Colour Television Chassis

CL 965320690-163.eps

020999

FTV1.9DE

AA

Contents Page

1 Introduction

2 Mechanical instructions

3. Blockdiagram

4Service modes

5 Preconditioner

6 VsVa supply

7 Audio Video control

8PDP- Limesco

9 Audio amplifier

10 LED panel

11 Switch panel

12 YUV / YC input

2

5

11

12

26

38

54

68

80

81

82

83

©

Copyright reserved 1999 Philips Consumer Electronics B.V. Eindhoven, The

Netherlands. All rights reserved. No part of this publication may be reproduced,

stored in a retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Published by JvR 9969 Service PaCE Printed in The Netherlands Subject to modification 5 3122 785 10036

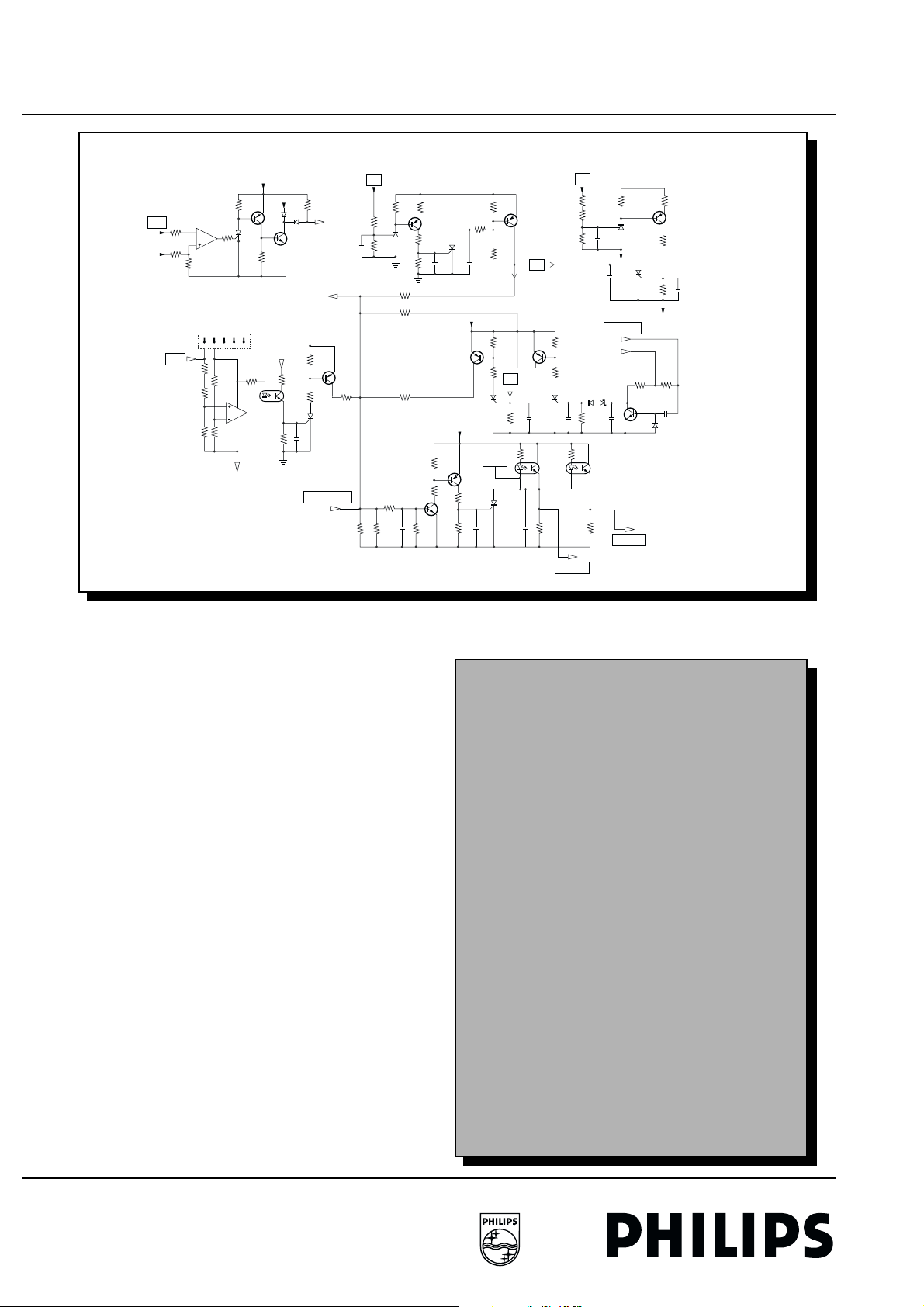

2 1. Introduction FTV1.9DE Display Box

1. Introduction

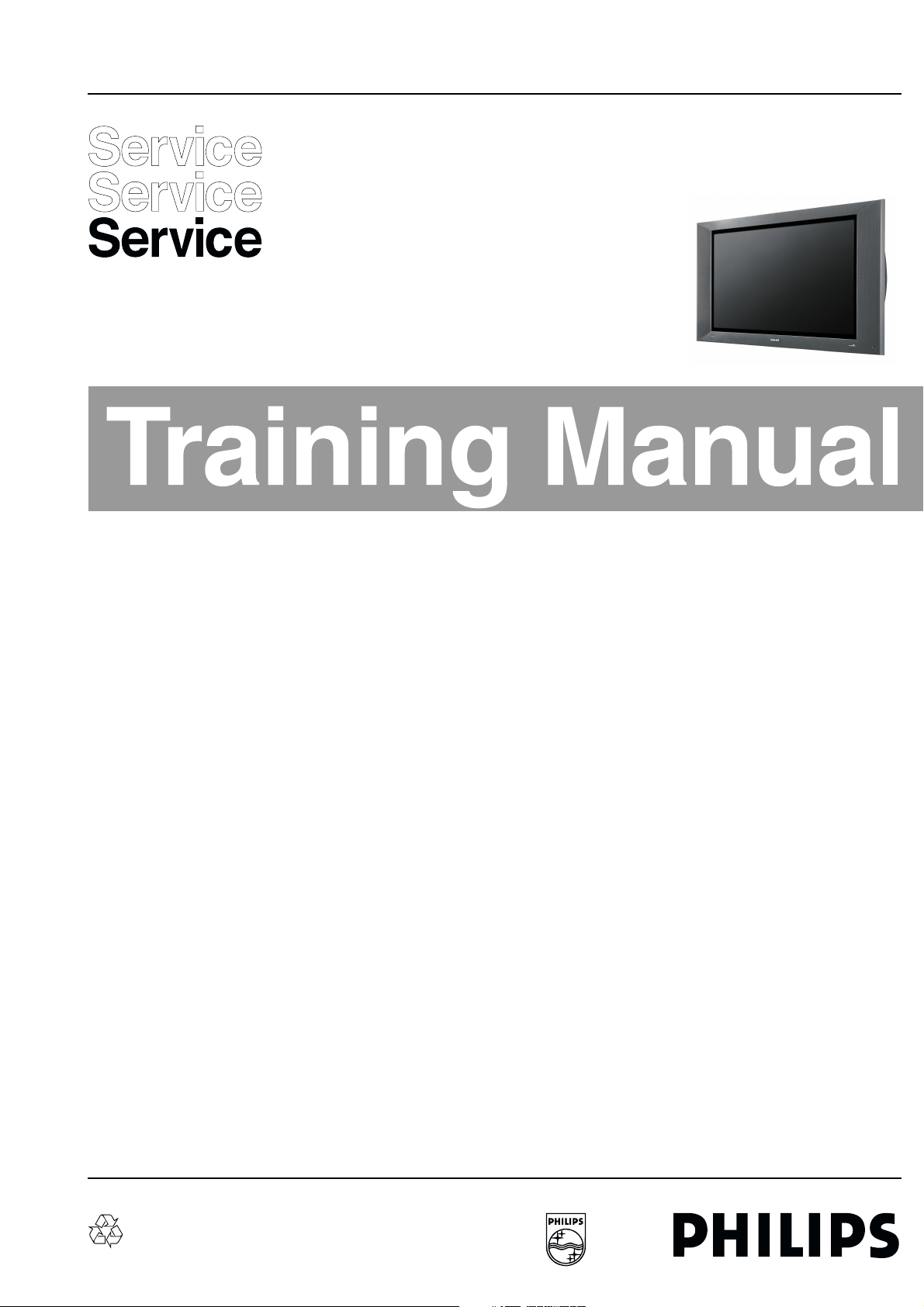

CONFIGURATIONS

TV-CONFIGURATION

R, G, B, HS, VS

RECEIVER BOX

µP µP

MONITOR-CONFIGURATION

PERSONAL COMPUTER

µP µP

CONFIG_IDENT

DIS_RC_5

UART

R, G, B, H, V

CONFIG_IDENT

DDC

DISPLAY BOX

DISPLAY BOX

The successor of the FTV1.5 is the FTV1.9, which had to be

cheaper,and had to make as much as possible "re-use" of

PWB's from the FTV1.5.

It is built around an E-Box (= Receiver Box) and a 42" Monitor

(= Display Box). Within the Monitor a Fujitsu Plasma Display

panel - version 5 - is used.

For the FTV1.9, the Monitor can be used in two applications.

• Stand-alone configuration, monitor is connected to a PC or

a laptop

• TV configuration, where the monitor is connected to the Ebox.

The Monitor is a separate device, which can also be sold and

serviced separately.

The monitor, as a stand-alone unit, can be serviced by using a

test pattern coming from the PDP-LIMESCO panel on the

monitor itself or via a PC/laptop by using ComPair via the

ComPair connector.

Personal notes

CL 96532069_002.eps

240899

FTV1.9 Family has been set up for Europe, USA, Asian and

LATAM markets.

The Europe type consisting of 1 version, having no diversity.

