Philips BDL4631V Schematic

Colour Television Chassis

QCS1.0S

LA

H_17540_000.eps

140108

Contents Page Contents Page

1. Technical Specifications, Connections, and Chassis

Overview 2

2. Safety Instructions, Warnings, and Notes 5

3. Directions for Use 6

4. Mechanical Instructions 7

5. Service Modes, Error Codes, and Fault Finding 14

6. Block Diagrams, Test Point Overview, and

Waveforms

Wiring Diagram 19

Block Diagram 20

7. Circuit Diagrams and PWB Layouts Diagram PWB

Scaler Board: Power [S-A01] 21 37

Scaler Board: HDMI Input [S-A02] 22 37

Scaler Board: HDMI Switch [S-A03] 23 37

Scaler Board: Analog Input [S-A04] 24 37

Scaler Board: Analog Switch & Output [S-A05] 25 37

Scaler Board: Scaler [S-A06] 26 37

Scaler Board: DDR-SDRAM [S-A07] 27 37

Scaler Board: MCU [S-A08] 28 37

Scaler Board: Fan Control-RTC [S-A08] 29 37

Scaler Board: Panel Interface [S-A09] 30 37

Scaler Board: Audio Amplifier [S-A10] 31 37

Scaler Board: Board Diagram [S-A11] 32 37

Scaler Board: Audio Input [S-A12] 33 37

Scaler Board: Video Decoder [S-A13] 34 37

Scaler Board: Video Decoder SDRAM [S-A14] 35 37

Scaler Board: RS232 [S-A15] 36 37

Keyboard Panel [B] 38 38

IR & LED Panel [L] 39 39

Power Board [P] 40 n.a.

Speaker Board [SP] 41 41

8. Alignments 43

9. Circuit Descriptions, Abbreviation List, and IC Data

Sheets 46

10. Spare Parts List 50

11. Revision List 51

©

Copyright 2008 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Published by JH 0862 BU CD Consumer Care Printed in the Netherlands Subject to modification EN 3122 785 17540

EN 2 QCS1.0S LA1.

Technical Specifications, Connections, and Chassis Overview

1. Technical Specifications, Connections, and Chassis Overview

Index of this chapter:

1.1 Technical Specifications

1.2 Connection Overview

1.3 Chassis Overview

Notes:

• Data below can deviate slightly from the actual situation,

due to the different set executions

• Specifications are indicative (subject to change).

1.1 Technical Specifications

1.1.1 Vision

Display type : LCP Display Panel

Screen size : 46" (117 cm), 16:9

Resolution (H × V pixels) : 1920 (× 3) × 1080

Typ. contrast ratio : 1500:1

Min. light output (cd/m

Display colours : 16.7 Million

Viewing angle (H / V degrees) : 176 / 176 degree

Connectivity : VGA-in

Supported video formats : 480i/p

Supported computer formats : 640 × 480 @ 60, 72,

2

) : 450

: VGA-out

:2× HDMI

: Component (YPbPr)

:2× Composite CVBS

: Composite CVBS-out

: S-video

: 3.5 mm audio in

: Audio L/R out

: L/R Speaker-out

: RS232-in

: RS232-out

: 576i

: 720p

: 1080i

: 720 × 400 @ 70 Hz

: 800 × 600 @ 60 Hz

: 1024 × 768 @ 60 Hz

: 1280 × 720 @ 60 Hz

: 1280 × 768 @ 60 Hz

: 1280 × 1024 @ 60 Hz

: 1360 × 768 @ 60 Hz

: 1600 × 1200 @ 60 Hz

: 1920 × 1080 @ 50,

75 Hz

60 Hz

1.1.3 Miscellaneous

Power supply:

- Mains voltage (V

- Mains frequency (Hz) : 50/60 Hz

Ambient conditions:

- Temperature range (°C) : +5 to +40

- Maximum humidity : 80% R.H.

Power consumption (values are indicative)

- Normal operation (W) : ≈ 285

- Stand-by (W) : <5

Dimensions (W × H × D in mm) : 1122 × 663 × 136

Weight (kg) : 32.6

Weight incl. packaging (kg) : 40.2

) : 100 - 240

AC

1.1.2 Sound

Sound systems : Mono

Maximum power (W

):2 × 7 @ 8 Ohm

RMS

:Stereo

Technical Specifications, Connections, and Chassis Overview

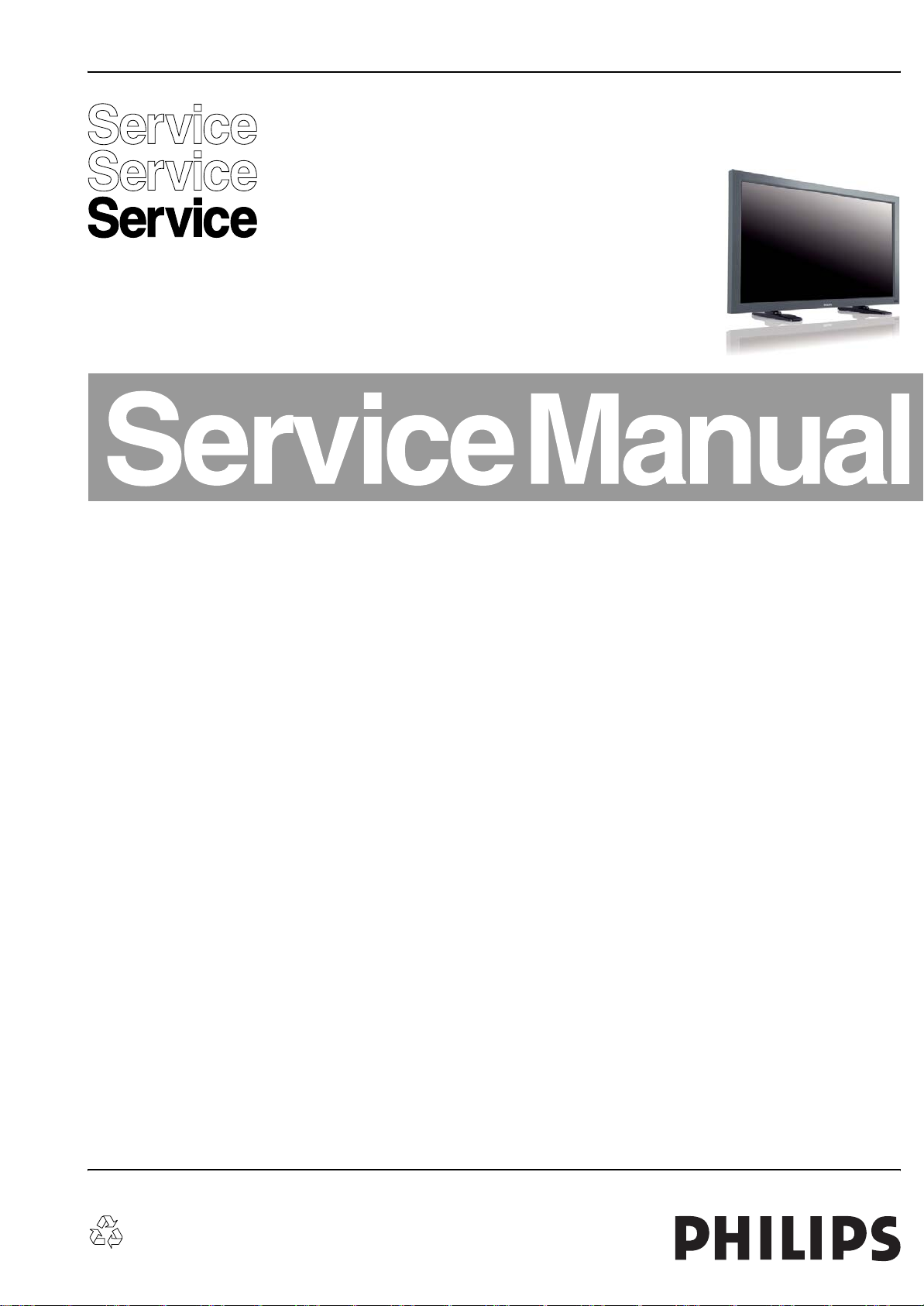

1.2 Connection Overview

EN 3QCS1.0S LA 1.

AUDIO IN 1

AUDIO IN 2, 3

AUDIO OUT

SPEAKER CONNECTIONS POWER SUPPLY RGB 1

Note: The following connector colour abbreviations are used

(acc. to DIN/IEC 757): Bk= Black, Bu= Blue, Gn= Green, Gy=

Grey, Rd= Red, Wh= White, and Ye= Yellow.

