Color Television Chassis

FUZ2.0U

LA

32MF338B/27

I_17710_000.eps

040308

Contents Page Contents Page

1. Specifications 2

2. Operating Controls and Functions 6

3. Important Safety Precautions 8

4. Standard Notes for Servicing 12

5. Directions for Use 17

6. Cabinet Disassembly Instructions 18

7. Troubleshooting 24

8. Block Diagrams

System Control Block Diagram 31

Video Block Diagram 32

Audio-1 Block Diagram 33

Audio-2 Block Diagram 34

Digital Signal Process Block Diagram 35

Inverter Block Diagram 36

Power Supply Block Diagram 37

9. Circuit Diagrams & PWB Layouts 38

Power Supply 1/3 Parts Location Guide 39

Power Supply 1/3 Diagram 40

Power Supply 2/3 Diagram 41

Power Supply 2/3 Parts Location Guide 42

Power Supply 3/3 Parts Location Guide 43

Power Supply 3/3 & Side Jack Diagram 44

Power Supply Board Layout ( Top Side ) 45

Power Supply Board Layout ( Bottom Side ) 46

Power Supply Board Parts Location Guide 47

Side Jack Board Layout ( Top & Bottom Side ) 48

Side Jack Board Parts Location Guide 48

Inverter & Junction-B Diagram 49

Inverter Parts Location Guide 50

Inverter Board Layout ( Top Side ) 51

Junction-B Board Layout ( Top & Bottom Side ) 51

Inverter Board Layout ( Bottom Side ) 52

Inverter Board Parts Location Guide 53

Function Diagram 54

©

Copyright 2008 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Function Diagram Parts Location Guide 54

Function Board Layout (Top & Bottom Side) 55

Function Board Parts Location Guide 55

IR Sensor & Junction-A Diagram 56

IR Sensor Diagram Parts Location Guide 56

IR Sensor Board Layout (Top & Bottom Side) 57

Junction-A Board Layout ( Top & Bottom Side ) 57

Digital Main 1/4 Diagram 58

Digital Main 2/4 Diagram 59

Digital Main 3/4 Diagram 60

Digital Main 4/4 Diagram 61

Digital Main Board Layout (Top Side) 62

Digital Main Board Layout (Bottom Side) 63

10. Waveforms 64

11. Wiring Diagram 65

12. Alignments 66

13. Abbreviations List 70

14. Structure & IC 73

15. Electrical Parts List 78

16. Mechanical Parts List 92

17. Revision List 93

Published by CS 0863 BU CD Consumer Care Printed in the Netherlands Subject to modification EN 3122 785 17710

2 FUZ2.0U LA

1. SPECIFICATIONS

1.1 Specifications

< TUNER / NTSC >

ANT. Input -----------------------75 Ω Unbal., F type

Description Condition Unit Nominal Limit

1. AFT Pull-in Range --- MHz ±2.3 ±2.1

20

20

23

2. Syncronizing Sens.

TV.ch.4

CA.ch.31

CA.ch.87

dBµ

dBµ

dBµ

---

---

---

< TUNER / ATSC >

Description Condition Unit Nominal Limit

1. Received Freq. Range (-28dBm) --- kHz --- ±100

-76/0

-76/0

-74/+4

2. ATSC Dynamic Range (min / max)

ch.4

ch.10

ch.41

dBm

dBm

dBm

---

---

---

< LCD PANEL >

Description Condition Unit Nominal Limit

1. Native Pixel Resolusion

2. Brightness --- cd/m

3. Viewing Angle

Horizontal

Ver ti ca l

Horizontal

Ver ti ca l

pixels

pixels

°

°

1366

768

2

320 ---

-88 to +88

-88 to +88

---

---

---

---

< VIDEO >

Description Condition Unit Nominal Limit

1. Over Scan

2. Color Temperature

3. Resolution (composite video)

Horizontal

Ver ti ca l

--x

y

Horizontal

Ver ti ca l

%

%

°K

---

---

line

line

5

5

12000

0.272

0.278

400

350

5±5

5±5

--±3%

±3%

---

---

< AUDIO >

All items are measured across 8 Ω load at speaker output terminal with L.P.F.

Description Condition Unit Nominal Limit

1. Audio Output Max Power

(ATSC 0dBfs)

2. Audio Distortion (NTSC) 500mW: Lch/Rch % 0.5/0.5 2.0/2.0

3. Audio Freq. Response (NTSC)

Note: Nominal specifications represent the design specifications. All units should be able to approximate these.

Some will exceed and some may drop slightly below these specifications. Limit specifications represent

the absolute worst condition that still might be considered acceptable. In no case should a unit fail to meet

limit specifications.

Lch/Rch W 10.0/10.0 9.0/9.0

-

6dB: Lch

-

6dB: Rch

Hz

Hz

70 to 10 k

70 to 10 k

---

---

< PICTURE / DISPLAY >

Description Specification

FUZ2.0U LA 3

1. Aspect ratio

2. Picture Enhancement

SOUND >

<

Description Specification

1. Output Power (RMS)

2. Sound Enhancement

3. Sound Mode

CONVENIENCE >

<

Description Specification

ON SCREEN DISPLAY LANGUAGE >

<

Description Specification

<

CONNECTIVITY >

Description Specification

Widescreen

Progressive Scan, 3D comb filter,

Smart Picture (4 models): Nature, Rich, Movie, Soft

2 x 10W

Mono, Stereo

Tr e bl e, B a s s

Auto Program, Closed Captioning Full Text, Sleeptimer

English, French, Spanish

1. Rear 75Ω / RF

COMPONENT 1- Component Video (YPbPr), Audio L/R input

COMPONENT 2- Component Video (YPbPr), Audio L/R input

VIDEO 1- Composite Video (Video In), S-Video, Audio L/R input

Coaxial digital audio output (Digital Only)

PC-VGA, Audio

HDMI 1, HDMI 2

2. Side Video 2- Composite Video (Video In), S-Video, Audio L/R input

<

WEIGHT & DIMENSIONS >

Description Specification

1. Weight (incl. Packaging):

2. Weight (excl. Packaging):

3. Carton Dimension

(W x H x D):

4. Product Dimension

(W x H x D):

<

POWER >

Description Specification

1. Power Consumption:

2. Standby Power Consumption:

3. Mains Power:

13.9 kg / 30.7 lbs

11 kg / 24.3 lbs

904 x 665 x 228 mm

35.6″ x 26.2″ x 9.0″

776 x 562 x 272 mm

30.6″ x 22.2″ x 10.7″

155W (Maximum)

< 1W

120V, 60Hz

4 FUZ2.0U LA

1.2 Technical Specifications

1.2.1 Technical Specifications

Panel : CMO

Active Area : 697.685mm(H) x

392.256mm(V)

Outline Dimension : 776.0mm(H) x 562.0mm(V) x

272.0mm(D)

Pixel Pitch : 0.17025mm(H) x

0.51075mm(V)

Pixel Format : 1366 x 768 (WXGA)

Color Depth : 8-bit, 16.7M colors

Luminance : 430 cd/m

Backlight : CCFL

Response Time : 8 msec.

Viewing Angle : 176/176 (L/R,U/D)

Contrast Ratio : 1500:1

Tuning system : PLL

CCFL MTBF : 40,000 hrs (min.)

Formats for PC : 800 x 600p 60Hz

(D-SUB 15pin) 1024 x 768p 60Hz

1280 x 768p 60Hz

1360 x 768p 60Hz

Formats for HDMI : 640 x 480p 60Hz

720 x 480i 30Hz (29.97Hz)

720 x 480p 60Hz (59.94Hz)

1920 x 1080i 30Hz (29.97Hz)

1280 x 720p 60Hz (59.94Hz)

Formats for : 720 x 480i 30Hz (29.97Hz)

Component 720 x 480p 60Hz (59.94Hz)

1920 x 1080i 30Hz (29.97Hz)

1280 x 720p 60Hz (59.94Hz)

Formats for S-in, : 720 x 480i 60Hz (59.94Hz)

NTSC & Video

Formats for ATSC : 640 x 480i 30Hz (29.97Hz)

640 x 480p 24Hz (23.976Hz)

640 x 480p 30Hz (29.97Hz)

640 x 480p 60Hz (59.94Hz)

704 x 480i 30Hz (29.97Hz)

704 x 480p 24Hz (23.976Hz)

704 x 480p 30Hz (29.97Hz)

704 x 480p 60Hz (59.94Hz)

1280 x 720p 24Hz (23.976Hz)

1280 x 720p

1280 x 720p

1920 x 1080i 30Hz (29.97Hz)

1920 x 1080p 24Hz (23.976Hz)

1920 x 1080p

1.2.2 Sound

Sound systems : Mono / Stereo / Sap

Maximum power : 2 x 10W

2

30Hz (29.97Hz)

60Hz (59.94Hz)

30Hz (29.97Hz)

1.2.3 Miscellaneous

Power supply

AC-input : 120V AC, 60Hz

Normal Operation

Power Consumption : < 155W

Standby power : < 1W

Power cord length : 1545 mm (min.)

Power cord type : NISPT-2

Power indicator : LED (On: Green, Standby:

Red)

Ambient conditions

Temperature : 0 to 50 °C

Humidity :

Power consumption

Normal Operation : < 155W

Standby power : < 1W

≦80%RH

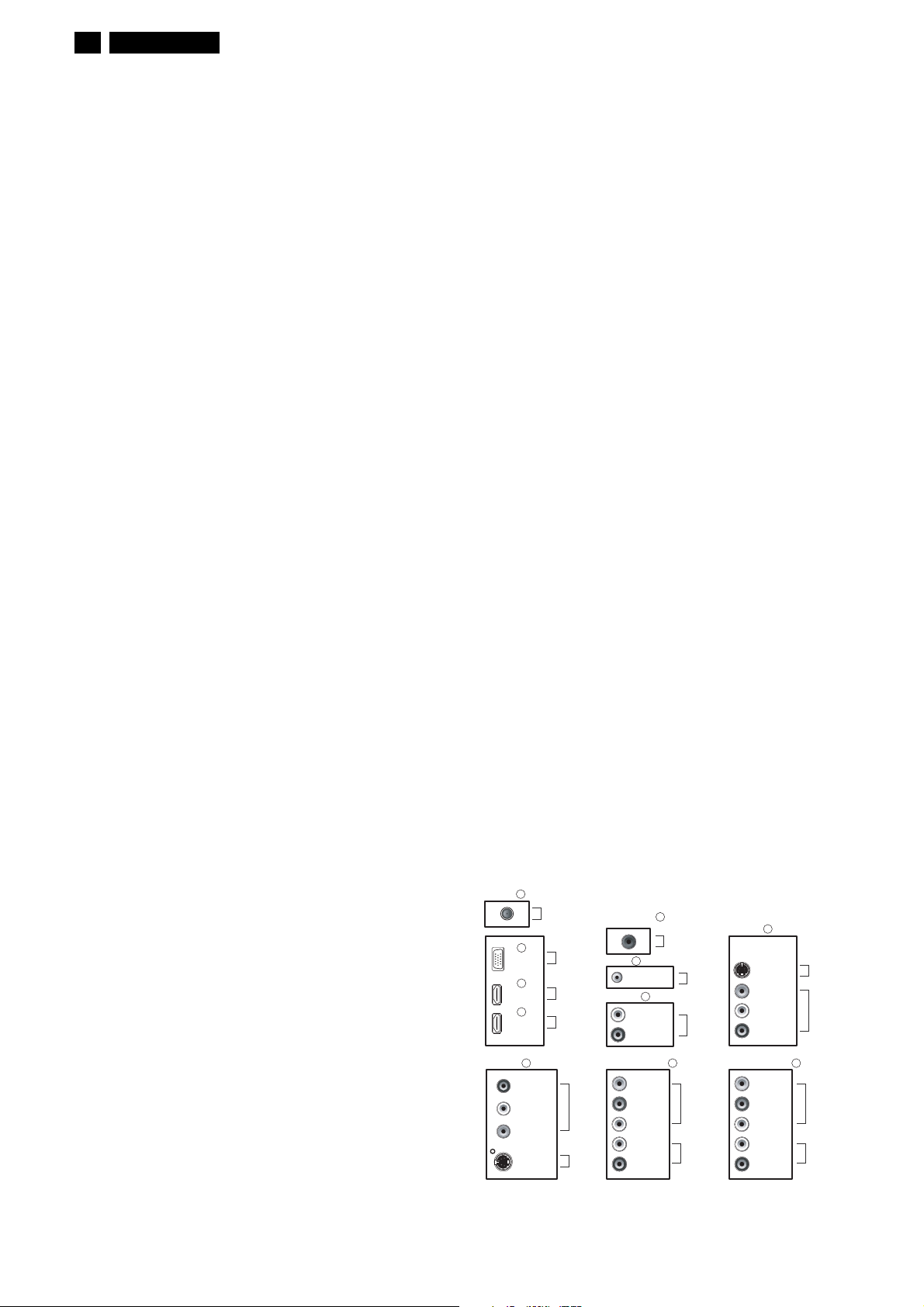

1.3 Connections

1.3.1 Signal Connector

(1)Tuner : NTSC / ATSC.

(2)D-SUB : VGA input (D-SUB 15 pins).

(3)HDMI 1 : HDMI 1 input with HDMI-IN audio

R/L.

(4)HDMI 2 : HDMI 2 input.

(5)DIGITAL AUDIO OUT :RCA jack.

(6)PC-IN Audio : Mini-jack.

(7)HDMI-IN Audio : Audio R/L (RCA jack) for

HDMI(DVI).

(8)VIDEO 1 : Video 1 (CVBS, RCA jack) and S-

Video 1 share with same audio R/

L (RCA jack).

(9)VIDEO 2 : Video 2 (CVBS, RCA jack) and S-

Video 2 share with same audio R/

L (RCA jack).

(10)COMPONENT 1 : Y/Pb/Pr component video1

(RCA jack) with audio R/L (RCA

jack).

(11)COMPONENT 2 : Y/Pb/Pr component video2

(RCA jack) with audio R/L (RCA

jack).

