Page 1

ORDER NO.

ARP3081

PLASMA DISPLAY

PDP-V402

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Type

LUBW/CA/1 AC120V

Model

PDP-V402

Note: Pages 26 - 77 and 82 - 89 were intentionally left out.

In PDP-V402, there are two different models (original model and value analysis model).

Confirm the mark and serial No. of the product rear side, and use each service manual.

Power Requirement

Remarks

PRODUCT REAR SIDE

Serial No.

1

(

∗ ∗ ∗ ∗ ∗

Discrimination Seal

(SILVER)

)

SERIAL NO.

Serial No. Service Manual

1 ∗ ∗ ∗ ∗ ∗

OTHER

CONTENTS: See note above for pages left out.

1.SAFETY INFORMATION....................................2

2.EXPLODED VIEWS AND PARTS LIST.............5

3.BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

.......................................................16

4.PCB CONNECTION DIAGRAM.......................90

5.PCB PARTS LIST...........................................133

6.ADJUSTMENT................................................145

7.GENERAL INFORMATION............................152

7.1DIAGNOSIS..............................................152

7.1.1 BURN-IN.........................................152

7.1.2 TROUBLESHOOTING...................154

7.1.3 DISASSEMBLY..............................157

7.1.4 WIRING DIAGRAM........................161

7.2 IC .....................................................166

8.PANEL FACILITIES AND SPECIFICATIONS

.....................................................169

ARP3081 [This manual]

ARP3034

ARP2981 (PDP-V401)

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS SERVICE, INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2000

T–ZZA OCT. 2000 Printed in Japan

Page 2

PDP-V402

1. SAFETY INFORMATION

This service manual is intended for qualified service technicians; it is not meant for the casual

do-it-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to

cause cancer, birth defects or other reproductive harm.

Health & Safety Code Section 25249.6 – Proposition 65

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement parts

must be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les

pièces de remplacement doivent avoir la même désignation.

1.1 SAFETY PRECAUTIONS

NOTICE : Comply with all cautions and safety related notes located

on or inside the cabinet and on the chassis.

The following precautions should be observed :

1. When service is required, even though the PDP UNIT an isolation

transformer should be inserted between the power line and the

set in safety before any service is performed.

2. When replacing a chassis in the set, all the protective devices

must be put back in place, such as barriers, nonmetallic knobs,

adjustment and compartment covershields, isolation resistorcapacitor, etc.

3. When service is required, observe the original lead dress. Extra

precaution should be taken to assure correct lead dress in the

high voltage circuitry area.

4. Always use the manufacture's replacement components.

Especially critical components as indicated on the circuit diagram

should not be replaced by other manufacture's.

Furthermore where a short circuit has occurred, replace those

components that indicate evidence of overheating.

5. Before returning a serviced set to the customer, the service

technician must thoroughly test the unit to be certain that it is

completely safe to operate without danger of electrical shock,

and be sure that no protective device built into the set by the

manufacture has become defective, or inadvertently defeated

during servicing. Therefore, the following checks should be

performed for the continued protection of the customer and

service technician.

6. Perform the following precautions against unwanted radiation

and rise in internal temperature.

• Always return the internal wiring to the original styling.

• Attach parts (Ground, Rear Cover, Shield Case) surely after

disassembly.

7. Perform the following precautions for the PDP panel.

• When the front case is removed, make sure nothing hits the

panel face, panel corner, and panel edge (so that the glass does

not break).

• Make sure that the panel vent does not break. (Check that the

cover is attached.)

• Handle the FPC connected to the panel carefully.

Twisting or pulling the FPC when connecting it to the connector

will cause it to peel off from the panel.

8. Pay attention to the following.

• Be sure to wire the fan. If the fan does not work, the temperature

will rise and cause the protection circuit to operate.

• When the front case is removed, infrared ray is radiated and

may disturb reception of the remote control unit.

• Pay extreme caution when the front case and rear panel are

removed because this may cause a high risk of disturbance to

TVs and radios in the surrounding.

2

Page 3

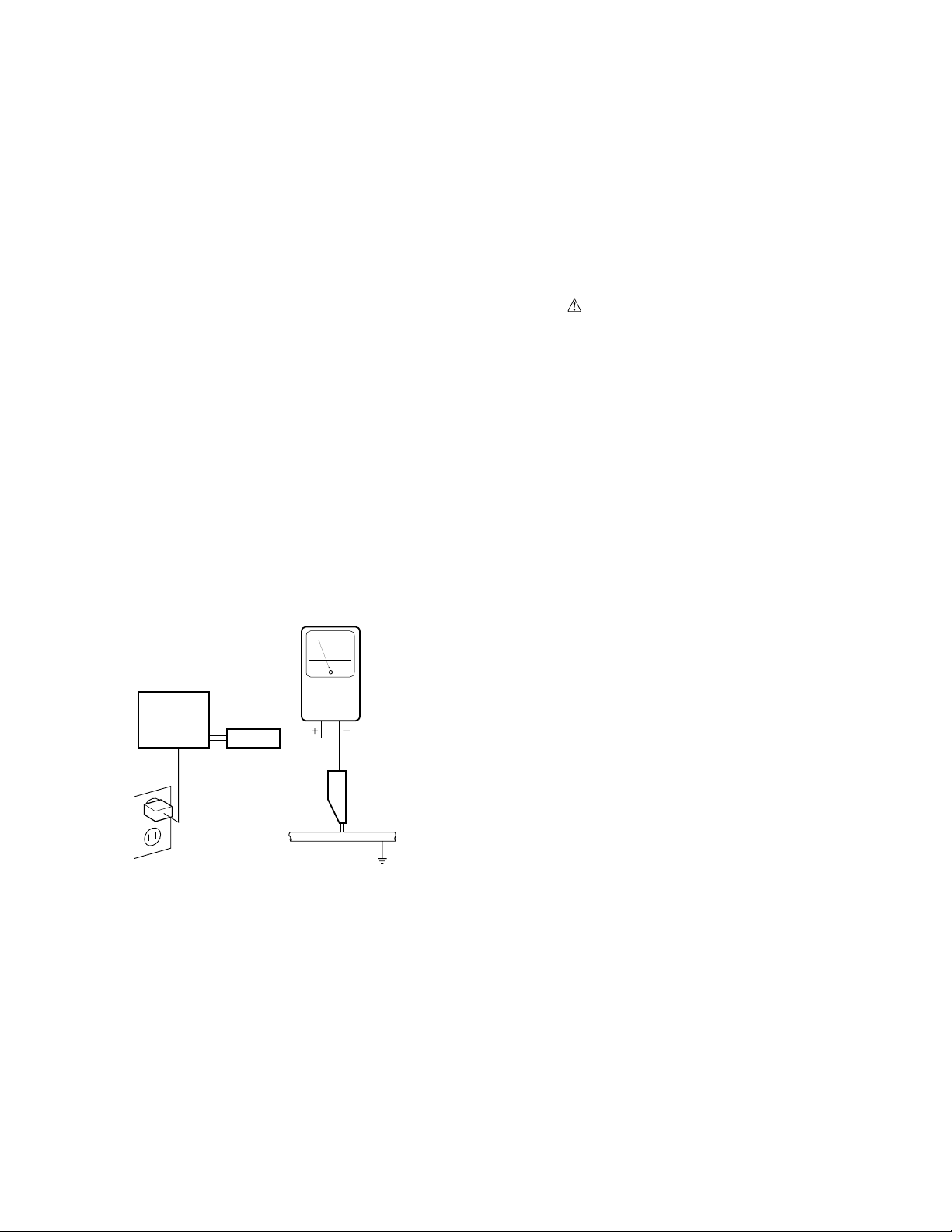

Leakage Current Cold Check

With the AC plug removed from an AC power source, place a

jumper across the two plug prongs. Turn the AC power switch on.

Using an insulation tester (DC 500V), connect one lead to the

jumpered AC plug and touch the other lead to each exposed metal

part (input/output terminals, screwheads, metal overlays, control

shafts, etc.), particularly any exposed metal part having a return

path to the chassis. Exposed metal parts having a return path to the

chassis should have a minimum resistor reading of 0.3MΩ and a

maximum resistor reading of 5MΩ. Any resistor value below or

above this range indicates an abnormality which requires corrective

action. Exposed metal parts not having a return path to the chassis

will indicate an open circuit.

Leakage Current Hot Check

Plug the AC line cord directly into an AC power source (do not use

an isolation transformer for this check).

Turn the AC power switch on.

Using a "Leakage Current Tester (Simpson Model 229 equivalent)",

measure for current from all exposed metal parts of the cabinet

(input/output terminals, screwheads, metal overlays, control shaft,

etc.), particularly any exposed metal part having a return path to the

chassis, to a known earth ground (water pipe, conduit, etc.). Any

current measured must not exceed 0.5mA.

PDP-V402

1.2 PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in PIONEER set have special

safety related characteristics. These are often not evident from

visual inspection nor the protection afforded by them necessarily

can be obtained by using replacement components rated for higher

voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in this Service Manual.

Electrical components having such features are identified by marking

with a

Manual.

The use of a substitute replacement component which dose not have

the same safety characteristics as the PIONEER recommended

replacement one, shown in the parts list in this Service Manual, may

create shock, fire or other hazards.

Product Safety is continuously under review and new instructions

are issued from time to time. For the latest information, always

consult the current PIONEER Service Manual. A subscription to, or

additional copies of, PIONEER Service Manual may be obtained at

a nominal charge from PIONEER.

on the schematics and on the parts list in this Service

Reading should

not be above

0.5 mA

Earth ground

Device

under

test

Also test with plug

reversed

(Using AC adapter

plug as required)

Test all exposed

metal surfaces

Leakage

current

tester

AC Leakage Test

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE SET TO THE CUSTOMER.

3

Page 4

PDP-V402

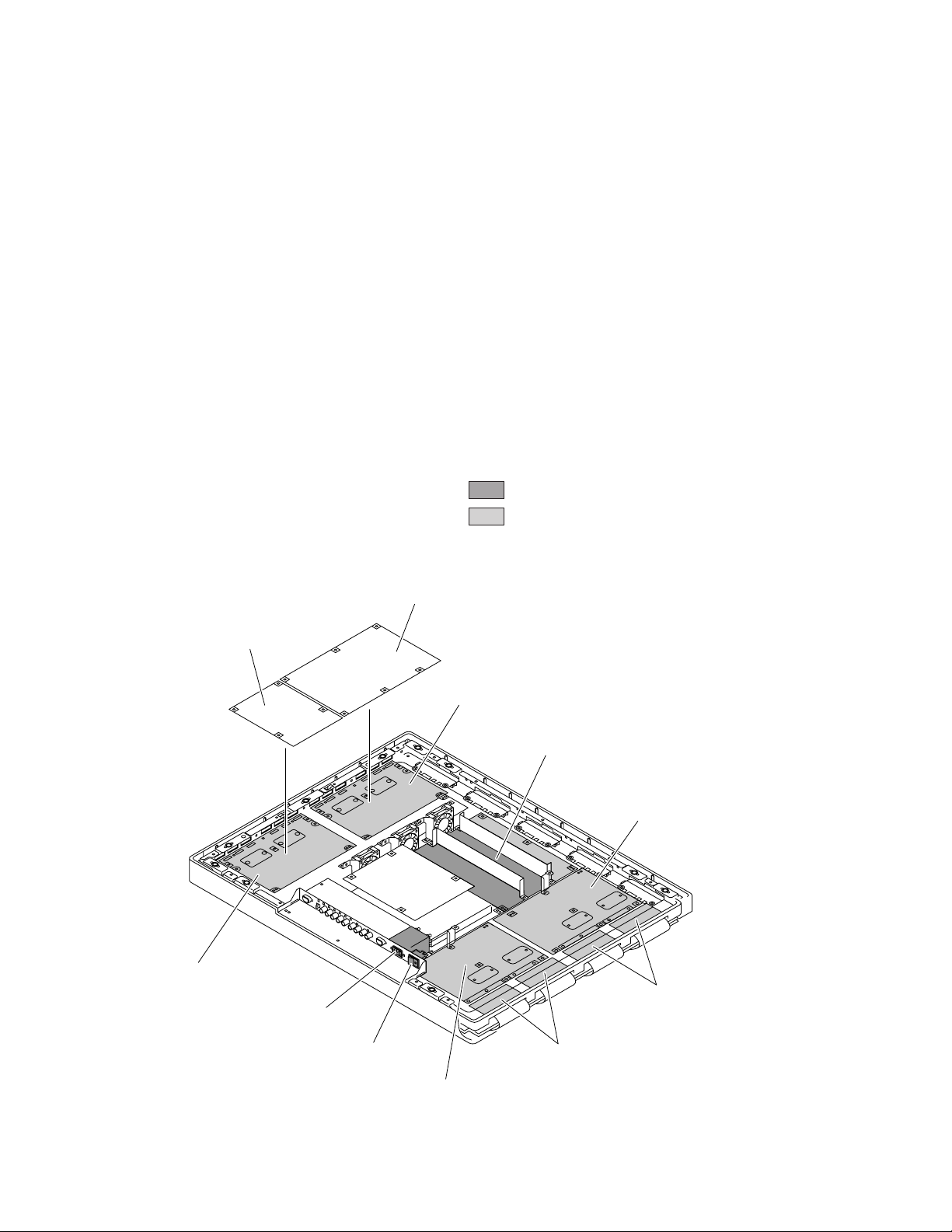

1.3 CHARGED SECTION AND HIGH VOLTAGE GENERATING POINT

7 Charged Section

The places where the commercial AC power is used without

passing through the power supply transformer.

If the places are touched, there is a risk of electric shock. In addition,

the measuring equipment can be damaged if it is connected to the

GND of the charged section and the GND of the non-charged

section while connecting the set directly to the commercial AC

power supply. Therefore, be sure to connect the set via an insulated

transformer and supply the current.

7 Charged Section

(Power supply primary side)

1. AC Power Cord

2. AC Inlet with Filter

3. Power Switch (S1)

4. Fuse (In the MAIN POWER ASSY)

5. STB Transformer and Converter Transformer

(In the MAIN POWER ASSY)

6. Other primary side of the MAIN POWER ASSY

ANALOG VIDEO ASSY

3D Y/C ASSY

7 High Voltage Generating Point

The places where voltage is 100V or more except for the charged

places described above. If the places are touched, there is a risk of

electric shock.

1. MAIN POWER ASSY ...................................... (170V)

2. X DRIVE (A) ASSY ......................................... (170V)

3. X DRIVE (B) ASSY ......................................... (170V)

4. Y DRIVE (A) ASSY ......................................... (170V)

5. Y DRIVE (B) ASSY ......................................... (170V)

6. SCAN MODULE (A) and (B) .......................... (150V)

For the places, refer to the EXPLODED VIEWS, the SCHEMATIC

DIAGRAM and the PCB CONNECTION DIAGRAM sections.

Part is charged section.

Part is the high voltage generating points other than the

charged section.

X DRIVE (B) ASSY

AC Inlet

Power Switch (S1)

X DRIVE (A) ASSY

MAIN POWER ASSY

Y DRIVE (A) ASSY

SCAN MODULE (B)

SCAN MODULE (A)

