Page 1

Colour Television Chassis

MG5.1E

AA

Contents Page

1 MG99 Light path

2 Introduction

3 Overall blockdiagram

4 Power supply

5 Scan circuits

6 Small signal panel

7 CRT drive circuit

8 Interface panel

9 SIDE JACK panel

10 Audio signal part

11 Digital convergence circuit

2

8

9

11

24

29

69

72

74

75

80

©

Copyright reserved 1999 Philips Consumer Electronics B.V. Eindhoven, The

Netherlands. All rights reserved. No part of this publication may be reproduced,

stored in a retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Published by LM 9972 Service PaCE Printed in the Netherlands Subject to modification 5 3122 785 10053

Page 2

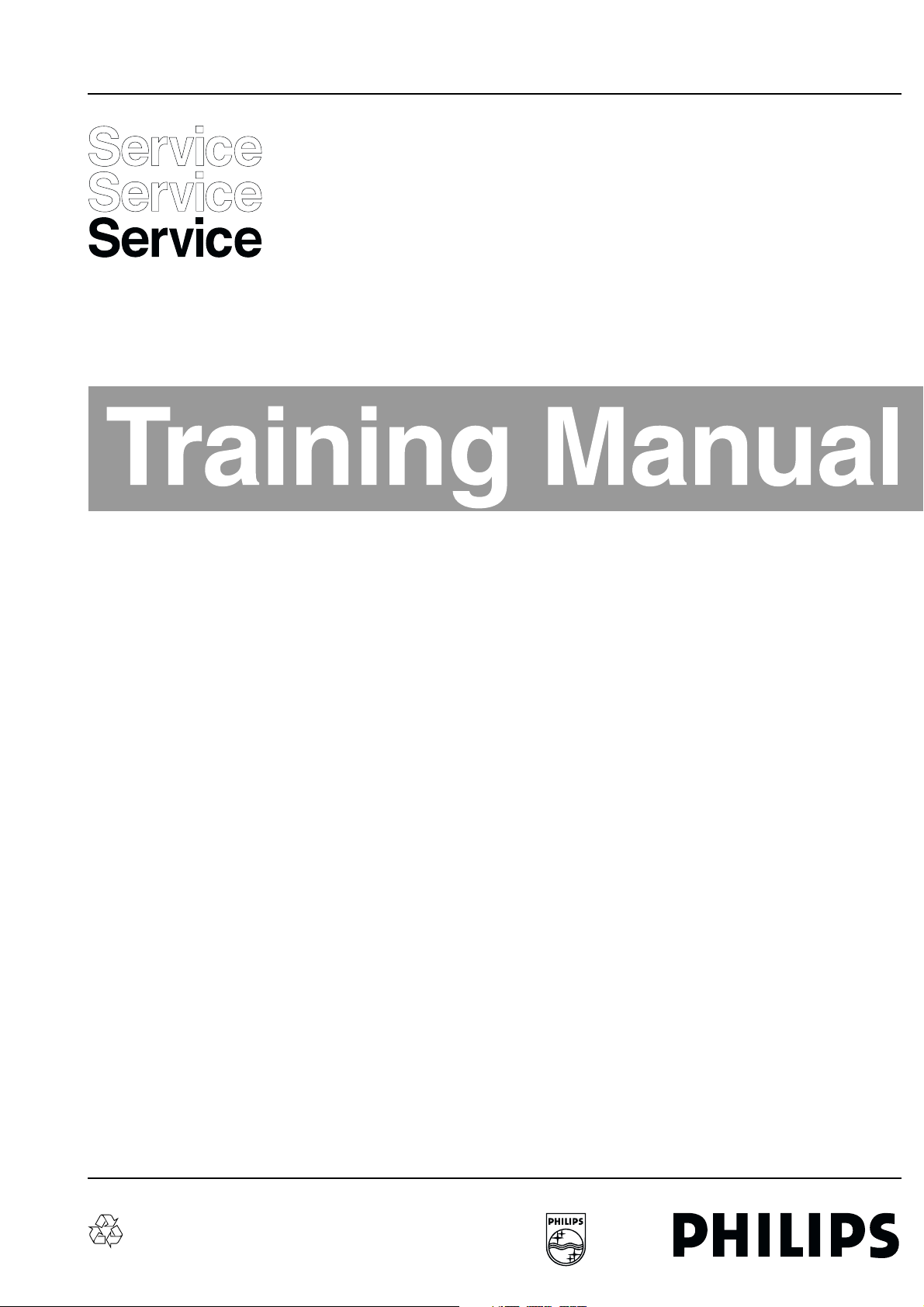

2 1. MG99 Light path MG5.1E

1. MG99 Light path

MIRROR

R+G+B

RED

GREEN

BLUE

FRESNAL

LENS

LENTICULAR

SCREEN

CL 96532100_078.eps

121199

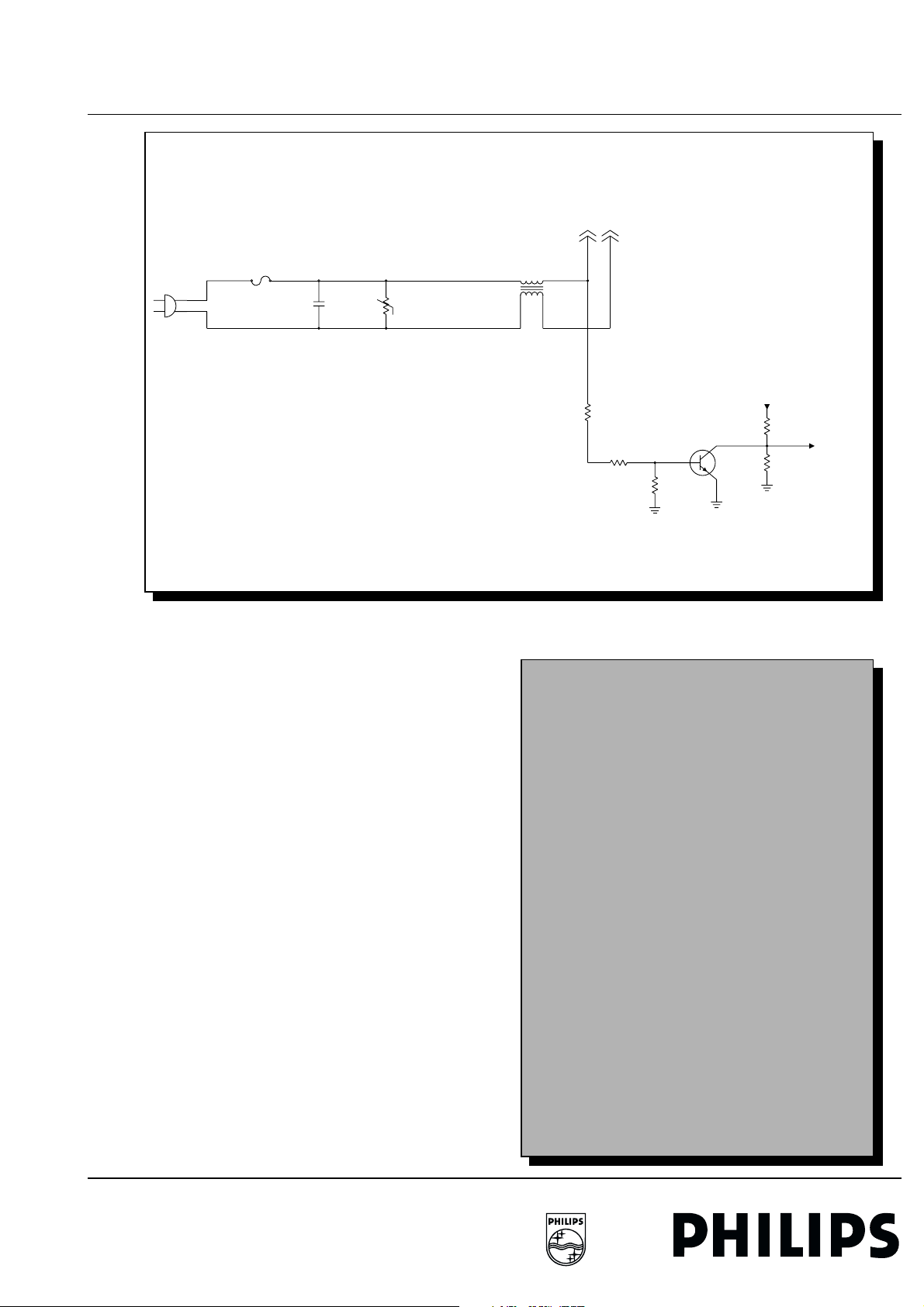

The MG99 Projection TV uses three single color tubes, Red,

Green, and Blue. (Figure 1-1) The output of each tube is

projected onto a mirror where it is then reflected onto a viewing

screen. The Tubes are converged so the light from each tube

strikes the same spot on the Fresnel Lens. The Fresnel Lens

equalizes and concentrates the light to provide equal light

uniformity across the screen. The Mirror is a first surface mirror

type which has the reflective coating on the outside of the

mirror. To prevent scratching of this surface, always use a soft

cotton cloth to clean it.

