Pioneer DJM-800, DJC-800RV Service manual

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2006

POWE R

PROFESSIONAL MIXER

MIC

MIC 1MIC 2

-

12

-

12

MIC

OFF ON

HARMONIC

SOUND COLOR FX

CRUSH

FADER START

1234

HEADPHONES

MONO SPLIT STEREO

MIXING

LEVEL

PHONES

MIC 1

LEVEL

0

MIC 2

LEVEL

0

HI

+

6

EQ

LOW

+

6

TALK

OVER

SWEEP

FILTER

MASTERCUE

0

/DIGITAL PHONOCD/DIGITAL PHON O

CD

LINE

TRIM

TRIM

OVER

OVER

10

10

+

9

+

9

7

7

HI

HI

4

4

2

2

1

1

0

0

+6-

26

+6-

26

MID

MID

–1

–1

–2

–2

EQ EQ EQ EQ

–3

–3

–5

–5

+

6

-

26

+6-

26

–7

–7

LOW

LOW

–10

–10

–15

–15

–24

–24

dB dB dB dB

+6-

26

+6-

26

COLOR

COLOR

LOW

LOW

HI

HI

CUE

CUE

10

9

8

7

6

5

4

3

2

1

0

CROSS FADER ASSIGN

A B

LINE

/DIGITAL PHONO

/DIGITAL

TRIM

OVER

10

+

9

7

HI

4

2

1

0

+6-

26

MID

–1

–2

–3

–5

+6-

26

–7

LOW

–10

–15

–24

+6-

26

COLOR

LOW

HI

CUE

10

10

9

9

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

0

0

A THRU BA THRU BA THRU B

LINE

OVER

10

7

4

2

1

0

26

–1

–2

–3

–5

26

–7

–10

–15

–24

26

LOW

A THRU B

TRIM

+

9

HI

+6-

MID

+6-

LOW

+6-

COLOR

HI

CUE CUE

BOOTH MONITO R

CROSS FADER

MASTER

LR

BALANCE

MONO STEREO

CH FADER

LEVEL

0

OVER

10

7

4

2

1

0

–1

–2

–3

–5

–7

–10

BEAT

–15

–24

MIDI START

/STOP

AUTO/ TAP

dB

TAP

RL

CUE

BEAT EFFECTS

PHASER

FLANGER

FILTER

REVERB

TRANS

ROBOT

PAN

CHORUS

REV DLY

ROLL

ECHO

REV ROLL

DELAY

SND/RTN

4

MIC

3

CF.A

2

CF.B

1

MASTER

0

TIME

LEVEL/DEPTH

MAX

MIN

ON/OFF

ORDER NO.

PROVISIONAL

DJM-800

DJ MIXER

DJM-800

ROTARY VOLUME KIT

DJC-800RV

ZXJ/WL5

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Model Type Power Requirement Remarks

DJM-800 KUCXJ AC120V

DJM-800 WYXJ5 AC220 - 240V

DJM-800 TLXJ AC110 - 120 / 220 - 240V

For details, refer to "Important Check Points for good servicing".

T-IZR MAR. 2006 printed in Japan

1234

SAFETY INFORMATION

A

This service manual is intended for qualified service technicians ; it is not meant for the casual do-ityourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained

to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to

causecancer, birth defects or other reproductive harm.

B

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement

parts must be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que

les pièces de remplacement doivent avoir la même désignation.

Health & Safety Code Section 25249.6 – Proposition 65

C

(FOR USA MODEL ONLY)

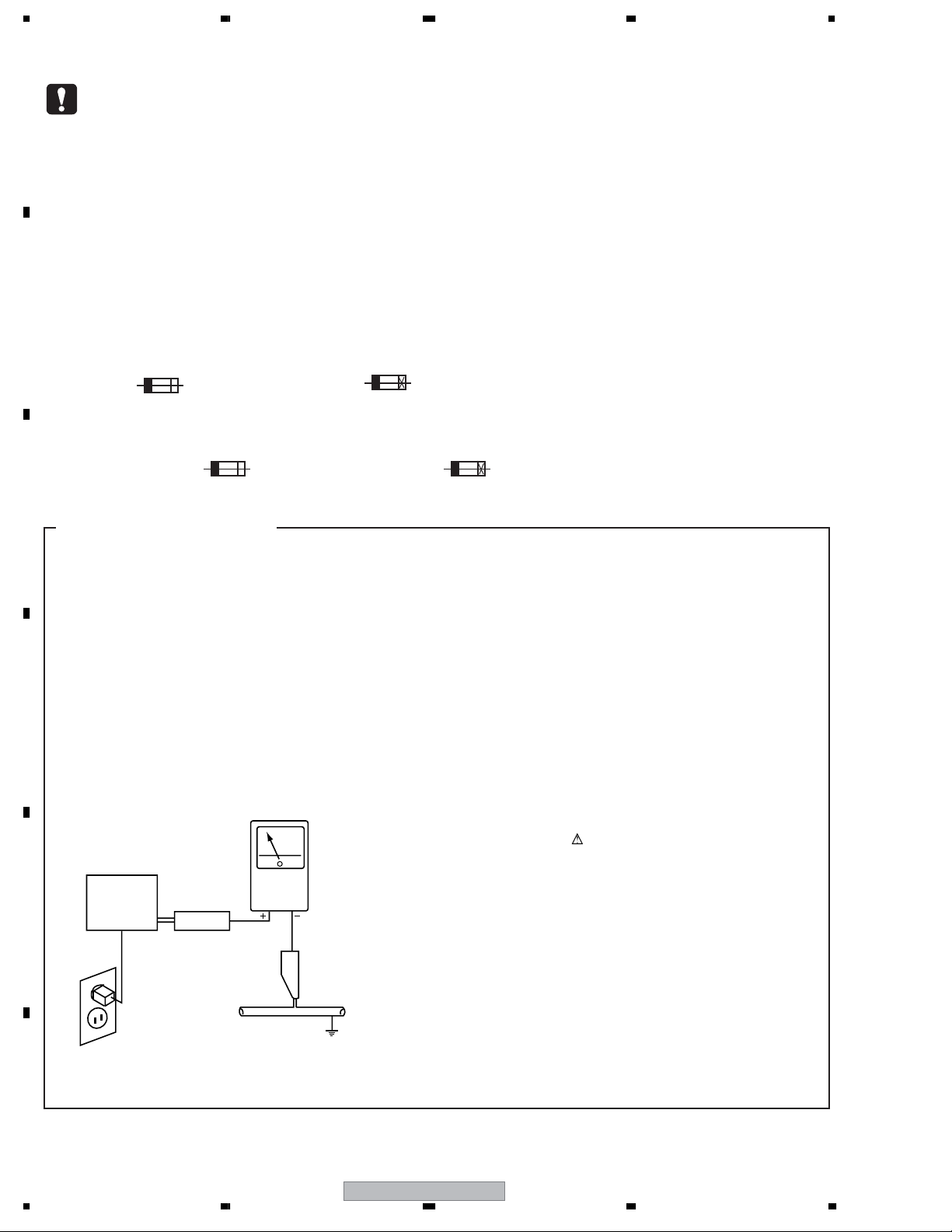

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and

service technician.

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground (waterpipe

, conduit, etc.) by connecting a leakage current tester

such as Simpson Model 229-2 or equivalent between the

D

earth ground and all exposed metal parts of the appliance

(input/output terminals, screwheads, metal overlays, control

shaft, etc.). Plug the AC line cord of the appliance directly

into a 120V AC 60Hz outlet and turn the AC power switch

on. Any current measured must not exceed 0.5mA.

Reading should

Leakage

Device

E

under

test

Also test with

plug reversed

(Using AC adapter

plug as required)

Test all

exposed metal

surfaces

current

tester

not be above

0.5mA

Earth

ground

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE APPLIANCE TO THE CUSTOMER.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance

have special safety related characteristics. These are

often not evident from visual inspection nor the protection

afforded by them necessarily can be obtained by using

replacement components rated for voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this Service Manual.

Electrical components having such features are identified

by marking with a on the schematics and on the parts list

in this Service Manual.

The use of a substitute replacement component which does

not have the same safety characteristics as the PIONEER

recommended replacement one, shown in the parts list in

this Service Manual, may create shock, fire, or other hazards.

Product Safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current PIONEER Service

Manual. A subscription to, or additional copies of, PIONEER

Service Manual may be obtained at a nominal charge

from PIONEER.

AC Leakage Test

F

2

1234

DJM-800

5678

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

0 Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

A

B

C

D

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

Make sure the proper amount is applied.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

56

DJM-800

E

F

3

7

8

1234

CONTENTS

1. SPECIFICATIONS ............................................................................................................................................ 5

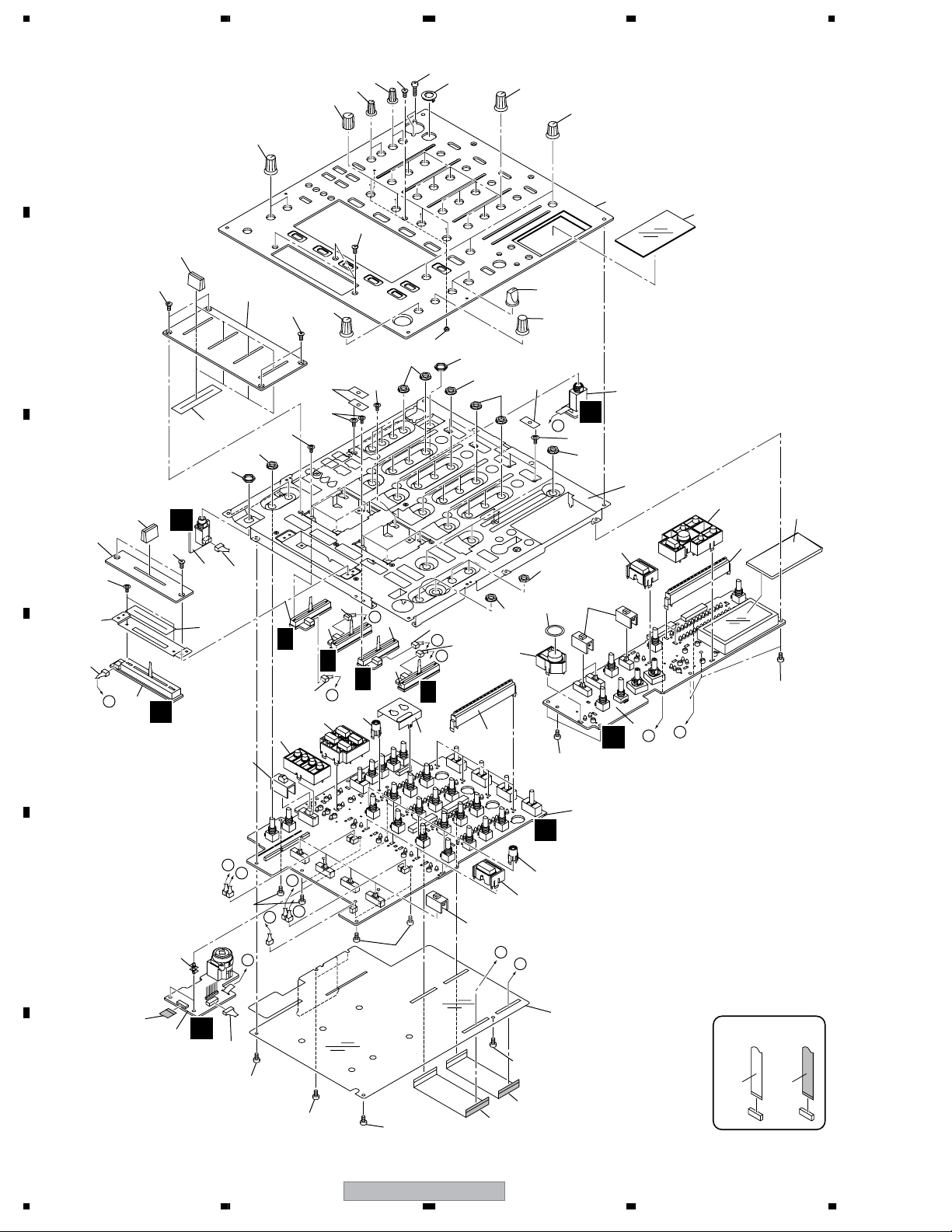

2. EXPLODED VIEWS AND PARTS LIST ............................................................................................................ 6

A

B

C

D

E

2.1 PACKING SECTION .................................................................................................................................. 6

2.2 EXTERIOR SECTION................................................................................................................................ 8

2.3 CONTROL PANEL SECTION .................................................................................................................. 10

