Plasma Display:

PDP-V401/V401E

Ceiling-suspension metal fixture for plasma display:

PDK-4001 PDK-4006

PDK-4002 PDA-4001

PDK-4003 PDA-4002

PDK-4004 PDP-S01-LR

PDK-4005

[Installation]

¶ We sell this equipment on the assumption that it

will be installed by a specialist with adequate training.

The equipment must be installed by trained vendors

or by your dealer.

¶ We are not responsible for injuries or damage

resulting from choice of unsuitable installation sites,

problems in assembly and installation, improper

installation, or natural disasters.

Note:

• We are not responsible for damage caused by defective

parts supplied by third parties.

• The performance of the equipment is guaranteed only

when assembly and adjustment are performed as

described herein.

• The specifications and descriptions given in this

technical manual are subject to change without notice.

For safety

In this manual, this symbol indicates important

precautions. Read these precautions carefully.

This manual gives precautions, general information, and examples for installation and handling of the plasma display

and its metal fixtures.

Carefully examine the structure, material, strength, and environmental conditions for the site at which the display is to

be installed before selecting an installation method. If the site is unsatisfactory, venders should not sell or install the

equipment.

TECHNICAL MANUAL (ver.2.1)

2

<Ver. 2.1>

Contents

Features ................................................................................................................................................................. 4

Specifications ......................................................................................................................................................... 6

2.1 List of specifications ................................................................................................................................... 6

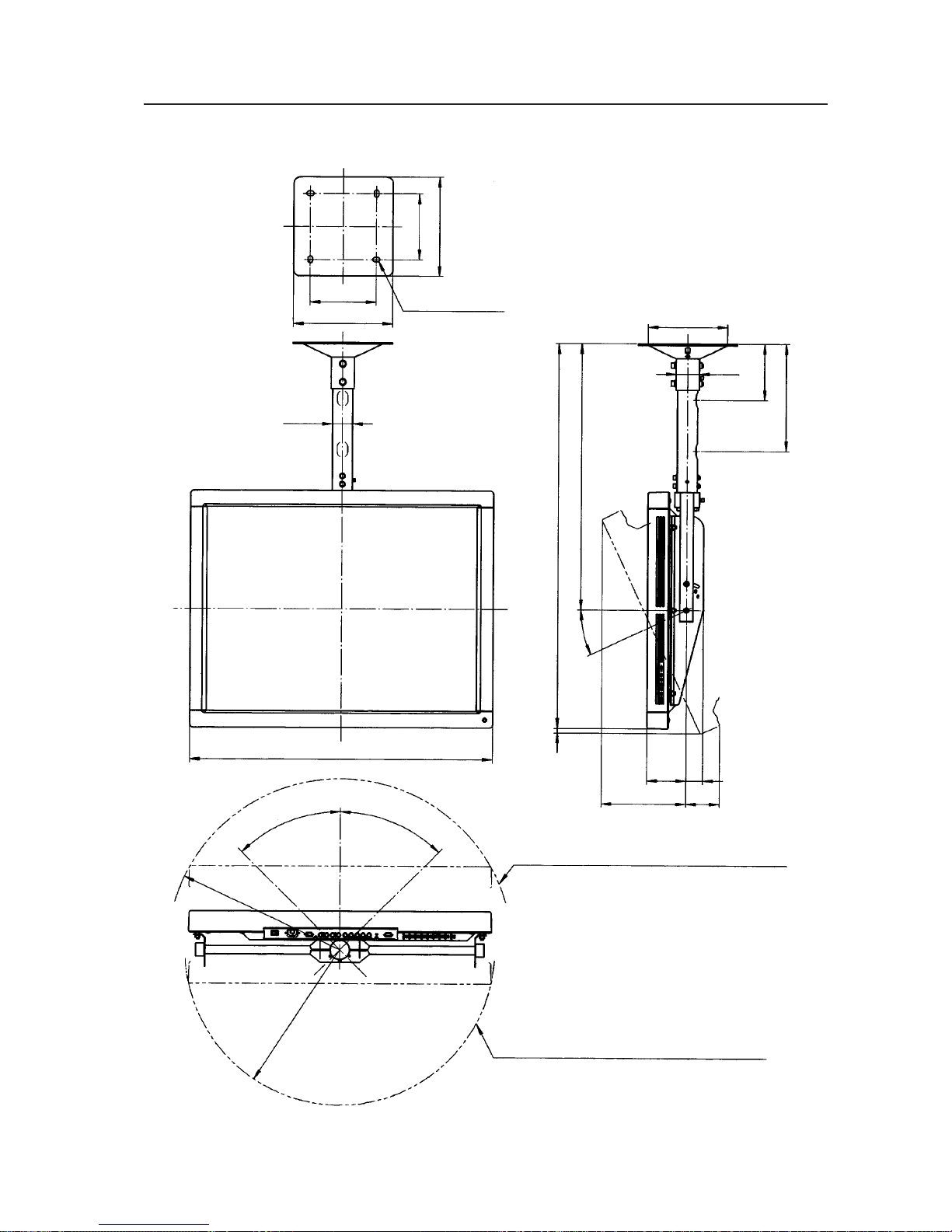

2.2 Outline drawing ........................................................................................................................................... 7

2.3 Part names .................................................................................................................................................. 8

2.4 Remote control ........................................................................................................................................... 9

Installation ............................................................................................................................................................ 10

3.1 Installation environment ............................................................................................................................ 10

3.2 Installation conditions ............................................................................................................................... 12

3.2.1 Radiation ............................................................................................................................................ 12

3.2.2 Calculating calorific values ................................................................................................................. 12

3.2.3 Installation position ............................................................................................................................ 13

3.2.4 Strain on surface where equipment is installed................................................................................. 15

3.3 Installation procedure ................................................................................................................................ 16

3.3.1 Precautions for transportation ........................................................................................................... 16

3.3.2 Unpacking .......................................................................................................................................... 16

3.3.3 Wiring ................................................................................................................................................ 18

3.4 Special installations ................................................................................................................................... 20

3.4.1 Fixing on a structure .......................................................................................................................... 20

3.4.2 Wall hanging ...................................................................................................................................... 22

3.4.3 Wall embedding ................................................................................................................................. 24

3.4.4 Ceiling suspension (using wires) ....................................................................................................... 28

3.4.5 Installation with the screen downward.............................................................................................. 30

3.4.6 Ceiling embedding ............................................................................................................................. 32

3.4.7 Installation on the floor ...................................................................................................................... 36

3.4.8 Installation under the floor ................................................................................................................. 38

3.4.9 Installation under the floor (using the PDM-4001) ............................................................................. 42

3.4.10 Wall hanging (vertically wall-hanging equipment) .............................................................................. 44

3.4.11 Wall embedding (vertically wall-embedding equipment) ................................................................... 46

3.4.12 Horizontal connections ...................................................................................................................... 50

3.4.13 Vertical connections........................................................................................................................... 54

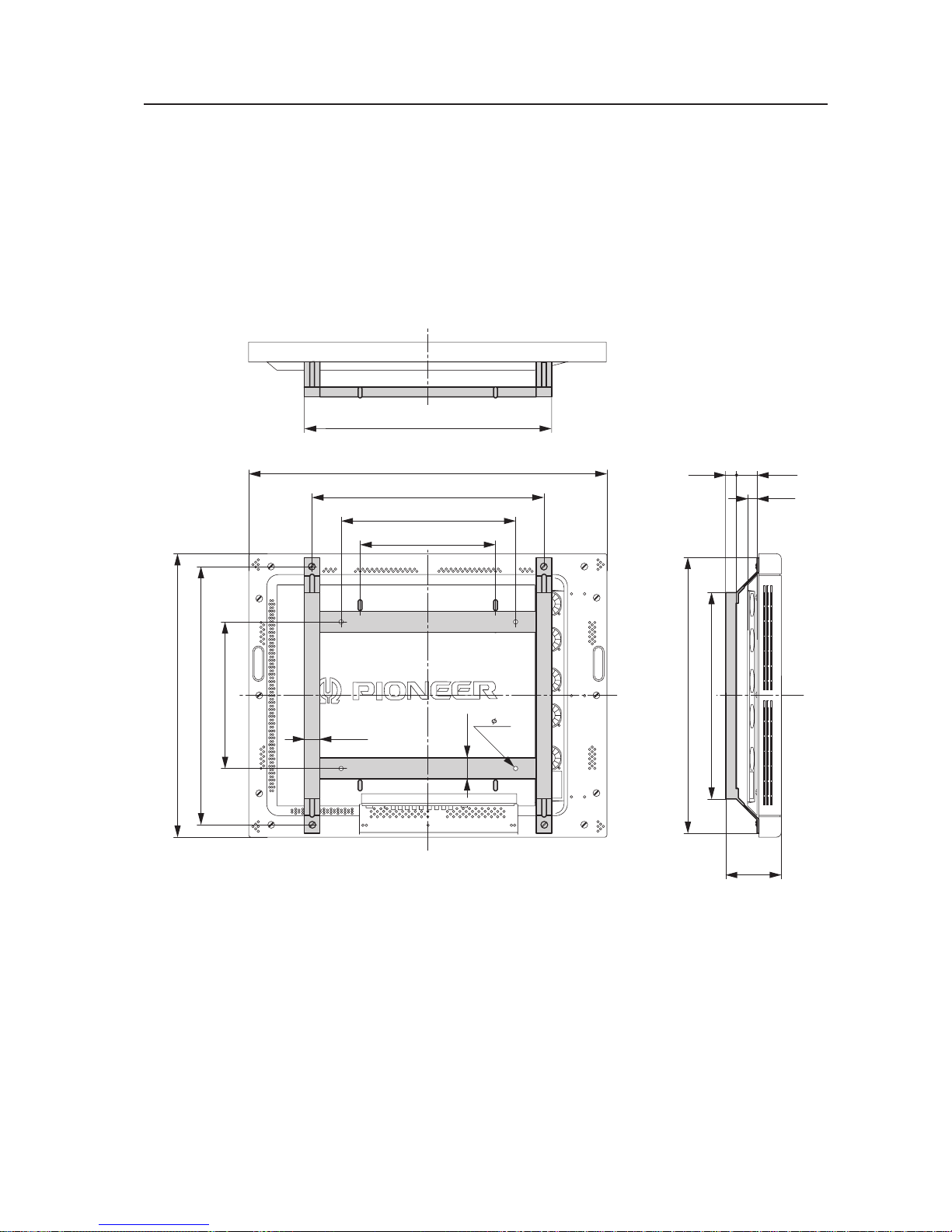

Mounting standard metal fixtures ..................................................................................................................... 56

4.1 Functions and features of standard metal fixtures ................................................................................... 56

4.2 Handling standard metal fixtures .............................................................................................................. 57

4.2.1 Precautions on handling metal fixtures.............................................................................................. 57

4.2.2 Precautions for vendors performing the installation .......................................................................... 57

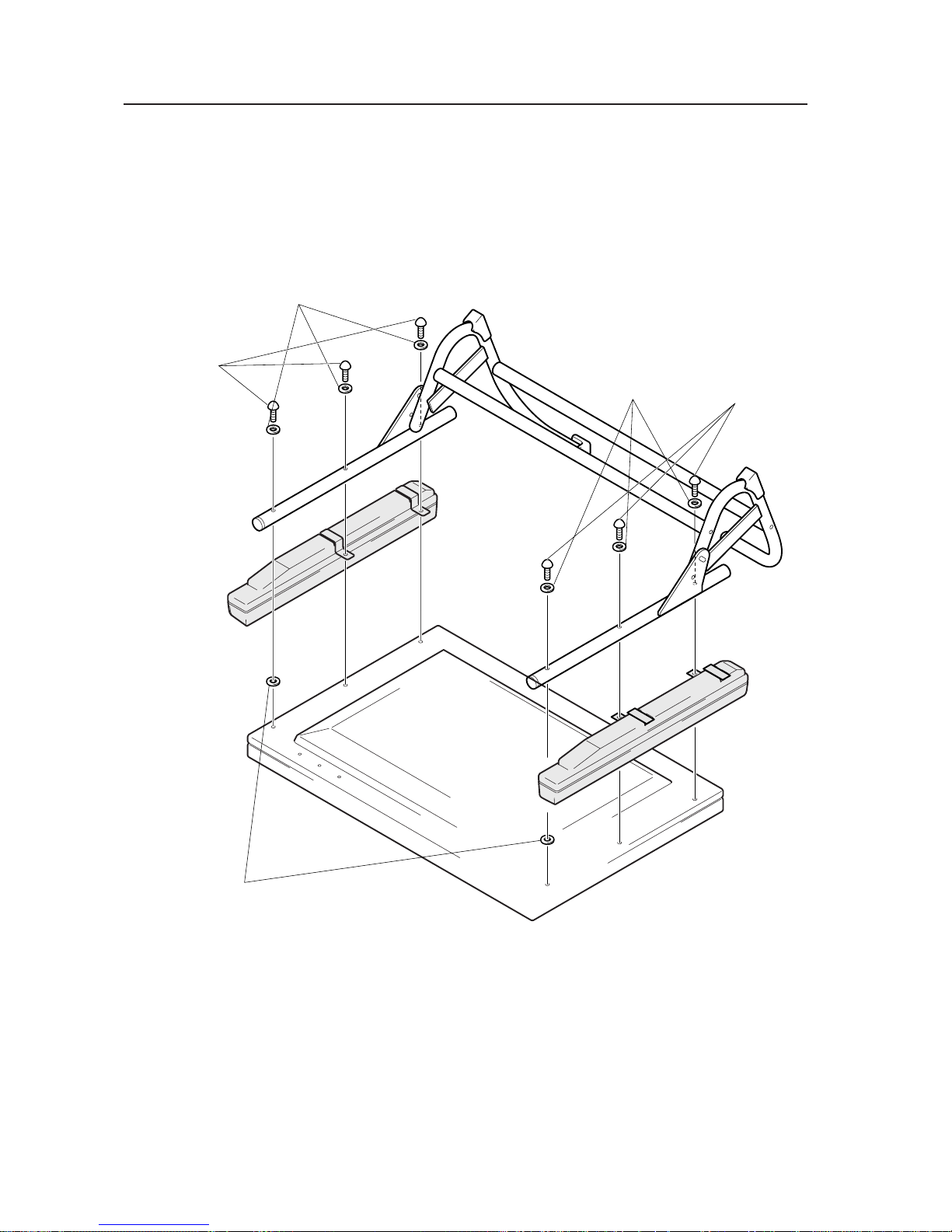

4.3 Stand (an accessory to PDP-V401 <PDP-V401E>) .................................................................................... 58

4.3.1 Installing the stand............................................................................................................................. 58

4.3.2 Outer-dimentions diagram ................................................................................................................. 59

4.4 Tilting stand: PDK-4001 ............................................................................................................................. 60

4.4.1 Specifications..................................................................................................................................... 60

4.4.2 Assembling and installing the metal fixture and mounting the plasma display ................................. 61

4.5 One-sided, ceiling-suspension metal fixture for the plasma display: PDK-4002 ....................................... 64

4.5.1 Specifications..................................................................................................................................... 64

4.5.2 Assembling and installing the metal fixture and mounting the plasma display ................................. 66

4.6 Double-sided, ceiling-suspension metal fixture for the plasma display: PDK-4003 .................................. 70

4.6.1 Specifications..................................................................................................................................... 70

4.6.2 Assembling and installing the metal fixture and mounting the plasma display ................................. 71

4.7 Ceiling-suspension metal fixture for the plasma display (head screw type): PDK-4004 ........................... 72

4.7.1 Specifications..................................................................................................................................... 72

4.7.2 Assembling and installing the metal fixture and mounting the plasma display ................................. 73

4.8 PDP bracket: PDK-4005 ............................................................................................................................ 76

4.8.1 Specifications..................................................................................................................................... 76

4.8.2 Assembling and installing the metal fixture and mounting the plasma display ................................. 77

4.9 Wall hanging metal fixture for the plasma display: PDK-4006 ..................................................................82

4.9.1 Specifications..................................................................................................................................... 82

4.9.2 Assembling and installing the metal fixture and mounting the plasma display ................................. 83

3

<Ver. 2.1>

Warning

• To prevent damage or injury, carefully read and follow this manual and all labels provided on the main display

body before undertaking assembly, installation, movement, or adjustment.

• To prevent fire and electric shock resulting from moisture infiltration, never use this system outdoors.

• To prevent injury, take care when handling the system's sharp edges.

• When installing the system at a height, create an off-limits zone to prevent injury or secondary damage in case of

falling equipment.

• To prevent fire and electric shock, never place foreign objects within or make modifications to the equipment.

• Always observe the following operating environmental conditions:

Temperature : 0 °C to 40 °C

Humidity : Relative humidity 20% to 80%

• Make sure the site is well-ventilated, and take care to maintain adequate ventilation following installation.

4.10Infrared reduction filter: PDA-4001, protective filter: PDA-4002 .............................................................. 90

4.10.1 Specifications and features (infrared reduction filter: PDA-4001) ...................................................... 90

4.10.2 Specifications and features (protective filter: PDA-4002) .................................................................. 91

4.10.3 Assembling and installing the metal fixture and mounting the plasma display ................................. 92

4.10.4 White balance .................................................................................................................................... 95

4.10.5 Mounting the PDP bracket: PDK-4005, with PDA-4001 and PDA-4002 mounted ............................. 95

4.

