Page 1

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2004

VZ

ORDER NO.

ARP3214

PDP-505PE

PLASMA DISPLAY

PDP-505PE

PRO-505PU

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

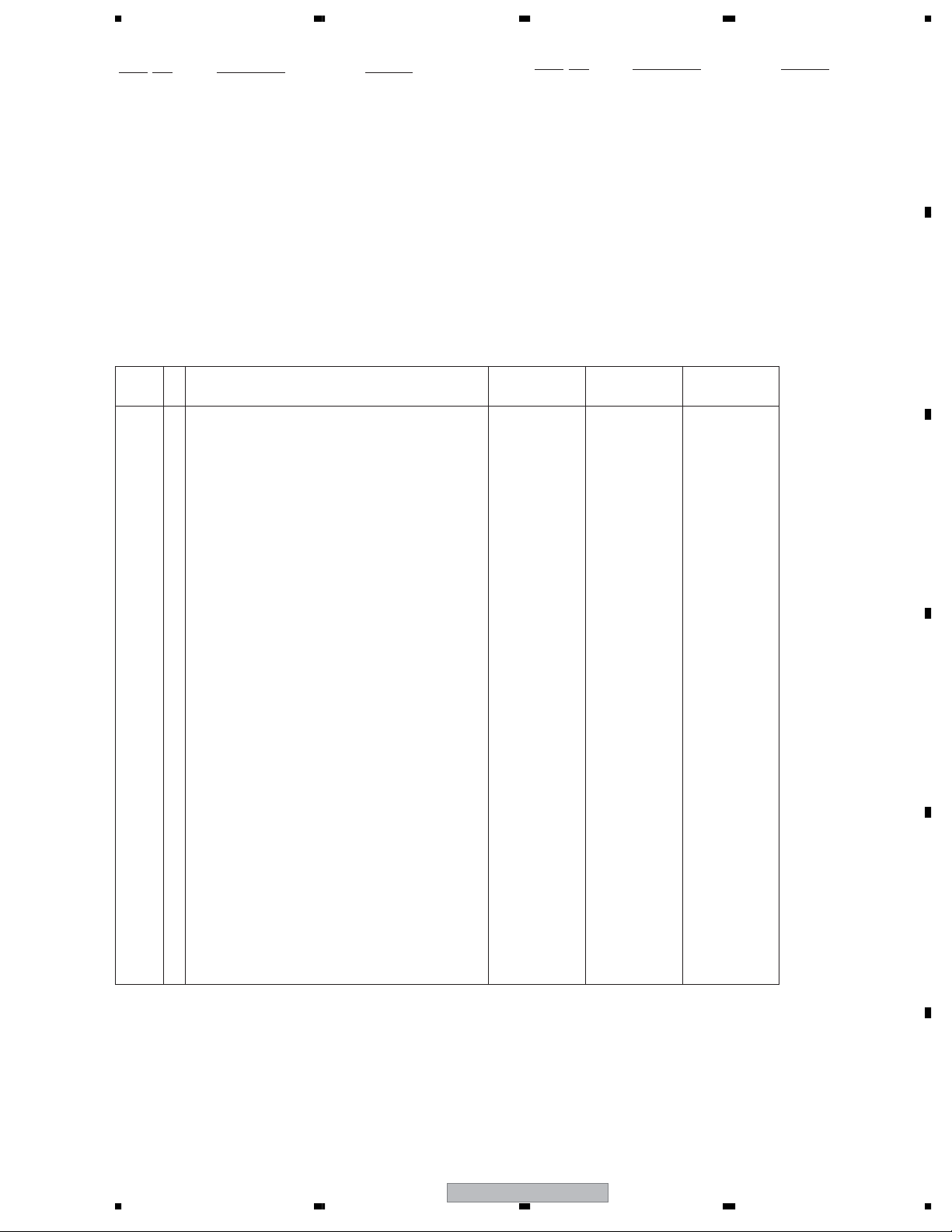

Model Type Power Requirement Remarks

PDP-505PE WYVI AC220 - 240V

PDP-505PE WYVIXK AC220 - 240V

PRO-505PU KUC AC120V

This service manual should be used together with the following manual(s).

Model No. Order No. Remarks

PDP-505PE

PRO-505PU

ARP3215 SCHEMATIC DIAGRAM, PCB CONNECTION DIAGRAM

For details, refer to "Important symbols for good services" .

T-ZZY AUG. 2004 printed in Japan

Page 2

1234

SAFETY INFORMATION

A

This service manual is intended for qualified service technicians ; it is not meant for the casual

do-it-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely,

you should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to

cause cancer, birth defects or other reproductive harm.

B

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement parts

must be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les pièces

de remplacement doivent avoir la même désignation.

Health & Safety Code Section 25249.6 - Proposition 65

C

SAFETY PRECAUTIONS

NOTICE : Comply with all cautions and safety related notes

located on or inside the cabinet and on the chassis.

The following precautions should be observed :

1. When service is required, even though the PDP UNIT an

isolation transformer should be inserted between the power line

and the set in safety before any service is performed.

2. When replacing a chassis in the set, all the protective devices

D

must be put back in place, such as barriers, nonmetallic knobs,

adjustment and compartment covershields, isolation resistorcapacitor, etc.

3. When service is required, observe the original lead dress. Extra

precaution should be taken to assure correct lead dress in the

high voltage circuitry area.

4. Always use the manufacture's replacement components.

Especially critical components as indicated on the circuit

diagram should not be replaced by other manufacture's.

Furthermore where a short circuit has occurred, replace those

components that indicate evidence of overheating.

E

5. Before returning a serviced set to the customer, the service

technician must thoroughly test the unit to be certain that it is

completely safe to operate without danger of electrical shock,

and be sure that no protective device built into the set by the

manufacture has become defective, or inadvertently defeated

during servicing. Therefore, the following checks should be

performed for the continued protection of the customer and

servicetechnician.

6. Perform the following precautions against unwanted radiation

and rise in internal temperature.

• Always return the internal wiring to the original styling.

• Attach parts (Gascket, Ferrite Core, Ground, Rear Cover,

Shield Case etc.) surely after disassembly.

7. Perform the following precautions for the PDP panel.

• When the front case is removed, make sure nothing hits the

panel face, panel corner, and panel edge (so that the glass does

not break).

• Make sure that the panel vent does not break. (Check that the

cover is attached.)

• Handle the FPC connected to the panel carefully.

Twisting or pulling the FPC when connecting it to the

connector will cause it to peel off from the panel.

8. Pay attention to the following.

• When the front case is removed, infrared ray is radiated and

may disturb reception of the remote control unit.

• Pay extreme caution when the front case and rear panel are

removed because this may cause a high risk of disturbance to

TVs and radios in the surrounding.

F

2

1234

PDP-505PE

Page 3

5678

Leakage Current Cold Check

With the AC plug removed from an AC power source, place a

jumper across the two plug prongs. Turn the AC power switch on.

Using an insulation tester (DC 500V), connect one lead to the

jumpered AC plug and touch the other lead to each exposed metal

part (input/output terminals, screwheads, metal overlays, control

shafts, etc.), particularly any exposed metal part having a return

path to the chassis. Exposed metal parts having a return path to

the chassis should have a minimum resistor reading of 0.3MΩ

and a maximum resistor reading of 5MΩ. Any resistor value

below or above this range indicates an abnormality which

requires corrective action. Exposed metal parts not having a

return path to the chassis will indicate an open circuit.

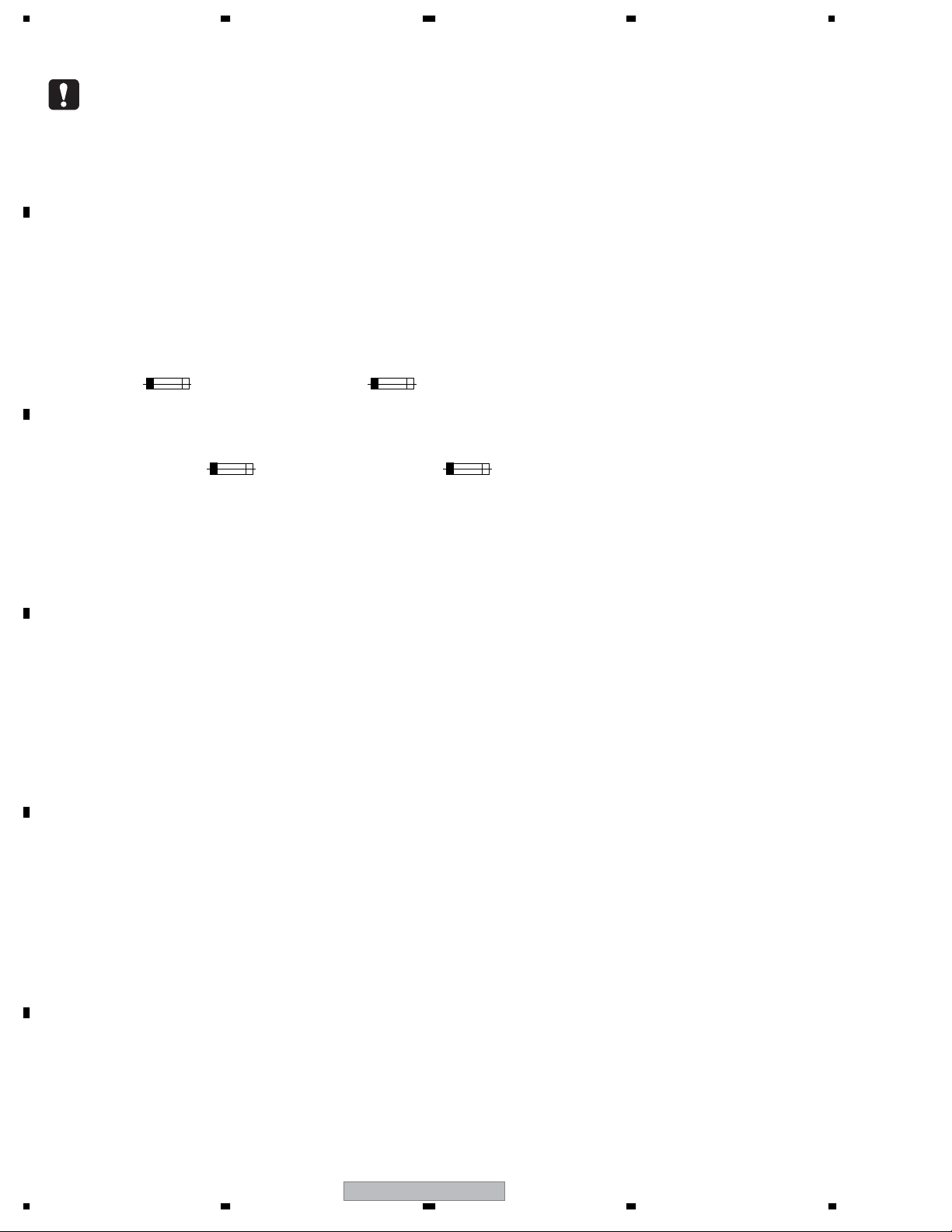

Leakage Current Hot Check

Plug the AC line cord directly into an AC power source (do not

use an isolation transformer for this check).

Turn the AC power switch on.

Using a "Leakage Current Tester (Simpson Model 229

equivalent)", measure for current from all exposed metal parts of

the cabinet (input/output terminals, screwheads, metal overlays,

control shaft, etc.), particularly any exposed metal part having a

return path to the chassis, to a known earth ground (water pipe,

conduit, etc.). Any current measured must not exceed 0.5mA.

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in PIONEER set have

special safety related characteristics. These are often not evident

from visual inspection nor the protection afforded by them

necessarily can be obtained by using replacement components

rated for higher voltage, wattage, etc. Replacement parts which

have these special safety characteristics are identified in this

Service Manual.

Electrical components having such features are identified by

marking with a on the schematics and on the parts list in this

Service Manual.

The use of a substitute replacement component which dose not

have the same safety characteristics as the PIONEER

recommended replacement one, shown in the parts list in this

Service Manual, may create shock, fire or other hazards.

Product Safety is continuously under review and new instructions

are issued from time to time. For the latest information, always

consult the current PIONEER Service Manual. A subscription to,

or additional copies of, PIONEER Service Manual may be

obtained at a nominal charge from PIONEER.

A

B

C

Reading should

not be above

0.5mA

Earth

ground

Device

under

test

Also test with

plug reversed

(Using AC adapter

plug as required)

Leakage

current

tester

Test all

exposed metal

surfaces

AC Leakage Test

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE SET TO THE CUSTOMER.

D

E

56

PDP-505PE

F

3

7

8

Page 4

1234

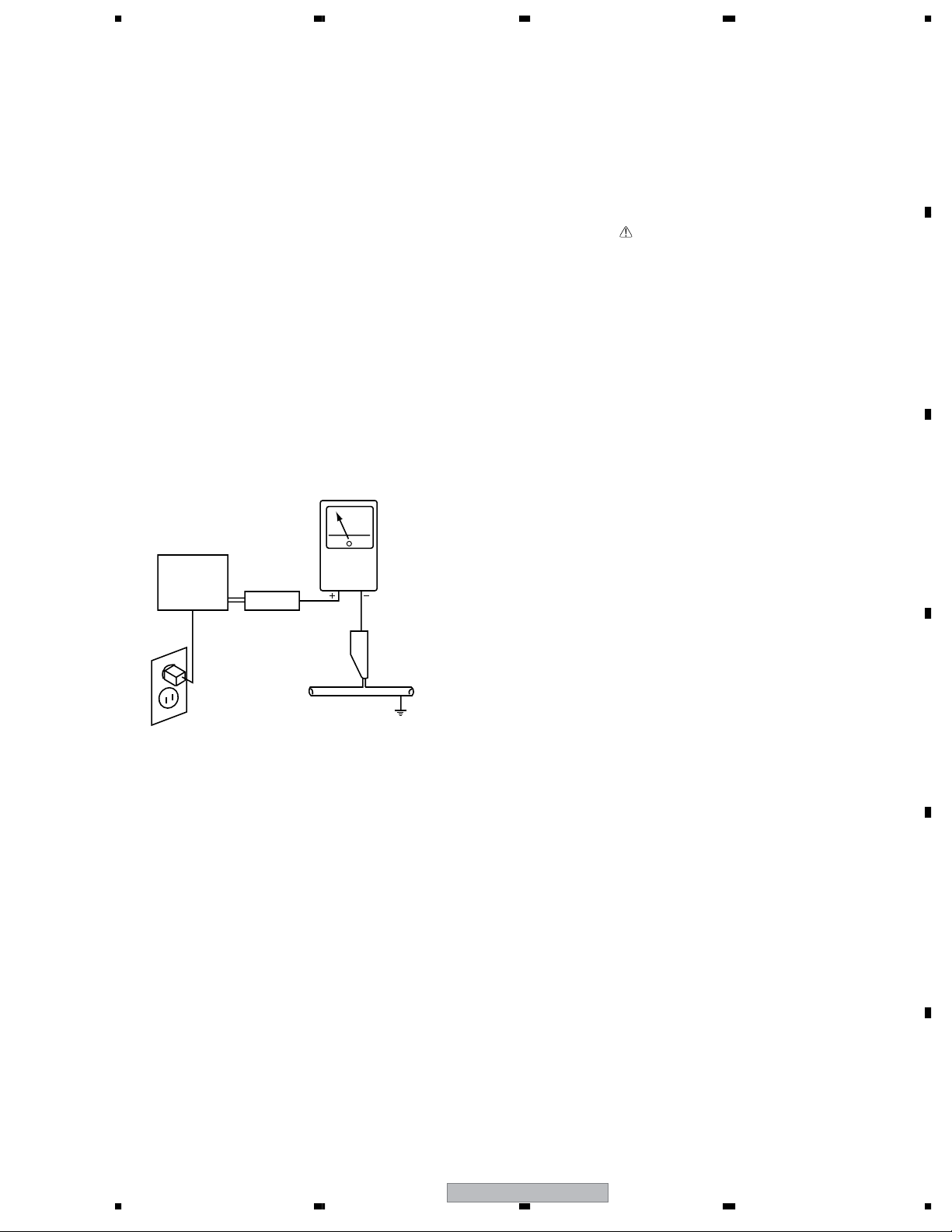

Charged Section

The places where the commercial AC power is used without

A

passing through the power supply transformer.

If the places are touched, there is a risk of electric shock. In

addition, the measuring equipment can be damaged if it is

connected to the GND of the charged section and the GND of the

non-charged section while connecting the set directly to the

commercial AC power supply. Therefore, be sure to connect the

set via an insulated transformer and supply the current.

1. AC Power Cord

2. AC Inlet with Filter

3. Power Switch (S1)

B

4. Fuse (In the POWER SUPPLY Unit)

5. STB Transformer and Converter Transformer

(In the POWER SUPPLY Unit)

6. Other primary side of the POWER SUPPLY Unit

C

: Part is Charged Section.

: Part is the High Voltage Generating Points

other than the Charged Section.

High Voltage Generating Point

The places where voltage is 100V or more except for the charged

places described above. If the places are touched, there is a risk of

electric shock.

1. POWER SUPPLY Unit................................................... (223V)

2. 50 X DRIVE Assy .......................................... (–230V to 223V)

3. 50 Y DRIVE Assy .......................................................... (353V)

4. 50 SCAN A Assy ............................................................ (353V)

5. 50 SCAN B Assy ............................................................(353V)

6. X CONNECTOR AAssy ................................ (–230V to 223V)

7. X CONNECTOR B Assy ............................... (–230V to 223V)

Discharge the VSUS voltage, as shown below:

[Method for discharging the VSUS voltage]

1. Set DRF_SW on the DIGITAL VIDEO Assy to ON (Drive

OFF status). *1, 2

2. Leave the switch at that position for about 20-30 seconds.

3. If the power is on, turn it off. Then return DRF_SW to the OFF

position. *3

Notes

*1: You can also set the unit to "Drive OFF status" by sending the

"DRF" RS232C command from the PC.

*2: DRF_SW can be switched whether the power is on or off.

*3: Power-down will occur if DRF_SW is set to OFF while the

power is on. (See "7.1.6 Power on/off function for the large-

signal system".)