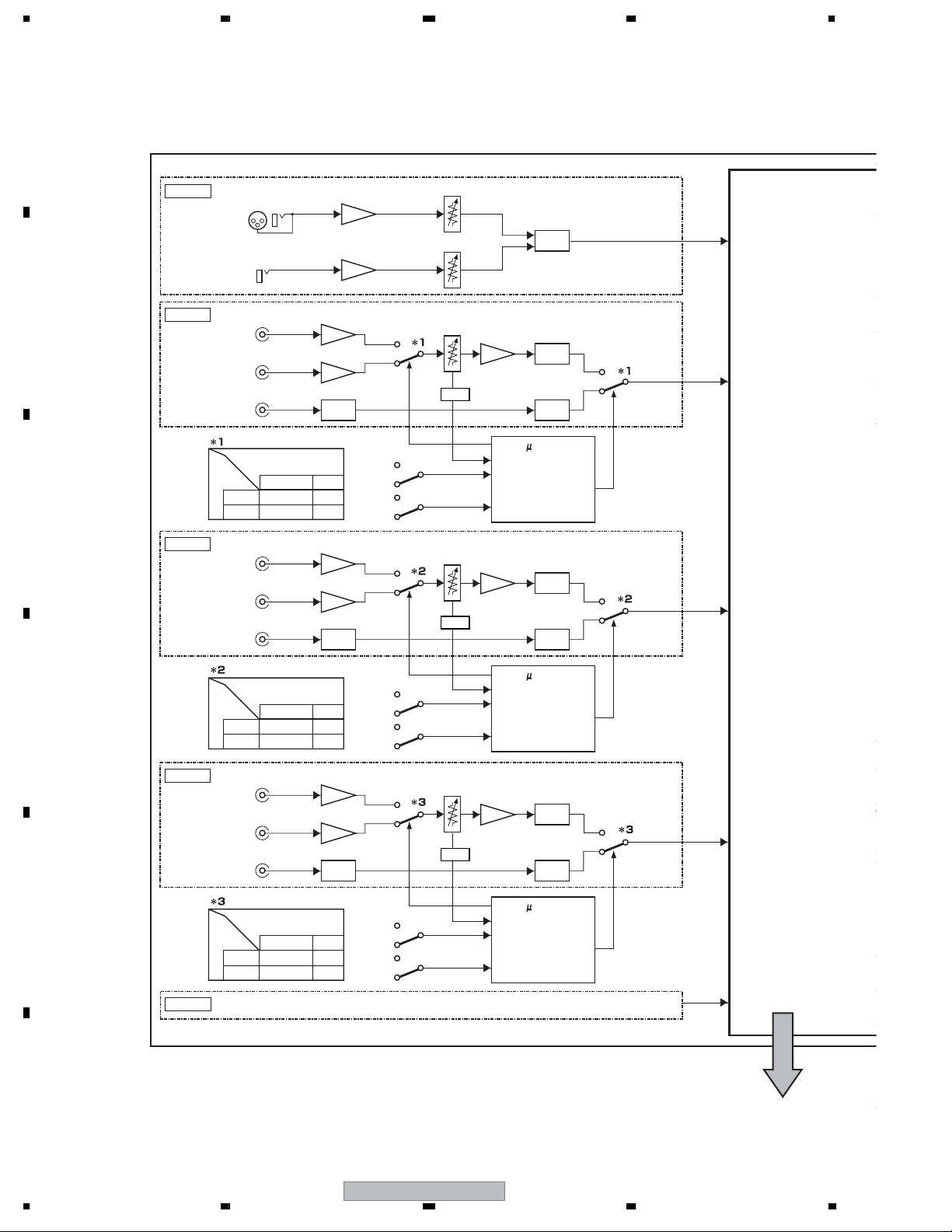

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM..........................................................................................12

3.1 OVERALL BLOCK DIAGRAM_1.............................................................................................................. 12

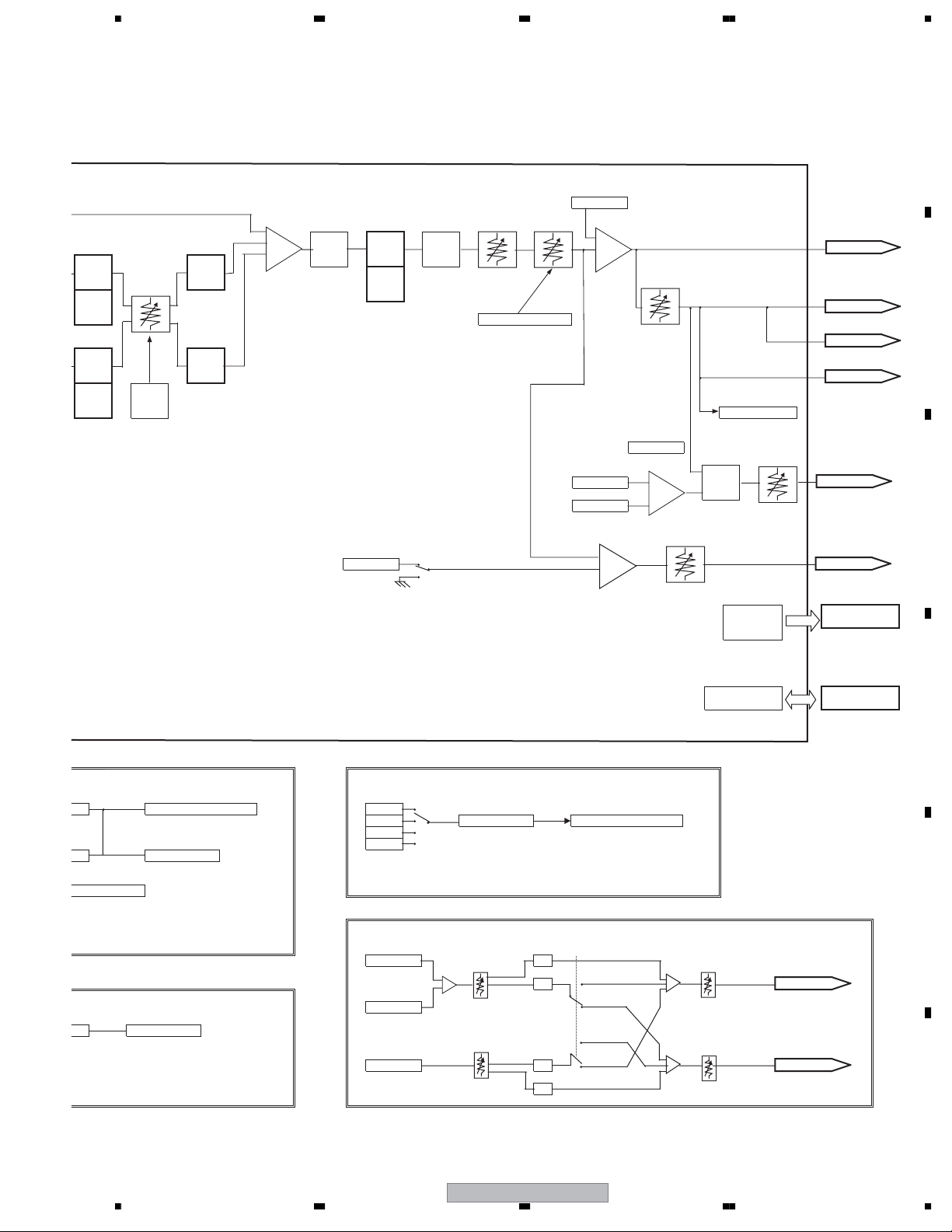

3.2 OVERALL BLOCK DIAGRAM_2.............................................................................................................. 14

3.3 OVERALL WIRING DIAGRAM................................................................................................................. 16

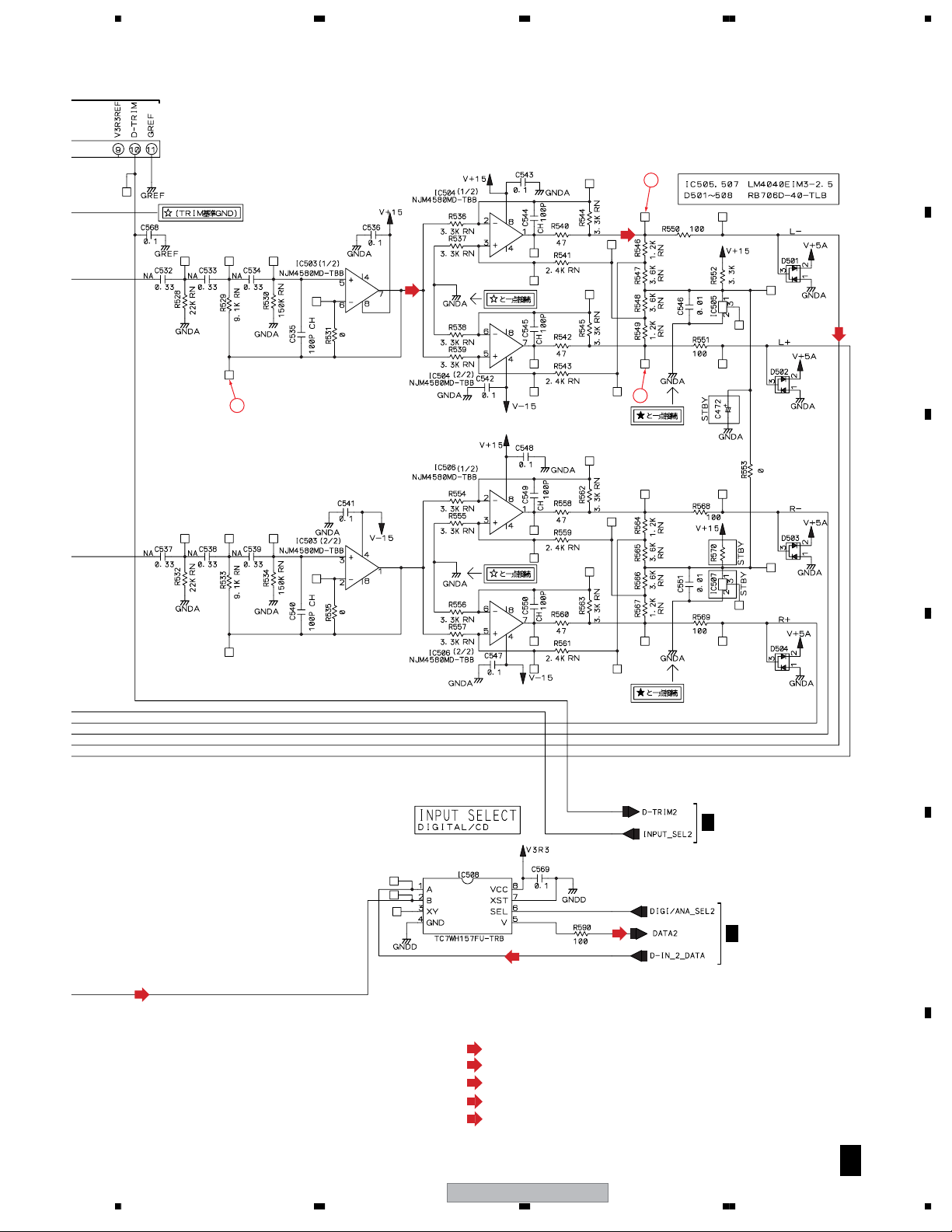

3.4 INPUT ASSY (1/6) ................................................................................................................................... 18

3.5 INPUT ASSY (2/6) ................................................................................................................................... 20

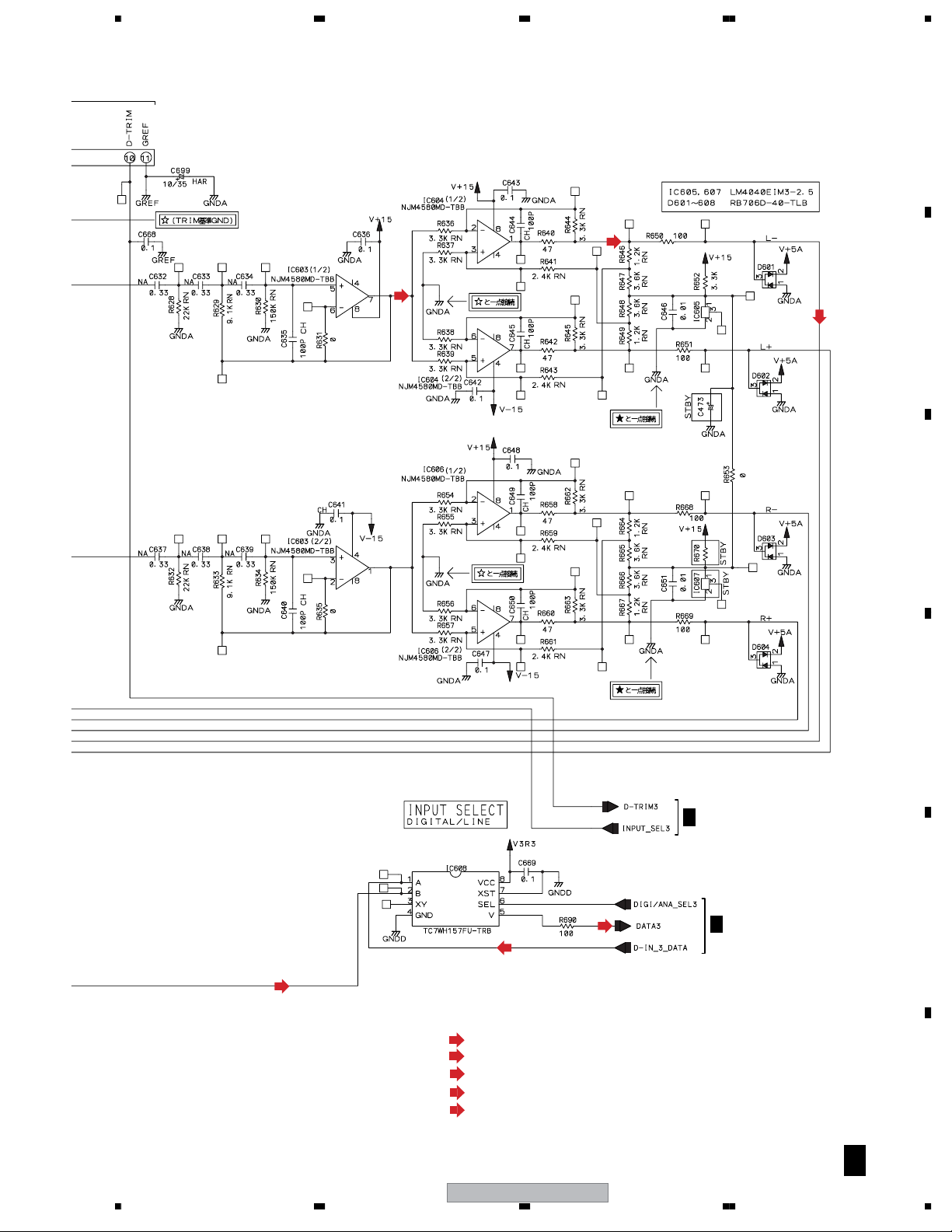

3.6 INPUT ASSY (3/6) ................................................................................................................................... 22

3.7 INPUT ASSY (4/6) ................................................................................................................................... 24