1

TUNER

TU1

2

D-SUB

3

HDMI 1

4

HDMI 2

9 10 11

VIDEO 2

AUDIO-R

AUDIO-L

VIDEO

S-VIDEO

JK3701

JK4001

JK4002

JK752

JK751

DIGITAL

AUDIO OUT

(COAXIAL)

6

PC-IN

AUDIO

HDMI-IN

AUDIO-L

AUDIO-R

Y

Pb

Pr

AUDIO-L

AUDIO-R

5

JK7515

JK7501

7

JK7705

JK7711

JK7712

VIDEO 1

COMPONENT 2COMPONENT 1

8

S-VIDEO

VIDEO

AUDIO-L

AUDIO-R

Y

Pb

Pr

AUDIO-L

AUDIO-R

JK7701

JK7702

JK7713

JK7714

FUZ2.0U LA 5

0

1.3.2 Input Signal

TV Signal type

RF Signal : Aerial input / 10mV(80dBuV)

Video signal : Video (RCA CVBS input) / 1Vpp

(300mV-sync, 700mV-video.)

S video input / 1VppY-signal,

300mVpp C-signal

COMPONENT Video (Y/Pb/Pr

input) / 1Vpp Y signal, 350mVpp Pb,

Pr signal

HDMI : Digital interface with 4 channels

TMDS signal

Audio signal :

Audio R/L for COMPONET 1.

Level :- Nominal : 0.5 V rms.

- Maximum : 1.5 V rms.

- Impedance > 10 k Ω.

Audio R/L for COMPONET 2.

Level :- Nominal : 0.5 V rms.

- Maximum : 1.5 V rms.

- Impedance > 10 k Ω.

Audio R/L for VIDEO 1.

Level :- Nominal : 0.5 V rms.

- Maximum : 1.5 V rms.

- Impedance > 10 k Ω.

Audio R/L for VIDEO 2.

Level :- Nominal : 0.5 V rms.

- Maximum : 1.5 V rms.

- Impedance > 10 k Ω.

Audio R/L for HDMI-IN.

Level :- Nominal : 0.5 V rms.

- Maximum : 1.5 V rms.

- Impedance > 10 k Ω.

PC Signal type

Analog Video : 0.7 Vp-p linear, positive polarity

Separate Sync.: TTL level, separate, positive or

negative polarity

Audio signal : Mini-jack audio input,

Level: - Nominal : 0.5 V rms.

- Maximum : 1.5 V rms.

- Impedance > 10 k Ω.

Digital Audio output : 0.5 V ~ 1 V Square Wave.

1.3.3 HDMI Pin assignment

Type A Connector

No.1

No.19

PIN No. SIGNAL

8 TMDS Data0 shield

9 TMDS Data0-

10 TMDS Clock+

11 TMDS Clock shield

12 TMDS Clock-

13 CEC

14 Reserved (N.C. on device)

15 SCL

16 SDA

17 DDC/CEC Ground

18 +5V Power

19 Hot Plug Detect

1.3.4 VGA Pin assignmentnput

1

6

11

PIN No. SIGNAL

1Red

2Green

3Blue

4GND

5Self test

6 Red GND

7 Green GND

8 Blue GND

9 +5V (Supply from PC)

10 Sync GND

11 GND

12 Bi-directional data (SDA)

5

1

15

No.18No.2

PIN No. SIGNAL

1TMDS Data2+

2TMDS Data2 shield

3TMDS Data2-

4TMDS Data1+

5TMDS Data1 shield

6TMDS Data1-

7TMDS Data0+

13 H-sync

14 V-sync

15 Data clock (SCL)

6 FUZ2.0U LA

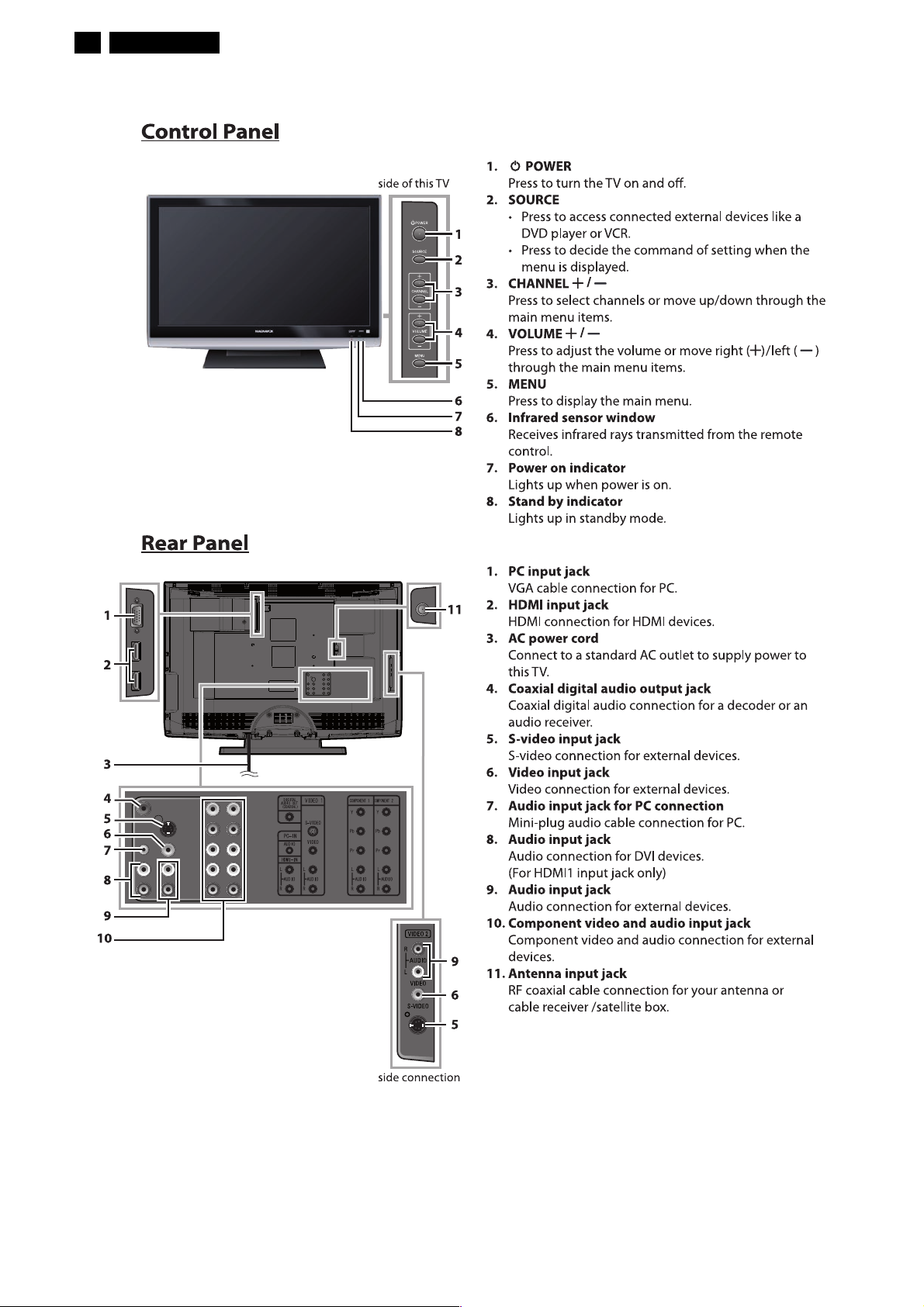

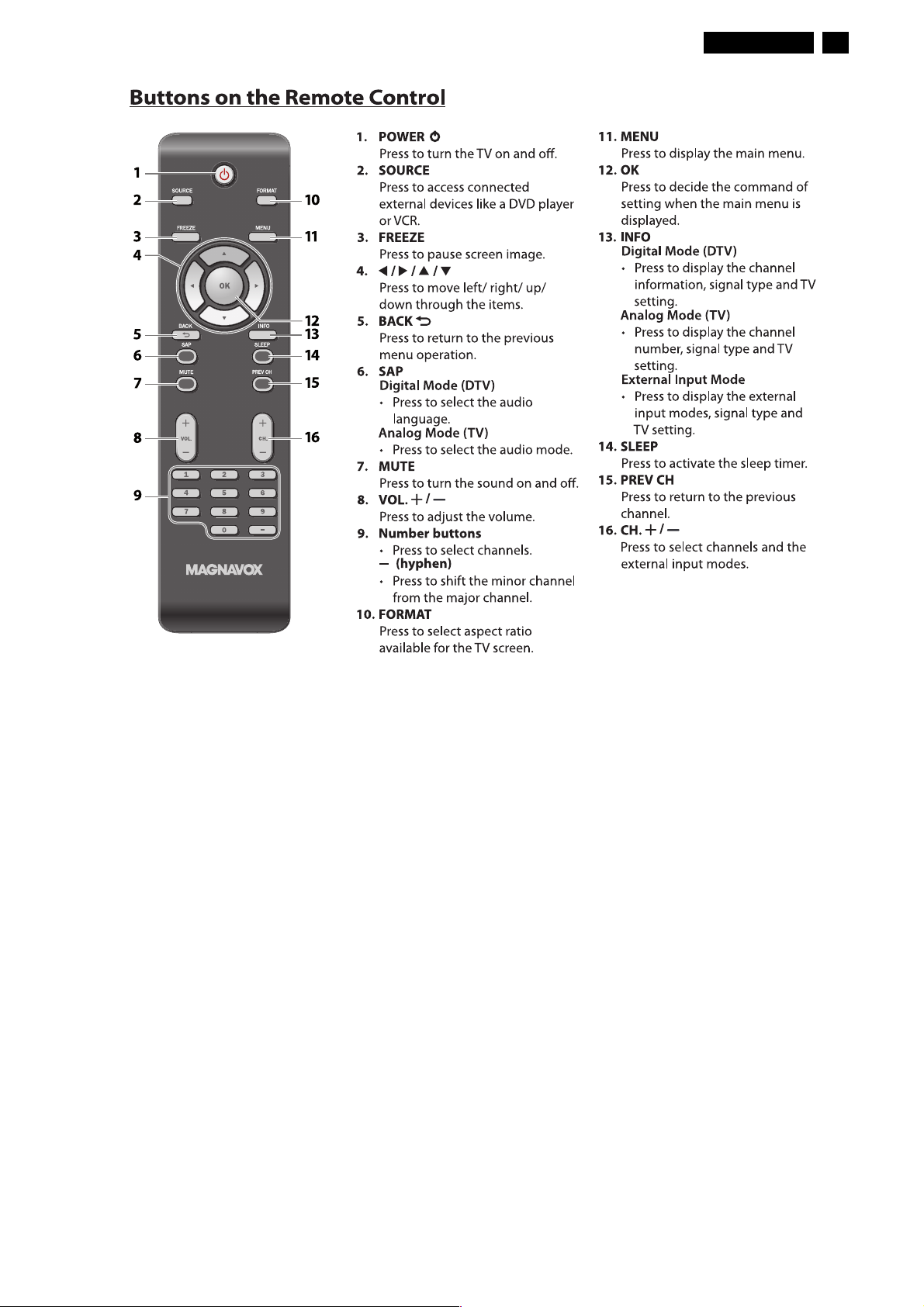

2. OPERATING CONTROLS AND FUNCTIONS

FUZ2.0U LA 7

8 FUZ2.0U LA

3. IMPORTANT SAFETY PRECAUTIONS

Prior to shipment from the factory, our products are strictly inspected for recognized product safety and electrical

codes of the countries in which they are to be sold. However, in order to maintain such compliance, it is equally

important to implement the following precautions when a set is being serviced.

Safety Precautions for LCD TV

Circuit

1. Before returning an instrument to the

customer, always make a safety check of the

entire instrument, including, but not limited to, the

following items:

a. Be sure that no built-in protective devices are

defective and have been defeated during

servicing. (1) Protective shields are provided

on this chassis to protect both the technician

and the customer. Correctly replace all missing

protective shields, including any removed for

servicing convenience. (2) When reinstalling

the chassis and/or other assembly in the

cabinet, be sure to put back in place all

protective devices, including but not limited to,

nonmetallic control knobs, insulating

fishpapers, adjustment and compartment

covers/shields, and isolation resistor/capacitor

networks. Do not operate this instrument or

permit it to be operated without all

protective devices correctly installed and

functioning. Servicers who defeat safety

features or fail to perform safety checks

may be liable for any resulting damage.

b. Be sure that there are no cabinet openings

through which an adult or child might be able to

insert their fingers and contact a hazardous

voltage. Such openings include, but are not

limited to, (1) spacing between the Liquid

Crystal Panel and the cabinet mask, (2)

excessively wide cabinet ventilation slots, and

(3) an improperly fitted and/or incorrectly

secured cabinet back cover.

c. Antenna Cold Check - With the instrument AC

plug removed from any AC source, connect an

electrical jumper across the two AC plug

prongs. Place the instrument AC switch in the

on position. Connect one lead of an ohmmeter

to the AC plug prongs tied together and touch

the other ohmmeter lead in turn to each tuner

antenna input exposed terminal screw and, if

applicable, to the coaxial connector. If the

measured resistance is less than 1.0 megohm

or greater than 5.2 megohm, an abnormality

exists that must be corrected before the

instrument is returned to the customer. Repeat

this test with the instrument AC switch in the off

position.

