Page 1

2011

DDJ-ERGO-V

This product is a model for destinations worldwide (except China and Korea).

It operates only on USB-bus power. No need to use an AC adapter.

DJ Controller

DDJ-ERGO-V

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

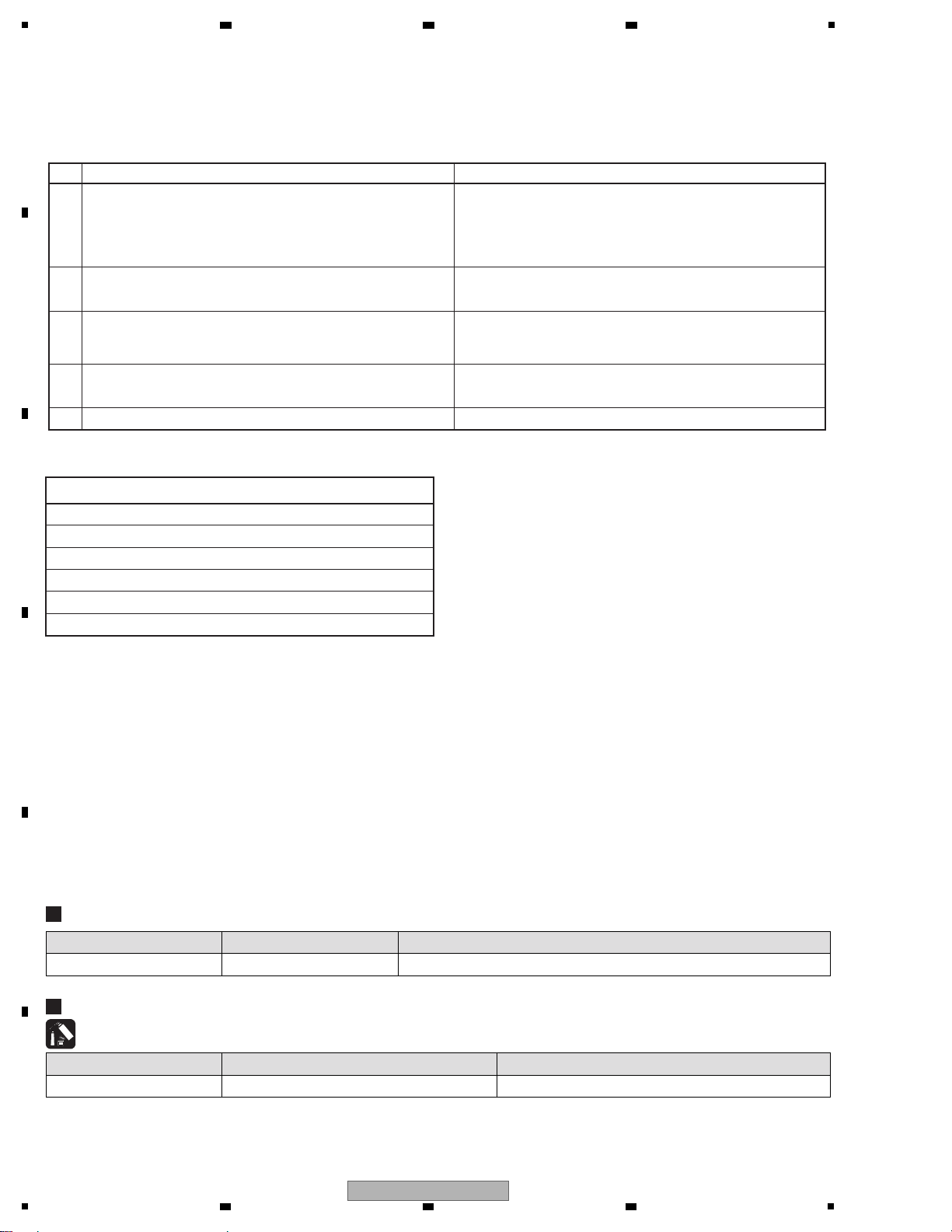

Model Type Power Requirement Remarks

DDJ-ERGO-V XJ5 DC 5 V

ORDER NO .

RRV4269

PIONEER CORPORATION 1-1, Shin-ogura, Saiwai-ku, Kawasaki-shi, Kanagawa 212-0031, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION

K-IZV NOV.

2011 Printed in Japan

Page 2

1

WARNING

This product may contain a chemical known to the State of California to cause cancer, or birth defects or other reproductive

harm.

Health & Safety Code Section 25249.6 - Proposition 65

This service manual is intended for qualified service technicians; it is not meant for the casual do-ityourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained

to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

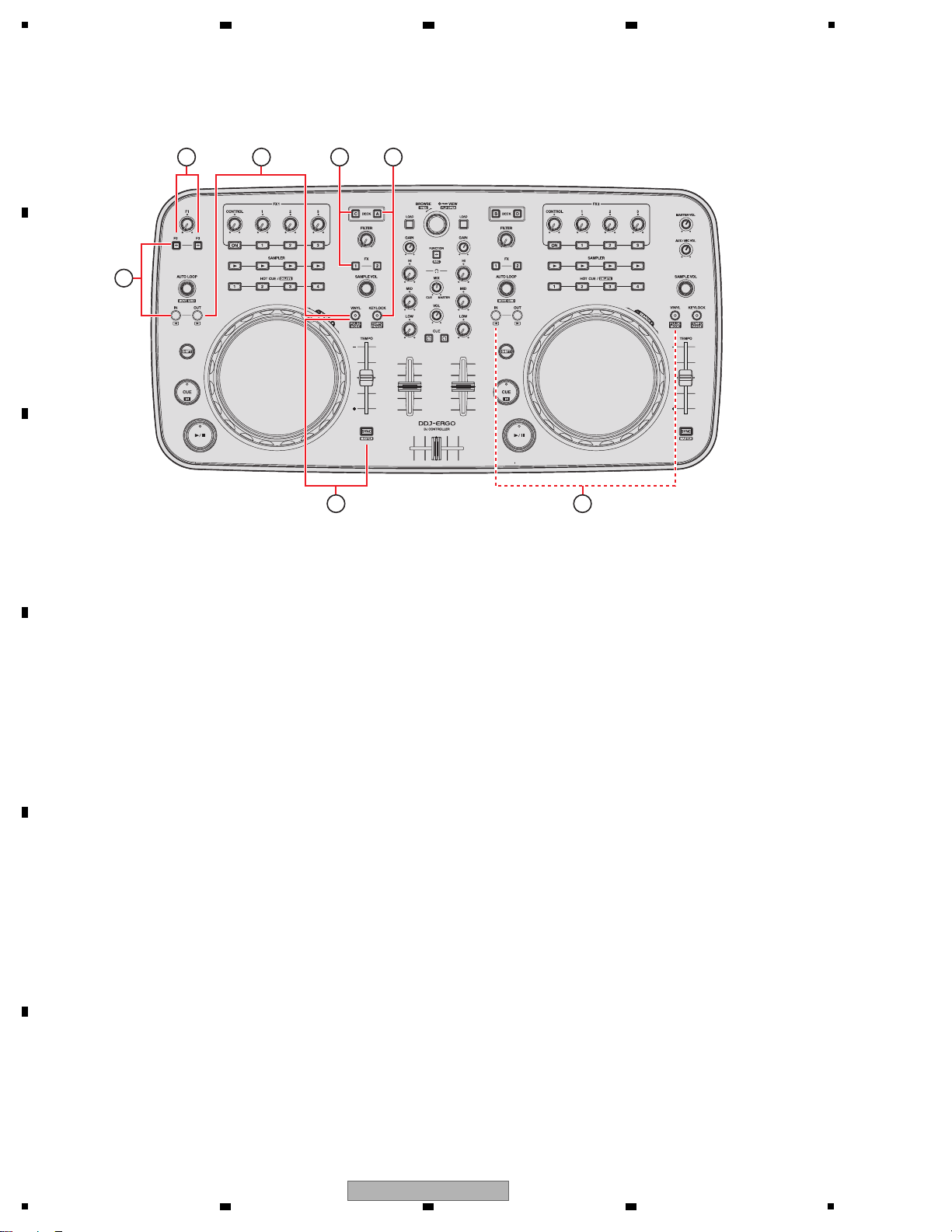

2 3 4

SAFETY INFORMATION

A

B

C

D

E

F

2

1

2 3 4

DDJ-ERGO-V

Page 3

5

6 7 8

CONTENTS

SAFETY INFORMATION..........................................................................................................................................................2

1. SERVICE PRECAUTIONS....................................................................................................................................................4

1.1 NOTES ON SOLDERING. .......................................... .......................................... ..........................................................4

1.2 SERVICE NOTICE............................................................................................. .............................................................4

2. SPECIFICATIONS.................................................................................................................................................................5

3. BASIC ITEMS FOR SERVICE..............................................................................................................................................6

3.1 CHECK POINTS AFTER SERVICING ............................. .......................................... ....................................................6

3.2 JIGS LIST.......................................................................................................................................................................6

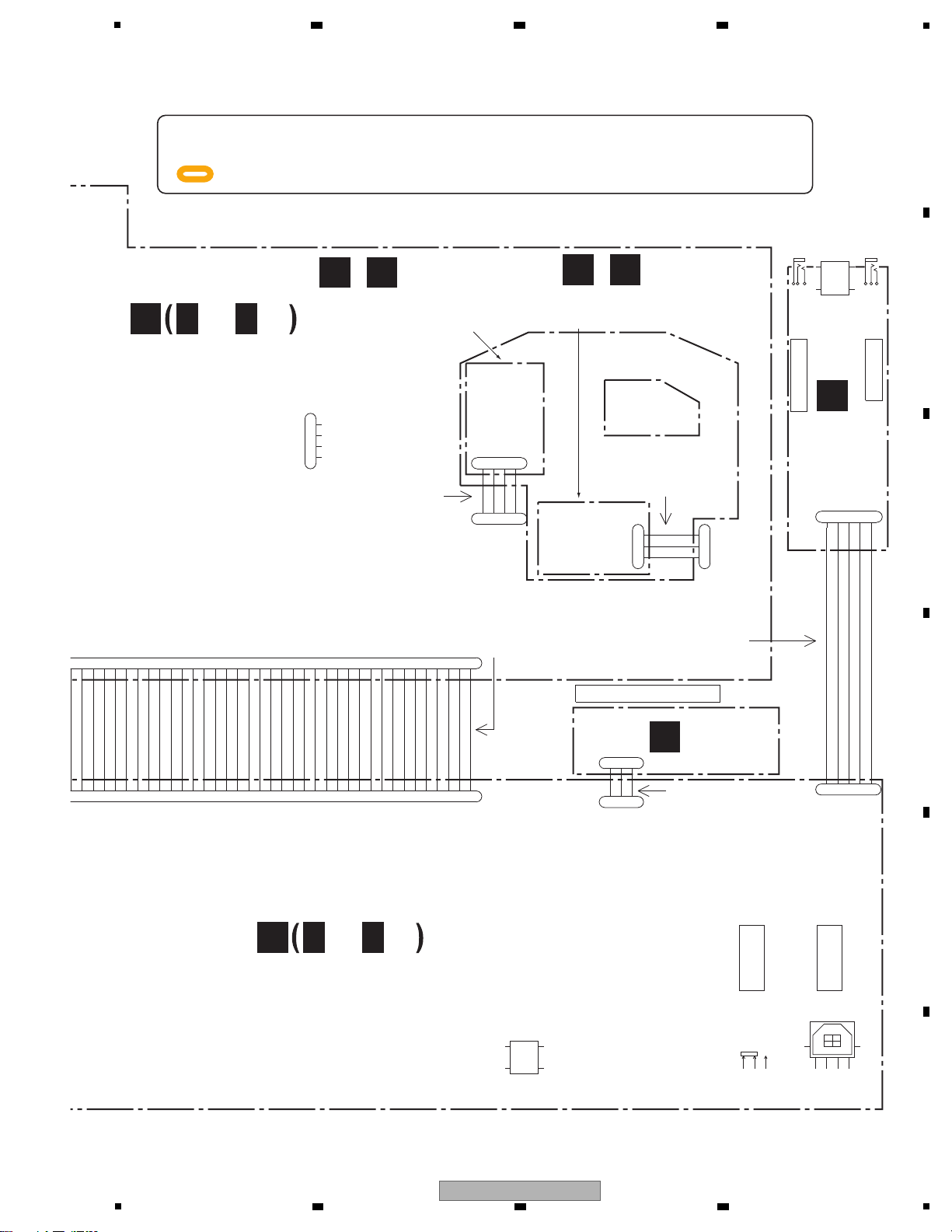

3.3 PCB LOCATIONS............................................... ... .......................................... ...............................................................7