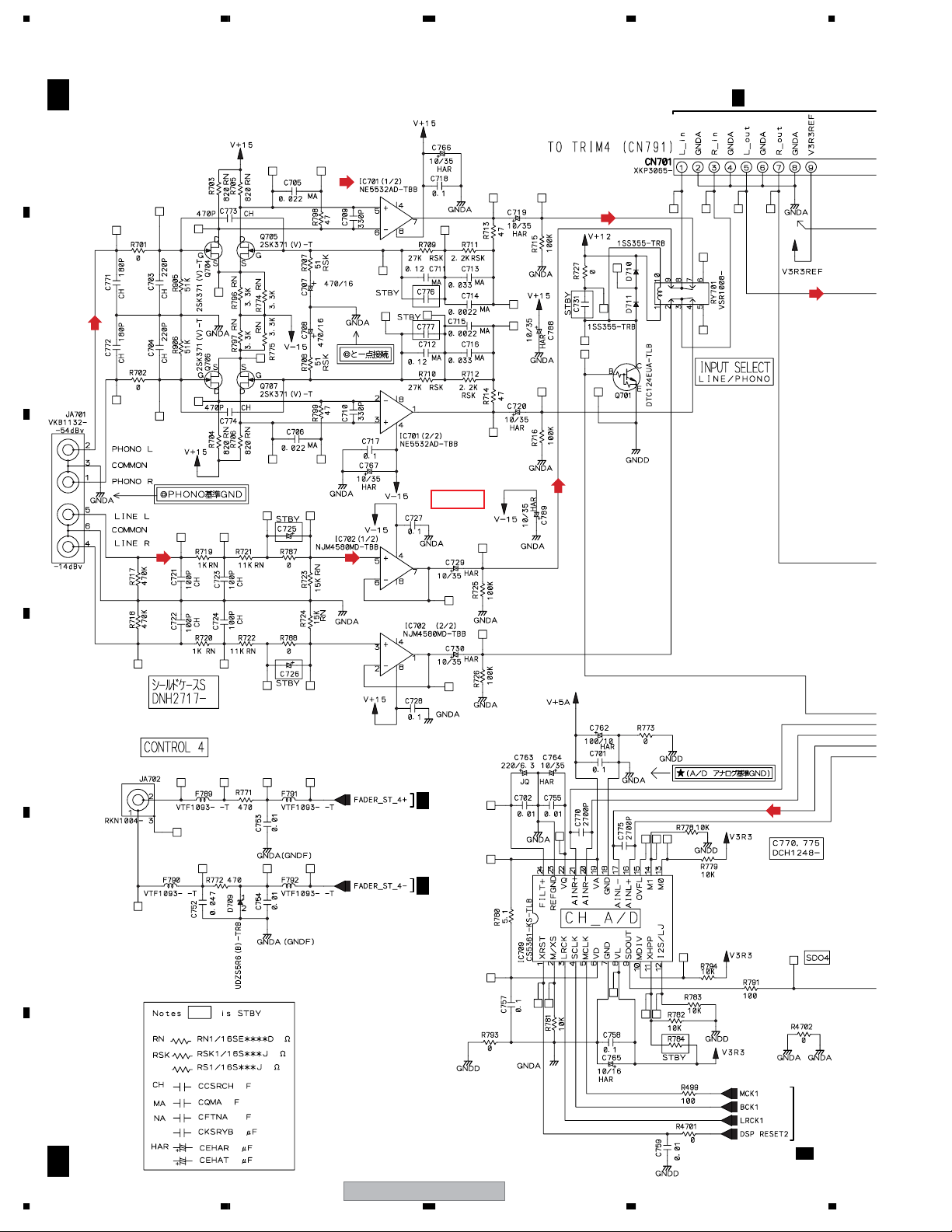

3.8 INPUT ASSY (5/6) ................................................................................................................................... 26

3.9 INPUT ASSY (6/6) ................................................................................................................................... 28

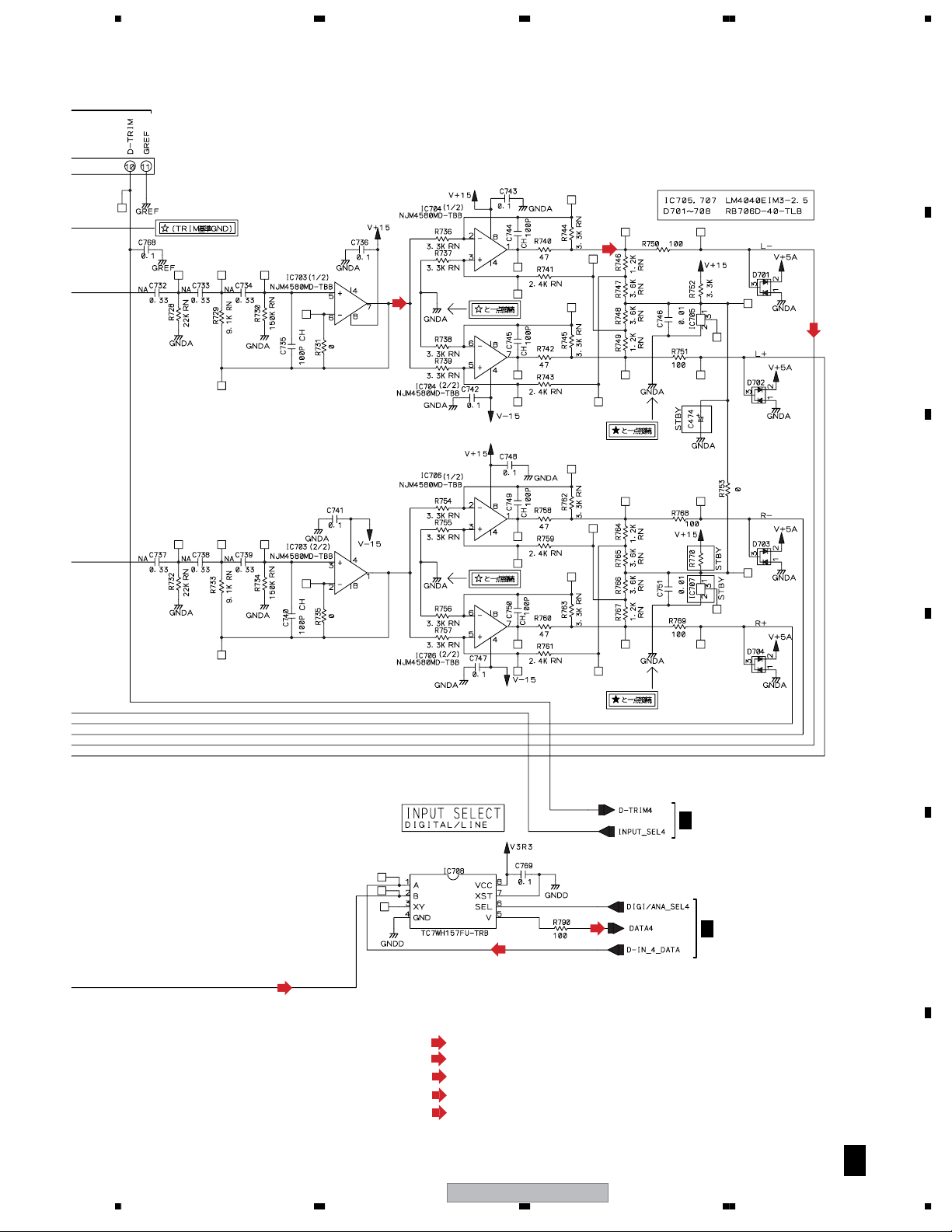

3.10 MIC 1 ASSY........................................................................................................................................... 30

3.11 PANEL 1 ASSY ...................................................................................................................................... 32

3.12 TRIM1 to TRIM 4 ASSYS....................................................................................................................... 36

3.13 MAIC 2 ASSY ........................................................................................................................................ 37

3.14 PANEL 2 ASSY ...................................................................................................................................... 38

3.15 CHFD 1 to CHFD 4 and CRSFD ASSYS............................................................................................... 40

3.16 DIGI A ASSY.......................................................................................................................................... 41

3.17 DSP ASSY (1/3)..................................................................................................................................... 42

3.18 DSP ASSY (2/3)..................................................................................................................................... 46

3.19 DSP ASSY (3/3)..................................................................................................................................... 50

3.20 OUTPUT ASSY (1/3) ............................................................................................................................. 54

3.21 OUTPUT ASSY (2/3) ............................................................................................................................. 56

3.22 OUTPUT ASSY (3/3) ............................................................................................................................. 58

3.23 DIGI C ASSY ......................................................................................................................................... 60

3.24 DIGI B ASSY.......................................................................................................................................... 64

3.25 SW POWER SUPPLY UNIT................................................................................................................... 66

3.26 VOLTAGES............................................................................................................................................. 68

3.27 WAVEFORMS ........................................................................................................................................ 73

4. PCB CONNECTION DIAGRAM ..................................................................................................................... 80

4.1 INPUT ASSY............................................................................................................................................ 80

4.2 PANEL 1 ASSY ........................................................................................................................................ 84

4.3 TRIM 1 to TRIM 4 and AC SW ASSYS .................................................................................................... 88

4.4 MIC1 and MIC2 ASSYS........................................................................................................................... 90

4.5 CHFD1, CHFD2, CHFD3 and CHFD4 ASSYS ........................................................................................ 91

4.6 PANEL 2 and DIGI A ASSYS................................................................................................................... 92

4.7 DSP ASSY ............................................................................................................................................... 96

4.8 OUTPUT ASSY...................................................................................................................................... 100

4.9 CRSFD, DIGI C and SLSW ASSYS....................................................................................................... 104

4.10 DIGIB ASSY......................................................................................................................................... 108

4.11 HP AMP and HP JACK ASSYS ........................................................................................................... 110

5. PCB PARTS LIST ......................................................................................................................................... 112

6. ADJUSTMENT ............................................................................................................................................. 119

7. GENARAL INFORMATION ........................................................................................................................... 120

7.1 DIAGNOSIS ........................................................................................................................................... 120

7.2 POWER ON SEQUENCE...................................................................................................................... 128

7.3 DISASSEMBLY ...................................................................................................................................... 129

7.4 IC INFORMATION.................................................................................................................................. 134

8. PANEL FACILITES ....................................................................................................................................... 149

9. ROTARY VOLUME KIT (DJC-800RV)........................................................................................................... 154

9.1 PACKING SECTION .............................................................................................................................. 154

9.2 EXTERIOR SECTION............................................................................................................................ 155

9.3 SCHEMATIC DIAGAM ........................................................................................................................... 156

9.4 DISASSEMBLY ...................................................................................................................................... 157

F

4

1234

DJM-800

5678

1. SPECIFICATIONS

SPECIFICATIONS

A

1. General

Power source .............................................................. AC 120 V, 60 Hz

Power consumption ..................................................................... 32W

Operating temperature ..................... +5 ˚C to +35 ˚C (+41 ˚F to +95 ˚F)

Operating humidity ....................5 % to 85 % (without condensation)

Weight ..........................................................................7.5 kg (16.54 lb )

Maximum dimensions ...................... 320 (W) x 381 (D) x 108 (H) mm

12-5/8 (W) x 15 (D) x 4-1/4 (H) in

2. Audio section

Sampling rate ............................................................................. 96 kHz

A/D, D/A converter ...................................................................... 24 bits

Frequency response

LINE ......................................................................... 20 Hz to 20 kHz

MIC .......................................................................... 20 Hz to 20 kHz

PHONO ......................................................... 20 Hz to 20 kHz (RIAA)

S/N ratio (at rated output)

LINE ....................................................................................... 104 dB

PHONO .................................................................................... 88 dB

MIC .......................................................................................... 84 dB

Distortion (LINE-MASTER 1) ....................................................0.005 %

Standard input level/Input impedance

PHONO 2 to 4 ............................................................ –52 dBu/47 kΩ

MIC 1, MIC 2 ............................................................... –52 dBu/3 kΩ

LINE, LINE/CD 1 to 4 ................................................. –12 dBu/22 kΩ

RETURN .................................................................... –12 dBu/22 kΩ

Standard output level/Load impedance/Output impedance

MASTER 1 ..............................................

MASTER 2 .......................................................... +2 dBu/10 k Ω/1 kΩ

REC ..................................................................... –8 dBu/10 kΩ /1 kΩ

BOOTH ............................................................. +2 dBu/600Ω /600Ω

SEND ................................................................ –12dBu/10 kΩ /1 kΩ

PHONES ................................................ +8.5 dBu/32Ω /22Ω or less

Rated output level/Load impedance

MASTER 1 ................................................................ +22 dBu/600Ω

MASTER 2 ................................................................. +20 dBu/10 kΩ

Crosstalk (LINE) ............................................................................ 88 dB

Channel equalizer response

HI ............................................................... –26 dB to +6 dB (13 kHz)

MID ............................................................. –26 dB to +6 dB (1 kHz)

LOW ............................................................ –26 dB to +6 dB (70 Hz )

Microphone equalizer response

HI ............................................................... –12 dB to +6 dB (10 kHz)

LOW .......................................................... –12 dB to +6 dB (100 Hz )

+2 dBu/600Ω /10 Ω or less

3. Input/output connector systems

PHONO input connectors

RCA pin jacks .................................................................................. 3

LINE/CD input connectors

RCA pin jacks .................................................................................. 4

LINE input connectors

RCA pin jacks .................................................................................. 1

MIC input connectors

XLR connector/phone jack (Ø6.3 mm) ...........................................1

Phone jack (Ø6.3 mm) .................................................................... 1

DIGITAL coaxial input connectors

RCA pin jacks .................................................................................. 4

RETURN input connectors

Phone jacks (Ø6.3 mm) .................................................................. 1

MASTER output connectors

XLR connectors ...............................................................................1

RCA pin jacks .................................................................................. 1

BOOTH output connectors

Phone jacks (Ø6.3 mm) .................................................................. 1

REC output connectors

RCA pin jacks .................................................................................. 1

SEND output connectors

Phone jacks (Ø6.3 mm) .................................................................. 1

DIGITAL coaxial output connector

RCA pin jack ....................................................................................1

MIDI OUT connector

5P DIN.............................................................................................. 1

PHONES output connector

Stereo phone jack (Ø6.3 mm) ........................................................ 1

CONTROL connector

Mini phone jacks (Ø3.5 mm) ..........................................................4

4. Accessories

Operating Instructions ......................................................................... 1

Power cord ........................................................................................... 1

Warranty card ......................................................................................1

Specifications and appearance are subject to change without notice.

B

C

D

56

DJM-800

E

F

5

7

8

1234

2. EXPLODED VIEWS AND PARTS LIST

NOTES:

A

Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on product are used for disassembly.

For the applying amount of lubricants or glue, follow the instructions in this manual.

(In the case of no amount instructions, apply as you think it appropriate.)