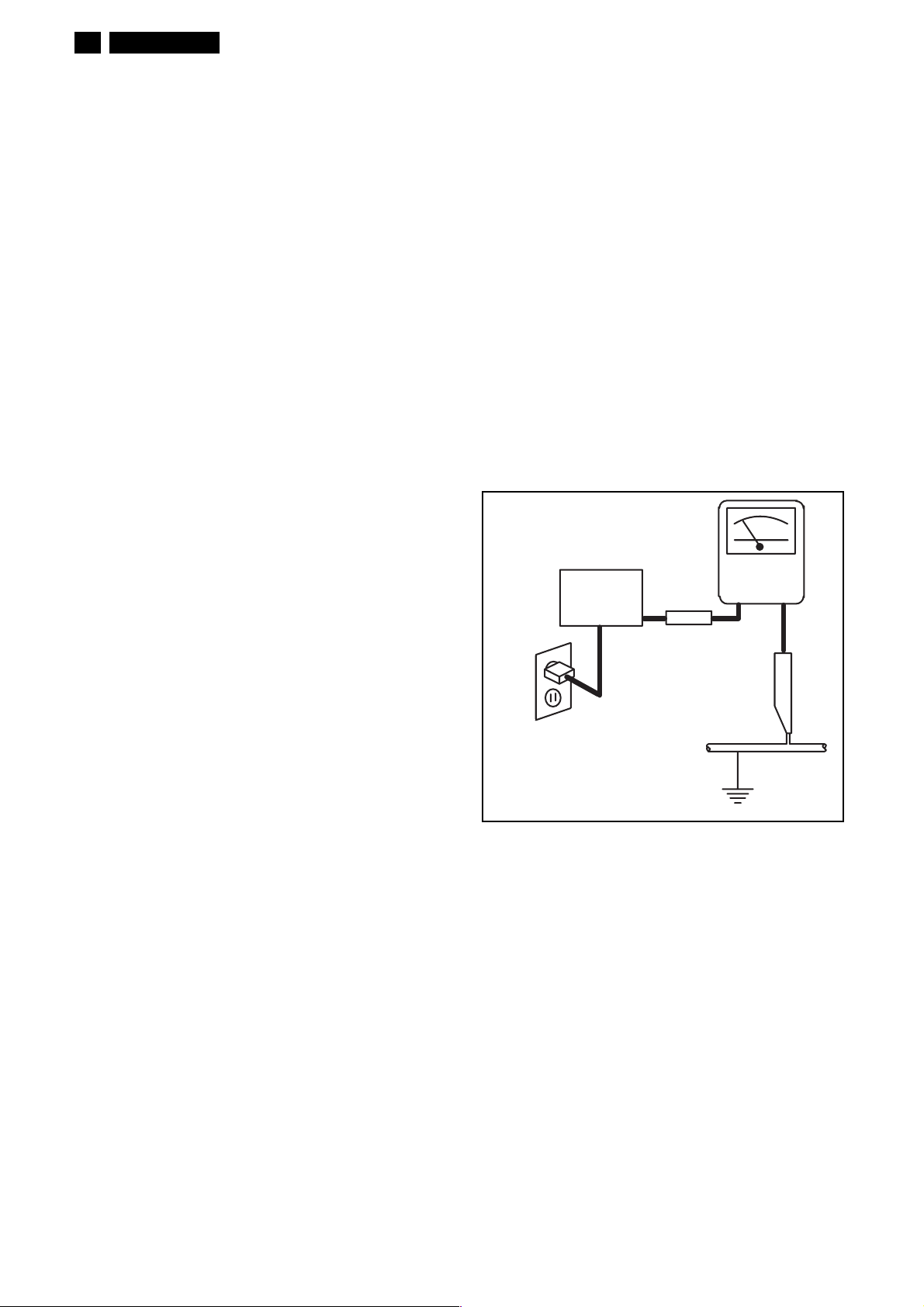

d. Leakage Current Hot Check - With the

instrument completely reassembled, plug the

AC line cord directly into a 120 V AC outlet. (Do

not use an isolation transformer during this

test.) Use a leakage current tester or a

metering system that complies with American

National Standards Institute (ANSI) C101.1

Leakage Current for Appliances and

Underwriters Laboratories (UL) 1410, (50.7).

With the instrument AC switch first in the on

position and then in the off position, measure

from a known earth ground (metal water pipe,

conduit, etc.) to all exposed metal parts of the

instrument (antennas, handle brackets, metal

cabinet, screw heads, metallic overlays, control

shafts, etc.), especially any exposed metal

parts that offer an electrical return path to the

chassis. Any current measured must not

exceed 0.5 milli-ampere. Reverse the

instrument power cord plug in the outlet and

repeat the test.

READING SHOULD

NOT BE ABOVE 0.5 mA

LEAKAGE

DEVICE

BEING

TESTED

TEST ALL EXPOSED

METAL SURFACES

ALSO TEST WITH

PLUG REVERSED

USING AC

ADAPTER PLUG

AS REQUIRED

ANY MEASUREMENTS NOT WITHIN THE

LIMITS SPECIFIED HEREIN INDICATE A

POTENTIAL SHOCK HAZARD THAT MUST

BE ELIMINATED BEFORE RETURNING THE

INSTRUMENT TO THE CUSTOMER OR

BEFORE CONNECTING THE ANTENNA OR

ACCESSORIES.

2. Read and comply with all caution and safety-

related notes on or inside the receiver cabinet, on

the receiver chassis, or on the Liquid Crystal

Panel.

3. Design Alteration Warning - Do not alter or add

to the mechanical or electrical design of this TV

receiver. Design alterations and additions,

including, but not limited to circuit modifications

and the addition of items such as auxiliary audio

and/or video output connections, might alter the

safety characteristics of this receiver and create a

hazard to the user. Any design alterations or

additions will void the manufacturer's warranty and

may make you, the servicer, responsible for

CURRENT

TESTER

+

EARTH

GROUND

_

FUZ2.0U LA 9

personal injury or property damage resulting

therefrom.

4. Hot Chassis Warning -

a. Some TV receiver chassis are electrically

connected directly to one conductor of the AC

power cord and maybe safety-serviced without

an isolation transformer only if the AC power

plug is inserted so that the chassis is

connected to the ground side of the AC power

source. To confirm that the AC power plug is

inserted correctly, with an AC voltmeter,

measure between the chassis and a known

earth ground. If a voltage reading in excess of

1.0 V is obtained, remove and reinsert the AC

power plug in the opposite polarity and again

measure the voltage potential between the

chassis and a known earth ground.

b. Some TV receiver chassis normally have 85V

AC(RMS) between chassis and earth ground

regardless of the AC plug polarity. This chassis

can be safety-serviced only with an isolation

transformer inserted in the power line between

the receiver and the AC power source, for both

personnel and test equipment protection.

c. Some TV receiver chassis have a secondary

ground system in addition to the main chassis

ground. This secondary ground system is not

isolated from the AC power line. The two

ground systems are electrically separated by

insulation material that must not be defeated or

altered.

5. Observe original lead dress. Take extra care to

assure correct lead dress in the following areas: a.

near sharp edges, b. near thermally hot parts-be

sure that leads and components do not touch

thermally hot parts, c. the AC supply, d. high

voltage, and, e. antenna wiring. Always inspect in

all areas for pinched, out of place, or frayed wiring.

Check AC power cord for damage.

6. Components, parts, and/or wiring that appear to

have overheated or are otherwise damaged

should be replaced with components, parts, or

wiring that meet original specifications.

Additionally, determine the cause of overheating

and/or damage and, if necessary, take corrective

action to remove any potential safety hazard.

7. Product Safety Notice - Some electrical and

mechanical parts have special safety-related

characteristics which are often not evident from

visual inspection, nor can the protection they give

necessarily be obtained by replacing them with

components rated for higher voltage, wattage, etc.

Parts that have special safety characteristics are

identified by a # on schematics and in parts lists.

Use of a substitute replacement that does not

have the same safety characteristics as the

recommended replacement part might create

shock, fire, and/or other hazards. The product's

safety is under review continuously and new

instructions are issued whenever appropriate.

Prior to shipment from the factory, our products

are strictly inspected to confirm they comply with

the recognized product safety and electrical codes

of the countries in which they are to be sold.

However, in order to maintain such compliance, it

is equally important to implement the following

precautions when a set is being serviced.

10 FUZ2.0U LA

Precautions during Servicing

A. Parts identified by the # symbol are critical for

safety.

Replace only with part number specified.

B. In addition to safety, other parts and assemblies

are specified for conformance with regulations

applying to spurious radiation. These must also be

replaced only with specified replacements.

Examples: RF converters, RF cables, noise

blocking capacitors, and noise blocking filters, etc.

C. Use specified internal wiring. Note especially:

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leads

D. Use specified insulating materials for hazardous

live parts. Note especially:

1) Insulation Tape

2) PVC tubing

3) Spacers

4) Insulators for transistors.

E. When replacing AC primary side components

(transformers, power cord, etc.), wrap ends of

wires securely about the terminals before

soldering.

F. Observe that the wires do not contact heat

producing parts (heat sinks, oxide metal film

resistors, fusible resistors, etc.)

G. Check that replaced wires do not contact sharp

edged or pointed parts.

H. When a power cord has been replaced, check that

5~6 kg of force in any direction will not loosen it.

I. Also check areas surrounding repaired locations.

J. Use care that foreign objects (screws, solder

droplets, etc.) do not remain inside the set.

K. When connecting or disconnecting the internal

connectors, first, disconnect the AC plug from the

AC supply outlet.

L. When installing parts or assembling the cabinet

parts, be sure to use the proper screws and

tighten certainly.

FUZ2.0U LA 11

Safety Check after Servicing

Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, parts and

wires have been returned to original positions. Afterwards, perform the following tests and confirm the specified

values in order to verify compliance with safety standards.

1. Clearance Distance

When replacing primary circuit components, confirm

specified clearance distance (d) and (d') between

soldered terminals, and between terminals and

surrounding metallic parts. (See Fig. 1)

Table 1: Ratings for selected area

Chassis or Secondary Conductor

Primary Circuit

AC Line Voltage Region

110 to 130 V

Note: This table is unofficial and for reference only. Be

sure to confirm the precise values.

U.S.A. or

Canada

Clearance

Distance (d), (d’)

≥ 3.2 mm

(0.126 inches)

2. Leakage Current Test

Confirm the specified (or lower) leakage current

between B (earth ground, power cord plug prongs) and

externally exposed accessible parts (RF terminals,

antenna terminals, video and audio input and output

terminals, microphone jacks, earphone jacks, etc.) is

lower than or equal to the specified value in the table

below.

Measuring Method: (Power ON)

Insert load Z between B (earth ground, power cord plug

prongs) and exposed accessible parts. Use an AC

voltmeter to measure across both terminals of load Z.

See Fig. 2 and following table.

d' d

Fig. 1

Exposed Accessible Part

Z

AC Voltmeter

(High Impedance)

Earth Ground

B

Power Cord Plug Prongs

Fig. 2

Table 2: Leakage current ratings for selected areas

AC Line Voltage Region Load Z Leakage Current (i) Earth Ground (B) to:

110 to 130 V

Note: This table is unofficial and for reference only. Be sure to confirm the precise values.

U.S.A. or

Canada

0.15 µF CAP. & 1.5 kΩ

RES. Connected in parallel

i ≤ 0.5 mA rms

Exposed accessible

parts

12 FUZ2.0U LA

4. STANDARD NOTES FOR SERVICING

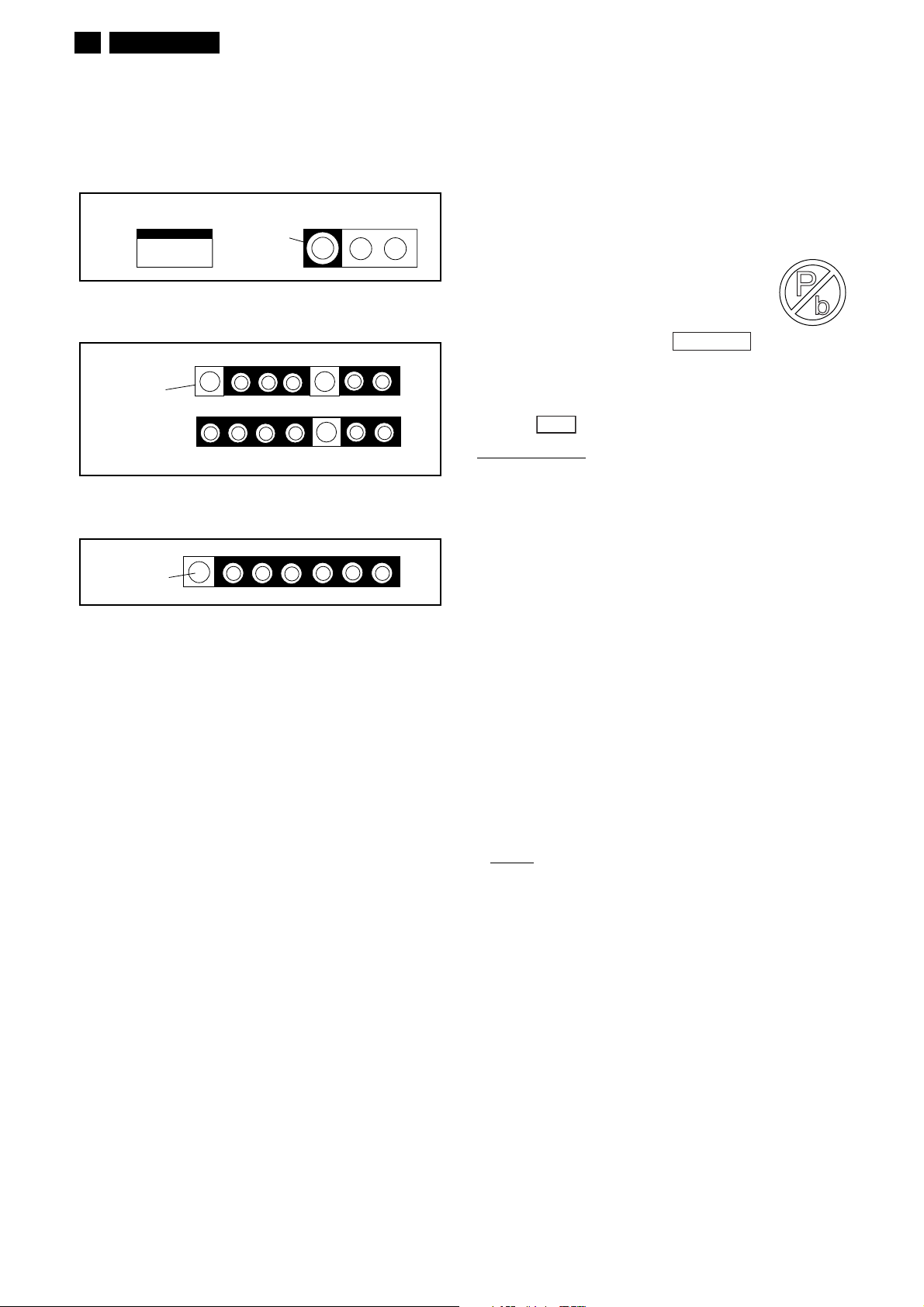

Circuit Board Indications

1. The output pin of the 3 pin Regulator ICs is

indicated as shown.

Top View

Out

2. For other ICs, pin 1 and every fifth pin are

indicated as shown.

Pin 1

3. The 1st pin of every male connector is indicated as

shown.

Pin 1

Input

In

Bottom View

5

10

Pb (Lead) Free Solder

When soldering, be sure to use the Pb free solder.

Information about lead-free soldering

Philips CE is producing lead-free sets from 1.1.2005

onwards.

IDENTIFICATION

Regardless of special logo (not always

indicated)

One must treat all sets from

onwards, according to the next rule:

Serial Number gives a 14-digit. Digit 5&6 shows the

YEAR, and digit 7&8 shows the WEEK.

So from onwards=from 1 Jan 2005 onwards

Important note

must be treated in this way as long as you avoid

mixing solder-alloys (leaded/ lead-free). So best to

always use SAC305 and the higher temperatures

belong to this.

Due to lead-free technology some rules have to be

respected by the workshop during a repair:

• Use only lead-free solder alloy Philips SAC305 with

order code 0622 149 00106. If lead-free solderpaste is required, please contact the manufacturer

of your solder-equipment. In general use of solderpaste within workshops should be avoided because

paste is not easy to store and to handle.

