Pioneer DV-380 Service manual

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2005

ORDER NO.

RRV3111

DV-380-S

DVD PLAYER

DV-380-S

DV-380-K

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Model Type Power Requirement Region No. Remarks

DV-380-S WYXTL AC220-240V 2

DV-380-S WVXTL AC220-240V 2

DV-380-K WYXTL AC220-240V 2

For details, refer to "Important Check Points for Good Servicing" .

T-ZZR MAR. 2005 printed in Japan

1234

SAFETY INFORMATION

A

This service manual is intended for qualified service technicians ; it is not meant for the casual doit-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trainedto properly and safely repair complex products such as those covered by this

manual.Improperly performed repairs can adversely affect the safety and reliability of the product

and mayvoid the warranty. If you are not qualified to perform the repair of this product properly and

safely, youshould not risk trying to do so and refer the repair to a qualified service technician.

WARNING !

THE AEL (ACCESSIBLE EMISSION LEVEL) OF THE LASER POWER OUTPUT IS LESS THAN CLASS 1

B

BUT THE LASER COMPONENT IS CAPABLE OF EMITTING RADIATION EXCEEDING THE LIMIT FOR

CLASS 1.

A SPECIALLY INSTRUCTED PERSON SHOULD DO SERVICING OPERATION OF THE APPARATUS.

LASER DIODE CHARACTERISTICS

FOR DVD : MAXIMUM OUTPUT POWER : 5 mW

FOR CD : MAXIMUM OUTPUT POWER : 5 mW

WAVELENGTH : 650 nm

WAVELENGTH : 780 nm

C

LABEL CHECK

Location: inside of the unit

: VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN. AVOID EXPOSURE TO BEAM.

: SICHTBARE UND UNSICHTBARE LASERSTRAHLUNG,WENNABDECKUNG GEÖFFNET NICHT DEM STRAHL AUSSETZEN !

: SYNLIG OG USYNLIG LASERSTRÅLING VED ÅBNING UNDGÅ UDSÆTTELSE FOR STRÀLING.

: SYNLIG OCH OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD BETRAKTA EJ STRÅLEN.

: AVATTAESSA ALTISTUT NÄKYVÄ JA NÄKYMÄTTÖMÄLLE LASERSATEIL YLLE. ÄLÄ KATSO SÄTEESEN.

: RADIACIÓN LÁSER VISIBLE E INVISIBLE AL ESTAR ABIERTO. EVITAR EXPOSICIÓN AL RAYO.

D

E

CAUTION

VORSICHT

ADVARSEL

VARNING

VARO!

CUIDADO

(The following caution label

appears on your unit.)

7260000356 SH

Additional Laser Caution

1. Laser Interlock Mechanism

• Laser diode is driving with Q2303,Q2305(650nm LD) and Q2302,

Q2304(780nm LD)on the DVD MT PCB Assy.

Therefore, when short-circuit between the emitter and collector of these

transistors or the base voltage is supplied for transistors turn on, the

laser oscillates. (failure mode)

• In the test mode ∗ , there is the mode that the laser oscillates except

for the disc judgment and playback. LD ON mode in the test mode

oscillates with the laser forcibly.

2. When the cover is open, close viewing through the objective lens with

the naked eye will cause exposure to the laser beam.

∗ : See page 51.

F

2

DV-380-S

1234

5678

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

0 Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

A

B

C

D

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

Make sure the proper amount is applied.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

56

DV-380-S

E

F

3

7

8

1234

CONTENTS

SAFETY INFORMATION ..................................................................................................................................... 2

1. SPECIFCATIONS ............................................................................................................................................. 5

2. EXPLODED VIEWS AND PARTS LIST ............................................................................................................ 6

A

B

C

D

2.1 PACKING SECTION .................................................................................................................................. 6

2.2 EXTERIOR SECTION................................................................................................................................ 8

2.3 05 DVD MECHA SECTION...................................................................................................................... 10

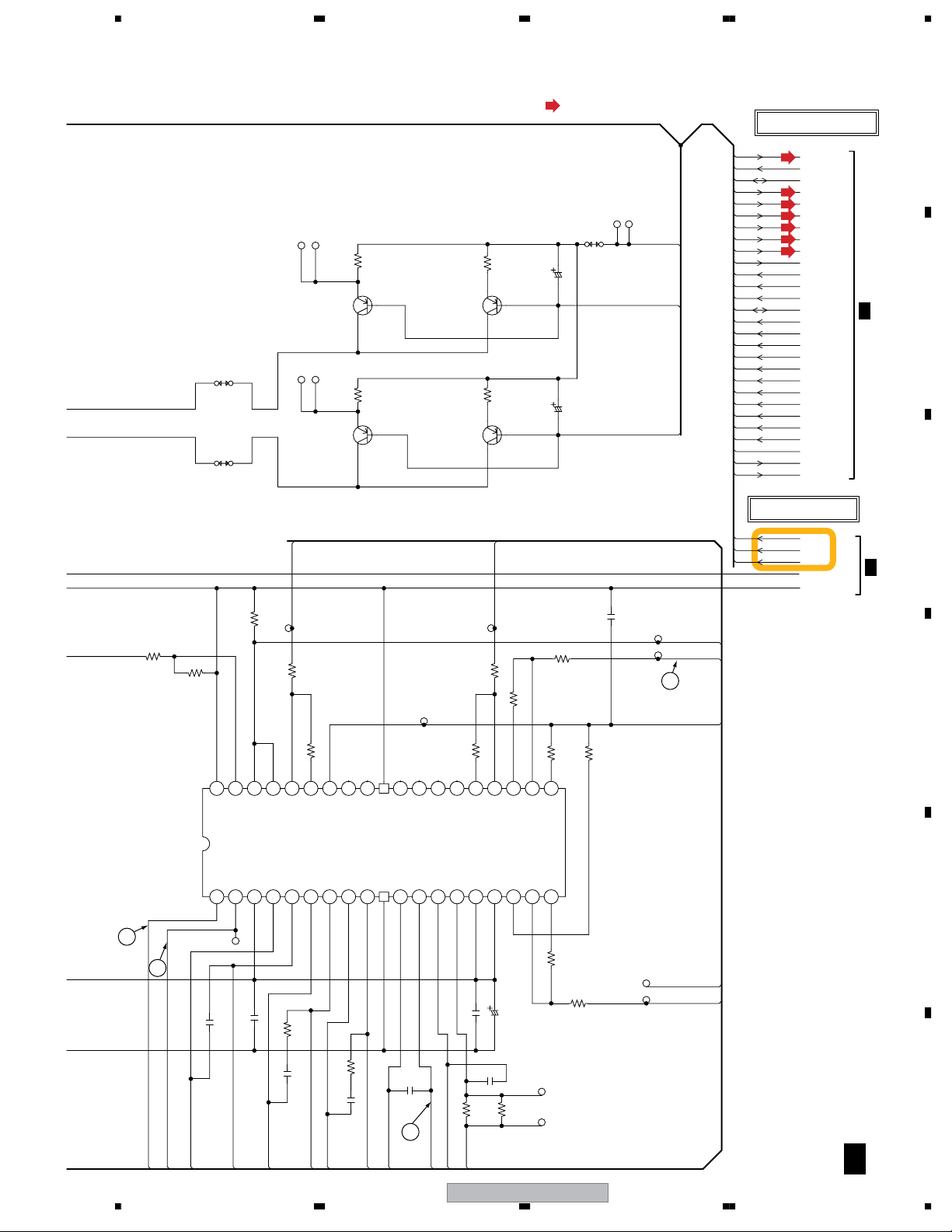

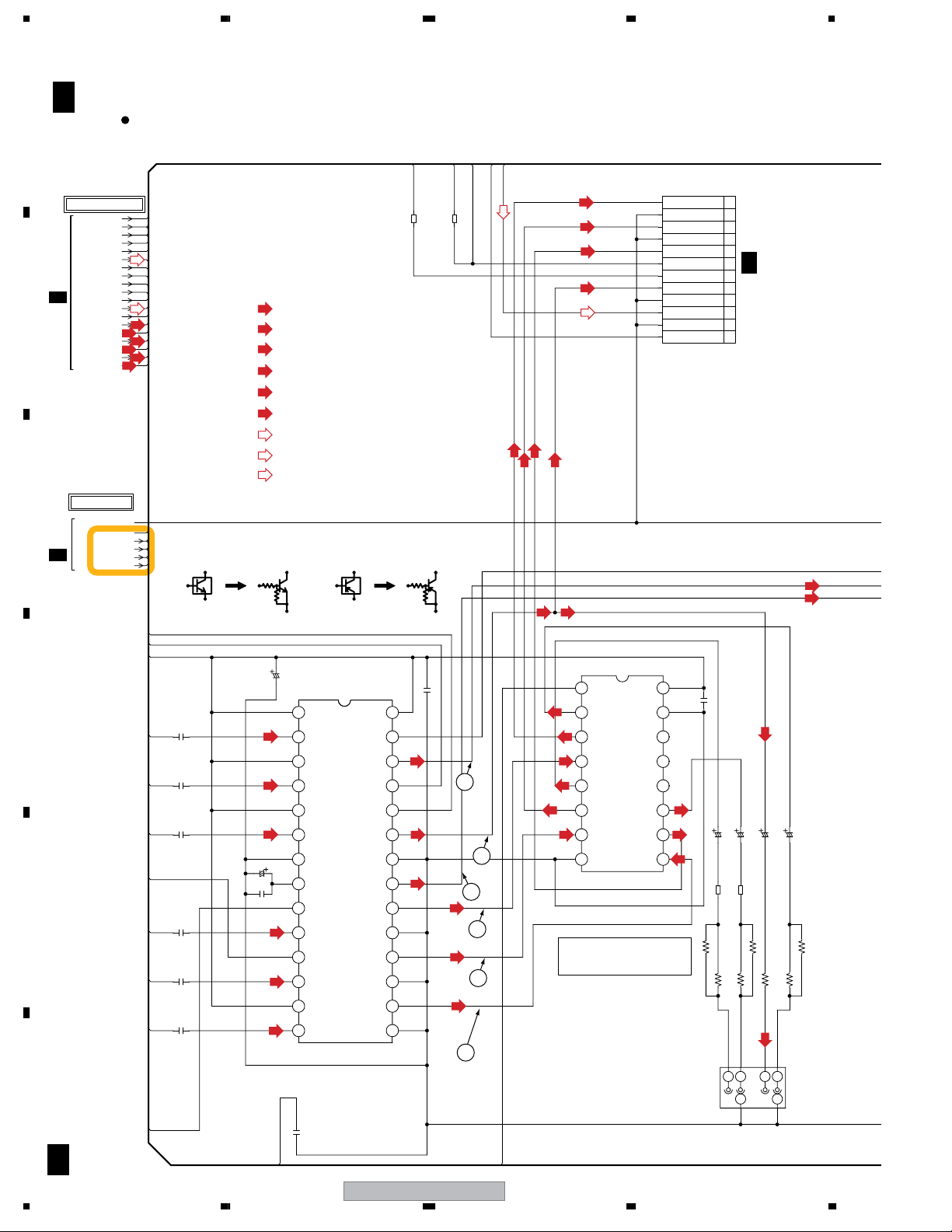

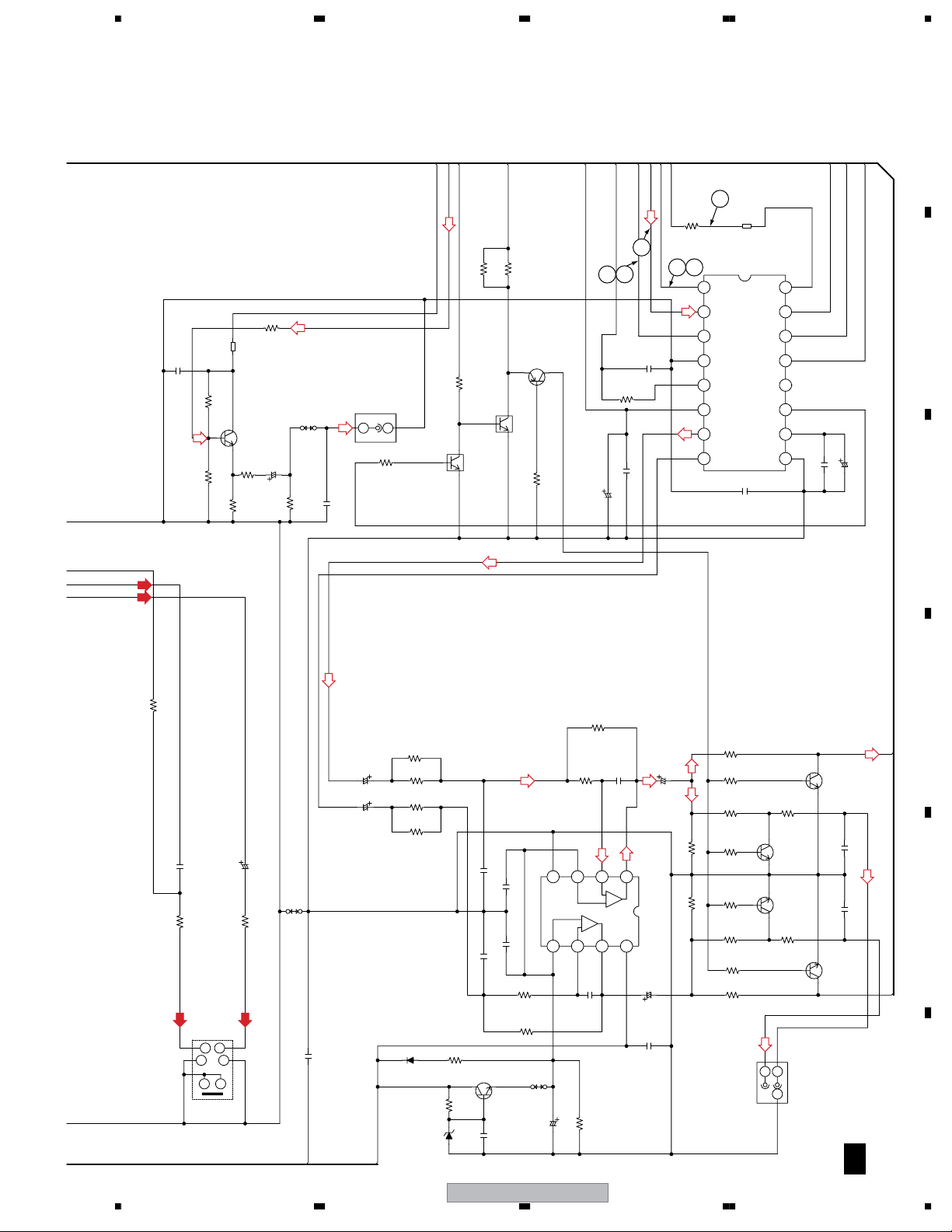

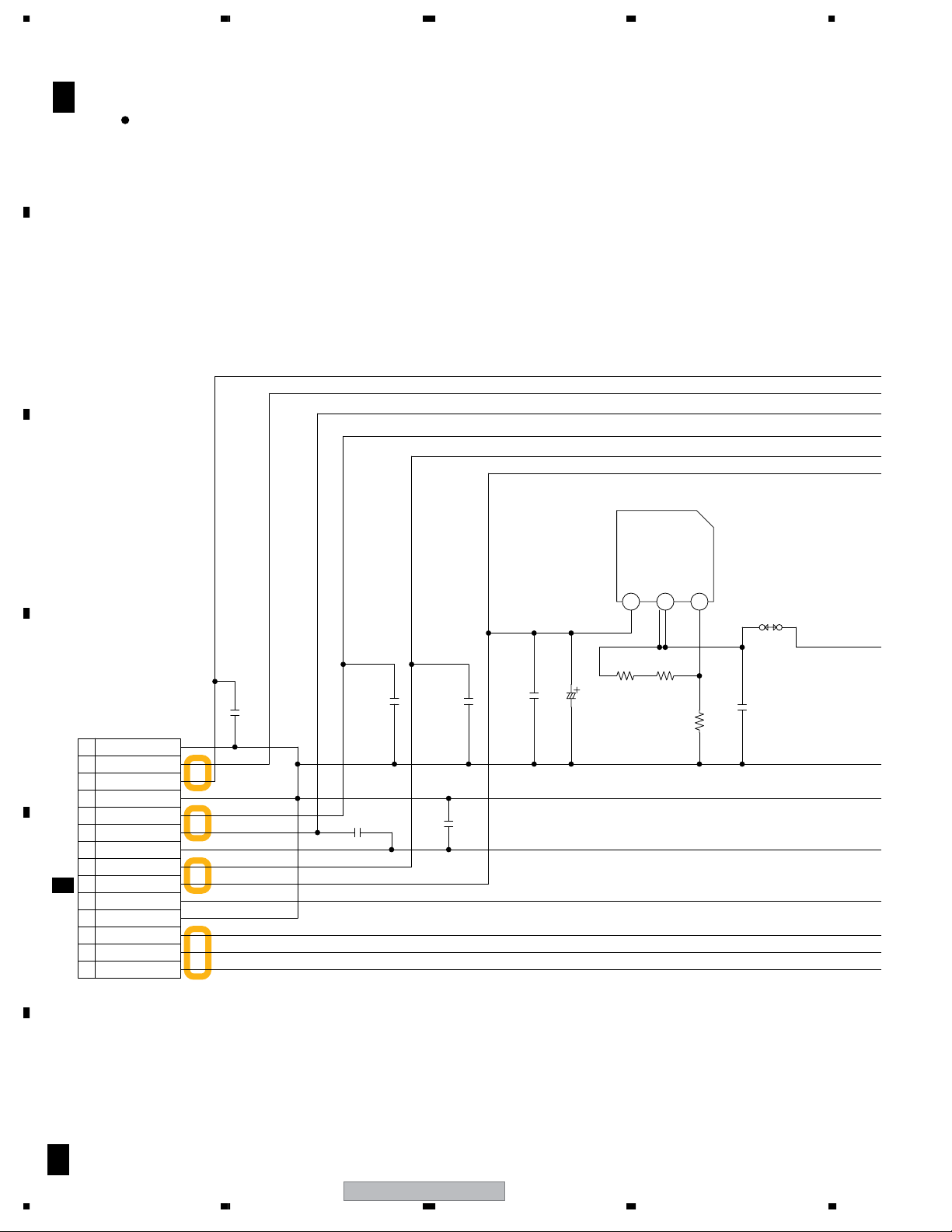

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM..........................................................................................12