1.2.1 Rear Connections

Spring Clip Speaker Connections: Audio - Out

EXTERNAL CONTROL RS-232

COMPOSITE VIDEO IN

COMPOSITE VIDEO BNC

RGB 2

HDMI

RGB 3

VGA

HDMI

Figure 1-1 Rear and Side I/O connections

18 - +5V j

19 - HPD Hot Plug Detect j

20 - Ground Gnd H

VGA RGB 3 & RGB OUT: Video RGB - In, Out

(OUT)

1

6

11

RGB OUT

VGA

E_06532_002.eps

5

10

15

050404

(IN)

(IN)

(OUT)

DVD/HD IN

YPbPr

I_17540_002.eps

280108

E_06532_045.eps

021107

Figure 1-2 Spring Clip Speaker Terminals

Bk - Speaker Left Gnd H

Rd - Speaker Left 7 W / 8 ohm j

Bk - Speaker Right Gnd H

Rd - Speaker Right 7 W / 8 ohm j

HDMI RGB 1 & 2: Digital Video, Digital Audio - In

19

18 2

1

E_06532_017.eps

250505

Figure 1-3 HDMI (type A) connector

1 -D2+ Data channel j

2 -Shield Gnd H

3 -D2- Data channel j

4 -D1+ Data channel j

5 -Shield Gnd H

6 -D1- Data channel j

7 -D0+ Data channel j

8 -Shield Gnd H

9 -D0- Data channel j

10 - CLK+ Data channel j

11 - Shield Gnd H

12 - CLK- Data channel j

13 - n.c.

14 - n.c.

15 - DDC_SCL DDC clock j

16 - DDC_SDA DDC data jk

17 - Ground Gnd H

Figure 1-4 VGA Connector

1 -Video Red 0.7 V

2 -Video Green 0.7 V

3 -Video Blue 0.7 V

/ 75 ohm jk

PP

/ 75 ohm jk

PP

/ 75 ohm jk

PP

4-n.c.

5 -Ground Gnd H

6 -Ground Red Gnd H

7 -Ground Green Gnd H

8 -Ground Blue Gnd H

9-+5V

+5 V jk

DC

10 - Ground Sync Gnd H

11 - n.c.

12 - DDC_SDA DDC data jk

13 - H-sync 0 - 5 V jk

14 - V-sync 0 - 5 V jk

15 - DDC_SCL DDC clock jk

DVD/HD IN: Cinch Video YPbPr - In, Audio - In

Gn - Video Green/Y 0.7 V

Bu -Video Blue/Pb 0.7 V

Rd - Video Red/Pr 0.7 V

/ 75 ohm jq

PP

/ 75 ohm jq

PP

/ 75 ohm jq

PP

1.2.2 Side Connections

Mini Jack: Audio IN1 - In

Wh - Audio L 0.5 V

Rd - Audio R 0.5 V

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

Cinch: Audio IN 2 & 3 - In

Wh - Audio L 0.5 V

Rd - Audio R 0.5 V

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

EN 4 QCS1.0S LA1.

