Page 1

42 & 61 Inch Plasma

Field Service and Training Guide

PRO-1410HD

PDP-614MX

PDP-424MV

Technical Training Department

1925 E. Dominguez Street

Long Beach, CA 90810

Page 2

Page 3

Contents

Preface

PDP-424MV PBC Layout 5 Adjustments (61 Inch Models) 31~37

PRO-1410HD & PDP-614MX PCB Layout 6 Disassembly (61 Inch Models) 38~41

Function OF The PCB Assemblies 7~9 Parts List (61 Inch Models) 42~43

Normal Power On Operation 10~11 Connector Pin Voltages And Signals (61 Inch) 44~49

42 & 61 Inch Common Troubleshooting

Power Failure (Flow Chart) 13 Missing Data Or Scan Symptoms 51

Blinking IN Green (Flow Chart) 14~15 Testing Data Relay Boards 52~53

Blinking In Red (Temperature Alarm) 16 Testing High Voltage Board And Scan ICs 54~55

Blinking In Red And Green (Flow Chart) 17 Testing High Voltage Board For No Picture 56~57

Lighting In Green Then Red (Flow Chart) 18 Digital Board Symptoms 58

No Picture (Flow Chart) 19 Power Off Symptoms 59~61

Audio Troubleshooting (Flow Chart) 20 Picture Problems (High Voltage Board) 62

Remote Troubleshooting (Flow Chart) 21~22 All Connector Locations 63

4 PC Board Replacement (Screws & Connectors) 29~30

12~24

42 Inch Section (PDP-424MV)

51~83

Closed Caption Troubleshooting (Flow Chart) 23~24 Screw Locations On PCB Assemblies 64

61 Inch Section (PRO-1410HD & PDP-614MX)

Testing Scan Board (Y-Drive) 26 Adjustments (42 Inch Model) 67~73

Testing Scan ICs And Common Board (X-Drive) 27 Disassembly (42 Inch Model) 74~77

Testing Data ICs And Digital Board Fuse 28 Connector Pin Voltages And Signals (42 Inch) 78~83

26~49 Parts List (42 Inch Model) 65~66

Page 4

Preface

4

This technical training guide will address

the disassembly and adjustments of 42 and

61 inch Pioneer Plasma Display models.

This guide was designed as a servicing aid

and is not intended to replace the service

manual. The student should have the

appropriate service manual on hand when

when using this guide. Data in the service

manual for this unit contains specific

information on safety, parts and adjustments.

Safety information

Important safety data for this Pioneer model

is contained in the service manual. Before

returning the unit to the customer, complete

all product safety obligations and tests.

Technicians who bypass safety features or

fail to carry out safety checks may expose

themselves and others to possible injury,

and may be liable for any resulting damages.

For more information on electronic

circuits and block diagrams refer

to the Service manual.

Lead in the solder used in this product

is a known reproductive toxicant which

may cause birth defects or other reproductive

harm. (California Health and Safety Code

Section 25249.5).

When servicing this or handling circuit

boards and other components which

contain solder, avoid unprotected skin

contact with the solder. Also, when

soldering do not inhale any smoke or

fumes produced.

Page 5

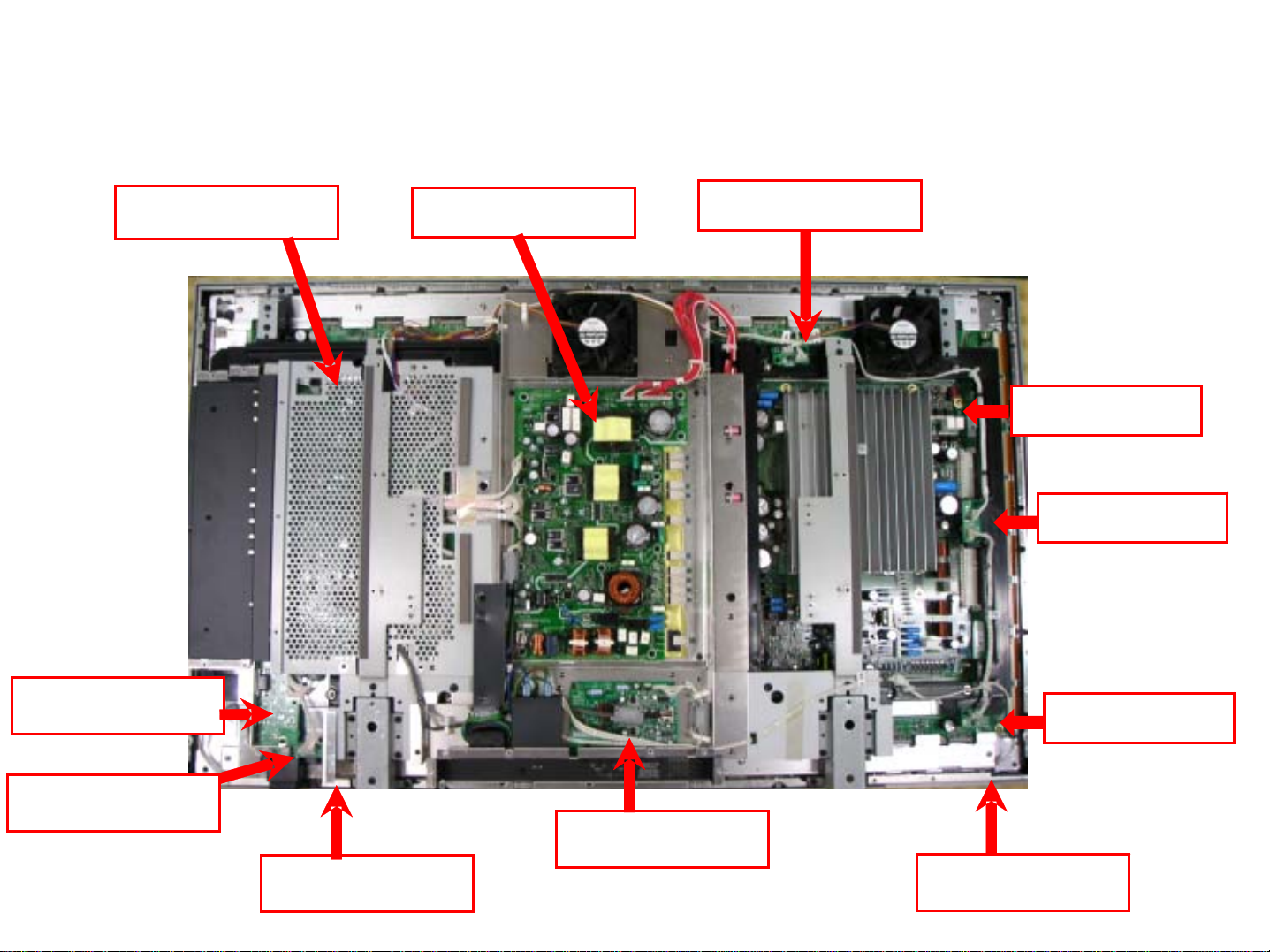

PDP-424MV PCB Layout

5

MAIN PWB

232C PWB

POWER UNIT

SENB PWB

High Voltage

SEND PWB

SENC PWB

PWR PWB

LED PWB

AUDIO PWB

CTL PWB

Page 6

PRO-1410HD & PDP-614MX

6

SENB PWB SEND PWB

MAIN PWB

POWER UNIT

Scanning PWB

232C PWB

PWR PWB

LED PWB

SENC PWB

AUDIO PWB

CTL PWB

Page 7

Function of the PCB’s

7

¾ MAIN PWB ASSY

Selector

zVideo selector(Video, RGB/YC/V)

zSync selector(Sync on green, HD,VD,Y)

Video decoder

z3.58NTSC Motion compensated 3D Y/C separation

zPAL Motion compensated 2D Y/C separation

zColor demodulation

zDigital chroma decoder

DVI receiver

z HDCP

Page 8

Function of the PCB’s

8

¾ MAIN PWB ASSY

AD converter

IP converter

Resolution converter(Frame rate converter)

Contrast,Bright

Color temperature adjustment

De-Gamma converter(Error diffusion,Dither)

LVDS(Low voltage differential signal)

OSD(On screen display)

SPLIT SCREEN

Page 9

Function of each PWB

9

¾ AUDIO PWB ASSY

AUDIO AMPLIFIER

¾ SENB PWB,SENC PWB ,SEND PWB

Temperature sensor

¾ 232C PWB

Remote in-out, 232C input terminal

¾ CTL PWB

INPUT SELECT/EXIT,LEFT/+,RIGHT/+

VOLUME UP/DOWN,PROCEED

¾ PWR PWB

Power switch

¾ LED PWB

POWER/STANDBY LED

¾ POWER UNIT

Page 10

Normal Power On Operation

10

¾61 & 42

Fan C

61 Only

2.

2.

9.

7.

2.

3.

6.

5.

CPU

4.

IC9503

7.

7.

7.

7.

8.

8.

1.

3.

Page 11

Normal Power On Operation

11

42 And 61 Inch Models

1. AC line attached to Power Supply.

2. Power Supply outputs a Power Mute voltage at +4.8 from Connector PM pin 5

(POMUTE). The Power Supply also outputs a +7 volt supply to the Main Microprocessor

at Connector PM pin 1 (M+7).

3. The +7 volt supply now on the Main PCB goes to the RS232 PCB, Power Switch PCB and

IC9503 the +5 volt regulator. Additionally the +7 volt supply returns back to the Power

Supply as one of the Power Start Up signals.

4. The +5 volt regulator (IC9503) outputs to the RS232 and Power Switch PCB’s. At this

time the Main Microprocessor sets the state to Standby and the front panel LED lights

Red.

5. From Standby pressing the Power button will send a +5 volt signal to the Main

Microprocessor from the Power Switch PCB Connector PW pin 2 (POIN).

6. The Main Microprocessor outputs the Power On +5 volt signal to the Power Supply from

Connector PM pin 3 (POWER). At this time the Power Relay engages.

7. The Power Supply upon receiving the Power On Signal supplies all other secondary

supply voltages.

8. After secondary supply voltages come up the power supplies for VS (170) and VD (65)

turn on.

