INTEGRATED CIRCUITS

DATA SH EET

PCB2421

1K dual mode serial EEPROM

Preliminary specification

Supersedes data of 1995 Oct 11

File under Integrated Circuits, IC12

1997 Apr 01

Philips Semiconductors Preliminary specification

1K dual mode serial EEPROM PCB2421

CONTENTS

1 FEATURES

2 GENERAL DESCRIPTION

3 ORDERING INFORMATION

4 BLOCK DIAGRAM

5 PINNING

6 FUNCTIONAL DESCRIPTION

6.1 Transmit-only mode (DDC1)

6.2 Initialization procedure

6.3 Bidirectional mode (DDC2B, I2C-bus mode)

6.3.1 Bidirectional mode bus characteristics

6.3.2 Bus not busy (A)

6.3.3 Start condition (B)

6.3.4 Stop condition (C)

6.3.5 Data valid (D)

6.3.6 Acknowledge

6.3.7 Slave address

6.4 Write operation

6.4.1 Byte write

6.4.2 Page write

6.5 Acknowledge polling

6.6 Write protection

6.7 Read operation

6.7.1 Current address read

6.7.2 Random read

6.7.3 Sequential read

6.8 Pin description

6.8.1 SDA

6.8.2 SCL

6.8.3 VCLK

6.8.4 WP

6.8.5 Test

6.8.6 n.c.

7 LIMITING VALUES

8 DC CHARACTERISTICS

9 EEPROM CHARACTERISTICS

10 AC CHARACTERISTICS

11 APPLICATION INFORMATION

11.1 Diode protection

11.2 Functional compatibility with microchip 24CL21

dual mode EEPROM

12 PACKAGE OUTLINES

13 SOLDERING

13.1 Introduction

13.2 DIP

13.2.1 Soldering by dipping or by wave

13.2.2 Repairing soldered joints

13.3 SO

13.3.1 Reflow soldering

13.3.2 Wave soldering

13.3.3 Repairing soldered joints

14 DEFINITIONS

15 LIFE SUPPORT APPLICATIONS

16 PURCHASE OF PHILIPS I2C COMPONENTS

1997 Apr 01 2

Philips Semiconductors Preliminary specification

1K dual mode serial EEPROM PCB2421

1 FEATURES

• Single supply with operation 4.5 to 5.5 V

• Completely implements DDC1/DDC2B interface for

monitor identification

• Low power CMOS technology

• Two-wire I2C-bus interface

• Self-timed write cycle (including auto-erase)

• Page-write buffer for up to 8 bytes

• Write-protect pin

• 100 kHz I2C-bus compatibility

• Designed for 10000 erase/write cycles minimum

• Data retention greater than 10 years

• 8-pin DIP and SO package

• Temperature range 0 to +70 °C.

3 ORDERING INFORMATION

TYPE NUMBER

NAME DESCRIPTION VERSION

PCB2421P DIP8 plastic dual in-line package; 8 leads (300 mil) SOT97-1

PCB2421T SO8 plastic small outline package; 8 leads; body width 3.9 mm SOT96-1

2 GENERAL DESCRIPTION

The Philips PCB2421 is a 128 × 8-bit dual mode serial

Electrically Erasable PROM (EEPROM).

This device is designed for use in applications requiring

storage and serial transmission of configuration and

control information. Two modes of operation have been

implemented: transmit-only mode (DDC1 mode) and

bidirectional mode (DDC2B, or I2C-bus mode). Upon

power-up, the device will be in the transmit-only mode,

sending a serial bitstream of the entire memory array

contents, clocked by the VCLK pin. A valid HIGH-to-LOW

transition on the SCL pin will cause the device to enter the

bidirectional mode, with byte selectable read/write

capability of the memory array. The PCB2421 is available

in a standard 8-pin dual in-line and 8-pin small outline

package operating in a commercial temperature range.

