Page 1

Colour Television Chassis

CL 965320690-163.eps

020999

FTV1.9DE

AA

Contents Page Contents Page

1. Technical specifications 2

2. Safety instructions, warnings and notes. 3

3. Directions for use 4

4. Mechanical instructions 8

5. Service modes, faultfinding and repair tips 12

Block- and wiring diagrams, Testpoints and

6.

oscillograms

Block diagram 19/20

IIC bus interconnection diagram 20

Testpoint overviews 21

Oscillograms 24

Supply voltage diagram 25

Wiring diagram 26

Electrical diagrams and PWB layouts Diagram PWB

7.

VsVa Supply (Diagram FD1) 27 29/30

VsVa Supply (Diagram FD2) 28 29/30

Pre-conditioner (Diagram PR1) 31 33

Pre-conditioner (Diagram PR2) 31 33

Pre-conditioner (Diagram PR3) 32 33

LED panel (Diagram LD) 34 34

Audio amplifier (Diagram A1) 35 37

Audio amplifier (Diagram A2) 36 37

Switch panel (Diagram SD) 38 38

Monitor microprocessor 39 40

AV control (Diagr. AVC1) 41 49/50

AV control (Diagr. AVC2) 42 49/50

AV control (Diagr. AVC3) 43 49/50

AV control (Diagr. AVC4) 44 49/50

AV control (Diagr. AVC5) 45 49/50

AV control (Diagr. AVC6) 46 49/50

AV control (Diagr. AVC7) 47 49/50

AV control (Diagr. AVC8) 48 49/50

PDP limesco (Diagram PD1) 51 60/61

PDP limesco (Diagram PD2) 52 60/61

©

Copyright reserved 1999 Philips Consumer Electronics B.V. Eindhoven, The

Netherlands. All rights reserved. No part of this publication may be reproduced,

stored in a retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

PDP limesco (Diagram PD3) 53 60/61

PDP limesco (Diagram PD4) 54 60/61

PDP limesco (Diagram PD5) 55 60/61

PDP limesco (Diagram PD6) 56 60/61

PDP limesco (Diagram PD7) 57 60/61

PDP limesco (Diagram PD8) 58 60/61

PDP limesco (Diagram PD9) 59 60/61

8. Electrical alignments 63

9. Circuit description and list of abbreviations 64

10. Spare parts list 66

Published by JR9970 Service PaCE Printed in The Netherlands Subject to modification 5 3122 785 10170

Page 2

GB 2 FTV1.9DE1.

Technical specifications

1. Technical specifications

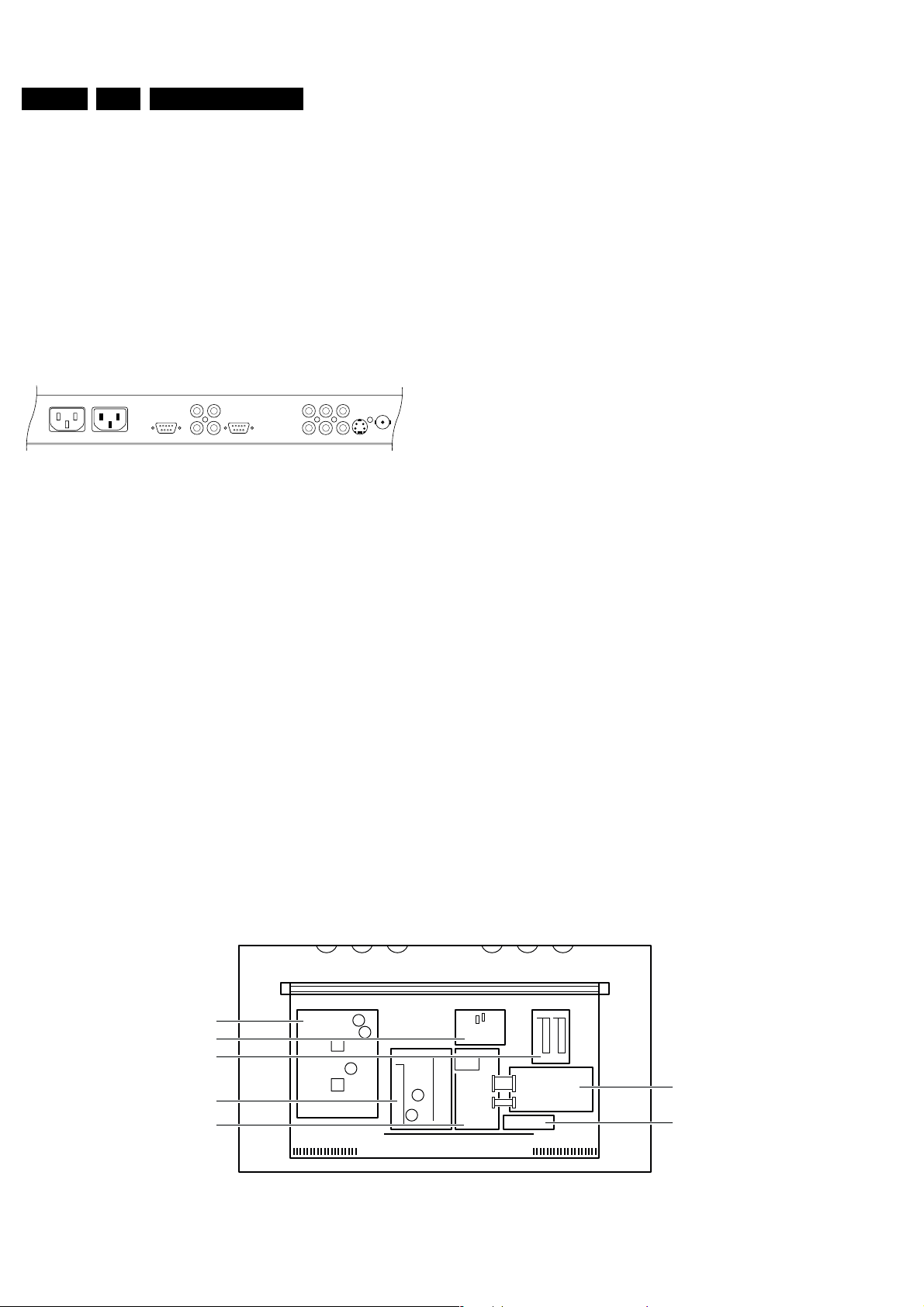

1.1 Technical data D-box

Mains voltage : 85 - 264Vac

Power dissipation : 400W

Stand-by dissipation : < 1W

1.2 Connection facilities

1.2.1 Specification of the terminal sockets

MAINS OUTLET MAINS INLET

VGA IN VGA OUT

VGA-in

1 - R (0.7Vpp 75

2 - G (0.7Vpp 75

3 - B (0.7Vpp 75

4 - Reserved

5 - Bus-gnd

6 - R-gnd

7 - G-gnd

8 - B-gnd

9 - RC5

10- GND

11- Config_Ident

12- Bus1 (TxD/

Rxd or SDA)

13- Hsync

14- Vsync

15- Bus2 (TxD/

RxD or SDA)

VGA-out

1 - R (0.7Vpp 75

L

AUDIO IN AUDIO OUT

R

Figure 1-1

Ω)

Ω)

Ω)

Ω)

: 50Hz - 60Hz

LRYUCVBS

AUDIO IN

V

Y/C

CVBS

S-VHS

CL96532058_005

240899

2 - G (0.7Vpp 75

3 - B (0.7Vpp 75

Ω)

Ω)

4 - Reserved

5 - gnd

6 - R-gnd

7 - G-gnd

8 - B-gnd

H

H

H

H

9 - Reserved

10- GND

11- Reserved

12- Reserved

13- Hsync

14- Vsync

15- Reserved

Audio VGA-in

- Cinch Audio L(0.5Vrms >= 10k

- Cinch Audio R(0.5Vrms >= 10k

Ω)

Ω)

q

q

Audio VGA-out

- Cinch Audio L(0.5Vrms >= 1k

- Cinch Audio R(0.5Vrms >= 1k

Ω)

Ω)

q

q

SVHS

1-GND

2-GND

H

H

H

H

H

3 - Y (1Vpp / 75

4 - C (0.3Vpp / 75

Audio_in:

- Cinch Audio L (0.5Vrms >= 10kΩ)

- Cinch Audio R (0.5Vrms >= 10kΩ)

Ω )

Ω )

H

H

j

j

q

q

CVBS

- BNC - CVBS (1Vpp / 75

Ω)

YUV

- Y (1Vpp / 75

3 - U (1Vpp / 75

4 - V (1Vpp / 75

Ω )

Ω )

Ω )

q

q

q

1.3 Chassis overview

VS/VA Supply

PDP Discharge

Audio Amplifier

Pre-conditioner

AV Control

Figure 1-2

CL 96532069_131.EPS

120899

PDP Limesco

YUV/YC Input

Page 3

Safety instructions, warnings and notes

2. Safety instructions, warnings and notes

GB 3FTV1.9DE 2.

2.1 Safety instructions

It is not allowed to operate the FTV-set without glass plate. One

function of this glass plate is to absorb Infrared Radiation.

Without this glass plate the level of Infrared Radiation produced

by the plasma display could damage your eyes.

1. Safety regulations require that during a repair:

– the set should be connected to the mains via an

isolating transformer ( in this particular case a

transformer of ≥ 800 VA);

– safety components, indicated by the symbol h ,

should be replaced by components identical to the

original ones;

2. Safety regulations require that after a repair the set must

be returned in its original condition. In particular attention

should be paid to the following points.

– Note: The wire trees should be routed correctly and

fixed with the mounted cable clamps.

– The insulation of the mains lead should be checked for

external damage.

– The electrical DC resistance between the mains plug

and the secondary side should be checked (only for

sets that have a mains isolated power supply). This

check can be done as follows:

• unplug the mains cord and connect a wire between

the two pins of the mains plug;

• set the mains switch to the on position (keep the

mains cord unplugged!);

• measure the resistance value between the pins of

the mains plug and the metal shielding of the tuner

or the aerial connection on the set. The reading

should be between 4.5 MΩ and 12 MΩ;

• switch off the TV and remove the wire between the

two pins of the mains plug.

– The cabinet should be checked for defects to avoid

touching of any inner parts by the customer.

hhhh

4. If DST reacts with 'error 2', there is no communication

between set and DST. Note that IR-transmitter LED is

positioned at right side of IR-receiver eye of the E-box.

