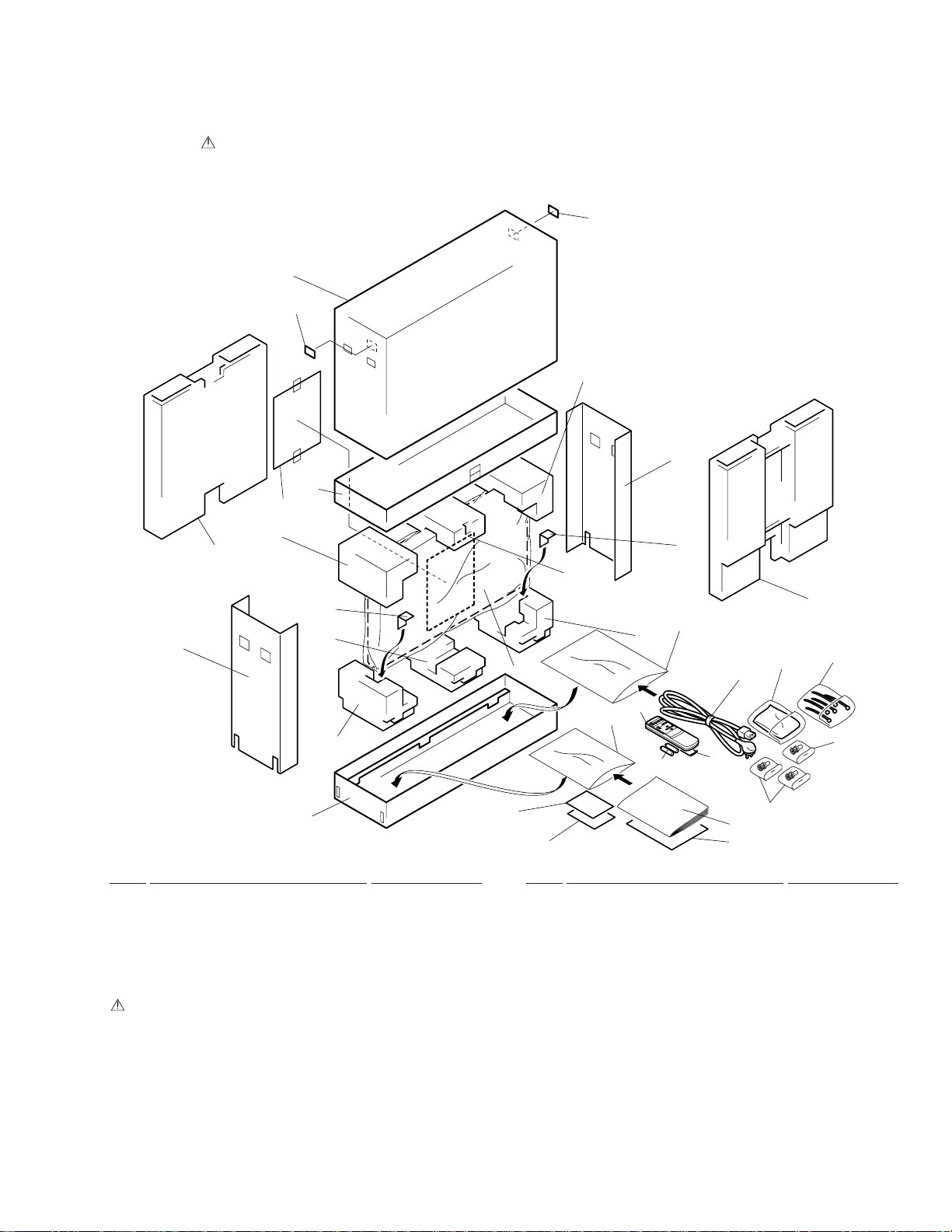

2. EXPLODED VIEWS AND PARTS LIST

NOTES:•Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part. Therefore, when

•

replacing, be sure to use parts of identical designation.

Screws adjacent to ¥ mark on the product are used for disassembly.

•

2.1 P ACKING

2

16

12

13

18

26

19

22

10

26

11

16

22

14

23

27

5

8

4

7

3

9

27

6

1

20

PARTS LIST

Mark No. Description Part No. Mark No. Description Part No.

NSP 1 Battery (R6P,AA) AEX-010

2 Rear Carton AHB1201

3 Binder Assy AEC1758

4 Wiping Cloth AED1174

5 Under Pad R AHA2213

6 Under Pad L AHA2214

7 AC Power Cord ADG1178

8 Mirror Mat AHG1284

9 Remote Control (SR) AXD1437

10 Under Pad C AHA2215

11 Upper Pad R AHA2216

12 Upper Pad L AHA2217

13 Upper Carton (501MX) AHD2980

13 Upper Carton (V501X) AHD2979

14 Upper Pad C AHA2218

15 Plasma Caution Sheet ARM1145

15

17

16 Side Carton AHB1196

17 Caution Sheet ARM1146

18 Protect Sheet SHC-925

19 Carton Cover AHD2975

20 UNDER CARTON ASSY AHD2976

21 Instruction Manual (501MX)

(English, French) ARE1337

21 Instruction Manual (V501X)

(English, French) ARE1339

22 Carton Spacer AHB1198

23 Front Carton AHB1200

24 BNC Conversion Connector

(501MX) AKX1052

NSP 25 Warranty Card (501MX) ARY1094

NSP 26 Label VRW1629

NSP 27 Literature Bag AHG-117

28 Battery Cover AZN2379

28

24

21

25

24

5

Page 6

PDP-501MX, PDP-V501X

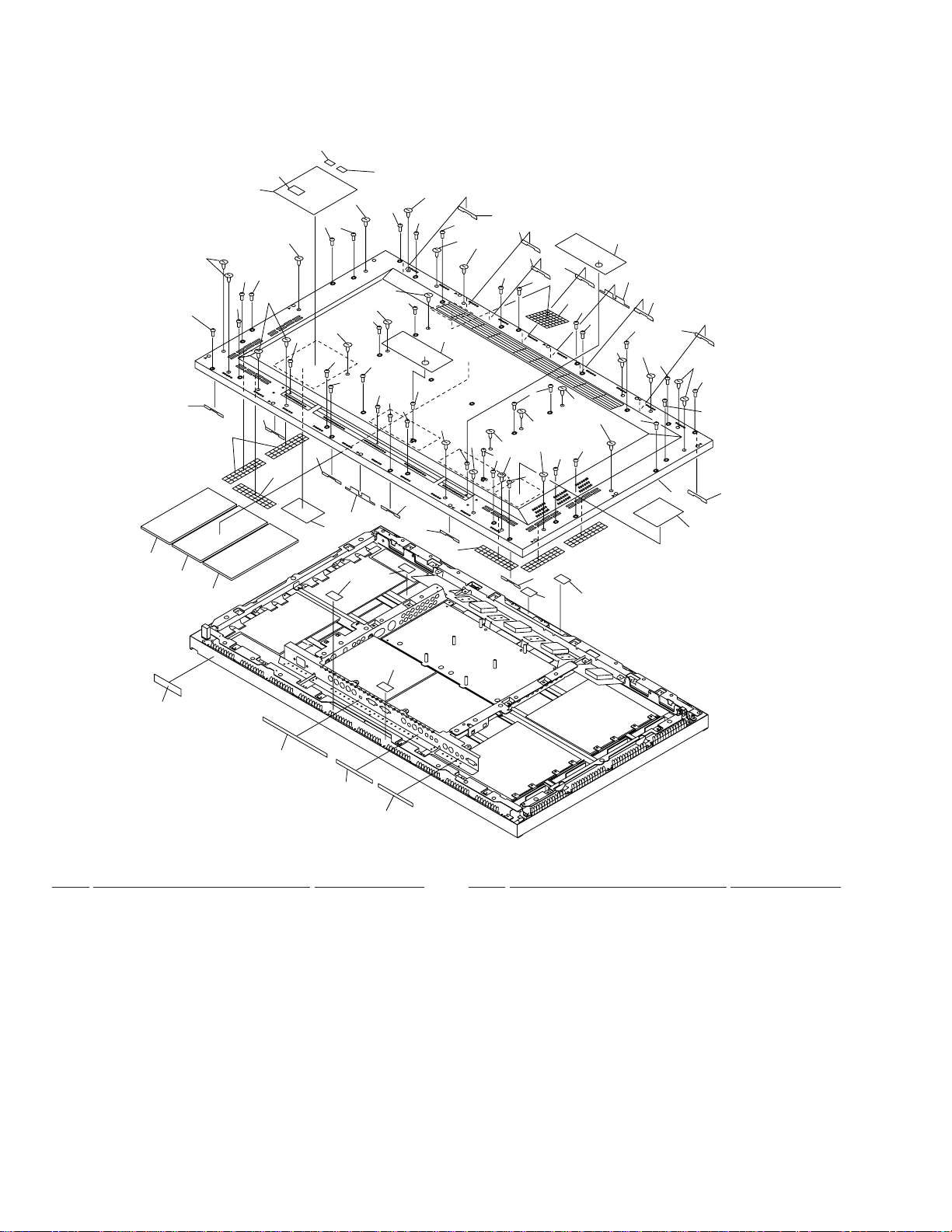

2.2 REAR CASE

7

9

2

2

15

6

2

5

23

3

3

6

23

14

14

3

8

11

2

15

6

2

6

2

6

6

6

5

6

23

25

26

13

12

2

5

6

2

6

10

6

5

6

2

23

23

14

22

6

2

6

22

2

22

6

2

2

6

22

5

6

2

2

2

6

5

23

12

16

24

4

5

6

2

2

15

21

22

6

22

2

2

6

2

5

15

6

1

22

20

27

17

18

PARTS LIST

Mark No. Description Part No.

NSP 1 Rear Case (M) (501MX) AMR3097

NSP 1 Rear Case (MB) (V501X) AMR3100

2 Hole Rivet AMR2969

3 Barrier AMR3049

4 Net F AED1185

5 Screw BPZ40P160FZK

6 Screw AMZ30P100FZK

NSP 7 UPC Code Label (501MX) AAX2673

NSP 7 UPC Code Label (V501X) AAX2674

NSP 8 Label VRW1629

NSP 9 Name Label (501MX) AAL2274

NSP 9 Name Label (V501X) AAL2285

10 Terminal Label L (501MX) AAX2662

10 Terminal Label L (V501X) AAX2680

NSP 11 Manufactured Label AAX-372

12 IC Protector Label AAX2642

6

21

19

Mark No. Description Part No.

NSP 13 Drive Voltage Label ARW1077

14 Net R AED1178

15 Screw BMZ40P120FMC

16 Terminal Label R (501MX) AAX2663

16 Terminal Label R (V501X) AAX2679

17 Terminal Label 3 AAX2641

18 Terminal Label 2 AAX2640

19 Terminal Label 1 AAX2639

NSP 20 Bolt Caution Label (501MX) AAX2656

NSP 20 Bolt Caution Label (V501X) AAX2681

21 IC Protector Label (F) AAX2675

22 Rear Shield US ANK1574

23 Rear Shield DS ANK1575

24 Rear Shield UB ANK1576

25 Rear Shield DB ANK1577

26 Solder Warning Label AAX2644

27 Serial Sheet AAX1322

Page 7

PDP-501MX, PDP-V501X

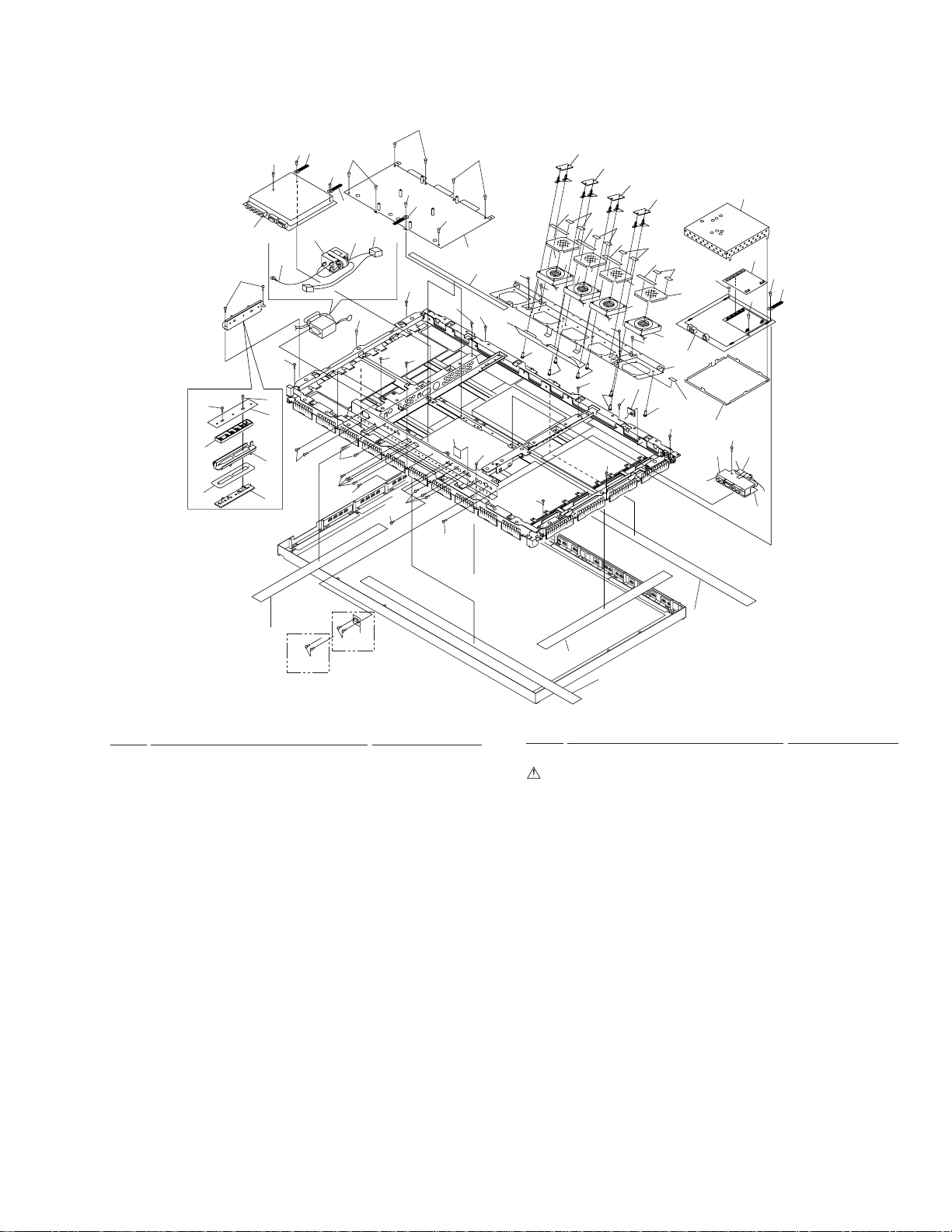

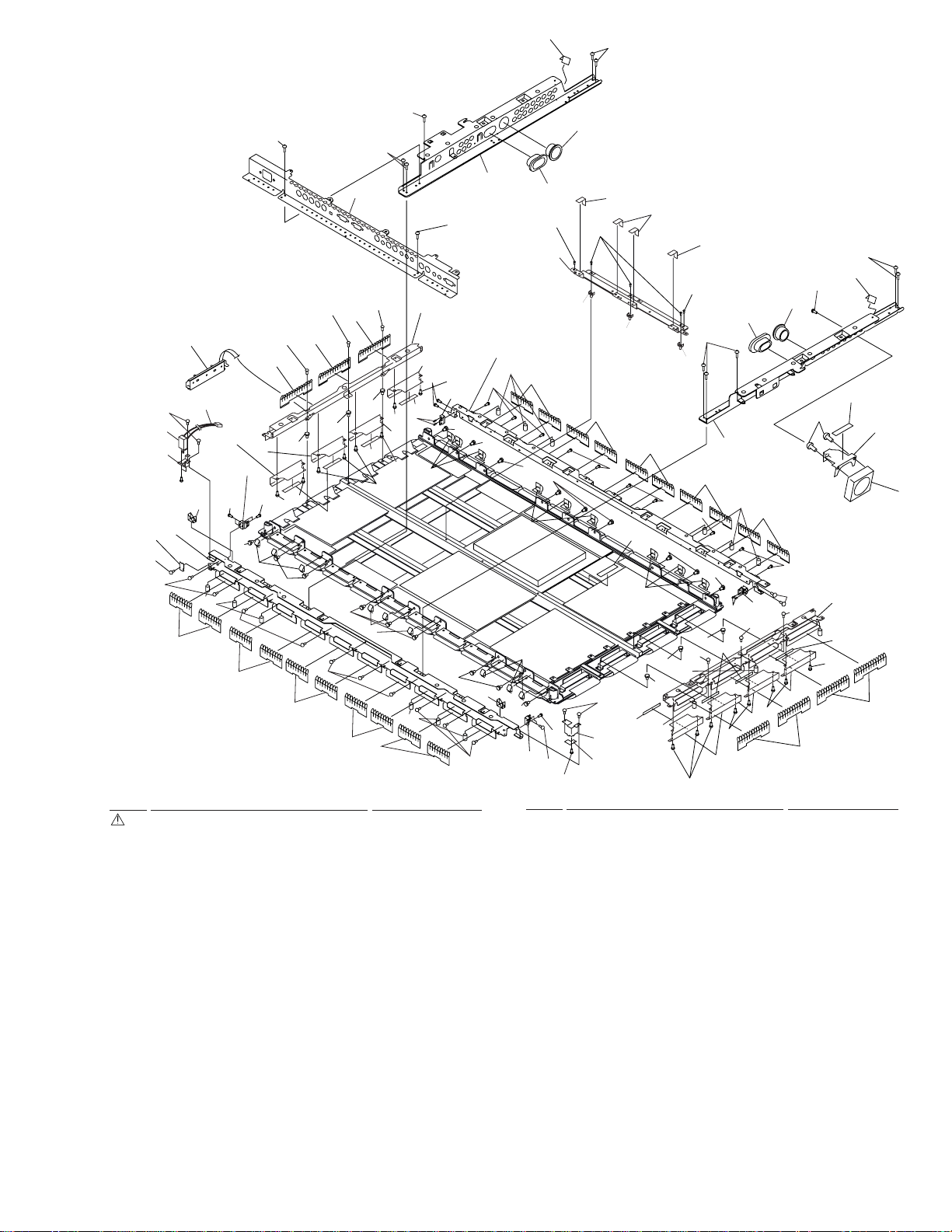

2.3 MAIN SECTION (1)

13

16

12

15

16

21

32

34

25

44

30

21

31

33

12

38

12

12

16

12

13

26

24

30

21

22

12

13

30

23

12

21

21

12

12

14

37

12

12

23

43

39

23

30

12

1

2

5

7

9

8

9

12

11

11

3

5

6

7

8

12

11

12

11

30

4

5

5

6

7

6

7

6

8

9

36

23

8

9

12

19

10

27

11

30

17

18

16

20

41

35

16

13

12

16

24

42

28

22

(for PDP-V501X)

40

12

(for PDP-501MX)

PARTS LIST

Mark No. Description Part No.

