Page 1

M1026A Anesthetic Gas Module

Service Guide

Anesthetic Gas Module

M1026A

Patient Monitoring

Page 2

Part Number M1026-9101A

*M1026-9101A*

S PHI

Page 3

1Table of Contents

Introduction 5

Description 5

Product Structure 5

Physical Specifications 5

Environmental Specifications 6

Performance Specifications 6

CO2 Measurement 7

AWRR derived from CO2 Waveform 7

N2O Measurement 7

O2 Measurement 7

Anesthetic Agent Measurement 7

Alarm Ranges 8

Alarm Delay 8

Apnea Alarm 8

INOP Alarms 8

General Measurement Principles 9

Theory of Operation 9

Main PC Board 10

Power Supply 11

Pneumatic System 11

Pump 12

Water t r ap 12

Sample Flow Through the Pneumatic Path 13

Agent Identification Assembly 13

Measurement Principle 14

O2 Sensor 14

Specifications 14

Measurement Principle 14

Infrared Measurement Assembly 15

Installation and Patient Safety 16

Physical Installation 16

Environment 17

Label Sheet 17

Making Connections to the AGM 17

Sample Gas Connections to the Gas Exhaust 18

Returning the Gas Sample 18

Setting Up the Gas Return 19

Removing the Gas Sample 20

Setup and Configuration Procedures 20

Altitude Configuration 20

3

Page 4

Connect Sample Input Tubing 20

Preventive Maintenance (PM) Tasks 20

Post-Installation Checks 21

Safety Requirements Compliance and Considerations 21

Explanation of Symbols Used 21

Power Supply Requirements 22

Grounding the System 22

Equipotential Grounding 23

Combining Equipment 23

Checking and Calibrating the Anesthetic Gas Module 23

Access Service Functions of the M1026A Anesthetic Gas Module 23

When and how to check the Philips M1026A Anesthetic Gas Module 25

Equipment required for checking 25

Checks and adjustments 26

Performance Leakage Check 26

Performance Diagnostic Check 27

Performance Flowrate Check 27

Total Flowrate Check and Adjustment in Purge Mode 27

Measurement Path Flowrate Check and Adjustment 28

Total Flowrate Check in Normal Mode 30

Zero Calibration 30

Barometric Pressure Check and Calibration 31

Span Calibration Check 32

Disposal of Empty Calibration Gas Cylinder 34

Maintaining the Anesthetic Gas Module 35

Preventive Maintenance (PM) Tasks 35

Cleaning 36

Replace PM Parts 36

Internal Nafion Tubing with Bacterial Filters and manifold Seals 36

Room-Air Filter 38

Pump Filter 39

Performance Checks 40

Other factors to maximize uptime or reduce cost of ownership: 40

Troubleshooting the Anesthetic Gas Module 40

Compatibility Criteria for the AGM and the IntelliVue Monitors 40

Flow Charts for Communication and Measurement Type Problems 40

Hardware Related Troubleshooting Strategy 45

INOPs 46

Calibration Checks 48

Calibration Checks Troubleshooting Table 49

Diagnostic Checks 50

Problem Solving Hierarchy 51

Pneumatic System Diagnostic Checks 52

O2 Assembly Diagnostic Checks 52

Optical Path Disgnostic Checks 55

4

Page 5

IR Measurement Assembly Diagnostic Checks 56

Agent ID Assmebly Diagnostic Checks 57

Power Supply Diagnostic Checks 58

Operating Temperature Diagnostic Checks 59

Test Points, Connectors and Jumpers 59

Tes t P o i n t s 5 9

Connectors 60

Jumpers 60

Repairing the Anesthetic Gas Module 62

Introduction 62

The Top Cover 64

Removal 64

Replacement 64

Lifting the IR Measurement Mounting Bracket 66

Removal 67

Replacement 67

Infrared Measurement Assembly Head 69

Transferring NVRAM Data to a Replacement Head 69

Sample Cell 73

Removal 73

Replacement 73

Solenoid Valve #1 77

Removal 77

Replacement 77

Power Supply Unit 79

Removal 79

Replacement 79

Main PC Board 80

Removal 80

Replacement 81

O2 Sensor 82

Removal 82

Replacement 83

Agent Identification Head 85

Removal 85

Replacement 86

Pump 87

Removal 87

Replacement 87

Fan 88

Removal 88

Replacement 88

Solenoid Valve #2 90

Removal 90

Replacement 90

5

Page 6

To p C o v e r P C B o a r d 91

Removal 91

Replacement 91

Watertrap Manifold and Protector 93

Removal 93

Replacement 93

Power Fuses 94

Removal 94

Replacement 94

Test and Inspection Matrix 94

When to Perform Test Blocks 98

Safety Test Appendix 99

Parts List 101

Calibration Equipment 106

6

Page 7

Introduction

This chapter contains the following information on the M1026A Anesthesia Gas Module:

• A description of the Module, including its physical, environmental and performance specifications

• A general explanation of the measurement principles that the Module uses to measure gas

concentrations

• The theory of operation of the Module: the layout of its components and how they work.

Description

The Philips M1026A Anesthetic Gas Module works together with the IntelliVue MP90 patient

monitors through an RS232 serial interface. It measures the airway gases of ventilated patients who are

under general gas anesthesia, or emerging from it.

1

1Anesthetic Gas Module

The module produces graphical wave data, and inspired and end-tidal numeric data for the following

gases:

•CO

•N

• One volatile anesthetic agent

•O

It also generates numerics for the patient’s airway respiration rate (AWRR).

The Agent Identification feature identifies which anesthetic agent is being used.

2

O

2

(optional)

2

Product Structure

The only version of the M1026A Anesthetic Gas Module compatible with the IntelliVue Monitoring

System is:

M1026A #A05: M1026A Watertrap with 5-Agent-ID (Hal, Iso, Enf, Des, Sev)

• #C03 (MUST-Option): adds fast O

Physical Specifications

Size (H x W x D)

90mm x 370mm x 467mm (3.54 x 14.6 x 18.4 in).

measurement

2

5

Page 8

1 Anesthetic Gas Module Introduction

Weight

8.2 kg (18 lb).

Environmental Specifications

Operating Temperature

15 to 40°C (59 to 104°F).

Storage Temperature

-40 to 65°C (-40 to 149°F).

Humidity Limit (Operating)

up to 95% RH max @ 40 °C (104 °F).

non-condensing

Humidity Limit (Storage)

up to 95% RH max @ 65 °C (149 °F).

non-condensing

Altitude Range (Operating)

-305 to 3048m (-1,000 to 10,000 ft).

Altitude Range (Storage)

-305 to 5,486m (-1,000 to 18,000 ft).

Warm-up Time

After switching on: 2 minutes to measure, 8 minutes for full specification accuracy.

Performance Specifications

All Performance and accuracy specifications are valid based on gas sample tubing M1658A, including

watertrap M1657B, and airway adapter 13902A.

Humidity Correction: For CO

Wet: p [mmHg] = c [Vol%] * (p_abs - p_H

Dry: p [mmHg] = c [Vol%] * p_abs /100

Where p = partial pressure, c = gas concentration, p_abs = pressure in breathing circuit, p_H

mmHg, partial pressure of water vapor of exhaled gas (37

For all other gases the readings are always given as dry values.

Sample Flow Rate: 150 ml/min.

Sample Delay Time: All measurements and alarms are subject to a delay of 3 seconds.

Total System Response Time = the sum of the delay time and the rise time.

the humidity correction can be set to “wet” or “dry”.

2

O)/100

2

o

C, 100% rh).

O = 47

2

6

Page 9

Introduction 1 Anesthetic Gas Module

CO2 Measurement

Range: 0 to 76 mmHg

Accuracy: 1.5 mmHg (0 - 40 mmHg)

2.5 mmHg (40 - 60 mmHg)

4.0 mmHg (60 - 76 mmHg)

Resolution: 1 mmHg

Rise-time: 410 msec typical

The total system response time is the sum of the sample delay time (3 seconds) and the rise time (410

msec typical)

AWRR derived from CO2 Waveform

Range: 0 to 60 rpm

Accuracy: ± 2 rpm

Resolution: 1 rpm

Detection Criteria: 6 mmHg variation in CO

N2O Measurement

Range: 0 to 85 vol%

Accuracy: 1.5 vol% + 5% relative

Resolution: 1 vol%

Rise-time: 510 msec typical

Measurement

O

2

Range: 0 to 100vol%

Accuracy: ± 2.5 vol% or 5% relative, whichever is the greater.

Resolution: 1 vol%

Rise-time: 450 msec typical

2

Anesthetic Agent Measurement

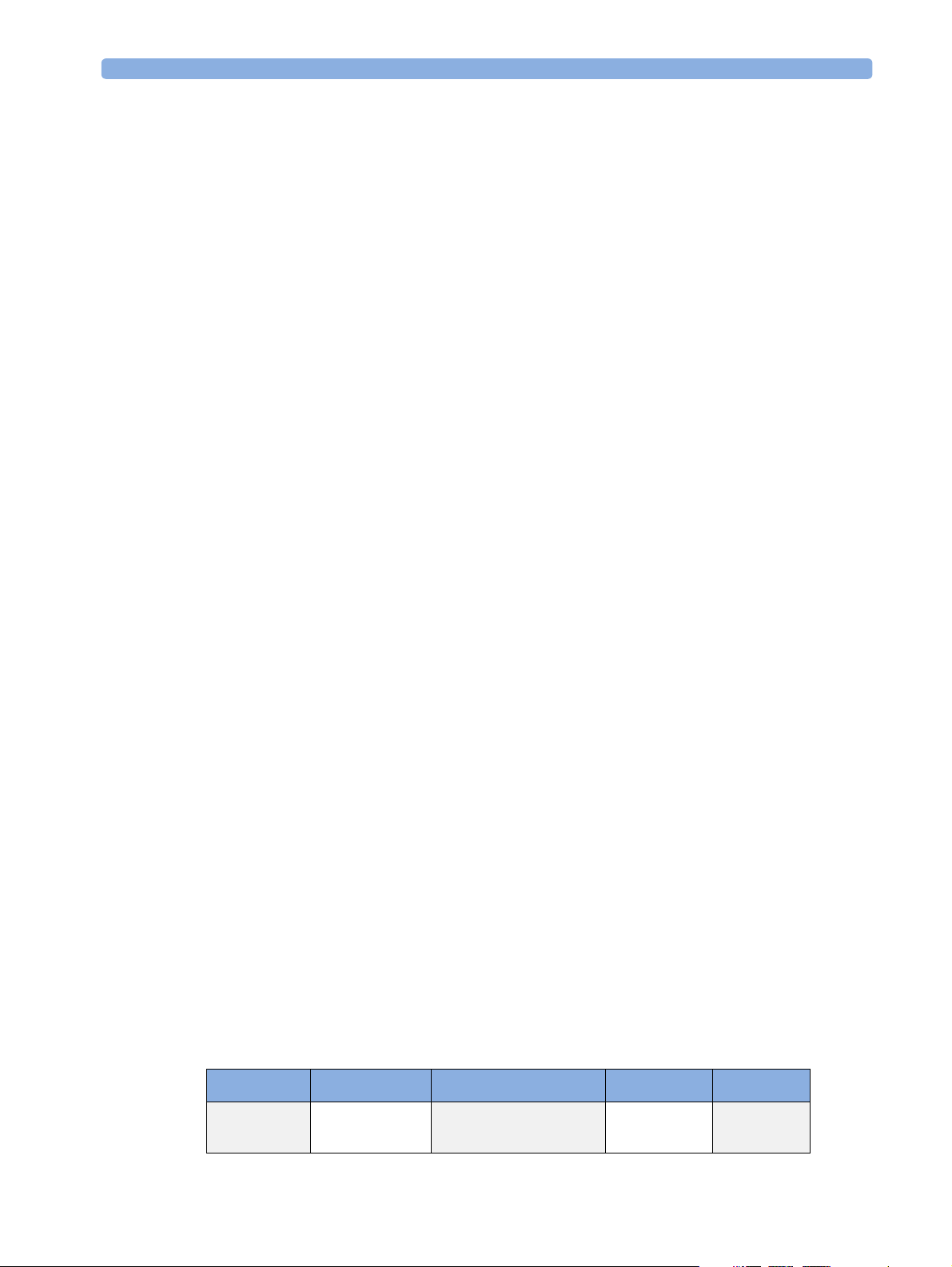

Agent Range (vol%) Accuracy Resolution Rise Time

Halothane 0 - 7.5 0.2 vol% + 4.0% relative 0.05 < 740

Enflurane 0 - 7.5 0.1 vol% + 4.0% relative 0.05 < 620

7

Page 10

1 Anesthetic Gas Module Introduction

Agent Range (vol%) Accuracy Resolution Rise Time

Isoflurane 0 - 7.5 0.1 vol% + 4.0% relative 0.05 < 610

Sevoflurane 0 - 9.0 0.1 vol% + 4.0% relative 0.05 < 570

Desflurane 0 - 20.0 0 . 1 v o l % + 6 . 0 % r e l a t i v e 0 . 0 5 ( 0 - 1 0 )

0.1 (10.1-20)

< 540

Alarm Ranges

Agent High Range Low Range

AWRR 10 - 60 rpm 0 - 59 rpm

ETCO

2

IMCO

2

inN2O 0 - 82 vol% none

inO

2

et SEV 0.1 - 9.0 vol% 0.0 - 8.9 vol%

in SEV 0.1 - 9.0 vol% 0.0 - 8.9 vol%

et DES 0.2 - 20.0 vol% 0.0 - 19.8 vol%

in DES 0.2 - 20.0 vol% 0.0 - 19.8 vol%

Halothane, Enflurane, Isoflurane

et 0.1 - 7.5 vol% 0.0 - 7.4 vol%

in 0.1 - 7.5 vol% 0.0 - 7.4 vol%

20 - 76 mmHg 10 - 75 mmHg

2 - 20 mmHg none

19-100 vol% 18 - 99 vol%

Alarm Delay

10 seconds if no automatic zero calibration occurs within that time.

Apnea Alarm

INOP Alarms

INOP alarms are triggered if:

• The Philips M1026A Anesthetic Gas Module is disconnected or switched off.

• The equipment malfunctions.

• The Agent-ID malfunctions.

• Zero calibration has failed.

8

Delay Range: 10 - 40 seconds

Criterion No detected breath within the adjusted delay time

Alarm: Within 2 seconds after this criterion is met, if no automatic zero

occurs

Page 11

Introduction 1 Anesthetic Gas Module

• Zero calibration is in progress.

• The gas sample tube is occluded, or the water trap is full.

• The Philips M1026A Anesthetic Gas Module is unable to measure.

• Gas contaminant is detected.

• Agent mixture detected.

• Anesthetic agent detected but not selected.

• The module is in warm-up mode.

• No breath detected.

• The Anesthetic Gas Module is incompatible with the monitor

General Measurement Principles

The Philips M1026A Anesthetic Gas Module uses a technique called Non-Dispersive Infrared Gas

Concentration Measurement (NDIR) to measure the concentration of gases.

