Pioneer DVL-919-E Service manual

DVD LD PLAYER

DVL-919

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

ORDER NO.

RRV2089

Type

KU/CA ‡ AC120V 1

RD/RA ‡ AC110-127/220-240V 1 Automatic select

Model

DVL-919

Power Requirement

Region No.

The voltage can be converted by

the following method.

CONTENTS

1. SAFETY INFORMATION

2. EXPLODED VIEWS AND PARTS LIST

3. SCHEMATIC DIAGRAM

4. PCB CONNECTION DIAGRAM

5. PCB PARTS LIST

6. ADJUSTMENT

...............................................

....................................................

......................................

................

.....................................

..........................

16

42

58

65

2

4

7. GENERAL INFORMATION

7.1 PARTS

7.1.1 IC

7.2 DISASSEMBLY/ASSEMBLY

7.3 BLOCK DIAGRAM

8. PANEL FACILITIES AND SPECIFICATIONS

.........................................................

...........................................................

.......................................

................................

.......................

....

80

80

80

82

84

86

PIONEER ELECTRONIC CORPORATION 4-1, Meguro 1-Chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS SERVICE, INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER ELECTRONIC (EUROPE) N.V. Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

c

PIONEER ELECTRONIC CORPORATION 1999

T – IZE JAN. 1999 Printed in Japan

DVL-919

1. SAFETY INFORMATION

This service manual is intended for qualified service technicians ; it is not meant for the casual do-ityourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained

to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to cause

cancer, birth defects or other reproductive harm.

Health & Safety Code Section 25249.6 – Proposition 65

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement parts must

be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les pièces

de remplacement doivent avoir la même désignation.

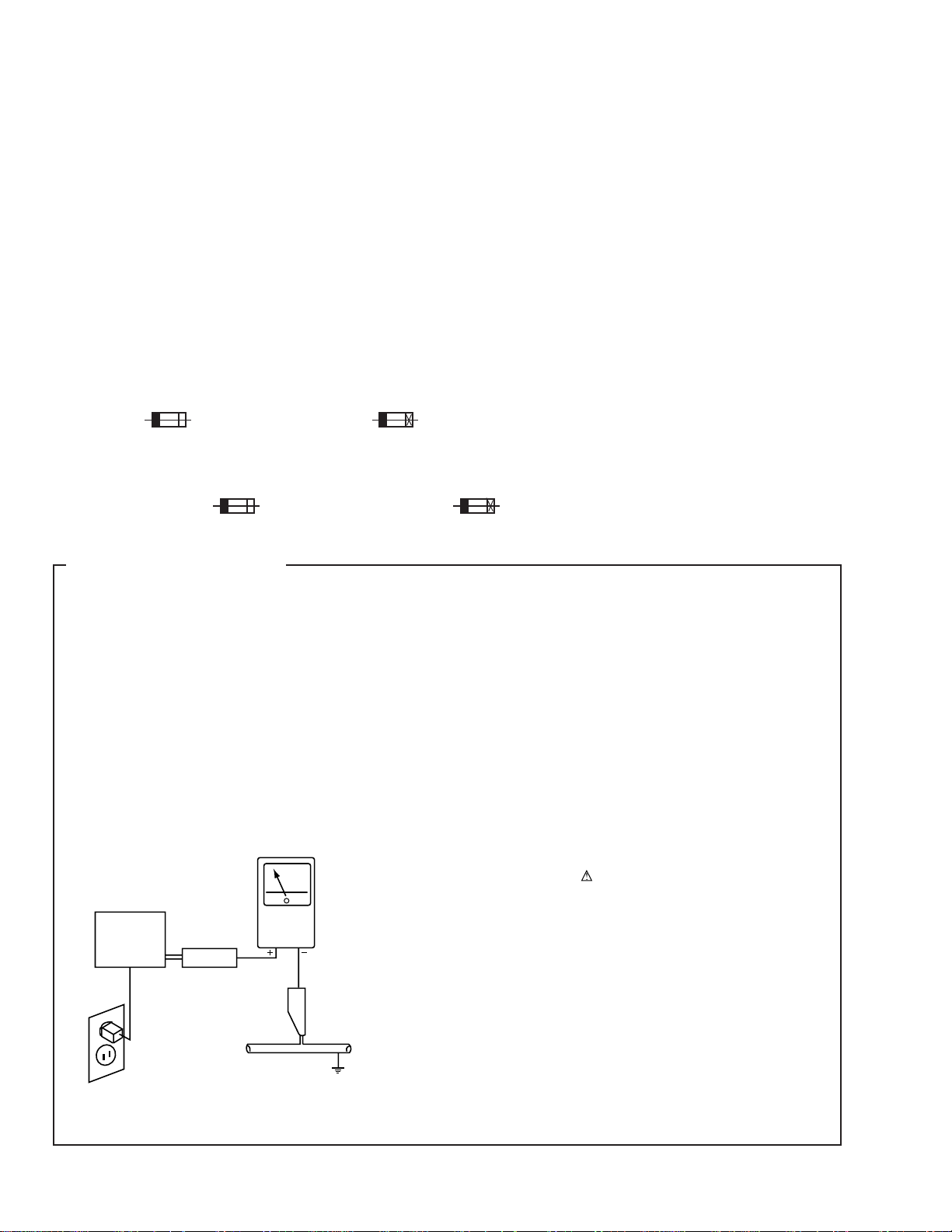

(FOR USA MODEL ONLY)

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and service

technician.

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground (water

pipe, conduit, etc.) by connecting a leakage current tester

such as Simpson Model 229-2 or equivalent between the

earth ground and all exposed metal parts of the appliance

(input/output terminals, screwheads, metal overlays, control

shaft, etc.). Plug the AC line cord of the appliance directly

into a 120V AC 60Hz outlet and turn the AC power switch

on. Any current measured must not exceed 0.5mA.

Reading should

not be above

0.5mA

Earth

ground

Device

under

test

Also test with

plug reversed

(Using AC adapter

plug as required)

Leakage

current

tester

Test all

exposed metal

surfaces

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE APPLIANCE TO THE CUSTOMER.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance

have special safety related characteristics. These are

often not evident from visual inspection nor the protection

afforded by them necessarily can be obtained by using

replacement components rated for voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this Service Manual.

Electrical components having such features are identified

by marking with a

in this Service Manual.

The use of a substitute replacement component which does

not have the same safety characteristics as the PIONEER

recommended replacement one, shown in the parts list in

this Service Manual, may create shock, fire, or other hazards.

Product Safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current PIONEER Service

Manual. A subscription to, or additional copies of, PIONEER

Service Manual may be obtained at a nominal charge from

PIONEER.

on the schematics and on the parts list

AC Leakage Test

2

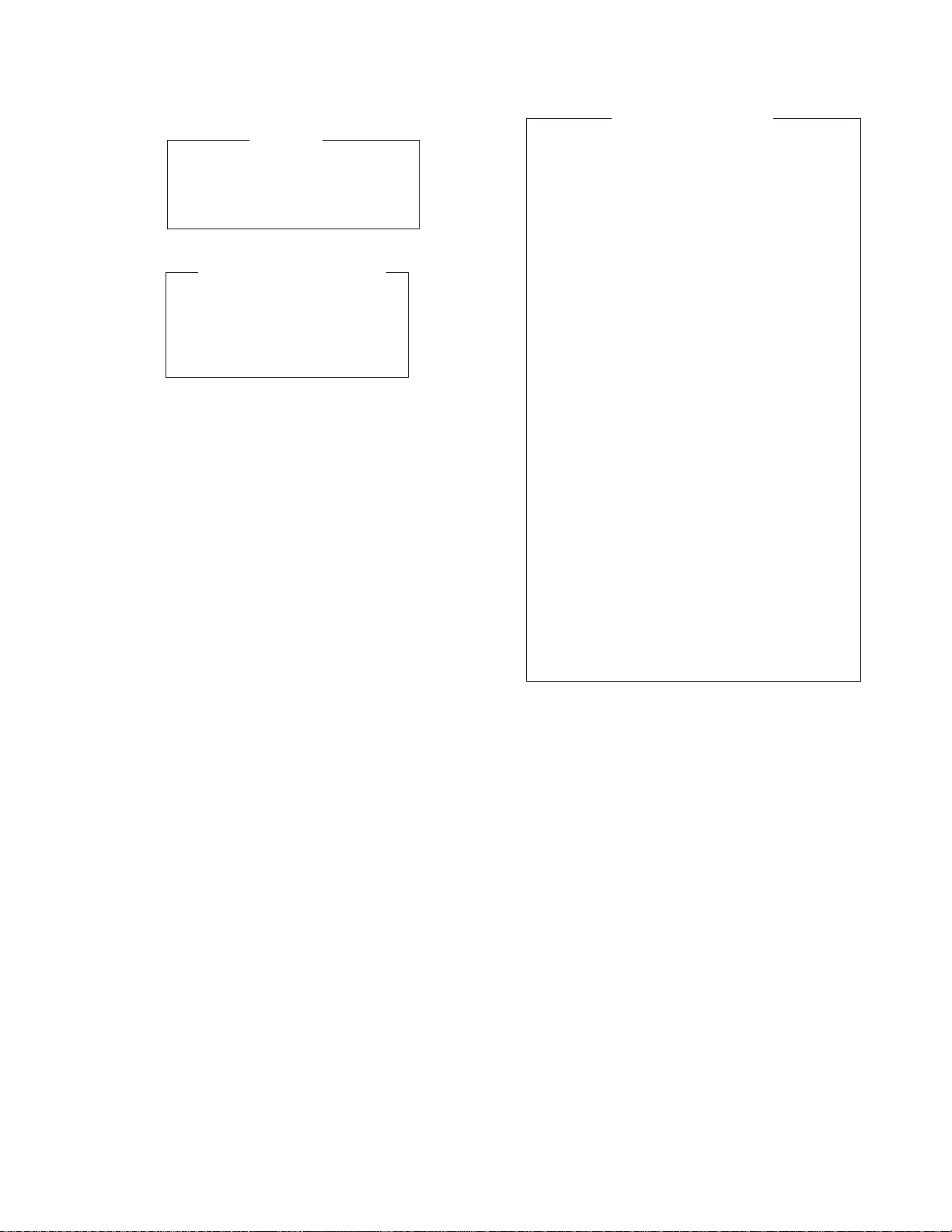

IMPORTANT

THIS PIONEER APPARATUS CONTAINS

LASER OF CLASS 1.

SERVICING OPERATION OF THE APPARATUS

SHOULD BE DONE BY A SPECIALLY

INSTRUCTED PERSON.

LASER DIODE CHARACTERISTICS

•FOR DVD

MAXIMUM OUTPUT POWER : 7 mW

WAVELENGTH : 650 nm

•FOR CD/LD

MAXIMUM OUTPUT POWER : 5 mW

WAVELENGTH : 780-785 nm

DVL-919

Additional Laser Caution

1. The ON/OFF statuses of the side-A/B detection switch

(Lever switch connecting to the TNMB assy), slider-position

detection switches (INNER and OUTER on the PKSB assy),

loading-status detection switches (SW1, 2 and 3 on the LMSB

assy), side B inside detection switch (S901 on the BISB assy)

and CLD pickup active detection switch (S903 on the LCSB

assy) are detected by the microprocessor (IC101 in the CLDM

assy). Also the DVD pickup active detection switch (S902

on the DCSB assy) is detected by the microprocessor (IC501

in the DVDM assy).

• To permit the laser diode of CLD pickup to oscillate, it is

required to set the CLD pickup active detection switch (S903 :

OFF) and the slider-position detection switches for the LD

ACTIVE status (INNER : OFF, OUTER: OFF), and to set the

loading-status detection switches for tilt neutral state (SW1 :

ON, SW2 : OFF, SW3 : ON). As long as these requirements

are not satisfied, the laser diode will not oscillate. When the

requirements are met in any way, the laser diode can oscillate.

The laser diode oscillation will continue if pin 13 of IC801 is

shorted to GND or the emitter and collector of Q834 are shorted

each other (fault condition) in the CLDM assy.

• To permit the laser diode of DVD pickup to oscillate, it is

required to set the DVD pickup active detection switch (S902

:OFF) and each switch and a state of laser diode are contents

same as state of CLD pickup mentioned above. The laser

diode oscillation will continue if pin 13 of IC101 is shorted to

+5V (fault condition) in the DVDM assy.

In the test mode ∗, the laser diode oscillates when the micro-

processor detects a PLAY signal, or when the PLAY key is

pressed (S104 ON in the FLKY assy), with the above require ments satisfied.

2. When the cover is open, close viewing through the objective

lens with the naked eye will cause exposure to a Class 1

laser beam.

∗ : Refer to page 68.