11

Speaker system: PDP-S01-LR ................................................................................................................ 96

4.11.1 Before operation ................................................................................................................................ 96

4.11.2 Specifications ..................................................................................................................................... 96

4.11.3 Assembling and installing the metal fixture and mounting the plasma display ................................. 97

4.11.4 Precautions for mounting different metal fixtures after the optional speakers are attached

to the plasma display main body ..................................................................................................... 100

Adjustment ......................................................................................................................................................... 106

5.1 Before making adjustments ................................................................................................................... 106

5.1.1 Operation mode ............................................................................................................................... 106

5.1.2 Picture quality and white-balance adjustment memory ................................................................... 110

5.1.3 Phase-adjustment memory.............................................................................................................. 111

5.1.4 Using the plasma display main body and the remote control together with the personal control ....... 111

5.1.5 Last memory.................................................................................................................................... 112

5.1.6 Aging................................................................................................................................................ 113

5.2 Performing adjustments on the plasma display operation panel and remote control ............................ 114

5.2.1 Menu mode ..................................................................................................................................... 114

5.2.2 Integrator mode ............................................................................................................................... 118

5.2.3 Precautions ...................................................................................................................................... 125

5.3 Outer control by RS232C........................................................................................................................ 126

5.3.1 Precautions ...................................................................................................................................... 126

5.3.2 Interface........................................................................................................................................... 127

5.3.3 RS232C commands table ................................................................................................................ 128

5.3.4 List of GET commands .................................................................................................................... 130

Precautions for functions and operation ......................................................................................................... 132

6.1 KEY LOCK/UNLOCK ............................................................................................................................... 132

6.1.1 Functions ......................................................................................................................................... 132

6.1.2 Setting method ................................................................................................................................ 132

6.2 Mask color select/off when NTSC is input ............................................................................................. 133

6.2.1 Functions ......................................................................................................................................... 133

6.2.2 Setting method ................................................................................................................................ 133

6.2.3 Precautions ...................................................................................................................................... 133

6.3 Mask color select when PC-9800

®

is input ............................................................................................ 134

6.3.1 Functions ......................................................................................................................................... 134

6.3.2 Setting method ................................................................................................................................ 134

6.3.3 Precautions ...................................................................................................................................... 134

6.4 Pseudo-contour ...................................................................................................................................... 134

6.5 Precautions ............................................................................................................................................. 135

Maintenance ...................................................................................................................................................... 136

Contents

4

<Ver. 2.1>

Features

Features and functions of the plasma display (PDP-V401/V401E)

¶ Materialization of high luminance (400 cd/m2)

Industry-leading luminance, equal to that of 30-inch class CRTs, is achieved by optimizing panel cell-structure.

¶ Sharp picture quality

Eight-bit (256-color) and full-color (16,770,000 colors) display, with Pioneer's unique pseudo-contour-reducing

technology that reduces plasma display noise.

¶ Thin and lightweight: 88 mm in depth and 30.8 kg in weight

Industry-leading compactness, 88 mm deep and 30.8 kg <31.6 kg> in weight, permits installation in places inappropriate

for ordinary displays.

< > shows the PDP-V401E.

¶ Best display for industrial and public purposes

Our plasma display (PDP-V401/V401E) is specifically designed for use as an industrial display. It has been designed

to provide the following features:

• An aspect ratio of 4:3 optimal for use as a public display

• A versatile mounting structure and metal fixtures permitting wall or vertical installation

• Integrator mode that enables fine adjustment

• Equipped with an RS232C serial connection port as an external control interface

• Other functions, including color temperature setting to allow retakes and a key lock to prevent tampering

Our plasma display has been designed for durability and reliability, features required in industrial displays. Its features

and quality allow use in a wide range of applications and locations.

5

<Ver. 2.1>

Features

6

<Ver. 2.1>

List of specifications

Applicable sources

1 Video system: NTSC <PAL/NTSC Dual>

2 Computer system

1.Resolution

AT-compatible: VGA (640 dots × 480 lines)

Macintosh

®

: 13-inch mode (640 dots × 480 line)

PC-9800

®

: Normal mode (640 dots × 400 line)

2.Synchronizing frequency:

AT-compatible: 31.5 kHz (horizontal), 60 Hz (vertical)

Macintosh

®

: 35 kHz (horizontal), 67 Hz (vertical)

PC-9800

®

: 24.8 kHz (horizontal), 56 Hz (vertical)

31.5 kHz (horizontal), 70 Hz (vertical)

Does not accommodate the interlaced mode of the computer.

Some types of computer have multiple indication modes.

However, some modes cannot be displayed even if the computer

meets the specifications. Please contact your dealer for further

information.

Power source ...................... 100 to 120 V AC, 50/60 Hz

<220 to 240 V AC , 50/60 Hz>

Inrush ................................ 70 A or less <30 A or less>

Power factor ............................................ 0.95 or more

Power consumption .............. 350 W (in standby: 2 W)

Outer dimensions........ 916 (W) × 714 (H) × 88 (D) mm

Weight .............................................. 30.8 kg <31.6 kg>

Operating environment temperature range

..................................................................... 0 to 40 °C

Operating environment humidity range

.................................... Relative humidity 20% to 80%

Operating environment air pressure range

.................................... 0.8 - 1.1 atmospheric pressure

Storage conditions (Package state)

Storage environment temperature range

............................................................ –10 to 45 °C

Storage environment humidity range

............................... Relative humidity 20% to 90%

Storage stack limit ............................ maximum of 10

Accessory

Power cord (PDP-V401 only) ........................................ 1

Remote control ............................................................ 1

AA battery .................................................................... 2

Stand ............................................................................ 2

Bolt ............................................................................... 2

Washer ......................................................................... 2

Cable clamp.................................................................. 3

Operating Instructions.................................................. 1

• Specifications and appearance are subject to change

without notice.

• < > shows the PDP-V401E.

2.1 List of specifications

Light emission panel...... 40-inch plasma display panel

Aspect ratio ............................................................. 4:3

No. of pixels ................... 640 × 480 (adaptable to VGA)

Pixel pitch

........... 1.26 (horizontal, RGB trio) × 1.26 (vertical) mm

No. of gradations ................................ 256 gradations/

16,770,000-color full color

Luminance ............................... 400 cd/m

2

(panel alone)

View angle ............................ Horizontal : 160° or more

Vertical : 160° or more

Input/output terminals

RGB Input

1 BNC Terminal R, G, B (fixed to 75 Ω input)

HD (H/V SYNC), VD (switching between 75 Ω /2.2 kΩ

input)

Switch VD according to the sync output impedance

of the connector. Switch VD to 2.2 kΩ except when

the sync output impedance is 75 Ω. (The terminal is

factory-set to 75 Ω.)

2 Mini Dsub 15P

Analog RGB, 0.7 Vp-p, 75 Ω input, G-on Sync input

(Sync 0 - 3 Vp-p)

Synchronization:

HD, VD 2.2 kΩ input, 2.0 - 5.0 Vp-p (Positive/Negative),

G-on Sync switch (G-on Sync ON/OFF Change over)

Turn the switch on only if images become greenish

(when the G-on Sync signal is applied) at RGB2 input.

Under normal circumstances, the switch is left off.

(The switch is factory-set to G-on Sync OFF.)

Video input ...... Single-system BNC terminal 75 Ω input

Composite 1 Vp-p

Y/C input .......... Double-system BNC terminal 75 Ω input

Control input.... Dsub 9P (RS232C control)

Video output .... Single-system BNC terminal 75 Ω output

(Note: Up to four units, including the unit

to which the signal is first input, may be

connected when the equipment is

connected in series using this output

terminal. However, increasing the

number of connected units may increase

the noise.)

7

<Ver. 2.1>

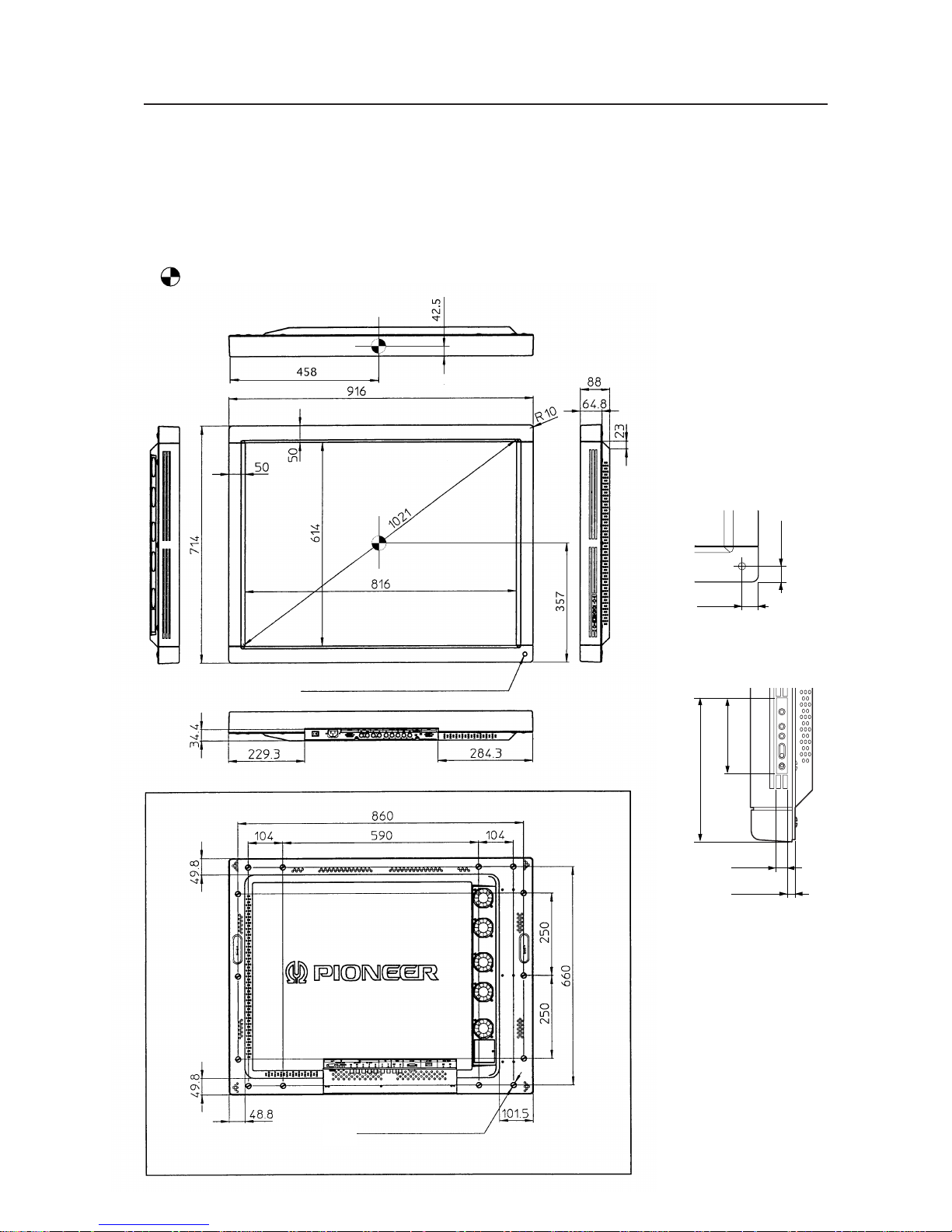

Outline drawing

φ12

(the opening for infrared remote control signals)

14-M8 (with φ16-hole rivet)

Rear View

2.2 Outline drawing

Plasma display main body weight : 30.8 kg <31.6 kg>

Material : Front - Plastic, Back - plate

Treatment : Front - Leather satin gray paint, Back - Semi-matte black paint

Packing specifications - See “3.3.2 Unpacking”

• < > shows the PDP-V401E.

: Location of center of gravity

<Light-accepting section

of the remote controller>

<Operation panel

of the main body>

24

24

202.5

107

14

14.8

8

<Ver. 2.1>

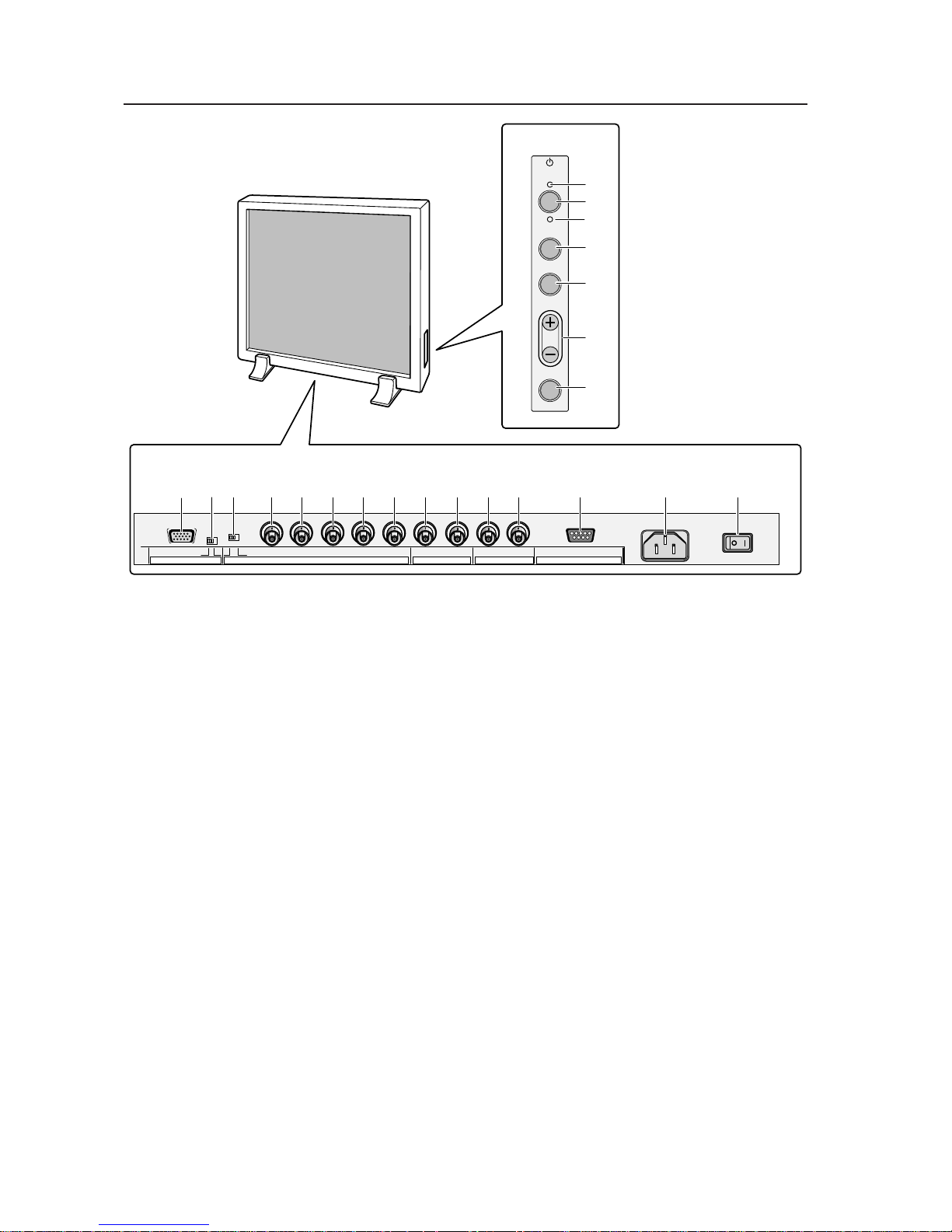

2.3 Part names

Part names

<Operation panel>

1 STANDBY/ON indicator

The switch lights in RED for STANDBY and GREEN for

ON mode.

2 Power button

Turns power on or off.

3 INPUT select button

Selects input.

4 MENU button

Used to switch the menu screen and normal screen.

5 ADJUST button

Used for picture adjustment.

6 SET button

Used to select a selected adjustment item during

picture adjustment.

<Terminals and power supply section>

RGB-2 input terminals

7 Mini D-SUB15 pin terminal

8 G-on SYNC mode select switch (ON/OFF)

If pictures take on a greenish cast when other

external equipment is connected to the RGB-2 input

terminal, turn on the G-on SYNC mode. Normally,

this switch is left off.

RGB-1 input terminals

9 Synchronizing signal input impedance select switch

(75 Ω /2.2 kΩ)

0 Vertical synchronizing signal input terminal:

Switching between 75 Ω /2.2 kΩ)

- Horizontal or composite synchronizing signal input

terminal: Switching between 75 Ω /2.2 kΩ

= Blue signal input terminal: 75 Ω

~ Green signal or synchronizing (ON SYNC) green

signal input terminal: 75 Ω

! Red signal input terminal: 75 Ω

Y/C input terminal

@ Color signal input terminal: 75 Ω

# Luminance signal input terminal: 75 Ω

VIDEO input/output terminal

$ Video output terminal: 75 Ω

(Note: Up to four units including the unit to which

the signal is first input may be connected when the

equipment is connected in series using this output

terminal. However, increasing the number of

connected units may increase noise.)

% Video input terminal: 75 Ω

^ Control signal input terminal (RS232C)

& AC INLET

* Main power switch

( KEY LOCK/UNLOCK button (hidden switch)

Use this button to disable or enable control through

the operation panel or by remote control.

STANDBY

/ON

INPUT

MENU

ADJUST

SET

VD HD B G R C Y OUT IN

75 2.2k

OFF ON

(Ω)

(H/V SYNC) RGB-1 (ON SYNC) Y/C

SYNCG ON SYNC

VIDEO RS-232CRGB-2

1

2

3

4

5

6

7

809-=~!@#$%^ *&

˚(

<Operation Panel>

<Terminals and power supply section>

(The terminals and power supply section are located at the back of the plasma display main body.)

9

<Ver. 2.1>

Y/C button

Sets Input Function to Y/C input.

