Page 1

ORDER NO.

RRV2363

MINIDISC RECORDER

MJ-NS1

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Type

ZPWXJ DC power supplied from other system component

¶ This product is a system(s) component.

This product does not function properly independently ; to avoid malfunctions, be

sure to connect it to the prescribed system component(s), otherwise damage may

result.

¶ Please connect it to the STEREO CD TUNER XC-NS1 and STEREO POWER AMPLI-

FIER M-NS1 for adjustment and operation inspection.

Model

MJ-NS1

Power Requirement Remarks

Component Model Service manual Remarks

STEREO CD TUNER XC-NS1 RRV2348 (RRV2341)

STEREO POWER AMPLIFIER M-NS1 RRV2349 (RRV2321)

SPEAKER SYSTEM S-NS1-LRW RRV2371 Except YPWXJ type

MINIDISC RECORDER MJ-NS1 RRV2363 This manual.

CONTENTS

1. SAFETY INFORMATION

2. EXPLODED VIEWS AND PARTS LIST

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

4. PCB CONNECTION DIAGRAM

5. PCB PARTS LIST

6. ADJUSTMENT

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS SERVICE, INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

c

PIONEER CORPORATION 2000

....................................................

.........................................................

...........................................

.....................

.....

...............................

7. GENERAL INFORMATION

2

7.1 DIAGNOSIS

3

8

21

26

29

7.1.1 SINGLE OPERATION METHOD

7.1.2 POWER ON SEQUENCE

7.1.3 DISASSEMBLY

7.2 IC

8. PANEL FACILITIES AND SPECIFICATIONS

...................................................................

...................................................

T – ZZV AUG. 2000 Printed in Japan

..................................

............

.......................

.......................................

......

37

37

37

38

40

43

46

Page 2

MJ-NS1

1. SAFETY INFORMATION

This service manual is intended for qualified service technicians; it is not meant for the casual

do-it-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

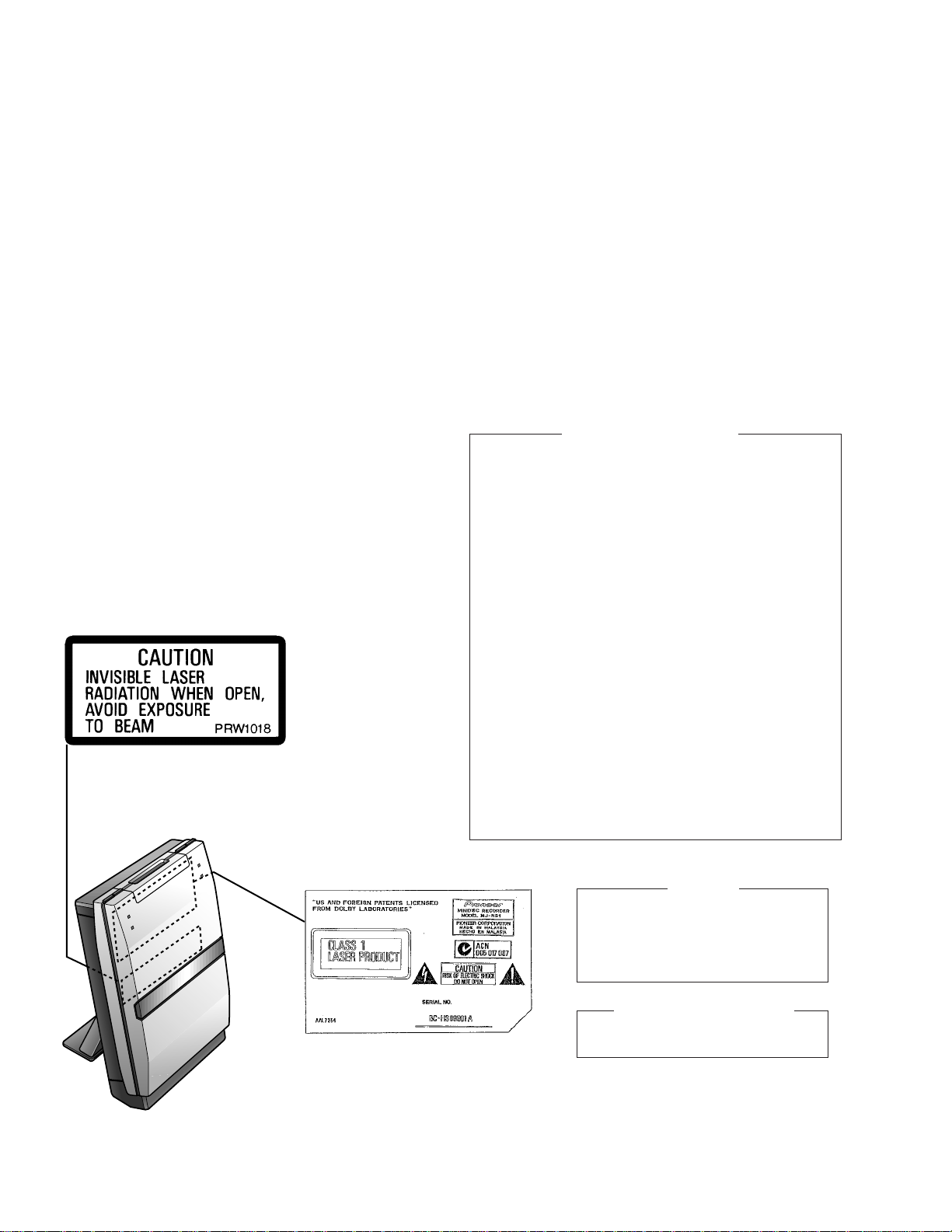

Additional Laser Caution

Control method of the current through a laser diode.

The resistor R105 on the CORE MAIN UNIT ASSY (For MD

mechanism assy) are for the limiting of current through a laser

diode.

LABEL CHECK

Control method of the laser output power

The laser pickup assy provide the photo-diodes and APC (Auto

Power Control) circuit.

The photo-diode detect output of the laser diode then IC104 control

the APC circuit according to the signal voltage of the photo-diode via

IC101.

The Variable resistancer on the FPC in the Laser pickup assy can

be adjusted the output level of Laser diode to fix the rated output

level.

Laser Interlock Switch

The loading position detect switch S101 is set to “ LOAD ON ” (ON:

low level, OFF: high level) position, IC104 get the “ LOAD ” signal,

and hand the laser “ LDON ” signal to No. 9 terminal (LDON) of the

Laser pickup assy.

Then a laser diode can be lighted exept when the level of signal

“LOAD ” is low.

∗ Refer to page 30.

IMPORTANT

THIS PIONEER APPARATUS CONTAINS

LASER OF CLASS 1.

SERVICING OPERATION OF THE APPARATUS

SHOULD BE DONE BY A SPECIALLY

INSTRUTED PERSON.

LASER DIODE CHARACTERISTICS

MAXIMUM OUTPUT POWER: 32 mW

WAVELENGTH: 785 nm

2

Page 3

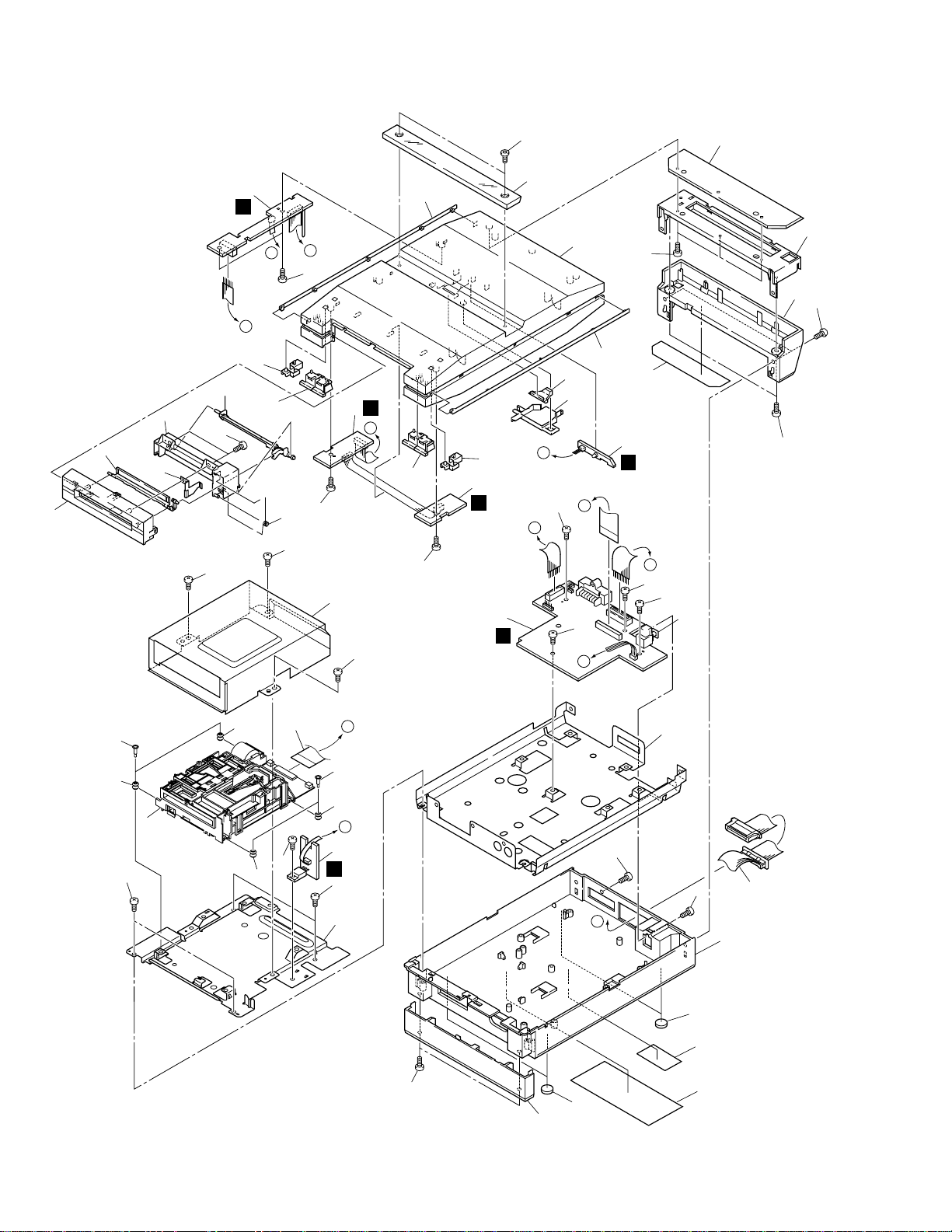

2. EXPLODED VIEWS AND PARTS LIST

NOTES:• Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

•

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on the product are used for disassembly.

•

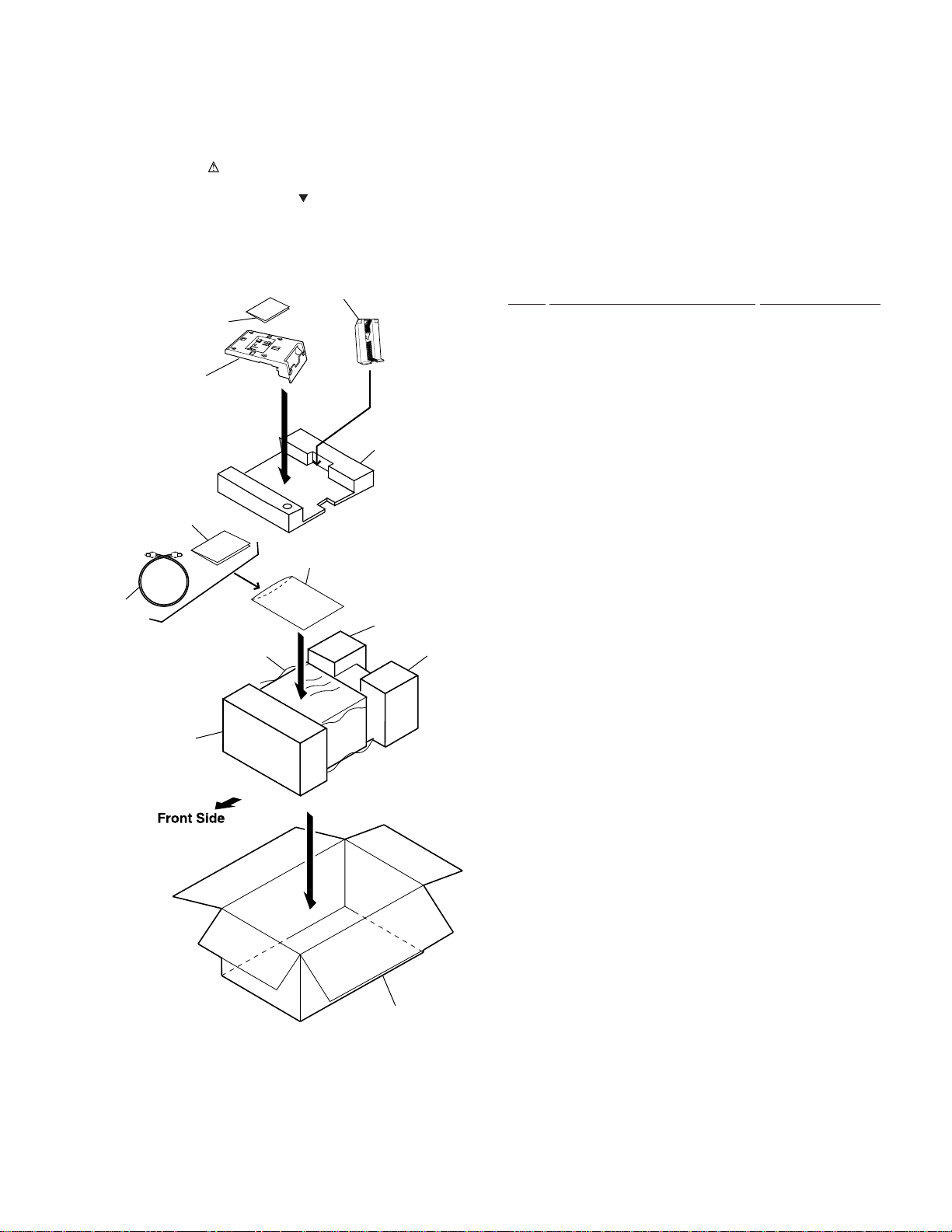

2.1 PACKING

(1) PACKING PARTS LIST

3

Mark No. Description Part No.

