Page 1

MINIDISC RECORDER

MINIDISC RECORDER

MJ-D707

TIMER

REC

OFF

PLAY

DISC LOADING MECHANISM

PUSH ENTER

EDIT

/

NO

NAME

ANALOG

COAX

OPT

0

1

2

3

4

5

6

7

8

9

10

INPUT SELECTOR REC LEVEL

DIGITAL

NR

REPEAT

A B

TIME SKIP

PLAY

MODE

REC

MODE

NAME

CLIP

DISPLAY

/ CHARA

STANDBY

POWER

— OFF _ ON

SYNCHRO

REC

MIN

MAX

PHONES

LEVEL

)

EJECT

$

$

!

!

#

*

&

Î

Legato Link Conversion

MJ-D707

MJ-17D

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

ORDER NO.

RRV1963

Type

Model

MJ-D707 MJ-17D

KU AC120V

MY –– AC220–230V

MY/GR/FR –– AC220–230V

CONTENTS

1. SAFETY INFORMATION....................................2

2. EXPLODED VIEWS AND PARTS LIST .............4

3. SCHEMATIC DIAGRAM...................................12

4. PCB CONNECTION DIAGRAM ....................... 28

5. PCB PARTS LIST.............................................37

6. ADJUSTMENT..................................................41

Power Requirement

Remarks

7. GENERAL INFORMATION .............................. 49

7.1 PARTS .......................................................49

7.1.1 IC .......................................................49

7.1.2 DISPLAY ...........................................60

7.2 DIAGNOSIS................................................61

7.2.1 DISASSEMBLY .................................61

7.2.2 DETAILS OF ERROR DISPLAY .......63

7.3 BLOCK DIAGRAM......................................65

8. PANEL FACILITIES AND SPECIFICATIONS

.......................................................66

PIONEER ELECTRONIC CORPORATION 4-1, Meguro 1-Chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS SERVICE, INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER ELECTRONIC (EUROPE) N.V . Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 501 Orchard Road, #10-00 Wheelock Place, Singapore 238880

PIONEER ELECTRONIC CORPORATION 1998

T–DZE JUNE 1998 Printed in Japan

Page 2

MJ-D707, MJ-17D

1. SAFETY INFORMATION

This service manual is intended for qualified service technicians; it is not meant for the casual

do-it-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to

cause cancer, birth defects or other reproductive harm.

Health & Safety Code Section 25249.6 – Proposition 65

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement parts

must be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les

pièces de remplacement doivent avoir la même désignation.

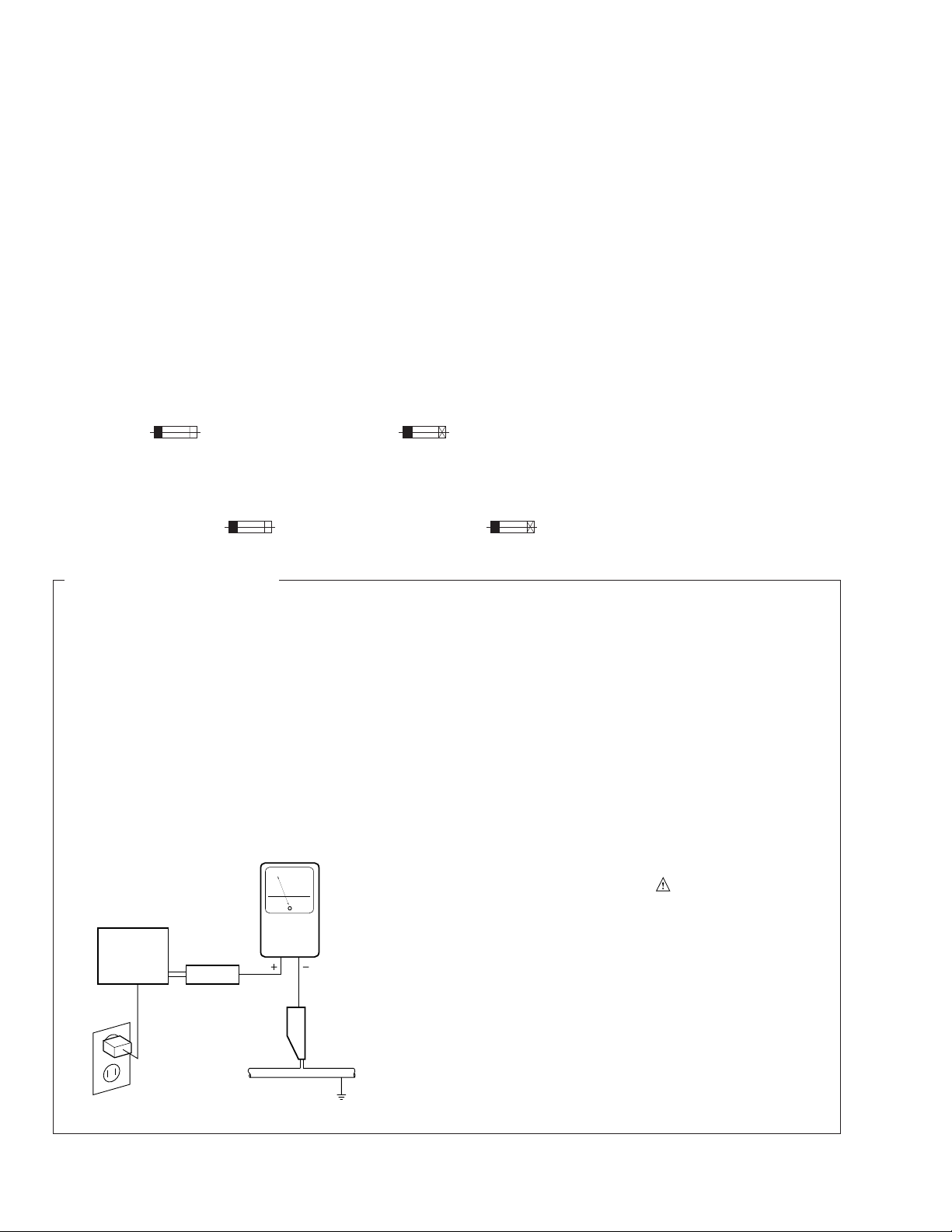

(FOR USA MODEL ONLY)

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and service

technician.

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground

(water pipe, conduit, etc.) by connecting a leakage

current tester such as Simpson Model 229-2 or

equivalent between the earth ground and all exposed

metal parts of the appliance (input/output terminals,

screwheads, metal overlays, control shaft, etc.). Plug

the AC line cord of the appliance directly into a 120V

AC 60 Hz outlet and turn the AC power switch on. Any

current measured must not exceed 0.5 mA.

Reading should

not be above

0.5 mA

Earth ground

Device

under

test

Also test with plug

reversed

(Using AC adapter

plug as required)

Leakage

current

tester

Test all exposed

metal surfaces

AC Leakage Test

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL SHOCK HAZARD AND MUST BE CORRECTED BEFORE RETURNING THE APPLIANCE

TO THE CUSTOMER.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance have special safety related characteristics. These

are often not evident from visual inspection nor the

protection afforded by them necessarily can be obtained by using replacement components rated for

voltage, wattage , etc. Replacement parts which have

these special safety characteristics are identified in

this Service Manual.

Electrical components having such features are

identified by marking with a

on the parts list in this Service Manual.

The use of a substitute replacement component which

does not have the same safety characteristics as the

PIONEER recommended replacement one, shown in

the parts list in this Service Manual, may create shock,

fire, or other hazards.

Product Safety is continuously under review and

new instructions are issued from time to time. For

the latest information, always consult the current

PIONEER Service Manual. A subscription to, or additional copies of, PIONEER Service Manual may be

obtained at a nominal charge from PIONEER.

on the schematics and

2

Page 3

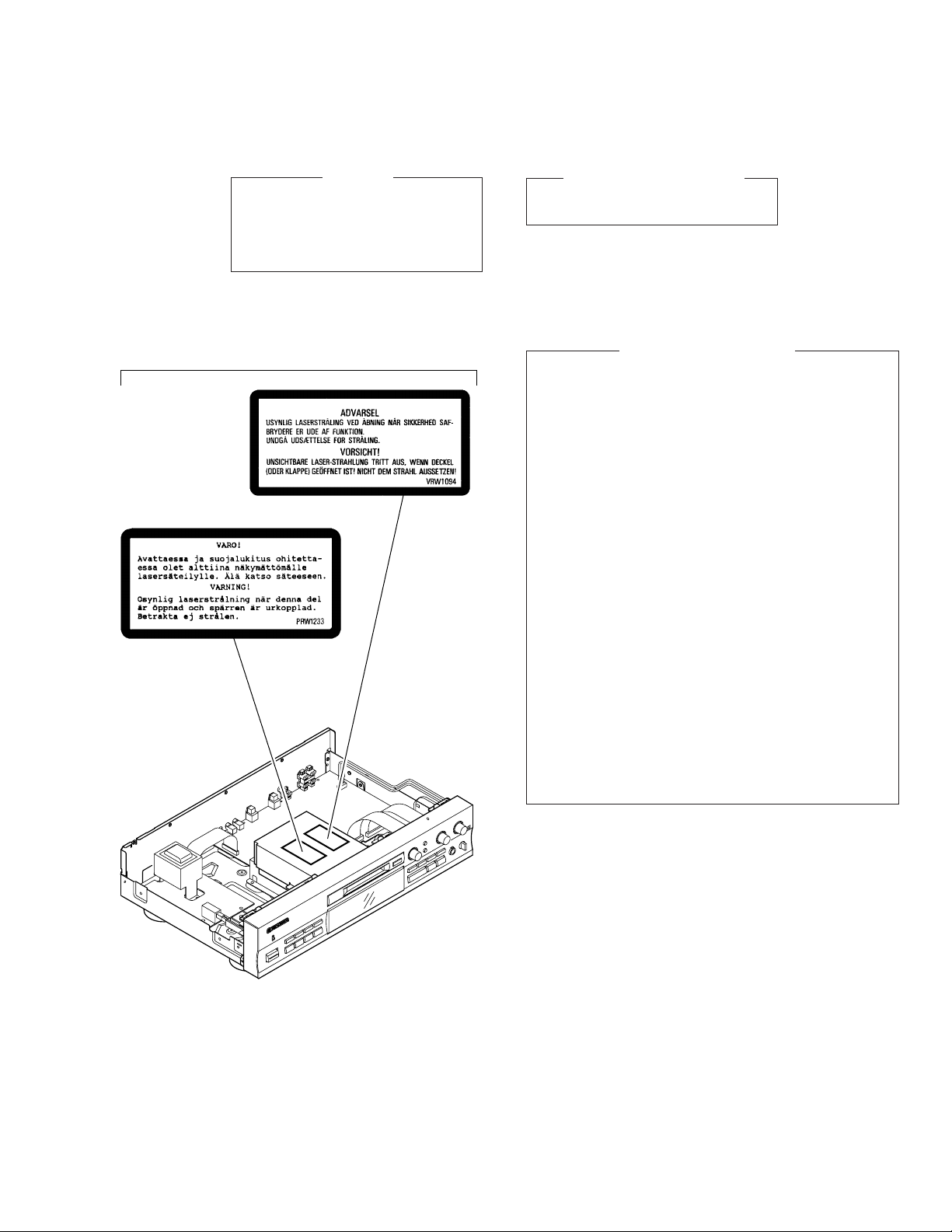

MJ-D707, MJ-17D

THIS PIONEER APPARATUS CONTAINS

LASER OF CLASS 1.

SERVICING OPERATION OF THE APPARATUS

SHOULD BE DONE BY A SPECIALLY

INSTRUTED PERSON.

LABEL CHECK

IMPORTANT

MY and MY/GR/FR types

LASER DIODE CHARACTERISTICS

MAXIMUM OUTPUT POWER: 32 mw

WAVELENGTH: 785 nm

Additional Laser Caution

Laser pick-up assembly

The output power at the objective lens of this assembly is 0.73 mW.

Control method of the current through a laser diode.

The resistor R105 on the CORD MAIN UNIT ASSY (For MD

mechanism assembly) are for the limiting of current through a laser

diode.

Control method of the laser output power

The laser pick-up assembly provide the photo-diodes and APC

(Auto Power Control) circuit.

The photo-diode detect output of the laser diode then IC104 control

the APC circuit according to the signal voltage of the photo-diode via

IC101.

The Variable resistancer on the FPC in the Laser pick-up assembly

can be adjusted the output level of Laser diode to fix the rated output

level.

Laser Interlock Switch

The loading position detect switch S101 is set to “ LOAD ON ” (ON:

low level, OFF: high level) position, IC104 get the “ LOAD ” signal,

and hand the laser “ LDON ” signal to No. 9 terminal (LDON) of the

Laser pick-up assembly.

Then a laser diode can be lighted exept when the level of signal

“LOAD ” is low.

∗ Refer to page 42.