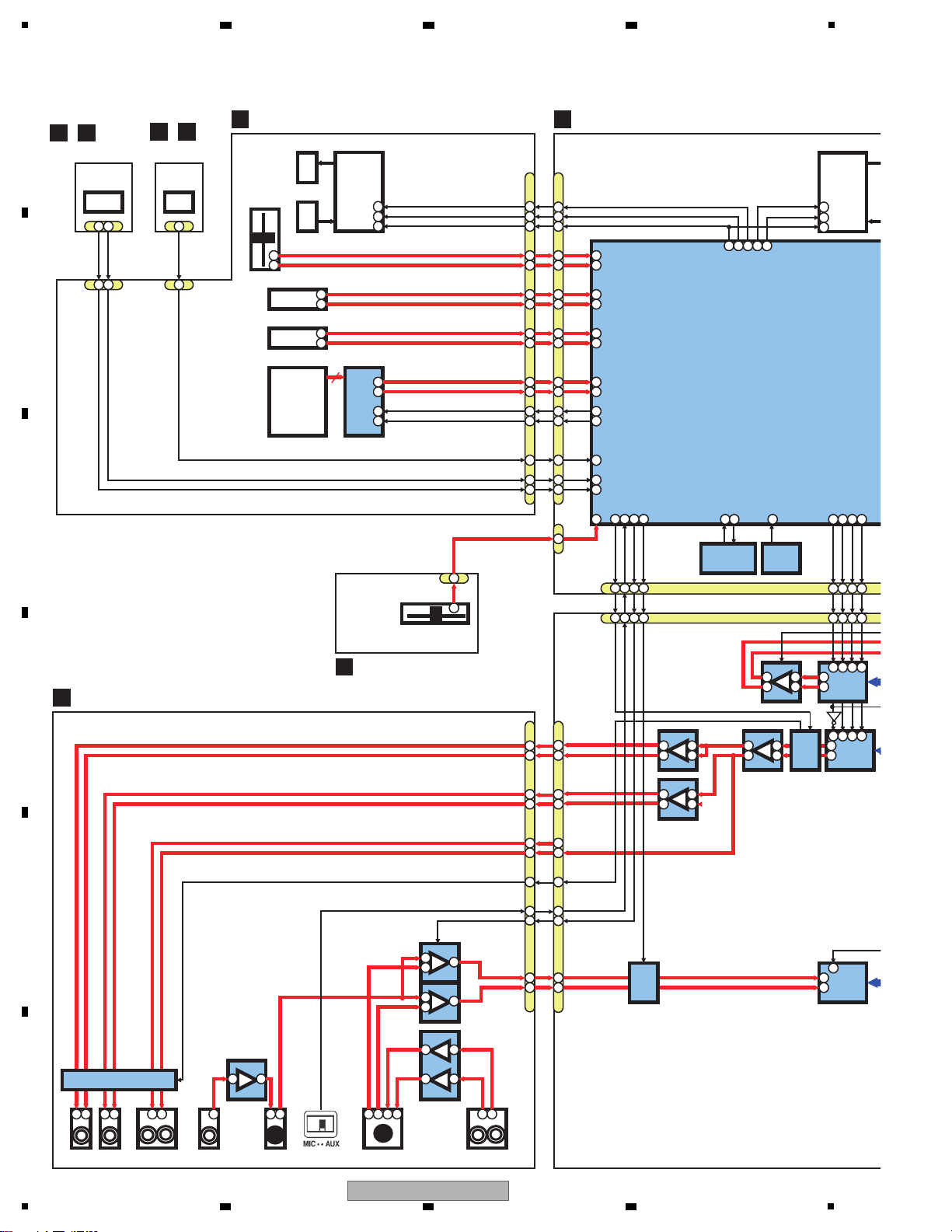

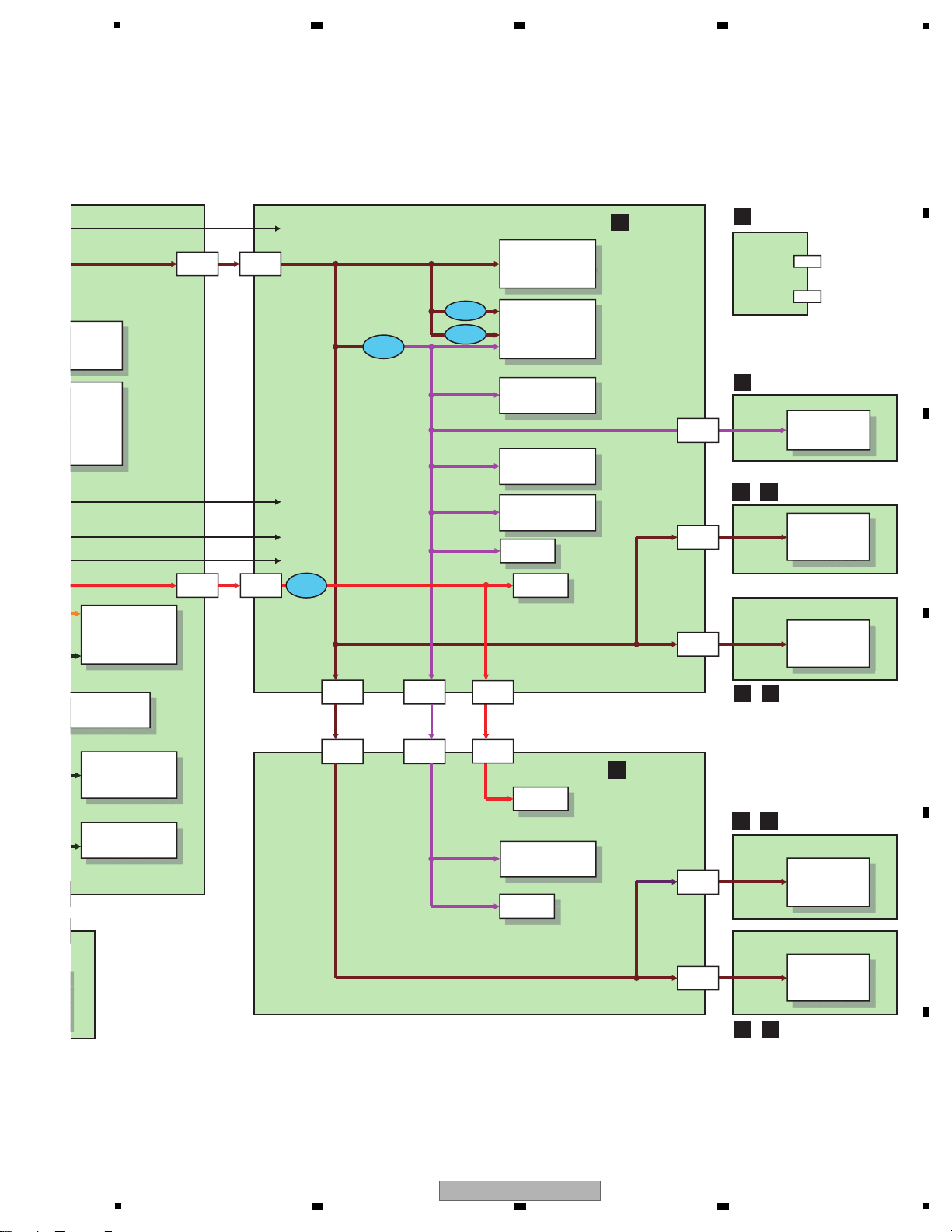

4. BLOCK DIAGRAM................................................................................................................................................................8

4.1 OVERALL WIRING DIAGRAM ................................................................................................. ......................................8

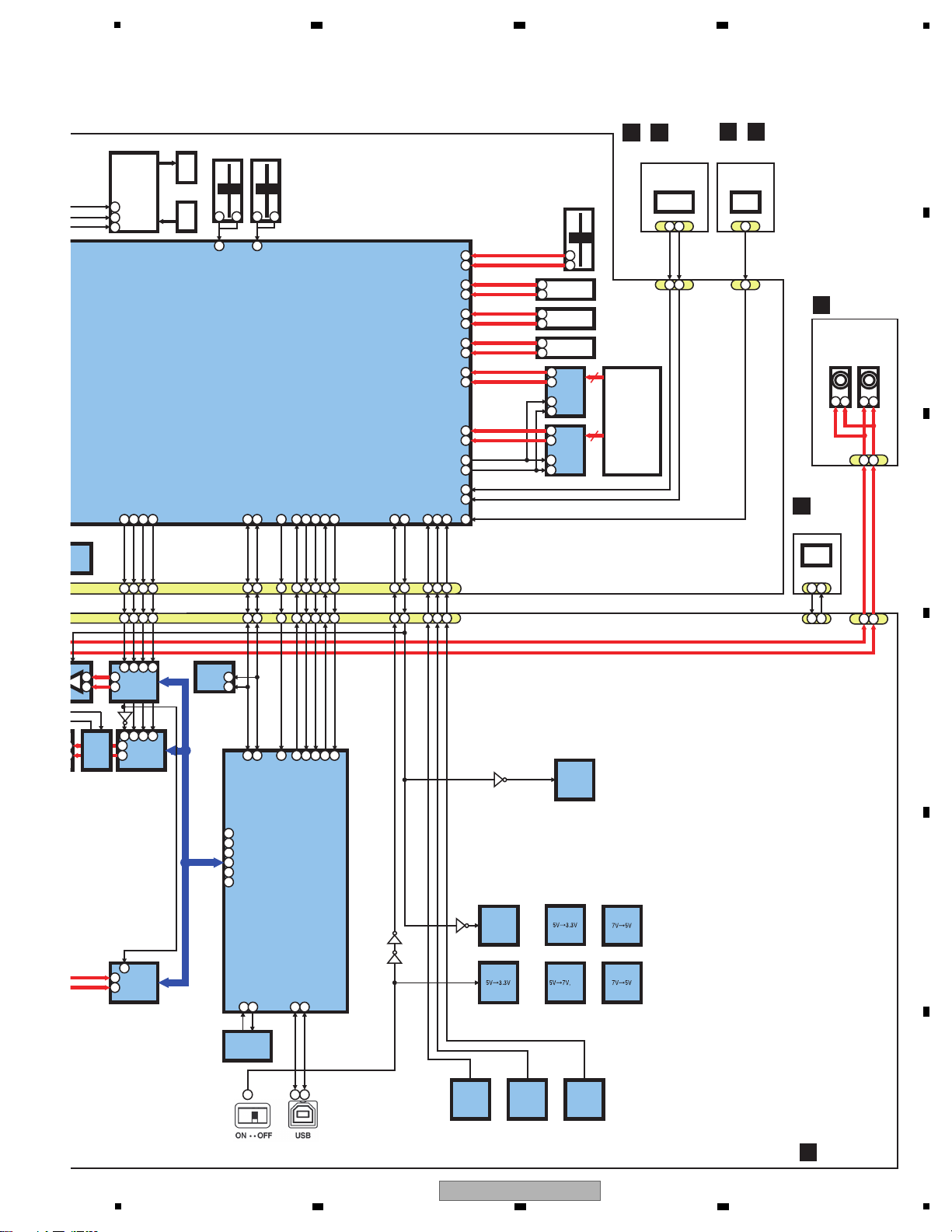

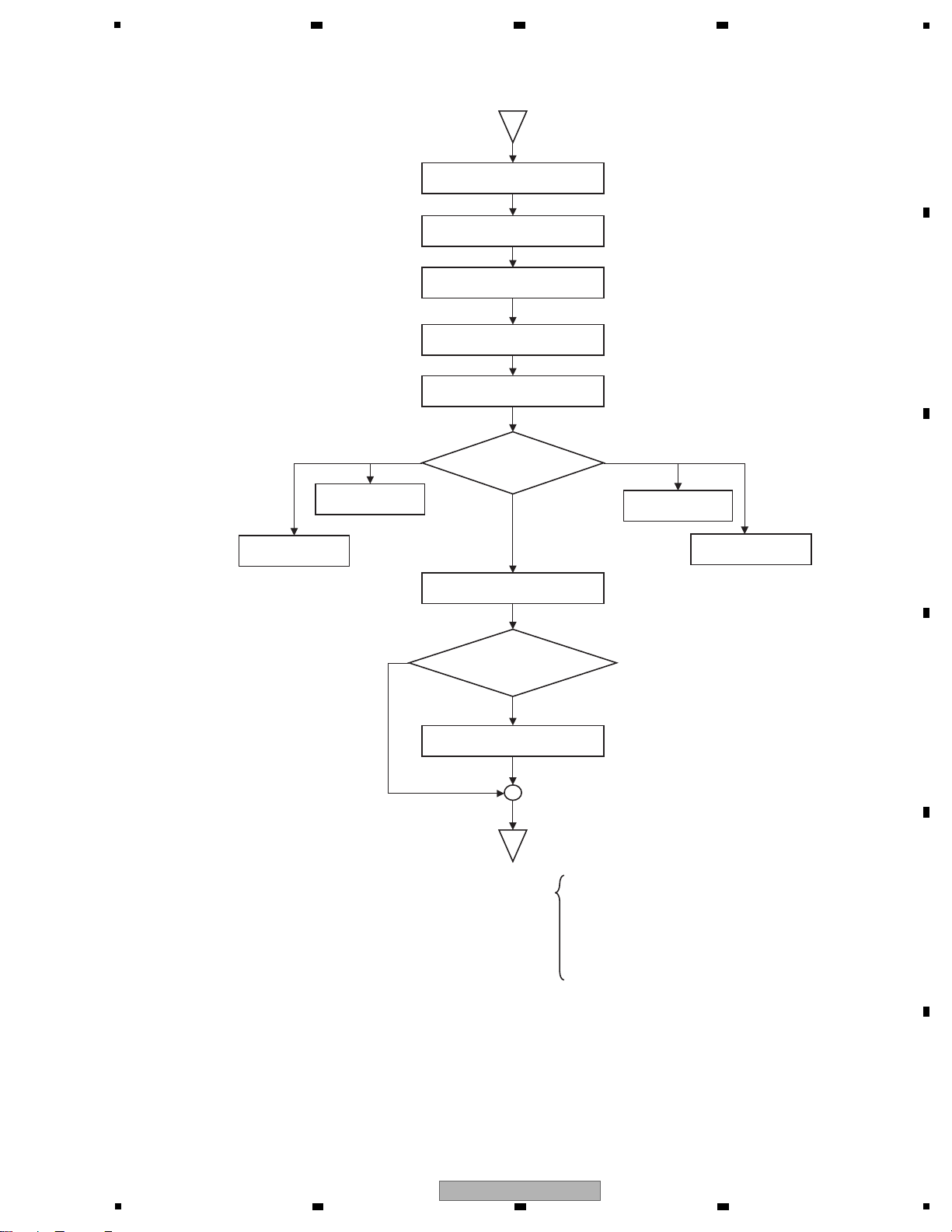

4.2 OVERALL BLOCK DIAGRAM............................. .......................................... ................................................................10

4.3 POWER BLOCK DIAGRAM .................................. .. .......................................... ...........................................................12

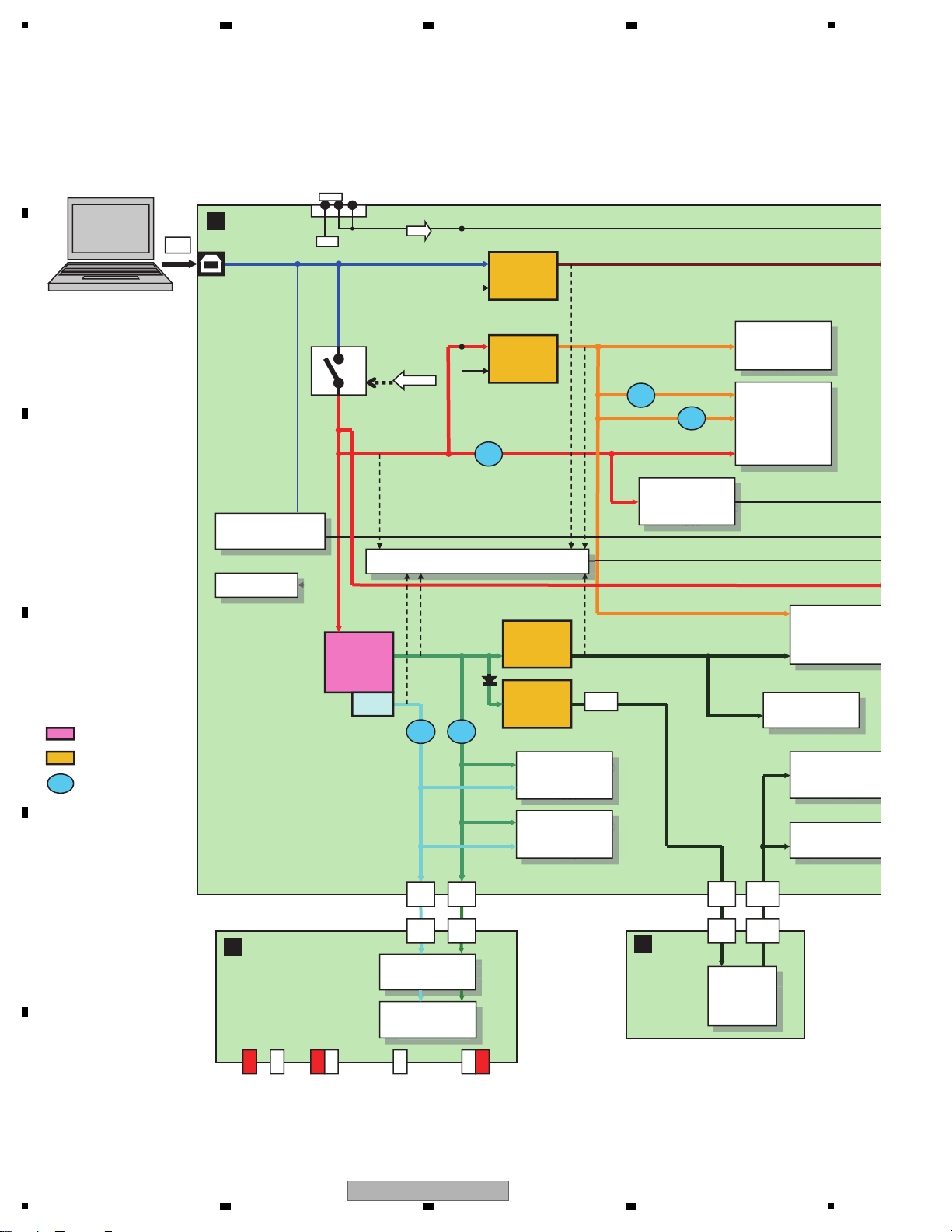

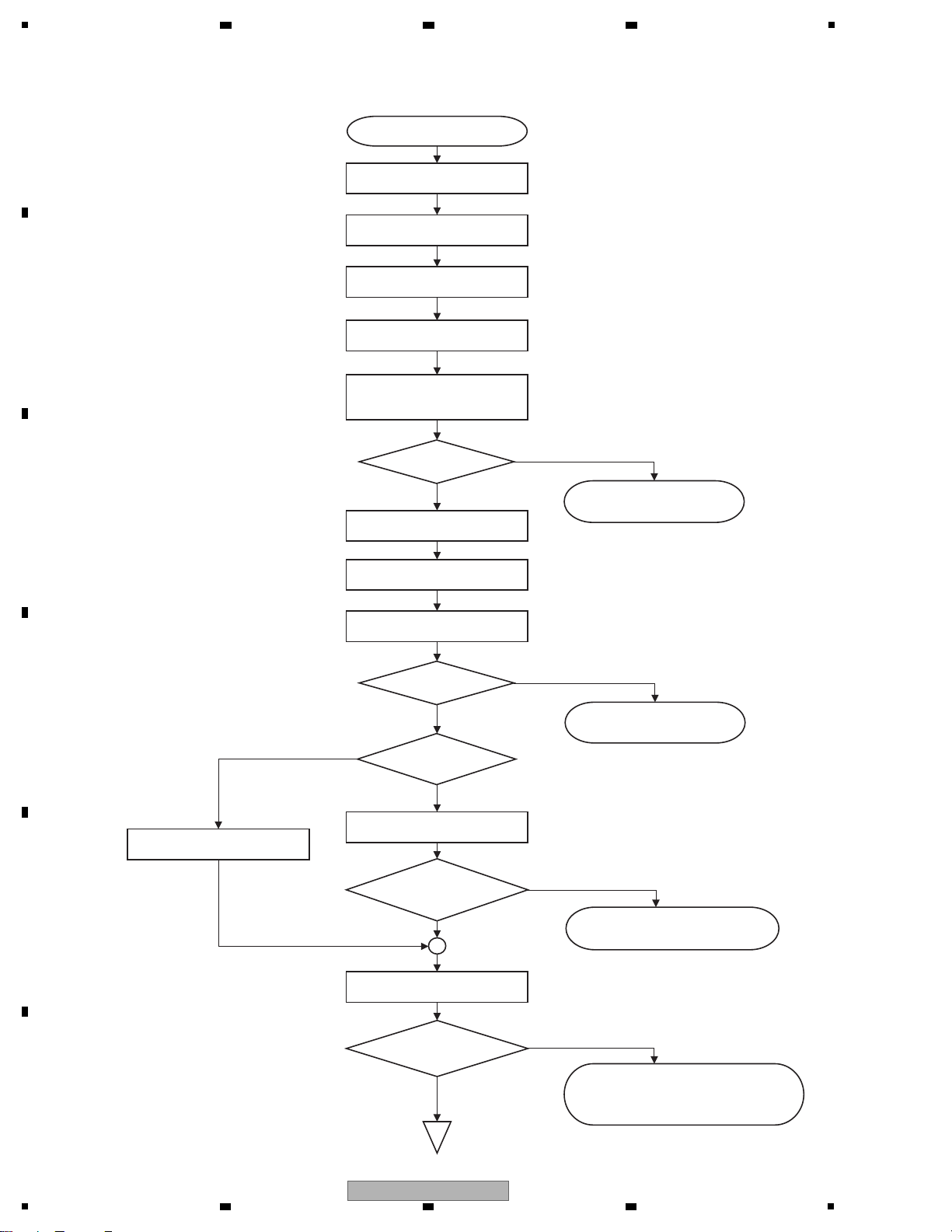

5. DIAGNOSIS........................................................................................................................................................................14

5.1 POWER ON SEQUENCE............................................................................. ................................................................14

5.2 TROUBLESHOOTING............ .......................................... .......................................... ..................................................16

5.3 VOLTAGE MONITORING.............................................................................. ................................................................25

5.4 ABOUT POWER-SAVING MODE...................................................................... ...........................................................26

5.5 OPERATION CHECK METHODS, USING VIRTUAL DJ................................................. .............................................27

6. SERVICE MODE.................................................................................................................................................................30

6.1 HOW T O ENTER EACH MODE ........................................................................ ... ... .....................................................30

6.2 FIRMWARE VERSION CONFIRMATION METHODS..................................................................................................31

6.3 SERVICE MODE.................................................................................... ......................................................................33

6.4 FACTORY RESET MODE.............................................................................................................................................36

6.5 POWER-SAVING MODE......................................... ... .......................................... ........................................................37

6.6 ERROR DISPLAY.........................................................................................................................................................37

6.7 ABOUT THE DEVICE......................................... .......................................... ................................................................37

7. DISASSEMBLY ...................................................................................................................................................................38

8. EACH SETTING AND ADJUSTMENT................................................................................................................................43

8.1 NECESSARY ITEMS TO BE NOTED...........................................................................................................................43

8.2 HOW T O PROGRAM COPY FOR USB CONTROLLER..................... ... ... ... ................................................ .. ... ...........43

8.3 HOW TO FIRMWARE UPDATE.................................. .......................................... ........................................................44

8.4 JOG DIAL ROTATION LOAD ADJUSTMENT...................................... ................................................ ... ......................45

9. EXPLODED VIEWS AND PARTS LIST...............................................................................................................................46

1 PACKING SECTION........................................... ... .......................................... .............................................................46

9.