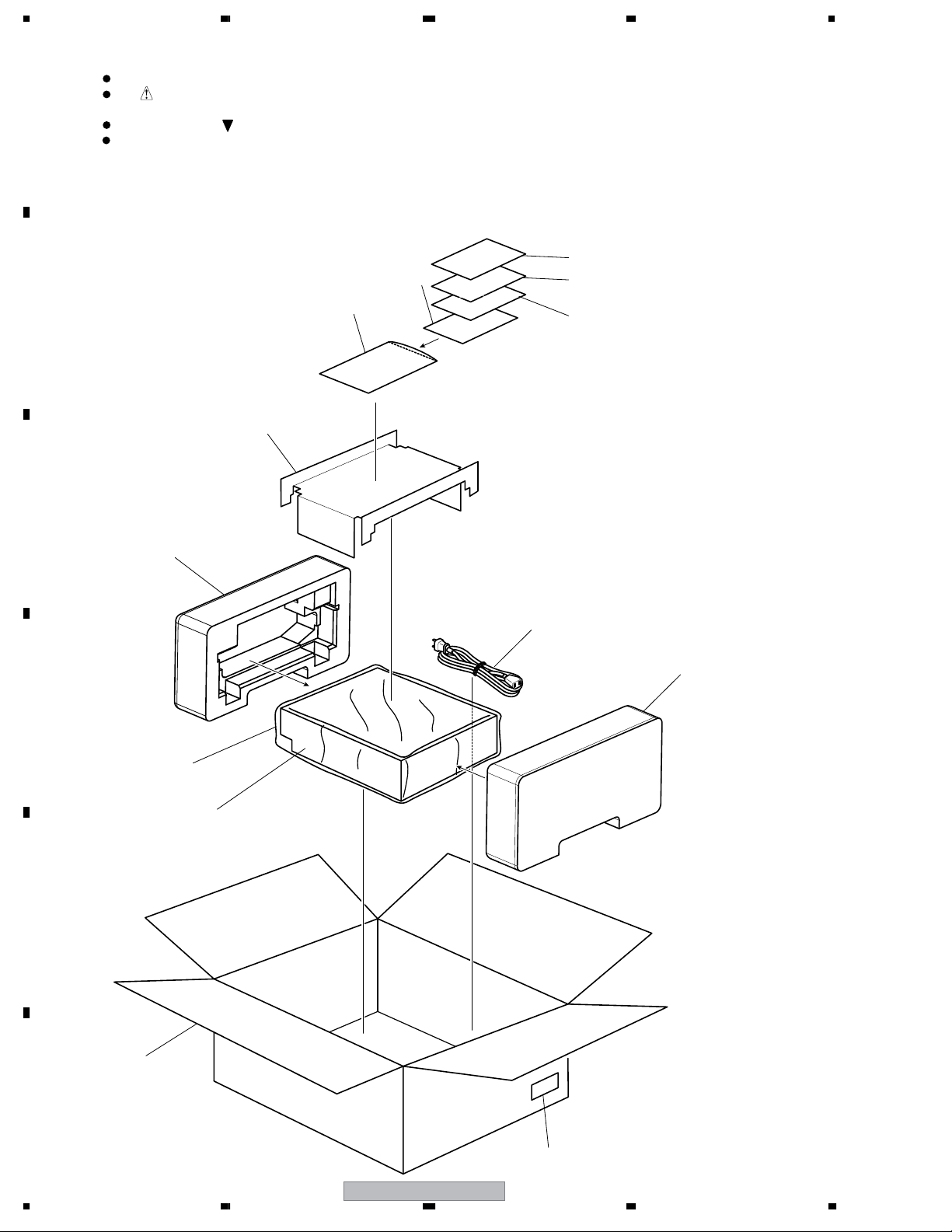

2.1 PACKING SECTION

B

C

13

5

9

4

12

11

3

8

2

D

7

FRONT

DJM-800

E

6

F

10

6

1234

DJM-800

>

5678

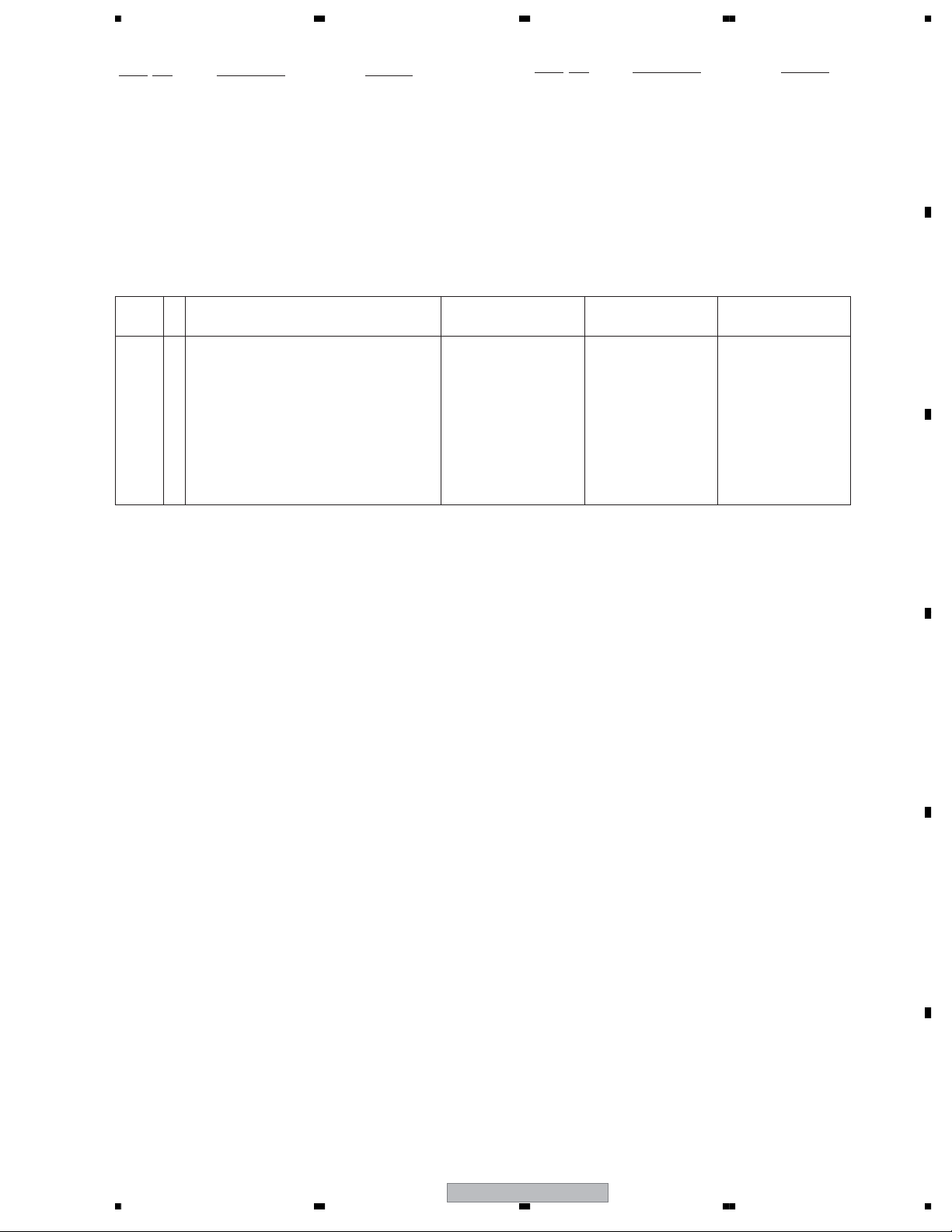

(1) PACKING SECTION PARTS LIST

No. Description Part No.

No. Description Part No.

Mark

1• • • •

2FRONT Pad DHA1698

3 REAR Pad DHA1699

4Top Pad DHA1705

5 Instruction Manual(M800) See Contrast table (2)

6Packing Case See Contrast table (2)

7Packing Sheet RHX1006

Mark

8 AC Power Cord See Contrast table (2)

NSP 9 Polyethylene Bag AHG7117

10 Label VRM1629

NSP 11 Warranty Card See Contrast table (2)

NSP 12 User Registration Sheet DRM1262

NSP 13 Correction Sheet See Contrast table (2)

(2) CONTRAST TABLE

DJM-800/WYXJ5, DJM-800/TLXJ and DJM-800/KUCXJ are constructed the same except for the fHollowing :

Mark No. Symbol and Description

5 Instruction Manual (English) DRB1393 Not used Not used

5 Instruction Manual (English, French) Not used DRB1392 Not used

German, Italian, Dutch, Spanish)

Instruction Manual (English, Spanish, Chinese) Not used Not used DRB1394

5

6Packing Case DHG2559 DHG2558 DHG2560

DJM-800

/KUCXJ

DJM-800

/WYXJ5

DJM-800

/TLXJ

A

B

>

NSP 11

NSP 13 Correction Sheet DRM1284 Not used Not used

8AC Power Cord DDG1028 ADG7062 ADG7062

Warranty Card

ARY7043 Not used Not used

C

D

56

DJM-800

E

F

7

7

8

1234

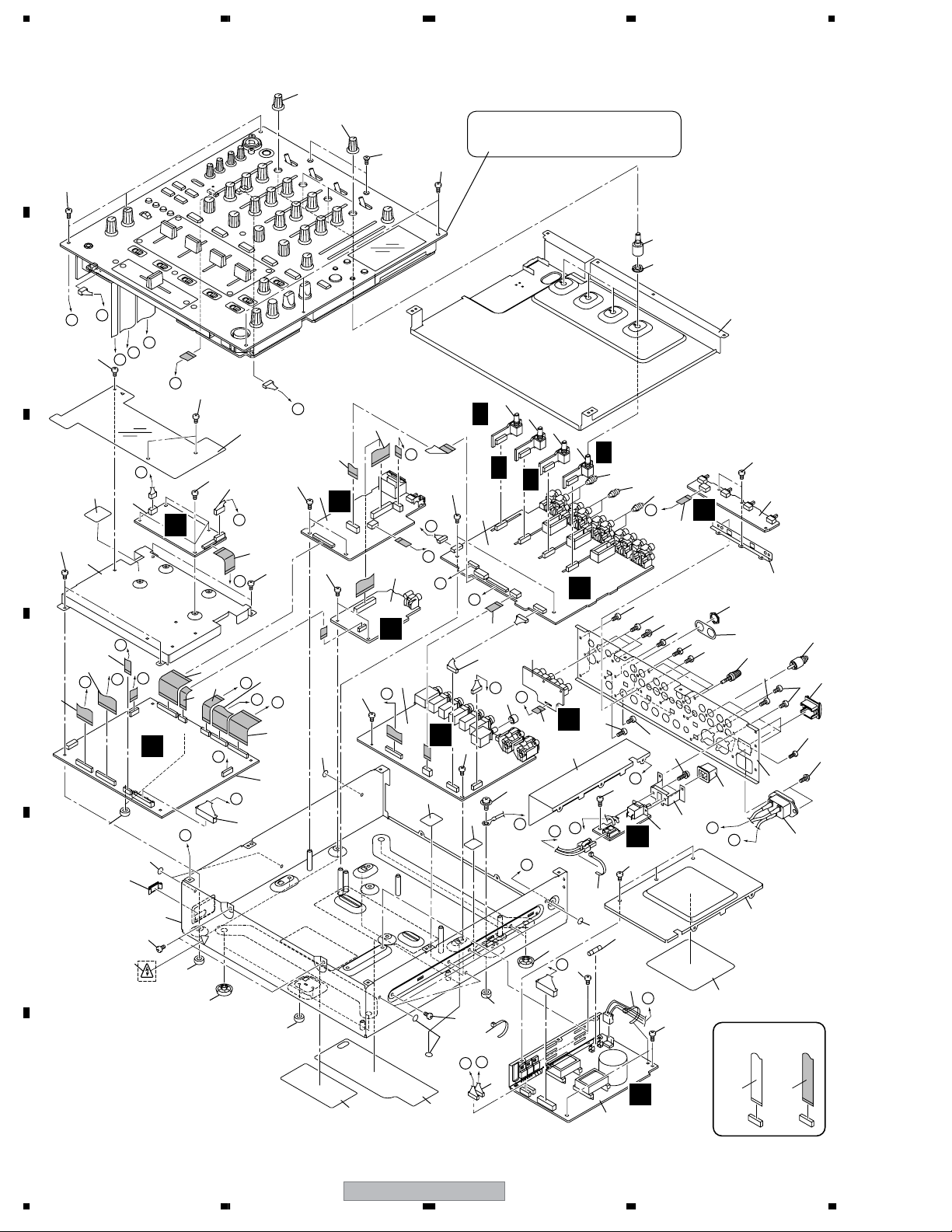

2.2 EXTERIOR SECTION

A

61

51

51

63

Refer to

"2.3 CONTROL PANEL SECTION".

61

50

64

B

C

59

22

D

S

A

O

P

59

Q

M

39

21

P

56

20

42

59

T

24

K

60

29

M

J

11

Q

60

T

R

L

7

J

45

S

12

O

59

31

60

8

B

19

59

K

N

27

16

17

M

O

18

L

J

59

I

16

I

K

47

6

E

A

30

48

47

60

71

I

K

1

33

4/4

K

23

C

5

49

68

3/4

Q

H

F

4

K

9

3

2/4

26

G

L

38

2

A

D

62

K

1/4

15

60

F

R

59

15

59

R

62

59

15

14

67

67

25

59

52

62

N

59

35

59

10

36

66

43

15

58

62

59

54

62

65

53

G

34

H

28

57

69

E

70

59

40

42

41

42

47

59

47

41

E

24

59

69

42

D

60

69

C

B

37

44

32

F

55

46

13

Q

NON-CONTACT

SIDE

CONTACT SIDE

8

1234

DJM-800

>

>

5678

EXTERIOR SECTION PARTS LIST

No. Description Part No.

Mark

1 INPUT Assy DWX2535

2 TRIM 4 Assy DWX2551

3 TRIM 3 Assy DWX2250

4 TRIM 2 Assy DWX2549

5 TRIM 1 Assy DWX2548

6 DSP Assy DWX2534

7 OUTPUT Assy DWX2544

8 DIGI C Assy DWX2547

9 DIGI A Assy DWX2555

10 SLSW Assy DWX2536

11 DIGI B Assy DWX2546

12 HP AMP Assy DWX2556

13 POWER SUPPLY Unit DWR1433

14 AC SW Assy DWX2545

15 Short Pin Plug AKM7008

16 Flexible Cable (31P) DDD1316

17 Flexible Cable (12P) DDD1317

18 Flexible Cable (25P) DDD1318

19 Flexible Cable (16P) DDD1313

20 Flexible Cable (10P) DDD1321

21 Flexible Cable (30P) DDD1322

22 Flexible Cable (25P) DDD1323

23 Flexible Cable (7P) DDD1326

24 Flexible Cable (12P) DDD1327

25 Flexible Cable (6P) DDD1328

26 Flexible Cable (7P) DDD1329

27 Flexible Cable (10P) DDD1333

>

28 AC Inlet Assy See Contrast table (2)

29 Flexible Cable (24P) DDD1330

30 Connector Assy(10P-12P) DKP3763

31 Connector Assy PF05EE-S22

32 Connector Assy PF05EE4S32

33 Connector Assy PF06EE-D12

NSP 34 Rear Panel See Contrast table (2)

35 Bracket TRIM DNF1728

36 Bracket SSW DNF1729

No. Description Part No.

