INTEGRATED CIRCUITS

DATA SH EET

TEA1504

GreenChip; SMPS control IC

Preliminary specification

File under Integrated Circuits, IC11

1998 Mar 17

Philips Semiconductors Preliminary specification

GreenChip; SMPS control IC TEA1504

PRODUCT HIGHLIGHTS

Distinctive features

• High level of integration leads to 20 to 50 fewer

components compared to power supply with discrete

components

• On-chip efficient startup current source giving fast

startup

• ON/OFF function replaces expensive mains switch with

functional switch

• Direct off-line operation (90 to 276 Vac)

• On-chip 5% accurate oscillator.

Green features

• Low power consumption in off-mode (<100 mW)

• Burst mode stand-by (<2 W) for overall improved

system efficiency

• Low power operation mode with lower frequency to

reduce switching losses.

Protection features

• Demagnetization protection

• Cycle by cycle current limitation with programmable

current trip level

• Accurate over voltage protection which tracks the output

voltage

• Over temperature protection

• Safe-restart mode with reduced power for system fault

conditions.

Highly versatile

• Usable in Buck and Flyback topology

• Interfaces both primary and secondary side feedback.

Output

OOB

14

Dem

13

12

NC

11

Gnd

NC

10

Vctrl

9

Iref

8

Vin

NC

NC

Driver

Isense

Vaux

1

2

3

4

5

6

7

DS

Fig.1 Typical Flyback Application.

GENERAL DESCRIPTION

The GreenChip, intended for off-line 90 to 276 Vac

power supply applications, is a monolithic high voltage

family of ICs that combines analog and digital circuits to

implement all necessary control functions for a switched

mode power supply. The functions include integrated high

voltage startup current source, voltage mode PWM

control, 5% accurate trimmed oscillator, bandgap derived

reference voltages, comprehensive fault protection, and

leading edge blanking. High level of integration leads to

cost effective power supplies that are compact, weigh less,

and at the same time give higher efficiency, are more

reliable and simple to design. Efficient green features lead

to very low power operation modes and a novel ON/OFF

function helps replace the expensive mains switch with a

low cost functional switch.

ORDERING INFORMATION

PACKAGE

TYPE NUMBER

NAME DESCRIPTION VERSION

TEA1504 DIP14 plastic dual in-line package; 14 leads (300 mil) SOT27-1

1998 Mar 17 2

Philips Semiconductors Preliminary specification

GreenChip; SMPS control IC TEA1504

FUNCTIONAL BLOCK DIAGRAM

OOB

14

5.5V

Vctrl

9

Dem

13

On/Off

Iref

-

+

Burst mode

stand-by

Sample &

Hold 1

Demag

Mgmnt

Vaux

8

Vaux management

+

-

Over temp

protection

Sample &

Hold 2

6

Error

Amp.

Oscillator

PWM

Comp.

+

-

Vin

Startup current

source

1

R

S

* Over current

protection

* Leading Edge

blanking

Frequency control

TEA1504

Q

DS

7

Driver

4

Isense

5

Negative

Clamp

Gnd

Fig.2 Functional Block Diagram.

1998 Mar 17 3

11

NC pins: 2, 3, 10 & 12

Philips Semiconductors Preliminary specification

GreenChip; SMPS control IC TEA1504

PINNING

SYMBOL PIN DESCRIPTION

Vin 1 MOSFET Drain connection

HVS 2 High voltage safety spacer

NC 3 Not connected

Driver 4 MOSFET gate driver output

Isense 5 Programmable current

sense resistor

Vaux 6 IC supply capacitor

DS 7 Supply for driver circuit

Iref 8 Reference resistor for

setting internal reference

currents

Vctrl 9 Feedback voltage for duty

cycle control

NC 10 Not connected

Gnd 11 Ground

NC 12 Not connected

Dem 13 Demagnetization input

signal from primary side

auxiliary winding

OOB 14 On/Off/Burst Mode input

signal

Vin

HVS

NC

Driver

Isense

Vaux

DS

1

2

3

TEA1504

4

5

6

7

Fig.3 Pin assignment.

