Page 1

OPEN/

CLOSE

0

Î

¡

1

¢

STANDBY/ON

4

DV-454-K

3

8

7

DVD PLAYER

DV-454-K

DV-454-S

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Model Power Requirement

DV-454-K AC220-240V 2

DV-454-K AC220-240V 2

DV-454-K AC220-240V 2

DV-454-S

DV-454-S

DV-454-S

WYXU

WYXU/FRGR

WVXU

WYXU

WYXU/FRGR

WVXU

Type

AC220-240V 2

AC220-240V

AC220-240V

Regional restriction

codes (Region No.)

2

2

ORDER NO.

RRV2610

Remarks

Confirm it

Serial No.

For details, refer to "Important symbols for good services".

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2002

T – ZZE MAY 2002 Printed in Japan

Page 2

1

SAFETY INFORMATION

A

This service manual is intended for qualified service technicians ; it is not meant for the casual doit-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trainedto properly and safely repair complex products such as those covered by this

manual.Improperly performed repairs can adversely affect the safety and reliability of the product

and mayvoid the warranty. If you are not qualified to perform the repair of this product properly and

safely, youshould not risk trying to do so and refer the repair to a qualified service technician.

23

4

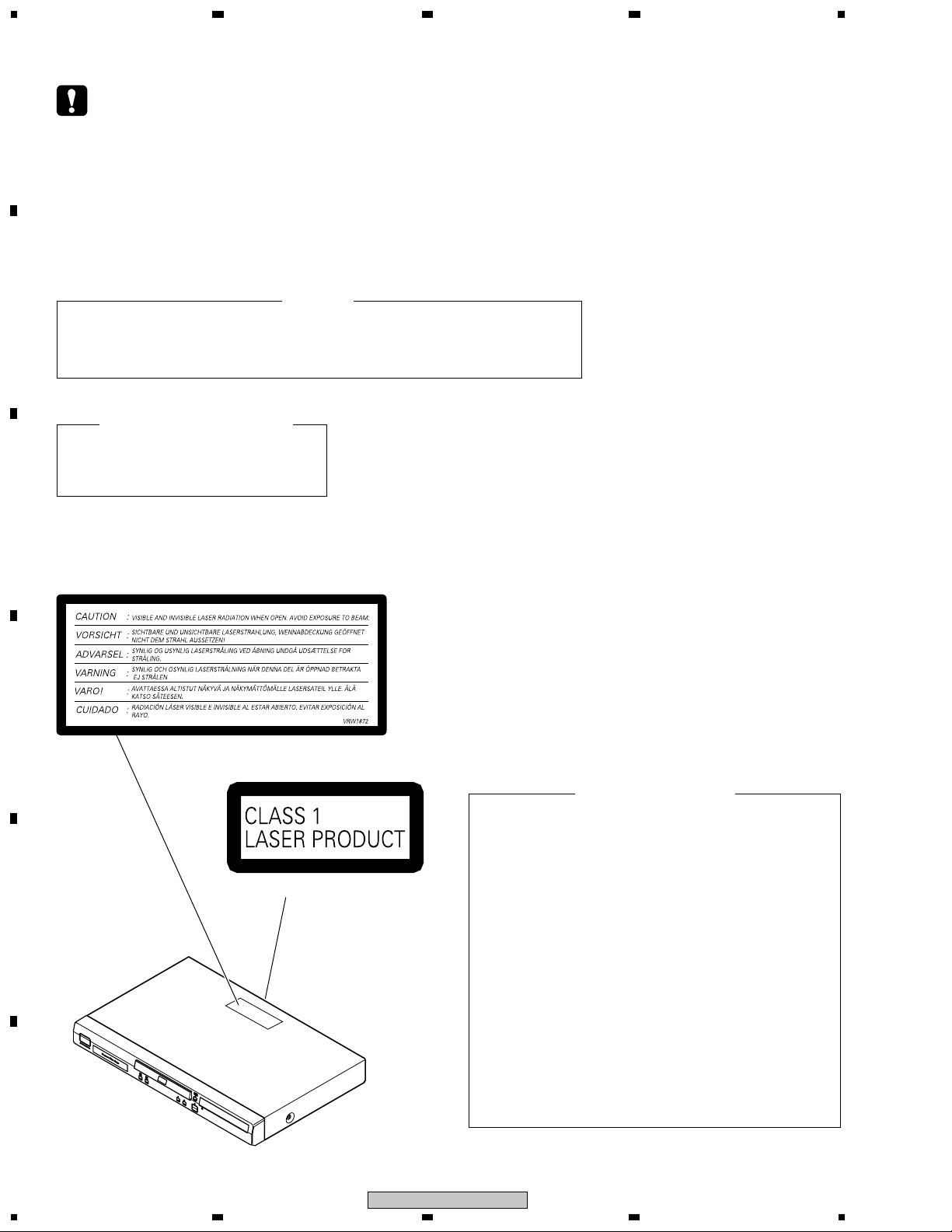

B

C

THE AEL (ACCESSIBLE EMISSION LEVEL) OF THE LASER POWER OUTPUT IS LESS THAN CLASS 1

BUT THE LASER COMPONENT IS CAPABLE OF EMITTING RADIATION EXCEEDING THE LIMIT FOR

CLASS 1.

A SPECIALLY INSTRUCTED PERSON SHOULD DO SERVICING OPERATION OF THE APPARATUS.

LASER DIODE CHARACTERISTICS

FOR DVD : MAXIMUM OUTPUT POWER : 5 mW

WAVELENGTH : 650 nm

FOR CD : MAXIMUM OUTPUT POWER : 5 mW

WAVELENGTH : 780 nm

WARNING !

LABEL CHECK

D

Additional Laser Caution

1. Laser Interlock Mechanism

• Loading switch (S101 on the LOAB Assy) is used for interlock

mechanism of the laser.

When this switch turned ON in SW2 (XCLOSE) side (OPEN signal is

0V and XCLOSE signal is 3.5V), a laser becomes the status which can

(Printed on the Rear Panel)

E

F

2

1234

DV-454-K

completely oscillation.

Furthermore, the laser completely oscillates in the disc judgment and

disc playback.

When player is power ON state and laser diode is not completely

oscillating, 780nm laser diode is always oscillating by half power.

• Laser diode is driving with Q101 (650nm LD) and Q102 (780nm LD)

on the FJMB Assy.

Therefore, when short-circuit between the emitter and collector of these

transistors or the base voltage is supplied for transistors turn on, the

laser oscillates. (failure mode)

• In the test mode ∗ , there is the mode that the laser oscillates except

for the disc judgment and playback. LD ON mode in the test mode

oscillates with the laser forcibly.

The interlock mechanism mentioned above becomes invalid in this

mode.

2. When the cover is open, close viewing through the objective lens with

the naked eye will cause exposure to the laser beam.

∗ : See page 53.

Page 3

5

678

[ Important symbols for good services ]

In this manual, the symbols shown-below indicate that adjustments, settings or cleaning should be made securely.

When you find the procedures bearing any of the symbols, be sure to fulfill them:

1. Product safety

You should conform to the regulations governing the product (safety, radio and noise, and other regulations), and

should keep the safety during servicing by following the safety instructions described in this manual.

2. Adjustments

To keep the original performances of the product, optimum adjustments or specification confirmation is indispensable.

In accordance with the procedures or instructions described in this manual, adjustments should be performed.

3. Cleaning

For optical pickups, tape-deck heads, lenses and mirrors used in projection monitors, and other parts requiring cleaning,

proper cleaning should be performed to restore their performances.

4. Shipping mode and shipping screws

To protect the product from damages or failures that may be caused during transit, the shipping mode should be set or

the shipping screws should be installed before shipping out in accordance with this manual, if necessary.

5. Lubricants, glues, and replacement parts

Appropriately applying grease or glue can maintain the product performances. But improper lubrication or applying

glue may lead to failures or troubles in the product. By following the instructions in this manual, be sure to apply the

prescribed grease or glue to proper portions by the appropriate amount.For replacement parts or tools, the prescribed

ones should be used.

A

B

C

Discs compatible with this

player

Any disc that displays one of the following

logos should play in this player. Other

formats, including DVD-Audio, DVD-RAM,

DVD-ROM, CD-ROM (except those that

contain MP3 files), SACD and Photo CD will

not play.

DVD-Video

Audio-CD

Video-CD CD-R CD-RW

D

E

F

DV-454-K

5

6

7

8

3

Page 4

CONTENTS

A

1

23

1. SPECIFICATIONS .................................................................................................................................................5

2. EXPLODED VIEWS AND PARTS LIST ............................................................................................................... 6

2.1 PACKING ........................................................................................................................................................ 6

2.2 EXTERIOR SECTION ..................................................................................................................................... 8

2.3 LOADING MECHANISM ASSY ................................................................................................................... 10

2.4 TRAVERSE MECHANISM ASSY-S ............................................................................................................ 14

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM ............................................................................................ 16

3.1 BLOCK DIAGRAM ....................................................................................................................................... 16

3.1.1 SIGNAL ROUTE ........................................................................................................................................ 16

B

3.1.2 POWER SUPPLY BLOCK ........................................................................................................................ 18

3.1.3 WAVEFORMS ........................................................................................................................................... 19

3.2 LOAB ASSY and OVERALL WIRING DIAGRAM ........................................................................................20

3.3 FJMB ASSY 1/5 [FRONT END BLOCK] ...................................................................................................... 22

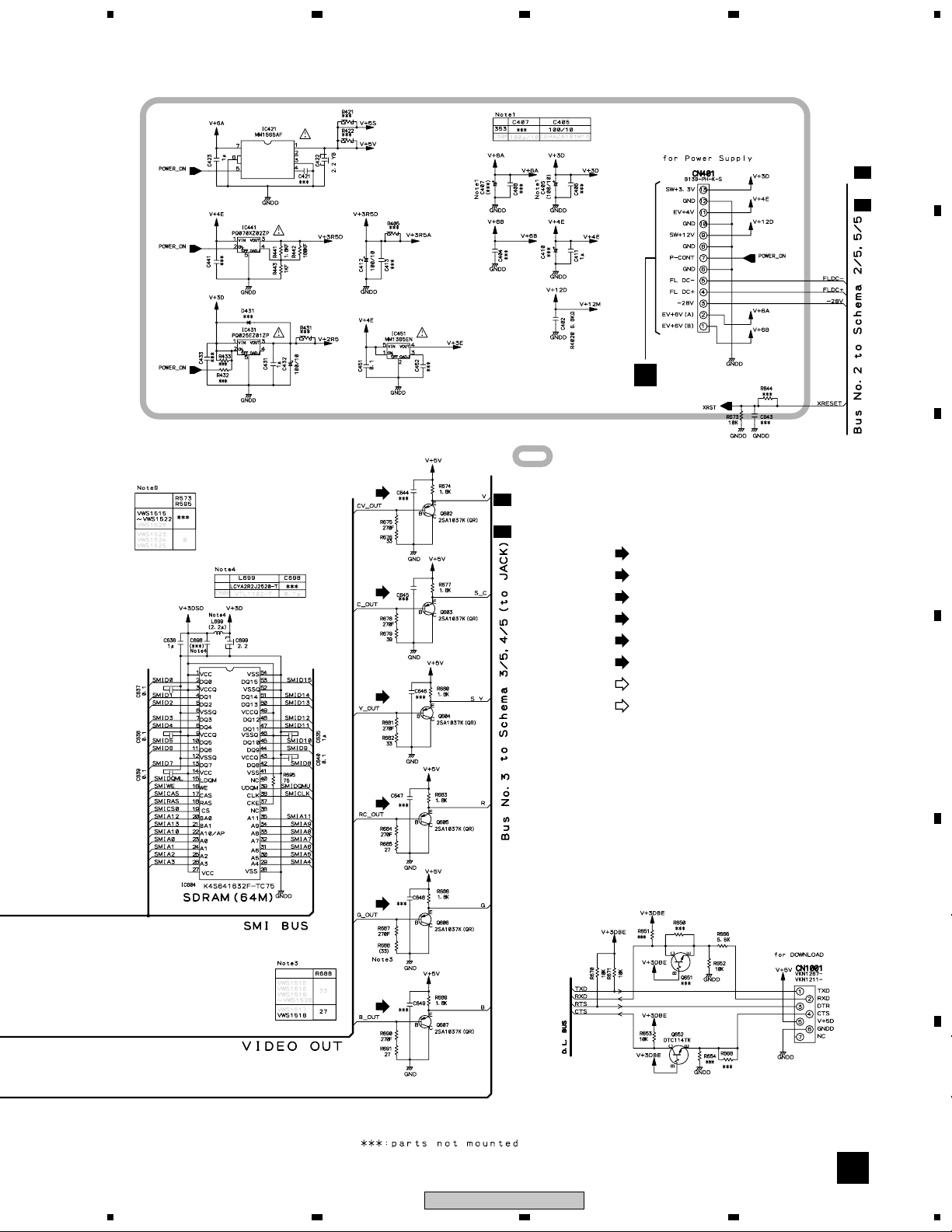

3.4 FJMB ASSY 2/5 [BACK END BLOCK] ........................................................................................................ 24

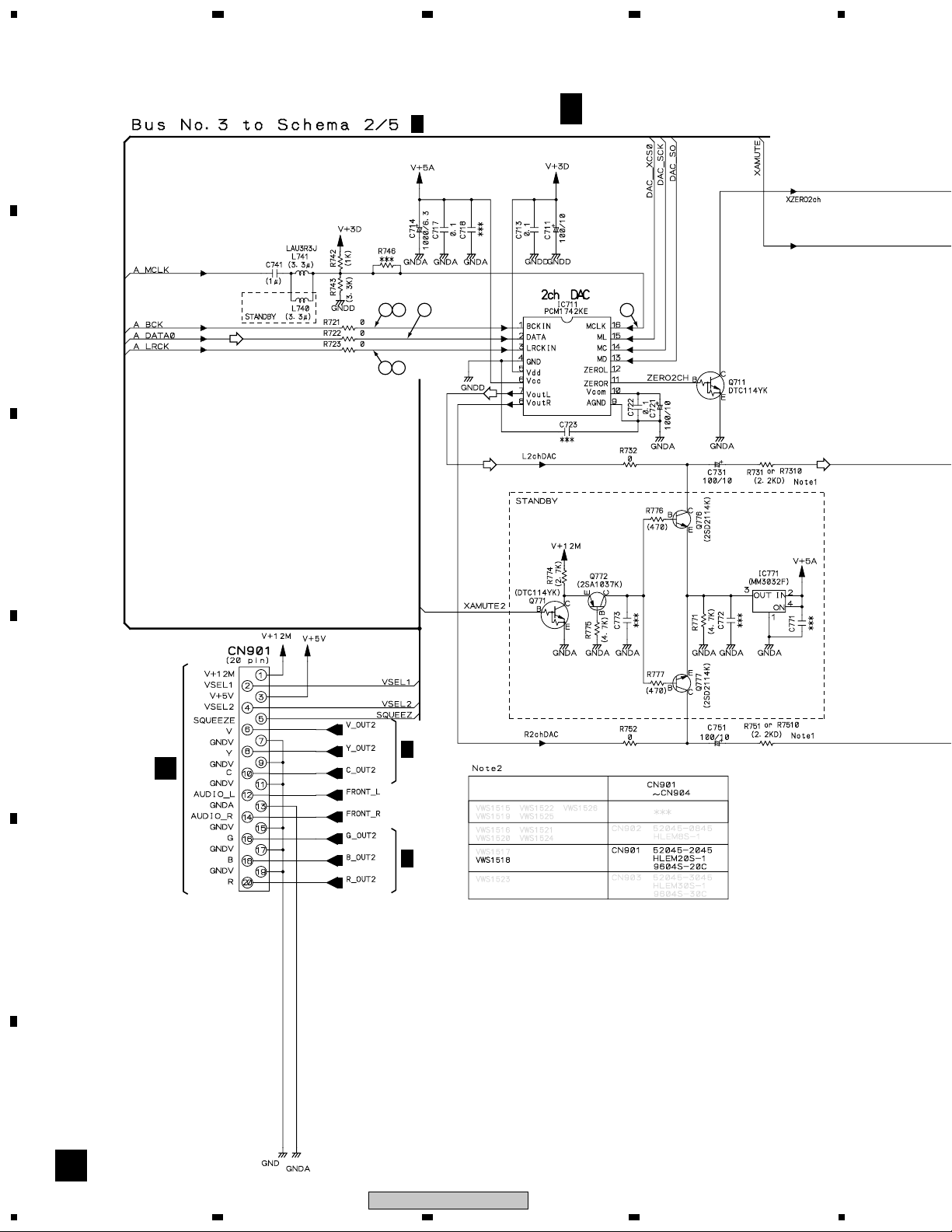

3.5 FJMB ASSY 3/5 [AUDIO BLOCK] ............................................................................................................... 26

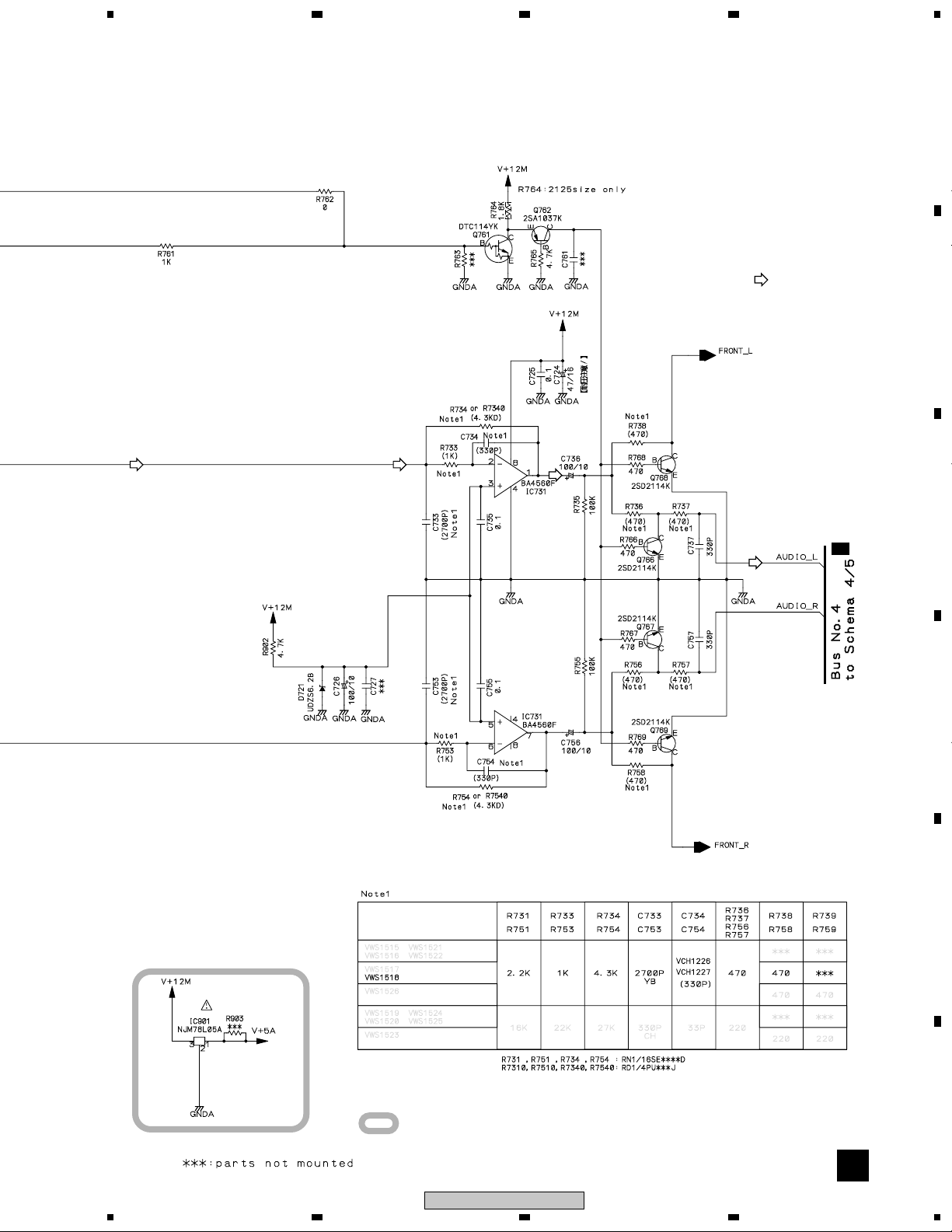

3.6 FJMB ASSY 4/5 [VIDEO BLOCK] ................................................................................................................ 28