PACKAGE

1997 Apr 01 3

Philips Semiconductors Preliminary specification

1K dual mode serial EEPROM PCB2421

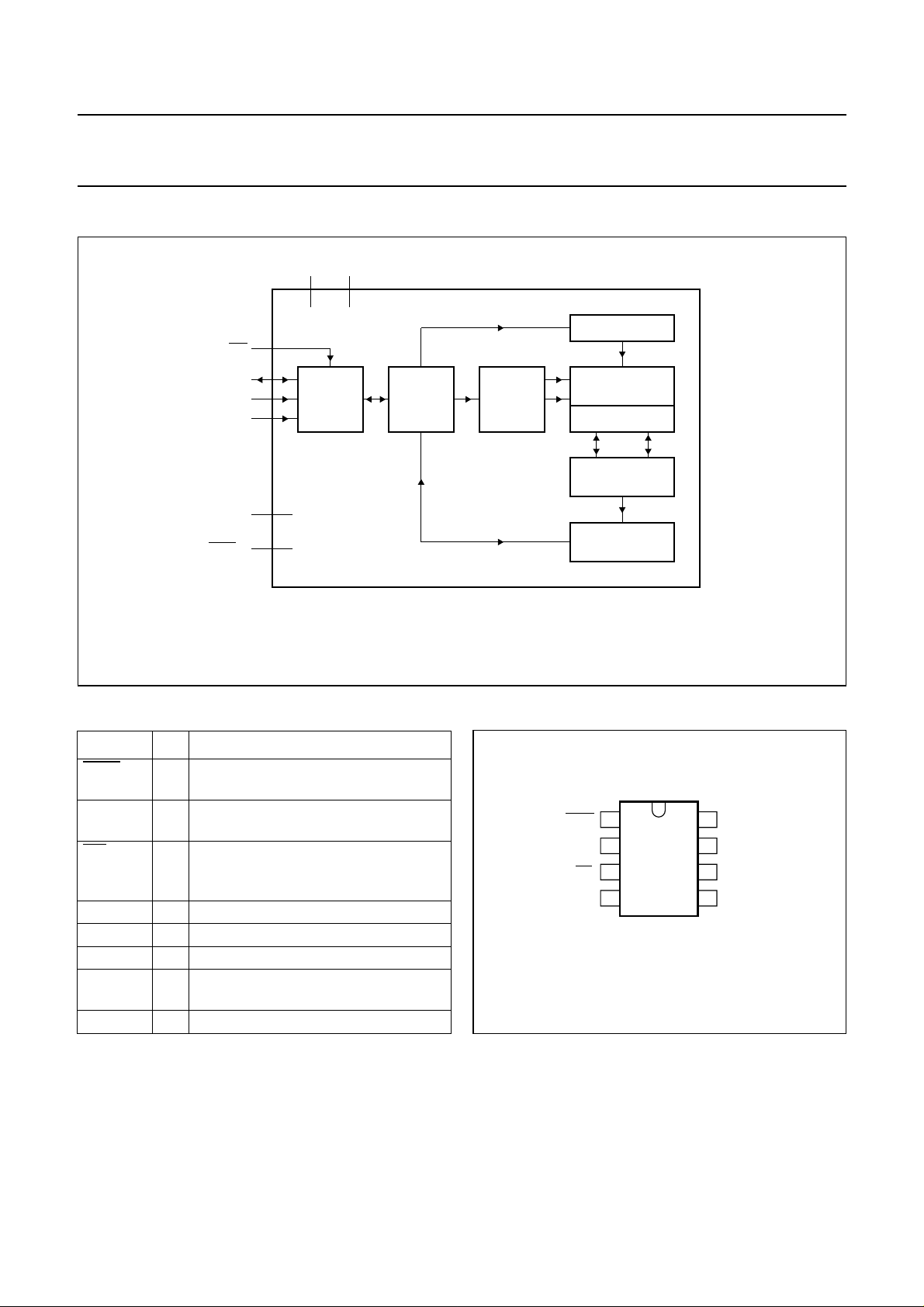

4 BLOCK DIAGRAM

V

V

ok, full pagewidth

SS

DD

48

WP

SDA

SCL

VCLK

3

5

6

7

I/O

CONTROL

LOGIC

MEMORY

CONTROL

LOGIC

PCB2421

n.c.

TEST

(1) Factory use only.

2

1

(1)

Fig.1 Block diagram.