1 DC FAN A ASSY AWZ6323

2 DC FAN B ASSY AWZ6324

3 DC FAN C ASSY AWZ6325

4 DC FAN D ASSY AWZ6326

5 Locking Card Spacer AEC1736

6 Fan Cushion B AEC1750

7 Fan Cushion A AEC1749

8 Fan Filter DNH1548

9 Fan Motor 80*25 AXM1032

NSP 10 Fan Angle ANG2237

11 Screw PPZ50P100FZK

12 Screw BMZ30P060FCU

13 Binder AEP-215

14 Power Supply Module AXY1029

15 RGB ASSY AWV1687

16 Screw AMZ30P080FCU

NSP 17 Analog Shield A ANK1536

NSP 20 Analog Shield B ANK1537

18 PROGRESSIVE BLOCK AWZ6222

19 VIDEO ASSY AWZ6305

21 Screw BPZ30P080FZK

22 Screw BBA1017

23 Screw BPZ40P160FZK

29

28

29

Mark No. Description Part No.

24 Ferrite Core ATX1031

25 AC Inlet with Filter AKP1180

26 Housing Wire ADX2406

27 SENSOR A ASSY AWZ6309

28 Panel Sheet B AMR2958

NSP 29 Panel Sheet H AMR3035

30 Screw BMZ40P120FMC

31 SIDE SWITCH ASSY AWZ6315

32 Control Button AAC1536

NSP 33 Control PCB Holder ANG2292

34 Blind Cover AMR3098

35 CONTROL ASSY AWZ6307

36 SENSOR B ASSY AWZ6310

37 Shield Gusket A ANK1578

38 Control Name Plate (501MX) AAK2719

38 Control Name Plate (V501X) AAK2720

39 Terminal Cover (501MX) AMR3099

40 Terminal Cover (232C) (501MX)ANG2294

NSP 41 232C Case A ANK1567

NSP 42 232C Case B ANK1568

43 Fan Barrier AMR3124

44 Ground Wire (J13) ADX2332

7

Page 8

PDP-501MX, PDP-V501X

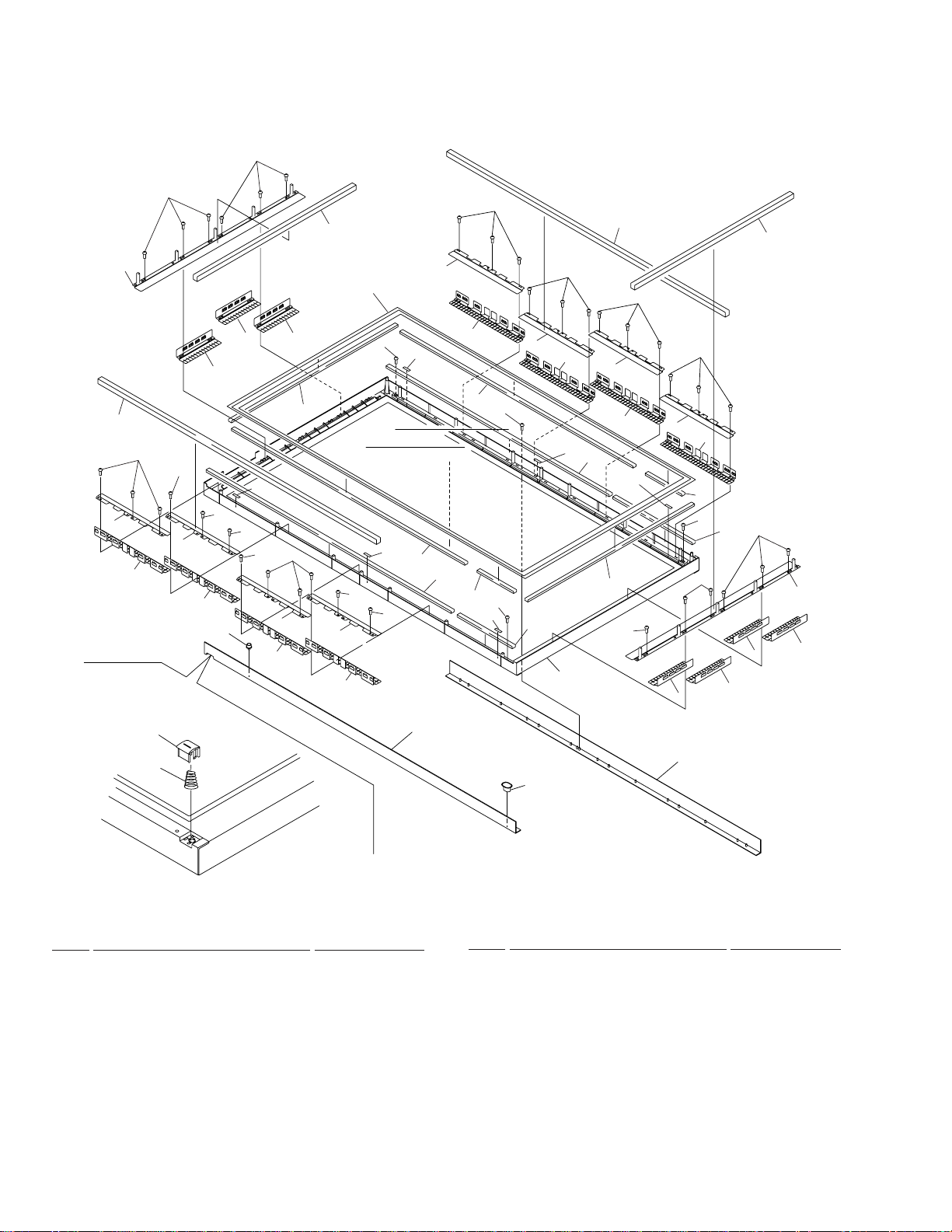

2.4 FRONT CASE SECTION

11

11

17

6

4

7

7

16

10

10

5

8

10

11

5

8

13

15

11

7

20

10

5

8

5

10

15

10

10

8

5

15

18

21

19

8

18

15

10

10

10

5

22

16

10

10

8

5

8

15

23

15

20

11

3

10

5

8

19

10

11

7

24

17

11

6

7

7

7

12

9

PARTS LIST

Mark No. Description Part No.

1 Sash U AAP1583

2 Sash D (N) AAP1591

3 Front Case (M) (501MX) AMB2632

3 Front Case (M) (V501X) AMB2624

4 PROTECT PANEL ASSY AMR3065

NSP 5 Panel Holder H ANG2228

6 Panel Holder V ANG2277

7 Panel Shield FV ANK1541

8 Panel Shield FH ANK1542

9 Coil Spring ABH1103

10 Screw PMZ40P080FMC

11 Screw BPZ40P080FZK

12 Power Button AAD4101

8

2

1

14

Mark No. Description Part No.

13 LED Lens AAK2695

14 Lens AAK2703

NSP 15 Sheet AED1176

16 Panel Cushion 50H AED1181

17 Panel Cushion 50V AED1182

18 Shield Gusket F ANK1583

19 Shield Gusket E ANK1582

20 Shield Gusket D ANK1581

21 Shield Gusket G ANK1584

22 Shield Gusket H ANK1585

23 Shield Gusket C ANK1580

24 Shield Gusket B ANK1579

Page 9

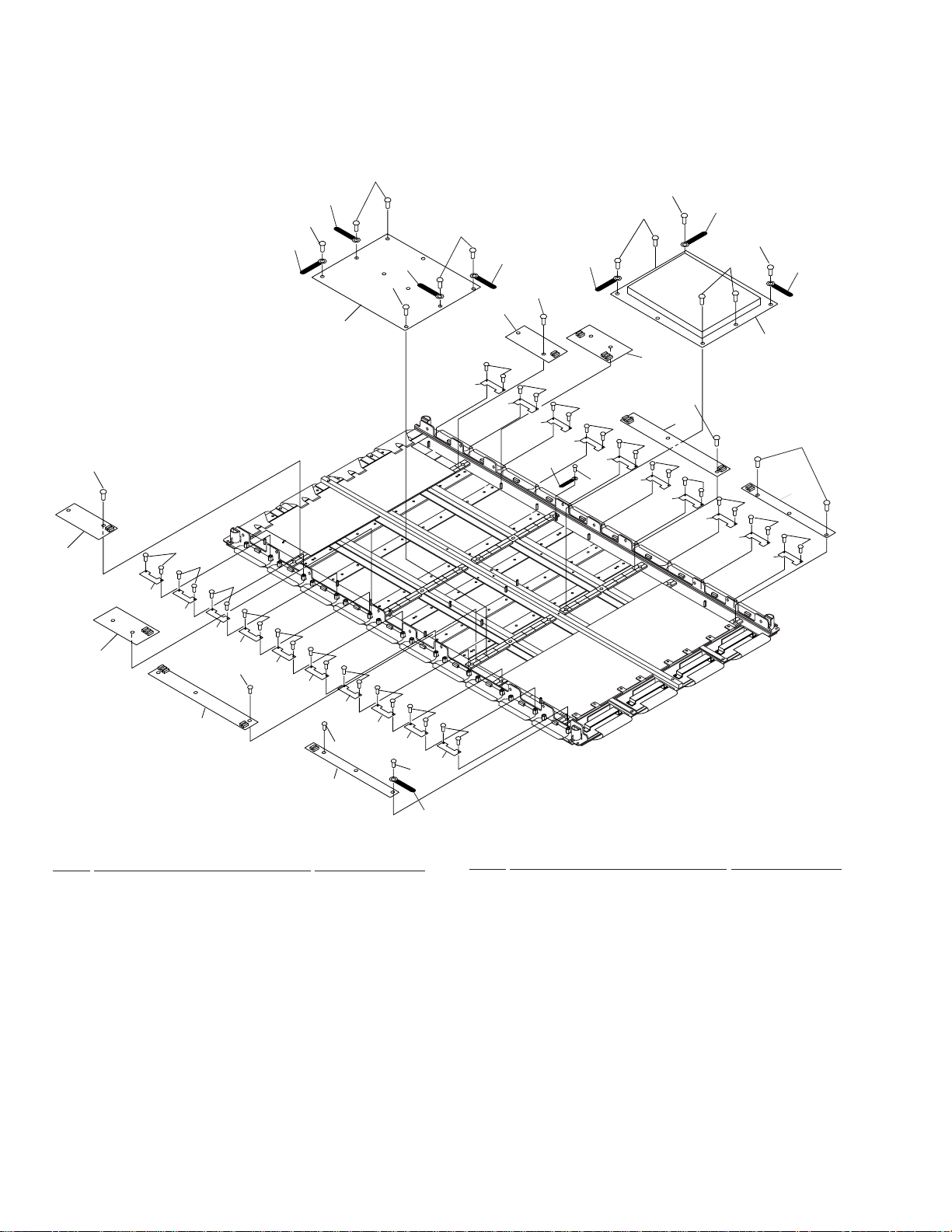

2.5 MAIN SECTION (1)

14

14

14

26

30

PDP-501MX, PDP-V501X

14

10

13

13

6

13

39

6

6

19

14

2

1

34

24

11

22

11

11

33

25

24

15

25

25

15

28

9

25

33

4

17

8

13

23

13

11

27

11

11

27

7

7

13

7

7

23

7

PARTS LIST

Mark No. Description Part No.

1 Power Switch ASG1082

2 Housing Wire (J12) ADX2407

3 Frame V ANG2232

4 Frame HD ANG2233

5 Frame HU ANG2234

33

27

3

24

28

22

11

14

25

11

13

32

31

18

14

21

12

26

21

26

14

14

26

31

30

25

14

26

5

13

23

7

21

37

7

38

36

11

27

11

11

13

37

7

13

11

27

13

7

11

29

15

23

22

35

7

13

28

3

13

13

11

23

13

25

24

33

25

24

24

25

27

9

14

11

22

15

28

20

16

33

11

11

23

8

Mark No. Description Part No.

NSP 21 PCB Mold AMR2115

22 Corner Holder AMR3067

23 VCP Cap AEC1760

24 FPC Shield ANK1550

25 Screw BBZ30P060FMC

33

25

6

6

6 Panel Shield RV ANK1539

7 Panel Shield RH ANK1540

8 Nyron Rivet AEC1671

9 Edging Saddle AEC1737

10 Terminal Panel ANG2310

11 Well Nut ABN1029

12 Screw AMZ30P140FCU

13 Screw BMB30P140FZK

14 Screw BMZ30P060FCU

15 Screw

16 IR RECEIVER ASSY AWZ6224

17 INDICAT OR ASSY AWZ6225

NSP 18 Center Frame ANG2230

NSP 19 Switch Holder ANG2239

NSP 20 Holder ANG2240

26 Frame Sheet AED1173

27 Shield Finger ABX1004

28 Screw AMZ30P100FZK

29 Sub Frame R ANG2303

NSP 30 Bush A AEC1738

NSP 31 Bush C AEC1740

32 Sub Frame L ANG2236

33 FPC Cushion AEB1341

34 FPC Shield (M) ANK1561

35 Fan Motor AXM1026

36 Fan Angle B ANG2301

37 Fan Cushion B AEC1750

38 Screw PPZ50P100FZK

39 Side Switch Assy AWZ6315

9

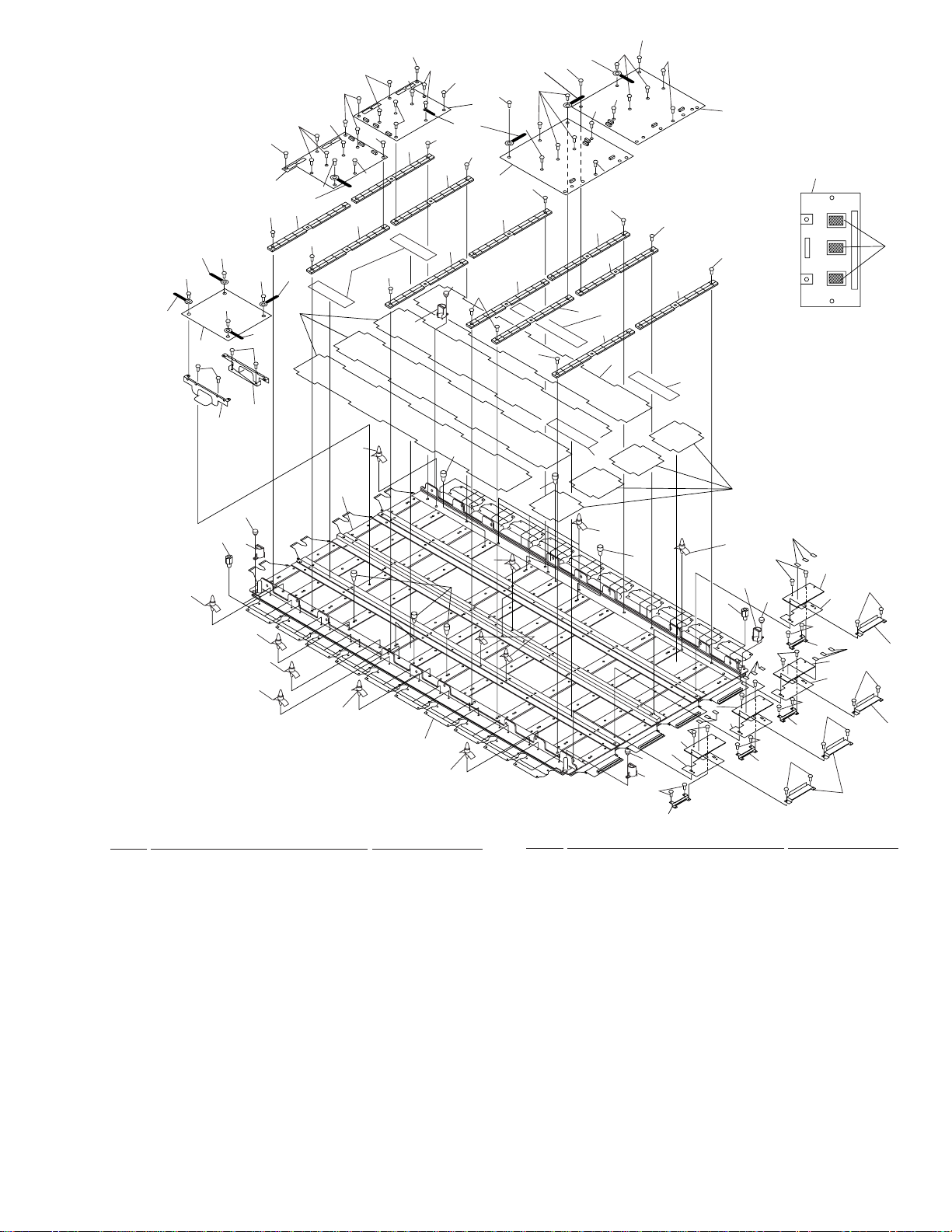

Page 10

PDP-501MX, PDP-V501X

2.6 MAIN SECTION (3)

13

25

2

4

25

1

2

4

2

4

2

25

4

2

4

25

2

12

14

5

6

3

23

21

4

3

3

19

3

3

15

4

3

16

17

1

4

9

3

3

3

18

3

20

22

4

8

3

3

24

3

24

22

20

7

11

18

4

16

3

3

3

17

4

19

3

3

3

21

4

3

23

15

10

2

PARTS LIST

Mark No. Description Part No.