Y DRIVE (B) ASSY

4

Page 5

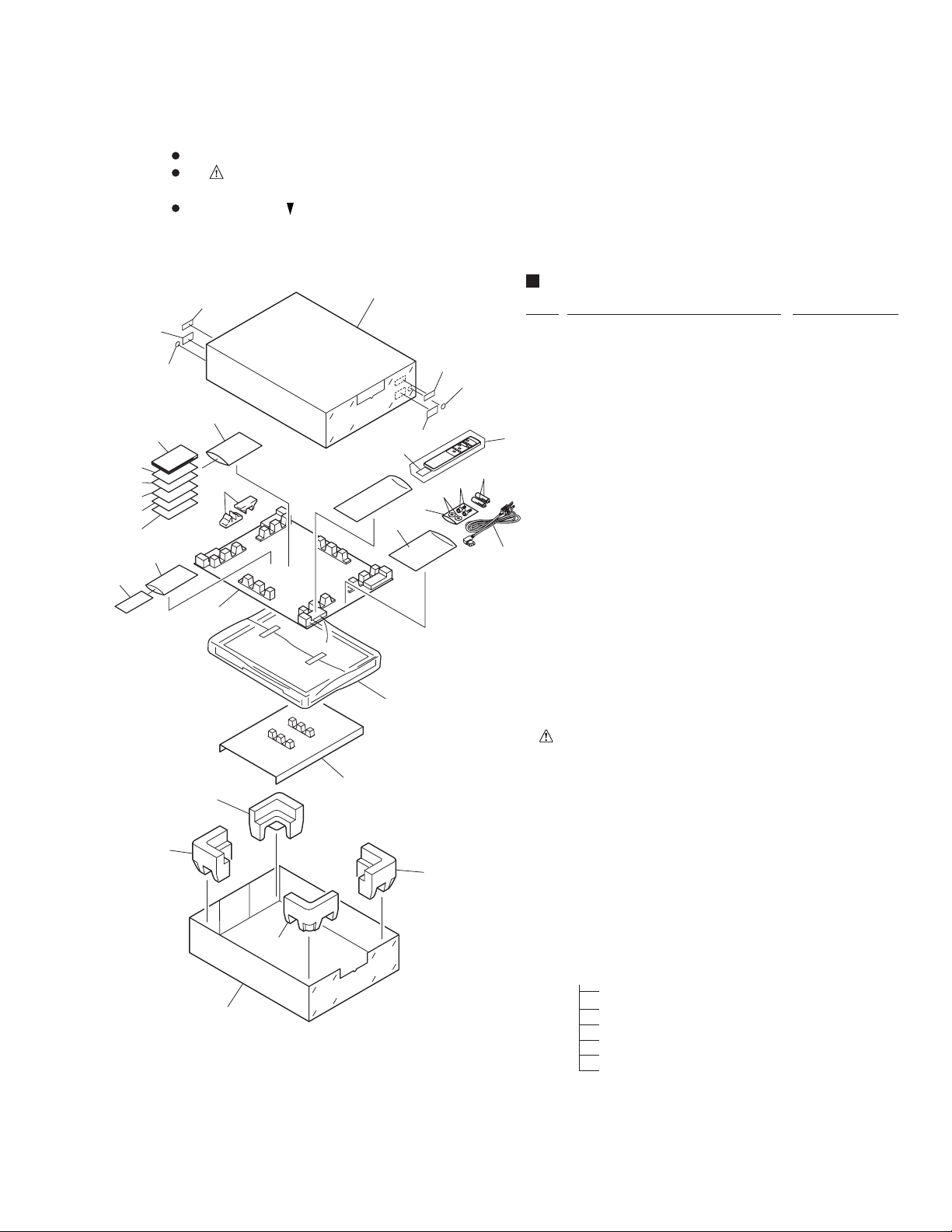

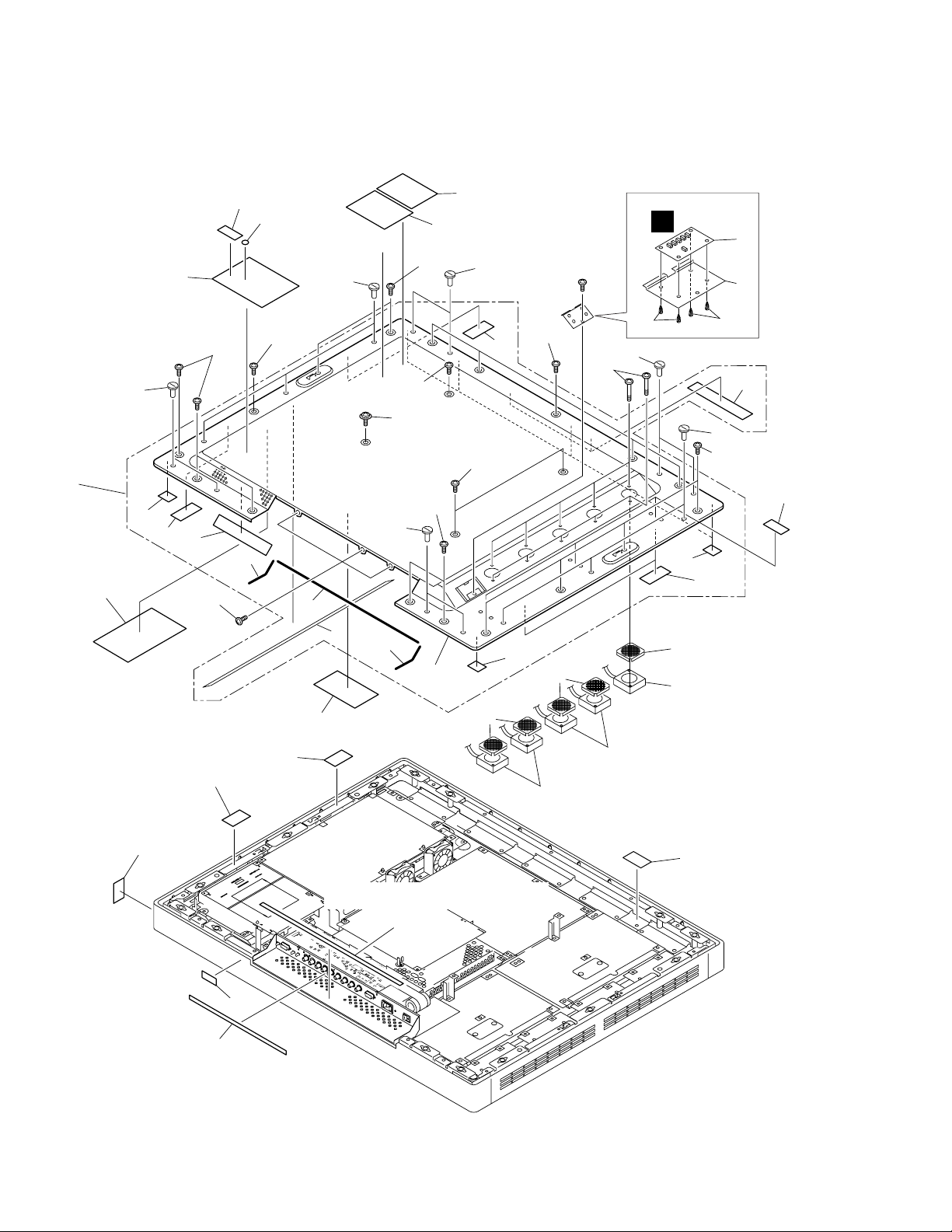

2. EXPLODED VIEWS AND PARTS LIST

NOTES : Parts marked by “ NSP ” are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

Screw adjacent to mark on the product are used for disassembly.

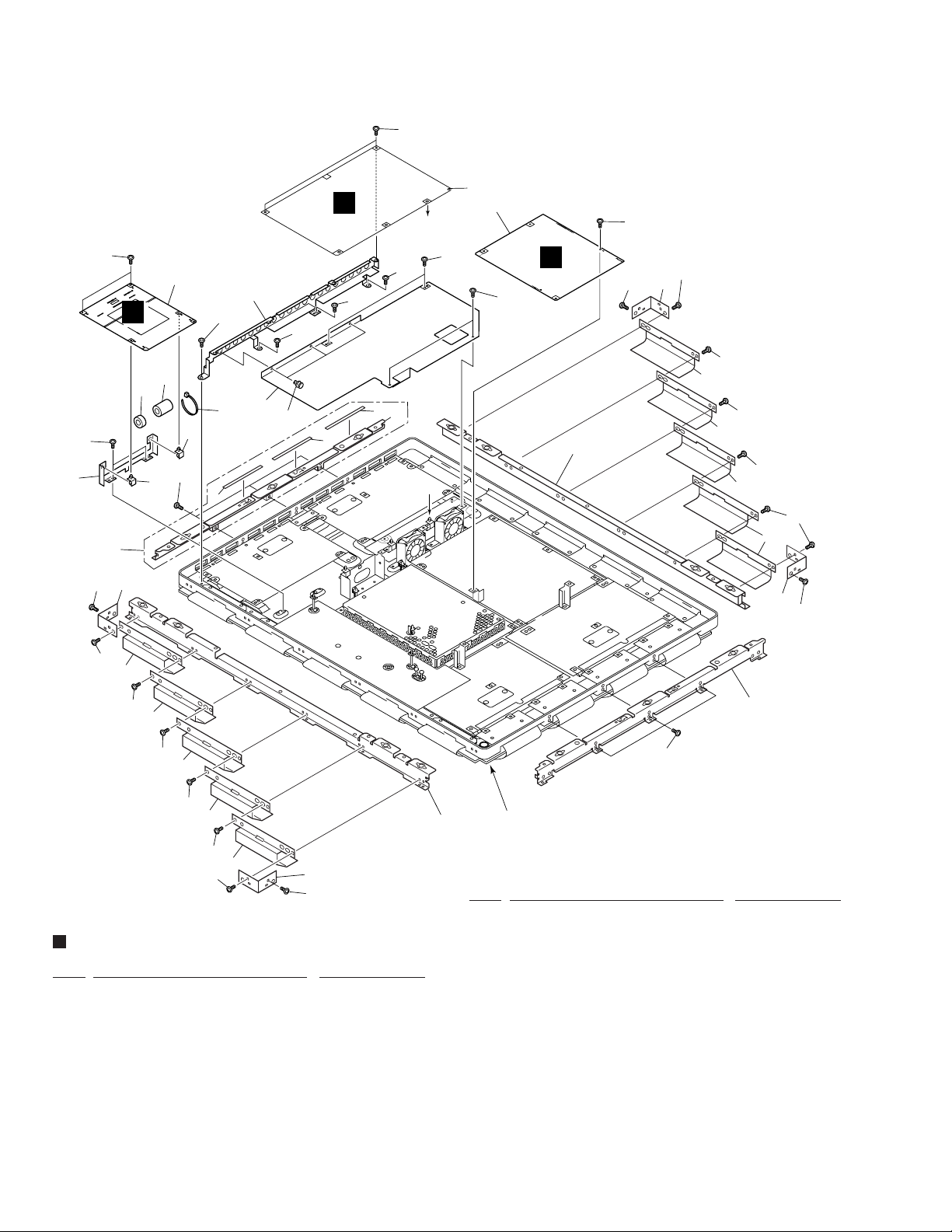

2.1 PACKING

PACKING PARTS LIST

Mark No. Description Part No.

20

6

PDP-V402

29

11

13

12

24

28

27

10

25

30

1 Under Pad A AHA2249

2 Under Pad B AHA2250

20

30

9

27

15

17

23

22

19

9

4

8

3

1

14

16

21

3 Under Pad C AHA2251

4 Upper Pad AHA2252

5 ...............................

6 Upper Carton AHD3052

7 Under Carton AHD3041

8 Mirror Mat AHG1273

NSP 9 Literature Bag AHG-117

10 Operating Instructions ARD1030

(English/Japanese)

11 Plasma Caution Sheet ARM1145

12 Plasma Caution Sheet ARM1147

13 Caution Sheet ARM1169

14 Remote Control Unit AXD1441

(CU-V153)

15 Battery Cover AZN2098

NSP 16 Batteries (R6P, AA) AEX1025

NSP 17 Vinyl Bag AHG-064

18 ...............................

19 Display Stand V AMR3232

20 Packing Label AAX2822

21 AC Power Cord BDG1025

22 Bolt (Hex) SMZ80H350FZB

23 Washer WB80FZB

NSP 24 Warranty Card ARY1102

NSP 25 Vinyl Pouch AHG-195

26 ...............................

2

2

1

7

NSP 27 Label VRW1629

28 Caution Sheet ARM1176

NSP 29 Warranty Card ARY1093

30 Discrimination Seal (SILVER) AAX2817

31 Packing Assy AHF1001

Packing Assy (AHF1001) is composed of the following parts.

31 Packing Assy AHF1001

1 Under Pad A AHA2249

2 Under Pad B AHA2250

3 Under Pad C AHA2251

4 Upper Pad AHA2252

6 Upper Carton AHD3052

7 Under Carton AHD3041

5

Page 6

PDP-V402

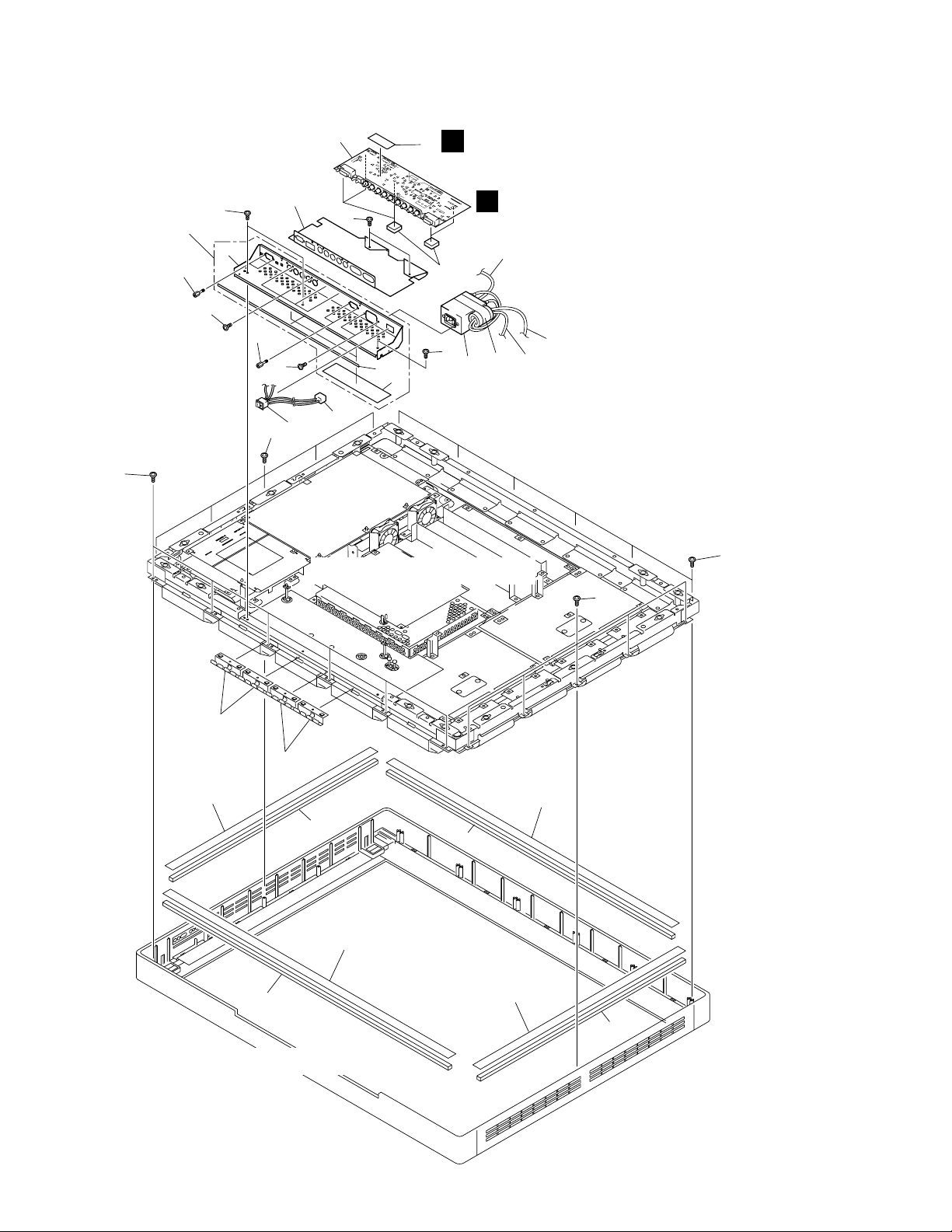

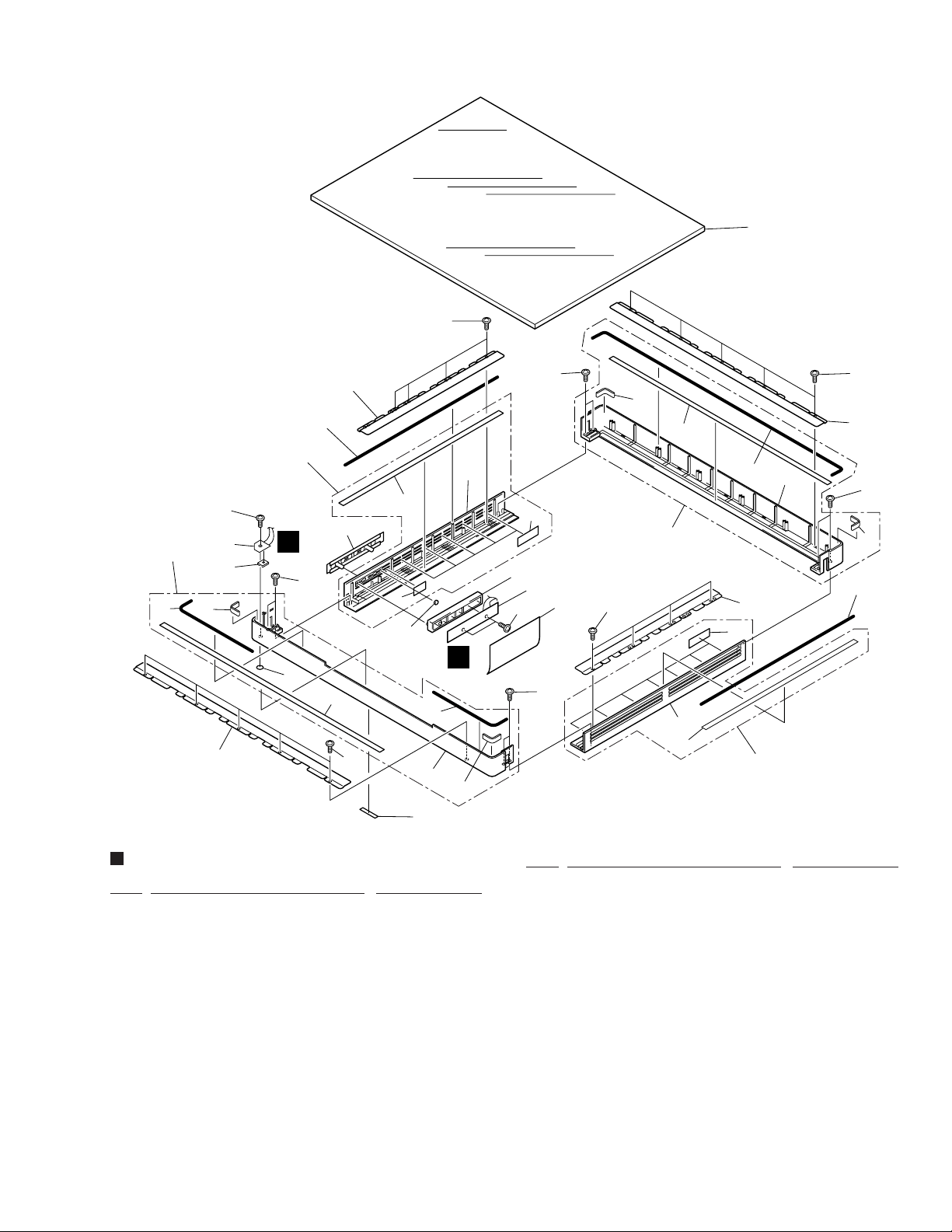

2.2 REAR PANEL SECTION

41

14

22

13

12

19

11

23

23

34

16

32

23

15

10

22

16

22

24

23

23

23

6

40

39

23

22

12

13

23

K

9

7

8

22

26

13

5

5

4

8

11

22

23

17

12

33

28

31

28

Refer to " MAIN UNIT SECTION (1/3)".

1

29

2

5

4

4

30

6

Page 7

REAR PANEL SECTION PARTS LIST

Mark No. Description Part No.

1 Label RS AAX2744

2 Label TP AAX2729

3 ...............................

4 Fan Motor (60×15) AXM1039

5 Fan Guard ANG2418

6 Rear Cover Assy ANE1572

7 PCB Cover ANG2186

8 Circuit Board Spacer AEC1862

9 FAN RELAY ASSY AWZ6535

10 Net RA AED1170

11 Net RC AED1171

12 Net FA AED1165

13 Net FB AED1184

14 Insulating Sheet R AEC1823

15 Shield Gusket E ANK1657

16 Shield Gusket D ANK1674

17 Cable Clamp Label ARW1076

18 ...............................

NSP 19 Label AAL2337

20 ...............................

21 ...............................

22 Hole Rivet AMR2969

23 Screw PMB30P080FZK

24 Screw ABA1283

25 ...............................

PDP-V402

26 Screw PPZ50P100FZK

27 ...............................

28 Cover Sheet AEC1824

29 Serial Seal AAX2732

NSP 30 Drive Voltage Label ARW1097

31 Solder Warning Label AAX2644

32 Discrimination Label (SILVER) AAX2816

33 Display Label AAX–359

NSP 34 Label VRW1629

35 ...............................

36 ...............................

37 ...............................

38 ...............................

NSP 39 Bolt Caution Label AAX2630

40 Cleaning Label AAX2751

41 Rear Cover Service Assy AEA1036

7

Page 8

PDP-V402

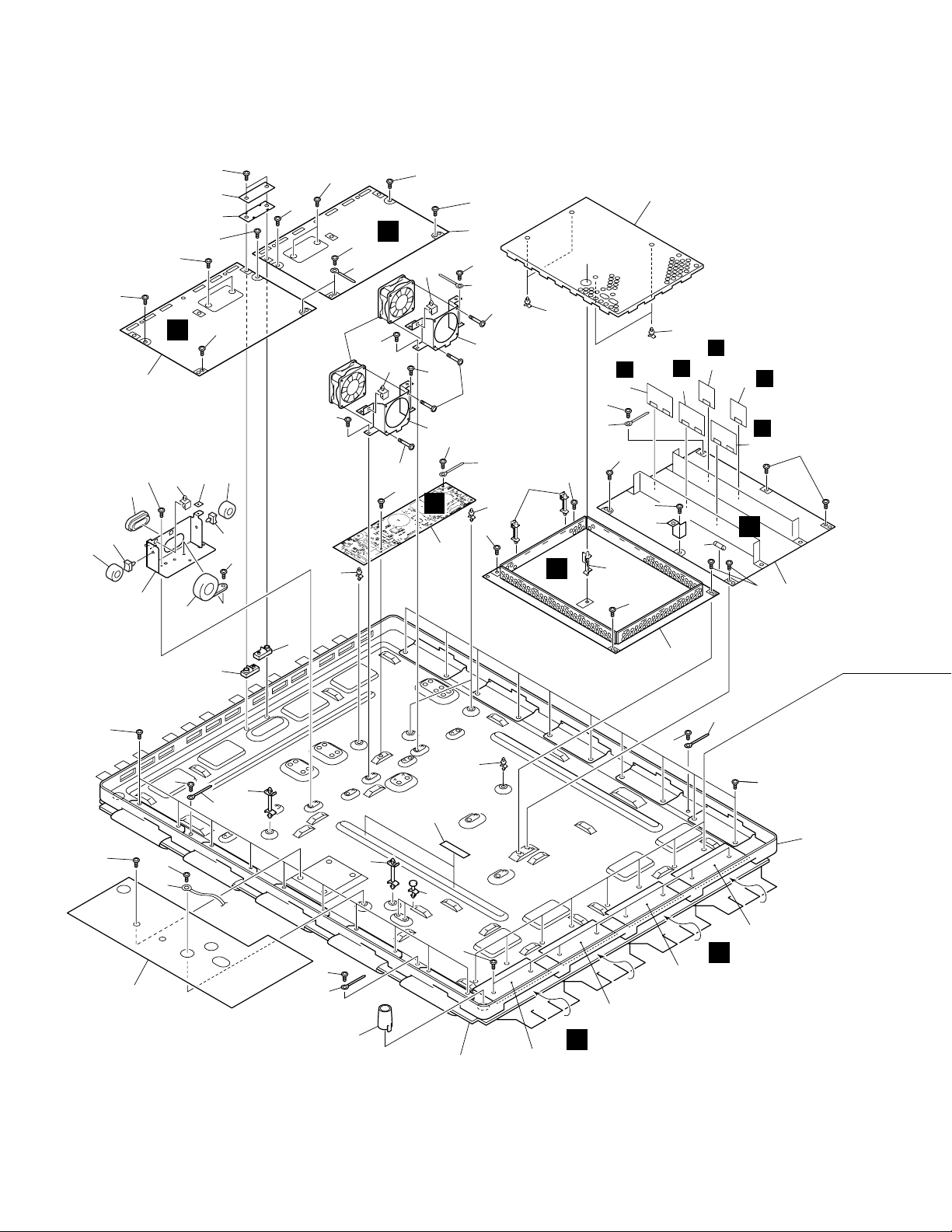

2.3 MAIN UNIT SECTION (1/3)

10

24

6

4

5

3

7

25

26

6

10

5

1

Refer to " MAIN UNIT SECTION (2/3)".