9. NOTE: Panel Alarm Input Line can shutdown the Power Supply (Low Normal).

Page 12

42 & 61 Inch Common Trouble Shooting

12

Page: Trouble Area:

13 Power Failure

14 & 15 Blinking in Green

16 Blinking in Red

17 Blinking in Red & Green

18 Lighting Green then Red

19 No Picture

20 Audio

21 &22 Remote

23 &24 Closed Caption

Page 13

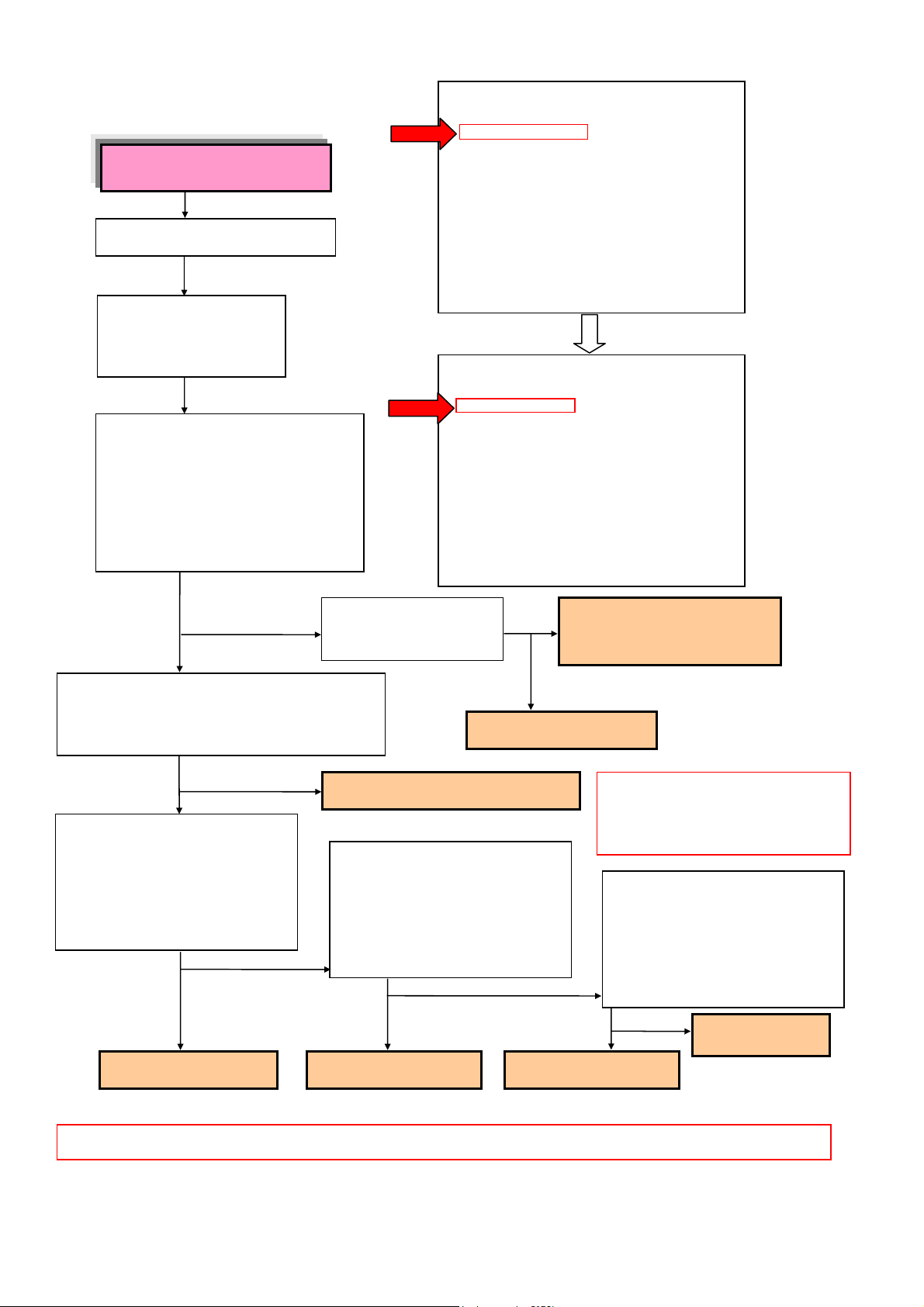

1. Power failure

13

8-2

PDP-614MX / PRO-1410HD / PDP-424MV

(1) The power supply is not turned on.

Move the main power setting for

OFF→ ON.

Is the POWER/STANDBY lamp lit?

(2) Blinking in green (Alarm of

temperature sensor error or fan error)

Go to (P14 & 15)

(3) Blinking in red after repeating

reciprocal flash in red and green

(POWER ON↔OFF) 3times (Alarm of

temperature error) Go to (P16).

(4) Reciprocal flashing in red and

green (Alarm of panel error) Go to

(P17).

(5) Lighting in green, and then in

red (Alarm of power line error) Go to

(P18).

Is a 5Vdc output available in the state that

the LD connector is disconnected and the

main power is turned ON?

YES

NO

Is a 5Vdc output available in the state that

the RS connector is disconnected and the

main power is turned ON?

YES

NO

The PW connector, PWR PWB or the MAIN

PWB is fault.

YES

The LD connector or the

LED PWB is fault.

The RS connector or the

232C PWB is fault.

(Caution) If any abnormality is sensed in such a

NO

Is the AC power

output available at

the AC connector

(power cord)?

YES

Is a 6.8Vdc output

available at Pin of

the PM connector?

YES

Is a 6.8Vdc output

available at Pin of

the PW connector?

YES

Is a 6.8Vdc output

available at Pin of

the PM connector?

YES

Is a 4.9Vdc output

available at Pin of

the PM connector?

NO

Is a 5Vdc output

available at Pin of

the PW connector?

NO NO NO

The MAIN PWB is fault.

manner that the LED flashes or lights, all

the power lines other than those of 7Vdc

(M+7V) and 5Vdc (M+5V) are automatically

turned off in about 10 seconds. When

checking the power lines other than those of

M+7V and M+5V, a circuit tester or the like

should have been connected in advance.

NO

The PW

connector or

the PWR PWB

is fault.

NO

The PM

connector or

the MAIN

PWB is fault.

NO

NO

The power cord is defective.

Is a 6.8Vdc output available in

the state that the LD connector

is disconnected and the main

power is turned ON?

The LD

YES

connector or

the LED PWB

NO

Is a 6.8Vdc output available in

the state that the PW connector

is disconnected and the main

power is turned ON?

NO

Is a 6.8Vdc output available in

the state that the PM connector

is disconnected and the main

power is turned ON?

is fault.

The PW

YES

connector or

the PWR PWB

is fault.

YES

The PM

connector or

the MAIN

PWB is fault.

NO

YES

The power unit is fault.

YES

Page 14

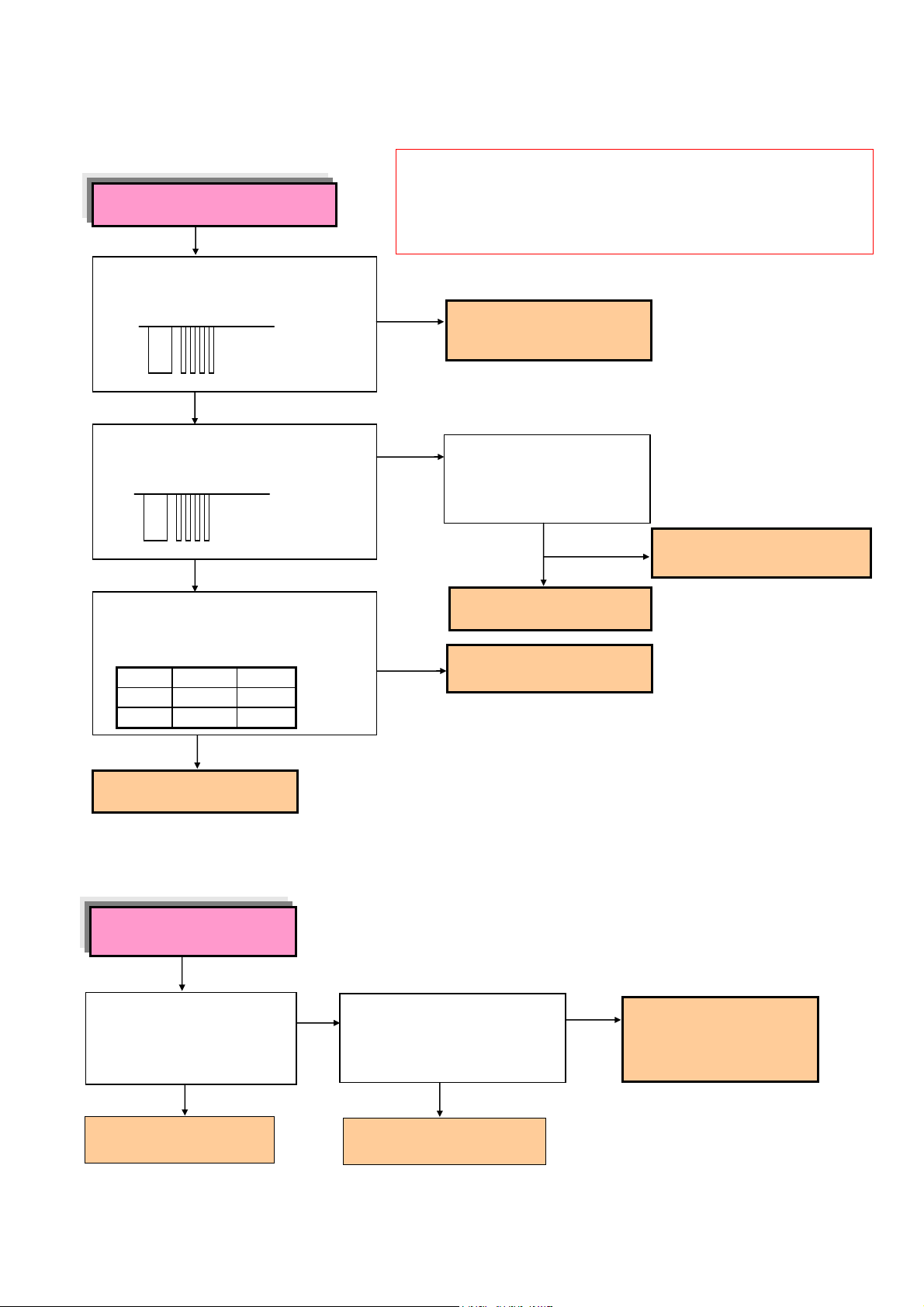

(2) Blinking in green

14

8-3

Alarm of te mperature sensor error

Blinking in green (intervals of 2 seconds)

Turn off the main power supply.

Pressing the [MENU] key of the product,

turn on the main power supply to cancel

alarming.

Press the remove control keys in the

sequential order of [POWER ON] →

[POWER ON] → [EXIT] → [DISPLAY] and

enter the factory adjustment menu. Press

the [MENU/ENTER] key to

display the FAN SET menu (P2/11).

Is there a display of

numerals (almost room

temperatures) at the right

side of [T1, T2, T3]?

YES

The MAIN PWB is fault.