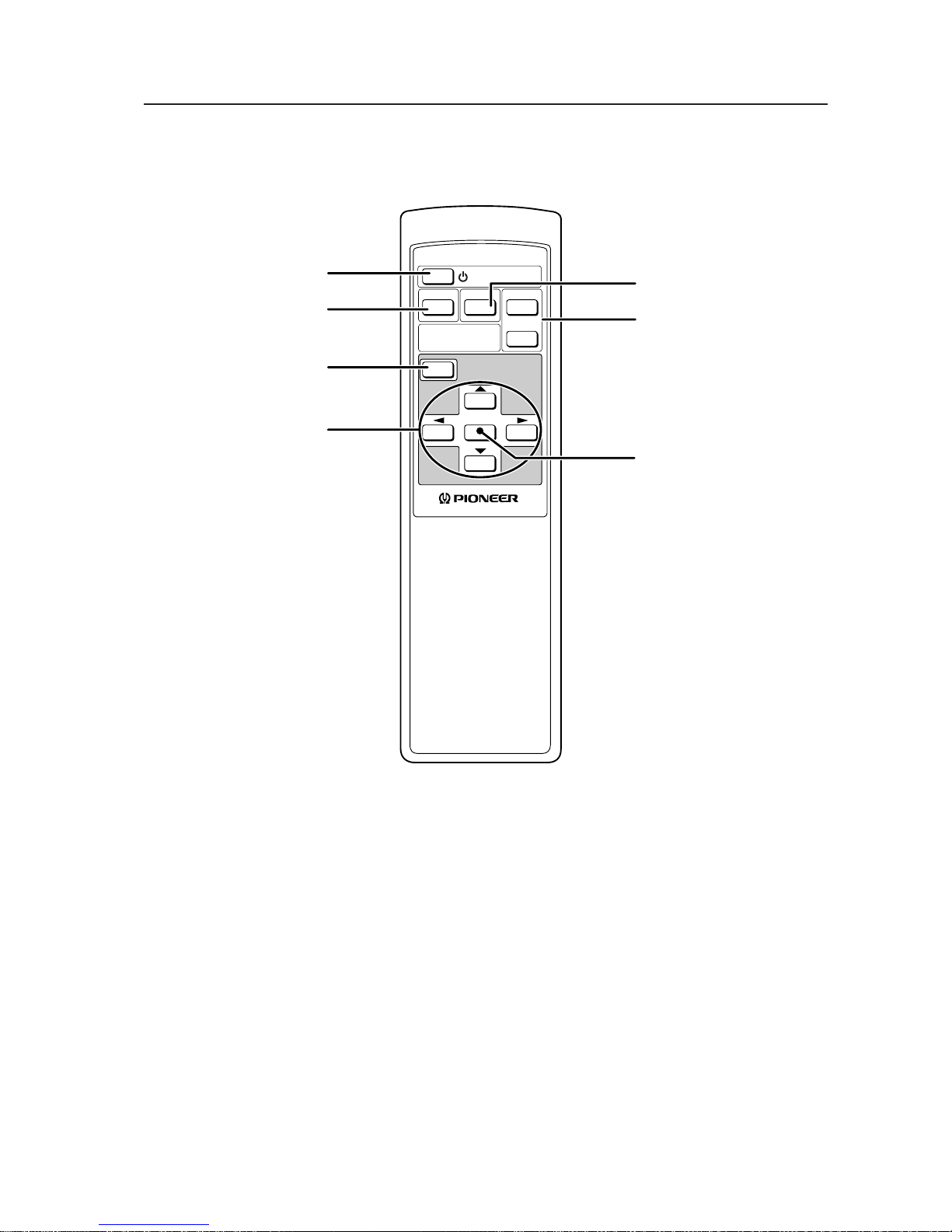

2.4 Remote control

Remote control

SET button

This button used to select an

adjustment item for picture

adjustment.

STANDBY/ON

VIDEO Y/C

SET

MENU

RGB 1

RGB 2

INPUT

SELECT

Î

CU-V153

RGB 1 and 2 buttons

These buttons set Input

Functions to RGB 1 (BNC

terminal) and RGB 2 (Mini DSUB terminal), respectively.

ADJUST button

Used to adjust images.

MENU button

Used to switch the menu

screen and normal screen.

VIDEO button

Sets Input Function to VIDEO

Input.

Power button

Turns power on or off.

10

<Ver. 2.1>

3.1 Installation environment

The plasma display and special metal fixture must be installed after careful discussion with the building owner and

manager of the building. Never undertake installation without careful consideration of the consequences. In addition,

contact the contractor responsible for building construction and interior structure design and confirm the structure and

safety of the building.

: Safety precautions

1) Structure of installation site

Be sure to use an appropriate installation method, after fully understanding the structure of the installation site.

There are many types of building structures and materials, and appropriate installation methods will vary accordingly.

When using a special metal mounting fixture, consult your dealer or the maker of the fixture.

Before drilling holes, always consider the location of wiring and piping within the building.

2) Load resistance of the installation site

Select an installation site capable of supporting the combined weight of the metal fixture and display.

“Sufficient strength to withstand” means sufficient strength to withstand a weight four times that of the

main body including the metal fixture.

3) Horizontal plane

Select a level, sturdy, installation site with sufficient load-bearing capacity.

When using suspension bolts, take care to distribute load evenly on the ceiling on the floor of the installation site.

4) Securing installation space

Select an installation site with adequate space for working. This work requires two or more people.

Remember to leave adequate space for future maintenance.

5) Peripheral equipment

Installation sites close to air conditioner outlets or light bulbs may be unsuitable due to potential damage from

dust, temperature, humidity, or condensation.

6) Dangerous location sites

Do not install the display at locations where it may be leaned against or grasped. Similarly, avoid installing at sites

subject to excessive vibration or physical shock.

7) Lighting

• For more visible display, avoid installation in very bright locations. Before choosing the location site and

method,carefully consider the location of lighting fixtures and direction and strength of sunlight.

• In bright locations, images may appear dark even if the luminance is increased. Adjusting picture brightness to

excessively high levels to compensate for extremely bright ambient lighting may reduce the service life of the

display panel.

8) Semi-outdoor installation

This machine is designed for indoor use. Installed semi-outdoors, the display will be subject to problems resulting

involving the following factors:

• Water, dust, etc.

• Changing temperature and humidity

• Air-borne salt

To ensure that pictures appear normal, avoid installation in locations subject to direct sunlight.

Installation environment

11

<Ver. 2.1>

9) Temperature and humidity

The installation site should conform to the following temperature and humidity conditions:

• Operating temperature range: 0 to 40 °C (Depending somewhat on installation conditions, see descriptions of

special installations and methods for installation of the standard metal fixture.)

• Operating humidity range: relative humidity 20% to 80%

• Storage temperature (Packege state): –10 to 45 °C

• Storage humidity (Packege state): relative humidity 20% to 90%

• Operating environment air pressure: 0.8 - 1.1 atmospheres

We recommend against installing electronic equipment, including this display, in high-humidity environments. If

the display must be installed at a site subject to humid conditions, observe the following:

• Never install the machine in environments having humidity falling outside the specification range.

• Ground the equipment.

• Do not allow condensation to form on any display surface.

10) Condensation

One common problem encountered during winter is condensation, drops of water that form on display surfaces

when the ambient temperature rises suddenly. Such moisture may adversely affect the performance of the display.

If condensation is observed, turn off the machine for one hour before attempting to use it again. Another solution

is to raise the ambient temperature gradually, if possible.

11) Power requirements

The voltage range required to ensure specified performance is ±10% of the rated voltage. Keep in mind that high-

impedance power distributing wires will produce an effect equivalent to a voltage drop. Watch for the following

cases, and recheck power distribution.

• The voltage drop between the switchboard and the plasma display is significant.

• When the power to the machine is turned on and off, voltage fluctuations are large.

Estimate the power consumption of this machine as 400 VA plus a safety margin.

The inrush current when the machine is turned on is approximately 70 A <30 A>.

< > shows the PDP-V401E.

12) Coverage of the remote control

The display communicates with the remote control through weak infrared signals, which typically reflect off display

surroundings. The operating range of the remote is affected by the reflective characteristics of surrounding objects.

If the range of coverage appears to be unusually short, check the following:

• Do the walls and platform for the display have a mirror or white finish?

• Are there objects near the infrared-accepting section?

• Are the remote control batteries weak or dead?

Other devices using infrared remote control and wireless systems may not work properly if located close to the

infrared-emission source of the display. Consult your dealer before using such equipment near the display.

Installation environment

12

<Ver. 2.1>

Installation conditions

3.2.2 Calculating calorific values

Estimate the maximum power consumption per device as 400 W plus a safety margin. Most of the power consumed

is converted to heat, so power consumption is roughly equivalent to generated heat.

1) Conversion to calories

[W] × 0.86 = [kcal/h]

Calorific value per display

400 × 0.86 = 344 [kcal/h]

2) Conversion to British thermal unit (BTU)

[W] × 3.41 = [B.t.u./h]

Calorific value per display

400 × 3.41 = 1256 [B.t.u./h]

Air flows out through five of the ventilation holes and flows in through the other holes. For special installations, such

as wall-hanging or embedding, additional restrictions apply concerning operating temperature. See “3.4 Special

installations”.

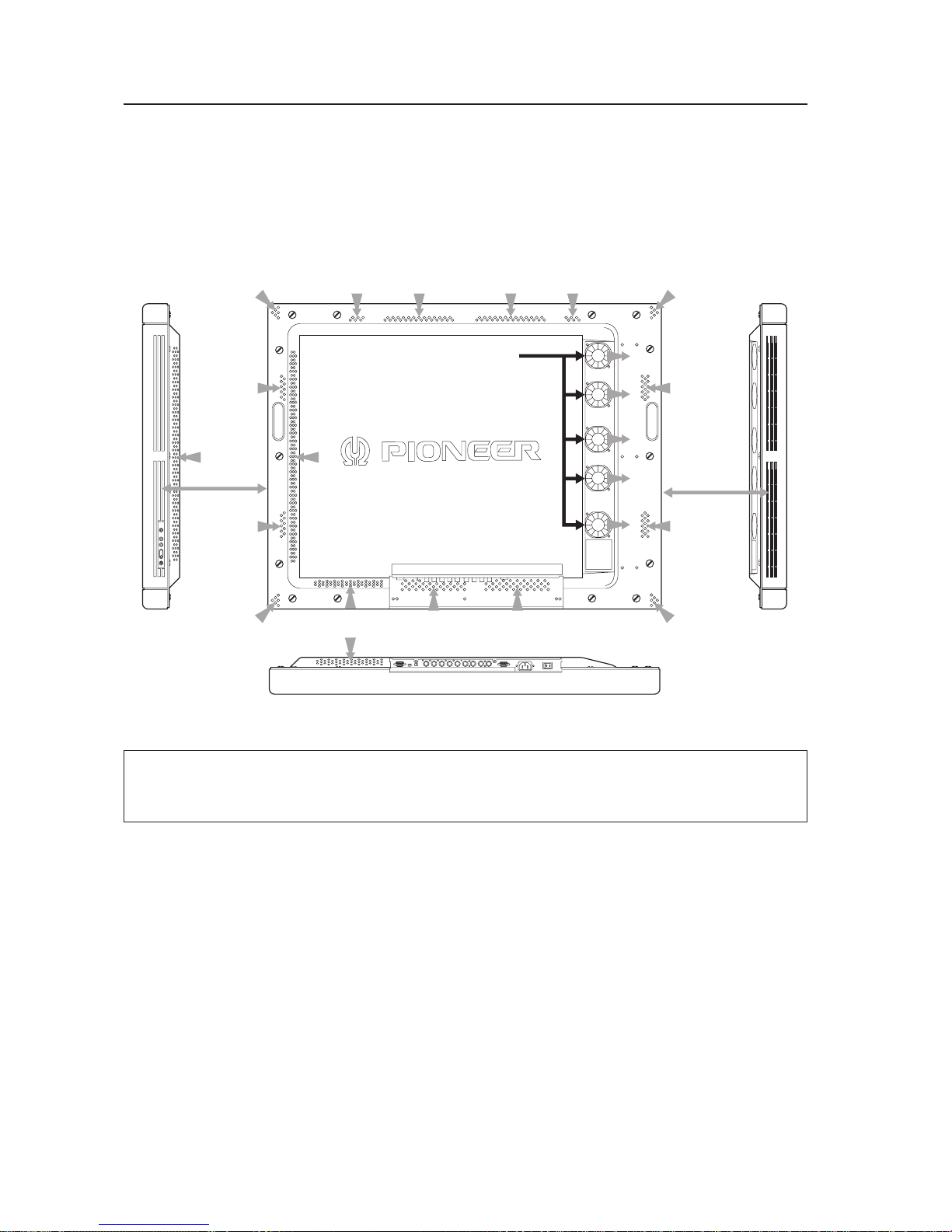

3.2 Installation conditions

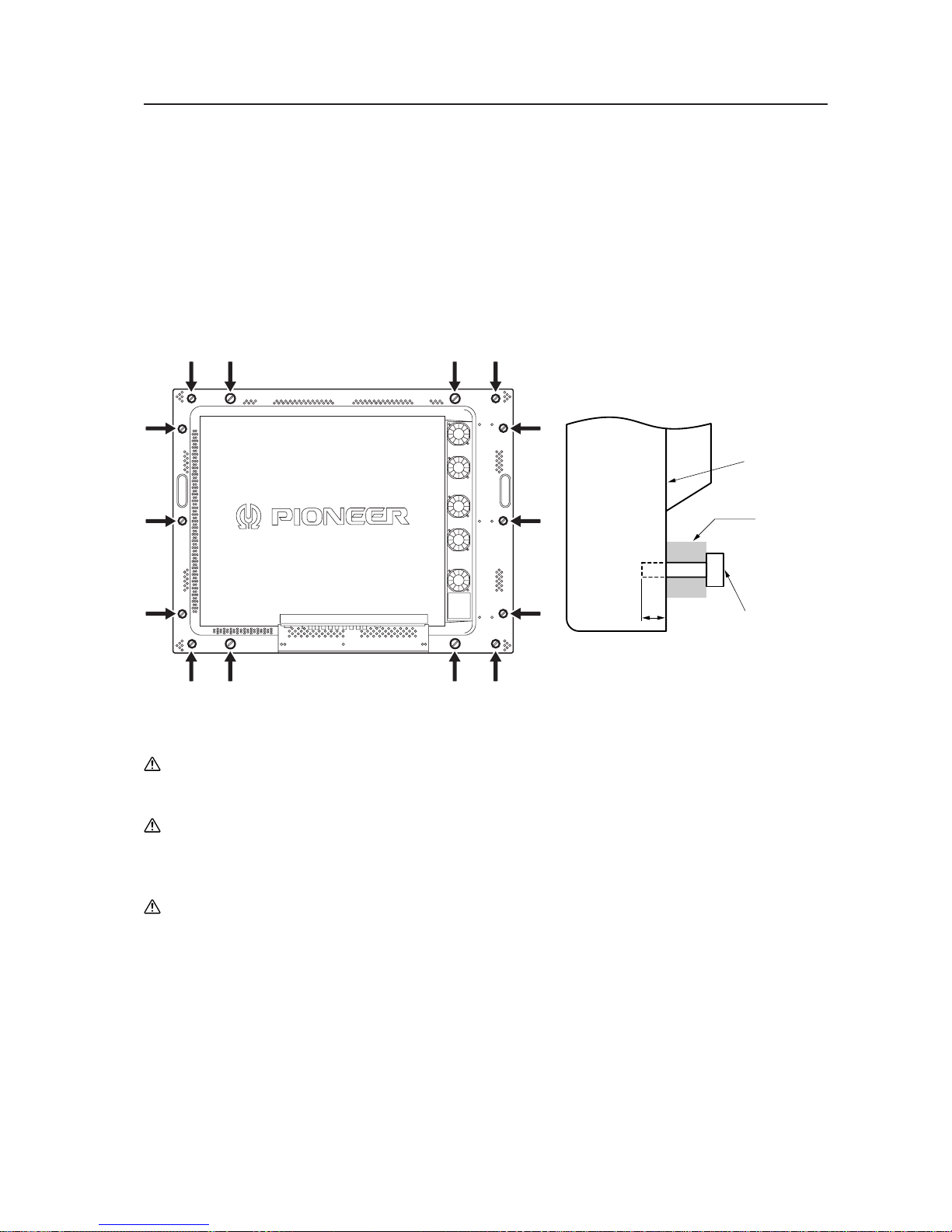

3.2.1 Radiation

This display comes with multiple ventilation holes for efficient radiation of heat. Avoid blocking any of these holes.

Ventilation holes are indicated by arrows in the following drawing.