1 Binder AEC-826

2 Binder AEP-215

3 Screw BMZ30P040FMC

4 Screw BPZ30P080FZK

5 DIGITAL VIDEO ASSY AWV1728

6 CABLE E ASSY AWZ6218

7 CABLE F ASSY AWZ6219

8 CABLE A ASSY AWZ6214

9 CABLE B ASSY AWZ6215

10 CABLE C ASSY AWZ6216

11 CABLE D ASSY AWZ6217

12 CABLE G ASSY AWZ6220

13 CABLE H ASSY AWZ6221

10

Mark No. Description Part No.

14 U-CON ASSY AWV1689

15 PUMP UP A ASSY AWZ6249

16 PUMP UP B ASSY AWZ6250

17 PUMP UP C ASSY AWZ6251

18 PUMP UP D ASSY AWZ6252

19 PUMP UP E ASSY AWZ6253

20 PUMP UP F ASSY AWZ6254

21 PUMP UP G ASSY AWZ6255

22 PUMP UP H ASSY AWZ6256

23 PUMP UP K ASSY AWZ6257

24 PUMP UP L ASSY AWZ6258

25 Screw AMZ30P140FCU

Page 11

2.7 MAIN SECTION (4)

21

21

21

12

12

16

7

8

11

7

11

11

7

34

21

11

11

7

21

1

1

11

7

2

28

31

12

PDP-501MX, PDP-V501X

12

11

21

25

21

8

21

11

12

12

15

7

7

11

8

14

8

8

5

11

32

21

21

21

8

10

8

11

11

10

10

77

10

7

10

10

10

11

8

8

29

8

8

2

30

11

10

13

17, 18, 19, 20

11

8

30

6

23

5

9

25

31

31

31

31

31

27

PARTS LIST

Mark No. Description Part No.

NSP 1 3D Y/C Holder ANG2293

NSP 5 Rivet AEC1748

2 Panel Shield L ANK1548

3 Panel Shield S ANK1553

4 Hot Plate ANG2231

6 Sheet AEH1027

7 Binder AEP-215

8 PCB Spacer AMR3037

9 Spacer AEF1026

10 Screw AMZ30P140FCU

11 Screw BMZ30P060FCU

12 Screw BPZ30P080FZK

13 Y DRIVE A ASSY AWV1695

14 Y DRIVE B ASSY AWV1696

15 X DRIVE A ASSY AWZ6242

16 X DRIVE B ASSY AWZ6243

17 SCAN A ASSY AWZ6226

31

32

19

3

31

25

9

26

6

31

32

33

31

32

11

20

26

5

25

22

4

Mark No. Description Part No.

18 SCAN B ASSY AWZ6227

19 SCAN C ASSY AWZ6228

20 SCAN D ASSY AWZ6229

21 Screw AMZ30P080FCU

22 Screw IPZ30P080FCU

NSP 23 FRAME ASSY(AL) ANA1544

NSP 24 Scan Heatsink ANH1544

NSP 25 Tube Cover AMR3036

NSP 26 PVC Sheet AMR3038

NSP 27 PLASMA PANEL ASSY AAV1229

NSP 28 Frame Barrier X AMR3062

NSP 29 Frame Barrier C AMR3063

NSP 30 Frame Barrier Y AMR3064

NSP 31 Circuit Board Spacer AEC1744

NSP 32 PCB Spacer AEC1573

NSP 33 Circuit Board Spacer AEC1743

34 3D Y/C SEP. ASSY AWZ6332

6

11

5

11

6

11

22

4

21

17

21

26

22

4

6

24

21

24

24

18

26

22

21

4

11

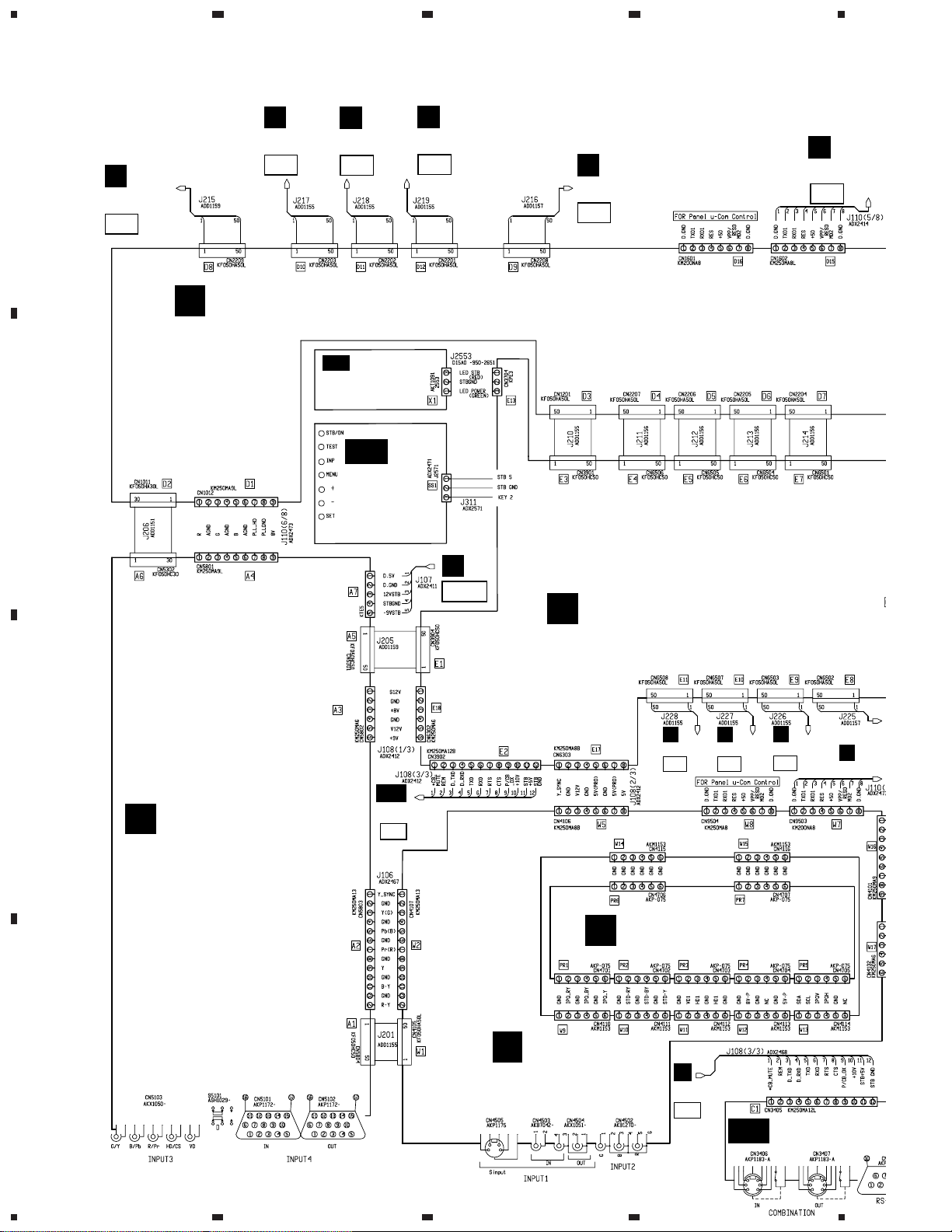

Page 12

1

2

S

23

PDP-501MX, PDP-V501X

3. SCHEMATIC DIAGRAM

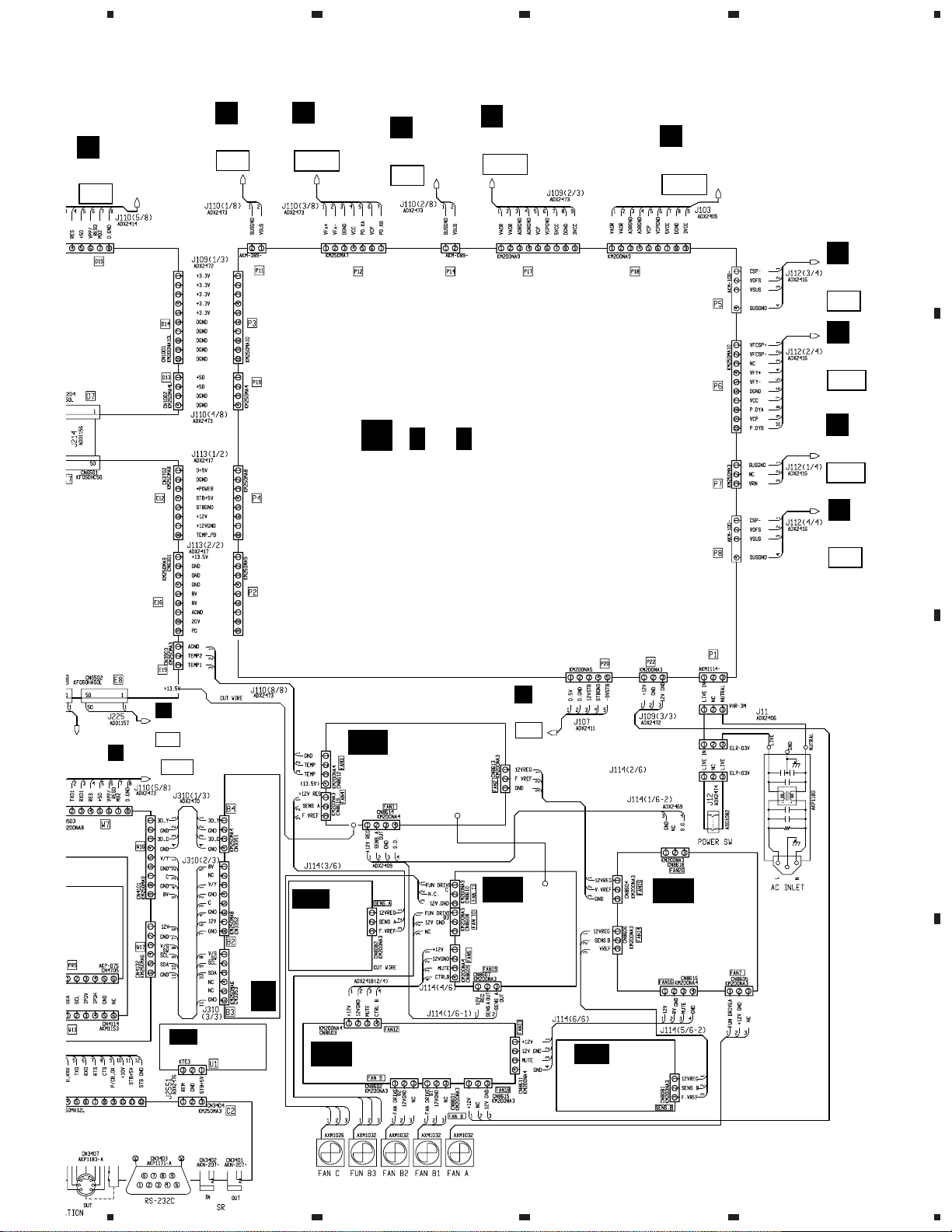

3.1 OVERALL CONNECTION DIAGRAM (1/2)

L

CN7103

A

T1

E

CN2604

F1

D

DIGITAL VIDEO ASSY (AWV1728)

L

CN7102

T2

AH

INDICATOR

ASSY

(AWZ6225)

L

CN7101

T3

G

CN3104

H1

4

A

CN4101

B7

B

AQ

SIDE

SWITCH

ASSY

(AWZ6315)

J5101

J

P20

I

U-CON ASSY (AWV1689)

N

CN7303

C

K1

N

CN7302

K2

AO

C

CN3405

C1

RGB ASSY (AWV1687)

N

CN7301

K3

D

CN160

PROGESSIVE BLOCK

B

(AWZ6222)

A

D

VIDEO ASSY

(AWZ6305)

12

1234

I

CN3902

E2

AO

CONTROL A

(AWZ6307)

Page 13

5

Note: When ordering service parts, be sure to refer to “EXPLODED VIEWS and

PARTS LIST” or “PCB PARTS LIST”

678

PDP-501MX, PDP-V501X

A

CN4101

B7

E

CN2601

F9

E

CN2602

F10

F

CN2601

G8

J

(

1/2 ,

J

L

CN7111

T15

2/2

J

)

POWER SUPPLY MODULE

(AXY1029)

N

CN7311

K15

G

CN3101

H8

G

CN3102

H11

G

CN3201

H10

H

CN3101

I 8

A

B

H

CN3104

301

D

CN1602

I 1

K

NTROL ASSY

Z6307)

D15

AG

J311

ADX2475

IR RECEIVE

ASSY

(AWZ6224)

A I

DC FAN A ASSY

(AWZ6323)

AM

AP

SENSOR A

ASSY

3D Y/C SEP. ASSY

(AWZ6332)

(AWZ6309)

AP

AK

DC FAN C ASSY

(AWZ6325)

AKC1002

K8601

DC FAN B

ASSY

(AWZ6324)

AJ

C

J5101

A7

Y312

YJSHA0-20-5/5

K8602

AKC1002

AN

SENSOR B

ASSY

(AWZ6310)

C

AL

DC FAN D

ASSY

(AWZ6326)

D

5

6

7

13

8

Page 14

1

P

0

P

4

1

PDP-501MX, PDP-V501X

23

4

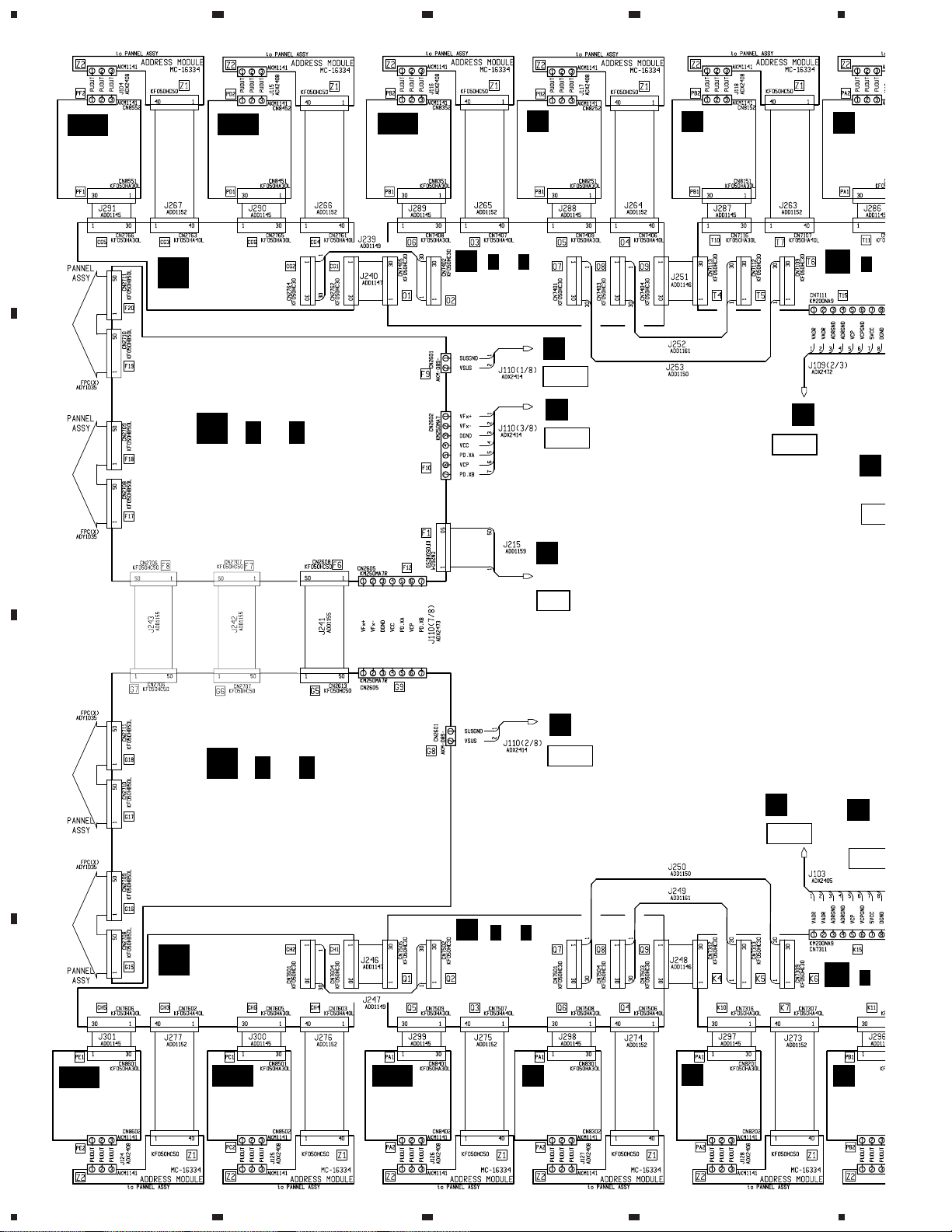

3.2 OVERALL CONNECTION DIAGRAM (2/2)

O

1/2,

Y

PUMP UP C

ASSY

(AWZ6251)

O

2/2

)

AE

PUMP UP K

A

ASSY

(AWZ6257)

Q

AC

PUMP UP G

ASSY

(AWZ6255)

CABLE G

ASSY

(AWZ6220)

AA

PUMP UP E

ASSY

(AWZ6253)

