Page 1

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION

2009

POWER

For details, refer to "Important Check Points for good servicing".

STANDBY

PURE AUDIO

ONOFF

PD-D9MK2-K

D9

SUPER AUDIO CD PLAYER

PD-D9MK2-K

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Model Type Power Requirement Remarks

PD-D9MK2-K SYXJ5 AC 220 V to 240 V

PD-D9MK2-K CUXJ AC 120 V

ORDER NO.

RRV3939

T- ZZK MAY

2009 Printed in Japan

Page 2

1

NOTICE

(FOR CANADIAN MODEL ONLY )

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement parts must

be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les pièces

de remplacement doivent avoir la même désignation.

This service manual is intended for qualified service technicians; it is not meant for the casual

do-it-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely,

you should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product may contain a chemical known to the State of California to cause cancer, or birth defects or other reproductive

harm.

Health & Safety Code Section 25249.6 - Proposition 65

ANY MEASUREMENTS NOT WITHIN THE

LIMITS OUTLINED ABOVE ARE INDICATIVE

OF A POTENTIAL SHOCK HAZARD AND

MUST BE CORRECTED BEFORE RETURNING THE APPLIANCE TO THE CUSTOMER.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance

have special safety related characteristics. These are

often not evident from visual inspection nor the

protection afforded by them necessarily can be obtained

by using replacement components rated for voltage,

wattage, etc. Replacement parts which have these

special safety characteristics are identified in this

Service Manual.

Electrical components having such features are

identified by marking with a on the schematics and

on the parts list in this Service Manual.

The use of a substitute replacement component which

does not have the same safety characteristics as the

PIONEER recommended replacement one, shown in the

parts list in this Service Manual, may create shock, fire,

or other hazards.

Product Safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current PIONEER

Service Manual. A subscription to, or additional copies

of, PIONEER Service Manual may be obtained at a

nominal charge from PIONEER.

(FOR USA MODEL ONLY)

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and service

technician.

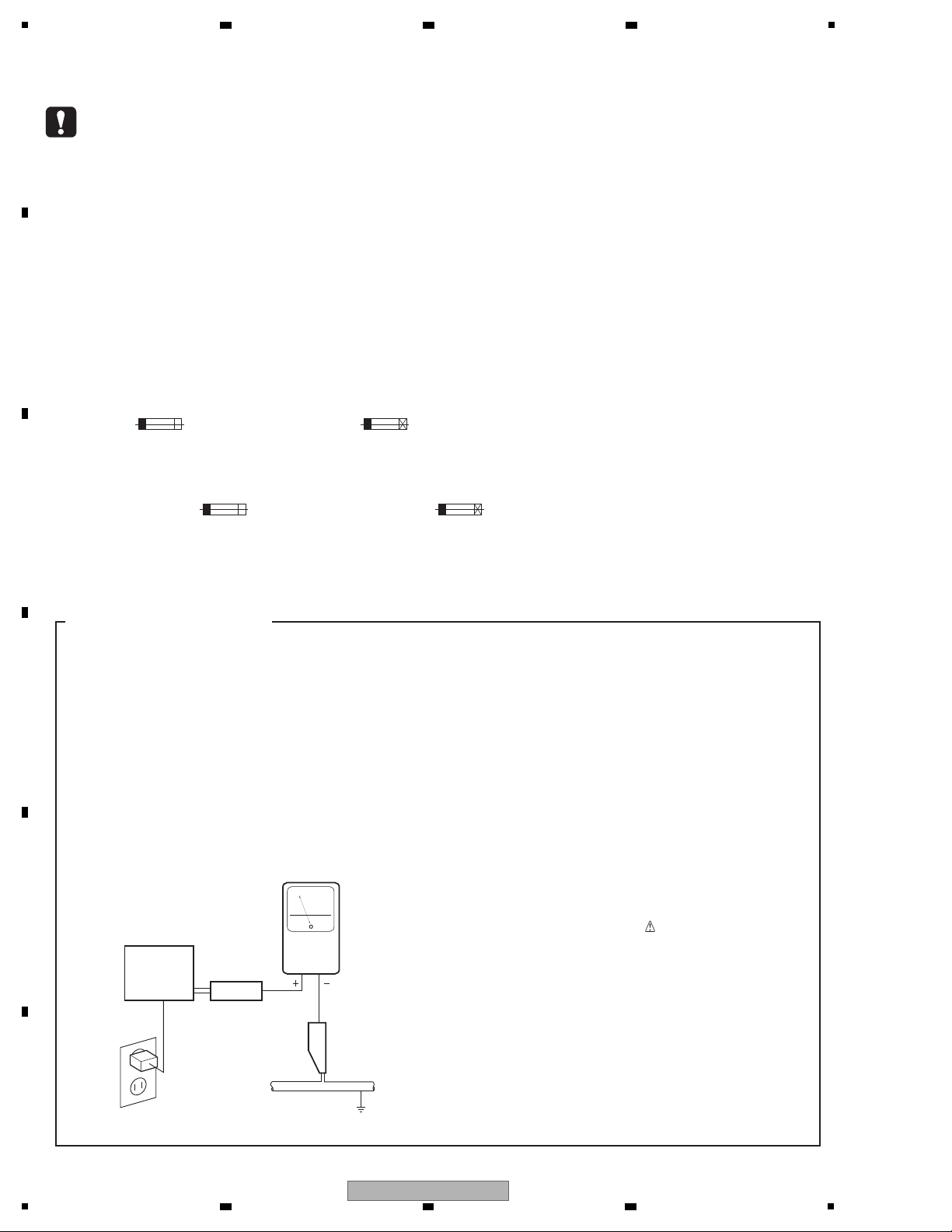

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground

(water pipe, conduit, etc.) by connecting a leakage

current tester such as Simpson Model 229-2 or

equivalent between the earth ground and all exposed

metal parts of the appliance (input/output terminals,

screwheads, metal overlays, control shaft, etc.). Plug

the AC line cord of the appliance directly into a 120V

AC 60 Hz outlet and turn the AC power switch on. Any

current measured must not exceed 0.5 mA.

Device

under

test

Leakage

current

tester

Earth

ground

Reading should

not be above

0.5 mA

Also test with

plug reversed

(Using AC adapter

plug as required)

Test al l

exposed metal

surfaces

AC Leakage Test

2 3 4

SAFETY INFORMATION

A

B

C

D

E

F

2

1

2 3 4

PD-D9MK2-K

Page 3

5

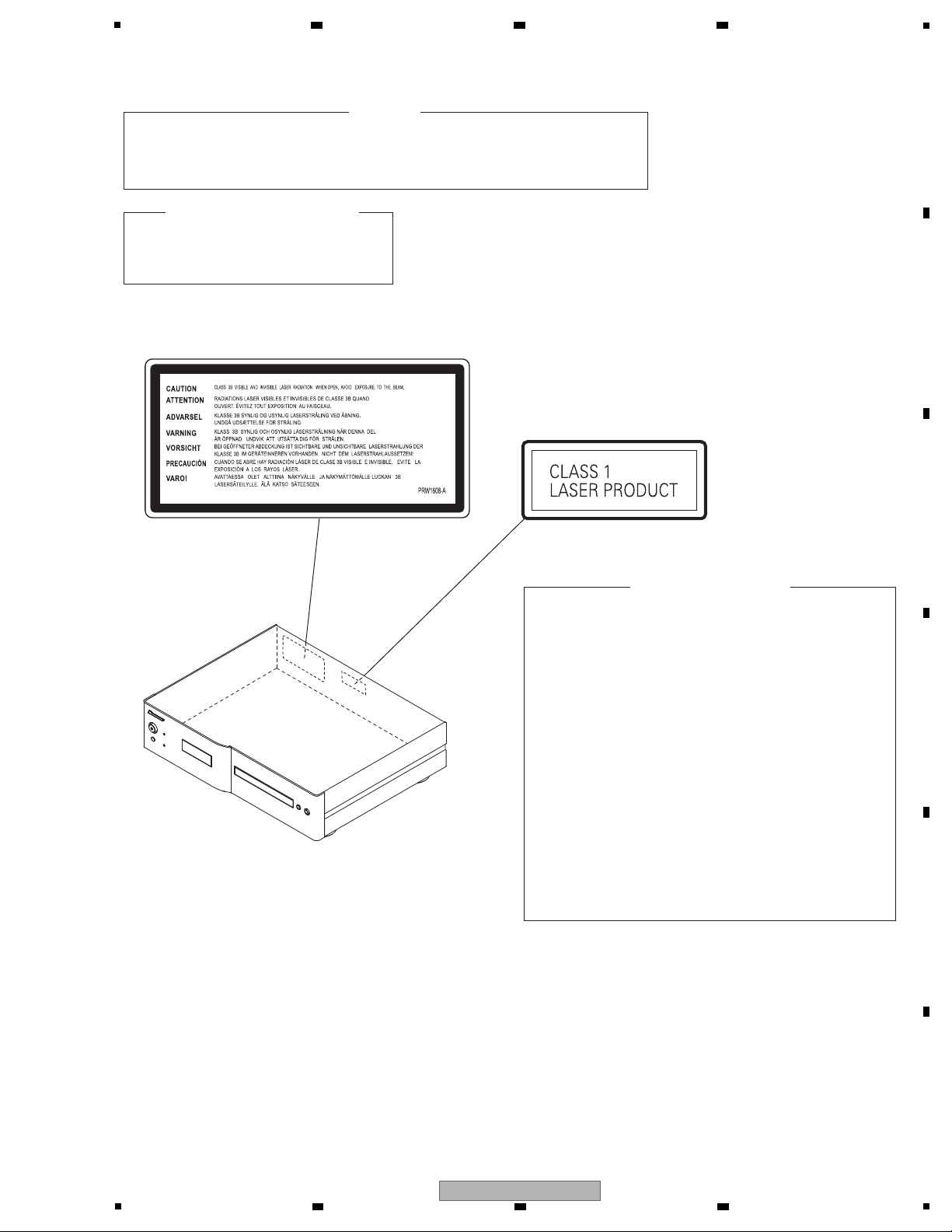

WARNING !

THE AEL (ACCESSIBLE EMISSION LEVEL) OF THE LASER POWER OUTPUT IS LESS THAN CLASS 1

BUT THE LASER COMPONENT IS CAPABLE OF EMITTING RADIATION EXCEEDING THE LIMIT FOR

CLASS 1.

A SPECIALLY INSTRUCTED PERSON SHOULD DO SERVICING OPERATION OF THE APPARATUS.

LASER DIODE CHARACTERISTICS

FOR CD : MAXIMUM OUTPUT POWER : 7 mW

WAVELENGTH : 780 nm

FOR SACD : MAXIMUM OUTPUT POWER : 5 mW

WAVELENGTH : 650 nm)

Additional Laser Caution

1. Laser Interlock Mechanism

• Loading switch (S101 on the LOAB Assy) is used for interlock

mechanism of the laser.

When this switch turned ON in SW2 (CLOSE) side (OPEN signal is

0V and CLOSE signal is 3.5V), a laser becomes the status which can

completely oscillation.

Furthermore, the laser completely oscillates in the disc judgment and

disc playback.

When player is power ON state and laser diode is not completely

oscillating, 780nm laser diode is always oscillating by half power.

• Laser diode is driving with Q307 (650nm LD) and Q308 (780nm LD)

on the DVDM Assy.

Therefore, when short-circuit between the emitter and collector of these

transistors or the base voltage is supplied for transistors turn on, the

laser oscillates. (failure mode)

• In the test mode ∗ , there is the mode that the laser oscillates except

for the disc judgment and playback. LD ON mode in the test mode

oscillates with the laser forcibly.

The interlock mechanism mentioned above becomes invalid in this

mode.

2. When the cover is open, close viewing through the objective lens with

the naked eye will cause exposure to the laser beam.

LABEL CHECK

SYXJ5, CUXJ types : PRW1608

(Printed on the Rear Panel )

∗ : Refer to page 38.

6 7 8

A

B

C

D

E

F

PD-D9MK2-K

5

6 7 8

3

Page 4

1

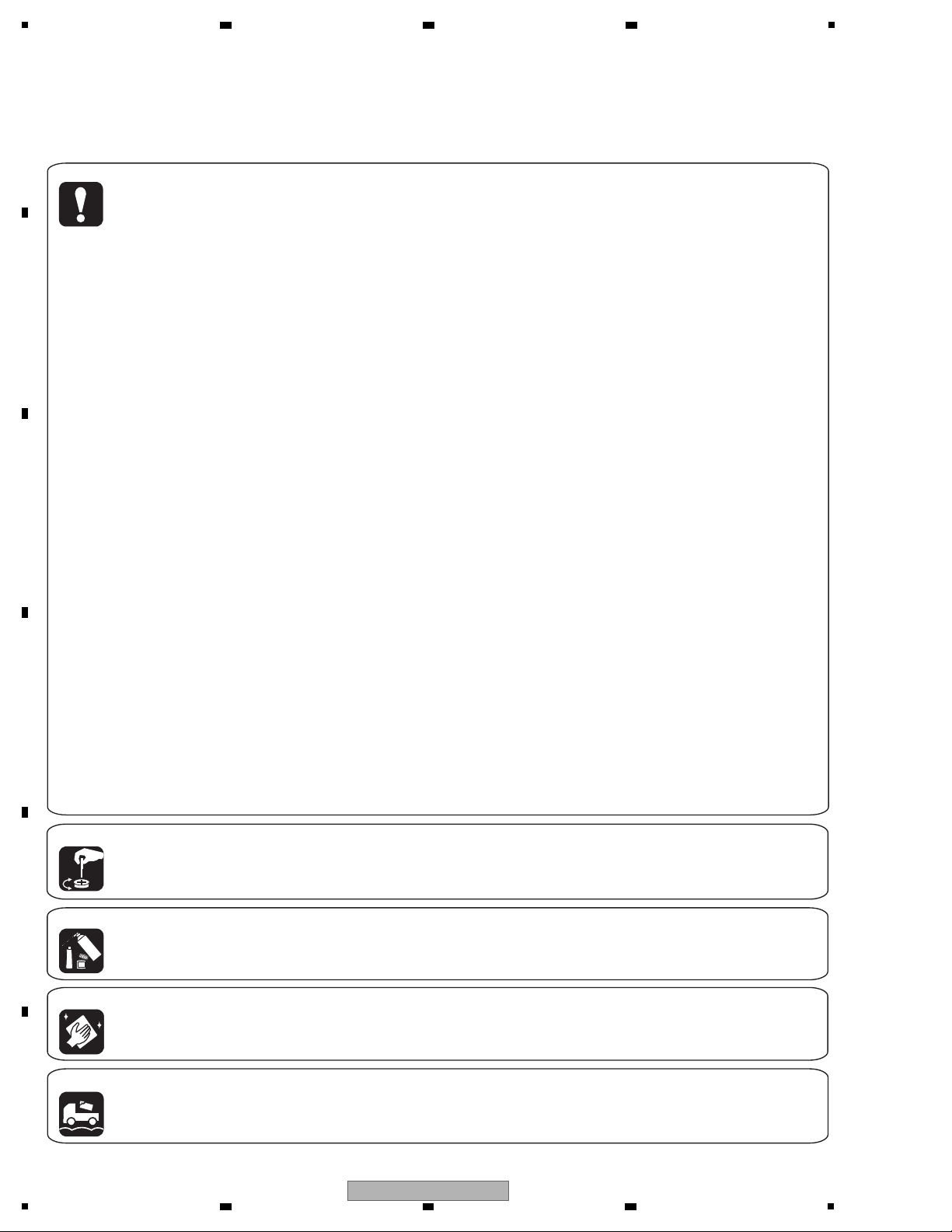

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

a Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

Make sure the proper amount is applied.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

A

2 3 4

B

C

D

E

F

4

1

PD-D9MK2-K

2 3 4

Page 5

5

6 7 8

CONTENTS

SAFETY INFORMATION.......................................................................................................................................................... 2

1. SERVICE PRECAUTIONS.................................................................................................................................................... 6

1.1 NOTES ON SOLDERING...............................................................................................................................................6

2. SPECIFICATIONS................................................................................................................................................................. 7

2.1 SPECIFICATIONS .......................................................................................................................................................... 7

2.2 PANEL FACILITIES.........................................................................................................................................................8

3. BASIC ITEMS FOR SERVICE ............................................................................................................................................10

3.1 CHECK POINTS AFTER SERVICING (SACD PLAYER) .............................................................................................10

3.2 PCB LOCATIONS .........................................................................................................................................................11

3.3 JIGS LIST .....................................................................................................................................................................12

4. BLOCK DIAGRAM .............................................................................................................................................................. 14

4.1 OVERALL WIRING DIAGRAM .....................................................................................................................................14

4.2 OVERALL BLOCK DIAGRAM.......................................................................................................................................16

5. DIAGNOSIS ........................................................................................................................................................................18

5.1 TROUBLESHOOTING.................................................................................................................................................. 18

5.2 SEQUENCE AFTER POWER ON/OFF........................................................................................................................ 22

5.3 METHOD FOR DIAGNOSING DEGRADATION OF THE LDS ON THE PICKUP ASSY .............................................26

6. SERVICE MODE................................................................................................................................................................. 27

6.1 TEST MODE.................................................................................................................................................................27

7. DISASSEMBLY ...................................................................................................................................................................28

8. EACH SETTING AND ADJUSTMENT................................................................................................................................ 36

8.1 ADJUSTMENT ITEMS AND LOCATION...................................................................................................................... 36

8.2 JIGS AND MEASURING INSTRUMENTS....................................................................................................................36

8.3 NECESSARY ADJUSTMENT POINTS ........................................................................................................................37

8.4 TEST MODE.................................................................................................................................................................38

8.5 MECHANISM ADJUSTMENT.......................................................................................................................................40

9. EXPLODED VIEWS AND PARTS LIST............................................................................................................................... 42

9.1 PACKING SECTION .....................................................................................................................................................42

9.2 EXTERIOR SECTION .................................................................................................................................................. 44

9.3 CHASSIS SECTION..................................................................................................................................................... 46

9.4 FRONT PANEL SECTION ............................................................................................................................................48

9.5 LOADER ASSY ............................................................................................................................................................50

9.6 TRAVERSE MECHANISM ASSY-S ..............................................................................................................................52

10. SCHEMATIC DIAGRAM.................................................................................................................................................... 54

10.1 DVDM ASSY (1/2) ...................................................................................................................................................... 54

10.2 DVDM ASSY (2/2) ...................................................................................................................................................... 56

10.3 AJKB ASSY ................................................................................................................................................................58

10.4 LCD, PLED, IR and KEY ASSYS................................................................................................................................60

10.5 PRIMARY, MNSW and REGULATOR ASSYS............................................................................................................62

10.6 CONNECTOR ASSY .................................................................................................................................................. 64

10.7 WAVEFORMS.............................................................................................................................................................65

11. PCB CONNECTION DIAGRAM........................................................................................................................................68

11.1 LOAB and DVDM ASSYS ...........................................................................................................................................68

11.2 AJKB ASSY ................................................................................................................................................................70

11.3 LCD ASSY.................................................................................................................................................................. 72

11.4 PLED, KEY and IR ASSYS.........................................................................................................................................74

11.5 PRIMARY ASSY ................................................................................................................