5 PINNING

SYMBOL PIN DESCRIPTION

TEST 1 factory use only: must be tied to VDD;

may not be left open-circuit

n.c. 2 may be tied to V

, VDD, or left

SS

open-circuit

WP 3 write protect input (LOW = write

protected, HIGH = not write protected);

may not be left open-circuit

V

SS

4 ground

SDA 5 serial data input/output

SCL 6 serial clock input/output (DDC2B)

VCLK 7 serial clock input (transmit-only mode,

DDC1)

V

DD

8 supply voltage

X

DECODER

handbook, halfpage

HV GENERATOR

EEPROM

ARRAY

PAGE LATCHES

Y

DECODER

SENSE AMPLIFIER

R/W CONTROL

MBG271

1

TEST

2

n.c. VCLK

WP SCL

V

SS

3

4

PCB2421

8

7

6

5

MBG272

Fig.2 Pin configuration.

V

DD

SDA

1997 Apr 01 4

Philips Semiconductors Preliminary specification

1K dual mode serial EEPROM PCB2421

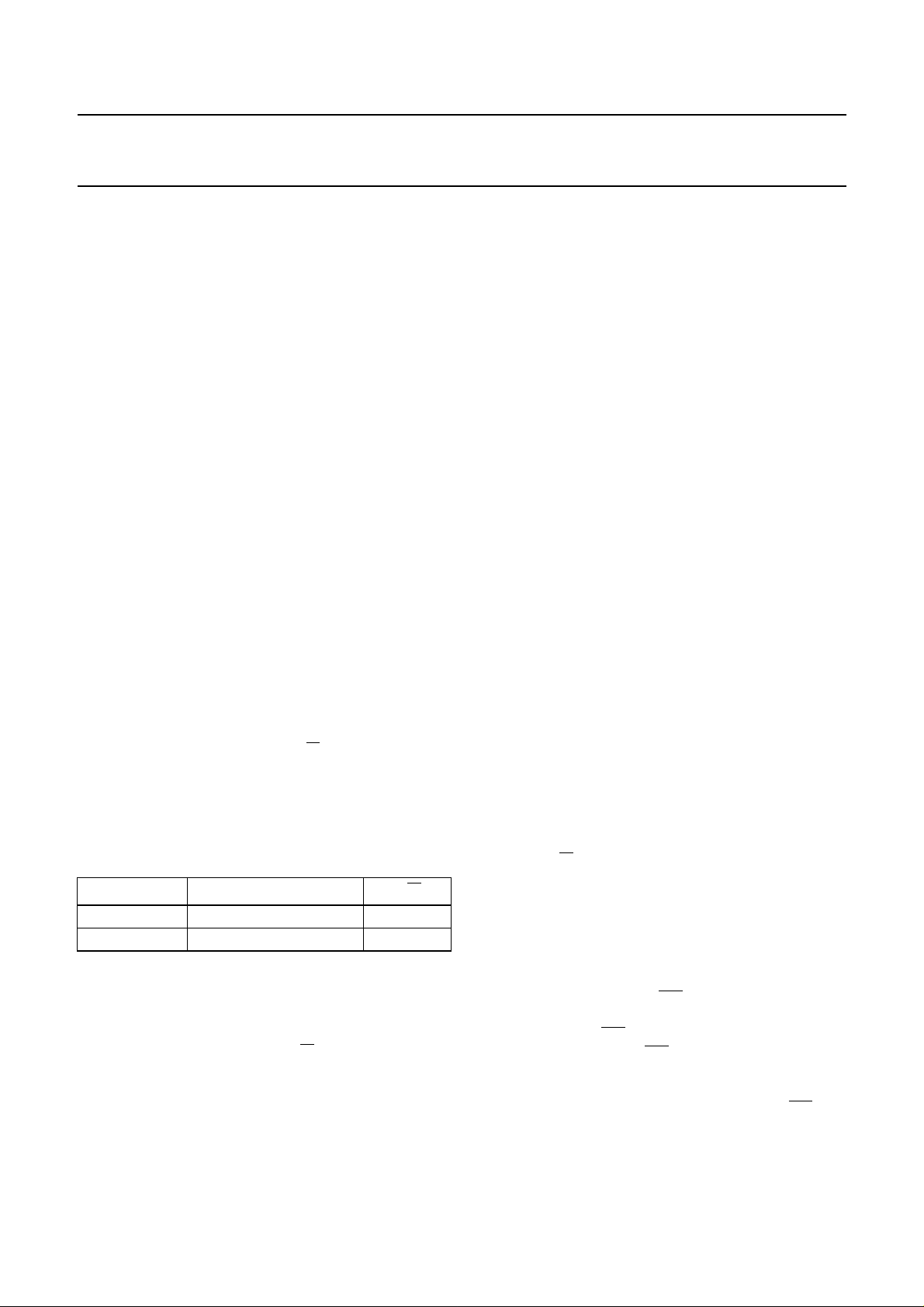

6 FUNCTIONAL DESCRIPTION

The PCB2421 operates in two modes, the transmit-only

mode (DDC1) and the bidirectional mode (DDC2, or

I2C-bus mode). There is a separate two-wire protocol to

support each mode, each having a separate clock input

and sharing a common data line (SDA). The device enters

the transmit-only mode (DDC1) upon power-up. In this

mode the device transmits data bits on the SDA pin in

response to a clock signal on the VCLK pin. The device will

remain in this mode until a valid HIGH-to-LOW transition is

placed on the SCL input. When a valid transition on SCL is

recognized, the device will switch into the bidirectional

mode (see Fig.3). The only way to switch the device back

to the transmit-only mode (DDC1) is to remove power from

the device.

6.1 Transmit-only mode (DDC1)

The device will power-up in the transmit-only mode. This

mode supports a unidirectional two-wire protocol for

transmission of the contents of the memory array

(see Fig.12). The PCB2421 requires that it be initialized

prior to valid data being sent in the transmit-only mode

(see Section “Initialization procedure”, and Fig.4).

In this mode, data is transmitted on the SDA pin in 8-bit

bytes, each byte followed by a ninth clock pulse during

which time SDA is left high-impedance. The clock source

for the transmit-only mode is provided on the VCLK pin;

a data bit is output on the rising edge on this pin. The 8 bits

in each byte are transmitted most significant bit first. Each

byte within the memory array will be output in sequence.