3

Page 4

MJ-D707, MJ-17D

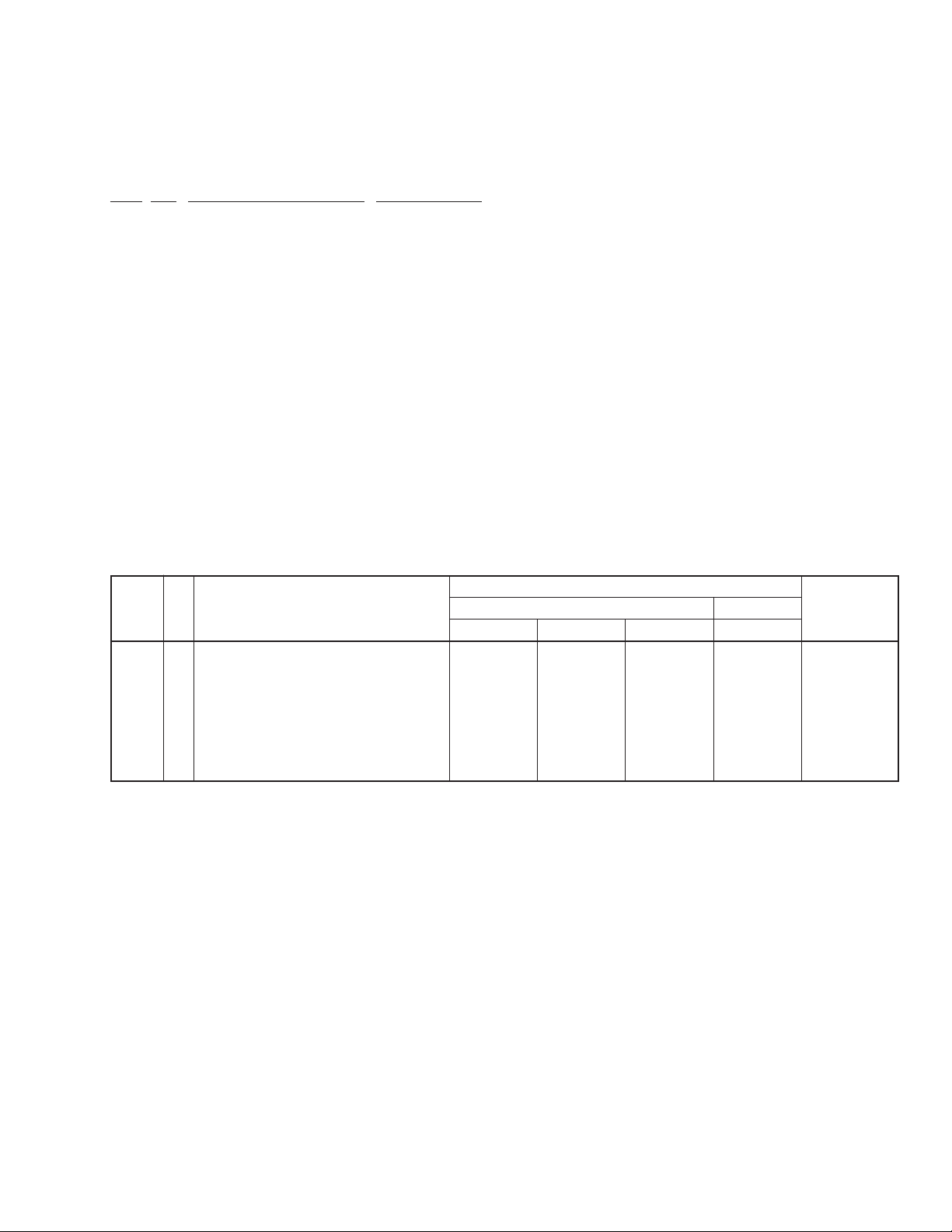

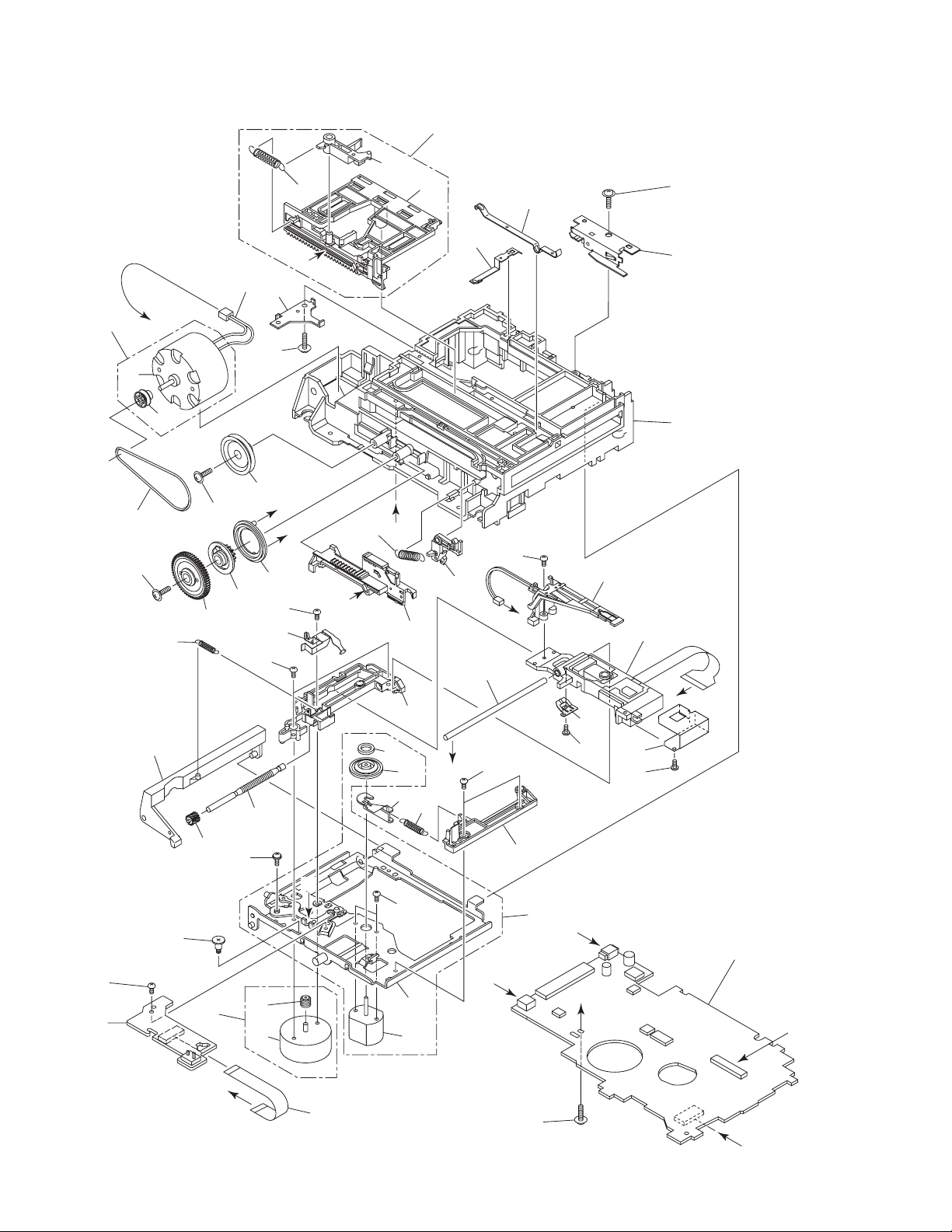

2. EXPLODED VIEWS AND PARTS LIST

NOTES : Parts marked by “ NSP ” are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

Screw adjacent to mark on the product are used for disassembly.

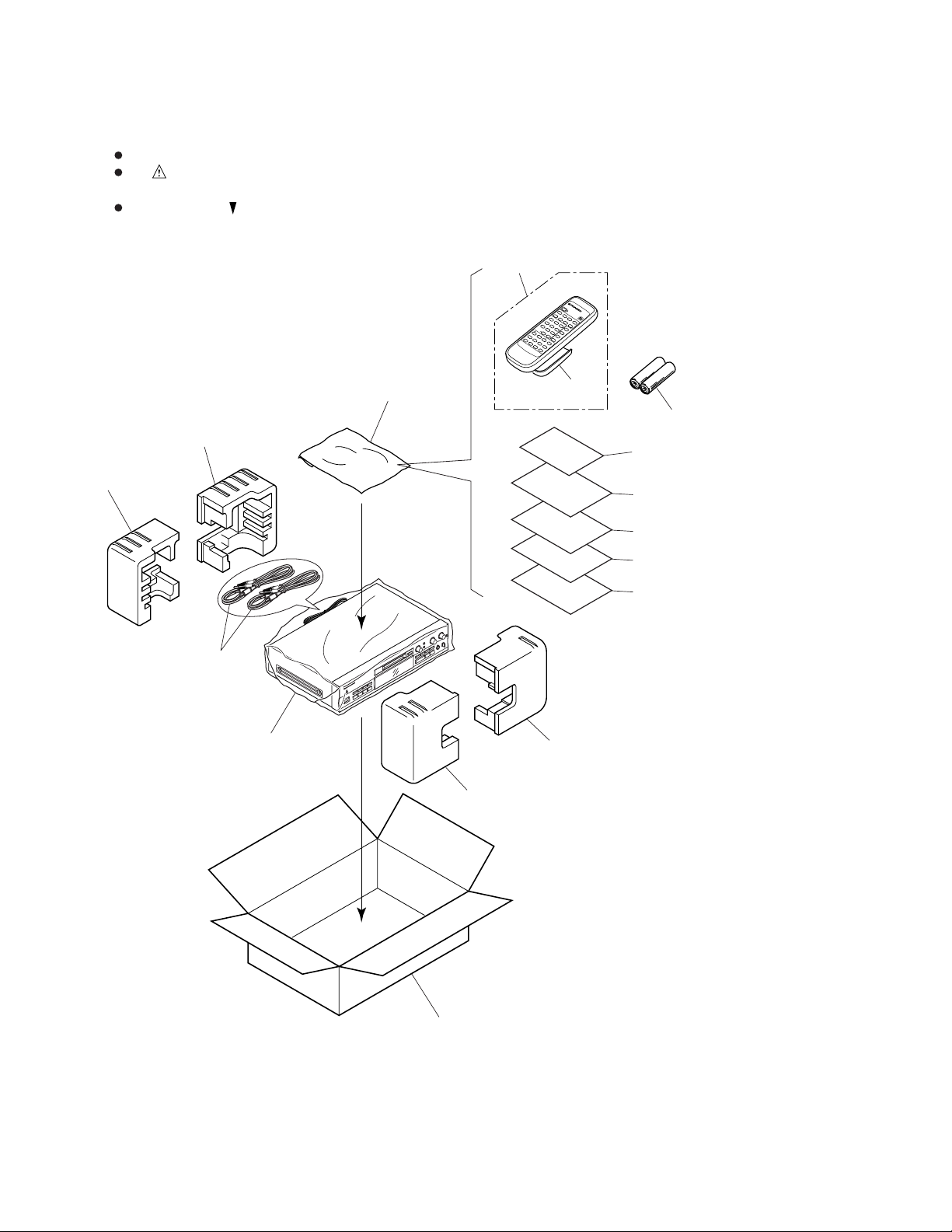

2.1 PACKING

2 (1/2)

2 (2/2)

6

RANDOMHI-LITE MEDLEY FADER

STANDBY/ ON

REPEAT PGM CHECK CLEAR

1 2 3

ABC DEF

GHI JKL MNO

4 5 6

PQRS TUV WXYZ

7 8 9

DISP

CHARA

/

MARK

EDIT

10/0

/

NO

REC

SYNCHRO

NAME

>

!

10

REC

CURSOR

NAME

CLIP

&

!

ENTERA B

$

*

MINIDISC

REMOTE CONTROL UNIT

#

RECORDER

$

TIME

SKIP

Î

9

7

8

10

11 (MJ-D707/KU, MY only)

12 (MJ-D707/MY, MY/GR/FR only)

13 (MJ-D707/MY only)

14 (MJ-17D/KU only)

5

4

1 (2/2)

1 (1/2)

3

4

Page 5

(1) PACKING PARTS LIST

Mark No. Description Part No.

1 Protector (F) RHA1238

2 Protector (R) RHA1239

3 Packing Case

4 Sheet (750 × 600 × 0.5) Z23–007

5 Audio Cord (L= 1m) PDE1248

6 Remote Control Unit RPX1131

(CU-MJ011)

7 Battery Cover RZN1156

NSP 8 Batteries (AA/R6P) VEM–013

9 Polyethylene Bag Z21–038

(0.03 × 230 × 340)

NSP 10 Warranty Card

See Contrast table (2)

See Contrast table (2)

MJ-D707, MJ-17D

11 Operating Instructions

12 Operating Instructions

13 Operating Instructions

14 Operating Instructions

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

(2) CONTRAST TABLE

MJ-D707/KU, MY, MY/GR/FR and MJ-17D/KU are constructed the same except for the following:

Part No.

Mark

No.

3 Packing Case RHG1876 RHG1874 RHG1874 RHG1877

NSP 10 Warranty Card ARY1044 ARY7008 ARY7008 ARY1026

11 Operating Instructions (English/Spanish) RRE1162 RRE1162 Not used Not used

12 Operating Instructions (French/German) Not used RRD1198 RRD1198 Not used

13 Operating Instructions Not used RRD1199 Not used Not used

14 Operating Instructions (English) Not used Not used Not used RRB1185

Symbol and Description

(Portuguese/Italian/Dutch/Swedish)

MJ-D707 MJ-17D

KU MY MY/GR/FR KU

Remarks

5

Page 6

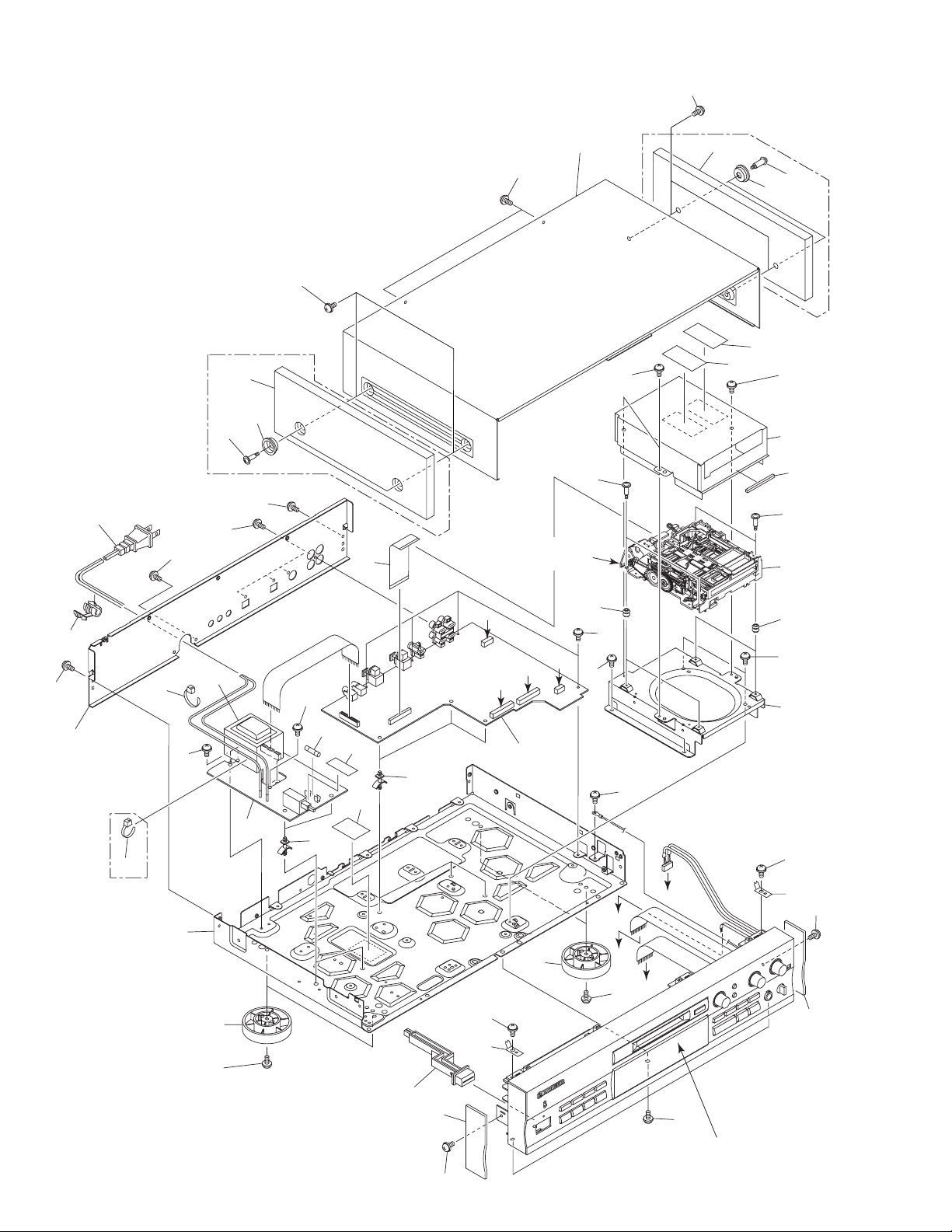

MJ-D707, MJ-17D

20 (Except MJ-17D/KU)

2.2 EXTERIOR

4

21

20 (Except MJ-17D/KU)

MJ-17D/KU only

28

25

24

21

21

MJ-17D/KU only

17

21

21

9

5

Refer to “2.4 MD

MECHANISM ASSY”.

29

31

30

25

24

21

14

35

9

16

3

21

11

23

MY and MY/GR/FR

types only

23

13

21

7

18

21

C

CN602

33

10

21

10

33

12

21

22

D

C

36

21

B

A

21

27

32

D

CN601

B

A

21

6

34

37

2

8

CN401

15

19

26

CN402

22

36

CN403

1

18

Refer to “2.3 FRONT PANEL SECTION”.

21

6

Page 7

(1) EXTERIOR PARTS LIST

MJ-D707, MJ-17D

Mark No. Description Part No.

1 MAIN UNIT ASSY

2 TRANS UNIT ASSY

3 Strain Relief

4 AC Power Cord

5 Lead Card 30P RDD1402

6 Fuse

7 Power Transformer RTT1316

NSP 8 PCB Holder PNW2100

9 Float Screw RBA1133

10 Float Rubber REB1328

11 Rear Panel

12 Mecha Angle RNB1133

13 Under Base RNB1134

14 Shield Case RNB1139

NSP 15 PC Support VEC1549

NSP 16 MD Mechanism Assy RXA1773

17 Bonnet PYY1147

18 Insulator PNW2766

19 POWER Button B RAC2207

20 Screw

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

Mark No. Description Part No.

21 Screw IBZ30P060FCC

22 Screw IBZ30P080FCC

23 Binder ZCA–SKB90BK

24 Screw

25 Wood Collar

26 Gold Mole (L)

27 Gold Mole (R)

28 Side Wood (L)

29 Side Wood (R)

30 Caution Label

31 Caution Label

32 Screw BBT30P080FCC

33 Screw RBA1132

34 Fuse Label

35 Case Spacer REB1330

36 Plate VNE1164

37 Fuse Caution Label

(2) CONTRAST TABLE

MJ-D707/KU, MY, MY/GR/FR and MJ-17D/KU are constructed the same except for the following:

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

Mark

Part No.

No.

