Page 1

Programmable Safety Systems

PSS-Range

PSS SB TESTER

Operating Manual

Item No. 20 757-03

The spirit of safety.

Page 2

All rights to this manual are reserved by Pilz GmbH & Co. Copies may be made for internal

purposes.

While every effort has been made to ensure that the information in this manual is accurate,

no responsibility can be accepted for errors or omissions contained within it.

We reserve the right to amend specifications without notice. We are grateful for any

feedback on the contents of this manual.

The names of products, goods and technologies used in this manual are trademarks of the

respective companies.

Page 3

Contents

Introduction 1-1

Validity of documentation 1-1

Overview of documentation 1-1

Definition of symbols 1-2

Overview 2-1

Range 2-1

Safety 3-1

Intended use 3-1

EMCD 3-1

Warranty and liability 3-1

Disposal 3-2

Operation 4-1

Supply 4-1

Charging the battery 4-1

Commissioning 4-2

Switching on 4-2

Setting the contrast 4-3

Switching the backlight on/off 4-3

Setting the time and date 4-4

Setting the signal runtime 4-5

Calibration 4-5

Performing the tests 4-6

Saving the test results 4-6

Uploading the test results to a PC 4-7

Deleting the test results 4-7

Operating Manual: PSS SB TESTER 1

Page 4

Contents

Tests/Measurements 5-1

Connection test 5-2

Performing the connection test 5-2

Separate test: Resistance between CAN_H and CAN_L 5-4

Separate tests: Short circuits between the bus cable wires 5-5

Screening test 5-6

Performing the screening test 5-6

Length measurement 5-9

Performing the length measurement 5-13

Signal test 5-16

Performing the signal test 5-16

Separate test: Measuring the voltage at Vcc 5-17

Separate test: Testing the transmission rate 5-18

Separate tests: Testing the electrical signal level 5-19

Separate tests: Testing the signal edges 5-20

Real-time mode 5-21

Performing the real-time measurement 5-21

Software 6-1

System requirements 6-1

Installation 6-1

Starting the software 6-1

Fault Diagnostics 7-1

Technical Details 8-1

2 Operating Manual: PSS SB TESTER

Page 5

Introduction

This operating manual is intended to give users all the information they

need to use the PSS SB TESTER.

To fully understand this manual you will need to be conversant with the

information found in the general documentation for the SafetyBUS p PSSrange. In particular you should read the SafetyBUS p System Description

and SafetyBUS p Installation Manual.

This documentation is intended for instruction and should be retained for

future reference.

Validity of documentation

This documentation is valid for the PSS SB TESTER from Version 2.0.

It is valid until new documentation is published. The latest documentation is

always enclosed with the unit.

Overview of documentation

The manual is divided into the following chapters:

1 Introduction

The introduction is designed to familiarise you with the contents,

structure and specific order of this manual.

2 Overview

This chapter provides a brief overview of the unit’s most important

features and its application range.

3 Safety

This chapter must be read as it contains important information on

safety regulations and intended use.

4 Operation

This chapter contains detailed information on how to operate the unit.

5 Tests/Measurements

This chapter describes the separate tests than can be performed

using the PSS SB TESTER.

6 Software

This chapter describes the software used to read the test results.

Operating Manual: PSS SB TESTER 1-1

Page 6

Introduction

7 Fault Diagnostics

When a fault is detected on SafetyBUS p, this chapter helps you find

the source of the fault and rectify it.

8 Technical Details

Definition of symbols

Information in this manual that is of particular importance can be identified

as follows:

DANGER!

This warning must be heeded! It warns of a hazardous situation that

poses an immediate threat of serious injury and death and indicates

preventive measures that can be taken.

WARNING!

This warning must be heeded! It warns of a hazardous situation that

could lead to serious injury and death and indicates preventive

measures that can be taken.

CAUTION!

This refers to a hazard that can lead to a less serious or minor injury plus

material damage, and also provides information on preventive measures

that can be taken.

NOTICE

This describes a situation in which the unit(s) could be damaged and also

provides information on preventive measures that can be taken.

INFORMATION

This gives advice on applications and provides information on special

features, as well as highlighting areas within the text that are of particular

importance.

1-2 Operating Manual: PSS SB TESTER

Page 7

Overview

The PSS SB TESTER is a hand-held device that can be used to carry out

various tests and measurements on SafetyBUS p. Each test may comprise

several separate tests.

• Connection test

- Checks the terminating resistors

- Checks the bus cable wires for short circuits

• Screening test

- Checks the cable screening for open circuits

• Length measurement

- Measures the length of the bus line

- Determines the location of a short circuit between CAN_H and CAN_L

• Signal test

- Tests the transmission rate

- Tests the electrical signal level on the lines CAN_H and CAN_L

- Tests the signal edges on the lines CAN_H and CAN_L

Range

• Real-time mode

- Measures the bus load

- Measures error rate, failure rate and number of errors

Once a test has been completed, the results can be read directly from the

device’s display or can be uploaded to a PC using the software provided.

