Philips FTL2.4A Schematic

Colour television Chassis

FTL2.4A

AA

E_14650_000.eps

160604

Contents Page Contents Page

1. Technical Specifications, Connections, And Chassis

Overview 2

2. Safety Instructions, Warnings, And Notes 5

3. Directions For Use 6

4. Mechanical Instructions 7

5. Service Modes, Error Codes, And Fault Finding 12

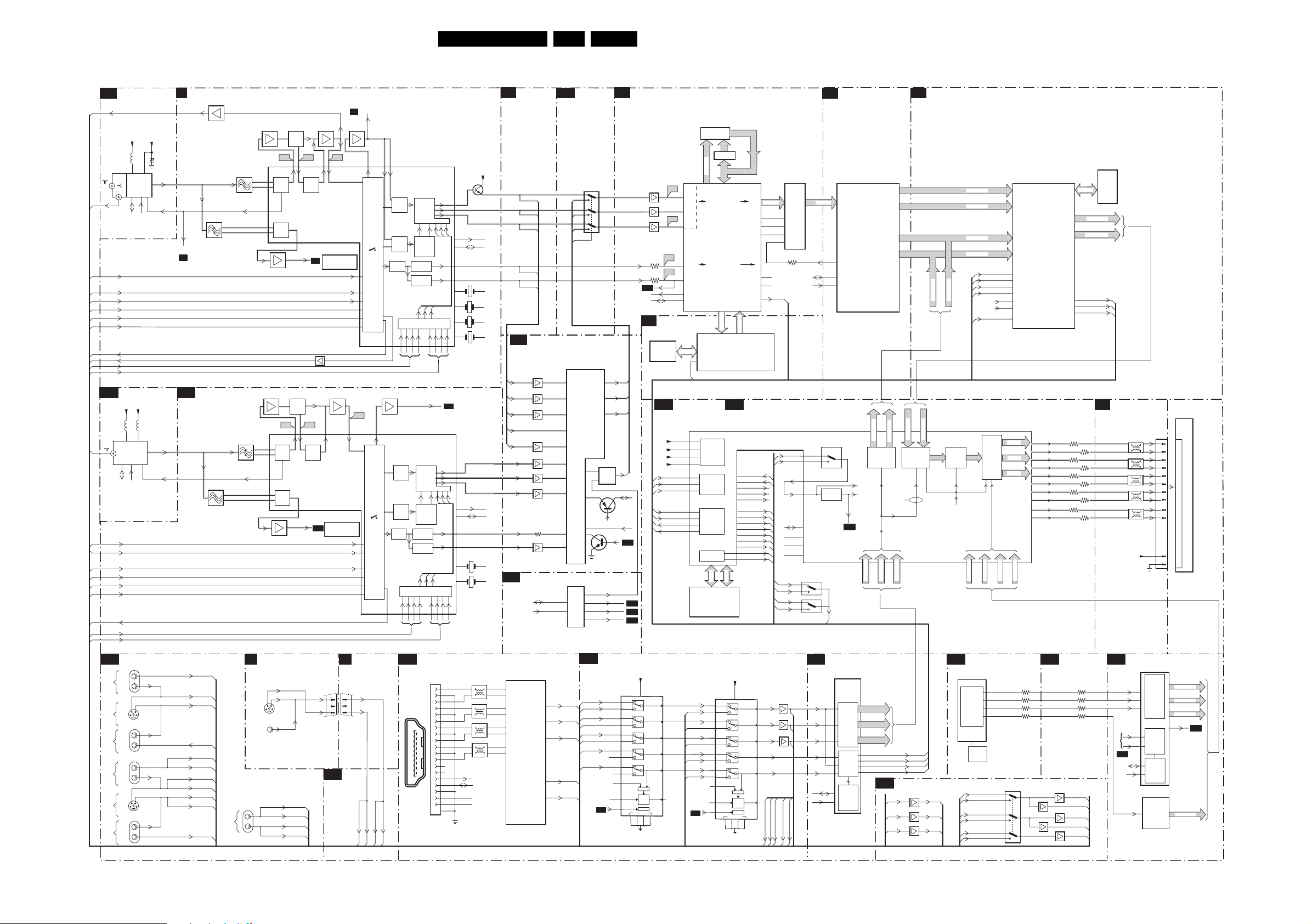

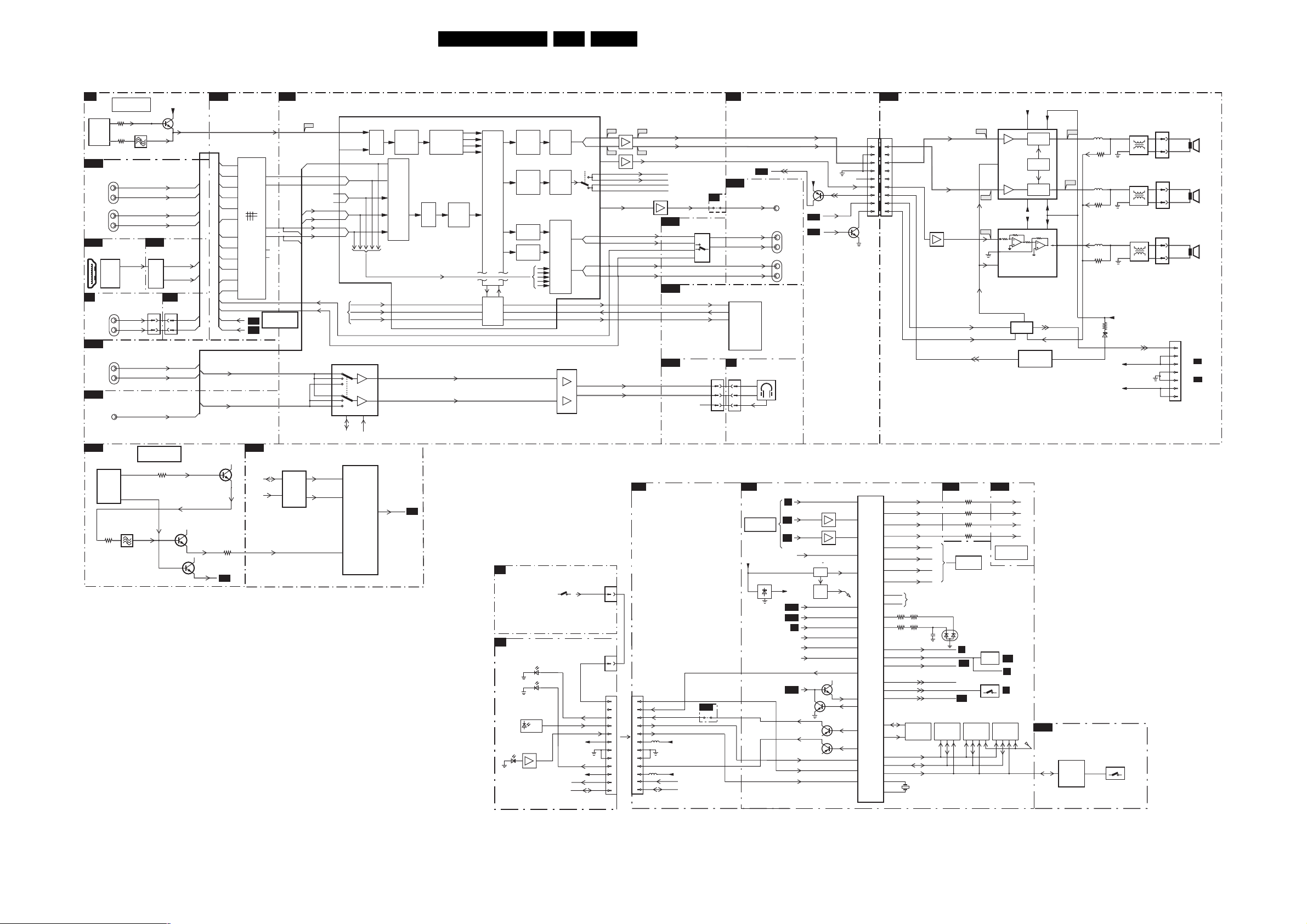

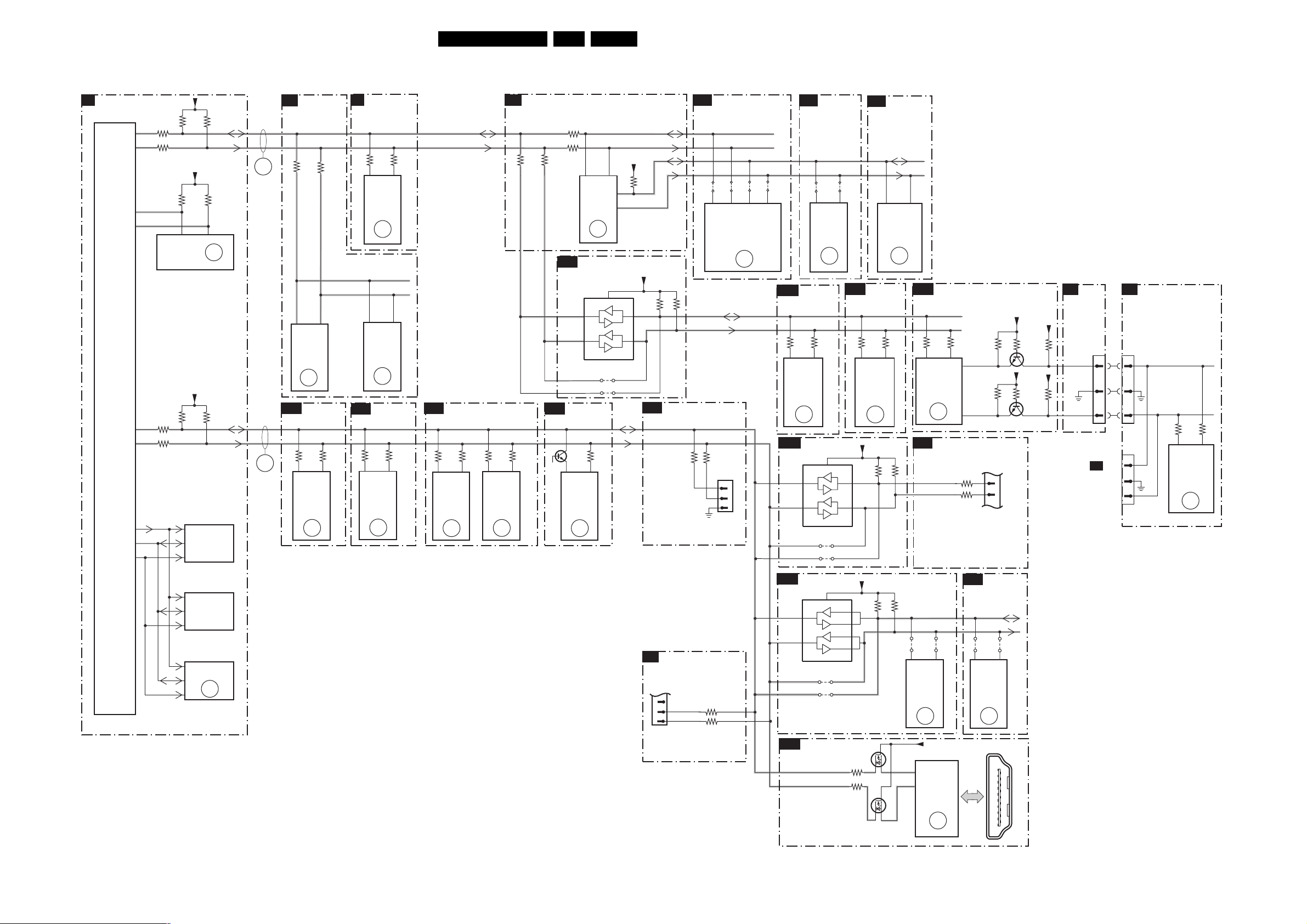

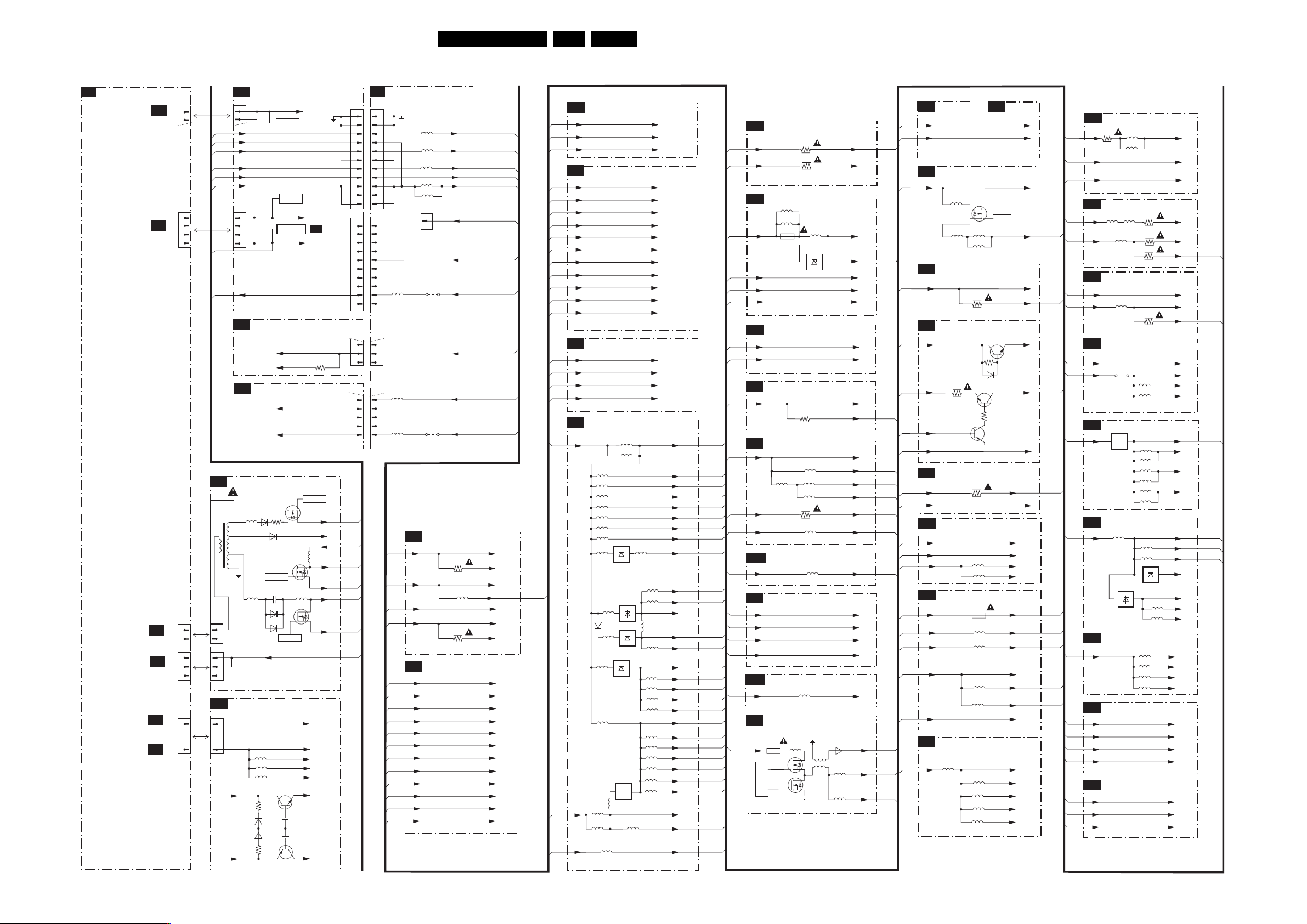

6. Block Diagrams, Testpoint Overviews, and

Waveforms

Wiring Diagram 23

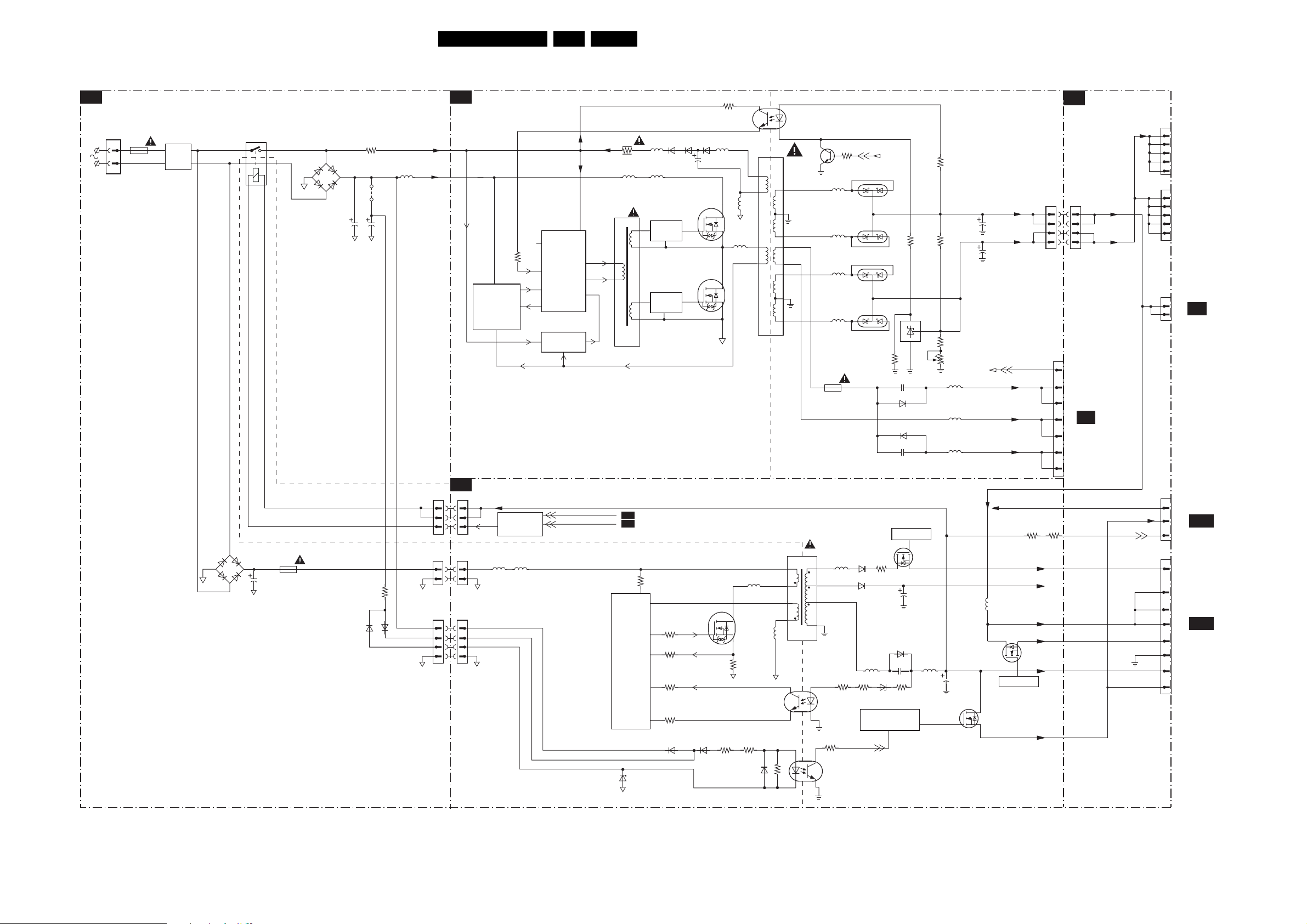

Block Diagram Supply 24

Block Diagram Video 25

Block Diagram Audio 26

I2C Overview 27

Supply Lines Overview 28

7. Circuit Diagrams and PWB Layouts Drawing PWB

LCD Supply Panel: Mains Filter + Standby (A1) 29 31-34

LCD Supply Panel: Supply (A2) 30 31-34

Ambi Light (One Panel) (AL) 35 36

Ambi Light (Two Panels) (AL) 37 38

SSB: IF, I/O Video Processing (B2) 39 73-84

SSB: PICNIC (B3A) 40 73-84

SSB: (FEM) Falconic Embedded Memory (B3B) 41 73-84

SSB: Eagle (B3C) 42 73-84

SSB: Columbus (B3D) 43 73-84

SSB: FBX Supply (B3E) 44 73-84

SSB: HOP (B4) 45 73-84

SSB: OTC-Flash (B5A) 46 73-84

SSB: Backlight Control (B5B) 47 73-84

SSB: OTC-Flash (B5C) 47 73-84

SSB: Audio Demodulator (B6A) 48 73-84

SSB: Dolby Digital Decoder (B6B) 49 73-84

SSB: Dolby Pro Logic Processor (B6C) 50 73-84

SSB: Audio Delay (B6D) 51 73-84

SSB: DC/DC Converter (B12) 52 73-84

©

Copyright 2005 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

SSB: Main Tuner (B13A) 53 73-84

SSB: Sub Tuner (B13B) 54 73-84

SSB: DC/DC Converter (B13C) 55 73-84

SSB: I/O 1 (B14A) 56 73-84

SSB: I/O 2 Connections (B14B) 57 73-84

SSB: I/O 3 Switch (B14C) 58 73-84

SSB: I/O 4 Audio (B14D) 59 73-84

SSB: I/O 5 (B14E) 60 73-84

SSB: I/O 6 Digital Input (B14F) 61 73-84

SSB: I/O 7 (B14G) 62 73-84

SSB: PIP HIP (B15A) 63 73-84

SSB: PIP Switch (B15B) 64 73-84

SSB: PIP Muppet (B15C) 65 73-84

SSB: HDI A/D Converter (B19A) 66 73-84

SSB: EPLD Control (B19B) 67 73-84

SSB: EPLD OSD (B19C) 68 73-84

SSB: EPLD I/O (B19D) 69 73-84

SSB: Backlight Control (B19E) 70 73-84

SSB: Screen Interface (B20) 71 73-84

SSB: Connection (B21) 72 73-84

Side I/O Panel (D) 85 86

Top Control Panel (E) 87 88

SCART 3 Panel (Only For EU) (H) 89 90

LED and Switch Panel (J) 91 92

LCD Standby & Audio Panel: Connections(SA1) 93 96-98

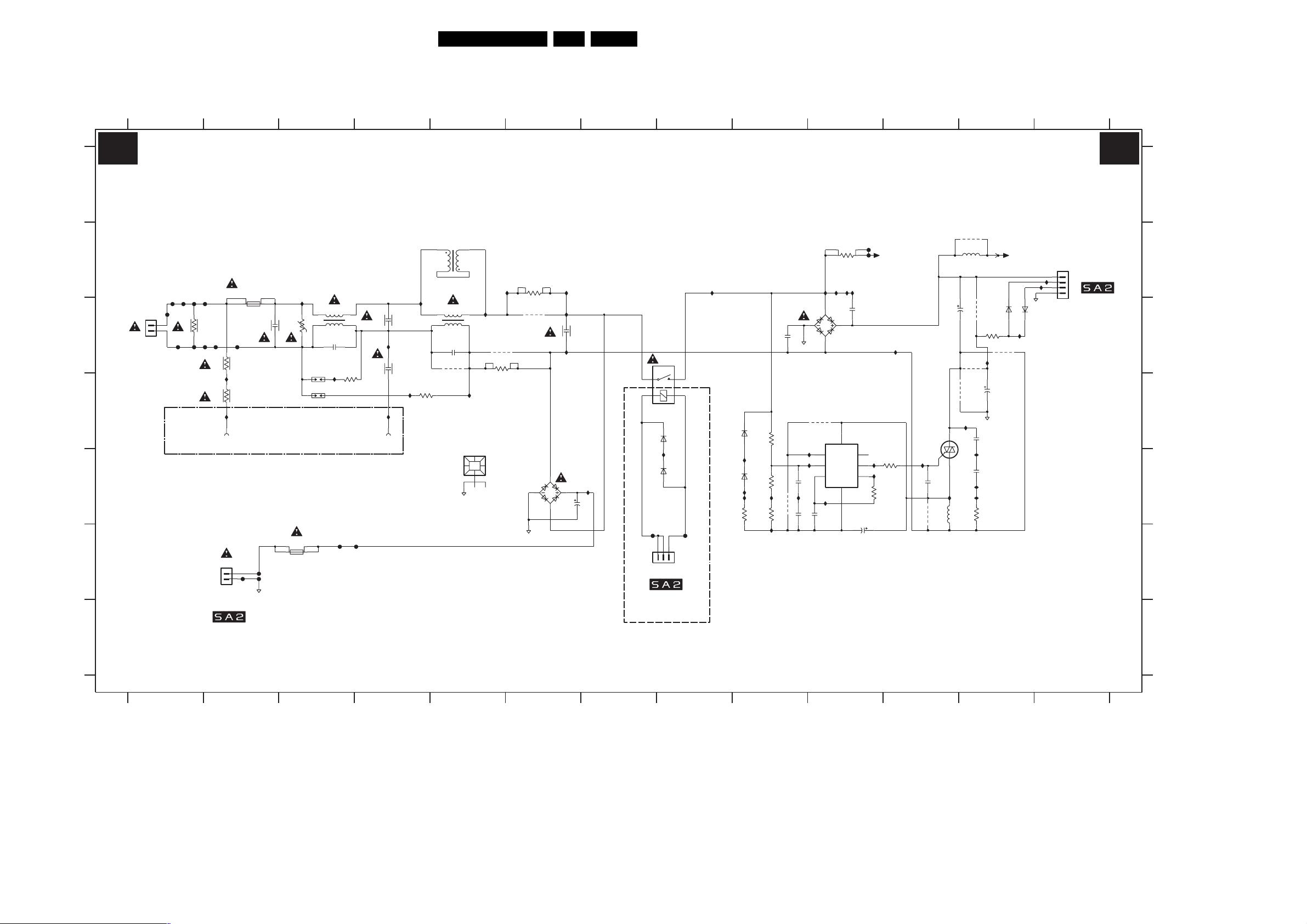

LCD Standby & Audio Panel: Standby (SA2) 94 96-98

LCD Standby & Audio Panel: Audio (SA3) 95 96-98

8. Alignments 99

9. Circuit Descriptions, Abbreviation List, And IC Data

Sheets 105

10. Spare Parts List 108

11. Revision List 122

Published by EL 0568 TV Service Printed in the Netherlands Subject to modification EN 3122 785 15500

EN 2 FTL2.4A AA1.

Technical Specifications, Connections, And Chassis Overview

1. Technical Specifications, Connections, And Chassis Overview

Index of this chapter:

1.1 Technical Specifications

1.2 Connections

1.3 Chassis Overview

Notes:

• Figures can deviate due to the different set executions.

• Specifications are indicative (subject to change).

1.1 Technical Specifications

1.1.1 Vision

Display type : LCD (LPL or Sharp)

Screen size : 32” (82 cm), 16:9

Resolution (HxV pixels) : 1366(*3)x768 WXGA

