Page 1

Steam Generator

GC7521

Philips Consumer Lifestyle

Service Manual

PRODUCT INFORMATION

Features

Fast & powerful crease removal

• Soleplate: SteamGlide

• Continuous steam output

• Continuous steam output: 120 g/min

• Vertical steam

• Steam pressure: Up to 5 Bar

• Variable steam settings

• Steam tip

• Power: 2400 W

Easy to use

• Water tank capacity: 1000 ml

• Filling and emptying water: Extra large filling hole

• Refill any time

• Heat-up time: 2 min

• Hose storage: Hose clip

• Power cord length: 1.8 m

• Cord freedom (swivel): 180 degree cord freedom

• Hose length: 1.7 m

Calc management

• Suitable for tap water

• Calc clean solution: Easy rinsing

TECHNICAL INFORMATION

Voltage : 220 - 240 V

Frequency : 50 - 60 Hz

Power Iron : 800 W

Boiler : 1370 W

Product dimension : 42.9 x 40 x 20.6 cm

Weight of iron : 1.2 kg

Weight of iron + base : 4.5 kg

Water advice

If the tap water in your area is very hard, it is advisable to mix

the tap water with an equal amount of demineralised water.

SteamGlide Soleplate

SteamGlide soleplate is the best Philips soleplate. It has great

scratch resistancy, glides excellent and is easy to clean.

Separate Water Tank

The seperate watertank allows you to re-fill the watertank

any time, even during ironing, without waiting.

Safety Information

• This product meets the requirements regarding interference

suppression on radio and TV.

• After the product has been repaired, it should function

properly and has to meet the safety requirements as

officially laid down at this moment.

Published by Philips Consumer Lifestyle Printed in the Netherlands © Copyright reserved Subject to modification