The PSS SB TESTER is supplied in a carry case. Items supplied are as

follows:

• PSS SB TESTER incl. battery

• Shorting plug for the screening test

• Adapter cable for connecting the PSS SB TESTER to SafetyBUS p

• USB cable for connecting the PSS SB TESTER to a PC

• Battery charger

• Operating Manual: PSS SB TESTER

• CD:

- Software for recording the test results on a PC

- Operating manual in PDF format

- Acrobat Reader

Operating Manual: PSS SB TESTER 2-1

Page 8

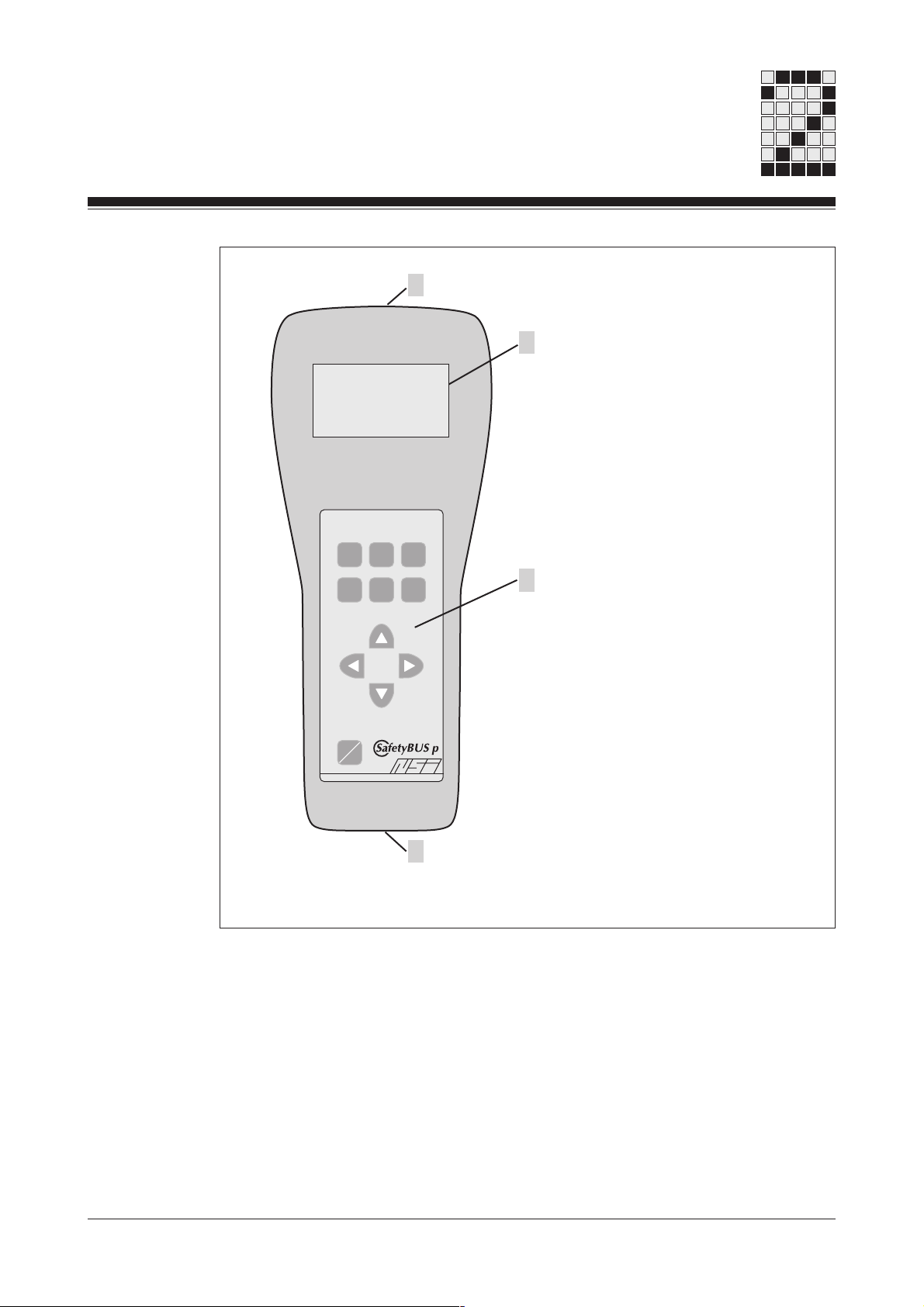

Overview

1

2

F2F1 F3

Fig. 2-1: View

ON

OFF

HLPESC VAL

4

3

1: SafetyBUS p interface

2: Single-colour graphic display

with backlight

3: Operator panel

4: USB port for uploading the test

results to a PC

2-2 Operating Manual: PSS SB TESTER

Page 9

Safety

Intended use

The PSS SB TESTER is designed for use in SafetyBUS p networks.

Specific data for the PSS SB TESTER is given in the chapter entitled

“Technical Details”. Use of the device outside the specifications given here

will be deemed as improper use.

Any component, technical or electrical modifications carried out will be

deemed as improper use.

Use of the PSS SB TESTER outside the areas described in this manual

will be deemed as improper use.

Intended use includes following the information in this manual.

The PSS SB TESTER is not a safety-related device.

EMCD

The device is designed for use in an industrial environment. Interference

may occur if used within a domestic environment.

Warranty and liability

All claims to warranty and liability will be rendered invalid if

• The module was used contrary to the purpose for which it was intended

• Damage can be attributed to not having followed the guidelines in the

manual

• Operating personnel are not suitably qualified.

• The housing was opened

• Any type of modification has been made (e.g. exchanging components

on the PCB boards, soldering work etc.).

Operating Manual: PSS SB TESTER

3-1

Page 10

Safety

Disposal

The module must be disposed of properly when it reaches the end of its

service life.