Technical Specifications, Connections, and Chassis Overview

Cinch: Audio - Out

Rd - Audio - R 0.5 V

Wh - Audio - L 0.5 V

/ 10 kohm kq

RMS

/ 10 kohm kq

RMS

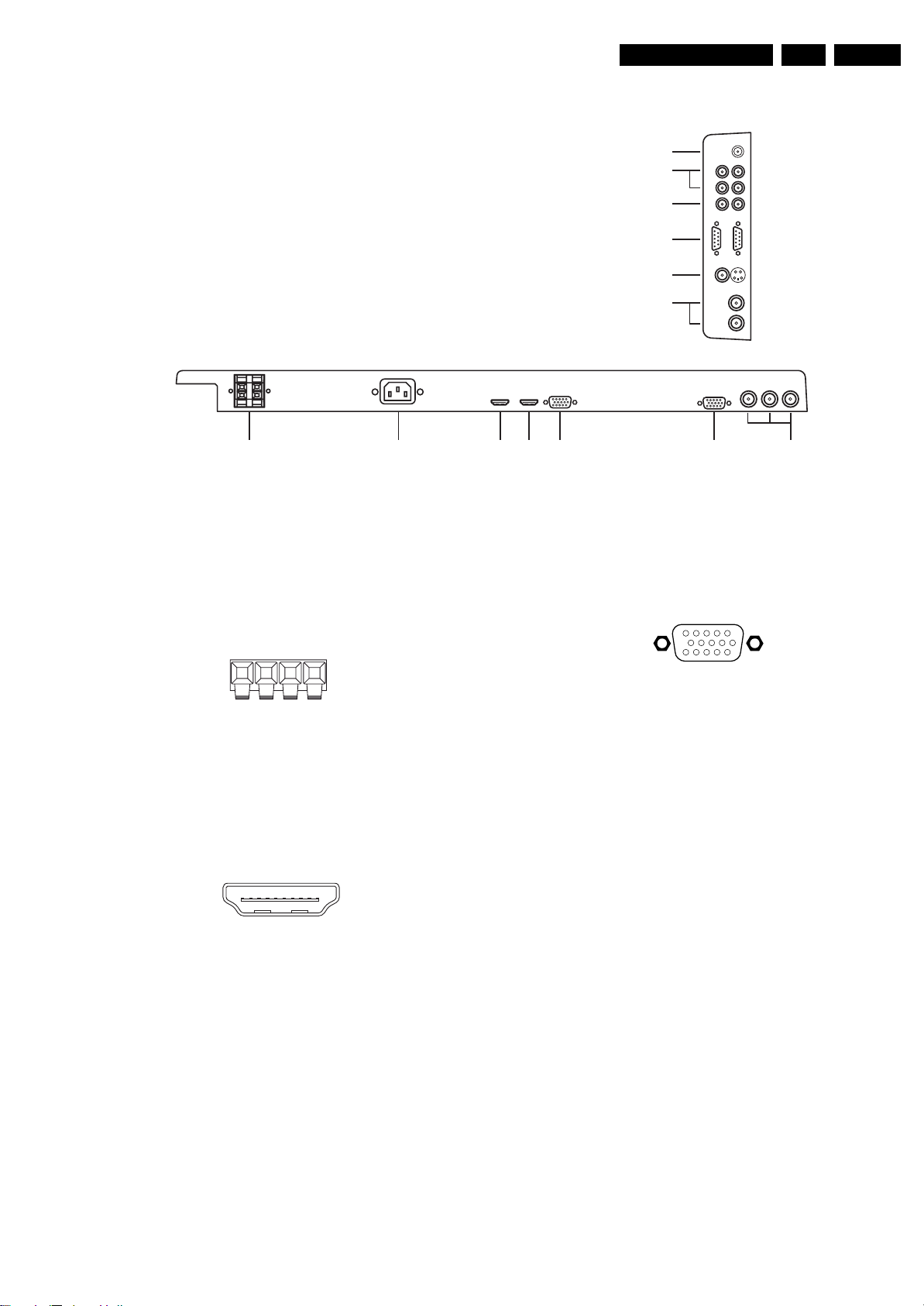

External Control Connector (RS232-UART) Out - In

1

6

5

9

E_06532_005.eps

050404

Figure 1-5 9-pin Sub-D Connector

1 -DCD Carrier Detect j

2 -RxD Receive j

3 -TxD Transmit k

4 -DTR Data Terminal Ready k

5 -Gnd Ground H

6 -DSR Data Set Ready j

7 -RTS Request To Send k

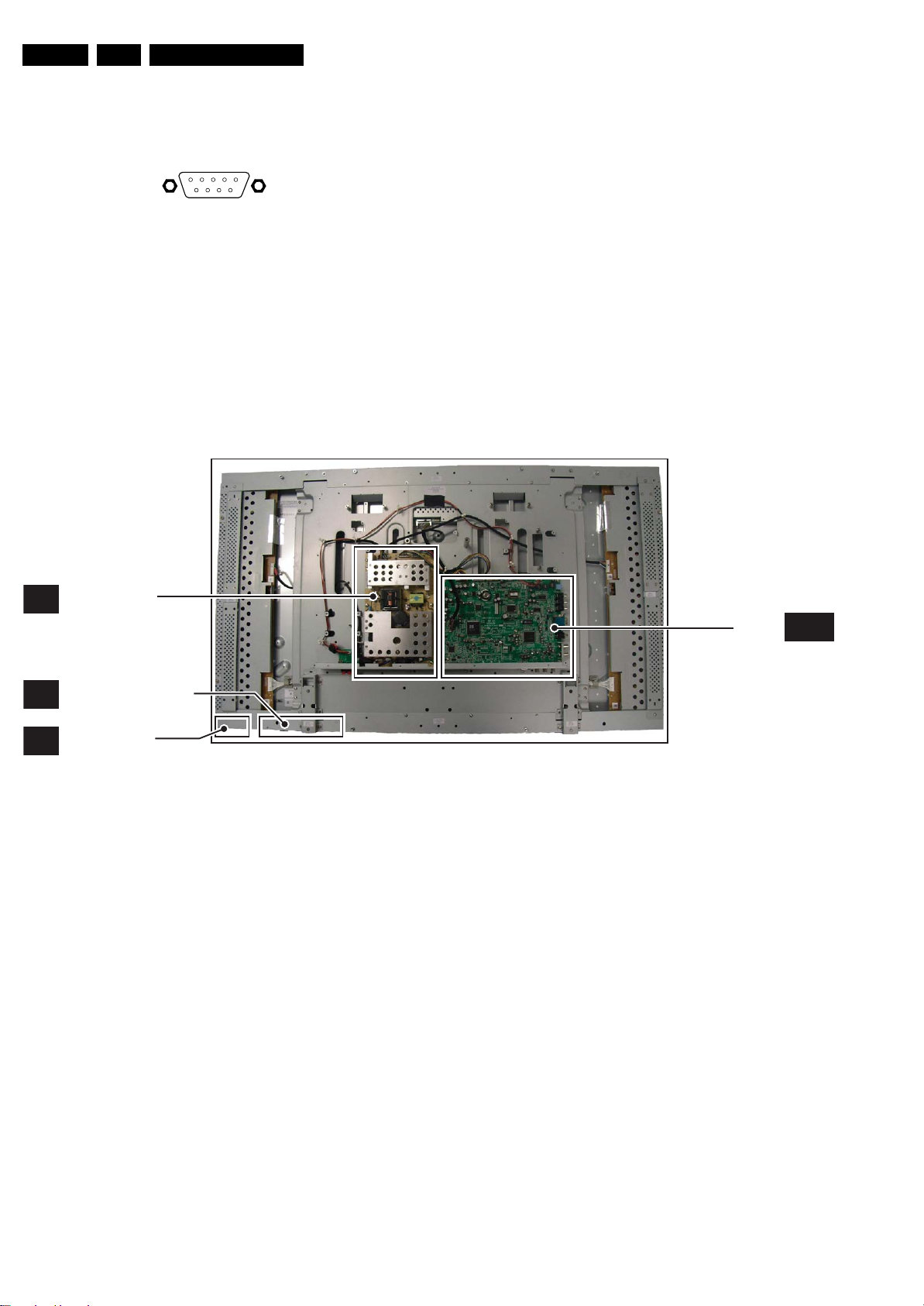

1.3 Chassis Overview

8 -CTS Clear To Send j

9 -RI Ring Indicator j

Cinch: Composite Video CVBS - In

Ye -Video CVBS 1 V

/ 75 ohm jq

PP

S-Video (Hosiden): Composite Video Y/C - In

1 -Ground Y Gnd H

2 -Ground C Gnd H

3 - Video Y 1 V

4 - Video C 0.3 V

/ 75 ohm j

PP

P / 75 ohm j

PP

BNC: Composite Video CVBS - In

Ye -Video CVBS 1 V

/ 75 ohm jq

PP

BNC: Composite Video CVBS - Out

Ye -Video CVBS 1 V

/ 75 ohm kq

PP

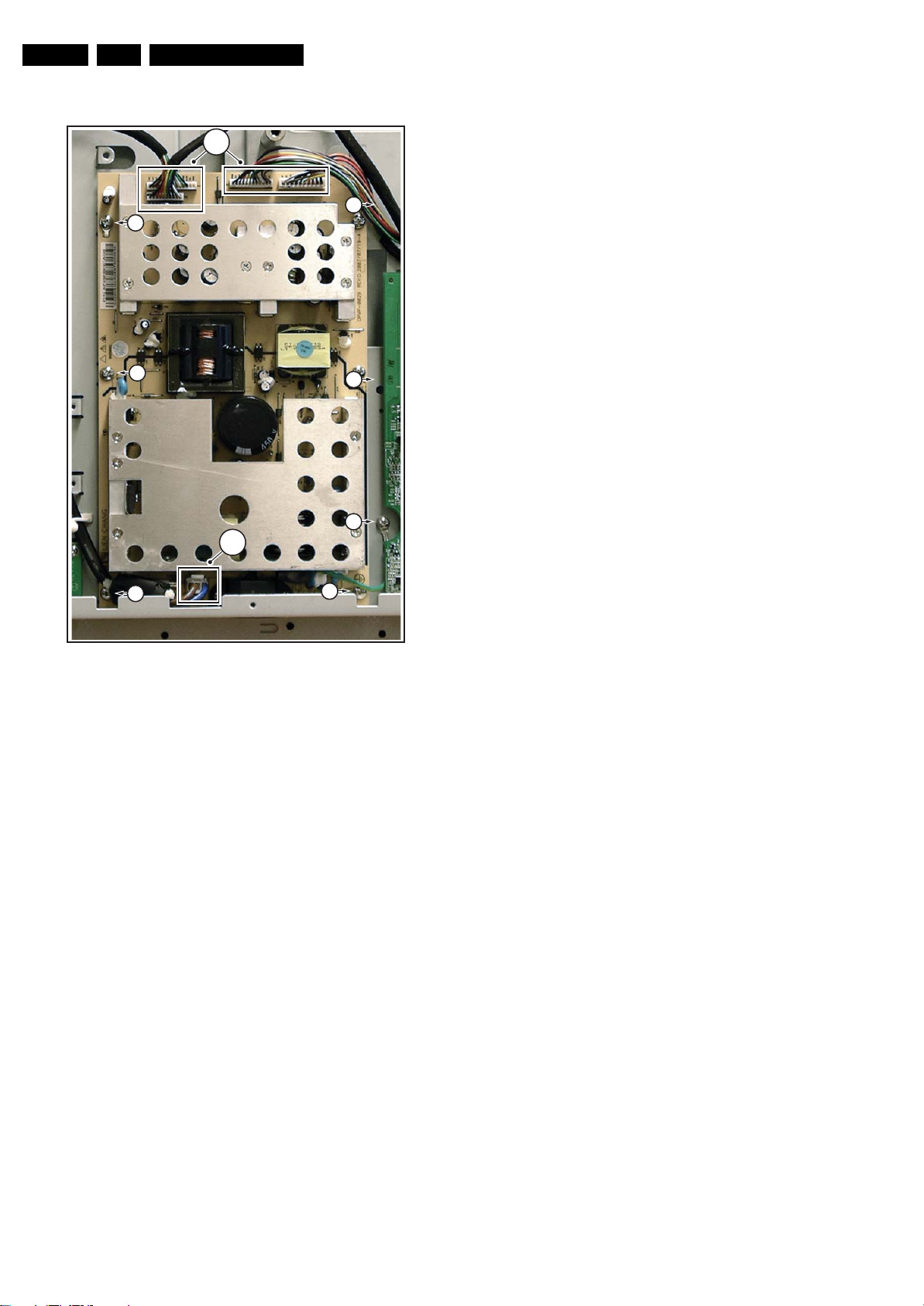

POWER BOARD

P

KEYBOARD & CONTROL

B

PANEL

IR & LED PANEL

L

Figure 1-6 PWB/CBA locations

I_17540_047.eps

310108

SCALER

BOARD

S-A

Safety Instructions, Warnings, and Notes

2. Safety Instructions, Warnings, and Notes

EN 5QCS1.0S LA 2.

Index of this chapter:

2.1 Safety Instructions

2.2 Warnings

2.3 Notes

2.1 Safety Instructions

Safety regulations require the following during a repair:

• Connect the set to the Mains/AC Power via an isolation

transformer (> 800 VA).

• Replace safety components, indicated by the symbol h,

only by components identical to the original ones. Any

other component substitution (other than original type) may

increase risk of fire or electrical shock hazard.

Safety regulations require that after a repair, the set must be

returned in its original condition. Pay in particular attention to

the following points:

• Route the wire trees correctly and fix them with the

mounted cable clamps.

• Check the insulation of the Mains/AC Power lead for

external damage.

• Check the strain relief of the Mains/AC Power cord for

proper function.

• Check the electrical DC resistance between the Mains/AC

Power plug and the secondary side (only for sets that have

a Mains/AC Power isolated power supply):

1. Unplug the Mains/AC Power cord and connect a wire

between the two pins of the Mains/AC Power plug.

2. Set the Mains/AC Power switch to the “on” position

(keep the Mains/AC Power cord unplugged!).

3. Measure the resistance value between the pins of the

Mains/AC Power plug and the metal shielding of the

tuner or the aerial connection on the set. The reading

should be between 4.5 Mohm and 12 Mohm.

4. Switch “off” the set, and remove the wire between the

two pins of the Mains/AC Power plug.

• Check the cabinet for defects, to prevent touching of any

inner parts by the customer.

2.2 Warnings

• Where necessary, measure the waveforms and voltages

with (D) and without (E) aerial signal. Measure the

voltages in the power supply section both in normal

operation (G) and in stand-by (F). These values are

indicated by means of the appropriate symbols.

2.3.2 Schematic Notes

• All resistor values are in ohms, and the value multiplier is

often used to indicate the decimal point location (e.g. 2K2

indicates 2.2 kohm).

• Resistor values with no multiplier may be indicated with

either an “E” or an “R” (e.g. 220E or 220R indicates 220

ohm).

• All capacitor values are given in micro-farads (μ = × 10

nano-farads (n = × 10

• Capacitor values may also use the value multiplier as the

decimal point indication (e.g. 2p2 indicates 2.2 pF).

• An “asterisk” (*) indicates component usage varies. Refer

to the diversity tables for the correct values.

• The correct component values are listed in the Spare Parts

List. Therefore, always check this list when there is any

doubt.