11.6 CONNECTOR and MNSW ASSYS ............................................................................................................................ 78

11.7 REGULATOR ASSY ................................................................................................................................................... 80

12. PCB PARTS LIST.............................................................................................................................................................. 82

......................................... 76

A

B

C

D

E

F

PD-D9MK2-K

5

6 7 8

5

Page 6

1

• For environmental protection, lead-free solder is used on the printed circuit boards mounted in this unit.

Be sure to use lead-free solder and a soldering iron that can meet specifications for use with lead-free solders for repairs

accompanied by reworking of soldering.

• Compared with conventional eutectic solders, lead-free solders have higher melting points, by approximately 40 ºC.

Therefore, for lead-free soldering, the tip temperature of a soldering iron must be set to around 373 ºC in general, although

the temperature depends on the heat capacity of the PC board on which reworking is required and the weight of the tip of

the soldering iron.

Do NOT use a soldering iron whose tip temperature cannot be controlled.

Compared with eutectic solders, lead-free solders have higher bond strengths but slower wetting times and higher melting

temperatures (hard to melt/easy to harden).

The following lead-free solders are available as service parts:

• Parts numbers of lead-free solder:

GYP1006 1.0 in dia.

GYP1007 0.6 in dia.

GYP1008 0.3 in dia.

2 3 4

1. SERVICE PRECAUTIONS

1.1 NOTES ON SOLDERING

A

B

C

D

E

F

6

1

2 3 4

PD-D9MK2-K

Page 7

5

Accessories

Remote control . . . . . . . . . . . . . . . . . . . . . . . . . . 1

AAA/IEC R03 dry cell batteries . . . . . . . . . . . . 2

RCA/phono stereo audio cable . . . . . . . . . . . . . 1

SR control cable . . . . . . . . . . . . . . . . . . . . . . . . . 1

Power cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Warranty card

Operating Instructions

Note

• Specifications and the design are subject

to possible modifications without notice,

due to improvements.

Specifications

General

System . . . . . . . . . . . . . . . Super Audio CD player

Power requirements . . . . . . . . . . . . . . . . .

SYXJ5: AC 220 V to AC 240 V, 50/60 Hz

CUXJ: AC 120 V, 60 Hz

Power consumption . . . . . . . . . . . . . . . . . . . .22 W

Power consumption (standby) . . . . . . . . . . . 0.4 W

Weight. . . . . . . . . . . . . . . . . . . . 11.0 kg (24 lbs 5oz)

Dimensions

. . . . . . . .420 mm (W) x 113 mm (H) x 340 mm (D)

(16

9

/16 in. (W) x 4 1/2 in. (H) x 13 3/8 in. (D))

Operating temperature . . . . . . . . +5 °C to +35 °C

Operating humidity . . . . . . . . . . . . . . . 5 % to 85 %

(no condensation)

Audio output (1 stereo pair)

Output level . . . . . . . . . . . . . .During audio output

200 mVrms (1 kHz, –20 dB)

Number of channels . . . . . . . . . . . . . . . . . . . . . . . 2

Jacks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . RCA

Digital audio characteristics

Frequency response . . . . . 4 Hz to 50 kHz (SACD)

4 Hz to 20 kHz (CD)

S/N ratio:

CD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115 dB

SACD . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110 dB

Dynamic range:

CD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 dB

SACD . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110 dB

Total harmonic distortion:

CD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.002 %

SACD . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.003 %

Wow and flutter . . . . . . . . . Limit of measurement

(±0.001 % W. PEAK) or lower

Digital output

Coaxial digital output. . . . . . . . . . . . . . . RCA jack

Optical digital output. . . . . . . Optical digital jack

Disc/content format playback

compatibility

This player is compatible with a wide range of

audio disc types and media formats. Playable

discs will generally feature one of the following

logos on the disc and/or disc packaging. Note

however that some disc types, such as

recordable CDs, may be in an unplayable

format.

Please also note that recordable discs cannot be

recorded using this player.

*“Super Audio CD” is a registered trademark.

Audio CD CD-R CD-RW

Super Audio CD*

2. SPECIFICATIONS

2.1 SPECIFICATIONS

6 7 8

A

B

C

D

E

5

PD-D9MK2-K

6 7 8

F

7

Page 8

1

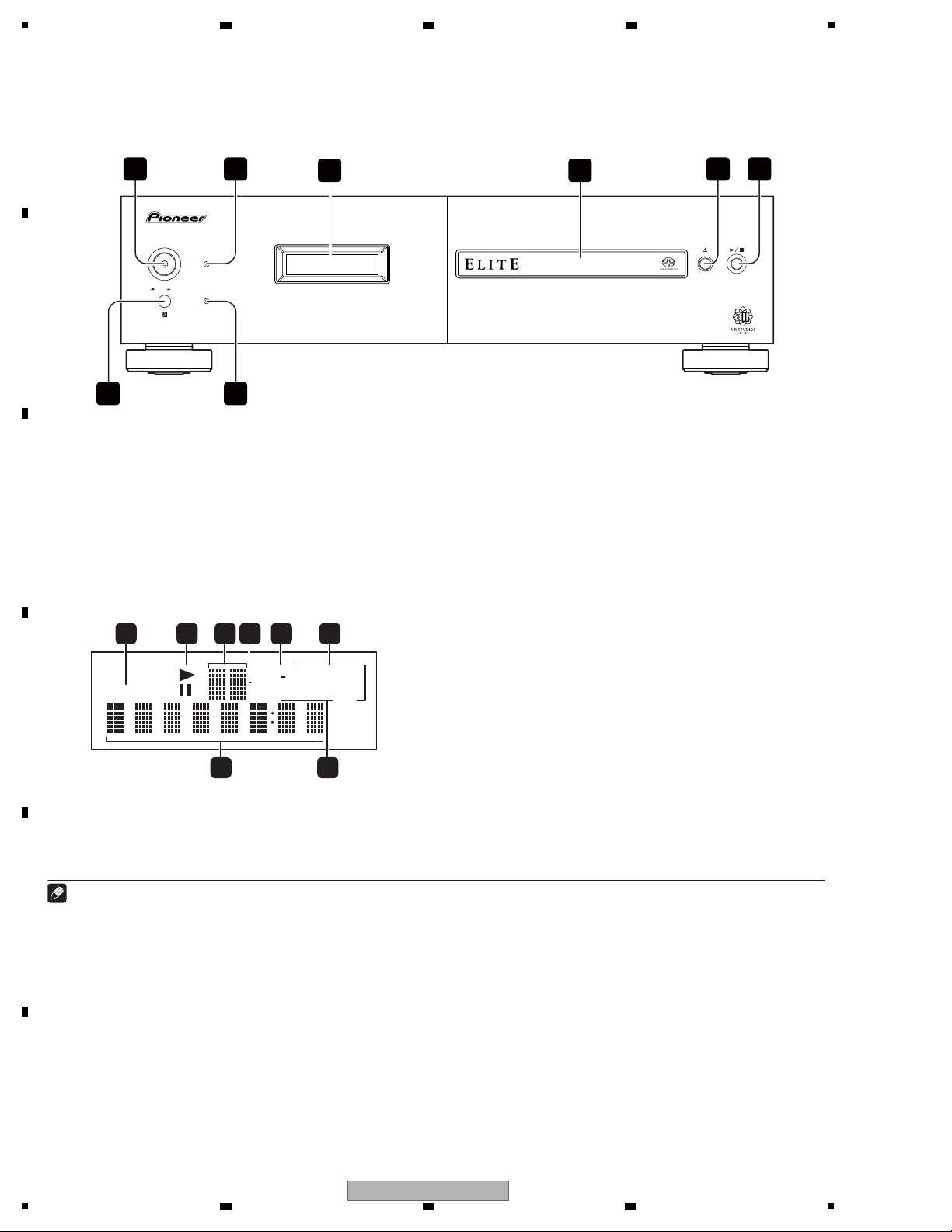

Front panel

1

POWER v

OFF wON

1

2 STANDBY indicator

3 Display

(below)

4 Disc tray

5 h

6 d/g

7 Remote sensor

8

PURE AUDIO

indicator

Display

1

TRACK – Lights when the track number is

indicated.

2

d/e – Light during playback/when paused.

3Scan display

– Shows the scan speed.

4 SACD – Lights during SACD playback.

5

LEGATO – Lights when Legato Link Pro is

switched on.

6(ALL)

REPEAT/RANDOM/PGM – Light to

indicate the playback mode.

7 Character display

8 TOTAL/REMAIN

–

Indicate the disc/track

information currently displayed.

ONOFF

POWER

STANDBY

PURE AUDIO

D9

3 4

1

7

2 5 6

8

Note

1 • When the unit is in the standby mode, if the power is turned off by pressing the main unit’s POWER button, the power will

not turn on if the button is pressed again. To turn on the power in this case, press either the remote control unit’s

CD PLAYER u button or a different button (other than the POWER button) on the main unit.

• When the unit is in the standby mode, if the power is turned off by unplugging the power cord, the power will not turn merely

by reconnecting the power cord. To turn on the power in this case, reconnect the power cord and then press either the remote

control unit’s CD PLAYER u button or a different button (other than the POWER button) on the main unit.

LEGATOLEGATO

ALLALL

TOTALTOTAL

REPEATREPEAT

PGMPGM

REMAINREMAIN

RANDOMRANDOM

TRACKTRACK

SACDSACD

1 2 3 4 5 6

7 8

2.2 PANEL FACILITIES

A

B

2 3 4

C

D

E

8

1

PD-D9MK2-K

2 3 4

F

Page 9

5

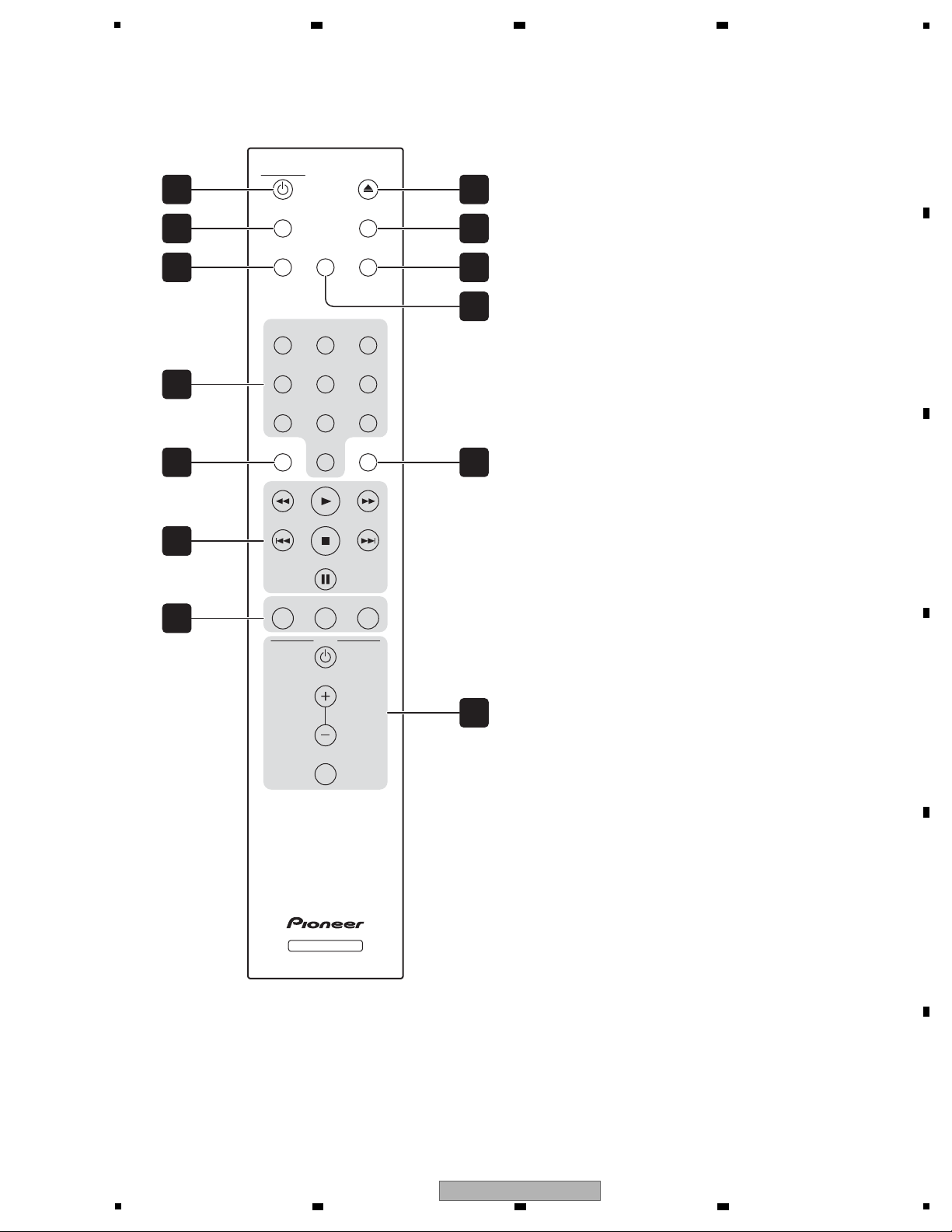

Remote control

1

CD PLAYER u

2

TIME

3

SACD/CD

4 Number buttons

5

CLEAR

6 Playback controls

7

PROGRAM

REPEAT

RANDOM

8

h OPEN/CLOSE

9

DIMMER

10

PURE AUDIO

11

LEGATO LINK

12

ENTER

13 AMP controls

Use to control Pioneer amplifier.

AMP u

VOLUME

MUTE

PROGRAM

REPEAT

VOLUME

RANDOM

AMP

SACD PLAYER

CD PLAYER

OPEN/CLOSE

TIME

DIMMER

SACD/CD

PURE AUDIO

CLEAR ENTER

LEGATO

LINK

123

456

7809

MUTE

1 8

9

10

12

13

11

2

3

4

6

7

5

6 7 8

A

B

C

D

5

PD-D9MK2-K

6 7 8

E

F

9

Page 10

1

Item to be checked regarding audio

Distortion

Noise

Volume too low

Volume too high

Volume fluctuating

Sound interrupted

No. Procedures Check points

1

2

3

4

Confirm the firmware version on Test Mode. The version of the firmware must be latest.

Update firmware to the latest one, if it is not the latest.

Confirm whether the customer complain has been solved.

If the customer complain occurs with the specific disc, use it for

the operation check.

The customer complain must not be reappeared.

Video, audio and operations must be normal.

Play back a CD.

(track search)

Audio and operations must be normal.

Check the appearance of the product. No scratches or dirt on its appearance after receiving it for

service.

Items to be checked after servicing / PD

To keep the product quality after servicing, confirm recommended check points shown below.

See the table below for the items to be checked regarding audio.

Cleaning

Before shipping out the product, be sure to clean the following positions by using the prescribed cleaning tools.

NamePosition to be cleaned Part No. Remarks

Refer to “9.6 Traverse Mechanism Assy-S”.Cleaning liquidPickup leneses GEM1004

Cleaning paper GED-008

No. Procedures Check points

1

Play back a SACD. *Models supporting SACD

(track search)

Audio and operations must be normal.