3-2 Operating Manual: PSS SB TESTER

Page 11

Operation

Supply

The PSS SB TESTER is supplied via a battery, which is located in the

back of the housing.

A charged PSS SB TESTER can be operated for 1 to 2 hours, depending

on the application conditions. If the battery charge drops to a particular

value during testing, the message “Charge battery” will be displayed and a

beep will sound. If the battery charge becomes so weak that the supply

can no longer be guaranteed, the PSS SB TESTER will switch off

automatically. The battery will need to be recharged. This takes approx. 1.5

hours.

INFORMATION

When the PSS SB TESTER is used for the first time or after storage

periods of more than 6 months, the battery will need to be charged for at

least 4 hours.

Charging the battery

• Plug the charger’s mains connector into a socket (110/230 VAC, 50 Hz).

• Take the PSS SB TESTER battery and plug it into the charger. The

charger is designed in such a way that the battery can only be inserted at

the correct polarity.

The start of the charging process is displayed via a red LED on the

charger’s connector (100 % on).

When the main charge is complete, the charger automatically switches to

“Conservation charging” mode and the LED flashes (25 % on, 75 % off).

If the main charge cannot be completed within 2 ½ hours, the charger

automatically switches to “Conservation charging” mode.

If the battery is extremely depleted, the LED will flash (50 % on, 50 % off)

when the battery is plugged into the charger. The battery is then charged

with a reduced charging current until the battery is regenerated and can be

switched to “normal” main charge mode.

Operating Manual: PSS SB TESTER 4-1

Page 12

Operation

INFORMATION

The battery should not be left in the charger over a long period of time

(several weeks).

• Charge the battery until the LED on the charger flashes (25 % on, 75 %

off)

• Remove the battery and place in the PSS SB TESTER.

Commissioning

Switching on

INFORMATION

Before the PSS SB TESTER is used for the first time, the battery must be

charged for at least 4 hours.

The PSS SB TESTER is switched on via the “ON/OFF” button.

When it is switched on, the unit description “PSS SB TESTER” and its

version is displayed briefly.

The “Start” window then appears. From this window you can access

various menus.

Key to the symbols and function of the buttons in the “Start” window:

: Select test/measurement

: Set transmission rate

F1: Display unit version

F2: Make one of the following settings:

- Set the contrast

- Switch the backlight on/off

- Set the time and date

- Set the signal runtime

- Calibration

F3: Save or delete test results

HLP: Call up help

ESC: Cancel function/close window

VAL: Carry out function

4-2 Operating Manual: PSS SB TESTER

Page 13

Setting the contrast

• Press F2 in the “Start” window.

• The “Settings” window opens. Use the arrow keys to move the cursor to

the symbol for “Contrast” and press VAL.

• Now you can use the “left” and “right” arrow keys to increase or reduce

the display’s contrast.

• Press VAL to save the setting.

The current setting is saved. A message confirms that the setting has been

saved. The “Settings” window is then displayed again. You can return to

the “Start” window by pressing ESC.

The contrast setting is stored in a memory that is supplied by the battery. If

the battery is removed, the contents of the memory will be retained for 10

minutes. If it takes longer for the battery to be replaced, the contents of the

memory will be lost.

Switching the backlight on/off

• Press F2 in the “Start” window.

• The “Settings” window opens. Use the arrow keys to move the cursor to

the symbol for “Backlight” and press VAL.

• Two symbols will appear.

If you wish to switch the backlight on, use the arrow keys to highlight the

symbol.

If you wish to switch the backlight off, highlight the symbol.

• Press VAL to save the setting.

The current setting is saved. A message confirms that the setting has been

saved. The “Settings” window is then displayed again. You can return to

the “Start” window by pressing ESC.

Operating Manual: PSS SB TESTER 4-3

Page 14

Operation

The information on the backlight is stored in a memory that is supplied by

the battery. If the battery is removed, the contents of the memory will be

retained for 10 minutes. If it takes longer for the battery to be replaced, the

contents of the memory will be lost.

Setting the time and date

• Press F2 in the “Start” window.

• The “Settings” window opens. Use the arrow keys to move the cursor to

the symbol for “Time and Date” and press VAL.

• The time and date are displayed. The ex-works setting is 01.01.2000 for

the date and 00:00 for the time.

The weekday is highlighted within a grey field. Use the “up” and “down”

arrow keys to set the required weekday.

You can then use the “right” arrow key to move the grey field to the

month; set the required month using the “up” and “down” arrow keys. Do

the same for the year, hour and minute.

• Press VAL to save the setting.

The current setting is saved. A message confirms that the setting has been

saved. The “Settings” window is then displayed again. You can return to

the “Start” window by pressing ESC.

The setting is stored in a memory that is supplied by the battery. If the

battery is removed, the contents of the memory will be retained for 10

minutes. If it takes longer for the battery to be replaced, the contents of the

memory will be lost.

4-4 Operating Manual: PSS SB TESTER

Page 15

Setting the signal runtime

To measure the length of the bus cable you will need to enter the signal

runtime. The ex-works setting for the signal runtime is 4.5 ns/m. This value

is valid for the Pilz standard cable for SafetyBUS p (order no. 311 070). If

you use a cable with a different signal runtime, you will need to amend the

set value.

• Press F2 in the “Start” window.

• The “Settings” window opens. Use the arrow keys to move the cursor to

the symbol for “Signal runtime” and press VAL.

• Use the arrow keys to enter the password “7041” and press VAL.

