Page 1

PDP-424MV

PLASMA DISPLAY

PDP-424MV

PDP-42MVE1

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

ORDER NO.

ARP3253

Model Type Power Requirement Remarks

PDP-424MV LUC AC120V

PDP-42MVE1 LDFK AC110-120V/220-240V

PDP-42MVE1 TXGB AC110-240V

For details, refer to "Important Check Points for good servicing" .

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2005

T – ZZR JAN. 2005 Printed in Japan

Page 2

CONTENTS

SAFETY INFORMATION ......................................................................................................... 2-1

SPECIFICATIONS.................................................................................................................... 3-1

TABLE OF SIGNAL SUPPORTED ........................................................................................... 4-1

PANEL FACILITIES .................................................................................................................. 5-1

PA RTS LIST ............................................................................................................................. 6-1

HOW TO DIAGNOSE THE PDP MODULE .............................................................................. 7-1

TROUBLESHOOTING ............................................................................................................. 8-1

METHOD OF ADJUSTMENTS ................................................................................................ 9-1

METHOD OF DISASSEMBLY................................................................................................ 10-1

METHOD OF PACKAGING.................................................................................................... 11-1

CONNECTION DIAGRAMS ................................................................................................... 12-1

CONNECTOR PIN EXPLANATION ....................................................................................... 13-1

BLOCK DIAGRAM ................................................................................................................. 14-1

2

1-1

Page 3

SAFETY INFORMATION

This service manual is intended for qualified service technicians ; it is not meant for the casual doit-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely,

you should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to

cause cancer, birth defects or other reproductive harm.

Health & Safety Code Section 25249.6 - Proposition 65

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement parts

must be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les pièces

de remplacement doivent avoir la même désignation.

SAFETY PRECAUTIONS

NOTICE : Comply with all cautions and safety related notes

located on or inside the cabinet and on the chassis.

The following precautions should be observed :

1. When service is required, even though the PDP UNIT an

isolation transformer should be inserted between the power line

and the set in safety before any service is performed.

2. When replacing a chassis in the set, all the protective devices

must be put back in place, such as barriers, nonmetallic knobs,

adjustment and compartment covershields, isolation resistorcapacitor, etc.

3. When service is required, observe the original lead dress. Extra

precaution should be taken to assure correct lead dress in the

high voltage circuitry area.

4. Always use the manufacture's replacement components.

Especially critical components as indicated on the circuit

diagram should not be replaced by other manufacture's.

Furthermore where a short circuit has occurred, replace those

components that indicate evidence of overheating.

5. Before returning a serviced set to the customer, the service

technician must thoroughly test the unit to be certain that it is

completely safe to operate without danger of electrical shock,

and be sure that no protective device built into the set by the

manufacture has become defective, or inadvertently defeated

during servicing. Therefore, the following checks should be

performed for the continued protection of the customer and

servicetechnician.

6. Perform the following precautions against unwanted radiation

and rise in internal temperature.

• Always return the internal wiring to the original styling.

• Attach parts (Gascket, Ferrite Core, Ground, Rear Cover,

Shield Case etc.) surely after disassembly.

7. Perform the following precautions for the PDP panel.

• When the front case is removed, make sure nothing hits the

panel face, panel corner, and panel edge (so that the glass does

not break).

• Make sure that the panel vent does not break. (Check that the

cover is attached.)

• Handle the FPC connected to the panel carefully.

Twisting or pulling the FPC when connecting it to the

connector will cause it to peel off from the panel.

8. Pay attention to the following.

• When the front case is removed, infrared ray is radiated and

may disturb reception of the remote control unit.

• Pay extreme caution when the front case and rear panel are

removed because this may cause a high risk of disturbance to

TVs and radios in the surrounding.

2-1

3

Page 4

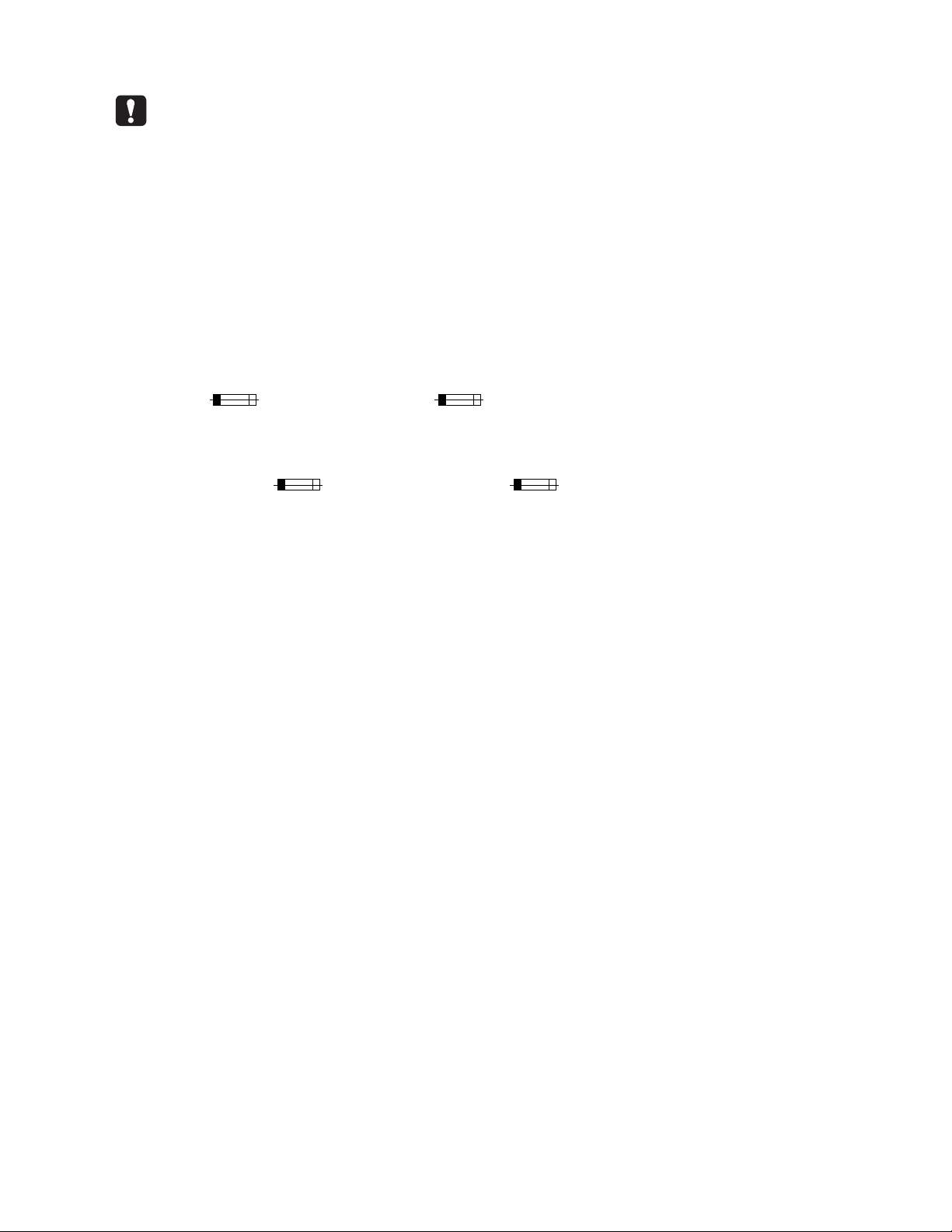

Leakage Current Cold Check

With the AC plug removed from an AC power source, place a

jumper across the two plug prongs. Turn the AC power switch on.

Using an insulation tester (DC 500V), connect one lead to the

jumpered AC plug and touch the other lead to each exposed metal

part (input/output terminals, screwheads, metal overlays, control

shafts, etc.), particularly any exposed metal part having a return

path to the chassis. Exposed metal parts having a return path to

the chassis should have a minimum resistor reading of 0.3MΩ

and a maximum resistor reading of 5MΩ. Any resistor value

below or above this range indicates an abnormality which requires

corrective action. Exposed metal parts not having a return path to

the chassis will indicate an open circuit.

Leakage Current Hot Check

Plug the AC line cord directly into an AC power source (do not

use an isolation transformer for this check).

Turn the AC power switch on.

Using a "Leakage Current Tester (Simpson Model 229

equivalent)", measure for current from all exposed metal parts of

the cabinet (input/output terminals, screwheads, metal overlays,

control shaft, etc.), particularly any exposed metal part having a

return path to the chassis, to a known earth ground (water pipe,

conduit, etc.). Any current measured must not exceed 0.5mA.

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in PIONEER set have

special safety related characteristics. These are often not evident

from visual inspection nor the protection afforded by them

necessarily can be obtained by using replacement components

rated for higher voltage, wattage, etc. Replacement parts which

have these special safety characteristics are identified in this

Service Manual.

Electrical components having such features are identified by

marking with a on the schematics and on the parts list in this

Service Manual.

The use of a substitute replacement component which dose not

have the same safety characteristics as the PIONEER

recommended replacement one, shown in the parts list in this

Service Manual, may create shock, fire or other hazards.

Product Safety is continuously under review and new instructions

are issued from time to time. For the latest information, always

consult the current PIONEER Service Manual. A subscription to,

or additional copies of, PIONEER Service Manual may be

obtained at a nominal charge from PIONEER.

Reading should

not be above

0.5mA

Earth

ground

Device

under

test

Also test with

plug reversed

(Using AC adapter

plug as required)

Leakage

current

tester

Test all

exposed metal

surfaces

AC Leakage Test

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE SET TO THE CUSTOMER.

4

2-2

Page 5

2-3

5

Page 6

6

2-4

Page 7

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

0 Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

Make sure the proper amount is applied.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

7

2-5

Page 8

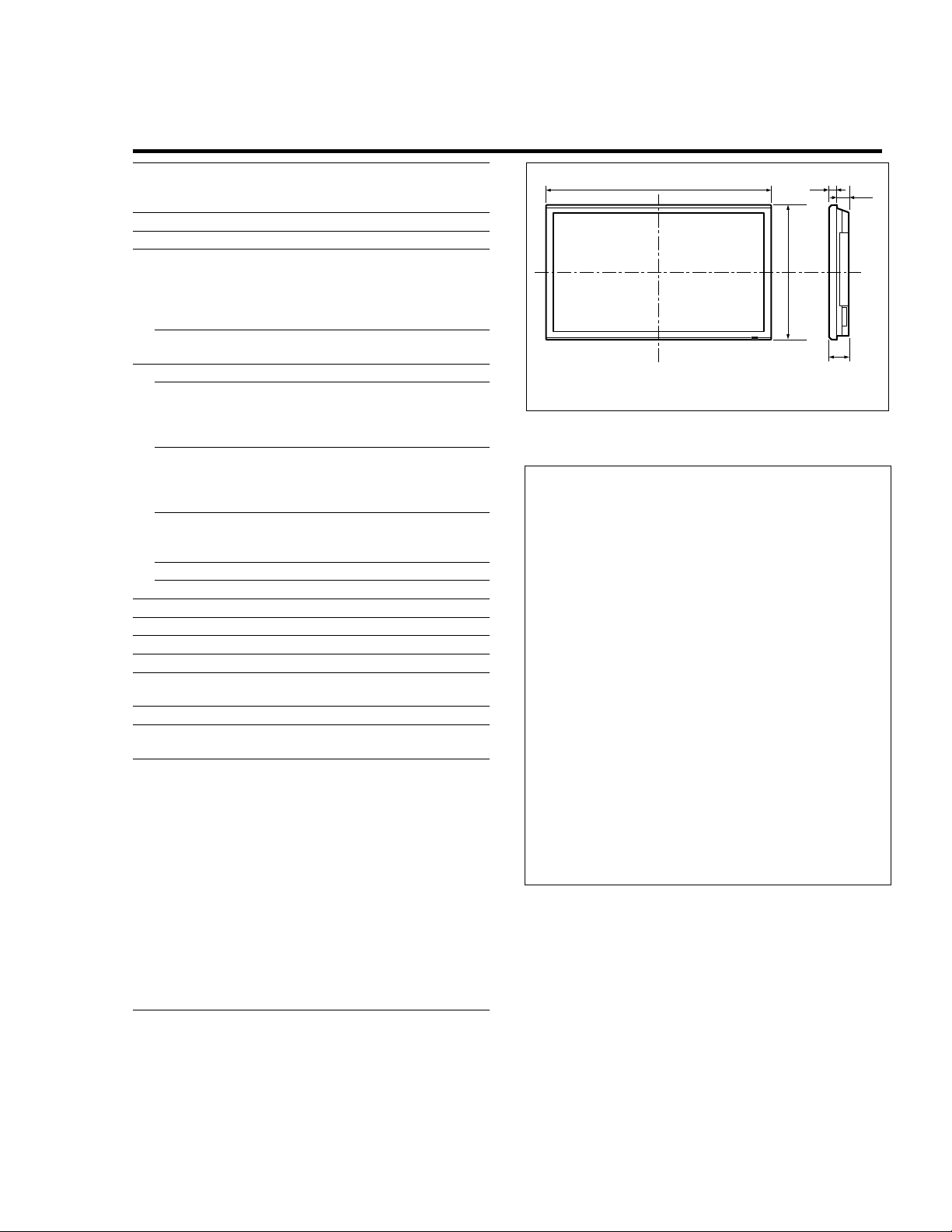

SPECIFICATIONS

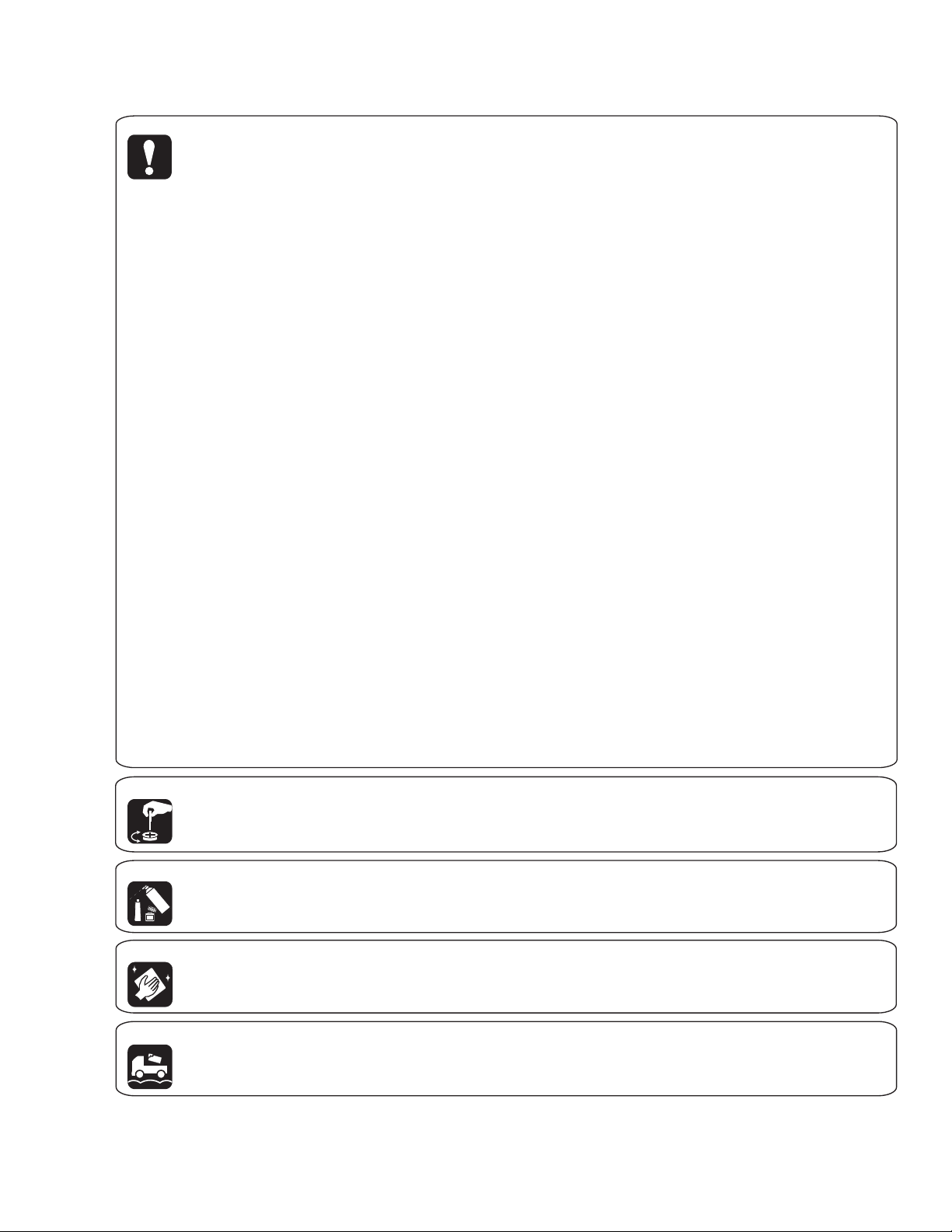

• PDP-424MV/LUC

Screen Size 36.3"(H) 20.4"(V) inches

921(H) 518(V) mm

diagonal 42"