FTV1.9DE Display Box 1. Introduction 3

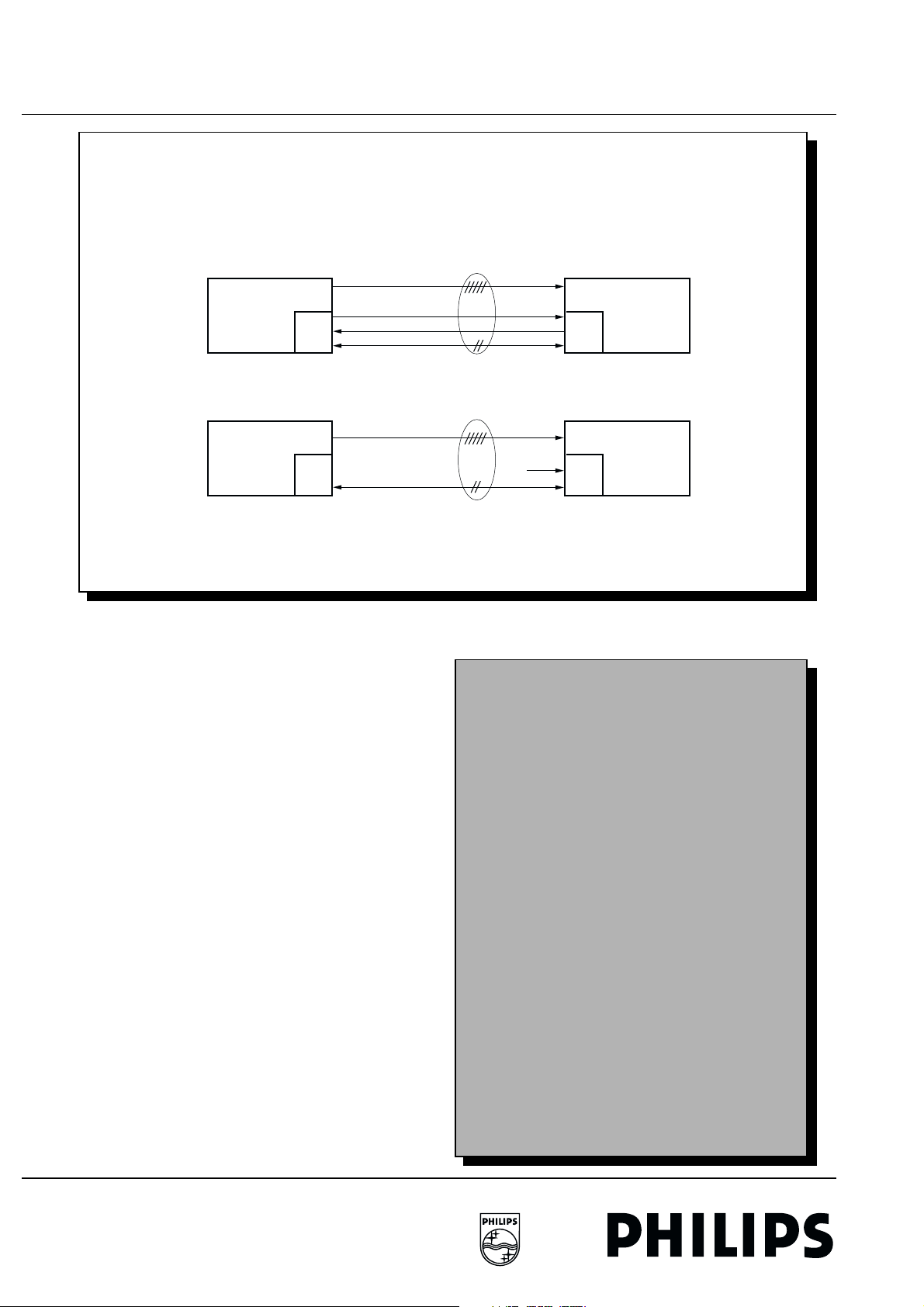

1.1 Description of used panels

1.1 Description of used panels

VS/VA Supply

PDP Discharge

Audio Amplifier

Pre-conditioner

AV Control

The panels are:

1. VsVa supply. At this panel all the supply voltages will be

generated for the display itself, the electronics of the display

and our PCB's. This panel contains also the fan control and

the protection circuits.

2. PDP Discharge Panel. Temporarily used in the DEMmodels of the FTV1.9. In the final models this panel is either

going to be integrated into the VsVa panel or is going to be

re-designed as a separate new panel. The function of this

panel is to discharge the big capacitor of the Vs-supply and

the Va-supply (minor reason). If these capacitors are not

discharged it can take up to 60 seconds before the set restarts after turning it OFF and ON again.

3. Audio amplifier. This panel is almost the same as the GFL

audio amplifier. Some small changes have been made like

other plugs, deleting a switch and external speaker

connectors and an adaptation of the outlines, just to mount

the panel at the backside of the Monitor.

4. Preconditioner. At this panel the mains input and mains

output (to connect the E-Box) is located. After the mains

input, the mains filter is placed. The panel contains also the

preconditioner. This is an auto voltage function from 95V ...

264VAC in to 380VDC out and the standby supply for the

P and the NVM.

µ

5. AV Control. At this panel the VGA, audio and control (UART

or DDC) signals enter the Monitor. These signals will be

buffered and are available at the output of this panel for

feedthrough (except the control signals). The same signals

will be fed to the Audio part (including an (optional) audio

CL 96532069_131.EPS

Personal notes

PDP Limesco

YUV/YC Input

120899

4 1. Introduction FTV1.9DE Display Box

1.1 Description of used panels

delay to correct the timing between video and audio) and to

the video control IC to control the RGB signals. Also the µP

for the panel control in the Monitor is located on this board.

The audio filters for the high and low/medium signals are

also located on the AV Control board.

6. PDP LIMESCO. This panel converts the analogue video

after gamma correction to a digital video signal, which is

connected to the PDP itself. The OSD generator is located

at the PDP LIMESCO, close to the LIMESCO IC for the

insertion of digital OSD information. The LIMESCO IC is

responsible for the scaling of the signals of the various

standard TV standards, VGA formats at this board. The H

and V position is corrected by an EPLD.

7. YUV YC input panel. This board gives the possibility to

attach several video formats to the stand-alone display. It

also has one stereo audio connection.

• Video input signals:

– YUV on three CINCHES (Y, Cb, Cr).

– YC on Hosiden connector (SVHS).

– CVBS on CINCH.

– CVBS on BNC.

• Audio input signals:

– L and R on 2 CINCHES.

• Output signal (AV Control):

– RBG-signal.

– H-sync and Vsync signal.

– L and R audio signal.