Figure 1-1

Personal notes

Page 3

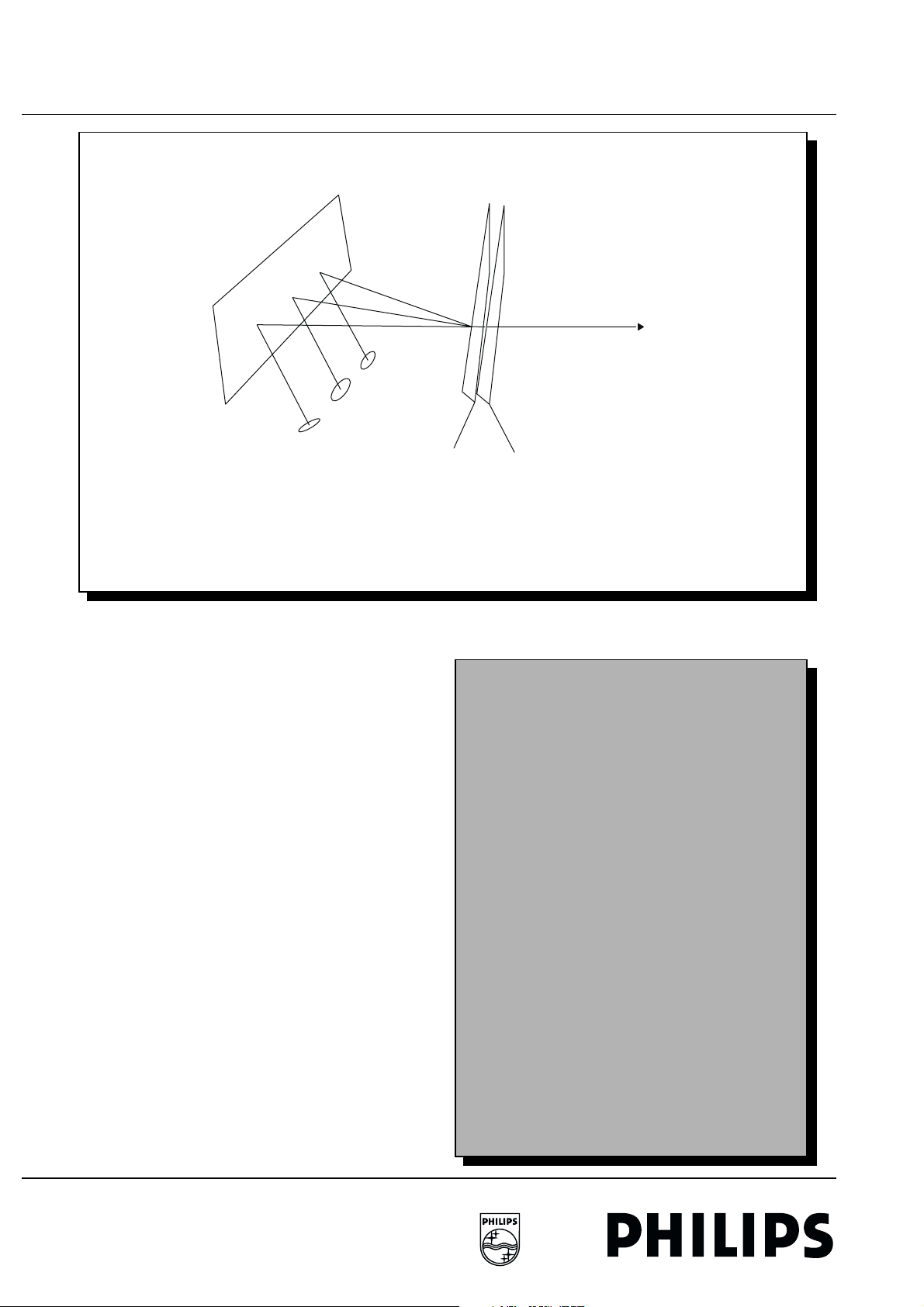

MG5.1E 1. MG99 Light path 3

OUTPUT

BLACK STRIPING

LIGHT

Figure 1-2

CL 96532100_079.eps

111199

The Lenticular Lens Screen calumniates the light from the

Fresnel Lens. (Figure 1-2) The Lenticular Lens increases

contrast by reducing the ambient light by the use of Black

Striping. The Prismatic formation of the screen allows for nearly

3X light output as compared to a flat screen. Caution should be

used when working with the screen. Damage can easily occur

in the form of scratching, or by using certain chemical screen

cleaners which can strip the black striping from the screen. To

clean the screen, use one drop of dish washing detergent in a

small bowl of water. (approximately 2 liters) Wipe the screen

with a soft cotton cloth in the direction of the stripes.

Personal notes

Page 4

4 1. MG99 Light path MG5.1E

C ELEMENT LENS

CRT

LIQUID COOLANTOUTPUT LENS

The Three CRT's are driven by 30KV of high voltage and 15KV

of focus voltage. (Figure 1-3) The Tube produces a highly

concentrated light output of color. A liquid coolant of Glycol is

used to transfer heat from the face of the tube to the

surrounding mechanical assembly. The

C-element lens seals the Coupling fluid within the coupler. The

C-element lens and Coupling fluid are part of the light path and

contribute to the properties of the optical system.

Figure 1-3

Personal notes

CL 96532100_080.eps

111199

Page 5

MG5.1E 1. MG99 Light path 5

1.1 MG99 LIGHT PATH PROBLEMS

1.1 MG99 LIGHT PATH PROBLEMS

Look at the edges of the screen. They may be bowed inward.

PROBLEM - BOTTOM CORNERS DARK

PROBLEM - BOTTOM CORNERS COLORED

There is no problem with the set. The viewing angle is too high.

Figure 1-4

Personal notes

CL 96532100_107.eps

021299

Page 6

6 1. MG99 Light path MG5.1E

1.1 MG99 LIGHT PATH PROBLEMS

Fresnel may be reversed. Carefully remove the fresnel and

point the grooves toward the viewer.

PROBLEM - BRIGTH AND DARK LINES ON A WHITE FIELD

Figure 1-5

CL 96532100_109.eps

151199

Personal notes

Page 7

MG5.1E 1. MG99 Light path 7

1.1 MG99 LIGHT PATH PROBLEMS

The Fresnel offset is pointing down. The center of the Fresnel

should be toward the top of the screen.

PROBLEM- UPPER CORNERS OF THE SCREEN DARK

Figure 1-6

CL 96532100_110.eps

151199

Personal notes

Page 8

8 2. Introduction MG5.1E

2. Introduction

The 1999 MG99 PTV chassis is designed for the European

market. It is available in a 46 inch (117 cm) and a 55 inch (140

cm) 16 by 9 aspect ratio screen sizes. Selected Video can be

displayed in either a 4 by 3, 14 by 9, or 16 by 9 aspect ratios.

The set has a viewing angle of 160 degrees.

The MG99 PTV is capable of receiving signal from PAL B/G,

PAL B/G 6OHz, PAL B/H, PAL D/K, PAL 1, PAL M, PAL N, PAL

plus, SECAM B/G, SECAM D/K, SECAM L, AND SECAM Li TV

systems. There are four composite video inputs which include

three SCART connectors, and a Side Jack panel. The systems

that can be applied to these inputs are NTSC 3.58, NTSC 4.43,

NTSC Play Back, PAL 4.43, PAL, B/G Play Back, SECAM, and

SECAM Play Back.

The set is equipped with a Frame and Line doubler to produce

a horizontal resolution greater than 800 lines. The picture

display is driven by three seven inch Red, Green, and Blue

tubes.

The Sound system is driven by a 2 times 20 watt power

amplifier. A switch in the rear of the set allows the sets internal

speakers to be driven by an external amplifier.

The following sets will be sold in Europe:

46PP9501/05U.K. and Ireland

55PP9501/05U.K. and Ireland

46PP9501/12Western Europe

55PP9501/12Western Europe

46PP9501/58Eastern Europe

55PP9501/58Eastern Europe

These units will be distributed from Philips Bundling Center in

Bruges, Belgium.