POWER SUPPLY Unit50 Y DRIVE Assy50 SCAN B Assy

D

E

50 SCAN A Assy

AC Inlet with Filter

Power Cord Power Switch

50 X DRIVE Assy

X CONNECTOR

A Assy

X CONNECTOR

B Assy

(S1)

F

4

1234

Fig.1 Charged Section and High Voltage Generating Point (Rear View)

PDP-505PE

Page 5

5678

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

0 Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

A

B

C

D

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

Make sure the proper amount is applied.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

56

PDP-505PE

E

F

5

7

8

Page 6

1234

CONTENTS

SAFETY INFORMATION..................................................................................................................................... 2

1. SPECIFICATIONS ............................................................................................................................................ 7

2. EXPLODED VIEWS AND PARTS LIST ............................................................................................................ 8

A

B

C

D

2.1 PACKING ................................................................................................................................................... 8

2.2 CHASSIS SECTION (1)........................................................................................................................... 10

2.3 CHASSIS SECTION (2)........................................................................................................................... 12

2.4 FRAME SECTION.................................................................................................................................... 14

2.5 MULTI BASE SECTION........................................................................................................................... 16

2.6 REAR SECTION ...................................................................................................................................... 18

2.7 FRONT SECTION.................................................................................................................................... 20

2.8 PANEL CHASSIS (50) Assy (AWU1092) ................................................................................................. 21

2.9 PDP SERVICE Assy 505P (AWU1097) ................................................................................................... 21

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM (Refer to “Service Manual: ARP3215”) ............................22

3.1 BLOCK DIAGRAM ................................................................................................................................... 22

3.1.1 OVERALL BLOCK DIAGRAM ........................................................................................................... 22

3.1.2 50 Y DRIVE ASSY............................................................................................................................. 24

3.1.3 50 X DRIVE ASSY............................................................................................................................. 25

3.1.4 PANEL IF ASSY................................................................................................................................. 26

3.1.5 DIGITAL VIDEO ASSY....................................................................................................................... 31

3.1.6 HD AUDIO AMP ASSY...................................................................................................................... 33

3.2 WAVEFORMS.......................................................................................................................................... 34

4. PCB CONNECTION DIAGRAM (Refer to “Service Manual: ARP3215”)

5. PCB PARTS LIST ........................................................................................................................................... 38

6. ADJUSTMENT ............................................................................................................................................... 46

6.1 ADJUSTMENT REQUIRED WHEN THE SET IS REPAIRED OR REPLACED ....................................... 46

6.2 DRIVE ASSY ADJUSTMENT ..................................................................................................................47

6.3 COMMAND .............................................................................................................................................. 48

6.3.1 RS232C COMMAND ......................................................................................................................... 48

6.4 METHOD FOR REPLACING THE SERVICE PANEL ASSY.................................................................... 56

7. GENERAL INFORMATION............................................................................................................................. 57

7.1 DIAGNOSIS ............................................................................................................................................. 57

7.1.1 PCB LOCATION ................................................................................................................................ 57

7.1.2 DIAGNOSIS OF SHUTDOWN/POWER-DOWN INDICATED BY LEDS............................................ 58

7.1.3 DIAGNOSIS WITH THE AID OF FACTORY MODE ..........................................................................63

7.1.4 OPERATION WHEN THE MEDIA RECEIVER IS NOT CONNECTED.............................................. 65

7.1.5 TEMPERATURE-COMPENSATION FUNCTION OF THE DRIVE-SYSTEM VOLTAGE.................... 65

7.1.6 POWER ON/OFF FUNCTION FOR THE LARGE-SIGNAL SYSTEM............................................... 66

7.1.7 BACKUP WHEN THE MAIN UNIT IS ADJUSTED ............................................................................ 67

7.1.8 TROUBLESHOOTING....................................................................................................................... 70

7.1.9 DISASSEMBLY.................................................................................................................................. 71

7.2 IC INFORMATION.................................................................................................................................... 75

8. PANEL FACILITIES ...................................................................................................................................... 101

E

F

6

1234

PDP-505PE

Page 7

5678

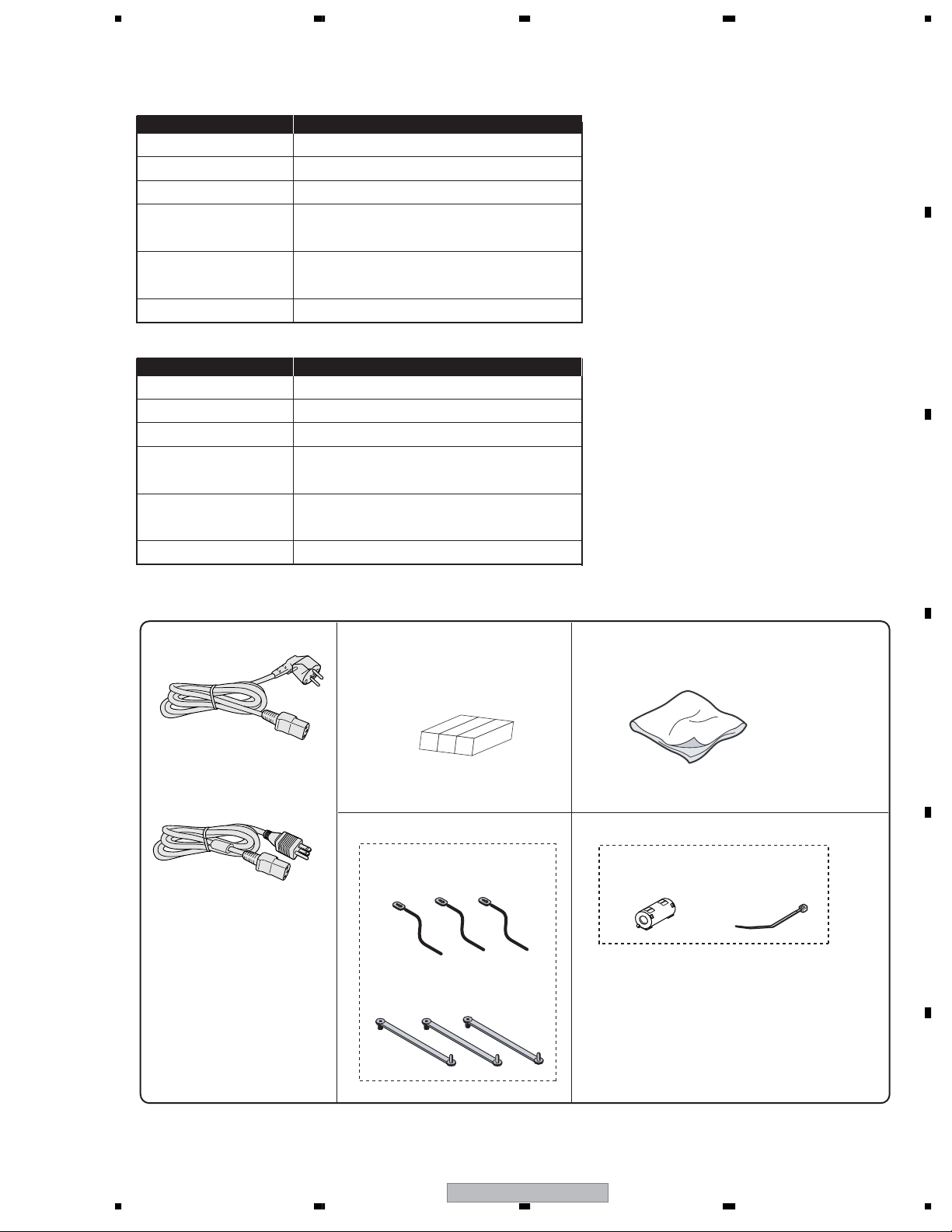

1. SPECIFICATIONS

50" Plasma Display

Item

Number of Pixels

Audio Amplifier

Surround System

Power Requirement 220-240V AC,50/60Hz,352W

Dimensions

Weight

Item

Number of Pixels

Audio Amplifier

Surround System

Power Requirement 120V AC,60Hz,363W

Dimensions

Model: PDP-505PE

1280 x 768 pixels

13 W + 13 W (1kHz, 10%, 8Ω)

SRS/FOCUS/TruBass

(0.4W Standby)

1270(W) x 737 (H) x 93 (D) mm

32.8 kg (72.3 lbs.)

Model: PRO-505PU

1280 x 768 pixels

13 W + 13 W (1kHz, 10%, 8Ω)

SRS/FOCUS/TruBass

(0.2W Standby)

1270(W) x 737 (H) x 93 (D) mm

1

/8(W)x 25 11/16(H)x 3 7/8(D)inches)

(44

A

B

C

Weight

• Accessories

Power Cord

(PDP-505PE: ADG1214)

(PRO-505PU: ADG1215)

32.8 kg (72.3 lbs.)

Speaker Cushion x1

(AEB1384)

(Except PRO-505PU)

Binder Assy (AEC1908)

• Bead Bands x3

• Speed Clamp x3

Wiping Cloth x1

(AED1208)

Ferrite Core

(ATX1039)

(PDP-505PE only)

D

• Cable Tie

E

56

PDP-505PE

F

7

7

8

Page 8

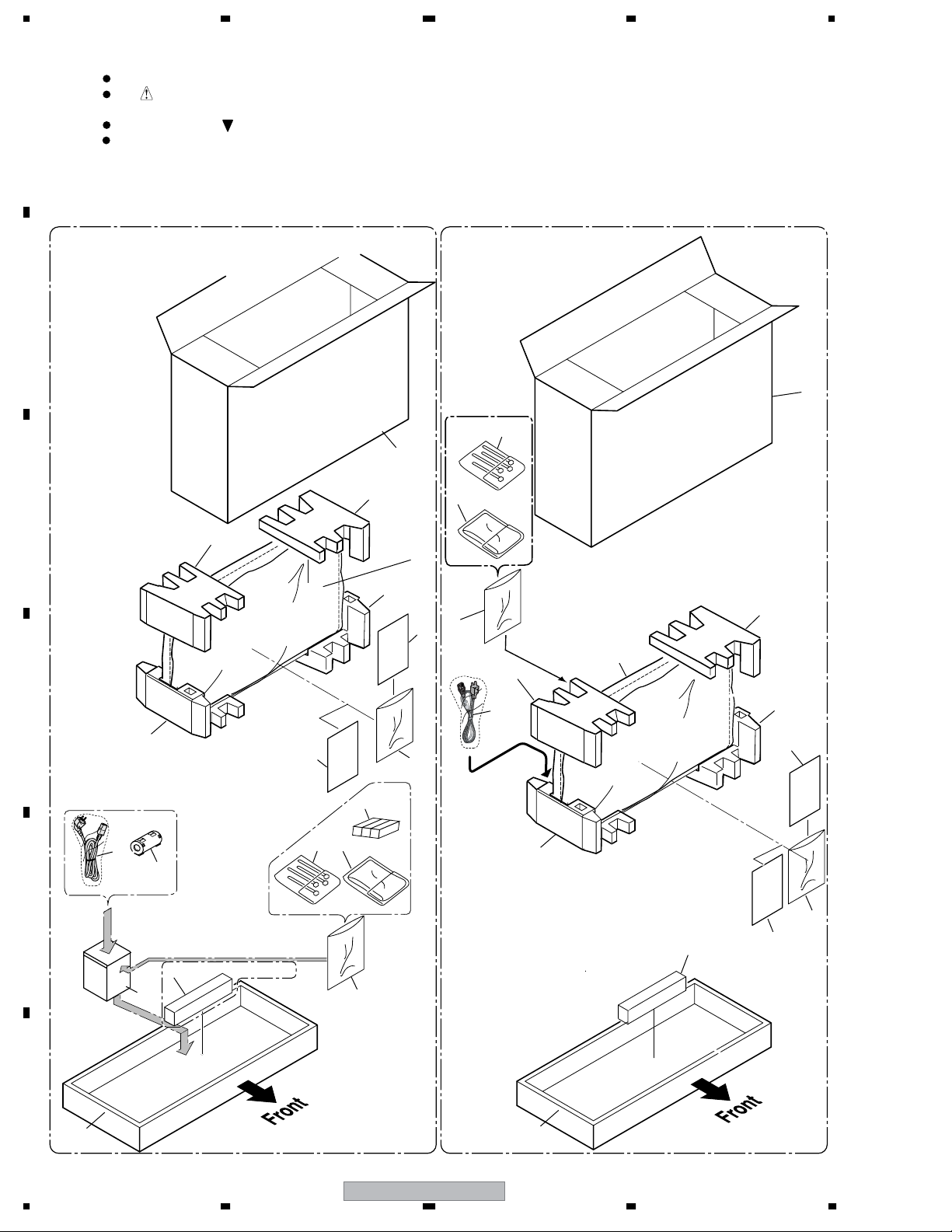

1234

2. EXPLODED VIEWS AND PARTS LIST

NOTES:

Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

A

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on product are used for disassembly.

For the applying amount of lubricants or glue, follow the instructions in this manual.

(In the case of no amount instructions, apply as you think it appropriate.)

2.1 PACKING

• PDP-505PE / WYVIXK types

B

C

• PRO-505PU / KUC type• PDP-505PE / WYVI

14

4

14

10

9

3

8

12

18

16

8

9

D

11

1

19

E

WYVIXK type only

6

5

7

17

4

3

18, 20

15

2

11

6

10

12

16

15

7

F

13

8

1234

PDP-505PE

13

Page 9

>

>

>

>

5678

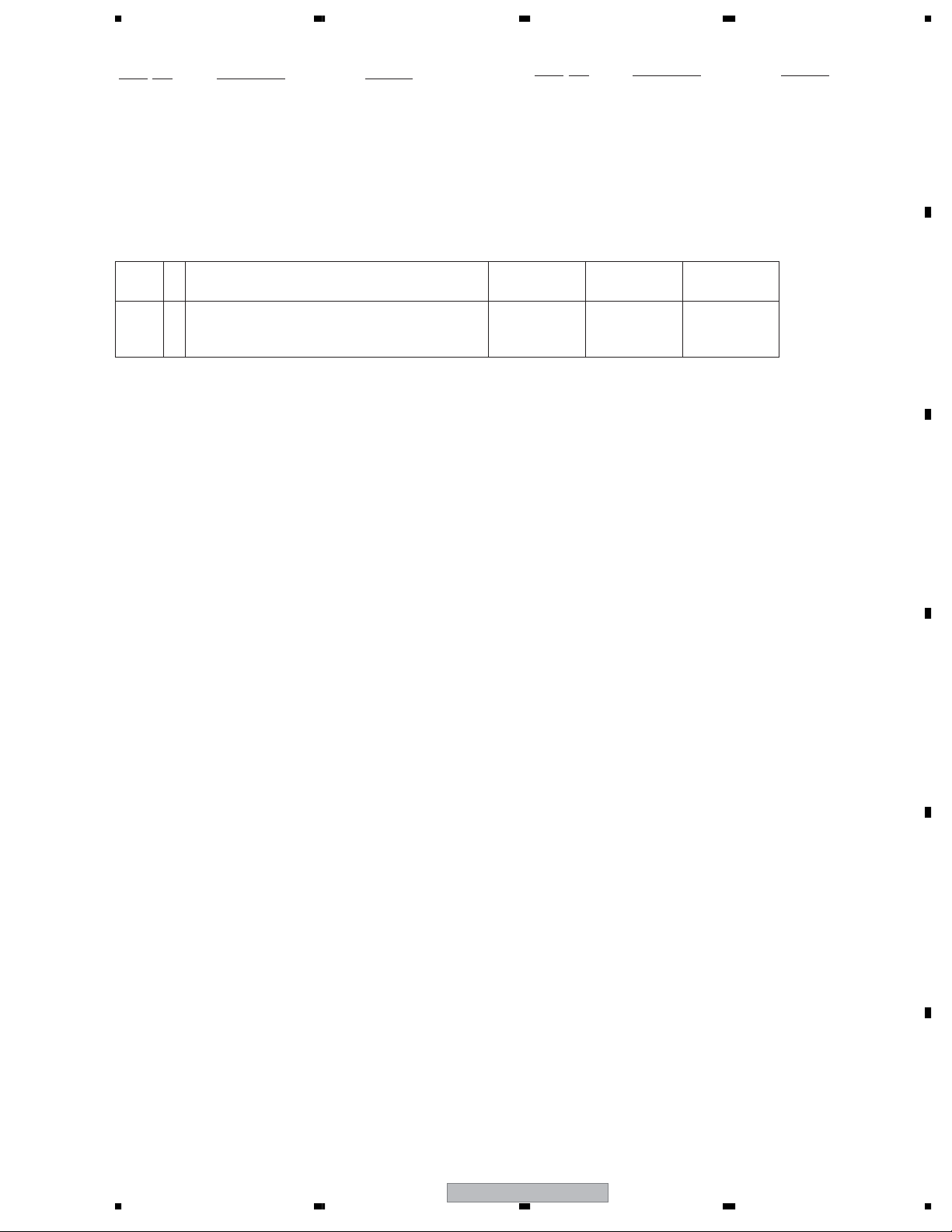

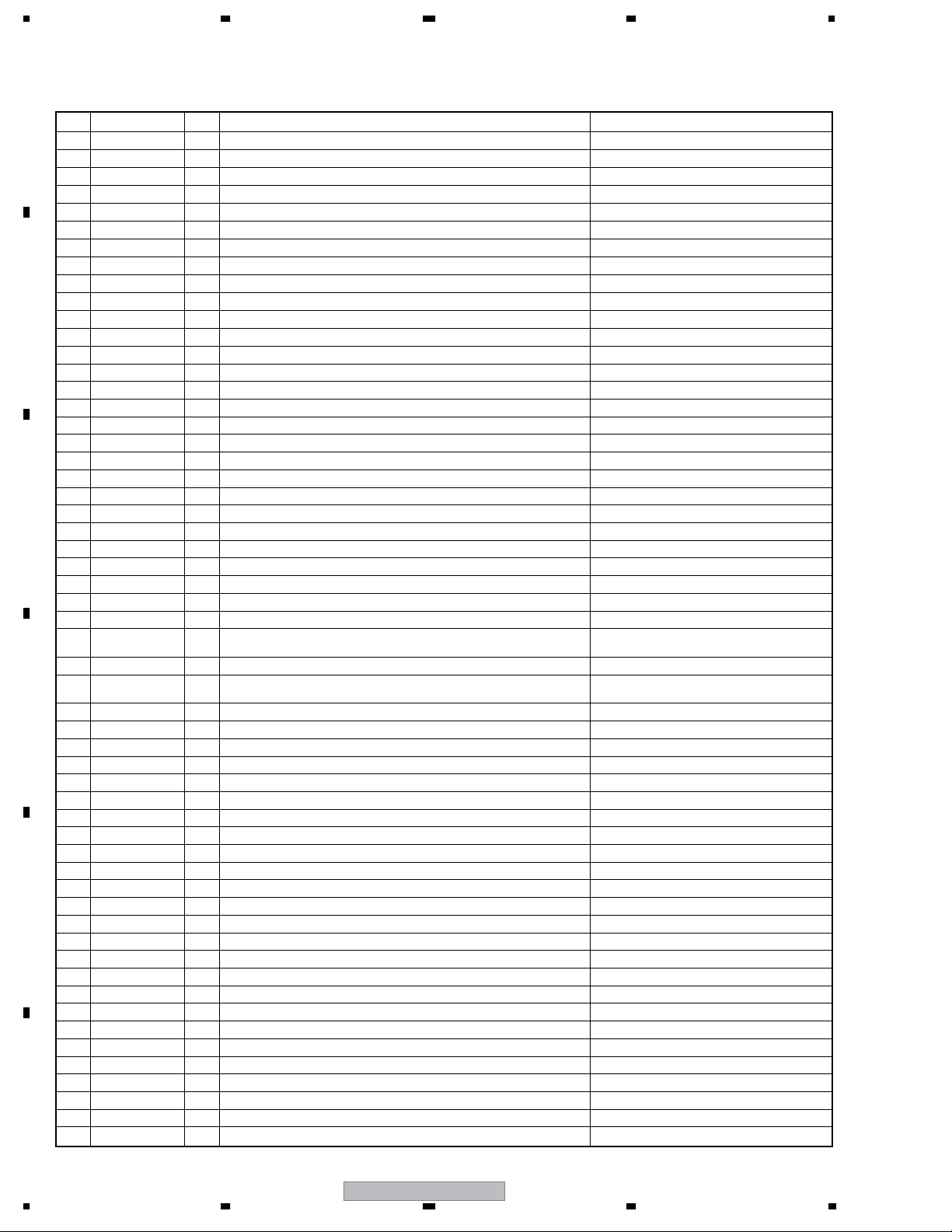

PACKING Parts List

No. Description Part No.