MJ-NS1

8

2

6

7

10

1

11

12

13(1/2)

13(2/2)

NSP 8 Warranty Card ARY7027

NSP 10 Polyethylene Bag Z21-038

1 Optical Digital Cable RKX1031

2 Stand A AXG7096

3 Stand B AXG7097

4 • • • • • • •

5 • • • • • • •

6 Spacer MD ,TC AHB7038

7 Operating Instructions ARE7266

(English/Chinese)

9 • • • • • • •

(230×340×0.03)

11 Sheet (550×550×0.5) Z23-026

12 Front Pad M (PLS) AHA7295

13 Rear Pad M (PLS) AHA7296

14 Packing Case AHD7901

14

3

Page 4

MJ-NS1

2.2 EXTERIOR

30

26

12

18

37

38

19

E

A

2

27

22(1/2)

32

23

31

C

B

38

3

D

A

27

14

22(2/2)

38

37

38

13

4

C

1

34

29

17

B

E

38

C

38

38

31

36

5

F

F

37

38

24

25

38

28

16

39

A

37

D

20

21

7

" Refer to

2.3 MD Mechanism"

38

21

21

37

8

21

E

20

D

6

10

38

B

38

11

38

24

F

15

38

15

40

35

9

33

4

Page 5

EXTERIOR PARTS LIST

Mark No. Description Part No.

MJ-NS1

NSP 2 RELAY UNIT AWU7576

NSP 3 KEY L UNIT AWU7577

NSP 4 KEY R UNIT AWU7652

NSP 5 BLUE UNIT AWU7653

NSP 6 IC UNIT AWU7654

NSP 7 MD Mechanism AXA7087

NSP 10 Bottom Chassis MDTC ANA7108

1 MAIN UNIT AWU7607

8 Lead Card 30P (J4101) ADD7280

(MAIN CN4101 ↔ MD CORE CN104)

9 Cord with Plug (J4103) ADE7065

(System Cable to CD Receiver)

11 Sub Chassis (MTL) AND7036

12 Disc Guard (MTL) ANG7319

13 Shield Case (FE) ANK7077

14 MD Spring ABH7189

15 Leg AEB7090

16 FL Holder (PLS) AMR7312

17 Illumination Holder AMR7317

18 MD Flap Holder (PLS) AMR7318

19 MD Cam (PLS) AMR7319

20 Float Screw (FE) RBA1133

21 Float Rubber (Rubber) REB1328

22 Button MD (PLS) AAD7582

23 Display Window MD (PLS) AAK7763

24 Rear Cap MD TC (PLS) AAK7772

25 FL window MD TC (PLS) AAK7793

26 Door NS (PLS) AAK7807

27 Lens MD TC (PLS) AAK7838

28 FL Cover AAK7841

29 Illuminate Lens (PLS) AAK7842

30 Sub Panel MD (PLS) AAP7069

31 Side Line (PLS) AAP7074

32 Screw (Steel) ABA7062

33 Bottom Base CDMD (PLS) AMA7017

NSP 35 Name Label (PAP) MD/ZP AAL7254

34 Top Panel MD (PLS) AMB7700

36 Connector Label ARW7110

37 Screw BBZ30P080FMC

38 Screw BBZ30P080FZK

39 Screw VBZ30P100FZK

40 Caution Label PRW1018

5

Page 6

MJ-NS1

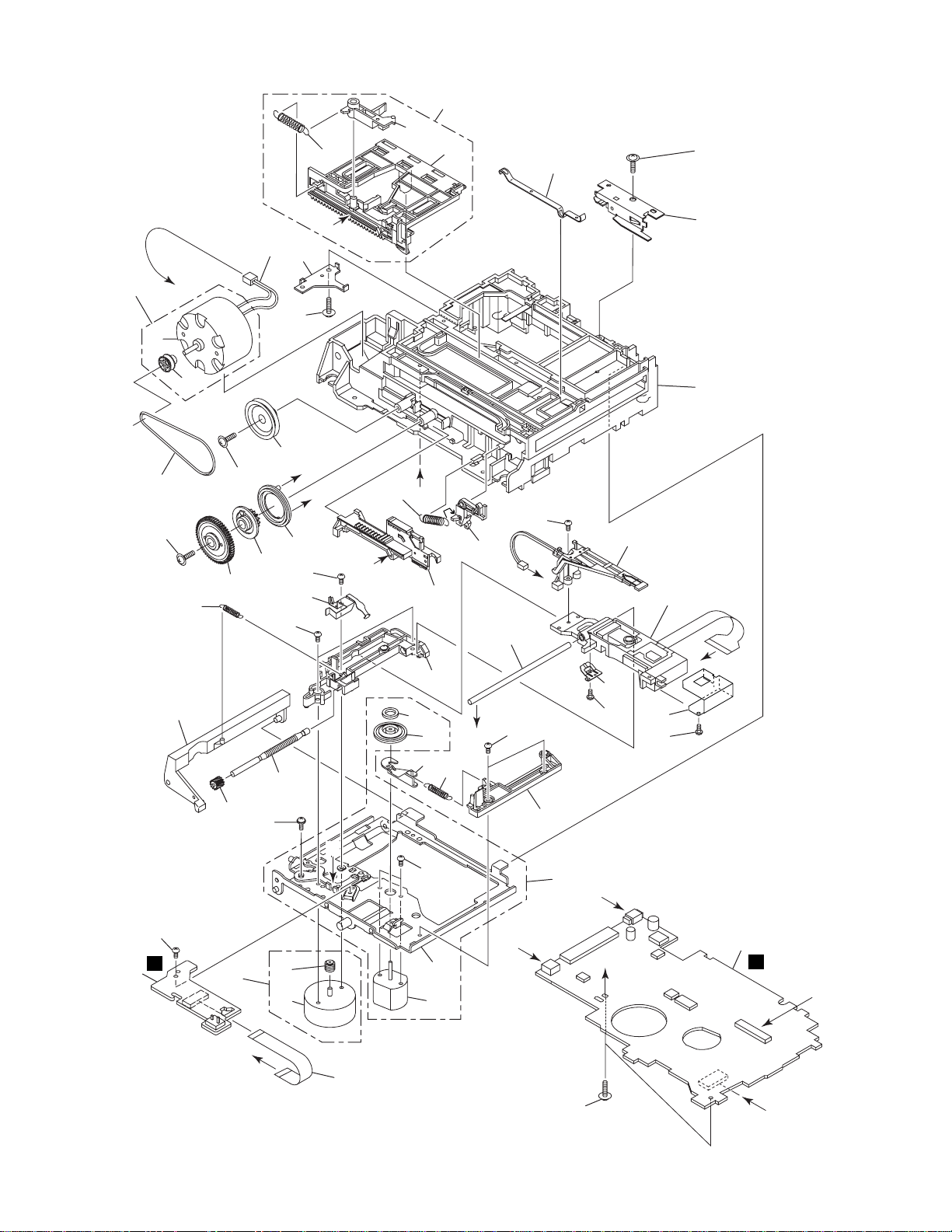

2.3 MD MECHANISM

19

21

18

20

37

6

51

52

8

37

34

E

4

9

17

A

54

53

24

14

37

13

12

40

15

40

26

E

F

5

G

41

16

35

F

11

B

27

10

36

C

28

44

33

31

23

40

H

25

39

29

3946

32

42

30

H

38

43

B

CN102

40

H

2

48

49

50 47

45

A

CN105

G

1

G

C

CN101

D

3

54

6

CN103

D

Page 7

MD MECHANISM PARTS LIST

MJ-NS1

Mark No. Description Part No.

1 MD CORE MAIN UNIT AWU7591

NSP 2 MD CORE SW UNIT AWU7592

3 Lead Card 7P RDD1403

4 Lead Wire 2P RKP1814

5 Lever Spring RBH1463

6 Clamp Spring RBK1074

7 • • • • • • • • • •

8 Loading Belt REB1329

9 Lock Plate RNE1949

10 Loading Base (ABS) RNK2323

11 Under Slider (POM) RNK2314

12 Gear Pulley (POM) RNK2316

13 Drive Gear (POM) RNK2317

14 Clutch Gear (POM) RNK2318

15 Flip Disk (POM) RNK2319

16 SW Lever RNK2320

17 Shutter Assy (FE) RXA1774

NSP 18 Upper Slider Assy RXA1782

19 Eject Spring RBH1461

20 Upper Slider (POM) RNK2324

21 Carrier (POM) RNK2315

22 • • • • • • • • • •

23 Spindle Spring RBH1460

24 Lifter Spring RBH1462

25 Screw Guide (SUS) RBK1072

26 S.H. Spring (SUS) RBK1073

27 Guide Shaft RLA1312

28 Lead Screw (SUS) RLA1311

29 Shield Case (FE) RNE1950

30 Reference Plate RNK2306

Mark No. Description Part No.

