Page 1

1002909-EN-02

PSEN op Protective Column 2-4/1

Operating Manual

General

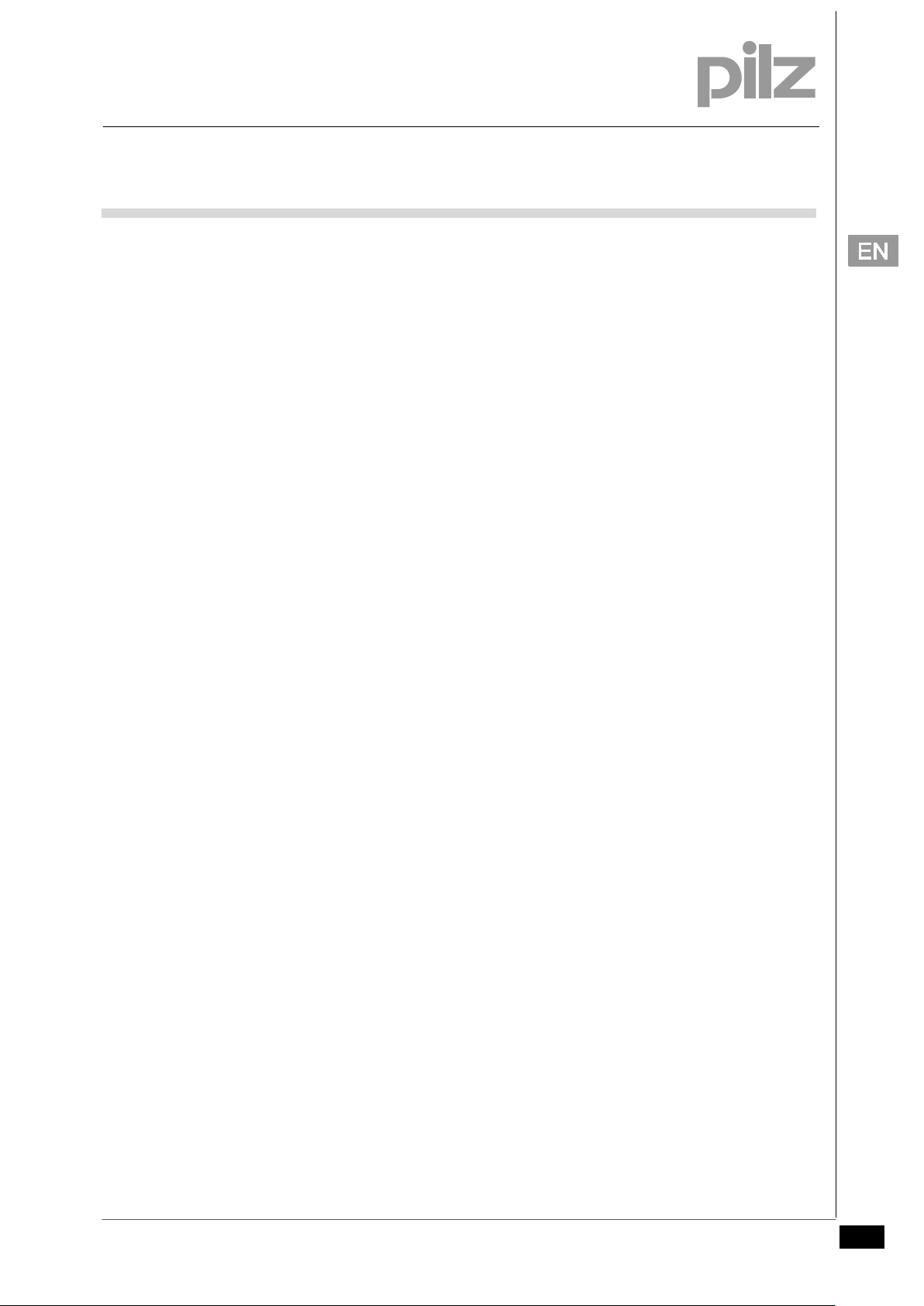

PSEN op Protective Column 2-4/1 is a column made of aluminium

and a base plate made of steel. The base plate consists of 2 plates

that can be adapted to the ground.

Deviation mirrors are already installed in the protective column.

They can be aligned independently of each other.

Overview

Features

Protects the installed deviation mirrors from accidental shock and

collisions.

One-piece profile made of coated aluminium with various lengths,

matching all height of PSEN op 2/4B (500 – 1200 mm).

Robust base plate consists of 2 plates, with pins for

compensating unevenness (levelling) and slot holes for angular

adjustment.

Spherical spirit level for easier level alignment.