11

13

17

21

27

L

5

A

12

18

14

2

15

10

10

22

22

8

20

9

19

19

9

8

20

Refer to " FRONT PANEL SECTION ".

8

Page 9

MAIN UNIT SECTION (1/3) PARTS LIST

Mark No. Description Part No.

1 Power Switch (S1) BSM1010

2 AC Inlet with Filter (CN1) AKP1211

3 Inlet Panel ANG2425

4 INPUT CONTROL Assy AWZ6554

5 Screw PMB30P080FZK

6 Screw BBA1017

7 Screw BPZ30P080FZK

NSP 8 Panel Sheet V AMR3154

NSP 9 Panel Sheet H AMR3172

10 Screw BPZ40P080FZK

11 Shield Gusket C ANK1655

12 Ground Wire (J50) ADX2332

13 2P Housing Wire (J51) ADX2584

14 Ferrite Core (L1) ATX1032

15 Wire (J53) ADX2586

16 Screw BBZ30P080FZK

17 Net RC AED1171

18 Wire (J52) ADX2585

19 Panel Cushion H AED1179

20 Panel Cushion V AED1180

PDP-V402

21 SYNC DET ASSY AWZ6548

22 Front Shield ANK1672

23 ...............................

24 Inlet Panel Service Assy AEA1048

25 Shield Sheet I/O ANK1675

26 Screw PMB30P060FCU

27 Cushion AEB1340

9

Page 10

PDP-V402

2.4 MAIN UNIT SECTION (2/3)

C

21

6

9

B

19

21

4

Q

23

22

20

3

14

18

19

19

12

7

19

7

2

20

20

5

24

1

10

20

1

15

1

20

17

B

17

B

16

19

18

19

12

12

19

19

12

19

12

18

19

19

19

12

19

12

19

12

19

19

12

18

19

MAIN UNIT SECTION (2/3) PARTS LIST

Mark No. Description Part No.

1 FPC Cushion AEB1343

NSP 2 PCB Angle A ANG2162

NSP 3 PCB Angle B ANG2163

4 3D Y/C ASSY AWQ1055

5 Shield Sheet ANK1669

6 ANALOG VIDEO ASSY AWQ1056

7 PCB Hinge AEC1694

8 ...............................

9 CONTROL ASSY AWZ6545

10 Rivet AEC1658

19

13

Refer to " MAIN UNIT SECTION (3/3)".

Mark No. Description Part No.

11 ...............................

12 FPC Shield H ANK1518

13 Angle D ANG2252

14 Angle B Service Assy AEA1046

15 Angle B ANG2434

16 Angle A ANG2250

17 Screw PMB30P080FZK

NSP 18 Corner Angle ANG2158

19 Screw ABA1266

20 Screw IBZ30P080FCC

21 Screw BMZ30P080FMC

22 Ferrite Core (L2) ATX1032

23 Ferrite Core (L3) ATX1031

24 Binder AEC1851

15

10

Page 11

J

I

13

16

16

16

16

15

21

29

15

14

8

8

7

6

4

3

17

2

25

26

18

27

10

12

14

22

8

8

5

23

24

31

27

11

19

8

2

1

21

17

28

8

27

27

19

30

20

9

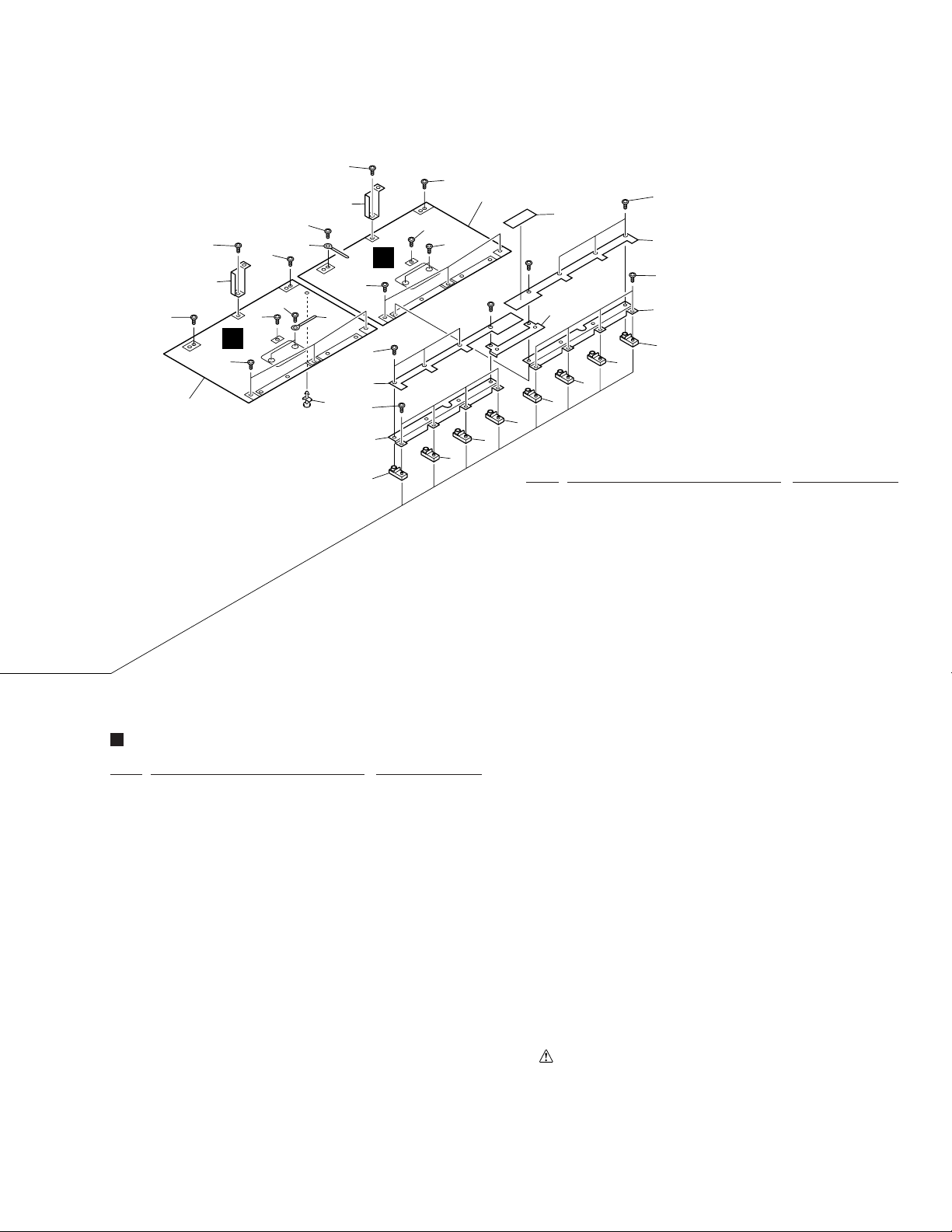

2.5 FRONT PANEL SECTION

PDP-V402

FRONT PANEL SECTION PARTS LIST

Mark No. Description Part No.

NSP 1 Front Case C AMB2605

2 Net FA AED1165

NSP 3 Front Case D AMB2606

4 Net FB AED1184

5 Control Name Plate AAK2706

6 LED Lens AAK2695

7 Control Button AAC1536

8 Screw BPZ30P080FZK

9 Front Case A AMB2603

10 Front Case B AMB2608

11 Lens AAK2698

12 Pioneer Seal ARW1088

13 Protect Panel Assy AMR3229

NSP 14 Panel Spacer A ANG2155

NSP 15 Panel Spacer B ANG2156

Mark No. Description Part No.

16 Screw BPZ40P080FZK

17 Shield Gusket B ANK1654

18 Shield Gusket H ANK1660

19 Shield Gusket A ANK1653

20 Shield Gusket F ANK1658

21 Shield Gusket G ANK1659

22 Shield Gusket I ANK1661

23 IR RECEIVER ASSY AWZ6526

24 Cushion Rubber AEB1336

25 FRONT KEY ASSY AWZ6525

NSP 26 Shield Sheet ANK1532

27 Cushion AEB1342

28 Front Case C Service Assy AEA1030

29 Front Case D Service Assy AEA1031

30 Front Case A Service Assy AEA1034

31 Front Case B Service Assy AEA1035

11

Page 12

PDP-V402

2.6 MAIN UNIT SECTION (3/3)

55

54

17

18

19

5

16

5

5

F

15

5

39

38

40

56

53

55

54

5

16

5

5

6

12

5

10

5

5

11

N

14

5

6

13

11

5

13

5

6

10

5

20

34

23

5

E

40

5

40

13

5

D

22

23

U

49

R

46

5

6

5

33

S

47

50

V

T

48

5

9

51

5

M

5

5

21

8

8

5

10

5

5

4

3

2

44

6

44

5

6

1

45

7

5

24

O

27

24

28

6

5

5

5

26

25

P

25

12

Page 13

PDP-V402

5

29

5

5

29

5

5

H

5

35

6

5

16

6

52

G

5

17

31

5

32

8

5

36

5

16

8

8

37

30

8

8

8

17

31

5

32

8

8

Mark No. Description Part No.

21 MAIN POWER ASSY AWR1077

22 Shield Case B ANK1517

23 PCB Spacer AEC1121

24 SCAN MODULE (A) AXF1104

25 SCAN MODULE (B) AXF1105

NSP 26 Aluminium Panel ANA1555

NSP 27 Plasma Panel Assy AAV1235

28 DIGITAL VIDEO ASSY AWP1069

NSP 29 Rear Panel Angle ANG2171

NSP 30 Hot Plate B ANG2160

MAIN UNIT SECTION (3/3) PARTS LIST

Mark No. Description Part No.

NSP 1 Pipe Cover AMR2935

2 Terminal Shield ANK1547

3 Ground Wire (J50) ADX2332

4 Screw FBT40P080FZK

5 Screw IBZ30P080FCC

6 Binder AEP-215

7 Insulating Sheet S AEC1822

8 Plate Spacer AMR3068

NSP 9 PCB Holder D ANG2165

10 Circuit Board Spacer AEC1696

NSP 11 Fan Angle ANG2166

12 Fan Motor (60×25) AXM1038

13 Screw PPZ50P100FZK

14 X DRIVE (A) ASSY AWP1078

15 X DRIVE (B) ASSY AWP1079

16 Screw BBZ30P140FMC

17 Screw ABZ30P100FMC

18 Barrier S AEC1821

NSP 19 Hot Plate S ANG2161

20 SUB POWER ASSY AWZ6173

31 Barrier L AEC1820

NSP 32 Hot Plate A ANG2159

33 Circuit Board Spacer AEC1720

34 R Free Spacer AEC1721

35 Y DRIVE (B) ASSY AWP1077

36 Y DRIVE (A) ASSY AWZ6533

37 Caution Label ARW1073

NSP 38 Core Holder ANG2433

39 Bush C AEC1740

40 PCB Hinge AEC1694

41 Shield Case B ANK1517

NSP 42 PCB Spacer AEC1121

43 ...............................

NSP 44 PCB Spacer AEC1104

45 Card Spacer AEC1706

46 RCC CONTROL (A) ASSY AWZ6174

47 RCC CONTROL (B) ASSY AWZ6175

48 RCC CONTROL (C) ASSY AWZ6176

49 OTL CONTROL (A) ASSY AWZ6177

50 OTL CONTROL (B) ASSY AWZ6178

51 Fuse (8A, FU1) REK1086

NSP 52 Spacer AEC1074

53 Insulation Rear Sheet AEC1866

54 Ferrite Core Holder AEC1818

55 Ferrite Core (L5, L6) ATX1037

56 Ferrite Core (L4) ATX1042

13

Page 14

PDP-V402

2.7 PDP SERVICE ASSY (AWU1026)

PDP SERVICE ASSY (AWU1026) is composed of the following parts.

Please refer to 2.1.2 to 2.1.4 and 2.1.6 for the illustrations of each part.

Mark No. Description Part No. Mark No. Description Part No.

2.1 REAR PANEL SECTION

28 Cover Sheet AEC1824

NSP 30 Drive Voltage Label ARW1097

2.3 MAIN UNIT SECTION (1/3)

NSP 8 Panel Sheet V AMR3154

NSP 9 Panel Sheet H AMR3172

2.4 MAIN UNIT SECTION (2/3)

1 FPC Cushion AEB1343

12 FPC Shield H ANK1518

13 Angle D ANG2252

15 Angle B ANG2434

16 Angle A ANG2250

NSP 18 Corner Angle ANG2158

19 Screw ABA1266

2.6 MAIN UNIT SECTION (3/3)

NSP 1 Pipe Cover AMR2935

5 Screw IBZ30P080FCC

7 Insulating Sheet S AEC1822

10 Circuit Board Spacer AEC1696

NSP 26 Aluminium Panel ANA1555

NSP 27 Plasma Panel Assy AAV1235

NSP 44 PCB Spacer AEC1104

45 Card Spacer AEC1706

OTHERS

NSP Address Module (A) MC-8795A-A

NSP Address Module (B) MC-8795B-A

NSP

NSP

NSP

NSP

Flexible Print Cable (A) (J65, J66)

Flexible Print Cable (B) (J67, J68)

Flexible Print Cable (A) (J77, J78)

Flexible Print Cable (B) (J79, J80)