(

O

CABLE E

ASSY

(AWZ6218)

W

PUMP UP A

ASSY

(AWZ6249)

X

PUMP U

ASSY

(AWZ625

L

(

L

1/3

J

P11

J

E

E

(

B

X DRIVE A ASSY

(AWZ6242)

1/2,

E

2/2

)

P12

J

P17

D

CN

D

D

CN2209

D8

J

C

F

F

(

)

2/2

F

1/2,

X DRIVE B ASSY

(AWZ6243)

P

1/2,

P

(

CABLE H

R

ASSY

(AWZ6221)

D

AF

PUMP UP L

ASSY

(AWZ6258)

AD

PUMP UP H

ASSY

(AWZ6256)

AB

PUMP UP F

ASSY

(AWZ6254)

CABLE F

ASSY

(AWZ6219)

P14

2/2

P

)

Z

PUMP UP D

ASSY

(AWZ6252)

X

PUMP UP B

ASSY

(AWZ6250)

J

P18

I

CN6

E11

(

N

W

PUMP U

ASSY

(AWZ62

1/3

N

14

1234

Page 15

5

678

PDP-501MX, PDP-V501X

MP UP B

SSY

WZ6250)

1/3 –

L

(

D

CN2203

D10

CABLE B ASSY

3/3

L

)

(AWZ6215)

D

CN2201

D

CN2202

D11

J

P6

J

P7

Z

PUMP UP D

ASSY

(AWZ6252)

D12

J

P5

AB

PUMP UP F

ASSY

(AWZ6254)

D

CN2208

1

2

3

4

G

(

Y DRIVE A ASSY

(AWZ6321)

1/4 –

G

K

D9

G

(

K

4/4

AD

PUMP UP H

ASSY

(AWZ6256)

2/2

K

1/2,

)

AF

PUMP UP L

ASSY

(AWZ6258)

)

CABLE A ASSY

(AWZ6214)

S

SCAN A

ASSY

(AWZ6226)

T

SCAN B

ASSY

(AWZ6227)

A

B

I

CN6508

E11

1/3 –

N

(

UMP UP A

SSY

WZ6249)

J

P8

I

CN6507

E10

CABLE D ASSY

3/3

N

)

(AWZ6217)

I

CN6503

E9

Y

PUMP UP C

ASSY

(AWZ6251)

I

CN6502

E8

H

(

1/4 –

H

Y DRIVE B ASSY

(AWZ6322)

M

AA

PUMP UP E

ASSY

(AWZ6253)

4/4

H

1/2,

M

(

AC

PUMP UP G

ASSY

(AWZ6255)

)

M

CABLE C ASSY

2/2

)

(AWZ6216)

AE

PUMP UP K

ASSY

(AWZ6257)

U

SCAN C

ASSY

(AWZ6228)

C

V

SCAN D

ASSY

(AWZ6229)