Mark

37 Shield Case DNH2697

38 Shield Case AC DNH2698

39 Shield Case DSP DNH2699

40 Chassis Assy DXB1881

41 Leg Assy REC-434

42 Spacer AEB7092

43 PHONE Spacer DEC2914

44 Barrier A DEC2915

45 Styling Sheet DXB1881

46 Bottom Cover DEC2918

47 Bling Label DEC2928

48 Barrier B DEC2944

49 Select Knob (S) DAA1166

50 Extension Shaft DNK4691

51 Rotary SW Knob S DAA1204

52 Bracket PSW DNF1730

53 POWER Knob DAC2306

54 POWER Knob Guard DNK4534

NSP 55 LABEL See Contrast table (2)

56 CAUTION Label DRW2312

57 Blind Cap DNK4218

58 Terminal Screw AKE-031

59 Screw BBZ30P060FTB

60 Screw BBZ30P080FTC

61 Screw BCZ30P080FTB

62 Screw BPZ30P080FTB

63 Screw CCZ30P060FTB

64 Flange Nut M7 DBN1011

65 Screw IBZ30P080FTB

66 Nut NKX2FTC

67 Screw PMH30P100FTB

68 Screw PMH40P080FTC

69 Binder (SKB-90BK) ZCA-SKB90BK

70 Caution LABEL See Contrast table (2)

71 Earth LABEL See Contrast table (2)

A

B

C

D

(2) CONTRAST TABLE

DJM-800/WYXJ5, /TLXJ and DJM-800/KUCXJ are constructed the same except for the fHollowing :

Mark No. Symbol and Description

28 AC Inlet Assy DKP3761 DKP3762 DKP3762

NSP 34 Rear Panel DNC1800 DNC1789 DNC1791

NSP 55 LABEL DRW2294 DRW2293 DRW2319

NSP 70 Caution LABEL DRW1975 Not used Not used

NSP 71 Earth LABEL DRW2276 Not used Not used

DJM-800

/KUCXJ

DJM-800

56

DJM-800

/WYXJ5

7

DJM-800

/TLXJ

E

F

9

8

1234

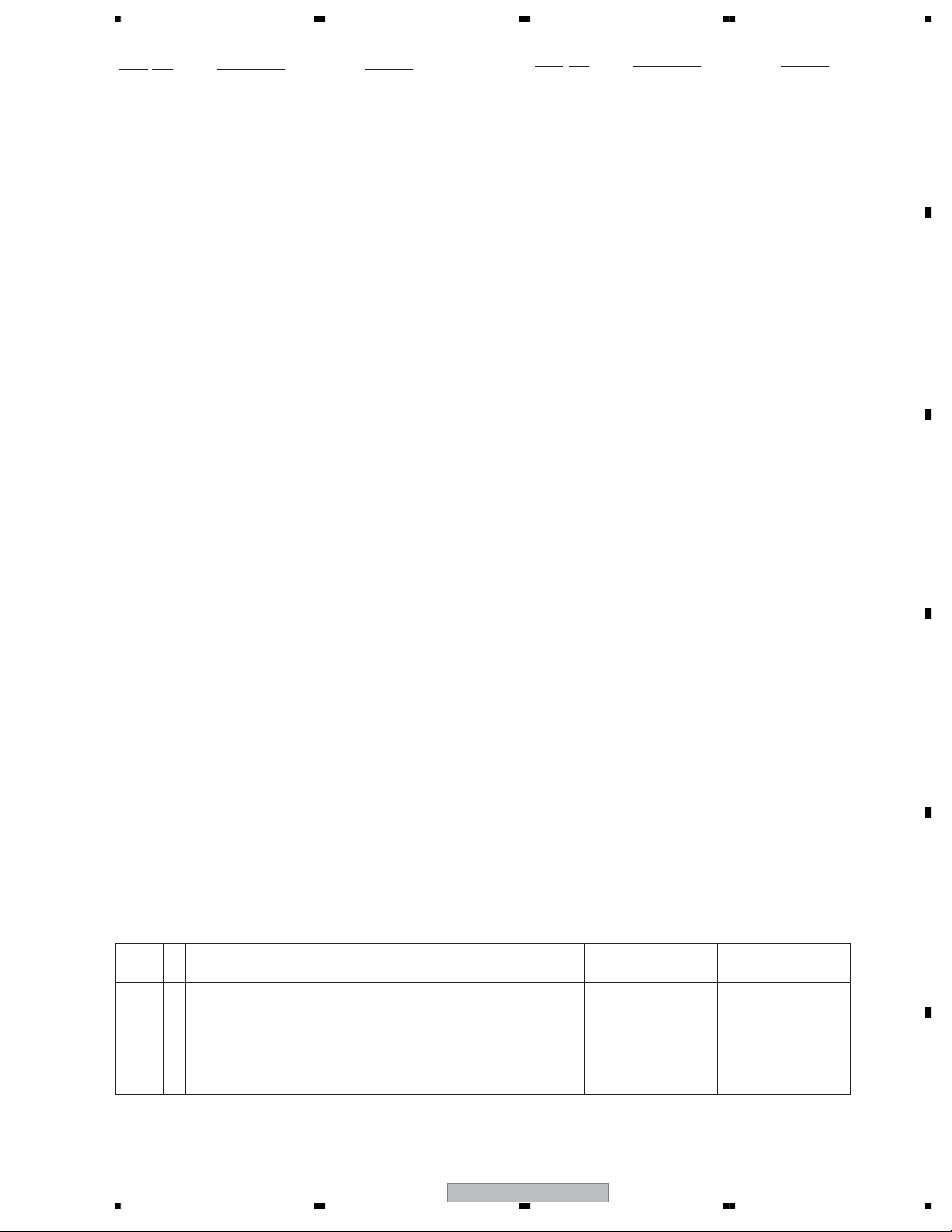

2.3 CONTROL PANEL SECTION

A

27

33

29

53

54

30

41

28

34

47

54

43

54

B

C

14

D

45

20

55

43

A

P

54

9

H

22

22

58

10

16

36

44

57

56

38

54

5

G

1/4

15

51

39

25

27

6

G

C

17

2/4

94

G

56

D

3/4

48

21

G

15

E

F

4/4

57

57

17

50

57

7

8

57

57

40

31

32

25

E

B

51

57

Dependence

86

23

52

F

35

3

19

4

G

46

37

50

H

24

52

2

C

C

D

E

26

11

1

F

10

1234

52

B

18

52

E

F

A

B

52

52

52

DJM-800

42

13

49

35

G

H

59

52

12

NON-CONTACT

SIDE

CONTACT SIDE

5678

CONTROL PANEL SECTION PARTS LIST

No. Description Part No.

Mark

1 MIC 1 Assy DWX2542

2PANEL 1 Assy DWX2552

3 MIC 2 Assy DWX2543

4PANEL 2 Assy DWX2554

5 CHFD 1 Assy DWX2537

6 CHFD 2 Assy DWX2538

7 CHFD 3 Assy DWX2539

8 CHFD 4 Assy DWX2540

9 CRS FD Assy DWX2541

10 HP JACK Assy DWX2553

No. Description Part No.

Mark

50

LEVEL Meter Assy

DXB1882

A

51 Screw AMZ26P040FTC

Screw

52

53

54

55

56

Screw

Screw

Screw

Screw

BBZ30P060FTB

BPZ30P120FTB

CCZ30P060FTB

DBA1262

DBA1298

57 Flange Nut M9 DBN1008

58 Nut NKX2FTC

11 Flexible Cable (12P) DDD1320

12 Flexible Cable (27P) DDD1324

13 Flexible Cable (30P) DDD1325

14 Housing Wire Assy PF03PP-D12

15 Housing Wire Assy PF04PP-D05

16 Housing Wire Assy PF04PP-D20

17 Housing Wire Assy PF04PP4D05

18 Housing Wire Assy PF05FF-D25

NSP 19 Panel Stay DND1254

20 CRF Syay DNF1726

21 MIC Syay DNF1727

22 Fader Packing DEC2903

23 SW Packing DEC2929

24 Barrier (FL) DEC2943

25 SW Packing DED1177

26 PC Support VEC1508

Rotary SW Knob (A)

27

28

Rotary SW Knob (B)

29

Rotary SW Knob S (A)

30

Rotary SW Knob S (B)

DAA1175

DAA1176

DAA1177

DAA1178

B

C

D

31 Select Knob DAA1179

32

Rotary SW Knob (C)

33

Rotary SW Knob (HM)

34

Rotary SW Knob (MA)

DAA1180

DAA1197

DAA1198

35 CUE Knob DAC2215

36 Slide SW Cap (A) DAC2219

37

SET Knob (TAP)

38

SET Knob (FS)

39

SET Knob (HM)

40

EFFECT Knob

DAC2300

DAC2301

DAC2302

DAC2304

41 MIC Cap DAC2309

42

Slide SW Cap

43

S lider Knob (L2)

44

CHF Panel

45

CRF Panel

DAC2310

DAC2371

DAH2426

DAH2427

46 Disply Panel DAH2428

47

Control Panel

48

LENS

49

LENS Holder

56

DNB1137

DNK4532

DNK4533

DJM-800

E

F

11

7

8

e

g

P

d

S

1234

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

3.1 OVERALL BLOCK DIAGRAM_1

A

B

CHn In

I

DSP BLOCK DIAGRAM

BLOCK DIAGRAM

CH1-CH4 COMMON

MI C

Digital in

Analog in

Digital Trim CHn Fad

Input of digital / analog is set by SelectSW

MIC 1

MIC 2

BPM

detect

CHx

CH 1

LINE

CD

DIGITAL

MIC1,2 In

2Band

MIC

EQ

C

CH 2

FPGA • Mode

[Dual PortRAM] • Volume data

PHONO

CPU

CD

I/F

Lo

ic

Bus • Switch data

DIGITAL

Send Out

Return In

BEAT

EFFECTS

(SND/RTN)

D

MIC AMP

3Band

CHn

EQ

COLOR

EFFECTS

[ch1~ 4]

EFFECTS

[CHx(pre)]

◊ 1 ◊ 2,3

MIC AMP

BUFFER

BUFFER

DIR

MIX

SW .

CD

DIGITAL

MIC SW Balance

Off

On

CD/DIGITAL

TalkOver

3-possi.

CD/DIGITAL

CD

DIGITAL

LINE SW.

LINE

LINE

LINE

PHONO AMP.

detect

[MIC]

LINE

CD

CD

DIGITAL

MIC

Low cut

MIC1,2 BPM

DIGITAL/CD

BUFFER

• CH Fader position

• CF Fader position

• Control Command

SW .

CD

DIGITAL/CD

DIGITAL

EFFECT CH SELECT

CD/DIGI TAL

CD

DIGITAL

CH1~ 4

CF_A/B

CD/DIGI TAL

MIC

PHONO SW.

Master

PHONO

PHONO

PHONO

DIR

PHONO

CD

CD

DIGITAL

BEAT

Send

Return

[CHx]

◊ 5

◊ 2,3,4

MIC 1 LEVEL

CUE

Monitor

[CHx]

MIC 2 LEVEL

TRIM

AD

MATRIX

Master

BEAT

55

EFFECTS

119

[MIC]

MATRIX

Send

Return

[MIC]

19

◊ 2,4

MIC

High cut

FilterFilter

TRIM

AD

MATRIX

59

119

MATRIX

20

CF Assign

BEAT

EFFECTS

[CHx(post)]

A/D

CH

Fader

Curve

3-possi.

CHx Level Meter CHx

BUFFER

Thru

CF_A

CF_B

3-possi.

A/D

SRC

-COM

MIC Data

VR AD

PHONO/LINE SW .

DIGIT AL SEL.

DIGITAL

/ANALOG SW.

Talk Over On/Off

28

BUFFER

A/D

SRC

-COM

VR AD

PHONO/LINE SW .

DIGIT AL SEL.

DIGITAL

/ANALOG SW.

