Page 1

PSS67 F 16DI SB-T

Programmable control systems PSS

®

Operating Manual– Item No. 21 869-01

Page 2

All rights to this documentation are reserved by Pilz GmbH & Co. KG. Copies may be made

for internal purposes.

Suggestions and comments for improving this documentation will be gratefully received.

The names of products, goods and technologies used in this documentation are registered

®

trademarks of the respective companies. Automation Workbench

PNOZ

®

, Primo®, PSS®, SafetyBUS p® are registered trademarks of Pilz GmbH & Co. KG.

, Pilz®, PIT®, PMI®,

Page 3

Contents

Introduction 1-1

Validity of documentation 1-1

Overview of documentation 1-2

Definition of symbols 1-3

Overview 2-1

Front view 2-2

Safety 3-1

Intended use 3-1

Categories in accordance with EN 954-1 3-2

Digital inputs 3-2

System requirements 3-2

CPU versions 3-2

System software versions 3-3

Safety guidelines 3-3

Use of qualified personnel 3-3

EMCD 3-3

Warranty and liability 3-4

Disposal 3-4

Operating Manual: PSS67 F 16 DI SB-T

1

Page 4

Contents

Function Description 4-1

Inputs 4-1

Signal detection at the inputs 4-2

Signal change behaviour 4-2

Test pulse outputs/24 VDC terminals 4-3

Internal wiring diagram 4-3

Installation 5-1

Supply Voltage 6-1

Wiring 7-1

Wiring the inputs and test pulse outputs 7-1

Notes on wiring 7-2

Labelling the module 7-2

Digital inputs 7-3

Test pulse outputs 7-3

Example: Single-channel, failsafe input device, without test pulse 7-5

Example: Single-channel, failsafe input device, without test pulse 7-6

Example: Dual-channel input devices, without test pulses 7-7

Example: Dual-channel input devices, without test pulses 7-8

Example: Single-channel, failsafe input device, with test pulse 7-9

Example: Single-channel, failsafe input device, with test pulse 7-10

Example: Dual-channel, failsafe input device, with test pulse 7-11

Example: Dual-channel, failsafe input device, with test pulse 7-12

2 Operating Manual: PSS67 F 16DI SB-T

Page 5

SafetyBUS p Interface 8-1

Operation and Maintenance 9-1

Commissioning 9-1

Setting the device address 9-2

Display elements 9-4

Recommissioning 9-5

Faults 9-5

Module configuration 9-5

Technical Details 10-1

Order reference 10-2

Operating Manual: PSS67 F 16 DI SB-T

3

Page 6

Page 7

Introduction

This operating manual explains the function and operation of the

decentralised input module PSS67 F 16DI SB-T.

This documentation is intended for instruction and should be retained for

future reference.

Please also refer to the other manuals in the PSS-range, in particular the

SafetyBUS p Manual, the “FS System Description” and the “ST System

Description”.

You will need to be conversant with the information in these manuals in

order to fully understand this manual.

Validity of documentation

This documentation is valid for the PSS67 F 16DI SB-T from Version 1.1. It

is valid until new documentation is published. The latest documentation is

always enclosed with the unit.

1-1Operating Manual: PSS67 F 16DI SB-T

Page 8

Introduction

Overview of documentation

1 Introduction

The introduction is designed to familiarise you with the contents,

structure and specific order of this manual.

2 Overview

This chapter provides information on the most important features of

the digital input module.

3 Safety

This chapter must be read as it contains important information on

safety regulations and intended use.

4 Function Description

This chapter describes the individual components of the digitial input

module: inputs and test pulse outputs.

5 Installation

This chapter explains how to install the digital input module.

6 Supply Voltage

This chapter explains what you need to consider when connecting

the supply voltage.

7 Wiring the Inputs and Test Pulse Outputs

This chapter describes the safety-related wiring of the inputs and test

pulse outputs.

8 SafetyBUS p Interface

This chapter describes the configuration of the SafetyBUS p interface.

9 Operation and Maintenance

This chapter describes the commissioning of the digital input module.

10 Technical Details

1-2 Operating Manual: PSS67 F 16DI SB-T

Page 9

Definition of symbols

Information in this manual that is of particular importance can be identified

as follows:

DANGER!

This warning must be heeded! It warns of a hazardous situation that

poses an immediate threat of serious injury and death and indicates

preventive measures that can be taken.

WARNING!

This warning must be heeded! It warns of a hazardous situation which

could lead to serious injury or death and indicates preventive measures

that can be taken.

CAUTION!

This refers to a hazard that can lead to a less serious or minor injury plus

material damage, and also provides information on preventive measures

that can be taken.

NOTICE

This describes a situation in which the unit(s) could be damaged and also

provides information on preventive measures that can be taken.

INFORMATION

This gives advice on applications and provides information on special

features, as well as highlighting areas within the text that are of particular

importance.

1-3Operating Manual: PSS67 F 16DI SB-T

Page 10

Introduction

Notes

1-4 Operating Manual: PSS67 F 16DI SB-T

Page 11

Overview

The module PSS67 F 16DI SB-T can be used in a rugged industrial

environment up to protection type IP67.

It has 16 digital inputs and 4 dedicated test pulse outputs.

The inputs are suitable for connecting single or dual-channel safety-related

input devices, with or without test pulses. The inputs can be assigned to

two I/O-Groups on SafetyBUS p.