Symbol and Description

MJ-D707 MJ-17D

KU MY MY/GR/FR KU

1 MAIN UNIT ASSY RWZ4309 RWZ4293 RWZ4293 RWZ4288

2 TRANS UNIT ASSY RWZ4313 RWZ4297 RWZ4297 RWZ4292

3 Strain Relief CM–22C CM–22B CM–22B CM–22C

4 AC Power Cord PDG1015 PDG1003 PDG1003 PDG1015

6 Fuse (1A/125V) REK1075 Not used Not used REK1075

6 Fuse (500mAL250V) Not used REK1019 REK1019 Not used

11 Rear Panel RNA2204 RNA2204 RNA2204 RNA2205

20 Screw

24 Screw Not used Not used Not used PBA1103

25 Wood Collar Not used Not used Not used PNW1238

26 Gold Mole (L) Not used Not used Not used RAH2865

27 Gold Mole (R) Not used Not used Not used RAH2866

28 Side Wood (L) Not used Not used Not used RMS1019

29 Side Wood (R) Not used Not used Not used RMS1020

30 Caution Label Not used RRW1233 RRW1233 Not used

31 Caution Label Not used VRW1094 VRW1094 Not used

34 Fuse Label RRW1294 Not used Not used RRW1294

37 Fuse Caution Label RRW–111 Not used Not used RRW–111

FBT40P080FZK FBT40P080FZK FBT40P080FZK

Not used

Remarks

7

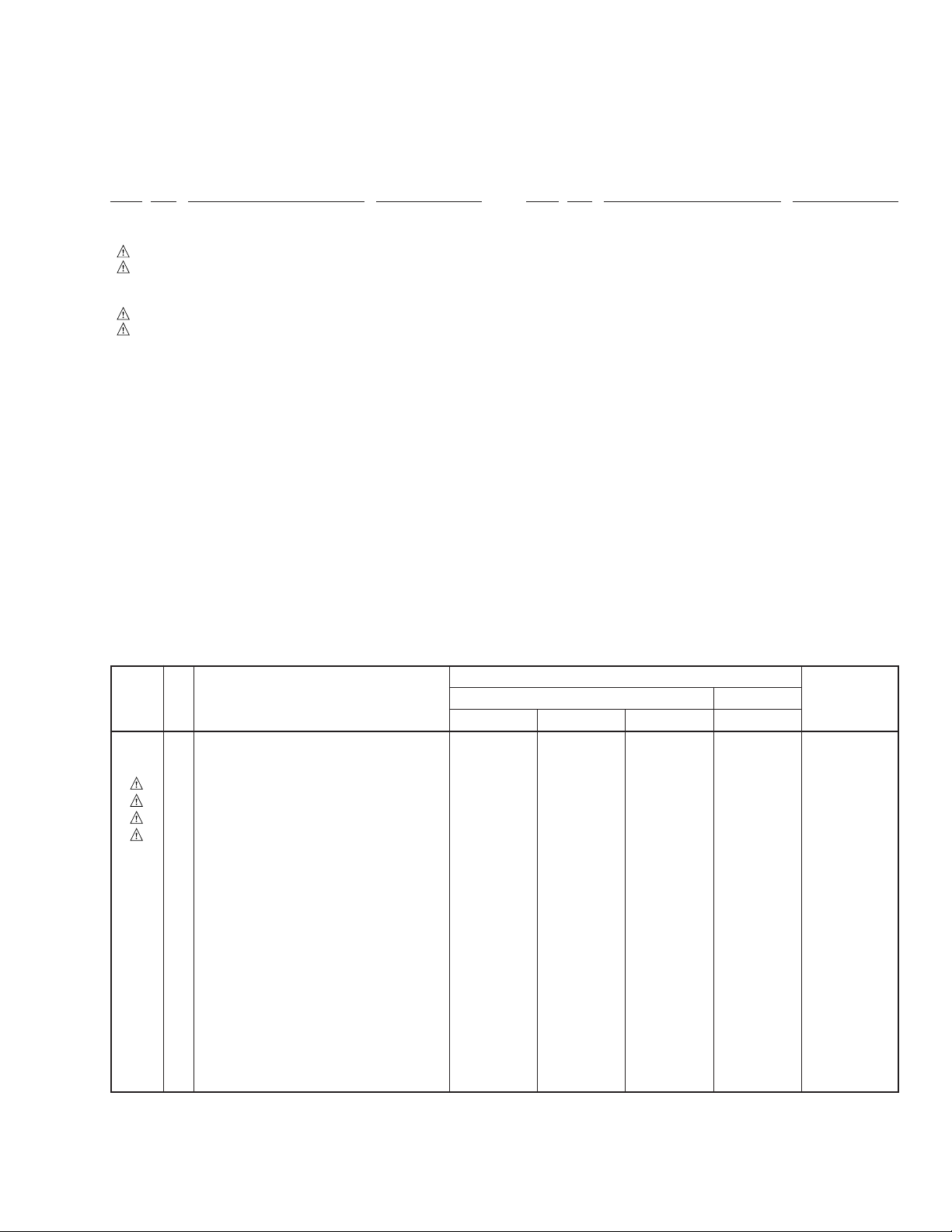

Page 8

MJ-D707, MJ-17D

2.3 FRONT PANEL SECTION

Not used

Cut

23

1

5

23

6

23

20

2

12 (1/2)

14

15

Cut

24

11

4

12 (2/2)

18

Cut

16

22

A

3

8

A

10

13

12 (1/2)12 (2/2)

21

9

7

17

19

8

Page 9

(1) FRONT PANEL SECTION PARTS LIST

Mark No. Description Part No.

MJ-D707, MJ-17D

1 DISPLAY UNIT ASSY

2 CONTROL UNIT ASSY

3 HEADPHONE UNIT ASSY

4 Door Holder RAH2852

5 Door Cam RAH2853

6 Door Spring RBH1459

7 Name Plate AAM7004

8 HEADPHONE Knob PAC1707

9 LED Lens PNW2019

10 VOL Knob RAC2197

11 PLAY Button B RAC2204

12 Slide Knob B RAC2208

13 JOG Knob B RAC2210

14 PLAY MODE Button B RAC2212

15 REC MODE Button B RAC2214

16 SEARCH Button B RAC2216

17 Front Panel

18 Door

19 Display Window RAH2862

20 FL Sheet

21 Panel Stay B RNT1250

22 Screw ABA7009

23 Screw PPZ30P100FMC

24 Edge Guard RBK1078

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

(2) CONTRAST TABLE

MJ-D707/KU, MY, MY/GR/FR and MJ-17D/KU are constructed the same except for the following:

Part No.

Mark

No.

1 DISPLAY UNIT ASSY RWZ4310 RWZ4294 RWZ4294 RWZ4289

2 CONTROL UNIT ASSY RWZ4311 RWZ4295 RWZ4295 RWZ4290

3 HEADPHONE UNIT ASSY RWZ4312 RWZ4296 RWZ4296 RWZ4291

17 Front Panel RAH2870 RAH2859 RAH2859 RAH2860

18 Door RAH2861 RAH2861 RAH2861 RAH2851

20 FL Sheet RAH2863 RAH2855 RAH2855 RAH2863

Symbol and Description

MJ-D707 MJ-17D

KU MY MY/GR/FR KU

Remarks

9

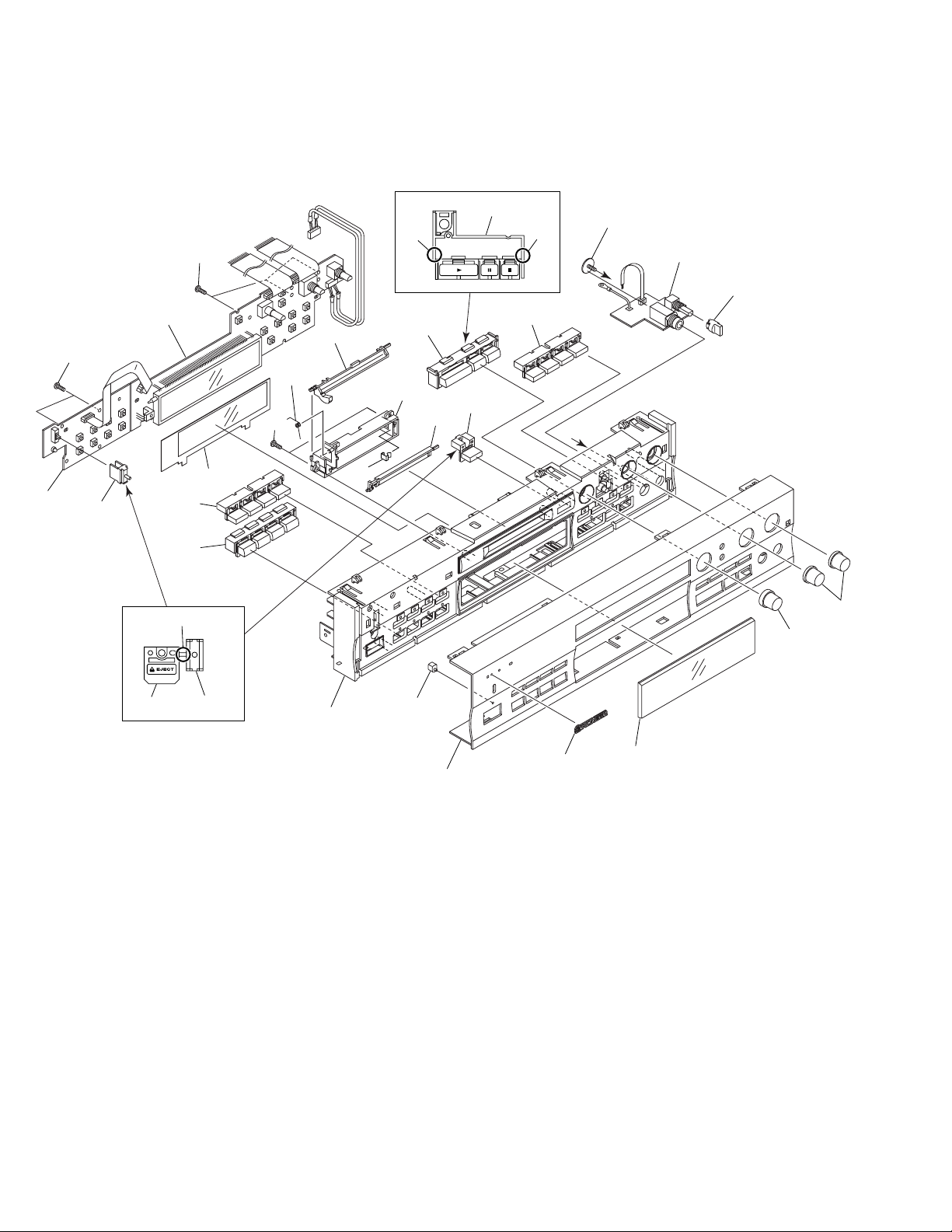

Page 10

MJ-D707, MJ-17D

2.4 MD MECHANISM ASSY

19

21

20

18

37

6

51

52

8

37

34

7

E

4

9

17

A

37

53

24

14

37

13

12

40

15

40

26

E

F

5

G

41

16

35

F

11

B

27

10

36

C

28

44

33

31

23

40

H

25

39

29

3946

10

40

32

42

30

H

38

22

43

B

CN102

1

A

2

48

49

50 47

45

CN105

G

C

CN101

D

3

37

CN103

D

Page 11

MD MECHANISM ASSY PARTS LIST

Mark No. Description Part No.

MJ-D707, MJ-17D

Mark No. Description Part No.

1 CORE MAIN UNIT ASSY RWZ4271

2 CORE SW UNIT ASSY RWZ4272

3 Lead Card 7P RDD1399

4 Lead Wire RKP1814

5 Lever Spring RBH1463

6 Clamp Spring 1 RBK1074

7 Clamp Spring 2 RBK1075

8 Loading Belt REB1329

9 Lock Plate RNE1949

10 Loading Base RNK2312

11 Under Slider RNK2314

12 Gear Pulley RNK2316

13 Drive Gear RNK2317

14 Clutch Gear RNK2318

15 Flip Disk RNK2319

16 SW Lever RNK2320

17 Shutter Assy RXA1774

NSP 18 Upper Slider Assy RXA1775

19 Eject Spring RBH1461

20 Upper Slider RNK2313

21 Carrier RNK2315

22 Screw RBA1129

23 Spindle Spring RBH1460

24 Lifter SP RBH1462

25 Screw Guide RBK1072

41 Screw JGZ17P040FZK

42 Screw PMB20P040FMC

43 Servo Base Assy REA1283

NSP 44 Clamp Magnet RMF1002

NSP 45 Servo Base RNE1946

NSP 46 Disc Table RNK2305

NSP 47 Spindle Motor RXM1091

48 Carriage Motor Assy REA1284

49 Worm RNK2308

NSP 50 Carriage Motor RXM1090

51 Loading Motor Assy REA1285

52 DC Motor /0.75W PXM1010

53 CA Pulley (1) VNL1197

26 S. H. Spring RBK1073

27 Guide Shaft RLA1310

28 Lead Screw RLA1311

29 Shield Case RNE1950

30 Reference Plate RNK2306

31 S. Holder RNK2307

32 Worm Wheel RNK2309

33 Hook RNK2310

34 Head Lifter RNK2311

35 MD Head RPB1062

36 MD Pick-up RWY1018

37 Screw IPZ20P080FMC

38 Screw JFZ17P020FZK

39 Screw JGZ14P020FMC

40 Screw JGZ17P030FMC

11

Page 12

1

MJ-D707, MJ-17D

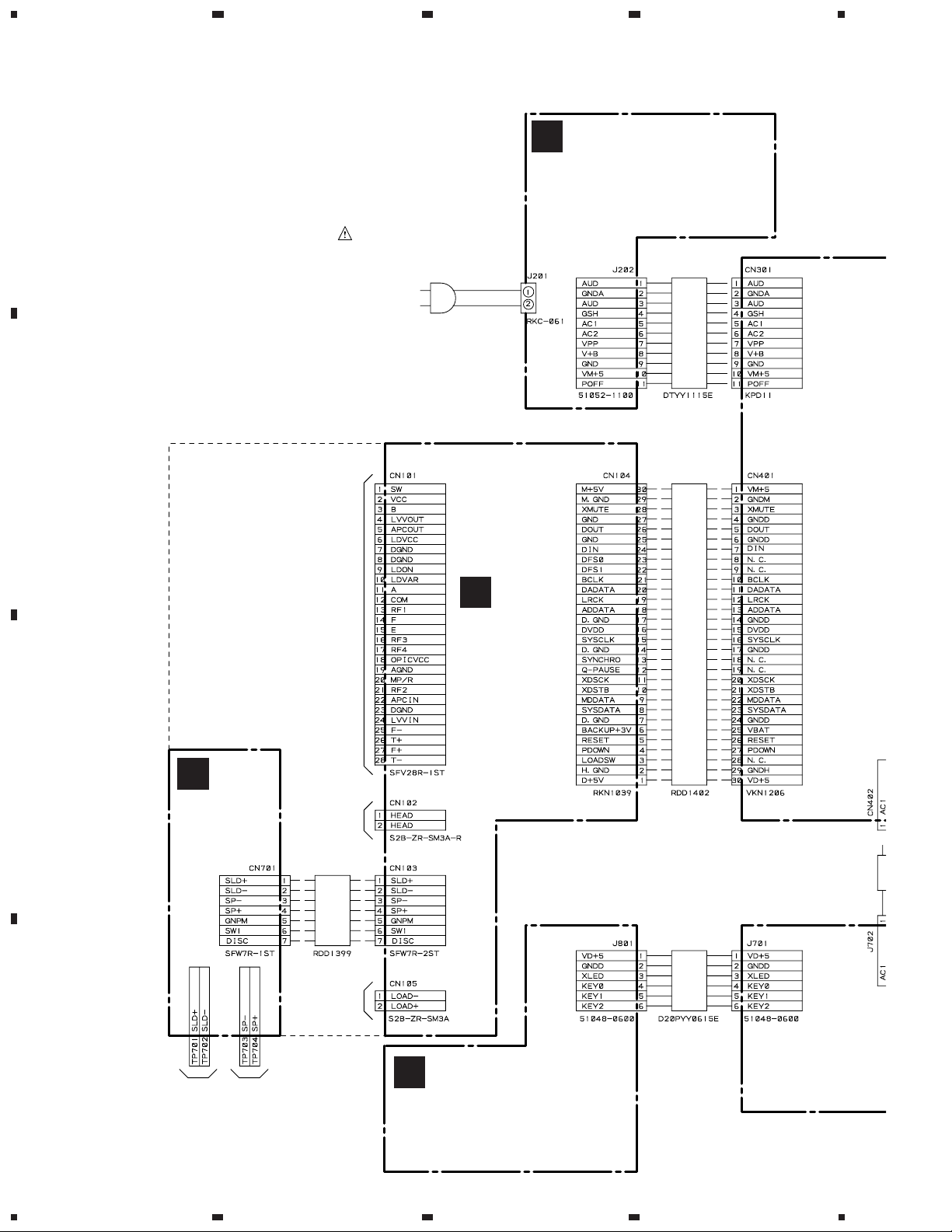

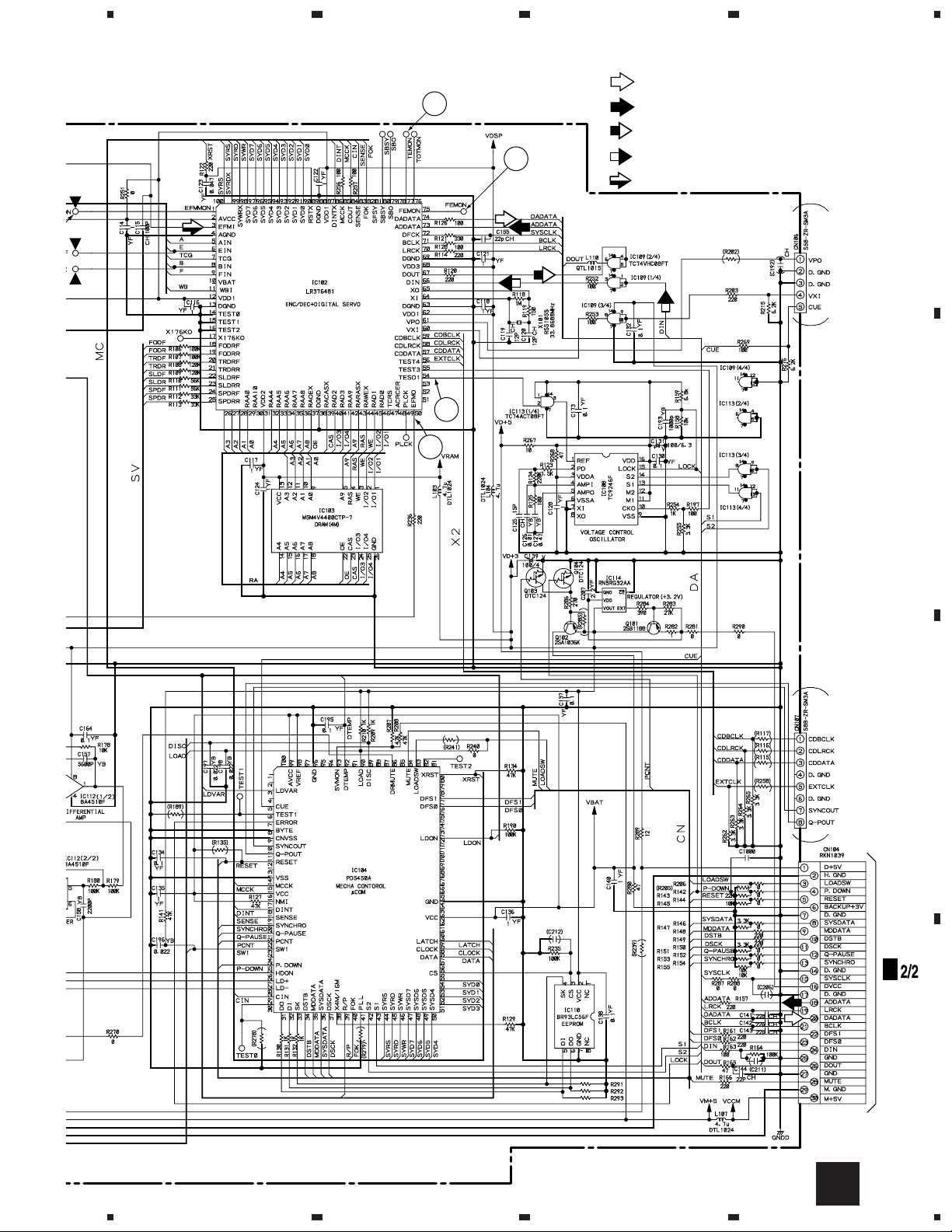

3. SCHEMATIC DIAGRAM

3.1 OVERALL CONNECTIONS

A

23

D

TRANS UNIT ASSY

(MJ-D707/KU : RWZ4313)

(MJ-D707/MY : RWZ4297)

(MJ-D707/MY/GR/FR : RWZ4297)

(MJ-17D/KU : RWZ4292)

AC POWER CORD

KU type : PDG1015

(AC120V/60Hz)

MY, MY/GR/FR type : PDG1003

(AC220–230V, 50/60Hz)

PARALLEL JUMPER

4

B

MD MECHANISM

ASSY

(RXA1773)

A

To

PICKUP

C

CORE MAIN

UNIT ASSY

(RWZ4271)

LEAD CARD

B

CORE SW

UNIT ASSY

(RWZ4272)

To

REC HEAD

LEAD CARD

JUMPER

(ORANGE)

(BLUE)

(BLACK)

(RED)

D

SLED

MOTOR

To

SPINDLE

MOTOR

To

To

MOTOR

LOADING

F

CONTROL UNIT ASSY

(MJ-D707/KU : RWZ4311)

(MJ-D707/MY : RWZ4295)

(MJ-D707/MY/GR/FR : RWZ4295)

PARALLEL

(MJ-17D/KU : RWZ4290)

12

1234

Page 13

5

678

MJ-D707, MJ-17D

Note : When ordering service parts, be sure to refer to "EXPLODED VIEWS and P AR TS LIST" or "PCB PAR TS LIST".