Aspect Ratio 16 : 9

Resolution 853(H) 480(V) pixels

Signals

Synchronization Range

Horizontal : 15.5 to 110 kHz

(automatic : step scan)

Vertical : 50.0 to 120 Hz

(automatic : step scan)

Input Signals

Input Terminals

(VIDEO1 and PC1 can also be used as OUTPUT terminals)

RGB, NTSC (3.58/4.43), PAL (B,G,M,N),

PAL60, SECAM, HD*

1

, DVD*1 , DTV*

PC

Visual 1 (Analog)

Visual 2 (Analog)

Visual 3 (Digital)

mini D-sub 15-pin 1

BNC (R, G, B, H/CS, V) 1*

DVI-D 24-pin 1*

3

2

Video

Visual 1

Visual 2

Visual 3

COMPONENT

Visual 1

Visual 2

BNC 1

RCA-pin 1

S-Video: DIN 4-pin 1

RCA-pin (Y, PB[CB], PR[CR]) 1*

BNC (Y, PB[CB], PR[CR]) 1*

1, *2

1

Audio Stereo RCA 3 (Selectable)

RS-232C D-sub 9-pin 1

Sound output 8W+8W at 6 ohm

Power Supply AC120-240V 50/60Hz

Current Rating 4.5A (maximum)

Power Consumption 270W (standby 0.9W)

Dimensions 40 (W) 24 (H) 3.5 (D) inches

1018 (W) 610 (H) 89 (D) mm

Weight 62.8 lbs / 28.5 kg (without stand)

Environmental Considerations

Operating Temperature

0°C to 40°C / 32°F to 104°F

Other Features Motion compensated 3D Scan Converter (NTSC,

PAL, 480I, 576I, 525I, 625I, 1035I, 1080I), 2-3

pull down Converter (NTSC, 480I, 525I, 1035I,

1080I (60Hz)), 2-2 pull down Converter (PAL,

576I, 625I, NTSC, 480I, 525I), Digital Zoom

Function (100-900% Selectable), Video Wall 4-25

multi screen, Self Diagnosis, Image Burn

reduction tools (ABL LOCK1~3, INVERSE,

WHITE, ORBITER (Auto1,2/Manual), SCREEN

WIPER), Color Temperature select (high/mid/mid

low/low, user has 4 memories), Key lock (Except

power SW), Auto Picture, Input Skip, Color

Detail Adjustment, Low Tone (3 mode), Auto ID,

Programmable Timer, Gamma Correction

(4 mode), Loop through interface, Plug and play

(DDC1, DDC2b, PC3: DDC2b only)

35

1018 (40")

1

(1.38")

610 (24")

Units are in mm

89

(3.5")

54

(2.13")

(inch)

The features and specifications may be subject to change without

notice.

*1HD/DVD/DTV input signals supported on this

system

480P (60 Hz) 480I (60 Hz)

525P (60 Hz) 525I (60 Hz)

576P (50 Hz) 576I (50 Hz)

625P (50 Hz) 625I (50 Hz)

720P (60 Hz) 1035I (60 Hz)

1080I (50 Hz) 1080I (60 Hz)

2

The 5-BNC connectors are used as PC2 and

*

COMPONENT2 input. Select one of them under

“BNC INPUT”.

3

*

Compatable with HDCP.

Supported Signals

• 640 x 480P @ 59.94/60Hz • 1920 x 1080I @ 50Hz

• 1280 x 720P @ 59.94/60Hz • 720 x 576P @ 50Hz

• 1920 x 1080I @ 59.94/60Hz • 1440 (720) x 576I @ 50Hz

• 720 x 480P @ 59.94/60Hz

• 1440 (720) x 480I @ 59.94/60Hz

Note: In some cases a signal on the plasma monitor may not be displayed

properly. The problem may be an inconsistency with standards from

the source equipment (DVD, Set-top box, etc...). If you do experience

such a problem please contact your dealer and also the manufacturer of

the source equipment.

8

3-1

Page 9

Specifications

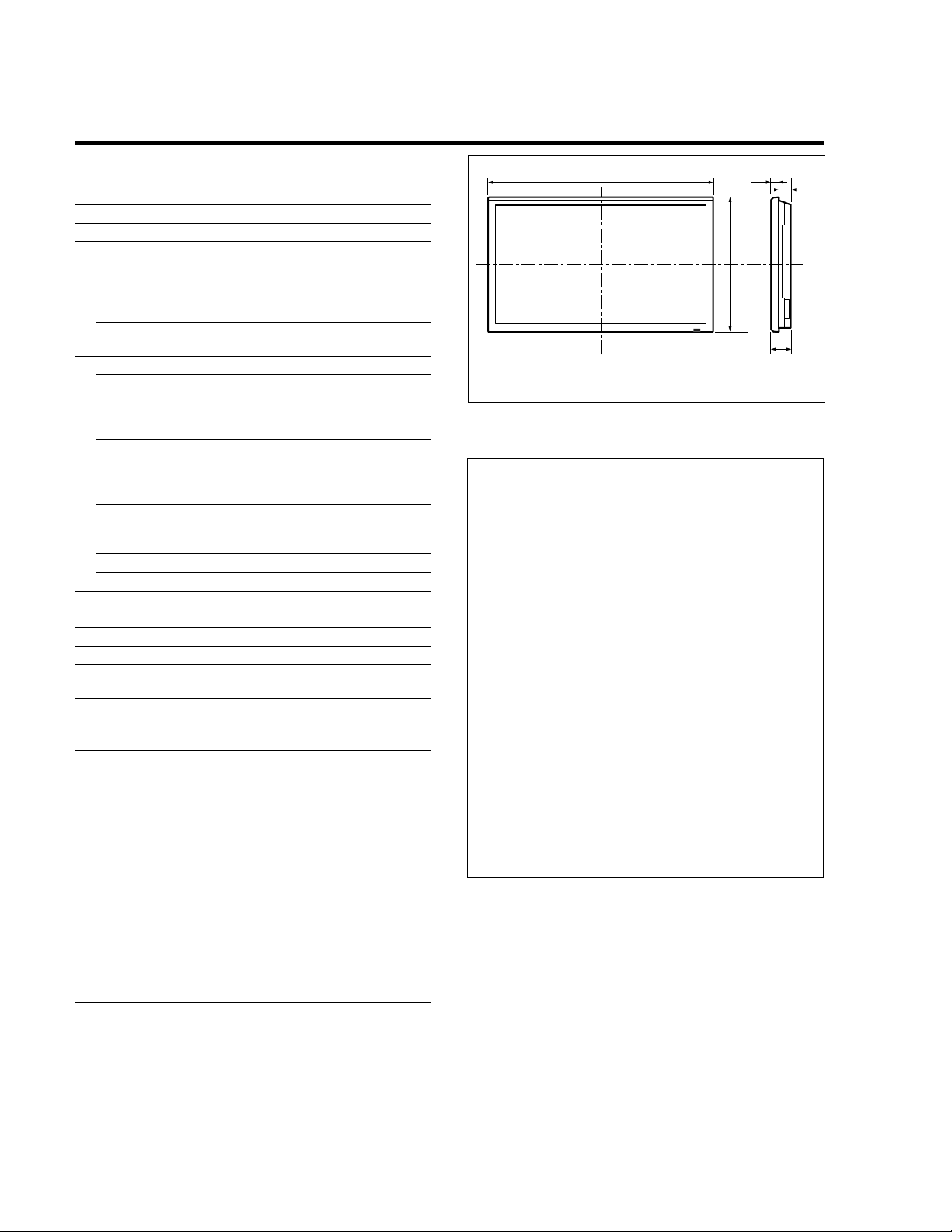

• PDP-42MVE1/LDFK and PDP-42MVE1/TXGB

Screen Size 36.3"(H) 20.4"(V) inches

921(H) 518(V) mm

diagonal 42"

Aspect Ratio 16 : 9

Resolution 853(H) 480(V) pixels

Signals

Synchronization Range

Horizontal : 15.5 to 110 kHz

(automatic : step scan)

Vertical : 50.0 to 120 Hz

(automatic : step scan)

Input Signals

Input Terminals

RGB, NTSC (3.58/4.43), PAL (B,G,M,N),

PAL60, SECAM, HD*

(VIDEO1 and PC1 can also be used as OUTPUT terminals)

1

, DVD*1 , DTV*

PC

Visual 1 (Analog)

Visual 2 (Analog)

Visual 3 (Digital)

mini D-sub 15-pin 1

BNC (R, G, B, H/CS, V) 1*

DVI-D 24-pin 1*

3

2

Video

Visual 1

Visual 2

Visual 3

COMPONENT

Visual 1

Visual 2

BNC 1

RCA-pin 1

S-Video: DIN 4-pin 1

RCA-pin (Y, PB[CB], PR[CR]) 1*

BNC (Y, PB[CB], PR[CR]) 1*

1, *2

1

Audio Stereo RCA 3 (Selectable)

RS-232C D-sub 9-pinx 1

Sound output 8W+8W at 6 ohm

Power Supply AC100-240V 50/60Hz

Current Rating 4.5A (maximum)

Power Consumption 270W (standby 0.9W)

Dimensions 40 (W) x 24 (H) x 3.5 (D) inches

1018 (W) x 610 (H) x 89 (D) mm

Weight 62.8 lbs / 28.5 kg (without stand)

Environmental Considerations

Operating

Temperature

0°C to 40°C / 32°F to 104°F

Other Features Motion compensated 3D Scan Converter (NTSC,

PAL, 480I, 576I, 525I, 625I, 1035I, 1080I), 2-3

pull down Converter (NTSC, 480I, 525I, 1035I,

1080I (60Hz)), 2-2 pull down Converter (PAL,

576I, 625I, NTSC, 480I, 525I), Digital Zoom

Function (100-900% Selectable), Video Wall 4-25

multi screen, Self Diagnosis, Image Burn

reduction tools (ABL LOCK1~3, INVERSE,

WHITE, ORBITER (Auto1,2/Manual), SCREEN

WIPER), Color Temperature select (high/mid/mid

low/low, user has 4 memories), Key lock (Except

power SW), Auto Picture, Input Skip, Color

Detail Adjustment, Low Tone (3 mode), Auto ID,

Programmable Timer, Gamma Correction

(4 mode), Loop through interface, Plug and play

(DDC1, DDC2b, PC3: DDC2b only)

35

1018 (40")

1

(1.38")

610 (24")

Units are in mm

89

(3.5")

54

(2.13")

(inch)

The features and specifications may be subject to change without

notice.

*1HD/DVD/DTV input signals supported on this

system

480P (60 Hz) 480I (60 Hz)

525P (60 Hz) 525I (60 Hz)

576P (50 Hz) 576I (50 Hz)

625P (50 Hz) 625I (50 Hz)

720P (60 Hz) 1035I (60 Hz)

1080I (50 Hz) 1080I (60 Hz)

2

*

The 5-BNC connectors are used as PC2 and

COMPONENT2 input. Select one of them under

“BNC INPUT”.

3

Compatable with HDCP.

*

Supported Signals

• 640 x 480P @ 59.94/60Hz • 1920 x 1080I @ 50Hz

• 1280 x 720P @ 59.94/60Hz • 720 x 576P @ 50Hz

• 1920 x 1080I @ 59.94/60Hz • 1440 (720) x 576I @ 50Hz

• 720 x 480P @ 59.94/60Hz

• 1440 (720) x 480I @ 59.94/60Hz

Note: In some cases a signal on the plasma monitor may not be displayed

properly. The problem may be an inconsistency with standards from

the source equipment (DVD, Set-top box, etc...). If you do experience

such a problem please contact your dealer and also the manufacturer of

the source equipment.

3-2

9

Page 10

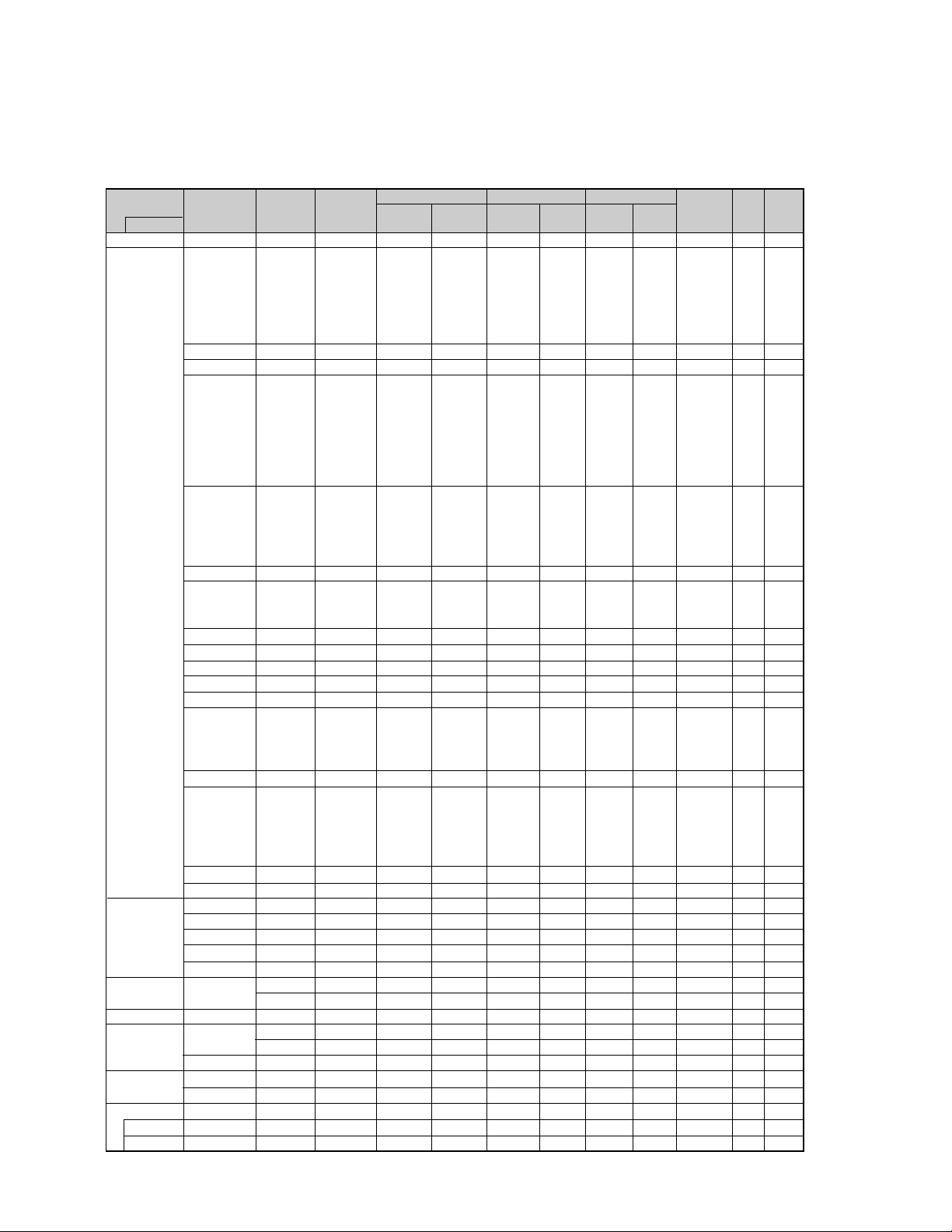

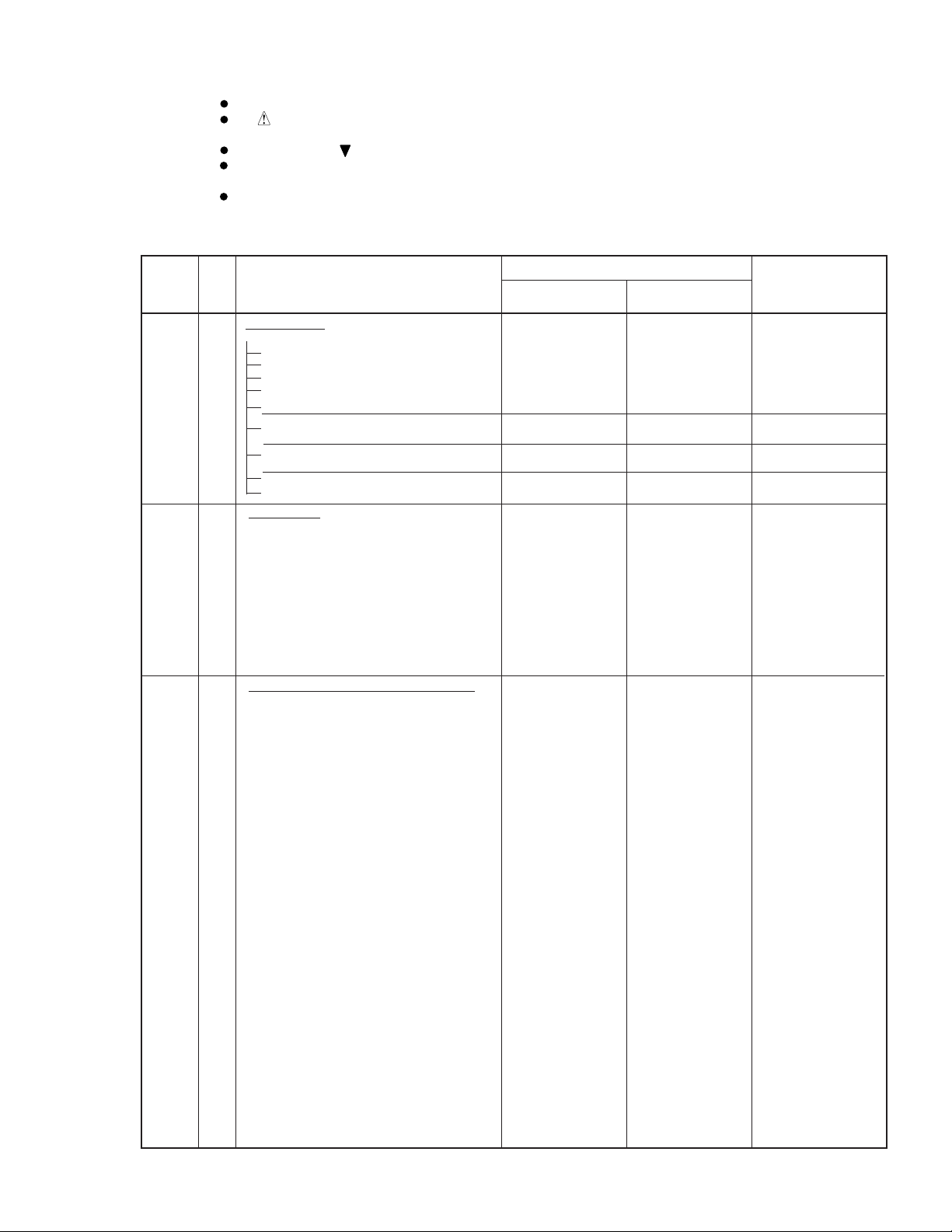

TABLE OF SIGNAL SUPPORTED

PDP-424MV/LUC

Supported resolution

•

When the screen mode is NORMAL, each signal is converted to a 640 dots 480 lines signal. (Except for *