Min. contrast ratio : 400:1 (LPL)

Min. light output (cd/m

2

) : 400 (LPL)

Typ. LCD response time (ms) : 10 (LPL)

Typ. Viewing angle (HxV degrees) : 176 (LPL)

Tuning system : PLL

Colour systems : PAL B/G, D/K, I

Supported computer formats (60 Hz) : VGA (640x480)

Supported video formats : 640x480i - 1fH

AV (playback only) : NTSC, PAL, SECAM

Tuner bands : UHF, VHF, S, Hyper

1.1.2 Sound

Sound systems : AV stereo,

Maximum power (W

) : 2 x 15 (int.)

RMS

1.1.3 Miscellaneous

Mains voltage (V

Mains frequency : 50 / 60 Hz

) : 220 - 240

AC

Ambient temperature (°C) : +5 to +40

Maximum humidity (R.H>) : 90%

Power consumption

- Normal operation (W) : 145

- Stand-by (W) : < 2

: 600:1 (Sharp)

: 400 (Sharp)

: 15 (Sharp)

: 170 (Sharp)

:NTSC M/N

: SECAM B/G, D/K, L/L’

: SVGA (800x600)

: XVGA (1024x768)

: WXGA (1280x768)

: 720x576i - 1fH

: 640x480p - 2fH

: 720x576p - 2fH

: 1920x1080i - 2fH

: 1920x1152i - 2fH

: 1280x720p - 3fH

:FM/FM B/G

: NICAM B/G, D/K, I

1.2 Connections

Note: The following connector colour abbreviations are used

(acc. to DIN/IEC 757): Bk= Black, Bu= Blue, Gn= Green,

Gy= Grey, Rd= Red, Wh= White, Ye= Yellow.

1.2.1 Side I/O

SIDE I/O

R

AUDIO

L

CVBS

S-video

E_14620_022.eps

290705

Figure 1-1 Side I/O connections

Headphone (Output)

- Headphone 32 - 600 ohm / 10 mW ot

Cinch: Video CVBS - In, Audio - In

Rd - Audio R 0.5 V

Wh - Audio L 0.5 V

Ye - Video CVBS 1 V

S-video (Hosiden): Video Y/C - In

1 -Ground Y Gnd H

2 -Ground C Gnd H

3 -Video Y 1 V

4 -Video C 0.3 V

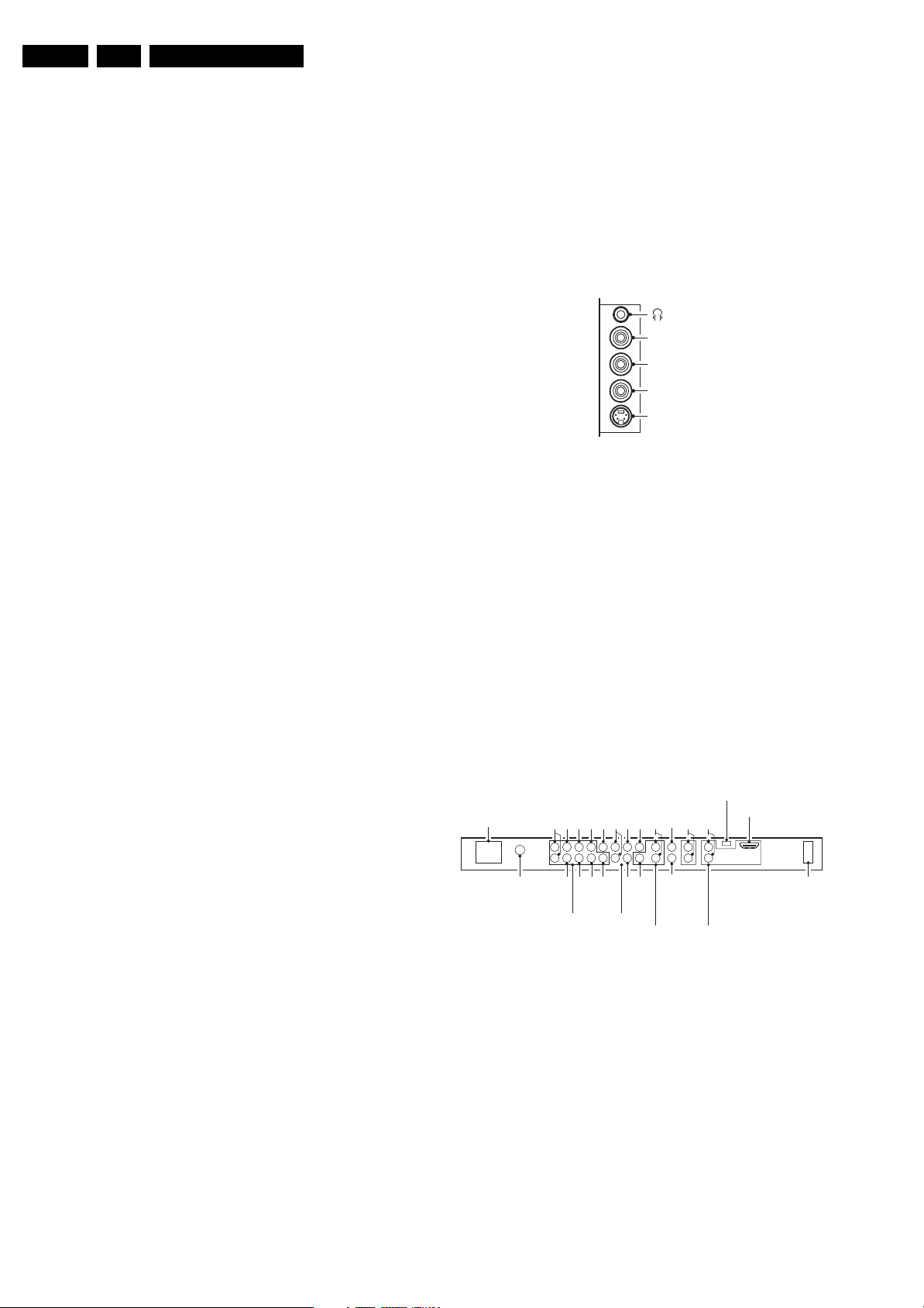

1.2.2 Rear Connections

MAINS

(PLASMA SETS)

AERIAL IN

AUDIO

R

L

AV2 IN

Pr/RPb/B

Y/GVS-VIDEO

AUDIOPrY

R

L

H

CVBS

Pb

S-VIDEO

AV1 IN

Figure 1-2 Rear connections

Aerial - In

- IEC-type (/79, 98) Coax, 75 ohm D

- F-type (/93) Coax, 75 ohm D

AV2 Cinch: Video CVBS/YPbPr/RGB - In, Audio - In

Wh - Audio L 0.5 V

Rd - Audio R 0.5 V

Bu - Video Pb/B 0.7 V

Rd - Video Pr/R 0.7 V

Ye - Video CVBS 1 V

Ge - Video Y/G 0.7 V

Bk - Sync H 0 - 5 V jq

Bk - Sync V 0 - 5 V jq

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

/ 75 ohm jq

PP

/ 75 ohm j

PP

P / 75 ohm j

PP

SERVICE

AUDIO

R

L

VIDEO

MONITOR

OUT

RMS

RMS

PP

PP

/ 75 ohm jq

PP

PP

AUDIO

AUDIO OUT

CENTRE IN

R

R

L

L

SUBW OUT

HDMI IN

/ 10 kohm jq

/ 10 kohm jq

/ 75 ohm jq

/ 75 ohm jq

/ 75 ohm jq

HDMI

19

18 2

1

(LCD SETS)

E_14620_144.eps

MAINS

140704

Technical Specifications, Connections, And Chassis Overview

AV2 S-Video: Y/C - In

1 -Ground Y Gnd H

2 -Ground C Gnd H

3 - Video Y 1 V

4 - Video C 0.3 V

AV1 S-Video: Y/C - In

1 - Ground Y Gnd H

2 - Ground C Gnd H

3 - Video Y 1 V

4 - Video C 0.3 V

AV1 Cinch: Video CVBS/YPbPr - In, Audio - In

Wh - Audio L 0.5 V

Rd - Audio R 0.5 V

Bu - Video Pb 0.7 V

Rd - Video Pr 0.7 V

Ge - Video Y 0.7 V

Monitor out

Ye - Video CVBS 1 V

Wh - Audio L 0.5 V

Rd - Audio R 0.5 V

Cinch: Sub woofer - Out, Centre - In

Bu - Centre 0.5 V

Bk - Sub woofer 0.5 V

/ 75 ohm j

PP

/ 75 ohm j

PP

/ 75 ohm j

PP

/ 75 ohm j

PP

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

/ 75 ohm jq

PP

/ 75 ohm jq

PP

/ 75 ohm jq

PP

/ 75 ohm kq

PP

/ 10 kohm kq

RMS

/ 10 kohm kq

RMS

/ 10 kohm jq

RMS

/ 10 kohm kq

RMS

EN 3FTL2.4A AA 1.