Specific Items to be Checked

2 3 4

3. BASIC ITEMS FOR SERVICE

3.1 CHECK POINTS AFTER SERVICING (SACD PLAYER)

A

B

C

D

E

F

10

1

2 3 4

PD-D9MK2-K

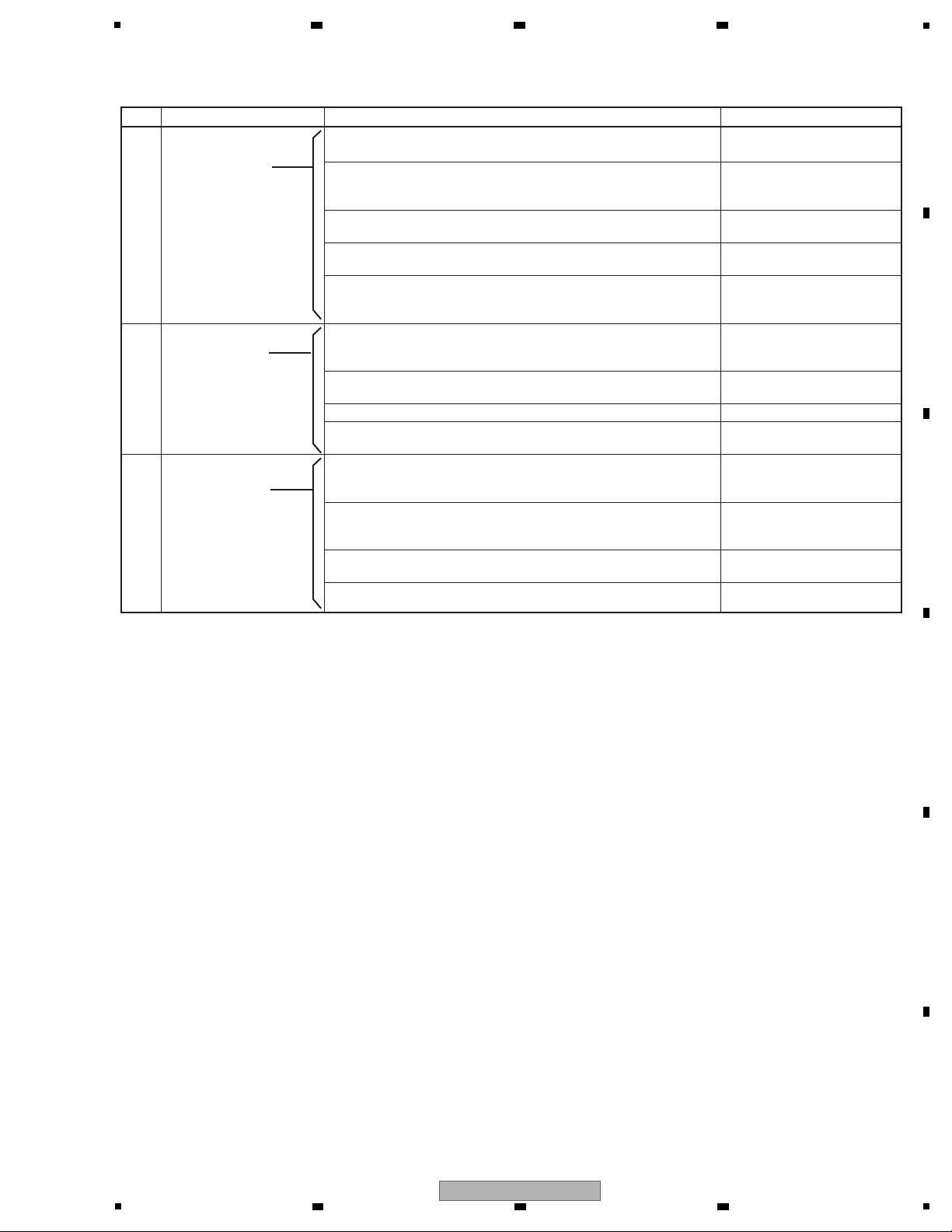

Page 11

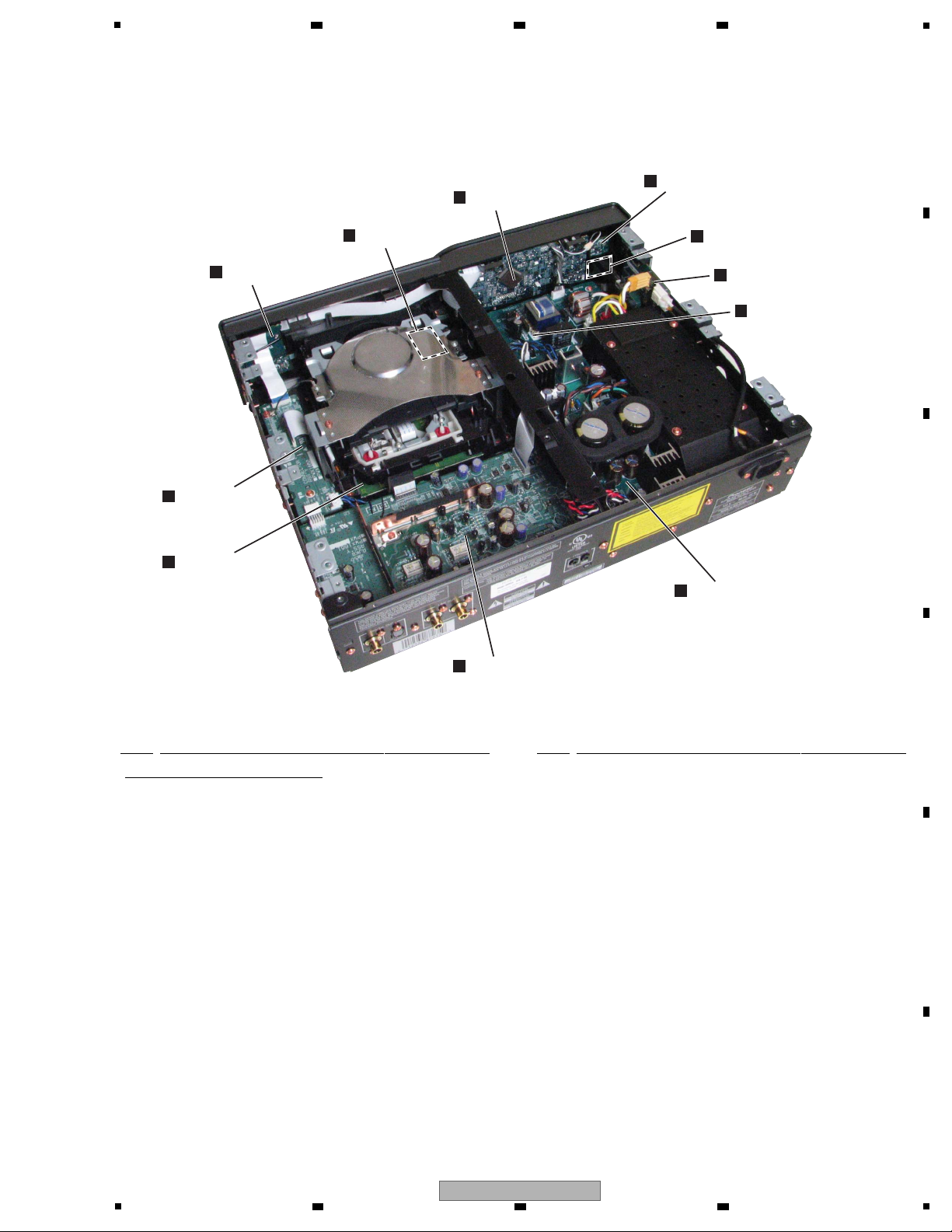

5

REGULATOR ASSY

J

AJKB ASSY

C

CONNECTOR

ASSY

H

KEY ASSY

G

LOAB ASSY

A

LCD ASSY

D

PLED ASSY

E

IR ASSY

K

MNSW ASSY

F

PRIMARY ASSY

I

DVDM ASSY

B

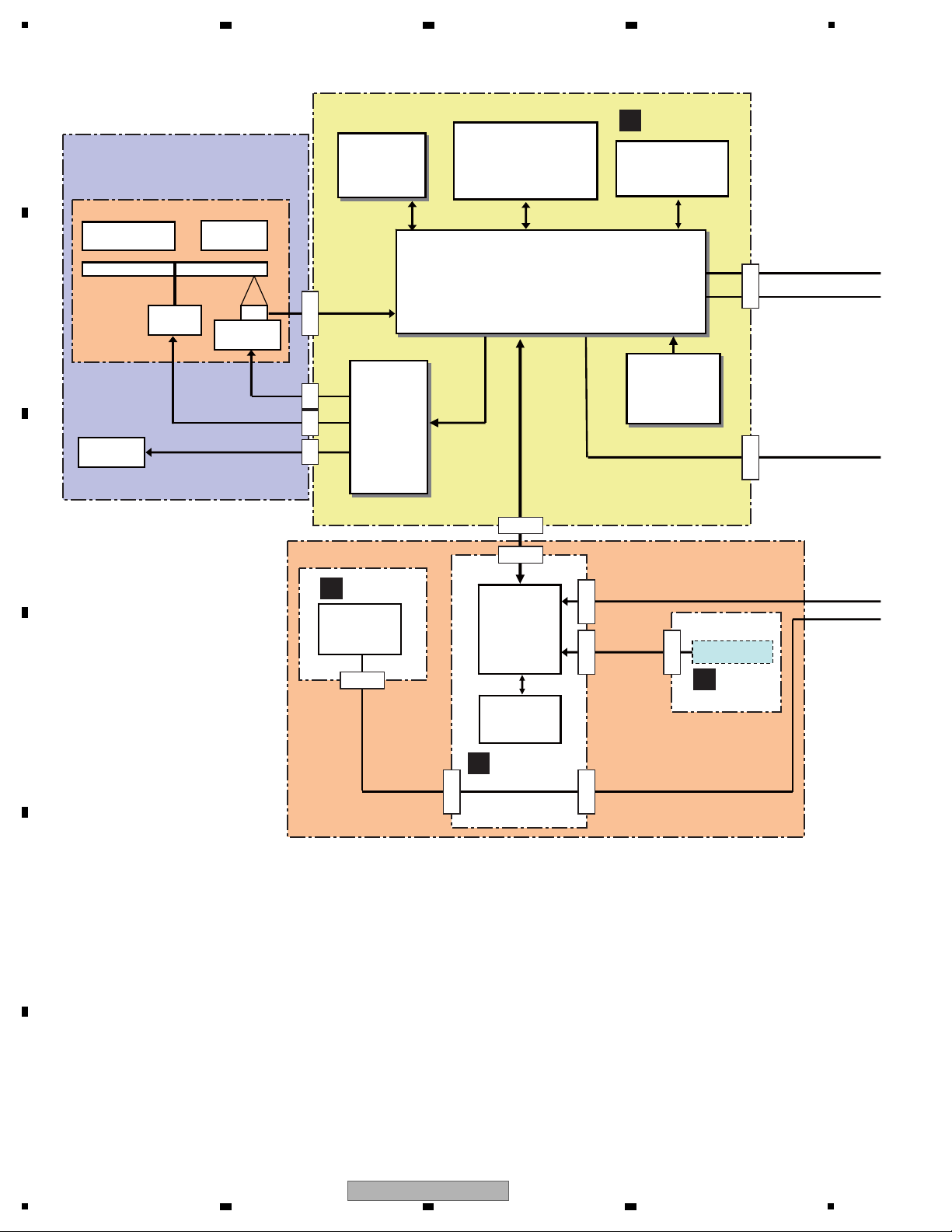

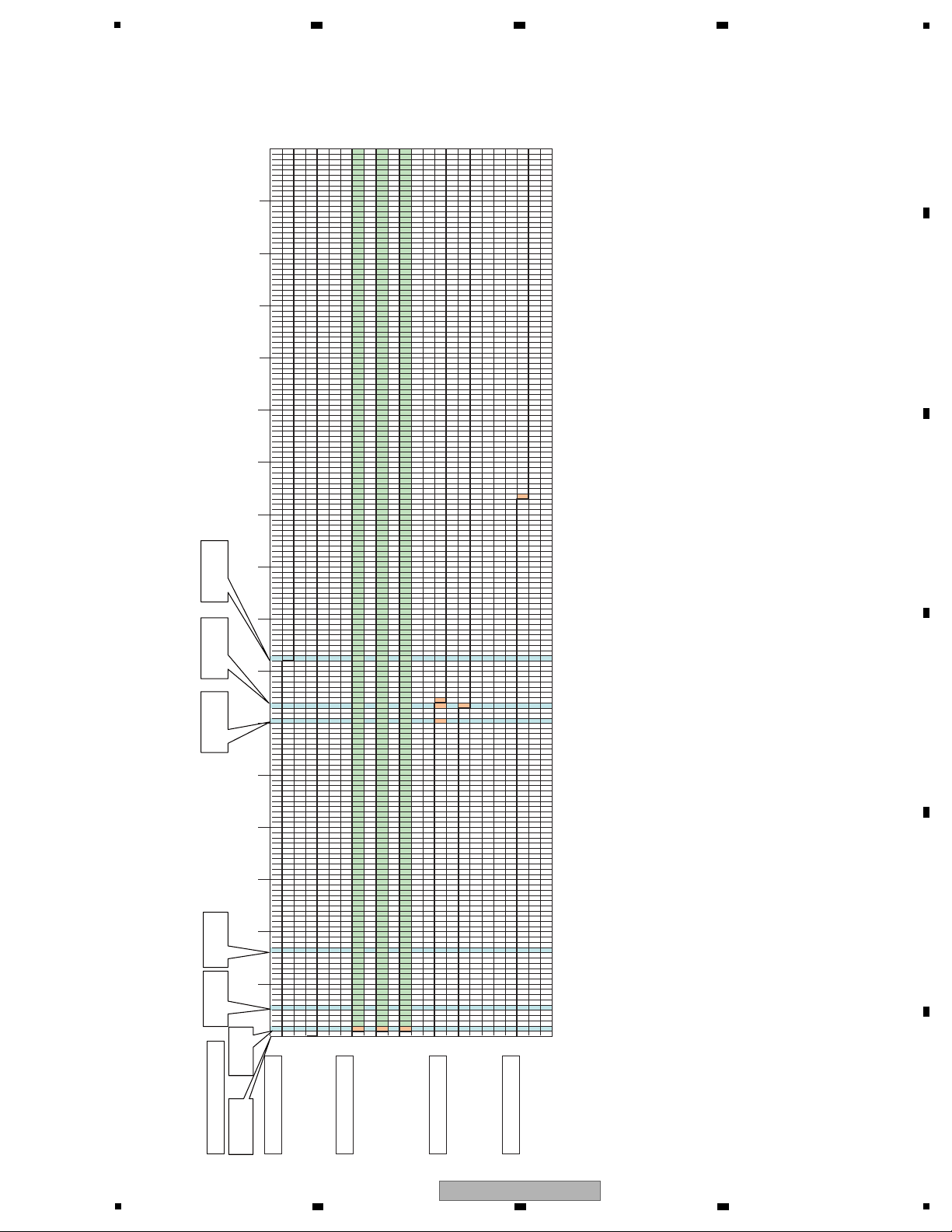

3.2 PCB LOCATIONS

6 7 8

A

B

Mark No. Description Part No.

LIST OF ASSEMBLIES

For PD-D9MK2-K/SYXJ5

NSP 1..LOADER ASSY PXA1648

NSP 2..LOAB ASSY VWG2346

1..DVDM ASSY AWM8184

1..FLKB ASSY PWM2371

2..IR ASSY(D9) PWX1653

2..MNSW ASSY(D9) PWX1654

2..LCD ASSY(D9) PWX1672

2..PLED ASSY(D9) PWX1677

2..KEY ASSY(D9) PWX1679

2..REGULATOR ASSY(D9) PWX1678

2..PRIMARY ASSY(D9 WY) PWX1681

1..AJKB ASSY PWM2375

2..AJKB ASSY(D9) PWX1685

2..CONNECTOR ASSY(D9) PWX1686

Mark No. Description Part No.