D

5

6

7

15

8

Page 16

1

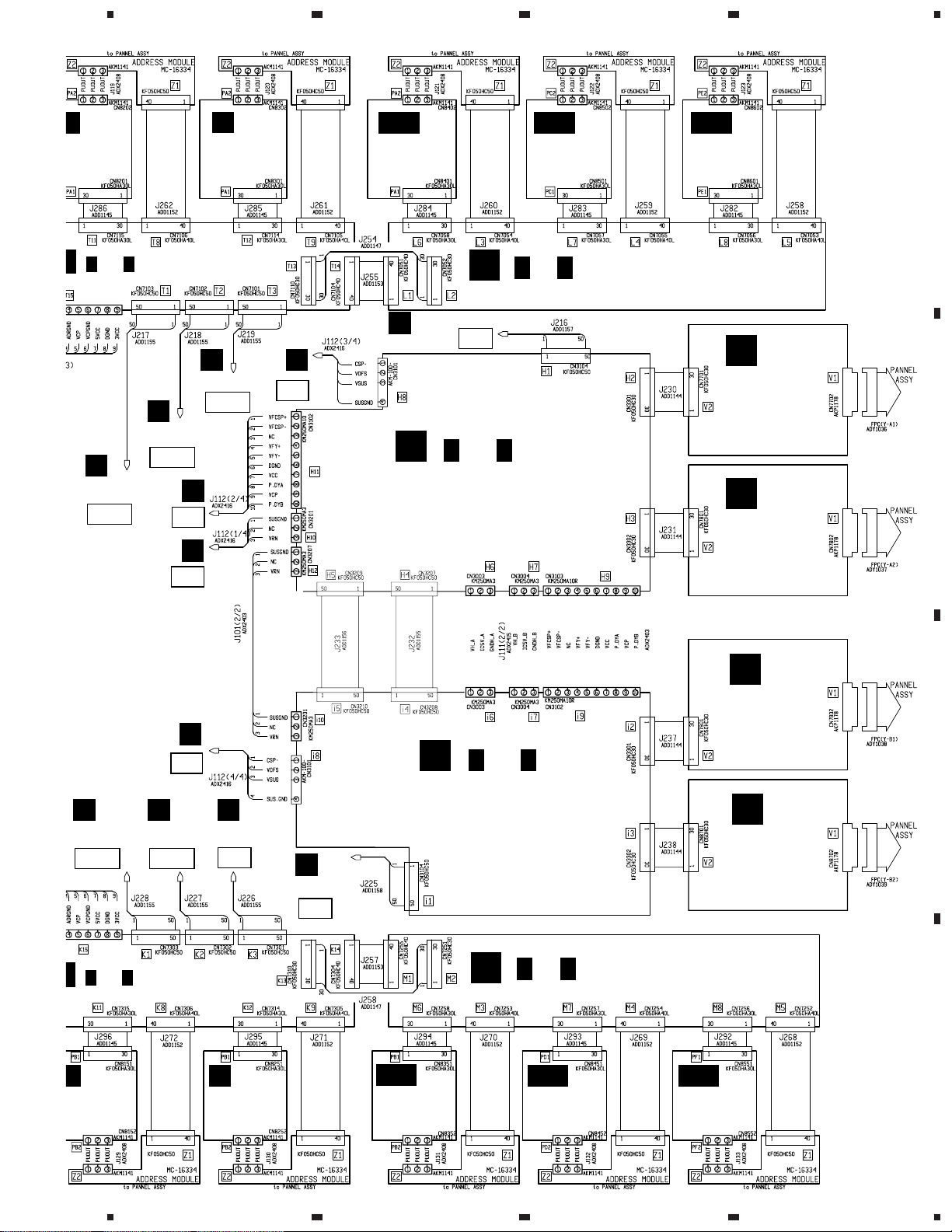

23

PDP-501MX, PDP-V501X

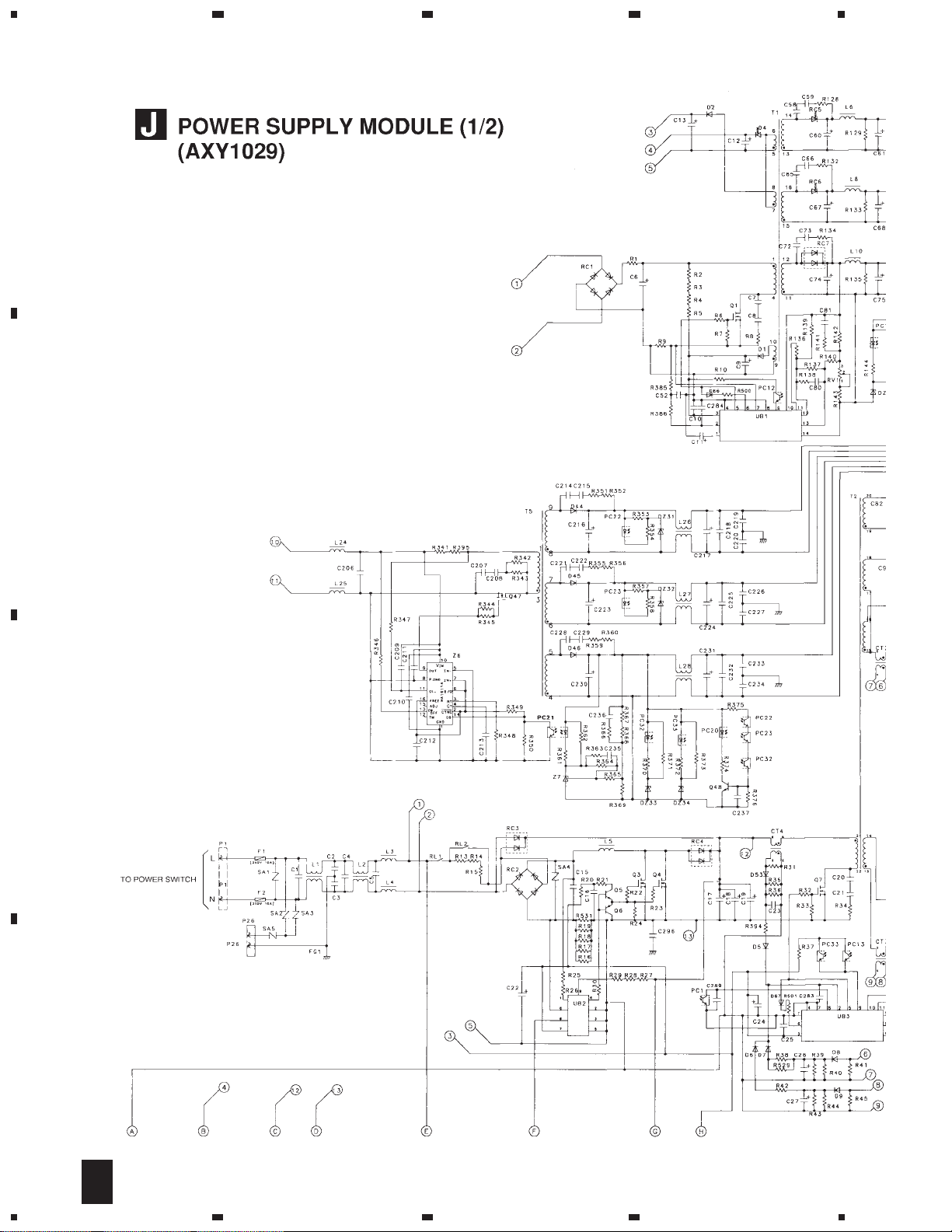

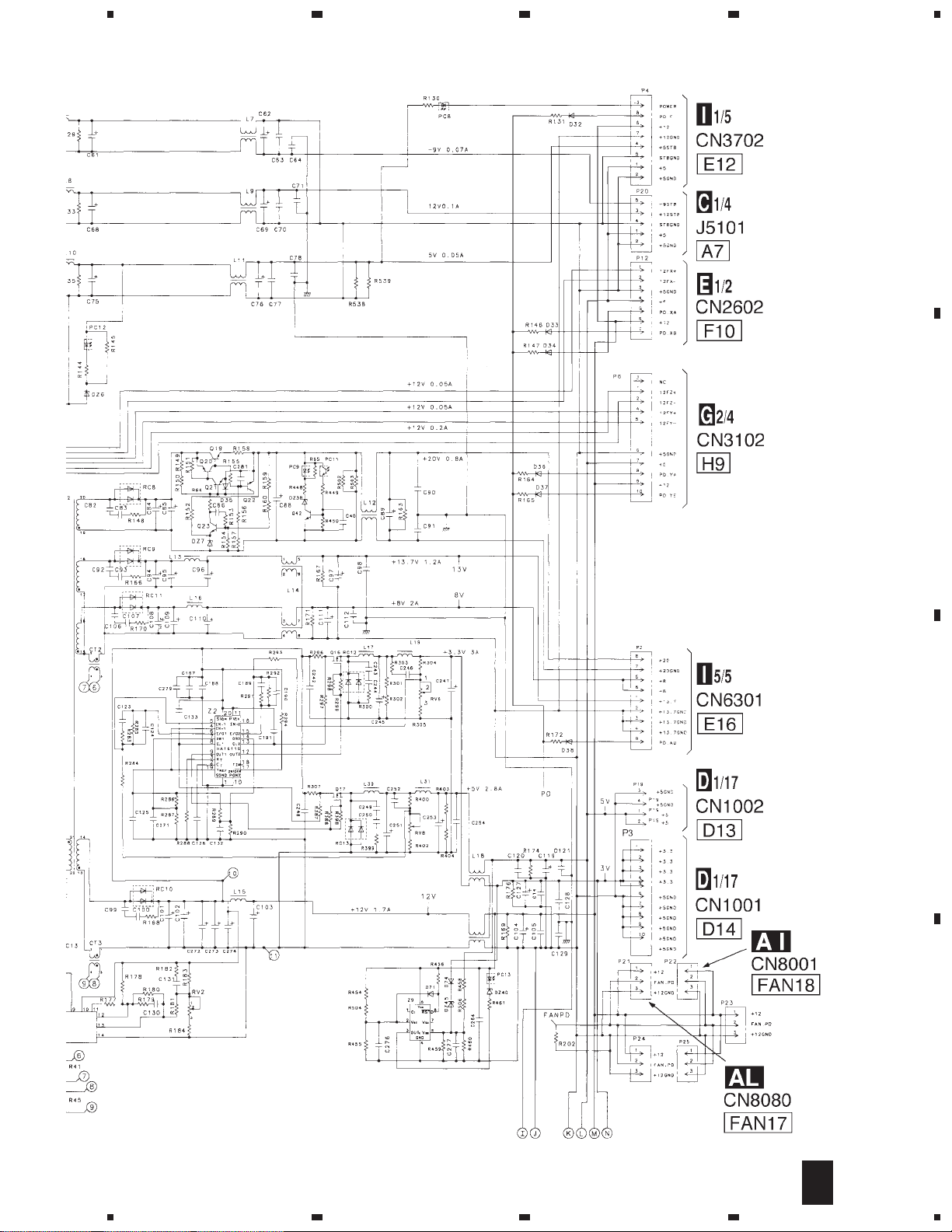

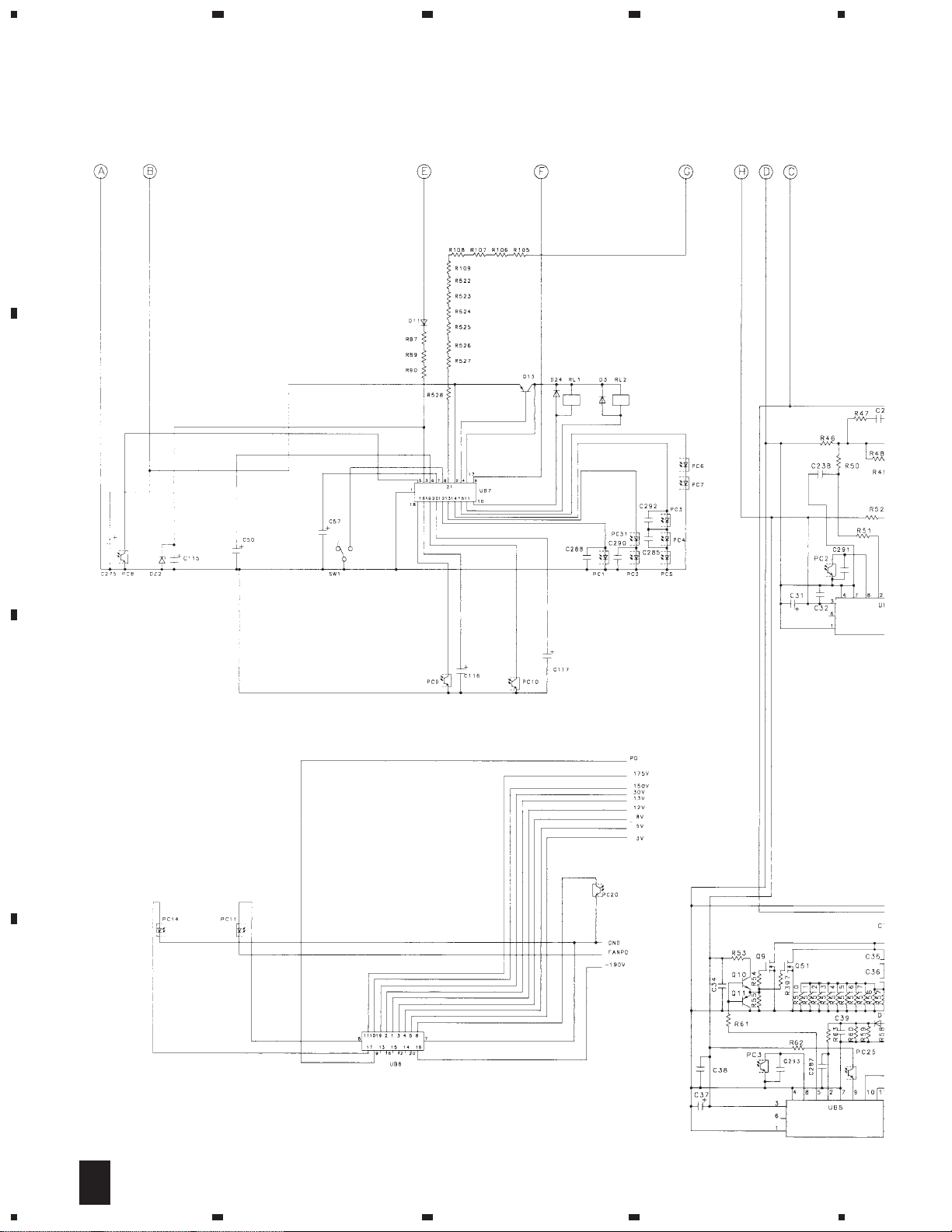

3.3 POWER SUPPLY MODULE (1/2)

A

B

4

C

D

J

16

1/2

1234

Page 17

5

678

PDP-501MX, PDP-V501X

A

B

5

6

J

7

C

D

17

1/2

8

Page 18

1

23

PDP-501MX, PDP-V501X

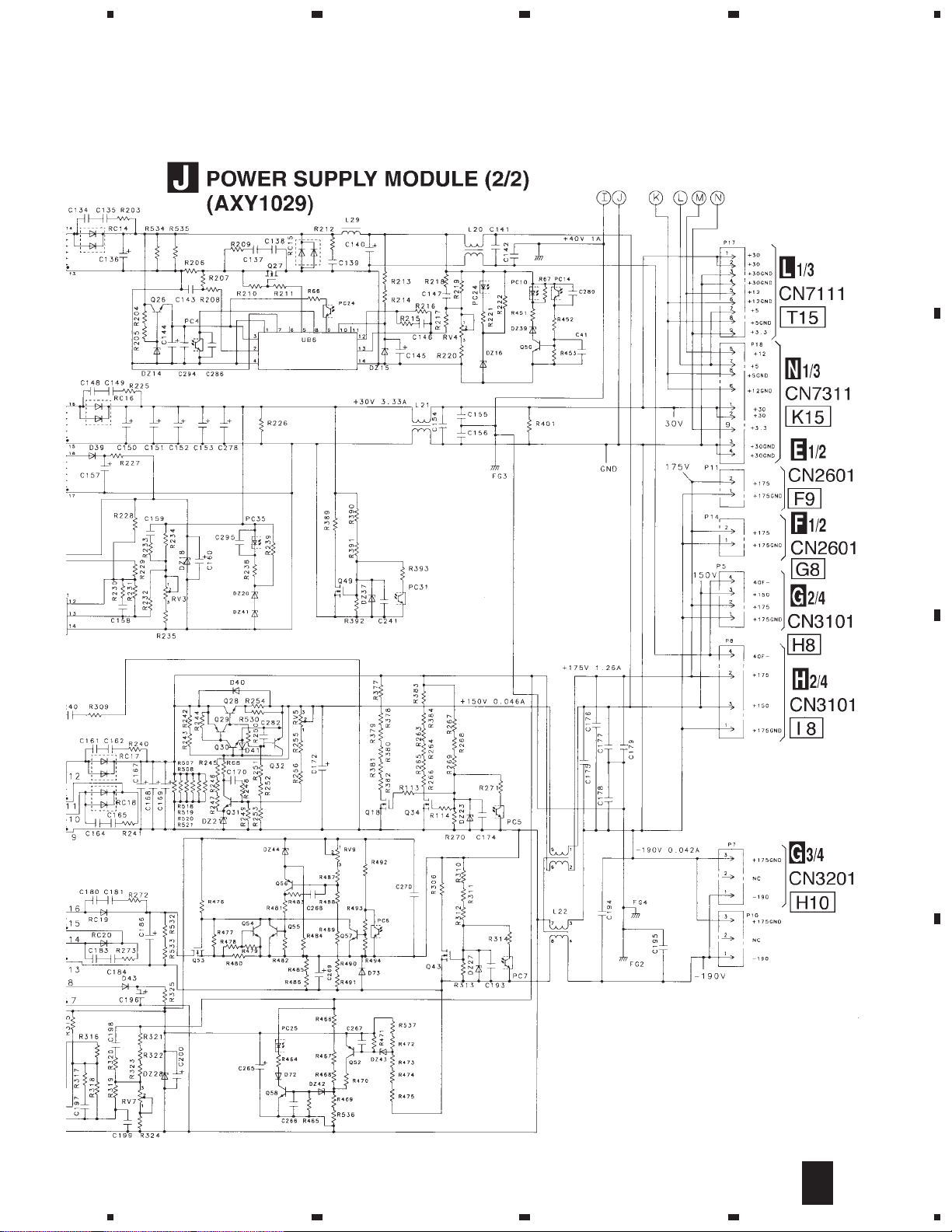

3.4 POWER SUPPLY MODULE (2/2)

A

B

4

C

D

18

J

2/2

1234

Page 19

5

678

PDP-501MX, PDP-V501X

A

B

5

6

J

7

C

D

19

2/2

8

Page 20

PDP-501MX ,PDP-V501X

4. PCB CONNECTION DIAGRAM

Mark No. Description Part No.

There is no information to be shown in this chapter.

5. PCB PARTS LIST

NOTES:

Mark No. Description Part No.

LIST OF ASSEMBLIES

NSP CONNECTOR ASS'Y AWV1647

NSP SCAN ASS'Y AWV1653

NSP PUMP UP ASSY AWV1656

NSP ANALOG VIDEO ASS'Y AWV1685

Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

When ordering resistors, first convert resistance values into code form as shown in the following examples.

Ex.1 When there are 2 effective digits (any digit apart from 0), such as 560 ohm and 47k ohm (tolerance is shown by J=5%,

and K=10%).

560

47k

0.5

1

56 x 10

47 x 103

R50

1R0

1

561

473

Ex.2 When there are 3 effective digits (such as in high precision metal film resistors).

5.62k RN1/4PC F562 x 10

DIGITAL VIDEO ASS'Y AWV1728

CABLE A ASS'Y AWZ6214

CABLE B ASS'Y AWZ6215

CABLE C ASS'Y AWZ6216

CABLE D ASS'Y AWZ6217

CABLE G ASS'Y AWZ6220

CABLE H ASS'Y AWZ6221

PROGRESSIVE BLOCK AWZ6222

IR RECEIVER ASS'Y AWZ6224

INDICAT OR ASS'Y AWZ6225

SCAN A ASS'Y AWZ6226

SCAN B ASS'Y AWZ6227

SCAN C ASS'Y AWZ6228

SCAN D ASS'Y AWZ6229

PUMP UP A ASSY AWZ6249

PUMP UP B ASSY AWZ6250

PUMP UP C ASSY AWZ6251

PUMP UP D ASSY AWZ6252

PUMP UP E ASSY AWZ6253

PUMP UP F ASSY AWZ6254

PUMP UP G ASSY AWZ6255

PUMP UP H ASSY AWZ6256

PUMP UP K ASSY AWZ6257

PUMP UP L ASSY AWZ6258

VIDEO ASS'Y AWZ6305

CONTROL ASS'Y AWZ6307

RGB ASS'Y AWV1687

U-CON ASS'Y AWV1689

1

5621

Mark No. Description Part No.

RD1/4PU J

RD1/4PU J

RN2H K

RS1P K

561

473

R50

1R0

5621

Mark No. Description Part No.

NSP X DRIVE A ASS'Y AWV1692

NSP X DRIVE B ASS'Y AWV1698

D

CABLE E ASS'Y AWZ6218

X DRIVE A ASS'Y AWZ6242

SENSER A ASSY AWZ6309

SENSER B ASSY AWZ6310

Y DRIVE A ASS'Y AWV1695

Y DRIVE A ASS'Y AWZ6321

DC FAN A ASSY AWZ6323

DC FAN B ASSY AWZ6324

Y DRIVE B ASS'Y AWV1696

Y DRIVE B ASS'Y AWZ6322

DC FAN C ASSY AWZ6325

DC FAN D ASSY AWZ6326

CABLE F ASS'Y AWZ6219

X DRIVE B ASS'Y AWZ6243

3D Y/C SEP. ASS'Y A WV1709

SIDE SWITCH A AWZ6315

3D Y/C SEP . ASS'Y AWZ6332

POWER SUPPLY MODULE AXY1029

DIGITAL VIDEO ASS'Y

SEMICONDUCTORS

IC1131,IC1151,IC1171 CXA3026Q

IC1242 CXA3106Q

IC1601 HD64F3048F16

IC1056 KIA431F

IC1301 PD4891B

IC1351 PD4892A

IC1401,IC1451,IC1501 PD4893B

IC1551 PD4894A

IC1271 PD5447A

IC1286 PDY038B

20

IC1603 PST9146N

IC1001-IC1004 TA78M05F

IC1901,IC1902,IC1951,IC1955-IC1957 TC74LCX541FT

IC1201,IC1221,IC1903-IC1906 TC74VHC541FT

IC1952-IC1954,IC2001-IC2010 TC74VHC541FT

Page 21

PDP-501MX, PDP-V501X

Mark No. Description Part No.

IC2101-IC2110 TC74VHC541FT

IC1046 TC74VHCT541AFT

IC1273 TC7SET00FU

IC1272 TC7SET08FU

IC1243,IC1244 TC7SH04FU

IC1651,IC1652 TC7W08FU

IC1604 TC7W14FU

IC1241 UPC78L05T

IC1701,IC1702,IC1751,IC1752 UPD481850GF-A12

IC1801,IC1802 UPD481850GF-A12

Q1072 ,Q1073 ,Q1082 ,Q1083 2SA1037K

Q1092 ,Q1093 2SA1037K

Q1071 ,Q1074 ,Q1081 ,Q1084 ,Q1091 2SC2412K

Q1094 ,Q1102 ,Q1103 ,Q1112 ,Q1113 2SC2412K

Q1122 ,Q1123 2SC2412K

D1601 -D1603 1SS352

D1901 AEL1171

COIL AND FILTERS

F1017 -F1020 ATF1184

F1551 -F1556 ,F1561 ,F1562 ATF1188

F1901 -F1908 ,F1951 -F1954 ATF1188

F2001 -F2010 ,F2101 -F2110 ATF1188

F1001 -F1014 ,F1241 ,F1242 ,F1921 ATF1189

F1971 ,F1972 ATF1189

SWITCH AND RELAY

S1601 ASG9003

CAP ACITORS

C1262 ,C1268 (0.33µF/16V) ACE1116

C1301 -C1310 ,C1351 -C1362

(1µF/16V) ACG1051

C1401 -C1412 ,C1451 -C1462

(1µF/16V) ACG1051

C1501 -C1512 ,C1551 -C1555

(1µF/16V) ACG1051

C1261 ,C1617 -C1621 CCSQCH101J50

C1203 -C1210 ,C1256 -C1258 ,C1264 CCSQCH220J50

C1276 -C1278 ,C1285 ,C1298 ,C1299 CCSQCH220J50

C1078 ,C1114 ,C1124 CCSQCH330J50

C1274 CCSQCH470J50

C1263 CCSQSL122J50

C1003 ,C1009 ,C1015 ,C1021 ,C1033 CEV101M6R3

C1037 ,C1056 ,C1057 ,C1133 ,C1145 CEV101M6R3

C1153 ,C1160 ,C1173 ,C1180 ,C1201 CEV101M6R3

C1243 ,C1245 ,C1254 ,C1271 ,C1289 CEV101M6R3

C1293 ,C1311 ,C1312 ,C1371 ,C1372 CEV101M6R3

C1421 ,C1422 ,C1471 ,C1472 CEV101M6R3

C1521 ,C1522 ,C1561 ,C1562 CEV101M6R3

C1631 ,C1632 ,C1721 -C1724 CEV101M6R3

C1771 -C1774 ,C1821 -C1824 CEV101M6R3

C1922 ,C1923 ,C1972 ,C1973 ,C1975 CEV101M6R3

C2021 ,C2022 ,C2121 ,C2122 CEV101M6R3

C1074 ,C1076 ,C1084 ,C1086 ,C1094 CEV1R0M50

C1096 ,C1275 ,C1606 CEV1R0M50

C1001 ,C1007 ,C1013 ,C1019 ,C1031 CEV221M10

C1035 ,C1240 CEV221M10

Mark No. Description Part No.

C1241 CEV470M16

C1602 CEV4R7M35

C1273 CFHSQ103J16

C1616 CKSQYB102K50

C1073 ,C1075 ,C1083 ,C1085 ,C1093 CKSQYB103K50

C1095 ,C1259 ,C1281 ,C1559 ,C1603 CKSQYB103K50

C1607 ,C1609 ,C1651 ,C1652 CKSQYB103K50

C1002 ,C1004 ,C1008 ,C1010 ,C1014 CKSQYF104Z25

C1016 ,C1020 ,C1022 ,C1032 ,C1034 CKSQYF104Z25

C1036 ,C1038 ,C1047 ,C1058 CKSQYF104Z25

C1063 ,C1064 ,C1071 ,C1072 CKSQYF104Z25

C1081 ,C1082 ,C1091 ,C1092 CKSQYF104Z25

C1102 ,C1103 ,C1112 ,C1113 CKSQYF104Z25

C1122 ,C1123 ,C1131 ,C1132 CKSQYF104Z25

C1134 -C1139 ,C1141 ,C1143 ,C1144 CKSQYF104Z25

C1146 ,C1151 ,C1152 ,C1154 -C1159 CKSQYF104Z25

C1161 ,C1163 ,C1164 ,C1166 CKSQYF104Z25

C1171 ,C1172 ,C1174 -C1179 ,C1181 CKSQYF104Z25

C1183 ,C1184 ,C1186 ,C1202 ,C1222 CKSQYF104Z25

C1242 ,C1244 ,C1246 -C1253 ,C1255 CKSQYF104Z25

C1260 ,C1266 ,C1267 ,C1272 ,C1279 CKSQYF104Z25

C1282 -C1284 ,C1287 ,C1288 CKSQYF104Z25

C1290 -C1292 ,C1294 ,C1296 ,C1297 CKSQYF104Z25

C1601 ,C1610 -C1613 ,C1701 -C1712 CKSQYF104Z25

C1751 -C1762 ,C1801 -C1812 CKSQYF104Z25

C1901 -C1906 ,C1921 ,C1951 -C1957 CKSQYF104Z25

C1971 ,C1974 ,C2001 -C2010 CKSQYF104Z25

C2101 -C2110 CKSQYF104Z25

RESISTORS

R1140 -R1143 ,R1160 -R1163 RA4C220J

R1180 -R1183 ,R1211 ,R1212 ,R1275 RA4C220J

R1201 ,R1202 ,R1213 ,R1214 RA4C470J

R1551 -R1558 ,R1561 -R1563 RA4C470J

R1901 -R1912 ,R1951 -R1958 RA4C470J

R1964 -R1967 ,R2001 -R2020 RA4C470J

R2101 -R2120 RA4C470J

R1278 RD1/4PU103J

R1295 RD1/4PU220J

R1059 ,R1061 ,R1271 RN1/10SE1001D

R1058 RN1/10SE1501D

R1060 RN1/10SE2001D

R1256 RN1/10SE2401D

R1257 RN1/10SE3301D

R1258 ,R1259 ,R1263 ,R1292 RS1/16S0R0J

R1311 -R1316 RS1/16S0R0J

R1021 ,R1248 ,R1252 -R1255 ,R1301 RS1/16S100J

R1351 ,R1559 RS1/16S100J

R1245 RS1/16S101J

R1203 -R1210 ,R1655 RS1/16S103J

R1246 ,R1609 RS1/16S104J

R1601 -R1603 ,R1617 RS1/16S123J

R1022 -R1027 ,R1241 -R1244 ,R1260 RS1/16S220J

R1262 ,R1272 ,R1273 ,R1287 -R1289 RS1/16S220J

R1921 RS1/16S221J

R1616 RS1/16S273J

R1922 RS1/16S331J

21

Page 22

PDP-501MX ,PDP-V501X

Mark No. Description Part No.

R1221 ,R1222 ,R1225 ,R1303 ,R1608 RS1/16S470J

R1620 -R1626 ,R1629 -R1632 ,R1634 RS1/16S470J

R1653 ,R1654 ,R1913 ,R1914 RS1/16S470J

R1959 -R1963 ,R1968 RS1/16S470J

R1223 ,R1604 -R1607 ,R1610 -R1615 RS1/16S472J

R1618 ,R1619 ,R1627 ,R1628 ,R1633 RS1/16S472J

R1635 -R1652 RS1/16S472J

Other Resistors RS1/10S&&&J

OTHERS

K1001 -K1022 ,K1025 -K1034 AKX9002

K1101 ,K1102 ,K1111 ,K1112 AKX9002

K1121 ,K1122 ,K1131 ,K1132 AKX9002

K1151 ,K1152 ,K1171 -K1173 AKX9002

K1201 -K1209 ,K1241 -K1253 AKX9002

K1261 -K1266 ,K1351 -K1357 ,K1401 AKX9002

K1451 ,K1501 ,K1551 -K1556 AKX9002

K1601 -K1606 ,K1951 -K1956 AKX9002

9102 ANK1517

X1552 (90.99MHz) ASS1131

CN1011 PLUG 30P KF050HA30L

CN1201,CN2201-CN2209

CN1001 PLUG 10P KM200NA10L

CN1002 PLUG 4P KM250MA4L

CN1602 PLUG 8P KM250MA8L

K

CABLE A ASS'Y

PLUG 50P KF050HA50L

SEMICONDUCTORS

IC7001,IC7002 TC74VHC541FT

IC7003-IC7008 TC74VHC574FT

COIL AND FILTERS

F7012 ,F7013 ATF1124

F7001 -F7009 ATF1188

L7001 -L7003 (100µH) ATH1065

CAPACITORS

C7010 ,C7011 CEHV101M16

C7013 -C7015 CEHV470M16

C7001 -C7009 ,C7012 CKSRYF104Z16

RESISTORS

R7001 -R7033 RA4C470J

OTHERS

K7001 -K7004 AKX9002

CN7056-CN7058 30P CONNECTOR KF050HA30L

CN7053-CN7055 40P CONNECTOR KF050HA40L

CN7052 30P CONNECTOR KF050HC30

CN7051 40P CONNECTOR KF050HC40

L

CABLE B ASS'Y

SEMICONDUCTORS

IC7121-IC7126 TC74VHC574FT

COIL AND FILTERS

F7130 ATF1124

F7141 -F7146 ATF1184

F7122 -F7127 ATF1188

L7101 -L7104 (100µH) ATH1065

Mark No. Description Part No.