3

DVL-919

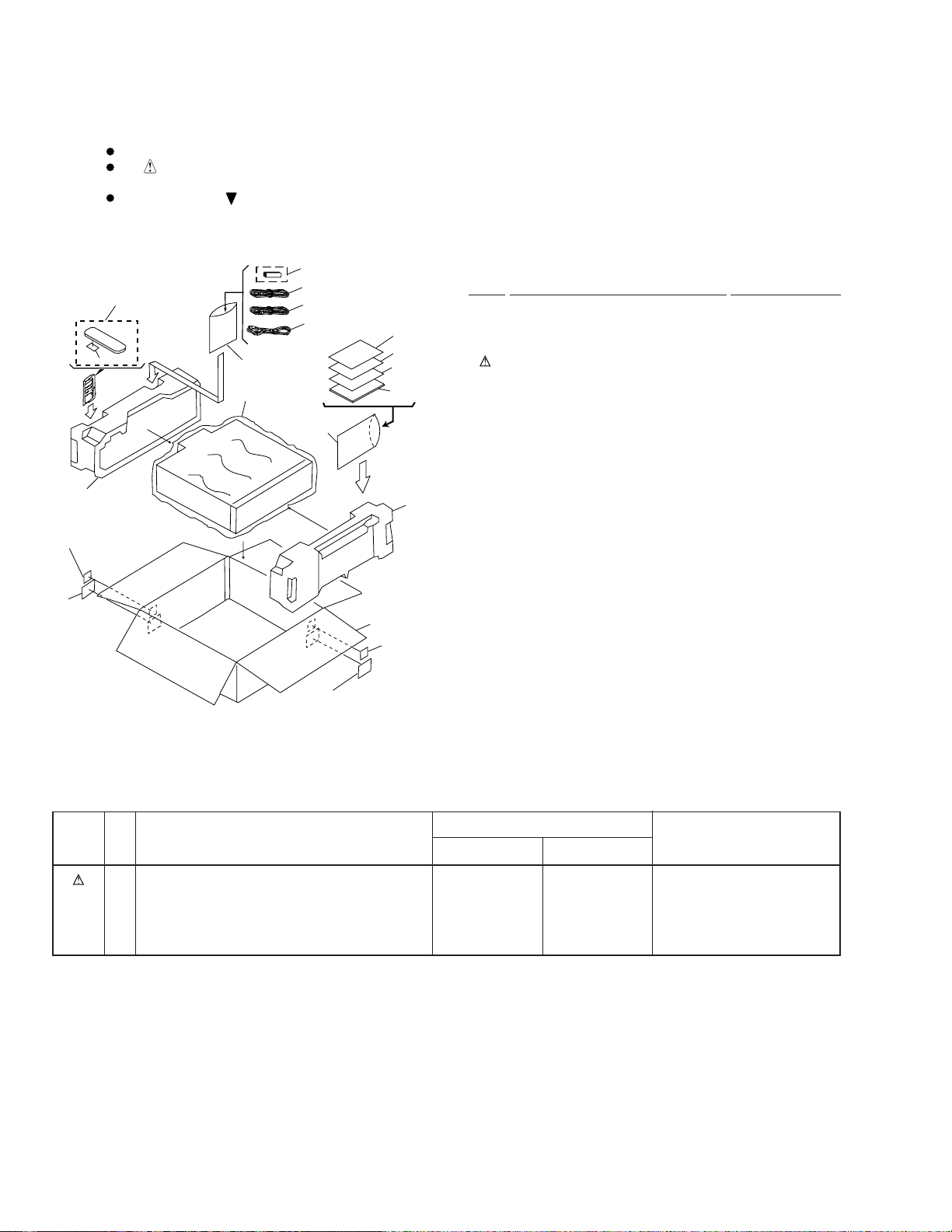

2. EXPLODED VIEWS AND PARTS LIST

NOTES:

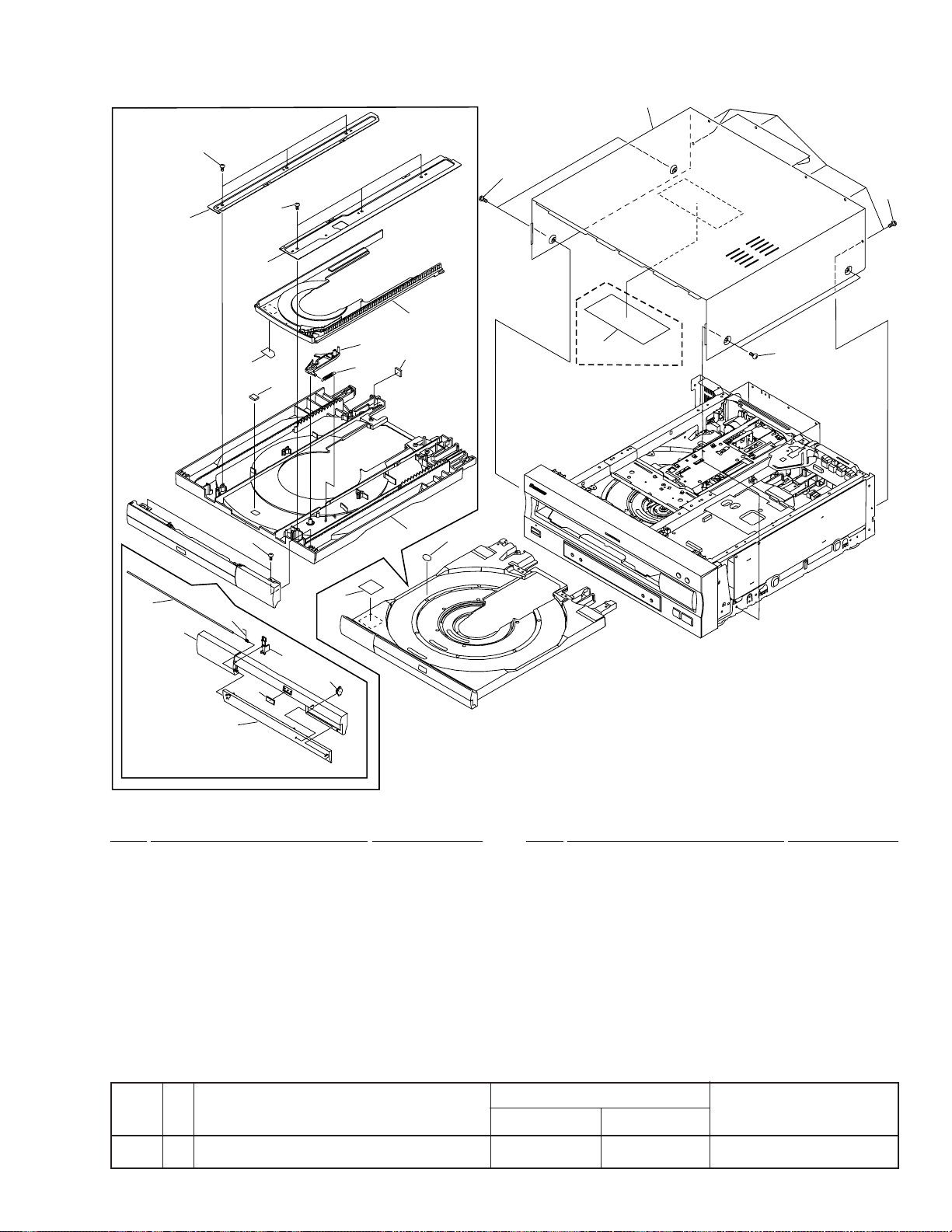

2.1 PACKING

Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on product are used for disassembly.

7

14

(RD/RA Type Only)

17

18

(RD/RA Type)

1

6

5

12

2

3

4

5

18

15

17

(RD/RA

Type Only)

(RD/RA Type)

8

11

10

9

13

(1) PACKING PARTS LIST

Mark No. Description Part No.

NSP 1 DRY CELL BATTERY(R6P,AA) VEM-013

2 VIDEO CORD(L=1.5m) VDE1036

3 AUDIO CORD(L=1.5m) VDE1033

4 POWER CORD See Contrast table (2)

5 POLYETHYLENE BAG Z21-038

6 REMOTE CONTROL UNIT VXX2609

(CU-DV030)

7 BATTERRY COVER VNK3703

NSP 8 CAUTION VRM1063

9 OPERA TING INSTR UCTIONS VRB1202

(English/French)

10 ERRATA VRX1031

NSP 11 WARRANTY CARD See Contrast table (2)

12 MIRROR MAT SHEET VHL1018

13 PAD F VHA1226

14 PAD R VHA1227

15 PACKING CASE See Contrast table (2)

16 • • • • •

17 REGION LABEL P1 See Contrast table (2)

18 RD/RA LABEL See Contrast table (2)

(2) CONTRAST TABLE

DVL-919/KU/CA and RD/RA are constructed the same except for the following :

Mark

No.

4 POWER CORD ADG7021 ADG7003

NSP 11 WARRANTY CARD ARY7023 ARY7025

15 PACKING CASE VHG1768 VHG1770

17 REGION LABEL P1 Not used VRW1708

18 RD/RA LABEL Not used VRW1711

Symbol and Description

KU/CA type RD/RA type

4

Part No.

Remarks

DVL-919

2.2 EXTERIOR SECTION

19

19

7

8

6

4

19

10

17

20

19

5

9

4

21

20

KU/CA Type only

1

2x12

18

13

3

11

14

16

15

12

(1) EXTERIOR SECTION PARTS LIST

Mark No. Description Part No.

1 LD TRA Y ASSY VXA2173

2 CUSHION VEC1682

NSP 3 CARRY LABEL VRW1289

4 DAMP CUSHION VEC1683

5 CD TRA Y VNK3922

6 TRAY LABEL VRW1628

7 GUIDE PLATE (R) VNE1939

8 GUIDE PLATE (L) VNE1938

9 LOCK PLATE VNL1703

10 LOCK PLATE SPRING VBH1188

Mark No. Description Part No.

11 TRAY PANEL VNK4355

12 DVD DOOR VNK4356

13 DOOR SPRING VBH1248

14 DOOR HOLDER VNL1817

15 DAMPER ASSY VXA1999

16 DV D PL ATE VAM1075

17 BONNET CASE S VXX2561

18 DOOR SHAFT VLL1506

19 SCREW BBZ30P080FMC

20 SCREW BCZ40P060FZK

21 65 LABEL See Contrast table (2)

(2) CONTRAST TABLE

DVL-919/KU/CA and RD/RA are constructed the same except for the following :

Mark

No.

Symbol and Description

KU/CA type RD/RA type

Part No.

Remarks

21 65 LABEL ARW7050 Not used

5

DVL-919

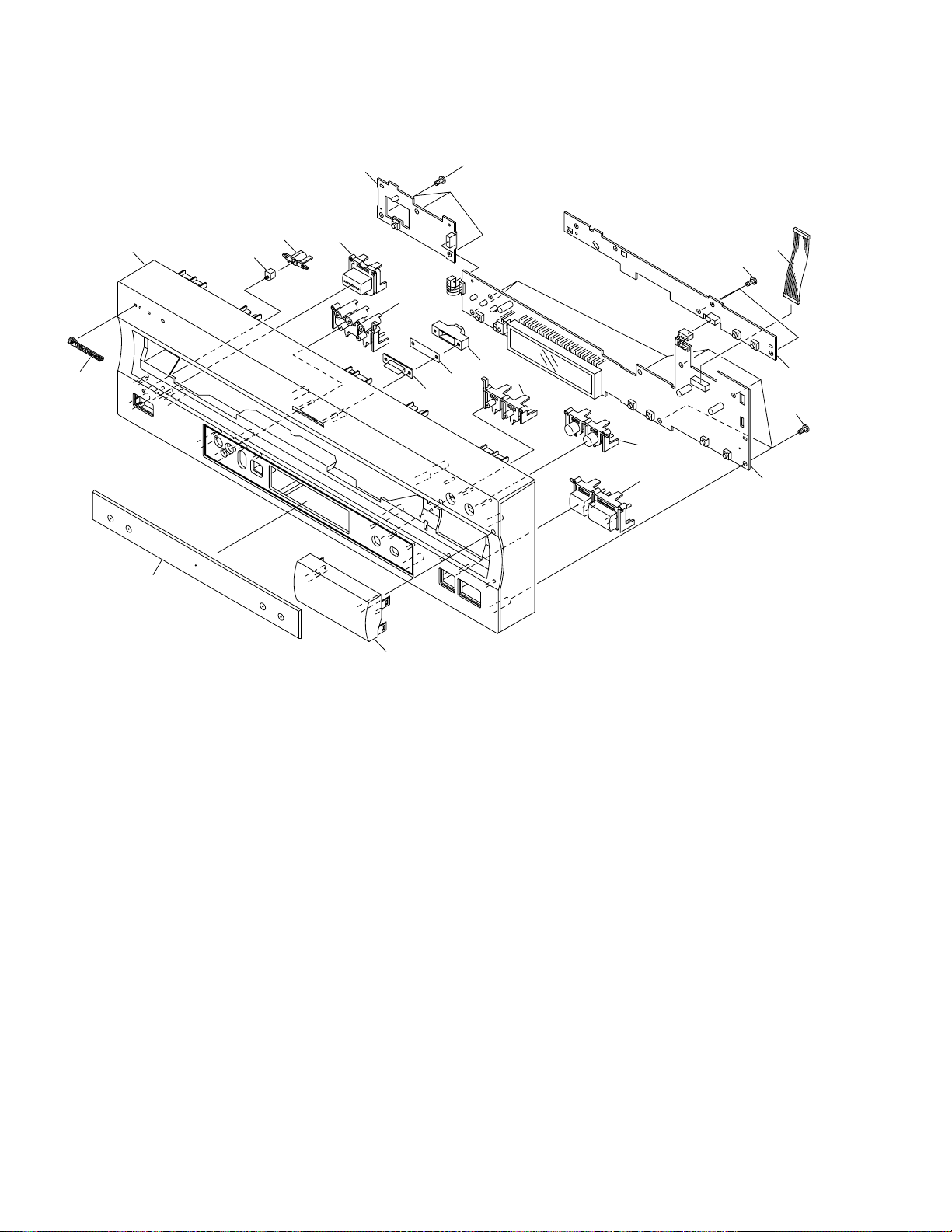

2.3 FRONT PANEL SECTION

11

16

4

16

10

15(2/2)

7

14(1/3)

14(2/3)

3

16

1

2

12

5

8

14(3/3)

6

9

15(1/2)

÷

FRONT PANEL SECTION PARTS LIST

Mark No. Description Part No.

1 FLKY ASSY VWG2005

NSP 2 PWSB ASSY VWG1994

NSP 3 DILB ASSY VWG1995

4 FLEXIBLE CABLE (14P) VDA1638

5 NAME PLATE PAM1776

6 LED LENS PNW2019

7 ILLUMINATION FILTER VEC1950

8 FL LENS VEC2015

9 POWER BUTTON VNK4101

10 ILLUMI HOLDER VNK4098

13

Mark No. Description Part No.