3.1 BLOCK DIAGRAM ................................................................................................................................... 12

3.2 OVERALL WIRING CONNECTION DIAGRAM........................................................................................ 14

3.3 DVD MT PCB ASSY (1/5)........................................................................................................................ 16

3.4 DVD MT PCB ASSY(2/5)......................................................................................................................... 18

3.5 DVD MT PCB ASSY(3/5)......................................................................................................................... 20

3.6 DVD MT PCB ASSY(4/5)......................................................................................................................... 22

3.7 DVD MT PCB ASSY(5/5)......................................................................................................................... 24

3.8 OPERATION 1 and OPERATION 2 PCB ASSYS .................................................................................... 26

3.9 POWER PCB ASSY (1/2) ........................................................................................................................ 28

3.10 POWER PCB ASSY (2/2) ...................................................................................................................... 30

3.11 WAVE FORMS....................................................................................................................................... 32

4. PCB CONNECTION DIAGRAM ..................................................................................................................... 35

4.1 LOADING and SW PCB ASSYS.............................................................................................................. 35

4.2 DVD MT PCB ASSY................................................................................................................................. 36

4.3 OPERATION 1 and OPERATION 2 PCB ASSYS .................................................................................... 40

4.4 POWER PCB ASSY................................................................................................................................. 42

5. PCB PARTS LIST ........................................................................................................................................... 44

6. ADJUSTMENT ............................................................................................................................................... 50

6.1 WHEN REPLACING DVD DECK ............................................................................................................. 50

6.2 TEST MODE ............................................................................................................................................ 51

6.3 TEST MODE IN........................................................................................................................................ 52

6.4 DISC REMOVAL METHOD...................................................................................................................... 53

7. GENERAL INFORMATION............................................................................................................................. 54

7.1 DIAGNOSIS ............................................................................................................................................. 54

7.1.1 DISPLAY SPECIFICATION OF THE TEST MODE............................................................................ 54

7.1.2 FUNCTIONAL SPECIFICATION OF THE SHORTCUT KEY ............................................................ 55

7.1.3 SPECIFICATION OF MODEL INFORMATION DISPLAY .................................................................. 56

7.1.4 FUNCTIONAL SPECIFICATION OF THE SERVICE MODE............................................................. 58

7.1.5 METHOD FOR DIAGNOSING DEGRADATION OF THE LDS ON THE PICKUP ASSY .................. 59

7.1.6 TROUBLE SHOOTING...................................................................................................................... 60

7.2 DISASSEMBLY ........................................................................................................................................ 63

7.3 DVD DECK SECTION.............................................................................................................................. 64

7.4 IC INFORMATION.................................................................................................................................... 68

7.5 DISC / CONTENT FORMAT PLAYBACK COMPATIBILITY ..................................................................... 78

8. PANEL FACILITIES ........................................................................................................................................ 80

8.1 FRONT PANEL SECTION ....................................................................................................................... 80

8.2 DISPLAY .................................................................................................................................................. 81

8.3 REMOTE CONTROL ............................................................................................................................... 82

E

F

4

1234

DV-380-S

5678

1. SPECIFCATIONS

A

Specifications

General

System . . . . . . . . . . . . . . . . . . . . . . DVD player

Power requirements . . AC 220–240 V, 50/60 Hz

Power consumption . . . . . . . . . . . . . . . . . 7 W

Power consumption (standby) . . . . . . 0.75 W

Weight . . . . . . . . . . . . . . . . . . . . . . . . 1.7 kg

Dimensions:

DV-380 . . . . . 420 (W) x 49.5 (H) x 213.6 (D) mm

Operating temperature . . . . . . . +5°C to +35°C

Operating humidity . . . . . . . . . . . . . 5% to 85%

(no condensation)

AV connector output

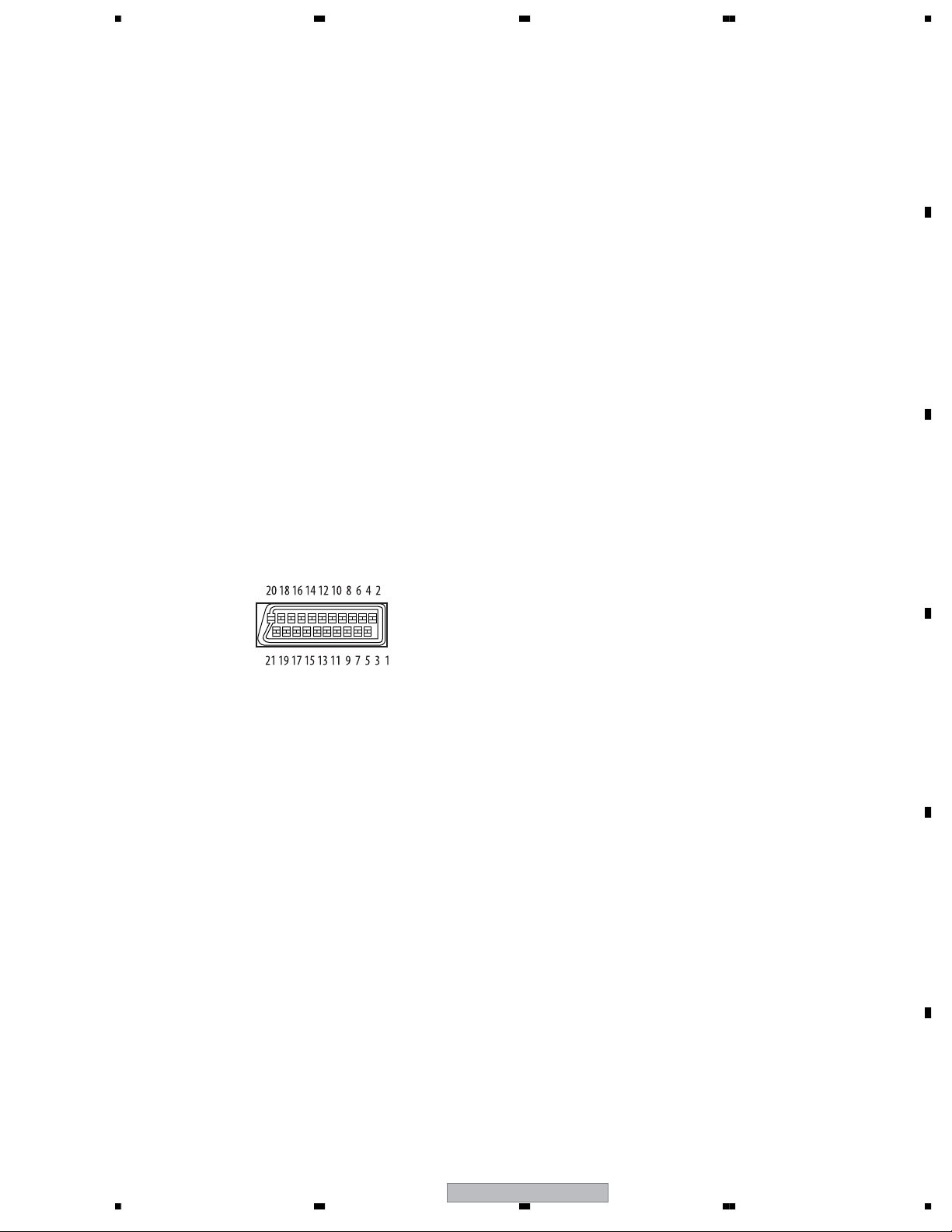

AV Connector (21-pin connector assignment)

AV connector output . . . . . . . 21-pin connector

This connector provides the video and audio

signals for connection to a compatible colour TV

or monitor.

S-video output

Y (luminance) - Output level . . . 1 Vp-p (75Ω )

C (color) - Output level. . . . . 286 mVp-p (75 Ω)

Jack . . . . . . . . . . . . . . . . . . . . . . . . . . . S-video

Video output

Output level . . . . . . . . . . . . . . . 1 Vp-p (75Ω)

Jack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . RCA

Audio output ( 1 stereo pair)

Output level . . . . . . . . . . During audio output

200 mVrms (1 kHz, –20 dB)

Number of channels . . . . . . . . . . . . . . . . . . . 2

Jacks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . RCA

Digital audio characteristics

Frequency response . . . . . . . . 4 Hz to 44 kHz

(DVD fs: 96 kHz)

S/N ratio . . . . . . . . . . . . . . . . . . . . . . . . . 115 dB

Dynamic range . . . . . . . . . . . . . . . . . . . . 101 dB

Total harmonic distortion . . . . . . . . . . 0.0023 %

Wow and flutter . . . . . . Limit of measurement

(±0.001% W. PEAK) or lower

B

C

PIN no.

. . . . . . . . . . . . . . . . . . . . . . .

1

Audio 2/R out

3. . . . . . . . . . . . . . . . . . . . . . . . . . Audio 1/L out

4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . GND

7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B out

8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Status

11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G out

15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . R out

17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . GND

19. . . . . . . . . . . . . . . . . . . . . . . . . . . Video out

21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . GND

Component video output

Y (luminance) - Output level. . . 1 Vp-p (75 Ω )

(color) - Output level . . . . 0.7 Vp-p (75Ω )

P

B

P

(color) - Output level . . . . . 0.7 Vp-p (75 Ω)

R

Jack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . RCA

Digital output

Coaxial digital output . . . . . . . . . . . . . RCA jack

Accessories

Audio/video cable. . . . . . . . . . . . . . . . . . . . . . . . 1

Power cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Remote control. . . . . . . . . . . . . . . . . . . . . . . . . . 1

AA/R6P dry cell batteries . . . . . . . . . . . . . . . . . 2

Warranty card. . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Operating Instructions

The specifications and design of this product are subject to

change without notice, due to improvement.

Published by Pioneer Corporation.

Copyright © 2005 Pioneer Corporation.

All rights reserved

D

E

F

56

DV-380-S

5

7

8

1234

2. EXPLODED VIEWS AND PARTS LIST

NOTES:

Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

A

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on product are used for disassembly.

For the applying amount of lubricants or glue, follow the instructions in this manual.

(In the case of no amount instructions, apply as you think it appropriate.)

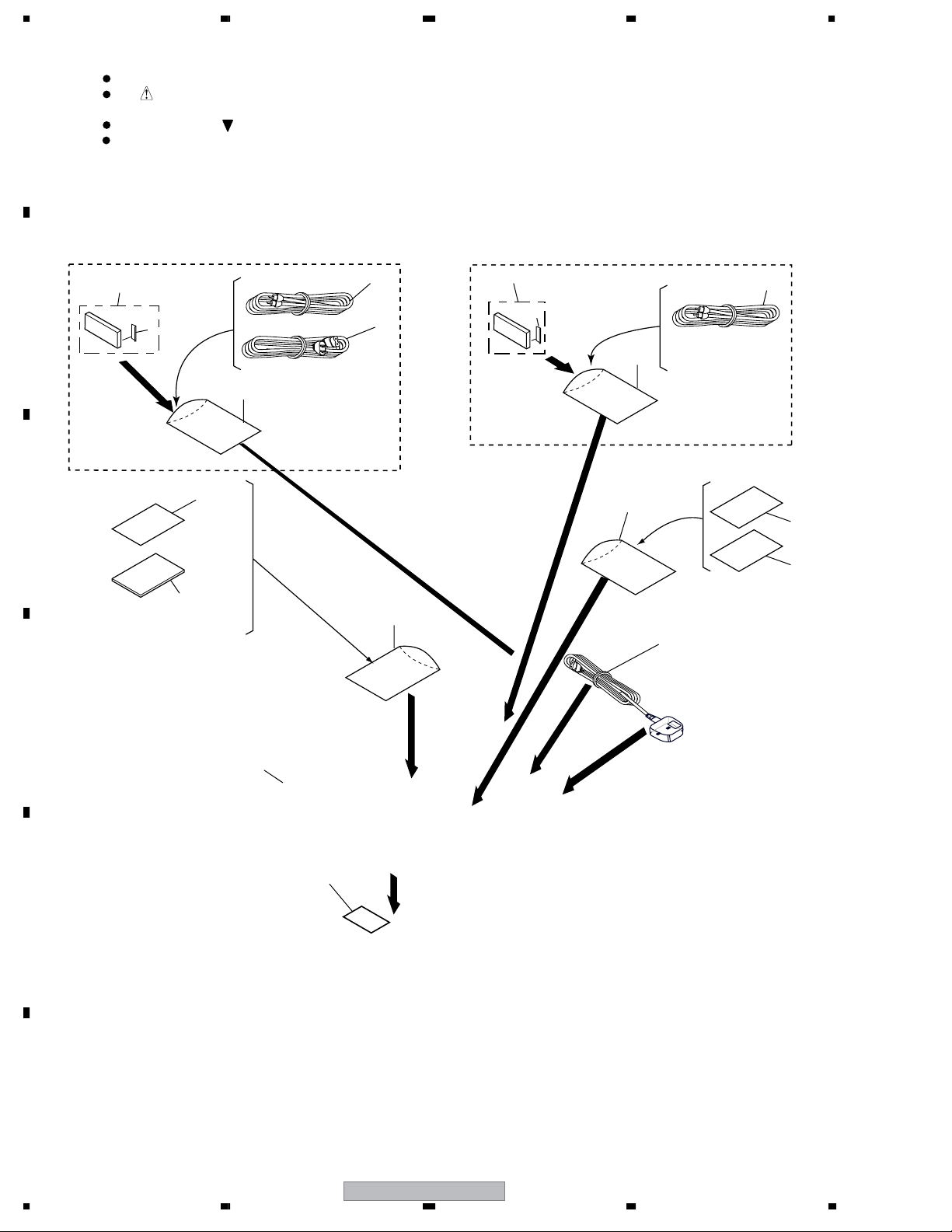

2.1 PACKING SECTION

3

B

4

6

C

For WYXTL type

16

For WVXTL type

2

1

3

4

16

12

2

6

7

"Operating Instructions"