Mark

1Power Cord See Contrast table (2)

2Power Cord See Contrast table (2)

3 Wiping Cloth AED1208

4 Binder Assy AEC1908

5 Code Case See Contrast table (2)

No. Description Part No.

Mark

11 Pad See Contrast table (2)

12 Pad See Contrast table (2)

13 Carton (50) See Contrast table (2)

14 Upper Carton See Contrast table (2)

15 Vinyl Bag See Contrast table (2)

A

6 Center Pad (50) See Contrast table (2)

NSP 7 Warranty Card See Contrast table (2)

8 Mirror Mat See Contrast table (2)

9Pad See Contrast table (2)

10 Pad See Contrast table (2)

16 Caution Card ARM1232

17 Speaker Cushion See Contrast table (2)

18 Vinyl Bag S See Contrast table (2)

19 Ferrite Core See Contrast table (2)

20 Poly Bag See Contrast table (2)

(2) CONTRAST TABLE

PDP-505PE/WYVIXK, PRO-505PU/KUC and PDP-505PE/WYVI are constructed the same except for the following :

Mark No. Symbol and Description

1Power Cord ADG1214 ADG1214 Not used

2Power Cord Not used Not used ADG1215

5 Code Case AHC1041 AHC1049 Not used

6 Center Pad (50) Not used AHA2335 Not used

NSP 7 Warranty Card ARY1114 ARY1114 ARY1134

8 Mirror Mat AHG1284 AHG1327 AHG1284

9Pad (50T-L) AHA2366 Not used AHA2366

9Pad (T-L) Not used AHA2381 Not used

10 Pad (50T-R) AHA2367 Not used AHA2367

10 Pad (T-R) Not used AHA2382 Not used

PDP-505PE

WYVI

PDP-505PE

WYVIXK

PRO-505PU

KUC

B

C

11 Pad (50B-L) AHA2368 Not used AHA2368

11 Pad (B-L) Not used AHA2383 Not used

12 Pad (50B-R) AHA2369 Not used AHA2369

12 Pad (B-R) Not used AHA2384 Not used

13 Carton (50) AHD3177 AHD3191 AHD3177

14 Upper Carton (505PE) AHD3265 Not used Not used

14 Upper Carton (50) Not used AHD3271 Not used

14 Upper Carton (50EL) Not used Not used AHD3281

15 Vinyl Bag AHG1340 Not used AHG1340

17 Speaker Cushion AEB1384 AEB1384 Not used

18 Vinyl Bag S AHG1338 Not used AHG1338

19 Ferrite Core ATX1039 ATX1039 Not used

20 Poly Bag Not used AHG1326 Not used

D

E

F

56

PDP-505PE

9

7

8

Page 10

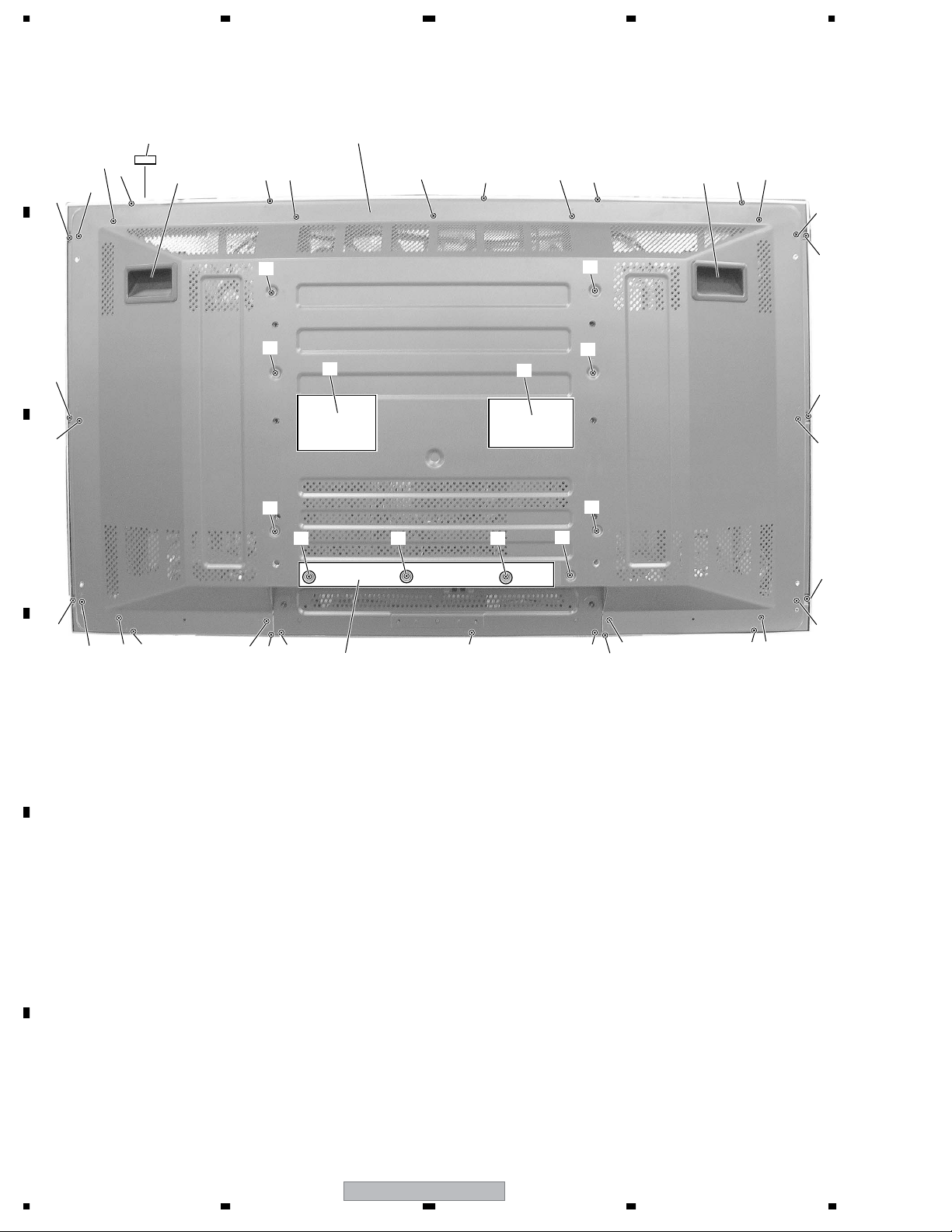

1234

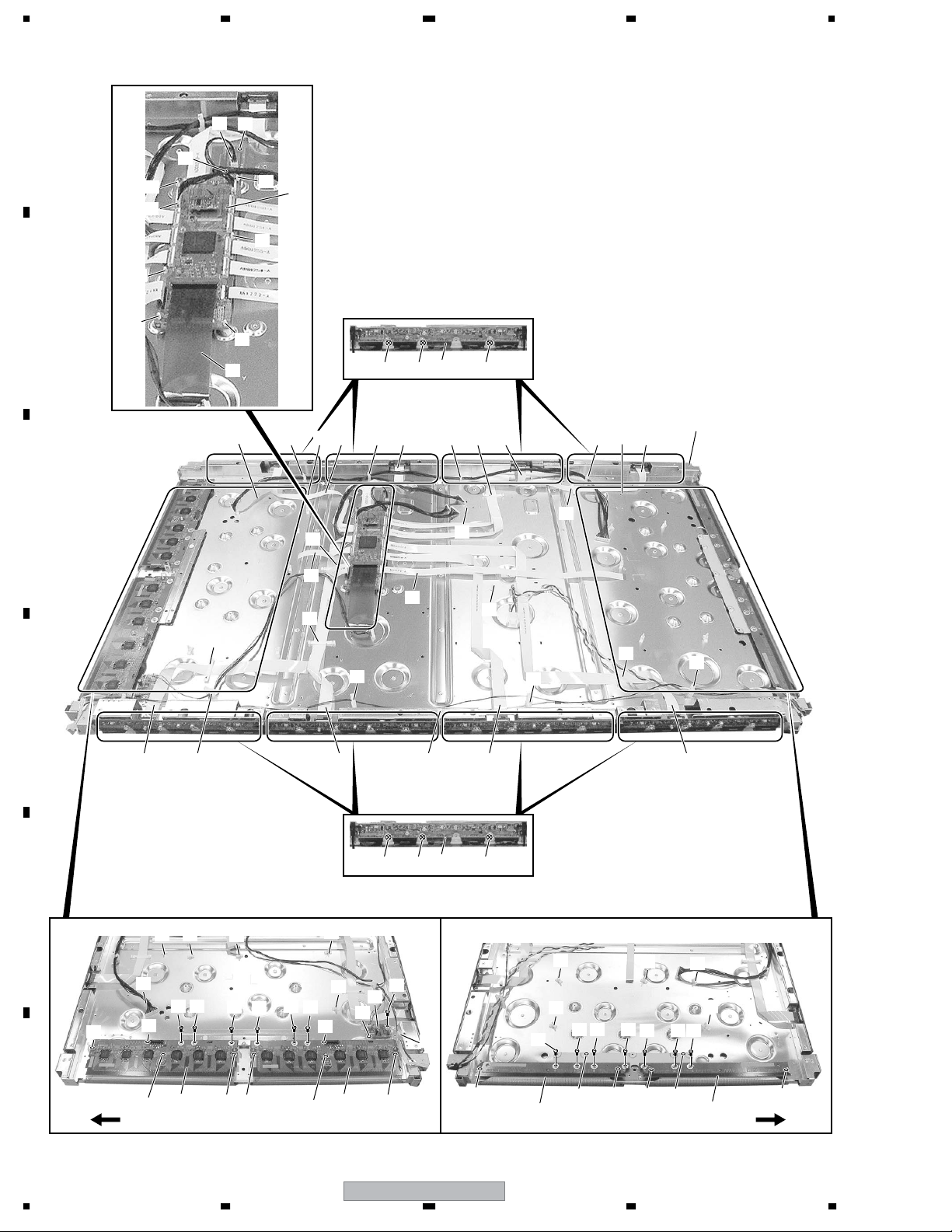

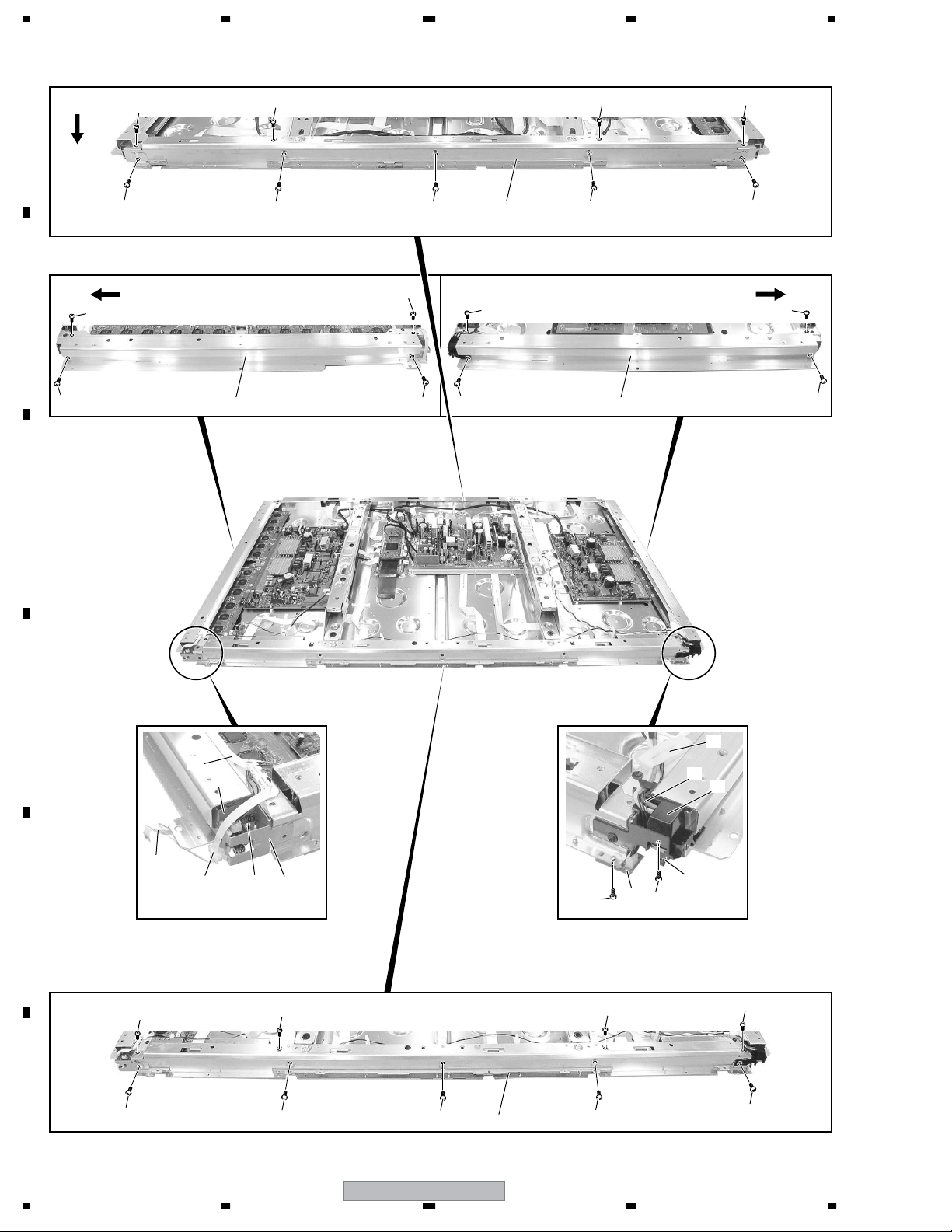

2.2 CHASSIS SECTION (1)

A

23

24

23

B

C

23

30

8

30

23

1

23

23

10

31 31 31

2734 22 11 27

22

3

2

143422 132727 12

22

28

19

20

22

22

27

D

15 16 27 17 1827

31 31 31

E

33

26

23

23

28

32

9

29

26

232324

26

23

3333 33

33

33

28

22

27

3

33

23

23

33 33 33

23

33 3333

27

23

23

2525

5

Upper

F

side

25

26 26 26

10

1234

25

4

7

PDP-505PE

25 3535 25

6

Upper

side

Page 11

5678

CHASSIS SECTION (1) parts List

No. Description Part No.

Mark

1 DIGITAL VIDEO Assy AWV2074

NSP 2 P. Chassis (505) Assy AWU1092

NSP 3 50 ADDRESS Assy AWZ6870

NSP 4 50 SCAN A Assy AWZ6878

NSP 5 50 SCAN B Assy AWZ6879

NSP 6 X CONNECTOR A Assy AWZ6880

NSP 7 X CONNECTOR B Assy AWZ6881

8PANEL SENSOR Assy AWZ6872

9 KEY CONTROL Assy AWZ6844

10 FPC (114P) ADY1088

11 Flexible Cable (J201) ADD1248

12 Flexible Cable (J202) ADD1249

13 Flexible Cable (J203) ADD1250

14 Flexible Cable (J204) ADD1251

15 Flexible Cable (J205) ADD1252

16 Flexible Cable (J206) ADD1253

17 Flexible Cable (J207) ADD1254

18 Flexible Cable (J208) ADD1255

19 Flexible Cable (J209) ADD1270

20 Flexible Cable (J210) ADD1271

21 • • • • •

22 Flat Clamp AEC1879

23 PCB Spacer AEC1941

24 PCB Support AEC1938

25 PCB Spacer AEC1944

26 PCB Support AEC1958

27 Wire Saddle AEC1745

28 PCB Spacer AEC1947

29 Wire Clip AEC1948

30 Nylon Rivet AEC1671

31 Screw VBB30P080FNI

32 Screw ABZ30P060FTC

33 Screw PMB30P060FNI

34 Rear corner label AAX3081

35 Card Spacer AEC2013

A

B

C

D

56

PDP-505PE

E

F

11

7

8

Page 12

1234

2.3 CHASSIS SECTION (2)

A

13

13

6

2

15

15

12

15

4

5

8

13

B

7

C

3

15

15

12

15

13

1

Upper

side

D

14

14

11

E

11

14

F

11

109

11

11

14

Upper

side

12

PDP-505PE

1234

Page 13

>

5678

CHASSIS SECTION (2) parts List

No. Description Part No.