NO

FAN SET

FAN SET

FAN MODE H CONT ENA –

FAN OFF/L – CONT UP –

FAN L/M – CONT TIME –

FAN M/H – UP STEP 2

SF SAVE 075 DOWN STEP 2

PLE SAVE 070 READ TIME 60

T ALM 095 TEMP LEVEL 1

RET TME 030

PLE TIME 001

T1 030 T2 025

T3 030 T4 – MODE 2

IC ERROR –

[MENU/ENTER] NEXT [EXIT] PREV 2/11

Is there a display of [-] for

all the numerals at the

right side of [T1, T2, T3]?

YES

Are there a 3.3Vdc

output at Pin and a

clock signal (3.3Vpp)

at Pins and of the

TS in the state that the

TS connector is

disconnected and the

main power supply is

turned on?

NO

NO

The TS connector

or the SENC PWB

is fault.

YES

When a [-] display is presented, the PWB with the symbol shown

below is fault. T1: SEND PWB, T2: SENB PWB, T3: SENC PWB

Are there a 3.3Vdc

output at Pin and a

clock signal (3.3Vpp)

at Pins and of the

TR in the state that the

TR connector is

disconnected and the

main power supply is

turned on?

YES

The TR connector

or the SEND PWB

is fault.

Are there a 3.3Vdc

output at Pin and a

NO

clock signal (3.3Vpp)

at Pins and of

the TM in the state

that the TM connector

is disconnected and

the main power

supply is turned on?

YES

The TM connector

or the SENB PWB

is fault.

NO

The MAIN PWB

is fault.

Page 15

Alarm of fan error

15

8-4

Blinking in green (intervals of

0.5seconds)

Turn off the main power supply.

Pressing the [MENU] key

of the product, turn on the

main power supply to

cancel alarming.

Is the fan running?

(Caution) When alarming is

canceled, [FAN MODE] of

FAN SET (P2/11) in the

factory adjustment menu

automatically moves from

[ENA] to [H], thus causing

the fan to run.

FAN SET

FAN MODE ENA CONT ENA –

FAN OFF/L – CONT UP –

FAN L/M – CONT TIME –

FAN M/H – UP STEP 2

FAN SAVE 075 DOWN STEP 2

PLE SAVE 070 READ TIME 60

T ALM 095 TEMP LEVEL 1

RET TME 030

PLE TIME 001

T1 030 T2 025

T3 030 T4 – MODE 2

IC ERROR –

[MENU/ENTER] NEXT [EXIT] PREV 2/11

FAN SET

FAN MODE H CONT ENA –

FAN OFF/L – CONT UP –

FAN L/M – CONT TIME –

FAN M/H – UP STEP 2

FAN SAVE 075 DOWN STEP 2

PLE SAVE 070 READ TIME 60

T ALM 095 TEMP LEVEL 1

RET TME 030

PLE TIME 001

T1 030 T2 025

T3 030 T4 – MODE 2

IC ERROR –

[MENU/ENTER] NEXT [EXIT] PREV 2/11

YES

NO

Is there a voltage output of 11.3Vdc for the

42inch model, and

9.3Vdc for the 61inch models respectively, at Pin

1 of the FA, FB, and FC connectors?

Is there a 3.3Vdc output

at Pin of the FA and

FB, FC connectors?

NO

Is there a voltage output of

11.3Vdc for the 42inch model,

and

9.3Vdc for the 61inch models,

respectively, when the FA

connector is disconnected and the

mains power is turned ON?

YES

YES

NO

The FAN-A/FAN-B/FAN-C is fault.

Is there a voltage output of

11.3Vdc for the 42inch model,

and

9.3Vdc for 61inch models,

respectively, when the FB

connector is disconnected and the

mains power is turned ON?

YES

The FAN-A is fault.

The FAN-B is fault.

YES

The fan is out of order on the

side where a 3.3Vdc output

is generated.

NO

The MAIN PWB is fault.

(Caution) The FAN-C and FC

Is there a voltage output of

11.3Vdc for 42 inch model, and

9.3Vdc for the 61 inch models,

respectively, when the FC

connector is disconnected and the

mains power is turned ON?

NO

NO

YES

The FAN-C is fault.

connectors are used

only for the 61 inch

Series.

The MAIN PWB

is fault.

(Caution) In the FAN MODE, [ENA] is automatically recovered when the main power is turned OFF → ON.

Page 16

(3) Blinking in red (Alarm of temperature error)

16

Since the internal temperature is too high in the product, the temperature protector has been actuated. In such

a case, the following actions should be taken immediately:

1. Turn off the main power supply and pull out the power cord from the wall outlet.

2. Wait for about 60 minutes until the temperature in the main unit lowers.

3. Check whether the heat discharge port is covered with dust or the like. If yes, remove the clogging substance.

4. If the unit is used where the ambient temperature is high, it should be moved to an adequate place (air

temperature ranging from 5°C to 35°C).

Page 17

(4) Alternation blinking in red and green (Alarm of PDP error)

17

(Caution) How to reset the alarming condition

Blinking in red and green

Move the main power

setting for OFF → ON.

Is there alternation blinking

in red and green?

Turn OFF the main power

supply.

With the [Menu] key of the

product kept pressed, turn

on the main power supply

to assume the [Voltage

Check Mode].

Pressing the [Input Select] key of the product, turn on the main power supply

of the main unit. In this state, keep pressing the [Input Select] key for more

than 2 seconds until alarming is canceled. Make confirmation by the method

specified below.

NO

Normal

YES

(Caution) When the main power supply is turned on with the

[Menu] key of the product kept pressed, it takes 30

seconds more to assume the state of [blinking in red and

green]. In this time period, the following voltage checks

should be carried out.

If the state of [blinking in red and green] is assumed

during this checking, take actions of [Alarm Canceling]

and [Voltage Check Mode Setup] again.

Is there a 3.3Vdc output at

Pin 94 of IC9501 in the

MAIN PWB? (See the

PWB Layout Diagram on

P4-20.)

Turn ON the main power

supply in the state that the

AD, PD, and PH connectors

are disconnected. In this

state, are there the outputs

of Vs (170Vdc), Vd (60Vdc),

and 5Vdc at the PD/PH

connectors as specified in

the table at right? In this

case, however, no images

are generate.

NO

YES

Test PDP Module Area.

YES

NO

The MAIN PWB is fault.

The Power unit is fault.

(Caution) The voltage values of Vd and Vs and also the connector

pin numbers can differ according to the PDP. The method

of checking these voltage values is obtainable from [2.

Adjustment of the power unit] in the method of adjustment

plus the table specified below.

Inch Vs Vd GND 5Vdc GND

42 PD-9pin PD-7pin PD-5pin PH-1pin PH-3pin

61

PD-9pin

PH-1pin

PD-7pin

PH-4pin

PD-5pin

PH-5pin

PD-4pin

PH-7pin

PD-5pin

PH-5pin

(

Page 18

(5) Lighting in green, and then in red (Alarm of power voltage error)

18

Unlike [lighting in red] in the STANDBY mode, [lighting in green] continues for about 30 seconds without any

output of images and audio signals. Since then, the mode turns into [lighting in red].

Lighting in red

Make an OFF → ON setting

twice for the main power

supply in order to reset the

alarming condition.

Is the LED lit in red after it

has been lit in green for about

30 seconds?

YES

When the main power supply is turned on in

the state that the AD, PD, and PH

connectors are disconnected, are there the

Vs (170Vdc) and Vd (60Vdc) outputs at Pins

- to Pins - of the PD connector and

a 5Vdc output at Pins - of the PH

connector? In this case, is the LED not

turned in red after it has been lit in green for

about 30 seconds? At that time, however, no

ima

ges are generated.

NO

When the main power supply is turned on in

the state that the PA and PV connectors are

disconnected from one after another, is

there a 12Vdc output at Pins - of the PA

connector or the 12Vdc and 6Vdc outputs at

Pins and - of the PV connector? In

this case, is the LED not turned in red after it

has been lit in green for about 30 seconds?

NO

(Caution) How to reset the alarming condition The

alarming condition can be reset when an

OFF→ ON setting is repeated twice for the

main power supply in the state that the

LED is lit in red. The interval between the

first and second settings is not particularly

specified.

Normal

YES

YES

Test PDP Module Area.

(Caution) The voltage values of Vd and Vs

can differ according to the PDP.

The method of checking these

voltage values is obtainable from

[2. Adjustment of the power unit]

in the method of adjustment.

The MAIN PWB or the

AUDIO PWB is fault.

Is there an output of 3.3Vdc available at Pins

~ and 2.5Vdc at Pins ~ in the

state that the PA and PV connectors are

returned to the former state, the main power

is turned ON, and the PN connector is

disconnected? In this case, however, this

check must be finished in 30 seconds.

Otherwise, there will be power tripping on

account of an alarm.

NO

YES

The MAIN PWB is fault.

NO

The Power unit or the

PN connector is fault.

Page 19

(8) No pictures [(Caution) The voltage outputs of Vs = 170V and Vd = 64V, 5Vdc are always generated, but the

19

LED is not flashing or lighting for alarming. However, the voltage values will differ according to the MODULE.]

No picture is displayed.

Make the setting of OFF→ ON

for the main power supply.

Does the priming glimpse?

YES

When the AD connector is disconnected, is

the LVDS signal normally output to each

pin of the AD connector? (For more details

of the signal, refer to the descriptions about

the connector pins.)

NO

YES

Test PDP Module Area.

NO

The MAIN PWB is fault.

The AD connector or the PDP is fault.

Page 20

3. Audio errors

20

(Caution) In regard to the method of audio input setting, refer to the specifications and the instruction

manual to confirm that all the setting is correct. Then, troubleshooting can be

carried out. It must be noted that the protector functions and no audio output is available if

the opposing electrodes of the speaker output or the speaker output and the ground (GND)

are short-circuited. In such a case, turn off the main power supply and make the

connections correctly. The protector is reset when the main power supply is turned on after

that

Audio errors

In the state that the speaker cable is

disconnected, is the audio signal output

available at the speaker terminal?

Is the voltage output specified below

NO

available at each pin of the PA connector

in the AUDIO PWB?

Pin_NO Name Voltage

1 S+12 12Vdc

2 S+12 12Vdc

3 S+12 12Vdc

4 GND GND

5 GND GND

6 GND GND

YES

Is the waveform specified below output to

the AU connector of the AUDIO PWB?

Pin6

Pin7

Pin5

Pin 1,3 • • • Audio signal waveform

5Vpp

5Vpp

3.5Vdc

YES

NO

NO

The speaker or the speaker

cable is fault.

The power unit or the PA

connector is fault.

The MAIN PWB or the AU

connector is fault.

The AUDIO PWB is fault.

YES

Page 21

4. Remote control not effective

21

(1) The wired remote control is not effective.

When a single item is used

The wired remote control is not

effective.

Is there a signal output specified below

at Pin 7 of the RS connector?