D

E

8-10

12

1

5

14

14

11

13

15

Front

F

6

1234

DV-380-S

>

>

5678

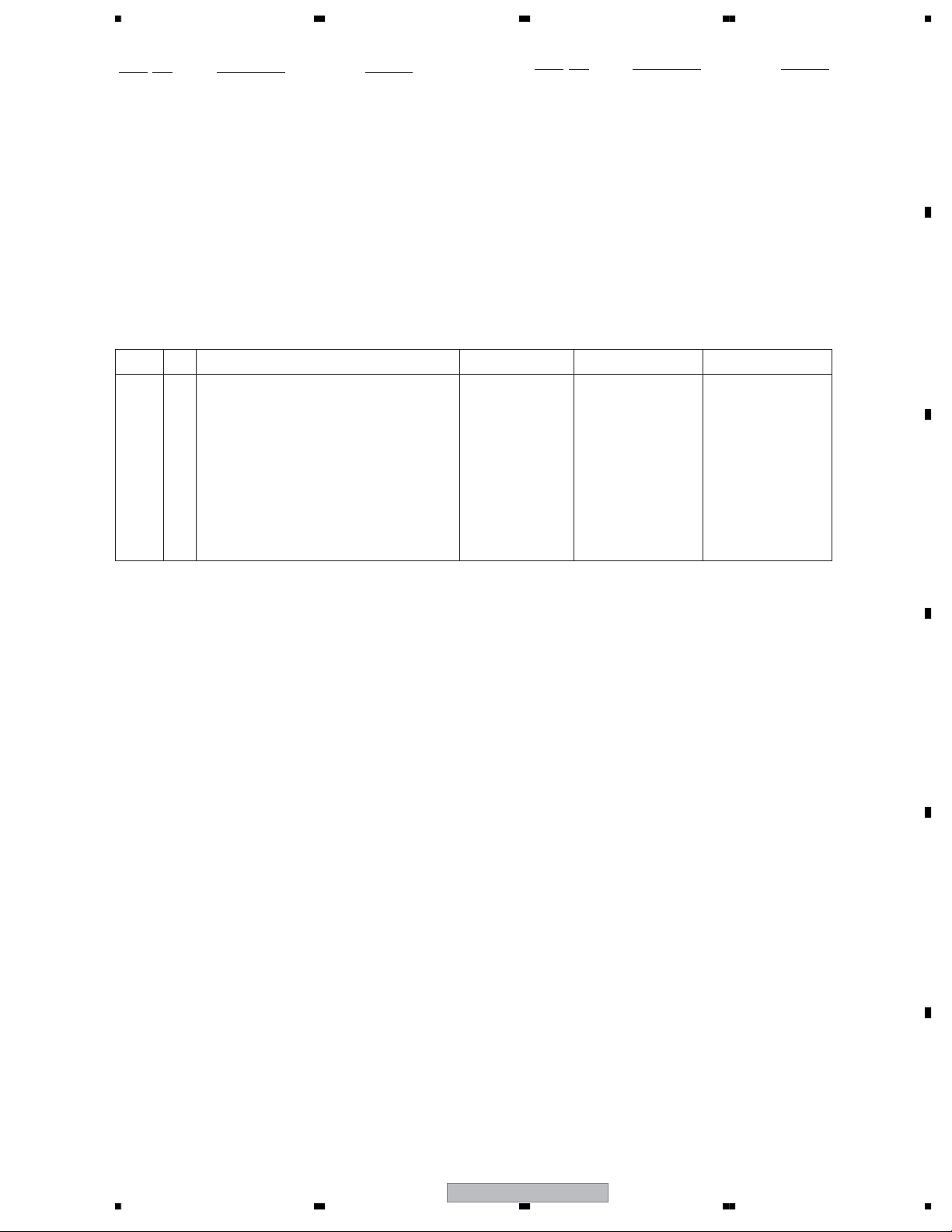

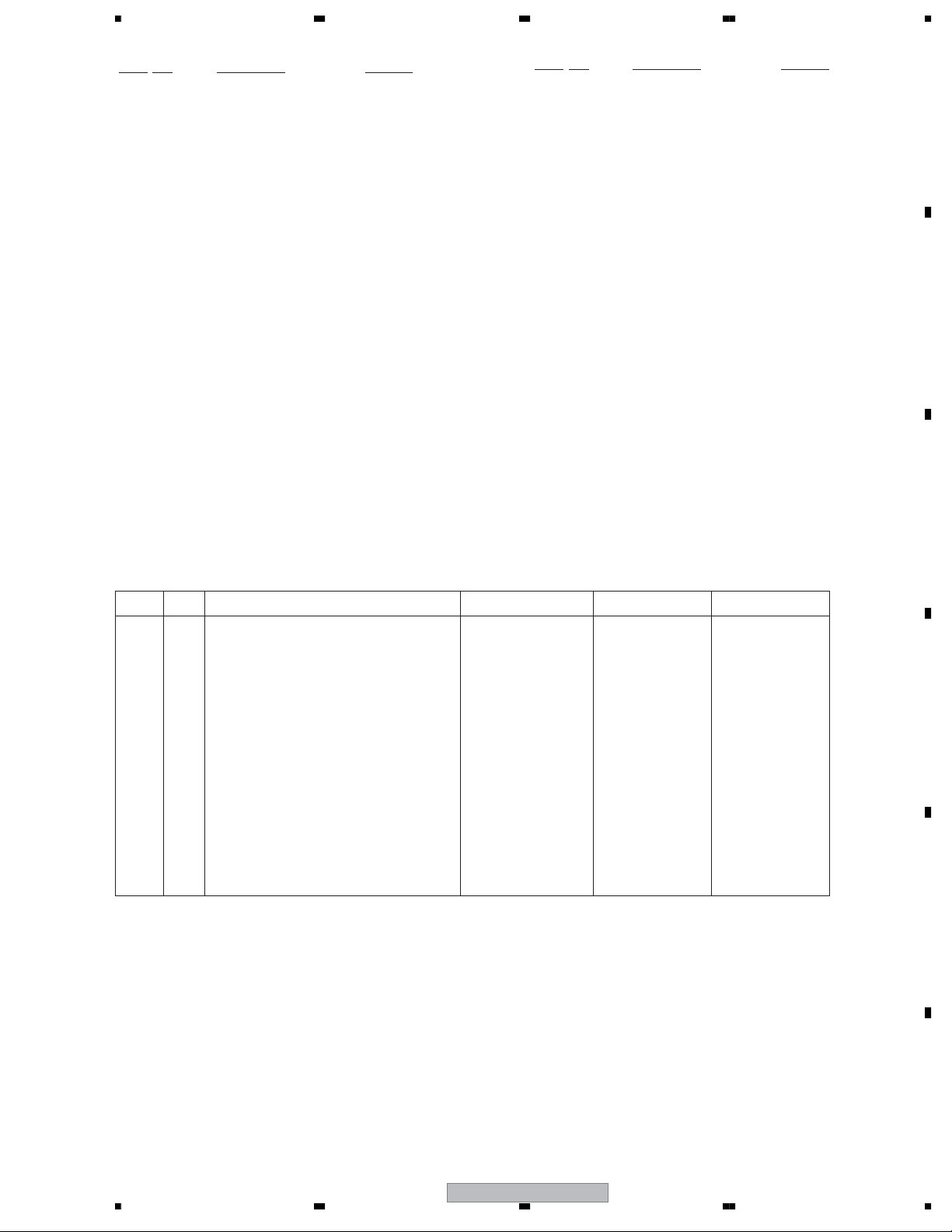

PACKING SECTION parts List

No. Description Part No.

Mark

1 Cord set AC See Contrast table (2)

2 Cord, RCA Pin 06CPBA2006

3 Remote Control VXX2914

4 Battery Cover VNK4998

NSP 5 Battery,Mangan (AR, R6P) 141L003010

NSP 6 Guarntee Card J2G50202A

7 Operating Instructions(English) See Contrast table (2)

8 Instruction Book See Contrast table (2)

9 Instruction Book See Contrast table (2)

10 Instruction Book See Contrast table (2)

No. Description Part No.

Mark

11 Package.Pad 792WHA0604

12 Polyethylene Bag,Instruction See Contrast table (2)

13 Gift Sheet 791WHA0108

14 Package See Contrast table (2)

15 Gift Box See Contrast table (2)

NSP 16 Poly. Bag 791WHAA040

A

(2) CONTRAST TABLE

DV-380-S/WVXTL and DV-380-S,-K/WYXTL are constructed the same except for the following :

Mark No. Symbol and Description DV-380-S/WVXTL DV-380-S/WYXTL DV-380-K/WYXTL

1 Cord set AC 1206138802 1206158802 1206158802

7 Instruction Manual (English) J2G50101B Not used Not used

8 Instruction Book (English, Italian) Not used J2G50321A J2G50321A

9 Instruction Book (German, French) Not used J2G50322A J2G50322A

10 Instruction Book (Spanish, Duch) Not used J2G50323A J2G50323A

12 Polyethylene Bag, Instruction JB5KD200 JB5KD400 JB5KD400

14 Package 792WHA0597 792WHA0588 792WHA0588

15 Gift Box 793WCD1608 793WCD1635 793WCD1634

B

C

D

56

DV-380-S

E

F

7

7

8

1234

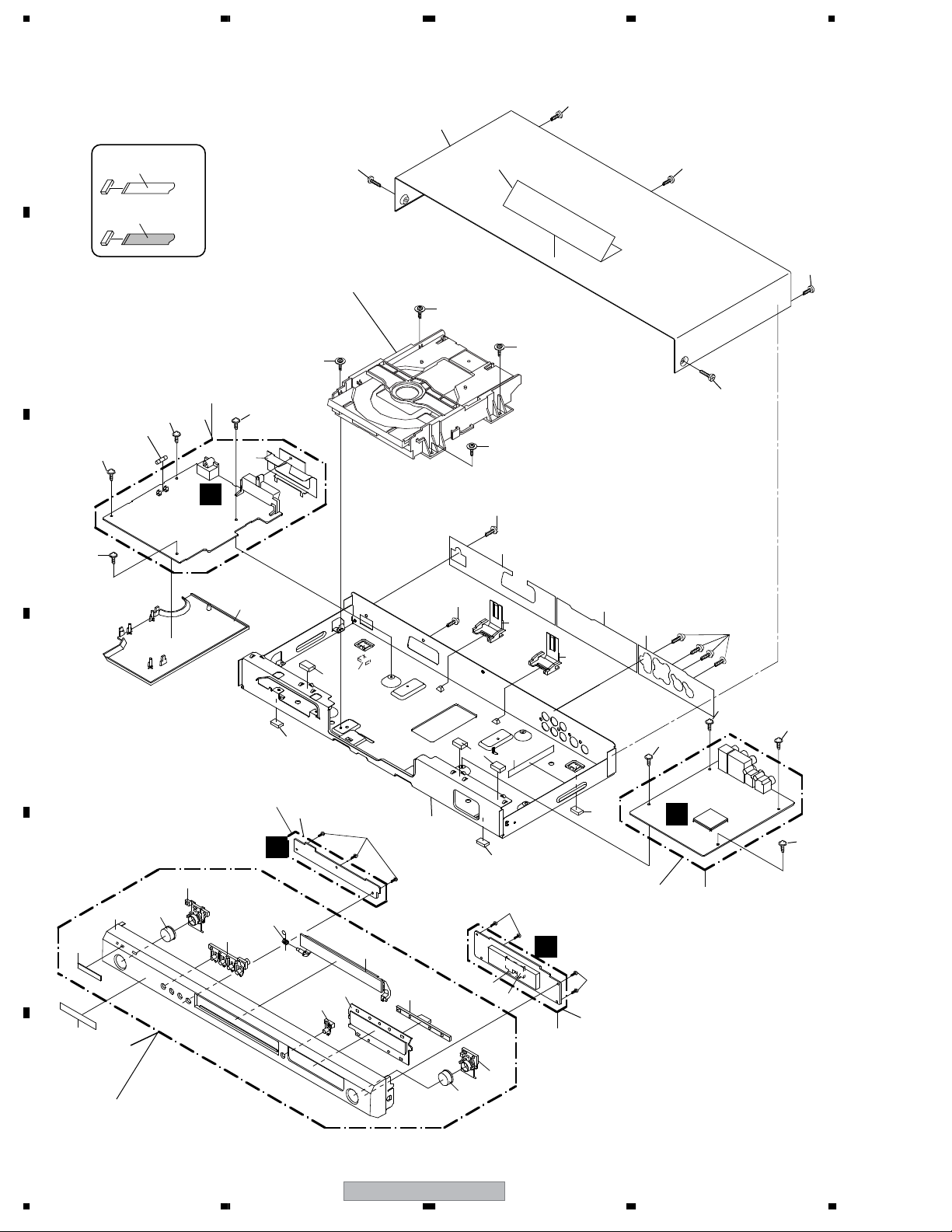

2.2 EXTERIOR SECTION

A

NON-CONTACT

SIDE

CONTACT SIDE

B

PCB240

(POWER PCB ASS'Y)

19

4

19

9

19

6

20

Refer to

"2.3 05 DVD MECHA ASSY".

5

18

F

C

19

14

17

18

18

18

21

25

20

20

20

20

11

13

16

D

13

PCB280

(OPERATION 2 PCB ASS'Y)

3

22

C

101H

E

101D

15

101A

101

101E

101J

101K

101I

101B

101C

101L

21

12

16

10

8

13

22

12

13

24

23

19

A

1

PCB130

(DVD PCB ASS'Y)

21

19

19

21

B

7

26

PCB270

(OPERATION 1 PCB ASS'Y)

22

2

101G

F

" FRONT PANEL SECTION".

8

1234

DV-380-S

101F

>

>

>

5678

EXTERIOR SECTION parts List

No. Description Part No.

Mark

1DVD MT PCB Assy A2G502A130

2 OPERATION 1 PCB Assy A2G502A270

3 OPERATION 2 PCB Assy A2G502A280

4POWER PCB Assy A2G502A240

5DVD MECHA ASSY A2F101A650

No. Description Part No.

Mark

21 Screw,Tap Tite(B)Pan (3x6) 810913060U

22 Screw,Tap Tite(P) (2.6x8) 811022680U

23 Sheet,Jack 1 7226310057

24 Sheet,Jack 2

25 Sheet,Jack 3 See Contrast table (2)

See Contrast table (2)

A

6 Shield,21Pin 761WSA0237

7 Plate. FIP 752WSA0466

8 Plate,Bottom 702WSA0243

9 Fuse (F501 : 1.6A) 080NT1R604

10 Sheet,Caution 7260000356

11 Plate,Cover power 755WPA0046

12 Holder,FFC 761WPA0396

13 Cushion,Leg VEB1349

14 Cabinet,Top See Contrast table (2)

15 POP Label 7236310006

16 Cushion (15x20x16) 8965TS1015

17 POP Label 7236310019

18 Screw,Tap Tite(S)-Bind Wash. 816423063U

19 Screw,Tap Tite(S) (3x5.5) 8107D3055U

20 Screw,Tap Tite(B) (3x6.0) See Contrast table (2)

26 Double,Face-Tape 7290000156

101 Front Cabi Assy

NSP 101A Cabinet,Front See Contrast table (2)

NSP 101B Plate,Display 711WPA0225

101C Flap,DVD

101D Badge,Brand See Contrast table (2)

NSP 101E Button,Cap power See Contrast table (2)

NSP101F Button,Cap Play See Contrast table (2)

NSP 101G Button,Frame 3 738WPA0131

NSP 101H Button,Frame 4 738WPA0137

NSP 101I Button,Frame 1

NSP 101J Button,Frame 2 See Contrast table (2)

101K Spring,Flap-DVD 743WKAA012

NSP 101L Holder,Display 761WPA0368

See Contrast table (2)

See Contrast table (2)

See Contrast table (2)

(2) CONTRAST TABLE

DV-380-S/WVXTL, DV-380-S/WYXTL and DV-380-K/WYXTL are constructed the same except for the following :

Mark No. Symbol and Description DV-380-S/WVXTL DV-380-S/WYXTL DV-380-K/WYXTL

14 Cabinet, Top

20 Screw,Tap Tite(B) (3x6.0) 8109K3060U 8109K3060U 8109K3060S

24 Sheet, Jack 2

25 Sheet, Jack 3 7226310059 7226310059 7226310071

101 Front Cabi Assy 7A7010078A 7A7010078A 7A7010095A

NSP 101A Cabinet, Front 701WPJ1318 701WPJ1318 701WPJ1333

101C Flap, DVD 712WPJ0914 712WPJ0914 712WPJ0932

101D Badge, Brand 7236310014 7236310014 7236310009

NSP 101E Button, Cap Power 737WPB0001 737WPB0001 737WPA0024

NSP 101F Button, Cap Play 737WPB0002 737WPB0002 737WPA0025

702WSB0114 702WSB0114 702WSB0115

7226310058 7226310058

7226310070

B

C

D

NSP 101I Button, Frame 1 738WPB0050 738WPB0050 738WPA0156

NSP 101J Button, Frame 2 738WPB0051 738WPB0051 738WPA0157

DV-380-S

56

7

E

F

9

8

1234

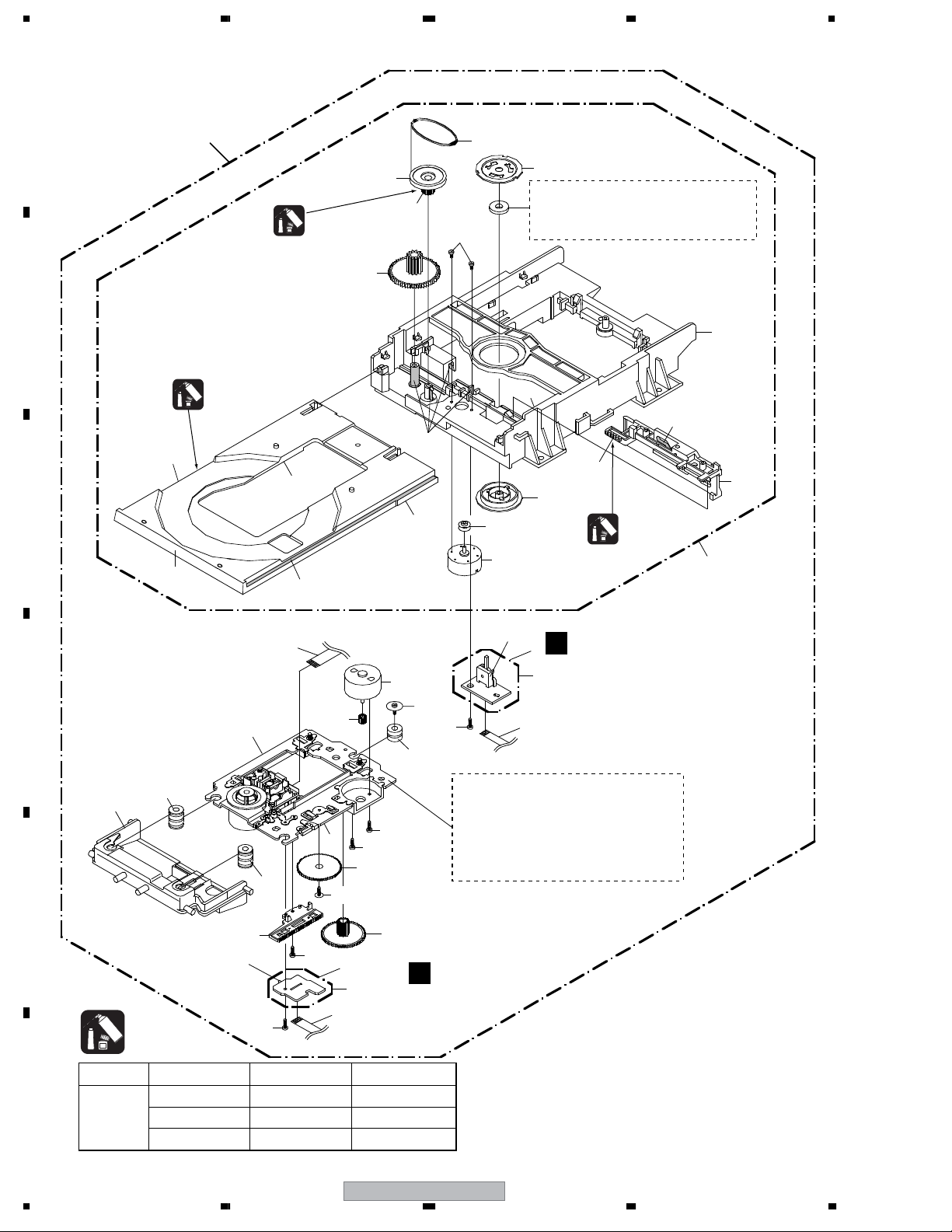

2.3 05 DVD MECHA SECTION

A

34

9

14

18

Cannot supply separately.

Lubricating Oil

GYA1001

AB

21

If the repair is needed, replace the

LOADER SUB ASS'Y.

15

B

11

Daifree

GEM1036

AB

AB

AB

AC

AB

C

AB

4

20

3

12

AC

AB

Lubricating Oil

GYA1001

23

19

29

6

CD2001

SW1

E

1

PCB610

5

22

2

32

31

10

Do not replace the parts. Because,

minute adjustments are needed if

this condition is disassembled

further more.

If the repair is needed, replace the

DVD MECHA ASS'Y.

D

D

35

8

13

AA

24

22

16

8

E

25

30

SW2

Note :

27

26

17

PCB640

(SW PCB ASS'Y)

(LOADING MOTOR PCB ASS'Y)

7

CD2302

28

33

CLASS

GREASE G-555G

F

PART NO.

GYA1001

GYA1001

PART NAME

GEM1036

G-313Y

FL-78A

CD2301

MARK

AA

AB

AC

NOTE:

Applying positions AA, AB and AC for the

grease are displayed for this section.