This works as follows:

• The gases that the Philips M1026A Anesthetic Gas Module can measure absorb infrared (IR) light.

• Each gas has its own absorption characteristic. The gas mixture is transported into a sample cell, and

an IR filter selects a specific band of IR light to pass through the gas. For multiple gas measurements,

multiple IR filters are used.

• The higher the concentration of gas in the mixture the more IR light it absorbs. This means that

higher concentrations of IR absorbing gas results in lower transmission of IR light.

• The amount of IR light transmitted through an IR absorbing gas is measured.

• From the amount of IR light transmitted, the concentration of gas can be calculated. This

calculation provides the gas concentration value.

gas cannot be measured with this technique as it does not absorb IR light. Hence O2 gas is

O

2

measured with a sensor that makes use of the paramagnetic properties of O

technique.

Theory of Operation

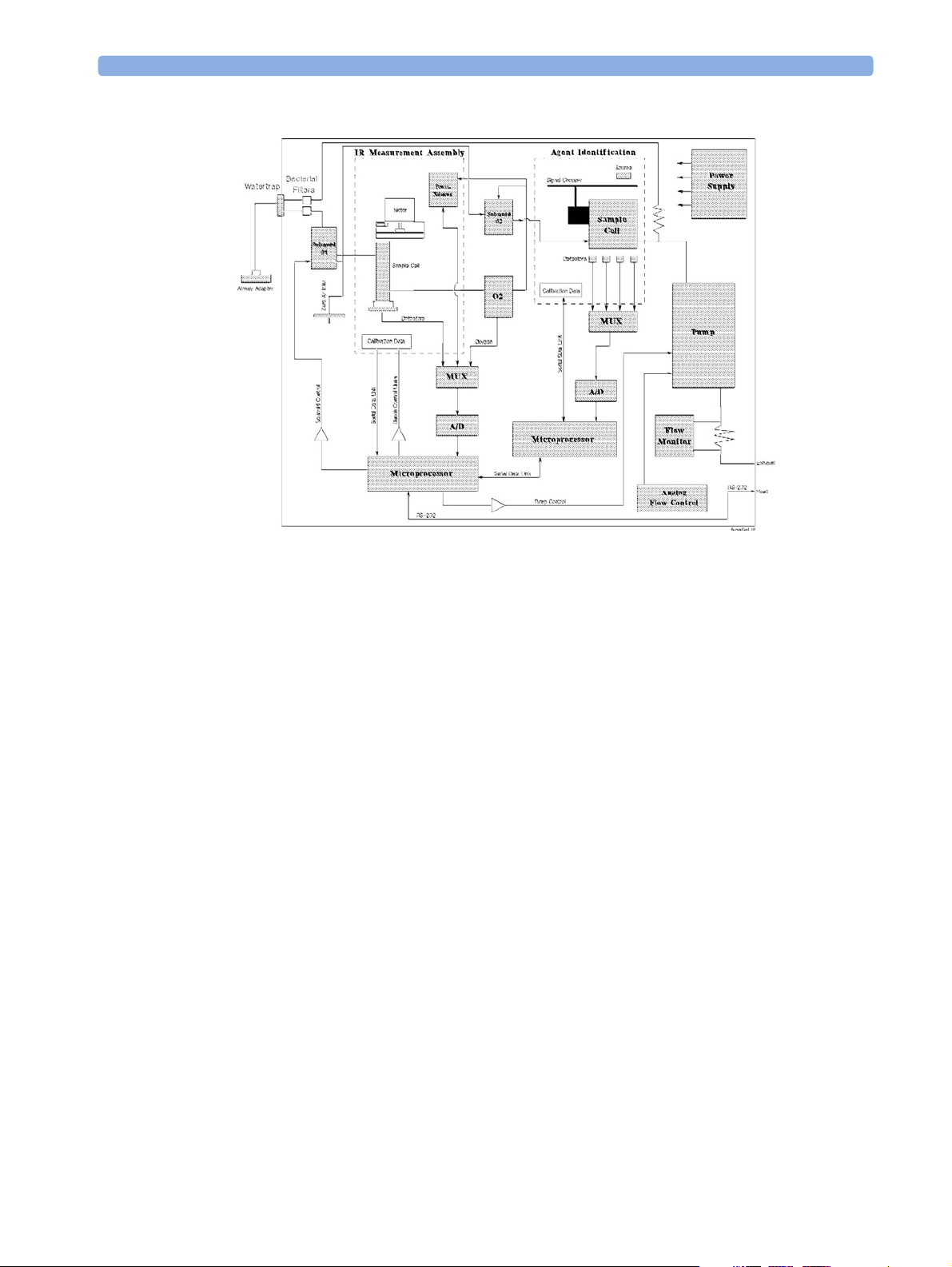

Figure 1 shows the functional blocks within the Philips M1026A Anesthetic Gas Module.

for its fast measurement

2

9

Page 12

1 Anesthetic Gas Module Introduction

The main components of the Philips M1026A Anesthetic Gas Module are:

• Main PC Board.

• Switching Power Supply.

• Pneumatic System.

• Agent Identification.

•O

• Infrared Measurement Assembly.

Main PC Board

This digital board:

• Controls the pneumatic system and the IR measurement assembly.

• Converts the preamplified analog output signal from the IR detector into a digital value. Under

software-controlled processing, this is then converted to a fully compensated gas concentration

value.

• Converts analog signals from the sample cell pressure sensor, transducer, sample cell temperature

thermistor, and the ambient temperature thermistor, into digital environmental data for gas

compensation and data reporting.

Figure 1 Anesthetic Gas Module Functional Block Diagram

Sensor.

2

10

• Converts an analog O

for CO

compensation and O2 data reporting.

2

signal, supplied by the O2 measurement system, into O2 concentration data

2

Page 13

Introduction 1 Anesthetic Gas Module

• Converts analog signals from the flow-control servo system and power supply into digital data for

status reporting.

• Processes the algorithm for end-tidal, inspired and respiration rate values.

• Controls the communication between the monitor and the Philips M1026A Anesthetic Gas Module

through an RS232 interface that uses a standard communications protocol.

• Contains the software program that controls the Philips M1026A Anesthetic Gas Module in a 128K

EPROM.

Power Supply

The input voltage is 100V - 240V. The output voltages are ±12V and +5V and the maximum output is

55W.

Pneumatic System

The main parts of the pneumatic system are:

•Watertrap.

• Pump assembly, including pump outlet filter.

• Two solenoid valves.

• Tubing system including:

– Differential pressure transducer and restrictor for control of the total flow.

–Measurement path.

– Drainage path parallel to measurement path.

• Ambient air reference filter.

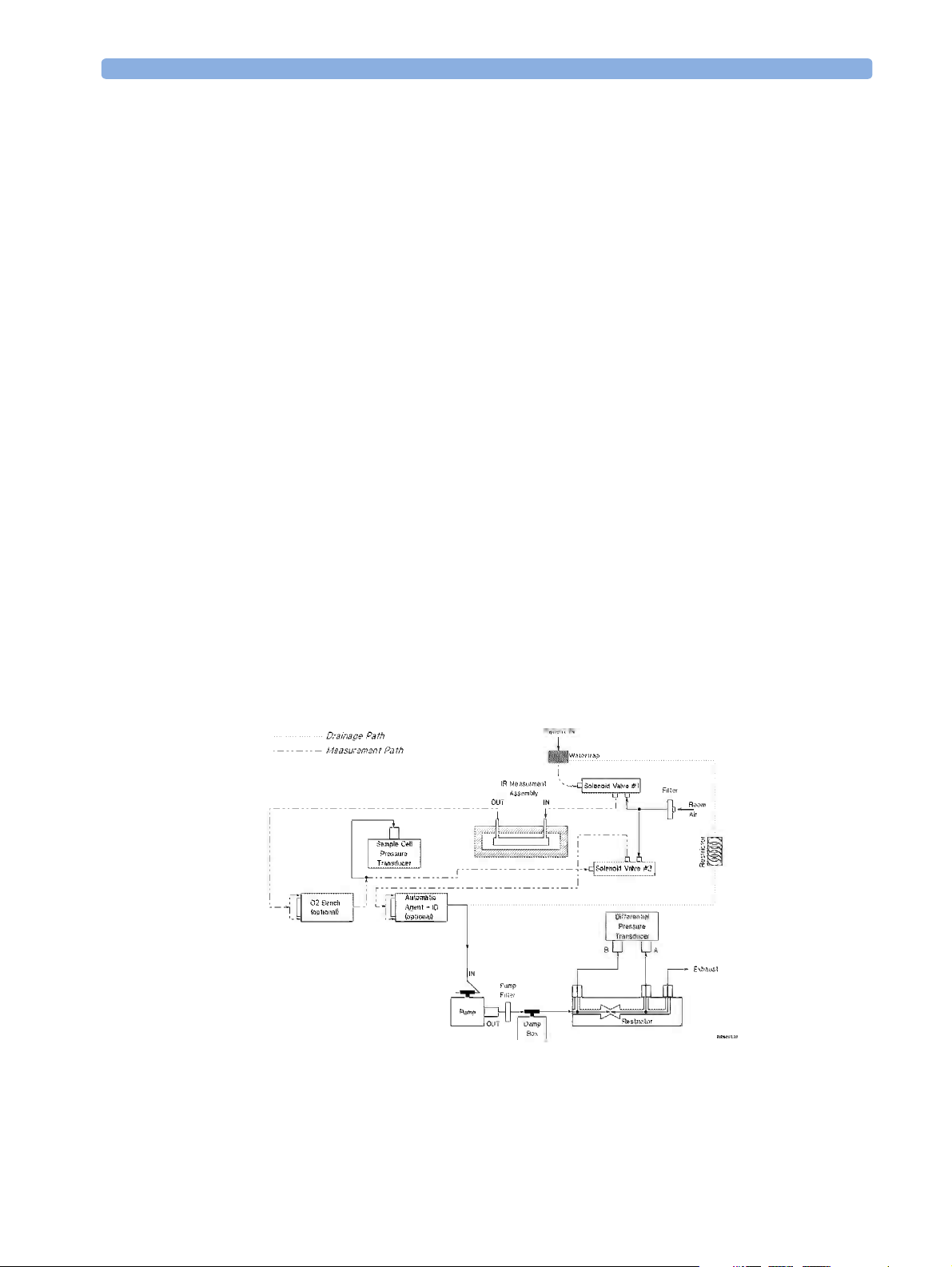

Figure 2 Pneumatic System

11

Page 14

1 Anesthetic Gas Module Introduction

The pneumatic system works in the following way:

1 Eliminates residual water and fluids from patient sample gas using the watertrap and eliminates

water vapor using Nafion Tubing.

2 Splits the patient’s sample gas flow (150ml/min) into the measurement path (120ml/min) and

drainage path (30ml/min).

3 Passes the patient’s sample gas in the measurement path at 120ml/min through the measurement

benches.

4 Delivers zero calibration gas to the sample cells for the periodic zeroing.

5 Exhausts the patient’s sample gas, the zero calibration gas, and the span calibration gas.

6 Monitors for an occlusion in the sampling pneumatics.

Pump

The servo-controlled pump is attached to the exhaust of the Anesthetic Gas Module. It generates the

flow through the system and pulls the gas from the airway adapter through the measurement

subsystems to the exhaust outlet. It also delivers the zero calibration gas to the sample cells of the

measurement subsystems for the periodic zero procedures and it exhausts the patient’s sample gas, the

zero calibration and field calibration gases.

Watertrap

The flow-rate control logic drives the pump as hard as necessary to maintain the selected flow rate. A

partial occlusion or an inefficient pump results in the pump being driven harder. A serious occlusion

results in the pump being driven at or near its maximum load. This triggers a sensing circuit, which

then reports an occlusion.

Water Separation Filters

Wate r Fuse s

Patient Sample Inlet

Wate r Res e rvo i r

12

Figure 3 Watertrap

Page 15

Introduction 1 Anesthetic Gas Module

The watertrap consists of two water separation filters, two water fuses and a water reservoir. The gas

sample coming from the patient may contain fluids which are separated from the gas at the first water

separation filter. The gas is then split into two paths, the “measurement” path with the main part of the

total gas flow (including water vapor) continuing on the “dry” side of the separation filter and the

“drainage” path (containing any liquid droplets) with the smaller amount of the total flow continuing

on the “wet” side of this filter. At the pump both gas paths are recombined.

The watertrap proper includes “water fuses” in both the “measurement” and the “drainage” paths,

consisting of a material that swells when getting wet (when the reservoir is full or when fluid penetrates

the separation filter and enters the “measurement” path) and blocks the respective path at the inlet of

the unit. Once the “water fuses” are blown, any passage of fluid is blocked and the gas flow resistance

increases so that an occlusion is detected.

Sample Flow Through the Pneumatic Path

• The drainage path serves to withdraw fluid separated from the gas sample into the watertrap

reservoir, so that the AGM interior is protected from fluid that might cause an occlusion in the

measurement path.The drainage path leads into the large watertrap reservoir where all liquid water

and other fluids are collected. When the drainage path leaves the watertrap through a water

separation filter and a through a water fuse it leads through internal Nafion tubing then through a

bacterial protection filter and flow restrictor directly to the pump. This flow restrictor determines

the percentage distribution between drainage and measurement path flow.

• The measurement path leads through a water separation filter and through a water fuse on into the

measurement system. The patient sample gas (on the measurement path) then flows through

internal Nafion tubing and through a bacterial protection filter to the first solenoid valve. Room air

for the zero calibration is alternatively input (via a dust filter) to this solenoid valve. The solenoid

valve switches between the two gases depending on the current mode of operation - normal

measurement or zero calibration.

The patient sample gas or zero calibration gas then flows through the measurement subassemblies:

• the IR Measurement Assembly (for measurement of anesthetic agent, CO

•the O

cell (if present)

2

and N2O)

2

• the Agent Identification assembly.

A second solenoid valve between the O

cell and the Agent Identification Assembly routes room air

2

directly to the Agent Identification Assembly for optimal purging of the assembly during zero

calibration.

From the Agent Identification Assembly the patient sample gas or zero calibration gas flows to the

pump. Before reaching the pump, it joins the drainage path again.

From here it is passed through a filter and damper to the flow sensor which consists of a differential

pressure transducer and a flow restrictor. The flow sensor determines, stabilizes and limits the flow rate

of the sampled gas.

After the gas has passed through the flow sensor it is routed through a second damper to the Sample

Gas output.

Agent Identification Assembly

The agent ID analyzer identifies which anesthetic agents are present in a gas sample drawn from the

patients’s airway. The anesthetic agents are identified from a set of known anesthetic gases.

13

Page 16

1 Anesthetic Gas Module Introduction

Isoflurane

Enflurane

Halothane

Sevoflurane

Desflurane

Measurement Principle

Sample gas passes through the agent identification head where the absorption characteristics of the gas

are measured. This is done using NDIR technology as described in General Measurement Principles.

The head outputs analog signals and sends them for processing to identify the anesthetic agent.

Data averaging is used to ensure accurate measurements when agent concentrations are low. The

information used to calculate the concentrations of the three agents includes:

• The preamplified outputs from the IR detector.