The 4 test pulse outputs are available via 8 M12 plug-in connectors. The

test pulses are permanently assigned to the inputs. The test pulse outputs

can also be configured as 24 VDC outputs.

The PSS67 F 16DI SB-T requires a 24 V supply, which provides power to

both the module electronics and the dedicated test pulse outputs.

The module is isolated from SafetyBUS p through optocouplers.

NOTICE

Before installing the module you should read and take note of the

information contained in the “SafetyBUS p Safety Manual”.

2-1Operating Manual: PSS67 F 16DI SB-T

Page 12

Overview

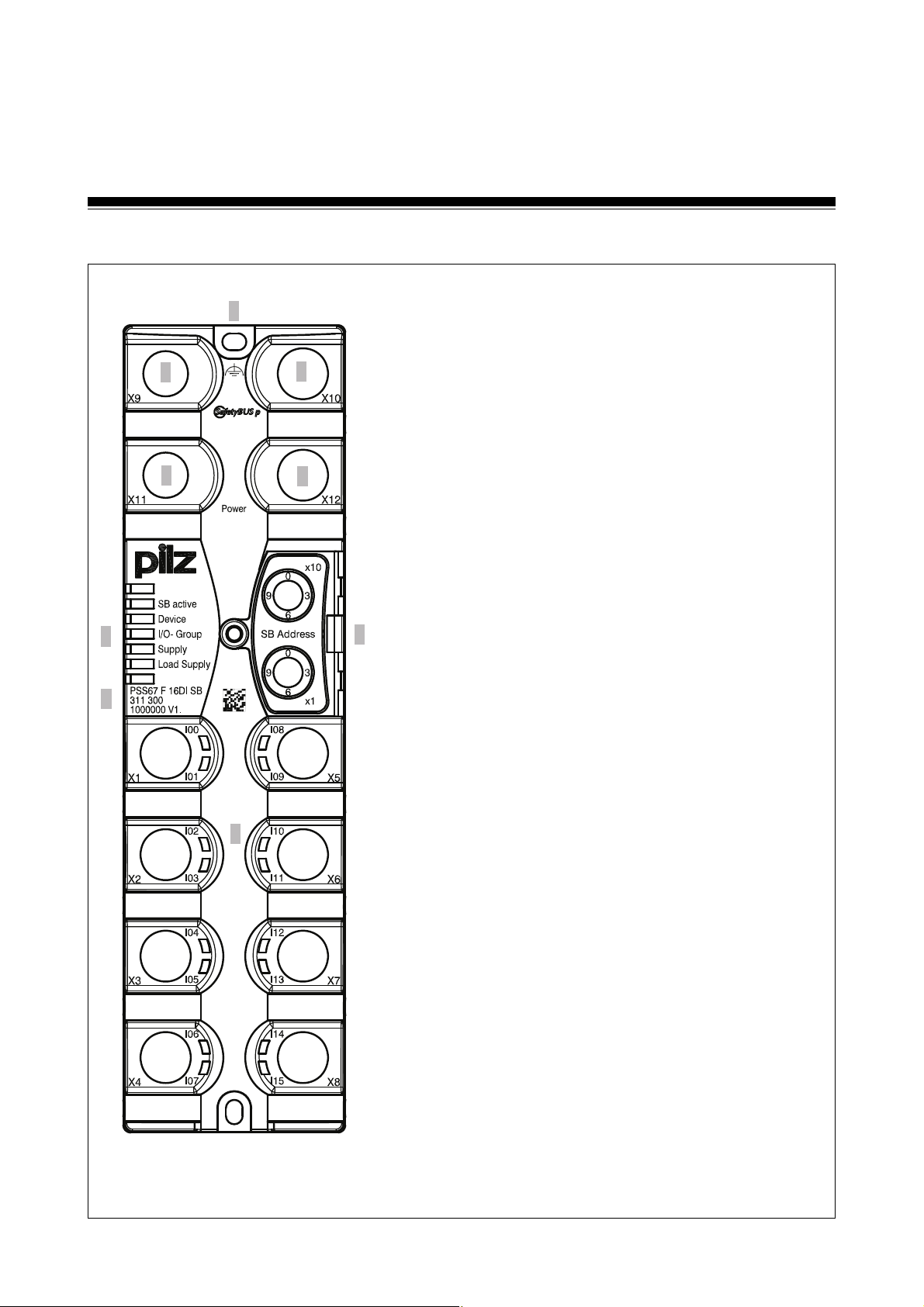

Front view

8

1

3

5

9

1

2

4

6

1: SafetyBUS p IN interface X9 (M12 male

connector)

2: SafetyBUS p OUT interface X10 (M12 female

connector)

3: Supply voltage connection IN

X11 (M12 male connector)

7

4: Supply voltage connection OUT

X12 (M12 female connector)

5: LEDs for operating status and

voltage supply

6: Rotary switch for setting the device address

on SafetyBUS p

7: Plug-in connectors for inputs and

test pulse outputs X1 to X8 (M12 female

connectors)

8: Functional earth connection

9: Labelling strip with:

•Device type

•Order number

•Serial number/hardware version

Fig. 2-1: Front view

2-2 Operating Manual: PSS67 F 16DI SB-T

Page 13

Safety

Intended use

The PSS67 F 16DI SB-T is a decentralised input module designed for use

on SafetyBUS p, where it has the function of an “Input/Output Device”.