9.2 EXTERIOR SECION............................. .......................................... ..............................................................................48

9.3 CONTROL PANEL SECTION....................... .......................................... ......................................................................50

9.4 JOG SECTION ................. ... .......................................... .......................................... .....................................................52

10. SCHEMATIC DIAGRAM......................................................................... .. .........................................................................54

10.1 JACK ASSY................................................................................................................................................................54

10.2 IFPW ASSY (1/3) and HPLC ASSY............................................................................................................................56

10.3 IFPW ASSY (2/3)........................................................................................................................................................58

10.4 IFPW ASSY (3/3)........................................................................................................................................................60

10.5 CDJ1 ASSY (1/2) ........................................................................................................................................................62

10.6 CDJ1 ASSY (2/2) ........................................................................................................................................................64

10.7 HPJK and CRFD ASSYS............................................................................................................................................66

10.8 CDJ2 ASSY (1/2) ........................................................................................................................................................67

10.9 CDJ2 ASSY (2/2) ........................................................................................................................................................68

10.10 JOG1 and JOG2 ASSYS..........................................................................................................................................70

10.11 TCH1 and TCH2 ASSYS..........................................................................................................................................71

10.12 VOLTAGES ...............................................................................................................................................................72

10.13 WAVEFORMS...........................................................................................................................................................73

11. PCB CONNECTION DIAGRAM..................... ... ... ................................................ .. ...........................................................78

11.1 JACK ASSY................................................................................................................................................................78

11.2 IFPW , HPLC and HPJK ASSYS.................................................................................................................................82

11.3 CDJ1 and CRFD ASSYS............................................................................................................................................86

11.4 CDJ2 ASSY................................................................................................................................................................90

11.5 JOG1, JOG2, TCH1 and TCH2 ASSYS.....................................................................................................................94

12. PCB PARTS LIST............................................................ .......................................... ........................................................95

A

B

C

D

E

F

DDJ-ERGO-V

5

6 7 8

3

Page 4

1

• For environmental protection, lead-free solder is used on the printed circuit boards mounted in this unit.

Be sure to use lead-free solder and a soldering iron that can meet specifications for use with lead-free solders for repairs

accompanied by reworking of soldering.

• Compared with conventional eutectic solders, lead-free solders have higher melting points, by approximately 40 ºC.

Therefore, for lead-free soldering, the tip temperature of a soldering iron must be set to around 373 ºC in general, although

the temperature depends on the heat capacity of the PC board on which reworking is required and the weight of the tip of

the soldering iron.

Do NOT use a soldering iron whose tip temperature cannot be controlled.

Compared with eutectic solders, lead-free solders have higher bond strengths but slower wetting times and higher melting

temperatures (hard to melt/easy to harden).

The following lead-free solders are available as service parts:

• Parts numbers of lead-free solder:

GYP1006 1.0 in dia.

GYP1007 0.6 in dia.

GYP1008 0.3 in dia.

Voltage Monitoring

This unit always monitors for power failure and will shut itself off immediately after an error is detected.

A power failure is indicated with flashing of the illumination LED of the channel fader for left side deck (deck A or C).

Other LEDs are unlit after an error is generated.

After the unit shuts itself off because of an error, disconnect the USB cable and wait at least 1 minute before

turning the unit back on.

Repair the unit according to the diagnostic procedures described in “5.3 VOLTAGE MONITORING.”

On Point-of-Sale Demo Mode

This product is provided with a Demo mode to be used when displayed on a stand in a shop.

Demonstrations with lighting of the LEDs on the control panel are automatically performed even if this product is connected

with a PC without the DJ application (VIRTUAL DJ LE) being started on the PC.

This mode will be established if no transmission or reception of MIDI signals is performed for 1 minute after the controller is

turned ON.

After VIRTUAL DJ LE is started, Normal Operation mode will be entered.

On the EEPROM on the IFPW ASSY

No program has been stored in the EEPROM (IC104) on the IFPW Assy (blank ROM) when it is supplied as a part for service.

After the EEPROM is replaced, be sure to copy the program for the USB controller to it. For details, see “8.2 HOW TO

PROGRAM COPY FOR USB CONTROLLER.”

2 3 4

1. SERVICE PRECAUTIONS

1.1 NOTES ON SOLDERING

A

B

C

D

1.2 SERVICE NOTICE

E

F

4

1

2 3 4

DDJ-ERGO-V

Page 5

5

General – Main Unit

Power supply.............................................................DC 5 V

Power consumption ..................................................500 mA

Main unit weight..............................................2.9 kg (6.4 lb)

Max. dimensions

.................. 554.8 mm (W) × 103.2 mm (H) × 279.8 mm (D)

(21.8 in. (W) × 4.1 in. (H) × 11 in. (D))

Tolerable operating temperature

......................................+5 °C to +35 °C (+41 °F to +95 °F)

Tolerable operating humidity

............................................5 % to 85 % (no condensation)

Audio Section

Rated output level

MASTER OUT 1..................................................4.2 Vrms

MASTER OUT 2..................................................2.1 Vrms

Total harmonic distortion

MASTER OUT 1...................................................0.006 %

MASTER OUT 2...................................................0.006 %

Frequency characteristic

MASTER OUT 1.......................................20 Hz to 20 kHz

MASTER OUT 2.......................................20 Hz to 20 kHz

S/N ratio (when playing on computer)

MASTER OUT 1..........................101 dB (at rated output)

MASTER OUT 2..........................101 dB (at rated output)

Input impedance

AUX..........................................................................24 kΩ

MIC...........................................................................11 kΩ

Output impedance

MASTER OUT 1.............................................1 kΩ or less

MASTER OUT 2.............................................1 kΩ or less

PHONES........................................................10 Ω or less

Input / Output terminals

USB terminal

B type...................................................................... 1 set

MASTER OUT 1 output terminal

TRS phone jack (Ø 6.3 mm).................................... 1 set

MASTER OUT 2 output terminal

RCA pin jacks..........................................................1 set

PHONES output terminal

Stereo phone jack (Ø 6.3 mm) ................................ 1 set

Stereo mini phone jack (Ø 3.5 mm)......................... 1 set

AUX input terminal

RCA pin jacks..........................................................1 set

MIC input terminal

Phone jack (Ø 6.3 mm)............................................ 1 set

For improvement purposes, specifications and design of this

unit and the included software are subject to change without

notice.

• USB cable

(DDE1128)

• VIRTUAL DJ LE software CD-ROM

(DXX2685)

• Driver software/operating instructions CD-ROM

(DRU1001)

• Read Before Use (Important)

(DRH1122)

• Quick Start Guide

(DRH1123)

• Hardware Diagram for Virtual DJ (Table of Supported Functions)

(DRH1124)

• Warranty card

• Service network list (for Japanese customers)

Accessories

2. SPECIFICATIONS

6 7 8

A

B

C

D

5

DDJ-ERGO-V

6 7 8

E

F

5

Page 6

1

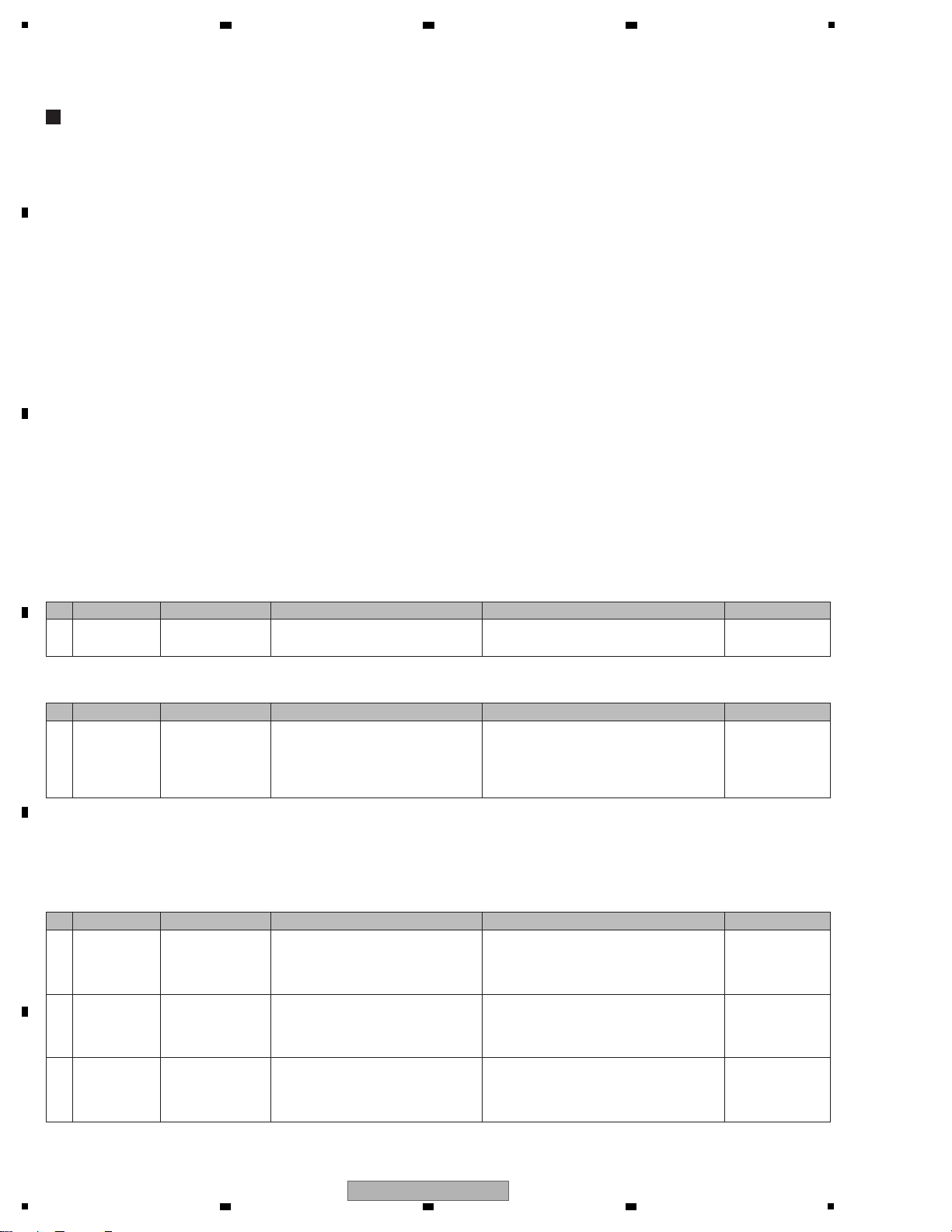

Items to be checked after servicing

To keep the product quality after servicing, confirm recommended check points shown below.

