Philips SL1ICS3001U-L6D, SL1ICS3001U-N5D, SL1ICS3001W-N5D Datasheet

INTEGRATED CIRCUITS

SL1 ICS30 01

Philips

I•CODE1 Label IC

Chip Specification

Product Specification

Revision 2.1

Public

Semiconductors

2000-05-02

I•CODE1 Chip Specification Rev. 2.1 May 2000

1 Contents

1 CONTENTS 2

2 DEFINITIONS 4

2.1 Life Support Applications ....................................................................................................4

2.2 Abbreviations ........................................................................................................................4

3 SCOPE 5

4 ORDERING INFORMATION 5

5 FUNCTIONAL DESCRIPTION 6

5.1 Basic Features.......................................................................................................................6

5.2 Block Diagram of the IC.......................................................................................................6

5.3 Memory Organisation...........................................................................................................7

5.3.1 Serial Number...................................................................................................................7

5.3.2 Write Access Conditions ..................................................................................................7

5.3.3 Special Functions (EAS/QUIET) .....................................................................................8

5.3.4 Family Code and Application Identifier ...........................................................................8

5.3.5 Configuration of delivered ICs.........................................................................................8

6 MECHANICAL DIE SPECIFICATIONS 9

7 MECHANICAL WAFER SPECIFICATIONS 10

7.1 Wafer Status ........................................................................................................................10

7.2 Backside Treatment ............................................................................................................10

8 DOCUMENTATION 11

8.1 Delivery Documentation.....................................................................................................11

8.2 Fail-Die Identification.........................................................................................................11

8.2.1 Ink Dot Specification......................................................................................................11

8.2.2 Wafer Mapping...............................................................................................................11

9 QUALITY ASSURANCE 12

9.1 Electrical Acceptance Test.................................................................................................12

9.2 Visual Inspection.................................................................................................................12

9.2.1 After Wafer Final Test....................................................................................................12

9.2.2 After Sawing (Film Frame Carrier)................................................................................12

10 PACKING 13

10.1 Storage Recommendations.................................................................................................13

10.2 Possible Forms of Delivery.................................................................................................13

10.2.1 Packing of Unsawn Wafers............................................................................................13

10.2.2 Packing of Sawn Wafers................................................................................................13

SL040521.doc/M Public Page 2 of 22

I•CODE1 Chip Specification Rev. 2.1 May 2000

11 HANDLING RECOMMENDATIONS 14

11.1 Sawing ..................................................................................................................................14

11.2 Die Attach.............................................................................................................................14

11.3 Wire Bonding.......................................................................................................................14

12 COIL SPECIFICATION 14

13 ELECTRICAL SPECIFICATIONS 15

14 HINTS FOR LABEL IC ENCAPSULATION 16

14.1 Protection against Visible Light.........................................................................................16

14.2 Protection against UV Light...............................................................................................16

14.3 Resistance to X-Rays ..........................................................................................................16

15 INLET/LABEL CHARA CTERISATION AND TEST 17

15.1 Characterisation of the Inlet/Label...................................................................................17

15.2 Final Test of the Inlet/Label...............................................................................................17

16 APPENDIX A: DIE PLAN 18

17 APPENDIX B: CLUS TER PLAN 19

18 APPENDIX C: CLUS TER MAP 20

19 APPENDIX D: WAFER MAP 21

SL040521.doc/M Public Page 3 of 22

I•CODE1 Chip Specification Rev. 2.1 May 2000

2 Definitions

Data sheet status

Objective specification This data sheet contains target or goal specifications for product development.

Preliminary specification This data sheet contains preliminary data; supplementary data may be published later.

Product specification This data sheet contains final product specifications.

Limiting values

Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one

or more of the limiting values may cause permanent damage to the device. These are stress ratings only and

operation of the device at these or at any other conditions above those given in the Characteristics section of the

specification is not implied. Exposure to limiting values for extended periods may affect device reliability.

Application information

Where application information is given, it is advisory and does not form part of the specification.

2.1 Life Support Applications

These products are not designed for use in life support appliances, devices, or systems where

malfunction of these products can reasonably be expected to result in personal injury. Philips

customers using or selling these products for use in such applications do so on their own risk and

agree to fully indemnify Philips for any damages resulting from such improper use or sale.

2.2 Abbreviations

ASCII American Standard Code for Information Interchange

CSC Cyclic Redundancy Check

EAN European Article Number

EAS Electronic Article Surveillance

EEPROM Electrically Erasable and Programmable Read Only Memory

EMI Electromagnetic Interference

ETSI European Telecommunications Standards Institute

FCC Federal Communications Commission

FFC Film Frame Carrier

Hex Value in hexadecimal notation

IC Integrated Circuit

ISM Industrial, Scientific, Medical

LSB Least Significant Bit or Byte

MSB Most Significant Bit or Byte

MTBF Mean Time Between Failure

PCB Printed Circuit Board

PCM Process Control Module

RF Radio Frequency

rms Root Mean Square

SNR Serial Number

UV Ultraviolet

SL040521.doc/M Public Page 4 of 22

I•CODE1 Chip Specification Rev. 2.1 May 2000

3 Scope

This specification describes the electrical, physical and dimensional properties of unsawn and sawn

wafers on FFC of I•CODE1 Label ICs on a Philips 6C15 IDFW process and is the base for delivery

of tested I•CODE1 Label ICs.