Five fans

Side slits

Side slits

13

<Ver. 2.1>

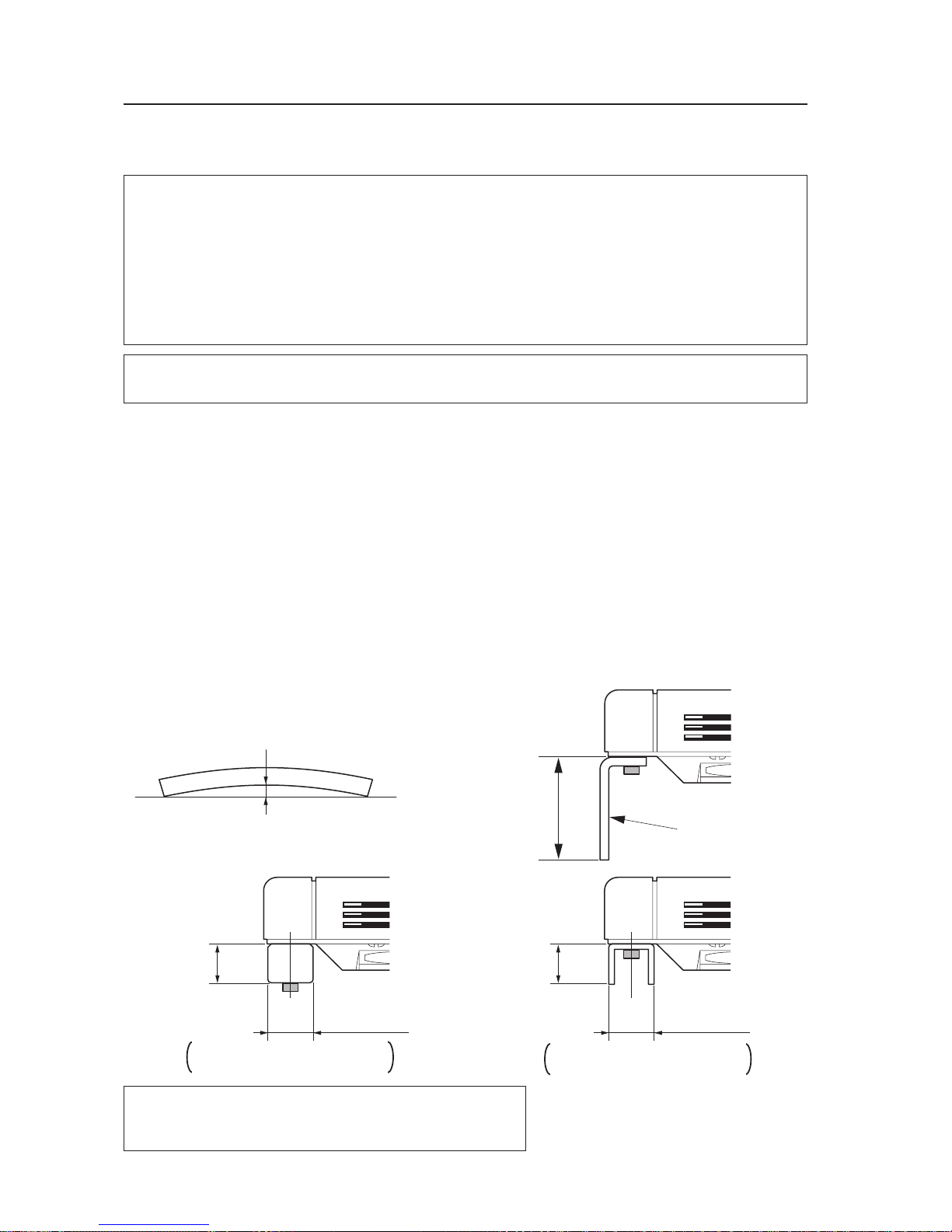

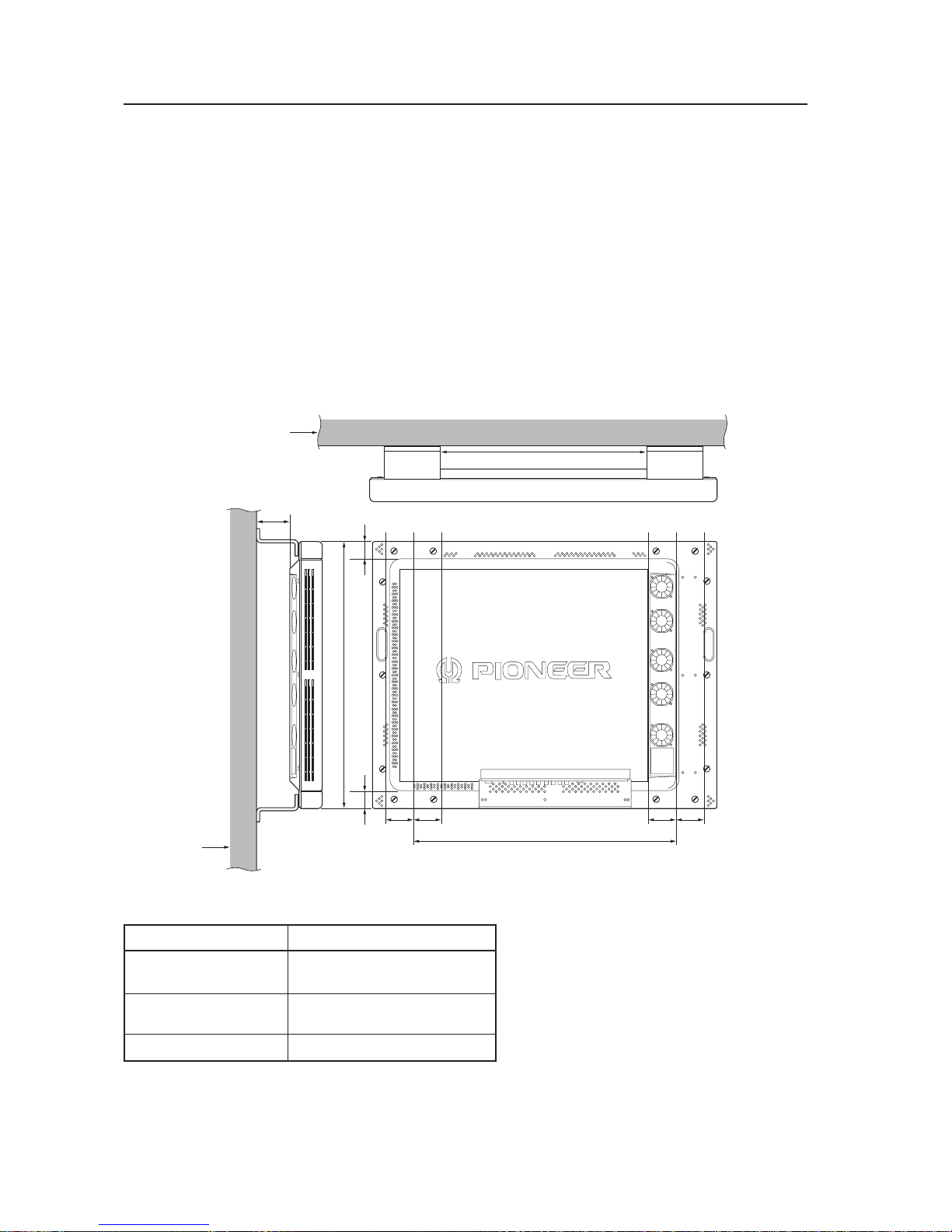

3.2.3 Installation position

We recommend using the metal installation fixture made by Pioneer. When using a different fixture, use the M8 bolt

hole provided on this display to mount the fixture to the display. Remove the hole rivets on the back of the plasma

display, if necessary for the particular fixture. Tighten bolts with a force of 60 kg.cm or less. Overtightening may

damage the blind nuts.

• The following figure indicates mounting holes that can be used. (Use a coin or similar object to turn the cap to

remove it.)

Installation conditions

Use bolts that do not penetrate more than 13 to 20 mm from the mounting surface of the machine (see the above

side view). If the bolts used are longer than the above, they may damage the inside of the machine.

Do not block ventilating holes or blowholes in the rear of the machine.

Hot air is emitted from the ventilating holes.

Care must be taken not to weaken or soil the wall at the back of the machine with the hot air from the holes.

Glass is used in this machine. It must always be mounted on the straight face.

Mounting surface

Metal fixture

13 to 20 mm

Bolt

14

<Ver. 2.1>

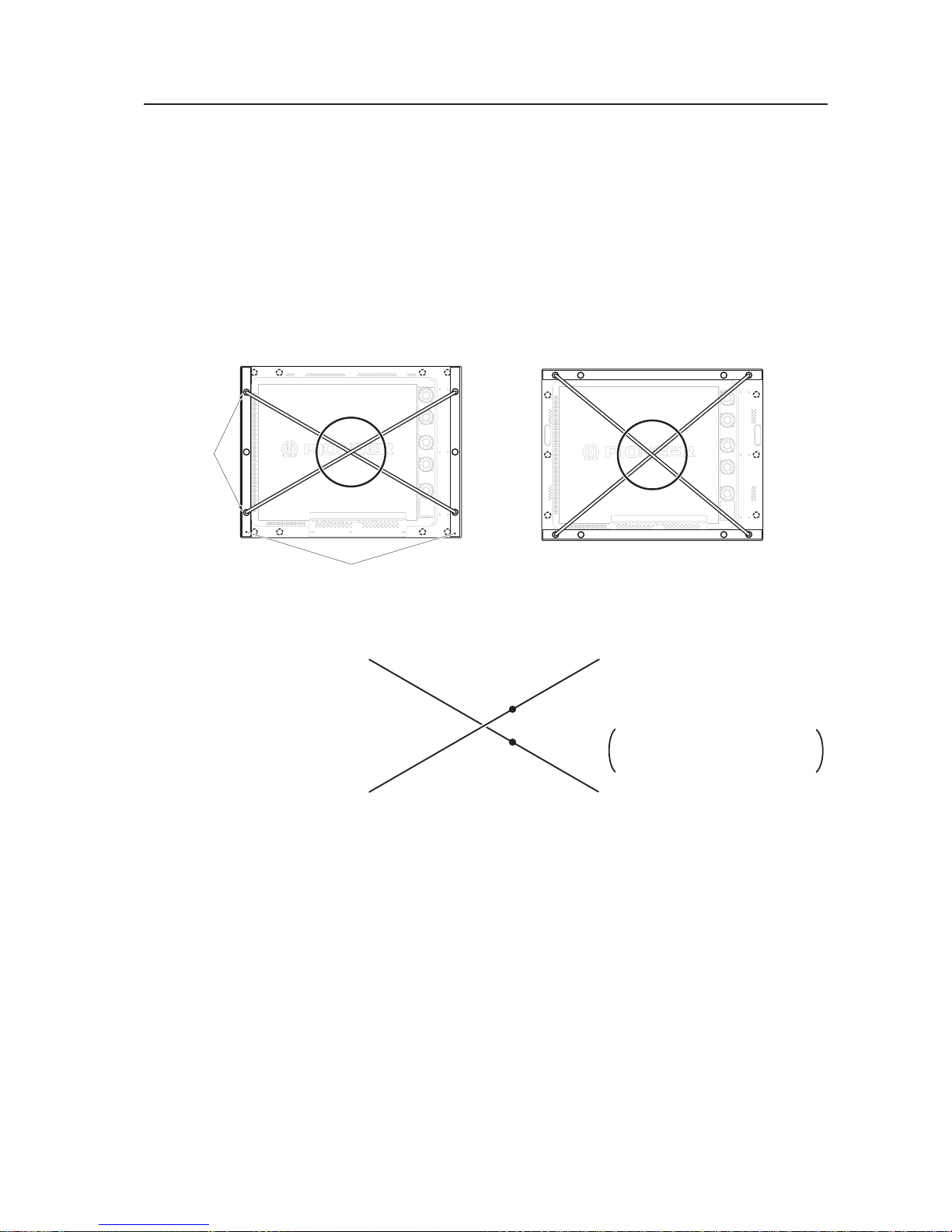

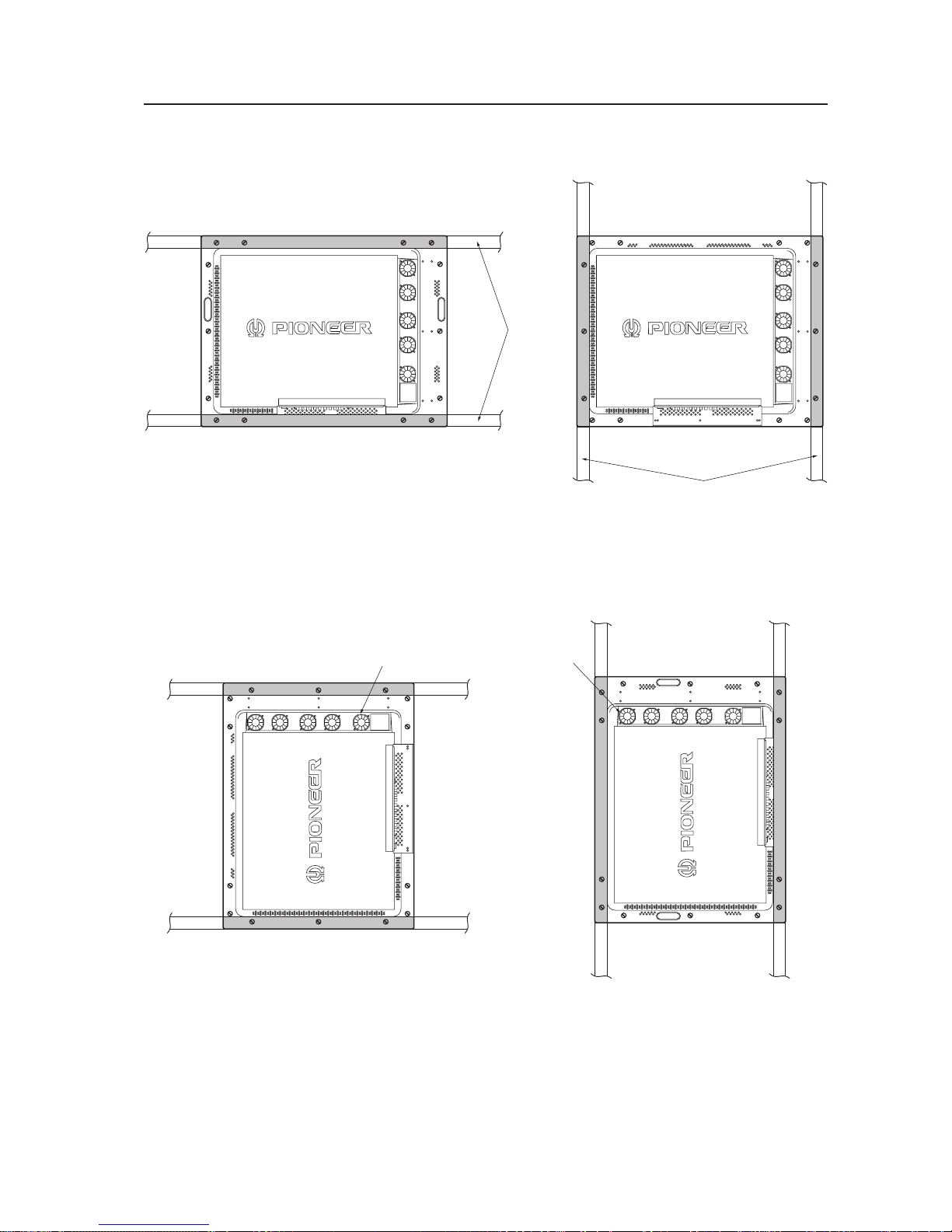

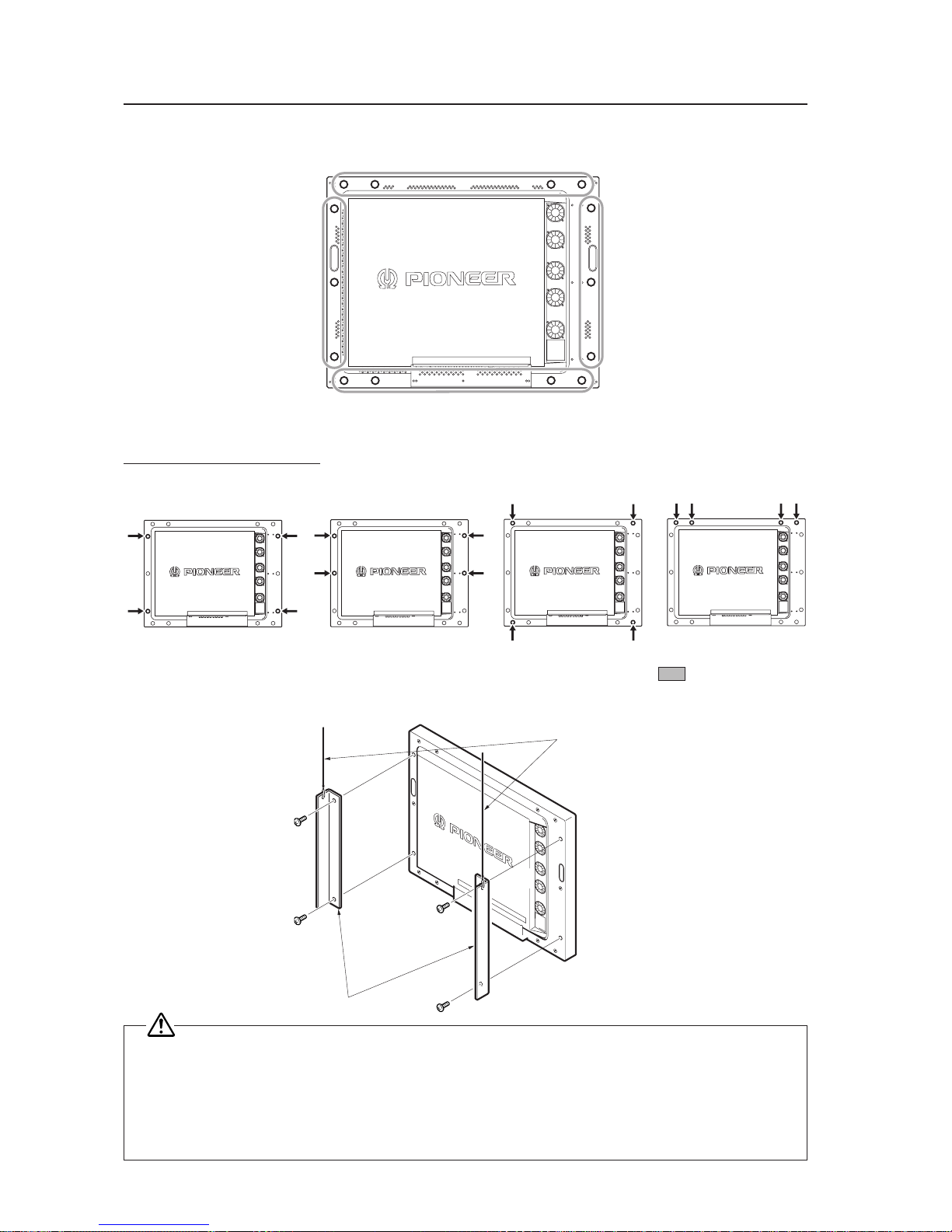

We recommend mounting at a minimum of 4 points, and at 6 or 8 points as shown below if possible. Avoid mounting

the display with the particular 4-point scheme shown below.

