Page 1

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2005

ORDER NO.

ARP3302

PDP-42A3HD

PLASMA DISPLAY

PDP-42A3HD

PDP-4214HD

< CAUTION >

This ARP3302 Supersedes ARP3270

THIS MANU

Model Type Power Requirement Remarks

PDP-42A3HD KUCXKA AC120V

PDP-42A3HD KUCXC AC120V

PDP-4214HD KUCXC AC120V

AL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

For details, refer to "Important symbols for good services".

T-ZZR OCT. 2005 printed in Japan

Page 2

1234

SAFETY INFORMATION

A

This service manual is intended for qualified service technicians ; it is not meant for the casual doit-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely,

you should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to

cause cancer, birth defects or other reproductive harm.

B

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement parts

must be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les pièces

de remplacement doivent avoir la même désignation.

Health & Safety Code Section 25249.6 - Proposition 65

C

SAFETY PRECAUTIONS

NOTICE : Comply with all cautions and safety related notes

located on or inside the cabinet and on the chassis.

The following precautions should be observed :

1. When service is required, even though the PDP UNIT an

isolation transformer should be inserted between the power line

and the set in safety before any service is performed.

2. When replacing a chassis in the set, all the protective devices

D

must be put back in place, such as barriers, nonmetallic knobs,

adjustment and compartment covershields, isolation resistorcapacitor, etc.

3. When service is required, observe the original lead dress. Extra

precaution should be taken to assure correct lead dress in the

high voltage circuitry area.

4. Always use the manufacture's replacement components.

Especially critical components as indicated on the circuit

diagram should not be replaced by other manufacture's.

Furthermore where a short circuit has occurred, replace those

components that indicate evidence of overheating.

E

5. Before returning a serviced set to the customer, the service

technician must thoroughly test the unit to be certain that it is

completely safe to operate without danger of electrical shock,

and be sure that no protective device built into the set by the

manufacture has become defective, or inadvertently defeated

during servicing. Therefore, the following checks should be

performed for the continued protection of the customer and

servicetechnician.

6. Perform the following precautions against unwanted radiation

and rise in internal temperature.

• Always return the internal wiring to the original styling.

• Attach parts (Gascket, Ferrite Core, Ground, Rear Cover,

Shield Case etc.) surely after disassembly.

7. Perform the following precautions for the PDP panel.

• When the front case is removed, make sure nothing hits the

panel face, panel corner, and panel edge (so that the glass does

not break).

• Make sure that the panel vent does not break. (Check that the

cover is attached.)

• Handle the FPC connected to the panel carefully.

Twisting or pulling the FPC when connecting it to the

connector will cause it to peel off from the panel.

8. Pay attention to the following.

• When the front case is removed, infrared ray is radiated and

may disturb reception of the remote control unit.

• Pay extreme caution when the front case and rear panel are

removed because this may cause a high risk of disturbance to

TVs and radios in the surrounding.

F

2

1234

PDP-42A3HD

Page 3

5678

Leakage Current Cold Check

With the AC plug removed from an AC power source, place a

jumper across the two plug prongs. Turn the AC power switch on.

Using an insulation tester (DC 500V), connect one lead to the

jumpered AC plug and touch the other lead to each exposed metal

part (input/output terminals, screwheads, metal overlays, control

shafts, etc.), particularly any exposed metal part having a return

path to the chassis. Exposed metal parts having a return path to

the chassis should have a minimum resistor reading of 0.3MΩ

and a maximum resistor reading of 5MΩ. Any resistor value

below or above this range indicates an abnormality which requires

corrective action. Exposed metal parts not having a return path to

the chassis will indicate an open circuit.

Leakage Current Hot Check

Plug the AC line cord directly into an AC power source (do not

use an isolation transformer for this check).

Turn the AC power switch on.

Using a "Leakage Current Tester (Simpson Model 229

equivalent)", measure for current from all exposed metal parts of

the cabinet (input/output terminals, screwheads, metal overlays,

control shaft, etc.), particularly any exposed metal part having a

return path to the chassis, to a known earth ground (water pipe,

conduit, etc.). Any current measured must not exceed 0.5mA.

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in PIONEER set have

special safety related characteristics. These are often not evident

from visual inspection nor the protection afforded by them

necessarily can be obtained by using replacement components

rated for higher voltage, wattage, etc. Replacement parts which

have these special safety characteristics are identified in this

Service Manual.

Electrical components having such features are identified by

marking with a on the schematics and on the parts list in this

Service Manual.

The use of a substitute replacement component which dose not

have the same safety characteristics as the PIONEER

recommended replacement one, shown in the parts list in this

Service Manual, may create shock, fire or other hazards.

Product Safety is continuously under review and new instructions

are issued from time to time. For the latest information, always

consult the current PIONEER Service Manual. A subscription to,

or additional copies of, PIONEER Service Manual may be

obtained at a nominal charge from PIONEER.

A

B

C

Reading should

not be above

0.5mA

Earth

ground

Device

under

test

Also test with

plug reversed

(Using AC adapter

plug as required)

Leakage

current

tester

Test all

exposed metal

surfaces

AC Leakage Test

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE SET TO THE CUSTOMER.

D

E

56

PDP-42A3HD

F

3

7

8

Page 4

1234

A

CAUTION

• Observe the caution matter, without fail

• The caution matters of given in the delivery specifications, etc., must be observed, without fail.

• Do not give shocks and vibration.

• The panel surface (display plane) of the PDP module is made of glass. If any shocks or vibration is applied, it may be broken and

the scattered glass chips will be a cause of injury

• Do not put anything.

B

• Transportation must be done by enough personnel.

• Do

not put anything on the PDP module. Otherwise, this can be a cause of injury as a result of falling down or dropping caused

by imbalance.

• The PDP module is heavy. In the case of transportation, unpacking, or packing, more than two persons should do it by supporting

the top and the bottom of the product.

7 Miscellaneous caution matters

(1) This PDP module uses highly integrated semiconductor parts. Since these parts are fragile to electrostatic

charges, earth bands should be used for handling. The product should be handled where measures have been

taken against electrostatic charges.

(2) For this product, the PDP modules and the PWBs are repaired by replacement in a unit. Therefore, the units of

C

the PWBs must not be repaired or disassembled. Otherwise, the validity of warranty will be lost.

(3) If this PDP module is used for the fixed character display or the like as in the case of a character display board,

a phenomenon of burning (not warranted) will occur. Burning is a phenomenon that the unevenness in the

brightness is caused in the display. In such a case, the brightness in the section where the integrated display

time is longer becomes lower than the brightness in another section where the integrated display time is shorter.

This phenomenon is in proportion to the integrated display time and the brightness. For this reason, to relieve

this difficulty during servicing, do not use any still picture, but use a display by motion pictures of a video or the

like. In addition, use “FULL” for the screen mode and avoid using any display by “NORMAL”, “TRUE”, or MULTI

SCREEN like side by side etc. If it is necessary to use only a still picture for unavoidable reasons, use a burning

relief function such as “PLE LOCK”, “ORBITER”, “SCREEN WIPER”, etc.

(4) When a PDP module is operated after a long time of storage, it may encounter a difficulty like a failure in

displaying a screen or unstability according to the condition of storage. In such a case, the PDP module should

D

be incorporated in the product and aging treatment should be carried out for about two hours (all screen display).

(5) Sulfides will deteriorate the PDP module and this is a cause of malfunction. Therefore, it is absolutely prohibited

to put any vulcanized rubber or a material containing sulfur in the vicinity of the PDP module.

(6) When taking out a PDP module from the maintenance package box, do it slowly so that the panel surface

does not get any shock or stress.

(7) If one touches the connector of the flexible cable exposed to the rear side of the PDP module, there is

danger of causing a poor contact. As such, it must be handled with utmost care. In addition, the flexible cable

is very weak in mechanical strength. Therefore, this cable must not be touched during handling.

(8) The panel surface of the PDP module is easy to be hurt and generate cracks. Therefore, it should be handled

very carefully. Never press or rub it with a hard thing. Never put it on a hard thing with the panel surface faced

downwards.

(9) When the panel surface of the PDP module is contaminated, gently wipe off the contaminant with a piece of

E

soft dry cloth. Liquid-state contamination can be removed by lightly pressing it, without rubbing it. If it is

difficult to remove the contamination, use a piece of cloth soaked with a neutral detergent. The cloth for

wiping off should be clean. Never use the same cloth repeatedly. If a cleansing detergent or water drops

should enter the module interior or be attached to the module surface other than the display plane at the time

of cleaning, this will give rise to the destruction of the product when the product is energized.

(10) When transporting this PDP module, use the packing materials specified in the list of parts. Once used,

such packing materials should not be used again.

(11) The PDP module is composed of a variety of parts, such as those made of materials like glass, metal,

plastics, etc. Therefore, when abandoning the PDP module, this should be done in accordance with the

relevant law of the nation or an autonomous body

F

4

1234

PDP-42A3HD

Page 5

5678

SAFETY SERVICE

7 Safety cautions

The matters to be observed without fail are explained below. These matters are indispensable for the preventi on of an

accident during the maintenance servicing, the [security of products] after the completi on of servicing work, and the

[prevention of the repeated occurrence of similar fault.]

(1) The degree of danger and material damage, caused as a result of wrong use by disregarding the contents of the display”

is distinguished and explained in the table below.

WARNING

CAUTION

(2) Kinds of the matters to be observed are classified and explained in the icons shown below.

This icon indicates a dangerous place where an electric shock is anticipated.

This icon indicates the contents of “caution” that must be borne in mind, without fail.

If this display is disregarded and equipment is handled wrongly, this can be a cause of physical injury and

a fire, thus leading a person to death or serious injury.

If this display is disregarded and equipment is handled wrongly, this may lead to personal injury or

material damage.

A

B

This icon indicates the contents of “caution” that must be practiced, without fail.

WARNING

• Observe the caution matter, without fail.

• In the place where a particular caution is needed during maintenance servicing, such a caution note is displayed with a label or a

stamp that is given to the cabinet, chassis, PWB, etc. These caution notes and also the caution matters of given

in the instruction manuals, etc., must be observed, without fail.

• Be careful of an electric shock or a burn.

• The PDP module involves the sections where high voltage and high temperature are prevalent. When equipment is energized,

therefore, use working gloves in order to prevent an electric shock and a burn. At the time of transportation, disassembly,

reassembly, and the replacement of parts, such a servicing job must be done after pulling out all the connector cables that have

been connected with external equipment.

• Modification of equipment is absolutely prohibited. Use the specified parts at all times.

• If any modification is performed, the validity of the manufacturer’s warranty is lost at that moment. The personnel who did this

modification is responsible for the physical injury or the like, if it should occur as a result of the modification. The parts used are

given the safety-based characteristics, such as non-flammability or sufficient

CAUTION

• Danger of explosion if battery is incorrectly replaced.

• Replace only with the same or equivalent type.

WARNING

C

D

E

56

PDP-42A3HD

F

5

7

8

Page 6

1234

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

A

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

B

C

D

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

0 Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

E

Make sure the proper amount is applied.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

F

6

1234

PDP-42A3HD

Page 7

5678

CONTENTS

SAFETY INFORMATION......................................................................................................................................2

1. SPECIFICATIONS

2. EXPLODED VIEWS AND PARTS LIST...........................................................................................................14

2.1 PACKING

2.2 EXTERIOR SECTION (1)

2.3 EXTERIOR SECTION (2)

2.4 FRONT PANEL SECTION ........................................................................................................................20

2.5 REAR SECTION.......................................................................................................................................21

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM ..........................................................................................22

3.1 BLOCK DIAGRAM....................................................................................................................................22

3.1.1 OVERALL BLOCK DIAGRAM

3.1.2 ATSC BLOCK

3.1.3 DISPLAY BLOCK

3.2 DIGITAL B/D SCHEMATIC DIAGRAM......................................................................................................30

3.3 DTT_ANALOG B/D...................................................................................................................................36

4. PCB DIAGRAM ...............................................................................................................................................44

4.1 DIGITAL B/D .............................................................................................................................................44

4.2 DTT_ANALOG B/D...................................................................................................................................46

4.3 CONTRPL IR & LED, SUB_AV&, SUB_KEY, EMI and POWER B/D ................................................48

5. PCB PARTS LIST............................................................................................................................................50

6. ADJUSTMENT ................................................................................................................................................53

6.1 ADJUSTMENT OF WHITE BALANCE

6.2 OPERATION TEST IN EACH MODE

6.3 TV .............................................................................................................................................................55

6.4 SPEAKER & INTERFACE

7. GENERAL INFORMATION .............................................................................................................................58

7.1 DIAGNOSIS..............................................................................................................................................58

7.1.1 OPERATION SEQUENCE FLOW

7.1.2 TROUBLE SHOOTING METHOD

7.1.3 DTT BASIC INSPECTION

7.1.4 BASIC INSPECTION

7.1.5 CPU / SYSTEM MEMORY INSPECTION

7.1.6 MPEG INSPECTION..........................................................................................................................96

7.1.7 A/ V INSPECTION..............................................................................................................................97

7.1.8 CHANNEL INSPECTION .................................................................................................................100

7.1.9 CHANNEL INSPECTION 2 ..............................................................................................................102

7.1.10 DISASSEMBLY ..............................................................................................................................104

7.2 HOW TO DIAGNOSE THE PDP MODULE.............................................................................................108