2.3.3 BGA (Ball Grid Array) ICs

Introduction

For more information on how to handle BGA devices, visit this

URL: www.atyourservice.ce.philips.com (needs subscription,

not available for all regions). After log-in, select “Magazine”,

then go to “Repair downloads”. Here you will find Information

on how to deal with BGA-ICs.

BGA Temperature Profiles

For BGA-ICs, you must use the correct temperature-profile,

which is coupled to the 12NC. For an overview of these profiles,

visit the website www.atyourservice.ce.philips.com (needs

subscription, but is not available for all regions)

You will find this and more technical information within the

“Magazine”, chapter “Repair downloads”.

For additional questions please contact your local repair help

desk.

-9

), or pico-farads (p = × 10

-12

-6

),

).

• All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD w). Careless handling

during repair can reduce life drastically. Make sure that,

during repair, you are connected with the same potential as

the mass of the set by a wristband with resistance. Keep

components and tools also at this same potential.

• Be careful during measurements in the high voltage

section.

• Never replace modules or other components while the unit

is switched “on”.

• When you align the set, use plastic rather than metal tools.

This will prevent any short circuits and the danger of a

circuit becoming unstable.

2.3 Notes

2.3.1 General

• Measure the voltages and waveforms with regard to the

chassis (= tuner) ground (H), or hot ground (I), depending

on the tested area of circuitry. The voltages and waveforms

shown in the diagrams are indicative. Measure them in the

Service Default Mode (see chapter 5) with a colour bar

signal and stereo sound (L: 3 kHz, R: 1 kHz unless stated

otherwise) and picture carrier at 475.25 MHz for PAL, or

61.25 MHz for NTSC (channel 3).

2.3.4 Lead-free Soldering

Due to lead-free technology some rules have to be respected

by the workshop during a repair:

• Use only lead-free soldering tin Philips SAC305 with order

code 0622 149 00106. If lead-free solder paste is required,

please contact the manufacturer of your soldering

equipment. In general, use of solder paste within

workshops should be avoided because paste is not easy to

store and to handle.

• Use only adequate solder tools applicable for lead-free

soldering tin. The solder tool must be able:

– To reach a solder-tip temperature of at least 400°C.

– To stabilize the adjusted temperature at the solder-tip.

– To exchange solder-tips for different applications.

• Adjust your solder tool so that a temperature of around

360°C - 380°C is reached and stabilized at the solder joint.

Heating time of the solder-joint should not exceed ~ 4 sec.

Avoid temperatures above 400°C, otherwise wear-out of

tips will increase drastically and flux-fluid will be destroyed.

To avoid wear-out of tips, switch “off” unused equipment or

reduce heat.

• Mix of lead-free soldering tin/parts with leaded soldering

tin/parts is possible but PHILIPS recommends strongly to

avoid mixed regimes. If this cannot be avoided, carefully

clear the solder-joint from old tin and re-solder with new tin.

EN 6 QCS1.0S LA3.

2.3.5 Alternative BOM identification

The third digit in the serial number (example:

AG2B0335000001) indicates the number of the alternative

B.O.M. (Bill Of Materials) that has been used for producing the

specific TV set. In general, it is possible that the same TV

model on the market is produced with e.g. two different types

of displays, coming from two different suppliers. This will then

result in sets which have the same CTN (Commercial Type

Number; e.g. 28PW9515/12) but which have a different B.O.M.

number.

By looking at the third digit of the serial number, one can

identify which B.O.M. is used for the TV set he is working with.

If the third digit of the serial number contains the number “1”

(example: AG1B033500001), then the TV set has been

manufactured according to B.O.M. number 1. If the third digit is

a “2” (example: AG2B0335000001), then the set has been

produced according to B.O.M. no. 2. This is important for

ordering the correct spare parts!

For the third digit, the numbers 1...9 and the characters A...Z

can be used, so in total: 9 plus 26= 35 different B.O.M.s can be

indicated by the third digit of the serial number.

Identification: The bottom line of a type plate gives a 14-digit

serial number. Digits 1 and 2 refer to the production centre (e.g.

AG is Bruges), digit 3 refers to the B.O.M. code, digit 4 refers

to the Service version change code, digits 5 and 6 refer to the

production year, and digits 7 and 8 refer to production week (in

example below it is 2006 week 17). The 6 last digits contain the

serial number.

Directions for Use

MODEL :

PROD.NO:

2.3.6 Board Level Repair (BLR) or Component Level Repair (CLR)

If a board is defective, consult your repair procedure to decide

if the board has to be exchanged or if it should be repaired on

component level.

If your repair procedure says the board should be exchanged

completely, do not solder on the defective board. Otherwise, it

cannot be returned to the O.E.M. supplier for back charging!

2.3.7 Practical Service Precautions

• It makes sense to avoid exposure to electrical shock.

• Always respect voltages. While some may not be

32PF9968/10

AG 1A0617 000001

Figure 2-1 Serial number (example)

While some sources are expected to have a possible

dangerous impact, others of quite high potential are of

limited current and are sometimes held in less regard.

dangerous in themselves, they can cause unexpected

reactions that are best avoided. Before reaching into a

powered TV set, it is best to test the high voltage insulation.

It is easy to do, and is a good service precaution.

MADE IN BELGIUM

220-240V 50/60Hz

VHF+S+H+UHF

S

~

BJ3.0E LA

E_06532_024.eps

128W

130606

3. Directions for Use

You can download this information from the following websites:

http://www.philips.com/support

http://www.p4c.philips.com

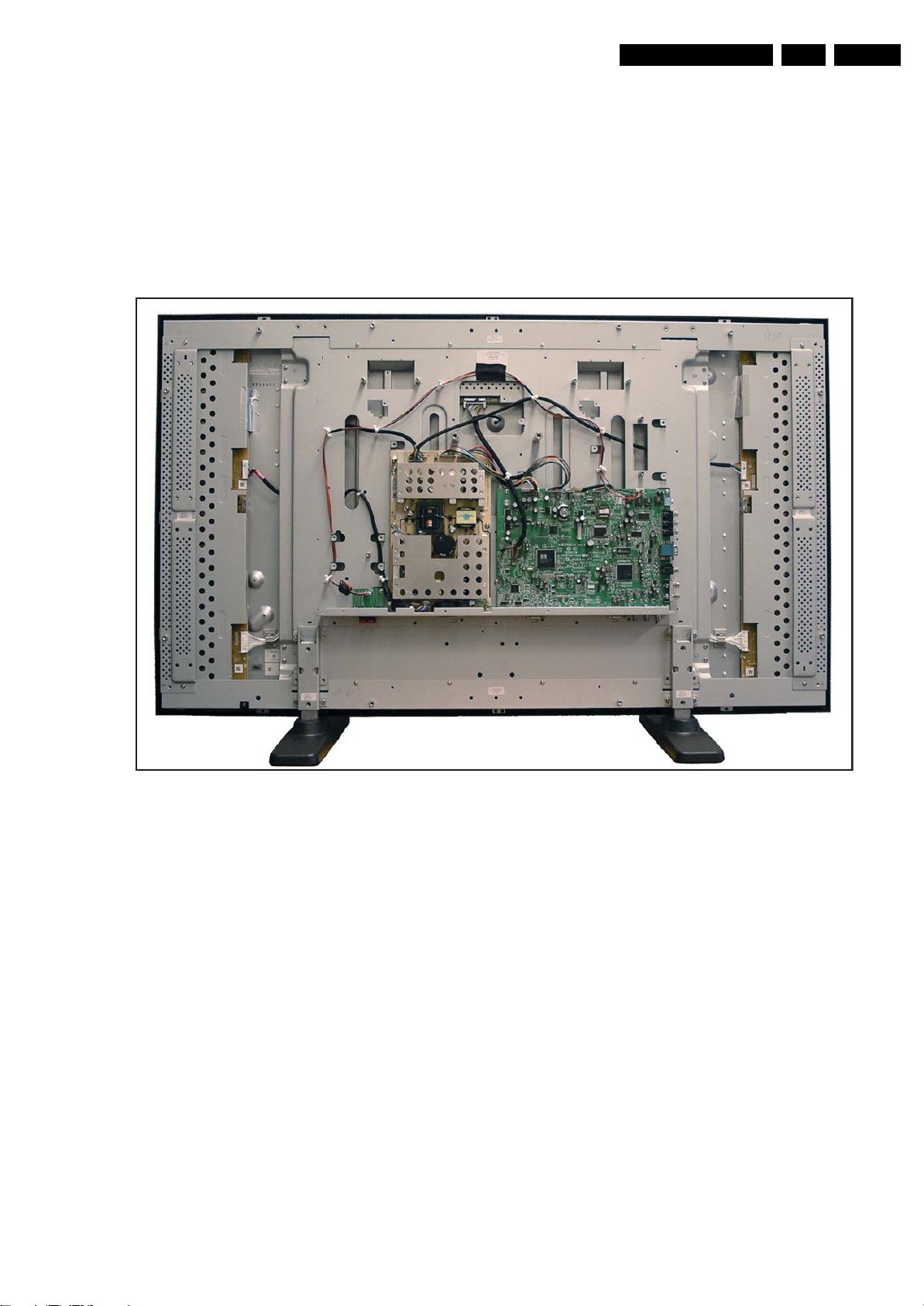

4. Mechanical Instructions

Mechanical Instructions

EN 7QCS1.0S LA 4.