11 ILLUMINATION LENS VNK4168

12 FRONT PANEL VNK4352

13 SUB PANEL VNK4415

14 PLAY BUTTON VNK4354

15 OPERATION BUTTON VNK4349

16 SCREW BBZ30P080FMC

6

DVL-919

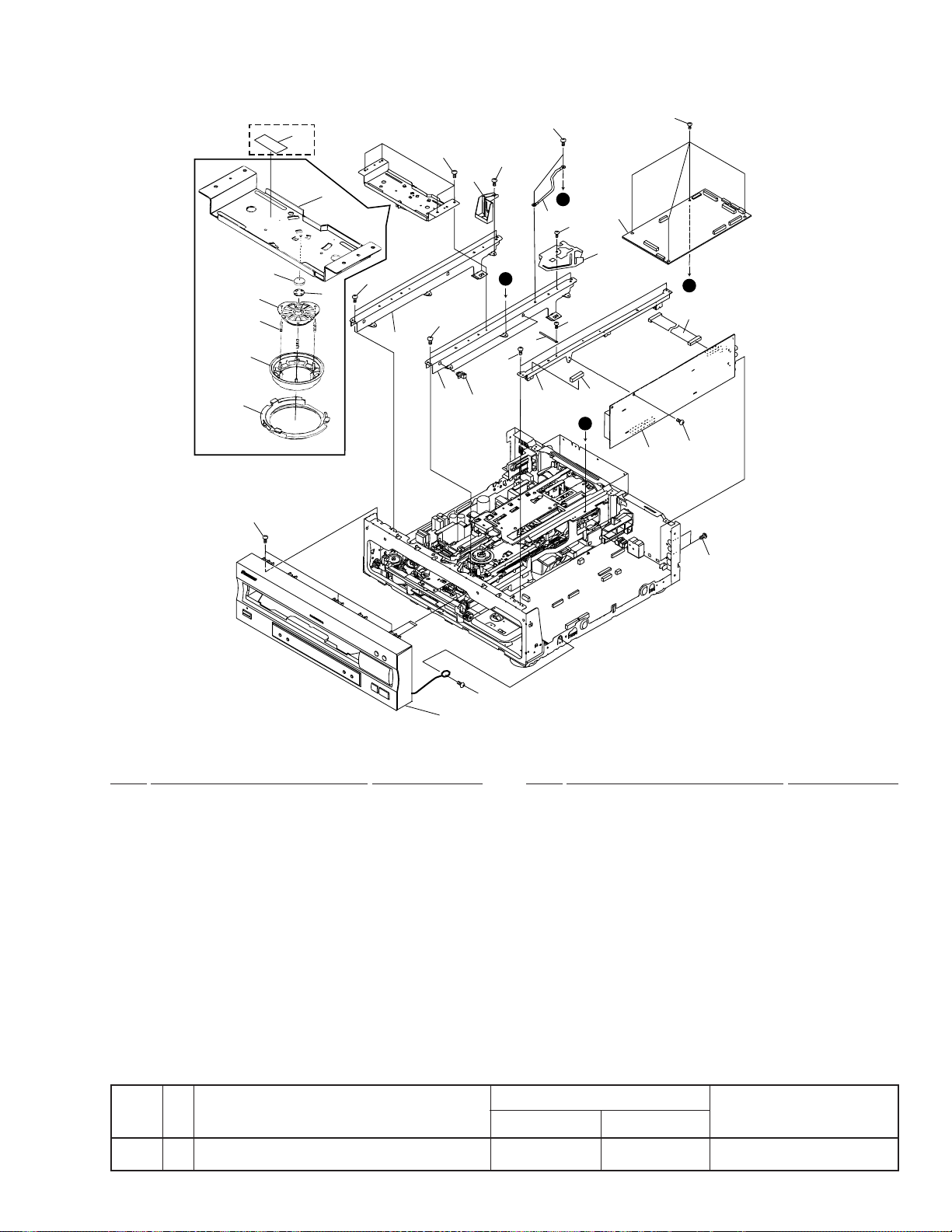

2.4 TOP VIEW SECTION

KU/CA

25

Type

only

1

2

6

5

x3

4

7

23

3

24

22

24

24

22

15

14

24

24

24

B

16

24

13

A

24

12

20

26

B

24

8

A

19

24

18

(1) TOP VIEW SECTION PARTS LIST

Mark No. Description Part No.

1 CENTER PLATE VNE2127

2 RUBBER MAT VEB1114

3 THRUST HOLDER VNL1663

4 CLAMPER VNL1648

5 CLAMPER SPRING VBH1192

6 CLAMPER HEAD VNL1649

7 CLAMPER HOLDER VNL1788

8 DVDM ASSY VWS1377

9 • • • • •

10 • • • • •

11 • • • • •

12 CORD CLAMPER RNH-184

13 CABLE HOLDER VEC1958

24

24

Refer to

"2.3 FRONT PANEL SECTION"

Mark No. Description Part No.

NSP 14 CORNER POST DEC1212

15 SHIPPING CAM VNL1729

NSP 16 CORD WITH PLUG DE007VF0

17 • • • • •

18 GYCB ASSY VWV1633

19 HOUSING ASSY(13P) VKP2196

NSP 20 PCB-HOLDER VNE2164

21 • • • • •

NSP 22 CENTER ANGLE VNE2126

23 SCREW IBZ30P080FMC

24 SCREW BBZ30P080FMC

25 FUSE CAUTION LABEL See Contrast table (2)

26 CUSHION VEC1982

(2) CONTRAST TABLE

DVL-919/KU/CA and RD/RA are constructed the same except for the following :

Mark

No.

25 FUSE CAUTION LABEL VRW1695 Not used

Symbol and Description

KU/CA type RD/RA type

Part No.

Remarks

7

DVL-919

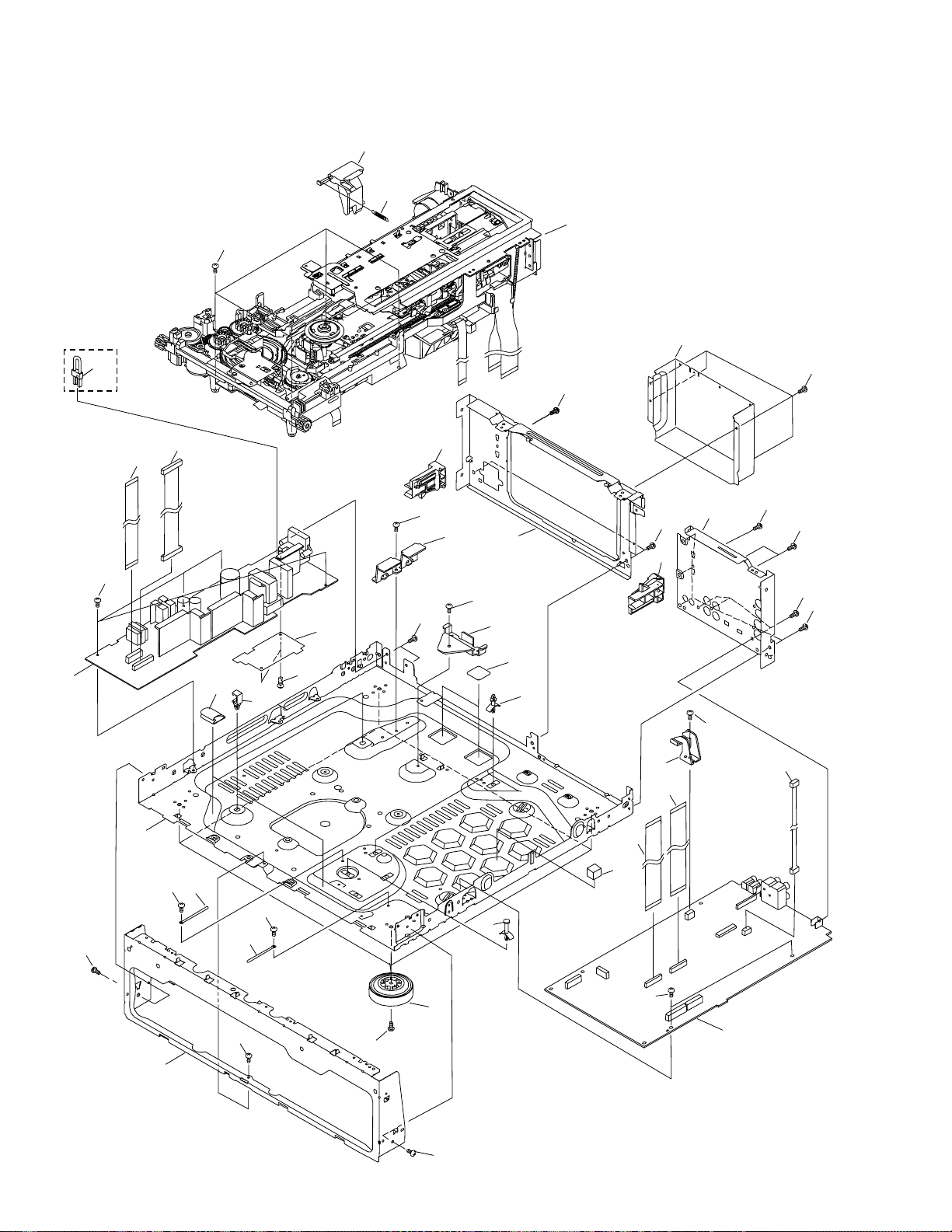

2.5 BOTTOM VIEW SECTION

20

RD/RA Type

only

36

32

16

15

33

21

28

32

19

26

32

7

32

9

Refer to

"2.6 LOADING MECHANISM SECTION"

18

29

32

32

32

28

27

32

32

32

32

6

1

32

17

32

11

3

8

32

8

32

34

2

32

10

4

32

22

23

23

35

5

32

25

13

32

8

(1) BOTTOM VIEW SECTION PARTS LIST

DVL-919

Mark No. Description Part No.

NSP 1 CHASSIS VNA1887

2 INSULATOR ASSY VXA2356

3 PCB HINGE VEC1174

NSP 4 PCB SPACER AEC1188

NSP 5 CIRCUIT BOARD SPACER VEC1957

6 POWER SUPPLY ASSY See Contrast table (2)

7 SHEET P VEC1874

8 CORD CLAMPER RNH-184

NSP 9 STOPPER VNE2088

10 SPACER VEC1939

11 SHELL CLIP DEC1184

12 • • • • •

13 CLDM ASSY VWS1358

14 • • • • •

15 HOUSING ASSY (14P) VKP2151

16 FLEXIBLE CABLE(15P) VDA1644

NSP 17 PANEL HOLDER VNA1686

NSP 18 MECHANISM ASSY VWT1149

NSP 19 CAM HOLDER L VNE2089

20 SHIPPING LEVER VNL1728

21 SHIPPING SPRING VBH1275

Mark No. Description Part No.

NSP 22 CAM HOLDER R VNE2090

23 FLEXIBLE CABLE(22P) VDA1652

24 • • • • •

25 HOUSING ASSY (4P) VKP2195

26 REAR PANEL R VNA1892

27 REAR PANEL L VNA2027

28 TRAY STOPPER VNL1707

29 REAR COVER See Contrast table (2)

30 • • • • •

31 • • • • •

32 SCREW BBZ30P080FMC

33 SCREW BBZ30P100FMC

34 RIVET RBM-003

NSP 35 SPACER VEC1989

NSP 36 HOUSING ASSY See Contrast table (2)

(2) CONTRAST TABLE

DVL-919/KU/CA and RD/RA are constructed the same except for the following :

Mark

No.

6 POWER SUPPLY ASSY VWR1286 VWR1287

29 REAR COVER VNA2028 VNA2056

NSP 36 HOUSING ASSY Not used VKP2189

Symbol and Description

KU/CA type RD/RA type

Part No.