• The thermistor output from the agent identification head.

• Zero calibration constants.

O2 Sensor

Specifications

Weight 335 g (0.75 lbs)

Size (HxWxD) 54 x 54 x 56 mm

Calibration Zero: Room Air

Measurement Principle

The O2 sensor uses a fast O2 measurement technique that utilizes O2 paramagnetic properties.

Two sealed spheres forming a dumb-bell assembly are filled with N

suspended in a symmetrical non-uniform magnetic field. The spheres take up a position away from the

most intense part of the field, due to the diamagnetic force on the dumbbells. The dumb-bell assembly

is then surrounded by the sample gas.

When the surrounding sample gas contains O

the magnetic field by the relatively stronger paramagnetic O

is proportional to the paramagnetism of the surrounding gases, and can therefore be taken as a measure

of the oxygen concentration.

Span: Suitable calibrated mixture

, the dumb-bell spheres are forced even further out of

2

. The dumb-bell assembly is

2

gas. The torque acting on the dumb-bell

2

14

This torque is measured by monitoring the current required in a servo system that attempts to return

the dumb-bells to their normal position.

Page 17

Introduction 1 Anesthetic Gas Module

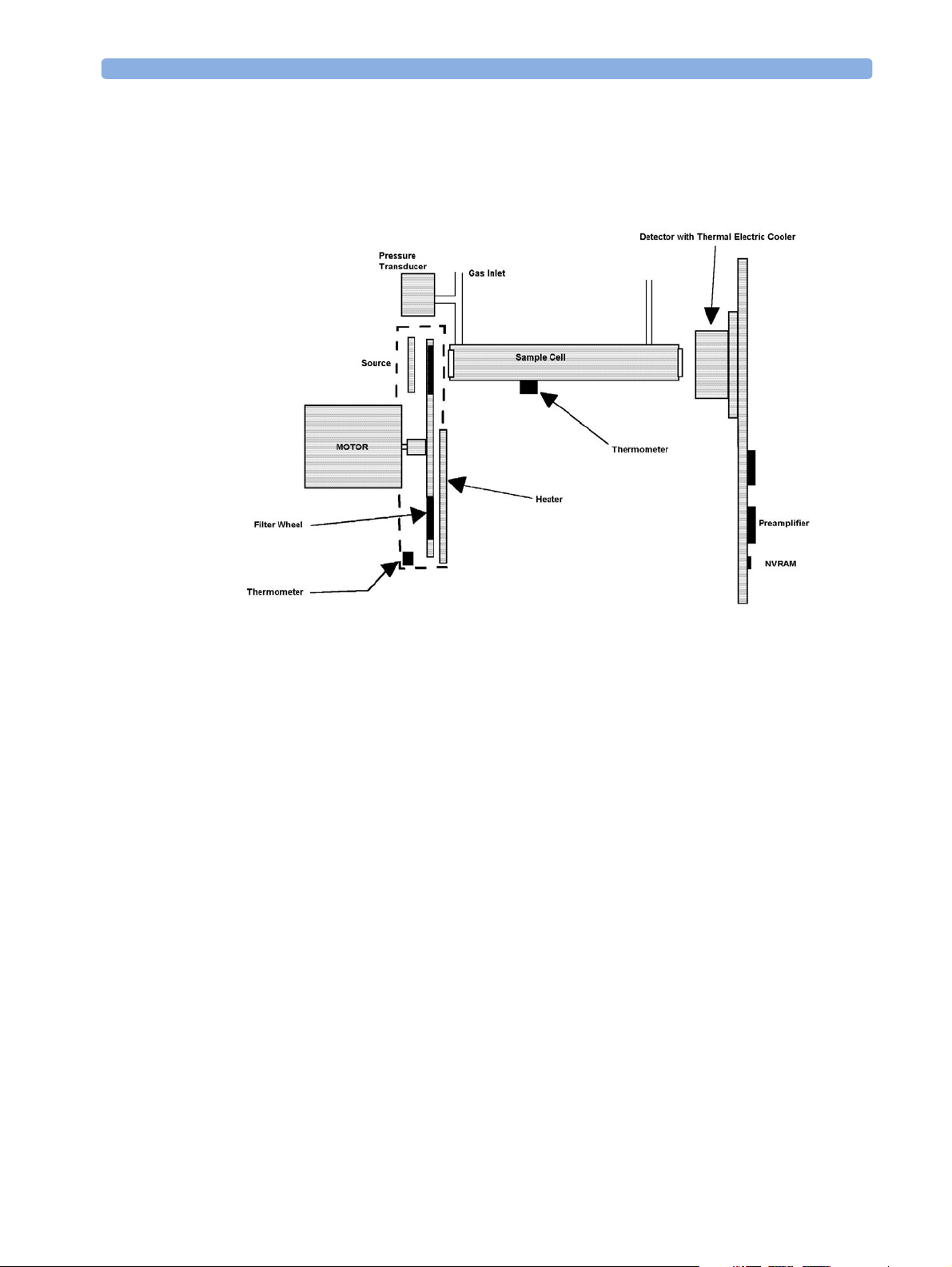

Infrared Measurement Assembly

The measurement assembly measures the IR light absorption of the gases in its sample cell (see Figure

4).

Figure 4 Anesthetic Gas Module Measurement Assembly

The measurement assembly contains the following subassemblies:

IR Source: The ceramic IR source is heated to 600°C by applyin g a constant

drive voltage across it.

Filter Wheel Assembly: The filter wheel assembly includes IR filters for the anesthetic agent,

CO

, N2O and a reference channel. A blank segment (dark period)

2

marks the beginning and end of the filter series.

Sample Cell: The sample cell is a stainless steel tube. It has non-IR absorbing

sapphire windows at both ends, and barbed inlet and outlet ports.

The inlet and outlet ports are placed as close as possible to the

windows so that the gas flows effectively through the cell.

Preamp Assembly The preamplifier board assembly includes an IR detector, an IR-

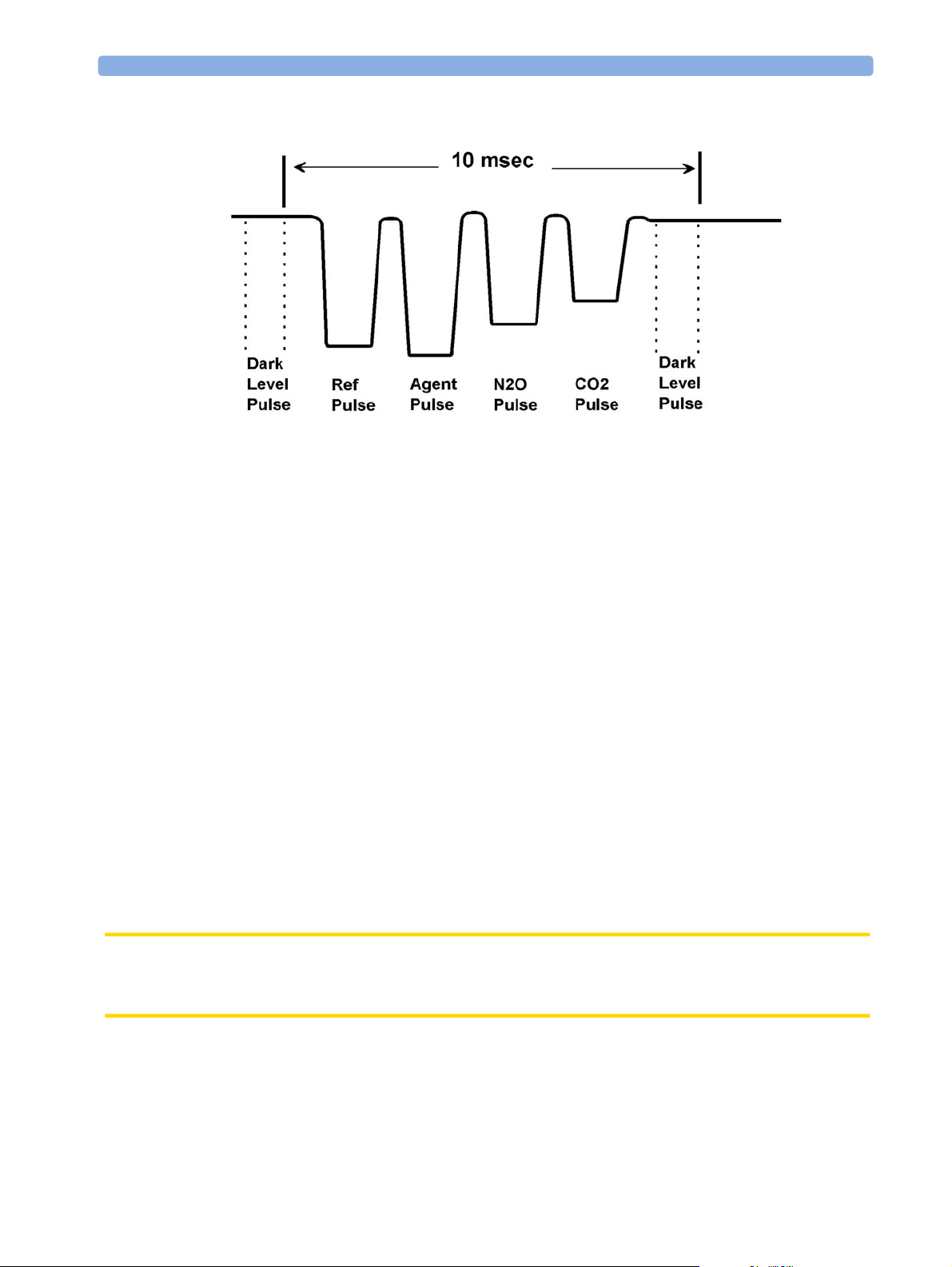

detector thermistor, a TE cooler, and a pre-amplification circuit. The

output from the preamplifier is a stream of pulses; this pulse train has

one pulse for each IR filter, and is terminated by a blank period (dark

level phase) (see Figure 5).

15

Page 18

1 Anesthetic Gas Module Installation and Patient Safety

Figure 5 IR Detector Output Signal

Installation and Patient Safety

This chapter describes how to install the Philips M1026A Anesthetic Gas Module. It details the

operating environment required by the Philips M1026A Anesthetic Gas Module as well as instructions

on how to affix the local language labels and physically connect it to the monitor. Next, the patient

safety information is detailed. Finally, this chapter describes the software setup required and any postinstallation checks that have to be performed before using the Philips M1026A Anesthetic Gas Module

together with a reminder of the preventive maintenance (PM) checks and their frequencies.

Where post-installation procedures are specific to installation, they are described in full in this chapter.

For procedures which are also used in other situations (for example calibration, preventative

maintenance, etc.), a reference to the description will be given.

Physical Installation

This section describes the operating and storage environment for the Philips M1026A Anesthetic Gas

Module, affixing the local-language labels, connecting to the monitor, and fitting the gas exhaust

return system.

CAUTION The Philips M1026A Anesthetic Gas Module must be positioned horizontally on a level surface. To

avoid condensed water collecting in the patient sample tube, it is recommended that the Philips

M1026A Anesthetic Gas Module is positioned at or above patient level, wherever possible.

16

Page 19

Installation and Patient Safety 1 Anesthetic Gas Module

Environment

WARNING Possible explosion hazard if used in the presence of flammable anesthetics.

The environment where the Philips M1026A Anesthetic Gas Module is used should be free from

vibration, dust, corrosive or explosive gases, and extremes of temperature and humidity.

For a cabinet mounted installation with the monitor, allow sufficient room at the front for operation

and sufficient room at the rear for servicing with the cabinet access door open.

The Philips M1026A Anesthetic Gas Module operates within specifications at ambient temperatures

between 15°C and 40°C, 8 minutes after switching it on.

Ambient temperatures that exceed these limits could affect the accuracy of this instrument and cause

damage to the components and circuits. Allow at least 2 inches (5cm) clearance around the instruments

for proper air circulation.

CAUTION If the Philips M1026A Anesthetic Gas Module has been stored at temperatures below freezing, it needs

a minimum of 4 hours at room temperature to warm up before any connections are made to it.

Make sure that the Philips M1026A Anesthetic Gas Module is free of condensation before operation.

Condensation can form when equipment is moved from one building to another, thus being exposed

to moisture and differences in temperature.

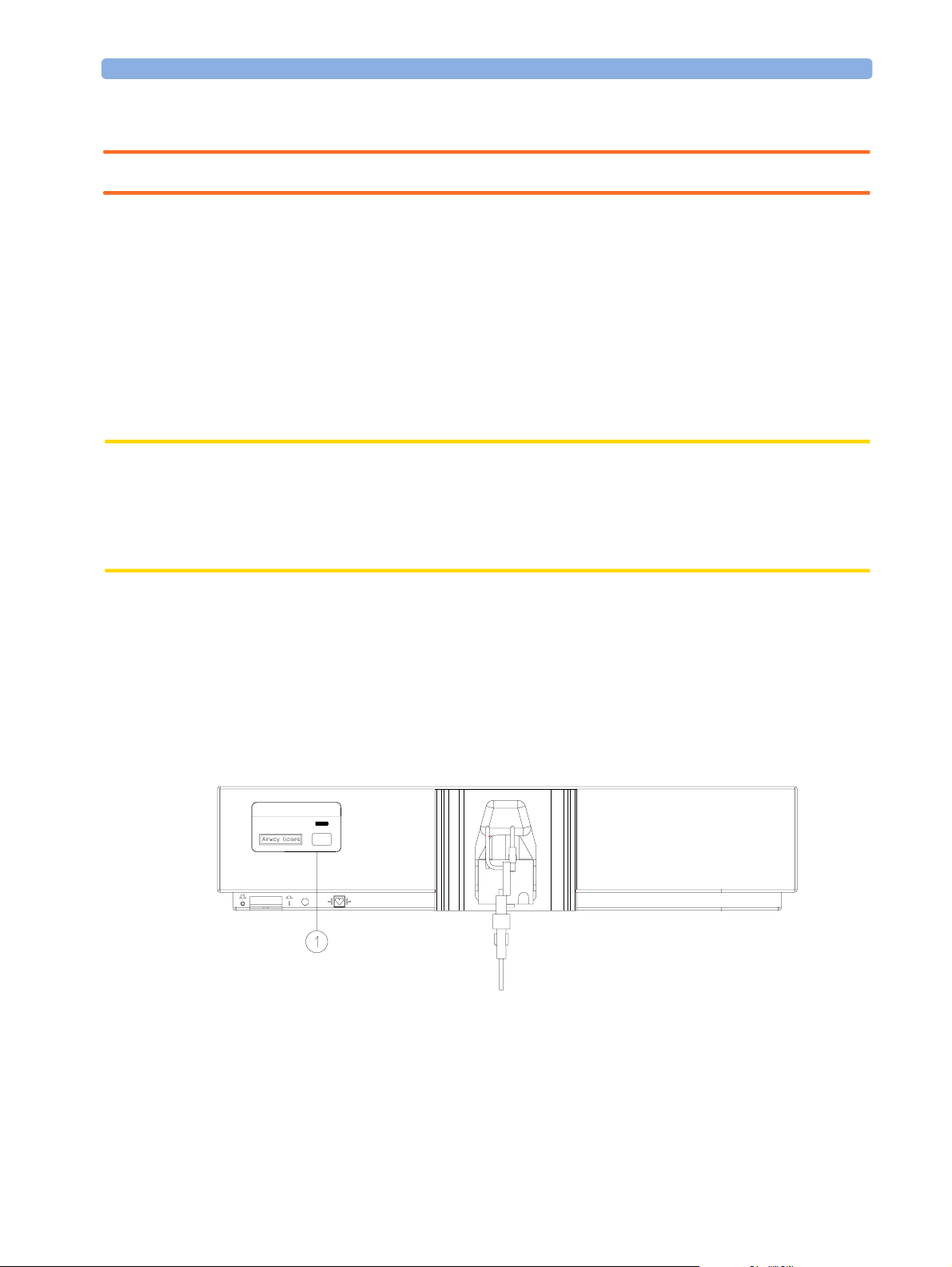

Label Sheet

There is a label sheet included with the Philips M1026A Anesthetic Gas Module which has the

translated versions for “Airway Gases”. You can stick a translated version over “Airway Gases” on the

left of the front panel. See (1) in Figure 6.