Index of this chapter:

4.1 Cable Dressing

4.2 Service Positions

4.3 Assy/Panel Removal

4.4 Set Re-assembly

4.1 Cable Dressing

Notes:

• Figures below can deviate slightly from the actual situation,

due to the different set executions.

• Follow the disassembly instructions in the described order.

4.2 Service Positions

When moving or laying down an LCD set, at least two people

must work together. Avoid any impact towards the PDP set.

For easy servicing of this set, there are a few possibilities

created:

• Foam bars (created for Service).

• Separately available stands.

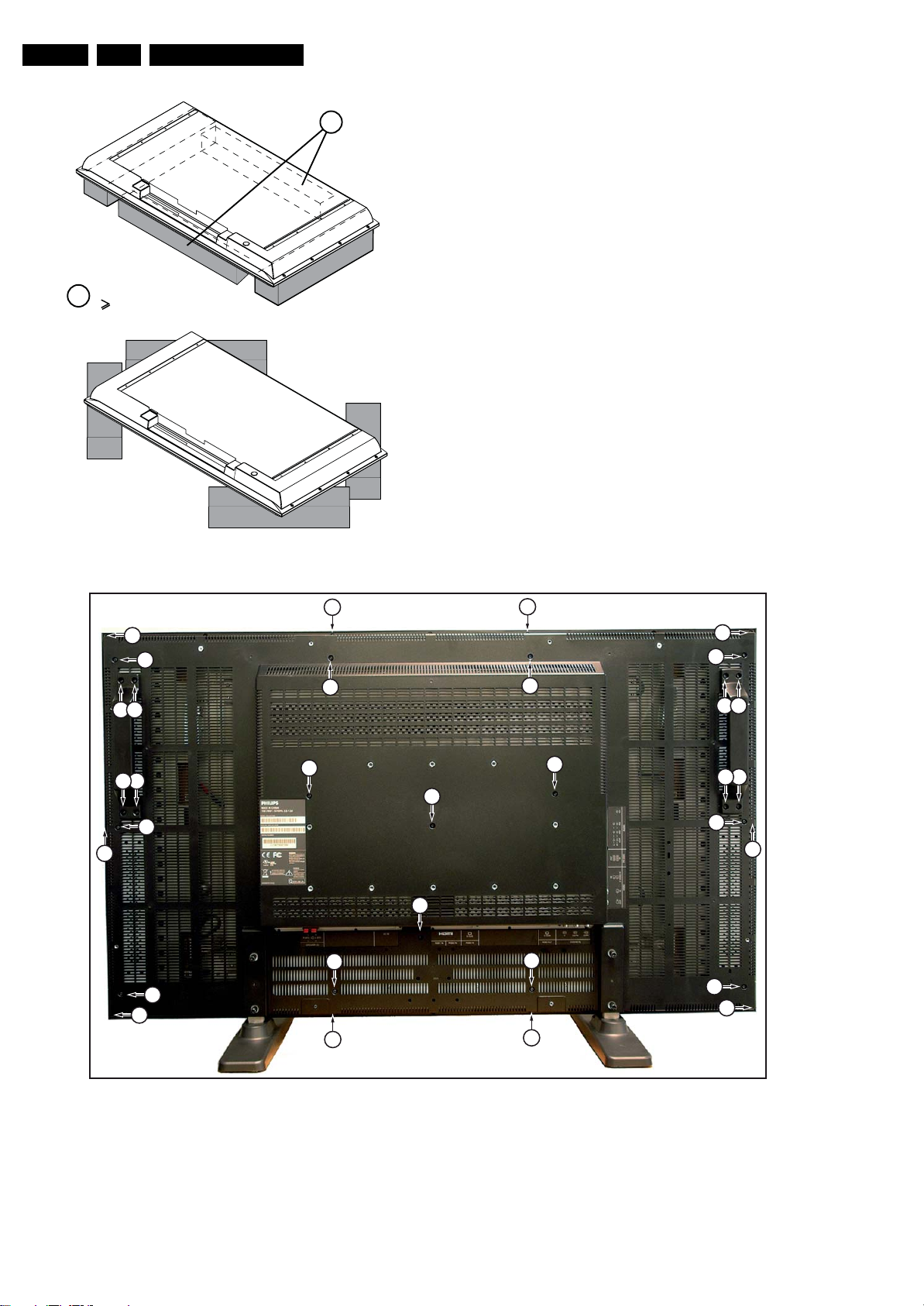

4.2.1 Foam Bars

The foam bars (order code 3122 785 90580 for two pieces) can

be used for all types and sizes of Flat TVs. See figure “Foam

bars” for details. Sets with a display of 42" and larger, require

four foam bars [1]. Ensure that the foam bars are always

supporting the cabinet and never only the display. Caution:

Failure to follow these guidelines can seriously damage the

display!

By laying the TV face down on the (ESD protective) foam bars,

a stable situation is created to perform measurements and

alignments. By placing a mirror under the TV, you can monitor

the screen.

Figure 4-1 Cable dressing

4.2.2 Stands

I_17540_012.eps

280108

For this set separately orderable stands are available, which

can also be used during service.

EN 8 QCS1.0S LA4.

Mechanical Instructions

4.3 Assy/Panel Removal

Required for sets

1

42"

1

E_06532_018.eps

171106

4.3.1 Back Cover

Warning: Disconnect the mains power cord before you open

the set.

Figure 4-2 Foam bars

1

1

1

1

1

1

1

11

1

1

1

1

1 1

1

11

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Refer to figure “Back Cover removal” for details.

1. Remove all screws [1] from the back cover.

2. Lift the back cover from the cabinet.

Figure 4-3 Back Cover removal

I_17540_014.eps

280108

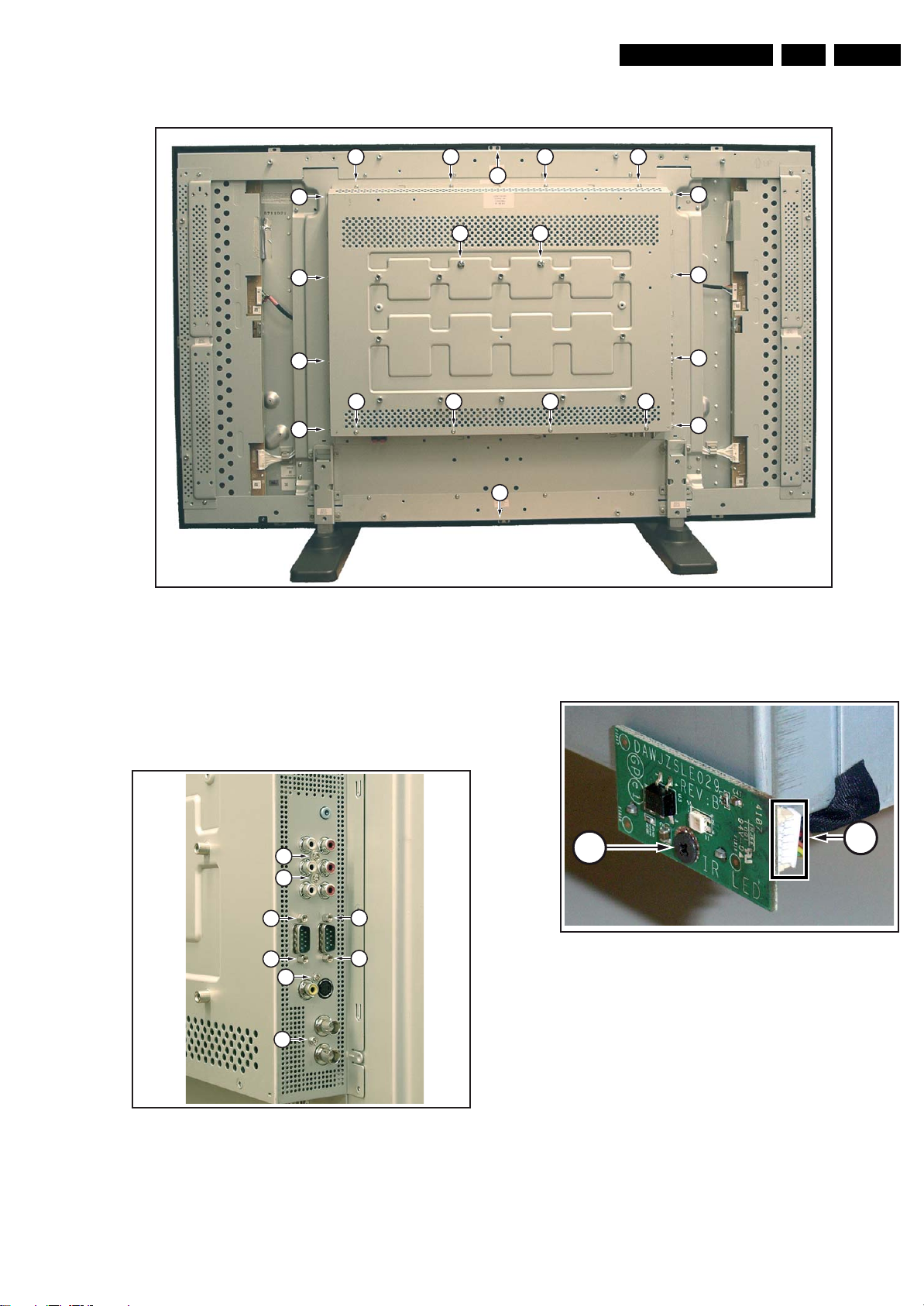

4.3.2 Front Cover and Shielding

Mechanical Instructions

EN 9QCS1.0S LA 4.