Mounting method — bad example

Mounting method — good example

A. 8-point mounting B. 6-point mounting

C. 4-point mounting (Metal fixture is mounted vertically.)

(Do not block ventilation holes.)

Installation conditions

(Do not block ventilation holes.) (Do not block the fan.)

D. 4-point mounting (Metal fixture is mounted horizontally.)

(Take care to avoid pinching power cord, signal cable, etc.)

15

<Ver. 2.1>

A

Installation conditions

3.2.4 Strain on surface where equipment is installed

1 This display uses glass in its display section. When using a third-party metal fixture, check that strain is 1 mm or

less by the following method.

2 Tightly fit a thread using a force of φ 0.1psi or less diagonally through the mounting bolt openings on the mounting

surface, as shown in the drawing.

3 Measure distance L of the intersection of the strings in the center section.

The relationship between strain and L is given by Strain = L × 2.

4 If L is 0, interchange the front and rear positions of two strings and check the distance again. If the value of L is not

0, it is the true value of L. If L is 0 after the position is changed, strain is approximately 0.

Holes for

mounting

bolts

Plasma display-mounting surface

(mounting metal fixture)

Enlarged drawing of the intersectional part A

(showing the part obliquely)

Thread

Right angle

A

ad

cb

a

c

d

b

a

d

e

f

cb

Point e is the center of the thread a-b.

Point f is the center of the thread c-d.

Distance between e and f = L

Points e and f are indicated in an en-

larged figure for more detailed under-

standing.

Thread

16

<Ver. 2.1>

3.3 Installation procedure

3.3.1 Precautions for transportation

1 Use two workers to move packages. Do not grasp the PP band during transportation. The band may snap and

result in injury.

2 For transportation and storage, keep the package horizontal. Do not stack packages longitudinally or laterally. If

packages are transported or stored while longitudinally stacked or laterally stacked, the company is guarantee will

be invalidated.

3 For transportation and storage, never stack more than ten packages, as indicated on the upper carton.

4 For transportation and storage, observe the conditions detailed on the upper carton.

5 To protect the glass surface of the display, avoid stepping on the package, placing heavy items on top, or sticking

sharp objects into the top.

* If the plasma display and fixture needs to be packed and transported again, follow the packing method and

precautions given below:

• Pack goods by reversing the procedure for unpacking given in “3.3.2 Unpacking”. Take care when replacing the

mirror mat to place the smooth face facing out, with the soft surface toward the product.

• Replace the remote control and the stand in the specified positions. If they are placed in the center of the upper

pad, the panel may be damaged during transportation.

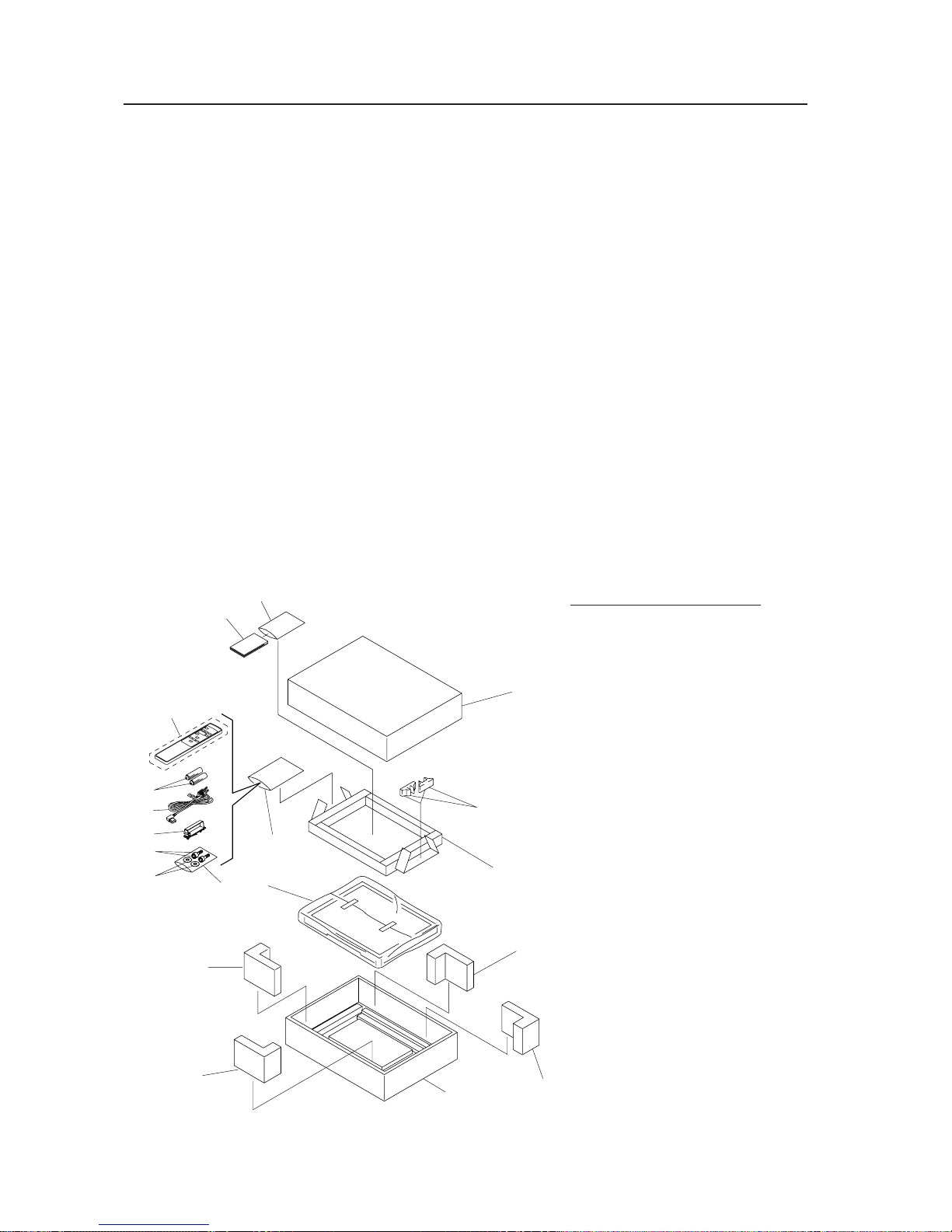

3.3.2 Unpacking

1) Packing specifications: 1130 (W) × 295 (H) × 852 (D) 39.5 kg <40.4 kg>

< > shows the PDP-V401E.

Installation procedure

No. Name

1. Upper carton

2. Stand

3. Upper pad

4. Mirror mat

5. Protector A

6. Under carton

7. Catalogue bag

8. Operating Instructions

9. Wrapping bag

10. Remote control (CU-V153)

11. Power cord (PDP-V401 only)

12. Cable clamp

13. 2P AA manganese dry cell, R6P

14. Plastic bag

15. Hexagonal-socket head bolt

16. Flat washer

1

2

5

5

6

5

5

4

3

16

14

15

12

11

13

10

9

7

8

17

<Ver. 2.1>

Installation procedure

2) Procedure for unpacking

1 Remove the PP band.

2 Slowly lift and remove the upper carton.

3 Remove the instruction manual (7 and 8), accessories (9), and stand (2), affixed to the upper pad with tape.

Caution: If the upper pad (3) is removed before first removing these items, the items may fall and damage the

product.

4 Remove the upper pad (3).

5 Remove the corner pad (5).

6 Remove the mirror mat (4).

7 Remove the product. (Requires two workers to remove the set.)

3) Movement after unpacking

Moving the product after unpacking requires two workers.

• Never drag the product on the floor.

• The display screen (front protective panel) is fragile. Move it slowly, and take care to avoid striking it or scraping

objects against it.

• Remove the protective film applied to the front protective panel only after construction and work are finished

and dust has settled.

18

<Ver. 2.1>

Installation procedure

3.3.3 Wiring

1) Power source connection

• Refer to Power cord connection on page 24 <36, 82> of the instruction manual.

• For power source capacity, see the description given in “3.1 Installation environment, 11) Power requirements”

in this manual.

2) Signal cable connection

(1) Connecting to a PC

• See the description given in Connecting to a PC , on pp. 19 to 20 <26 to 29, 72 to 75> of the instruction

manual.

(2) Connecting to a video cassette recorder

• See the description given in Connection to a video cassette recorder , on pp. 21 to 23 <30 to 35, 76 to

81> of the instruction manual.

(3) Precautions

• Use coaxial cables. For video signals, use the 3C-2V for lengths of 15 m or less, and the 5C-2V for lengths of

30 m or less. Since data signals are more easily degraded than video signals, use a thick cable (e.g. a 5C-2V

cable) for data communications, even for lengths of 15 m or less. Try to minimize the distance between the

signal transmission device and the plasma display unit.

• If a video cable is wired close to a dimmer, neon tube, air conditioner, or other device, or if it is wired in

parallel to a cable television cable, display performance may be affected.

< > shows the PDP-V401E.

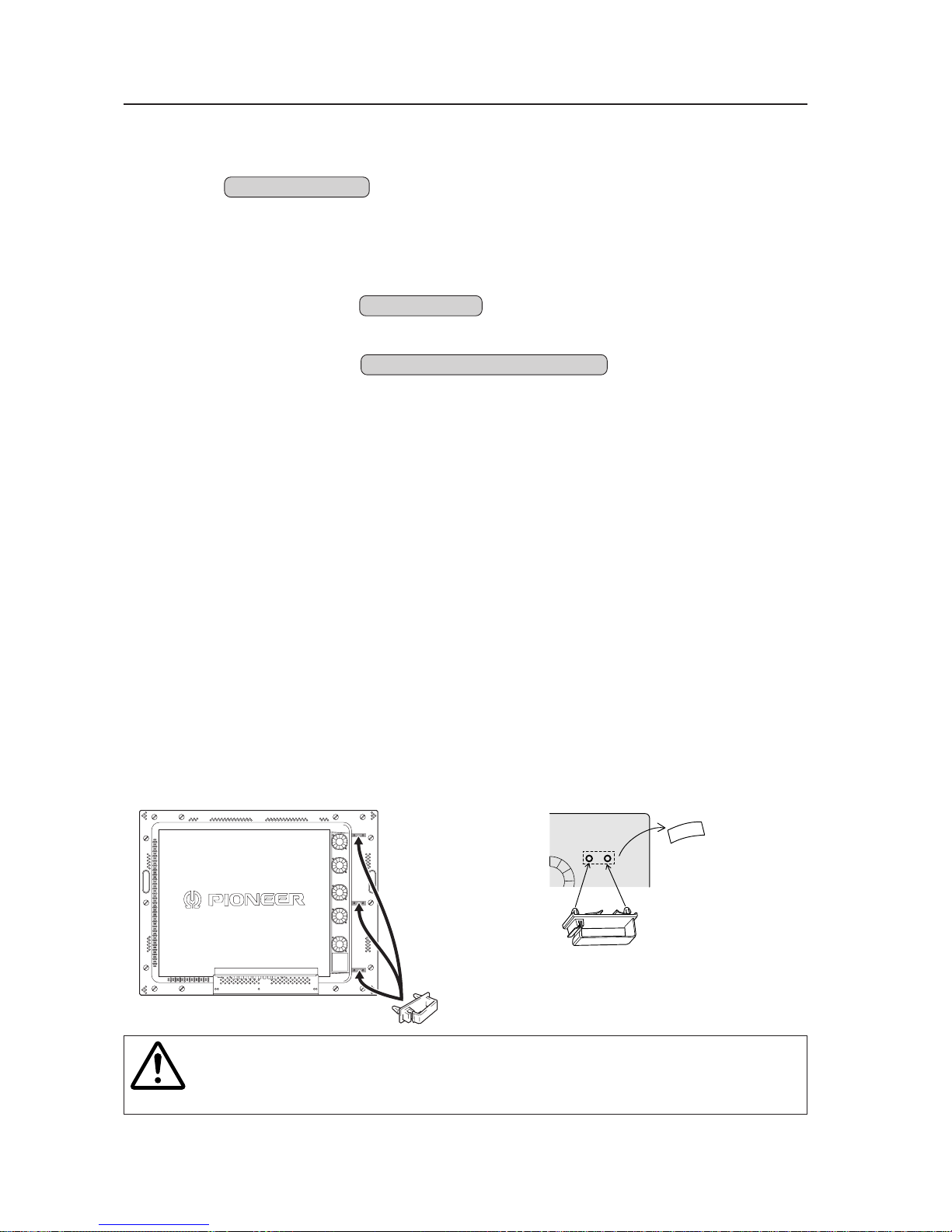

3) Treatment of wires

• For long-term or permanent installations, rather than short-term installations for specific events, use wires of

the proper length, carefully considering the placement of all other wires.

• Place wires so that no load or force is applied to the connecting terminals. For short-term use, wires may be

bundled with string. For long-term installations, form wire bunches using cable clamps.

4) Mounting cable clamp

Use a cable clamp to form cable bunches in the upward direction, as shown in the drawing.

Cable clamps are supplied for bundling connection cables.

Follow these steps when using cable clamps:

Caution

Peel off the label covering the mounting holes before attaching the cable clamps.

When cables are inserted in a cable clamp, keep the clamp at least 10 cm from the wall to allow

ventilation.

<Back>

Peel off the paper at the back and insert the supplied

cable clamp into the mounting holes until it clicks.

19

<Ver. 2.1>

Installation procedure

20

<Ver. 2.1>

Special installations (Fixing on a structure)

3.4 Special installations

This display may be installed in several different positions, including wall-hanging and wall-embedding. Conditions,

including temperature, may restrict the use of certain positions or installation methods.

Consider installation methods and conditions, and see the description given in “3.1 to 3.3” in this chapter.

All the measurement conditions in this manual are set in conformity with the following:

• 100% white light is applied.

• After sufficient aging

All measurements should be performed under the same conditions. The aging time needed for measurement

depends on the size of the installation space, but the standard time is approximately 2.5 hours.

“Sufficient strength to withstand” means sufficient strength to withstand a weight four times that of the main body

including the metal fixture.

3.4.1 Fixing on a structure

To fix the machine on a structure, observe the following conditions:

1 Before fixing on a structure, make sure that the space around the structure is open.

2 After fixing on a structure, the distortion of the unit must be within 1 mm.

3 Do not block holes other than those shown blocked in the fixing figure on the next page.

4 Use a structure 20 mm or less in thickness.

(In the case of the fixing examples 1 and 4 on the next page, the thickness of the structure is not limited.)

5 If an L-shaped structure is used, the thickness of the structure must be 100 mm or less.

6 Use a structure with sufficient strength.

7 Care must be taken not to apply stress to the power cable.

* The descriptions in 2 - 7 indicate the common precautions for fixing the machine on the structure in “wall-hanging”

and “wall-embedding.”

✩ Operating temperature requirements

• Ambient temperature requirement: 0 to 40°C (Examples 1 and 2)

• Ambient temperature requirement: 0 to 35°C (Examples 3 and 4)

20 mm or less

in thickness

36 mm or less in width

The thickness of the examples 1 and

4 on the next page is not limited.

The thickness of the examples 1 and

4 on the next page is not limited.

20 mm or less

in thickness

36 mm or less in width

Distortion of the unit is 1mm max.

1mm MAX.

100 mm

or less

L-shaped structure

21

<Ver. 2.1>

Special installations (Fixing on a structure)

Example 1:

Beams

Beams

Ambient temperature requirement: 0 to 40°C

Example 2:

Ambient temperature requirement: 0 to 40°C

Ambient temperature requirement: 0 to 35°C

Ambient temperature requirement: 0 to 35°C

Example 3: Example 4:

Mount the display with the fans on the upper side.