Take into account that receiver-LED on DST is positioned

not in the middle but at the left side. Point corresponding

LED's to each other. In case the amount of Infrared

produced by the screen pollutes the communication, the

set can be set in Standby-mode. Then still the errormessages can be retrieved.

2.2 Warnings

1. ESD

All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD w). Careless handling during

repair can reduce life drastically. When repairing, make sure

that you are connected with the same potential as the mass of

the set by a wristband with resistance. Keep components and

tools also at this same potential.

1. Available ESD protection equipment:

2. Never replace modules or other components while the unit

3. When making settings, use plastic rather than metal tools.

w

– complete kit ESD3 (combining all 6 prior products -

small table mat) 4822 310 10671

– wristband tester 4822 344 13999

is switched on.

This will prevent any short circuits and the danger of a

circuit becoming unstable.

2.3 Notes

1. A glass plate is positioned before the plasma display. This

glass plate can be cleaned with a slightly humid cloth. If

due to circumstances there is some dirt between the glass

plate and the plasma display panel it is recommended to do

some maintenance by a qualified service employee only.

2. Never disconnect the power display cable when the set is

operating

3. With DST no failures (error-codes) can be red, when the

set is in Service-mode.

Page 4

GB 4 FTV1.9DE3.

3. Directions for use

73mm /2.87"

406mm /16"

Directions for use

5

5

10

x 4x 4

a

4

x 2

b

4

Page 5

Directions for use

a

b

6

x 6

L

GB 5FTV1.9DE 3.

VGA OUT

AUDIO OUT

R

AUDIO IN

MAINS INLET

1 32 42

VGA IN

5

Page 6

GB 6 FTV1.9DE3.

15-pin D sub

(2-row)

15-pin mini D sub

(3-row)

a

VGA 640x480 31.468 kHz 60 Hz

Use of the remote control

Computer Display modes

VGA 640x400 31.468 kHz 70 Hz

VGA 640x350 31.468 kHz 70 Hz

MAC II 640x480 35.000 kHz 67 Hz

SVGA 800x600 35.156 kHz 56 Hz

XGA 1024x768 45.000 kHz 56 Hz

Directions for use

the monitor.

A green indicator lights up and the screen comes on.

When the monitor does not receive a certain VGA signal the screen remains

black.

When a VGA computer is connected, the selection is made automatically.

A message is displayed when the monitor does not support one of the above

mentioned VGA modes.

Switch your computer to a correct display mode.

Insert the mains plug 5 (see previous page for the illustration) supplied

into the mains inlet at the back of the monitor and in the wall socket.

Please, only use the supplied rim-earthed mains cord with its built-in filter.

&

Operation

Remote control: remove the cover of the battery compartment.

Insert the 2 batteries supplied (Type LR6AA-1.5V).

The batteries supplied do not contain the heavy metals mercury and cadmium.

Nevertheless in many countries batteries may not be disposed of with your

household waste. Please check on how to dispose of batteries according to local

regulations.“Switch the monitor on : Press the power button B at the right side of

é

Make sure that your PC is switched on and is in the correct display mode.

English

printed on the first pages of this instruction booklet.

Make sure that the wall mount is being fixed securely enough so that it meets

Unpacking and wall mounting instructions

For the unpacking instructions follow the illustrated steps printed on the

safety standards.The weight of the monitor (excl. packaging) is about 43 kg.

packaging (outside and inside).

For the wall mounting instructions follow the illustrated steps ‘ to §

Connect your computer

L

(right) and

AUDIO IN R

connector at the rear side of the

VGA IN

monitor.Fix the connectors firmly with the screws on the plug.

outputs of your Multimedia computer and to the

Connect one end of the VGA cable 1 supplied to the video card of the

computer and the other end to the

In case of a Multimedia computer,connect the audio cable 2 to the audio

(left) inputs of the monitor.

Daisy chaining

The Active Loop Through facility makes it possible to make a daisy chain with

a second VGA monitor.“Connect one end of another VGA cable 3 to the

&

é

inputs

R

and

connector of a

connector at

VGA IN

AUDIO IN L

VGA OUT

outputs of the monitor and to the

R

and

with the monitor.

of the second VGA monitor.

the rear side of the monitor and the other end to the

second VGA monitor.

Note: only use the VGA cables supplied or use cables that are specially delivered

In case of a Multimedia computer, also connect the audio cables 4 to the

AUDIO L

Connect your Apple Macintosh* computer

Attention: Macintosh computers with separate H and V synchronisation signals

can be used together with the supplied adaptor. Macintosh computers with

Composite Sync and Sync on Green signals may need a special (not

supplied) adaptor or cable. Contact your dealer.

‘

connector on the back of the

VGA IN

1234

off off on on

Connect the supplied switchable adaptor for Apple video connectors to one

end of a VGA cable.

Put the DIP switches on the adaptor in the following positions :

monitor.

Connect the end of the VGA cable with the adaptor to the video card of the

computer and the other end to the

2

1

Screw the connectors down firmly.

* Apple Macintosh is a registered trademark of Apple Computer, Inc.

Page 7

Directions for use

VGA OK

FRONT o

AV1 p MENU π

AV2 œ

AV3

¬

AV4

SMART

CONTROLS

PICTURE SOUND

- CH/P +-V+

B

Transport

Keep the original packaging to transport the

monitor if needed.

higher altitude, the picture becomes

unstable and the picture performance is

deteriorating. Bringing the set below 2000

m it works fine again.Transportation has

End of life directives

Philips is paying a lot of attention to

produce environmentally-friendly in green

focal areas.Your new monitor contains

materials which can be recycled and

reused.

At the end of its life specialised companies

no influence.

Control of peripheral equipment

The infrared signals of the screen may

influence the reception sensitivity of other

peripherals. Solution:replace the batteries

of the remote control or change position

of other equipment. E.g.keep away a

can dismantle the discarded monitor to

concentrate the reusable materials and to

minimise the amount of materials to be

disposed of.

Please ensure you dispose of your old

monitor according to local regulations.

How to dispose of batteries ?

The batteries supplied do not contain the

heavy metals mercury and cadmium.

wireless headphone from within a radius

of 1.5 m.

No stable or not synchronised VGA

picture

Check if you have selected the correct

VGA mode in your PC (640x480,

640x400, 640x350,MAC II, SVGA, XGA).

No picture or no sound

Are the supplied cables connected

Nevertheless in many countries batteries

may not be disposed of with your

household waste. Please ensure you dispose

of batteries according to local regulations.

properly? (The power cable to the display,

the VGA cables, the audio cables,...)

Is your PC switched on?

Do you see a black screen and the

indicator in front of the monitor lights up

Miscellaneous

. Ambient temperature: + 5~ + 45°C

. Maximum operating altitude: 2000 m

. Mains: AC 100-240V

green, this means that the display mode is

not supported.

Switch your VGA source to a correct

mode.

Display: 42.5 kg

. Power consumption: around 350W

. Standby consumption: 1 W

. Weight (excl. packaging)

Remote control

If your monitor no longer responds to the

remote control, the batteries may be

Display: 122.2 x 68.1 x 14.6 cm

. Dimensions (wxhxd):

. Wall mounting bracket included

exhausted.

If your problem is not solved:

Switch your monitor off and then on

again.

Never attempt to repair a defective

monitor yourself.

Check with your dealer or call a TV

GB 7FTV1.9DE 3.

technician.

Tips

Ambient temperature

Do not hang up the monitor above a

central heating or other heating sources.

Active Loop Through

The Active Loop Through facility makes it

possible to make a daisy chain for VGA.

Maximum 2 sets.

Care of the screen

Clean the anti-reflex coated flat glass

screen with a slightly damp soft cloth. Do

not use abrasives solvents as it can

damage the glass surface of the screen.

Plasma Display characteristics

When switching over to another picture

after having displayed the same still picture

for a long time (many hours), it may

happen that some parts from the previous

picture will remain on screen due to a

kind of memory effect.This ghost picture

will disappear after some time.To avoid

this effect change the pictures regularly or

for PC use you can turn on a screen saver

in your computer.

Philips has built in an automatic shift of

the picture every 5 minutes to avoid this

effect and to prolong the life of the

screen.

Very incidentally and after a longer period

of unuse (approx. 1 year) the screen may

display some strange colour deficiencies.

This is quite normal for plasma displays

and these effects will disappear after the

set has been turned on for some time.

A plasma display consists of more than 1,2

Million colour pixels. It is within industry

standards that very few pixels (< 0.001%)

may be defective, even for a new set.

There is however no reason to doubt

about the quality of the set.

The plasma display technology operates

with rare gases which are being influenced

by air pressure. Up to an altitude of 2000

m above sea-level, the display is

functioning fine. Operating the set at a

4

3

menu on/off

VGA

no function

menu.

to activate your choice

OK

no function

no function

no function

VGA

FRONT

to switch the

MENU

no function

B

Use of the remote control

Use of the remote control

mode, press the p or π keys to

VGA

cursor keys to select your choice and to

alter a selected adjustment

pπ Picture format

In

switch between a 4:3 or a 16:9 picture

format.

¬ Mute key

temporarily mute the sound or restore it

no function

- CH/P +

SMART CONTROLS

PICTURE/SOUND

VGA menu

menu.

VGA

key to switch on the

MENU

Press the

Select one of the symbols with the o and œ keys:

H for contrast

&

é

for colour temperature

for horizontal picture position

G for brightness,

VGA

key again to switch off the

MENU

for vertical picture position

Press the p and π keys to alter the selected adjustment.

Press the

V for volume

“

‘

AV1 , AV2, AV3,AV4

V press - or + to adjust the volume

Page 8

GB 8 FTV1.9DE4.