8. PANEL FACILITIES

14

16

18

22

23

26

53

54

56

58

60

88

89

94

135

8

A

B

C

D

56

PDP-42A3HD

E

F

7

7

8

Page 8

1234

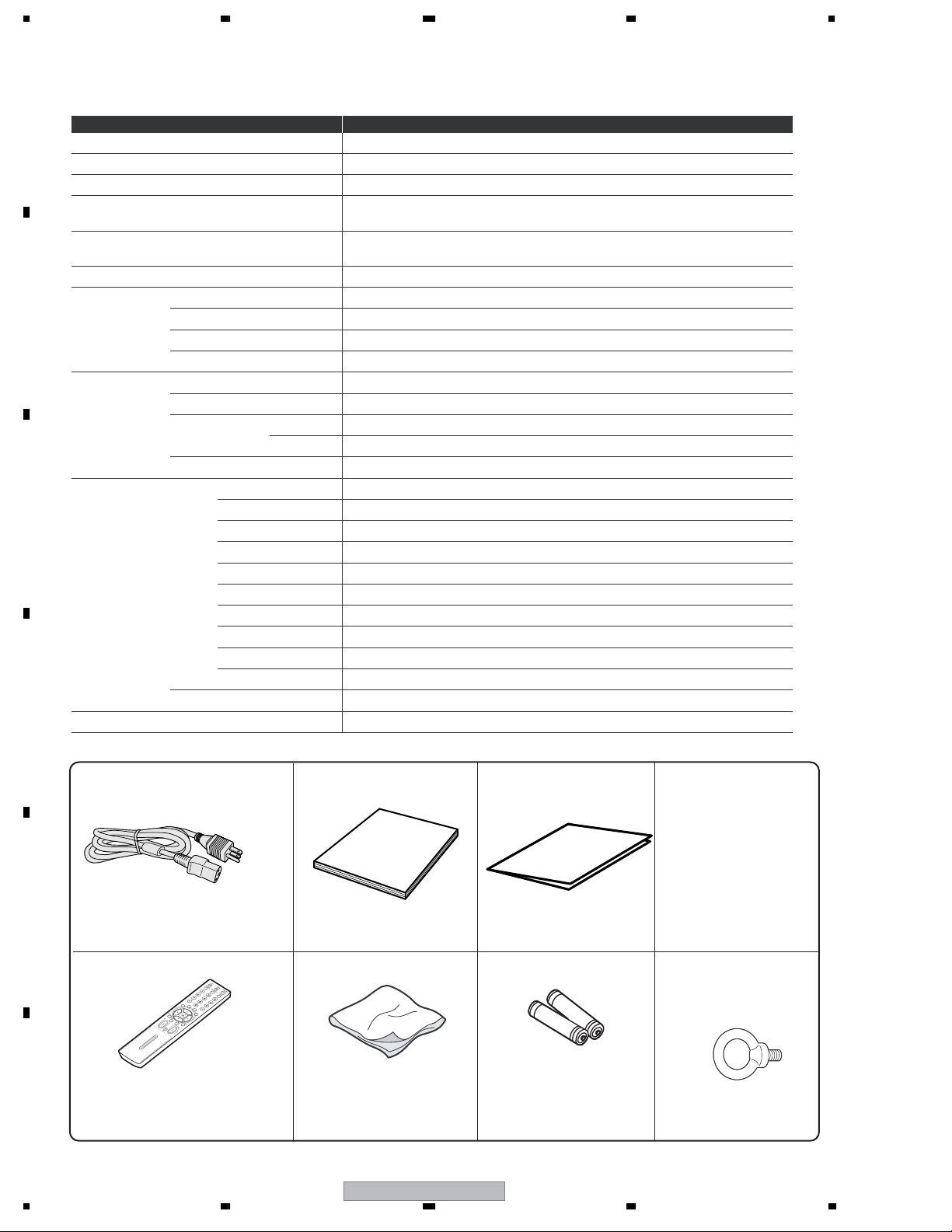

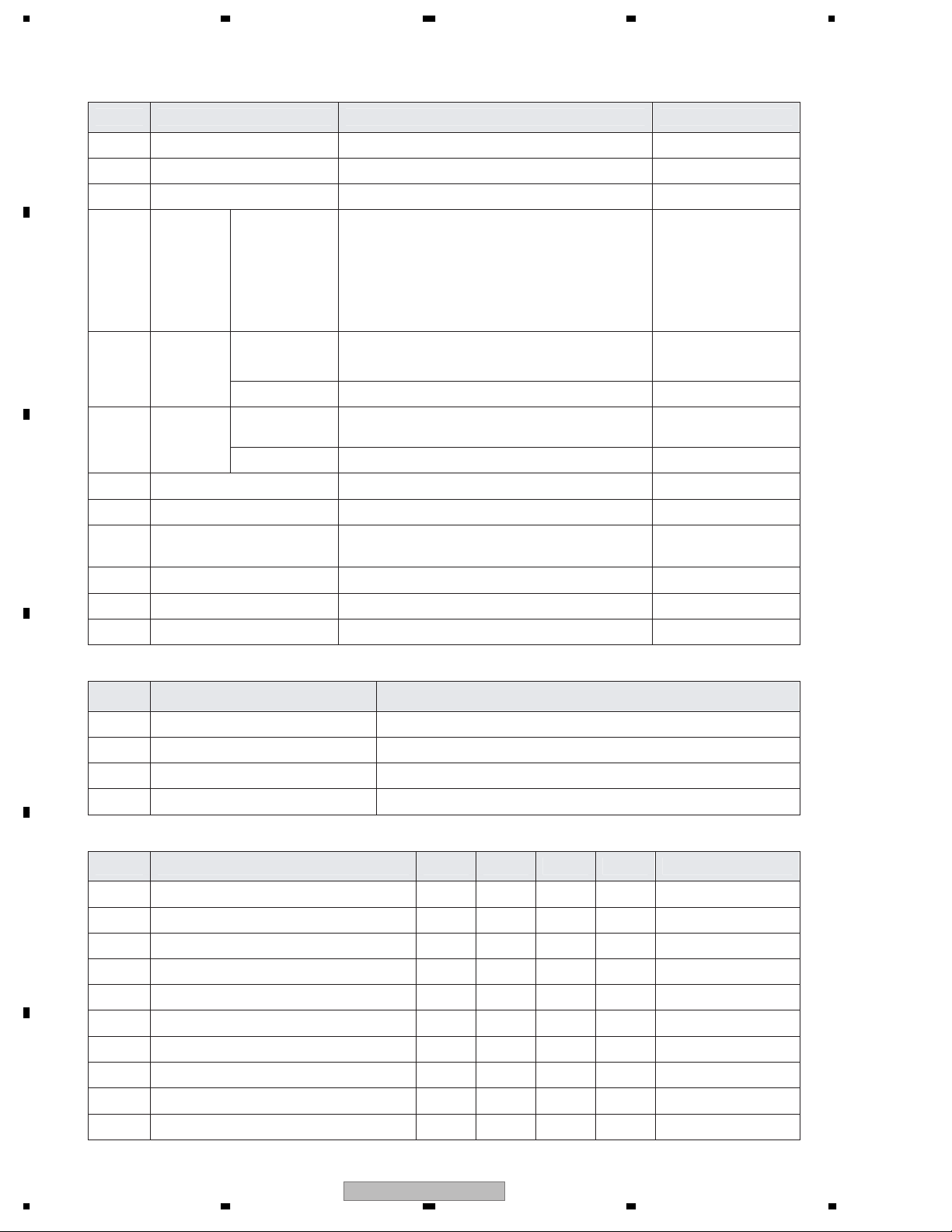

1. SPECIFICATIONS

A

B

C

D

Specifications

Item 42" Plasma Display, Model: PDP-42A3HD/PDP-4214HD

Number of Pixels 1024 x 768 pixels

Audio Amplifier 10 W +10 W (1 kHz, 1 %, 4 Ω)

Surround System SRS TruSurround XT

Power Requirement

Dimensions (with stand) 1235 (W) x 699 (H) x252 (D) mm

Weight (with stand) 40.5 kg (89.3 lbs.)

Reception System (Digital) ATSC Digital TV system

Circuit type 8VSB demodulation

Tuner VHF 2–13ch, UHF 14–69ch

Audio format Dolby Digital

Reception System (Analog) American TV standard NTSC system

Tuning System FS

Tuner VHF/UHF VHF 2–13ch, UHF 14–69ch

CATV 1–125ch

Audio multiplex BTSC system

Terminal

OSD English/French/Spanish

Rear DTV-ANTENNA IN 75Ω UNBAL, F Type for DTV in

ANTENNA/CABLE IN 75 Ω UNBAL, F Type for VHF/UHF/CATV in

VIDEO1 S-VIDEO in, VIDEO in, AUDIO in

VIDEO2 S-VIDEO in, VIDEO in, AUDIO in

COMPONENT 1 COMPONENT VIDEO in, AUDIO in

COMPONENT 2 COMPONENT VIDEO in, AUDIO in

HDMI HDMI in, AUDIO in

MONITOR OUT VIDEO out, AUDIO out

DIGITAL OUT OPTICAL out

RS-232C Service only

Side VIDEO3 S-VIDEO in, VIDEO in, AUDIO in

• Accessories

120 V AC, 60 Hz, 270 W (max)

(2.5 W Standby)

(45 5/8 (W) x 271/2 (H) x 10 (D) inches)

• Design and specifications are subject to change without notice.

Power Cord

E

F

8

(01300-0390)

Operating Instructions

Remote control unit

(01400-0520)

Wiping Cloth x1

(00999-0060)

PDP-42A3HD

1234

Warranty card

AAA size battery x2

(Alkaline battery)

Hook x 2

(30191-01-001)

Page 9

5678

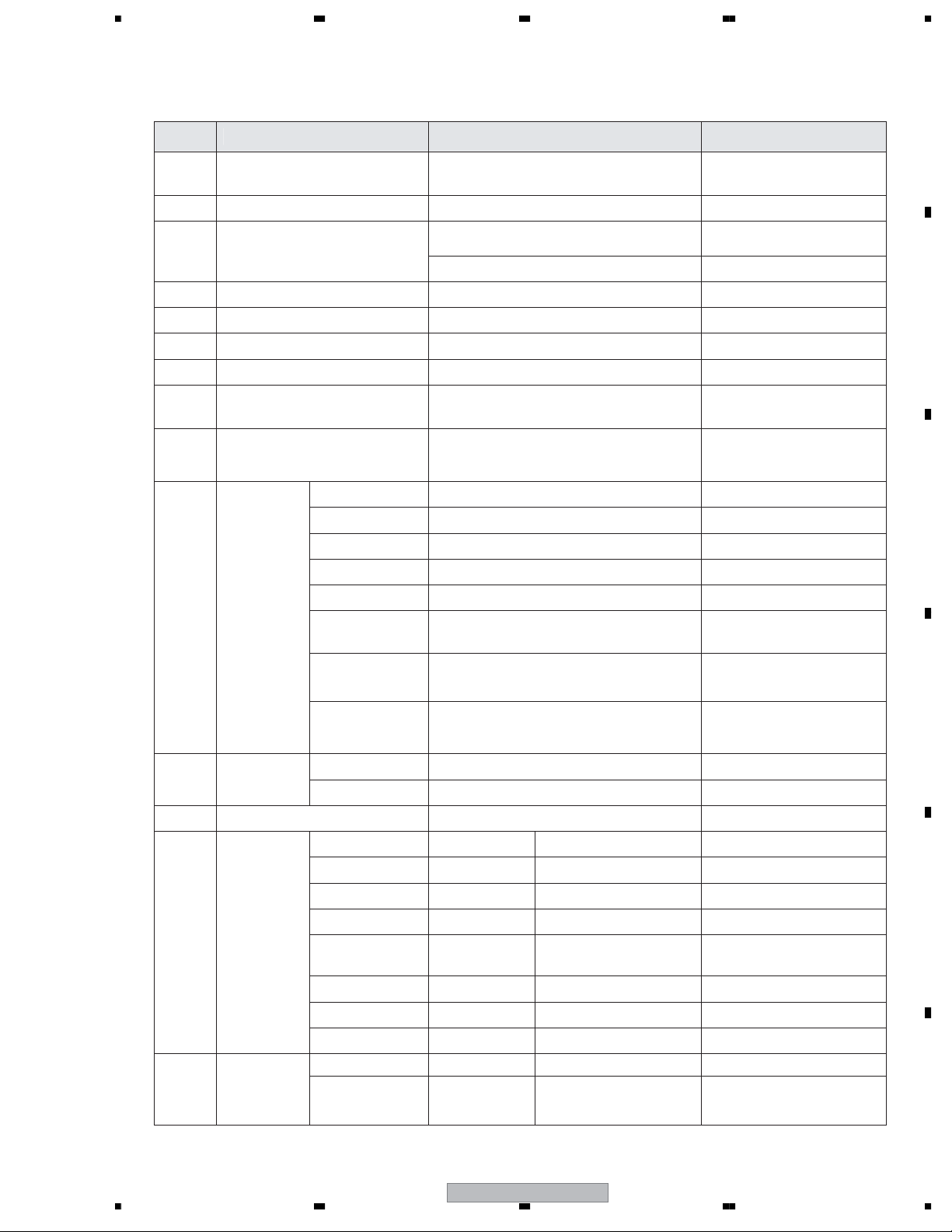

2. H/W specification

1) General Specification

No Item Specification Remark

A

1-1

Video input

applicable system

NTSC/M

1-2 Input Voltage AC 120V to 240V, up to 65Hz, 6A

1-3

Power Consumption

Operation mode : Max. 270W

Standby mode : TBD

250 Standand/350 Dynamic Mode

1-4 Market US, CANADA

1-5 Picture Size 42 inch (918(H) x 518(V))

1-6 Aspect ratio Wide (16:9)

1-7 Tuning System FS

1-8 Operating Environment

1-9 Storage Environment

Te mp. : 0 ~ 40°C

Humidity : 20 ~ 80%

Te mp : -20 ~ 60°C

Humidity : 10 ~ 90%

Model name NP42H5MF01

Size 987.0 X 584.0 x 63.6mm

Pixel Pitch 0.897 X 0.675 x RGB

Resolution 1024 X 768

Weight 16.00Kg (Typ.)

Power

consumption

250W (Typ.) / 320W (Max.)

1-10

PDP

Module

B

C

180~200V 1.2A(internal PLE),

1.9(External PLE), 20A(Max)

60~70V 1.7A (Average)

1-11

Speaker

Regularity

Sustain Power

Data Power

Impedance 4 Ω

Input power 15.0W (Typ.) / 20W (Max.)