General recommendations are given for storage, handling and processing of wafers as well as

assembly of labels.

Reference documents: MIL-STD 883D Method 3023

MIL-STD 883D Method 3015

SNW-FQ-627

PICTOH-QS007

General Specification for 6” Wafer (Prod. Spec.)

General Quality Specification

I•CODE1 Label IC, Coil Design Guide

This product specification is valid for VCOL1V0 from mask revision P/B upwards.

4 Ordering Information

Following ordering options are available:

Type Name Description Ordering Code

SL1 ICS30 01W/N5D Sawn wafer on foil (FFC), 150 µm, inked and mapped 9352 644 66005

SL1 ICS30 01U/N5D Unsawn wafer, 150 µm, inked and mapped 9352 644 65025

SL1 ICS30 01U/L6D

Unsawn wafer, 525 µm, mapped (not inked)

9352 644 64025

SL040521.doc/M Public Page 5 of 22

I•CODE1 Chip Specification Rev. 2.1 May 2000

5 Functional Description

5.1 Basic Features

The I•CODE1 Label IC is a dedicated chip for intelligent label applications like logistics and retail

(including EAS) as well as baggage and parcel identification in airline business and mail services.

The I•CODE system offers the possibility of operating labels simultaneously in the field of the

reader antenna (Anticollision). It is designed for long range applications.

Whenever connected to a very simple and cheap type of antenna (as a result of the 13.56 MHz

carrier frequency) made out of a few windings printed, winded, etched or punched coil the

I•CODE1 Label IC can be operated without line of sight up to a distance of 1.5 m (gate width).

5.2 Block Diagram of the IC

The label requires no internal power supply. Its contactless interface generates the power supply

and the system clock via the resonant circuitry by inductive coupling to the reader. The interface

also demodulates data that are transmitted from the reader to the I•CODE Label, and modulates the

electromagnetic field for data transmission from the I•CODE Label to the reader.

Data are stored in a non-volatile memory (EEPROM). The EEPROM has a memory capacity of 512

bit and is organised in 16 blocks consisting of 4 bytes each (1 block = 32 bits). The higher 12 blocks

contain user data and the lowest 4 blocks contain the serial number, the write access conditions and

some configuration bits.

SL040521.doc/M Public Page 6 of 22

I•CODE1 Chip Specification Rev. 2.1 May 2000

â

MSB LSB

â

â

MSB LSB

â

â

MSB LSB

â

â

MSB LSB

â

1|1

1|1

0|0

0|0

1|1

1|1

1|1

1|1

1|1

1|1

1|1

1|1

1|1

1|1

1|1

1|1

Funct.

Access

Data

.....

.....

.....

.....

.....

.....

.....

.....

.....

.....