Remarks

9

DVL-919

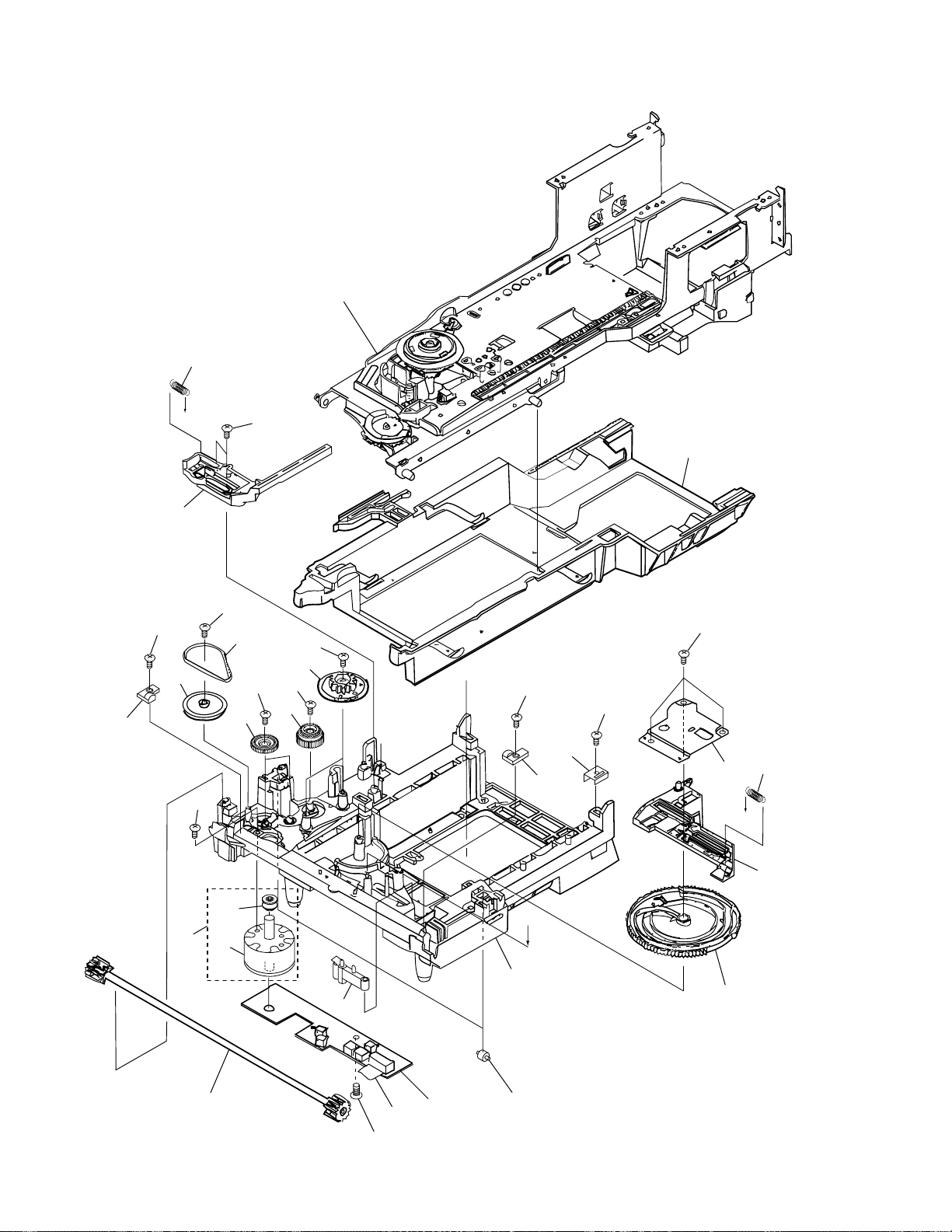

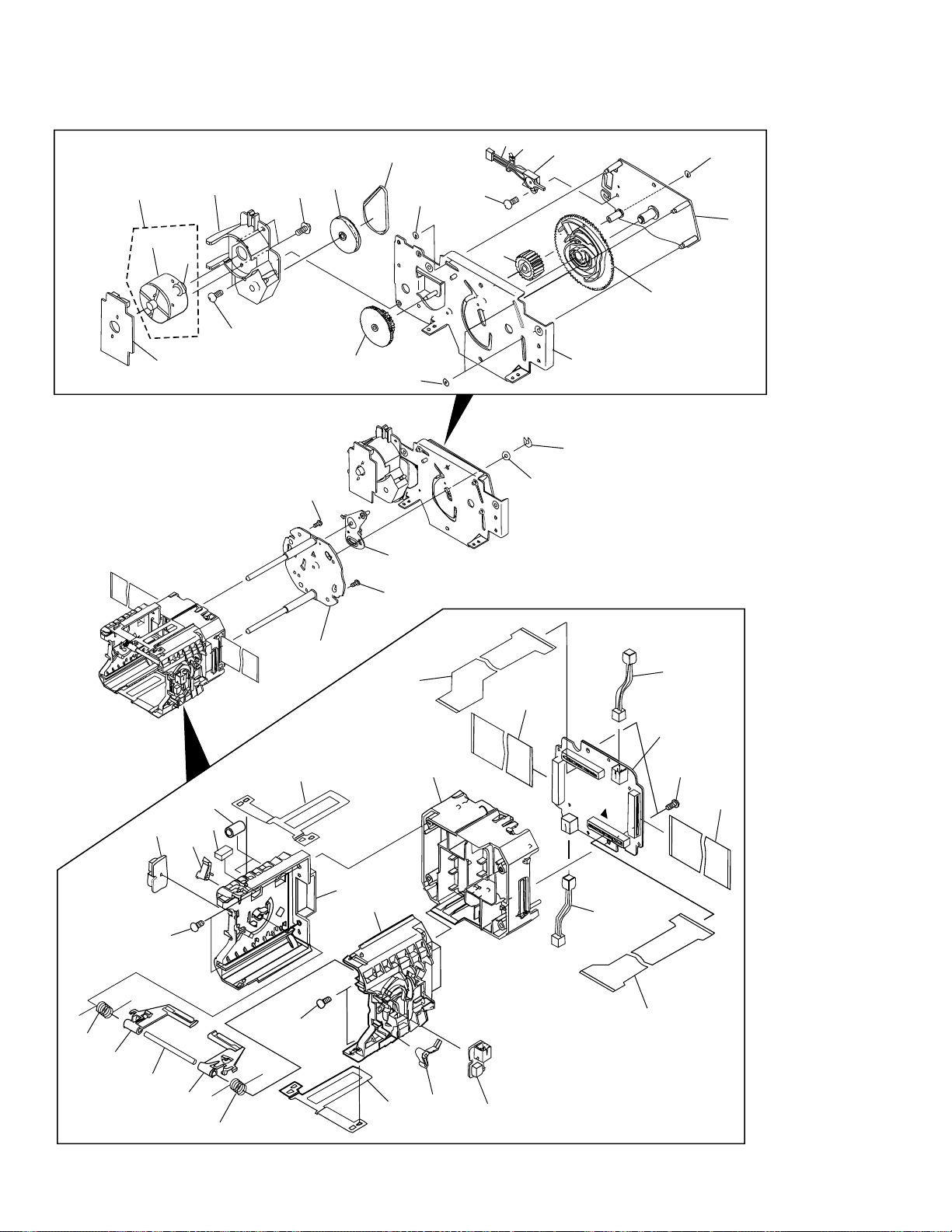

2.6 LOADING MECHANISM SECTION

Refer to

"2.7 SERVO MECHANISM SECTION (1/2)"

2

B

4

3

6

7

11

3

1

3

5

10

3

8

3

3

9

B

3

3

25

26

3

2324

A

22

10

12

15

13

14

18

A

20

21

17

16

3

19

÷

LOADING MECHANISM SECTION PARTS LIST

DVL-919

Mark No. Description Part No.

1 Clamp Cam B VNL1765

2 CDP Spring VBH1191

3 Screw Z39-019

4 CD Plate VNL1685

5 Rubber Belt VEB1184

6 Gear Pulley VNL1662

7 Slider (L) VNL1665

8 Twin Gear VNL1626

9 Center Gear VNL1660

10 Double Gear VNL1661

11 Screw BMZ26P040FMC

12 Loading Motor Assy VXX2045

13 Carriage Motor VXM1033

NSP 14 Motor Pulley VNL1630

15 Synchro Gear Assy VXA2105

Mark No. Description Part No.

16 Flexible Cable (10P) VDA1645

NSP 17 LMSB Assy VWG1554

18 MB Switch Lever VNL1664

19 Roller VNL1042

20 Mechanism Base VNK3239

21 Cam Gear VNL1625

22 Cam Plate VNL1631

23 CAS Spring VBH1190

24 Shaft Holder VNE1942

25 CAM Holder VNE2032

26 Slider (R) VNL1666

11

DVL-919

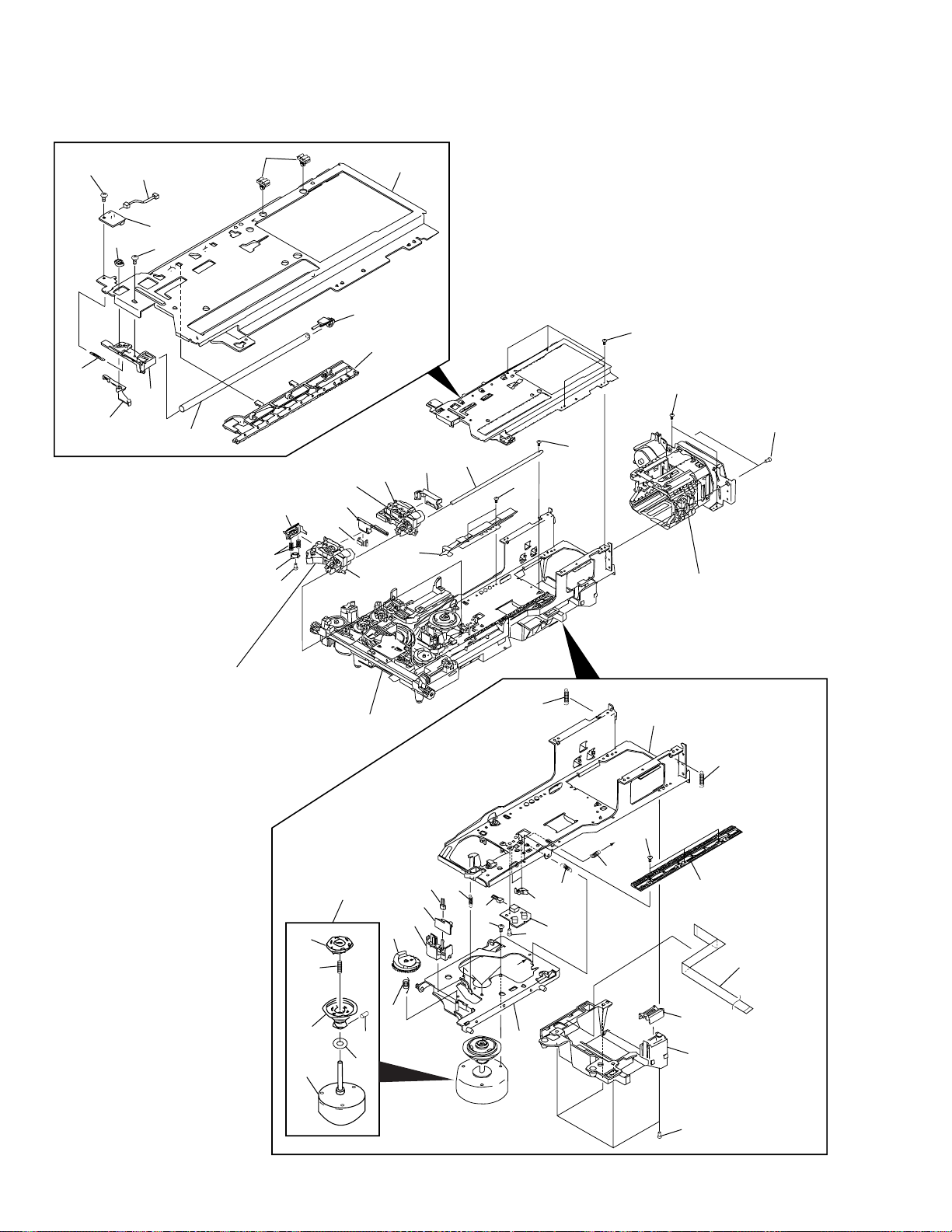

2.7 SERVO MECHANISM SECTION (1/2)

1

2

5

6

8

7

4

14

13

55

9

11

10

12

Refer to

"2.9 DVD CARRIAGE ASSY"

23

24

25

26

Refer to

"2.10 CLD CARRIAGE ASSY"

Refer to

"2.6 LOADING MECHANISM SECTION"

57

21

22

20

18

19

16

17

15

28

58

58

Refer to

"2.8 SERVO MECHANISM

SECTION (2/2)"

27

28

12

52

47

49

48

56

50

51

46

45

44

43

42

41

38

40

33

A

34

35

36

37

39

A

32

29

30

53

31

15

÷

SERVO MECHANISM SECTION (1/2) PARTS LIST

DVL-919

Mark No. Description Part No.

1 Mini Clamp VEC2030

2 Screw BBZ26P060FMC

3 • • • • •

4 Tilt Base (Upper) VNE2062

5 Housing Assy (2P) VKP2136

NSP 6 BISB Assy VWG1796

7 Screw BPZ20P040FZK

8 B Cam VNL1725

9 Support Spring VBH1273

10 SW Lever B VNL1723

11 Shaft Holder VNL1724

12 CA Shaft (Upper) VLL1486

13 CA Rack (Upper) VNL1722

14 Shaft Stay VNL1726

15 Screw BBZ30P080FMC

16 Screw PPZ20P060FMC

17 CA Shaft (Lower) VLL1496

18 TAN Guide VNE2061

19 FPC Holder A VNL1751

20 DVD Carriage Assy VWT1146

21 FPC Holder B VNL1801

22 CLD Carriage Assy VWT1141

23 CA Guide VNL1668

24 TAN Spring (B) VBH1264

25 TAN Lever (B) VNL1669

Mark No. Description Part No.

31 Flexible Cable Cover VNL1727

32 Motor Base VNE1941

33 Screw IBZ26P060FMC

34 Tilt Spring VBH1263

35 Thrust Spring VBH1245

36 CA Switch Lever VNL1644

NSP 37 PKSB Assy VWG1555

38 Housing Assy (3P) VKP2045

39 Screw IBZ26P120FMC

40 Screw PMA30P050FMC

41 Tilt Spring B VBH1287

42 Housing Assy (3P) VKP2046

NSP 43 FG Assy VWG1556

44 FG Base VNL1781

45 Tilt Cam VNL1643

46 Tilt Cam Spring VBH1243

47 PRC Hub VNL1684

48 Centering Spring VBH1269

49 R Turn Tab le Assy VXA2354

NSP 50 Oil Stopper VBF1002

51 Screw ZMD30H030FBT

NSP 52 Spindle Motor VXM1057

53 Cover S VNL1780

54 • • • • •

55 Screw BBZ30P050FZK

26 Screw PMZ20P060FZK

27 Tilt Base (Under) VNL1711

28 Tilt Rear Spring VBH1274

29 CA Rack (Lower) VNL1712

30 Flexible Cable (6P) VDA1642

56 Spindle Motor Assy VXX2579

57 FPC Holder VNL1789

58 Screw BCZ30P080FMC

13

DVL-919

2.8 SERVO MECHANISM SECTION (2/2)

8

40

4

2

3

5

1

7

6

11

35

35

36

13

9

39

10

14

12

33

35

15

28

5

16

5

17

18

25

38

37

27

26

26

5

24

34

20

19

21

5

22

20

14

30

31

32

31

30

5

27

25

29

23

÷

SERVO MECHANISM SECTION (2/2) PARTS LIST

Mark No. Description Part No.

NSP 1 TNMB Assy VWG1793

NSP 3 Motor Pulley VNL1630

2 Carriage Motor VXM1033

4 Motor Holder VNL1717

5 Screw BBZ30P080FMC

DVL-919

Mark No. Description Part No.

NSP 21 CNNB Assy VWG1792

22 Flexible Cable (27P) VDA1643

23 PU FPC-A VNP1582

24 PCB Holder VNL1716

25 FC Guide VNE2059

6 Screw BMZ26P040FMC

7 Gear Pulley VNL1662

8 Rubber Belt VEB1184

9 Housing Assy (3P) VKP2137

10 Lever Switch DSK1003

11 Middle Gear VNL1720

12 Turn Panel Assy VXA2337

13 Gear S VNL1719

14 Turn Cam Gear VNL1718

15 Swing Plate Assy VXA2289

16 Turn Lever Assy VXA2292

17 Turn Plate Assy VXA2290

18 PU FPC-B VNP1583

19 Flexible Cable (26P) VDA1653

20 Connector Assy PG02KK-E10

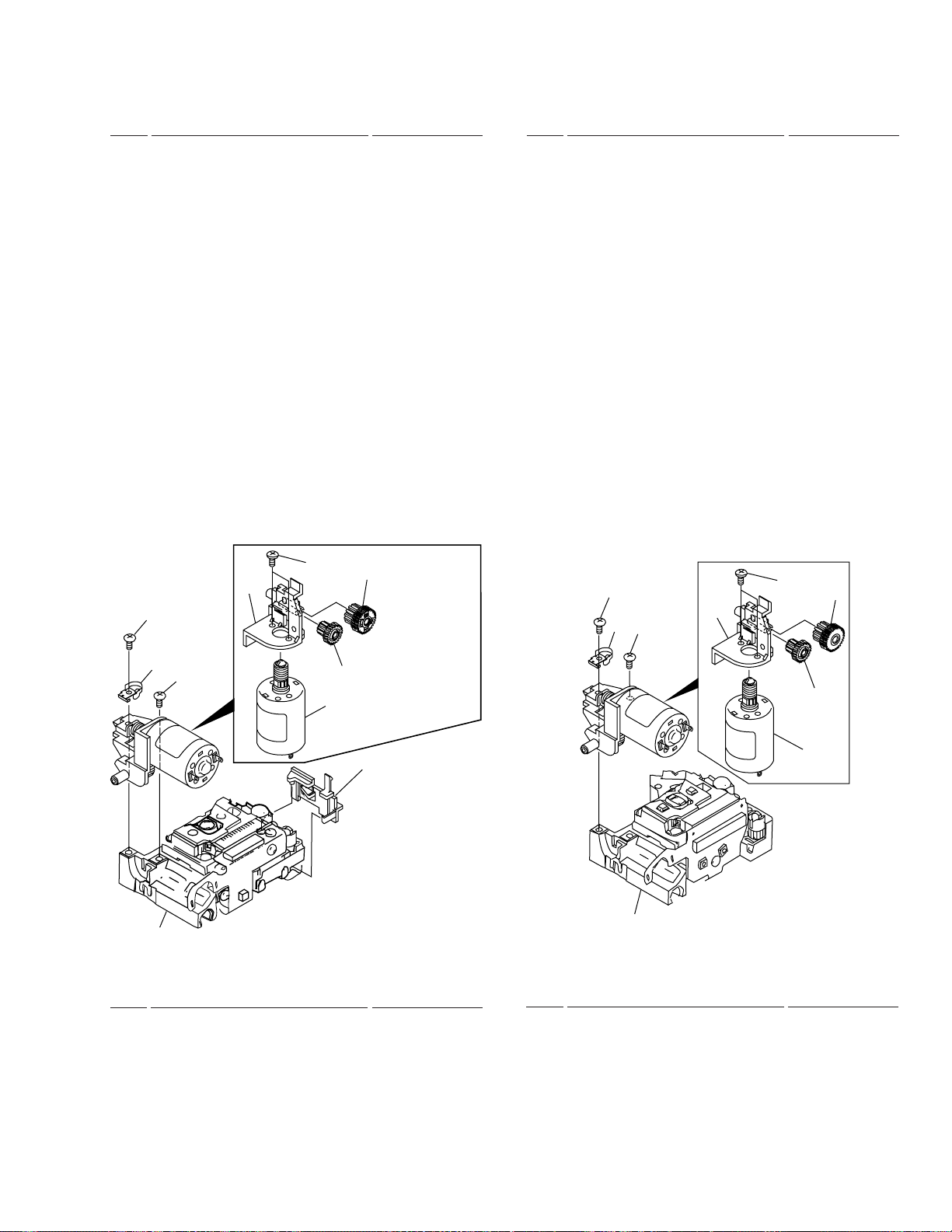

2.9 DVD CARRIAGE ASSY

8

4

7

5

7

2

1

3

26 PU Holder VNL1715

27 SW Lever C VNL1714

NSP 28 LCSB Assy VWG1795

NSP 29 DCSB Assy VWG1794

30 FC Arm Spring VBH1272

31 FC Arm VNL1713

32 Tilt Shaft VLL1175

33 E Ring YE30FUC

34 Washer WA42D080D050

35 Washer WT26D070D050

36 Screw PMA26P060FMC

37 Cushion VEC1917

38 Tube VEB1273

39 Binder Z09-056

40 Loading Motor Assy VXX2045

2.10 CLD CARRIAGE ASSY

6

5

6

4

7

1

2

6

This part is no service part.