Mechanical instructions

4. Mechanical instructions

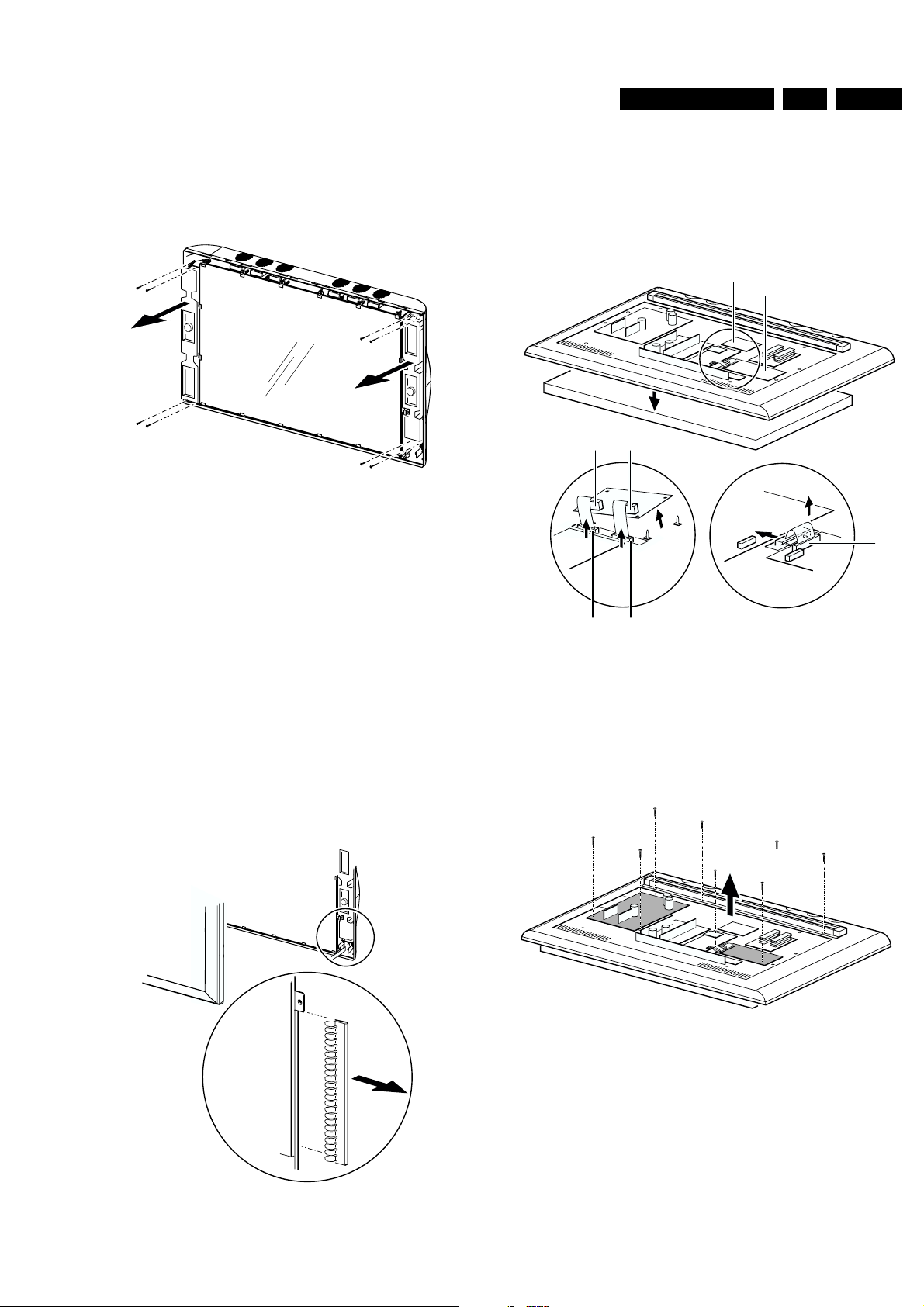

4.1 Introduction:

There are pre-defined service positions for the following

panels:

1. VS/VA SUPPLY panel.

2. PDP DISCHARGE panel.

3. AUDIO AMPLIFIER panel.

4. PRE-CONDITIONER panel.

5. AV CONTROL panel.

6. PDP LIMESCO panel.

7. YUV/YC INPUT panel.

8. LED DISPLAY panel.

9. SWITCH DISPLAY panel.

Before these panels can be accessed, the rear cover has to be

removed:

2

1

CL 96532069_130.EPS

120899

4.1.1 VS/VA SUPPLY panel.

VS/VA Supply

FD07

1

2

4

CL 96532069_132.EPS

Figure 4-3

1. Disconnect Fan Supply cable from connector FD07 in the

upper left corner [1].

2. Remove the 7 fixation screws of the panel [2].

3. Place panel on the 2 hinges, which are located near the

right corners of the panel [3].

4. Use the mechanical service part (extension cable

assembly, 12NC: 3122 785 90006) to extend the Fan

Supply cable [4].

5. The copper side is now accessible from the left.

3

120899

Figure 4-1

1. Place the Display Box in the service stand via 2 reinforced

cushions (order code: 3122 126 30181).

2. Remove the 9 fixation screws of the rear cover.

3. Remove the rear cover (during removal push it slightly

upwards).

VS/VA Supply

PDP Discharge

Audio Amplifier

Pre-conditioner

AV Control

CL 96532069_131.EPS

Figure 4-2

1. All panels are now accessible.

120899

PDP Limesco

YUV/YC Input

4.1.2 PDP DISCHARGE panel.

As in the FTV 1.5, this panel must be exchanged completely if

defective.

4.1.3 AUDIO AMPLIFIER panel.

Audio Amplifier

1

2

3

2

CL 96532069_134.EPS

120899

Figure 4-4

Page 9

Mechanical instructions

GB 9FTV1.9DE 4.

1. Some testpoints are accessible at the B-side [1].

2. If this is not sufficient, remove the 3 fixation screws of the

panel [2].

3. Panel now can be hinged on the left side to access the Aside (soldering side) [3].

4.1.4 PRECONDITIONER panel.

Pre-conditioner

3

2

2

1

5

5

1

5

CL 96532069_135.EPS

Figure 4-5

1. Disconnect the 2 grounding wires from the shielding plate

by pressing the small lever on the connector while pulling

[1].

2. Remove the 2 ferrite ring cores from their fixations [2].

3. Remove the 5 fixation screws of the panel [3].

4. Place panel on the 2 hinges, which are located, near the

left corners of the panel [4].

5. Reconnect grounding wires to the extra connectors on the

shielding plate at the left side [5].

6. The copperside becomes accessible now from the right

side.

4.1.6 PDP LIMESCO panel.

PDP Limesco

1

4

1

2

1

1

CL 96532069_137.EPS

4

120899

Figure 4-7

120899

All SMC's are located on the B-side, so all testpoints are

accessible. In case some components must be (de)soldered,

the hinge construction can be used to access the A-side.

1. Remove the 4 fixation screws of the panel [1].

2. Panel can now be hinged to access soldering side [2].

4.1.7 YUV/YC INPUT panel.

YUV/YC Input

4.1.5 AUDIO VIDEO CONTROL panel.

AV Control

CL 96532069_136.EPS

Figure 4-6

This panel has no service position for accessing the A-side,

however all service test points are accessible at the B-side (see

Service Manual).

In case some components must be (de)soldered, all fixation

screws (6 for the panel, 5 at the metal connector plate) and all

cables must be removed to access the A-side.

120899

SVHS BNC

3

2

2

1

CL 96532069_138.EPS

120899

Figure 4-8

This panel has no pre-defined service position. For access of

the A-side, the panel has to be removed:

1. Remove the 4 screws at the metal connector plate [1].

2. Remove the 2 fixation screws of the panel [2].

3. Panel can be removed now to access the A-side [3].

Page 10

GB 10 FTV1.9DE4.

Mechanical instructions

4.1.8 LED DISPLAY panel.

2

1

Figure 4-9

1. Remove 2 x 2 screws at the sides and 4 screws at the

bottom of the front cover [1].

2. Remove the front cover (it hinges at the top). During

removal unplug the cable of the LED DISPLAY panel at the

SWITCH DISPLAY panel (connector SD11) [2].

2

CL 96532069_139.EPS

120899

4.1.9 SWITCH DISPLAY panel.

1. Remove front cover (for a description see Chapter 1.1.8

'LED DISPLAY panel').

3

CL 96532069_141.EPS

Figure 4-11

1. The SWITCH DISPLAY panel can be removed now by

unscrewing 3 fixation screws [3].

4.2 Exchanging parts

120899

3

CL 96532069_140.EPS

Figure 4-10

1. The LED DISPLAY panel can be removed now by

unscrewing 1 fixation screw [3].

120899

Some parts of the FTV1.9 Display Box must be exchanged if

defective:

1. GLASS PLATE.

2. LOUDSPEAKER.

3. PLASMA DISPLAY PANEL [PDP].

4.2.1 Exchanging of the GLASS PLATE.

1. First unplug (remove Mains and VGA cable) the Display

Box .

2. Remove front cover (for a description see Chapter 1.1.8

'LED DISPLAY panel').

2

5

34

CL 96532069_142.EPS

120899

Figure 4-12

1. Now the GLASS PLATE can be removed by unscrewing all

screws [3] and removing all glass clips [4].

Page 11

Mechanical instructions

CL 96532069_145.EPS

120899

1

4

5

3

2

3

FD173 FD171

PDP Discharge

PDP Limesco

PD3

CN24

CN23

FOAM CUSHION

GB 11FTV1.9DE 4.

4.2.2 Exchanging of a LOUDSPEAKER.

1. First unplug (remove Mains and VGA cable) the Display

Box.

2. Remove front cover (for a description see Chapter 1.1.8

'LED DISPLAY panel').

3

4

3

CL 96532069_143.EPS

Figure 4-13

1. The LOUDSPEAKER can now be removed by

disconnecting its cable and removing the 4 fixation screws

at the top and bottom of the speakerbox. Be sure to remove

the correct screws, otherwise the speaker system will be

damaged (it is an airtight system).

1. Remove all copper EMC SHIELDING springs mounted

around the display [6].

2. Now flip the complete Display Box and place it with the

Plasma Display down on a foam cushion. Be 100 % sure

a large foam cushion is placed underneath the PDP, as it

will drop about 10 mm after removing its fixation screws ! !

3. Disassemble metal rear cover (for a description see

Chapter 1.1 'Introduction').

3

4

3

120899

4.2.3 Exchanging of the PDP.

1. First unplug (remove Mains and VGA cable) the Display

Box.

2. Place the rear side of the Display Box on a foam cushion

(be sure the metal rear cover is mounted in order to prevent

damaging of the electronic panels).

3. Remove front cover (for a description see Chapter 1.1.8

LED DISPLAY panel).

4. Now the GLASS PLATE can be removed by unscrewing all

screws and removing all glass clips (for a description see

Chapter 1.2.1. 'Exchanging of the GLASS PLATE').

6

Figure 4-14

CL 96532069_144.EPS

120899

Figure 4-15

1. Disconnect the following cables:

– Cables coming from connectors CN23 and CN24 of the

PDP DISPLAY panel [3] (for easiest access lift the

PDP DISCHARGE panel from its fixations [2]).

– Flat cable on connector PD3 of the PDP LIMESCO

panel [4]. Also remove the ferrite 'flat cable shield'

completely by unlocking its fixations [5].