1-12 Power on time Max. 15sec

CVBS input 3 set Video + Audio(R+L) Side(1set), Rear(2set)

S-Video Input 3 input Y/C Side(1), Rear(2)

COMPONENT 2 set YPbPr + Audio(R+L) Rear(2 set)

HDMI input 1 input HDMI HDMI(19 pin)

1-13 Input

HDMI

Audio input

1 input Audio(R+L) Rear(1)

RF in (Digital) 1 input Split Ant input Rear(1)

RF in (Analog) 1 input Split Ant input Rear(1)

RS232C 1 input Rear(9 pin)

A/V output 1 set CVBS+ Audio(R+L) Rear(1 set)

1-14 Output

External

audio output

1 output SPDIF digital audio Optical Jack

D

E

F

56

PDP-42A3HD

9

7

8

Page 10

1234

2) Feature and Function

A

No Item Specification Remark

2-1 Remote Control Unit AXD1522

2-2 Closed Caption CC1 ~ CC4, TEXT1 ~ TEX4,

2-3 V-Chip USA Rating / CANADA Rating system

IN PUT

MENU

2-4 Local key TV

VOL ( , ),

CH ( , )

8 keys

OK

B

User control

2-5 Picture

POWER

Brightness/ Contrast/ Sharpness/ Color/ Tint/

Noise Reduction/ Color Temperature

Mode Standard/ Dynamic/ Movie/ Mild/ Game/ User

2-6 Sound

User Control

Bass/Treble/ Balance/ AV

SRS TruSurround-XT/ Digital Audio output

L/(Auto Volume Level)/

Effect Flat/ Speech/ Movie/ Music/ User

2-7 Stereo sound BTSC (with SAP)

C

2-8 OSD language English / Spanish / French

2-9

3D DCF / 3D NR

(digital comb filter)

YES

2-10 De-interlace YES

2-11 DCTI / DLTI YES

2-12 PIP & double windows YES

3) Safety and Public Regulation

No Item Remark

D

3-1 cUL60650 UL6500, UL60650, CSA-C22.2 No 60065

3-2 FCC prat15 class B

3-3 ICES-003

3-4 BETS-7

4) Audio

No Item Min Typ Max Unit Remark

4-1 S/N Ratio 60 65 70 dB

E

4-2 Frequency Response(Low) 30 25 20 Hz

4-3 Frequency Response(High) 18 19 20 kHz

4-4 Distortion 0.5 1 1.5 %

4-5 Audio Output, L/R 400 500 600 mV

rms

4-6 Stereo Separation (Cross talk) -45 -50 -55 dB

4-7 Pilot signal Detection Sensitivity -70 - - dB

4-8 Speaker Impedance 3.5 4 4.5 ohm

F

4-9 Speaker Power Rating - 15 20 W

4-10 Power amp max out 8 10 12 W

10

1234

PDP-42A3HD

Page 11

5678

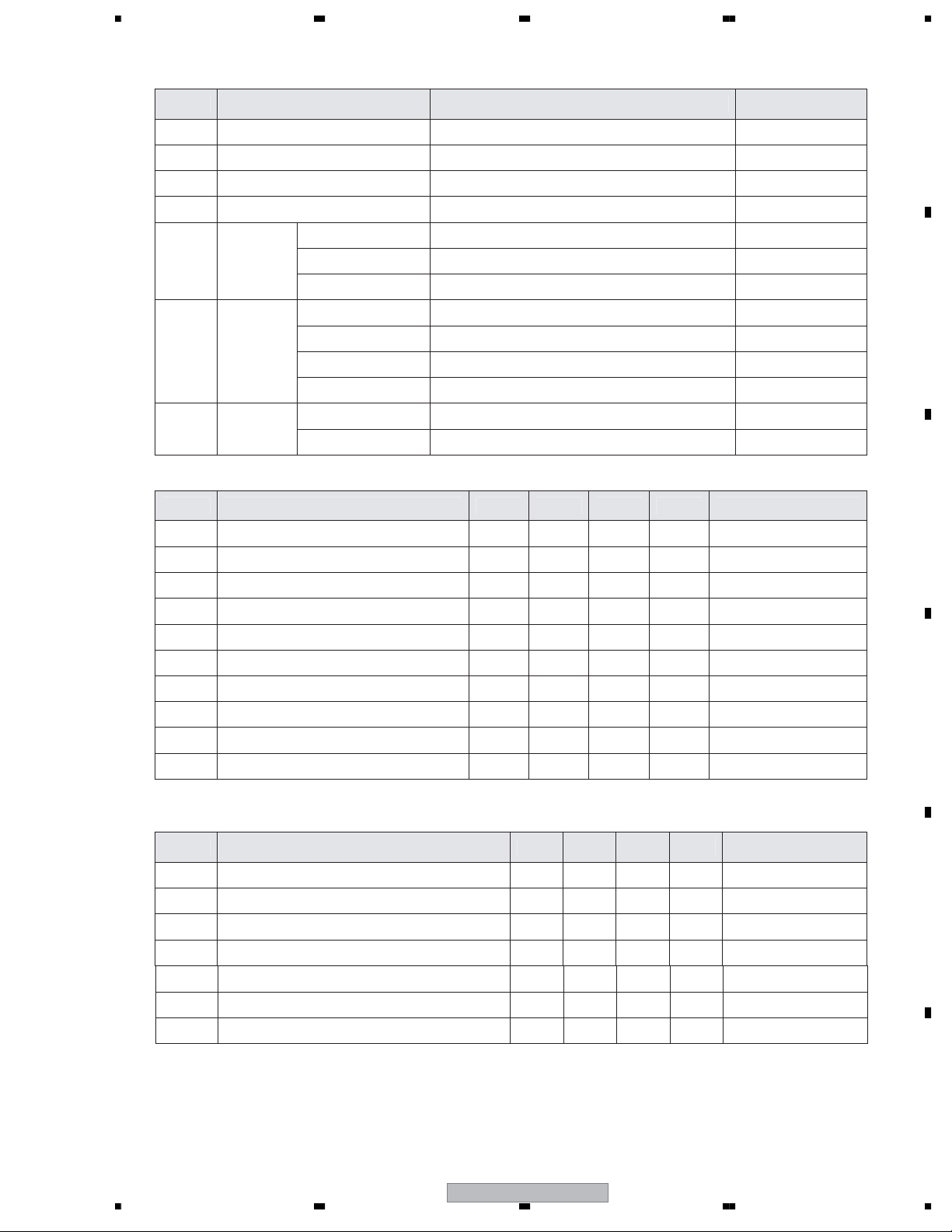

5) ATSC

No Item Specification Remark

5-1 CPU Zoran’s TL955B2-SH

5-2 Flash Memory 4 Mbytes

5-3 SDRAM 64 Mbytes DDR

5-4 EEPROM 16 Kbytes

Format ATSC

5-5 Channel

CH CH2-13(VHF), CH14-69(UHF)

Modulation VSB modulation

Transport stream MPEG-2 ISO/IEC 13818

5-6

Video

Decoder

Profile Level MPEG-2 Main Profile @ High Level (HD)

Input Rate Max. 80Mbits/s

Video Resolution Max. 1920 * 1080i

Audio Format MPEG/MusicCam Layer I & II, Dolby AC-3

Audio Mode Single / Dual mono / Stereo / Joint stereo

5-7

Audio

Decoder

6) Power (SMPS)

No Item Min Typ Max Unit Remark

6-1 AC Power Shut Down Voltage 75 - - V

6-2 D+190 170 195 V

6-3 D+65 55 70

6-4 D+5 4.75 5.25 V

6-5 D+3.3 3.0 3.6 V

6-6 D+2.5 2.3 2.7 V

6-7 A+12 11.5 13.2 V

6-8 A+6 5.7 6.3 V

6-9 M+7 6.7 7.5 V

6-10 S+12 11.5 13.2 V

A

B

C

D

7) AV Interface

No Item Min Ty p Max Unit Remark

7-1 Audio Input Level 0.4 0.5 0.6 V PAL:0.5Vrms(Typ.)

7-2 Audio Input Dynamic Range 1.8 2 2.2 V

7-3 Video Output Level 0.85 1.0 1.15 Vpp CVBS, 75 ohm

7-4 Audio Output Frequency Response(Low) 30 25 20 Hz

7-5 Audio Output Frequency Response(High) 18 19 20 kHz

7-6 Audio Output S/N 55 60 65 dB

7-7 Audio Output Distortion 0.1 0.5 1 %

56

PDP-42A3HD

7

E

F

11

8

Page 12

1234

3. S/W specification

A

1) Menu-Map

Main Sub

Scan Channels

Analog Channel Band Air / STD / HRC / IRC

Start

Band Air / STD / HRC / IRC

Channel <number>

TUNER

Scan Analog Channel

SETUP

B

Name Channel <Character>

Fine Tune <<< >>>

Start

Channel <number>

Scan Digital Channel

Start

Edit Channel List

Mode Standard, Dynamic, Movie, Game, User

Brightness 0~50~100(Bar <number>)

Contrast 0~50~100(Bar <number>)

C

AV

SELECTION

Sharpness 0~50~100(Bar <number>)

Color Bar <number>

Tint R50~G50(Bar <number>)

Noise Reduction On, Off

Color Temp Mid, High, Low

Effect Flat, Speech, Movie, Music, User

Bass 0~100(Bar <number>)

Treble 0~100(Bar <number>)

D

Sound

Balance L50~0~R50(Bar <number>)

Auto Volume Level On, Off

SRS TruSurround-XT On, Off

Digital Audio Output PCM, Dolby Digital

Aspect Ratio Zoom, Cinema, Full, 4:3, Wide

Main Input

Digital CH, Analog CH, AV-1, AV-2, AV-3, S-AV-1, S-AV-2,

S-AV-3, Component1, Component2, HDMI

PIP/TWIN Mode Off, PIP, TWIN1, TWIN2

Digital CH, Analog CH, AV-1, AV-2,

E

Screen

PIP/TWIN

PIP/TWIN Input

PIP Position

AV-3, S-AV-1, S-AV-2, S-AV-3,

Component1, Component2, HDMI

Right-Bottom, Left-Bottom,

Left-Top, Right-Top

Orbiter On, Off

Screen Saver

Orbiter Range Small, Medium, Large

Full White On, Off

System

Menu Language English, Spanish, French

Audio Language English, Spanish, French, German, Italian, Japanese, Korean

F

Clock Setting

Date

12

PDP-42A3HD

1234

Page 13

5678

2) Function

Function Remark

Menu Language English / Spanish / French

Audio Language

English / Spanish / French / German / Italian /

Japanese / Korean

Dolby Support

SRS TruSurround-XT Support

MacroVision Support

Closed Caption CC1 ~ CC4, TEXT1 ~ TEX4

Bit-mapped Closed Caption Support only ATSC

V-Chip USA Rating / CANADA Rating system

4. Mechanical specification

No Item Content Remark

Width (W) Depth (D) High (H)

1 TV Size

Before Package

(without Stand)

Before Package

(with Stand)

Package 1420 mm 375 mm 862 mm

1235 mm 118 mm 672 mm

1235 mm 252 mm 689 mm

A

B

C

2 TV weight

Net TV 40.5 Kg

With stand

Package 43 Kg

Type Detachable

4 Stand

Size (W) 720 x ((D) 252 x (H) 142 mm

Cabinet Front Min. UL94-5V PC+ABS

Back Cover AL

5 Material

knob ABS

Housing / Package without PBDE, PBBE, Hg, Cd), ODC’S

5. Remote Control Unit

No Item Min Typ Max Unit Remark

1 Function test

2 REMOCON Working Sensitivity, Distance 7 m

3 REMOCON Working Sensitivity, Angle 30 °

6. Accessories

No Item Unit Remark

D

E

1 Power Cord 1 3.0m

2 User manual 1 English

3 Remote Control Unit 1

4 Battery 1.5V, AAA (ALKALINE) 2

56

PDP-42A3HD

7

F

13

8

Page 14

1234

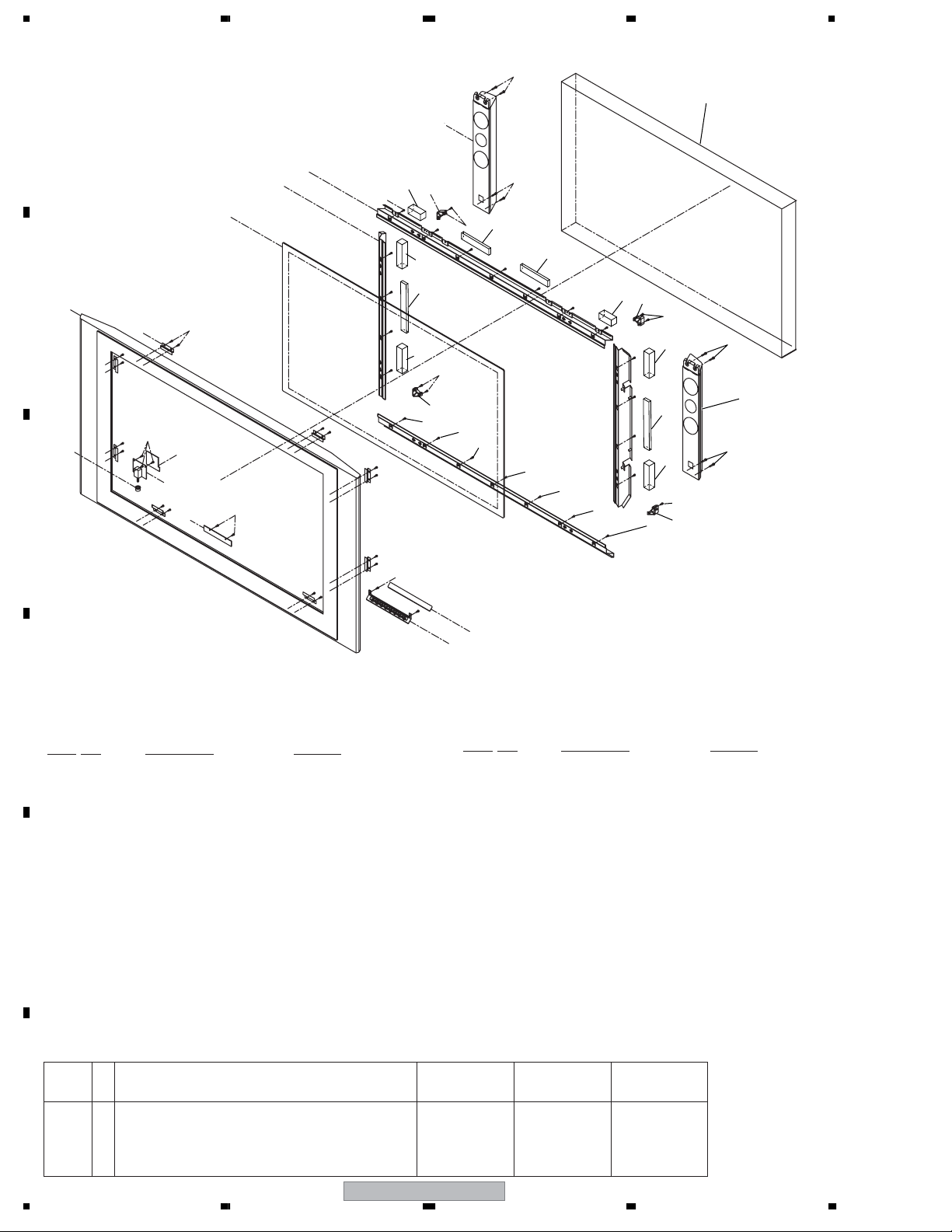

2. EXPLODED VIEWS AND PARTS LIST

NOTES:

A

Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on product are used for disassembly.