÷

DVD CARRIAGE ASSY PARTS LIST

Mark No. Description Part No.

1 CA Gear (A) VNL1782

2 CA Gear B Assy VXX2471

3 Slider Motor Assy VXX2472

4 Motor Holder VNL1779

5 Thrust Holder VBK1058

6 CA Guide B VNL1721

7 Screw BBZ20P050FZK

8 Screw PMA20P033FUC

3

This part is no service part.

÷

CLD CARRIAGE ASSY PARTS LIST

Mark No. Description Part No.

1 CA Gear (A) VNL1782

2 CA Gear (B) VNL1639

3 Slider Motor Assy VXX2472

4 Motor Holder VNL1779

5 Thrust Holder VBK1058

6 Screw PBZ20P050FMC

7 Screw PMA20P033FUC

15

1

23

4

DVL-919

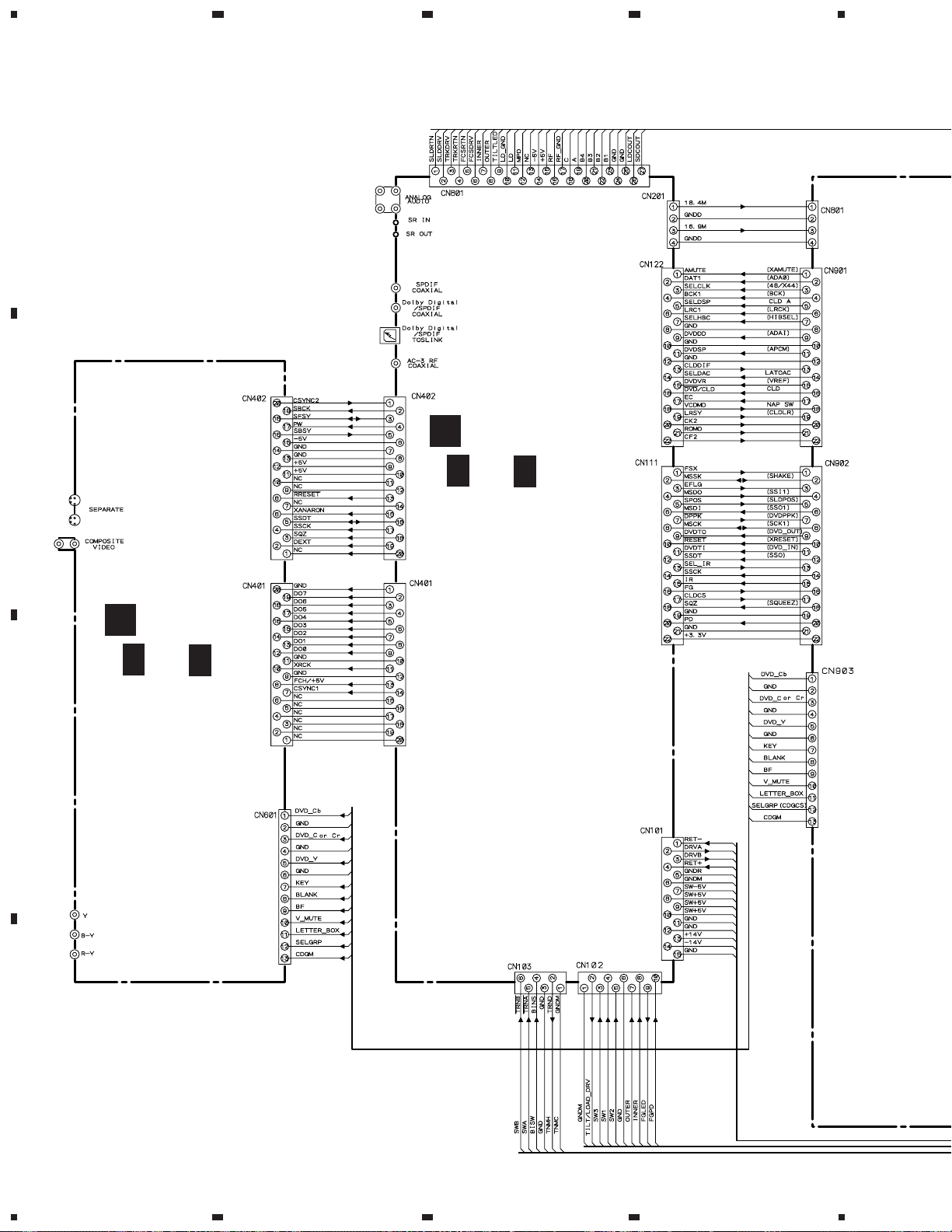

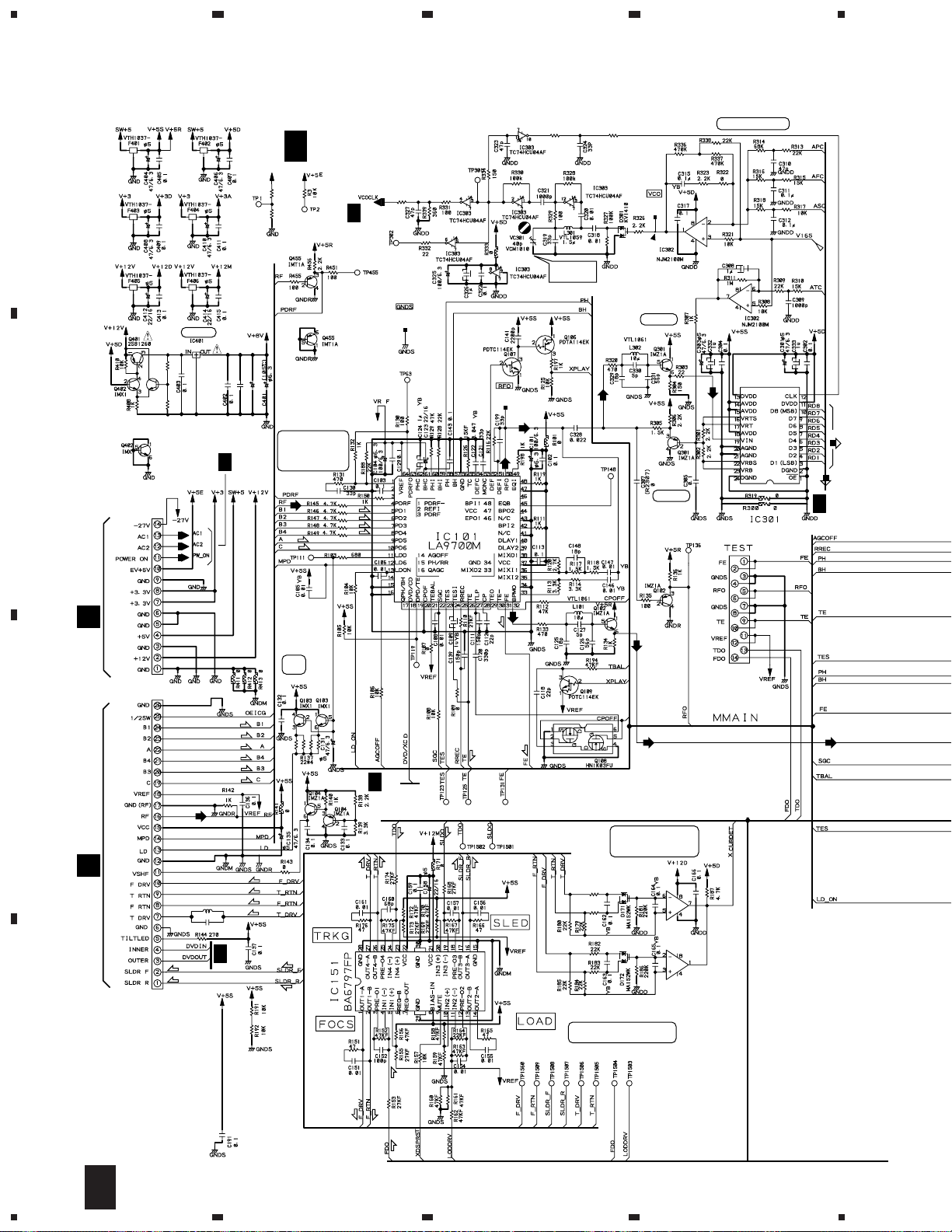

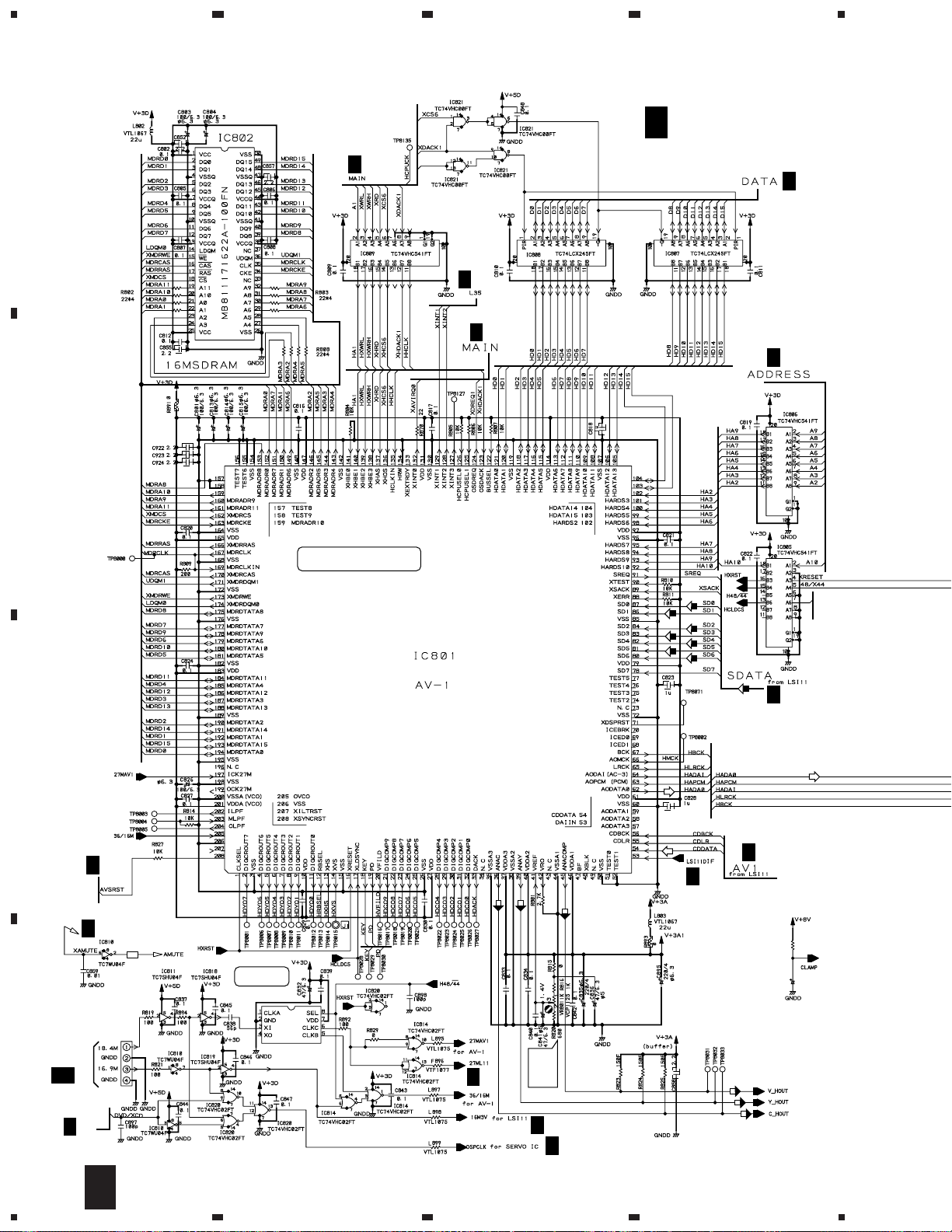

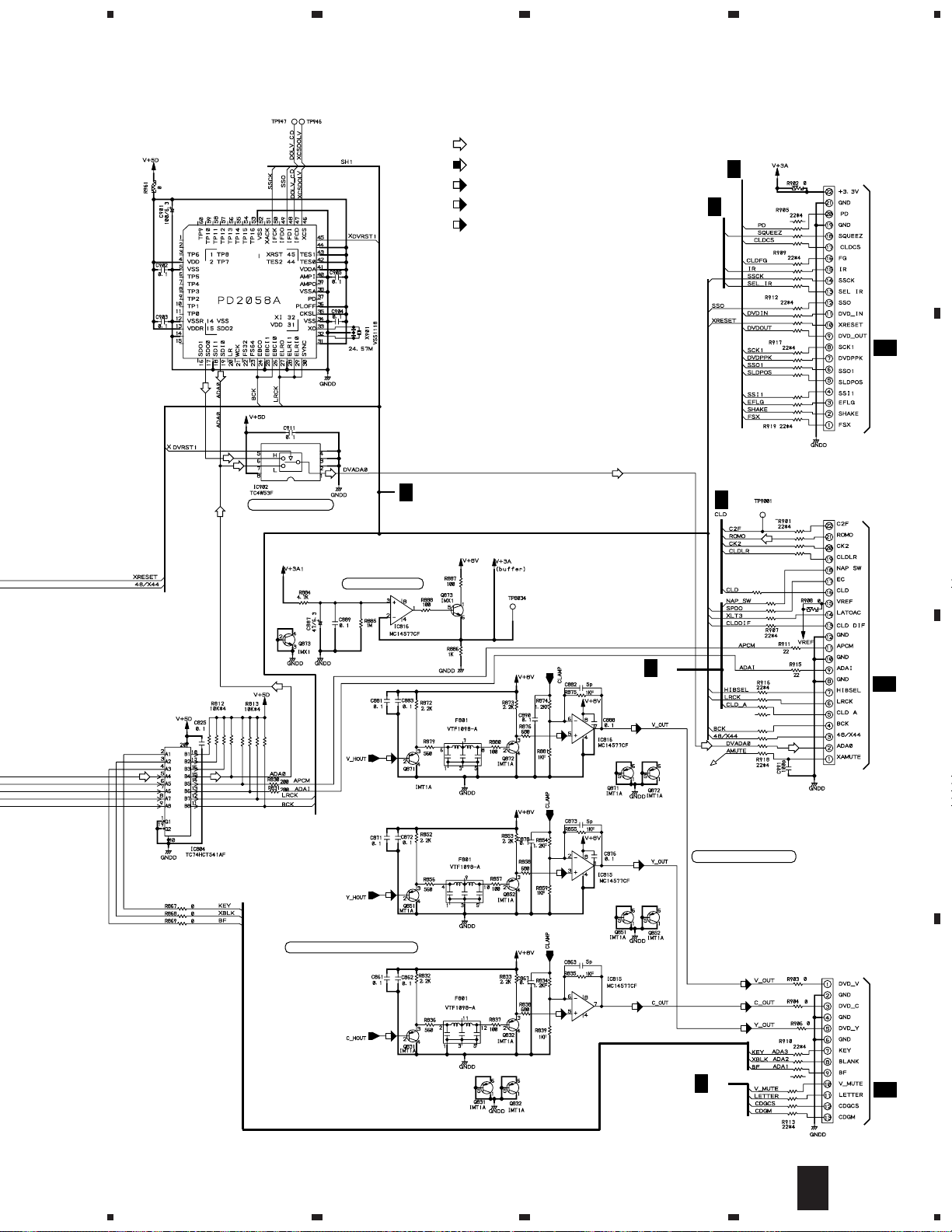

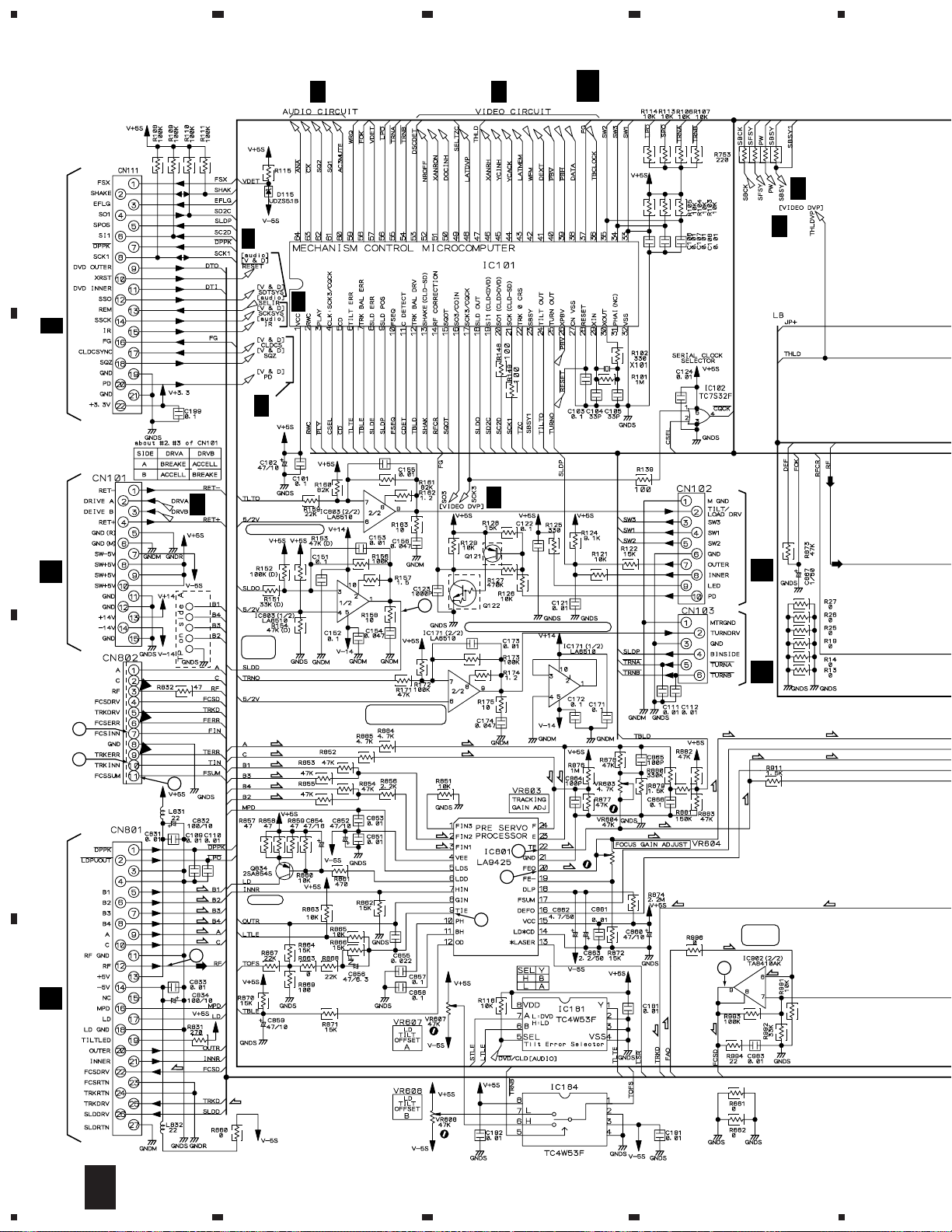

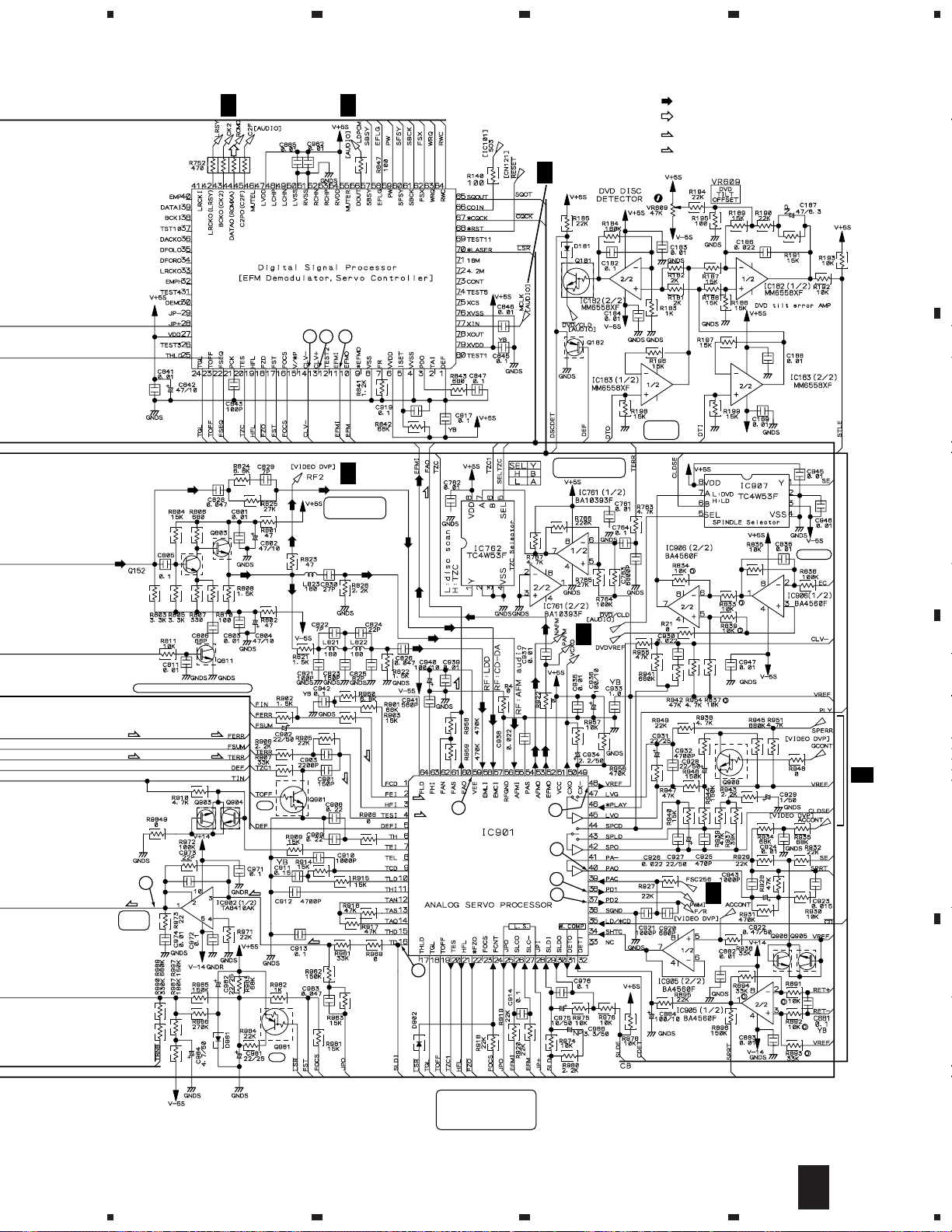

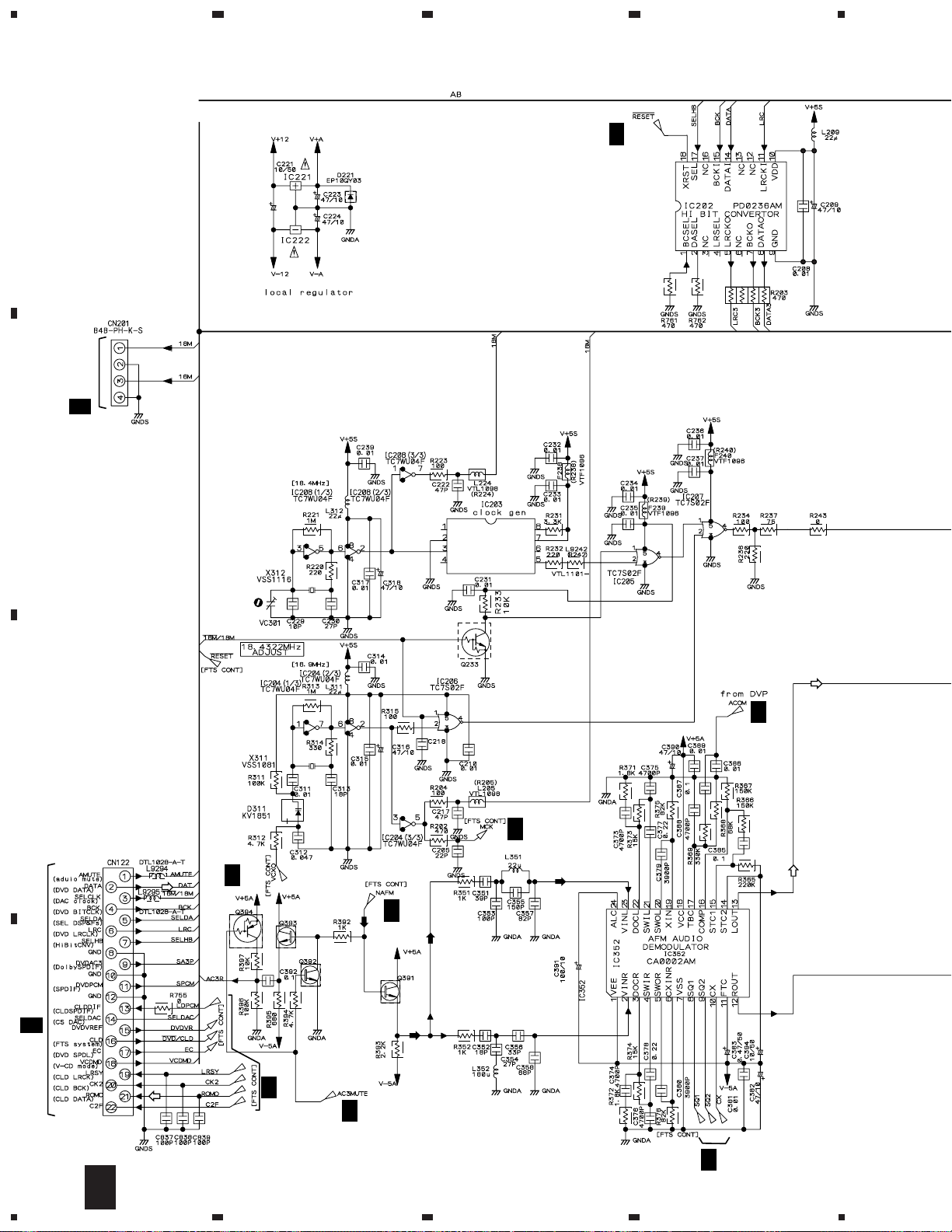

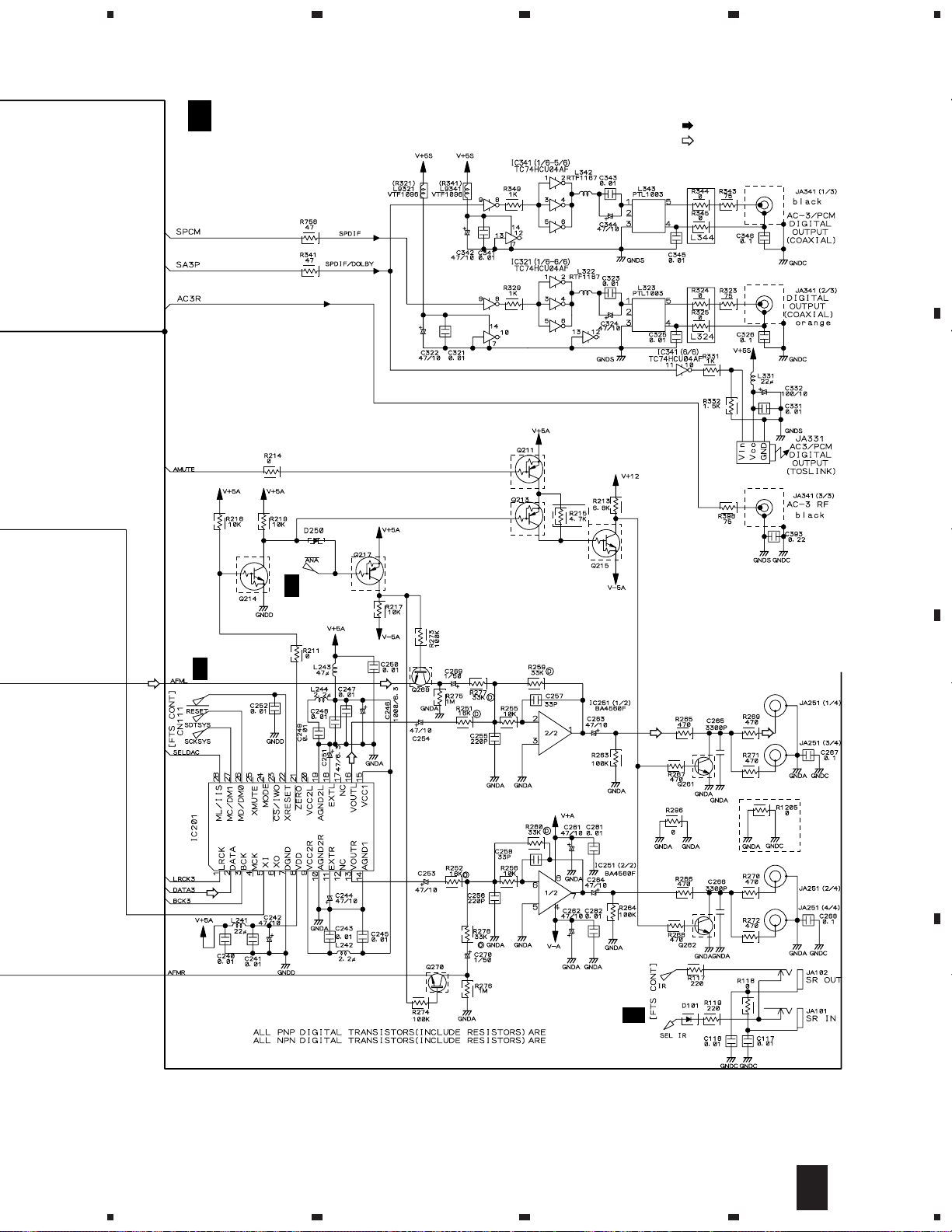

3. SCHEMATIC DIAGRAM

3.1 OVERALL WIRING DIAGRAM, LMSB, PKSB, FG, CNNB, TNMB, DCSB, LCSB

and BISB ASSEMBLIES

A

J

B

( )

J

1/3 –

CLDM ASSY

(VWS1358)

J

3/3

K

( )

K

1/2,

GYCB ASSY

(VWV1633)

C

K

2/2

D

16

1234

5

678

DVL-919

Note : When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS LIST" or "PCB P ARTS LIST".

: RF SIGNAL ROUTE

(F)

: FOCUS SERVO LOOP LINE

(T)

: TRACKING SERVO LOOP LINE

(S)

: SLIDER SERVO LOOP LINE

CLD CARRIAGE ASSY

(VWT1141)

