PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2003

PDP-433PU

For details, refer to "Important symbols for good services".

Serial No.

Confirm it

WYVI6 SS

WYVI6XK UK

PLASMA DISPLAY

PDP-433PU

PDP-433PE

PDP-433PG

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Model Type Power Requirement Remarks

PDP-433PU KUC AC120V

PDP-433PE WYVI6 AC220-240V

PDP-433PE WYVI6XK AC220-240V

PDP-433PG TLDPKBR AC110-240V

ORDER NO.

ARP3143

This service manual should be used together with the following manual(s).

Model No. Order No. Remarks

PDP-433PU, PDP-433PE, PDP-433PG ARP3144 SCHEMATIC DIAGRAM and PCB DIAGRAM

This product is component of system.

Component System Service Manual Remarks

Plasma Display System PDP-4330HD PDP-433HDE PDP-433HDG -

PDP-R03U - - ARP3113

• Media Receiver - PDP-R03E - ARP3148

--PDP-R03G ARP3149

• Plasma Display PDP-433PU PDP-433PE PDP-433PG ARP3143, ARP3144 This Service Manual

T-ZZV MAR. 2003 printed in Japan

1234

SAFETY INFORMATION

A

This service manual is intended for qualified service technicians ; it is not meant for the casual

do-it-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely,

you should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to

cause cancer, birth defects or other reproductive harm.

B

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement parts

must be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les pièces

de remplacement doivent avoir la même désignation.

C

Health & Safety Code Section 25249.6 - Proposition 65

SAFETY PRECAUTIONS

NOTICE : Comply with all cautions and safety related notes

located on or inside the cabinet and on the chassis.

The following precautions should be observed :

1. When service is required, even though the PDP UNIT an

isolation transformer should be inserted between the power line

and the set in safety before any service is performed.

D

2. When replacing a chassis in the set, all the protective devices

must be put back in place, such as barriers, nonmetallic knobs,

adjustment and compartment covershields, isolation resistorcapacitor, etc.

3. When service is required, observe the original lead dress. Extra

precaution should be taken to assure correct lead dress in the

high voltage circuitry area.

4. Always use the manufacture's replacement components.

Especially critical components as indicated on the circuit

diagram should not be replaced by other manufacture's.

Furthermore where a short circuit has occurred, replace those

E

components that indicate evidence of overheating.

5. Before returning a serviced set to the customer, the service

technician must thoroughly test the unit to be certain that it is

completely safe to operate without danger of electrical shock,

and be sure that no protective device built into the set by the

manufacture has become defective, or inadvertently defeated

during servicing. Therefore, the following checks should be

performed for the continued protection of the customer and

servicetechnician.

6. Perform the following precautions against unwanted radiation

and rise in internal temperature.

• Always return the internal wiring to the original styling.

• Attach parts (Gascket, Ferrite Core, Ground, Rear Cover,

Shield Case etc.) surely after disassembly.

7. Perform the following precautions for the PDP panel.

• When the front case is removed, make sure nothing hits the

panel face, panel corner, and panel edge (so that the glass does

not break).

• Make sure that the panel vent does not break. (Check that the

cover is attached.)

• Handle the FPC connected to the panel carefully.

Twisting or pulling the FPC when connecting it to the

connector will cause it to peel off from the panel.

8. Pay attention to the following.

• When the front case is removed, infrared ray is radiated and

may disturb reception of the remote control unit.

• Pay extreme caution when the front case and rear panel are

removed because this may cause a high risk of disturbance to

TVs and radios in the surrounding.

F

2

1234

PDP-433PU

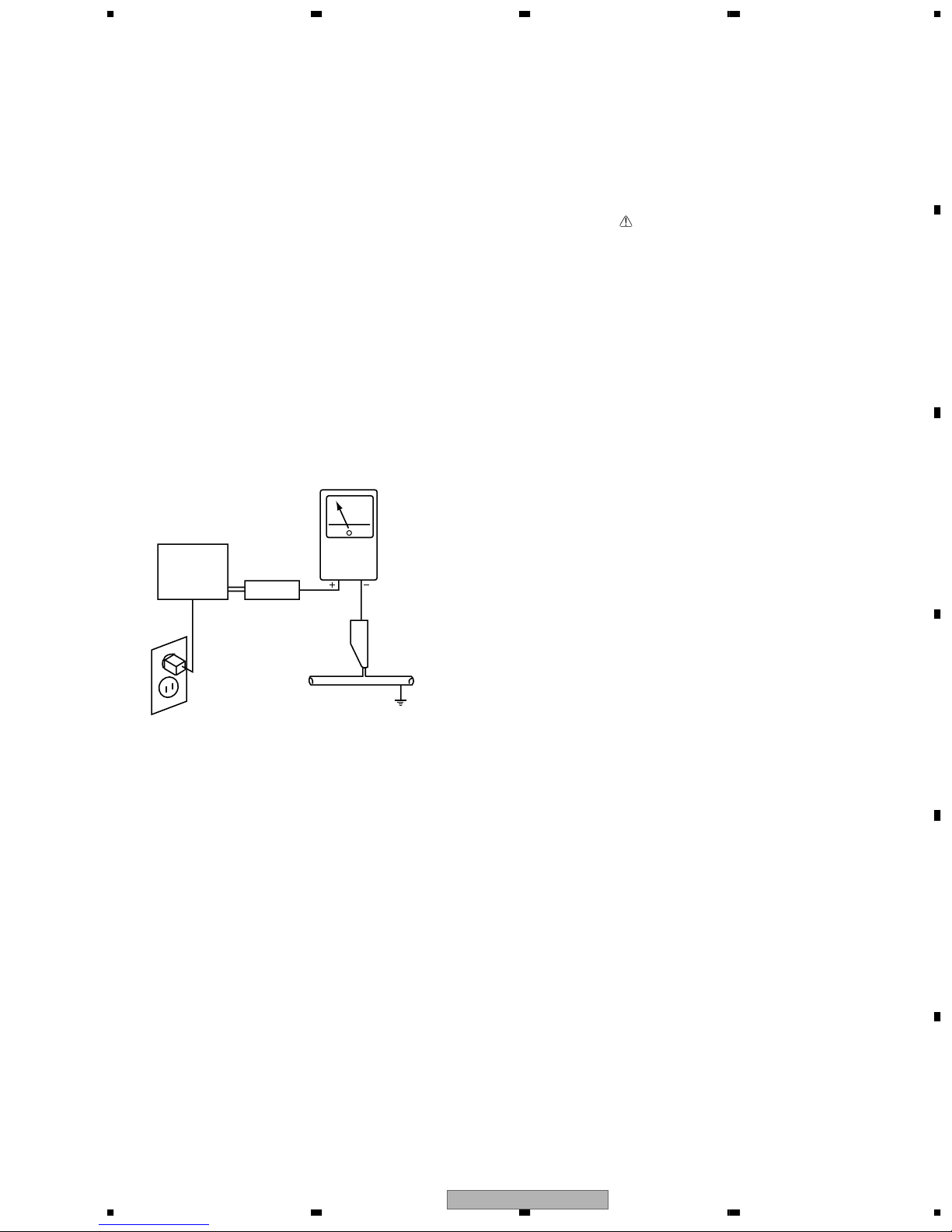

Leakage Current Cold Check

With the AC plug removed from an AC power source, place a

jumper across the two plug prongs. Turn the AC power switch on.

Using an insulation tester (DC 500V), connect one lead to the

jumpered AC plug and touch the other lead to each exposed metal

part (input/output terminals, screwheads, metal overlays, control

shafts, etc.), particularly any exposed metal part having a return

path to the chassis. Exposed metal parts having a return path to

the chassis should have a minimum resistor reading of 0.3MΩ

and a maximum resistor reading of 5MΩ. Any resistor value

below or above this range indicates an abnormality which

requires corrective action. Exposed metal parts not having a

return path to the chassis will indicate an open circuit.

Leakage Current Hot Check

Plug the AC line cord directly into an AC power source (do not

use an isolation transformer for this check).

Turn the AC power switch on.

Using a "Leakage Current Tester (Simpson Model 229

equivalent)", measure for current from all exposed metal parts of

the cabinet (input/output terminals, screwheads, metal overlays,

control shaft, etc.), particularly any exposed metal part having a

return path to the chassis, to a known earth ground (water pipe,

conduit, etc.). Any current measured must not exceed 0.5mA.

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE SET TO THE CUSTOMER.

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in PIONEER set have

special safety related characteristics. These are often not evident

from visual inspection nor the protection afforded by them

necessarily can be obtained by using replacement components

rated for higher voltage, wattage, etc. Replacement parts which

have these special safety characteristics are identified in this

Service Manual.

Electrical components having such features are identified by

marking with a on the schematics and on the parts list in this

Service Manual.

The use of a substitute replacement component which dose not

have the same safety characteristics as the PIONEER

recommended replacement one, shown in the parts list in this

Service Manual, may create shock, fire or other hazards.

Product Safety is continuously under review and new instructions

are issued from time to time. For the latest information, always

consult the current PIONEER Service Manual. A subscription to,

or additional copies of, PIONEER Service Manual may be

obtained at a nominal charge from PIONEER.

Leakage

current

tester

Reading should

not be above

0.5mA

Device

under

test

Test all

exposed metal

surfaces

Also test with

plug reversed

(Using AC adapter

plug as required)

Earth

ground

AC Leakage Test

5 678

A

B

C

D

E

56

PDP-433PU

F

7

8

3

1234

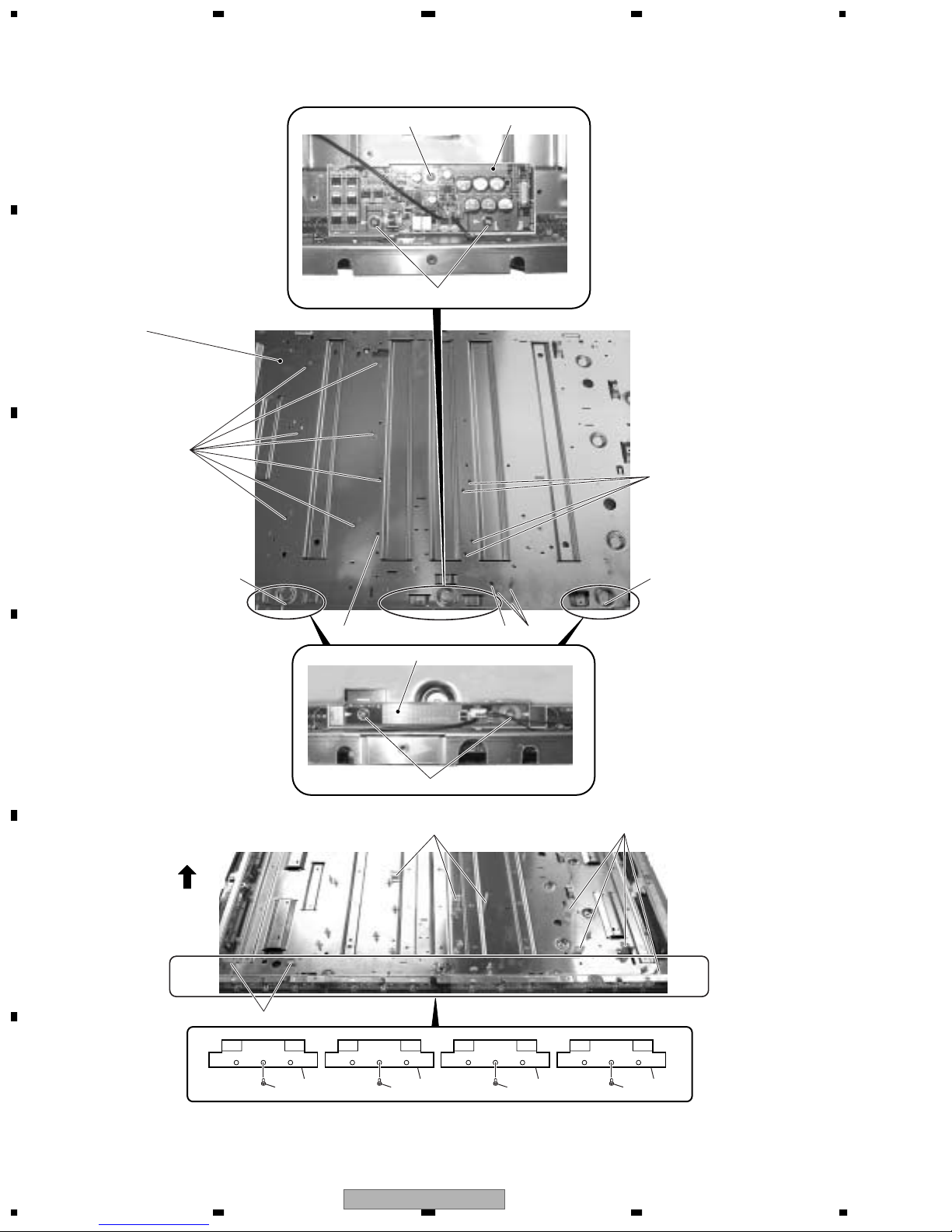

Charged Section

The places where the commercial AC power is used without

passing through the power supply transformer.