31 S. Holder RNK2307

32 Worm Wheel RNK2309

33 Hook (POM) RNK2310

34 Head Lifter RNK2311

35 MD Head RPB1063

36 MD Pick-Up RWY1019

37 Screw (FE) Z39-019

38 Screw JFZ17P020FZK

39 Screw JGZ14P020FMC

40 Screw JGZ17P028FMC

41 Screw JGZ17P040FMC

42 Screw PMB20P040FMC

43 Servo Base Assy REA1283

NSP 44 Clamp Magnet RMF1002

NSP 45 Servo Base RNE1951

NSP 46 Disk Table RNK2305

NSP 47 Spindle Motor RXM1091

48 Carriage Motor Assy REA1284

49 Worm RNK2308

NSP 50 Carriage Motor RXM1090

51 Loading Motor Assy REA1290

52 DC Motor /0.75W PXM1010

53 CA Pulley RNK2322

54 Screw BPZ20P080FMC

7

Page 8

1

23

MJ-NS1

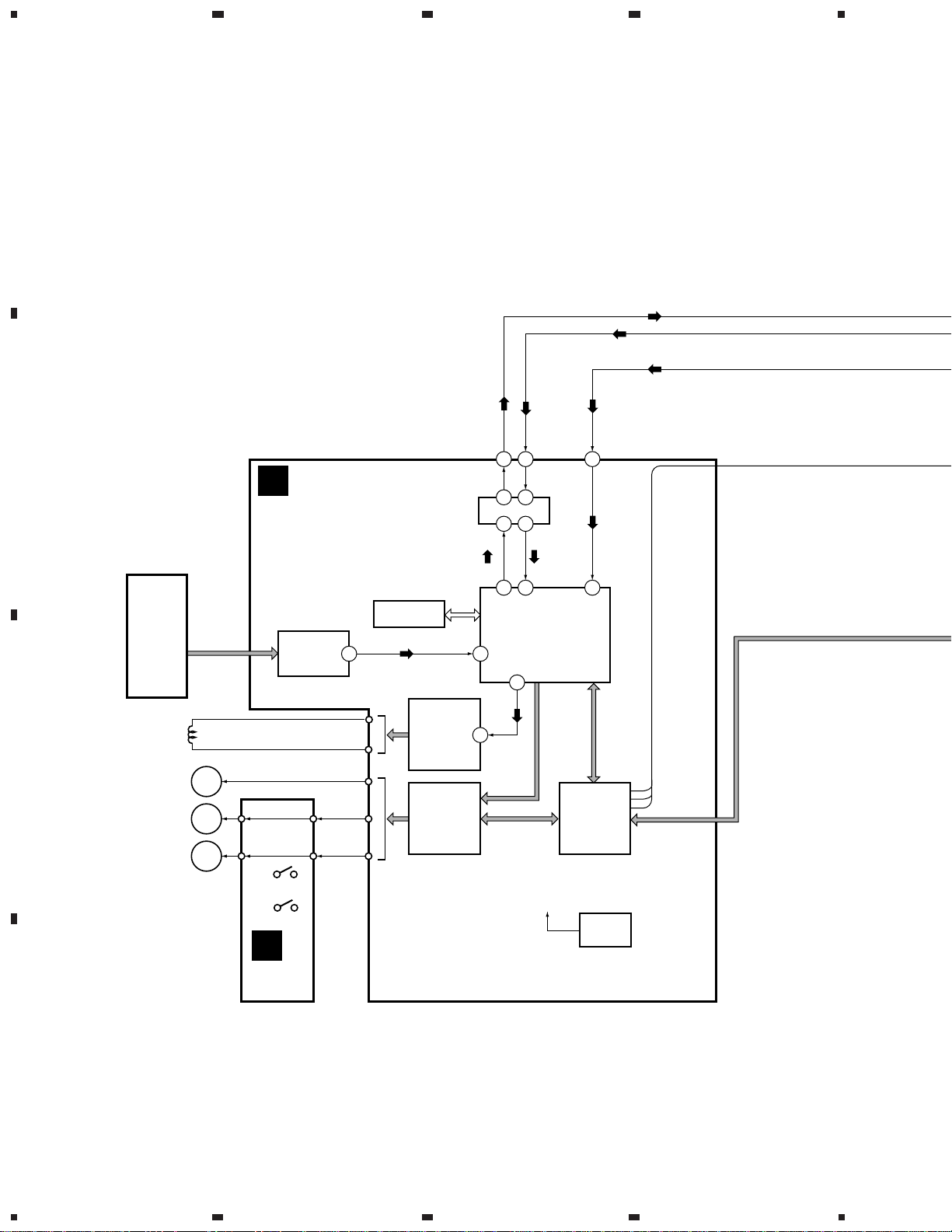

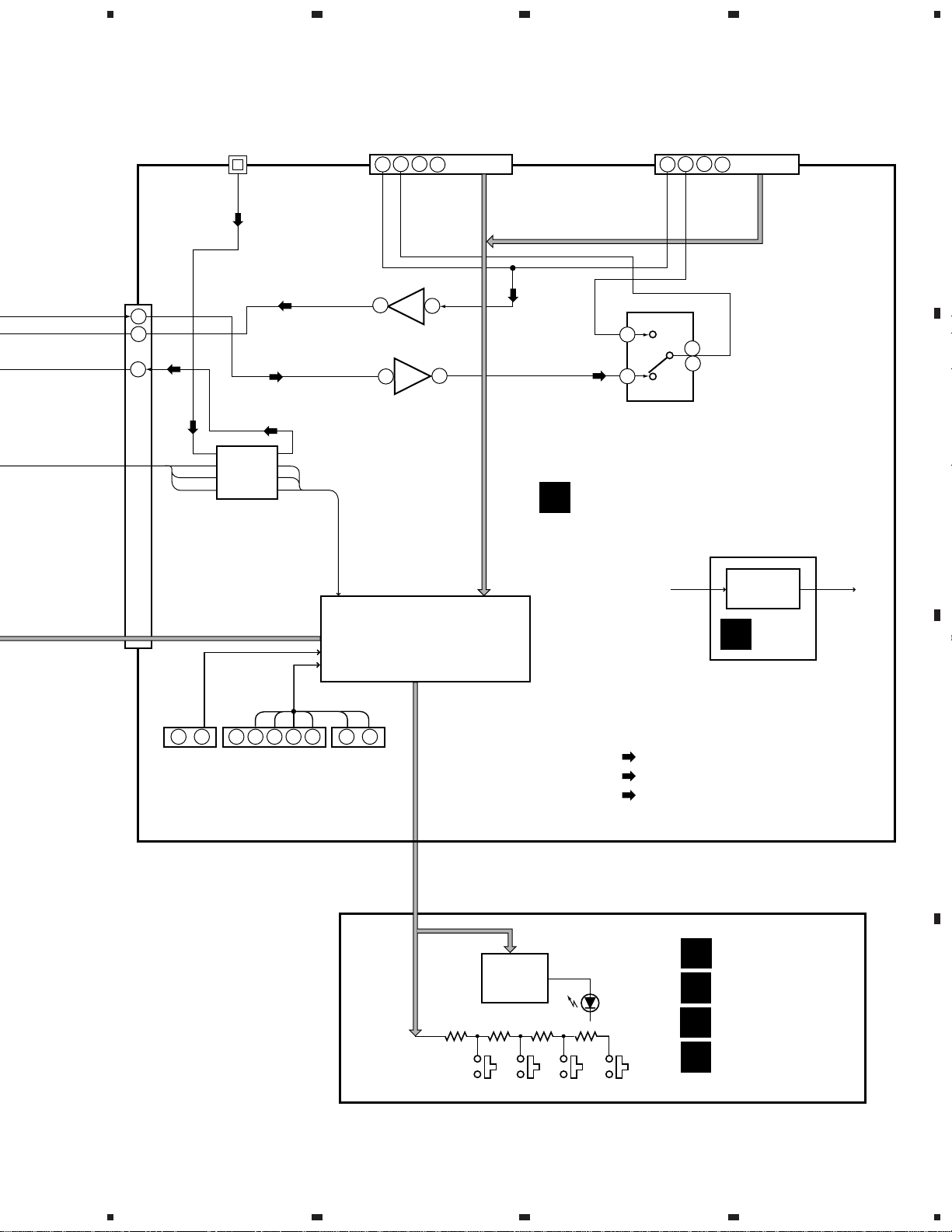

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

A

3.1 BLOCK DIAGRAM

(REC)

(MD)

AOUT-L

B

CN104

MD CORE MAIN UNIT

G

IC110

(AK4519VF)

Audio Codec

AIN-L

25 26

19 6

15 12

DIN

15

(D) (D)

4

(MD)

(REC)

(D)

IC103

(MSM51V4400D70TSK)

DRAM

MD PICKUP

REC HEAD

CN101

C

LOADING

CARRIAGE

SPINDLE

M

M

M

IC101

(IR3R55M)

RF Amp.

CN701

DISC

INSIDE

40

CN102

CN105

CN103

(RF)

IC107

(BD7910FV)

Head

Driver

IC106

(M56788FP)

5ch Motor

Driver

(MD)

74 73

Encoder/Decoder

3

7

H

MD CORE

SW UNIT

(REC)

DADATA

ADDATA

IC102

(LR376487)

+

Digital Servo

50

(REC)

VD+3

DIN

66

IC104

(PD5593A)

MD Mecha

Control

IC106

(RN5RG32AA)

+3.2V Reg.

CONTROL

CONTROL

CN106

D

8

1234

Page 9

5

678

MJ-NS1

Note : When ordering service parts, be sure to refer to "EXPLODED VIEWS and P AR TS LIST" or "PCB PARTS LIST".

OPT

DIGITAL IN

JA4601

CN4103

To CD Receiver

10

13

12

15

CN4102

From Deck

10

13

12

15

A

CN4101

AOUT-L

6

AIN-L

5

DIN

16

(D)

(D)

(D)

DIN

DSTB

MDDATA

MUTE

(TC74HCT08AF)

3V → 5V CONVERTER

(MD)

IC4102

(BA4558F-HT)

(REC)

(D)

IC4201

REC AMP

IC4202

(BA4558F-HT)

PB BUFFER

6

39

PBL

RECL

1

3

System Control U-com

PBR

RECR

3

1

IC4101

(PDG257A)

SDATA

SCLK

DREQ

DDATA

DCLK

(REC)

A

1

(MD)

4

(BU4066BCF)

OUTPUT SELECTOR

MAIN UNIT

RECL

IC4203

PBL

2

3

V+7.5V

RECR

PBR

B

IC4006

(NJM7805FA)

5V REG.

IC UNIT

B

VD+5V

TEST3

CN4107

TEST1

CN4105

1 3 2 11 2 3 4 5

GNDD

GNDD

MECAH TEST

INPUT

+SEARCH

FF

–SEARCH

REW

TEST2

CN4106

P-ON

CN4104

J4901

Key Input

Q4906

EJECT

Q4901-

LED Driver

REC STOP PLAY/PAUSE

(MD)

: AUDIO SIGNAL ROUTE (MD)

(D)

: DIGITAL SIGNAL ROUTE

(REC)

: AUDIO SIGNAL ROUTE (REC)

KEY-R UNIT

C

MONO

REC

DIGITAL

PLAY

D

E

F

KEY-L UNIT

RELAY UNIT

BLUE UNIT

C

D

9

5

6

7

8

Page 10

1

23

MJ-NS1

3.2 OVERALL CONNECTION DIAGRAM

A

SHF

SHF

B

4

IC UNIT

(AWU7654)

B

G

C

MD CORE

SW UNIT

(AWU7592)

MD CORE MAIN UNIT

(AWU7591)

H

KEY-R UNIT

(AWU7652)

D

10

1234

C

Page 11

5

678

MJ-NS1

A

A

MAIN UNIT (AWU7607)

B

C

5

KEY-L UNIT

D

(AWU7577)

F

E

D

RELAY UNIT

(AWU7576)

6

7

BLUE UNIT

(AWU7653)

11

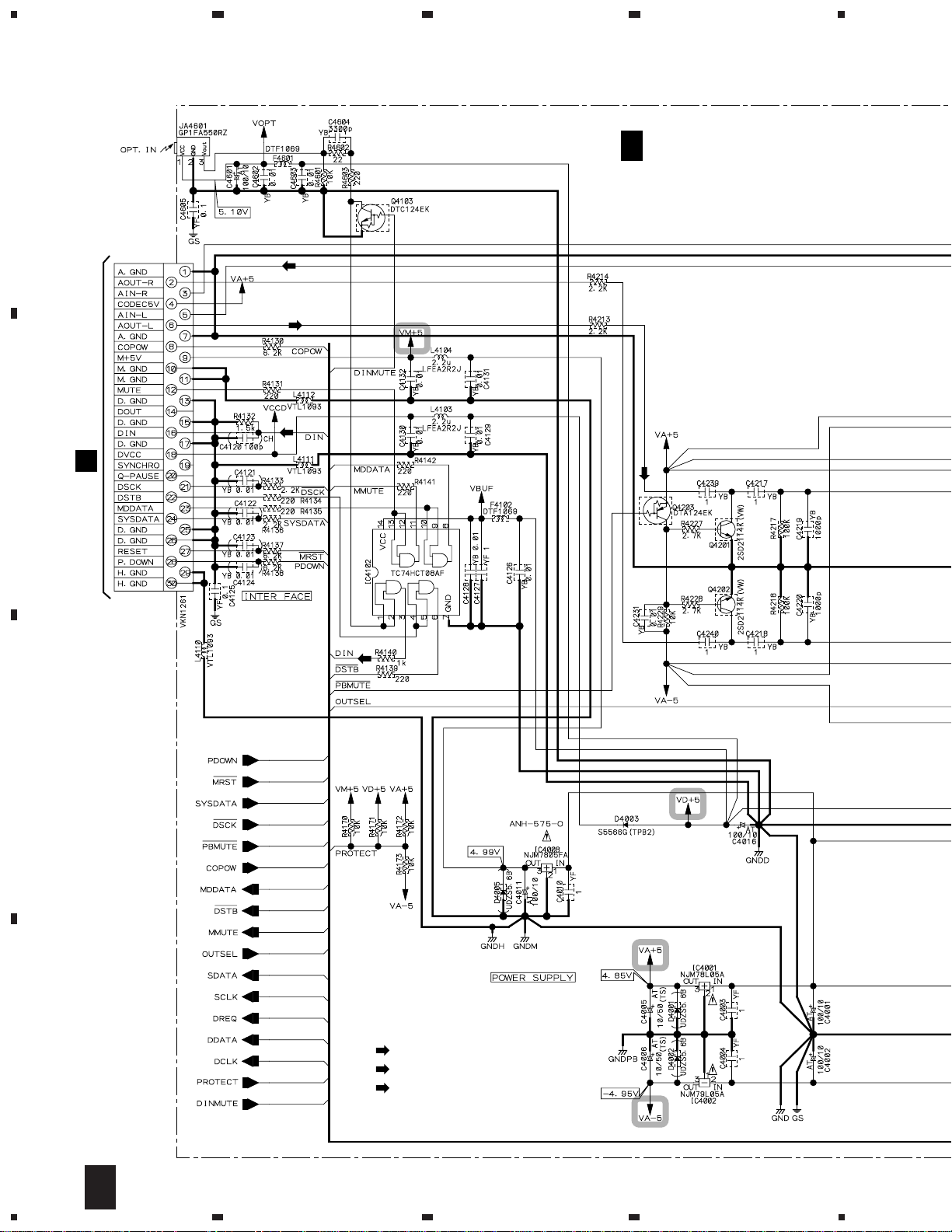

8

Page 12

1

MJ-NS1

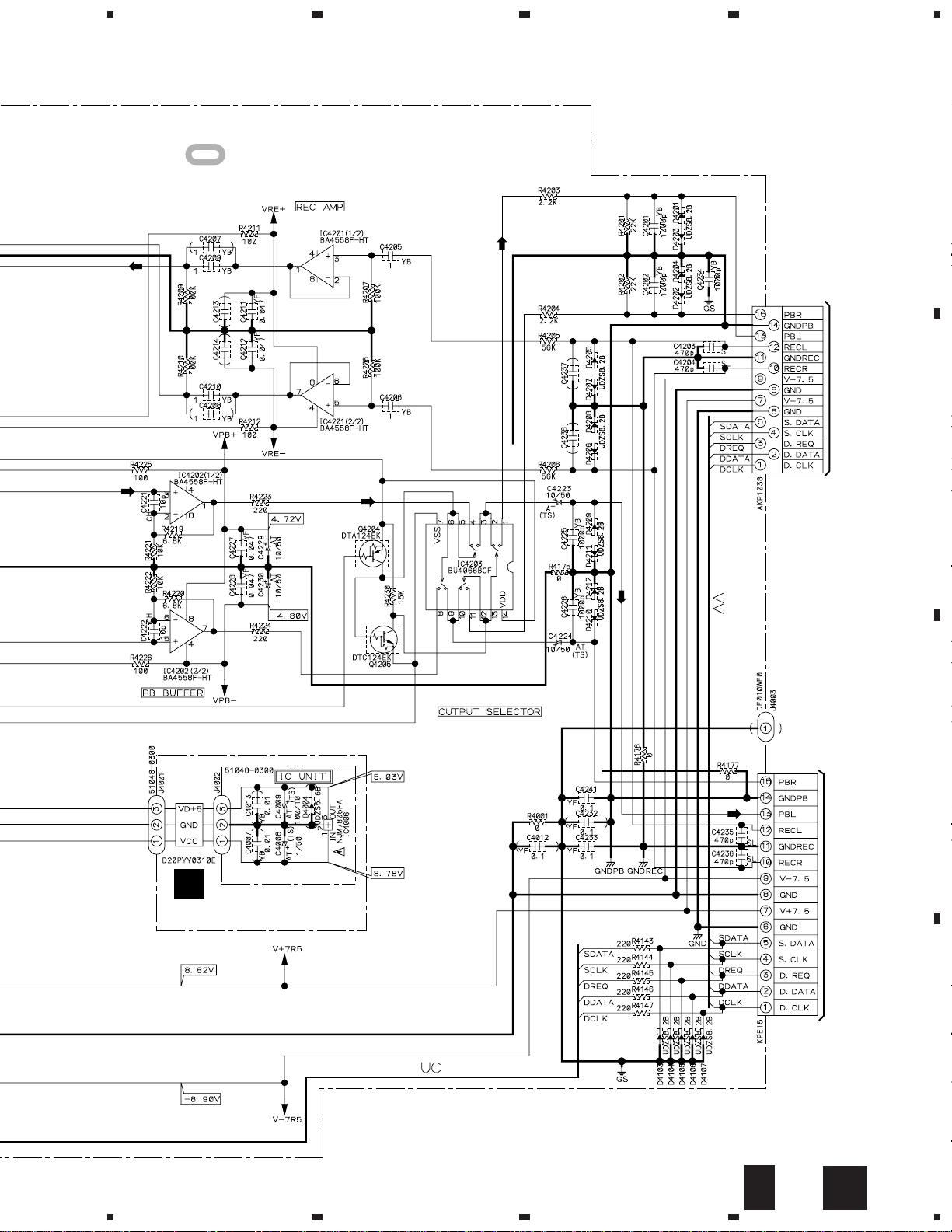

3.3 MAIN UNIT (1/2)

A

CN104

B

G

(REC)