OE IC

(T)

(T)

(F)

(F)

(F)

(F)

DVD CARRIAGE ASSY

(VWT1146)

FOR 232C

I

( )

I

1/3 –

DVDM ASSY

(VWS1377)

I

3/3

G

LCSB ASSY

(VWG1795)

S903 S902

(T)

(T)

(F)

(F)

(F)

(F)

CNNB ASSY

D

(VWG1792)

F

DCSB ASSY

(VWG1794)

SLIDER MOTOR

ASSY

VXX2472

A

B

OE IC

VXX2045

M

(F)

(T)

(F)

(T)

(S)

(S)

PKSB ASSY

B

(VWG1555)

(S)

SLIDER MOTOR ASSY

VXX2472

TNMB ASSY

E

(VWG1793)

VXX2579

SPINDLE MOTOR ASSY

(F)

(T)

(F)

(T)

(S)

D101

GP1S24

C

FG ASSY

(VWG1556)

BISB ASSY

(VWG1796)

H

S901

C

D

(F)

(T)

(F)

(T)

(S)

(S)

(VWR1286:KU/CA)

(VWR1287:RD/RA)

(F)

(T)

(F)

(T)

(S)

(S)

AC POWER CORD

(ADG7021:KU/CA)

(ADG7003:RD/RA)

LOADING MOTOR ASSY

A

LMSB ASSY

(VWG1554)

POWER SUPPLY ASSY

O

N

L

FLKY ASSY

(VWG2005)

DILB ASSY

(VWG1995)

PWSB ASSY

(VWG1994)

GFEDCBA

5

6

7

H

8

17

1

DVL-919

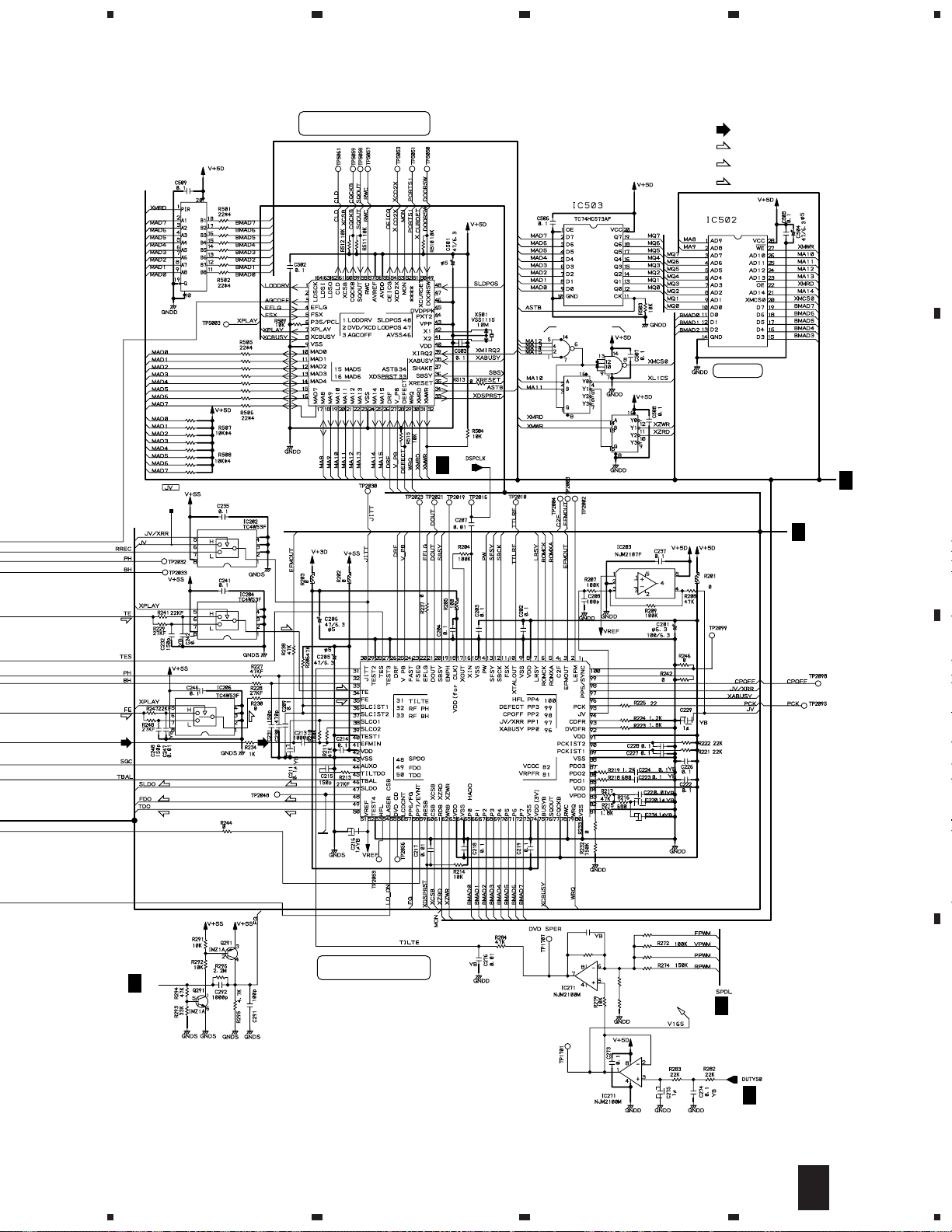

3.2 DVDM ASSY (1/3)

A

4

2

3

Q403

IMX1

B

S14B-PH-SM3

CN101

+8V Reg.

BA178M08FP

R407 10k R409 12k

23

VCO Offset

adj.

5W

VTL1074

L342

(6/6)

VKF1001

TP300

BUFFER

BUFFER

VTL1074

L335

VKF1001

TP100

(5/6)

(1/6)

(4/6)

I

R1

33k

R2

22k

1µ

100/16

C416

C417

47/10

IC101:

I

2/3

(T)

(T)

DVDM ASSY

1/3

(VWS1377)

I

PRE SERVO

PROCESSOR

for DVD

RF SIGNAL

(F)

(F)

(F)

(F)

2/3

VTL1074

L340

VKF1001

TP400

(2/6)