A

If the places are touched, there is a risk of electric shock. In

addition, the measuring equipment can be damaged if it is

connected to the GND of the charged section and the GND of the

non-charged section while connecting the set directly to the

commercial AC power supply. Therefore, be sure to connect the

set via an insulated transformer and supply the current.

1. AC Power Cord

2. AC Inlet with Filter

3. Power Switch (S1)

4. Fuse (In the SW POWER SUPPLY Module)

B

5. STB Transformer and Converter Transformer

(In the SW POWER SUPPLY Module)

6. Other primary side of the SW POWER SUPPLY Module

C

SCAN (A)

Assy

Y DRIVE

Assy

High Voltage Generating Point

The places where voltage is 100V or more except for the charged

places described above. If the places are touched, there is a risk of

electric shock.

1. SW POWER SUPPLY Module ...................................... (215V)

2. X DRIVE Assy ...............................................(–280V to 215V)

3. Y DRIVE Assy ................................................................(345V)

4. SCAN (A) Assy ..............................................................(345V)

5. SCAN (B) Assy .............................................................. (345V)

6. X CONNECTOR (A) Assy ............................ (–280V to 215V)

7. X CONNECTOR (B) Assy ............................ (–280V to 215V)

: Part is Charged Section.

: Part is the High Voltage Generating Points

other than the Charged Section.

Top

SCAN (B)

Assy

D

∗ Remove the IF Earth Metal (No.14 on the page 25)

beforehand when inclines the power supply unit

as the right figure.

E

SW POWER SUPPLY

Module

AC Inlet with Filter

Power Cord

Front

X CONNECTOR (A)

Assy

X DRIVE

Assy

X CONNECTOR (B)

Assy

Power Switch

(S1)

Fig.1 Charged Section and High Voltage Generating Point (Rear View)

F

4

1234

PDP-433PU

5 678

[ Important symbols for good services ]

In this manual, the symbols shown-below indicate that adjustments, settings or cleaning should be made securely.

When you find the procedures bearing any of the symbols, be sure to fulfill them:

A

1. Product safety

You should conform to the regulations governing the product (safety, radio and noise, and other regulations), and

should keep the safety during servicing by following the safety instructions described in this manual.

2. Adjustments

To keep the original performances of the product, optimum adjustments or specification confirmation is indispensable.

In accordance with the procedures or instructions described in this manual, adjustments should be performed.

3. Cleaning

For optical pickups, tape-deck heads, lenses and mirrors used in projection monitors, and other parts requiring cleaning,

proper cleaning should be performed to restore their performances.

B

4. Shipping mode and shipping screws

To protect the product from damages or failures that may be caused during transit, the shipping mode should be set or

the shipping screws should be installed before shipping out in accordance with this manual, if necessary.

5. Lubricants, glues, and replacement parts

Appropriately applying grease or glue can maintain the product performances. But improper lubrication or applying

glue may lead to failures or troubles in the product. By following the instructions in this manual, be sure to apply the

prescribed grease or glue to proper portions by the appropriate amount.For replacement parts or tools, the prescribed

ones should be used.

C

D

56

PDP-433PU

E

F

7

8

5

1234

CONTENTS

SAFETY INFORMATION.....................................................................................................................................2

A

B

C

D

E

1. SPECIFICATIONS ............................................................................................................................................ 7

2. EXPLODED VIEWS AND PARTS LIST ............................................................................................................ 8

2.1 PACKING ................................................................................................................................................... 8

2.2 UNDER LAYER SECTION (1) .................................................................................................................10

2.3 UNDER LAYER SECTION (2) .................................................................................................................12

2.4 UNDER LAYER SECTION (3) .................................................................................................................14

2.5 UNDER LAYER SECTION (4) .................................................................................................................16

2.6 UNDER LAYER SECTION (5) .................................................................................................................18

2.7 MIDDLE LAYER SECTION (1)................................................................................................................. 20

2.8 MIDDLE LAYER SECTION (2)................................................................................................................. 22

2.9 UPPER LAYER SECTION (1).................................................................................................................. 24

2.10 UPPER LAYER SECTION (2)................................................................................................................ 26

2.11 FRONT CASE SECTION....................................................................................................................... 28

2.12 REAR SECTION....................................................................................................................................30

2.13 PDP SERVICE ASSY 433 (AWU1069)..................................................................................................31

2.14 PANEL CHASSIS (43) ASSY (AWU1067)............................................................................................. 32

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM..........................................................................................34

3.1 BLOCK DIAGRAM...................................................................................................................................34

3.1.1 OVERALL DIAGRAM............................................................................................................................ 34

3.1.2 MR INTERFACE ASSY......................................................................................................................... 36

3.1.3 DIGITAL VIDEO ASSY.......................................................................................................................... 38

3.1.4 X DRIVE ASSY.....................................................................................................................................39

3.1.5 Y DRIVE ASSY .....................................................................................................................................40

3.1.6 SUB ADDRESS A and B ASSYS .........................................................................................................42

3.1.7 ADR RESONANCE ASSY....................................................................................................................43

3.1.8 ADR CONNECT A, B, C and D ASSYS................................................................................................ 44

3.1.9 AUDIO AMP and SP TERMINAL ASSYS ............................................................................................. 45

3.2 WAVEFORMS.......................................................................................................................................... 46

4. PCB CONNECTION DIAGRAM ............................................................................................Refer to ARP3144

5. PCB PARTS LIST ........................................................................................................................................... 50

6. ADJUSTMENT ...............................................................................................................................................60

6.1 SERVICE FACTORY MODE.................................................................................................................... 60

6.1.1 How to Enter the Service Factory Mode ............................................................................................... 61

6.1.2 General Information about the Plasma Display and Media Receiver....................................................62

6.1.3 Adjustment and Setting Item of the Plasma Display.............................................................................64

6.2 ADJUSTMENT REQUIRED WHEN THE SET IS REPAIRED OR REPLACED....................................... 67

6.3 ADJUSTMENT......................................................................................................................................... 68

6.4 COMMANDS............................................................................................................................................ 71

6.4.1 RS-232C Commands............................................................................................................................ 71

6.4.2 GET Commands ................................................................................................................................... 75

7. GENERAL INFORMATION............................................................................................................................. 77

7.1 DIAGNOSIS.............................................................................................................................................77

7.1.1 CONFIGRATION OF THE PC BOARD ................................................................................................. 77

7.1.2 DIAGNOSIS FOR SHUTDOWN AND POWER-DOWN DIAGNOSIS BY LED.....................................78

7.1.3 DISASSEMBLY .....................................................................................................................................85

7.2 IC INFORMATION.................................................................................................................................... 89

8. PANEL FACILITIES ...................................................................................................................................... 108

(For SCHEMATIC DIAGRAM, refer to ARP3144)

F

6

1234

PDP-433PU

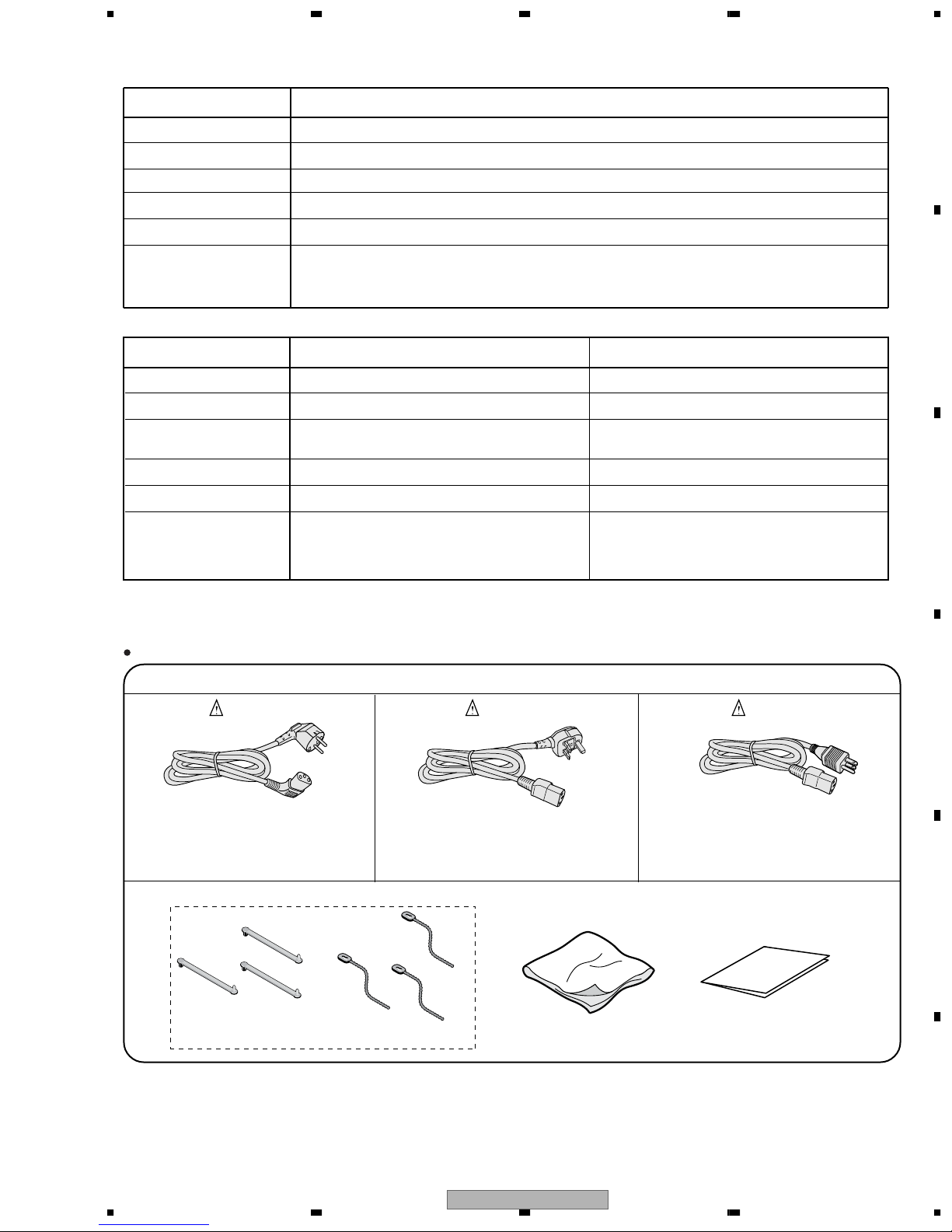

Power cord

(For U.K., and Eir (For North America)e)

Cleaning cloth

Three speed clamps

Three bead bands

Warranty card

Accessories

(For Europe, except U.K. and Eire)

(ADG1173)

Binder Assy (AEC1908)

(ADG1193) (ADG1208)

(AED1208)

• Design and specifications are subject to change without notice.

Item Model: PDP-433PU

Number of Pixels 1024 × 768 pixels

Audio Amplifier 12 W + 12 W (10% distortion)

Power Requirement AC 120 V, 60 Hz, 318 W (0.6 W Standby)

Dimensions 1070 (W) × 630 (H) × 98 (D) mm [42

1/8 (W) × 2413/16 (H) × 37/8 (D) inch]

Weight 31.5 kg (69.4 lbs)

Accessories

Power Cord, Cleaning Cloth, Three speed clamps, Three bead bands,

Warranty card

Item Model: PDP-433PE

Number of Pixels

1024 x 768 pixels

Audio Amplifier

12 W + 12 W (10 % distortion)

Power Requirement

AC 220–240 V, 50/60 Hz, 320 W

(0.6 W Standby)

Dimensions

1070 (W), 630 (H), 98 (D) mm

Weight

31.5 kg

Accessories Power Cord, Cleaning Cloth, Three speed

clamps, Three bead bands,

Warranty card

Model: PDP-433PG

1024 x 768 pixels

12 W + 12 W (10 % distortion)

AC 110–240 V, 50/60 Hz, 319 W

(0.8 W Standby)

1070 (W), 630 (H), 98 (D) mm

31.5 kg

Cleaning Cloth, Three speed clamps, Three

bead bands,

5 678

1. SPECIFICATIONS

A

B

C

D

56

PDP-433PU

7

E

F

7

8

1234

2. EXPLODED VIEWS AND PARTS LIST

NOTES:

A

2.1 PACKING

B

C

Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on product are used for disassembly.