Cinch: Audio - Out

Rd - Audio - R 0.5 V

Wh - Audio - L 0.5 V

/ 10 kohm kq

RMS

/ 10 kohm kq

RMS

Cinch: HDMI Audio - In

Rd - Audio - R 0.5 V

Wh - Audio - L 0.5 V

Service connector (ComPair)

1 - SDA-S I

2 - SCL-S I

2

2

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

C Data (0 - 5 V) jk

C Clock (0 - 5 V) j

3 - Ground Gnd H

HDMI: Digital Video, Digital Audio - In

19

18 2

1

E_06532_017.eps

250505

Figure 1-3 HDMI (type A) connector

1 - D2+ Data channel j

2 - Shield Gnd H

3 - D2- Data channel j

4 - D1+ Data channel j

5 - Shield Gnd H

6 - D1- Data channel j

7 - D0+ Data channel j

8 - Shield Gnd H

9 - D0- Data channel j

10 - CLK+ Data channel j

11 - Shield Gnd H

12 - CLK- Data channel j

13 - n.c.

14 - n.c.

15 - DDC_SCL DDC clock j

16 - DDC_SDA DDC data jk

17 - Ground Gnd H

18 - +5V j

19 - HPD Hot Plug Detect j

20 - Ground Gnd H

EN 4 FTL2.4A AA1.

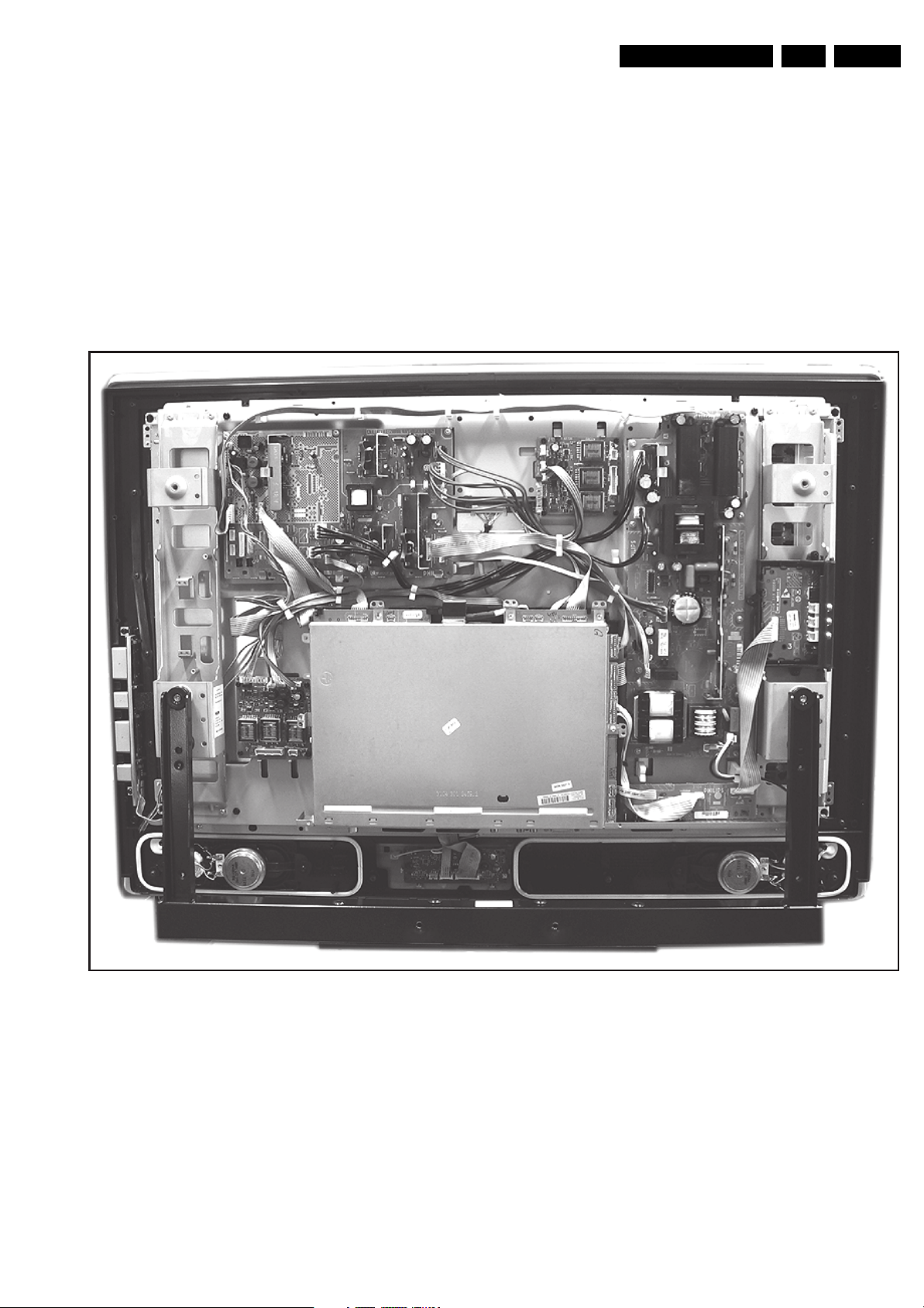

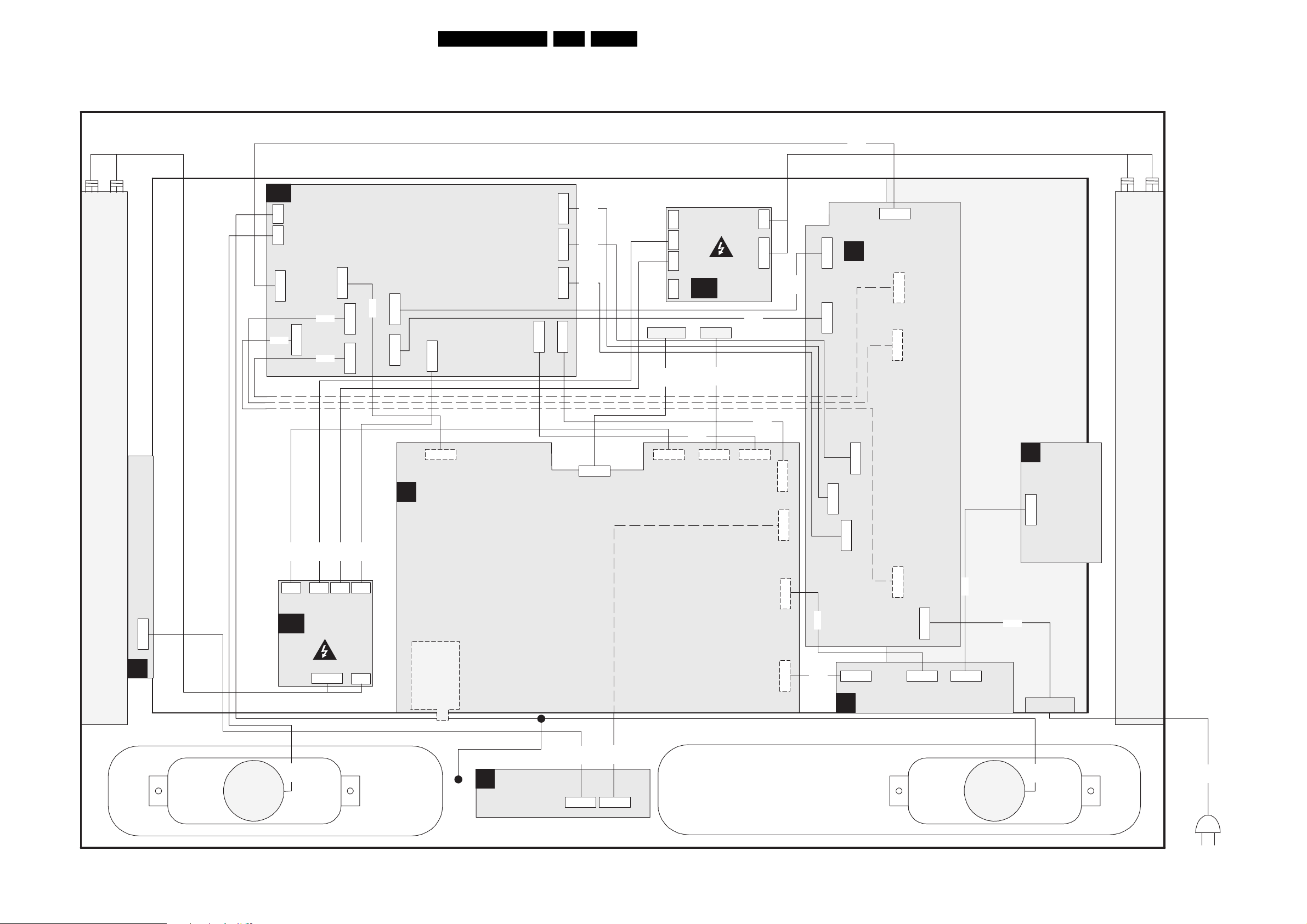

1.3 Chassis Overview

AMBI LIGHT PANEL

AL

Technical Specifications, Connections, And Chassis Overview

STANDBY SUPPLY/

SA

AUDIO PANEL

SIDE CONTROL PANEL

E

AMBI LIGHT PANEL

AL

SMALL SIGNAL

B

BOARD

LED PANEL

J

Figure 1-4 PWB locations

MAIN SUPPLY

PANEL

SIDE I/O PANEL

SCART3 PANEL

(only for Europe)

E_14620_167.eps

A

D

H

290705

Safety Instructions, Warnings, And Notes

2. Safety Instructions, Warnings, And Notes

EN 5FTL2.4A AA 2.

Index of this chapter:

2.1 Safety Instructions

2.2 Warnings

2.3 Notes

2.1 Safety Instructions

Safety regulations require the following during a repair:

• Connect the set to the Mains/AC Power via an isolation

transformer (> 800 VA).

• Replace safety components, indicated by the symbol h,

only by components identical to the original ones. Any

other component substitution (other than original type) may

increase risk of fire or electrical shock hazard.

Safety regulations require that after a repair, the set must be

returned in its original condition. Pay in particular attention to

the following points:

• Route the wire trees correctly and fix them with the

mounted cable clamps.

• Check the insulation of the Mains/AC Power lead for

external damage.

• Check the strain relief of the Mains/AC Power cord for

proper function.

• Check the electrical DC resistance between the Mains/AC

Power plug and the secondary side (only for sets that have

a Mains/AC Power isolated power supply):

1. Unplug the Mains/AC Power cord and connect a wire

between the two pins of the Mains/AC Power plug.

2. Set the Mains/AC Power switch to the "on" position

(keep the Mains/AC Power cord unplugged!).

3. Measure the resistance value between the pins of the

Mains/AC Power plug and the metal shielding of the

tuner or the aerial connection on the set. The reading

should be between 4.5 Mohm and 12 Mohm.

4. Switch "off" the set, and remove the wire between the

two pins of the Mains/AC Power plug.

• Check the cabinet for defects, to prevent touching of any

inner parts by the customer.

2.2 Warnings

Service Default Mode (see chapter 5) with a colour bar

signal and stereo sound (L: 3 kHz, R: 1 kHz unless stated

otherwise) and picture carrier at 475.25 MHz for PAL, or

61.25 MHz for NTSC (channel 3).

• Where necessary, measure the waveforms and voltages

with (D) and without (E) aerial signal. Measure the

voltages in the power supply section both in normal

operation (G) and in stand-by (F). These values are

indicated by means of the appropriate symbols.

• The semiconductors indicated in the circuit diagram and in

the parts lists, are interchangeable per position with the

semiconductors in the unit, irrespective of the type

indication on these semiconductors.

2.3.2 Schematic Notes

• All resistor values are in ohms, and the value multiplier is

often used to indicate the decimal point location (e.g. 2K2

indicates 2.2 kohm).

• Resistor values with no multiplier may be indicated with

either an "E" or an "R" (e.g. 220E or 220R indicates 220

ohm).

• All capacitor values are given in micro-farads (µ= x10

nano-farads (n= x10

• Capacitor values may also use the value multiplier as the

decimal point indication (e.g. 2p2 indicates 2.2 pF).

• An "asterisk" (*) indicates component usage varies. Refer

to the diversity tables for the correct values.

• The correct component values are listed in the Spare Parts

List. Therefore, always check this list when there is any

doubt.

2.3.3 Rework on BGA (Ball Grid Array) ICs

General

Although (LF)BGA assembly yields are very high, there may

still be a requirement for component rework. By rework, we

mean the process of removing the component from the PWB

and replacing it with a new component. If an (LF)BGA is

removed from a PWB, the solder balls of the component are

deformed drastically so the removed (LF)BGA has to be

discarded.

-9

), or pico-farads (p= x10

-12

-6

),

).

• All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD w). Careless handling

during repair can reduce life drastically. Make sure that,

during repair, you are connected with the same potential as

the mass of the set by a wristband with resistance. Keep

components and tools also at this same potential. Available

ESD protection equipment:

– Complete kit ESD3 (small tablemat, wristband,

connection box, extension cable and earth cable) 4822

310 10671.

– Wristband tester 4822 344 13999.

• Be careful during measurements in the high voltage

section.

• Never replace modules or other components while the unit

is switched "on".

• When you align the set, use plastic rather than metal tools.

This will prevent any short circuits and the danger of a

circuit becoming unstable.

2.3 Notes

2.3.1 General

• Measure the voltages and waveforms with regard to the

chassis (= tuner) ground (H), or hot ground (I), depending

on the tested area of circuitry. The voltages and waveforms

shown in the diagrams are indicative. Measure them in the

Device Removal

As is the case with any component that, is being removed, it is

essential when removing an (LF)BGA, that the board, tracks,

solder lands, or surrounding components are not damaged. To

remove an (LF)BGA, the board must be uniformly heated to a

temperature close to the reflow soldering temperature. A

uniform temperature reduces the risk of warping the PWB.

To do this, we recommend that the board is heated until it is

certain that all the joints are molten. Then carefully pull the

component off the board with a vacuum nozzle. For the

appropriate temperature profiles, see the IC data sheet.

Area Preparation

When the component has been removed, the vacant IC area

must be cleaned before replacing the (LF)BGA.

Removing an IC often leaves varying amounts of solder on the

mounting lands. This excessive solder can be removed with

either a solder sucker or solder wick. The remaining flux can be

removed with a brush and cleaning agent.

After the board is properly cleaned and inspected, apply flux on

the solder lands and on the connection balls of the (LF)BGA.

Note: Do not apply solder paste, as this has been shown to

result in problems during re-soldering.

Device Replacement

The last step in the repair process is to solder the new

component on the board. Ideally, the (LF)BGA should be

EN 6 FTL2.4A AA3.

Directions For Use

aligned under a microscope or magnifying glass. If this is not

possible, try to align the (LF)BGA with any board markers.

So as not to damage neighbouring components, it may be

necessary to reduce some temperatures and times.

More Information

For more information on how to handle BGA devices, visit this

URL: www.atyourservice.ce.philips.com (needs subscription,

not available for all regions). After login, select “Magazine”,

then go to “Workshop Information”. Here you will find

Information on how to deal with BGA-ICs.

2.3.4 Lead-free Solder

Philips CE is producing lead-free sets (PBF) from 1.1.2005

onwards.

Identification: The bottom line of a type plate gives a 14-digit

serial number. Digits 5 and 6 refer to the production year, digits

7 and 8 refer to production week (in example below it is 1991

week 18).

– To stabilise the adjusted temperature at the solder-tip.

– To exchange solder-tips for different applications.

• Adjust your solder tool so that a temperature of around

360°C - 380°C is reached and stabilised at the solder joint.

Heating time of the solder-joint should not exceed ~ 4 sec.

Avoid temperatures above 400°C, otherwise wear-out of

tips will increase drastically and flux-fluid will be destroyed.

To avoid wear-out of tips, switch “off” unused equipment or

reduce heat.

• Mix of lead-free soldering tin/parts with leaded soldering

tin/parts is possible but PHILIPS recommends strongly to

avoid mixed regimes. If this cannot be avoided, carefully

clear the solder-joint from old tin and re-solder with new tin.

• Use only original spare-parts listed in the Service-Manuals.

Not listed standard material (commodities) has to be

purchased at external companies.

• Special information for lead-free BGA ICs: these ICs will be

delivered in so-called "dry-packaging" to protect the IC

against moisture. This packaging may only be opened

shortly before it is used (soldered). Otherwise the body of

the IC gets "wet" inside and during the heating time the

structure of the IC will be destroyed due to high (steam-)

pressure inside the body. If the packaging was opened

before usage, the IC has to be heated up for some hours

(around 90°C) for drying (think of ESD-protection!).

Do not re-use BGAs at all!

• For sets produced before 1.1.2005, containing leaded

soldering tin and components, all needed spare parts will

be available till the end of the service period. For the repair

of such sets nothing changes.

E_06532_024.eps

230205

Figure 2-1 Serial number example

Regardless of the special lead-free logo (which is not always

indicated), one must treat all sets from this date onwards

according to the rules as described below.

P

b

Figure 2-2 Lead-free logo

Due to lead-free technology some rules have to be respected

by the workshop during a repair:

• Use only lead-free soldering tin Philips SAC305 with order

code 0622 149 00106. If lead-free solder paste is required,

please contact the manufacturer of your soldering

equipment. In general, use of solder paste within

workshops should be avoided because paste is not easy to

store and to handle.

• Use only adequate solder tools applicable for lead-free

soldering tin. The solder tool must be able:

– To reach a solder-tip temperature of at least 400°C.

In case of doubt whether the board is lead-free or not (or with

mixed technologies), you can use the following method:

• Always use the highest temperature to solder, when using

SAC305 (see also instructions below).

• De-solder thoroughly (clean solder joints to avoid mix of

two alloys).