BS Panel Label AAX2745

ADY1033

ADY1034

ADY1041

ADY1042

PACKING

NSP Corner Pad AHA2207

NSP Upper Carton AHD2968

NSP Under Carton AHD2969

NSP Holder Plate AHK1007

Button Bolt ABA1259

Packing Sheet AHG1291

Washer WB80FZB

14

Page 15

PDP-V402

15

Page 16

1

23

PDP-V402

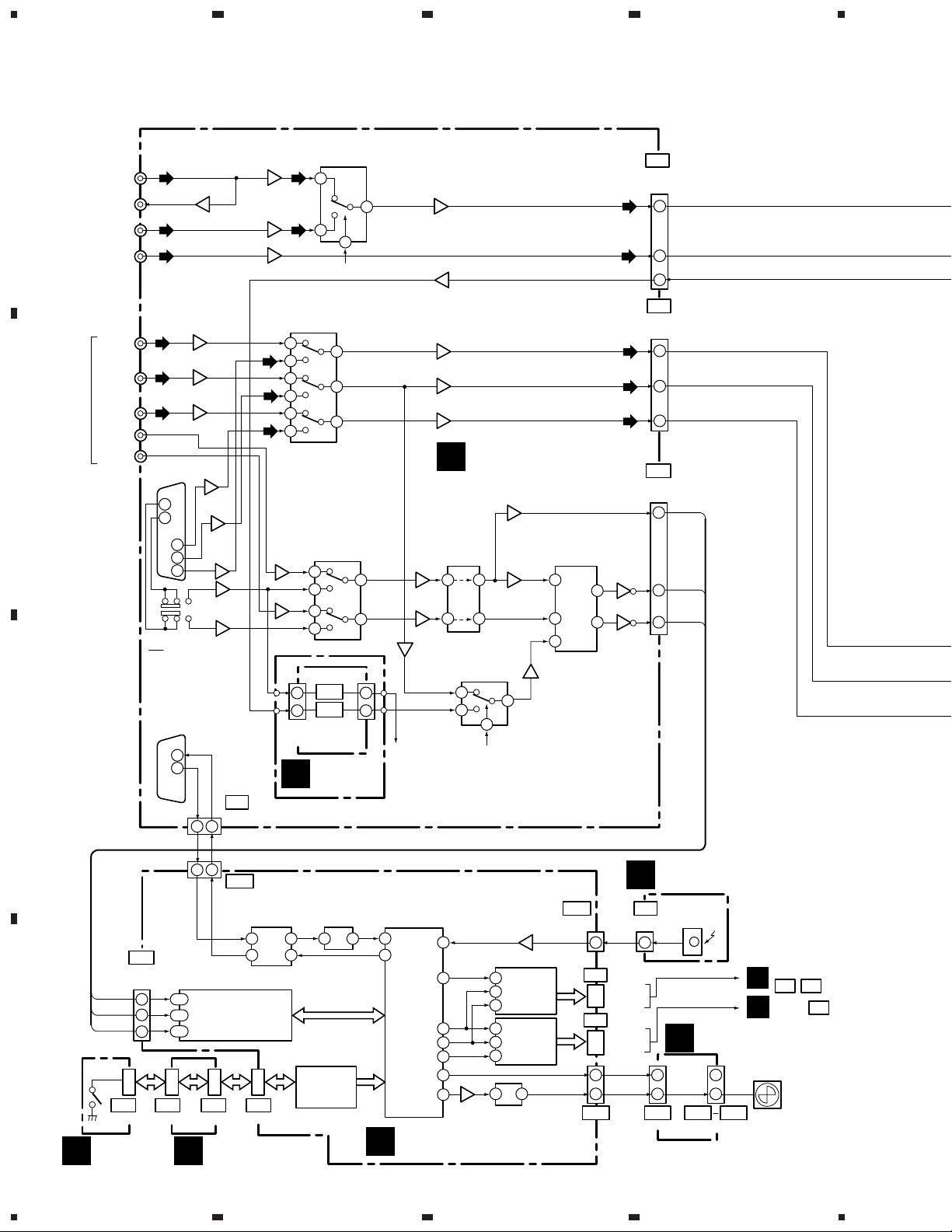

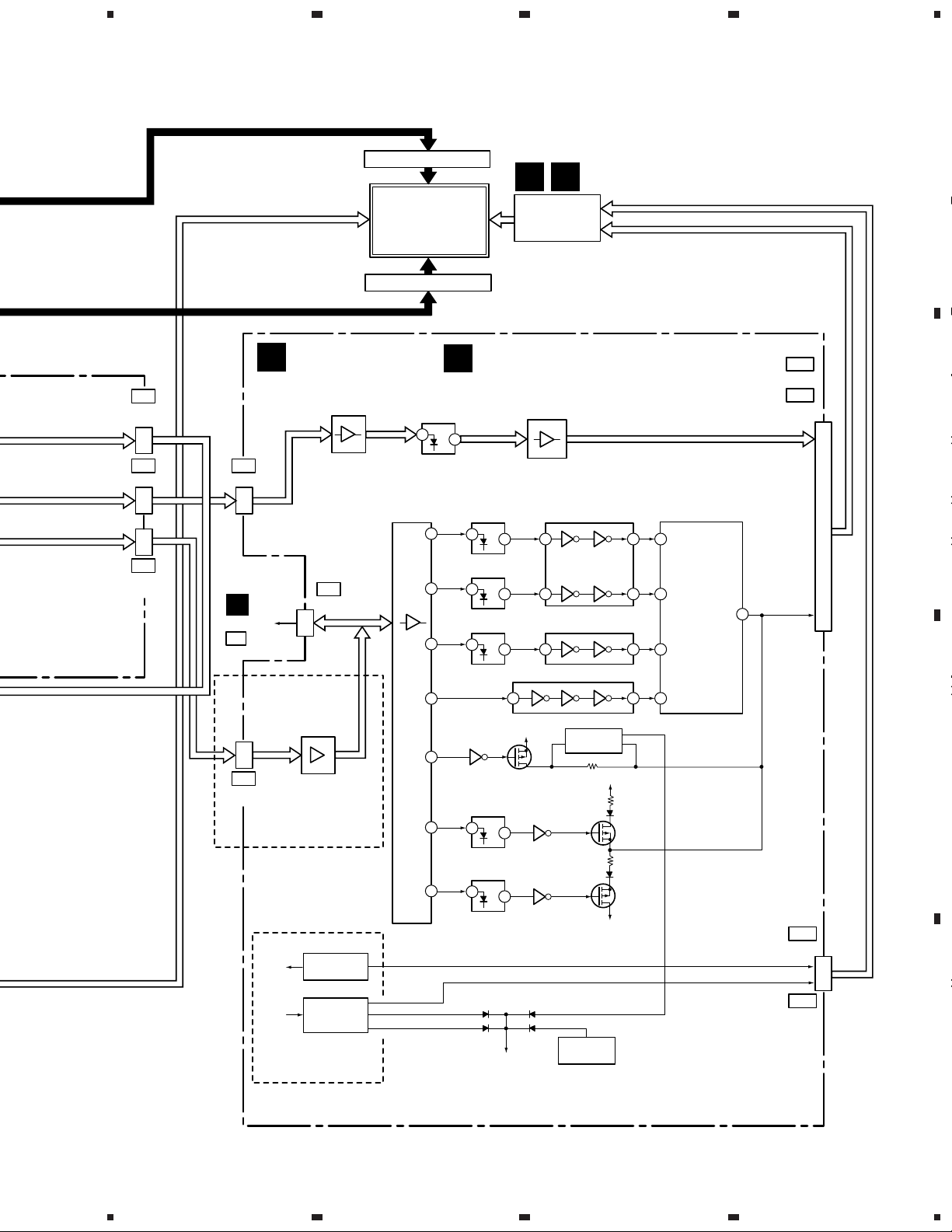

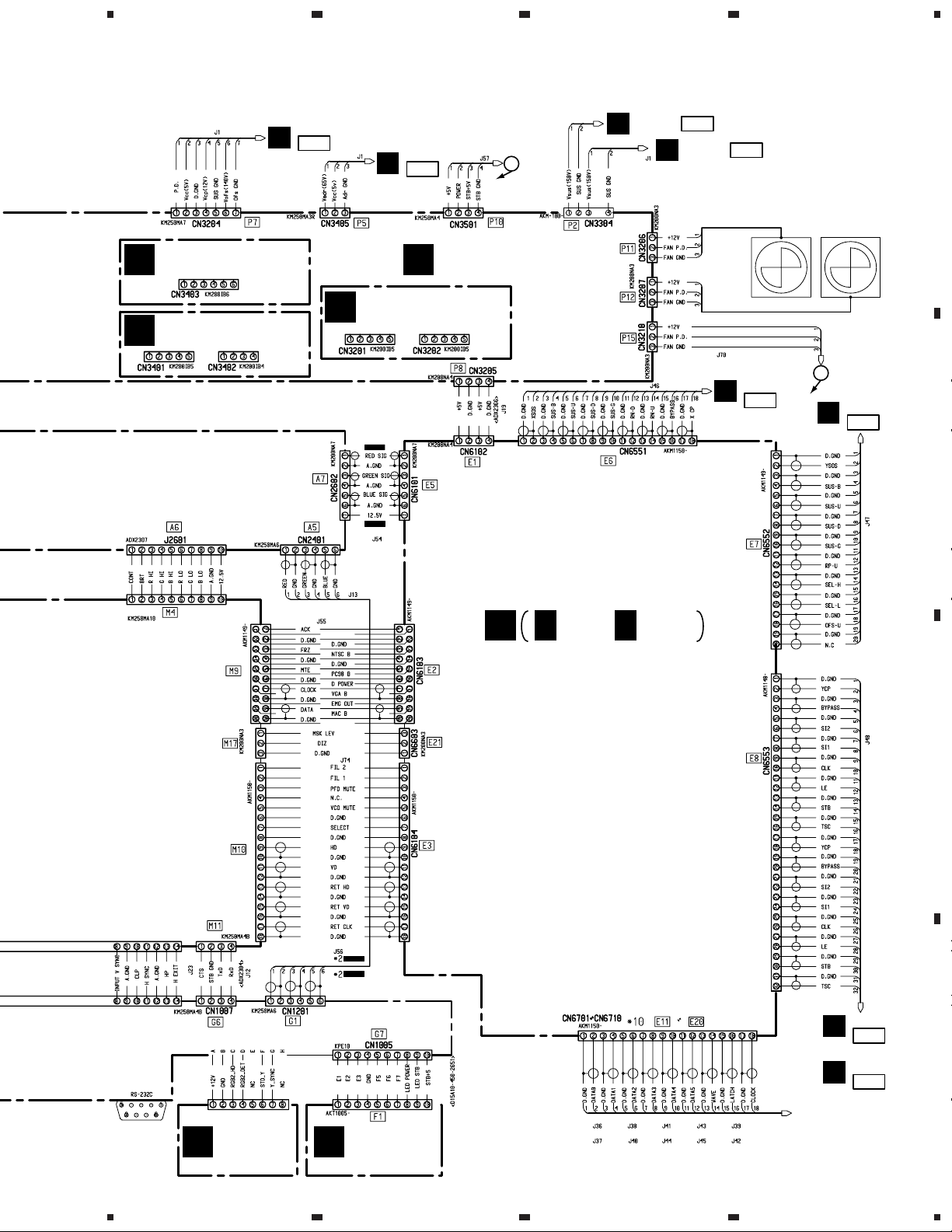

3. SCHEMATIC DIAGRAM AND BLOCK DIAGRAM

3.1 BLOCK DIAGRAM

IC1005

A

C. VIDEO

IN

C. VIDEO

OUT

RED

GREEN

RGB1

BLUE

HD/CS

B

VD

RGB2

Y

C

(V)

(Y)

(C)

(R)

(G)

(B)

CN1203

14

13

3

2

1

S1201

ON – OFF

Q1029-Q1033

Q1201

Q1202

Q1203

Q1204

Q1205

B

G

Q1206

R

HD

VD

Q1034

Q1028

Q1027

(R)

(G)

(B)

Q1038

Q1039

STD_Y

CN1006

TXD

2

RXD

C

RS-232C

3

G6

CN1007

4 3

RXD

TXD

4 3

M11

CN7003

IC7003

MC145407F

RXD

9

TXD

8

RS-232C

RECEIVER/DRIVER

IC7502

CPLD

CN7351

INHSYNC

INVSYNC

HD

M5

(14P)

6

8

11

122

120

EPM7256AETC144-10

113

D

M6

G8

G7

F1

CN7800

FRONT KEY

I

ASSY

CN1005

A

CN7000

CN1004

INPUT CONTROL

ASSY

NJM2233BLA

(V)

(Y)

IC1201

TC4053BF

1

2

3

5

13

12

TC4053BF

Q1040

Q1041

Q7750-Q7752

RGB2_HD

3

C

6

F

Q7753,Q7754

(8P)

CN7750

L

(4P)

(4P)

TC7566FU

13

IC7000 PD5136

KEY INPUT

MICRO-

COMPUTER

6

4

8

7

Y/C SW

15

4

14

IC1001

1

2

3

5

DET

LPF

HD

15

VD

4

4

7

SYNC DET

ASSY

SYSTEM CONTROL

IC7004

MICROCOMPUTER

1212

B

Q1035

Q1037

Q1207

Q1208

Q1209

A

INPUT CONTROL ASSY

COMP.

IC1002

Q1001-

NJM319M

Q1004

4 4

Q1005-

Q1008

9127

Q1036

D

G

RGB2_DET

IC7002

M38869FFAHP

RXD/SDA2

21

20

TXD

OSD_CEB

DAC_CEB

CONTROL ASSY

NJM2233BLA

BNC_G

SYNC_Y

REM_IN REM

22

46

CLK

7

DATA

8

47

PD

15

FAN

14

IC1006

6

8

CN. SW

PQ20VZ1U

Q1010

Q1009

4

7

4

5

PD5385A

6

2

3

M62358FP

1

4 3

IC7900

VIDEO

IC7253

OSD

IC7252

DAC

HD

IN

VD

IN

IN

SYNC

PROCESSOR

IC1004

CXA1616S

18

1

21

7

Q1045

M12

CN7001

(3P)

1 3

M7

M4

2

CN7901

1

(3P)

M19 FR1 FR2 FR6

G2

CN1002

(8P)

(V/Y)

(C)

V/Y

3

C

5

3DY

1

G1

CN1201

(6P)

(R)

(G)

(B)

R OUT

1

G OUT

3

B OUT

5

G4

CN1001

(14P)

HD

11

INPUT

HSYNC

6

INPUT

VSYNC

8

IR RECEIVER

J

ASSY

X7850

H1

REMOTE

CN7850

CN7251

(11P)

CN7250

(10P)

P.D

12V/8.8V

SENSOR

(3P)

K

2

1

CN5801 CN5802-CN5806

4

J2202

C

A2 A8

J2601

C

FAN RELAY ASSY

2

1

FAN

A6

16

1234

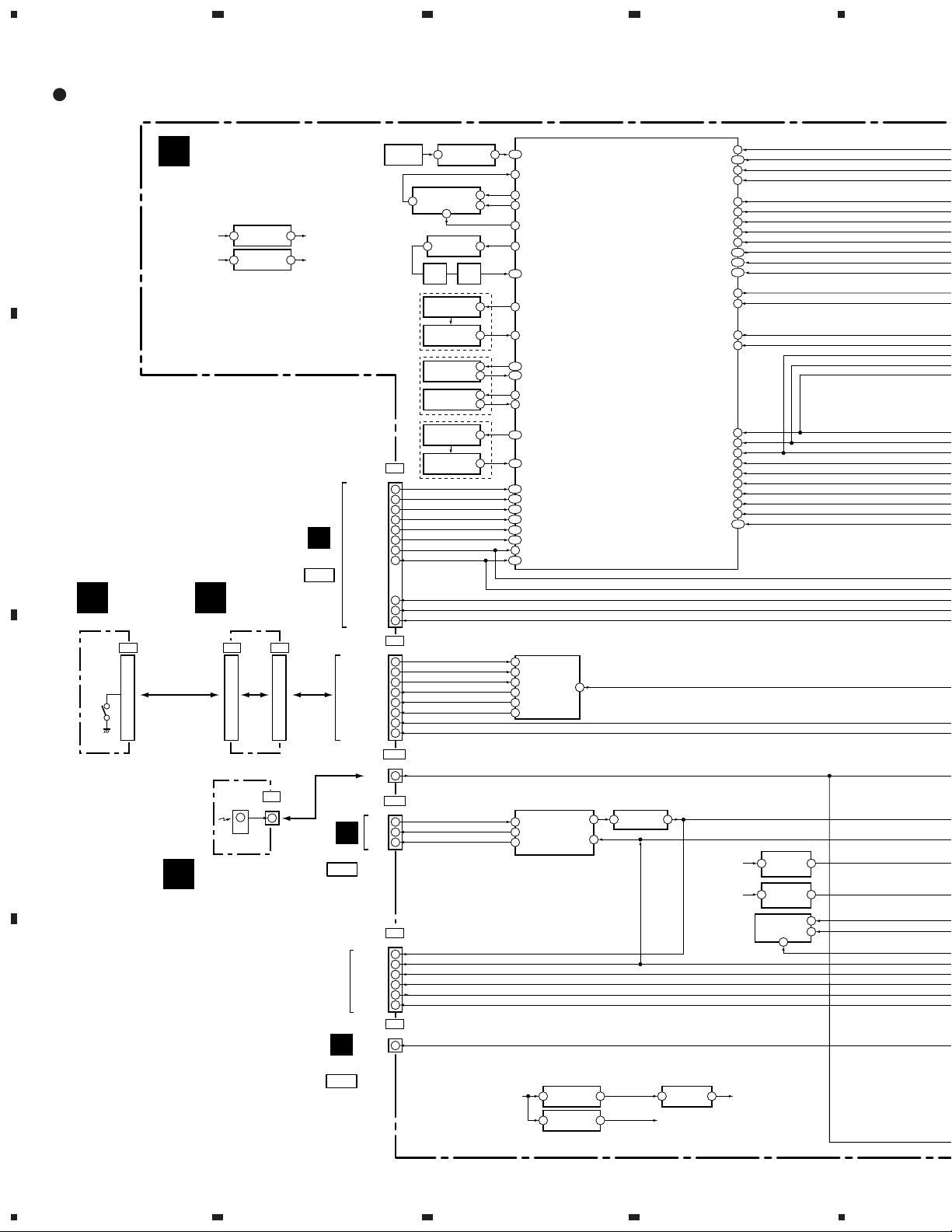

Page 17

5

678

PDP-V402

V/Y

C

3DY

3D_Y

3D_C

CN2401

R SIG

G SIG

B SIG

B2

CN3203

(8P)

3

5

1

A1

CN2201

(4P)

1

3

(6P)

A5

(R)

1

(G)

3

(B)

5

VIDEO AMP

IC3204

TK15420M

(V/Y)

(C)

Q

(Y)

(C)

5 7

3

1

3D Y/C ASSY

BLACK LEVEL

CONTROL

Q2801-Q2803 Q2811

IC2801 PA0028

17

RGB SELECT

IC2401

NJM2283M

1

16

14

11

9

8

(R)

(G)

(B)

Q3206 Q3205

(V/Y)

Q3210 Q3209

(C)

12

5 6

(R)

3

(G)

5

(B)

6

F3201

LPF

F3202

LPF

DELAY

DL2802

Q2403-Q2426

10dB

AMP

10dB

AMP

10dB

AMP

10dB

AMP

10dB

AMP

10dB

AMP

UPD64082GF-3BA

(V/Y)

(C)

MA0-8 MO0-15

Q2813

(Y) (Y)

6MHz

LPF

6MHz

LPF

6MHz

LPF

16MHz

LPF

16MHz

LPF

16MHz

LPF

IC3205

88 84

AY1

AY0

3D Y/C SEP.

AC1

96 83

MSM5416258B-30JD

IC2802 PA0030

RGB SELECT

AC0

4M DRAM

IC3206

SHARPNESS

CONTROL

7 58

9

Q2814

IC2402

NJM2283M

1

16

14

11

9

8

(R)

3

(G)

5

(B)

6

Q3224

(Y)

Q3217

(C)

(C)

Q2648,Q2629

Q2649,Q2627

Q2650,Q2631

F3203

Q3220,Q3223

LPF

F3205

Q3214,Q3218

LPF

Q3208

RGB DECODE

IC2201 TA8759BN

Y

C

20

Q2607-Q2610

41

R OUT

G OUT

42

B OUT

43

IC2601 M51387P

(R)

OSD

Q2611-Q2614

(G)

OSD

Q2615-Q2618

(B)

OSD

1

5

3

6

8

13

IC2602

TC74HC4066AF

PEDESTAL CLAMP

(Y)

(C)

(R)

(G)

(B)

RGB AMP

IN

OUT

3

R

R

IN

OUT

7

G

G

IN

OUT

11

B

B

CLAMP PULSE

B4

CN3204

(4P)

Q2651

29

Q2652

25

Q2653

21

3D_Y

1

3D_C

3

(R)

(G)

(B)

CN2602

(7P)

A7

A

B

A

R OUT

1

G OUT

3

B OUT

5

C

(V/Y)

: V/Y Signal Route

(Y)

: Y Signal Route

(C)

: C Signal Route

(R)

: R Signal Route

(G)

: G Signal Route

(B)

: B Signal Route

ANALOG VIDEO ASSY

C

CONTROL ASSY

B

IC7002

M38869FFAHP

SYSTEM CONTROL

MICROCOMPUTER

IC7502

EPM7256AETC144-10

98

HD OUT

CPLD

VD OUT

100

IC7501

TD74BC541F

3217

18

M10

CN7501

(18P)

HD

9

VD

11

D

B

17

5

6

7

8

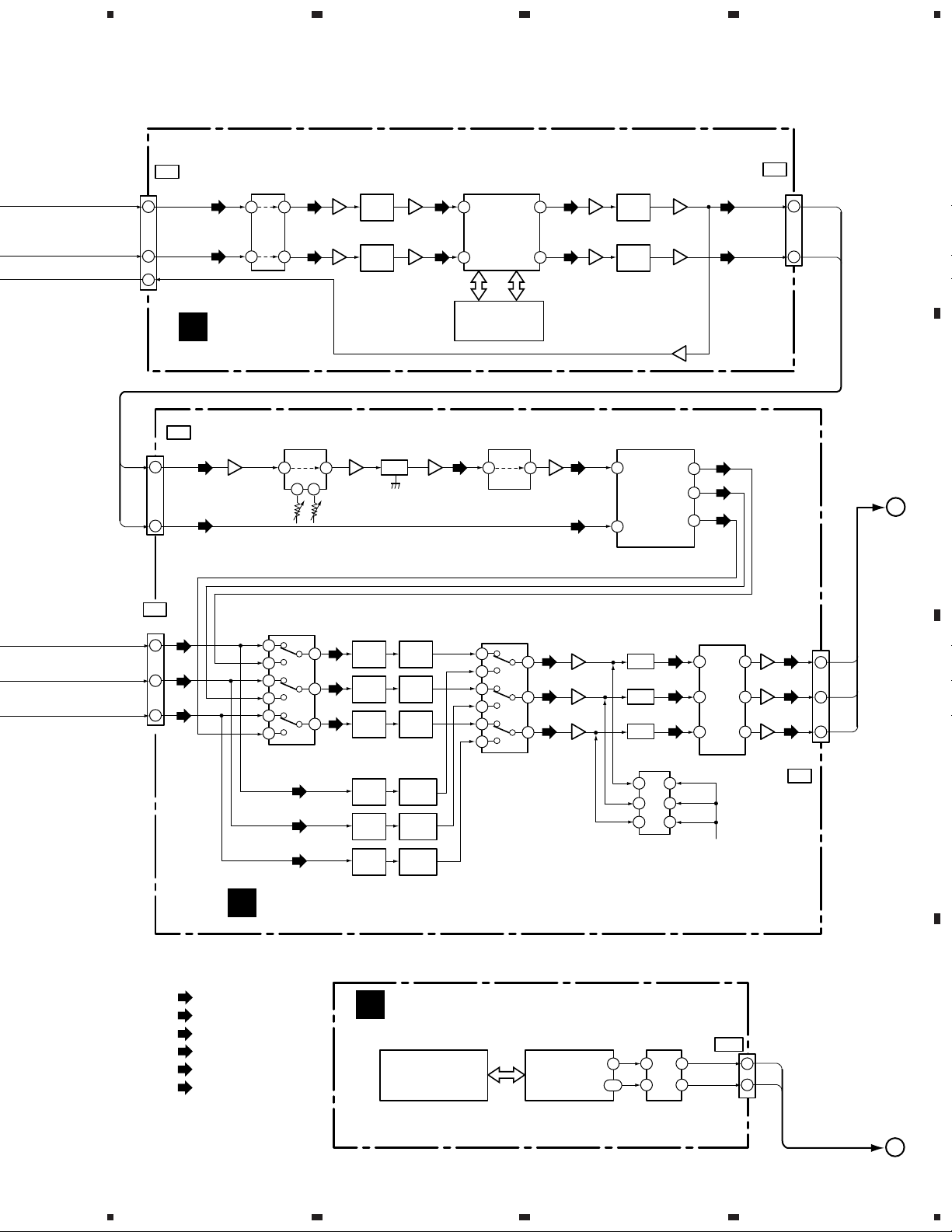

Page 18

1

PDP-V402

23

4

A/D CONVERTER

A

R IN

G IN

B IN

(R)