• When the screen mode is FULL, each signal is converted to a 853 dots 480 lines signal. (Except for *3)

Computer input signals supported by this system

Model

Signal Type

IBM PC/AT

compatible

computers*

Apple

Macintosh*

8

*

Work Station

(EWS4800)

Work Station (HP)

Work Station

(SUN)

8

6,

8

*

8

*

8

*

Work Station

(SGI)

IDC-3000G

PAL625P

NTSC525P

Dots lines

640 400

640 480

848 480

852 480*

800 600

1024 768

1152 864

1280 768

1280 768*

1280 800*

1280 854*

1360 765

1360 768

1376 768

1280 1024

1680 1050*

1600 1200

1920 1200*

1920 1200RB

640 480

832 624

1024 768

1152 870

1440 900*

1280 1024

1280 1024

1152 900

1280 1024

1024 768

1280 1024

768 576

640 480

Vertical

frequency

(Hz)

100.4

120.4

1

120.0

100.6

9

9

9

100.1

9

9

9

*

9

70.1

59.9

72.8

75.0

85.0

60.0

60.0

56.3

60.3

72.2

75.0

85.1

99.8

60.0

70.1

75.0

85.0

75.0

56.2

59.8

69.8

60.0

60.0

60.0

60.0

59.9

60.0

75.0

85.0

60.0

60.0

65.0

70.0

75.0

85.0

60.0

60.0

66.7

74.6

74.9

75.1

60.0

60.0

71.2

72.0

66.0

76.0

76.1

60.0

60.0

50.0

59.9

Horizontal

frequency

(kHz)

31.5

31.5

37.9

37.5

43.3

51.1

61.3

31.0

31.7

35.2

37.9

48.1

46.9

53.7

63.0

75.7

48.4

56.5

60.0

68.7

80.5

67.5

45.1

48.0

56.0

49.7

53.1

47.7

47.7

48.3

64.0

80.0

91.1

108.5

65.3

75.0

81.3

87.5

93.8

106.3

74.6

74.0

35.0

49.7

60.2

68.7

56.0

64.6

75.1

78.1

61.8

71.7

81.1

49.7

63.9

31.4

31.5

Sync Polarity

Horizontal

NEG

NEG

NEG

NEG

NEG

NEG

NEG

POS

NEG

POS

POS

POS

POS

POS

POS

POS

NEG

NEG

POS

POS

NEG

POS

POS

POS

NEG

NEG

NEG

POS

POS

NEG

POS

POS

POS

POS

NEG

POS

POS

POS

POS

POS

NEG

NEG

Sync on G

Sync on G

Sync on G

Sync on G

NEG

NEG

NEG

– –

C Sync

C Sync

C Sync

– –

– –

NEG

NEG

Vertical

NEG

NEG

NEG

NEG

NEG

NEG

NEG

POS

NEG

POS

POS

POS

POS

POS

POS

POS

NEG

NEG

POS

POS

NEG

POS

POS

NEG

POS

NEG

NEG

POS

POS

POS

POS

POS

POS

POS

NEG

POS

POS

POS

POS

POS

NEG

NEG

Sync on G

Sync on G

Sync on G

Sync on G

NEG

NEG

NEG

– –

C Sync

C Sync

C Sync

– –

– –

NEG

NEG

Presence

Horizontal

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

– –

– –

– –

– –

YES

YES

YES

– –

– –

– –

– –

– –

– –

YES

YES

Vertical

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

– –

– –

– –

– –

YES

YES

YES

– –

– –

– –

– –

– –

– –

YES

YES

2, *4

)

Screen mode

NORMAL

(4:3)

2*3

YES*

3

YES*

3

YES*

3

YES*

3

YES*

3

YES*

3

YES*

– –

– –

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

– –

– –

– –

– –

– –

– –

– –

– –

4

YES*

4

YES*

4

YES*

4

YES*

– –

YES

YES

YES

YES

YES

– –

– –

3

YES*

YES

YES

YES

– –

4

YES*

4

YES*

4

YES*

YES

YES

4

YES*

YES

4

YES*

7

YES*

7

YES*

FULL

(16:9)

YES

YES

YES

YES

YES

YES

YES

YES*

YES*

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES*

YES*

3

3

7

7

RGB

select*

– –

STILL

– –

STILL

– –

– –

– –

WIDE2

WIDE1

STILL

STILL

– –

– –

– –

– –

– –

STILL

– –

STILL

– –

– –

STILL

WIDE1

WIDE3

WIDE1

WIDE1

WIDE2

WIDE1

WIDE1

WIDE2

STILL

– –

– –

– –

WIDE4

– –

– –

– –

– –

– –

WIDE2

WIDE3

– –

– –

WIDE1

WIDE1

– –

– –

– –

– –

– –

– –

– –

– –

– –

– –

MOTION

5

DVI

NO

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

NO

YES

YES

YES

YES

NO

YES

YES

YES

YES

YES

NO

YES

YES

NO

NO

NO

NO

– –

YES

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

YES

YES

YES

NO

NO

Memory

4

5

7

8

9

41

42

19

17

11

12

13

14

15

43

44

24

25

26

27

45

51

52

80

66

21

37

22

22

53

29

30

40

47

38

54

55

56

57

58

81

88

6

16

28

39

89

29

48

59

60

61

30

62

29

31

32

10

4-1

Page 11

*1 Only when using a graphic accelerator board that is capable of displaying 852 480.

*2 Display only 400 lines with the screen center of the vertical orientation located at the center.

*3 The picture is displayed in the original resolution. The picture will be compressed for other signals.

*4 Aspect ratio is 5:4. This signal is converted to a 600 dots 480 lines signal.

*5 Normally the RGB select mode suite for the input signals is set automatically. If the picture is not displayed properly, set the

RGB mode prepared for the input signals listed in the table above.

*6 To connect the monitor to Macintosh computer, use the monitor adapter (D-Sub 15-pin) to your computer's video port.

*7 Other screen modes (ZOOM and WIDE) are available as well.

*8 When viewing a moving picture at a vertical frequency greater than 65Hz, the picture may sometimes be unstable (jumpy).

If this occurs, please set the refresh rate of the external equipment to 60Hz.

To view 480I@60Hz (480 interlaced lines, 60Hz refresh rate) or 576I@50Hz (576 interlaced lines, 50Hz refresh rate) when

sync polarity is “Sync on Green”, set “RGB SELECT” to “MOTION”.

*9 CVT standard compliant.

NOTE:

• While the input signals comply with the resolution listed in the table above, you may have to adjust the position and size of the

picture or the fine picture because of errors in synchronization of your computer.

• This monitor has a resolution of 853 dots 480 lines. It is recommended that the input signal should be VGA, wide VGA, or

equivalent.

• With digital input some signals are not accepted.

• The sync may be disturbed when a nonstandard signal other than the aforementioned is input.

• If you are connecting a composite sync signal, use the HD terminal.

What is HDCP/HDCP technology?

HDCP is an acronym for High-bandwidth Digital Content Protection. High bandwidth Digital Content Protection (HDCP) is a system

for preventing illegal copying of video data sent over a Digital Visual Interface (DVI).

If you are unable to view material via the DVI input, this does not necessarily mean the PDP is not functioning properly. With the

implementation of HDCP, there may be cases in which certain content is protected with HDCP and might not be displayed due to the

decision/intention of the HDCP community (Digital Content Protection, LLC).

•“IBM PC/AT” and “VGA” are registered trademarks of International Business Machines, Inc. of the United States.

•“Apple Macintosh” is a registered trademark of Apple Computer, Inc. of the United States.

4-2

11

Page 12

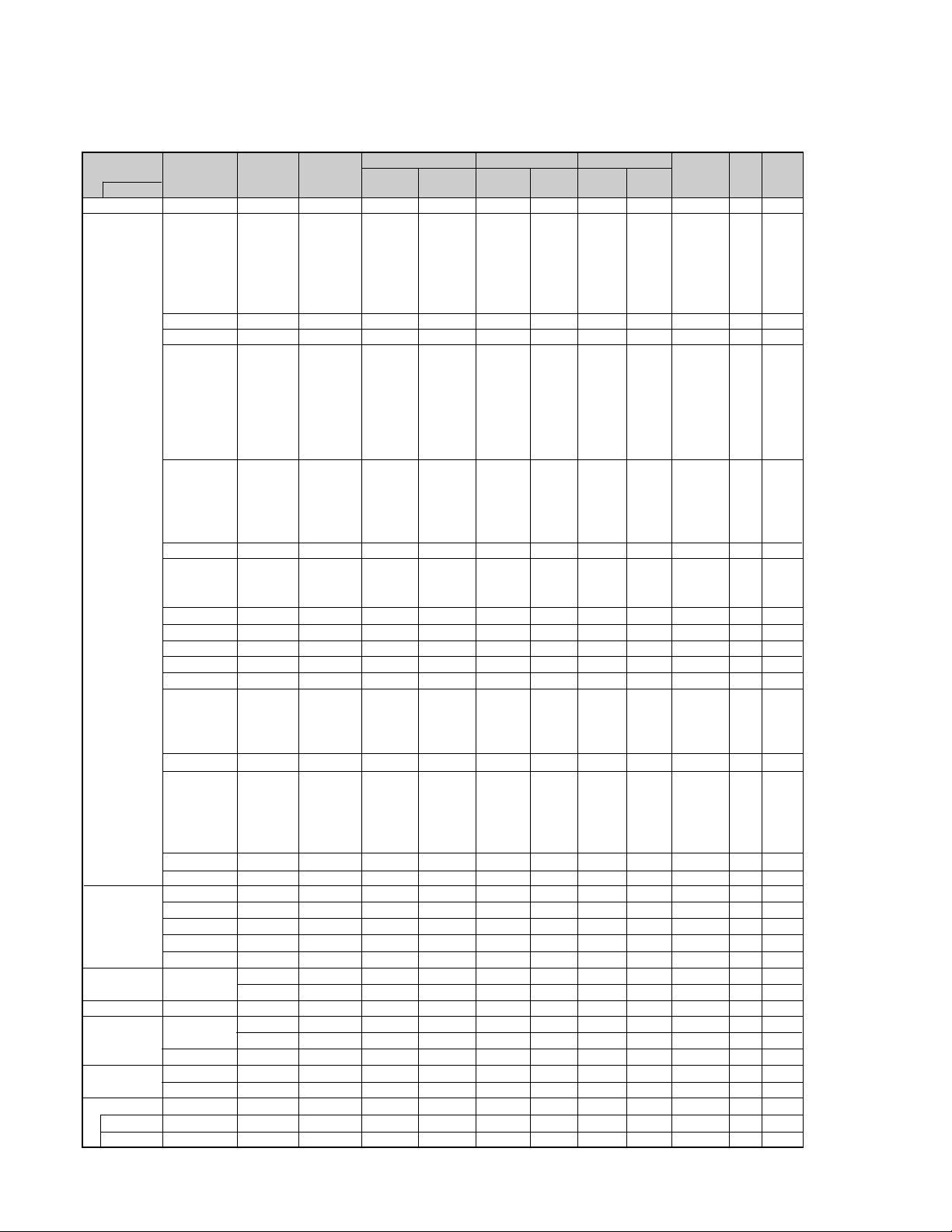

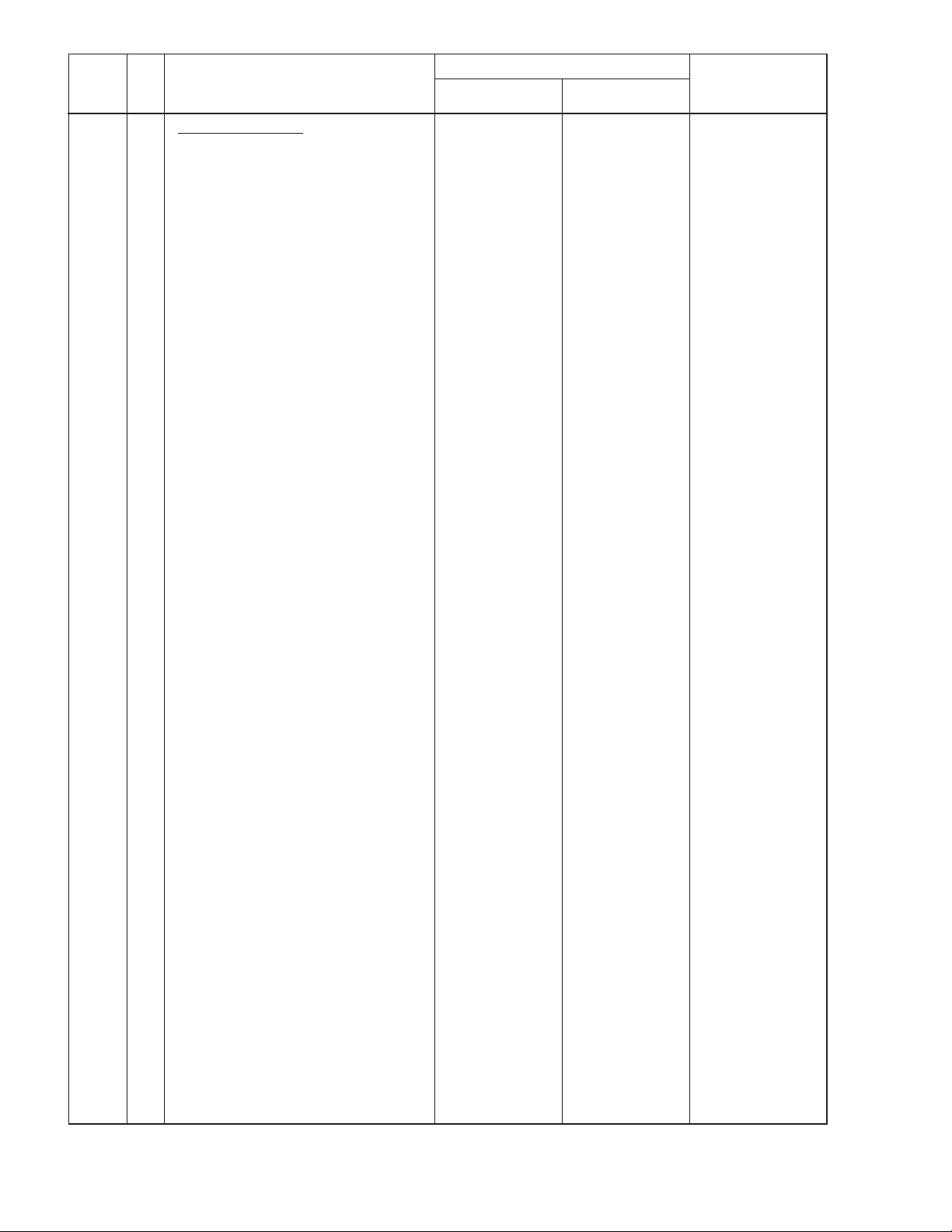

PDP-42MVE1/LDFK & /TXGB

Supported resolution

•

When the screen mode is NORMAL, each signal is converted to a 640 dots 480 lines signal. (Except for *

•When the screen mode is FULL, each signal is converted to a 853 dots 480 lines signal. (Except for *3)

Computer input signals supported by this system

Model

Signal Type

IBM PC/AT

compatible

computers*

Apple

Macintosh*

8

*

Work Station

(EWS4800)