Personal notes

Page 9

9 3. Overall blockdiagram MG5.1E

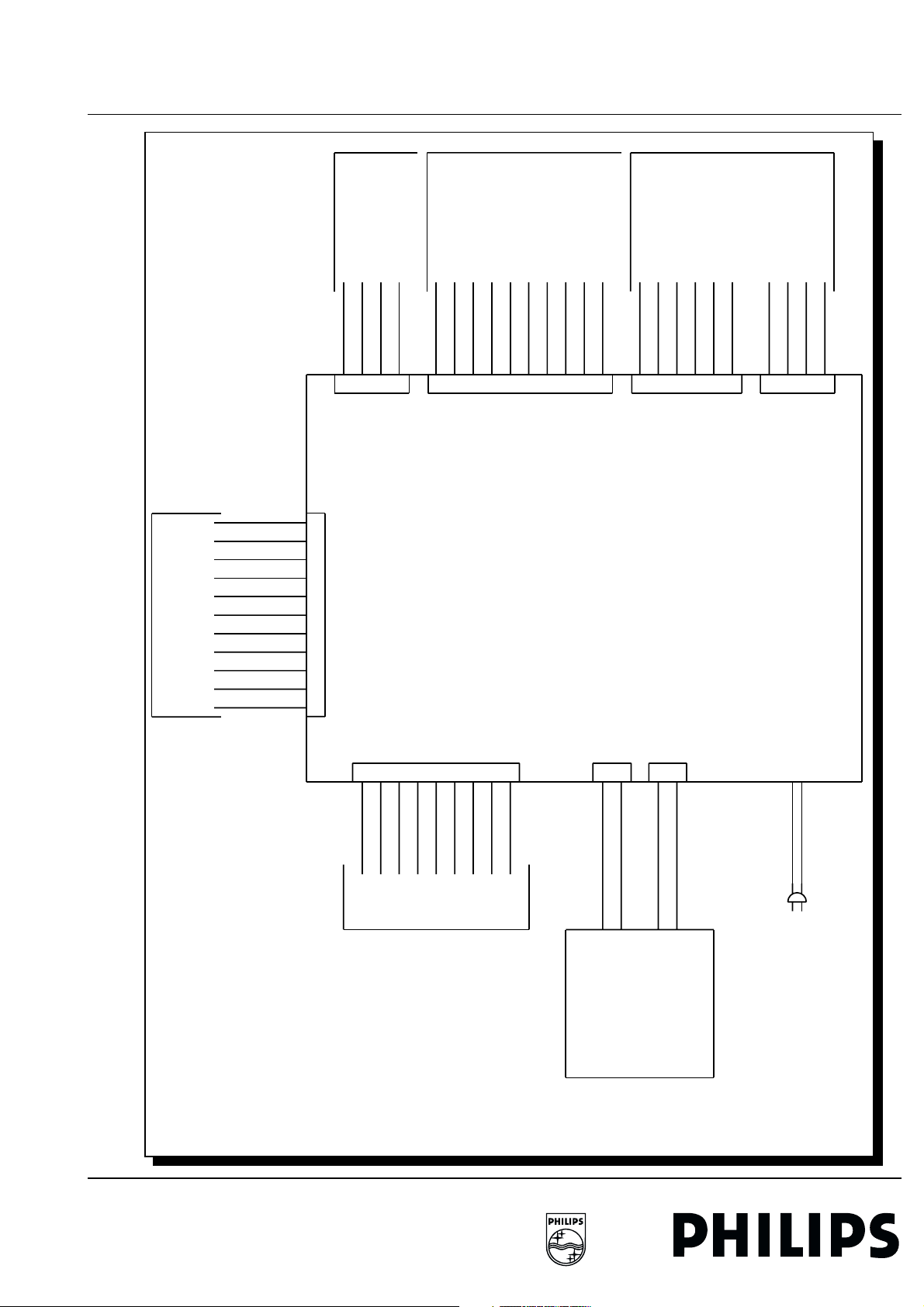

3. Overall blockdiagram

Y_CVBS

SIDE JACK

PANEL

MG99 SMALL

SIGNAL PANEL

C

L

R

Y

R

G

B

CRT

DRIVE

CIRCUIT

DELAY

SVM

MODULE

BLUE

CRT

R

G

B

GREEN

CRT

RED

CRT

AC

SWITCH

PANEL

LINE SYNC

FRAME SYNC

POWER

SUPPLY

CONV R, G, B, FB

LEFT AUDIO

RIGHT AUDIO

+5V STBY

+15V STBY

+130V

+38V

-38V

+33V

+15V

-15V

-7V7

+8V6

+5V2

INTENSITY

CONTROL

INTERFACE PANEL

AUDIO

AMPLIFIER

LINE

DRIVE

FRAME

DRIVE

HV

CIRCUIT

HV/SCAN

PANEL

SPEAKER

SWITCH

CONV R, G, B, FB

CONVERGENCE

PANEL

LINE SYNC

FRAME SYNC

FOCUS/G2

BLOCK

CONV

YOKES

FOCUS

G2

CL 96532100_081.eps

191199

Figure 3-1

Page 10

10 3. Overall blockdiagram MG5.1E

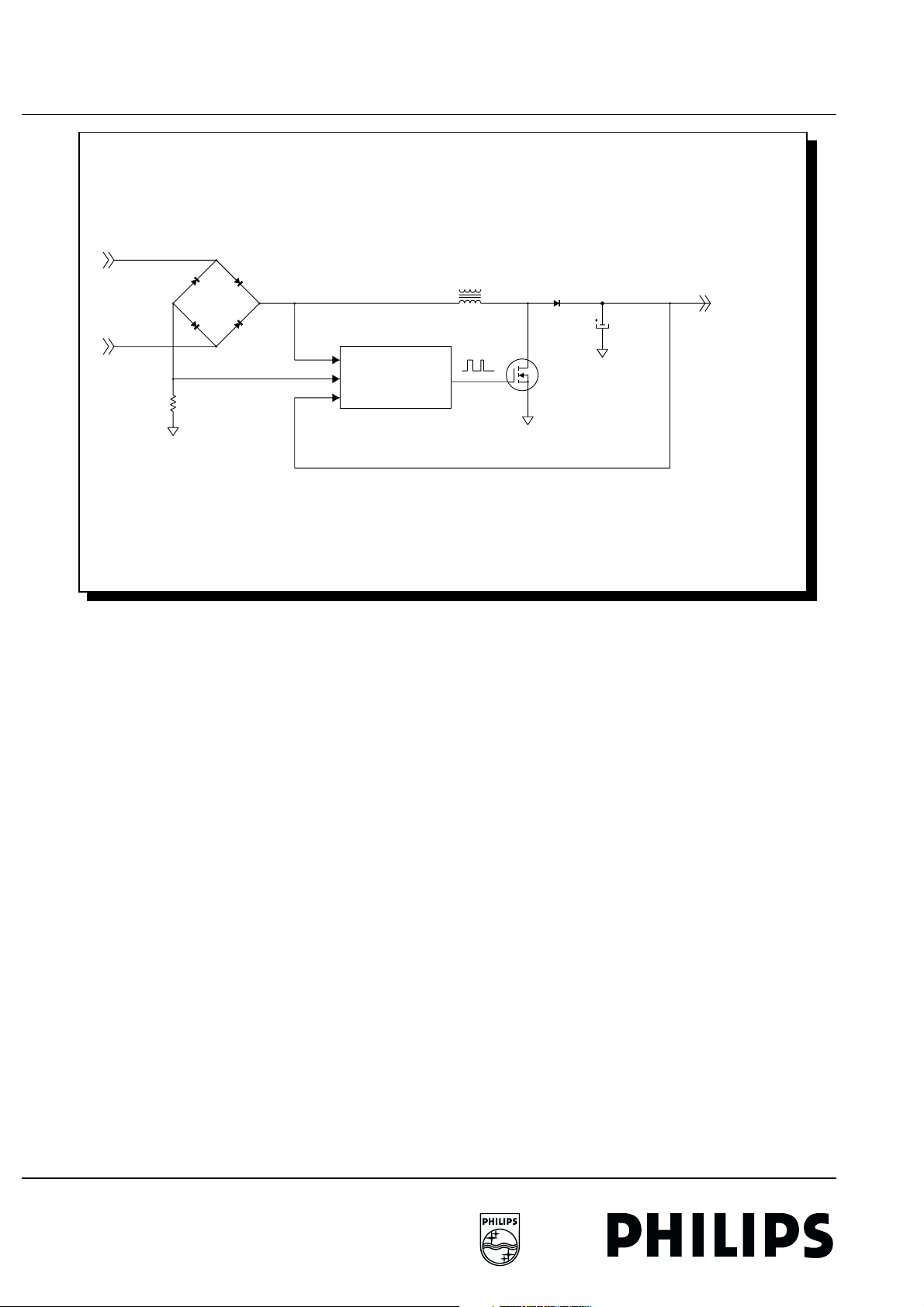

There are eleven PC boards in the MG99 chassis. (Figure 3-1)

They are the Small Signal panel, Side Jack panel, Power

Supply panel, Interface panel, SVM module, Blue CRT panel,

Green CRT panel, Red CRT panel, High Voltage Scan panel,

and Convergence panel.

Whenever AC power is applied to the set and the Mains switch

is turned On, the Power Supply panel produces a 5 and a 15

volt standby supplies. When the set is turned On by the channel

up button on the Front Keyboard or the Remote Control, the

130 volt, 38 volt, -38 volt, 33 volt, 15 volt, -15 volt, -7.7 volt, 8.6

volt, and 5.2 volt supplies are switched On.

Frame and Line drive from the Small Signal panel is routed

through the Interface Panel to the Frame Drive and Line Drive

circuits on the High voltage Scan panel. The High Voltage scan

panel produces the High Voltage and Sync to the Convergence

panel. Focus voltage from the High Voltage circuit is fed to a

Focus/G2 block which provides Focus and G2 voltage to the

three CRT'S. During the Convergence adjustment mode, Red,

Green, Blue, and Fast Blanking from the Convergence Panel is

fed to the Small Signal panel to generate the adjustment grid.

The Small Signal panel selects video from the Antenna input,

one of the three Scart connectors, or the Side Jack panel. The

Small Signal panel outputs Red, Green, and Blue drive to the

CRT drive circuit located on the Interface Panel. The CRT drive

circuit then provides drive for the three CRT panels.

Personal notes

Left and Right channel audio from the Small Signal panel is

routed through the Interface Panel to the Audio Amplifier panel.

The Audio Amplifier panel has its own separate Switch Mode

power supply. The output of the Audio Amplifier is then fed to

the Speaker Switch panel which selects between the Audio

Amplifier or External Audio from a separate amplifier.

Luminance or Y from the Small Signal panel is fed to a Delay

circuit on the Interface panel before being applied to the SVM

panel. The Scan Velocity Module speeds up the beam during

light to dark transitions in the picture to provide a sharper

image.

Page 11

11 4. Power supply MG5.1E

4. Power supply

AC

INPUT

CIRCUIT

AC

SWITCH

PANEL

POWER

FACTOR

CORRECTION

CIRCUIT

STBY

POWER

SUPPLY

+5V STBY

+15V STBY

ON/OFF

AC power is applied to the set on the Power Supply panel.

(Figure 4-1) It is then fed to the Mains switch on the AC switch

panel located on the front of the set. It is then fed back to the

Power Supply panel and to the Power Factor Correction circuit.

If the AC mains is 240 volts, the output of the Power Factor

correction circuit is approximately 329 volts DC in standby and

350 volts DC when the set is turned On. The Power Factor

correction circuit is turned Off during standby. This is a "HOT"

chassis. When troubleshooting this or any power supply,

always use an isolation transformer.

The Standby Power supply produces a 5 and a 15 volt supplies.

It also provides operating voltage for the Power Factor

Correction and the Audio Amplifier power supply. The Power

Factor correction circuit is turned Off when the set is in the

Standby mode.

The Main Switch Mode Power supply produces a 130 volt, a 33

volt, a 35 volt, a -35 volt, a 15 volt, and a

-15 volt supply. The Main SMPS and the Power Factor

Correction Circuit is switched On by a Low from the Small

Signal panel.

Figure 4-1

MAIN

SMPS

POWER

SUPPLY

+15V

+15V

-15V

5V2

REG

8V6

REG

-7V7

REG

Personal notes

+130V

+33V

+35V

-35V

+15V

-15V

+5V2

+8V6

-7V7

CL 96532100_082.eps

121199

Page 12

MG5.1E 4. Power supply 12

TO AC SW BD

1221

1000

5A

2000

680n

3011

The applied AC voltage is fed to a 5 amp fuse and then to the

Mains switch on the AC switch panel. (Figure 4-2) The AC

voltage is fed to transistor 7000 and then to the Small Signal

panel for clock synchronization.

Figure 4-2

4

5001

1

3004

3.3M

3005

3.3M

3006

470K

Personal notes

7000

3007

6.8K

+5VSTBY

3008

10K

50_60HZ

CL 96532100_083.eps

121199

The Standby Supply produces the 5 volt and 15 volt standby

supplies. (Figure 4-3) The output of the Power Factor correction

circuit PFCOUT is applied to Pin 5 of 7211 through Pins 2 and

4 of the switching transformer 5202. When the supply voltage

is first applied, voltage through the internal startup resistor Rs

is applied to capacitor 2283 via Pin 4. When the capacitor

charges to 5.7 volts, the internal oscillator switches On driving

the internal FET switch. When the voltage across capacitor

2283 drops below 4.7 volts, the IC turns Off. This cycle repeats

until the 5 volt standby supply turns Shunt Regulator 6205 On.

The supply voltage for the IC is then supplied to Pin 4 through

7213. Operating voltage to Pin 5 of 7213, the Audio Amplifier

power supply, and the Power Factor correction circuit is

supplied by Pin 5 of 5202. During normal operation, the 5 volt

standby source is monitored by the Shunt Regulator 6205. If

the 5 volt supply should increase, the Shut Regulator will cause

more current to flow through the LED inside the opto-isolator

7213. This will reduce the resistance of the transistor inside

7213. As a result, more current will flow through the Sensing

resistor inside 7211, which will reduce the On time of the FET

inside the IC. This will reduce the output voltage to the correct

level. This supply operates at approximately 100 KHz.

Page 13

MG5.1E 4. Power supply 13

RESET

+5VSTBY

SOURCE

2282

1uF

5234

3245

2210

7209

RESET

3222

+15VSTBY

2270

6204

1098

2

6200

6207

22uF

3240

1K5

100uF

4

6236

1K

39K

6231

3247

180

3246

2K4

2213

1000uF

+5VSTBY

2208

100

2226

3223

22n

3239

2K4

3244

33K

47

1

6205

SHUT

REGULATOR

2

7213

4

5

3287

470

5

CONTROL

5214

+5VSTBY

3215

5233

5211

7204

3241

1K

PFC

1

6K8

7208

GND_C

6201

8.2V

2209

100uF

3230

1K5

2211

.1

3216

6235

2269

100

7

5202

1

5

GND_C

2228

100

10

3213

10K

5

GND_C

4

7206

2

7205

+5VSTBY

3212

10K

7214

3289

3214

10K

ON_OFF

100K

2284

3288

10n

10K

PFCOUT

Figure 4-3

2206

GND_C

220uF

S

R

7211

INTERNAL

4

SUPPLY

PWM

-

5.7V

4.7V

S

R

5.7V

GND_C

1,2,3,7,8

2283

CL 96532100_084.eps

011299

GND_C

47uF

Page 14

14 4. Power supply MG5.1E

To troubleshoot the Standby Supply, first check the supply

voltage on Pin 5 of 7211. If there is no secondary voltage and

7211 is working correctly, startup pulses should be seen at Pin

5 of the IC. If the IC is pulsing and there is no secondary

voltage, there is a problem with the outputs of 5202 or with the

feedback circuit. If 7211 is not pulsing, either the IC or capacitor

2283 is defective.