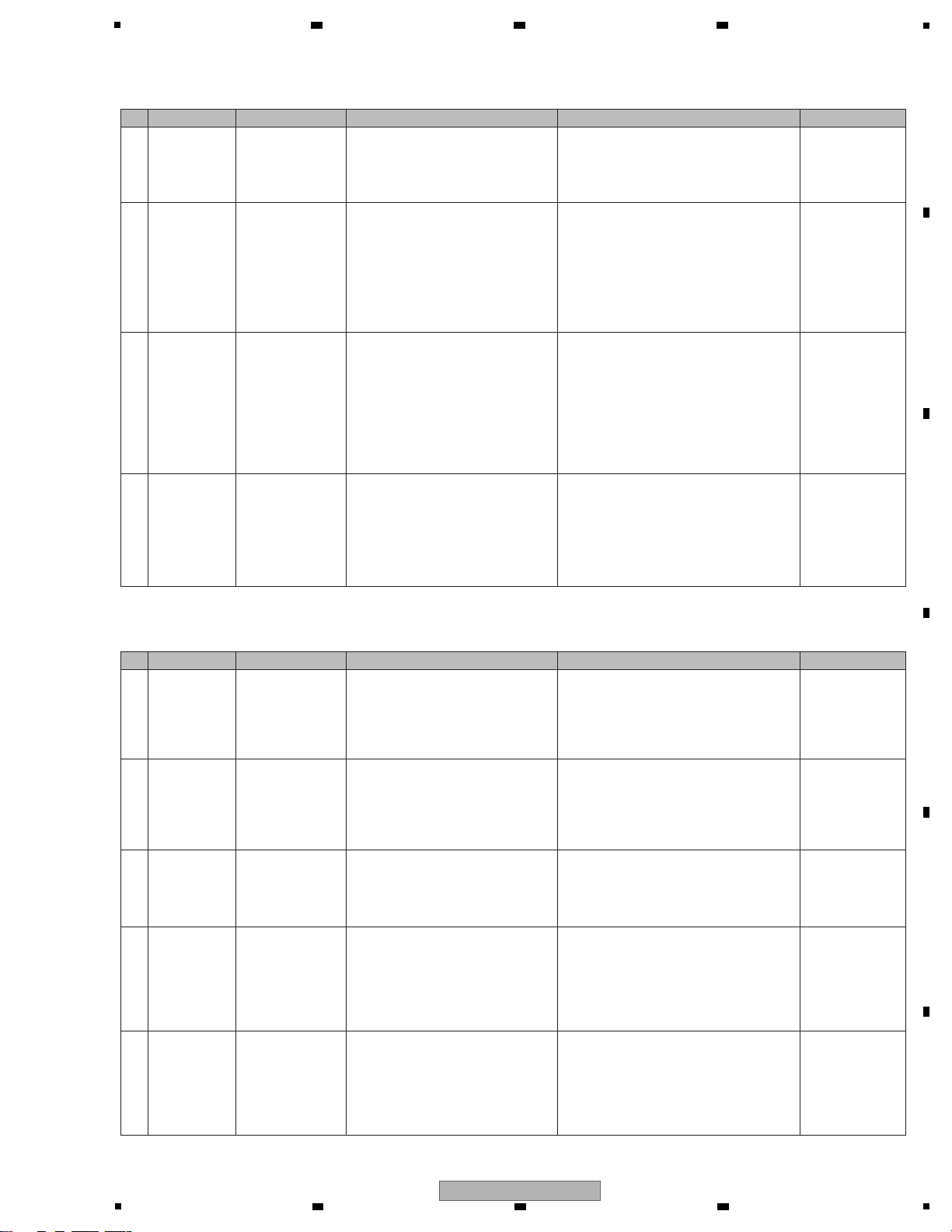

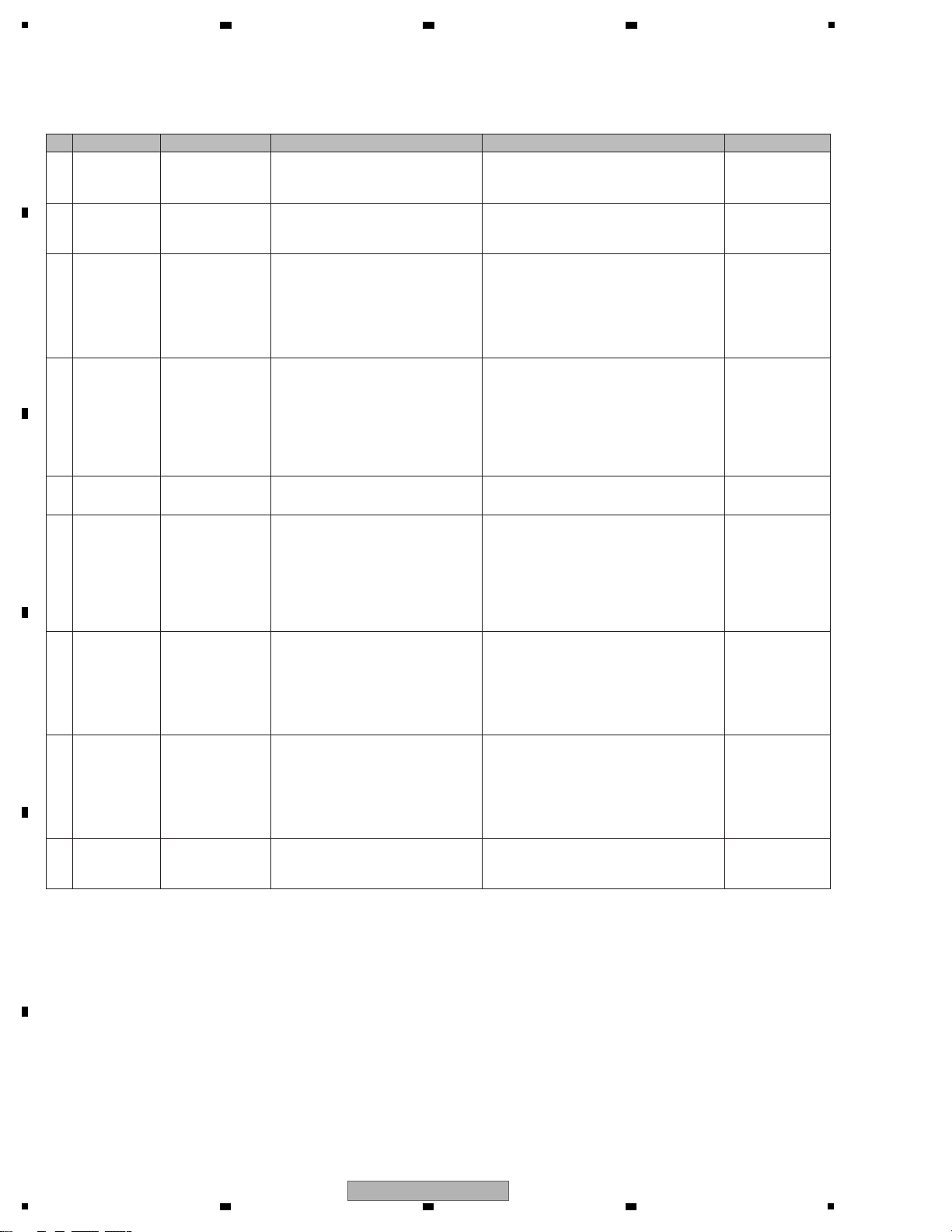

No. Procedures Check points

1

Confirm that the customer complaint has been resolved.

If the problem pointed out by the customer occurs with a specific

source or operation, such as PC input, AUX/MIC input, Fader, or

Volume, input that specific source then perform that specific

operation for checking.

The customer complain must not be reappeared.

Audio and operations must be normal.

2

Confirmation of operation of operating elements

Enter Service mode.

There must be no errors in operations of each button, Rotary

selector, Volume, Fader, Slider and JOG.

3

Check the analog audio output.

Connect this unit with a PC with the DJ application (Virtual DJ LE)

installed, via USB, then operate the DJ application (Virtual DJ LE).

There must be no errors, such as noise, in audio signals and

operations of the MASTER/HEADPHONES outputs.

4

Check the analog audio input.

Input an audio signal via AUX/MIC.

Audio and operations must be normal.

5 Check the appearance of the product. No scratches or dirt on its appearance after receiving it for service.

Item to be checked regarding audio

Distortion

Noise

Volume too low

Volume too high

Volume fluctuating

Sound interrupted

See the table below for the items to be checked regarding audio.

Lubricants and Glues List

Name Part No. Remarks

Lubricating oil GYA1001 Refer to “9.4 JOG SECTION”.

Jigs List

Jig Name Part No. Purpose of use / Remarks

USB cable GGP1193 for PC connection

2 3 4

3. BASIC ITEMS FOR SERVICE

3.1 CHECK POINTS AFTER SERVICING

A

B

C

D

3.2 JIGS LIST

E

F

6

1

2 3 4

DDJ-ERGO-V

Page 7

5

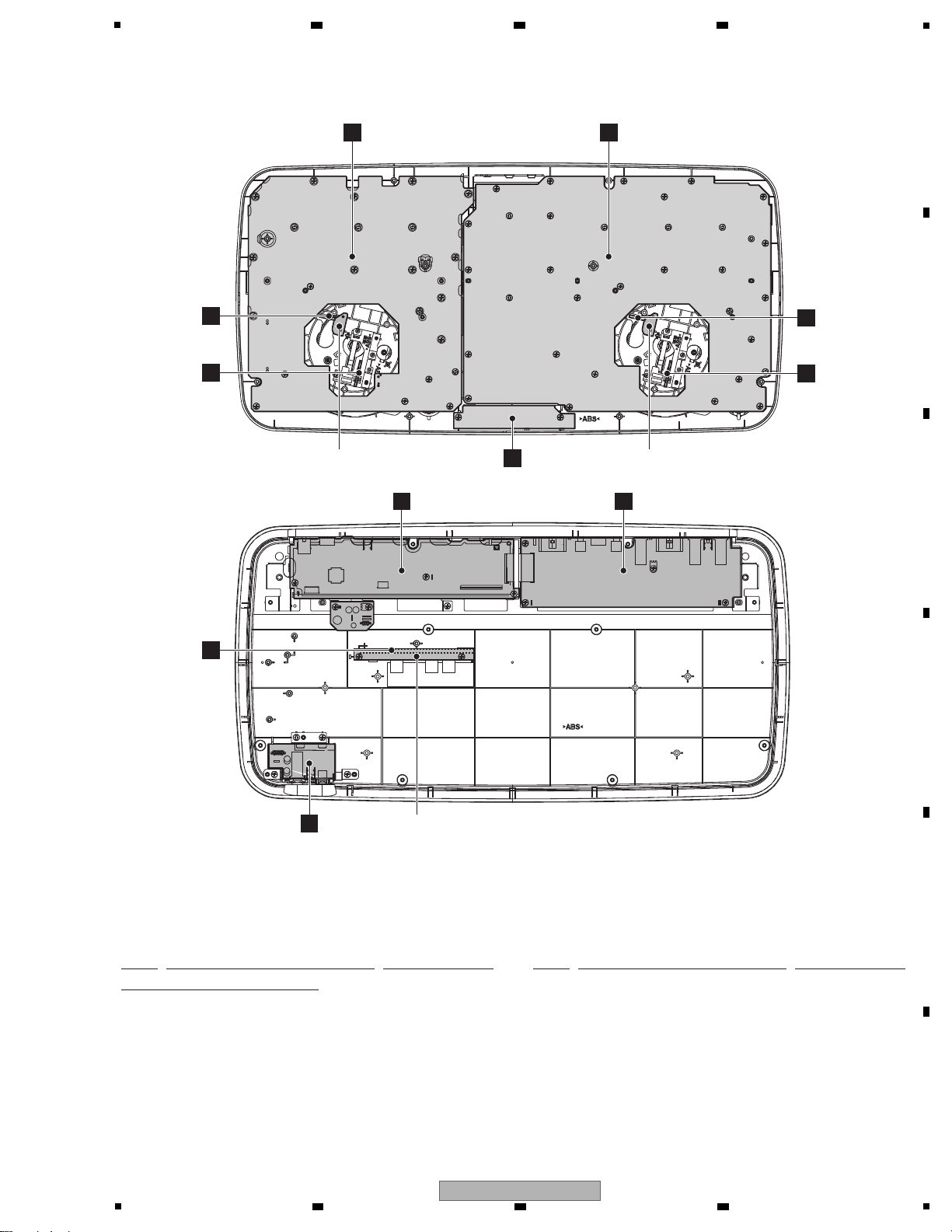

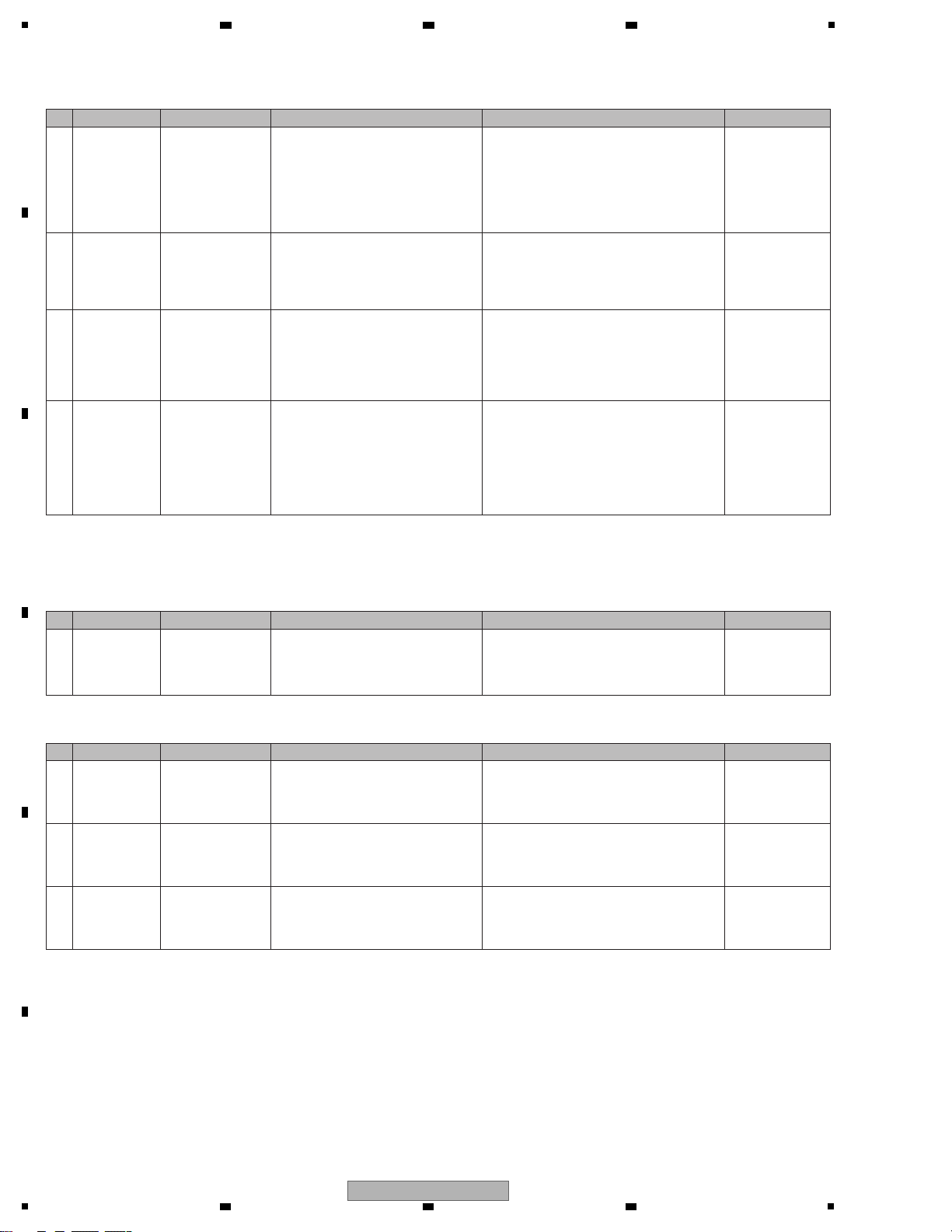

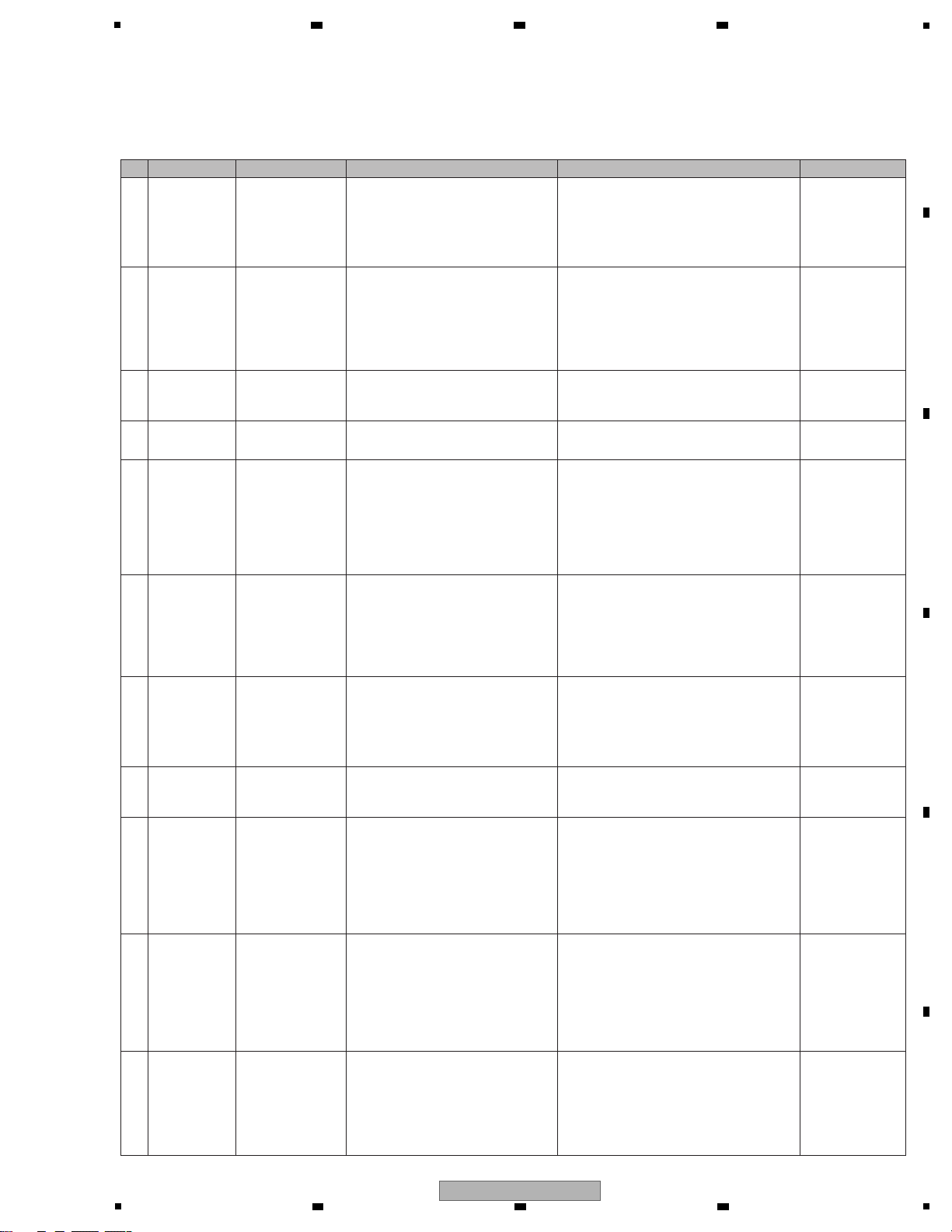

NSP 1..PLMX ASSY DWM2450

2..JOG1 ASSY DWS1436

2..TCH1 ASSY DWS1437

2..JOG2 ASSY DWS1438

2..TCH2 ASSY DWS1439

2..CDJ1 ASSY DWX3302

2..HLD1 ASSY DWX3309

2..HLD2 ASSY DWX3310

NSP 1..PLJK ASSY DWM2451

2..CDJ2 ASSY DWX3303

2..JACK ASSY DWX3304

2..CRFD ASSY DWX3305

2..HPJK ASSY DWX3306

2..HLD3 ASSY DWX3311

2..HPLC ASSY DWX3324

1..IFPW ASSY DWX3301

Mark No. Description Part No. Mark No. Description Part No.

LIST OF ASSEMBLIES

NOTES: - Parts marked by “NSP” are generally unavailable because they are not in our Master Spare Parts List.