1

(G)

3

(B)

5

MB40C558PF

Q6101

MB40C558PF

Q6102

MB40C558PF

Q6103

IC6101

4-11

RV(0-7)

21

IC6105

21

GV(0-7)

4-11 165-172

IC6106

4-11

BV(0-7)

21

153,154,

158-163

174-181

E5

CN6101

(7P)

(R)

(G)

B

(B)

A

E3

CN6104

(18P)

HD

9

VD

11

IC6206

PDY055A

EPLD

: R Signal Route

: G Signal Route

: B Signal Route

IC6001

TC74ACT541FT

7

8

9

UD

AYW1006

MICROCOMPUTER

89

4

IC6008

VD OUT

76

77

3

81

HD IN

VD IN

13

12

11

DIGITAL VIDEO ASSY

D

89-92,

94-100

73-77,

IC6201

PD4800A

GAMMA

193 192 188

HD

UAD

80-85,87

59-64,

66-71

SDT

55

SCK

57

CLK2I

184

VD

REF_H

IC6601

REF_H

GCLK

100

13

IC6005IC6005

12

80

83

PANEL

88

HDVD

10

11

IC6006

PDY053A

EPLD

RD(0-11)

GD(0-11)

BD(0-11)

12

13

5

6

236-246,

249

250-256,

258-262

263,264,

269-278

281

280

SPR

SCK

87

PD4799A

SDT

88

IC6005:

IC6007

IC6007: TC74VHCU04FT

IC6008:

IC6007

21

IC6007

4

TLC2932IPW

IC6301

PD4801A

SFMC

287

92

IC6501

DRVC

TC74VHC04FS

TC74ACT04FT

VCO

FIN_A

OUT

PLL

IC6003

UPPER

ADDRESS

DATA

(0-29)

LOWER

ADDRESS

DATA

(0-29)

3

IC6705-IC6708

TC74ACT541FT

IC6701-IC6704

TC74ACT541FT

DRAM

(×4)

IC6401-IC6404

LC32V4265JL-25S

IC6551

PDY054A

EPLD

21 22

25 27

5 7

5 7

IC6555IC6554

2 14

2 14

VR6553

VR6552

VR6551

SUSTAIN PULSE ADJ

E11 E15

CN6701

CN6705

(18P)

E16 E20

CN6706

CN6710

(18P)

IC6553

TC74ACT541FT

IC6556

TC74ACT540FT

IC6552

TC74ACT541FT

IC6554,IC6555

TC74HC4538AFT

DUAL MMV

VR6554

|

|

PHOTO COUPLER

BUS BUFFER

IC4009

TC74HC541AF

C

(17P)

X9

F

CN4009

CN4009

X9

X4

CN4008

IC4008

TC74HC541AF

BUS BUFFER

(18P)

X DRIVE (A)

ASSY ONLY

D

T4001,IC4007

D-D CONV.

VSUS

(170V)

B

BLOCK

D4010

P.D

IC4012-IC4014,IC4020:

HCPL-M611

IC4012

18

1

IC4013

17

1

IC4014

16

1

SUS-G

15

INA

14

INB

13

IC4020

12

1

XCP

11

VRN(-180V)

D4017

P.D CIRCUIT

IC4005

SUS-B

5

SUS-U

5

SUS-D

5

IC4015

1 12 21

TC74AC04F

3 10 4

1 12 5

IC4022

TC74AC04F

1 12 14

TC74AC04F

RESET

IC4023

TC74AC04F

1 12

5

VCP+12V

Q4001

VCP+12V

IC4017

STK795-120C

PDP PULSE

MODULE

Q4005,Q4007

Charge

Pump

E

F

SUS OUT

7

SUS-MSK

(BYPASS)

CIRCUIT

X DRIVE (A)

ASSY

X DRIVE (B)

ASSY

X12 X17

CN4012

|

CN4017

(8P)

18

1234

Page 19

5

678

PDP-V402

E6

CN6551

(18P)

E8

CN6553

(32P)

E7

CN6552

(20P)

Y4

CN5007

G

CN5009

Y9

Y DRIVE (A) ASSY

G

BUS BUFFER

IC5010

TC74HC541AF

(16P)

(17P)

Y9

CN5009

ADDRESS MODULE (B)

PLASMA

PANEL ASSY

ADDRESS MODULE (A)

H

PHOTO COUPLER

IC5027-IC5032

HCPL-M611

1

5

PHOTO COUPLER

BUS BUFFER

IC5009

TC74HC541AF

IC5017,IC5018,IC5023-IC5025:

HCPL-M611

IC5025

18

1

IC5024

17

1

IC5023

16

1

O P

SCAN MODULE

(A), (B)

Y DRIVE (B) ASSY

BUS BUFFER

IC5019

TC74HC541AFT

IC5014

TC74AC04F

1 12 4

5 10 5

IC5015

TC74AC04F

1 12 14

5

5

5

SUS-B

SUS-U

SUS-D

IC5037

STK795-120C

PDP PULSE

MODULE

CN5013

CN5011

SUS OUT

7

A

Y11

(15P)

Y13

(15P)

B

Y5

CN5008

BUS BUFFER

IC5008

TC74HC541AF

(20P)

Y DRIVE (B)

ASSY ONLY

HDF-0505S

VCC

D-D CONV.

(5V)

T5001,IC5007

D-D CONV.

VSUS

(170V)

Y DRIVE (A)

ASSY ONLY

BLOCK

15

PR-U

14

SEL-H

13

SEL-L

12

VH OVER VOLTAGE DET.

VH UNDER VOLTAGE DET.

SUS-G

Q5007

IC5017

1

IC5018

1

IC5022

TC74AC04F

1 12 21

VSUS170V

Q5006

IC5020,IC5026

5

FET

DRIVER

IC5021,IC5038

5

FET

DRIVER

D5024D5020

D5021D5044

P.D

Q5012

CURRENT

DET.

VCSP(=VOFS)

CSP.GND

(=VOFS-VCSP)

VCP+12V

P.D DET.

Q5001

Q5008

Q5009

PLUS RESET

BLOCK

CN5010

CN5012

C

Y12

(7P)

Y14

(7P)

D

19

5

6

7

8

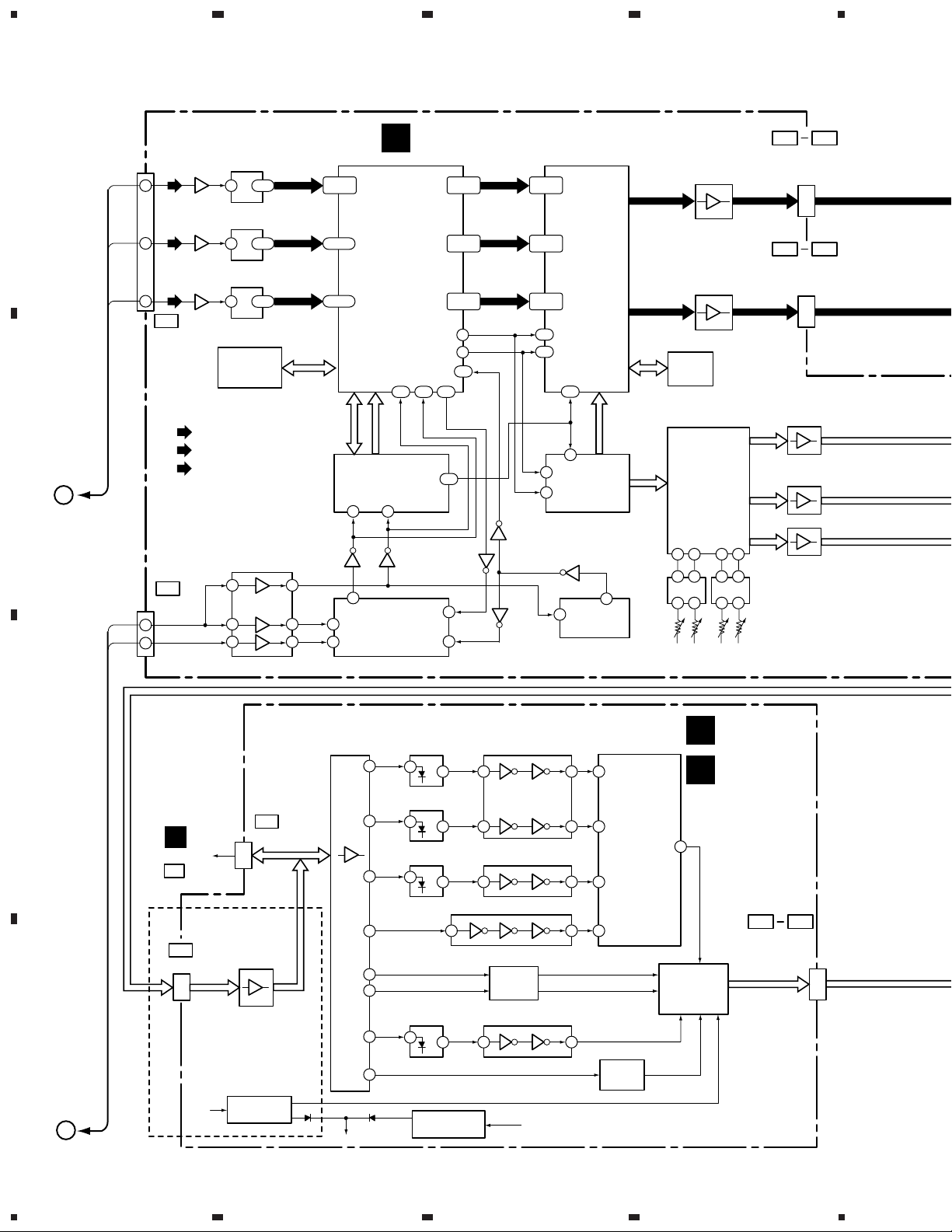

Page 20

PDP-V402

A

1

CONTROL BLOCK

CONTROL ASSY

B

VCCD5V (5V)

VCCAF12 (12V)

IC7500

1 3

PQ3DZ13

IC7654

3 1

UPC78L05T

23

1 2

IC7653

TC74ACT04FT

2

2

UPC1379C

LPF

IC7652 (1/2)

TC74HC4538

IC7652 (2/2)

TC74HC4538

IC7503 (1/2)

TC74HC4538

IC7503 (2/2)

TC74HC4538

IC7506

TC7WU04FU

9

IC7650

VCO

125

CLK_13M

AFC_VOUT

60

AFC_VIN

62

13

AFC_HIN

66

11

AFC_RETH

56

NTSC_PAL

72

3

128

AFC_CLK

68

5

NTSC_CS2

70

9

CS_REJ

11

10

CP

140

142

CP_1US

H_SYNC1

6

5

H_SYNC2

7

2

IC7502

EPM7256AETC144-10

CPLD

PFD_MUTE

CP_VIDEO

VP_MUTE

VCCPLD (3.3V)

VCCAF05 (5V)

X7500

ASS1128

TCK

TDO

TMS

FIL_1

FIL_2

SELECT

HD_OUT

VD_OUT

RET_HD

RET_VD

OSD_HD

OSD_VD

TDI

104

100

102

106

4

89

20

4

84

87

91

96

98

44

42

46

48

IC7504 (1/2)

TC74HC4538

B

A

CN1001

INHSYNC

INVSYNC

CLP

HP

HEXIT

SYNC_ST

RGB_SW

CN7351

HD

M5

IC7504 (2/2)

TC74HC4538

6

8

10

11

13

14

4

2

10

HD

5

138

/HD_OUT

134

122

HD_SEP

120

VD_SEP

118

CP_SEP

113

HD_COMP

HP_SEP

111

HEXT_SEP

109

25

SYNC_ST

116

RGB_SW

NTSC

MAC

VGA60_75

V_MUTE

FR_SEL

PAL/NTSC

OUTSYNC

H.SYNC

V.SYNC

CLR_PLD

127

30

29

75

31

22

16

18

14

12

G4

FRONT

I

KEY

ASSY

C

J

D

INPUT

A

CONTROL

ASSY

H1

CN7850

1

G8

G7F1

REMOTE

SENSOR

IR RECEIVER

ASSY

SERIAL I/O

MODE OF

INTERNAL FLASH

MEMORY MODE-2

LED_POWER

A

CN1007

G6

M

CN3501

P10

RGB_SEL

Y/C_SW

OPTION1

LED_STB

REM

RXD

TXD

CTS

SDA2

VDD

*RST

PGM_OE

SCL2

BUSY2

POWER

CN7000

E1

E2

E3

F5

F6

F7

M12

CN7001

M11

CN7003

CN7004

CN7005

M6

M8

M2

3

1

5

10

9

8

6

5

4

3

2

1

4

3

1

5

3

7

6

4

1

2

VCC+12(12V)

8

IC7000

9

PD5136

10

Key Input

13

Microcomputer

12

11

IC7003

9

MC145407F

8

RS-232C

17

RECEIVER/DRIVER

IC7250

3 1

NJM78L09UA

IC7251

3 1

NJM78L09UA

19

12

13

IC7004

2

TC7S66FU

VCCA9V(9V)

VCCA5V(5V)

1

VCCCPU (5V)

VCCD5V (5V)VCCD5V (5V)

IC7901

1 3

PQ20VZ1U

5 4

PST9146N

5 4

PST9146N

24LC64(I)SN

64k EEPROM

VCCFN1(5V)

IC7005

Reset IC

IC7006

Reset IC

IC7001

8

6

5

20

1234

Page 21

NTSC

52

MAC

53

9

VGA60_75

V_MUTE

40

FR_SEL

62

PAL/NTSC

70

69

OUTSYNC

12

H.SYNC

13

V.SYNC

60

CLR_PLD

SYNC_ST

57

RGB_SW

44

RGB_SEL

43

Y/C_SW

45

1

OPTION1

5

678

PDP-V402

M13

CN7500

TCK

1

TDO

2

DIZ

MSKLEV

H.BLK

V.BLK

PNEL_CEB

D_POWER

ACK

PC98

VGA

PMUTE

MSK

D_RESET

EMG_OUT

RGB_SW

50_60

FOR ALTERA ISP

BYTE BRASTER

TMS

3

4

TDI

FIL_1

2

FIL_2

1

PFD_MUTE

3

SELECT

7

HD

9

VD

11

13

RET_HD

15

RET_VD

M10

CN7501

M16

CN7358

H.BLK

1

V.BLK

2

M17

CN7350

33

32

38

40

35

36

34

56

54

51

64

63

48

44

41

1

IC7352

2

TC74VHC541FT

3

18

17

2

1

CN7352

17

19

13

9

7

16

1

15

17

5

3

11

18

CN7355

1

2

6

DIZ

MSKLEV

M9

VGA60_75

MAC_B

NTSC_B

DATA

CLK

D_POWER

ACK

PC98_B

VGA_B

PMUTE

MSK

D_RESET

EMG_OUT

M3

RGB_SW

NTSC

50/60

D

C

D

D

C

CN6104

CN2801

CN6603

CN6103

J2203

E3

A12

E21

E2

A3

A

B

23

KEY_IN

LED_POW

37

LED_STB

38

22

REM_IN

RXD/SDA2

21

20

TXD

*RST

25

59

RESET2

(E)SCL

49

(E)SDA

50

EP_RST

17

24

CNVSS

55

PGM_OE

19

SCL2

BUSY2

18

26

POWER

IC7002

M38869FFAHP

System Control

Microcomputer

STD_MON

SDA

SCL

RGB2_DET

CANAL_SW

OSD_CEB

CLK

DATA

DAC_CEB

FAN

FAN_TEMP

PD_TEMP

CN7354

M1

STD_MON_STD

58

3

2

80

79

46

7

8

47

14

PD

15

6

M5233FP

IC7902

4

6

5

2

3

1

3 2

17 18

19 18

M62358FP

TH7900

NTH4G42B

104F01

IC7254

TC74VHC541AFT

IC7253

PD5385

OSD

IC7252

DAC

VCC+12(12V)