23

A

MAIN UNIT (1/2) (AWU7607)

(MD)

(D)

4

1/2

(MD)

CN4101

C

D

(D)

(MD)

: AUDIO SIGNAL ROUTE (MD)

(D)

: DIGITAL SIGNAL ROUTE

(REC)

: AUDIO SIGNAL ROUTE (REC)

3V-5V

Converter

12

1/2

A

1234

Page 13

5

678

MJ-NS1

(REC)

(MD)

: The power supply is shown with the marked box.

(MD)

(MD)

A

From DECK

B

CN4102

(MD)

B

IC UNIT (AWU7654)

5

C

(MD)

To CD RECEIVER

CN4103

1/2

A

6

7

B

8

13

D

Page 14

1

23

MJ-NS1

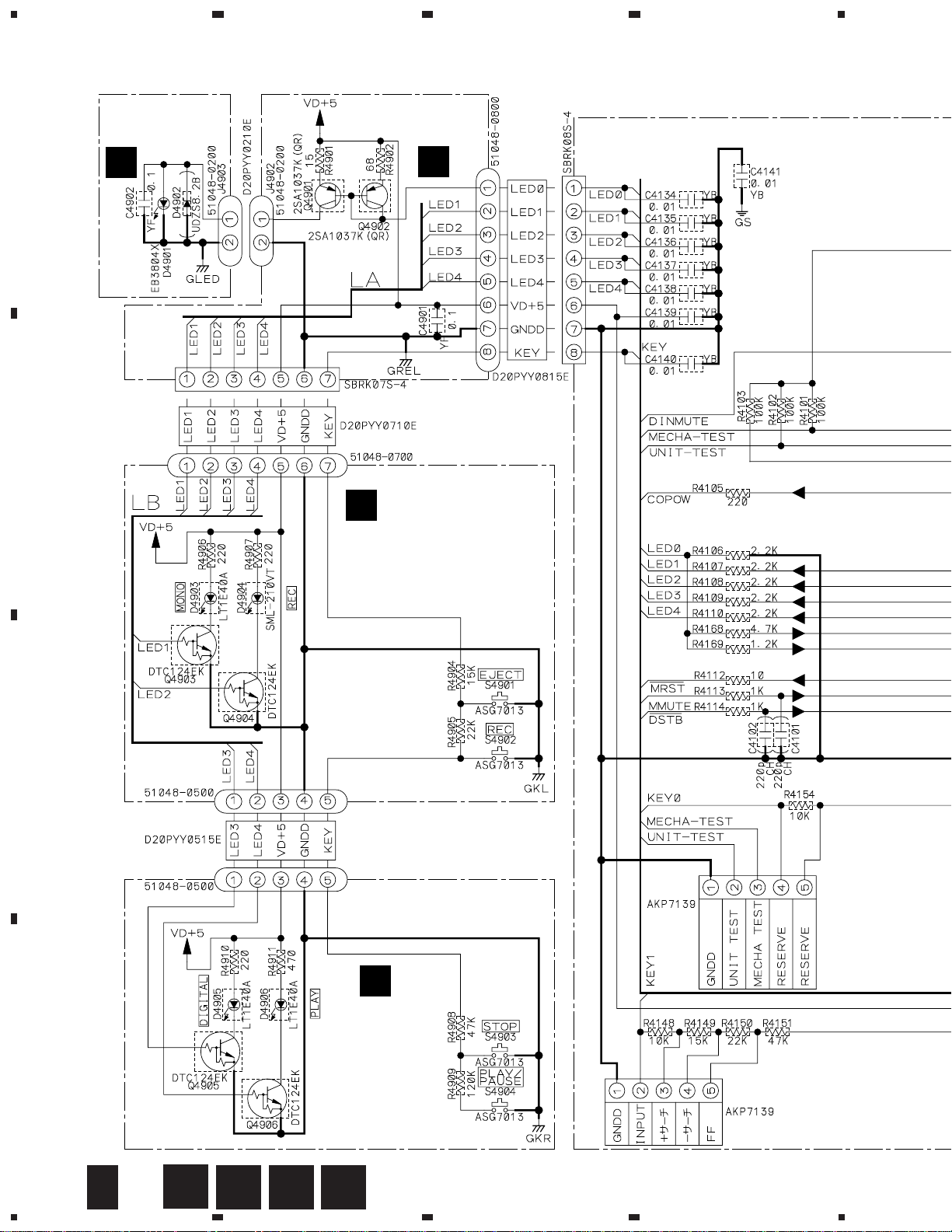

3.4 MAIN UNIT (2/2), KEY-R, KEY-L, RELAY and BLUE UNITS

4

BLUE UNIT

(AWU7653)

A

B

F

RELAY UNIT

(AWU7576)

CN4901

J4904

KEY-L UNIT

D

(AWU7577)

E

J4901

CN4104

SWITCHES

S4901 : EJECT

S4902 : REC

C

J4907

J4908

TEST3

CN4107

C

KEY-R UNIT

(AWU7652)

D

SWITCHES

S4903 : STOP

S4904 : PLAY/

PAUSE

14

2/2

A

1234

C

D

E F

TEST1

CN4105

Page 15

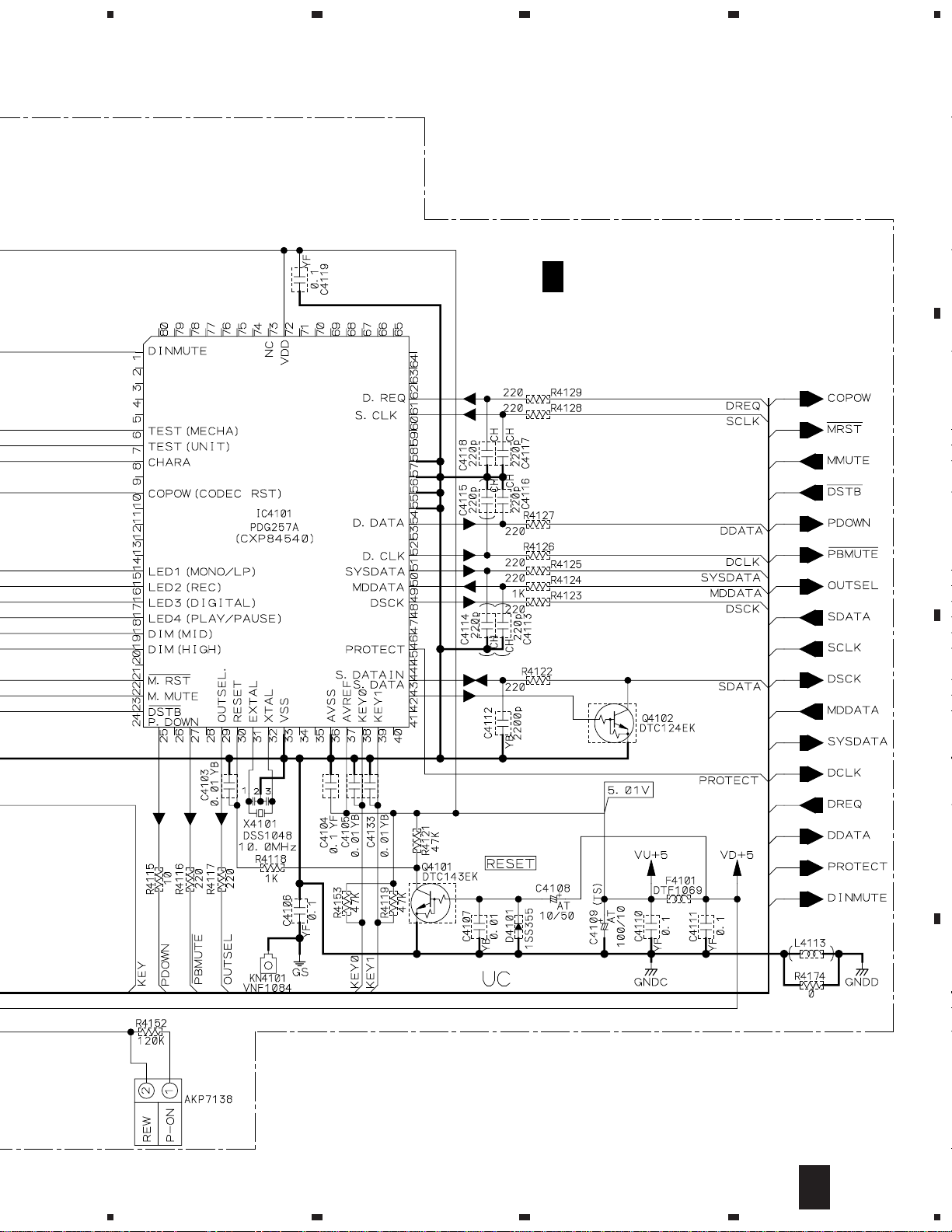

5

678

MJ-NS1

A

A

2/2

MAIN UNIT (2/2) (AWU7607)

B

SYSTEM CONTROL U-COM

C

TEST2

CN4106

5

D

2/2

A

6

7

8

15

Page 16

1

23

MJ-NS1

3.5 MD CORE MAIN and MD CORE SW UNITS

MD CORE MAIN UNIT

A

B

G

(AWU7591)

(RF)

(RF)

(RF)

(RF)

(RF)

(RF)

RF AMP

(RF)

(RF) (RF)

(RF)

(RF) (RF)

1

2

HEAD DRIVER

4

3

(RF)

(REC)

(REC)

(REC)

(REC)

(REC)

MD PICKUP

RWY1019

LOADING MOTOR

ASSY

REA1290

C

CARRIAGE MOTOR

ASSY

REA1284

SPINDLE

MOTOR

RXM1091

9

7

8

(REC)

(REC)

(REC)

5ch MOTOR DRIVER

H

MD CORE SW

UNIT

(AWU7592)

D

16

G

H

1234

Page 17

5

678

MJ-NS1

(RF)

: The power supply is shown with the marked box.

6

5

10

11

(MD)

(REC)

ENC/DEC

+

DIGITAL SERVO

DRAM (4M)

(D)

(CD)

4

(REC)

(D)

(D)

12

(RF)

: RF SIGNAL ROUTE

(D)

: DIGITAL SIGNAL ROUTE

(MD)

: AUDIO SIGNAL ROUTE (MD)

(REC)

: AUDIO SIGNAL ROUTE (REC)

(REC)

(REC)

(MD) (MD)

13

(REC)

14

AUDIO CODEC

(MD)

A

Not used

15

B

(REC)(REC)

10/16

C

REGULATOR

(+3.2V)

MD MECHA.

CONTROL µCOM

(D)

(D)

(D)

(D)

CN4101

1/2

A

EEPROM

(MD)

(REC)

D

G

5

6

7

8

17

Page 18

MJ-NS1

WAVEFOAM OF EACH PART

Note : The number with indicate the each measuring point number of the schematic diagram.

MD CORE MAIN UNIT

G

IC101 - pin 35 (ADIPO)

1

MODE: PLAY

DISC : GGF1328 (MMD–212)

V : DC500mV/div. H : 10µsec/div.

IC101 - pin 30 (WBO)

2

MODE: PLAY

DISC : GGF1328 (MMD–212)

V : DC1V/div. H : 10µsec/div.

GND

IC102 - pin 75 (FE MON)

5

MODE: PLAY

DISC : TGYS1 or MMD-110

V : DC100mV/div. H : 2msec/div.

Note : Connect the filter circuit below

at measuring.

FE MON

39 kΩ

To Oscilloscope

820pF

GND

CN103 - pin 1 (SLD +)

7

MODE: PLAY

V : DC500mV/div. H : 2msec/div.

CN103 - pin 4 (SP +)

8

MODE: PLAY

V : DC500mV/div. H : 5msec/div.

GND

IC102 - pin 1 (EFM MON)

3

MODE: PLAY

DISC : TGYS1 or MMD-110

V : DC500mV/div. H : 0.5msec/div.

IC102 - pin 50 (EFMO)

4

MODE: REC

DISC : GGF1277 or MMD-317

V : DC1V/div. H : 0.2µsec/div.