Check if the correct grease is applied for each

position.

10

DV-380-S

1234

>

>

5678

05 DVD MECHA SECTION parts List

No. Description Part No.

Mark

1 Loading Motor PCB Assy A2F101A610

2 Gear,Middle 92P100117A

3 Loading Motor 1515S98004

4 Pulley,Motor 92P100097A

5 FEED Motor 1515S98004

6 Cord Jumper (24P)(CD2001) 122H002305

7 Cord Jumper (CD2302) 122H051602

8 Insulator (F) 92P200013A

9 Belt,Loading 92P200015A

10 Insulator (R) 92P200016A

A

11 Frame,main 92P100119A

12 Tray (B) 92P100127A

13 Holder ,Traverse 92P100125A

14 Gear,Pulley 92P100123A

15 Gear,Main 92P100124A

16 Gear,Feed 92P100116A

17 SW PCB Assy (PCB640) A2F101A640

NSP 18 Magnet,Clamper 92P400007A

19 Loader SUB Assy 92AAA0019A

20 Clamper 92P100122A

21 Screw,Pan (M1.7x3 P3) 814011730U

22 Screw,Pan (M1.7x2.3 P3) 814011723U

23 Rack,Loading 92P100121A

24 Gear,Motor 92P100088A

25 Feed Rack Assy 92AAA0017A

26 Screw,T-Tite(B) (M1.7x5.0 P3) 813381750U

27 Screw,Gear Feed 92P700007A

28 Cord Jumper (CD2301) 122H061605

29 Switch (SW1) 0515S32003

30 Push Switch (SW2) 0500101036

31 Screw,Tap Tite(P) (2.6x8) 811022680U

32 Sems.Tap Tite(P) (2x8) 816112080U

33 Screw (Bind 2x8) 811022080U

>

34 DVD MECHA ASSY A2F101A650

NSP 35 Traverse Sub ASSY 92AAA0016A

B

C

D

56

DV-380-S

E

F

11

7

8

1234

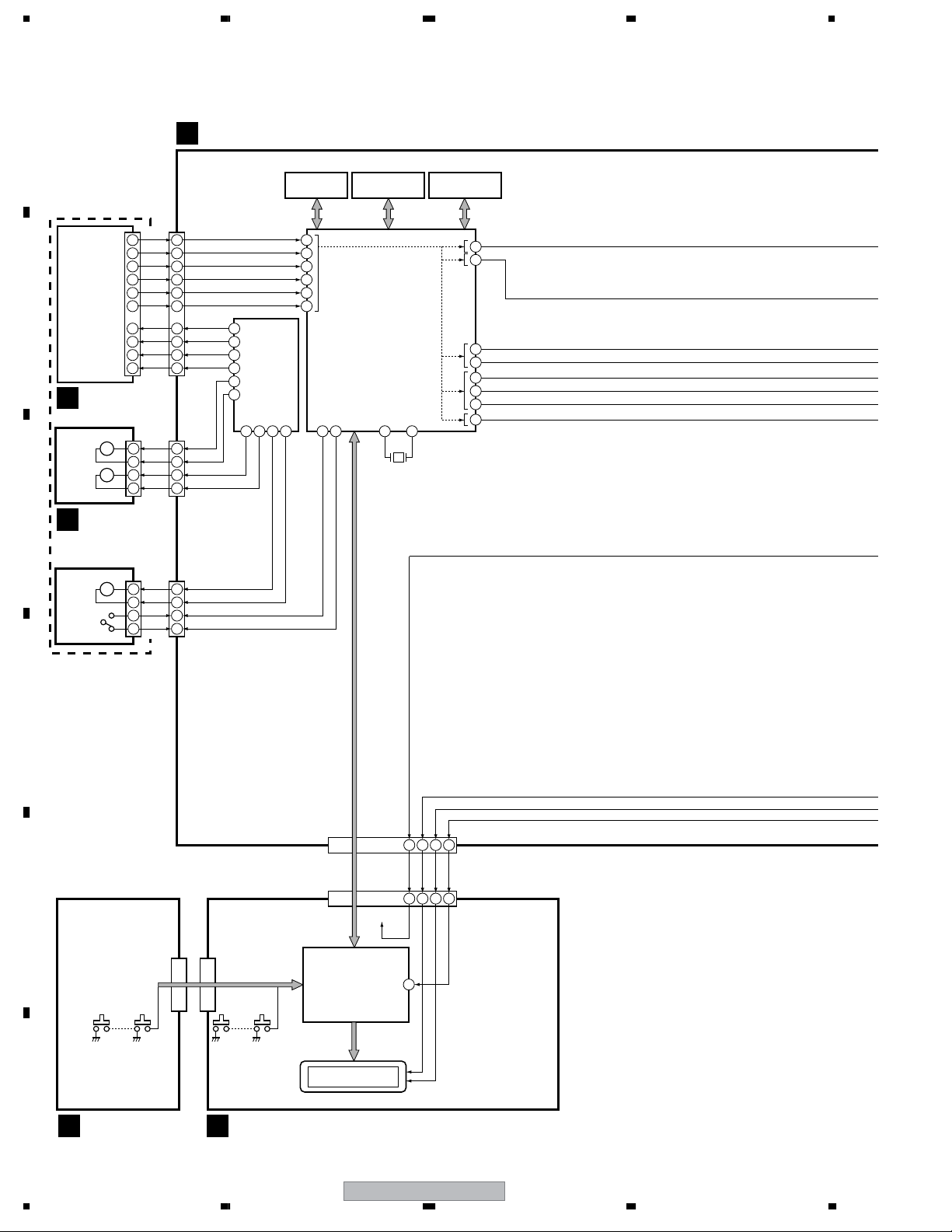

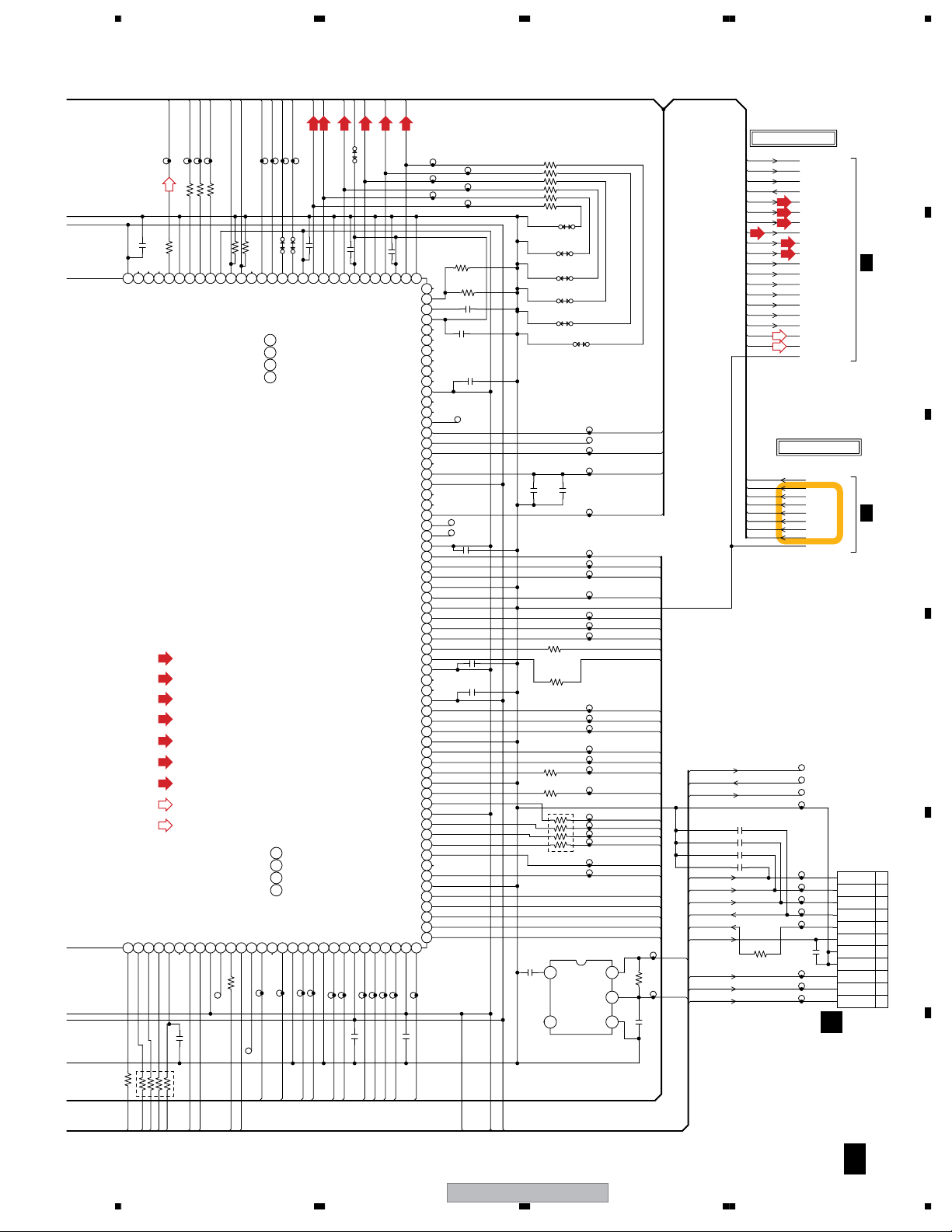

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

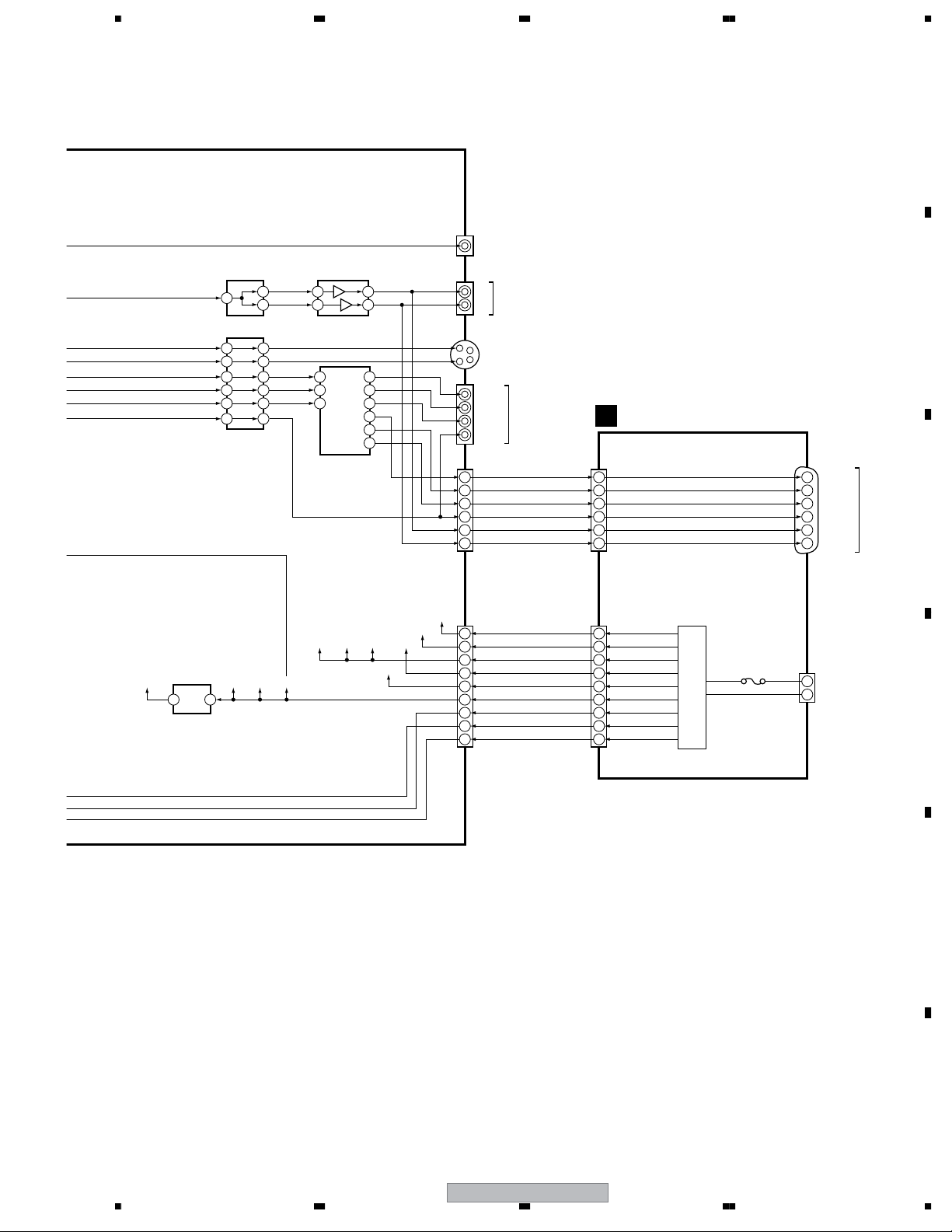

3.1 BLOCK DIAGRAM

A

DVD MT PCB ASSY

A

DVD MECHA

ASSY

PICKUP

B

D

SW PCB ASSY

SPINDLE

M

MOTOR

SLED

M

MOTOR

C

E

LOADING MOTOR

PCB ASSY

LOADING

M

MOTOR

SW1

A

11 11

B

10 10

C

7 7

D

6 6

E

5 5

F

2 2

T+

21 21

T–

22 22

F+

23 23

F–

24 24

SP1+

6 1

SP1–

5 2

SLD+

4 3

SLD–

3 4

LD+

2 4

LD–

1 5

OPEN

3 3

CLOSE

5 1

CP2301

CP2303CD2301

CP2302CD2302

7

6

9

IC2301

8

Motor Drive

11

10

16Mbit Flash

IC

51213 4 48

IC4004

3

4

5

2

18

19

IC4005

64Mbit SDRAM

IC4002

MPEG / MICON

/ RF-AMP

49

228 229

X4001

(27MHz)

IC4001

EEPROM

225

217

194

196

203

200

202

198

ASPDIF

ASDAT0

S_Y

S_C

R/CR

G/Y

B/CB

CVBS

D

CP4002

10101111996

-28V

V+3E

FLDC–

FLDC+

6

E

V+3E

CP601

CP603CP602

IC651

FIP Driver IC

V651 FL TUBE

30

F

OPERATION 2

C

PCB ASSY

OPERATION 1

B

PCB ASSY

12

DV-380-S

1234

5678

A

J8004

DIGITAL OUT

IC8004

Audio DAC

2 ch

2

6

21

2

26

14

16 9

10

20

12

18

4

23

IC8002

Video Driver

6 ch

V-OUT L

7 2

V-OUT R

8

S_Y OUT

S_C OUT

R/CR out

G/Y out

B/CB out

V out

IC8003

Audio LPF

& AMP

6

4

7

IC8001

4 ch BUS SW

1

7

2

5

11

10

3

6

COAXIAL

J8003

L

AUDIO OUT

R

J8002

S VIDEO OUT

J8001

Y

CB

VIDEO

OUT

CR

CVBS

CP8001 CP503

5

1

3

8

10

12

R

G

B

CVBS

AUDIO L

AUDIO R

POWER PCB ASSY

F

8

12

10

5

3

1

J8101

15

11

7

19

3

1

R

G

B

CVBS

L

R

SCART

B

C

V+1P8

(CORE)

IC4006

REG+1.8V IC

2 3

V+3A V+3E

V+3

(AUDIO VIDEO DAC)

(MPEG SDRAM FLASH)

(FLIP/LED/IR/RESET)

(AUDIO DAC)

V+5A

(VIDEO OPT/COAX)

(OPU)

V+5V V+5S

V+3F

(F/E)

V+6A

V+12AT

(MOTOR)

(AUDIO AMP)

V+12

(AUDIO MUTE)