12/05

Page 2

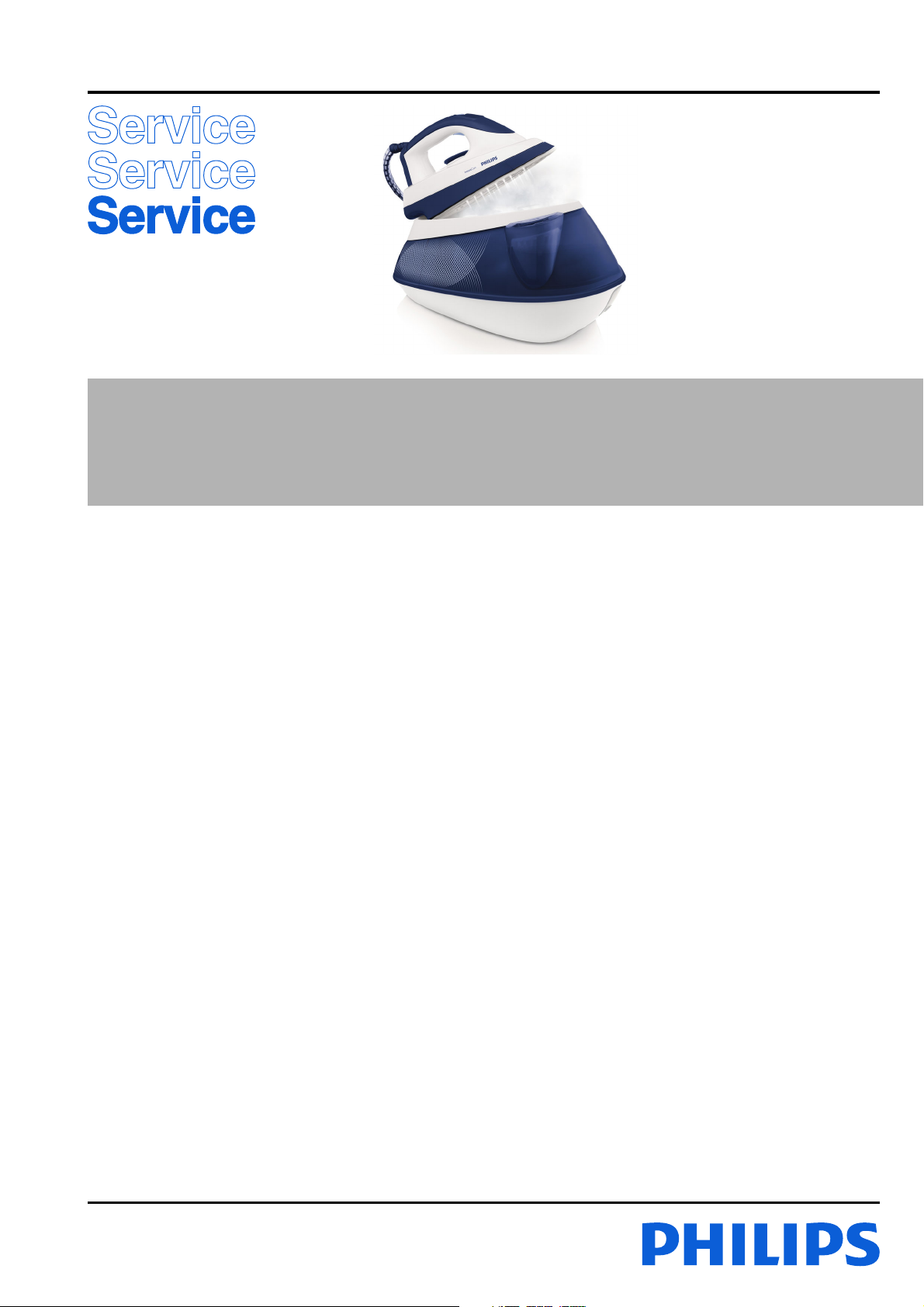

DISASSEMBLY ADVICE - IRON

GC7521

BACKPLATE 18

HOSE CORD ASSY 19

Remove Screw A

Disassemble BACKPLATE 18

Remove Screw B1, B2

Remove Clamping plate

Remove Power cord quick-connect S, E, L, N

Disassemble Steam hose

Disassemble HOSE CORD ASSY 19

Steam hose

Black

Hose clip(a)

S

B2

B1

Brown

Power cord

N

Blue

Clamping

plate

BlueGreen

NLE

Fig 1. Wiring at rear HOUSING (Part 1)

INLAY 17

STEAM LOCK 13

LAMP ASSY 8

MICROSWITCH ASSY 11

TRIGGER 12

THERMOSTAT DIAL ASSY 15

HOUSING PRINTED 10

SOLEPLATE COVER 6

THERMOSTAT BUSH 9

BRAIDED RUBBER HOSE 3

SOLEPLATE ASSY 1

Remove Screw A

Disassemble BACKPLATE 18

Release Inlay rear catch

Disassemble INLAY 17

Disassemble STEAM LOCK 13

Disassemble MICROSWITCH ASSY 11

Remove Screw C

Disassemble TRIGGER 12

Disassemble THERMOSTAT DIAL 15

Black

(Microswitch)

Blue

(Lamp assy)

Fig 2. Wiring at rear HOUSING (Part 2)

NS

Blue

(Micro switch)

White

(Lamp assy)

Fig 3.