G

HEADPHONE UNIT ASSY

(MJ-D707/KU : RWZ4312)

(MJ-D707/MY : RWZ4296)

(MJ-D707/MY/GR/FR : RWZ4296)

(MJ-17D/KU : RWZ4291)

( )

C

MAIN UNIT ASSY

(MJ-D707/KU : RWZ4309)

(MJ-D707/MY : RWZ4293)

(MJ-D707/MY/GR/FR : RWZ4293)

(MJ-17D/KU : RWZ4288)

C

1/2,

C

2/2

PARALLEL

JUMPER

A

B

PARALLEL JUMPER PARALLEL JUMPER

E

DISPLAY UNIT ASSY

(MJ-D707/KU : RWZ4310)

(MJ-D707/MY : RWZ4294)

(MJ-D707/MY/GR/FR : RWZ4294)

(MJ-17D/KU : RWZ4289)

5

6

C

D

13

7

8

Page 14

1

23

MJ-D707, MJ-17D

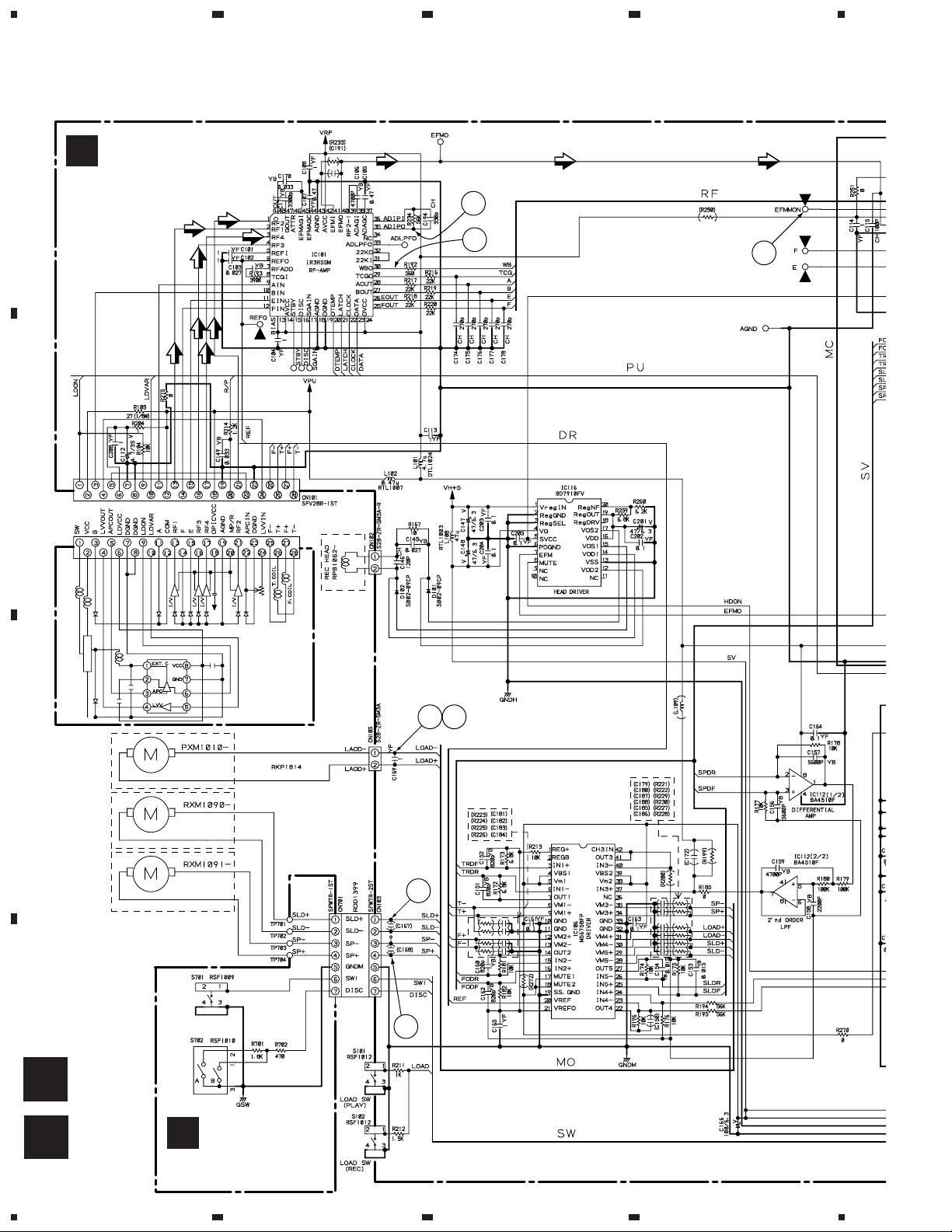

3.2 CORE MAIN UNIT and CORE SW UNIT ASSEMBLIES

A

A

CORE MAIN

UNIT ASSY

(RWZ4271)

1

4

2

3

B

PICKUP

LOADING MOTOR

C

SLED MOTOR

SPINDLE MOTOR

INSIDE SW

YELLOW

BLACK

ORANGE

BLUE

BLACK

RED

1011

8

9

D

B

A

A : DISC PROTECT

B : DISC MEDIA DETECT

B

CORE SW

UNIT ASSY

14

1234

(RWZ4272)

Page 15

5

¶ 1 – - are waveform Nos. on pages 26 and 27.

678

MJ-D707, MJ-17D

SIGNAL ROUTE

: PLAYBACK SIGNAL

6

5

7

4

: REC SIGNAL

: OUTPUT DIGITAL AUDIO SIGNAL

: INPUT DIGITAL AUDIO SIGNAL

: RF SIGNAL

A

B

C

YB

0.01

(INSIDE)

C

CN401

D

R291–R293 : 47k

A

5

6

7

8

15

Page 16

MJ-D707, MJ-17D

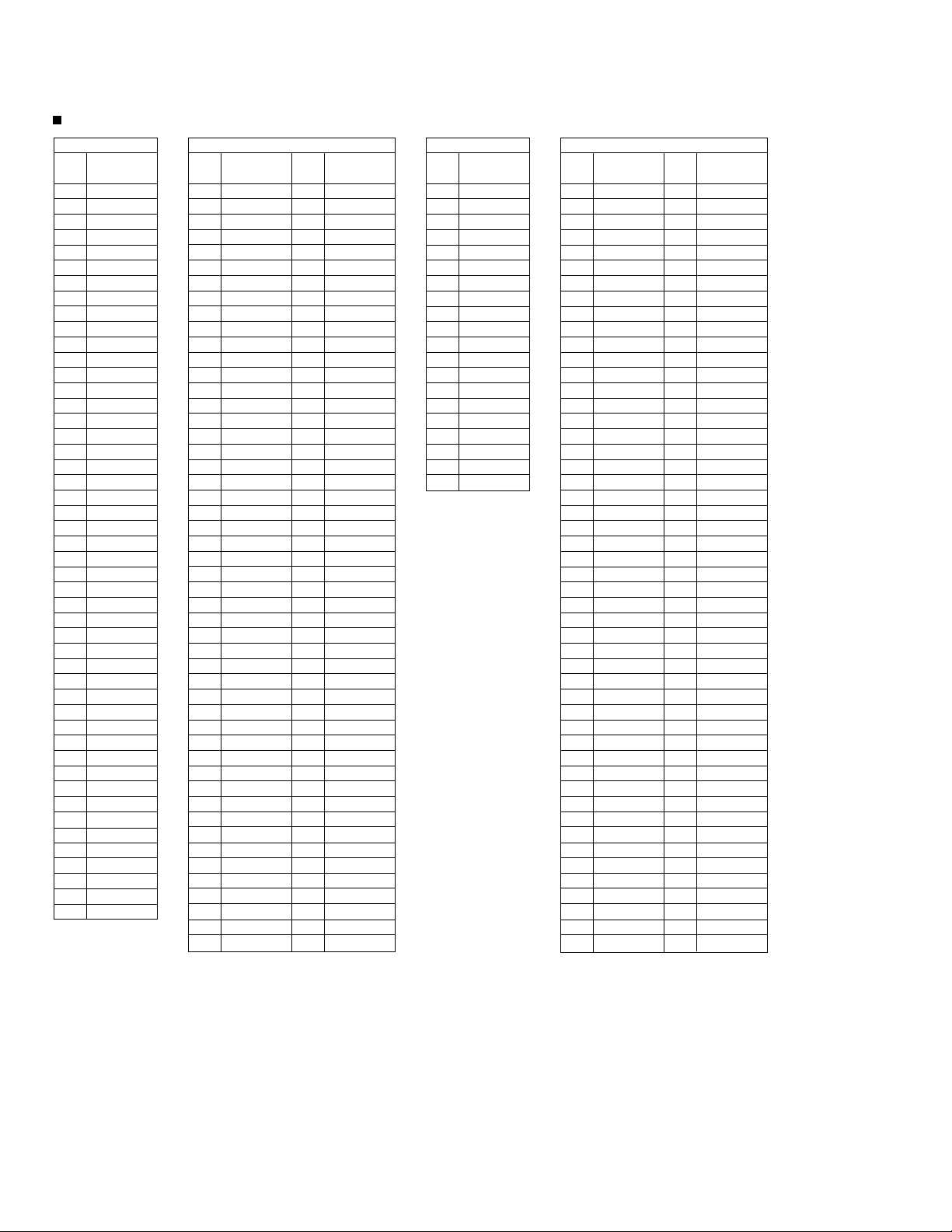

Voltages of CORE MAIN UNIT ASSY

PIN

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

IC101

VOLTAGE

0.78V

0.73V

0.77V

0.75V

1.61V

1.61V

0.75V

1.61V

1.61V

1.61V

1.61V

1.61V

3.19V

3.19V

0V

0V

3.19V

0V

0V

1.5V

3.2V

0V

0V

3.19V

2.0V

0V

1.40V

1.42V

1.40V

1.63V

1.61V

1.61V

0V

0V

0V

1.62V

0.59V

1.61V

1.61V

1.61V

1.61V

3.19V

0V

1.08V

1.61V

1.61V

0V

0.74V

PIN

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

VOLTAGE

IC102

1.53V

3.18V

1.65V

0V

1.42V

0V

1.59V

1.41V

1.97V

1.39V

1.64V

3.18V

0V

0V

0V

0V

1.69V

1.52V

1.70V

1.47V

1.47V

1.65V

1.54V

1.69V

1.51V

0.82V

2.0V

2.0V

1.81V

1.4V

0.82V

1.67V

1.67V

1.67V

2.86V

1.32V

2.23V

0V

2.4V

1.2V

1.5V

0V

2.0V

3.0V

1.2V

1.2V

0.02V

3.04V

1.57V

0.05V

PIN

NO.

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

VOLTAGE

1.59V

0V

0V

1.59V

1.8V

0V

0V

0V

0V

0V

0.56V

3.18V

0V

1.5V

1.5V

3.2V

1.6V

3.2V

0V

1.6V

1.6V

1.48V

0V

0V

1.68V

1.82V

1.59V

0.35V

0.02V

3.2V

3.2V

0.02V

0.03V

1.9V

1.56V

3.1V

3.2V

0V

3.19V

0.5V

0.5V

0.5V

0.5V

0.9V

0.5V

0.5V

0.5V

0.8V

3.18V

0.06V

PIN

NO.

1

2

3

4

5

9

10

11

12

13

14

15

16

17

18

22

23

24

25

26

IC103

VOLTAGE

1.2V

1.2V

3.0V

2.0V

0V

2.23V

1.32V

2.86V

1.67V

3.18V

1.67V

1.67V

1.67V

2.86V

1.32V

2.23V

2.4V

1.2V

1.5V

0V

PIN

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

IC104

VOLTAGE

0V

0V

0.22V

0.03V

1.29V

2.21V

3.13V

0V

0V

0V

0V

3.03V

1.43V

0V

1.57V

3.2V

3.19V

3.1V

0.03V

0V

0V

3.18V

3.2V

0V

2.67V

3.19V

0V

0V

2.4V

0.24V

0V

0.3V

3.2V

1.56V

1.0V

0V

2.77V

0V

3.18V

0.02V

3.19V

3.2V

0V

0.05V

3.18V

3.19V

0.51V

0.4V

0.3V

0.55V

PIN

NO.

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

VOLTAGE

0.54V

0.6V

0.6V

0.6V

0V

0V

0V

0V

3.2V

0V

0V

3.2V

0V

0V

3.2V

0V

0V

0V

0V

0V

0V

3.1V

3.2V

0V

0V

3.2V

0V

0V

0V

3.2V

0V

3.19V

0V

3.19V

0V

3.18V

3.2V

0V

1.03V

1.6V

0.56V

1.49V

1.49V

0.68V

0.61V

0V

0.53V

3.2V

3.2V

0V

16

Page 17

MJ-D707, MJ-17D

PIN

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

IC106

VOLTAGE

1.6V

0.49V

1.61V

4.99V

4.99V

1.61V

1.62V

2.46V

2.51V

0V

0V

2.54V

2.45V

1.62V

1.62V

1.61V

3.17V

0V

1.61V

1.61V

1.61V

1.61V

1.36V

1.36V

1.61V

1.61V

1.63V

2.41V

2.55V

2.47V

2.48V

0V

0V

2.79V

2.18V

0V

1.69V

5.0V

4.99V

1.67V

1.69V

1.69V

PIN

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

PIN

NO.

1

2

3

4

5

IC108

VOLTAGE

2.47V

2.63V

4.87V

2.63V

1.59V

0V

0V

4.87V

0V

2.25V

4.94V

4.94V

4.94V

4.94V

3.12V

4.94V

IC114

VOLTAGE

0V

4.19V

3.21V

2.81V

0V

PIN

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

PIN

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

IC109

VOLTAGE

2.77V

2.77V

3.2V

1.58V

1.58V

1.56V

0V

0V

0V

0V

0V

0V

0V

3.2V

IC116

VOLTAGE

4.98V

0V

0V

4.99V

3.2V

0V

0.03V

3.18V

0V

0V

0V

0.22V

0V

0.25V

0.25V

2.82V

0.16V

4.94V

2.82V

1.33V

PIN

NO.

1

2

3

4

5

6

7

8

IC110

VOLTAGE

0V

3.2V

0V

3.2V

0V

0.11V

0V

0V

PIN

NO.