For the applying amount of lubricants or glue, follow the instructions in this manual.

(In the case of no amount instructions, apply as you think it appropriate.)

20

21

1

22

PDP-433PG

Only

PDP-433PG

Only

PDP-433PU

Only

PDP-433PE

Only

21

20

22

2

3

11

11

16

17

11

Except

PDP-433PU

19

4

14

13

9

Except

PDP-433PU

18

7

5

23

2

11

Except

6

PDP-433PG

15

D

E

F

8

1234

PDP-433PU

>

>

>

>

>

>

5 678

PACKING parts List

Mark

Mark

No. Description Part No.

1Packing Case(43) See Contrast table (2)

2 Carton(43) AHD3100

3Pad(43U) AHA2282

4 Mirror Mat AHG1284

5 SP Caution Sheet ARM1218

NSP 6 Warranty Card See Contrast table (2)

7Pad(43L) AHA2283

8• • • • •

9Power Cord Case See Contrast table (2)

10 • • • • •

11 Vinyl Bag AHG1310

12 • • • • •

No. Description Part No.

13 Wiping Cloth AED1208

14 Binder Assy AEC1908

(Speed Clampx3, Bead Bandx3)

15 Power Cord See Contrast table (2)

16 Power Cord See Contrast table (2)

17 Power Cord See Contrast table (2)

18 Caution Sheet See Contrast table (2)

19 Ferrite Core See Contrast table (2)

20 Label (Blue 16) AAX2787

21 Label (Green 16) AAX2956

22 MIC Label See Contrast table (2)

23 SP Spacer AEC1925

(2) CONTRAST TABLE

PDP-433PU/KUC, PDP-433PE/WYVI6, PDP-433PE/WYVI6XK and PDP-433PG/TLDPKBR are constructed the

same except for the following:

Mark No. Symbol and Description PDP-433PU/KUC

1Packing Case(43) AHD3115 AHD3114 AHD3138 AHD3116

NSP 6 Warranty Card ARY1112 ARY1114 ARY1114 Not used

9Power Cord Case AHC1037 AHC1037 AHC1039 AHC1037

15 Power Cord ADG1208 Not used Not used Not used

16 Power Cord Not used ADG1173 ADG1173 Not used

PDP-433PE/

WYVI6

PDP-433PE/

WYVI6XK

PDP-433PG/

TLDPKBR

A

B

C

17 Power Cord Not used ADG1193 ADG1193 Not used

18 Caution Sheet Not used ARM1213 ARM1213 ARM1213

19 Ferrite Core Not used ATX1039 ATX1039 ATX1039

22 MIC Label Not used Not used Not used AAX2951

D

E

56

PDP-433PU

F

7

8

9

1234

2.2 UNDER LAYER SECTION (1)

A

Refer to

B

C

"2.14 PANEL CHASSIS (43) ASSY

(AWU1067)".

9

10

13

14

1

10

2

1110

12

2 or 3

D

14

8

Upper side

E

8

3

8

7

13

F

10

1234

6

13

PDP-433PU

5

4

1313

5 678

UNDER LAYER SECTION(1) parts List

Mark

No. Description Part No.

1 ADR RESONANCE Assy AWZ6751

2 BRIDGE C Assy AWZ6730

3 BRIDGE D Assy AWZ6731

NSP 4 ADR CONNECT A Assy AWZ6678

NSP 5 ADR CONNECT B Assy AWZ6679

NSP 6 ADR CONNECT C Assy AWZ6680

NSP 7 ADR CONNECT D Assy AWZ6681

8 Wire Saddle AEC1904

NSP 9 Panel Chassis (43) Assy AWU1067

10 Circuit Board Spacer AEC1872

NSP 11 PCB Spacer AEC1121

12 Circuit Board Spacer AEC1873

13 Screw VBB30P100FNI

14 Screw ABA1301

A

B

C

D

E

56

PDP-433PU

F

7

8

11

1234

2.3 UNDER LAYER SECTION (2)

A

14 14

3

Upper side

B

13

8

C

4 5 6

1

9

14

13

14

13

8

9

D

17

E

11

17

10

14

1212

18

11

Upper

side

2

7

16

14

14

16

15

Upper

side

F

12

1234

PDP-433PU

5 678

UNDER LAYER SECTION(2) parts List

Mark

No. Description Part No.

1 DIGIT AL VIDEO Assy AWV1971

2X DRIVE Assy AWV1985

NSP 3 ADR CONNECT A Assy AWZ6678

NSP 4 ADR CONNECT B Assy AWZ6679

NSP 5 ADR CONNECT C Assy AWZ6680

NSP 6 ADR CONNECT D ASSY AWZ6681

NSP 7 Drive Heatsink Assy ANH1598

NSP 8 Metal Fitting ANG2464

NSP 9 Heat Sink ANH1594

10 Silicone Sheet AEH1039

11 Coil Silicon Sheet AEH1048

12 Circuit Board Spacer AEC1872

13 Screw ABZ30P060FMC

14 Screw VBB30P100FNI

15 Screw PMB30P060FNI

16 Drive Silicon Sheet AEH1041

17 Insulation Sheet A AEC1923

18 Insulation Sheet B AEC1924

A

B

C

D

E

56

PDP-433PU

F

7

8

13

1234

2.4 UNDER LAYER SECTION (3)

A

B

2

Upper

side

C

Upper side

11

10

8

D

E

3

4

10

8

4

8

1

9

Upper

side

F

5

9

7

14

1234

6

PDP-433PU

5 678

UNDER LAYER SECTION(3) parts List

Mark

No. Description Part No.

1Y DRIVE Assy AWZ6749

2 Circuit Board Spacer AEC1872

NSP 3 Drive Heatsink Assy ANH1598

4Drive Silicon Sheet AEH1041

5 Scan IC Spring (43L) ABK1029

6 Scan IC Spring (43R) ABK1030

7 Scan Insulation Sheet (43) AMR3287

8 Screw VBB30P100FNI

9 Screw PMB30P060FNI

10 Insulation Sheet A AEC1923

11 Insulation Sheet B AEC1924

A

B

C

D

E

56

PDP-433PU

F

7

8

15

1234

2.5 UNDER LAYER SECTION (4)

A

1 or 2

7

B

C

Upper side

12

18

17

18

2

13

7

13 13

8

14 15

10

18

12

13

1

3

5

D

E

F

19

17 6

4

17

16

1234

PDP-433PU

5 678

UNDER LAYER SECTION(4) parts List

Mark

No. Description Part No.

1 BRIDGE A Assy AWZ6728

2 BRIDGE B Assy AWZ6729

3 SENSOR ASSY AWZ6696

4 ADR RESONANCE Assy AWZ6751

5Brind Plate AMR3313

6 Insulation Sheet AMR3343

NSP 7 Heat Sink ANH1594

8 Silicone Sheet AEH1039

9• • • • •

10 Rivet BEC1066

11 • • • • •

12 Metal Fitting ANG2464

13 Wire Saddle AEC1904

NSP 14 PCB Spacer AEC1121

15 Circuit Board Spacer AEC1873

16 • • • • •

17 Screw ABA1301

18 Screw ABZ30P060FMC

19 Screw VBB30P100FNI

A

B

C

D

E

F

56

PDP-433PU

7

8

17

1234

2.6 UNDER LAYER SECTION (5)

A

Upper side

B

12

35

37

13

15

C

14

1

White

Tape

27

29

27

30

2 10

16

27

5

3

K3

SA2SA1

326

27 27

31

39

7

4

43

17

36

TE1

D16

D9

D8

D1

D18

D6

Y1

Y2

D12

41

D13

28

D10

D11

D15

D14

D2

D3

D17

34

20

D7

X1

X2

33

38

18

19

25

26

42

27

27

40

SA1SA2

K3

White

21

4

24

27

8

27 27

3

2223

115

9

2

39

Tape

39

1

D

E

F

18

1234

PDP-433PU

5 678

UNDER LAYER SECTION(5) parts List

Mark

No. Description Part No.