(3/6)

5W

1/2

LPF

4

IC302(1/2):VLXO D

2/2

ADC1175CIJMX

(ROM)

I

(ROM)

2/3

CN202

O

LD

DRV.

CN103

VKN1430

(F)

(F)

(T)

(F)

C

CN902

D

L100

C100

(S)

(S)

(F)

(T)

(F)

(T)

(F)

(T)

47µ

YB

1µ

I

3/3

(S)

(S)

I

3/3

(T)

(T)

(T)

(F)

5W

(F)

(T)

(S)

(S)

(S)

IC171:

FOCS. EeTRK. DRIVE

CURRENT DETECTOR

R177

22k

R178

22k

IC151:TRK.,FOCS., SLD. and

LOADING DRIVER

2/2

IC171

BA10393F

1/2

IC171

BA10393F

CN201

VKN1324

D

(F)

18

I

1/3

(F)

(F)

(F)

1234

IC506

TC74VHCT245AFT

AGCOFF

VKF1001

TP200

5

678

DVL-919

IC501:MECHANISM CONTROL

MICROCOMPUTER for DVD

IC501

PD4889A

IC504

TC74VHC20FT

IC505(1/2)

TC74VHC139FT

IC505(2/2)

I

3/3

TC74VHC139FT

: RF SIGNAL ROUTE

(F)

: FOCUS SERVO LOOP LINE

(T)

: TRACKING SERVO LOOP LINE

(S)

: SLIDER SERVO LOOP LINE

SRM2B256SLMX70

256K SRAM

FSX,EFLG,SLDPOS,

DVDPRK,SHAKE,

SCKI,SSI1,SSO1,CLD

I

2/3

XRESET,SBSY,PW,

SFSY,SBCK,MON,

C2F,FG

A

B

I

3/3

(T)

(F)

LD-ON

(T)

(T)

(F)

(F)

IC201

LC78650NE

C

(S)

(F)

CLDFG

I

3/3

(S)

(F)

(T)(T)

SPDO

IC201:Digital Signal Processor

(Servo Control for DVD)

C271 2200p

R277

220k

2/2

R271 470k

68k

R275

330k

R276

1/2

R273 330k

I

2/3

D

I

2/3

1/3

I

5

6

7

8

19

1

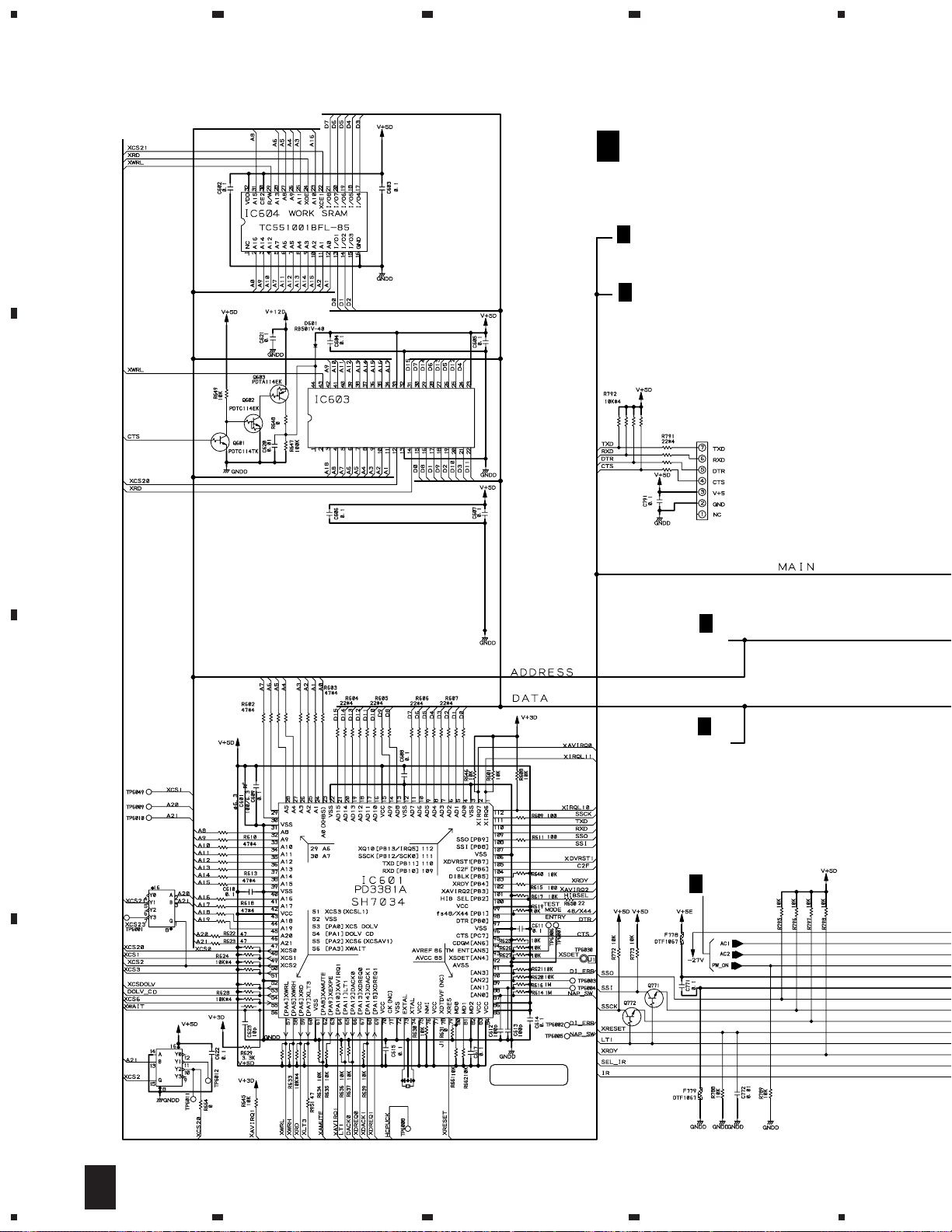

DVL-919

3.3 DVDM ASSY (2/3)

23

4

I

DVDM ASSY

A

(1M)