22

<Ver. 2.1>

Special installations (Wall hanging)

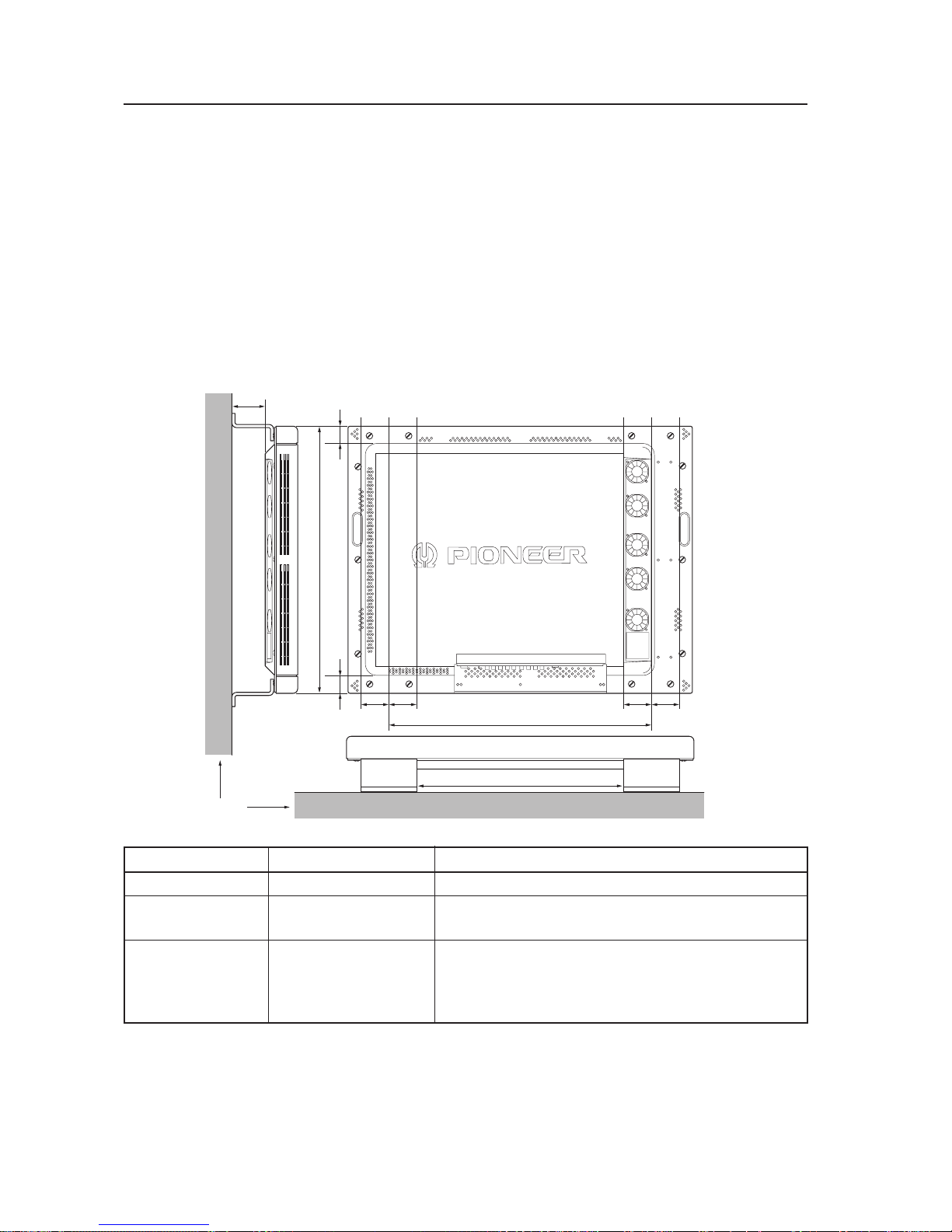

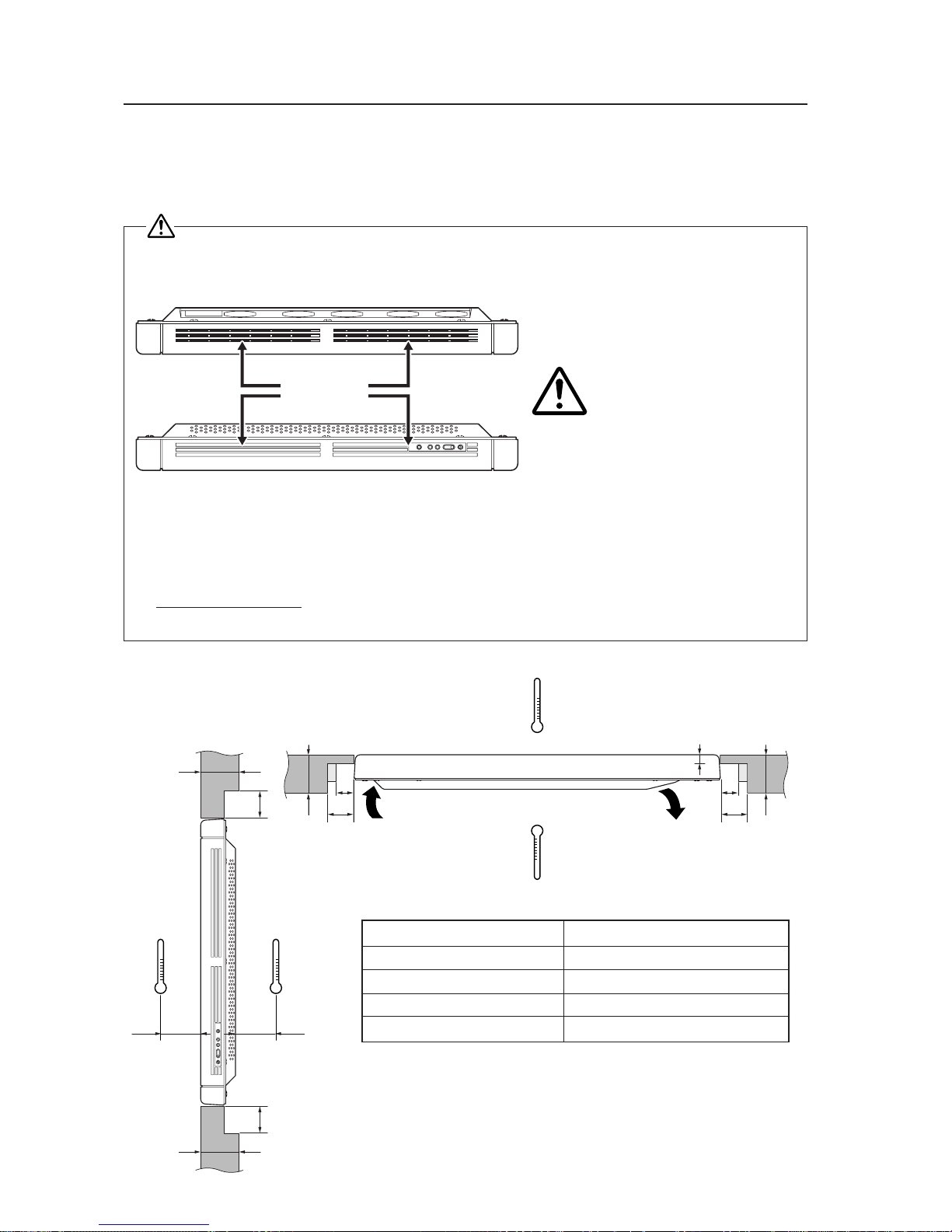

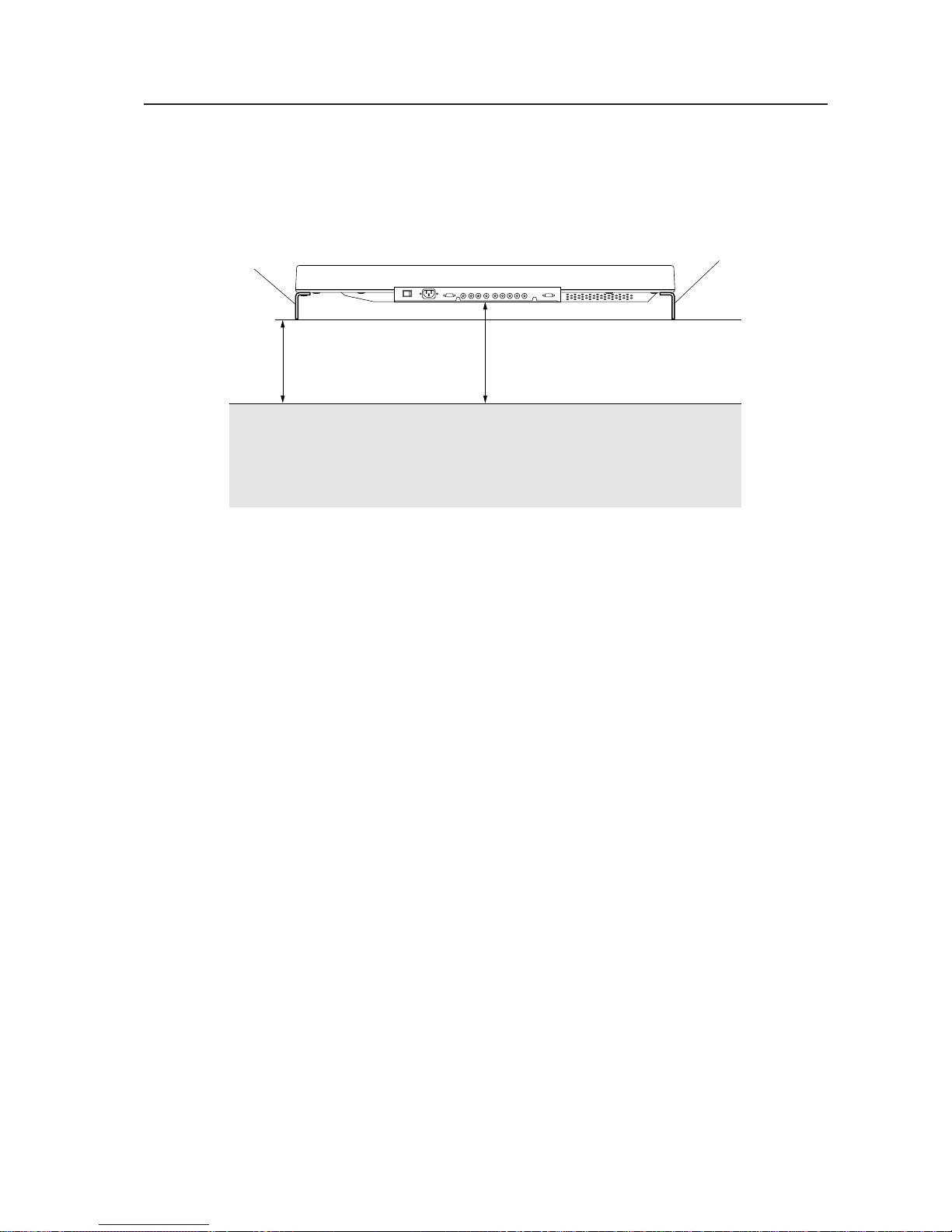

3.4.2 Wall hanging

This display may be wall-mounted. Since this form of mounting affects ventilation patterns inside, observe the following

requirements:

1 When mounting plate metal, avoid blocking any ventilation holes. Use plate metal of the size indicated in the

following drawing.

2 Provide space for adequate ventilation between the wall and the display.

3 Use plate metal having sufficient strength (with a safety factor of approximately four), and attach at four points (4-

point mounting) as shown below. Since wall installations involve certain hazards, always follow double-safety

procedures.

4 The following table lists proper operating temperatures. Use the display within the listed range of outside air

temperature.

5 Keep deformation of the display to 1 mm, including twisting and bending.

Clearance A to the wall

100 mm or more

50 mm or more

Less than 100 mm

0 to less than 50 mm

Operating temperatures

0 to 40 °C

0 to 40 °C (Animation)

0 to 35 °C (Still)

0 to 30 °C

Remarks

When this display is used with its back surface close to the

wall, interior temperatures will rise. The inner sensor is

activated at approximately 30 °C. Luminance decreases by 30%

and fan speed increases.

Do not block this area at either the top or bottom.

40mm

Do not block this area at either the left or right.

40mm

A

75mm 75mm

Wall

694 mm (center indicated)

75mm 75mm

23

<Ver. 2.1>

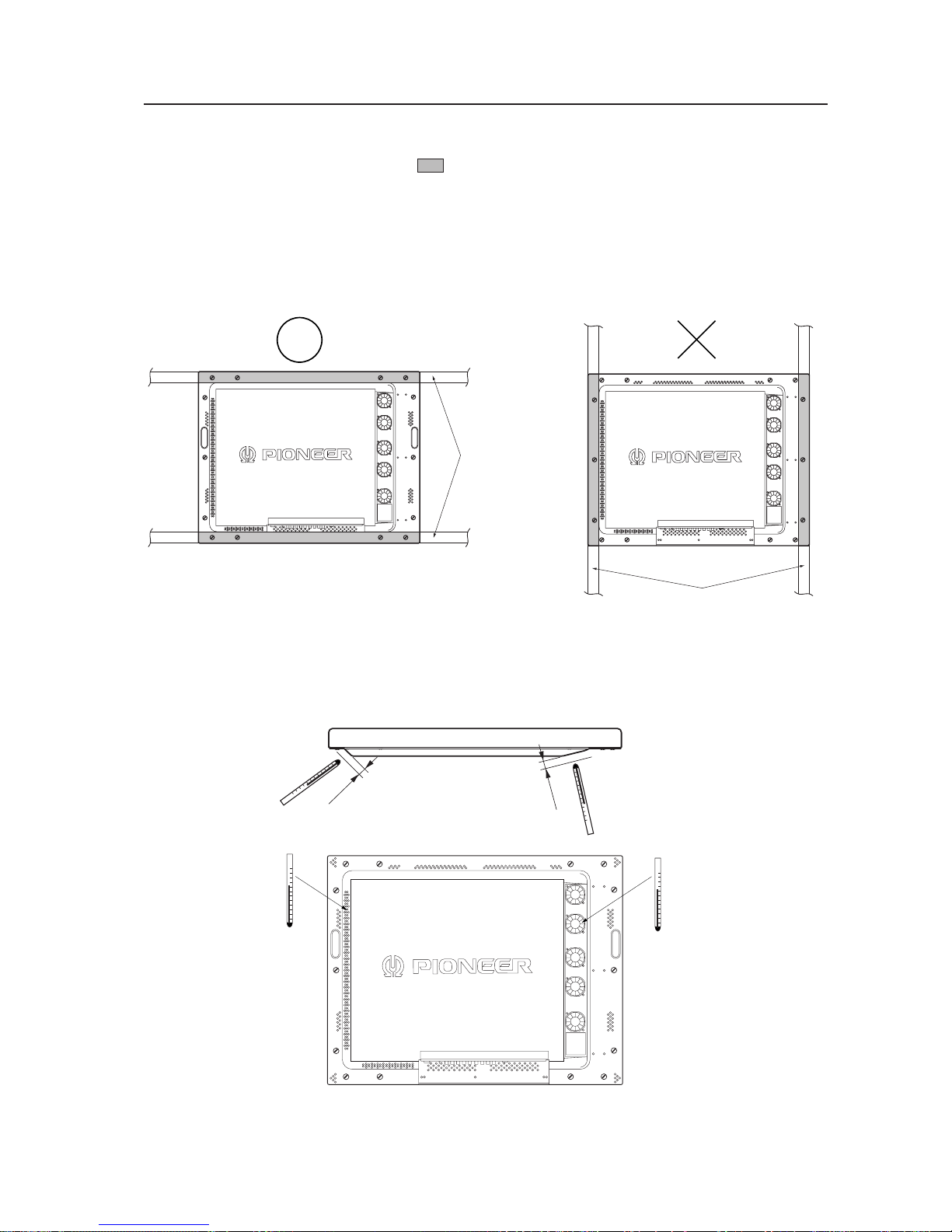

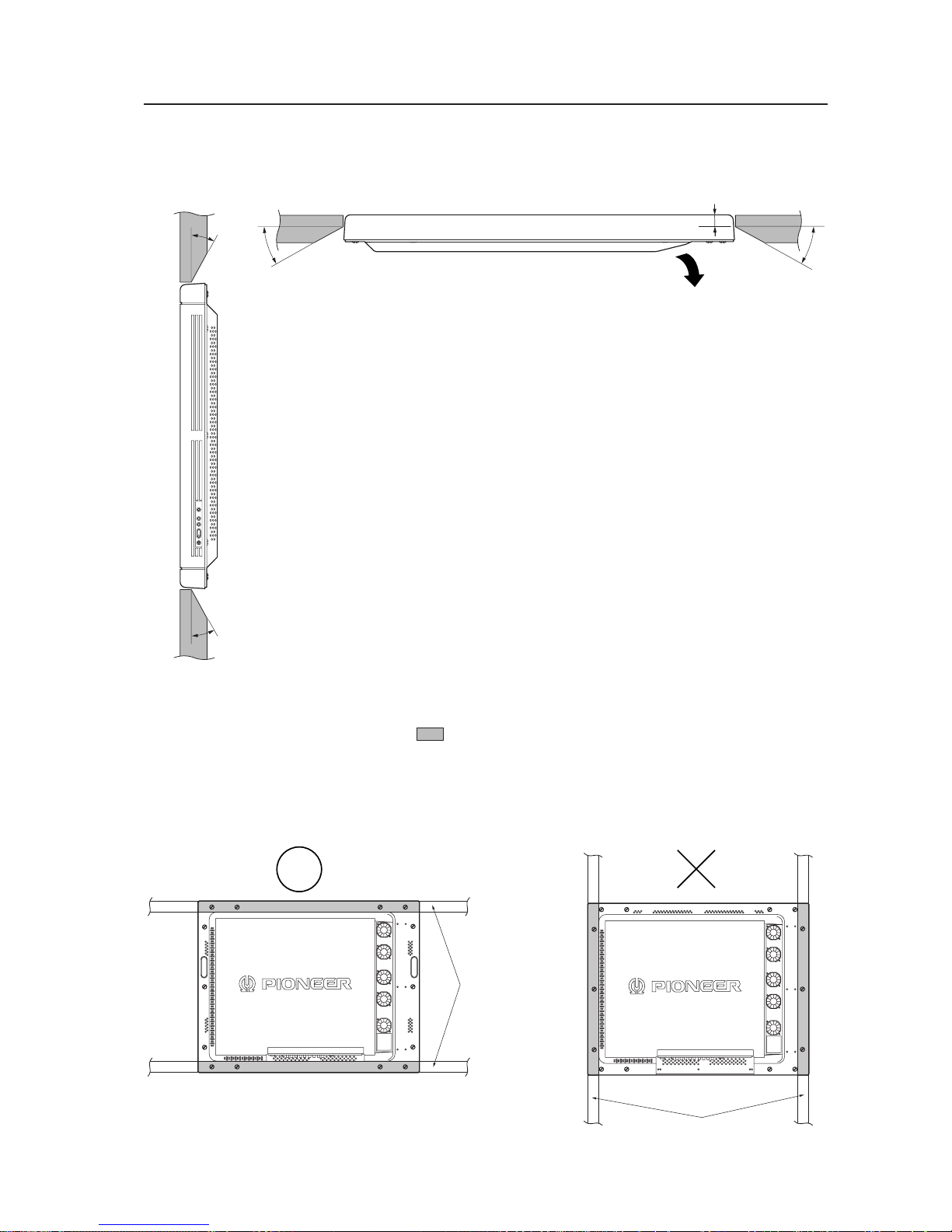

Special installations (Wall hanging)

Securing method: Basically, the unit is secured as indicated below. Keep open all areas other than the shaded parts.