• The signal runtime is displayed. Use the arrow keys to set the signal

runtime to the required value.

• Press VAL to save the setting.

The current setting is saved. A message confirms that the setting has been

saved. The “Settings” window is then displayed again. You can return to

the “Start” window by pressing ESC.

Calibration

The setting is stored in a memory that is supplied by the battery. If the

battery is removed, the contents of the memory will be retained for 10

minutes. If it takes longer for the battery to be replaced, the contents of the

memory will be lost.

Calibration is reserved for Pilz customer service.

Operating Manual: PSS SB TESTER 4-5

Page 16

Operation

Performing the tests

All the tests are described in detail in the chapter entitled “Tests/

Measurements”. This section is only intended to explain how to save,

upload and delete the test results.

Saving the test results

With the exception of the results for real-time mode, all the test results can

be saved.

The connection test, screening test, signal test and length measurement

each have a specific memory area available within the PSS SB TESTER.

This division within the memory enables tests to be performed at different

times; the respective results can be saved and then all the results can be

uploaded to the PC together. When you save the results of a test, the old

data in the test's memory area is overwritten.

Example: The user performs the connection test, saves the results and

switches off the tester. Two hours later the user then performs the signal

test, stores the results and again switches off the tester.

The current results from the connection test and signal test are saved

within the tester, along with the results from an earlier length

measurement.

• After carrying out a test, switch to the “Start” window and press F3.

• The “Memory” window opens. Use the arrow keys to move the cursor to

the symbol for “Save” and press VAL.

• The “Save” window opens. Press VAL.

The test results are saved. A message confirms that the results have been

saved. The “Start” window is then displayed again.

The test results are stored in a memory that is supplied by the battery. If

the battery is removed, the contents of the memory will be retained for 10

minutes. If it takes longer for the battery to be replaced, the contents of the

memory will be lost.

4-6 Operating Manual: PSS SB TESTER

Page 17

Uploading the test results to a PC

The saved results can be uploaded to a PC, where they can be saved as a

text file.

• Connect the PSS SB TESTER to a USB port on the PC.

• Start the “PSS SB TESTER” software (see Chapter 6).

• Click the “Upload” button.

• The “Save as” window is opened. Enter the directory and the name of the

file in which the test results are to be saved.

• The data is uploaded and saved. When the upload is complete, close the

“Upload of the results” window.

The file containing the results is displayed in a standard text editor.

Deleting the test results

Before each series of tests, the memory containing the test results should

be cleared to avoid mixing up new results with the results from previous

tests. Then it will no longer be possible to upload results to the PC.

• Press F3 in the “Start” window.

• The “Memory” window opens. Use the arrow keys to move the cursor to

the symbol for “Delete” and press VAL.

• The “Delete” window opens. Press VAL.

The test results are deleted. A message confirms that the results have

been deleted. The “Start” window is then displayed again.

Operating Manual: PSS SB TESTER 4-7

Page 18

Operation

Notes

4-8 Operating Manual: PSS SB TESTER

Page 19

Tests/Measurements

The PSS SB TESTER can be used to perform various tests and

measurements on SafetyBUS p:

• Connection test

• Screening test

• Length measurement

• Signal test

• Real-time measurements

These tests and measurements are described in this chapter.

To be able to carry out the measurements, the PSS SB TESTER will need

to be added to SafetyBUS p. The PSS SB TESTER therefore has a

SafetyBUS p interface. The 9-pin connector on the supplied cable is

attached to this interface. The adapter on the other end of the cable is

attached between a SafetyBUS p device and the SafetyBUS p cable. The

point at which the PSS SB TESTER must be added depends on the test or

measurement that is to be performed.

Female 9-pin D-Sub connector

1: n.c.

2: CAN_L

1

5

Fig. 5-1: SafetyBUS p interface assignment

6

9

3: CAN_GND

4: n.c.

5: CAN_SHLD

6: n.c.

7: CAN_H

8: n.c.

9: Vcc

n.c. = not connected

Operating Manual: PSS SB TESTER 5-1

Page 20

Tests/Measurements

Connection test

The connection test comprises the following separate tests:

• Measuring the resistance between CAN_H and CAN_L

• Test for short circuit between CAN_H and Vcc

• Test for short circuit between CAN_L and Vcc

• Test for short circuit between CAN_H and CAN_GND

• Test for short circuit between CAN_L and CAN_GND

• Test for short circuit between CAN_H and CAN_SHLD

• Test for short circuit between CAN_L and CAN_SHLD

The connection test corresponds to a resistance measurement.

The tester also detects components between the cables that are not

resistors (diodes, capacitors, ...).

Where resistance values are low (0 ... 1000 Ohm), the measuring accuracy

of the tester reaches the order of ± 5 %, if no capacitors or diodes are

found.

Performing the connection test

• Add the PSS SB TESTER at any point within SafetyBUS p.

• Switch on the PSS SB TESTER.

• Highlight the symbol in the “Start” window and press VAL.

• The “SafetyBUS p” window opens, in which you can select the test/

measurement. Use the arrow keys to move the cursor to the symbol for

“Connection test” and press VAL.

• The following question is displayed: “SafetyBUS p is switched off?”.

Make sure that SafetyBUS p is switched off, i.e. all devices on

SafetyBUS p must be switched off and there must be no voltage present

on the “Vcc” line.

Then press VAL.