8. LED Display panel. At this panel, the LED's and the IRReceiver is located.

9. Switch Display panel. At this panel, the low power mains

switch is located. With this switch a relay is controlled to

switch ON and OFF the monitor

Personal notes

FTV1.9DE Display Box 2. Mechanical instructions 5

CL 96532069_132.EPS

120899

1

2

3

4

VS/VA Supply

FD07

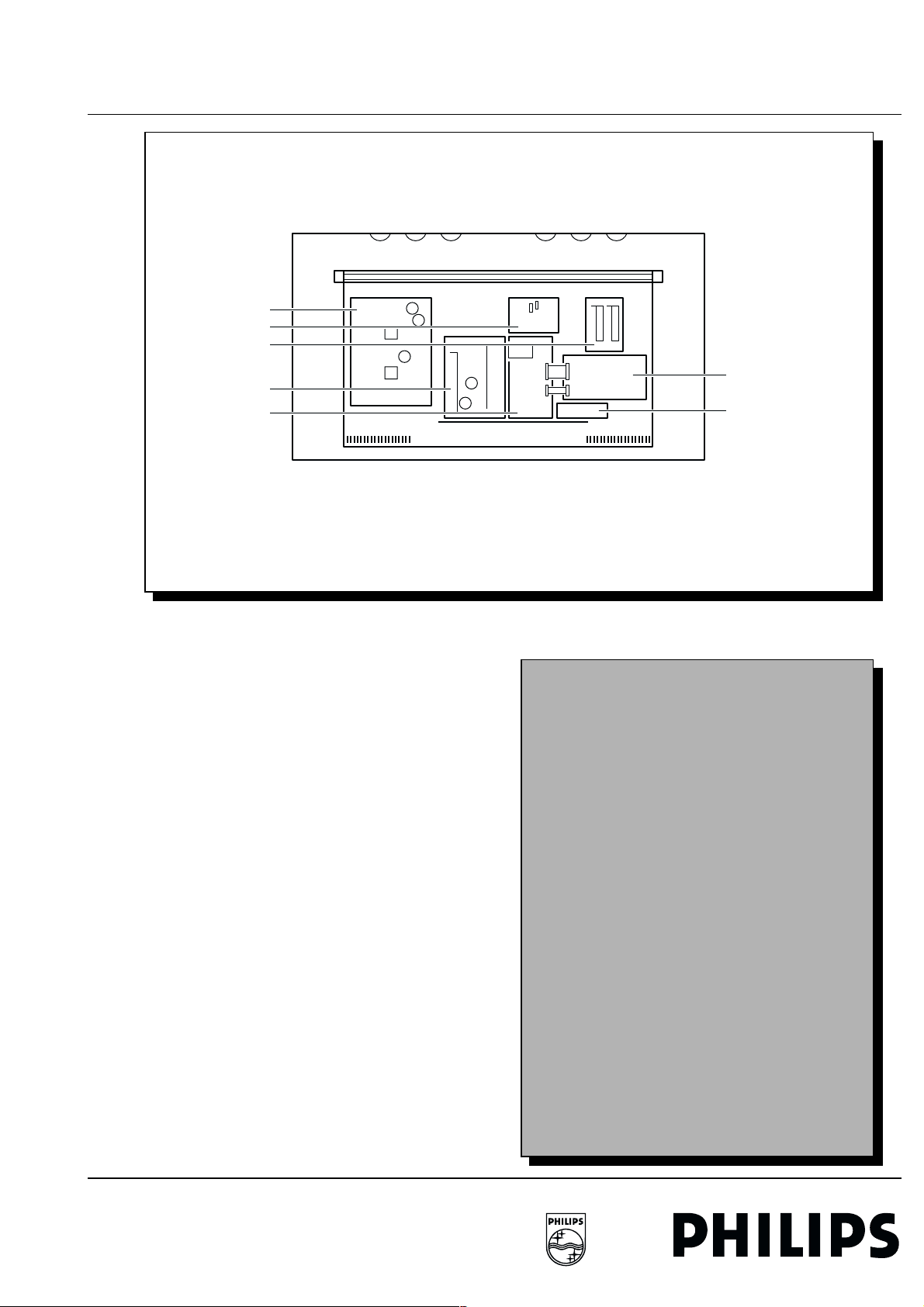

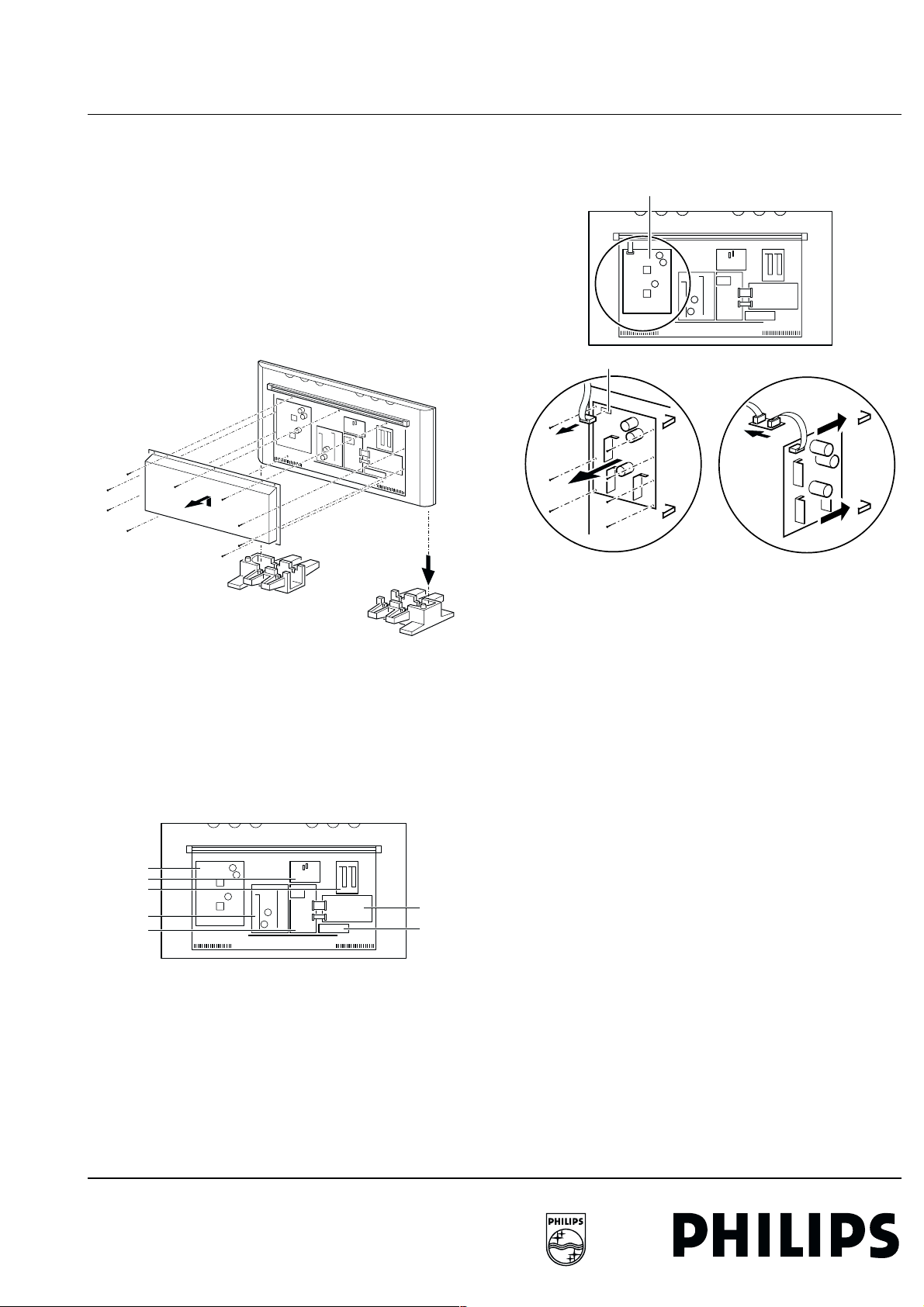

2.1 Introduction:

2. Mechanical instruction s2.1Introduction:

There are pre-defined service positions for the following panels:

1. VS/VA SUPPLY panel.

2. PDP DISCHARGE panel.

3. AUDIO AMPLIFIER panel.

4. PRE-CONDITIONER panel.

5. AV CONTROL panel.

6. PDP LIMESCO panel.

7. YUV/YC INPUT panel.

8. LED DISPLAY panel.

9. SWITCH DISPLAY panel.

Before these panels can be accessed, the rear cover has to be

removed:

2

VS/VA SUPPLY panel.

1

CL 96532069_130.EPS

120899

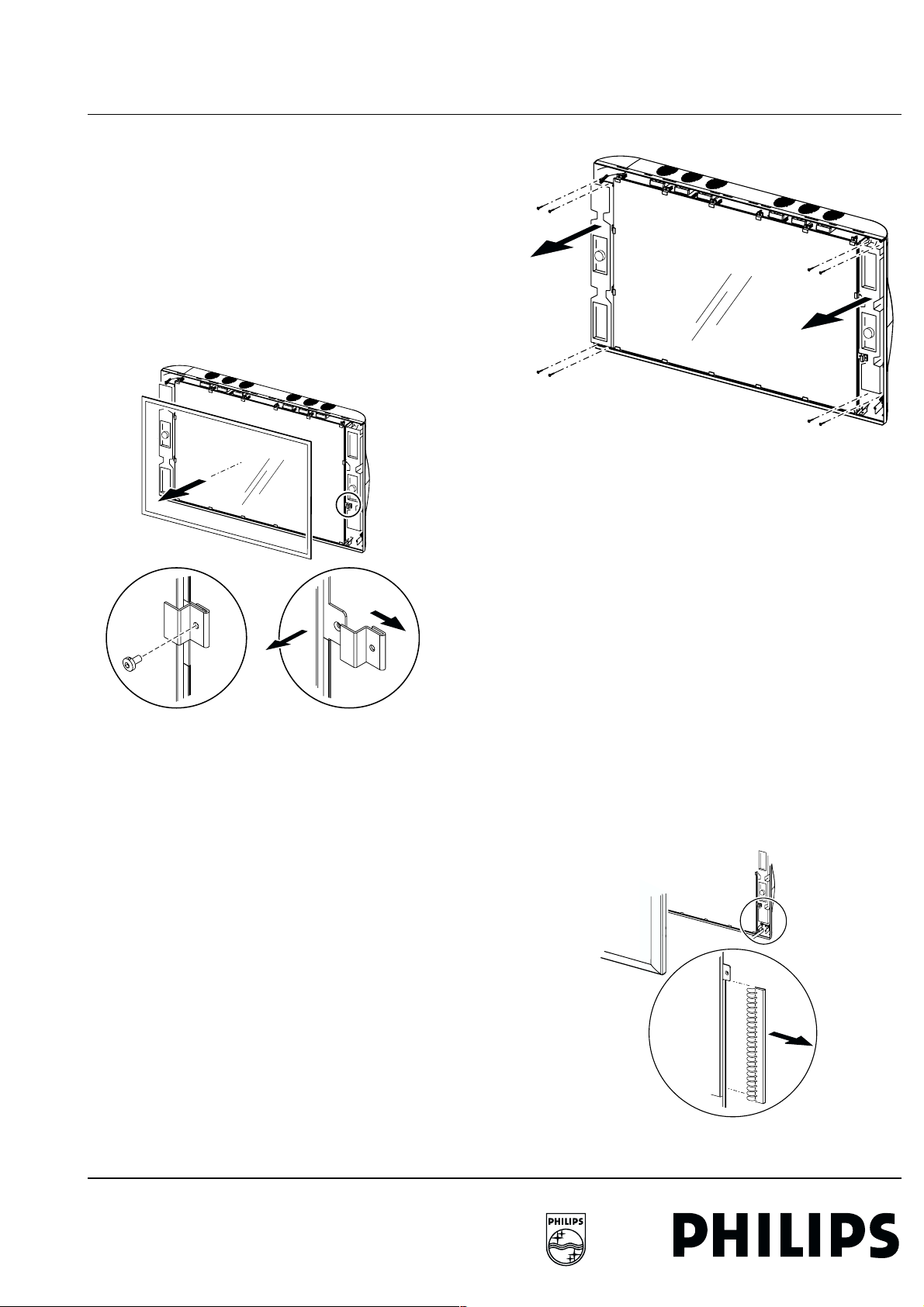

Figure 2-1

1. Place the Display Box in the service stand via 2 reinforced

cushions (order code: 3122 126 30181).

2. Remove the 9 fixation screws of the rear cover.

3. Remove the rear cover (during removal push it slightly

upwards).

VS/VA Supply

PDP Discharge

Audio Amplifier

Pre-conditioner

AV Control

CL 96532069_131.EPS

Figure 2-2

PDP Limesco

YUV/YC Input

120899

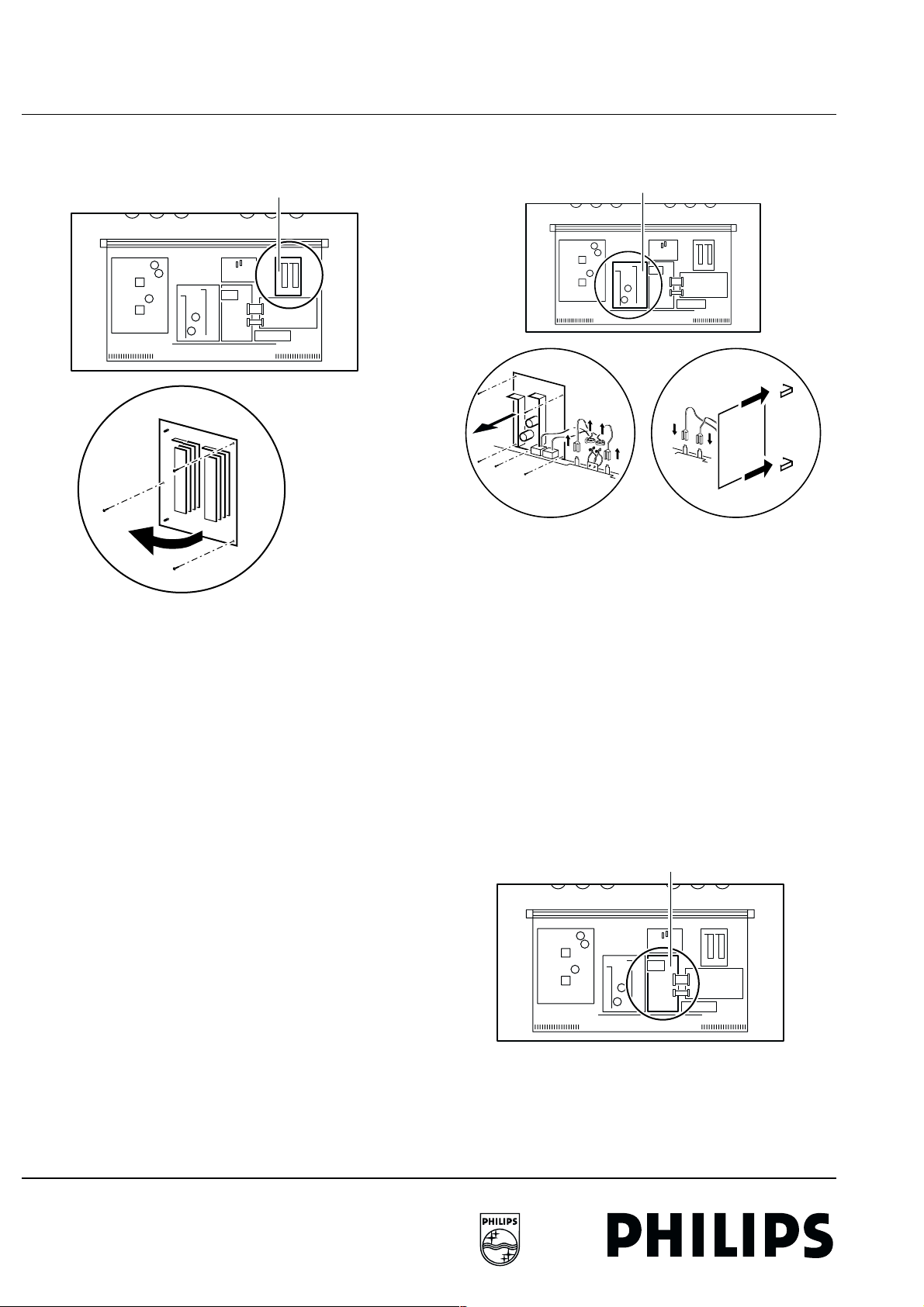

Figure 2-3

1. Disconnect Fan Supply cable from connector FD07 in the

upper left corner [1].

2. Remove the 7 fixation screws of the panel [2].

3. Place panel on the 2 hinges, which are located near the

right corners of the panel [3].

4. Use the mechanical service part (extension cable

assembly, 12NC: 3122 785 90006) to extend the Fan

Supply cable [4].

5. The copper side is now accessible from the left.

PDP DISCHARGE panel.

As in the FTV 1.5, this panel must be exchanged completely if

defective.