Caution: For BGA-ICs, you must use the correct temperatureprofile, which is coupled to the 12NC. For an overview of these

profiles, visit the website www.atyourservice.ce.philips.com

(needs subscription, but is not available for all regions)

You will find this and more technical information within the

"Magazine", chapter "Workshop information".

For additional questions please contact your local repair help

desk.

2.3.5 Practical Service Precautions

• It makes sense to avoid exposure to electrical shock.

While some sources are expected to have a possible

dangerous impact, others of quite high potential are of

limited current and are sometimes held in less regard.

• Always respect voltages. While some may not be

dangerous in themselves, they can cause unexpected

reactions that are best avoided. Before reaching into a

powered TV set, it is best to test the high voltage insulation.

It is easy to do, and is a good service precaution.

3. Directions For Use

You can download this information from the following websites:

http://www.philips.com/support

http://www.p4c.philips.com

4. Mechanical Instructions

Mechanical Instructions

EN 7FTL2.4A AA 4.

Index of this chapter:

4.1 Cable Dressing

4.2 Service Position

4.3 Assy/PWB Removal

4.4 Display (Dis)Assembly

4.5 Set Re-assembly

4.1 Cable Dressing

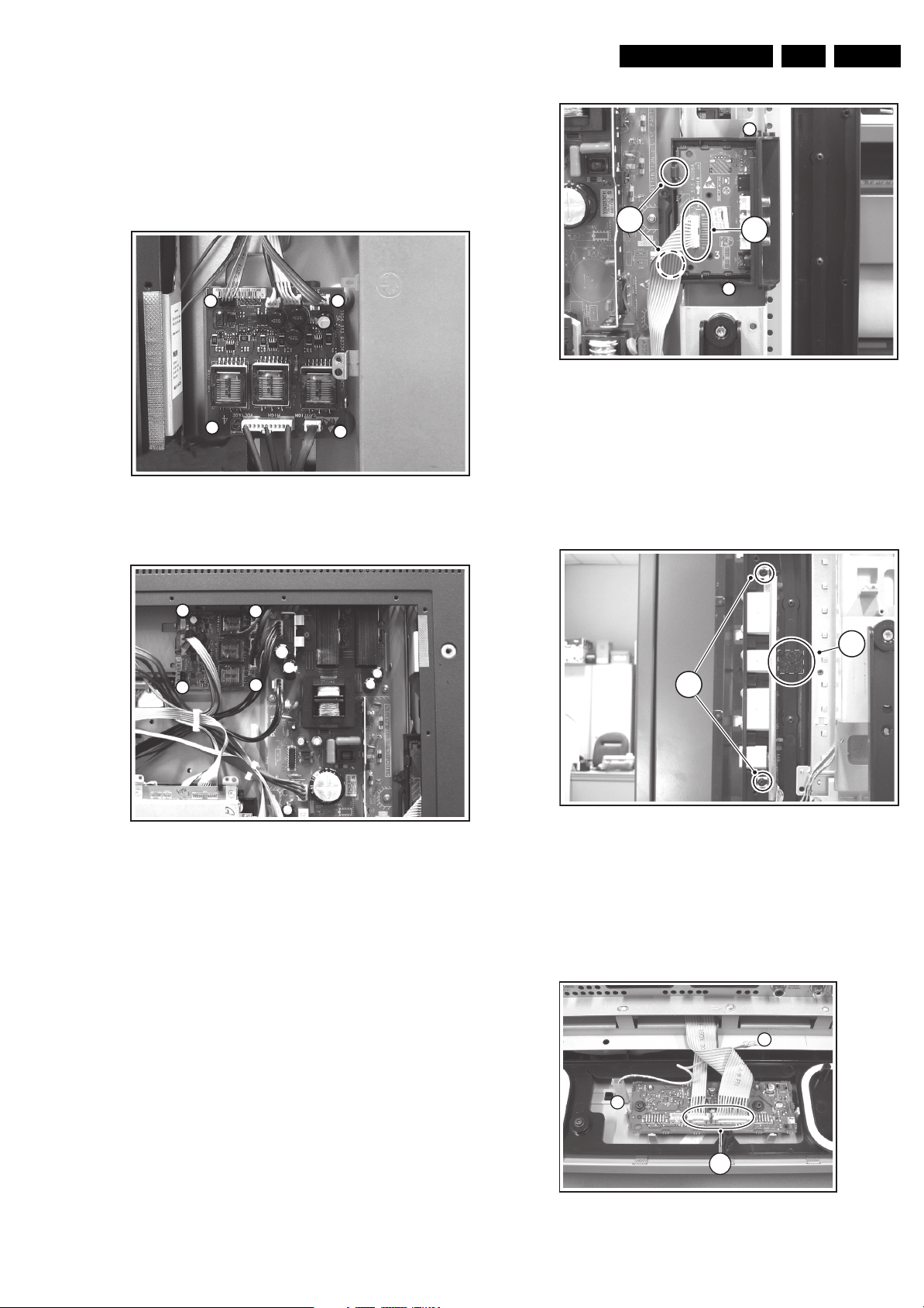

4.1.1 Chassis

Notes:

• Figures below can deviate slightly from the actual situation,

due to the different set executions.

• Follow the disassemble instructions in described order.

Figure 4-1 Chassis cable dressing (photo from Europe version)

F_15490_010.eps

230605

EN 8 FTL2.4A AA4.

s

5

Mechanical Instructions

4.2 Service Position

For easy servicing of this set, there are a few possibilities

created:

• The buffers from the packaging.

• Foam bars (created for Service).

• Aluminium service stands (created for Service).

4.2.1 Foam Bars

E_06532_018.eps

Figure 4-2 Foam bars

The foam bars (order code 3122 785 90580 for two pieces) can

be used for all types and sizes of Flat TVs. By laying the TV

face down on the (ESD protective) foam bars, a stable situation

is created to perform measurements and alignments.

By placing a mirror under the TV, you can monitor the screen.

170504

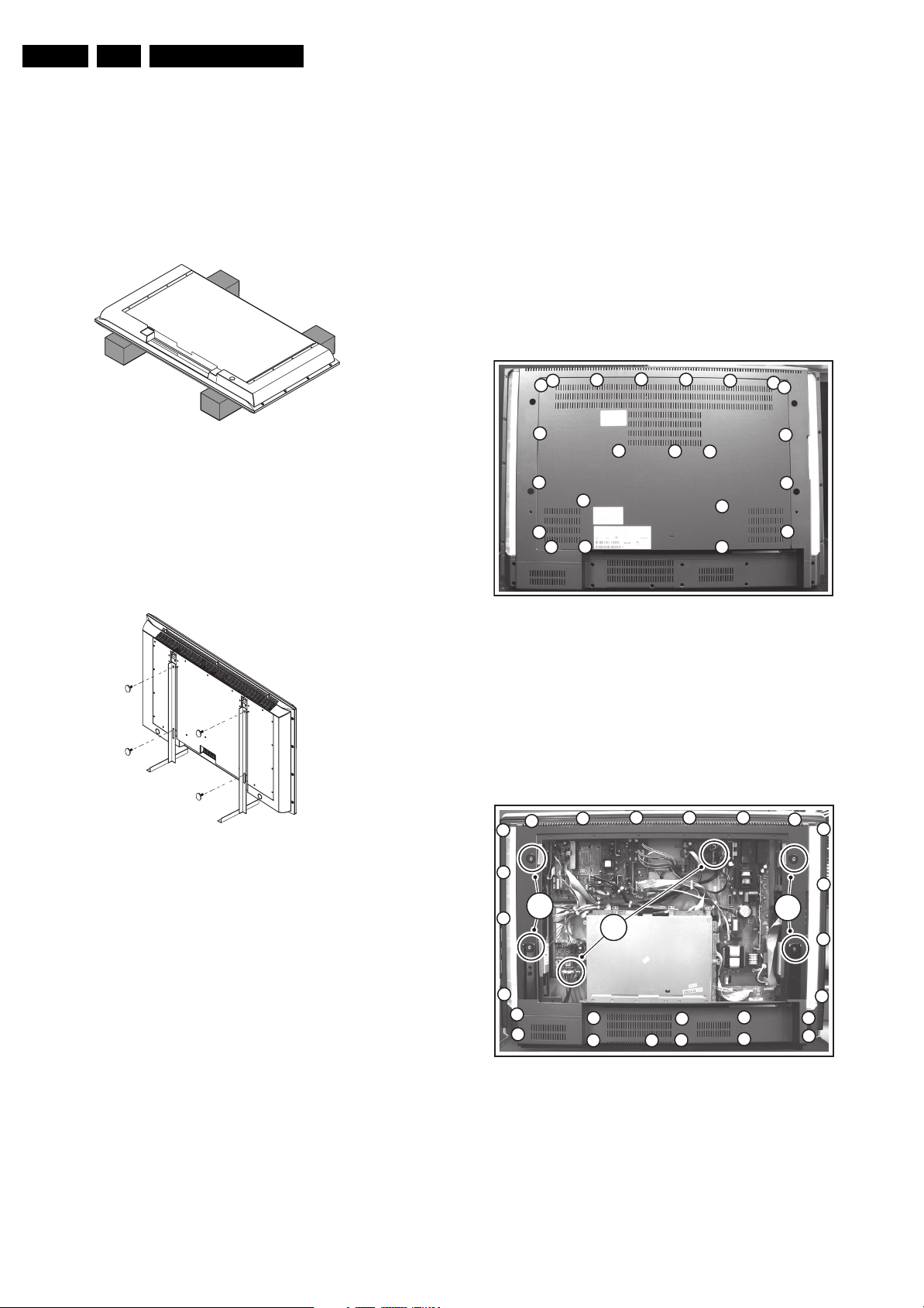

4.3 Assy/PWB Removal

4.3.1 Metal Back Plate

Caution: Disconnect the mains power cord before you remove

the metal back plate.

1. Place the TV set upside down on a table top, using the

foam bars (see part "Foam Bars").

Caution: do not put pressure on the display, but let the

monitor lean on the speakers or the Front cover.

2. Remove all T10 parker screws [1] from the top, left, and

right sides of the metal back plate.

3. Remove all T10 tapping screws [2] from the centre and

bottom of the metal back plate.

4. Lift the back plate from the TV. Make sure that wires and

flat foils are not damaged during the removal.

1

1

1

1

1

2

1

2

1

2

1

1

1

2

2

2

2

1

1

1

1

1

4.2.2 Aluminium Stands

E_06532_019.eps

170504

Figure 4-3 Aluminium stands (Mk1)

The new (Mk2) aluminium stands (order code 3122 785 90690)

can also be used to do measurements, alignments, and

duration tests. The stands can be (dis)mounted quick and easy

by means of sliding them in/out the "mushrooms".

Important: For (older) FTV sets without these "mushrooms", it

is obligatory to use the provided screws, otherwise it is possible

to damage the monitor inside!.

Figure 4-4 Metal back plate

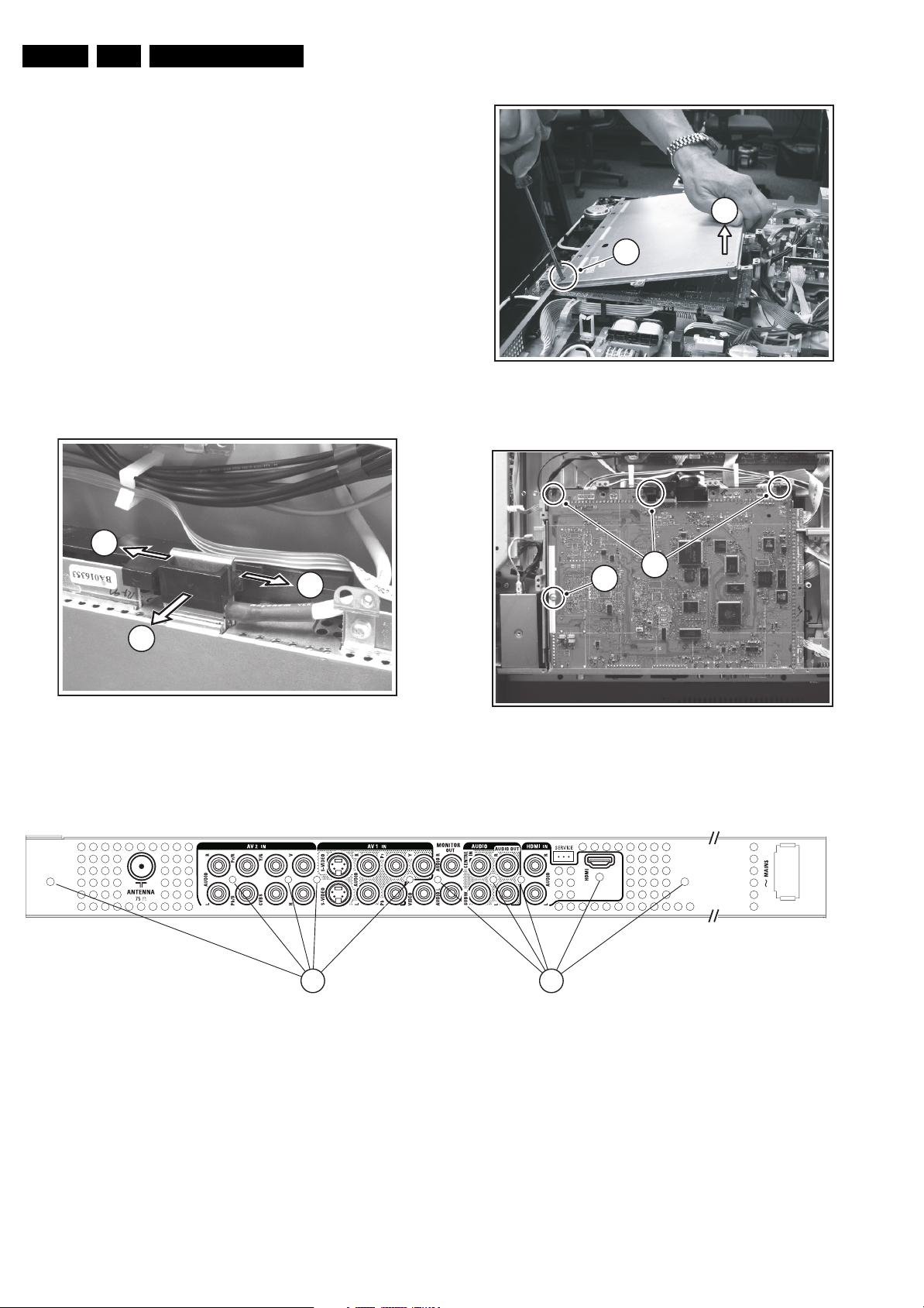

4.3.2 Rear Cover

1. Disconnect all connectors [1] at both AmbiLight Inverters.

2. Remove all T10 parker screws [2] around the edges of the

rear cover.

3. Remove the four "mushrooms" [3] from the back plate.

4. Lift the rear cover from the TV.

2

2

2

2 2 2

2

3

2

1

2

2

2

2

2 2

2

2

F_15490_011.eps

3

2

2

F_15490_012.ep

2

230605

2

2

2

2

2

2

23060

Figure 4-5 Rear cover

4.3.3 LCD Supply Panel

1. Disconnect all cables from the LCD supply panel.

2. Remove all mounting screws from the LCD supply panel.

3. Take out the panel.

4.3.4 AmbiLight Inverter Panel

Mechanical Instructions

EN 9FTL2.4A AA 4.

These models are equipped with two AmbiLight Inverters

(however some early models can have only one inverter).

1. Disconnect all cables from the AmbiLight Inverter panel.

2. Remove all mounting screws [1] from the AmbiLight

Inverter panel.

3. Take out the panel.

1

1

1

1

F_15490_014.eps

230605

Figure 4-6 AmbiLight inverter (left lower side)

3

Figure 4-8 Side I/O panel

4.3.7 Control Panel

1. Remove the glued foam block [1].

2. Remove the assy mounting screws [2].

3. Take out the assy.

4. Release the clamps and take out the panel.

2

1

2

F_15490_024.eps

240605

1

1

1

1

Figure 4-7 AmbiLight inverter (right upper side)

4.3.5 Stand-by Supply/Audio Panel

1. Disconnect all cables from the Stand-by Supply/Audio

panel.

2. Remove all T10 mounting screws at the top of the Standby Supply/Audio panel.

3. Take out the panel (it hinges at the bottom side).

4.3.6 Side I/O Panel

F_15490_013.eps

230605

2

Figure 4-9 Local keyboard

4.3.8 LED Panel

1. Disconnect all cables [2] from the LED panel.

2. Remove the mounting screws from the LED panel.

3. Take out the panel.

1

F_15490_016.eps

240605

1

1. Disconnect the cable [1] from the Side I/O panel.

2. Remove the assy mounting screws [2].

3. Take out the assy.

4. Release the clamps [3] and take out the panel.

1

2

F_15490_025.eps

020805

Figure 4-10 LED panel & speaker grid grounding wire

EN 10 FTL2.4A AA4.

4.3.9 Speakers

1. After removal of the cover plate, you can access the

speakers.

2. Be sure that the foam that makes the unit airtight is not

damaged. Otherwise replace it.