For the applying amount of lubricants or glue, follow the instructions in this manual.

(In the case of no amount instructions, apply as you think it appropriate.)

2.1 PACKING

B

C

D

E

F

14

PDP-42A3HD

1234

Page 15

5678

PACKING PARTS LIST

No. Description Part No.

No. Description Part No.

Mark

1 Accessory Box PAU-42THD 30751-04-000

2 Remote control Unit (AXD1522) 01400-0520

3 Cable Power Cord P04117A 01300-0390

4 Bag Vinyl B (260*360*0.03) 10711-01-002

NSP 5 Battery 1.5V, AAA(ALKALINE) • • • •

6 Hook 30191-01-001

7 Manual (English) 20010-0260

NSP 8 Warranty Card 20300-0160

NSP 9 Card (Register) 20300-0170

10 Wiping Cloth 00999-0060

11 Gift Box-Bottom 30701-05-000

Mark

12 Cushion Bottom-right 30711-04-005

13 Cushion Bottom-left 30711-04-004

NSP 14 PDP-42A Set • • • •

15 Mirror Mat 30721-07-001

16 Cushion Top-center 30711-04-003

17 Cushion Top-left 30711-04-001

18 Pulp Pad Top 30740-02-001

19 Silicagel (3g) 10731-01-001

20 Gift Box-Top See Contrast table(2)

21 Cushion Top-right 30711-04-002

24 Guide Supporter-Box 30313-01-000

(2) CONTRAST TABLE

PDP-42A3HD/KUCXKA, /KUCXC and PDP-4214HD/KUCXC are constructed the same except for the following :

Mark No. Symbol and Description

20 Gift Box-Top 30701-04-001 30701-04-001 Not used

20 Gift Box-Top Not used Not used 30701-04-002

PDP-42A3HD

/KUCXKA

PDP-42A3HD

/KUCXC

PDP-4214HD

/KUCXC

A

B

C

D

>

E

56

PDP-42A3HD

F

15

7

8

Page 16

1234

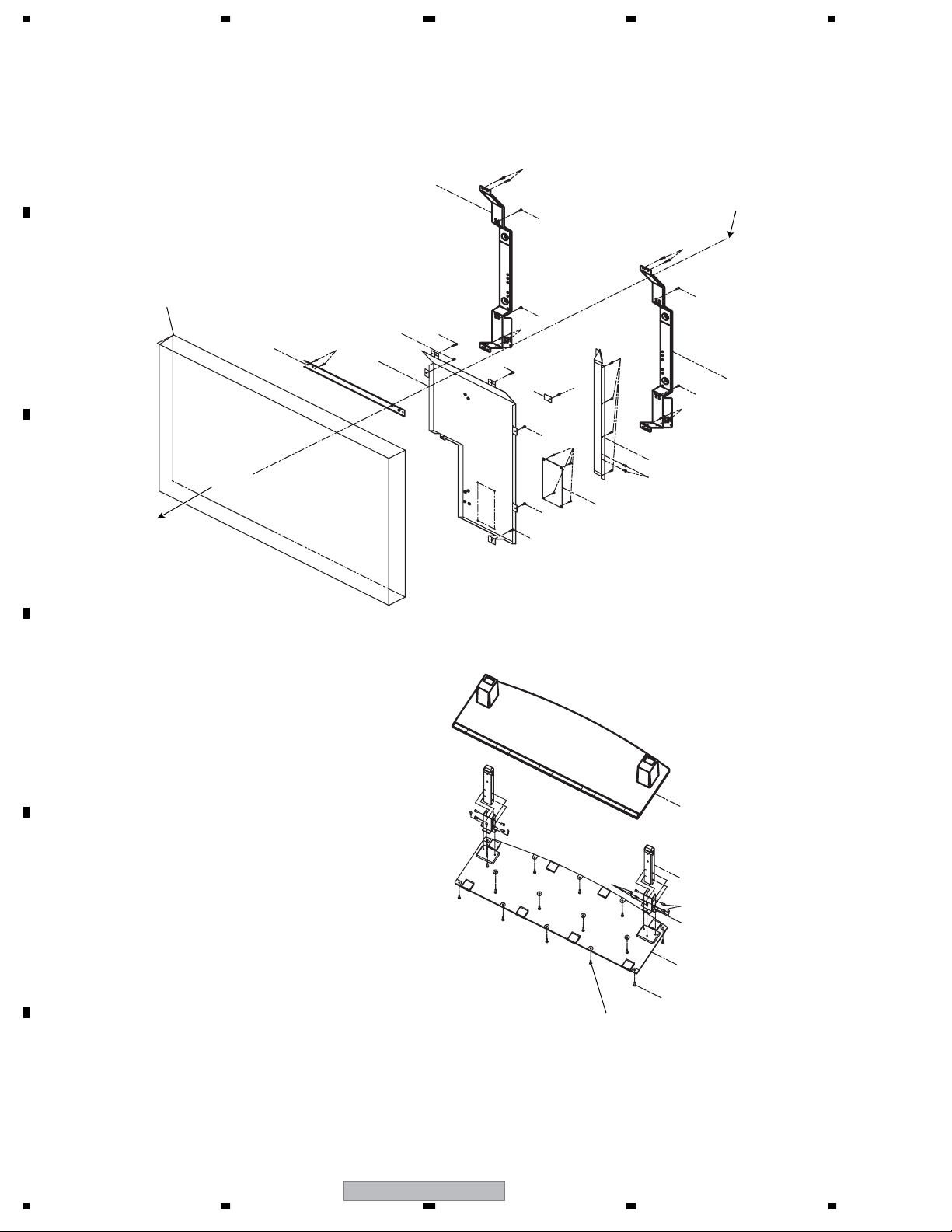

2.2 EXTERIOR SECTION (1)

A

5

8

To "2.3 Exterior Secton(2)

10

5

14

15

10

9

10

5

B

C

2.4 Front Panel

D

PDP Panel

Section

10

5

2

3

7

4

5

5

18

13

6

13

6

5

16

1

21

24

E

26

F

16

1234

PDP-42A3HD

25

24

23

22

26

Page 17

5678

EXTERIOR SECTION (1) PARTS LIST

Mark No. Description Part No.

1 SUB AV & AMP Assy 220-2050

2 BRKT SMPS-N 30168-01-000

NSP 3 Screw M4x10, SEMS, FNI • • • •

4 SHIELD SIDE 30103-02-000

5 Screw T4x16, 2S, T/T,BH,BLK M1305401617

6 Screw M4x8,BH,BLK M1015400817

NSP 7 Screw M4x10, SEMS,FNI • • • •

8 ASS’Y BRKT V-SUPPORTER-L 01433-0040

9ASS’Y BRKT V-SUPPORTER-R 01433-0050

NSP 10 Screw M5x12, SEMS, FNI • • • •

11 • • • •

12 • • • •

13 Screw M3x8, SEMS, ZNW M1040300815

14 BRKT SIDE AV-USA 30166-02-001

Mark No. Description Part No.

15 Screw T3x8, 2S, T/T,BH,BLK M1305300817

16 Screw M4x8, SEMS, ZNW M1040400815

17 • • • •

18 SENSOR Assy 010-2742

19 • • • •

20 • • • •

21 ASSY STAND See Contrast table(2)

22 ASSY BRKT BASE 01433-0090

23 BRKT LEG SUPPORTER 30169-01-000

24 Screw M4x8, SEMS, BLK M1040400815

25 ASSY STAND LEG 01425-0020

26 Screw T4x10, 2S,T/T M1308401017

(2) CONTRAST TABLE

PDP-42A3HD/KUCXKA, /KUCXC and PDP-4214HD/KUCXC are constructed the same except for the following :

Mark No. Symbol and Description

21 ASSY STAND 01425-0030 01425-0030 01425-0040

PDP-42A3HD

/KUCXKA

PDP-42A3HD

/KUCXC

PDP-4214HD

/KUCXC

A

B

C

D

E

56

PDP-42A3HD

F

17

7

8

Page 18

1234

2.3 EXTERIOR SECTION (2)

A

B

10

21

To "2.5 Rear Section

10

11

4

10

9

10

12

10

3

10

10

C

22

To "2.2 Exterior Section(1)

D

10

12

10

10

8

18

19

18

20

16

17

10

14

16

16

14

13

7

6

1

10

10

10

10

2

15

E

F

18

1234

PDP-42A3HD

Page 19

5678

EXTERIOR SECTION (2) PARTS LIST

Mark No. Description Part No.

1 SMPS Assy 150-2040

2 DTT_ANALOG Assy 010-2640

3 DIGITAL Assy 010-2741

4 EMI FILTER PCB Assy 150-2050

5• • • •

6 BRKT FAN-TOP 30172-01-001

7FAN D05X12TL(50x50x10) 10511-07-001

8 Screw M3x12, SEMS,ZNW M1040301215

9 ASSY SHIELD MAIN 01434-0010

10 Screw M4x8, SEMS,ZNW M1040300815

11 BRKT N-FILTER 30173-01-000

12 Screw M4x6, SEM(E),ZNW M1033400615

13 BRKT REAR BOTTOM 30104-03-001

14 Screw T4x16,SS,T/T,BH,BLK M1305401617

15 BRKT MAIN AV-USA 30165-02-001

16 Screw T3x8,2S,T/T,BH,BLK M1305300817

17 Screw M3x8,3S,HH,FNI M1116300805

18 Screw M4x8,BH,BLK M1015400817

19 Wsher (Ø10) M1231111002

20 NUT UNF 3/8INCH832 M1211210002

21 ASSY SHIELD MAIN TOP 01434-0020

22 ASSY BRKT MAIN SUPPORTER 01433-0060

A

B

C

D

E

F

56

PDP-42A3HD

19

7

8

Page 20

1234

2.4 FRONT PANEL SECTION

A

18

PDP PANEL

16

12

13

21

14

5

11

15

22

20

1

B

10

5

22

19

18

19

21

14

22

15

18

15

14

5

3

4

2

5

C

6

5

5

5

5

5

5

20

22

15

14

5

17

18

9

8

7

D

FRONT PANEL SECTION PARTS LIST

Mark

Mark No. Description Part No.

1 ASSY CABINET FRONT See Contrast table (2)

2POWER SW Assy 150-2040

3 KNOB POWER See Contrast table (2)

4 INSULATION SHEET-POWER 30321-01-000

5 Screw T3x8,2S,T/T,BH,BLK M1305300817

6 CONTROL IR & LED Assy 220-2060

7 KNOB CONTROL See Contrast table (2)

E

8 SUB KEY Assy 220-2040

9

10 ASSY BRKT FILTER GUIDE-L 01433-0010

11 PDP OPTICAL FILTER 05100-0020

Screw T3x12,2S,T/T,BHW,ZNW M1308301215

No. Description Part No.

12 ASSY BRKT FILTER HOR 01433-0020

13 ASSY BRKT FILTER VER 01433-0030

14 GUIDE PANEL-N 30297-01-000

15 Screw M3x6,FH,ZNW M1011300615

16 SPEAKER(With wire assy:1170) 02400-0060

17 SPEAKER(With wire assy:350) 02400-0050

18 Screw T4x14,2S,T/T,PHW,ZNW M1308401415

19 EMI GASKET (45*10*1.0) 30501-05-006

20 EMI GASKET (100*10*1.0) 30501-05-007

21 EMI GASKET (40*10*10T) 30501-05-008

22 EMI GASKET (110*15*15) 30501-05-009

(2) CONTRAST TABLE

PDP-42A3HD/KUCXKA, /KUCXC and PDP-4214HD/KUCXC are constructed the same except for the following :

Mark No. Symbol and Description

F

1 ASSY CABINET FRONT (42A3HD) 01421-0130 01421-0130 Not used

1 ASSY CABINET FRONT (4214HD) Not used Not used 01421-0140

3 KNOB POWER 30251-04-001 30251-04-001 30251-04-002

7 KNOB CONTROL 30252-04-001 30252-04-001 30252-04-002

20

1234

PDP-42A3HD

/KUCXKA

PDP-42A3HD

PDP-42A3HD

/KUCXC

PDP-4214HD

/KUCXC

Page 21

5678

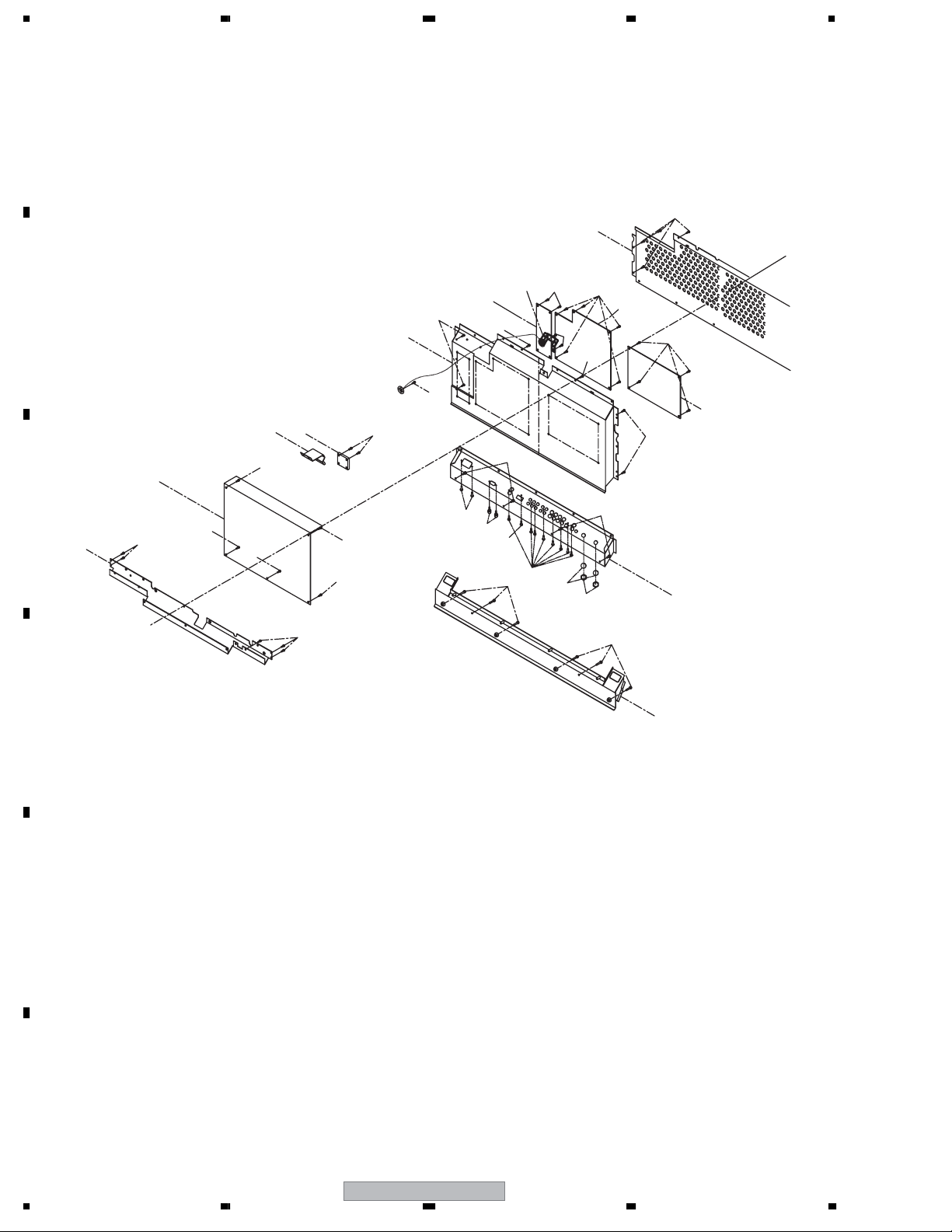

2.5 REAR SECTION

3

2

1

To "2.3 Exterior Section(2)

5

5

4

5

5

6

7

2

8

5

5

6

7

9

5

5

5

5

A

B

C

REAR SECTION PARTS LIST

Mark

No. Description Part No.