5-2 Operating Manual: PSS SB TESTER

Page 21

The PSS SB TESTER then checks whether “Vcc” is without voltage. If this

is the case, the test is performed and the following message appears on

the display: “Connection test in progress”.

If voltage is present at “Vcc”, the test will not be carried out because the

test results could be corrupted or the Tester could be damaged.

NOTICE

While the connection test is in progess, no voltage must be supplied to the

“Vcc” pin and SafetyBUS p must not be switched on, otherwise there is the

risk of the test results being corrupted or the Tester being damaged.

When the test is complete, the “Results” window is displayed. Each line

corresponds to a separate test. A code is entered at the end of each line :

- “x”: Negative test result

- “v”: Positive test result

- “c”: Test was corrupted due to capacitance between the cables. The

measured values should not be viewed as accurate.

- “d”: Test was corrupted due to a diode or similar component between the

cables. The measured values should not be viewed as accurate.

To look at the result of a single test in more detail you can move the cursor

to that test and then press VAL.

You can return to the “Results” window by pressing ESC.

Operating Manual: PSS SB TESTER 5-3

Page 22

Tests/Measurements

Separate test: Resistance between CAN_H and CAN_L

Abbreviation for this separate test in the “Results” window:

R CAN_H/CAN_L

Measurement of the resistance between CAN_H and CAN_L. You can use

this measurement to detect whether the terminating resistors are present

and whether they are the correct size (120 Ω each).

In the upper section of the detailed display of results from this separate

test, four pieces of information are displayed: the lower limit, the upper

limit, the measured value and the result.

As the parallel connection of two 120 Ω ferrule resistors should have a

resistance value of 60 Ω, a lower limit of 50 Ω and an upper limit of 85 Ω is

pre-assigned. If the value measured on the resistor lies between the upper

and lower limit, the resistor will be assessed as “OK”.

Example: lower limit value: 50 Ω

upper limit value: 85 Ω

measured value 119.3 Ω

result: not OK

If you scroll down in the detailed display you will be able to see whether

the circuit between CAN_H and CAN_L is open, i.e. whether or not there is

a terminating resistor.

Three pieces of information are displayed: the limit value, the measured

value and the result.

The limit value of 250 000 Ω is pre-assigned. If the value measured on the

resistor is greater than or equal to the limit value, the circuit is assessed as

open.

Example: limit value 250 000 Ω

measured value 119.3 Ω

result: No open circuit

5-4 Operating Manual: PSS SB TESTER

Page 23

Separate tests: Short circuits between the bus cable wires

Abbreviations for these separate tests in the “Results” window:

• KS CAN_H/Vcc

• KS CAN_L/Vcc

• KS CAN_H/CAN_GND

• KS CAN_L/CAN_GND

• KS CAN_H/CAN_SHLD

• KS CAN_L/CAN_SHLD

Test for short circuit between the bus cable wires.

The PSS SB TESTER measures the resistance between the wires.

In the detailed display of results from these separate tests, three pieces of

information are displayed: the limit value, the measured value and the

result.

The limit value of 170 Ω is pre-assigned. If the value measured at the

resistor is less than or equal to the limit value, a short circuit is detected.

Example: limit value 170 Ω

measured value 0 Ω

result: short circuit

INFORMATION

You can use the length measurement to establish the location of a short

circuit between CAN_H and CAN_L, see the section entitled “Length

measurement”.

Operating Manual: PSS SB TESTER 5-5

Page 24

Tests/Measurements

Screening test

The screening test can be used to check for breaks in the cable screening.

You can therefore determine whether the cable screening is attached

correctly to each bus connector.

The screening test corresponds to a resistance measurement between

CAN_H and CAN_SHLD. The PSS SB TESTER is inserted at one end of

SafetyBUS p, while at the other end a plug is inserted, which produces a

short circuit between CAN_H and CAN_SHLD. If the value measured at

the resistor is greater than the pre-assigned limit value of 200 Ω, an open

circuit is detected.

NOTICE

The connection test must be performed before the screening test. This is

the only way to be sure that there are no short circuits, which would

corrupt the result of the screening test.

Performing the screening test

• Add the PSS SB TESTER and the shorting plug to SafetyBUS p as

shown in Fig. 5-2.

• Switch on the PSS SB TESTER.

• Highlight the symbol in the “Start” window and press VAL.

• The “SafetyBUS p” window opens, in which you can select the test/

measurement. Use the arrow keys to move the cursor to the symbol for

“Screening test” and press VAL.

• The following question is displayed: “SafetyBUS p is switched off?”.

Make sure that SafetyBUS p is switched off, i.e. all devices on

SafetyBUS p must be switched off and there must be no voltage present

on the “Vcc” line.

Then press VAL.

The PSS SB TESTER then checks whether “Vcc” is without voltage. If this

is the case, the test is performed and the following message appears on

the display: “Screening test in progress”.

5-6 Operating Manual: PSS SB TESTER

Page 25

Tested screening

Bus

subscribers

Terminating

resistor

Shorting

plug

Terminating

resistor

F2F1 F3

HLPESC VAL

ON

OFF

Bus

subscribers

Terminating

resistor

F2F1 F3

HLPESC VAL

ON

OFF

Tested

screening

Shorting

plug

Fig. 5-2: Screening test

Operating Manual: PSS SB TESTER 5-7

Page 26

Tests/Measurements

If voltage is present at “Vcc”, the test will not be carried out because the

test results could be corrupted or the Tester could be damaged.