CAPACITORS

C7104 ,C7128 CEHV101M16

C7129 -C7131 CEHV470M16

C7103 ,C7121 -C7127 CKSRYF104Z16

RESISTORS

R7121 -R7144 RA4C470J

Other Resistors RS1/10S&&&J

OTHERS

K7101 -K7103 AKX9002

CN7114-CN7116 30P CONNECTOR KF050HA30L

CN7105-CN7107 40P CONNECTOR KF050HA40L

CN7109,CN7110,CN7112,CN7113

CN7104 40P CONNECTOR KF050HC40

CN7101-CN7103 50P CONNECTOR KF050HC50

M

CABLE C ASS'Y

30P CONNECTOR KF050HC30

SEMICONDUCTORS

IC7201,IC7202 TC74VHC541FT

IC7203-IC7208 TC74VHC574FT

COIL AND FILTERS

F7210 ,F7212 ATF1124

F7201 -F7209 ATF1188

L7201 -L7203 (100µH) ATH1065

CAPACITORS

C7210 ,C7212 CEHV101M16

C7213 -C7215 CEHV470M16

C7201 -C7209 ,C7211 CKSRYF104Z16

RESISTORS

R7201 -R7233 RA4C470J

OTHERS

K7201 -K7204 AKX9002

CN7256-CN7258 30P CONNECTOR KF050HA30L

CN7252-CN7254 40P CONNECTOR KF050HA40L

CN7251 30P CONNECTOR KF050HC30

CN7255 40P CONNECTOR KF050HC40

N

CABLE D ASS'Y

SEMICONDUCTORS

IC7321-IC7326 TC74VHC574FT

COIL AND FILTERS

F7330 ATF1124

F7341 -F7346 ATF1184

F7322 -F7327 ATF1188

L7301 -L7304 (100µH) ATH1065

CAPACITORS

C7304 ,C7328 CEHV101M16

C7329 -C7331 CEHV470M16

C7303 ,C7321 -C7327 CKSRYF104Z16

RESISTORS

R7321 -R7344 RA4C470J

Other Resistors RS1/10S&&&J

OTHERS

K7301 -K7303 AKX9002

CN7314-CN7316 30P CONNECTOR KF050HA30L

CN7305-CN7307 40P CONNECTOR KF050HA40L

CN7309,CN7310,CN7312,CN7313

30P CONNECTOR KF050HC30

22

Page 23

PDP-501MX, PDP-V501X

Mark No. Description Part No.

CN7304 40P CONNECTOR KF050HC40

CN7301-CN7303 50P CONNECTOR KF050HC50

Q

CABLE G ASS'Y

SEMICONDUCTORS

IC2762,IC2763 TC74VHC541FT

IC2764-IC2767 TC74VHC574FT

COIL AND FILTERS

F2767 ,F2768 ATF1124

F2761 -F2766 ATF1188

L2761 ,L2762 (100µH) ATH1065

CAPACITORS

C2782 ,C2784 CEHV101M16

C2785 ,C2786 CEHV470M16

C2781 ,C2783 CKSQYF104Z50

C2768 -C2773 CKSRYF104Z16

RESISTORS

R2767 -R2788 RA4C470J

OTHERS

K2761 -K2763 AKX9002

CN2765,CN2766 30P CONNECTOR KF050HA30L

CN2761,CN2763 40P CONNECTOR KF050HA40L

CN2762,CN2764 30P CONNECTOR KF050HC30

R

CABLE H ASS'Y

SEMICONDUCTORS

IC7601,IC7602 TC74VHC541FT

IC7603-IC7606 TC74VHC574FT

COIL AND FILTERS

F7601 ,F7608 ATF1124

F7602 -F7607 ATF1188

L7601 ,L7602 (100µH) ATH1065

CAPACITORS

C7601 ,C7611 CEHV101M16

C7609 ,C7610 CEHV470M16

C7602 ,C7612 CKSQYF104Z50

C7603 -C7608 CKSRYF104Z16

RESISTORS

R7601 -R7622 RA4C470J

OTHERS

K7601 -K7603 AKX9002

CN7605,CN7606 30P CONNECTOR KF050HA30L

CN7602,CN7603 40P CONNECTOR KF050HA40L

CN7601,CN7604 30P CONNECTOR KF050HC30

SCAN ASS'Y

CAPACITORS

C2553 CEAS220M50

Mark No. Description Part No.

IC4719 SAA4990H

IC4702 SAA7165WP

IC4718 TC74HC4066AF

IC4714 TC74HCT04AF

IC4716 TC74HCT08AF

IC4703 TDA8755T

IC4705,IC4706 TMS4C2973-26

IC4707,IC4708 UPC29L33T

IC4709-IC4711 UPC78L05T

Q4707 ,Q4709 2SA1037K

Q4704 ,Q4706 ,Q4712 2SA1162

Q4701 ,Q4703 ,Q4705 ,Q4711 2SC2712

D4706 ,D4712 1SS352

D4705 ,D4711 1SV232

COIL AND FILTERS

F4703 ,F4704 ATF1124

F4701 ATF1186

L4706 ATG1060

F4715 ATG1063

L4704 ,L4705 ,L4710 ,L4713 ,L4714 LCTA100J3225

L4707 -L4709 LCTA1R5J3225

L4712 LCTA1R8J3225

L4701 ,L4702 LCTA221J3225

CAPACITORS

C4771 ,C4773 ,C4774 ,C4776 ,C4778 CCSQCH121J50

C4780 CCSQCH121J50

C4721 ,C4772 ,C4775 ,C4779 CCSQCH150J50

C4731 ,C4732 ,C4805 CCSQCH220J50

C4704 ,C4706 ,C4718 ,C4719 CCSQCH221J50

C4761 ,C4762 CCSQCH221J50

C4746 CCSQCH270J50

C4747 ,C4760 CCSQCH331J50

C4730 CCSQCH390J50

C4748 ,C4749 CCSQCH680J50

C4811 CCSQCH8R0D50

C4702 ,C4703 ,C4715 ,C4717 ,C4765 CEV100M16

C4810 ,C4816 ,C4817 CEV100M16

C4785 ,C4787 ,C4789 ,C4791 ,C4812 CEV220M16

C4814 ,C4819 CEV220M16

C4711 CEV2R2M50

C4701 ,C4777 CEV470M6R3

C4705 ,C4707 ,C4744 CEV4R7M35

C4763 CKSQYB272K50

C4712 ,C4713 CKSQYB333K50

C4708 ,C4710 ,C4743 ,C4764 ,C4806 CKSQYF103Z50

C4709 ,C4714 ,C4716 ,C4720 ,C4722 CKSQYF104Z50

C4725 -C4729 ,C4750 ,C4752 -C4756 CKSQYF104Z50

C4759 ,C4766 -C4770 ,C4781 -C4784 CKSQYF104Z50

C4786 ,C4788 ,C4790 ,C4792 -C4800 CKSQYF104Z50

B

PROGRESSIVE BLOCK

SEMICONDUCTORS

IC4713 CD74HCT4046AM

IC4722 M51952BML

IC4720 PE6001A9

IC4701 PST9146N

IC4704 SAA4952WP

C4804 ,C4808 ,C4809 ,C4813 ,C4815 CKSQYF104Z50

C4818 CKSQYF104Z50

C4742 CKSQYF473Z50

RESISTORS

Other Resistors RS1/10S&&&J

OTHERS

K4701 -K4703 AKX9002

X4701 (12MHz) ASS1133

23

Page 24

PDP-501MX ,PDP-V501X

Mark No. Description Part No.

AG

IR RECEIVER ASS'Y

SEMICONDUCTORS

IC2551 SBX8035-H

Q2551 2SC2712

D2553 1SS352

CAPACITORS

C2554 CKSRYB472K50

C2551 CKSRYF104Z16

RESISTORS

R2564 RS1/16S101J

R2561 ,R2562 RS1/16S223J

R2563 RS1/16S472J

AH

INDICATOR ASS'Y

SEMICONDUCTORS

D2552 AEL1170

OTHERS

J2553 D15A03-950-2651

S

SCAN A ASS'Y

SEMICONDUCTORS

IC7702,IC7703,IC7705-IC7708 HCPL-M611

IC7701 ICL7667CBA

IC7709-IC7711 SN755862PJA

IC7704 UPC78L05T

Q7701 ,Q7702 2SK2518

COIL AND FILTERS

L7701 VTL1007

CAPACIT ORS

C7718 -C7721 ,C7727 -C7730

C7736 -C7739 (0.1µF/250V) ACG1059

C7704 ,C7707 ,C7709 ,C7711 ,C7713 CCSQCH220J50

C7722 -C7726 ,C7731 -C7735 CCSQCH220J50

C7702 CCSQCH470J50

C7717 CEHAQ100M2D

C7715 CEHV101M16

C7705 CEHV470M16

C7701 ,C7703 ,C7706 ,C7708 ,C7710 CKSQYF104Z50

C7712 ,C7714 ,C7716 ,C7740 -C7746 CKSQYF104Z50

(0.1µF/250V) ACG1059

RESISTORS

Other Resistors RS1/10S&&&J

OTHERS

CN7701 30P CONNECTOR KF050HC30

T

SCAN B ASS'Y

SEMICONDUCTORS

IC7802,IC7803,IC7805-IC7808 HCPL-M611

IC7801 ICL7667CBA

IC7809-IC7811 SN755862PJA

IC7804 UPC78L05T

Q7801 ,Q7802 2SK2518

COIL AND FILTERS

L7801 VTL1007

Mark No. Description Part No.

CAP ACITORS

C7818 -C7821 ,C7827 -C7830

C7836 -C7839 (0.1µF/250V) ACG1059

C7804 ,C7807 ,C7809 ,C7811 ,C7813 CCSQCH220J50

C7822 -C7826 ,C7831 -C7835 CCSQCH220J50

C7802 CCSQCH470J50

C7817 CEHAQ100M2D

C7815 CEHV101M16

C7805 CEHV470M16

C7801 ,C7803 ,C7806 ,C7808 ,C7810 CKSQYF104Z50

C7812 ,C7814 ,C7816 ,C7840 -C7846 CKSQYF104Z50

(0.1µF/250V) ACG1059

RESISTORS

Other Resistors RS1/10S&&&J

OTHERS

CN7801 30P CONNECTOR KF050HC30

U

SCAN C ASS'Y

SEMICONDUCTORS

IC7902,IC7903,IC7905-IC7908 HCPL-M611

IC7901 ICL7667CBA

IC7909-IC7911 SN755862PJA

IC7904 UPC78L05T

Q7901 ,Q7902 2SK2518

COIL AND FILTERS

L7901 VTL1007

CAP ACITORS

C7918 -C7921 ,C7927 -C7930

C7936 -C7939 (0.1µF/250V) ACG1059

C7904 ,C7907 ,C7909 ,C7911 ,C7913 CCSQCH220J50

C7922 -C7926 ,C7931 -C7935 CCSQCH220J50

C7902 CCSQCH470J50

C7917 CEHAQ100M2D

C7915 CEHV101M16

C7905 CEHV470M16

C7901 ,C7903 ,C7906 ,C7908 ,C7910 CKSQYF104Z50

C7912 ,C7914 ,C7916 ,C7940 -C7946 CKSQYF104Z50

(0.1µF/250V) ACG1059

RESISTORS

Other Resistors RS1/10S&&&J

OTHERS

CN7901 30P CONNECTOR KF050HC30

V

SCAN D ASS'Y

SEMICONDUCTORS

IC8702,IC8703,IC8705-IC8708 HCPL-M611

IC8701 ICL7667CBA

IC8709-IC8711 SN755862PJA

IC8704 UPC78L05T

Q8701 ,Q8702 2SK2518

COIL AND FILTERS

L8701 VTL1007

CAP ACITORS

C8718 -C8721 ,C8727 -C8730

C8736 -C8739 (0.1µF/250V) ACG1059

C8704 ,C8707 ,C8709 ,C8711 ,C8713 CCSQCH220J50

(0.1µF/250V) ACG1059

24

Page 25

PDP-501MX, PDP-V501X

Mark No. Description Part No.

C8722 -C8726 ,C8731 -C8735 CCSQCH220J50

C8702 CCSQCH470J50

C8717 CEHAQ100M2D

C8715 CEHV101M16

C8705 CEHV470M16

C8701 ,C8703 ,C8706 ,C8708 ,C8710 CKSQYF104Z50

C8712 ,C8714 ,C8716 ,C8740 -C8746 CKSQYF104Z50

RESISTORS

Other Resistors RS1/10S&&&J

OTHERS

CN8701 30P CONNECTOR KF050HC30

W

PUMP UP A ASSY

SEMICONDUCTORS

IC8151 ICL7667CBA

IC8152 ICP-S1.0

Q8151 2SJ327-Z

Q8152 2SK2796S

D8151 D1FL20U

CAPACITORS

C8154 ,C8155 CCSQCH221J50

C8152 CEHAQ101M63

C8151 CFTXA474J50

C8153 CKSQYF103Z50

C8156 CKSQYF104Z50

RESISTORS

R8151 -R8154 RS2MMF180J

Other Resistors RS1/10S&&&J

OTHERS

CN8152 AKM1141

K8151 -K8155 AKX9002

CN8151 30P CONNECTOR KF050HA30L

X

PUMP UP B ASSY

SEMICONDUCTORS

IC8201 ICL7667CBA

IC8202 ICP-S1.0

Q8201 2SJ327-Z

Q8202 2SK2796S

D8201 D1FL20U

CAPACITORS

C8204 ,C8205 CCSQCH221J50

C8202 CEHAQ101M63

C8201 CFTXA474J50

C8203 CKSQYF103Z50

C8206 CKSQYF104Z50

RESISTORS

R8201 -R8204 RS2MMF180J

Other Resistors RS1/10S&&&J

OTHERS

CN8202 AKM1141

K8201 -K8205 AKX9002

CN8201 30P CONNECTOR KF050HA30L

Y

PUMP UP C ASSY

SEMICONDUCTORS

IC8251 ICL7667CBA

Mark No. Description Part No.

IC8252 ICP-S1.0

Q8251 2SJ327-Z

Q8252 2SK2796S

D8251 D1FL20U

CAPACITORS

C8254 ,C8255 CCSQCH221J50

C8252 CEHAQ101M63

C8251 CFTXA474J50

C8253 CKSQYF103Z50

C8256 CKSQYF104Z50

RESISTORS

R8251 -R8254 RS2MMF180J

Other Resistors RS1/10S&&&J

OTHERS

CN8252 AKM1141

K8252 -K8255 AKX9002

CN8251 30P CONNECTOR KF050HA30L

Z

PUMP UP D ASSY

SEMICONDUCTORS

IC8301 ICL7667CBA

IC8302 ICP-S1.0

Q8301 2SJ327-Z

Q8302 2SK2796S

D8301 D1FL20U

CAPACITORS

C8304 ,C8305 CCSQCH221J50

C8302 CEHAQ101M63

C8301 CFTXA474J50

C8303 CKSQYF103Z50

C8306 CKSQYF104Z50

RESISTORS

R8301 -R8304 RS2MMF180J

Other Resistors RS1/10S&&&J

OTHERS

CN8302 AKM1141

K8301 -K8305 AKX9002

CN8301 30P CONNECTOR KF050HA30L

AA

PUMP UP E ASSY

SEMICONDUCTORS

IC8351 ICL7667CBA

IC8352 ICP-S1.0

Q8351 2SJ327-Z

Q8352 2SK2796S

D8351 D1FL20U

CAPACITORS

C8354 ,C8355 CCSQCH221J50

C8352 CEHAQ101M63

C8351 CFTXA474J50

C8353 CKSQYF103Z50

C8356 CKSQYF104Z50

RESISTORS

R8351 -R8354 RS2MMF180J

Other Resistors RS1/10S&&&J

OTHERS

CN8352 AKM1141

K8352 -K8355 AKX9002

CN8351 30P CONNECTOR KF050HA30L

25

Page 26

PDP-501MX ,PDP-V501X

Mark No. Description Part No.

AB

PUMP UP F ASSY

SEMICONDUCTORS

IC8401 ICL7667CBA

IC8402 ICP-S1.0

Q8401 2SJ327-Z

Q8402 2SK2796S

D8401 D1FL20U

CAPACITORS

C8404 ,C8405 CCSQCH221J50

C8402 CEHAQ101M63

C8401 CFTXA474J50

C8403 CKSQYF103Z50

C8406 CKSQYF104Z50

RESISTORS

R8401 -R8404 RS2MMF180J

Other Resistors RS1/10S&&&J

OTHERS

CN8402 AKM1141

K8401 -K8405 AKX9002

CN8401 30P CONNECTOR KF050HA30L

AC

PUMP UP G ASSY

SEMICONDUCTORS

IC8451 ICL7667CBA

IC8452 ICP-S1.0

Q8451 2SJ327-Z

Q8452 2SK2796S

D8451 D1FL20U

CAPACITORS

C8454 ,C8455 CCSQCH221J50

C8452 CEHAQ101M63

C8451 CFTXA474J50

C8453 CKSQYF103Z50

C8456 CKSQYF104Z50

RESISTORS

R8451 -R8454 RS2MMF180J

Other Resistors RS1/10S&&&J

OTHERS

CN8452 AKM1141

K8451 -K8455 AKX9002

CN8451 30P CONNECTOR KF050HA30L

AD

PUMP UP H ASSY

SEMICONDUCTORS

IC8501 ICL7667CBA

IC8502 ICP-S1.0

Q8501 2SJ327-Z

Q8502 2SK2796S

D8501 D1FL20U

CAPACITORS

C8504 ,C8505 CCSQCH221J50

C8502 CEHAQ101M63

C8501 CFTXA474J50

C8503 CKSQYF103Z50

C8506 CKSQYF104Z50

RESISTORS

R8501 -R8504 RS2MMF180J

Mark No. Description Part No.