3

333

1

3

3

2 2

3

3

3

3

3 3 3 3

3

3

1

I_17540_013.eps

280108

Figure 4-4 Front Cover and Shielding removal [1/2]

Refer to figure “Front Cover and Shielding removal” for details.

1. Remove screws [1].

2. Lift the front cover from the set.

3. Remove screws [2] and [3] from the shielding.

4. Now gently lift the shielding from the set while pushing it

sidewards, away from the power switch.

2

2

2

2

2

2

2

2

4.3.3 LED / IR Panel

1

Figure 4-6 LED / IR Panel removal

Refer to figure “LED / IR Panel removal” for details.

1. Remove the fixation screw[1].

2. Take out the panel.

3. Disconnect the cable [2] from the rear of the panel.

When defective, replace the whole unit.

2

I_17540_003.eps

280108

Figure 4-5 Front Cover and Shielding removal [2/2]

4.3.4 Keyboard Control Panel

I_17540_011.eps

280108

EN 10 QCS1.0S LA4.

1

Figure 4-7 Keyboard Control Panel removal

Refer to figure “Keyboard Control Panel removal” for details.

1. Remove back- and front cover as described earlier.

2. Remove the fixation screws [1].

3. Take out the panel assembly and release the connector.

When defective, replace the whole unit.

Mechanical Instructions

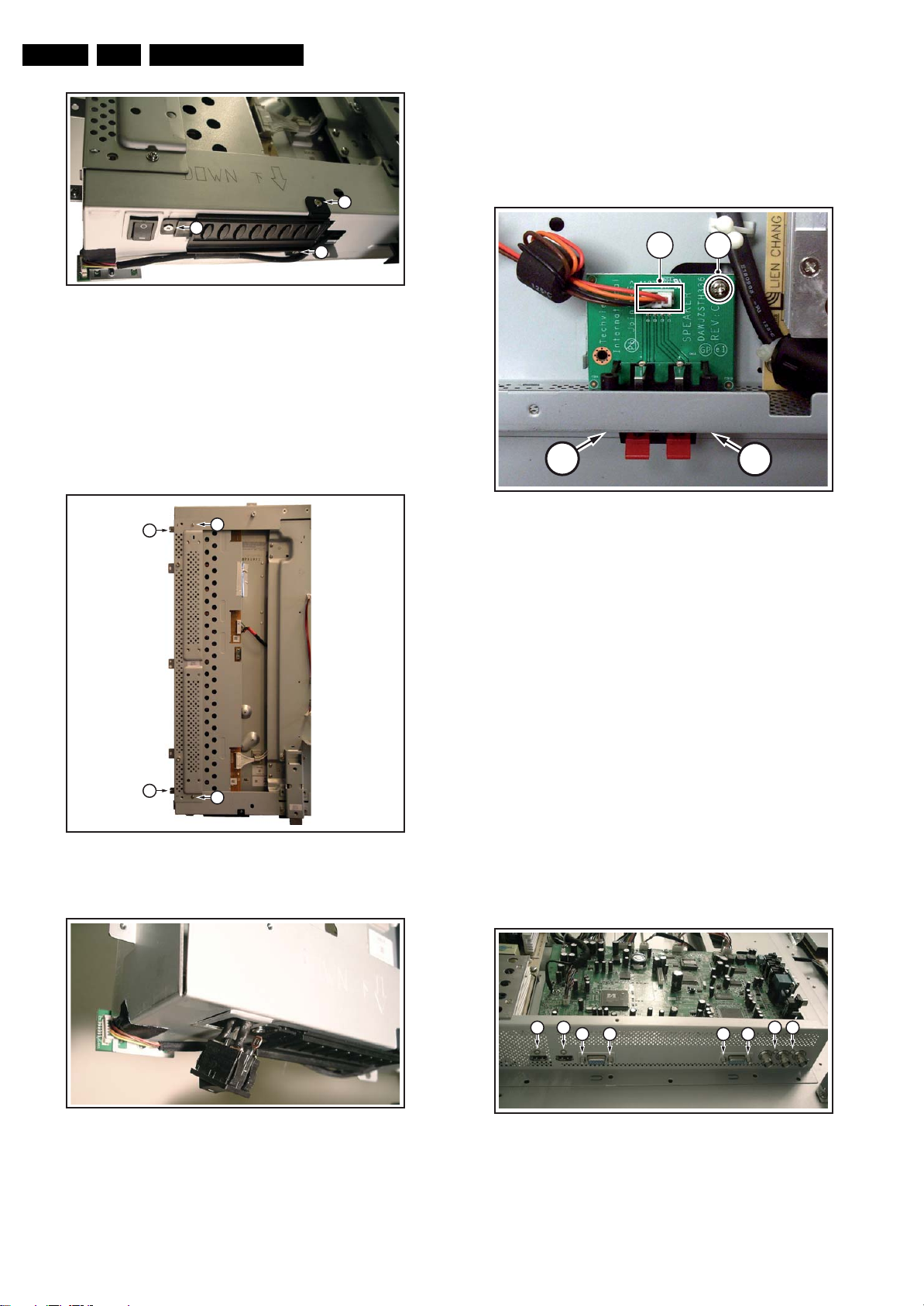

4.3.6 Speaker Panel

1

1

I_17540_006.eps

280108

2. Remove the fixation screws [1] from the rim and remove it.

3. Now the clips that hold the power switch can be released

via the backside of the switch.

When defective, replace the whole unit.

1 2

4.3.5 Power Supply Switch

1

1

Figure 4-8 Power Supply Switch removal [1/2]

2

2

I_17540_004.eps

280108

1

Figure 4-10 Speaker Panel removal

Refer to figure “Speaker Panel removal” for details.

1. Unplug the connector [1] from the speaker panel.

2. Remove the fixation screws [2].

3. Take out the panel.

When defective, replace the whole unit.

4.3.7 Small Signal Panel (SSB)

Refer to figures “SSB Connector Plate” and “SSB” for details.

1. Remove the screws [1] securing the connector plate.

2. Do NOT forget to unplug the LVDS connector [2] from the

SSB. Important: Be careful, as this is a very fragile

connector!

3. Remove the ground cable screw [3].

1

4. Unplug the other connectors [4] from the SSB.

5. Remove all fixation screws [5] securing the SSB.

I_17540_005.eps

280108

6. Lift out the SSB.

When defective, replace the whole unit.

Notes:

• Pay special attention to the EMC foam on the SSB

shielding. These must be replaced in their initial positions

during set re-assembly.

I_17540_008.eps

Figure 4-9 Power Supply Switch removal [2/2]

Refer to figure “Power Supply Switch removal” for details.

1. Remove back- and front cover as described earlier.

280108

1 1

1 1 1 1

Figure 4-11 SSB Connector Plate

1 1

I_17540_009.eps

280108

Mechanical Instructions

EN 11QCS1.0S LA 4.

5

5 5

4

3

5

2

5

5

Figure 4-12 SSB

I_17540_010.eps

280108

EN 12 QCS1.0S LA4.