GND

GND

(MD Mechanism Assy TP)

IC102 - pin 77 (TE MON)

6

MODE: PLAY

DISC : TGYS1 or MMD-110

V : DC500mV/div. H : 2msec/div.

Note : Connect the filter circuit below

at measuring.

TE MON

REFO

39 kΩ

To Oscilloscope

820pF

GND

CN105 - pin 1 (LOAD –)

9

MODE: STOP

V : DC1V/div. H : 1msec/div.

MODE: EJECT

V : DC1V/div. H : 1msec/div.

GND

GND

18

GND

(MD Mechanism Assy TP)

REFO

GND

Page 19

MJ-NS1

IC102 - pin 74 (DADATA)

10

MODE: PLAY (1kHz 0dB)

DISC : TGYS1 or MMD-110

V : DC1V/div. H : 0.2µsec/div.

IC102 - pin 73 (ADDATA)

11

MODE: REC (ANALOG)

DISC : GGF1277 or MMD-317

V : DC1V/div. H : 0.2µsec/div.

GND

GND

IC110 - pin 11 (BCLK)

14

MODE: PLAY (1kHz 0dB)

DISC : TGYS1 or MMD-110

V : DC1V/div. H : 0.1µsec/div.

IC110 - pin 19 (OUTL)

15

MODE: PLAY (1kHz 0dB)

DISC : TGYS1 or MMD-110

V : DC500mV/div. H : 0.2msec/div.

GND

GND

IC110 - pin 9 (SYSCLK)

12

MODE: PLAY (1kHz 0dB)

DISC : TGYS1 or MMD-110

V : DC1V/div. H : 50nsec/div.

IC110 - pin 10 (LRCK)

13

MODE: PLAY (1kHz 0dB)

DISC : TGYS1 or MMD-110

V : DC1V/div. H : 5µsec/div.

GND

GND

19

Page 20

MJ-NS1

VOLTAGE OF EACH PART

MD CORE MAIN UNIT (1kHz 0dB PLAY)

G

IC101

Pin

Voltage

No.

1 0.78 25 2

2 0.73 26 0

3 0.77 27 1.4

4 0.75 28 1.42

5 1.61 29 1.4

6 1.61 30 1.63

7 0.75 31 1.61

8 1.61 32 1.61

9 1.61 33 0

10 1.61 34 0

11 1.61 35 0

12 1.61 36 1.62

13 3.19 37 0.59

14 3.19 38 1.61

15 0 39 1.61

16 0 40 1.61

17 3.19 41 1.61

18 0 42 3.19

19 0 43 0

20 1.5 44 1.08

21 3.2 45 1.61

22 0 46 1.61

23 0 47 0

24 3.19 48 0.74

Pin

(V)

No.

Voltage

IC102 IC103 IC104

Pin

Voltage

No.

(V)

1 1.53 51 1.59

2 3.18 52 0

3 1.65 53 0

4 0 54 1.59

5 1.42 55 1.8

6 0 56 0

7 1.59 57 0

8 1.41 58 0

9 1.97 59 0

10 1.39 60 0

11 1.64 61 0.56

12 3.18 62 3.18

13 0 63 0

14 0 64 1.5

15 0 65 1.5

16 0 66 3.2

17 1.69 67 1.6

18 1.52 68 0.96

19 1.7 69 0

20 1.47 70 1.6

21 1.47 71 1.6

22 1.65 72 1.48

23 1.54 73 0

24 1.69 74 0

25 1.51 75 1.68

26 0.82 76 1.82

27 2 77 1.59

28 2 78 0.35

29 1.81 79 0.02

30 1.4 80 3.2

31 0.82 81 3.2

32 1.67 82 0.02

33 1.67 83 0.03

34 1.67 84 1.9

35 2.86 85 1.56

36 1.32 86 3.1

37 2.23 87 3.2

38 0 88 0

39 2.4 89 3.19

40 1.2 90 0.5

41 1.5 91 0.5

42 0 92 0.5

43 2 93 0.5

44 3 94 0.9

45 1.2 95 0.5

46 1.2 96 0.5

47 0.02 97 0.5

48 3.04 98 0.8

49 1.57 99 3.18

50 0.05 100 0.06

Pin

(V)

No.

Voltage

(V)

Pin

Voltage

No.

(V)

1 1.2

2 1.2

33

42

5 1.45

678-

9 1.80

10 0.8

11 2.36

12 1.21

13 3.18

14 1.21

15 2.45

16 1.26

17 1.65

18 1.32

19 20 21 22 2.23

23 2.4

24 1.2

25 1.2

26 0

Pin

Voltage

Pin

No.

(V)

1 0 51 1.2

2 0 52 1.2

3 0.22 53 1.0

4 3.18 54 1.1

5 1.29 55 0

6 0 56 0

7 0 57 0

8 0 58 0

9 0 59 3.2

10 0 60 0

11 0 61 0

12 2.83 62 3.2

13 1.53 63 0

14 0 64 0

15 1.57 65 3.2

16 3.2 66 0

17 3.19 67 0

18 3.1 68 0

19 0 69 0

20 0 70 0

21 0 71 0

22 3.18 72 3.1

23 3.2 73 3.2

24 0 74 0

25 2.92 75 0

26 3.19 76 3.2

27 0 77 0

28 0 78 0

29 1.5 79 0

30 0 80 3.2

31 0 81 0

32 0 82 0

33 0 83 0

34 0 84 3.19

35 1.17 85 0

36 0 86 3.18

37 2.27 87 3.2

38 0 88 0

39 3.18 89 1.03

40 0 90 3.17

41 0 91 0

42 3.2 92 1.49

43 0 93 2.48

44 0 94 0

45 3.18 95 0

46 3.19 96 0

47 0.51 97 0

48 0.4 98 3.2

49 1.3 99 3.2

50 1.1 100 0

No.

Voltage

IC105

Pin

No.

(V)

10

2 3.2

30

40

50

60

70

80

IC106

Pin

No.

1 1.69 22 1.61

2 1.69 23 1.61

3 1.67 24 0

4 4.99 25 3.17

5 5.0 26 3.17

6 0 27 1.61

7 0 28 1.62

8 1.63 29 0

9 2.14 30 1.57

10 2.15 31 2.54

11 0 32 2.38

12 2.48 33 0

13 2.47 34 2.51

14 2.55 35 2.46

15 2.41 36 1.62

16 1.63 37 1.61

17 1.61 38 4.99

18 1.61 39 4.99

19 1.36 40 1.61

20 1.36 41 4.86

21 1.61 42 1.6

IC107

Pin

No.

1 4.98

20

30

4 4.99

5 3.2

60

7 0.03

8 3.18

90

10 0

11 0

12 0.73

13 0

14 0.9

15 0.85

16 2.94

17 0.85

18 4.94

19 2.94

20 1.33

Voltage

(V)

Voltage

(V)

Voltage

(V)

IC108

Pin

Voltage

No.

10

2 4.19

3 3.21

4 2.81

50

Pin

Voltage

No.

(V)

(V)

IC109

Pin

Voltage

No.

(V)

1 1.4

2 1.4

3 1.4

4 1.58

5 1.58

6 1.56

70

80

90

10 0

11 0

12 0

13 0

14 3.2

IC110

Pin

Voltage

No.

(V)

1 3.12

2 3.12

3 1.38

4 1.39

5 1.39

6 1.38

7 2.84

8 2.84

9 1.55

10 1.58

11 1.56

12 0.95

13 0

14 3.12

15 0.98

16 0

17 0

18 3.18

19 1.38

20 1.38

21 0

22 0

23 3.12

24 3.12

20

Page 21

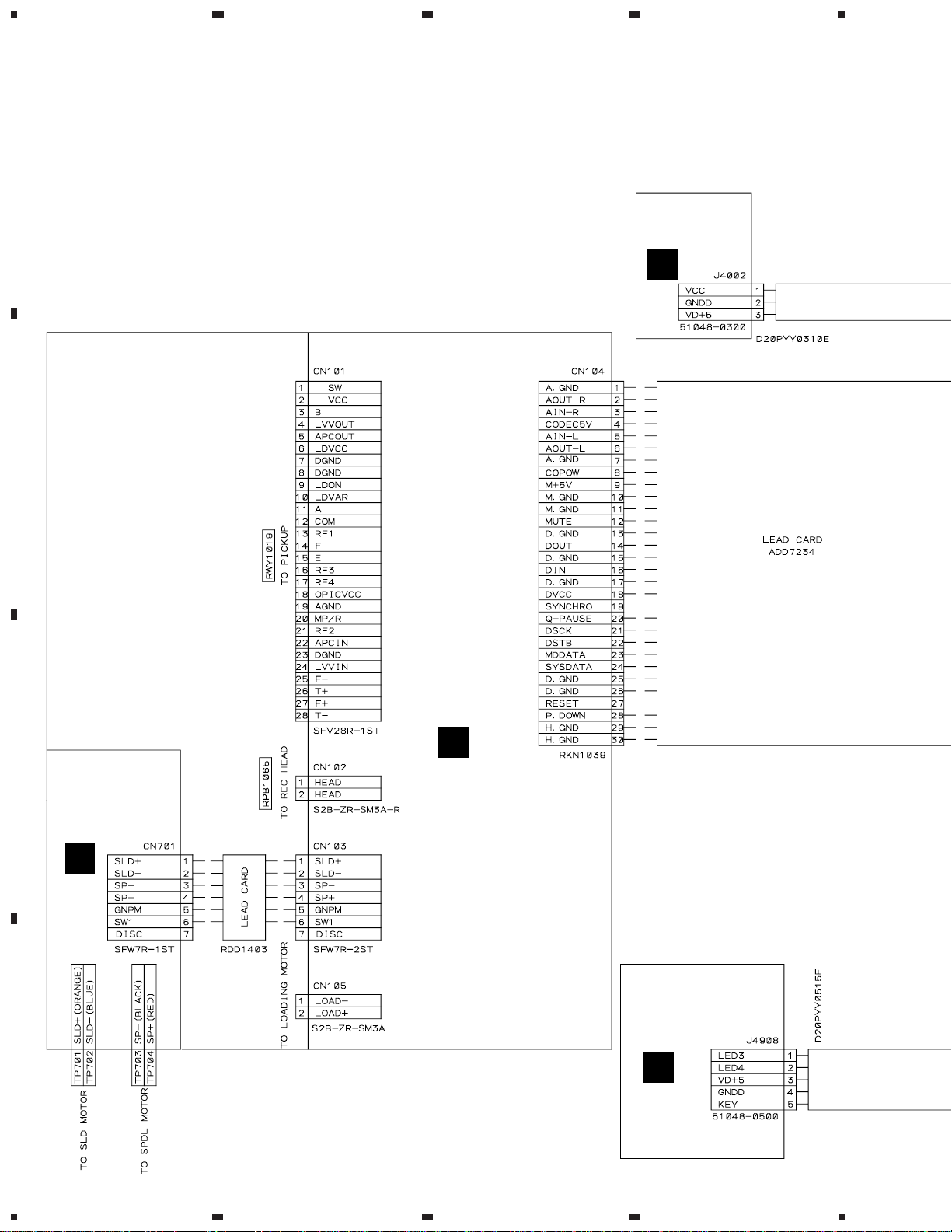

4. PCB CONNECTION DIAGRAM

NOTE FOR PCB DIAGRAMS:

1. Part numbers in PCB diagrams match those in the schematic

diagrams.

2. A comparison between the main parts of PCB and schematic

diagrams is shown below.

Symbol in PCB

Diagrams

BCE

BCE

DGS

Symbol in Schematic

Diagrams

BCE

BCEBCE

DGSDGS

BCE

Part Name

Transistor

Transistor

with resistor

Field effect

transistor

MJ-NS1

Resistor array

3-terminal

regulator

3. The parts mounted on this PCB include all necessary parts

for several destination.

For further information for respective destinations, be sure

to check with the schematic diagram.