For PD-D9MK2-K/CUXJ

NSP 1..LOADER ASSY PXA1648

NSP 2..LOAB ASSY VWG2346

1..DVDM ASSY AWM8184

1..FLKB ASSY PWM2373

2..IR ASSY(D9) PWX1653

2..MNSW ASSY(D9) PWX1654

2..LCD ASSY(D9) PWX1672

2..PLED ASSY(D9) PWX1677

2..KEY ASSY(D9) PWX1679

2..REGULATOR ASSY(LOW) PWX1680

2..PRIMARY ASSY(D9 KU) PWX1683

1..AJKB ASSY PWM2375

2..AJKB ASSY(D9) PWX1685

2..CONNECTOR ASSY(D9) PWX1686

C

D

E

F

PD-D9MK2-K

5

6 7 8

11

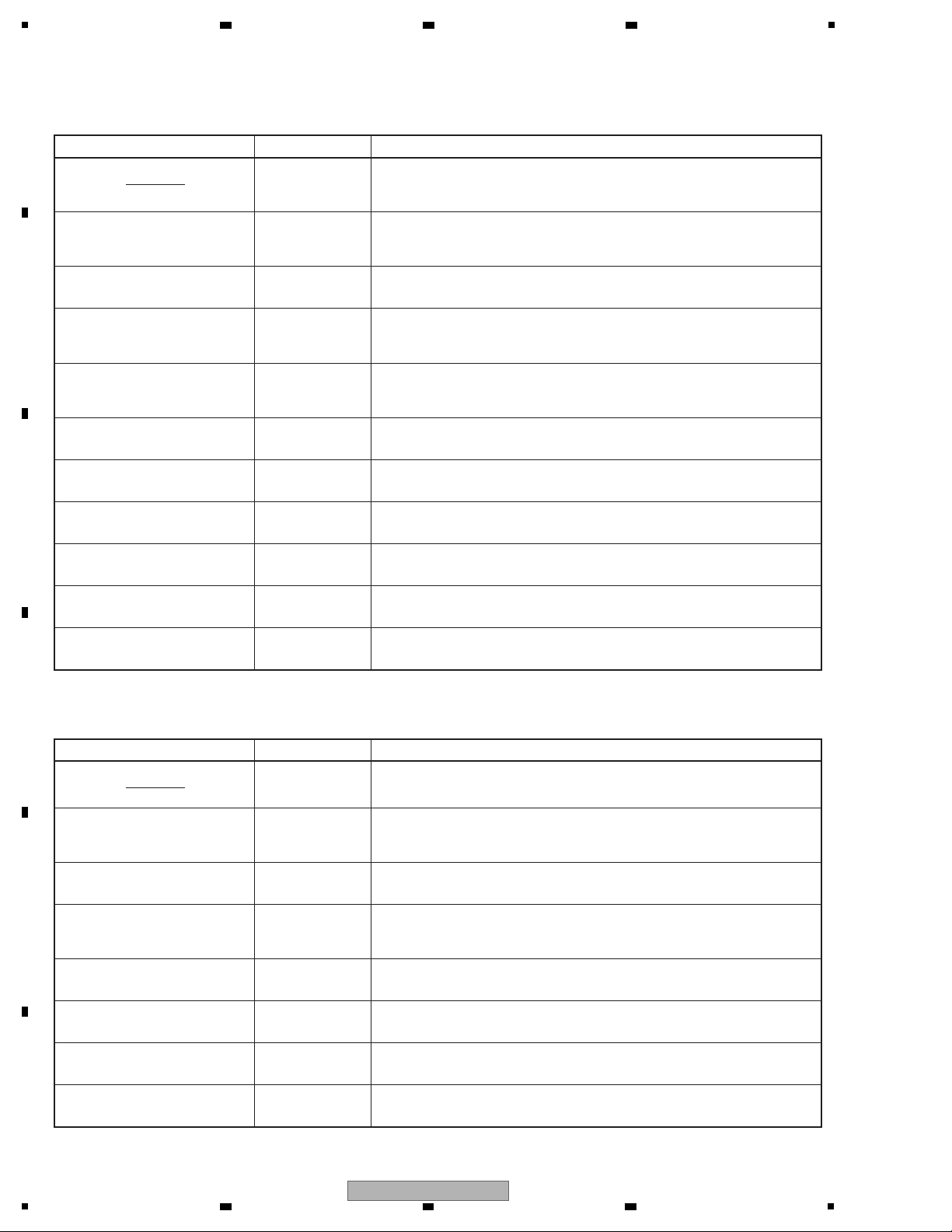

Page 12

1

Service Remote Control Unit GGF1381

DVD Test Disc (DVD-Video) GGV1025

adjustment, diagnosis

Name Jig No. Remarks

Check of DVD-Video

CD Test Disc STD-905 Check of CD

5P FFC GGD1425 Diagnosis of DVDM ASSY

17P FFC GGF1157 Diagnosis of DVDM ASSY

Jigs list

Silicone Adhesive GYA1011

refer to "9.4 FRONT PANEL SECTION"

Lubricating Oil GYA1001

GEM1036

Daifree

Name Lubricants and Glues No. Remarks

refer to "9.5 LOADER ASSY"

refer to "9.5 LOADER ASSY"

GEM1037Silicone Adhesive

refer to "9.6 TRAVERSE MECHANISM ASSY-S"

GYL1001Screw tight

refer to "8.5 MECHANISM ADJUSTMENT"

Lubricants and Glues list

2 3 4

3.3 JIGS LIST

A

B

C

D

E

F

12

PD-D9MK2-K

1

2 3 4

Page 13

5

6 7 8

A

B

C

D

E

F

PD-D9MK2-K

5

6 7 8

13

Page 14

1

AJKB ASSY

(PWX1685)

C

LCD ASSY

(PWX1672)

D

PLED ASSY

(PWX1677)

E

IR ASSY

(PWX1653)

K

MNSW ASSY

(PWX1654)

F

PRIMARY ASSY

(PD-D9MK2-K/SYXJ5:

PWX1681)

(PD-D9MK2-K/CUXJ:

PWX1683)

I

REGULATOR ASSY

(PD-D9MK2-K/SYXJ5: PWX1678)

(PD-D9MK2-K/CUXJ:PWX1680)

J

SYXJ5: ADG7062

CUXJ: ADG7061

SYXJ5: PTT1372

CUXJ: PTT1371

SYXJ5: PTT1374

CUXJ: PTT1373

2 3 4

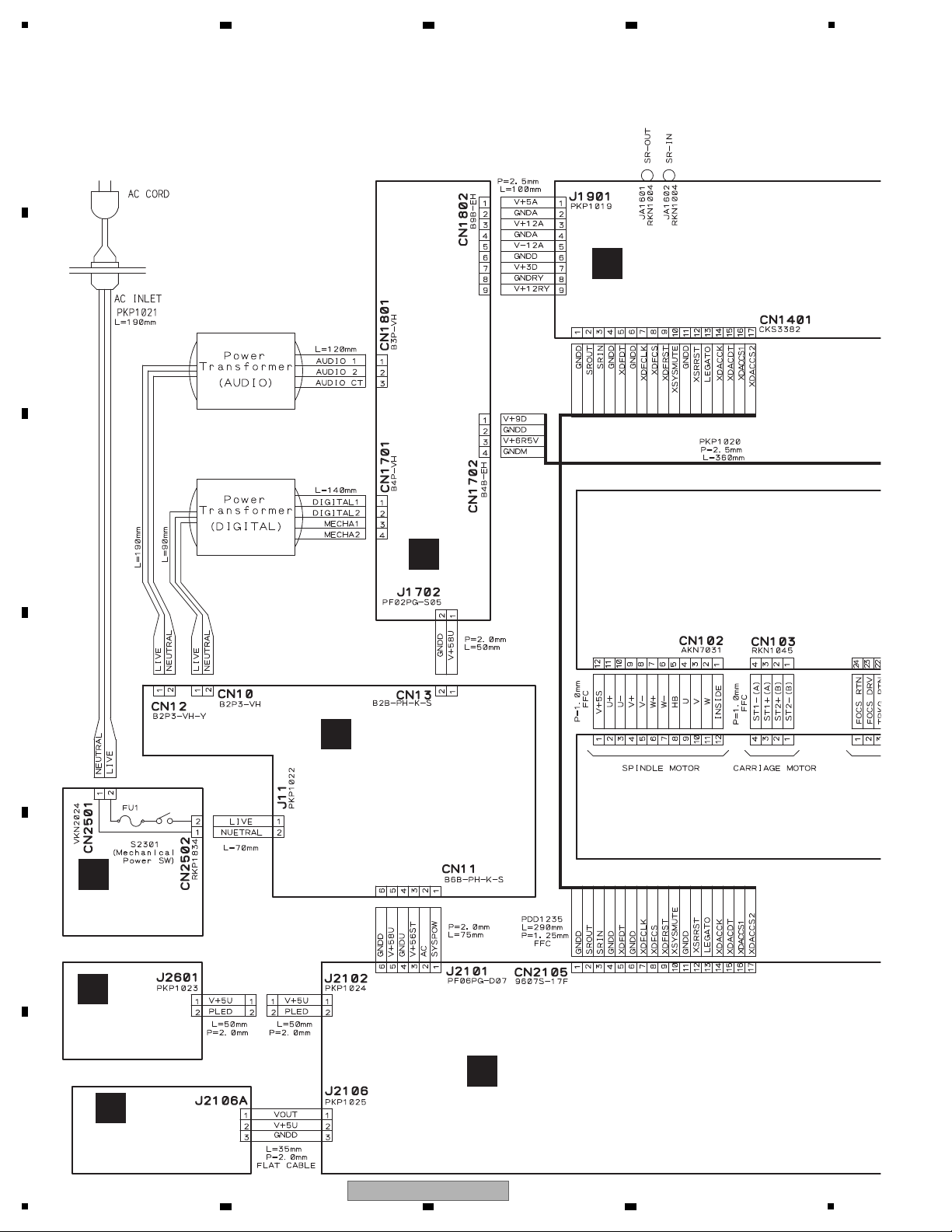

4. BLOCK DIAGRAM

4.1 OVERALL WIRING DIAGRAM

A

B

C

D

E

F

14

PD-D9MK2-K

1

2 3 4

Page 15

5

V+3D

SW2

LOAD+

LOAD-

SW1

S5B-PH-K-S

CN601

CN602

LOADING

MOTOR

ASSY

: VXX2912

1

2

DVDM ASSY

(AWM8184)

CONNECTOR ASSY

(PWX1686)

H

KEY ASSY

(PWX1679)

G

LOAB ASSY

(VWG2346)

A

MECHA ASSY

B

B

()

1/2,B2/2

6 7 8

A

B

C

D

E

F

PD-D9MK2-K

5

6 7 8

15

Page 16

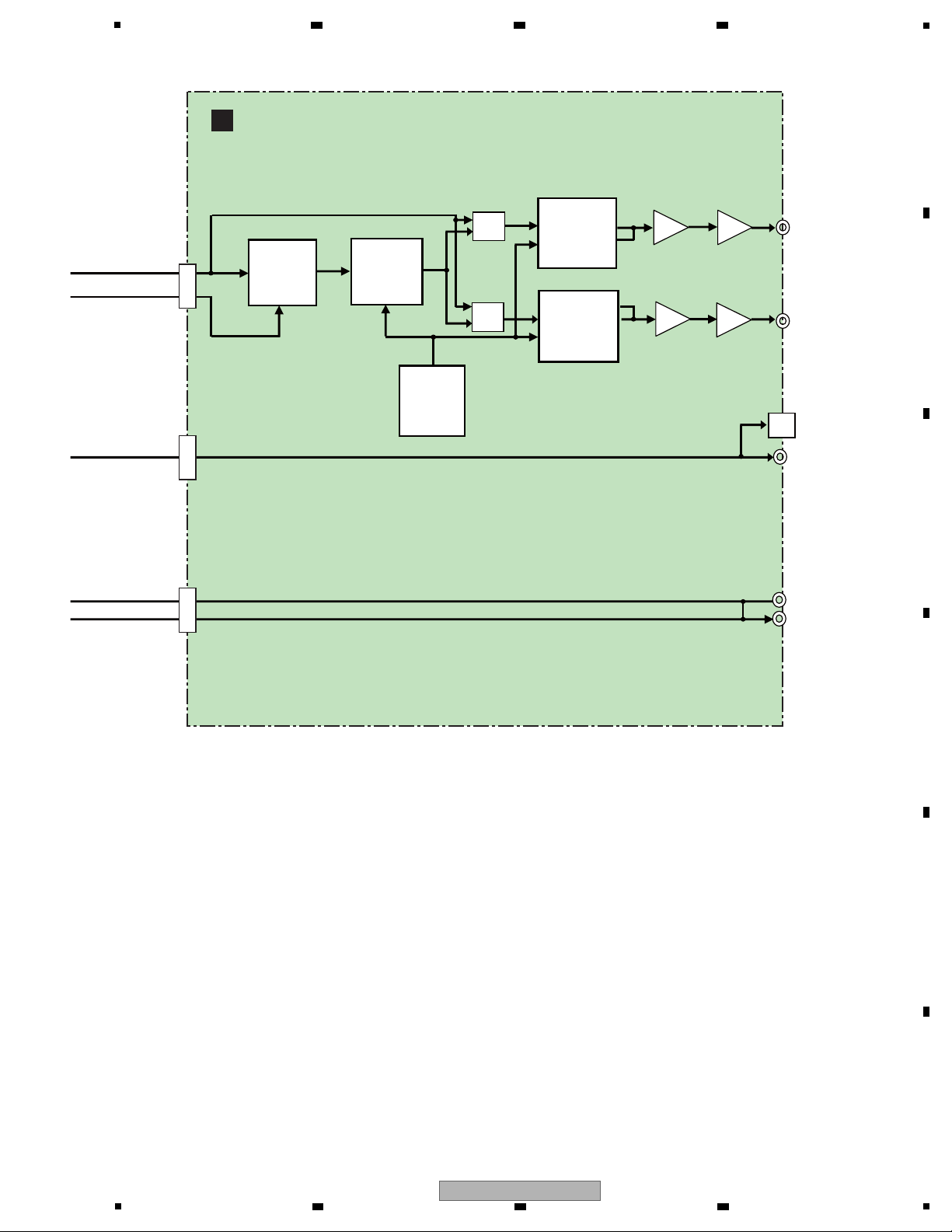

1

CN101

CN953

CN901(1/2)

CN2105

J2104

CN1401

J2106

J2104A

CN901(2/2)

CN2106

J2106A

CN103

CN102

CN104

IC201

MAIN DECODER

(CD,SACD)

1389EE

3.3V&1.8V

64M SDRAM

IC202

KS641632H-TC75

3.3V

IC203

PGM FLASH MEMORY

16M

AYW7197

3.3V

EEPROM

IC204

4k

3.3V

S-24C04AFJ

LOADING

MOTOR

SPDL

MOTOR

PU

STEPPING

MOTOR

TRAVERSE

05 PICK

UP

IC101

SERVO

DRIVER

BD7995EFS

6.5&5V

IC2101

SYSTEM

CONTROL

CPU

5V

PDC170B

LCD Display

AAV7118

5V

KEY

S2301, S2302

IR

GP1UM28XK

5V

Front Panel Block

X202

Clock OSC

ASS7103

(27MHz)

3.3V

SPDIF

DVDM ASSY

B

LCD ASSY

D

KEY ASSY

G

IR ASSY

K

2 3 4

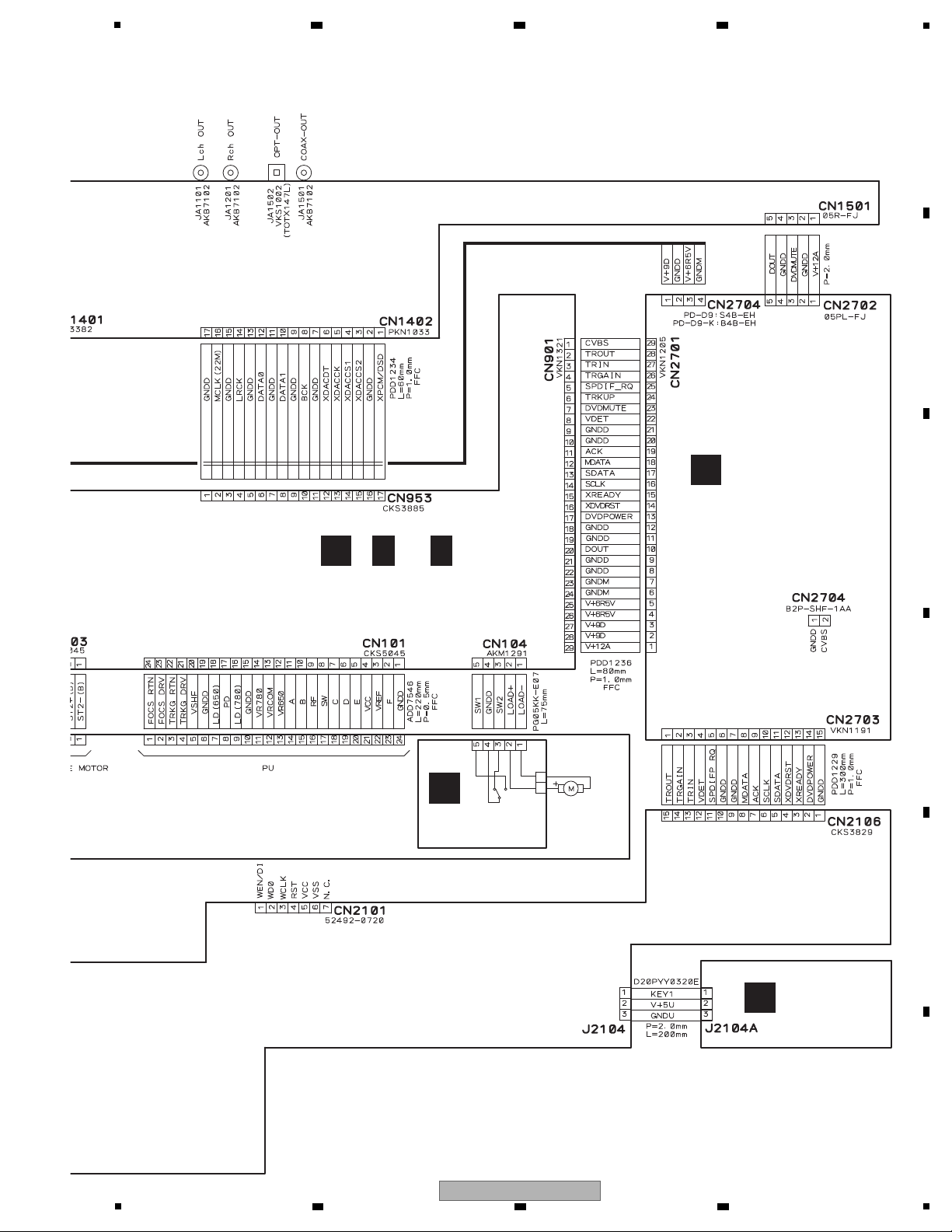

4.2 OVERALL BLOCK DIAGRAM

A

B

C

D

E

F

16

1

2 3 4

PD-D9MK2-K

Page 17

CN1402

CN1501

CN1401

OPTICAL OUT

COAXIAL OUT

SR-IN

SR-OUT

L

R

JA1101

JA1201

JA1502

JA1501

JA1602

JA1601

LPF

IC1101

(1/2)

IC1101

(2/2)

IC1201

(2/2)

IC1201

(1/2)

(PCM)

IC1401

AQE

PD0274A

3.3V

(DSD)

MCLK

IC1251

IC1151

192k,24bit,

2chDAC

WM8741

3.3V&5V

192k,24bit,

2chDAC

WM8741

3.3V&5V

SEL

SEL

IC1152

IC1252

IC1402

SRC

SRC4192

3.3V

X1401

Clock OSC

ASS7101

(22MHz)