1

2

2

1

1

3

2

2

1

CL 96532069_146.EPS

Figure 4-16

1. Now remove the 8 large screws which hold the PDP:

– 4 screws are located at the top: they also hold the

aluminium wall mount [1].

– The other 4 are located at the bottom: the 2 outer

screws are hidden behind panels. Therefor unscrew

the VS/VA SUPPLY and the PDP-LIMESCO panel

(grey panels) [2].

2. Lift encasing from PDP and replace PDP [3].

120899

Page 12

GB 12 FTV1.9DE5.

Service modes, fault finding and repair tips

5. Service modes, fault finding and repair tips

For the FTV1.9, the Monitor can be used in two applications.

• A stand-alone configuration, a separate device which can

also be sold and serviced separately.

• TV configuration, where the monitor is combined with the

E-box.

The monitor, as a stand-alone unit, can be serviced by using a

test pattern coming from the PDP-LIMESCO panel on the rear

of the monitor itself or via a PC/laptop by using ComPair via the

ComPair connector.

In this chapter the following paragraphs are included:

1. Test points

2. Dealer Service Tool (DST)

3. Service Modes

4. Error code buffer and error codes

5. The "blinking LED" procedure

6. Fault-finding tips

7. ComPair

5.1 Test points

The FTV1.9 chassis is equipped with test points in the service

printing. These test points are referring to the functional blocks:

• A1-A2-A3, etc.: Test points for the Audio amplifier (A)

• C1-C2-C3, etc.: Test points for the AV control circuit

(AVC)

• FD1-FD2-FD3, etc.: Test points for the VsVa supply (FD1FD2) and the PDP discharge panel

• L1-L2-L3, etc.: Test points for the PDP LIMESCO

(PD1-PD9)

• PR1-PR2-PR3, etc.: Test points for the Pre-conditioner

(PR1-PR3)

• Y1-Y2-Y3, etc: Test points for the Y/C YUV monitor

panel (UY1-YC4)

Measurements are performed under the following conditions:

Video: colour bar signal; Audio: 3 kHz left, 1 kHz right

5.2 Dealer Service Tool (DST)

For easy installation and diagnosis the dealer service tool

(DST) RC7150 can be used. When there is no picture (to

access the error code buffer via the OSD), DST can enable the

functionality of displaying the contents of the entire error code

buffer via the blinking LED procedure, see also paragraph 5.5.

The ordering number of the DST (RC7150) is 4822 218 21232.

5.2.1 Installation features for the dealer

The dealer can use the RC7150 for programming the TV-set

with pre-sets. 10 Different program tables can be programmed

into the DST via a GFL TV-set (downloading from the GFL to

the DST; see GFL service manuals) or by the DST-I (DST

interface; ordering code 4822 218 21277). For explanation of

the installation features of the DST, the directions for use of the

DST are recommended (For the FTV1.9 chassis, download

code 4 should be used).

Display Box (TV Configuration), please check chapter 5 in the

Training Manual of the Receiver Box.

5.3.1 Service Default Mode (SDM)

The purpose of the SDM is:

• Provide a situation with predefined settings to get the same

measurements as in this manual.

• Access to the error buffer via the blinking LED procedure.

• Inspection of the error buffer.

• Possibility to overrule software protections via the service

pins (caution: override of software protections! ).

Entering the SDM:

• By transmitting the "DEFAULT" command with the RC7150

Dealer Service Tool (this works both while the set is in

normal operation mode or in the SAM).

• By pressing on a standard RC the following sequence 0, 6,

2, 5, 9, 6 followed by the "MENU" key.

• By short-circuiting the SDM pin on the µP panel.

In the SDM the following information is displayed on the

screen:

--------------------------------------------------------------

F19DBC X.Y_12345 (1) LLLL (2) SDM (3)

ERR 02 01 14 ## ## ## ## ## ## ##

--------------------------------------------------------------

Explanation notes/references:

(1) Software identification of the main micro controller

(F19DBC X.Y_12345)

• F19D is the chassis name for FTV1.9 display

• B is the region identification

• C is the language cluster

• X = (main version number)

• Y = (subversion number)

• ##### are 5 digits of the serial number

(2) "LLLL" Normal display operation in hours

(3) "SDM" To indicate that the TV set is in the service default

mode

(4) "ERR 02 01 14 ## ## ## ## ## ## ## ##" This line shows

the contents of the error buffer (max. 10 errors). The last error

that occurred is displayed at the most left position. When less

then 10 errors have occurred the rest of the line is empty. When

the errorlist is empty " No errors" is displayed. No duplicate

errors.

Exit the SDM:

Push the "STANDBY" button on the Remote Control.

The SDM sets the following pre-defined conditions:

• Volume level is set to 25% (of the maximum volume level).

• Linear Audio and Video settings are set to 50%.

• Colour temperature is set to normal.

The following functions are "overruled" in SDM since they

interfere with diagnosing/repairing a set

• Video blanking.

• Slow demute.

• Anti-ageing.

• Automatic switch to "Standby" when H- and/or V-sync

signals are lost.

All other controls operate normally.

5.2.2 Diagnose features for service

FTV1.9 sets can be put in two service modes via the RC7150.

These are the Service Default Mode (SDM) and the Service

Alignment Mode (SAM).

5.3 Service Modes

Below described sequence is only valid for the "Monitor Only

Configuration". When a Receiver box is connected to the

5.3.2 Service Alignment Mode (SAM)

The purpose of the SAM is to align and or adjust settings.

For recognition of the SAM, "SAM" is displayed at the top of the

right side of the screen

Entering the SAM-menu:

• By pressing the "ALIGN" button on the RC7150 Dealer

Service

• Standard RC sequence 062596 followed by the "OSD"

button.

Page 13

Service modes, fault finding and repair tips

GB 13FTV1.9DE 5.

• By short-circuiting the SAM pin on the µP panel (Caution:

override of software protections ! ! )

In the SAM the following information is displayed on the screen:

--------------------------------------------------

F19DBC X.Y_12345 SAM

ERROR## ## ## ## ##

WHITE POINT

PDP TEST PATTERN [ON/OFF]

STORE

RESET ERROR BUFFER

--------------------------------------------------

The menus and submenus

White point

The white point sub menu contains the following items:

•RED

• GREEN

•BLUE

• COLOUR TEMPERATURE

PDP Test pattern

By selecting this item, all OSD disappears from the screen. The

screen now changes from light grey to dark grey in a slow

regular rhythm. One can so easily check if all pixels of the

monitor are correct.

Store

The change values are stored in the NVM.

Reset Error Buffer

This option will reset the error buffer.

Exit the SAM:

Push the "STANDBY" button on the Remote Control.

SAM menu control:

Menu items can be selected with the "UP" or "DOWN" key.

Entry into the selected items (sub menus) is done by the

"LEFT" or "RIGHT" key. The selected item will be highlighted.

With the same "LEFT/RIGHT" keys, it is possible to increase/

decrease the value of the selected item.

Return to the former screen by pushing the "MENU" button.

The item values are stored in NVM if the sub menu is left.

5.3.3 Customer Service Mode (CSM) Display

FTV1.9 monitors are equipped with the "Customer Service

Mode" (CSM). CSM is a special service mode that can be

activated and de-activated by the customer, upon request of

the service technician/dealer during a telephone conversation

in order to identify the status of the set. This CSM is a 'read

only' mode, therefore modifications in this mode are not

possible.

Entering the Customer Service Mode.

• By pressing on RC03333/01 the following sequence :

Picture, sound, cursor up, cursor down, cursor left, cursor

right followed by the “MUTE” button.

Exit the Customer Service Mode.

• pressing the "MENU" or any key on the Remote Control

handset (except "P+" or "P-")

• switching off the TV set with the mains switch.

All settings that were changed at activation of CSM are set

back to the initial values

The Customer Service Mode information screen

The following information is displayed on screen:

--------------------------------------------------

CUSTOMER SERVICE MENU

• Software version F19DBC X.Y_#####)

• Code 1: contains the last 5 error codes

• Code 2: contains the first 5 error codes with the last

received error at the most left-hand side.

• Service unfriendly modes

--------------------------------------------------

5.4 Error code buffer and error-codes

The error code buffer contains all errors detected since the last

time the buffer was erased. The buffer is written from left to

right.

In case of non-intermittent faults, clear the error buffer before

starting the repair to prevent that "old" error codes are present.

If possible check the entire content of the error buffers. In some

situations an error code is only the RESULT of another error

code (and not the actual cause).

Note: a fault in the protection detection circuitry can also lead

to a protection

The error code buffer will be cleared in the following cases:

• exiting SDM or SAM with the "Standby" command on the

remote control

• transmitting the commands "DIAGNOSE-9-9-OK" with the

DST.

Leaving SDM or SAM with the mains switch does not reset the

error buffer.

Examples:

ERROR: 0 0 0 0 0 : No errors detected

ERROR: 6 0 0 0 0 : Error code 6 is the last and only detected

error

ERROR: 5 6 0 0 0 : Error code 6 was first detected and error

code 5 is the last detected (newest) error

Error

-nr

1 +5V +5V pin at µP is low.

2 8V6 8V6 pin at µP is low.

3 Fan_prot Gives an indication that 1 or more

4Over-

5 DC_prot Audio-amplifier IC, its supply or the

6 Over_volta

7 Vrr Powersupply of the display is not

8 Power_OKEPower supply or modules that uses

9 Blocked

10 Blocked

11 TDA9860 No acknowledge of Audio controller

12 TDA4885 No acknowledge of Video controller

13 MC141585No acknowledge of OSD Generator

14 uPD93687

Type of

Error Possible defect/cause

FAN(s) does not function, or that 1

or more fan control circuits is defect

temp_prot

ge_prot

NVM IIC

bus

slow IIC

bus

GD-LBD

Temperature at the heatsink of the

VsVa supply or the Preconditioner

is too high

Audio amplifier is defect

Vs or Va supply voltage is too high

correct. Ignorance of the signal

during startup by the software.

this voltage. If this signal is NOT

activated means that all supply

voltages are available (exception

Audio supply )

NVM IIC bus is not correct

Slow IIC bus is not correct

No acknowledge of Limesco

Page 14

GB 14 FTV1.9DE5.

Service modes, fault finding and repair tips

Error

-nr

15 PCF8574ATNo acknowledge of I/O Expander

16 NVM No acknowledge of NVM

17 Communic

Type of

Error Possible defect/cause

Fault in the communication

ation

5.5 The "blinking LED" procedure

The contents of the error buffer can also be made visible

through the "blinking LED" procedure. This is especially useful

when there is no picture. There are two methods:

• When the SDM is entered, the LED will blink the contents

of the error-buffer. Error-codes = 10 are shown as followed.