Typical application areas

The accessories of PSEN op Protective Column 2-4/1 are

particularly suited for environments where vehicles such as forklifts

or automated guided vehicles can move freely.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany 1

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de Original document

Page 2

1002909-EN-02

PSEN op Protective Column 2-4/1

Operating Manual

NOTICE

Fig. 1

In case the product is used for body protection the specifications of the directive EN

ISO 13855 "Positioning of safeguards with respect to the approach speeds of

parts of the human body" must be observed.

2 Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de Original document

Page 3

1002909-EN-02

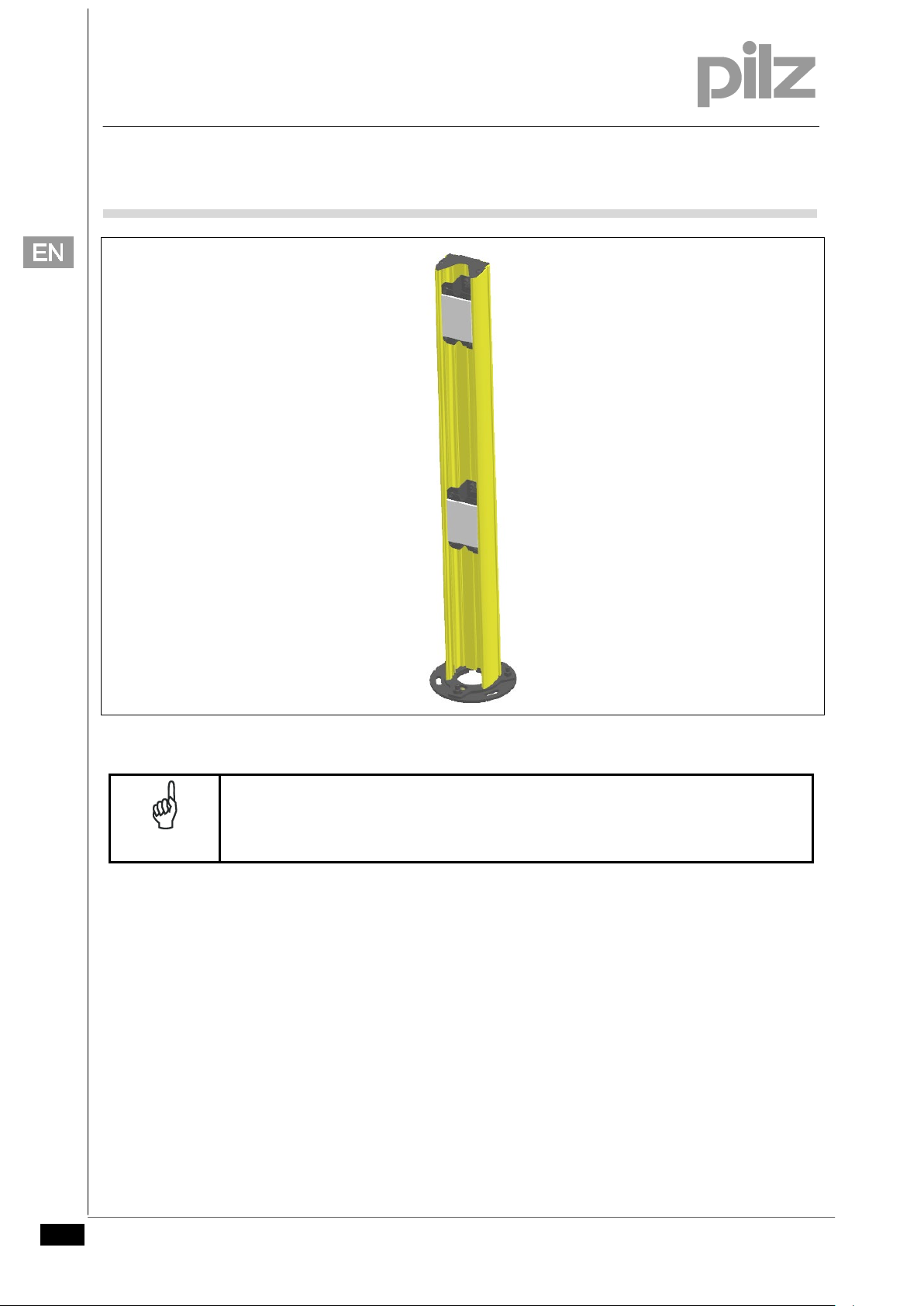

Slot holes for

Spirit level

PSEN op Protective Column 2-4/1

Operating Manual

Assembly

The profile of PSEN op Protective Column 2-4/1 is supplied with

pre-installed deviating mirrors and does not require mechanical

installation.

Levelling and angular adjustment of the plates

The grooves on the base plate are used to define the required angle

position. Tighten the slot holes on the bottom plate with the screws

M10 on the floor (not entirely). Slightly loosen the counter nuts on

the top plate and align any unevenness using the spirit level. Then

fix the screws M10 completely. Finally, check again whether the

protective column is straight, readjust if necessary and tighten the

counter nuts again (Fig. 2).