The following is deemed improper use:

• Any component, technical or electrical modification to the digital input

module

• Use of the digital input module outside the areas described in this

manual

• Use of the digital input module outside the documented technical details

(see chapter entitled “Technical Details”).

3-1Operating Manual: PSS67 F 16 DI SB-T

Page 14

Safety

Categories in accordance with EN 954-1

WARNING!

Please note: To achieve the corresponding category or requirement class,

the whole system including all safety-related components (parts, devices,

user program etc.) must be included in the assessment. For this reason,

Pilz cannot accept liability for the correct classification into a category or

requirement class.

Digital inputs

Depending on the application area and its respective regulations, the

inputs may be used without test pulses for applications up to Category 3,

in accordance with EN 954-1. The possibility of a short circuit occurring in

the external wiring between different inputs or against the supply must be

eliminated through appropriate wiring.

For Category 4 applications, shorts between the input contacts must be

detected. This can be achieved through the use of the module’s test pulses

or, depending on the type of input device, through a feasibility test or

through detection of shorts across the contacts on the input device (e.g.

light grid) (for connection examples please see “Wiring the Inputs and

Outputs”).

System requirements

CPU versions

The PSS67 F 16DI SB-T is supported by the following SafetyBUS pcompatible programmable safety and control systems:

• PSS SB CPU from Version 1.3

• PSS1 SB CPU from Version 1.3

• PSS SB 3006 IBS-S PCP from Version 1.2

• PSS SB 3056 from Version 1.2

• PSS(1) SB CPU3 from Version 1.4

• all Compact 3rd Generation PSS, e.g. PSS SB 3047-3 ETH-2

3-2 Operating Manual: PSS67 F 16DI SB-T

Page 15

System software versions

The following system software is required in order to configure the module:

• PSS WIN-PRO from Version 1.7.0

Safety guidelines

Failure to keep to the following safety regulations will render all warranty

and liability claims invalid:

• All health and safety / accident prevention regulations for the particular

area of application must be observed.

• Before using the unit it is necessary to perform a safety assessment in

accordance with the Machinery Directive 98/37/EC.

Use of qualified personnel

The safety system may only be assembled, installed, programmed,

commissioned, operated, maintained and decomissioned by qualified

personnel. Qualified personnel are people who, because they are:

EMCD

• Qualified electrical engineers and

• Have received training from qualified electrical engineers,

are suitably experienced to operate devices, systems, plant and machinery

in accordance with the general standards and guidelines for safety

technology.

The module PSS67 F 16DI SB-T is designed for use in an industrial

environment. Interference may occur if used within a domestic environment.

3-3Operating Manual: PSS67 F 16 DI SB-T

Page 16

Safety

Warranty and liability

All claims to warranty and liability will be rendered invalid if:

• The module PSS67 F 16DI SB-T was used contrary to the purpose for

which it was intended

• Damage can be attributed to not having followed the guidelines in the

manual

• Operating personnel are not suitably qualified

• Any type of modification has been made (e.g. exchanging components

on the PCB boards, soldering work etc.).

Disposal

The module PSS67 F 16DI SB-T must be disposed of properly when it

reaches the end of its service life.

3-4 Operating Manual: PSS67 F 16DI SB-T

Page 17

Function Description

Inputs

Single and dual-channel input devices can be connected to the inputs, with

or without test pulses. The inputs are equipped with input filters.

Input signals must show a “High” (“1” signal) of 15 VDC (+15 ... +30 VDC)

and a “Low” (“0” signal) of 0 VDC (-3 ... +5 VDC).

The input status is signalled to the CPU on the controlling PSS via

SafetyBUS p. Green LEDs indicate the status of the inputs. An LED lights

up as soon as a “1” signal is present at the input.

Diagnostic circuitry checks the function of the inputs and the input filter. If

an error is detected, all the outputs in the affected I/O-Group are shut down

and the I/O-Group switches to a STOP condition. The module then triggers

an error telegram on SafetyBUS p and stores the error in its error buffer.

Where test pulses are not used, inputs with single-channel input devices

can be used in applications up to and including Category 2 in accordance

with EN 954-1; in the case of dual-channel input devices, this extends to

Category 3 applications. The possibility of a short circuit occurring in the

external wiring between different inputs or against the supply must be

eliminated through appropriate wiring.

Test pulses must be used for applications with single-channel input

devices above Category 2 and for applications with dual-channel input

devices above Category 3.

Connection examples can be found in the chapter entitled: “Wiring the

Inputs and Test Pulse Outputs”.

The inputs can be assigned to two I/O-Groups. Please refer to the section

entitled “Setting the device address”.

Operating Manual: PSS67 F 16DI SB-T

4-1

Page 18

Function Description

Signal detection at the inputs

To guarantee that a signal at an input (“0” signal or “1” signal) is detected, it

must be present for a certain time period. This period must be longer than

the event timeout configured in the PSS WIN-PRO system software. Once

a signal has been detected, a corresponding event telegram will be

triggered.

A signal (“0” signal or “1” signal) is ignored if it does not exceed the pulse

suppression time of 300 µs. In this case, no event telegram is triggered.