When the set is turned On, transistor 7214 will turn Off turning

7205 On. This will turn the Optoisolator 7206 On turning

transistor 7204 On, switching the operating voltage to the

Power Factor Correction circuit. It also switches the operating

voltage to the power supply on the Audio Amplifier panel on the

line labeled "CONTROL".

Personal notes

Page 15

MG5.1E 4. Power supply 15

4.1 European power factor correction circuit

4.1 European power factor correction circuit

AC IN

AC CURRENT

CAPACITOR

CHARGE

VOLTAGE

BRIDGE

AB

The input to most switching power supplies consists of a bridge

rectifier and a large electrolytic capacitor. (Figure 4-4) When

AC power is applied, the Capacitor will charge to approximately

1.4 times the RMS value of the applied AC voltage. This type of

supply does not draw current from the AC power source

through out the entire AC cycle. When the capacitor charge falls

to point "A", the instantaneous value of the AC voltage exceeds

the charge of the capacitor. The bridge diodes are then forward

biased, causing current to flow from the AC source. Current will

continue to flow from the AC line until the AC sinusoidal voltage

reaches its peak at Point "B". At this point, the charge on the

capacitor will exceed the AC line voltage reversing the bridge

diodes. This results in an AC current waveform that is narrow

and distorted compared to the AC voltage waveform. Non

sinusoidal waveforms have a high harmonic content, with

excessive peaks which results in a low power factor of 0.5 to

0.6. Power Factor is a ratio of real power divided by apparent

power. Excessive harmonics and peak currents reduce the

efficiency of the power distribution system.

The MG5.1 Projection TV without Power Factor correction has

a high harmonic content of 85 percent, creating a Power Factor

of 0.5. Current spikes of 7 amps will also be created in the AC

supply. With the Power Factor correction circuit, the peak

current is limited to 1.58 amps, with the harmonic content being

reduced to 4.5 percent. The Power Factor is increased to 0.99.

The ideal Power Factor is one, which occurs when the current

is sinusoidal and in phase with the voltage. The European

standard IEC1000 limits the current harmonic content of

equipment supplied by the AC Mains.

Figure 4-4

CAP

CL 96532100_085.eps

LOAD

121199

Personal notes

Page 16

16 4. Power supply MG5.1E

4.1 European power factor correction circuit

AC INPUT

BRIDGE

CURRENT SENSE

REGULATOR

DRIVE

7102

The MG5.1 Power Factor correction circuit uses a Boost

regulator to smooth out the current draw from the AC line

improving the Power Factor to 0.99, which is accomplished by

drawing current from the AC source throughout the entire AC

cycle making the current waveform sinusoidal. (figure 4-5) Input

to the module is connected to the AC Mains. The output

supplies are approximately 350 volts DC to the Main and

Standby Switched mode Power Supply circuit. The Boost

Regulator circuit produces a higher output voltage than the

input voltage. The regulator drive circuit compares 6103's

output voltage, the input voltage from the bridge, and the

voltage across the current sensing resistors to control the On

time of 7104. This will maintain the output voltage at 350 volts

DC and limit the input current to acceptable levels. When 7104

is On, current flow through 5109 stores energy in the choke.

When 7104 turns Off, 5109 reverses polarity and charges 2110.

Using this type of regulation, current is drawn from the AC

source throughout the entire cycle, keeping the current

waveform sinusoidal. When the AC cycle is at its low point,

7104 is on for a longer period of time. When the AC voltage is

at its peak, 7104 is on for a shorter time to store the same

amount of energy in 5109 to maintain the output voltage at 350

volts.

Figure 4-5

5109

5

3

6103

7104

2110

350V DC OUT

CL 96532100_086.eps

121199

If the Boost regulator circuit should become inoperative, due to

a loss of regulator drive, operating voltage is still applied to the

set. The supply voltage to the switching supplies will drop from

350 volt to approximately 329 volts depending on the Mains

voltage. Since the customer would not detect a failure, the

operation of this circuit should be checked after any repair of

the set.

Page 17

MG5.1E 4. Power supply 17

4.2 Full power factor correction circuit

350V DC OUT

PFCOUT

(329V)

GND_C

2105

3105

470p

5106

5103

6R8

6103

5105

35

5109

GND_B

2107

1n

3126

3M3

GND_B GND_B

2118

47K

1uF

3125

GND_B

1K

3119

GND_B

2120

7104

3117

220p

10K

GND_B

GND_B

PFC

2113

3115

100uF

47

GND_B

6104

3114

5108

19V

(25V)

47

20

15

LATCH

LOGIC

1.28

-

+

R

OUTPUT

Q

S

VCC

19

16

2110

470uF

5107

13

15

OVP

V REF

5.11 V

4.3V

3

3134

470K

3108

3M3

3110

39K

3109

47K

11

5006

3010

5003

2R2

1222-1

5005

3120

5K6

0.23V

IPK

5.11V

2

5.45V

5

9

8

5.45V5.11V

13

14

3127

3118

390

2116

2n2

18K

GND_B

3128

1K8

3123

1K8

2115

.33

3124

330K

CL 96532100_087.eps

191199

+

-

2114

R490

1M

C485

C486

R493

1n5

3121

33K

3111

1M

.22

.22

INST LINE VOLTAGE

33K

STARTUP VOLTAGE

FOR FULL

POWER SECTION

6000

0.36V MAX

3133

0R1

3132

0R1

R491

5004

5007

3131

3130

FROM AC

SW BOARD

1222-4

0R1

0R1

GND_B

GND_HA

330K

OSCILLATOR

17 18

7102

4

7

1.5-5.5V

GILBERTS

6

5.11V

+

MULTIPLIER

-

COMPARATOR

CURRENT

AMPLIFIER

-

+

Figure 4-6

Page 18

18 4. Power supply MG5.1E

4.2 Full power factor correction circuit

An explanation of the full Power Factor Correction circuit is now

given. (Figure 4-6) The Power Factor Correction circuit is a

fixed-frequency Pulse-Width modulated boost regulator power

supply. Operating frequency is approximately 60 kilohertz. Due

to the low power consumption of the set during the standby

mode, the Power Factor Correction circuit is turned Off. The

operating voltage, PFC, on Pin 19 of 7102 is turned Off. When

the set is turned On, the operating voltage is switched to Pin 19

of 7102. Once the circuit is in operation, a 5.11 volt internal

reference voltage on Pin 11 is applied to Pin 6 of the IC. Output

of the bridge rectifier is fed to the IC on Pins 4 and 7. Feedback

from the output circuit is fed to Pin 14 where it is multiplied with

the Bridge output. Inputs to the Gilberts Multiplier produce an

error signal that is fed to the current amplifier. The Gilberts

Multiplier multiplies the bridge output voltage with the output

voltage on D438. The 5.11 volt reference is used to provide a

clamping reference for the other inputs. Input current is

sampled by resistors 3130, 3131, 3132, and 3133. This sample

is added to the error signal from the Multiplier going into Pin 8.

The error signal is amplified and then compared to the oscillator

ramp to determine the reset point for the latch. When the

oscillator goes low, the latch is set making output "Q" High. With

the other inputs to the AND gate High, Pin 20 then goes High,

turning 7104 On. By comparing the input and output voltage,

the On time of 7104 is increased when the AC voltage is at its

low point to maintain the 350 volt DC output. When the AC input

voltage is at its peak, 7104 is On for a shorter period.

Personal notes

The IPK circuit connected to Pin 2 is an overcurrent protection

circuit which resets the latch if there is excessive current

through the return resistors. This will reduce the On time of

7104. In a like manner, the OVP, Over Voltage Protection,

circuit will reset the latch removing drive to Pin 20 is the output

voltage exceeds 392 volts.

To check the operation of this circuit when the set is operating

correctly, check the PFCOUT voltage. This voltage should be

approximately 350 volts. If the output voltage is approximately

329 volts, this circuit is not working. Check the operating

voltage on Pin 19 of 7102. Then check the output drive on Pin

20 and at the gate of 7104. There are three grounds on the Hot

side of the supply. Ground HA is connected directly to the

bridge 6000. Ground "B" is the ground for the Power Factor

Correction circuit. If the current sensing resistors 3130 through

3133 should open, this would remove the ground for all the

switching supplies and make the set inoperative. Ground "C" is

the ground for the switching supplies. When ground "B" passes

through the choke 5106, it becomes ground "C".

Startup up voltage for the Full Power supply is taken from the

neutral side of the AC mains.

Page 19

MG5.1E 4. Power supply 19

4.3 Full power supply

+15V

2326

3331

3330

22K

22K

2312

+33V

470P

5305

5304

+130V

14

4

PFOUT

2314

6305

2350

2313

22uF

470uF

470P

6

3446

3346

12

470R

3345

6315

10

470R

8

+35V

2318

100n

2317

1000u

5307

2316

1000u

2315

5306 6306

1516171819

3307

33R

2

470p

7301

6304

5302

100n

-15V

2332

-35V

5314

100n

1000u

1000uF

2319

1V

+

B

FLIP

470p

3308

6302

3310

2307

-

FLOP

3309

1302

0R47

0R1

330R

4A

6309 5313

202122

10

11

GND_C

GND_C

6303

2311

1N

2308

R

2331

2330

2319

GND_C

2322

2321

2321

63075308

3305

10K

GND_C

3306

10R

3

4

7

A

Q

S

100n

100n

470u

2327

470u

3329

330R

2328

3319

12

3328

1u

100R

3326

4K7

1

7303

VCC

5

6301

2302

3316

1K

GND_C

15K

GND_C

3318

150K

VCC

GND_C

GND_C

2324

14

-

5312

2m2

2323

470p

3315

15K

2.5V

+

C

5312

2325

100n

1301

4A

5310

6308

470p

3447

2.7K

3317

15K

5

13

FB

7302

3324

150K

3323

2K7

+130V

2334

3325

10K

3327

100R

2303

STARTUP

3300

100uF

22K

3461

27K

GND_C

2333

24

7303

+5VSTBY

3322

3344

7309

3304

1K

7300

1305

+5VSTBY

470R

130V

10K

ADJ

ON_OFF

3343

3303

100K

2349

10K

6313

3321

SOFT

UNDER

2346

100N

VCC

START

VOLTAGE

LOCKOUT

9.4/14.5

18V

1

8K2

6

17V

3320

OVERVOLTAGE

8K2

VCC

GND-C

DEMAG

VCC

8

OSCILLATOR STANDBY

REFERENCE

SECTION

9

FROM

STBY

SYNC

2442

1N

10

11

2443

1uF

15

16

3313

10K

CL 96532100_088.eps

011299

Figure 4-7

Page 20

20 4. Power supply MG5.1E

4.3 Full power supply

When the set is turned On, the Main Switch Mode power supply

is turned On. (Figure 4-7) This supply produces the +130 volt,

+33 volt, +35 volt, -35 volt, -15 volt, and +15 volt supplies.