2

3

5

6

8

9

12

13

14

P.CON+12V

AT+12V for MUTE

P.CON+5V

P.CON+6V

P.CON+3.3V

AT+3.3V

FL DC–

FL DC+

-28V

CP502CP4003

2

3

5

6

8

9

12

13

14

T501

Power Transformer

F501

Fuse

J501

L

N

AC IN

D

E

56

DV-380-S

F

13

7

8

1234

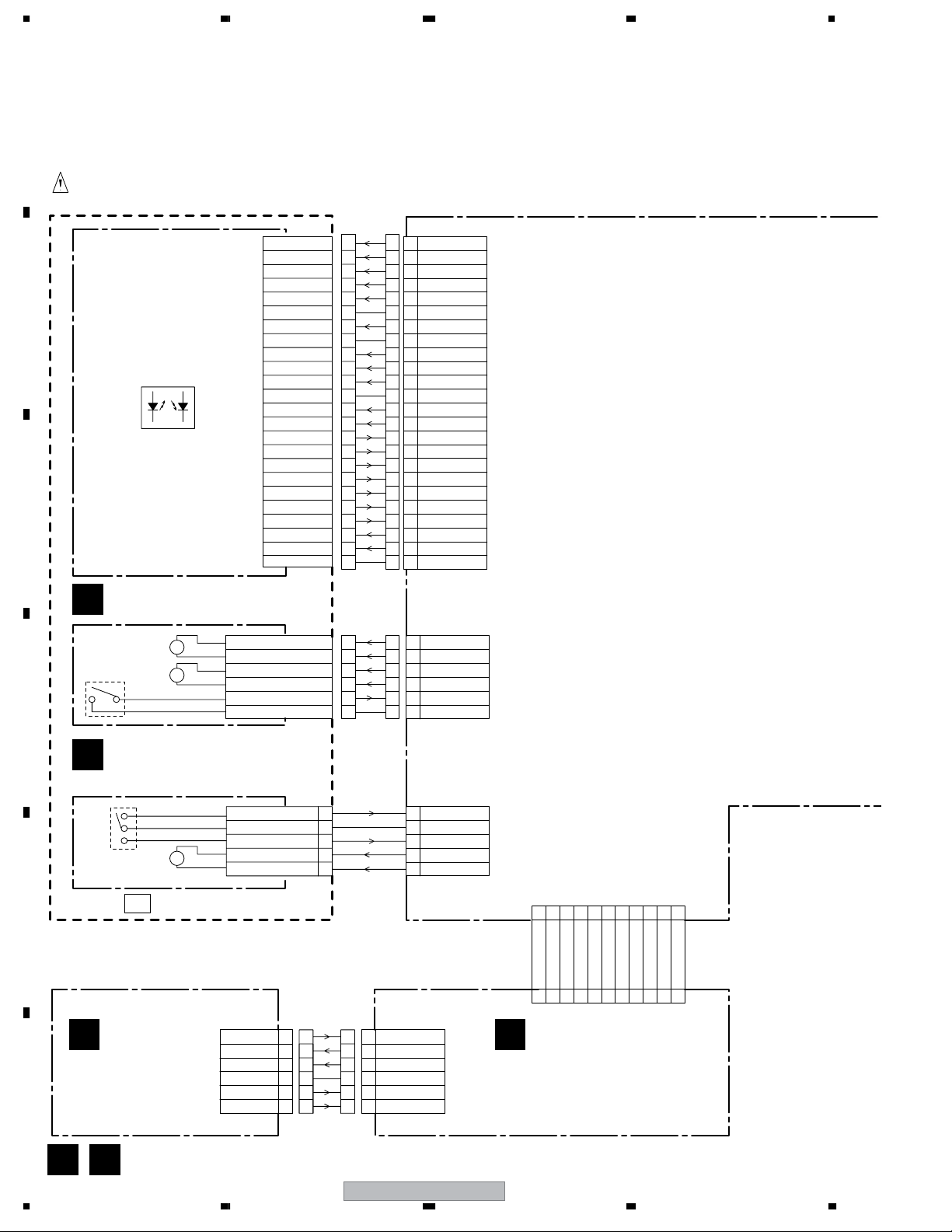

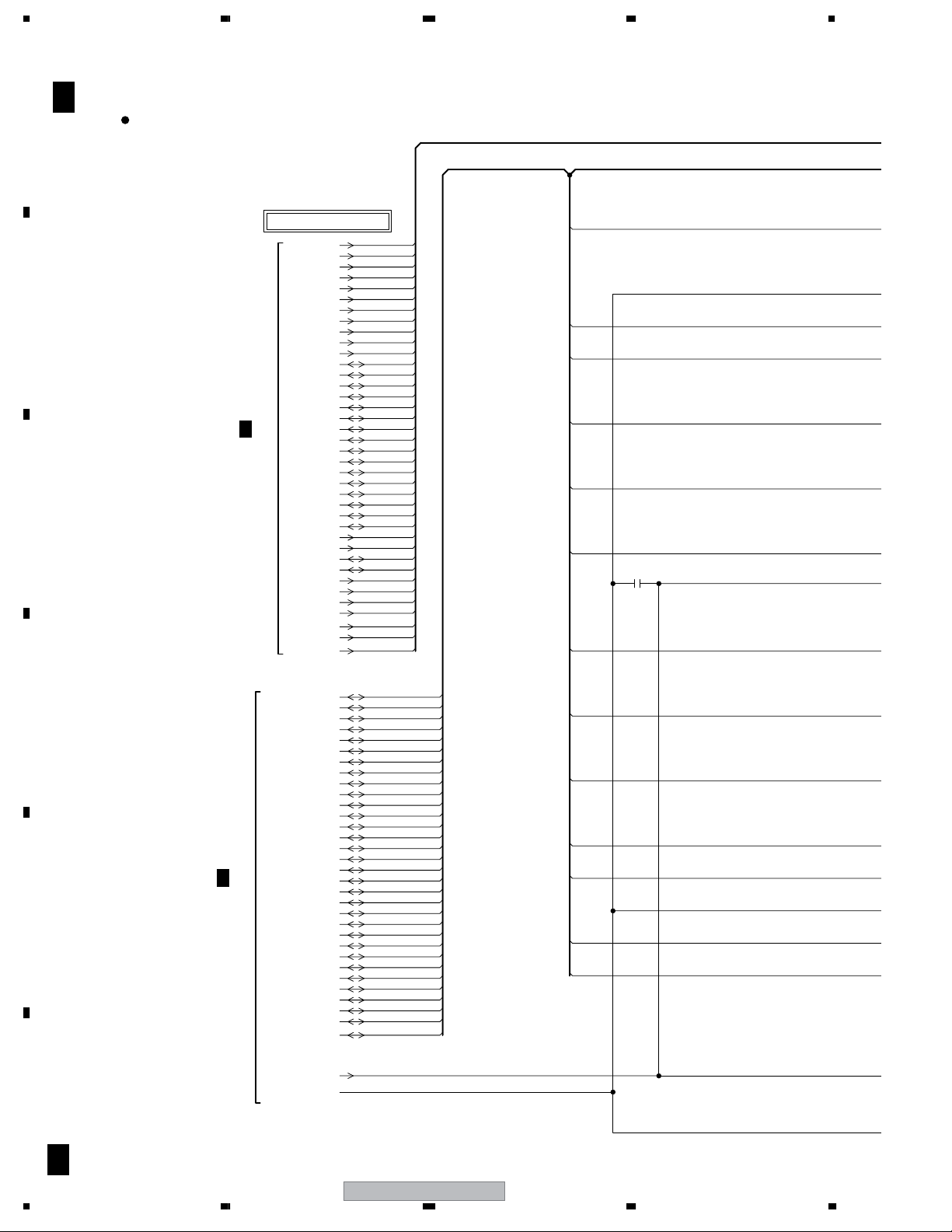

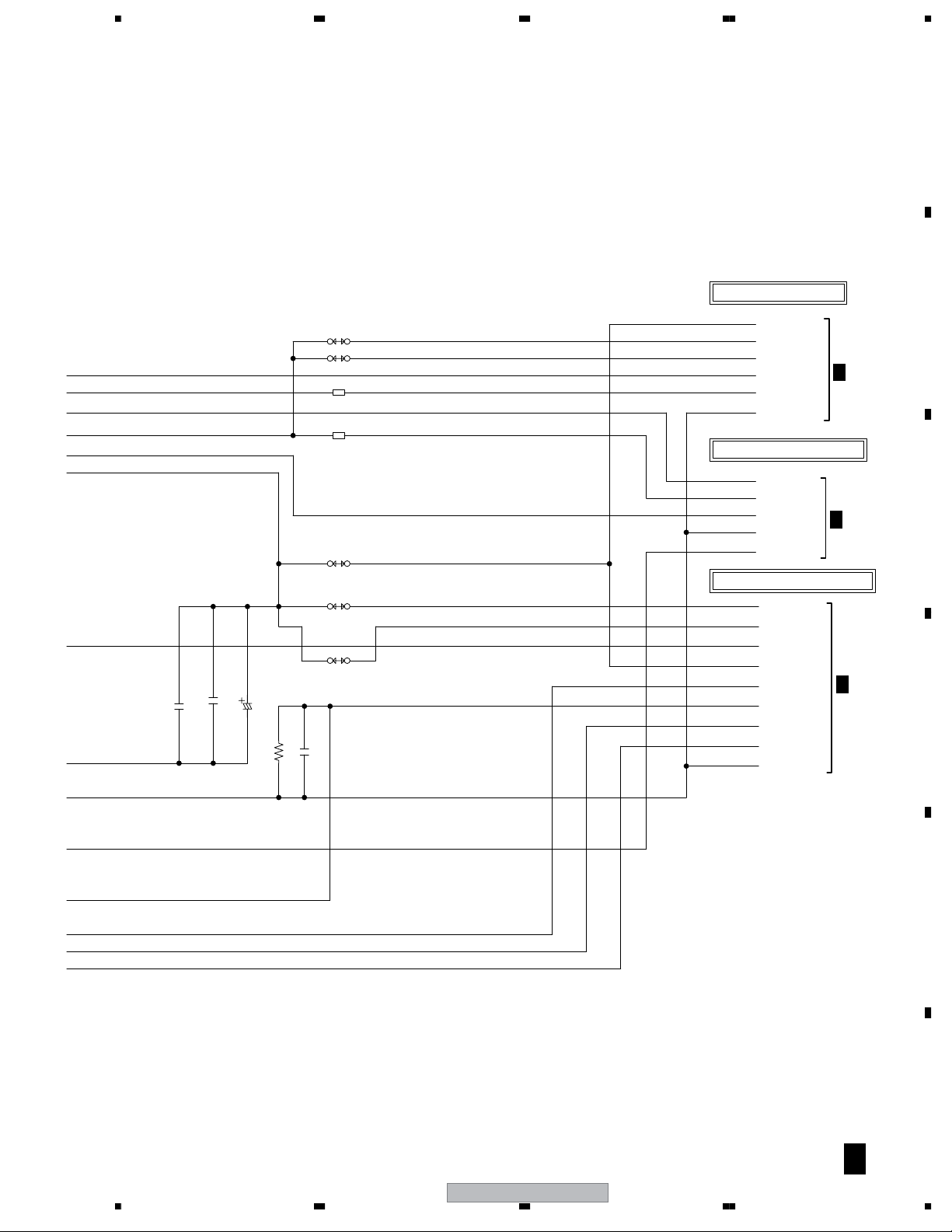

3.2 OVERALL WIRING CONNECTION DIAGRAM

A

DVD MECHA ASSY (A2F101A650)

CP2301

FF+

T-

T+

B

OPTICAL PICKUP

C

NC

GND(CD)

VOL(DVD)

GND(DVD)

LD(DVD)

GND(DVD)

VOL(CD)

MON(COM)

MON(DVD)

A

B

RF

DVD/CD(SW)

C

D

E

VCC

VREF

F

GND

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

24

23

22

21

20

19

LD_DVD(650)

18

17

16

15

14

13

12

11

10

VRF(RF_OUT)

9

SW1(DVD/CD)

8

7

6

5

4

3

2

1

FOCS RTN

FOCS DRV

TRKG RIN

TRKG DRV

NC

GND

PD/GND

LD_CD(780)

GND

VR780(CD)

VRCOM

VR650(DVD)

A

B

C

D

E

VCC

VS

F

GND

D

ESE22MH24

D

E

SSS-13-2

E

FG SENSER

C

OPERATION 2

PCB ASSY

(A2G502A280)

F

SW PCB ASSY

(A2F101A640)

M2601

SPINDLE

MOTOR

SW2

JCV9B06

M2602

BCZ3B03

SLED MOTOR

M

M

LOADING MOTOR

PCB ASSY

(A2F101A610)

SW1

M2603

M

BCZ3B52

LOADING MOTOR

069EV63050

CD2301

2H062102

SPINDLE MOTOR (+)

SPINDLE MOTOR (-)

FEED MOTOR (+)

FEED MOTOR (-)

PICK UP INNER LIMIT SWITCH

LOADING MOTOR(+)

LOADING MOTOR(-)

GND(SW)

CD2302

2H052601

SW-2(CLOSE)

GND(SW)

SW-1(OPEN)

CP602

SW1

POWER

PAUSE/–SKIP

+SKIP

STOP

SW2

1

2

2

3

3

4

4

5

5

6

6

CD603(6P FFC)

122H062801

6

5

4

3

2

1

1

1

2

3

4

5

6

SP1+

2

SP1-

3

SLD+

4

SLD-

5

LIMIT SW

6

SW(GND)

CP2303

FFC

CP2302

5

4

3

2

1

61

5

4

3

2

1

CP603

069EV63050

6

5

PAUSE/–SKIP

4

3

2

1

1

2

3

4

5

SW1

POWER

+SKIP

STOP

SW2

CLOSE

GND(D)

OPEN

LD+

LD-

CP4002

069EVB3030

CD601(11P FFC)

122H0B1002

CP601

OPERATION 1

PCB ASSY

(A2G502A270)

CLK

069EVB3050

B

STB

DI (M to F)

DO (F to M)

987654321

1110

DGND

DGND

FL DC+

I R

V+ 3E

– 28V

FL DC –

987654321

1110

D E

14

DV-380-S

1234

5678

÷

When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS LIST" or

"PCB PARTS LIST".

÷

The > mark found on some component parts indicates the importance of the safety factor

A

of the part. Therefore, when replacing, be sure to use parts of identical designation.

÷

: The power supply is shown with the marked box.

B

CP4003

CP502(14P)

Cord Connector

06C32E3504

GND

P. CON+ 12V

069S2E0629

AT+12V for MUTE

3

2

1

3

2

1

3

2

1

3

2

1

CP502

GND

P. CON+ 12V

AT+12V for MUTE

A

A 1/5- A 5/5

DVD MT PCB ASSY (A2G502A130)

: MPEG/MICON/RF-AMP BLOCK

A 1/5

: MEMORY BLOCK

A 2/5

: LOADER/MOTOR DRV BLOCK

A 3/5

: AUDIO/VIDEO JACK BLOCK

A 4/5

: POWER PORT BLOCK

A 5/5

B

GND

P. CON+5V

5

4

5

4

5

4

GND

P. CON+5V

GND(M)

P. CON+6V

P. CON+3.3V(AT)

8

7

645

6

8

7

6

8

7

6

8

7

GND(M)

P. CON+6V

P. CON+3.3V

STBY L

AT+3.3V

9

10

9

10

9

10

9

10

AT+3.3V

P. ON-H

FL DC –

GND(D)

12

11

12

11

12

11

12

11

FL DC –

GND(D)

FL DC +

– 28V

14

13

14

13

14

13

14

13

– 28V

FL DC +

G

CP8001

069J7C0599

1

1

12

12

CP503

G/Y

069J7C0599

GND

2

2

11

11

GND

3

3

10

10

B/CB

GND

4

9

9

GND

R

5

8

8

R/CR

FS

RGB-H

6

7

7

6

7

6

FS

RGB-H

CVBS

87645

8

5

5

CVBS

GND

9

9

4

4

GND

GND

AUDIO L

11

10

11

10

2

3

2

3

GND

AUDIO L

AUDIO R

12

12

CD8001(12P FFC)

122HC0C3001

1

1

AUDIO R

J8001

CVBS

Y

U

V

J8002

Y

C

J8003

L

R

J8004

COAXIAL

J8101

SCART

VIDEO OUT

(COMPOSITE)

S VIDEO OUT

AUDIO OUT

DIGITAL OUT

C

D

E

F

F 1/2, F 2/2

POWER PCB ASSY (A2G502A240)

: POWER BLOCK

F 1/2

: 21PIN/D/DIGITAL AUDIO BLOCK

F 2/2

56

DV-380-S

J501

LIVE

NEUTRAL

1

2

BLUE

BROWN

AC IN

F

15

7

8

1234

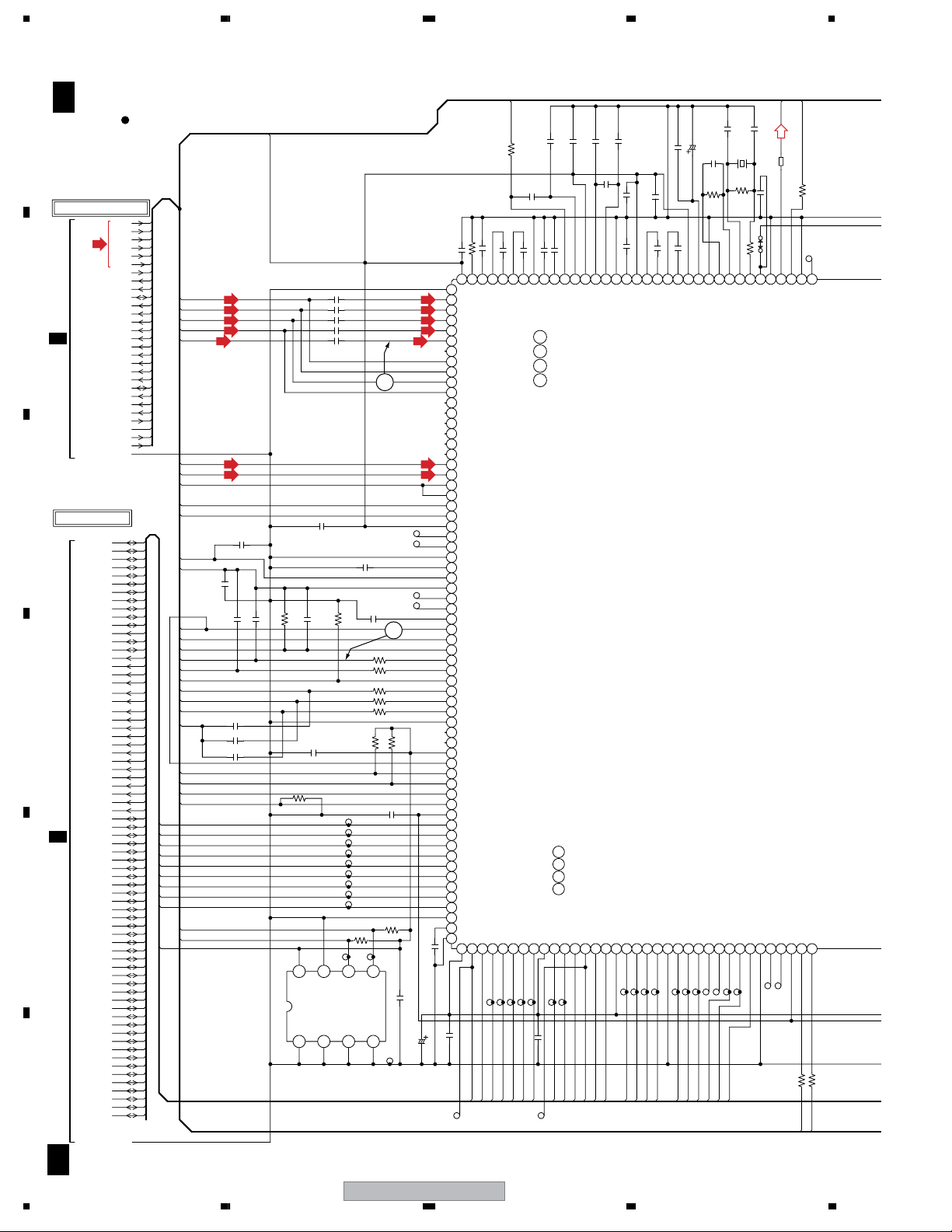

3.3 DVD MT PCB ASSY (1/5)

A 1/5

A

FROM/TO LOADER/MOTOR DRV

B

3/5A2/5A

D_ G N D {2,3,4,5}

C

FROM/TO MEMORY

SDCKE{ 2}

SDCLK{ 2}

DRAS# {2}

DCAS# {2}

D

E

F

DVD MT PCB ASSY (A2G502A130)