Other Resistors RS1/10S&&&J

OTHERS

CN8502 AKM1141

K8501 -K8505 AKX9002

CN8501 30P CONNECTOR KF050HA30L

AE

PUMP UP K ASSY

SEMICONDUCTORS

IC8551 ICL7667CBA

IC8552 ICP-S1.0

Q8551 2SJ327-Z

Q8552 2SK2796S

D8551 D1FL20U

CAPACITORS

C8554 ,C8555 CCSQCH221J50

C8552 CEHAQ101M63

C8551 CFTXA474J50

C8553 CKSQYF103Z50

C8556 CKSQYF104Z50

RESISTORS

R8551 -R8554 RS2MMF180J

Other Resistors RS1/10S&&&J

OTHERS

CN8552 AKM1141

K8551 -K8555 AKX9002

CN8551 30P CONNECTOR KF050HA30L

AF

PUMP UP L ASSY

SEMICONDUCTORS

IC8601 ICL7667CBA

IC8602 ICP-S1.0

Q8601 2SJ327-Z

Q8602 2SK2796S

D8601 D1FL20U

CAPACITORS

C8604 ,C8605 CCSQCH221J50

C8602 CEHAQ101M63

C8601 CFTXA474J50

C8603 CKSQYF103Z50

C8606 CKSQYF104Z50

RESISTORS

R8601 -R8604 RS2MMF180J

Other Resistors RS1/10S&&&J

OTHERS

CN8602 AKM1141

K8601 -K8605 AKX9002

CN8601 30P CONNECTOR KF050HA30L

A

VIDEO ASS'Y

SEMICONDUCTORS

IC9003,IC9504 BA7655AF

IC9205 CXA1875AM

IC4502,IC4503 MC14577CF

IC4501 NJM2234M

IC9961 PA0030

IC9001 TA8759BN

26

Page 27

PDP-501MX, PDP-V501X

Mark No. Description Part No.

IC4101 TC4052BF

IC4102,IC9502 TC4053BF

IC9505 TC74ACT541FS

IC9503,IC9801 TC74HC4053AF

IC9002,IC9507 TC74HC4538AF

IC9501 TDA4566

IC9506 UPC1862GS

Q4104 ,Q4123 ,Q4137 ,Q4520 ,Q9008 2SA1037K

Q9522 ,Q9523 ,Q9542 ,Q9544 ,Q9547 2SA1037K

Q9551 ,Q9552 ,Q9801 -Q9803 ,Q9844 2SA1037K

Q9858 ,Q9874 ,Q9895 ,Q9912 2SA1037K

Q9921 -Q9923 ,Q9926 ,Q9941 ,Q9944 2SA1037K

Q4106 ,Q4108 -Q4111 ,Q4113 2SC2412K

Q4115 ,Q4116 ,Q4121 ,Q4124 ,Q4127 2SC2412K

Q4129 -Q4132 ,Q4134 ,Q4511 -Q4513 2SC2412K

Q4521 ,Q9003 -Q9006 ,Q9009 -Q9014 2SC2412K

Q9101 ,Q9102 ,Q9501 ,Q9503 -Q9507 2SC2412K

Q9509 -Q9521 ,Q9525 -Q9527 2SC2412K

Q9530 -Q9536 ,Q9538 -Q9541 ,Q9543 2SC2412K

Q9545 ,Q9546 ,Q9548 -Q9550 ,Q9821 2SC2412K

Q9823 -Q9825 ,Q9841 -Q9843 2SC2412K

Q9855 -Q9857 ,Q9871 -Q9873 ,Q9911 2SC2412K

Q9913 ,Q9942 ,Q9943 ,Q9945 ,Q9946 2SC2412K

Q9971 2SC2412K

Q4114 2SK208

Q4509 ,Q9508 ,Q9524 ,Q9528 ,Q9529 DTC124EK

Q9972 ,Q9973 DTC124EK

D4105 -D4107 ,D4502 -D4508 1SS226

D9208 ,D9209 1SS226

D4102 ,D4523 ,D9001 ,D9002 ,D9004 1SS352

D9501 -D9504 ,D9801 ,D9841 1SS352

D9003 RD5.1MB

COIL AND FILTERS

F4108 ,F9202 ,F9501 -F9508 ATF1124

F4101 -F4107 ATF1128

DL9941,DL9942 ATN1029

L4109 ,L9962 LCTA100J3225

L4107 LCTA101J3225

L4106 LCTA120J3225

L4108 LCTA150J3225

L9006 ,L9007 LCTA270J3225

L4110 LCTA3R9J3225

L9963 ,L9964 LCTA4R7J3225

L9961 LCTA5R6J3225

L4105 ,L9855 ,L9871 LCTA6R8J3225

CAPACITORS

C9056 ,C9579 (0.22µF/16) ACE9008

C9554 ,C9963 -C9965 ,C9967 CCSQCH100D50

C9061 CCSQCH101J50

C9563 ,C9586 CCSQCH102J50

C9004 CCSQCH120J50

C4111 ,C4122 CCSQCH121J50

C9961 CCSQCH150J50

C4129 CCSQCH151J50

C9005 CCSQCH181J50

Mark No. Description Part No.

C9941 CCSQCH220J50

C4110 ,C9030 ,C9032 ,C9055 ,C9555 CCSQCH221J50

C9561 CCSQCH221J50

C9576 ,C9855 ,C9871 ,C9962 CCSQCH330J50

C9003 ,C9577 CCSQCH390J50

C9553 CCSQCH470J50

C9049 ,C9050 CCSQCH471J50

C9856 ,C9872 CCSQCH560J50

C4123 ,C9029 ,C9031 CCSQCH680J50

C4109 CCSQCH821J50

C4112 CCSQSL122J50

C9560 CCSQSL152J50

C9578 CCSQSL1R0C50

C9565 CCSQSL222J50

C9966 CEAS100M50

C4107 ,C4115 ,C4116 ,C4522 CEV100M16

C9039 CEV100M50

C9518 ,C9971 CEV101M16

C4514 ,C4517 ,C9225 ,C9583 CEV101M6R3

C9057 ,C9564 ,C9566 ,C9569 CEV1R0M50

C4501 ,C4502 ,C4511 ,C4526 ,C9065 CEV220M16

C9502 ,C9505 -C9507 ,C9511 ,C9512 CEV220M16

C9544 ,C9545 ,C9570 ,C9896 CEV220M16

C4121 ,C9102 ,C9103 ,C9230 CEV220M6R3

C9534 -C9536 ,C9547 ,C9550 ,C9552 CEV220M6R3

C9592 -C9594 ,C9822 -C9824 ,C9913 CEV220M6R3

C9925 CEV220M6R3

C4108 ,C4117 CEV330M10

C9969 CEV330M25

C4118 ,C4127 ,C4131 ,C4506 ,C4525 CEV470M16

C9023 ,C9025 ,C9047 ,C9503 ,C9509 CEV470M16

C9514 ,C9516 ,C9522 ,C9537 ,C9539 CEV470M16

C9541 ,C9590 ,C9801 ,C9804 ,C9806 CEV470M16

C9858 ,C9891 ,C9911 ,C9943 CEV470M16

C4518 ,C4527 ,C9069 ,C9520 ,C9524 CEV470M6R3

C9526 ,C9528 ,C9530 ,C9532 ,C9548 CEV470M6R3

C9551 ,C9567 ,C9573 ,C9574 ,C9588 CEV470M6R3

C4523 ,C9559 ,C9580 CEV4R7M35

C9067 ,C9068 ,C9843 ,C9857 ,C9873 CEVNP100M16

C9916 CEVNP100M16

C9058 CEVNP1R0M50

C9007 CEVNP2R2M50

C9026 ,C9582 CEVR47M50

C9043 CFHS223J16

C9045 CFHSP104J16

C9011 ,C9012 ,C9059 CFHSP563J16

C4532 ,C9006 ,C9044 ,C9581 ,C9587 CFHSQ103J16

C9046 CFHSQ472J16

C9037 CKSQYB102K50

C4106 ,C4119 ,C4128 ,C4132 CKSQYB103K50

C4134 ,C4135 ,C4139 ,C4505 ,C4513 CKSQYB103K50

C4515 ,C4516 ,C4524 ,C4530 ,C4531 CKSQYB103K50

C4534 ,C9010 ,C9015 ,C9033 ,C9038 CKSQYB103K50

C9051 ,C9054 ,C9062 -C9064 CKSQYB103K50

27

Page 28

PDP-501MX ,PDP-V501X

Mark No. Description Part No.

C9070 -C9072 ,C9101 ,C9519 ,C9521 CKSQYB103K50

C9523 ,C9525 ,C9556 ,C9557 ,C9562 CKSQYB103K50

C9571 ,C9585 ,C9802 ,C9805 ,C9807 CKSQYB103K50

C9821 ,C9841 ,C9842 ,C9844 ,C9859 CKSQYB103K50

C9892 ,C9912 ,C9923 ,C9942 ,C9968 CKSQYB103K50

C9972 -C9976 CKSQYB103K50

C4113 CKSQYB392K50

C9213 CKSQYF102Z50

C9226 ,C9231 ,C9504 ,C9508 ,C9510 CKSQYF103Z50

C9513 ,C9515 ,C9517 ,C9527 ,C9529 CKSQYF103Z50

C9531 ,C9533 ,C9538 ,C9540 CKSQYF103Z50

C9542 ,C9543 ,C9549 ,C9558 ,C9568 CKSQYF103Z50

C9572 ,C9575 ,C9584 ,C9589 ,C9591 CKSQYF103Z50

C9770 ,C9771 CKSQYF103Z50

C4504 ,C9024 ,C9034 -C9036 CKSQYF104Z50

C9040 -C9042 ,C9048 ,C9066 ,C9501 CKSQYF104Z50

C9803 CKSQYF104Z50

C4519 CKSQYF473Z50

RESISTORS

R9988 ,R9989 RD1/4PU471J

R4232 ,R4233 RD1/4PU681J

R9113 RD1/4PU821J

R9713 RN1/10SE8202D

VR9005 VRTS6VS102

VR9002-VR9004 VRTS6VS103

Other Resistors RS1/10S&&&J

OTHERS

CN4502 PIN JACK(3P-AU) AKB1270

JA4503 JACK AKB7096

CN4505 SIN SOCKET AKP1175

CN4504 CONNECTOR AKX1051

K4501 ,K4502 ,K9502 ,K9921 ,K9924 AKX9002

K9961 ,K9971 -K9973 AKX9002

X9003 (503kHz) ASS1019

X9502 CRYSTAL (14.31818MHz) ASS1056

X9002 CRYSTAL (3.579545MHz) ASS1091

X9501 (503kHz) ASS1112

CN9501 50P CONNECTOR KF050HA50L

CN4107 PLUG 12P KM250MA13

CN4102 PLUG 6P KM250MA6

CN9502 PLUG 8P KM250MA8B

CN4101 PLUG 9P KM250MA9

5001 SCREW TERMINAL VNE1949

AO

CONTROL ASS'Y

SEMICONDUCTORS

IC3401 MC145407F

IC3402 TC74HC00AF

Q3405 ,Q3409 ,Q3411 2SA1162

Q3404 ,Q3406 -Q3408 ,Q3410 2SC2712

D3401 ,D3402 ,D3416 -D3418 1SS352

D3404 -D3411 RD15MB

Mark No. Description Part No.

SWITCHES AND RELAYS

S3401 ASH1010

CAP ACITORS

C3404 ,C3406 ,C3409 ,C3410 CEV100M35

C3403 ,C3408 ,C3412 CEV470M16

C3405 ,C3407 ,C3411 CKSQYB103K50

C3402 CKSQYB472K50

RESISTORS

Other Resistors RS1/10S&&&J

OTHERS

CN3401,CN3402JACK AKN-207

CN3403 SOCKET (9P D-SUB)AKP1171

CN3406,CN3407 6P MINIDIN SOCKETAKP1183

CN3404 PLUG 3P KM250MA3

3401 SCREW TERMINAL VNE1949

C

RGB ASS'Y

SEMICONDUCTORS

IC5102 24LCS21A

IC6001 AN5390FBS

IC6002 AN5395FBP

IC5101,IC5802,IC6003 BA7657F

IC5109 L T1260CS

IC5307 M52036SP

IC5801 M52337SP

IC5805 M62358FP

IC6145 NJM072BM-E

IC5112 NJM2234M

IC5103-IC5106 NJM360M

IC5301 PDY052A

IC5310 PE1007A

IC6005 PQ20VZ1U

IC5107,IC5309,IC6006 TA78M05F

IC5108 TA79L05F

IC6004 TC74HC4066AF

IC5312 TC74HC4538AFS

IC5311 TC74VHC123AFT

IC5111,IC5302,IC5303,IC5306,IC5308 TC74VHCT541AFT

IC5803 TC74VHCT541AFT

IC5304 TC74VHCU04FS

IC5804 TC7S32F

Q5118 ,Q5120 ,Q5127 ,Q5132 ,Q5134 2SA1037K

Q5136 ,Q5155 -Q5158 ,Q5282 ,Q5302 2SA1037K

Q5808 -Q5810 ,Q5825 -Q5827 2SA1037K

Q5954 -Q5956 ,Q6008 ,Q6010 -Q6019 2SA1037K

Q6146 ,Q6148 2SA1037K

Q5103 ,Q5106 ,Q5117 ,Q5119 2SC2412K

Q5125 ,Q5126 ,Q5128 ,Q5131 ,Q5133 2SC2412K

Q5135 ,Q5303 ,Q5304 ,Q5801 2SC2412K

Q5804 -Q5807 ,Q5811 ,Q5814 -Q5818 2SC2412K

Q5821 -Q5824 ,Q6001 -Q6007 ,Q6009 2SC2412K

Q6147 ,Q6149 2SC2412K

Q5123 ,Q5301 ,Q5305 DTC124EK

Q5283 FS30AS-06

D5108 ,D5802 -D5805 ,D5807 ,D5808 1SS184

28

Page 29

PDP-501MX, PDP-V501X

Mark No. Description Part No.

D5103 ,D5105 ,D5106 ,D5109 -D5111 1SS226

D5113 -D5120 ,D5125 -D5130 1SS226

D6003 ,D6004 1SS226

D5102 ,D5104 ,D5121 ,D5122 1SS352

D5303 -D5306 ,D5806 ,D6145 1SS352

D6148 ,D6149 HSS104-02

D6005 ,D6006 RD10MB

D5112 ,D6001 RD6.8MB

COIL AND FILTERS

F5301 -F5304 ATF1116

F5803 -F5805 ,F6001 -F6007 ATF1124

L5101 -L5104 LCTA470J3225

L6002 LCTA820J3225

L6001 LCTAR22J3225

SWITCHES AND RELAYS

S5101 ASH1029

CAP ACITORS

C6044 ,C6079 ,C6080 ,C6084

(0.22µF/16V) ACE9008

C6108 -C6110 CCDSL121J50

C5331 ,C5338 CCSQCH151J50

C5326 ,C5813 ,C5820 ,C5826 ,C6081 CCSQCH221J50

C5334 ,C5353 -C5356 ,C5359 -C5361 CCSQCH471J50

C5365 ,C5369 CCSQCH471J50

C5303 ,C5304 CCSQCH7R0D50

C6056 CCSQCH820J50

C6023 ,C6025 ,C6026 CEAS3R3M50

C5118 ,C5121 ,C5145 ,C5148 ,C5324 CEV100M16

C6006 -C6008 ,C6021 ,C6073 ,C6146 CEV100M16

C6149 CEV100M16

C5170 ,C5176 ,C5178 ,C5193 CEV101M6R3

C5808 ,C5809 ,C5836 ,C5860 CEV101M6R3

C5877 ,C5878 ,C5889 ,C5890 ,C5897 CEV101M6R3

C6093 CEV101M6R3

C5325 ,C5814 ,C5819 ,C5825 CEV1R0M50

C6001 ,C6002 ,C6022 ,C6031 CEV1R0M50

C5197 ,C6020 CEV220M16

C5198 CEV220M6R3

C5157 ,C5174 ,C5180 ,C5307 CEV470M16

C5311 -C5314 ,C5329 ,C5332 ,C5333 CEV470M16

C5344 ,C5345 ,C5363 ,C5364 ,C5806 CEV470M16

C5811 ,C5816 ,C5821 ,C5823 ,C5838 CEV470M16

C5841 -C5843 ,C5845 ,C5847 ,C5862 CEV470M16

C5866 ,C5868 ,C5875 ,C5880 ,C5887 CEV470M16

C5892 ,C5894 ,C6010 ,C6012 ,C6014 CEV470M16

C6030 ,C6034 ,C6037 ,C6038 ,C6040 CEV470M16

C6048 ,C6070 ,C6075 ,C6078 ,C6083 CEV470M16

C6086 ,C6088 ,C6091 ,C6096 ,C6098 CEV470M16

C6107 CEV470M16

C5119 ,C5122 ,C5123 ,C5126 ,C5133 CEV470M6R3

C5140 ,C5142 ,C5146 ,C5149 ,C5150 CEV470M6R3

C5154 ,C5196 ,C5199 CEV470M6R3

C5335 ,C5336 ,C6047 ,C6060 CEV4R7M35

C5120 ,C5147 CEVNP100M16

C6016 ,C6032 ,C6033 CEVNP1R0M50

C5101 ,C5112 ,C5113 ,C5128 ,C5129 CEVNP470M10

Mark No. Description Part No.