When the On/Off line goes Low, transistor 7309 is turned Off,

turning transistor 7300 On. This switches relay 1305 On.

Startup voltage from the neutral side of the AC mains will

charge capacitor 2303 to 14.5 volts which will overcome the

undervoltage lockout of IC 7302. After the Soft Start capacitor

2443 charges, the oscillator inside the IC will turn On. Each

cycle of the oscillator will set the flip-flop which will cause Pin 3

to go High. This will turn the FET switch 7301 On. Voltage is

applied to the Drain of 7301 through Pins 4 and 8 of 5300 from

the Power Factor Correction circuit. Current through sensing

resistors 3308 and 3309 will develop a voltage which is applied

to comparator "B" connected to Pin 7. When the voltage on Pin

7 reaches the reference voltage on the inverting input, the FlipFlop will be reset. The voltage on the inverting side of

comparator "B" is limited to 1 volt. Therefore, the ramp voltage

on Pin 7 will not exceed 1 volt. The circuit will continue to

operate until the charge on capacitor 2303 falls below 9.4 volts

shutting the IC Off. Each time 7301 is turned On, energy is

stored in transformer 5300. Voltage from the Hot secondary on

Pin 10 is rectified by 6301. When the output of this circuit has

sufficient energy to maintain 2303 above 9.4 volts, the IC then

operates in steady state.

Personal notes

When IC 7302 develops a normal steady state operation, the

130 volt supply is sampled by resistors 3324, 3323, and 3322.

This sample voltage is then sent to Shunt regulator 7303 which

drives the feedback optoisolator 7303. The feedback voltage on

Pin 14 is then compared with an internal 2.5 volt reference by

comparator "C". Comparator "C" then sets the reference

voltage on the inverting side of comparator "B" to control the On

time of the drive at Pin 3. If the voltage on Pin 14 increases due

to the 130 volt supply increasing, the On time of the pulse on

Pin 3 will be reduced. If the 130 volt supply decreases, the

voltage on Pln 14 would decrease, causing the On time of the

pulse on Pin 3 to increase. This is used to keep the 130 volt

supply at the correct voltage. Variable resistor 3322 is used to

adjust the 130 volt supply to the correct level.

The overvoltage protection circuit of the IC will shut the IC down

if the VCC level on Pin 1 exceeds 17 volts.

To troubleshoot this circuit, first check the On/Off line from the

Small Signal Panel to ensure that it is going Low. Then check

for the presence of startup voltage on Pin 1 of the regulator IC

7302. If the IC is working correctly, this voltage will be changing

from 9.4 to 14.5 volts. If the startup voltage is not present, check

the startup resistor 3300 and the bridge rectifier. If the voltage

on Pin 1 is changing, check the drive signal on Pin3. Then

check for signal on the gate and drain of 7301. An excessive

load on the secondary, a short on the 130 volt line for example,

would cause the supply to pulse with little or no voltage on the

secondary.

Page 21

MG5.1E 4. Power supply 21

191199

TO SCAN

HIGH VOLTAGE

TO

AUDIO

AMPLIFIER

TO

CONVERGENCE

PANEL

PANEL

CL 96532100_052.eps

TO

INTERFACE

PANEL

11

50/60 HZ

10

STBY RTN

9

+5V STBY

-7V7

8

SSGND

7

6

SS GND

5

5V

+8V6

4

3

+15V

2

130V RTN

+130V

1

1202

160V DCNC160V RTN

1

CONTROL

+15V

-35V

-35V

RTN

RTN

+35V

+35V

-15V

15V RTN

+15V

+15V

+15V RTN

+5V STBY

STBY RTN

ON/OFF

NC

2

3

4

1203127612121205

1

234

1

56789

2

1210

4

3

POWER

SUPPLY

567

PANEL

8

9

10

1222

5

4

6

1221

1

2

3

+130V

4

+130V

+130V RTN

213

1220

+130V RTN

SS GND

SS GND

+5V2

+5V2

TO

MG99

+8V6

5V STBY

SMALL

SIGNAL

PANEL

+33V

+15V

ON/OFF

Figure 4-8

AC SW BOARD

Page 22

22 4. Power supply MG5.1E

4.3 Full power supply

The Power Factor Correction, Standby, and Full Power circuits

are all located on the Power Supply panel. (Figure 4-8) The

Standby supply feeds the 5 volt standby supply to the Small

Signal panel via Pin 5 of connector 121 0. The Standby voltage

is present whenever power is applied to the set and the Mains

switch is On. The On/Off Command from the Small Signal panel

is fed to the Power Supply on Pin 8 of connector 121 0. This Pin

will measure 5 volts when the set is in the standby mode and 0

volts when the set is turned On. The +33, +15, +8.6, and +5.2

volt supplies to the Small Signal panel are developed after the

set is turned On.

The +130, +15, +8.6, -7.7, and 5 volt standby voltages are fed

to the Interface panel on connector 1202. The 50/60 Hz signal

is a sync signal from the AC power mains which is used to

provide sync to the clock circuit on the Small Signal panel.

350 volts from the Power Factor Correction circuit is fed to the

Audio Amplifier on connector 1203. The Control line on Pin 4 of

1203 provides the operating voltage for the switching power

supply on the Audio Amplifier panel. This Control voltage is

switched Off when the set is in the Standby mode.

Connector 1276 routes power to the Convergence panel while

connectors 1212 and 1211 feeds power to the Scan High

Voltage panel.

Personal notes

Page 23

MG5.1E 4. Power supply 23

4.3 Full power supply

AC INPUT

BRIDGE

CURRENT SENSE

REGULATOR

DRIVE

7102

The +15 volt source is fed to transistor 7308. (Figure 4-9) This

is a Buck Switch regulator circuit which produces the 5.2 volt

source. Transistor 7308 is turned On and Off by the Switching

regulator IC 7307. To maintain the 5.2 volt source at the correct

voltage, the output is sampled and fed to Pin 5 of the IC. The

voltage on Pin 5 is then compared with an internal reference.

This drives the Pulse Width Modulator which controls the On

time of 7308.

Figure 4-9

5109

5

3

6103

7104

Personal notes

2110

350V DC OUT

CL 96532100_086.eps

121199

The -15 volt source is fed to linear regulator 7305 to produce

the -7.7 volt source. The +15 volt source is also fed to the 8.6

volt regulator 7306 to develop the 8.6 volt source.

Page 24

24 5. SCAN CIRCUITS MG5.1E

5. SCAN CI RCUITS 5.1Lin e Drive

RED

YOK E

GREEN

YOK E

BLUE

5801

10

2825

470p

9

FIL

3818

1R

8

3865

+240V

+13V

6802

12

0R47

2815

+130V

7

2827

2824

13

680p

1000u

3819

3815

3828

68K

2816

68K

1R

470p

14

6

0R27

6801

-13V

6803

5

2814

3825

2826

1000u

2850

+130V

68u

68K

470p

3867

3

3823

1R

68K

15

+28V

A

6850

16

1

2851

100u

2899

4n7

7802

2822

2818

3821

2817

430n

820p

470R

3n3

6806

2811

330p

3814

33R

2834

2819

5805

430n

5804

27n

6808

5803

2805

3681

100n

3452

2K2

YOK E

4R7

3805

+15V

100R

2573

3590

3453

2n2

100K

4R7

2u2

2452

7552

3457

2K2

3454

7553

4R7

7551

3591

3571

3455

3456

2K2

2K2

4R7

100R

3458

2K2

2820

A

4u7

3834

1R

3835

3K3

2836

6830

2837

LV

3806

2838

3837

1K

1n

12K

1

4

5802

6

8

1n

3839

330K

7830

2839

10n

10u

3812

100K

+130V

2809

100n

3811

3810

2810

2898

2K2

2K2

330u

220U

2806

1n

2807

4

1

3808

100n

3813

3

2

2K2

3807

1R

5800

330R

7803

3829

7801

3809

3830

15R

1509-1

330R

470R

+15V

HDRV

LINE

DRIVE

Figure 5-1

+28V

2801

100n

3803

100R

3840

2800

1M

1u

E_W

7800

3802

3866

3801

68K

18K

27K

1507-4

H_PUL

3800

3890

100R

1K5

1511-1

HFB

3817

470R

HPUL

+15V

1509-7

FBSO

3836

270R

+28V

3831

3832

3K3

7804

3833

100R

HPUL_BLNK

CL 96532100_089.eps

68K

2804

10u

121199

Page 25

MG5.1E 5. SCAN CIRCUITS 25

5.1 Line Drive

Line Drive from the Small Signal panel is fed to connector 1509

Pin 1 and then to buffer transistor 7803. (Figure 5-1) Transistor

7803 then drives the Line driver transistor 7801. Line drive is

then fed to the Line output transistor 7802. Transistor 7802

drives the three Line Yokes and the Scan transformer 5801.

The Scan transformer produces a 240 volt supply for the CRT

drive circuits, a Filament drive for the CRT'S, a plus and minus

13 volt supply for the Frame drive circuit. It also produces a 28

volt supply for the beam limiter circuit in the High Voltage circuit.

The output of the Line Output transistor 7802 is also fed to

buffer transistors 7800 and 7804 to produce a Line Sync pulse

(HPUL) and Line feedback pulses to the Small Signal panel (HPUL and HFB). The output of transistor 7804 also produces a

Line Blanking pulse (HPUL-BLNK).

Drive for geometry correction from the Small Signal panel on

the E-W line drives transistors 7553, 7551, and 7552. This

circuit drives the return side of the Line Yokes to provide

Horizontal corrections to the geometry. Geometry correction

drive, E-W, is also fed to transistor 7830 which produces drive

for the Dynamic Focus, LV. The Line component to the

Dynamic Focus is added in transformer 5802.

Personal notes

The Line Sync (HPUL) is used to synchronize the High Voltage

drive. If this pulse is missing, the High Voltage circuit will shut

down. A loss of drive to the Line Yokes will cause the High

Voltage to shut down.

Page 26

26 5. SCAN CIRCUITS MG5.1E

5.2 Frame Drive circuit

5.2 Frame Drive circuit

6550

3554

1

VERT

OUT

100R

9

3585

10K

VDRVP

1509-5

1509-7

VDRV

2570

470p

3572

100R

2567

470p

3573

100R

2564

470p

2571

470p

3551

1K8

3550

1K8

3583

1R

2511

100n

3

2

VERT

DRIVER

Frame Drive from the Small Signal panel (FDRVP and VDRV)

is fed to the Frame Output IC 7550. (Figure 14) This circuit is

powered by a +13 volt supply connected to Pin 8 and a -13 volt

supply connected to Pin 6 which are supplied by the Line Drive

circuit. Pin 5 of 7550 provides drive for the the three Frame

yokes. Frame drive feedback from the return side of the yokes

is fed back to Pin 2 of 7550. Frame sync (VPUL) for the High

Voltage shutdown circuit is output on Pin 4 of the IC. Output

from Pin 7 is buffered by transistor 7590 to produce a Frame

Sync pulse (VFB) for the Small Signal panel.