MPEG/MICON/RF-AMP BLOCK

V+3

A{3}

B{3}

(RF)

C{3}

D{3}

E{3}

F { 3}

MDI1 {3}

LDO1 { 3}

LDO2 {3}

V1P4 { 3}

DMSO {3}

FMSO {3}

TRCLOSE { 3}

TROPEN {3}

PWMOUT1 {3}

TRSO {3}

FOSO {3}

TROUT {3}

TRIN {3}

STBY { 3}

V20 {3}

LIMIT {3}

IOA { 3}

DEICG {3}

RF {3}

OPO {3}

OP+ {3}

OP- {3}

MA0 {2}

MA1 {2}

MA2 {2}

MA3 {2}

MA4 {2}

MA5 {2}

MA6 {2}

MA7 {2}

MA8 {2}

MA9 {2}

MA10 { 2}

MA11 {2}

DBA0 {2}

DBA1 {2}

DCS#{ 2}

DWE#{ 2}

DQM0{ 2}

DQM1{ 2}

DQ0 {2}

DQ1 {2}

DQ2 {2}

DQ3 {2}

DQ4 {2}

DQ5 {2}

DQ6 {2}

DQ7 {2}

DQ8 {2}

DQ9 {2}

DQ10{ 2}

DQ11{2}

DQ12{ 2}

DQ13{ 2}

DQ14{ 2}

DQ15 {2}

A0 {2}

A1 {2}

A2 {2}

A3 {2}

A4 {2}

A5 {2}

A6 {2}

A7 {2}

A8 {2}

A9 {2}

A10 { 2}

A11 { 2}

A12 { 2}

A13 { 2}

A14 { 2}

A15 { 2}

A16 { 2}

A17 { 2}

A18 { 2}

A19 { 2}

A20 {2}

AD0 {2}

AD1 {2}

AD2 {2}

AD3 {2}

AD4 {2}

AD5 {2}

AD6 {2}

AD7 {2}

PWR# {2}

PCE# {2}

PRD# {2}

D_GND {2,3,4,5}

(D)

D

(A)

A

(B)

B

(C)

C

(RF) (RF)

RF

(E)

E

(F)

F

MDI1

LDO2

LDO1

C4005

0.1B

V20

V1P4

0.1B

C4007

0.1B

C4009

C4008

OPO

OP-

OP+

DMSO

FMSO

TROPEN

PWMOUT1

TRSO

FOSO

C4001 0.0022B

V1P4

C4002

270P

ADIN

TROUT

TRIN

STBY

TRCLOSE(ENDM)

A2

A3

A4

A5

A6

A7

A8

A18

A19

SDA

SCL

(V+3D)

V+3

C4003

150P

CH

C4014 1B

C4015 1B

C4016 1B

C4017 1B

C4080 1B

C4013

680K

R4003

0.015B

C4091

CH

C4012

R4002 10K

TP4036

VCC

EEPROM

NC

IC4001

BR24L16FJ-WE2

1234

0.1B

0.0022B

0.1B

NC

C4019

10K

R4026

R4015

R4016

R4017

R4018

R4019

TP4001

TP4002

TP4003

TP4004

TP4005

TP4006

TP4007

TP4008

TP4009

R4014 10K

WP

SCL

NC

V+3 RF

1

0.1B

C4 020

0.1B

17

10K

15K

22K

22K

22K

10K

R4011

C4021 0.1B

R4013 10K

TP4037

5678

SDA

GND

TP4107

R4012

3. 3V

C4022

(D)

(A)

(B)

(C)

(E)

(F)

X40 0 1

100K

TP4032

R4027

XTALI

A17

C4049

100

XTALO

IOA0 (PU)

11P C H

829

W

RFVDD18

DVSS (3)

TP4033

ASPDIF

(D)

B4007

MMZ1608R102CT

C4 0 50 0 . 1 B

SPDIF

RFGND18

XUWR (PU)

XURD (PU)

UWR#

URD#

TP4034

R4034

POWER_ON

1K

R4001

TP4035

222223224225226227228229230231232233234235236237238239240

(3) DVSS

(PD) ASDATA4

MC_DATA (PD)

DVDD18

UP1_2 (PU)

UP1_3 (PU)

33

33

R4035

FP_DI

FP_SCK

V1P4

C4034

100K

R4022

C4033

0. 001 B

B

C4028 0.1 B

252

NC

OSP

HIGHA5 (PU)

HIGHA6 (PU)

TP4016

TP4017

A14

A13

C4101 0.1 B

250251

NC

RFGND

253

254

255

256

HIGHA3 (PU)

HIGHA4 (PU)

TP4018

TP4019

C4030

A12

A11

TP4096

0.03

C4031

IOCE#

0. 1 B

C4026

R4020 15K

C4027 0.1 B

255256

253254

1219

AGND

DVDA

3

DVDB

4

DVDC

5

DVDD

6

DVDRF[P

789

NC

DVDRF[N

MA

MB

MC

1011

MD

SA

NC

121314151617182021222324

NC

SB

NC

SC

NC

SD

NC

CDFON

NC

CDFOP

TNI

TPI

MIDI1

MIDI2

LDO2

LDO1

SVDD3

TP4010

CSO/RFOP

2526272829

TP4011

RFLV/RFON

SGND

V2REFO

V20

VREFO

30313233343536373839

TP4012

FEO

TP4013

TEO

TEZIS[LV

OP_OUT

OP_INN

OP_INP

DMO

FMO

TROPENPWM

PWMOUT1/V_ADIN9

40414243444546474849

TRO

FDO

USB_VSS

NC

NC

NC

10K

0. 1 B

C4023

NC

USB_VDD3

FG/V_ADIN8 (PU)

TDI/V_ADIN4 (JTAG)

TMS/V_ADIN5 (JTAG)

TCK/V_ADIN6 (JTAG)

50

TDO/V_ADIN7 (JTAG)

51525354

DVDD18

IOA2 (PU)

IOA3 (PU)

IOA4 (PU)

55

IOA5 (PU)

56575859

IOA6 (PU)

IDA7 (PU)

HIGHA0 (PU)

IOA18 (PU)

6061626364

IOA19 (PU)

DVSS

APLLCAP

APLLVSS

65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99

1. 8V

C4 0 24 0 .0015 B

2206. 3V Y K

C4025

TP4014

0. 1 B

IOWR#

PWR#

TP4015

A16

A15

22P C H

C4032 0.1 B

HRFZC

CRTPLP

OSN

RFGC

IREF

AVDD3

65

66

67

68

DVDD3

HIGHA2 (PU)

TP4020

TP4021

0. 1 B

A10

A9

C4102

C4035

0. 1 B

C4104

1B

NC

RFVDD3

RFRPDC

RFRPAC

APLLVSSVDD3

XIOWR

A16

HIGHA7 (PU)

IOCA1 (PU)

HIGHA1 (PU)

IOA20

XIOCS (PU)

A20

A1

PCE#

0. 1 B

NC

XIODE

PRD#

C4103

241242243244245246247248249

0. 1 B

C4105

NC

ADCVSS

DVDD3

AD0

TP4023

TP4022

AD0

B0.1

C4 043 0 .1 B

C4041

B

1

LPFOP

ADCVDD3

AD1

AD2

TP4024

AD1

AD2

B

C4042

0.047

LPFIN

AD3

TP4025

AD3

C4048

10P C H

C4047

CH

390P

C4045 0 . 47 B

C4046 1 025V K A

100BT02701

27MHz

R4024

R4025

750K

B

C4044

0.047

JITFO

LPFON

PLLVSS

PLLVDD3

IDACEXLP

IC4002

MT1389FE/C2-L

JITFN

LPFIP

MPEG/MICON/RF-AMP

DVSS (18)

AD4

AD5

AD6

IOA2/V_ADIN0

ALE (PU)

AD7

TP4030

TP4027

AD5

TP4028

TP4029

AD6

AD7

A17

TP4031

A0

TP4026

AD4

A 1/5

16

DV-380-S

1234

5678

SD

ABCK

ALRCK

TP4041

3

R4050 3 3

R4047 3

ABCK

(PD) ALRCK

DVDD3

PU3_5 (PU)

220P C H

TXD

IOA

DEICG

P4043T

R4052 1 0K

DVDD3

SPLRCK

SPBCK/ADTA5

ICE (PD)

XPRST (PU)IRXINT0 (PU)

TP4044

R4051 3 3

IR

URST#

XAMUTE

R4054 1 0K

SPDATA

TP4095

TP4045

DQM0

SPMCLK

192

191

190

189

ACLK

ASDAT0

TP4039

TP4038

(DA)

R4046 1 0

33

0. 1 B

R4043

C4053

NCNC

NC

DVDD18

(PD) ASDATA3

(RF)

(SY)

(SC)

(R/CR)

(G/Y)

(B/CB)

(DA)

UP1_4 (PU)

UP1_5 (PU)

100 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115 116 117 118 119 120 121 122 123 124 125 126 127 128

33

R4036

STB

FP_DO

ACLK

(18) DVSS

(PD) ASDATA1

(PD) ASDATA2

(PD) ASDATA0

: RF SIGNAL ROUTE

: VIDEO SIGNAL ROUTE

: S VIDEO SIGNAL ROUTE (Y ch)

: S VIDEO SIGNAL ROUTE (C ch)

: VIDEO SIGNAL ROUTE (R/CR ch)

: VIDEO SIGNAL ROUTE (G/Y ch)

: VIDEO SIGNAL ROUTE (B/CB ch)

(D)

: AUDIO DATA SIGNAL ROUTE

: AUDIO SIGNAL ROUTE (Digital)

UP1_6 (PU)

UP1_7 (PU)

UP3_0 (PU)

UP3_1 (PU)

UP3_4 (PU)

NC

C4 0 54

NR4001

4D03WGJ0330T5E

SCL

SDA

RXD

LIMIT

DAC_XCS0

TP4049

TP4047

TP4046

W832

HSYN/V_ADIN2

YUT7/ASDATA5

YUV0/CIN

FS

VREF

DACVDDC

125

RD0

126

RD15

DVDD3

127

128

RD14

DQM0

DQS0

RD7

P4048T

DQ7

R/CR

B/CB

(B/CB)

(R/CR)

TP4050

W833

C4 0 60 0 . 1 B

DVDD3

YUV5/B

YUV6/R

VSYN/V_ADIN1

DVSS (18)

RD6

RD5

DVSS (3)

TP4051

TP4052

TP4053

DQ6

DQ5

DQ4

SCK

G/Y

V+3 A

CVBS

(G/Y)

W834

C4061

YUV4/G

DACVSSA

DACVDDA

(PU) RD3/ASDATA5

RD4

RD3

DVDD18

TP4054

TP4055

0. 1 B

C4062

DQ3

DQ2

S_C

(SC)

0. 1 B

YUV2/C

DACVSSB

YUV3/CVBS

(PD) DQM2

(PD) DQM3

(PU) RD30

(18) DVSS

(3) DVSS

(18) DVSS

RD2

RD1

TP4056

TP4057

DQ1

DQ0

S_Y

(SY)

C4063

DACVDDB

DVDD3

RD24

RD25

RD26

DVDD18

RD29

DVDD3

RA4

RA5

RA6

RA7

(3)DVSS

RA8

RA9

RA11

CKE

RCLK

DVDD3

DVDD18

RA10

XRCS

DVDD3

XRAS

XCAS

XRWE

DQM1

DQS1

RD8

(3) DVSS

RD9

RD10

RD11

RD12

RD13

TP4058

C4 0 64

DQ15

0. 1 B

193194195196197198199200201202203204205206207208209210211212213214215216217218219220221

YUV1/Y

DACVSSC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

RA3

RA2

RA1

RA0

BA1

BA0

TP4059

0. 1 B

DQ14

TP4060

TP4061

TP4062

V+3 V

R4061

2. 7K+ - 1%

R40621 5K

C4066 1 B

C4067

NC

NC

0. 1B

NC

NC

NC

C4071

NC

NC

NC

NC

NC

NC

TP4064

TP4065

C4068 0.1 B

NC

NC

129 130 131 132 133 134 135 136 137 138 139 140 141 142 143 144 145 146 147 148 149 150 151 152 153 154 155 156 157 158 159 160 161 162 163 164 165 166 167 168 169 170 171 172 173 174 175 176 177 178 179 180 181 182 183 184 185 186 187 188 189 190 191 192

TP4063

C4072

0. 1 B

C4073

V+3

TP4066

TP4067

TP4068

0. 1 B

0.1

B

3.3V

V+3 D

R4064 1 50 + - 1%

R4065 1 50 + - 1%

R4066 1 50 + - 1%

R4067 1 50 + - 1%

R4068 1 50 + - 1%

R4069 1 50 + - 1%

C4116

R4082 33

R4070 33

R4071 33

4D03WGJ0330T5E

C4090

1. 8V

0. 0082

B

V+1R8

W816

W811

W812

W813

W814

W815

TP4089

VSEL2

TP4090

TP4091

TP4092

C4110

100P C H

100P C H

TP4093

TP4069

TP4070

TP4071

TP4072

TP4073

TP4074

TP4075

R4005

100

TP4076

TP4077

TP4078

TP4079

TP4080

TP4081

TP4082

TP4083

TP4084

TP4085

TP4086

NR4002

TP4087

TP4088

IC4003

BD5229G-TR

1

V_OUT

CT

23

VDD

NCNC

45

VSS

RESET IC

VSEL1

LETTER

SQUEEZE

I/XP

MA4

MA5

MA6

MA7

MA8

MA9

MA11

SDCKE

SDCLK

MA3

MA2

MA1

MA0

MA10

DBA1

DBA0

DCS#

DRAS#

DCAS#

DWE#

DQM1

DQ8

DQ9

DQ10

DQ11

DQ12 IR

DQ13

TP4108

URST#

1K

R4084

V+3 E

TP4094

C4 0 74

0. 1 B

V+3(V+3D)

RXD

TXD

D_GND

C4076 3 3P

C4077 1 00P

C4078 3 3P

C4079 1 00P

FP_SCK

FP_DI

STB

FP_DO

V+3 E

FLDC+

-28V

FLDC-

FROM/TOVIDEO/AUDIO

(R/CR)

(B/CB)

(G/Y)

(SC)

(SY)

(D)

(DA)

CH

CH

CH

CH

R4007

100

FROM/TOPOWER PORT

VSEL1 {4}

LETTER {4}

SQUEEZE {4}

I/XP{4}

R/CR {4}

B/CB {4}

G/Y {4}

CVBS {4}

S_C { 4}

S_Y { 4}

SD{4}

SCK {4}

DAC_XCS0 {4}

XAMUTE {4}

ALRCK {4}

ABCK {4}

ACLK {4}

ASDAT0 {4}

ASPDIF {4}

D_GND{2,3,4,5}

POWER_ON {5}

V+1R8 {5}

V+3 {2,5}

V+3E {5}

V+3A {4,5}

FLDC- {5}

FLDC+ {5}

-28V {5}

D_GND {2,3,4,5}

TP4103

TP4040

TP4042

TP4106

TP4104

TP4105

TP4097

TP4099

TP4098

1

C4 1 14

B

TP4100

TP4101

TP4102

B

4/5A

A

5/5

PP DEL

V+3 D

RXD

TXD

GND

CP4002

00_6232_011_006_800+

CLK

1

DI (Mto F)

2

STB

3

DO(F to M)

4

IR

5

V+3E

6

DGND

7

DGND

8

FLDC+

9

-28V

10

FLDC-

11

CP601

A

B

C

D

E

F

56

DV-380-S

A 1/5

17

7

8

1234

3.4 DVD MT PCB ASSY(2/5)

A

B

C

A 2/5

DVD MT PCB ASSY (A2G502A130)

MEMORY BLOCK

FROM/TOMPEG/MICON/DSP

DQ0 {1}

DQ1 { 1}

DQ 2 { 1}

DQ 3 { 1}

DQ 4 { 1}

DQ 5 { 1}

DQ 6 { 1}

DQ 7 { 1}

DQ 8 { 1}

DQ 9 { 1}

DQ10 { 1}

DQ11 { 1}

DQ12 { 1}

DQ13 { 1}

DQ14 { 1}

DQ15 { 1}

MA0 {1}

MA1 {1}

1/5A

MA2 {1}

MA3 {1}

MA4 {1}

MA5 {1}

MA6 {1}

MA7 {1}

MA8 {1}

MA9 {1}

MA10 {1}

MA11 {1}

DWE# {1}

SDCKE {1}

SDCLK {1}

DQM 1 { 1}

DQM 0 { 1}

DCAS# {1}

DRAS# { 1}

DBA1 {1}

DBA0 {1}

DCS# {1}

A17

A0

AD7

AD6

AD5

AD4

C4081

0. 001 B

AD3

A0 { 1}

D

1/5A

E

A1 { 1}

A2 { 1}

A3 { 1}

A4 { 1}

A5 { 1}

A6 { 1}

A7 { 1}

A8 { 1}

A9 { 1}

A10 { 1 }

A11 { 1}

A12 { 1}

A13 { 1}

A14 { 1}

A15 { 1}

A16 { 1}

A17 { 1 }

A18 { 1 }

A19 { 1 }

A20 { 1}

AD0 { 1}

AD1 { 1}

AD2 { 1}

AD3 { 1}

AD4 { 1}

AD5 { 1}

AD6 { 1}

AD7 { 1}

PRD# { 1}

PCE# {1}

PWR# {1}

V+3 { 1 , 5 }

D_GND {1,3,4,5}

(V+3D)