NSP 1 ADR CONNECT A Assy AWZ6678

NSP 2 ADR CONNECT B Assy AWZ6679

NSP 3 ADR CONNECT C Assy AWZ6680

NSP 4 ADR CONNECT D Assy AWZ6681

5 ADR RESONANCE Assy AWZ6751

6 BRIDGE A Assy AWZ6728

7 BRIDGE B Assy AWZ6729

8 BRIDGE C Assy AWZ6730

9 BRIDGE D Assy AWZ6731

10 SUB ADDRESS A Assy AWZ6692

11 SUB ADDRESS B Assy AWZ6693

12 SCAN (A) Assy AWZ6724

13 SCAN (B) Assy AWZ6725

14 Y DRIVE Assy AWZ6749

15 DIGIT AL VIDEO Assy AWV1971

16 SENSOR Assy AWZ6696

17 X CONNECTOR (A) Assy AWZ6726

18 X CONNECTOR (B) Assy AWZ6727

19 X DRIVE Assy AWV1985

20 J204 Flexible Flat Cable ADD1207

A

B

C

21 J209 Flexible Flat Cable ADD1206

22 J210 Flexible Flat Cable ADD1204

23 J211 Flexible Flat Cable ADD1199

24 J212 Flexible Flat Cable ADD1201

25 J201 Flexible Flat Cable ADD1194

26 J202 Flexible Flat Cable ADD1194

27 Flat Clamp AEC1879

28 J203 Flexible Flat Cable ADD1198

29 J205 Flexible Flat Cable ADD1202

30 J206 Flexible Flat Cable ADD1200

31 J207 Flexible Flat Cable ADD1208

32 J208 Flexible Flat Cable ADD1205

33 Power Sheet (43) AMR3284

34 Rivet BEC1066

35 J110 3P Housing Wire ADX2741

36 J108 8P Housing Wire ADX2740

37 J102 Wire E ADX2738

38 J103 13P Housing Wire ADX2766

39 J116,J117 4P Housing Wire ADX2783

40 J120 Wire L ADX2763

41 J101 13P Housing Wire ADX2768

42 J109 8P Housing Wire ADX2743

43 Nylon Binder AEC-093

D

E

56

PDP-433PU

F

7

8

19

1234

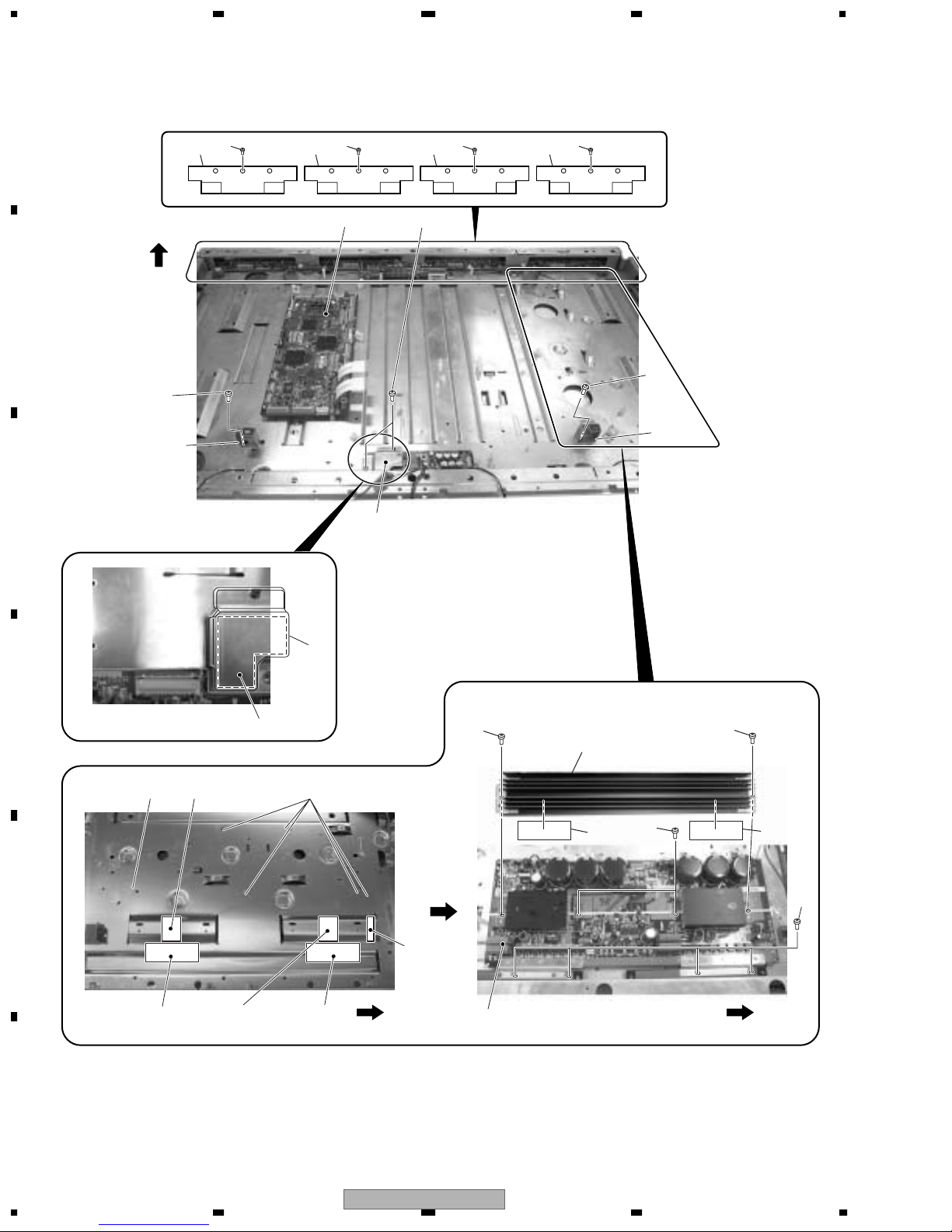

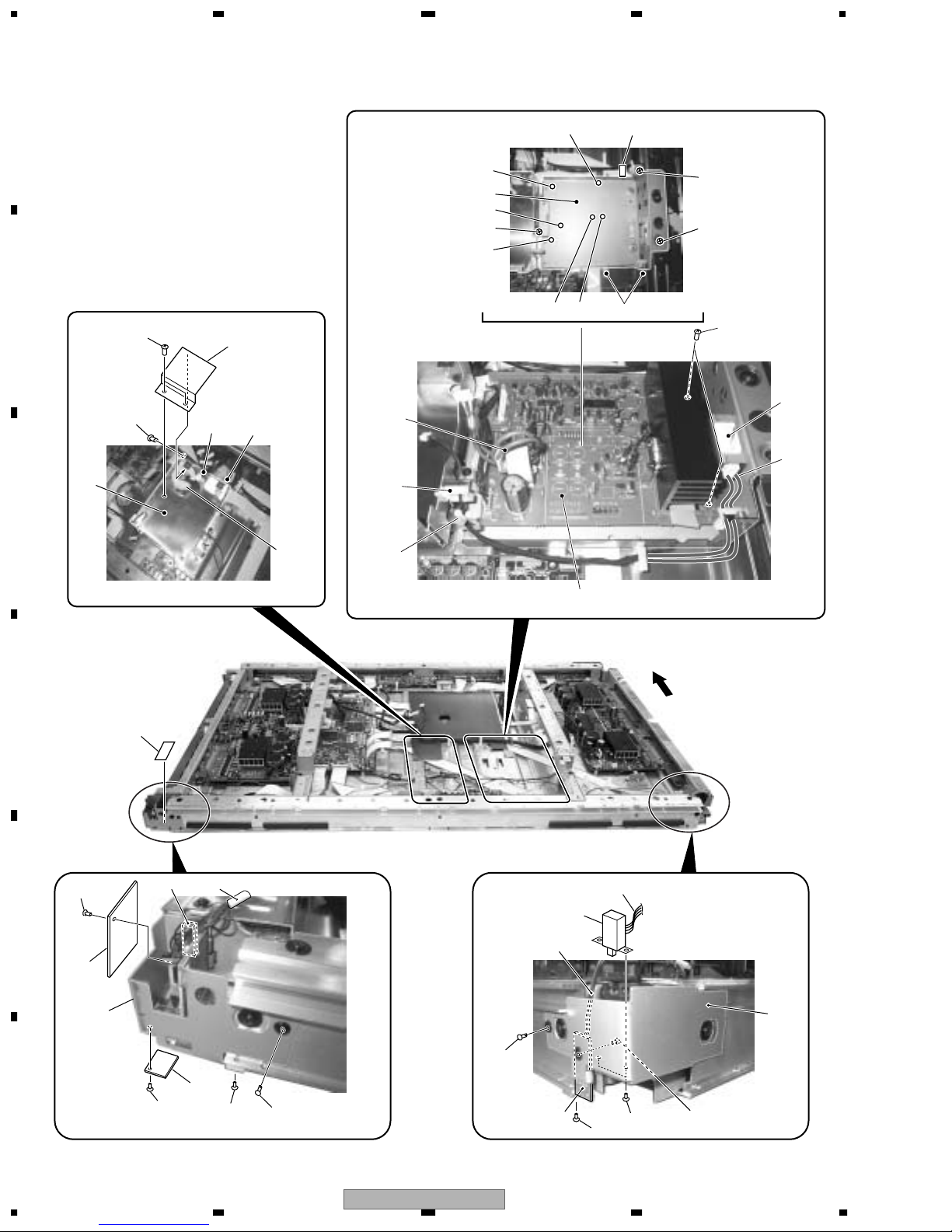

2.7 MIDDLE LAYER SECTION (1)

A

11

B

C

D

Upper side

Upper side

12

Upper side

12

1

5

3

7

11

4

6

12

2

11

12

2

Upper side

11

11

E

F

14

8

9

9

20

1234

14

11

PDP-433PU

11

10

13

8

11

10

5 678

MIDDLE LAYER SECTION(1) parts List

Mark

No. Description Part No.

NSP 1 Front Chassis HU (43) ANA1698

NSP 2 Card Spacer AEC1902

3 Niplocker AEC1803

4 Card Corner Holder BEC1144

5 Sub Frame L ANG2517

6 Sub Frame R ANG2518

NSP 7 Front Chassis HL (43) ANA1699

NSP 8 Front Chassis V (43) ANA1702

9 FPC Cushion (43) AEB1371

10 Insulation Sheet C AEC1927

11 Screw ABA1294

12 Screw BMZ30P060FMC

13 VR Cushion AEB1374

14 V Cushion AED1205

A

B

C

D

E

56

PDP-433PU

F

7

8

21

1234

2.8 MIDDLE LAYER SECTION (2)

A

14

8

16

17

14

29

16

B

5

27

9

C

6

7

8

10

11

8

13

16

14

8

1

29

29

28

12

15

Upper side

D

30

E

2

F

21

19

30

31

20

25

22

3

32

22

4

23

32

24

18

26

30

22

1234

PDP-433PU

5 678

MIDDLE LAYER SECTION(2) parts List

Mark

No. Description Part No.

1AUDIO AMP Assy AWZ6687

2FRONT KEY CONN Assy AWZ6657

3 IR (P) Assy AWZ6658

4 LED Assy AWZ6655

5 Nylon Rivet AEP-211

6 IF Sheet AMR3298

7 Edge Saddle AEC1571

8 Wire Saddle AEC1745

9 IF Shield ANA1675

10 L2 T oroidal Core A TX1042

11 J214 3P Housing Wire ADX2735

12 S2 Power Switch ASG1089

13 Niplocker BEC1136

14 PCB Spacer AEC1570

15 J215 3P Housing Wire ADX2757

16 Spacer AEC1360

17 Audio Base ANA1687

18 Screw BMZ30P060FZK

19 V Cushion AED1205

20 J113 Wire PJ ADX2742

>

A

B

C

NSP 21 IR Holder ANG2494

22 Nylon Rivet AEC1671

23 S1 Power Switch ASG1082

24 J106 Wire PC ADX2827

25 J104 3P Housing Wire ADX2748

NSP 26 Switch Holder ANG2493

27 Screw ABA1294

28 Screw PMB30P060FNI

29 Screw AMZ30P060FZK

30 Screw BMZ30P040FMC

31 Gasket R ANK1695

32 Screw ABZ30P050FZK

D

E

56

PDP-433PU

F

7

8

23

1234

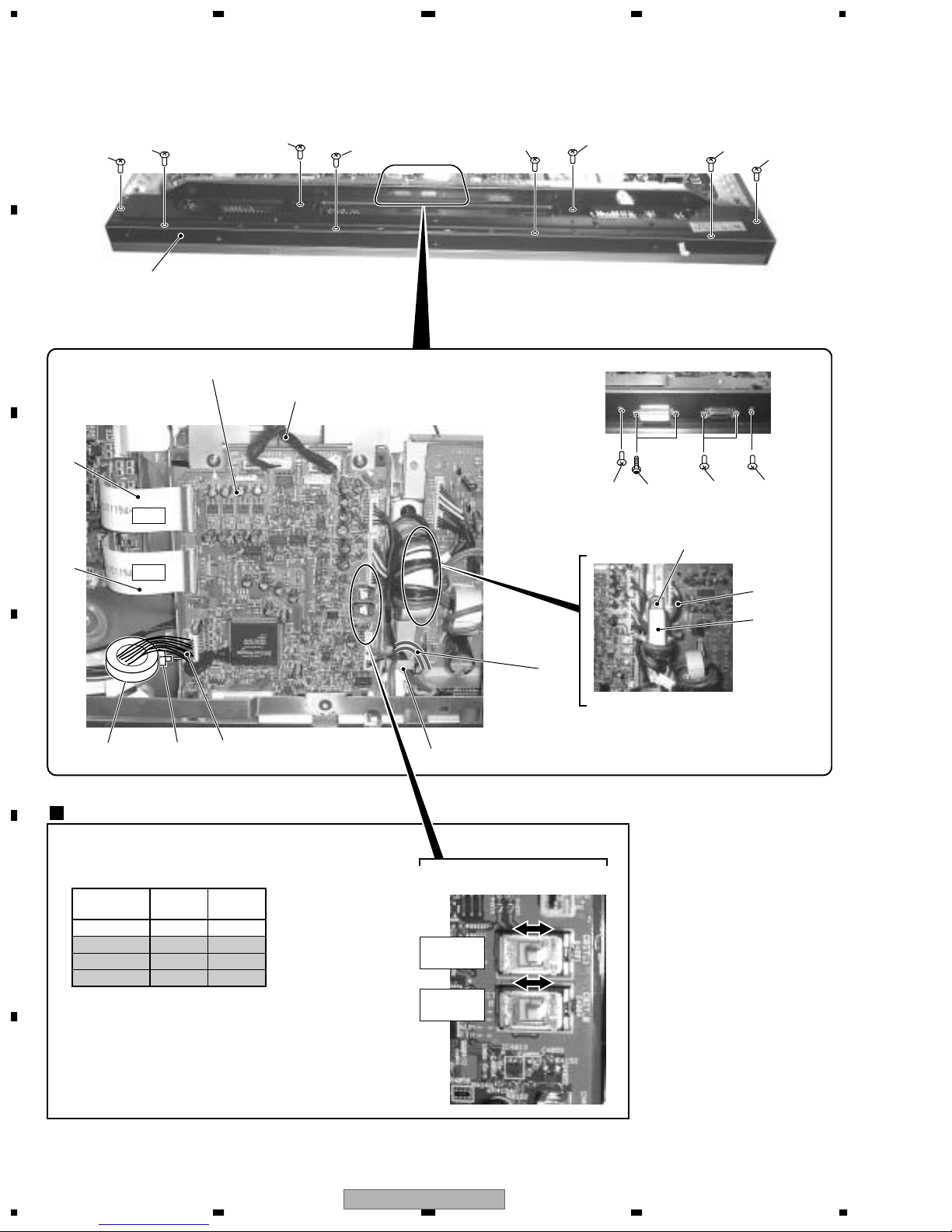

2.9 UPPER LAYER SECTION (1)

A

13

13

2

B

1

4

C

12

J201

J202

14

13

5

1413

15

14

17

16

13

13

14

6

7

8

D

3

10

11

9

Caution in the MR INTERFACE Assy Replacement

Set the slide switches in accordance with applicable

model when replacing the MR INTERFACE Assy.