5W

5W

5W

B

VYW1612

MBM29F400TA-70PF

PGM 4MFLASH MEMORY

2/3

(VWS1377)

I

1/3

C2F,XRESET

I

3/3

XCSDOLV,DOLV-CD,XWRL,XWRH,

XRD,XLT3,XAMUTE,XDREQ1,CDGM,

HCPUCK,IR,SEL-IR,XDVRST1,

XAVIRQ0,48/X44,HIBSEL,XCS6,

XDACK1,NAP SW,C2F

CN106

VKN1411

I

A2-A10

DATA

I

I

1/3

3/3

3/3

ADDRESS

C

IC605(1/2)

TC74VHC139FT

5W

5W

D

IC605(2/2)

TC74VHC139FT

X602

VSS1114

20MHz

SYSTEM CONTROL

MICROCOMPUTER

Q771,Q772:

PDTC114TK

20

2/3

I

1234

5

: AUDIO SIGNAL ROUTE

(ROM)

: ROM DATA SIGNAL ROUTE

I

3/3

SDATA

(ROM)(ROM)

(ROM)

678

DVL-919

A

I

3/3

I

1/3

3/3

B

I

I

3/3

I

1/3

(ROM)

(ROM)

DRAM

I

1/3

I

1/3

VKN1418

CN105

I

3/3

MONITOR OUTPUT

SERVO

I

3/3

I

1/3

C

I

3/3

I

3/3

I

3/3

I

3/3

L

CN101

5

1/3

I

TC74VHC14FT

I

3/3

6

7

I

1/3

I

2/3

8

21

D

1

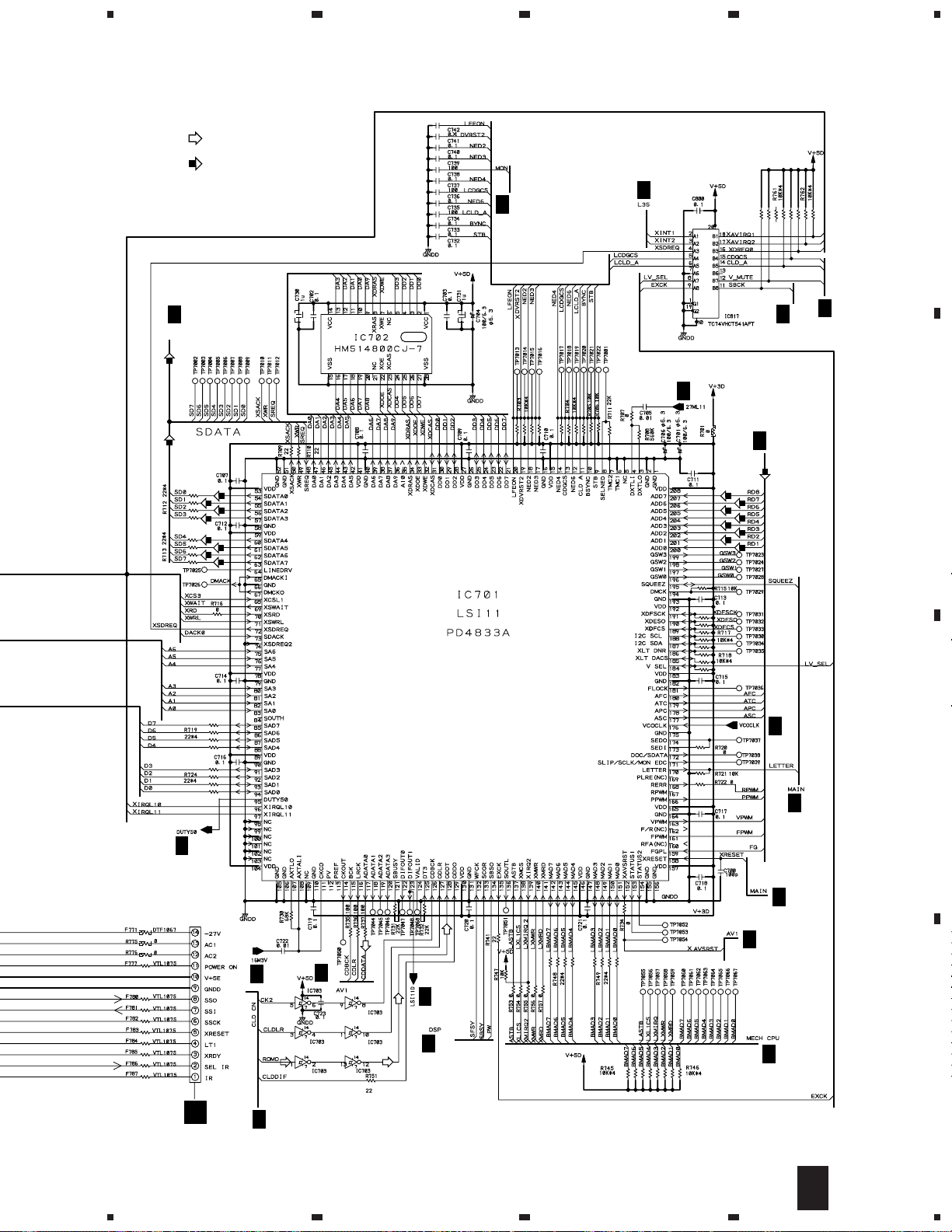

DVL-919

23

4

3.4 DVDM ASSY (3/3)

A

B

(1/4)

(2/4)

I

2/3

(4/4)

(3/4)

I

2/3

I

2/3

I

DVDM ASSY

3/3

(VWS1377)

I

2/3

I

2/3

AUDIO and VIDEO DECODE for

DVD(MPEG2)/VIDEO CD(MPEG)

(ROM)

MB86371C

(ROM)

CLDCS

2/3

I

C

I

I

2/3

(Y)

(C)

I

2/3

F952

(2/3)

VTF1080

CLOCK

GENERATOR

(1/4)

(COM)

I

2/3

2/3

R845

C892

4.7

47/10

(1/4)

(4/4)

(3/4)

Video

Output

I

2/3

Level

Adj.

I

2/3

I

(COM)

(Y)

(C)

1/3

S4B-PH-SM3

CN801

22

2/3

J

I

1/3

CN201

3/3

I

D

(3/3)

(1/3)

(3/4)

(2/4)

IC813

CY2081SL-611

(4/4)

(2/4)

1234

5

678

DVL-919

: AUDIO SIGNAL ROUTE

IC901

(ROM)

: ROM DATA SIGNAL ROUTE

(COM)

: COMPOSITE VIDEO SIGNAL ROUTE

(Y)

: Y SIGNAL ROUTE

(C)

: C SIGNAL ROUTE

I

1/3

I

2/3

CN902

VKN1426

A

CN111

1/3

J

B

DATA SELECTOR SW

I

HIBSEL,48/X44,XRESET,XLT3

IC816,Q873:BUFFER

1/2

(COM)

(Y)

2/3

L.P.F.

L.P.F.

(COM)

(Y)

I

2/3

R958

22

CN901

VKN1426

CN122

I

1/3

2/3

J

2/2

(COM)

C

1/2

(Y)

IC815,816(2/2):VIDEO AMP.

Q871,872,851,852,831,832:BUFFER

(C)

L.P.F.

(COM)

2/2

(C)

(C)

(C)

(Y)

CN903

S13B-PH-SMB

CN601

D

I

2/3

3/3

I

5

6

7

8

2/2

K

23

1

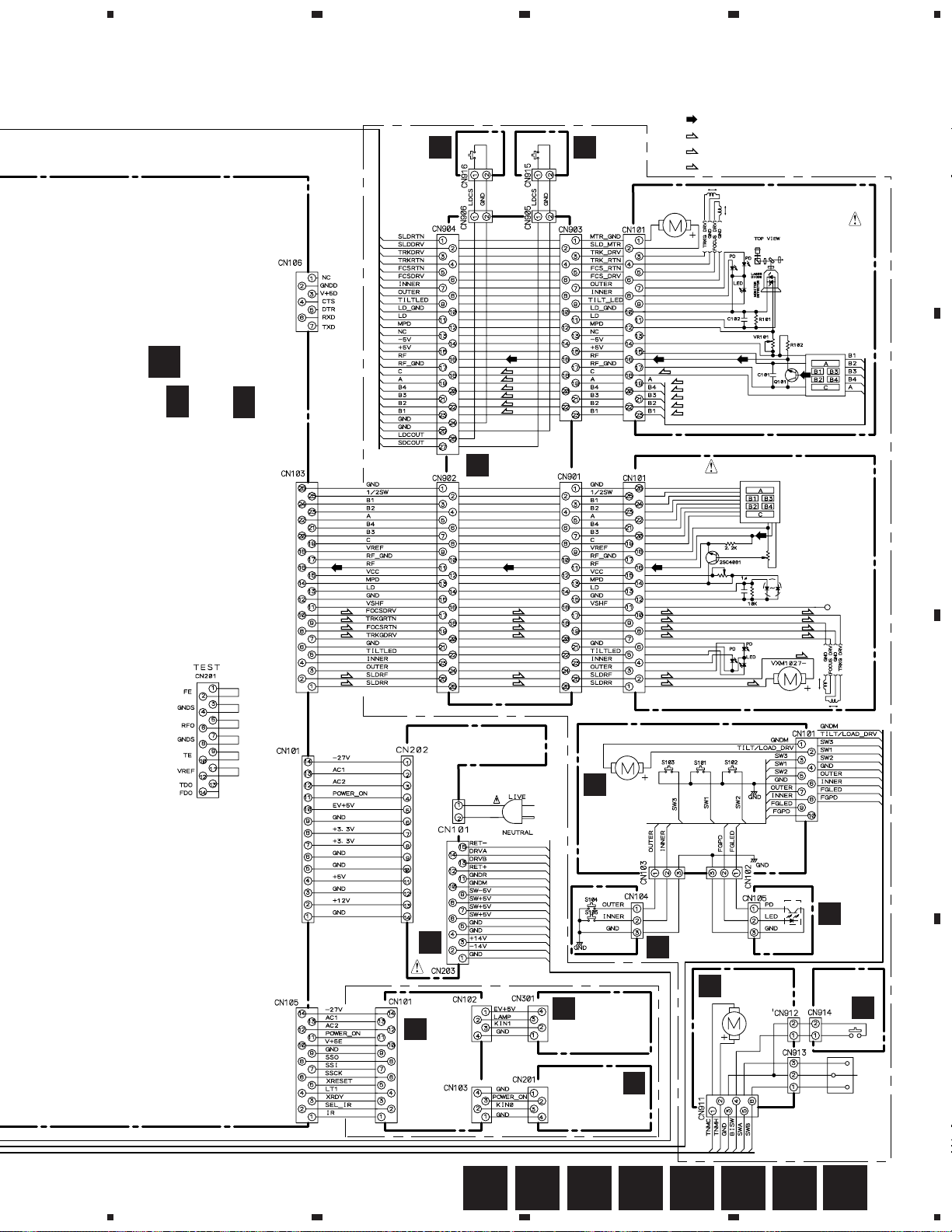

DVL-919

23

4

3.5 CLDM ASSY (1/3)

A

CN902

3/3

I

B

CN203

O

J

3/3

2/3,3/3

J

J

3/3

J

TILT/LOARD DRIVE

J

2/3

2/3

2PB709A

J

J

3/3

3/3

PD0266A2

J

CLDM ASSY

1/3

(VWS1358)

X101:9MHz

VSS1040

J

3/3

J

CN101

A

3/3

SLDR.

DRIVE

1

PDTC124EK

Q121,122:FG SIGNAL WAVE FORMER

CN911

E

TURN

7

C

10

11

(F)

(F)

(F)

(F)

(T)

(T)

12

(T)

(T)

(F)

(F)

(F)

(F)

LD DRV.

CN904

MECHANISM DRIVE

(F)

(F)

(T)

(T)

20

9

22

(T)

(T)

(T)

(T)

(F)

(F)

(F) (F)

(T)

(F)

(T)

(T)

(F)

9

FOCUS

DRIVE

(T)

(T)

(F)

D

(T)

(F)

(F)

D

24

1/3

J

1234

(F)

(T)

5

678

DVL-919

Q803,Q811:

2PD601A

J

2/3

IC908

LC78625E

14

13 11

Q152: RF AMP.

Q803: BUFFER

J

J

2/3

3/3

: RF SIGNAL ROUTE

: AUDIO SIGNAL ROUTE

(F)

: FOCUS SERVO LOOP LINE

(T)

: TRACKING SERVO LOOP LINE

Q181:

PDTC124EK

2/3

J

1SS355

2PB709A

IC183:

BUFFER

TRK. ZERO.CROS

COMPARATOR

(F)

A

B

2SC3082K

RF CORRECTION ON/OFF/SW

(F)

(T)

1

(T)

TRK.

DRIVE

(F)

(T)

2PD601A

BUFFER

2/3

J

(F)

(F)

(T)

5W

PDTC124EK

(T)

(T)

(F)

(T)

60

LA9430M

(FCS.,TRK. and SPDL.)

48

40

38

37

Q908: PDTC124EK

3/3

J

3/3

J

C

16

5

1SS355

Q981: PDTA124EK

1SS355

5W

D

Q903–906: LIMITER

IC905(2/2): BUFFER

IC905(1/2): SPDL. ERR.

Q908: SPDL. GAIN CONT.

6

7

Q905,Q906: 2PD601A

1/3

J

8

25

1

DVL-919

3.6 CLDM ASSY (2/3)

A

CN801

3/3

I

B

23

1/3

J

IC221:

NJM78L08A

IC222:

NJM79L08A

IC203:

CY2081SL-611

4

C

CN901

3/3

I

18.432MHz

20p

VCM-008

1/3

J

16MHz

1/3

J

1/3

J

1/3

J

Q391-Q393:

J

1/3

2PD601A

J

1/3

1/3

J

D

26

2/3

J

1234

J

5

CLDM ASSY

2/3

(VWS1358)

678

DVL-919

: RF SIGNAL ROUTE

: AUDIO SIGNAL ROUTE

A

1/3

J

PE8001A

TOTX178

1SS355

1/3

J

2PD601A

VKB1070

2SD2114K

B

C

2PD601A

2SD2114K

1/3

1SS355

J

PDTA124EK

PDTC124EK

5

6

7

RKN1004

J

2/3

8

D

27

Loading...

Loading...