1 ASSY SHIELD MAIN TOP 01434-0020

2 Screw M3x8,SEMS,ZNW M1040300815

3 ASSY REAR BACK 01428-0020

4 Screw M4x8,BH,BLK M1015400817

5 Screw T4x16,2S,T/T,BH,BLK M1305401617

Mark No. Description Part No.

6RUBBER CAP 30602-01-001

7 Screw M4x12,SEMS,BLK M1040401217

8 ID Label See Contrast table (2)

9Warning Label 20500-0990

(2) CONTRAST TABLE

PDP-42A3HD/KUCXKA, /KUCXC and PDP-4214HD/KUCXC are constructed the same except for the following :

Mark No. Symbol and Description

8 ID Label 20500-0980 20500-0980 20500-1000

PDP-42A3HD

/KUCXKA

PDP-42A3HD

/KUCXC

PDP-4214HD

/KUCXC

D

E

56

PDP-42A3HD

F

21

7

8

Page 22

1234

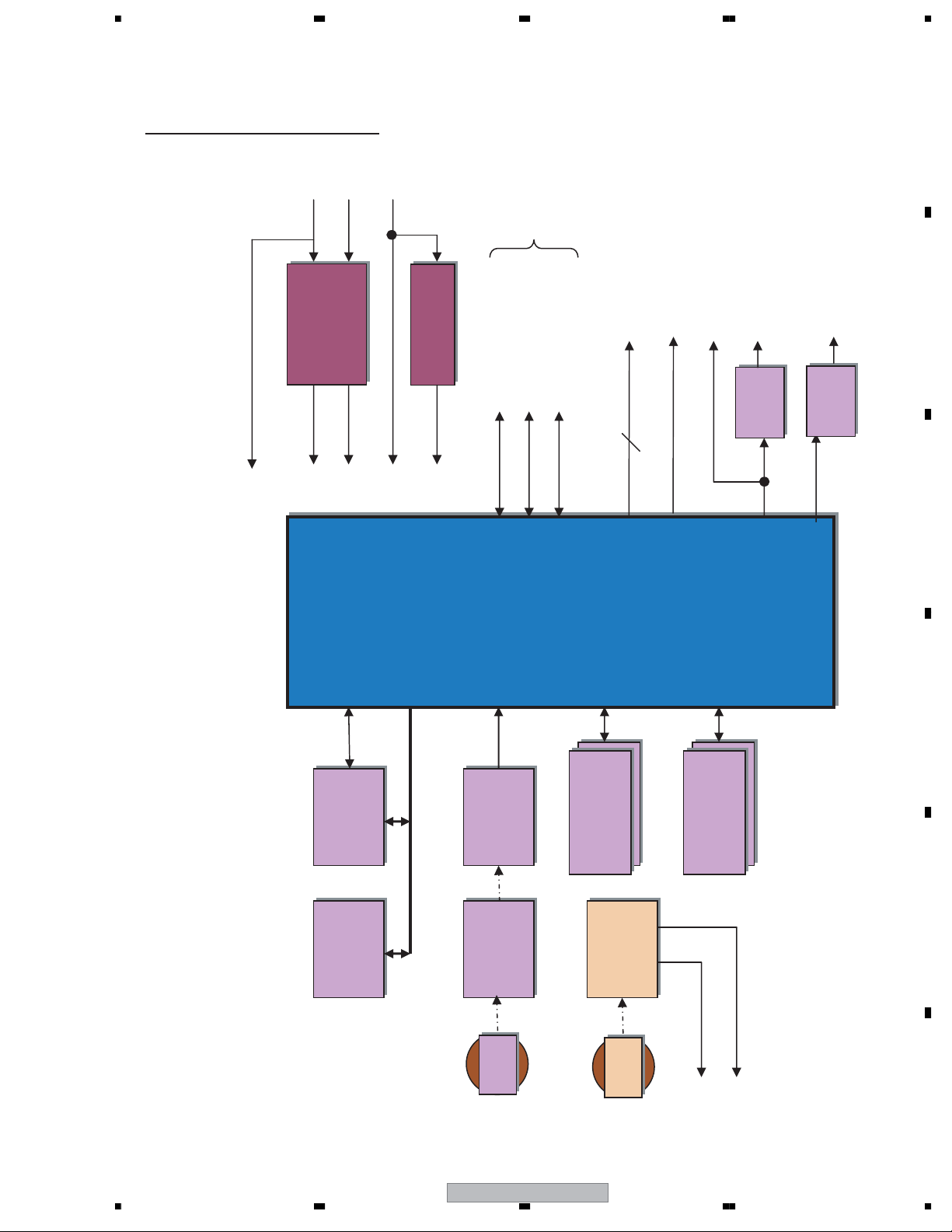

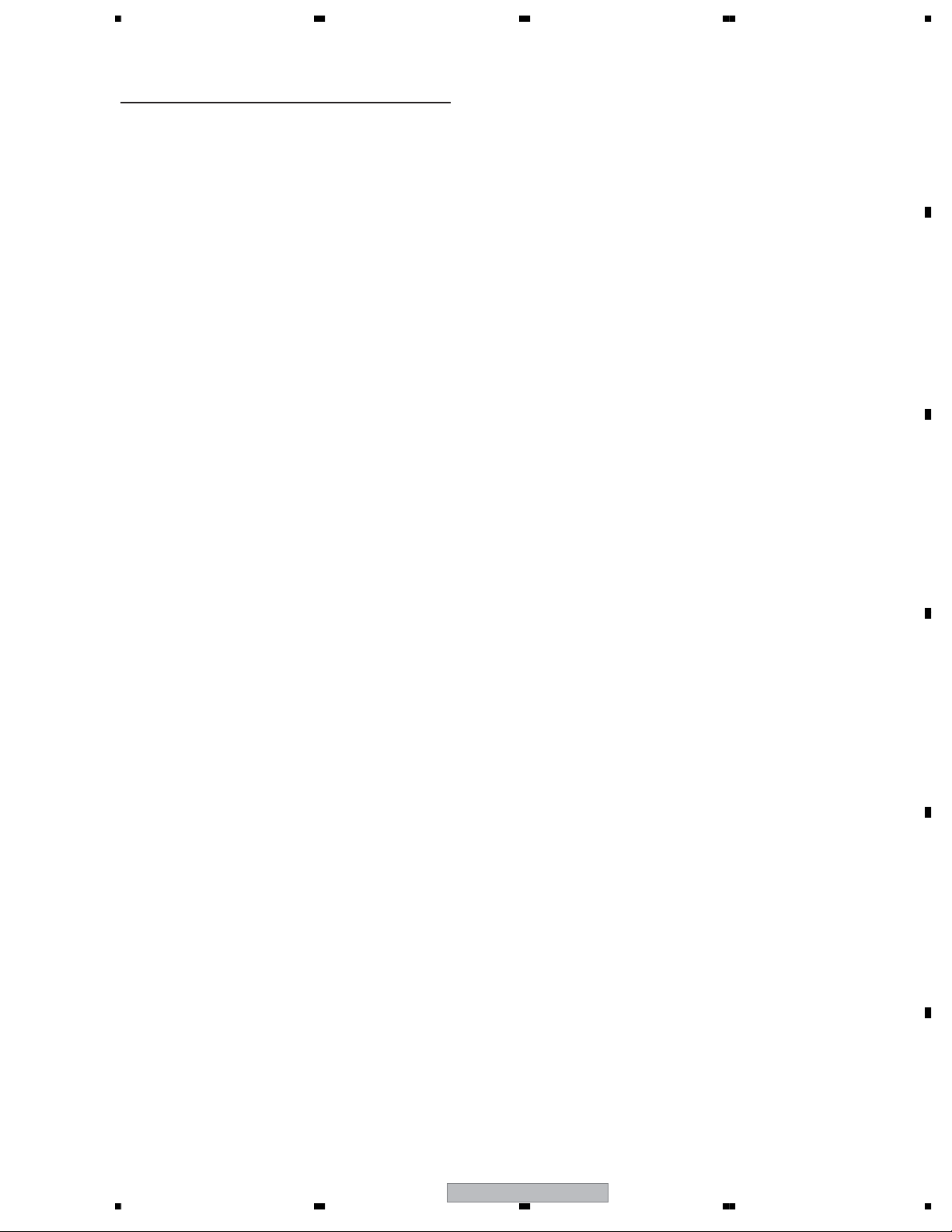

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

3.1 BLOCK DIAGRAM

3.1.1 OVERALL BLOCK DIAGRAM

A

B

C

D

E

F

22

1234

PDP-42A3HD

Page 23

5678

ATS

/PDIF

3.1.2 ATSC BLOCK

ATSC BLOCK

+3.3V

+A6VCC

. DC-DC

Converter

+2.5V

+1.2V

+3.3V

+5.0V

+2.5V

+2.5V

Linear Reg.

+1.2V

Communication

UART0 (Commu nication)

UART1 (RS232C)

A

To Disp lay Board

L/R ATSC

IIS (ATSC)

ATSC YPbPr Out

UART2 (RS232C)

For Deb ug

ATSC CVBS Out

(720P/108 0i)

DAC

DAC

Audio

Audio

Digital-

Digital-

S/PDIF Out

SW

SW

B

3

C S/PDIF

ATS

C

Flash

EEPROM

4MByte

16KB

150

150

MDIN

MDIN

CPU

(TL955B2-SH)

Channel

Decoder

Digital

Tuner

DDR SDRM

32MByte

Analog

D

DDR SDRM

32MByte

E

Tuner

CVBS NTSC

SIF_A

ATSC

ATSC

Jack Ant

56

PDP-42A3HD

7

NTSC

NTSC

F

23

8

Page 24

1234

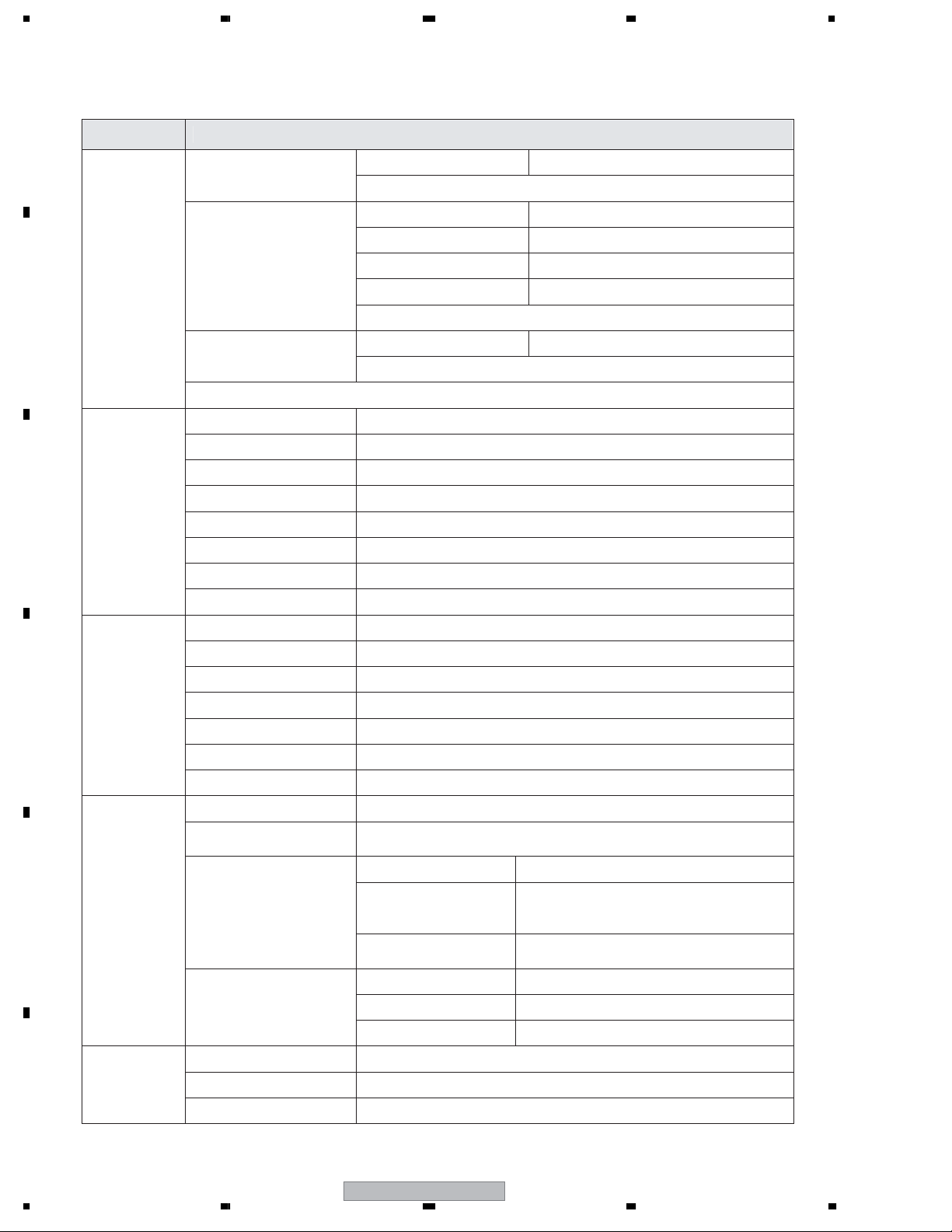

1. Digital PCB Block Explanation

A

A : Component Video input Block(BA7657)