-

The > mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

E

HPJK ASSY

F

CRFD ASSY HLD1 ASSYHLD2 ASSY

HLD3 ASSY

H

JOG1 ASSY

J

TCH1 ASSY

B

IFPW ASSY

A

JACK ASSY

D

CDJ1 ASSY

G

CDJ2 ASSY

• Bottom view

C

HPLC ASSY

I

JOG2 ASSY

K

TCH2 ASSY

3.3 PCB LOCATIONS

6 7 8

A

B

C

5

6 7 8

DDJ-ERGO-V

D

E

F

7

Page 8

1

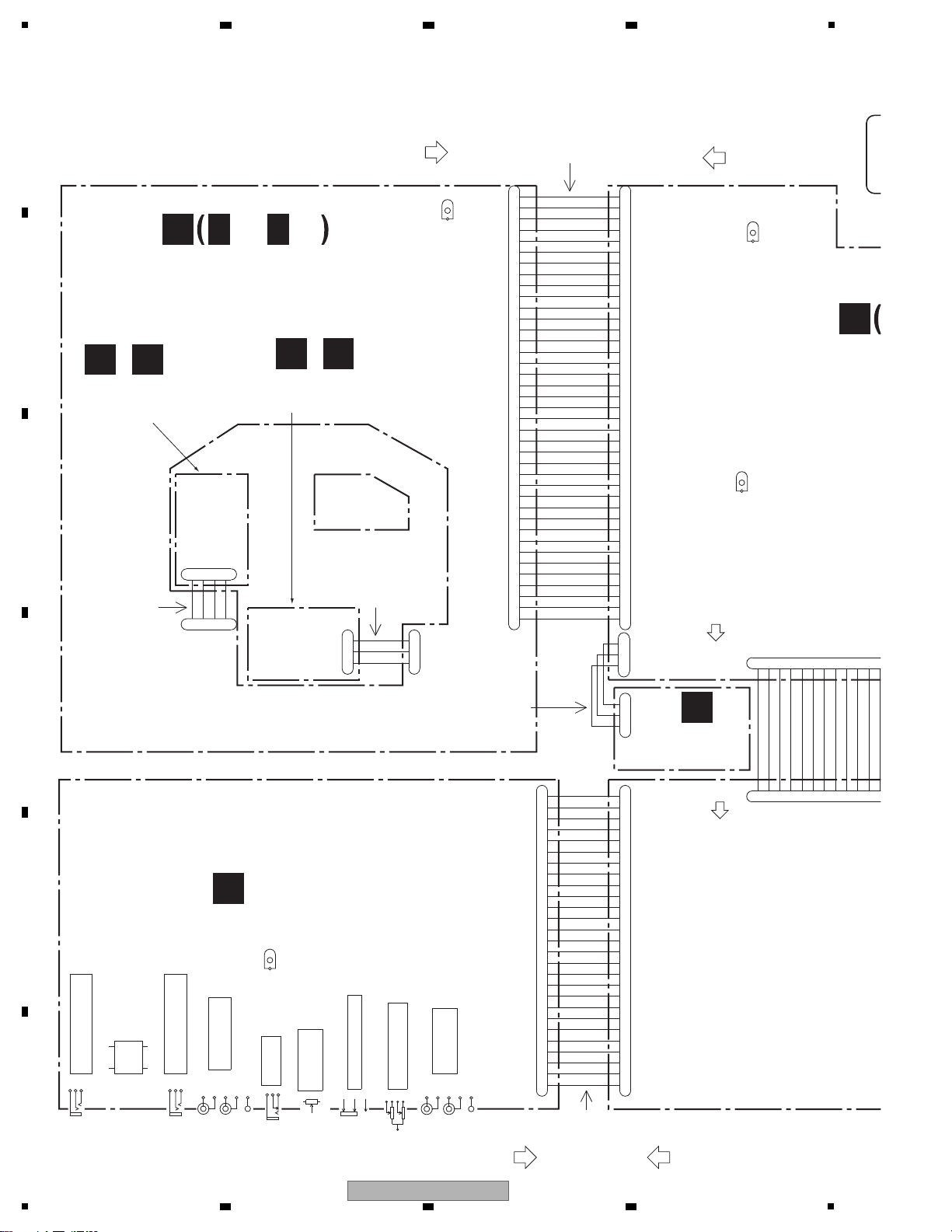

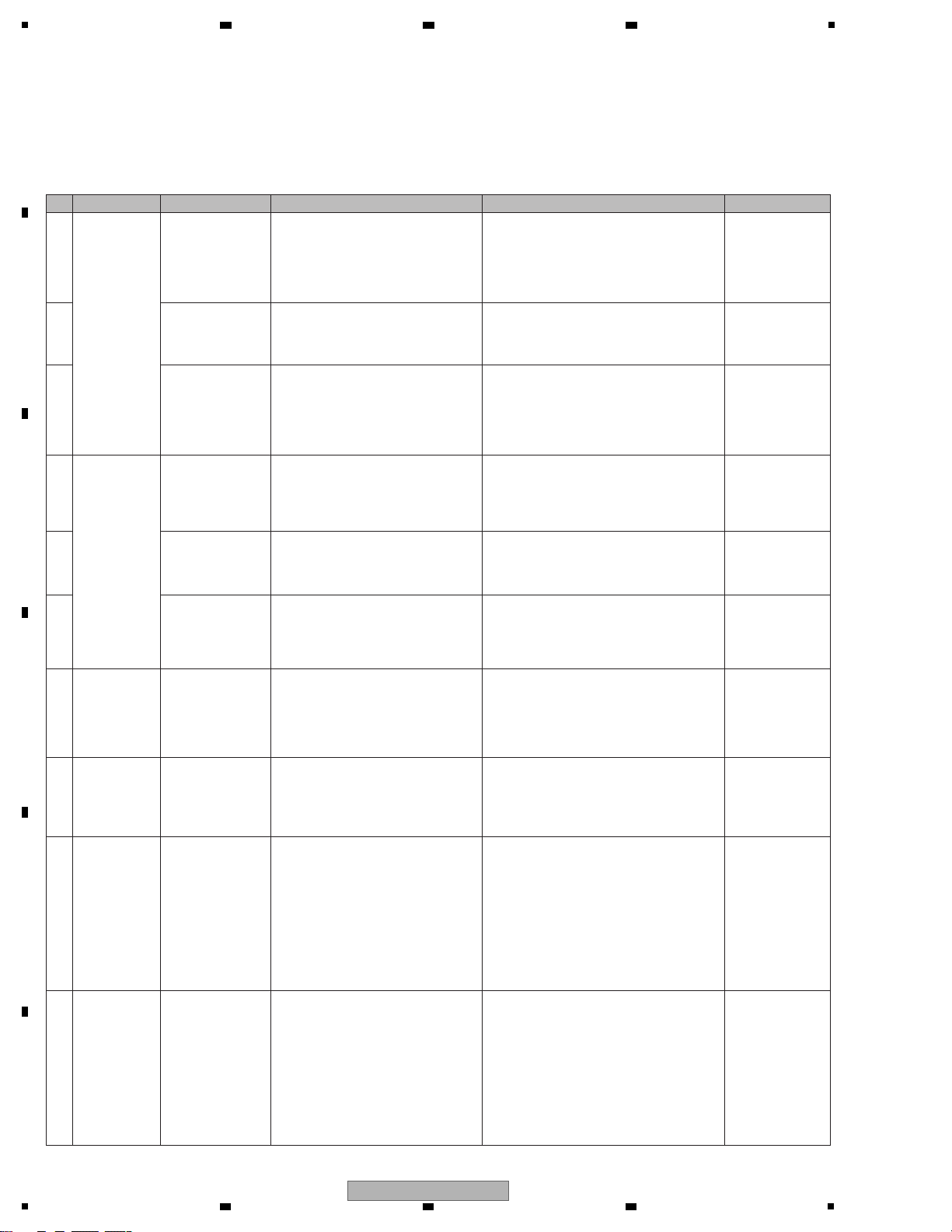

A

JACK ASSY

(DWX3304)

F

CRFD ASSY

(DWX3305)

Either the JOG1 Assy or JOG2 Assy is assembled here. The JOG1 Assy and

JOG2 Assy are interchangeably used and handled similarly in their production

management.

Either the TCH1 Assy or TCH2 Assy is assembled here. The TCH1 Assy and

TCH2 Assy are interchangeably used and handled similarly in their production

management.

DCS1115-A

VR2901

1

324

5

JA294

DKN1622-A

231

JA2901

DKN1614-A

2

3

1

JA2903

AKB7181-A

543

2

1

DCS1111-A

VR2902

1

3

2

S2901

DSH1025-A

123

JA2902

AKB7181-A

54321

51048-0300

JH1002

1

V+3R3_AD

2

AD_CRSFD

3

GND_AD

CN2801

52151-0310

1

GND_D

2

JOG_TCH1/2

3

V+3R3_UCOM

PF04PG-B05

CN2701

1

GND_D2V+3R3_UCOM

3

JOG_DIAL1/2_0

4

JOG_DIAL1/2_1

JA2905

DKN1622-A

231

AKF7002-A

KN2903

1

AKF7002-A

KN1501

1

AKF7002-A

KN1001

1

KN2902

VNE1948-A

GND1

1

GND2

2

GND3

3

GND4

4

VKN1842-A

CN101

1

MIC_AUXIN_L

2

GND_AI

3

MIC_AUXIN_R

4

V-6_J

5

V+7_J

6

GND_AI

7

GND_AI

8

GND_AI

9

GND_AO

10

GND_AO

11

MASTER1_L+

12

GND_AO

13

MASTER1_L-

14

GND_AO

15

MASTER2_L

16

GND_AO

17

GND_AO

18

GND_AO

19

MASTER2_R

20

GND_AO

21

MASTER1_R+

22

GND_AO

23

MASTER1_R-

24

GND_AO

25

MUTE

26

MIC_AUXIN_SW

27

MIC_AUXIN_SEL

VKN2097-A

CN2001

1

V+3R3_AD

2

GND_AD

3

LED_8

4

LED_7

5

LED_9

6

ENC_ABL2_0

7

LED_10

8

ENC_ABL2_1

9

LED_11

10

ENC_V OL2_0

11

LED_12

12

ENC_V OL2_1

13

KEY_IN_7

14

SW_AD_B

15

KEY_IN_6

16

AD_PTCHFD2_1

17

KEY_IN_5

18

AD_PTCHFD2_2

19

KEY_IN_4

20

LED_14

21

GND_D

22

AD_FX2

23

GND_D

24

AD_VOL2

25

V+3R3_UCOM

26

SW_AD_A

27

GRID_7

28

JOG_TCH2

29

GRID_6

30

JOG_DIAL2_0

31

GRID_5

32

JOG_DIAL2_1

33

GRID_4

34

GRID_0

35

GRID_3

36

GRID_1

37

GRID_2

38

GND_LED

39

V+5_LED

VKN2097-A

CN1003

1

V+5_LED

2

GND_LED

3

GRID_2

4

GRID_1

5

GRID_3

6

GRID_0

7

GRID_4

8

JOG_DIAL2_1

9

GRID_5

10

JOG_DIAL2_0

11

GRID_6

12

JOG_TCH2

13

GRID_7

14

SW_AD_A

15

V+3R3_UCOM

16

AD_VOL2

17

GND_D

18

AD_FX2

19

GND_D

20

LED_14

21

KEY_IN_4

22

AD_PTCHFD2_2

23

KEY_IN_5

24

AD_PTCHFD2_1

25

KEY_IN_6

26

SW_AD_B

27

KEY_IN_7

28

ENC_V OL2_1

29

LED_12

30

ENC_V OL2_0

31

LED_11

32

ENC_ABL2_1

33

LED_10

34

ENC_ABL2_0

35

LED_9

36

LED_7

37

LED_8

38

GND_AD

39

V+3R3_AD

CN2002

KM200NA4L

1

GND_D

2

V+3R3_UCOM

3

JOG_DIAL2_04JOG_DIAL2_1

51048-0300

JH2001

1

GND_D

2

JOG_TCH2

3

V+3R3_UCOM

51048-0300

CN2601

1

V+3R3_AD

2

AD_CRSFD

3

GND_AD

VKN2097-A

CN1004

1

V+3R3_UCOM2GND_D3VBUS_DET

4

GND_D

5

A_MUTE6USB_CTRL17FAULT_DET28USB_XRST9PWR_ON10USB_ERR11FAULT_DET12MIC AUXIN SW

VKN1842-A

CN2901

1

MIC_AUXIN_SEL

2

MIC_AUXIN_SW

3

MUTE

4

GND_AO

5

MASTER1_R-

6

GND_AO

7

MASTER1_R+

8

GND_AO

9

MASTER2_R

10

GND_AO

11

GND_AO

12

GND_AO

13

MASTER2_L

14

GND_AO

15

MASTER1_L-

16

GND_AO

17

MASTER1_L+

18

GND_AO

19

GND_AO

20

GND_AI

21

GND_AI

22

GND_AI

23

V+7_J

24

V-6_J

25

MIC_AUXIN_R

26

GND_AI

27

MIC_AUXIN_L

VKN2097-A

CN102

28

MIC AUXIN SW

29

FAULT_DET

30

USB_ERR

31

PWR_ON

32

USB_XRST

33

FAULT_DET2

34

USB_CTRL1

35

A_MUTE

36

GND_D

37

VBUS_DET

38

GND_D

39

V+3R3_UCOM

AKF7002-A

KN2901

1

AUX IN VOL

MIC IN

AUX IN

MIC IN VOL

MASTER2

MIC/AUX SELECT

MASTER1_R

MASTER1_L

VERTICAL

CONTACTSIDE

VERTICAL

CONTACTSIDE

VERTICAL

VERTICAL

CONTACTSIDE

CONTACTSIDE

VERTICAL

VERTICAL

CONTACTSIDE

HORIZONTAL

LENGTH=70mm

DDD1585PITCH=1mm

SAME FACE

FFC 27P

FFC 39P

PITCH=1mm

SAME FACE

DDD1587LENGTH=125mm

D20PDY0305E

LENGTH=50mm

PITCH=2mm

PARALLEL JUMPER WIRE

LR

RL

VERTICAL

LENGTH=100mm

CONNECTOR ASS'Y

D20PDY0310E

HORIZONTAL

VERTICAL

PITCH=2mm

PARALLEL JUMPER WIRE

HORIZONTAL

LENGTH=50mm

HLD1/2 ASSY

DWX3309/3310- /J

BOARD IN - PH

CONTACTSIDE

CDJ1

(DWX

D

CDJ2 ASSY

(DWX3303)

G

G G

1/2, 2/2

J K

TCH1 ASSY/TCH2 ASSY

(DWS1437/DWS1439)

/

H I

JOG1 ASSY/JOG2 ASSY

(DWS1436/DWS1438)

/

-

-

-

Either

JOG2

manag

2 3 4

4. BLOCK DIAGRAM

4.1 OVERALL WIRING DIAGRAM

A

B

C

D

E

F

8

1

2 3 4

DDJ-ERGO-V

Page 9

5

E

HPJK ASSY

(DWX3306)

C

HPLC ASSY

(DWX3324)

H I

JOG1 ASSY/JOG2 ASSY

(DWS1436/DWS1438)

/

J K

TCH1 ASSY/TCH2 ASSY

(DWS1437/DWS1439)

/

CN1801

52151-0310

1

GND_D

2

JOG_TCH1/2

3

V+3R3_UCOM

PF04PG-B05

CN1701

1

GND_D

2

V+3R3_UCOM

3

JOG_DIAL1/2_0

4

JOG_DIAL1/2_1

DKN1237-A

JA102

123

4

RT1

RT2

CN103

52147-0510

1

GND_F22GND_F2

3

HP_L

4

GND_AH

5

HP_R

JA1901

DKN1622-A

231

S101

DSH1025-A

123

KN101

VNE1948-A

GND1

1

GND2

2

GND3

3

GND4

4

CN104

52151-0310

1

V+5_HP

2

GND_D

3

V+5_HP_OUT

CN1001

NM

1

DBG_CNVSS

2

MAIN_XRST

3

GND_D

4

V+3R3_UCOM

CN1002

KM200NA4L

1

GND_D

2

V+3R3_UCOM

3

JOG_DIAL1_04JOG_DIAL1_1

51048-0300

JH1001

1

GND_D

2

JOG_TCH1

3

V+3R3_UCOM

3

VBUS_DET

4

GND_D

5

A_MUTE6USB_CTRL17FAULT_DET28USB_XRST9PWR_ON10USB_ERR11FAULT_DET12MIC_AUXIN_SW13ADC_DAC_XRST

14

MIC_AUXIN_SEL15USB_BUSY16USB_REQ17MIC_AUXIN_MUTE18GND_D19EEP_SCL20GND_D

21

EEP_SDA22GND_D

23

GND_D24GND_D25PWR_SW26GND_D27DAC_CDTI28GND_D29DAC_CS30GND_D31DAC_CCLK32GND_D33USB_CTRL234GND_D35GND_D36GND_LED37V+5_LED38GND_LED39V+5_LED

51048-0300

JH3001

1

V+5_HP2GND_D3V+5_HP_OUT

51048-0500

JH1901

1

GND_F22GND_F2

3

HP_L4GND_AH5HP_R

1

V+5_LED

2

GND_LED

3

V+5_LED

4

GND_LED

5

GND_D6GND_D

7

USB_CTRL2

8

GND_D

9

DAC_CCLK

10

GND_D

11

DAC_CS

12

GND_D

13

DAC_CDTI

14

GND_D

15

PWR_SW

16

GND_D17GND_D18GND_D

19

EEP_SDA

20

GND_D

21

EEP_SCL

22

GND_D

23

MIC_AUXIN_MUTE

24

USB_REQ

25

USB_BUSY

26

MIC_AUXIN_SEL

27

ADC_DAC_XRST

28

MIC_AUXIN_SW

29

FAULT_DET

30

USB_ERR

31

PWR_ON

32

USB_XRST

33

FAULT_DET2

34

USB_CTRL1

35

A_MUTE

36

GND_D

37

VBUS_DET

KN1901

VNE1948-A

GND1

1

GND2

2

GND3

3

GND4

4

JA1902

XKN3017-A

2

3

1

FOR UCOM DEBUG

VERTICAL

VERTICAL

VERTICAL

HORIZONTAL

DDD1586LENGTH=325mm

PITCH=1mm

FFC 39P

SAME FACE

PITCH=2mm

LENGTH=200mm

PARALLEL JUMPER WIRE

D20PDY0520E

D20PDY0310E

PITCH=2mm

PARALLEL JUMPER WIRE

LENGTH=100mm

HP JACK

Mini JACK

DWX3309/3310- /J

HLD1/2 ASSY

LENGTH=50mm

BOARD IN - PH

HORIZONTAL

CONNECTOR ASS'Y

HLD3 ASSY DWX3311- /J

PITCH=2mm

LENGTH=100mm

PARALLEL JUMPER WIRE

D20PDY0310E

USB-B JACK

POWER SW

CDJ1 ASSY

(DWX3302)

D

D D

1/2, 2/2

IFPW ASSY

(DWX3301)

B

B B

1/3- 3/3

-

When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS LIST" or "PCB PARTS LIST".