S4001

E

PDP-433P → →

PDP-433PU → →

PDP-433PE ← →

PDP-433PG ← →

Note 1 : When there is not S4004, set only S4001.

Note 2 : When there are not S4001 and S4004, setting

CBIT_1

is unnecessary.

S4004

CBIT_0

S4001

(CBIT_1)

S4004

(CBIT_0)

F

24

1234

PDP-433PU

5 678

UPPER LAYER SECTION(1) parts List

Mark

No. Description Part No.

1 MR INTERFACE Assy AWZ6699

2Terminal Panel ANG2534

3 L6 Ferrite Core ATX1037

4 J201 Flexible Flat Cable ADD1194

5 J118 Wire P ADX2765

6 J111 14P Housing Wire ADX2730

7 L3 T oroidal Core A TX1042

8 J214 3P Housing Wire ADX2735

9 J104 3P Housing Wire ADX2748

10 Ferrite Core Holder AEC1818

11 J113 Wire PJ ADX2742

12 J202 Flexible Flat Cable ADD1194

13 Screw TBZ40P080FZK

14 Screw AMZ30P060FZK

15 Screw BBA1051

16 Screw PMZ26P080FZK

17 Screw ABA1294

A

B

C

D

E

56

PDP-433PU

F

7

8

25

1234

2.10 UPPER LAYER SECTION (2)

PDP-433PU Only

15

10

17

14

3

9

A

B

C

11

13

16

15

12

8

7

5

6

18

7

P6

P2P1

D

E

1

P5

P3

P4

100V

200V

SW101

P7

F

26

1234

PDP-433PU

>

>

>

5 678

UPPER LAYER SECTION(2) parts List

Mark

Mark

No. Description Part No.

1 SW Power Supply Module AXY1059

2• • • • •

3 IF Earth Metal ANA1690

4• • • • •

5 L1 Ferrite Core ATX1032

6 CN1 AC Inlet with Filter AKP1223

7 J105 Wire PB ADX2826

8 J114 Earth Wire ADX2709

9 SP TERMINAL Assy AWZ6688

10 J101 13P Housing Wire ADX2768

No. Description Part No.

11 J118 Wire P ADX2765

12 J103 13P Housing Wire ADX2766

13 J102 Wire PE ADX2738

14 Screw PMB30P060FNI

15 Screw AMZ30P060FZK

16 Screw BPZ30P080FZK

17 Solder Warning Label See Contrast table (2)

18 Screw BMZ30P060FZK

(2) CONTRAST TABLE

PDP-433PU/KUC, PDP-433PE/WYVI6, PDP-433PE/WYVI6XK and PDP-433PG/TLDPKBR are constructed the

same except for the following:

Mark No. Symbol and Description PDP-433PU/KUC

17 Solder Warning Label AAX2644 Not used Not used Not used

PDP-433PE/

WYVI6

PDP-433PE/

WYVI6XK

PDP-433PG/

TLDPKBR

A

B

C

D

E

56

PDP-433PU

F

7

8

27

1234

2.11 FRONT CASE SECTION

A

17

16

PDP-433PU

Only

7

15

21

13

Foil Side

1

20

4

5

3

12

2

B

19

18

C

12

12

6

12

7

7

D

8

E

F

9

8

12

10

7

10

12

7

11

8

8

7

9

28

1234

PDP-433PU

>

5 678

FRONT CASE SECTION parts List

Mark

Mark

No. Description Part No.

1FRONT KEY Assy AWZ6656

2Front Case 43 (P) AMB2725

3 Rivet AEC1877

4 L5 Ferrite Core ATX1043

5 Lead Cover (P) AMR3341

6 Pioneer Badge AAM1091

NSP 7 Panel Holder (43) ANG2519

8 Spacer AEC1896

9Panel Cushion V (43) AED1201

10 Panel Cushion H (43) AED1200

11 Protect Panel Assy (43) AMR3303

No. Description Part No.

12 Screw ABZ30P050FZK

13 Screw VMZ30P060FZK

14 • • • • •

15 Serial Seal AAX2609

16 J213 Flexible Flat Cable ADD1193

NSP 17 Flexible Seal (P) AEH1052

18 Power Button AAD4113

19 Coil Spring ABH1108

20 Energy Star Label See Contrast table (2)

21 HDTV Label See Contrast table (2)

(2) CONTRAST TABLE

PDP-433PU/KUC, PDP-433PE/WYVI6, PDP-433PE/WYVI6XK and PDP-433PG/TLDPKBR are constructed the

same except for the following:

Mark No. Symbol and Description PDP-433PU/KUC

20 Energy Star Label AAX2865 Not used Not used Not used

21 HDTV Label AAX2891 Not used Not used Not used

PDP-433PE/

WYVI6

PDP-433PE/

WYVI6XK

PDP-433PG/

TLDPKBR

A

B

C

D

E

56

PDP-433PU

F

7

8

29

1234

2.12 REAR SECTION

A

11

4

4

4

3

10

3

5

4

67

33

4

4

PDP-433PG

12

Only

4

B

4

3

C

D

REAR SECTION parts List

Mark No. Description Part No.

1 Rear Case 43P ANE1607

2 Gasket L43 ANK1698

3 Screw AMZ30P060FZK

4 Screw TBZ40P080FZK

5 Cleaning Label Gray AAX2926

NSP 6 Name Label (HD) Gray See Contrast table (2)

7 Bolt Caution Label Gray AAX2928

E

3 38 93

2

Bottom View

Mark No. Description Part No.

3

8Terminal Display Label P Gray See Contrast table (2)

9Terminal Display Label L Gray See Contrast table (2)

10 Label (Blue 8) AAX2786

11 Label (Green 8) AAX2955

12 MIC Label See Contrast table (2)

3

4

1

(2) CONTRAST TABLE

PDP-433PU/KUC, PDP-433PE/WYVI6, PDP-433PE/WYVI6XK and PDP-433PG/TLDPKBR are constructed the

same except for the following:

Mark No. Symbol and Description PDP-433PU/KUC

NSP 6 Name Label (HD) Gray AAL2426 AAL2425 AAL2429 AAL2427

8Terminal Display Label P Gray AAX2929 AAX2929 AAX2939 AAX2929

9Terminal Display Label L Gray AAX2930 AAX2935 AAX2940 AAX2930

12 MIC Label Not used Not used Not used AAX2949

F

PDP-433PE/

WYVI6

PDP-433PE/

WYVI6XK

PDP-433PG/

TLDPKBR

30

1234

PDP-433PU

5 678

2.13 PDP SERVICE ASSY 433 (AWU1069)

PDP SERVICE ASSY 433 parts List

Mark No. Description Part No.

Panel Chassis (43) Assy AWU1067

NSP Front Chassis V (43) ANA1702

NSP Front CHassis HU (43) ANA1698

NSP Front Chassis HL ANA1700

Sub Frame L ANG2517

Sub Frame R ANG2518

Scan IC Spring (43L) ABK1029

Scan IC Spring (43R) ABK1030

NSP Metal Fitting ANG2464

FPC Cushion 50 AEB1371

NSP PCB Spacer AEC1121

Locking Card Spacer AEC1736

Circuit Board Spacer AEC1872

Circuit Board Spacer AEC1873

Spacer AEC1896

A

B

NSP Card Spacer AEC1902

Wire Saddle AEC1904

Panel Cushion H (43) AED1200

Panel Cushion V (43) AED1201

V Cushion AED1205

Insullation Sheet AMR3263

Scan Sheet (43) AMR3287

Card Corner Holder BEC1144

Insulation Sheet C AEC1927

Panel Caution Sheet ARM1217

Brind Plate AMR3313

Insulation Sheet AMR3343

Screw ABA1283

Screw ABA1294

Screw ABZ30P060FMC

Screw BMZ30P060FMC

Screw PMB30P060FNI

Screw VBB30P100FNI

Bolt ABA1259

Corner Pad AHA2293

Upper Carton AHD3139

Under Carton AHD3140

Packing Sheet AHG1291

Washer WB80FZB

VR Cushion AEB1374

C

D

E

Niplocker AEC1803

Static Plate AHK1013

Plate AHK1014

Screw BYC40P220FMC

Washer WC60FZK

56

PDP-433PU

F

7

8

31

1234

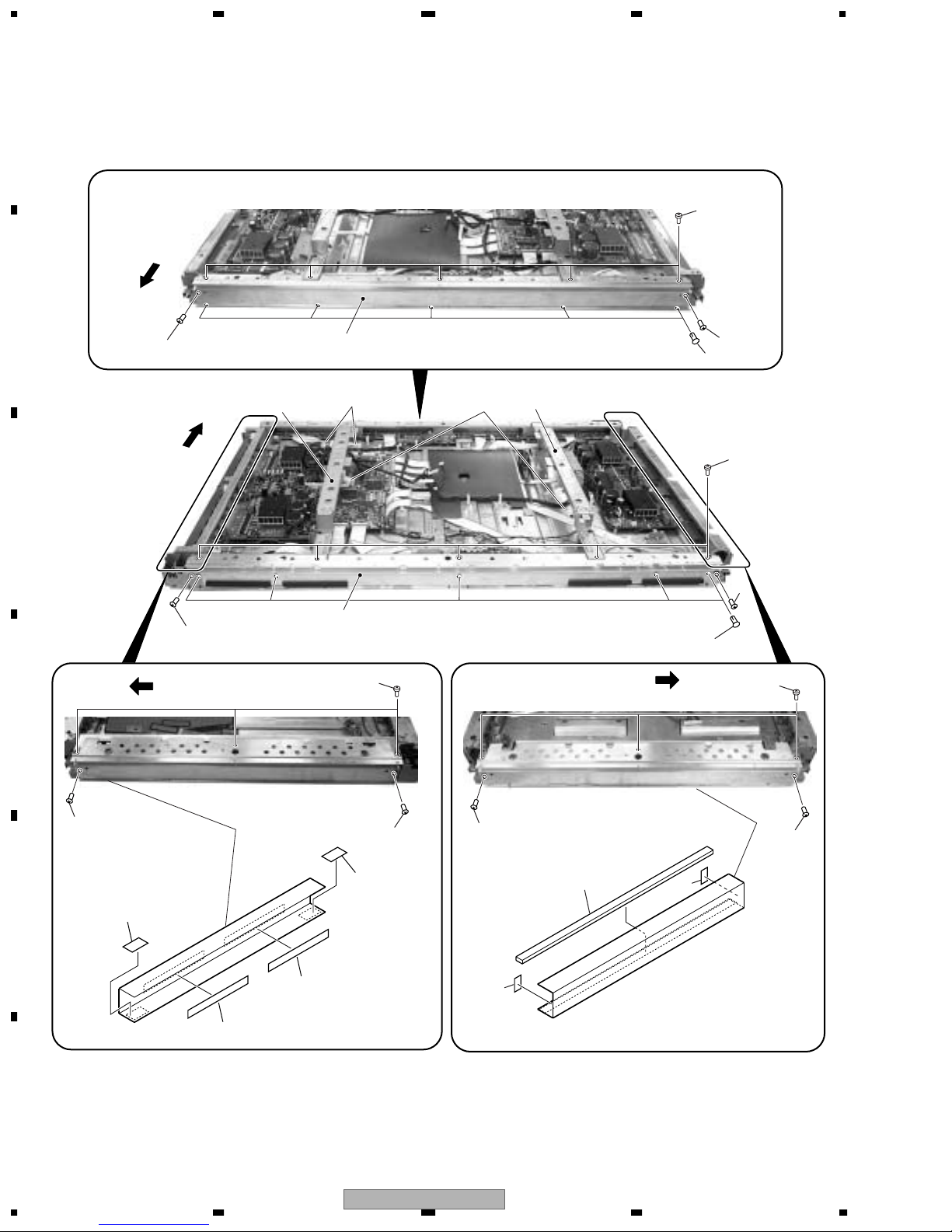

2.14 PANEL CHASSIS (43) ASSY (AWU1067)

PANEL CHASSIS(43) ASSY parts List

Mark No. Description Part No.