A long blink of 1second which is an indication of the

decimal digit, followed by a pause, followed by n short

blinks. When all the error-codes are displayed, the

sequence is finished with a led display of about 3 seconds.

The sequence starts again.

• With the DST all error codes in the error buffer can be

made visible. Transmit the command: "DIAGNOSE x OK"

where x is the position in the error buffer to be made visible

x ranges from 1, (the last (actual) error) to 10 (the first

error). The LED will operate in the same way as in the

previous point, but now for the error code on position x.

Example:

Error code position 1 2 3 4 5

Error buffer: 12 9 5 0 0

• after entering SDM: 1 long blink of 1 sec. + 2 short blinks

- pause - 9 short blinks - pause - 5 short blinks - pause long blink of 3 sec. --etc.

• after transmitting "DIAGNOSE- 1- OK" with the DST: 1 long

blink 2 short blinks - pause - 1 long blink + 2 short blinks

- etc.

• after transmitting "DIAGNOSE- 2- OK" with the DST: blink

(9x) - pause - blink (9x) - etc.

• after transmitting "DIAGNOSE- 3- OK" with the DST: blink

(5x) - pause - blink (5x) - etc.

• after transmitting "DIAGNOSE- 4- OK" with the DST:

nothing happens

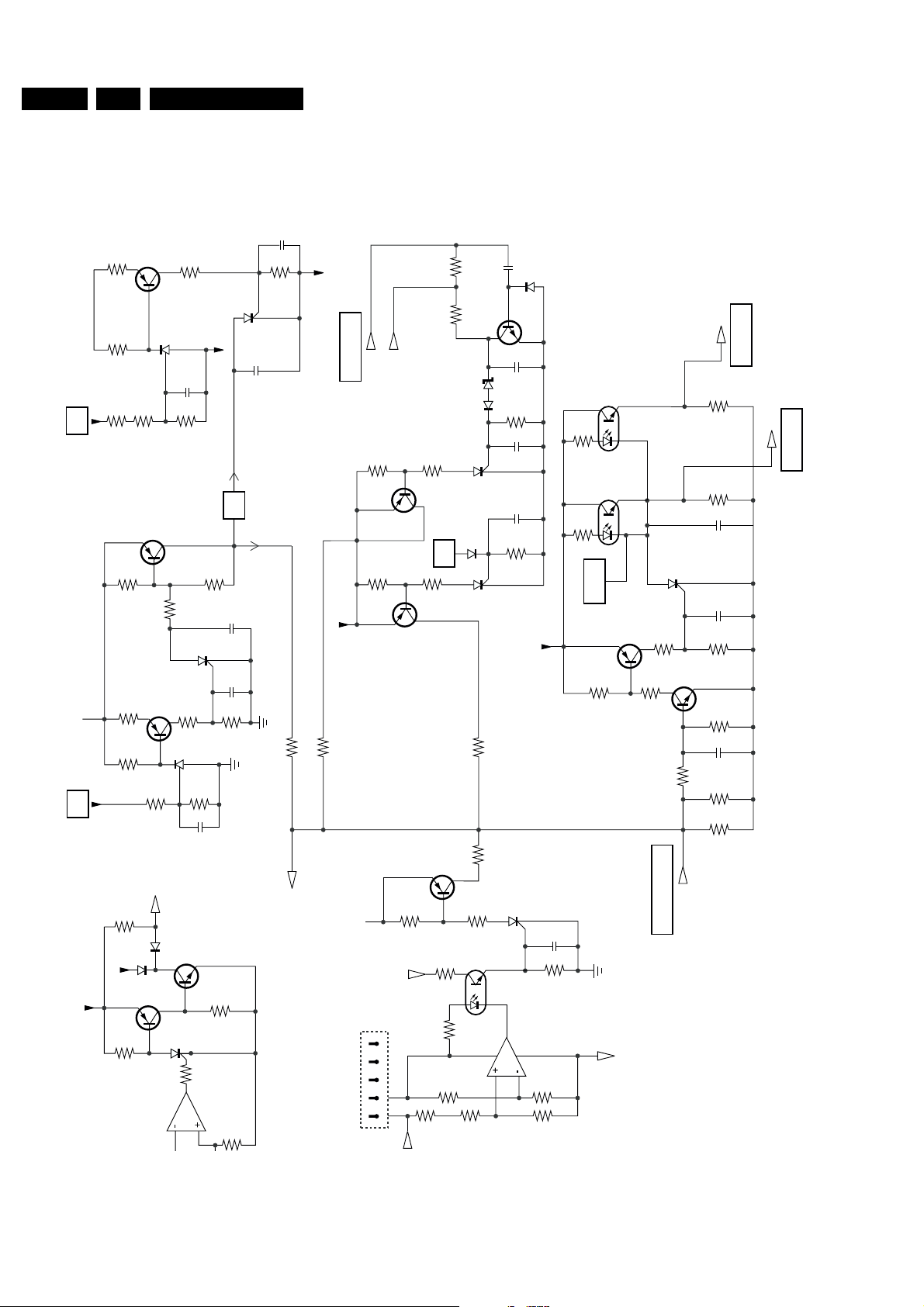

5.6 Protection structure

5.6.1 General

The protection structure of the FTV1.9 D-box is shown at figure

5.5.

The FTV1.9 monitor has one microprocessor, which is situated

on the AV-control panel and is supplied by the 5V standby

supply. The microprocessor is even active when the set is

switched to standby. The microprocessor controls the "supplyon" line which switches first relay 5680 and then relay 5690.

In de standby-mode or the protection-mode the "supply-on" line

is "low" and both relays are switched off. The preconditioner is

disconnected from the mains.

The protections of the FTV1.9 monitor can be divided into 5

subgroups:

– Fan_prot

– Over_temp_prot

– DC_prot

– Over_voltage_prot

–Vrr

For the Fan-, Over_temp, DC and the Over_voltage protections

the signals for the µP are latching, using the 5Vstby_switched

for powering the circuits permanently. The µP has sufficient

time for diagnosis and for storing the error-codes in the NVM.

Vrr, which is an indication of the powersupply of the display is

correct, is directly fed to the µP.

5.6.2 Signal line "PROTECTION STATUS" and errorcodes

When one of the protection mechanism is triggered, the

5Vstby-switched is connected via a saturated transistor and a

pre-defined resistor to signal line "protection status", which is

connected to the µP.

Signal line "protection status" is connected to ground via

resistor R3378 and 3379. For each separate fault condition

mechanism we get a pre-defined voltage at the µΠ.

This results in the following table

Protectionmode

None ----- < 0.3V none

Fan_prot 1K

Vs or

Va_prot

Temp_prot 220

DC-prot 68

Vrr ------ ------ 7

Protection signal Vrr coming from the PDP, to indicate that the

powersupply is ok or not ok ( "1" or "0" ) is directly connected

to the µP. Error-code 7 is stored in the NVM and the set is

switched to standby.

When one of the protections is activated, the power supplies of

the Vs and Va are shut down and the set is switched to

standby.

5.6.3 Fan protection

When this protection is activated, the Va- and Vs power supply

are shut down. The set is switched to the standby mode and

error-code 3 is stored in the NVM.

The fan voltage is powered by 17V, but clamped to 12V to

prevent damage. In order to be able to verify whether the fans

are running, a fault detection circuit is implemented for each of

the 6 fans. A running fan gives pulses in the same speed as the

rotation of the blades. The circuit uses these pulses to trigger

the discharge of an elcap. The elcap is continuously charged

through a resistor.

Example : Capacitor C2319 is charged through R3356 and at

every pulse discharged by T7322. When fan 6 is blocked,

C2314 is charged via D6326 en triggers thyristor 7315,

because C2319 is no longer discharged via T7322. The current

now flows from the 5Vstby-switched via resistor 3383 and 3325

driving transistor T7321 into saturation. The voltage dividing of

R3323 and resistor R3378 and 3379 now determine the

voltage "protection status". (neglect the Vce of 0.2V of T7321.).

Reset of the VsVa-supply.

Transistor T7339 is shorted now by the presence of the

"protection status" signal. T7339 connects resistor R3376 and

R3389 to ground, switching on T7338. Thyristor 7333 is now

triggered, shorting signal PROTS to ground. To follow the

signal flow, go to the right upper corner of schematic FD1.

Connecting PROTS to ground, will start a current flow through

opto-coupler diode 7103 and the opto-coupler transistor

connects supply voltage Vcc2 to the fault input ( pin 10 ) of IC

7101. When the voltage at pin 10 exceeds 1.0V, IC7101 stops

oscillating. The Va-supply stops functioning.

To continue the signal flow, go to the right upper corner of

schematic FD2. Connecting PROTS to ground also results in a

current flow through the opto-coupler diode of 7003. The optocoupler transistor connects supply voltage Vcc1 to the fault

input ( pin 10 ) of IC 7001. When the voltage at pin 10 exceeds

1.0V, IC7001 stops oscillating. The Vs-supply stops

functioning.

Series

resistor

Ω

Ω

470

Ω

Ω

Voltage at "protectionstatus" line

0.30V < Vprot < 1.90V 3

1.90V < Vprot < 2.80V 4

2.80V < Vprot < 3.75V 5

3.75V < Vprot < 4.7V 6

Errorcode

Page 15

Service modes, fault finding and repair tips

GB 15FTV1.9DE 5.

5.6.4 Vs and Va protection

Va protection

When this protection is activated, the Va- and Vs power supply

are shut down. The set is switched to the standby mode and

error-code 4 is stored in the NVM.

When the Va-supply exceeds the 68V, regulator 7112 is

triggered and will switch on T7113. Capacitor 2132 is charged

via the 5Vstby-switched and will trigger thyristor 7114, which

will switch on T7341. The voltage dividing of R3386 and

resistor R3378 and 3379 now determine the voltage "protection

status". ( neglect the Vce of 0.2V of T7341 ). See schematic

FD2.

The presence of the voltage at "protection status" line will

eventually reset the VsVa-supply. For more info see

subparagraph - Reset of the VsVa-supply.

Vs protection

When this protection is activated, the Vs power supply is shut

down. The set is switched to the standby mode and error-code

4 is stored in the NVM.