-

The > mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

-

: The power supply is shown with the marked box.

Either the JOG1 Assy or JOG2 Assy is assembled here. The JOG1 Assy and

JOG2 Assy are interchangeably used and handled similarly in their production

management.

Either the TCH1 Assy or TCH2 Assy is assembled here. The TCH1 Assy and

TCH2 Assy are interchangeably used and handled similarly in their production

management.

6 7 8

A

B

C

D

5

DDJ-ERGO-V

6 7 8

E

F

9

Page 10

1

CN 2001 CN1003

PC1701 IC1801

LED_7-12,14 LED_0-6,13

/PC2701 /IC2801

VR2206 KEY_IN_4-7 KEY_IN_0-3,7

TEMPO SLIDER GRID_0-7 GRID_0-7

CN1701 CN1801

AD_PTCHFD2_1

/CN2701

/CN2801

AD_PTCHFD2_2

ENC_ABL2_0

ENC_ABL2_1

CN 2002 JH2001 S2225

AUTO LOOP

ENC_VOL2_0

ENC_VOL2_1

S2226

SAMPLE VOL

AD_FX2

AD_VOL2

7

SW_AD_A

SW_AD_B

JOG_TCH2

JOG_DIAL2_1

JOG_DIAL2_0

XIN

XOUT

MAIN_XRST

AD_CRSFD JH1002

CN2601

CN1004

CROSS FADER

CN102

Lch

Rch

A_MUTE

MASTER1_L- L

MASTER1_L+ R

MASTER1_R-

MASTER1_R+

MASTER2_R

MASTER2_L

MUTE

MIC_AUXIN_SW

MIC_AUXIN_SEL

Rch

MIC_AUXIN_R

MIC_AUXIN_L

Lch

CN 2901 CN101

S2901

MASTER1 OUT MASTER2 OUT MIC IN MIC IN VOL MIC/AUX SELECT AUX IN VOL A UX IN

MIC_AUXIN_SEL

MIC_AUXIN_SW

A_MUTE

VR2901 VR2902 JA2902

ADC_DAC_XRST

MIC_AUXIN_MUTE

DAC CS

JA2904

JA2905

JA2903

JA2901

132

3

2

3

2

13

6217

IC507

627

1

IC506

537

1

IC505

IC501

DAC

1

1

1

1

2

2

1

2

2

2

3

1

13

IC2902

3

5

1

7

IC2901

IC2903

IC2904

5

5

2

7

2

7

111111

2

2

3

1

2

1

1

5

7

9

1

MUTE CIRCUIT

1

IC502

DAC

IC504

113

5

1

7

IC503

ADC

1

2

MUTE

CIRCUIT

34 2

34 2

3

3

2

IC2201

SW IC

VOL

MATRIX

Circuit

KEY

LED

ROTARY

ROTARY

1

32

2

2

1

1

9

1

14

2

6

82

1

1

12

1

2

1

2

2

2

MATRIX

Circuit

1

8

1

1

1

1

2

2

2

3

3

3

2

IC

UCO

2

2

2

8

8

10

8

9

9

7

8

8

8

9

91

322

1

232

511

4

333

124

2

1

2

5678

5678

5

IC1001

Reset IC

1

X1001

4MHz CERAMIC

RESONATOR

11

MUTE

CIRCUIT

H

G

CDJ2 ASSY

F

CRFD ASSY

A

JACK ASSY

D

CDJ1 ASSY

I

JOG1/2 ASSY

/

J K

TCH1/2 ASSY

/

2 3 4

4.2 OVERALL BLOCK DIAGRAM

A

B

C

D

E

F

10

DDJ-ERGO-V

1

2 3 4

Page 11

5

CH FADER A CH FADER B

VR1208 VR1213

PC1701 IC1801

/PC2701 /IC2801

RID_0-7 TEMPO SLIDER

AD_FADER_A

AD_FADER_B

CN1701 CN1801

/CN2701 /CN2801

S1234

BROWSE CN1002 JH1001

S1232

AUTO LOOP

JA1901

JA1902

S1233

SAMPLE VOL

HP JACK

Mini JACK

8

8

JH1901

HP_L HP_R

JOG_DIAL1_0

JOG_DIAL1_1

JOG_TCH1

AIN_XRST

JH3001

CN103

CN104

Lch

Rch

XIN XOUT

P_SW

S101

JA102

POWER SW

PWR_SW

USB_DP

ADC_DAC_XRST

DAC_CCLK

DAC_CS

DAC_CDTI

FAULT_DET

FAULT_DET 2

USB_CTRL2

USB_BUSY

USB_ERR

USB_CTRL1

USB_REQ

VBUS_DET

EEP_SDA

USB_XRST

PWR_ON

EEP_SCL

USB_DN

IC102

USB uCom

TUSB3200A

3

32

32

5

34 2

34 2

35

Cap

IC501

DAC

1

1

IC502

DAC

113

5

IC503

ADC

1

2

3

3

3

4

3

3

Master Data

HP Data

MIC/AUX Data

BCL

LRCK

MCLK

78

1

232

1

VOL

MATRIX

Circuit

KEY

LED

ROTARY

ROTARY

IC1201

SW IC

1

3

1

9

4

2

2

1

2

1

IC1201

SW IC

1

3

1

9

IC1002

UCOM IC

6

2

2

8

8

9

9

4

5

1

1

8

8

10

8

91

232

333

2

1

2

Q306

FET

IC307

VBUS

DETECT

VBUS

DETECT

CIRCUIT

3

8

1

2

4

2

1

43

3

6

3

7

3

1

2

1

2

2

1

123921373

3

POWER

DETECT

CIRCUIT

5678

5678

5

001

et IC

IC201

EEPROM

5

6

X101

6MHz Xtal

55

ROTARY

2

14

4

22

99

5V

Discharge

Circit

IC305

REG

IC301

REG

IC303

REG

IC304

REG

IC302

-6V

DDC

55

MUTE

CIRCUIT

3

3

1

AD_FX1

SW_AD_A

AD_MIX1

ENC_VOL1_0

ENC_ABL1_0

ENC_BRWS_0

AD_PITCH1_1

31

31

V+5_HPV+5_HP_OUT

432 4332 31 2114

- B

B

IFPW ASSY

E

HPJK ASSY

C

HPLC ASSY

H I

JOG1/2 ASSY

/

J K

TCH1/2 ASSY

/

6 7 8

A

B

C

D

E

F

5

6 7 8

DDJ-ERGO-V

11

Page 12

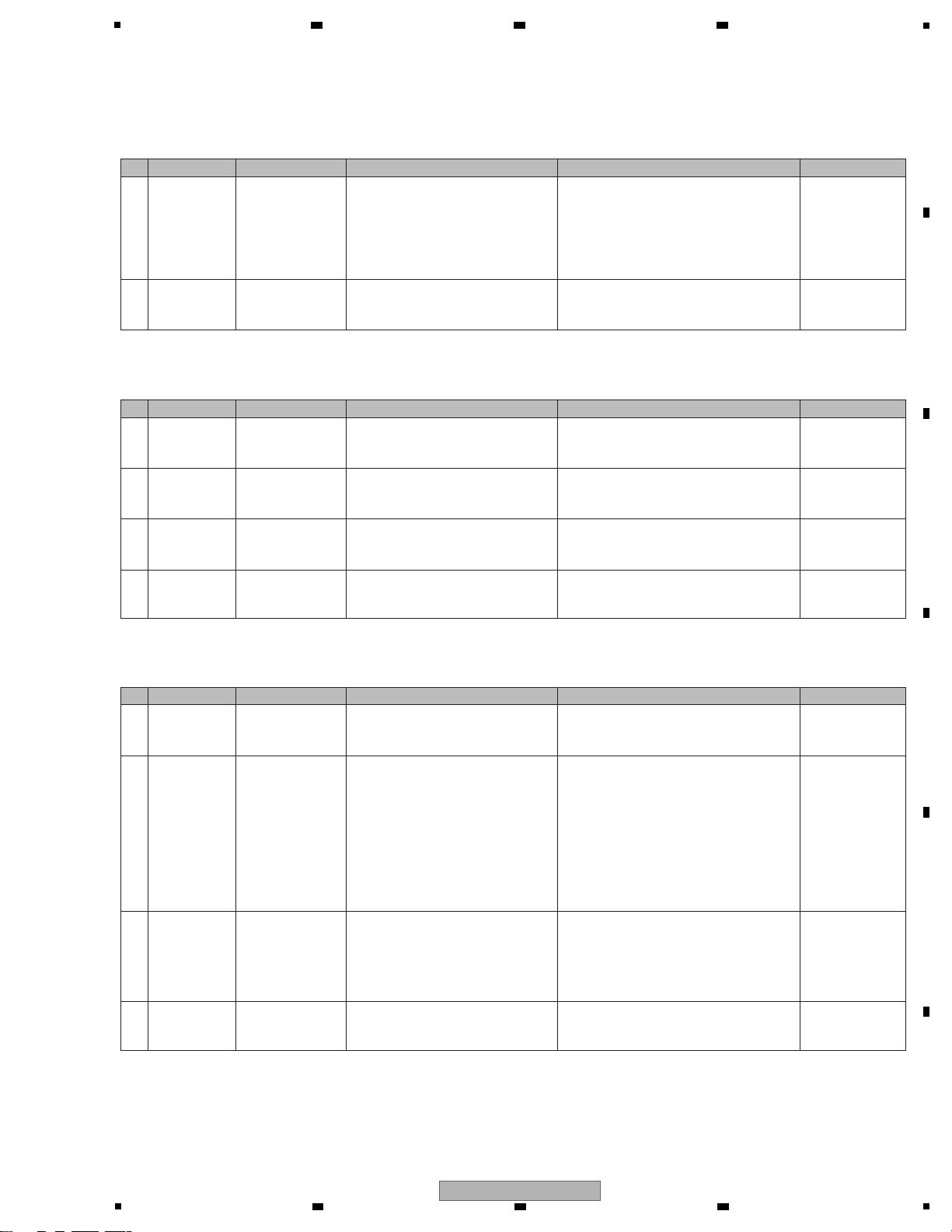

1

ON OFF

P_SW to uc

CONT

CONT

FAULT_DET2 to uc

VBUS_DET to uc

FAULT_DET to uc

DC/DC CONVERTER

REGULATOR

USB ucom

IC102

DAC (HP)

IC502

IC501

DAC (MASTER)

IC505

IC506, 507

OPAMP

IC2901, 2902

IC2904

(for MIC/AUX)

V+5_A

IC302

D/D_CONV

V+7

V+VBUS

USB

ADC (MIC/AUX)

IC503

V+7_J

V+7_J

EEPROM

IC104

RESET IC

IC307

V+5_USB

AMP (HP)

MIC

AUX IN

FILTER, COIL, BEADS

V-6_J

V-6_J

V-6_J

V+7_J

V+7_J

V-6_J

3.3V_REG1

IC304

IC303

Q306

V+5_D

L105

L106

L107

GND

PSW

PWRON

V+5_LED

USB BUS POWER

VOLTAGE DETE CT

V+5_D

DISCHARGE

V+5_D

IC301

IC305

V+5_HP

Charge

Capacitor

V+5_HP_OUT

V+VBUS

1

Ω

V+5_HP

OPAMP

(for MIC/AUX)

L501L502

V+3R3_USB

V+5_HP

_OUT

V+5_HP

_OUT

POWER SLIDE SW

POWER FAULT

V-6

B

IFPW ASSY

V+3R3_UCOM

5V→3.3V

NJM2878F3-33

3.3V_REG2

5V→3.3V

NJM2878F3-33

V+3R3_USB

CTF1629-

CTF1629-

CTF1629-

S-80942CNMC-G9C

7V→5V

NJM2878F3-05

5V_REG

7V→5V

5V_REG

NJM2878F3-05

7V→-6V

5V→7V

NJM2392M

ATH1170-

ATH1170-

OPAMP (MASTER2)

NJM4580MD

OPAMP (MASTER1)

NJM4580MD

A

JACK ASSY

MASTER1(TRS)

MASTER2

C

HPLC ASSY

V+5

_HP

V+5

_HP

BH3547F

IC504

AK4387ET

AK4387ET

AK5358AET

TUSB3200A

S-24CS64A0I

4.3 POWER BLOCK DIAGRAM

A

2 3 4

B

C

D

E

F

12

1

DDJ-ERGO-V

2 3 4

Page 13

P_SW to ucom

HP Jack (Phone)

HP Jack (Mini)

FAULT_DET2 to ucom

VBUS_DET to ucom

FAULT_DET to ucom

MAIN ucom

IC1002

DAC (HP)

IC502

IC501

TEMPO SLIDER

DCV1011

ADC (MIC/AUX)

IC503

CH FADER_A, B

DCV1024

CROSS FADER

DCV1023

V+3R3

_UCOM

V+3R3

_UCOM

V+3R3

_UCOM

V+3R3

_UCOM

V+3R3

_UCOM

V+3R3

_UCOM

VR

LED

V+3R3

_AD

V+3R3

_AD

ANALOG SW

RESET IC

IC1001

L1003

V+3R3_AD

AMP (HP)

V+5_LED

Photointerrupter

Photointerrupter

Photointerrupter

Photointerrupter

V+5

_LED

V+5

_LED

V+5

_LED

V+5

_LED

LED

L1004

V+3R3

_AD

VR

TEMPO SLIDER

DCV1011

CTF1629-

L1001

L1002

D

CDJ1 ASSY

G

CDJ2 ASSY

E

HPJK ASSY

F

CRFD ASSY

H I

JOG1/2 ASSY

/

H I

JOG1/2 ASSY

/

J K

TCH1/2 ASSY

/

J K

TCH1/2 ASSY

/

BH3547F

IC504

AK4387ET

AK4387ET

AK5358AET

DTH1211-

V+3R3

_UCOM

V+3R3

_UCOM

S-80927CNMC-G8X

2.7V DET

R5F3650ENFA-U0

TC74HC4052AF

PC1801/PC2801

GP1S094HCZ0F

PC1801/PC2801

GP1S094HCZ0F

PC1701/PC2701

PC1701/PC2701

SEDS-7573

SEDS-7573

5

6 7 8

A

B

C

D

E

DDJ-ERGO-V

5

6 7 8

F

13

Page 14

1

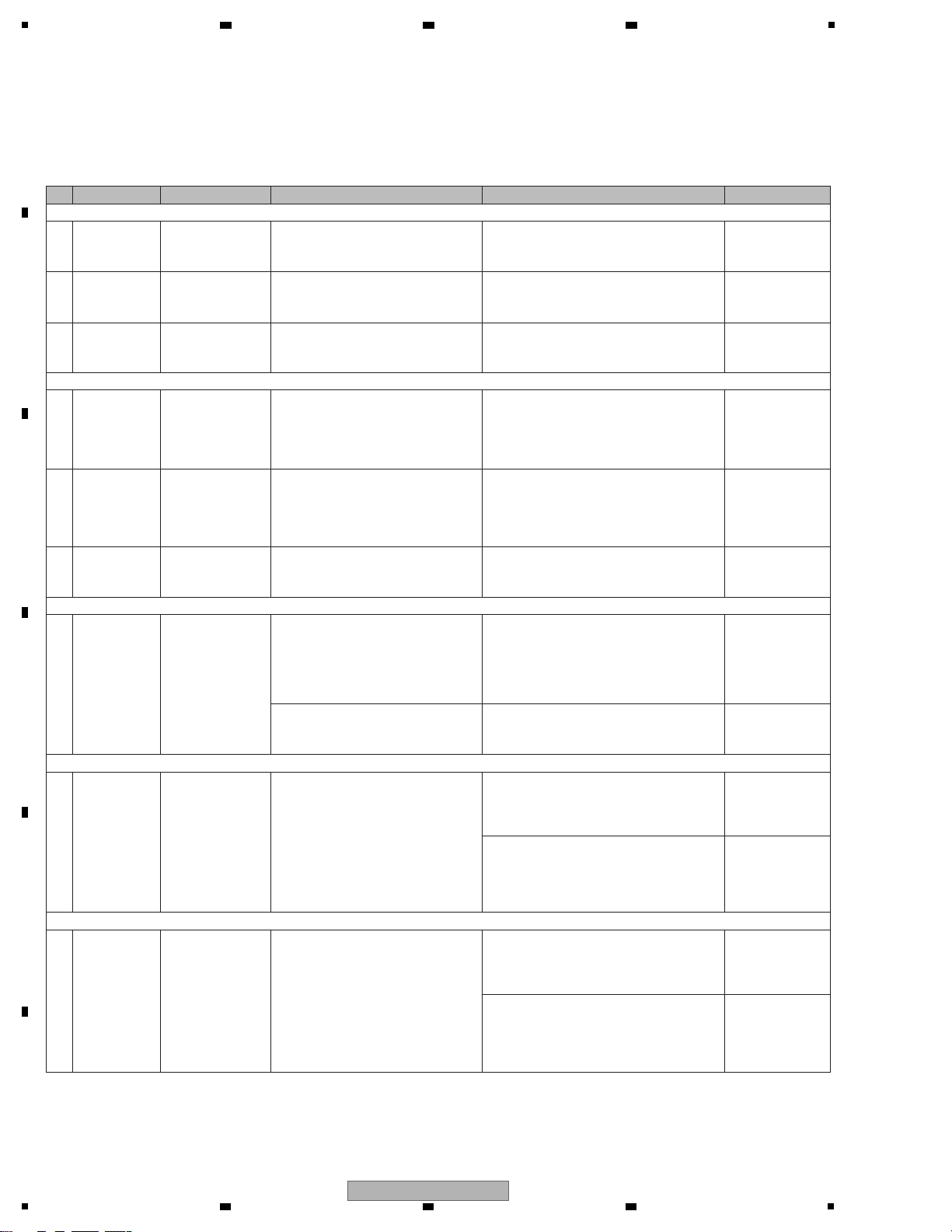

Y

N

Note: The TUSB3200A is started up after

loading the program from the EEPROM.