A

NSP SCAN FUKUGO ASSY AWV1969 *

NSP ADDRESS FUKUGO ASSY AWV1928 *

NSP Address Module (IC1 - IC32) AXF1114

NSP FPC (J1,J2) ADY1079

NSP FPC (J3,J4) ADY1080

NSP 1..Chassis Assy (43) ANA1712

NSP 2..Chassis (43) ANA1668

NSP 2..Base Chassis (43) ANA1669

NSP 2..Scan Heatsink (43) ANH1610

B

NSP 2..Corner Angle A ANG2457

NSP 2..Corner Angle B ANG2458

2..Insulation Seet A AEC1923

2..Insulation Seet B AEC1924

NSP 2..Tube Cover AMR3262

2..Rear Coner Label AAX2862

2..Silicone Sheet 43 AEH1043

2..Adhesive Tape 43 AEH1044

2..Adhesive Tape B 43 AEH1054

C

2..Panel Silicone Sheet AEH1055

2..Silicone Sheet B43 AEH1056

Pin Grommet AEC1015

Scan Silicone Sheet AEH1058

NSP Plasma Panel Assy (43) AAV1239

Screw VBB30P100FNI

Protection Tape AEH1059

No. Description Part No.

Mark

D

NSP 1..SCAN FUKUGO ASSY AWV1969

2..SCAN (A) ASSY AWZ6724

2..SCAN (B) ASSY AWZ6725

2..X CONNECTOR (A) ASSYAWZ6726

2..X CONNECTOR (B) ASSYAWZ6727

2..BRIDGE A ASSY AWZ6728

2..BRIDGE B ASSY AWZ6729

2..BRIDGE C ASSY AWZ6730

2..BRIDGE D ASSY AWZ6731

NSP 1..ADDRESS FUKUGO ASSY AWV1928

E

NSP 2..ADR CONNECT A ASSY AWZ6678

NSP 2..ADR CONNECT B ASSY AWZ6679

NSP 2..ADR CONNECT C ASSY AWZ6680

NSP 2..ADR CONNECT D ASSY AWZ6681

2..ADR RESONANCE ASSYAWZ6751

F

32

1234

PDP-433PU

5 678

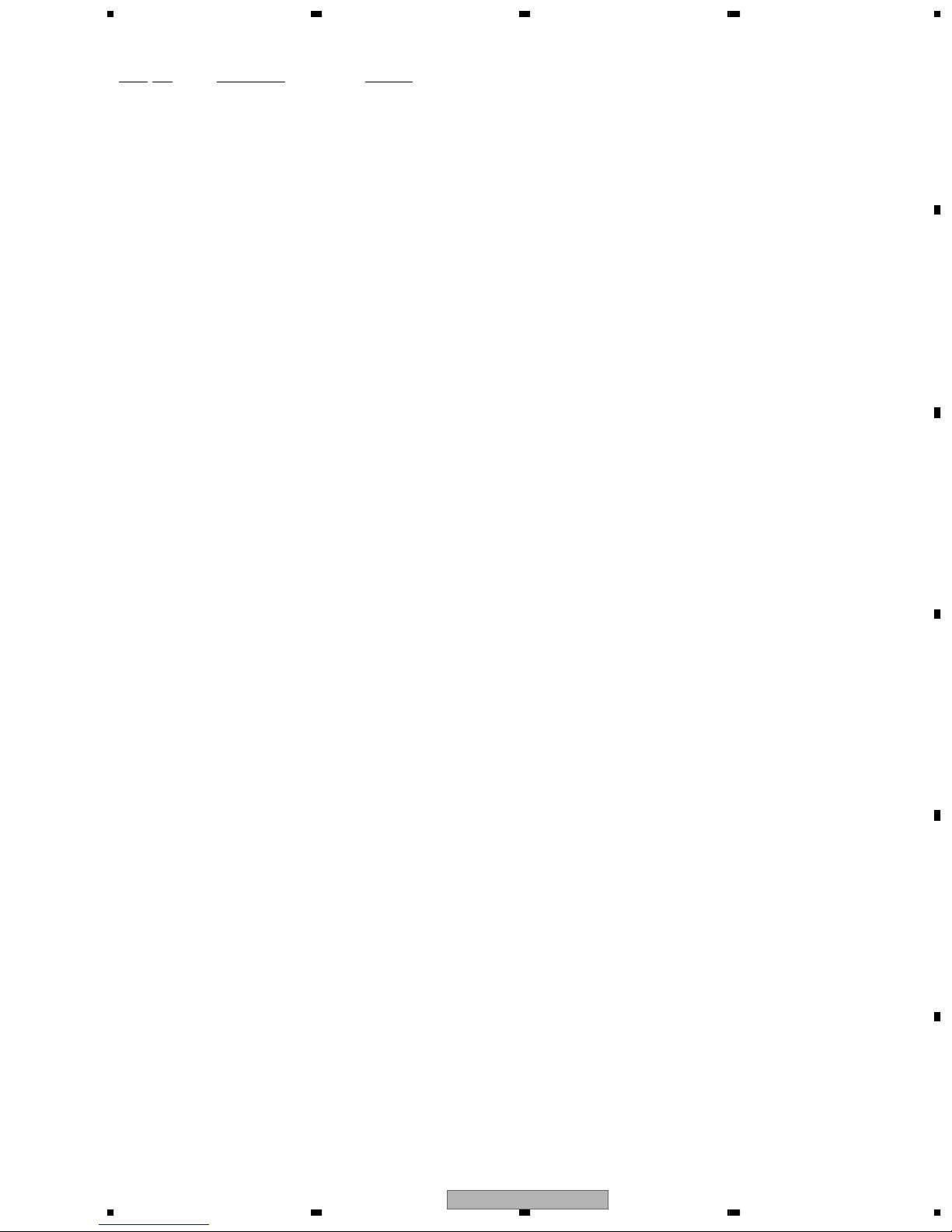

PDP Service Assy 433 (AWU1069)

Circuit Board Spacer

(AEC1872)

Circuit Board Spacer

(AEC1872)

Caution in Replacement of Chassis Block

Please order the PDP Service Assy 433 (AWU1069) when replacing the Chassis block.

PDP Service Assy 433 is all common use parts for business, consumer models and module.

It is supplied by installing the Circuit Board Spacer (AEC1872) and the Wire Saddle (AEC1904) as follows.

Therefore it is necessary to remove them in accordance with the models.

Confirm the character of the seal carved near the parts, and then remove them.

P: for Consumer models only

W: for Module only

PW : Common use for Consumer models and Module

∗ In case of this unit(433PU, 433PE or 433PG), remove the part that "W" is marked(one part).

(There is marking of "P" nearby.)

Wire Saddle

(AEC1904)

A

B

C

D

E

56

PDP-433PU

F

7

8

33

1234

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

3.1 BLOCK DIAGRAM

3.1.1 OVERALL DIAGRAM

A

B

C

D

E

SCAN (A) ASSY

(UPPER)

IC6201

SEL_PULSE

IC6202

SEL_PULSE

IC6203

SEL_PULSE

IC6204

SEL_PULSE

IC6205

SEL_PULSE

IC6206

SEL_PULSE

SCAN (B) ASSY

(LOWER)

IC6001

SEL_PULSE

IC6002

SEL_PULSE

IC6003

SEL_PULSE

IC6004

SEL_PULSE

IC6005

SEL_PULSE

IC6006

SEL_PULSE

FRONT KEY

ASSY

FRONT KEY CONN

ASSY

ADD

ADD

ADD

ADD

ADD

ADD

ADD

ADD

ADD

ADD

ADD

ADD

IC5

VCC_VH

PSUS

IC5

VCC_VH

IC5

VCC_VH

IC5

VCC_VH

IC5

VCC_VH

IC5

VCC_VH

IC5

VCC_VH

SCAN

IC5

VCC_VH

IC5

VCC_VH

IC5

VCC_VH

IC5

VCC_VH

IC5

VCC_VH

DriverICDriver

IC

ADR CONNECT A

ASSY

Y DRIVE ASSY

Y4

PSUS

VCC_VH

SCAN

PSUS

Y3

VCC_VH

Y5

PSUS

Y6

AA1

V_IC5V

V_IC5V

DriverICDriver

IC

DriverICDriver

IC

CLK/LE

IC6501

Buffer IC

VC_VF+ VC_VF- V_OFS VCC_VH V_IC5V

DC/DC Conv.

VCP

Y-SUS

MASK

Block

VCP

Y-SUS

MASK

Block

Scan Signal

VC_VF+

Block

+5V +15V

VSUS

IC2206

Pulse Module

+15V VSUS

+Reset Block

+5V +15V VSUS

IC2204

Pulse Module

+15V

Soft-D

Block

VC_VF- V_OFS

Offset

Block

V_IC5V

Photo Coupler

Block

DriverICDriver

SENSOR

ASSY

Drive

Signal

Drive

Signal

IC

VADR2

BGA1

BRIDGE A

ASSY

TE1

Y1

Y2

Logic

Block

DriverICDriver

IC

VADR2

CLAMP

ADR CONNECT B

ASSY

AB1

D8 D9 D16

D1

+12V

V+5V_STB

+12V

DC/DC Conv.

V+3V

IC1703

XY Drive

Gen.

TXD/RX

Module

DIGITAL VIDEO

ASSY

KL_U0:2

XDRV_SIG

ADL_LE_UL

ADL_LE_DL

V+3V

X180

Clock

Gen.

IC1301 (IC31 L)

Sub-Field Conv.

for Left with Field Memory

V+3V

IC1101

Panel UCOM

+12V

D18

D6

Sequence Pattern

YDRV_SIG

SCAN_SIG

V+3V_I

V+2V_I

IC1401 (IC31 R)

Sub-Field Conv.

for Right with Field Memory

ADCLK_DR

V+5V_STB

IC120

Module

UCOM

D13D12

DriverICDriver

IC

ADR RESONANCE

ASSY

V+5V

V+3V

V+2V

V+3V_IC

V+2V_IC

V+3V

IC119

Flash

ROM

DriverICDriver

IC

CLK/LE

IC6601

Buffer IC

SUB ADDRESS A

ASSY

D11

V+2V

V+3V

V+5V_STB

D2

BA2:9

BB2:9

GA2:9

GB2:9

RA2:9

RB2:9

TXD0/RX0

RE

LED_SIG

I2

D3D17

DriverICDriver

K2

K1

SAA3

+60

SAA1 SAA2

D10

D7

D4

D15

D14

IC

VADR2

Q6706 - Q6711

VADR Gen.

ADR_CO

SW21 KL21 KL22

IR (P)

ASSY

RE1

F

ADR CONNECT D

ASSY

DriverICDriver

AD1

DriverICDriver

IC

IC

CLK/LE

IC6901

Buffer IC

DriverICDriver

34

1234

SUB ADDRESS B

ASSY

ADR RESONANCE

DriverICDriver

ASSY

IC

CLK/LE

IC6801

Buffer IC

DriverICDriver

BRIDGE C

ASSY

BGC1

CLAMP

VADR2

VADR2

DriverICDriver

IC

IC

ADR CONNECT C

ASSY

DriverICDriver

AC1

IC

SAB1 SAB2

K2

IC

+60

SAB3

K1

Q6706 - Q6711

VADR2

DriverICDriver

ADR_CO

VADR Gen.

IC

PDP-433PU

5 678

Note : When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS LIST" or "PCB PARTS LIST".

DriverICDriver

VADR2

IC

DriverICDriver

ADR CONNECT C

ASSY

K3

IC

DriverICDriver

IC

AC1

CLK/LE

DriverICDriver

IC6801

Buffer IC

VADR2

VADR2

CLAMP

DriverICDriver

IC

IC

BGB1

BRIDGE B

ASSY

DriverICDriver

IC

ADR CONNECT D

ASSY

AD1

DriverICDriver

CLK/LE

DriverICDriver

IC6901

Buffer IC

IC

IC

A

SW POWER SUPPLY MODULE

SW POWER SUPPLY Block

+13.5V

-9V

T101

Switching

+13.5V

+6.5V

+15V

+12V

STB5V

-9V

+6.5V

T102

+12V

Q115

Switching

Q117

STB5V

Switching

Q119

VADR

Switching

VSUS_CONT

+15V

M111

Q112

M114

STB5V

T105T105T104T103

LIVE

NEUTRAL

SECONDARY

+13.5V

P1 P2 P5 P6 P3 P4

AUDIO AMP ASSY

R23

L

R

FOCUS

SRS

R27

R24

R11

AUDIO_SIG (L/R)

A24

A21

TRAP SW

L

R

Volume & Tone

A22

R3

R22

R21

R2

KEY1

KEY2

EEPROM

(HDCP KEY)

• Scalling

• Gamma

TMDS Receiver

V+5V_ST

V+5V_ST

IC4203

IC4204

(Sil861)

IC4201

EEPROM

(EDID)

I2C

Interface

Copy Guard

Release

TMDS

Receiver

I2C_BUS (SCL/SDA)

IC4011

I/O Expander

LED_SIG

TXD/RXD

SR_UP

SR_DW

TMDS with HDCP

R26

MR INTERFACE

ASSY

V+5V_DIG

System Cable Connector

RC101

PRIMARY

POWER (RELAY)

VSUS

-9V

IC5202

& Balance

L, R

IC5201

SRS & Focus

L, R

IC5002

Power Amp.