The fixing method marked

cannot be used for the unit.

When the unit is fixed on a structure, select a structure of the proper thickness and height. Care

must also be taken regarding the number of fixing bolts to be used (see “3.4.1 Fixing on a structure”).

<Reference> After installation, measure the temperatures in the area shown in the figure below to make sure

that the values are within the specified range.

Bad example of blocking exhaust

<Incorrect><Correct>

Beams

Exhaust side

(temperature of the

exhaust from FAN)

Room temperate

+ 15 °C or less

Intake side

Room temperature

+ 5 °C or less

Beams

10 mm

10 mm

24

<Ver. 2.1>

3.4.3 Wall embedding

This display is designed to accommodate embedding in a wall. Note that the allowable range of outside-air temperature

depends on the installation conditions. Please observe the following requirements:

1 If the unit must be embedded in the wall, you must not block the side slots of the unit.

Avoid blocking the ventilating holes in the rear as much as possible.

2 Use a metal mounting fixture that does not block the side slits or the back ventilation holes, and attach at a

minimum of four points. To avoid breaking the PDP panel, limit any twisting or bending stress applied to the

display to 1 mm or less.

3 Do not use cable clamps for this installation method. Cable clamps can interfere with proper ventilation and

result in device failure.

4 Installation conditions and ambient operating temperatures:

(1) If the back of the display will be unobstructed:

Never block the side slots. Avoid

blocking the ventilating holes of the

unit as much as possible.

Side slits

Special installations (Wall embedding)

A ≥ 100 mm, B ≤ 150 mm

A ≥ 100 mm, B ≥ 150 mm

A ≤ 100 mm, B ≤ 80 mm

A ≤ 100 mm, B ≥ 80 mm

X, Y space upper temperature limits

40 °C

40 °C (Animation), 35 °C (Still)

40 °C

35 °C

C

B

A

B

A

B

C

B

X

Y

Intake

MAX 20 mm

Exhaust

Take C to be 30 mm or more.

A

A

100 mm100 mm

Caution

25

<Ver. 2.1>

(2) When there is open space behind the wall and the angle (shape) as shown in the figure can be maintained on

the wall back:

If the back of the wall is tilted at 30 °C or less, the X, Y space temperature

may be set to a limit of 40 °C, regardless of wall thickness.

Special installations (Wall embedding)

MAX 20 mm

X

Y

30°

30°

30°

30°

Exhaust

Beams

Beams

Securing method: Basically, the unit is secured as indicated below. Keep open all areas other than the shaded parts.

The fixing method marked

cannot be used for the unit.

When the unit is fixed on a structure, select a structure of the proper thickness and height. Care

must also be taken regarding the number of fixing bolts to be used (see “3.4.1 Fixing on a structure”).

Bad example of blocking exhaust

<Incorrect><Correct>

26

<Ver. 2.1>

Special installations (Wall embedding)

A

\\

X

Y

A

B

A

C

Exhaust

B

(3) When the back of the wall is in a closed space:

Operating this display in confined spaces is not recommended.

• If the display is to be used in confined spaces, observe the following conditions shown in the drawing above:

A ≥ 150 mm

B ≥ 250 mm

C ≥ 30 mm

• Keep the temperature in the closed space “Y” and the open space “X” at 40 °C or less. In particular,

the space “Y” should be ventilated sufficiently by the air conditioner or fan so that hot air is not

trapped in the space.

Thus, everywhere in “Y” must be kept at 40°C or less. If hot air remains in the

closed space, the temperature may rise, causing a malfunction or fire. As a precaution in case of accidents,

the inner wall should have sufficient heat resistance or fire resistance. Direct air from the air conditioner in the

direction of the arrow (from where no fan is installed to where a fan is provided).

70 mm or less (on both left and right) MAX. 20 mm (on both left and right)

Flow of air from the

air conditioner

Exhaust fan (air flow rate:

2 m3/min or more)

Intake port

A

C

100 mm100 mm

27

<Ver. 2.1>

Special installations (Wall embedding)

<Reference> After installation, measure the temperatures in the area shown in the figure below to make sure

that the values are within the specified range.

Beams

Exhaust side

(temperature of the

exhaust from FAN)

Room temperate

+ 15 °C or less

Intake side

Room temperature

+ 5 °C or less

Beams

10 mm

10 mm

Securing method: Basically, the unit is secured as indicated below. Keep open all areas other than the shaded parts.

The fixing method marked

cannot be used for the unit.

When the unit is fixed on a structure, select a structure of the proper thickness and height. Care

must also be taken regarding the number of fixing bolts to be used (see “3.4.1 Fixing on a structure”).

Bad example of blocking exhaust

<Incorrect><Correct>

28

<Ver. 2.1>

Special installation (Ceiling suspension (using wires))

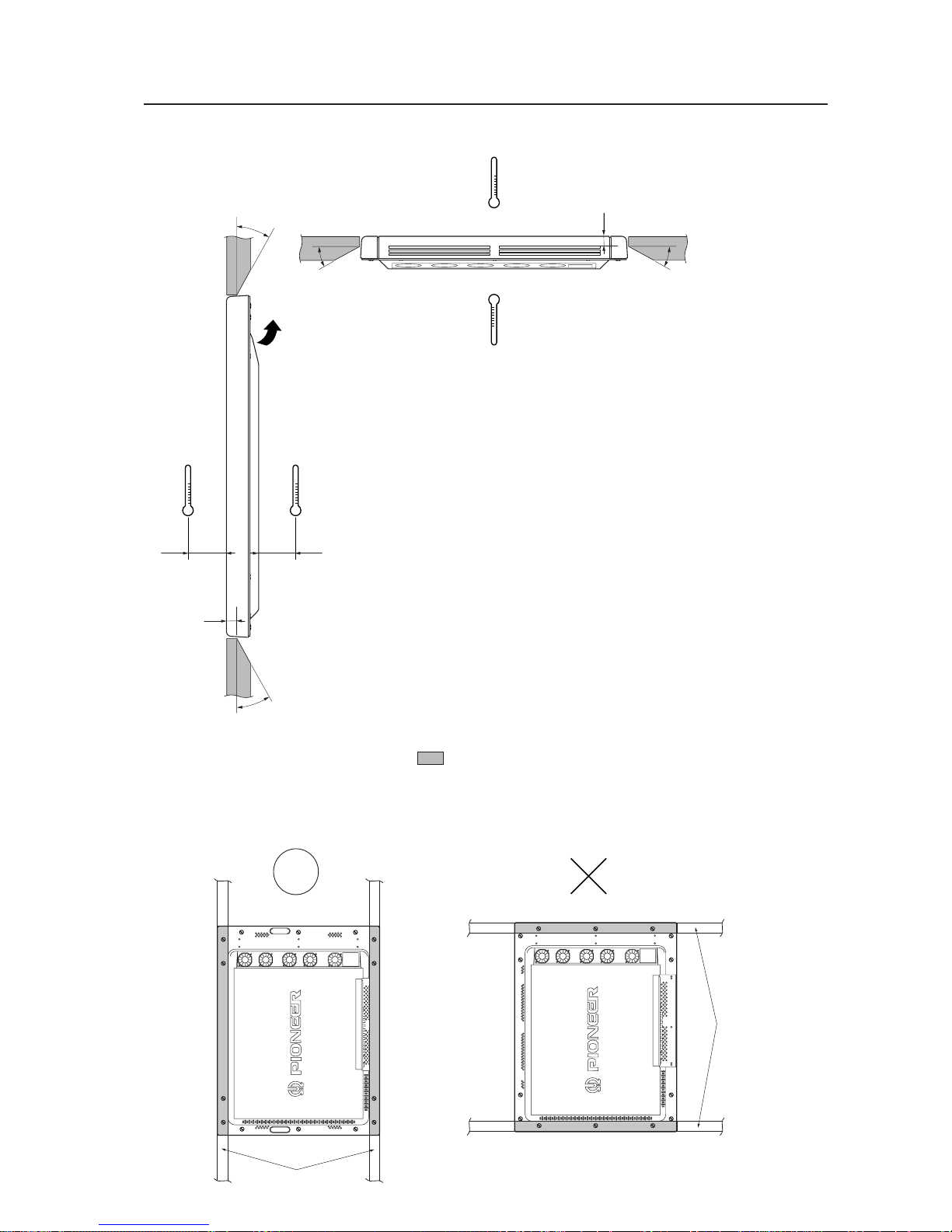

3.4.4 Ceiling suspension (using wires)

When suspending the display by wires, use a combination of two mounting rows, as shown in the diagram above (rows

A - B or C - D, from rows A - D). This is done to safeguard against subjecting the display to twisting forces. Use a

minimum of four mounting points.

Use the following metal fixture to keep load from centering on the two mounting points at the top. As discussed in

3.4.1 Fixing on a struc, avoid blocking any ventilation holes other than those in the shaded (

).

When attaching cables to the ceiling, install two cables at two independent points for safety.

‡‡

‡

×

Good example Bad example

AB

C

D

Wire

Metal fixture

If the display is

suspended close to a

wall, provide at least

300 mm clearance

between that wall

and the display.

Use mounting screws with minimum strength equal to that of mild steel cable, or stronger screws with hexagonal

socket heads.

The cable must be capable of supporting a load four times as heavy as the total weight of the display (30.8 kg

<31.6 kg>) plus the weight of the metal fixture, if one is used.

Provide auxiliary back-up cables to safeguard against breakage of main cables due to earthquakes etc..

< > shows the PDP-V401E.

29

<Ver. 2.1>

Special installation (Ceiling suspension (using wires))

Should the distance between the wall face and the unit be 300 mm or less, treat the clearance in the rear cover of the

pop or that of the fixture nearer to the wall as the clearance A and apply the wall hanging conditions in 3.4.2.

wall hanging.

A or more

Wall

Metal fixture Metal fixture

A

PDP

30

<Ver. 2.1>

Special installation (Installation with the screen downward)

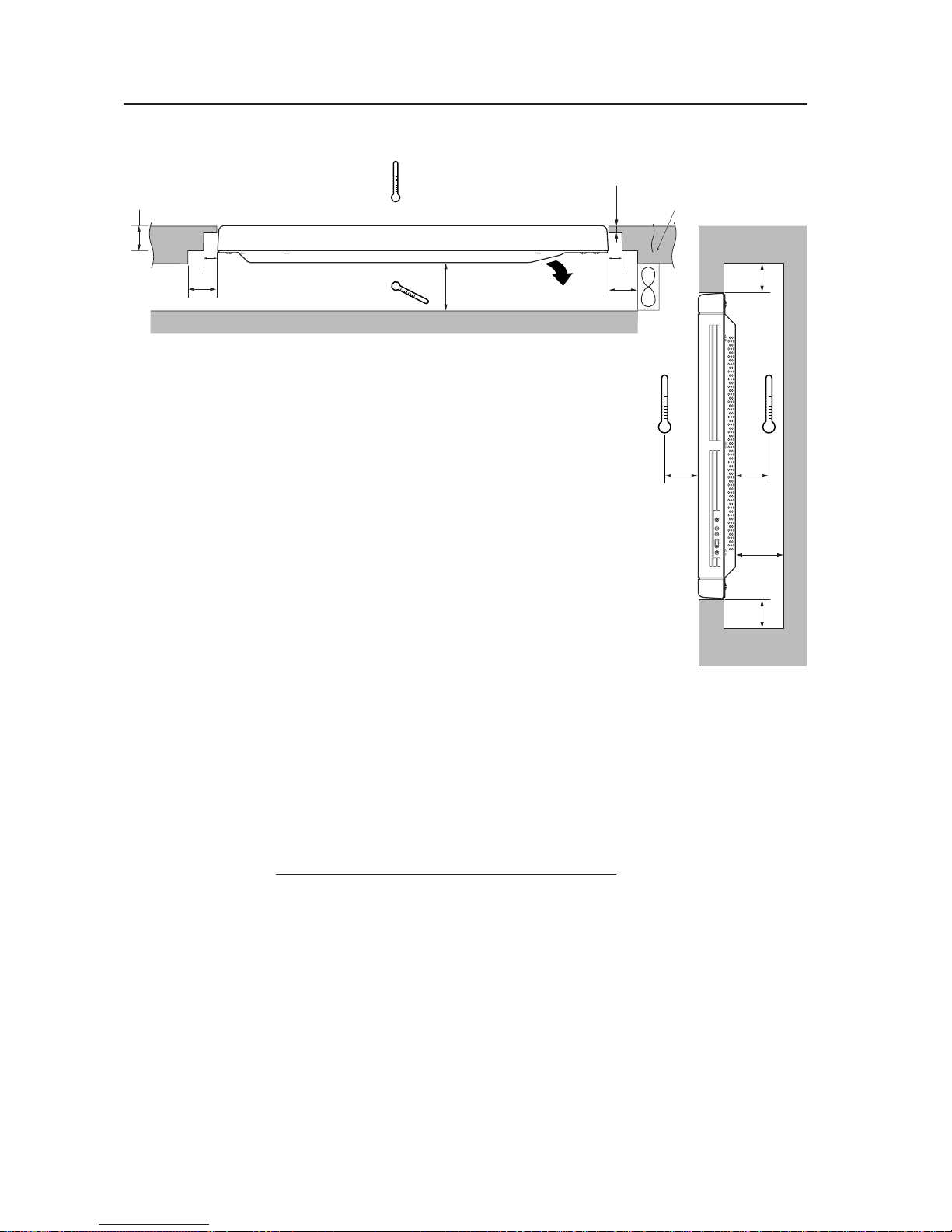

3.4.5 Installation with the screen downward

This display is designed to be installed with the screen downward, but certain uses can interfere with proper ventilation.

Please observe the following conditions:

1 Use plate metal that keeps all single holes clear and has dimensions no larger than those given in the following

table.

2 Leave adequate ventilation space between the display and the ceiling.

3 Use plate metal having sufficient strength (incorporating a safety factor of approximately four), and secure at the

four points indicated in the following drawing (four-point mounting). Mounting plate metal on a ceiling involves

certain hazards. Make sure you provide adequate back-up safety measures.

4 Recommended ambient operating temperatures are given in the following table. Operate the display within this

range of temperatures.

5 The ceiling should closely approximate a perfectly flat plane. Keep deformation pressures applied to the display,

such as twisting and bending, at or below 1 mm.

Clearance A to the ceiling

100 mm or more

50 mm or more

Less than 100 mm

Less than 50 mm

Ambient operating temperatures

0 to 35 °C (Animation)

0 to 30 °C (Still)

0 to 30 °C

Cannot be used.

Ceiling

Do not block this area on either the top or the bottom.

Do not block this area on either the top or the bottom.

75mm

40mm

40mm

A

75mm

694 mm (center indicated)

75mm 75mm

Ceiling

31

<Ver. 2.1>

Beams

Beams

Intake side

Room temperature

+ 5 °C or less

Special installation (Installation with the screen downward)

<Reference> After installation, measure the temperatures in the area shown in the figur below to make sure

that the values are within the specified range.

Exhaust side

(temperature of the

exhaust from FAN)

Room temperate

+ 15 °C or less

10 mm

10 mm

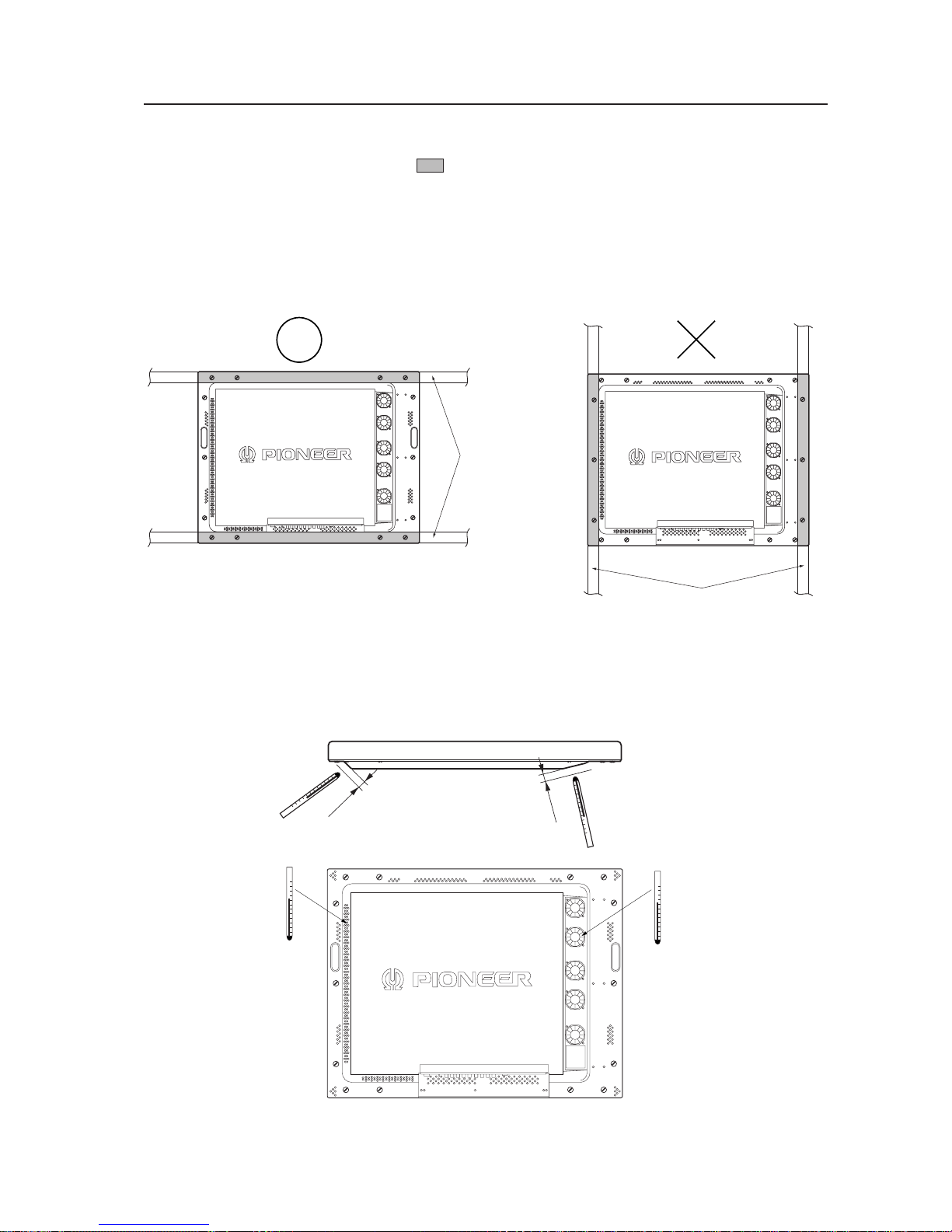

Securing method: Basically, the unit is secured as indicated below. Keep open all areas other than the shaded parts.