1

2

3

4

5

6

7

8

IC112

VOLTAGE

1.66V

1.62V

1.62V

0V

1.67V

1.67V

1.67V

3.19V

PIN

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

IC113

VOLTAGE

4.95V

3.96V

0V

0V

0V

0V

0V

0V

4.94V

4.12V

3.19V

0V

0V

4.94V

17

Page 18

1

D

e

23

MJ-D707, MJ-17D

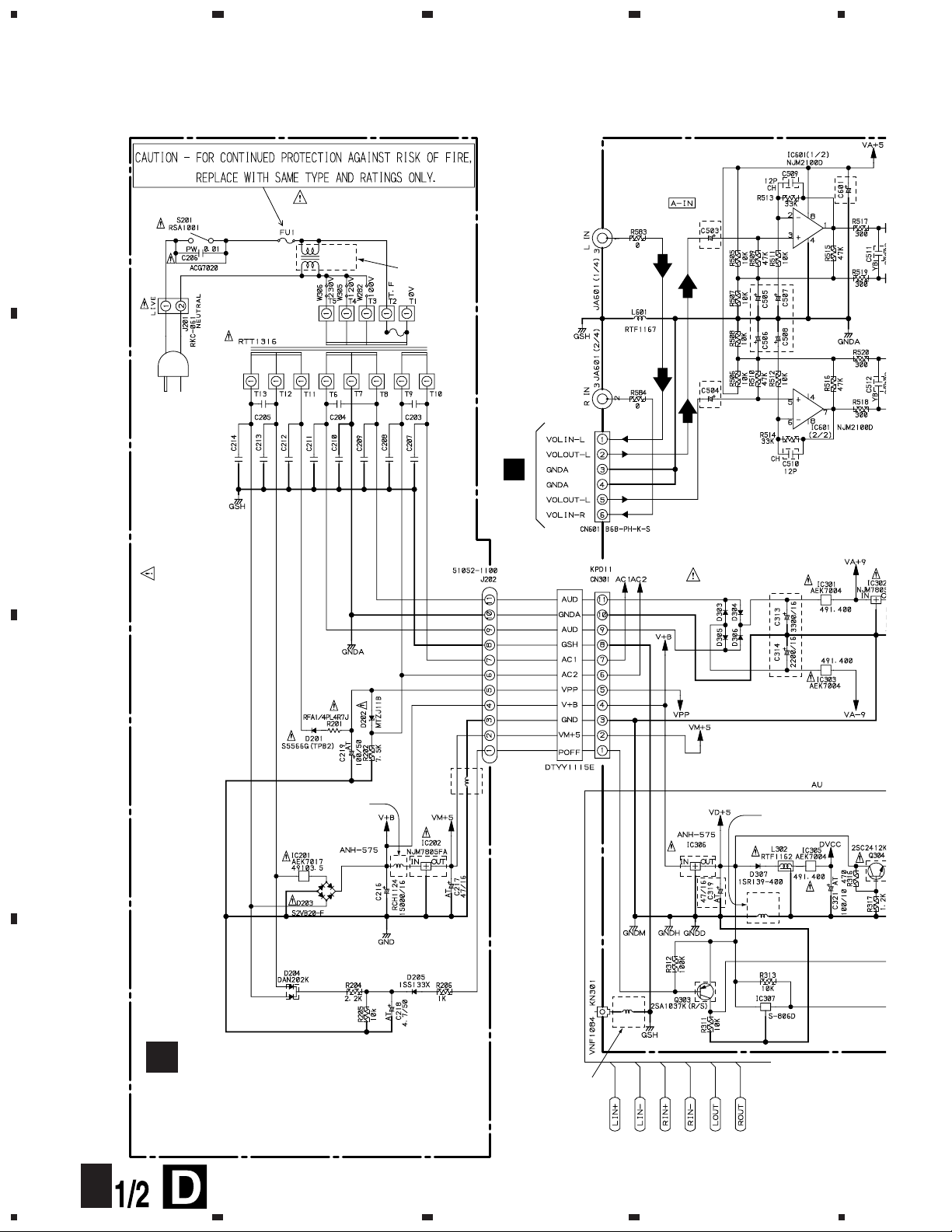

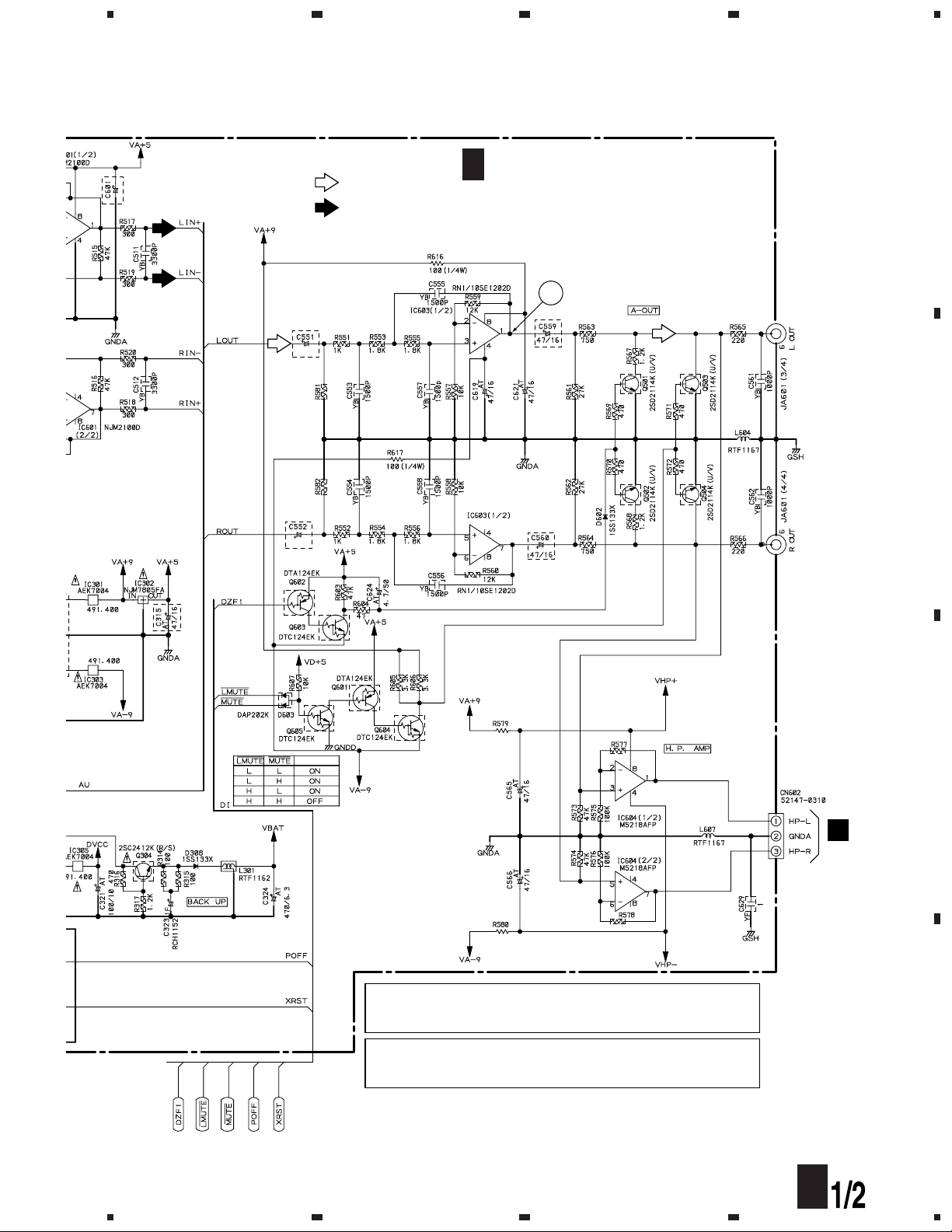

3.3 MAIN UNIT ASSY (1/2) and TRANS UNIT ASSY

4

A

S201 : POWER

H201, H202

: AKR1004

JUMPER

KU type : W305

MY, MY/GR/FR type : W306

POWER TRANSFORMER

B

FU1 FUSE

KU type : REK1075 (1A/125V)

MY, MY/GR/FR type : REK1019 (500mA/250V)

L201

VTL-262

MY and MY/GR/FR

types only

E

C503, C504

MJ-D707/KU : CEAT470M16

other models : CEBA220M25

JA601 : RKB1032

C50

MJoth

J704

C203–C205, C207–C214 : CFTLA, 0.1

AC POWER CORD

KU type : PDG1015

(AC120V/60Hz)

MY, MY/GR/FR type : PDG1003

(AC220–230V, 50/60Hz)

D303–D306 : S5566G(TPB2)

C313, C314

MJ-D707/KU : CEAT

other models : PCH1120 (C313)

: PCH1121 (C314)

C315, C319

MJ-D707/KU : CEAT470M16

C

L202 : RTF1167

MY and MY/GR/FR

L203 : RTF1167

MY and MY/GR/FR

types only

HEAT SINK

D

D

TRANS UNIT ASSY

(MJ-D707/KU : RWZ4313)

types only

MY and MY/GR/FR

types only

HEAT SINK

BA05T

L305

RTF1167

other models : PCH1123

MY and MY/GR/FR

types only

L304

RTF1167

(MJ-D707/MY : RWZ4297)

(MJ-D707/MY/GR/FR : RWZ4297)

(MJ-17D/KU : RWZ4292)

18

C

1234

Page 19

5

¶ % is waveform Nos. on page 27.

678

MJ-D707, MJ-17D

C505 – C508, C601

MJ-D707/KU : CEAT470M16

other models : RCH1133

SIGNAL ROUTE

: PLAYBACK SIGNAL

: REC SIGNAL

C551, C552, C559, C560

MJ-D707/KU : CEAT

other models : CEBA

2.2/50

470k470k

2.2/50

C

1/2

IC603 : NJM4580D

MAIN UNIT ASSY (1/2)

(MJ-D707/KU : RWZ4309)

(MJ-D707/MY : RWZ4293)

(MJ-D707/MY/GR/FR : RWZ4293)

(MJ-17D/KU : RWZ4288)

18

A

B

120 (C313)

121 (C314)

T470M16

1123

Y/GR/FR

LINE MUTE

100 (1/4W)

68k

68k

100 (1/4W)

CAUTION : FOR CONTINUED PROTECTION AGAINST RISK OF FIRE.

REPLACE ONLY WITH SAME TYPE NO. 49103.5 MFD, BY

LITTELFUSE INK. FOR IC201(AEK7017).

CAUTION : FOR CONTINUED PROTECTION AGAINST RISK OF FIRE.

REPLACE ONLY WITH SAME TYPE NO. 491.400 MFD, BY

LITTELFUSE INK. FOR IC301, IC303, IC305(AEK7004).

C

G

J901

D

C

5

6

7

8

19

Page 20

1

F

MJ-D707, MJ-17D

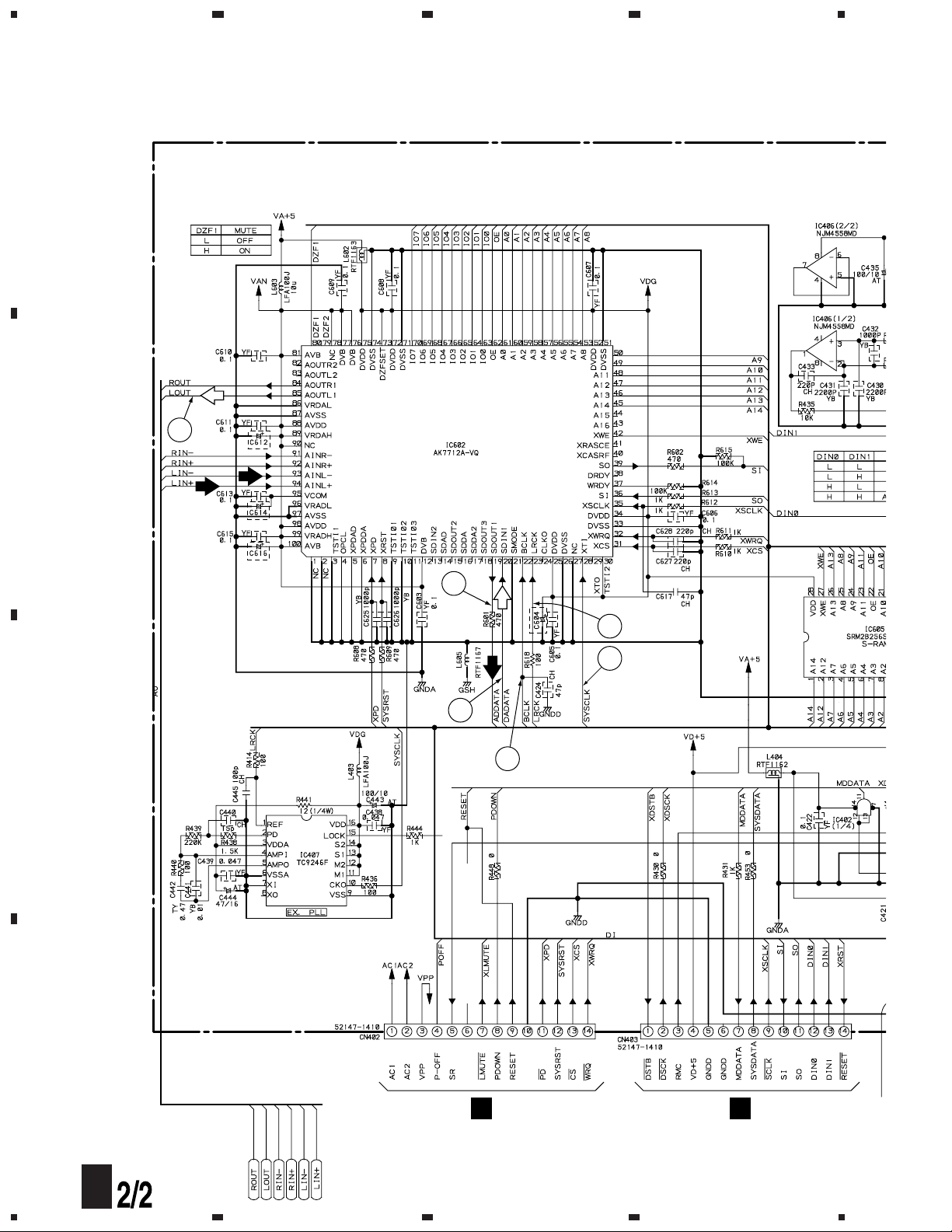

3.4 MAIN UNIT ASSY (2/2)

A

17

23

4

B

DSP (built-in 20 bit ADC/DAC)

13

C614

MJ-D707/KU : CEAT221M6R3

other models : VCH1081

15

12

14

C604, C612, C616

MJ-D707/KU : CEAT470M16

other models : VCH1081

C

16

D

L306 : RT

MY and M

types only

20

E

J702

E

J703

C

1234

Page 21

5

¶ = – # are waveform Nos. on pages 26 and 27.

678

MJ-D707, MJ-17D

C

2/2

MAIN UNIT ASSY (2/2)

(MJ-D707/KU : RWZ4309)

(MJ-D707/MY : RWZ4293)

(MJ-D707/MY/GR/FR : RWZ4293)

(MJ-17D/KU : RWZ4288)