4. Viewpoint of PCB diagrams

Capacitor

Connector

SIDE A

P.C.Board Chip Part

SIDE B

21

Page 22

1

23

MJ-NS1

4.1 MAIN , KEY-R ,KEY-L ,RELAY

BLUE and IC UNITS

4

A

B

MAIN UNIT

A

IC4001

IC4002

From

DECK

To

CD TUNER

G

CN104

(ANP7348-B)

KEY-L UNIT

D

C

KEY-R UNIT

C

D

(ANP7348-B)

(ANP7348-B)

E

BLUE UNIT

F

IC UNIT

B

RELAY UNIT

(ANP7348-B)

(ANP7348-B)

22

SIDE A

A

1234

CB

ED F

Page 23

IC4203

IC4202

1

IC4201

234

MJ-NS1

A

MAIN UNIT

A

Q4103

IC4101

IC UNIT

B

(ANP7348-B)

KEY-L UNIT

D

KEY-R UNIT

C

B

C

(ANP7348-B)

SIDE B

1

(ANP7348-B)

(ANP7348-B)

RELAY UNIT

E

D

BLUE UNIT

F

(ANP7348-B)

A

2

3

CB

(ANP7348-B)

ED F

23

4

Page 24

1

23

MJ-NS1

4.2 MD CORE MAIN and MD CORE SW UNITS

4

A

MD CORE

G

MAIN UNIT

IC108

Q102

Q101

IC104

B

IC103

IC102

IC106

C

(ANP7353-B)

MD CORE

H

IC101

SW UNIT

(ANP7353-B)

D

SIDE A

24

G

H

1234

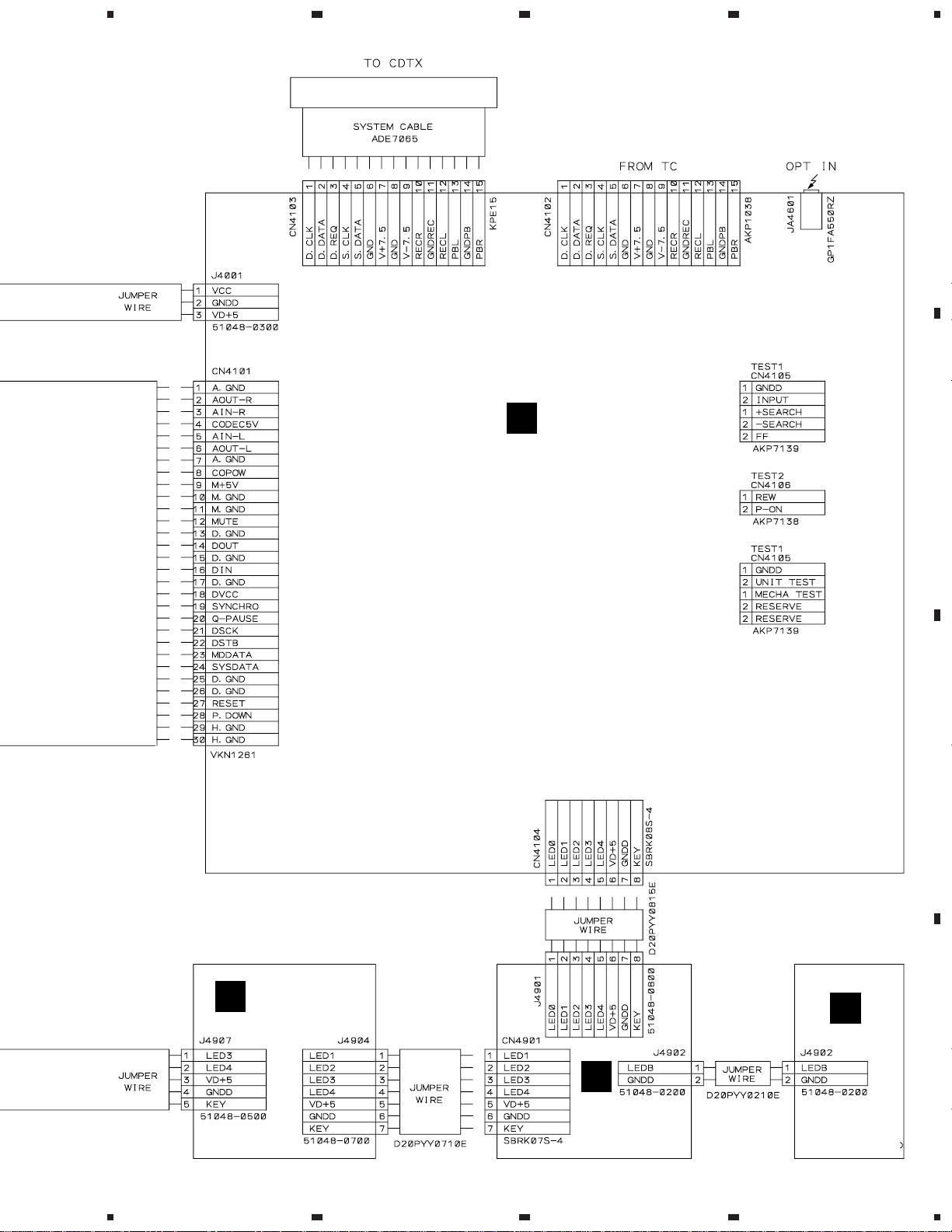

Page 25

1

234

MJ-NS1

IC107

IC110

IC105

IC109

LOADING

MOTOR ASSY

CN4101

A

REC HEAD

MD CORE

G

MAIN UNIT

A

B

CARRIAGE

MOTOR ASSY

SPINDLE

MOTOR

(ANP7353-B)

SIDE B

MD CORE

H

SW UNIT

MD PICKUP

C

(ANP7353-B)

D

G

1

2

3

H

4

25

Page 26

MJ-NS1

Mark No. Description Part No.

Mark No. Description Part No.

5. PCB PARTS LIST

NOTES:•Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

Mark No. Description Part No.

LIST OF ASSEMBLIES

NSP MD MAIN ASSY AWM7522

NSP RELAY UNIT AWU7576

NSP KEY L UNIT AWU7577

NSP KEY R UNIT AWU7652

NSP BLUE UNIT AWU7653

NSP IC UNIT AWU7654

NSP MD CORE SW UNIT AWU7592

The mark found on some component parts indicates the importance of the safety factor of the part.

•

Therefore, when replacing, be sure to use parts of identical designation.

When ordering resistors, first convert resistance values into code form as shown in the following examples.

•

Ex.1 When there are 2 effective digits (any digit apart from 0), such as 560 ohm and 47k ohm (tolerance is shown by J=5%,

and K=10%).

560 Ω→56 × 10

47k Ω→47 × 10

0.5 Ω→R50 ..................................................................................... RN2H

1

→ 561 ........................................................ RD1/4PU 5 6 1 J

3

→ 473 ........................................................ RD1/4PU 4 7 3 J

R 5 0

1 Ω→1R0 ..................................................................................... RS1P 1 R 0 K

Ex.2 When there are 3 effective digits (such as in high precision metal film resistors).

5.62k Ω→ 562 × 10

1

→ 5621 ......................................................RN1/4PC 5 6 2 1 F

Mark No. Description Part No.

C4103,C4105,C4107,C4126 CKSQYB103K50

C4128-C4141,C4231,C4602,C4603 CKSQYB103K50

MAIN UNIT AWU7607

MD CORE UNIT AWM7516

MD CORE MAIN UNIT AWU7591

RESISTORS

C4205,C4206,C4209,C4210 CKSQYB105K10

C4217,C4218,C4239,C4240 CKSQYB105K10

C4112 CKSQYB222K50

C4604 CKSQYB332K50

C4104,C4106,C4110,C4111,C4119 CKSQYF104Z25

C4125,C4233,C4241,C4605 CKSQYF104Z25

C4003,C4004,C4010,C4127 CKSQYF105Z16

C4211,C4212,C4227,C4228 CKSQYF473Z25

All Resistors RS1/10S J

K

A

MAIN ASSY

SEMICONDUCTORS

IC4201,IC4202 BA4558F-HT

IC4008 NJM7805FA

IC4001 NJM78L05A

IC4002 NJM79L05A

IC4203 BU4066BCF

IC4101 PDG257A

IC4102 TC74HCT08AF

Q4201,Q4202 2SD2114K

Q4203,Q4204 DTA124EK

Q4102,Q4103,Q4205 DTC124EK

Q4101 DTC143EK

D4101 1SS355

D4003 S5566G(TPB2)

D4103-D4107,D4201-D4212 UDZS8.2B

COILS AND FILTERS

F4101,F4102,F4601 DTF1069

L4103,L4104 LFEA2R2J

L4110-L4112 VTL1093

CAPACITORS

C4221,C4222 CCSQCH100D50

C4115-C4118 CCSQCH221J50

C4203,C4204,C4235,C4236 CCSQSL471J50

C4005,C4006,C4108,C4223,C4224 CEAT100M50

C4229,C4230 CEAT100M50

C4001,C4002,C4011,C4016,C4109 CEAT101M10

C4601 CEAT101M10

C4201,C4202,C4219,C4220 CKSQYB102K50

C4225,C4226,C4234 CKSQYB102K50

OTHERS

3P Cable Holder 51048-0300

CN4102 15P Socket AKP1038

CN4106 Header (2P) AKP7138

CN4105,CN4107 Header (5P) AKP7139

Heat Sink ANH-575

X4101 (10.0 MHz) DSS1048

JA4601 Optical Module GP1FA550RZ

CN4103 15P Jumper Connector KPE15

PCB Binder VEF1040

CN4101 30P FFC Connector VKN1261

KN4101 Earth Plate VNF1084

B

IC UNIT

SEMICONDUCTORS

IC4006 NJM7805FA

CAPACITORS

C4009 CEAT101M10

C4008 CEAT1R0M50

OTHERS

3P Cable Holder 51048-0300

J4002 3P Parallel Cable D20PYY0310E

C

KEY-R UNIT

SEMICONDUCTORS

Q4905,Q4906 DTC124EK

D4905,D4906 LT1E40A

26

Page 27

MJ-NS1

Mark No. Description Part No.

SWITCHES AND RELAYS

S4903,S4904 ASG7013

RESISTORS

All Resistors RS1/10S J

OTHERS

5P Cable Holder 51048-0500

D

KEY-L UNIT

SEMICONDUCTORS

Q4903,Q4904 DTC124EK

D4903 LT1E40A

D4904 SML-210VT

SWITCHES AND RELAYS

S4901,S4902 ASG7013

RESISTORS

All Resistors RS1/10S J

OTHERS

5P Cable Holder 51048-0500

7P Cable Holder 51048-0700

J4907 5P Parallel Cable D20PYY0515E

J4904 7P Parallel Cable D20PYY0710E

Mark No. Description Part No.

G

MD CORE MAIN UNIT

SEMICONDUCTORS

IC110 AK4519VF

IC107 BD7910FV

IC105 BR93LC56F

IC101 IR3R55M

IC102 LR376487

IC106 M56788FP

IC103 MSM51V4400D70TSK

IC108 RN5RG32AA

IC104 PD5593A

IC109 TC74VHC08FT

Q101 2SB1188

Q102 2SC4081

D101 SBE803

D102 UDZ3.6B

COILS AND FILTERS

chip coil (4.7µH)

L101,L103,L104,L107 DTL1024

L108 chip solid inductor QTL1015

L105 chip coil (47µH) RTL1003

L102 chip coil (0.47µH) RTL1007

L116 chip beeds VTL1093

L109-L115 chip beeds VTL1105

SWITCHES AND RELAYS

S101,S102 RSF1012

E

RELAY UNIT

SEMICONDUCTORS

Q4901,Q4902 2SA1037K

CAPACITORS

C4901 CKSQYF104Z25

RESISTORS

All Resistors RS1/10S J

OTHERS

2P Cable Holder 51048-0200

8P Cable Holder 51048-0800

J4902 2P Parallel Cable D20PYY0210E

J4901 8P Parallel Cable D20PYY0815E

CN4901 Jumper Connector SBRK07S-4

PCB Binder VEF1040

F

BLUE UNIT

SEMICONDUCTORS

D4901 EB3804X

CAPACITORS

C4902 CKSQYF104Z25

OTHERS

2P Cable Holder 51048-0200

CAPACITORS

C122,C186,C215 CCSQCH101J50

C127,C128 CCSQCH120J50

C151 CCSQCH220J50

C105-C109 CCSQCH271J50

C110 CCSQCH331J50

C201,C202 CCSQCH470J50

C191,C192,C207,C209,C211 CEV100M16

C214 CEV100M16

C145,C189,C198,C213 CEV101M4

C152 CEV101M6R3

C195,C196 CEV220M6R3

C180,C182,C188 CEV470M6R3

C120 CEV4R7M35

C217 CKSQYB102K50

C139,C148,C212,C216 CKSQYB103K50

C218,C219 CKSQYB103K50

C129 CKSQYB104K25

C101,C102,C104,C117,C118 CKSQYB105K10

C166,C167 CKSQYB153K50

C193,C194 CKSQYB222K50

C137,C141,C142 CKSQYB223K50

C103,C185 CKSQYB273K50

C116 CKSQYB332K50

C115,C121 CKSQYB333K50

C112 CKSQYB472K50

C133 CKSQYB473K16

C111,C114 CKSQYB474K16

C174,C175 CKSQYB562K50

C154,C157,C162,C163 CKSQYB821K50

C135,C140,C143,C146,C155 CKSQYF104Z25

C176,C181,C183,C184,C187 CKSQYF104Z25

27

Page 28

MJ-NS1

Mark No. Description Part No.

C190,C197,C199,C204-C206 CKSQYF104Z25

C208,C210 CKSQYF104Z25

C119,C123-C126,C130,C132 CKSQYF105Z16

C134,C136,C138,C147,C164 CKSQYF105Z16

C177 CKSQYF105Z16

RESISTORS

R111 RS1/8S270J

Other Resistors RS1/10S J

OTHERS

CN104 30P Connector RKN1039

X101 (33.8MHz) RSS1055

CN105 ZR Connector S2B-ZR-SM3A

CN102 Connector 2P S2B-ZR-SM3A-R

CN106 PH Connector S5B-PH-SM3

CN101 Connector for flex. cable SFV28R-1ST

CN103 Connector for flex. cable SFW7R-2ST

H

MD CORE SW UNIT

SWITCHES AND RELAYS

S701 RSF1009

S702 RSF1010

RESISTORS

All Resistors RS1/10S J

Mark No. Description Part No.

OTHERS

CN701 Flexible Connector SFW7R-1ST

28

Page 29

6. ADJUSTMENT

6.1 MD SECTION ADJUSTMENT

Jigs and Measuring Instructions

• Thermometer

• Oscilloscope

• Optical Power Meter

• Jitter Meter

6.1.1 Necessary Adjustment Points

Exchange

PICKUP

• Test Disc

For servo system adjustment : GGF1328 (MMD-212)

For recording/playback inspection : GGF1328 (MMD-212), GGF1277 (or MMD-317)

TGYS1 (or MMD-110), Commercial discs

Adjustment pointsWhen

2 8

= Page 31–36

MJ-NS1

Exchange

Servo Base Assy (SPINDLE MOTOR)

Exchange

MD CORE MAIN UNIT

Exchange

MD HEAD

Exchange

Loading Mechanism Assy

Exchange

Servo Mechanism Assy

3 8

41 8

8

3 8

= Page 32–36

= Page 31,

33–36

= Page 36

= Page 32–36

Exchange

MD Mechanism Assy

(Loading Mechanism Assy +

Servo Mechanism Assy)

3 8

= Page 32–36

29

Page 30

MJ-NS1

6.1.2 Test Mode

Use the Remote Control Unit of Accessory or Service Remote Control Unit (GGF1067) at the Test Mode.