U

"1"-Signal

"0"-Signal

t1: Pulse duration to guarantee signal detection for “1” signals or “0” signals

(> Event Timeout)

t2: Max. pulse duration for pulse suppression with “1” signals or “0” signals

(300 µs)

Fig. 4-1: Signal detection at the inputs

Signal change behaviour

If a signal at an input changes, the module will send an event telegram.

The module must then wait for a confirmation telegram (ACK) from the

Master LD before it can send out a new event telegram.

If there is another signal change while the module is waiting for the

telegram, the module’s behaviour will depend on the configured signal

change behaviour.

t

1

t

1

t

2

t

4-2 Operating Manual: PSS67 F 16DI SB-T

Page 19

Two behaviour modes can be configured in the software’s configurator:

• “default”:

The signal changes are not registered.

• “Fast”:

Each signal change is temporarily stored in a FIFO telegram buffer. Once

the confirmation telegram arrives, the module sends consecutive event

telegrams for each detected signal change from the FIFO telegram buffer.

Test pulse outputs/24 VDC pins

The four test pulse outputs T0 to T3 may only be used for test pulses or as

24 VDC outputs.

The test pulse outputs are suitable for testing the wiring of input devices.

All safety-related inputs must operate in accordance with the failsafe

principle (on switching off).

Two test pulses are available on each plug-in connector; these test pulses

are permanently assigned to the inputs. The assignment of the test pulses

to the inputs cannot be changed in the system software’s configurator.

If the test pulse outputs are not being used, they can be configured as

24 VDC pins in the system software’s configurator (default setting).

Internal wiring diagram

The diagram on page 4-4 shows an internal wiring diagram of the

PSS67 F 16DI SB-T.

Operating Manual: PSS67 F 16DI SB-T

4-3

Page 20

Function Description

I

0

I

15

24 V DC

24 V DC

Test

Test

I

15

I

14

I

13

I

12

I

11

I

10

I

9

I

8

I

7

I

6

I

2

I

4

I

3

I

2

I

1

I

1

T

3

0

1

0

0

T3 / 24 V DC

T3 / 24 V DC

T2 / 24 V DC

T2 / 24 V DC

T1 / 24 V DC

/ 24 V DC

1

T

0

0

1

0

T

1

T

/ 24 V DC

0

/ 24 V DC

T

0

1

T

3

0

1

24 V DC

0

1

T

0

0

1

24 V DC

0

3,3 nF

1,2 M

OUT

CPU

(2-channel)

IN

DC

DC

5 V

24 V

Fig. 4-2: Internal wiring diagram of the PSS67 F 16DI SB-T

3,3 nF

3,3 nF

T3 / 24 V DC

T3 / 24 V DC

T2 / 24 V DC

T2 / 24 V DC

T1 / 24 V DC

/ 24 V DC

T

1

T

/ 24 V DC

0

/ 24 V DC

T

0

Ground

Ground

Supply

4-4 Operating Manual: PSS67 F 16DI SB-T

Page 21

Installation

Caution!

Electrostatic discharge can damage components on the

PSS67 F 16DI SB-T.

Ensure against discharge before touching the module, e.g. by touching an

earthed, conductive surface or by wearing an earthed armband.

The unit must be fastened to a flat mounting surface, so that there is no

strain on the housing when the module is screwed down. The mounting

distances will depend on which plug-in connectors are used and the

bending radius of the cables

To install the system, proceed as follows:

• Drill 2 x M4 holes (internal thread) in the mounting surface, as shown in

• Connect the functional earth to the upper fixing screw. If the functional

Fig. 5-1 (tolerance: ± 0.2 mm/0.01").

earth cannot be connected to the upper fixing screw, you will need to

connect the functional earth to Pin 5 of the M12 connector for the supply

voltage.

• Use two fixing screws to attach the module to the mounting plate.

Operating Manual: PSS67 F 16DI SB-T 5-1

Page 22

Installation

(1.18")

(0.18")

(2.36")

(8.1")

35.5 (1.4")

(1")

(8.46")

(1.18")

(0.18")

Fig. 5-1: Installing the PSS67 F 16DI SB-T, dimensions stated in mm (")

5-2 Operating Manual: PSS67 F 16DI SB-T

Page 23

Supply Voltage

Please note the following:

• When selecting the power supply, please refer to the requirements stated

under “Technical Details”.

• Overvoltage or interference voltage can damage or even destroy the

electronics on the PSS67 F 16DI SB-T. If this occurs, the affected I/OGroups will switch to a STOP condition and all the outputs in the affected

groups will be switched off. You should therefore take note of the relevant

EMC measures.

• WARNING!

Safe electrical isolation must be ensured for the external 24 V supply.

Failure to do so could result in electric shock. Power supplies must

conform to EN 60950, section 2.3, EN 60742 or EN 50178.

• To achieve the lowest possible residual ripple, we recommend that you

install a three-phase bridge rectifier or regulated supply.

• The “Ground” connection to the earth bar or earth fault monitor must be in

accordance with the relevant national regulations (e.g. EN 60204-1,

NFPA 79:17-7, NEC: Article 250).

INFORMATION

The module’s output circuits have been designed to guarantee maximum

safety. To achieve this, extensive tests are carried out internally.