29

CHx

147

MIC 1

MIC 2

BPM

+

+

143

detect

[CF_A]

BPM

detect

[CF_B]

CH 1

BEAT

EFFECTS

[CF_A(pre)]

◊ 5

Return

[CF_A]

BEAT

EFFECTS

[CF_B(pre)]

◊ 5

Return

[CF_B]

Send

Send

◊ 2,3,4

◊ 2,3,4

CROSS

Fader

Cross

Fader

Curve

3-

D

144

CH 2

/// BEAT EFFECT (SND/RTN) ///

CH 3

PHONO

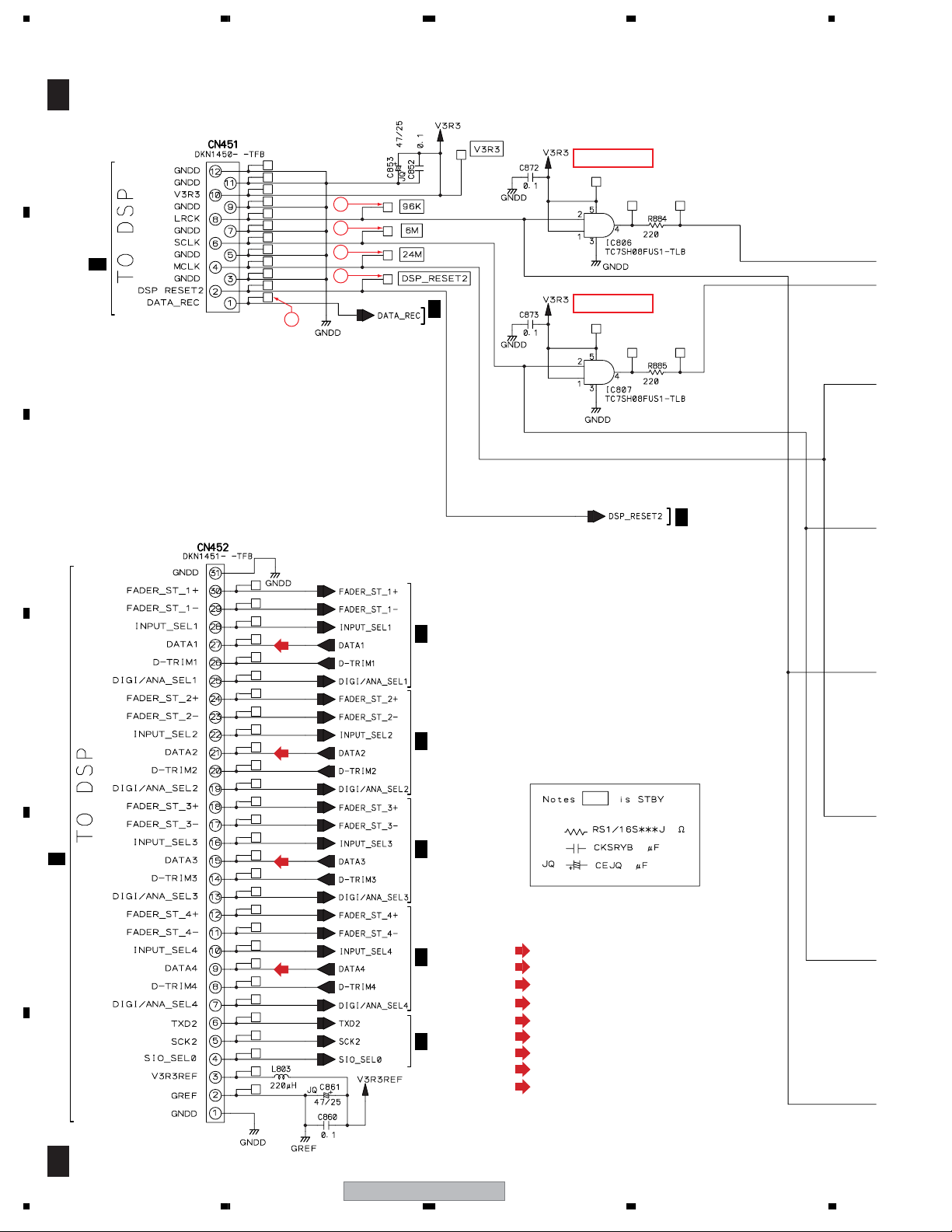

EFFECT CH SELECT

CH1~ 4

CF_A/B

MIC

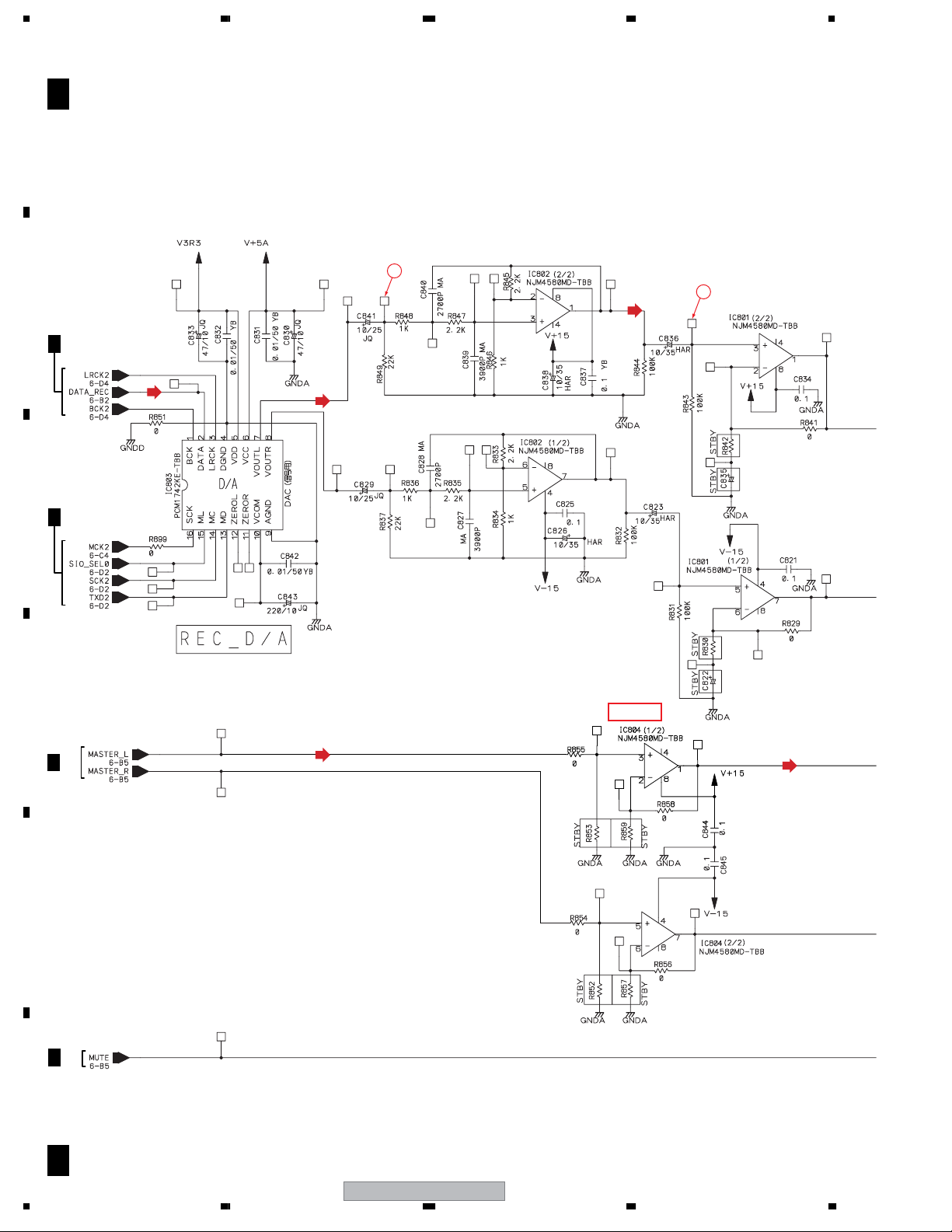

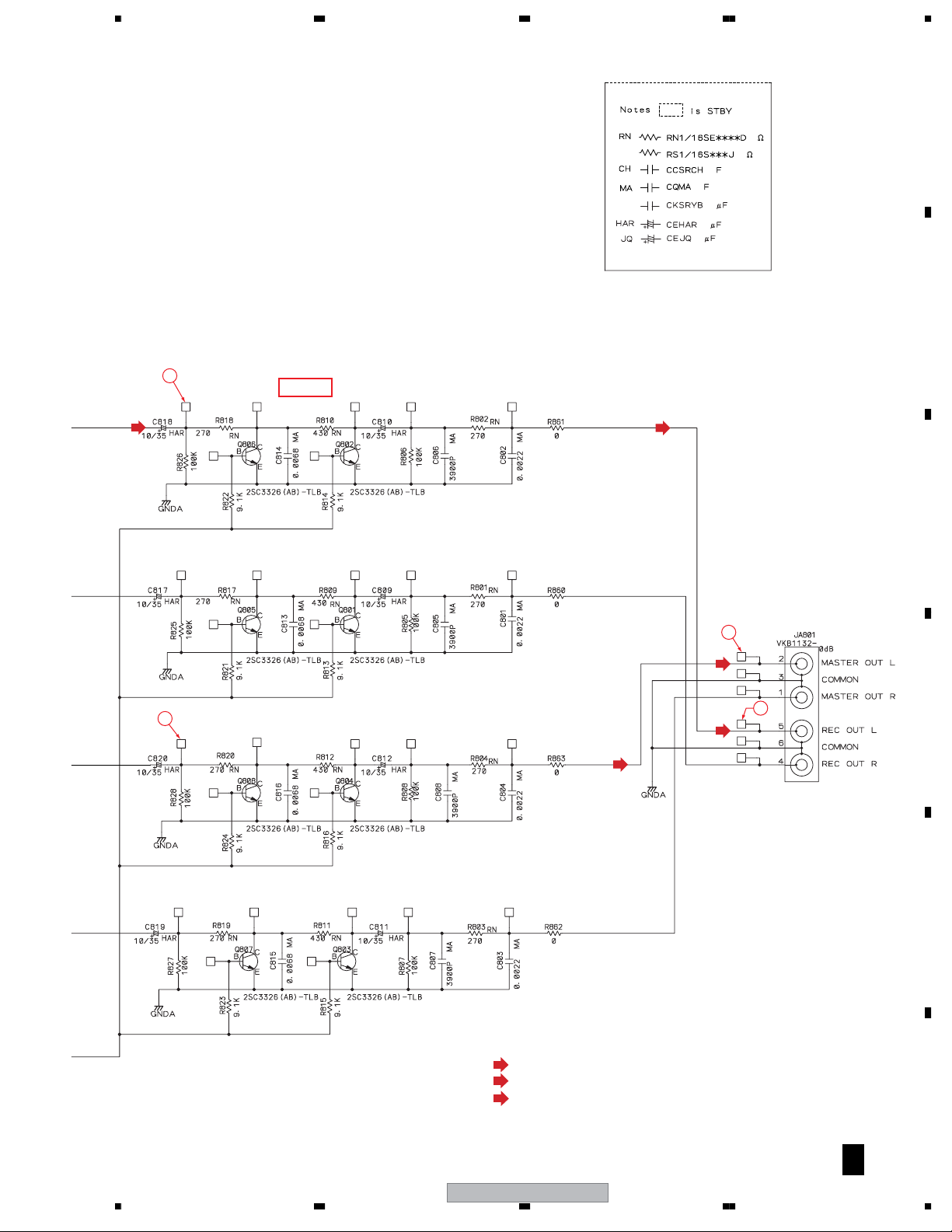

LINE

Master

Return Level Effect SW

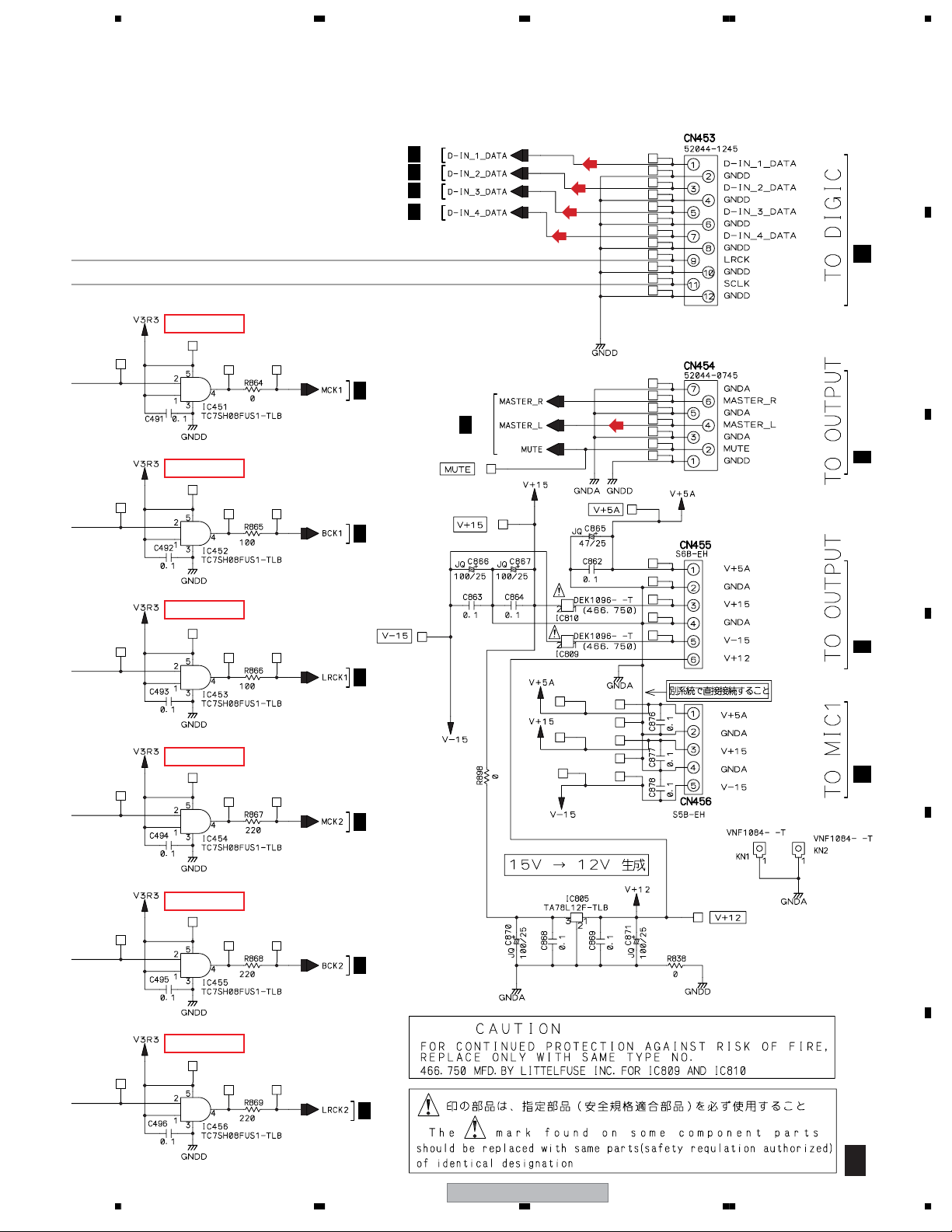

DIGITAL

Return In

E

LINE/DIGI TAL

SW .

LINE

DIGITAL/LINE

DIGITAL

/// BEAT EFFECT (Other) ///

CH 4

EFFECT CH SELECT

CH1~ 4

CF_A/B

MIC

Master

EFFECT Processor

PHONO AMP.

BUFFER

No Cable

DIR

Cable Exist

LINE/DIGI TAL

CableCheck

PHONO SW.

LINE

DIGITAL

MIX RATIO Effect Out

PHONO

PHONO

PHONO

PHONO

LINE/CD

ANALOG

DIGITAL

Effect SW CH1 ~ 4 In

TRIM

SEND Out

Effect Out

119

EFFECT CUE

MATRIX

same as CH 3

EFFECT CUE

BUFFER

AD

MATRIX

60

-COM

VR AD

PHONO/LINE SW .

DIGIT AL SEL.

21

DIGITAL

/ANALOG SW.