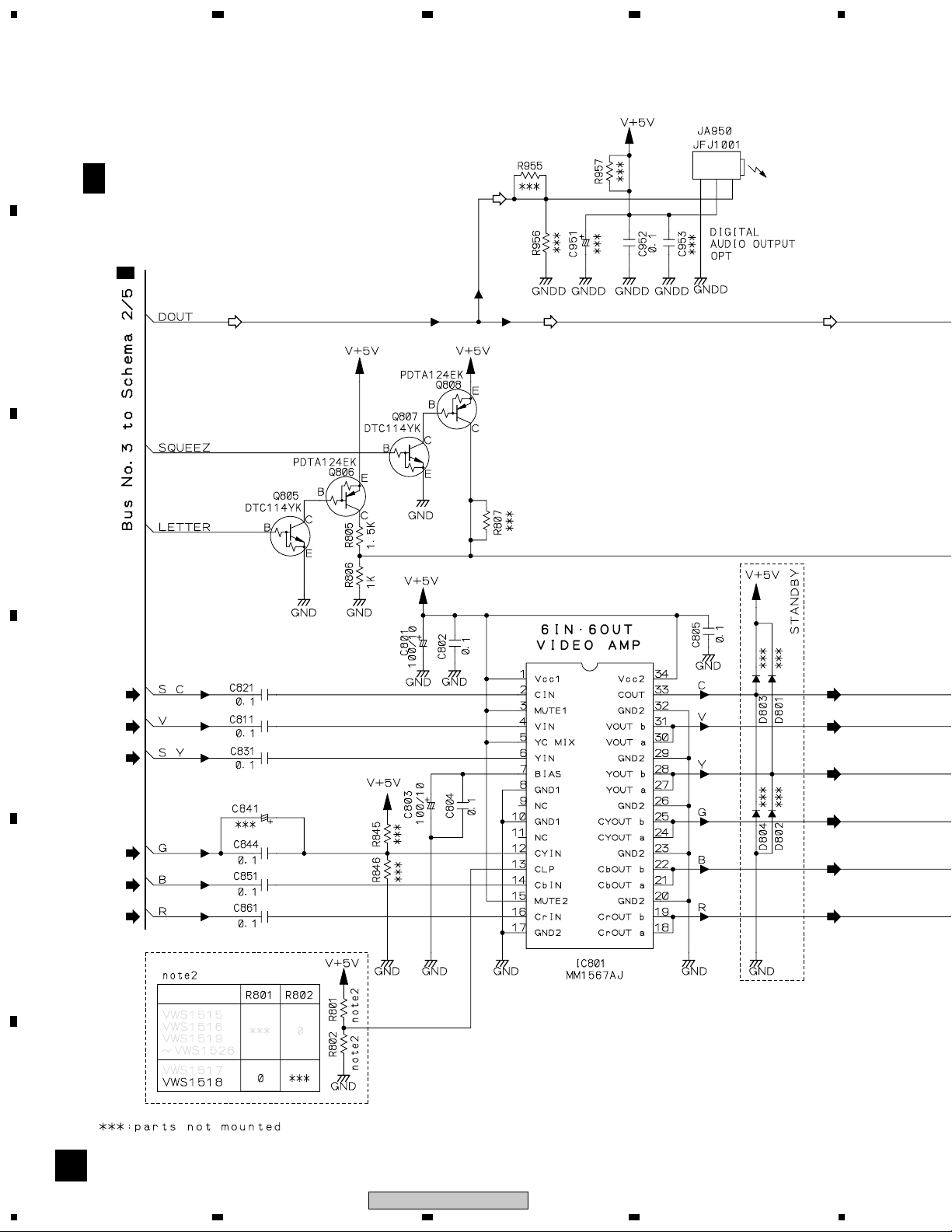

3.7 FJMB ASSY 5/5 [FL CONTROL BLOCK] .................................................................................................... 30

3.8 IRKY and PSWB ASSYS ............................................................................................................................. 32

3.9 POWER SUPPLY UNIT (VWR1352) ........................................................................................................... 34

C

3.10 POWER SUPPLY UNIT (VWR1354) ......................................................................................................... 35

3.11 SCRB ASSY ............................................................................................................................................... 36

4. PCB CONNECTION DIAGRAM ......................................................................................................................... 39

4.1 LOAB ASSY ................................................................................................................................................. 39

4.2 FJMB ASSY.................................................................................................................................................. 40

4.3 IRKY and PSWB ASSYS ............................................................................................................................. 44

4.4 POWER SUPPLY UNIT (VWR1352) ........................................................................................................... 45

4.5 POWER SUPPLY UNIT (VWR1354) ........................................................................................................... 46

4.6 SCRB ASSY ................................................................................................................................................. 47

5. PCB PARTS LIST ............................................................................................................................................... 48

D

6. ADJUSTMENT .................................................................................................................................................... 51

6.1 ADJUSTMENT ITEMS AND LOCATION ..................................................................................................... 51

6.2 JIGS AND MEASURING INSTRUMENTS ................................................................................................... 51

6.3 NECESSARY ADJUSTMENT POINTS ....................................................................................................... 52

6.4 TEST MODE ................................................................................................................................................. 53

6.5 MECHANISM ADJUSTMENT ...................................................................................................................... 54

7. GENERAL INFORMATION ................................................................................................................................ 57

7.1 DIAGNOSIS.................................................................................................................................................. 57

7.1.1 TEST MODE.............................................................................................................................................. 57

E

7.1.2 DISPLAY OF THE MECHANISM ERROR HISTORY .............................................................................. 63

7.1.3 TEST POINTS LOCATION & WAVEFORMS ........................................................................................... 66

7.1.4 TROUBLE SHOOTING ............................................................................................................................. 71

7.1.5 SEQUENCE AFTER THE POWER ON .................................................................................................... 73

7.1.6 DISASSEMBLY ......................................................................................................................................... 74

7.2 IC .................................................................................................................................................................. 79

7.3 CLEANING ................................................................................................................................................... 97

8. PANEL FACILITIES ............................................................................................................................................ 98

4

F

4

1234

DV-454-K

Page 5

5

1. SPECIFICATIONS

678

General

System ........................... DVD-Video, Video CD

CD and MP3 files

Power requirements.... AC 220–240 V, 50/60 Hz

Power consumption..................................14 W

Power consumption (standby)

Weight .................................................... 2.5 kg

Dimensions

DV-454 ............ 420 (W) x 55 (H) x 278 (D) mm

Operating temperature..............+5°C to +35°C

Operating humidity .........................5% to 85%

S-Video output

Y (luminance) - Output level..........1 Vp-p (75 Ω)

C (color) - Output level.......... 286 mVp-p (75 Ω)

Jack .............................................. S-Video jack

Video output

Output level ..................................1 Vp-p (75 Ω)

Jack ...................................................RCA jack

AV connector output

AV Connectors (21-pin connector assignment)

AV connector input/output ..... 21-pin connector

This connector provides the video and audio

signals for connection to a compatible colour

TV or monitor.

..................... 0.3 W

(no condensation)

Audio output (1 stereo pair)

Output level .......................During audio output

200 mVrms (1 kHz, –20 dB)

Number of channels ...................................... 2

Jacks ................................................. RCA jack

Digital audio characteristics

Frequency response................... 4 Hz to 44 kHz

(DVD fs: 96 kHz)

S/N ratio ................................................118 dB

Dynamic range ...................................... 101 dB

Total harmonic distortion .....................0.0016 %

Wow and flutter..............Limit of measurement

(0.001% W. PEAK) or lower

Digital output

Optical digital output ...........Optical digital jack

Coaxial digital output ......................... RCA jack

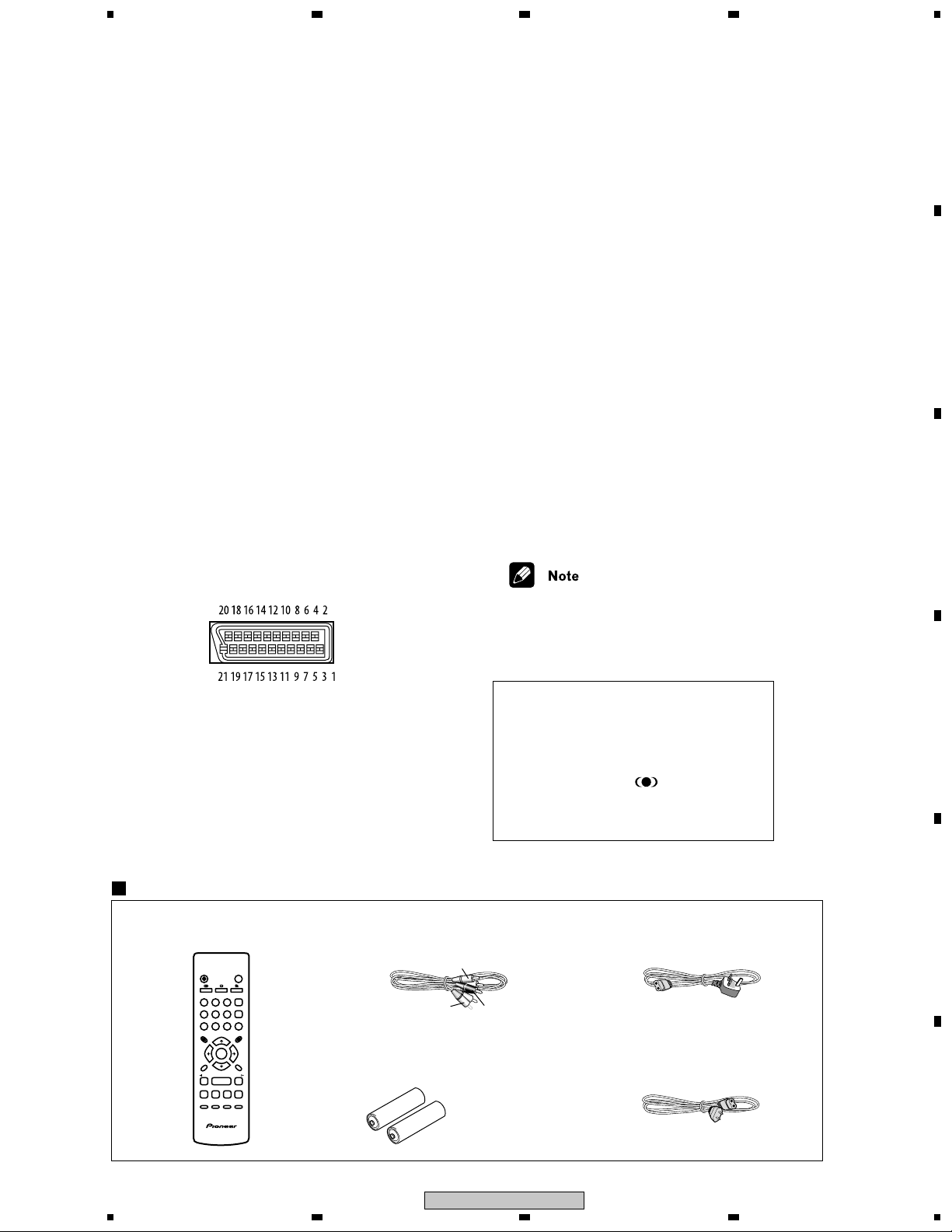

Accessories

Audio/video cable ...........................................1

Power cable.................................................. . 1

Remote control............................................... 1

AA/R6P dry cell batteries ............................... 2

Operating Instructions ....................................1

Warranty card .................................................1

• The specifications and design of this

product are subject to change without

notice, due to improvement.

A

B

C

PIN no.

1 ........................................................... Audio 2/R out

3 ........................................................... Audio 1/L out

4 ..........................................................................GND

7 .........................................................................B out

8 .......................................................................Status

11 ....................................................................... G out

15 ................................................................R or C out

17 ........................................................................GND

19 ................................................... Video out or Y out

21 ........................................................................GND

Accessories

Remote Control : VXX2800

OPEN/CLOSE

STANDBY/ON

0

ANGLEAUDIO

SUBTITLE

CLEAR

23

1

ENTER

56

4

0

789

TOP MENU

MENU

ENTER

SETUP

RETURN

E/

/e

13

¡

8

4

7

¢

PLAY MODE SURROUND ZOOM DISPLAY

Audio/Video Cable (L=1.5m): XDE3049

Yellow

AA/R6P Dry Cell Batteries

White

• Manufactured under license from Dolby

Laboratories. “Dolby” and the double-D

symbol are trademarks of Dolby Laboratories.

• “DTS” is a registered trademark of Digital

Theater Systems, Inc.

• TruSurround and the

® symbol are

trademarks of SRS Labs, Inc. TruSurround

technology is incorporated under license from

SRS Labs, Inc.

Power Cable [WVXU Type]

: ADG1156

Red

Power Cable [Other Types]

: ADG1154

D

E

F

DV-454-K

5

6

7

8

5

Page 6

1

23

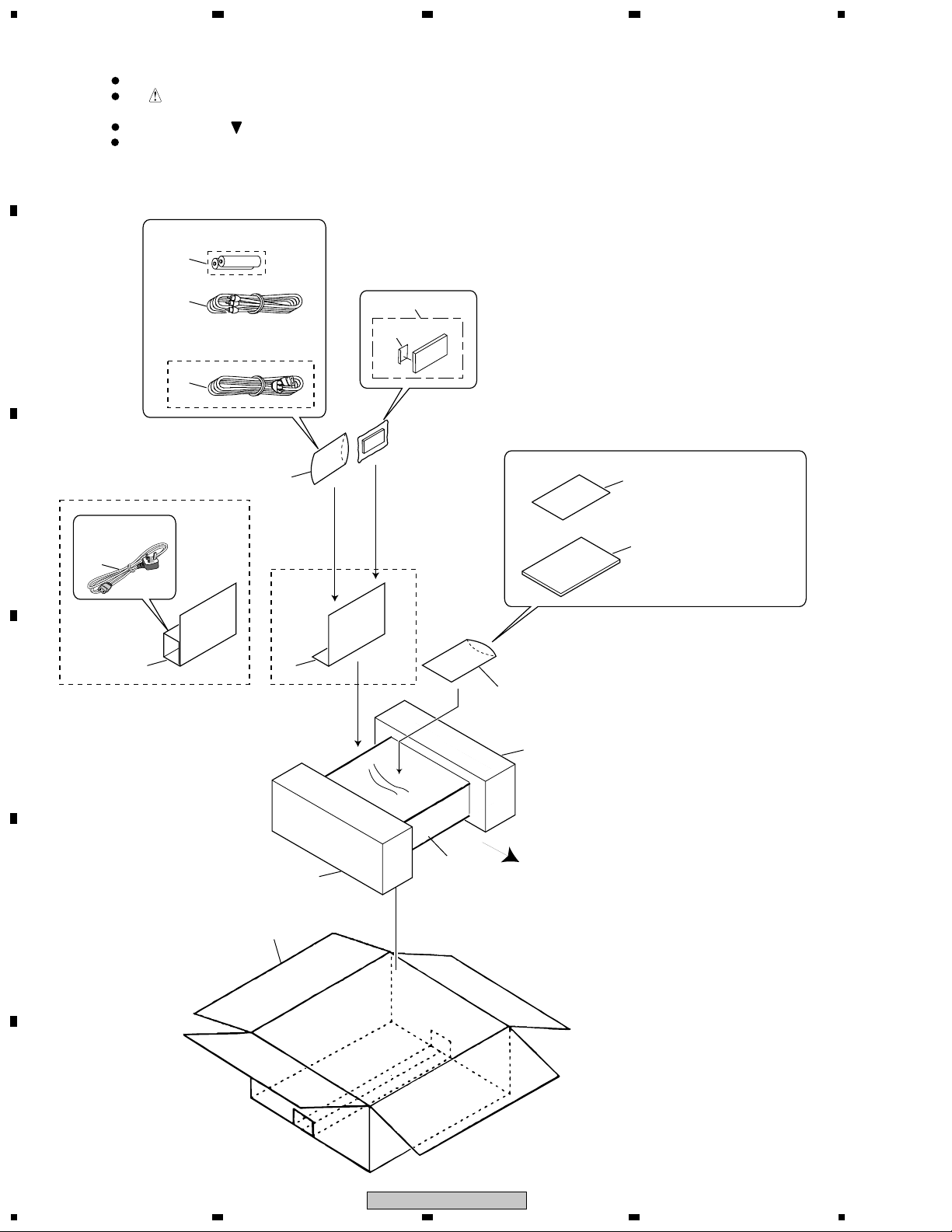

2. EXPLODED VIEWS AND PARTS LIST

NOTES:

A

2.1 PACKING

Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on product are used for disassembly.

For the applying amount of lubricants or glue, follow the instructions in this manual.

(In the case of no amount instructions, apply as you think it appropriate.)