• Use only adequate solder tools applicable for lead-

free solder alloy. The solder tool must be able

• To reach at least a solder-temperature of 400°C,

• To stabilize the adjusted temperature at the solder-

• To exchange solder-tips for different applications.

• Adjust your solder tool so that a temperature around

360°C

solder joint. Heating-time of the solder-joint should

not exceed ~ 4 sec. Avoid temperatures above

400°C otherwise wear-out of tips will rise drastically

and flux-fluid will be destroyed. To avoid wear-out of

tips switch off un-used equipment, or reduce heat.

0501

: In fact also products of year 2004

tip

- 380°C is reached and stabilized at the

1 Jan 2005

FUZ2.0U LA 13

• Mix of lead-free solder alloy / parts with leaded

solder alloy / parts is possible but PHILIPS

recommends strongly to avoid mixed solder alloy

types (leaded and lead-free).

If one cannot avoid or does not know whether

product is lead-free, clean carefully the solder-joint

from old solder alloy and re-solder with new solder

alloy (SAC305).

• Use only original spare-parts listed in the Service-

Manuals. Not listed standard-material (commodities)

has to be purchased at external companies.

• Special information for BGA-ICs:

- always use the 12nc-recognizable soldering

temperature profile of the specific BGA (for desoldering always use the lead-free temperature

profile, in case of doubt)

- lead free BGA-ICs will be delivered in so-called

'dry-packaging' (sealed pack including a silica gel

pack) to protect the IC against moisture. After

opening, dependent of MSL-level seen on indicatorlabel in the bag, the BGA-IC possibly still has to be

baked dry. (MSL=Moisture Sensitivity Level). This

will be communicated via AYS-website.

Do not re-use BGAs at all.

• For sets produced before 1.1.2005 (except products

of 2004), containing leaded solder-alloy and

components, all needed spare-parts will be available

till the end of the service-period. For repair of such

sets nothing changes.

Alternative BOM Identification

In September 2003, Philips CE introduced a change in

the way the serial number is composed. from this data

on, the third digit in the serial number (example:

AG2B0335000001) indicates the number of the

alternative BOM (Bill of Materials used for producing

the specific model of TV set). It is possible that the

same TV model on the market is produced with e.g.

two different types of displays, coming from two

different O.E.M.s. By looking at the third digit of the

serial number, the service technician can see if there

is more than one type of B.O.M. used in the production

of the TV set he is working with. He can then consult

the At Your Service Web site, where he can type in the

Commercial Type Version Number of the TV set (e.g.

28PW9515/12), after which a screen will appear that

gives infomation about the number of alternative

B.O.M.s used. If the third digit of the serial number

contains the number 1 (example: AG1B033500001),

then there is only one B.O.M. version of the TV set on

the market. If the third digit is a 2 (example:

AG2B0335000001), then there are two different

B.O.M.s. Information about this is important for

ordering the correct spare parts! For the third digit, the

numbers 1...9 and the characters A...Z can be used,

so in total: 9 plus 26 = 35 different B.O.M.s can be

indicated by the third digit of the serial number.

For additional questions please contact your local

repair-helpdesk.

14 FUZ2.0U LA

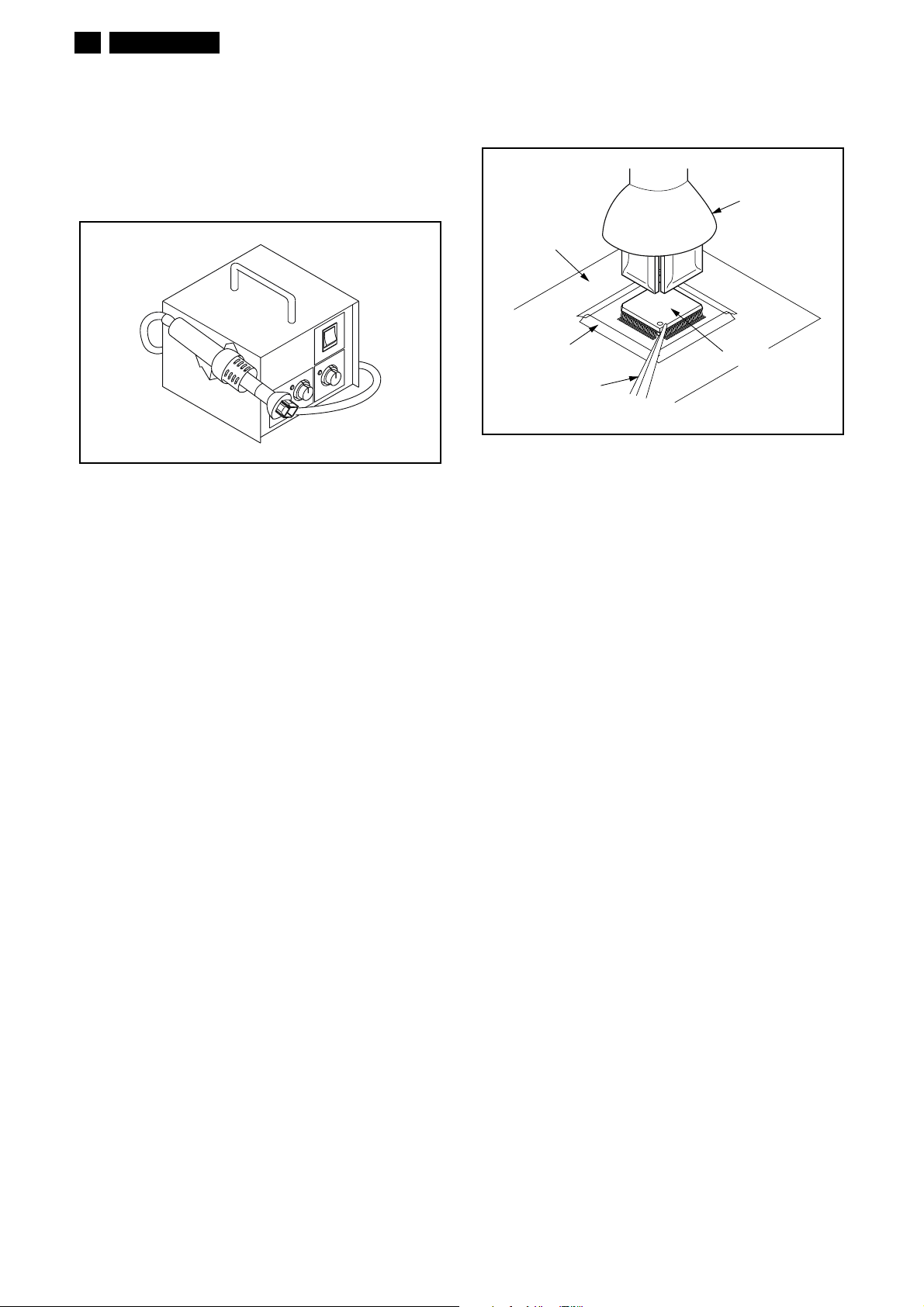

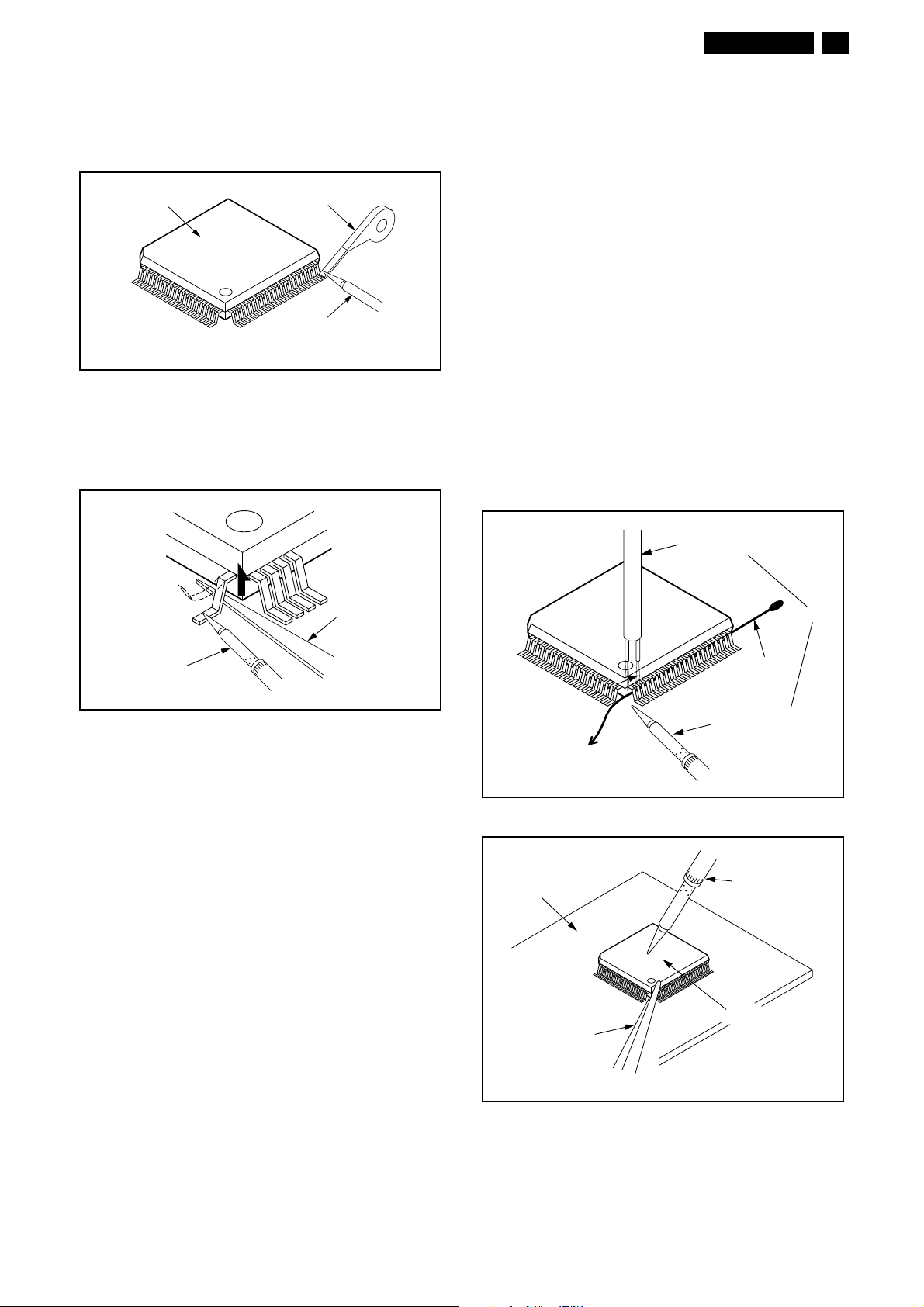

How to Remove / Install Flat Pack-IC

1. Removal

With Hot-Air Flat Pack-IC Desoldering Machine:

1. Prepare the hot-air flat pack-IC desoldering

machine, then apply hot air to the Flat Pack-IC

(about 5 to 6 seconds). (Fig. S-1-1)

Fig. S-1-1

2. Remove the flat pack-IC with tweezers while

applying the hot air.

3. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

4. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

3. The flat pack-IC on the CBA is affixed with glue, so

be careful not to break or damage the foil of each

pin or the solder lands under the IC when

removing it.

Hot-air

Flat Pack-IC

Desoldering

CBA

Masking

Tape

Tweezers

Machine

Flat Pack-IC

Fig. S-1-2

CAUTION:

1. The Flat Pack-IC shape may differ by models. Use

an appropriate hot-air flat pack-IC desoldering

machine, whose shape matches that of the Flat

Pack-IC.

2. Do not supply hot air to the chip parts around the

flat pack-IC for over 6 seconds because damage

to the chip parts may occur. Put masking tape

around the flat pack-IC to protect other parts from

damage. (Fig. S-1-2)

FUZ2.0U LA 15

With Soldering Iron:

1. Using desoldering braid, remove the solder from

all pins of the flat pack-IC. When you use solder

flux which is applied to all pins of the flat pack-IC,

you can remove it easily. (Fig. S-1-3)

Flat Pack-IC

Desoldering Braid

Soldering Iron

Fig. S-1-3

2. Lift each lead of the flat pack-IC upward one by

one, using a sharp pin or wire to which solder will

not adhere (iron wire). When heating the pins, use

a fine tip soldering iron or a hot air desoldering

machine. (Fig. S-1-4)

With Iron Wire:

1. Using desoldering braid, remove the solder from

all pins of the flat pack-IC. When you use solder

flux which is applied to all pins of the flat pack-IC,

you can remove it easily. (Fig. S-1-3)

2. Affix the wire to a workbench or solid mounting

point, as shown in Fig. S-1-5.

3. While heating the pins using a fine tip soldering

iron or hot air blower, pull up the wire as the solder

melts so as to lift the IC leads from the CBA

contact pads as shown in Fig. S-1-5.

4. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

5. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

Note: When using a soldering iron, care must be

taken to ensure that the flat pack-IC is not

being held by glue. When the flat pack-IC is

removed from the CBA, handle it gently

because it may be damaged if force is applied.