+13V

8

FB GEN

DRIVER

VERT

OUT

6

-13V

Figure 5-2

3562

4R7

2565

100n

2557

100uF

2559

100n

-13V

3565

220R

7

2557

4

100uF

5

Personal notes

VPUL

3595

33K

3563

220R

+15V

7590

3592

330R

2558

68n

3594

100R

3593

1K

CL 96532100_090.eps

2822

220R

3824

220R

3826

220R

1511

VFB

RED

YOKE

GREEN

YOKE

BLUE

YOKE

121199

A failure in this circuit would cause the High Voltage to shut

down. A problem in this circuit could be caused by a loss of

drive from the Small Signal panel or a failure in the Line Sweep

circuit. An open Yoke connection would also cause the Frame

drive from the IC to shut down.

Page 27

MG5.1E 5. SCAN CIRCUITS 27

5.3 High Voltage circuit

+130V

HD DIV

2914

330uF

3931

1M

39331M2923

+15V

3919

1K5

3918

15K

3996

1K

6907

3964

10R

3965

1M

2931

470n

3947

620R

2919

150n

3989

680R

3973

82K

3942

100K

3963

2K2

3932

5K6

3939

2K2

3943

2K2

+15V

1n

7901

+15V

3920

1K

3954

39K

7903

6900

ABL

6951

6950

6V8

3968

22K

3967

470R

3955

33K

FB

GND

DAG

EHT

FOCUS

5900

1

3

2915

3n9

3938

30R

5902

2924

820P

6902

2924

820P

2929

330P

6910

7906HVOUT

2913

1000uF

6909

3980

4K7

3923

15K

2910

1uF

3937

33K

3930

10K

6905

2909

2N2

+130V

3934

0R27

3961

68R

3962

10R

5901

2933

330P

7952

2907

15N

3915

820R

10

5

6

3950

33R

2916

6N8

3917

1K

3916

1K

+15V

3957

1K5

7909

3922

1K5

+15V

+28V

+28V

+15V

+5VSTBY

6916

6914

150K

3999

+15VSTBY

6915

3949

56R

680K

8

2922

470uF

3945

2917

100n

-13V

6906

2927

1u

3940

14K

3971

100K

3982

7K5

3981

7K5

3959

1K

47K

3975

100R

3969

7907

7908

3994

47K

2918

2u2

3941

56K

3948

1K

1

7902

COMPARATOR

CIRCUIT

3

3946

15K

3924

180R

-13V

3909

180R

ON/OFF

3951

10K

7

6

LATCH

4

2

3991

1K

2921

4.7uF

+15V

3962

100R

3913

2900

220uF

3900

220R

3901

10K

3902

12K

3995

12K

3905

120K

3906

1K5

2903

1uF

2902

1n

4K7

+15V

1

7900

REGULATOR

PRE-DRIVER

PHASE

DETECTOR

OSCILLATOR

567

3

4

2904

10n

3907

5K6

3908

1K5

+15V

3910

7905

2908

10n

3914

10K

HPUL

+15V

3928

1K8

3990

1K8

8

2

2905

100n

3912

10K

3503

2906

10n

3911

15R

10K

+15V+15V

3998

15R

2503

120K

680p

2920

4u7

3993

120R

3944

120R

6904

7501

+15V

3508

47K

7502

3926

100R

2911

4u7

3921

CL 96532100_091.eps

4K7

BLANKING

18K

121199

+15V

3500

4K7

3501

10K

6500

+15V

+15V +15V

+15V

3511

3512

10K

3513

39K

3514

10K

6505

3927

10K

7904

+15V

7953

6501

3510

470K

+15V

2501

470N

3503

+15V

120K

6502

6552

6V8

3505

220R

VPUL

6501

3506

120K

6502

3507

3K3

Figure 5-3

Page 28

28 5. SCAN CIRCUITS MG5.1E

5.3 High Voltage circuit

Line Drive (HPUL) from the Line Drive circuit is applied to

transistor 7905 and then to Pin 3 of IC 7900. This Pulse is used

to phase lock the oscillator for the High Voltage drive. This

circuit will default to a frequency 31.25 KHz if no signal is

applied. The Sync signal will have a frequency of 31.25 KHz if

a PAL or SECAM signal is applied to the set. If an NTSC signal

is applied to the set, the frequency will be approximately 31.5

KHz. Drive for the High Voltage output transistor is output on

Pin 1 of the IC. This signal drives transistor 7952, pre driver,

and the High Voltage Output transistor 7906. The High Voltage

transformer 5900 outputs 30 KV to the High Voltage

Distribution block. Feedback from the Block is fed to the Shunt

Regulator 7901 where it is compared with an internal 2.5 volt

reference. The output of the Shunt Regulator drives transistor

7903 which drives Pin 8 of 7900. The voltage on Pin 8 of 7900

determines the On time of the signal at Pin 1 of the IC. The

width of this pulse determines the On time of the High Voltage

output transistor 7906. The On time of 7906 determines the

amount of energy stored in 5900 which sets the level of the

High Voltage. The voltage on Pin 8 of 7900 has an operating

range of 4.5 to 4.8 volts.

Beam Current is monitored from the bottom of the diode stack

in the High Voltage Transformer and fed to transistors 7907 and

7908. Increases in Beam Current will lower the output voltage

of the these transistors. This voltage is applied to Pin 8 of 7900

to make minor corrections to the High Voltage. It is also fed

back to the Video Circuits on the Small Signal panel via the ABL

line to make minor changes in the Picture level to compensate

for changes in Beam Current. This voltage is also fed to Pin 1

of 7902 where it is compared with an internal 3.5 volt reference.

Excessive beam current would cause this voltage to drop below

3.5 volts which would set the internal latch of 7902. Pin 6 of the

IC would go Low which would turn transistor 7909 On. This

would keep transistor 7952, High Voltage driver, On. The High

Voltage would be shut Off. A High applied to Pin 7 of 7902 by

turning the set Off would reset the latch.

the point where it is not usable. The High Voltage will then be

shut down. When 7501 turns On it applies a High on the

Blanking line. This is applied to the CRT drive circuit on the

Interface panel to blank the CRT drive signal.

The focus voltage from 5900 is fed to the Focus/G2 block

mounted on the TV chassis. Therefore, an easy way to

determine if the High Voltage has failed would be to measure

the the G2 voltage on one of the CRT panels. If High Voltage

has failed, check the voltage on the anode of 6901. If this

voltage is approximately 0.7 volts, the High Voltage has shut

down due to a loss of Frame or Line drive. If this voltage is

approximately 15 volts, the Frame and Line drive circuits are

working correctly. Next, check the voltage on Pin 6 of IC 7902.

If this voltage is zero, the problem was caused by an

overvoltage or overcurrent condition.

Before attempting any component level repair on this circuit,

the CRT panels should be unplugged from the CRT'S. This is

to prevent damage to the Phosphors of the CRT's is case drive

is applied to the CRT's while Frame or Line drive is missing.

Personal notes

The High Voltage is shut down if it increase beyond the

designed safety limits. Pin 6 of the High voltage transformer is

rectified by 6904 and is fed to Pin 3 of 7902 where it is

compared with an internal reference. The normal voltage at this

Pin is approximately 25 volts DC. If the voltage on Pin 3 goes

above 28 volts for more than 800 ms, the Latch inside 7902 will

be set, shutting the High Voltage Off.

To prevent damage to the, CRT's in the event of a failure in the

Frame or Line drive circuits, the High voltage is shut down. The

Line Drive pulse (HPUL) is rectified by diode 6502 and is

applied to the base of transistor 7953. The Frame drive pulse

(VPUL) is rectified by 6502 and is also applied to the base of

7953. As long as Frame and Line drive is present, the voltage

at the Base of 7953 will keep the transistor turned Off.

Transistor 7501 will turn On through resistor 3501 and zener

diode 6500. This will turn 7503 On, turning 7502 Off, which

turns 7904 Off - If the Frame or Line drive should fail, transistor

7953 turns On, turning 7501 Off, turning 7503 Off, turning 7502

On, which turns 7904 On. This turns 7903 On hard which

causes the voltage on Pin 8 of 7900 to go above 4.8 volts. The

pulse width of the drive on Pin 1 of 7900 will then decrease to

Page 29

MG5.1E 6. SMALL SIGNAL PANEL 29

6.1 Block diagram

6. SMALL SIGNAL PANE L6.1Block diagram

TDA9320HUV13XX

SAA4978

TOPIC

TDA9178

HA/V

A

HD/V

SAA5800

TDA933XH

D

ROTATION

Chassis name

The 'MG' chassis is the successor of the MD1, MD2, GFLchassis. The MG architecture is global and can be produced all

over the world.

Explanation chassis name MGX.YZ

X depends on specification

Y depends on introduction-timing

Z region e.g. E(urope); A(sia Pacific); U(SA)

This manual deals with the MG5.1E.

A small signal panel (SSP) is used and a large signal panel

(LSP). On the LSP there are only a few SMD’s, but the SSP is

further integrated. There are no modules anymore; the FBX

(feature-box) is integrated on the chassis. Due to the fact that

all features are flat on one board, repair down to component

level is an absolute must.

For this reason there is a lot of diagnostic support built-in in the

chassis:

• customer service mode (CSM) as used in the MD2.2-

chassis. It decreases the number of nuisance calls.

• service default mode (SDM). Predefined state of the set.

• service alignment mode (SAM) to do all kind of alignments,

select test patterns, display error codes,....

• full support of the dealer service tool (DST).

Figure 6-1

CL 86532047_001.eps

140798

New tools and service features

A lot of additional service “features” are built in the MG5.1E.

These “features” can be addressed with a new tool called

ComPair (Computer Aided Repair). This is an interface that can

receive the error codes and can send RC5 and RC6-codes. To

this interface belongs also software and a CD-ROM with the

service manual, circuit descriptions and fault finding trees. In

this way searching for components on the PCB and schematics

is history.

Explanation Small Signal (fig 6.1). The tuner type UV1316 is a

PLL tuner and delivers the IF-signal to the HIP (High-end Input

Processor (TDA9320H)). The HIP has the following functions:

•IF-part

• video source select and record select

• colour decoder (PAL/SECAM/NTSC)

• synchronisation

Three scart connectors can be used. Scart 1 and 2 are full scart

and scart 3 is only cvbs. Scart 2 is meant for VCR, thus on this

scartpin 10 is used for Easylink and there is possibility for y/c in/

out. The cvbs-out on pin 19 can be used for WYSIWYR (= what

you see is what you record). A digital combfilter can be used to

have Y/C separation. The HIP delivers the signal to the PICNIC

(SAA4978). The PICNIC takes care of:

• ADC (9 bits) (was FRONTIC)

• DAC (was ECOBENDIC)

• 100 Hz (was ECOBENDIC)

• Panorama mode (super zoom) (was PANIC)

Page 30

30 6. SMALL SIGNAL PANEL MG5.1E

6.1 Block diagram

• Noise reduction (was LIMERIC)

• Dynamic contrast (was SMARTIC)

For digital scan the PROZONIC (SAA4990) is required, that

can be connected to the PICNIC. The PROZONIC was already

used in the GFL- and MD2-chassis.