Fig. 2

bottom screws

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany 3

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de Original document

Page 4

1002909-EN-02

PSEN op Protective Column 2-4/1

Operating Manual

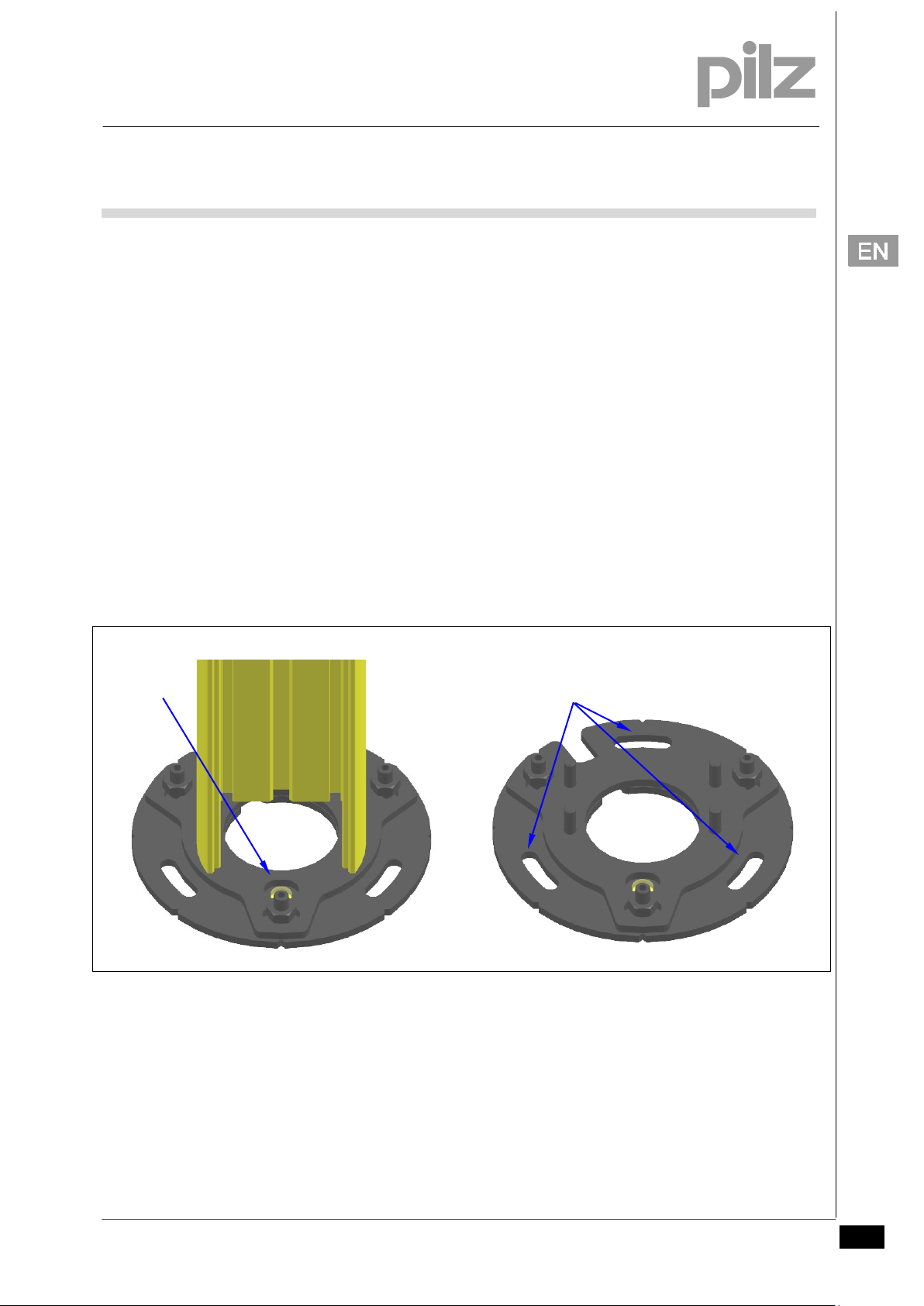

Installing the PSEN op Protective Base/1 accessories

Screw the additional plate to the floor and mount the 3 springs on

the spacers. Fix the protective column with the base plate so that

the slot holes of the bottom plate are right above the springs. Insert

the screws M10 together with the washers (PSEN op Protective

Base/1 accessories) into the slot holes and compress the 3 springs

equally when affixing the screws (Fig. 3). Align the protective

column as described in "Levelling and angular adjustment of the

plates".

The optimum working height of the springs (distance between base

plate and additional plate) is ca. 42 mm.