PAD M1026A

Figure 6 Label for the Philips M1026A Anesthetic Gas Module

Making Connections to the AGM

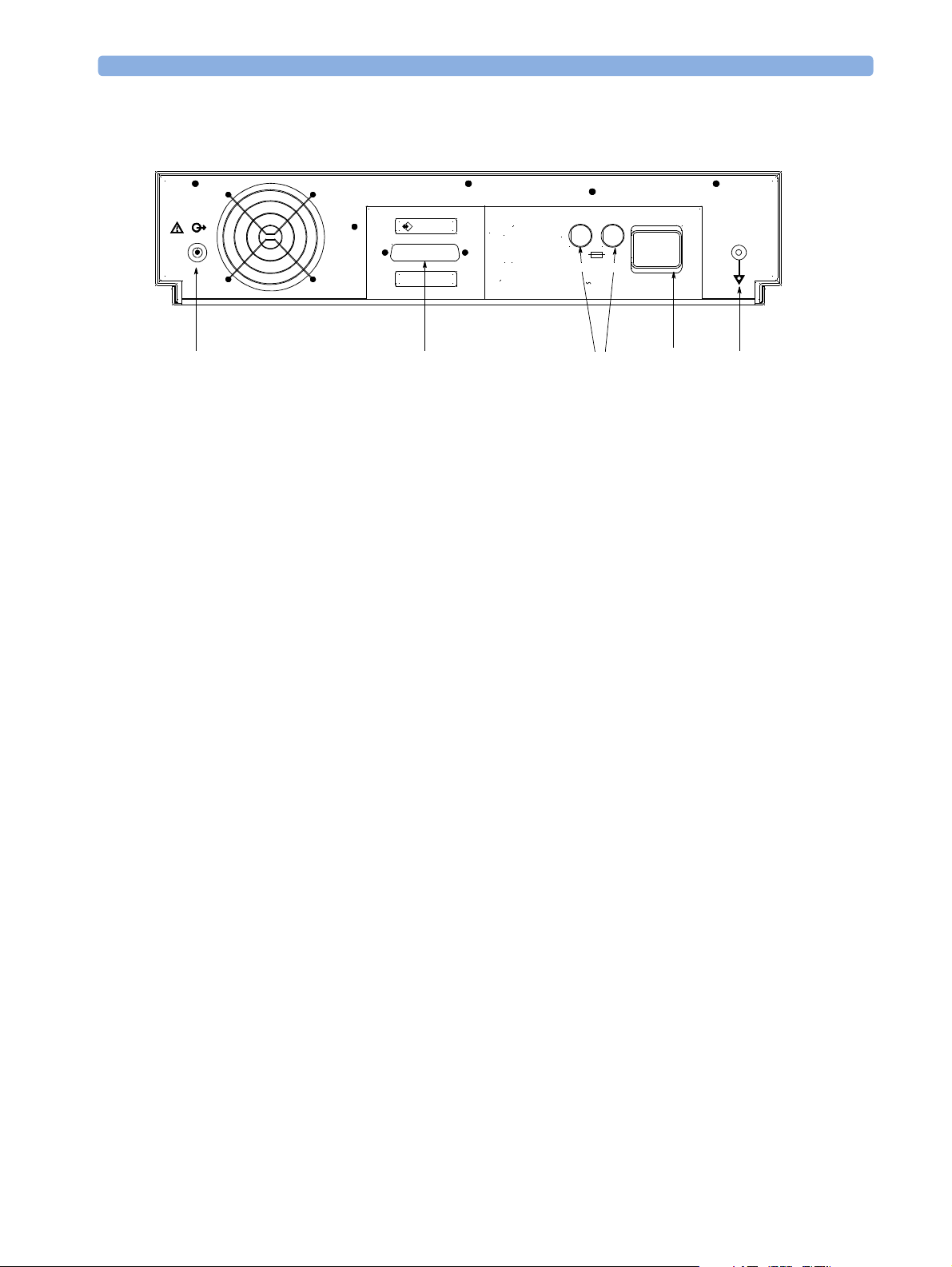

All connections to the AGM are made on its rear panel. Refer to Figure 7.

17

Page 20

1 Anesthetic Gas Module Installation and Patient Safety

600VA max.

100-240V

50-60 Hz

brear2d.tif

MONITOR

RS 232

T1.6 H 250V

60/140

(6)

Gas

Outlet

(2)

RS232

Connector

(5)

Fuses

Figure 7 The Rear Panel

1 Local power connector; this is a 3-pin connector, used to connect the AGM to the local line voltage

supply.

The module can be operated from an ac power source of 100 - 240 V ± 10%, 50/60 Hz. The

adjustment is made automatically by the power supply inside the module.

2 RS232 Connector (RS232 Interface); this is a 25-pin “D” type connector, used to connect the

AGM to the RJ45 connector of the monitor (Slot 08a, 07a, 04a, 03a, or 02a, - MIB I/O port - see

Connection of Devices via the MIB/RS232 Interface in the Installation Instructions section).

The connection can be made with the following cables:

– M1026A#K11 1 m (M1026-61001)

– M1026A#K12 3 m (M1026-61002)

– M1026A#K13 10 m (M1026-61003)

(1)

Local

Power

Connector

(4)

Equipotential

Grounding

Terminal

3 Equipotential Grounding Terminal; this is used to connect the AGM to the hospital’s grounding

system.

4 Line protection fuses, T1.6 H 250V.

5 Anesthetic gas exhaust. If N

O and/or other inhalation anesthetics are used during anesthesia,

2

pollution of the operating room should be prevented. Once the gas sample has passed through the

AGM, it should either be returned to or removed from the anesthesia circuit.

Sample Gas Connections to the Gas Exhaust

Returning the Gas Sample

You will need the following equipment to return the gas sample to the anesthesia circuit:

18

Page 21

Installation and Patient Safety 1 Anesthetic Gas Module

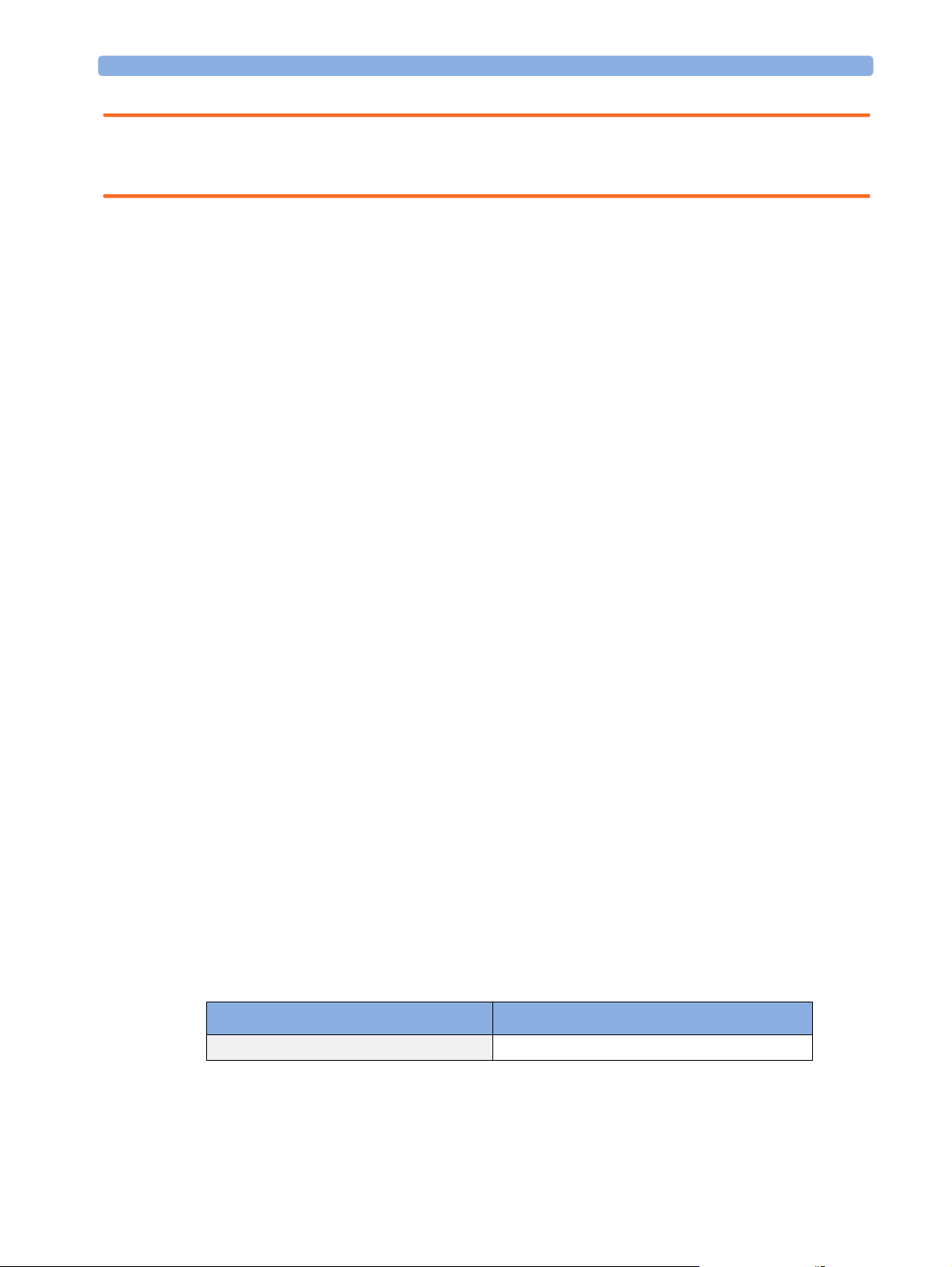

Equipment Part Number Comments

Gas Exhaust Return Line M1655A Tu b i ng i n cl u d e s t wo p ar t s :

Tube A = 50cm long

Tube B = 3m long

Gas Exhaust Return Filter M1656A Single patient use only

NOTE

The M1655A may not be available in all countries.

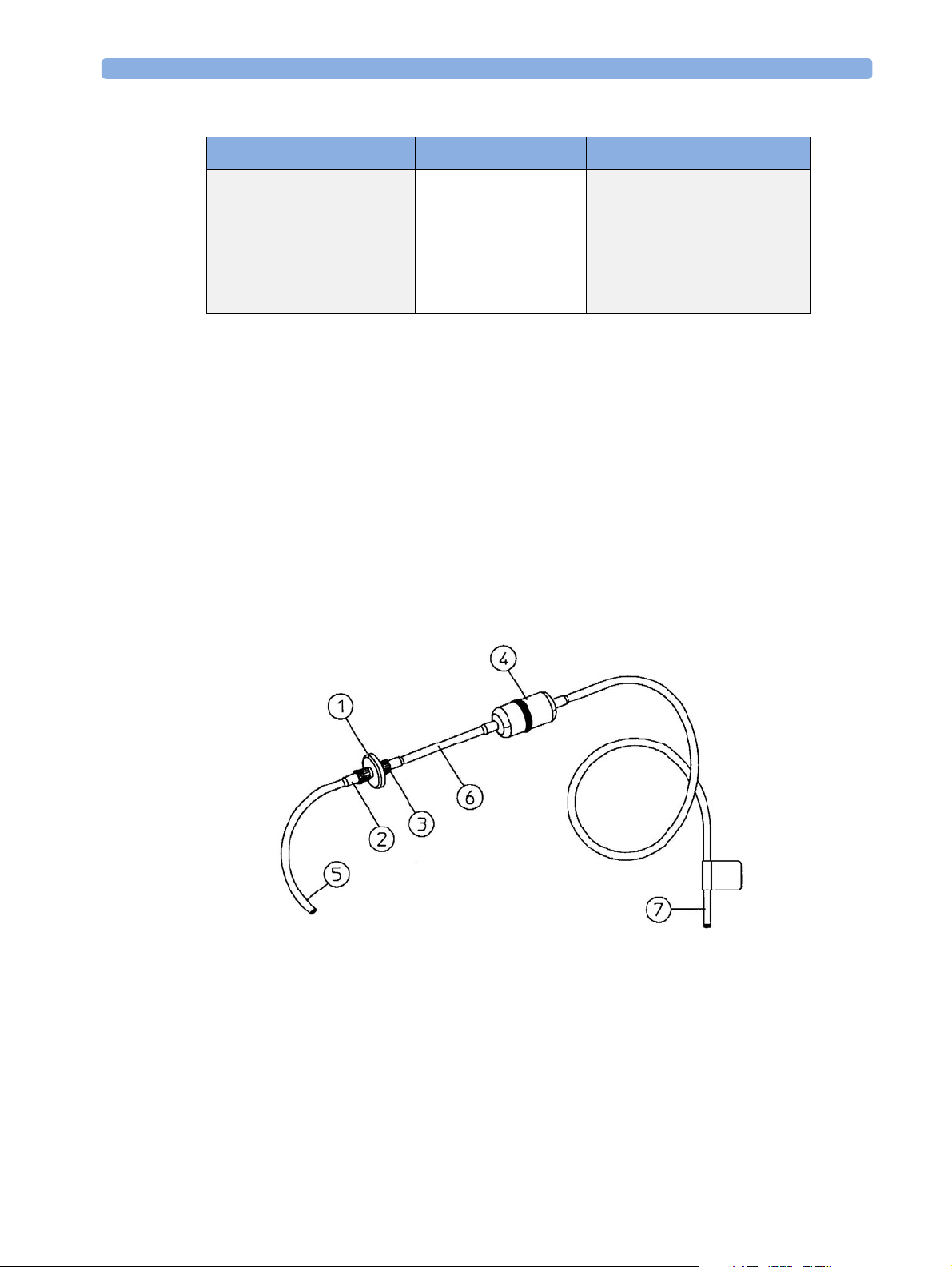

Setting Up the Gas Return

(see diagram Figure 8)

1 Fit the male luer lock connection (2) of the shorter tube, to the female side of the M1656A Gas

Exhaust Return Filter.