3.3Vpp

Is there a signal output specified below

at Pin 3 of the M2003? (Refer to the

PWB layout diagram on Page P4-21.)

NO

5Vpp

When the RS connector is

disconnected, is there a signal output

specified below at the RS connector of

the

MAIN PWB?

Pin No. Pin name Voltage

1 M+5V 5Vdc

5 M+3.3V 3.3Vdc

YES

(Caution) The wired remote control is not effective if the setting

of [PLE LINK], or [Repeat TIMER] is ON, or if the

setting of [ID NUMBER] has been made. Therefore,

such a setting should be turned off, without. Since

then, troubleshooting can be carried out.

YES

NO

The RS connector or the

MAIN PWB is fault.

Is there a 3.3Vdc output

at Pin 2 of the M2003?

(Refer to the PWB layout

diagram on Page P4-21.)

YES

The remote control or the

remote control cable is fault.

NO

The RS232C PWB is fault.

NO

The RS connector or the

MAIN PWB is fault.

YES

The 232C PWB is fault.

When a daisy chain (including the video wall) is used

The wired remote control

is not effective.

Are the 0Vdc and 5Vdc

outputs respectively available

at Pins 9 and 10 of the RS

connector in the standard

product of 232C PWB?

The MAIN PWB is fault.

NO

Is there a clock signal output at

YES

Pin 3 of the M2004? (Refer to

the PWB layout diagram on

Page P8-19.)

The 232C PWB is fault.

NO

Check the products of

YES

second and thereafter

according to “1 When a

single item is used.”

Page 22

(2) The wireless remote control is not effective.

22

(Caution) Since the detection of “wired” or “wireless” is conducted for the remote control

through the remote terminal, it is necessary to pull out the remote control cable

from the remote terminal. Troubleshooting should be carried out after

confirming that “IR REMOTE” is set at ON and that “ID NUMBER” is at ALL

according to the user’s menu.

The wireless remote control is not

effective.

Is there a 0Vdc output at Pin 12 of the

RS connector?

YES

Is there a signal output specified

below at Pin 6 of the PW connector?

5Vp-p

NO

Is there a signal output specified

below at Pin 1 of the LD connector?

5Vp-p

The LED connector or the LED PWB is fault.

NO

NO

YES

YES

When the RS connector is disconnected,

is there a 0Vdc output at Pin 12 of the RS

connector in the MAIN PWB?

YES

The 232C PWB or the RS

connector is fault.

NO

The MAIN PWB is fault.

The PW connector or the

PWR PWB i

s fault.

Page 23

5. The closed caption (CC) is displayed incorrectly.)

23

(Note) Only the models for North America. The PCB-5044 (CCD PWB) is not installed in other

Are there voltage outputs of

3.3Vdc and 6.0Vdc as specified

in Fig. 1 on next page?

Is there a CLK waveform output

(3.3Vp-p) of 27MHz at Point A of Fig. 1,

and also a digital waveform output

(3.3Vp-p) of H/L at Point B (in 3

places)? In addition, is there an analog

video signal waveform output (1Vp-p)

at Point C?

Is there a digital waveform output

(3.3Vp-p) of H/L at Point D of Fig. 1?

models. Checks are needed by applying a signal output to the video input circuit, which is

equivalent to the closed caption.

CC is displayed incorrectly.

In the state that the CCD PWB is

dislodged, are there a voltage output

YES

NO

of 6.0Vdc at Pin 3 of the PV

connector and 3.3Vdc at Pin 1 of the

PN connector in the MAIN PWB?

YES

The CCD PWB is fault.

NO

The MAIN PWB is fault.

NO

YES

NO

The CCD PWB is fault.

The MAIN PWB

is fault.

YES

Is there a digital waveform output

(3.3Vp-p) at Point E (in 4 places) of Fig.

1?

YES

NO

The CCD PWB is fault.

The MAIN PWB is fault.

Waveform at Point B/D/E

Check point: Check voltage and see whether a change in H/L is present.

3.3Vp-p

Waveform at Point C

NTSC video signal (with gray scale input)

1Vp-p

Page 24

24

A

B

C

6V

3.3V

E

D

<Fig. 1 CCD PWB Pattern Diagram>

Page 25

61 Inch Section (PRO-1410HD & PDP614MX)

25

Page: Topics Covered:

26 Testing Scan board (Y drive)

27 Testing Scan IC’s and Common

board (X drive)

28 Testing Data IC’s & Digital board

fuse

29~30 PC board replacement (screws &

connector locations)

31~37 Adjustments

38~41 Disassembly

42~43 Parts List

44~49 Connector pin Voltages and Signals

Page 26

Points of failure diagnosis for a Board Assy (PKG)

26

The fuses and/or fusible resistors shown in the photos below may be blown by electric

surges caused by a failure. In such a case, replace the corresponding PKG.

Failure diagnosis of the Scanning Board (Y-Drive)

Fusible resistor (R12) located

at the upper-left corner of the

Scanning PKG: Approx. 1.0 Ω

(1/2 W)

Fusible resistor (R29) located

at the upper-left corner of the

Scanning PKG: Approx. 4.7 Ω

(1/4 W)

Fusible resistor (R108A)

located at the lower-right corner

of the Scanning PKG: Approx.

2.2 Ω (1 W)

Fusible resistor (R113) located

at the lower-right corner of the

Scanning PKG: Aapprox. 4.7 Ω

(2 W)

OK: Short-

circuited,

NG: Open

OK: Short-

circuited,

NG: Open

Glass fuses (F1 and F2)

located at the upper-left

corner of the Scanning

PKG

Fusible resistor (R111) located

at right center of the Scanning

PKG: Approx. 10 Ω (1 W)

Failure diagnosis of the Power IC on the Scanning Board

OK: Short-

circuited,

NG: Open

OK: Short-

circuited,

NG: Open

PH2311

PH2312

D

(58~62)

E

(53~56)

F

(47~51)

G

(42~45)

H

(37~40)

I

(32~35)

PH2311(rear view)

Note: A, D, and E are ground.

A

(59~62)

B

(54~57)

52

49

C

E

G

I

(42)

(38)

(34)

(46)

D

(43)

F

(40)

H

(35)

J

(32)

PH2312(rear view)

11

11

27

30

31

1

13

A

20

B

C

1

8

9

(14~15)

(23~26)

(28~31)

Result:

Result:

Check points

Between A and B

Between B and H

Between C and I

Between D and E

Between F and G

OK: k Ω or more,

NG: Short-circuited

Check points

Between A and B

Between C and D

Between E and F

Between G and H

Between I and J

OK: k Ω or more,

NG: Short-circuited

Note: C and G are ground.

Page 27

Failure diagnosis of the Scanning IC

27

Check with a tester the resistance value between any pins indicated as NEGA and POSI of the

connector in the photos below. If a positive and a negative pin of the connector on the Scanning

Relay PKGs are short-circuited and remains short-circuited even after the connectors on the

Scanning PKG and Scanning Relay PKG are disconnected, the Scanning IC on the Scanning Relay

PKG is in failure.

Scanning PKG Scanning PKG

NEGA

NEGA

POSI

POSI

Check points

Between any pins of

NEGA and POSI blocks

Scanning Relay PKG

(upper connector)

Failure diagnosis of the Common Board (X Drive)

Glass fuses (F1 and F2) at

the upper-right corner of

the Common PKG

POSI

POSI

NEGA

NEGA

OK: k Ω or more,

NG: Short-circuited

Fusible resistor (R101) at the

lower-right corner of the Common

PKG: Approx. 2.2 Ω (1 W)

Scanning Relay PKG

(lower connector)

OK: Short-

circuited,

NG: Open

Failure diagnosis of the Power HIC on the Common Board

D

(58~62)

E

(53~56)

F

(47~51)

G

(42~45)

H

(37~40)

I

(32~35)

PH2311

(rear view)

PH2311

Check points

Between A and B

Between B and H

Between C and I

Between D and E

Between F and G

Note: A and D are ground.

1

9

11

A

(13~16)

20

B

(23~26)

C

(28~31)

Result:

OK: k Ω or more,

NG: Short-circuited

OK: Short-

circuited,

NG: Open

Page 28

Failure diagnosis of the Data IC

28

Failure symptom: The image in any block of the screen is not displayed.

Check with a tester between Pin 5 or 6 (Vd line of Data IC)

and ground of each Signal Relay PKG.

OK: Open

NG: Short-

circuited,

CN2

CN8CN8CN2

CN8

CN3

CN8

CN3

Failure diagnosis of the Digital PKG

Chip fuse (FU701) at the

upper-right corner of the digital

PKG

CN8

OK: Short circuited,

NG: Open

Page 29

Replacement method for a Board Assy and notes on replacement

29

Preparation

Place a cushion on the workbench and set the module to be repaired on it.

Note: With the glass surface facing downward, be sure that the entire glass surface is

against the cushion.

Disconnection of connectors and cables

Disconnect all the connectors on the PKG to be repaired.

(When a Signal Relay PKG is to be removed, remove the heat sink beforehand.)

Common Branch

PKG (upper): One

connector

Common Branch

PKG (lower): One

connector

Flat cable

(longitudinal type)

Signal Relay PKG (upper

left): 7 connectors

Common board:

10 connectors

Digital PKG: 8

connectors

Signal Relay PKG (lower

left): 8 connectors

Flat cable

Lock. Lock. Lock. Lock.

(horizontal type 1)

Signal Relay PKG (upper

center): 10 connectors

Recovery Relay PKG

Signal Relay PKG (lower

center): 10 connectors

Flat cable

(horizontal type 2)

Signal Relay PKG

(upper right): 8 connectors

Scanning PKG:

8 connectors

Signal Relay PKG

(lower right): 8 connectors

Cable type

Scanning Relay PKG

(upper): 5 connectors

Scanning Relay PKG

(lower): 5 connectors

Unlock. Unlock. Unlock. Unlock.

Page 30

How to remove/reattach the Board Assy (PKGs)

30

Notes: · Be sure not to drop a screwdriver or screw on a PKG or a cable.

· When removing/reattaching a screw, be sure not to leave any tiny metal shavings, because

they may cause a failure.

· Before removing Signal Relay PKGs, remove the heat sink.

· Be sure not to apply any stress to a PKG, connector, or cable when reattaching them.

· Reattach Signal Relay PKGs before reattaching the heat sink.

Heat sink: 17 screws

Common Branch PKG

(upper): One screw

Common PKG: 8 screws

Common Branch PKG

(lower): One screw

Signal Relay PKG

(upper left): 4 screws

Digital PKG:

4 screws

Signal Relay PKG

(lower left): 4 screws

Signal Relay PKG (upper

center): 5 screws

Recovery Relay PKG :11screws

Signal Relay PKG

(lower center): 5 screws

Signal Relay PKG (upper

right): 5 screws

Scanning PKG: 9 screws

Signal Relay PKG

(lower right): 5 screws

Confirmation of connector connection

Check whether or not the connectors indicated by circles are correctly connected.