Sharp

Pin

Fine Tip

Soldering Iron

3. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

4. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

Fig. S-1-4

To Solid

Mounting Point

CBA

Hot Air Blower

or

Iron Wire

Soldering Iron

Fig. S-1-5

Fine Tip

Soldering Iron

Tweezers

Flat Pack-IC

Fig. S-1-6

16 FUZ2.0U LA

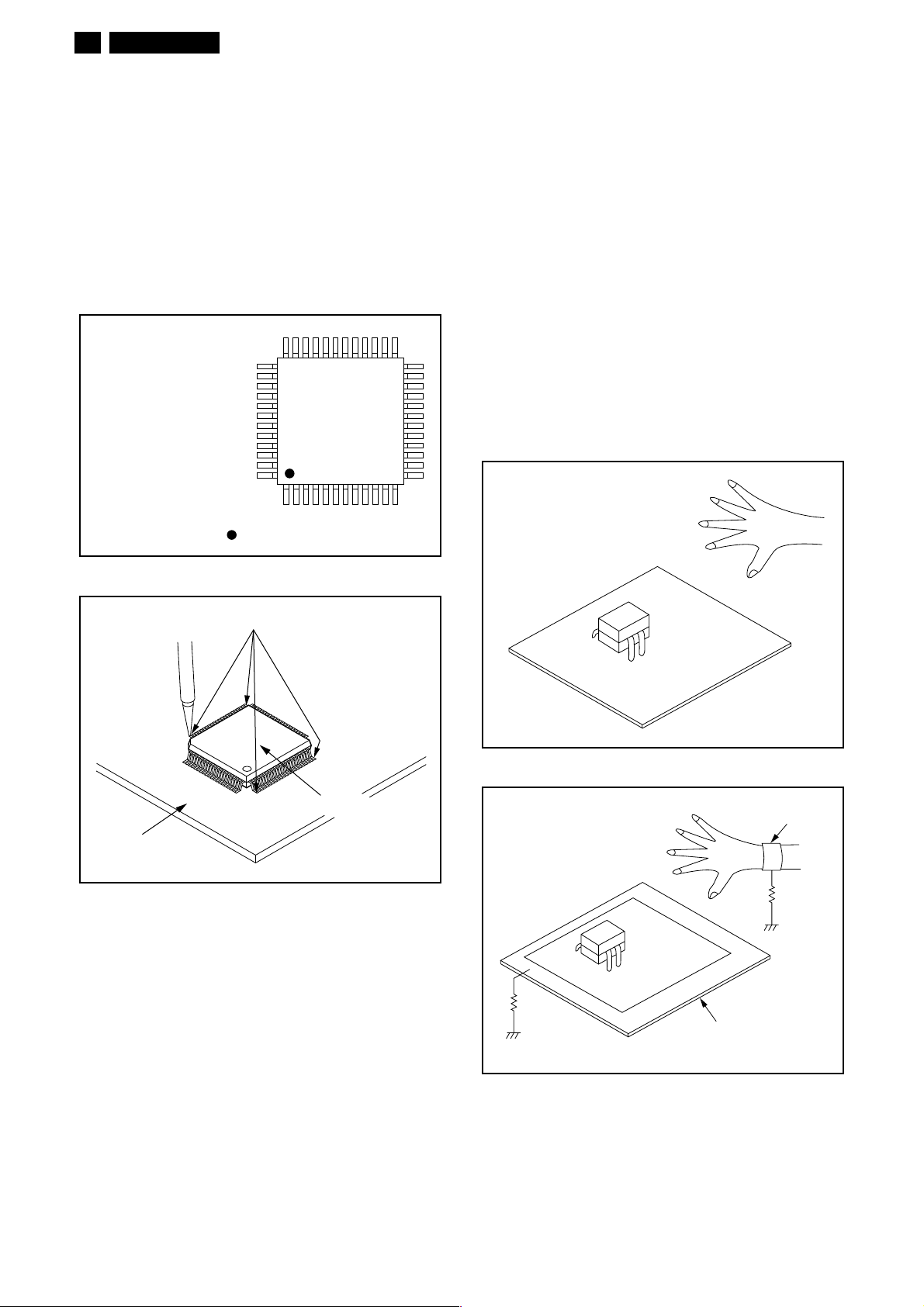

2. Installation

1. Using desoldering braid, remove the solder from

the foil of each pin of the flat pack-IC on the CBA

so you can install a replacement flat pack-IC more

easily.

2. The “●” mark on the flat pack-IC indicates pin 1.

(See Fig. S-1-7.) Be sure this mark matches the 1

on the PCB when positioning for installation. Then

presolder the four corners of the flat pack-IC. (See

Fig. S-1-8.)

3. Solder all pins of the flat pack-IC. Be sure that

none of the pins have solder bridges.

Example :

Pin 1 of the Flat Pack-IC

is indicated by a " " mark.

Fig. S-1-7

Instructions for Handling Semiconductors

Electrostatic breakdown of the semi-conductors may

occur due to a potential difference caused by

electrostatic charge during unpacking or repair work.

1. Ground for Human Body

Be sure to wear a grounding band (1 MΩ) that is

properly grounded to remove any static electricity that

may be charged on the body.

2. Ground for Workbench

Be sure to place a conductive sheet or copper plate

with proper grounding (1 MΩ) on the workbench or

other surface, where the semi-conductors are to be

placed. Because the static electricity charge on

clothing will not escape through the body grounding

band, be careful to avoid contacting semi-conductors

with your clothing.

<Incorrect>

CBA

Presolder

Flat Pack-IC

Fig. S-1-8

<Correct>

1MΩ

CBA

Grounding Band

1MΩ

CBA

Conductive Sheet or

Copper Plate

5. Directions for Use

You can download this infomation from the following website:

http://www.philips.com/support

http://www.p4c.philips.com

OSD Menu list

Menu Label

EXIT

Picture

Setup

Features

Language English

Smart Picture

Reset Picture Setting

Color temperature Cool

Energy Saving slider

Reset Sound Setting

Channel List

Manual Register

Antenna

Closed Caption

PC Settings

HDMI1 Audio Auto

Español

Français

Live TV Label

Picture Mode

Movie expand Movie expand

Nature

Rich

Movie

Soft

redilsssenthgirB

redilstsartnoC

redilsroloC

redilstniT

redilsssenprahS

Off

Reset to default

Normal

Warm

redilselberTdnuoS

redilsssaB

Off

Reset to default

kcaBmargorpotuA

Air

Analog Cable

Auto

Conventional CC Off

Auto Adjustment slider

Horizontal Position slider

Vertical Position slider

Digital

Analog

langis 9:61 roflangis 3:4 rof

lamroNlamroN

mooZ9:61

ediWediW

FUZ2.0U LA 17

reyaL ht5reyaL ht4reyaL dr3reyaL dn2reyaL ts1

CC-1

CC-2

CC-3

CC-4

T-1

T-2

T-3

T-4

ffOCC VTD

CS-1

CS-2

CS-3

CS-4

CS-5

CS-6

nOgnitteS resUelytS CC

Off

Font Style

Font Size

Font Color

Font Opacity

Back Color

Back Opacity

Edge Color

Edge Type

kcol sgnitar eivoM SUniP retnElortnoC latneraP

US TV ratings lock

Canadian English Rating

Canadian French Rating

Region ratings lock

Clear Regions lock

Change Pin

redilskcolC

redilsesahP

reyaL ht5reyaL ht4reyaL dr3reyaL dn2reyaL ts1

18 FUZ2.0U LA

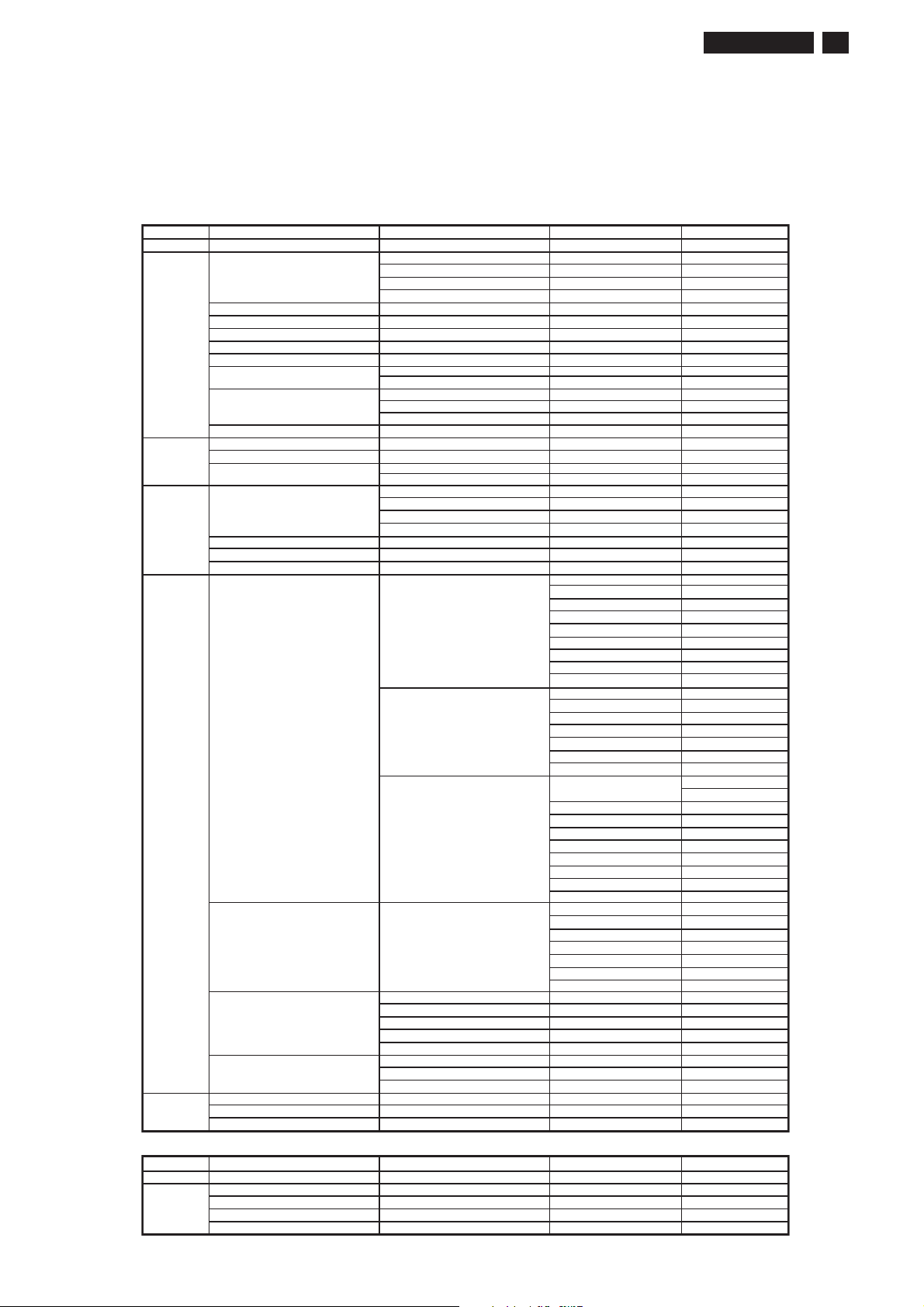

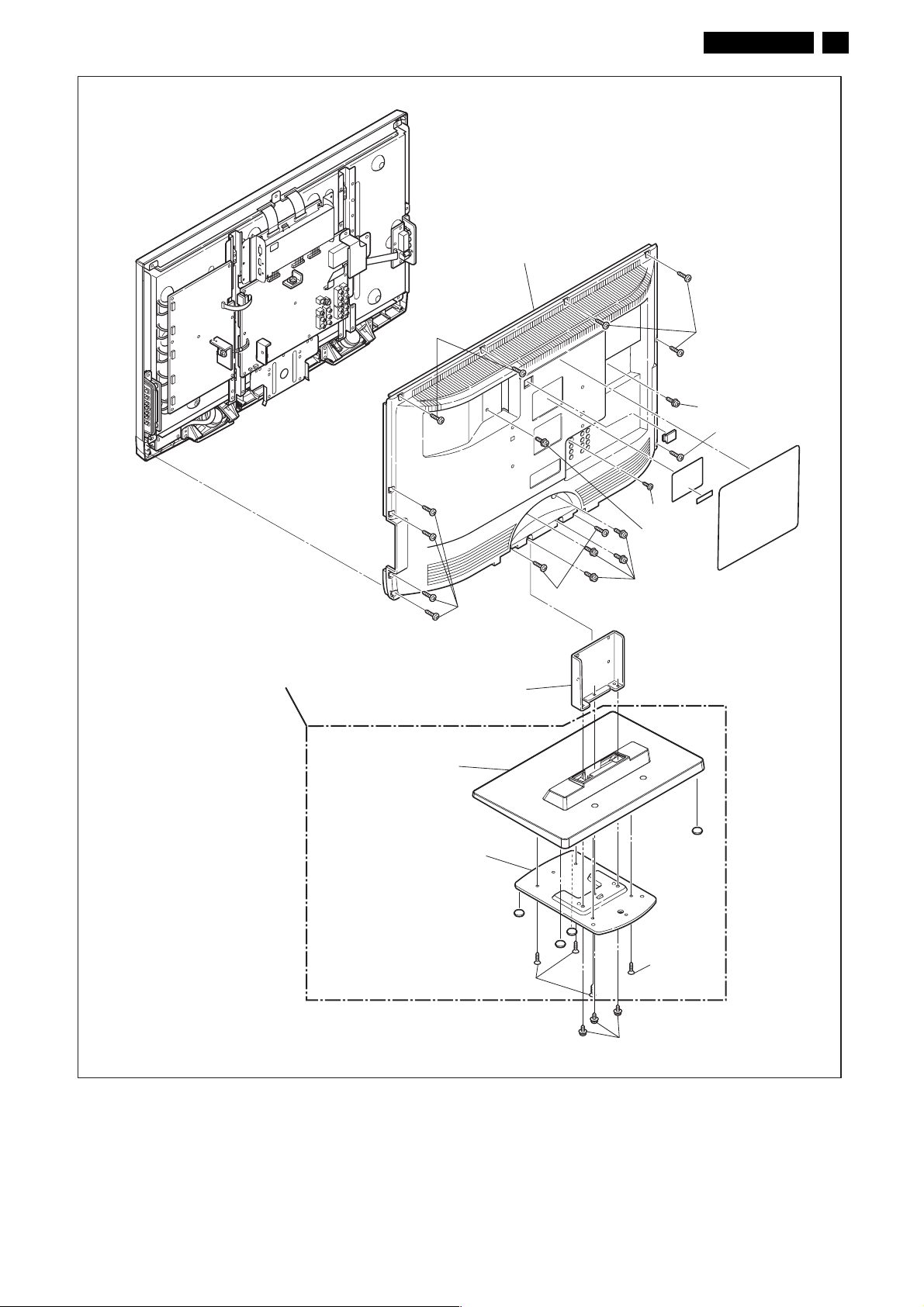

6. CABINET DISASSEMBLY INSTRUCTIONS

1. Disassembly Flowchart

This flowchart indicates the disassembly steps for the

cabinet parts, and the Board in order to gain access to

item(s) to be serviced. When reassembling, follow the

steps in reverse order. Bend, route and dress the

cables as they were.