L406

RTF1167

A

SIGNAL ROUTE

: PLAYBACK SIGNAL

: REC SIGNAL

: OUTPUT DIGITAL AUDIO SIGNAL

: INPUT DIGITAL AUDIO SIGNAL

B

RKB1021

MY and MY/GR/FR

types only

R455 : MY, MY/GR/FR types only

L307

RTF1167

MY and MY/GR/FR

types only

C

KU type only

D

L306 : RTF1167

MY and MY/GR/FR

types only

A

CN104

C

5

6

7

8

21

Page 22

1

(

(

(

(

23

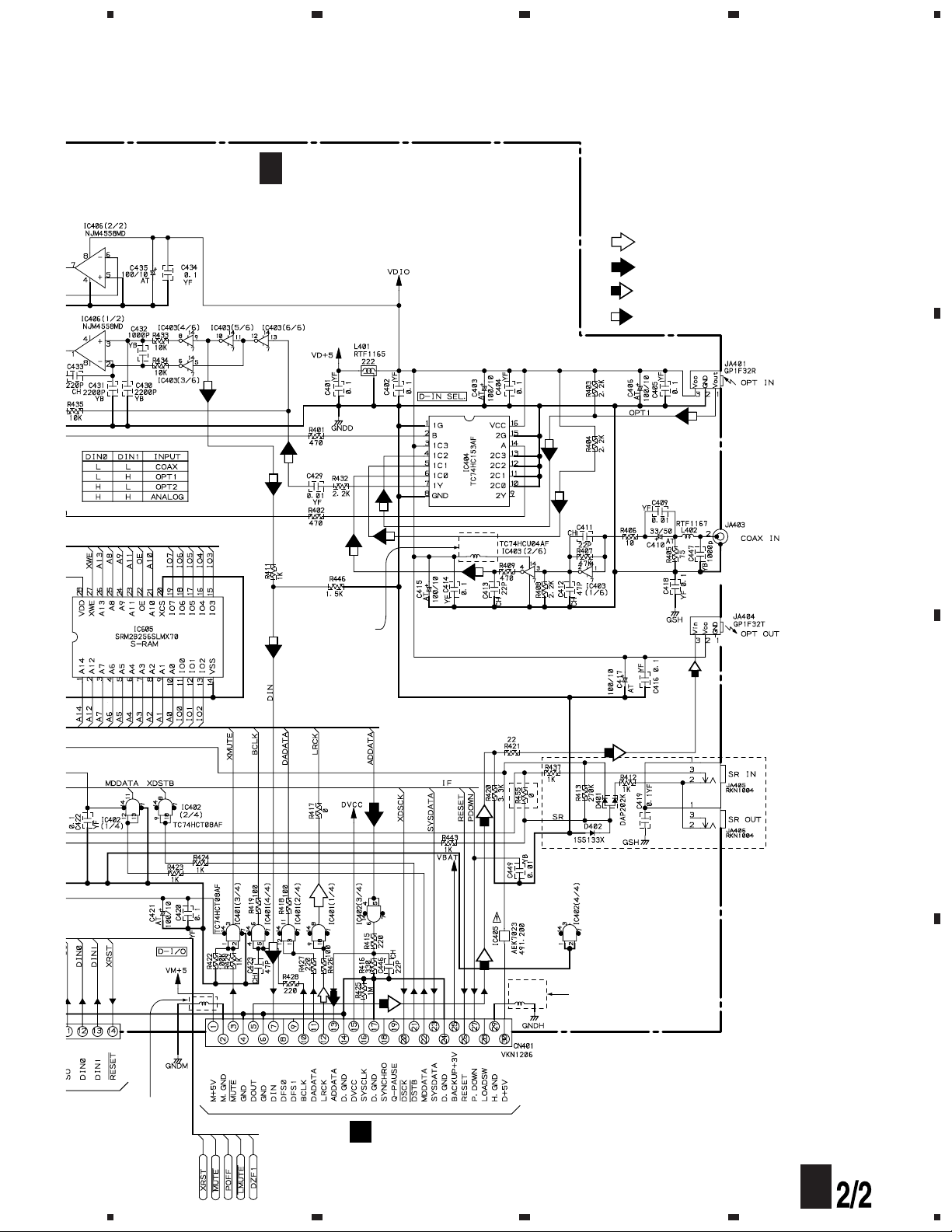

MJ-D707, MJ-17D

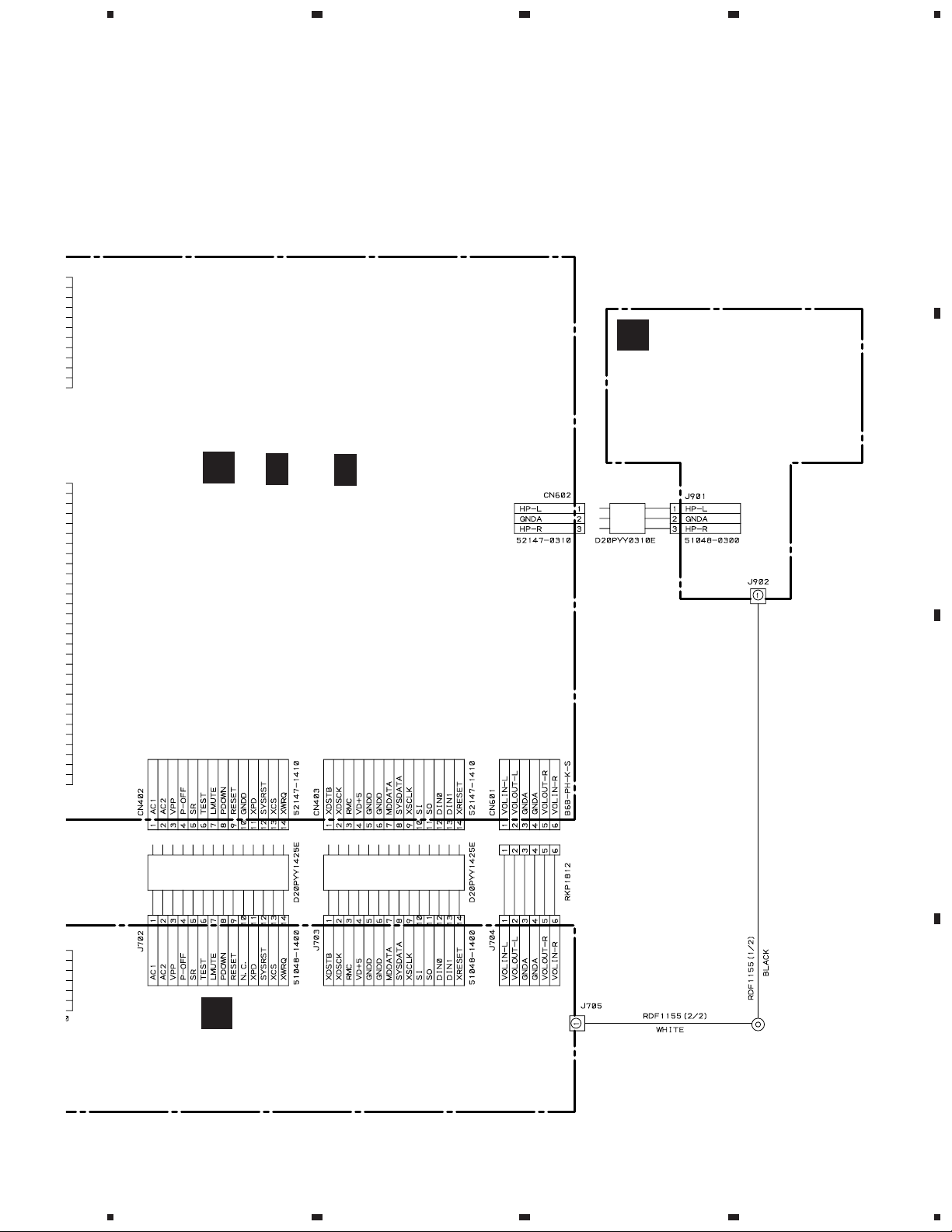

3.5 DISPLAY UNIT, CONTROL UNIT and HEADPHONE UNIT ASSEMBLIES

A

B

4

PDG222B

C

SYSTEM CONTROLER

CN402

(MD µ-COM)

(MD µ-COM)

(MD µ-COM)

C

C

CN403

CHASSIS

D

22

1234

Page 23

5

678

MJ-D707, MJ-17D

A

G

HEADPHONE UNIT ASSY

(MJ-D707/KU : RWZ4312)

(MJ-D707/MY : RWZ4296)

(MJ-D707/MY/GR/FR : RWZ4296)

(MJ-17D/KU : RWZ4291)

B

C

CN602

E

DISPLAY UNIT ASSY

(MJ-D707/KU : RWZ4310)

(MJ-D707/MY : RWZ4294)

(MJ-D707/MY/GR/FR : RWZ4294)

(MJ-17D/KU : RWZ4289)

C

CN601

C903, C904 : CCSQCH, 100P

RDF1155(1/2) BLACK

CHASSIS

F

CONTROL UNIT ASSY

(MJ-D707/KU : RWZ4311)

(MJ-D707/MY : RWZ4295)

(MJ-D707/MY/GR/FR : RWZ4295)

(MJ-17D/KU : RWZ4290)

HEADPHONE OUT

DISPLAY UNIT ASSY

S701 : JOG DIAL

S702 : FAST REVERSE

S703 : NAME

S704 : EDIT/NO

S705 : FAST FORWARD

S706 : SYNCHRO REC

S707 : RECORD

S708 : STOP

S709 : MD EJECT

S710 : PAUSE

S711 : PLAY

S712 : INPUT SELECTOR

CONTROL UNIT ASSY

S801 : TIMER

S802 : DISPLAY/CHARA

S803 : NAME CLIP

S804 : DIGITAL NR

S805 : REC MODE

S806 : TIME SKIP

S807 : A-B

S808 : REPEAT

S809 : PLAY MODE

C

D

23

5

6

7

8

Page 24

MJ-D707, MJ-17D

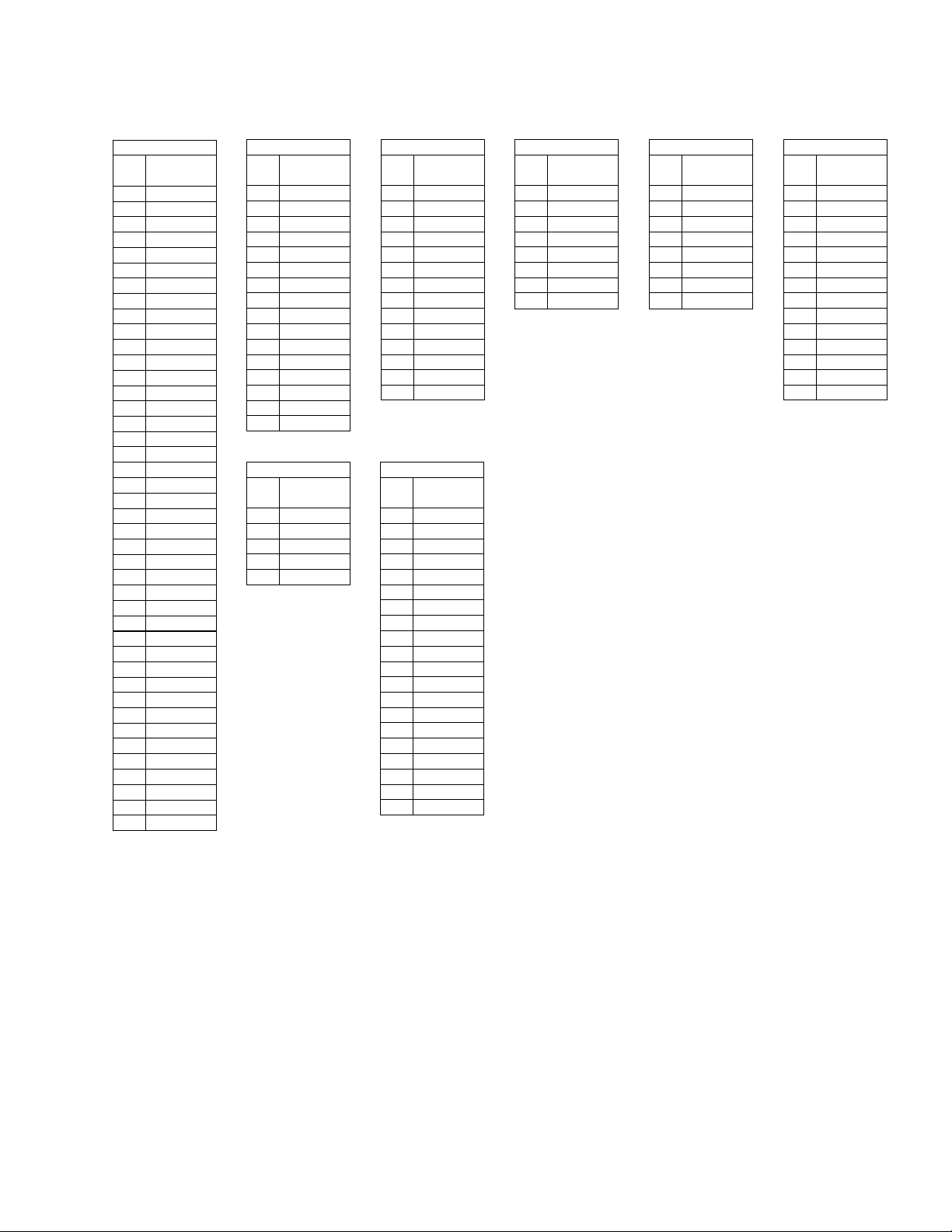

Voltages of MAIN UNIT ASSY

PIN

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

PIN

NO.

1

2

3

4

5

6

7

8

IC401

VOLTAGE

3.2V

3.2V

5.0V

1.6V

1.6V

2.5V

0V

2.5V

1.6V

1.6V

1.6V

1.0V

1.0V

5.0V

IC406

VOLTAGE

4.6V

5.0V

0V

0V

0V

4.6V

4.6V

5.0V

PIN

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

PIN

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

IC402

VOLTAGE

0V

0V

0V

0V

0V

0V

0V

2.5V

1.6V

1.6V

1.6V

1.0V

1.0V

5.0V

IC407

VOLTAGE

2.5V

2.7V

5.0V

2.7V

1.7V

0V

0V

5.0V

0V

2.3V

5.0V

5.0V

5.0V

5.0V

5.0V

5.0V

PIN

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

PIN

NO.

1

2

3

4

5

6

7

8

PIN

NO.

1

2

3

4

5

6

7

8

IC403

VOLTAGE

2.5V

2.5V

2.5V

3.4V

0V

5.0V

0V

0V

4.7V

4.7V

0V

0V

4.5V

5.0V

IC601

VOLTAGE

2.55V

2.55V

2.55V

0V

2.55V

2.55V

2.55V

5.06V

IC604

VOLTAGE

0V

0V

0V

0V

0V

0V

0V

8.89V

PIN

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

PIN

NO.

1

2

3

4

5

6

7

8

PIN

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

IC404

VOLTAGE

0V

4.3V

5.0V

5.0V

5.0V

3.4V

5.0V

0V

0V

0V

0V

0V

0V

5.0V

0V

5.0V

IC603

VOLTAGE

0.028V

0.013V

0.013V

–9.31V

0.013V

0.013V

0.027V

8.49V

IC605

VOLTAGE

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

4.7V

2.5V

2.5V

2.5V

0V

2.5V

2.5V

2.5V

2.5V

2.5V

0V

0.5V

2.5V

2.5V

2.5V

2.5V

2.5V

4.8V

5.0V

PIN

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

IC602

VOLTAGE

0V

0V

0V

0V

0V

0V

5.0V

5.0V

0V

0V

0V

5.0V

0V

0V

0V

0V

0V

0V

0V

0V

0V

2.5V

2.5V

0V

5.0V

0V

0V

2.3V

2.6V

5.0V

0.15V

4.9V

0V

5.0V

4.9V

0.18V

4.8V

4.8V

0.15V

1.7V

0.3V

3.3V

2.5V

2.5V

3.3V

2.5V

2.5V

2.5V

2.5V

2.5V

PIN

NO.

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

VOLTAGE

0V

5.0V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

0V

5.0V

5.0V

0V

5.0V

0V

5.02V

5.02V

5.02V

0V

5.02V

2.5V

2.5V

2.5V

2.5V

0V

0V

5.02V

5.02V

5.02V

2.5V

2.5V

2.5V

2.5V

2.51V

0V

0V

5.02V

5.02V

5.02V

24

Page 25

Voltages of DISPLAY UNIT ASSY

IC701

PIN

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

VOLTAGE

– 28.0V

– 28.0V

5.0V

0V

5.0V

0V

5.0V

5.0V

5.0V

0V

4.9V

5.0V

0V

4.9V

5.0V

5.0V

5.0V

5.0V

0.1V

4.9V

2.5V

4.6V

1.6V

0V

4.9V

0V

0V

5.0V

5.0V

5.0V

5.0V

5.0V

5.0V

0V

5.0V

5.0V

0V

5.0V

2.3V

2.4V

0V

5.0V

0V

5.0V

– 30.3V

0V

0V

0V

0V

– 30.3V

PIN

NO.

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

VOLTAGE

– 23.3V

– 11.9V

– 14.2V

– 18.9V

– 16.6V

– 14.5V

– 23.5V

– 21.1V

– 23.3V

– 12.3V

– 14.4V

– 23.5V

– 18.8V

– 18.8V

– 12.2V

– 14.4V

– 14.3V

– 12.1V

– 16.6V

– 16.7V

– 12.1V

– 16.4V

– 16.5V

– 18.8V

– 12.1V

– 14.4V

– 23.5V

– 19.1V

– 21.2V

– 14.4V

– 18.9V

– 18.9V

– 16.6V

– 16.7V

– 16.7V

– 29.5V

– 28.0V

– 28.0V

5.0V

– 28.0V

– 28.0V

– 28.0V

– 28.0V

– 28.0V

– 28.0V

– 28.0V

– 28.0V

– 28.0V

– 28.0V

– 28.0V

MJ-D707, MJ-17D

25

Page 26

MJ-D707, MJ-17D

Waveforms

Note: The encircled numbers denote measuring point in the schematic diagram and the PCB connection diagram.

IC101-pin35 (ADIPO)

1

(CORE MAIN UNIT ASSY)

MODE: PLAY

DISC: GGF1328 (MMD–212)

DC500mV/div., 10 µSec/div.

IC102-pin50 (EFMO)

4

(CORE MAIN UNIT ASSY)

MODE: REC

DISC: GGF1328 (MMD–212)

DC1V/div., 0.2 µSec/div.

–– GND

–– GND

IC101-pin30 (WBO)

2

(CORE MAIN UNIT ASSY)

MODE: PLAY

DISC: GGF1328 (MMD–212)

DC1V/div., 10 µSec/div.

IC102-pin75 (FE MON)

5

(CORE MAIN UNIT ASSY)

MODE: PLAY

DISC: TGTS1 or MMD–110

DC100mV/div., 2mSec/div.

–– GND

–– GND

IC102-pin1 (EFM MON)

3

(CORE MAIN UNIT ASSY)

MODE: PLAY

DISC: TGTS1 or MMD–110

DC500mV/div., 0.5mSec/div.

Measurement Method

FE MON

39 kΩ

REFO

(MD Mechanism Assy TP)

–– GND

To Oscilloscope

820pF

IC102-pin77 (TE MON)

6

(CORE MAIN UNIT ASSY)

MODE: PLAY

DISC: TGTS1 or MMD–110

DC500mV/div., 2mSec/div.

CN103-pin1 (SLD +)

8

(CORE MAIN UNIT ASSY)

MODE: PLAY

DC500mV/div., 2mSec/div.

–– GND

–– GND

Measurement Method

TE MON

9

39 kΩ

REFO

(MD Mechanism Assy TP)

CN103-pin4 (SP +)

(CORE MAIN UNIT ASSY)

MODE: PLAY

DC500mV/div., 5mSec/div.