Scanning Relay PKG

(upper): 6 screws

Scanning Relay PKG

(lower): 5 screws

Heat sink: 17 screws

Signal Relay PKG

(upper left): 7 connectors

Common board:

10 connectors

Digital PKG:

8 connectors

Signal Relay PKG (lower

left): 8 connectors

Signal Relay PKG (upper

center): 10 connectors

Common branch PKG

Signal Relay PKG (lower

center): 10 connectors

Signal Relay PKG (upper

right): 8 connectors

Scanning PKG:

8 connectors

Signal Relay PKG (lower

right): 8 connectors

Scanning Relay PKG

(upper): 5 connectors

Scanning Relay PKG

(lower): 5 connectors

Page 31

31

METHOD OF ADJUSTMENTS

PDP-614MX & PRO-1410HD

■Adjusting conditions

Adjustments should be carried out in the procedures of A to C specified below. However, any

adjustments other than the items A to C below are not required.

A. When the “PDP module (PDP-NP61C2MF01)” is replaced, adjustments

should conform to the adjusting items of [1 and 2] specified below.

B. When the “POWER UNIT” is replaced, adjustments should conform to the

adjusting item of [2] specified below.

C. When the “MAIN PWB” is replaced, adjustments should conform to the

adjusting item of [3] specified below.

■Adjusting items

1. Clearing of the usage time (Using the remote control)

(1) Press the keys in the order of [POWER ON] → [POWER ON] → [EXIT] → [DISPLAY] in order to

enter the factory adjustment menu.

(2) Press the [MENU/ENTER] key to select the [USAGE TIME] menu (8/11). Then, the integrated time

[34567 (hours)] (example) accumulated till the present time is displayed when the main power supply

is turned on (except for the standby mode).

USAGE TIME

34567H

232C-ALARM RX 0

T X 0

[MENU/ENTER] NEXT [EXIT] PREV 8/11

(3) When the keys are pressed in the order of [MUTE] → POSITION/CONTROL [ ] →

POSITION/CONTROL [ ] → [OFF TIMER], the display is cleared to [00000H]. At that time, the

characters of [RESET] are displayed for about 5 seconds on the right side of time display.

USAGE TIME

00000H RESET

232C-ALARM RX 0

T X 0

[MENU/ENTER] NEXT [EXIT] PREV 8/11

Page 32

2. Adjustment of the power unit (Using a screwdriver for general-purpose

32

adjustments)

2-1. Adjustment of the Vs voltage

(1) Enter a color bar input by means of either video signal of VIDEO input, or DVD/HD input, or RGB

input, and turn on the power switch of the main unit.

(2) Turn the volume control (RV6) in the power unit and make adjustments until the voltages of CH2 and

CH1 (D, GND) of the power unit attain the voltage values specified for the PDP (Vs value of the

voltage regulation indicator label on below the figure) ±1V.

2-2. Adjustment of the Vd voltage

(1) Enter a color bar input by means of either video signal of VIDEO input, or DVD/HD input, or RGB

input, and turn on the power switch of the main unit.

(2) Confirm that the voltages of CH4 and CH1 (D, GND) of the power unit are maintained at the voltage

values specified for the PDP (Vd value of the voltage regulation indicator label on below the figure)

±1V.

Otherwise, turn the volume control (RV5) until the voltage attains the voltage values specified for the

PDP (Vd value of the voltage regulation indicator label on below the figure) ±1V.

2-3. Adjustment of the +5V voltage

(1) Display a color bar by means of either video signal of VIDEO input, or DVD/HD input, or RGB input.

(2) Confirm that the voltages of CH3 and CH1 (D, GND) of the power unit are maintained at “5.15 ±

0.1V”. Otherwise, turn the volume control (RV2) until the voltage attains “5.15 ± 0.1V”.

SERIAL NO.

********

Vd= **V

Vs=***V

CODE -01

OR

Vs/Vd/100/185/220 V

555/84.2/782/10204 K

347 W/0 /2 P

(Caution) Rear-side view when the back cover is removed The label is concealed between the MAIN

PWB and PDP. Check it by peeping through the space from above. The label position can

be changed, without notice.

Page 33

* Top view of the power unit (Adjustment VR location)

V

33

P

V

P

M

P

N

Adjustmen

t of 5

RV3

D+3.3 ADJ

CH1

D.GND

CH3

Vcc

RV5

D+70 ADJ

PD

CH4

Vd

PH

CH2

Vs

Adjustment of

the Vs voltage

RV2

D+5 ADJ

RV6

D+170 ADJ

Adjustment of

P

A

the Vd voltage

AC

Page 34

34

3. Adjustments after the replacement of the MAIN PWB (Using the remote control)

3-1. Product serial No. registration

(1) Press the keys in the order of [POWER ON] → [POWER ON] → [EXIT] → [DISPLAY] in order to

enter the factory adjustment menu.

(2) Press the [MENU/ENTER] key to select the [MONITOR INFORMATION] No. menu. (Example : PDP

-614MX)

(3) Press the [WIDE] key 4 times to display a cursor in the lower column of [SERIAL/NUMBER].

MODEL NAME

: PDP-614MX

SERIAL/NUMBER

:

SOFT WARE VERSION

: F123

USAGE TIME

: 00000H

T1 025 T2 025

T3 025 T4 - -

[MENU/ENTER] NEXT [EXIT] PREV

MODEL NAME

: PDP-614MX

SERIAL/NUMBER

:

SOFT WARE VERSION

: F123

USAGE TIME

: 00000H

T1 025 T2 025

T3 025 T4 - -

[MENU/ENTER] NEXT [EXIT] PREV

MONITOR INFORMATION

MONITOR INFORMATION

(Caution 1)

(Caution 2)

(Caution 1) No modification is possible here because this modification is already finished by 3-2.

(Caution 2) No modification is possible here because registration is already finished at the time of

Factory shipment setting (initial setting).

shipment in terms of maintenance parts.

(4) Moving the POSITION/CONTROL keys of [ ] and [ ], select the numerals and characters of

the serial number that is listed in the serial label located on the rear surface of the product. Register

the serial number. (Blank → 0 ~ 9 → A ~ Z)

(5) Moving the POSITION/CONTROL keys of [ ] and [ ], select the next digit by means of a

cursor.

(6) Repeat the processes of (4) and (5) above and register the serial number completely.

Page 35

35

(Example) When entering a serial number of [DISS00001XX]

Move the POSITION/CONTROL keys of [ ] and [ ] to select [2].

MODEL NAME

: PDP-614MX

SERIAL/NUMBER

: D

SOFT WARE VERSION

: F123

USAGE TIME

: 00000H

T1 025 T2 025

T3 025 T4 - -

[MENU/ENTER] NEXT [EXIT] PREV

MONITOR INFORMATION

Move the POSITION/CONTROL keys of [ ] and [ ] to select the next digit.

MODEL NAME

: PDP-614MX

SERIAL/NUMBER

: D

SOFT WARE VERSION

: F123

USAGE TIME

: 00000H

T1 025 T2 025

T3 025 T4 - -

[MENU/ENTER] NEXT [EXIT] PREV

MONITOR INFORMATION

Page 36

36

Repeat the procedures of and above, and enter all inputs of [DISS00001XX] from the left side.

(7) Following the above, setting must be carried out without fail according to “3-2. Factory shipment

setting (Initial setting)”

MODEL NAME

: PDP-614MX

SERIAL/NUMBER

: 00001XXDISS

SOFT WARE VERSION

: F123

USAGE TIME

: 00000H

T1 025 T2 025

T3 025 T4 - -

[MENU/ENTER] NEXT [EXIT] PREV

MONITOR INFORMATION

3-2.Factory shipment setting (Initial setting)

(1) Press the [MENU/ENTER] ke to select the [FUNCTION] menu.

(2) Move the POSITION/CONTROL keys of [ ] and [ ] to the item of [SHIP]. Then, move the

POSITION/CONTROL keys of [ ] and [ ] to select [DESTINATION ALPHABETS] shown below.

(The asterisks * shown below denote the numerals or the characters.)

J : PDP-615PRO : Specifications for use in Japan

A : PDP-614MX / PRO-1410HD : Specifications for North America

G : PDP-615EX : Specifications for European countries

FUNCTION

SCART OFF SAFEL MODE ---

SHIP A PLE TEST OFF -LIMIT-VD OFF VD2 VLIM 5HZ

LIMIT-PC ON VD2 YCORB -GAMMA MD 12 VD2 YCOREN ON

VOL OFFSET 2 VD2 CORB -FHCRT COMP 3 VD2 COREN ON

ACTVH TIME 2 VD OUT 10

PSC-T OFF ROTATE PTN 1

EXT-PC OFF BLUE GAIN OFF

[MENU/ENTER] NEXT [EXIT] PREV

(3) Press the keys in the order of [MUTE] → POSITION/CONTROL [ ] → POSITION/CONTROL

[ ] → [OFF TIMER] to make “Factory shipment setting”. When “Factory shipment setting” is

executed, the red characters of [SET] is shown for about 5 seconds on the right side of the

[DESTINATION ALPHABETS]. The setting is finished when these red characters of [SET] go out. In

regard to the factory shipment setting values, refer to the descriptions given below.

Page 37

37

FUNCTION

SCART OFF SAFEL MODE--SHIP A SET PLE TEST OFF --

LIMIT-VD OFF VD2 VLIM 5HZ

LIMIT-PC ON VD2 YCORB 1

GAMMA MD 10 VD2 YCOREN ON

VOL OFFSET 2 VD2 CORB 1

FHCRT COMP 3 VD2 COREN ON

ACTVH TIME 2 VD OUT 8

PSC-T OFF ROTATE PTN 1

EXT-PC OFF BLUE GAIN OFF

[MENU/ENTER] NEXT [EXIT] PREV

(4) Press the keys of the remote control in the order of [POWER ON] → [POWER ON] → [EXIT] →

[DISPLAY] in order to withdraw from the Factory shipment setting.