Work Station (HP)

8

6,

8

*

*

Work Station

8

(SUN)

*

Work Station

(SGI)

IDC-3000G

PAL625P

NTSC525P

Dots lines

640 400

640 480

848 480

852 480*

800 600

1024 768

1152 864

1280 768

1280 768*

1280 800*

1280 854*

1360 765

1360 768

1376 768

1280 1024

1680 1050*

1600 1200

1920 1200*

1920 1200RB

640 480

832 624

1024 768

1152 870

1440 900*

1280 1024

8

1280 1024

1152 900

1280 1024

1024 768

1280 1024

768 576

640 480

Vertical

frequency

(Hz)

100.4

120.4

1

120.0

100.6

9

9

9

100.1

9

9

9

*

9

70.1

59.9

72.8

75.0

85.0

60.0

60.0

56.3

60.3

72.2

75.0

85.1

99.8

60.0

70.1

75.0

85.0

75.0

56.2

59.8

69.8

60.0

60.0

60.0

60.0

59.9

60.0

75.0

85.0

60.0

60.0

65.0

70.0

75.0

85.0

60.0

60.0

66.7

74.6

74.9

75.1

60.0

60.0

71.2

72.0

66.0

76.0

76.1

60.0

60.0

50.0

59.9

Horizontal

frequency

(kHz)

31.5

31.5

37.9

37.5

43.3

51.1

61.3

31.0

31.7

35.2

37.9

48.1

46.9

53.7

63.0

75.7

48.4

56.5

60.0

68.7

80.5

67.5

45.1

48.0

56.0

49.7

53.1

47.7

47.7

48.3

64.0

80.0

91.1

108.5

65.3

75.0

81.3

87.5

93.8

106.3

74.6

74.0

35.0

49.7

60.2

68.7

56.0

64.6

75.1

78.1

61.8

71.7

81.1

49.7

63.9

31.4

31.5

Sync Polarity

Horizontal

NEG

NEG

NEG

NEG

NEG

NEG

NEG

POS

NEG

POS

POS

POS

POS

POS

POS

POS

NEG

NEG

POS

POS

NEG

POS

POS

POS

NEG

NEG

NEG

POS

POS

NEG

POS

POS

POS

POS

NEG

POS

POS

POS

POS

POS

NEG

NEG

Sync on G

Sync on G

Sync on G

Sync on G

NEG

NEG

NEG

– –

C Sync

C Sync

C Sync

– –

– –

NEG

NEG

Vertical

NEG

NEG

NEG

NEG

NEG

NEG

NEG

POS

NEG

POS

POS

POS

POS

POS

POS

POS

NEG

NEG

POS

POS

NEG

POS

POS

NEG

POS

NEG

NEG

POS

POS

POS

POS

POS

POS

POS

NEG

POS

POS

POS

POS

POS

NEG

NEG

Sync on G

Sync on G

Sync on G

Sync on G

NEG

NEG

NEG

– –

C Sync

C Sync

C Sync

– –

– –

NEG

NEG

Presence

Horizontal

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

– –

– –

– –

– –

YES

YES

YES

– –

– –

– –

– –

– –

– –

YES

YES

Vertical

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

– –

– –

– –

– –

YES

YES

YES

– –

– –

– –

– –

– –

– –

YES

YES

2, *4

)

Screen mode

NORMAL

YES*

YES*

YES*

YES*

YES*

YES*

YES*

(4:3)

– –

– –

FULL

(16:9)

2*3

3

3

3

3

3

3

YES*

YES*

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

– –

– –

– –

– –

– –

– –

– –

– –

4

YES*

4

YES*

4

YES*

4

YES*

– –

YES

YES

YES

YES

YES

– –

– –

3

YES*

YES

YES

YES

– –

4

YES*

4

YES*

4

YES*

YES

YES

4

YES*

YES

4

YES*

7

YES*

YES*

YES*

7

YES*

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

3

3

7

7

RGB

select*

– –

STILL

– –

STILL

– –

– –

– –

WIDE2

WIDE1

STILL

STILL

– –

– –

– –

– –

– –

STILL

– –

STILL

– –

– –

STILL

WIDE1

WIDE3

WIDE1

WIDE1

WIDE2

WIDE1

WIDE1

WIDE2

STILL

– –

– –

– –

WIDE4

– –

– –

– –

– –

– –

WIDE2

WIDE3

– –

– –

WIDE1

WIDE1

– –

– –

– –

– –

– –

– –

– –

– –

– –

– –

MOTION

5

DVI

NO

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

NO

YES

YES

YES

YES

NO

YES

YES

YES

YES

YES

NO

YES

YES

NO

NO

NO

NO

– –

YES

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

YES

YES

YES

NO

NO

Memory

4

5

7

8

9

41

42

19

17

11

12

13

14

15

43

44

24

25

26

27

45

51

52

80

66

21

37

22

22

53

29

30

40

47

38

54

55

56

57

58

81

88

6

16

28

39

89

29

48

59

60

61

30

62

29

31

32

12

4-3

Page 13

*1 Only when using a graphic accelerator board that is capable of displaying 852 480.

*2 Display only 400 lines with the screen center of the vertical orientation located at the center.

*3 The picture is displayed in the original resolution. The picture will be compressed for other signals.

*4 Aspect ratio is 5:4. This signal is converted to a 600 dots 480 lines signal.

*5 Normally the RGB select mode suite for the input signals is set automatically. If the picture is not displayed properly, set the

RGB mode prepared for the input signals listed in the table above.

*6 To connect the monitor to Macintosh computer, use the monitor adapter (D-Sub 15-pin) to your computer's video port.

*7 Other screen modes (ZOOM and WIDE) are available as well.

*8 When viewing a moving picture at a vertical frequency greater than 65Hz, the picture may sometimes be unstable (jumpy).

If this occurs, please set the refresh rate of the external equipment to 60Hz.

To view 480I@60Hz (480 interlaced lines, 60Hz refresh rate) or 576I@50Hz (576 interlaced lines, 50Hz refresh rate) when

sync polarity is “Sync on Green”, set “RGB SELECT” to “MOTION”.

*9 CVT standard compliant.

NOTE:

• While the input signals comply with the resolution listed in the table above, you may have to adjust the position and size

of the picture or the fine picture because of errors in synchronization of your computer.

• This monitor has a resolution of 853 dots 480 lines. It is recommended that the input signal be VGA, wide VGA or

equivalent.

• With digital input some signals are not accepted.

• The sync may be disturbed when a nonstandard signal other than the aforementioned is input.

• If you are connecting a composite sync signal, use the HD terminal.

What is HDCP/HDCP technology?

HDCP is an acronym for High-bandwidth Digital Content Protection. High bandwidth Digital Content Protection (HDCP) is a system

for preventing illegal copying of video data sent over a Digital Visual Interface (DVI).

If you are unable to view material via the DVI input, this does not necessarily mean the PDP is not functioning properly. With the

implementation of HDCP, there may be cases in which certain content is protected with HDCP and might not be displayed due to the

decision/intention of the HDCP community (Digital Content Protection, LLC).

*“IBM PC/AT” and “VGA” are registered trademarks of International Business Machines, Inc. of the United States.

*“Apple Macintosh” is a registered trademark of Apple Computer, Inc. of the United States.

4-4

13

Page 14

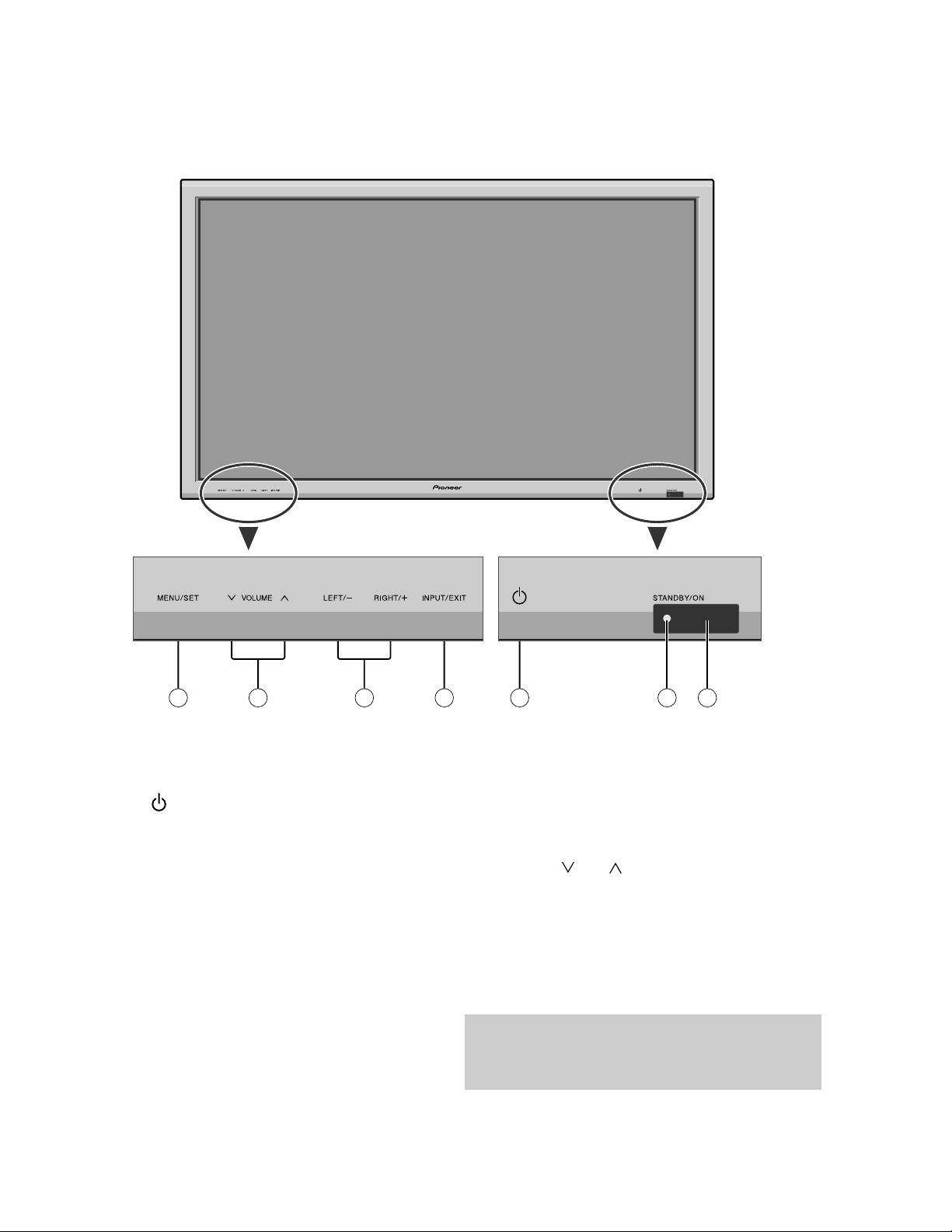

PANEL FACILITIES

PDP-424MV

Front View

7

1 Power ( )

Turns the monitor’s power on and off.

2 Remote sensor window

Receives the signals from the remote control.

3 STANDBY/ON indicator

When the power is on ............................. Lights green.

When the power is in the standby mode ... Lights red.

4 INPUT/EXIT

Switches the input.

The available inputs depend on the setting of “BNC

INPUT”, “RGB SELECT” and “DVI SET-UP”.

Functions as the EXIT buttons in the On-Screen

Display (OSD) mode.

456

5 LEFT/– and RIGHT/+

6 VOLUME

7 MENU/SET

1 3 2

Functions as the CURSOR (/ ) buttons in the On-

Screen Display (OSD) mode.

and

Adjusts the volume. Functions as the CURSOR (▲/

▼) buttons in the On-Screen Display (OSD) mode.

Sets the On-Screen Display (OSD) mode and displays

the main menu.

WARNING

The Power on/off switch does not disconnect the plasma

display completely from the supply mains.

14

5-1

Page 15

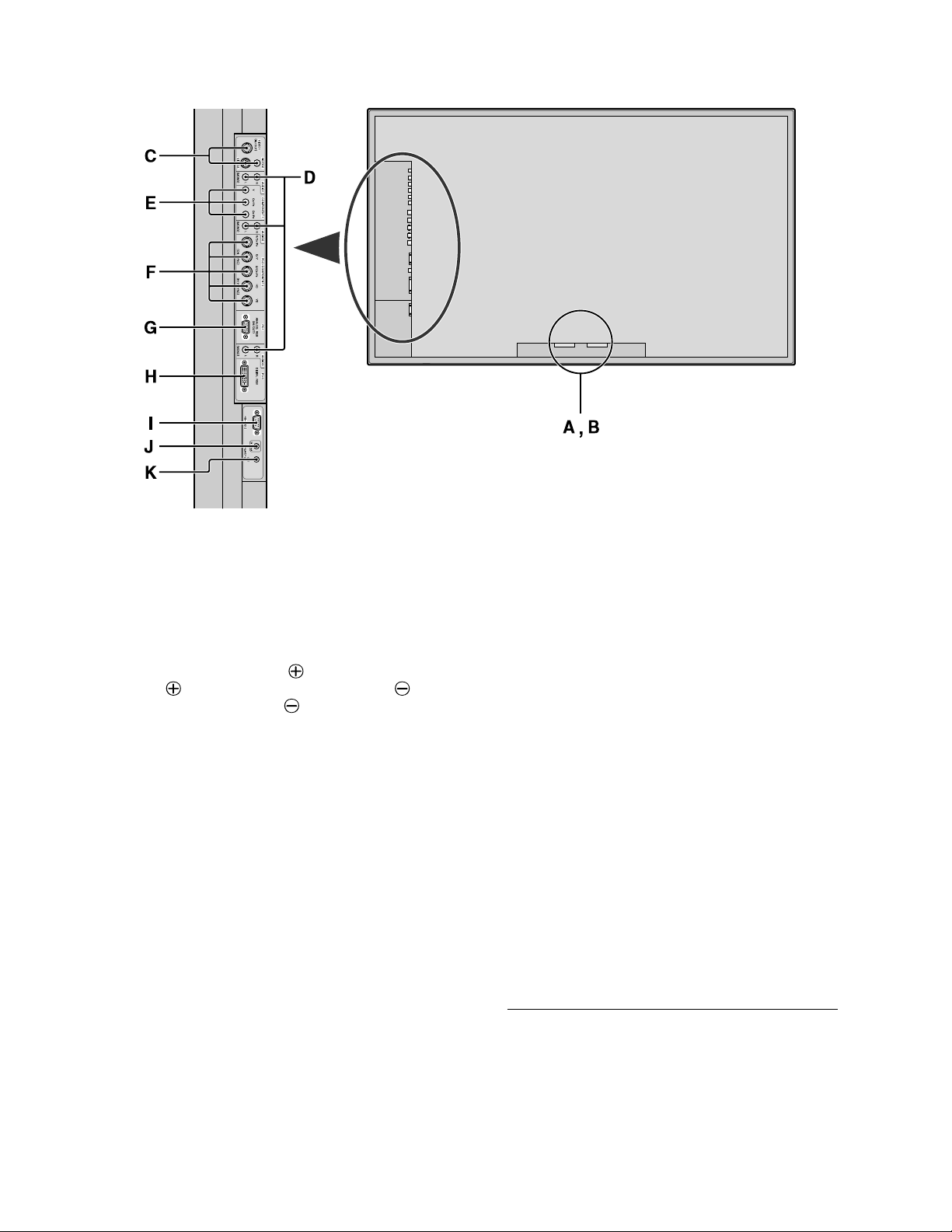

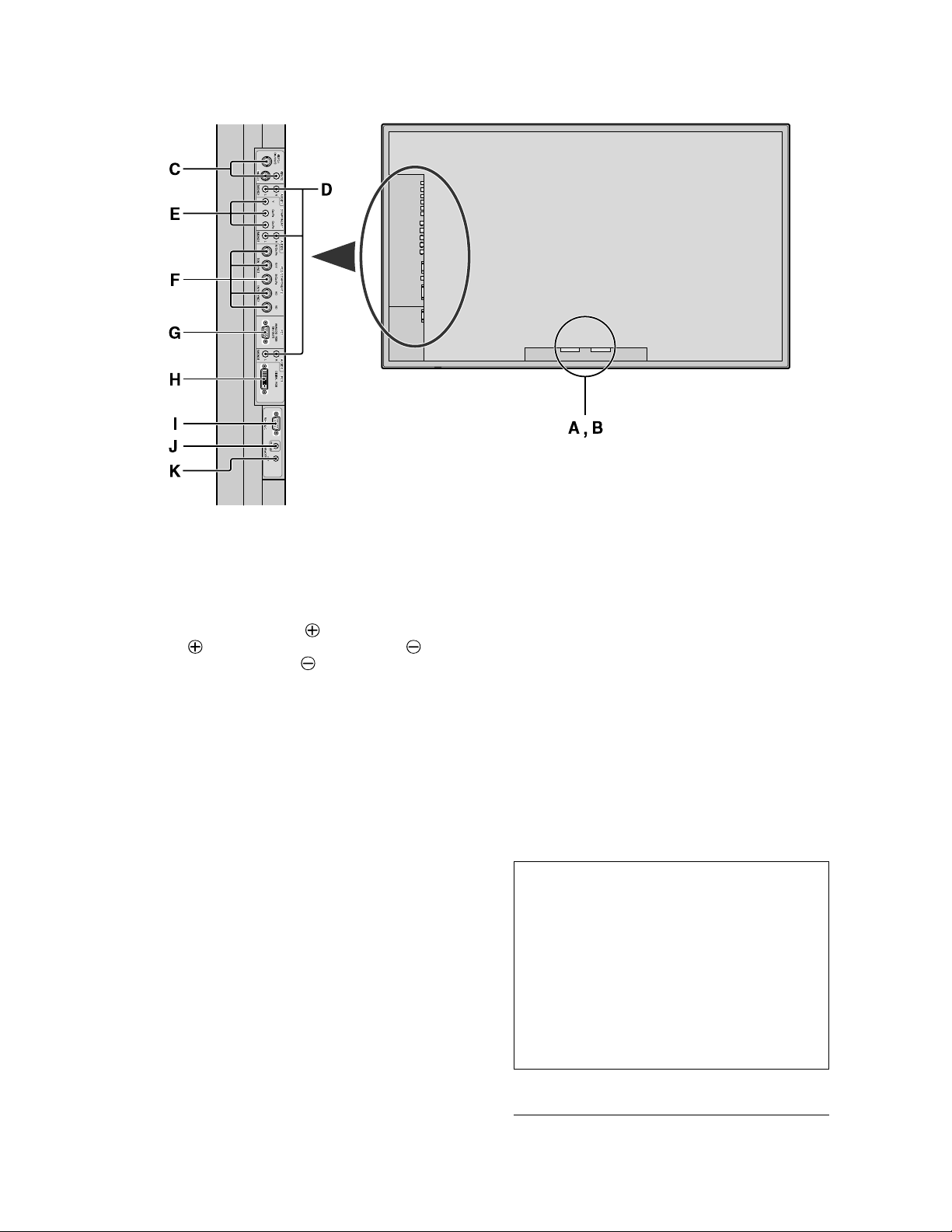

Rear View/Terminal Board

A AC IN

Connect the included power cord here.