B : ADC and HDMI receiver Block(MST3388M)

C : Real Timer Block(M41T81)

D : RS232 communication part

E : Micom Block(SDA6001+K4S641632H-TC60+AM29LV160DT)

F : Deinterlace Block(MDIN150+K4S643232H-TC60)

G : Sub-Video Decoder Block(VPC3230)

H : Scaler Block(ASI510)

B

I : LVDS transmitter Block(DS90C387)

A

C

F

G

B

D

H

E

E

C

I

F

24

1234

D

PDP-42A3HD

Page 25

5678

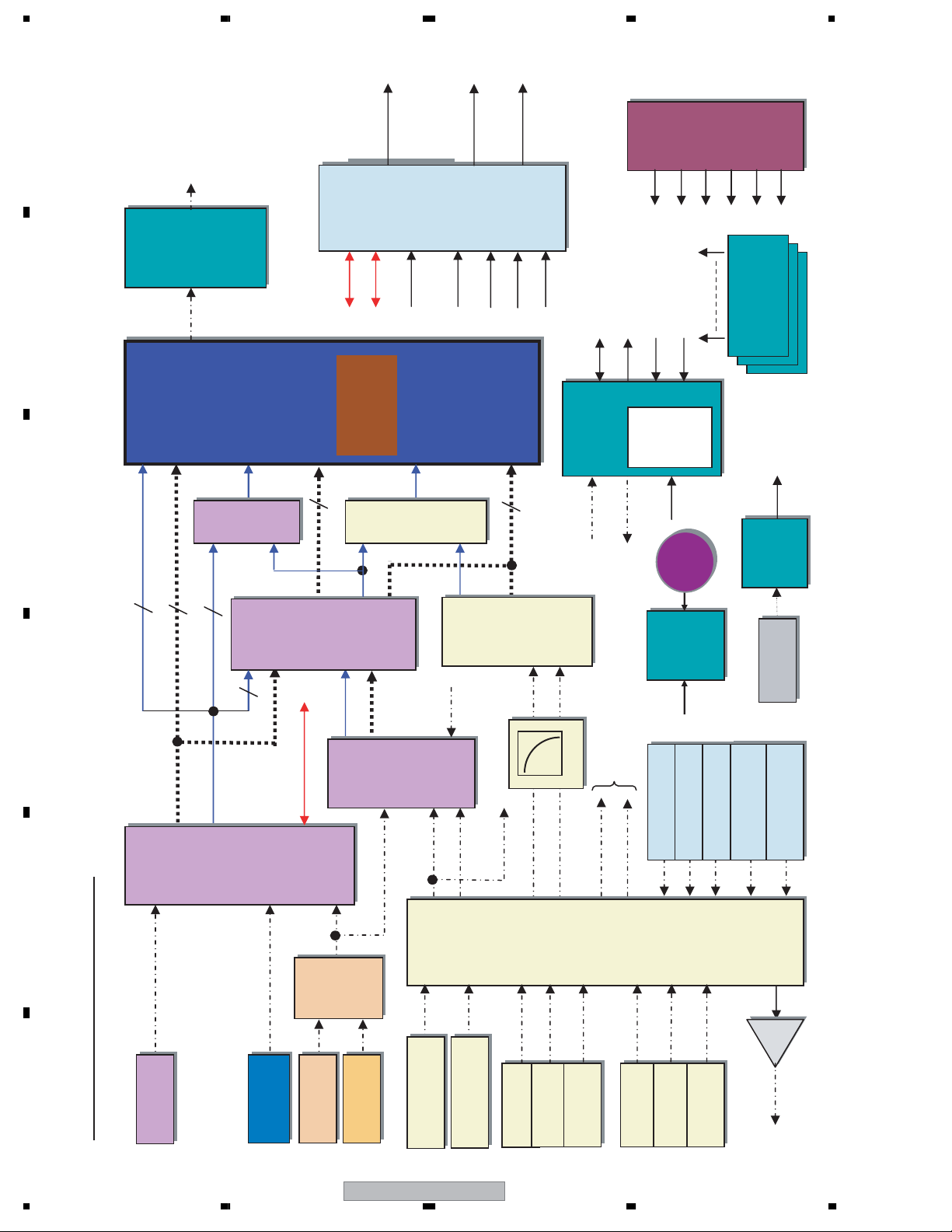

Block Description of DTT

A

1. DC-DC Block is composed of Regulators(BA05(5V), LP3965ES(1.2V), LP2995MX(VREF,VTT)) and

SMPS powers(2V5VCC,3V3VCC,A6VCC).

2. UART Communication is composed of UART1(Communication), UART2(RS232), UART3(RS232 for

debug)

3. The EEPROM block stores the current states, channels, and other user setting values.

B

4. The Flash Rom block stores operation source.

5. ATSC input block is composed of Digital tuner(DTT7608) and channel Decorder(LGDT3303).

6. NTSC input block is composed of Analog Tuner and connects in Video decorder(uPD64012).

7. DDR SDRAM block is composed of 4 32MByte and stores the current Video and information

instantly.

8. The CPU block functions MPEG decoder, converts the video format and control the related IC.

C

9. The Audio DAC converts from IIC Audio to L/R Analog Audio.

10. The SPDIF outputs 5.1Ch Dolby Digital audio signal.

D

56

PDP-42A3HD

E

F

25

7

8

Page 26

1234

LI

NE_OU

3.1.3 DISPLAY BLOCK

A

P

L/R SC2

(CXA2069)

L/R Aux.

(Headp hone)

L/R Main

(Power Amp)

. M7V

. A6VCC

. A12VCC

. 12VCC

. 2V5VCC

. 3V3VCC

Audio

(2069,

Audio

J-

J-

L003

L003

LVDS Tx

DS90C387

150

150

MDIN

D-INO[23:0]

24

MDIN

HDMI I2S

150

B

C

(~DE)

4

D

D- H/ V Sync & clk

30

A-INE[23:0]

5

24

(~ SOG)

8 Bit

4

MDIN

A- H/ V Sync & c lk

MUX

(2069,

ATSC I2S

ASI510

(Scaler)

8 Bit

(I/P)

Audio

MSP44X0,

4052)

MSP44X0,

4052)

SIF _A

L/R Main

(CXA2069)

V-H/ V Sync & clk

MUX

For CC

RGB/FB

MSP44X0

L/R ATSC

L/R DTV2

L/R DTV1

V-IN [ 15:0]

16

VPC3230

(Decode)

IIC

SDA6000M

MICOM_CVBS

LED

RGB/FB

Key

Tele-t ext

Rx/Tx

I/R

IIC

Real

Real

C/C

5Vst

Bat.

Bat.

Timer

Timer

(M41T81)

(M41T81)

I/O

Expender

Rx/Tx

232C

MAX232

MAX232

RS232C

RS232C

LPF

uPD

RGB

9886

9886

MST3388

E

F

HDMI

HDMI

-11 0

HDMI I2S & S/ PDIF

ATSC

ATSC

7657

BA7657

YPbPr 1

YPbPr 1

7657

Display BLOCK

26

1234

(Video

64012

~ 480P

CVBS1

YPbPr 2

YPbPr 2

PDP-42A3HD

Decode ,

C/C & 3D)

C2

MICOM_CVBS

CVBS2/ Y2

CVBS 2

CVBS 1

CVBS 2

CVBS 1

Y1/C1

ATSC_CVBS

NTSC_CVBS

ATSC_CVBS

NTSC_CVBS

To MSP

Audio L- Main

Audio R-Main

(A_S/W)

CXA2069

Y/C 1

CVBS 3

CVBS 3

Y/C 1

L/R SC2

L/R SC2

Y/C 2

Y/C 2

L/R CVBS1

L/R CVBS1

Y/C 3

Y/C 3

L/R CVBS2

L/R CVBS3

L/R CVBS2

CVBS & Audio

L/R CVBS3

NE_OU

LI

L/R PC

L/R PC

T

Page 27

5678

2. DTT & Analog PCB Block Explanation

A : Channel Demodulator Block(LGDT3303)

B : ATSC Tuner Block(DTT7608)

C : Analog Tuner Block(FQ1236)

D : DDR SDRAM Block(HY5DU281622ET-H x 4)

E : MPEG Decoder Block(TL955B2-SH)

F : Audio Decoder Block(MSP4440)

G : Video Switch Block(CX2069Q)

H : Flash Rom Block(E28F320J3A)

I : Power input Block

J : Main Video decoder Block(uPD64012+HY57V161610DTC-7)

D

A

A

B

I

C

H

E

B

D

J

C

F

G

E

56

PDP-42A3HD

F

27

7

8

Page 28

1234

3. Digital PCB Block Explanation

A

A : Indication LED Block

B : Audio AMP Block(TA2024B)

C : AV input Block

D : Control key Block

B

A

B

C

C

D

D

E

F

28

1234

PDP-42A3HD

Page 29

5678

Block Description of Display

1. The ADC & HDMI receiver composes ADC and HDMI receiver.

2. The Video Decoder is composed of uPD64012 and VPC3230, converts from analog signal to

digital video signal.

3. The CXA2069 switches input signal and selects the signal.

4. The MDIN150 is de-interlacer, it functions that interlaced signal converts de-interlaced signal and

improves picture quality.

A

5. The ASI510 is scaler IC, scaling video signal it interfaces with related IC and outputs 24 bit RGB

format video.

The SDA6001 is composed of micom and closed caption block, it controls related IC, power on/off

6.

system, and signal flowing system.

7. IO expander functions that it increases the IO port from receiving IIC communication signal.

8. The real timer(M41T81) is timer with using the clock generator.

Factory Mode

1. The method of factory mode

• To enter the test mode press keys on Remote control in

sequence as below.

B

C

D

INPUT 0 9 1 7

•You can adjust the register of IC, but this operation is very critical in set operation.