L, R

L, R

SP21

SP OUT

RL101

+15V

VSUS

+12V

+12V

+15V

+12V+13.5V

IC5001

Reg.

SP TERMINAL

ASSY

V MID CLAMP Block

CLAMP

CLAMP

P7

LIVE

AC IN

NEUTRAL

VM1

X DRIVE ASSY

X1

DC/DC

Conv.

Block

Drive

Signal

+5V

Logic

Block

X2

Drive

Signal

L1

LED

ASSY

VSUS

+5V

IC3200

Pulse

Module

+Reset

Pulse

Block

+5V

IC3201

Pulse

Module

+15V

+15VV_RN

+15VVSUS

VCP

X_SUS

MASK

VCP

X_SUS

MASK

X3

P_SUS

P_SUS

X4

B

C

X CONNECTOR (A) ASSYX CONNECTOR (B) ASSY

D

E

K3

VADR2

DriverICDriver

ADR CONNECT B

ASSY

IC

DriverICDriver

56

AB1

IC

DriverICDriver

IC

CLK/LE

IC6601

Buffer IC

DriverICDriver

BRIDGE D

ASSY

BGD1

CLAMP

VADR2

VADR2

IC

DriverICDriver

ADR CONNECT A

ASSY

IC

DriverICDriver

PDP-433PU

AA1

IC

DriverICDriver

IC

7

CLK/LE

IC6501

Buffer IC

DriverICDriver

F

IC

35

8

1234

3.1.2 MR INTERFACE ASSY

A

B

C

CN4003 (DVI)

TMDS

6

DDC_SCL

7

DDC_SDA

14

DDC5V

CN4002 (MDR)

15

SR_UP

11

M_TXD

1

M_RXD

IC4204

TMDS_RXCORE CONTENT_PROTECTION

IC4201

(DDC_ROM)

Q4014 (REM_CUT)

Q4018 (INV)

C4043

(HPF)

IC4006 (REM_SLICER)

Q4008 (2.5V_REG)

IC4006 (TTL → CMOS CONVERT)

IC4006 (BUFF)

Q4201, Q4202

(5V ↔ 3.3V

I2C_LEVEL_SHIFT)

IC4010

(NON_SYSTEM_DET)

SCALING

IC4011

(I/O_EXPANDER)

IC4005

(I/O_EXPANDER)

S4001, S4004, etc

(MODEL_INFO)

IC4012 (IC2_SW)

IC4013

(STB_DET)

IC4203

(CONF_ROM)

Q4001, Q4002 (I2C_SW)

V+5V_DIG

Q4005, Q4006

(5V ↔ 3.3V

I2C_LEVEL_SHIFT)

8bit_DIGITAL

× RGB

DDC_SCL

DDC_SDA

PMST

A_SCL

A_SDA

RXD0

TXD0

CN4004, CN4005

14

SR_DOWN

D

5

SM_POW

7

8

CCKM

CSEN2

R4093

R4098

(BIAS)

E

2010

SPL

13

4

SPR

Q4012 (INV) REM

Q4007 (BUFF)

IC4010 (BUFF)

IC4007 (COMPR)

+

IC4008, IC4009 (REM_SW)

Q4011 (DRIVER)

Q4401 (BUFF)

Q4402 (BUFF)

SM_POW

CCKM

SW_TRG

F_KEY1

F_KEY2

LED_G

LED_R

I2C

L_CH

R_CH

CN4401

LED_G

CN4007

REM

KEY1

KEY2

LED_R

CN4009

F

36

1234

PDP-433PU

5 678

No. Name Description Voltage at INPUT4 NTSC Input

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

M_RXD

GND

SENCE

SPR

SMPOW

GND

CCKM

CSEN2

CSEN1

SPL

M_TXD

GND

SPR

SR_DW

SR_UP

GND

FRASH_W

SRST

GND

SPL

232C bus (PDP → MR)

Connecting detection for MR

Audio signal R ch

MR relay control

System activation detection

System activation signal

Not used

Audio signal L ch

232C bus (MR → PDP)

Audio signal R ch

Remote control signal

MDR connecting detection signal

multiplex remote control signal

Not used

Not used

Audio signal L ch

0-5V swing square wave

0.0V DC

Analog audio signal wave

3.5V DC

1.9V DC

5.0V DC

Analog audio signal wave

0-3.3V swing square wave

Analog audio signal wave

5.0V DC

3.75V DC

Analog audio signal wave

No. Name Description Voltage at INPUT4 NTSC Input

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

RX2RX2+

GND

NC

NC

DDC_SCL

DDC_SDA

NC

RX1RX1+

GND

NC

NC

DDC_+5V

GND

HPD

RX0RX0+

GND

NC

NC

GND

RXC+

RXC-

DVI signal

DVI signal

I2C for DDC

I2C for DDC

DVI signal

DVI signal

I2C power supply for DDC

HOT_PLUG detection

DVI signal

DVI signal

DVI signal

DVI signal

DVI signal

DVI signal

0-5V swing square wave

0-5V swing square wave

DVI signal

DVI signal

5.0V DC

5.0V DC

DVI signal

DVI signal

DVI signal

DVI signal

CN4002 (MDR Connector) (↔ Media Receiver)

CN4004 (50P_FFC Connector) (↔ DIGITAL VIDEO Assy) CN4005 (50P_FFC Connector) (↔ DIGITAL VIDEO Assy)

CN4003 (DVI Connector) (↔ Media Receiver)

No. Name Description Voltage at INPUT4 NTSC Input

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

GND

GND

NC

NC

NC

NC

BB0

BA0

BB1

BA1

BB2

BA2

BB3

BA3

BB4

BA4

BB5

BA5

BB6

BA6

BB7

BA7

GND

GND

NC

NC

NC

NC

GB0

GA0

GB1

GA1

GB2

GA2

GB3

GA3

GB4

GA4

GB5

GA5

GB6

GA6

GB7

GA7

GND

GND

NC

NC

GND

GND

8 bit video signal

8 bit video signal

8 bit video signal

8 bit video signal

8 bit video signal

8 bit video signal

8 bit video signal

8 bit video signal

8 bit video signal

8 bit video signal

8 bit video signal

8 bit video signal

8 bit video signal

8 bit video signal

8 bit video signal

8 bit video signal

8 bit video signal

8 bit video signal

8 bit video signal

8 bit video signal

8 bit video signal

8 bit video signal

8 bit video signal

8 bit video signal

8 bit video signal

8 bit video signal

8 bit video signal

8 bit video signal

8 bit video signal

8 bit video signal

8 bit video signal

8 bit video signal

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave

No. Name Description Voltage at INPUT4 NTSC Input

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

NC

NC

NC

NC

RB0

RA0

RB1

RA1

RB2

RA2

RB3

RA3

RB4

RA4

RB5

RA5

RB6

RA6

RB7

RA7

GND

CLK

GND

DE

GND

HD

GND

VD

GND

A_SCL

F_KEY1

PMST

SMPOW

A_MUTE

CCKM

M_STATE

SW_STC

A_NG

SW_TRG

F_KEY2

A_SDA

*LED_G

TXD0

*LED_R

RXD0

DDC_SCL

REM

DDC_SDA

GND

GND

8 bit video signal

8 bit video signal

8 bit video signal

8 bit video signal

8 bit video signal

8 bit video signal

8 bit video signal

8 bit video signal

8 bit video signal

8 bit video signal

8 bit video signal

8 bit video signal

8 bit video signal

8 bit video signal

8 bit video signal

8 bit video signal

Clock

Data enable

Horizontal sync. signal

Vertical sync. signal

I2C bus

Front key signal 1

MDR connecttion Detect signal

MR relay control

Audio mute

System activation detect

SiI861 I2C bus master infomation

Not used

Not used

System activation signal

Front key signal 2

I2C bus

Green LED control signal

232C bus

Red LED control signal

232C bus

I2C for DDC

Remote control signal

I2C for DDC

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave

0-3.3V swing square wave (40MHz)

0-3.3V swing square wave (+ polarity)

0-3.3V swing square wave

(- polarity 48.4kHz)

0-3.3V swing square wave

(- polarity 60.0Hz)

0-5V swing square wave

5.0V DC

3.75V DC

5.0V DC

0.0V DC

1.9V DC

0.0V DC

5.0V DC

5.0V DC

0-5V swing square wave

0.0V DC

0-5V swing square wave

5.0V DC

0-5V swing square wave

0-5V swing square wave

5.0V DC

0-5V swing square wave

Voltages

A

B

C

D

E

F

56

PDP-433PU

7

8

37

1234

3.1.3 DIGITAL VIDEO ASSY

A

MR INTERFACE

B

C

IC4005

Expander

IC4011

Expander

AUDIO

ASSY

IC4204

SiI861

To

MR

To

Assy

RGB 2 phase 8 bit

VD

HD

DE

CLK

RXDO

TXDO

A_SCL, A_SDA

DIGITAL VIDEO ASSY

Reflesh-rate

Det.

AND

CN1201

EXT_RXD

EXT_TXD

RXDO

TXDO

WE_PN

3.3V

Line

Buffer

RESET

EXD RXD

EXD TXD

RESET

Address BUS

Control Signal

3.3V

IC1191

Flash ROM

3.3V

HD

VD

Reset IC

Data BUS

(HD64F2328VF)

Panel Microcomputer

3.3V → 5.0V5.0V → 3.3VReset IC

RST PU

IC1207

(M30624FGAFP)

Module Microcomputer

AC_OFF

PD_TRIGGER

TEMP1

3.3V

2.5V

VD 31

IC1101

IC1301 (IC31 L)

(PD6358)

DRAM

IC1401 (IC31 R)

(PD6358)

DRAM

3.3V

APLR

RXD

BUSY

REQ_PU

RST2

IC1703 (IC23)

(PE5064)

Address

Resonance

STOPB

Control

PC_VIDEO

ADR_K_EMG

AND

APD MUTE

STB5V

RELAY

5V

IIC BUS

Address Data

Address Data

OR

ADR PD

OR

Sustain

Control

ADR K PD U

ADR K PD D

STB5V

EEP

ROM

DCC_PD

5V

RESONANCE

Panel W/B ADJ.

Hour/Pulse meter

DEW DET

5V

Converter

ADR CONNECT A - D

Assy (Left section)

ADR CONNECT A - D

Assy (Right section)

Y DRIVE Assy

X DRIVE Assy

ADR

Assy

pn

3.3V

2.5V

DC/DC

Block

STB5V

D

THERMAL

SENSOR

Assy

DIG. ADR. PD

SW POWER SUPPLY Module

12V

STB5V

E

F

38

1234

PDP-433PU

5 678

23

21

579

1113151719

PN_MUTE

XNR-U

XSUS-B

XSUS-U

XSUS-D

XSUS-G

XSUS-MSK

XCP-MSK

XNR-D1

XNR-D2

CN3001

X2

12348

11

CN3101

X1

XNR_U

XNR_U

24536

65234

9

IC3004

TC74ACT540FT

IC3008

TC74ACT541FT

18

17

14

1415181716

16

15

152346897

10

IC3008

PE1012A

202322211917161815

2345786

9

IC3001

TC74ACT541FT

IC3102

HCPL-M611

IC3101

TC74ACT541FT

IC3200

STK795-470

Pulse Module

IC3201

STK795-470

Pulse Module

T3701

VRN D-D CONV.

XCP-MSK

XSUS-MSK

VCP

PLD

SUSOUT A

37-40

29,30

K3105

PSUS

K3107

IC3103,IC3104

TND301S

Q3103,

Q3107

Q3104,

Q3109

Q3105,

Q3124

Q3106,

Q3125

SUSOUT B

37-40

29,30

K3106

IC3106,IC3107

TND301S

Q3110,

Q3114

Q3111,

Q3115

Q3112,

Q3126

Q3113,

Q3127

To

X CONNECTOR

ASSY

IC3110

TND301S

IC3113

TND301S

charge pump

circuit

From DIGITAL VIDEO ASSY

Photo

coupler

2-9 11-18

+15V

DGND

XDRIVE_PD

XDC_DC_PD

VSUS

SUSGND

SUSGND

SUSGND

P.D.