Note1 : It is impossible to enter the Test Mode in the Single Operation Mode.

Note2 : Unit Test Mode (U-TEST) is for inspection by the function checker of the production line.

Power on state and MD function

short the MECHA TEST pin.

[DISPLAY OF THE TESTMODE START]

No Disc Disc set

Service test mode

Press the MD 6 key.

MD mechanism test

about 1 sec.

tsm???? e??

EJECT

Correspondence key of the Test mode

Command Name

TEST MODE Short-circuit the MECHA TEST pin ESC (A85F)

EJECT 0 (MD EJECT) of the main unit key

MENU next 1

MENU next 2

MENU next 3

MENU previous

SET (Decision, Execution)

STOP

CHANGE (switch)

Set UP ¡ (SCAN) ¡ (SCAN) (A810)

Set DOWN

FORWARD

REVERSE

Remote Control Unit of

Accessory+(Main Unit Key)

MENU

¶ (REC) of the main unit key

CANCEL

DISPLAY

6 of the main unit key

7 (STOP) of the main unit key

SET SEARCH (A842)

1 (SCAN) 1 (SCAN) (A811)

+

– 4 (SKIP) (A853)

Remote Control Unit

1 (STILL) (A854)

FRM / TIM (A841)

CHAP (A840)

CHP / TIM (A813)

CLEAR (A845)

PLAY (A817)

7 / EJECT (A816)

¢ (SKIP) (A852)

CLD Service

(GGF1067)

tsm???? e??

GRT AJST

SR Code

Test Point

30

SIDE A

TEST MODE

SHORT

MAIN UNIT

Page 31

6.1.3 MD Mechanism Assy Adjustment and Check

MJ-NS1

1 Temperature Check

Note: When IC101 (RF-AMP) or IC104 (mechanical controller) has been exchanged or when a correction changing VD+3 has been made,

be sure to correctly perform all steps up to step 7.

Step No.

1

2 Press the ¶ (REC) key. TEMP??&& The microcomputer starts measuring

3

When && is 80 (not passed) TEMP??80 80 is the default value (unadjusted).

4

5 Change && with the + key and – key.

6

Operation Keys and Operation Method FL Display Status Remarks

In the Power ON state, selecting MD function,short the

"MECHA TEST pin".

When && is 80 or more at this time, the adjustment is

OK (step 4 and following can be omitted.)

Measure the ambient temperature T (°C) and check

that the measuring value (??) is within the standard in

regard to the microcomputer set value (&&).

Note: When the indication of the measuring value

(??) is not stable, and the ambient temperature T (°C)

is 25 °C or less, set to the lower value.

When the ambient temperature is over 25 °C, set to

the higher value.

Turn off the power of the CD tuner.

(Please perform this check soon after the power has been switched on.)

EJECT Test mode

??: Measuring

End

TEMP

µ-com Measuring value µ-com Set value

Room Temperature

[T (°C)]

11.6 to 16.9 Measuring value (??) –2

17.0 to 22.3 Measuring value (??) –1

22.4 to 27.6 Measuring value (??)

27.7 to 33.0 Measuring value (??) +1

33.1 to 38.4 Measuring value (??) +2

TEMP 7B 7B

hex= (?? – &&)

Data writes to the EEPROM and turns

the system power to off. Test mode

returns to the normal mode.

When the

microcomputer value

is

value

&&: Set value

79

7A

7B

7C

7D

–

+

2 Laser Power Check

Step No.

1 EJECT Test mode

2

3

4

5 Press the SET key. rpw REC power output status

6

7 Press the 7 (STOP) key. The LD goes out.

Operation Keys and Operation Method

In the Power ON state, selecting MD function,short the

"MECHA TEST pin".

Press the SET key (Remote control unit). ppw PLAY power output status

Measure the laser power with an optical power meter.

At this time, check that the measuring value (PLAY

power) meets the standard value of the table on the

right.

Note: When the standard value on the right is applied,

the numerical value immediately after entry into test

mode 2 shall be taken as the standard.

At this time, check that the measuring value (REC

power) meets the standard value of the table on the

right.

FL Display

ppw

µ-com

Measuring value

ppw May be omitted.

rpw

hex=(?? – &&)

+02 to +04 0.69 ± 0.12

–01 to +01 0.67 ± 0.1

–02 to –04 0.63 ± 0.1

hex=(?? – &&)

+02 to +04 6.18 ± 0.93

–01 to +01 5.79 ± 0.87

–02 to –04 5.47 ± 0.82

TEMP

Status

Standard value

Standard value

Remarks

Laser wavelength:

780 nm

µ-com

Set value

(mW)

(mW)

31

Page 32

MJ-NS1

3 Grating Adjustment

Press the 0 (MD EJECT) key to take out the cartridge of Optical power meter in the state of step 7 of 2 , and then it is possible from steps 2

of this item.

Step No.

1 EJECT Test mode

2 Insert the test disc GGF1328 (MMD-212).

3 Press the 6 key.

4

5 Press the 7 (STOP) key. Adjustment end

Operation Keys and Operation Method FL Display Status

In the Power ON state, selecting MD function,short the

"MECHA TEST pin".

Connect an oscilloscope according to the following

connection diagram and loosen the screw A at the

side of the adjustment hole. Turn the hole with a

screwdriver until the Lissajous waveform becomes as

shown in the figure, and then tighten the screw A.

LOADING

GRT AJST

LON :

LAg :

GEG :

GRT AJST Lissajous waveform a:b = Within 3:1

Grating adjustment state

Playback is started in tracking open state.

(The servo is closed only for focus and

spindle.)

Connection Diagram

Remarks

REFO

EOUT

Ocsilloscope

100kΩ

100kΩ

MD CORE MAIN UNIT

FOUT

470p

470p

a

b

Lissajous waveform

a:b = Within 3:1

SIDE A

Adjustment

Hole

Screw A

32

Page 33

4 Preliminary Adjustment

It is possible from steps 3 of this item in the state of step 5 of 3 .

MJ-NS1

Step No.

1 EJECT

2 Insert the test disc GGF1328 (MMD-212).

3 Press the 7 (STOP) key. Return to menu display.

4 Press the MENU key (until "AUT YOBI" is displayed). Preliminary adjustment mode

5

6

7

Note: When this adjustment is performed after defocus adjustment has been performed, defocus is returned to the initial state, and defocus

adjustment must be performed.

Operation Keys and Operation Method FL Display Status

In the Power ON state, selecting MD function,short the

"MECHA TEST pin".

Preliminary adjustment starts when the 6 key is

pressed.

Press the 7 (STOP) key.

Turn off the power of the CD tuner.

LOADING

GRT AJST

tsm????e??

AUT YOBI

HAo :

RFg :

PTG :

|

Can't ADJ.

COMPLETE

AUT YOBI Return to menu display.

Test mode

Defective adjustment

(problem with the servo system)

Adjutment end

Data writes to the EEPROM and turns the

system power to off. Test mode returns to

the normal mode.

Remarks

5 Normal Adjustment

Step No.

1 EJECT

2 Insert the test disc GGF1328 (MMD-212).

3 Press the MENU key (until "AUT YOBI" is displayed). Normal adjustment mode

4

5

Operation Keys and Operation Method FL Display Status

In the Power ON state, selecting MD function,short the

"MECHA TEST pin".

Normal adjustment starts when the 6 key is

pressed.

Press the 7 (STOP) key.

LOADING

GRT AJST

AUT AJST

PEG :

HAG :

|

Can't ADJ.

COMPLETE

AUTO AJST Return to menu display.

Test mode

Defective adjustment

(problem with the servo system)

Adjutment end

Remarks

33

Page 34

MJ-NS1

6 Defocus Adjustment

It is possible from steps 3 of this item in the state of step 5 of 5 .

Step No.

1 EJECT

2

3 Press the MENU key.(until "deFO AJST" is displayed.) deFO AJST

4

5

6 Press the ¶ (REC) key.

7

8

9

10 Press the 6 key. COMPLETE

11 Turn off the power of the CD tuner. Release from the test mode.

Operation Keys and Operation Method FL Display Status

In the Power ON state, selecting MD function,short the

"MECHA TEST pin".

Insert the test disc GGF1328 (MMD-212).

Press the 6 key.

of c

Defocus Value C1 Error Value

Check the jitter value and end the adjustment when

the intermediate jitter value is 29 nsec or less.

Press the ¶ (REC) key. of-04 c0020

When J+ is larger than J-, press the ¶ (REC) key and

display the C1 error when the focus offset is applied

up to +0.4µm.

(Do nothig when J- is larger than J+.)

Change the value with 1 and ¡ keys until the

value becomes the same.

LOADING

GRT AJST

PEG :

FESpp :

of000c0015

of+04 c0032

of+04 c0032

of+04 c0032

of+03 c0025

of+02 c0020

Test mode

Defocus mode is entered, and after

automatic execution of normal adjustment,

the C1 error at the time of focus offset 0 is

displayed.

The C1 error with application of a focus

offset of about 0.4µm on the + side is

displayed. The jitter value (J+) at this time

is recorded.

The C1 error with application of a focus

offset of about 0.4µm on the – side is

displayed. The jitter value (J–) at this time

is recorded.

When the smaller offset of the jitter value

has been corrected mistakenly, press the

ENTER key and return to step 4.

The mean value of the changed set value

and the offset of the other setting limit is

written into the EEPROM as the

compensation offset.

Remarks

Connection Diagram

Jitter Meter

LEVEL

GND

MD CORE MAIN UNIT

SIDE A

JITTER

EFM MON

REFO

34

Page 35

7 Jitter/C1 Error Check at the time of Playback

Step No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Operation Keys and Operation Method

In the Power ON state, selecting MD function,short the

"MECHA TEST pin".

Insert the test disc GGF1328 (MMD-212).

Perform "5 Normal Adjustment" (steps 3 to 5).

Press the ¶ (REC) key.

Press the SET key and display the inner

circumference address.

Press the 6 key and display the C1 error for the

inner circumference.

Press the DISPLAY key.

Press the DISPLAY key.

Press the 7 (STOP) key.

Press the SET key and display the inner

circumference address.

Press the ¶ (REC) key and display the intermediate

circumference address. Perform steps 6 to 9 in this

condition.

Press the SET key and display the inner

circumference address.

Press the ¶ (REC) key twice to display the outer

circumference address. Perform steps 6 to 9 in this

condition.

Press the 0 (MD EJECT) key, eject the test disc

GGF1328 (MMD-212), and insert TGYS1 (or MMD-

110).

Perform steps 3 to 13 and check the jitter/C1 error with

the test disc TGYS1 (or MMD-110).

FL Display

LOADING

GRT AJST

AUT AJST

TEST PLAY TEST PLAY mode

ADRES 0050

a0050 c0015

A0062 c0013

AVE. c0012

a006F c0017

TEST PLAY

ADRES 0050

ADRES 03C0

a03C0 c0009

TEST PLAY

ADRES 0050

ADRES 0700

a0700 c0008

TEST PLAY

LOADING

GRT AJST

a0062 c0009

a03d2 c0007

a0712 c0006

EJECT

EJECT

MJ-NS1

Status

Test mode

Check that the jitter value meets the

standard value of the following table.

GGF1328 (MMD-212) jitter value

Inner circumference 31 nsec or less

Intermediate circumference 29 nsec or less

Outer circumference 29 nsec or less

Seven data are acquired, the largest and

the smallest value are discarded, and fixed

display is made for the mean value of the

remaining five data. Check that this value

is 200 or less.

The fixed display of the C1 error is enabled.

Check that the jitter value meets the

standard value of the following table.

TGYS1 (or MMD-110) jitter value

Inner circumference 29 nsec or less

Intermediate circumference 27 nsec or less

Outer circumference 27 nsec or less

Remarks

Intermediate and outer

circumference may be omitted.

Press the 0 (MD EJECT) key.

16

Power OFF Release from the test mode.

17

Connection Diagram

Jitter Meter

LEVEL

GND

JITTER

REFO

EJECT

MD CORE MAIN UNIT

EFM MON

The test disc TGYS1 (or MMD-110) is ejected.

SIDE A

35

Page 36

MJ-NS1

8 Jitter/C1 Error Check at the time of Recording/Playback

Step No.

1 EJECT

2

3 AUTO AJST

4 TEST REC

5

6

7

8

9 Perform step 6.

10

11

12 Perform step 6.

13

14

Operation Keys and Operation Method

In the Power ON state, selecting MD function,short the

"MECHA TEST pin".

Insert the test disc GGF1277 (or MMD-317).

Perform "5 Normal Adjustment" (steps 3 to 5).

Press the ¶ (REC) key.

Press the SET key and display the inner

circumference address.

When the 6 key is pressed, TEST REC starts, and

when 25 addresses or more have been sent, stop by

pressing the 7 (STOP) key.

Press the SET key and display the inner

circumference address.

Press the ¶ (REC) key and display the intermediate

circumference.

Press the SET key and display the inner

circumference address.

Press the ¶ (REC) key twice and display the outer

circumference address.

Press the ¶ (REC) key.

Perform steps 5 to 13 of " 7 Jitter/C1 Error Check at

the time of Playback".

At the time of self-recording, wait for seven addresses

after TEST PLAY start, and then press the DISPLAY

key and enter into mean value mode.

(Good recording may not be possible for several

addresses at the beginning.)