Mark

1POWER SUPPLY Unit AXY1085

2 50 X DRIVE Assy AWZ6877

3 50 Y DRIVE Assy AWV2082

4 Wire A (J101) ADX2945

5 11P Housing Wire (J102) ADX2950

6 12P Housing Wire (J103) ADX2951

7 9P Housing Wire (J106) ADX2949

8 3P Housing Wire (J109) ADX2948

9 SUB Frame L Assy (50P) ANG2638

10 SUB Frame R Assy (50P) ANG2561

11 Wire Saddle AEC1745

12 Screw PMB30P060FNI

13 Screw ABZ30P060FTC

14 Screw AMZ30P080FTC

15 Screw VBB30P080FNI

A

B

C

D

E

56

PDP-505PE

F

13

7

8

Page 14

1234

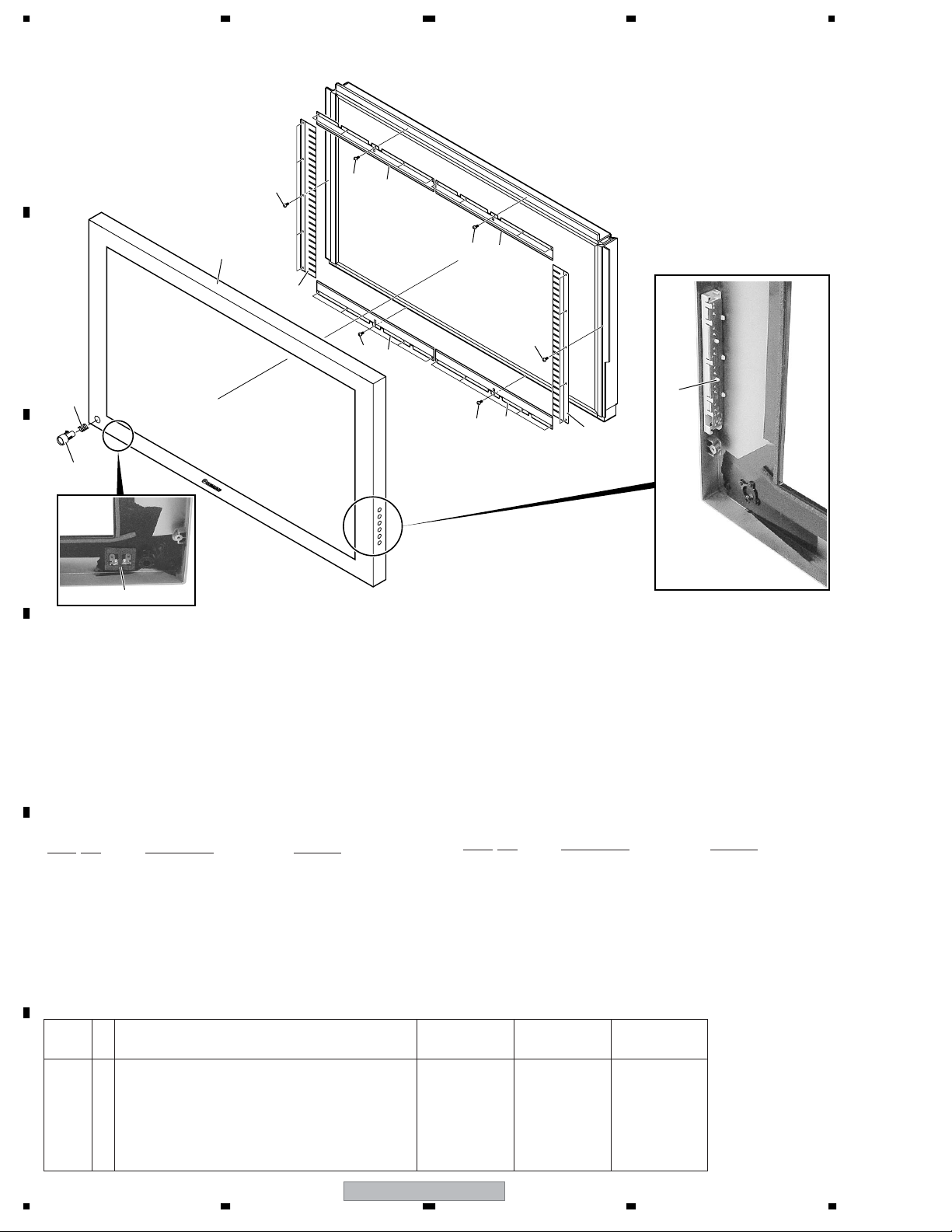

2.4 FRAME SECTION

A

Upper

side

Upper

side

B

17

C

17

17

17

16

1515

17

17

17

8 9

17

16

156

17

17

17

Upper

side

17

D

10

11

1

5

14

E

17

F

17

16

15

1318

15

7

18

2

16

15

4

12

3

15

17

17

14

PDP-505PE

1234

Page 15

5678

FRAME SECTION parts List

No. Description Part No.

Mark

1PANEL IR Assy AWZ6845

2PANEL LED Assy AWZ6842

3Power Switch (S1) ASG1092

4 Housing Wire (50)(J110) ADX2964

5 Flexible Cable (J211) ADD1225

6Front Chassis HU Assy (50) ANA1792

7Front Chassis HD Assy (50) ANA1793

8Front Chassis VL (50) ANA1794

9Front Chassis VR (50) ANA1795

10 Clamp AEC1884

11 Flat Clamp AEC1879

12 Switch Holder AMR3402

13 IR Holder ANG2665

14 Wire Clip AEC1948

15 Screw BPZ30P080FTB

16 Screw AMZ30P080FTC

17 Screw AMZ30P060FTB

18 Screw ABZ30P060FTC

>

A

B

C

D

E

56

PDP-505PE

F

15

7

8

Page 16

1234

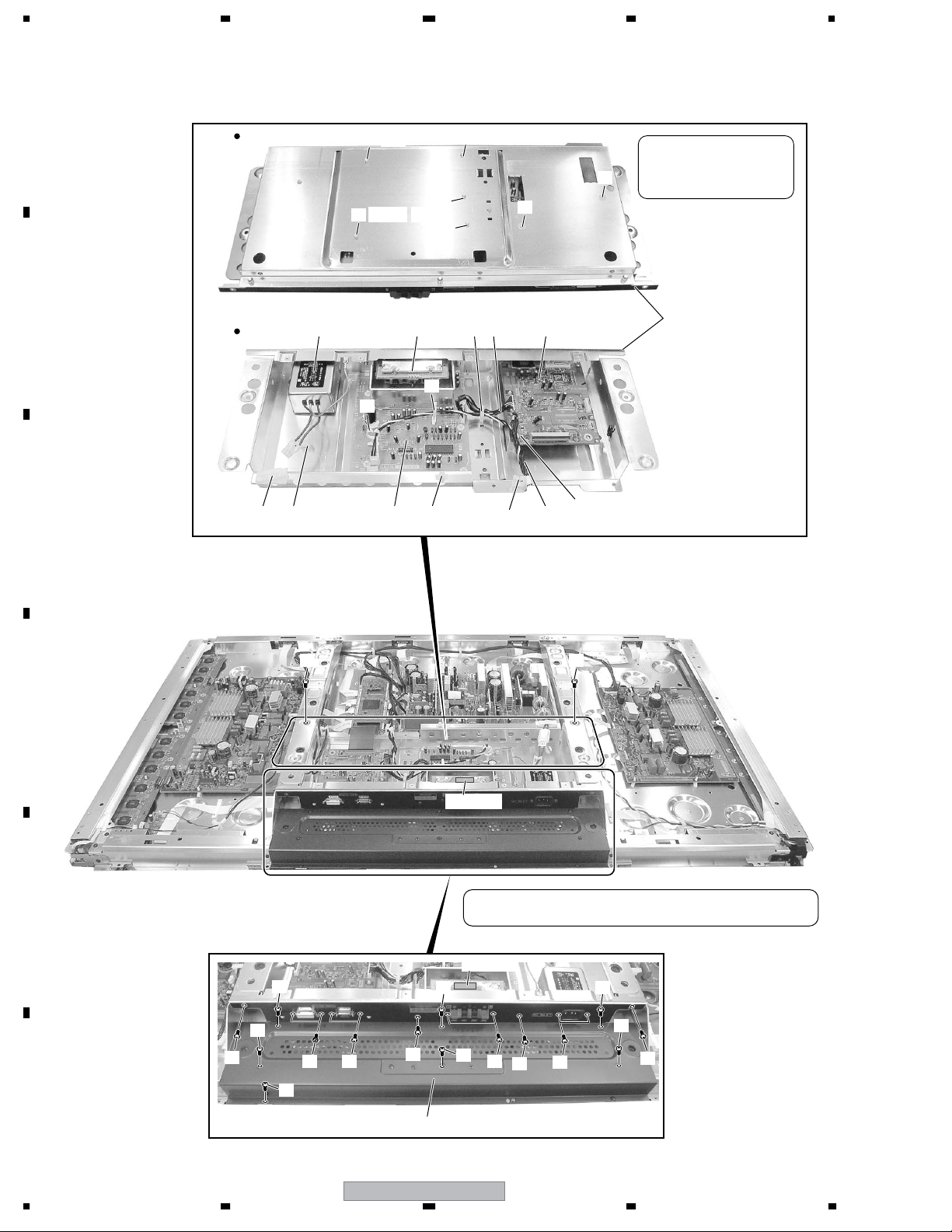

2.5 MULTI BASE SECTION

A

Back side

12

(Note)

12

(Note)

(Note)

12

12

12

(Note)

Note:

The No. 12 parts must be

inserted from the front

9

surface.

9

B

15

13

16

5211 14

Front side

C

D

4 615

13

13

15

17 17

7

(Note)

20

Note: When servicing, be sure to glue on the Gasket (AU)

E

17

17

17

F

16

1234

18 19

17

PDP-505PE

17

17

17

8

and make sure that they won't peel off.

(Note)

20

17

17

21

17

17

17

Page 17

5678

MULTI BASE SECTION parts List

No. Description Part No.

Mark

1PANEL IF Assy AWZ6841

2 HD AUDIO AMP Assy AWZ6863

3 HD SP TERMINAL Assy AWZ6864

4AC Inlet (CN1) AKP1263

5 3P/8P Housing Wire (J104) ADX2922

6 13P Housing Wire (J105) ADX2947

7 Multi Base (P) Assy ANA1786

8 Under Cover Assy ANG2589

9 Locking Card Spacer V0 AEC2005

10 • • • • •

11 Clamp AEC1884

12 PCB Spacer AEC1941

13 HL 18 AEC1980

14 SB Spacer AEC2002

NSP 15 Wire Saddle AEC1745

16 Screw PMB30P060FNI

17 Screw AMZ30P060FTB

18 Hexagon Headed Screw BBA1051

19 Screw PMZ26P060FTB

20 Gasket (AU) ANK1745

21 Screw BPZ30P080FTB

>

A

B

C

D

E

F

56

PDP-505PE

17

7

8

Page 18

1234

2.6 REAR SECTION

A

7

8

6

8

6

2 2

1

6

8

8

6

8

6

8

6

8

8

B

8

6

8

C

6

6

8

8

8

8 6

3

8 8

6 6

5

8

4

8

8

8

8

8

6

6

8

6

6

6

8

6

8

D

E

F

18

PDP-505PE

1234

Page 19

5678

REAR SECTION parts List

No. Description Part No.

No. Description Part No.

Mark

1 Rear Case (50P) ANE1626

2 Inner Grip Assy AMR3434

NSP 3 Name Label See Contrast table (2)

4Volt caution Label See Contrast table (2)

5Terminal Label See Contrast table (2)

Mark

6 Screw ABZ30P100FTB

7 Serial Sheet AAX3143

8 Screw AMZ30P060FTB

(2) CONTRAST TABLE

PDP-505PE/WYVIXK, PRO-505PU/KUC and PDP-505PE/WYVI are constructed the same except for the following :

Mark No. Symbol and Description

NSP 3 Name Label AAL2568 AAL2580 AAL2570

4Volt Caution Label AAX3117 AAX3005 AAX3117

5Terminal Label AAX2998 AAX3006 AAX2997

PDP-505PE

WYVI

PDP-505PE

WYVIXK

PRO-505PU

KUC

A

B

C

D

E

56

PDP-505PE

F

19

7

8

Page 20

1234

2.7 FRONT SECTION

A

8

2

4

B

6

3

• Rear view

C

7

8

5

8

5

8

5

8

8

1

5

4

D

FRONT SECTION parts List

No. Description Part No.

No. Description Part No.

Mark

1PANEL KEY Assy AWZ6843

2Front Case Assy See Contrast table (2)

3Power Button AAD4127

E

NSP 4 Panel Holder V (50) ANG2663

5Panel Holder H Assy 50 See Contrast table (2)

Mark

6 Coil Spring ABH1114

7 Blind Cushion AEB1383

8 Screw ABZ30P060FTC

(2) CONTRAST TABLE

PDP-505PE/WYVIXK, PRO-505PU/KUC and PDP-505PE/WYVI are constructed the same except for the following :

Mark No. Symbol and Description

2Front Case Assy (50PE) AMB2834 AMB2834 Not used

2Front Case Assy (50EL) Not used Not used AMB2836

F

5Panel Holder H Assy 50 ANG2678 Not used ANG2678

5Panel Holder H Not used ANG2662 Not used

5 Gasket Not used ANK1740 Not used

PDP-505PE

WYVI

PDP-505PE

WYVIXK

PRO-505PU

KUC

20

PDP-505PE

1234

Page 21

5678

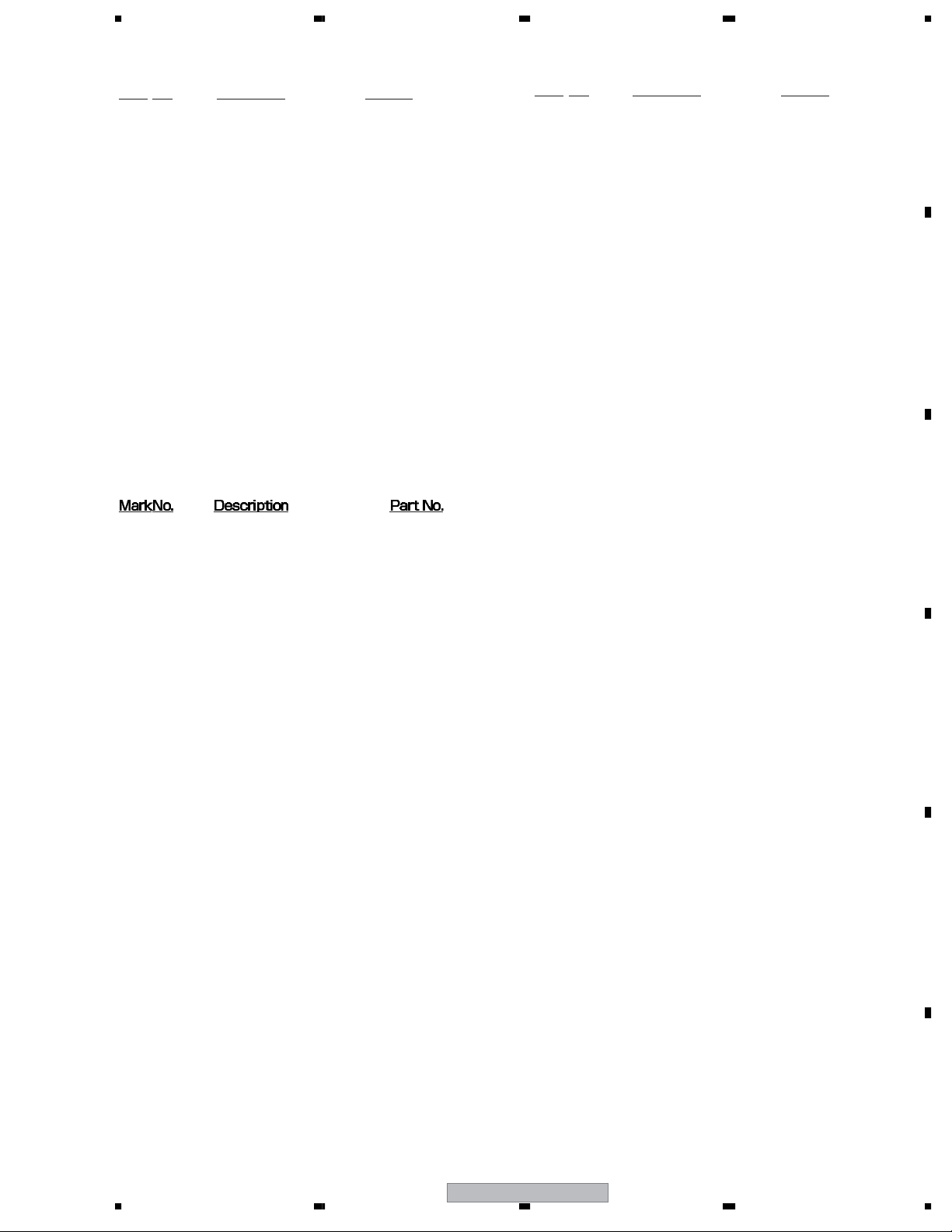

2.8 PANEL CHASSIS (50) Assy (AWU1092)

PANEL CHASSIS (50) Assy (AWU1092) parts List

No. Description Part No.

Mark

NSP 1..50 ADDRESS Assy AWV2080

NSP 2..50 ADDRESS Assy AWZ6870

NSP 1..50 SCAN Assy AWV2083

NSP 2..50 SCAN A Assy AWZ6878

NSP 2..50 SCAN B Assy AWZ6879

NSP 2..X CONNECTOR A Assy AWZ6880

NSP 2..X CONNECTOR B Assy AWZ6881

NSP P. Panel (50LC) Assy AWU1103

NSP Adress Module (IC1-IC40) AXF1129

NSP FPC (50XGA-X) ADY1084

NSP FPC (50XGA-Y) ADY1085

NSP Chassis Assy (505) ANA1803

PCB Spacer AEC1944

PCB Support AEC1958

Edge Card Spacer AEC1998

Mark

Rivet (Plastic) AMR1066

FC Spacer AMR3370

NSP Adhesive ZBA-KE3424S

NSP Lotion ZLX-AP7

NSP Tape ZTA-8101-12

NSP Double Faced Tape ZTB-5015-18

NSP Tape ZTC-POLYCA-20

NSP Tape ZTC-900UL-15

NSP Silicone Rubber ZTX-HC20-15

NSP Silicone Rubber ZTX-HC50-15

NSP Wiping Cloth ZTX-MX100-13

NSP Film

NSP Film ZTX-2102Y45-5

No. Description Part No.