2. Self-check mode and error code is not applicable in this set.

56

PDP-42A3HD

7

8

E

F

29

Page 30

1234

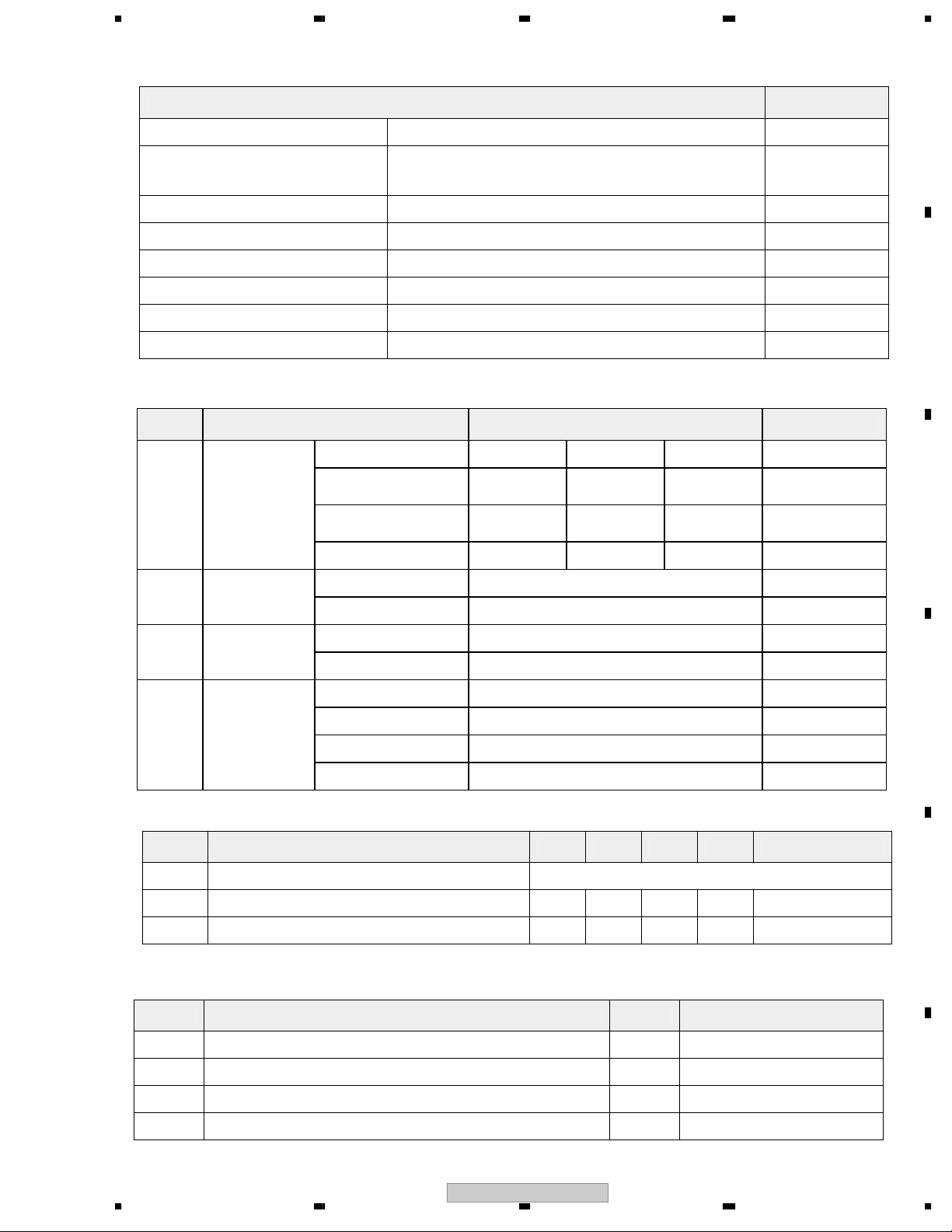

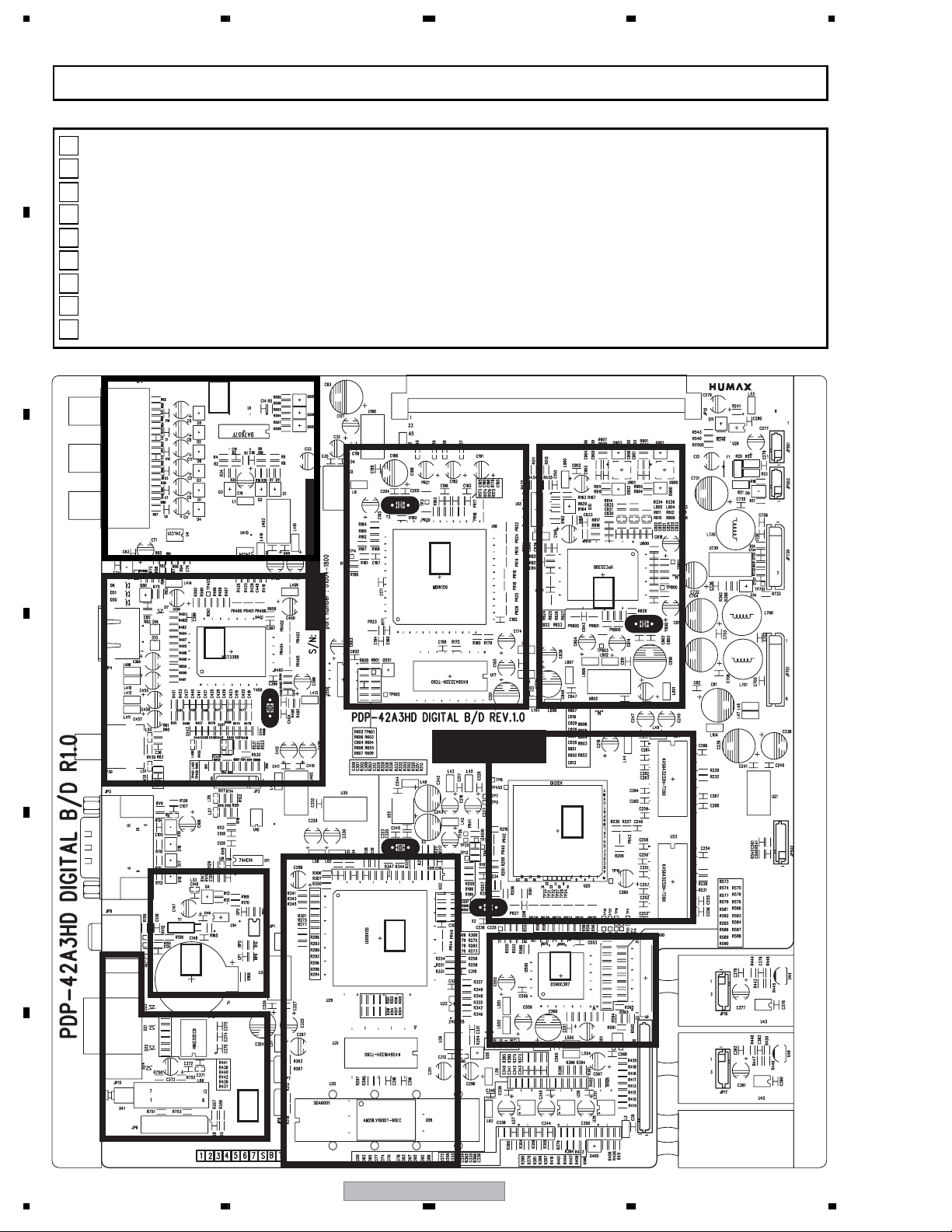

3.2 DIGITAL B/D SCHEMATIC DIAGRAM

A

DIGITAL B/D PCB

B

C

D08

T01

JP730

-N

D09

-Q

T14 T15

JP701

D

D07

-K

T03

D07

-K

T03

E

F

U2

U1

U4

D07

T02

-J

JP4

U401

D01

-A

T02 T03

D08

T02

-P

30

PDP-42A3HD

1234

Page 31

5678

D08

-L

T03 T04 T05 T06

JP701

A

B

C

U28

U29

D02

T01

D02

T01

-B

D

-B

E

D08

T02

-P

D01

T01

56

: Please refer to the diagram that corresponds to the number (and following letter).

-A

: Please refer to the troubleshooting table that corresponds with the number.

PDP-42A3HD

F

31

7

8

Page 32

1234

A

GB[0..7] 6,7

B

C

VAUPLL

VDDP VDDCVPLL

VMPLL

VDVI VADC

GB1

GB2

GB0

1 8

2 7

3 6

PR400

220*4

838281807978777662616059585756555049484746454443686970717296979899

DATA0

DATA1

VDDC

92

VDDC

75

VDDC

67

106

AVDD_PLL

123

VDDP

102

VDDP

90

VDDP

88

VDDP

86

VDDP

73

VDDP

65

VDDP

53

VDDP

39

32

126

29

4

AVDD_DVI

113

AVDD_DVI

119

HSYNC0

U401

236

GG[0..7] 6,7

GB3

GB7

GG2

GG1

GB4

GB5

GB6

GG0

1 8

2 7

1 8

4 5

PR401

DATA2

DATA3

DATA4

AVDD_AUPLL

AVDD_MPLL

AVDD_ADC

AVDD_ADC

AVDD_ADC

VSYNC0

BIN0P

BIN0N

7

3 6

2 7

3 6

4 5

PR402

220*4

220*4

DATA5

DATA6

DATA7

DATA8

DATA9

SOGIN0

GIN0P

GIN0N

RIN0P

RIN0N

8

9

1011121314151617181920

GG3

GG4

4 5

1 8

PR403

DATA10

DATA11

HSYNC1

GG5

GG6

2 7

3 6

220*4

DATA12

DATA13

VSYNC1

GG7

4 5

DATA14

DATA15

BIN1P

GR[0..7] 6,7

GR0

1 8

PR404

BIN1N

GR2

GR1

2 7

3 6

220*4

DATA16

DATA17

SOGIN1

GIN1P

GR3

GR4

1 8

4 5

PR405

DATA18

DATA19

GIN1N

RIN1P

21

GR5

GR6

2 7

3 6

220*4

DATA20

DATA21

RIN1N

GR7

4 5

DATA22

DATA23

22232425262728

G_CLKA 4,6,7

G_SOG_DE 4,7

4 5

R659 100

PR406

220*4

DATACK

SOGOUT/DE

MST3388M

BIN2P

BIN2N

SOGIN2

G_HSYNC 4,6,7

2 7

3 6

HSOUT

GIN2P

G_VSYNC 4,6,7

G_FIELD 4,6

1 8

VSOUT

FIELD/GPO

GIN2N

RIN2P

RIN2N

HDMI_DOUT 12

R497 220

AUSDO

HDMI_CLK 12

R498 100

AUSCK

R499 220

TP403 TP08

HDMI_WS 12

1

R501 220

AUWS

AMUTE

RX0N

108

R500 OPEN_100

100

109

D

R657

5VSTB

R419 OPEN_101

VDVI VDDP

I2S_MCLK 12

HSPDIF 12

C406

R656 391/F

C408 104p

R502 OPEN_100

101

120

12813641423334

REXT

MCKO

VREFP

SPDIFO

RX0P

RX1N

RX1P

RX2N

RX2P

RXCKN

111

112

114

115

117

OPEN_101

C407 104p

VREFN

RXCKP

118

124

C448 104p

R429 101

HDET_PWR1

105p

A0

DDCSCL

DDCSDA

125

R658

R426

R425

MCL

103

103

103

MDA

INT

SCL

403738

U410

C404 220p

XOUT

SDA

123

A0A1A2

VCC

SCL

WP

865

7

14.31818MHz/20pF

Y400

XIN

HWRESET

35

4

VSS

CAT24WC08W

SDA

C405 220p

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

127

122

116

110

107

105

104

103

91

89

87

74

66

54

31

30

5

121

95

94

93

85

84

64

63

52

51

A

E

F

D01

32

R483 100

R489 100

R485 100

R484 100

R453 OPEN_102

OPEN_103

R454

C444

OPEN_221p

R452 OPEN_101

PC_Vin1

R451 OPEN_102

222

R131

C443

OPEN_330p/50V

OPEN_CIL10J1R8KNC

L400

PC_Hin

R521 OPEN_000

R482 100

C422

680

C419 102p

R474 391

000

R481 100

RX0-1

RX0+1

RX1-1

473p

R476

473p

C420 473p

C417

R478 680

C418

R477 330

OPEN_221p

R528

M_COMP_Y

C424 473p

C426 473p

C431 473p

R466 330

000

DTT_PbX

C425 102p

R470 391

R530 000

C445

R526

R472 680

R471 330

C427

DTT_YX2

C430

R468 680

OPEN_221p

OPEN_221p

473p

C429 473p

R469 330

000

DTT_PrX

R527

473p

R475

000

M_COMP_Pb2

C446

C423

330

C421

OPEN_221p

R531

473p

C428

680

R473

OPEN_221p

M_COMP_Y 2

R520 OPEN_000

C437 473p

M_COMP_Pb 2

R455 330

R523 OPEN_000

PC_Bin

C438

C440 102p

R456 391

R486

PC_Gin1

C441 473pR457 330

OPEN_221p

OPEN_000

R460 680

C436 473p

C439

C442 473p

R458 680

OPEN_221p

C435 473p

R459 330

R524 OPEN_000

PC_Rin

C447

OPEN_221p

R522 OPEN_000

C434 473p

R461

M_COMP_Pr

R465 102

R464

1

R462 102

680

TP402

R463

C432

L403

OPEN_CIL10J1R8KNC

1

TP401

TP08

C433

OPEN_101

TP08

330p

R467

222

103

221p

C416 473p

R479 330

000

R491 101

R488 100

R490 101

R487 100

C413

103p

RX1+1

RX2-1

RX2+1

RXC-1

RXC+1

DDC_CLK1

DDC_DATA1

R493 101

R492 101

R494 101

R496

103

R495 101

473p

HDMI_INT9

SCL05,6,10

SDA05,6,10

DVI_RESET9

C415

R480 680

C414

OPEN_221p

R529

M_COMP_Pr

PDP-42A3HD

1234

Page 33

5678

B

L57

3V3STB

2V5S

L58

MD[0..15]

L59

3V3STB

C289

C295

C294

C293

C292

C291

C290

BLM31PG601SN1

Vcc_M2

C297

C296

Vcc_AM29LV

BLM31PG601SN1

10uF/16V

104p

104p

104p

104p

104p

104p

C301

C300

C299

MA[0..20]