1. All panels are now accessible.

6 2. Mechanical instructions FTV1.9DE Display Box

2.1 Introduction:

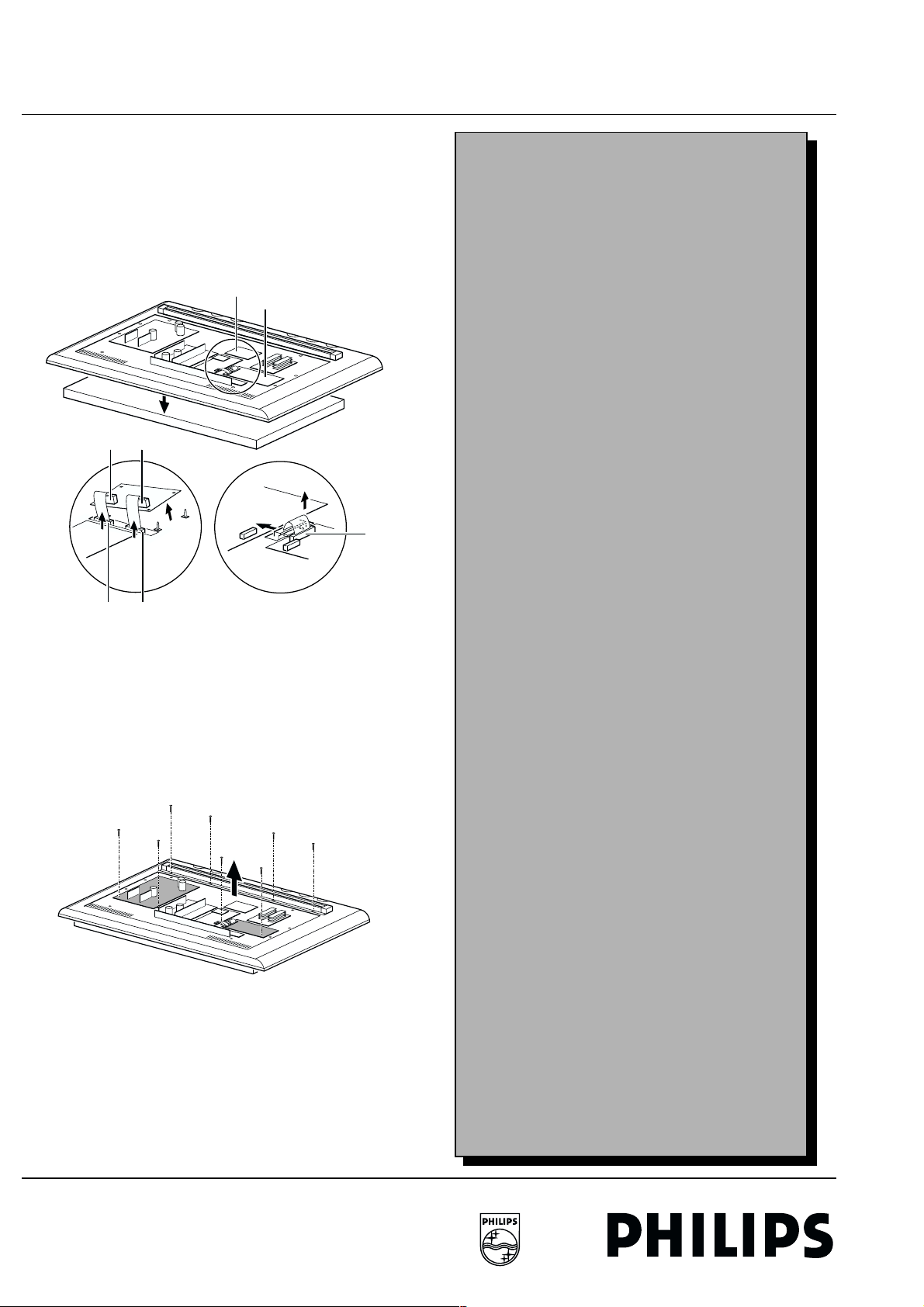

AUDIO AMPLIFIER panel.

Audio Amplifier

1

2

3

2

Figure 2-4

1. Some testpoints are accessible at the B-side [1].

2. If this is not sufficient, remove the 3 fixation screws of the

panel [2].

3. Panel now can be hinged on the left side to access the Aside (soldering side) [3].

CL 96532069_134.EPS

120899

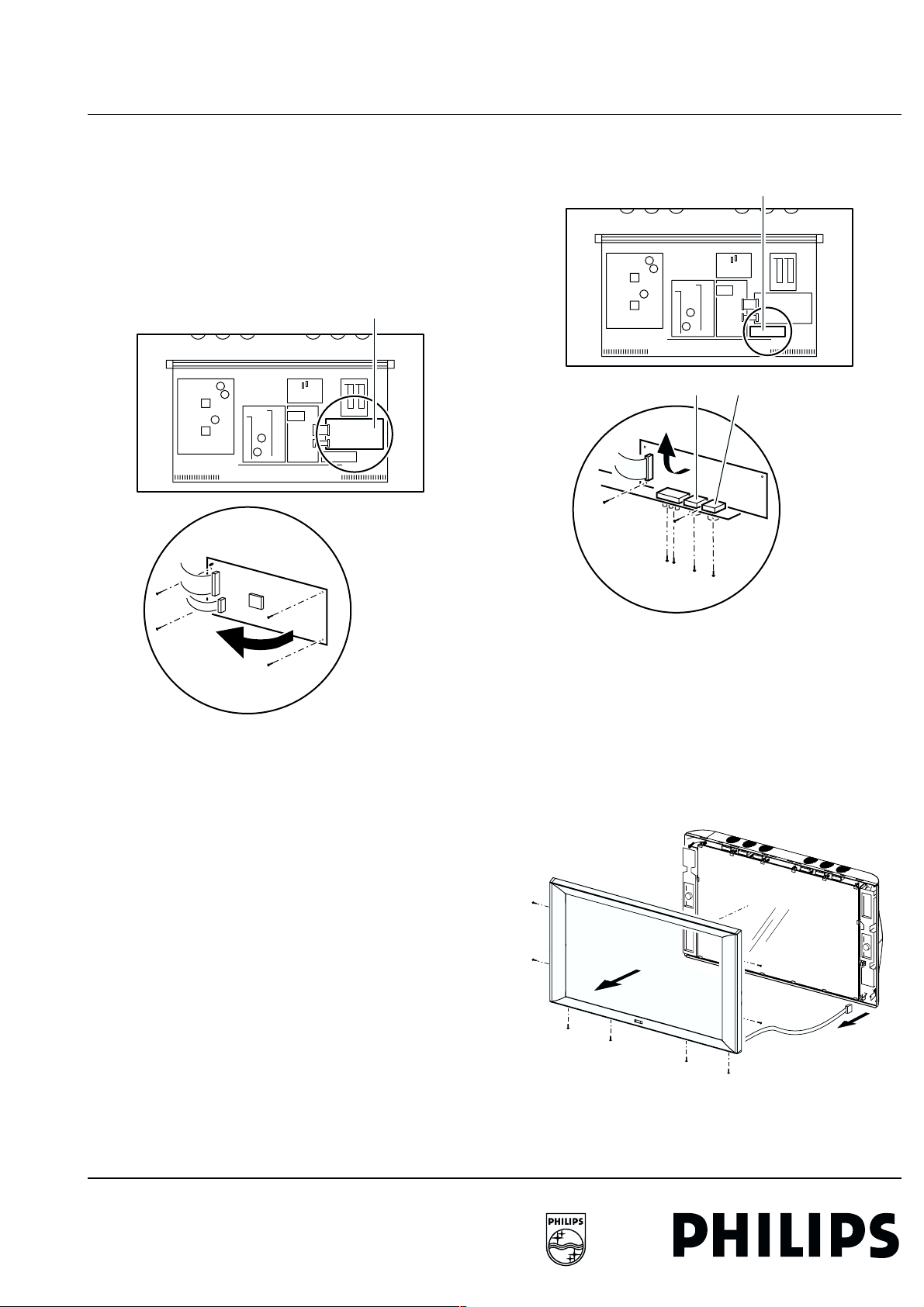

PRECONDITIONER panel.

Pre-conditioner

4

3

1

2

2

1

Figure 2-5

5

5

5

4

CL 96532069_135.EPS

120899

1. Disconnect the 2 grounding wires from the shielding plate

by pressing the small lever on the connector while pulling

[1].

2. Remove the 2 ferrite ring cores from their fixations [2].

3. Remove the 5 fixation screws of the panel [3].

4. Place panel on the 2 hinges, which are located, near the left

corners of the panel [4].

5. Reconnect grounding wires to the extra connectors on the

shielding plate at the left side [5].

6. The copperside becomes accessible now from the right

side.

AUDIO VIDEO CONTROL panel.

AV Control

Figure 2-6

CL 96532069_136.EPS

120899

FTV1.9DE Display Box 2. Mechanical instructions 7

YUV/YC Input

2

1

3

CL 96532069_138.EPS

120899

SVHS BNC

2

CL 96532069_139.EPS

120899

1

2

2

2.1 Introduction:

This panel has no service position for accessing the A-side,

however all service test points are accessible at the B-side (see

Service Manual).

In case some components must be (de)soldered, all fixation

screws (6 for the panel, 5 at the metal connector plate) and all

cables must be removed to access the A-side.