When the last byte in the memory array is transmitted, the

output will wrap around to the first location and continue.

The bidirectional mode clock (SCL) pin must be held HIGH

for the device to remain in the transmit-only mode.

When the device has been switched into the bidirectional

mode, the VCLK input is disregarded. This mode supports

a two-wire bidirectional data transmission protocol

2

(I

C-bus protocol). In the I2C-bus protocol, a device that

sends data on the bus is defined to be the transmitter, and

a device that receives data from the bus is defined to be

the receiver. The bus must be controlled by a master

device that generates the bidirectional mode clock,

controls access to the bus, and generates the START and

STOP conditions, while the PCB2421 acts as slave. Both

master and slave can operate as transmitter or receiver,

but the master device determines which mode is activated.

6.3.1 B

IDIRECTIONAL MODE BUS CHARACTERISTICS

The following bus protocol has been defined:

• Data transfer may be initiated only when the bus is not

busy

• During data transfer, the data line must remain stable

whenever the clock line is HIGH. Changes in the data

line while the clock line is HIGH will be interpreted as a

START or STOP condition.

Accordingly, the following bus conditions have been

defined (see Fig.6).

6.3.2 B

US NOT BUSY (A)

Both data (SDA) and clock (SCL) lines remain HIGH.

6.3.3 S

TART CONDITION (B)

A HIGH-to-LOW transition of the SDA line while SCL is

HIGH determines a START condition. All commands must

be preceded by a START condition.

6.3.4 S

TOP CONDITION (C)

6.2 Initialization procedure

At power-on, after VDD has stabilized, the device will be in

the transmit-only mode. Nine clock cycles on the VCLK pin

must be given to the device for it to perform internal

synchronization. During this period, the SDA pin will be in

a high-impedance state. On the rising edge of the tenth

clock cycle, the device will output the first valid data bit

which will be the most significant bit of a byte. The device

will power-up with address pointer at 00H (see Fig.4).

2

6.3 Bidirectional mode (DDC2B, I

C-bus mode)

The PCB2421 can be switched into the bidirectional mode

(see Fig.3) by applying a valid HIGH-to-LOW transition on

the bidirectional mode clock (SCL).