Mechanical Instructions

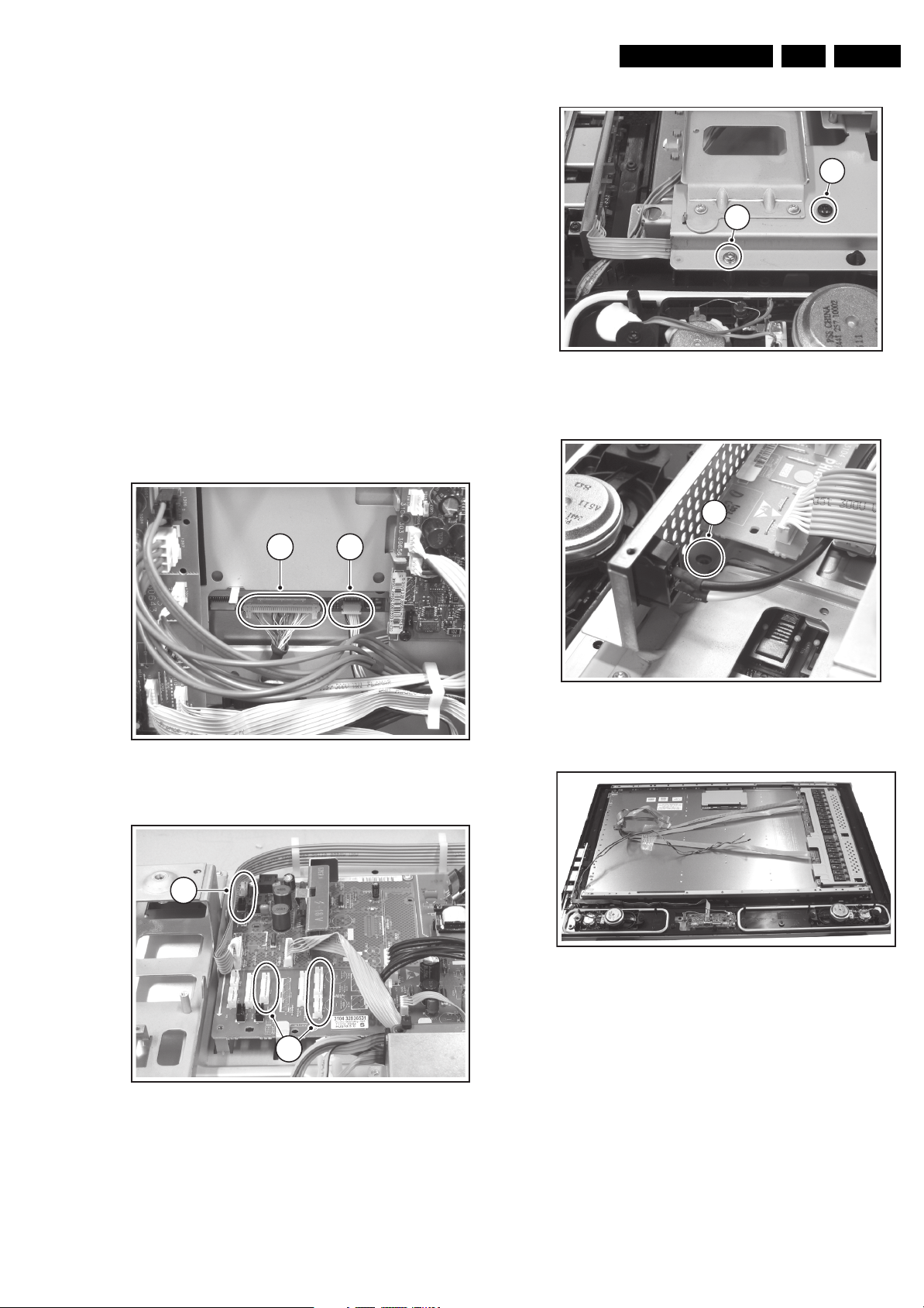

4.3.10 SSB

1. Remove the LVDS connector locking bracket [1][2].

2. Remove all shielding fixing screws.

3. Slide, and lift the shielding at the top [3]. The panel hinges

at the connector side. At the same time, use a screwdriver

to carefully prize the shielding at the bottom side [4], and

remove the shielding. The SSB is now accessible.

4. To remove the whole SSB, unscrew all fixing screws from

the connector plate [5]. See figure “Connector plate”.

5. Disconnect the LVDS cable, and all other cables.

6. Remove the mounting screw [8] from the SSB.

7. Bend the brackets [9] away (may require some force), lift

the SSB, and take it out.

1

1

2

For

PDP

4

Figure 4-12 SSB top shielding

9

8

3

F_15490_015.eps

230605

F_15490_017.eps

Figure 4-11 LVDS connector locking bracket

5 5

240605

Figure 4-14 Connector plate

Figure 4-13 SSB brackets

F_15490_027.eps

240605

F_15500_046.eps

020805

4.3.11 AmbiLight Lamp Unit

The AmbiLight lamp units are located in the TV’s rear cover.

1. Remove the cable clamps.

2. Remove all mounting AmbiLight screws.

3. Slide the AmbiLight unit to the side and take out the unit.

Mechanical Instructions

EN 11FTL2.4A AA 4.

6

4.4 Display (Dis)Assembly

Important: Be sure to work in a dust free environment during

the following activities. In addition, the use of (fabric) hand

gloves is advised.

1. Important: Unplug the cables [1][2] at the LCD panel. Be

careful, as the LVDS connector [1] is very fragile!

2. Unplug the backlight and loudspeaker connectors [3][4].

3. Remove all T10 screws [5] from the mounting frame.

4. Remove all mounting LCD panel screws [6][7].

5. Lift the metal frame (together with all PWBs) from the LCD

panel. During lift, free the backlight and speaker cables.

6. After removal of the frame, you can lift the LCD display

from the set.

1 2

Fragile !

5

F_15490_019.eps

Figure 4-17 LCD panel disassembly (part 1)

3th SCART panel

(only for Europe)

7

240605

F_15490_018.eps

Figure 4-15 LCD panel connectors

3

4

F_15490_021.eps

Figure 4-16 Speaker and LCD backlight cables

240605

240605

Figure 4-18 LCD panel disassembly (part 2)

Figure 4-19 Bare LCD panel after frame removal

4.5 Set Re-assembly

To re-assemble the whole set, execute all processes in reverse

order.

Note: While re-assembling the TV, make sure that:

• All cables are placed and connected in their original

position (see figure “Chassis cable dressing” in the

beginning of this chapter and/or the “Wiring Diagram” in

chapter 6).

• LVDS connector (SSB) is secured with plastic clamp.

• The "grounding" wire between metal speaker grid and

frame is reconnected. See item [1] in figure “LED panel &

speaker grid grounding wire“.

F_15490_020.eps

290705

F_15490_022.eps

240605

EN 12 FTL2.4A AA5.

Service Modes, Error Codes, And Fault Finding

5. Service Modes, Error Codes, And Fault Finding

Index of this chapter:

5.1 Test Points

5.2 Service Modes

5.3 Problems And Solving Tips (Related To CSM)

5.4 Service Tools

5.5 Error Codes

5.6 The Blinking LED Procedure

5.7 Protections

5.8 Repair Tips

5.9 Software Downloading

5.1 Test Points

The chassis is equipped with test points printed on the circuit

board assemblies.

Perform measurements under the following conditions:

• Service Default Mode.

• Video: colour bar signal.

• Audio: 3 kHz left, 1 kHz right.

5.2 Service Modes

Service Default Mode (SDM) and Service Alignment Mode

(SAM) offer several features for the service technician, while

the Customer Service Mode (CSM) is used for communication

between a Philips Customer Care Centre (P3C) and a

customer.

There is also the option of using ComPair, a hardware interface

between a computer (see requirements below) and the TV

chassis. It offers the ability of structured troubleshooting, test

pattern generation, error code reading, software version readout, and software upgrading.

Minimum requirements: a Pentium processor, Windows 95/

98, and a CD-ROM drive (see also paragraph “ComPair”).

Remark: The silk screen printing is not correct for the SAM/

SDM indication. For the correct location of these pins, see

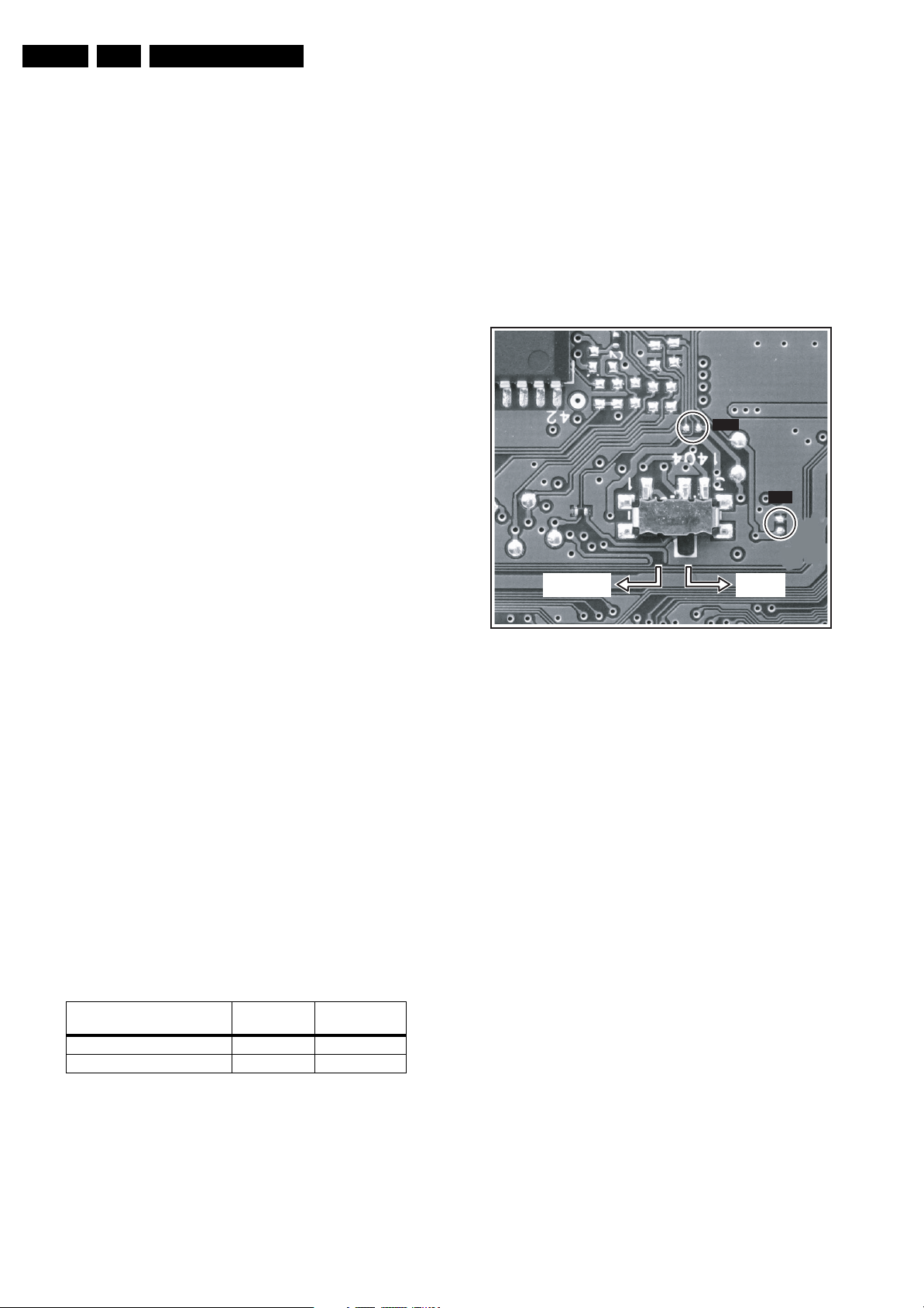

figure ”Service pads”.

5.2.1 Service Default Mode (SDM)

Purpose

• To create a pre-defined setting, to get the same

measurement results as given in this manual.

• To override SW protections.

• To start the blinking LED procedure.

– Smart modes.

– Auto store of personal presets.

– Auto user menu time-out.

How To Activate SDM

Use one of the following methods:

• Use the standard RC-transmitter and key in the code

“062596”, directly followed by the “MENU” button.

Note: It is possible that, together with the SDM, the main

menu will appear. To switch it off, push the “MENU” button

again.

SDM

SAM

SW UPGRADE

MODE

Figure 5-1 Service pads

• Short for a moment the two solder pads on the SSB, with

the indication “SDM” (see figure ”Service pads”). Activation

can be performed in all modes, except when the TV has a

problem with the main microprocessor.

Caution: If the SDM is activated via the pins, all the

software-controlled protections are de-activated.

• Use the DST-emulation feature of ComPair.

• Use the “DEFAULT” button on the Dealer Service Tool

(RC7150).

How To Navigate

When you press the “MENU” button on the RC transmitter, the

TV will toggle between the SDM and the normal user menu

(with the SDM mode still active in the background).

NORMAL

TV MODE

E_14620_151.eps

290704

Specifications

Table 5-1 SDM default settings

Default

Region Freq. (MHz)

Europe, AP-PAL/Multi 475.25 PAL B/G

NAFTA, AP-NTSC, LATAM 61.25 (ch. 3) NTSC M

• All picture settings at 50% (brightness, colour, contrast).

• All sound settings at 50%, except volume at 25%.

• All service-unfriendly modes (if present) are disabled, like:

– (Sleep) timer.

– Child/parental lock.

–Blue mute.

– Automatic volume limiter (AVL).

– Auto switch-off (when no video signal was received for

10 minutes).

– Skip/blank of non-favourite pre-sets.

system

How To Exit SDM

Use one of the following methods:

• Switch the TV to STANDBY via the RC-transmitter.

• Press the “EXIT” button on the DST.

• Via a standard customer RC-transmitter: key in “00”sequence.

5.2.2 Service Alignment Mode (SAM)

Purpose

• To perform (software) alignments.

• To change option settings.

• To easily identify the used software version.

• To view operation hours.

• To display (or clear) the error code buffer.

Specifications

• Operation hours counter.

• Software version.

Service Modes, Error Codes, And Fault Finding

EN 13FTL2.4A AA 5.

• Option settings.

• Error buffer reading and erasing.

• Software alignments.

How To Activate SAM

Use one of the following methods:

• Via a standard RC transmitter: key in the code “062596”

directly followed by the “OSD [i+]” button. After activating

SAM with this method a service warning will appear on the

screen, you can continue by pressing any digit key on the

RC.

• Short for a moment the two solder pads on the SSB with

the indication "SAM" (see figure ”Service pads”).

Depending on the software version, it is possible that a

service warning will appear. You can continue by pressing

any digit key on the RC.

• Use the DST-emulation feature of ComPair.

• Press the ALIGN button on the DST while the TV is in the

normal operation

After activating this mode, “SAM” will appear in the upper right

corner of the screen.

Contents Of SAM:

• Operation Hours. Displays the accumulated total of

operation hours (not the stand-by hours).

• Hardware Info.

– ROM Version. Displays the date of the software and

the software version of the ROM

Ex.: TX24EU_1.0_01234 = AAAABB_X.Y_NNNNN.

• AAAA= the chassis name.

• BB= the region: EU= Europe, AP= Asia Pacific

PAL/Multi, AN= Asia Pacific NTSC, US= USA, LT=

LATAM.

• X.Y= the software version, where X is the main

version number (different numbers are not

compatible with one another) and Y is the sub

version number (a higher number is always

compatible with a lower number).

• NNNNN= last five digits of 12nc code software.

– FBX Version. Displays the software version of the

FBX

– SW VERSION EPLD. Displays the software version of

the EPLD.

• Errors. (followed by maximal 10 errors). The most recent

error is displayed at the upper left (for an error explanation

see paragraph “Error Codes”).

• Defective Module. Here the module that generates the

error is displayed. If there are multiple errors in the buffer,

which are not all generated by a single module, there is

probably another defect. It will then display the message

“UNKNOWN” here.

• Reset Error Buffer. When you press the “OK” button, the

error buffer is reset.

• Alignments. This will activate the “ALIGNMENTS” submenu.

• Dealer Options. Extra features for the dealers.

• Service Options. Extra features for Service.

• Initialise NVM. The moment the processor recognises a

corrupted NVM, the “initialise NVM” line will be highlighted.

Now, you can do two things (dependent of the service

instructions at that moment):

– Save the content of the NVM via ComPair for

development analysis, before initialising. This will give

the Philips Service department an extra possibility for

diagnosis (e.g. when Development asks for this).

– Initialise the NVM (same as in the past, however now it

happens conscious).

Note: When you have a corrupted NVM, or you have replaced

the NVM, there is a high possibility that you will not have picture

any more because your display option is not correct. So, before

you can initialize your NVM via the SAM, you need to have a

picture and therefore you need the correct display option. This

code can be found on the option code sticker inside the set.

• Store. All options and alignments are stored when

pressing the “OK”-button

• Functional Test. All devices are tested via the “OK”

button. Eventual errors are displayed in the error buffer.

The error buffer is not erased, the content returns when this

test is terminated.

• Daily Menus. With the “OK” button, you can go to the

normal user menu. SAM is still active in the background.

With the “MENU” button, you return from the user menu to

SAM menu. This feature can be helpful to quickly change

some settings in the user menu.

• SW Maintenance.

• Upgrade. More info see paragraph Software

downloading.

• Events. Not useful for service purposes. In case of

specific software problems, the development

department can ask for this info.

• BDM Info. Broadcast Debug Menu info. The purpose

of this menu is to debug the broadcast, not the TV. The

menu gives an overview of what is received on the

current preset.