Remove Screws D1, D2, D3

Disassemble HOUSING PRINTED 10

Remove HOSE CLIP 4

Disassemble BRAIDED RUBBER HOSE 3

Remove Screws E1, E2, E3

Disassemble SOLEPLATE COVER 6

2-7

Page 3

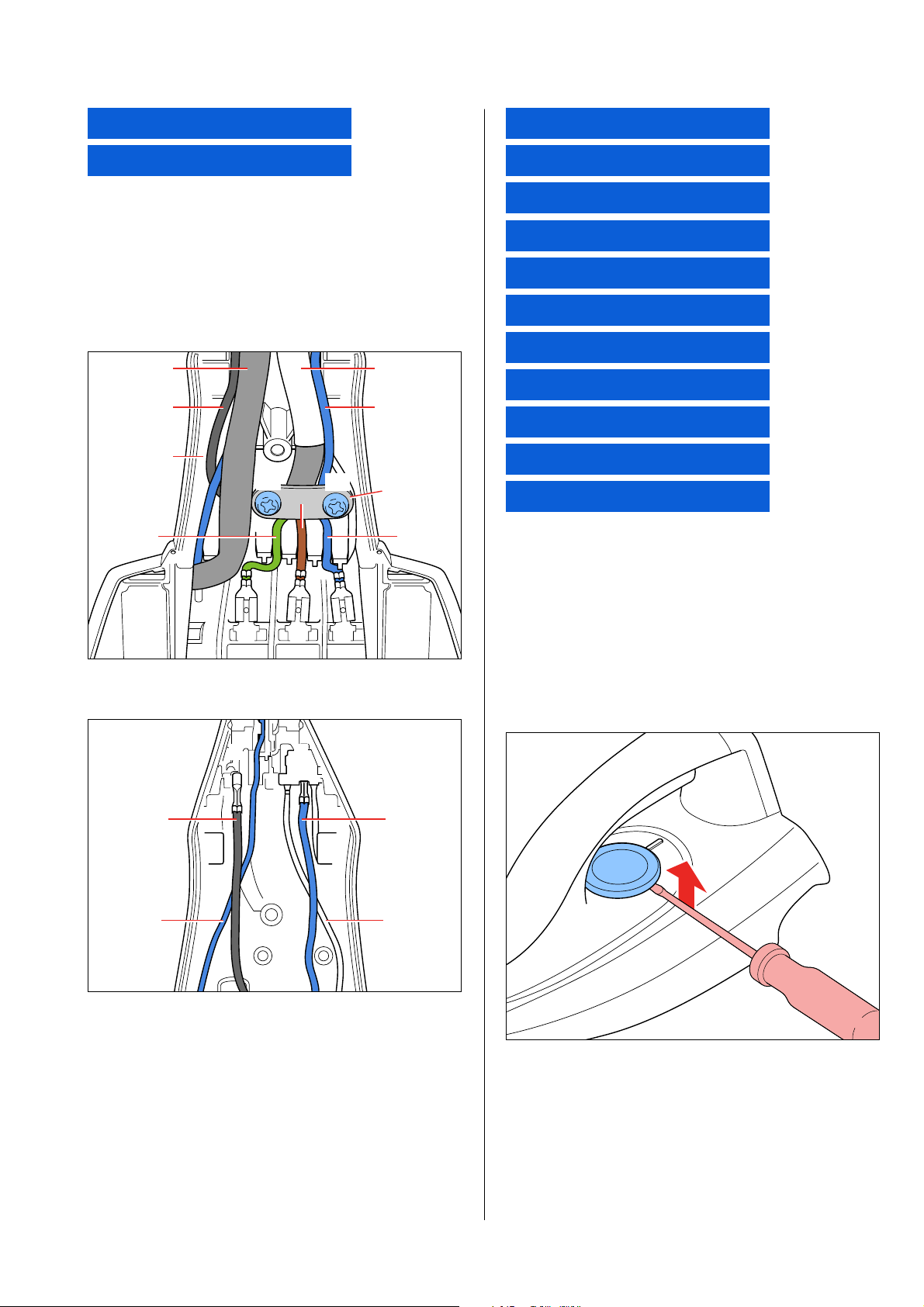

PARTS LIST - IRON & ELECTRICAL DIAGRAM

Pos Service code Description Remark

1

4239 021 68981

3

4239 015 59301

4

4239 010 10281

5

4239 015 70153

6

4239 026 48631

8

4239 021 36861

9

4239 026 13222

10

4239 021 69791

11

4239 021 31793

12

4239 026 48171

13

4239 026 48181

14

4239 010 09293

15

4239 021 69111

17

4239 026 48671

18

4239 026 48681

Soleplate assy 230 V

Braided rubber hose

Hose clip-braided rubber hose

Ryton ring

Soleplate cover

Lamp mounted assy

Thermostat bush

Housing printed

Microswitch assy

Trigger

Steam lock

Trigger spring

Thermostat dial assy

Inlay

Backplate

19 4239 021 69091 Hose cord mounted assy

GC7521

Steamglide-Non SOS

White

Blue

Blue

Blue

Blue

Blue

Thermistor 1

Trigger

Switch

L

S

N

Thermostat

Thermal

Fuse

Heating

Element

Pump

L

N

M

Boiler Electronics

Electrovalve

Thermal

Fuse

Boiler

Heating

Element

L

N

STAND IRON

Fig 4. Electrical diagram

3-7

Page 4

EXPLODED VIEW - IRON

13

GC7521

10

14

17

C

D1

11

E2

12

8

A

18

15

B1

D3

S

B2

N

19

L

E

D2

3

E3

E1

6

9

5

4

1

4-7

Page 5

DISASSEMBLY ADVICE - STAND

GC7521

TRAY RUBBER CAP 30

TRAY ASSY 33

DOOR ASSY

Remove TRAY RUBBER CAP 30 (3x)

Remove Screw F1, F2, F3

Disassemble TRAY ASSY 33

Remove Screw G

Disassemble DOOR ASSY

FRONT PANEL PRINTED 37

POWER BOARD

LIGHT SWITCH 44

Remove TRAY RUBBER CAP 30 (3x)