14

13

12

11

10

OOB

Dem

NC

Gnd

NC

Vctrl

9

Iref

8

FUNCTIONAL DESCRIPTION

The GreenChip family of ICs are highly integrated, with

most common PWM functions like error amplifier,

oscillator, bias current generator, and band gap based

reference voltage circuits fully integrated in the ICs.

High level of integration leads to easy and cost effective

design of power supplies. The ICs have been fabricated in

a Philips proprietary high voltage BCDMOS process that

enables devices of up to 650 V to be fabricated on the

same chip with low voltage circuitry.

An efficient on-chip startup circuit enables fast startup and

dissipates negligible power after start up. On-chip

accurate oscillator generates a saw tooth waveform which

is used by the voltage mode feedback control circuitry to

generate a pulse width modulated signal for driving the

gate of the power MOSFET. A novel regulation scheme is

used to implement both primary and secondary side

regulation to minimize external component count.

Protection features like over voltage, over current, over

temperature, and demagnetization protection, give

comprehensive safety against system fault conditions.

The GreenChip offers some advanced features that

greatly enhance the efficiency of the overall system.

Off-mode reduces the power consumption of the IC below

100 mW. Burst mode stand-by reduces the power

consumption of the system to below 2 W. Low power

operation mode reduces the operating frequency of the

system, when the system is working under low load

conditions, to reduce the switching losses.

Startup current source and vaux management

A versatile on-chip startup current source makes an

external, highly dissipative, trickle-charge circuit

unnecessary. Refer to Fig.2 for a block diagram of the IC.

The startup current source derives power from the mains

via the Vin (drain) pin. It supplies current (see Istart-low

and Istart-high in Chapter “Characteristics”) to charge the

Vaux (IC supply) capacitor and at the same time provides

current to the control circuitry of the IC. Once the Vaux

capacitor is charged to its startup voltage level (11 V), the

on chip oscillator starts oscillating and the IC starts

switching the power MOSFET. Power is then supplied to

the load via the secondary winding. Figure 1 shows a

typical flyback application diagram. The Vaux capacitor is

also supplied by an auxiliary winding on the primary side.