3.3V

MCLK

AJKB ASSY

C

5

6 7 8

A

B

C

D

E

F

PD-D9MK2-K

5

6 7 8

17

Page 18

1

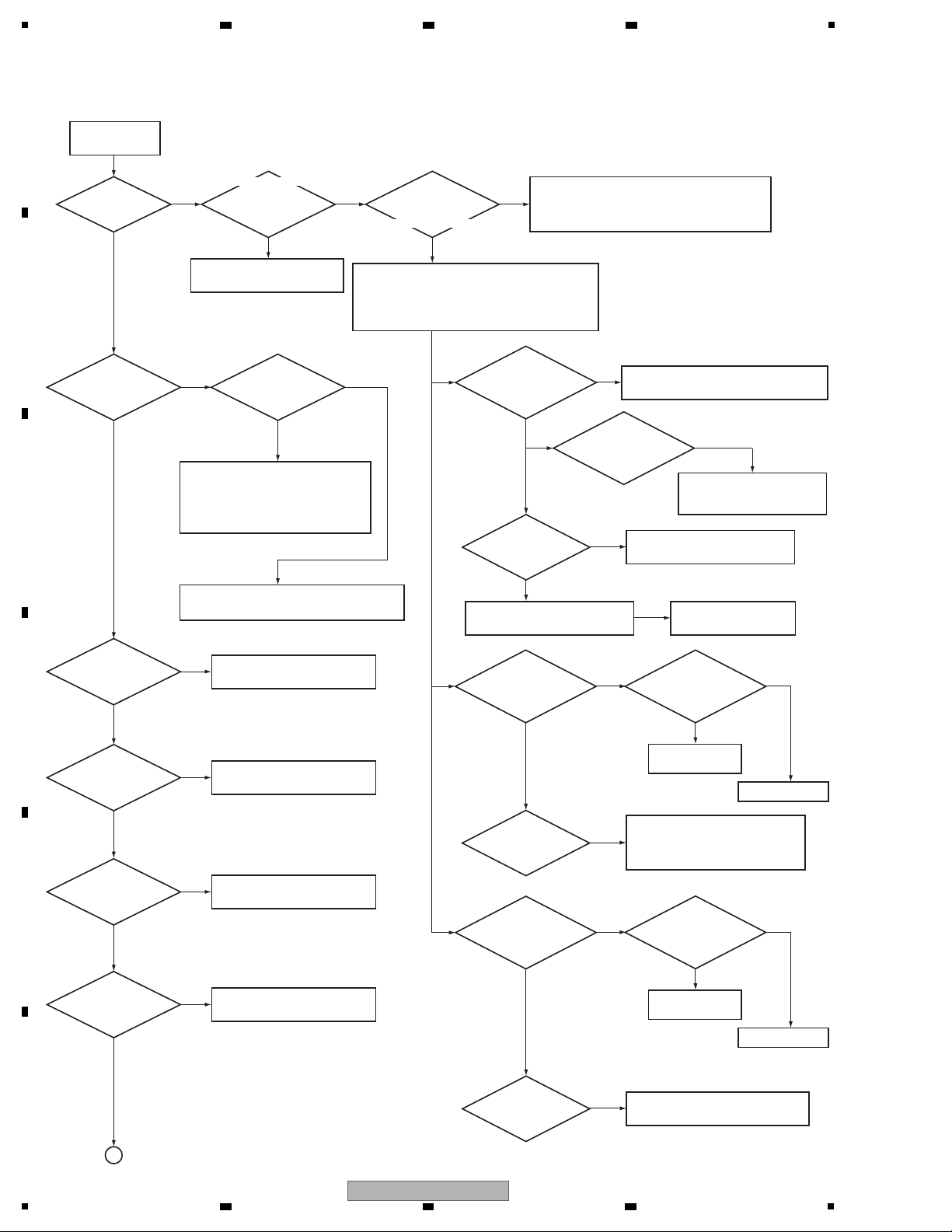

Start

(Power → ON)

Lighting LCD

come out of the pure audio

mode or dimmer mode

Refer to Addendum No. 1.

Appearance some waveform on

LCD communication line

(LCCDT,LCDCK,LCDCS,LCDRS)

Confirm the port logic of BLOFF

and DIMMER when operate

Confirmation HB at CN1801or change

D1801,D1802,D1803D1804

<confirmation>

FU1

Connection between J1702 and CN13

Power line CN11 3 : 5.6V,CN11 5 : 5.8V

<confirmation>

D1809 is shorten

HB at CN1802 and J1901

CN1802 3 is +13V

Ye s

Ye s

No

No

No

<confirmation>

input and output of F2201,Q2103 is 5V

Ye s

No

No

LCD

displays

correctly

V2201 1

is 4.4V and

V2201 2 is

5V

Ye s

No

Tray movement

(open/close)

Refer to Addendum No. 2.

Ye s

No

Focus

movement

OK?

Refer to Addendum No. 3.

Ye s

No

Spindle

movement

OK?

Refer to Addendum No. 4.

Ye s

No

Can stop

spicdle movement

(stop key react)

Ye s

No

<confirmation>

Connection between CN1802 and J1901

Connection between CN1501 and CN2702

Connection between CN2701 and CN901

Connection between CN1702 and CN2704

Ye s

Ye s

Ye s

No

No

Change parts D1805,Q1801,

Q1802 in turn

Change parts D1807,Q1803,

in turn

No

<confirmation>

HB at IC1101,IC1201

No

(V+3D line)

CN1802 3

is 3.3V

<confirmation>

HB at J1901,CN1802,

IC1151,IC1152,IC1251,IC1252,

IC1401-IC1406

No

Ye s

<confirmation>

HB at CN1701

Change IC1701

No

LCD

disappers and

flashing pure

audio LED

(V+12V line)

Cathode of 1801,

D1802 is

+17V

(V+5V line)

CN1802 1 is +5V

Ye s

No

(V+9D line)

D1701 1 is +7.5V

Is status of

IC1701 OK?

Ye s

<confirmation>

HB at CN1701

Change IC1702

No

No

Is status of

IC1702 OK?

CN1702 3

is +6.5V

<confirmation>

HB at CN1702,CN2704,IC101

No

Ye s

(V+6R5V line)

D1702 1

is +8.5V

A

Working

at pure audio

mode or

dimmer?

5. DIAGNOSIS

5.1 TROUBLESHOOTING

A

2 3 4

B

C

D

E

F

18

PD-D9MK2-K

1

2 3 4

Page 19

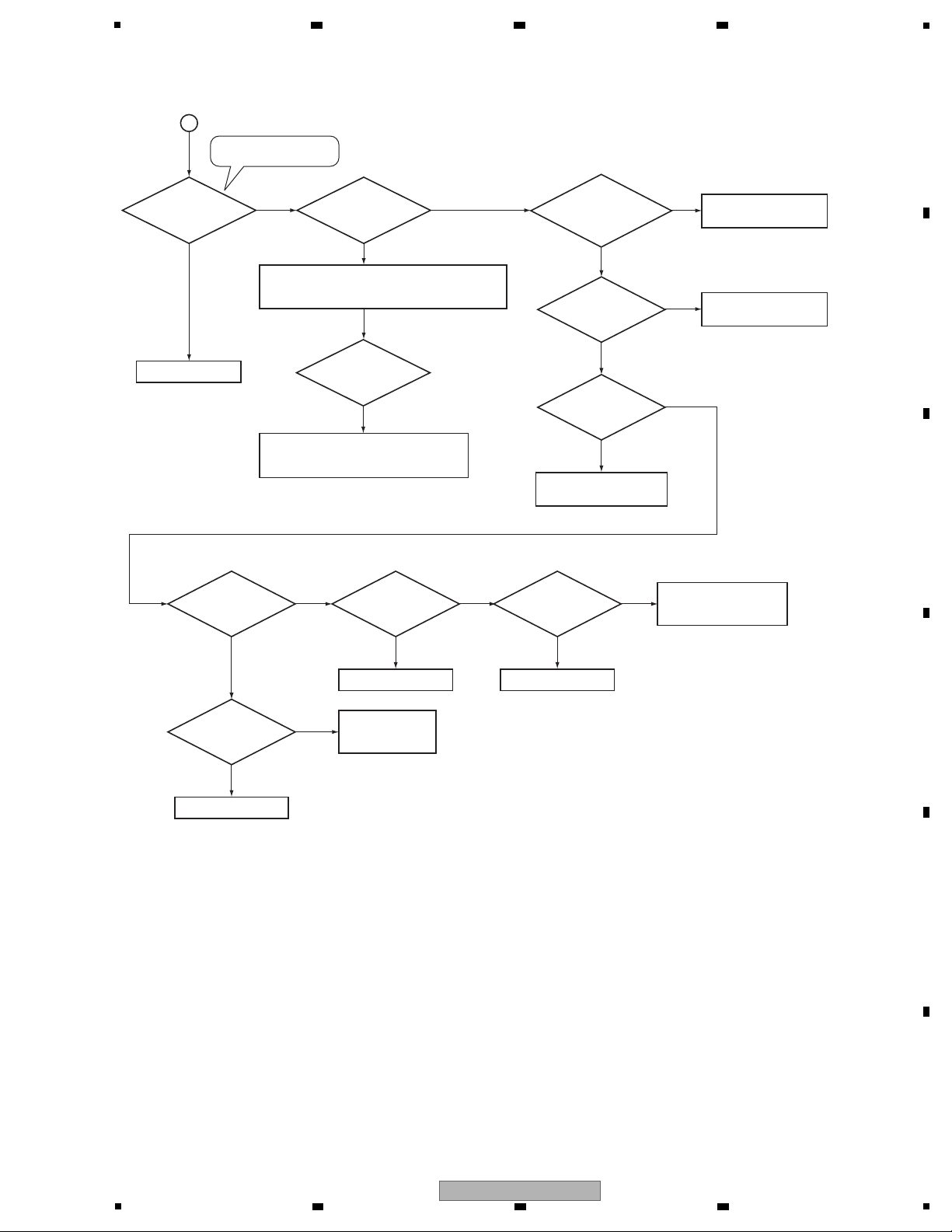

no ploblem

<confirmation>

HB of CN1801

CN1802 is -13V

Change parts

D1808,Q1804,

in turn

Ye s

No

Audio

analog output

is OK?

only analog output at

SACD mode

All output

audio signal

are OK?

Ye s

Only

optical or coaxial

output

Ye s

Ye s

No

<confirmation>

IC201-225

Connection between CN953and CN1402

<confirmation>

Input and output of IC1501

V+3DO is 3.3V

Ye s

RY1302 a

is 0V

Ye s

Ye s

No

Change parts D1806,

Q1804,Q1805 in turn

Ye s

<confirmation>

HB at IC1101,IC1201

Ye s

Change RY1302

No

<confirmation>

XSYSMUTE : H

DVDMUTE : L

<confirmation>

HB at CN1701 or

change D1709,D1710

No

IC1707 1 is

+17V

Ye s

Change IC1707

No

status of IC1706

is OK?

Ye s

Change IC1706

No

No

(V+12RY line)

RY1302 1 is

+12V

NoNo

(V-12V line)

anode of D1803,

D1804 is -17V

A

5

6 7 8

A

B

C

D

5

PD-D9MK2-K

6 7 8

E

F

19

Page 20

1

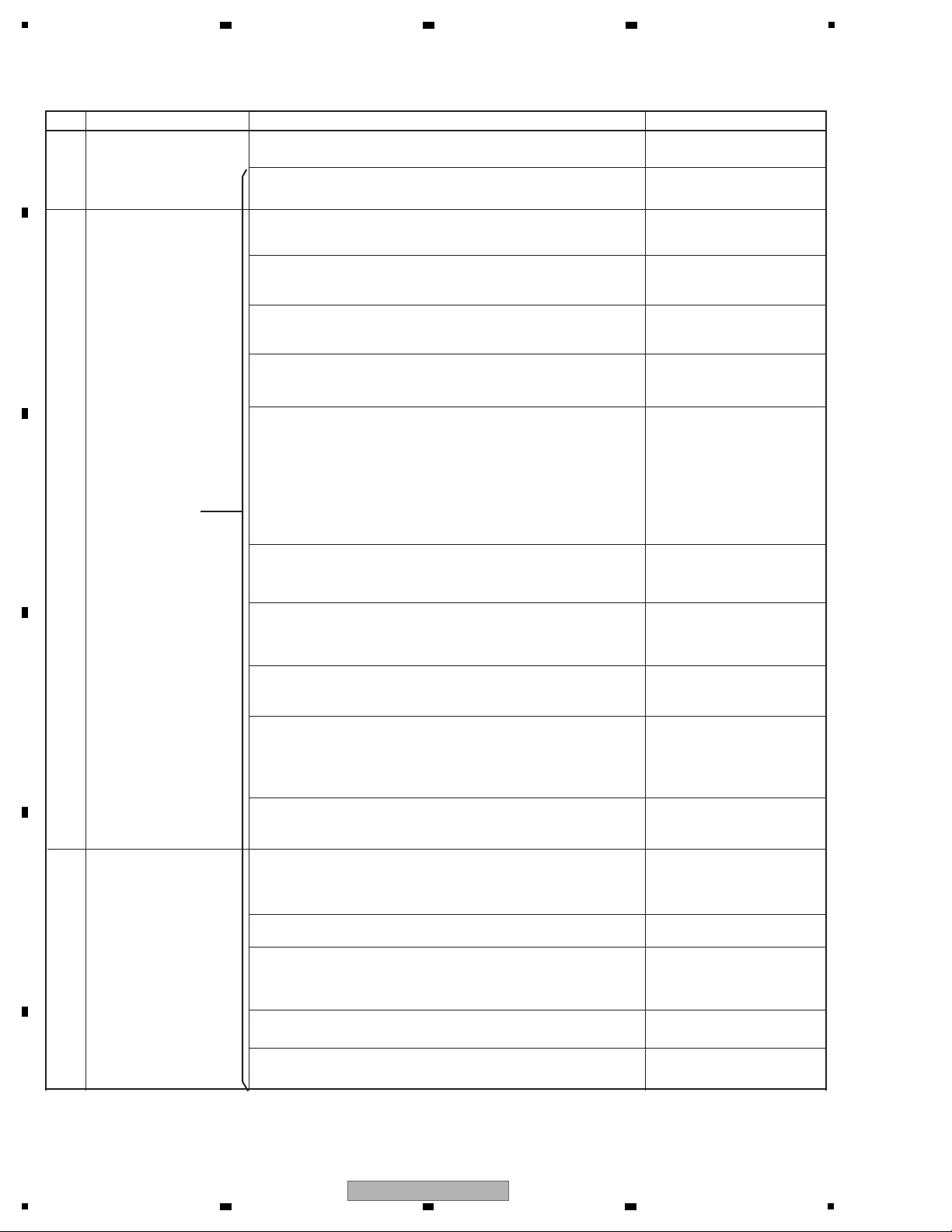

No. Symptoms Diagnosis Contents Possible Defective Points

1 The power is not turned on. Are wires of output connector (POWER SUPPLY Unit) and CN901

(DVDM Assy) disconnected or damaged ?

Connector / cable

Check that the following voltage is output :

+ side of C739 : 3.3V

DVDM Assy

3.3V Regulator IC (IC341)

2

An opening screen is not

displayed on the monitor

(The FL display lights. The

mechanism does not work.)

Are the signals output from IC201-pin 98 (MDATA) and pin 99 (SCLK)

on the DVDM Assy ? (in the range of 0-3V)

DVDM Assy

DVD IC (IC201)

Are the signals input into IC2101-pin 50 (MDATA) and pin 51 (SCLK) on

the LCD Assy ? (in the range of 0-3V)

LCD Assy

UCOM (IC2101)

Check that the following voltage are output :

IC751-pin 1 on the DVDM Assy : 5V

DVDM Assy

5V Regulator IC (IC751)

Is a resonator (X202: 27MHz) on the DVDM Assy oscillating ?

DVDM Assy

Crystal resonator (X202)

• Is a signal input into IC203-pin26 (PCE#) on the DVDM Assy ?

(Is a signal "H" for 80 mS and then "L" after the power is turned

on ?)

→ Communication with flash ROM.

• Are the signals input into IC202-pin 16 (DWE#), pin 19 (DCS#)

and pin 38 (SDCLK) on the DVDM Assy ?

(Is a signal fluctuating ?)

→ Communication with SDRAM

DVDM Assy

DVD IC (IC201)

Flash ROM (IC203)

SDRAM (IC202)

Is a signal output from IC203-pin 28 (PRD#) on the DVDM Assy?

(Is a signal fluctuating for several hundred mS after the power is turned

on ?)

DVDM Assy

Flash ROM (IC203)

Is a signal input into IC2101-pin 67 (DVD ACK) on the LCD Assy ?

(Is a signal fluctuating ?)

→ Communication with FL Control IC

DVDM Assy

DVD IC (IC201)

LCD Assy

UCOM (IC2101)

Is a signal output from IC2101-pin 30 (XREADY) on the LCD Assy ? (Is

a signal fluctuating in the range of 0-5V ?)

LCD Assy

UCOM (IC2101)

Are the signals output from IC2101-pin 49 (SDATA) on the LCD Assy ?

(in the range of 0-5V)

DVDM Assy

DVD IC (IC201)

LCD Assy

UCOM (IC2101)

Are the signals of IC204-pin 5(SDA) and pin 6(SCL) on the DVDM Assy

fluctuating for one or two seconds after the power is turned ?

DVDM Assy

EEPROM (IC204)

Addendum No.1

3

A tray cannot be opened.

(An opening screen is

displayed on the monitor)

LOAB Assy

Tray SW (S101)

Is the signal input into IC101-pin 11 (TROPEN) on the DVDM Assy ?