Momentary interruptions to the “Supply” voltage during a test procedure

can falsify the test result, causing the following malfunction:

If the “Supply” voltage is interrupted momentarily, the unbuffered test pulse

outputs will transmit a “0” signal. The buffered module electronics reads

this signal at the pulsed inputs, thereby triggering the user's programmed

reaction. Example: The system reacts as though an E-STOP button has

been operated, although this is not the case: there has been a supply

interruption.

Remedy: “Supply” must be buffered.

Operating Manual: PSS67 F 16DI SB-T

6-1

Page 24

Supply Voltage

Use a 5-pin M12 plug-in connector to connect the module to the external

supply voltage.

The module also has an M12 socket which is physically next to the M12

connector; this is used to distribute the supply voltage to other modules.

SafetyBUS p

Supply

Fig. 6-1: Example for the supply and the forwarding of the supply voltages

Supply

WARNING!

The current carrying capacity of the M12 connectors is 4 A per contact.

Exceeding the permissible current carrying capacity may lead to connector

damage. Please note that the connection for the outgoing supply voltage

is not monitored for overload

6-2 Operating Manual: PSS67 F 16DI SB-T

Page 25

Functional earth

You can connect the functional earth to the upper fixing screw or to Pin 5 of

the M12 connector for the supply voltage.

INFORMATION

We recommend that you connect the functional earth to the upper fixing

screw.

3

4

X11(male connector) X12(female connector)

Fig. 6-2: Pin assignment for the supply voltage

Operating Manual: PSS67 F 16DI SB-T

55

2

2

1

1

3

1: + 24 VDC

2: Reserved for output devices

3: O V

4: Reserved for output devices

5: Functional earth

4

6-3

Page 26

Supply Voltage

Notes

6-4 Operating Manual: PSS67 F 16DI SB-T

Page 27

Wiring

Wiring the inputs and test pulse outputs

2

5

1

Fig. 7-1 Pin assignment of the inputs and test pulses

3

1: Test pulse X /24 V DC

2: Input X

3: 0 V

4: Input X+1

5: Test pulse X+1/ 24 V DC

4

This chapter describes the safety-related wiring of the digital inputs plus

the test pulse outputs.

CAUTION!

In order to guarantee protection type IP67, unused connectors should be

sealed using the blind plugs supplied.

CAUTION!

Make sure that the plug-in connectors are connected to the input devices

correctly. Once you have run a function test to check that the connectors

are connected to the input devices correctly, the inputs should be labelled.

If the inputs are connected to the input devices incorrectly, life-threatening

situations may arise on the plant.

INFORMATION

We recommend you use ready-made connectors to connect the inputs and

test pulse outputs.

INFORMATION

Please refer to the technical details for information on the maximum cable

runs when connecting input devices.

Operating Manual: PSS67 F 16DI SB-T 7-1

Page 28

Wiring

Notes on wiring

Where safety-related applications are concerned, it is essential that short

circuits and open circuits are unable to cause a hazardous condition within

a plant.

WARNING!

Safe separation is required when connecting a device with a circuit with

over 25 V AC or 60 V DC

The following terms are important:

• Signal inputs with frequent operation

These are signals that change status on several occasions within a

period of time.

• Single-channel safe input devices

These are positively-driven, normally-closed contacts which open on

actuation (failsafe principle).

• Elimination of short circuits between signals

This is possible within electrically-enclosed areas and also outside

electrically-enclosed areas for signals conducted in different multicore

cables. However, all components must meet the relevant regulations in

accordance with EN, DIN and VDE.

• In principle, the possibility of earth faults and open circuits cannot be

eliminated. With multi-channel input devices with frequent operation,

short circuits and open circuits can be detected via feasibility checks in

the control program.

The input test on the module uses test pulses to enable the operating

program of the PSS67 F 16DI SB-T to carry out a test to detect open

circuits and short circuits. The following pages contain details of

connection examples which may be of use when wiring the unit.

Labelling the module

You can label the SafetyBUS p and supply voltage connections, as well as

the inputs. 12 blank labels are supplied with the module. In addition you

can order a DIN A4 sheet with 264 labels as an accessory (order

no. 331 250).

7-2 Operating Manual: PSS67 F 16DI SB-T

Page 29

Digital inputs

Features:

• 16 digital inputs I0 ... I

• The inputs are connected using 8 5-pin M12 plug-in connectors. Two

inputs are available on each M12 plug-in connector.

• Only input signals that operate in accordance with the failsafe principle

(on switching off) are permitted for safety-related applications.

• Signals may be connected using unshielded cables.

Test pulse outputs

Features:

• 4 test pulse outputs T

• The assignment of test pulses to inputs is permanently specified and

cannot be configured using the system software’s configurator.

• Test pulses cannot be addressed via the PSS process I/O-image.

• Test pulses must only be used for test signals.

• Identical test pulses within a test pulse group (see Fig. 7.4) can take a

maximum 250 mA load. If you use all the test pulses, the maximum

permitted current load per plug-in connector and test pulse is 125 mA.