NSP Silicone Rubber

A

ZTC-EM7KB0R85T-15W

B

ZTX-2102Y35-2R5

2.9 PDP SERVICE Assy 505P (AWU1097)

PDP SERVICE Assy 505P (AWU1097) parts List

NSP 1..P.Chassis (505) Assy AWU1092

1..Front Chassis HU Assy (50) ANA1792

1..Front Chassis HD Assy (50) ANA1793

1..Front Chassis VL (50) ANA1794

1..Front Chassis VR (50) ANA1795

1..Sub Frame L Assy (50P) ANG2638

1..Sub Frame R Assy (50P) ANG2561

1..Wire Saddle AEC1745

1..PCB Support AEC1938

1..PCB Spacer AEC1941

1..PCB Spacer AEC1947

1..Wire Clip AEC1948

1..Card Spacer AEC2013

1..Caution Label AAX3031

1..Drive Voltage Label ARW1097

1..Screw ABZ30P100FTB

1..Screw AMZ30P060FTB

1..Screw AMZ30P080FTC

1..Screw VBB30P080FNI

1..Screw BPZ30P080FTB

NSP 1..Front Case Assy (50SVC) AMB2849

2..Panel Cushion H (50) AED1257

2..Panel Cushion V (50) AED1258

NSP 2..Front Case (50P) AMB2823

1..Rear Case (50P) ANE1614

NSP 1..Vinyl Pouch AHG-195

1..Pad (50T-L) AHA2366

1..Pad (50T-R) AHA2367

1..Pad (50B-L) AHA2368

1..Pad (50B-R) AHA2369

1..Carton(50) AHD3177

1..Upper Carton (505SVC) AHD3290

1..Protect Sheet AHG1331

1..Rear corner label(15) AAX3081

C

D

E

F

56

PDP-505PE

21

7

8

Page 22

1234

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

3.1 BLOCK DIAGRAM

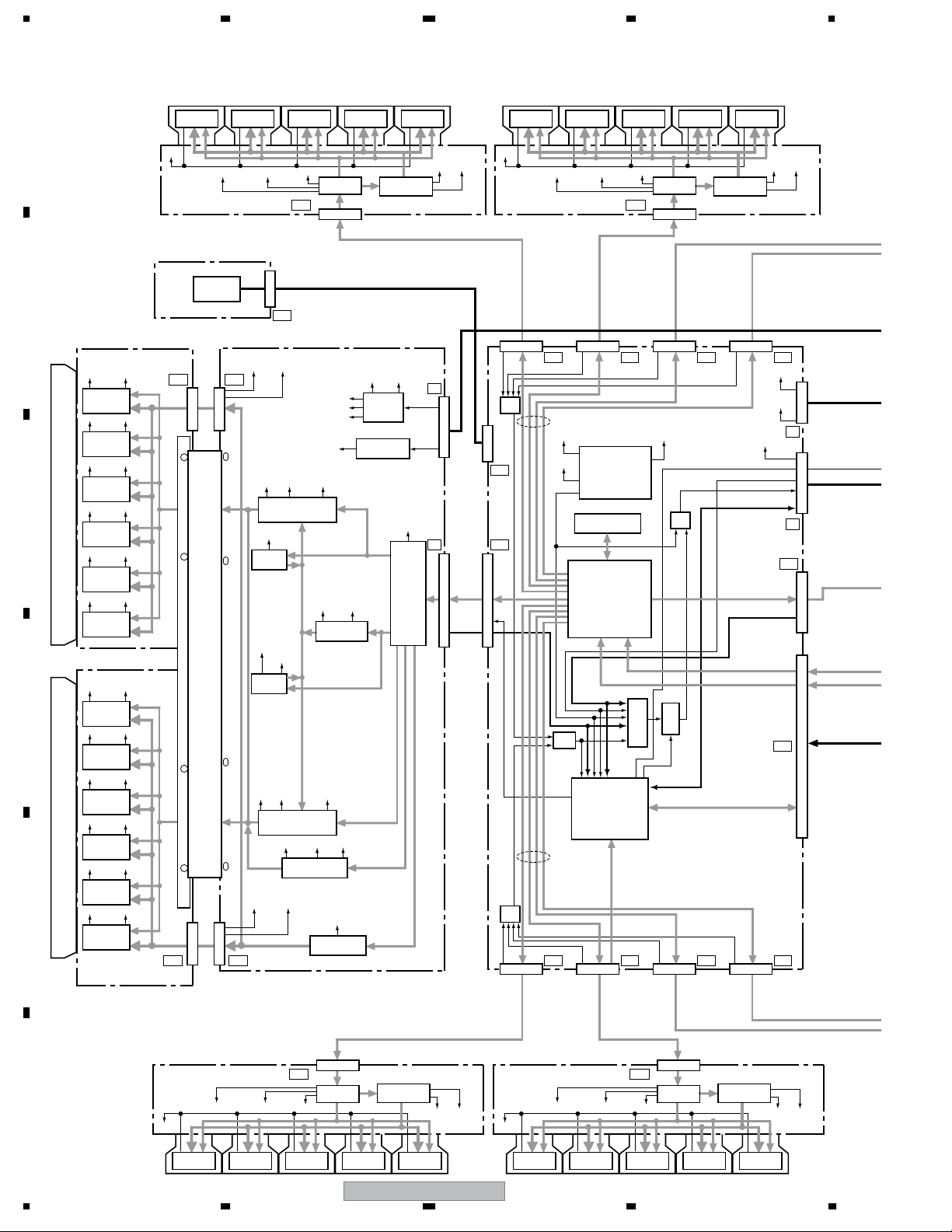

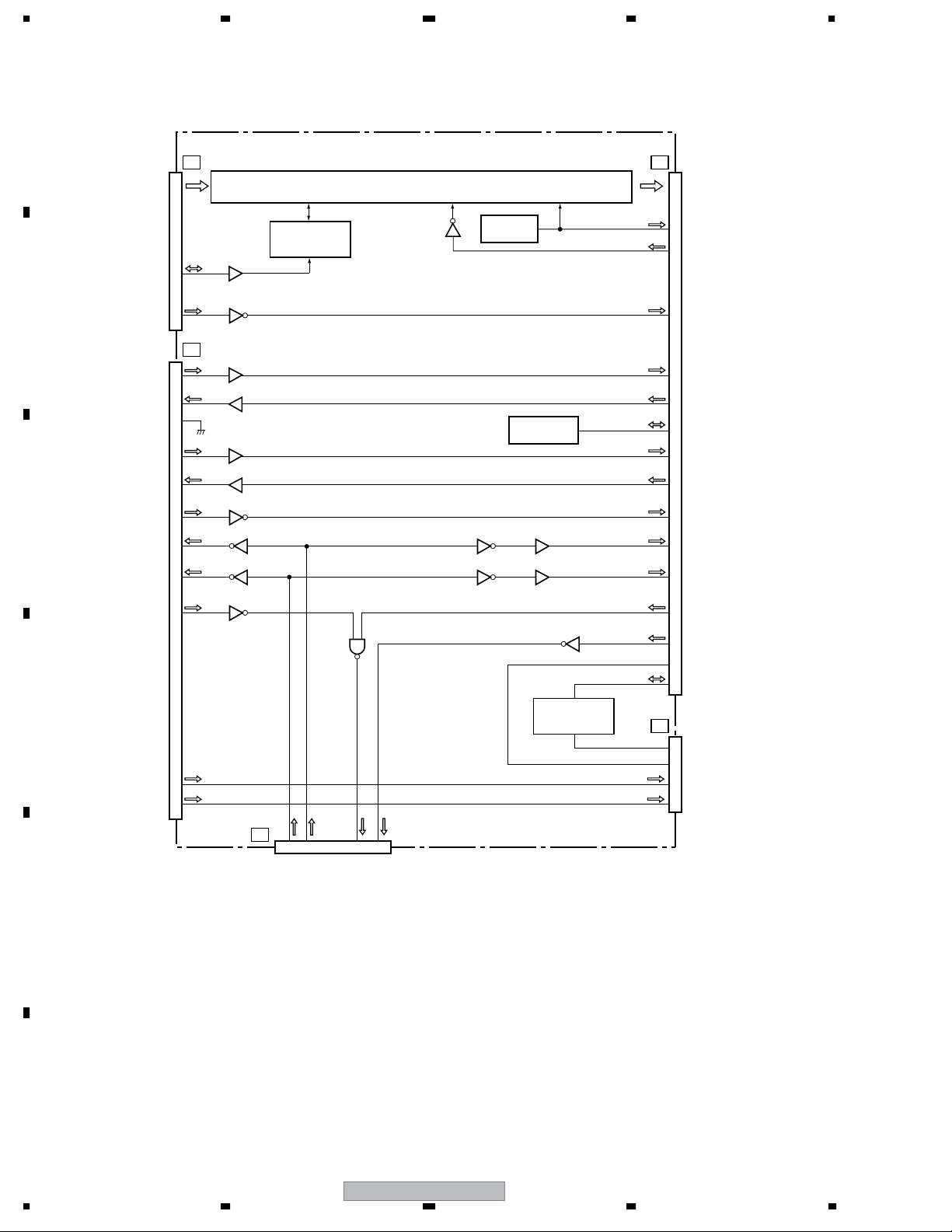

3.1.1 OVERALL BLOCK DIAGRAM

A

DRIVER IC

IC1551

DRIVER IC

IC1552

DRIVER IC

IC1553

DRIVER IC

IC1554

DRIVER IC

IC1555

DRIVER IC

IC1551

DRIVER IC

IC1552

DRIVER IC

IC1553

DRIVER IC

IC1554

DRIVER IC

IC1555

V+5V

V+3V_IC5

V+3V_PLLV+3V_LVDS

AD1

IC1501

CN1501

V+ADR

RESONANCE

50 ADDRESS ASSY

V+9V

BLOCK

V+60V

V+5V

V+9V

V+3V_IC5

V+3V_PLLV+3V_LVDS

AD1

IC1501

CN1501

V+ADR

RESONANCE

BLOCK

50 ADDRESS ASSY

V+60V

PANEL SENSOR ASSY

SENSOR

IC1072

B

50 SCAN B ASSY

VCC

_VH

VCC

_VH

VCC

_VH

VCC

_VH

VCC

_VH

VCC

_VH

VCC

_VH

VCC

_VH

VCC

_VH

VCC

_VH

VCC

_VH

VCC

_VH

PSUS

PSUS

SB1 Y2

SCAN

CN3201

SCAN

CN3001

SA1 Y3

CN2101

CN2102

IC5V

ADD

SEL_PULSE

IC3201

IC5V

ADD

SEL_PULSE

IC3202

IC5V

ADD

SEL_PULSE

IC3203

C

D

E

IC5V

ADD

SEL_PULSE

IC3204

IC5V

ADD

SEL_PULSE

IC3205

IC5V

ADD

SEL_PULSE

IC3206

IC5V

ADD

SEL_PULSE

IC3001

IC5V

ADD

SEL_PULSE

IC3002

IC5V

ADD

SEL_PULSE

IC3003

IC5V

ADD

SEL_PULSE

IC3004

IC5V

ADD

SEL_PULSE

IC3005

IC5V

ADD

SEL_PULSE

IC3006

50 SCAN A ASSY

CN1071

TE1

V_IC5V

VCC_VH

+16.5V

+5V

PSUSPSUS

MASK MOD

IC2307

+16.5V

SOFT-D

BLOCK

+16.5V

VSUS

+RESET

BLOCK

+5V +15V VSUS

MASK MOD

+5V +16.5V V_OFS

VCC_VH

V_IC5V

Scan Signal

50 Y DRIVE ASSY

V_OFS

VC_VF-

VC_VF+

+5V

VSUS

Drive

Signal

+5V

+16.5V

RESONANCE

BLOCK

IC2303

OFFSET

BLOCK

V_IC5V

Photo Coupler

BLOCK

DC_DC

CONV

BLOCK

REGULATOR

Drive

Signal

Drive

Signal

V_IC5VVCC_VH

LOGIC

BLOCK

VSUS

+5V

Y4

CN2301

+6.5V

Y1 D13

SCAN

YSUS

CN2001

VH_UV_PD

YDRIVE_PD

YRESNC_PD

YDD_CHV_PD

IC5V_UV_PD

CN5501

ADR_

PD0

OR

CN5202

D4

CN5521

OR

ADR_

PD4

CN5505

D5

ADR_PD1

LVDS

V+3V_D

V+1V_D

DCC_PD

FLASH MEMORY

SUB-FILD CONV.

XY DRV SEQUENCE

PATTERN GEN.

OR

Vofs

MODULE UCOM

LVDS

ADR_PD5

D9

CN5502

D6

ADR_PD2

CN5503

DIGITAL VIDEO ASSY

V+12V

DC-DC

CONVERTER

MODULE

AXY1086

IC5305

IC5401

PEG054A

IC5201

CN5506

&

PSIZU

ADR_PD6

D10

OR

OR

PD_MUTE

RELAY, PD_TRIGGER

CN5507

D7

ADR_PD3

PD

ADR_PD7

D11

CN5504

V+60V

V+6.5V

V+12V

Vsus_ADJ.

PD_PWDN

XSUS

XSUSTN_PD

XDD_CNV_PD

XDRIVE_PD

DCLK, DE

HD, VD

RA IN, GA IN, BA IN

RB IN, GB IN, BB IN

CN5508

D8

D15

D12

D2

CN5601 CN5602

D1

D14

CN5511

CN5001

CN1501

AD1

V+3V_PLLV+3V_LVDS

F

V+5V

DRIVER IC

IC1551

DRIVER IC

IC1552

V+3V_IC5

DRIVER IC

IC1553

22

50 ADDRESS ASSY

DRIVER IC

IC1554

RESONANCE

BLOCK

V+ADR

IC1501

PDP-505PE

V+9V

DRIVER IC

IC1555

V+60V

V+5V

DRIVER IC

IC1551

V+3V_PLLV+3V_LVDS

DRIVER IC

IC1552

AD1

V+3V_IC5

DRIVER IC

IC1553

CN1501

50 ADDRESS ASSY

DRIVER IC

IC1554

RESONANCE

V+ADR

IC1501

BLOCK

DRIVER IC

IC1555

V+9V

V+60V

1234

Page 23

5678

DRIVER IC

IC1551

V+5V

RA IN, GA IN, BA IN

RB IN, GB IN, BB IN

CN4004

DRIVER IC

IC1552

V+3V_PLLV+3V_LVDS

P4

VSUS

+6.5V

+16.5V

M601

VSUS_

P3

CONT

P5

+6.5V

VADR

P2

Vsus_ADJ.