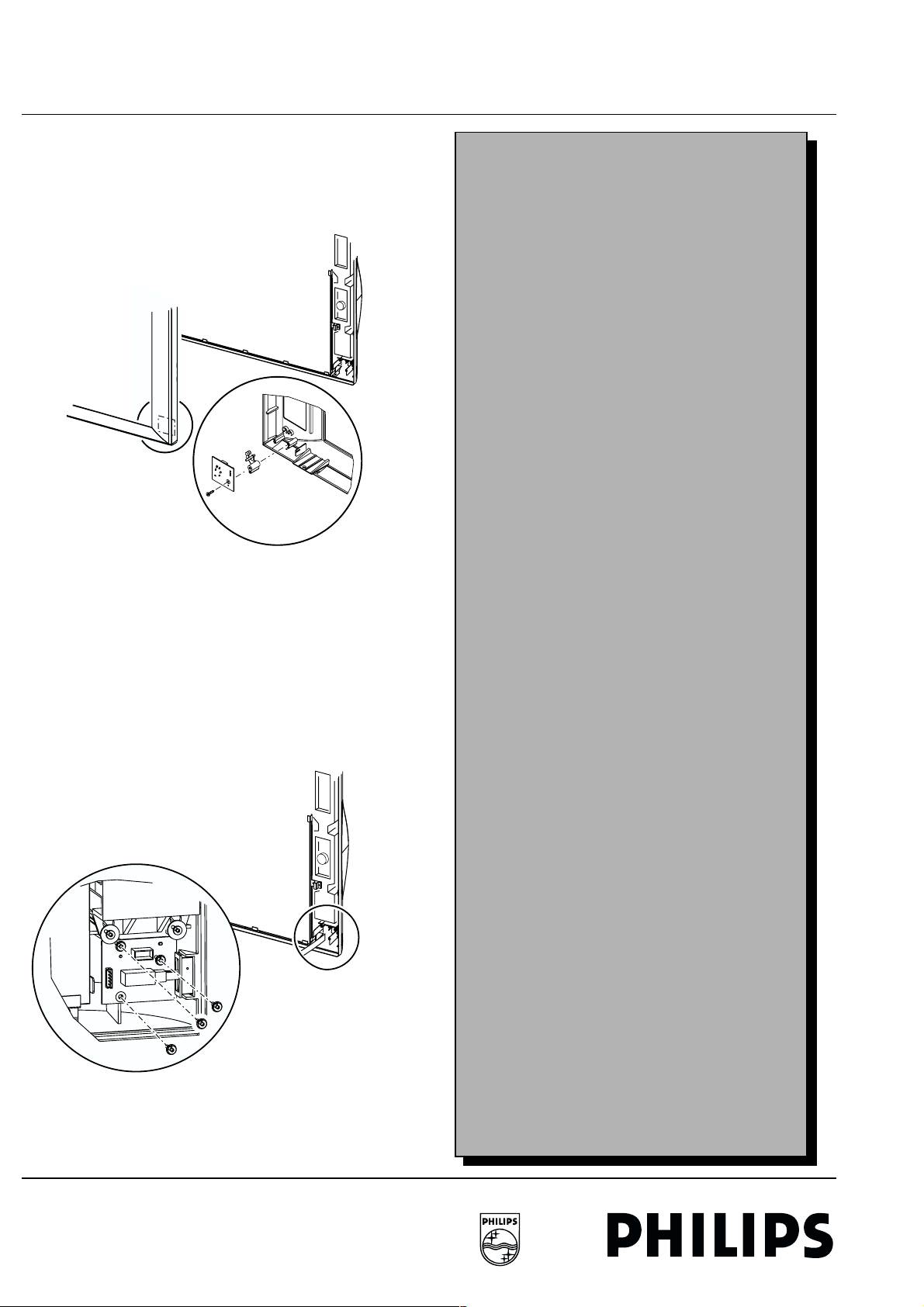

PDP LIMESCO panel.

PDP Limesco

YUV/YC INPUT panel.

1

1

1

2

1

CL 96532069_137.EPS

Figure 2-7

All SMC's are located on the B-side, so all testpoints are

accessible. In case some components must be (de)soldered,

the hinge construction can be used to access the A-side.

1. Remove the 4 fixation screws of the panel [1].

2. Panel can now be hinged to access soldering side [2].

120899

Figure 2-8

This panel has no pre-defined service position. For access of

the A-side, the panel has to be removed:

1. Remove the 4 screws at the metal connector plate [1].

2. Remove the 2 fixation screws of the panel [2].

3. Panel can be removed now to access the A-side [3].

LED DISPLAY panel.

Figure 2-9

8 2. Mechanical instructions FTV1.9DE Display Box

2.1 Introduction:

1. Remove 2 x 2 screws at the sides and 4 screws at the

bottom of the front cover [1].

2. Remove the front cover (it hinges at the top). During

removal unplug the cable of the LED DISPLAY panel at the

SWITCH DISPLAY panel (connector SD11) [2].

3

Personal notes

CL 96532069_140.EPS

Figure 2-10

120899

1. The LED DISPLAY panel can be removed now by

unscrewing 1 fixation screw [3].

SWITCH DISPLAY panel.

1. Remove front cover (for a description see Chapter 2.1.8

'LED DISPLAY panel').

3

CL 96532069_141.EPS

Figure 2-11

120899

1. The SWITCH DISPLAY panel can be removed now by

unscrewing 3 fixation screws [3].

FTV1.9DE Display Box 2. Mechanical instructions 9

CL 96532069_143.EPS

120899

3

3

3

3

4

4

2.2 Exchanging parts

2.2 Exchanging p arts

Some parts of the FTV1.9 Display Box must be exchanged if

defective:

1. GLASS PLATE.

2. LOUDSPEAKER.

3. PLASMA DISPLAY PANEL [PDP].

Exchanging of the GLASS PLATE.

1. First unplug (remove Mains and VGA cable) the Display

Box .

2. Remove front cover (for a description see Chapter 2.1.8

'LED DISPLAY panel').

2

5

34

CL 96532069_142.EPS

Figure 2-12

120899

1. Now the GLASS PLATE can be removed by unscrewing all

screws [3] and removing all glass clips [4].

Exchanging of a LOUDSPEAKER.

1. First unplug (remove Mains and VGA cable) the Display

Box.

2. Remove front cover (for a description see Chapter 2.1.8

'LED DISPLAY panel').

Figure 2-13

1. The LOUDSPEAKER can now be removed by

disconnecting its cable and removing the 4 fixation screws

at the top and bottom of the speakerbox. Be sure to remove

the correct screws, otherwise the speaker system will be

damaged (it is an airtight system).

Exchanging of the PDP.

1. First unplug (remove Mains and VGA cable) the Display

Box.

2. Place the rear side of the Display Box on a foam cushion (be

sure the metal rear cover is mounted in order to prevent

damaging of the electronic panels).

3. Remove front cover (for a description see Chapter 2.1.8

LED DISPLAY panel).

4. Now the GLASS PLATE can be removed by unscrewing all

screws and removing all glass clips (for a description see

Chapter 2.2.1. 'Exchanging of the GLASS PLATE').

Figure 2-14

6

CL 96532069_144.EPS

120899

10 2. Mechanical instructions FTV1.9DE Display Box

2.2 Exchanging parts

1. Remove all copper EMC SHIELDING springs mounted

around the display [6].

2. Now flip the complete Display Box and place it with the

Plasma Display down on a foam cushion. Be 100 % sure a

large foam cushion is placed underneath the PDP, as it will

drop about 10 mm after removing its fixation screws ! !

3. Disassemble metal rear cover (for a description see

Chapter 1.1 'Introduction').

PDP Discharge

PDP Limesco

FOAM CUSHION

1

FD173 FD171

Personal notes

4

CL 96532069_145.EPS

3

CN24

2

5

3

CN23

Figure 2-15

1. Disconnect the following cables:

– Cables coming from connectors CN23 and CN24 of the

PDP DISPLAY panel [3] (for easiest access lift the PDP

DISCHARGE panel from its fixations [2]).

– Flat cable on connector PD3 of the PDP LIMESCO

panel [4]. Also remove the ferrite 'flat cable shield'

completely by unlocking its fixations [5].

1

2

2

1

1

3

2

2

1

PD3

120899

CL 96532069_146.EPS

120899

Figure 2-16

1. Now remove the 8 large screws which hold the PDP:

– 4 screws are located at the top: they also hold the

aluminium wall mount [1].

– The other 4 are located at the bottom: the 2 outer screws

are hidden behind panels. Therefor unscrew the VS/VA

SUPPLY and the PDP-LIMESCO panel (grey panels)

[2].

2. Lift encasing from PDP and replace PDP [3].

FTV1.9DE Display Box 3. Block diagram 11

3. Block diagram

For the block diagram see Service Manual chapter 6.

The power is supplied by the VsVa supply (which is an LLC

converter). The Pre-conditioner delivers the input voltage of

380 V.

The output voltages of the VsVa supply are:

• Va: 55 V + 5 * Vra (Vra varies between 0 and 2 V).

• Vs: 165 V + 10 * Vrs (Vrs varies between 0 and 2 V).

• +5 V, 8.6 V and the +/- V_audio.

The controls located on the µP panel, which is a panel on the

AV Control panel, are activated by the keyboard on the Front I/

O and RC5 signals from the remote control receiver on the LED

panel.

Audio signals coming from the YUV Y/C panel or from the AV

Control are selected and processed at IC7940 (TDA9860). The

outcoming L/R signals are filtered (HPF) and corrected for low

frequency by the DBE-circuit, before they are fed to the Audio

amplifier.

CVBS signals (BNC connector or CINCH) at the YUV Y/C panel

are first passed through a comb-filter IC7012. The output

signals (Y and C) of IC7012 and the Y/C signal from the SVHS

connector are selected by IC7010. The output Y/C are fed to

YUV/RGB matrix IC7013 (TDA8854).

The YUV signals (CINCH) are processed separately in a RGB

matrix and transferred to IC7013. The selected RGB_YC output

signals from IC7013 are fed to the AV Control panel.

RGB signals coming from the Receiver Box or PC, the normal

RGB_VGA or separate RGB_YC signals are selected by the

source select switch (IC7360). The output signals are fed to the

video control IC7300. The RGB output signals from IC7300 are

buffered and transferred to the PDP LIMESCO panel. Here the

signals are prepared and processed (gamma correction;

filtered; digitised by an ADC), buffered and fed to the display.

OSD-signals are added on the display via the PDP LIMESCO

IC.

RGB_VGA input signal are buffered and passed through to the

VGA-out connector.

Personal notes

12 4. Service modes FTV1.9DE Display Box

2.2 Exchanging parts

4. Service modes

For the FTV1.9, the Monitor can be used in two applications.

• A stand-alone configuration, a separate device which can

also be sold and serviced separately.

• TV configuration, where the monitor is combined with the Ebox.

The monitor, as a stand-alone unit, can be serviced by using a

test pattern coming from the PDP-LIMESCO panel on the rear

of the monitor itself or via a PC/laptop by using ComPair via the

ComPair connector.

In this chapter the following paragraphs are included:

1. Test points

2. Dealer Service Tool (DST)

3. Service Modes

4. Error code buffer and error codes

5. The "blinking LED" procedure

6. Fault-finding tips

7. ComPair

Personal notes

FTV1.9DE Display Box 4. Service modes 13

4.1 Test points

4.1 Test poi nts

The FTV1.9 chassis is equipped with test points in the service

printing. These test points are referring to the functional blocks:

• A1-A2-A3, etc.: Test points for the Audio amplifier (A)

• C1-C2-C3, etc.: Test points for the AV control circuit (AVC)

• FD1-FD2-FD3, etc.: Test points for the VsVa supply (FD1FD2) and the PDP discharge panel

• L1-L2-L3, etc.: Test points for the PDP LIMESCO (PD1PD9)

• PR1-PR2-PR3, etc.: Test points for the Pre-conditioner

(PR1-PR3)

• Y1-Y2-Y3, etc: Test points for the Y/C YUV monitor panel

(UY1-YC4)

Measurements are performed under the following conditions:

Video: colour bar signal; Audio: 3 kHz left, 1 kHz right

Personal notes

14 4. Service modes FTV1.9DE Display Box

4.2 Dealer Service Tool (DST)

4.2 Dealer Service Tool (DST)

For easy installation and diagnosis the dealer service tool

(DST) RC7150 can be used. When there is no picture (to

access the error code buffer via the OSD), DST can enable the

functionality of displaying the contents of the entire error code

buffer via the blinking LED procedure, see also paragraph 5.5.

The ordering number of the DST (RC7150) is 4822 218 21232.

Installation features for the dealer

The dealer can use the RC7150 for programming the TV-set

with pre-sets. 10 Different program tables can be programmed

into the DST via a GFL TV-set (downloading from the GFL to

the DST; see GFL service manuals) or by the DST-I (DST

interface; ordering code 4822 218 21277). For explanation of

the installation features of the DST, the directions for use of the

DST are recommended (For the FTV1.9 chassis, download

code 4 should be used).