B EXT SPEAKER L and R

Connect speakers (optional) here. Maintain the correct

polarity. Connect the

EXT SPEAKER terminal and the (negative)

speaker wire to the

both LEFT and RIGHT channels.

Please refer to your speaker’s owner’s manual.

C VIDEO1, 2, 3 (BNC, RCA, S-Video)

Connect VCR’s, DVD’s or Video Cameras, etc. here.

VIDEO1 can be used for Input or Output

D AUDIO1, AUDIO2, AUDIO3

These are audio input terminals.

The input is selectable. Set which video image to allot

them from the SOUND menu screen.

E COMPONENT1

Connect DVD’s, High Definition or Laser Discs, etc.

here.

F PC2/COMPONENT2

PC2: You can connect an analog RGB signal

and the syncronization signal.

COMPONENT2

:You can connect DVDs, High

Definition sources, Laser Discs, etc.

here.

This input can be set for use with an

RGB or component source

(positive) speaker wire to the

EXT SPEAKER terminal on

G PC1 (mini D-Sub 15pin)

Connect an analog RGB signal from a computer, etc.

here. This input can be used for Input or Output

H PC3

I RS-232C

J REMOTE IN

K REMOTE OUT

* The 1/8 Stereo Mini cable must be purchased separately.

(DVI 24pin)

Connect a digital signal (TMDS) from a source with a

DVI output.

Never connect any component to this connector

without first consulting your Pioneer installation

technician.

This connector is used for plasma display setup

adjustments.

Connect the remote cable* to the remote control’s

remote jack to obtain wired remote control.

Connect the remote cable* to the REMOTE IN jack of

the other display monitor to obtain wired remote

control.

5-2

15

Page 16

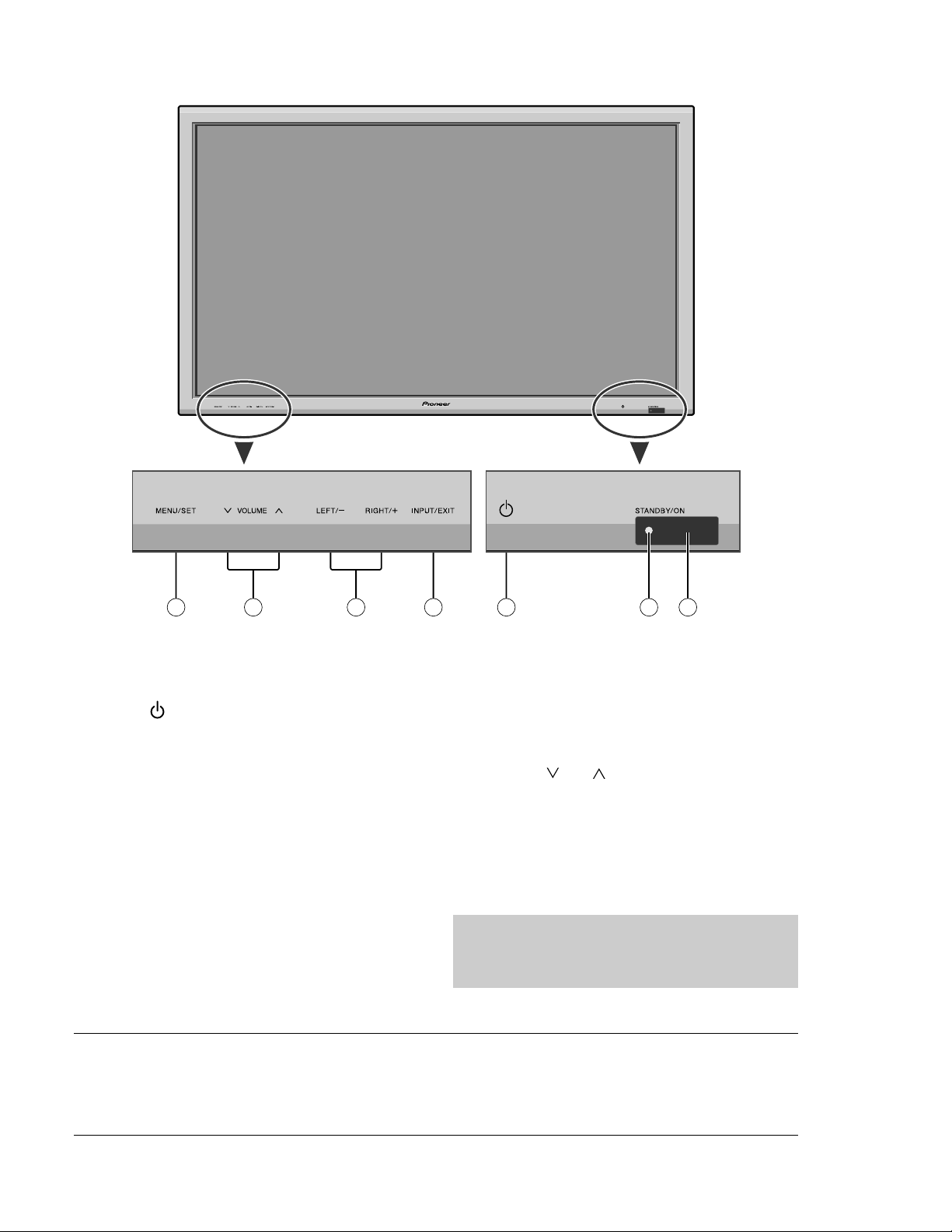

PDP-42MVE1/LDFK & /TXGB

Front View

7

1 Power ( )

Turns the monitor’s power on and off.

2 Remote sensor window

Receives the signals from the remote control.

3 STANDBY/ON indicator

When the power is on ............................. Lights green.

When the power is in the standby mode ... Lights red.

4 INPUT/EXIT

Switches the input.

The available inputs depend on the setting of “BNC

INPUT”, “RGB SELECT”, “D-SUB SELECT” and

“DVI SET-UP”.

Functions as the EXIT buttons in the On-Screen

Display (OSD) mode.

Note:

output signal, which is RGB with composite sync.

Your dealer can supply a special SCART cable, which will enable you to use the RGB with composite sync signal.

To obtain the special cable as well as for further information, please contact your dealer.

Please refer to page 19 for selection of the correct mode in the on-screen display.

This plasma monitor has the capasity to display images when connected to European DVD players with a SCART

456

5 LEFT/– and RIGHT/+

6 VOLUME

7 MENU/SET

1 3 2

Functions as the CURSOR ( / ) buttons in the OnScreen Display (OSD) mode.

and

Adjusts the volume. Functions as the CURSOR (/

) buttons in the On-Screen Display (OSD) mode.

Sets the On-Screen Display (OSD) mode and displays

the main menu.

WARNING

The Power on/off switch does not disconnect the plasma

display completely from the supply mains.

16

5-3

Page 17

Rear View/Terminal Board

A AC IN

Connect the included power cord here.

B EXT SPEAKER L and R

Connect speakers (optional) here. Maintain the correct

polarity. Connect the

EXT SPEAKER terminal and the (negative)

speaker wire to the

both LEFT and RIGHT channels.

Please refer to your speaker’s owner’s manual.

C VIDEO1, 2, 3 (BNC, RCA, S-Video)

Connect VCR’s, DVD’s or Video Cameras, etc. here.

VIDEO1 can be used for Input or Output (see page

24).

D AUDIO1, AUDIO2, AUDIO3

These are audio input terminals.

The input is selectable. Set which video image to allot

them from the SOUND menu screen.

E COMPONENT1

Connect DVD’s, High Definition or Laser Discs, etc.

here.

F PC2/COMPONENT2

PC2: You can connect an analog RGB signal

and the syncronization signal.

COMPONENT2

:You can connect DVDs, High

Definition sources, Laser Discs, etc.

here.

This input can be set for use with an

RGB or component source (see page

17).

(positive) speaker wire to the

EXT SPEAKER terminal on

H PC3

I RS-232C

J REMOTE IN

K REMOTE OUT

(DVI 24pin)

Connect a digital signal (TMDS) from a source with a

DVI output.

Never connect any component to this connector

without first consulting your Pioneer installation

technician.

This connector is used for plasma display setup

adjustments.

Connect the remote cable* to the remote control’s

remote jack to obtain wired remote control.

Connect the remote cable* to the REMOTE IN jack of

the other display monitor to obtain wired remote

control.

Information

•For Y/CB/Cr, connect to the COMPONENT1 or PC2/

COMPONENT2 terminals.

•For SCART, this unit provides three ways to connect:

· SCART1: Connect R/G/B and composite sync. to

the PC2/COMPONENT2 terminals. (R, G, B and

HD connector)

· SCART2: Connect R/G/B to the COMPONENT2

terminals and composite sync. to the VIDEO1

terminal.

· SCART3: Connect R/G/B and composite sync. to

the PC1 terminal.

G PC1 (mini D-Sub 15pin)

Connect an analog RGB signal from a computer, etc.

here. This input can be used for Input or Output (see

page 24).

* The 1/8 Stereo Mini cable must be purchased separately.

17

5-4

Page 18

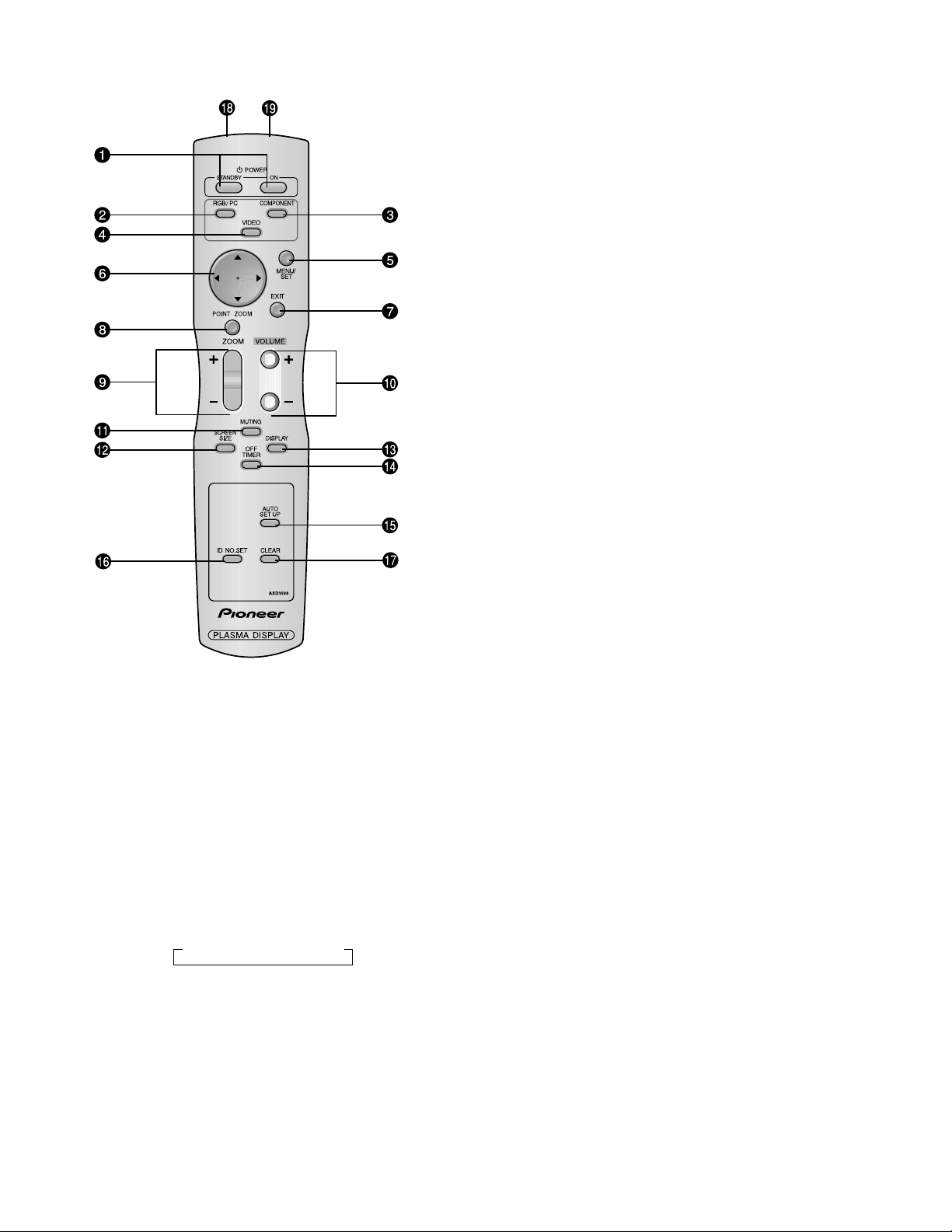

Remote Control

1 POWER ON/STANDBY

Switches the power on/standby.

(This does not operate when STANDBY/ON indicator

of the main unit is off.)

2 RGB/PC

Press this button to select RGB/PC as the source.

RGB/PC can also be selected using the INPUT/EXIT

button on the monitor.

3 COMPONENT

Press this button to select COMPONENT as the source.

COMPONENT can also be selected using the INPUT/

EXIT button on the monitor.

4 VIDEO

Press this button to select VIDEO as the source.

→ VIDEO1 → VIDEO2 → VIDEO3

7 EXIT

Press this button to exit the OSD controls in the main

menu. Press this button during the display of the sub

menu to return to the previous menu.

8 POINT ZOOM

Press this button to display the pointer.

9 ZOOM (+ /–)

Enlarges or reduces the image.

0

VOLUME (+/–)

Adjusts the sound volume.

- MUTING

Mutes the sound.

= SCREEN SIZE

Automatically detects the signal and sets the aspect ratio.

SCREEN SIZE button is not active for all signals.

~ DISPLAY

Displays the source settings on the screen.

! OFF TIMER

Activates the off timer for the unit.

@ AUTO SET UP

Press this button to adjust PHASE, CLOCK, Position,

and Contrast automatically, or to switch the screen size

to ZOOM mode automatically with the superimposed

caption displayed fully only when the picture contains

dark areas above and below the picture.

# ID NO. SET

Set the ID number in the remote control. The remote

control can then be used only for a display with the

same ID number. When several displays are used

together they can be controlled individually.

$ CLEAR

Clears the number set by the ID NO. SET button.

% Remote control signal transmitter

Transmits the remote control signals.

^ Remote Jack

Insert the plug of the remote cable (The 1/8 Stereo

Mini cable) here when using the supplied remote

control in the wired condition.

VIDEO can also be selected using the INPUT/EXIT

button on the monitor.

5 MENU/SET

Press this button to access the OSD controls.

Press this button during the display of the main menu

to go to the sub menu.

6 CURSOR ( / /

Use these buttons to select items or settings and to

adjust settings.

18

/ )

5-5

Page 19

PDP-424MV

PDP-42MVE1/LDFK, /TXGB

PARTS LIST

NOTES:

Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on product are used for disassembly.

For the applying amount of lubricants or glue, follow the instructions in this manual.

(In the case of no amount instructions, apply as you think it appropriate.)