Y

N

Y

N

N

Y

Y

N

Note: Start the updating program on the PC.

Power ON

Operation clock setting: 32 MHz

Port initial setting

I2C serial initial setting

Peripheral device power: ON

Power failure?

Unit stopped by power failure

Power failure indication by LEDs

Canceling reset of the USB

Controller (TUSB3200A)

Starting opening indication

Checking communication

with the USB controller

Has communication

been established?

Abnormal stopping of the TUSB3200A

LED indication for USB controller error

CRC check of the main flash

CRC error?

(FLASH NG?)

Waiting until power supply

stabilizes then performing

power-failure detection

Finishing opening indication

Unit stopped by power failure

Power failure indication by LEDs

Power voltage

< 4.2 V?

Resetting the USB Controller

(TUSB3200A)

Waiting for a recovery/updating request

LED indication for flash ROM error

Power failure?

A

5. DIAGNOSIS

5.1 POWER ON SEQUENCE

A

B

2 3 4

C

D

E

F

14

1

DDJ-ERGO-V

2 3 4

Page 15

5

Normal mode

N

Y

* To normal main loop processing

• Power failure monitoring/Power voltage monitoring

• Power ON/OFF SW monitoring

• MIC/AUX switching

• Detection of change in operating elements

• DAC control

• USB transmission (transmission of operating element data)

• USB reception (reception and indication of display data)

Interruption initial setting

Serial communication

initial setting

Timer initial setting

A/D conversion initial setting

MIC/AUX initial setting

Operation mode

judgment

Service mode

(Test mode)

JOG Load

Measurement mode

Display initial setting

DAC initial setting

A

Mode for version

confirmation

Factory Reset

mode

Has reset of the USB

Controller been canceled?

6 7 8

A

B

C

D

E

F

DDJ-ERGO-V

5

6 7 8

15

Page 16

1

[0] Prior Confirmation

[0-1] Checking in Service Mode

[0] Prior Confirmation

[0-1] Checking in Service Mode

[0-2] Checking Internal Cables

[1] Failure in Startup (Failure in power-on)

[1-1] Failure in the power system

[1-2] Failure in the microcomputer system

[2] Display (LED indicators)

[2-1] Any one of the LEDs does not light.

[2-2] Several LEDs do not light or abnormal light

[3] Operations (Buttons/Rotary selectors/Volumes/Faders

/Sliders/JOG)

[3-1] The buttons are disabled.

[3-2] Rotary selector not controllable

[3-3] VRs or faders or sliders not controllable

[3-4] Abnormalities regarding the JOG

[4] USB connection

[4-1] The unit cannot be recognized by the PC when

connected to the PC via USB connection.

[5] AUDIO OUT

[5-1] The MASTER OUT1/MASTER OUT2 is not output.

[5-2] The HEAD PHONE signal is not output.

[6] AUDIO IN

[6-1] The input signal to AUX/MIC is not output

[7] Basic Operation Check of the MAIN UCOM

1 ——— Service mode Identify a failure point. After a failure point is identified, see the section

referenced in this manual.

6. SERVICE MODE

[0-2] Checking Internal Cables

1 Disconnection,

breakage, or

loose connection

of internal cables

Cables Check that all the cables are securely

connected. Check that there is no

breakage in the cables.

Securely connect a cable if it is not connected.

If a cable is broken, replace it.

Note: If an FFC cable is disconnected, be careful of

the orientation of the contacts when reconnecting it,

referring to the printed guide on the board.

4.1 OVERALL

WIRING DIAGRAM

Contents

[1] Failure in Startup (Failure in power-on)

[1-1] Failure in the power system

1 Failure in the

power system (1)

LED indications of

the unit

Set the POWER switch to ON.

Check if the CH Fader LED on the left

deck is flashing.

If it is, power failure in other than V+VBUS and

V+3R3_UCOM is suspected.

See “6 Failure in the power system (2)” in this

table.

4.3 POWER BLOCK

DIAGRAM

5.3 VOLTAGE

MONITORING

2 Failure in USB-

bus power

IFPW Assy

V+VBUS

Set the POWER switch to OFF.

Check that the voltage of the V+VBUS

power line is in the range of 4.75–5.25 V.

If the voltage is outside the range of 4.75–5.25 V,

failure in the USB-bus power and its periphery

may be suspected. Check the USB cable and

USB connector.

4.3 POWER BLOCK

DIAGRAM

10.12 VOLTAGES

1

3

Control error of the

V+3R3_UCOM

regulator on the

IFPW Assy

IFPW Assy

CDJ1 Assy

Set the POWER switch to ON.

Check the voltage at Pin 1 (CONT) of the

V+3R3_UCOM regulator.

If the voltage at Pin 1 (CONT) of the

V+3R3_UCOM regulator is low, the S101 power

switch or Q301, or their peripheral circuits may

be defective.

4.3 POWER BLOCK

DIAGRAM

In a case where the unit is not started after the USB cable is connected and the unit is turned ON

No. Cause Diagnostics Point Item to be Checked Corrective Action Reference

No. Cause Diagnostics Point Item to be Checked Corrective Action Reference

No. Cause Diagnostics Point Item to be Checked Corrective Action Reference

5.2 TROUBLESHOOTING

A

2 3 4

B

C

D

E

F

16

1

DDJ-ERGO-V

2 3 4

Page 17

5

6 Power failure (2)

Identification of

defective Assy

JACK Assy

HPJK Assy

HPLC Assy

Disconnect the cables from each Assy in

order to confirm which Assy’s power is

abnormal.

If the voltage returns to a normal level when the

cables from either the JACK Assy or HPJK Assy

are disconnected, the internal circuits of the

corresponding Assy may be defective. If the

voltage returns to a normal level when the cables

from the HPLC Assy are disconnected, either

the internal circuits of the HPLC Assy or the

circuit to which power is supplied from

V+5_HP_OUT inside the IFPW Assy may be

defective.

4.1 OVERALL

WIRTING DIAGRAM

4.3 POWER BLOCK

DIAGRAM

7 Power failure (3)

Identification of

defective power

system

FAULT_DET

IFPW Assy

Deactivate the voltage monitoring circuit

then check the section with improper

voltage.

The voltage monitoring circuit can be deactivated by

removing R337 (0 Ω) on the FAULT_DET.

See the notes in “5.3 VOLTAGE MONITORING”

before proceeding to further diagnostics.

To identify the section with improper voltage, check

the voltage at each point on the IFPW Assy.

4.3 POWER BLOCK

DIAGRAM

5.3 VOLTAGE

MONITORING

10.12 VOLATGES

10.13 WAVEFORMS

1256789a

cd1238

[1-2] Failure in the microcomputer system

1 Power failure in

the MAIN UCOM

CDJ1 Assy Check the power terminal of the

MAIN UCOM (IC1002).

Check the power and voltage are normal.

Check the power line and the parts, such as coils

(beads), resistors, and capacitors.

If no problem was found with the parts, power line,

and conduction between the power supply and

GND, the MAIN UCOM (IC1002) may be defective.

10.12 VOLATGES

2

2 MAIN UCOM

Reset circuit

error

CDJ1 Assy Check the Reset terminal (pin 12) of the

MAIN UCOM (IC1002).

In normal operation the voltage of the Reset

terminal (Pin 17) is high.

If it is low, check if the voltage at V+3R3_UCOM is

2.7 V or less.

Check the reset line, resistors, capacitors, and

the Reset IC (IC1001).

10.12 VOLATGES

10.13 WAVEFORMS

2

3 MAIN UCOM

X'tal error

CDJ1 Assy Check the oscillation waveforms of the

X'tal (X1001).

In normalcy, oscillate it at 24 MHz. If the oscillation

waveforms are abnormal, check the resistor on the

oscillation-signal line, the capacitor, and X'tal

(X1001). If nothing is wrong with these parts, the

MAIN UCOM (IC1002) may be defective.

10.13 WAVEFORMS

I

4 MAIN UCOM

startup error

CDJ1 Assy After startup, check the lighting statuses of

the LEDs.

(For example, although some of the LEDs

light properly, the unit is not started up

properly.)

Refer to “6.6 ERRROR DISPLAY”.

If there is no corresponding error indication,

reload the program via USB.

(8.3 HOW TO FIRMWARE UPDATE)

If the normal status is not recovered after all

above steps are performed, the MAIN UCOM

(IC1002) may be defective.

6.6 ERROR DISPLAY

8.3 HOW TO

FIRMWARE UPDATE

5 Power failure in

the USB

Controller

IFPW Assy Check if a voltage error was detected.

Check the power terminal of the USB

Controller (IC102).

If the detected voltage error is confirmed, check

conduction between the power supply and GND.

Check the power line and the parts, such as coils

(beads), resistors, and capacitors.

If no problem was found with the parts, power line,

and conduction between the power supply and GND,

the USB Controller (IC102) may be defective.

5.3 VOLTAGE

MONITORING

10.13 WAVEFORMS

578

4 Power failure in

the MAIN UCOM

on the IFPW

Assy

IFPW Assy Set the POWER switch to ON.

If V+3R3_UCOM is abnormal

(2.7 V or less)

Disconnect the FFC connected between the

IFPW Assy and CDJ 1 Assy. If the voltage of the

V+3R3_UCOM returns to a normal level, the

regulator (IC304) or its peripheral circuits may

be defective.

4.3 POWER BLOCK

DIAGRAM

10.12 VOLATGES

2

5 Power failure in

the MAIN UCOM

CDJ1 Assy

CDJ2 Assy

JOG1, JOG2 Assy

TCH1, TCH2 Assy

Set the POWER switch to ON.

If V+3R3_UCOM is abnormal

(2.7 V or less)

Disconnect the cables from the JOG1, JOG2,

TCH1, and TCH2 Assys. If the voltage at

V+3R3_UCOM returns to a normal level, the

internal circuits of the JOG1, JOG2, TCH1, or

TCH2 Assy may be defective. If the voltage does

not return to a normal level, the MAIN UCOM

(IC1002) or its peripheral circuits and the circuits

to which power is supplied from the

V+3R3_UCOM may be defective.

4.3 POWER BLOCK

DIAGRAM

10.12 VOLATGES

2

No. Cause Diagnostics Point Item to be Checked Corrective Action Reference

No. Cause Diagnostics Point Item to be Checked Corrective Action Reference

6 7 8

A

B

C

DDJ-ERGO-V

5

6 7 8

D

E

F

17

Page 18

1

[2] Display (LED indicators)

[2-1] Any one of the LEDs does not light.

1 Defective LED,

Defective LED

signal line

Periphery of the

abnormal LED

Check the difference in electrical potentials

between the positive and negative electrodes

of the LED that does not light (normally, it

must be within approx. 2.0–3.6 V).

If the difference is outside the normal range, the

signal lines at the periphery of the corresponding

LED, resistors, or the LED itself may be defective.

10. SCHEMATIC

DIAGRAM

10.13 WAVEFORMS

$%&'

[2-2] Several LEDs do not light or abnormal light

1 Defective LED

signal line,

Defective

MAIN UCOM

CDJ1 Assy

CDJ2 Assy

Check the output signal of MAIN UCOM

(IC1002).

If the output signal is abnormal, the MAIN UCOM

(IC1002) and LED signal line may be defective.

10. SCHEMATIC

DIAGRAM

10.13 WAVEFORMS

$%&'

2 Defective LED Periphery of the

abnormal LED

Check the connections of the LED then

check the forward voltage (approx. 2.2 V)

between both ends of the LED.

If the signal waveform is abnormal, the LED

may be defective.

10. SCHEMATIC

DIAGRAM

10.13 WAVEFORMS

$%&'

3

Defective transistor

for LED drive

CDJ1 Assy

CDJ2 Assy

Check the transistors for LED drive. If the signal waveform is abnormal, the transistor

may be defective.

10. SCHEMATIC

DIAGRAM

10.13 WAVEFORMS

$%&'

6 USB Controller

Reset circuit

error

IFPW Assy Check the voltage of Reset terminal

(pin 10) of the USB Controller (IC102).

In normal operation, the voltage of the Reset

terminal (pin 10) is high.

If the voltage of the Reset terminal is low, check

the reset line, resistors, capacitors.

If no problem is found, the USB Controller

(IC102) or MAIN UCOM (IC1002) may be

defective.

10.13 WAVEFORMS

4

7 USB Controller

X'tal error

IFPW Assy Check the oscillation waveforms of the

X'tal (X101).

In normalcy, oscillate it at 6 MHz.

If the oscillation

waveforms are abnormal, check the resistor on

the oscillation-signal line, the capacitor, and X'tal

(X101). If nothing is wrong with these parts, the

USB CONTROLLER (IC102) may be defective.

10.13 WAVEFORMS

5

8 I2C communica-

tion error of

USB Controller

start up

IFPW Assy Check the I2C communication waveforms

of the EEPROM (IC104) immediately after

startup.

Data of the EEPROM (IC104) are loaded only

during startup.

If an error is generated, check the power supply

to the EEPROM, resistors, capacitors.

If no problem is found, the EEPROM (IC104) or

USB Controller (IC102) may be defective.

10.13 WAVEFORMS

67

9 EEPROM error IFPW Assy Reload the program via USB. If no problem is found with the communication

waveform in "8.2 HOW TO PROGRAM COPY

FOR USB CONTROLLER" above, reload the

program via USB.

If reloading is successfully performed, the USB

Controller (IC102) may be defective.

If reloading fails, the EEPROM (IC104) may be

defective.

8.2 HOW TO

PROGRAM COPY FOR

USB CONTROLLER

No. Cause Diagnostics Point Item to be Checked Corrective Action Reference

No. Cause Diagnostics Point Item to be Checked Corrective Action Reference

No. Cause Diagnostics Point Item to be Checked Corrective Action Reference

A

2 3 4

B

C

D

E

F

18

1

DDJ-ERGO-V

2 3 4

Page 19

5

[3-3] VRs, Faders or sliders not controllable

1 Loose

connection

CDJ1 Assy

CDJ2 Assy

CRFD Assy

Check that the signal lines (AD_****)

between the VRs/faders/sliders and

MAIN UCOM (IC1002) are all right.

If the signals are not normal, signal line, resistor,

capacitor may be defective.

———

2 Defective VR,

Defective Fader,

Defective Slider

CDJ1 Assy

CDJ2 Assy

CRFD Assy

Check the voltage at each signal line

when the corresponding VR is turned or

the corresponding fader/slider is moved.

VRs: If the voltage of the signal line does not

change between 3.3 V and 0 V, that VR may be

defective.

Faders: If the voltage of the signal line does not

change between 3.3 V and 0 V, that VR may be

defective.