To Oscilloscope

820pF

–– GND

IC102-pin54 (TES01)

7

(CORE MAIN UNIT ASSY)

MODE: STOP

DC2V/div., 10 µSec/div.

CN105-pin1 (LOAD –)

10

(CORE MAIN UNIT ASSY)

MODE: STOP

DC1V/div., 1mSec/div.

–– GND

–– GND

26

Page 27

MJ-D707, MJ-17D

CN105-pin1 (LOAD –)

11

(CORE MAIN UNIT ASSY)

MODE: EJECT

DC1V/div., 1mSec/div.

CN602-pin20 (DA DATA)

14

(MAIN UNIT ASSY)

MODE: PLAY (1 kHz, 0 dB)

DC2V/div., 0.5 µSec/div.

–– GND

–– GND

IC602-pin28 (SYS CLK)

12

(MAIN UNIT ASSY)

MODE: STOP

DC2V/div., 50nSec/div.

IC602-pin23 (LRCK)

15

(MAIN UNIT ASSY)

MODE: PLAY (1 kHz, 0 dB)

DC2V/div., 10 µSec/div.

–– GND

–– GND

IC602-pin19 (AD DATA)

13

(MAIN UNIT ASSY)

MODE: REC (ANALOG)

DISC: GGF1328 (MMD-212)

DC2V/div., 0.5 µSec/div.

IC602-pin22 (BCLK)

16

(MAIN UNIT ASSY)

MODE: PLAY (1 kHz, 0 dB)

DC2V/div., 0.2 µSec/div.

–– GND

–– GND

CN602-pin85 (LOUT)

17

(MAIN UNIT ASSY)

MODE: PLAY (1 kHz, 0 dB)

DC2V/div., 0.2mSec/div.

–– GND

IC603-pin1

18

MODE: PLAY (1 kHz, 0 dB)

(MAIN UNIT ASSY)

AC2V/div., 0.2mSec/div.

–– GND

27

Page 28

1

23

MJ-D707, MJ-17D

4. PCB CONNECTION DIAGRAM

A

NOTE FOR PCB DIAGRAMS :

1. Part numbers in PCB diagrams match those in the schematic

diagrams.

2. A comparison between the main parts of PCB and schematic

diagrams is shown below.

Symbol In PCB

Diagrams

BCE

BCE

D

Symbol In Schematic

Diagrams

BCEBCE

BCE

DGGSS

BCE

DGS

Part Name

Transistor

Transistor

with resistor

Field effect

transistor

4

3. The parts mounted on this PCB include all necessary parts for

several destinations.

For further information for respective destinations, be sure to

check with the schematic diagram.

4. View point of PCB diagrams.

Connector

Capacitor

SIDE A

P.C.Board

Chip Part

SIDE B

B

Resistor array

3-terminal

regulator

4.1 CORE SW UNIT ASSEMBLY

B

CORE SW UNIT ASSY

C

SPINDLE MOTOR

SLED MOTOR

A

CN103

D

SIDE A

(RNP1721-B)

SIDE B

28

1234

Page 29

1

234

4.2 CORE MAIN UNIT ASSEMBLY

A

CORE MAIN UNIT ASSY

1

2

5

6

8

3

B

CN701

MJ-D707, MJ-17D

¶ 1 – - are waveform Nos. on pages 26 and 27.

A

7

SIDE A

B

1011

9

IC101

IC106 IC102 IC103 IC104 IC114

(RNP1721-B)

Q101

Q102

SIDE B

C

LOADING

MOTOR

IC113

C

CN401

PICKUP

ASSY

REC

HEAD

4

IC112 IC108 IC113

1

2

Q103

IC110 IC116

3

(RNP1721-B)

IC109

Q104

29

4

D

Page 30

1

23

MJ-D707, MJ-17D

4.3 MAIN UNIT and TRANS UNIT ASSEMBLIES

4

A

B

SIDE A

D

TRANS UNIT ASSY

C

MAIN UNIT ASSY

H

J10

C

D

NEUTRAL

LIVE

AC POWER

CORD

IC201

(RNP1726-C)

A

CN104

30

IC305 IC301 IC303

1234

Page 31

5

678

MJ-D707, MJ-17D

¶ = – % are waveform Nos. on page 25.

H

J1001

17

18

E

SIDE A

A

J102

B

4

12

15

16

14

(RNP1726-C)

E

J102

3 IC405 IC307

13

E

J103

G

J901

C

D

31

5

6

7

8

Page 32

1

MJ-D707, MJ-17D

SIDE B

A

C

MAIN UNIT ASSY

B

23

4

C

(RNP1726-C)

D

IC604 Q504

Q502

IC605

Q503 IC602 IC407 IC406 IC404IC403

Q501

Q604 Q601

Q603 Q605 Q303

Q602

IC401

IC402

32

1234

Page 33

5

678

MJ-D707, MJ-17D

SIDE B

A

D

TRANS UNIT ASSY

B

Q304

5

(RNP1726-C)

6

C

D

33

7

8

Page 34

1

23

MJ-D707, MJ-17D

4.4 DISPLAY UNIT and CONTROL UNIT ASSEMBLIES

A

E

DISPLAY UNIT ASSY

B

4

SIDE A

SIDE A

C

F

CONTROL UNIT ASSY

(RNP1726-C)

SIDE B

D

(RNP1726-C)

34

1234

Page 35

5

678

MJ-D707, MJ-17D

C

CN402

SIDE B

C

CN403

C

(RNP1726-C)

CN601

SIDE A

F

CONTROL UNIT ASSY

A

B

(RNP1726-C)

SIDE B

5

6

E

DISPLAY UNIT ASSY

35

7

8

C

D

Page 36

1

MJ-D707, MJ-17D

4.5 HEADPHONE UNIT ASSEMBLY

A

G

HEADPHONE UNIT ASSY

B

23

C

CN602

4

(RNP1726-C)

SIDE A

C

SIDE B

D

36

1234

Page 37

MJ-D707, MJ-17D

5. PCB PARTS LIST

NOTES : Parts marked by “ NSP ” are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

When ordering resistors, first convert resistance values into code form as shown in the following examples.

Ex. 1 When there are 2 effective digits (any digit apart from 0), such as 560 ohm and 47k ohm (tolerance is shown by

J = 5%, and K = 10%).

560 Ω = 56 × 10

47k Ω = 47 × 10

0.5 Ω = R50 ...................................................................... RN2H Â 5 0 K

1 Ω = 1R0 ......................................................................... RS1P 1 Â 0 K

Ex. 2 When there are 3 effective digits (such as in high precision metal film resistors).

5.62k Ω = 562 × 10

LIST OF WHOLE PCB ASSEMBLIES

Mark Remarks

NSP MD MECHANISM ASSY RXA1773 RXA1773 RXA1773 RXA1773

Symbol and Description

CORE UNIT ASSY RWM2041 RWM2041 RWM2041 RWM2041

CORE MAIN UNIT ASSY RWZ4271 RWZ4271 RWZ4271 RWZ4271

CORE SW UNIT ASSY RWZ4272 RWZ4272 RWZ4272 RWZ4272

1

= 561................................................... RD1/4PU 5 6 1 J

3

= 473 .................................................. RD1/4PU 4 7 3 J

1

= 5621 ........................................... RN1/4PC 5 6 2 1 F

Part No.

MJ-D707 MJ-17D

KU MY MY/GR/FR KU

NSP MOTHER UNIT ASSY RWM2051 RWM2048 RWM2048 RWM2047

MAIN UNIT ASSY RWZ4309 RWZ4293 RWZ4293 RWZ4288

DISPLAY UNIT ASSY RWZ4310 RWZ4294 RWZ4294 RWZ4289

CONTROL UNIT ASSY RWZ4311 RWZ4295 RWZ4295 RWZ4290 ∗1

HEADPHONE UNIT ASSY RWZ4312 RWZ4296 RWZ4296 RWZ4291 ∗2

TRANS UNIT ASSY RWZ4313 RWZ4297 RWZ4297 RWZ4292

∗1 Although RWZ4311, RWZ4295 and RWZ4290 are different in part number, they have the same service parts.

∗2 Although RWZ4312, RWZ4296 and RWZ4291 are different in part number, they have the same service parts.

CONTRAST OF PCB ASSEMBLIES

D

TRANS UNIT ASSY

RWZ4313, RWZ4297 and RWZ4292 are constructed the same except for the following:

Mark Symbol and Description

L201 Not used VTL–262 Not used

L202, L203 Not used RTF1167 Not used

E

DISPLAY UNIT ASSY

RWZ4313 RWZ4297 RWZ4292

RWZ4310, RWZ4294 and RWZ4289 are constructed the same except for the following:

Part No.

Remarks

Mark

Symbol and Description

Part No.

RWZ4310 RWZ4294 RWZ4289

R798 RS1/10S104J Not used Not used

R799 Not used RS1/10S104J RS1/10S104J

Remarks

37

Page 38

MJ-D707, MJ-17D

MAIN UNIT ASSY

C

RWZ4309, RWZ4293 and RWZ4288 are constructed the same except for the following:

Mark

Symbol and Description

Part No.

RWZ4309 RWZ4293 RWZ4288

D401 DAP202K Not used DAP202K

D402 1SS133X Not used 1SS133X

L304–L307, L406 Not used RTF1167 Not used

C313 CEAT332M16 PCH1120 PCH1120

(3300µF/16V) (3300µF/16V)

C314 CEAT222M16 PCH1121 PCH1121

(2200µF/16V) (2200µF/16V)

C315, C319 CEAT470M16 PCH1123 PCH1123

(470µF/6.3V) (470µF/6.3V)

C419 CKSQYF104Z25 Not used CKSQYF104Z25

C503, C504 CEAT470M16 CEBA220M25 CEBA220M25

C505–C508, C601 CEAT470M16 RCH1133 RCH1133

(100µF/10V) (100µF/10V)

C551, C552 CEAT2R2M50 CEBA2R2M50 CEBA2R2M50

C559, C560 CEAT470M16 CEBA470M10 CEBA470M10

C604, C612, C616 CEAT470M16 VCH1081 VCH1081

(220µF/10V) (220µF/10V)

C614 CEAT221M6R3 VCH1081 VCH1081

(220µF/10V) (220µF/10V)

C619, C621 CEAT470M16 PCH1124 PCH1124

(47µF/50V) (47µF/50V)

R412, R437 RS1/10S102J Not used RS1/10S102J

R413 RS1/10S274J Not used RS1/10S274J

R455 Not used RS1/10S0R0J Not used

R618 RS1/10S622J RS1/10S101J RS1/10S101J

Remarks

JA405, JA406 JACK (Remote Control) RKN1004 Not used RKN1004

PARTS LIST FOR MJ-D707/KU

Mark No. Description Part No. Mark No. Description Part No.

A

CORE MAIN UNIT ASSY

SEMICONDUCTORS

IC112 BA4510F

IC116 BD7910FV

IC110 BR93LC56F

IC101 IR3R55M

IC102 LR376481

IC106 M56758FP

IC103 M5M4V4400CTP-7

IC104 PD5450A

IC114 RN5RG32AA

IC113 TC74ACT08FT

IC109 TC74VHC08FT

IC108 TC9246F

Q102 2SA1036K

Q101 2SB1188

Q103, Q104 DTC124EU

D101, D102 SB02-09CP

COILS AND FILTERS

L101, L103, L104, L107 (4.7 µH) DTL1024

L110 QTL1015

L108 (47 µH) RTL1003

L102 (0.47 µH) RTL1007

SWITCHES AND RELAYS

S101, S102 RSF1012

CAPACITORS

C115 CCSQCH101J50

C119, C120 CCSQCH120J50

C146 CCSQCH121J50

C125 CCSQCH150J50

C141–C144, C155 CCSQCH220J50

C174–C178 CCSQCH271J50

C194 CCSQCH331J50

C139 CEV101M4

C131, C166 CEV101M6R3

C147, C148, C201 CEV470M6R3

38

Page 39

MJ-D707, MJ-17D

Mark No. Description Part No. Mark No. Description Part No.

C112 CEV4R7M35

C193 CKSQYB102K50

C126, C1000 CKSQYB103K50

C153, C154 CKSQYB153K50

C158 CKSQYB222K50

C196–C198 CKSQYB223K50

C103, C145 CKSQYB273K50

C171 CKSQYB332K50

C149, C170 CKSQYB333K50

C106, C159 CKSQYB472K50

C127 CKSQYB474K16

C156, C157 CKSQYB562K50

C151, C152, C160, C162 CKSQYB821K50

C130, C132, C134, C137, C138 CKSQYF104Z25

C161, C163, C164, C173, C195 CKSQYF104Z25

C202–C205 CKSQYF104Z25

C101, C102, C104, C108 CKSQYF105Z16

C113, C114, C116–C118 CKSQYF105Z16

C121, C122, C124, C128 CKSQYF105Z16

C135, C136, C140, C165, C169 CKSQYF105Z16

C207, C208 CKSQYF105Z16

C123 CKSQYF473Z25

C105, C107 CKSQYF474Z16

RESISTORS

R105 RS1/8S270J

Other Resistors RS1/10S J

OTHERS

CN104 30P CONNECTOR RKN1039

X101 (33.8688MHz) RSS1055

CN105 ZR CONNECTOR S2B-ZR-SM3A

CN102 2P CONNECTOR S2B-ZR-SM3A-R

CN101 CONNECTOR SFV28R-1ST

CN103 CONNECTOR SFW7R-2ST

IC406 NJM4558MD

IC603 NJM4580D

IC302 NJM7805FA

IC307 S-806D

IC605 SRM2B256SLMX70

IC404 TC74HC153AF

IC401, IC402 TC74HCT08AF

IC403 TC74HCU04AF

IC407 TC9246F

Q303 2SA1037K

Q304 2SC2412K

Q501–Q504 2SD2114K

Q601, Q602 DTA124EK

Q603–Q605 DTC124EK

D307 1SR139-400-TA

D308, D402, D602 1SS133X

D401, D603 DAP202K

D303–D306 S5566G(TPB2)

COILS AND FILTERS

L403, L603 LFA100J

L301, L302, L404 RTF1162

L602 RTF1163

L401 RTF1165

L402, L601, L604, L605, L607 RTF1167

CAPACITORS

C445 CCSQCH101J50

C509, C510 CCSQCH120J50

C440 CCSQCH150J50

C411, C413, C446 CCSQCH220J50

C433, C627, C628 CCSQCH221J50

C412, C423, C617 CCSQCH470J50

C321, C403, C406, C415, C417 CEAT101M10

C421, C435, C443 CEAT101M10

C551, C552 CEAT2R2M50

C614 CEAT221M6R3

B

CORE SW UNIT ASSY

SWITCHES AND RELAYS

S701 RSF1009

S702 RSF1010

RESISTORS

All Resistors RS1/10S J

OTHERS

CN701 CONNECTOR SFW7R-1ST

MAIN UNIT ASSY

C

SEMICONDUCTORS

IC301, IC303, IC305 (400mA/125V) AEK7004

IC405 (200mA/125V) AEK7023

IC602 AK7712A-VQ

IC306 BA05T

IC604 M5218AFP

IC601 NJM2100D

C314 CEAT222M16

C410 CEAT330M50

C313 CEAT332M16

C315, C319, C444, C503–C508 CEAT470M16

C559, C560, C565, C566, C601 CEAT470M16

C604, C612, C616, C619, C621 CEAT470M16

C324 CEAT471M6R3

C624 CEAT4R7M50

C442 CFTYA474J50

C432, C447, C561, C562 CKSQYB102K50

C625, C626 CKSQYB102K50

C441, C449 CKSQYB103K50

C553–C558 CKSQYB152K50

C430, C431 CKSQYB222K50

C511, C512 CKSQYB332K50

C409, C429 CKSQYF103Z50

C401, C402, C404, C405, C414 CKSQYF104Z25

C416, C418–C420, C422, C434 CKSQYF104Z25

C603, C605–C611, C613, C615 CKSQYF104Z25

C629 CKSQYF105Z16

C438, C439 CKSQYF473Z25

C323 (1.00F/5.5V) RCH1152

39

Page 40

MJ-D707, MJ-17D

Mark No. Description Part No. Mark No. Description Part No.