Reference Nos. indicate the pages and Nos. in the service manual for the base model.

7

and

PDP-424MV/LUC and PDP-42MVE1/LDFK, /TXGB are constructed the same except for the following:

Symbol

Mark

Symbol and Description

PDP MODULE

P01 PDP-NP42B3MF01AB 9S900064 9S900064

PKG42B3G1

1

2

PKG42B3J4/42D2J4/35B2J4

3

PKG42B3J3

4

PKG42B3J1

PKG42B3J2

5

PKG42B3E1

6

PKG42B3E1

PKG42B3E2

7

PKG42B3E2

8

PKG42B3E3

PKG42B3C2

9

A01 MAIN1 PWB ASSY

A02 232C PWB ASSY

A03 CTL PWB ASSY

A04 PWR PWB ASSY

A05 LED PWB ASSY

PWB ASSYS

Part No.

PDP-424MV/LUC

9S899523

9S899627

9S899282

9S899524

9S899525

9S899351

9S899528

9S899355

9S899531

9S899443

9S899847

937M2M02

937F0SA2

937F0SB2

937F0SC2

937F0SD2

PDP-42MVE1/LDFK

/TXGB

9S899523

9S899627

9S899282

9S899524

9S899525

9S899351

9S899528

9S899355

9S899531

9S899443

9S899847

937M3M02

937F0SA2

937F0SB2

937F0SC2

937F0SD2

Remarks

01D

01A

01A

02B

02B

01C

01D

01C

01D

03J-06

A06 SENB PWB ASSY 937F7SE2

A07 SENC PWB ASSY 937F7SF2

A08 SEND PWB ASSY 937F7SG2

A09 AUDIO PWB ASSY 937F7SH2

A11 POWER UNIT

CN-01 CONNECTOR 1P

CN-02 CONNECTOR 2-WP(PI)

FL31 CORE,FERRITE SFT-72SNB

FL32 FERRITE CORE ZCAT2032-930

FL33 FERRITE CORE ESD-R-19

INLET AC INLET 10DKDG3S(Y1)

CN-AD CABLE 31P L390

CN-AU CONNECTOR 7P(AU)

CN-LD CONNECTOR 5P(LD)

CN-PA CONNECTOR 6P(PA)

CN-PD CONNECTOR 10P(PD)

CN-PH CONNECTOR 4P(PH)

CN-PM CONNECTOR 7P(PM)

CN-PN CONNECTOR 12P(PN)

CN-PV CONNECTOR 8P(PV)

CN-PW CONNECTOR 8P(PW)

CN-RS CONNECTOR 12P(RS)

CN-SW1 CONNECTOR 3P(SW)

CN-SW2 CONNECTOR 3P(SW)

CN-TM CONNECTOR 4P(TM)

CN-TR CONNECTOR 4P(TR)

CN-TS CONNECTOR 4P(TS)

FL01 FERRITE CORE ZCAT2032-930

FL02 FERRITE CORE ZCAT2032-930

FL03 FERRITE CORE ZCAT2032-930

FL04 FERRITE CORE ZCAT2032-930

FL05 CORE,FERRITE TFT-081813N

FL06 FERRITE CORE ZCAT1518-0730

FL07 FERRITE CORE ZCAT1518-0730

FL08 FERRITE CORE ZCAT1518-0730

MISCELLANEOUS ELECTRICAL PARTS

3S110211

7SW1W004

7SWXV006

6S170003

6S170005

6S170007

6S760016

7S530036

7SW7W003

7SU512LD

7SU621PA

7SW0W007

7SW4W010

7SU710PM

7SUB13PN

7SU813PV

7SC807PW

7SCB08RS

7SB3W005

7SW3W004

7SC428TM

7SC418TR

7SC410TS

6S170005

6S170005

6S170005

6S170005

6S170004

6S170006

6S170006

6S170006

937F0SE2

937F0SF2

937F0SG2

937F0SH2

3S110211

7SW1W004

7SWXV006

6S170003

6S170005

6S170007

6S760016

7S530036

7SW7W003

7SU512LD

7SU621PA

7SW0W007

7SW4W010

7SU710PM

7SUB13PN

7SU813PV

7SC807PW

7SCB08RS

7SB3W005

7SW3W004

7SC428TM

7SC418TR

7SC410TS

6S170005

6S170005

6S170005

6S170005

6S170004

6S170006

6S170006

6S170006

6-1

19

Page 20

Symbol

GKT01 GASKET(L20*10*T15)

GKT02 GASKET(L70*10*T1)

GKT03 GASKET(L20*5*T1)

GKT04 GASKET(L20*5*T1)

GKT05 GASKET(L300*5*T1)

GKT06

GKT07 GASKET(L100*10*T3)

SRW01 SCREW(UNC4-40/4-40)

SRW02 CBIPS*3*8*3KF

SRW03 CBIPS*3*8*3KF

SRW04 CBIPS*3*8*3KF

SRW05 CBIPS*3*8*3KF

SRW06 CBIPS*3*8*3KF

SRW07 CBIPS*3*8*3KF

SRW08 CBIPS*3*8*3KF

SRW09 CBIPS*4*12*15KFE

SRW10 CBIPS*4*12*15KFE

SRW11 ET-CBIMS*4*8*3KF

SRW12 TP-M3*6*3KF

SRW13 TP-M3*6*3KF

SRW14 TP-M3*6*3KF 24N04581

SRW15 TP-M3*6*3KF 24N04581

SRW16 TP-M3*6*3KF 24N04581

SRW17 TP-M3*6*3KF 24N04581

SRW18 TP-M3*6*3KF 24N04581

SRW19 TP-M3*6*3KF 24N04581

SRW21 TP-M3*6*3KF 24N04581

SRW23 PL-CPIMS*4*10*15BFE 29N01461

SRW24 PTN3*12*15KFE 29N01491

SRW25 PTN3*12*15KFE 29N01491

Mark

Symbol and Description

MECHANISM PARTS

GASKET(L100*10*T8)

PDP-424MV/LUC

29C01491

29C00361

29C00511

29C00511

29C01481

29C01831

29C01841

32990229

24N03691

24N03691

24N03691

24N03691

24N03691

24N03691

24N03691

29N01401

29N01401

24N04001

24N04581

24N04581

Part No.

PDP-42MVE1/LDFK

, /TXGB

29C01491

29C00361

29C00511

29C00511

29C01481

29C01831

29C01841

32990229

24N03691

24N03691

24N03691

24N03691

24N03691

24N03691

24N03691

29N01401

29N01401

24N04001

24N04581

24N04581

24N04581

24N04581

24N04581

24N04581

24N04581

24N04581

24N04581

29N01461

29N01491

29N01491

Remarks

SRW26 TP-M3*4*3KF 29N01191

SRW27 P-CPIMS*3*6*3KF 29N01201

SRW28 P-CPIMS*3*6*3KF 29N01201

SRW29 P-CPIMS*3*6*3KF 29N01201

SRW30 SCREW PL-CPIMS*3*10*15KFE 29N01431

SRW31 SCREW PL-CPIMS*3*10*15KFE 29N01431

SRW32 SCREW PL-CPIMS*3*10*15KFE 29N01431

SRW33 CPIMS*NO.6-32UNC*8*3GF 29N01131

SRW34 CBIPS*4*12*15KFE 29N01401

M01

M02

M03

M04 EDGE SADDLE(TSB-1915)

M05 BARRIER(INLET)

M06 SERIAL LABEL 29L07101

M07 EDGING SADDLE(EDS-1208U) 29C00461

M08 CLAMP(MWC-2S) 29C01401

M09 CLAMP(WS-2W-V0) 29C01421

M10 EDGE SADDLE(TES-016NV) 29C01431

M11 Not used Not used

M12 BAND(L200) 29C01462

M13 LUG(L60) 29C01471

M14 LUG(L60) 29C01471

M15 EDGING(L56)T0.5 29C01541

M16 EDGING(L18)T0.5 29C01551

M17 SHIELDING SHEET(330*10) 29C01651

M18 COVER CONTROL(424MV) 29F01231

M19 CORNER PIECE BL 29F00531

M20 CORNER PIECE BR 29F00541

NSP

LEAD CLAMPER(D5.2)

Not used Not used

24C00091

Not used Not used

24C05151

29J01321

29N01191

29N01201

29N01201

29N01201

29N01431

29N01431

29N01431

29N01131

29N01401

24C00091

24C05151

29J01321

29L07101

29C00461

29C01401

29C01421

29C01431

29C01462

29C01471

29C01471

29C01541

29C01551

29C01651

29F01231

29F00531

29F00541

20

6-2

Page 21

Symbol

Mark

MECHANISM PARTS

M21 CORNER PIECE TL 29F00571

M22 CORNER PIECE TR 29F00581

M23 FRAME 29F00712

M24 BOTTON CONTROL(424MV) 29G00441

M25 CAP(POWER SW) 29G00261

M26 COVER(POWER SW)

M27 BRACKET FILTER A

M28 BRACKET FILTER B

M29 BRACKET FILTER BTM

M30 BRACKET FILTER TOP

M31 BRACKET FILTER SIDE L

M32 BRACKET POWER

M33 BRACKET MAIN(42XM3)

M34 BRACKET AUDIO(42XM3)

M35 BRACKET 232C(42XM3)

M36 BRACKET FILTER C

M37 SHIELD COVER MAIN

M38 SHIELD COVER L

M39 SHIELD COVER R

M40 BRACKET OPTION L

M41 SHIELD PLATE MAIN(42XM3) 29H03541

M42 BRACKET FILTER SIDE R 29H02371

M43 BRACKET STAND ASSY 29H02612

M44

M45 BRACKET OPTION R 29H02753

M46 GS COVER 29H02782

M47 PLATE 232C ASSY(424MV) 29H03831

M48 CUSHION(960*8*T5) 29J00902

M49 CUSHION(528*8*T5) 29J00912

M50 BARRIER(PS) 29J00992

NSP

NSP

NSP

NSP

NSP

NSP

NSP

NSP

NSP

NSP

NSP

Symbol and Description

PDP-424MV/LUC

29G00272

29H02121

29H02132

29H02142

29H02152

29H02161

29H02191

29H03511

29H03521

29H03531

29H02311

29H03571

29H03581

29H03591

29H02353

Not used

Part No.

PDP-42MVE1/LDFK

, /TXGB

29F00571

29F00581

29F00712

29G00441

29G00261

29G00272

29H02121

29H02132

29H02142

29H02152

29H02161

29H02191

29H03511

29H03521

29H03531

29H02311

29H03571

29H03581

29H03591

29H02353

29H03541

29H02371

29H02612

Not used

29H02753

29H02782

29H03831

29J00902

29J00912

29J00992

Remarks

M51 BARRIER(BACK-S) 29J01002

M52 CUSHION(420*20*T0.4) 29J01051

M53 BARRIER(LD) 29J01061

M54 BARRIER(PA) 29J01072

M55

M56 CUSHION(720*8*T0.4) 29J01111

M57 SILICONE SHEET(AUDIO)T 29J01291

M58 CUSHION(40*20*T0.4) 29J01141

M59 CUSHION(20*10*T1) 29J01151

M60 FILTER 29KS0121

M61 NAME PLATE(424MV) 29L07451

M62 EARTH LABEL(20x40) 29L0316

M63 GS COVER LABEL 29L03642

M64 TERMINAL PANEL B(424MV) 29P01611

M65 BACK COVER ASSY 956Y4651

M66 TERMINAL PANEL S(424MV) 29P01601

M67 FRONT PANEL ASSY(424MV) 29DS0611

M68

M69

M70

M71

M72 AUDIO HEAT SINK 29H03561

M73 INLET COLLAR 29F00481

M74 PIONEER LOGO BADGE AAM1101

M75 WARRANTY ENVELOPE(100*220) 78047921

M76 WARRANTY CARD MX JAPAN 7S810131

NSP

NSP

NSP

NSP

NSP

Not used Not used

Not used

Not used

Not used

Not used Not used

29J01002

29J01051

29J01061

29J01072

29J01111

29J01291

29J01141

29J01151

29KS0121

29L07461

29L07441

29L03642

29P01611

956Y4651

29P01601

29DS0611

Not used

Not used

Not used

29H03561

29F00481

AAM1101

29L07441

Not used

6-3

21

Page 22

Symbol

Mark

Symbol and Description

PDP-424MV/LUC

Part No.

PDP-42MVE1/LDFK

, /TXGB

PRINTED & PACKING MATERIALS

SHT001 INSTRUCTIONS PDP-424MV

SHT001 INSTRUCTIONS PDP-42MVE1 7S802171

SHT002

CAUTION SHEET JAPAN

SHT002 CAUTION SHEET FOREIGN

SHT003

CAUTION SHEET FOREIGN

SHT003 WARRANTY CARD MVE EU

SHT004

SHT005

SHT006

PK01

PK02

BURNING CAUTION SHEET

CAUTION SHEET

NSP

WARRANTY CARD MX USA

POWER CORD U3 L3.0M L

REM-T HAND UNIT AXD1498

PK02 REM-T HAND UNIT AXD1498 3S120242

PK03

PK04

PK05

PK06

PK07

PK08

PK09

PK10

PK11

PK12

PK13

PK14

PK15

PK16

PK16 CARTON BOX T(424MVE1)

PK17

PK18

PK19

STOPPER

NSP

BAG,POLYETHYLENE(150*370)

JOINT

NSP

POLYETHYLENE BAG(70*100)

BRACKET(SAFE)

PROTECTION SHEET

CUSHION(TL)

CUSHION(TR)

CUSHION(BL)

CUSHION(BR)

CUSHION(BC)

CARTON BOX(B)

ACCESSORY BOX(42VP4)

CARTON BOX T(424MV)

FERRITE CORE ZCAT2032-930

NSP

BATTERY,DRY CELL LR03-2SJ

CORE,FERRITE SFT-72SNB

PK20

PK21

PK22

PK23

PK24

PK25

PK26

PL-CPIMS*4*10*3KF

PK27

PK28

PK29

PK30

PK31

PK32

PK33

PK34

PK35

WIPING CLOTH

POWER CORD CASE(42)

7S802161

Not used

7S820291

Not used

7S820271

Not used

7S820281

7S820301

7S810121

7S552001

3S120242

Not used

24282431

24813191

24CS0551

24M15221

24P01591

29M00481

29MS2411

29MS2421

29MS2431

29MS2441

29MS2451

29MS2461

29MS2471

29MS3281

Not used

6S170005

4S490005

6S170003

Not used

Not used

910E4026

Not used

Not used

Not used

Not used

Not used

Not used

Not used

Not used

Not used

Not used

Not used

29J01491

29MS3301

Not used

Not used

7S820271

Not used

7S810241

Not used

Not used

Not used

Not used

Not used

24282431

24813191

24CS0551

24M15221

24P01591

29M00481

29MS2411

29MS2421

29MS2431

29MS2441

29MS2451

29MS2461

29MS2471

Not used

29MS3291

6S170005

4S490005

6S170003

Not used

Not used

910E4026

Not used

Not used

Not used

Not used

Not used

Not used

Not used

Not used

Not used

Not used

Not used

29J01491

29MS3301

Remarks

22

6-4

Page 23

(PDP-NP42B3MF01AB)

1. List of tools required for repair

2. Points of failure diagnosis for a Board Assy (PKG)

*

Power source please do measurement of each ohmic value by status of OFF.

3. Replacement method of a Board Assy (PKG)

and notes on replacement

4. Adjustments after replacement of parts in the module

5. Operation check

1. List of tools required for repair

a) Phillips screwdriver: For detaching/reattaching PKGs

b) Antistatic wrist strap:

To be used when electronic components, such as PKGs, are to be handled

c) Signal generator (PC, etc.):For voltage adjustment and display check

d) Powe: For voltage adjustment and display check

f)Tester: For cable check, voltage adjustment, etc.

g) Cushion: To be used when the PKGs are to be replaced

Note: Be sure to wear a wrist strap when you detach/reattach PKGs (Board Assy) to protect

electronic components from being damaged by electrostatic charges.