Tempo slider: If the value of the voltage of the

AD_PITCH1/2_2 signal is other than 1.65 V, or if

the voltage of the AD_PITCH1/2_1 signal does

not change between 3.3 V and 0 V, the

tempo slider may be defective.

10.13 WAVEFORMS

gQUVWX

3

Defective

VOL SW IC,

Loose connection

CDJ1 Assy

CDJ2 Assy

Check the voltage of the signal output

from the VOL SW ICs (IC1201, IC1202,

IC2201) while the VR is turned.

If the voltage output from the VOL SW IC does

not fluctuate within the range between 3.3 V and

0 V at the AD_MIX1/2, AD_VOL1/2, or AD_FX1/2

signal line after selection, one of the VOL SW ICs

(IC1201, IC1202, IC2201) or the SW_AD_A/B

switching-signal line may be defective.

10.13 WAVEFORMS

gRST

4 Defective MAIN

UCOM (IC1002)

CDJ1 Assy If the symptom persists after the above

corrections.

The MAIN UCOM (IC1002) may be defective.

[7] Basic Operation

Check of the MAIN

UCOM

[3] Operations (Buttons / Rotary selectors / Volumes / Faders / Sliders / JOG)

[3-1] The buttons are disabled.

1

Loose connection,

defective switches,

defective diodes,

d

efective transistors

CDJ1 Assy

CDJ2 Assy

Periphery of the

abnormal button

Check that the signal line from the

corresponding switch to the transistor at

the switching-detection section up to the

MAIN UCOM (IC1002) is all right.

If other switches that are connected to the same

signal line operate normally, the corresponding

switch or the diode on the signal line for the

corresponding switch may be defective. If other

switches do not operate either, a transistor in the

switching-detection section or its peripheral

circuits may be defective.

10.13 WAVEFORMS

NOP

2 Defective MAIN

UCOM (IC1002)

CDJ1 Assy If the symptom persists after the above

corrections.

The MAIN UCOM (IC1002) may be defective.

[7] Basic Operation

Check of the MAIN

UCOM

4 Defective MAIN

UCOM (IC1002)

CDJ1 Assy If the symptom persists after the above

corrections.

The MAIN UCOM (IC1002) may be defective.

[7] Basic Operation

Check of the MAIN

UCOM

[3-2] Rotary selector not controllable

1 Defective

AUTO_LOOP

CDJ1 Assy

CDJ2 Assy

Check that the signal lines (ENC_ABL1_0/1,

ENC_ABL2_0) are normal during rotation of

the rotary selector.

If the signals are not normal, signal line, resistor,

the rotary selector may be defective.

10.13 WAVEFORMS

YZ

2 Defective

SAMPLE VOL

CDJ1 Assy

CDJ2 Assy

Check that the signal lines (ENC_VOL1_0/1,

ENC_ABL2_0) are normal during rotation of

the rotary selector.

If the signals are not normal, signal line, resistor,

the rotary selector may be defective.

10.13 WAVEFORMS

YZ

3 Defective

BROWSE

CDJ1 Assy Check that the signal lines

(ENC_BRWS_0/1) are normal during

rotation of the rotary selector.

If the signals are not normal, signal line, resistor,

the rotary selector may be defective.

10.13 WAVEFORMS

YZ

No. Cause Diagnostics Point Item to be Checked Corrective Action Reference

No. Cause Diagnostics Point Item to be Checked Corrective Action Reference

No. Cause Diagnostics Point Item to be Checked Corrective Action Reference

6 7 8

A

B

C

D

E

F

DDJ-ERGO-V

5

6 7 8

19

Page 20

1

8 Improper

adjustment or

assembly of the

JOG dial

The JOG dial turns too freely. (The load value for the JOG dial is outside the specified range.)

JOG section Check that the load value for the JOG dial

is within the specified range, referring to

“Measuring method” in “8.4 JOG Dial

Rotation Load Adjustment.”

If it is outside the specified range, adjust the position

of the Adjust Plate to change the load value for the

JOG dial, referring to “Load adjustment method” in

“8.4 JOG Dial Rotation Load Adjustment.”

8.4 JOG DIAL

ROTATION LOAD

ADJUSTMENT

During the above adjustment, if the upper-limit

adjustment position of the Adjust Plate is reached,

oil may have been spattered on the Adjust Plate.

Replace the washer, load gear, and cam plate with

new ones, then reassemble.

8.4 JOG DIAL

ROTATION LOAD

ADJUSTMENT

9

Improper

adjustment of

the JOG dial or

defective washer,

gear, or cam plate

Resistance to turning the JOG dial is too strong. (The load value for the JOG dial is outside the specified range.

JOG section Check that the load value for the JOG dial

is within the specified range, referring to

“Measuring method” in “8.4 JOG Dial

Rotation Load Adjustment.”

If it is outside the specified range, adjust the position

of the Adjust Plate to change the load value for the

JOG dial, referring to “Load adjustment method” in

“8.4 JOG Dial Rotation Load Adjustment.”

8.4 JOG DIAL

ROTATION LOAD

ADJUSTMENT

During the above adjustment, if the lower-limit

adjustment position of the Adjust Plate is reached,

shavings from the worn-out washer may have

increased the friction. Replace the washer, load gear,

and cam plate with new ones, then reassemble.

8.4 JOG DIAL

ROTATION LOAD

ADJUSTMENT

[3-4] Abnormalities regarding the JOG dial

1

Loose connection

Turning of the JOG dial is not detected.

CDJ1 Assy

CDJ2 Assy

JOG1/2 Assy

Check the JOG_DIAL1/2_0 and

JOG_DIAL1/2_1 waveforms while the Jog

dial is rotated.

If either waveform is abnormal, connection of

that signal line may be loose or the resistor or

the capacitor may be defective.

10.13 WAVEFORMS

2"#

4

Loose connection

Pressing on the JOG dial cannot be detected.

CDJ1 Assy

CDJ2 Assy

TCH1/2 Assy

Check the signal level of the JOG_TCH1/2

when the JOG dial is pressed.

If the signal level of the JOG_TCH1/2 does not

become L when the dial is pressed and H when

the dial is released (not pressed,) loose

connection of the signal line or a defective

resistor, capacitor, transistor may be suspected.

10.13 WAVEFORMS

2!

7 Defective gear,

Defective JOG

dial B

Noise is heard when the JOG dial is turned.

JOG section There may be any scratches on the gear

or some foreign matter between the gears.

If there are any scratches, replace the scratched

gear with a new one.

If there is any foreign matter, remove it then

replace the gears with new ones.

Gears to be replaced: Load gear, Encoder gear,

JOG shaft

———

There may be any scratches or some

foreign matter on the JOG dial B or the

Roller B Assy.

If there are any scratches, replace the scratched

gear with a new one.

If any foreign matter is attached, remove it.

———

5

Defective TCH1/2

photo interrupter

TCH1/2 Assy Check the signal level of the JOG_TCH1/2

when the JOG dial is pressed.

If the signal level of the JOG_TCH1/2 does not

become L when the dial is pressed and H when

the dial is released (not pressed,) a defective

photo interrupter (IC1801, IC2801) and

peripheral circuit may be suspected.

10.13 WAVEFORMS

2!

2

Defective JOG1/2

photo interrupter

JOG1/2 Assy Check the JOG_DIAL1/2_0 and

JOG_DIAL1/2_1 waveforms while the Jog

dial is rotated.

If either waveform is abnormal, the photo

interrupters (PC1701, PC2701) may be defective.

10.13 WAVEFORMS

2"#

3

Defective

MAIN

UCOM (IC1002)

CDJ1 Assy If the symptom persists after the above

corrections.

The MAIN UCOM (IC1002) may be defective.

[7] Basic Operation

Check of the MAIN

UCOM

6

Defective

MAIN

UCOM (IC1002)

CDJ1 Assy If the symptom persists after the above

corrections.

The MAIN UCOM (IC1002) may be defective.

[7] Basic Operation

Check of the MAIN

UCOM

After the JOG Assy is disassembled then reassembled, be sure to check that the load value for the JOG dial is within the

specified range. Refer to the "8.4 JOG DIAL ROTATION LOAD ADJUSTMENT".

No. Cause Diagnostics Point Item to be Checked Corrective Action Reference

A

2 3 4

B

C

D

E

F

20

DDJ-ERGO-V

1

2 3 4

Page 21

5

4 1012 VOLTAGES

10.13 WAVEFORMS

demn

6

Loose connection

/defective parts

IFPW Assy Check the digital input signals to DAC

(IC501) for MASTER OUT.

• MCLK: pin 1

• BCLK: pin 2

• MASTER_DATA: pin 3

• LRCK: pin 4

• ADC_DAC_XRST: pin 5

If any of those signals is abnormal, connection

of the corresponding signal line may be loose or

the resistor, capacitor, USB Controller (IC102),

or MAIN UCOM (IC1002) may be defective.

10.13 WAVEFORMS

bcdlvw

7

MASTER OUT1

Loose connection

/defective parts

JACK Assy

IFPW Assy

Identify the point where the audio signal is

interrupted on the line from CN101 to the

jacks (JA2904/JA2905).

The audio signal may be interrupted by a loose connection

of the signal line or by a defective resistor, capacitor,

transistor, operational amps (IC506, IC507,) or jacks.

10.13 WAVEFORMS

xyz

8

MASTER OUT2

Loose connection

/defective parts

JACK Assy

IFPW Assy

Identify the point where the audio signal is

interrupted on the line from CN101 to the

jacks (JA2903).

The audio signal may be interrupted by a loose

connection of the signal line or by a defective resistor,

capacitor, transistor, or jacks.

10.13 WAVEFORMS

xA

Mute signal

Loose connection

/defective parts

IFPW Assy Check the levels of the MUTE and

A_MUTE audio muting signals.

Normally, the MUTE signal must be low (muting

canceled). When it is high, muting is activated and no

sound is output. The MUTE signal becomes high,

possibly because connection of the corresponding

signal line is loose or the Muting circuit (Q501) or

Muting Drive circuit (Q502, Q508, Q509, D506, etc.)

is defective.

5 1012 VOLTAGES

10.13 WAVEFORMS

demn

Mute signal

Loose connection

/defective parts

IFPW Assy

CDJ1 Assy

Check the level of the A_MUTE audio

muting signal.

Normally, the A_MUTE signal must be low (muting

canceled). When it is high, muting is activated and no

sound is output. The A_MUTE signal becomes high,

possibly because connection of the signal line is loose

or the transistor (Q507) or MAIN UCOM (IC1002) is

defective.

[5] AUDIO OUT

[5-1] The MASTER OUT1/MASTER OUT2 is not output.

0

Wrong input setting

of the application

installed on the PC

Input setting of the

application installed

on the PC

Check that the input setting of the

application installed on the PC is

appropriate.

The PC will not recognize the unit if the input

setting of the application installed on the PC is

inappropriate.

Operating instructions

1 ——— MASTER OUT1

terminal

MASTER OUT2

terminal

Identify the connector(s) that do(es) not

output signals.

Check if no signal is output from both MASTER 1

and 2 or either of them.

• If neither MASTER 1 nor 2 connector outputs,

go to [2].

• If only the MASTER 1 connector does not output,

go to [7].

• If only the MASTER 2 connector does not output,

go to [8].

———

3 ——— IFPW Assy Check that an audio signal is output from

DAC (IC501 pin 10, 11).

• If an audio signal is output, go to [4] or [5].

• If an audio signal is not output, go to [6].

10.13 WAVEFORMS

xyz

2

Loose connection

/defective parts

IFPW Assy Check the audio signal (MASTER2_L/R),

using pins 15 and 19 of the CN101 on the

IFPW Assy.

If audio signal is output, loose connection or

defective parts in the JACK Assy may be suspected.

• If an audio signal is output, go to [7] or [8].

• If an audio signal is not output, go to [3].

10.13 WAVEFORMS

xA

[4] USB connection

[4-1] The unit cannot be recognized by the PC when connected to the PC via USB connection.

0

Wrong input setting

of the application

installed on the PC

Input setting of the

application installed

on the PC

Check that the input setting of the

application installed on the PC is

appropriate.

The PC will not recognize the unit if the input

setting of the application installed on the PC is

inappropriate.

Operating instructions

1 Failure in startup IFPW Assy

CDJ1 Assy

Check the lighting statuses of the LEDs

during startup.

If no LED lights, see [1] Failure in Startup. [1] Failure in Startup

2 Defective USB

Controller

IFPW Assy Check the communication waveforms of

the USB_DP/DN lines.

If the unit is connected to a PC via the USB cable,

communication will be performed through the USB

DP/DN lines.

If communication cannot be performed, check the

USB cable, connectors, internal cables, resistors,

capacitors, and filters.

If nothing is wrong with them, check the items listed

in “[1-2] Failure in the microcomputer system”.

[1-2] Failure in the

microcomputer

system

10.13 WAVEFORMS

ef

No. Cause Diagnostics Point Item to be Checked Corrective Action Reference

No. Cause Diagnostics Point Item to be Checked Corrective Action Reference

6 7 8

A

B

5

6 7 8

DDJ-ERGO-V

C

D

E

F

21

Page 22

1

7 10.13 WAVEFORMS

bcdlvw

Loose connection

/defective parts

IFPW Assy Check the digital input signals to DAC

(IC502) for HP.

• MCLK: pin 1

• BCLK: pin 2

• MASTER_DATA: pin 3

• LRCK: pin 4

• ADC_DAC_XRST: pin 5

If any of those signals is abnormal, connection

of the corresponding signal line may be loose or

the resistor, capacitor, USB Controller (IC102),

or MAIN UCOM (IC1002) may be defective.

8 ———

Loose connection

/defective parts

HPJK Assy Identify the point where the audio signal is

interrupted on the line from JH1901 to the

jacks (JA1901/JA1902).

The audio signal may be interrupted by a loose

connection of the signal line or by a defective

resistor, capacitor, or jack.

6 10.12 VOLTAGES

Mute signal

Loose connection

/defective parts

IFPW Assy Check the level of the muting signal for the

HP AMP at Pin 2 of IC504.

The level must be high (muting canceled) in

normal state. When it is low, muting is activated

and no sound is output. The muting signal level

becomes high, possibly because connection of

the corresponding PWR_ON signal line is loose.

If the muting signal level is high (normal,) the

HP AMP may be defective.

[5-2] The HEAD PHONE signal is not output.

0

Wrong input setting

of the application

installed on the PC

Input setting of the

application installed

on the PC

Check that the input setting of the

application installed on the PC is

appropriate.

The PC will not recognize the unit if the input

setting of the application installed on the PC is

inappropriate.

Operating instructions

1

Loose connection

IFPW Assy

HPLC Assy

HPJK Assy

Check the connections between the

IFPW Assy and HPLC Assy, and between

the IFPW Assy and HPJK Assy.

If normal, go to [2]. ———

2

Loose connection

/defective parts

IFPW Assy Check the audio signal (HP_L/R), using

pins 3 and 5 of the CN103 on the IFPW

Assy.

If no audio signal is output, connection between

the IFPW and HPLC Assys may be loose or

these Assys may be defective. Go to [3].

If an audio signal is output, connection between

the IFPW and HPJK Assys may be loose,

connections inside the HPJK Assy may be loose,

or these Assys may be defective. Go to [8].

10.13 WAVEFORMS

BC

3

Loose connection

/defective parts

IFPW Assy

HPLC Assy

Check the voltages, using pin 1 (V+5_HP),

pin3 (V+5_HP_OUT) of the CN104 on the

IFPW Assy .

The normal voltage level is approximately 5 V.

If the voltage is abnormal, the HPLC Assy may

be defective, connection of the V+5_HP and

V+5_HP_OUT lines on the IFPW Assy may be

loose, or a connection IC (5V REG IC305,

DAC IC502 for HP, HP AMP IC504, etc.) may be

defective.

If the voltage is normal, go to [4].

10.12 VOLTAGES

ef

5

Loose connection

/defective parts

IFPW Assy Check the audio input signal, using

pins 3 and 5 of the HP AMP (IC504).

Check the audio output signal, using

pins 1 and 7 of the HP AMP (IC504).

If the output signal is normal, connection of the

audio signal between HP AMP IC504 and

CN103 may be loose.

If the input signal is abnormal, connection of the

audio input signal line may be loose or the

resistor or capacitor may be defective.

If the input signal is normal but the output signal

is abnormal, go to [6].

———

4 ——— IFPW Assy Check the audio output signal, using

pins 10 and 11 of the HP DAC (IC502).

• If an audio signal is output, go to [5].

• If an audio signal is not output, go to [7].

10.13 WAVEFORMS

BC

No. Cause Diagnostics Point Item to be Checked Corrective Action Reference

A

2 3 4

B

C

D

E

F

22

1

2 3 4

DDJ-ERGO-V

Page 23

5

8

Loose connection

/defective parts

JACK Assy

Check the external Audio input signal

(AUX IN), using pin 7 for IC2903/IC2904

(SW AMP).

If a signal is input, go to [10].

If no signal is input, check for the audio signal that is

input to the AUX connector (JA2902) and

transmitted to the SW AMP (IC2903, IC2904).

If the input signal is abnormal, connection of the

corresponding signal line may be loose or the resistor,