At open: 3.3V, At close: 0V

DVDM Assy

DVD IC (IC201)

Are the signals output from IC101-pin 1 and pin 2 (CN103-pin 1 and

pin 2) on the DVDM Assy ?

Pin 2: Approx. 6V during opening tray approx. 0V during closing tray.

Pin 1: Approx. 0V during opening tray approx. 6V during closing tray.

DVDM Assy

FTS Driver IC (IC101)

Are wires of CN104 and CN103 on the DVDM Assy disconnected or

damaged ?

Connector / cable

Does the voltage of CN102-pin 1 on the DVDM Assy change to 0V by

pressing the Inside switch.

Inside switch

Does the voltage of CN104-pin 3 and pin 5 on the DVDM Assy change

normally ?

Pin 3 (SW2(TRIN)): Tray is fully closed: "L"

Pin 5 (SW1(TROUT)): Tray is fully opened: "L"

A

2 3 4

B

C

D

E

F

20

1

PD-D9MK2-K

2 3 4

Page 21

5

No. Symptoms Diagnosis Contents Possible Defective Points

4

Playback impossible

(no focusing)

Are the signals output from IC101-pin 3 (FOCS_DRV) and pin 4

(FOCS_RTN) on the DVDM Assy ?

DVDM Assy

FTS Driver IC (IC101)

Does 650-nm LD emit light ?

Does a pickup lens move up / down ?

Does an actuator spring bend ?

Pickup

Are plastic parts damaged ? Or is a shaft detached ?

Is the turntable detached or tilted ?

Mechanism section (motor)

Is flexible cable of CN101 on the DVDM Assy disconnected or

damaged ?

Flexible cable / connector

Is signal output from IC201-pin 42 (FOSO) on the DVDM Assy ?

(Device control of about 1.4 V is output usually. It is fluctuated by about

250 mV with focus up / down.)

DVDM Assy

DVD IC (IC201)

5

Playback impossible

(Spindle does not turn)

Are the signals output from IC101-pin 30 (W), pin 33 (V) and pin 35 (U)

on the DVDM Assy ?

Is pin 26 (STBY) fixed LOW ? (pin 26 is High at playback: 3V)

DVDM Assy

FTS Driver IC (IC101)

Is there any part detached from the spindle motor ?

Or Is there any foreign object lodged in it ?

Mechanism section

(Spindle motor)

Are wires of CN102 on the DVDM Assy disconnected or damaged ? Flexible cable / connector

Is signal output from IC201-pin 37 (DMSO) on the DVDM Assy ?

DVDM Assy

DVD IC (IC201)

6

Playback impossible

(Playback stops)

Does 650-nm LD deteriorate ?

If the voltage at each both ends of R322 and R325 on the DVDM Assy

is 0.4 V or more, the 650-nm LD is definitely deteriorated.

650-nm LD deteriorated.

(When playback of a DVD is

impossible)

Does 780-nm LD deteriorate ?

If the voltage at each both ends of R321 and R326 on the DVDM Assy

is 0.4 V or more, the 780-nm LD is definitely deteriorated.

780-nm LD deteriorated.

(When playback of a CD is

impossible)

Is there abnormality in FG waveform ? (IC201-pin 47)

DVDM Assy

FG output : FTS Driver IC (IC101)

Are there scratches or dirt on the disc ? Disc

Addendum No.2

Addendum No.4

Addendum No.3

6 7 8

A

B

C

D

E

F

PD-D9MK2-K

5

6 7 8

21

Page 22

1

Set time for the current step Elapsed time Details on control

0 msec

POWER ON start, Various initial settings 1

All keys are masked.

XSYSMUTE ON

+ 60 msec 60 msec

Various initial settings 2

SYSPOW ON

When the power is turned on, the HELLO display is requested (3.5 sec).

+ 240 msec 300 msec

Various initial settings 3

RESET L ⇒ H

+ 60 msec 360 msec

Various initial settings 4

Control of the LCD driver starts.

Data transmission

Various initial settings 5

SRC reset

RESET L ⇒ H

+ 240 msec 600 msec

+ 120 msec 1890 msec

Various initial settings 9

Masking of all keys is canceled.

+ 390 msec 1770 msec

Various initial settings 8

+ 480 msec 1380 msec

Various initial settings 7

Bus communication starts.

+ 300 msec 900 msec

Various initial settings 6

DAC setting

+ 3120 msec 5010 msec

Various initial settings a

Temporary data transmission

+ 30 msec 5040 msec

POWER ON completed

Normal POWER-ON sequences

Normal POWER-OFF sequences

Set time for the current step Elapsed time Details on control

0 msec

POWER OFF start, Various settings 1

The mask flags for all keys are set.

+ 30 msec 30 msec

(Note 1)

Various settings 2

Whether the DVD is turned power-off or not is checked.

Bus communication is terminated.

+ 120 msec 150 msec

Various settings 3

+ 330 msec 480 msec

Various settings 4

+ 1320 msec 1800 msec

Various settings 4

All the indications on the LCD are deleted.

Various settings 5

Bus communication is terminated.

+ 90 msec 1890 msec

+ 240 msec 2130 msec Processing for the ports required when the power is turned off

+ 30 msec 2160 msec

POWER OFF completed

(passes every loop in the POWER OFF)

Note 1: In this step, the unit wait for the DVD module to turn the power off. If the DVD module takes a longer time to turn itself off,

the elapsed time will become longer, by just that much.

2 3 4

5.2 SEQUENCE AFTER POWER ON/OFF

A

B

C

D

E

F

22

1

PD-D9MK2-K

2 3 4

Page 23

5

Display only POWER-ON sequences

Display only POWER-OFF sequences

Set time for the current step Elapsed time Details on control

0 msec

Display only POWER ON start, Various initial settings 1

Masking of all keys is canceled.

The normal operation keys are masked.

POWER MUTE ON

SYSTEM POWER1 ON (Pin 91: H)

+ 60 msec 60 msec

Various initial settings 2

+ 240 msec 300 msec

Various initial settings 3

Switched 5 V ON completed (power supply is stabilized)

Masking of the normal operation keys is canceled.

SYSTEM POWER2 ON (Pin 92: H)

+ 60 msec 360 msec

Various initial settings 4

Power-on of the LCD driver starts.

+ 330 msec 690 msec

Display Only POWER ON completed

Set time for the current step Elapsed time Details on control

0 msec

Display only POWER OFF start, Various settings 1

• The mask flags for all the keys are set.

• The mask flags for the normal operation keys are set.

• Muting the power system (SYSTEM MUTE REQUEST)

• Power-off of the LCD driver starts.

+ 4120 msec 4120 msec

Various settings 2

+ 120 msec 4240 msec

Various settings 3

+ 760 msec 5000 msec

Various settings 4

• Masking of all keys is canceled.

• Muting of the power system is canceled.

• Other than in an emergency power-off, the unit awaits for a while.

• SYSTEM POWER2 OFF (Pin 92: H)

+ 240 msec 5240 msec

Display only POWER OFF completed

• SYSTEM POWER1 OFF (Pin 91: H)

6 7 8

A

B

C

D

E

5

PD-D9MK2-K

6 7 8

F

23

Page 24

1

POWER-ON timing waveform

300 600 900 1200 1500 1800 2100 2400 2700 4800 5100

SYSTEM

ok SYSPOW

(41pin )

ok XSYSMUTE

(38pin)

DVD control

DVD ON/OFF

XDVD RESET

ok SYSTEM BUS

(DVD)

SRC control

XSRCRST

(79pin)

DAC control

XDACCLK (65pin)

XDACDT (64pin)

XDACCS1 (63pin)

XDACCS2 (62pin)

LCD control

ok LCD setting

ok LCD reset

others

Subsequently, H or L is output, as appropriate.

(Port setting)

Other output port

PON4

600msec300msec 360msec

1 Standby → On

PON1

60msec

KEY input

0msec

PON2 PON3

PON5

900msec 1380msec 1770msec 1890msec 5010msec

PON6

PON9

5040msec

PON10

Mute cancel

PON7 PON8

A

2 3 4

B

C

D

E

F

24

1

2 3 4

PD-D9MK2-K

Page 25

5

SYSTEM

DVD control

LCD control

Others

POWER-OFF timing waveform

300 600 900 1200 1500 1800 2100 2400 2700 3000 3300 3600 3900 4200 4500 4800

SYSPOW

(41pin )

XSYSMUTE

(38pin)

DVD ON/OFF

(1pin/DVD ON/OFF)

XDVDRESET

(93pin/XDVDRST)

SYSTEM BUS(DVD)

(30,49,50,51,67pin)

LCD setting

(26,27,28pin)

LCD reset

(36pin/XLCDRST)

XDimmer

(70pin/DIMMER)

POFF4

2 On → Standby

POFF1

30msec

150msec 480msec 1800msec 1890msec 2130msec

POFFGO

0msec

POFF2 POFF3

POFF5 POFF6

6 7 8

A

B

C

D

E

5

PD-D9MK2-K

6 7 8

F

25

Page 26

1

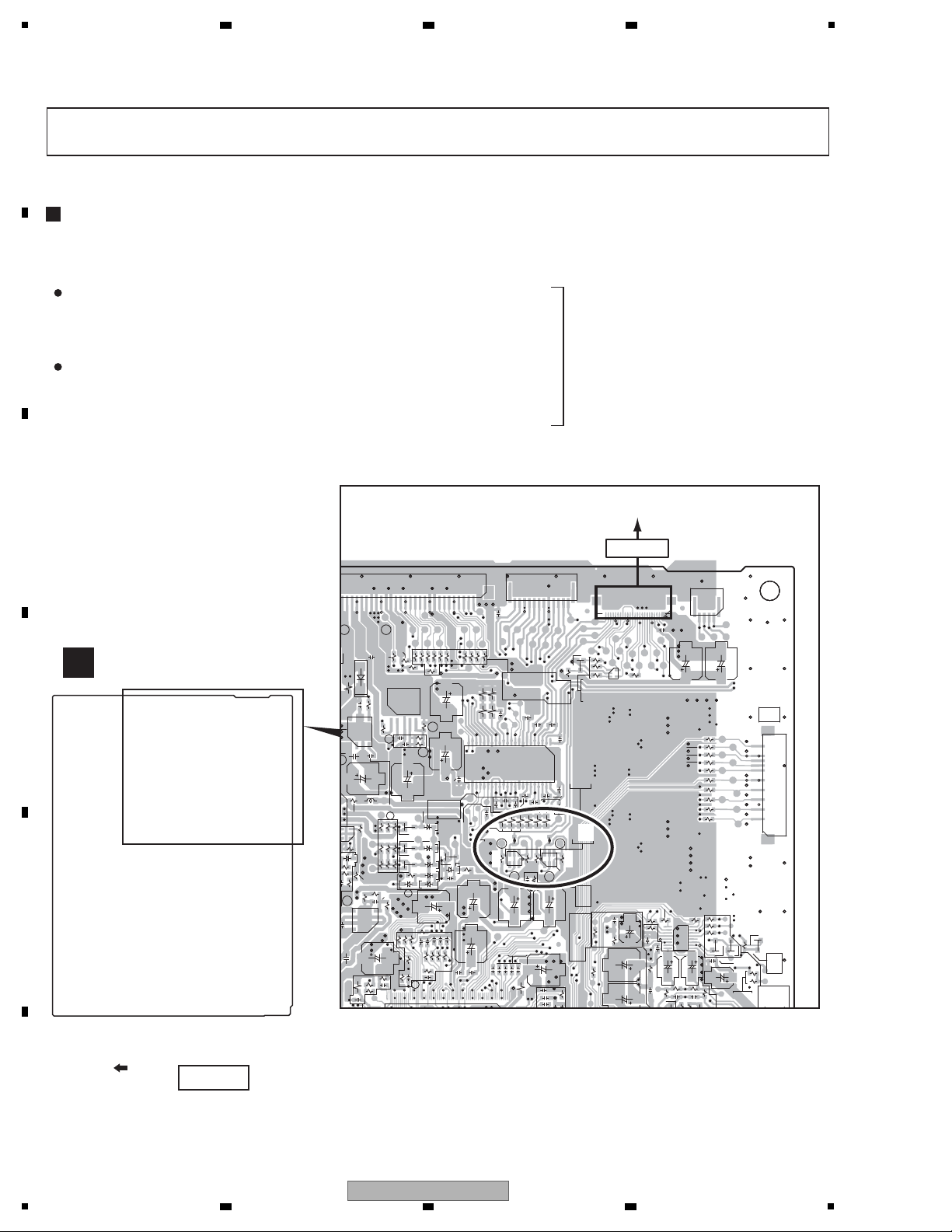

DVDM ASSY

B

SIDE A

Front side

D

Q

Q

0

9

2

V

5

R326

R325

R322

R321

Case when this diagnosis is required :

When playback of any disc, including a test disc (DVD: GGV1025, CD: STD-905), won't play or doesn't play

How to diagnose

In the case mentioned above, degradation of the laser diodes (LDs) mounted on the 05SD Pickup Assy is suspected.

Measure the voltage between the two ends of one of the resistors mentioned below.

If the measurements show degradation

of an LD, replace the 05SD Pickup Assy.

Measure the voltage between the both ends of R322 or R325 on the DVDM

Assy. If the voltage is 0.4 V or higher, the 650-nm LD is degraded.

No playback of a DVD (Test Mode), No playback of a SACD :

Measure the voltage between the both ends of R321 or R326 on the DVDM

Assy. If the voltage is 0.4 V or higher, the 780-nm LD is degraded.

No playback of a CD :

05SD PICKUP ASSY

CN101

2 3 4

5.3 METHOD FOR DIAGNOSING DEGRADATION OF THE LDS ON THE PICKUP ASSY

A

B

C

UP SIDE

GNDD

8V

R904

R901

Q702

C1002

D751

IC761

R751

C751

5

D

E

7

R761

E

1

4

5

L751

C752

R750

C

R736

13

R734

R737

R712

R713

C712

3.3V

5

4

R714

1

8

IC711

C221

C713

64

R2

6

CN901

R906

R762

GNDM

6.5V

C761

C132

C131

C145

C144

C146

D881

Q881

Q801

C206

A

C801

R214

C204

D

12

C140

1

R154

R152

R907

R905

R903

C104

C101

R153

R151

22

C161

C143

LD_CD

R134

R132

R131

R321

D801

C203

R801

3.3V

C215

C344

C346

C345

C347

C213

R207

1

R918

C310

C343

R910

25

R911

R919

L309

R912

C103

C151

CN102

R913

R914

1

IC101

R314

R915

C152

C153

C102

L308

BOTTOM SIDE

1

Q304

R136

R133

R135

C141

C142

C133

Q308

R325

R326

LD_DVD

R322

Q307

3.3V

C320

R310

C309

C505

C506

R594

R502

R595

C202

R5

R315

R318

R313

24

31

C503

C502

54

Q305

CN101

R373

BOTTOM SIDE

C371

R504

UP SIDE

CN103

41

1

C374

C373

LF

CN953

C509

17

C508

R601

R602

BOTTOM SIDE

1

R520

Q506

R507

R508

R509

R940

R939

R938

R937

R936

R935

R934

R933

R932

R931

R505

IC501

R506

1

9

F

26

1

PD-D9MK2-K

2 3 4

Page 27

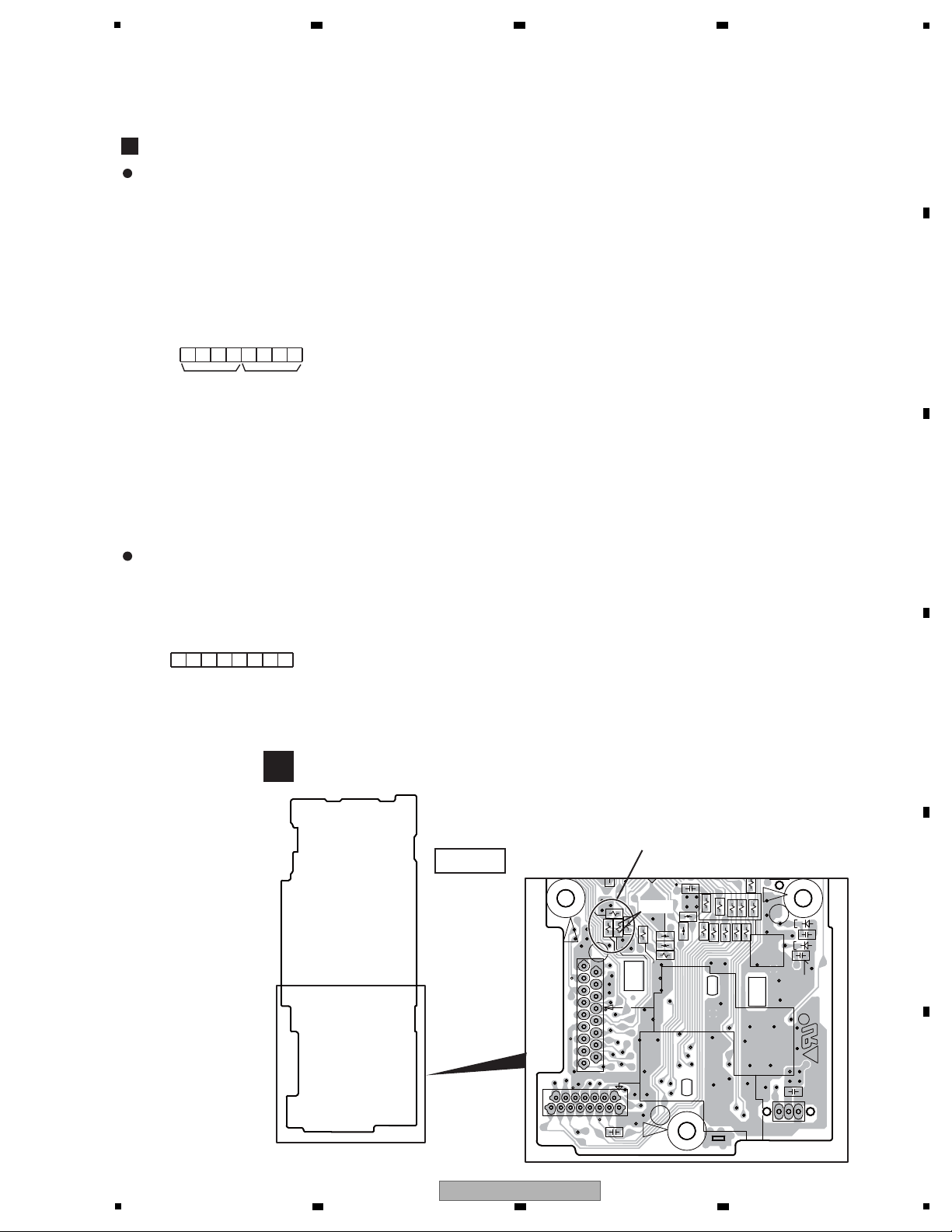

5

2

60

The Version Display Mode Functional Specification

Mechanical control computer

How to display the version of the mechanical control computer

1

Power-on in DVD mode

With the AC power off, turn the AC power on by pulling up Pin 44 of IC2101 with 5 V (by short-circuiting R2109).