2 Fit the female luer lock connection (3) of the longer tube, to the male side of the M1656A Gas

Exhaust Return Filter.

3 Fit the open end (7) of the longer tube to the AGM’s Anesthetic Gas Exhaust.

4 Fit the open end (5) of the shorter tube to the ventilation circuit.

Figure 8 Setting Up the Gas Return

1 M1656A Gas Exhaust Return Filter

M1655A Gas Exhaust Return Line comprising:

2 Female luer lock

3 Male luer lock

19

Page 22

1 Anesthetic Gas Module Installation and Patient Safety

Dampener

4

5 Shorter tube

6 Connecting tube

7 Longer tube - connected to AGM exhaust port

Removing the Gas Sample

To remove the gas sample from the anesthesia circuit, a scavenging system needs to be connected to the

AGM’s Anesthetic Gas Exhaust. If you intend to use a scavenging system with the AGM, one of the

following parts must also be connected to protect it against malfunction:

1 A ventilator reservoir where the suction pressure does not exceed 0.3-0.4 mmHg or

2 A scavenging interface, properly set and maintained (see scavenging interface manufacturer’s

instructions).

Setup and Configuration Procedures

This section describes final setting up and configuration procedures that must be completed after the

AGM is connected to the monitor and switched on but before the AGM is used for monitoring.

Altitude Configuration

The altitude setting for the monitor is important as it is used as a reference to check the AGM ambient

pressure measurement.

See the Installation Instructions section for details.

Connect Sample Input Tubing

Connect the sample input tubing to the watertrap at the patient sample inlet on the water separation

filter. For details, refer to the Instructions for Use.

Preventive Maintenance (PM) Tasks

The preventive maintenance (PM) tasks are described in detail in chapter 5 of this guide. Here is a

short list of the PM tasks and how often they must be performed.

To ensure operation of the Philips M1026A Anesthetic Gas Module within specified limits:

1 Check the ventilator fan in the AGM for proper operation and build-up of dust and lint every 6

months.

2 Check the AGM’s calibration at least once every 12 months, or whenever the validity of the

readings is in doubt.

3 Replace the internal Nafion; tubing, room air filter, and pump filter, internal bacterial filters and

watertrap manifold seals, using the PM kit, every 12 months.

20

4 Test the pump using the test procedure provided in the PM Kit every 12 months. The square-

shaped pump should be cleaned before testing; the round-shaped pump may not be cleaned.

5 Check electrical safety (ground impedance test and enclosure leakage current test) at least every 12

months.

All safety and maintenance checks must be made by qualified service personnel.

Page 23

Installation and Patient Safety 1 Anesthetic Gas Module

WARNING Failure to implement a satisfactory maintenance schedule by the individual, hospital or institution

responsible for the operation of this equipment may cause equipment failure and possible health

hazards.

Post-Installation Checks

See Test and Inspection Matrix for details.

WARNING Do not use the instrument for any monitoring procedure on a patient if you identify anything which

indicates impaired functioning of the instrument.

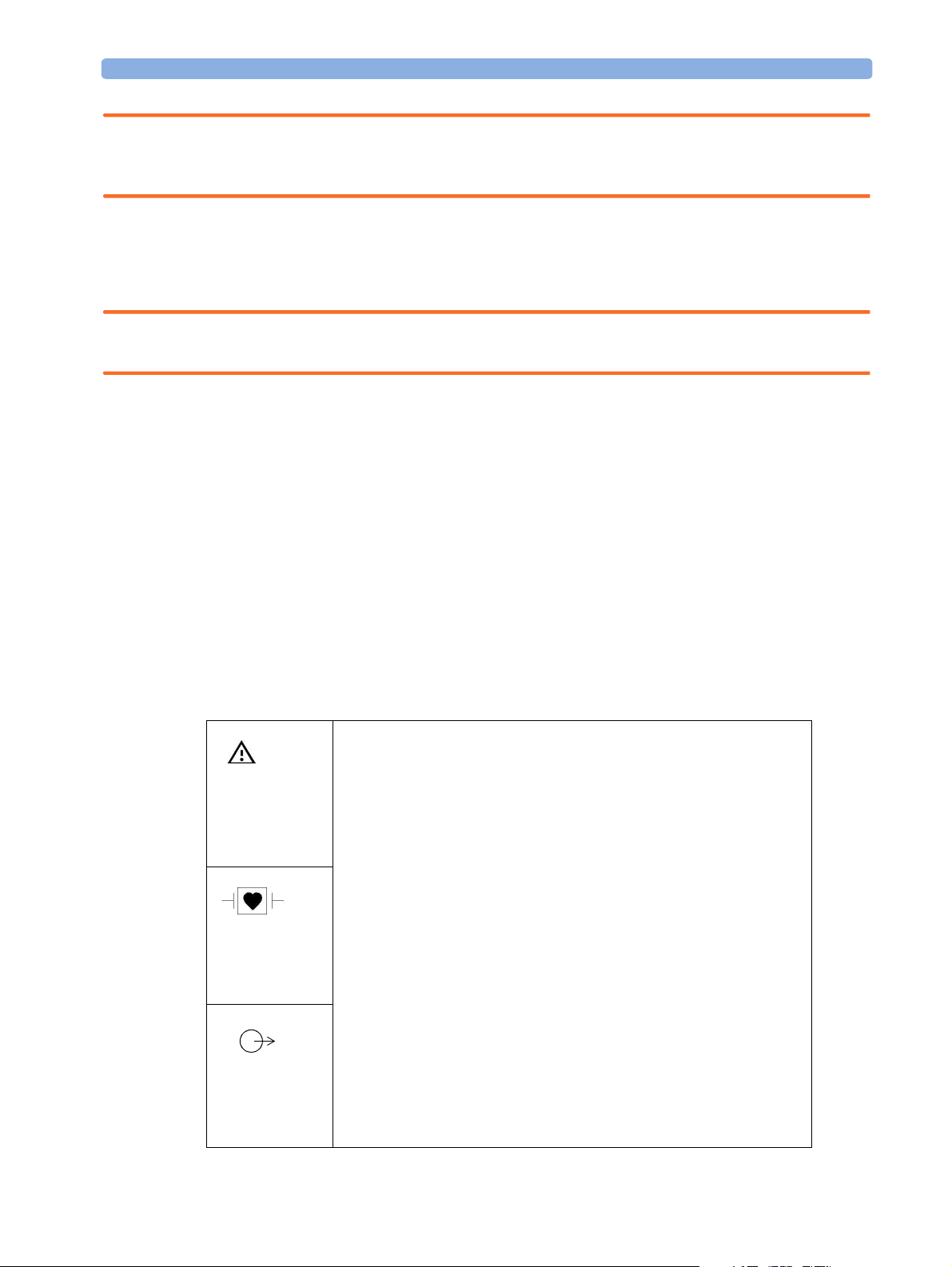

Safety Requirements Compliance and Considerations

The Philips M1026A Anesthetic Gas Module complies with the following international safety

requirements for medical electrical equipment:

• UL 2601-1

• IEC-60601-1

• CSA C22.2 No. 601.1-M90

• EN 60601-1

• EN 60601-1-2

Explanation of Symbols Used

Attention, consult accompanying documents.

Indicates that the instrument is type CF and is designed to have special

protection against electric shocks (particularly regarding allowable leakage

currents, having an F-Type isolated (Floating) applied part), and is

defibrillator proof.

A gas output (this symbol is also used to indicate an electrical output on the

monitor).

21

Page 24

1 Anesthetic Gas Module Installation and Patient Safety

A gas input (on the monitor this symbol can also stand for a video or 60V dc

input).

Equipotential grounding terminal.

RS232 communication port.

Fuse.

Protective earth ground.

Electrical shock hazard.

The Anesthetic Gas Module is protected against the effects of defibrillation and electrosurgery.

Power Supply Requirements

The system and the Anesthetic Gas Module can both be operated from an AC supply of 100 - 240V

±10%, 50 - 60Hz.

Grounding the System

To protect the patient and hospital personnel, the cabinet of the installed equipment has to be

grounded. The equipment is supplied with a detachable 3-wire cable which grounds the instrument to

the power line ground (protective earth) when plugged into an appropriate 3-wire receptacle. If a 3wire receptacle is not available, consult the hospital electrician.

22

Page 25

Checking and Calibrating the Anesthetic Gas Module 1 Anesthetic Gas Module

WARNING Do not use a 3-wire to 2-wire adapter.

Equipotential Grounding

Protection class 1 instruments are already included in the protective grounding (protective earth)

system of the room by way of grounding contacts in the power plug. For internal examinations on the

heart or the brain, Computer Module and Display Module of the System and the Philips M1026A

Anesthetic Gas Module must have separate connections to the equipotential grounding system.

One end of the equipotential grounding cable (potential equalization conductor) is connected to the

equipotential grounding terminal on the instrument’s rear panel and the other end to one point of the

equipotential grounding system. The equipotential grounding system assumes the safety function of

the protective grounding conductor if ever there is a break in the protective grounding system.

Examinations in or on the heart (or brain) should only be carried out in rooms designed for medical

use incorporating an equipotential grounding system.

Combining Equipment

If it is not evident from the instrument specifications whether a particular instrument combination is

hazardous or not, for example, due to summation of leakage currents, the user should consult the

manufacturers concerned or an expert in the field, to ensure that the necessary safety of all instruments

concerned will not be impaired by the proposed combination.

Checking and Calibrating the Anesthetic Gas Module

This chapter explains how to check the Anesthetic Gas Module to ensure that it is operating within its

specified limits. A list of the equipment required to carry out the checks is included, as well as step-by

step instructions for the calibrations.

If you receive fail indications while testing, refer to the troubleshooting section of this chapter for

guidance. If you are instructed to remove or replace parts of the Anesthetic Gas Module refer to the

respective section.

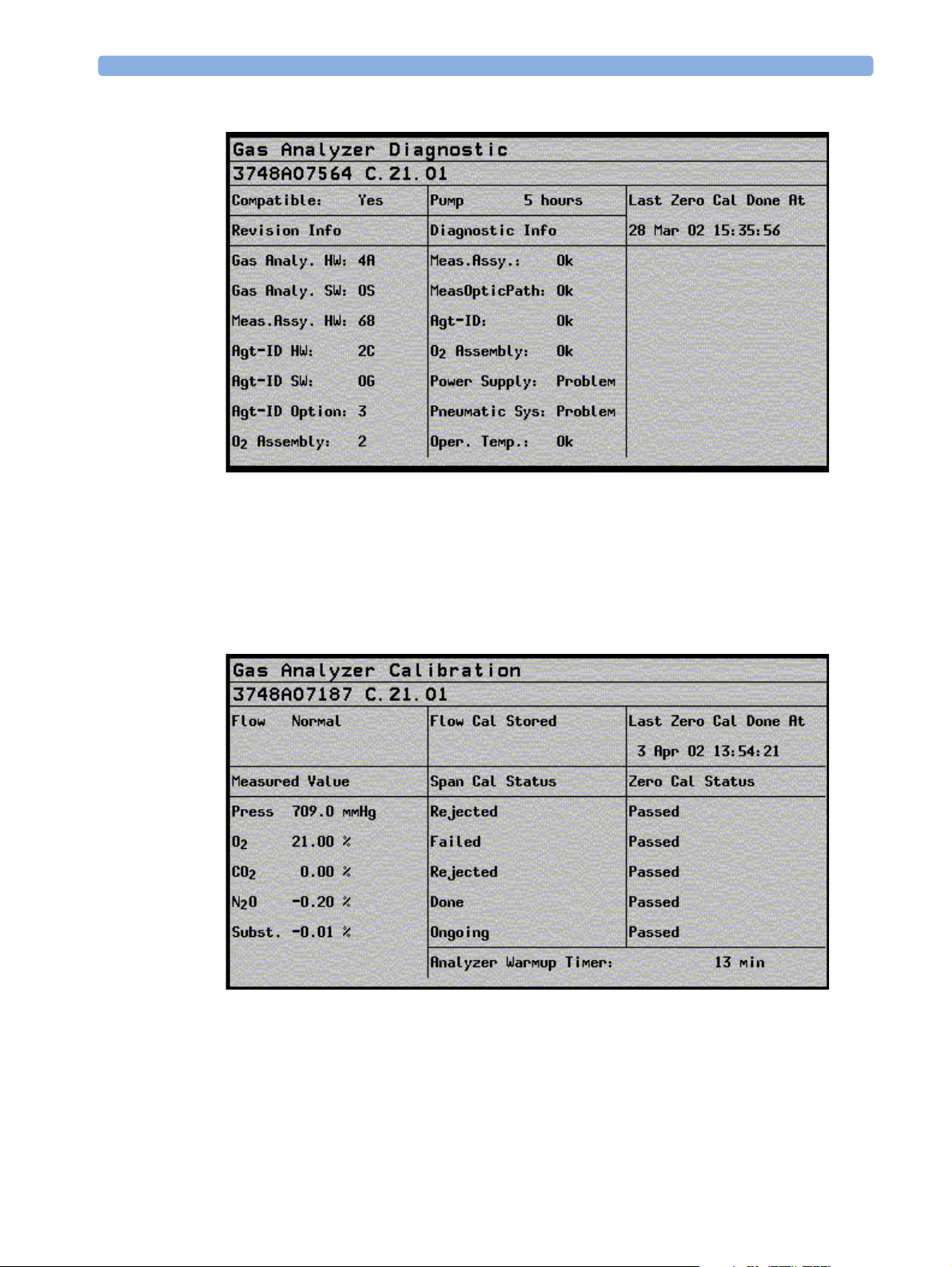

Access Service Functions of the M1026A Anesthetic Gas Module

Enter service mode and select the service screen (see Testing and Maintenance for instructions on

entering service mode). In the

Analyzer Diagnostic

displayed. In this window you can as well start the flow calibration, the barometric pressure calibration

and the gas span calibration.

Setup Gas Analyzer menu can be accessed by either going to the Main Setup menu and

The

selecting

Gas Analyzer, or by pressing the setup key on the Anesthetic Gas Module.

Setup Gas Analyzer menu you can choose whether the Gas

window or the Gas Analyzer Calibration window should be

23

Page 26

1 Anesthetic Gas Module Checking and Calibrating the Anesthetic Gas Module

Figure 9 Gas Analyzer Diagnostic Window

This window provides you with diagnostic information about the AGM. In the

Analyzer

menu select Service Window then select Calibration to access this window.

Setup Gas

24

Figure 10 Gas Analyzer Calibration window

Page 27

Checking and Calibrating the Anesthetic Gas Module 1 Anesthetic Gas Module

This window provides you with information about all calibrations that can be performed on the

Anesthetic Gas Module. In the

Diagnostic to access this window.

Setup Gas Analyzer menu select Service Window then select

When and how to check the Philips M1026A Anesthetic Gas Module

To ensure that the Philips M1026A Anesthetic Gas Module operates with the specified limits, it must

be checked:

1 After installation

2 Every 12 months or if the measurements are in doubt.

3 After repairing the AGM

If you find values outside the tolerance limits while checking, the Philips M1026A Anesthetic Gas

Module must be recalibrated. Tolerance values are given at the end of each section.