For natural motion the MELZONIC can be used. These two ICs

are mentioned in the blockdiagram as 2fh-features.

For sets with PAL+ the same concept is used as in the MD2chassis and this is also connected to the PICNIC. From the

PICNIC the signal is fed to the TOPIC (The most Outstanding

Picture Improvement IC) TDA9178. This IC handles various

picture improvements, e.g. sharpness. This IC works together

with the PICNIC to handle auto-DNR. If there is noise in the

videosignal then the DNR has to be high, but the sharpness

must be low. So also the other possibility if the signal is perfect

then the DNR is not necessary (DNR low) and the sharpness

can be higher. (First introduced sets will not have Topic-ICs and

also not a light sensor.)

noisy signal high low

good signal low high

Personal notes

The customer can select AUTO TV for a very high performance.

Auto TV contains algorithms for contrast-improvement,

sharpness, noise reduction and better colour behaviour. Via a

light sensor the influence of the ambient light can be used for

optimal contrast/brightness control.

After the TOPIC the YUV-signals are fed to the HOP (High-end

Output Processor (TDA933X)). In the HOP is the video control

part and geometry integrated. The RGB-signals from TXT/OSD

are inserted via the HOP. This IC has all functions from a

videoprocessor and geometry control (like the DDP in

MD2).The cut-off control is a little different: via the service menu

there is an indication that the VG2-setting is correct (later in the

first sets). The geometry part delivers the H-drive, V-drive and

also a drivesignal for rotation. Blue mute is possible for:

•HOP

•OTC

• PICNIC

For the MG5.1E blue mute is made via the PICNIC and perhaps

in future sets from the OTC. The soundpart is built up around

the MSP3410D (all versions have NICAM) for IF sound

detection, sound controls, source select. The sound for the

subwoofer is derived from L and R. To the MSP3410 a new IC

can be added: called SEDSP (Sound Effects Digital Sound

Processing IC (SAA7712H)). This IC takes care of Dolby

prologic decoding and some other features like virtual DOLBY,

incredible surround, DBE, equaliser, ...

Page 31

MG5.1E 6. SMALL SIGNAL PANEL 31

6.1 Block diagram

1010

degaussing

+t

Rs

+t

Rp

7020

~

220V

+5V Standby

7020

7020

+5V Standby

IC7520

MC44603

10

Blockdiagram supply-part

I2C bus.

In MG5.1E three different I2C busses are used:

1. Slow I2C bus (SCL/SDA-S); speed 100 kHz used for

various IC's

2. Fast I2C bus (SCL/SDA-F); speed 400 kHz. (In the OTC

there is only one hardware I2C bus. The two busses are

made by a very fast switch.)

3. I2C bus for NVM (SCL/SDA-NVM). This short I2C-bus is

used to avoid data corruption in the Non Volatile Memory.

Microprocessor = OTC2.5 (On screen display, Teletext and

Control, level 2.5 Txt) with integrated teletext (SAA5800). This

IC takes care of the analogue Input- and Output-processing.

The OTC, ROM and RAM are supplied with 3.3V. This voltage

is derived from the +5V Standby.

start

3517/3520

13

14

Figure 6-2

IC7556

TL431

Personal notes

7213

7808

7212

DCDC

convertor

M34063A

CL 86532047_002.eps

+140

(Vbat)

+8V6

5V2

Page 32

32 6. SMALL SIGNAL PANEL MG5.1E

6.1 Block diagram

+5V2+13

7421

HOP

Hdrive

Vdrive+

Vdrive-

7600

TDA8177

+13V

-15V

Blockdiagram deflection

Vdefl

Explanation Large Signal (fig 6.2 + 6.3). In MG5.1E there is a

separate Standby supply that is used to reduce the Standby

power. The main power supply is completely switched off via a

relay and only the Standby supply is operational in Standby. A

second relay (no triac) is used for switching off the degaussing

circuitry. The degaussing is not switched from Standby to on.

The power supply is a Fixed Frequency Supply with an

operating frequency of 40 kHz. For the control part the

MC44603 is used (also known from a lot of other chassis).

Secondary a DCDC-converter (MC34063A) is used for

stabilisation of the 5V2 for various circuitry. The Standbycommand is also fed to the FFS to ensure quick switch-off of

the power supply.

Figure 6-3

+140V

(Vbat)

Hdefl

2432/2434

east/west modulator

CL 86532047_003.eps

Personal notes

+13

140798

In fig 6-3 the blockdiagram is drawn for the line output stage.

There is no seriesswitch as in MD2- and GFL-chassis, because

this function is now integrated in the HOP. In case of a flash or

protection the line output stage is switched off by the HOP. The

complete geometrycontrol is integrated in the HOP. The V-drive

is also coming from the HOP and the amplifier is realised with

TDA8177.

Page 33

MG5.1E 6. SMALL SIGNAL PANEL 33

6.2 Service Modes / ComPair

6.2 Service Modes / C omPair

Service Modes

In the MG the following service modes are available:

• SAM (service alignment mode)

• SDM (service default mode)

• CSM (customer service mode)

This looks very much alike the MD2.2. (For details see service

manual.) The DST tool can still be used, but an upgrade version

of this is the ComPair tool (a PC-based diagnosis system).

Difference related to previous sets: With an 12C bus error, the

set will not be placed in protection anymore.

ComPair (tool)

ComPair (Computer Aided Repair) is a new tool for repairing

the new TV-sets and the new high-end video-recorders. With

the help of ComPair, repairing a set will be more time effective

even without much knowledge of the set. By guiding the

technician with the help of self-diagnostics and documents with

text and oscilloscope waveforms on the screen of the PC,

repair-time will decrease as well in the SSPas in the LSP part

of the set. ComPair consists of an electronic interface

connected to the computer, to make via infra-red

communications a link to the upmarket TV-sets and via a wired

I2C a link to Basic TV-sets and high-end video recorders, and

a Windows based computer program. ComPair is running on a

486 PC with Windows 3.1 onwards. Infra-red commands,

received from the ComPair interface, are converted into I2C

commands towards devices connected to the I2C bus. In this all

registers from ICs can be read to make a good diagnose.

Personal notes

Step-wise start-up/step-wise shutdown (feature of

ComPair)

With ComPair it will also be possible to start-up the set step by

step. In this way it is possible to distinguish which part of the

start-up routine (hence with circuitry) is causing the problem

(see also chapter 17). The repairman will be guided by ComPair

by means of fault-finding instructions with text and

oscilloscope waveforms. By going a step downwards a certain

protection can be de-activated again, and measurements can

be performed.

Page 34

34 6. SMALL SIGNAL PANEL MG5.1E

6.3 Control and TXT

ON/OFF

+5V STBY 3V STBY

7009

3V3

7006

7007

8V6

5V2

H

V

KEYBOARD

3V3

470E

POR

3V3

3V3

111

74

105

106

83

84

107

+5VSTBY

7012

8V6113

SAA 5800

OTC 2.5

5VSTBY

OSD/TXT

MAINS-SWITCH

3059

470

470

100

90

104

77

78

79

FADING

80

108

100E

AFC tuner

93

109

115

96

103

PANEL

3054

SERVICE

SEND

LED

STANDBY

R

G

B 10R

HIP

HSEL (OPTIONAL)

STATUS 3

I/O CNTR - BUS OUT I/O

I/O CNTR - BUS IN I/O

FRONT DETECT

IR

receiver

+

TLUV

5300

RG

HOP

IC

16/9 DETECT

6Mc

3209

3V3

STBY

ROM CE

ROM CS

3206

1123

ROM

16Mbit

(2Mbyte)

AO A19 AO A17 AO A8

16

17

18

73

RAM_CS

40 43 42 41

12 14

FLASH

RAM

EPG

RAM_DEWERAM_DE

CASHN

CASL

41 71 73 69 70

RAM

TXT

CONTROL

90

94

95

2

I C-0

2

I C-1

RaSN

5

PEAKING

7

I C-SLOW

I C-FAST

WE

I C-3

SELECT CL/VL

RESET AUDIO

SOUND EN ABLE

CVBS for txt

PEAKING

FILTER

2

2

TUNER

HIP

2

NVM

32 Kbit

FBX

HOP

VIDEO

SEL

MSP

3410

AUDIO

SELECT

TOPIC

CL 86532047_004.eps

051098

Figure 6-4

Page 35

MG5.1E 6. SMALL SIGNAL PANEL 35

6.3 Control and TXT

Control part

Remote Control

In MG5.1E a new remote control is introduced which uses RC6,

because new commands are used like cursor control in 8

directions. There are two mode buttons on the side of the

remote control: One for VCR and the other for DVD/SAT (digital

source).

OTC

The SAA5800 (IC7003) is called the OTC (OSD, TXT and

CONTROL). In this IC the microprocessor and the TXTdecoder are integrated. The SAA5800 is also called the

OTC2.5 because also TXT-level 2.5 is supported.

The OTC has also :

• RGB outputs for blending. The contrast (for blending) is

software controlled.

• OTC 2.5 has various I/O ports for I2C, RC5, LED, ....

The software for MG can be 2 MB (Megabyte). For sets with

nexTView (also called EPG) a 512 KB flash-RAM IC7013 is

used to store the Electronic Program Guide. For TXT-data 440

pages can be stored in a RAM IC7001. This is a DRAM of 4 Mbit

and this IC is also used to store data of a working set. The Non

Volatile Memory IC7008 is a 32 kbit version M24C32W6. All ICs

in this part are supplied with 3V3. For this voltage a 3V3

stabiliser is used (IC7009). At start-up the POR is generated

with TS7006/7007. During a reset all I/O pins are high. When a

POR is generated the TV-set is in Standby mode. Via pins 105

and 106 the 8V6 and the 5V2 are sensed. If one of them is not

present, the FFS-supply is switched off. The OTC will generate

an error code to indicate what was wrong.

The horizontal and vertical flyback pulses are also fed to the

OTC for stable OSD and TXT. To create good stable pulses the

HFB(H) and VFB(V) are inverted and fed to the OTC. The RGBoutputs (77/78/79) together with fading (pin 80) is fed to the

HOP.

The fading pin has in fact a double function:

• Make transparent menu

• Fast-blanking for TXT

In MG5.1E there are three I2C-busses used:

• Slow I2C bus for tuner, fbx, video- and audio-selection

• Fast I2C bus for the HIP, HOP, MSP3410 and the TOPIC

• NVM- I2C bus for the Non Volatile Memory to prevent data

corruption (=I2C3)

The OTC has also a connection with mains switch/led panel:

• Driving the “ON” and “Standby”-leds . The green led gives a

quick indication that the 8V6 is present.<----- Service tip

• MG5.1E has an IR-send led connected to pin 90 for

communication with DST or ComPair.