Remove Screw F1, F2, F3

Disassemble TRAY ASSY 33

Remove Screw H1, H2

Disassemble FRONT PANEL 37

Disassemble LIGHT SWITCH 44

Disassemble POWER BOARD

WATER TANK ASSY 34

HOSE CORD CAP 36

BOILER ASSY 38

BRAIDED RUBBER HOSE -

BOILER

PUMP ASSY 45

INLET TUBE - PUMP

DE-AIR TUBE

RINSE RUBBER COUPLING 50

RINSE BUSH

RINSE CAP ASSY 52

Remove TRAY RUBBER CAP 30 (3x)

Remove Screw F1, F2, F3

Disassemble TRAY ASSY 33

Remove Screw H1, H2

Disassemble FRONT PANEL 37

Disassemble HOSE CORD CAP 36

Disassemble RINSE CAP ASSY 52

Disassemble RINSE BUSH

Disassemble RINSE RUBBER COUPLING 50

Remove Screws K1, K2, K3, K4

Disconnect INLET TUBE - PUMP

Disconnect DE-AIR TUBE

Disassemble WATER TANK ASSY 34

Disassemble BRAIDED RUBBER HOSE - BOILER

Disassemble PUMP ASSY 45

Remove Torx screws L1, L2, L3

Disassemble TOP SPACER

Disassemble BOILER ASSY 38

PARTS LIST - STAND

Pos Service code Description Remark

30

4239 015 59651

33

4239 021 68791

34

4239 021 69812

36

4239 026 48751

37

4239 021 69801

38

4239 021 39542

40

4239 017 09892

42

4239 010 10261

Tray rubber cap

Tray assy

Water tank assy

Hose cord knob

Front panel

Boiler assy

Electrovalve

Inox clamp

Blue

White

Blue

Blue

Printed

High End

Pos Service code Description Remark

44

4239 026 48761

45

4239 022 66211

50

4239 015 56761

52

4239 021 69131

55

2422 070 98368

56

4239 021 69201

65

4239 026 42081

Note: For Pos 45, please replace both components together when either one is faulty.

The 2 components come as a service kit.

Light switch

Control boardPump assy kit

Rinse rubber coupling

Rinse cap assy Blue

Cordset

Stand bottom assy

De-air valve

EU

White

High End

5-7

Page 6

EXPLODED VIEW - STAND

GC7521

30

F3

37

H1

F1

33

F2

G

K1

K2

H2

34

36

52

45

44

55

50

65

Cord

clamp

L1

L2

Clamping

plate

40

42

38

L3

56

K4

K3

6-7

Page 7

REPAIR INSTRUCTIONS

GC7521

• Due to the high wattage of the iron, only the specified cord set must be used.

• Should damage be observed on the HOSE-CORD ASSY or CORDSET 55, they must be replaced.

Continued usage is not allowed.

• When replacing the MICROSWITCH ASSY 9, please dress the 2 attached wires such that they are free of tension.

Pulling force on the wires may affect the steam triggering.

• To avoid damage to the sealing & components of the BOILER ASSY 38, NEVER clean the boiler assy with vinegar,

descaling agent or other corrosive chemicals.

• When replacing ELECTROVALVE 40 or PUMP ASSY 45, please be reminded to apply loctite at the joints for good

sealing.

• After the product has been repaired, it should function properly and has to meet the safety requirements & legal regulations

as laid down & officially established at this moment.

• The following tests are common checks that are conducted on a repaired product before it is returned to the consumer.

1. Soleplate temperature

Check that soleplate temperature is within IEC requirement.

Measure the temperature of the soleplate after the iron has reached steady state i.e connected to the mains for at least

15minutes. The table below shows the temperature requirement.

Marking

(1 dot)

•

(2 dots)

••

(3 dots)

•••

Soleplate temperature (Deg C)

Minimum Maximum Nominal + Tolerance

70 120

100 160

140 210

95 25

130 30

175 35

Material, for example

Acetate, elastane, polyamide, polyproylene

Cupro, polyester, silk, triacetate, viscose, wool

Cotton, linen

2. Leakage current

Check that leakage current is within IEC requirement.

Measure leakage current between LIVE/NEUTRAL & EARTH.

IEC requirement is that at 230 V supply, the EARTH leakage current must be less than 0.75 mA.

3. Water leakage / Functionality

Check that there is no water leakage from any part of the product during operation.

Check that the functionality of the product (product dependent) eg. steaming, variable steam, SOS, ASO etc is working

properly.

4. Loose part

Check that there are no loose parts eg. extra screw in the product that can cause short-circuit or product malfunction.

==

Testpoint

7-7

Loading...

Loading...