The basic steps to check the Philips M1026A Anesthetic Gas Module are:

1 Enter Service Mode at the monitor and wait for first automatic zero calibration after the warm-up

period.

2 Perform:

a. a leakage check

b. a flowrate check

to ensure that there are no leaks in the gas system and that the flowrates are set correctly.

3 Perform Zero calibration.

4 Check that there are no reported errors.

5 Check the Barometric Pressure calibration; perform it if necessary.

6 Check the Span calibration of gases; perform it if necessary.

7 If Barometric Pressure or Span calibrations were performed, re-perform Zero calibration.

WARNING Only perform Zero, Barometric Pressure and gas Span calibration checks when the top cover is closed.

Light and electro-magnetic interference can affect the measurements.

Equipment required for checking

The following equipment is required for checking the AGM. Part numbers are given in the Parts List

section.

1 Electronic Flowmeter M1026-60144 (Instructions are provided with the flowmeter. See also

Service Note M1026A-034).

2 Span Calibration Equipment.

–Calibration Gas.

–Calibration Tubing

25

Page 28

1 Anesthetic Gas Module Checking and Calibrating the Anesthetic Gas Module

WARNING Philips Calibration Gas contains Halocarbon 22. Halocarbon 22 is represented in the Calibration

menu by “Substitute”, which is the default. If you are using another calibration gas, this must be

selected in the menu.

Checks and adjustments

The following sections explain the steps needed to carry out the checks and adjustments. A complete

check and calibration procedure requires approximately 45 minutes, including waiting time.

NOTE Make sure that the watertrap is attached.

Performance Leakage Check

Complete the following steps to do a performance leakage check:

NOTE Do not perform the leakage check while a Zero calibration is running.

1 Switch on the Philips M1026A Anesthetic Gas Module and the monitor.

2 Wait until the Anesthetic Gas Module enters the warm up phase.

3 Connect a flowmeter to the exhaust outlet of the Philips M1026A Anesthetic Gas Module.

4 Connect the watertrap to the watertrap manifold.

5 Note the flowrate.

6 Block the gas inlet at the watertrap inlet connector (use your fingertip).

The reading at the flowmeter should decrease to Zero (see table below). If it does not, systematically

block the pneumatic path at various points before the pump to isolate the leakage point. (See Figure

2, "Pneumatic System" for tubing connections.) When the fault has been corrected, repeat the

leakage check.

7 Connect the flowmeter to the inlet.

8 Note the flowrate.

9 Block the Anesthetic Gas Module exhaust (using your finger tip).

10 Check the effect of blocking the exhaust.

The reading at the flowmeter should decrease to Zero (see Table 4-1). If it does not, systematically

block the pneumatic path at various points after the pump to isolate the leakage point. (See Figure 2,

"Pneumatic System" for tubing connections.) When the fault has been corrected, repeat the leakage

check.

26

Items Value / Tolerance

Leakage Range: 0 → 4 ml/min

Page 29

Checking and Calibrating the Anesthetic Gas Module 1 Anesthetic Gas Module

Performance Diagnostic Check

Complete the following to do a performance diagnostic check:

1 Enter the service mode of the monitor and let the Philips M1026A Anesthetic Gas Module

complete the warm-up phase (the

2 Make sure that the watertrap is attached.

3 In the Setup Gas Analyzer menu select Service Window then select Diagnostic to

access the

4 Check that no permanent problems are reported for the Philips M1026A Anesthetic Gas Module

in the

Gas Analyzer Diagnostic window.

Gas Analyzer Diagnostic window.

GA WARMUP INOP disapears).

Performance Flowrate Check

Always perform a leakage check before the flowrate check. Three flowrates need to be checked in the

following order:

1 To t a l f lo w i n Purge mode.

2 Flow in Measurement Path in Normal mode.

3 To t a l f lo w i n Normal mode.

These flowrate checks are described in the following three procedures.

The total flow is measured by connecting the flowmeter to the exhaust, the measurement path flow is

measured by connecting the flowmeter to the gas inlet with a special test fixture.

The Flowrate values are summarized in the following table:

Total Flowrate Va lu e

Purge 310 ml/min

Normal 150 ml/min

NOTE Do not perform the flowrate check while a Zero calibration is running.

Total Flowrate Check and Adjustment in Purge Mode

To make the flowrate measurements and any necessary adjustment:

1 Enter the service mode of the monitor and let the Philips M1026A Anesthetic Gas Module

complete the warm-up phase (the

2 In the Setup Gas Analyzer menu select Service Window then select Calibration to

access the

3 Enter the Setup Gas Analyzer menu and select Start Flow Cal.

Gas Analyzer Calibration window.

GA WARMUP INOP disapears).

4 Select Flow Rate.

5 Select Purge for purge flow (310 ml/min).

6 Connect a flowmeter to the exhaust port of the Philips M1026A Anesthetic Gas Module.

27

Page 30

1 Anesthetic Gas Module Checking and Calibrating the Anesthetic Gas Module

7 Note the actual flowrate by following the instructions accompanying the flowmeter. If the actual

flowrate is outside the tolerance, it must be adjusted. If no adjustments are required, select Stop

Flow Cal.

Total Flowrate in Purge Mode To l er a nc e

310 ml/min +/- 15 ml/min

Flowrate Adjustment:

8 Remove the Philips M1026A Anesthetic Gas Module top cover (see “The Top Cover” on page 64)

9 Correct the flowrate by adjusting potentiometer R125 on the Main PC board until the required

value is achieved.

Flowrate Calibration:

10 If you have made adjustments you must save the settings. Therefore select Store Flow Cal and

confirm when prompted.

The system then runs through various flowrates and switches the pump off before it saves the

values internally.

The flow display in the Calibration window reflects these changes and the status “Flow Cal

Stored” appears.

11 Disconnect the flowmeter from the exhaust port.

Measurement Path Flowrate Check and Adjustment

The flowrate of the measurement path is checked using a test fixture in the form of a modified

watertrap. In order to perform the flow rate check, the following equipment is required:

• Flow Split Test Tool M1026-60136

• Electronic Flowmeter M1026-60144

NOTE 1 Check that the test fixture is still valid for use. It must be less than two years old. The test fixture is

labelled with a “Received” date that needs to be filled in when the test fixture is received.

2 The flow value that is labelled on the test fixture is to be used to perform the measurement path

flowrate check. It is only valid for this test fixture.

3 Check the test fixture visually for leaks. Regularly perform a leakage check with the test fixture

attached instead of the watertrap. Block both lines (drainage and measurement) at the same time

while performing the leakage check. Block the measurement line with a luer cap or a similar device

and the drainage line with your fingertip. If a leak exists, replace the test fixture.

WARNING Always handle the test fixture carefully and avoid contact with dust. Do not change or modify the test

line/loops as this can change the flow resistance.

28

Make sure that there are no sharp bends or kinks in the tubing that leads to the test fixture. If a kink is

visible, replace the fixture and use the new one.

Page 31

Checking and Calibrating the Anesthetic Gas Module 1 Anesthetic Gas Module

xxx

To make the flowrate measurements and any necessary adjustment:

1 Enter the service mode of the monitor and let the Philips M1026A Anesthetic Gas Module

complete the warm-up phase (the

GA WARMUP INOP disapears).

2 In the Setup Gas Analyzer menu select Service Window then select Calibration to

access the

Gas Analyzer Calibration window.

3 Enter the Setup Gas Analyzer menu and select Start Flow Cal.

4 Select Flow Rate.

5 Select Normalfor normal flow (150 ml/min).

6 Remove the watertrap from its manifold and connect the flow split test fixture to the Philips

M1026A Anesthetic Gas Module.

7 Connect the measurement line of the test fixture to the flowmeter using the mal Luer Lock.

Check:

8 Note the actual flowrate by following the instructions accompanying the flowmeter. If the actual

flowrate is outside the tolerance, it must be adjusted. The target value for the flow is labelled on the

test-fixture. If no adjustments are required, select Stop Flow Cal.

Measurement Path Flowrate To l e ra n c e

Value labelled on Test Fixture +/- 3 ml/min

Flowrate Adjustment:

29

Page 32

1 Anesthetic Gas Module Checking and Calibrating the Anesthetic Gas Module

Remove the Philips M1026A Anesthetic Gas Module top cover (see the respective section in this

9

manual)

10 Correct the flowrate by adjusting potentiometer R126 on the Main PC board until the required

value is achieved.

Flowrate Calibration:

11 If you have made adjustments you must save the settings. Therefore select Store Flow Cal and

confirm when prompted.

The system then runs through various flowrates and switches the pump off before it saves the

values internally.

12 Disconnect the flowmeter from the test-fixture.

13 Replace test-fixture with watertrap

Total Flowrate Check in Normal Mode

To make the flowrate measurements and any necessary adjustment:

1 Enter the service mode of the monitor and let the Philips M1026A Anesthetic Gas Module

complete the warm-up phase (the

GA WARMUP INOP disapears).

2 Enter the Setup Gas Analyzer menu and select Start Flow Cal.

3 Select Flow Rate.

4 Select Normal for normal flow (150 ml/min).

5 Connect a flowmeter to the exhaust port of the Philips M1026A Anesthetic Gas Module.

Check:

6 Note the actual flowrate by following the instructions accompanying the flowmeter. If the actual

flowrate is outside the tolerance, check all tubing for occlusions (for example kinks, dirt) and

replace if necessary. Repeat flowrate check. If the flowrate is still no within tolerance, exchange the

Nafion tubing, bacterial filters and restrictor in the drainage path (provided with the Internal

Tubing Kit and the Preventive Maintenance Kit) before repeating flowrate check.

If no adjustments are required, select Stop Flow Cal.

Total Flowrate in Normal Mode To l er a nc e

has to be between 132 ml/min

170 ml/min

7 Disconnect the flowmeter from the exhaust port.

Zero Calibration

NOTE Only perform a zero calibration with the top cover closed. Light and electro-magnetic interference may

affect the measurements. Zero calibration is not possible during warm-up.

Complete the following to perform a zero calibration in service mode:

1 In the Setup Gas Analyzer menu select Service Window.

2 Select Calibration to access the Gas Analyzer Calibration window.

30

Page 33

Checking and Calibrating the Anesthetic Gas Module 1 Anesthetic Gas Module

In the Setup Gas Analyzer menu select Zero Cal and press Confirm when prompted to.

3

4 Wait until zero calibration is complete. In the Gas Analyzer Calibration window a OK /

Failed indication is displayed against each channel. If a Failed indication cannot be cleared by

another zero calibration refer to the appropriate section of this manual and correct the fault. Then

repeat this procedure.

Barometric Pressure Check and Calibration

For this calibration you need the absolute barometric pressure at your hospital location. Normally this

value can be provided by the hospital as it is needed in the laboratory.

If the hospital cannot provide an accurate value for the barometric pressure, call the local airport or

weatherstation. Since airports and weatherstations normally provide you with a pressure that has been

corrected to sea level, ensure that the value you are given is an uncorrected absolute barometric pressure

reading! The following table shows you typical barometric pressures at various altitudes.