FL Display

Test mode

LOADING

GRT AJST

TEST REC mode

a0050 pw0D

a0069 pw0D

TEST REC

a0050 pw0D

a03C0 pw0D

a03D9 pw0D

TEST REC

a0050 pw0D

a0700 pw0D

a0719 pw0D

TEST REC

TEST PLAY TEST PLAY mode

a0069 c0009

a03D9 c0007

a0719 c0006

Note:

When the initial address (0050) part of the

inner circumference (or intermediate/outer

circumference) has been used 1000 times

or more, press the 2 (SCAN) key and shift

the address by 10 hex. (The address is

shifted (up to 10 times) according to the

use frequency of the disc.)

Check that the jitter/C1 error at the

inner/intermediate/outer circumference of

GGF1277, and check that the jitter value

satisfies the standard value of the

following table.

GGF1277 jitter value

Status

Inner circumference 33 nsec or less

Intermediate circumference 31 nsec or less

Outer circumference 31 nsec or less

Remarks

Intermediate and outer

circumference may be omitted.

Press the 0 (MD EJECT) key.

15

Turn off the power of the CD tuner. Release from the test mode.

16

Connection Diagram

Jitter Meter

LEVEL

GND

JITTER

REFO

EJECT

MD CORE MAIN UNIT

EFM MON

The test disc (GGF1277) is ejected.

SIDE A

36

Page 37

7. GENERAL INFORMATION

SIDE B

MAIN UNIT

DC +9V

POWER SUPPLY POINT

DC –9V

GND

7.1 DIAGNOSIS

7.1.1 SINGLE OPERATION MODE

How to enter the single operation mode

1. Supply DC power to CN4103 power supply pin of the MD MAIN

UNIT. (Pin7 : +9V ,Pin8 : GND ,Pin9 : –9V)

2. Short-circuit the "P-ON" pin and "GND" pin.

Key operation in the single operation mode

[REC] : To record

[PLAY] : To playback

[STOP] : To stop the recording and playing

[EJECT] : To eject

[INPUT] (IN) : To switch the input in the recording mode

(Digital/Analog)

[+] : To search track forward

[–] : To search track reverse

[CUE] (FF) : To forward

[REV] : To reverse

MD key

MJ-NS1

About the recording input switch

Recording input is able to switch with the "INPUT" key.

Digital and analog are selected alternately whenever press the

"INPUT" key. Initial value is the Digital input mode.

Note:

(1) Recording input can switch only during REC PAUSE.

(2) Blue LED of the center of MD flashes in the single operation

mode.

(3) It cannot enter the adjustment mode of the mechanism unit in

the single operation mode.

Test Point

Short-circuit

MAIN UNIT

SIDE A

37

Page 38

MJ-NS1

7.1.2 POWER ON SEQUENCE

Outline

• When MD mechanism is normal, an operation of MD is decided whether communication is done normally.

When MD mechanism does not perform a correct operation, first confirm waveform of communication. (Refere to step 1.)

• The command that System controller transfers please refer to 4 from step 2.

1. Reset and communication

When it becomes the state that a mechanism controller can communicate,

Mech.

power

supply

PDOWN

RESET

DSTB

turn DSTB into "L".

DSCK

SYSDATA

MDDATA

System controller confirms that

DSTB became "L", and output

a clock. System controller and

Mechanism controller output

data in accordance with it.

2. Power ON

User

System controller

Mech.

controller

(MD mech.)

RESET

System controller always grasps the state of MD mechanism.

1 byte

32 byte

1 communication

Power on

Power on

command issue

INIT STANDBY EJECT END (NO DISC state)

Mechanism controller turns

DSTB into "H" if received

32 bytes.

38

Page 39

3. Disc insertion and TOC READ

MJ-NS1

User

System controller

Mech.

controller

(MD mech.)

4. PLAY

User

Insert a disc

TOC READ

command issue

EJECT END (NO DISC state)

• System controller always grasps the state of MD mechanism.

• Mechanism controller (MD mechanism) detects it when inserts a disc, and start loading.

• When do not perform a disc loading, it cannot conclude with defectiveness of MD Mechanism immediately.

Because when communication between System controller and mecanism controller does not complete,

do not perform a disc loading either.

Press the MD PLAY key

LOAD STOP STOPTOC READ

System controller

Mech.

controller

(MD mech.)

PLAY

command issue

STOP

• System controller always grasps the state of MD mechanism.

SEARCH PLAY

39

Page 40

MJ-NS1

7.1.3 DISASSEMBLY

Top Panel and MD Mechanism

Rear side

MD

Mechanism

1

1

17

KEY-R UNIT

KEY-L UNIT

IND UNIT

16

Top Panel MD

IC UNIT

3

× 3

MAIN UNIT

RELAY UNIT

12

14

Go to MD Mechanism Assy

MD Mechanism Assy

MD Shield Case

5

× 4

• Removal of the MD Mechanism Assy

1 Remove a screw A.

2 Disconnect the connectors (CN102, CN103 and CN105), open

the hook of part A, and tilt the upper side of the MD CORE

MAIN UNIT to the front.

3 Disconnect the connector (CN101) at the rear of the MD

CORE MAIN UNIT and remove the MD CORE MAIN UNIT.

2

CN105

Screw A

1

CN102

2

MD CORE MAIN UNIT

CN101

CN103

2

Part A

3

40

Page 41

MJ-NS1

4 Shift part B to the position shown in the figure while raising the

Under Slider. (At the same time, the Upper Slider moves to the

front.)

5 Remove the Lock Plate. (One screw C)

4

Part B

Under Slider

Upper Slider

• Removal of the MD Pickup

1 Remove the MD Head. (One screw A)

2 Remove the Screw Guide at the lower side of the MD Pickup.

(One screw B)

3 Remove the S. H. Spring. (One screw C)

4 Remove the hook of the S. H. Spring as shown in the figure.

Remove the hook after the

4

screw has been removed.

1

Screw A (M1.7 × 4)

MD Head

Screw C

3

(M1.7 × 3)

S. H. Spring

Servo Mechanism

Assy

Screw C

Lock Plate

5

6 Remove the Servo Mechanism Assy.

Servo Mechanism

Assy

6

• Caution for the time of installation of the servo

mechanism assy

Move the MD Pickup to the innermost circumference.

The Servo Mechanism Assy is not installed other than the

innermost circumference.

Screw Guide

2

5 Raise the left side of the Guide Shaft and pull it out to the left.

6 Remove the MD Pickup. (With the front facing down, remove it

to the front. At this time, the MD Pickup can be removed more

easily when the Reference Plate is removed.)

Guide

5

Shaft

Hook

Reference Plate

Screw B

(M1.4 × 2)

6

MD Pickup

41

Page 42

MJ-NS1

• MD Pickup Installation

Perform installation in reverse order of the removal. (Please use

care as the MD Head mounting screw can be crushed easily.

MD Head mounting screw tightening torque: 1.1 kg • cm

When the Reference Plate has been removed, confirm that the

hook is engaged with the shaft of the spindle motor. (Take care

that the mounting reference boss does not ride up.)

• S. H. Spring Installation

S. H. Spring

1

Insert

• Removal of the Head Lifter

1 Remove the Lifter SP.

2 Tilt the Head Lifter to the rear and push part A to disengage it.

Head Lifter

1

Lifter SP

Push

2

Part A

• Head Lifter Installation

1 Install part A in the Servo Base with the Head Lifter tilted to the

back.

2 Match the Head Lifter and the Servo Base as shown in the

figure, and then engage part B.

3 While holding part B with your hand, tilt the Head Lifter to the

front and install the Lifter SP.

2

Push in while changing

the point.

3

Press in with a screwdriver

or similar until the hook

becomes engaged.

Head Lifter

Head Lifter

Servo Base

Push

Part B

Part B

3

2

Part A

Matching

position

1

42

Confirm from the rear that the tip of

the hook is engaged sufficiently.

Page 43

MJ-NS1

7.2 IC

• The information shown in the list is basic information and may not correspond exactly to that shown in the schematic diagrams.

PDG257A [MAIN UNIT (2/2) : IC4101]

• System Control U-COM

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

FUCTION

PF3

PF4

PF5

PF6

PF7

PD0

PD1

PD2

PD3

PD4

PD5

PD6

PD7

PC0

PC1

PC2

PC3

PC4

PC5

PC6

PC7

PH0

PH1

PH2

PH3

PH4

PH5

PH6

PH7

RST

EXTAL

XTAL

Vss

PE6

PE7

Avss

Avref

PA0/AN0

PA1/AN1

PA2/AN2

PA3/AN3

PA4/AN4

PA5/AN5

PA6/AN5

PA7/AN7

PB0/LAT0

PB1/CS0

PB3/SCK0

PB3/SI0

PB4/SC0

PIN NAME NOTE ACTIVE

D.MUTE

(NC)

(NC)

(NC)

(NC)

TEST

TESTU

CHARA

(NC)

COPOW

(NC)

(NC)

(NC)

(NC)

LED1

LED2

LED3

LED4

DIM(MID)

DIM(HIGH)

(NC)

M.RST

M.MUTE

DSTB

P.DOWN

(NC)

XPBMUTE

(NC)

OUTSEL

RESET

EXTAL

XTAL

VSS

(NC)

(NC)

AVSS

AVREF

KEY0

KEY1

(NC)

(NC)

S.DATA

S.DATAIN

(NC)

PROTECT

(NC)

(NC)

DSCK

MD DATA

SYS DATA

I/O

DIN MUTE H: MUTE

O

O

O

O

O

MECHA TEST MODE Input

I

UNIT TEST MODE Input

I

CHARACTER Exist or Not (types) input L : Chara. exist

I

O

Codec Power control

O

O

O

O

big current port (12mA)

O

MONO LP big current port (12mA)

O

REC big current port (12mA)

O

DIGITAL big current port (12mA)

O

PLAY big current port (12mA)

O

H : light L : dark

O

H : H : L :

O

big current port (12mA)

O

MD MECHANISM control Rest Input

O

MD MECHANISM control MUTE request Input

I

MD MECHANISM control communication request Input

I

MD MECHANISM control power down detection output

O

O

MDPBMUTE output

O

O

PBSELECT output L : MD H: other

O

RESET

I

input terminal for ceramic oscillator device (10MHz)

I

output terminal for ceramic oscillator device

O

O

O

O

O

key detection input 0

I

key detection input 1

I

O

O

system bus data output

O

system bus data input

I

O

abnornal voltage detection input normal : 2.5V

I

O

O

MD MECHANISM control communication clock output

O

MD MECHANISM control communication data input

I

MD MECHANISM control communication data output

O

H

L

L

H

H

H

H

H

L

L

L

L

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

43

Page 44

MJ-NS1

No.

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

• I/O port is able to select function as input or output by 1bit unit.

FUCTION

PB5/SCK1PF4

PB6/SI1

PB7/SO1

PE0/EC0

PE1/EC1

PE2/CINT

PE3/NM1

PE4/PWM0

PES/TO/PWM1

PI0/INT0

PI1/INT1

PI2/INT2

PI3/INT3

PI4

PI5

PI6

PI7

PG0

PG1

PG2

PG3

VDD

NC

PG4

PG6

PG6

PG7

PF0

PF1

PF2

PIN NAME NOTE ACTIVE

D.CLK

(NC)

D.DATA

(to GND)

(to GND)

(to GND)

(to GND)

(NC)

(NC)

S.CLK

D.REQ

(NC)

(NC)

(NC)

(NC)

(NC)

(NC)

(NC)

(NC)

(NC)

(NC)

VDD

(NC)

DSTB

(NC)

(NC)

(NC)

(NC)

(NC)

(NC)

I/O

I/O

I/O

I

I

I

I

I

O

O

I

I

-

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

MD display communication clock output

MD display communication data output

Take care to use also device test terminal

Take care to use also device test terminal

system bus clock input

MD display communication request input

-

44

Page 45

AK4519VF [MD CORE MAIN UNIT : IC110]

• Audio Codec IC

MJ-NS1

.

.

.

45

Page 46

MJ-NS1

8. PANEL FACILITIES AND SPECIFICATIONS

4

3

5

2

6

1

7

8

9

Top Panel

1. 6 – Press to play an MD, or pause one that's already

playing (press again to restart playback). In record mode,

also use to start or pause recording.

2. 7 – Press to stop playback or recording of the current MD.

3. MD loading slot

4. ¶ – Press to record.

5. 0 – Press to eject the MD.

46

Front Panel

6. MD REC indicator – Lights up during record or record-pause

mode.

7. Mono indicator – Lights up when recording in mono.

8. PLay indicator – Lights up while paused or during playback.

9. Digital indicator – Lights up when MD recorder is in digital

signal input mode.

Page 47

SPECIFICATIONS

Recording method Magnetic field modulation

overwritten type

Playback method ........Non-contact optical type

Sampling frequency 44.1KHz,32KHz,48KHz

Frequency response................... 20Hz – 20KHz

Wow and flutter............... Limit of measurement

(±0.001% W.PEAK) or less (EIAJ)

Power requirements ...................................... DC

Dimensions ........ 170(W) × 268(H) × 66 (D) mm

(without stands)

Weight ........................................................ 1.5kg

Accessories

Optical digital cable .......................................... 1

Stand A.............................................................. 1

Stand B............................................................. 1

Operating instructions ...................................... 1

Note: Specifications and design subject to possible

modification without notice,due to improvement.

MJ-NS1

Cleaning external surfaces

To clean this unit,wipe with a soft,dry cloth. For

stubborn dirt,wet a soft cloth with mild detergent

solution made by diluting one part detergent to 5

or 6 parts water,wring well,then wipe off the dirt.

Use a dry cloth to wipe the surface dry. Do not

use volatile liquids such as benzene and thinner

which may damage the surfaces.

Accessories

Optical digital cable

(RKX1031)

Stand A

(AXG7096)

Stand B

(AXG7097)

47

Loading...

Loading...