Note: When the unit is turned on in DVD mode, "-DVD-" is indicated on the LCD.

2 Displaying the version of the mechanical control computer

Press the [ESC] then the [CHAP] key on the remote control unit for DVD Test mode (GGF1381) to indicate the version of

the mechanical control computer.

Ex. (1) : This means that the part number is " AYW7153 ".

(2) : This means that the version is " 1.06 ".

3 Canceling version display

• Press the [ESC] key on the remote control unit.

• Press the [POWER] button to turn the unit off.

Note: Even if you intend to continuously use the unit after displaying the error rate, be sure to turn the power off then back

on again.

System control computer

Displaying the version of the system control computer

1

Displaying the version of the system control computer

With the unit on, press and hold the [/] key on the main unit for 8 seconds. The version (part number) of the system

control computer will be displayed.

Ex.

2 Canceling version display

The version display will automatically disappear after a while.

PDC1 48 A

71 5 3 1 - 0 6

(1) (2)

LCD ASSY

D

SIDE B

R2109

Short

6 7 8

6. SERVICE MODE

6.1 TEST MODE

A

B

C

51

L2102

R2146

17.GNDD

16.SROUT

15.SRIN

14.SRIN

13.XDFDT

12.GNDD

11.XDFCLK

10.XDFCS

9.XDFRST

8.XSYSMUTE

13.TRIN

12.VDET

14.TRGAIN

A

L2105

L2104

R2102

R2156

7.ACK

8.MDATA

9.10.GNDD

11.SPDIF_RQ

6.SCLK

5.SDATA

R2145

4.XDVDRST

3.XREADY

R21

R2112

R2151

R2150

6.XSRRST

5.LEGATO

4.XDACCK

3.XDACDT

2.XDACCS1

1.XDACCS2

C2107

1.GNDD

2.DVDPOWER

50

50

R2142

TEST MODE

1

51

L2103

R2143

DVD MODE

15.TROUT

C2112

R2147

R2109

R2119

B

17

1

15

C2211

R2152

R2144

R2149

7.GNDD

E

R2176

1

D2204

C2205

D2203

C2204

3

R

1.KEY1

C

2.V+5U

3.GNDD

D

E

F

PD-D9MK2-K

5

6 7 8

27

Page 28

1

1

Remove the Top Panel by removing the twelve screws.

2

Remove the Side Panel L and R by removing the ten screws.

3

Press the STANDBY/ON button to turn on the power.

4

Press the OPEN/CLOSE button to open the Tray.

5

Remove the Tray Panel.

6

Set the Test Disc.

7

Press the OPEN/CLOSE button to close the Tray.

(Test Disc is clamped.)

8

Press the STANDBY/ON button to turn off the power.

9

Pull out the Power cord.

Top Panel, Side Panel L and R, Tray Panel

1

4

7

6

5

Tray Panel

Screwdriver (small)

Screwdriver (small)

LOADER ASSY

Tray open

Slit

Test Disc

Tr ay

How to open the Tray when the power cannot be on

Insert a Screwdriver (small) into the Slit located at the bottom of

the unit, and slide the projection of the Drive Cam in the LOADER

ASSY in the direction of the arrow, as indicated in the photo. If the

Tray pops out a little, fully pull it out by hand.

Diagnosis of PCB's

Note 1: Do NOT look directly into the pickup lens. The laser beam may cause eye injury.

Note 2: Even if the unit shown in the photos and illustrations in this manual may differ from your product, the procedures

described here are common.

Note 3: For performing the diagnosis the DVDM ASSY side B, the following jigs for service is required:

• Cable for service (GGD1425)

83

Drive cam

Projection

Bottom view

1111

74

Top Panel

Side Panel L

Side Panel R

1

×8

2

×6

2

×2

2

×2

2 3 4

7. DISASSEMBLY

A

B

C

D

E

F

28

1

PD-D9MK2-K

2 3 4

Page 29

8

Grounding wire

LOADER ASSY

LOADER ASSY

Chassis

11

Grounding wire

Mecha Cover 989

2

×3

1

7

×2

7

×2

5

×4

Mecha Angle

DVDM ASSY

2

1

Remove the screw which secure Grounding wire in place.

6

Remove the Mecha Angle.

9

Extend the Grounding wire which were removed in

procedures 1 and connect them to Chassis for grounding.

11

Raise the LOADER ASSY.

10

Connect a extension jig cable between DVDM ASSY (CN953)

and AJKB ASSY (CN1402).

Remove the three screws.

2

Remove the Mecha Cover 989.

3

4

Disconnect the one flexible cable.

Remove the four screws.

5

8

Slightly lift the LOADER ASSY and displace it slightly

backward.

Remove the four screws.

7

Diagnosis

Note: Service cable 5P (GGD1425) is required when

diagnosing the DVDM ASSY side B.

3

4

17P FFC

extension jig cable

(GGF1157)

10

CN953

CN1402

5

6 7 8

A

B

C

D

E

PD-D9MK2-K

5

6 7 8

F

29

Page 30

1

Removing the Traverse Mechanism Assy-S and 05SD Pickup Assy-S

1

LOADER Assy

1

Short-circuit point by soldering.

2

Disconnect the three flexible cables.

Note: After replacement, connect the flexible

cable for pickup, then remove the

soldered joint (open).

1

222

Rear view

Bottom view

DVDM Assy

LOADER Assy

05SD Pickup Assy-S

1

Remove the one screw.

2

Remove the bridge 04.

3

Pull out the tray, then remove it by pressing the

hook.

1

2

3

Bridge 04

Front side

Hook

Tr ay

Loading base Triangle

PinDrive cam

-2

3

-2

Note when reinserting the tray

When reinserting the tray, first align the triangle

printed on the loading base and the pin of the drive

cam, then insert the tray.

Bridge 04, Tray

2

1

A

2 3 4

B

C

D

E

F

30

1

PD-D9MK2-K

2 3 4

Page 31

1

Traverse Mechanism Assy-S

3

Dislodge the two flexible cables from their factory

placement.

2

Unhook the four hooks.

3

Remove the Traverse Mechanism Assy-S

× 2

2

× 2

2

3

Traverse Mechanism Assy-S

1

1

Front Side

Flexible cable

for the spindle motor

Flexible cable for the pickup

Bottom view

5

6 7 8

A

B

C

D

E

F

PD-D9MK2-K

5

6 7 8

31

Page 32

1

3

2

2

Adjustment screw

(skew screw VK1)

Adjustment screw

(skew screw VK1)

Adjustment screw

(skew screw VK1)

Adjustment spring

(skew spring VK1)

05SD Pickup Assy-S

4

Note: The 05SD Pickup Assy can be removed

without removing the Traverse Mechanism

Assy-S.(shown as Step .)

Note: Be careful not to lose the adjustment spring

(skew spring VK1).

Flexible cable for the pickup

05SD Pickup Assy-S

1

Front Side

1

Disconnect the flexible cable for the pickup.

2

Remove the two adjustment screws.

3

Remove the 05SD Pickup Assy.

Bottom view

05SD Pickup Assy-S

3

A

2 3 4

B

C

D

E

F

32

1

PD-D9MK2-K

2 3 4

Page 33

5

Note: The screw is secured with the silicone

adhesive.

Make sure to apply the silicone adhesive after

reattaching the screw.

4

Remove the one screw.

4

Silicone Adhesive

GEM1037

05SD Pickup Assy

Joint VK1B

Joint spring VK1

: Conductive surface

Arrangement of the flexible cable for the spindle motor

Front Side

Hook

Hook

Bottom view

6 7 8

A

B

C

D

E

F

PD-D9MK2-K

5

6 7 8

33

Page 34

1

Front Side

Note:

Be sure to move the 05SD Pickup Assy to the innermost perimeter.

: Conductive surface

Arrangement of the flexible cable for the pickup

2

3

7

2

Attach the flexible cable for the pickup to the connector.

6

Fold the flexible cable along the hook.

7

Pass the flexible cable through the hook.

3

Pass the flexible cable through the hook.

Bottom View

Make sure that the cable is loose

Backing

Backing

Reference line

Hook

Hook

4

5

5

Pass the flexible cable through the hook.

4

Hook the part folded in Step 1 to the hook.

Hook

Reference line

6

Hook

1

Fold the flexible cable for the pickup with the backing outward

in the illustration below.

76 mm

1

Hook

Hook

A

2 3 4

B

C

D

E

F

34

1

2 3 4

PD-D9MK2-K

Page 35

5

How to adjust the Front Panel (when replacing the Front Panel L)

Front Panel L Front Panel R

Adjust this gap to zero (0).

Set the top and bottom edges of the Front Panel L even with R and tighten the screws.

Screw for securing the Front Panel L

(Tighten the screw while adjusting the gap.)

OK NG

Rear face of the Panel ASSY

6 7 8

A

B

C

D

5

PD-D9MK2-K

6 7 8

E

F

35

Page 36

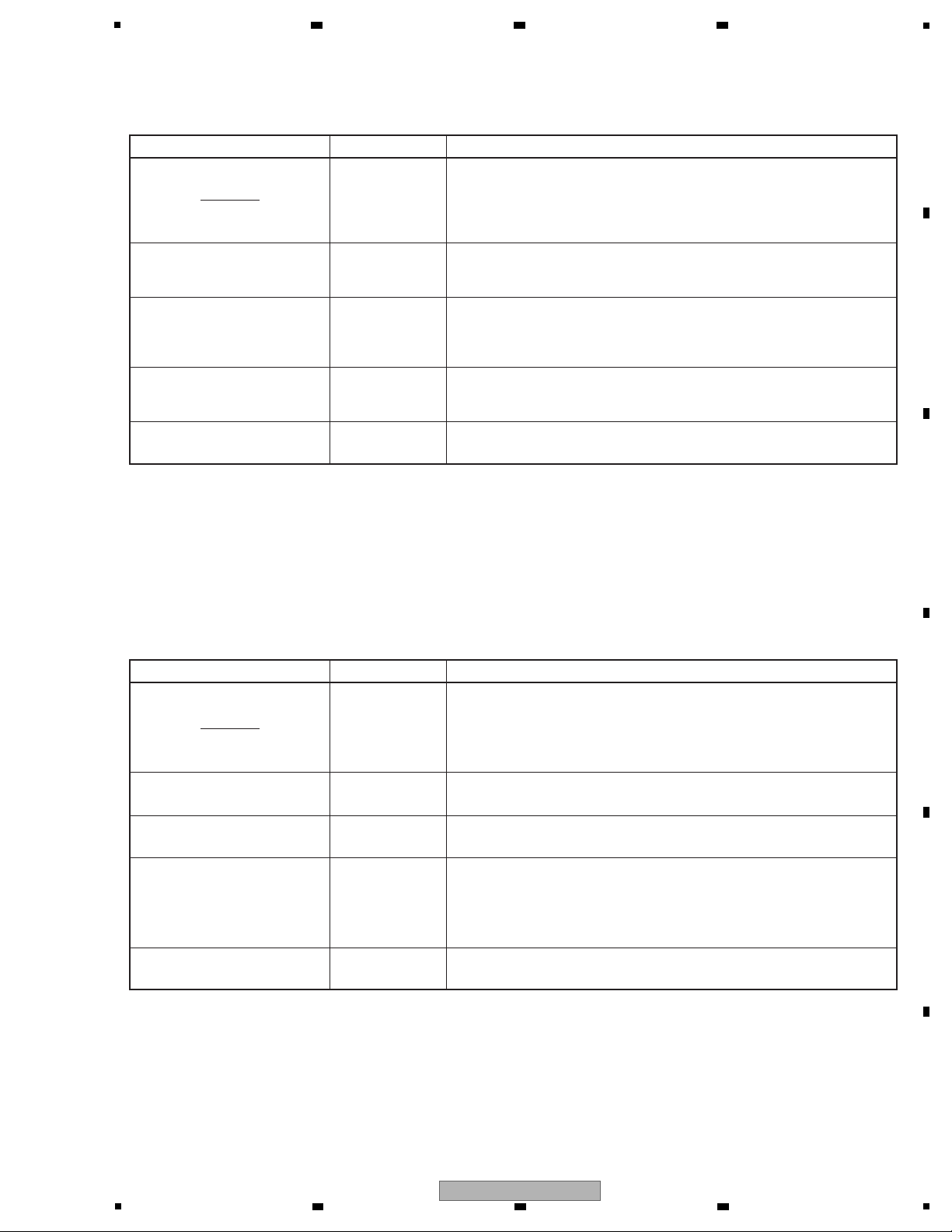

1

1

2

Adjustment Items

[Mechanism Part]

[Electrical Part]

Tangential and Radial Height Coarse Adjustment

DVD (CD) Error Rate Adjustment

Electrical adjustments are not required.

Adjustment Points (Mechanism Part)

Cautions: After adjustment, adjustment screw locks with the

Screw tight.

1 2

Radial

adjustment

screw

1 2

Tangential

adjustment

screw

Screwdriver (large)

Precise screwdriver

DVD test disc

(GGV1025)

Test mode remote control

unit (GGF1381)

Screw tight

(GYL1001)

Screwdriver (medium)

Soldering iron

2 3 4

8. EACH SETTING AND ADJUSTMENT

8.1 ADJUSTMENT ITEMS AND LOCATION

A

B

C

D

8.2 JIGS AND MEASURING INSTRUMENTS

E

F

36

1

2 3 4

PD-D9MK2-K

Page 37

5

∗ After adjustment, screw locks

with the Screw tight.

1, 2

Mechanical

point

Electric

point

Mechanical

point

Electric

point

Mechanical

point

Electric

point

LOAB and DVDM ASSYS

Exchange Parts of Mechanism

Exchange PCB Assy

When Adjustment Points

Exchange the 05SD Pickup Assy

Exchange the Traverse Mechanism

Assy-S

Exchange PC Board

∗ After adjustment, screw locks

with the Screw tight.

2

Mechanical

point

Electric

point

Exchange the Spindle Motor

8.3 NECESSARY ADJUSTMENT POINTS

6 7 8

A

B

C

D

E

F

PD-D9MK2-K

5

6 7 8

37

Page 38

1

POWER ON

GGF1381

Test mode

remote control

unit

GGF1381

Test mode

remote control

unit

<TRAY OPEN> <TRAY CLOSE>

OPEN/CLOSE

(Player)

OPEN/CLOSE

Press the play key

( ) of the normal

remote control unit.

(Player)

TEST MODE: PLAY

TEST MODE: OFF

An error rate is displayed

ESC

<PLAY>

ESC

5

DISC SET

Notes:

• The audio signal are outputted during the test mode.

• The SKIP key and the SCAN key are effective during the test mode.

Note:

Even if you intend to continuously

use the unit after displaying the error

rate, be sure to turn the power off then

back on

How to display the error rate

Power-on in DVD mode

With the AC power off, turn the AC power on by pulling up

Pin 44 of IC2101 with 5 V (by short-circuiting R2109).

(See next page. )

Note: When the unit is turned on in DVD mode, "-DVD-" is

indicated on the LCD.

POWER

ON

DVD disc

POWER

OFF

990E - 6

The error rate is displayed as above.

But this means " 9.90E - 6 ".