A/D

SRC

F

12

DJM-800

/// COLOR EFFECT (Harmonic) ///

CH1 ~ 4 In

Friqency Counter Sen

145

CH 3

EFFECT Processor CH1

Effect Contror (from CPU)

30

/// COLOR EFFECT (Others) ///

146

CH 4

EFFECT Processor CH1 ~ 4

To DSP BLOCK DIAGRAM

1234

5678

A

D610A003BPYPA225-K

DSP

PHONES

MASTER

BOOTH

REC

SEND

RETURN

13

27

20

18

17

150

D/A

MASTER ATT.

D/A

SRC DI T

BUFFER AMP.

D/A

BUFFER

D/A

D/A

A/D

BUFFER

AMP.

AMP.

MUTE

MUTE

MUTE

MUTE

MUTE

MUTE

PHONES

B

MASTER 1

MASTER 2

DIGITAL OUT

BOOTH

REC

C

SEND

D

RETURN

64M 4M

SDRAM

÷

When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS LIST" or

FLASH

ROM

FPGA

XC3S50-

4TQG144C-K

-COM

HD64F2377-K

(PEG236A8-K)

"PCB PARTS LIST".

÷

The > mark found on some component parts indicates the importance of the safety factor

of the part. Therefore, when replacing, be sure to use parts of identical designation.

÷

: The power supply is shown with the marked box.

DJM-800

56

7

E

F

13

8

1234

e

g

P

d

3.2 OVERALL BLOCK DIAGRAM_2

A

CHn In

I

DSP BLOCK DIAGRAM

CH1-CH4 COMMON

Digital in

Analog in

Digital Trim CHn Fad

Input of digital / analog is set by SelectSW

BPM

detect

CHx

B

MIC1,2 In

2Band

MIC

EQ

C

FPGA • Mode

[Dual PortRAM] • Volume data

Send Out

Return In

Bus • Switch data

CPU

I/F

Lo

BEAT

EFFECTS

(SND/RTN)

ic

D

3Band

CHn

EQ

MIX

• CH Fader position

• CF Fader position

• Control Command

EFFECT CH SELECT

MIC SW Balance

TalkOver

3-possi.

MIC1,2 BPM

COLOR

EFFECTS

[ch1~ 4]

Off

On

CH1~ 4

CF_A/B

MIC

Master

EFFECTS

[CHx(pre)]

◊ 1 ◊ 2,3

detect

[MIC]

MIC

Low cut

BEAT

Send

Return

[CHx]

◊ 5

◊ 2,3,4

CUE

Monitor

[CHx]

BEAT

EFFECTS

[MIC]

Send

Return

[MIC]

◊ 2,4

MIC

High cut

FilterFilter

CF Assign

BEAT

EFFECTS

[CHx(post)]

CH

Fader

Curve

3-possi.

CHx Level Meter CHx

Master

MIC Data

Talk Over On/Off

Thru

CF_A

CF_B

3-possi.

CHx

BPM

+

+

detect

[CF_A]

BPM

detect

[CF_B]

BEAT

EFFECTS

[CF_A(pre)]

◊ 5

Return

[CF_A]

BEAT

EFFECTS

[CF_B(pre)]

◊ 5

Return

[CF_B]

Send

Send

◊ 2,3,4

◊ 2,3,4

CROSS

Fader

Cross

Fader

Curve

3-

/// BEAT EFFECT (SND/RTN) ///

EFFECT CH SELECT

CH1~ 4

CF_A/B

MIC

Master

Return Level Effect SW

Return In

E

/// BEAT EFFECT (Other) ///

EFFECT CH SELECT

CH1~ 4

CF_A/B

MIC

Master

EFFECT Processor

No Cable

Cable Exist

CableCheck

MIX RATIO Effect Out

Effect SW CH1 ~ 4 In

SEND Out

Effect Out

EFFECT CUE

EFFECT CUE

/// COLOR EFFECT (Harmonic) ///

CH1 ~ 4 In

/// COLOR EFFECT (Others) ///

Friqency Counter Sen

EFFECT Processor CH1

Effect Contror (from CPU)

EFFECT Processor CH1 ~ 4

F

14

DJM-800

1234

s

e

+

5678

A

BEAT

EFFECTS

[CF_A(pre)]

Send

Return

[CF_A]

BEAT

EFFECTS

[CF_B(pre)]

Send

Return

[CF_B]

Master

Balance Talk Over

Talk Over On/Off

◊ 5

MIC Data

BEAT

EFFECTS

[Master]BEAT

Send

Return

[Master]

◊ 2,4

Master

Mono⇔

Stereo

MIC Monitor SW

BPM

detect

+

CROSS

Fader Master Level

◊ 2,3,4

Cross

Fader

Curve

◊ 2,3,4

EFFECTS

CF_A(post)]

◊ 2,3

BEAT

EFFECTS

CF_B(post)]

◊ 2,3

3-Posi.

◊ 1 : Ch1 ~ 4 processes the same effect.

◊ 2 : Boil

effectch Select

◊ 3 : Position of effect input is set in either front and back of fader by specification of Effect.

◊ 4 : I do SEND/RETURN of CH set in SND/RTN select by EffectCHSELECT.

◊ 5 : I detect B P M of CH selected by EFFECT CHSELECT.

[Master]

SW and do of effect attention for selected setting.

MIC Data

CH x CUE

Effect CUE

CH x MIX Data

+

Master Level Meter

Master CUE

+

Booth Level

+

• DSP Status FPGA

• BPM Detect data

• Harmonic Detect data

• CH Level Meter

• Master Level Meter

H.P.

MIX

CPU

I/F

Logic

H.P. Level

Rec Out

Master Out1

Master Out2

Digital Out

H.P. Out

Booth Out

[Dual PortRAM]

B

C

EFFECT Processor SD-RAM

D

/// BPM DET. ///

r Send to CPU

sor CH1 ~ 4 Out

from CPU)

or CH1 ~ 4 Out Mono Split

EFFECT CH SELECT

CH1~ 4

CF_A/B

MIC

Master

◊ I detect B P M only for CH which EFFECT CH SELECT appears, and was Counter.

/// H.P. MIX ///

CHx CUE CUE Balance L H.P.Level

BPM COUNTER

+

EFFECT CUE

Master Balanc

Master CUE L

Send to CPU

H.P.MONOSPLIT/STEREO SW

R

R

Mono Split

Stereo

Stereo

H.P.Level

+

E

H.P. Out Lch

H.P. Out Rch

F

DJM-800

56

7

8

15

1234

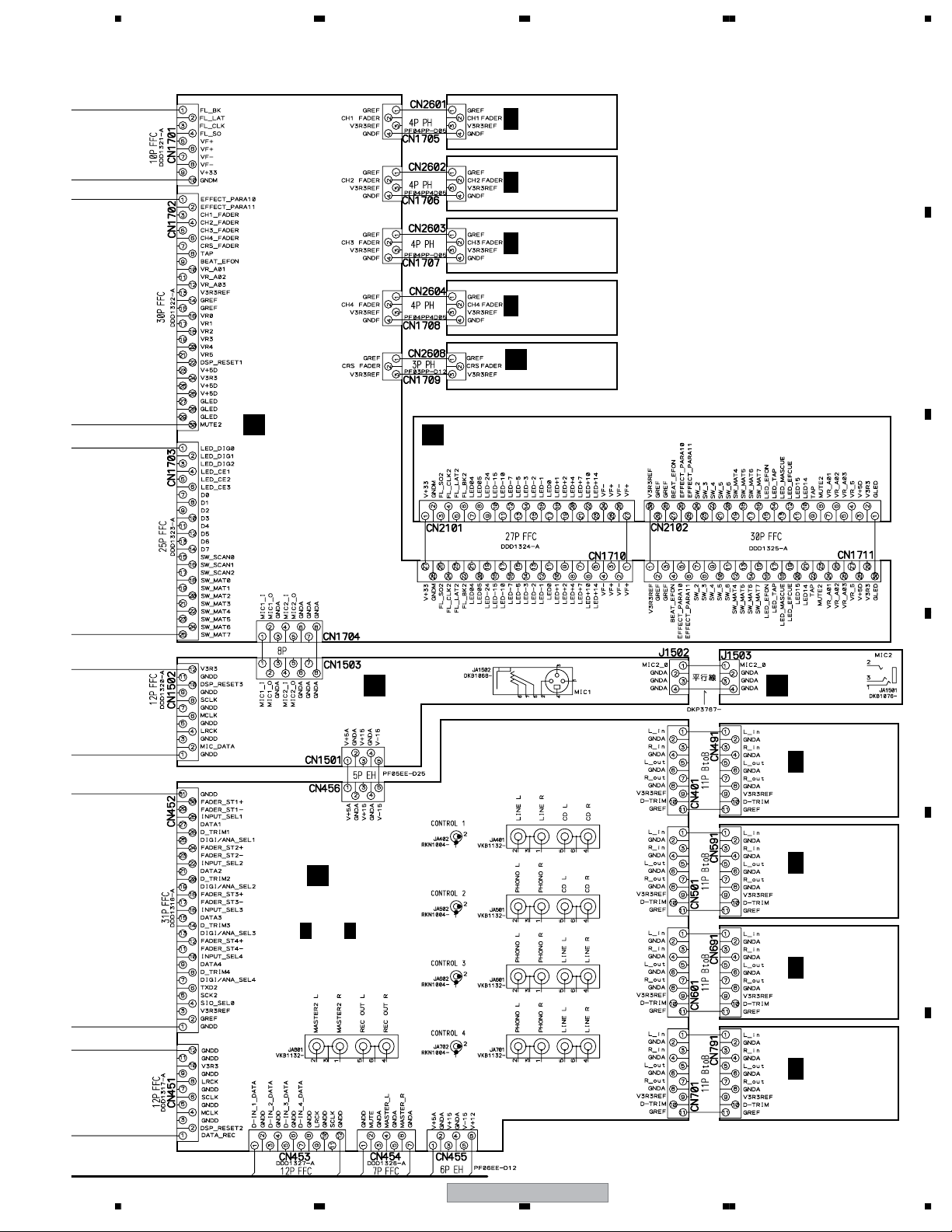

3.3 OVERALL WIRING DIAGRAM

A

B

C

P

HP JACK(DWX2553)

ACSW

R

(DWX2545)

OUTPUT(DWX2544)

J

J J

1/3–( 3/3)

O

SW POWER SUPPLY

Q

HPAMP

(DWX2556)

I

DSP

(DWX2534)

I I

DIGIC(DWX2547)

K

1/3–( 3/3)

D

E

DIGIB(DWX2546)

M

F

SLSW

N

(DWX2536)

DIGIA

L

(DWX2555)

16

DJM-800

1234

5678

PANEL1(DWX2552)

C

G 1/4

CHFD1(DWX2537)

G 2/4

CHFD2(DWX2538)

G 3/4

CHFD3(DWX2539)

G 4/4

CHFD4(DWX2540)

H

CRSFD(DWX2541)

PANEL2(DWX2554)

F

A

B

C

A

INPUT

(DWX2535)

A A

1/6–( 6/6)

MIC1

B

(DWX2542)

MIC2

E

(DWX2543)

D 4/4

TRIM1(DWX2548)

D 3/4

TRIM2(DWX2549)

D 2/4

TRIM3(DWX2550)

D 1/4

TRIM4(DWX2551)

D

E

F

56

DJM-800

17

7

8

1234

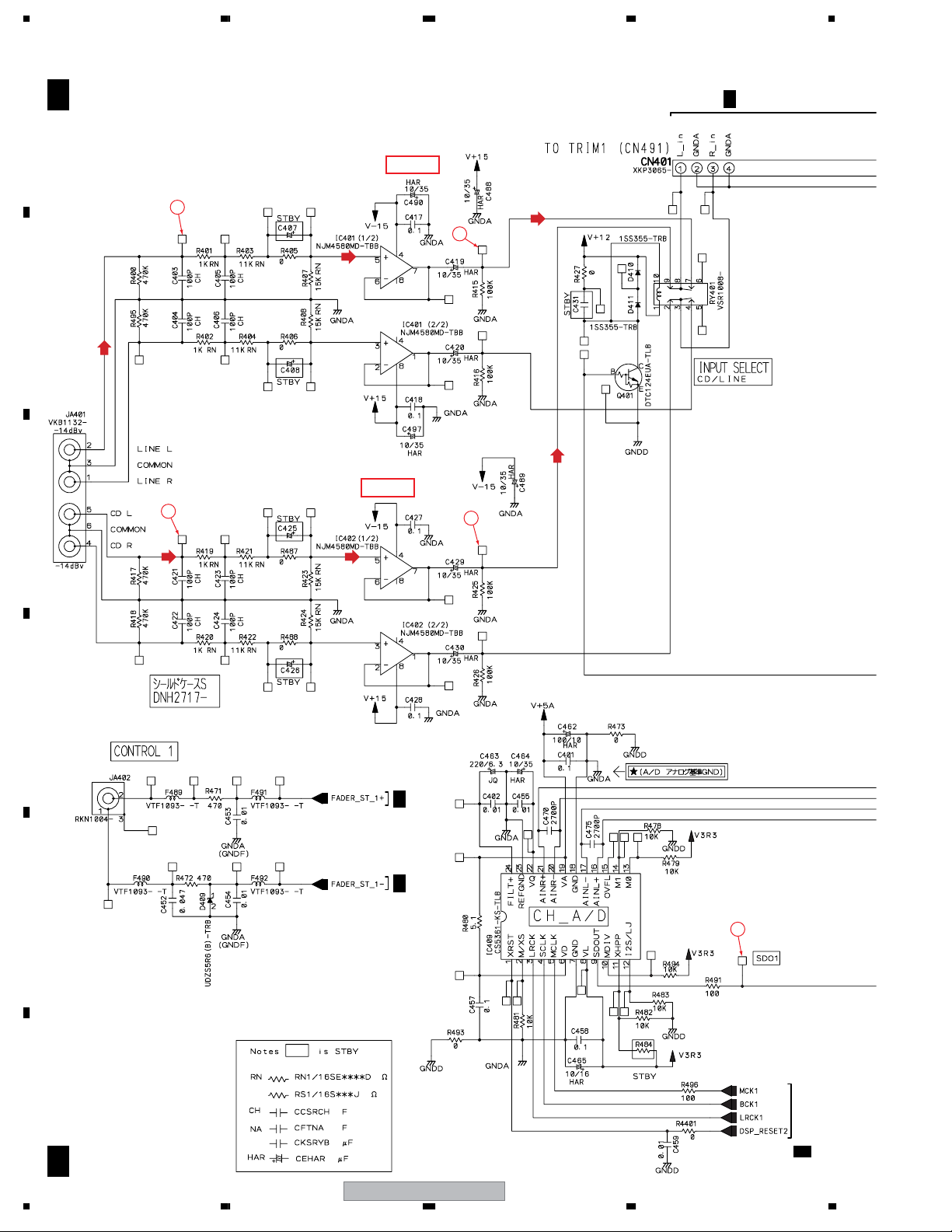

3.4 INPUT ASSY (1/6)

A

B

C

A 1/6

(LI)