15

to T

0

3

Operating Manual: PSS67 F 16DI SB-T 7-3

Page 30

Wiring

Test pulse group 1

Test pulse group 2

T0

2 x 125 mA

T2 T3

2 x 125 mA

T1

2 x 125 mA

2 x 125 mA

I0 I1

T0 T1

I2 I3

T0 T1

I4 I5

T2 T3

I6 I7

T2 T3

I0 I1

T0 T1

I8 I9

T0 T1

I10 I11

T0 T1

I12 I13

T2 T3

I14 I15

T2 T3

2 x 125 mA

T0 T1

2 x 125 mA

T2 T3

2 x 125 mA

2 x 125 mA

Test pulse group 3

Test pulse group 4

Fig. 7-2 Current load on the test pulses

7-4 Operating Manual: PSS67 F 16DI SB-T

Page 31

Example: Single-channel, failsafe input device, without test pulse

Features:

• Depending on the application area and its respective regulations, this

connection diagram is suitable for input devices with frequent and

infrequent operation in accordance with EN 954-1, up to Category 2.

The possibility of a short circuit occurring in the external wiring between

different inputs or against the supply must be eliminated through

appropriate wiring.

• The input device must be approved for failsafe applications.

• Please read the instructions provided with the input device.

CAUTION!

A short circuit in the cable between the input device and input with the 24

VDC line or between adjacent input devices will not be detected.

Depending on the type of input device connected, this could create a risk to

both personnel and machinery (e.g. E-STOP). Always ensure that the unit

is suitably wired to eliminate the risk of short circuits.

Operating Manual: PSS67 F 16DI SB-T 7-5

Page 32

Wiring

Example: Single-channel, failsafe input device, without test pulse

L-

24 V

L+

Single-channel,

failsafe input device

Please ensure safety regulations and EMC guidelines are met!

Test pulse T0

I0 I1

T0 T1

I2 I3

T0 T1

I4 I5

T2 T3

I6 I7

T2 T3

I8 I9

T0 T1

I10 I11

T0 T1

I12 I13

T2 T3

I14 I15

T2 T3

7-6 Operating Manual: PSS67 F 16DI SB-T

Page 33

Example: Dual-channel input devices, without test pulses

Features:

• This type of connection is mainly used for signal inputs with frequent

operation.

• Depending on the application area and its respective regulations, this

connection diagram is suitable for input devices with frequent operation

and diverse channels, up to Category 4 in accordance with EN 954-1,

provided the functionality of both input device channels is monitored in

the user program via a feasibility check.

• Depending on the application area and its respective regulations, this

connection diagram is suitable for input devices with infrequent

operation up to Category 3 in accordance with EN 954-1, provided the

functionality of both input device channels is monitored in the user

program via a feasibility check.

• If you are using input devices with different (diverse) channels, adjacent

inputs may be used. Short circuits will be detected in the user program

via the feasibility check (see example in the PSS-Range Programming

Manual).

CAUTION!

A short circuit in the cable between the input device and input with the

24 VDC line or between adjacent input devices will not be detected.

Depending on the type of input device connected, this could create a risk to

both personnel and machinery (e.g. E-STOP). Always ensure that the unit

is suitably wired to eliminate the risk of short circuits.

Operating Manual: PSS67 F 16DI SB-T 7-7

Page 34

Wiring

Example: Dual-channel input devices, without test pulses

L-

24 V

L+

Dual-channel input

device with different

(diverse) channels

Please ensure safety regulations and EMC guidelines are met!

24 V

24 V

I0 I1

T0 T1

I2 I3

T0 T1

I4 I5

T2 T3

I6 I7

T2 T3

I8 I9

T0 T1

I10 I11

T0 T1

I12 I13

T2 T3

I14 I15

T2 T3

7-8 Operating Manual: PSS67 F 16DI SB-T

Page 35

Example: Single-channel, failsafe input device, with test pulse

Features:

• Depending on the application area and its respective regulations, this

connection diagram is suitable for applications up to Category 2 in

accordance with EN 954-1.

• The input device must be approved for failsafe applications.

• Please read the instructions provided with the input device.

• Short circuits between the cable from the test pulse to the input device

and the cable from the input device to the input will not be detected.

• Only input devices with N/C contacts can be tested.

Operating Manual: PSS67 F 16DI SB-T 7-9

Page 36

Wiring

Example: Single-channel, failsafe input device, with test pulse

L-

24 V

L+

Singlechannel,

failsafe input

device

Single-channel,

failsafe input

device with

supply voltage

from the test

pulse

0

24

S21

S11

A1

Test pulse T0

A2

12 22

I0 I1

T0 T1

I2 I3

T0 T1

I4 I5

T2 T3

I6 I7

T2 T3

I8 I9

T0 T1

I10 I11

T0 T1

I12 I13

T2 T3

I14 I15

T2 T3

Please ensure safety regulations and EMC guidelines are met!

7-10 Operating Manual: PSS67 F 16DI SB-T

Page 37

Example: Dual-channel, failsafe input device, with test pulse

Features:

• Depending on the application area and its respective regulations, this

connection diagram is suitable for applications up to Category 4 in

accordance with EN 954-1.

• This type of connection is mainly used for signal inputs with infrequent

operation.

• On input devices with identical channels, each channel should be given

a separate test pulse, where possible. This will ensure that all short

circuits are detected, with the exception of short circuits which short out

the input device (cable from the test pulse to the input device and cable

from the input device to the input).

• If the input device has only one test pulse, a short circuit between the

cables from the input device to the inputs will not be detected. In this

case the unit should be suitably wired to avoid the risk of this type of short

circuit. If diverse input devices are used, this type of error will be

detected.