8.4 TEST MODE

A

2 3 4

B

C

D

E

F

38

PD-D9MK2-K

1

2 3 4

Page 39

5

2

60

Short

Service Test mode connecting point

LCD ASSY

D

SIDE B

R2109

6 7 8

A

B

D2204

C2205

D2203

C2204

3

R

1.KEY1

C

2.V+5U

3.GNDD

C

D

L2104

L2102

R2146

17.GNDD

15.SRIN

14.SRIN

13.XDFDT

12.GNDD

11.XDFCLK

10.XDFCS

9.XDFRST

12.VDET

L2105

R2102

R2156

R2145

7.ACK

8.MDATA

9.10.GNDD

11.SPDIF_RQ

6.SCLK

5.SDATA

4.XDVDRST

3.XREADY

R21

R2112

R2152

R2144

R2151

R2150

7.GNDD

6.XSRRST

5.LEGATO

4.XDACCK

3.XDACDT

2.XDACCS1

1.XDACCS2

C2107

1.GNDD

2.DVDPOWER

R2176

R2149

1

E

C2112

R2109

R2119

B

C2211

50

50

R2142

TEST MODE

1

51

51

L2103

16.SROUT

R2143

DVD MODE

8.XSYSMUTE

13.TRIN

15.TROUT

14.TRGAIN

A

15

R2147

17

1

E

F

PD-D9MK2-K

5

6 7 8

39

Page 40

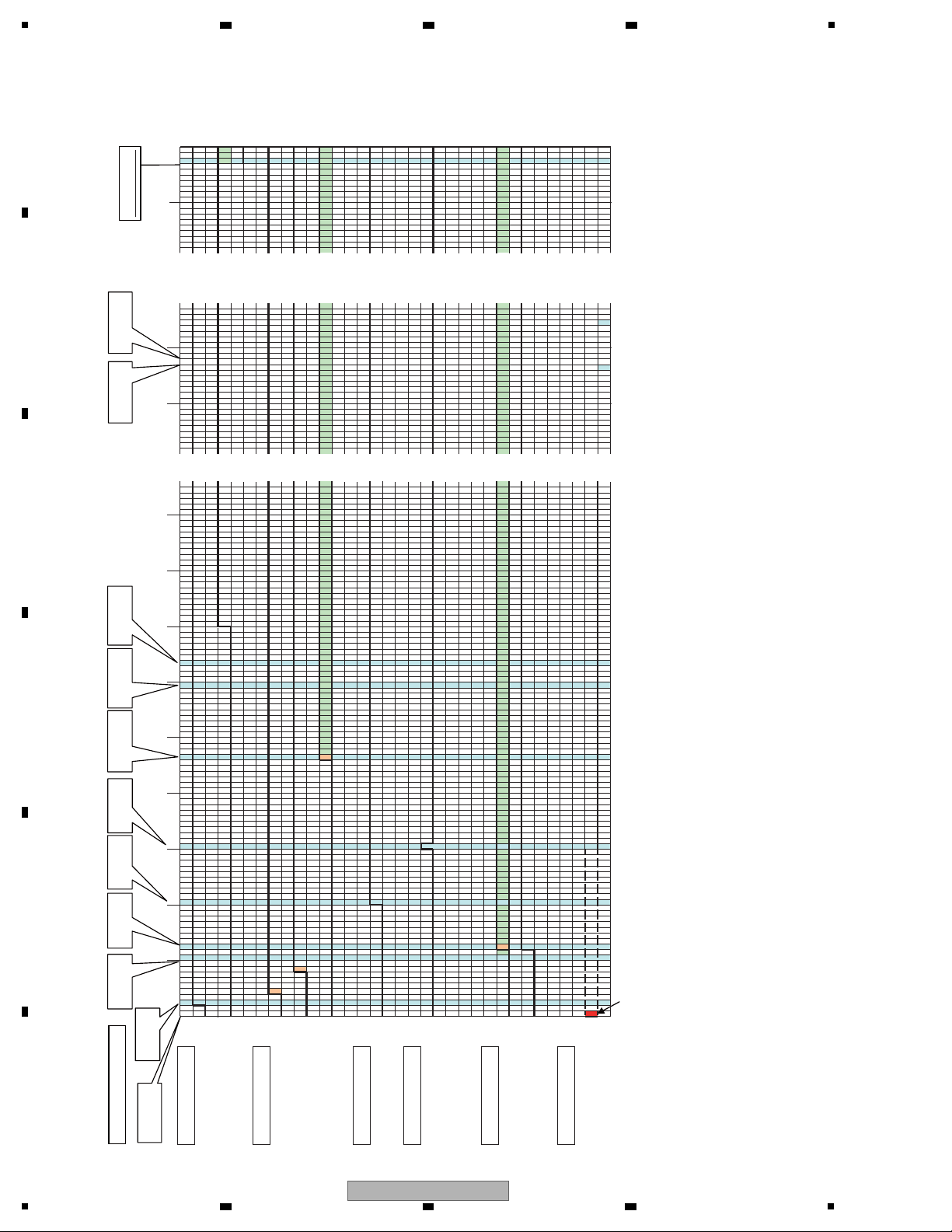

1

• Remove the 05SD Pickup Assy from the Traverse Mechanism Assy-S.

• Remove the joint and the joint spring of the 05SD Pickup Assy.

• Put the joint between the Tangential (or Radial) adjustment screw and the mechanism base

and turn each screw to adjust the height.

(Refer to "8.1 ADJUSTMENT ITEMS AND LOCATION".)

START

Tangential and Radial Height Coarse Adjustment

1

Note:

Before removing the flexible cable for the

pickup, soldering of the pickup circuit is

necessary.

For details, see "7. DISASSEMBLY".

• Pass through the guide shaft to a new 05SD Pickup Assy.

• Attach it to the Traverse Mechanism Assy-S.

• Attach the Traverse Mechanism Assy-S to the 05 LOADER Assy.

• Turn it over and attach the joint and the joint spring.

• Arrange the flexible cables.

(Refer to "7. DISASSEMBLY".)

7.5mm

Joint

Mechanism base

05SD Pickup Assy

05SD Pickup Assy

Joint

Joint Spring

Guide Shaft

2 3 4

8.5 MECHANISM ADJUSTMENT

A

B

C

D

E

F

40

1

2 3 4

PD-D9MK2-K

Page 41

5

Player

• Play the DVD test disc

at inner track

(around #30000) (Play title1)

*

At stop mode, press 1 , then ENTER

key of the set remote control.

Traverse Mechanism

Assy-S

Adjust the radial adjustment

screw so that

ERROR RATE becomes

around "5E-4".

Traverse Mechanism

Assy-S

Fasten the radial

adjustment screw so that

ERROR RATE becomes

around "1E-3".

START

DVD Error Rate Adjustment

2

Service mode end

Disc playback normally.

• The measurement of

block error rate

If error rate is OK,

locks a root of

tangential and radial

adjustment screws with

the Screw tight.

Screw tight: GYL1001

Tu rn the POWER OFF in

case of NG once, and

perform the adjustment

once again.

5

ESC

ESC

Service mode

Service mode end

ESC

NG

OK

• Play the DVD test disc

at inner track

• Display ERROR RATE

on the LCD display

5

ESC

Notes:

• Use disc: GGV1025

• Unfasten the radial adjustment screw

by 90 degrees step till ERROR RATE

becomes around "1E-3" again .

• Record the number of rotation (N1).

(memorizing how much the screw was rotated.)

• Fasten the radial adjustment screw

till the number of rotation becomes

harf of N1.

Traverse Mechanism

Assy-S

Fasten the tangential

adjustment screw so that

ERROR RATE becomes

around "1E-3".

• Unfasten the tangential screw

by 90 degrees step till ERROR RATE

becomes around "1E-3" again .

• Record the number of rotation (N1).

• Fasten the tangential adjustment screw

till the number of rotation becomes

harf of N1.

In this check, the error rate

that is less than "5E-5"is

better.

CHECK

5ESC

A

B

B

C

Best Radial point

C

Best tangential point

1E-3

5E-4

Rotation of Radial screw

and Tangential screw

Anticlock wise Clock wise

Best point

AA

BC

ERROR

RATE

990E - 6

The error rate is displayed as above.

But this means " 9.90E - 6 ".

• Play the DVD test disc at outer track

(around #200000) (Play title 22)

*

At stop mode, press 2 , 2 , then

ENTER

key of the set remote control.

6 7 8

A

B

C

D

E

F

PD-D9MK2-K

5

6 7 8

41

Page 42

1

NOTES: - Parts marked by “NSP” are generally unavailable because they are not in our Master Spare Parts List.

-

The > mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

-

Screws adjacent to b mark on product are used for disassembly.

-

For the applying amount of lubricants or glue, follow the instructions in this manual.

(In the case of no amount instructions, apply as you think it appropriate.)

CUXJ type Only

No.9:

CUXJ type Only

SYXJ5 type Only

SYXJ5 type Only

CUXJ type Only

CUXJ type Only

2 3 4

9. EXPLODED VIEWS AND PARTS LIST

A

9.1 PACKING SECTION

B

C

D

E

F

42

1

2 3 4

PD-D9MK2-K

Page 43

5

6 7 8

(1) PACKING SECTION PARTS LIST

Mark No. Description Part No.

NSP 1 Energy Star Label See Contrast table (2)

2Label (WEEE) See Contrast table (2)

> 3Power Cable See Contrast table (2)

> 4Power Cable See Contrast table (2)

5 • • • • •

6 Packing Sheet RHC1023

NSP 7 Polyethylene Bag AHG7117

NSP 8 Label VRW1629

9 Protection Sheet See Contrast table (2)

NSP 10 AAA/IEC R03 dry cell batteries VEM1049

Mark

No. Description Part No.

15 • • • • •

16 PAD L PHA1355

17 PAD R PHA1356

NSP 18 Spacer PHC1097

19 Packing Case See Contrast table (2)

20 Remote Control PWW1177

21 Battery Cover PZN1108

22 RCA Audio Cable XDE3047

(red/white plugs)

23 SR control cable XDE3063

A

NSP 11 Warranty Card See Contrast table (2)

NSP 12 Warranty Card See Contrast table (2)

13 Operating Instructions See Contrast table (2)

14 Operating Instructions See Contrast table (2)

(2) CONTRAST TABLE

PD-D9MK2-K/SYXJ5 and PD-D9MK2-K/CUXJ are constructed the same except for the following :

Mark No. Symbol and Description

PD-D9MK2-K/

SYXJ5

NSP 1 Energy Star Label Not used AAX8022

2Label (WEEE) ARW7322 Not used

> 3AC Power Cord ADG7062 Not used

> 4AC Power Cord Not used ADG7061

9 Protection Sheet Not used PHF1002

NSP 11 Warranty Card Not used PRY1007

NSP 12 Warranty Card ARY7128 ARY7007

13 Operating Instructions (En, Frca) Not used PRD1077

14 Operating Instructions PRE1300 Not used

(En, Fr, De, It, Nl, Es, Ru)

19 Packing Case PHG2467 PHG2469

PD-D9MK2-K/

CUXJ

B

C

D

E

F

PD-D9MK2-K

5

6 7 8

43

Page 44

1

CONTACT SIDE

NON-CONTACT

SIDE

Refer to

"9.3 CHASSIS SECTION".

Refer to

"9.4 FRONT PANEL SECTION".

A

A

C

C

B

B

PRIMARY

CN11

AJKB

CN1401

MNSW

CN2501

CONNECTOR

CN2703

Tape

19 X 40

Tape

19 X 50

Tape

19 X 50

9.2 EXTERIOR SECTION

A

B

C

2 3 4

D

E

F

44

1

2 3 4

PD-D9MK2-K

Page 45

5

(1) EXTERIOR SECTION PARTS LIST

Mark No. Description Part No.

1Cusion AEC7224

2Insulater ANL7028

3 Top Panel PAN1414

4 Side Panel L PAN1415

5 Side Panel R PAN1416

6 7 8

Mark

No. Description Part No.

21 Caution Label PRW1608

NSP 22 Label VRW1629

23 • • • • •

24 Screw ABA1192

25 Screw ABA1193

A

6 SR Sheet L PEB1319

7 • • • • •

8 Spacer SR PEC1052

9 Beam Sheet VEC2503

10 Bottom Spacer R PEB1335

11 Spacer FT PEC1051

12 Spacer ST PEB1341

13 AC Inlet Assy PKP1021

14 Rear Panel See Contrast table (2)

NSP 15 Bottom Plate T PNB1672

NSP 16 Bottom Plate B PNB1673

NSP 17 Bottom Cover PNB1674

26 Screw ABA7002

27 Screw ABA7017

28 Screw 4X19 ABA4120

29 Deco. Screw 4X10 ABA7136

30 Screw BBT30P080FCC

31 Screw BBT30P100FCC

32 Screw BBZ30P080FCC

33 Screw BBZ30P200FCC

34 Screw CBZ30P080FCC

35 Screw IBZ30P060FCC

36 Screw BBZ30P100FCC

18 • • • • •

19 Beam L PNS1064

20 Beam S PNS1065

(2) CONTRAST TABLE

PD-D9MK2-K/SYXJ5 and PD-D9MK2-K/CUXJ are constructed the same except for the following :

Mark No. Symbol and Description

PD-D9MK2-K/

SYXJ5

14 Rear Panel PNA2644 PNA2646

PD-D9MK2-K/

CUXJ

B

C

D

E

F

PD-D9MK2-K

5

6 7 8

45

Page 46

1

CONTACT SIDE

NON-CONTACT

SIDE

CUXJ type ONLY

Refer to

"9.5 LOADER ASSY

SECTION".

F

H

H

D

D

I

J

J

K

L

M

K

L

M

N

O

O

P

I

F

A a

A a

B a

B a

B b

B b

C a

E a

G a

G a

G b

G b

G c

G c

G d

G d

E a

E b

E b

C a

C b

C b

A b

A b

N

P

LCD

J2102

LCD

J2101

LCD

CN2106

Tape

19 X 60

Tape

19 X 20

Tape

19 X 20

Tape

19 X 20

Tape

19 X 20

Tape

19 X 50

Tape

19 X 40

F

C

H

B

I

E

J

LCD

CN2105

LCD

CN2105

Tape

19 X 40

CUXJ type ONLY

9.3 CHASSIS SECTION

A

B

2 3 4

C

D

E

1

F

46

2 3 4

PD-D9MK2-K

Page 47

5

6 7 8

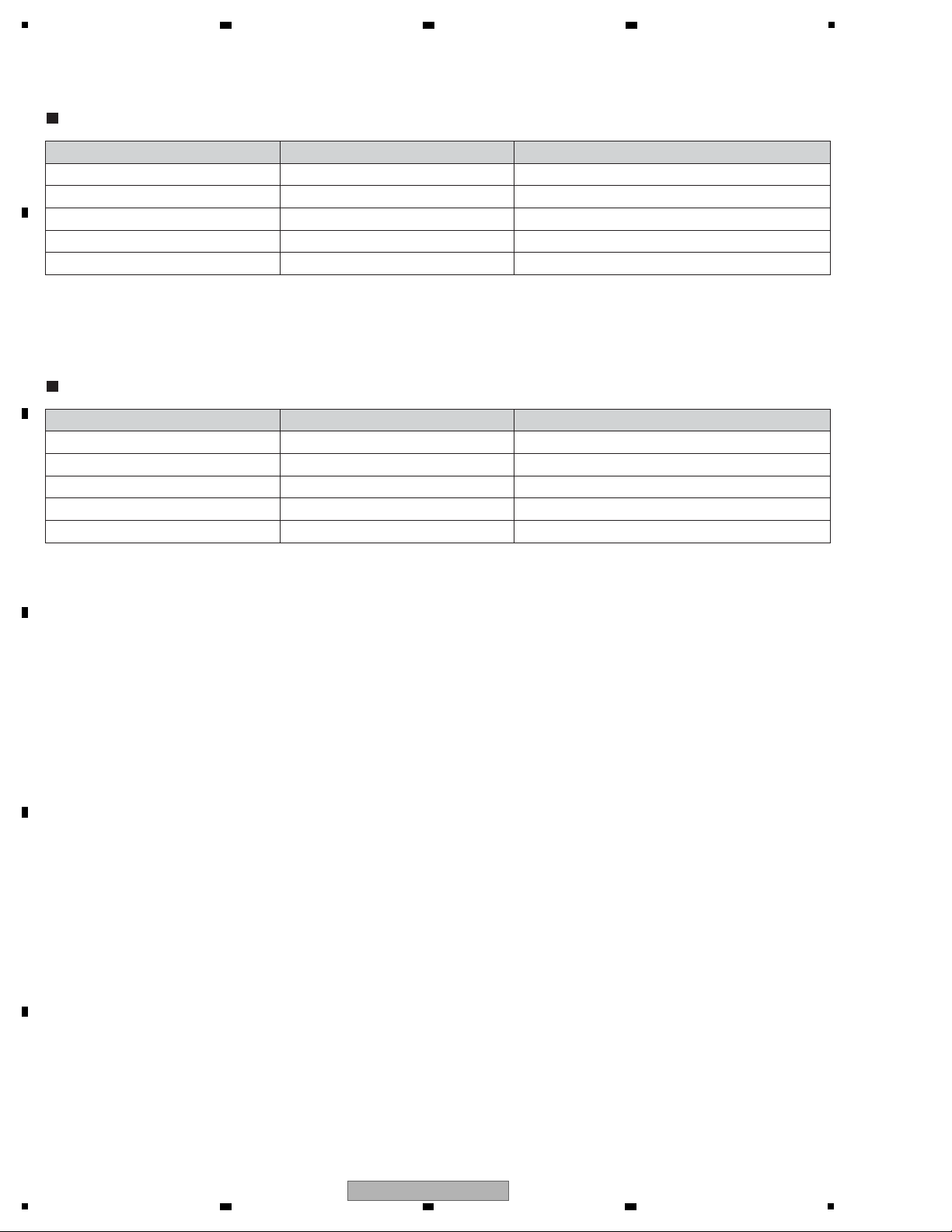

(1) CHASSIS SECTION PARTS LIST

Mark No. Description Part No.

1 DVDM Assy AWM8184

2MNSW Assy PWX1654

3 PLED Assy PWX1677

4 REGULATOR Assy See Contrast table (2)

5 PRIMARY Assy See Contrast table (2)

Mark

No. Description Part No.

31 PCB Angle L PNB1670

32 Mecha Angle PNB1671

33 Side Angle L PNB1677

34 Side Angle R PNB1678

35 PCB Holder PNW2029

A

6 AJKB Assy PW X1685