3

4

B

WVXU Type Only

C

1

17

D

8

WYXU and WYXU/FRGR

Types Only

1

4

11

7

14

WYXU

and WYXU/FRGR

Types Only

2

5, 6, 15, 16

"Operating Instructions"

4

10

13

9

FRONT

E

F

6

1234

12

DV-454-K

Page 7

5

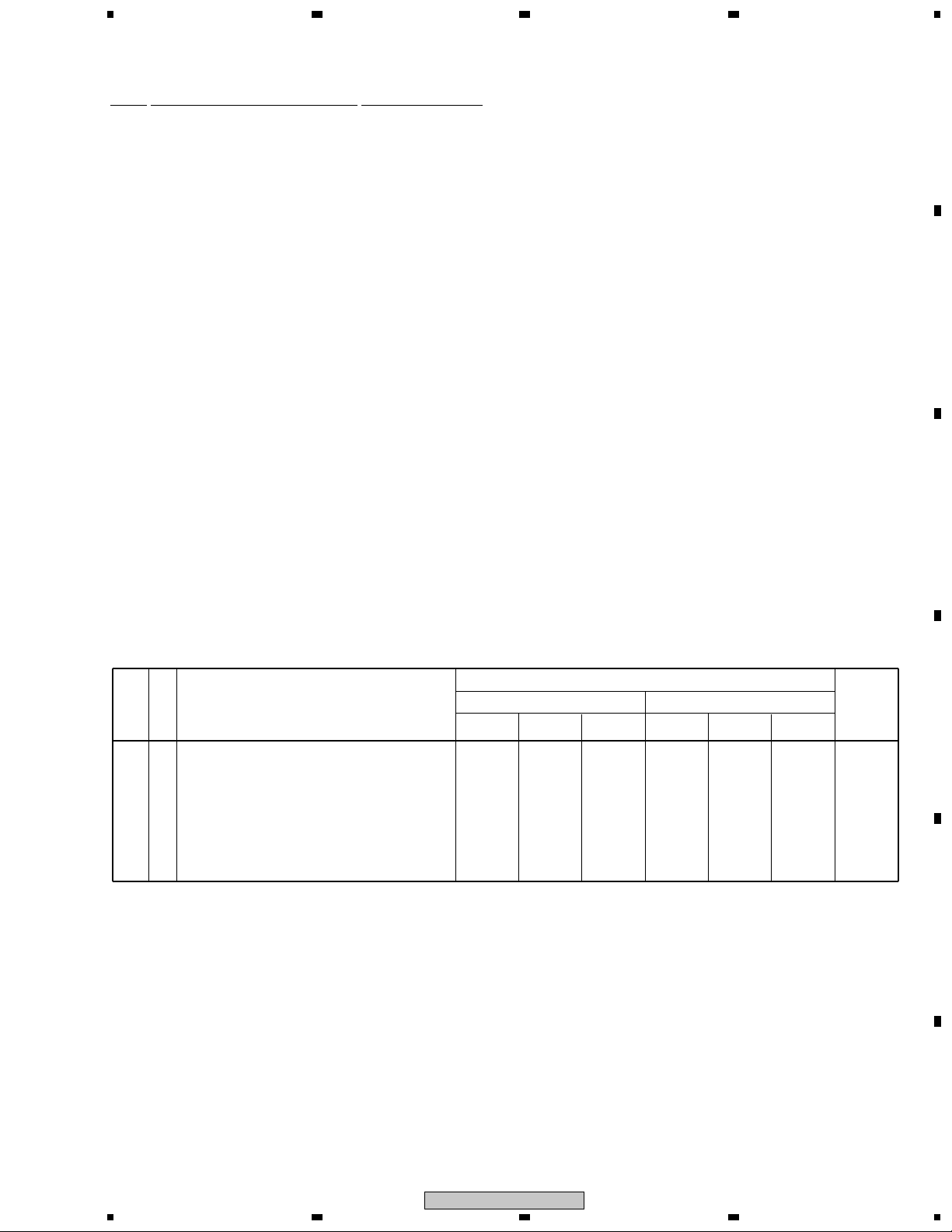

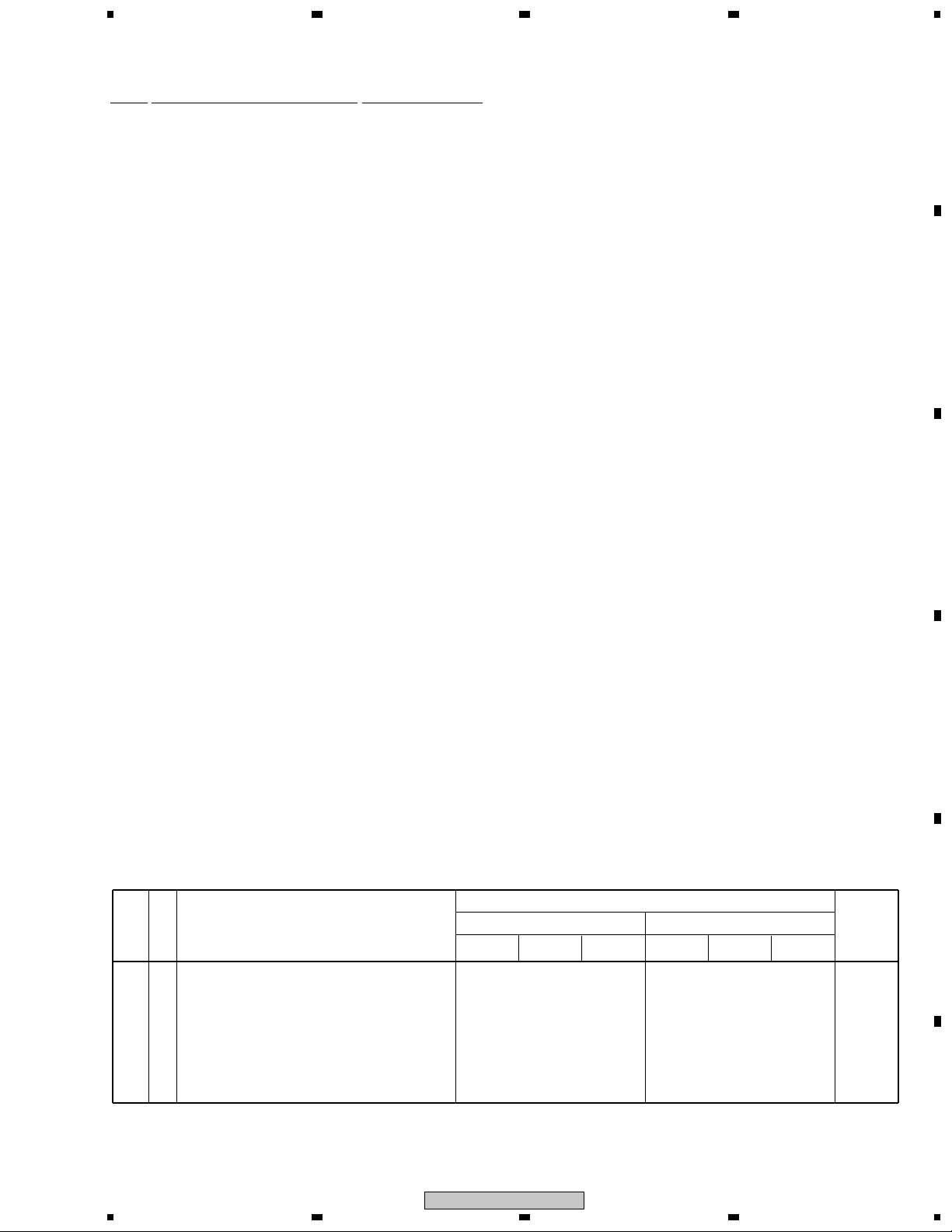

(2) CONTRAST TABLE

Mark No. RemarksSymbol and Description

Part No.

DV-454-K DV-454-S

WYXU

WYXU/FRGR

WVXU WYXU

WYXU/FRGR

WVXU

> 1

5

6

11

12

15

16

17

Power Cable

Operating Instructions (English / Italian)

Operating Instructions (French / German)

Paper Board

Packing Case

Operating Instructions (Spanish / Dutch)

Operating Instructions (English)

Accessory Box

ADG1154

VRD1151

VRD1152

VHC1089

VHG2185

VRD1153

Not used

Not used

ADG1154

Not used

VRD1152

VHC1089

VHG2201

Not used

Not used

Not used

ADG1156

Not used

Not used

Not used

VHG2181

Not used

VRB1286

VHC1092

ADG1154

VRD1151

VRD1152

VHC1089

VHG2182

VRD1153

Not used

Not used

ADG1154

Not used

VRD1152

VHC1089

VHG2203

Not used

Not used

Not used

ADG1156

Not used

Not used

Not used

VHG2202

Not used

VRB1286

VHC1092

DV-454-K/WYXU, WYXU/FRGR, WVXU, DV-454-S/WYXU, WYXU/FRGR and WVXU are constructed the same except for the

following :

678

(1) PACKING PARTS LIST

Mark No. Description Part No.

> 1 Power Cable See Contrast table (2)

NSP 2 Warranty Card ARY7022

NSP 3 AA/R6P Dry Cell Battery VEM1030

4 Polyethylene Bag VHL1051

5 Operating Instructions See Contrast table (2)

(English / Italian)

6 Operating Instructions See Contrast table (2)

(French / German)

7 Remote Control VXX2800

8 Audio/Video Cable (L=1.5m) XDE3049

9 Pad L VHA1297

10 Pad R VHA1298

11 Paper Board See Contrast table (2)

12 Packing Case See Contrast table (2)

13 Seat Z23-007

14 Battery Cover VNK4997

15 Operating Instructions See Contrast table (2)

(Spanish / Dutch)

A

B

16 Operating Instructions See Contrast table (2)

(English)

17 Accessory Box See Contrast table (2)

C

D

E

5

6

DV-454-K

7

F

7

8

Page 8

1

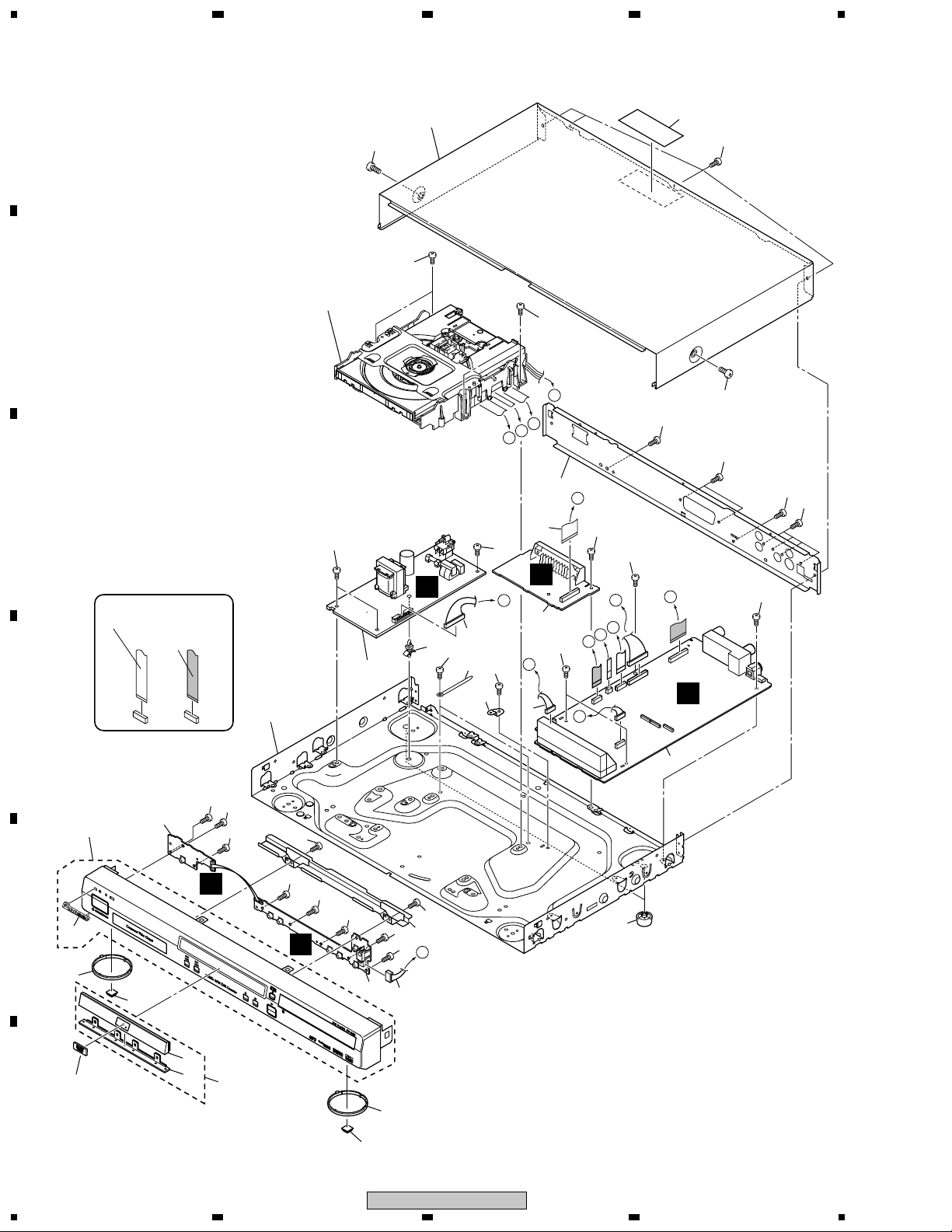

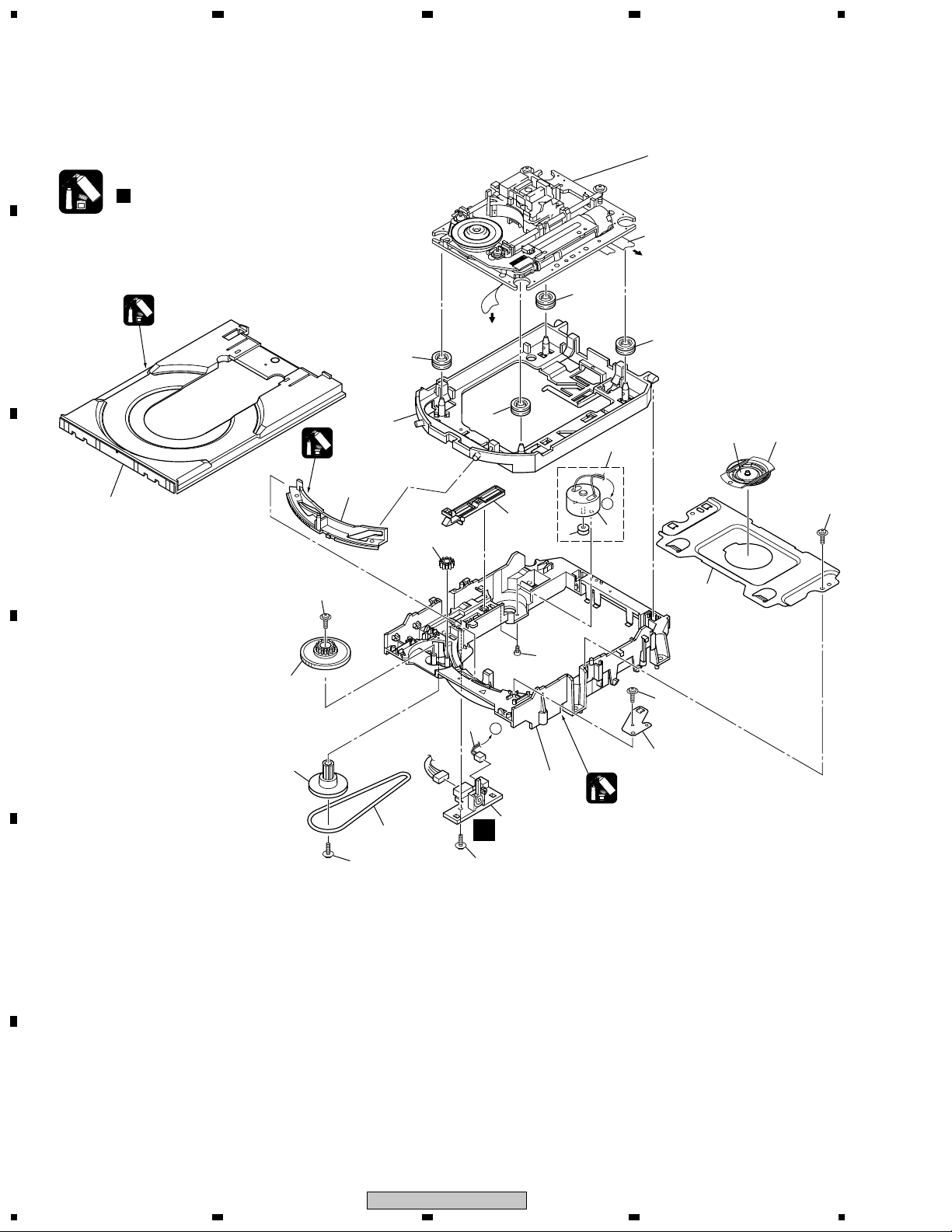

2.2 EXTERIOR SECTION

23

4

A

25

Refer to

"2.3 LOADING MECHANISM ASSY".

B

C

NON-CONTACT

SIDE

CONTACT

SIDE

8

22

7

23

E

26

11

22

10

23

F

E

D

C

13

G

28

22

22

22

G

B

5

22

27

22

F

B

E

D

C

23

32

23

25

23

23

23

G

22

14

24

18

24

12

24

24

C

24

24

16

24

17

24

24

A

1

4

29

D

24

19

2

D

E

F

29

20

15

16

30

31

6

A

9

B

3

8

1234

DV-454-K

Page 9

5

(2) CONTRAST TABLE

Mark No. RemarksSymbol and Description

Part No.

DV-454-K DV-454-S

WYXU

WYXU/FRGR

WVXU WYXU

WYXU/FRGR

WVXU

13

18

19

20

25

26

30

31

Rear Panel

Tray Panel Assy

Front Panel Assy

Pioneer Badge

Screw

Bonnet Case S

Tray Panel

Sub Panel

VNA2441

VXA2514

VXA2497

VAM1130

BCZ40P060FZK

VXX2831

VNK4976

VNK5043

VNA2439

VXA2506

VXA2498

VAM1129

BCZ40P060FNI

VXX2823

VNK4979

VNK4977

DV-454-K/WYXU, WYXU/FRGR, WVXU, DV-454-S/WYXU, WYXU/FRGR and WVXU are constructed the same except for the

following :

(1) EXTERIOR PARTS LIST

678

Mark No. Description Part No.

NSP 1 IRKY Assy VWG2344

NSP 2 PWSB Assy VWG2345

3 FJMB Assy VWS1518

4 Connector Assy PF05PP-Q12

5 Connector Assy PF13PP-D25

6 Connector Assy PG05KK-E37

> 7 POWER SUPPLY Unit VWR1354

(or VWR1352)

NSP 8 Loading Mechanism Assy VWT1197

9 Leg Assy SX AEC7113

10 Cord Clamper RNH-184

11 Pcb Support VEC2184

NSP 12 Base Chassis VNA2410

13 Rear Panel See Contrast table (2)

14 PCB Base VNE2278

15 DVD V Plate VAM1120

16 Rubber Foot VEB1325

17 FP Angle VNE2270

18 Tray Panel Assy See Contrast table (2)

19 Front Panel Assy See Contrast table (2)

20 Pioneer Badge See Contrast table (2)

21 ••••••

22 Screw BBZ30P060FMC

23 Screw BBZ30P080FZK

24 Screw BBZ30P100FZK

25 Screw See Contrast table (2)

A

B

C

26 Bonnet Case S See Contrast table (2)

27 SCRB Assy VWV1903

28 Flexible Cable (20P) VDA1892

29 Ring VNK4982

30 Tray Panel See Contrast table (2)

31 Sub Panel See Contrast table (2)

32 Label VRW1872

D

E

F

5

6

DV-454-K

7

9

8

Page 10

1

2.3 LOADING MECHANISM ASSY

A

23

4

Note :

Refer to

" Application of Lubricant".

B

C

23

Daifree

GEM1036

Lubricating Oil

GYA1001

13

22

12

To FJMB

CN251

8

8

17

16

8

A

4

2

Refer to

"2.4 TRAVERSE MECHANISM

ASSY-S".

6

To FJMB

CN151

8

3

5

18

19

20

22

21

15

22

D

14

9

22 22

E

7

A

10

A

11

1

Lubricating Oil

GYA1001

F

10

1234

DV-454-K

Page 11

5

LOADING MECHANISM ASSY PARTS LIST

•

678

Mark No. Description Part No.