DET.

18171615131214

11

14

16

18

20

14

16

18

20

VSUS 225V

VRN UVP

VRN OVP

Q3116

Q3120

Q3122

Q3128

XNR-D1

XNR-D2

VRN-300V

XDRIVE_PD

3.1.4 X DRIVE ASSY

A

B

C

D

56

PDP-433PU

7

E

F

39

8

1234

3.1.5 Y DRIVE ASSY

A

CLR

27

CLK

25

OC1

LE

AB

SI1

SI2

30

31

40

42

43

45

IC2001

TC74ACT541FT

OC2-1

B

OC2-2

Photo Coupler

Photo Coupler

Photo Coupler

Photo Coupler

Photo Coupler

Photo Coupler

Photo Coupler

Photo Coupler

IC2501,IC2502,

IC2505,IC2510,

IC2512,IC2513,

IC2514,IC2525,

HCPL-M611

TC74ACT540FT

Photo Coupler

IC2516

HCPL-M611

C

IC2504

TC74ACT540FT

IC2506

TC74ACT540FT

+13.5V

IC5V

VH

IC2503

SUS muteDET.

circuit

IC2005

33

24

19

21

9

10

12

18

13

16

15

22

46

Y2

1

2

3

4

5

6

7

10

11

13

14

TC74ACT541FT

TC74ACT540FT

Vsus

D. GND

IC2007

IC2006

PE1013

P.D.

DET.

IC5V UVP

VOFS UVP

VOFS OVP

TC74ACT541FT

IC5V, VF

D-D CONV.

VOFS D-D

CONV.

OC2-2

PN_MUTE

YPR-U1

YPR-U2

YSUS-B

YSUS-U

YSUS-D

D

YOFS

YSUS-G

YCP-MSK

YSUS-MSK

YSOFT-D

DEW_DET

E

+15V

D. GND

+13.5V

-9V

YDRIVE_PD

YDC_DC_PD

VOFS_ADJ

VSUS

VSUS

SUSGND

SUSGND

F

SUSGND

VH UVP

VH OVP

VH D-D CONV.

-9V

IC2004

TC74ACT541FT

IC2005

YPR-U1

YCP-MSK

YPR-U2

YSUS-MSK

YSOFT-D

YOFS

IC5V

VF+

VF-

VOFS

VH

Y5

VH

Pulse Module

14

(STK795-470)

16

18

20

Pulse Module

14

(STK795-470)

16

18

20

charge pump

To SCAN ASSY

(Lower)

CN2501CN2502

To SCAN ASSY

(Upper)

Y3

IC2206

IC2214

circuit

Photo Coupler

IC2202

HCPL-M611

Photo Coupler

IC2208

HCPL-M611

40

1234

PDP-433PU

5 678

A

YPR-U1

YPR-U2

SUSOUT A

37-40

29,30

5V

15V

Vsus

SUSOUT B

37-40

29,30

5V

15V

Vsus

VSUS

IC2203

TND301S

K2203

K2212

VCP

IC2212

TND301S

Q2218

IC2213

TND301S

Q2220

IC2216

TND301S

Q2226

IC2217

TND301S

Q2232

Q2204

Q2219

Q2221

Q2217

Q2233

Q2215

Q2228

Q2227

Q2216

Q2205

K2220

PSUS

TO

Y CONNECTOR

ASS'Y

B

C

D

IC2201

TC74ACT541FT

2-9

56

11-18

IC2204

TND301S

IC2210

TND301S

SUSGND

Q2210

Q2211

PDP-433PU

PSUS

E

F

7

8

41

1234

3.1.6 SUB ADDRESS A and B ASSYS

A

+60V

ADRGND

CN8801

H : V MID CLAMP OFF

L : V MID CLAMP ON

B

C

D

V MID SW

ADRK EMG1

+12V

DGND

ADR-B ADR EMG 1 Block

ADR-U

ADR-D

ADRK. PD

CN8802

(DC+AC) (-AC) 5V

SW

ADR-D

ADR-U

ADR-B

+12V

DGND

VADR

ADRGND

ADROUT

CN8803

H : EMG1 OFF

L : EMG1 ON

Current - Voltage

Convert Block

R8801 - R8805 Q8801

P.D. Output Block

Q8803, Q8831 Q8805, Q8806

BUFF Block

IC8801 IC8801 D8804

Additional

Block

IC8802 IC8802 IC8803

(DC) CLK

Inversion

Block

Conparator

(EMG : ON)

Conparator

(EMG : OFF)

IC8804

Over Current DET. Block

ADR Output

Resistance Load Block

+5V REG

Flip / Flop

CLR

12V

E

F

42

1234

PDP-433PU

5 678

+60V

+60V

+60V

+60V

CN6702 IC6704 C6703 - C6708

12V

Address Resonance Output Block

ADROUT

ADRGND

ADR B

VADR

C6720 Q6706

DGND

Q6707

+12V

IC6701 Q6701, Q6704 ADR U

ADR-B

C6721 Q6708

ADR-U

Q6709

ADR-D

SW

CN6701

ADR OUT

L6704

IC6702 Q6702, Q6705

VADR

V MID

ADR D

ADRGND

C6722 Q6710

DGND

Q6711

SW

CN6703

DGND IC6703 Q6703, Q6712 V MID

C6716

ADRGND

ICP-S1, 0

ADR-B

Pre-Drive

ADR-U

Pre-Drive

ADR-U

Drive

ADR-D

Pre-Drive

ADR-D

Drive

ADR-B

Drive

CAUTION :

FOR CONTINUED PROTECTION AGAINST RISK OF FIRE.

REPLACE ONLY WITH SAME TYPE NO. ICP-S1.0 MFD

BY ROHM CO., LTD. FOR IC6704.

3.1.7 ADR RESONANCE ASSY

A

B

C

D

E

56

PDP-433PU

F

7

8

43

1234

3.1.8 ADR CONNECT A, B, C and D ASSYS

A

Address Module

(TCP)

Address Module

(TCP)

Address Module

(TCP)

Address Module

(TCP)

ADR PD

ADR OUT

BRIDGE ASSY

OPEN PD

HZ

HZ

LBLK

HBLK

LE

CLK

LBLK

HBLK

LE

CLK

B

DATA_R

DATA_G

DATA_B

DATA_R

DATA_G

DATA_B

DATA_R

DATA_G

DATA_B

DATA_R

DATA_G

DATA_B

DATA_R

DATA_G

DATA_B

CN6501

DATA_R

DATA_G

DATA_B

DATA_R

DATA_G

DATA_B

DATA_R

DATA_G

DATA_B

Q6502, Q6503

Buffer

IC6501

C

D

E

F

44

1234

PDP-433PU

3.1.9 AUDIO AMP and SP TERMINAL ASSYS

4 22

1

14

11 12

96

8

7

11

12

13

14

A24

L

R

STB SW

CN5001

IC5202

(CXA2021S)

Audio Pre-Amp.

A_MUTE

SCL

SDA

FOCUS

SRS

AUDIO AMP ASSY

SP TERMINAL ASSY

30

1

L

R

IC5201

(NJM2193L)

Focus & SRS

Audio Processor

IC5002

(LA4628)

Audio

Power Amp.

19

12

1

6

L

R+

R–

L+

L–

R

17 18 4 5

2

3

5

6

8

9

11

13

A22

J5003

R+

L5301

ATF1206

L5352

ATF1206

R–

L+

L–

2

3

5

6

4

3

1

2

SP21

CN5302 CN5301

SPEAKER

TERMINAL

IC5201 (NJM2193L)IC5202 (CXA2021S) IC5002 (LA4628)

No. Voltage (V) No. Voltage (V)

1 5.9 12 5.25

2013 1.73

3 5.95 14 5.95

4 5.94 15 5.92

5 5.98 16 5.91

6 6.02 17 5.93

7 6.02 18 5.92

8 7.38 19 5.94

9 5.95 20 5.95

10 1.55 21 11.91

11 5.24 22 5.9

No. Voltage (V) No. Voltage (V)

1 5.95 16 11.91

2 5.94 17 0

3 5.84 18 0

4 5.98 19 5.98

5 5.98 20 5.91

6 5.97 21 5.97

7 5.98 22 5.98

8 5.98 23 5.98

9 5.98 24 5.98

10 5.97 25 5.97

11 5.97 26 5.98

12 5.98 27 5.98

13 5.96 28 5.84

14 5.98 29 5.94

15 0 30 5.95

No. Voltage (V)

1 1.6

2 7.5

30

4 3.37

5 2.29

6 1.6

7 1.97

8 7.3

9 7.3

10 0

11 7.3

12 0

13 7.3

14 15

5 678

A

B

C

D

E

56

PDP-433PU

F

7

8

45

1234

3.2 WAVEFORMS

DIGITAL VIDEO ASSY

A

K1327 (VDI)

1

K1328 (HDI)

V: 2V/div. H: 4msec/div.

K1326 (DEI)

4

K1333 (VCLKL)

V: 2V/div. H: 4µsec/div.

K1308 (VDRB)

8

IC1501 - pin 15 (LBLK)

V: 2V/div. H: 2msec/div.

B

C

D

K1327 (VDI)

1

K1328 (HDI)

V: 2V/div. H: 10µsec/div.

K1327 (VDI)

2

CN1004 pin 49 (R DIGITAL VIDEO)

V: 2V/div. H: 4msec/div.

K1328 (HDI)

3

K1326 (DEI)

V: 2V/div. H: 4µsec/div.

K1326 (DEI)

4

K1333 (VCLKL)

V: 2V/div. H: 10nsec/div.

K1308 (VDRB)

5

R1713 - pin 7 (XSUS_B)

V: 2V/div. H: 2msec/div.

K1308 (VDRB)

6

R1703 - pin 8 (YSUS_B)

V: 2V/div. H: 2msec/div.

K1308 (VDRB)

9

IC1501 - pin 13 (LE)

V: 2V/div. H: 2msec/div.

IC1501 - pin 13 (LE)

10

IC1501 - pin 11 (ADRCLK)

V: 2V/div. H: 200nsec/div.

IC1501 - pin 13 (LE)

10

IC1501 - pin 11 (ADRCLK)

V: 2V/div. H: 20nsec/div.

K1308 (VDRB)

7

R1343 - pin 8 (RDAT_DL0)

E

V: 2V/div. H: 4msec/div.

F

46

1234

PDP-433PU

5 678

ADR RESONANCE ASSY

4

CH1 : Q6706 Drain

CH2 : Q6710 Soruse

V: 10V/div.

(Input : PC, Signal : Color bar)

3

CH1 : Q6706 Drain

CH2 : Q6710 Soruse

V: 10V/div.

(Input : VIDEO, Signal : Color bar)

2

CH1 : D6706 Cathode

CH2 : D6703 Cathode

CH3 : D6708 Cathode

V: 2V/div.

(Input : VIDEO, Signal : Color bar)

1

CH1 : IC6702 - pin 2

CH2 : IC6701 - pin 2

CH3 : IC6703 - pin 2

V: 1V/div.

(Input : VIDEO, Signal : Color bar)

ADR CONNECT A - D

ASSY

2

CH1 : IC6501 - pin 5 (HBLK)

CH2 : IC6501 - pin 3 (LBLK)

CH3 : IC6501 - pin 2 (HZ)

V: 1V/div.

(Input : VIDEO, Signal : Color bar)

1

CH1 : IC6501 - pin 8 (CLK)

CH2 : IC6501 - pin 6 (LE)

CH3 : IC6501 - (DATA)

V: 1V/div.

(Input : VIDEO, Signal : Color bar)

5

CH1 : Q6708 Drain

CH2 : Q6710 Drain

V: 10V/div.

(Input : VIDEO, Signal : Color bar)

SUB ADDRESS A, B

ASSY

2

CH1 : IC8801 - pin 3

CH2 : IC8801 - pin 7

CH3 : IC8802 - pin 1

V: 2V/div. H: 2msec/div.

(Input : VIDEO, Signal : Color bar)

1

CH1 : IC8801 - pin 3

CH2 : IC8801 - pin 7

CH3 : IC8802 - pin 1

V: 2V/div. H: 2msec/div.

(Input : VIDEO, Signal : Color bar)

CH1

H :

2msec/div

CH2

CH3

V MID CLAMP ASSY

2