Operating Manual: PSS67 F 16DI SB-T 7-11

Page 38

Wiring

Example: Dual-channel, failsafe input device, with test pulse

L-

24 V

L+

Dual-channel input device

with diverse channels

Dual-channel input device

with identical channels

Please ensure safety regulations and EMC guidelines are met!

Test pulse T1

Test pulse T0

Test pulse T1

Test pulse T0

I0 I1

T0 T1

I2 I3

T0 T1

I4 I5

T2 T3

I6 I7

T2 T3

I8 I9

T0 T1

I10 I11

T0 T1

I12 I13

T2 T3

I14 I15

T2 T3

7-12 Operating Manual: PSS67 F 16DI SB-T

Page 39

SafetyBUS p Interface

The module is connected to SafetyBUS p using a 5-pin A-coded M12

connector (X9). A 5-pin A-coded M12 socket (X10) is available to distribute

the bus signal to the other bus subscribers.

The X10 socket can also be used for bus subscriber termination.

To avoid reflection on the bus cable, the last bus subscriber must be fitted

with a terminating resistor. If the module is connected using 1:1 connection

cable, the terminating resistor is plugged into the free X10 socket . The

M12 terminator (Order no. 311 032) PSS SB M12 TERMINATOR is used

for termination via the SafetyBUS p socket.

55

4

X9 (male connector) X10 (female connector)

Fig. 8-1 Pin assignment of the SafetyBUS p interface

23

2

1

1

3

1: Shield

2: n.c.

3: CAN_GND (white)

4: CAN_H (green)

5: CAN_L

n.c. = not connected

4

8-1Operating Manual: PSS67 F 16DI SB-T

Page 40

SafetyBUS p Interface

Notes

8-2 Operating Manual: PSS67 F 16DI SB-T

Page 41

Operation and Maintenance

Operation and maintenance

Commissioning

• Install the digital input module as described in the chapter entitled

“Installation” on page 5-1.

• Connect the inputs and outputs as described in the chapter entitled

“Wiring the Inputs and Outputs” on page 7-1.

• Connect the supply voltage for the digital input module as described in

the chapter entitled “Supply Voltage” on page 6-1.

• Connect SafetyBUS p

• Set the device address.

• Configure the module using the system software’s configurator

9-1Operating Manual: PSS67 F 16DI SB-T

Page 42

Operation and Maintenance

Setting the device address

In order to operate the module on SafetyBUS p you will need to set the

device address that was defined for the module in the system software’s

configurator.

To do this you will need to use a screwdriver to open the transparent cover

on the rotary switches.

Use the rotary switches to set the required address. The rotary switch

labelled “x1” is used to set the units and the rotary switch labelled “x10” is

used to set the tens.

Permitted device addresses are in the range 32D ... 95D. The same applies

if the module is configured for SafetyBUS p 1 in the

SafetyBUS p Configurator on the PSS WIN-PRO system software. The

offset of 100D for device addresses on SafetyBUS p 1 is calculated

automatically from the bus configuration.

Rotary switch

"SB Address"

x10

x1

The I/O-Groups to which the module belongs must also be defined in the

system software’s configurator.

The module can be divided into sections A and B for this purpose. Section

A and section B may belong to different I/O-Groups. The module may either

have section A alone, section B alone, or both section A and section B. The

inputs can be assigned to both sections at will.

Membership of section A or section B is used in conjunction with the

device address to form the addresses under which the inputs can be

addressed by the controlling PSS.

Key

Set the tens

Set the unit

Example:

Device address 51D

In the process image of the controlling PSS, the inputs from Section A are

addressed under the device address as slot number and bit number

9-2 Operating Manual: PSS67 F 16DI SB-T

Page 43

0 ... 15. The inputs from Section B are addressed under the device address

as slot number and bit number 16 ... 31; this corresponds to an offset of 16

in the bit number.

So if input I6 from Section A is reconfigured into Section B, for example, the

address will change from x.06 to x.22.

Example: Device address is 36

Input Section Address Input Section Address

I

0

I

1

I

2

I

3

I

4

I

5

I

6

I

7

A E36.00 I

A E36.01 I

B E36.18 I

B E36.19 I

B E36.20 I

A E36.05 I

A E36.06 I

A E36.07 I

8

9

10

11

12

13

14

15

A E36.08

A E36.09

A E36.10

A E36.11

A E36.12

B E36.29

B E36.30

B E36.31

WARNING!

Any errors made when setting the device address will result in the loss of

the safety function.

If the same device address is set on two modules or the device addresses

of two modules are transposed, the controlling PSS may unknowingly

address the wrong inputs/outputs.

This will cause the plant to malfunction. The safe operation of the plant is

no longer guaranteed.

To avoid this, the greatest possible care must be taken when setting the

device addresses.

The device address may not be modified while the module is being

operated on SafetyBUS p (“SB active” LED lights up green or flashes),

otherwise all the I/O-Groups configured on the module will switch to a

STOP condition.

If it is necessary to change the set device address while the bus is running,

you will need to disconnect the module from SafetyBUS p while you make

the change. When you re-establish the connection to SafetyBUS p, the

module will quickly be ready for operation again (“Device” LED lights up

green).

9-3Operating Manual: PSS67 F 16DI SB-T

Page 44

Operation and Maintenance

Display elements

Status LEDs

Each input is assigned a status LED (I00 to I15).