NSP 1 LOAB Assy VWG2279

2 Traverse Mechanism Assy-S VXX2782

3 Loading Motor Assy VXX2505

4 Motor Pulley PNW1634

5 Carriage DC Motor / 0.3W PXM1027

6 Flexible Cable (26P) VDA1865

7 Connector Assy 2P VKP2253

8 Float Rubber VEB1327

9 Belt VEB1330

10 Stabilizer VNE2253

11 Loading Base VNL1917

12 Float Base DVD VNL1918

13 Drive Cam VNL1919

14 Gear Pulley VNL1921

15 Loading Gear VNL1922

16 Drive Gear VNL1923

17 SW Lever VNL1925

18 Clamper Plate VNE2251

19 Bridge VNE2252

20 Clamper VNL1924

A

B

C

21 Screw JGZ17P028FMC

22 Screw Z39-019

23 Tray VNL1920

D

E

F

DV-454-K

5

6

7

8

11

Page 12

1

23

4

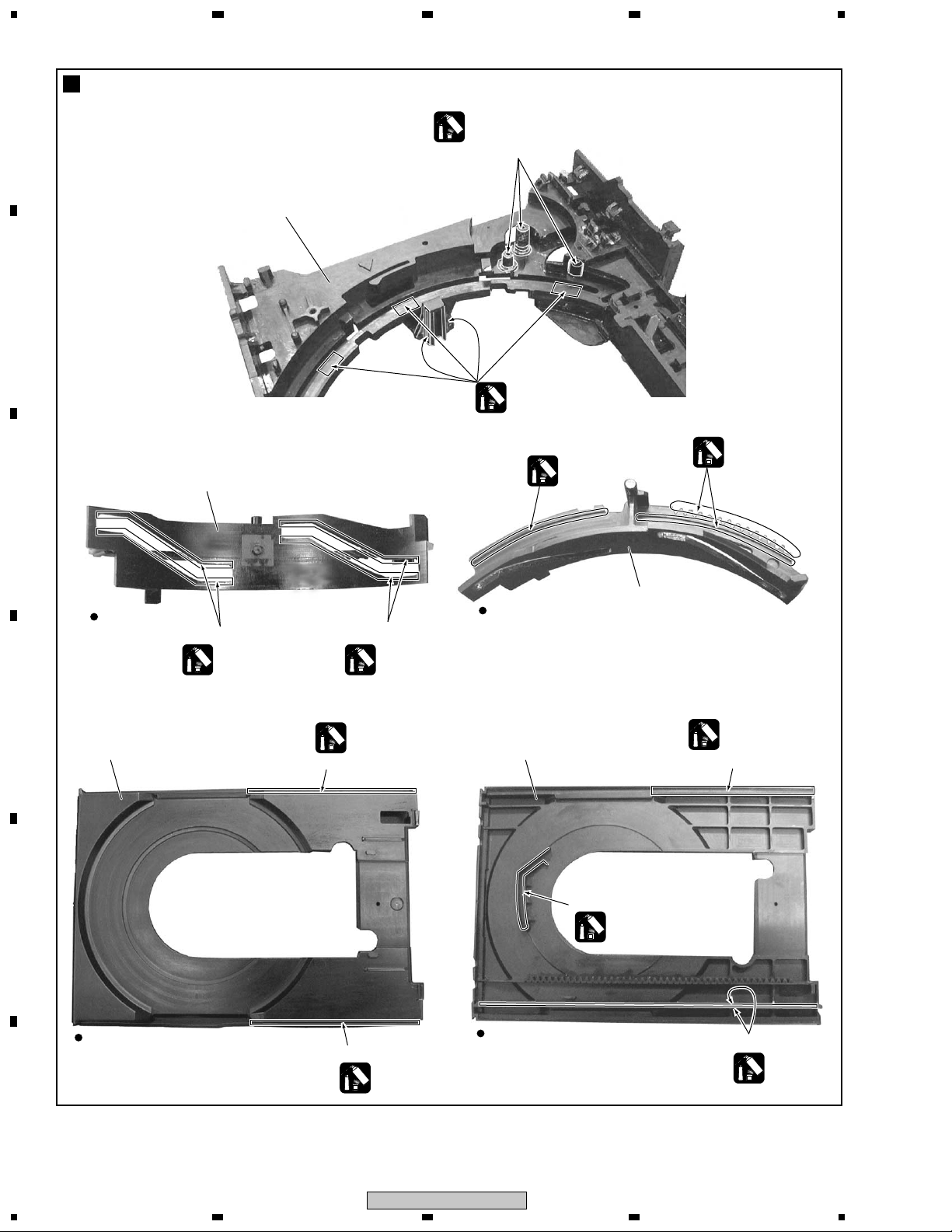

Application of Lubricant

A

Lubricating Oil

GYA1001

Around the shaft

No. 11

Loading Base

B

Lubricating Oil

GYA1001

Lubricating Oil

No. 13

Drive Cam

Lubricating Oil

GYA1001

GYA1001

C

No. 13

Rear View

Inner side of a ditch

Lubricating Oil

GYA1001

D

No. 23

Tray

E

Inner side of a ditch

Lubricating Oil

GYA1001

Daifree

GEM1036

Concave of unevenness

Top View

No. 23

Tray

Inner side of a ditch

Drive Cam

Daifree

GEM1036

Concave of unevenness

Daifree

GEM1036

Top View

Concave of unevenness

Daifree

GEM1036

F

12

1234

DV-454-K

Bottom View

Side of the rib

Daifree

GEM1036

Page 13

5

678

A

B

C

D

E

F

DV-454-K

5

6

7

8

13

Page 14

1

23

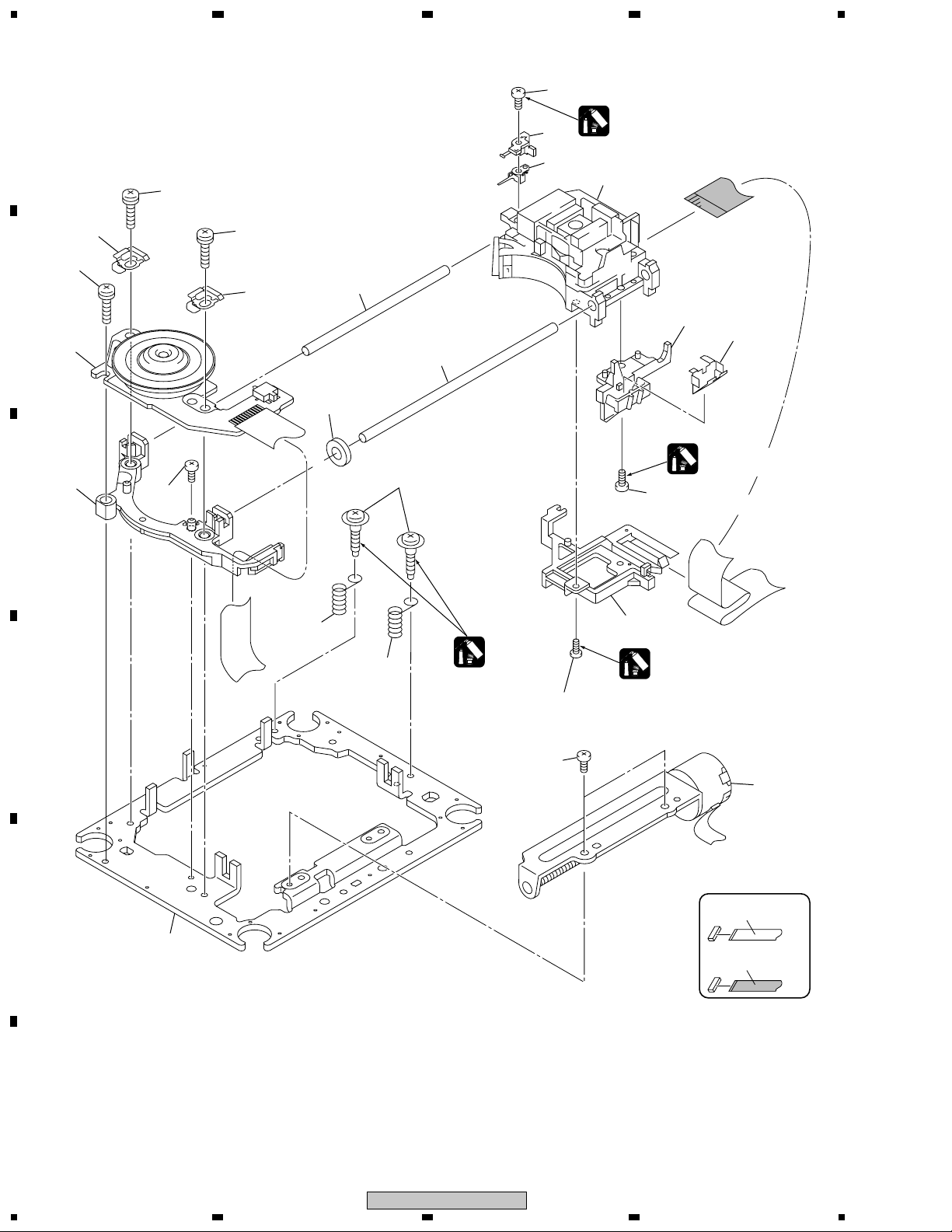

2.4 TRAVERSE MECHANISM ASSY-S

A

18

17 (Torque : 0.12 ± 0.01 N•m)

Silicone Adhesive

12

8

GEM1037

3

4

10

18

B

1

13

C

D

16

18

10

7

14

6

19

4 (Adjustment Screw)

5

Screw Tight

5

GYL1001

17 (Torque : 0.12 ± 0.01 N•m)

17

(Torque : 0.12 ± 0.01 N•m)

15

Silicone Adhesive

GEM1037

9

Silicone Adhesive

GEM1037

16

2

NON-CONTACT

E

11

F

14

1234

DV-454-K

SIDE

CONTACT SIDE

Page 15

5

TRAVERSE MECHANISM ASSY-S PARTS LIST

•

678

Mark No. Description Part No.

1 Spindle Motor VXM1088

(or VXM1089)

2 Stepping Motor VXM1090

(or VXM1091)

3 Pickup Assy-S OXX8003

4 Skew Screw VBA1080

5 Skew Spring VBH1335

6 Guide Bar VLL1514

7 Sub Guide Bar VLL1515

8 Hold Spring VNC1017

9 Joint Spring VNC1019

10 Support Spring VNC1020

NSP 11 Mechanism Chassis VNE2248

12 Slider VNL1811

13 Spacer VNL1913

14 Joint VNL1914

15 FFC Holder VNL1915

A

B

16 Screw BBZ20P050FZK

17 Tapping Screw OBA8009

18 Screw PMA26P100FMC

19 Damper Sheet VEB1335

C

D

E

F

DV-454-K

5

6

7

8

15

Page 16

1

23

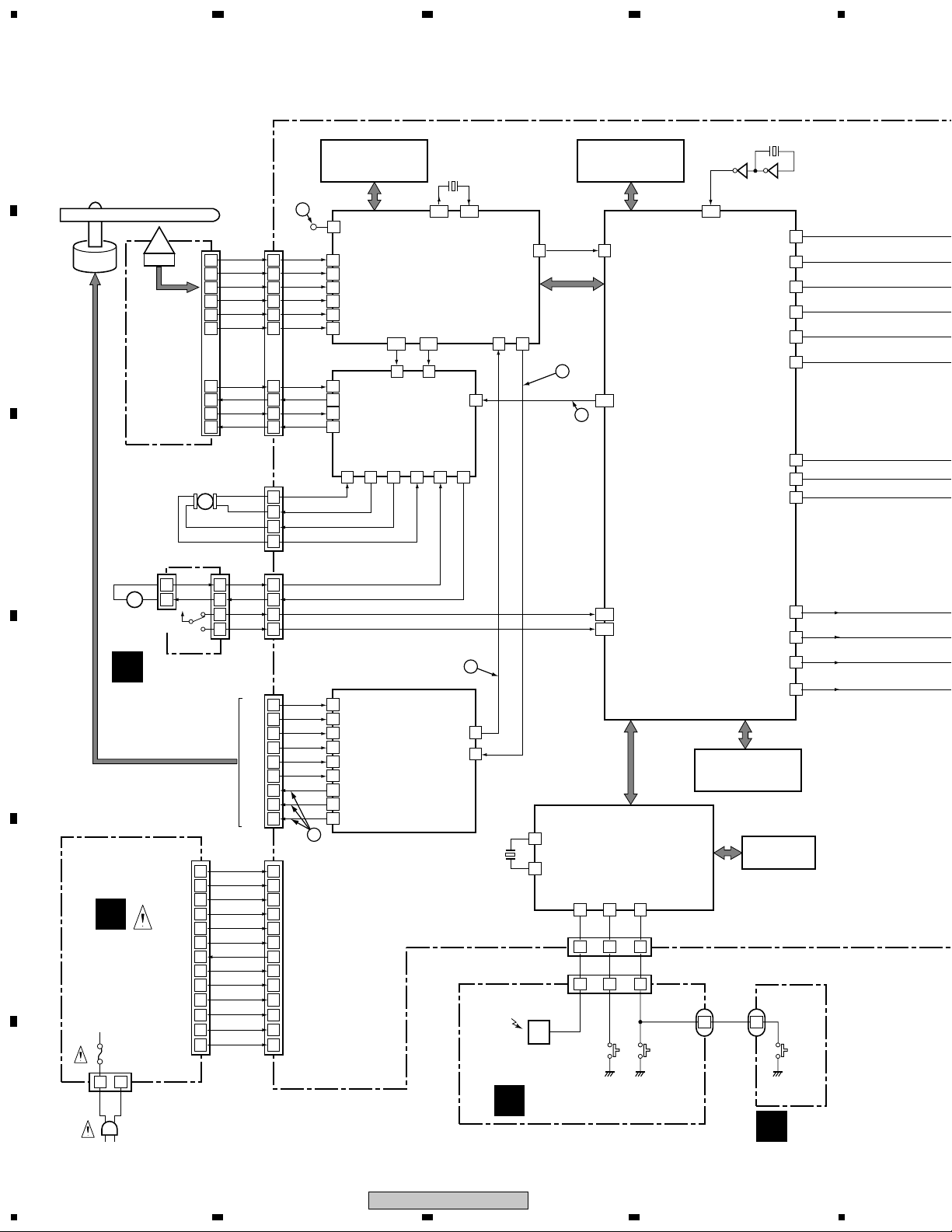

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

3.1 BLOCK DIAGRAM

A

3.1.1 SIGNAL ROUTE

Spindle

Motor

B

PICKUP

C

Loading

Motor

Assy

M

A

D

VWR1352: CN101

VWR1354: CN2

E

F

E

POWER

SUPPLY

UNIT

F1

1 2

LIVE

NEUTRAL

AC IN

CN1

(2P)

(26P)

20

21

15

16

19

ASSY

17

24

25

26

23

Stepping

Motor

(Carriage)

T_RTN

T_DRV

F_RTN

F_DRV

M

CN601

(5P)

3.3V

1

2

S101

+–

CN602

(2P)

1

2

LOAB ASSY

1

2

3

4

5

6

7

8

9

10

11

12

13

EV+6V(B)

EV+6V(A)

-28V

FLDC+

FLDC-

GND

P-CONT

GND

SW+12V

GND

EV+4V

GND

SW+3.3V

(13P)

B1

B2

B3

B4

A

C

ST1-

ST1+

ST2+

ST2-

LOD-

LOD+

SW2

SW1

H1+

Work RAM for Error Correction

IC302

K6T1008V2E-TB70

1M SRAM

1

RF(TP)

CN151

7

6

12

11

8

10

3

2

1

4

CN3

4

3

2

1

CN52

1

2

33

55

CN251

9

8

7

6

5

4

10

11

12

(26P)

(4P)

(5P)

(12P)

3

RFSACD

L6315ATXXTY

A

10

FRONT END IC

B

12

C

18

D

16

E

25

F

24

VM4-

13

VM4+

12

M56788AFP

10

VM3+

VM3-

9

Focus, Tracking,

Stepper and

Loading Drive

VM1+

VM1-35VM2-31VM2+32VM5-15VM5+

34

XCLOSE

OPEN

H1+

9

H1-H1-

10

H2+H2+

11

BA6664FM

H2-H2-

12

H3+H3+

13

• Spindle Drive

H3-H3-

14

• FG Detection

A1A1

7

A2A2

4

A3A3

2

IC301

• RF Demodulation

• Servo Control

• Servo Decode

• Error Correction

FACT

123

FDO

3 20

IN3-

IC351

FTS Driver

IC251

Spindle

Driver

17

CN401

(13P)

1

2

3

4

5

6

7

8

9

10

11

12

13

X301

20MHz

131

132

FREOUT FREIN

OUT_DATA(0) S_DATA

TACT

124

TDO

IN4-

IN5-

17

14

2

24

FG

EC

22

REMOTE

RECEIVER

UNIT

PC(2) PC(6)

FG

FG

SPDL PDM

X11

5MHz

C

Work RAM for MPEG Decode

K4S641632F-TC75

64M SDRAM

FE_DATA

84

4238

SPDL

PDM

LOAD_DRV

16

16

116

15

205

204

IC11 PE5314B

3

4

IC301

SPS-444L-H

FL CONTROL

X1

MICROCOMPUTER

• Main Unit Key Input

X2

• Remote Control Receive

• FL Display Control

KEY1

IR

17

21

5 2 1

IR

5 2 1

IRKY ASSY

IC604

120

PIXCLK

HSYNC

_PWM0

IC601

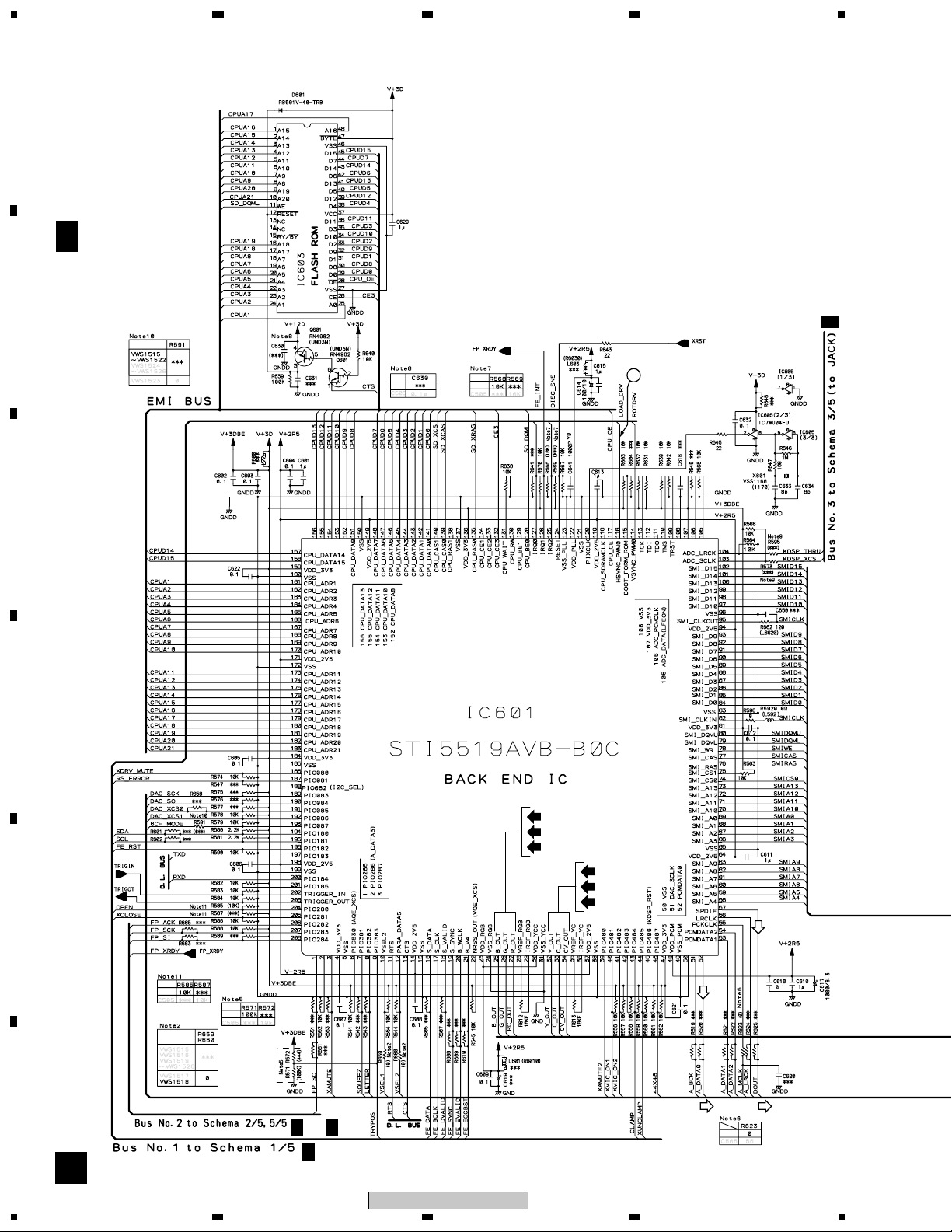

STI5519AVB-B0C

BACK END IC

• System Control

• MPEG Video Decode

• Video Encode

• Video DAC

• Audio Decode

(MP3, Dolby)