When the Vs supply exceeds the 198V, regulator 7012 is

triggered and will switch on T7016. Capacitor 2032 is charged

via the 5Vstby-switched and will trigger thyristor 7013. Thyristor

7013 is fired and connects signal Aa to ground. To follow the

signal flow, go to the right upper corner of schematic FD1.

When signal Aa is shorted to ground, T7341 is switched on.

The voltage dividing of R3386 and resistor R3378 and 3379

now determine the voltage "protection status". ( neglect the

Vce of 0.2V of T7341 ). See schematic FD2.

The presence of the voltage at "protection status" line will

eventually reset the VsVa-supply. For more info see

subparagraph - Reset of the VsVa-supply.

5.6.5 Temperature Protection

When this protection is activated, the Va- and Vs power supply

are shut down. The set is switched to the standby mode and

error-code 5 is stored in the NVM.

When the temperature of the heatsink on the Preconditioner

panel or on one of the 2 heatsink on the VsVa panel exceeds

the 110°C, the PTC resistance increases drastically. The

voltage at pin 3 of IC7330 will drop and the output of 7330 will

do the same. The current flow through opto-coupler diode 7331

results also in a current flow through the opto-coupler transistor

and will trigger thyristor 7332. The fired thyristor switches

transistor 7337 on. The voltage dividing of R3339 and resistor

R3378 and 3379 now determine the voltage "protection status".

( neglect the Vce of 0.2V of T7337 ).

The presence of the voltage at "protection status" line will

eventually reset the VsVa-supply. For more info see

subparagraph - Reset of the VsVa-supply.

5.6.6 DC Protection - Audio Amplifier

When this protection is activated, the Va- and Vs power supply

are shut down. The set is switched to the standby mode and

error-code 6 is stored in the NVM.

In case of a fault in the Audio amplifier or when a DC voltage

appears on the speaker output, a signal called DCPROT is

generated. See schematic FD2 - F7. In case of a fault,

thyristor 7314 is triggered and switches on T7340. The voltage

dividing of R3380 and resistor R3378 and 3379 now determine

the voltage "protection status". ( neglect the Vce of 0.2V of

T7340 ).

The presence of the voltage at "protection status" line will

eventually reset the VsVa-supply. For more info see

subparagraph - Reset of the VsVa-supply.

5.6.7 Vrr - PDP supplies

Vrr is a logical signal ( "high" in normal circumstances ) that

comes from the PDP. It's purpose is to trigger the switch-off of

the Pre-conditioner supply in case Vrr becomes "low" , to

trigger the shutdown of the VsVa supply and to initialise that

error-code 7 is stored in the NVM.

When signal Vrr becomes "low", see FD1 - section F13, the

output of IC7301-B becomes "high". This results in two actions.

It will trigger thyristor 7302 and short signal PROTS to ground.

This results eventually in a reset of the VsVa supply.

Switching on T7371, which again switches on T7370 via the

5Vstby-switched supply. Signal-line "supply-on" is now

grounded. This results in switching off relay 5680 and 5690,

disconnecting the mains from the pre-conditioner. The standby

supply ( 5Vstby-switched ) is still functional. (See Fig. 5-5)

5.7 Fault finding tips

5.7.1 Pre-conditioner

The Pre-conditioner delivers the following output voltages:

• 5 VSTBY

• 5 VSTBY_switched

• 380 VDC

• Internal 12 VSTBY to supply the relay, which switches the

mains input

To trouble shoot the pre-conditioner, first check the LED of the

display-box.

• No red, green or orange LED indicates the absence of the

+5Vstby_switched at the VsVa panel.

Check the +5Vstby_switched on pin 5 of connector PR08. If

this voltage is present check the presence of this voltage at the

VsVa-panel on pin 2 of connector FD04. See the wiring

diagram of the monitor for more details.

If the voltage is not present, check R3508 and fuse 1500. In

case of a defective R3508, check/replace item 7500, optocoupler 7501, regulator 7502, and diode 6501 + 6502.

In case of an open circuit of fuse 1500, check/replace bridge

6500 and capacitor C2501.

If both component are alive, measure the voltage at pin 5 of

IC7500 - Topswitch. If the waveforms resemble a burst-signal,

the output is too heavy loaded. Check the output diode D6504

and capacitor C2508 of the 12VSB and diode 6505 and

capacitor C2510 of the 5VSTBY.

• The red LED is blinking (+5Vstby is OK!), which is an

indication of a protection.

Disconnect the VGA-cable between the E-box and the Monitor.

Now the Monitor is operating as a stand-alone unit.

Switch the monitor via the DST, (command "Default") or via the

RC (special sequence) to the SDM.

Automatically the orange coloured LED of the monitor will blink

the content of the error-buffer. If the sequence contains errorcode 8, the cause could be a defective pre-conditioner. Errorcode 8 is an indication that the +5V and/or the Vs/Va of the

VsVa supply are not correct.

In case of error-code 4, switch OFF the set and check the

temperature of the heatsink. In case of a high temperature of

the heatsink, check MOSFET T7610 and the drive-circuit

around T7640, T7641 and T7608.

In case of error-code 8, remove connector PR09 from the

board. Short-circuit pin 2 of T7681 to ground, simulation of

"SUPPLY_ON". (Caution - Protections overruled!!!)

Measure voltage at C2616. Is voltage 380Vdc?

Yes, the cause was a too heavy load/short-circuit at the VsVapanel.

No, measure the voltage at C2606/C2607. Is this voltage a DCvoltage of approx. 300V with a strong ripple at a mains-input of

230Vac? If NO, check if relay 5690 is activated via the

transistors T7684 + T7690. Check also PTC's 3600, 3601 and

3602 at their resistor-value.

Page 16

GB 16 FTV1.9DE5.

Service modes, fault finding and repair tips

Voltage is present at C2606. Check/replace NFR 3663 and

3668, if one of them is an open-circuit. In case R3663 is an

open circuit, check/replace diode 6660, 6661 and capacitor

C2664 plus IC 7660. If IC7660 is defect, check/replace IC 7650

and C2262. In case of an open circuit of NFR 3668, replace IC

7650.

NFR 3663 and NFR 3668 are not defect. Measure waveform at

base of T7608. Is a square waveform present at gate of T7610?

Check/replace MOSFET T7610 and the drive-circuit around

T7640, T7641 and T7608.

5.7.2 VsVa-supply

The red LED is blinking (+5Vstby is OK!), which is an indication

of a protection.

Disconnect the VGA-cable between the E-box and the Monitor.

The Monitor is now operating as a stand-alone unit.

Switch the monitor via the DST, (command "Default") or via the

RC (special sequence) to the SDM.

• Error-code 1, check the +5V supply

Check fuse 1103. If the fuse is an open circuit, check/replace

IC 7201. If fuse 1103 is OK, check the presence of the 17V. I

this voltage is not present check fuse 1102 + 1104 and D6121

+ D6122. If the 17V is present, then remove connector FD05.

The reason could be a too heavy load or a short-circuit of the

+5V supply. If after disconnection of connector FD05 the set

still goes into protection, check D6203, NFR 3205 and the

circuit around IC 7201.

• Error-code 2, check the 8V6 supply

Check regulator IC 7203, NFR 3099 and D6204.

• Error-code 8 there is something wrong with the

POWER_OKE signal. When the POWER_OKE signal is

low, the Vs and Va and the +5V are available.

Measure the voltage Va at C2120. Is the voltage between 55V

and 65V? If not check fuse 1105 and D6120. If both

components are OK, the cause could be a too heavy load.

Measure the voltage Vs at C2020. Is the voltage between 165V

and 185V? If not check D6020. If D6020 is OK, the cause could

be a too heavy load.

If both voltage are not present, check fuse 1004 at the input.

If fuse 1004 is an open circuit, check the MOSFET's 7005 and

7006 for a short-circuit. In case of short-circuit use the repairkit.

If fuse 1004 is OK, check the voltage at pin 15 of IC 7001. Is the

voltage at pin 15 approx. 16-17V? If NO, check NFR 3002 and

D6002 + D6030. If YES, check the waveforms FD49 and FD50

at pin 14 and 12. If they are present, check pulse transformer

5001 and the driver-circuits around MOSFET 7005 and 7006.

If the waveforms FD49 and FD50 are not present, replace

IC7001.

• Error-code 5, check the audio-supply or the Audio amplifier

IC.

Check/replace fuse 1201 + 1202 and diode 6201 + 6202. If the

components are OK, check the audio-amplifier IC.

• Error-code 6, check the Vs and/or the Va supply voltage.

The regulation-circuit of one of these voltages is not working

correctly.

For the Va supply check opto-coupler 7102 and IC 7110.