This winding is coupled to the secondary side winding

1998 Mar 17 4

Philips Semiconductors Preliminary specification

GreenChip; SMPS control IC TEA1504

supplying the output capacitor. As the output capacitor

voltage increases and approaches its nominal value, the

re-supply of the Vaux capacitor is done by the auxiliary

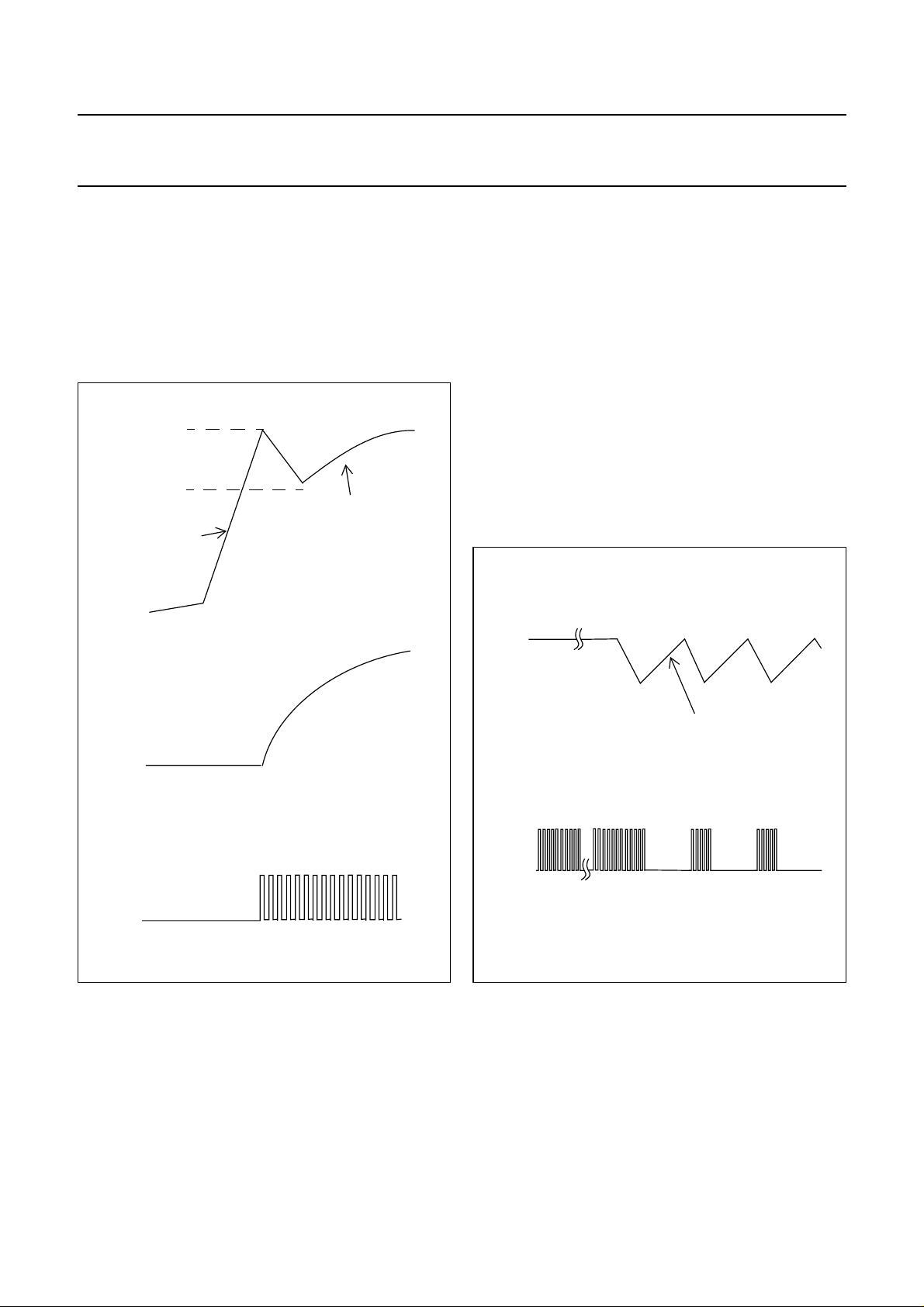

winding. Figure 4 shows relevant waveforms at startup.

For successful take over of supply of Vaux capacitor by the

auxiliary winding, it is important that the re-supply of Vaux

capacitor starts before its voltage drops to its Under

Voltage Lockout (UVLO) level of 8.15 V.

Vaux

11V

8.15V

Istartup charging

Vaux cap

charging of Vaux cap

taken over by Auxiliary

Winding

circuit, the output voltage will rise till it reaches the OVP

level. The IC will detect this state and stop switching.

In absence of switching of the power device, the Vaux

capacitor will not be re-supplied and its voltage will drop till

it reaches UVLO level. Once the Vaux voltage drops to

UVLO level, the startup current source is re-activated and

it charges the Vaux capacitor to its start level and the

system goes through a cycle similar to the startup cycle.

Figure 5 shows the relevant waveforms during safe-restart

mode. The charging current (see Irestart-prot in

Chapter “Characteristics”) from the startup circuit during

the safe-restart mode is lower than the normal startup

current (see Istart-high in Chapter “Characteristics”) in

order to implement a low “hiccup” duty cycle. This helps

insure devices on the output secondary winding do not get

destroyed during output short circuit, violating safety

conditions.

Vaux

Normal operation

Fault condition

Vout

Vgate

Off

Fig.4 Normal startup waveforms.

The startup current source also helps implement the

safe-restart or “hiccup” mode during system fault

conditions like output short circuit, output open circuit, and

Over Voltage Protection (OVP). In all the above fault

situations, the IC reacts by inhibiting the normal operation

of the system and stops delivering power to the output.

In case of output short circuit, the Vaux capacitor is no

longer supplied by the auxiliary winding and its voltage

drops till it reaches the UVLO level. If the output is an open

Switching

Startup current source

charging Vaux capacitor

Vgate

Switching

Off

Fig.5 Safe-restart mode waveforms.

The startup current source also plays a key role in

implementation of burst mode stand-by (see Irestart-stdby

in Chapter “Characteristics”), which will be explained later.