1997 Apr 01 5

A LOW-to-HIGH transition of the SDA line while SCL is

HIGH determines a STOP condition. All operations must

be ended with a STOP condition.

6.3.5 D

ATA VALID (D)

The state of the data line represents valid data when, after

a START condition, the data line is stable for the duration

of the HIGH period of the clock signal. The data on the line

must be changed during the LOW period of the clock

signal. There is one clock pulse per bit of data. Each data

transfer is initiated with a START condition and terminated

with a STOP condition. The maximum number of data

bytes transferred between the START and STOP

conditions during a write operation is 8 bytes (see Section

“Page write” and Fig.5).

Philips Semiconductors Preliminary specification

1K dual mode serial EEPROM PCB2421

The maximum number of data bytes transferred between

START and STOP conditions during a read operation is

unlimited.

6.3.6 A

CKNOWLEDGE

The PCB2421, when addressed in DDC2B mode, is

obliged to generate an acknowledge after the reception of

each byte. The master device must generate an extra (9th)

clock pulse which is associated with this acknowledge bit.

The PCB2421 does not generate an acknowledge if an

internal programming cycle is in progress (SDA line is left

HIGH during the 9th clock pulse). The PCB2421 generates

an acknowledge by pulling down the SDA line during the

acknowledge pulse in such a way that the SDA line is

stable LOW during the HIGH period of the acknowledge

related clock pulse. Set-up and hold times must also be

taken into account. The master receiver must signal an

end of data to the PCB2421 by not generating an

acknowledge bit on the last byte that has been clocked out

of the slave transmitter. In this case, the slave transmitter

PCB2421 must leave the data line HIGH to enable the

master to generate the STOP condition.

6.3.7 S

LAVE ADDRESS

and will be written into the address pointer of the

PCB2421. After receiving another acknowledge signal

from the PCB2421, the master device will transmit the data

word to be written into the addressed memory location.

The PCB2421 acknowledges again and the master

generates a STOP condition. This initiates the internal

write cycle, and during this time the PCB2421 will not

generate acknowledge signals.

6.4.2 P

AGE WRITE

For a page write, the write control byte, word address, and

the first data byte are transmitted to the PCB2421 in the

same way as in a single byte write. But instead of

generating a STOP condition the master transmits up to

eight data bytes to the PCB2421 which are temporarily

stored in the on-chip page buffer and will be written into the

memory after the master has transmitted a STOP

condition. After the receipt of each word, the three lower

order address pointer bits are internally incremented by

one. The higher order four bits of the word address remain

constant. A maximum of 8 bytes can be written in one

operation. As with the byte write operation, once the STOP

condition is received an internal write cycle will begin

(see Figs 5 and 8).

After generating a START condition, the bus master

transmits the slave address (MSB first) consisting of a 7-bit

device address (1010000) for the PCB2421. The eighth bit

of the slave address determines if the master device wants

to read or write to the PCB2421 (R/W bit) (see Fig.7).

The PCB2421 monitors the bus for its corresponding slave

address all the time. It generates an acknowledge bit if the

slave address was true and it is not in a programming

mode.

Table 1 Slave address

OPERATION SLAVE ADDRESS R/

W

Read 1010000 1

Write 1010000 0

6.4 Write operation

6.4.1 B

YTE WRITE

Following the START condition from the master, the

device address (7 bits), and the R/W bit (logic LOW for

write) is placed on the bus by the master transmitter. This

indicates to the addressed slave receiver that a byte with

a word address will follow after it has generated an

acknowledge bit during the ninth clock cycle. Therefore the

next byte transmitted by the master is the word address

6.5 Acknowledge polling

Since the device will not acknowledge during a write cycle,

this can be used to determine when the cycle is complete

(this feature can be used to maximize bus throughput).

Once the STOP condition for a write command has been

issued from the master, the device initiates the internally

timed write cycle. Acknowledge (ACK) polling can be

initiated immediately. This involves the master sending a

START condition followed by the control byte for a write

command (R/

W = 0). If the device is still busy with the write

cycle, then no ACK will be returned. If the cycle is

complete, then the device will return the ACK and the

master can then proceed with the next read or write

command. See Fig.9 for flow diagram.