• The remote control signal comes in on pin 100. This can be

RC5 or RC6 commands.

by an extra fast-blanking signal from pin 81. In future sets this

circuitry will be deleted. In the previous chassis there was

separate memory to store the TXT information. In MG the RAM

(IC7001) of the microprocessor is also used for the TXTdecoder.

NexTView

NexTView allows the user to display a program guide on the TV

screen which contains extensive information for each program.

This information can be displayed in a number of different

summaries:

– DAY: The daily summary shows, from the current moment,

the program schedule for several stations for a short time

ahead.

– CHANNEL: The channel summary shows the program

schedule for one station.

– THEME: The theme summary shows, for each theme, the

program schedule of the various stations. These themes

consist of sport, film, culture, etc. and is determined from

the station side.

NexTView does not have to restrict itself to information about

the station which is being viewed, but also offers information

about other stations. In the various summaries 3 different

commands can be given for the various program overviews.

These commands appear as follows:

– WATCH: The set immediately switches over to the station

concerned.

– REMINDER: The start time and date and the station of the

program concerned is stored in the TV reminder list. The TV

will give an OSD-message with the program information, or

switch on the set at the correct moment (provided the set is

in Standby) and tune to the station concerned.

– RECORD: The timer of the video recorder with ‘Easylink

Plus’ is programmed with the data of the program

concerned. There has to be a video recorder (with Easylink

Plus) connected to SCART2 otherwise the ‘RECORD’

function will not be highlighted. The connection is via pin 10

from SCART. This means that it has to be a full SCART or

at least pin 10 has to be wired.

In order to be able to realise nexTView, two teletext type data

flows, Datastream 1 and 2, are transmitted with various subcode pages of information. This data flow can transport limited

information (max. 40 pages). Datastream 1 is quick repeating

with a repetition time of approximately 20 to 30 seconds.

However, Datastream 2 has a much longer repetition time of

approximately half an hour and has a large transport capacity.

– Datastream 1 contains information of the station which is

being viewed.

– Datastream 2 contains up to one week of advance

information from various stations which are covered by the

provider.

TXT

The TXT-decoder in the OTC gets two video signals: Direct to

pin 5 and via the peaking filter (for Scandinavian countries) to

pin 7. The input is selected via country selection in the

installation menu. The RGB-outputs are available on pins 77/

78/79. Fast blanking is realised via pen 80, but TS7017 and

TS7018 are added to create a nice fast blanking signal that is

needed in the TXT-mixed mode. These transistors are driven

Page 36

36 6. SMALL SIGNAL PANEL MG5.1E

6.3 Control and TXT

Realisation of nexTView in MG5.1E

MG5.1E knows two executions of nexTView called “This

Channel EPG” and “Multi Channel Composite EPG”. “Multi

Channel Composite EPG” makes use of both Datastream 1 and

Datastream 2. Due to the size, in particular of Datastream 2 and

the pass time which is coupled with that, a number of additional

provisions have to be made in the set. Therefore, an extra Flash

Memory is used in order to retain the information. Both the

interpretation and storage of Datastream 2 require calculating

capacity of the microprocessor. This all can not be performed

during normal operation. Datastream 2 is then also stored at the

moment that the set is in Standby. For this the set will go into

Semi-standby (also see Power Supply chapter). The Semistandby mode can be recognised by both the Standby and the

"On"-LED illuminating. In the Semi-standby mode the entire

small signal is switched on and it will be tuned to the nexTView

provider which has been assigned during installation. The

microprocessor can now use its full calculating capacity in order

to load the Flash Memory. After the Datastream 2 has been

completely stored the set will switch to Standby. This takes

place after approximately half an hour. After this the set will

check every 12 hours whether the information in Datastream 2

has changed. To do this the set again switches to Semi-standby

and the Flash Memory is erased and re-loaded when the

information in Dataflow 2 has changed. Every morning at 5:40

the nexTView information will also be re-loaded because then

information for the previous day can be deleted from the Flash

Memory.

“This Channel EPG” makes use of Datastream 1only. This data

is loaded in the RAM as soon as the set is switched on. Only

data of the current and next day is loaded and this is only data

of the station watched. No Flash Memory is used.

As soon as the set is put in standby after watching, the set will

go to semi-standby for updating the so called CNI numbers. For

this the set tunes to all pre-installed presets and tries to detect

the CNI number of the broadcaster. A CNI number is an unique

identification number assigned to a broadcaster and is

available in TXT package 8/30. This CNI number will be stored

in the EAROM as part of the preset information. As more then

one broadcasters can be available on a certain preset more

then one CNI number can be registered under one preset.

These CNI numbers are used to identify the right broadcatser

when EPG features like Watch, Record and Remind are used.

If no nexTView provider is available the set will show a

nexTView alike screen including a TXT page as soon as the

nexTView feature is activated. This TXT page can be set to the

TXT program guide if available. Some of the nexTView features

as record can still be used in this case.

Personal notes

Page 37

MG5.1E 6. SMALL SIGNAL PANEL 37

g

g

g

g

g

g

g

g

g

g

)

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

y

(

)

g

(

)

g

y

g

g

g

g

y

y g

g

g

g

g

g

(

)

g

g

SAA5800 pin description

pin nr. pin name Description I/O Level pin nr. pin name Description I/O Level

1 IREF_DEC Iref decouple I analogue 61 A7 Address bit O digital

2 IREF Current reference input I analogue 62 A8 Address bit O digital

3 REF+ ADC voltage reference

4 CVBS0_R Reference for video

5 CVBS0 Composite video signal 0 I analogue 65 A18 Address bit O digital

6 CVBS1_R Reference for video

7 CVBS1 Composite video signal 1 I analogue 67 A21 Address bit O digital

8 STN/BLACK ADC current reference

9 VDDA Analogue power I 3V3 69 RASn DRAM Row address

10 VSSA Analo

11 TEST0 Ground I gnd 71 CASHn DRAM Column address

12 TEST1 Ground I gnd 72 CASLn DRAM Column address

13 TEST2 Ground I

14 TEST3 Ground I

15 TEST4 Ground I

16 OSCOUT 6 MHz Oscillator out O analo

17 OSCIN 6 MHz Oscillator in I analo

18 OSCGND Oscillator local ground

19 VDDN1 Digital power (connect to

20 VDD1 Di

21 VSSD1 Di

22 D11 Data bit I/O di

23 D4 Data bit I/O di

24 D3 Data bit I/O di

25 D12 Data bit I/O di

26 D10 Data bit I/O di

27 D5 Data bit I/O di

28 D2 Data bit I/O di

29 D13 Data bit I/O digital 89 P0.4|RXD Reserved for switching

30 D9 Data bit I/O di

31 D6 Data bit I/O di

32 D1 Data bit I/O di

33 D14 Data bit I/O di

34 D8 Data bit I/O di

35 D7 Data bit I/O di

36 D0 Data bit I/O digital 96 P1.3|INT0 Switch to service default

37 D15 Data bit I/O di

38 VDDP1 Peripher

39 VSSP1 Periphery ground 1 I gnd 99 P1.6|INT3 Fixed Beam Current

40 ROM_OEn ROM output enable O active low 100 P1.6|RC5 IR receiver I active low

41 RAM_OEn RAM output enable O active low 101 VDDD3 Di

42 RAM_CSn SRAM chip select

43 ROM_CSn ROM chip select O active low 103 P2.0|PWM0 Front detect: Signal

44 A16 Address bit O di

45 A0 Address bit O di

46 A15 Address bit O di

47 A1 Address bit O di

48 A14 Address bit O di

49 VDDP2 Peripher

50 VSSP2 Peripher

51 A2 Address bit O di

52 A13 Address bit O di

53 A3 Address bit O di

54 A12 Address bit O di

55 A4 Address bit O di

56 A11 Address bit O digital 116 P3.3 Beam Current protection

57 A5 Address bit O digital 117 P3.4 DC protection (DC-PROT) I active high

58 A10 Address bit O di

59 A6 Address bit O di

60 A9 Address bit O digital 120 P3.7|P50_OUT Easy link out O digital

decouplin

nal 0

si

nal 1

si

decouplin

ue ground Ignd 70 WEn Write enable O active low

reference

VDDD1

ital power 1 I 3V3 80 FADING Blendin

ital ground 1 Ignd 81 DATA/VIDEOn Data indicator O high active

power 1 I 3V3 98 P1.5|INT2 - - -

FLASH RAM

power 2 I 3v3 109 P2.6|STATUS3 Status SCART 3 I active low

round 2 Ignd 110 P2.7 - - -

I analogue 63 A17 Address bit O digital

I analogue 64 A19 Address bit O digital

I analogue 66 A20 Address bit O digital

I analogue 68 A22 Address bit O digital

strobe

strobe high byte

strobe low byte

nd 73 EAn External rom access I active low

nd 74 RESET Reset I active low

nd 75 VDDD2 Digital power 2 I 3V3

ue 76 VSSD2 Digital ground 2 Ignd

ue 77 R Red O analogue

I gnd 78 G Green O analogue

I 3V3 79 B Blue O analogue

ital 82 FRAME Frame indicator O high active

ital 83 HSYNC Horizontal display sync I active low

ital 84 VSYNC Vertical display sync I active low

ital 85 P0.0|SCL0 SCL Slow I2C bus I/0 digital

ital 86 P0.1|SDA0 SDA Slow I2C bus I/O digital

ital 87 P0.2|SCL1 SCL Fast I2C bus I/O digital

ital 88 P0.3|SDA1 SDA Fast I2C bus I/O digital

ital 90 P0.5|TXD IR Led for Service O digital

ital 91 P0.6|COR SDA EAROM I/O digital

ital 92 P0.7 SCL EAROM O digital

ital 93 P1.0|T0 Status SCART 4 I active low

ital 94 P1.1|T1 Reset audio O active low

ital 95 P1.2|T2 Sound mute O active low

ital 97 P1.4|INT1 Easy link out I digital

O active low 102 VSSD3 Digital ground 3 I gnd

ital 104 P2.1|PWM1 Standb

ital 105 P2.2|ADC1 PROTECTION +8V6 I active high

ital 106 P2.3|PROTECTION +5V2 PROTECTION +5V2 I active high

ital 107 P2.4|KEYBOARD KEYBOARD I analogue

ital 108 P2.5|AGC - - -

ital 111 VDDP3 Periphery power 3 I 3V3

ital 112 VSSP3 Periphery ground 3 Ignd

ital 113 P3.0|LED0 Stand-by LED O low: LED on

ital 114 P3.1|LED1 - - ital 115 P3.2 - - -

ital 118 P3.5 - - ital 119 P3.6|SERVICE MODE Service mode input I low active

SCAVEM

mode