Fig. 3

4 Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de Original document

Page 5

1002909-EN-02

Screws M8x12

Screws M4x20

Screws M8x12

PSEN op Protective Column 2-4/1

Operating Manual

Aligning the deviating mirrors

To adjust the height of the deviating mirrors loosen the screws

M5x12 and position the deviating mirrors in the protective column as

required. Then tighten the screws again. If the protective column is

in vertical position, make sure that the deviating mirrors do not slip

downward.

The 3 screws M4x20 are used to level the deviation mirrors (Fig.4).

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany 5

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de Original document

Fig. 4

Page 6

1002909-EN-02

Number of mirrors

Operating range

Operating range

Transmitter

deviating

mirrors

deviating

mirrors

Receiver

PSEN op Protective Column 2-4/1

Operating Manual

Use of a deviating mirror reduces the effective operating range by

about 15%. This percentage increases further when using two or

three deviating mirrors.

In the table below the operating ranges are indicated, based on

the number of the mirrors used.

Without mirror 6 m 19 m

1 5.1 m 16.5 m

2 4.3 m 13.7 m

3 3.7 m 11.6 m

Installing PSEN op Protective Column 2-4/1 with PSEN op Mirror/1

Fig. 5

6 Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de Original document

Define the area to be protected and the exact positions where the

deviating mirrors, the transmitter and receiver units of the light

curtain are to be installed. The "Order reference" table combines

the recommended pairs of product and corresponding accessory.

Fix the PSEN op Protective Column 2-4/1 on the floor in the

required position. When using an additional plate (PSEN op

Protective Base/1) perform the installation as described in the

"Installing the PSEN op Protective Base/1 accessories" section.

Page 7

1002909-EN-02

ith PSEN op

4/1. The tolerances can be compensated by levelling and

angular adjustments of the protective columns and the laser pointer. Do not

PSEN op Protective Column 2-4/1

Operating Manual

Align the deviating mirror to ca. 45° to the optical path. PSEN op

Protective Column 2-4/1 allows regulation around the vertical axis

by +/- 5° (s. section "Levelling and angular adjustment of the

plates").

Position the laser pointer at the upper part of the transmitter unit

and align the unit so that the laser beam is horizontal in the

middle of the first deviating mirror. The height of the laser pointer

and the height where the pointer hits have to be identical.

Repeat the procedure and align the laser pointer at the bottom

part of the unit. Repeat these steps several times, if necessary.

Align the first deviation mirror so that the laser beam hits the

second deviating mirror in the position described before.

The laser pointer has mechanical tolerances when combined w

NOTICE

Protective Column 2-

compensate the tolerances by changing the deviating mirror position.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany 7

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de Original document

Page 8

1002909-EN-02

PSEN op2B-2-050

PSEN op4B-2-050

PSEN opSB-4B-2-050

PSEN op2B-3-080

PSEN op4B-3-080

PSEN opSB-4B-3-080

PSEN op2B-4-090

PSEN op4B-4-090

PSEN opSB-4B-4-090

PSEN op2B-4-120

PSEN op4B-4-120

PSEN opSB-4B-4-120

PSEN op Protective Column 2-4/1

Operating Manual

Order reference

PSEN op Protective Column 2-4/1

Product type Description Order no.

PSEN op Protective Column 2-050/1 Protective Stand 2 mirror H500 630961

PSEN op Protective Column 3-080/1 Protective Stand 3 n mirror H800 630962

PSEN op Protective Column 4-090/1 Protective Stand 4 mirror H900 630963

PSEN op Protective Column 4-120/1 Protective Stand 4 mirror H1200 630964

Table of suitable light curtains

Product type Light curtain

PSEN op Protective Column 2-050/1

PSEN op Protective Column 3-080/1

PSEN op Protective Column 4-090/1

PSEN op Protective Column 4-120/1

The preceding table only includes the models of the PSEN op 2/4B ranges. The

NOTICE

PSEN op Protective accessories can also be used with the light curtains of the

PSEN op 2/4xx ranges.

Accessories

Product type Description Order no.

PSEN op Protective Base/1

Double plate with compensation

springs

630955

8 Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de Original document

Page 9

1002909-EN-02

PSEN op Protective Column 2-4/1

Operating Manual

Dimensions

Base plate and additional plate:

Fig. 6

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany 9

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de Original document

Page 10

1002909-EN-02

PSEN op Protective Column 2-4/1

Operating Manual

PSEN op Protective Column 2-050/1

PSEN op Protective Column 3-080/1

PSEN op Protective Column 4-090/1

10 Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de Original document

Page 11

1002909-EN-02

PSEN op Protective Column 2-4/1

Operating Manual

PSEN op Protective Column 4-120/1

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany 11

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de Original document

Loading...

Loading...