For the Vs supply check opto-coupler 7002 and IC 7010

5.8 ComPair

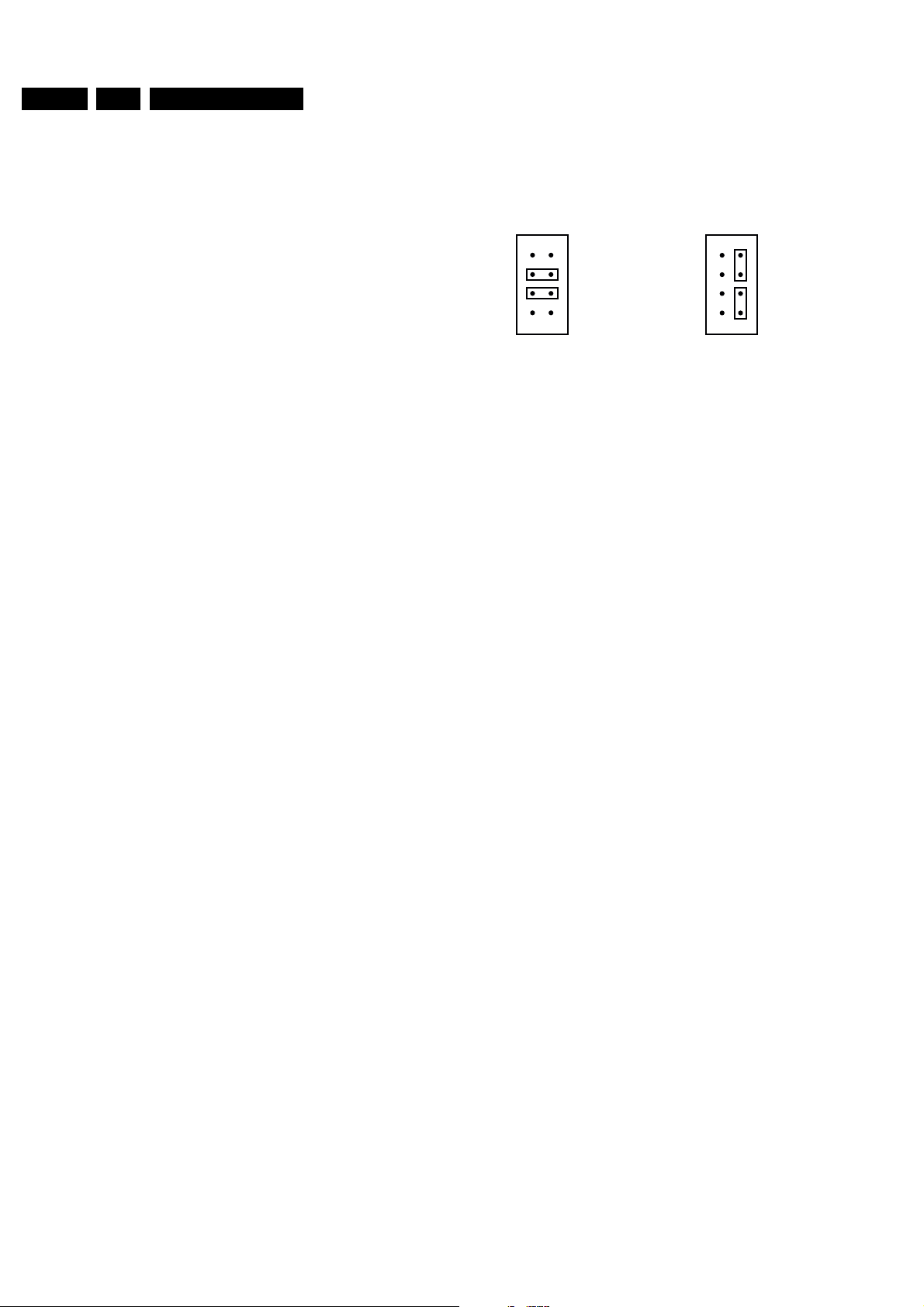

5.8.1 ComPair mode

The figure below shows how to do it.

ComPair

TOPVIEW B-SIDE

AVC39

5

6

7

8

DEFAULT MODE

4

3

2

1

Figure 5-1

After switching ON the set, the red LED will blink as an

indication that the monitor is in the ComPair mode.

5.8.2 Introduction

ComPair (Computer Aided Repair) is a service tool for Philips

Consumer Electronics products. ComPair is a further

development on the DST service remote control allowing faster

and more accurate diagnostics. ComPair has three big

advantages:

• ComPair helps you to quickly get an understanding how to

repair the FTV1.9 in short time by guiding you step by step

through the repair procedures.

• ComPair allows very detailed diagnostics (on I2C level)

and is therefore capable of accurately indicating problem

areas. You do not have to know anything about I2C

commands yourself; ComPair takes care of this.

• ComPair speeds up the repair time since it can

automatically communicate with the FTV1.9 (when the

microprocessor is working) and all repair information is

directly available. When ComPair is installed together with

the SearchMan FTV1.9 electronic manual, schematics and

PCBs are only a mouse-click away.

ComPair consists of a Windows based faultfinding program

and an interface box between PC and the (defective) product.

The ComPair interface box is connected to the PC via a serial

or RS232 cable. In case of the FTV1.9 chassis, the ComPair

interface box and the FTV1.9 communicate via an I2C cable

(bi-directional) The ComPair fault finding program is able to

determine the problem of the defective television. ComPair can

gather diagnostic information in 2 ways:

1. Communication to the television (automatic)

2. Asking questions to you (manually)

ComPair combines this information with the repair information

in its database to find out how to repair the FTV1.9.

Automatic information gathering

Reading out the error buffer, ComPair can automatically read

out the contents of the entire error buffer.

Diagnosis on I2C level. ComPair can access the I2C bus of the

television. ComPair can send and receive I2C commands to

the micro controller of the television. In this way it is possible for

ComPair to communicate (read and write) to devices on the

I2C busses of the FTV1.9.

AVC39

5

6

7

8

ComPair MODE

CL 96532069_149.eps

4

3

2

1

190899

The monitor, as a stand-alone unit, can be diagnosed via a PC/

laptop by using ComPair via the ComPair connector. Before

connecting the ComPair-cable at the AV Control panel on

connector AVC34, the monitor must be put in the "ComPair Mode ". This can be done by changing the jumpers at

connector AVC39. Connector AVC39 is situated under the uP

panel.

Manual information gathering

Automatic diagnosis is only possible if the micro controller of

the television is working correctly and only to a certain extend.

When this is not the case, ComPair will guide you through the

faultfinding tree by asking you questions and showing you

examples. You can answer by clicking on a link (e.g. text or an

Page 17

Service modes, fault finding and repair tips

86532027_003.EPS

050898

PC VCR I2CPower

9V DC

GB 17FTV1.9DE 5.

waveform pictures) that will bring you to the next step in the

faultfinding process.

A question could be: Do you see snow? (Click on the correct

answer)

YES / NO

An example can be: Measure testpoint I7 and click on the

correct oscillogram you see on the oscilloscope

I7 B7502

1V / div DC

10µs / div

Figure 5-2

By a combination of automatic diagnostics and an interactive

question/answer procedure, ComPair will enable you to find

most problems in a fast and effective way.

Additional features

Beside fault finding, ComPair provides some additional

features like:

• Uploading/downloading of pre-sets

• Managing of pre-set lists

• Emulation of the Dealer Service Tool

9. Plug the mains adapter in the mains outlet and switch ON

the interface. The green and red LED's light up together.

The red LED extinguishes after approx. 1 second (the

green LED remains lit).

10. Start-up Compair and select "File" menu, "Open...:; select

"FTV1.9 Fault finding" and click "OK"

11. Click on the icon (Fig. 5-3) to switch ON the communication

mode (the red LED on the Compair interface wil light up)

12. Switch on the television set with the mains switch

13. When the set is in standby. Click on "Start-up in ComPair

mode from standby" in the ComPair FTV1.9 fault finding

tree, otherwise continue.

Figure 5-3

5.8.3 Searchman (Electronic Service Manual)

If both ComPair and SearchMan are installed, all the

schematics and PCB's of the faulty set are available when

clicking on the hyper-link of a schematic or a PCB in ComPair.

Example : Measure the DC-voltage on capacitor C2568

(Schematic/Panel) at the Monocarrier.

Clicking on the PCB hyper-link, automatically shows the PCB

with a highlighted capacitor C2568. clicking on the schematic

hyper-link, automatically shows the position of a highlighted

capacitor C2568 at the schematic.

5.8.4 Connecting the ComPair interface

The ComPair Browser software should be installed and setup

before connecting ComPair to the FTV1.9. (See the ComPair

Browser Quick Reference Card for installation instructions):

1. Connect the RS232 interface cable to a free serial (COMM)

port on the PC and the ComPair interface PC connector

(connector marked with "PC").

2. Place the ComPair interface box straight in front of the

television with the infrared window (marked "IR") directed

to the television LED. The distance between ComPair

interface and television should be between 0.3 and 0.6

meter. (Note: make sure that (also) in the service position,

the ComPair interface infra red window is pointed to the

standby LED of the television set (no objects should block

the infra red beam)

3. Connect the mains adapter to the connector marked

"POWER 9V DC" on the ComPair interface

4. Switch the ComPair interface OFF

5. Switch the television set OFF with the mains switch

6. Remove the rear cover of the television set

7. Connect the interface cable (4822 727 21641) to the

connector on the rear side of the ComPair interface that is

marked "I2C" (See Figure 5-4)

8. Connect the other end of the interface cable to the

ComPair connector AVC34 (0334) at the right/bottom side

of the AV-Control panel.

Figure 5-4

The set has now started up in ComPair mode. Follow the

instruction in the FTV1.9 fault finding tree to diagnose the set.

Note that the OSD works but that the actual user control is

disabled

5.8.5 Preset installation

Presets can be installed in 2 ways with the FTV1.9.

• Via infra red

– only sending TO the television

– the rearcover does NOT have to be removed

Click on "File" "Open" and select "TV - use ComPair as DST"

to use infra red

• Via cable

– sending TO the television and reading FROM the

television

– the rearcover has to be removed

Click on "File" "Open" and select "FTV1.9 fault finding" to use

the cable

Presets can be installed via menu "Tools", "Installation",

"Presets".

5.8.6 Ordering ComPair

ComPair order codes:

• Starterkit ComPair + SearchMan software + ComPair

interface (excluding transformer): 4822 727 21629

• ComPair interface (excluding transformer): 4822 727

21631

• ComPair transformer (continental) Europe: 4822 727

21632

• ComPair transformer United Kingdom: 4822 727 21633

• Starterkit ComPair software: 4822 727 21634

Page 18

GB 18 FTV1.9DE5.

Service modes, fault finding and repair tips

• Starterkit SearchMan software: 4822 727 21635

• Starterkit ComPair + SearchMan software: 4822 727

21636

• ComPair CD (update): 4822 727 21637

2032

5VSTBY-SWITCHED

VS

3036

3035

3033

3384

7016

3058

7341

7012

3385

3037

2037

3034

7114

FD1

3394

[C-14]

AA

21352132

7013

2038

3038

PROT-FAN 1-6

5VSTBY-SWITCHED

17V

7321

7340

• SearchMan CD (update): 4822 727 21638

• ComPair interface cable (for FTV1.9): 4822 727 21641

280999

7316-7321

7103

3139

7315

3039

6371

DC

7314

5VSTBY-SWITCHED

7003 7103

PROTS

7338

3111

3011

7333

7339

CL 96532058_086.eps

7101-PIN10

7001-PIN10

5VSTBY-SWITCHED

VA

5VSTBY-SWITCHED

VCC

3136

3135

SUPPLY-ON

7371

7113

3133

[PR3]

7301

7112

7302

3137

7370

3134

2134

3138

3386

CONNECTOR

FD06-12

3323

5VSTBY-SWITCHED

CONNECTOR

D09

3380

3379 3378

7331

3332

3339

7330-A

8

3

7332

PROTECTION-STATUS

4

2

3333

7337

17V

45

3331

Figure 5-5

Page 19

Block diagrams

6. Block diagrams

Block diagram (Part 1)

19FTV1.9DE 6.