OSD_R

OSD_G

OSD_B

OSD_BLK

SHARP

COLOR

TINT

CONTRAST

BRIGHT

R_HI

G_HI

B_HI

R_LOW

G_LOW

B_LOW

17

15

13

12

9

18

19

16

17

20

21

4

5

6

7

IC7900

1 3

PQ20VZ1U

4

4

3

2

CN7002

1

2

3

CN7251

10

9

5

6

7

8

1

2

3

1

2

3

4

5

6

7

8

M4

CN7250

CN7900

2

CN7901

1

2

SDA

SCL

M18

RGB2_DET

CN_SW

REM_OUT

M7

CLP_P

V.MUTE

OSD_R

OSD_G

OSD_B

OSD_BLK

SHARP

COLOR

TINT

CONT

BRT

R HI

G HI

B HI

R LOW

G LOW

B LOW

M20

P.D

M19

12V/8.8V

P.D

A

C

C

M

CN3201

Q

CN1009

J2202

J2601

CN3210

B3

G9

C

A8

A6

P15

D

FR1FR2-FR6

IC7903

5

M5233FP

TH7901

NTH4G42B

104F01

FAN × 5

FAN RELAY

K

ASSY

21

5

6

7

8

Page 22

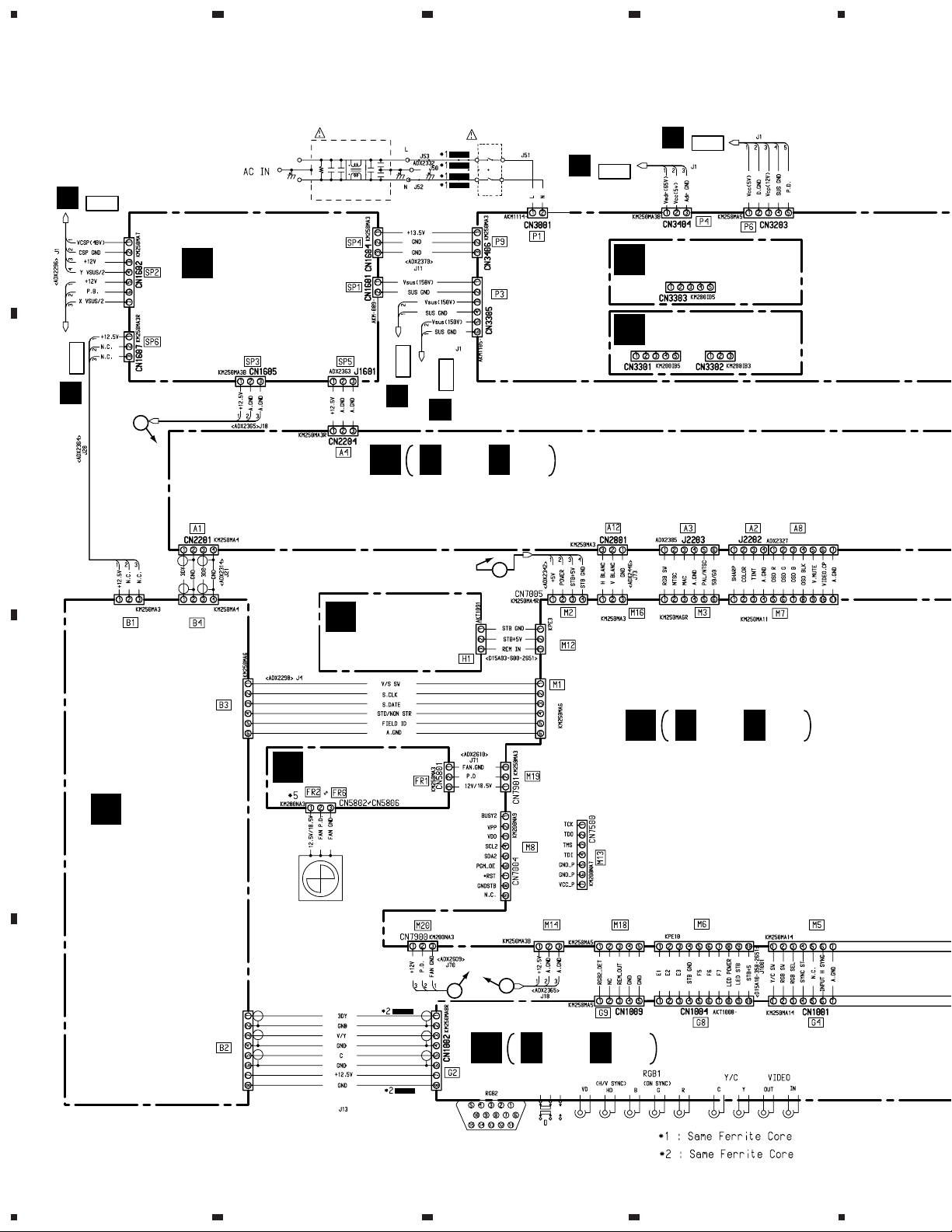

1

23

PDP-V402

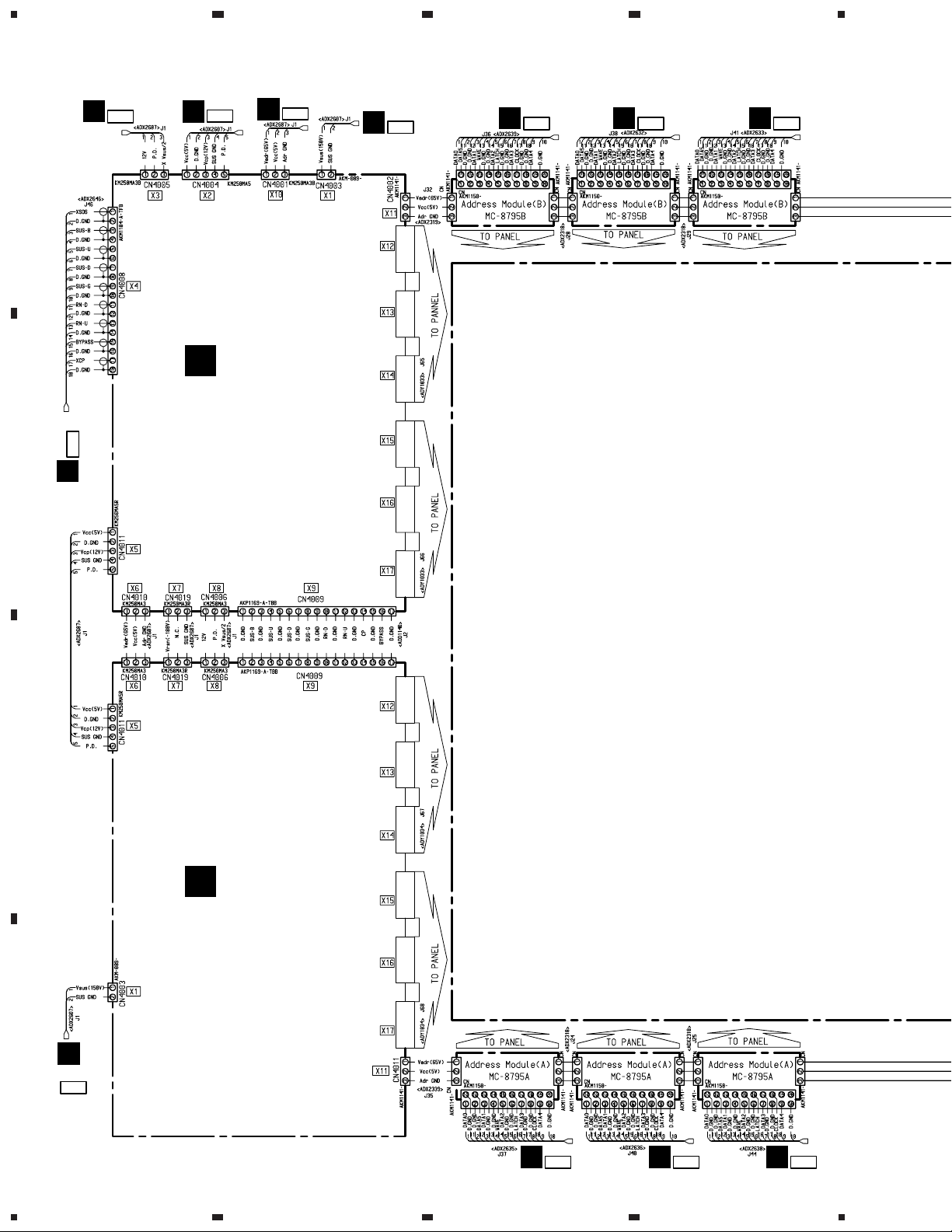

3.2 OVERALL WIRING DIAGRAM

4

AC INLET

AKP1211

A

CN5005

G

Y3

AC100–120V

50/60 Hz

LIVE

NEUTRAL

ADX2586

ADX2585

S1: POWER SW

BSM1010

ADX2584

E

CN4001

X10

E

ADX2607

CN4004

X2

ADX2607

OTL CONTROL (A) ASSY

U

N

(AWZ6177)

SUB POWER ASSY

(AWZ6173)

RCC CONTROL (A) ASSY

R

K

ADX2607

X3

CN4005

E

A

B

C

X1

F

X1

CN4003

CN4003

E

C 1/4- C 4/4

(AWZ6174)

ANALOG VIDEO ASSY

(AWQ1056)

B

B

CN7355CN7358

B 1/6- B 6/6

CN7251

CONTROL ASSY

(AWZ6545)

CN3204CN3202

CN3201

C

FAN RELAY ASSY

K

(AWZ6535)

IR RECEIVER

J

ASSY

(AWZ6526)

CN7850

CN7001

CN7354

3D Y/C ASSY

Q

(AWQ1055)

FAN MOTOR ×5

AXM1039

CN7650 CN7002 CN7000 CN7351

J81

ADX2614

INPUT CONTROL ASSY

(AWZ6554)

A

A

A 1/2- A 2/2

KM250MA8R

D

CN3203

C

22

ADX2650

1234

Page 23

5

678

PDP-V402

Note : When ordering service parts, be sure to refer to "EXPLODED VIEWS and PAR TS LIST" or "PCB PARTS LIST".

ADX2607

G

OTL CONTROL (B) ASSY

V

(AWZ6178)

RCC CONTROL (B) ASSY

S

(AWZ6175)

CN5004

Y2

ADX2607

G

CN5001

Y16

ADX2361

MAIN POWER ASSY

M

(AWR1077)

RCC CONTROL (C) ASSY

T

(AWZ6176)

ADX2652

H

ADX2646

Y1

CN5003

ADX2609

E

Y1

CN4008

X4

FAN MOTOR ×2

AXM1038

C

CN5008

H

A

Y5

B

ADX2630ADX2341

CN5003

G

B

ADX2607

CN7250

CN7003

ADX2608

CN7352

CN7501 CN7350

ADX2644

ADX2645

ADX2651

D.RESET

VGA60_75

ADX2649

D

D 1/10- D 10/10

DIGITAL VIDEO ASSY

(AWP1069)

J7800

G

and

H

CN5007

Y4

CN5007

Y4

C

D

CN7750 CN7800

L

B8B-PH-SM3

SYNC DET

ASSY

(AWZ6548)

5

FRONT KEY

I

ASSY

(AWZ6525)

ADX2639

ADX2632 ADX2633 ADX2633 ADX2634

ADX2635 ADX2636 ADX2638 ADX2638 ADX2637

6

7

To ADDRESS

MODULE

23

8

Page 24

1

PDP-V402

23

4

CN1602

N

SP2

A

M

CN3203

P6

M

CN3404

P4

M

CN3305

P3

D

CN6701

E11

D

CN6702

E12

D

CN6703

E13

E

X DRIVE (A) ASSY

(AWP1078)

E6

B

CN6551

D

PLASMA PANEL ASSY

(AAV1235)

C

F

X DRIVE (B) ASSY

(AWP1079)

D

M

CN3305

P3

24

CN6706

D

E16

1234

D

CN6707

E17

D

CN6708

E18

Page 25

5

678

PDP-V402

D

CN6704

E14

D

CN6705

E15

SCAN MODULE (B)

(AXF1105)

P

SCAN MODULE (B)

(AXF1105)

CN1602

N

SP2

M

G

Y DRIVE (A) ASSY

(AWZ6533)

P2

M

CN3405CN3304

P5

M

CN3204

P7

A

D

CN6553

E8

B

P

SCAN MODULE (A)

(AXF1104)

O

H

Y DRIVE (B) ASSY

(AWP1077)

CN6553

D

M

CN3304

C

E8

P2

D

5

CN6709

E19

D

CN6710

E20

SCAN MODULE (A)

(AXF1104)

O

6

CN6552

D

E7

25

7

8

D

Page 26

1

PDP-V402

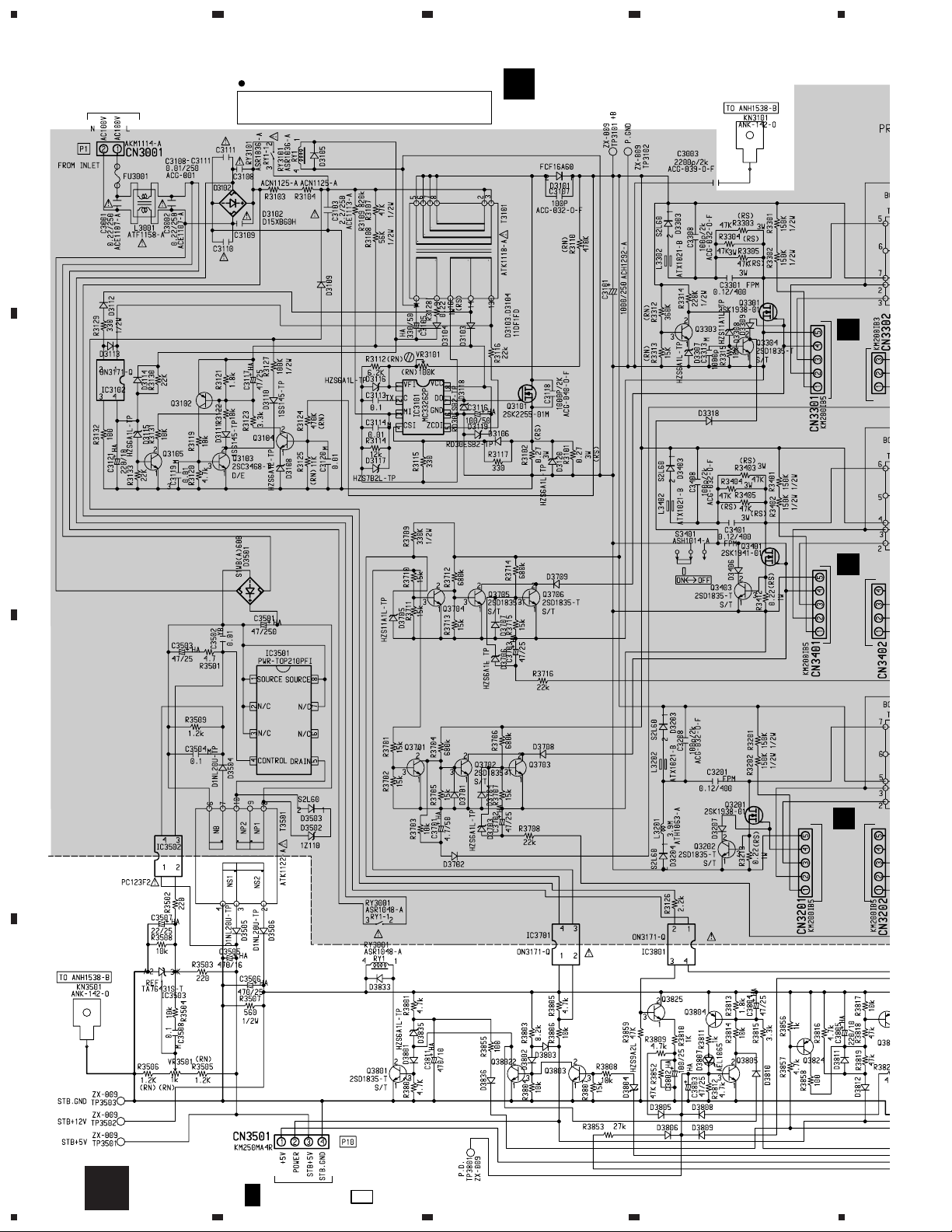

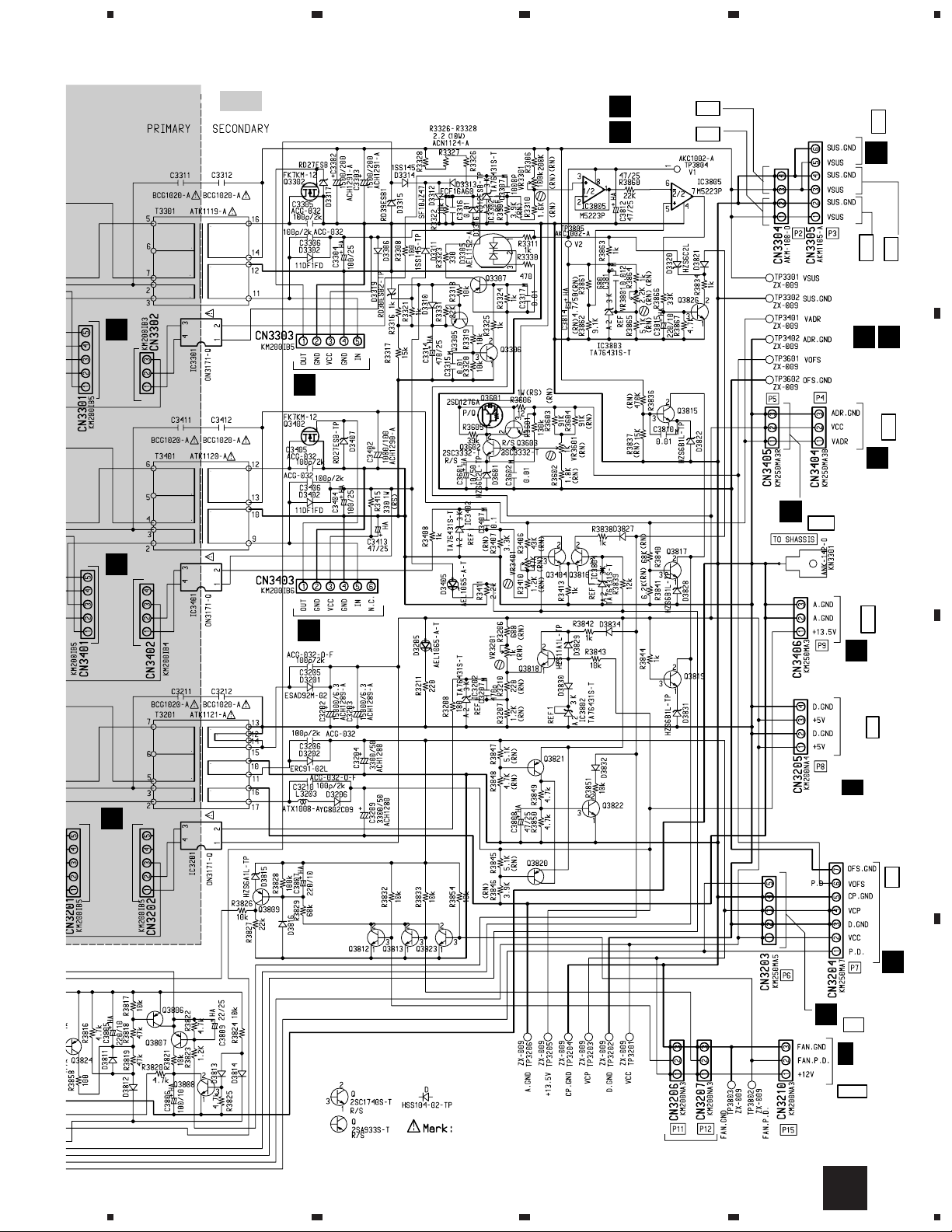

3.30 MAIN POWER ASSY

To POWER SWITCH

A

23

NOTE FOR FUSE REPLACEMENT

CAUTION: FOR CONTONUED PROTECTION AGAINST RISK OF FIRE.

PEPLACE ONLY WITH SAME TYPE AND RATINGS ONLY.

J

M

4

MAIN POWER ASSY (AWR1077)

R

CN7101

CN7102

B

C

S

CN7151

CN7152

T

CN7201

CN7202

D

78

M

B 1/6

CN7005

M2

1234

Page 27

5

678

PDP-V402

7)

R

CN7101

CN7102

1000P

/AC400

1000P

/AC400

: Charged section

1000P

/AC400

CN7251

1000P

/AC400

U

H

CN5003

G

CN5003

Y1

Y1

CN5001

G

Y16

X1

E

CN4003

X1

SP1

CN1601

CN4003

F

N

X10

CN4001

E

A

B

S

CN7151

CN7152

T

CN7201

CN7202

1000P

/AC400

1000P

/AC400

V

CN7301

SP4

CN1604

N

E1

CN6102

C

D 1/10

Y2

CN5004

G

CN4004

E

X2

Be sure to use parts od identical designation.