Data

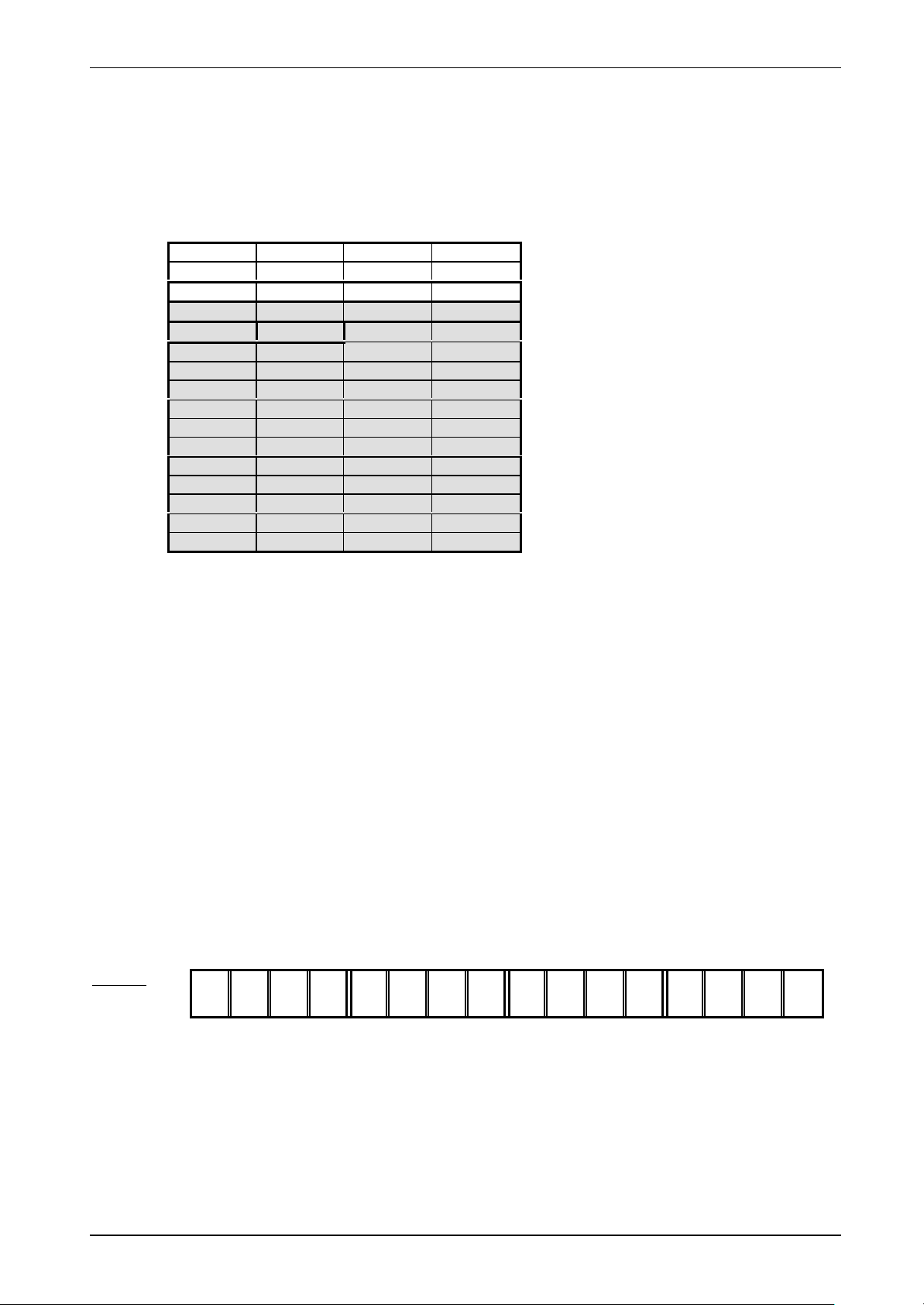

5.3 Memory Organisation

The 512 bit EEPROM memory is divided into 16 blocks. A block is the smallest access unit. Each

block consists of 4 bytes (1 block = 32 bits). Bit 0 in each byte represents the least significant bit

(LSB) and bit 7 the most significant bit (MSB), respectively.

Byte 0 Byte 1 Byte 2 Byte 3

Block 0 SNR0 SNR1 SNR2 SNR3 Serial Number (lower bytes)

Block 1 SNR4 SNR5 SNR6 SNR7 Serial Number (higher bytes)

Block 2 F0 FF FF FF Write Access Conditions

Block 3 x x x x Special Functions (EAS/QUIET)

Block 4 x x x x Family Code/Application Identifier/User Data

Block 5 x x x x User Data

Block 6 x x x x :

Block 7 x x x x :

Block 8 x x x x :

Block 9 x x x x :

Block 10 x x x x :

Block 11 x x x x :

Block 12 x x x x :

Block 13 x x x x :

Block 14 x x x x :

Block 15 x x x x User Data

The values (in hexadecimal notation) shown in the table above are stored in the EEPROM after the

wafer production process. The contents of blocks marked with ‘x’ in the table are not defined at

delivery.

5.3.1 Serial Number

The unique 64 bit serial number is stored in blocks 0 and 1 and is programmed during the

production process. SNR0 in the table represents the least significant byte and SNR7 the most

significant byte, respectively.

5.3.2 Write Access Conditions

The Write Access Condition bits in block 2 determine the write access conditions for each of the

16 blocks. These bits can be set only to 0 (and never be changed to 1), i.e. already write protected

blocks can never be written to from this moment on. This is also true for block 2. If this block is set

into write protected state by clearing of bits 4 and 5 at byte 0, no further changes in write access

conditions are possible.

Byte 0 Byte 1 Byte 2 Byte 3

Block 2:

Write Access

Conditions

for Block à

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 2 1 0 7 6 5 4 11 10 9 8 15 14 13 12

Special

Write

Serial

Number

User

|

|

|

|

User

The ones in the 16 pairs of bits have to be cleared together if the corresponding block is wanted to

be write protected forever (1|1 à write access enabled, 0|0 à write access disabled). Writing of bit

pairs 1|0 or 0|1 to block 2 is not allowed!

It is extremely important to be particularly careful when clearing the Write Access bits in

block 2, as you can lose write access to all of the blocks on the label in case of a mistake.

Of course you can use this feature to put the label into a hardware write protected state!

SL040521.doc/M Public Page 7 of 22

Loading...

Loading...