• Sub-picture Decode

XCLOSE

OPEN

8M FLASH ROM

KEY0

22

CN11

(5P)

KEY0

KEY1

CN301

(5P)

1 1

4

X601

27MHz

3562

IC605 TC7WU04FU

B_OUT

25

G_OUT

26

R_OUT

27

Y_OUT

32

C_OUT

33

CV_OUT

34

PIO381

7

PIO382

8

SPDIF

57

DAC_SCLK

PCMDATA0

IC603

VYW1978

KEY3

J301

(3P)

PCKCLK

LRCLK

V11

FL TUBE

51

52

55

56

D

PSWB ASSY

SQUEEZ

LETTER

DOUT

A_BCK

A_DATA0

A_MCLK

A_LRCK

16

1234

DV-454-K

Page 17

5

678

A

Q607

Q606

Q605

Q604

Q603

Q602

S_C

Q807,Q808

Q805,Q806

R721

R722

R723

G

R

S_Y

B

V

4 7

8

3

5 6

FJMB ASSY

B

Cb IN

14

CY IN

12

16

Cr IN

Y IN

6

C IN

2

V IN

4

MM1567AJ

6 IN • 6 OUT

VIDEO AMP

• LPF

• AMP

• Driver

BCKIN

1

DATA

2

MCLK

16

LRCKIN

3

YOUT b

IC801

Audio 2ch DAC

YOUT a

COUT

VOUT b

VOUT a

CYOUT b

CYOUT a

CrOUT b

CrOUT a

CbOUT b

CbOUT a

IC711

PCM1742KE

28

27

33

31

30

25

24

19

18

22

21

Vout L

Vout R

Y

C

V

G

R

B

Y_OUT2

C_OUT2

LOUT

7

ROUT

8

V_OUT2

G_OUT2

13

C832

14

C822

9

C812

R_OUT2

B_OUT2

AUDIO LPF

BA4560F

IC731-1/2

IC731-2/2

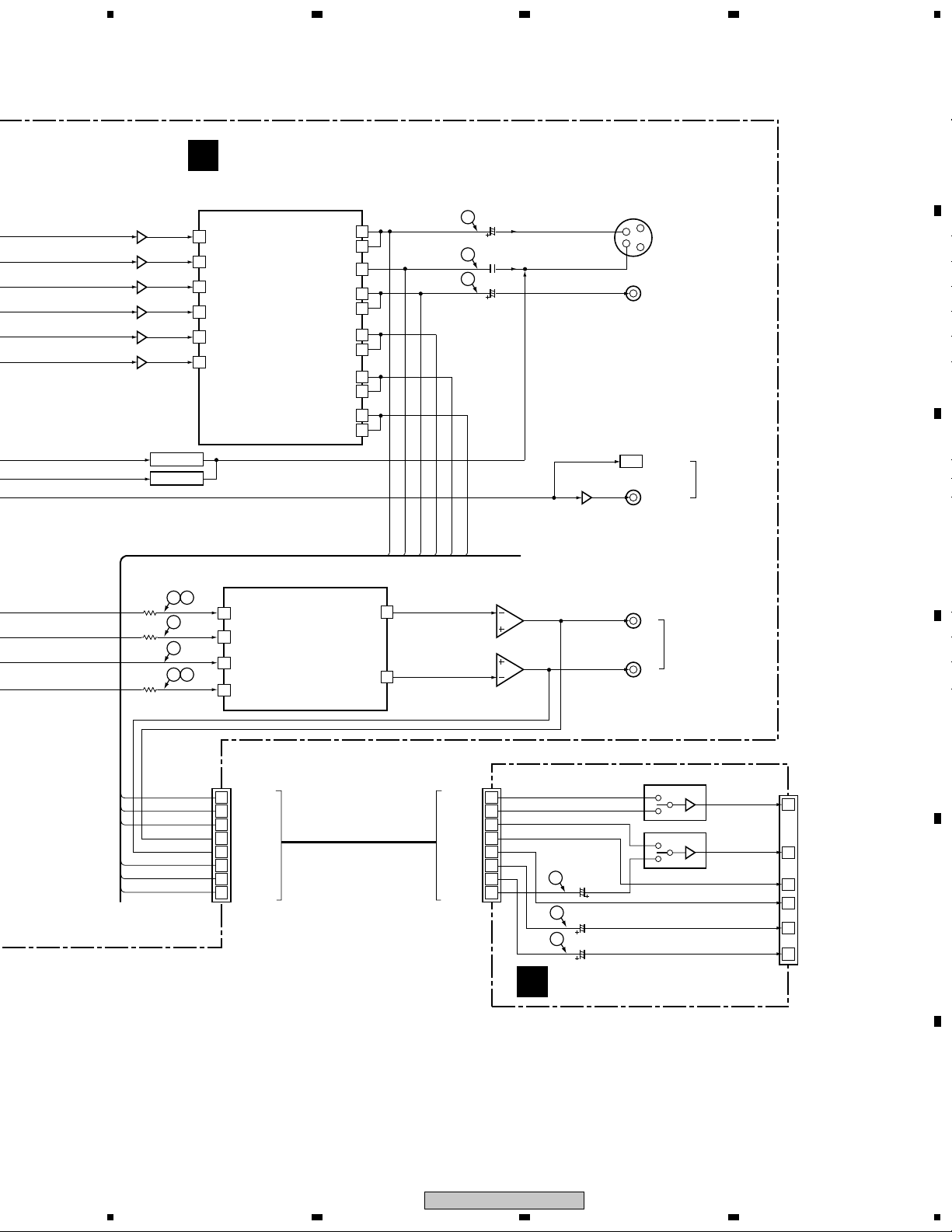

1– $: Refer to "3.1.3 WAVEFORMS".

Y

C

Q941

2

1

3

5

7

6

JA950

S VIDEO

COMPOSITE

VIDEO OUT

OPTICAL

COAXIAL

L

AUDIO

OUT

R

DIGITAL

OUT

B

C

V_OUT2

Y_OUT2

C_OUT2

FRONT_L

FRONT_R

G_OUT2

B_OUT2

R_OUT2

6

8

10

12

14

16

18

20

V

Y

C

AUDIO_L

AUDIO_R

G

B

R

CN901

(20P)

AUDIO_L

AUDIO_R

D

CN101

(20P)

15

V

13

Y

11

C

9

7

G

5

B

3

R

1

10

C403

11

C501

12

C601

SCRB ASSY

G

IC301 MM1507XN

46H

IC401 MM1505XN

64L

2

L

2

H

JA101

(21P)

EURO

CONNECTOR

V/Y

19

R/C

15

AUD. LOUT

3

AUD. ROUT

1

G

11

B

7

E

F

DV-454-K

5

6

7

8

17

Page 18

1

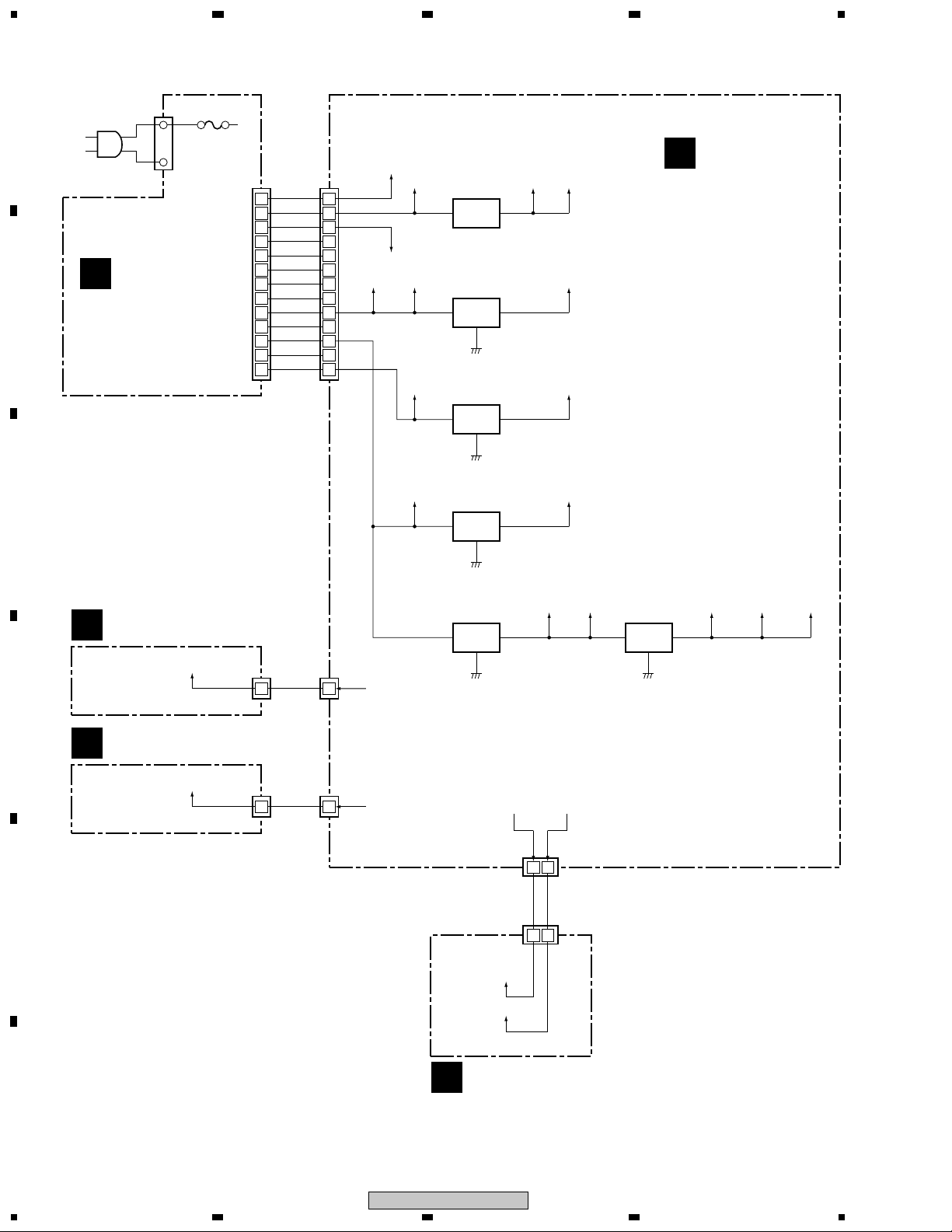

3.1.2 POWER SUPPLY BLOCK

23

4

A

AC IN

B

POWER SUPPLY

ASSY

E

LIVE

NEUTRAL

F1

VWR1351: CN101

VWR1353: CN2

(13P)

1

2

3

4

5

6

7

8

9

10

11

12

13

EV+6V (B)

EV+6V (A)

-28V

FLDC+

FLDC-

GND

P-CONT

GND

SW+12V

GND

EV+4V

GND

SW+3.3V

CN401

1

2

3

4

5

6

7

8

9

10

11

12

13

(13P)

V+6B

V+6A

-28V

V+12M V+5AV+12D

IC421

MM1565AF

+5V Reg.

V+5S V+5V

IC901

NJM78L05A

+5V Reg.

31

2

IC431

PQ025EZ01ZP

V+3D V+2R5

+2.5V Reg.

IN OUT

FJMB ASSY

B

IC451

MM1385EN

V+4E

C

+3V Reg.

IN OUT

V+3E

IC303

BA18BC0FP

+1.8V Reg.

13

2

LOAB ASSY

A

V+3D

CN601

(5P)

4 4

CN52

(5P)

V+3R5D

IC441

PQ070XZ02ZP

+3.5V Reg.

VIN VOUT

V+3R5D V+3R5A V+1RBD V+1RBA1 V+1RBA2

D

IRKY ASSY

C

V+3E

CN301

(5P)

3 3

CN11

(5P)

V+3E

V+12M V+5V

CN901

(20P)

1 3

E

1 3

CN101

(20P)

V+12M

V+5V

SCRB ASSY

G

F

18

DV-454-K

1234

Page 19

5

678

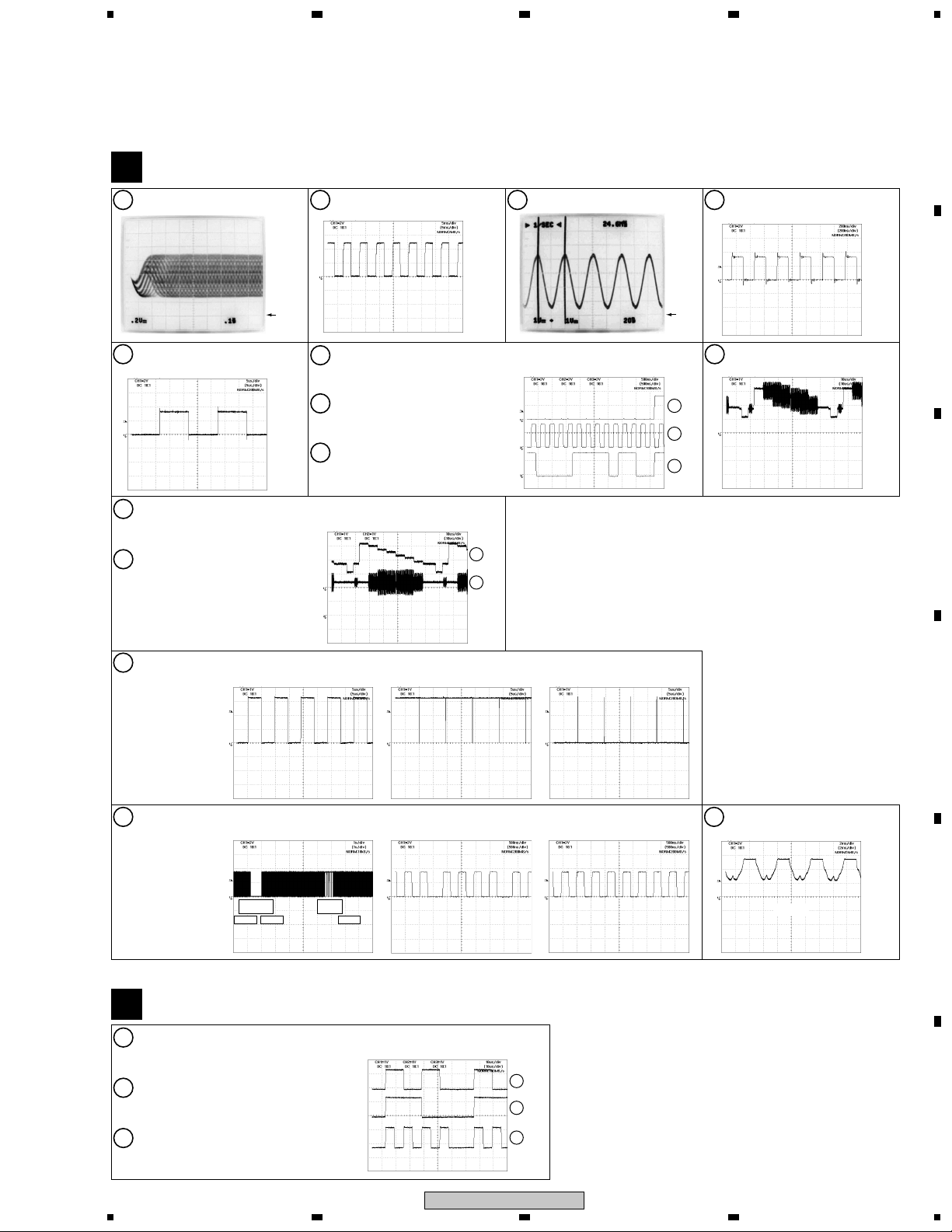

3.1.3 WAVEFORMS

Note : The encircled numbers denote measuring point in the schematic diagram.

Measurement condition

: No. 1 to 2 and 9 to 14 : reference A1 (DVD), T2-chp 19, Color-bar

No. 3 to 8 : reference A1 (DVD), T2-chp 1

FJMB ASSY

B

IC301 - pin 3 [RF]

1

V: 200mV/div. H: 0.1µsec/div.

Foot of R723 (IC711 - pin 3)

5

[AUDIO DAC -LRCK]

V: 2V/div. H: 5µsec/div.

Foot of C832 (IC801 - pin 27, 28)

13

[S Video output -Y]

V: 1V/div. H: 10µsec/div.

Foot of C822 (IC801 - pin 33)

14

[S Video output -C]

V: 1V/div. H: 10µsec/div.

GND

IC251 - pin 24 [FG]

2

V: 1V/div. H: 5msec/div.

Foot of R723 (IC711 - pin 3)

6

[AUDIO DAC -LRCK]

V: 2V/div. H: 500nsec/div.

Foot of R721 (IC711 - pin 1)

7

[AUDIO DAC -BCK]

V: 2V/div. H: 500nsec/div.

Foot of R722 (IC711 - pin 2)

8

[AUDIO DAC -DATA]

V: 2V/div. H: 500nsec/div.

(Waveform of DATA is unsettled.)

34

13

14

IC711 - pin 16 [AUDIO DAC -MCK]

V: 1V/div. H: 20nsec/div.

6

7

8

GND

Foot of R721 (IC711 - pin 1)

[AUDIO DAC -BCK]

V: 2V/div. H: 200nsec/div.