+12V

PS.PD

EXT.PD

RELAY

STB

3.3V

P1 P6

CN4001

R1

V+3V

V+6.5V

ACTV

R4

DCLK, DE

HD, VD

EEPROM

for Backup

B_SDA

B_SCL

DRIVER IC

V+3V_IC5

AD1

SECONDARY

+6.5V

TMDS RECEIVER

IC4202

TMDS

CN4003

IC1553

STB3.3

MUTE

DDC

DRIVER IC

IC1501

CN1501

T5

T4

T2

T3

T1

PANEL IF ASSY

FET SW

R3

IC1554

DRIVER IC

V+ADR

RESONANCE

BLOCK

IC1555

V+9V

V+60V

50 ADDRESS ASSY

Switching

Q14

Q13

+390V

D133

D31,D32

M341

PFC

Q1,Q2

RL1

RELAY

& PD

Switching

Q11

Switching

Q12

Switching

M1

Switching

PRIMARY

POWER SUPPLY UNIT

A_SCL,A_SDA,SRS

Bus

Buffer

Bus

V+3V_STB

Buffer

CN4002

MDR CONNECTORDVI CONNECTOR

V+5V

RC1

NEUTRAL

V+6.5V

FOCUS,TRUBASS

A_MUTE

ST_BY

A_NG

AUDIO L

AUDIO R

LED_R,G

KEY

REM

STB

_MT

R2

DRIVER IC

IC1551

P7

LIVE

R7

CN4009

CN4010

R8

DRIVER IC

IC1552

DRIVER IC

IC1553

V+3V_IC5

V+3V_PLLV+3V_LVDS

AD1

DRIVER IC

IC1554

V+ADR

IC1501

CN1501

RESONANCE

50 ADDRESS ASSY

LIVE

NEUTRAL

DRIVER IC

IC1555

BLOCK

MAIN POWER

V+9V

S1

V+60V

50 X DRIVE ASSY

X2

DC_DC

VSUS

CONV

BLOCK

+6.5V

REGULATOR

Drive

+5V

Signal

X1

LOGIC

BLOCK

CN1001 CN1201

CN3504

A4

+9V

A1 A3 SP2 SP1

L,R

WOW IC

IC3501

L,R

Drive

Signal

+16.5V

RESONANCE

BLOCK

+16.5V

+9V

VOL IC

IC3502

V_RN

+5V

+16.5V

MASK MOD

IC1203

V_RN

-RESET

+16.5VVSUS

IC1207

+16.5V

IC3504

+16.5V

PULSE

BLOCK

+5V

+5V

VSUS

SUS

OUT

+5V

SUS

OUT

MASK MOD

L,R L,R

POWER AMP

PSUS

PSUS

L,R L,R

CN3503

HD AUDIO AMP ASSY

PANEL

LED

CN4751 CN3501

ASSY

L1

CN4852

KL2 KL1 SW1

KEY CONTROL

ASSY

CN4851

CN4801

PANEL KEY

ASSY

PANEL IR

CN4901

RE1

ASSY

AC INLET

X CONNECTOR

A ASSY

X CONNECTOR

B ASSY

J3701

CN3701

HD SP TERMINAL

ASSY

A

B

C

D

SPEAKER

E

V+5V

DRIVER IC

IC1551

CN1501

V+3V_PLLV+3V_LVDS

DRIVER IC

IC1552

AD1

V+3V_IC5

DRIVER IC

IC1553

50 ADDRESS ASSY

DRIVER IC

IC1554

RESONANCE

BLOCK

V+ADR

IC1501

DRIVER IC

IC1555

V+9V

V+60V

V+5V

DRIVER IC

IC1551

V+3V_PLLV+3V_LVDS

DRIVER IC

IC1552

PDP-505PE

56

AD1

V+3V_IC5

DRIVER IC

IC1553

7

CN1501

50 ADDRESS ASSY

DRIVER IC

IC1554

RESONANCE

V+ADR

IC1501

BLOCK

DRIVER IC

IC1555

V+9V

V+60V

F

23

8

Page 24

1234

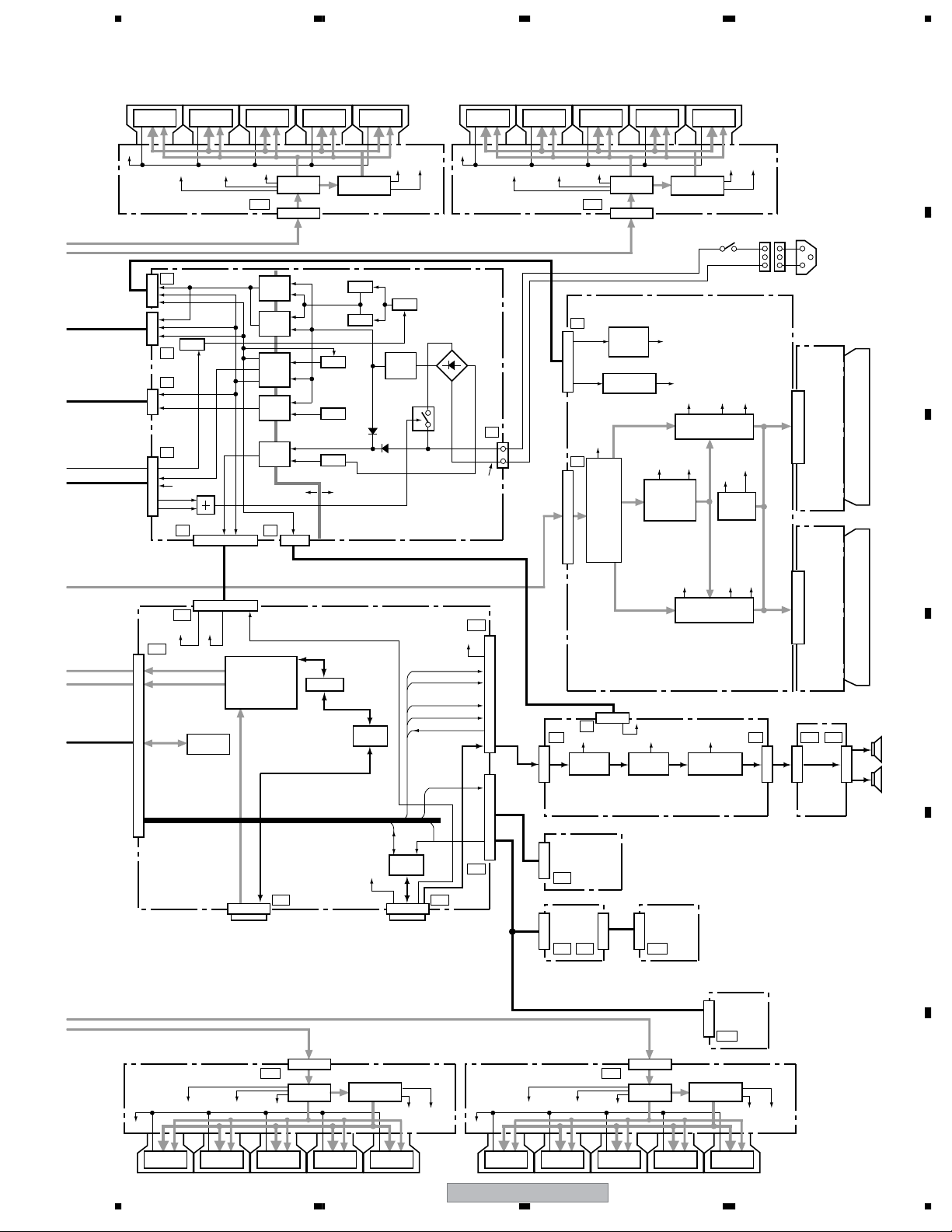

3.1.2 50 Y DRIVE ASSY

• Block Diagram

A

50 Y DRIVE ASSY

Y1

IC5V

VH

Y2

To

50 SCAN B ASSY

CN2101CN2102

CE

B

C

D

CLK2

CLR

OC2

OC1

YPR-U

YSOFT-D

YSUS-G

YSUS-B

YSUS-U2

From DIGITAL VIDEO ASSY

YSUS-D2

YSUS-U1

YSUS-D1

YSUS-MSK

YOFS

YSUS-PD

SCN_5V_PD

Y_DD_PD

SCAN_PD

YDRIVE_PD

Photo CouplerCLK1

Photo Coupler

Photo Coupler

Photo Coupler

Photo Coupler

Photo Coupler

SI

Photo Coupler

CN2001

VH

Y3

YSUS

-U2

5V

YSUS-D2

YSUS-U1

5V

YSUS-D1

To

50 SCAN A ASSY

YPR-U

YSOFT-D

IC2202

HB

DRIVER

SUS

HB

XSUS

P.D.

Circuit

GND

SUS

GND

IC2201

DRIVER

IC2203

YSUS-G

YSUS-B

L2204

L2202

VSUS

L2205

L2203

VSUS

16.5V

VSUS

16.5V

5V

5V

Mask Module

IC2303

STK795-513A

Mask Module

IC2307

STK795-513A

To

SCAN ASSY

YSUS-MSK

YOFS

IC2302

Photo

Coupler

IC2304

IC2311

E

Y4

CN2301

1

16.5V

2

DGND

3

6.5V

DGND

4

N.C.

5

6

N.C.

7

VSUS VSUS

VSUS

8

N.C.

9

F

SUSGND

SUSGND

From POWER SUPPLY UNIT

10

11

P.D.

DET.

IC2305

REGULATOR

IC5V UVP

5V

VOFS OVP

VOFS UVP

VH OVP

VH UVP

VSUS

IC5V, VF

D-D CONV.

D-D CONV.

VH D-D

CONV.

24

VOFS

VF+

VF-

IC5V

VOFS

VH

PDP-505PE

1234

Page 25

5678

3.1.3 50 X DRIVE ASSY

• Block Diagram

A

X1

XSUS-G

XSUS-B

XSUS-U2

XSUS-D2

XSUS-U1

XSUS-D1

XSUS-MSK

XCP-MSK

XSUS_PD

XDD_PD

XDRV_PD

From DIGITAL VIDEO ASSY

SUSGND

SUSGND

From POWER SUPPLY UNIT

CN1001

XNR-D

X2

CN1201

1

16.5V

2

DGND

3

6.5V

DGND

4

N.C.

5

6

N.C.

7

VSUS VSUS

VSUS

8

N.C.

9

10

11

12

N.C.

50 X DRIVE ASSY

P.D.

DET.

IC1205

REGULATOR

5V

VRN UVP P.D.

XNR-D

VRN OVP

P.D.

XSUS

-U2

5V

XSUS-D2

XSUS-U1

5V

XSUS-D1

XCP-MSK

XSUS-MSK

VSUS

D-D CONV.

T1401

IC1101

HB

DRIVER

IC1102

HB

DRIVER

XSUS

P.D.

Circuit

Charge Pump

Circuit

IC1202

Photo

Coupler

IC1204

VRN-235V

SUS

GND

SUS

GND

VCP

XSUS-G

XSUS-B

L1102

L1104

L1103

L1105

VSUS

16.5V

VSUS

16.5V

5V

5V

Mask Module

IC1203

STK795-512A

Mask Module

IC1207

STK795-512A

PSUS

To

X CONNECTOR ASSY

B

C

D

56

PDP-505PE

E

F

25

7

8

Page 26

1234

3.1.4 PANEL IF ASSY

• Block Diagram

A

PANEL IF ASSY

R3

TMDS

CN4003CN4002

6: DDC_SCL

7: DDC_SDA

B

C

DVI CONNECTOR

14: DDC_+5V

11: MTXD

2: MRXD

3: P_ST_B

10: MR_ST_B

7: REQ

8: STB3V

9: KEY_B

14: REM_B

MDR CONNECTOR

15: STB_MT

I2C BUFFER

R2

IC4006 BUF

IC4006 BUF

IC4006 BUF

IC4006 BUF

Q4004 INV

Q4006 INV

Q4006 INV

Q4009 INV

D

IC4202

TMDS RECEIVER

IC4206

Q4004

INV

Q4215

5V ↔ 3.3V

I2C LEVEL SHIFT

Q4007,

Q4011

NOR

Q4017

INV

IC4205

RESET IC

Q4006 INV

Q4006 INV

IC4002

BACKUP ROM

IC4006 BUF

IC4006 BUF

Q4011 INV

Q4001

5V ↔ 3.3V

I2C LEVEL SHIFT

R4

RSTBTMD

DVI_MUTE

DVI_OFF

RXD0

TXD0

B_SCL, B_SDA

CN4004CN4009

MR_ST_B

REQ_MD

MR_AC_OFF

KEY_B

REM_B

LED_R_B

LED_G_B

A_NG,A_MUTE,STB_SW,

FOCUS,TRUBASS,SRS

A_SCL, A_SDA

R7

13: AUDIO_R

20: AUDIO_L

R8

REM

CN4010

KEY

LED R

LED G

R_IN

L_IN

E

F

26

PDP-505PE

1234

Page 27

5678

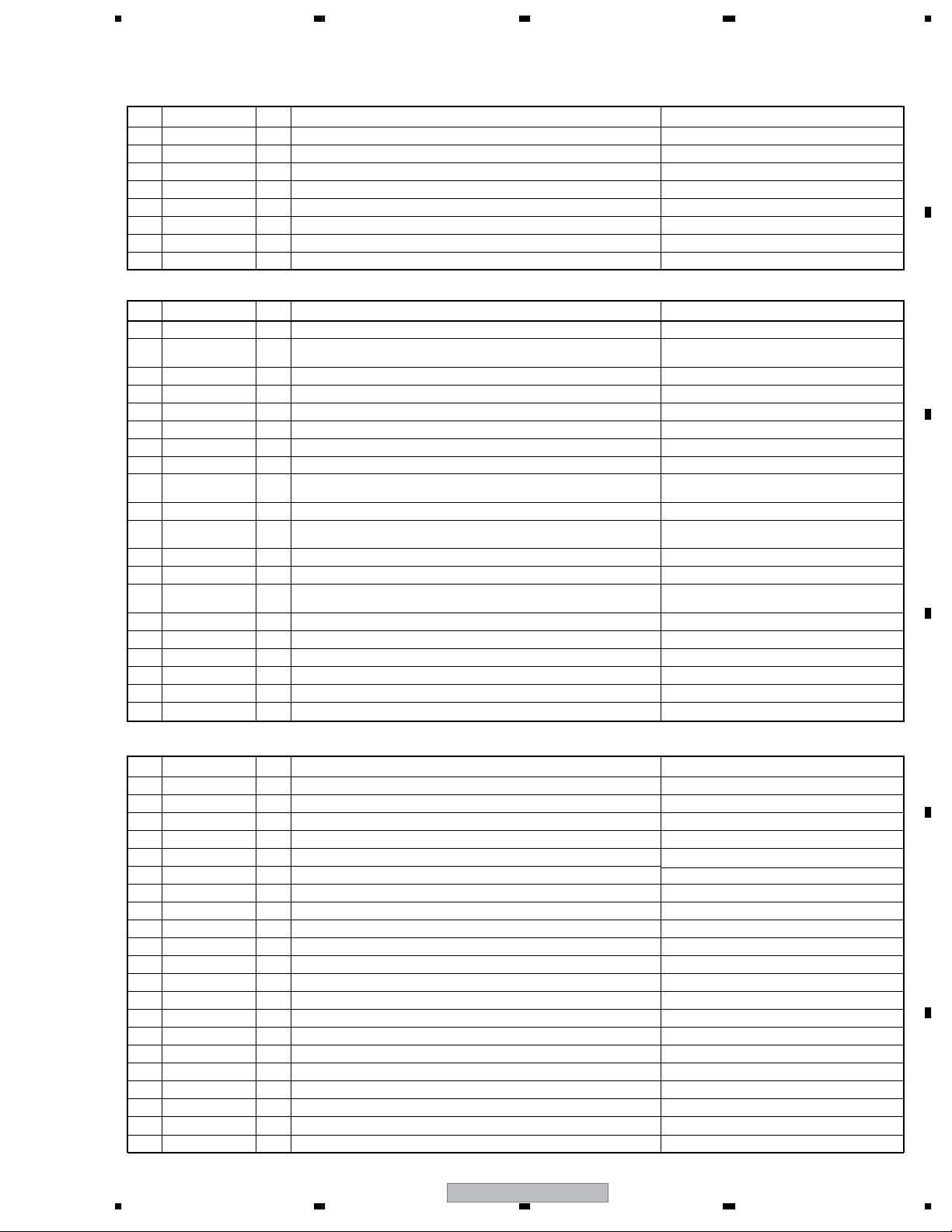

• Voltages

CN4001 (R1) < ⇔ POWER SUPPLY UNIT >

No. Signal Name I/O Signal Description Voltages at NTSC Signal Input

1 6.5V I +6.5V power supply +6.8VDC

2 6.5V I +6.5V power supply +6.8VDC

3 Vcc_GND − GND

4 Vcc_GND − GND

5 STB3.3V I Power supply +3.3V input of module UCOM at panel side +3.3VDC

6 STB_GND − GND

7 STB3.3MUTE O Standby control (+3.3V mute) +3.3 VDC

8 AC_DET I Primary power supply (AC) state input at panel side +3.0VDC

CN4002 (R2) < ⇔ MEDIA RECEIVER >

No. Signal Name I/O Signal Description Voltages at NTSC Signal Input

1 MR_ST_B I

2 MRXD O

3 P_ST_B O

4 ACT3V O

5 AC_OFF O

6 GND

7 REQ O

8 STB3V I

9 KEY_B O

10 MR_ST_B' I

11 MTXD I

12 GND

13 AUDIO_R I

14 REM_B O

15 STB_MT I

16 GND

17 NC

18 FIELD I

19 GND

20 AUDIO_L I

Connection state detecting signal with MR

UART communication transmission data with the main UCOM (external PC)

at MR side

Connection state output for the MR

Power supply +3.3V output of module UCOM at panel side

Primary power supply (AC) state output at panel side

−

GND

Communication request to the main UCOM (external PC) at the MR

Standby power supply (+3.3V) input from the MR

Function key code signal output at panel side

Connection state detecting signal with the MR

UART communication receive data with the main UCOM (external PC) at

the MR side

−

GND

R ch audio signal input Audio R signal

Remote control code signal output

Standby control input

−

GND

−

Not connected

FIELD control signal

−

GND

L ch audio signal input Audio L signal

0VDC

0-3.3V amplitude square wave

0VDC

+3.3VDC

0VDC

0-3.3V amplitude square wave

+3.3VDC

0-3.3V amplitude square wave (at key

operation)

0VDC

0-3.3V amplitude square wave

0-3.3V amplitude square wave (at remocon

code transmission)

0VDC

−

0VDC

A

B

C

D

CN4003 (R3) < ⇔ MEDIA RECEIVER >

No. Signal Name I/O Signal Description Voltages at NTSC Signal Input

1 RX2- I

2 RX2+ I

3 GND

4 N.C

5 N.C

6 DDC_SCL I

7 DDC_SDA I

8 N.C

9 RX1- I

10 RX1+ I

11 GND

12 N.C

13 N.C

14 DDC_+5V I

15 GND

16 HPD O

17 RX0- I

18 RX0+ I

19 GND

20 N.C

21 N.C

56

DVI signal DVI differential signal (-)

DVI signal DVI differential signal (+)

−

GND

−

Not connected

−

Not connected

I2C signal for DDC

I2C signal for DDC 0-5V amplitude square wave

−

Not connected

DVI signal DVI differential signal (-)

DVI signal DVI differential signal (+)

−

GND

−

Not connected

−

Not connected

I2C power supply for DDC

−

GND

Hot plug detection

DVI signal DVI differential signal (-)

DVI signal DVI differential signal (+)

−

GND

−

Not connected

−

Not connected

−

−

0-5V amplitude square wave

−

−

−

+5VDC

+5VDC

−

−

PDP-505PE

7

8

E

F

27

Page 28

1234

• Voltages

CN4003 (R3) < ⇔ MEDIA RECEIVER >

A

No. Signal Name I/O Signal Description Voltages at NTSC Signal Input

22 GND

23 RXC+ I

24 RXC- I

CN4009 (R7) < ⇔ HD AUDIO AMP ASSY >

No. Signal Name I/O Signal Description Voltages at NTSC Signal Input

1 A_NG I

2 V+6.5 O

3 GNDA

4 L_IN O

B

5 GNDA

6 R_IN O

7 ST_BY O

8 A_MUTE O

9 SCL O

10 SDA O

11 FOCUS O

12 SRS O

13 TRUBASS O

−

GND

DVI signal DVI differential signal (-)

DVI signal DVI differential signal (+)

Abnormal detecting signal of the audio block

+6.5V power supply

−

GND

L ch audio signal Audio L signal

−

GND

R ch audio signal Audio R signal

Standby signal of the audio block +3.3V DC

Audio mute signal input 0V DC

I2C control signal for audio 0-3.3V amplitude square wave

I2C control signal for audio 0-3.3V amplitude square wave

Focus function control signal +3.3V DC

SRS function control signal +3.3V DC

TRUBASS function control signal +3.3V DC

+3.3V DC

+6.8V DC

CN4010 (R8) < ⇔ PANEL LED ASSY, PANEL IR ASSY, KEY CONTROL ASSY >

C

No. Signal Name I/O Signal Description Voltages at NTSC Signal Input

1 LED_G O

2 LED_R O

3 AC_OFF O

4 STB3V O

5 STBGND

6 REM I

7 STB+3V O

8 KEY I

9 STBGND

D

LED control (green)

LED control (red)

Primary power supply (AC) state output at the panel side

+3.3V power supply +3.3V DC

− GND

Remote control code signal input

+3.3V power supply +3.3V DC

Function key code signal input at the panel side

− GND

+2.1VDC

0VDC

0VDC

0-3.3V amplitude square wave (at remocon

code transmission)

0-3.3V amplitude square wave (at key operation)