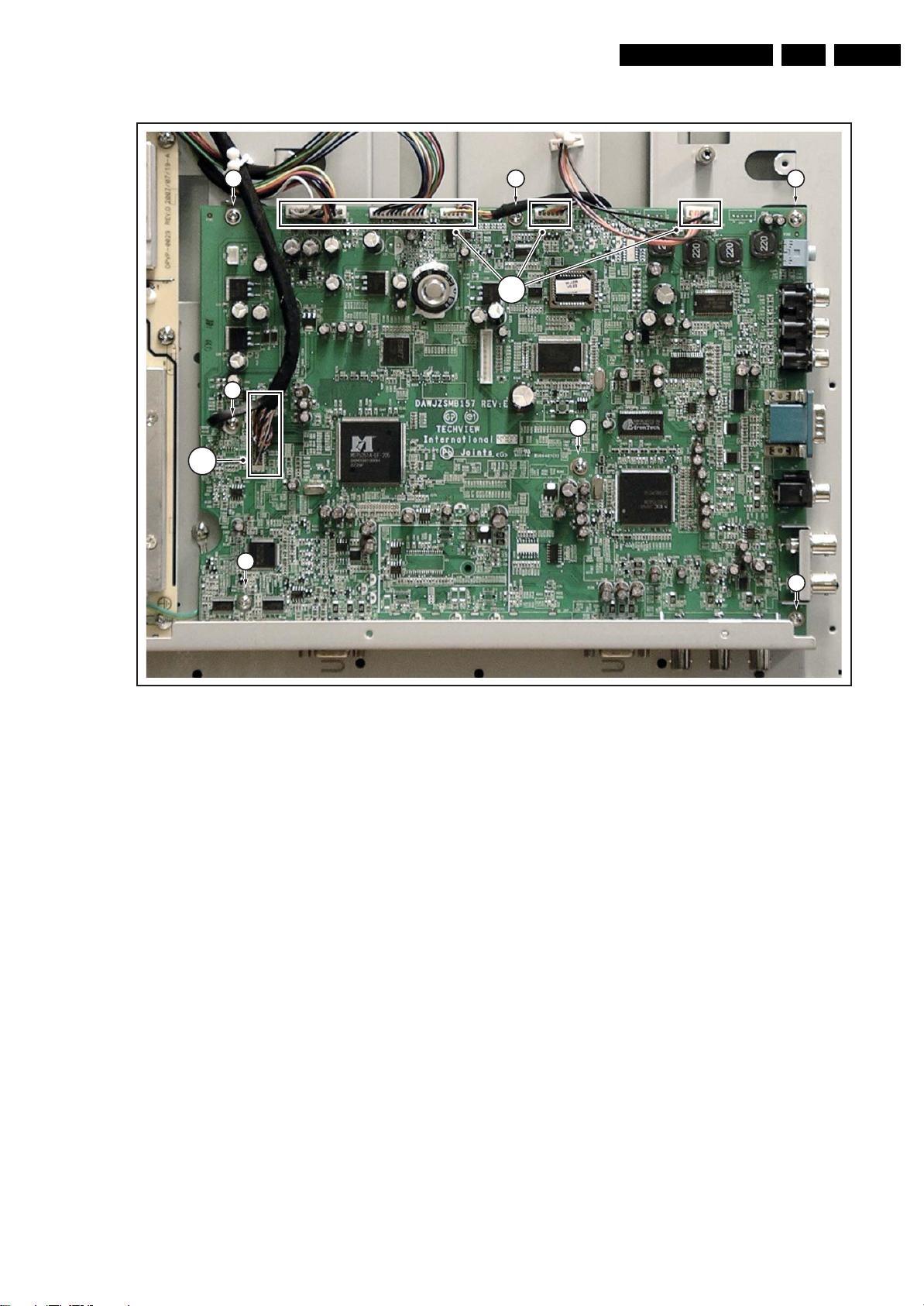

4.3.8 Main Supply Panel

3

Mechanical Instructions

1

3

3

1

3

Figure 4-13 Main supply panel.

1. Refer to figure “Main supply panel”.

2. Unplug connectors [1].

3. Remove the grounding screw [2].

4. Remove the fixation screws [3].

5. Take the board out.

When defective, replace the whole unit.

3

2

3

I_17540_045.eps

310108

4.3.9 LCD Panel

Important: Be sure to work in a dust free environment during

the following activities. In addition, the use of (fabric) hand

gloves is advised.

Mechanical Instructions

EN 13QCS1.0S LA 4.

4

4

2

1

3

4

4

Figure 4-14 Plasma panel disassembly

4

4

3

4

4

I_17540_001.eps

280108

1. First remove front cover, back cover and shielding as

described earlier.

2. Place the TV set face down on the foam bars. Place the

bars at each of the four the edges of the set, so they will

support the front frame and not only the glass plate!

3. Remove the grounding screw [1] that secures the cabling.

4. Do NOT forget to unplug the LVDS connector [2] from the

SSB. Important: Be careful, as this is a very fragile

connector!

5. Unplug the connectors from the backlight inverters [3].

6. Remove the screws [4].

7. Now gently lift the complete subframe from the LCD panel.

When defective, replace the whole unit.

4.4 Set Re-assembly

To re-assemble the whole set, execute all processes in reverse

order.

Notes:

• While re-assembling, make sure that all cables are placed

and connected in their original position. See figure “Cable

dressing”.

• Pay special attention not to damage the EMC foams at the

SSB shields. Make sure, that EMC foams are put correctly

on their places.

EN 14 QCS1.0S LA5.

Service Modes, Error Codes, and Fault Finding

5. Service Modes, Error Codes, and Fault Finding

Index of this chapter:

5.1 Compatibility Mode

5.2 Service Mode

5.1 Compatibility Mode

This chassis does not contain specific test points, since all

defect boards should be replaced.

Perform measurements under the following conditions:

• Environmental: t

• Service signal: 100% Full White signal

This monitor saves all previously made settings, unless

separately made user settings override this. All timings must be

properly phased, sized and centred. The aspect ratio is

depending on the input signal scaled and centred. At full screen

the input timing is set to completely fill the screen, regards less

of scaling artifacts.

5.1.1 Overscan

Component over scan: 5~8%

5.1.3 Compatibility

Mode Aspect Ratio Handling

Standard Resolution Full Screen Aspect Ratio Composite SVHS YPbPr RGB HDMI

VESA 640 × 480 @ 60 Hz 1920 × 1 080 16 : 9 No No No Yes Yes

VESA 640 × 480 @ 72 Hz 1920 × 1 080 16 : 9 No No No Yes Yes

VESA 640 × 480 @ 75 Hz 1920 × 1 080 16 : 9 No No No Yes Yes

VESA 800 × 600 @ 60 Hz 1920 × 1 080 16 : 9 No No No Yes Yes

VESA 1024 × 600 @ 60 Hz 1920 × 1 080 16 : 9 No No No Yes Yes

PD40 1280 × 768 @ 60 Hz 1 920 × 1080 16 : 9 No No No Yes Yes

VESA (M9) 1 280 × 768 @ 60 Hz 1920 × 1080 16 : 9 No No No Yes Yes

VESA 1280 × 1024 @ 60 Hz 1920 × 1080 16 : 9 No No No Yes Yes

M9 1360 × 768 @ 60 Hz 1 920 × 1080 16 : 9 No No No Yes Yes

VESA 1360 × 768 @ 60 Hz 1920 × 1 080 16 : 9 No No No Yes Yes

VESA 1600 × 1200 @ 60 Hz 1920 × 1080 16 : 9 No No No Yes Yes

M9 1920 × 1080 @ 50 Hz 1920 × 1080 16 : 9 No No No Yes Yes

SMPTE 1920 × 1080 @ 60 Hz 1920 × 1080 16 : 9 No No No Yes Yes

PAL 576i @ 50 Hz 1 920 × 1080 16 : 9 Yes Yes Yes No Yes

NTSC 480i @ 60 Hz 1920 × 1080 16 : 9 Yes Yes Yes No Yes

DVD 480p @ 60 Hz 1920 × 1080 16 : 9 No No Yes No Yes

= 25 ±2°C, RH = 65 ±10%

env

720 × 400 @ 70 Hz 1920 × 1080 16 : 9 No No No Yes Yes

1280× 720 @ 60 Hz 1920 × 1080 16 : 9 No No No Yes Yes

1920× 1080 @ 60 Hz 1920 × 1080 16 : 9 No No No Yes Yes

720p @ 50 Hz 1920 × 1080 16 : 9 No No Yes No Yes

720p @ 60 Hz 1920 × 1080 16 : 9 No No Yes No Yes

1080i @ 50 Hz 1920 ×

1080i @ 60 Hz 1920 × 1080 16 : 9 No No Yes No Yes

AV over scan: 5~9%

HDMI over scan: No over scan for PC input, 5~9% for video

source.

PC: No over scan

5.1.2 Display Processor performance

The display processor performance (excluding scaling

artifacts) has to be judged according to the following

definitions:

• Compatibility mode: correctly recognizes the proper

resolution and applies the correct display scaling to the

image. (i.e. a 1280 × 720 signal is properly recognized).

• Properly sized/centred: The entire image (use display mate

“side tics” pattern) perfectly fits the screen. Even one pixel

off in horizontal or vertical direction, makes this test fail.

• Properly phased: The display processor automatically

computes the correct A/D response so that a Win98

shutdown or all display mate moire patterns are correctly

displayed. Most critical on the panels native mode, no

unstableness of the image may be observed.

• HD compatibility: All HD timings have to work through

YPbPr, HDMI, and RGB.

1080 16 : 9 No No Yes No Yes

5.2 Service Mode

5.2.1 Factory Mode

There are two ways to enter the factory mode:

1. On the set:

• Push the y button and turn on the AC power.

2. With the remote control:

• Turn on the set and provide a signal source on an input

(this to prevent to enter the power save mode). On the

remote control press “-”, ”-”, “+”, “+”, “-”, “+”, “-”, “+”,

“SET”, “MENU”.

• Please note that this set does not respond on the

standard Philips remote controllers, but only responds

to the with the set supplied remote control.

Figure 5-1 Remote control.