Foot of C812 (IC801 - pin 30, 31)

9

[Composite Video output]

V: 1V/div. H: 10µsec/div.

A

B

C

IC601 - pin 116 [LOAD_DRV]

15

V: 1V/div. H: 5µsec/div.

IC301 - pin 42 [SPDL_PDM]

16

Accelertar

STOP STOPPLAY

SCRB ASSY

G

Foot of C403 (FJMB: IC801 - pin 21, 22)

10

[Video output -R]

V: 2V/div. H: 10µsec/div.

Foot of C501 (FJMB: IC801 - pin 24, 25)

11

[Video output -G]

V: 1V/div. H: 10µsec/div.

Foot of C601 (FJMB: IC801 - pin 18, 19)

12

[Video output -B]

V: 2V/div. H: 10µsec/div.

5

[Tray stops] [Tray is opening] [Tray is closing]

[STOP→PLAY→STOP] [STOP]

ON

Brakes

ON

GND-R(0)→

GND-G(-)→

GND-B(=)→

[PLAY]

V: 2V/div. H: 500nsec/div. V: 2V/div. H: 500nsec/div. V: 2V/div. H: 2msec/div.V: 2V/div. H: 1sec/div.

10

11

12

DV-454-K

6

D

CN251 - pin 12, 11, 10

17

(IC251 - pin 2, 4, 7)

[Spidle driver -A3, A2, A1]

[PLAY]

E

F

19

7

8

Page 20

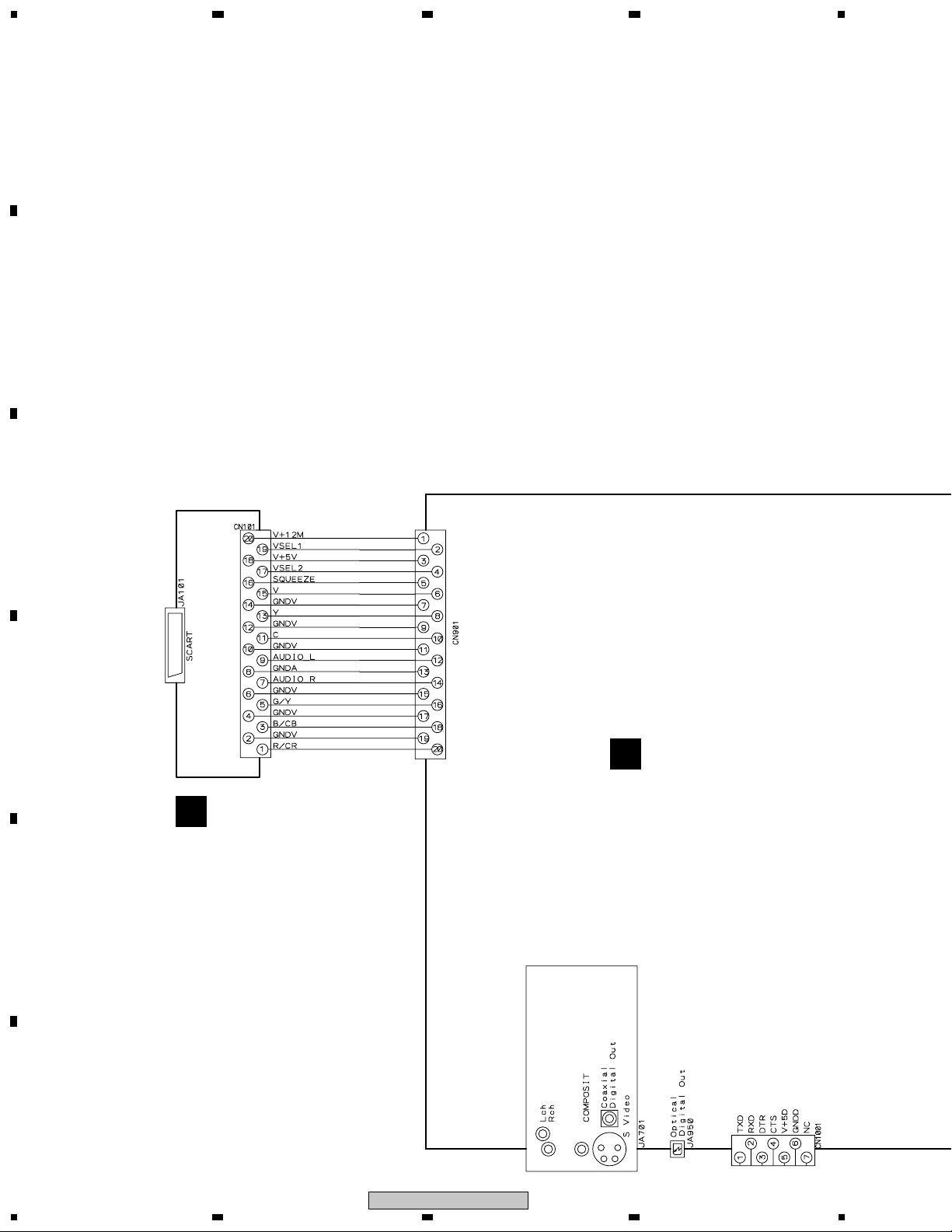

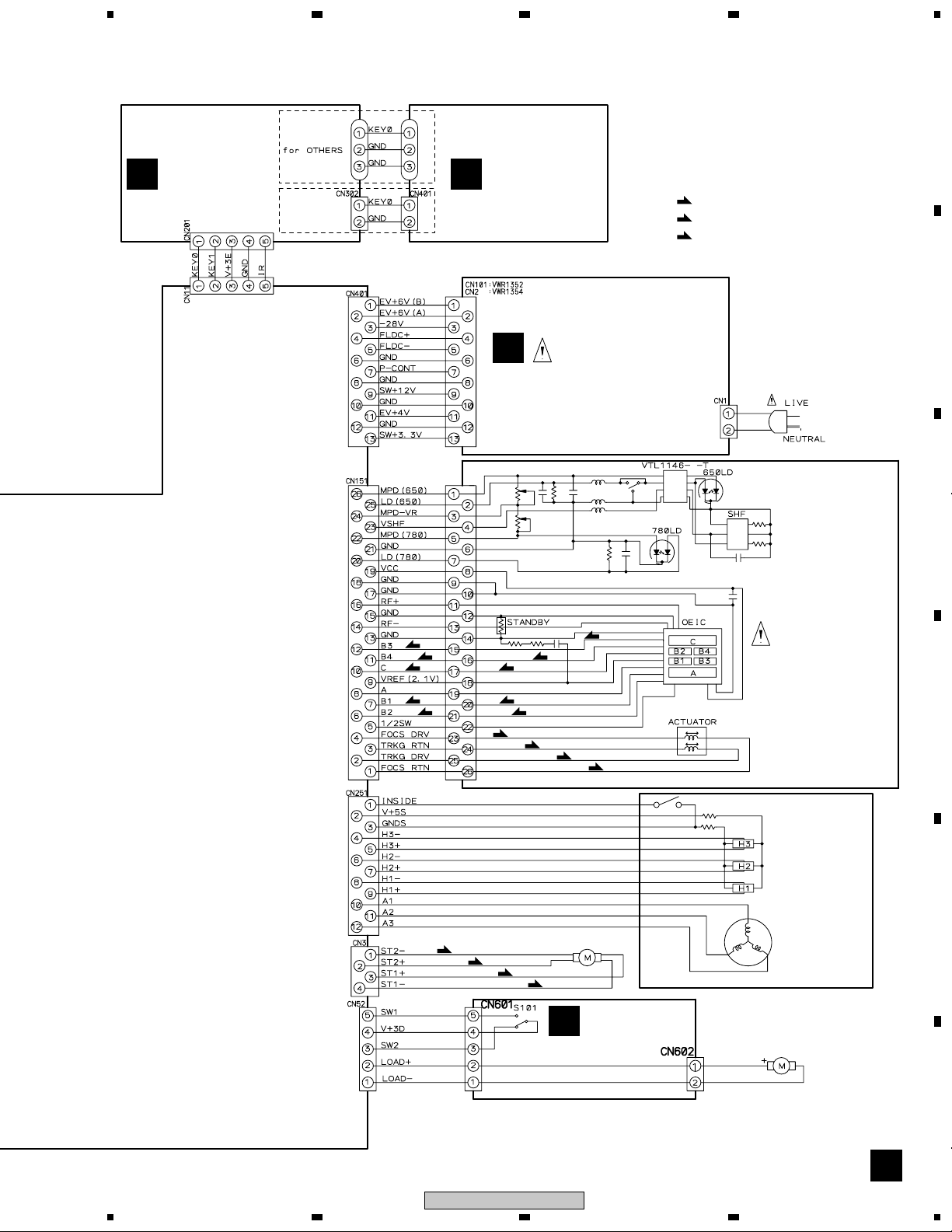

1

3.2 LOAB ASSY and OVERALL WIRING DIAGRAM

A

B

23

4

C

D

FJMB ASSY

B

(VWS1518)

SCRB ASSY

G

(VWV1903)

E

F

ABCDE

20

1234

DV-454-K

Page 21

5

Note : When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS LIST" or "PCB PARTS LIST"

678

A

IRKY ASSY

C

(VWG2344)

for ##XCN type

PSWB ASSY

D

(VWG2345)

E

POWER SUPPLY UNIT

(VWR1352 or VWR1354)

(F)

: FOCUS SERVO LOOP LINE

(T)

: TRACKING SERVO LOOP LINE

(S)

: SLIDER SERVO LOOP LINE

B

C

(F)

(F)

(T)

(F)

(F)

(F)

(S)

(S)

(S)

(F)

(T)

(F)

(F)

(T)

(T)

STEPPING MOTOR

: VXM1090

(S)

(F)

(F)

LOAB ASSY

A

(VWG2279)

PICKUP ASSY-S

(OXX8003)

SPINDLE

MOTOR

: VXX1088

LOADING

MOTOR ASSY

: VXX2505

D

E

F

CDAB A

DV-454-K

5

6

7

8

21

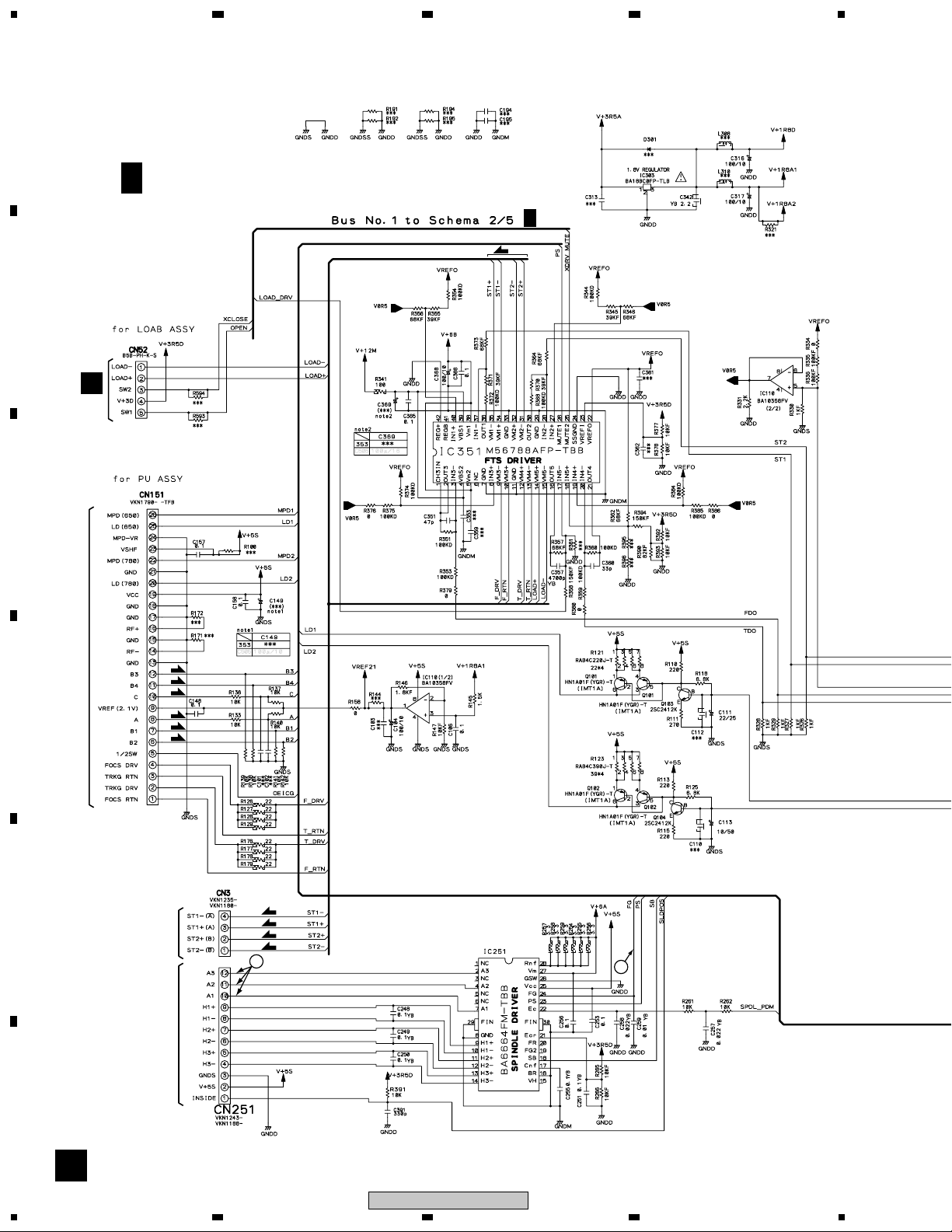

Page 22

1

23

3.3 FJMB ASSY 1/5 [FRONT END BLOCK]

A

4

B 1/5

B

FJMB ASSY (VWS1518)

B

2/5

(S)

A

CN601

C

(F)

(F)

PICKUP ASSY

D

E

STEPPING

(T)

(T)

(F)

(F)

MOTOR

17

(S)

(S)

(S)

(S)

2

SPINDLE

MOTOR

F

1/5

B

22

1234

DV-454-K

Page 23

5

678

A

B

B

2/5

1, 2, #, $: Refer to "3.1.3 WAVEFORMS".

(F)

: FOCUS SERVO LOOP LINE

(T)

: TRACKING SERVO LOOP LINE

(S)

: SLIDER SERVO LOOP LINE

VCC33DAC

C

454

D

1

VCC18MN

16

E

(F)

(F)

(F)

(F)

(T)

(T)

F

1/5

B

DV-454-K

5

6

7

8

23

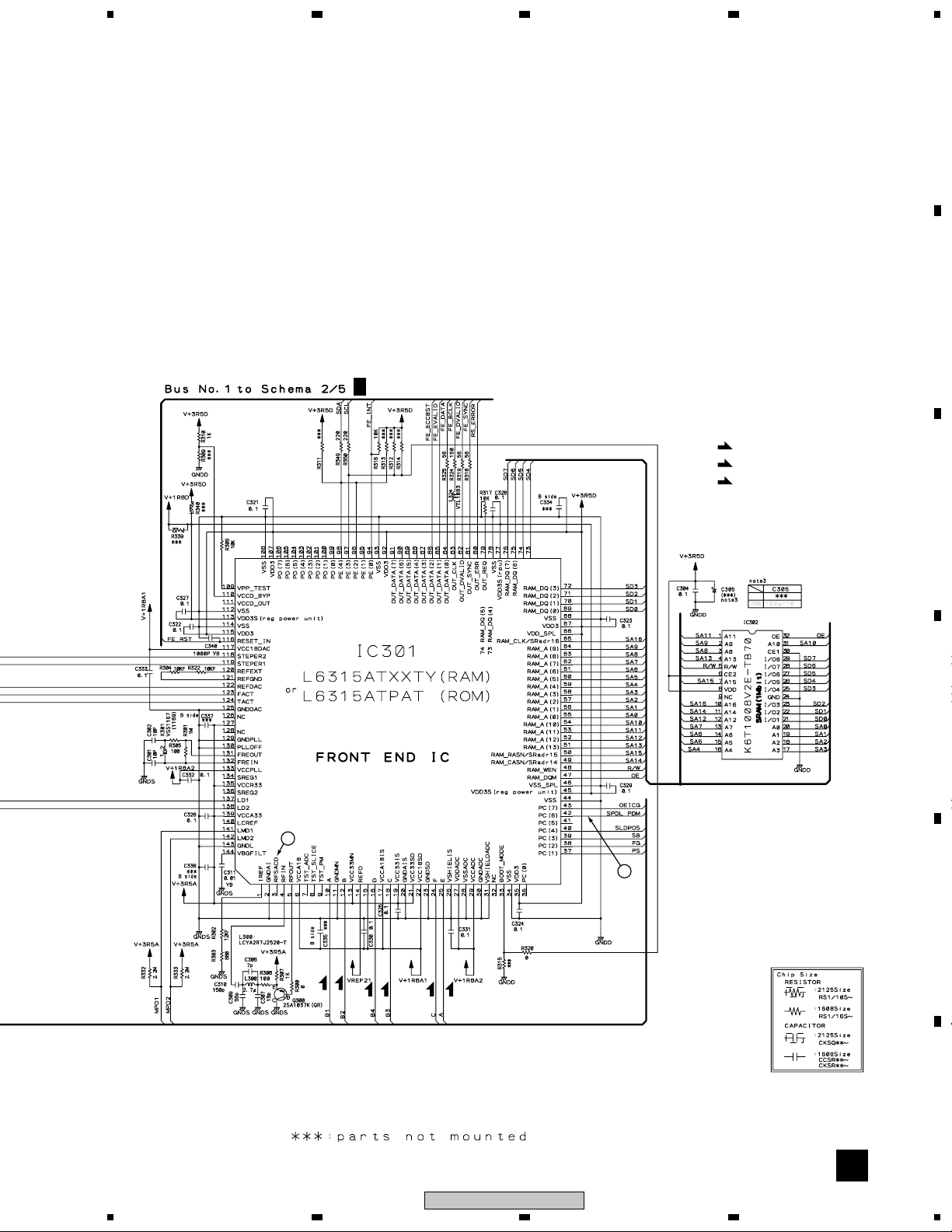

Page 24

1

23

3.4 FJMB ASSY 2/5 [BACK END BLOCK]

A

VYW1978

4

FJMB ASSY

(8M)

B 2/5

B

C

(VWS1518)

3/5

B

454

454

15

D

(B)

(G)

(R)

(S_Y)

(S_C)

(V)

E

454

454

F

2/5

B

24

1234

B

2/5B5/5

B

1/5

DV-454-K

(D)

(D)

454

Page 25

5

678

A

5/5

B

2/5

B

B

E

VWR1352: CN101

VWR1354: CN2

: The power supply is shown with the marked box.

(V)

454

(S_C)

(S_Y)

4/5

B

3/5

B

@: Refer to "3.1.3 WAVEFORMS".