CN4801 (SW1) < ⇔ KEY CONTROL ASSY >

No. Signal Name I/O Signal Description Voltages at NTSC Signal Input

1 STBGND

2G1 O

3G0 O

4D5 I

5D6 I

6D7 I

E

−

GND 0V DC

Key scan signal 0V DC

Key scan signal 0V DC

Key scan signal +3.3V DC

Key scan signal +3.3V DC

Key scan signal +3.3V DC

F

28

1234

PDP-505PE

Page 29

5678

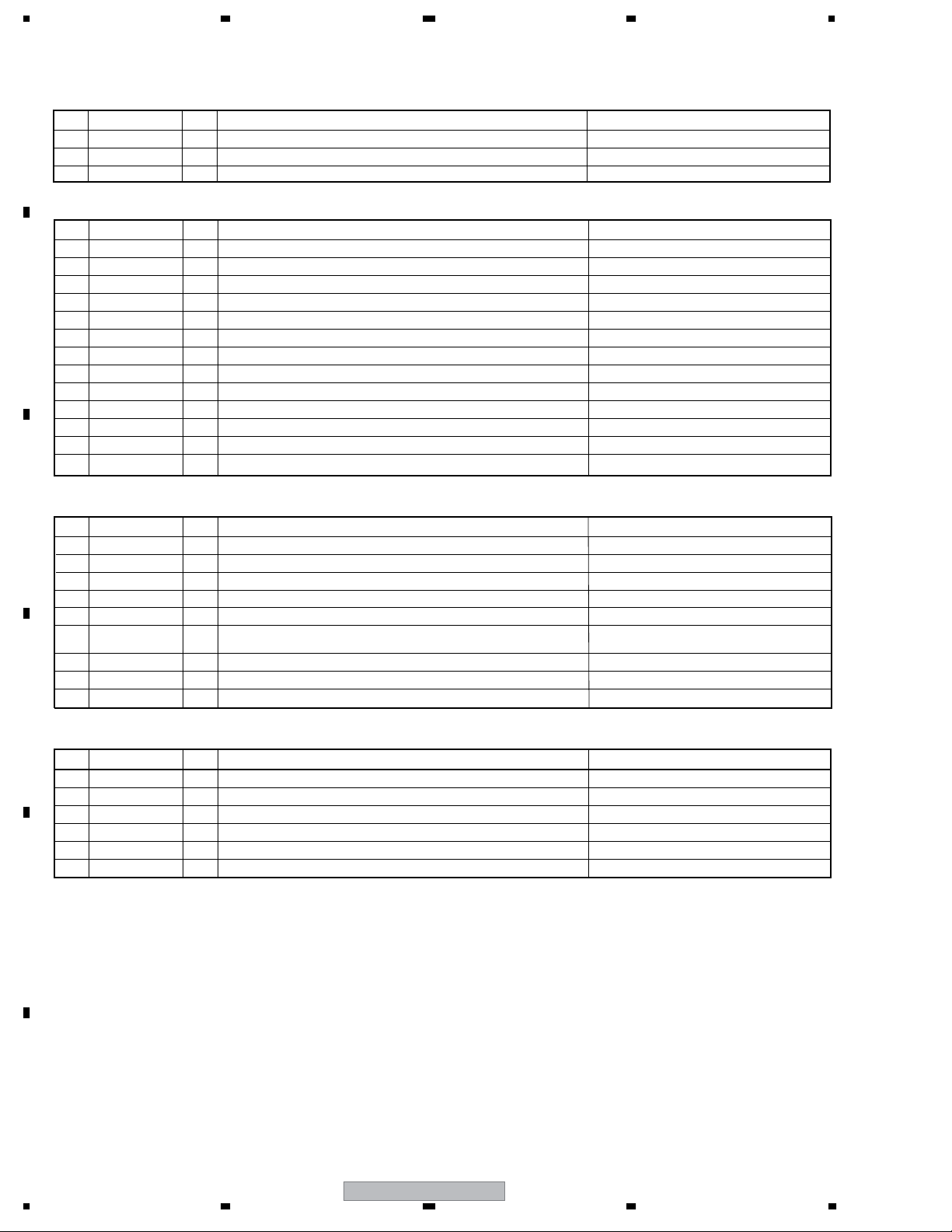

• Voltages

CN4004 (R4) < ⇔ DIGITAL VIDEO ASSY > (1/2)

No. Signal Name I/O Signal Description Voltages at NTSC Signal Input

1 GND

2 GND

3

GND

GND

4

5 BA0 O

6 BA1 O

7 BA2 O

8 BA3 O

9 BA4 O

10 BA5 O

11 BA6 O

12 BA7 O

13 GND

14 GND

GND

15

GND

16

17 GA0 O

18 GA1 O

19 GA2 O

20 GA3 O

21 GA4 O

22 GA5 O

23 GA6 O

24 GA7 O

25 GND

26 GND

GND

27

GND

28

29 RA0 O

30 RA1 O

31 RA2 O

32 RA3 O

33 RA4 O

34 RA5 O

35 RA6 O

36 RA7 O

37

GND\

38 DCLK O

39 GND

40 DEI O

41 HDI O

42 VDI O

43 FIELD O

44 APL_DT

45

GND

GND

46

47 BB0 O

48 BB1 O

49 BB2 O

50 BB3 O

51 BB4 O

52 BB5 O

53 BB6 O

54 BB7 O

55 GND

56 GND

57

GND

GND

58

−

GND

−

GND

−

GND

−

GND

8bit video signal output (BLUE even number) 0-3.3V amplitude square wave

8bit video signal output (BLUE even number) 0-3.3V amplitude square wave

8bit video signal output (BLUE even number) 0-3.3V amplitude square wave

8bit video signal output (BLUE even number) 0-3.3V amplitude square wave

8bit video signal output (BLUE even number) 0-3.3V amplitude square wave

8bit video signal output (BLUE even number) 0-3.3V amplitude square wave

8bit video signal output (BLUE even number) 0-3.3V amplitude square wave

8bit video signal output (BLUE even number) 0-3.3V amplitude square wave

−

GND

−

GND

−

GND

−

GND

8bit video signal output (GREEN even number) 0-3.3V amplitude square wave

8bit video signal output (GREEN even number) 0-3.3V amplitude square wave

8bit video signal output (GREEN even number) 0-3.3V amplitude square wave

8bit video signal output (GREEN even number) 0-3.3V amplitude square wave

8bit video signal output (GREEN even number) 0-3.3V amplitude square wave

8bit video signal output (GREEN even number) 0-3.3V amplitude square wave

8bit video signal output (GREEN even number) 0-3.3V amplitude square wave

8bit video signal output (GREEN even number) 0-3.3V amplitude square wave

−

GND

−

GND

−

GND

−

GND

8bit video signal output (RED even number) 0-3.3V amplitude square wave

8bit video signal output (RED even number) 0-3.3V amplitude square wave

8bit video signal output (RED even number) 0-3.3V amplitude square wave

8bit video signal output (RED even number) 0-3.3V amplitude square wave

8bit video signal output (RED even number) 0-3.3V amplitude square wave

8bit video signal output (RED even number) 0-3.3V amplitude square wave

8bit video signal output (RED even number) 0-3.3V amplitude square wave

8bit video signal output (RED even number) 0-3.3V amplitude square wave

−

GND

Synchronous signal output (clock) 0-3.3V amplitude square wave (42.5MHz)

−

GND

Synchronous signal output (data enable)

Synchronous signal output (Horizontal sync.)

Synchronous signal output (Vertical sync.)

FIELD control signal 0V DC

Not connected

−

GND

−

GND

8bit video signal output (BLUE odd number) 0-3.3V amplitude square wave

8bit video signal output (BLUE odd number) 0-3.3V amplitude square wave

8bit video signal output (BLUE odd number) 0-3.3V amplitude square wave

8bit video signal output (BLUE odd number) 0-3.3V amplitude square wave

8bit video signal output (BLUE odd number) 0-3.3V amplitude square wave

8bit video signal output (BLUE odd number) 0-3.3V amplitude square wave

8bit video signal output (BLUE odd number) 0-3.3V amplitude square wave

8bit video signal output (BLUE odd number) 0-3.3V amplitude square wave

−

GND

−

GND

−

GND

−

GND

−

−

−

−

−

−

−

−

−

−

−

−

−

−

0-3.3V amplitude square wave (positive polarity)

0-3.3V amplitude square wave (negative polarity)

0-3.3V amplitude square wave (negative polarity)

−

−

−

−

−

−

−

A

B

C

D

E

F

56

PDP-505PE

29

7

8

Page 30

1234

• Voltages

CN4004 (R4) < ⇔ DIGITAL VIDEO ASSY > (2/2)

A

No. Signal Name I/O Signal Description Voltages at NTSC Signal Input

59 GB0 O

60 GB1 O

61 GB2 O

62 GB3 O

63 GB4 O

64 GB5 O

65 GB6 O

66 GB7 O

67 GND

68 GND

B

C

D

E

F

GND

69

70

GND

71 RB0 O

72 RB1 O

73 RB2 O

74 RB3 O

75 RB4 O

76 RB5 O

77 RB6 O

78 RB7 O

79 GND

80 MASK

81 MODE

82 MODEL

83 DITHER

84 V+3VACTV O Power supply +3.3V output of module UCOM at panel side +3.3VDC

85 B_SDA I E2PROM control signal for backup

86 RXD0 O

87 REM_B O Remote control code signal output

88 TXD0 I

89 KEY_B O Function key code signal output at panel side

90 REQ_MD I

91 LED_R_B I LED control (red) +3.3VDC

92 MR_AC_OFF O AC state output at MR side 0VDC

93 LED_G_B I LED control (green) 0VDC

94 POWER Not connected −

95 DVI_MUTE I DVI mute signal input 0VDC

96 MR_ST_B O Connection state detecting signal with MR 0VDC

97 A_MUTE I Audio mute signal input 0VDC

98 OP_DET

99 A_NG O Abnormal detecting signal of audio block +3.3VDC

100 PNL_MUTE Not connected −

101 A_SCL I I2C control signal for audio

102 STB_SW I Standby signal of audio block +3.3VDC

103 A_SDA I I2C control signal for audio

104 DDC_WP I

105 TRUBASS I TRUBASS function control signal +3.3VDC

106 B_SCL I E2PROM control signal for backup

107 FOCUS I FOCUS function control signal +3.3VDC

108 DVI_OFF O Connection detecting signal of DVI connector 0VDC

109 SRS I SRS function control signal +3.3VDC

110 RSTBTMD O TMDS IC reset signal +3.3VDC

111 MAX_PLS1 Not connected −

112 L_SYNC O TMDS IC synchronous detecting signal +3.3VDC

113 MAX_PLS2 Not connected −

114 GND

8bit video signal output (GREEN odd number) 0-3.3V amplitude square wave

8bit video signal output (GREEN odd number) 0-3.3V amplitude square wave

8bit video signal output (GREEN odd number) 0-3.3V amplitude square wave

8bit video signal output (GREEN odd number) 0-3.3V amplitude square wave

8bit video signal output (GREEN odd number) 0-3.3V amplitude square wave

8bit video signal output (GREEN odd number) 0-3.3V amplitude square wave

8bit video signal output (GREEN odd number) 0-3.3V amplitude square wave

8bit video signal output (GREEN odd number) 0-3.3V amplitude square wave

−

GND

−

GND

−

GND

−

GND

8bit video signal output (RED odd number) 0-3.3V amplitude square wave

8bit video signal output (RED odd number) 0-3.3V amplitude square wave

8bit video signal output (RED odd number) 0-3.3V amplitude square wave

8bit video signal output (RED odd number) 0-3.3V amplitude square wave

8bit video signal output (RED odd number) 0-3.3V amplitude square wave

8bit video signal output (RED odd number) 0-3.3V amplitude square wave

8bit video signal output (RED odd number) 0-3.3V amplitude square wave

8bit video signal output (RED odd number) 0-3.3V amplitude square wave

−

GND

Not connected

Not connected

Not connected

Not connected

UART communication receive data with the main UCOM (external PC) at MR side

UART communication transmission data with the main UCOM (external PC) at MR side

Communication request to the main UCOM at MR side

GND

GND

−

GND

−

−

−

−

0-3.3V amplitude square wave

0-3.3V amplitude square wave

0-3.3V amplitude square wave (at remocon

code transmission)

0-3.3V amplitude square wave

0-3.3V amplitude square wave (at key

operation)

0-3.3V amplitude square wave

0-3.3V amplitude square wave

0-3.3V amplitude square wave

0-3.3V amplitude square wave

30

PDP-505PE

1234

Page 31

5678

LVDS

(R,G,B) x10bit x2

YSUSA,YSUSB

SCAN

Works by passive standby power

Works by active standby power

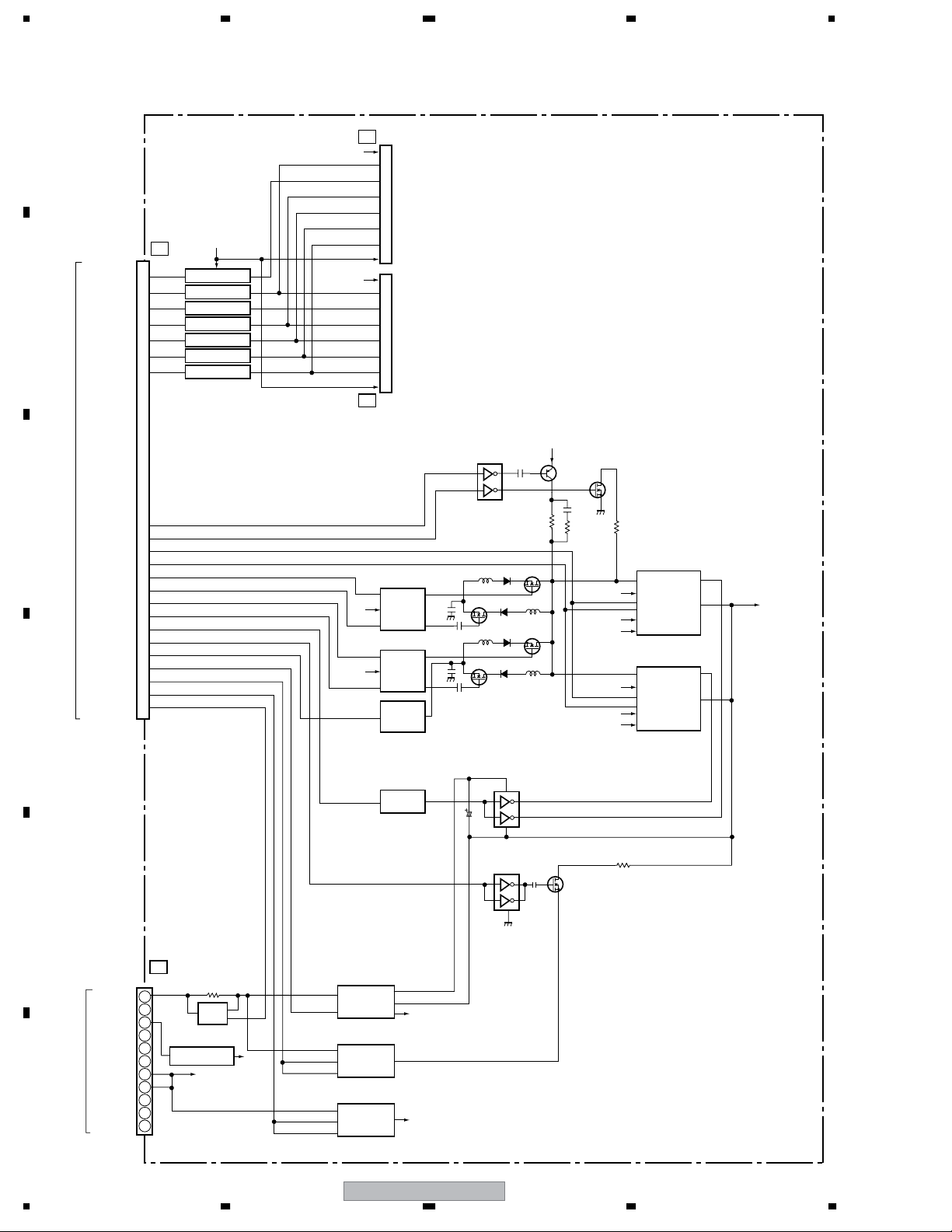

3.1.5 DIGITAL VIDEO ASSY

• Block Diagram

CN5001

From PANEL IF ASSY

Works by passive standby power

Works by passive standby power Works by active standby power

DIGITAL VIDEO ASSY

(R,G,B) x10bit x2

(R,G,B) x10bit x2

HD, VD, CLK, DE

OR

OR

1.5V

3.3V

RST

RST

IC

IC

For HD model

3 STATE3STATE

3STATE

For panel module

Xtal

RST2

IC4_RST

DVI_DET

MSTATE

RSTBTMDS

L_SYNC

VD_IN

DVI_MUTE

OP_DET

WE_IC4

A_SCL/A_SDA

Excepting panel module

RXD0

TXD0

REQ

CST3

MODEL

B_SCL/B_SDA

MRAC_DET

MODE

KEY

REM

POWER

PNL_MUTE

DITHER

MAX_PLS1

MAX_PLS2

MASK1

STB_SW

SRS

FOCUS

TRUBASS

A_MUTE

LED_R

LED_G

AC_DET

THEATER

MANTA

RST

TXD

CLK

IC4_CE

MODULE UC OM

IC5201

DRIVE_OFF

IC4

Works by active standby power

LVDS

LVDS

YSUSA,YSUSB

YSUSA,YSUSB

YSUSA, YSUSB

SCAN

SCAN

SCAN

XSUSA, XSUSB

FLASH

Sequence data

TCKTMS

TRST TDI

TDO

MUTE

RXD

IC4_BUSY

REQ_IC4

PD_TRG

EEPRST

ADR_PD

SCAN_PD

YDRV_PD

YRES_PD

YDC_PD

IC5V_PD

XSUS_PD

XDC_PD

XDRV_PD

PS_PD

DCC_PD

YDRV_UC

XDRV_UC

PD_MUTE

PSIZE

PSW_D

RESET

TEMP1

E_SCL

E_SDA

DC- DC

CONV.