Following items are displayed:

P r e s e t n r : -- UTC: - - : - - : --

P r e s e t n a m e : ----- LTO: - - : - - : --

Time: - - : - - : --

C N I N V M : ---- Date: - - / - - / ----

C N I F 1 : ----

C N I F 2 : ---- Time TXT: - - : - - : --

C N I V P S : ---- Time 8/30 F1: - - : - - : --

M o r n i n g P r o g : --- Date 8/30 F1: - - / - - / ----

N a m e 8 / 3 0 F 1 : ----- LTO 8/30 F1: - - : - - : --

N a m e 8 / 3 0 F 2 : -----

N a m e T X T : ----- WSS G1: - - - -

S i g n a l S t r e n g t h :--- WSS G2: - - - -

WSS G3: - - -

E P G S e r v i c e : --- WSS G4: - - -

E_14620_050.eps

170504

Figure 5-2 Broadcast debug menu overview

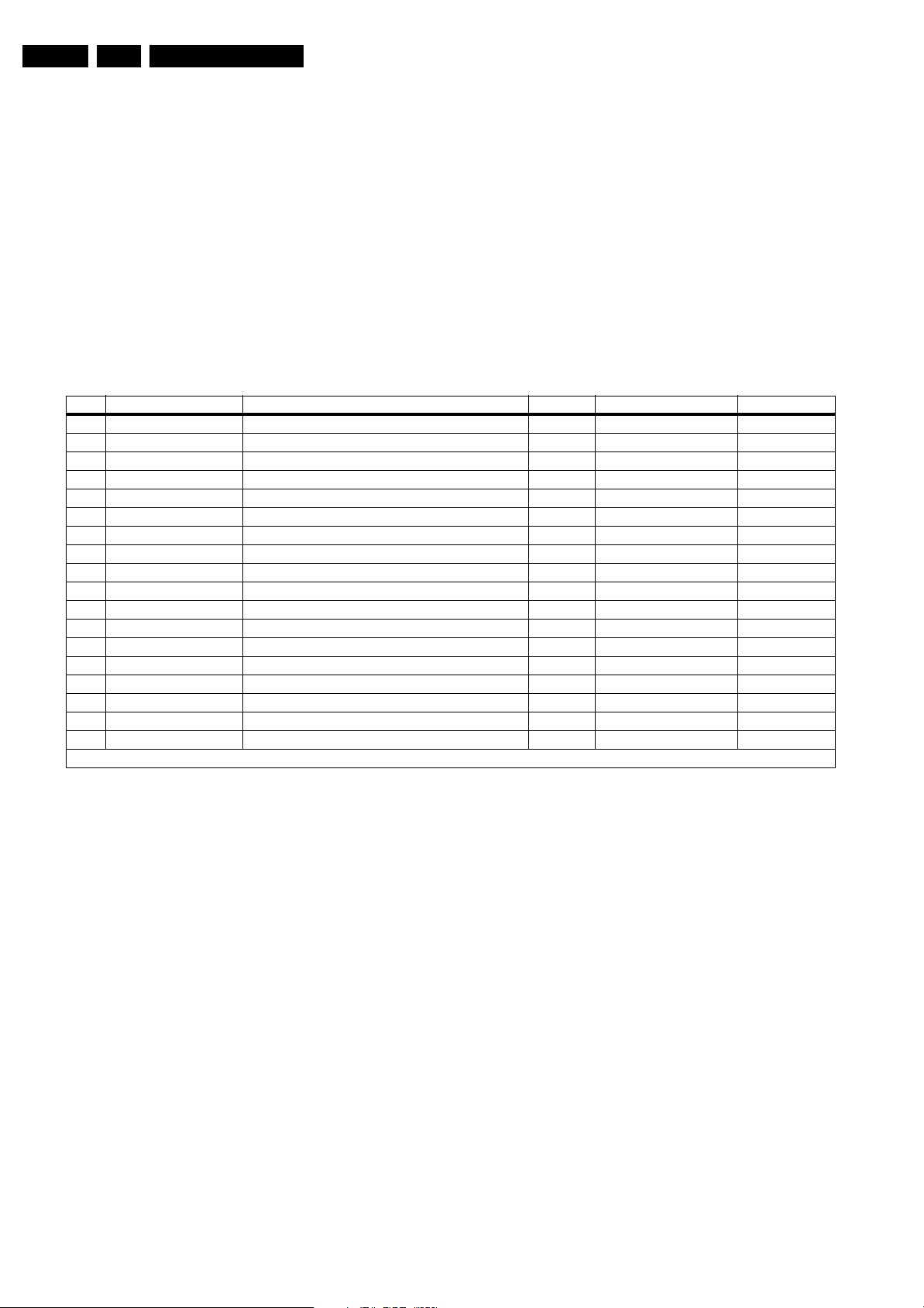

Table 5-2 Broadcast debug menu explanation

Item Source Description

Presetnr Set Preset number of the current selected preset.

Presetname Set Preset name of the current selected preset.

CNI NVM Broadcaster CNI number stored in NVM for the current preset.

CNI F1 Broadcaster CNI number from transmitted Packet 8/30 Format

CNI F2 Broadcaster CNI number from transmitted Packet 8/30 Format

CNI VPS Broadcaster CNI number from transmitted VPS line.

Morning Prog Broadcaster "ARD" or "ZDF" according to dedicated bit in 8/30

Name 8/30 F1 Broadcaster Name extracted from status message of 8/30

Name 8/30 F2 Broadcaster Name extracted from status message of 8/30

Name TXT Broadcaster Name extracted from TXT header.

Signal Strength FBX Noise figure measured for selected preset.

EPG Service Set EPG Service stored in NVM for current preset

UTC Set UTC (Universal Time Code formerly known as

LTO Set LTO (Local Time Offset) used in the TV. Used by

Time Set Current time running in the TV. Was extracted at

Date Set Current date running in the TV. Was extracted at

Time TXT Broadcaster TXT header time from the selected preset.

Time 8/30 F1 Broadcaster UTC time from 8/30 Format 1.

Date 8/30 F1 Broadcaster Date from 8/30 Format 1.

LTO 8/30 F1 Broadcaster LTO from 8/30 Format 1.

WSS G1 Broadcaster WSS Group 1 (Aspect Ratio) bits 0 1 2 3

WSS G2 Broadcaster WSS Group 2 (Enhanced Services) bits 4 5 6 7

WSS G3 Broadcaster WSS Group 3 (Subtitles) bits 8 9 10

WSS G4 Broadcaster WSS Group 4 (Reserved) bits 11 12 13

1.

2.

Format 1.

Format 1.

Format 2.

displayed as "TXT", "MCP", "SCP", "OCP".

Greenwich Mean Time) used in the TV.

EPG for all NextView displays. (= Time TXT

header - Time 8/30 F1)

start-up, then maintained by software.

start-up, then maintained by software.

EN 14 FTL2.4A AA5.

Service Modes, Error Codes, And Fault Finding

How To Navigate

• In SAM, you can select the menu items with the “CURSOR

UP/DOWN” key on the RC-transmitter. The selected item

will be highlighted. When not all menu items fit on the

screen, move the “CURSOR UP/DOWN” key to display the

next/previous menu items.

• With the “CURSOR LEFT/RIGHT” keys, it is possible to:

– (De) activate the selected menu item.

– Change the value of the selected menu item.

– Activate the selected sub-menu.

How To Exit SAM

Use one of the following methods:

• Press the “MENU” button on the RC-transmitter, or

• Switch the TV to STANDBY via the RC-transmitter, or

• Press the “EXIT” button on the DST.

5.2.3 Customer Service Mode (CSM)

Purpose

When a customer is having problems with his TV-set, he can

call his dealer. The service technician can than ask the

customer to activate the CSM, in order to identify the status of

the TV. Now, the service technician can judge the severity of

the complaint. In many cases, he can advise the customer how

to solve the problem, or he can decide if it is necessary to visit

the customer.

The CSM is a read only mode; therefore, modifications in this

mode are not possible.

How To Activate CSM

Use the following method:

Key in the code “123654” via the standard RC transmitter.

Note: Activation of the CSM is only possible if there is no (user)

menu on the screen!

How To Navigate

By means of the “CURSOR-DOWN/UP” knob on the RCtransmitter, you can navigate through the menus.

Contents Of Csm

CUSTOMER SERVICE MENU 1

• Software Version (example: TX24EU_1.0_01234).

Displays the built-in software version. In case of field

problems related to software, software can be upgraded

(for more details, see paragraph Software downloading).

You will find details of the software versions in the chapter

“Software Survey” of the “Product Survey - Colour

Television” publication. This publication is generated four

times a year.

• Feature Box. The 12NC-number of the built-in Feature

Box software.

• Set Type. This information is very helpful for a help desk/

workshop as reference for further diagnosis. In this way, it

is not necessary for the customer to look at the rear of the

TV-set.

• Code 1. Gives the latest five errors of the error buffer. As

soon as the built-in diagnose software has detected an

error the buffer is adapted. The last occurred error is

displayed on the left most position. Each error code is

displayed as a 3-digit number. When less than 10 errors

occur, the rest of the buffer is empty (000). See also

paragraph Error Codes for a description.

• Code 2. Gives the first five errors of the error buffer. See

also paragraph Error Codes for a description.

• Volume. Gives the last status of the volume as set by the

customer. The value can vary from 0 (volume is minimum)

to 100 (volume is maximum). Volume values can be

changed via the volume key on the RC-transmitter.

• Brightness. Gives the last status of the brightness as set

by the customer. The value can vary from 0 (brightness is

minimum) to 100 (brightness is maximum). Brightness

values can be changed via the “CURSOR LEFT” and

“CURSOR RIGHT” keys on the RC-transmitter after

pressing the “MENU” button and selecting “PICTURE” and

“BRIGHTNESS”.

• Contrast. Gives the last status of the contrast as set by the

customer. The value can vary from 0 (contrast is minimum)

to 100 (contrast is maximum). Contrast values can be

changed via “CURSOR LEFT” and “CURSOR RIGHT”

keys on the RC-transmitter after pressing the “MENU”

button and selecting “PICTURE” and “CONTRAST”.

• Colour. Gives the last status of the colour saturation, as

set by the customer. The value can vary from 0 (colour is

minimum) to 100 (colour is maximum). Colour values can

be changed via “CURSOR LEFT” and “CURSOR RIGHT”

keys on the RC-transmitter after pressing the “MENU”

button and selecting “PICTURE” and “COLOUR”.

• Hue. Only relevant for NTSC-signals (e.g. some NTSCDVD-discs).

CUSTOMER SERVICE MENU 2

• Sharpness. Gives the sharpness value. The value can

vary from 0 (sharpness is minimum) to 7 (sharpness is

maximum). In case of bad antenna signals, a too high

value of the sharpness can result in a noisy picture.

Sharpness values can be changed via the “CURSOR

LEFT” and “CURSOR RIGHT” keys on the RC-transmitter

after pressing the “MENU” button and selecting “PICTURE”

and “SHARPNESS”.

• Headphone Volume. Gives the last status of the head

phone volume, as set by the customer. The value can vary

from 0 (volume is minimum) to 100 (volume is maximum).

Head phone volume values can be changed via the

“CURSOR LEFT” and “CURSOR RIGHT” keys on the RCtransmitter after pressing the “MENU” button and selecting

“SOUND” and “HEADPHONE VOLUME”.

• Dolby. Indicates whether the received transmitter

transmits Dolby sound (“ON”) or not (“OFF”). Attention: The

presence of Dolby can only be tested by the software on

the Dolby Signalling bit. If a Dolby transmission is received

without a Dolby Signalling bit, this indicator will show “OFF”

even though a Dolby transmission is received.

• Surround Mode. Indicates the by the customer selected

surround mode (or automatically chosen mode). Possible

values are “OFF”, “INCREDIBLE SURROUND” OR

“DOLBY VIRTUAL”. These settings can be influenced after

pressing the “MENU” button and selecting “SOUND” and

SURROUND MODE”. It can also have been selected

automatically by signalling bits (internal software).

• Tuner Frequency. Indicates the frequency the selected

transmitter is tuned to. The tuner frequency can be

changed via the “CURSOR LEFT” and “CURSOR RIGHT”

keys for fine tune after opening the installation menu and

selecting “INSTALL” and “MANUAL INSTALL”.

• Digital Option. Gives the selected digital mode,

“PROGRESSIVE SCAN”, “MOVIE PLUS” or “PIXEL

PLUS”. Change via “MENU”, “PICTURE”, “DIGITAL

OPTIONS”.

• Centre Trim. Not applicable for this set.

• TV System. Gives information about the video system of

the selected transmitter.

– BG: PAL BG signal received.

– DK: PAL DK signal received.

– I: PAL I signal received.

– L/La: SECAM L/La signals received.

– M: NTSC M signal received with video carrier on 38.9

MHz.

CUSTOMER SERVICE MENU 3

• Balance. Indicates the balance settings, between “-50”

and “+50”. Change via “MENU”, “SOUND”, and

“BALANCE”. Not applicable for Dolby Pro Logic sets.

• Centre Mode. Not applicable for this TV.

Service Modes, Error Codes, And Fault Finding

EN 15FTL2.4A AA 5.

• DNR. Gives the selected DNR setting (Dynamic Noise

Reduction), “OFF”, “MINIMUM”, “MEDIUM”, or

“MAXIMUM”. Change via “MENU”, “PICTURE”, “DNR”

• Noise Figure. Gives the noise ratio for the selected

transmitter. This value can vary from 0 (good signal) to 127

(average signal) and to 255 (bad signal). For some

software versions, the noise figure will only be valid when

“Active Control” is set to “medium” or “maximum”.

• Source. Indicates which source is used and the video/

audio signal quality of the selected source.

Example: Tuner, Video/NICAM) Source: “TUNER”,

“EXT1”, “EXT2”, “EXT3”, “EXT4”, “SIDE”, “AV1”, “AV2”,

“AV3” or “AV4”. Video signal quality: “VIDEO”, “S-VIDEO”,

“RGB 1FH”, “YPBPR 1FH 480P”, “YPBPR 1FH 576P”,

“YPBPR 1FH 1080I”, “YPBPR 2FH 480P”, “YPBPR 2FH

576P”, “YPBPR 2FH 1080I”, “RGB 2FH 480P”, “RGB 2FH

576P” or “RGB 2FH 1080I”. Audio signal quality:

“STEREO”, “SPDIF 1”, “SPDIF 2”, or “SPDIF”.

• Audio System. Gives information about the audio system

of the selected transmitter: “ANALOGUE MONO”,

“ANALOGUE STEREO”, “PCM 2/0”, “DD 1/0”, “DD 2/0

LtRt”, “DD 2/0 L0R0”, “DD 2/1”, “DD 2/2”, “DD 3/0”, “DD 3/

1”, “DD 3/2”, “DD 1+1”, “MPEG 1/0”, “MPEG 2/0”, “MPEG

2/0 LtRt”, “MPEG 2/1”, “MPEG 2/2”, “MPEG 3/0”, “MPEG

3/1”, “MPEG 3/2”, “MPEG 1+1” or “MPEG 2+2”.

• Tuned Bit. Gives information about the tuning method of

the stored pre-set. If a channel is found via “automatic

installation”, you will see the value “YES”. When you

change this (automatically found) frequency via “fine tune”

adjustment (installation menu - manual installation), the

displayed value will change to “NO”. Therefore, when you

see the value “NO” in this line, it is an indication that the

received channel is a non-standard signal (e.g. of a VCR).

• Surround Speakers. Not applicable in this set.

• On Timer. Indicates if the “On Timer” is set “ON” or “OFF”

and if the timer is “ON” also displays start time, start day

and program number. Change via “MENU”, “TV”,

“FEATURES”, and “ON TIMER”.

• Preset Lock. Indicates if the selected preset has a child

lock: “LOCKED” or “UNLOCKED”. Change via “MENU”,

“TV”, “FEATURES”, “CHILD LOCK”, and “CUSTOM

LOCK”.

CUSTOMER SERVICE MENU 4

• Child Lock. Indicates the last status of the general child

lock: “UNLOCK”, “LOCK”, or “CUSTOM LOCK”. Change

via “MENU”, “TV”, “FEATURES”, “CHILD LOCK”, and

“LOCK”.

• Age Lock. Indicates the last status of the EPG rating for

child lock: “OFF”, “4 YEARS”, “6 YEARS”, “8 YEARS”, “10

YEARS”, “12 YEARS”, “14 YEARS” or “16 YEARS”. This is

only displayed if child lock is set to “CUSTOM LOCK”

• Lock After. Indicates at what time the child lock is set:

“OFF” or e.g. “18:45” (lock time). This is only displayed if

child lock is set to “CUSTOM LOCK”

• Category Lock. Indicates the last status of the EPG theme

child lock: “MOVIES”, “NEWS”, “SHOWS”, “SPORTS”,

“CHILDREN”, “MUSIC”, “CULTURE”, or “SERIES”. This is

only displayed if child lock is set to “CUSTOM LOCK”. It is

possible that more than one value is shown.

• Program Category. Indicates the theme of the selected

transmitter: “MOVIES”, “NEWS”, “SHOWS”, “SPORTS”,

“CHILDREN”, “MUSIC”, “CULTURE”, or “SERIES”.

• TV Ratings Lock. Only applicable for US.

• Movie Ratings Lock. Only applicable for US.

• V-Chip TV Status. Only applicable for US.

CUSTOMER SERVICE MENU 5

• V-Chip Movie Status. Only applicable for US.

• Options 1. Gives the option codes of option group 1 as set

in SAM (Service Alignment Mode).

• Options 2. Gives the option codes of option group 2 as set

in SAM (Service Alignment Mode).

• AVL. Indicates the last status of AVL (Automatic Volume

Level): “ON” or “OFF”. Change via “MENU”, “TV”,

“SOUND”, “AVL”

• Delta Volume. Indicates the last status of the delta volume

for the selected preset as set by the customer: from “-12”

to “+12”. Change via “MENU”, “TV”, “SOUND”, “DELTA

VOLUME”.

• Front Spkr Dist. Not applicable for this TV.

• Front Spkr Dist. Not applicable for this TV.

How to exit CSM

Use one of the following methods:

• After you press a key on the RC-transmitter (with exception

of the “CHANNEL”, “VOLUME” and digit (0-9) keys), or

• After you switch the TV-set “OFF” with the mains switch.

Note: When you de-activate CSM, it is possible (depending on

the software version) that the size of the picture changes. This

can be solved by pushing “P+” and then “P-”.

5.3 Problems And Solving Tips (Related To CSM)

Note: Below described problems are all related to the TV

settings (visible in the CSM menu). The procedures to change

the value (or status) of the different settings are described

above. New value(s) are automatically stored.

5.3.1 Picture Problems

Snowy/Noisy Picture

1. Check in CSM line NOISE FIGURE. In case the value is

"127" or higher, and the value is also high on other

programs, check the aerial cable/aerial system. For some

software versions, the noise figure will only be valid when

“Active Control” is set to “medium” or “maximum”.