[Factory shipment setting values]

1. Initial setting values for the user menu

MENU A,AW,G,GW,W,WW J,JW

POWER ON/OFF ON ON

VOLUME 10step 10step

INPUT MODE VIDEO1 VIDEO1

WIDE MODE STADIUM STADIUM

AUTO PICTURE OFF (RGB1~3) OFF (RGB1~3)

HD SELECT 1080B * 1080B

LANGUAGE ENGLISH JAPANEASE

COLOR SYSTEM AUTO AUTO

All items intended to recover the initial values

through the selection of [All Reset] in the user menu

* 1080I for *PX-***R**

2. Field menu initial setup values (applicable in common to all models)

MENU A G W J

SHIP A G W J AW,GW,

PSC-LIMIT OFF OFF OFF OFF OFF

LIMIT-PC ON ON ON ON ON

U-SCAN OFF OFF OFF OFF OFF

SERVICE

MONITOR

INFORMATION

V-FREQ OT AUTO 60Hz 60Hz AUTO AUTO

V-FREQ VD AUTO 60Hz 60Hz AUTO AUTO

SYNCLEVEL1 TTL TTL TTL TTL TTL

SYNCLEVEL2 TTL TTL TTL TTL TTL

SUB-ORB *1 ON ON ON ON ON

PIC FREEZE *1 ON ON ON ON ON

LOCATION USA Europe other Japan *2

Initial values Initial values

AW,GW,

WW,JW

WW,JW

*1:PX-50XM4/50XR4,PX-61XM3/61XR3 Selies only.

*2:Monitor information when SHIP is for AW, GW, WW, JW setup

Page 38

Removing the BACK COVER

38

(5)SRW33

(5)SRW33

PL-CPIMS*4*12*15KFE

PL-CPIMS*4*12*15KFE

29N01431 *14p

29N01431 *14p

(1)SRW34

(1)SRW34

PL-CPIMS*4*16*3KF

PL-CPIMS*4*16*3KF

910E4066 *4p

910E4066 *4p

M31 GS COVER

M31 GS COVER

29H02782

29H02782

(Caution) Replacement is

(Caution) Replacement is

impossible unless the NAME

impossible unless the NAME

PLATE is removed.

PLATE is removed.

M03 SERIAL LABEL

M03 SERIAL LABEL

24L44731

24L44731

(Caution) This is not a service part.

(Caution) This is not a service part.

M56 SPEAKER LABEL

M56 SPEAKER LABEL

29L03552

29L03552

(3)SRW35 PL-CPIMS*3*10*15KFE

(3)SRW35 PL-CPIMS*3*10*15KFE

29N01431 *14p

29N01431 *14p

(4)SRW32

(4)SRW32

CBIPS*4*12*15KFE

CBIPS*4*12*15KFE

29N01401 *12p

29N01401 *12p

M57 NAME PLATE

M57 NAME PLATE

M55 AC IN LABEL

M55 AC IN LABEL

29L00491

29L00491

(2)M18 HANDLE

(2)M18 HANDLE

29F00591 *2p

29F00591 *2p

(6)M58 BACK COVER(61XM2)

(6)M58 BACK COVER(61XM2)

29P01271

29P01271

M63 LABEL(EARTH)

M63 LABEL(EARTH)

24L44791

24L44791

(Caution) To be used only for the PX-61XM3.

(Caution) To be used only for the PX-61XM3.

Page 39

Removing the POWER UNIT

39

(2)PSU POWER UNIT

(2)PSU POWER UNIT

3S110161

3S110161

(1)SRW14 PL-CPIMS*4*12*15KFE

(1)SRW14 PL-CPIMS*4*12*15KFE

29N01441 *6p

29N01441 *6p

Page 40

Removing the upper CHASSIS ASSY

40

(6)SRW05,06 PL-CPIMS*6*20*15KFE

(6)SRW05,06 PL-CPIMS*6*20*15KFE

29N01451 *10p

29N01451 *10p

(7)SRW07,08,09,11,13

(7)SRW07,08,09,11,13

PL-CPIMS*4*12*15KFE

PL-CPIMS*4*12*15KFE

29N01441 *22p

29N01441 *22p

(4)CONNECTOR

(4)CONNECTOR

(5)CONNECTOR 4p

(5)CONNECTOR 4p

(Caution) Remove the ferrite

(Caution) Remove the ferrite

core first.

core first.

(3)SRW17 TP-M3*6*3KF

(3)SRW17 TP-M3*6*3KF

24N04581

24N04581

(Caution) For mounting, it should

(Caution) For mounting, it should

be tightened together with the

be tightened together with the

round terminal of the AD cable.

round terminal of the AD cable.

(8)CHASSIS ASSY

(8)CHASSIS ASSY

(2)M40 SHIELD COVER MAIN

(2)M40 SHIELD COVER MAIN

29H03021

29H03021

(1)SRW31 PL-CPIMS*4*12*15KFE

(1)SRW31 PL-CPIMS*4*12*15KFE

29N01481 *8p

29N01481 *8p

Page 41

PDP Panel Assembly

41

(4)CN-PH CN 9P(PH) 360W,1007-20

(4)CN-PH CN 9P(PH) 360W,1007-20

7SW9W008

7SW9W008

(3)CN-PD CN 10P(PD) 920W,1007-20

(3)CN-PD CN 10P(PD) 920W,1007-20

7SW0W010

7SW0W010

(5)PDP PDP-NP61C2MF01AA

(5)PDP PDP-NP61C2MF01AA

3S361002

3S361002

(2)CN-AD CABLE 31P L390

(2)CN-AD CABLE 31P L390

(1) SCREW

(1) SCREW

(Caution) This screw is used

(Caution) This screw is used

to fasten the PWB of the PDP.

to fasten the PWB of the PDP.

The right bottom corner is regarded

The right bottom corner is regarded

as the mounting basis.

as the mounting basis.

7S530036

7S530036

Page 42

PDP MODULE

42

PARTS LIST (61 Inch Models)

PART NAME

NAME VER *1

1 PKG61C2F1 02C 9S899790 1

2 PKG61C2G1 02A 9S899669 1

3 PKG61C2C1 05C-27 9S899791 1

PKG61C2C1 05D-27 9S899731 1

PKG61C2C1 05C-28 9S899792 1

PKG61C2C1 05D-28 9S899793 1

4 PKG61C2G2 02A 9S899670 1

5 PKG61C2G3 02A 9S899671 1

6 PKG61C2E1 02B 9S899660 1

7 PKG61C2E2 02B 9S899661 1

8 PKG61C2J1 01B 9S899583 1

9 PKG61C2J2 01B 9S899584 1

10 PKG61C2J3 01B 9S899585 1

11 PKG61C2J4 01B 9S899586 1

12 PKG61C2J5 01B 9S899587 1

13 PKG61C2J6 01B 9S899588 1

14 PKG61C2J7 01A 9S899589 1

PART No. Qty NOTE

Scanning PKG

Common PKG

Digital PKG

Cf. interchangeability list

Common Branch PKG (upper)

Common Branch PKG (lower)

Scanning Relay PKG (upper)

Scanning Relay PKG (lower)

Signal Relay PKG (upper left)

Signal Relay PKG (upper center)

Signal Relay PKG (upper right)

Signal Relay PKG (lower left)

Signal Relay PKG (lower center)

Signal Relay PKG (lower right)

Recovery Relay PKG

*1 : Version number of the Board Assy (PKG) is written down in the Board Assy itself.

8 9 10

14

4

5

12

6

7

11

3

12

13

Page 43

Board ASSY interchangeability list 61 Inch Models)

43

Note:In the Board ASSY (PKG) replacement, You can exchange it in a version of high rank than a

replacement target version besides a compatible version.

Digital PKG follows the following list, and exchange it.

Digital PKG

PKG61C2C1

Replacement Target Version Compatible Version

01A - 00, 01, 02, 03

01B - 03, 05, 07, 11

02A - 03,

02B - 03, 05, 07, 11

02C - 10, 17, 21

03B - 13, 15, 25

03C - 23, 25, 27

04C - 23, 25, 27

04D - 25, 27

05C - 25, 27

05D - 25, 27

01B - 04, 06, 08, 12

02B - 04, 06, 08, 12

02C - 18, 22

03B - 14, 16

03C - 24, 28

04C - 24, 26, 28

04D - 26, 28

05C - 26, 28

05D - 26, 28

Exchange it for

05C-27 (9S899791)

or

05D-27 (9S899731).

Exchange it for

05C-28 (9S899792)

or

05D-28 (9S899793).

Page 44

PDP-614MX & PRO-1410HD

44

CONNECTOR PIN EXPLANATION

(Caution) The operating voltages specified below are used in common irrespective of the presence of signals. In this case, however, part of the operating voltages (red characters) may change according

to the signal conditions when the main power supply is turned on (POWER button ON).

Status of LED lighting: ★ for lighting in green, ★★ for unlighting, and ★★★ for lighting in red. Vol.1

Pin No. Pin name Function

Name

PN 1 D+3.3 0 3.3 3.3 0 0 0

2 D+3.3 0 3.3 3.3 0 0 0

3 D+3.3 0 3.3 3.3 0 0 0

4 D.GND GND 000000

5 D.GND GND 000000

6 D.GND GND 000000

7 D+2.5 0 2.5 2.5 0 0 0

8 D+2.5 0 2.5 2.5 0 0 0

9 D+2.5 0 2.5 2.5 0 0 0

10 D.GND GND 000000

11 D.GND GND 000000

12 D.GND GND 000000

PM 1 M+7 6.8 6.8 6.8 6.8 6.8 6.8

2 D.GND GND 000000

3 POWER Power control 0 4.9 4.9 0 0 0

4 D.GND GND 000000

5 POMUTE Mute signal for AC power OFF 4.8 4.8 4.8 4.8 4.8 4.8

6 SW7 Power start control 0 6.8 6.8 6.8 6.8 0

7

PV 1 A+12 12V power supply for analog circuits 0 12 12 0 0 0

AU 1 AU_L Audio signal L

RS 1 M+5V 5V power supply for microcomputer 055550

NC

2 A.GND GND 000000

3 A+6 6V power supply for analog circuits 066000

4 A+6 6V power supply for analog circuits 066000

5 A.GND GND 000000

6 A.GND GND 000000

7 NC Non-connection terminal ------

8 NC Non-connection terminal ------

2GNDGND 000000

3 AU_R Audio signal R

4GNDGND 000000

5 MUTE Mute signal of audio output 3.5

6 SCL7 Clock line of the I2C bus 0 Clock signal

7 SDA7 Data line of the I2C bus 0 Clock signal

2 TXD RS232 driver output 0 Clock signal

3GNDGND 000000

4 RXD RS232 receiver input 0 Clock signal

5 M+3.3V 3.3V power supply for microcompute

6GNDGND 000000

7 REMIN2/RXD1Data signal of

8 RESET SW NC ------

9 PLE_CTL PLE control 42VM5

10 TXD1 RS232 driver

3.3V power supply for digital circuits

3.3V power supply for digital circuits

3.3V power supply for digital circuits

2.5V power supply for digital circuits

2.5V power supply for digital circuits

2.5V power supply for digital circuits

7V power supply for microcomputer

Non-connection terminal ------

CH

CH

wired remote

control

output

42VM5

42VP5

42XM3

50XM4

61XM3

42VR5

42XR3

50XR4

61XR3

42VP5

42XM3

50XM4

61XM3

42VR5

42XR3

50XR4

61XR3

42VM5

42VP5

42XM3

50XM4

61XM3

Basic operation (Numerical unit: Vdc; except for the case when units are individually indicated)

AC power ON

(Power cord

connected to

the wall outlet)

★★

r 0 3.3 3.3 3.3 3.3 0

Main power ON

(POWER button ON) ★

No signal With signal

0 Selected input

signals are

output.