(V)

: V SIGNAL ROUTE

(S_C)

: S-VIDEO OUT C SIGNAL ROUTE

(S_Y)

: S-VIDEO OUT Y SIGNAL ROUTE

(R)

: R SIGNAL ROUTE

(G)

: G SIGNAL ROUTE

(B)

: B SIGNAL ROUTE

: AUDIO SIGNAL ROUTE

(D)

: AUDIO(DIGITAL) SIGNAL ROUTE

C

D

(R)

(G)

E

(B)

F

2/5

B

DV-454-K

5

6

7

8

25

Page 26

1

23

3.5 FJMB ASSY 3/5 [AUDIO BLOCK]

4

A

B

2/5

B

C

4 87

5 6

B 3/5

FJMB ASSY (VWS1518)

3

D

B

4/5

G

CN101

B

4/5

E

F

26

B

3/5

DV-454-K

1234

Page 27

5

678

A

3– 8: Refer to "3.1.3 WAVEFORMS".

: AUDIO SIGNAL ROUTE

B

4/5

B

C

D

E

: The power supply is shown with the marked box.

3/5

B

DV-454-K

5

6

7

8

27

F

Page 28

1

23

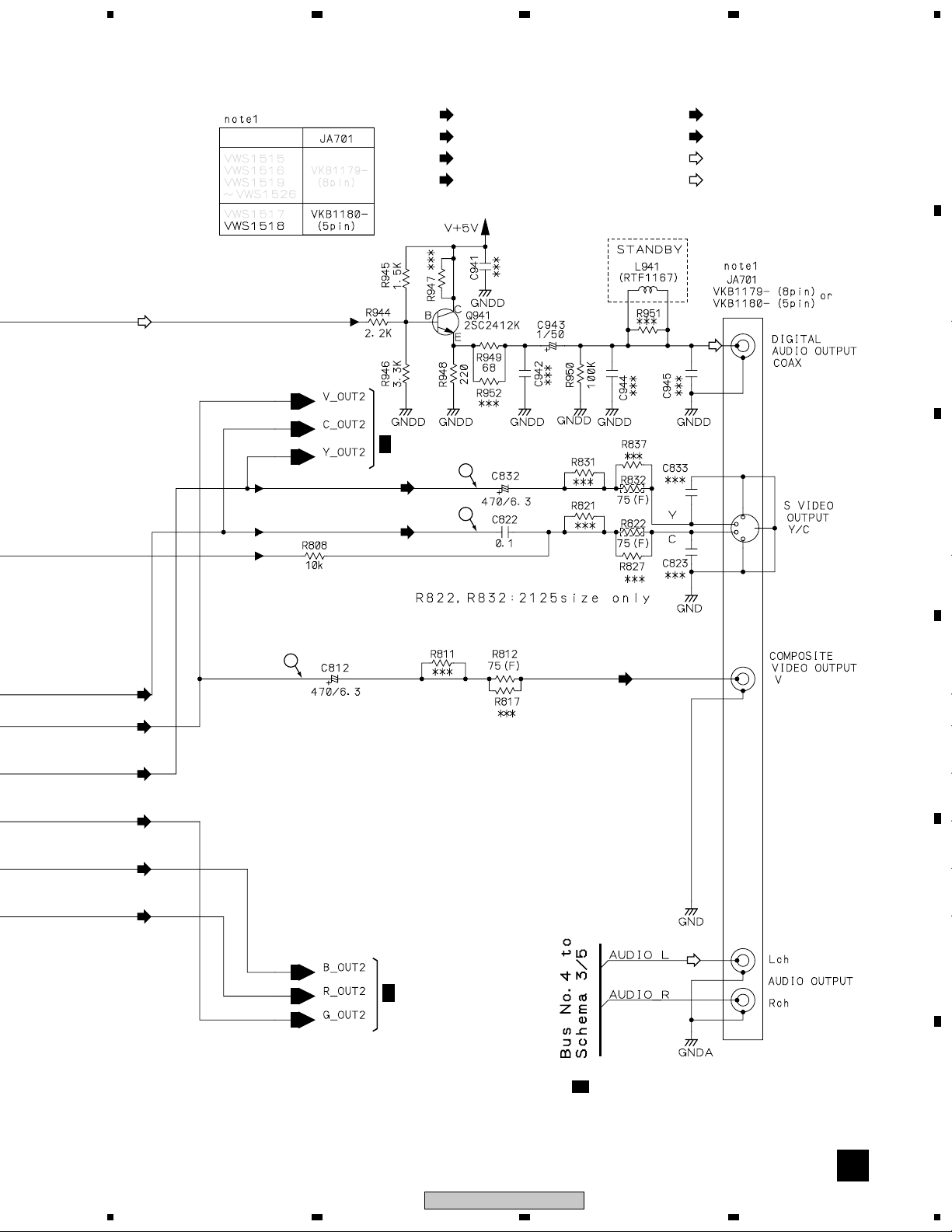

3.6 FJMB ASSY 4/5 [VIDEO BLOCK]

A

4

B 4/5

FJMB ASSY (VWS1518)

(D)

2/5

B

B

C

(D) (D) (D)

(S_C)

D

E

F

(V)

(S_Y)

(G)

(B)

(R)

(S_C)

(V)

(S_Y)

(G)

(B)

(R)

28

B

4/5

DV-454-K

1234

Page 29

5

678

(D)

B

(S_Y)

(S_C)

3/5

(V)

: V SIGNAL ROUTE

(S_C)

: S-VIDEO OUT C SIGNAL ROUTE

(S_Y)

: S-VIDEO OUT Y SIGNAL ROUTE

(R)

: R SIGNAL ROUTE

13

14

(G)

: G SIGNAL ROUTE

(B)

: B SIGNAL ROUTE

: AUDIO SIGNAL ROUTE

(D)

: AUDIO(DIGITAL) SIGNAL ROUTE

(D)

A

B

C

(S_C)

(S_Y)

(G)

(B)

(R)

9

(V)

(V)

D

E

B

3/5

3/5

B

9, ~, !: Refer to "3.1.3 WAVEFORMS".

4/5

B

DV-454-K

5

6

7

8

29

F

Page 30

1

23

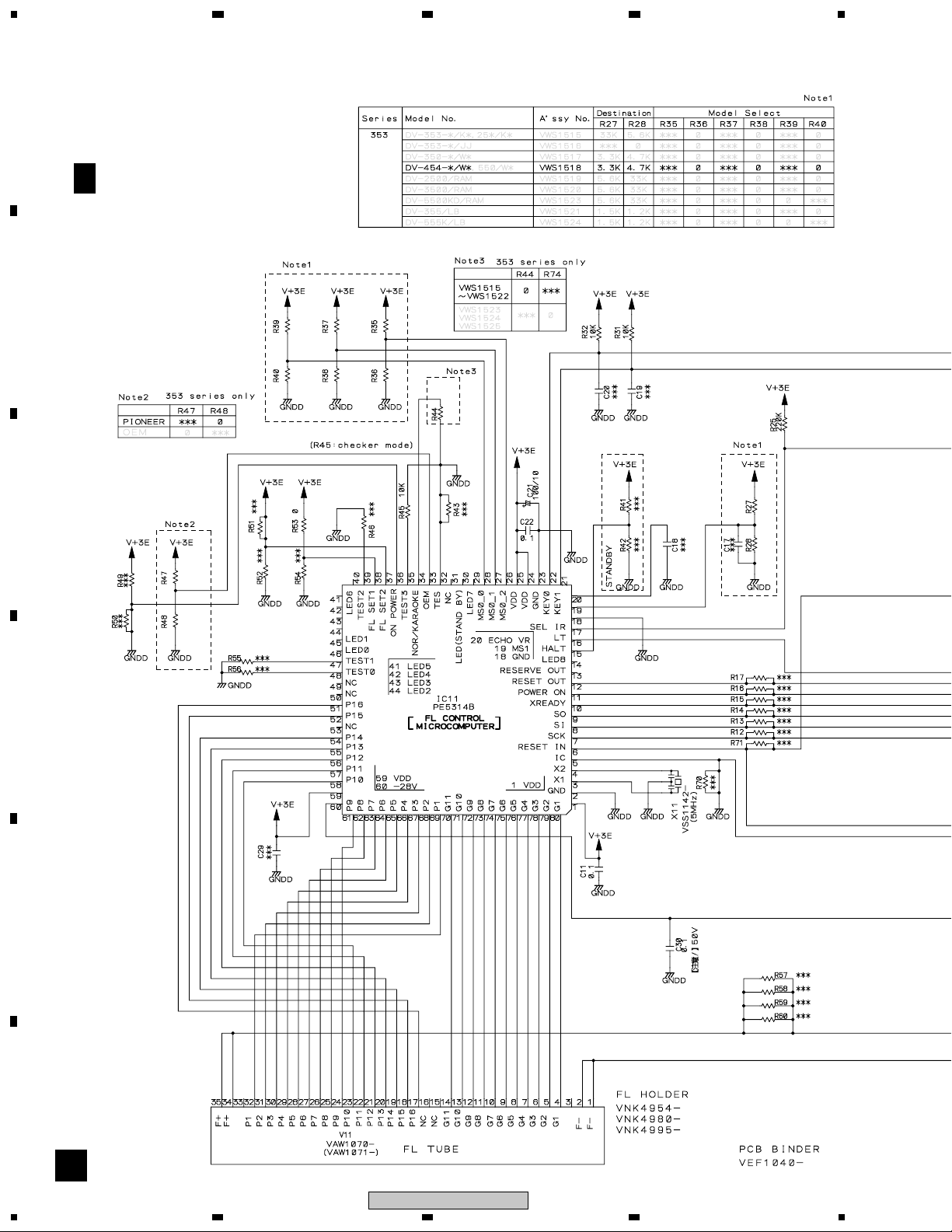

3.7 FJMB ASSY 5/5 [FL CONTROL BLOCK]

A

4

B 5/5

B

C

FJMB ASSY (VWS1518)

D

E

(XJ)

F

(XU, XQ)

(XCN)

30

B

5/5

DV-454-K

1234

Page 31

5

678

A

B

A

CN601

454 454

C

454

2/5

B

D

E

F

5/5

B

DV-454-K

5

6

7

8

31

Page 32

1

3.8 IRKY and PSWB ASSYS

A

23

4

S301 : 0 OPEN/CLOSE

S302 : 3

S303 : 8

B

S304 : 7

S305 : ¡¢

S306 : 41

B 5/5

CN11

C

IRKY ASSY

C

(VWG2344)

D

E

F

32

C

DV-454-K

1234

Page 33

5

VKP2277

678

A

B

PSWB ASSY

D

(VWG2345)

S401 : STANDBY/ON

VKP2277

for ##XCN type

C

D

E

: The power supply is shown with the marked box.

F

D

DV-454-K

5

6

7

8

33

Page 34

1

23

3.9 POWER SUPPLY UNIT (VWR1352)

A

CN101

1.6A

2.0A

B

AEK7066

AEK7067

B 2/5

1.6A

AEK7012

4

CN401

C

D

E

800mA

AEK7063

250V T2AH

REK1101

2A

POWER SUPPLY UNIT (VWR1352)

F

E

• In case of repairing, use the described parts only to prevent an accident.

• Please write the red mark on the board when the primary section of POWER SUPPLY (SYPS) Unit is repaired.

• Please take care to keep the space, not touching other parts when replacing the parts.

NOTE OF SPARE PARTS IN POWER SUPPLY (SYPS) UNIT

E

34

1234

CN1

AC IN

E

DV-454-K

Page 35

5

678

3.10 POWER SUPPLY UNIT (VWR1354)

B 2/5

800mA

AEK7063

CN401

AEK7066

2.0A

AEK7067

1.6A

1.6A

AEK7066

A

CN2

B

2.5A

REK1102

T2.5AH 250V

CN1

C

D

E

AC IN

POWER SUPPLY UNIT (VWR1354)

• In case of repairing, use the described parts only to prevent an accident.

• Please write the red mark on the board when the primary section of POWER SUPPLY (SYPS) Unit is repaired.

• Please take care to keep the space, not touching other parts when replacing the parts.

NOTE OF SPARE PARTS IN POWER SUPPLY (SYPS) UNIT

E

E

5

F

E

DV-454-K

6

7

8

35

Page 36

1

3.11 SCRB ASSY

23

4

A

B

C

SCRB ASSY(VWV1903)

G

D

B 3/5

CN901

E

F

10

36

G

DV-454-K

1234

Page 37

5

12

678

A

B

11

C

D

E

: The power supply is shown with the marked box.

0– =: Refer to "3.1.3 WAVEFORMS".

F

G

DV-454-K

5

6

7

8

37

Page 38

1

A

B

23

4

C

D

E

F

38

1234

DV-454-K

Page 39

5

678

4. PCB CONNECTION DIAGRAM

NOTE FOR PCB DIAGRAMS :

1. Part numbers in PCB diagrams match those in the schematic

diagrams.

2. A comparison between the main parts of PCB and schematic

diagrams is shown below.

Symbol In PCB

Diagrams

BCE

BCE

D

Symbol In Schematic

Diagrams

BCEBCE

BCE

BCE

DGGSS

DGS

Part Name

Transistor

Transistor

with resistor

Field effect

transistor

Resistor array

3. The parts mounted on this PCB include all necessary parts for

several destinations.

For further information for respective destinations, be sure to

check with the schematic diagram.

4. View point of PCB diagrams.

Connector

Capacitor

SIDE A

P.C.Board

Chip Part

SIDE B

A

B

4.1 LOAB ASSY

3-terminal

regulator

LOAB ASSY

A

(VNP1837-B)

C

D

E

A

M

LOADING

MOTOR

ASSY

5

CN601

CN52

B

SIDE A SIDE B

6

DV-454-K

7

F

A

39

8

Page 40

1

C606

R663

5

R

R

R

VREF

N

5

E

T

4.2 FJMB ASSY

23

4

A

B

C

D

E

SIDE A

FJMB ASSY

B

V11

Q81

IC451

R593

R84

R372

R371

Q83

C366

C365

R346

R345

R356

R355

R354

R344

1732

17

32

5

1

C452

R52

GND

41 60

41

CMKM-P3X

C29

C30

60

CN52 CN1

CN52

CN15

5

51

R594

C361

22

2242

42

R384

R385

C368

IC302

C451

R47

R48

R39

R38

R74

R51

R40

R43

R36

R45

R46

61 80

C15

C22

4021

R44

IC11

R11

C14

1

IC12

5

12

R191

R362

R394

21

1

121

R386

C329

C369

C305

16

C304

116

1

IC301

C20

R37

C19

R35

21 40

120

8061

KN901

CN601

A

R192

KN902

IC351

C359

C353

R374

R391

R375

R376

C351

C324

361

36

37

37

C323

72

72

73

73

C328

R31

R32

V+4E

R318

C21

C31

201

R17

R16

X11

R15

C11

R12

R71

R70

R673

PC

C258

C257

R262

GNDS

C331

C325

1

18

R317

L324

8

R320

R319

R27

R325

R324

5

CN11

5

10

CN12

R14

R13

R644

R73

R72

C643

R266

C251

R261

C18

R265

C17

C330

R28

1

12

C255

30

28 15

C253

C256

108

16 9

16

9

C319

R312

IC304

R314

R62

L61

13

13

SEDR+

L-POS

D-SENS

T-POS

C277

C276

1

IC271

252714

1

R297

Cross-grain

15

30

28

1

108

SEDR-

14 27

25

R305

C302

R326

144

144

C332

C322

109

109

7

8

R296

C311

C326

V+3D

GNDM

R301

R322

C340

C316

C321

R310

R349

CN16

26 13

1

direction

14

29

1

C301

C333

C327

R309

R306

14

29

1

R333

R332

R304

261

2

R298

V+5S

IC251

R154

C106

R330

C630

1

L274

L271

C274

R147

+

V

Q601

R290

C271

R289

R153

R145

E

4

X601

C278

L272

IC110

C629

R152

Q105

R149

R647

CN61

2548

C317

IC605

R640

C633

C111

4

5

C614

R641

D601

C631

R639

Q271

R271

R151

4

R567

R150

C113

815

D301

C651

R643

1

8

R564

1

4

4

C641

CN251

R111

R125

C110

1

IC603

R276

C112

R273

R146

R405

R648

Q104

8

8

5

5

Q103

C104

IC303

C313

C604

R118

171

17

X301

C632

R645

C634

R646

25

48

R272

R128

R129

1

R123

4

5

5

C108

C342

R565

C616

R642

C613

CN6011

242

C615

R638

C603

242

CN6012

241

124

R275

Q272

M

CN3CN251

R177

R178

R179

R127

R126

Q101

R121

Q102

R110

R142

1

IC111

4

C650

1

C640

R695

8

8

C635

R630

R566

105

105

123

123

156

156

242

FJMB

SPINDLE MO

M

GND

RF+

MPD78

LD65

MPD65

VCC

LD78

GND

GND

VSHF

GND

MPDVR

R176

CN3

1

1

R141

28

28

54

54

104

157

123

157

R547

4

4

R100

GND

IC604

104

IC601

CN6013

C157

R115

R662

26

26

25

25

C102

R156

R155

C636

R172

27

1

R113

27

1

C605

ST

RF-

GND

C158

R171

C103

C639

C638

C637

R574

CN1

C107

B3

C149

R588

B4

G

C

R589

CN11

CN301

C

(VNP1867-C)

Q83Q81

IC302

IC12 Q601IC271

IC301IC11IC451

IC351

IC304

IC251 Q105

IC110

IC605

Q104 IC604

IC303

IC603Q271 Q272

Q102

IC111

Q101Q103

IC601

F

B

40

1234

DV-454-K

Page 41

5

VSHF

678

NDLE MOTOR

STEPPING MOTOR

M

CN151

B4CB3

RF-

GND

GND

RF+

MPD78

VCC

LD78

GND

GND

C157

00

D

04

601

R662

26

26

R115

R156

R155

25

25

C102

R172

27

1

C636

GND

1 27

C605

R113

C158

R171

C103

C639

C638

C637

R574

CN151

C149

C107

R588

A

VREFB11/2SW

1

C148

GND

R622

R624

R619

C611

C606

R589

R663

R590

2

2

1

R133

C412

208

B

PICKUP

ASSY

T DRV

F RTN

T RTN

F DRV

B2

12

1

IC441

C407

C441

C620

R623

R625

53

53

52

52

R613

1

1

208

R552

R665

R583

R575

R602

R584

CN401

75

C423

14

1

C422

R433

D431

C433

C432

R741

C741

R621

R620

C610

R561

R558

R612

C609

R687

C608

C607

R553

R551

R543

R586

R661

R585

R587

R658

R581

R577

L740

R562

C617

C619

R580

CN401

57

IC421

4

C421

GND

C431

IC431

R746

R556

R675

R681

R688

Q606

R690

R691

R572

R591

R579

R578

R601

C410

R743

L741

R722

R554

R432

Q604

R659

R721

R676

Q602

R682

Q607

13

R557

R544

R684

DCFC

13

R678

Q605

VWR1352: CN101

E

VWR1354: CN2

44

V+5V

44

C405

1

R723

20

R576

V+12M

1

CN950

SIDE

R685

Q603

R660

R542

R901

PRINTED

R679

Q711

IC711

C723

C718

10 20

C711

V+5V

IC921

GND

WARNING

THIS PRODUCT CONTAINS LEAD IN SOLDER

AND CERTAIN ELECTRICAL PARTS

CONTAIN CHEMICALS WHICH ARE

KNOWN TO

TO CAUSE

OTHER REPRODUCTIVE HARM.