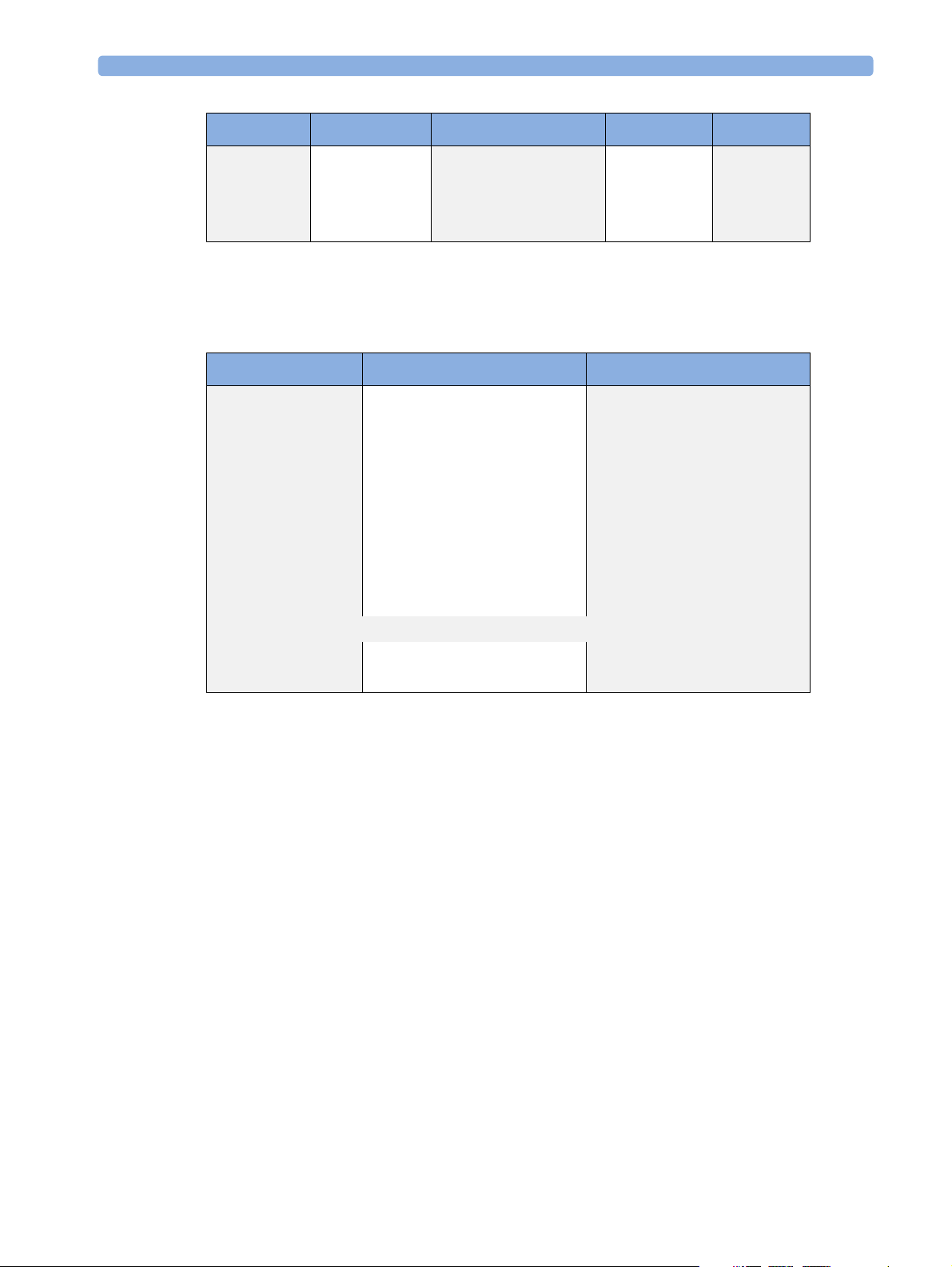

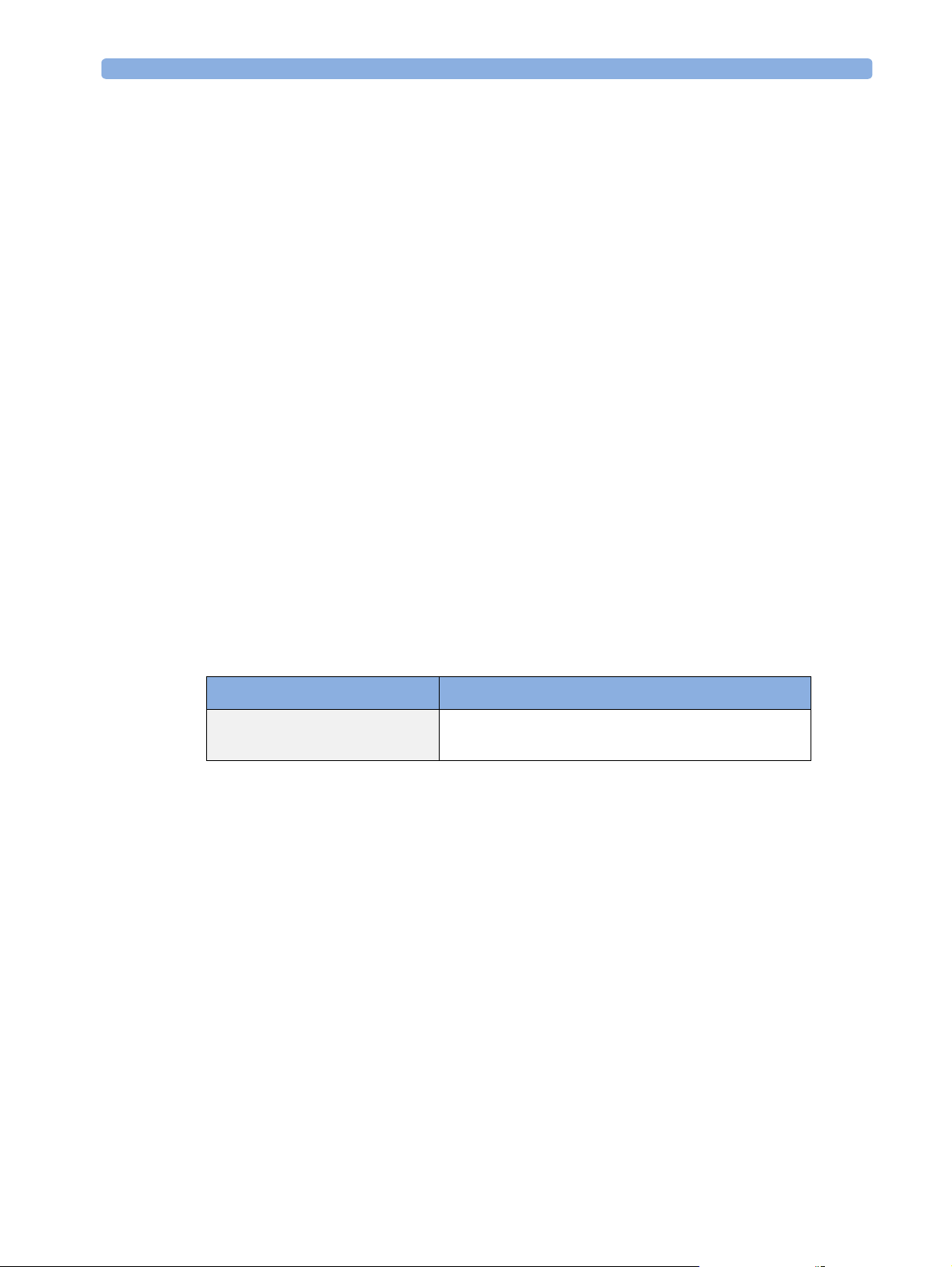

Altitude Typ ic al

Barometric

Pressure

Altitude Typi ca l

Barometric

Pressure

Altitude Typi ca l

Barometric

Pressure

0 m 760 mmHg 1100 m 664 mmHg 2200 m 577 mmHg

100 m 751 mmHg 1200 m 656 mmHg 2300 m 570 mmHg

200 m 742 mmHg 1300 m 648 mmHg 2400 m 562 mmHg

300 m 733 mmHg 1400 m 639 mmHg 2500 m 555 mmHg

400 m 724 mmHg 1500 m 631 mmHg 2600 m 548 mmHg

500 m 715 mmHg 1600 m 623 mmHg 2700 m 540 mmHg

600 m 707 mmHg 1700 m 616 mmHg 2800 m 533 mmHg

700 m 698 mmHg 1800 m 608 mmHg 2900 m 526 mmHg

800 m 689 mmHg 1900 m 600 mmHg 3000 m 519 mmHg

900 m 681 mmHg 2000 m 592 mmHg

1000 m 672 mmHg 2100 m 585 mmHg

If only a corrected (to sea-level or 0 meters) reading is available, uncorrect the reading for the altitude

you are on using the following equation:

p

typical

p

barometricpcorrected

where:

=

------------------------- -

×

760mmHg

p

corrected

p

typical

ambient air pressure corrected to sea-level

=

typical atmospheric pressure at a given altitude

=

Conversion: 1 mmHg = 1.33 hPa = 0.03937 inHg

31

Page 34

1 Anesthetic Gas Module Checking and Calibrating the Anesthetic Gas Module

NOTE

Only perform a Barometric Pressure check and calibration with the top cover closed. Light and electromagnetic interference may affect the measurements. Pressure calibration is not possible during warmup.

Complete the following to steps to perform a barometric pressure check and calibration:

1 Get the absolute barometric pressure at your hospital location.

2 Enter the service mode of the monitor and let the Philips M1026A Anesthetic Gas Module

complete the warm-up phase (the

3 In the Setup Gas Analyzer menu, select Service Window.

4 Select Calibration to access the Gas Analyzer Calibration window.

GA WARMUP INOP disapears).

Check:

5 Check if the barometric pressure displayed next to the Press label. in the calibration window is

within the tolerance limits. A zero calibration is automatically started in order to display the

calibrated pressure value. This value is updated with each following zero calibration.

Measured Value To l er a nc e

Barometric Pressure +/- 5 mmHg

Calibration:

6 Enter the Setup Gas Analyzer menu and select Start Press. Cal.

7 Select the value representing the current absolute barometric pressure and confirm when prompted

8 After calibration has been completed, check if the barometric pressure displayed next to Press. in

the calibration window is within the tolerance limits.

Span Calibration Check

NOTE The Philips M1026A Anesthetic Gas Module should run for at least 30 minutes before continuing

with the following calibration procedures. This is to allow the module to reach a stable measurement

condition. The Analyzer Warmup timer in the Calibration window indicates the time span since the

last power on.

Only perform Span calibration checks when the top cover is closed. Light and electro-magnetic

interference can affect the measurements.

Before performing a Span calibration check, you must first perform:

• Performance Leakage Check.

• Performance Diagnostic Check.

• Performance Flowrate Check .

•Zero Calibration Check .

32

• Barometric Pressure Calibration Check .

• Ensure that there is enough gas in the calibration gas bottle.

• Check tubing assembly.

Page 35

Checking and Calibrating the Anesthetic Gas Module 1 Anesthetic Gas Module

Figure 11 Span Calibration Equipment including Gas Canister and Spray Valve

CAUTION Ensure that the room you are working in is well-ventilated, and that the Philips M1026A Anesthetic

Gas Module exhaust is properly connected to the gas scavenging system.

1 In the Setup Gas Analyzer menu select Service Window.

2 Select Calibration to access the Gas Analyzer Calibration window.

3 Select the Select Cal Agent item from the Setup Gas Analyzer menu.

4 Pre-select the agent that is being used during calibration. If Halocarbon 22 is in use, select

Subst..

5 Connect the calibration gas bottle, the reservoir bag and the sample line as shown in Figure 11,

"Span Calibration Equipment including Gas Canister and Spray Valve".

6 Wait u nt i l th e GA OCCLUSION INOP appears on the monitor. Now wait for another 10 seconds

to let the Anesthetic Gas Module completely evacuate the reservoir bag.

7 Now fill the reservoir bag with gas.

CAUTION Do not pressurize the reservoir bag.

Do not attempt the calibration process if tere are any visible leaks in the bag or tubing.

Prevent the bag from emtying before the calibration procedure is complete.

33

Page 36

1 Anesthetic Gas Module Checking and Calibrating the Anesthetic Gas Module

Check

8 Check if the readings for the different gases in the Gas Analyzer Calibration window are

within the specified tolerance limits.

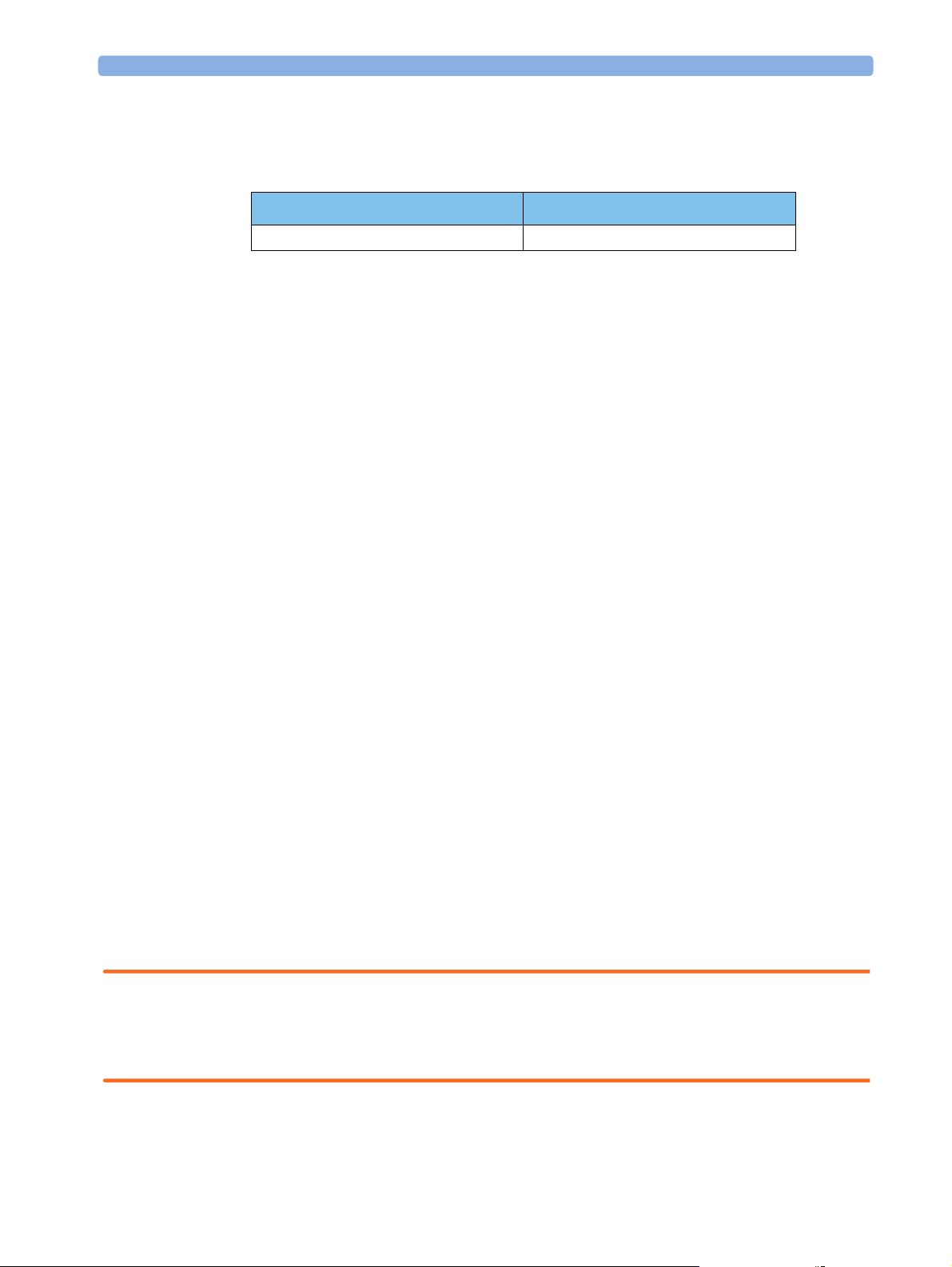

Gas M1660A value Tol e r a n c e L i mi t s

O

2

CO

2

N2O40%+/- 2.0%

Anesthetic Agent

or Halocarbon 22 as substitute

52% +/- 1.0%

5% +/- 0.1%

3% +/- 0.1%

9 Perform a span calibration for each gas that you find out of its tolerance limits.

Calibration

10 In the Setup Gas Analyzer menu select the calibration item for each gas that you want to

calibrate. You must have completed the flow adjusment in order to perform these calibrations. The

different items are:

Start O2 Cal

Start CO

Start N

Start Agent

Cal

2

O Cal

2

Cal

11 .Select the concentration of the appropriate gas in your test gas and confirm when prompted to.

12 Wait for the calibration to finish. Check that in the Gas Analyzer Calibration window a

Done indication is displayed against the gas that you wanted to calibrate. If not, repeat the span

calibration for this gas.

If you still get a failure refer to the troubleshooting section of this chapter and correct the fault.

Then repeat span calibration.

13 Repeat steps 10 to 12 until all the gases that were out of tolerance are calibrated.

14 If any calibration was necessary, perform a zero calibration and repeat the Span Calibration Check.

15 Remove the calibration gas from the system and purge with room air for 10 seconds. Then check

that the values in the

Gas Analyzer Calibration window reflect the concentrations present

in room air inside the tolerance limits:

at 20.9% +/- 0.2%

O

2

at 0% +/- 0.1%

CO

2

N

O at 0% +/- 0.3%

2

Agent at 0% +/- 0.1%

If this is not the case, repeat all calibration checks and procedures.

These values are valid for the Philips M1660A Calibration Gas Mixture.

For other calibration gas mixtures use the values specified for the mixture, applying the same tolerance

limits as given in this table for the Philips mixture (for example Japanese users should calibrate the

Anesthetic GAs Module using the DOT29M1060 gas mixture of Schott Medical Products).

Disposal of Empty Calibration Gas Cylinder

1 Empty cylinder completely by pushing in the pin of the valve.

34

Page 37

Maintaining the Anesthetic Gas Module 1 Anesthetic Gas Module

2 Once the cylinder is empty, drill a hole in the cylinder

CAUTION Be careful to assure that the cylinder is completely empty before you try to drill the cylinder.

3 Write "Empty" on the cylinder and place it with your scrap metal or, if you do not collect scrap

metal for recycling, dispose of the cylinder.

Maintaining the Anesthetic Gas Module

WARNING Failure to implement a satisfactory maintenance schedule by the individual, hospital or institution

responsible for the operation of this equipment may cause equipment failure and possible health

hazards.

This chapter describes the Preventive Maintenance tasks (PMs) required to keep the Philips M1026A

Anesthetic Gas Module in good working order. PMs are performed to a timetable before problems

arise as a means to reduce failures.