0 Selected input

signals are

output.

(5Vac) when

data are

received; 5Vdc

when no data

are received.

(5Vac) when

data are

received; 5Vdc

when no data

are received.

used during

data

transmission

(3.3Vac)

3.3Vdc when

no data are

received.

(3.3Vac) when

data are

received;

3.3Vdc when

no data are

received.

0 Clock signal

(3.3Vac) when

data are

received;

3.3Vdc when

no data are

received.

000000 -

0 3.3V duning

data

transmission

for Video

WOLL

0V when no

data are

transmitted

000000 -

0 Clock signal

used during

data

transmission

(5Vac) 5Vdc

when no data

are

transmitted.

Selected input

signals are

output.

Selected input

signals are

output.

3.5→0 3.5→0

Clock signal

(5Vac) when

data are

received; 5Vdc

when no data

are received.

Clock signal

(5Vac) when

data are

received; 5Vdc

when no data

are received.

Clock signal

used during

data

transmission

(3.3Vac)

3.3Vdc when

no data are

received.

Clock signal

(3.3Vac) when

data are

received;

3.3Vdc when

no data are

received.

Clock signal

(3.3Vac) when

data are

received;

3.3Vdc when

no data are

received.

3.3V duning

data

transmission

for Video

WOLL

0V when no

data are

transmitted

Clock signal

used during

data

transmission

(5Vac) 5Vdc

when no data

are

transmitted.

Power

management

★★

000 -

000 -

3.5

000 -

110 -

Clock signal

used during

data

transmission

(3.3Vac)

3.3Vdc when

no data are

received.

Clock signal

(3.3Vac) when

data are

received;

3.3Vdc when

no data are

received.

Clock signal

(3.3Vac) when

data are

received;

3.3Vdc when

no data are

received.

3.3V duning

data

transmission

for Video

WOLL

0V when no

data are

transmitted

Clock signal

used during

data

transmission

(5Vac) 5Vdc

when no data

are

transmitted.

Clock signal

used during

data

transmission

(3.3Vac)

3.3Vdc when

no data are

received.

Clock signal

(3.3Vac) when

data are

received;

3.3Vdc when

no data are

received.

Clock signal

(3.3Vac) when

data are

received;

3.3Vdc when

no data are

received.

Main power

Standby

★★★

OFF

★★

3.5→0

00 -

00 -

AC power OFF

(Power cord

pulled out of

the wall outlet)

3.5

0

0-

0-

Signal direction

★★

-

POWER→MAIN

-

POWER→MAIN

-

POWER→MAIN

-

-

-

-

POWER→MAIN

-

POWER→MAIN

-

POWER→MAIN

-

-

-

-

POWER→MAIN

-

-

MAIN→POWER

-

4.8→-

POWER→MAIN

-

POWER→MAIN

POWER→MAIN

-

-

-

POWER→MAIN

-

POWER→MAIN

-

-

-

-

MAIN→AUDIO

-

MAIN→AUDIO

-

3.5→- MAIN→AUDIO

MAIN→AUDIO

MAIN→AUDIO

-

MAIN→RS232C

MAIN→RS232C

-

RS232C→MAIN

-

MAIN→RS232C

RS232C→MAIN

MAIN→RS232C

MAIN→RS232C

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Page 45

Basic operation (Numerical unit: Vdc; except for the case when units are individually indicated)

45

AC power ON

Pin No. Pin name Function

Name

42VR5

42XR3

50XR4

11 232C_SHUT ON/OFF control for TXD0 driver 0 3.3 3.3 3.3 3.3 0 12 REM Insertion

TM 1 SCL5 Clock line of the I2C bus 0 Clock signal

2GNDGND 000000 -3 VDD+3.3V 3.3V power supply for analog signals 0 3.3 3.3 0 0 0

4 SDA5 Data line of the I2C bus 0 During data

TR 1 SCL5 Clock line of the I2C bus 0 Clock signal

2GNDGND 000000 -3 VDD+3.3V 3.3V power supply for analog signals 0 3.3 3.3 0 0 0

4 SDA5 Data line of the I2C bus 0 During data

TS 1 SCL5 Clock line of the I2C bus 0 Clock signal

2GNDGND 000000 -3 VDD+3.3V 3.3V power supply for analog signals 0 3.3 3.3 0 0 0

4 SDA5 Data line of the I2C bus 0 During data

FA 1 FAN-CTL Voltage-

2GNDGND 000000

3 ALARM 42VM5

detection for

wired remote

control input

controllable

power supply

signal output

61XR3

42VM5

42VP5

42XM3

50XM4

61XM3

42VR5

42XR3

50XR4

61XR3

42VM5

42VP5

42VR5

42XM3

42XR3

50XM4

50XR4

61XM3

61XR3

42VP5

42VR5

(Power cord

connected to

the wall outlet)

★★

Main power ON

(POWER button ON) ★

No signal With signal

000000 -

0 3.3V when a

wired remote

control is

connected/

When not

connected.

-------(NC for Model R)

used during

data

transmission

(3.3Vac)

3.3Vdc when

no data are

transmitted.

exchange:

Clock signal

(3.3Vac), Data

not

exchanged:

3.3Vdc

used during

data

transmission

(3.3Vac)

3.3Vdc when

no data are

transmitted.

exchange:

Clock signal

(3.3Vac), Data

not

exchanged:

3.3Vdc

used during

data

transmission

(3.3Vac)

3.3Vdc when

no data are

transmitted.

exchange:

Clock signal

(3.3Vac), Data

not

exchanged:

3.3Vdc

--------

0 11.5Vdc

during highspeed

revolution

(Fan mode H);

8.5Vdc during

medium speed

revolution

(Fan mode M);

6.5Vdc during

low-speed

revolution

(Fan mode L)

0 11.6Vdc

during highspeed

revolution

(Fan mode H);

7.8Vdc during

medium speed

revolution

(Fan mode M);

5.3Vdc during

low-speed

revolution

(Fan mode L)

0 9.3Vdc during

high-speed

revolution

(Fan mode H);

7.6Vdc during

medium speed

revolution

(Fan mode M);

5.3Vdc during

low-speed

revolution

(Fan mode L)

--------FAN lock detect

3.3V when a

wired remote

control is

connected/

When not

connected.

Clock signal

used during

data

transmission

(3.3Vac)

3.3Vdc when

no data are

transmitted.

During data

exchange:

Clock signal

(3.3Vac), Data

not

exchanged:

3.3Vdc

Clock signal

used during

data

transmission

(3.3Vac)

3.3Vdc when

no data are

transmitted.

During data

exchange:

Clock signal

(3.3Vac), Data

not

exchanged:

3.3Vdc

Clock signal

used during

data

transmission

(3.3Vac)

3.3Vdc when

no data are

transmitted.

During data

exchange:

Clock signal

(3.3Vac), Data

not

exchanged:

3.3Vdc

11.5Vdc

during highspeed

revolution

(Fan mode H);

8.5Vdc during

medium speed

revolution

(Fan mode M);

6.5Vdc during

low-speed

revolution

(Fan mode L)

11.6Vdc

during highspeed

revolution

(Fan mode H);

7.8Vdc during

medium speed

revolution

(Fan mode M);

5.3Vdc during

low-speed

revolution

(Fan mode L)

9.3Vdc during

high-speed

revolution

(Fan mode H);

7.6Vdc during

medium speed

revolution

(Fan mode M);

5.3Vdc during

low-speed

revolution

(Fan mode L)

Power

management

3.3V when a

wired remote

control is

connected/

When not

connected.

Standby

★★

★★★

3.3V when a

wired remote

control is

connected/

When not

connected.

000 -

000

000 -

000

000 -

000

000 -

000 -

000 -

AC power OFF

Main power

(Power cord

pulled out of

OFF

the wall outlet)

★★

0-

★★

-

-

-

-

-

-

-

Signal direction

MAIN→RS232C

RS232C→MAIN

MAIN→SENB

MAIN→SENB

MAIN←→SENB

SENB→SEND

SENB→SEND

SENB←→SEND

SEND→SENC

SEND→SENC

SEND←→SENC

MAIN→FAN

-

Page 46

Basic operation (Numerical unit: Vdc; except for the case when units are individually indicated)

46

AC power ON

Pin No. Pin name Function

Name

42XM3

42XR3

50XM4

50XR4

61XM3

FB 1 FAN-CTL Voltage-

2GNDGND 000000

3 ALARM 42VM5

FC 1 FAN-CTL Voltage-

2GNDGND 000000

3 ALARM 42VM5

AD1GNDGND 000000

2GNDGND 000000

3 ALARM Module alarm signal 0 5Vdc during

4 GND GND 0 0 0 0 0 0

controllable

power supply

FAN lock detect

signal output

controllable

power supply

FAN lock detect

signal output

61XR3

42VM5

42VP5

42VR5

42XM3

42XR3

50XM4

50XR4

61XM3

61XR3

42VP5

42VR5

42XM3

42XR3

50XM4

50XR4

61XM3

61XR3

42VM5

42VP5

42VR5

42XM3

42XR3

50XM4

50XR4

61XM3

61XR3

42VP5

42VR5

42XM3

42XR3

50XM4

50XR4

61XM3

61XR3

(Power cord

connected to

the wall outlet)

★★

Main power ON

(POWER button ON) ★

No signal With signal

0 0V during

normal fan

operation;3.3V

dc while the

fan is stopped.

--------

0 11.5Vdc

during highspeed

revolution

(Fan mode H);

8.5Vdc during

medium speed

revolution

(Fan mode M);

6.5Vdc during

low-speed

revolution

(Fan mode L)

0 11.6Vdc

during highspeed

revolution

(Fan mode H);

7.8Vdc during

medium speed

revolution

(Fan mode M);

5.3Vdc during

low-speed

revolution

(Fan mode L)

0 9.3Vdc during

high-speed

revolution

(Fan mode H);

7.6Vdc during

medium speed

revolution

(Fan mode M);

5.3Vdc during

low-speed

revolution

(Fan mode L)

--------

0 0V during

normal fan

operation;3.3V

dc while the

fan is stopped.

--------

0 9.3Vdc during

high-speed

revolution

(Fan mode H);

7.6Vdc during

medium speed

revolution

(Fan mode M);

5.3Vdc during

low-speed

revolution

(Fan mode L)

--------

0 0V during

normal fan

operation;3.3V

dc while the

fan is stopped.

normal PDP

operation; 0V

when the PDP

is out of order.