AD2

AD1

AD0

PRD#

PCE#

A1

F

A 2/5

18

DV-380-S

1234

5678

A

64Mbit SDRAM

IC4005 K4S641632H-UC75

110111213141516171819 22021222324252627

16Mbit FLASH

484746454443424140393837363534333231302928272625

A16

BYTE#

VSS

D1 5

D7

D14

D6

D13

D5

D12

D4

VCC

D11

D3

D10

D2

D9

D1

D8

D0

OE#

VSS

CE#

A0

IC4004 S29AL016D

RESET#

RY/BY#

1. 2

3. 3

0

0. 7

1. 9

1. 3

NC

1. 2

0. 6

NC

0. 7

0. 8

NC

3. 3

1. 6

NC

1. 6

1. 3

NC

1. 2

1. 4

NC

1. 4

0. 9

NC

1. 6

2. 6

0

2. 6

2. 5

A15

A14

A13

A12

A11

A10

A9

A8

A19

NC NC

WE#

NC

NC

A18

A17

A7

A6

A5

A4

A3

A2

A1

1. 7

110111213141516171819 22021222324 3

1. 0

0. 8

1. 5

456789

2. 5

1. 3

1. 6

1. 5

0

0

3. 31. 6

0

0. 1

W820

NC

0. 1

NC

0

NC

1. 6

0. 7

1. 4

1. 6

1. 6

1. 3

1. 7

2. 5

1. 6

R4087

A16

A15

A14

A13

A12

A11

A10

A9

A20

PWR#

A19

A18

A8

A7

A6

A5

A4

A3

A2

10K

DQ15

DQ14 DQ6

DQ13 DQ5

DQ12 DQ4

DQ11 DQ3

DQ10 DQ2

DQ9 DQ1

DQ8 DQ0

C4082

0. 1 B

DQM1 DWE#

SDCLK DCAS#

SDCKE DRAS#

MA11 DBA0

MA9 DBA1

MA8 MA10

MA7 MA0

MA6 MA1

MA5 MA2

MA4 MA3

DQ15

VSSQ

VQ14

DQ13

VCCQ

DQ12

DQ11

VSSQ

DQ10

DQ9

VCCQ

DQ8

VSS

NC

NC

UDQM

CLK

CKE

NC

NC

A11

A9

A8

A7

A6

A5

A4

VSS

28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54

VCCVSS

DQ0

VCCQ

DQ1

DQ2

VSSQ

DQ3

DQ4

VDDQ

DQ5

DQ6

VSSQ

DQ7

VCC

LDQM

WE

ASC

ASR

CS

BA0

BA1

A10/AP

VCC

3

456789

A0

A1

A2

A3

C4088

0. 1 B

DQ7

B

C

DQM0

D

DCS#

E

56

DV-380-S

B

B

0.1

C4084

0.1

C4085

C4086

10006. 3V Y K

F

A 2/5

19

7

8

1234

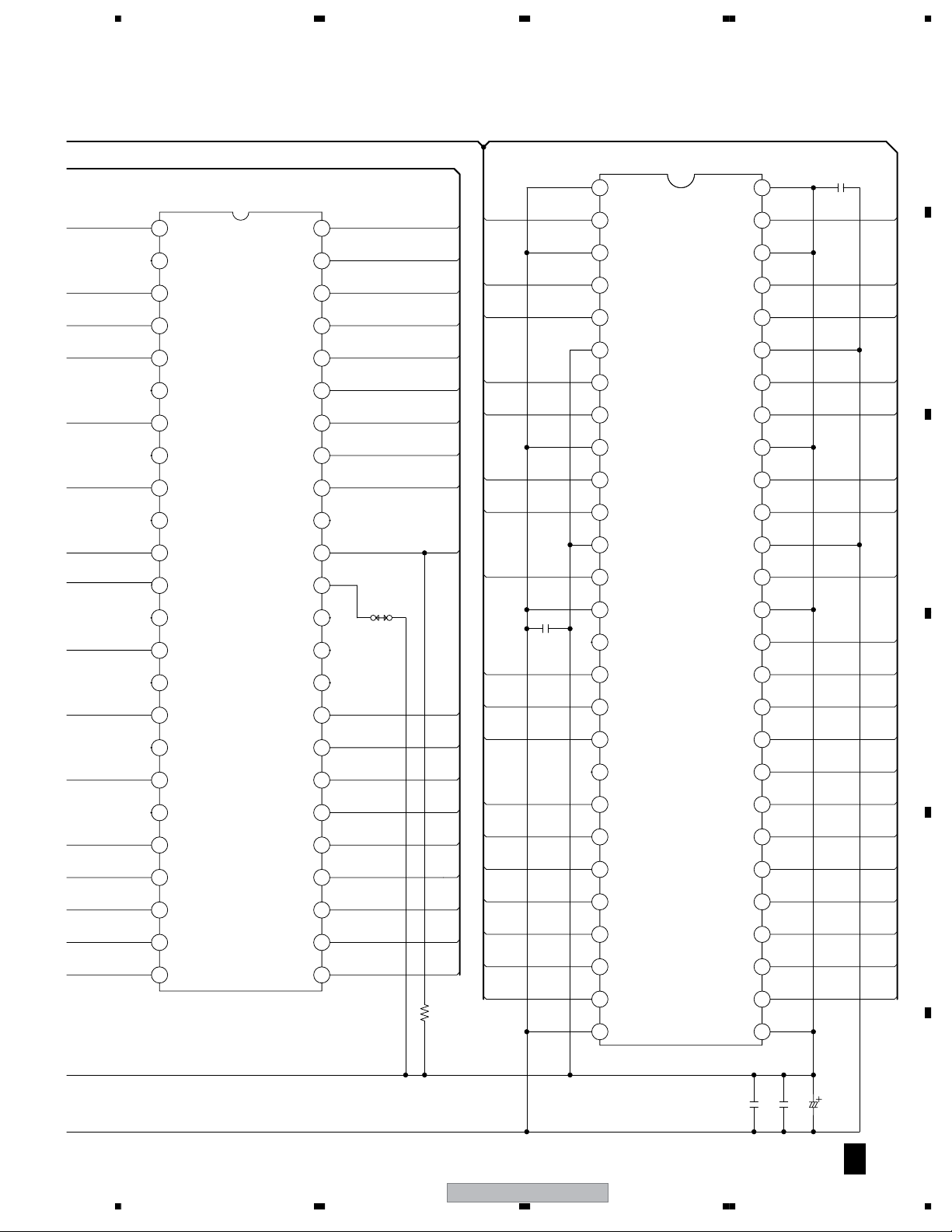

3.5 DVD MT PCB ASSY(3/5)

A

B

C

A 3/5

CP2301

09-5000-024-001-001

1

GND

2

F

3

VS

4

VCC

E

5

6

D

C

7

SW1(DVD/CD)

8

VRF(RF_OUT)

9

10

B

11

A

12

VR650(DVD)

13

VRCOM

14

VR780(CD)

To PICKUP

15

GND

16

LD_CD(780)

PD/GND

17

LD_DVD(650)

18

GND

19

20

NC NC

TRKG DRV

21

22

TRKGRTN

23

FOCS DRV

24

FOCS RTN

DVD MT PCB ASSY (A2G502A130)

LOADER/MOTOR DRV BLOCK

(F)

(E)

(D)

(C)

(RF)

(B)

(A)

TP2303

C230 3 0 . 1 B

C230 1 0 . 1 B

JG001

JG002

JG003

JG004

JG005

JG006

JG007

C2302 0 . 1 B

TP2301

TP2304

TP2305

TP2306

TP2307

TP2308

TP2309

TP2302

TP2310

TP2311

TP2312

TP2313

TP2314

TP2315

TP2316

TP2317

TP2318

TP2319

(E)

(D)

(C)

(RF)

(B)

(A)

DEICG

V+5 S

(F)

F

V20

E

D

C

IOA

RF

B

A

MDI1

T+

T-

F+

F-

Q2306

2SK3018T106

2SK3018T106

D

G

S

Q2307

D

S

R2307

G

KTC3875S_Y_RTK

R2306

C2325

0. 001 B

100K

100K

Q2301

V+5 S

R2308

IOA

10K

R2309

10K

CP2302

00_6232_005_006_800+

5

LOAD-

4

LOAD+

3

OPEN

CD2302

2

GND

CLOSE

1

E

D

CP2303

00_6232_006_006_800+

SW(GND)

6

LIMIT SW

5

4

3

CD2301

2

D

1

SLD-

SLD+

SPD-

SPD+

TP2324

TP2325

TP2326

TP2327

TP2328

R2338

10K

E

FG

TP2331

TP2320

TP2321

TP2322

TP2323

LOAD-

LOAD+

TROUT

TRIN

C2323

0. 1 B

LIMIT

MOT_SLED-

MOT_SLED+

MOT_SPDL+

V+3 F

OPO

OP-

OP+

MOT_SPDL-

R2319

C2322

150K

2329R

1

V+6 A

R2342

680K

0. 0022 B

R2331

150K

1B

C2314

F

20

A 3/5

DV-380-S

1234

5678

(RF)

W809

W817

CD

JG008

TP2341

LD DRIV for CD

Q2302

KTA1504S_Y_RTK

DVD

JG009

TP2342

LD DRIV for DVD

Q2303

KTA1504S_Y_RTK

4. 7

R2320

3. 3

R2321

3.1 3.1

2.0

3. 3

4. 7

D DRIV for CDL

Q2304

KTA1504S_Y_RTK

LD DRIV for DVD

Q2305

KTA1504S_Y_RTK

R2322

R2323

: RF SIGNAL ROUTE

FROM/TO MPEG/MICON/RF-AMP

(RF)

RF {1}

DEICG {1}

V20 {1}

(A)

A { 1 }

(B)

B { 1 }

RF33

JG010

W819

4. 7

3. 3

3. 3

00

4. 7

2.52.5

2.0

C2320

C2321

10010V Y K

10010V Y K

TP2332

V+3 F

LDO1

LDO2

(C)

(D)

(E)

(F)

C { 1}

D { 1}

E { 1 }

F { 1}

MDI1 {1}

LDO2 {1}

LDO1 {1}

IOA {1}

V1P4 {1}

LIMIT {1}

TROUT {1}

TRIN {1}

STBY {1}

DMSO {1}

Fv

TRCLOSE {1}

TROPEN {1}

PWMOUT1 {1}

TRSO {1}

FOSO {1}

OPO {1}

Ov

OP- {1}

1/5A

A

B

15

R2310

R2337

2. 7K

5. 6K

MOTOR DRIVE IC

16

TRSO

R2311

0

3. 3

4. 1

S-GND

VCONT

REV

FWD

IC2301 LA6565

123456789 101112131415161718

0

0

5. 9

TP2340

C2312

C2313

0. 01 B

10K

3. 3

MUTE1

VCC2

0. 1

1B

TP2329

R2312

1. 4

VIN4-

MUTE234

VLD+

VLD-

0

R2335

TRACK

15K + - 1%

R2313

1. 4

2. 6

2. 2

VIN4

VD4+

10K + - 1%

1. 4

2. 6

1. 4

VREF-IN

VD4-

2. 6

NC

NC

000. 9

REG-OUT

VREF-OUT

VD3-

VD3+

2. 601. 5

38

37

TP2339

NCNCNC

1. 6

1. 6

VIN+OP

REG-IN

VD2-

VD2+

3. 7

2. 6

VIN-OP

VD1-

5. 9

24252627282930313233343536

2. 6

R2316

NC

1. 4

VO_OP

VD1+

5. 9

C2307

TP2330

R2317

10K + - 1%

VIN3VCC1

1B

FOSO

1. 4

5. 9

FOCUS

56K + - 1%

R2318

1. 1

VIN3-

VCCS

1. 4

C230610010V Y K

10 K + - 1%

1. 4

20212223

VIN2

VIN1+A

1. 4

R2326

VIN2-

VIN1-A

R2328

R2325

1. 4

19

VIN 1 VIN2+

1. 4

15K + - 1%

R2327

4. 7K

10K + - 1%

R2330

10K + - 1%

C2305

4. 7K

0. 1 B

SPINDLE

SLED

TP2335

TP2336

TP2333

TP2334

17

STBY

DMSO

V1P4

PWMOUT1

FMSO

FROM/TO POWER PORT

V+3 F { 5 }

V+5 S { 5}

V+9 A

D_GND {1,2,4,5}

M_GND {5}

C

5/5A

D

E

TRCLOSE

TROPEN

R2332

MOT_SLED-

MOT_SLED+

C2308

0. 1 B

1. 2

R2333

TP2337

1. 2

TP2338

LOAD-

LOAD+

R2334

C2310

2. 2

C2309

0. 1 B

0. 01 B

C2311

0. 01 B

18

T-

T+

F-

F+

MOT_SPDL-

MOT_SPDL+

DV-380-S

56

F

A 3/5

21

7

8

1234

3.6 DVD MT PCB ASSY(4/5)

A

B

C

D

E

F

22

A 4/5

FROM/TO MPEG/MICON/DSP

DAC_XCS0 {1}

LETTER {1}

SQUEEZE {1}

XAMUTE {1}

ACLK {1}

ASPDIF {1}

SCK {1}

SD {1}

VSEL1 {1}

1/5A5/5A

I/XP {1}

ABCK{1}

ASDAT0{1}

ALRCK{1}

R/CR{1}

B/CB{1}

G/Y {1}

CVBS {1}

S_C {1}

S_Y {1}

FROM/TO POWER

D_GND {1,2,3,5}

V+12AT {5}

V+12 {5}

V+5V {5}

V+5A {5}

V+3A {1,5}

A 4/5

DVD MT PCB ASSY (A2G502A130)

AUDIO/VIDEO JACK BLOCK

CD8001

CP8001

2H0C3001

ASP/FS

S_C_OUT

S_Y_OUT

CVBS_OUT

VCC

/EN

IMSA-9604S-12C

S1D

S2D

DD

S1C

S2C

DC

(CR)

(R)

910111213141516

(R/CR)

B/CB

R/CR

RGB-H

AUDIO L

AUDIO R

NC

NC

NC

G/Y

GND

GND

FS

CVBS

GND

GND

C8008

R8016

1

2

3

4

5

6

F 1/2

7

CP503

8

9

10

11

12

0. 1 B

CR_OUT

CB_OUT

4706. 3V Y K

4706. 3V Y K

C8024

C8023

B8001

R8024

C8026

B8002

MMZ1608R102CT

MMZ1608R102CT

1. 2K

1.2K

R8017

75 + - 1%

75 + - 1%

R8027

R8029

CB

CR

CVBS

H1H2EH1H2

23

1

E

J8001

MSP-244V10-95_NI_FE_LF

CVBS/Y/U/V

(SC)

(SY)

Y_OUT

10006. 3V Y K

10006. 3V Y K

C8022

1.2K

R8018

75 + - 1%

75 + - 1%

R8028

Y

56

4

SQUEEZE

B8006

MMZ1608R102CT

VSEL1

P-H/I-L_RGB-H

B8007

MMZ1608R102CT

AUDIO_R

AUDIO_L

(G)

(B)

(R)

G/Y_OUT

B/U_OUT

R/V_OUT

(DA)

(D)

(R/CR)

(B/CB)

(G/Y)

(SC)

(SY)

CAUTION: DIGITAL TRANSISTOR CAUTION: DIGITAL TRANSISTOR

LETTER

SQUEEZE

V+5V

C8001

S_C

0. 1 B

C8003

CVBS

1B

C8006

S_Y

1B

VSEL1

C8002

G/Y

1B

C8004

B/CB

0. 1 B

C8005

R/CR

0. 1 B

: VIDEO SIGNAL ROUTE

(SY)

: S VIDEO SIGNAL ROUTE (Y ch)

(SC)

: S VIDEO SIGNAL ROUTE (C ch)

(R/CR)

: VIDEO SIGNAL ROUTE (R/CR ch)

(G/Y)

: VIDEO SIGNAL ROUTE (G/Y ch)

(B/CB)

: VIDEO SIGNAL ROUTE (B/CB ch)

(D)

: AUDIO DATA SIGNAL ROUTE

(DA)

: AUDIO SIGNAL ROUTE (Digital)

: AUDIO SIGNAL ROUTE (L ch)

VIDEO DRIVER 6CH

C8017

10010V Y K

5.1 5.1

(SC)

2.5

5.1

1.8

5.1

(SY)

1.8

C8014

10010V Y K

2.5

C8015

3.3

0. 1 B

(G/Y)

1.8

(B/CB)

2.5

5.1

(R/CR)

2.5

MM1623BFBE

11011121314

Vcc1

23456789

C in

MUTE1

V in

YC MIX

Y in

0

GND1

BIAS

I/P

CY in

0

CLP

nG

Cb i ND2

MUTE2

Cr in

IC8002

Vc c 2

DC out

C uot

V out

GND2

Y out

CY out

GND2

Cb out

Cr out

GND2

(G)

(R)

(B)

4CH BUS SW

IC8001

SN74CBT3257PWR

12345678

0. 1 B

C8016

0

2.5

(SC)

0

S1

0

S2

2.6

0

2.6

21 22 23 24 25 26 27 28

(SY)

2.6

0

2.5

0

2.5

0

15 16 17 18 19 20

(G/Y)

(B/CB)

(R/CR)

14

9

13

10

11

(G/Y)

(B/CB)

IN

(Y)

S1A

(G/Y)

S2A

DA

(CB)

S1B

(B)

S2B

DB

GND

YUV only ---> W810,W821,W822 ON

RGB only ---> W863,W864,W865 ON

YUV/RGB both ---> IC8001 MOUNT,JP DEL

12

I/XP

0. 1 B

C8010

P-H/I-L_RGB-H

VSEL1

DV-380-S

1234

C8036

5678

A

SD

DAC_XCS0

0.1 B

C8075

C8076

SCK

B

10010V Y K

C

1B

(DA)

R8037

R8036

B8004

MMZ1608R102CT

1. 8K

COAXIAL DRIV

8005

Q

KTC3875S_Y_RTK

R8039

3. 9K

68

220

R8038

R8035

2.2K

C8038

150V K A

R8040

W824

100K

(DA)