Where a PM requires either a calibration or replacement procedure, you will be referred to the relevant

chapter of this guide. The PMs are listed, within a table, in ascending order of the frequency they are

performed.

All checks that require the instrument to be opened must be made by qualified service personnel.

CAUTION Take precautions when dealing with potentially contaminated parts, such as tubing and other

components of the patient circuit. Wear gloves, mask and gown while handling components that come

into contact with the patient’s exhalant gas or fluids.

Preventive Maintenance (PM) Tasks

Here is a list of the PM tasks required to ensure satisfactory operation of the Philips M1026A

Anesthetic Gas Module within its specified limits and how often they must be performed.

• Check the ventilator fan in the AGM for proper operation every 6months.

• Check the AGM’s calibration at least once every 12 months, or whenever the validity of the readings

is in doubt. Refer to Checking and Calibrating the Anesthetic Gas Module for details.

• Replace the internal Nafion tubing, room air filter, and pump filter, two internal bacterial filters,

and two watertrap manifold seals using the PM kit, every 12 months.

• Test the pump using the test procedure provided in the PM Kit every 12 months. If the test fails,

replace the pump.

• Check electrical safety (ground impedance and enclosure leakage current test) at least every 12

months.

35

Page 38

1 Anesthetic Gas Module Maintaining the Anesthetic Gas Module

Cleaning

Each time the top cover is removed from the AGM for repair or calibration, you should take the

opportunity to clean the inside of the module, as the fan may draw debris such as dust and lint into the

enclosure.

WARNING Switch off the instrument and disconnect it from the mains power supply. Take standard electrostatic

precautions. For example, wrist strap connected to electrical ground.

The user should be encouraged to periodically clean the exterior casing of the AGM. The outside of the

gas sample tubing should be cleaned before connecting to the next patient.

Replace PM Parts

Every 12 months the PM parts should be replaced for new with the PM kit (Philips Part Number

M1026-60132). The PM kit comprises an internal Nafion tubing with two internal bacterial filters,

pump filter, room-air filter, and two internal bacterial filters, and two seals for the watertrap manifold.

Internal Nafion Tubing with Bacterial Filters and manifold Seals

36

Figure 12 Removing the Nafion Tubing, Bacterial Filters and Watertrap Manifold Seals

Removal

Page 39

Maintaining the Anesthetic Gas Module 1 Anesthetic Gas Module

To remove the Nafion tubing, filters and manifold seals (refer to Figure 12):

1 Ensure that the module is switched off and isolated from the mains power supply. Remove the top

cover of the module. Check if the module needs cleaning (because of dust, lint, etc.).

2 Unscrew the cable clamps (1) holding the Nafion tubing in place on the main PC board.

3 Unscrew the bacterial filters (2) at the metal bracket.

4 Remove the Nafion tubing connections (3) from the watertrap manifold.

5 Remove the two screws (4) holding the watertrap manifold on the protector. The screws are

accessible from the rear side of the front cover through two holes provided for this purpose.

6 Pull out the two seals from the tubing connectors of the manifold using pointed tweezers; slide one

side of the tweezers between the seal and the connector, then grasp and pull.

Replacement

To replace the Nafion tubing, filters and manifold seals (refer to Figure 12):

1 Take a new seal in the tweezers and press it onto the fitting in the tubing connector. Push down on

the seal using the handle of the tweezers (or another blunt instrument), taking care not to damage

the seal, until it sits properly. Repeat with the second seal.

2 Screw the watertrap manifold onto the protector through the holes in the front cover.

3 Replace the Nafion tubing connection to the watertrap manifold. Take care to attach the tubing

with the red mark at the end to the connector with the red marking (this indicates the “drainage”

path). The gap between the end of the nafion tubing and the manifold connectors (visible through

the purple connector tubing) must be less than 1mm.

4 Replace the Nafion tubing connection to the metal bracket. Screw on the bacterial filters, again

matching the red markings.

5 Attach the cable clamps to the Nafion tubing (if not already attached) and screw the cable clamps

onto the main PC board.

37

Page 40

1 Anesthetic Gas Module Maintaining the Anesthetic Gas Module

Room-Air Filter

Figure 13 Removing and Replacing the Room-Air Filter

Removal

To remove the room-air filter (refer to Figure 13):

1 Using a cross-tipped screwdriver, remove the screw and washer (1) securing the room-air filter’s

mounting bracket.

2 Remove the pneumatic tubing (2) from the underside of the room-air filter.

3 Using a flat-tipped screwdriver, pry off the short section of tubing (4) that secures the room-air

filter to its bracket (3).

4 Remove the room-air filter from its bracket.

Replacement

To replace the room-air filter (refer to Figure 13):

1 Push the room-air filter into the locating hole provided in its bracket (3).

2 Push on the short section of tubing (4) that secures the room-air filter to its bracket.

3 Replace the pneumatic tubing (2) to the underside of the room-air filter.

4 Using a cross-tipped screwdriver, replace the screw and washer (1) securing the room-air filter’s

mounting bracket.

38

Page 41

Maintaining the Anesthetic Gas Module 1 Anesthetic Gas Module

Pump Filter

Figure 14 Removing and Replacing the Pump Filter

Removal

To remove the pump filter (refer to Figure 14):

1 Using a cross-tipped screwdriver, remove the screw securing the pump filter(1).

2 Lift the pump filter and remove the pneumatic tubing from the pump exhaust (2).

3 Press the filter out of its plastic clip and remove the tubing from the underside of the pump filter

(3).

Replacement

To replace the pump filter (refer to Figure 14):

1 Connect the open tubing end that comes with the filter to the pump exhaust (2). Ensure that the

elbow connector on the pump filter is connected to the pump exhaust.

2 Replace the pump filter and secure with the screw (1).

3 Pass the tubing through the clip and connect it to the underside of the filter and slide the pump

filter into its plastic clip (3).

4 Replace the top cover of the module.

39

Page 42

1 Anesthetic Gas Module Troubleshooting the Anesthetic Gas Module

Performance Checks

See Test and Inspection Matrix.

Other factors to maximize uptime or reduce cost of ownership:

Electromechanical devices in general have limited life expectancies and failure rates higher than devices

with only electronic components. Thus, lower cost electromechanical devices such as pumps and

solenoids should be pro-actively considered for replacement.

We recommend exchanging the pump M1026-60330 after 6000 hours.

Changing the solenoids after 3000 hours will also maximize AGM uptime.

Any change in recommended exchange intervals will be communicated via Service Notes.

Troubleshooting the Anesthetic Gas Module

This chapter provides a recommended procedure for locating and identifying faults on the Philips

M1026A Anesthetic Gas Module.

It details how to proceed when hardware or measurement related INOPs occur.

It details how to proceed when errors are flagged for:

• Failed calibration checks and procedures

• Failed diagnostic checks.

In addition, it provides flow charts for communication and measurement type problems.

Equipment needed for troubleshooting:

•Flowmeter

• Flow Split Test Kit

•PM Kit

• Multimeter

• Calibration equipment

•Tubing kit

Compatibility Criteria for the AGM and the IntelliVue Monitors

Compatibility criteria can be checked in the Gas Analyzer Diagnostic Window. For compatibility with

the IntelliVue patient monitors the AGM must fulfill the follwoing requirements:

Protocol Revision: C.21.xx or greater

Agt_ID Option: 3

Assembly: 2

O

2

Flow Charts for Communication and Measurement Type Problems

The first flow chart shows three common types of problems and the identification information needed

about the AGM.

40

Page 43

Troubleshooting the Anesthetic Gas Module 1 Anesthetic Gas Module

Obtain:

–AGM Serial No.

–AGM SW Revision

Problem Call

–Options

(see lables on rearpanel and Gas

Analyzer Diagnostic

window)

AGM/IntelliVue Communication type problem

Measurement type problem

- No INOP available

A

Figure 15 Troubleshooting - Problem Identification

To access the identification information, refer to the

Diagnostic

window

Hardware related INOPs/ solid

or intermittent problems

B

See INOPs

Check Gas Analyzer

Calibration and Diagostic

window and follow the troubleshooting tables if problems are

reported.

Revision Info column of the Gas Analyzer

Figure 16 Gas Analyzer Diagnostic Window

41

Page 44

1 Anesthetic Gas Module Troubleshooting the Anesthetic Gas Module

This window gives such information as serial number, software revision and options configured:

The second flow chart continues from the first at the point A “Communication Problem”.

A

Communication

problem from the

beginning. (LED steadily

on)

Checks to perform.

Check that the Anesthesia

SW bundle #H30 is

installed on the monitor.

(Set monitor into Standby

mode and check for

“IntelliVue Anesthesia

#H30”).

If not order upgrade to

Anesthesia SW.

Check for correct RS232

config and correct MIB

port. Correct the settings if

necessary.

Check for proper physical

connections/cables (see

chapter 2).

Problem

Done

fixed

Problem

not fixed

Communication problem occurs

during operation, indicated by

flashing LED and INOP GA

EQUIP MALFUNCT.

Still communication

problem

Connect and run AGM on

other IntelliVue monitor.

Communication

problem fixed

Troubleshoot original

IntelliVue monitor

• follow troubleshooting table

Power Supply

Diagnostic

Checks

•check all internal

cables for damage /

loose fit

42

if that does not help,

replace the motherboard

Figure 17 Troubleshooting - Communication Problems

Page 45

Troubleshooting the Anesthetic Gas Module 1 Anesthetic Gas Module

The third flow chart continues from the first, from the point B “Measurement-type Problem - No

INOP”.

B

Gas measurement

accuracy problems,

Check accessories for

leaks, kinks and other

damages. Replace if

necessary.

Check connections for

blockages. If any,

remove them.

Problem

not fixed

Problem fixed

Use Calibration gas

(M1660A) in SERVICE

MODE (not in

Monitoring mode) and

perform a complete

calibration check of

suspect channels(s).

(incl. leakage and

flowrate checks)

Calibration

check failed

Calibration

check passed

Perform a full

calibration

Calibration

failed

Calibration

passed

Follow troubleshooting

table Calibration

Checks for failed

calibrations.

Automatic

O2 is not measured

agent

identification

problems.

Check if sample line is

connected. If not,

connect it.

Check on IntelliVue if

C

parameter O2 is on.

If not, turn it on.

Problem

DONE

not fixed

Follow

troubleshooting table

O2 Assembly

Diagnostic Checks.

DONE, AGM

measures correctly.

DONE, AGM measures

correctly.

Problem

fixed

DONE

Agent is not measured

Check if sample line is

connected. If not,

connect it.

Check on IntelliVue if

parameter Agent is on.

If not, turn it on.

Problem

Problem fixed

not fixed

DONE

Follow

troubleshooting table

Agent ID Assembly

Diagnostic Checks.

Disappearing

waves

D

Figure 18 Troubleshooting - Measurement Problems with No INOPS

Flow charts illustrated in Figure 19 and Figure 20 follow on from here.

43

Page 46

1 Anesthetic Gas Module Troubleshooting the Anesthetic Gas Module

The fourth flow chart continues from the third, from point C “Agent ID Problems”:

C

Check Agent-ID in Gas

Analyzer

Diagnostic window.

Agent-ID

reported

Check for correct agent

configuration (auto/

manual mode). Correct

setting is necessary.

Problem

not fixed

Problem fixed

Check if there is a

change from one agent

to another.

Agent-ID not reported

DONE

Explain that the transit time

in the anesthesia circuit is up

to 10-15 min. before the new

Check the cable

connections of the AgentID. Reconnect cables if

necessary.

Problem

Problem fixed

not fixed

Follow troubleshooting

table Agent ID

Assembly

Diagnostic Checks

DONE

agent can be detected (time

No agent

exchange

Problem fixed

Check if an agent is

administered while the

problem is observed.

Agent is

present

No agent present

Use Cal. gas in

monitoring mode.

until the old agent is washed

out, operating with low flow).

The INOP “Agent Mixture”

identifies an agent exchange

(two agents present at one

time).

DONE

Correct identification

DONE, agent-ID works properly

Halocarbon 22 must be

identified as Halothane

(they are very similar).

No correct

Follow troubleshooting table Agent

ID Assembly Diagnostic

Checks

44

Figure 19 Troubleshooting - Agent ID Problems

The fifth flow chart also continues from the third, from point D “Disappearing Waves”:

Page 47

Troubleshooting the Anesthetic Gas Module 1 Anesthetic Gas Module

D

Disappearing waves in

warmup mode.

Wait if it also occurs in

normal mode.

Yes No

Disconnect exhaust tubing

if available.

Problem

not fixed

Perform flowrate check and

pump test which is

provided in the PM kit. I f

pump test failes, replace

pump, if flow check fails

read just and calibrate

flowrates.

Problem

fixed

Problem

fixed

DONE

DONE

Problem not

fixed

Keep unit running for >90 min.

Take care that the Gas Analyzer

is not configured to go into

standby during that time. If

standby configuration has to be

altered, switch it back again

Check Gas Analyzer

Calibration and

Diagnostic window and follow

troubleshooting tables for reported

errors.

DONE

Figure 20 Troubleshooting - Disappearing Waves

Hardware Related Troubleshooting Strategy

Overall troubleshooting strategy for hardware related problems/hardware and measurement related

AGM INOPs:

1 Always perform a leak and flowrate check before continuing any other troubleshooting. If any

check fails, first fix leak and/or flowrate problem and repeat a zero calibration. Then check whether

problems still exist.

There are only two device conditions that make it impossible to perform a leak/flowrate check:

– Pump is not running:

Check for proper electrical connection and check that AGM is not in Standby Mode. If OK,

replace pump.

– INOP "GAS AN. EQUIP MALF": see “INOPs” on page 46.

2 After the first zero calibration, always check which AGM INOP’s are displayed in Monitoring

Mode. Refer to “INOPs” on page 46 where you can find a listing of possible root causes and their

45

Page 48

1 Anesthetic Gas Module Troubleshooting the Anesthetic Gas Module

corrective actions to the most common hardware and measurement related AGM INOP’s. Check

out the possible problems in the order given in the table!

3 After the first zero calibration, always check which problems are flagged in the Gas Analyzer

Diagnostic window. Troubleshoot flagged problems in the Gas Analyzer Diagnostic window

following the hierarchy given in “Problem Solving Hierarchy” on page 51 and the related

troubleshooting tables and/or troubleshoot zero calibration failures.

INOPs

Check out the possible problems in the order given in the following table.

INOP Possible Problem/Cause Corrective action

GA. NOT

AVAILABLE

GA

INCOMPATIBLE

GAEQUIP MALF Either AGM - monitor connection

GAS OCCLUSION External occlusion (inlet or exhaust

AGM not switched on. Switch on AGM

AGM not properly connected.

This version of the AGM is

incompatible with the monitor

problem, serious problem with a

subassembly or Main PC Board

problem.

Serious IR measurement head

problem.

accessories).

Internal occlusion

Weak/defective pump

Leakage between pump and flow

restrictor

Flow transducer incorrectly

connected to flow restrictor

Check physical connections.

Disconnect AGM.