Diagnose features for service

FTV1.9 sets can be put in two service modes via the RC7150.

These are the Service Default Mode (SDM) and the Service

Alignment Mode (SAM).

Personal notes

FTV1.9DE Display Box 4. Service modes 15

4.3 Service Modes

4.3 Service Modes

Below described sequence is only valid for the "Monitor Only

Configuration". When a Receiver box is connected to the

Display Box (TV Configuration), please check chapter 4 in the

Training Manual of the Receiver Box.

Service Default Mode (SDM)

The purpose of the SDM is:

• Provide a situation with predefined settings to get the same

measurements as in this manual.

• Access to the error buffer via the blinking LED procedure.

• Inspect the error buffer.

• Possibility to overrule software protections via the service

pins (caution: override of software protections! ).

Entering the SDM:

• By transmitting the "DEFAULT" command with the RC7150

Dealer Service Tool (this works both while the set is in

normal operation mode or in the SAM).

• By pressing on a standard RC the following sequence 0, 6,

2, 5, 9, 6 followed by the "MENU" key.

• By short-circuiting the SDM pin on the µP panel.

In the SDM the following information is displayed on the screen:

--------------------------------------------------------------

F19DBC X.Y_12345 (1) LLLL (2) SDM (3)

ERR 02 01 14 ## ## ## ## ## ## ##

--------------------------------------------------------------

Explanation notes/references:

(1) Software identification of the main micro controller (F19DBC

X.Y_12345)

• F19D is the chassis name for FTV1.9 display

• B is the region identification

• C is the language cluster

• X = (main version number)

• Y = (subversion number)

• ##### are 5 digits of the Serial number

(2) "LLLL" Normal display operation in hours

(3) "SDM" To indicate that the TV set is in the service default

mode

(4) "ERR 02 01 14 ## ## ## ## ## ## ##" This line shows the

contents of the error buffer (max. 10 errors). The last error that

occurred is displayed at the most left position. When less then

10 errors have occurred the rest of the line is empty. When the

errorlist is empty " No errors" is displayed. No duplicate errors.

Exit the SDM:

Push the "Standby" button on the Remote Control.

The SDM sets the following pre-defined conditions:

• Volume level is set to 25% (of the maximum volume level).

• Linear Audio and Video settings are set to 50%.

• Colour temperature is set to normal.

The following functions are "overruled" in SDM since they

interfere with diagnosing/repairing a set

• Video blanking.

• Slow demute.

• Anti-ageing.

• Automatic switch to "Standby" when H- and/or V-sync

signals are lost.

All other controls operate normally.

Service Alignment Mode (SAM)

The purpose of the SAM is to align and or adjust settings.

For recognition of the SAM, "SAM" is displayed at the top of the

right side of the screen

Entering the SAM-menu:

• By pressing the "ALIGN" button on the RC7150 Dealer

Service Tool

• Standard RC sequence 062596 followed by the "OSD"

button.

• By short-circuiting the SAM pin on the µP panel (Caution:

override of software protections ! ! )

In the SAM the following information is displayed on the screen:

--------------------------------------------------

F19DBC X.Y_12345 SAM

ERROR## ## ## ## ##

WHITE POINT

PDP TEST PATTERN [ON/OFF]

STORE

RESET ERROR BUFFER

--------------------------------------------------

The menus and submenus

White point

The white point sub menu contains the following items:

•RED

• GREEN

•BLUE

• COLOUR TEMPERATURE

PDP Test pattern

By selecting this item, all OSD disappears from the screen. The

screen now changes from light grey to dark grey in a slow

regular rhythm. One can so easily check if all pixels of the

monitor are correct.

Store

The change values are stored in the NVM.

Reset Error Buffer

This option will reset the error buffer.

Exit the SAM:

Push the "Standby" button on the Remote Control.

SAM menu control:

Menu items can be selected with the "UP" or "DOWN" key.

Entry into the selected items (sub menus) is done by the "LEFT"

or "RIGHT" key. The selected item will be highlighted.

With the same "LEFT/RIGHT" keys, it is possible to increase/

decrease the value of the selected item.

Return to the former screen by pushing the "MENU" button. The

item values are stored in NVM if the sub menu is left.

16 4. Service modes FTV1.9DE Display Box

4.3 Service Modes

Customer Service Mode (CSM) Display

FTV1.9 monitors are equipped with the "Customer Service

Mode" (CSM). CSM is a special service mode that can be

activated and de-activated by the customer, upon request of

the service technician/dealer during a telephone conversation

in order to identify the status of the set. This CSM is a 'read only'

mode, therefore modifications in this mode are not possible.

Entering the Customer Service Mode.

• By pressing on RC03333/01 the following sequence :

Picture, sound, cursor up, cursor down, cursor left, cursor

right followed by the button (MUTE)

Exit the Customer Service Mode.

• pressing the "MENU" or any key on the Remote Control

handset (except "P+" or "P-")

• switching off the TV set with the mains switch.

All settings that were changed at activation of CSM are set back

to the initial values

The Customer Service Mode information screen

Personal notes

The following information is displayed on screen:

--------------------------------------------------

CUSTOMER SERVICE MENU

• Software version F19DBC X.Y_#####)

• Code 1: contains the last 5 error codes

• Code 2: contains the first 5 error codes with the last

received error at the most left-hand side.