6.6 Write protection

Pin 3 is a write protect input (

WP). In the DDC1 mode, the

PCB2421 can only be read according to the DDC1

protocol, hence the WP input has no effect in this mode.

In the DDC2B mode, whenWP is connected to ground, the

entire EEPROM is write-protected, regardless of other pin

states. When connected to VDD, write-protection is

disabled and the EEPROM may be programmed. WP may

not be left open-circuit.

1997 Apr 01 6

Philips Semiconductors Preliminary specification

1K dual mode serial EEPROM PCB2421

Table 2 Mode configurations

DDC

DCC1 X

WP MODE

(1)

R

DCC2 1 R/W

0R

Note

1. Where X = don’t care.

6.7 Read operation

Read operations are initiated in the same way as write

operations with the exception that the R/W bit of the slave

address is set to logic 1. There are three basic types of

read operations: current address read, random read, and

sequential read.

6.7.1 C

URRENT ADDRESS READ

The PCB2421 contains an address counter that maintains

the address of the last word accessed, internally

incremented by one. Therefore, if the previous access

(either a read or write operation) was to address ‘n’, the

next current address read operation would access data

from address n + 1. Upon receipt of the slave address with

R/W set to logic 1, the PCB2421 issues an acknowledge

and transmits the eight bit data word. The master will not

acknowledge the transfer but does generate a STOP

condition and the PCB2421 discontinues transmission

(see Fig.10).

6.7.2 R

ANDOM READ

Random read operations allow the master to access any

memory location in a random manner. To perform this type

of read operation, the word address must first be set. This

is done by sending the word address to the PCB2421 as

part of a normal write operation. After the word address is

sent, the master generates a REPEATED START

condition following the acknowledge. This terminates the

write operation, but not before the internal address pointer

is set. The master then issues the control byte again but

with the R/W bit set to logic 1. The PCB2421 will then issue

an acknowledge and transmits the 8-bit data word.

The master will not acknowledge the transfer but does

generate a STOP condition and the PCB2421

discontinues transmission (see Fig.11).

6.7.3 S

EQUENTIAL READ

Sequential reads are initiated in the same way as a

random read except that after the PCB2421 transmits the

first data byte, the master issues an acknowledge as

opposed to a STOP condition in a random read.

This directs the PCB2421 to transmit the next sequentially

addressed 8-bit word. To provide sequential reads the

PCB2421 contains an internal address pointer which is

incremented by one at the completion of each operation.

This address pointer allows the entire memory contents to

be serially read during one operation.

6.8 Pin description

6.8.1 SDA

This pin is used to transfer addresses and data into and

out of the device, when the device is in the bidirectional

(I2C-bus, DDC2B) mode. In the transmit-only mode

(DDC1), which only allows data to be read from the device,

data is also transferred on the SDA pin. This pin is an

open-drain terminal, therefore the SDA bus requires a

pull-up resistor connected to VDD (typically 10 kΩ for

100 kHz). See brochure

(order no. 9398 393 40011) or

“The I2C-bus and how to use it”

“Data Handbook IC12”

.

6.8.2 SCL

This pin is the clock input for the bidirectional mode

2

(I

C-bus, DDC2B), and is used to synchronize data

transfer to and from the device. It is also used as the

signalling input to switch the device from the transmit-only

mode to the bidirectional mode. It must remain HIGH for

the chip to continue operation in the transmit-only mode

(DDC1).

6.8.3 VCLK

This pin is the clock input for the transmit-only mode

(DDC1). In the transmit-only mode, each bit is clocked out

on the rising edge of this signal. In DDC2B mode, this input

is a don’t care.

6.8.4

WP

This pin is used to inhibit writing of the EEPROM. When

this pin is connected to ground, writing of the EEPROM is

inhibited. When connected to VDD (and VCLK = VDD), the

EEPROM can be programmed. WP may not be left

open-circuit. WP input is a ‘don’t care’ in DDC1 mode.

6.8.5

TEST

Pins 1 is a TEST pin for factory use only. It must be

connected to VDD in the application.

6.8.6

N.C.

This pin has no connection and may be tied to VSS, VDD or

left open-circuit.