RGB INPUT RGB OUTPUT VIDEO CONTROL

AVC1

H

V

H

V

YC1

CVBS

BNC

CVBS

CINCH

SVHS

Y

U

V

L

R

15P "D" SHELL

CONNECTOR

6

CONFIG_IDENT

UART-IN-DDC

HS-SYNC

VS-SYNC

H-SYNC_OUT

V-SYNC_OUT

11

7

12

8

13

9

14

10

15

15P "D" SHELL

CONNECTOR

6

11

7

12

8

13

9

14

10

15

1

2

3

4

5

UART-OUT-DDC

1

2

3

4

5

INPUT CONNECTORS

+ RGB MATRIX

CVBS

CVBS

7008

7005

7002

Y

3

C

4

EF

EF

EF

AUDIO L

AUDIO R

2

1

R-IN-VGA

G-IN-VGA

B-IN-VGA

R

G

B

10

7810, 7811

7820, 7821

7830, 7831

7000 : 7007

R

MATRIX

G

MATRIX

B

MATRIX

7414, C+D

13

YC2

AVC2

C1

C2 C3

D15_RC5

R

G

B

7414, A+B

C11

H

1

4

7414, C+D

C12

V

5

8

HV

COMB FILTER + I/O EXPANDER

7012

12

13

R-IN

G-IN

B-IN

TDA9181

1416Y

SDA

SCL

13

12

C

1

2

15

14

COMB

FILTER

R

G

B

R

G

B

7010, A+B

7HHCT4053D

7009

PCF8574AT

I/O

EXPANDER

AVC3

R-YC

G-YC

B-YC

14

15

7330

R

7345

7340

G

7335

7350

B

7355

H-SYNC BUFF

H-SYNC

H-YC

V-SYNC

V-YC

7360

74AC4053V

3

5

1

2

13

12

7370

74HCT4053D

2

1

5

3

RGB OUTPUT MATRIX

YC3

7013

TDA8854

YC21

PAL/NTSC

SECAM

20

DECODER

SYNC. PROC. +

YC4

OUTPUT CONNECTOR

7017-A

12

13

B

7023

7300

TDA4885

C55

4

6

C54

3

CLAMPING

CONTRAST

C53

10

H-SYNC

V-SYNC

RGB/YUV

MATRIX

42 43

41

RGB

7017-B

2

1

A

H+V

6

SYNC

SEPARATOR

7024, BA7046F

BLANKING

LIMITING

CLIPPING

INPUT

LIMITING

CLAMPING

51715 11

EAB D

40

45

U

46

V

15

H

2

V

4

15

14

15

4

YY

R-Y

B-Y

14

OUTPUT

GAIN

AMPLIFIER

OUTPUT

IIC

CLAMPING

16

C47

39

47

48

B

C48

C

RGB

MATRIX

7026

65

PULSE

A

FORMER

7025

1

5

INTERCONNECT

PD1

AVC02 PD02

7311,7320

C37

C40

C43

C51

2

5

8

10

12

13

15

16

18

20

30

R

7308,7322

G

25

7306,7324

B

20

A

SDA

B

SCL

C

D

E

C52

0312

ON

0312

AVC3

7018

R

33

32

31

1

7020

G

3

7022

B

5

CONTRAST

R-YC

G-YC

B-YC

L2

L5

L7

L8

SDA

SCL

L13

L14

AVC5

B

H-YC

HD

8

HD

4

V-YC

VD

VD

8

9

RED GAMMA + ADC

PD2

GAMMA

CORR.

GREEN GAMMA + ADC

PD3

GAMMA

CORR.

BLUE GAMMA + ADC

PD4

GAMMA

CORR.

LOGIC CONTROL + I/O

PD7

7350

EPF6016

EPLD

26

H/V SYNC

POLARITY

3

CONVERTER

CONTROL

STANDBY

SCL1 DDC

SDA1 DDC

UART-IN

UART-OUT

LED-RED

LED-GREEN

SCL2

SDA2

37

36

39

38

35

41

20

21

72

114

only socket

8

1

2

3

4

5

8

9

13

14

7123

TDA8714T/6

LPF ADC

7173

LPF ADC

7223 7214

LPF

L106

7357

EPC1441

7307

7355

3

4

ADC

EEPROM

EEPROM

BUFFER

L107

42 PIN

1

6

2

7

22

10

23

11

24

12

SDA NVM

SCL NVM

18

17

DATA

CLOCK

REQ

SDA

SCL

7400

M24C16-BN6

INPUT

PD9

BUFFER

7212

8x

BUFFER

7213

8x

BUFFER

8x

BUFFER

7351

PCF8574AT

I/O

EXPANDER

HSYNC_PDP

VSYNC_PDP

NVM

56

C76

C75

TO

AVC6

MONITOR µP PANEL

1

2

3

4

5

PD5

8x

8x

8x

SDA

SCL

STANDBY

RESET

SCL1 DDC

SDA1 DDC

SCL2

SDA2

SCAN CONVERTER + OSD

7320 µPD93687GD-LBD

SCAN

CONVERTER

(LIMESCO)

OSD

7327, MC141585

4 MHz

CLOCK

7353, 74LVU040

7001

P87C695

1

9

1000

10

13

14

15

18

19

PD8

8x

8x

8x

PD6

5

41

40

61

62

57

58

59

55

56

7316

BUFFER

7317

BUFFER

7318

BUFFER

SDA NVM

SCL NVM

UART_IN

UART_OUT

DATA

CLOCK

REQ

LED RED

LED GREEN

OUTPUT

BUFFER

8x

8x

8x

PLL's

PLL-A

PLL-B

L139

L138

PD03

8x

R

8x

G

8x

PDP

Plasma

B

Display

Panel

19

17

MUP37

0437

1

3015

2

3

6

SAM

7

SDM

8

CSM

6

7

8

9

10

3017

3016

11

12

13

14

AUDIO PROCESSING

AVC6

REQ

CLOCK

DATA

22

L

C42

REQ

CLOCK

DATA

22

R

C43

7910

M65830P

4

5

6

7920

M65830P

4

5

6

DELAY

DELAY

AUDIO CONTROL

AVC7

7940

SDA

SCL

28

30

32

TDA9860

3

1

5

INPUT

SELECTION

17 16

SOUND

ENABLE

24

9

26

7

ENABLE

7970-A

LM833D

15

1

1332

C46

7970-B

LM833D

15

7

1345

C49

23

10

SOUND

VOLUME

BASS

TREBLE

BALANS

C51

C52

7968:

7972

8V6

3940

C101

6

18

15

L_OUT

R_OUT

AUDIO FILTER + DBE

AVC8

C102

L

C107

R

TO

FD20

FD2

7250-A

LM833N

2

7200-A+B

2

7250-B

6

7220, A+B

2

A20

1

2

3

4

5

C54

1

L-MID-LOW

C55

7

L-HIGH

C57

7

R-HIGH

C58

7

R-MID-LOW

1101

3.15AT

1102

3.15AT

A

OUTPUT AMPLIFIER

2

3

5

6

A6

A5

A8

A7

-V5ND

+V5ND

7540

TDA2616Q

9

1

2

7550

TDA2616Q

9

1

2

DC

PROT.

7560 : 7561

LED PANEL DISPLAY

A40

A2

1

6

4

A41

6

A4

4

L-HIGH

2

3

L-MID-LOW

4

1

R-HIGH

2

3

R-MID-LOW

4

LD

6002

TSOP1736

6001

TLMV3100

1

4

+5V_SWITCHED

2

3

1

2

3

LD11 SD11

GREEN

RED

D15_RC5

SD

1

2

3

4

5

SWITCH PANEL

DISPLAY

1002

SD10

1

2

3

4

5

6

7

CONNECTOR DIAGRAM

1601

T200mA

+5VSTBY-SWITCHED

+5VSTBY-SWITCHED-RELAIS

+5VSTBY

C70

SDA

DISREG

SCL

LED-GREEN

LED-RED

C71

AVC34

1

2

3

COMPAIR

CONNECTION

+5VSTBY-SWITCHED

STANDBY

POWER OK

VRR

SOUNDENABLE

+5VSTBY

POR

PROTECTION

STATUS

CL 96532058_17A.eps

VC04AVC4

2

3

4

6

8V6

7

9

10

11

12

260899

Page 20

Block diagrams

20FTV1.9DE 6.

Block diagram (Part 2)

2

1

STBY-

SWITCHED

5680

CONTROL

VOLTAGE

SUSTAINING

1400

6.3A

1401

6.3A

PR2

4

3

6

5

VS

6021

6022

VS:

MAINS FILTER

PR1

AC

INLET

42

31

PR2

PRECONDITIONER

PR3

A

B

VS-SUPPLY

FD2

1004

T2A

7001

MC34067P

FD1

1004

PR30

+5V

5400:

5402

MAINS

FILTER

AB

3600 3601

+t +t

42

31

+12VSB

6

5

AB

1005

1A

3026

+VS Adj.

+5V

7684

7690

DELAY

AUX

7311

7313

FAN

SUPPLY

STANDBY SUPPLY

PR2

1500

500mA

43

41

3602

-t

7681

ACTIVATING

CIRCUIT

6020

FD7

FD68

1

1

2

7500

TOP210

CONTROL

2021

6500

2

3

5

4

6600

SUPPLY_ON

+VS

+VS

+VA

TO 6x

FANS

PR6

2505

5605

FD55

3508

6503

7501

TCDT1102G

FD57

5500

2

3

1

4

5605

16

4

7650

MC33368

CONTROL

CIRCUIT

FD171 FD171

1

3

7

I2C bus interconnection diagram

Serivce JMP's:

Normal operation: A in, B out.

Slow bus to NVM bus: A out, B in.

AVC-5

SDA

NVM

SCL

7400

ERR:16

IIC BUS NVM

M24C16

UART

OR

DDC

3401 3402

3460

A

A

3461

BB

SDA

SCL

3463

AVC-5

µP

83C380

7401

5500

2508

2510

1

PR8

PR9

3

7502

TL431CLP

+12VSB

+5VSTBY

3505

3504

+5V

Adj.

6504

9

8

6505

7

6

CLOCK

REQ

DATA

AUDIO

DELAY

IC-RIGHT

7920

M65830

3462

+5V STANDBY SWITCHED

5610

15

1

6

2

6611

+380V

2616

PR12

PRO9

1

2

3

ACV34

SERVICE

PLUG

TO: AVC-4

SLOW IIC BOX

+5V STANDBY SWITCHED

3438 3437

AVC02 - PD02

11

PR17

7610

STY34NB50

3942 3941 3306 3305 3375 3374 3386 33873372 3371

AVC-7 AVC-3 PD-5 PD-7PD-5

PDP-DISCHARGE

FD

DISCHARGE

CIRCUIT

7200

7201

7203

FD172

10