• Service unfriendly modes

--------------------------------------------------

FTV1.9DE Display Box 4. Service modes 17

4.4 Error code buffer and error-codes

4.4 Error code buffer and error-codes

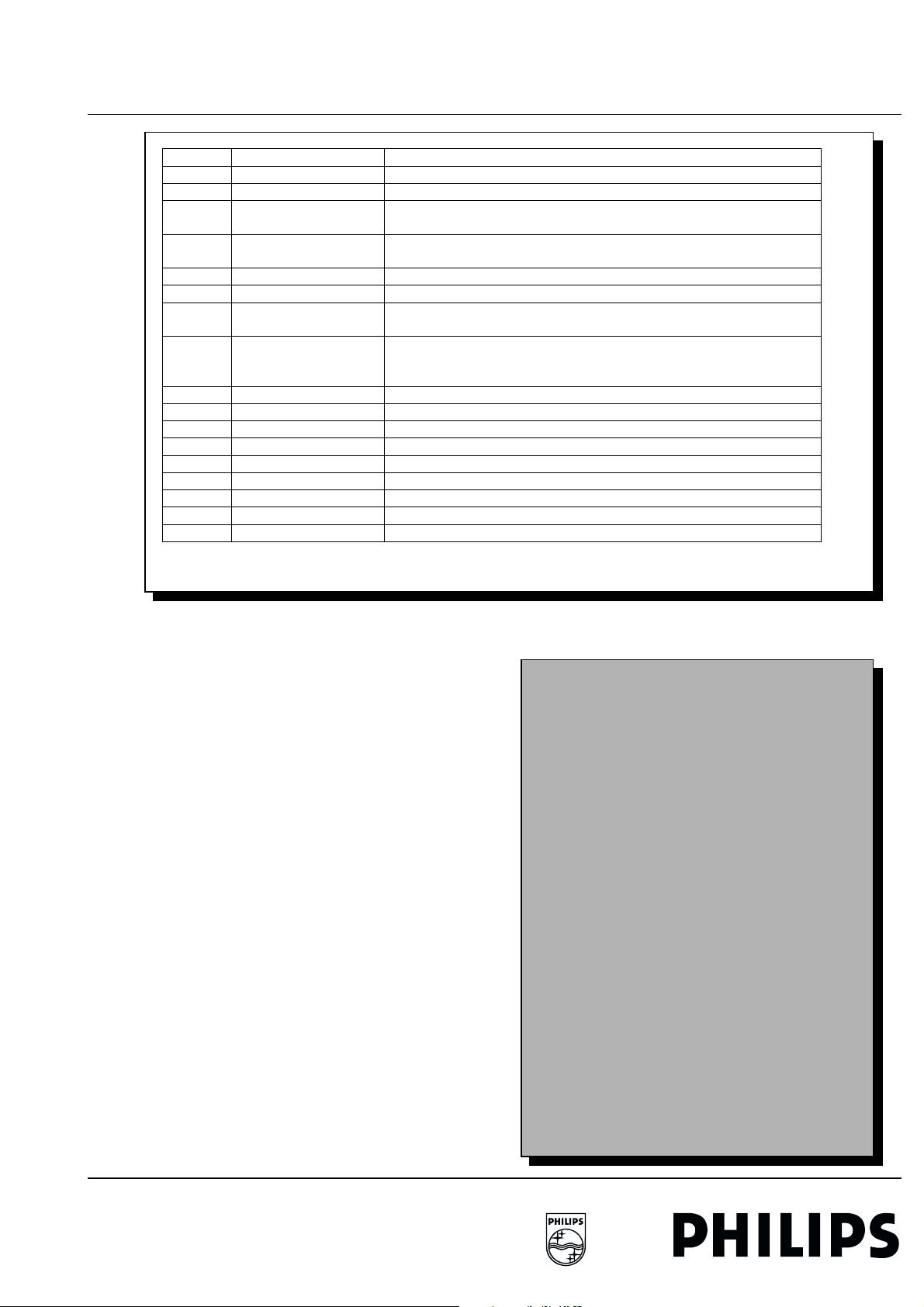

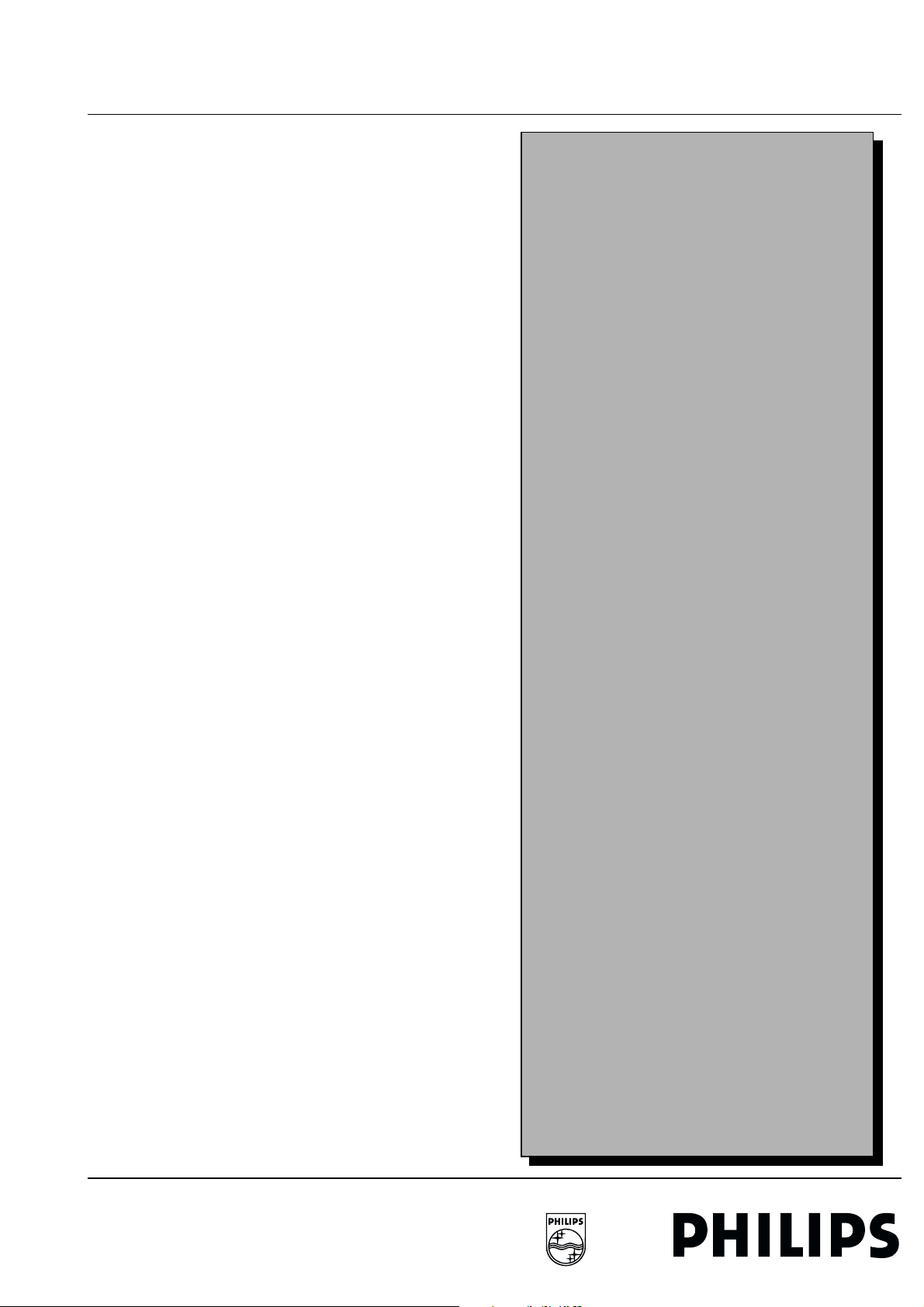

Error-nr Type of Error Possible defect/cause

1 +5V

2 8V6

3 Fan_prot Gives an indication that 1 or more FAN(s) does not function, or that 1 or

4 Over-temp_prot Temperature at the heatsink of the VsVa supply or the Preconditioner is

5 DC_prot Audio-amplifier IC, its supply or the Audio amplifier is defect

6 Over_voltage_prot Vs or Va supply voltage is too high

7 Vrr Powersupply of the display is not correct. Ignorance of the signal during

8 Power_OKE Power supply or modules that uses this voltage. If this signal is NOT

9 Blocked NVM IIC bus NVM IIC bus is not correct

10 Blocked slow IIC bus Slow IIC bus is not correct

11 TDA9860 No acknowledge of Audio controller

12 TDA4885 No acknowledge of Video controller

13 MC141585 No acknowledge of OSD Generator

14 uPD93687GD-LBD No acknowledge of Limesco

15 PCF8574AT No acknowledge of I/O Expander

16 NVM No acknowledge of NVM

17 Communication Fault in the communication

Figure 1 : Error-code list of the D-box

+5V pin at uP is low.

8V6 pin at uP is low

more fan control circuits is defect

too high

startup by the software.

activated means that all supply voltages are available (exception Audio

supply )

ch5-table1-mon.eps

041099

The error code buffer contains all errors detected since the last

time the buffer was erased. The buffer is written from left to

right.

In case of non-intermittent faults, clear the error buffer before

starting the repair to prevent that "old" error codes are present.

If possible check the entire content of the error buffers. In some

situations an error code is only the RESULT of another error

code (and not the actual cause).

Note: a fault in the protection detection circuitry can also lead to

a protection

The error code buffer will be cleared in the following cases:

• exiting SDM or SAM with the "Standby" command on the

remote control

• transmitting the commands "DIAGNOSE-9-9-OK" with the

DST.

The error buffer is not reset by leaving SDM or SAM with the

mains switch.

Examples:

ERROR: 0 0 0 0 0 : No errors detected

ERROR: 6 0 0 0 0 : Error code 6 is the last and only detected

error

ERROR: 5 6 0 0 0 : Error code 6 was first detected and error

code 5 is the last detected (newest) error

Personal notes

18 4. Service modes FTV1.9DE Display Box

4.5 The "blinking LED" procedure

4.5 The "blink ing LED" procedu re

The contents of the error buffer can also be made visible

through the "blinking LED" procedure. This is especially useful

when there is no picture.

There are two methods:

• When the SDM is entered, the LED will blink the contents of

the error-buffer. Error-codes = 10 are shown as followed. A

long blink of 1second which is an indication of the decimal

digit, followed by a pause, followed by n short blinks. When

all the error-codes are displayed, the sequence is finished

with a led display of about 3 seconds. The sequence starts

again.

• With the DST all error codes in the error buffer can be made

visible. Transmit the command: "DIAGNOSE x OK" where x

is the position in the error buffer to be made visible x ranges

from 1, (the last (actual) error) to 10 (the first error). The

LED will operate in the same way as in the previous point,

but now for the error code on position x.

Example:

Error code position 1 2 3 4 5

Error buffer: 12 9 5 0 0

• after entering SDM: 1 long blink of 1 sec. + 2 short blinks pause - 9 short blinks - pause - 5 short blinks - pause long blink of 3 sec. --etc.

• after transmitting "DIAGNOSE- 1- OK" with the DST: 1 long

blink 2 short blinks - pause - 1 long blink + 2 short blinks etc.

• after transmitting "DIAGNOSE- 2- OK" with the DST: blink

(9x) - pause - blink (9x) - etc.

• after transmitting "DIAGNOSE- 3- OK" with the DST: blink

(5x) - pause - blink (5x) - etc.

• after transmitting "DIAGNOSE- 4- OK" with the DST:

nothing happens

Personal notes

FTV1.9DE Display Box 4. Service modes 19

4.6 Protections

4.6 Protections

All protections are handled by the hardware. The SW will only

monitor the hardware to generate error codes for the service.

The hardware switches to protection when one of the following

protections becomes active: FAN_PROT,

OVER_TEMP_PROT, DC_PROT, OVER_VOLTAGE_PROT

and Vrr.

When 1 of these protections occur, the HW will switch the set

to STANDBY.

The error must be read out by the microprocessor and the error

code must be generated. The microprocessor keeps the set in

STANDBY and starts the blinking red led. It is not allowed to

start up as long as the protections are present.

For the error code generation, the following levels of the A/D

converter are defined:

Input voltage at A/D converter [V]: Sort protection:

< 0.300 V No protection

0.3 < V < 1.875 FAN_PROT

1.875 < V < 2.813 OVER_VOLTAGE_PROT

2.813 < V < 3.75 OVER_TEMP_PROT

3.75 < V < 4.688 DC_PROT

Personal notes

20 4. Service modes FTV1.9DE Display Box

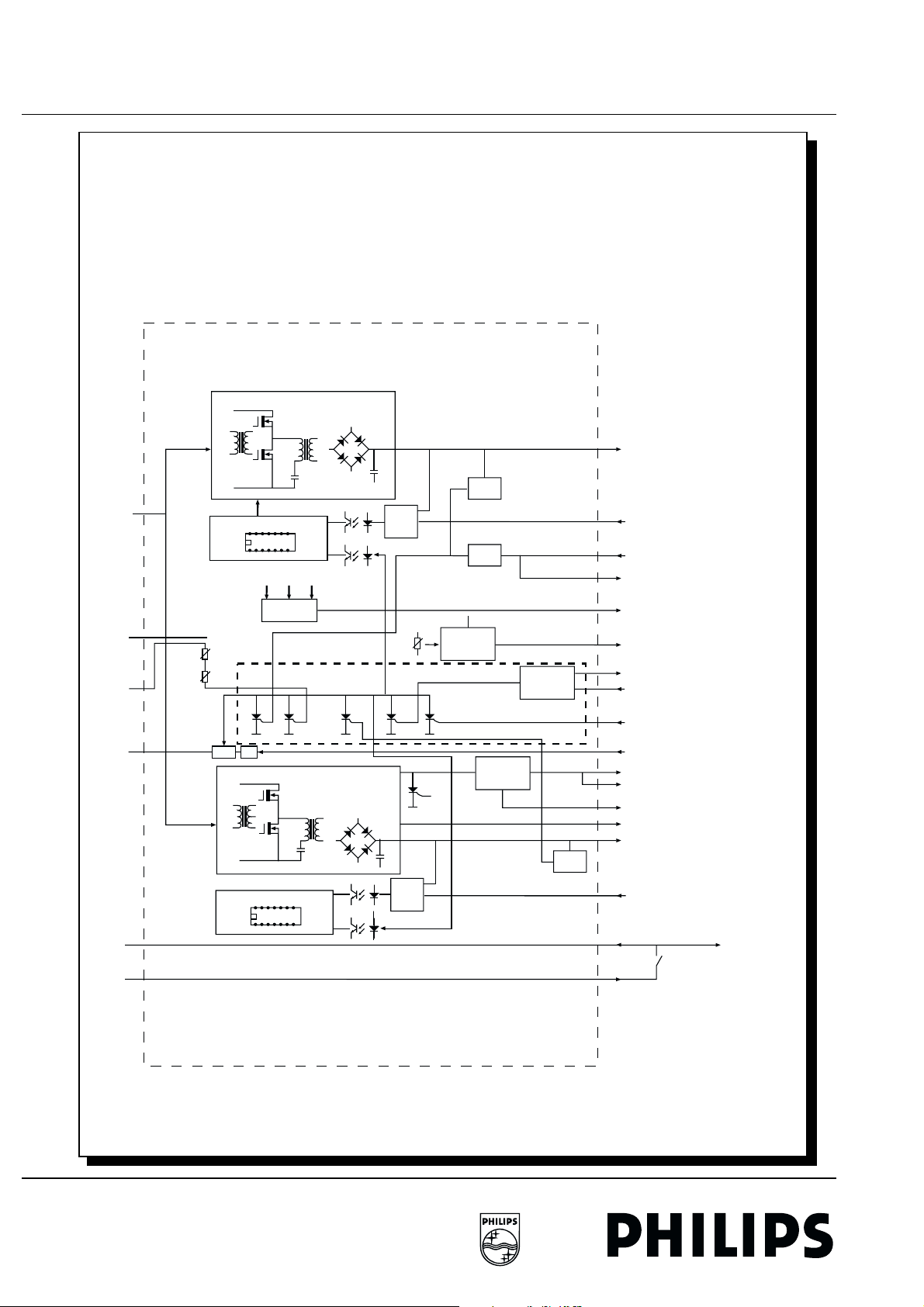

DISPLAY SUPPLY MODULE

LLC Converter

Vs

OVP

380 V

DC

LLC Control

Error

Amp.

SENSE

Vrs

TEMP

Voc

ok

Vs Va

POWER OK

ptc

ptc

Vs OVP

AND -1

Protection

Circuit

Va OVP

LLC Converter

LLC Control

ptc

Fan

Protect

Error

Amp.