HEALTH & SAFETY CODE SECTION

25249.2

CN903

C771

IC771

C721

C772

C722

916

916

18

C717

81

C713

Q772

C714

Q771

A

+5

V

8

8

CN951

GND

C801

C644

R674

C645

R677

R680

R686

C844

C646

C647

R683

C648

THE STATE OF CALIFORNIA

CANCER,BIRTH DEFECTS OR

- PROPOSITION 65

R775

IC901

C731

1

1

R771

C773

R773

C649

C841

CN901

R734

R7310

C751

R7510

R726

C802

C851

C861

R689

CN901

CN902

R733

Q796

C755

R761

R7340

R753

R754

C794

R774

C726

C821

117

C733

C753

R7540

C811

C831

C735

C724

C795

C754

R793

C803

R944

R945

C734

R764

C805

1

8

Q794

1834

R946

IC731

R763

D803

D802

C862

IC801

Q941

R947

C725

Q795

D804

D801

CN904

Q762

R762

Q761

Q791Q792

R794

C941

R765

C761

R795

R948

R949

G

C822

R952

R738

C736

C756

C943

CN101

1

1

R758

Q766

R766

Q767

R767

C852

C842

C812

C832

6

R822

L941

R808

C951

KN903

7

R955

JA701

1012

8

R827

R821

Q768

R768

R769

JA702

3

4

Q769

JA950

CN1001

9

1

5

2

7

1

SIDE A

71

A

B

C

D

E

604

601 Q606

IC441 Q711

IC431

5

IC421

Q602

Q607

Q605

Q603

IC711 Q772

Q771Q604

IC921

6

IC771

IC901

DV-454-K

Q796

Q762 Q768

Q761

Q795 Q767

IC801

Q941

7

Q769IC731

Q766Q791Q792Q794

F

B

41

8

Page 42

1

8

Q

7

3

23

4

A

B

C

D

E

SIDE B

R865

C843

R812

R817

C757

R811

7

1

C813

R956

C758

R855

C953

R847

C823

C945

CN1001

R735

C737

R757

+12V

R739

R755

R844

R843

R837

R957

R831

C952

R756

R951

1

VSEL1

L861

+5V

VSEL2

C833

CN904

SQUEEZE

GNDV GNDV

VYC

C738

R759

R737

R736

C853

R853

R854

R857

C863

R864

R863

R867

R832

C944

R950

C942

GND

GNDA

AUDIO_L

AUDIO_R

L851

R805

G/Y

CN902

GND

B/CB

R797

R730

R806

R/CR

R796

D721

R807

ASPECT

+5V

C727

GND

CN901

R902

C804

Q806

GNDA

+12V

R802

+5V

R731

R801

Q808

GND

+3V

R732

R751

R846

Q805

CN903

GNDD

DACSO

DACSCK

Q776

Q777

R777

MCLK

1

Q807

R668

R666

R671

ALRCK

CN951

R845

ADATA1

ABCK

R776

R670

ADATA2

R752

R903

6CHMODE

DACXCS0

NC

R744

8

+12V

GNDA

Q652

XAMUTE2

XAMUTE

MIC

R921

MIC

GNDA

R653

R651

R654

MICON2

44

+3V

GNDA

20

R710

XNOR/KARA

ECHOVR

R650

C406

1

CN950

DACSO

DACSCK

GNDD

ADATA0OUT

LRCLKOUT

KDSPTHRU

KDSPXCS

XRESET

GND

R652

13

MCLK

GNDD

GNDD

LRCLKIN

ADATA0IN

BCKIN

BCKOUT

GNDA

44X48

MIC

R745

+5V

+5V

Q651

L601

C402

V

V+3D

C618

C411

+12M

R607

R560

CN401

V+12D

V+4E

V+3D

R742

V+12M

V+5V

R559

C408

R441

R422

R609

FLDC-

R443

R605

R571

R431

V+2R5

FLDC+

-28VP-CONT

R442

R545

R608

R582

12

C601

R610

R600

R421

C413

GND

C602

C621

GND

R541

C612

000

-A1

C404

ST1-

V+6B

V+12M

V+6A

V+5S

C101

R136

222

111

FJMB

ST1+

ST2-

ST2+

R138

R139

L592

R596

GND

R563

555

444

333

L603

274

6

Q273

R283

Q776

Q777

Q808 Q807

Q806

Q805

Q652 Q2

Q651

Q27

F

B

42

1234

DV-454-K

Page 43

5

678

C404

GND

D

111

000

-A1

FJMB

ST1-

ST2+

ST1+

V+6B

V+12M

V+6A

V+5S

R138

C101

R136

L592

R596

R563

444

333

222

ST2-

R139

GND

L603

555

4

CN3

V+5S

V+4E

V+3R5D

V+3DSD

777

666

Q274

R286

Q273

R283

1

GNDS

V+5S

H3-

INSIDE

V+3D

C698

R631

R632

R604

C622

R568

VWS

999

888

H3+

R546

R569

R285

R282

H2-

R140

R281

C391

117

H1-

H2+

H1+

A3

A2

A1

ST2-

R137

R157

L699

C699

R603

ST2+

R570

CN251

ST1-

ST1+

R158

ST1+

R144

CN61

EV3

GND

-28V

FLDC+

FLDCP-ON

LT1

XRESET

XREADY

S(FtoM)

S(MtoF)

SCK

GND

V+6B

V+12M

V+6A

L310

R327

R321

R573

R595

R316

R328

R299

R331

C299

C248

C249

R254

R329

C250

L308

R293

R255

C272

R291

R256

R302

C336

R339

R340

R257

R350

R294

Q275

R258

R303

113

C194

C334

R336

C195

C310

1

R259

KEY0

C335

CN11

R194

R195

KEY1

C309

EV3IR

C337

R315

GND

R22

R21

C13

R20

R19

C12

L300

IR

CN12

C259

5

R25

R300

C308

R313

R311

Q300

GND

V+3E

R307

C307

R308

R335

R26

R341

R42

R90

CN15

15

R360

R357

R351

R353

R379

R334

V+6B

R41

R18

R24

R23

CN52

C357

R392

R50

R396

R395

C360

R49

R54

R380

R53

GND

R361

FJMB ASSY

B

SW2

LOAD-

V+3D

SW1

LOAD+

R377

R378

R368

R55

R373

R81

C362

R82

R364

R56

0

1

R359

R370

R390

R393

R358

SIDE B

R83

Q82

C81

0

0

123

1

0

123456789

CBA

R57

R58

R59

R60

A

B

C

D

E

Q274

Q273

(VNP1867-C)

Q300

Q82

Q275

F

B

DV-454-K

5

6

7

8

43

Page 44

1

4.3 IRKY and PSWB ASSYS

A

PSWB ASSY

D

23

4

VWG2345-

PSWB

VWG

POWER ON

S401

CMKS-P3X

B

31

1

1

for ##XCN type

1

CN302

REV

S306

S305

1

1

CN401

1

for OTHERS

PC

31

CMKS-P3X

IRKY

VWG2344-

VWG

IRKY ASSY

C

S304

S303

L321

OPEN/

CLOSE

PLAYPAUSESTOPFWD

S302

S301

5

5

CN301

1

C302

54

31

IC301

21

CN301

CN11

B

C

SIDE A

(VNP1868-B)

SIDE B

D

1

2.3.GND

31

E

D

(VNP1868-B)

CN302

1

1.KEY0

1

CMKS-P3X

REV

POWER ON

PSWB ASSY

FWD

R313R314

VWG

VWG2345-

PSWB

GND

1

IRKY

VWG

VWG2344-

1

1

KEY0

CN401

KEY0

GND

GND

3

31

STOP

CMKS-P3X

R312

IRKY ASSY

C

PAUSE

R321

R311

R303

R301

R302

PLAY

CN301

CLOSE

OPEN/

KEY0

KEY1

V+3E

GND

IR

51

R322

R323

C301

D301

F

C D

44

DV-454-K

C D

1234

Page 45

5

678

4.4 POWER SUPPLY UNIT (VWR1352)

SIDE A SIDE A

AC IN

POWER SUPPLY UNIT

E

Q2

A

B

C

Q1

Q20

Q320

IC103

IC201

Q412

VR201

CN401

B

CN101

D

E

E

Q411

Q410

F

E

DV-454-K

5

6

7

8

45

Page 46

1

23

4.5 POWER SUPPLY UNIT (VWR1354)

4

A

B

C

SIDE A SIDE A

AC IN

POWER SUPPLY UNIT

E

IC3

IC2

D

IC1

IC4

CN401

B

CN2

E

F

E

46

Q6

E

DV-454-K

1234

Page 47

5

4.6 SCRB ASSY

Production

Code

678

A

SCRB ASSY

G

PYKC F6

SIDE A

SIDE B

W121

W120

W119

GNDV

W118

+5V

(VNP1868-B)

(VNP1868-B)

JA101

SCRB

VWV1902VWV1903-

VWV

GNDV

GNDV

W116

W117

GNDV

+12V

AUDIO_L

NC

AUDIO_R

GNDV

GNDV

CN101(20P)

20.+12V

18.+5V

W115

W114

16.SQUEEZE

14.GNDV

12.GNDV 11.C

10.GNDV 9.AUDIO_L

8.GNDA 7.AUDIO_R

6.GNDV 5.G/Y

4.GNDV 3.B/CB

2.GNDV 1.R/CR

GNDA

C601

W113

+5V

SQUEEZE

BNCGNDV

19.VSEL1

17.VSEL2

15.V

13.Y

GNDV

C501

W112

NC

+5V

NC

GNDV

GNDV

G

C404

W111

W110

GNDV

R/C

BLANK

GNDV

V/Y

NC

GNDV

CN102(14P)

11.VSEL2

9.V

7.Y

5.C

3.AUDIO_L

1.AUDIO_R

W103

C403

C304

W109

W108

14.+12V 13.VSEL1

12.+5V

10.SQUEEZE

8.GNDV

6.GNDV

4.GNDV

2.GNDA

+5V

W102

GNDV

W107

R

W101

VSEL2

AUDIO_L

GNDA

W106

14

AUDIO_R

W105

W104

SIDE

C111

20

2010

CONTACT

CN102

1

1

CN101

1

B

CN901

B

CN101

C

Q201

Q202

R203

+5V

C102

R104

R108

R107

R106

R201

C201

C202

R202

R204

R206

R205

C203

+12V

GNDV

R101

D101

R109

C103

GNDV

GNDV

C101

Q101

R103

R102

Q102

C902

1

R902

R901

C901

2

R105

R801

C801

R701

2.GNDV

4.GNDV

6.GNDV

8.GNDA

10.GNDV

12GNDV

14.GNDV

16.SQUEEZE

18.+5V

20.+12V

+5V

D601

D602

R601

R603

C701

C602

R602

R501

R503

1.R/CR

3.B/CB

5.G/Y

7.AUDIO_R

9.AUDIO_L

11.C

13.Y

15.V

17.VSEL2

19.VSEL1

+5V

D501

D502

R502

D401

+5V

D402

R401

C502

R403

CN101(20P)

2.GNDA

4.GNDV

6.GNDV

8.GNDV

10.SQUEEZE

12.+5V

14.+12V

1

3

R402

R303

C405

R301

6

4

C401

R302

IC401

D302

C305

CN102(14P)

1.AUDIO_R

3.AUDIO_L

5.C

7.Y

9.V

11.VSEL2

13.VSEL1

1

3

D301

+5V

21

20

AUDIO_R

GNDA

C402

C302

C303

14

SCRB ASSY

R

IC301

GNDV

G

AUDIO_L

6

4

VSEL2

C301

VWV

1

CN101

1

CN102

20

D

E

VWV1903VWV1902-

SCRB

F

G

G

DV-454-K

5

6

7

8

47

Page 48

1

23

5. PCB PARTS LIST

NOTES:•Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

Mark No. Description Part No.

A

The mark found on some component parts indicates the importance of the safety factor of the part.

•

Therefore, when replacing, be sure to use parts of identical designation.

When ordering resistors, first convert resistance values into code form as shown in the following examples.

•

Ex.1 When there are 2 effective digits (any digit apart from 0), such as 560 ohm and 47k ohm (tolerance is shown by J=5%,

and K=10%).

560 Ω→56 × 10

47k Ω→47 × 10

0.5 Ω→R50 ..................................................................................... RN2H

1 Ω→1R0 ..................................................................................... RS1P 1 R 0 K

Ex.2 When there are 3 effective digits (such as in high precision metal film resistors).

5.62k Ω→ 562 × 10

1

→ 561 ........................................................ RD1/4PU 5 6 1 J

3

→ 473 ........................................................ RD1/4PU 4 7 3 J

1

→ 5621 ...................................................... RN1/4PC 5 6 2 1 F

Mark No. Description Part No.

R 5 0

4

K

Mark No. Description Part No.

B

7 LIST OF ASSEMBLIES

NSP 1..LOADING MECHANISM ASSY VWT1197

NSP 2..LOAB ASSY VWG2279

1..FJMB ASSY VWS1518

NSP 1..KEYB ASSY VWM2122

NSP 2..IRKY ASSY VWG2344

NSP 2..PSWB ASSY VWG2345

> 1..POWER SUPPLY UNIT VWR1354

C

D

1..SCRB ASSY VWV1903

(or VWR1352)

Mark No. Description Part No.

7 PCB PARTS LIST

LOAB ASSY

SWITCHES AND RELAYS

S101 REAF SWITCH VSK1011

OTHERS

CN602 CONNCTOR S2B–PH–K

CN601 CONNCTOR S5B–PH–K

PRINTED CIRCUIT BOARD VNP1837

FJMB ASSY

SEMICONDUCTORS

IC110 BA10358FV

> IC303 BA18BC0FP

IC731 BA4560F

IC251 BA6664FM

IC604 K4S641632F–TC75

IC302 K6T1008V2E–TB70

IC301 L6315ATXXTY

IC351 M56788AFP

> IC451 MM1385EN

> IC421 MM1565AF

> IC901 NJM78L05A

> IC431 PQ025EZ01ZP

> IC441 PQ070XZ02ZP

E

F

48

1234

DV-454-K

IC801 MM1567AJ

IC711 PCM1742KE

IC11 PE5314B

IC12 PST3228

IC601 STI5519AVB–B0C

IC605 TC7WU04FU

IC603 VYW1978

Q300, Q602–Q607, Q762 2SA1037K

Q81, Q83 2SA1602A

Q103, Q104, Q82, Q941 2SC2412K

Q766–Q769 2SD2114K

Q652 DTC114TK

Q711, Q761, Q805, Q807 DTC114YK

Q101, Q102 HN1A01F

Q806, Q808 PDTA124EK

Q601 RN4982

D601 RB501V–40

D721 UDZS6.2B

Page 49

5

678

Mark No. Description Part No.

COILS AND FILTERS

L741 LAU3R3J

L699 LCYA2R2J2520

L300 LCYA2R7J2520

L324 CHIP BEADS VTL1083

CAPACITORS

C301, C302 CCSRCH100D50

C310 CCSRCH151J50

C307 CCSRCH180J50

C360 CCSRCH330J50

C391, C737, C757 CCSRCH331J50

C351 CCSRCH470J50

C309 CCSRCH560J50

C308 CCSRCH7R0D50

C633, C634 CCSRCH8R0D50

C113 CEAT100M50

C104, C21, C316, C317, C368 CEAT101M10

C405, C412, C432, C614, C711 CEAT101M10

C721, C726, C731, C736, C751 CEAT101M10

C756, C801, C803 CEAT101M10

C617, C714 CEAT102M6R3

C943 CEAT1R0M50

C111 CEAT220M25

C724 CEAT470M16

C812, C832 CEAT471M6R3

C342, C422 CKSQYB225K10

C699 CKSQYF225Z16

C14, C340, C641 CKSRYB102K50

C259, C311 CKSRYB103K50

C248–C251, C255 CKSRYB104K16

C257, C258 CKSRYB223K50

C733, C753 CKSRYB272K50

C357 CKSRYB472K50

C106, C11, C148, C157, C158 CKSRYF104Z25

C22, C253, C256, C304 CKSRYF104Z25

C321–C333, C365, C366, C451 CKSRYF104Z25

C602–C609, C612, C618 CKSRYF104Z25

C621, C622, C632, C637–C640 CKSRYF104Z25

C713, C717, C722, C725, C735 CKSRYF104Z25

C755, C802, C804, C805, C811 CKSRYF104Z25

C821, C822, C831, C844, C851 CKSRYF104Z25

C861, C952 CKSRYF104Z25

C30 CKSRYF104Z50

C411, C423, C431, C601 CKSRYF105Z10

C610, C611, C613, C615, C629 CKSRYF105Z10

C635, C636, C741 CKSRYF105Z10

C734, C754 (330P/50V) VCH1226

RESISTORS

R121 RAB4C220J

R123 RAB4C390J

R731, R751 RN1/16SE2201D

R734, R754 RN1/16SE4301D

R341 RS1/10S101J

R764 RS1/10S182J

R126–R129, R176–R179 RS1/10S220J

R254–R259 RS1/10S3R3J

R822, R832 RS1/10S75R0F

R326–R330, R443 RS1/16S1001F

Mark No. Description Part No.

R147, R265, R266, R304, R322 RS1/16S1002F

R377, R378, R392, R393 RS1/16S1002F

R344, R351, R353, R354 RS1/16S1003D

R359, R360, R368, R372 RS1/16S1003D

R374, R375, R384, R385 RS1/16S1003D

R335, R336 RS1/16S1003F

R302 RS1/16S1202F

R358, R394 RS1/16S1503F

R146, R441 RS1/16S1801F

R612, R613 RS1/16S1802F

R442 RS1/16S1803F

R675, R678, R681, R684, R687 RS1/16S2700F

R690 RS1/16S2700F

R345, R355, R370, R371 RS1/16S3902F

R346, R356, R357, R362, R364 RS1/16S6802F

R373 RS1/16S6802F

R812 RS1/16S75R0F

R390 RS1/16S8202F

OtherResistors RS1/16S###J

OTHERS

CN901 20P CONNECTOR 52045–2045

CN401 CONNECTOR B13B–PH–K

CN11, CN52 CONNECTOR POST B5B–PH–K

JA950 JFJ1001

OPT. LINK OUT 8MB/S

V11 FL TUBE VAW1070

FLEXIBLE CABLE VDA1681

PCB BINDER VEF1040

JA701 JACK VKB1180

CN3 4P CONNECTOR VKN1180

CN251 12P CONNECTOR VKN1188

CN1001 7P CONNECTOR VKN1211

CN151 26P CONNECTOR VKN1790

FL HOLDER VNK4980

X11 (5MHz) VSS1142

X301 (20MHz) VSS1167

X601 (27MHz) VSS1168

IRKY ASSY

SEMICONDUCTORS

IC301 SPS–444L–H

COILS AND FILTERS

L301, L311 VTL1084

SWITCHES AND RELAYS

S301–S306 ASG7013

CAPACITORS

C301 CKSRYF104Z25

RESISTORS

All Resistors RS1/16S###J

OTHERS

3P CABLE HOLDER 51048–0300

J301 3P JUMPER WIRE D20PDD0315E

CN301 CONNECTOR S5B–PH–K

A

B

C

D

E

F

DV-454-K

5

6

7

8

49

Page 50

1

23

4

Mark No. Description Part No.

A

PSWB ASSY

SWITCHES AND RELAYS

S401 ASG7013

OTHERS

3P CABLE HOLDER 51048–0300

B