B 6/6

CN7900

M20

D

To FAN

M

5

6

7

8

79

Page 28

1

PDP-V402

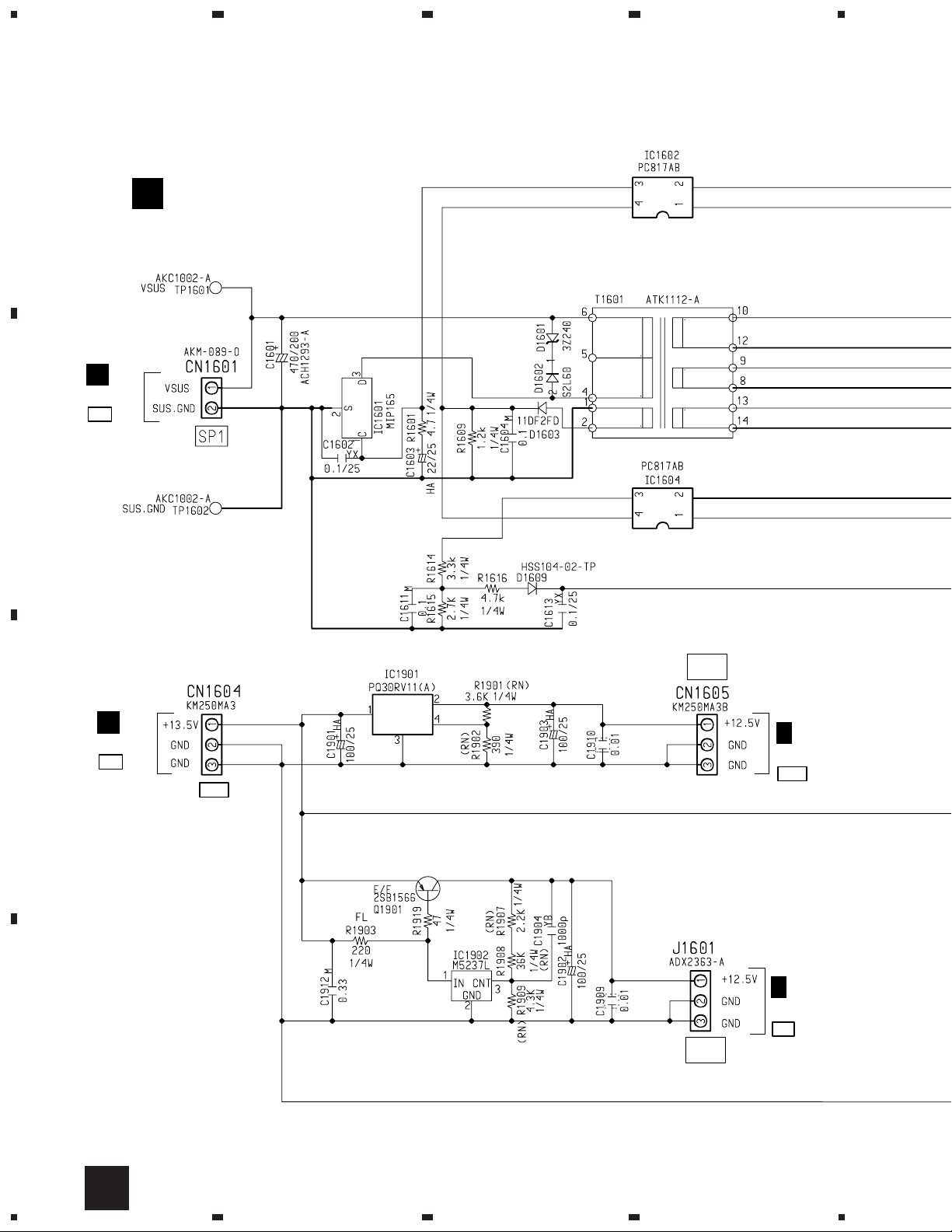

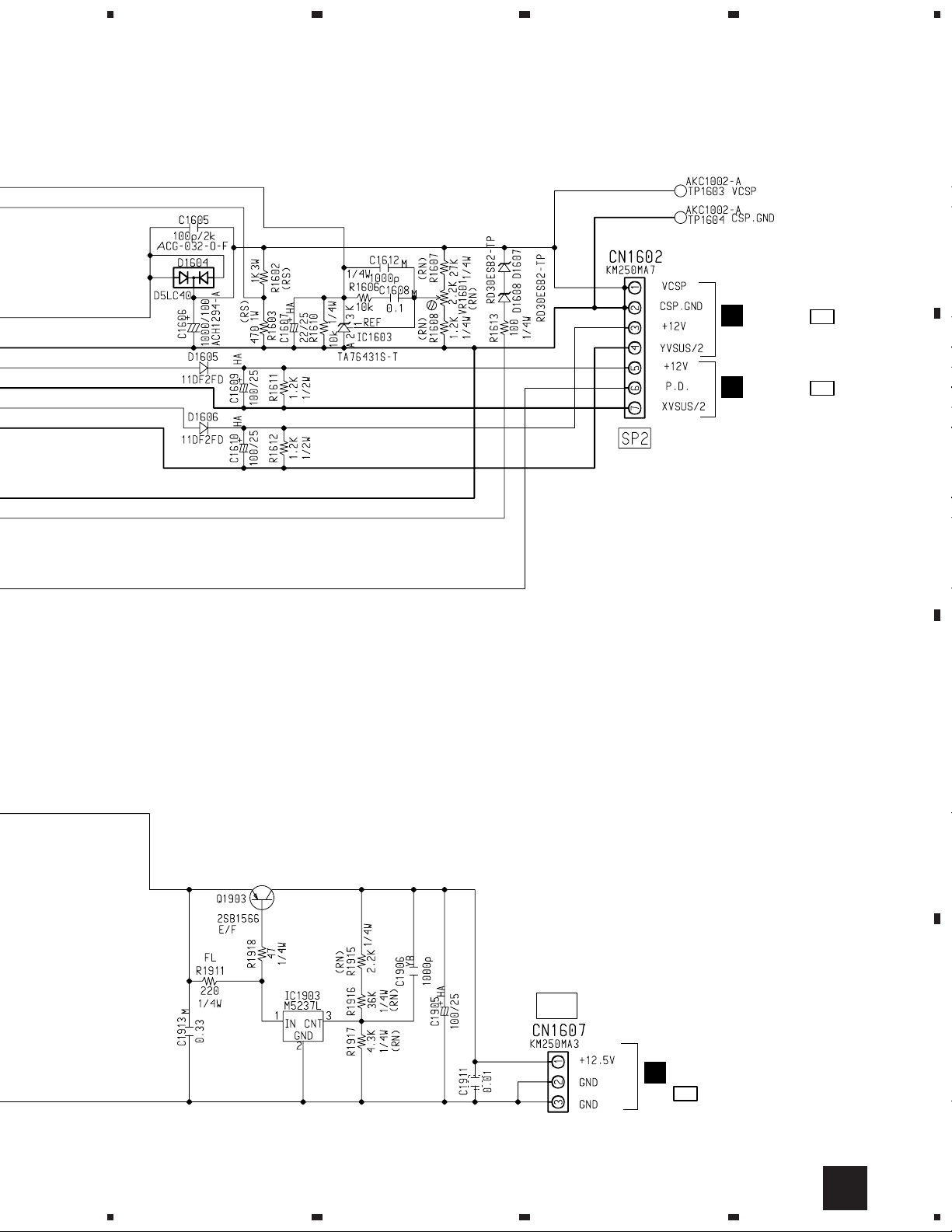

3.31 SUB POWER SUPPLY

A

SUB POWER ASSY

N

(AWZ6173)

M

CN3305

P3

B

23

4

SP3

M

CN3406

C

P9

SP4

B 5/6

CN7650

M14

C 2/4

CN2204

A4

SP5

D

80

N

1234

Page 29

5

678

PDP-V402

A

G

E

CN5005

CN4005

Y3

X3

B

C

SP6

Q

CN3202

B1

N

5

6

7

8

81

D

Page 30

1

Y

L

23

PDP-V402

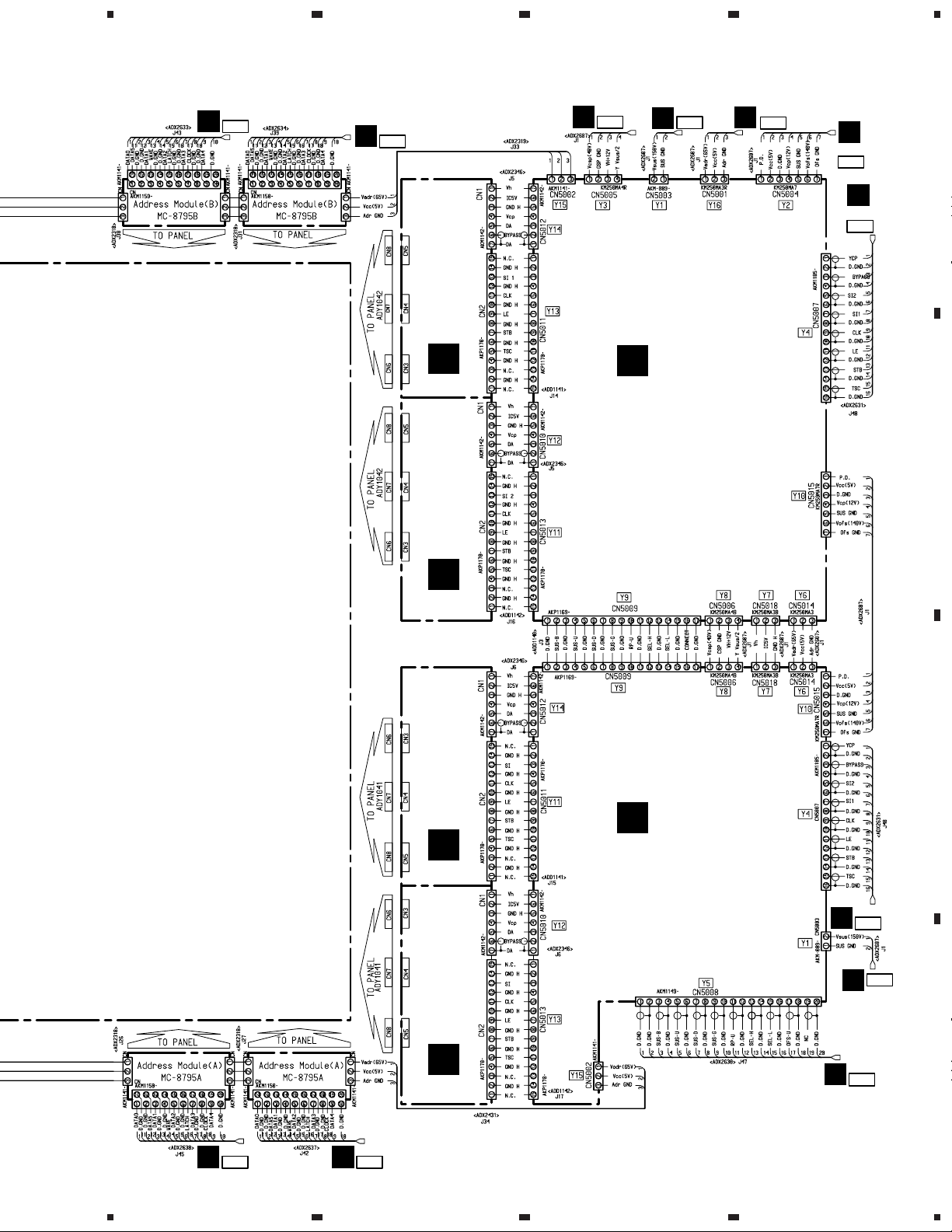

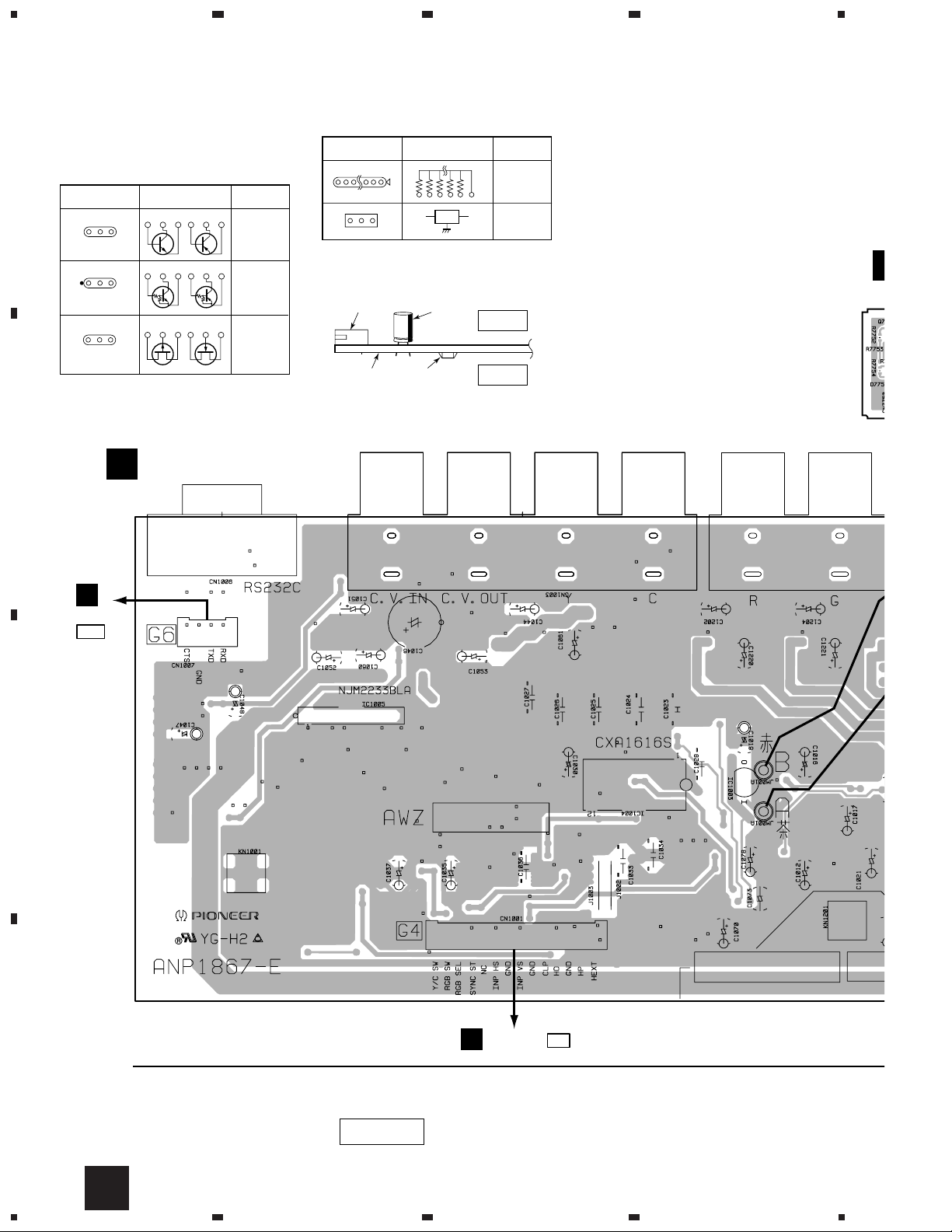

4. PCB CONNECTION DIAGRAM

NOTE FOR PCB DIAGRAMS:

1. Part numbers in PCB diagrams match those in the schematic

A

diagrams.

2. A comparison between the main parts of PCB and schematic

diagrams is shown below.

Symbol in PCB

Diagrams

BCE

BCE

DGS

Symbol in Schematic

Diagrams

BCE

BCE

BCEBCE

DGSDGS

Part Name

Transistor

Transistor

with resistor

Field effect

transistor

4.1 INPUT CONTROL, FRONT KEY, SYNC DET ASSYS

Symbol in PCB

Diagrams

3. The parts mounted on this PCB include all necessary parts

for several destination.

For further information for respective destinations, be sure

to check with the schematic diagram.

4. Viewpoint of PCB diagrams

P. C. Board Chip Part

Symbol in Schematic

Diagrams

CapacitorConnector

Part Name

Resistor array

3-terminal

regulator

SIDE A

SIDE B

4

S

B

INPUT CONTROL ASSY

A

B

CN7003

M11

C

CN7351

B

D

IC1005 IC1004 IC1003

M5

SIDE A

90

A

1234

Page 31

5

678

PDP-V402

FRONT KEY ASSY

I

A

L

SYNC DET ASSY

(ANP1968-C)

(ANP1968-C)

B

B

CN7000

M6

(ANP1867-E)

CN7002

B

5

6

M18

IC1006

CN3203

Q

B2

CN2401

C

7

A5

LIA

8

91

C

D

Page 32

PDP-V402

Q

A

1

FRONT KEY ASSY

I

23

(ANP1968-C)

L

SYNC DET ASSY

4

B

INPUT CONTROL ASSY

A

C

(ANP1968-C)

Q1204 Q1206 Q1038 Q1039 Q1041

D

Q1208 Q1207

Q1205

Q1025 Q1024

Q1040 Q1203

Q1001 – Q1007IC1001Q1046IC1201 Q1037Q1036Q1209

Q1048

Q1008

SIDE B

92

1234

LIA

Page 33

5

678

PDP-V402

A

)

B

C

Q1203 Q1202 Q1201 Q1027 Q1028 Q1026 Q1034

7 IC1002

Q1008

048

Q1045 Q1044

5

Q1042 Q1043 Q1010

Q1015Q1047 Q1014Q1013 Q1016 Q1017

Q1019Q1020 Q1018

6

Q1022

(ANP1867-E)

Q1035Q1012Q1021Q1009

7

Q1029 – Q1032

Q1033

A

8

D

93

Page 34

1

Q

PDP-V402

23

4

4.2 CONTROL ASSY

A

B

IC7654

Q7653

Q7657

Q7650

Q7656

Q7854

IC7650

Q7260 Q7257

Q7254 Q7255

Q7259 Q7258

Q7253 Q7256

Q7259 Q7258

Q7253 Q7256

Q7659

IC7252

IC7653

IC7652IC7352

IC7254

IC7350

N

CN1605

SP3

VR7650

D

CN6103

E2

CONTROL ASSY

B

D

IC7500

IC7006

IC7506

Q7359

Q7360

Q7015

Q7016

CN6603

E21

D

CN6104

E3

IC7351

IC7502

C

IC7501

IC7505

IC7507

Q7364

Q7350–Q7353

Q7361 Q7366

D

94

SIDE A

CN1001

A

G4

C

J2203

A3

CN7850

J

H1

B

1234

Page 35

5

678

PDP-V402

C

J2601

A6

C

J2202

A8A2

A

Q7251

IC7901

Q7250

IC7902

Q7261 Q7269

IC7903

Q7268

Q7905

Q7906

Q7900

Q7904

Q7014

Q7368

Q7367

Q7365

Q7362

Q7909

B

M

CN3120

P15

Q7266

Q7252

IC7253

IC7900

Q7907

Q7908

Q7008

Q7012

K

CN5801

FR1

C

CN2801

A12

A

CN1009

G9

A

CN1007

G6

IC7254

IC7002

IC7503

IC7504

Q7019

IC7005

Q7020

IC7001

Q7001

Q7000

IC7000

Q7017

Q7021

Q7002

Q7007

C

IC7003

H1 B3

Q

CN3201

5

M

CN3501

P10

CN1004

A

6

G8

(ANP1968-C)

7

Q7013

Q7018

B

8

D

95

Page 36

PDP-V402

A

B

1

23

CONTROL ASSY

B

4

C

D

SIDE B

96

B

1234

Page 37

5

678

PDP-V402

A

B

C

D

(ANP1968-C)

B

5

6

7

8

97

Page 38

1

C

PDP-V402

4.3 ANALOG VIDEO ASSY

23

4

CN7251

B

A

B

ANALOG VIDEO ASSY

C

M7

B

Q

CN3204

B4

C

D

98

SIDE A

CN7358

B

M16

C

1234

CN1201

A

G1

Page 39

5

678

PDP-V402

B

CN7355

M3

CN7251

B

M7

CN7250

B

M4

CN6101

D

E5

N

J1601

SP5

VR2201

Q2651

Q2652

Q2653

IC2802

IC2601

IC2201

A

B

(ANP1894-C)