C5135 ,C5137 ,C5139 ,C5152 ,C5153 CEVNP470M10

C5114 -C5116 ,C5899 ,C5901 ,C5903 CEVNP470M6R3

C6100 ,C6102 ,C6104 CEVNP470M6R3

C5117 ,C5144 CEVNP4R7M16

C6003 -C6005 CEVR10M50

C5102 -C5107 ,C5134 ,C5136 ,C5138 CFHSQ103J16

C5367 ,C6017 ,C6018 ,C6042 ,C6052 CFHSQ103J16

C6061 ,C6062 ,C6064 ,C6065 ,C6069 CFHSQ103J16

C5337 CFHSQ472J16

C6145 CFTYA474J50

C5109 ,C5111 ,C5124 ,C5125 ,C5127 CKSQYB103K50

C5130 -C5132 ,C5141 ,C5143 ,C5151 CKSQYB103K50

C5155 ,C5156 ,C5169 ,C5192 CKSQYB103K50

C5194 ,C5195 ,C5200 ,C5201 ,C5301 CKSQYB103K50

C5328 ,C5339 ,C5341 -C5343 CKSQYB103K50

C5347 ,C5348 ,C5357 ,C5358 ,C5805 CKSQYB103K50

C5807 ,C5810 ,C5812 ,C5829 -C5831 CKSQYB103K50

C5837 ,C5844 ,C5846 ,C5848 ,C5861 CKSQYB103K50

C5863 ,C5867 ,C5869 ,C5874 ,C5876 CKSQYB103K50

C5879 ,C5881 ,C5886 ,C5888 ,C5891 CKSQYB103K50

C5893 ,C5895 ,C5896 ,C5898 ,C5900 CKSQYB103K50

C5902 ,C5904 ,C5906 ,C6011 ,C6013 CKSQYB103K50

C6015 ,C6019 ,C6035 ,C6036 ,C6039 CKSQYB103K50

C6041 ,C6043 ,C6046 ,C6049 -C6051 CKSQYB103K50

C6053 -C6055 ,C6057 -C6059 ,C6063 CKSQYB103K50

C6066 -C6068 ,C6071 ,C6072 ,C6074 CKSQYB103K50

C6076 ,C6077 ,C6082 ,C6085 ,C6087 CKSQYB103K50

C6090 ,C6092 ,C6094 ,C6097 ,C6099 CKSQYB103K50

C6101 ,C6103 ,C6105 ,C6106 CKSQYB103K50

C5815 ,C5817 ,C5818 ,C5822 ,C5824 CKSQYB223K50

C5827 ,C5828 ,C5832 ,C5833 CKSQYB223K50

C5839 ,C5840 ,C5849 -C5859 CKSQYB223K50

C5108 ,C5865 ,C6095 CKSQYB471K50

C6009 CKSQYB473K50

C5302 ,C5308 -C5310 ,C5315 -C5323 CKSQYF104Z25

C5330 ,C5340 ,C5346 ,C5362 ,C5366 CKSQYF104Z25

C6089 ,C6148 CKSQYF104Z25

C5864 ,C6027 -C6029 ,C6045 CKSQYF104Z50

C5173 ,C5175 ,C5177 ,C5179 CKSRYF103Z50

RESISTORS

R6127 -R6129 RD1/4PU221J

R6094 RN1/10SE1001D

R5120 ,R5131 ,R5172 ,R5183 RN1/10SE1002D

R5833 ,R5835 -R5839 RN1/10SE1301D

R5868 ,R5878 ,R5879 RN1/10SE3601D

R5128 ,R5139 ,R5180 ,R5191 ,R5974 RN1/10SE3901D

R5121 ,R5132 ,R5173 ,R5184 ,R5869 RN1/10SE4701D

R5873 -R5877 ,R5976 ,R6002 ,R6154 RN1/10SE4701D

R5127 ,R5138 ,R5179 ,R5190 ,R6153 RN1/10SE5601D

R6093 RN1/10SE6201D

R6130 RN1/4PC6201F

R5975 RS1/10S2201D

R5840 ,R5842 ,R5843 RS1/2S681J

Other Resistors RS1/10S&&&J

29

Page 30

PDP-501MX ,PDP-V501X

Mark No. Description Part No.

OTHERS

J5101 BORD IN WIRE ADX2411

CN5101,CN5102 15PD-SUB SOCKET AKP1172

CN5103 AKX1050

K5302 -K5306 ,K5311 -K5315 AKX9002

K5318 -K5321 ,K5802 ,K5803 AKX9002

K5805 -K5807 ,K6002 ,K6003 AKX9002

K6005 -K6008 ,K6020 -K6023 AKX9002

X5301 (16.000MHz) ASS1128

CN5302 30P CONNECTOR KF050HC30

CN5301,CN5804 50P CONNECTOR KF050HC50

CN5803 PLUG 12P KM250MA13

CN5802 PLUG 6P KM250MA6

I

U-COM ASS'Y

SEMICONDUCTORS

IC3704 24LC64(I)SN

IC6471 HG62G010R29FB

IC3703 PD5435A9

IC6302,IC6303,IC6401 PQ20VZ1U

IC6301,IC6304 PQ30RV21

IC3702,IC3705 PST9146N

IC6305,IC6402 TA78M05F

IC6441 TA8667F

IC6431 TC35071F

IC6481 TC74ACT74FS

Mark No. Description Part No.

C6414 CCSRCH820J50

C6301 ,C6305 ,C6309 CEAS471M25

C3744 ,C3906 ,C6420 CEV100M16

C3703 ,C3704 ,C3706 ,C3742 ,C3924 CEV101M6R3

C6317 ,C6321 ,C6408 ,C6471 ,C6477 CEV101M6R3

C6481 CEV101M6R3

C3747 ,C6446 CEV1R0M50

C3746 CEV220M16

C6304 ,C6324 CEV2R2M50

C3714 ,C3749 ,C6310 ,C6314 ,C6315 CEV470M16

C6319 ,C6401 ,C6404 ,C6406 ,C6411 CEV470M16

C6441 ,C6519 CEV470M16

C6431 CEV470M6R3

C6416 CEVNP100M16

C6302 ,C6303 ,C6306 -C6308 CKSQYF103Z50

C6311 -C6313 ,C6316 ,C6318 ,C6320 CKSQYF103Z50

C6322 ,C6323 CKSQYF103Z50

C3725 ,C3726 ,C3730 ,C3731 CKSRYB102K50

C3735 -C3741 ,C3743 ,C3745 ,C3754 CKSRYB102K50

C6419 ,C6422 ,C6473 CKSRYB102K50

C3705 ,C3707 -C3709 ,C3712 ,C3713 CKSRYB103K50

C3715 ,C3901 ,C3905 ,C3907 CKSRYB103K50

C6445 CKSRYB822K50

C6402 ,C6403 ,C6405 ,C6407 ,C6409 CKSRYF103Z50

C6412 ,C6417 CKSRYF103Z50

C6418 ,C6432 ,C6434 ,C6435 CKSRYF104Z16

IC3906 TC74HC02AF

IC6482 TC74HC4040AF

IC6505,IC6506 TC74LCX541FT

IC6507,IC6510 TC74VHC541FT

IC3901,IC3903 TC74VHCT541AFT

Q3710 -Q3713 ,Q3715 ,Q3717 ,Q3718 2SA1162

Q3725 ,Q3726 ,Q6423 2SA1162

Q3701 ,Q3716 ,Q6411 -Q6413 ,Q6417 2SC2712

Q6421 ,Q6441 ,Q6451 ,Q6452 2SC2712

Q6461 ,Q6462 2SC2712

Q6418 ,Q6419 ,Q6442 2SC2714

Q3709 2SC2878

Q6422 2SK208

D3706 ,D3707 ,D3709 -D3712 1SS226

D6423 1SS269

D6421 ,D6422 ,D6451 1SS352

D3721 HSS104-02

D3704 ,D3705 ,D3708 ,D3713 RD6.8MB

COIL AND FILTERS

L6401 ATC1037

F6401 -F6404 ATF1128

F6507 -F6509 ,F6514 ATF1188

L3701 LCTA100J3225

L6411 LCTA4R7J3225

CAPACITORS

C6433 CCSRCH101J50

C6413 ,C6415 CCSRCH121J50

C3710 ,C3711 ,C3916 ,C3917 CCSRCH220J50

C6410 ,C6421 ,C6453 CCSRCH221J50

C6442 -C6444 ,C6452 ,C6462 ,C6472 CKSRYF104Z16

C6474 -C6476 ,C6482 -C6484 CKSRYF104Z16

C6506 -C6508 ,C6510 ,C6520 CKSRYF104Z16

RESISTORS

R6517 ,R6518 ,R6520 ,R6521 RA4C470J

R6523 ,R6524 ,R6530 ,R6535 -R6537 RA4C470J

R4019 RD1/4PM473J

R3784 ,R3827 ,R3898 ,R3914 -R3925 RS1/16S0R0J

R3932 -R3935 ,R4007 RS1/16S0R0J

R3701 ,R3702 ,R3720 ,R3721 RS1/16S101J

R3748 -R3750 ,R3765 ,R3816 ,R3886 RS1/16S101J

R3909 -R3913 ,R3949 -R3956 RS1/16S101J

R3986 ,R3987 ,R3990 -R3992 ,R6411 RS1/16S101J

R6418 ,R6425 ,R6427 ,R6437 RS1/16S101J

R6440 ,R6441 ,R6448 ,R6451 ,R6453 RS1/16S101J

R6457 ,R6460 ,R6461 ,R6467 RS1/16S101J

R6471 -R6473 ,R6481 ,R6482 RS1/16S101J

R3783 ,R3826 ,R3877 ,R3899 RS1/16S102J

R3901 -R3908 ,R3926 -R3929 RS1/16S102J

R3941 -R3948 ,R3988 ,R3989 RS1/16S102J

R6474 -R6478 RS1/16S102J

R3736 ,R3741 ,R3811 ,R3813 ,R3818 RS1/16S103J

R3823 ,R3824 ,R3878 ,R3889 ,R6434 RS1/16S103J

R6439 ,R6454 ,R6455 ,R6464 ,R6465 RS1/16S103J

R6416 RS1/16S104J

R6415 RS1/16S122J

R3897 RS1/16S123J

R6413 RS1/16S151J

R3887 RS1/16S152J

30

Page 31

PDP-501MX, PDP-V501X

Mark No. Description Part No.

R3879 ,R6447 RS1/16S153J

R6412 RS1/16S162J

R6442 RS1/16S183J

R3705 ,R3706 ,R3710 -R3712 ,R3719 RS1/16S221J

R3722 -R3735 ,R3737 -R3740 RS1/16S221J

R3742 -R3747 ,R3751 -R3764 ,R3767 RS1/16S221J

R3774 -R3778 ,R3780 -R3782 RS1/16S221J

R3814 ,R3815 ,R3817 ,R3819 -R3821 RS1/16S221J

R3707 ,R3708 ,R3766 ,R3768 ,R3769 RS1/16S222J

R3844 ,R3883 ,R6423 ,R6459 RS1/16S222J

R3810 ,R3839 ,R3869 ,R3870 ,R3881 RS1/16S223J

R3939 ,R6420 -R6422 ,R6458 RS1/16S223J

R3822 ,R3867 RS1/16S224J

R6431 RS1/16S271J

R6426 RS1/16S272J

R3885 RS1/16S392J

R6446 RS1/16S393J

R6452 ,R6462 RS1/16S432J

R3884 ,R6519 ,R6522 ,R6525 RS1/16S470J

R3888 RS1/16S471J

R3713 -R3715 ,R3812 ,R3825 RS1/16S472J

R3832 ,R3833 ,R3846 ,R3872 ,R3873 RS1/16S472J

R4009 -R4014 ,R6456 ,R6466 RS1/16S472J

R3847 -R3854 ,R3856 -R3866 ,R3868 RS1/16S473J

R3874 ,R3875 ,R3882 ,R3995 ,R4006 RS1/16S473J

R4020 ,R6435 RS1/16S473J

R3880 RS1/16S562J

R3779 RS1/16S563J

R6414 RS1/16S681J

R4003 ,R4005 ,R6436 ,R6444 RS1/16S682J

R6445 RS1/16S754J

R3834 ,R3835 ,R3840 -R3843 ,R3871 RS1/16S822J

R3930 ,R3931 ,R6424 ,R6443 RS1/16S822J

R3703 RS1LMFR47J

R6311 RS2LMF150J

R6401 RS2LMF220J

R6315 ,R6316 RS3LMF100J

R6317 RS3LMF3R3J

Other Resistors RS1/10S&&&J

OTHERS

K3703 ,K3706 -K3713 AKX9002

KN6304 GROUND PLATE ANK-142

X3702 CRYSTAL (9.8304MHz) ASS1127

6303 SCREW BMZ30P060FCU

CN6502,CN6503,CN6507,CN6508

50P CONNECTOR KF050HA50L

CN3901,CN3904,CN6501,CN6504-CN6506

50P CONNECTOR KF050HC50

CN3902 PLUG 12P KM250MA12B

CN3903 PLUG 3P KM250MA3

CN6302 PLUG 6P KM250MA6

CN3702 PLUG 8P KM250MA8

CN6303 PLUG 8P KM250MA8B

CN6301 PLUG 9P KM250MA9

CN3704 3P CONNECTOR KPE3

Mark No. Description Part No.

O

CABLE E ASS'Y

SEMICONDUCTORS

IC7421,IC7422 TC74VHC541FT

IC7423-IC7426 TC74VHC574FT

COIL AND FILTERS

F7401 ,F7425 ATF1124

F7421 -F7424 ,F7426 ,F7427 ATF1188

L7401 ,L7402 (100µH) ATH1065

CAPACITORS

C7404 ,C7428 CEHV101M16

C7401 ,C7402 CEHV470M16

C7403 ,C7421 -C7427 CKSRYF104Z16

RESISTORS

R7421 -R7442 RA4C470J

OTHERS

K7401 -K7404 AKX9002

CN7408,CN7409 30P CONNECTOR KF050HA30L

CN7406,CN7407 40P CONNECTOR KF050HA40L

CN7401-CN7405 30P CONNECTOR KF050HC30

E

X DRIVE A ASS'Y

SEMICONDUCTORS

IC2606-IC2609 HCPL-M611

IC2612 PE1006A

IC2610,IC2611 STK795-120A

IC2605 TC74ACT541FS

IC2613 TC74VHC541FT

IC2601-IC2604 UPC78L05T

Q2603 ,Q2605 ,Q2608 ,Q2611 ,Q2714 2SA1162

Q2604 ,Q2606 ,Q2607 ,Q2609 ,Q2610 2SC2712

Q2612 ,Q2614 ,Q2713 2SC2712

Q2702 ,Q2703 2SJ281

Q2708 2SK2167

D2604 ,D2605 ,D2607 ,D2703 1SS352

D2601 ,D2602 D1FL20U

COIL AND FILTERS

L2601 -L2604 ATH1020

L2605 ,L2606 ,L2701 ATH1064

L2607 (100µH) ATH1066

L2609 (47µH) ATH1067

L2608 (22µH) ATH1068

CAPACITORS

C2622 ,C2623 (2.2µF/250V) ACE1113

C2620 ,C2621 (470µF/200V) ACH1293

C2708 (100µF/250V) ACH1301

C2608 ,C2609 ,C2611 ,C2612 ,C2619 CEHV101M16

C2713 ,C2714 CEHV101M16

C2613 ,C2626 CEHV221M16

C2607 ,C2610 CEHV331M16

C2614 -C2618 CEHV470M16

C2602 -C2604 ,C2606 CKSQYF104Z50

C2601 ,C2605 ,C2625 ,C2627 ,C2629 CKSRYB103K50

RESISTORS

R2620 ,R2624 ,R2626 ,R2632 ,R2634 RA4C470J

R2616 ,R2617 RD1/2PM4R7J

R2734 RS1LMF563J

31

Page 32

PDP-501MX ,PDP-V501X

Mark No. Description Part No.

R2730 RS2LMF562J

R2738 RS3LMF122J

R2737 RS3LMF561J

Other Resistors RS1/10S&&&J

OTHERS

CN2601 PLUG 2P AKM-089

K2601 ,K2602 ,K2604 -K2606 AKX9002

K2608 ,K2609 ,K2611 ,K2613 -K2616 AKX9002

K2702 AKX9002

KN2601 GROUND PLATE ANK-142

CN2708-CN2711 50P CONNECTOR KF050HB50L

CN2604,CN2608,CN2706,CN2707

CN2602 PLUG 7P KM250MA7

CN2605 PLUG 7P KM250MA7R

AM

SENSER A ASSY

50P CONNECTOR KF050HC50

SEMICONDUCTORS

IC8058 LM50CIM3

CAPACITORS

C8079 CKSQYF103Z50

C8091 CKSQYF104Z50

RESISTORS

Other Resistors RS1/10S&&&J

OTHERS

CN8084 3P SOCKET KP200IA3L

AN

SENSER B ASSY

Mark No. Description Part No.

Q3301 ,Q3305 2SA1162

Q3104 ,Q3106 ,Q3107 ,Q3109 ,Q3110 2SC2712

Q3112 ,Q3114 ,Q3302 ,Q3306 ,Q3309 2SC2712

Q3215 2SJ181S

Q3103 ,Q3202 ,Q3203 2SJ281

Q3201 2SJ449

Q3205 ,Q3216 2SK2167

Q3006 ,Q3012 ,Q3206 -Q3209 2SK2255-01M

Q3204 2SK2355

Q3101 2SK2796S

Q3005 ,Q3011 FS14UM-9

Q3003 ,Q3004 ,Q3009 ,Q3010 FS30AS-06

D3104 ,D3105 ,D3107 ,D3209 ,D3320 1SS352

D3322 1SS352

D3311 1Z180

D3001 ,D3002 ,D3004 ,D3005 D1FL20U

D3101 ,D3102 ,D3106 ,D3201 -D3206 D1FL20U

D3313 ,D3314 ,D3325 ,D3326 D1FL20U

D3315 D1FL40

D3318 RD110P

D3319 RD15MB

D3316 ,D3317 ,D3321 ,D3327 ,D3328 RD33MB

D3312 S2L60

COIL AND FILTERS

L3101 ,L3102 ,L3105 ,L3106 ATH1020

L3001 ,L3002 ,L3103 ,L3107 ATH1064

L3109 ,L3110 ,L3201 (100µH) ATH1066

L3104 ,L3301 ,L3302 (47µH) ATH1067

L3108 (22µH) ATH1068

SEMICONDUCTORS

IC8055 LM50CIM3

CAPACITORS

C8078 CKSQYF103Z50

C8093 CKSQYF104Z50

RESISTORS

Other Resistors RS1/10S&&&J

G

Y DRIVE A ASS'Y

SEMICONDUCTORS

IC3307 AN1431M

IC3013-IC3018,IC3110-IC3113 HCPL-M611

IC3205,IC3206 HCPL-M611