NOTICE

While the screening test is in progess, no voltage must be supplied to the

“Vcc” pin and SafetyBUS p must not be switched on, otherwise there is the

risk of the test results being corrupted or the Tester being damaged.

When the test is complete, three pieces of information are displayed: the

limit value, the measured value and the result.

The limit value of 200 Ω is pre-assigned. If the value measured at the

resistor is greater than or equal to the limit value, an open circuit is

detected.

Example: limit value 200 Ω

measured value 10 Ω

result: no open circuit

5-8 Operating Manual: PSS SB TESTER

Page 27

Length measurement

The length measurement can be used to establish the length of bus lines

longer than 25 m.

The Tester measures the runtime of a pulse on the bus line and uses this

to calculate the cable runs. The basis for the calculation is the cable’s

signal runtime.

The ex-works setting for the signal runtime is 4.5 ns/m. This value is valid

for the Pilz standard cable for SafetyBUS p (order no. 311 070). If you use

a cable with a different signal runtime, you will need to amend the set

value. See the “Operation” chapter, section entitled “Commissioning”.

INFORMATION

If the following devices are connected to SafetyBUS p:

• PSS(1) SB CPU up to Version 2.1

• PSS SB 3006 IBS-S up to Version 1.8

• PSS SB 3006 DP-S up to Version 1.5

• PSS SB 3006 CN-A up to Version 1.2

• PSS SB 3056 up to Version 1.8

• PSS SB ROUTER up to Version 1.1

• PSS SB DI8O8 up to Version 1.6

• PSS SB DI16 up to Version 1.4

the measured value will deviate from the actual physical cable runs by 1.5

m per device. However, the measured cable runs correspond to the

effective electrical cable runs on SafetyBUS p, i.e. the cable runs that are

the key factor in selecting the transmission rate.

Operating Manual: PSS SB TESTER 5-9

Page 28

Tests/Measurements

The bus topology must be taken into account in the measurement:

• Main line without stub lines

The PSS SB TESTER is connected to one end of the bus line. The

terminating resistors at both ends of the bus line must be removed.

Measured cable runs

Bus

subscribers

Remove

terminating resistor

Remove

terminating resistor

F2F1 F3

HLPESC VAL

ON

OFF

Fig. 5-3: Main line without stub lines

5-10 Operating Manual: PSS SB TESTER

Page 29

• Main line with stub lines

It is not possible to perform a length measurement on a main line with

stub lines. The stub lines have to be removed.

Measured cable runs

Bus

subscribers

Remove

Remove

stub line

terminating resistor

F2F1 F3

HLPESC VAL

ON

OFF

Separate

terminating resistor

Fig. 5-4: Main line with stub lines

Operating Manual: PSS SB TESTER 5-11

Page 30

Tests/Measurements

• Main line with Bridge or Router

Bus

Measured cable runs

subscribers

Remove

F2F1 F3

HLPESC VAL

ON

OFF

terminating resistor

Fig. 5-5: Main line with Bridge or Router

• Main line with sub branches

Measured cable runs

PSS SB Router1

PSS SB BRIDGE

Bus

subscribers

Remove

terminating

resistor

F2F1 F3

HLPESC VAL

ON

OFF

PSS SB Router1

PSS SB BRIDGE

PSS SB ACTIVE JUNCTION BASIS0

Remove

terminating

resistor

Fig. 5-6: Main line with sub branches

5-12 Operating Manual: PSS SB TESTER

Page 31

Performing the length measurement

• Add the PSS SB TESTER to SafetyBUS p as shown in Figs. 5-3 to 5-6.

• Switch on the PSS SB TESTER.

• Highlight the symbol in the “Start” window and press VAL.

• The “SafetyBUS p” window opens, in which you can select the test/

measurement. Use the arrow keys to move the cursor to the symbol for

“Length measurement” and press VAL.

• The following question is displayed: “SafetyBUS p is switched off?”.

Make sure that SafetyBUS p is switched off, i.e. all devices on

SafetyBUS p must be switched off.

On the PSS SB BRIDGE, both sides of the Bridge must be without

voltage.

• Press VAL.

When the test is complete, a measured curve appears on the display.

Fig. 5-7 shows a typical measured curve.

Fig. 5-7: Typical measured curve for length measurement

Operating Manual: PSS SB TESTER 5-13

Page 32

Tests/Measurements

Function of the keys in this window:

F1: Activate/deactivate cursor (symbol <–>)

F2: Enlarge view (symbol Z+)

F3: Reduce view (symbol Z-)

< >: Move view to left or right

VAL: Perform new measurement

ESC: Close window

The key factor in the measured curve is the falling edge.

• Press F1. The cursor is inserted. Using the arrow keys, move the cursor

approximately to the start of the falling edge.

• Press F1 to deactivate the cursor. The view can only be enlarged when

the cursor is deactivated.

• Now use F2 and F3 to adjust the view so that the falling edge is clearly

visible.

• Press F1 to reactivate the cursor. Now move the cursor precisely to the

start of the falling edge. The cable runs are then displayed beneath the

measured curve.

Cursor

Fig. 5-8: Cursor position to determine the cable runs

5-14 Operating Manual: PSS SB TESTER

Page 33

If there is a short circuit on SafetyBUS p between CAN_H and CAN_L, the

measured curve will deviate from the typical curve: a step is visible within

the measured curve. On long bus lines, you will need to enlarge the view to

make the step visible.