I_17540_007.eps

280108

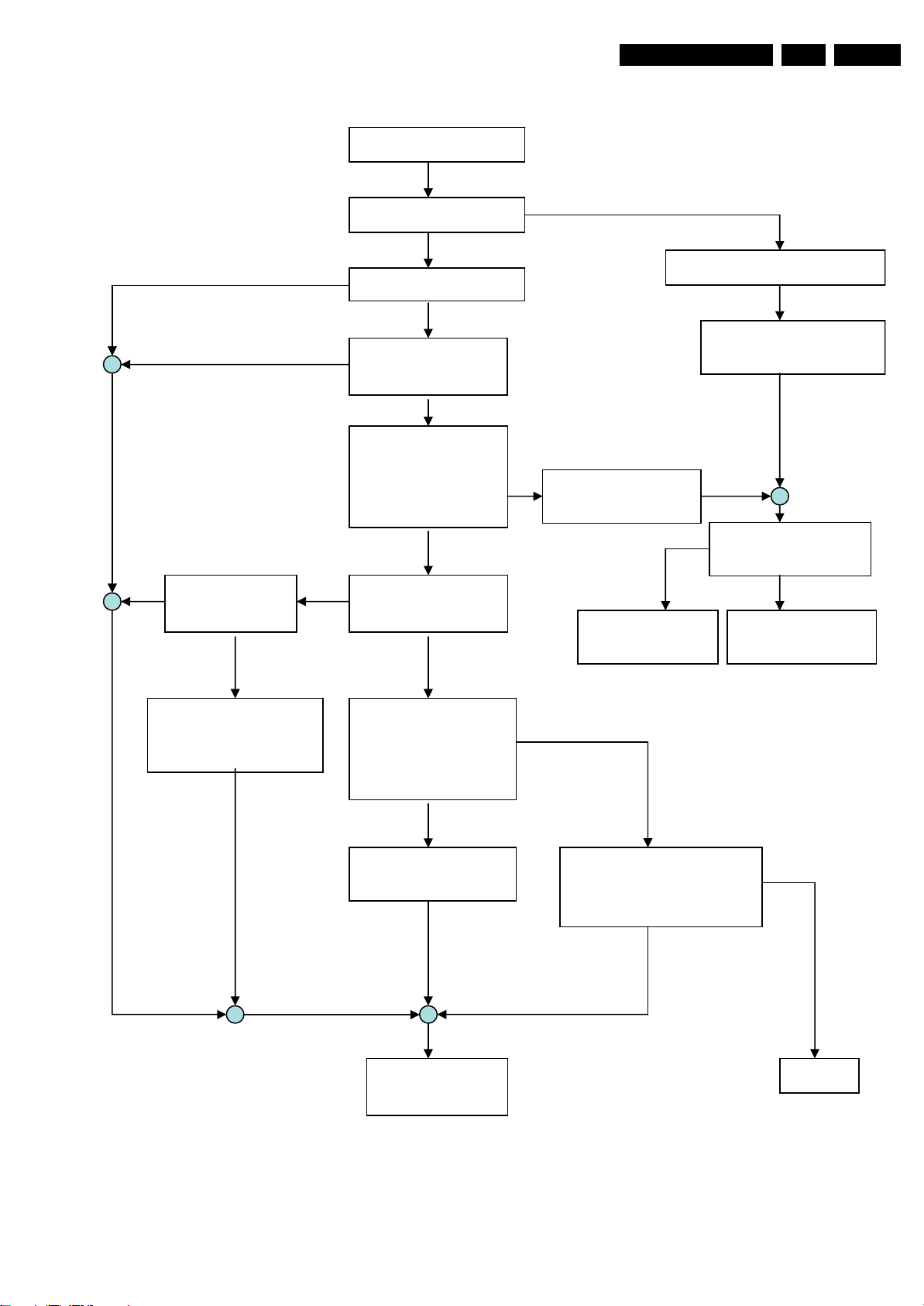

5.2.2 Repair flow chart

Service Modes, Error Codes, and Fault Finding

No Image appear

EN 15QCS1.0S LA 5.

Not OK

Check CN2

pin10 > 2V?

OK

Orange

Not OK

Not OK

LED Bright ?

OK

Check LED status

Green

Check CN7

pin1 > 3.3V?

OK

Check CN7

pin9/20=12V?,

CN2 pin7/8

=24V?

OK

Check LCD

Back Light

OK

Not OK

Check CN2 cable

connection

Replace Power

board

Not OK

Check CN7 pin6 = 5 V?

Not OK

Check cable from

CN7(MB) connection

OK, Well

connection

Check Power

Board AC power

OK

Check P1(PWB)

connection

Not OK

Check cable

connection between

PWB and Panel

OK, Well

connection

Disconnected the

Signal cable, Is

the screen show

“No Signal”?

NG

Check CN1(MB)

cable connection

OK, Well

connection

Replace Main

board

OK

Connected the Signal

cable again,

Check Image

Not OK

OK

END

I_17540_042.eps

310108

EN 16 QCS1.0S LA5.

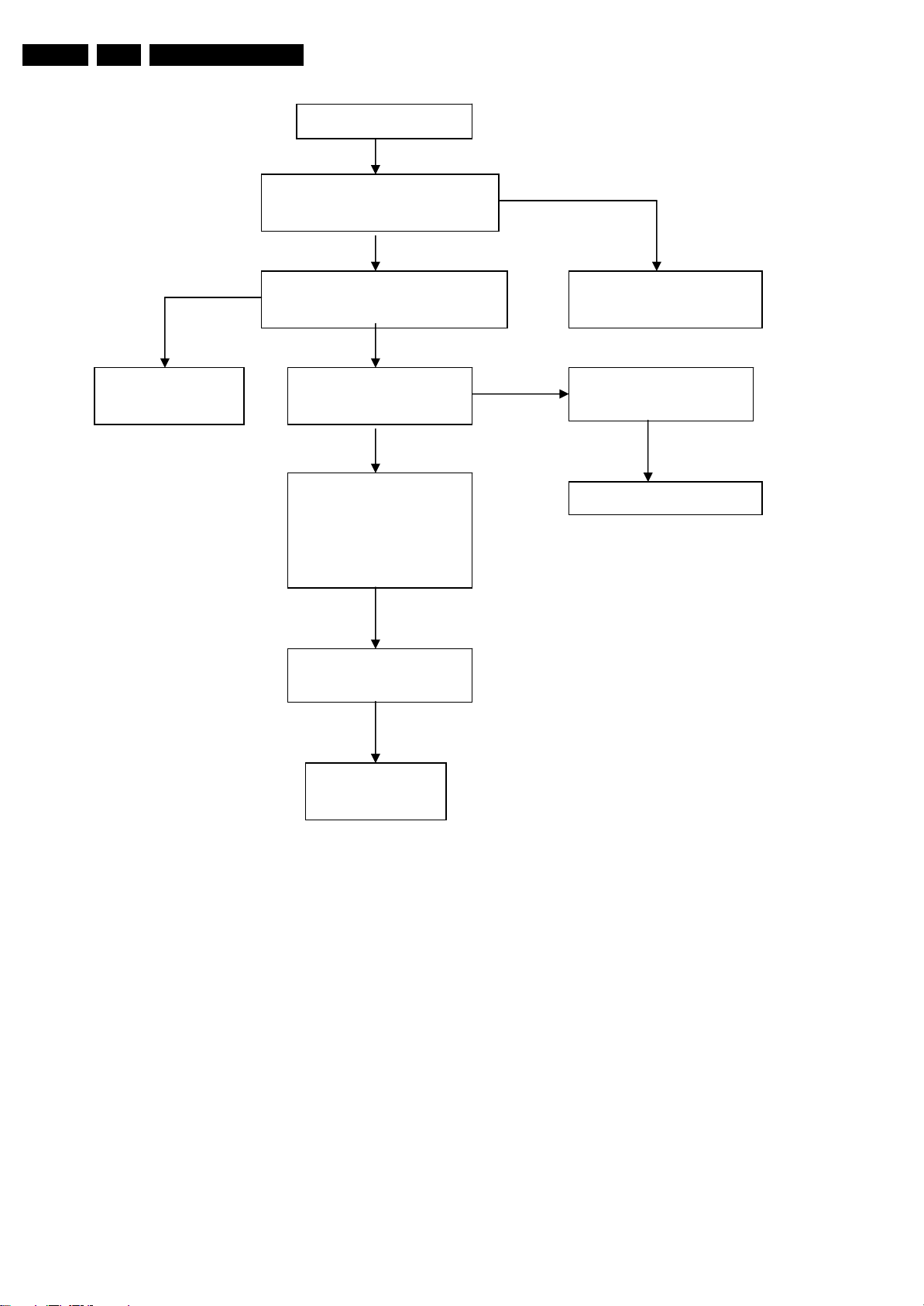

Service Modes, Error Codes, and Fault Finding

No Audio

Is Audio Input Source

selection correct?

Not OK

Reset mute

and Volume

OK

Is Mute and volume setting

OK?

OK

Check CN2 pin1/2

=12V?

OK

Check connector

connectted between

MB(CN5/CN6) and

CN13(Speaker

Interface)

OK, Well

connection

Check Speaker

Terminal connection

Not OK

Not OK

Select correct Audio

Input Source

Check CN2 cable

connection

OK, Well

connection

Replace Power board

OK, Well

connection

Replace Main

board

I_17540_043.eps

310108

Loading...

Loading...