1997 Apr 01 7

Philips Semiconductors Preliminary specification

1K dual mode serial EEPROM PCB2421

handbook, full pagewidth

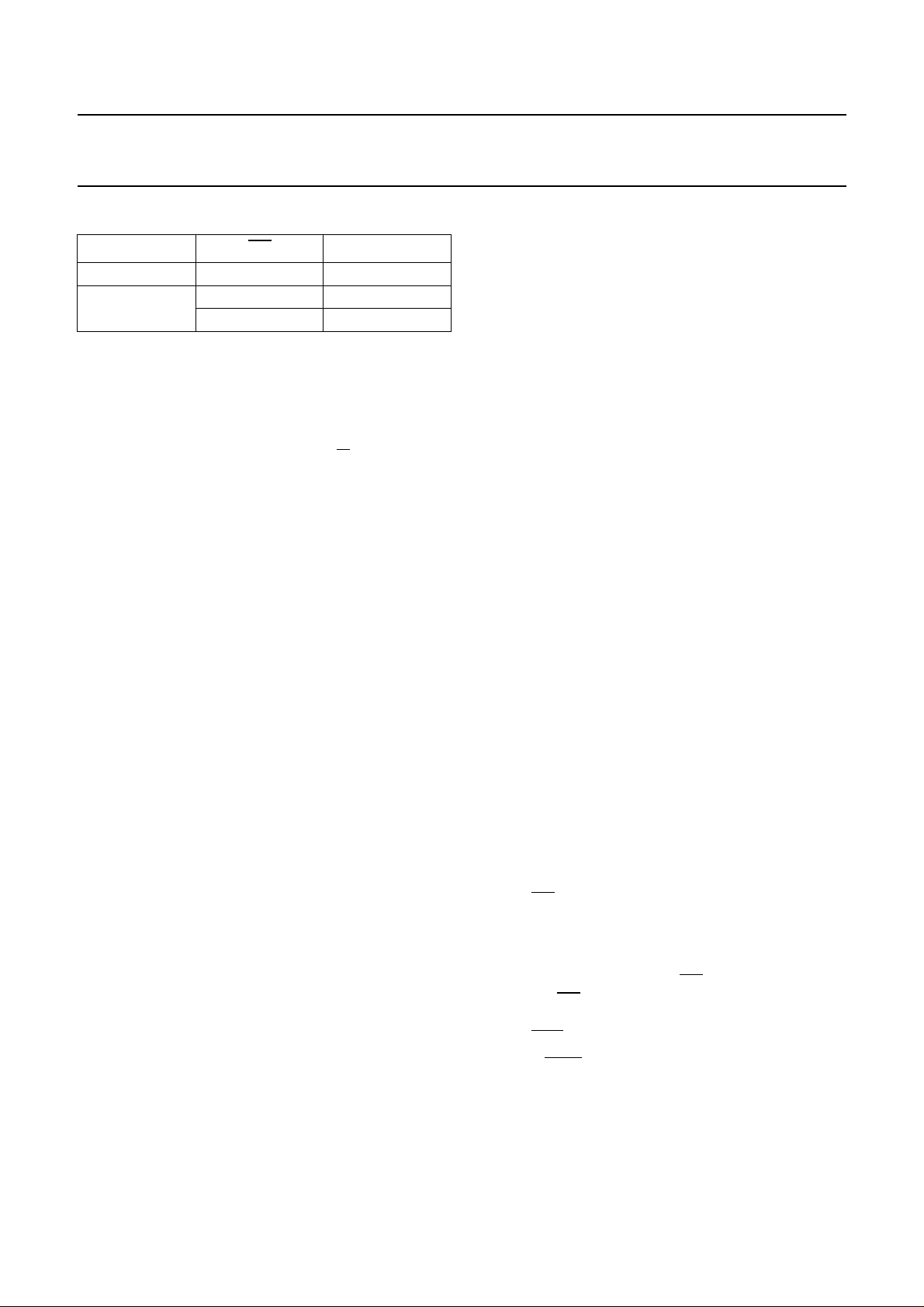

SCL

SDA

VCLK

transmit only mode

(DDC1)

t

VHZ

bidirectional mode

Fig.3 Mode transition diagram.