VR2802

VR2803

VR2801

IC2801

C

D

C

5

6

7

8

99

Page 40

PDP-V402

Q

9

2

A

B

1

ANALOG VIDEO ASSY

C

23

4

C

D

Q2615 Q2616 Q2611 Q2614 Q2607 Q2610 IC2602

Q2631 Q2650 Q2627 Q2649 Q2629 Q2648

SIDE B

100

C

1234

Q2635 Q2633 Q2634Q2603 Q2604

Q2608Q2612Q2618

Q2637Q2609Q2613Q2617

IC2402

Q2601Q2602 Q2605 Q2606

Q2636

Q2646Q2626

Q2642 Q2621 Q2630Q2641

Q2416 Q2415 Q2408 Q2413 Q2407 Q2412 Q2409 Q2414

Q2644

Q2620

Q2638

Q2619

Q2632Q2411

Q2640Q2645

Q2639

Q2647

Q2625Q2624 Q2628Q2623

Q2417 Q2405 Q2403

IC2603

Q2431

Q2428

Q2433

Q221

Q2404

Q2437

Q2406

Q2410

Q

Page 41

5

4

678

PDP-V402

A

B

C

(ANP1894-C)

Q2431

Q2428

Q2433

Q2219 Q2228

Q2404

Q2437

Q2406

Q2410

14

Q2213 Q2212 Q2211 Q2210 Q2806 Q2820 Q2814 Q2216

Q2223

Q2424 Q2421

Q2423 Q2422 Q2425 IC2401

Q2227 Q2208 Q2209 Q2228

Q2224 Q2206 Q2207 Q2225

Q2420 Q2419 Q2426 Q2418

5

6

Q2203 Q2204 Q2202

Q2804 Q2810 Q2809

Q2807 Q2819Q2817

7

Q2813

Q2812

Q2811Q2205Q2215Q2214

Q2801Q2802Q2803Q2201

Q2816 Q2816 Q2815

Q2808

C

8

101

D

Page 42

1

PDP-V402

4.4 DIGITAL VIDEO ASSY

DIGITAL VIDEO ASSY

D

A

IC6102

IC6101

Q6101

IC6206

IC6105

Q6102

IC6604

IC6106

Q6103

B

C

CN2602

A7

23

M

CN3205

P8

4

IC6201

IC6103

B

IC6104

CN7352

M9

IC6601

B

CN7350

IC6603

C

IC6001

Q6002

IC6005

Q6001

IC6006

IC6002

IC6007

IC6008

IC6003

IC6004

IC6503

IC6305

Q6004

M17

B

CN7501

M10

E21

Q6003

IC6602

D

SIDE A

102

D

1234

Page 43

5

ADDRESS MODULE (B)

678

PDP-V402

A

E

CN4008

X4

H

CN5008

Y5

G

CN5007

Y4

and

H

CN5007

Y4

IC6705

IC6708

IC6308

IC6405

IC6502

IC6553

IC6401

IC6402

IC6301

IC6552

IC6403

IC6404

IC6556

IC6501

IC6551

B

C

ADDRESS MODULE (A)

5

IC6305

IC6554

IC6555

IC6701

VR6551

IC6704

VR6554

D

(ANP1866-D)

D

6

7

103

8

Page 44

PDP-V402

A

B

1

DIGITAL VIDEO ASSY

D

23

4

C

D

SIDE B

104

D

1234

Page 45

5

678

PDP-V402

A

Q6105

Q6104

Q6106

Q6107

B

C

D

(ANP1866-D)

D

5

6

7

105

8

Page 46

1

PDP-V402

4.5 X DRIVE (A) ASSY

23

4

A

B

CN3305

M

P3

ADDRESS

MODULE

(B)

X DRIVE (A) ASSY

E

PLASM PANEL ASSY

CN4010

F

X6

CN3404

C

D

M

D

P4

CN6551

E6

IC4003

IC4015 IC4022

IC4002 IC4001

IC4014IC4008 IC4013 IC4012 IC4009

F

IC4005

CN4009

X9

IC4007

IC400

SIDE A

106

E

1234

Page 47

5

678

PDP-V402

A

CN1602

N

SP2

B

F

F

CN4006

X8

CN4019

X7

C

4007

VR4002

IC4017 Q4011

5

CN4011

F

Q4012 Q4013 Q4014IC4021 IC4024

X5

M

IC4019 IC4023

IC4028IC4004IC4011IC4006

Q4003

Q4004IC4010 Q4007 Q4005

6

CN3203

P6

Q4001

Q4002

Q4006IC4020

7

(ANP1970-B)

Q4008

E

8

D

107

Page 48

PDP-V402

A

B

1

X DRIVE (A) ASSY

E

23

4

C

D

SIDE B

108

E

1234

Page 49

5

678

PDP-V402

A

B

C

(ANP1970-B)

D

109

E

5

6

7

8

Page 50

1

PDP-V402

4.6 X DRIVE (B) ASSY

23

4

A

B

M

CN3305

P3

ADDRESS

MODULE

(A)

X DRIVE (B) ASSY

F

PLASM PANEL ASSY

CN4010

E

X6

C

CN4009

E

IC4003

IC4015 IC4022

D

IC4002 IC4001

IC4014IC4008 IC4013 IC4012 IC4009

IC4005

X9

IC4007

IC400

SIDE A

110

F

1234

Page 51

5

678

PDP-V402

A

B

E

E

CN4006

X8

CN4019

X7

C

4007

VR4002

IC4017 Q4011

5

CN4011

E

Q4012 Q4013 Q4014IC4021 IC4024

X5

IC4019 IC4023

IC4028IC4004IC4011IC4006

Q4003

Q4004IC4010 Q4007 Q4005

6

Q4001

Q4002

Q4006IC4020

7

(ANP1970-B)

Q4008

F

8

D

111

Page 52

PDP-V402

A

B

1

X DRIVE (B) ASSY

F

23

4

C

D

SIDE B

112

F

1234

Page 53

5

678

PDP-V402

A

B

C

(ANP1970-B)

D

113

F

5

6

7

8

Page 54

1

5

PDP-V402

4.7 Y DRIVE (A) ASSY

A

M

CN3304

P2

23

Y DRIVE (A) ASSY

G

4

CN1

P

P

D

CN2

CN1

CN2

CN6553

E8

B

C

Y14

Y13

Y12

Y11

Y14

Y11 Y13Y12

D

IC5003

IC5022 IC5015 IC5023 IC5024

SIDE A

114

G

1234

CN5014

H

Y6

IC5002 IC5001 IC5011 IC5019

IC5008 IC5010 IC5009

CN3405

M

P5

IC5014 IC5025 IC5005 IC5013

H

CN5009

Y9

VR5003

ADDRESS

MODULE(B)

CN5018

H

IC5030IC5029IC5028IC5027

Y7

IC5031 IC5032

IC

IC5006

Page 55

5

678

PDP-V402

A

B

Y13

H

CN5015

Y10

H

CN5006

Y8

N

CN1602

SP2

C

5032

IC5004

IC5018 IC5039

IC5006

VR5002

5

Q5006

Q5007 Q5012

Q5001 Q5002

Q5010 Q5011

(ANP1971-B)

CN3204

M

P7

Q5008 Q5009IC5020 IC5033

IC5034

IC5017 IC5007 IC5038

Q5003

6

7

IC5018

IC5035 IC5021IC5026

G

115

8

D

Page 56

PDP-V402

A

B

1

Y DRIVE (A) ASSY

G

23

4

C

D

SIDE B

116

G

1234

Page 57

5

678

PDP-V402

A

B

C

(ANP1971-B)

G

5

6

7

117

8

D

Page 58

1

5

PDP-V402

23

4

4.8 Y DRIVE (B) ASSY

A

M

CN3304

P2

CN1

O

O

CN2

CN1

CN2

B

Y14

Y13

Y12

Y11

Y DRIVE (B) ASSY

H

Y14

CN6552

D

D

E7

CN6553

E8

C

Y11 Y13Y12

D

IC5003

IC5022 IC5015 IC5023 IC5024

SIDE A

118

H

1234

CN5014

G

Y6

IC5002 IC5001 IC5011 IC5019

IC5008 IC5010 IC5009

IC5014 IC5025 IC5005 IC5013

G

CN5009

Y9

VR5003

ADDRESS

MODULE(A)

CN5018

G

IC5030IC5029IC5028IC5027

Y7

IC5031 IC5032

IC

IC5006

Page 59

5

678

PDP-V402

A

B

Y13

G

CN5015

Y10

G

CN5006

Y8

C

5032

IC5004

IC5018 IC5039

IC5006

VR5002

5

Q5006

Q5007 Q5012

Q5001 Q5002

Q5010 Q5011

6

Q5008 Q5009IC5020 IC5033

IC5034

IC5017 IC5007 IC5038

Q5003

(ANP1971-B)

IC5035 IC5021IC5026

IC5018

H

7

119

8

D

Page 60

PDP-V402

A

B

1

Y DRIVE (B) ASSY

H

23

4

C

D

SIDE B

120

H

1234

Page 61

5

678

PDP-V402

A

B

C

(ANP1971-B)

H

5

6

7

121

8

D

Page 62

1

PDP-V402

4.9 MAIN POWER ASSY

MAIN POWER ASSY

M

A

23

E

F

CN4003

CN4003

X1

X1

CN1601

N

SP1

G

CN5001

Y16

H

CN5003

Y1

4

G

CN5003

Y1

E

CN40

X10

B

U

CN7251

V

CN7301

R

CN7101

C

R

CN7102

S

CN7151

S

CN7152

T

CN7201

T

CN7202

D

SIDE A

122

M

1234

Page 63

5

678

PDP-V402

003

E

CN4001

X10

N

CN1604

SP4

D

CN6102

E1

E

CN4004

X2

G

CN5004

Y2

FAN

MOTOR

B

CN7900

M20

B

CN7005

M2

VR3201

VR3601

VR3301

VR3401

VR3501

Q3819

Q3820

Q3307

Q3826

IC3302

IC3803

Q3404

Q3305

IC3805

Q3306

Q3302

Q3402

Q3823

Q3818

IC3802

IC3202

Q3821

Q3822

Q3817

Q3815

IC3804

Q3816

Q3805

Q3206

Q3201

Q3802

Q3801

Q3803

Q3813

Q3601

Q3812

Q3811

Q3603

Q3810

Q3602

Q3809

Q3806

Q3807

Q3808

Q3804

Q3824

A

B

VR3101

Q3825

IC3801 IC3503

IC3701

IC3301

IC3201

Q3704

Q3705

Q3706

IC3501

Q3701

Q3702

Q3703

Q3202

Q3201

Q3301

Q3101

Q3401

Q3303

Q3304

Q3104

IC3102

IC3101

Q3105

Q3102

Q3103

C

D

(ANP1864-D)

5

6

7

S1: POWER SW

M

8

123

Page 64

PDP-V402

A

B

1

M

23

MAIN POWER ASSY

4

C

D

SIDE B

124

M

1234

Page 65

5

678

PDP-V402

A

B

C

D

(ANP1864-D)

M

5

6

7

125

8

Page 66

1

R

23

PDP-V402

4.10 SUB POWER, RCC CONTROL (A), (B), (C),

OTL CONTROL (A), (B) ASSYS

4

CN3202

A

B

Q

B1

C

CN2204

A4

M

CN3406

P9

B

CN7650

M14

M

CN3305

P3

Q1904 Q1901 Q1902IC1903

C

RCC CONTROL (C) ASSY

T

IC1902 IC1901

RCC CONTROL (B) ASSY

S

(ANP1867-E)

CN3201

M

D

Q7201 Q7151IC7201 IC7151

M

CN3202

M

CN3401

M

(ANP1867-E)

CN3402

126

SIDE A

N

S T

1234

Page 67

5

SUB POWER ASSY

N

678

PDP-V402

A

B

(ANP1867-E)

CN5005

G

IC1601 IC1602 IC1603

RCC CONTROL (A) ASSY

R

)

IC1604

(ANP1867-E)

Y3

OTL CONTROL

U

(A) ASSY

CN4005

E

(ANP1867-E)

X3

VR1601

OTL CONTROL

V

(B) ASSY

C

(ANP1867-E)

CN3301

M

Q7101 IC7101 Q7253

5

M

CN3302

CN3303

M

Q7252

IC7251

6

Q7251

7

N

CN3403

M

Q7303

Q7302

IC7301

Q7301

R U V

8

D

127

Page 68

1

S

PDP-V402

23

4

A

B

SUB POWER ASSY

N

OTL CONTROL

C

V

(B) ASSY

OTL CONTROL

U

(A) ASSY

RCC CONTROL (A) ASSY

R

(ANP1867-E)(ANP1867-E)(ANP1867-E)

D

SIDE B

128

N

R U V

1234

Page 69

5

678

PDP-V402

A

B

67-E)

RCC CONTROL (B) ASSY

S

RCC CONTROL (C) ASSY

T

(ANP1867-E)

C

(ANP1867-E)(ANP1867-E)

D

N

5

6

7

S T

129

8

Page 70

1

PDP-V402

4.11 3D Y/C ASSY

3D Y/C ASSY

Q

A

B

23

4

Q3220

Q3208

|

Q3223

Q3222

Q3214

|

Q3218

Q3224

Q3201

IC3203

Q3225

Q3203

Q3204

Q3205

Q3212

IC3205

Q3206

Q3210

C

IC3204

IC3202

IC3206

IC3201

D

C

CN2201

A1

N

CN1607

SP6

CN7354

B

M1

CN1002

A

G2

(ANP1974-A)

SIDE A

130

Q

1234

Page 71

1

3D Y/C ASSY

Q

234

PDP-V402

A

B

C

D

(ANP1974-A)

SIDE B

Q

1

2

3

131

4

Page 72

1

23

PDP-V402

4.12 IR RECEIVER, FAN RELAY ASSYS

A

J

IR RECEIVER ASSY

B

CN7001

M12

(ANP1968-C)

B

CN7901

M19

FAN RELAY ASSY

K

4

B

(ANP1971-B)

SIDE A

FAN MOTOR

SIDE B

C

J

IR RECEIVER ASSY

FAN RELAY ASSY

K

(ANP1968-C)

(ANP1971-B)

D

132

J

K

1234

Page 73

5. PCB PARTS LIST

NOTES:•Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

•

Therefore, when replacing, be sure to use parts of identical designation.

When ordering resistors, first convert resistance values into code form as shown in the following examples.

•

Ex.1 When there are 2 effective digits (any digit apart from 0), such as 560 ohm and 47k ohm (tolerance is shown by J=5%,

and K=10%).

560 Ω→56 × 10

47k Ω→47 × 10

1

→ 561 ........................................................ RD1/4PU 5 6 1 J

3

→ 473 ........................................................ RD1/4PU 4 7 3 J

0.5 Ω→R50 ..................................................................................... RN2H R 5 0 K

Ex.2 When there are 3 effective digits (such as in high precision metal film resistors).

5.62k Ω→ 562 × 10

1

→ 5621 ...................................................... RN1/4PC 5 6 2 1 F

1 Ω→1R0 ..................................................................................... RS1P

1 R 0

PDP-V402

K

Mark No. Description Part No.

LIST OF ASSEMBLIES

NSP COMPLEX (A) ASSY AWV1875

INPUT CONTROL ASSY AWZ6554

SUB POWER ASSY AWZ6173

RCC CONTROL (A) ASSY AWZ6174

RCC CONTROL (B) ASSY AWZ6175

RCC CONTROL (C) ASSY AWZ6176

OTL CONTROL (A) ASSY AWZ6177

OTL CONTROL (B) ASSY AWZ6178

NSP COMPLEX (B) ASSY AWV1861

CONTROL ASSY AWZ6545

FRONT KEY ASSY AWZ6525

IR RECEIVER ASSY AWZ6526

SYNC DET ASSY AWZ6548

3D Y/C ASSY AWQ1055

ANALOG VIDEO ASSY AWQ1056

DIGITAL VIDEO ASSY AWP1069

X DRIVE (A) ASSY AWP1078

X DRIVE (B) ASSY AWP1079

Y DRIVE (B) ASSY AWP1077

MAIN POWER ASSY AWR1077

NSP Y DRIVE (A)/SENSOR ASSY AWV1854

Y DRIVE (A) ASSY AWZ6533

FAN RELAY ASSY AWZ6535

SCAN MODULE (A) AXF1104

SCAN MODULE (B) AXF1105

Mark No. Description Part No.

D1001-D1004,D1006,D1007 1SS226

D1009-D1012,D1016,D1017 1SS226

D1201-D1206 1SS226

D1005,D1008,D1013-D1015,D1207 RD15MB

COILS

L1001 ATH1046

L1002 ATX1008

SWITCHES

S1001 ASH1029

S1201,S1202 ASH1046

CAPACITORS

C1004,C1006 CCSQCH470J50

C1014 CEANP100M35

C1009 CEANP100M50

C1001-C1003,C1005,C1013 CEANP101M10

C1040,C1073 CEANP1R0M50

C1010 CEANPR22M50

C1044,C1051-C1053,C1056,C1202 CEAS101M10

C1204,C1206,C1208,C1210,C1212 CEAS101M10

C1007,C1017,C1019,C1021,C1030 CEAS101M25

C1037,C1048,C1058,C1060-C1062 CEAS101M25

C1064,C1214,C1219-C1221 CEAS101M25

C1054 CEAS102M16

C1046 CEAS102M6R3

C1078 CEAS1R0M50

C1011,C1012,C1015,C1016,C1035 CEAS470M25

INPUT CONTROL ASSY

A

SEMICONDUCTORS

IC1004 CXA1616S

IC1005,IC1006 NJM2233BLA

IC1002 NJM319M

IC1003 NJM78L05A

IC1001,IC1201 TC4053BF

Q1001,Q1004,Q1005,Q1008,Q1009 2SA1162

Q1011-Q1018,Q1024-Q1026 2SA1162

Q1030,Q1031,Q1033,Q1042,Q1043 2SA1162

Q1207-Q1209 2SA1162

Q1002,Q1003,Q1006,Q1007,Q1010 2SC2712

Q1019-Q1022,Q1027-Q1029,Q1032 2SC2712

Q1034-Q1041,Q1044,Q1045 2SC2712

Q1047,Q1048,Q1201-Q1206 2SC2712

C1047,C1070,C1072 CEAS470M25

C1025,C1028 CFTLA104J50

C1033 CFTLA223J50

C1023,C1026 CFTLA224J50

C1024 CFTLA684J50

C1032 CKSQYB102K50

C1008,C1018,C1020,C1022,C1031 CKSQYB103K50

C1038,C1042,C1043,C1045 CKSQYB103K50

C1049,C1050,C1055,C1059,C1063 CKSQYB103K50

C1065,C1066,C1071,C1201,C1203 CKSQYB103K50

C1205,C1207,C1209,C1211,C1213 CKSQYB103K50

C1215,C1216,C1225-C1230 CKSQYB103K50

C1079 CKSQYB221K50

C1067-C1069,C1222-C1224 CKSQYF104Z50

C1036 CQMA164J50

C1027 CQMA182J50

C1034 CQMA562J50

133

Page 74

PDP-V402

Mark No. Description Part No.

RESISTORS

R1254-R1256 RD1/4PU751J

R1023 RD1/4PU753J

R1021,R1029 RS1/10S1002F

R1022 RS1/10S1102F

R1030 RS1/10S1202F

R1025,R1033 RS1/10S2701F