INPUT ASSY(DWX2535)

8

(LI)

BUFFER

1

(CDI)

(CDI)

BUFFER

CN491

4/4

D

(LI)

9

(CDI)

2

D

6/6

A

6/6A

E

7

F

2/6,3/6,4/6,6/6A

A 1/6

18

DJM-800

1234

5678

A

5

3

(CH1)

(CH1)

4

(CH1)

(CH1)

B

6

C

(CH1)

(CH1D)

(D1)

AUDIO SIGNAL ROUTE

(LI)

: LINE INPUT L CH SIGNAL

(CDI)

: CD INPUT L CH SIGNAL

(CH1)

: CH1 L CH SIGNAL

(D1)

(CH1Y)

: CH1 DIGITAL SIGNAL

: CH1 Y CH SIGNAL

(CH1Y)

D

6/6A

E

6/6A

F

56

DJM-800

A 1/6

19

7

8

1234

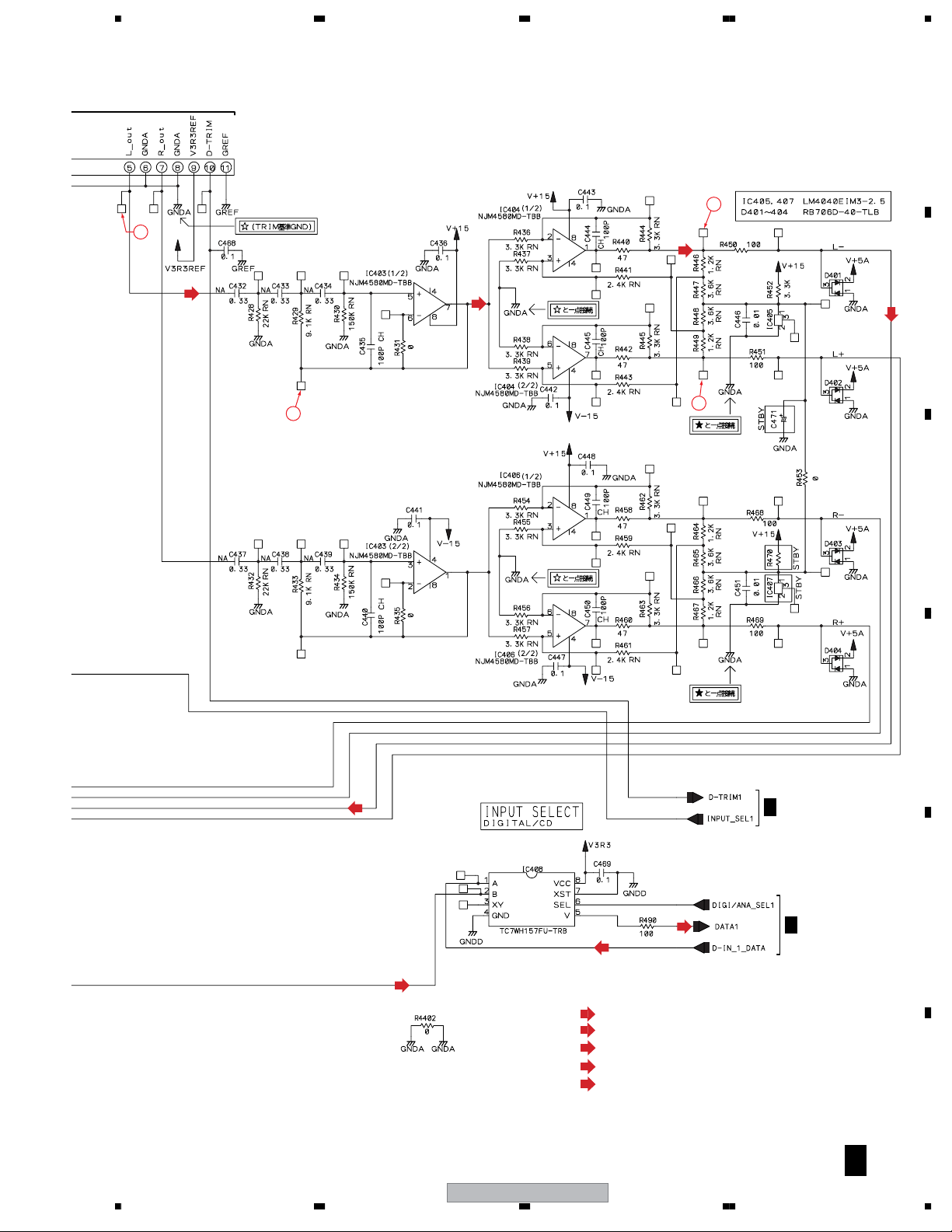

3.5 INPUT ASSY (2/6)

A

A 2/6

INPUT ASSY(DWX2535)

CN591

3/4

D

(PI)

10

11

B

C

(PI)

(CDI)

(CDI)

12

(PI)

13

(CH2)

(CDI)

BUFFER

D

A

6/6

(CH2)

6/6A

E

17

F

20

A 2/6

1/6,3/6,4/6,6/6A

DJM-800

1234

5678

A

15

(CH2)

(CH2)

14

16

(CH2)

B

C

D

(CH2D)

(CH2Y)

(D2)

AUDIO SIGNAL ROUTE

(PI)

: PHONO INPUT L CH SIGNAL

(CDI)

: CD INPUT L CH SIGNAL

(CH2)

: CH2 L CH SIGNAL

(D2)

(CH2Y)

: CH2 DIGITAL SIGNAL

: CH2 Y CH SIGNAL

DJM-800

56

6/6A

E

6/6A

F

A 2/6

21

7

8

1234

3.6 INPUT ASSY (3/6)

A

A 3/6

INPUT ASSY(DWX2535)

(PI)

(PI)

CN691

2/4

D

(CH3)

B

C

D

(PI)

(LI)

(LI)

(LI)

BUFFER

E

F

22

A 3/6

A

6/6

(CH3)

6/6A

1/6,2/6,4/6,6/6A

DJM-800

1234

5678

A

(CH3)

(CH3)

(CH3)

B

(D3)

(CH3Y)

C

D

6/6A

E

6/6A

(CH3D)

AUDIO SIGNAL ROUTE

(PI)

: PHONO INPUT L CH SIGNAL

(LI)

: LINE INPUT L CH SIGNAL

(CH3)

: CH3 L CH SIGNAL

(D3)

(CH3Y)

: CH3 DIGITAL SIGNAL

: CH3 Y CH SIGNAL

DJM-800

56

F

A 3/6

23

7

8

1234

3.7 INPUT ASSY (4/6)

A

B

A 4/6

INPUT ASSY (DWX2535)

(PI)

(PI)

(PI)

CN791

1/4

D

(CH4)

(LI)

(CH4)

A

BUFFER

6/6

C

(LI)

(LI)

D

6/6A

E

F

24

1/6,2/6,3/6,6/6A

A 4/6

DJM-800

1234

5678

A

(CH4)

(CH4)

(CH4)

B

(D4)

(CH4Y)

C

D

6/6A

E

6/6A

(CH4D)

AUDIO SIGNAL ROUTE

(PI)

: PHONO INPUT L CH SIGNAL

(LI)

: LINE INPUT L CH SIGNAL

(CH4)

: CH4 L CH SIGNAL

(D4)

: CH4 DIGITAL SIGNAL

(CH4Y)

: CH4 Y CH SIGNAL

DJM-800

56

F

A 4/6

25

7

8

1234

3.8 INPUT ASSY (5/6)

A

B

C

A 5/6

6/6A

6/6A

INPUT ASSY (DWX2535)

(RECD)

(REC)

18

(REC)

19

D

(MA)

6/6A

E

BUFFER

(MA)

6/6A

F

A 5/6

26

DJM-800

1234

5678

A

B

(REC)

22

20

MUTE

(MA)

(REC)

(MA)

(REC)

23

21

C

D

AUDIO SIGNAL ROUTE

(RECD)

: REC DIGITAL CH SIGNAL

(REC)

: REC L CH SIGNAL

(MA)

: MASTER L CH SIGNAL

DJM-800

56

E

F

A 5/6

27

7

8

1234

3.9 INPUT ASSY (6/6)

A

B

C

A 6/6

CN3

INPUT ASSY (DWX2535)

28

27

1/3

I

24

26

25

A

5/6

LRCK BUFFER

BCK BUFFER

1/6,2/6,3/6,4/6

A

(CH1Y)

D

(CH2Y)

CN2

1/3

I

E

(CH3Y)

(CH4Y)

1/6A

2/6A

3/6A

AUDIO SIGNAL ROUTE

(CH1Y)

4/6A

5/6A

: CH 1 Y CH SIGNAL

(CH2Y)

: CH 2 Y CH SIGNAL

(CH3Y)

: CH 3 Y CH SIGNAL

(CH4Y)

: CH 4 Y CH SIGNAL

(D1)

: CH1 DIGITAL SIGNAL

(D2)

: CH2 DIGITAL SIGNAL

(D3)

: CH3 DIGITAL SIGNAL

(D4)

: CH4 DIGITAL SIGNAL

(MA)

: MASTER L CH SIGNAL

F

28

A 6/6

DJM-800

1234

5678

A

MCK BUFFER

BCK BUFFER

(D4)

(D1)

(D2)

(D3)

CN1203

1/6A

A

2/6

A

3/6

4/6

A

K

B

1/6,2/6,3/6,4/6A

5/6A

(MA)

CN902

1/3

J3/3

C

1/6,2/6,3/6,4/6A

LRCK BUFFER

MCK BUFFER

BCK BUFFER

LRCK BUFFER

CN904

J

1/6,2/6,3/6,4/6A

D

CN1501

B

5/6A

E

5/6A

5/6A

DJM-800

56

F

A 6/6

29

7

8

1234

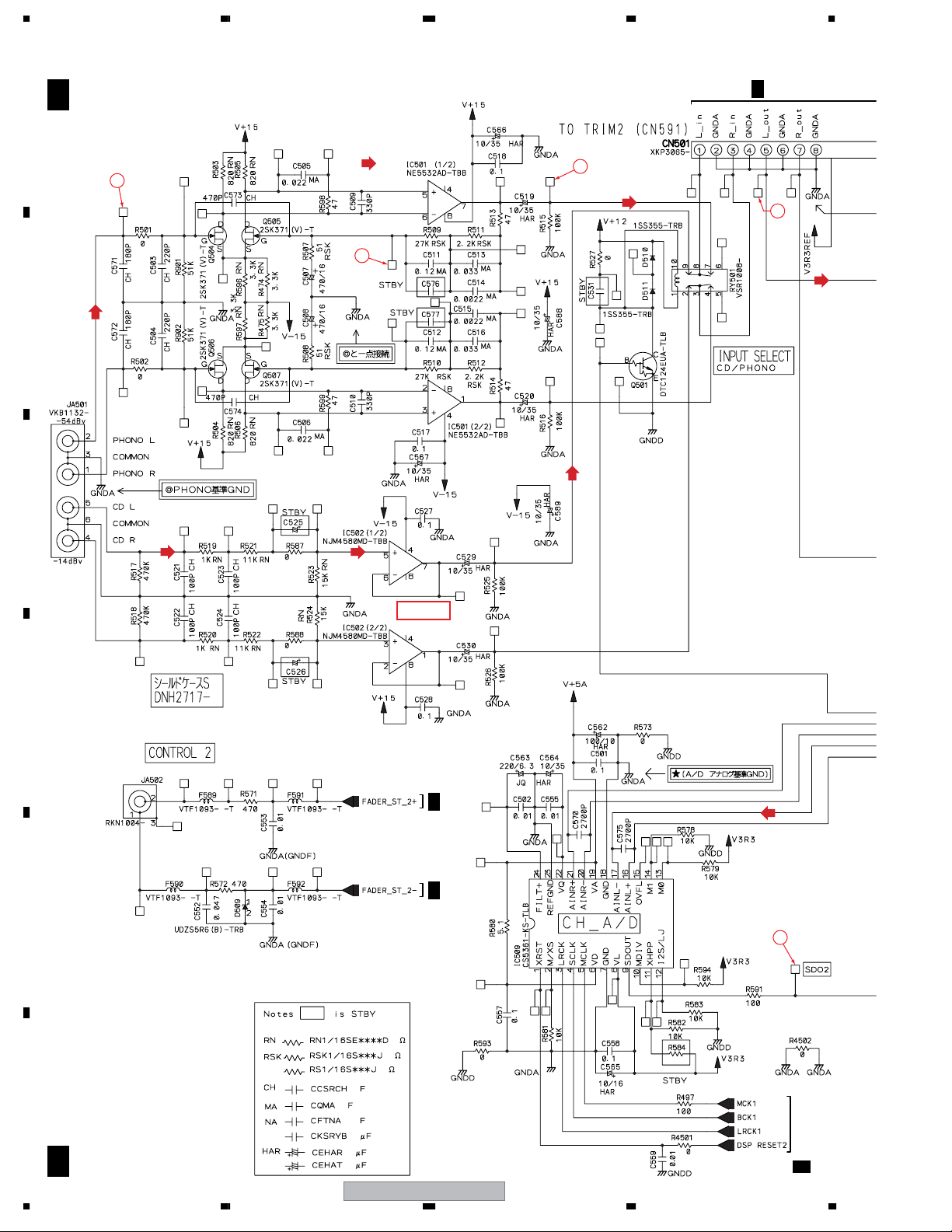

3.10 MIC 1 ASSY

MIC1 (DWX2542)

B

A

1

B

(MIC1)

(MIC1) (MIC1)

C

(MIC2) (MIC2)

(MIC2)

J1503

(MIC1)

(MIC2)

E

D

E

F

B

30

1234

DJM-800

Loading...

Loading...