You can establish the location of the short circuit from this step. To do this,

the cursor must be positioned on the rising edge of the step.

Cursor

Step

Fig. 5-9: Cursor position to determine the location of a short circuit

The measured curve also shows if a terminating resistor was not removed

when the measurement was made: the measured curve is constant over

the whole measuring range of 6.7 km.

Fig. 5-10: Measured curve when terminating resistor is not removed

Operating Manual: PSS SB TESTER 5-15

Page 34

Tests/Measurements

Signal test

The signal test comprises the following separate tests:

• Measures the voltage at Vcc

• Tests the transmission rate for all devices

• Tests the electrical signal level on the lines CAN_H and CAN_L for all

devices

• Tests the signal edges on the lines CAN_H and CAN_L for all devices

Performing the signal test

Before performing the signal test, the transmission rate must be set in the

PSS SB TESTER.

• Switch on the PSS SB TESTER.

• Highlight the symbol in the “Start” window and press VAL.

• A window opens, in which you can set the transmission rate. Use the

arrow keys to move the cursor to the symbol for the required

transmission rate and press VAL.

You can now perform the signal test. SafetyBUS p must be in operation.

• Add the PSS SB TESTER at any point within SafetyBUS p.

• Highlight the symbol in the “Start” window and press VAL.

• The “SafetyBUS p” window opens, in which you can select the test/

measurement. Use the arrow keys to move the cursor to the symbol for

“Signal test” and press VAL.

5-16 Operating Manual: PSS SB TESTER

Page 35

The display will show the message “Signal test in progress” and the value

of the voltage at Vcc. The test may take up to 5 minutes. The test can be

aborted by pressing ESC.

When the test is complete, the “Results” window is opened. This displays a

list showing all the devices on SafetyBUS p, i.e. all the devices that have

been detected.

A code is shown behind each device:

- “v”: the device is error free

- “x”: the test has detected a fault for the device

You can use F2 to switch between the faulty devices.

To look at the result for a device in more detail you can move the cursor to

that device and then press VAL.

The “Device xx” window is opened, which displays the results of the

separate tests for the device.

A code is entered at the end of some lines :

- “v”: no fault detected

- “x”: fault detected

To look at the result of a single test in more detail you can move the cursor

to that test and then press VAL.

You can return to the previous window by pressing ESC.

Separate test: Measuring the voltage at Vcc

The voltage at Vcc is measured once at the start of the signal test. This

value is displayed while the signal test is running.

Operating Manual: PSS SB TESTER 5-17

Page 36

Tests/Measurements

Separate test: Testing the transmission rate

Abbreviation for this separate test in the “Device xx” window:

Transmission rate

Each device on SafetyBUS p is tested to ensure it has the correct

transmission rate.

In the detailed display of the result from this separate test, four pieces of

information are displayed: the lower limit, the upper limit, the measured

value and the result.

The limit values are pre-assigned for each transmission rate that can be

set on SafetyBUS p.

Transmission rate

in kBit/s

20

50

125

250

500

If the value measured for the transmission rate lies between the upper and

lower limit, the transmission rate is assessed as good.

Example: lower limit: 247.5 KBit/s

upper limit: 252.5 KBit/s

measured value: 250,000 KBit/s

result: OK

Lower limit

in kBit/s

19.80

49.50

123.75

247.50

495.00

Upper limit

in kBit/s

20.20

50.50

126.25

252.50

505.00

5-18 Operating Manual: PSS SB TESTER

Page 37

Separate tests: Testing the electrical signal level

Abbreviations for these separate tests in the “Device xx” window:

• Rec. Level CAN_H

• Dom. Level CAN_H

• Rec. Level CAN_L

• Dom. Level CAN_L

Each device on SafetyBUS p is tested to ensure the signals it is sending

have the correct level. The recessive and dominant level of CAN_H and

CAN_L are tested.

In the detailed display of the result from these separate tests, four pieces

of information are displayed: the lower limit, the upper limit, the measured

value and the result.

The limit values for the recessive and dominant level are pre-assigned:

Level

Recessive level

Lower limit

in VDC

2.0

Upper limit

in VDC

3.0

CAN_H

Dominant level

2.8

4.5

CAN_H

Recessive level

2.0

3.0

CAN_L

Dominant level

0.5

2.3

CAN_L

If the value measured for the level lies between the upper and lower limit,

the level is assessed as “OK”.

If the level is incorrect, an error message is issued.

Operating Manual: PSS SB TESTER 5-19

Page 38

Tests/Measurements

Example for “Dom. Level CAN_H”:

lower limit: 2.8 V

upper limit: 4.5 V

measured value: 3.5 V

test result: OK

Separate tests: Testing the signal edges

Abbreviations for these separate tests in the “Device xx” window:

• Rising edge CAN_H

• Falling edge CAN_H

• Rising edge CAN_L

• Falling edge CAN_L

Each device on SafetyBUS p is tested to ensure the signals it is sending

have the correct edges. The rise and fall time of the signals on CAN_H and

CAN_L are measured.

Mean signal - 10 %

Mean signal +10 %

Rise time Fall time

Fig. 5-11: Rise/fall time

The measured time is shown in the detailed display of the result from

these separate tests.

Example for “Rising edge CAN_H”:

measured value: 86 ns

5-20 Operating Manual: PSS SB TESTER

Page 39

Real-time mode

Real-time mode comprises the following measurements:

• Bus load

• Error rate

• Failure rate

• Number of errors

Performing the real-time measurement

Before performing the real-time measurement, the transmission rate must

be set in the PSS SB TESTER.