2. Check in CSM lines SHARPNESS and NOISE FIGURE. In

case the value of line SHARPNESS is "3" or "4" and the

value of line NOISE FIGURE is high ("127" or higher),

decrease the "Sharpness” value.

Picture Too Dark

1. Press “Menu”, “TV”, “Picture”, “Smart Picture”. In case the

picture improves, increase the “Brightness” or the

“Contrast” value. The new value(s) are automatically

stored (in “personal” pre-set) for all TV channels.

2. Check in CSM line BRIGHTNESS and CONTRAST. If the

value of these lines is low (< "10"), increase the

“Brightness” or the “Contrast” value via the user menu.

Picture Too Bright

1. Press “Menu”, “TV”, “Picture”, “Smart Picture”. In case the

picture improves, decrease the “Brightness” or the

“Contrast” value. The new value(s) are automatically

stored (in “personal” pre-set) for all TV channels.

2. Check in CSM lines BRIGHTNESS and CONTRAST. If the

value of these line is high (> 50), decrease the “Brightness”

value or increase the “Contrast” value via the user menu.

White Line Around Picture Elements And Text

1. Press “Menu”, “TV”, “Picture”, “Smart Picture”. In case the

picture improves, decrease the “Sharpness” value. The

new value is automatically stored (in “personal” pre-set) for

all TV channels.

2. Check in CSM line “Sharpness”. If the value is high,

decrease it. The new value is automatically stored for all

TV channels.

No Picture

Check in CSM line TUNED BIT. In case the value is “No”, install

the required program again. Open the installation menu and

perform manual installation.

EN 16 FTL2.4A AA5.

Service Modes, Error Codes, And Fault Finding

No Picture Or Unstable Picture

A scrambled or decoded signal is received.

Black And White Picture

Check in CSM line COLOUR. In case the value is low (< "10"),

increase the “Colour” value via the user menu. The new value

is automatically stored for all TV channels.

No Colours/colour Lines Around Pcture Elements Or Colours Not Correct Or Unstable Picture

1. Check in CSM line TV SYSTEM. If a “strange” system pops

up, something has gone wrong during installation. Reinstall the channel.

2. If in CSM line TV SYSTEM is “L”, then the installed system

for this pre-set is “France” (SECAM standard). if the

country requires a PAL standard, “West Europe” is

required. Install the required program again: open the

installation menu and perform manual installation. Select

system “West Europe”.

Menu Text Not Sharp Enough

1. Press “MENU”, “TV”, “PICTURE”, “SMART PICTURE”. In

case picture improves, decrease the contrast value. The

new value(s) are automatically stored for all TV channels.

2. Check line “Contrast”. If the value is high, decrease the

contrast value.

5.3.2 Sound Problems

buffer. Diagnosis is done on I

access the I

send and receive I

2

C/UART bus of the television. ComPair can

2

C/UART commands to the micro

2

C/UART level. ComPair can

controller of the television. In this way, it is possible for

ComPair to communicate (read and write) to devices on

2

the I

C/UART buses of the TV-set.

• Manually (by asking questions to you): Automatic

diagnosis is only possible if the micro controller of the

television is working correctly and only to a certain extend.

When this is not the case, ComPair will guide you through

the fault finding tree by asking you questions (e.g. Does the

screen give a picture? Click on the correct answer: YES /

NO) and showing you examples (e.g. Measure test-point I7

and click on the correct oscillogram you see on the

oscilloscope). You can answer by clicking on a link (e.g.

text or a waveform picture) that will bring you to the next

step in the fault finding process.

By a combination of automatic diagnostics and an interactive

question / answer procedure, ComPair will enable you to find

most problems in a fast and effective way.

How To Connect

This is described in the chassis fault finding database in

ComPair.

TO

UART SERVICE

CONNECTOR

TO

I2C SERVICE

CONNECTOR

NO Sound From Left and Right Speaker

Check line 6 “Volume”. The value is low. Increase the value of

“Volume”. The new value(s) are automatically stored (in

“personal” pre-set) for all TV channels.

5.4 Service Tools

5.4.1 ComPair

Introduction

ComPair (Computer Aided Repair) is a service tool for Philips

Consumer Electronics products. ComPair is a further

development on the European DST (service remote control),

which allows faster and more accurate diagnostics. ComPair

has three big advantages:

1. ComPair helps you to quickly get an understanding on how

to repair the chassis in a short time by guiding you

systematically through the repair procedures.

2. ComPair allows very detailed diagnostics (on I

is therefore capable of accurately indicating problem areas.

You do not have to know anything about I

yourself because ComPair takes care of this.

3. ComPair speeds up the repair time since it can

automatically communicate with the chassis (when the

microprocessor is working) and all repair information is

directly available. When ComPair is installed together with

the Force/SearchMan electronic manual of the defective

chassis, schematics and PWBs are only a mouse click

away.

Specifications

ComPair consists of a Windows based fault finding program

and an interface box between PC and the (defective) product.

The ComPair interface box is connected to the PC via a serial

(or RS-232) cable.

For this chassis, the ComPair interface box and the TV

communicate via a bi-directional service cable via the service

connector(s).

The ComPair fault finding program is able to determine the

problem of the defective television. ComPair can gather

diagnostic information in two ways:

• Automatic (by communication with the television): ComPair

can automatically read out the contents of the entire error

2

C level) and

2

C commands

PC VCR I2CPower

9V DC

E_06532_021.eps

180804

Figure 5-3 ComPair interface connection

How To Order

• Starter kit ComPair32/SearchMan32 software and

ComPair interface (excl. transformer): 3122 785 90450.

• ComPair interface (excl. transformer): 4822 727 21631.

• Starter kit ComPair32 software (registration version): 3122

785 60040.

• Starter kit SearchMan32 software: 3122 785 60050.

• ComPair32 CD (update): 3122 785 60070 (year 2002),

3122 785 60110 (year 2003 onwards).

• SearchMan32 CD (update): 3122 785 60080 (year 2002),

3122 785 60120 (year 2003), 3122 785 60130 (year 2004).

• ComPair firmware upgrade IC: 3122 785 90510.

• Transformer (non-UK): 4822 727 21632.

• Transformer (UK): 4822 727 21633.

• ComPair interface cable: 3122 785 90004.

• ComPair interface extension cable: 3139 131 03791.

• ComPair UART interface cable: 3122 785 90630.

Note: If you encounter any problems, contact your local

support desk.

Stepwise Start-up

Under normal circumstances, a fault in the power supply, or an

error during start-up, will switch the television to protection

mode. ComPair can take over the initialisation of the television.

In this way, it is possible to distinguish which part of the startup routine (hence which circuitry) is causing the problem.

Take notice that the transition between two steps can take

some time, so give the set some time to reach a stable state.

During the transition time, the LED can blink strangely.

Service Modes, Error Codes, And Fault Finding

EN 17FTL2.4A AA 5.

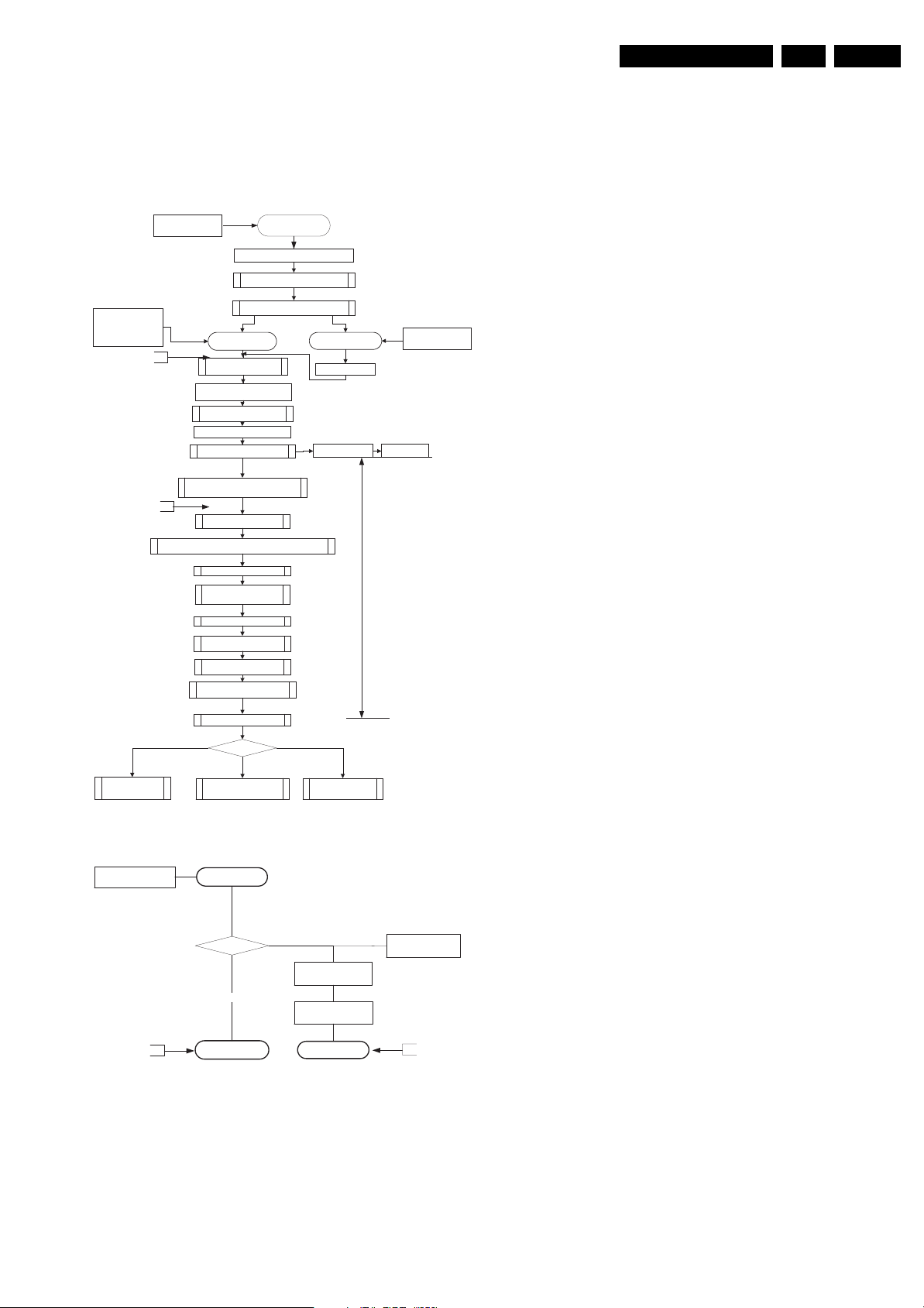

Stepwise start- up explanation

This is realised via ComPair and is very helpful when a

protection is activated (see also chapter “Protections”). The

following diagram shows the start-up procedure of the set.

Every step of the stepwise start-up (also called trapped startup) in the diagram corresponds with the number of times the

LED blinks.

OUT

OTC gets supply voltage

OTC resets, Initialise IO pins

Reset Audio= HIGH

Read NVM identification

enable watchdog

Stand by bit = OFF

OFF

Time out:

30X200msec

Goto protection

400msec>t>200msec

Start time extraction

Start P50 recording

Start EPG loading

Standby bit = OFF

Ambient light ON

Trapped Startup 1

Trapped Startup 2

Mains cord IN

Stand by

Put Standby line LOW

CPU GO becomes HIGH

Set STBYEN,VCCON,PFCON= 1

Only FHP (opt 27)

Keep sound amplifiers muted

with sound enable = HIGH

+5V and +8V is switched ON

+8V and +5V get their nominal

level, detected by the OTC

Activate protection algorithms for +8V and

+5V and I²C (start I²C protection the

moment the component is initialised).

Read rest of NVM

information

Initialize HIP: IF, source selection, 2fh input, video processing

Switch ON the sync output: set_syncout_tristate= OFF

Initialize tuner

Initialize 3D Combfilter

or Initialize Columbus

Initialize PICNIC + screen info

Initialize rest of PIP/DW

module

Start TXT acquisition

and time extraction

Reset Audio = LOW

and Initialize MSP

5.4.2 LVDS Tool

Introduction

This service tool (also called “ComPair Assistant 1“) may help

you to identify, in case the TV does not show any picture,

whether the Small Signal Board (SSB) or the display of a Flat

TV is defective.

Furthermore it is possible to program EPLDs with this tool

(Byteblaster). Read the user manual for an explanation of this

feature.

Since 2004, the LVDS output connectors in our Flat TV models

are standardised (with some exceptions). With the two

delivered LVDS interface cables (31p and 20p) you can cover

most chassis (in special cases, an extra cable will be offered).

Tact switch

When operating, the tool will show a small (scaled) picture on

a VGA monitor. Due to a limited memory capacity, it is not

possible to increase the size when processing high-resolution

LVDS signals (>= 1280x768). Generally this tool is intended to

determine if the SSB is working or not. Thus to determine if

LVDS, RGB, and sync signals are okay.

How To Connect

Connections are explained in the user manual, which is

delivered with the tool.

Note: To use the LVDS tool, you must have ComPair release

2004-1 (or later) on your PC (engine version >= 2.2.05).

For every TV type number and screen size, one must choose

the proper settings via ComPair. The ComPair file will be

updated regularly with new introduced chassis information.

How To Order

• LVDS tool (incl. two LVDS cables: 31p and 20p):

3122 785 90671.

• Service Manual LVDS tool:

3122 785 00810.

Initialize EBILD

Screen type

Start up LCD

opt 3,4,5,6

Initialize PDP FHP

opt 2,8

Initialize PDP SDI

opt 0,1,7

Figure 5-4 Stepwise start-up part 1

Start up LCD

Trapped Startup 3

Start

Stand-by bit set ?

yes

Semi stand by

no

Ebild Power ON

Output Blanking OFF

LAMP ON

ON

Figure 5-5 Stepwise start-up part 2

Note: When the set is in stepwise mode and, due to stepping-

up, a protection is activated, the set will really go into protection

(blinking LED). The set will not leave the stepwise-mode

however. If state X is the state where the set went to protection,

stepwise start-up will return to state X-1. At state (X-1)

diagnostic measurements can be performed. Also, in the short

time the set is in state X but not yet in protection, you can also

do some measurements.

E_14620_048.eps

080805

LCD ON

Trapped Startup 4

E_14620_049.eps

170504

5.5 Error Codes

5.5.1 Introduction

The error code buffer contains all detected errors since the last

time the buffer was erased. The buffer is written from left to

right, new errors are logged at the left side, and all other errors

shift one position to the right.

When an error has occurred, the error is added to the list of

errors, provided the list is not full or the error is a protection

error.

When an error occurs and the error buffer is full, then the new

error is not added, and the error buffer stays intact (history is

maintained), except when the error is a protection error.

To prevent that an occasional error stays in the list forever, the

error is removed from the list after 50+ operation hours.

When multiple errors occur (errors occurred within a short time

span), there is a high probability that there is some relation

between them.

5.5.2 How To Read The Error Buffer

Use one of the following methods:

• On screen via the SAM (only if you have a picture).

Examples:

– 0 0 0 0 0: No errors detected

– 6 0 0 0 0: Error code 6 is the last and only detected

error

– 9 6 0 0 0: Error code 6 was first detected and error code

9 is the last detected error

• Via the blinking LED procedure (when you have no

picture). See next paragraph.

•Via ComPair.

EN 18 FTL2.4A AA5.

Service Modes, Error Codes, And Fault Finding

5.5.3 How To Clear The Error Buffer

Use one of the following methods:

• By activation of the “RESET ERROR BUFFER” command

in the SAM menu.

• With a normal RC, key in sequence “MUTE” followed by

“062599” and “OK”.

• When you transmit the commands “DIAGNOSE” - “99” “OK” with ComPair (or with a DST).

• If the content of the error buffer has not changed for 50+

hours, it resets automatically.