5V OVP

Delay

17V

FAN

PROTECTION

17V

DC_DC

Converter

OVP

SENSE

Vrr

Vrr to µP

POWER OK

Fans (1-5)Speed Control

FAN PROT

PROT-FAN (1-5)

DC PROT (Audio)

STBY

+5V

Vcc

+8V6

+/- V Audio

Va

Vra

5VSTBY-SWITCHED

On/Off

Switch

5VSTBY

TO µP

CL 96532069_112.eps

240899

FTV1.9DE Display Box 4. Service modes 21

4.6 Protections

POWER_OKE

For ease of start-up and fault diagnosis a POWER_OKE signal

is generated. The signal is high when the voltages that are

sensed are in the right level. This signal is mixed with signals

derived from Vs and the Va. The POWER_OKE signal will be

high when simultaneously:

5V = 5V

17V >12.8V

Vs >135V

Va > 45V

In all other cases the output is low.

Personal notes

22 4. Service modes FTV1.9DE Display Box

4.6 Protections

5VSTBY-SWITCHED

VCC

VDD

+5V

7301

CONNECTOR

D09

TEMP

45

3331

3332

3333

7371

7302

8

3

7330-A

2

4

7370

CONNECTOR

FD06-12

5VSTBY-SWITCHED

17V

7331

PROTECTION-STATUS

7332

SUPPLY-ON

[PR3]

7337

2134

3339

3379 3378

5VSTBY-SWITCHED

VA

3136

3135

3133

7113

7112

3137

3134

3138

3386

3323

3380

5VSTBY-SWITCHED

5VSTBY-SWITCHED

7339

3384

7341

3385

7114

3394

21352132

7314

PROTS

7333

7321

DC

6371

3039

7003 7103

7340

7338

VS

5VSTBY-SWITCHED

3033

3058

3034

2037

FD1

[C-14]

AA

7315

3011

7001-PIN10

2038

PROT-FAN 1-6

17V

3139

7103

3111

7101-PIN10

3035

7012

7013

3038

7316-7321

CL 96532058_086.eps

3036

7016

3037

2032

280999

Protection structure

The protection structure of the FTV1.9 D-box is shown at figure

above.

The FTV1.9 monitor has one microprocessor, which is situated

on the AV-control panel and is supplied by the 5V standbysupply. The microprocessor is even active when the set is

switched to standby. The microprocessor controls the "supplyon" line which switches first relay 5680 and then relay 5690.

In de standby-mode or the protection-mode the "supply-on" line

is "low" and both both relays are switched off. The

preconditioner is disconnected from the mains.

The potections of the FTV1.9 monitor can be divided into 5

subgroups:

– Fan_prot

– Over_temp_prot

– DC_prot

– Over_voltage_prot

–Vrr

For the Fan-, Over_temp, DC and the Over_voltage protections

the signals for the µP are latching, using the 5Vstby_switched

for powering the circuits permanently. The µP has sufficient

time for diagnosis and for storing the error-codes in the NVM.

Vrr, which is an indication of the powersupply of the display is

correct, is directly fed to the µP.

Personal notes

FTV1.9DE Display Box 4. Service modes 23

4.6 Protections

Signal line "PROTECTION STATUS" and errorcodes

When one of the protection mechanism is triggered, the

5Vstby-switched is connected via a saturated transistor and a

pre-defined resistor to signal line "protection status", which is

connected to the µP.

Signal line "protection status" is connected to ground via

resistor R3378 and 3379. For each seperate fault condition

mechanism we get a pre-defined voltage at the

µΠ.

This results in the following table

Protectionmode

None ----- < 0.3V none

Fan_prot 1K

Vs or

Va_prot

Temp_prot 220

DC-prot 68

Vrr ------ ------ 7

Series

resistor

Ω

Ω

470

Ω

Ω

Voltage at "protectionstatus" line

0.30V < Vprot < 1.90V 3

1.90V < Vprot < 2.80V 4

2.80V < Vprot < 3.75V 5

3.75V < Vprot < 4.7V 6

Errorcode

Protection signal Vrr coming from the PDP, to indicate that the

powersupply is ok or not ok ( "1" or "0" ) is directly connected

to the µP. Error-code 7 is stored in the NVM and the set is

switched to standby.

When one of the protections is activated, the power supplies of

the Vs and Va are shut down and the set is switched to standby.

Fan protection

When this protection is activated, the Va- and Vs power supply

are shut down. The set is switched to the standby mode and

error-code 3 is stored in the NVM.

The fan voltage is powered by 17V, but clamped to 12V to

prevent damage. In order to be able to verify whether the fans

are running, a fault detection circuit is implemented for each of

the 6 fans. A running fan gives pulses in the same speed as the

rotation of the blades. The circuit uses these pulses to trigger

the discharge of an elcap. The elcap is continuously charged

through a resistor.

Example : Capacitor C2319 is charged through R3356 and at

every pulse discharged by T7322. When fan 6 is blocked,

C2314 is charged via D6326 en triggers thyristor 7315,

because C2319 is no longer discharged via T7322. The current

now flows from the 5Vstby-switched via resistor 3383 and 3325

driving transistor T7321 into saturation. The voltage "protection

status" is now determined by the voltage dividing of R3323 and

resistor R3378 and 3379. ( neglect the Vce of 0.2V of T7321. ).

Reset of the VsVa-supply.

Transistor T7339 is shorted now by the presence of the

"protection status" signal. T7339 connects resistor R3376 and

R3389 to ground, switching on T7338. Thyristor 7333 is now

triggered, shorting signal PROTS to ground. To follow the

signal flow, go to the right upper corner of schematic FD1.

Connecting PROTS to ground, will start a current flow through

opto-coupler diode 7103 and the opto-coupler transistor

connects supply voltage Vcc2 to the fault input ( pin 10 ) of IC

7101. When the voltage at pin 10 exceeds 1.0V, IC7101 stops

oscillating. The Va-supply stops functioning.

To continue the signal flow, go to the right upper corner of

schematic FD2. Connecting PROTS to ground also results in a

current flow through the opto-coupler diode of 7003. The optocoupler transistor connects supply voltage Vcc1 to the fault

input ( pin 10 ) of IC 7001. When the voltage at pin 10 exceeds

1.0V, IC7001 stops oscillating. The Vs-supply stops

functioning.

Vs and Va protection

Va protection

When this protection is activated, the Va- and Vs power supply

are shut down. The set is switched to the standby mode and

error-code 4 is stored in the NVM.

When the Va-supply exceeds the 68V, regulator 7112 is

triggered and will switch on T7113. Capacitor 2132 is charged

via the 5Vstby-switched and will trigger thyristor 7114, which

will switch on T7341. The voltage "protection status" is now

determined by the voltage dividing of R3386 and resistor

R3378 and 3379. ( neglect the Vce of 0.2V of T7341 ). See

schematic FD2.

The presence of the voltage at "protection status" line will

eventually reset the VsVa-supply. For more info see

subparagraph - Reset of the VsVa-supply.

Vs protection

When this protection is activated, the Vs power supply is shut

down. The set is switched to the standby mode and error-code

4 is stored in the NVM.

When the Vs supply exceeds the 198V, regulator 7012 is

triggered and will switch on T7016. Capacitor 2032 is charged

via the 5Vstby-switched and will trigger thyristor 7013. Thyristor

7013 is fired and connects signal Aa to ground. To follow the

signal flow, go to the right upper corner of schematic FD1.

When signal Aa is shorted to ground, T7341 is switched on. The

voltage "protection status" is now determined by the voltage

dividing of R3386 and resistor R3378 and 3379. ( neglect the

Vce of 0.2V of T7341 ). See schematic FD2.

The presence of the voltage at "protection status" line will

eventually reset the VsVa-supply. For more info see

subparagraph - Reset of the VsVa-supply.

Temperature Protection

When this protection is activated, the Va- and Vs power supply

are shut down. The set is switched to the standby mode and

error-code 5 is stored in the NVM.

When the temperture of the heatsink on the Preconditioner

panel or on one of the 2 heatsink on the VsVa panel exceeds

the 110°C, the PTC resistance increases drastically. The

voltage at pin 3 of IC7330 will drop and the output of 7330 will

do the same. The current flow through opto-coupler diode 7331

results also in a current flow through the opto-coupler transistor

and will trigger thyristor 7332. The fired thyristor switches

transistor 7337 on. The voltage "protection status" is now

24 4. Service modes FTV1.9DE Display Box

4.6 Protections

determined by the voltage dividing of R3339 and resistor

R3378 and 3379. ( neglect the Vce of 0.2V of T7337 ).

The presence of the voltage at "protection status" line will

eventually reset the VsVa-supply. For more info see

subparagraph - Reset of the VsVa-supply.

DC Protection - Audio Amplifier

When this protection is activated, the Va- and Vs power supply

are shut down. The set is switched to the standby mode and

error-code 6 is stored in the NVM.

In case of a fault in the Audio amplifier or when a DC voltage

appears on the speaker output, a signal called DCPROT is

generated. See schematic FD2 - F7. In case of a fault, thyristor

7314 is triggered and switches on T7340. The voltage

"protection status" is now determined by the voltage dividing of

R3380 and resistor R3378 and 3379. ( neglect the Vce of 0.2V

of T7340 ).

The presence of the voltage at "protection status" line will

eventually reset the VsVa-supply. For more info see

subparagraph - Reset of the VsVa-supply.

Vrr - PDP supplies

Personal notes

Vrr is a logical signal ( "high" in normal circumstances ) that

comes from the PDP. It's purpose is to trigger the switch off of

the Pre-conditioner supply in case Vrr becomes "low" , to trigger

the shutdown of the VsVa supply and to initialise that errorcode 7 is stored in the NVM.

When signal Vrr becomes "low", see FD1 - F13, the output of

IC7301-B becomes "high". This results in two actions.

It will trigger thyristor 7302 and short signal PROTS to ground.

This results eventually in a reset of the VsVa supply.

Switching on T7371, which again switches on T7370 via the

5Vstby-switched supply. Signal-line "supply-on" is now

grounded. This results in switching off relay 5680 and 5690,

disconnecting the mains from the pre-conditioner. The standby

supply( 5Vstby-switdhed ) is still functional.

FTV1.9DE Display Box 4. Service modes 25

4.7 Alignments

4.7 Alignment s

Electrical Alignments

Pre-conditioner +5Vstby (PR3)

Connect a voltmeter to capacitor C2510 (PR2). With the aid of

R3504 adjust the voltage to 5.2 V +/- 50 mV.

Va-supply (Addressing of the PDP - FD1)

De-activated the PDP.

Connect a voltmeter to capacitor C2120 (FD1). With the aid of

R3126 adjust the voltage to 55 V +/- 0.5 V.

Vs-supply (Sustain pulses - FD2)

De-activated the PDP.

Connect a voltmeter to capacitor C2020 (FD2). With the aid of

R3026 adjust the voltage to 165 V +/- 0.5 V.

Software Alignments

See chapter 4.3.2. "Service Alignment Mode (SAM)".

Personal notes

26 5. Preconditioner FTV1.9DE Display Box

5.1 Caution

5. Preconditioner5.1Caution

When repairing the Preconditioner supply the hidden mainsswitch must be used to disconnect the monitor from the mains.

The pre-conditioner and the VsVa supply remains under

tension if the mains-cable is still connected to the mains socket

and the mains switch is NOT pressed.

Personal notes

Loading...

Loading...