The corresponding LED will light when its respective input has the status

“1”, otherwise it will remain unlit.

“Supply” LED

Indicates the presence of the supply voltage, “Supply”.

“Device” LED

This dual-colour LED indicates the device status.

• Red: A device error has occurred. The device error may involve one or

both of the I/O-Groups configured on the module.

• Flashing red: There is a periphery error.

• Green: The module is operating without error.

• LED off: A system error is preventing the module from starting up.

“SB active” LED

Indicates the presence of a connection between the module and the

Management Device.

• Green: Connection to the Management Device has been established

• LED off: No contact with SafetyBUS p (faulty wiring or Management

Device not in operation)

• Flashing green: There is contact with SafetyBUS p, but the Management

Device does not recognise the module (faulty device address or

configuration)

“I/O-Group” LED

Indicates the status of the I/O-Groups configured on the module.

• Green: All I/O-Groups configured on the module have “RUN” status

• LED off: All I/O-Groups configured on the module have “STOP” status

• Flashing green: One of the I/O-Groups configured on the module has

“STOP” status.

9-4 Operating Manual: PSS67 F 16DI SB-T

Page 45

“Load Supply” LED

Reserved for output devices

Recommissioning

NOTICE

When recommissioning, errors may occur when plugging in the connectors

as there is no protection against them being inserted incorrectly. Always

carry out a function test when recommissioning to ensure you exclude the

possibility of such an error.

Faults

If the module is defective or there is a wiring error, all the outputs in the

affected I/O-Group are shut down and the I/O-Group switches to a STOP

condition. An error telegram is then triggered on SafetyBUS p and the error

is entered in the error buffer of the PSS67 F 16DI SB-T.

An error message appears on the display of the controlling PSS. The error

stack display in the programming device can be used to locate the error

(see “SafetyBUS p System Description”).

Module configuration

The procedure for configuring SafetyBUS p and the module PSS67 F 16DI

SB-T is described in the online help of the PSS WIN-PRO system software.

9-5Operating Manual: PSS67 F 16DI SB-T

Page 46

Operation and Maintenance

Notes

9-6 Operating Manual: PSS67 F 16DI SB-T

Page 47

Technical Details

Electrical data

Supply voltage 24 VDC

Voltage tolerance -15 %/+20 %

Residual ripple DC 5%

Current consumption 90 mA plus load currents taken from the

test pulse outputs

Galvanic isolation Yes, between inputs and

SafetyBUS p

Connection B-coded M12 connector

SafetyBUS p

Transmission rate Max. 500 kBit/s

Cable runs Max. 3500 m

Transmission type Differential two-wire cable

Connection A-coded M12 connector

Digital inputs

Number of inputs 16

Type according to 61101-2 24 VDC Type 1

Separation of supply Yes, between inputs and SafetyBUS p

“1” Signal +15 ... +30 VDC

“0” Signal -3 ... +5 VDC

Input current Typ. 3.5 mA

Input delay < 1 ms

Pulse suppression < 300 µs

Status indicator Green LED

Dedicated test pulses

Number 4 (configurable in pairs as test pulse or

24 VDC output)

Output current at “1” signal Max. 0.125 A per pin

Total load capacity Max. 0.25 A per test pulse group

Cable runs Between test pulse output and input

Max. 100 m

10-1Operating Manual: PSS67 F 16DI SB-T

Page 48

Technical Details

Environmental data

Protection type (EN 60529) IP67

Mounting position Any

Climatic suitability EN 60068-2-1, EN 60068-2-2,

EN 60068-2-14

Ambient temperature

(EN 60068-2-14) -40 ... +60 °C

Storage temperature (EN 60068-2-1/-2) -40 ... +70 °C

EMC EN 61000-4-2, EN 61000-4-3, EN 61000-4-4,

EN 61000-4-5, EN 61000-4-6, EN 61000-6-2,

EN 61000-6-4

Vibration (EN 60068-2-6) 10 ... 150 Hz, 1g

10 ... 55 Hz, 0,35 mm

Shock (EN 60068-2-27) 15g, 11 ms

(EN 60068-2-29) 10g, 16 ms

Mechanical data

Weight 500 g

Dimensions (H x W x D) 215 x 60 x 35,5 mm

The names of products, goods and technologies used in this manual are trademarks of the respective companies.

The standards current on 2007/10 apply.

Order reference

Description Order No.

Marking labels (264 pcs.) 311 250

Cover for unused male connectors 311 252

Cover for unsed female connectors 311 251

10-2 Operating Manual: PSS67 F 16DI SB-T

Page 49

10-3Operating Manual: PSS67 F 16DI SB-T

Page 50

Technical Details

10-4 Operating Manual: PSS67 F 16DI SB-T

Page 51

...

In many countries we are

represented by our subsidiaries

and sales partners.

Please refer to our Homepage

for further details or contact our

headquarters.

Pilz GmbH & Co. KG

Sichere Automation

Felix-Wankel-Straße 2

73760 Ostfildern, Germany

Telephone: +49 711 3409-0

Telefax: +49 711 3409-133

E-Mail: pilz.gmbh@pilz.de

www

www.pilz.com

Technical support

+49 711 3409-444

21 869-01, 2007-12 Printed in Germany

Loading...

Loading...