5.5.4 Error Codes

In case of non-intermittent faults, clear the error buffer before

you begin the repair. This to ensure that old error codes are no

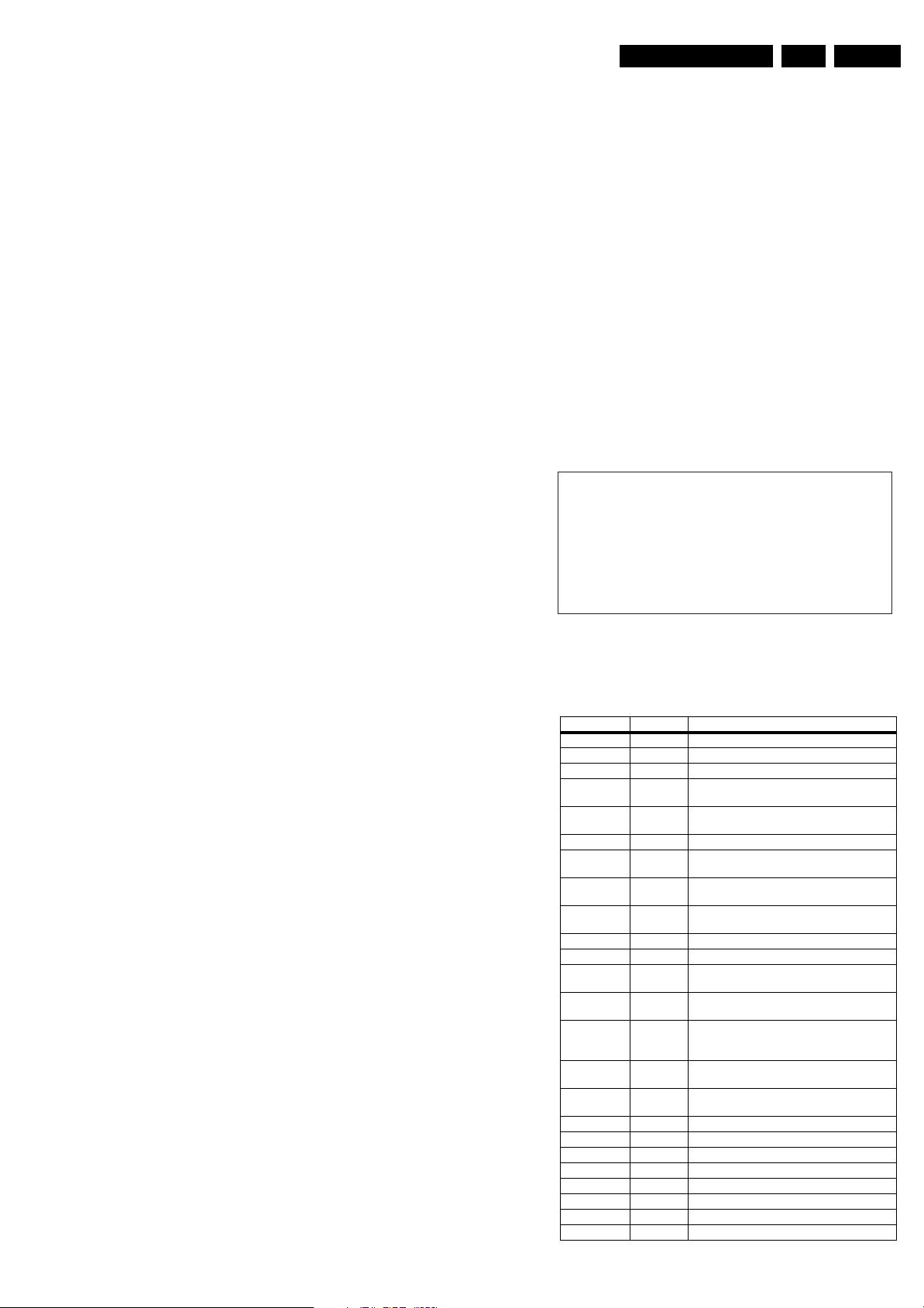

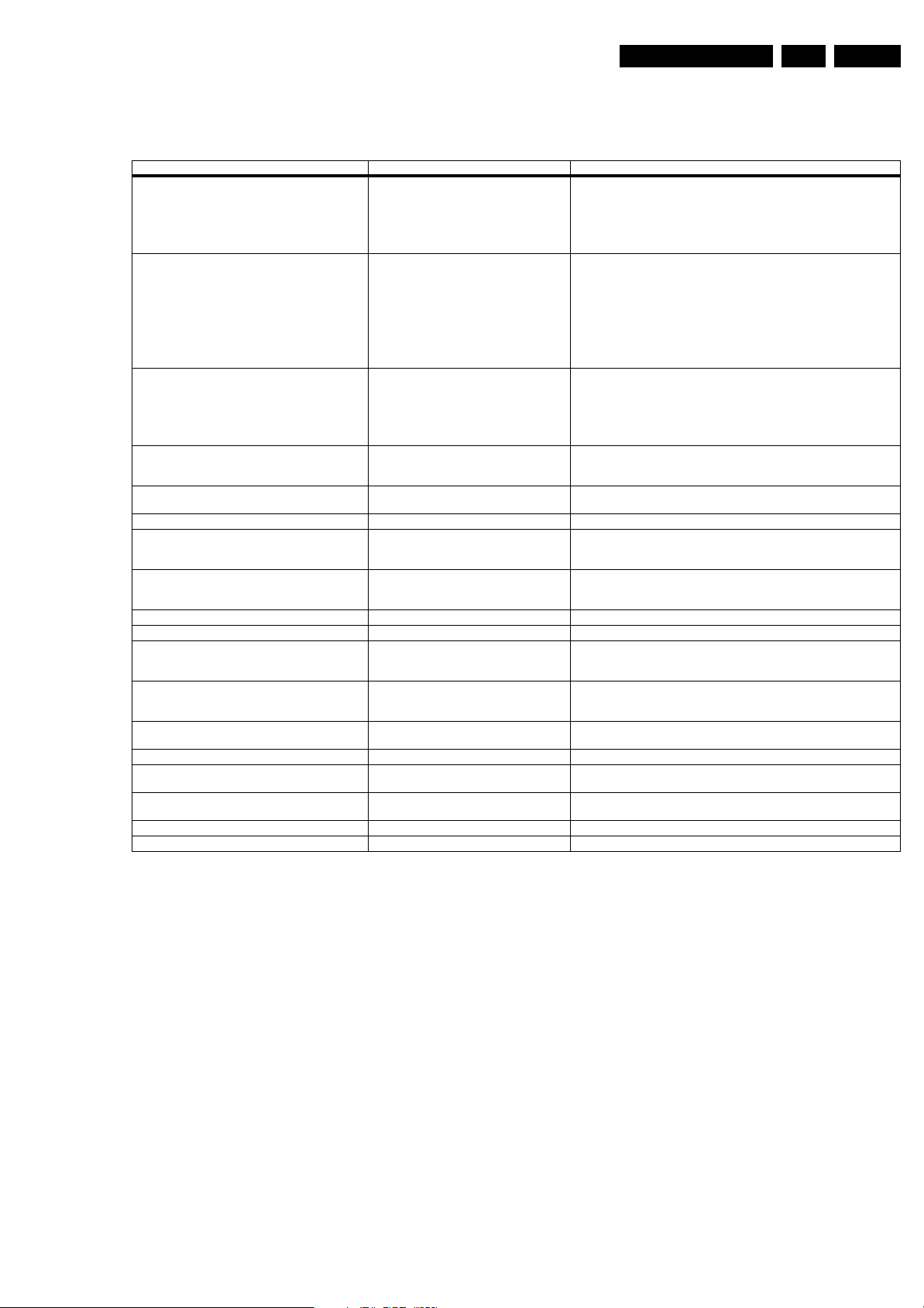

Table 5-3 Error Code Overview

Error Device Description Def. item Def. Module indication Diagr.

1 M24Cxx NVM, spontaneous blinking error 1 7011 - B5a

3 SAA4978 PICNIC 7713 Feature Box B3a

4 Supply 5 V 5V protection - +5V Supply B5a

5 Supply 8 V 8V protection - +8V Supply B5a

6Slow I

2

C bus blocked Spontaneous blinking error 6 - Slow I2C Blocked 8 TDA932x HIP High-end Input Processor 7323 Chroma IF IO B2

13 UV1318/... Tuner protection 1T01 Tuner B13a

14 MSPxxxx ITT sound processor 7A02 Audio module B6a

2

18 Fast I

C bus blocked Spontaneous blinking error 18 - Fast I2C Blocked 21 M62320 I/O Expander 7P56 Video Dual Screen B15b

26 SAA4998 FEM (Falconic with Embedded Memory) 7760 +3V (FBX) Supply B3b

27 T6TX5 Eagle 1C 7720 +3V (FBX) Supply B3c

32 M29W400xx Flash Ram (EPG) 7012 EPG Memory B5a

35 T6TU5 Columbus 7752 Video Control B3d

55 DC/DC converter One of the voltages is not ok + protection error - MSB 76 Audio supply Audio supply protection - - 118 AD9883A AD converter 7L01 HD B19a

121 EPLD EPLD error 7V01 Video control B19d

Note: If error 3 or error 55 appears, sometimes error 16 is also logged. Error 16 is a non existing error.

longer present. Before clearing the buffer, write down the

content, as this history can give you significant information.

If possible, check the entire contents of the error buffer. In

some situations, an error code is only the result of another error

code and not the actual cause (e.g., a fault in the protection

detection circuitry can also lead to a protection).

There are various errors:

2

•I

C device errors.

2

•I

C bus errors.

• Protection errors.

• Errors not related to an I

2

C device, but of importance:

– FEM (Falconic with Embedded Memory) (Error 26):

at start-up, after initialisation of the PICNIC, the

presence of the FEM can be checked.

– Eagle (Error 27): at start-up, after initialisation of the

PICNIC, the presence of the Eagle can be checked.

Note:

• Error codes 1, 6, or 18 are protection codes and in this

case, supplies of some circuits will be switched “off”. Also,

in protection, the LED will blink the number of times

equivalent to the most recent error code.

Service Modes, Error Codes, And Fault Finding

EN 19FTL2.4A AA 5.

5.6 The Blinking LED Procedure

5.6.1 Introduction

Via this procedure, you can make the contents of the error

buffer visible via the front LED. This is especially useful for fault

finding, when there is no picture.

When the SDM is activated, the front LED will show (blink) the

contents of the error-buffer. Error-codes > 10 are shown as

follows:

– A long blink of 750 ms (which is an indication of the decimal

digit),

– A pause of 1.5 s,

– “n” short blinks (where “n” = 1 - 9),

– When all the error-codes are displayed, the sequence

finishes with a LED blink of 3 s,

– The sequence starts again.

Note: For error codes >100, the first two digits (hundred-andten) are considered as one digit (one long blink)

Example: Error 12 9 6 121 0.

After activation of the SDM, the front LED will show:

– 1 long blink of 750 ms (which is an indication of the decimal

digit) followed by a pause of 1.5 s,

– 2 short blinks followed by a pause of 3 s,

– 9 short blinks followed by a pause of 3 s,

– 6 short blinks followed by a pause of 3 s,

– 12 long blinks of 750 ms (which is an indication of “120”)

followed by a pause of 1.5 s,

– 1 short blink followed by a pause of 3 s,

– 1 long blink of 3 s to finish the sequence,

– The sequence starts again.

Note: If errors 1, 6, or 18 occur, the LED always gives the last

occurred error even if the TV is NOT in service mode.

protection mode is indicated by the blinking of the front LED at

a frequency of 3 Hz (or by a coded blinking in special cases).

The content of the error buffer can be read via the service menu

(SAM), the blinking LED procedure or via DST/ComPair.

To get a quick diagnosis, this chassis has three service-modes

implemented:

• The Customer Service Mode (CSM).

• The Service Default Mode (SDM). Start-up of the TV in a

predefined way.

• The Service Alignment Mode (SAM). In this mode, items

of the TV can be adjusted via a menu.

You can activate both SDM and SAM modes via the “service

pads” on the SSB (see figure “Service pads”), via an RCtransmitter (DST or standard RC), or via ComPair. It is not

possible to activate the SAM in “stand-by”; the TV has to be in

“normal operation” mode.

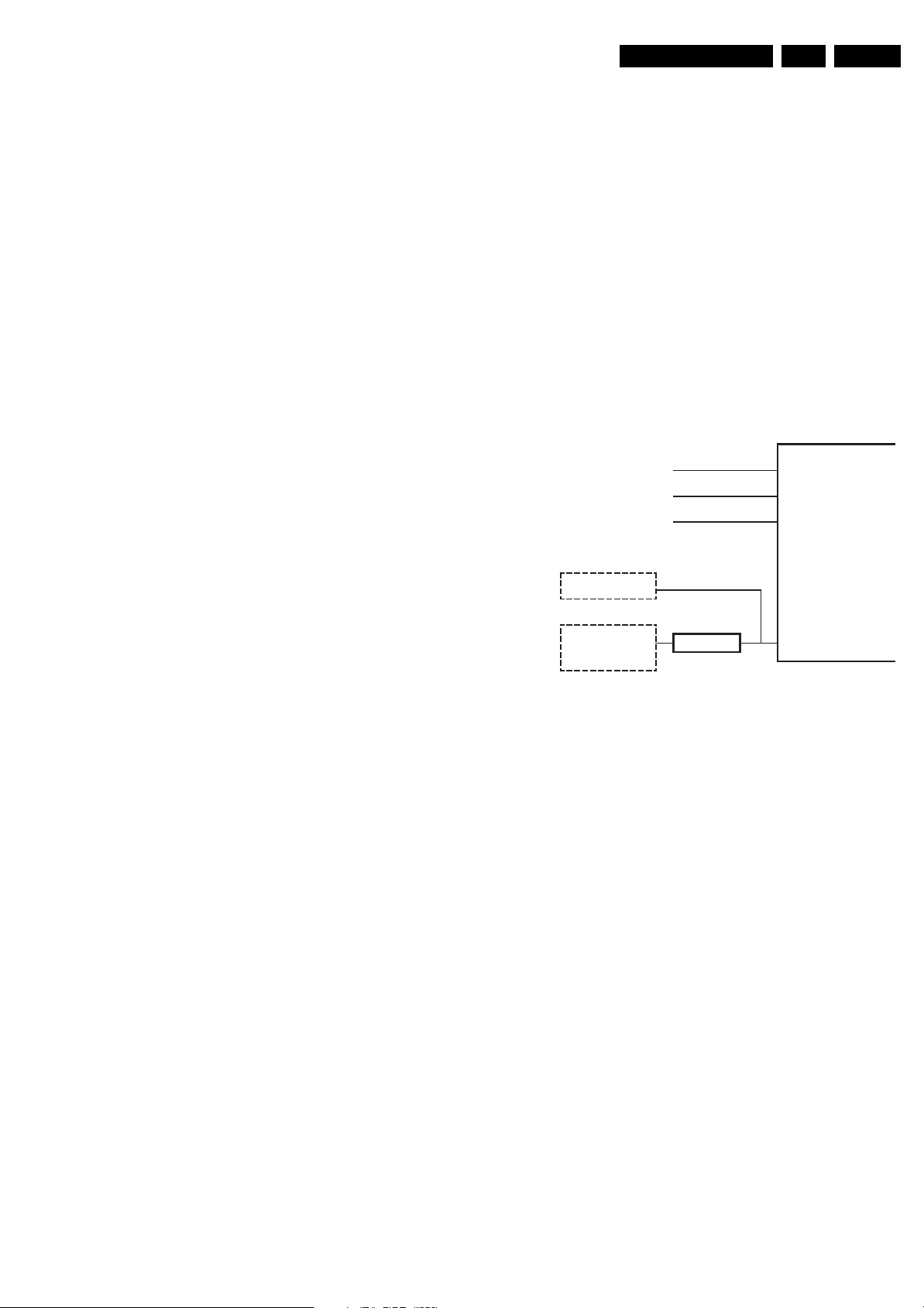

The “Protection Diagram” shows the structure of the protection

system. See diagram below.

TUNER

FAST I2C BUS BLOCKED

SLOW I2C BUS BLOCKED

EPLD

+

FBX

+

3D COMB

DC_PROT (from audio)

+8V_CON

+5V_CON

DC/DC

PROTECTION

IRQ-DIGITAL (98)

+8V SENSE (105)

+5V SENSE (106)

I2C

OTC

E_14650_032.eps

170604

5.6.2 How To Activate

Use one of the following methods:

• Activate the SDM (only via soldering pads marked “SDM”

on SSB, see figure “Service pads”). The blinking front LED

will show the entire contents of the error buffer (this works

in “normal operation” mode and in “protection” mode).

• Transmit the commands “MUTE” - “062500” - “OK” with a

normal RC. The complete error buffer is shown. Take

notice that it takes some seconds before the blinking LED

starts.

• Transmit the commands “MUTE” - “06250x” - “OK” with a

normal RC (where “x” is a number between 1 and 5). When

x= 1 the last detected error is shown, x= 2 the second last

error, etc.... Take notice that it takes some seconds before

the blinking LED starts.

• “DIAGNOSE X” with the DST (where “x” is a number

between 1 and 5). When x= 1 the last detected error is

shown, x= 2 the second last error, etc.... When x = 0 all

errors are shown.

5.7 Protections

5.7.1 Introduction

This chassis has only one microprocessor (OTC), which

remains active during Stand-by. This because power of the

microprocessor and the attached memory chip set is coming

from the 3V3 supply, which is derived from the 5V Stand-bycircuitry. Therefore, in both Power-on as in Stand-by mode, the

microprocessor is connected to this power supply.

If a fault situation is detected, an error code will be generated

and if necessary, the TV is put in protection mode. The

Figure 5-6 Protection diagram

There are several types of protections:

2

•I

C related protections.

• OTC related protections (via polling on I/O pins or via

algorithms).

• Hardware protection

All protections are explained below.

5.7.2 I

2

C Related Protections

In normal operation, some registers of the I

are refreshed every 200 ms. During this sequence, the I

buses and the I

2

An I

C protection will take place if the SDA and SCL lines are

2

C ICs are checked.

2

short-circuited to ground, or to each other. An I

occur, if the power supply of the IC is missing.

DC/DC protection: When a 3V3 supply is short-circuited, the

DC/DC converter switches “off” and goes in protection. The

FBX, EPLD IC, and 3D comb IC have no supply voltage and

give no acknowledge. In this case, the TV should go into

protection. An error code is written in the NVM: DC/DC error.

FBX protection: the FBX protection is not available any more.

It is replaced by the DC/DC protection.

5.7.3 OTC Related Protections

If a protection is detected at an OTC input, the OTC will start to

scan all protection inputs every 200 ms for 5 times. If the

protection on one of the inputs is still active after 1 s, the

microprocessor will put the TV in the protection mode. Before

the scanning is started, a so-called “ESD refresh” is carried out.

C controlled ICs

2

C error will also

2

C

EN 20 FTL2.4A AA5.

Service Modes, Error Codes, And Fault Finding

This is done, because the interrupt on one of the inputs is

possibly caused either by a flash or by ESD. As a flash or ESD

can influence IC settings, the HIP, MSP, 3D Comb and wireless

module (not used in this set) are initialised again, to ensure the

normal picture and sound conditions of the TV.

8 V and 5 V protections: The microprocessor senses the

presence of the 8 V and 5 V (via the “+5V_CON” and

“+8V_CON” lines). If one (or both) of these voltages is (are) not

present, an error code is stored in the error buffer of the NVM,

and the TV is put in the protection mode.

Audio Supply protection: The OTC senses if the audio

module is in protection via IRQ-DIGITAL (pin 98 of OTC). If this

is the case, the OTC puts the TV in protection.

5.7.4 Hardware Protection

Short-circuiting the 3V3 supply from the DC/DC converter will

shut down the DC/DC converter. The absence of the 3V3

supply line is also sensed via I

2

C (see description Audio Supply