RESISTORS

R579, R580, R616, R617 RD1/4PU101J

R441 RD1/4PU120J

R559, R560 RN1/10SE1202D

Other Resistors RS1/10S J

OTHERS

CN602 3P JUMPER CONNECTOR 52147-0310

CN402, CN403 52147-1410

CN601 KR CONNECTOR B6B-PH-K-S

JA401 OPTICAL LINK IN GP1F32R

JA404 OPTICAL LINK OUT GP1F32T

CN301 11P JUMPER CONNECTOR KPD11

JA403 1P JACK RKB1021

JA601 4P JACK with SHIELD PLATE RKB1032

JA405, JA406 JACK RKN1004

CN401 30P CONNECTOR VKN1206

KN301, KN601 EARTH METAL FITTING VNF1084

E

DISPLAY UNIT ASSY

14P JUMPER CONNECTOR

HEAT SINK ANH-575

PCB BINDER VEF1040

SEMICONDUCTORS

IC701 PDG222B

CAPACITORS

C801 CKSQYF104Z25

RESISTORS

All Resistors RS1/10S J

OTHERS

6P CABLE HOLDER 51048-0600

G

HEADPHONE UNIT ASSY

COILS AND FILTERS

L901–L903 RTF1167

CAPACITORS

C901, C902 CKSQYF104Z25

C903, C904 CCSQCH101J50

RESISTORS

VR901 (500 Ω–B) RCV1123

Other Resistors RS1/10S J

OTHERS

901 3P CABLE HOLDER 51048-0300

J901 3P JUMPER WIRE D20PYY0310E

JA901 HEADPHONE JACK RKN1002

SWITCHES AND RELAYS

S712 RSB1027

S701 RSC1003

S702–S711 VSG1009

CAPACITORS

C701 CEAL220M6R3

C707, C708, C712 CKSQYB103K50

C703, C709 CKSQYF103Z50

C702, C704–C706, C710, C711 CKSQYF104Z25

RESISTORS

VR701 (50 kΩ–A) RCV1118

Other Resistors RS1/10S J

OTHERS

J701 6P PARALLEL WIRE D20PYY0615E

J702, J703 14P JUMPER WIRE D20PYY1425E

V701 FL TUBE RAW1164

J704 6P CONNECTOR ASSY RKP1812

X701 (8.388MHz) RSS1042

F

CONTROL UNIT ASSY

6P CABLE HOLDER 51048-0600

REMOTE RECEIVER UNIT GP1U27X

SEMICONDUCTORS

D801 SLP9118C51H

SWITCHES AND RELAYS

S801 RSH1041

S802–S809 VSG1009

D

TRANS UNIT ASSY

SEMICONDUCTORS

IC201 (3.5A/125V) AEK7017

IC202 NJM7805FA

D205 1SS133X

D204 DAN202K

D202 MTZJ11B

D203 S2VB20

D201 S5566G (TPB2)

SWITCHES AND RELAYS

S201 RSA1001

CAPACITORS

C206 (10000pF/AC250V) ACG7020

C219 CEAT101M50

C217 CEAT470M16

C218 CEAT4R7M50

C203–C205, C207–C214 CFTLA104J50

C216 (15000pF/16V) RCH1124

RESISTORS

R201 RFA1/4PL4R7J

Other Resistors RS1/10S J

OTHERS

H201, H202 FUSE CLIP AKR1004

CABLE HOLDER (11P) 51052-1100

HEAT SINK ANH-575

TERMINAL RKC-061

40

Page 41

6. ADJUSTMENT

JIGS AND MEASURING INSTRUMENTS

MJ-D707, MJ-17D

Thermometer

Oscilloscope

Optical Power Meter

Test Disc

For servo system adjustment ............................................. GGF1328 (MMD-212)

For recording/playback inspection...................GGF1328 (MMD-212), GGF1277,

Jitter Meter

6.1 NECESSARY ADJUSTMENT POINTS

Exchange

PICKUP

Exchange

Servo Base Assy (SPINDLE MOTOR)

Exchange

CORE MAIN UNIT ASSY

TGYS1 (or MMD-110), Commercial discs

Adjustment pointsWhen

3 , 4

3 , 4

= Page 44, 45

= Page 44, 45

= Page 44, 45

4

Exchange

MD HEAD

Exchange

Loading Mechanism Assy

Exchange

Servo Mechanism Assy

Exchange

MD Mechanism Assy

(Loading Mechanism Assy +

Servo Mechanism Assy)

3 , 4

3 , 4

= Page 44, 45

= Page 44, 45

41

Page 42

MJ-D707, MJ-17D

6.2 TEST MODE

There are two test modes: test mode 1 for main unit operation check

and test mode 2 for MD mechanism assy adjustment and check.

6.2.1 Test Mode 1 (main unit operation check)

How to enter into test mode 1

1) Hold the “ENTER” key and the “STOP” key depressed and press the POWER switch.

2) SYSTEM TEST will be displayed on the FL display.

Operation check for the operation keys

Operation Keys FL Display Contents

REC (¶)

PLAY (3)

STOP (7) Same operation as in normal mode

JOG (4, ¢)

CUE (¡)

REV (1)

EJECT (0) Disc ejection (no TOC writing)

DIGITAL-NR DSP OK ! ! Normal DSP IC operation

DSP ERROR1 Communication between the DSP IC and the system controller is not

possible.

DSP ERROR2 Calculation in the DSP IC not correct

Operation check for other keys

When each key is pressed, display according to the following table shall be made on the FL display.

Operation Keys FL Display

OFF SYSTEM TEST

TIMER SW REC Entire FL lit

PLAY Entire FL not lit

A–B A–B

REPEAT REPEAT

PLAY MODE PLAY MODE

TIME SKIP TIME SKIP

NAME CLIP NAME C L I P

Operation Keys FL Display

JOG (Push) ENT ER

EDIT/NO EDI T /NO

NAME NAME

SYNCHRO REC SYNCHRO REC

Cancellation of Test Mode 1

Press the POWER switch.

DISPLAY/CHARA DISP

REC MODE REC MODE

42

Page 43

MJ-D707, MJ-17D

TEMP

µ-com Measuring value

11.6 to 16.9 +1 to +3

17.0 to 22.3 0 to +2

22.4 to 27.6 –1 to +1

27.7 to 33.0 0 to –2

33.1 to 38.4 –1 to –3

79

7A

7B

7C

7D

hex=

( – )

Room Temperature

[ T (°C) ]

µ-com Set value

When the

microcomputer

value is

+

–

6.2.2 Test Mode 2 (MD Mechanism Assy Adjustment, Check)

1 Temperature Check (Please perform this check soon after the power has been switched on.)

Note: When IC101 (RF-AMP) or IC104 (mechanical controller) has been exchanged or when a correction changing VD+3 has been made,

be sure to correctly perform all steps up to step 7.

Step No. Operation Keys and Operation Method FL Display Status Remarks

1 Power ON while holding the ENTER key and the EJECT Test mode

PLAY key depressed.

2 Press the NAME CLIP key. TEMP The microcomputer starts measuring.

3 When is 80 or more at this time, the adjustment End

is OK (step 4 and following can be omitted).

When is 80 (not passed) TEMP 8 0 80 is the default value (unadjusted).

4 Measure the ambient temperature T (°C) andcheck

hat the measuring value ( ) is within the standard

in regard to the microcomputer set value ( ).

Note: When the indication of the measuring value

( ) is not stable, and the ambient temperature

T (°C) is 25 °C or less, set to the lower value.

When the ambient temperature is over 25 °C, set to

the higher value.

: Measuring

value

: Set value

2 Laser Power Check

Step No. Operation Keys and Operation Method FL Display Status Remarks

5 Change with the TIME SKIP key (UP) and the TEMP 7B 7B

A-B key (DOWN).

6 Press the EDIT/NO key. No Disc Writing to EEPROM is made and

return is made automatically from

test mode to normal mode.

1 Power ON while holding the ENTER key and the EJECT Test mode

PLAY key depressed. 780 nm

2 Press the NAME key. ppw PLAY power output status

3 Measure the laser power with an optical power meter. ppw

4 At this time, check that the measuring value (PLAY ppw May be omitted.

power) meets the standard value of the table on the

right.

Note: When the standard value on the right is applied,

the numerical value immediately after entry into test

mode 2 shall be taken as the standard.

5 Press the NAME key. rpw REC power output status

6 At this time, check that the measuring value (REC rpw

power) meets the standard value of the table on the

right.

7 Press the STOP key. The LD goes out.

µ-com

Measuring value

( – ) (mW)

( – ) (mW)

TEMP

hex = Standard Value

+02 to +04 0.69±0.12

–01 to +01 0.67±0.1

–02 to –04 0.63±0.1

hex = Standard Value

+02 to +04 6.18±0.93

–01 to +01 5.79±0.87

–02 to –04 5.47±0.82

µ-com

Set value

Laser Wavelength:

43

Page 44

MJ-D707, MJ-17D

Ocsilloscope

b

a

470p

470p

100kΩ

100kΩ

3 Grating Adjustment

Step No. Operation Keys and Operation Method FL Display Status Remarks

1 Power ON while holding the ENTER key and the PLAY EJECT Test mode

key depressed.

2 Insert the test disc GGF1328 (MMD-212). LOADING

GRT AJST Grating adjustment status

3 Press the PLAY key. LON : Playback is started in tracking open

LAg : status. (The servo is closed only for

GEG : focus and spindle.)

4 Connect an oscilloscope according to the following GRT AJST Lissajous waveform a:b = Within 3:1

connection diagram and loosen the screw A at the side

of the adjustment hole. Turn the hole with a screwdriver

until the Lissajous waveform becomes as shown in the

figure, and then tighten the screw A.

5 Press the STOP key. Adjustment end

Connection Diagram

Lissajous waveform

a:b = Within 3:1

CORE MAIN UNIT ASSY

EOUT

FOUT

SIDE A

Adjustment

Hole

Screw A

Adjustment

Point

REFO

4 Preliminary Adjustment

Step No. Operation Keys and Operation Method FL Display Status Remarks

1 Power ON while holding the ENTER key and the PLAY EJECT Test mode

key depressed.

2 Insert the test disc GGF1328 (MMD-212). LOADING

3 Press the REC MODE key (until RST YOBI is displayed). RST YOBI

4 Press the PLAY key. Preliminary adjustment result display

5 Press the REC MODE key several times and display GTG :

the GTG (GROOV TRACKING GAIN) value.

6 Use the TIME SKIP key (UP) and the A-B key (DOWN) GTG : 4

to adjust the value of to 4 or more.

GRT AJST

mode

44

Page 45

MJ-D707, MJ-17D

4 Preliminary Adjustment

Step No. Operation Keys and Operation Method FL Display Status Remarks

7 Press the STOP key. RST YOBI Return to menu display

8 Press the REC MODE key (until AUT YOBI is displayed). AUT YOBI Preliminary adjustment mode

9 Preliminary adjustment starts when the PLAY key is HAo :

pressed. LAg :

PTG :

|

Can't ADJ. Defective adjustment

(problem with the servo system)

COMPLETE Adjustment end

10 Press the STOP key. AUT YOBI Return to menu display

11 Press the EDIT/NO key. EEPROM W Writing to the EEPROM

Toc Reading

GGF1328

(MMD-212)

Note: When this adjustment is performed after defocus adjustment has been performed, defocus is returned to the initial status, and defocus

adjustment must be performed.

5 Normal adjustment

Step No. Operation Keys and Operation Method FL Display Status Remarks

1 Power ON while holding the ENTER key and the PLAY EJECT Test mode

key depressed.

2 Insert the test disc GGF1328 (MMD-212). LOADING

GRT AJST

3 Press the REC MODE key (until AUTO AJST is displayed). AUTO AJST Normal adjustment mode

4 Normal adjustment starts when the PLAY key is pressed. PEG :

HAG:

|

Can't ADJ. Defective adjustment

(problem with the servo system)

COMPLETE Adjustment end

5 Press the STOP key. AUTO AJST Return to menu display

6 Defocus adjustment

Step No. Operation Keys and Operation Method FL Display Status Remarks

1 Power ON while holding the ENTER key and the EJECT Test mode

PLAY key depressed.

2 Insert the test disc GGF1328 (MMD-212). LOADING

GRT AJST

3 Press the REC MODE key deFO AJST

(until deFO AJST is displayed).

4 Press the PLAY key. PEG : Defocus mode is entered, and after automatic

of c

Deforcus Value C1 Error Value

5 Check the jitter value and end the adjustment when

the intermediate jitter value is 29 nsec or less.

6 Press the NAME CLIP key. of+04 c0032 The C1 error with application of a focus offset of

FESpp : execution of normal adjustment, the C1 error at

of000c0015 the time of focus offset 0 is displayed.

about 0.4 µm on the + side is displayed.

The jitter value (J+) at this time is recorded.

45

Page 46

MJ-D707, MJ-17D

6 Defocus adjustment

Step No. Operation Keys and Operation Method FL Display Status Remarks

7 Press the NAME CLIP key. of-04 c0020 The C1 error with application of a focus offset of

about 0.4 µm on the – side is displayed.

The jitter value (J–) at this time is recorded.

8 When J+ is larger than J-, press the REC MODE of+04 c0032

key and display the C1 error when the focus offset

is applied up to +0.4 µm.

(Do nothing when J- is larger than J+.)

9 Change the value with CUE (1)/REV (1) until of+04 c0032 When the smaller offset of the jitter value has

the value becomes the same. of+03 c0025 been corrected mistakenly, press the NAME key

of+02 c0020 and return to step 4.

10 Press the PLAY key. COMPLETE The mean value of the changed set value and

the offset of the other setting limit is written into

the EEPROM as the compensation offset.

11 Power OFF Test mode is ended.

Connection diagram

Jitter Meter

LEVEL

GND

CORE MAIN UNIT ASSY

JITTER

REFO

SIDE A

EFM MON

7 Jitter/C1 Error Check at the time of Playback

Step No. Operation Keys and Operation Method FL Display Status Remarks

1 Power ON while holding the ENTER key and the EJECT Test mode

PLAY key depressed.

2 Insert the test disc GGF1328 (MMD-212). LOADING

GRT AJST

3 Perform “ Normal Adjustment ” (step 3, step 4). AUTO AJST

4 Press the NAME CLIP key. TEST PLAY TEST PLAY mode

5 Press the NAME key and display the inner ADRES 0050

circumference address.

6 Press the PLAY key and display the C1 error for a0050 c0015 Check that the jitter value meets the standard

the inner circumference. value of the following table.

GGF1328 (MMD-212) jitter value

Inner circumference 31 nsec or less

Intermediate circumference

Outer circumference 29 nsec or less

29 nsec or less

7 Press the REC key. A0062 c0013 Seven data are acquired, the largest and the

AVE. c0012 smallest value are discarded, and fixed display

is made for the mean value of the remaining

five data. Check that this value is 200 or less.

46

Page 47

MJ-D707, MJ-17D

7 Jitter/C1 Error Check at the time of Playback

Step No. Operation Keys and Operation Method FL Display Status Remarks

8 Press the REC key. a006F c0017 The fixed display of the C1 error is ended.

9 Press the STOP key. TEST PLAY

10 Press the NAME key and display the inner ADRES 0050

circumference address.

11 Press the NAME CLIP key and display the ADRES 03C0

intermediate circumference address. a03C0 c0009

Perform steps 6 to 9 in this condition. TEST PLAY

12 Press the NAME key and display the inner ADRES 0050

circumference address.

13 Press the NAME CLIP key twice to display the ADRES 0700

outer circumference address. a0700 c0008

Perform steps 6 to 9 in this condition. TEST PLAY

14 Press the EJECT key, eject the test disc EJECT

GGF1328 (MMD-212), and insert TGYS1 (or LOADING

MMD-110.) GRT AJST

15 Perform steps 3 to 13 and check the jitter/C1 a0062 c0009 Check that the jitter value meets the standard

error with the test disc TGYS1 ( or MMD-110). a03d2 c0007 value of the following table.

a0712 c0006

TGYS1 ( or MMD-110) jitter value

Inner circumference 29 nsec or less

Intermediate circumference

Outer circumference 27 nsec or less

27 nsec or less

Intermediate

and

outer

circumference

may be

omitted.

16 Press the EJECT key. EJECT The test disc TGYS1 ( or MMD-110) is ejected.

17 Power OFF Test mode is ended.

Jitter Meter

LEVEL

GND

CORE MAIN UNIT ASSY

JITTER

REFO

SIDE A

EFM MON

Connection diagram

47

Page 48

MJ-D707, MJ-17D

Jitter/C1 Error Check at the time of Recording/Playback

Step No. Operation Keys and Operation Method FL Display Status Remarks

1 Power ON while holding the ENTER key and the EJECT Test mode

PLAY key depressed.

2 Insert the test disc (GGF1277). LOADING

GRT AJST

3 Perform “ Normal Adjustment ” (step 3, step 4). AUTO AJST

4 Press the NAME CLIP key twice. TEST REC TEST REC mode

5 Press the NAME key and display the inner a0050 pw0D

circumference address.

6 When the PLAY key is pressed, TEST REC starts, a0069 pw0D

and when 25 addresses or more have been sent, TEST REC

stop by pressing the STOP key.

7 Press the NAME key and display the inner a0050 pw0D

circumference address.

8 Press the NAME CLIP key and display the a03C0 pw0D

intermediate circumference.

9 Perform step 6. a03D9 pw0D

TEST REC

10 Press the NAME key and display the inner a0050 pw0D

circumference address.

11 Press the NAME CLIP key twice and display the a0700 pw0D

outer circumference address.

12 Perform step 6. a0719 pw0D

TEST REC

13 Press the NAME CLIP key. TEST PLAY TEST PLAY mode

14 Perform steps 5 to 13 of “ Jitter/C1 Error Check a0069 c0009 Check the jitter/C2 error at the inner/

at the time of Playback ”. a03D9 c0007 intermediate/outer circumference of GGF1277,

At the time of self-recording, wait for seven a0719 c0006 and check that the jitter value satisfies the

addresses after TEST PLAY start, and then press standard value of the following table.

the REC key and enter into mean value mode.

(Good recording may not be possible for several

addresses at the beginning.)

Note:When the initial address (0050) part of

the inner circumference (or intermediate/

outer circumference) has been used 1000

times or more, press the CUE key and

shift the address by 10hex. (The address

is shifted (up to 10 times) according to the

use frequency of the disc.)

GGF1277 jitter value

Inner circumference 33 nsec or less

Intermediate circumference

Outer circumference 31 nsec or less

31 nsec or less

Intermediate

and

outer

circumference

may be

omitted.