[18] Function Board

[19] Speaker

Holder (L,R)

[20] Speaker(s)

[16] Junction-A

Board

[17] IR Sensor

Board

[14] Stand Holder

[4] Rear Cabinet

[7] Shield (T)

[8] Shield Box

[9] Digital Main

Board Unit

[10] Power Supply

Board

[11] Inverter Board

[13] PCB Holder

(L,R)

[15] LCD Module

Assembly

[21] Front Cabinet

[6] Side Jack Board

[5] Jack Holder (A)

Stand Assembly

[1] Stand Base

Plate

[2] Stand Cover

[3] Stand Hinge

[12] Junction-B

Board

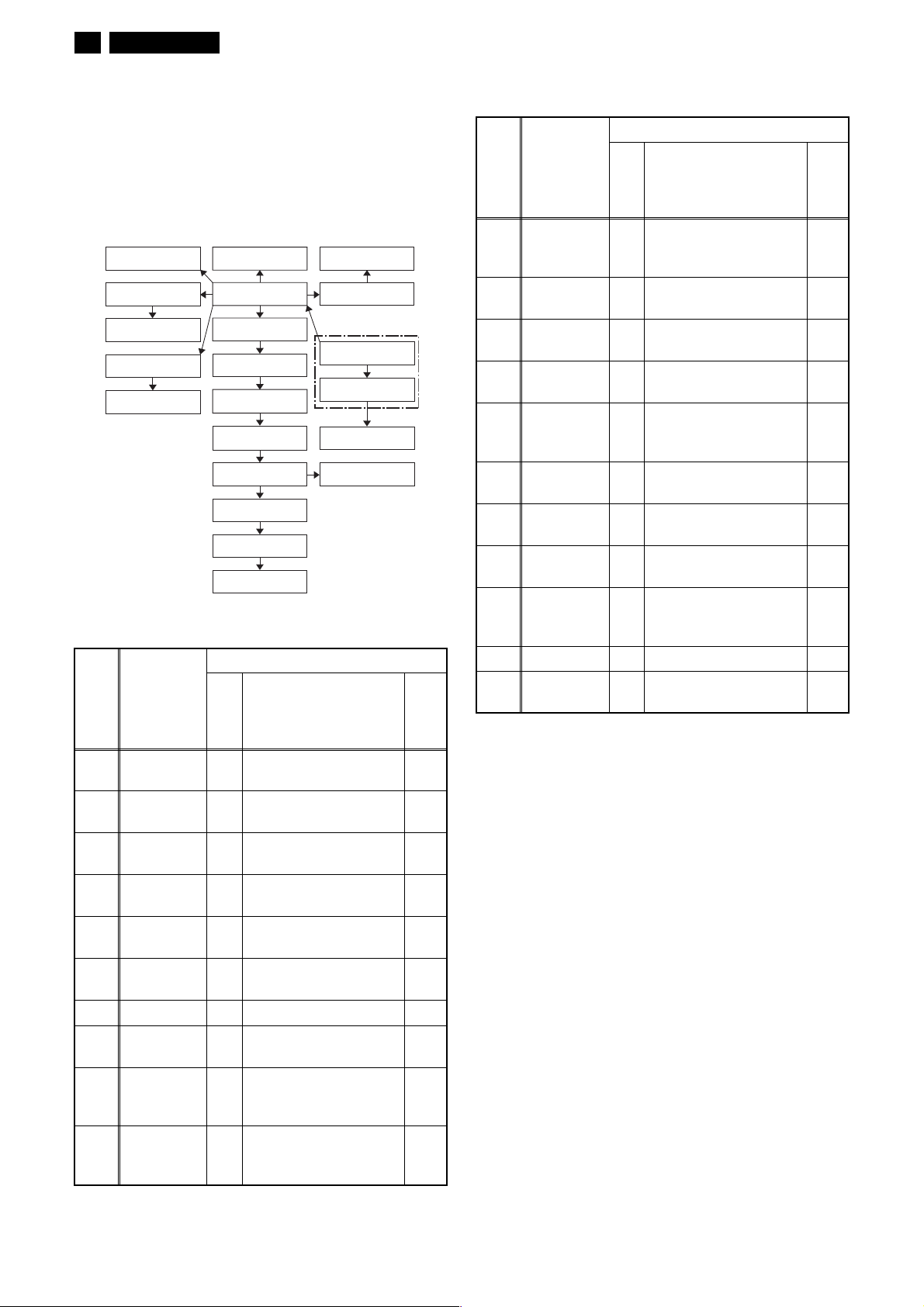

2. Disassembly Method

Removal

Step/

Loc.

Part

No.

Stand Base

[1]

Plate

Stand

[2]

Cover

Stand

[3]

Hinge

Rear

[4]

Cabinet

Jack Holder

[5]

(A)

Side Jack

[6]

Board

[7] Shield (T) D2 (S-9), (S-10), (N-1) ---

[8] Shield Box D2

Digital Main

[9]

Board UnitD2D5

Power

[10]

Supply

Board

Remove/*Unhook/

Fig.

No.

Unlock/Release/

Unplug/Unclamp/

Note

Desolder

D1 4(S-1), 3(S-2), 4(S-3) ---

D1 --------------- ---

D1 --------------- ---

D1 12(S-4), (S-5), 2(S-6) ---

D2 (S-7) ---

D2

2(S-8), *CN751 ---

D5

2(S-11), 2(S-12),

3(S-13), 4(S-14)

*CN3601, *CN3701,

*CN3704, *CN4501,

*CN4502

7(S-15), *CN102,

D2

*CN501, *CN801,

D5

*CN802, *CN1901

---

---

---

Removal

Step/

Loc.

No.

Part

Remove/*Unhook/

Fig.

No.

Unlock/Release/

Unplug/Unclamp/

Note

Desolder

7(S-16), *CN1050,

D3

*CN1100, *CN1150,

D5

*CN1200, *CN1250

D3

Desolder ---

D5

---

D3 4(S-17) ---

D3 2(S-18), 2(S-19) ---

[11]

[12]

[13]

[14]

Inverter

Board

Junction-B

Board

PCB Holder

(L,R)

Stand

Holder

LCD

[15]

Module

D4 4(S-20) ---

Assembly

[16]

[17]

[18]

Junction-A

Board

IR Sensor

Board

Function

Board

D4

Desolder ---

D5

D4

2(S-21), *CL102A ---

D5

D4

2(S-22) ---

D5

Speaker

[19]

Holder

D4 4(S-23) ---

(L,R)

[20] Speaker(s) D4 --------------- ---

Front

[21]

↓

(1)

Cabinet

↓

(2)

D4 --------------- ---

↓

(3)

↓

(4)

↓

(5)

Note:

(1) Order of steps in procedure. When reassembling,

follow the steps in reverse order. These numbers

are also used as the Identification (location) No. of

parts in figures.

(2) Parts to be removed or installed.

(3) Fig. No. showing procedure of part location

(4) Identification of parts to be removed, unhooked,

unlocked, released, unplugged, unclamped, or

desoldered.

N = Nut, L = Locking Tab, S = Screw,

CN = Connector

* = Unhook, Unlock, Release, Unplug, or Desolder

e.g. 2(S-2) = two Screws (S-2),

2(L-2) = two Locking Tabs (L-2)

(5) Refer to the following "Reference Notes in the

Ta b le . "

[4] Rear Cabinet

FUZ2.0U LA 19

Stand Assembly

[2] Stand Cover

(S-4)

(S-4)

[3] Stand Hinge

(S-4)

(S-6)

(S-4)

(S-5)

(S-6)

(S-1)

(S-4)

[1] Stand Base Plate

(S-3)

(S-3)

(S-2)

Fig. D1

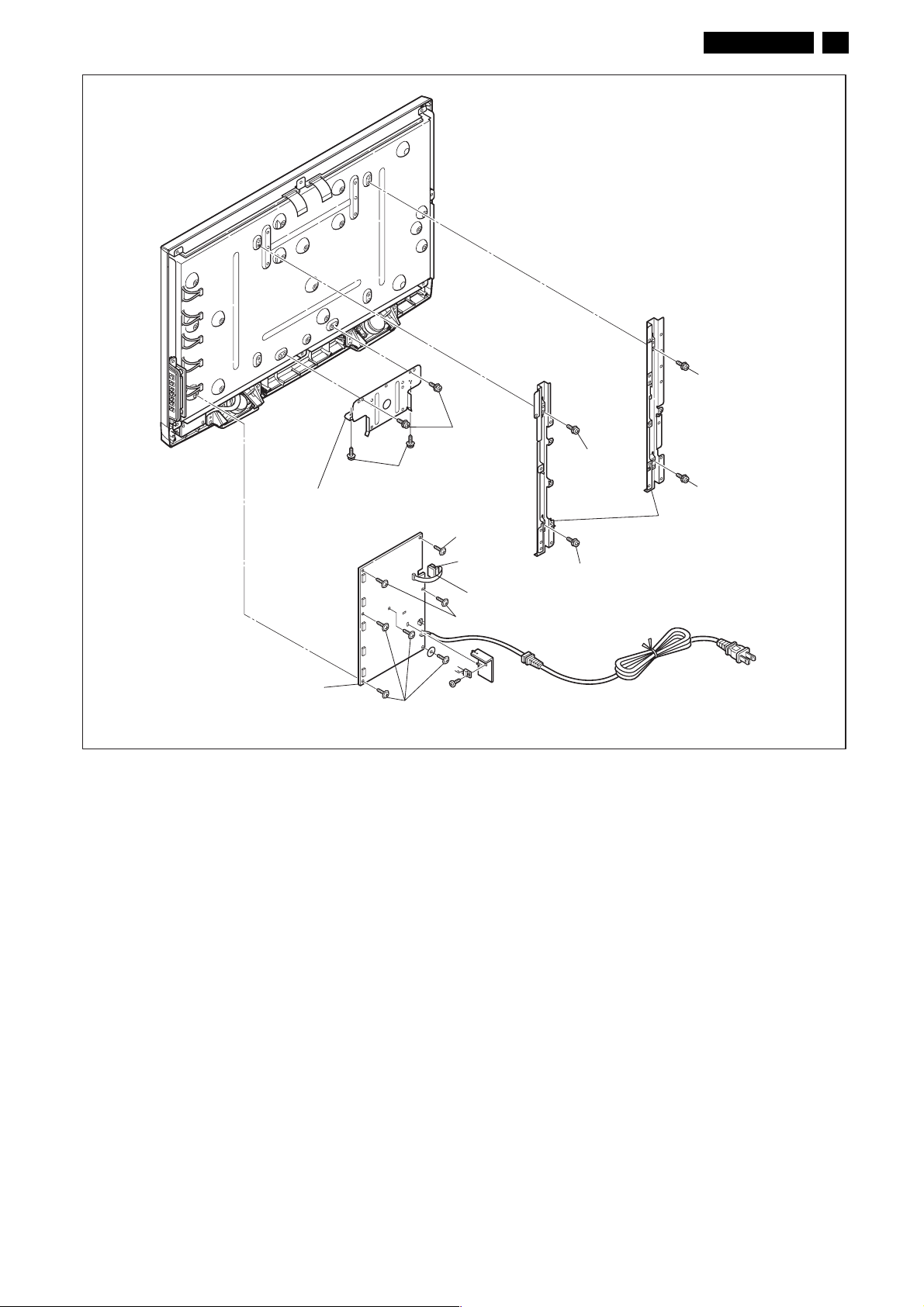

20 FUZ2.0U LA

[9] Digital Main

Board Unit

[8] Shield Box

(S-13)

(S-11)

[10] Power Supply Board

(S-12)

(S-13)

(S-7)

(S-15)

(S-14)

(S-14)

[6] Side Jack

Board

(N-1)

(S-15)

(S-15)

[5] Jack Holder (A)

(S-7)

(S-8)

[7] Shield (T)

(S-10)

(S-9)

Fig. D2

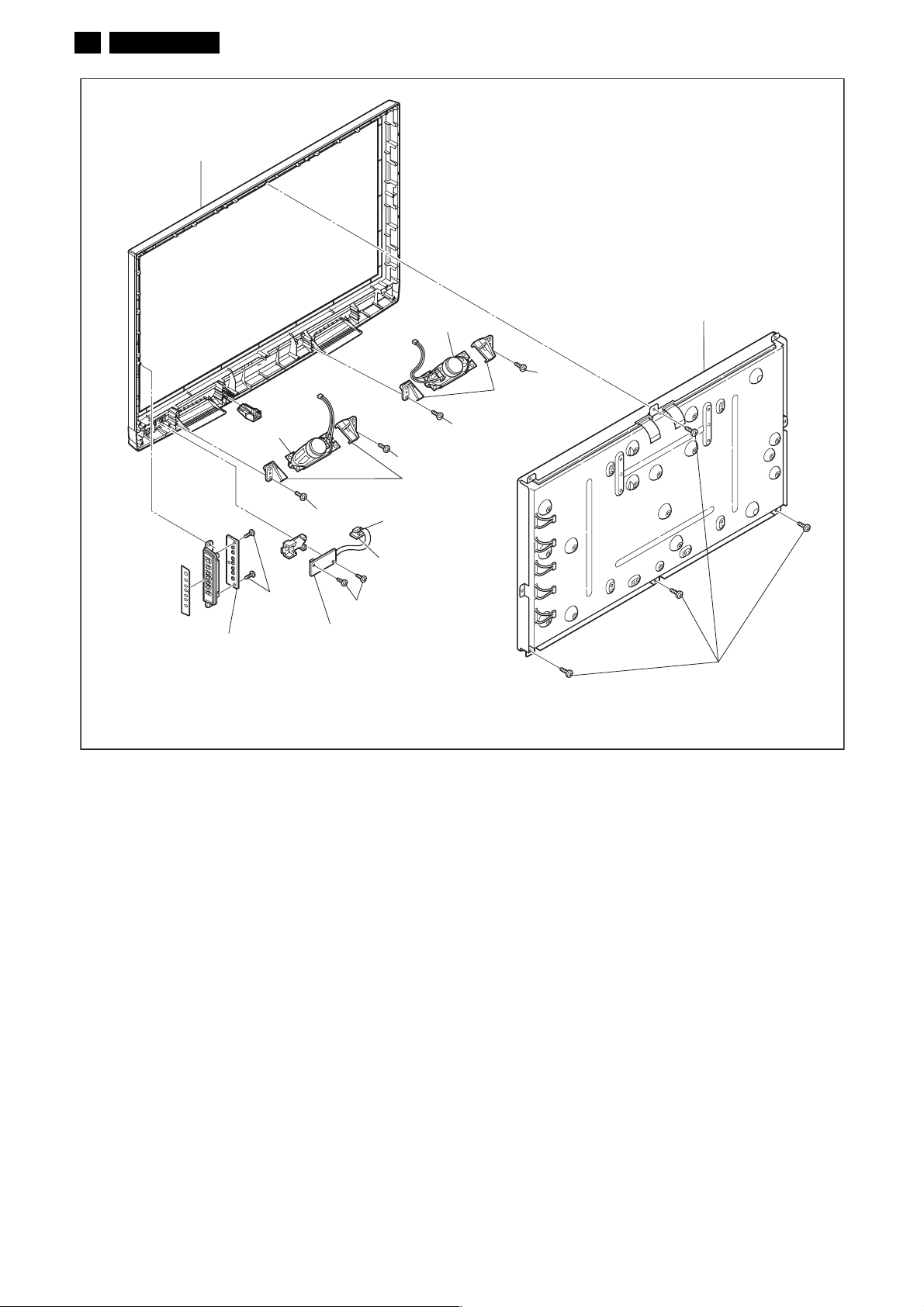

(S-19)