(DA)

C8042

COAXIAL

J8004

MSP-251V-05NI-FE-LF

H

2

R8044

10K

100PCH

V+5A

V+3A

ABCK

ACLK

5

C8061

6

R8065

10

C8063

K

10006. 3

VY

ALRCK

8

C8068

0. 1 B

0. 1 B

ASDAT0

(D)

3

R8070

33

AUDIO DAC 2CH

4 7

12345678

BCKIN

(D)

DATA

LRCKIM

GND

VDD

5V

VCC

V-OUT L

V-OUT R

B8003

MMZ1608R102CT

IC8004

PCM1742KEG/2K

MCLK

ZERO L

ZERO R

VCOM

AGND

C8074

330P C H

ML

MC

MD

NC

910111213141516

V+5V

ASPDIF

XAMUTE

V+12AT

(DA)

3.9K

3.9K

R8051

R8014

JACK MUTE CTL

Q8014

KTA1504S_Y_RTK

R8046

MUTE CTL

2. 2K

Q8013

MUTE CTL

Q8010

DTC114YUA

R8056

4. 7K

E

1

DTC114YUA

(SC)

(SY)

R8021

10K

R8060

270K

C8021

R8026

(SC)

C8053

10010V Y K

C8051

10010V Y K

0. 1 B

75 + - 1%

C8025

R8023

4706. 3V Y K

W866

75 + - 1%

(SY)

GND

R8059

10K + - 1%

R8049

10K + - 1%

R8048

270K

C8056

C8057

560P C H

560P C H

C8058

C8059

0. 1 B

0. 1 B

R8061

10K + - 1%

R8067

+-1%

18K

R8066

C8069

10K

100P C H

+- 1%

6.3 6.3 6.30

-VS

5678

6.3 6.3 6.3

+

-

C8067

100PC H

+

12.5

C8073

4716V YK

1234

IC8003

BA4560F-E2

+VS

AUDIO LPF&

C8070

4716V Y K

R8073

R8074

R8082 2 20 + - 1%

R8083

470

R8080

220 + - 1%

R8081

22K

470

R8078

22K

470

R8079

220 + - 1%

R8076

470

R8077

220 + - 1%

R8085

220 + - 1%

2SD2114K

Q8018

Q8019

2SD2114K

R8084

220 + - 1%

MUTE SW

MUTE SW

AUDIO_L

2SD2114K

Q8021

MUTE SW

C8077

C8078

MUTE SW

Q8020

2SD2114K

AUDIO_R

330P C H

330P C H

D

E

34

C

12

56

J8002

MDC-070V-B_LF

Y/C SEPA

Y

C8046

VSEL1

C100PH

V+12

D8007

1SS355

R8057

100

R8054

D8005

REF VOL GEN

Q8016

KTC3875S_Y_RTK

12. 5

6. 3

6. 8

2. 2K

C8062

1B

UDZS6.8B

R8063 1 8K + - 1%

W870

C8066

DV-380-S

56

C8072

0. 1 B

680K

R8069

10010V Y K

LR

H1H2

23

1

E

J8003

MSP-242V2-01NI-FE_LF

L/R

F

A 4/5

23

7

8

1234

3.7 DVD MT PCB ASSY(5/5)

A

B

C

A 5/5

DVD MT PCB ASSY (A2G502A130)

POWER PORT BLOCK

IC4006

SIP1117L-ADJ-TP

REG+1.8V IC

ADJVIN VOUT

123

3.3 1.8 0.6

R4039

R4037

68 + - 1%

15

476. 3V K A

0. 1 B

C4 0 9 5

R4044

C4112

C4039

0. 001 B

1B

C4094

D

E

CP4003

A2001WV2-14P

1

P.CON+12V

2

AT+12V for MUTE

3

4

5

6

CP502

7

P.CON+3.3V(AT)

8

9

F 1/2

10

11

12

13

14

GND

GND

P.CON+5V

P.CON+6V

GND(M)

AT+3.3V

STBY L

GND(D)

FL DC-

FL DC+

-28V

116V B

C4040

C4109

0. 1 B

1B

C4093

W853

1B

C4096

39 + - 1%

F

24

A 5/5

DV-380-S

1234

5678

A

FROM/TO AUDIO/VIDEO

B

W847

W848

B4002

MMZ1608R102CT

B4001

MMZ1608R102CT

(AUDIO DAC)

V+5A

(VIDEO/OPT/COAX)

V+5V

(AUDIO MUTE)

V+12AT

(AUDIO AMP)

V+12

(MOTOR)

V+6A

(OPU)

V+5S

V+3A {1,4}

V+5A {4}

V+5V {4}

V+12AT {4}

V+12 {4}

D_GND {1,2,3,4}

FROM/TO LOADER/MOTOR DRV

4/5A

C4098

1B

C4099

0. 001 B

C4100

V+6A {3}

(F/E)

V+3F

W850

W851

W852

2206. 3V Y K

0. 01 B

C4052

R4033 10K

(AUDIO/VIDEO DAC)

V+3A

(MPEG/SDRAM/FLASH)

V+3

(FIP/LED/IR/RESET)

V+3E

(CORE)

V+1R8

V+5S {3}

V+3F {3}

D_GND {1,2,3,4}

M_GND {3}

FROM/TO MPEG/MICON/RF-AMP

V+3 {1,2}

V+3E {1}

V+1R8 {1}

V+3A {1,4}

FLDC- {1}

POWER_ON {1}

FLDC+ {1}

-28V {1}

D_GND {1,2,3,4}

A

3/5

C

1/5A

D

E

56

DV-380-S

F

A 5/5

25

7

8

1234

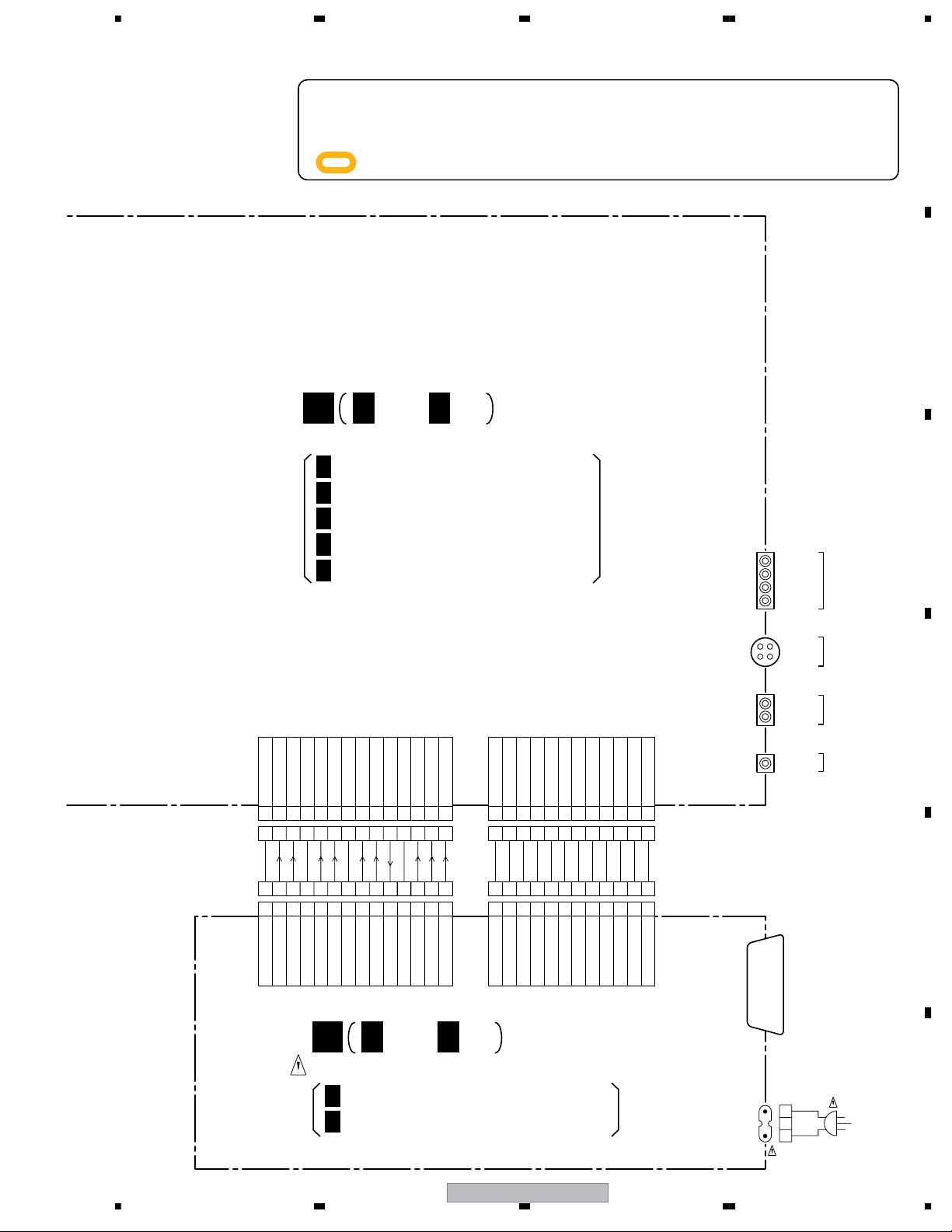

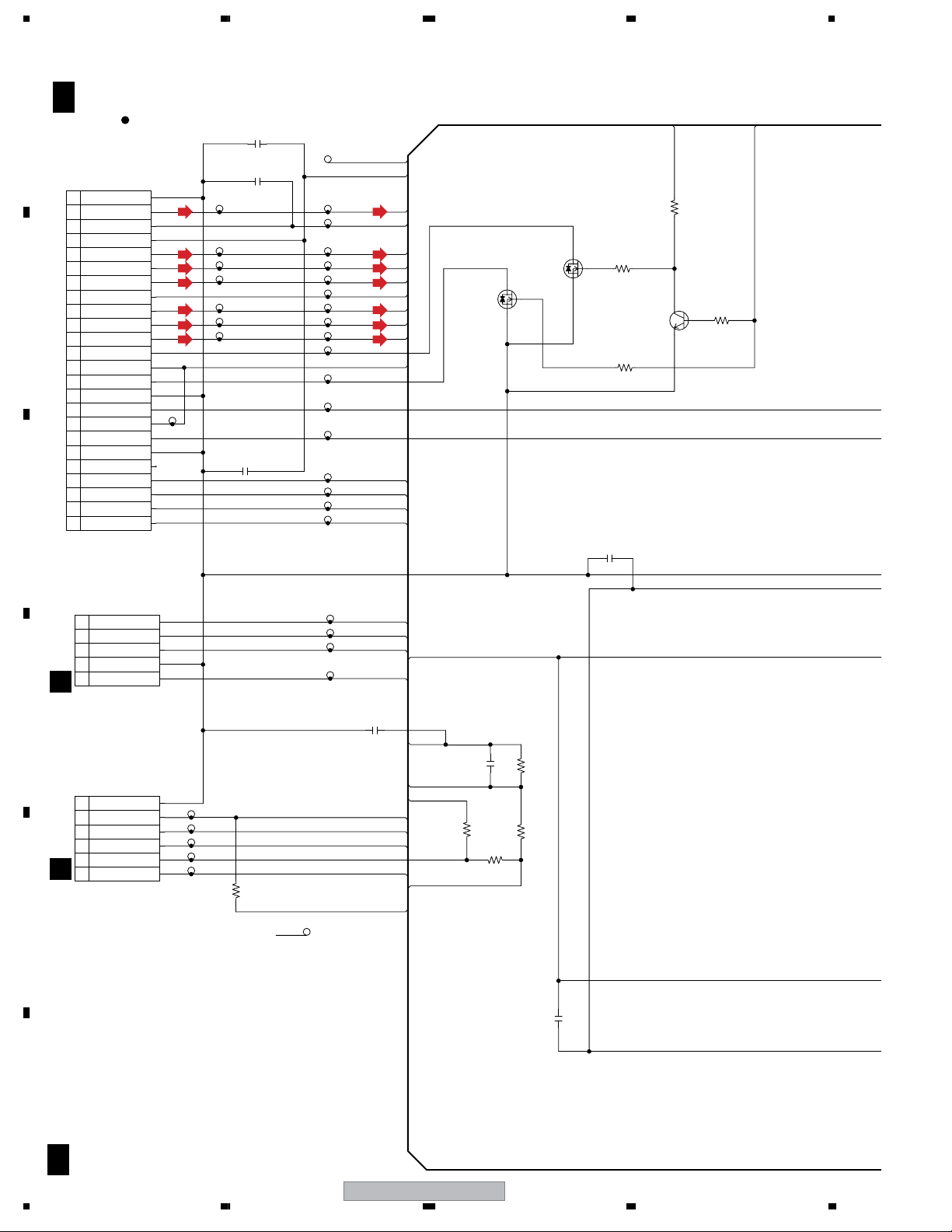

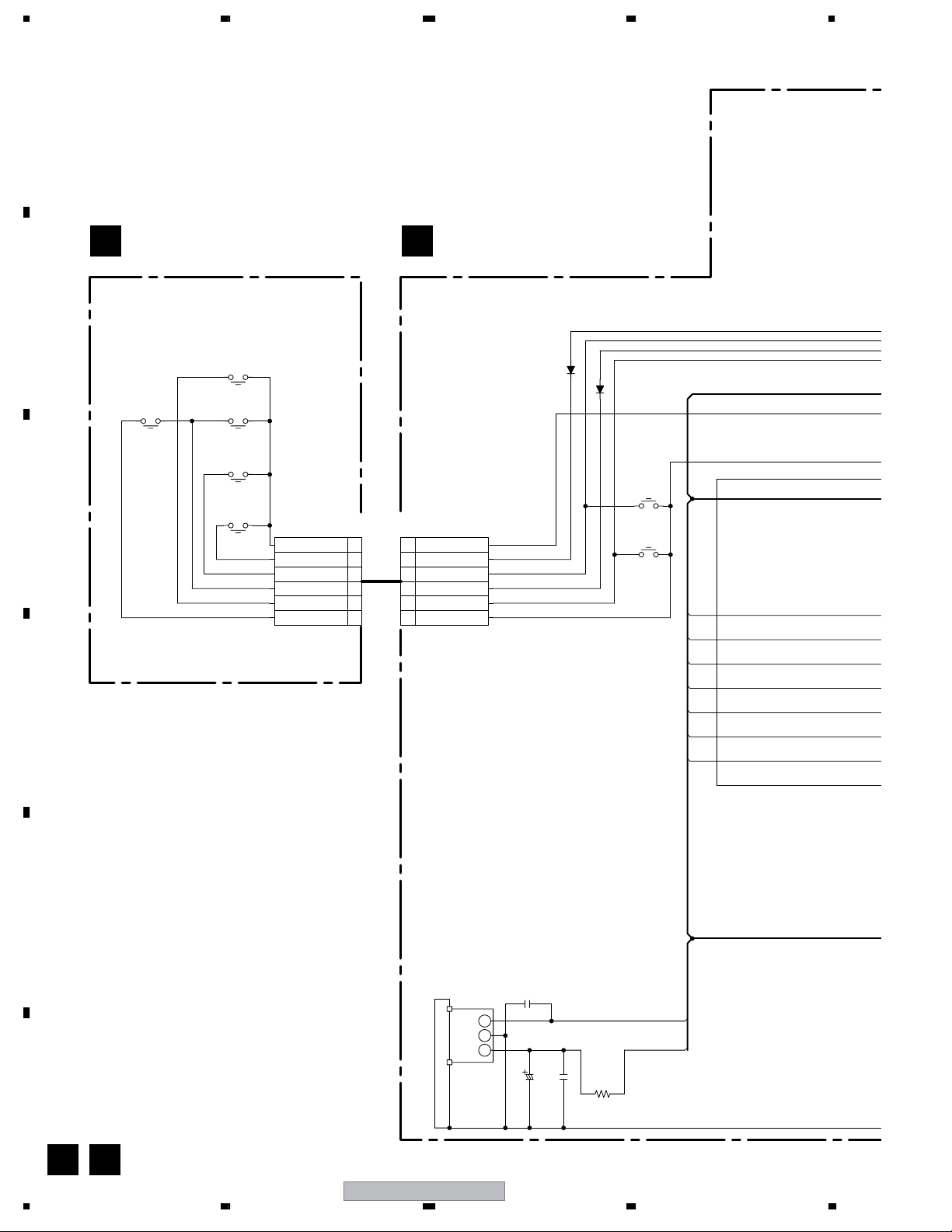

3.8 OPERATION 1 and OPERATION 2 PCB ASSYS

A

OPERATION 2 PCB ASSY

C

(A2G502A280)

OPERATION 1 PCB ASSY

B

(A2G502A270)

B

EVQ11L05R

POWER

SW667

EVQ11L05R

SW665

PAUSE

C

D

OPERATION 2 PCB ASSY

SW660 : STOP

SW662 : +SKIP

EVQ11L05R

SW664

-SKIP

EVQ11L05R

SW662

+SKIP

EVQ11L05R

SW660

STOP

00_6232_006_102_800+

CP602

SW2 SW2

STOP STOP

+SKIP +SKIP

PAUSE/-SKIP PAUSE/-SKIP

POWER POWER

V+3E

LED1

6

5

4

3

2

SW1 SW1

1

CP603

00_6232_006_102_800+

1

2

3

4

5

6

SW2

V+3E

LED1

OPERATION 1 PCB ASSY

SW663 : PLAY

SW666 : EJECT

1SS133

D656

1SS133

D658

SW663

EVQ11L05R

EVQ11L05R

PLAY

EJECT

SW666

SW1

P7

P6

P5

P4

P3

P2

P1

SW664 : - SKIP

SW665 : PAUSE

SW667 : POWER

E

F

26

B C

OS651

ROM-N340TAO

Vout

GND

B+

C659

0.001 B

1

2

3

0.1B

476.3V KA

C651

C674

R666

2.2 1 /4W

IR

V+3E

DV-380-S

1234

Loading...

Loading...