(DDC2)

MBG275

book, full pagewidth

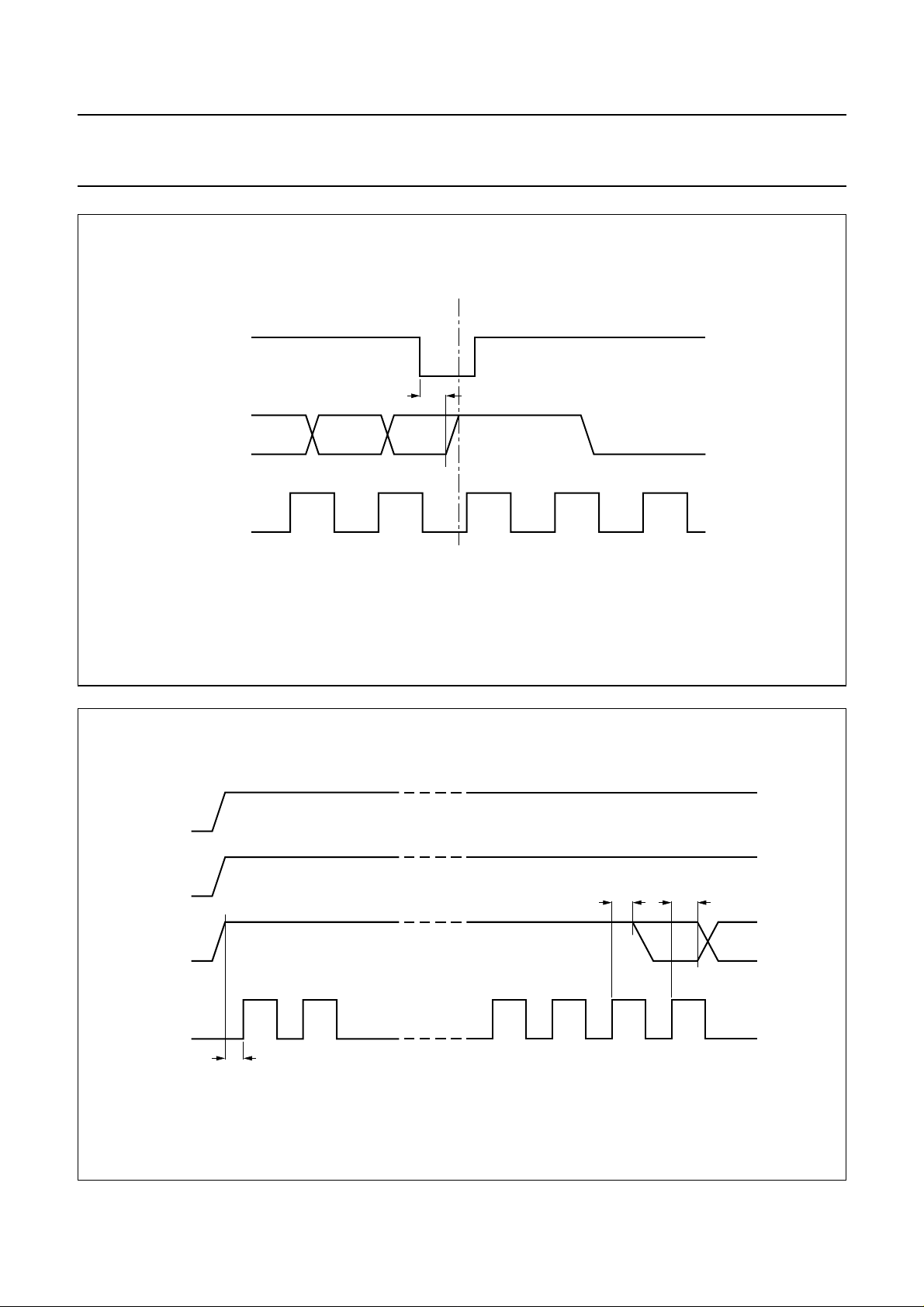

V

DD

SCL

SDA

VCLK

high-impedance for 9 clock cycles

t

VPU

Fig.4 Device initialization diagram.

1997 Apr 01 8

t

VAA

t

VAA

bit 8 bit 7

11109812

MBG276

Loading...

Loading...