HOW TO DIAGNOSE THE PDP MODULE

7-1

23

Page 24

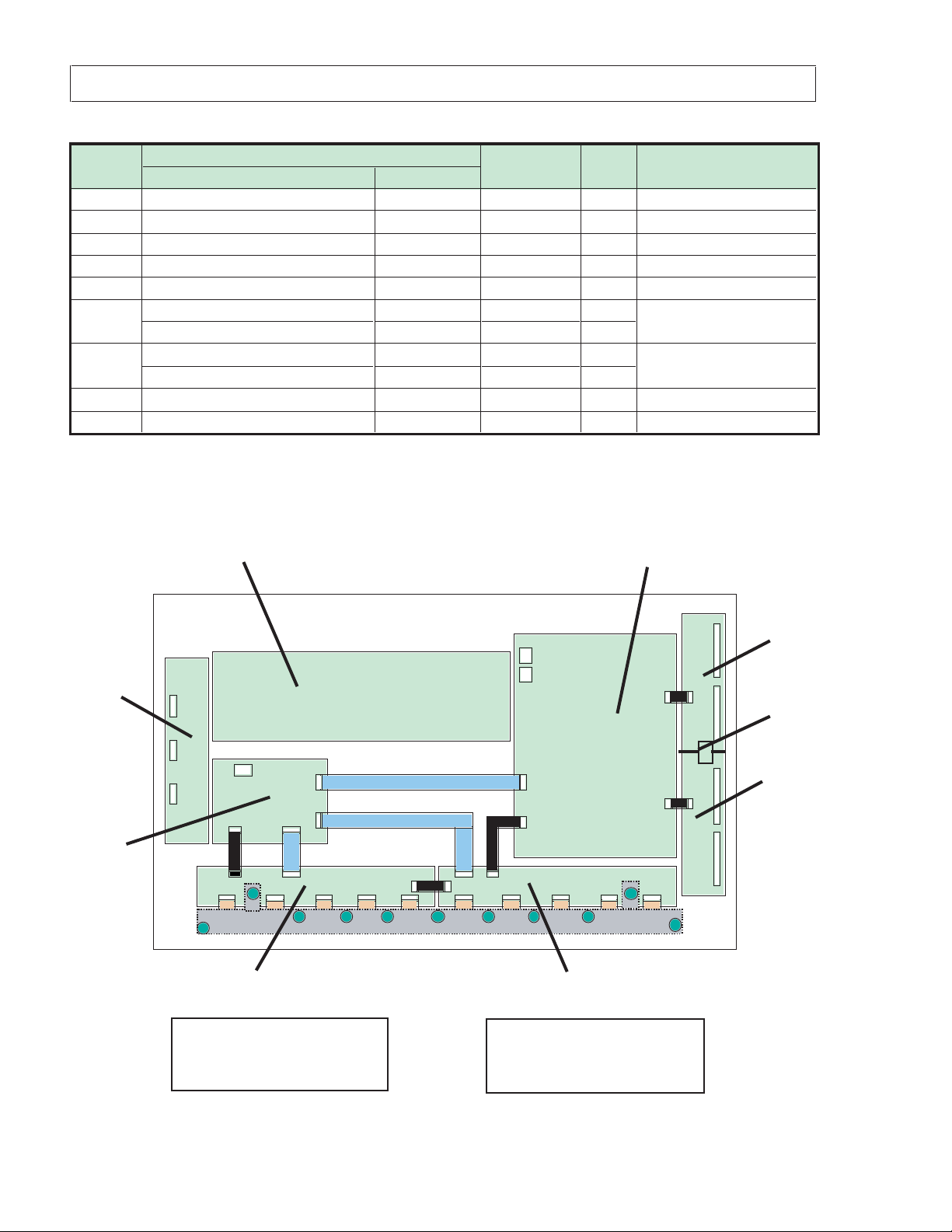

PDP-NP42B3MF01AB

PARTS LIST

2

PART NAME

PART NO QTY NOTE

Scanning relay PKG-U

Digital PKG

1

Scanning relay PKG-U

SYMBOL

1 PKG42B3G1 01D 9S899523 1 High voltage PKG

2 PKG42B3J4 01A 9S899627 1 Common divergence PKG

3 PKG42B3J3 01A 9S899282 1 Common relay PKG

4 PKG42B3J1 02B 9S899524 1 Signal relay PKG (left)

5 PKG42B3J2 02B 9S899525 1 Signal relay PKG (right)

PKG42B3E1 01C 9S899351 1

6

PKG42B3E1 01D 9S899528 1

PKG42B3E2 01C 9S899355 1

7 Scanning relay PKG-D

PKG42B3E2 01D 9S899531 1

8 PKG42B3E3 Version nothing 9S899443 1 Scanning relay PKG-C

9 PKG42B3C2 03J-06 9S899847 1

Notes: • The version of a board assy (PKG) is indicated on the label on the board assy.

TYPE NAME VERSION

• When replacing the scanning relay board assys (PKG-C), make sure that the PKG-U (PKG42B3E1)

and PKG-D (PKG42B3E2) of the same version are used, to ensure correct scanning timing.

3

Common relay PKG

Digital PKG

Common divergence PKG

9

Signal relay PKG (left)

4

Version label of the board assy (PKG)

• Part name

• Serial number

• HW version • SW version

High voltage PKG

Signal relay PKG (right)

5

• Part name

• Serial number

• Version number

6

8

7

Scanning relay PKG-D

24

Digital PKG

Other PKG

7-2

Page 25

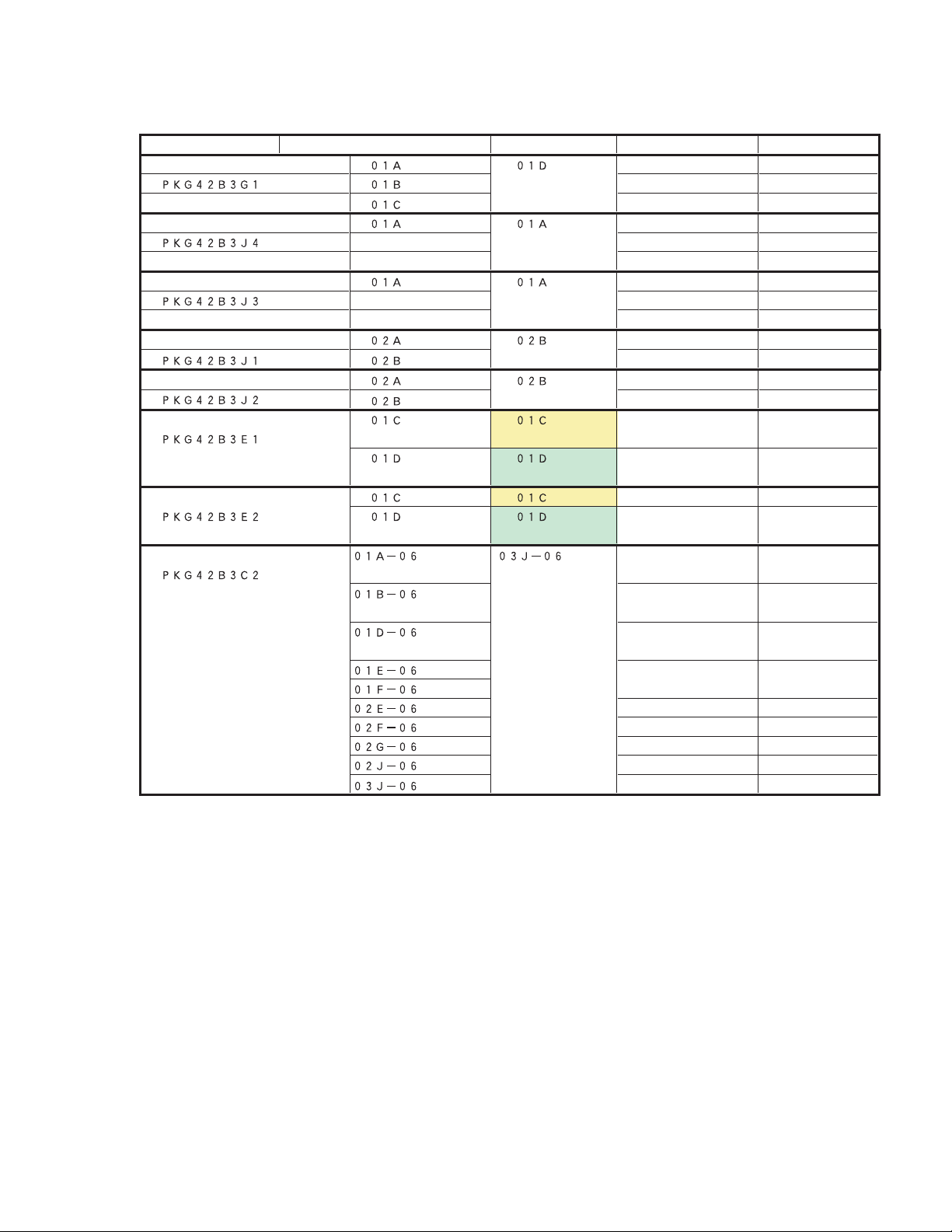

Compatible table of the board version

Part Name of PKG

High voltage PKG

Common divergence PKG

Common relay PKG

Signal relay PKG (left)

Signal relay PKG (right)

Scanning relay PKG-U

Scanning relay PKG-D

Digital PKG

Target Version

Compatible Version

Conditions

Remarks

Note: By referring to the table on compatible versions of the board assys, make sure that board

assys of compatible versions are used.

7-3

25

Page 26

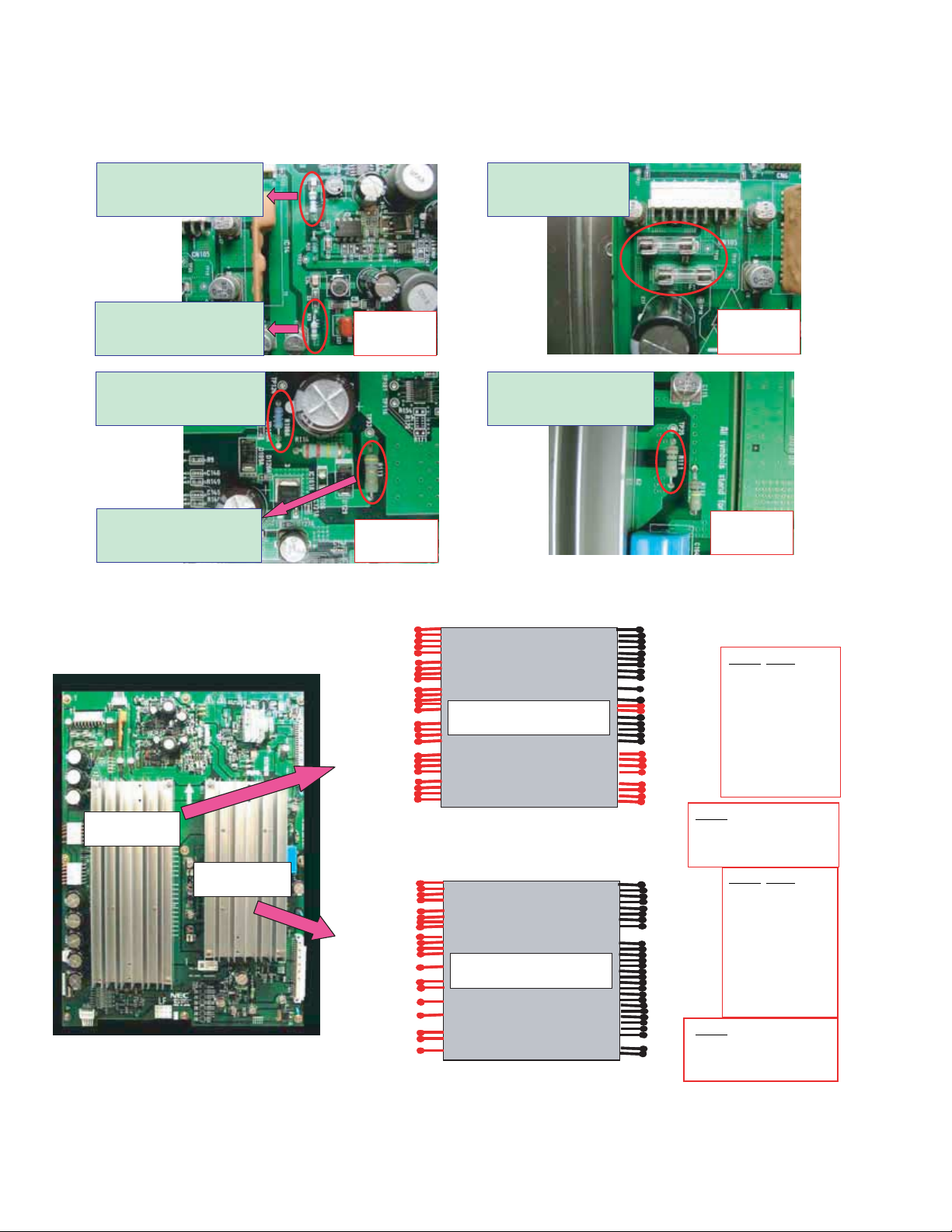

2. Points of failure diagnosis for a Board Assy (PKG)

The fuses and/or fusible resistors shown in the photos below may be blown by electric

surges caused by a failure. In such a case, replace the corresponding PKG.

Failure diagnosis of the Scanning PKG

Fusible resistor (R12) located

at the upper-left corner of the

Scanning PKG: Approx. 1.0 Ω

(1/2 W)

Fusible resistor (R29) located

at the upper-left corner of the

Scanning PKG: Approx. 4.7 Ω

(1/4 W)

OK: Short-

circuited,

NG: Open

Glass fuses (F1 and F2)

located at the upper-left

corner of the Scanning

PKG

OK: Short-

circuited,

NG: Open

Fusible resistor (R108A)

located at the lower-right corner

of the Scanning PKG: Approx.

2.2 Ω (1 W)

Fusible resistor (R113) located

at the lower-right corner of the

Scanning PKG: Aapprox. 4.7 Ω

(2 W)

OK: Short-

circuited,

NG: Open

Fusible resistor (R111) located

at right center of the Scanning

PKG: Approx. 10 Ω (1 W)

Failure diagnosis of the Power HIC on the Scanning PKG

D

(58~62)

E

(53~56)

F

(47~51)

G

(42~45)

H

(37~40)

I

(32~35)

PH2311(rear view)

PH2311

Note: A, D, and E are ground.

1

11

9

13

A

20

B

C

(14~15)

(23~26)

(28~31)

Result:

OK: k Ω or more,

NG: Short-circuited

OK: Short-

circuited,

NG: Open

Check points

Between A and B

Between B and H

Between C and I

Between D and E

Between F and G

26

PH2312

A

(59~62)

B

(54~57)

52

49

C

E

G

I

(42)

(38)

(34)

(46)

D

(43)

F

(40)

H

(35)

J

(32)

PH2312(rear view)

Note: C and G are ground.

7-4

1

8

11

27

30

31

Check points

Between A and B

Between C and D

Between E and F

Between G and H

Between I and J

Result:

OK: k Ω or more,

NG: Short-circuited

Page 27

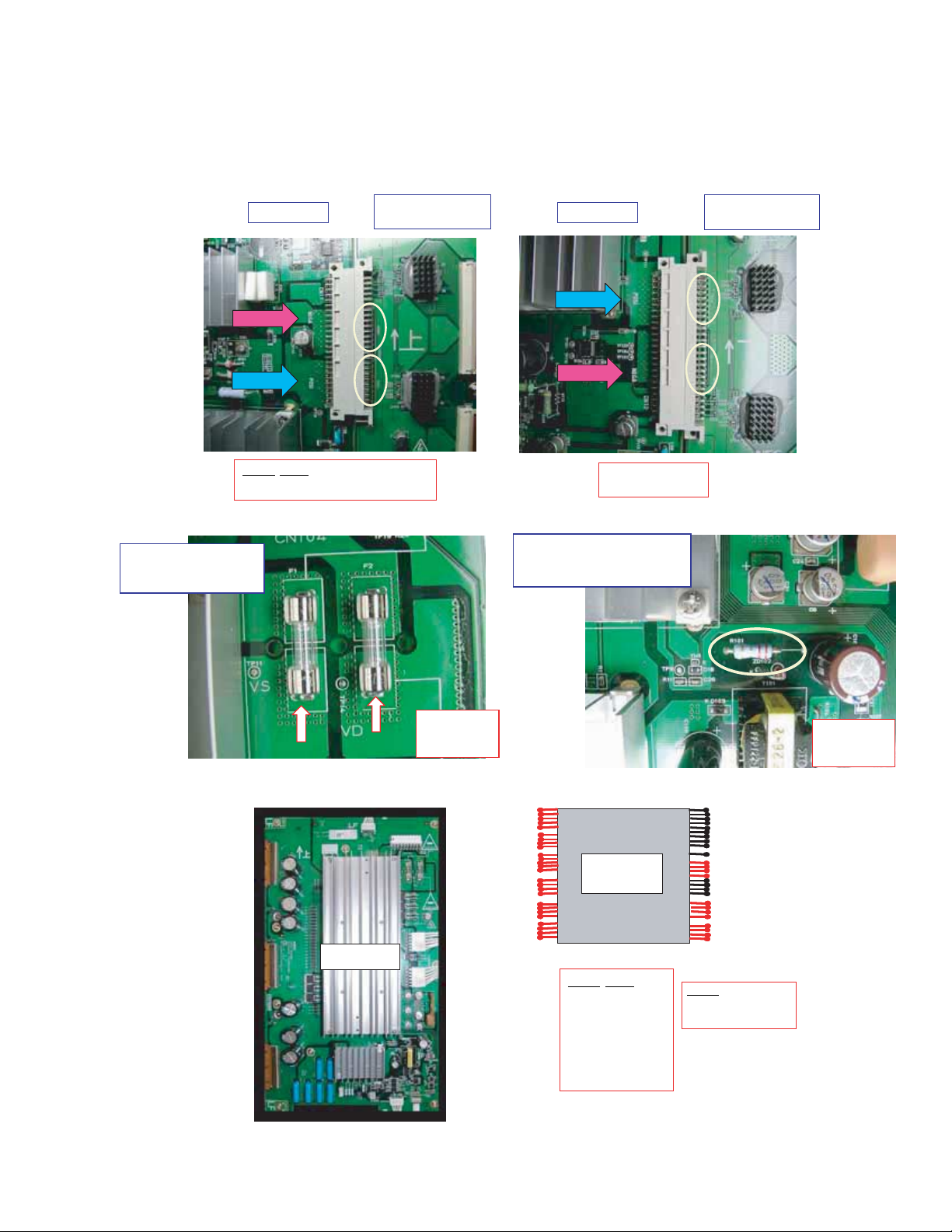

Failure diagnosis of the Power HIC on the Common PKG

1

11

9

20

OK: Short-

circuited,

NG: Open

OK: Short-

circuited,

NG: Open

Failure diagnosis of the Scanning IC

Check with a tester the resistance value between any pins indicated as NEGA and POSI of the

connector in the photos below. If a positive and a negative pin of the connector on the Scanning

Relay PKGs are short-circuited and remains short-circuited even after the connectors on the

Scanning PKG and Scanning Relay PKG are disconnected, the Scanning IC on the Scanning Relay

PKG is in failure.