The fixing method marked

cannot be used for the unit.

When the unit is fixed on a structure, select a structure of the proper thickness and height. Care

must also be taken regarding the number of fixing bolts to be used (see “3.4.1 Fixing on a structure”).

Bad example of blocking exhaust

<Incorrect><Correct>

32

<Ver. 2.1>

Special installation (Ceiling embedding)

3.4.6 Ceiling embedding

This display is designed to accommodate embedding in a ceiling. Note that the allowable range of outside-air temperature

depends on the installation conditions. Please observe the following requirements:

1 If the unit must be embedded in the ceiling, you must not block the side slots of the unit. Avoid blocking the

ventilating holes in the rear as much as possible.

2 Use a metal mounting fixture that does not block the side slits or the back ventilation holes for airflow, and

attach at a minimum of four points. To avoid breaking PDP panel, limit any twisting or bending stress applied to

the display to 1 mm or less.

3 Do not use cable clamps for this installation method. Cable clamps can interfere with proper ventilation and

result in device failure.

4 Installation conditions and ambient operating temperatures:

(1) When the space above the ceiling is not enclosed:

Side slits

Never block the side slots. Avoid

blocking the ventilating holes in the

rear of the unit as much as

possible.

Caution

A ≥ 100 mm, B ≤ 150 mm

A ≥ 100 mm, B ≥ 150 mm

A ≤ 100 mm, B ≤ 80 mm

A ≤ 100 mm, B ≥ 80 mm

X, Y space upper temperature limits

35 °C

35 °C (Animation), 30 °C (Still)

35 °C

30 °C

C

B

A

B

A

B

C

B

Y

X

MAX 20 mm

Intake (holes other than

that of fan)

Exhaust

Take C to be 30 mm or more.

A

A

100 mm 100 mm

33

<Ver. 2.1>

(2) When there is open space behind the wall and the angle (shape) as shown in the figure can be maintained on

the wall back:

If the space above the ceiling is open at an angle of 30° or less, the X, Y

space temperature can be set up to 35 °C, regardless of ceiling thickness.

Y

X

30°

30°

30°

30°

MAX 20 mm

Special installation (Ceiling embedding)

Beams

Beams

Securing method: Basically, the unit is secured as indicated below. Keep open all areas other than the shaded parts.

The fixing method marked

cannot be used for the unit.

When the unit is fixed on a structure, select a structure of the proper thickness and height. Care

must also be taken regarding the number of fixing bolts to be used (see “3.4.1 Fixing on a structure”).

Bad example of blocking exhaust

<Incorrect><Correct>

34

<Ver. 2.1>

Special installation (Ceiling embedding)

Y

X

C

A

\\

A

Exhaust

A

A

B

(3) When the back of the ceiling is in the closed space

Operating this display in confined spaces is not recommended.

• If the display is to be used in confined spaces, observe the following conditions,

shown in the drawing above:

A ≥ 150 mm

B ≥ 250 mm

C ≥ 30 mm

• Keep the temperature in the closed space “Y” and the open space “X” at 40°C

or less. In particular, the space “Y” should be ventilated sufficiently by the air

conditioner or fan so that hot air is not trapped in the space. Thus, everywhere

in “Y” must be kept at 40 °C or less. If hot air remains in the closed space, the

temperature may rise, causing a malfunction or fire. As a precaution in case of

accidents, the inner wall should have sufficient heat resistance or fire resistance.

Direct air from the air conditioner in the direction of the arrow (from where no fan is

installed to where a fan is provided).

Exhaust

fan

(air flow rate 2 m3/

min or more)

Flow of air from the air conditioner

Intake port

70 mm or less

(on both left and right)

MAX. 20 mm

(on both left and right)

C

B

100

mm

100

mm

35

<Ver. 2.1>

Special installation (Ceiling embedding)

<Reference> After installation, measure the temperatures in the area shown in the figure below to make sure

that the values are within the specified range.

Beams

Exhaust side

(temperature of the

exhaust from FAN)

Room temperate

+ 15°C or less

Intake side

Room temperature

+ 5°C or less

Beams

10 mm

10 mm

Securing method: Basically, the unit is secured as indicated below. Keep open all areas other than the shaded parts.

The fixing method marked

cannot be used for the unit.

When the unit is fixed on a structure, select a structure of the proper thickness and height. Care

must also be taken regarding the number of fixing bolts to be used (see “3.4.1 Fixing on a structure”).

Bad example of blocking exhaust

<Incorrect><Correct>

36

<Ver. 2.1>

Special installation (Installation on the floor)

3.4.7 Installation on the floor

This display is designed to accommodate floor installation, but certain specific installations may interfere with adequate

ventilation. Always observe the following conditions:

1 Use plate metal that keeps all single holes clear and has dimensions no larger than those given in the following

table.

2 Leave adequate ventilation space between the display and the floor.

3 Use plate metal having sufficient strength, and attach at the four points indicated in the following drawing (four-

point mounting).

4 Recommended ambient operating temperatures are listed in the following table. Operate the display within this

temperature range.

5 The ceiling should closely approximate a perfectly flat plane. Keep deformation pressures upon the display, such

as twisting and bending, at or below 1 mm.

Do not block this area at the top or bottom.

75mm

40mm

Do not block this area at the left or right.

40mm

A

75mm

Floor

694 mm (center indicated)

75mm 75mm

Clearance A to the floor

100 mm or more

50 mm or more

Less than 100 mm

Less than 50 mm

Ambient operating temperatures

0 to 35 °C

0 to 30 °C

Cannot be used.

Remarks

37

<Ver. 2.1>

Special installation (Installation on the floor)

<Reference> After installation, measure the temperatures in the area shown in the figure below to make sure

that the values are within the specified range.

Beams

Beams

10 mm

10 mm

Securing method: Basically, the unit is secured as indicated below. Keep open all areas other than the shaded parts.

The fixing method marked

cannot be used for the unit.

When the unit is fixed on a structure, select a structure of the proper thickness and height. Care

must also be taken regarding the number of fixing bolts to be used (see “3.4.1 Fixing on a structure”).

Bad example of blocking exhaust

<Incorrect><Correct>

Exhaust side

(temperature of the

exhaust from FAN)

Room temperate

+ 15 °C or less

Intake side

Room temperature

+ 5 °C or less

38

<Ver. 2.1>

3.4.8 Installation under the floor

• If protective glass or similar material is used, the following installation conditions must be observed:

600 mm or more

Intake

Exhaust

B

B

C

C

Protective glass surface

| Looking in the direction of the arrow (see the next page)

If the display is used in the closed space, observe the following conditions in the above environment:

A ≥ 20 mm (clearance between the protective glass and PDP)

B ≥ 100 mm (clearance between the PDP and side wall)

C ≥ 50 mm (clearance between the PDP and side wall)

D ≥ 290 mm (clearance between the surface of the PDP and the mounting surface under

the floor)

E ≥ D – 65 mm

F ≥ 180 mm

G ≥ 600 mm

In the closed space, keep the temperature at 30 °C or less.

Special installation (Installation under the floor)

A + 50 mm

or less

A

60 mm

or less

Exhaust fan

Flow of air from the air conditioner

Intake port

Tempered glass, etc. (permeable)

BB

A + 50 mm

or less

60 mm or

less

Exhaust port

600 mm or more

Floor

C

G

F

C

E

D

Exhaust

39

<Ver. 2.1>

Conditions for embedding under the floor

| Looking in the direction of the arrow (see the previous page)

aa

a

a

C. L.

A + 50 mm or less

60 mm or less

C. L.

600 mm or more

ab

a

a = b

The size of the intake port is the same as that of the

exhaust port.

For the exhaust port only, add a fan at the position

indicated in the left figure (in the case of a single fan).

Fan placement....Place a fan in an upper position.

* The maximum air flow rate of the fan is 2.0 m

3

/min.

In the case of two fans:

Special installation (Installation under the floor)

40

<Ver. 2.1>

Special installation (Installation under the floor)

Beams

Beams

Do not install the horizontal beam at

the same time as the vertical beam.

Beams

Beams

Securing method: Basically, the unit is secured as indicated below. Keep open all areas other than the shaded parts.

The fixing method marked

cannot be used for the unit.

When the unit is fixed on a structure, select a structure of the proper thickness and height. Care

must also be taken regarding the number of fixing bolts to be used (see “3.4.1 Fixing on a structure”).

<Correct><Correct>

Bad example of blocking exhaust

<Incorrect>

41

<Ver. 2.1>

* Using our multi-installation fixture (PDM-4001) eliminates the need to set the temperature after

installation.

For the installation conditions for the multi-installation fixture (PDM-4001), see the next page.

Special installation (Installation under the floor)

10 mm

10 mm

<Reference> After installation, measure the temperatures in the area shown in the figure below to make sure

that the values are within the specified range.

Exhaust side

(temperature of the

exhaust from FAN)

Room temperate

+ 15 °C or less

Intake side

Room temperature

+ 5 °C or less

42

<Ver. 2.1>

Special installation (Installation under the floor (using the PDM-4001))

3.4.9 Installation under the floor (using the PDM-4001)

• If protective glass or similar material is used, the multi-installation fixture (PDM-4001) shown in the following figure is

very useful.

600 mm or more

Intake

Exhaust

BB

C

C

Protective glass surface

| Looking in the direction of the arrow (see the next page)

If the display is used in the closed space, observe the following conditions in the above environment:

A ≥ 20 mm (clearance between the protective glass and PDP)

B ≥ 100 mm (clearance between the PDP and side wall)

C ≥ 50 mm (clearance between the PDP and side wall)

In the closed space, keep the temperature at 30 °C or less.

A + 50 mm

or less

A

60 mm

or less

Exhaust fan

Flow of air from the air conditioner

Intake port

Tempered glass, etc. (permeable)

Multi-installation fixture (PDM-4001)

BB

C

291mm

A + 50 mm

or less

60 mm or

less

Exhaust port

600 mm or more

Floor

Exhaust

C

43

<Ver. 2.1>

Special installation (Installation under the floor (using the PDM-4001))

Conditions for embedding under the floor:

| Looking in the direction of the arrow (see the previous page)

aa

a

a

C. L.

A + 50 mm or less

60 mm or less

C. L.

600 mm or more

ab

a

a = b

The size of the intake port is the same as that of the

exhaust port.

For the exhaust port only, add a fan at the position

indicated in the left figure (in the case of a single fan).

Fan placement....Place a fan in an upper position.

* The maximum air flow rate of the fan is 2.0 m

3

/min.

In the case of two fans:

44

<Ver. 2.1>

Special installation (Wall hanging (vertically wall-hanging equipment))

3.4.10 Wall hanging (vertically wall-hanging equipment)

This display is designed to accommodate a range of wall installations. For this type of installation, carefully consider all

installation specifics before beginning work, since these factors can significantly affect the temperature of the air

surrounding the display. Please observe the following requirements:

1 Use plate metal that keeps all single holes clear and has dimensions no larger than those given in the following

table.

2 Leave adequate ventilation space between the wall and the display.

3 Mount a metal plate with sufficient strength at each of the four positions indicated in the following figure (four-

point stopping).

Mounting the display on the wall involves danger. Be sure to take double safety measures.

4 Recommended ambient operating temperatures are listed in the following table. Operate the display within this

temperature range.

5 The surface of the wall should closely approximate a perfectly flat plane. Keep deformation pressures on the

display, such as twisting and bending, at or below 1 mm.

Do not block this area on either the top or the bottom.

40mm

Do not block this area to the left or right.

40mm

A

Wall

75mm

694 mm (center indicated)

75mm

75mm

75mm

Clearance A to the wall

100 mm or more

50 mm or more

Less than 100 mm

0 to less than 50 mm

Ambient operating temperatures

0 to 35 °C

0 to 30 °C

Cannot be used.

Remarks

45

<Ver. 2.1>

Intake side

Room temperature

+ 5 °C or less

Exhaust side

(temperature of the

exhaust from FAN)

Room temperate

+ 15 °C or less

Beams

Special installation (Wall hanging (vertically wall-hanging equipment))

Beams

<Reference> After installation, measure the temperatures in the area shown in the figure below to make sure

that the values are within the specified range.

10 mm

10 mm

Securing method: Basically, the unit is secured as indicated below. Keep open all areas other than the shaded parts.

The fixing method marked

cannot be used for the unit.

When the unit is fixed on a structure, select a structure of the proper thickness and height. Care

must also be taken regarding the number of fixing bolts to be used (see “3.4.1 Fixing on a structure”).

Bad example of blocking exhaust

<Incorrect><Correct>

46

<Ver. 2.1>

Special installation (Wall embedding (vertically wall-embedding equipment))

3.4.11 Wall embedding (vertically wall-embedding equipment)

This display is designed to accommodate embedding in a wall. Since the allowable range of outside-air temperature

depends on the installation conditions. Please observe the following conditions:

1 If the unit must be embedded in the wall, the side slots of the unit must not be blocked. Avoid blocking the

ventilating holes in the rear as much as possible.

2 Use a metal mounting fixture that does not block the side slits or the back ventilation holes, and attach at a

minimum of four points. To avoid breaking the PDP panel, limit any twisting or bending stress applied to the

display to 1 mm or less.

3

Do not use cable clamps for this installation method. Cable clamps can interfere with proper ventilation and

result in device failure.

4 Installation conditions and ambient operating temperatures:

(1) If the space behind the wall is open

Never block the side slots. Avoid

blocking the ventilating holes of the

rear of the unit as much as possible.

Side slits

Caution

A ≥ 100 mm, B ≤ 150 mm

A ≥ 100 mm, B ≥ 150 mm

A ≤ 100 mm, B ≤ 80 mm

A ≤ 100 mm, B ≥ 80 mm

X, Y space upper temperature limits

35 °C

35 °C (Animation), 30 °C (Still)

35 °C

30 °C

C

B

A

B

A

B

C

B

Install the display with

the fan on top.

MAX. 20 mm

(for both top

and bottom)

Take C to be 30 mm or more.

A

A

Y

X

XY

100

mm

100

mm

Exhaust

47

<Ver. 2.1>

(2) When there is open space behind the wall and the angle (shape) as shown in the figure can be maintained on

the wall back:

If the rear wall is tilted at 30° or less, the X, Y space temperature can be

set up to 35 °C, regardless of the wall thickness.

X

Y

30°

30°

30°

30°

MAX. 20 mm

(both top and

bottom)

Exhaust

Special installation (Wall embedding (vertically wall-embedding equipment))

X

Y

100

mm

100

mm

Beams

Beams

Bad example of blocking exhaust

<Incorrect><Correct>

Securing method: Basically, the unit is secured as indicated below. Keep open all areas other than the shaded parts.

The fixing method marked

cannot be used for the unit.

When the unit is fixed on a structure, select a structure of the proper thickness and height. Care

must also be taken regarding the number of fixing bolts to be used (see “3.4.1 Fixing on a structure”).

MAX. 20mm

48

<Ver. 2.1>

Operating this display in confined spaces is not recommended.

• If the display is to be used in confined spaces, observe the following

conditions, shown in the drawing above:

A ≥ 150 mm

B ≥ 250 mm

C ≥ 30 mm

• Keep the temperature in the closed space “Y” and the open space

“X” at 40 °C or less. In particular, the space “Y” should be ventilated

sufficiently by the air conditioner or fan so that hot air is not trapped

in the space.

Thus, everywhere in “Y” must be kept at 40 °C or less.

If hot air remains in the closed space, the temperature may rise, causing a

malfunction or fire. As a precaution in case of accidents, the inner wall

should have sufficient heat resistance or fire resistance. Direct air from the

air conditioner in the direction of the arrow (from where no fan is installed

to where a fan is provided).

Special installation (Wall embedding (vertically wall-embedding equipment))

(3) If the space behind the wall is enclosed:

A

X

Y

Flow of air from air

conditioner

70 mm or

less

(both left

and right)

A

B

A

C

Intake hole

Exhaust

B

\

Exhaust fan

(air flow rate:

2 m3/min or more)

MAX. 20 mm

(both left and

light)

A

X

Y

C

100

mm

100

mm

49

<Ver. 2.1>

Special installation (Wall embedding (vertically wall-embedding equipment))

Beams