C298

C310

105p

123

A0A1A2

VCC

WP

U32

24LC128

865

7

3V3STB

104p

C308

KEY1 9

R304 101

R305 101

124

125

P5.0/ADC

MD8

MD9

R311

472

R310

472

C309

P5.2

KEY2 9

T_SENSE 9

R307 102

R309 102

R308 102

R306 101

P5.2

P5.3

126

127

9493979910098101

P5.1/ADC

P5.2/ADC

P5.3/ADC

P5.14/T4EUD

D10

D12

D11D8D9

67667257636256

MD13

MD10

MD12

MD11

CE_EXT

CSROM

123

JP8

MD0

2

K4S641632H-TC60

37114

U31

CLKEN

3V3STB

MICOM PCB

104p

ASI_ALE 7

R313 101

P6.2

P6.2/FIELD

P5.15/T2EUD

D13

D14

D15

51

MD14

MD15

CE_FLASH

R312

MD2

MD3

MD1

DQ0

DQ1

DQ2A5DQ3

CKE

VCC

VCC

L60

BLM18PG121SN1D

C306

104p

C305

104p

3V3STB

SCL01 12

104p

104p

104p

SDA01 12

R254 000

R251 000

87

21

123

119

116

111

106

85

69

61

53

42

32

14

C304

C303

C302

104p

104p

104p

U29

10uF/16V

Vcc_M2

R252 OPEN

R253 472

R250 472

MA18

MA17

MA0

MA1

MA4

MA3

104p

10uF/16V

BLM31PG601SN1

U28

MA2

25

24232221201918876543214817

A0

A1A2A3A4A5A6A7A8A9

VCC

37

D0D1D2D3D4D5D6D7D8D9D10

293133353840424430323436394143

AM29LV160DT-90EC

MD0

MD4

MD1

MD2

MD3

R256 472

VDDA4

VDDA3

VDDA2

VDDA1

R255 OPEN

MA5

MD5

R258 472

VDD25_2

VDD25_1

VDD33_8

VDD33_7

VDD33_6

VDD33_5

VDD33_4

VDD33_3

VDD33_2

VDD33_1

A1

36

MA0

MA1

R257 OPEN

R259 472

MA19

MA7

MA6

MD7

MD6

VS_ON

SDA0 3,5,6

SCL0 3,5,6

IR_IN 9

101

R265

P3.12

IR_IN

R264 472

R266 472

R262 472

P3.5

P3.4

P3.3

74475767778798081

P3.5/T4IN

P3.0/SCL0

P3.1/SDA0

P3.2/CAPIN

P3.3/T3OUT

P3.4/T3EUD

A2A7A6A0A4A5A3

35242637332734

MA6

MA3

MA4

MA5

MA7

MA2

R263 000

R260 472

R261 OPEN

123

JP7

MA20

MA11

MA8

MA12

MA9

MA13

MA10

A10

A11

A12

A13

D11

D12

D13

MD12

MD9

MD11

MD8

MD13

MD10

IRP_IN

101

R270

P3.13

R268 472

R269 472

R271 472

P3.6

P3.8

P3.7

P3.6/T3IN

P3.7/T2IN

A9

A8

25292839233038

MA9

MA10

MA8

MA16

R267 472

MA14

MA16

MA15

A14

A15

D14

D15

45

MD14

MD15

UART_MT 12

R276 101

R273 101

R272 472

P3.9

88

83

P3.8/MRST

P3.9/MTSR

P3.10/TxDO

A11

A10

A12

MA11

MA12

MA13

R275 472

MA17

MA19

MA18

16

9

A16

A17

A18

47

Vcc_AM29LV

R274 000

UART_MR 12

R278 472

R281 472

R279 472

P3.13

P3.15

P3.12

9182908992

P3.12

P3.15

P3.13/SCLK

P3.11/RxDO

A14/ RAS

A13

A16/P4.0

A15/ CAS

40

MA16

MA17

MA14

MA15

R277 OPEN

MA20

10

A19

A20

BYTE

RP

12

RESET#

R280 OPEN

A18/P4.2

A17/P4.1

181922

MA18

CE_FLASHWRRD

11

26

CE

WE

NC

NC

14

13

R283 101

JL_SDIJL_SCK

R282 472

567

A19/P4.3

17

16

MA19

MA20

28

OE

15

ASI_RESET 7

NBLK 11

TIME_INT 4

R286 101

R288 101

JL_SCK

NSLE

JL_SDO

R290 472

R287 472

JL_SDI

NSLE

JL_SDO

855

P2.8/EX0IN

P2.9/EX1IN

P2.10/EX2IN

A20/P4.4

CS3/P4.5

15

MD0

R289 OPEN

R284 OPEN R285 472

LDQM

CE_FLASH

RB

NSLE 11

PLE 11

NSDATA 11

R296 101

R299 101

R293 000

P2.12

P2.13

P2.14

R298 472

R295 472

R292 472

P2.13

P2.14

P2.12

91011

P2.11/EX3IND0

P2.12/EX4IN

P2.13/EX5IN

D2

71

65

MD1

MD3

MD2

R297 OPEN

R294 OPEN

R291 OPEN

WR

CLKEN

CSSDRAM

GND

27

GND

46

NSCK 11

IRP_OUT

104p

C307

R15 101

R301 472

R302 103

R303 103

BL_ON BL_ON

12

P2.14/EX6IN

P2.15/EX7IN

SDA6001

D6D4D5D1D7

D3

5870645954

MD7

MD5

MD4

MD6

R300 OPEN

UDQM

PDP-42A3HD

56

4

VSS

SCL

SDA

R315 101

R317 101

P6.3/SCL1

P6.4/SDA1

CSROM

RD

47

46

R316 000

R314 000

CSROM

RD

000

Vcc_M2

MD5

MD4

DQ4

DQ5

VCC

VCCQ

3

27

SDA3

ASI_RD 7

ASI_WR 7

R322 101

R320 101

P6.6

P6.5

P6.5/-

P6.6/SDA2

CSSDRAM

CLKEN

MEMCLK

43

44

45

R319 000

R321 220

R323 000

CLKSDRAM

CLKEN

CSSDRAM

R318

472

MD6

MD7

MD8

42444547485051

DQ6

DQ7

DQ8

VCCQ

VCCQ

VCCQ

9

43

49

C311

10uF/16V

C312

104p

R324 000

WR

MD9

SCL3

R326 000

WR

R325 000

LDQM

MD10

DQ9

CC_R 5,12

R328 000

112

R

LDQM

495048

R327 000

UDQM

MD11

DQ10

NC

CC_G 5,12

113

G

UDQM

DQ11

NC

CC_B 5,12

R329 000

114

C313 104p

MD12

C315

C314

R330 102

105

B

R331

MICOM_CVBS12

MD13

DQ12

104p

104p

CC_FB 5,12

CC_V_SYNC 5,12

CC_H_SYNC 5,12

3V3STB

R333 101

R332 101

TRIG_IN

103

102

HS

BLANK

VS/VCS

CVBS1B

CVBS1A COR

RST

73

120

121 104

R338 750

R339 000

JTAG_RST

101

C316

104p

RESET#

MA0

MD14

MD15

53

DQ13

DQ14

DQ15

VSS

VSS

VSS

VSSQ

2841546124652

C319

C318

7

OPEN_101p

C357

OPEN_101p

C354

OPEN_101p

C353

OPEN_101p

C352

C356

101p

C355

101p

OPEN_472

R345 472

R341 472

R343 OPEN_472

R340

TCK

TDO

TMS

TDI

TRIG_OUT

3

1

2

95

96

TDI

TCK

TMS

TDO

P6.0/TRIG_IN

P6.1/TRIG_OUT

CVBS2

XTAL2

XTAL1

109

108

117

R344

105

X3

6MHz/18pF

C320

200p

MA4

MA2

MA3

MA1

MA6

MA5

MA7

24

25426

29530731

A0

A1

A2

A3

A4

A6

VSSQ

VSSQ

VSSQ

104p

C322

104p

104p

32833

A7

R247 OPEN_101

R367 OPEN_101

R336 OPEN_101

R334 OPEN_101

VSSA4

VSSA3

VSSA2

VSSA1

TMODE

VSSD10

VSSD9

VSSD8

VSSD7

VSSD6

VSSD5

VSSD4

VSSD3

VSSD2

VSSD1

R347 750

C323

200p

MA9

MA8

A8

MA10

341022

A9

3

BA033CCOFP

U34

1

L61

7VSTB 3V3STB

122

118

115

110

128

107

84

68

60

52

41

31

13

86

20

MA13

MA12

MA11

3511211320

A10

A11

A12

C325

C327

OUT

Vin

C326

C324

BLM31PG601SN1

R350

LDQM

A13

4,12

100uF/16V

104p

GND

4

NC

2

104p

220uF/16V

000

MA15

MA14

UDQM

15363923184019

17

/RAS

DQML

DQMU

99,12

WR

CSSDRAM

16

/CS

/WE

/CAS

CLKSDRAM

38

CLK

A

B

C

D

E

F

D02

33

8

Page 34

1234

C

A

A_RESET 16,20

SCL01 15

SDA01 15

R923

104p

C848

R954 101

R955 101

R921 101

104p

OPEN_473

C847

SLA0

7271706968676665646362616059585756555453525150494847464544434241403938

SCL

SDA

SCL0

RSTB

DVDD1

RGRED

HD

73

VD

74

VBLK

75

FILD

76

RDEO

77

DVDD3

78

BCKM

79

DGND

80

FDIO0

81

FDIO1

82

FDIO2

83

FDIO3

84

FDIO4

85

DVDD1

86

FDIO5

87

FDIO6

88

FDIO7

89

FDIO8

90

FDIO9

91

DGND

92

DFBI

93

DYSI

94

DYMI

95

DCGI

96

DCBI

97

DCRI

98

DVDD3

99

FCKQ

100

FOCP

101

FCSI

102

DVDD1

103

TEST

104

TM0

105

TM1

106

TM2

107

SMC

108

SCKSET

AVDD1

ATS1

ATS2

AVDD3

ATS3

109

110

111

112

113

114

115

TP827 TP08

TP826 TP08

VPC_FIELDS 15

VPC_VSYNCS 15

VPC_HSYNCS 15

1

1

101*4

B

C

D

15

15

15

C114

C856

C855

C854

C853

PR719

1 8

2 7

3 6

4 5

R925 100

15

15

15

15

15

VPC_C0

VPC_C1

VPC_C2

VPC_C3

VPC_C4

VPC_C5

VPC_C6

VPC_C7

PR720 101*4

331p

OPEN

_331p

OPEN

_331p

OPEN

_331p

OPEN

_331p

4 5

3 6

2 7

1 8

4 5

3 6

2 7

1 8

C852

C851

PR721 101*4

104p

104p

R974 101

3V3U

1V5VD

104p

C850

104p

C849

R969 101

DGND

BCLK8

AGND

AGND

116

R920 000

117

VPC_CLK 15

C846

ROCK

VCLY

104p

DVDD1

VCOM1

118

119

ROY0

AVI

120

VPC_Y0 15

PR718

ROY1

ROY2

VLPF1

ASYI

121

1 8

122

VPC_Y6 15

VPC_Y7 15

VPC_Y5 15

VPC_Y4 15

VPC_Y3 15

VPC_Y1 15

VPC_Y2 15

101*4

101*4

2 7

3 6

4 5

1 8

2 7

3 6

4 5

PR717

ROFDIE

C845 104p

ROY3

ROY4

ROY5

ROY6

ROY7

ROY8

DGND

ROY9

DVDD1

ROFDIE

FCLK8

U711

uPD64012

VRB1

ACYI

VRT1

ACSI

AVDD3

VRT2

ASCI

VRB2

AGI

VCOM2

ACBI

123

124

125

126

127

128

129

130

131

132

133

FCKM

VRT3

134

XI

DGND

ABI

VRB3

135

C843

3V3U

XO

VCOM3

136

137

104p

DVDD3

SDRDQ15

AVDD3

VCOM4

138

139

104p

C844

DVDD1

SDRDQ0

SDRDQ14

ACRI

VLPF2

ARI

140

141

C842

Y700

24.576MHZ/20pF

C841

37

SDRDQ1

SDRDQ2

SDRDQ13

VRB4

VRT4

AGND

142

143

144

200p

200p

SDRDQ12

SDRDQ3

DVDD1

SDRDQ11

SDRDQ4

SDRDQ10

SDRDQ5

DGND

SDRDQ9

SDRDQ6

SDRDQ8

SDRDQ7

DVDD3

SDRWE

SDRCAS

SDRCLK

SDRRAS

SDRCKE

SDRCS

DVDD1

SDRA0

SDRA1

SDRA2

DGND

SDRA3

SDRA4

SDRA5

DVDD3

SDRA6

SDRA7

SDRA8

DGND

SDRA9

SDRA10

SDRABP

DVDD3

1V5VD

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

3V3U

C834

C833

C832

C831

C830

104p

104p

104p

104p

104p

101*4

PR710

101*4

PR711

101*4

PR713

101*4

PR712

4 5

3 6

2 7

1 8

4 5

3 6

2 7

1 8

4 5

3 6

2 7

1 8

4 5

3 6

2 7

1 8

4 5

3 6

2 7

1 8

4 5

3 6

2 7

1 8

4 5

3 6

2 7

1 8

4 5

3 6

2 7

PR709

1 8

101*4

PR706 101*4

PR705 101*4

SDRDQ[15..0] 19

SDRDQ15

SDRDQ0

SDRDQ14

SDRDQ1

SDRDQ13

SDRDQ2

SDRDQ12

SDRDQ3

SDRABP 19

SDRA[10..0] 19

SDRCS 19

SDRCKE 19

SDRRAS 19

SDRCLK 19

SDRCAS 19

SDRWE 19

SDRDQ11

SDRDQ4

SDRDQ10

SDRDQ5

SDRDQ9

SDRDQ6

SDRDQ8

SDRDQ7

4 5

3 6

2 7

1 8

PR708 101*4

SDRA0

PR707 101*4

SDRA1

SDRA2

SDRA3

SDRA4

SDRA5

SDRA6

SDRA7

SDRA8

SDRA9

SDRA10

E

F

D03

34

R905

R904

PR704

103*4

R903103

R902103

R964103

R131103

R130103

R129103

VDEC3V3

1V5VA

103

103

1 8

2 7

3 6

4 5

C789

104p

R972 473

104p

C807

C111

104p

C818

104p

331p

+5V

3V3VA

104p

104p

C790

C795

104p

10uF/16V

C791

C792

C793

R971 473

R970 473

C808 103p

R134 101

R132 101

R133 101

VCVBS117

104p

C809 103p

Y117

C794

104p

C810 OPEN_103p

104p

C797

104p

104p

104p

C798

C800

C799

C796

C812 103p

C106 103p

C117

Y15

104p

C814 OPEN_103p

CB15

C801

104p

C802

103p

C104

C112

C113

104p

C804

C803

331p

331p

104p

104p

C816 OPEN_103p

104p

C805

C806

103p

C105

CR15

R90

OPEN_102

R89

OPEN_102

R88

OPEN_102

C43

OPEN_104p

L4

OPEN_BLM31PG601SN1

C42

OPEN_47uF/16V

R95 000

R93 000

CC_GD CC_RD CC_BD

R91 000

OPEN_KST4403

Q5

13

2

OPEN_KST4403

Q4

13

2

OPEN_KST4403

Q3

13

2

CC_G15 CC_R15 CC_B15

R96

R94

R92

OPEN_101

OPEN_101

OPEN_101

CC_VD15

CC_HD15

R900 OPEN_101

R897 OPEN_101

R899 OPEN_101

R898 101

R896 101

R901 OPEN_101

R138,R135,R136,R13 7

R87 OPEN_000

R110 000

1

1

TP866

TP867

CC_GD

CC_BD

CC_RD

CC_FB15

TP08

TP08

PDP-42A3HD

1234

Page 35

5678

D

A6VCC

L800

HDMI_CLK 15

+5V

OPEN_BLM31PG601SN1

HDMI_WS 15

HDMI_DOUT 15

L815

L95

BLM31PG601SN1

5VAM

C898

220uF/16V

3

GND

4

OUT

NC

2

Vin

U750 OPEN_BA05CCOFP

1

C897

OPEN_104p/50V

C896

OPEN_100uF/16V

R605 101

A_RESET 16,1 8

BLM31PG601SN1

C899

C902

C901

C900

MSP_DVCC

101p

C903

104p

R604

R603

R602

47uF/16V

101p

104p

R976 OPEN_000

R975 OPEN_000

ADATAO07

A

RHP 17

LHP 17

MAIN_L

MAIN_R

C904

331p

C905

331p

RHP 17

C600

R601 OPEN_101

000

000

000

R977 OPEN_000

R979 101

R978 101

SCL115,17

SDA115,17

SCLK7

LRCLK7

LHP 17

R640 101

C601

331p

VREF2

ADR_SEL

R981 000

DACM_L

DACM_R

D_CTR_OUT1

D_CTR_OUT0

R982 OPEN_ 000

R641 101

NCNCNC

U751

0

MSP44X

NC

NC

NC

TP

AUD_CL_OUT

050p

C942

R607 OPEN_220

C943

I2S_MCLK15

R995 101

Y800

OPEN_220p

331p

R600 OPEN_101

252627282930313233343536373839

MSP4440G-QA-C13-500

DACA_L

DACA_R

24

NC

23

I2S_DA3

22

RESETQ

21

I2S_WS3

20

I2S_CL3

19

NC

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

NC

DVSS

DVSS

DVSS

DVSUP

DVSUP

DVSUP

ADR_CL

ADR_DA

I2S_WS

I2S_CL

I2C_DA

I2C_CL

R980

I2S_DA_IN2

ADR_WS

I2S_DA_IN1

I2S_DA_OUT

STANDBYQ

000

MSP_DVCC

R993 101

SC2_OUT_L

SC2_OUT_R

XTAL_IN

XTAL_OUT

18.432MHz/15pF

050p

C941

RSC1 17

R994 101

VREF1

TESTEN

C940 560p

C944

LSC1 17