All reference voltages are derived from a temperature

compensated, on-chip, band-gap. The bandgap reference

voltage is also used, together with an external resistor

connected at the Iref pin, to generate accurate,

temperature independent, bias currents in the chip.

1998 Mar 17 5

Philips Semiconductors Preliminary specification

GreenChip; SMPS control IC TEA1504

Sample and Hold

GreenChip ICs employ voltage mode feedback for

regulating the output voltage. In primary feedback mode,

a novel Sample and Hold circuit is used. The Sample and

Hold circuit works by sampling the current into the demag

pin, which is related to the output voltage via Rdem, during

the time that the secondary current is flowing:

V

out=Iref

× R

dem+Vdem+

This sampled current information is stored on the external

capacitor connected to the Vctrl pin. The pulse width

modulator uses this voltage information to set the duty

cycle of operation for the power MOSFET. In secondary

feedback, the feedback voltage is provided by an

opto-coupler.

Pulse Width Modulator

The pulse width modulator, which is made up of an

inverting error amplifier and a comparator (Fig.2), drives

the power MOSFET with a duty cycle which is inversely

proportional to the voltage at the Vctrl pin. In primary

feedback, this is the voltage on the Sample and Hold

capacitor and in secondary feedback, this voltage is

provided by an opto-coupler. A signal from the oscillator

sets a latch that turns on the power MOSFET. The latch is

reset by the signal from the pulse width modulator or by the

duty cycle limiting circuit. The latching PWM mode of

operation prevents multiple switching of the power switch.

The maximum duty cycle is set internally at 80%. Figure 6

shows the normal switching operation of the IC.

Oscillator

The oscillator is used to set the switching duty cycle by

comparing the oscillator ramp to the output of the error

amplifier in the pulse width modulator circuit. The oscillator

is fully integrated and works by charging and discharging

an internal capacitor between two voltage levels to create

a sawtooth waveform with a rising edge which is 80% of

the oscillator cycle. This ratio is used to set a maximum

switching duty cycle of 80% for the IC. The oscillator is

internally trimmed to 5% accuracy. The oscillator

frequency can be adjusted between 49 to 91 kHz

(see f

osc-h-range

in Chapter “Characteristics”) by changing

the external reference resistor (see Rref in

Chapter “Characteristics”) that sets the chip bias currents.

This gives additional flexibility to the power supply

designer in the choice of his system components.

The frequency is correlated with the value of the Rref

resistor:

f

oscfosc typical–

f

osc-typical

and f

osc-h

is specified in Chapter “Characteristics”, f

. The operating Rref resistor range is specified in

24.900

× Hz[]=

-----------------Rref

osc-l

Chapter “Characteristics”, Rref.

Multi Frequency Control

The oscillator is also capable of working at a lower

frequency (see f

in Chapter “Characteristics”). A ratio

osc-l

of 1 : 2.5 is maintained between high and low frequency of

the oscillator. Low frequency operation is invoked if the

power supply is working at or below one ninth of its peak

power. By working at a lower frequency, the switching

losses in the power supply are reduced. A novel scheme

is used to ensure that the transfer of high to low frequency

and vice versa has no effect on the regulation of the output

voltage.

Gate Driver

The gate driver has a totem-pole output stage that has

current sourcing capability of 120 mA and a current sink

capability of 500 mA. This is to enable fast turn on and turn

off of the power device for efficient operation. In the DIL14

controller version, the driver supply and driver output pins

are available separately to the power supply designer.

In this way the power supply designer can control the

source and sink currents of the gate driver circuit with a

minimum of external components.

Demagnetization Protection

This feature guarantees discontinuous conduction mode

operation for the power supply which simplifies the design

of feedback control and gives faster transient response.

Demagnetization protection is an additional protection

feature that protects against saturation of the

transformer/inductor. Demagnetization protection also

protects the power supply components against excessive

stresses at startup, when all energy storage components

are completely discharged, and during shorted output

system fault condition.

Negative Clamp

The negative clamp circuit does not let the voltage at the

demag pin go below −0.4 V, when the auxiliary winding

voltage goes negative during the time that the power

device is turned on, to ensure correct operation of the IC.

1998 Mar 17 6

Loading...

Loading...