[14] Stand Holder

(S-18)

(S-16)

FUZ2.0U LA 21

(S-17)

(S-17)

(S-17)

[13] PCB Holder (L,R)

[11] Inverter Board

(S-16)

Desolder

(S-17)

[12] Junction-B Board

(S-16)

Fig. D3

22 FUZ2.0U LA

[21] Front Cabinet

[20] Speaker

(S-22)

[18] Function

Board

[20] Speaker

(S-23)

(S-23)

Desolder

[16] Junction-A

Board

(S-21)

[17] IR Sensor

Board

(S-23)

[19] Speaker

Holder (L,R)

[15] LCD Module Assembly

(S-23)

[19] Speaker

Holder (L,R)

(S-20)

Fig. D4

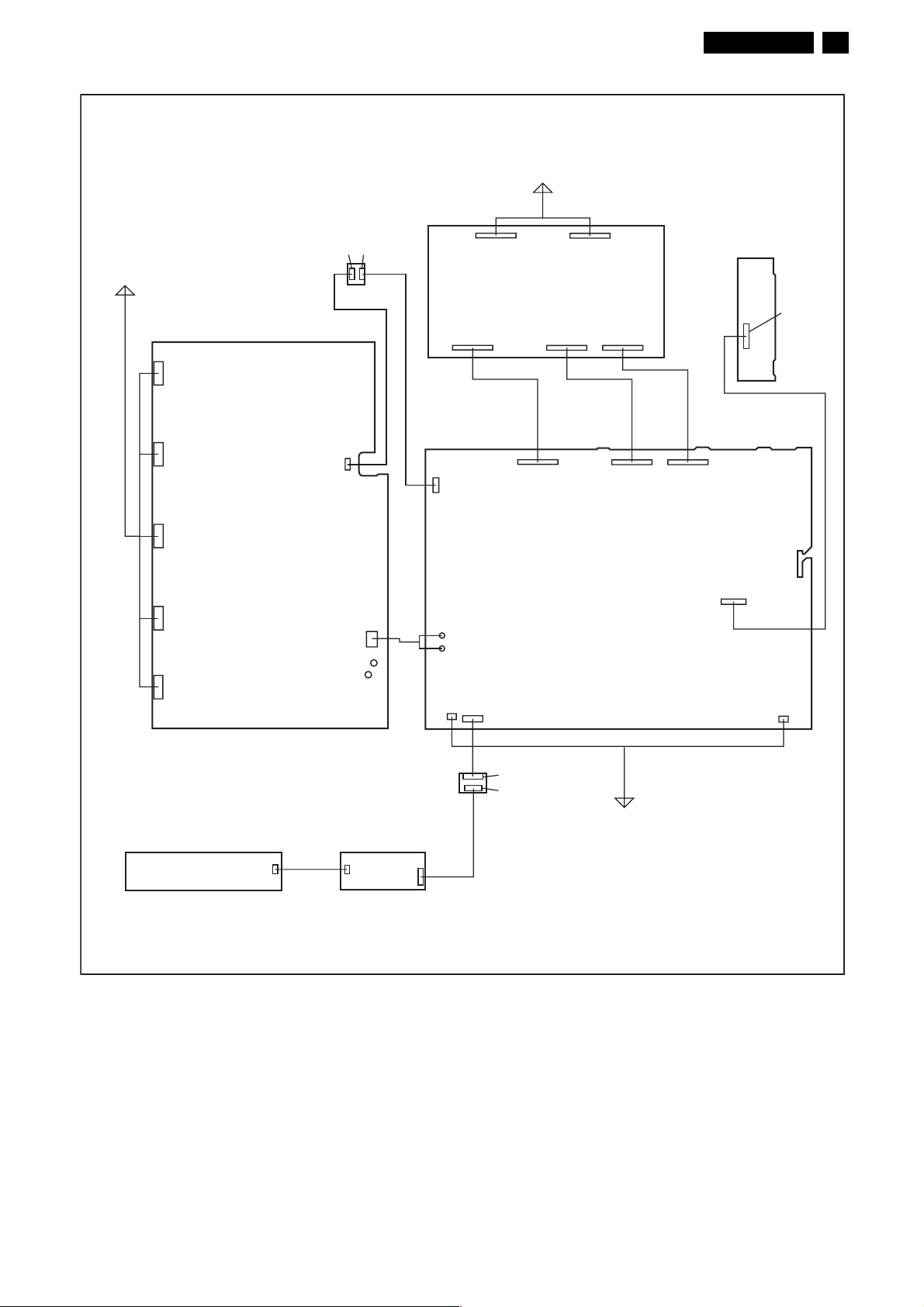

TV Cable Wiring Diagram

To LCD

Module

Assembly

Inverter Board

CN1050

CN1100

Junction-B

Board

CL1000A

FUZ2.0U LA 23

To LCD Module

Assembly

Digital Main

Board Unit

CN1000CL1000B

CN4501 CN4502

CN3601 CN3701

CN3704

Side Jack

Board

CN751

Power Supply

Board

CN301 CN302 CN303

CN501

CN1150

CN1200

CN1250

Function Board

CL102B

CN1901

AC CORD

Junction-A

Board

IR Sensor Board

CL101A

CL102A

CN601

CN802

CN102

CN101

CL101B

CN701

CN801

To Speaker

Fig. D5

24 FUZ2.0U LA

7. TROUBLESHOOTING

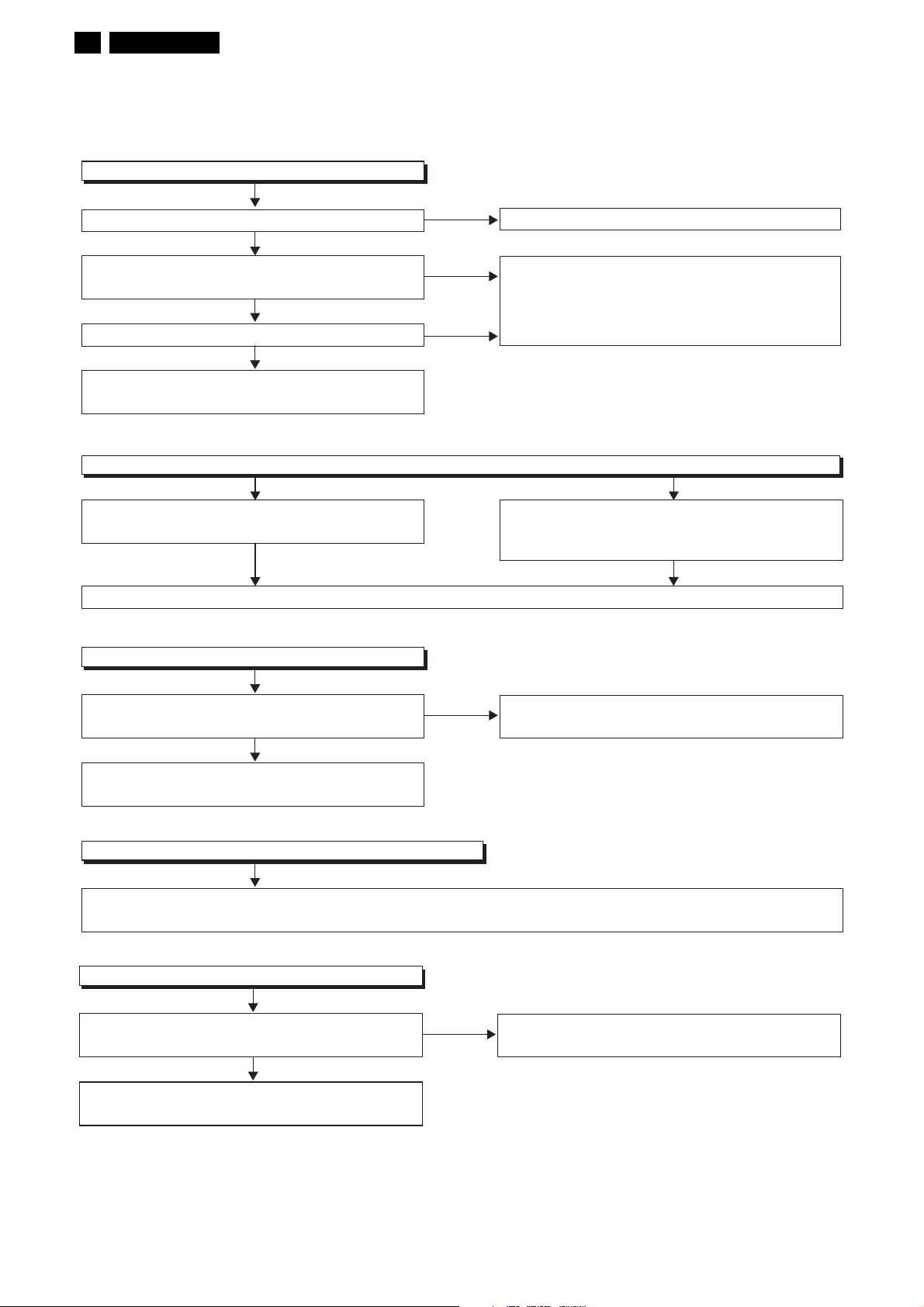

7.1 Power Supply Section

FLOW CHART NO.1

The power cannot be turned on.

Is the fuse (F1901) normal?

Ye s

Is normal state restored when once unplugged

power cord is plugged again several seconds?

Ye s

Is the AL +13V line voltage normal?

Ye s

Check each rectifying circuit of the secondary

circuit and service it if defective.

FLOW CHART NO.2

The fuse blows out.

Check the presence that the primary component

is leaking or shorted and service it if defective.

After servicing, replace the fuse.

FLOW CHART NO.3

When the output voltage fluctuates.

No

No

No

See FLOW CHART No.2 <The fuse blows out.>

Check if there is any leak or short-circuiting on the

primary circuit component, and service it if defective.

(C601, D1901, D1902, D1903, D1904, Q601, Q603,

T601)

Check the presence that the rectifying diode or circuit

is shorted in each rectifying circuit of secondary side,

and service it if defective.

Does the photocoupler circuit on the

secondary side operate normally?

Ye s

Check IC603, D603, D607 and their periphery,

and service it if defective.

FLOW CHART NO.4

When buzz sound can be heard in the vicinity of power circuit.

Check if there is any short-circuit on the rectifying diode and the circuit in each rectifying circuit of the secondary side,

and service it if defective. (IC637, D503, D632, D633, D636, D637, D638, D639, D640, D647, D669)

FLOW CHART NO.5

+40V is not output.

Is approximately 40V voltage supplied to the

cathode of D636?

Ye s

Check if there is any leak or short-circuit on

the loaded circuit, and service it if defective.

No

No

Check IC603, D631, Q631 and their periphery,

and service it if defective.

Check C639, D636 and their periphery circuit, and

service it defective.

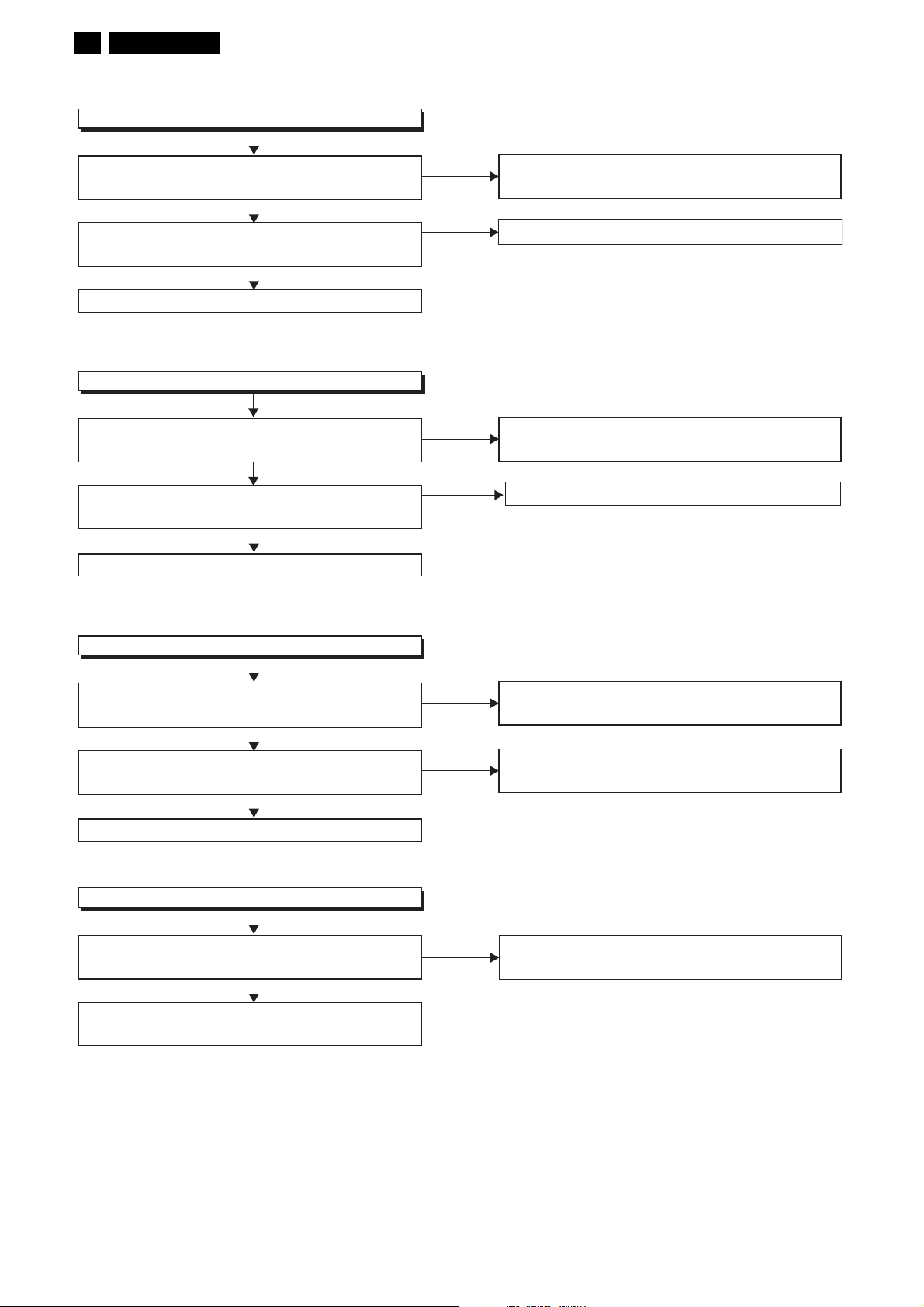

FLOW CHART NO.6

AL+13V is not output.