Failure diagnosis of the Common PKG

Glass fuses (F1 and F2) at

the upper-right corner of

the Common PKG

Fusible resistor (R101) at the

lower-right corner of the Common

PKG: Approx. 2.2 Ω (1 W)

A

(13~16)

B

(23~26)

C

(28~31)

D

(58~62)

E

(53~56)

F

(47~51)

G

(42~45)

H

(37~40)

I

(32~35)

Check points

Check points

Between A and B

Between B and H

Between C and I

Between D and E

Between F and G

OK: k Ω or more,

NG: Short-circuited

Between any pins of

NEGA and POSI blocks

PH2311

NEGA

NEGA

POSI

POSI

NEGA

NEGA

POSI

POSI

Scanning Relay PKG

(upper connector)

Scanning PKG Scanning PKG

Scanning Relay PKG

(lower connector)

PH2311

(rear view)

Result:

OK: k Ω or more,

NG: Short-circuited

Note: A and D are ground.

7-5

27

Page 28

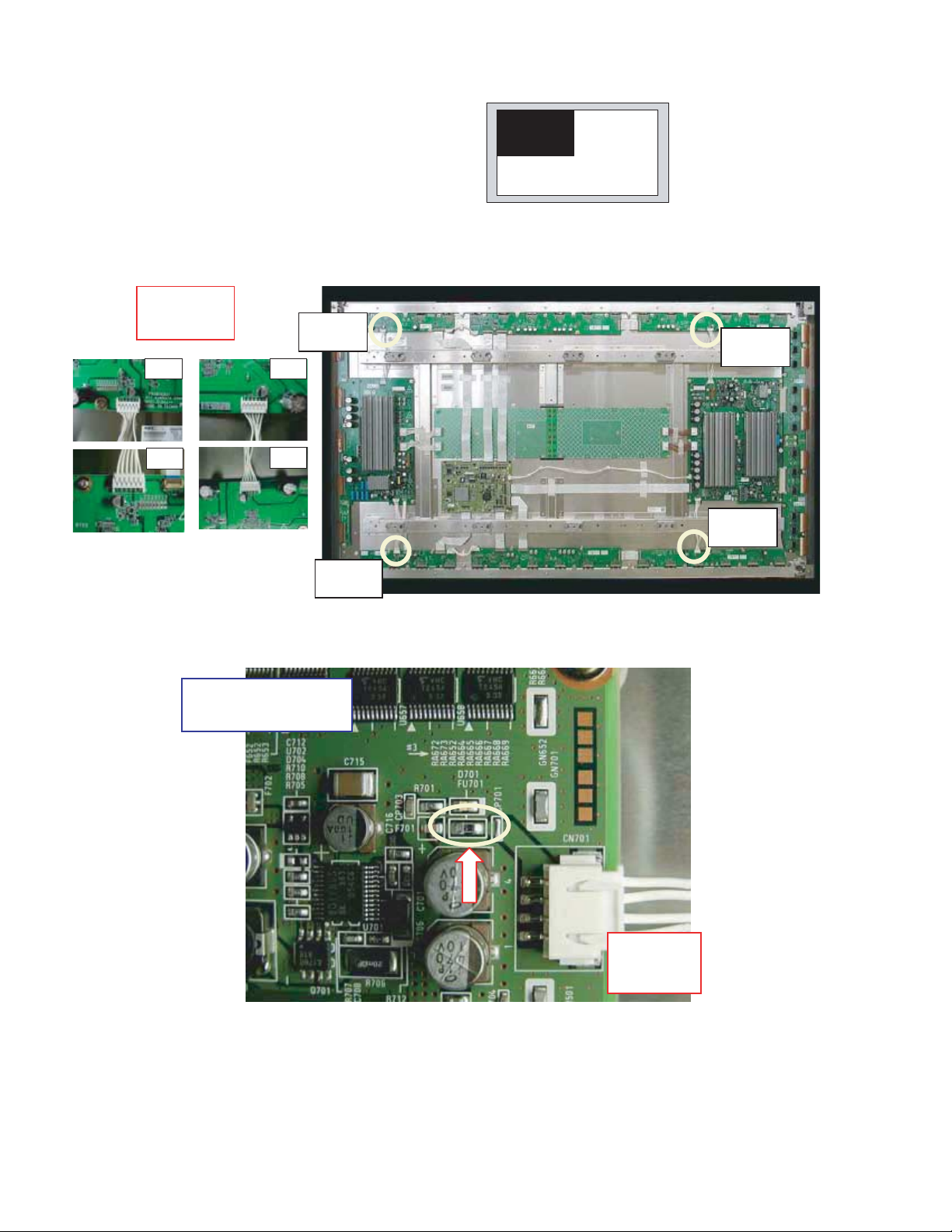

Failure diagnosis of the Data HIC

Failure symptom: The image in any block of the screen is not displayed.

Check with a tester between Pin 5 or 6 (Vd line of Data IC)

and ground of each Signal Relay PKG.

OK: Open

NG: Short-

circuited,

CN2

CN8CN8CN2

CN8

CN3

CN8

CN3

Failure diagnosis of the Digital PKG

Chip fuse (FU701) at the

upper-right corner of the digital

PKG

CN8

28

7-6

OK: Short circuited,

NG: Open

Page 29

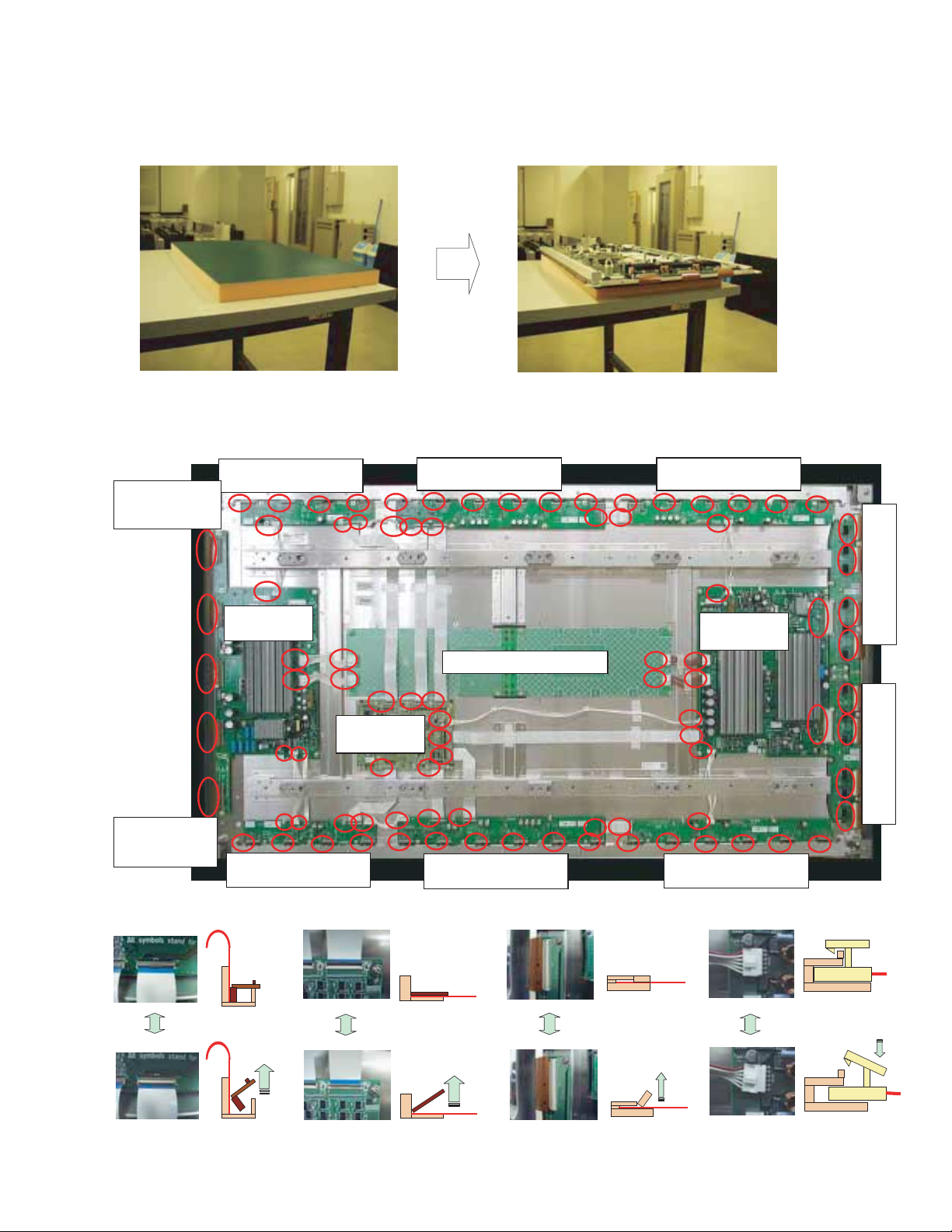

3. Replacement method for a Board Assy (PKG) and notes on replacement

Preparation

Place a cushion on the workbench and set the module to be repaired on it.

Note: With the glass surface facing downward, be sure that the entire glass surface is

against the cushion.

Common Branch

PKG (upper): One

connector

Common board:

10 connectors

Flat cable

(longitudinal type)

Flat cable

(horizontal type 1)

Flat cable

(horizontal type 2)

Cable type

Digital PKG: 8

connectors

Scanning PKG:

8 connectors

Common Branch

PKG (lower): One

connector

Signal Relay PKG (upper

left): 7 connectors

Signal Relay PKG (upper

center): 10 connectors

Signal Relay PKG

(upper right): 8 connectors

Signal Relay PKG

(lower right): 8 connectors

Signal Relay PKG (lower

center): 10 connectors

Signal Relay PKG (lower

left): 8 connectors

Scanning Relay PKG

(upper): 5 connectors

Scanning Relay PKG

(lower): 5 connectors

Disconnection of connectors and cables

Disconnect all the connectors on the PKG to be repaired.

(When a Signal Relay PKG is to be removed, remove the heat sink beforehand.)

Recovery Relay PKG

Lock. Lock. Lock. Lock.

Unlock. Unlock. Unlock. Unlock.

7-7

29

Page 30

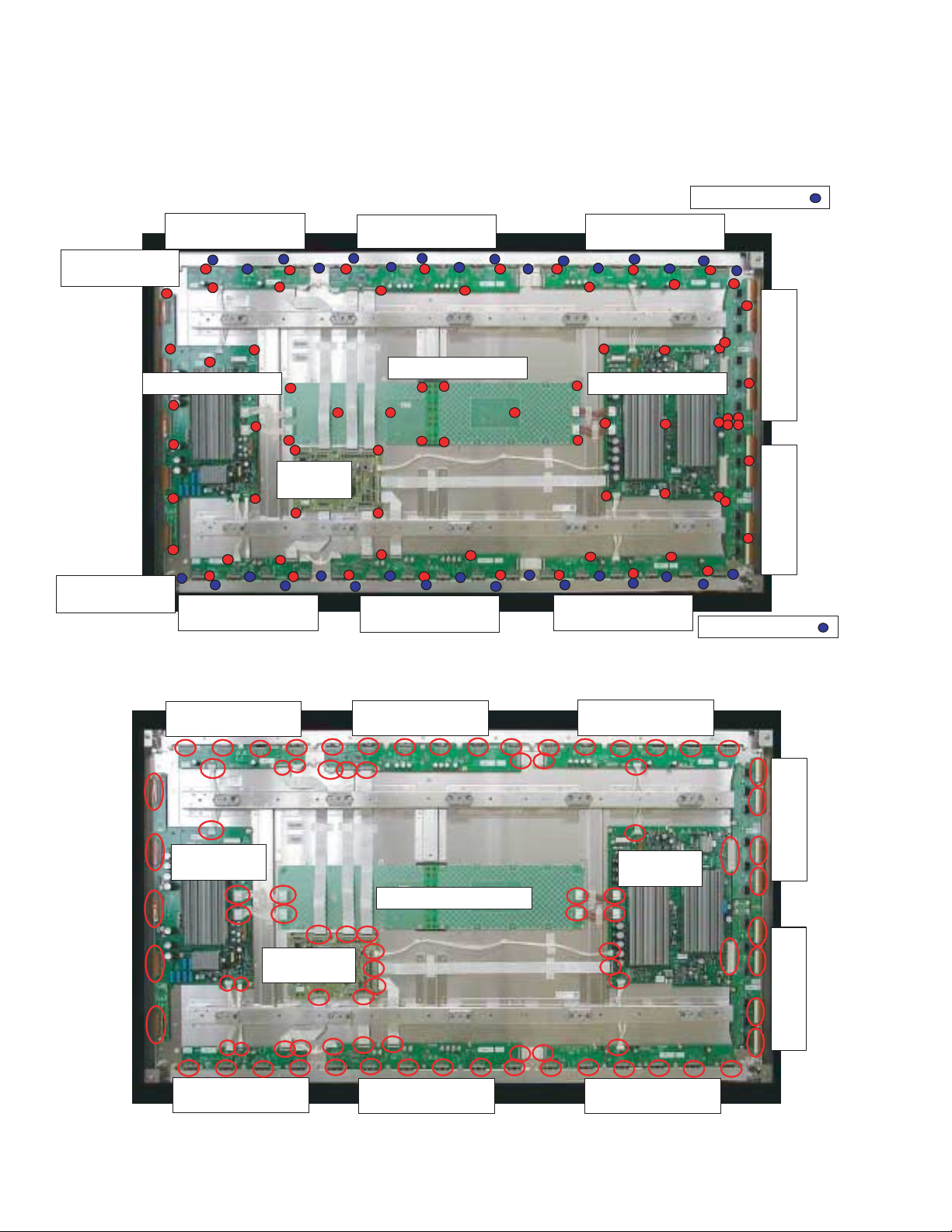

How to remove/reattach the Board Assy (PKGs)

Notes: · Be sure not to drop a screwdriver or screw on a PKG or a cable.

· When removing/reattaching a screw, be sure not to leave any tiny metal shavings, because

they may cause a failure.

· Before removing Signal Relay PKGs, remove the heat sink.

· Be sure not to apply any stress to a PKG, connector, or cable when reattaching them.

· Reattach Signal Relay PKGs before reattaching the heat sink.

Heat sink: 17 screws

Common Branch PKG

(upper): One screw

Common PKG: 8 screws

Common Branch PKG

(lower): One screw

Signal Relay PKG

(upper left): 4 screws

Digital PKG:

4 screws

Signal Relay PKG

(lower left): 4 screws

Signal Relay PKG (upper

center): 5 screws

Recovery Relay PKG :11screws

Signal Relay PKG

(lower center): 5 screws

Signal Relay PKG (upper

right): 5 screws

Scanning PKG: 9 screws

Signal Relay PKG

(lower right): 5 screws

Confirmation of connector connection

Check whether or not the connectors indicated by circles are correctly connected.

Scanning Relay PKG

(upper): 6 screws

Scanning Relay PKG

(lower): 5 screws

Heat sink: 17 screws

Signal Relay PKG

(upper left): 7 connectors

Common board:

10 connectors

Digital PKG:

8 connectors

Signal Relay PKG (lower

left): 8 connectors

Signal Relay PKG (upper

center): 10 connectors

Common branch PKG

Signal Relay PKG (lower

center): 10 connectors

Signal Relay PKG (upper

right): 8 connectors

Scanning PKG:

8 connectors

Signal Relay PKG (lower

right): 8 connectors

Scanning Relay PKG

(upper): 5 connectors

Scanning Relay PKG

(lower): 5 connectors

30

7-8

Page 31

Confirmation of connector connection and locking statuses

: OK : NG

Between the Data IC and Signal

Relay PKG (photo)

Between the Signal Relay PKG

(photo) and Digital PKG

Between the Signal Relay PKG

and Digital PKG (photo)

Between the panel and

Common PKG (photo)

Between the Scanning PKG

(photo) and Recovery Relay PKG

Between the Signal Relay PKG

and Scanning PKG (photo)

Between the Scanning Relay PKG

(photo) and panel

Between the Scanning PKG (photo)

and Signal Relay PKG (photo)

7-9

31

Page 32