0V during

normal fan

operation;3.3V

dc while the

fan is stopped.

11.5Vdc

during highspeed

revolution

(Fan mode H);

8.5Vdc during

medium speed

revolution

(Fan mode M);

6.5Vdc during

low-speed

revolution

(Fan mode L)

11.6Vdc

during highspeed

revolution

(Fan mode H);

7.8Vdc during

medium speed

revolution

(Fan mode M);

5.3Vdc during

low-speed

revolution

(Fan mode L)

9.3Vdc during

high-speed

revolution

(Fan mode H);

7.6Vdc during

medium speed

revolution

(Fan mode M);

5.3Vdc during

low-speed

revolution

(Fan mode L)

0V during

normal fan

operation;3.3V

dc while the

fan is stopped.

9.3Vdc during

high-speed

revolution

(Fan mode H);

7.6Vdc during

medium speed

revolution

(Fan mode M);

5.3Vdc during

low-speed

revolution

(Fan mode L)

0V during

normal fan

operation;3.3V

dc while the

fan is stopped.

5Vdc during

normal PDP

operation; 0V

when the PDP

is out of order.

Power

management

Standby

★★

★★★

000 -

000 -

000 -

000 -

000 -

000 -

000 -

000 -

Main power

OFF

★★

AC power OFF

(Power cord

pulled out of

the wall outlet)

★★

Signal direction

-

-

-

-

-

FAN→MAIN

MAIN→FAN

-

FAN→MAIN

FAN→MAIN

-

FAN→MAIN

-

-

PDP→MAIN

-

Page 47

Basic operation (Numerical unit: Vdc; except for the case when units are individually indicated)

play

47

AC power ON

Pin No. Pin name Function

Name

5 PS+ PSS input PS+ 0 PSS LVDS

6 PS- PSS input PS- 0 PSS LVDS

7 MSEL 42V5 compatible interface OFF 000000

8GNDGND 000000

9 RH+ OSD system output H+ 0 OSD LVDS

10 RH- OSD system output H– 0 OSD LVDS

11 RG+ OSD system output G+ 0 OSD LVDS

12 RG- OSD system output G- 0 OSD LVDS

13 RF+ Mode system output F+ 0 Video mode

14 RF- Mode system output F- 0 Video mode

15GNDGND 000000

16 RE+ Video system output E+ 0 Video mode

17 RE- Video system output E- 0 Video mode

18 RD+ Video system output D+ 0 Video mode

19 RD- Video system output D– 0 Video mode

(Power cord

connected to

the wall outlet)

★★

Main power ON

(POWER button ON) ★

No signal With signal

serial differen

tial PS+ input

0Vac; Bias

1.1Vdc

serial differen

tial PS+ input

0Vac; Bias

1.4Vdc

serial

differential H+

output 0Vac;

Bias 1.1Vdc

serial

differential Houtput 0Vac;

Bias 1.4Vdc

serial

differential G+

output 0.3Vac;

Bias 1.25Vdc

serial

differential Goutput 0.3Vac;

Bias 1.25Vdc

LVDS serial

differential F+

output 0.3Vac;

Bias 1.25Vdc

LVDS serial

differential Foutput 0.3Vac;

Bias 1.25Vdc

LVDS serial

differential E+

output 0Vac;

Bias 1.1Vdc

LVDS serial

differential Eoutput 0Vac;

Bias 1.4Vdc

LVDS serial

differential D+

output 0Vac;

Bias 1.1Vdc

LVDS serial

differential Doutput 0Vac;

Bias 1.4Vdc

PSS LVDS

serial differen

tial PS+ input

0.3Vac; Bias

1.25Vdc

PSS LVDS

serial differen

tial PS+ input

0.3Vac; Bias

1.25Vdc

OSD LVDS

serial

differential H+

output 0Vac;

Bias 1.1Vdc

OSD LVDS

serial

differential Houtput 0Vac;

Bias 1.4Vdc

OSD LVDS

serial

differential G+

output 0.3Vac;

Bias 1.25Vdc

OSD LVDS

serial

differential Goutput 0.3Vac;

Bias 1.25Vdc

Video mode

LVDS serial

differential F+

output 0.3Vac;

Bias 1.25Vdc

Video mode

LVDS serial

differential Foutput 0.3Vac;

Bias 1.25Vdc

Video mode

LVDS serial

differential E+

output 0Vac;

Bias 1.1Vdc

* Only for the

PX-42VP4

Series, 0.3Vac

and bias 1.25

Vdc in theater

mode when

60Hz motion

pictures are

displayed.

Video mode

LVDS serial

differential Eoutput 0.3Vac;

Bias 1.25Vdc

* Only for the

PX-42VP4

Series, 0.3Vac

and bias 1.25

Vdc in theater

mode when

60Hz motion

pictures are

dis

Video mode

LVDS serial

differential D+

output 0.3Vac;

Bias 1.25Vdc

Video mode

LVDS serial

differential Doutput 0.3Vac;

Bias 1.25Vdc

Power

management

★★

000 -

000 -

000 -

000 -

000 -

000 -

000 -

000 -

000 -

000 -

ed.

000 -

000 -

Standby

★★★

Main power

OFF

★★

AC power OFF

(Power cord

pulled out of

the wall outlet)

★★

Signal direction

-

-

-

PDP→MAIN

PDP→MAIN

-

-

MAIN→PDP

MAIN→PDP

MAIN→PDP

MAIN→PDP

MAIN→PDP

MAIN→PDP

-

MAIN→PDP

MAIN→PDP

MAIN→PDP

MAIN→PDP

Page 48

Basic operation (Numerical unit: Vdc; except for the case when units are individually indicated)

48

AC power ON

Pin No. Pin name Function

Name

20 RCLK+ Video system output clock+ 0 Video data

21 RCLK- Video system output clock– 0 Video data

22GNDGND 000000

23 RC+ Video system output C+ 0 Video data

24 RC- Video system output C– 0 Video data

25 RB+ Video system output B+ 0 Video data

26 RB- Video system output B– 0 Video data

27 RA+ Video system output A+ 0 Video data

28 RA- Video system output A– 0 Video data

29GNDGND 000000

30 GND GND 000000

31 GND GND 000000

LD 1 REMIN1 Infrared remote control data 0 Clock signal

2 LEDCTL1 Standby red LED control 0 0 0 3.3 3.3 0

3 LEDCTL2 POWER ON green LED control 0 3.3 3.3 0 0 0

4GNDGND 000000

5 M+5V 5V power supply for microcomputer 055550

PW 1 SW7 Power start control 0 6.8 6.8 6.8 6.8 0

2 POIN Power start detection 0 3.3 3.3 3.3 3.3 0

3GNDGND 000000

4 M+5V 5V power supply for microcomputer 055550

5 M+7V 7V power supply for microcomputer 0 6.8 6.8 6.8 6.8 6.8

6 REMIN1 Infrared remote control data 0 Clock signal

7 LEDCTL1 Standby red LED control 0 0 0 3.3 3.3 0

8 LEDCTL2 POWER ON green LED control 0 3.3 3.3 0 0 0

SW 1 CTL1 Key input detection 0 0.7~2.8Vdc

2 CTL2 Key input detection 0 0.7~2.8Vdc

3GNDGND 000000

PA 1 S+12 +12V power supply for audio circuits 0 12 12 0 0 0

2 S+12 +12V power supply for audio circuits 0 12 12 0 0 0

3 S+12 +12V power supply for audio circuits 0 12 12 0 0 0

4GNDGND 000000

(Power cord

connected to

the wall outlet)

★★

Main power ON

(POWER button ON) ★

No signal With signal

clock LVDS

serial

differential

clock+ output

0.3Vac; Bias

1.25Vdc

clock LVDS

serial

differential

clock- output

0.3Vac; Bias

1.25Vdc

LVDS serial

differential C+

output 0.3Vac;

Bias 1.25Vdc

LVDS serial

differential Coutput 0.3Vac;

Bias 1.25Vdc

LVDS serial

differential B+

output 0Vac;

Bias 1.1Vdc

LVDS serial

differential Boutput 0Vac;

Bias 1.4Vdc

LVDS serial

differential A+

output 0Vac;

Bias 1.1Vdc

LVDS serial

differential Aoutput 0Vac;

Bias 1.4Vdc

(5Vac) when

data are

received; 5Vdc

when no data

are received.

(5Vac) when

data are

received; 5Vdc

when no data

are received.

when key

inputs are

entered;

3.3Vdc when

no key inputs

are entered.

when key

inputs are

entered;

3.3Vdc when

no key inputs

are entered.

Video data

clock LVDS

serial

differential

clock+ output

0.3Vac; Bias

1.25Vdc

Video data

clock LVDS

serial

differential

clock- output

0.3Vac; Bias

1.25Vdc

Video data

LVDS serial

differential C+

output 0.3Vac;

Bias 1.25Vdc

Video data

LVDS serial

differential Coutput 0.3Vac;

Bias 1.25Vdc

Video data

LVDS serial

differential B+

output 0Vac;

Bias 1.1Vdc

Video data

LVDS serial

differential Boutput 0.3Vac;

Bias 1.25Vdc

Video data

LVDS serial

differential A+

output 0.3Vac;

Bias 1.25Vdc

Video data

LVDS serial

differential Aoutput 0.3Vac;

Bias 1.25Vdc

Clock signal

(5Vac) when

data are

received; 5Vdc

when no data

are received.

Clock signal

(5Vac) when

data are

received; 5Vdc

when no data

are received.

0.7~2.8Vdc

when key

inputs are

entered;

3.3Vdc when

no key inputs

are entered.

0.7~2.8Vdc

when key

inputs are

entered;

3.3Vdc when

no key inputs

are entered.

Power

management

★★

000 -

000 -

000 -

000 -

000 -

000 -

000 -

000 -

Clock signal

(5Vac) when

data are

received; 5Vdc

when no data

are received.

Clock signal

(5Vac) when

data are

received; 5Vdc

when no data

are received.

0.7~2.8Vdc

when key

inputs are

entered;

3.3Vdc when

no key inputs

are entered.

0.7~2.8Vdc

when key

inputs are

entered;

3.3Vdc when

no key inputs

are entered.

Clock signal

(5Vac) when

data are

received; 5Vdc

when no data

are received.

Clock signal

(5Vac) when

data are

received; 5Vdc

when no data

are received.

0.7~2.8Vdc

when key

inputs are

entered;

3.3Vdc when

no key inputs

are entered.

0.7~2.8Vdc

when key

inputs are

entered;

3.3Vdc when

no key inputs

are entered.

Standby

★★★

Main power

OFF

★★

AC power OFF

(Power cord