FUZ2.0U LA 25

Is approximately 13V voltage supplied to the

cathode of D638?

Ye s

Check if there is any leak or short-circuit on

the loaded circuit, and service it if defective.

FLOW CHART NO.7

AL+3.3V is not output.

Is approximately 6.6V voltage supplied to the

cathode of D669?

Ye s

Check IC637, D654, D657 and their periphery circuit,

and service it if defective.

FLOW CHART NO.8

P-ON+5V is not output.

Is approximately 6.6V voltage supplied to the

collector of Q637?

Ye s

Is approximately 6V voltage supplied to the

base of Q637?

Ye s

Replace Q637.

No

No

No

No

Check C638, D638, D639 and their periphery circuit,

andservice it defective.

Check C654, D669 and their periphery circuit, and

service it if defective.

See FLOW CHART No.7

See FLOW CHART No.10

FLOW CHART NO.9

LCD+24.5V is not output.

Is approximately 36V voltage supplied to the

cathode of D636?

Ye s

Is approximately 36V voltage supplied to the

collector of Q632?

No

Is the voltage of base on Q632 lower than the

voltage of emitter on Q632 when turning the

power on?

Ye s

Replace Q632.

No

Ye s

No

Check C639, D636 and their periphery circuit, and

service it if defective.

Check D641, D652 and their periphery circuit, and

service it if defective.

Check Q634 and P-ON-H1 line, and

service it if defective.

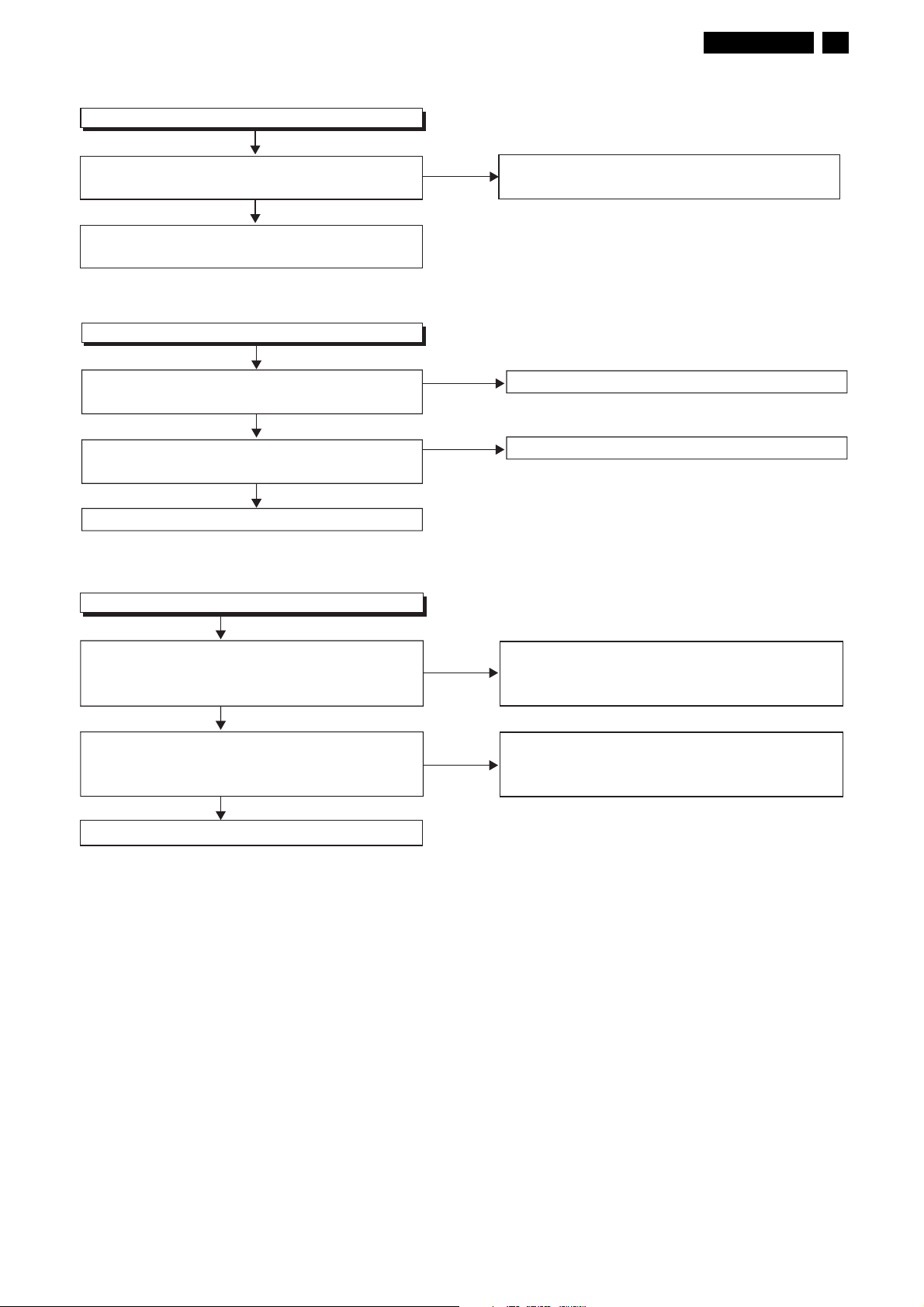

26 FUZ2.0U LA

FLOW CHART NO.10

LCD+13V is not output.

Is approximately 15V voltage supplied to the

cathode of D633?

Ye s

Is approximately 14V voltage supplied to the

base of Q645?

Ye s

Replace Q645.

FLOW CHART NO.11

LCD-6.8V is not output.

Is approximately -9V voltage supplied to the

anode of D637?

Ye s

Is approximately -9V voltage supplied to the

base of Q646?

Ye s

Replace Q646.

No

No

No

No

Check C633, D633 and their periphery circuit, and

service it if defective.

See FLOW CHART No.9

Check C663, D637 and their periphery circuit, and

service it if defective.

See FLOW CHART No.9

FLOW CHART NO.12

P-ON+3.3V (LCD+3.3V) is not output.

Is approximately 5V voltage supplied to the

cathode of D632?

Ye s

Is approximately 4V voltage supplied to the

base of Q638?

Ye s

Replace Q638.

FLOW CHART NO.13

+3.0V is not output.

Is approximately 3V voltage supplied to the

cathode of D647?

Ye s

Check if there is any leak or short-circuit on

the loaded circuit, and service it if defective.

No

No

No

Check C634, D632 and their periphery circuit, and

service it if defective.

Check Q639, Q671 and their periphery circuit, and

service it if defective.

Check C664, D647 and their periphery circuit, and

service it if defective.

FLOW CHART NO.14

+3.0V(1) is not output.

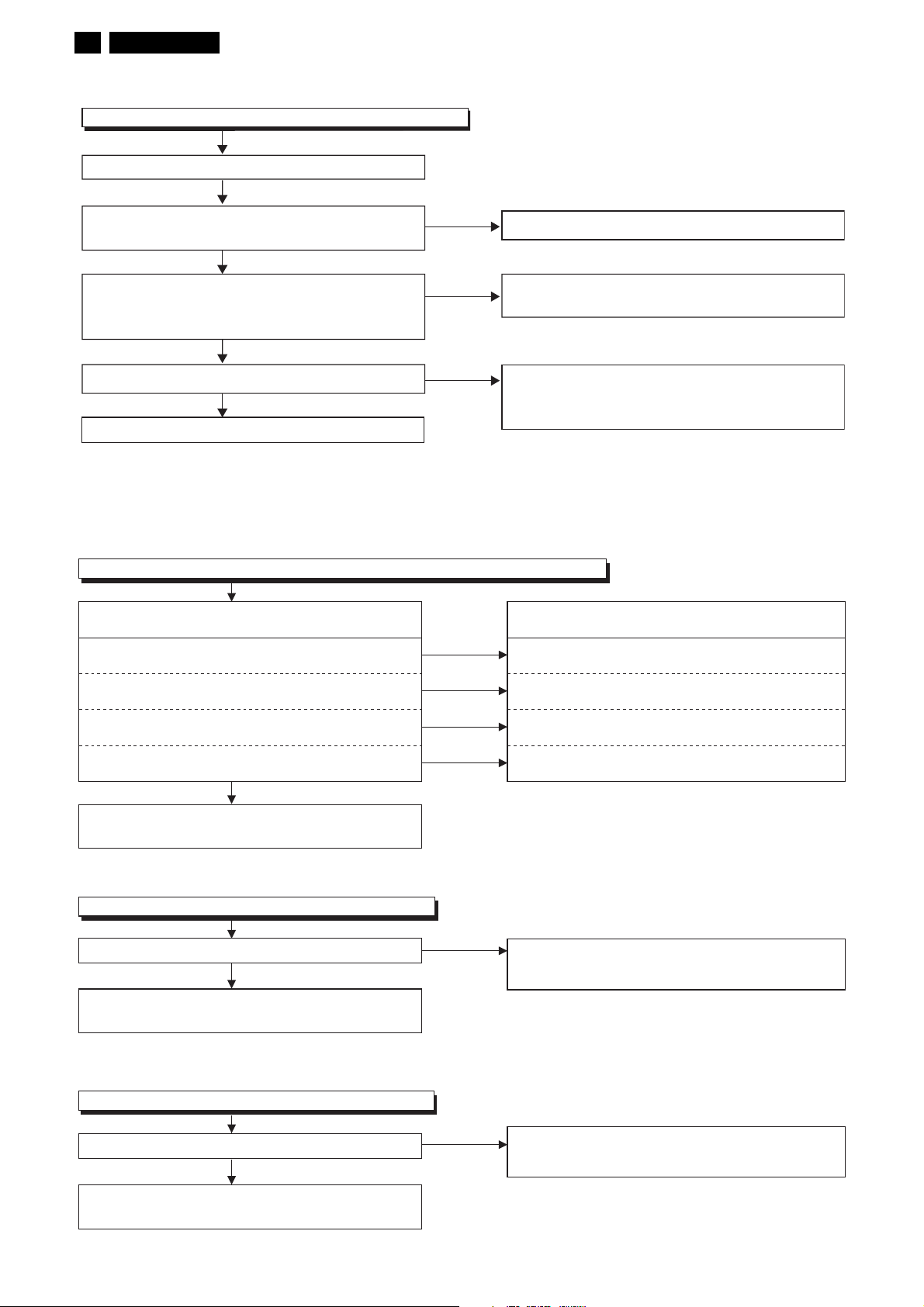

FUZ2.0U LA 27

Is approximately 3V voltage supplied to the

cathode of D640?

Ye s

Check if there is any leak or short-circuit on

the loaded circuit, and service it if defective..

FLOW CHART NO.15

P-ON+9V is not output.

Is approximately 13V voltage supplied to the

collector of Q801?

Ye s

Is approximately 10V voltage supplied to the

base of Q801?

Ye s

Replace Q801.

FLOW CHART NO.16

The key operation is not functioning.

No

No

No

Check C642, D640 and their periphery circuit, and

service it if defective.

See FLOW CHART No.6

See FLOW CHART No.10

Are the contact point and installation state of the key

switches (SW108, SW109, SW110, SW111,

SW112, SW113, SW114) normal?

Ye s

When pressing each switches (SW108, SW109,

SW110, SW111, SW112, SW113, SW114) do the

voltage of Pin(1) on CN301 increase?

Ye s

Replace Digital Main Board Unit.

No

No

Re-install the switches (SW108, SW109, SW110,

SW111, SW112, SW113, SW114) correctly or

replace the poor switch.

Check the switches (SW108, SW109, SW110,

SW111, SW112, SW113, SW114) and their

periphery, and service it if defective.

28 FUZ2.0U LA

FLOW CHART NO.17

No operation is possible from the remote control unit.

Operation is possible from the remote control unit.

Is 3.3V voltage supplied to Pin(2) terminal of the

infrared remote control receiver (RCV101)?

Ye s

Is the "L" pulse sent out Pin(1) terminal of receiver

(RCV101) when the infrared remote control is

activated?

Ye s

Is the "L" pulse supplied to the Pin(4) of CN301?

Ye s

Replace Digital Main Board Unit.

No

No

No

7.2 Video Signal Section

FLOW CHART NO.18

Picture does not appear normally. (Video input/S-Video input/Y/Pb/Pr input)

Are the video signals outputted to the specific

terminal?

Are the video signals outputted to the

Pin(23) of CN302?

Are the luminance signals outputted to the

Pin(19) of CN302?

Are the chrominance signals outputted to the

Pin(21) of CN302?

Are the component video(Y/Pb/Pr) signals outputted

to the Pin(14, 16, 17) of CN302?

Ye s

No

No

No

No

Check AL+3.3V line and service it if defective.

Replace the infrared remote control receiver

(RCV101) or the remote control unit.

Check the line between Pin(1) terminal of receiver

(RCV101) and Pin(4) of CN301 , and service

it if defective.

Check the line between each pin of CN302 and input

terminal and service it if defective.

Check the video signal line and IC7001,

and service it if defective.

Check the luminance signal line and IC7001,

and service it if defective.

Check the chrominance signal line and IC7001,

and service it if defective.

Check the component video(Y/Pb/Pr) signal line

and IC7001, and service it if defective.

Replace Digital Main Board Unit or LCD Module

Assembly.

FLOW CHART NO.19

Picture does not appear normally. (Tuner input (Digital))

Are the DIF signals outputted to the Pin(20, 22) of CN303?

Ye s

Replace Digital Main Board Unit or LCD Module

Assembly.

FLOW CHART NO.20

Picture does not appear normally. (Tuner input(Analog))

Are the video signal outputted to Pin(11) of CN303?

Ye s

Replace Digital Main Board Unit or LCD Module

Assembly.

No

No

Check the line between Pin(20, 22) of CN303 and

Pin(20, 21) of TU1 and TU1(Tuner Unit),

and service it if defective.

Check the line between Pin(11) of CN303 and

Pin(4) of TU1 and TU1(Tuner Unit),

and service it if defective.

Loading...

Loading...