BUSY

RXD1

CLK1

CNVSS

TXD1

VOFS

VSUS

RELAY

ROM

ROM

EEP

Xtal

JTAG

FLASH

writing

&

Writing

AND

3.3V

RST

50 ADDRESS ASSY x8

IC5

PANEL

SIZE

OR

50 Y DRIVE

ASSY

PD

SCAN

ASSY

Video signal

Sync. signal

3-wire serial down

3-wires serial up

Signal for JTAG

Parallel bus

IIC communication

Asynchronous serial down

Asynchronous serial up

Others

A

B

MUTE

PD

PD

PD

PD

PD

Connector

disconnection

detection

Vofs

50 X DRIVE

ASSY

C

MUTE

PD

PD

PD

OR

D

Connector

disconnection

PD

MUTE

OR

8bit

DAC

IC

detection

Vrst

Vm adj: STB

PANEL SENSOR ASSY

Terrmal

sensor

E

CN4001

POWER SUPPLY ASSY

ASSY

From PANEL IF

Mechanism

SW for Mute

RELAY CONTROL

POWER ON

RELAY

STB_MT

STB3.3V

AC_DET

AC- OFF

DRIVE

OF

PD

LED

F

PDP-505PE

56

Vsus

Each

OR

PD

31

F

7

8

Page 32

1234

• Voltages

CN5601 (D1)

A

No. Signal Name I/O Signal Description Voltages at NTSC Signal Input

1 +12V I

2 +12V I

3 GND_D

4 GND_D

5PD O

6 VSUS_ADJ O

7 PS_PD I

8 RELAY O

9 DRF O

10 AC_DET I

B

11 PD_TRIGGER I

CN5602 (D2)

No. Signal Name I/O Signal Description Voltages at NTSC Signal Input

1 VADR I

2 VADR I

3 N.C

4 GND_ADR

5 GND_ADR

C

6 +6.5V I

7 GND_D

+12V power input

+12V power input

GND

−

GND

−

Power down signal

VSUS adjustment signal

Power-down detecting signal of POWER SUPPLY block

Relay control signal

Drive control signal

Primary side power (AC) state output at panel side

Power down trigger

Address drive power (+61V) input

Address drive power (+61V) input

Not connected

GND

−

GND

−

+6.5V power input

GND

−

+12VDC

+12VDC

0VDC

0VDC

+3.3VDC

0VDC

+3.0VDC

+3.3VDC

+61VDC

+61VDC

+6.8VDC

D

E

F

32

PDP-505PE

1234

Page 33

5678

3.1.6 HD AUDIO AMP ASSY

A1

+6.5V

R_Audio

L_Audio

SCL, SDA

SRS,FOCUS,TRUBASS

HD AUDIO AMP ASSY

+9.0V +9.0V

WOW IC

IC3501

+9.0V

From POWER SUPPLY Unit

+16.5V

VOLUME IC

IC3502

BUFFER

A

CN3504

A2

B

From PANEL IF ASSY

A_Mute

ST-BY

A_NG_B

+16.5V

CN3501

REGULATOR

IC3503

DC DETECT

BLOCK

CN3503

POWER AMP

IC3504

+

R_OUT+

R_OUT-

L_OUT -

L_OUT

J3701

HD SP TERMINAL ASSY

L OUTR OUT

A3

SP2

+16.5V

IC

SP1

C

D

E

56

PDP-505PE

F

33

7

8

Page 34

1234

3.2 WAVEFORMS

DIGITAL VIDEO ASSY (4/6)

A

• DIGITAL IF BLOCK

CH1: TP5102 (VD)

1

CH2: TP5101 (HD)

V: 2V/div. H: 2msec/div.

CH1: TP5101 (HD)

3

CH2: TP5103 (DE)

V: 2V/div. H: 2µsec/div.

CH1

CH2

B

CH1: TP5102 (VD)

1

CH2: TP5101 (HD)

V: 2V/div. H: 4µsec/div.

CH1

CH2

C

CH1: TP5102 (VD)

2

CH2: TP5103 (DE)

V: 2V/div. H: 2msec/div.

CH1

CH1

CH2

CH1: TP5101 (HD)

3

CH2: TP5103 (DE)

V: 2V/div. H: 40nsec/div.

CH1

CH2

CH1: TP5101 (HD)

4

CH2: CN5001-pin 77 (DCLK)

V: 2V/div. H: 40nsec/div.

CH1

CH2

D

CH1: TP5102 (VD)

2

CH2: TP5103 (DE)

V: 2V/div. H: 4µsec/div.

CH1

CH2

E

F

CH2

CH1: TP5102 (VD)

5

CH2: CN5001-pin 86 (RA_IN2)

V: 2V/div. H: 2msec/div.

CH1

CH2

34

PDP-505PE

1234

Page 35

5678

PANEL IF ASSY (1/2)

• TMDS RX BLOCK

CH1: K4005 (VDI)

1

CH2: K4006 (HDI)

V: 2V/div. H: 5msec/div.

CH1

CH2

CH1: K4005 (VDI)

1

CH2: K4006 (HDI)

V: 2V/div. H: 10µsec/div.

CH1

CH2

CH1: K4006 (HDI)

3

CH2: K4003 (DEI)

V: 2V/div. H: 5µsec/div.

CH1

CH2

CH1: K4003 (DEI)

4

CH2: K4002 (DCLK)

V: 2V/div. H: 5µsec/div.

CH1

CH2

A

B

C

CH1: K4005 (VDI)

2

CH2: CN4004-pin 29 (RAO)

V: 2V/div. H: 5msec/div.

CH1

CH2

CH1: K4003 (DEI)

4

CH2: K4002 (DCLK)

V: 2V/div. H: 10nsec/div.

CH1

CH2

D

E

56

PDP-505PE

F

35

7

8

Page 36

1234

50 X DRIVE ASSY, 50 Y DRIVE ASSY and 50 SCAN A ASSY

A

• 50 X SUS BLOCK, 50 Y LOGIC BLOCK, 50 Y SUS BLOCK

1

Drive Output Waveform (1 field,color-bar)

CH1: R1226 (XPSUS) - K1201 (SUSGND)

(50 X DRIVE ASSY)

CH2: R2348 (YPSUS) - K2301 (SUSGND)

(50 Y DRIVE ASSY)

CH3: K3001 (Scan OUT) - K2301 (SUSGND)

(50 SCAN A ASSY)

V: 100V/div. H: 2msec/div.

CH1

B

CH2

CH3

3

Control Signal (Sustain Waveform Gen.)

CH2: K2016 (YSUS-G) - K2010 (DGND)

CH3: K2025 (YSUS-U1) - K2010 (DGND)

CH4: K2022 (YSUS-U2) - K2010 (DGND)

CH5: K2026 (YSUS-B) - K2010 (DGND)

CH6: K2024 (YSUS-D2) - K2010 (DGND)

CH7: K2027 (YSUS-D1) - K2010 (DGND)

(50 Y DRIVE ASSY)

V: 1V/div. H: 500nsec/div.

CH2

CH3

CH4

CH5

CH6

CH7

Reset Pulse

1

CH1: R1226 (XPSUS) - K1201 (SUSGND)

(50 X DRIVE ASSY)

CH2: R2348 (YPSUS) - K2301 (SUSGND)

(50 Y DRIVE ASSY)

CH3: K3001 (Scan OUT) - K2301 (SUSGND)

(50 SCAN A ASSY)

V: 100V/div. H: 100µsec/div.

C

CH1

CH2

CH3

Sustain Pulse (1 sub-sub-field)

1

CH1: R1226 (XPSUS) - K1201 (SUSGND)

(50 X DRIVE ASSY)

CH2: R2348 (YPSUS) - K2301 (SUSGND)

(50 Y DRIVE ASSY)

D

CH3: K3001 (Scan OUT) - K2301 (SUSGND)

(50 SCAN A ASSY)

V: 50V/div. H: 5µsec/div.

Scan Control Signal (1 field, color-bar)

4

CH2: K2006 (SI) - K2029 (DGND)

CH3: K2009 (OC1) - K2029 (DGND)

CH4: K2004 (OC2) - K2029 (DGND)

CH5: K2007 (CLR) - K2029 (DGND)

CH6: K2003 (CLK2) - K2029 (DGND)

CH7: K2008 (LE) - K2029 (DGND)

(50 Y DRIVE ASSY)

V: 1V/div. H: 2msec/div.

CH2

CH3

CH4

CH5

CH6

CH7

X Drive Pulse Control Signal (color-bar)

5

CH1: R1226 (XPSUS) - K2301 (SUSGND)

V: 100V/div. H: 2msec/div.

CH2: K1016 (XCP-MSK) - K1020 (DGND)

CH3: K1015 (XSUS-MSK) - K1020 (DGND)

CH4: K1014 (XNR-D) - K1020 (DGND)

V: 1V/div. H: 2msec/div.

(50 X DRIVE ASSY)

CH1

CH1

CH2

CH2

CH3

CH3

CH4

Sustain Waveform

E

2

CH1: R2348 (YPSUS) - K2301 (SUSGND)

(50 Y DRIVE ASSY)

V: 50V/div. H: 500nsec/div.

Y Drive Pulse Control Signal (color-bar)

6

CH1: R2348 (YPSUS) - K2301 (SUSGND)

V: 50V/div. H: 2msec/div.

CH2: K2015 (YSUS-MSK) - K2010 (DGND)

CH3: K2017 (YSOFT-D) - K2010 (DGND)

CH4: K2023 (YPR-U) - K2010 (DGND)

V: 1V/div. H: 2msec/div.

(50 Y DRIVE ASSY)

CH1

CH1

CH2

CH3

F

36

PDP-505PE

CH4

1234

Page 37

5678

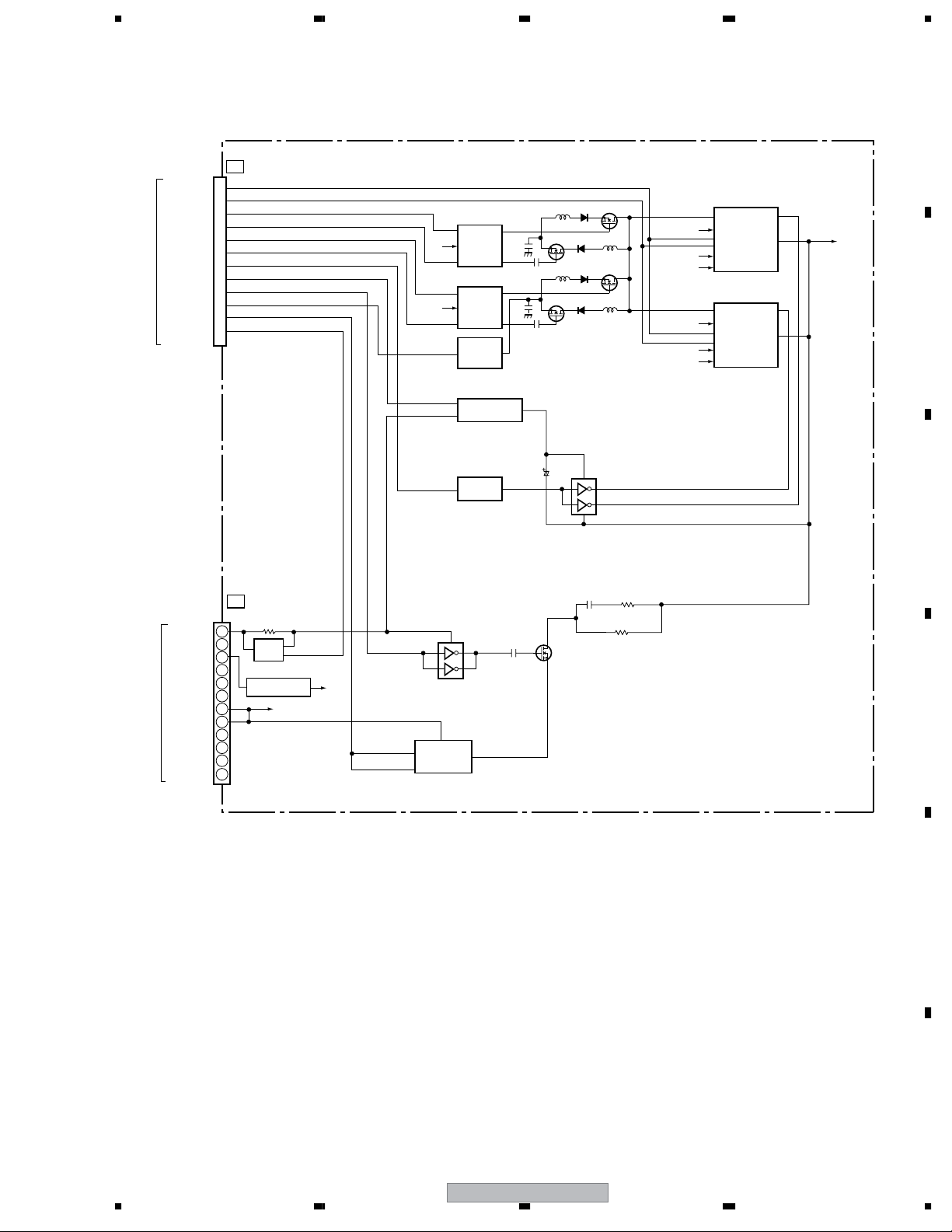

50 ADDRESS ASSY

• ADR RESONANCE BLOCK (VIDEO and PC)

CH1: IC1601-pin 2 (ADR_B2)

1

CH2: IC1603-pin 4 (ADR_U1)

CH3: IC1603-pin 2 (ADR_D1)

V: 1V/div.

(Input: VIDEO, Signal: Color-bar)

CH1

CH2

CH3

CH1

CH2

CH3

CH1: IC1601-pin 2 (ADR_B2)

2

CH2: IC1602-pin 4 (ADR_U2)

CH3: IC1602-pin 2 (ADR_D2)

V: 1V/div.

(Input: VIDEO, Signal: Color-bar)

CH1

CH2

CH3

CH1

CH2

CH3

H:

2msec/div.

H:

1µsec/div.

H:

2msec/div.

H:

1µsec/div.

3

CH2

CH3

CH4

CH2

CH3

CH4

4

CH2

CH3

CH4

CH2

CH3

CH4

CH2: Q1601-pin 4 (ADR_B2)

CH3: Q1603-pin 4 (ADR_U1)

CH4: Q1603-pin 2 (ADR_D1)

V: 10V/div.

(Input: VIDEO, Signal: Color-bar)

CH2: Q1601-pin 4 (ADR_B2)

CH3: Q1602-pin 4 (ADR_U2)

CH4: Q1602-pin 2 (ADR_D2)

V: 10V/div.

(Input: VIDEO, Signal: Color-bar)

H:

1µsec/div.

H:

1µsec/div.

H:

1µsec/div.

H:

1µsec/div.

CH1: Q1601 Drain (V+ADR)

5

CH2: Q1603 Source

CH3: Q1602 Source

V: 10V/div.

(Input: VIDEO, Signal: Color-bar)

CH1

CH2

CH3

CH1

CH2

CH3

CH1: Q1601 Drain (V+ADR)

6

CH2: Q1603 Source

CH3: Q1602 Source

V: 10V/div.

(Input: VIDEO, Signal: B/W(1×8))

CH1

CH2

CH3

CH1

CH2

CH3

H:

2msec/div.

H:

1µsec/div.

H:

2msec/div.

H:

1µsec/div.

A

B

C

50 ADDRESS ASSY

• ADR LOGIC BLOCK

CH1: IC1553-pin 18 (CLK input)

1

CH2: IC1553-pin 16 (LE input)

CH3: IC1553-pin 9 (DATA input)

V: 1V/div.

(Input: VIDEO, Signal: Color-bar)

CH1

CH2

CH3

CH1

CH2

CH3

CH1: IC1553-pin 23 (HBLK input)

2

CH2: IC1553-pin 19 (LBLK input)

CH3: IC1553-pin 25 (HZ input)

V: 1V/div.

(Input: VIDEO, Signal: Color-bar)

CH1

CH2

CH3

CH1

CH2

CH3

H:

2msec/div.

H:

200nsec/div.

H:

2msec/div.

H:

50µsec/div.

D

E

56

PDP-505PE

F

37

7

8

Page 38

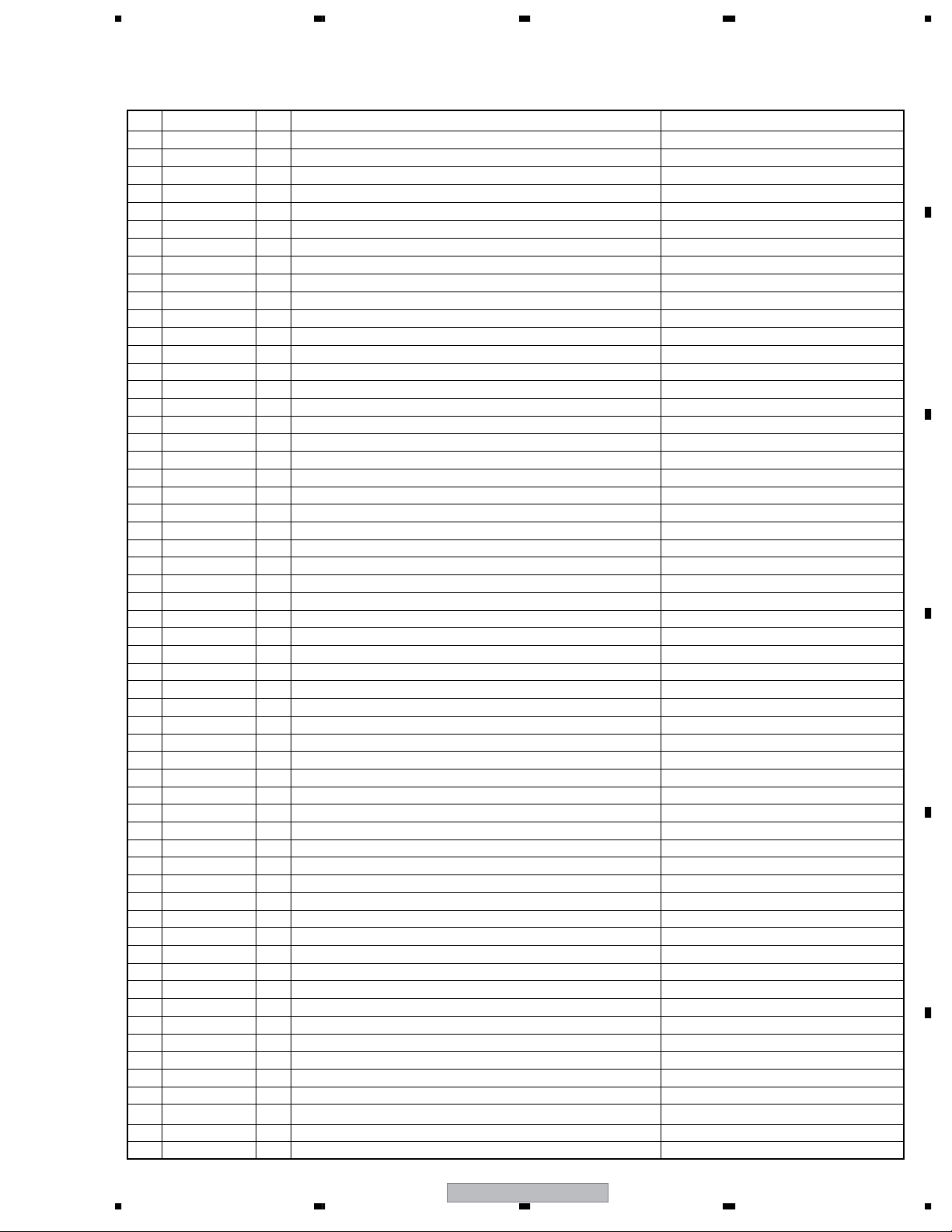

1234

5. PCB PARTS LIST

NOTES:

A