• Switch on the PSS SB TESTER.

• Highlight the symbol in the “Start” window and press VAL.

• A window opens, in which you can set the transmission rate. Use the

arrow keys to move the cursor to the symbol for the required

transmission rate and press VAL.

You can now perform the real-time measurement. SafetyBUS p must be in

operation.

• Add the PSS SB TESTER at any point within SafetyBUS p.

• Highlight the symbol in the “Start” window and press VAL.

• The “SafetyBUS p” window opens, in which you can select the test/

measurement. Use the arrow keys to move the cursor to the symbol for

“Real-time mode” and press VAL.

The “Real-time mode” window appears and the results of the various

measurements are displayed.

The test can be aborted by pressing ESC.

Press F1 to reset the number of errors.

Operating Manual: PSS SB TESTER 5-21

Page 40

Tests/Measurements

Notes

5-22 Operating Manual: PSS SB TESTER

Page 41

Software

To transfer the test results from the PSS SB TESTER to a PC you will need

to install the Upload-Software.

System requirements

• Operating system: Windows 98, ME, 2000 or XP

• Hard drive: Approx. 1 MB of available disk space

• USB port

Installation

• Insert the CD into the CD drive.

• Go to the “Upload-Software” directory and call up the file “setup.exe”.

• Follow the on-screen instructions.

Starting the software

Open the directory in which you installed the Upload-Software and call up

the file “Results_MT.exe”.

Fig. 6-1: Upload-Software

Chapter 4 describes how to upload the test results, in the section entitled

“Uploading the test results to a PC”.

Operating Manual: PSS SB TESTER 6-1

Page 42

Software

Notes

6-2 Operating Manual: PSS SB TESTER

Page 43

Fault Diagnostics

If you detect faults on SafetyBUS p, the following tables may help you to

find the source of the fault and to rectify it.

Connection test

Problem

Resistance between

CAN_H and CAN_L

< 50 Ω

Resistance between

CAN_H and CAN_L

> 85 Ω

Short circuit detected

Length measurement

Problem

Error message

“Measurement not OK” is

displayed

Cause

A terminating resistor has an

invalid value or there are too

many terminating resistors

present

A terminating resistor is

missing or has an invalid value

Short circuit

Cause

Length of bus line < 25 m

Correcting the problem

Check the terminating

resistors, both terminating

resistors must have a value of

120 Ω

Check the terminating

resistors, both terminating

resistors must have a value of

120 Ω

Check the wiring

Correcting the problem

Cable runs < 25 m cannot be

measured

Operating Manual: PSS SB TESTER 7-1

Page 44

Fault Diagnostics

Signal test

Problem

Device’s signal level lies

outside the measurable

range

Error message “Problem

CAN_L” is displayed

Error message

“Measurement not OK” is

displayed

Device’s transmission

rate is incorrect

Error message "Network

config"

Cause

Connection is faulty or device

is defective

Short circuit between CAN_L

and earth

Connection between PSS SB

TESTER and SafetyBUS p is

interrupted or SafetyBUS p is

inactive

Device is defective

The transmission rate set on

the PSS SB TESTER may not

match the actual transmission

rate on SafetyBUS p

Correcting the problem

Check the connection. If

nothing helps, change the

device

Check line from CAN_L

Check whether SafetyBUS p

is active (SafetyBUS p status

LED on the PSS and devices

must be lit), check the

connection

Change the device

Check the transmission rate

setting

Real-time mode

Problem

Failure rate (fr/s) > 0

Cause

The transmission rate set on

the PSS SB TESTER may not

match the actual transmission

rate on SafetyBUS p

Correcting the problem

Check the transmission rate

setting

7-2 Operating Manual: PSS SB TESTER

Page 45

Technical Details

Electrical data

Supply voltage Battery: Ni-Cd 4.8 VDC, 2100 mAh

Charger: 110/230 VAC, 50 Hz

Display

Display type Single-colour graphic LC display

Resolution 128 x 64 pixels

Contrast adjustment Yes

Back lighting Yes

Operator elements

Keyboard type Short-stroke keys with positive feedback

No. of keys 3 function keys,

3 special keys (ESC, HLP, VAL),

4 cursor keys

Interfaces

Interfaces SafetyBUS p,

USB

Environmental data

Protection type IP30 with battery inserted

Ambient temperature 0 ... 50 °C

Storage temperature -20 ... +70 °C

Condensation Not permitted

EMC EN 61326-1, EN 61000-4-2/-3,

EN 55022 A

Mechanical data

Housing material ABS

Weight 510 g

Dimensions (H x W x D) 232 x 97 x 52 mm

Operating Manual: PSS SB TESTER 8-1

Page 46

Technical Details

Notes

8-2 Operating Manual: PSS SB TESTER

Page 47

Hotline

+49 711 3409-444

...

In many countries we are

represented by sales partners.

Please refer to our Homepage

for further details or contact our

headquarters.

Pilz GmbH & Co. KG

Sichere Automation

Felix-Wankel-Straße 2

73760 Ostfildern, Germany

Telephone: +49 711 3409-0

Telefax: +49 711 3409-133

E-Mail: pilz.gmbh@pilz.de

www

www.pilz.com

20 757-03-01/05 Printed in Germany

Loading...

Loading...